Apparatus and method for locally polishing glass plate, and apparatus and method for producing glass product

A grinding device and glass plate technology, applied in grinding devices, grinding automatic control devices, manufacturing tools, etc., can solve problems such as residue, low efficiency, and inability to remove, and achieve high grinding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

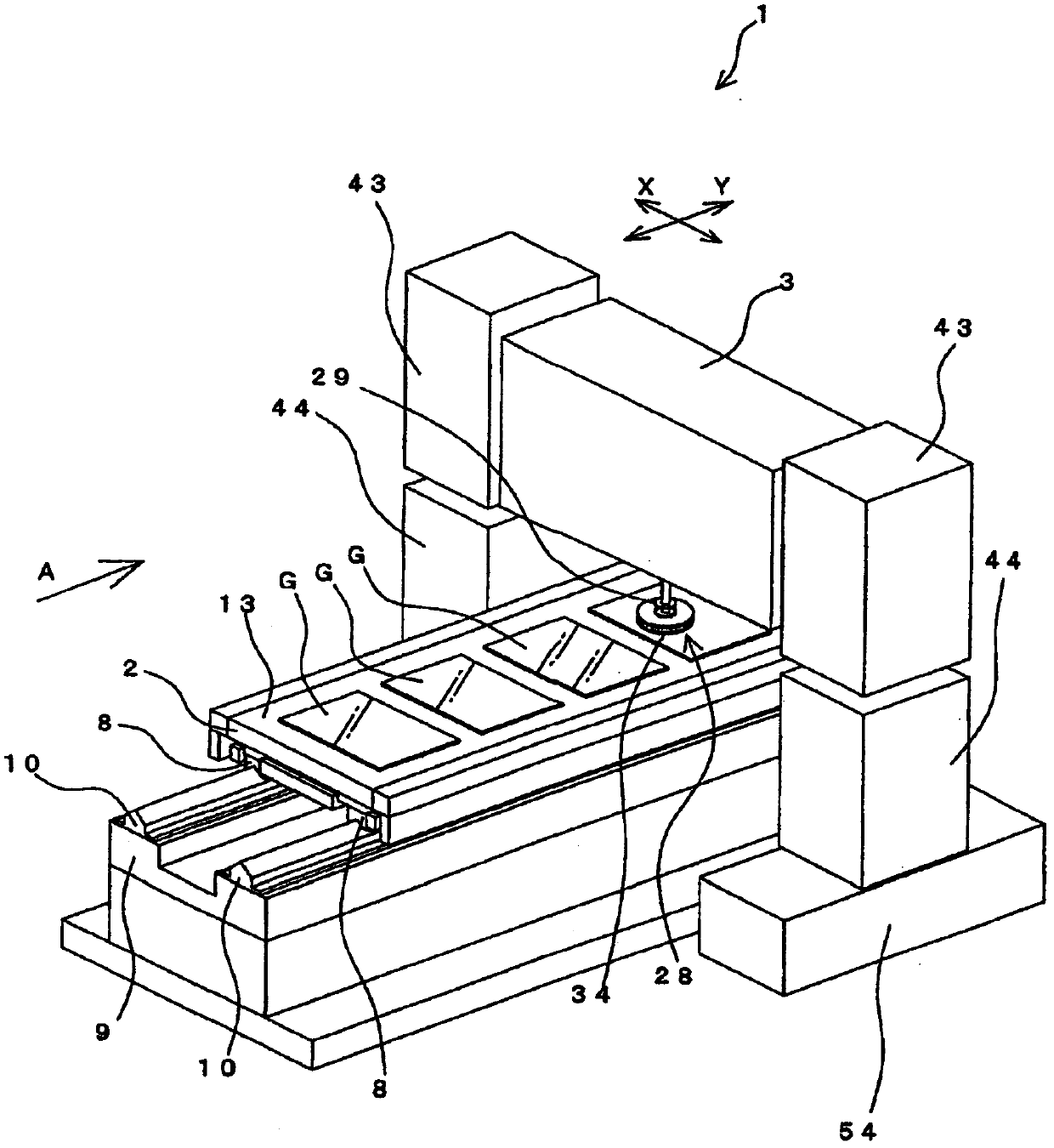

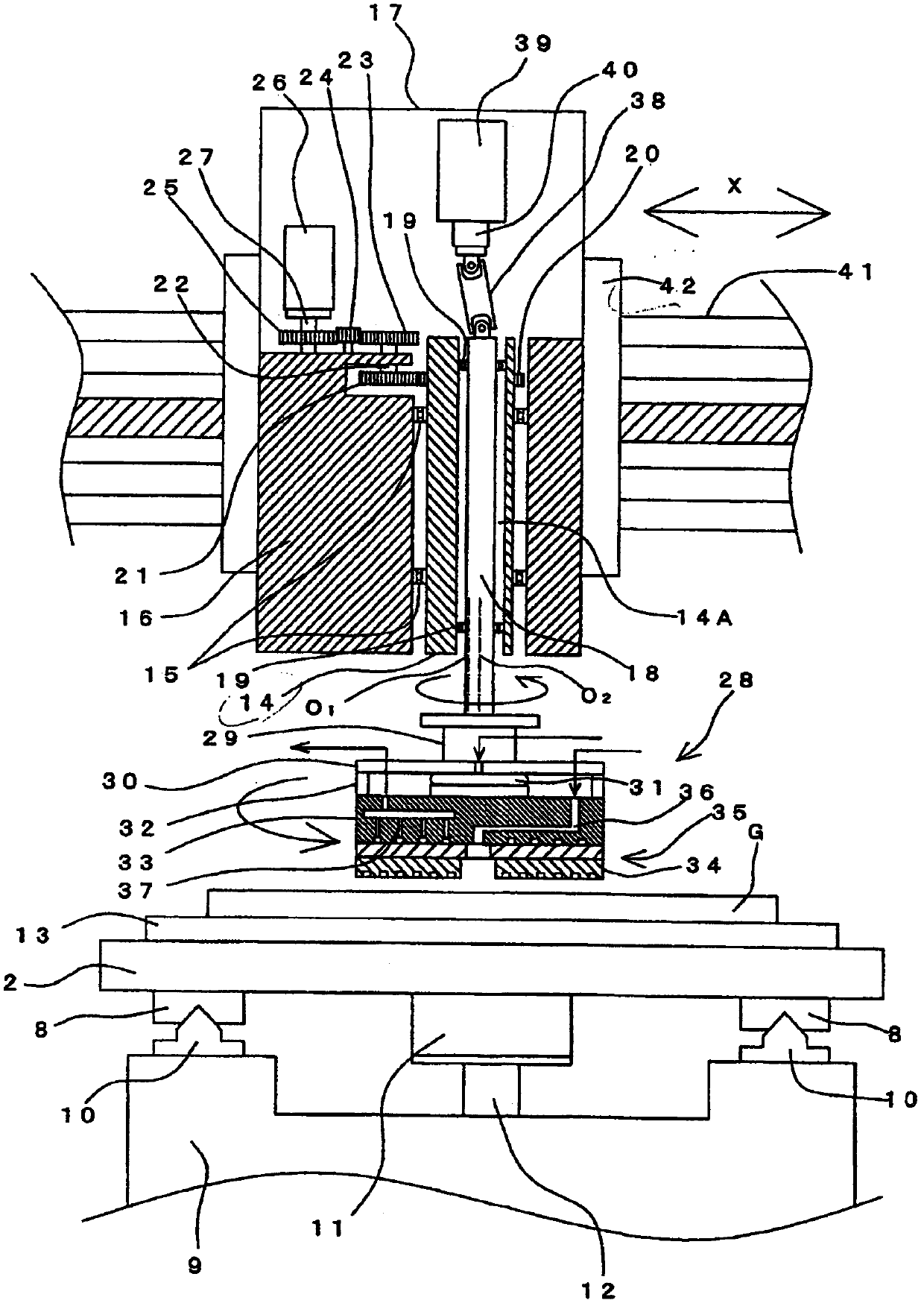

[0044] Hereinafter, preferred embodiments of a glass plate partial grinding device, a glass plate partial grinding method, a glass product manufacturing device, and a glass product manufacturing method of the present invention will be described with reference to the drawings.

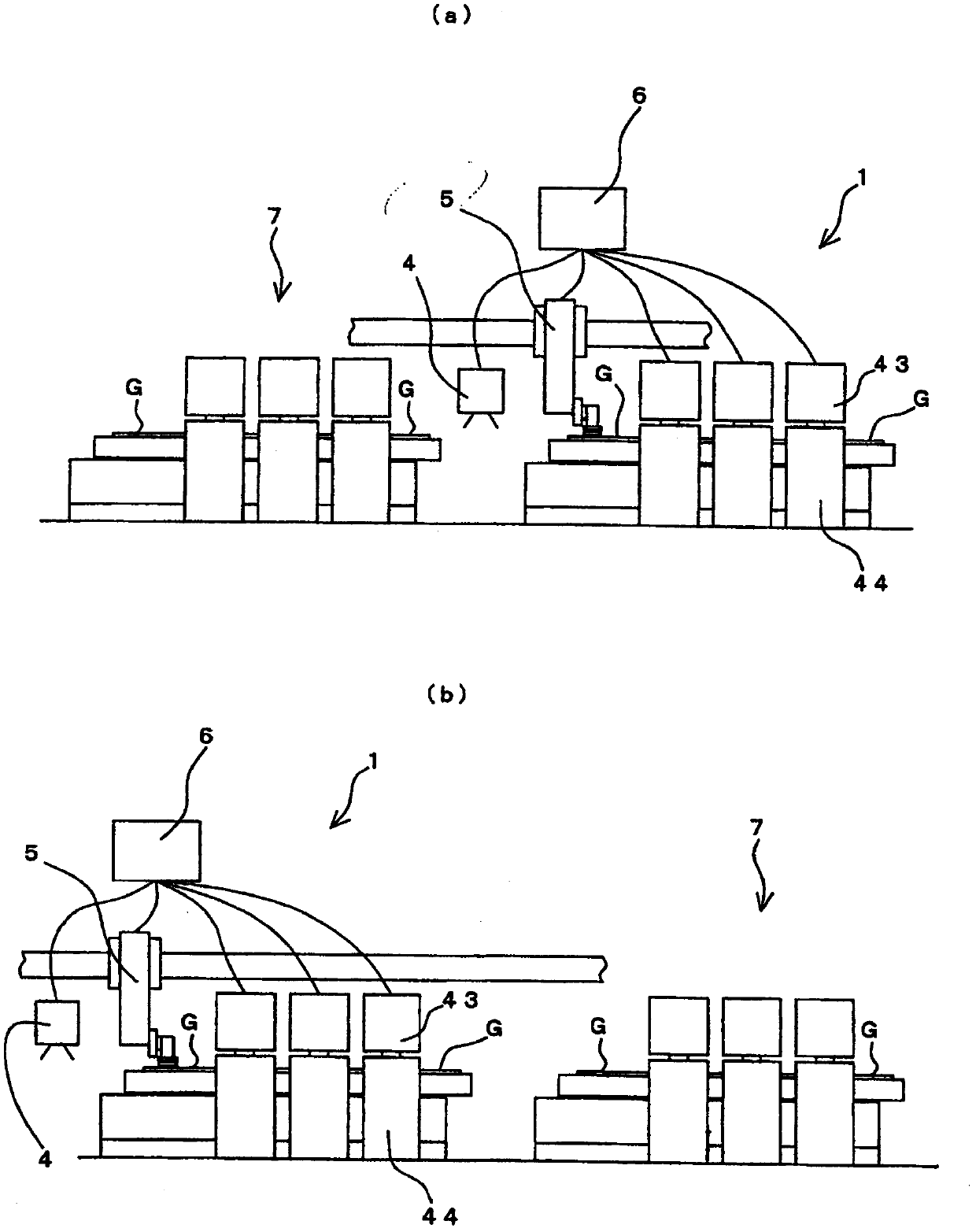

[0045] The local grinding device 1 is provided with: a table 2 holding a glass plate G; and a plurality of ( figure 1 Only one grinder 3, 3 is shown in the figure. In addition, if figure 2 (a) or figure 2 As shown in (b), the local grinding device 1 is equipped with an optical detection unit 4 based on laser light and the like, and a transport unit 5. The transport unit 5 is composed of X, Y, and Z moving axes and suction arms. Controlled by control unit 6. A full-surface polishing device 7 is arranged at a position before or after the partial polishing device 1 .

[0046] As the full-surface polishing device 7 , a full-surface polishing device that polishes the entire surface of a glass plate us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com