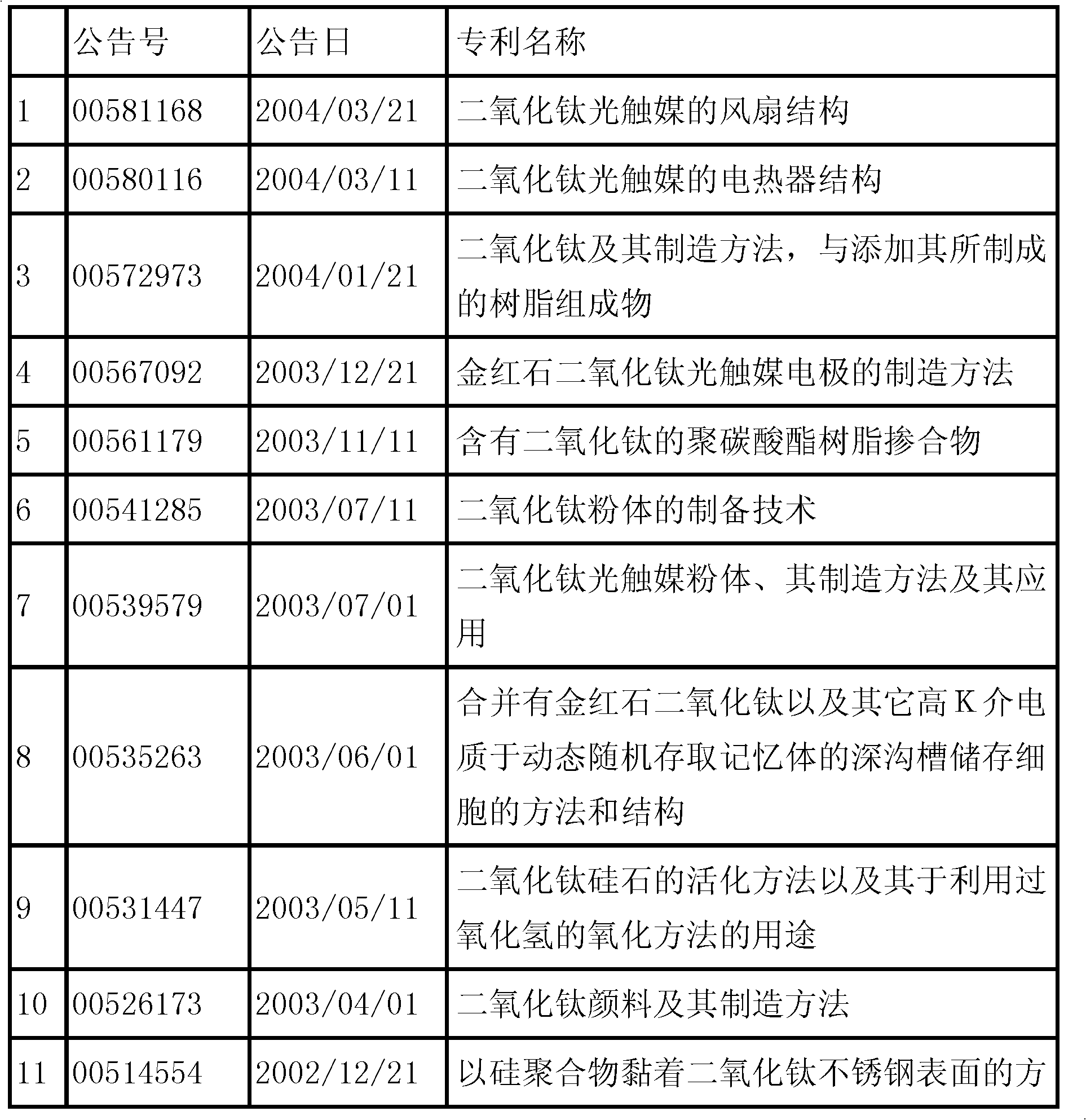

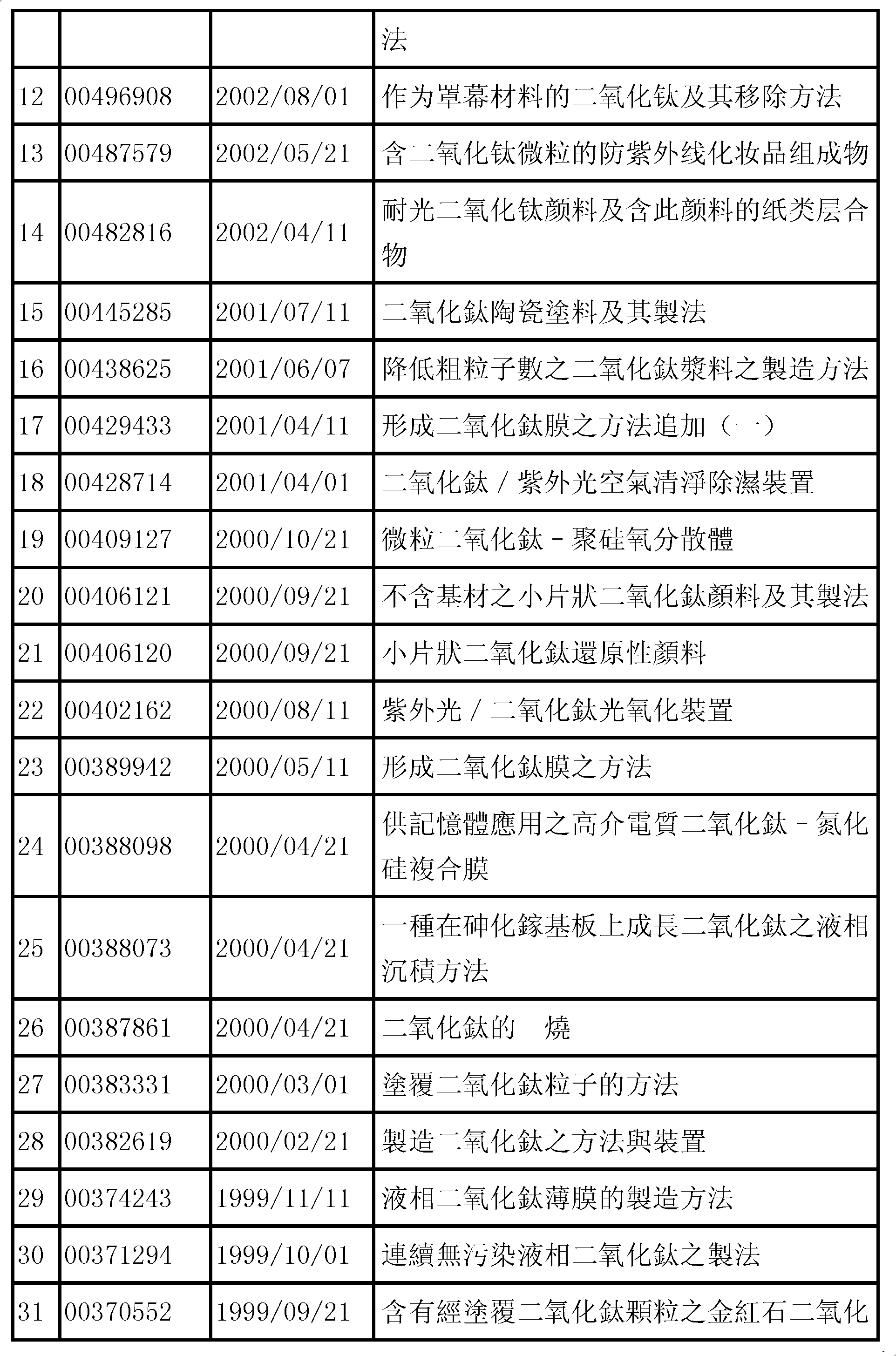

Patents

Literature

235results about How to "Solve cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Umbrella-shaped electrostatic spinning sprayer and electrostatic spinning method

ActiveCN103088443AOvercoming easy blockageOvercome efficiencySpinnerette packsFilament/thread formingNumerical controlFiber

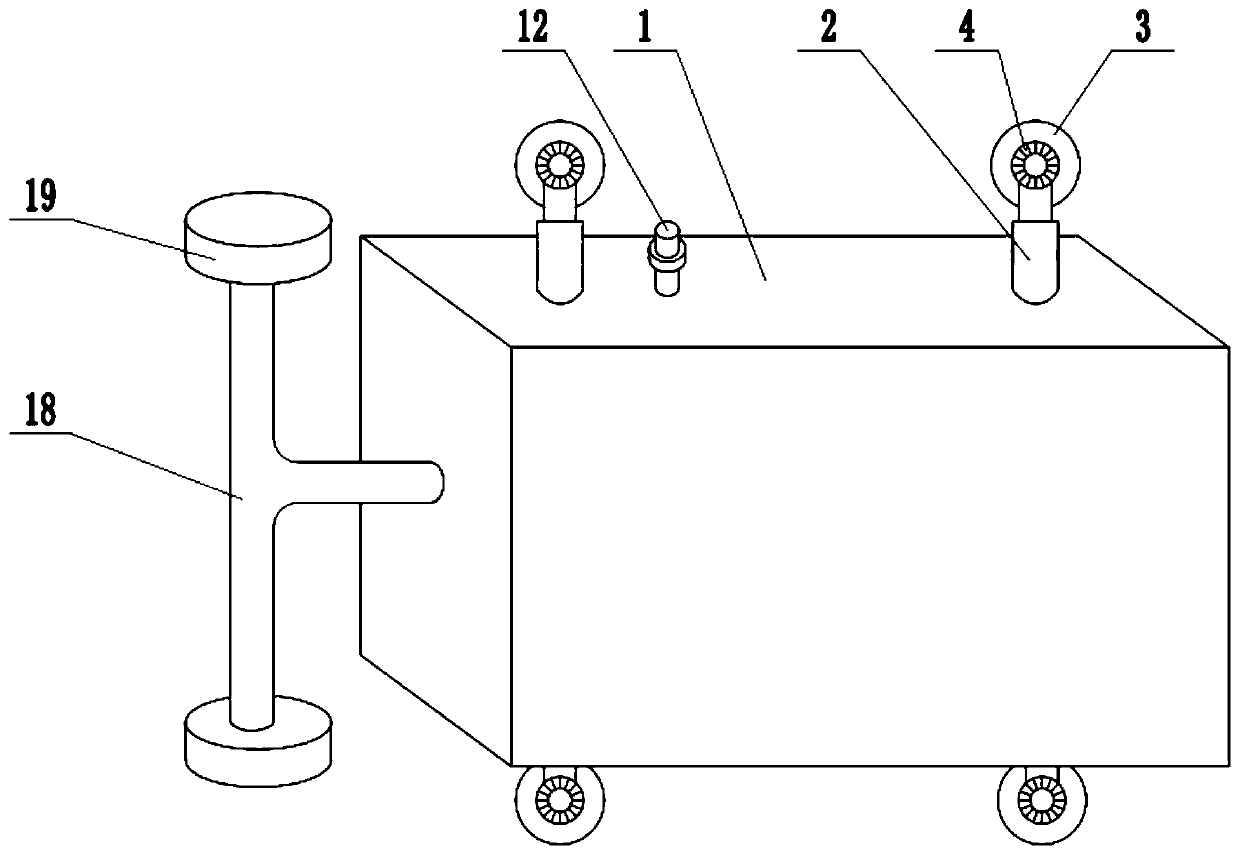

The invention relates to an umbrella-shaped electrostatic spinning sprayer and an electrostatic spinning method. The sprayer comprises an umbrella-shaped spinning nozzle, a numerical control type infusion device and a solution collecting groove, wherein the numerical control type infusion device mainly comprises a solution propeller and a controller; the middle of the umbrella-shaped spinning nozzle is provided with a cylindrical hollow portion, and an output end of the solution propeller is placed into the cylindrical hollow portion of the umbrella-shaped spinning nozzle; the controller controls flow velocity and flow of spinning solutions; and the solution collecting groove is placed in the bottom of the umbrella-shaped spinning nozzle. The electrostatic spinning method comprises that a binding post on the umbrella-shaped spinning nozzle is connected with a high-voltage positive electrode, conducting polymer solutions are continuously added to the umbrella-shaped spinning nozzle which is horizontally placed through the numerical control type infusion device, electrostatic spinning is started, collection is achieved through a collecting device, and nano-fibers are formed. The sprayer avoids blocking phenomena, and is easy to clean and good in stability; and the electrostatic spinning method improves production efficiency and the yield of electrostatic spinning.

Owner:DONGHUA UNIV

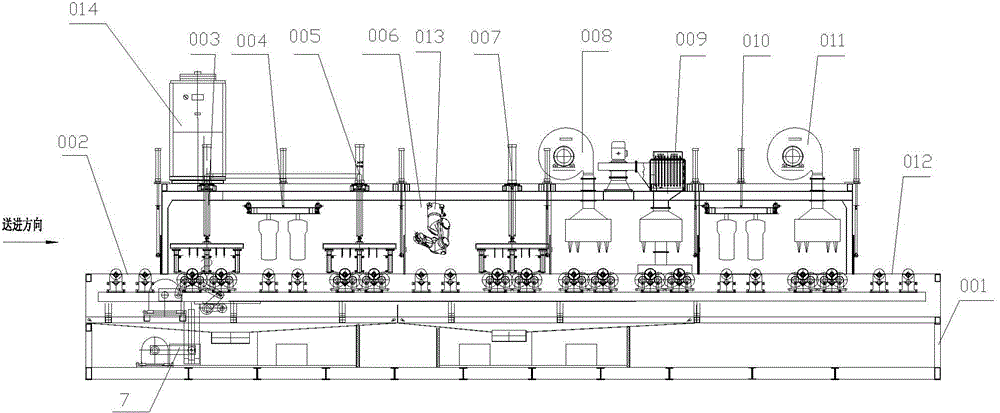

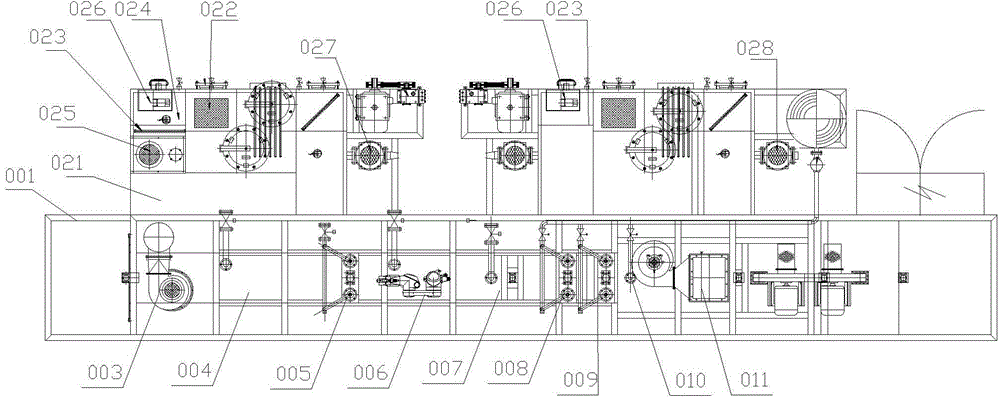

Crankshaft cleaning machine

ActiveCN105312269ASolve cleaningSolve productivityLiquid surface applicatorsCoatingsSurface cleaningWind shear

The invention provides a crankshaft cleaning machine. The crankshaft cleaning machine comprises a rack as well as a first surface cleaning system, a surface ultrasonic cleaning system, a second surface cleaning system, an oil duct cleaning system, a surface rinsing system, a surface blow-drying system, a hot air drying system, an ultrasonic oil immersion system and a wind-shear oil blowing system which are arranged on the rack sequentially, a workpiece conveying system for conveying workpieces is further arranged on the rack and comprises a lifting and conveying mechanism and a tool adjusting mechanism. The crankshaft cleaning machine is designed for cleaning an automobile crankshaft and integrates advanced combined means such as ultrasonic waves, high-pressure spray, ultrahigh-pressure spray, rotation, flexible robot hole alignment, ultrasonic oil immersion, oil blowing and the like so as to be applied to crankshaft cleaning, drying and rustproofing processes, and the tool adjusting mechanism of the conveying system can adjust the width automatically to adapt to cleaning of products in various specifications.

Owner:CHONGQING KEBEN TECH

Pipe desilting device for municipal engineering

The invention relates to the field of desilting equipment, in particular to a pipe desilting device for municipal engineering. The pipe desilting device comprises a shell, idler wheels, a brush head and a liquid storage box, wherein electric telescopic rods are mounted at the top and the bottom of the shell; the idler wheels are mounted at the top ends of the electric telescopic rods; a first telescopic mechanism is rotatably connected with the right side wall of the shell; the side wall of the first telescopic mechanism is hinged to a support rod; the brush head is hinged to the free end of the support rod; the liquid storage box is mounted in the shell; a stirring mechanism is mounted in the liquid storage box; a T-shaped water pipe is mounted on the left side wall of the shell; sprayersare mounted at the upper and lower ends of the T-shaped water pipe; and a rotary mechanism is further mounted on the side wall of the shell. Through arranging the angle-adjustable brush head, the brush head better fits the inner wall of a pipeline to clean the inner wall of the pipeline and scrape sludge attached to the inner wall of the pipeline; and through arranging the rotatable sprayers, thespraying range is greatly enlarged, so that the spraying dead angle is reduced to spray cleanout fluid more uniformly.

Owner:陈建

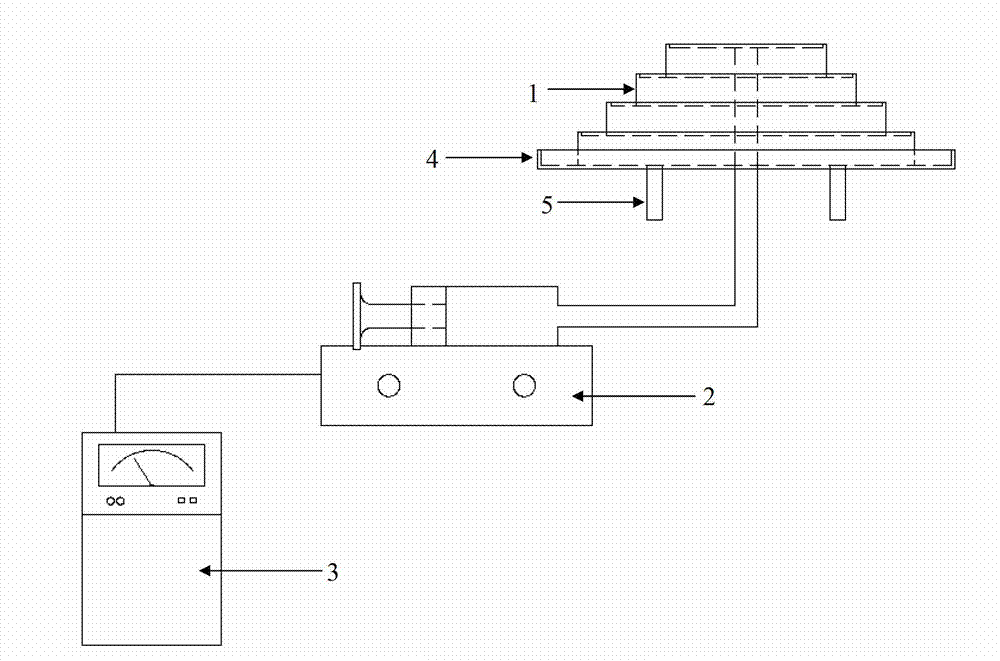

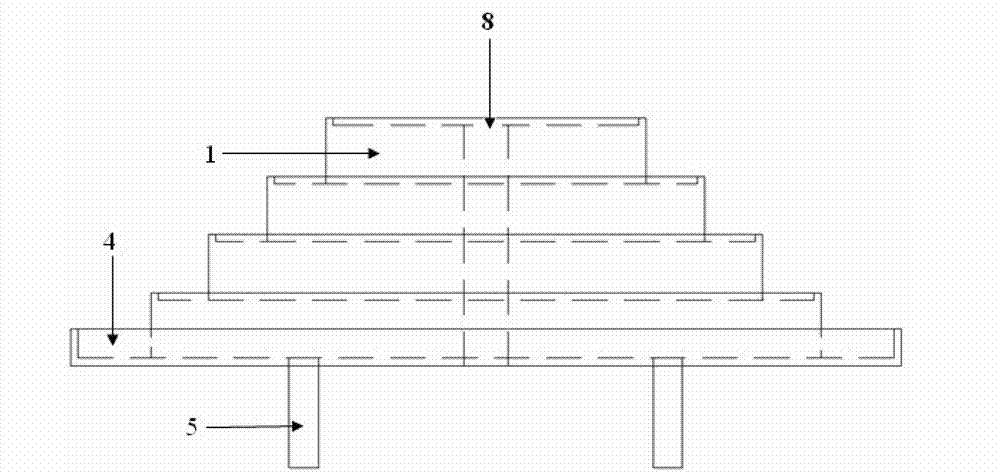

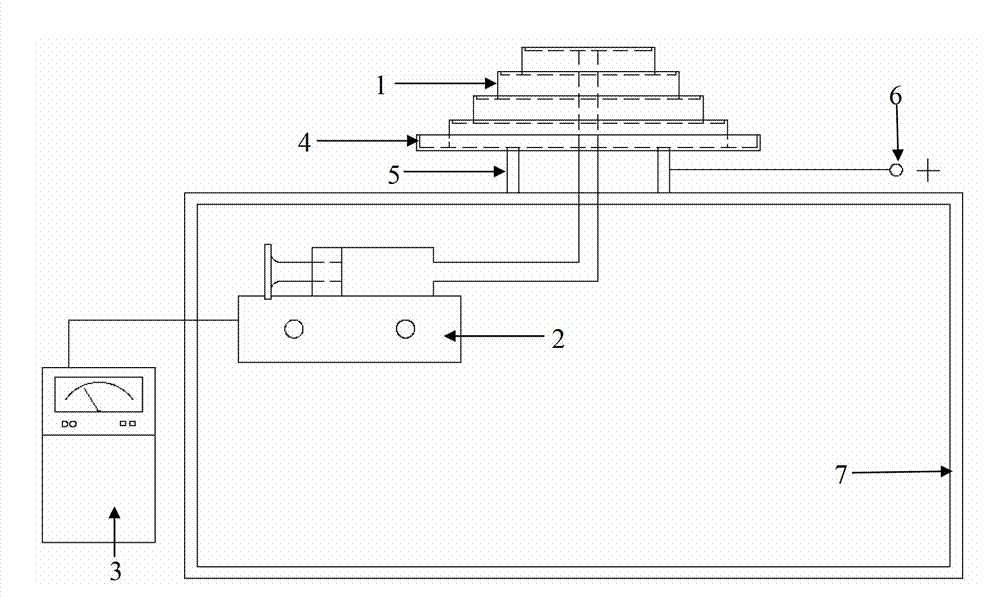

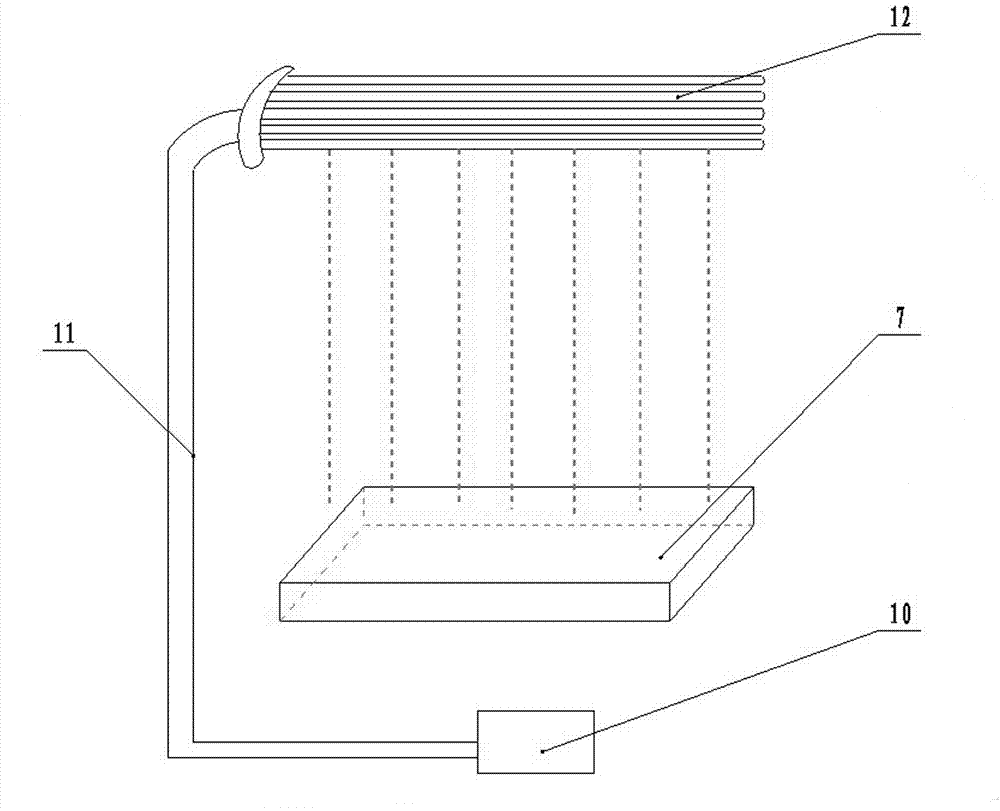

Immersed vacuum membrane distillation plant and sewage treatment technology using the same

ActiveCN102417210AIncreased distillation throughputReduce pollutionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentConcentration polarizationMeasuring instrument

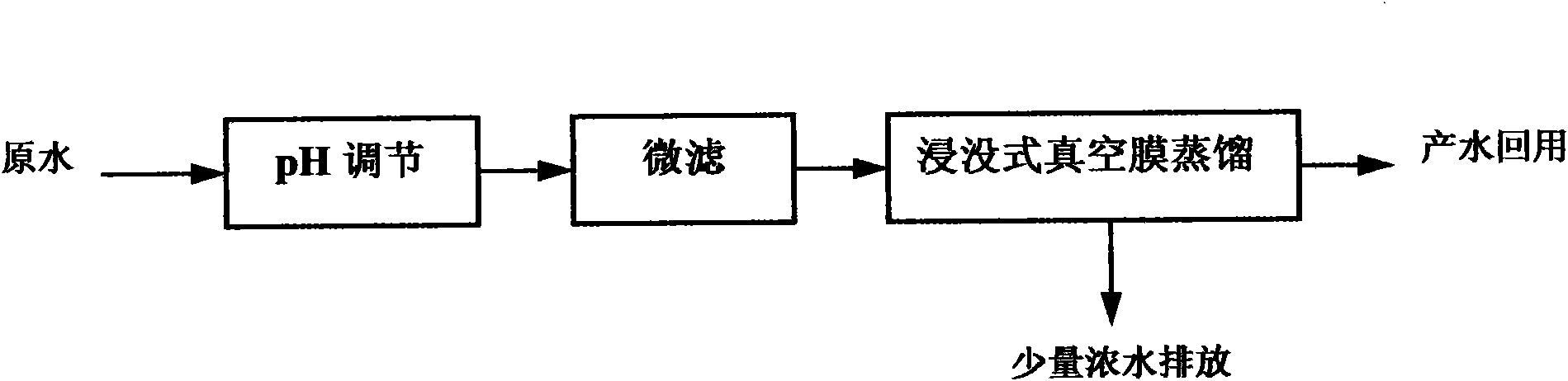

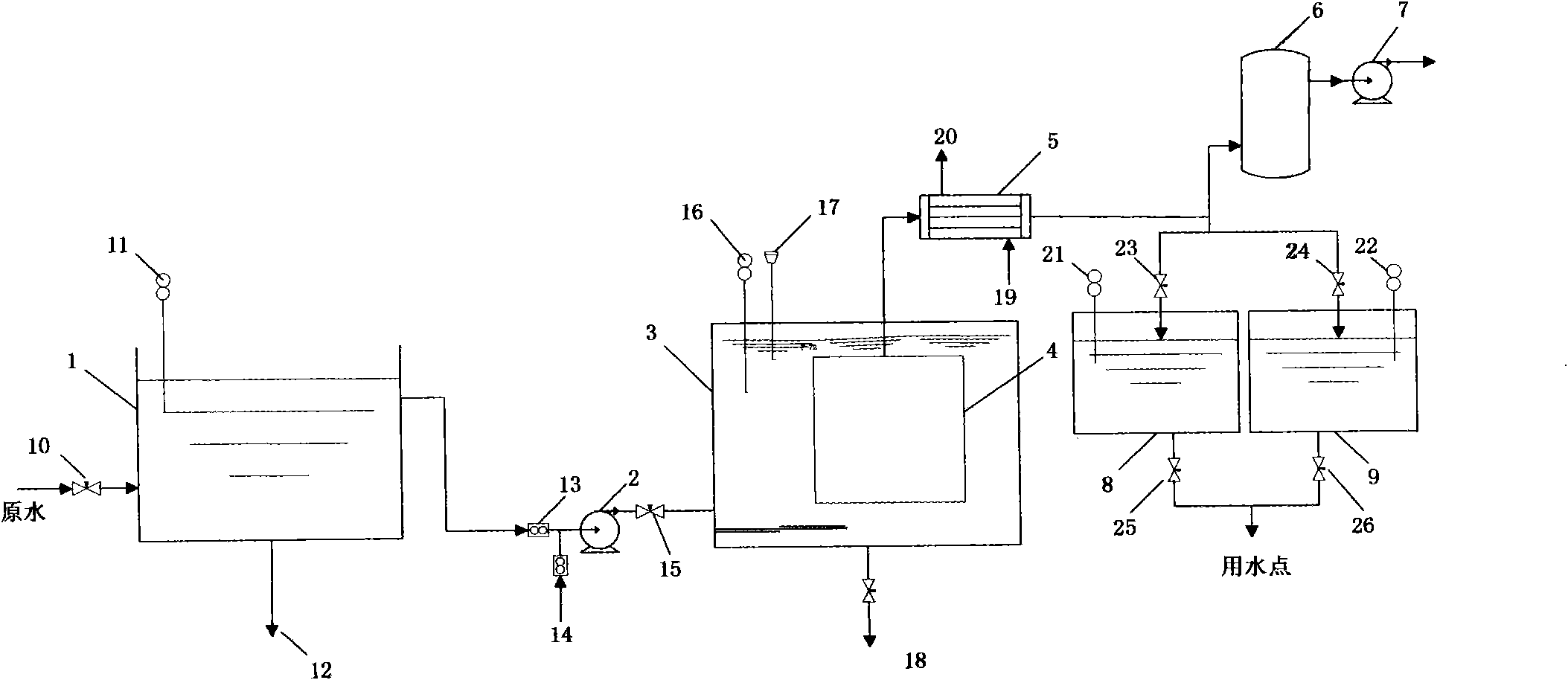

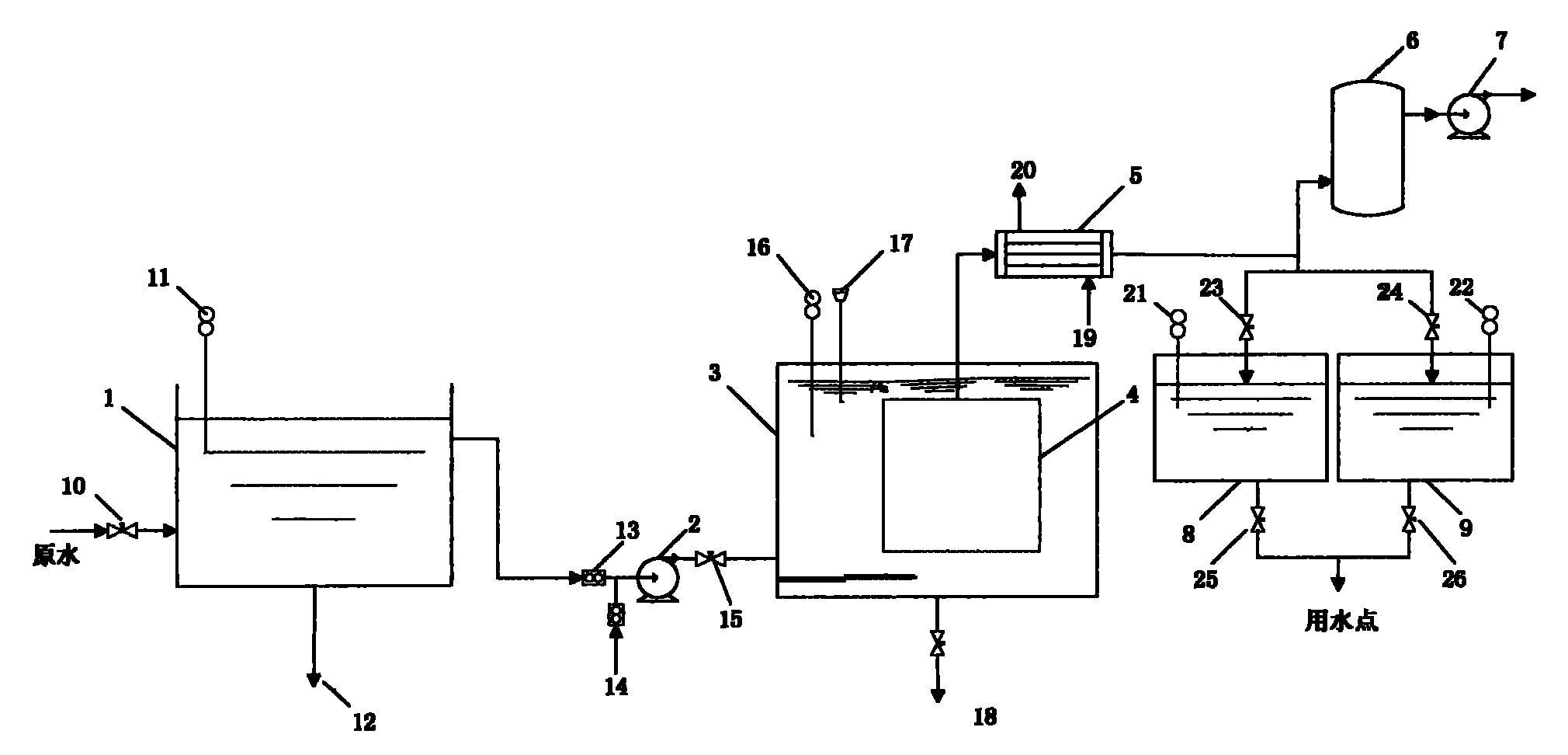

The invention relates to an immersed vacuum membrane distillation plant and a sewage treatment technology using the same. The immersed vacuum membrane distillation plant comprises a raw water storage tank, a gas dissolving pump, a raw water heating water tank, a membrane distillation hydrophobic membrane module, a condenser, a vacuum buffer tank, a vacuum pump, a water producing tank, a valve, a measuring instrument, and an automatic controller. The sewage treatment technology is characterized in that: raw water is subject to pH regulation, microfiltration and other pretreatment, then the pretreated raw water enters into the raw water storage tank, the sewage in the raw water storage tank is subject to gas-water mixing through the gas dissolving pump, and then the gas-water mixture enters into the raw water storage tank for heating to a specific temperature, membrane distillation is carried out at the specific temperature, the produced water after membrane distillation is directly reused, and a little thick water is treated concentrately. According to the invention, the use of the plant in sewage treatment reduces the effect of concentration polarization and temperature difference polarization in the sewage, reduces membrane pollution, increases the membrane distillation flux, prolongs the operation period of the membrane module, reduces the heat loss of the pipeline, and increases the heat utilization rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ultrasonic self-cleaned extractor hood and method thereof

ActiveCN106439960ARealize automatic cleaningFast cleaningDomestic stoves or rangesLighting and heating apparatusUltrasonic sensorEngineering

The invention discloses an ultrasonic self-cleaned extractor hood and a method thereof. The ultrasonic self-cleaned extractor hood comprises a controller, a machine shell and a centrifugal fan arranged in the machine shell. A cleaning liquid sucking and discharging pump and a cleaning liquid sucking and discharging port are formed in the machine shell. One connector of the cleaning liquid sucking and discharging pump communicates with the cleaning liquid sucking and discharging port through a pipeline. The other connector of the cleaning liquid sucking and discharging pump directly communicates with the bottom of a volute through a pipeline. At least two through holes are formed in the bottom of the volute. Ultrasonic transducers are fixed to the lower sides of the through holes. The fan, the cleaning liquid sucking and discharging pump and the ultrasonic transducers are connected with the controller. The problem that an extractor hood in the prior art is hard to clean or the cleaning effect is not ideal is effectively solved. The ultrasonic self-cleaned extractor hood is high in automation degree, automation cleaning of the extractor hood is truly achieved, and very high practical value is achieved.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

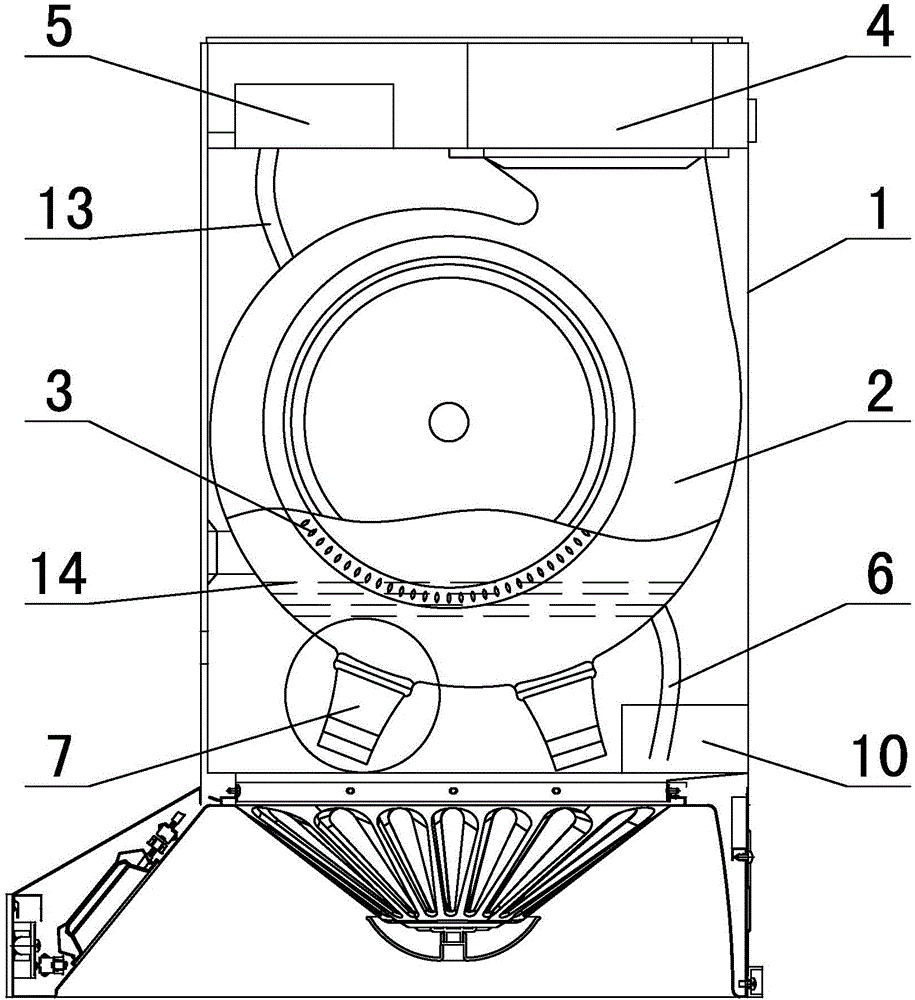

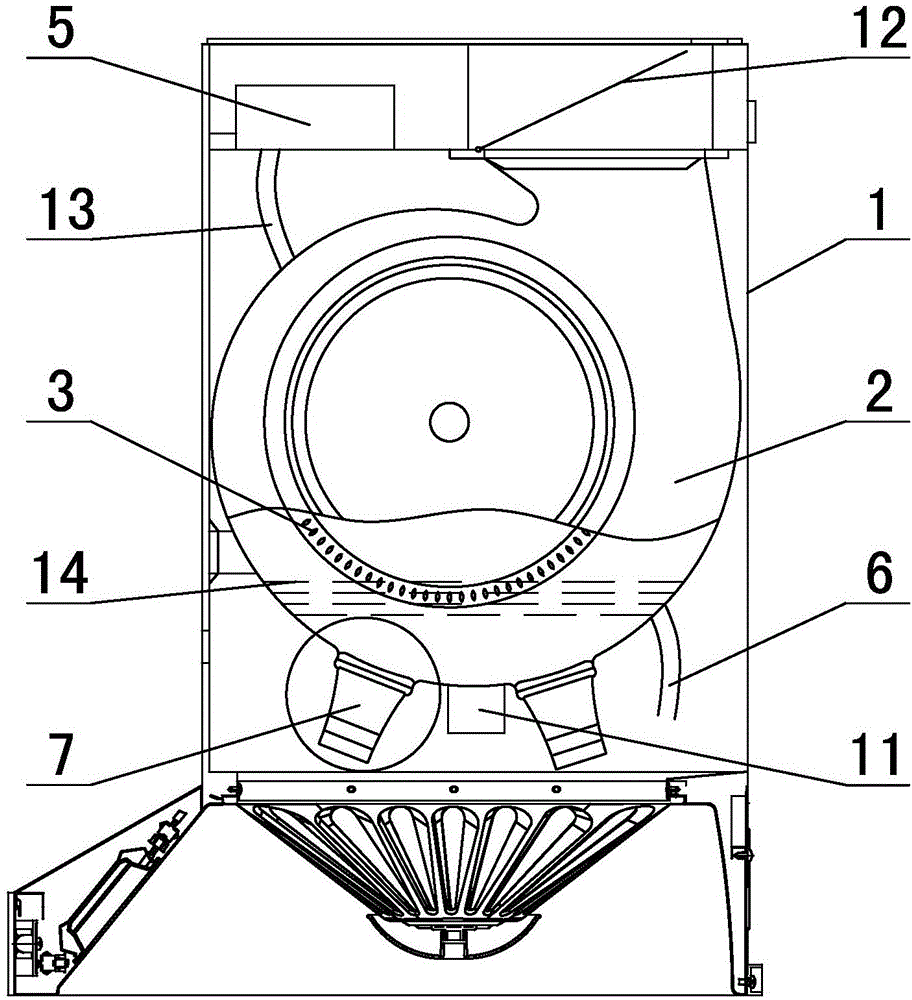

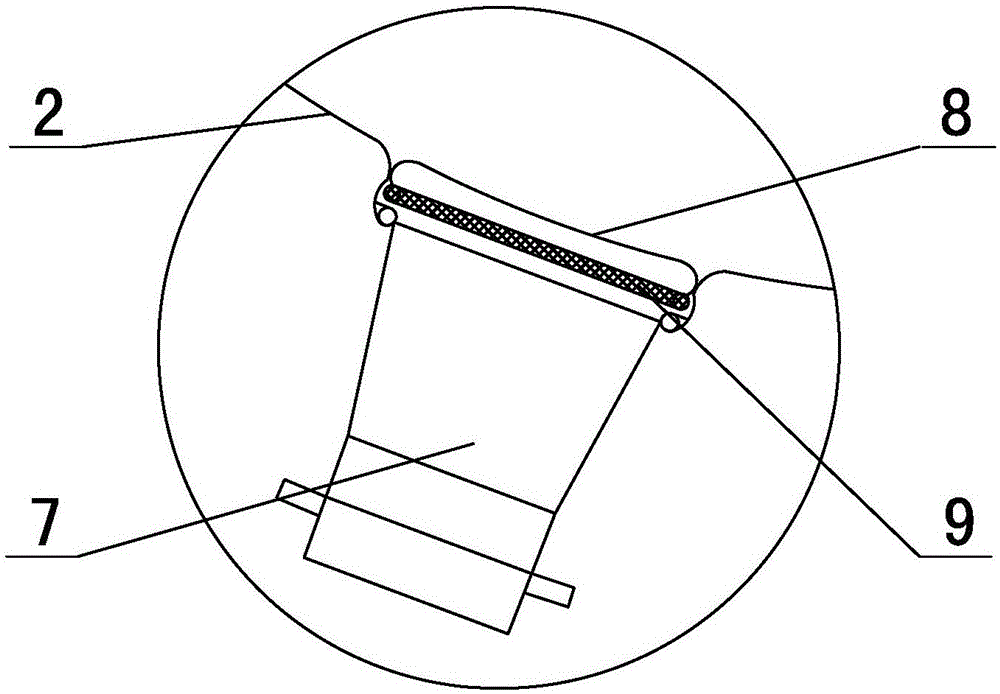

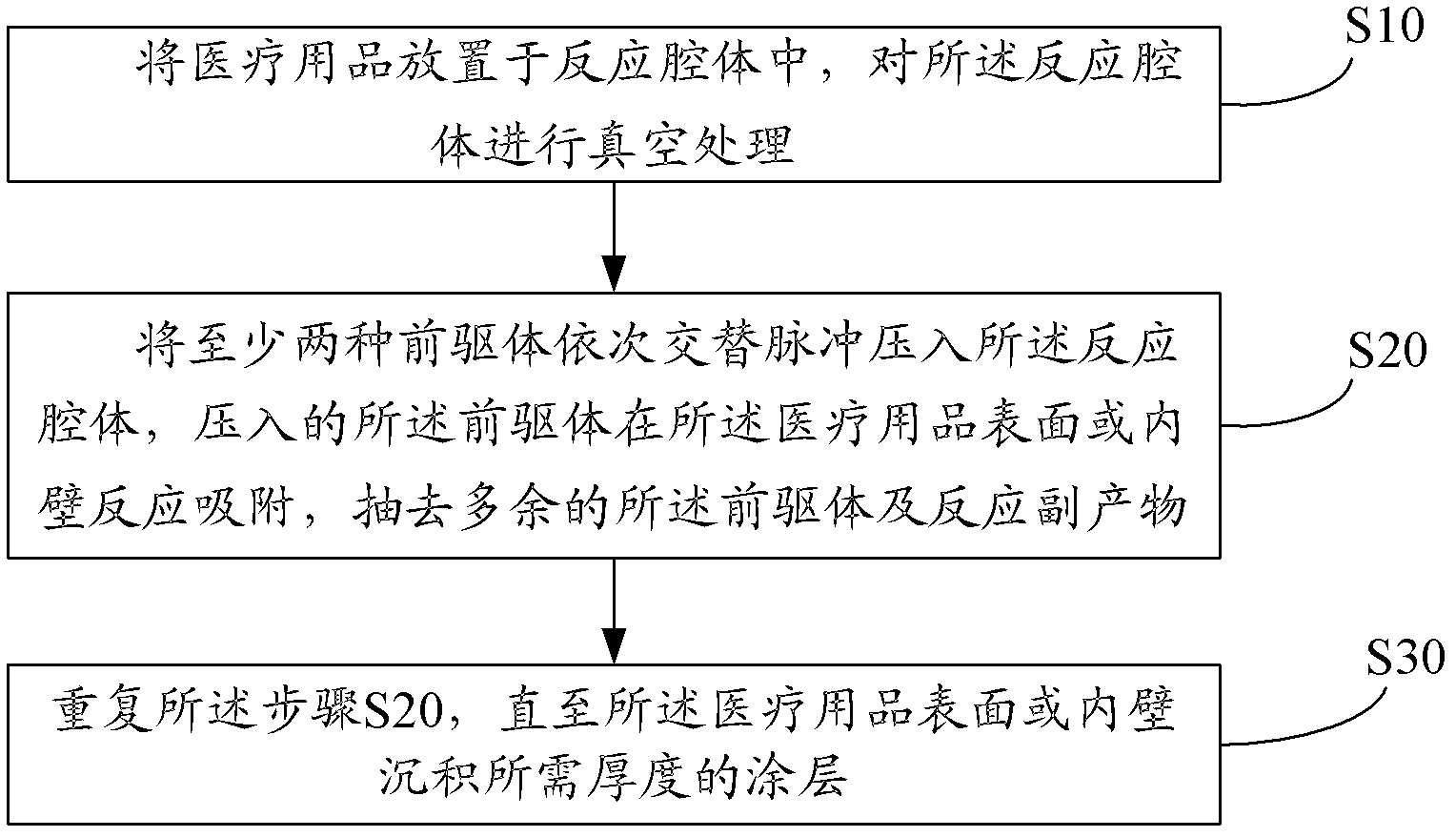

Preparation method for coatings of medical supplies and products thereof

InactiveCN103132045AUniform thicknessGood coating effectChemical vapor deposition coatingBiocompatibility TestingMedical treatment

The invention discloses a preparation method for coatings of medical supplies. The preparation method includes a first step of placing the medical supplies into a reaction cavity, and carrying out vacuum treatment on the reaction cavity, a second step of pressing at least two types of precursors into the reaction cavity in sequence in a pulse alternating mode, enabling the pressed precursors to carry out reaction and absorption on the surfaces or the inner walls of the medical supplies, sucking out the redundant precursors and reaction accessory substances, and a third step of repeating the second step until that coatings with needed thickness are deposited on the surfaces or the inner walls of the medical supplies. The invention further discloses the novel medical supplies manufactured through the preparation method. The preparation method can be used for preparing the coatings which are even in thickness, good in biocompatibility, antimicrobial, antiallergic, corrosion resisting, non-toxic, insulated or conductive, fully coated or partially coated, and smooth on the surfaces or the inner walls of any kinds of medical supplies.

Owner:英作纳米科技(北京)有限公司

Low-rosin cleaning-free scaling powder for tin-lead soldering paste and preparation method thereof

InactiveCN101085497ASolve cleaningSolve strong corrosiveWelding/cutting media/materialsSoldering mediaSolventChemistry

The invention relates to the colophonium and water free soldering flux is made of 5%-10% active agent, 12%-7% film forming matter, 0.1%-1% surface active agent, 0.1%-1% anti-oxidant and solution agent. It is simple in process, extensive in material resource, and low in cost. It is cleaning free, little in residue, and environment friendly.

Owner:XIAN UNIV OF TECH

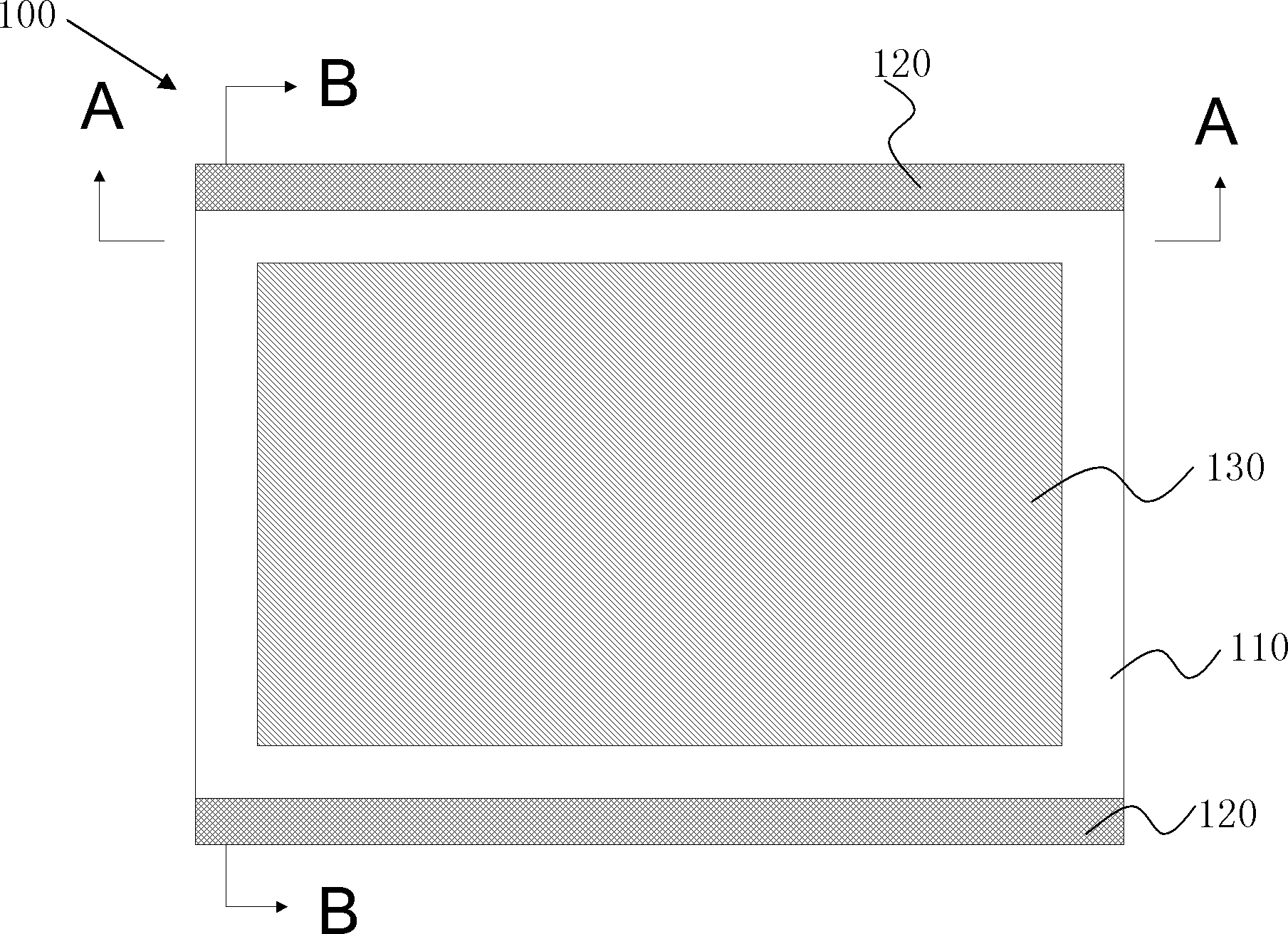

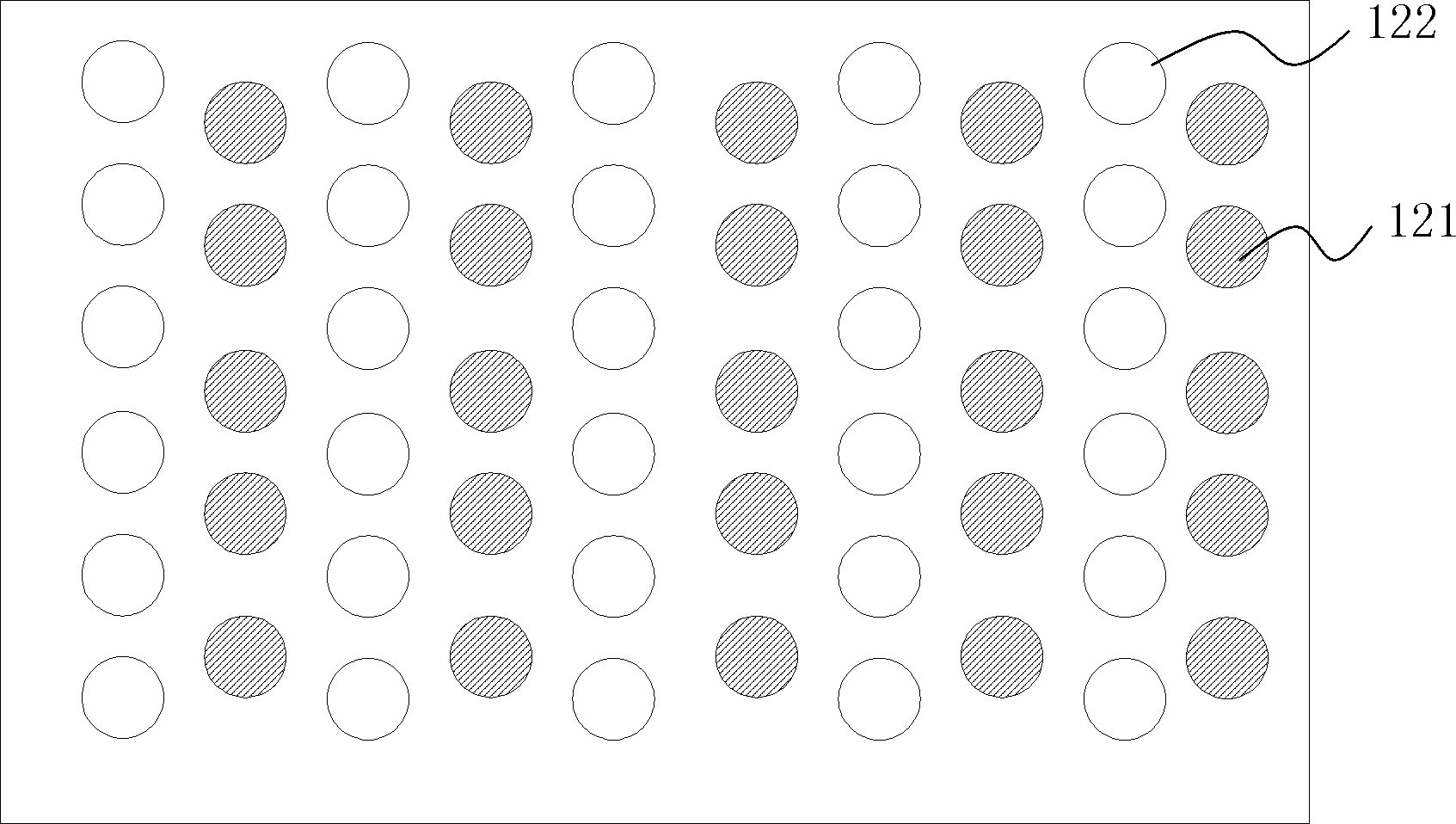

Cleaning device and cleaning method of glass substrate

InactiveCN102489470ALow costEasy to cleanFlexible article cleaningCleaning using liquidsMegasonic cleaningEngineering

The invention relates to a cleaning device and a cleaning method of a glass substrate. The cleaning device of the glass substrate, provided by the invention, comprises a cleaning groove, a first frequency generator used for sending ultrasonic wave with a first frequency and a second frequency generator used for sending ultrasonic wave with a second frequency, wherein the first frequency generator and the second frequency generator are arranged on the both sides of the cleaning groove. In the invention, the glass substrate is cleaned by utilizing the ultrasonic waves with different frequencies, so that the cost is reduced and the good cleaning effect is realized.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

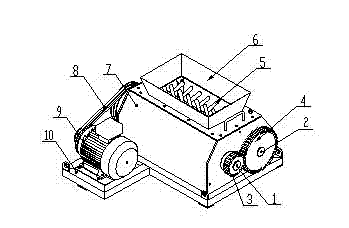

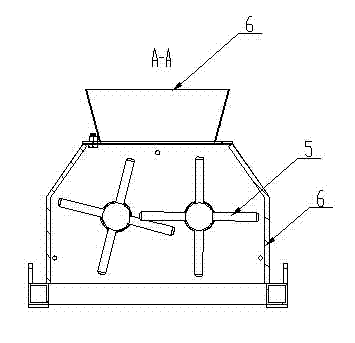

Double-shaft spike-tooth beater

The invention provides a double-shaft spike-tooth beater which comprises a rack and a machine case, a motor, a belt and two parallel shafts arranged on the rack; the two parallel shafts are arranged in the machine case; and a feed hopper and a discharge hopper are arranged on the rack. The beater is characterized that the two parallel driving and driven shafts are respectively provided with spike teeth and a pair of mutually engaged and connected driving and driven gears; the number of the teeth of the driving gear is less than that of the driven gear, and the motor is driven by the belt to connect with the driving shaft. The spike teeth on the driving and driven shafts are uniformly distributed, and the spike teeth on the two shafts are interlaced to keep certain distances. The beater is reasonable and simple in structure, easy to produce and manufacture, convenient in use and good in effect, and solves the problem that the fruit and vegetable skins are hard to be uniformly beaten before being washed and dried; with the transmission of the gears, double-shaft reversing, differential and alternative beating driven by one motor is realized, therefore, the beater has good security and lower cost, and can be operated conveniently and further can uniformly beat the fruit and vegetable.

Owner:扬州福尔喜果蔬汁机械有限公司

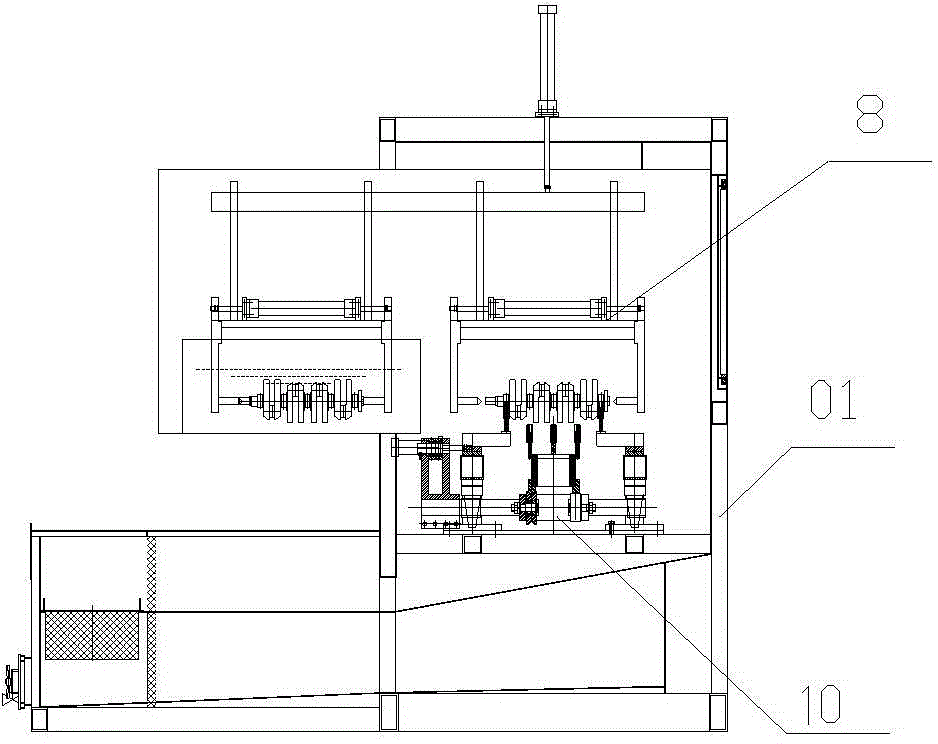

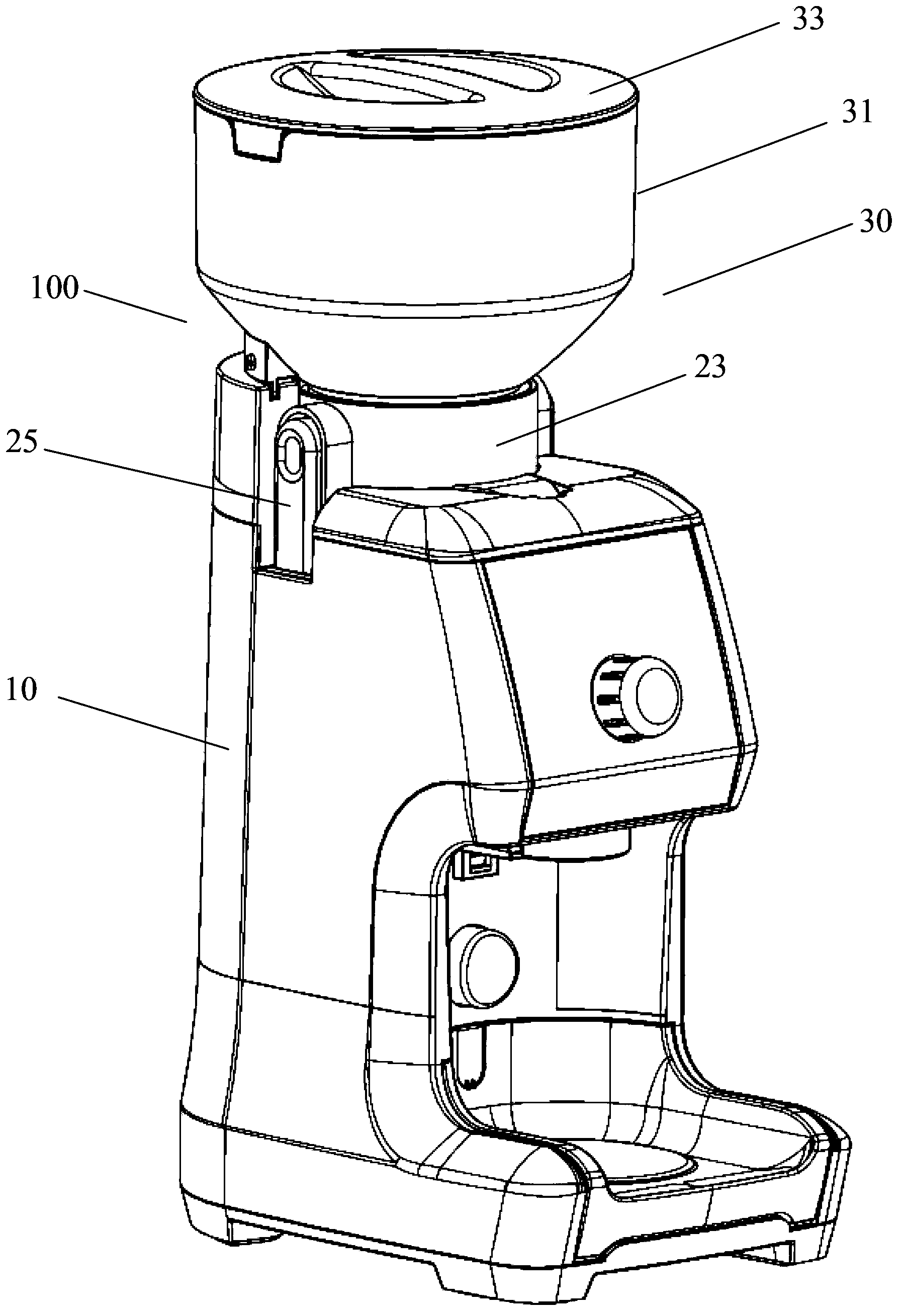

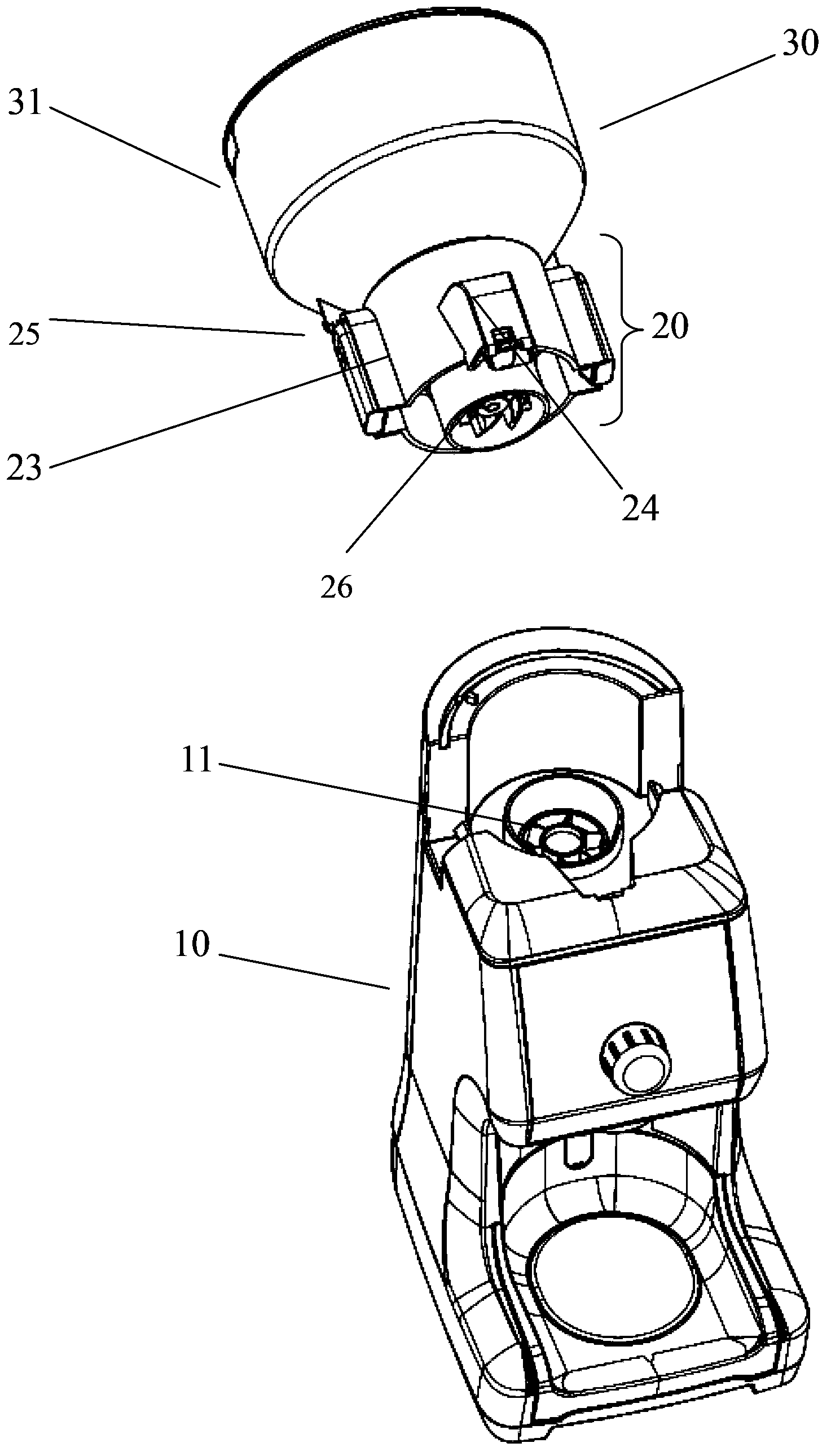

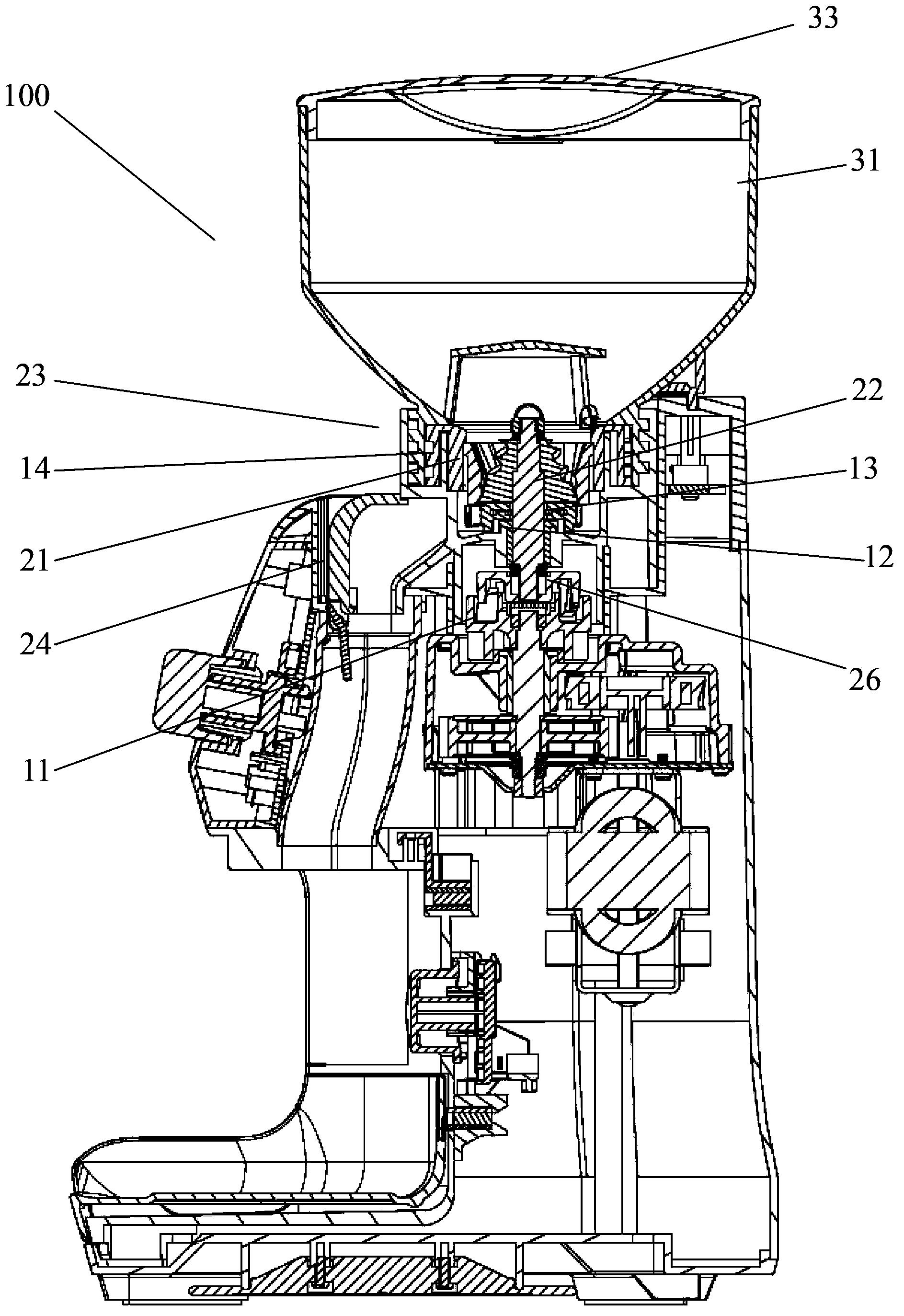

Coffee bean grinding machine

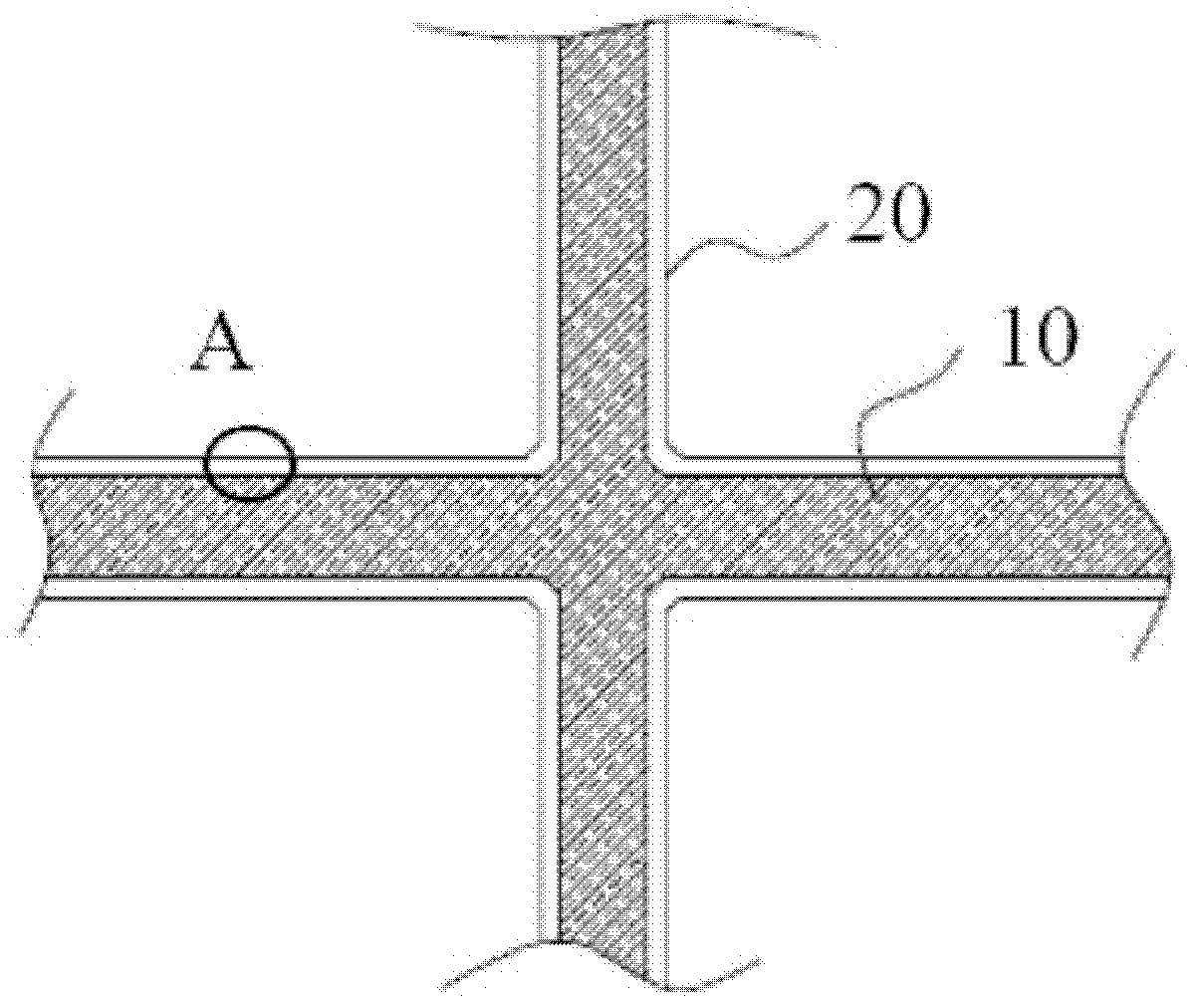

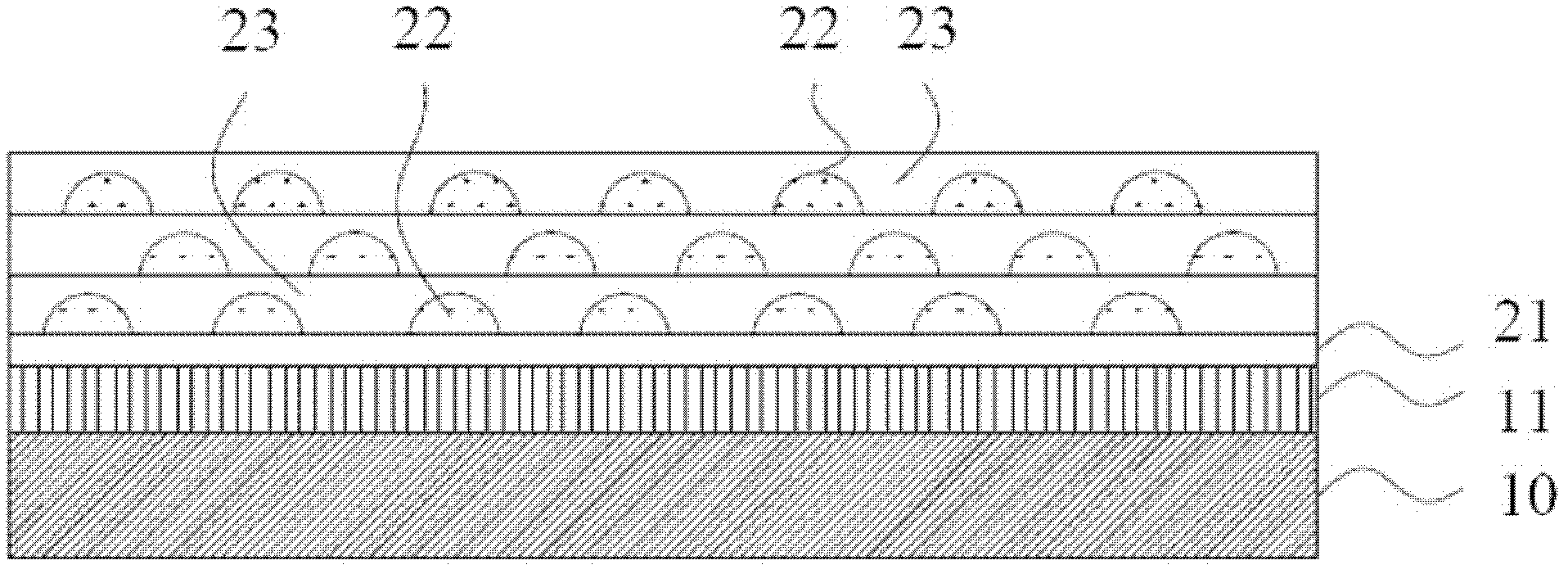

The invention relates to a coffee bean grinding machine. The coffee bean grinding machine comprises a main body (10) driven by a motor, a detachable grinding head assembly (20) arranged at the top of the main body (10), and a hopper device (30) arranged at the top of the detachable grinding head assembly (20), wherein the detachable grinding head assembly (20) comprises grinding heads (21, 22), a locking unit (25) and a coupling (26), the top of the main body (10) is provided with a motor connector (11), and the hopper device (30) comprises a hopper (31) and a hopper cover (33). According to the coffee bean grinding machine, the pair of grinding heads of the detachable grinding head assembly can well grind coffee beans and effectively solves the defects such as blocking and cleaning difficulty; an open-close assembly is used for avoiding spilling of coffee powder; the locking unit is used for locking the position of the grinding head assembly to improving the grinding quality during the grinding process and reduce any form of vibration.

Owner:SUNPOWER ELECTRICAL SHENZHEN +1

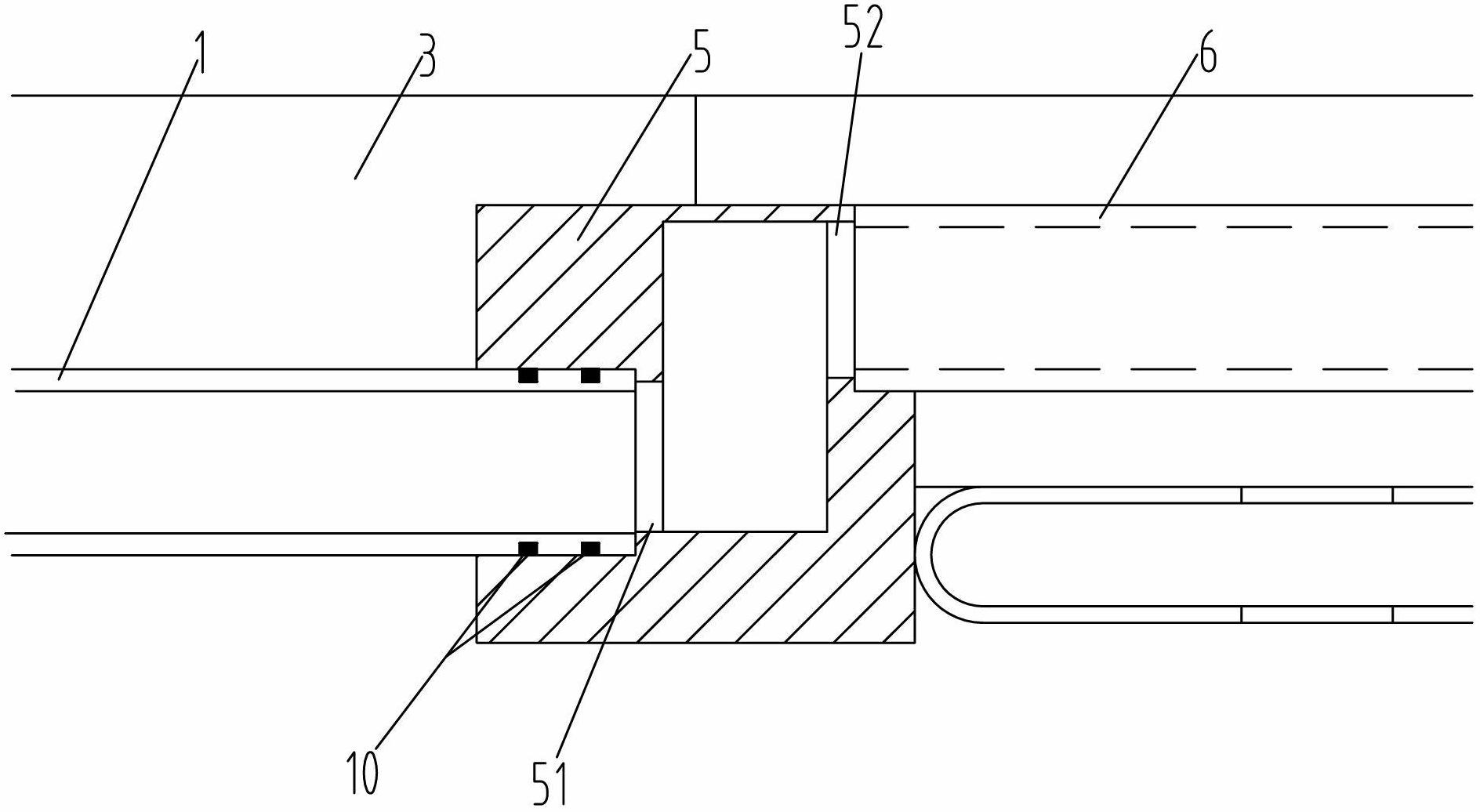

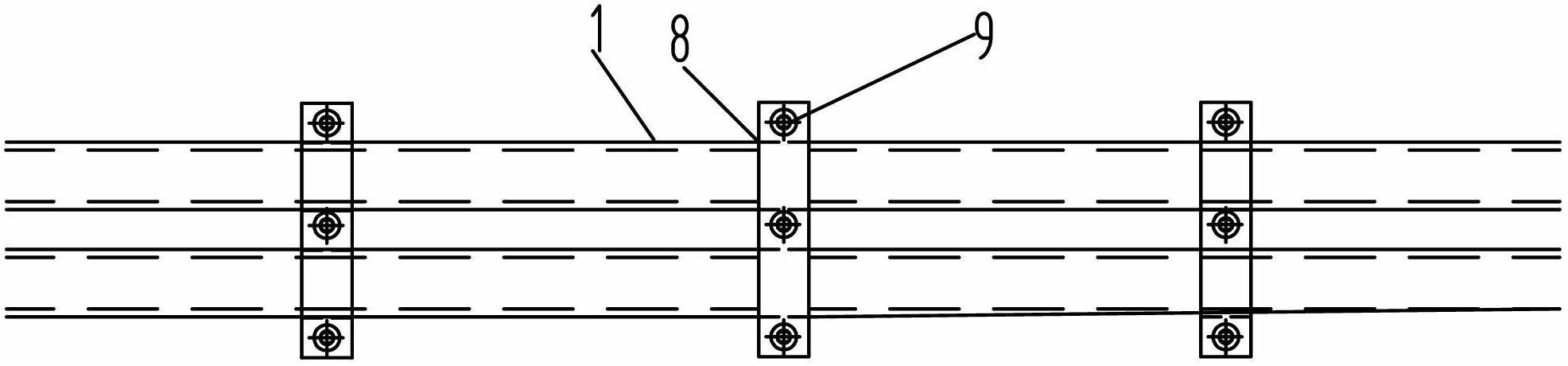

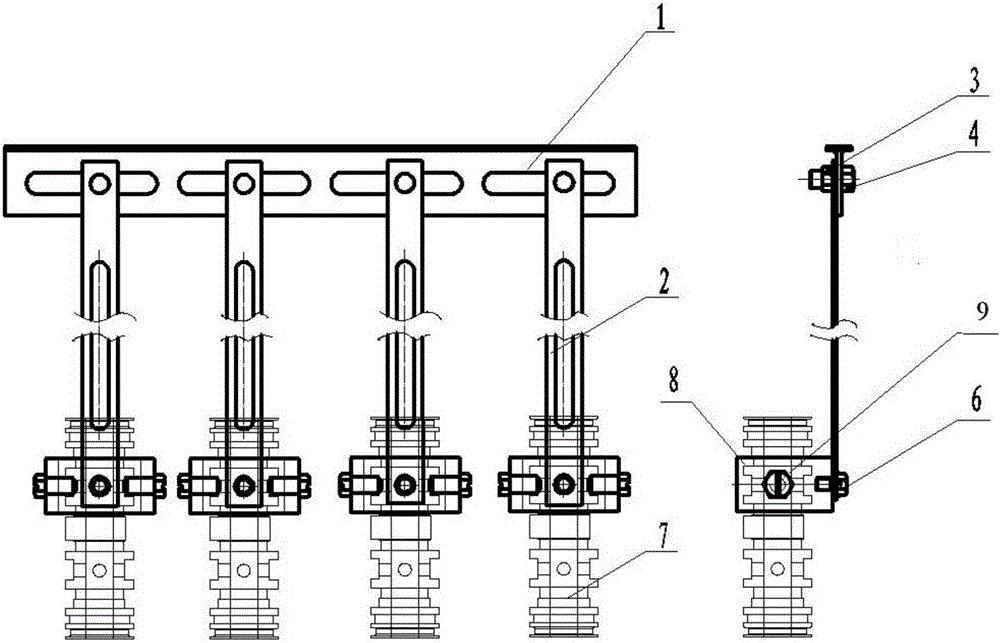

Shield machine synchronous grouting pipeline system and shield machine with same

ActiveCN102661155ASolve cleaningSolve problems such as inconvenient replacementUnderground chambersTunnel liningTunnel engineeringShield machine

The invention discloses a shield machine synchronous grouting pipeline system and a shield machine with the same, belonging to the technical field of tunnel engineering. The system comprises multiple grouting pipelines; each grouting pipeline comprises a first grouting pipe, a gate valve, a fixing structure, a transition block and a second grouting pipe; the gate valve is detachably connected with one end of the first grouting pipe; the first grouting pipe is detachably mounted on the inner wall of the shield tail through the fixing structure; the transition block is arranged on the inner wall of the shield tail; a first connection hole and a second connection hole are arranged at the two ends of the transition block respectively and communicated with each other; the other end of the first grouting pipe is detachably connected with the first connection hole; one end of the second grouting pipe is connected with the second connection hole; and the other end of the second grouting pipe is communicated with a gap at the shield tail. According to the invention, since the first grouting pipe is detachably mounted on the inner wall of the shield tail through the fixing structure, the first grouting pipe can be independently dismantled for cleaning or replacement, the maintenance time of the grouting pipeline system is shortened, and the construction efficiency is improved.

Owner:WUHAN MARINE MACHINERY PLANT

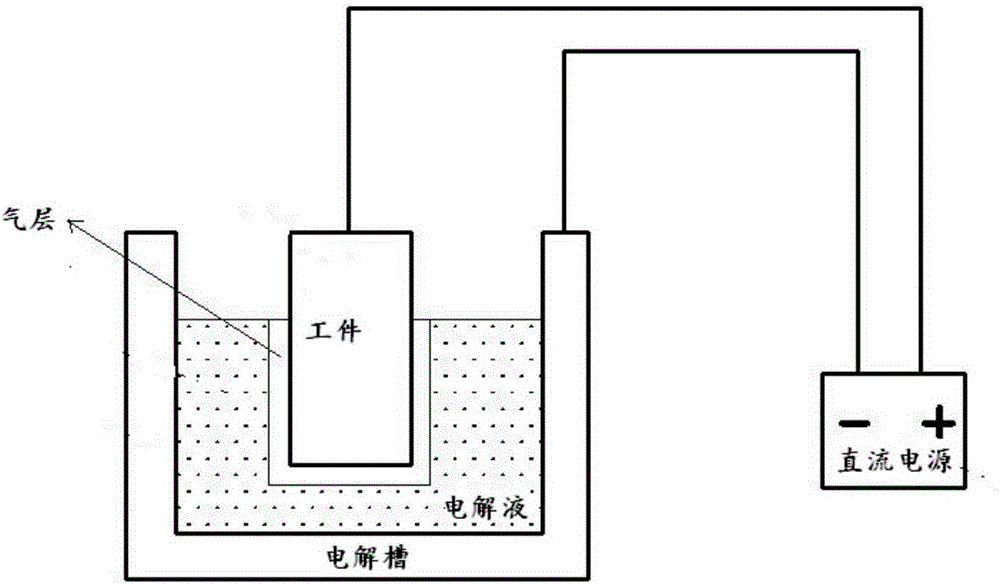

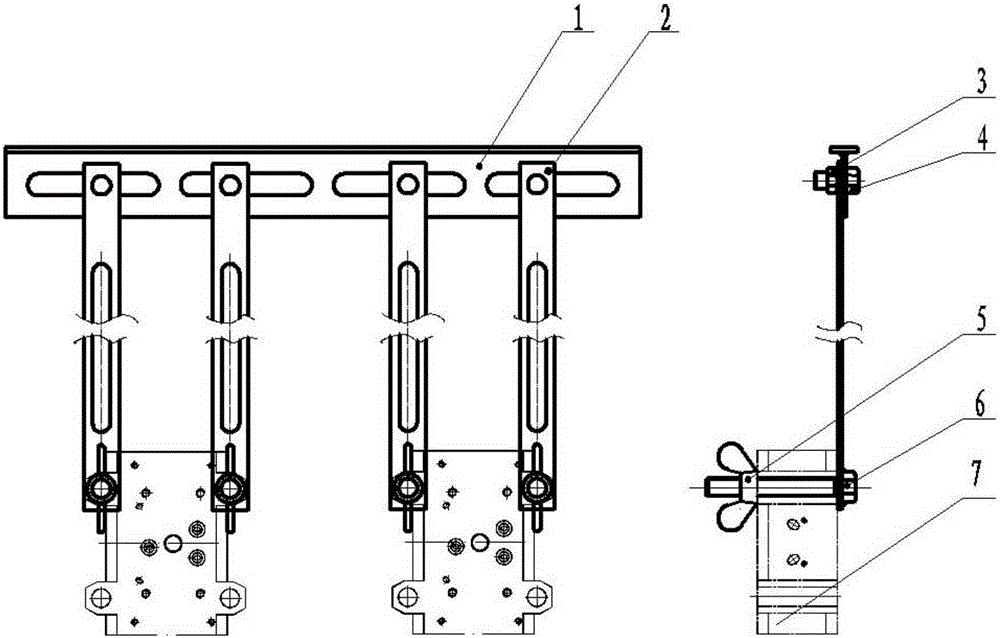

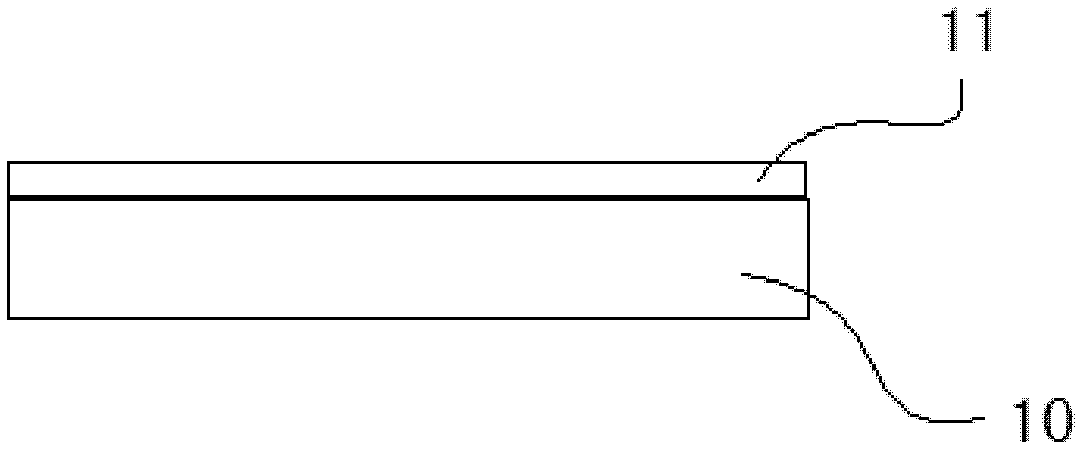

Electrolyte-plasma polishing technique for stainless steel precise structural part

InactiveCN105220218AImprove the finishSolve the existence of tiny glitchesDirect currentAmmonium sulfate

The invention discloses an electrolyte-plasma polishing technique for a stainless steel precise structural part. The electrolyte-plasma polishing technique for the stainless steel precise structural part comprises the following steps that (1) 0.01-0.03 mm technological allowance is set before the stainless steel precise structural part is polished; (2) the stainless steel precise structural part is installed on a special polishing tool, the tool comprises an insertion plate and steel sheets, a plurality of sliding grooves are formed in the insertion plate, one steel sheet is installed in each sliding groove, the steel sheets can slide horizontally along the sliding grooves, the structural part to be polished is fixedly arranged at the lower ends of the steel sheets, the clamping surface of the tool makes close contact with the surface of the structural part, and ablation of the surface of the part caused by abnormal discharging is prevented; (3) ammonium sulfate polishing liquid with the concentration being 2%-4% is added into an electrolytic bath, and the temperature of the polishing liquid is controlled between 80 DEG C and 95 DEG C; and (4) the structural part which is clamped through the tool in the step (2) is placed in the polishing liquid in the step (3), and polishing is conducted through direct currents for 2-10 min.

Owner:北京实验工厂有限责任公司 +1

Composite titanium dioxide photocatalyst sol coating material component and coating method thereof

InactiveCN102653639AImprove hydrophilic propertiesImprove hydrophilicityPretreated surfacesCoatingsWater wetRoom temperature

The invention discloses a composite titanium dioxide photocatalyst sol coating material component which is good in water-wet behavior in case of no light lay irritation or insufficient light lay irritation and a coating method of the composite titanium dioxide photocatalyst sol coating material component, aiming at improving the water-wet behavior of the titanium dioxide photocatalyst in case of no light lay irritation or insufficient light lay irritation, wherein the coating material which is formed by proportioning titanium dioxide photocatalyst sol and hydroxyl-containing porous metal oxide sol in proper proportion is coated on the surface of a base material, and a layer of functional coating layer is formed on the surface of the base material after the coating layer is dried at normal temperature and solidified in a heating way. Under the condition of sufficient light lay irritation, the coating layer has the chemical decomposition or degradation characteristic of the titanium dioxide photocatalyst, can decompose or degrade the organic pollutant adhered to the surface face of the base material, and further has the physical hydrophilic soil release. The coating layer is good in the water-wet behavior in case of no light lay irritation or insufficient light lay irritation, so that the dirt on the surface can be easily washed to be removed by the means that the base material is washed by water, therefore, the cleanness of the base material can be kept.

Owner:GREENCOAT TECH

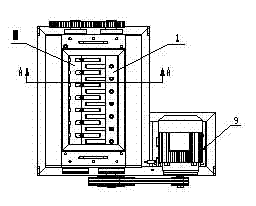

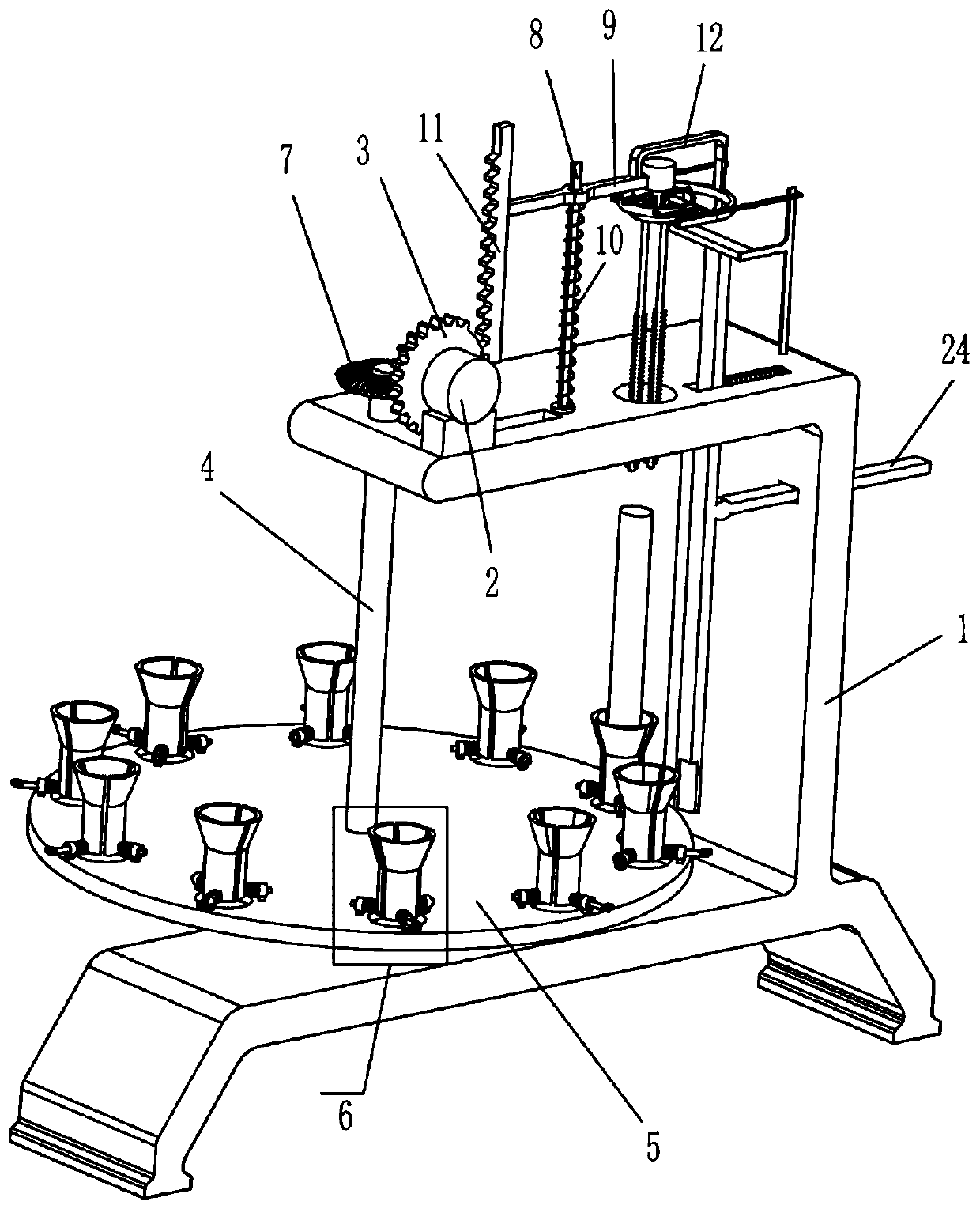

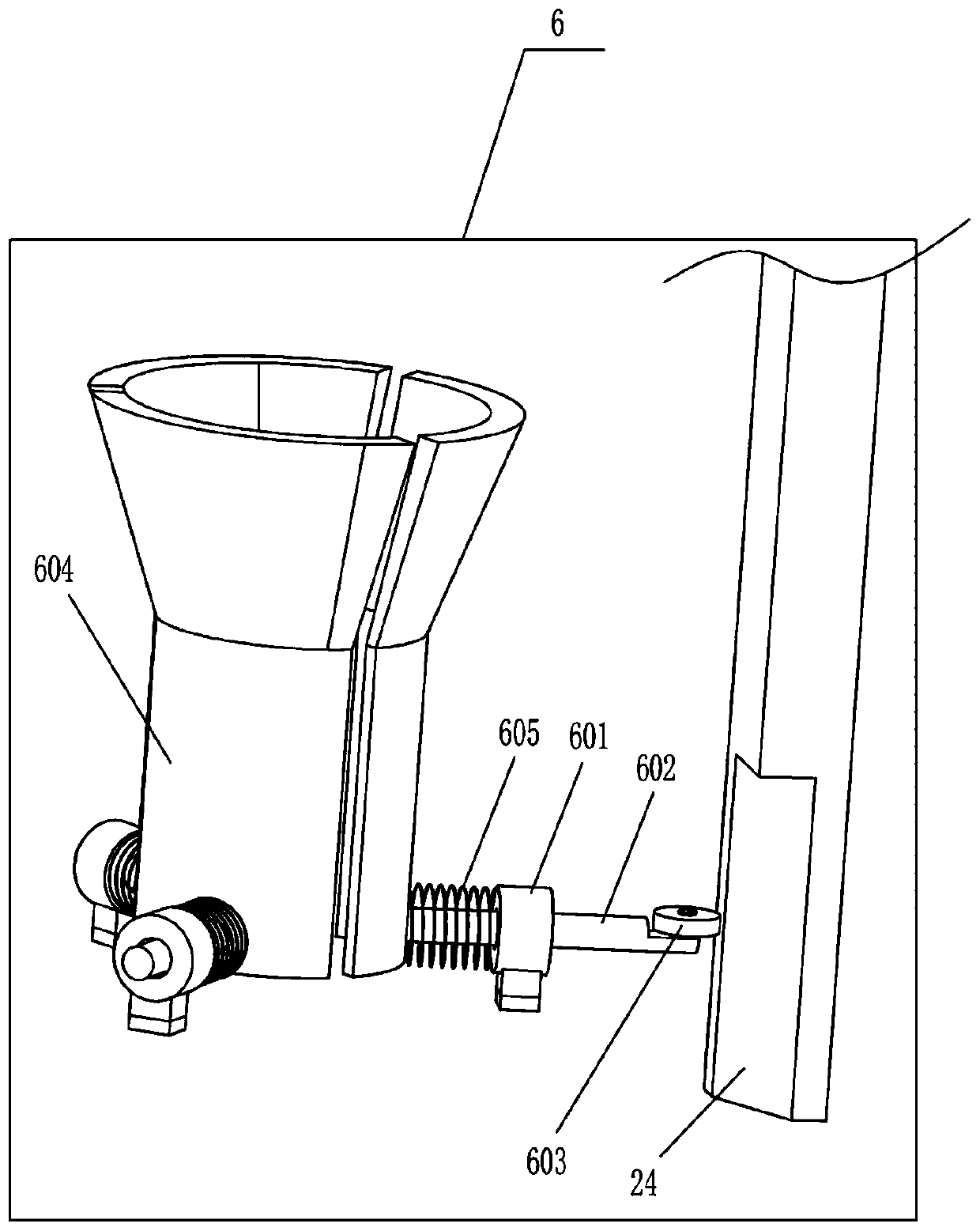

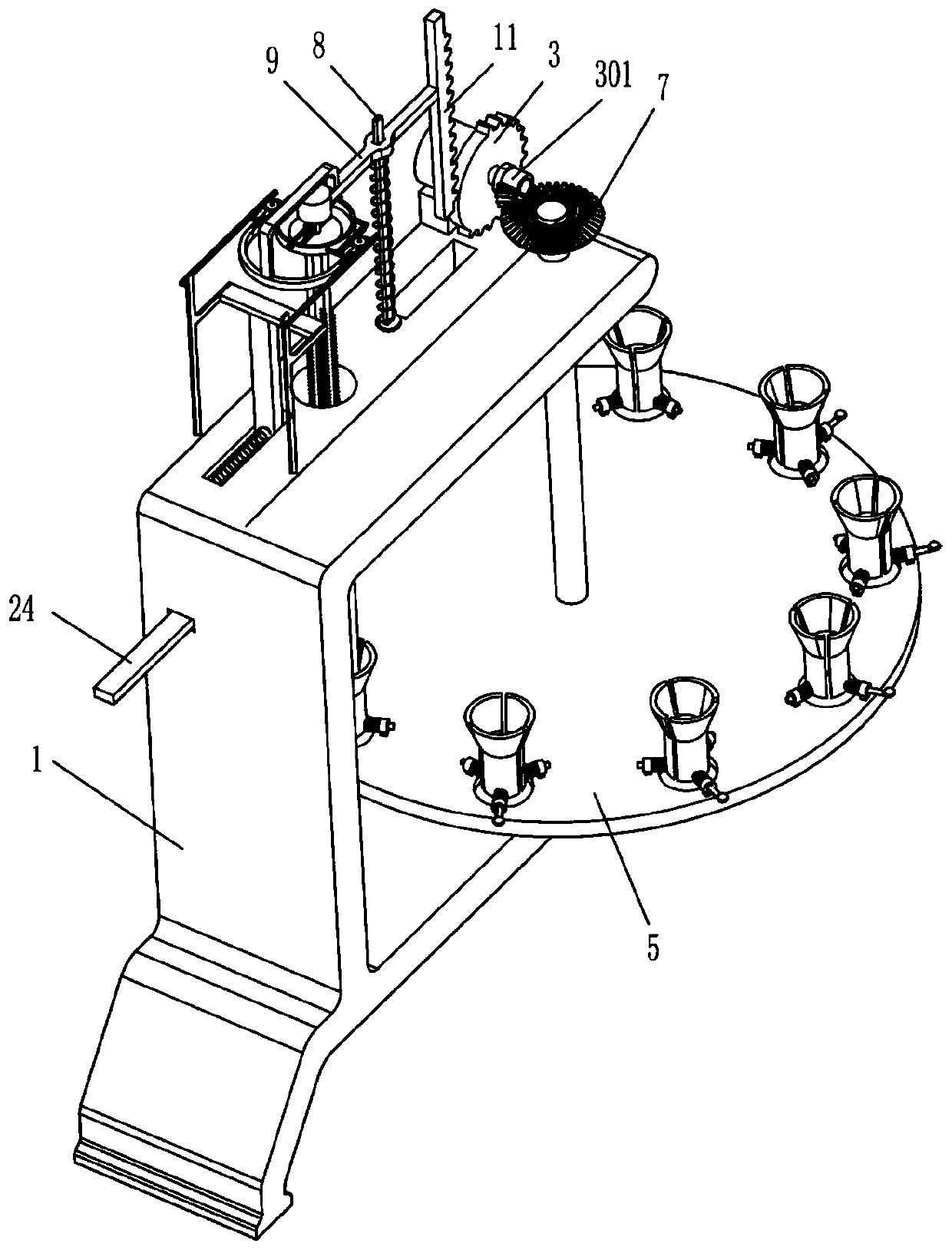

Cleaning device suitable for interiors of test tubes of different sizes

ActiveCN111451233AAchieve mechanical cleaningSolve cleaningHollow article cleaningGear wheelElectric machinery

The invention relates to the technical field of test tube cleaning, in particular to a cleaning device suitable for interiors of test tubes of different sizes. The invention aims to provide the test tube interior cleaning device which can be used for quickly and thoroughly cleaning test tubes, is high in cleaning efficiency and good in effect and can meet the cleaning requirements of the test tubes with different inner diameters. According to the technical scheme, the cleaning device suitable for the interiors of the test tubes of different sizes comprises a support, a transmission motor, a sector gear, a tooth-missing bevel gear, a rotating shaft and the like; and the transmission motor is fixedly installed on one side face of the support, the sector gear is installed on an output shaft of the transmission motor, the tooth-missing bevel gear and the sector gear are coaxially arranged, and the rotating shaft is installed on the support through a bearing and penetrates through the support. According to the cleaning device, mechanical cleaning of the test tube is achieved, and the problems that due to the fact that the test tube is too long, cleaning is inconvenient and not thoroughwhen the test tube is manually cleaned through a hairbrush are solved; and the cleaning requirements of the interiors of test tubes with different thicknesses can be met, the application range is wide, and practicability is high.

Owner:惠州帝恩科技有限公司

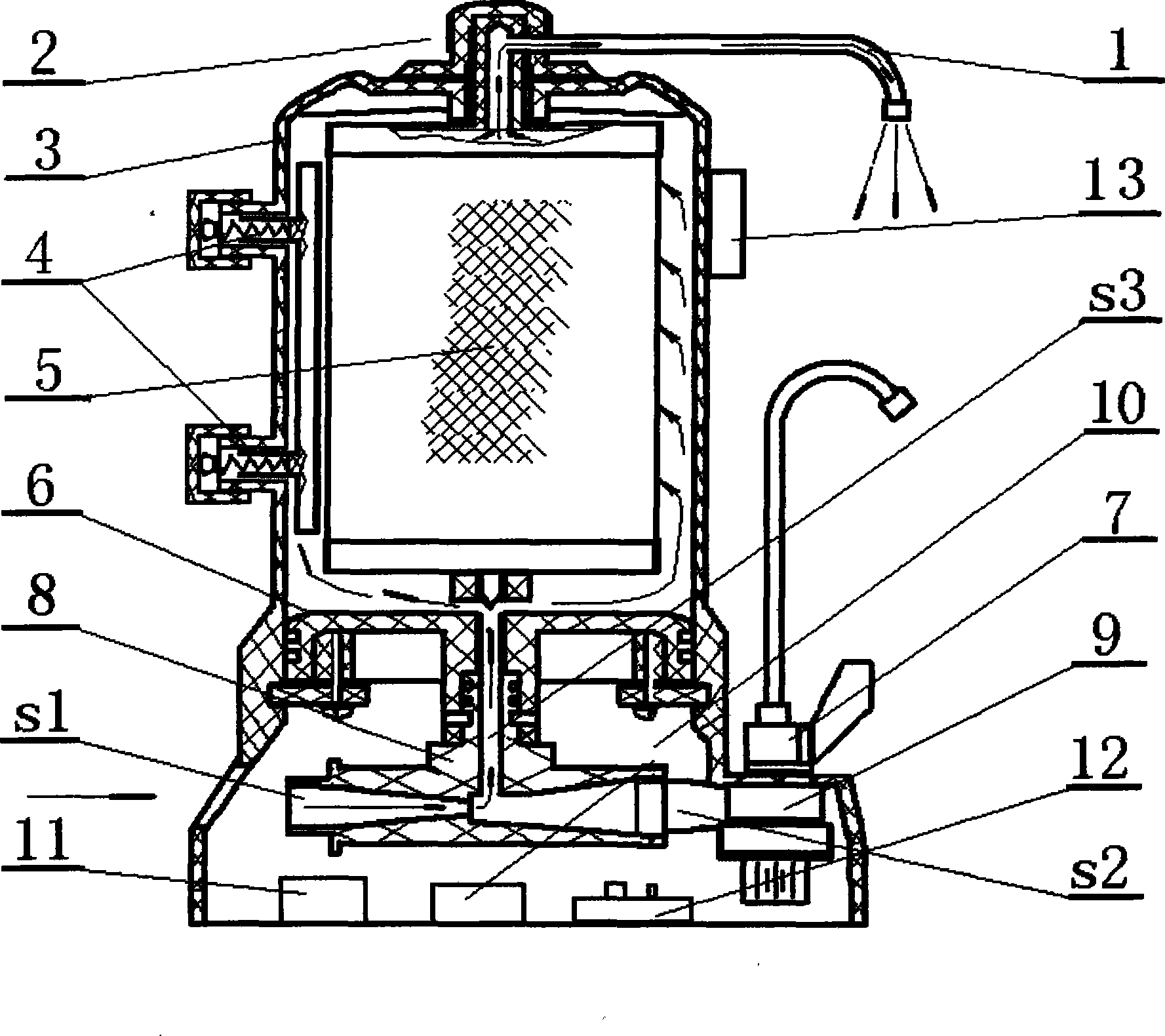

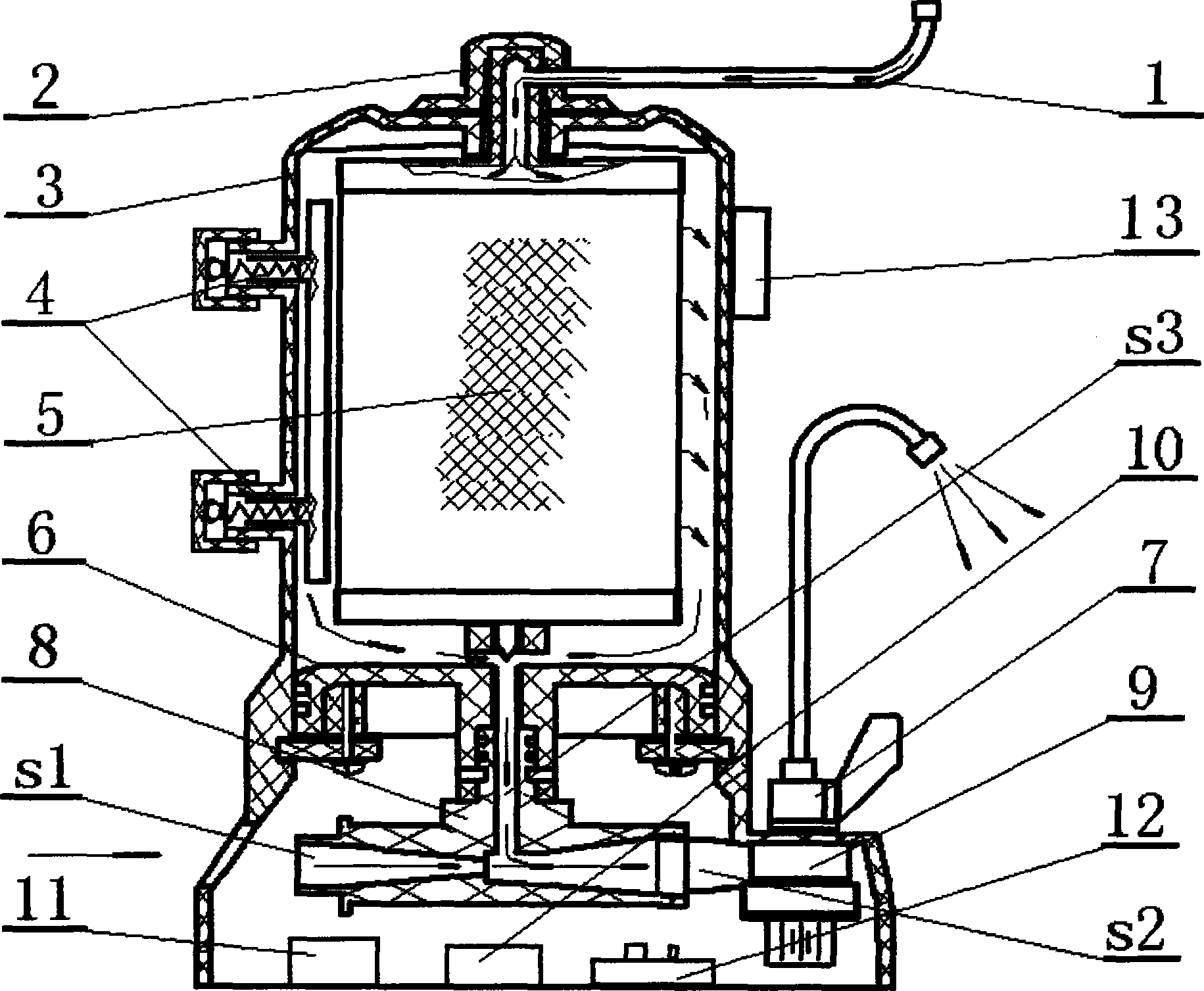

Self-generating multifunctional self-cleaning water purifier

InactiveCN101503256ASolve easy blockageSolve cleaningBatteries circuit arrangementsMultistage water/sewage treatmentOzone generatorWater wheel

The invention discloses a method of a multifunctional self-generating and self-cleaning water purifier and a device. The device comprises an outer casing, a cleaning handwheel, a cleaning brush and a support frame, a ceramic filter element, various water purifying filter materials, a lower blanking cover, an ejector, a water wheel generator, a discharge cock, a water purifying cock, a storage battery, an ozone generator and a switch, an illuminating lamp and a switch, a control circuit and an external socket. The water purifying function is achieved by adopting the ceramic filter element and the water purifying filter materials which can enable tap water to pass through the device; the self-cleaning function of normally and reversely pumping and cleaning is achieved by the ejector; the disassembly-free, the friction and the self-cleaning functions are achieved by the strip-shaped emery stick of the cleaning brush through mutually rotating the ceramic filter element; and the flow speed of water flow is improved by the ejector, so that the generator works to achieve the self-generating function, the illuminating function, the function of disinfecting the water purifier, the ozone water function and the power supply function, thereby solving the problems that the ceramic filter element carries out water purification and the self-cleaning is achieved without disassembly; and moreover, the invention has the advantages of simple structure and convenient operation and simultaneously can also achieve the multifunction.

Owner:黄光智

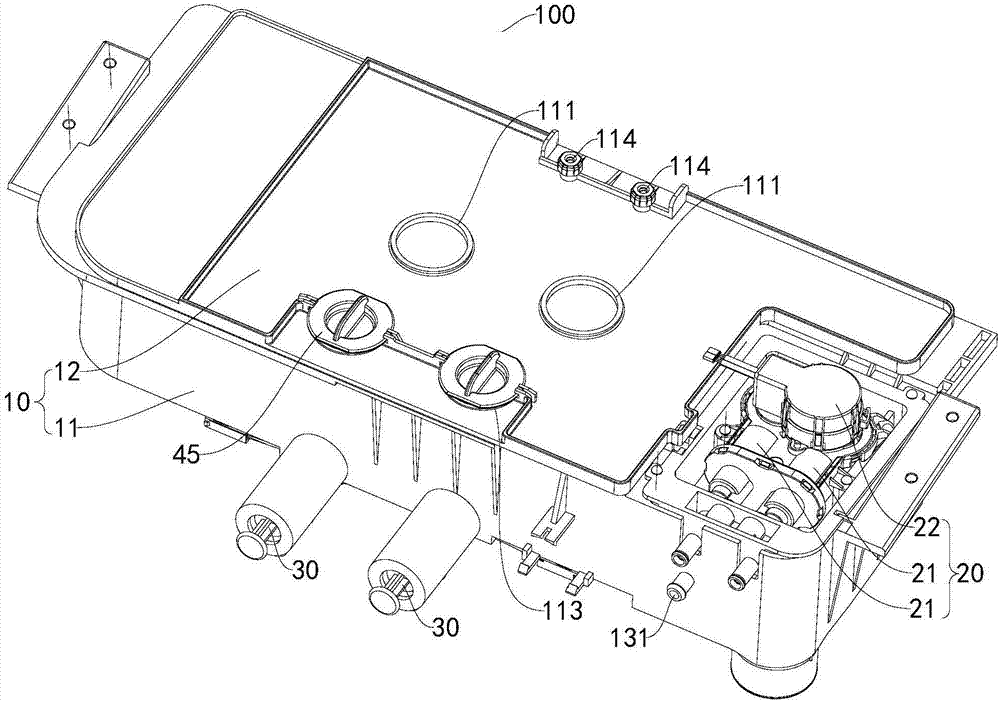

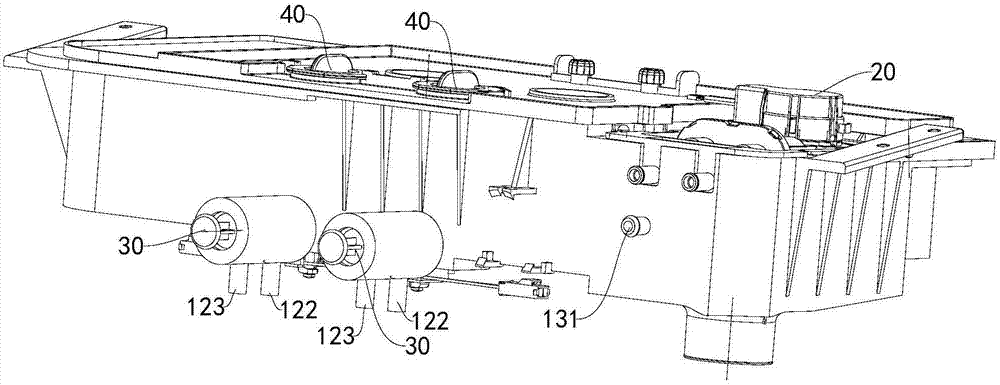

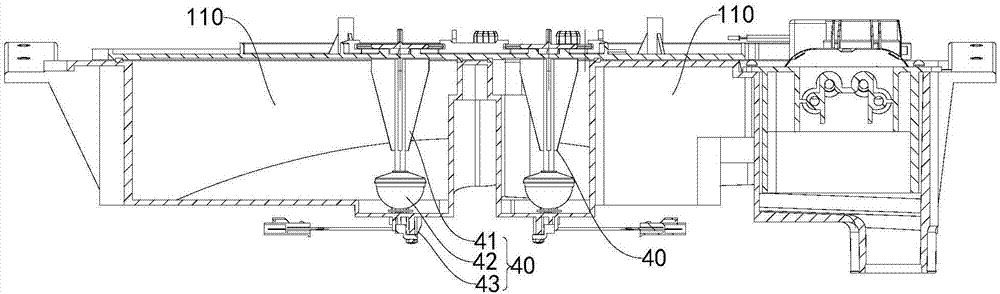

Washing equipment and releasing device used for washing equipment

ActiveCN107881712AEasy to disassemble and operateEasy to cleanTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionWater flowWaste management

The invention discloses a releasing device used for washing equipment and the washing equipment provided with the releasing device. The releasing device comprises a shell, a releasing mechanism and acleaning device, wherein an accommodation cavity and a cleaning cavity are defined in the shell, the accommodation cavity is communicated with the cleaning cavity, the releasing mechanism is communicated with the accommodation cavity and used for inputting a clothes treating agent in the accommodation cavity to a washing cavity of the washing equipment, and the cleaning device is suitable for making at least part of cleaning fluid in the cleaning cavity form impact water flow to clean the accommodation cavity. According to the releasing device, the cleaning effect is good, and the capacity islarge.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

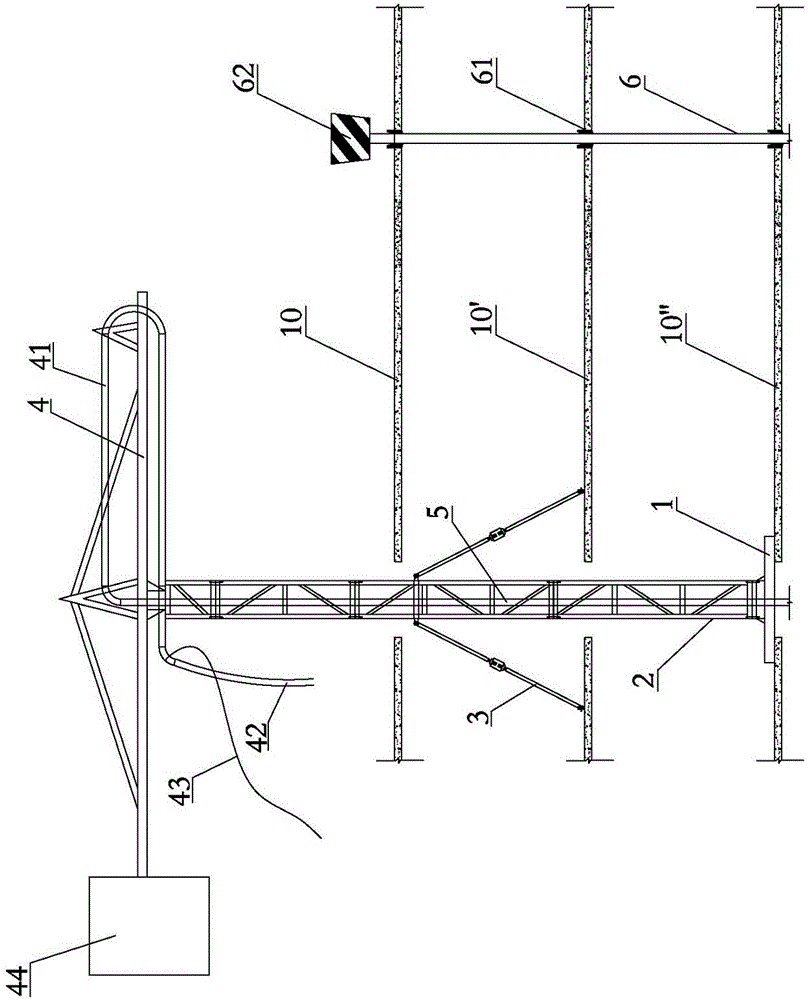

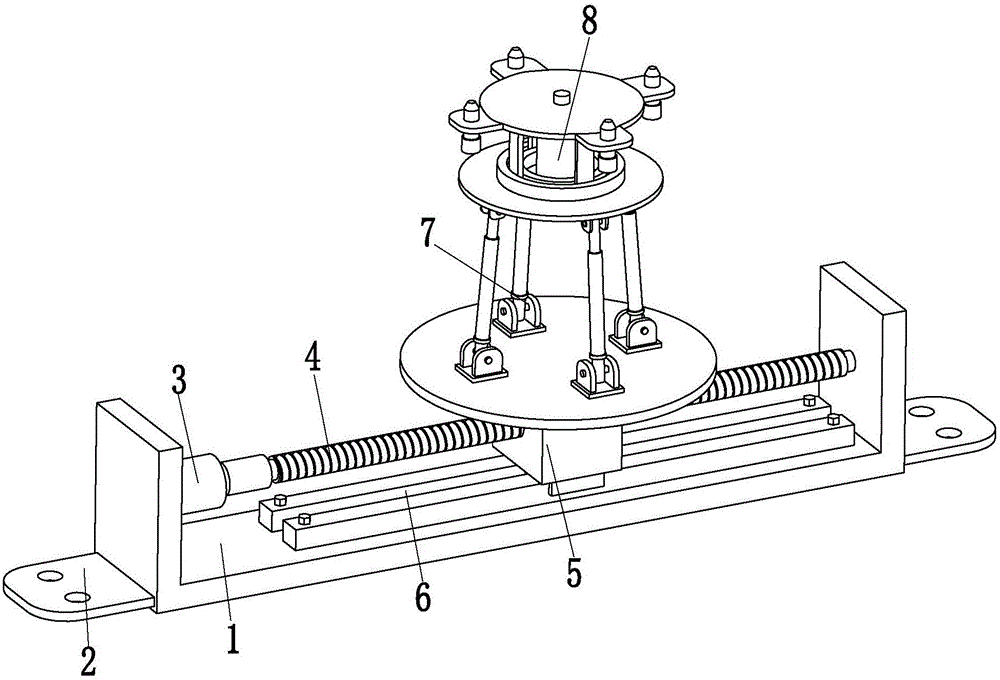

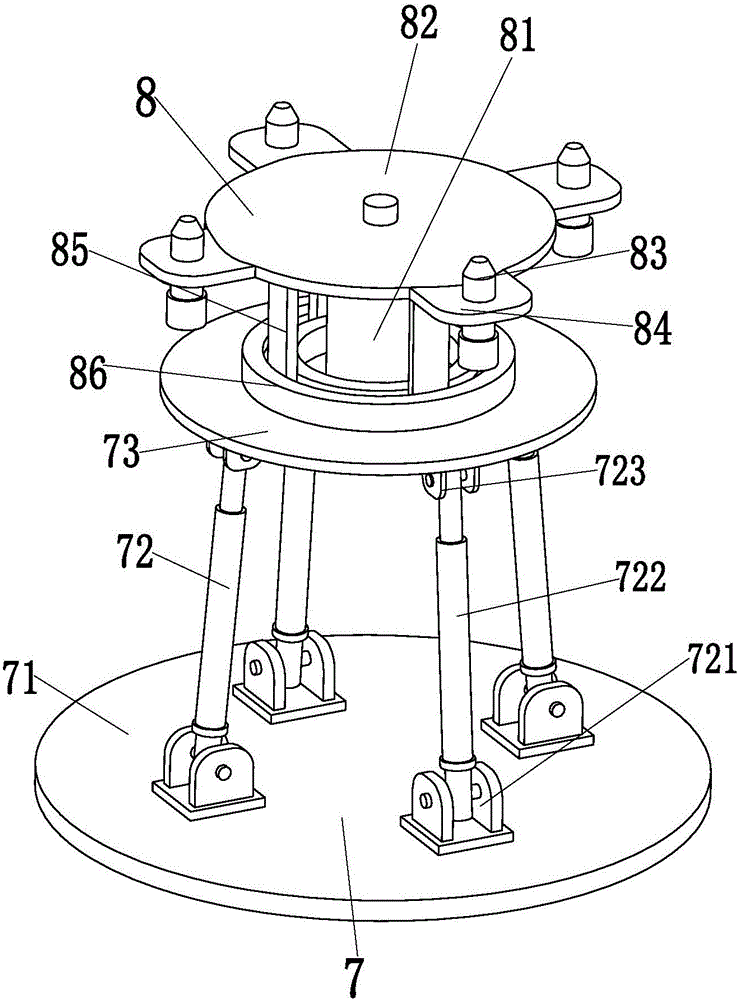

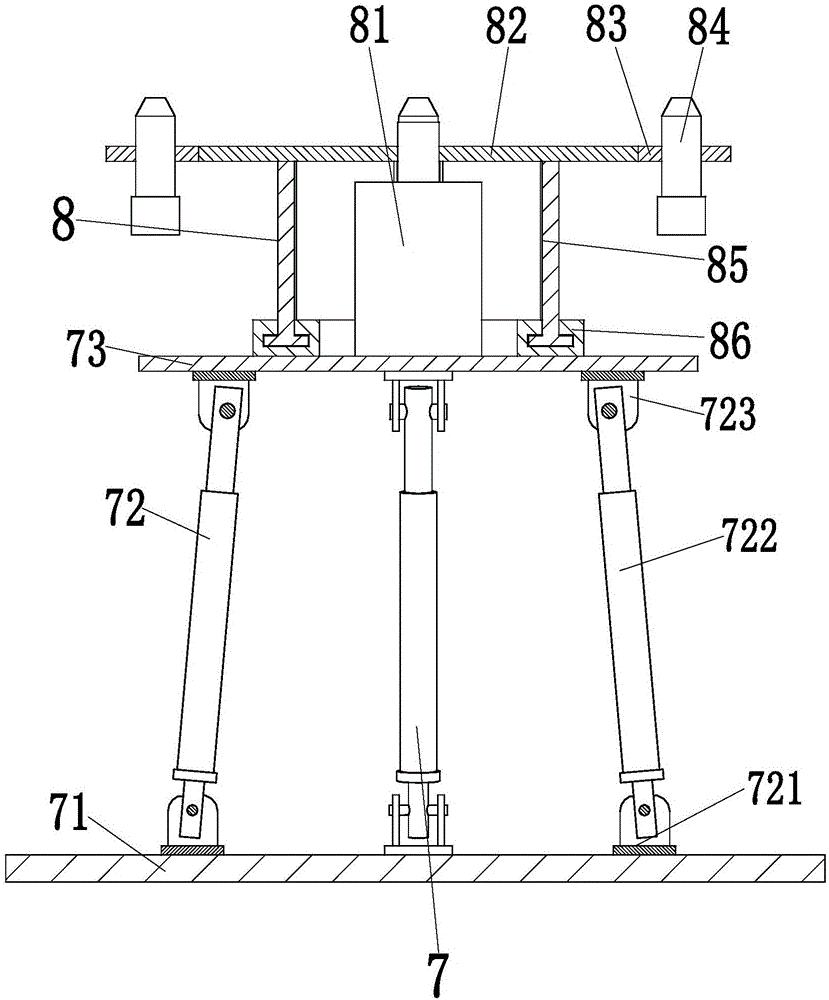

Novel material distribution device and floor concrete casting construction method of novel material distribution device

InactiveCN104975719ASolve the impact of cumbersome installation workSolve cleaningBuilding material handlingMaterial distributionRebar

The invention provides a novel material distribution device and a floor concrete casting construction method of the novel material distribution device, wherein the novel material distribution device mainly comprises a foundation section, a standard section, a material distribution rod, a pump pipe and a pump pipe loop, wherein the foundation section is fixed on the lower two layers of a construction layer; the standard section is fixed on the standard section; the standard section sequentially passes through holes reserved in the lower layer of the construction layer and the construction layer but is not in contact with the holes; the material distribution rod is fixed above the standard section; the pump pipe is connected with one end of the material distribution pipe arranged on the material distribution rod; the other end of the material distribution pipe is connected with a hose used for concrete casting; the pump pipe loop is specially used for cleaning a material distribution machine; and waste water can be directly conveyed into a collecting device arranged on the ground. The novel material distribution device and the floor concrete casting construction method of the concrete casting construction method can solve the following technical problems that the problem of damage of a conventional floor concrete cast pump pipe to floor steel bars is solved; the problem of influence of the vibration of the conventional floor concrete cast pump pipe on a formwork support frame system and a formwork system is solved; and the problems of pollution and cleaning complexity of the conventional floor concrete cast pump pipe are solved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

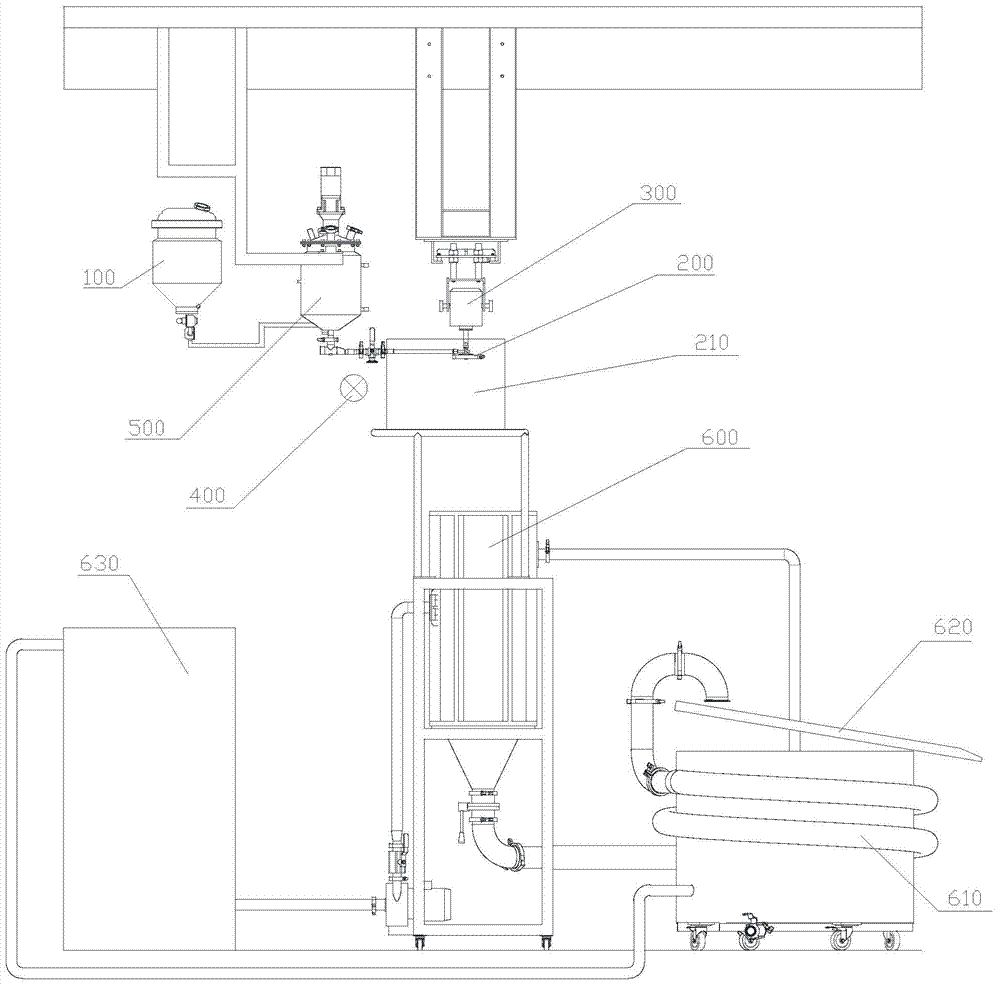

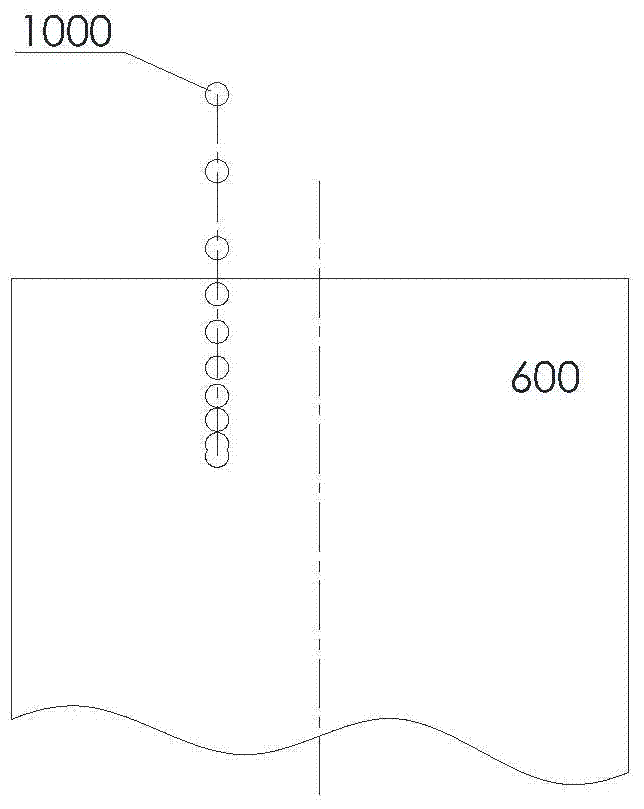

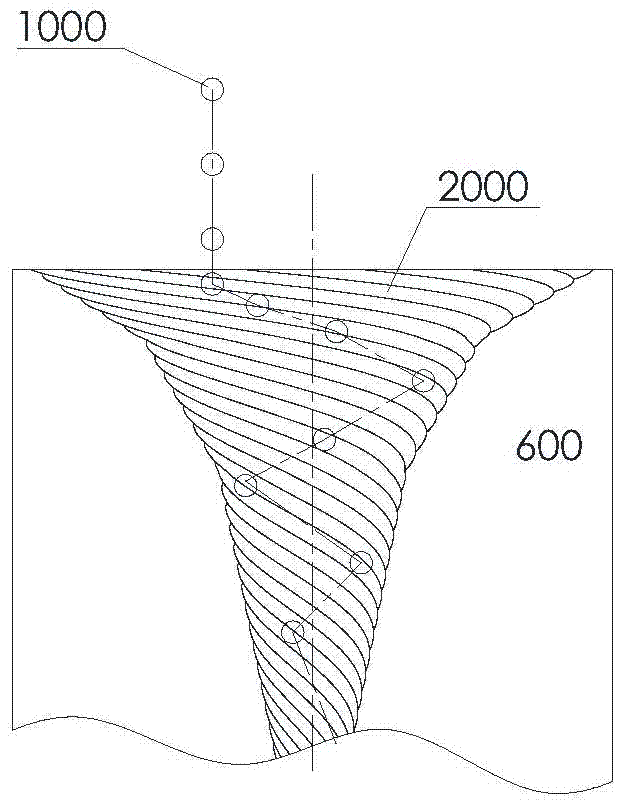

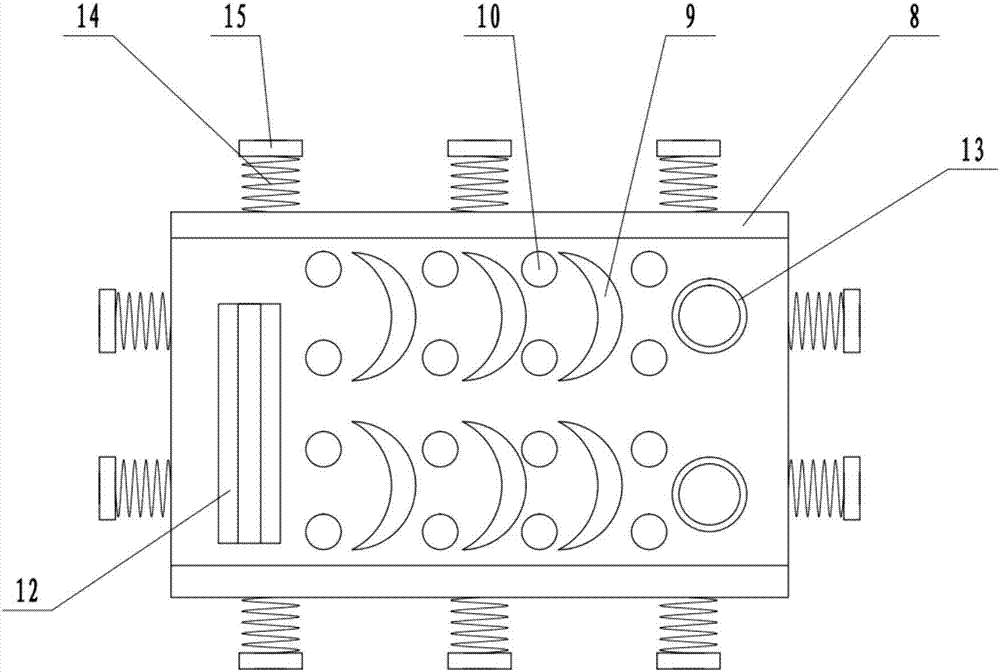

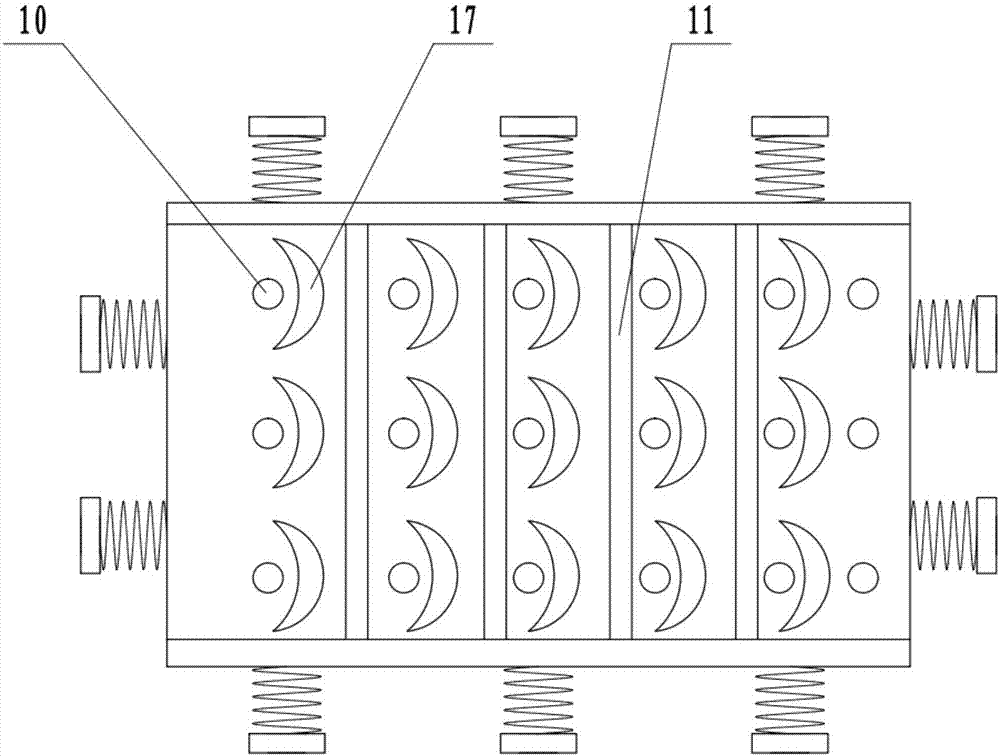

Liquid cooling dropping pill production line

InactiveCN104274327AReduce impactSmooth feedingPharmaceutical product form changeMelting tankEngineering

The invention provides a liquid cooling dropping pill production line, which comprises a dropping pill system, a liquid cooling circulation system and a control system, wherein the dropping pill system comprises a material melting tank and a dropper connected with the material melting tank, a vibration device is arranged between the material melting tank and the dropper, an on-line monitoring device is arranged on the dropper, the on-line monitoring device comprises a pulse signal emitting mechanism, the emitting frequency of the pulse signal emitting mechanism is identical to the vibration frequency of the vibration device, and the control system controls and regulates dropping parameters according to the monitoring results of the on-line monitoring device. The liquid cooling dropping pill production line has the advantages that the high-frequency cutting dropping is combined, the dropping pill quality is detected in real time on line and is controlled and regulated, the yield is improved, and the drilling pill diameter range is expanded; a plurality of tangential inlets are formed inside the tank wall of a cooling tank, and the impact force caused by cooling liquid surface on liquid drips when the liquid drips enter the cooling tank can be effectively reduced; the swarming and the pulse can be effectively eliminated, so the material conveying of a dropping pill machine is stable; the dropping pill cooling time is increased through regulating the length-to-diameter ratio of a discharging pipeline, the quality is ensured, and meanwhile, the energy consumption is reduced.

Owner:TIANJIN TASLY PHARMA CO LTD

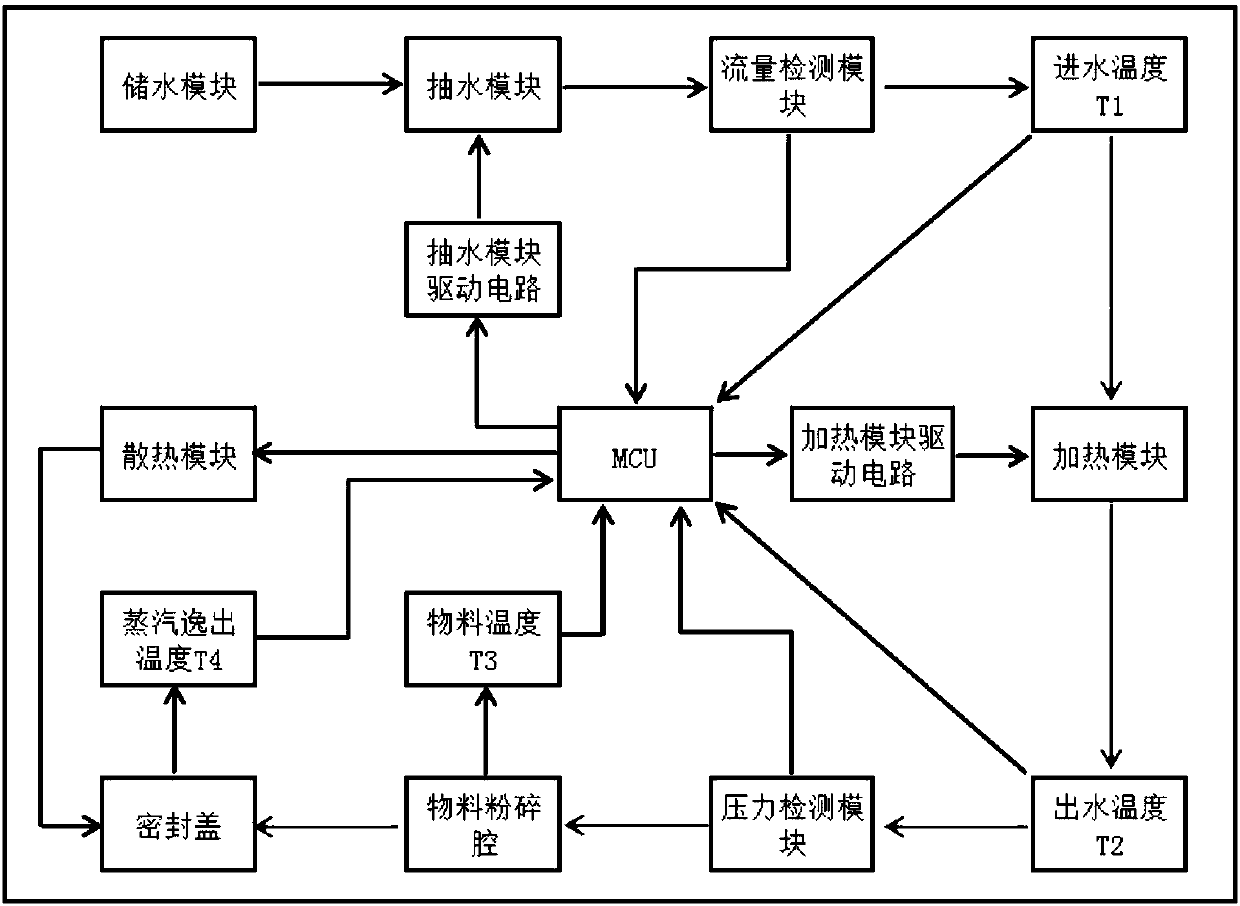

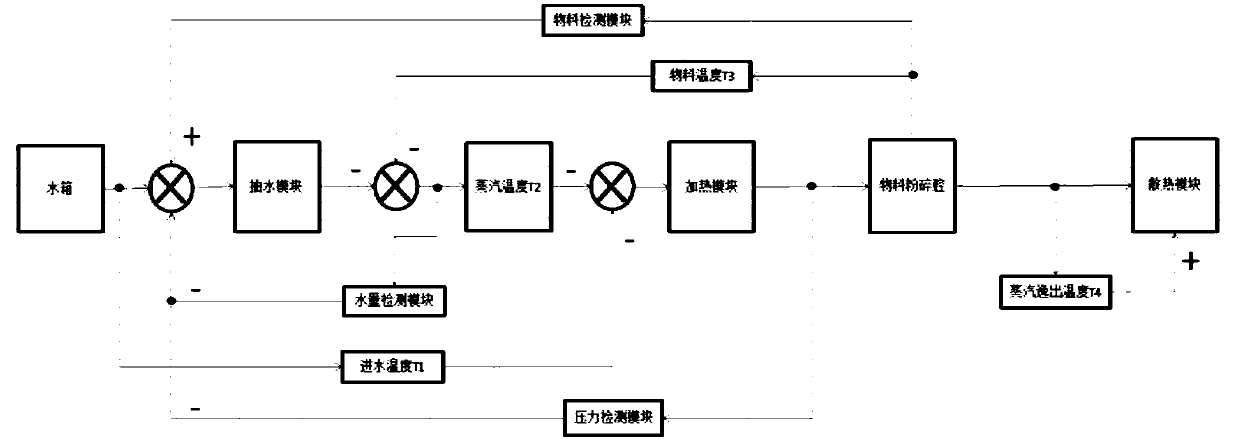

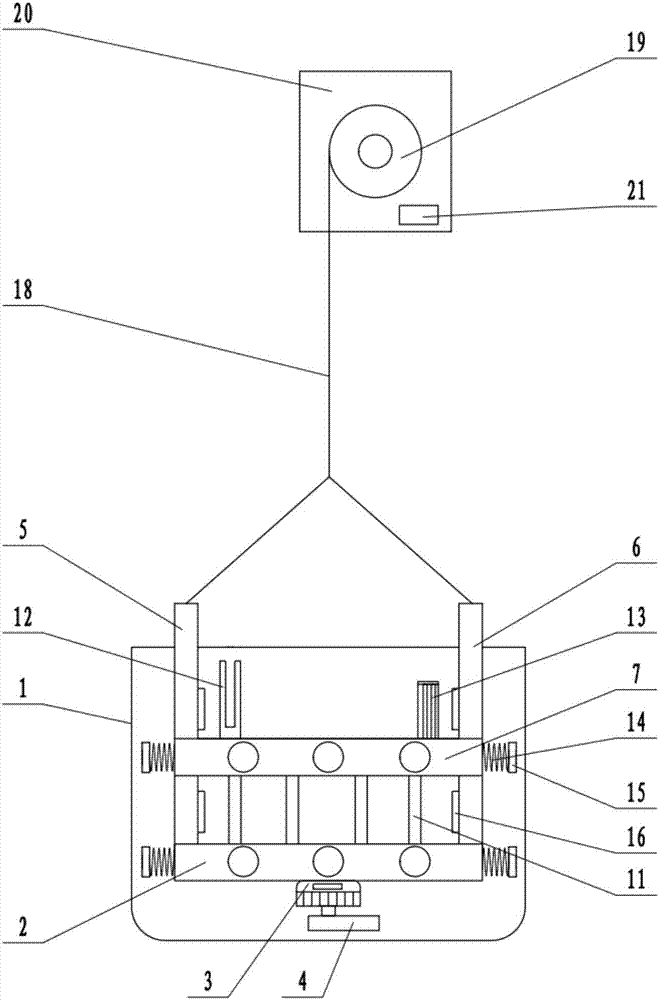

Heating control method of food processing machine

ActiveCN108041975ASolve the problem of multi-functional pulping needsSolve the paste tubeSteam cooking vesselsWater dischargeWater vapor

The embodiment of the invention discloses a heating control method of a food processing machine. A heating system of the food processing machine includes a steam generation device; the steam generation device includes a heating tube; the heating tube can convert water entering the steam generation device into steam; and the heating system can heat a material through the output steam. The heating control method includes: controlling a water discharging state of the steam generation device by controlling the water feeding speed and the water discharging temperature of the steam generation deviceso as to achieve various heating manners.

Owner:JOYOUNG CO LTD

Lifting type sink basket with cleaning function

InactiveCN107157422ASolve cleaningSolve storage problemsTableware washing/rinsing machine detailsKitchenware cleanersEngineeringWinch

The invention discloses a lifting type sink basket with a cleaning function. The lifting type sink basket comprises a sink, a lower bottom plate, a left fixing rack, a right fixing rack, an upper bottom plate, guardrails, partition plates and a fixing rack, wherein the lower bottom plate is arranged inside the sink; a motor is fixedly connected with the lower surface of the lower bottom plate; an eccentric gear is fixedly connected with a shaft extension end of the motor; the left fixing rack and the right fixing rack are respectively and fixedly connected with the left end and the right end of the lower bottom plate; the upper bottom plate is arranged above the lower bottom plate; a plurality of springs are fixedly connected around the upper bottom plate; a plurality of ultrasonic wave generators are fixedly connected with opposite sides of the left fixing rack and the right fixing rack. Articles such as dishes and chopsticks to be cleaned are placed in corresponding positions of the lower bottom plate and the upper bottom plate, the lower bottom plate and the upper bottom plate are driven to vibrate inside the sink through the eccentric gear, a liquid is driven to vibrate through the ultrasonic wave generator, then the articles such as the dishes and the chopsticks can be cleaned, a winch is powered on to lift up the lower bottom plate and the upper bottom plate from the sink, and the articles such as the dishes and the chopsticks can be dried naturally.

Owner:FOSHAN ZHENGLUE INFORMATION TECH CO LTD

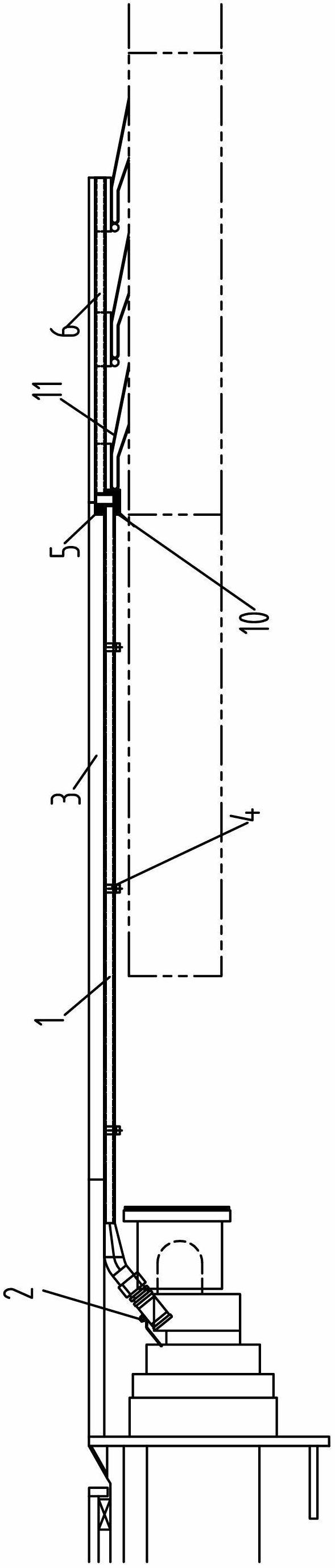

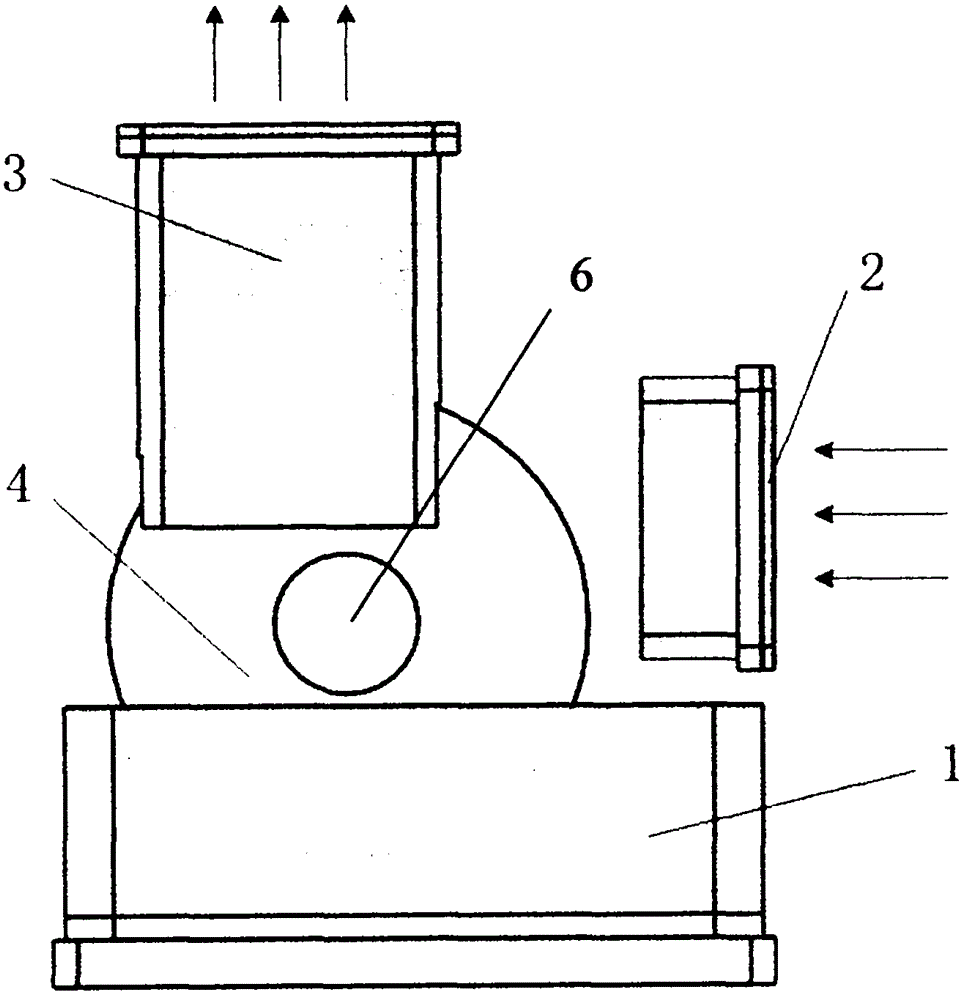

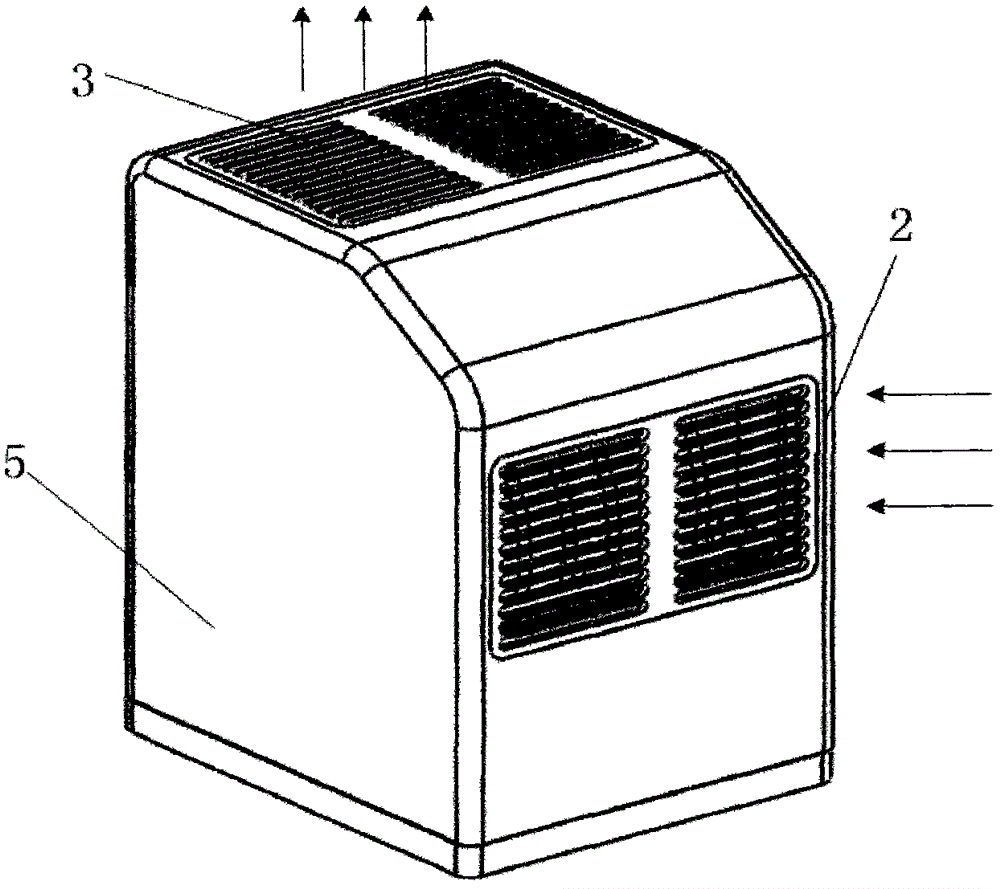

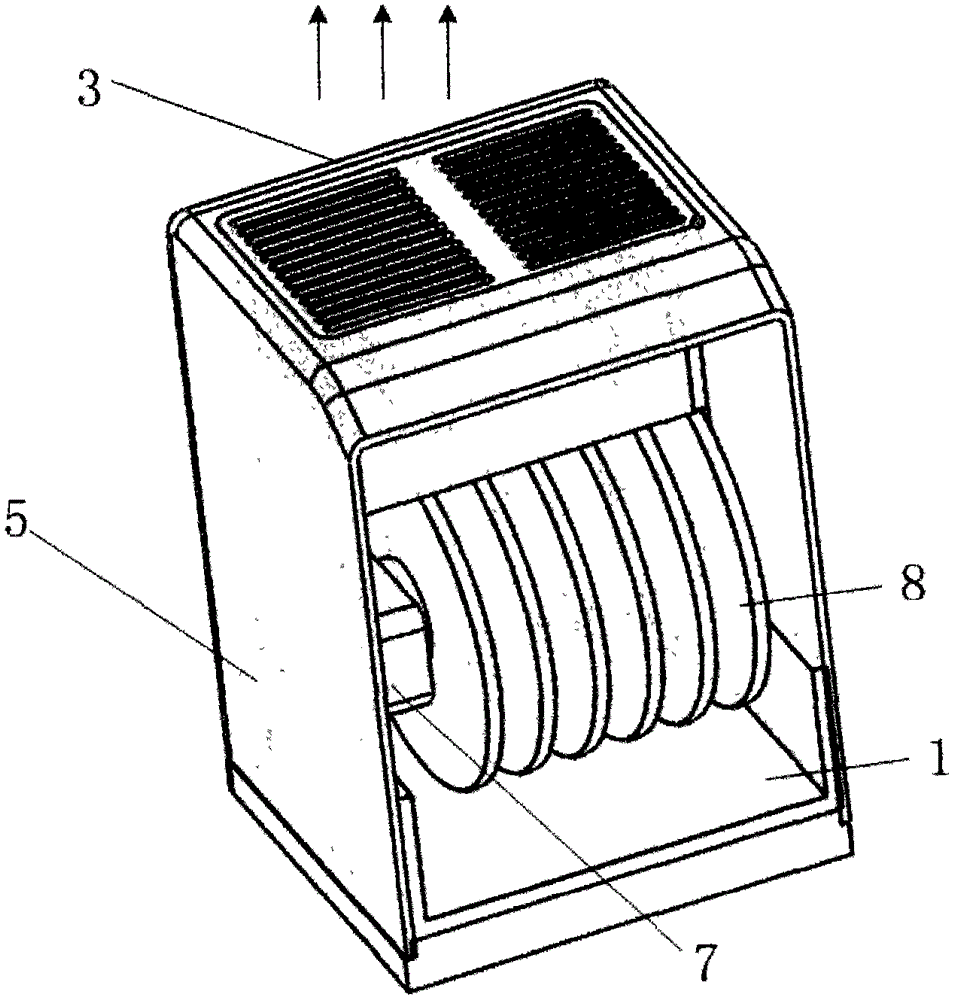

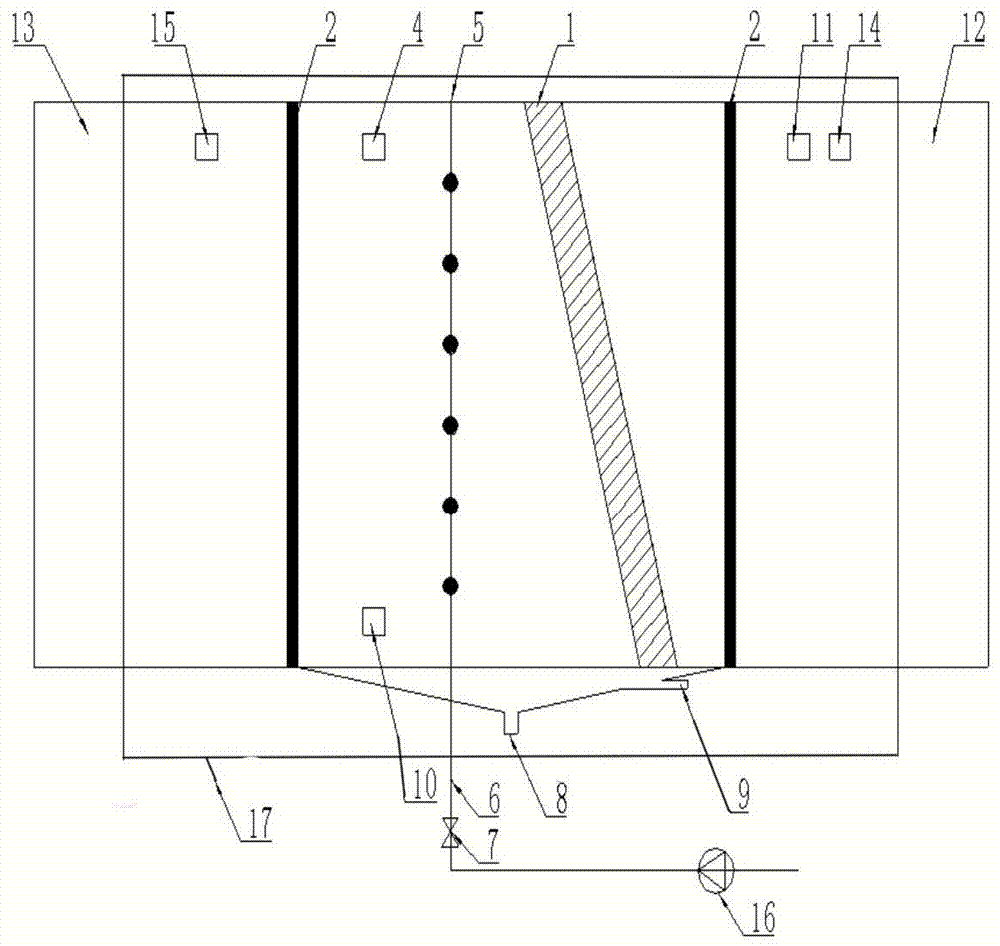

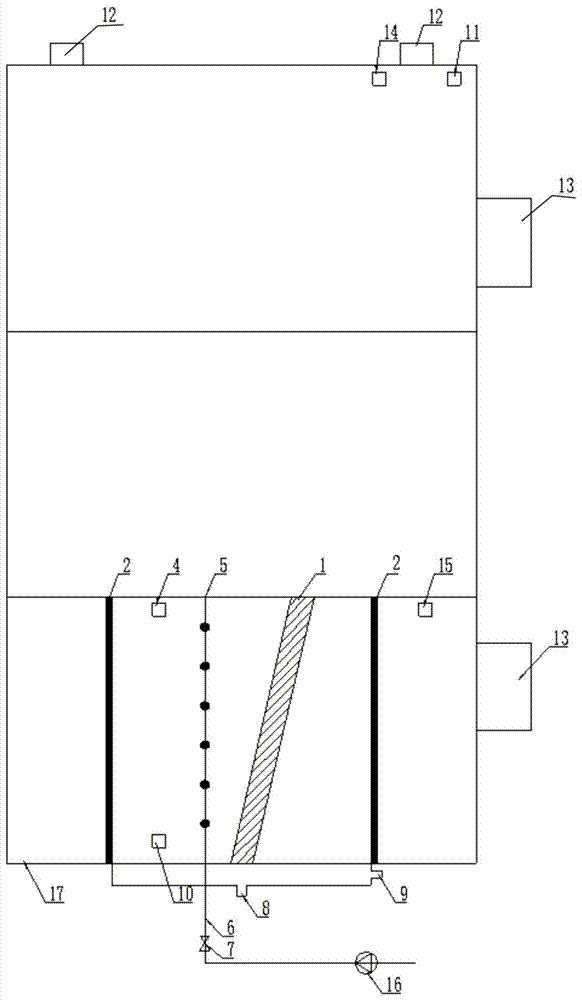

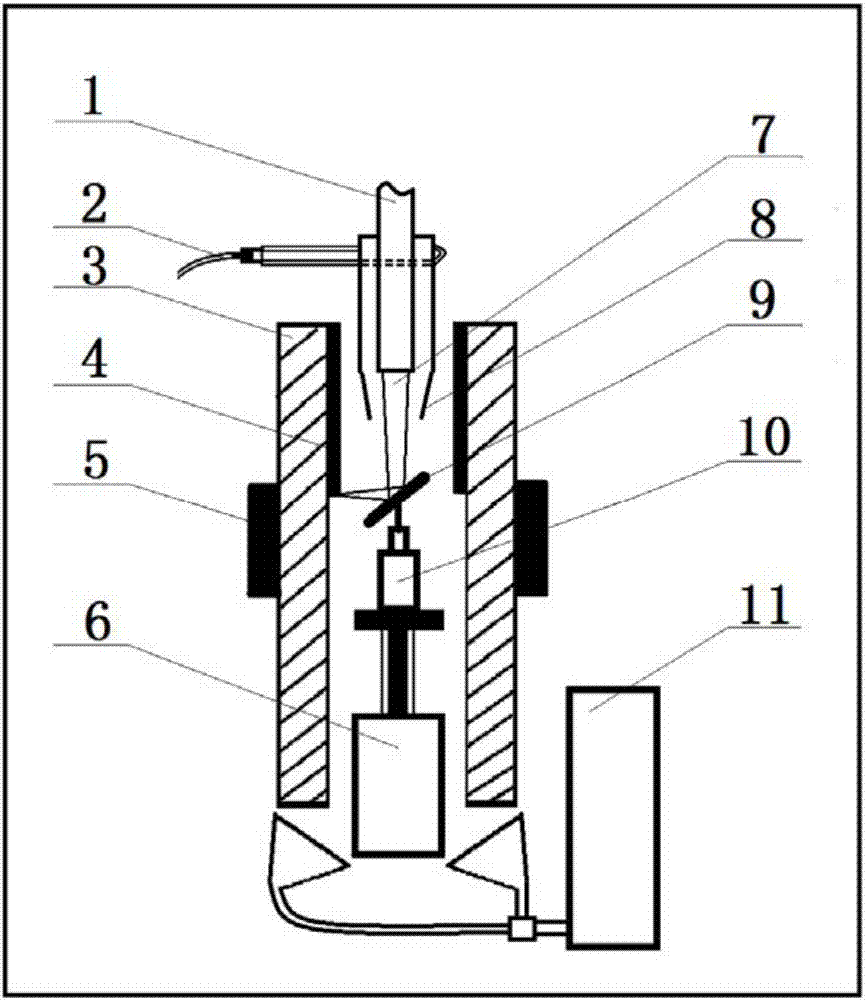

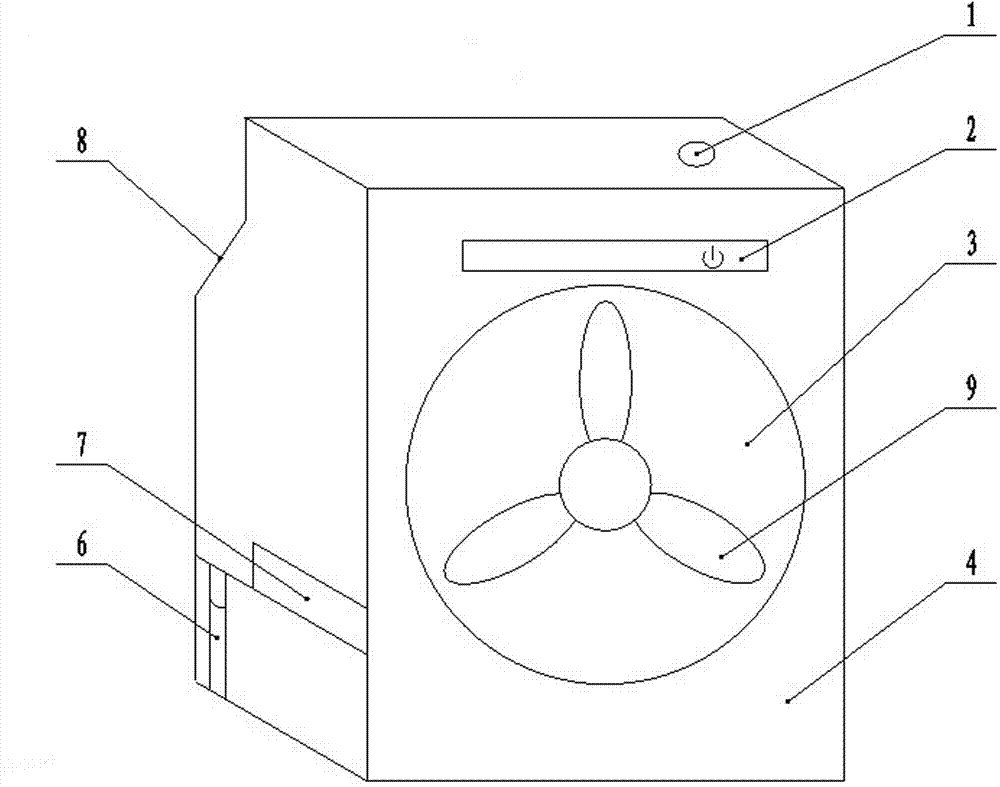

Water adsorption type air purifier

InactiveCN104587767AAddressing Structural ComplexitySolve cleaningCombination devicesUsing liquid separation agentCouplingEngineering

The invention relates to air purifiers, and concretely relates to a water adsorption type air purifier which realizes purification of air and solves the problems that mechanical filtering equipment in a conventional air purifier is inconveniently to clean and the filtering effect is not good. The water adsorption type air purifier comprises a water tank 1, an air purification box housing 5, an air outlet and a fan 3, a roller type filter screen 4 is disposed above the water tank 1, the air outlet 3 is arranged on the air purification box housing 5, an air inlet and a fan 2 are arranged at the outer side of the cylindrical air purification screen 4, the side end of the cylindrical air purification screen 4 is connected with a rotating shaft 6, and the rotating shaft is connected with a motor 7 via a shaft coupling, and vanes 8 of the cylindrical air purification screen 4 are provided with filter pores. The purifier employs a gas film-forming manner, helps to greatly improve the exchange rate of air and a liquid and enable air to be fully contacted with water, and thus the purifier possesses extremely high purification efficiency and humidification efficiency, and has the performances obviously better than those of market water-washing air purifiers employing other water washing design manners. The air purifier is compact in structure, small in volume, concise, beautiful and elegant in appearance, simple to control, and convenient for usage and maintenance.

Owner:BEIJING JIAXIN CHENGYE TECH

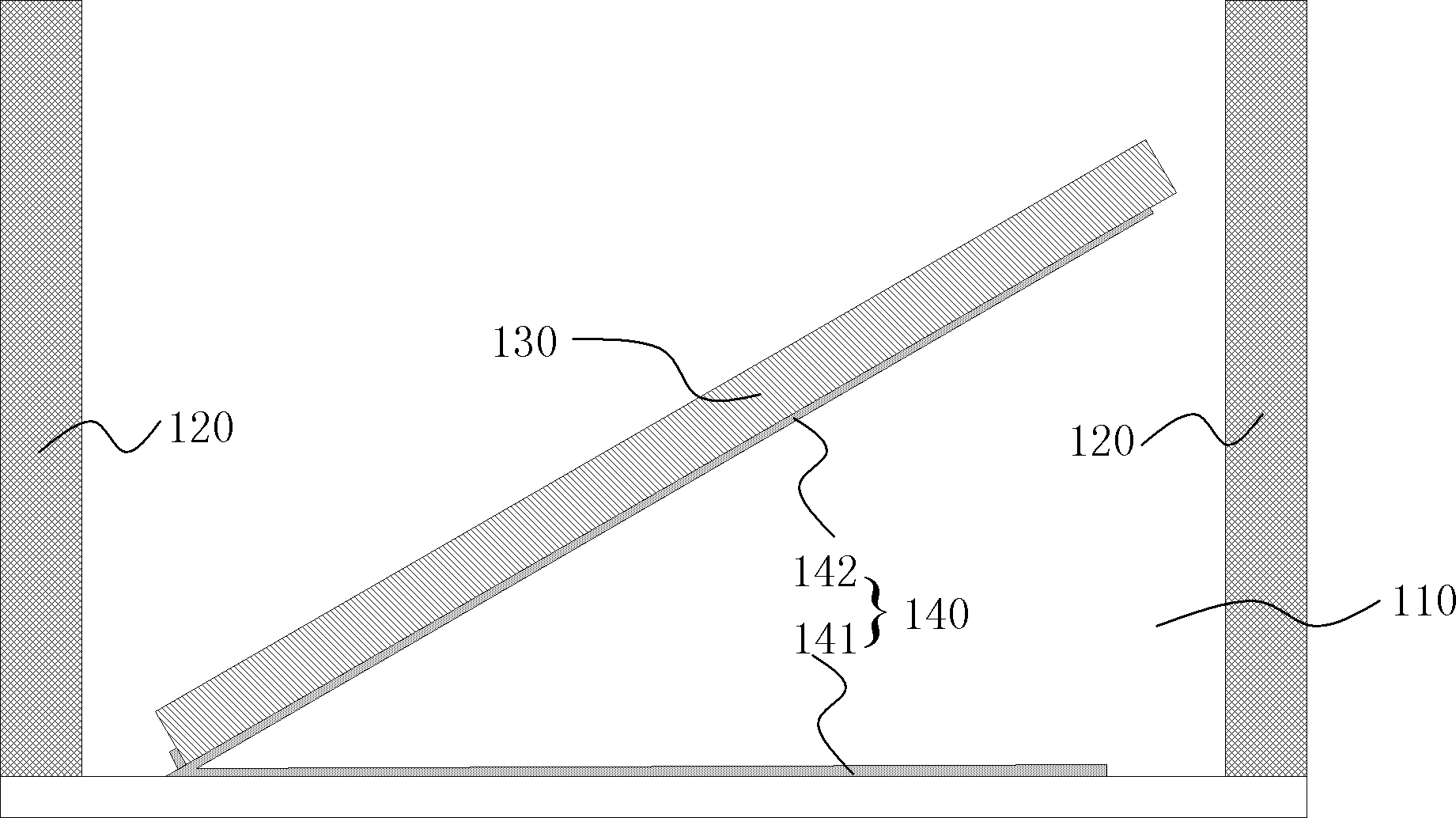

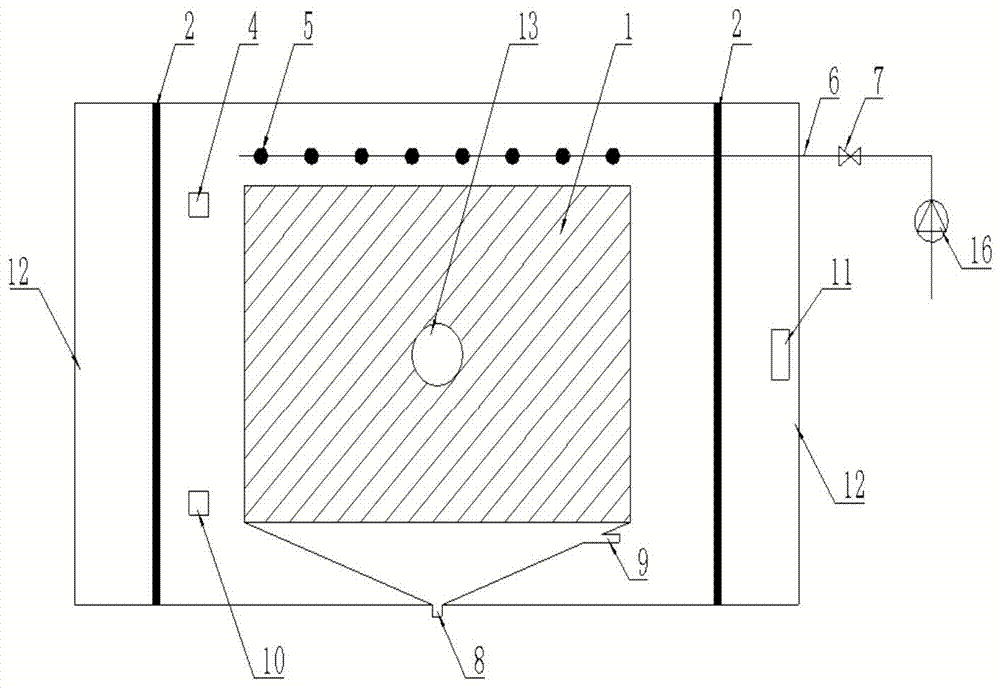

Fresh air circulating device provided with full-automatic washable HEPA strainer

PendingCN107152742AConstant Filtration EfficiencyConstant filter resistanceSpace heating and ventilation safety systemsDispersed particle filtrationHEPAFiltration

The invention discloses a fresh air circulating device provided with a full-automatic washable HEPA strainer. The device comprises a box, the HEPA strainer, spray headers, a drainage outlet and baffles. The baffles are arranged in the box and can partition the box into an air inlet area, a filtration area and an air outlet area. The filtration area is internally provided with a heater, a humidity sensor, the spray headers and the HEPA strainer. The HEPA strainer has an inclination angle. An outdoor temperature sensor is arranged in the air inlet area. An air outlet is internally provided with a resistance air quality inductor and an indoor temperature sensor. A blowdown channel formed by the drainage outlet and an overflow port is formed in the lower side of the filtration area. The fresh air circulating device uses the HEPA strainer, the baffles, electromagnetic regulating valves, the automatic top spraying headers and the like are automatically started to perform cleaning after the resistance air quality inductor senses a value reaching a setting numerical value, the filtration efficiency and resistance are kept unchanged, accordingly the trouble of operation maintenance for equipment and additional expenses are reduced, and convenience is provided for users and product service providers.

Owner:河南华欧净化设备有限公司

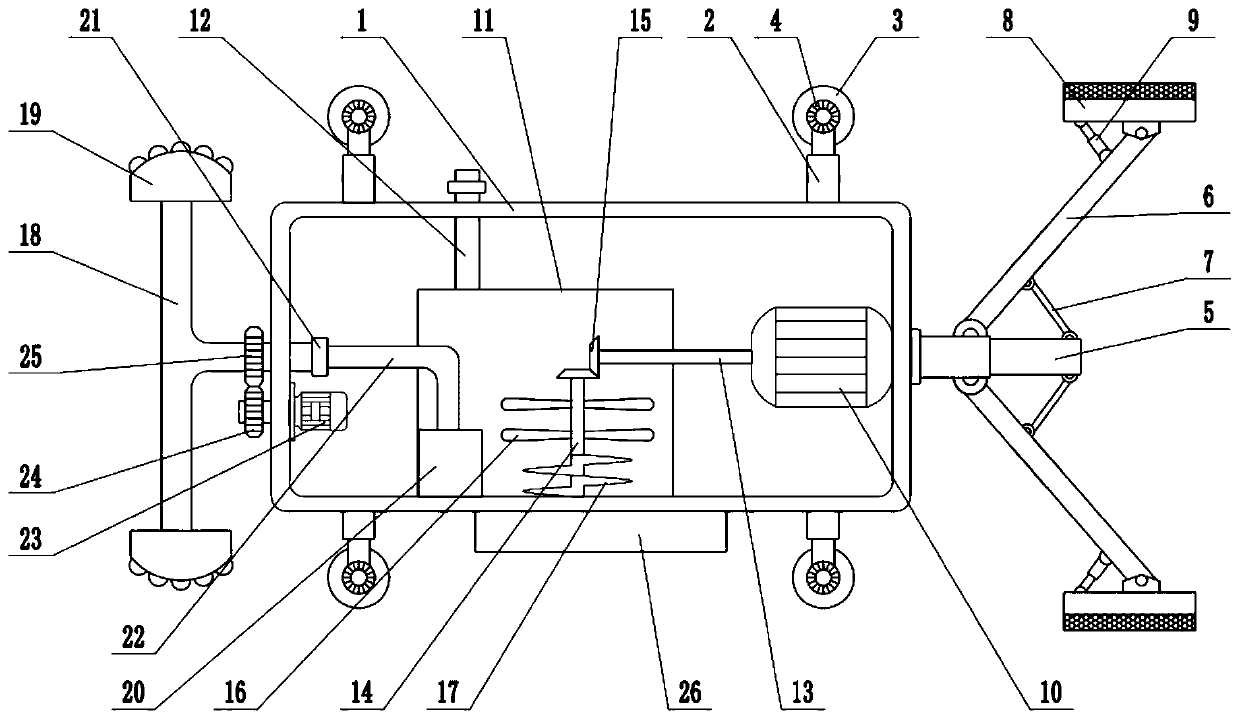

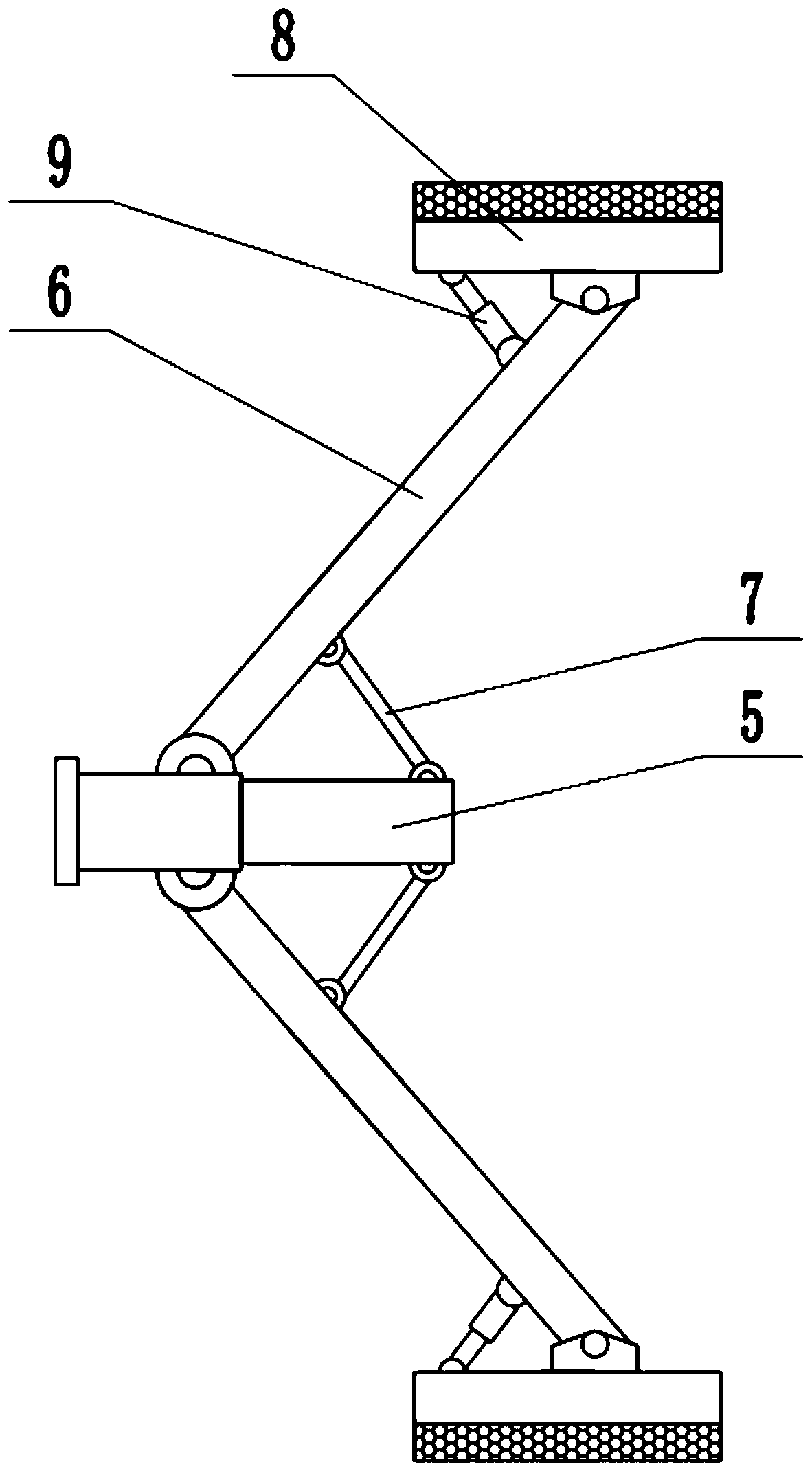

Electric vehicle cleaning device

InactiveCN105857263ARealize the function of adjustable cleaning heightGood dynamic responseCleaning apparatus for vehicle exteriorsNew energyElectric machinery

The invention relates to an electric vehicle cleaning device. The electric vehicle cleaning device comprises a concave support, and two installation lugs are symmetrically arranged at the two ends of the concave support; a rotating motor is installed on the inner wall of the left end of the concave support through a motor base, a lead screw is connected to an output shaft of the rotating motor, the right end of the lead screw is installed on the inner wall of the right side of the concave support through a bearing, and the lead screw is driven to rotate through the rotating motor; a moving block is installed in the middle of the lead screw in a threaded connection mode, two linear slide rails are installed on the lower end face of the moving block and symmetrically installed on the inner wall of the concave support through screws, and the linear slide rails play a role of limiting the motion direction of the moving block; a rigid support device is installed on the upper end face of the moving block, and a high pressure cleaning device is installed on the upper end face of the rigid support device. According to the electric vehicle cleaning device, stable automated rotating and cleaning functions of new energy vehicles can be achieved, and the electric vehicle cleaning device has the advantages of being good in rigid support performance, free of manual cleaning, high in degree of automation, good in cleaning effect, uniform in degree of washing and the like.

Owner:永康市蓝特工贸有限公司

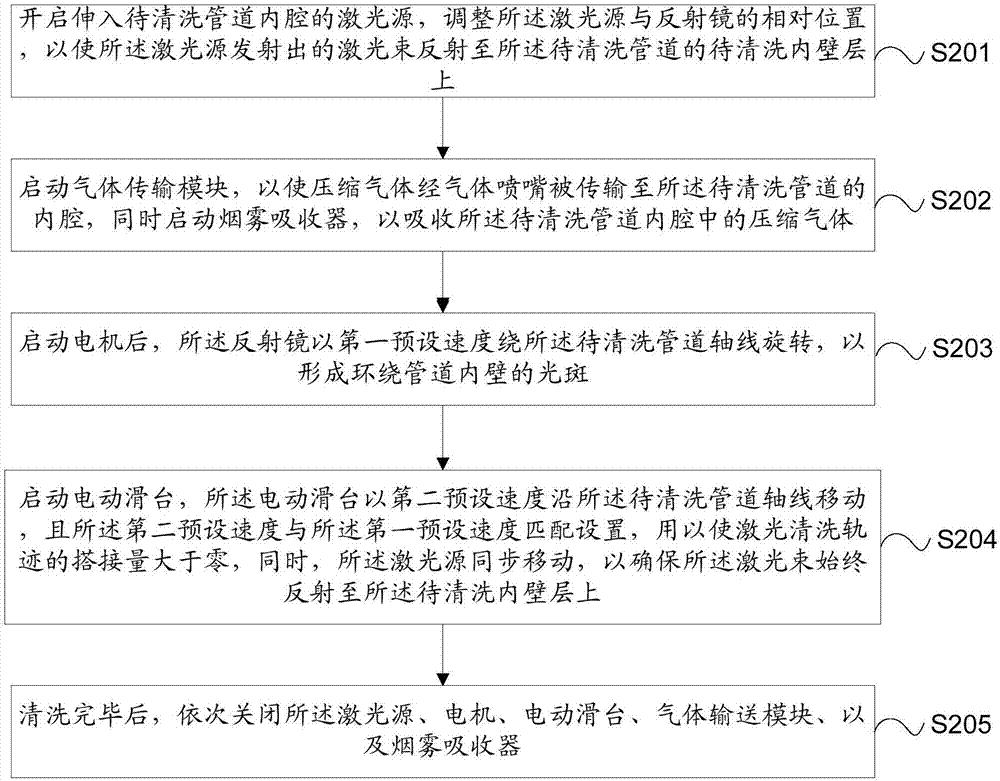

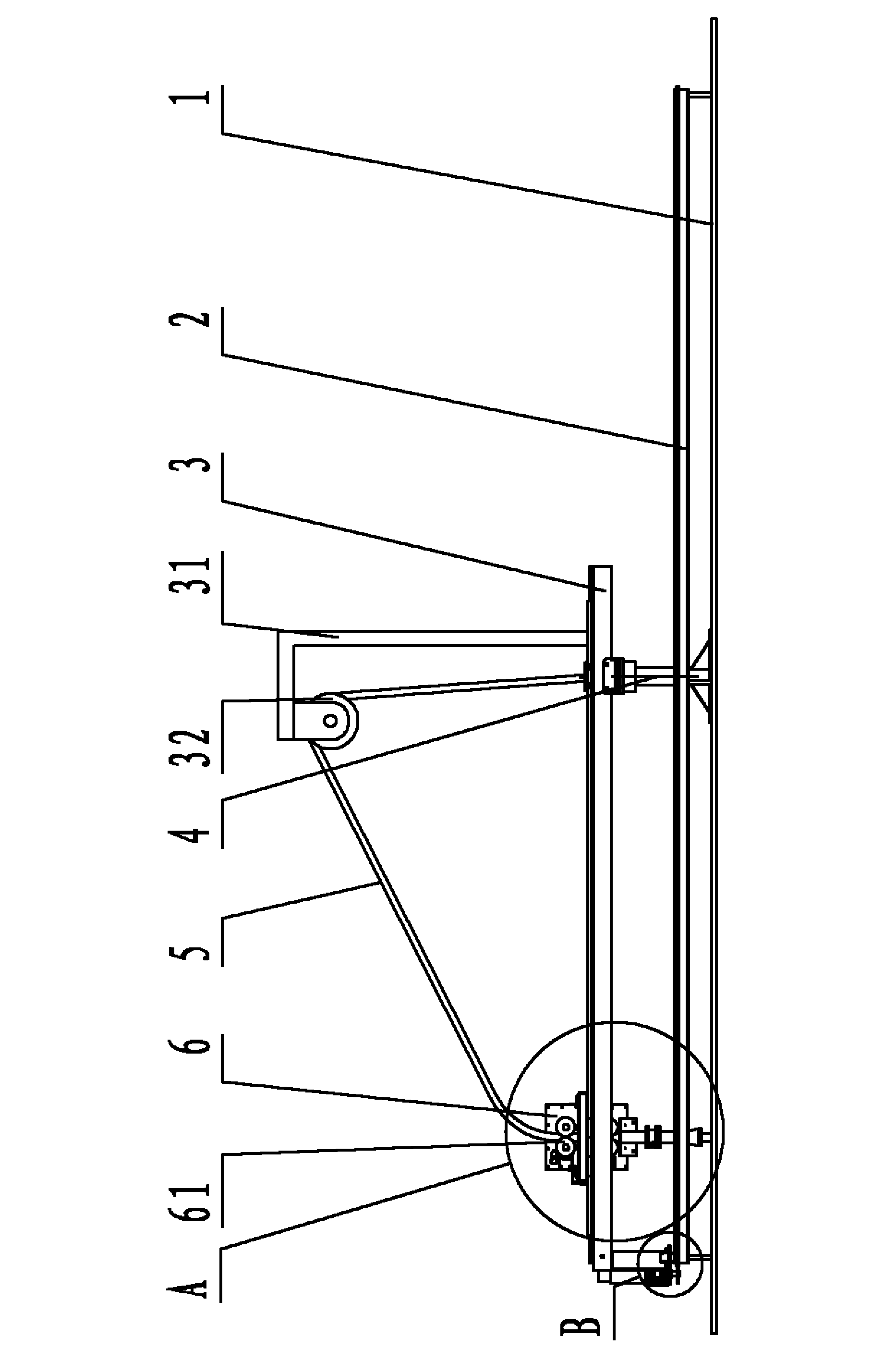

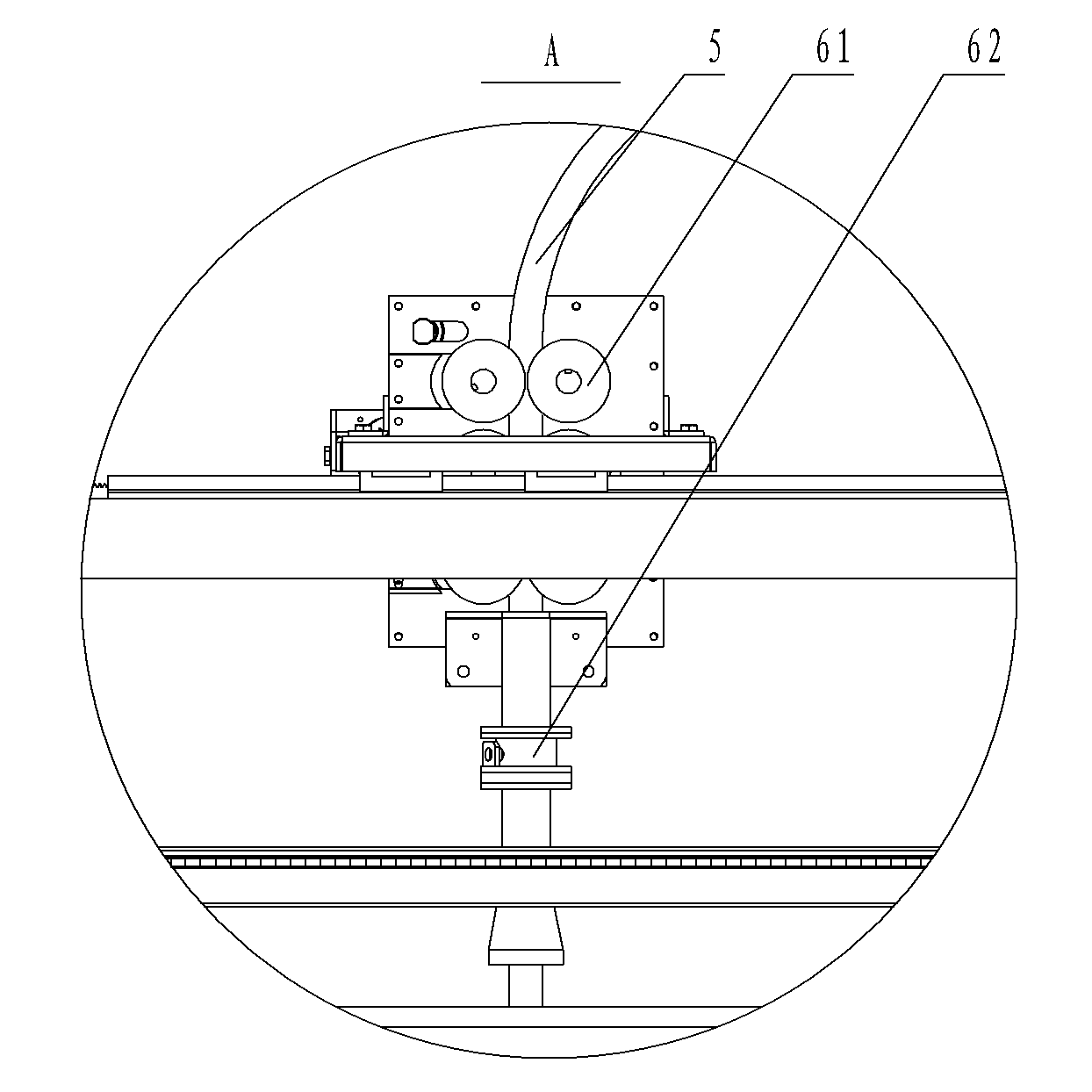

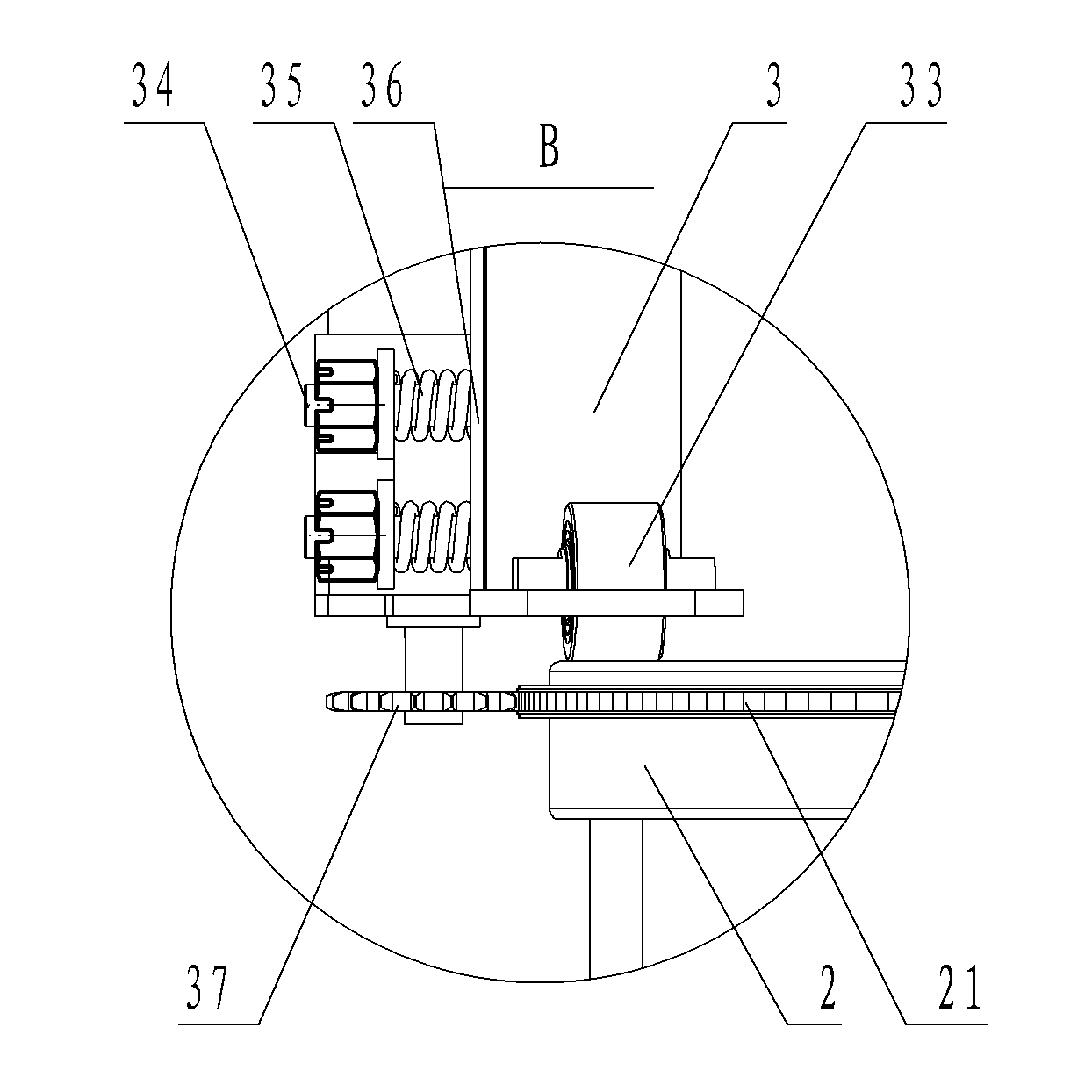

Laser cleaning device and method

ActiveCN106925893AFree transferFree reflectionMetal working apparatusLaser beam welding apparatusCoaxial lineSpray nozzle

The invention discloses a laser cleaning device and method. The device includes a laser source, a gas nozzle, a gas conveying module, a reflector, a motor, an electric sliding table and a smog absorber; the laser source can emit the laser beam towards the inner cavity of a pipe to be cleaned; the reflector can reflect the laser beam to an inner wall layer to be cleaned; the gas conveying module is communicated with the gas nozzle for transferring compressed gas to the inner cavity of the pipe to be cleaned; the laser source, the gas nozzle and the motor are coaxially arranged, the coaxial line is overlapped with the axis of the pipe to be cleaned; the reflector is fixed on the motor; the motor is fixed on the electric sliding table and is rotated around the axis of the pipe to be cleaned; the electric sliding table is moved along the axis of the pipe to be cleaned; the gas nozzle fits the outer wall of the laser source; and the smog absorber is corresponding to the gas nozzle. The laser cleaning method and the method solve the problems that the existing laser cleaning device is difficult to operate when cleaning the inner wall of the pipe and the cleaning effect is poor, and realizes the purposes of simplifying cleaning of the inner wall of the pipe and improving the inner wall cleaning effect of the pipe.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Cleaning machine for heat exchange pipe of evaporator

InactiveCN102305574AEliminate accident hazards that accidentally injure operatorsEasy to useFlush cleaningEngineeringEvaporator

The invention discloses a cleaning machine for a heat exchange pipe of an evaporator. A hollow stand column is hinged with a stander of the cleaning machine; one end of the stander is arranged on an annular rail through a stander wheel; a stander driving device is arranged between the annular rail and the stander; a cleaning handpiece is arranged on the stander through a rail; a handpiece drivingdevice for driving the cleaning handpiece to walk on the stander is arranged between the cleaning handpiece and the stander; the cleaning handpiece comprises a plurality of clamping wheels for clamping water gun pipes; and a guide wheel of at least one water gun pipe is arranged above the hollow stand column. By the cleaning machine for the heat exchange pipe of the evaporator, the problems of low use security and high operation labor intensity of the conventional cleaning equipment can be solved, and an effect of preventing the water gun pipes from being coiled with other parts can be achieved; therefore, the cleaning machine is particularly applicable to cleaning for pipes of the evaporator in a pot body.

Owner:柳州市汉森机械制造有限公司 +1

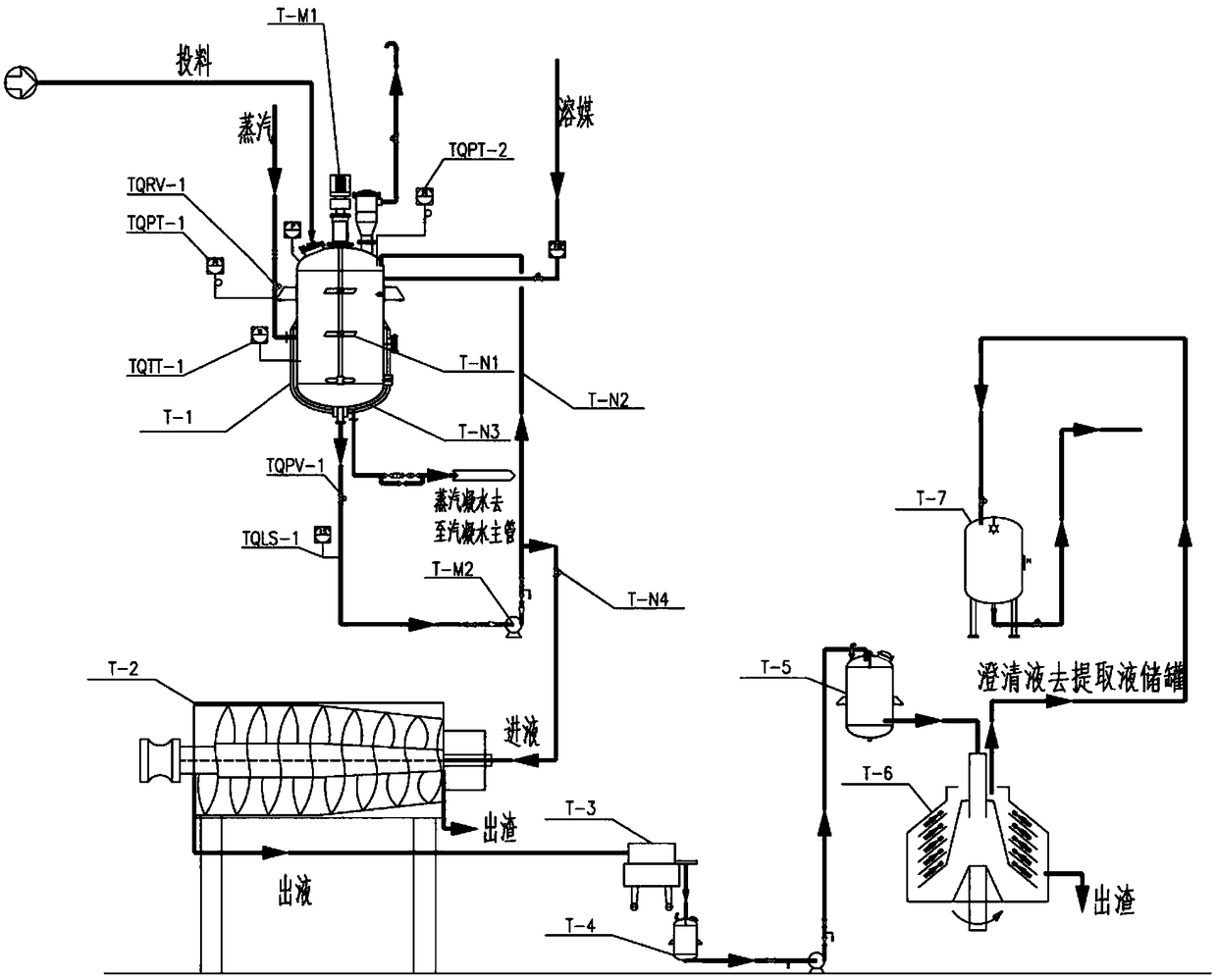

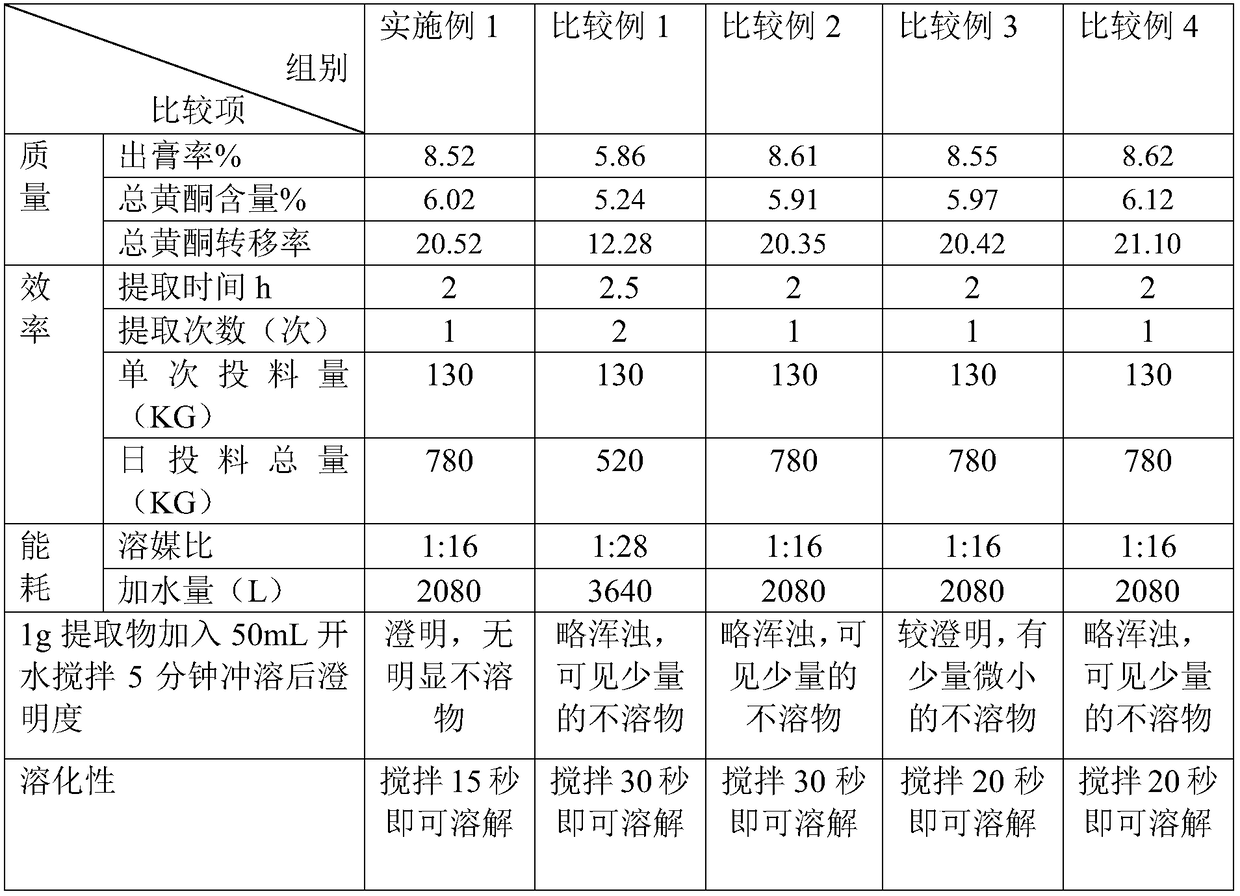

Traditional Chinese medicine automatic extraction and separation device and extraction and separation method and application thereof

PendingCN109126191ADissolves quicklySolve easy blockageSolid solvent extractionFiltration circuitsFiltrationSeparation method

The invention relates to a traditional Chinese medicine automatic extraction and separation device and an extraction and separation method and an application thereof. The traditional Chinese medicineautomatic extraction and separation device is characterized in that the extraction and separation device comprises a dynamic extraction tank and a combined solid-liquid separation module; after extraction, extraction solution and dregs in the dynamic extraction tank are introduced into the combined solid-liquid separation module for solid-liquid separation; the combined solid-liquid separation module comprises three solid-liquid separation devices. The traditional Chinese medicine automatic extraction and separation device has the advantages of improving the adaptability of traditional Chinesemedicine extraction and the filtration efficiency of traditional Chinese medicine extracts, strengthening separation, and reducing production cost and consumption.

Owner:JIANGYIN TIANJIANG PHARMA

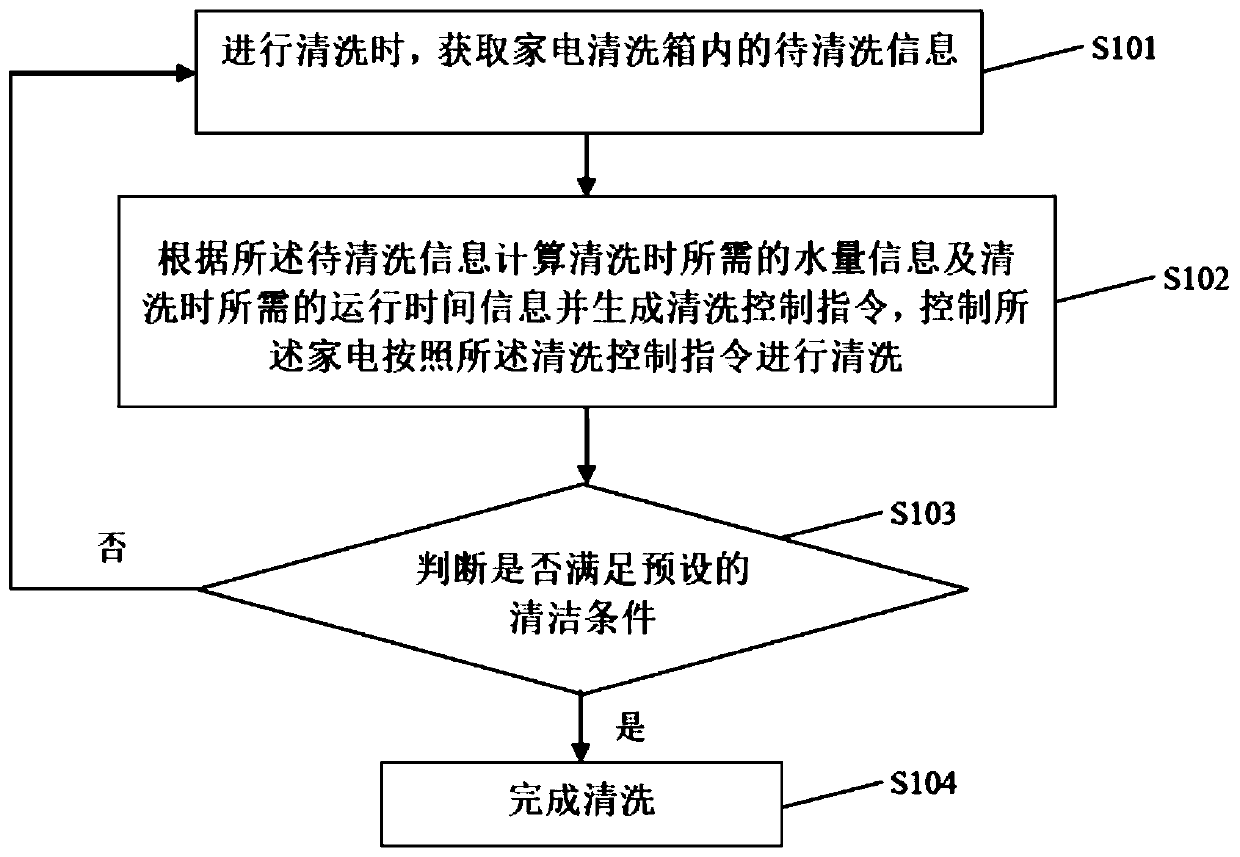

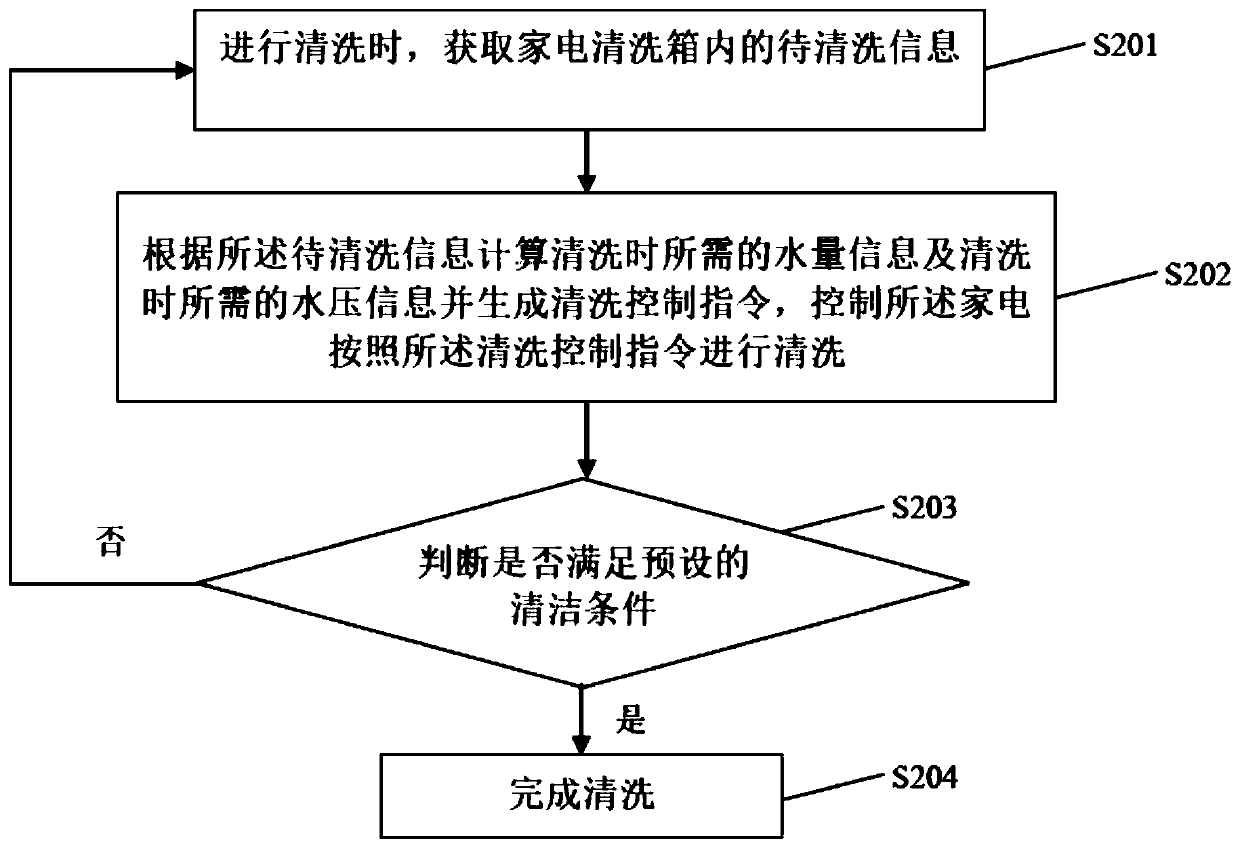

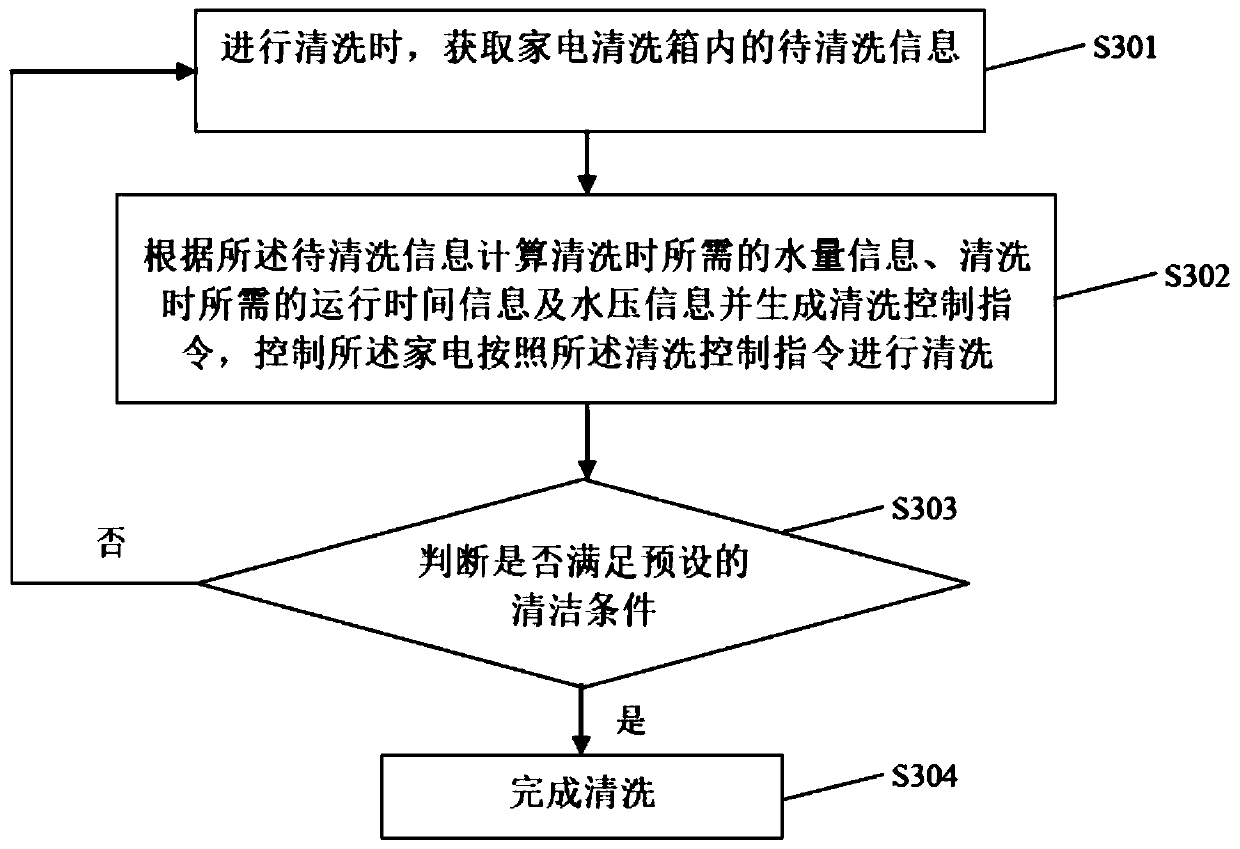

Cleaning control method for home appliance cleaning box and home appliance

InactiveCN109730616AImprove experienceImprove comfortTableware washing/rinsing machine detailsKitchen equipmentWater savingWater volume

The invention belongs to the technical field of home appliances, and in particular relates to a cleaning control method for a home appliance cleaning box and a home appliance. The method comprises thefollowing steps: acquiring to-be-cleaned information in the home appliance cleaning box during cleaning and calculating water volume information needed during cleaning according to the to-be-cleanedinformation and generating a cleaning control command; and controlling the home appliance to be cleaned according to the cleaning control command. The method can control the water volume, and the water inlet amount, the frequency of a circulating water pump, the spray amount and the water inlet amount are related to quantity or clean degree of to-be-cleaned bowls and chopsticks, so that the problem of halfway cleaning, poor cleaning effect and waste of water and electric energy is solved to a great extent. A user does not need to arrange or adjust the water inlet amount manually, so that the cleaning efficiency can be improved, the water is saved, a purpose of being efficient and energy-saving is achieved, and the use experience and comfort level are improved.

Owner:GREE ELECTRIC APPLIANCES INC

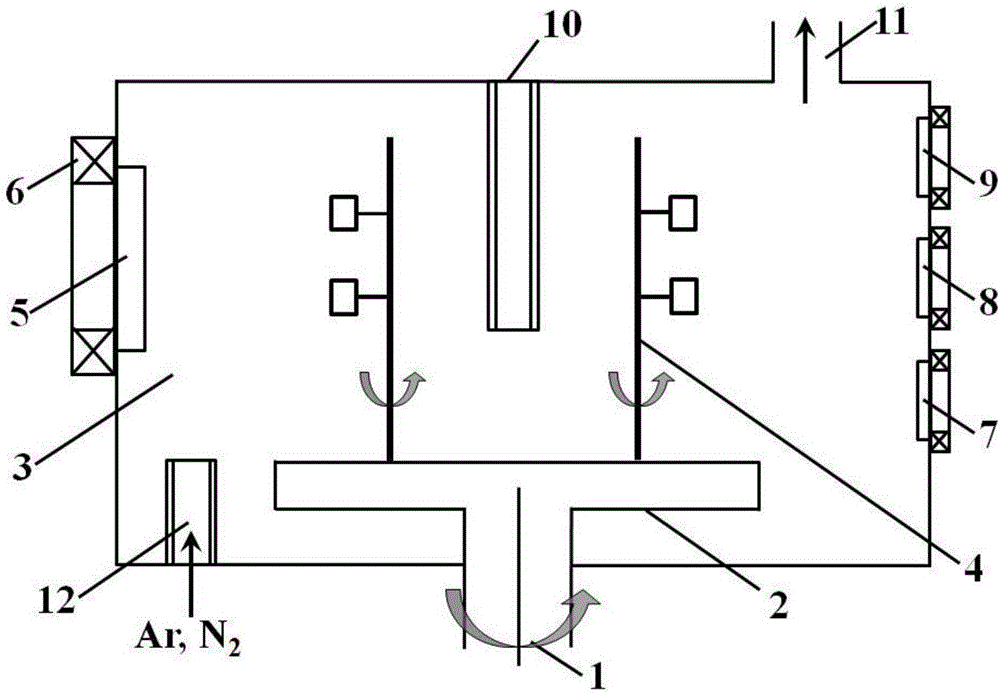

Method for preparing high-temperature alloy cutting tool coating in ion source enhanced arc ion plating mode

InactiveCN106835031ASolve cleaningSolve etchingVacuum evaporation coatingSputtering coatingOxidation resistantSuperalloy

The invention discloses a method for preparing a high-temperature alloy cutting tool coating in an ion source enhanced arc ion plating mode. The method comprises the steps that a high-temperature alloy cutting tool is pretreated and then placed to a rotating stand rod in a vacuum chamber of ion source enhanced arc ion plating equipment, a rectangular arc Ti target serves as a bottom Ti source, and the sputtering rate of the arc Ti target is controlled by adjusting the current of the arc Ti target; a round arc CrAl target serves as a Cr and Al element source for preparing aCrAlN coating, and the sputtering rate of the arc CrAl target is controlled by adjusting the current of the arc CrAl target; high-purity Al and high-purity N2 enter the vacuum chamber through the ion sources, wherein the Ar serves as the ionizing gas, and an effective glow discharging process is guaranteed; and the N2 serves as the reaction gas and is ionized to be combined with Cr and Al elements, and the CrAlN coating is formed on the surface of the high-temperature alloy cutting tool in a deposition mode. According to the prepared CrAlN coating, the anti-oxidization temperature of the coating is 1000 DEG C, the microhardness is Hv3500, and requirements of the high-temperature alloy cutting tool for the abrasion resistance, the thermal fatigue resistance and the anti-oxidization performance can be well met.

Owner:XI AN JIAOTONG UNIV

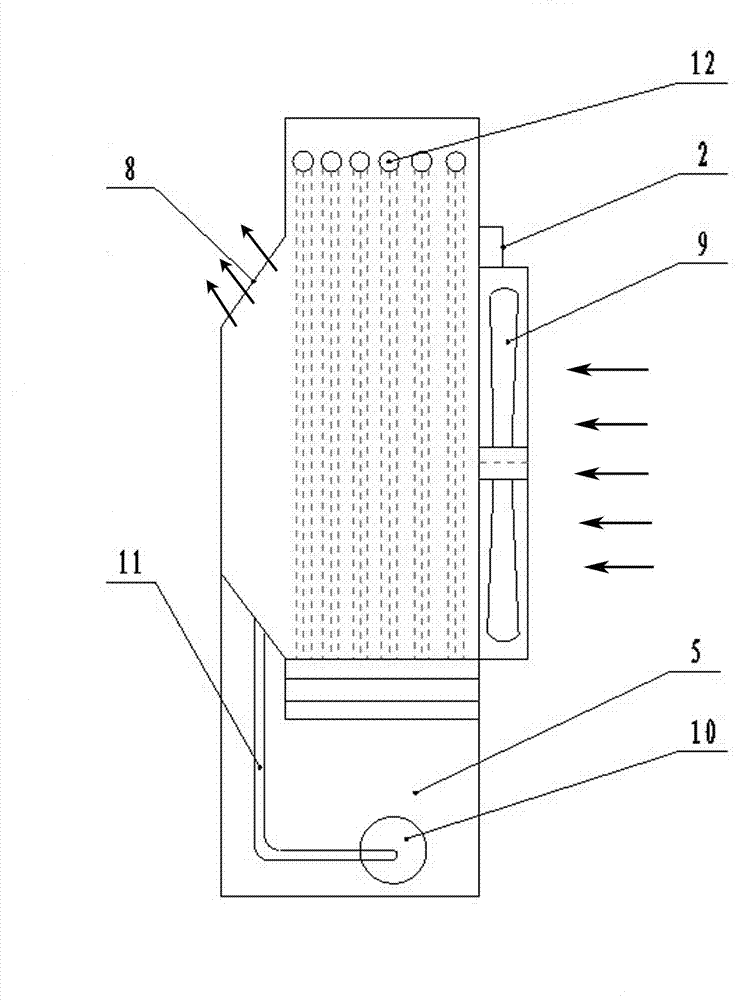

Water-washing air purifier

InactiveCN103111145ATo achieve the effect of purifying the airAct as humid airUsing liquid separation agentSprayerWater filter

The invention relates to an air purifier, and in particular relates to a water-washing air purifier aiming at solving the problems that mechanical filter equipment of an existing air purifier is inconvenient to clean and has a poor filter effect. The water-washing air purifier comprises a shell (4) with an air inlet (3) and an air outlet (8), wherein fan blades (9) are arranged on the air inlet (3); a water tank (5) is arranged at the inner bottom of the shell (4); a water pump (10) is arranged in the water tank (5) and is connected with a sprayer (12) which is arranged at the inner top of the shell (4) through a pipeline (11) and is used for forming sprayed water into a water curtain wall (13) covering the air inlet (3); a water filter (7) for collecting circulating water is arranged below the sprayer (12); and the water outlet of the water filter (7) is communicated with the water tank (5). The air purifier disclosed by the invention is reasonable in design, simple in structure, energy-saving, environment-friendly, safe, reliable, and low in cost.

Owner:关润林

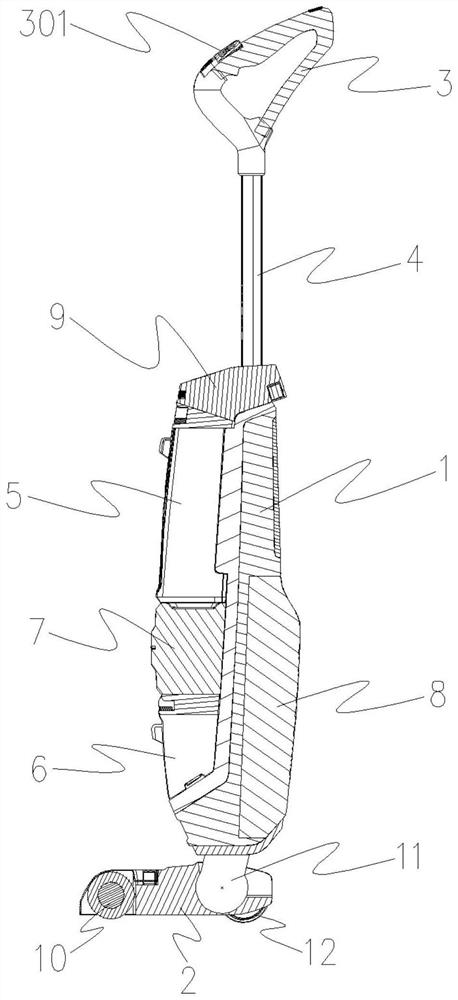

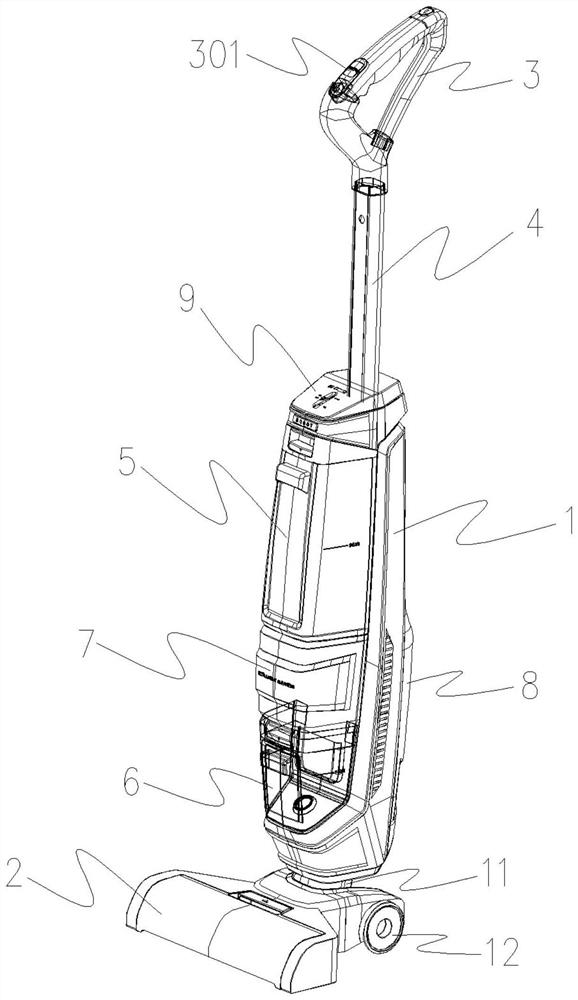

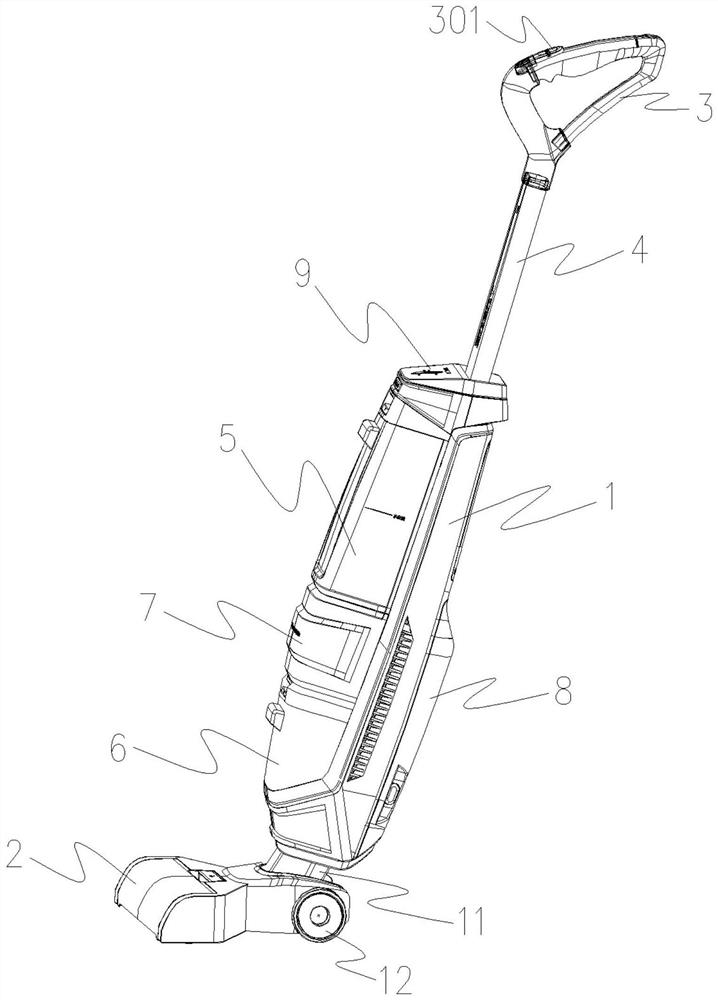

Household floor cleaning device

PendingCN112493940AEasy to view in real timeEasy to operateCarpet cleanersFloor cleanersHome useSewage

The invention relates to a household floor cleaning device which comprises a body, a cleaning head assembly, a handle assembly and a connecting rod, the cleaning head assembly is connected with the body, the handle assembly is connected with the body through the connecting rod, the body is provided with a clear water tank and a sewage tank, the sewage tank is located above the clear water tank, the clear water tank is configured to provide clear water, the sewage tank is configured to recover sewage, and the gravity center of the household floor cleaning device is gradually raised in the cleaning process. According to the household floor cleaning device, the gravity center of the household floor cleaning device is located at the lower position before cleaning is started, user operation isquite easy, no load bearing feeling exists, a user can observe the dirt degree of floor in time through the clear water tank, the water spraying amount and the cleaning strength are increased according to the actual situation, the problem of repeated cleaning caused by insufficient cleaning degree is solved, and a user can check the condition in the sewage tank in real time, so that the user experience is greatly enhanced.

Owner:SENKEINO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com