Electrolyte-plasma polishing technique for stainless steel precise structural part

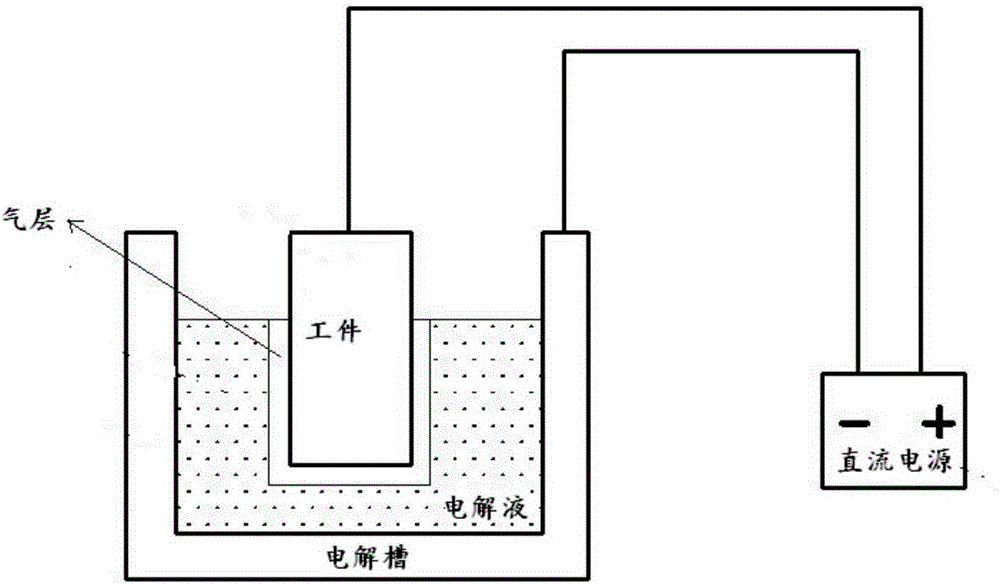

A technology of precision structural parts and process methods, applied in the field of precision machining, can solve the problems of deep long holes, intersecting holes, many blind holes, difficult to completely remove tiny burrs, complex internal structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Taking the shell of the servo valve, the core component of the aerospace servo mechanism, as an example, the general process of existing processing is: heat treatment (quenching and tempering) → milling (shape processing) → heat treatment (quenching) → honing (semi-finishing hole) → flat grinding ( Finishing parts shape)→finishing (finishing holes)→cleaning (removing dirt)→general inspection.

[0034] The overall processing flow after adding the polishing process of the present invention is: heat treatment (quenching and tempering) → milling (shape processing) → heat treatment (quenching) → honing (semi-finishing hole, reserve a process allowance of 0.01 to 0.03 mm for electrolyte-plasma polishing )→Plain grinding (finishing the shape of the part, reserve a process allowance of 0.01~0.03mm for electrolyte-plasma polishing)→electrolyte-plasma polishing (application of special polishing process parameters, with special lifting fixture for parts, to remove tiny burrs in int...

Embodiment 2

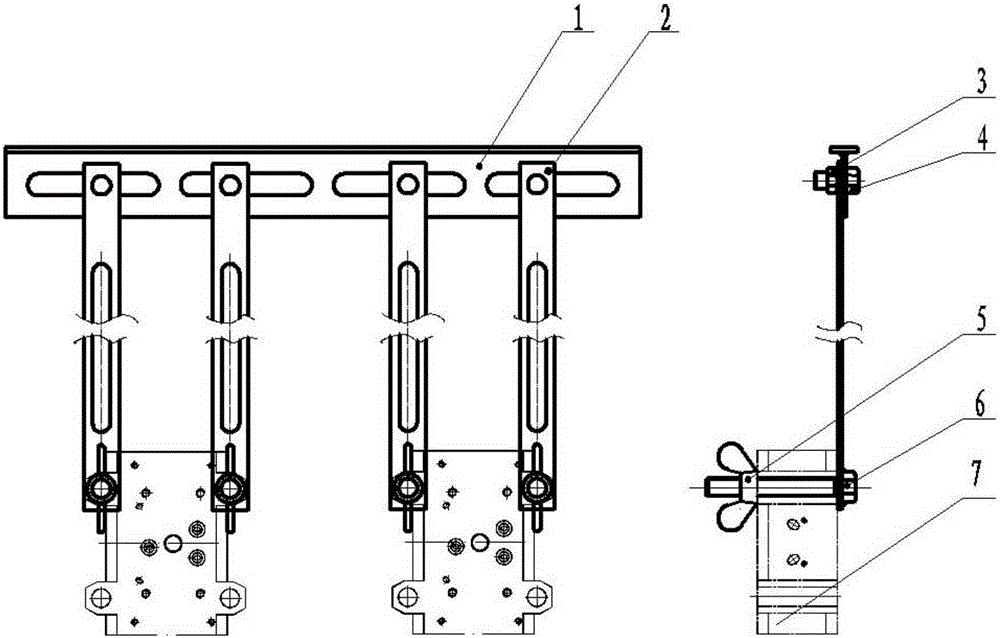

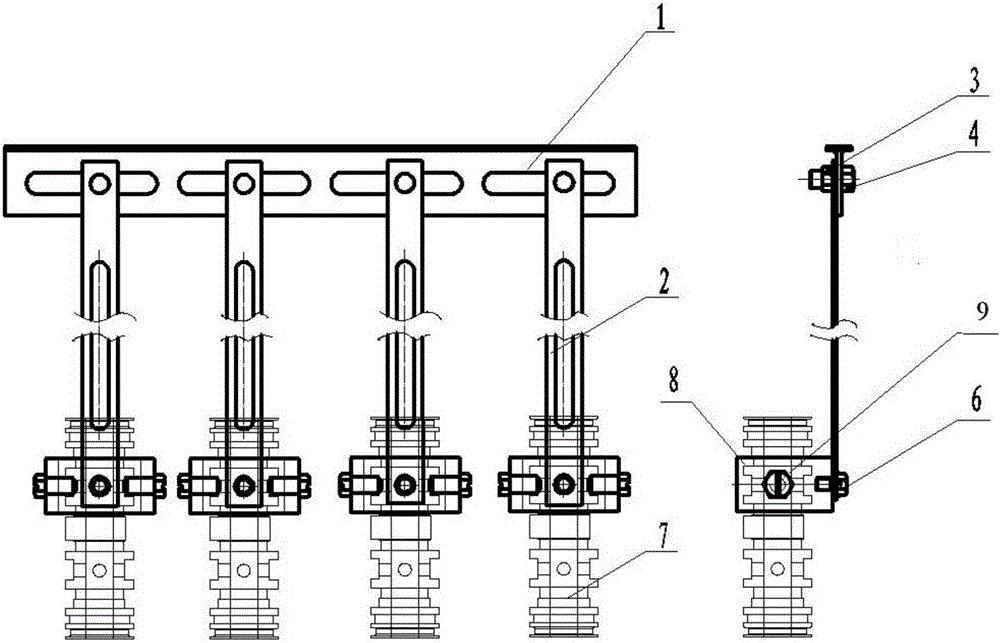

[0038] Taking the valve sleeve of the servo valve, the core component of the aerospace servo mechanism, as an example, the schematic diagram installed on the tooling is as follows: image 3 As shown, the structure 7 (valve sleeve) to be polished is installed on the back-shaped block 8 through screws 9 to ensure that the clamping surface is in close contact with the surface of the structural part, and the back-shaped block 8 is installed on the lower end of the steel sheet 2 through bolts 6 on the mounting hole.

[0039] For valve sleeve parts, the technical state before electrolyte-plasma polishing is: 0.01mm process allowance is left between the outer circle and the main hole, the cylindricity of the main hole is <0.005mm, the cylindricity of the outer circle is less than 0.005mm, and the polishing process parameters The concentration of polishing solution is 2%; the polishing temperature is 85°C; the polishing time is 4 minutes. After polishing, the actual measurement: the s...

Embodiment 3

[0041] Taking the spool of the servo valve, the core component of the aerospace servo mechanism, as an example, the schematic diagram installed on the tooling is as follows: Figure 4 As shown, the structure 7 (spool) to be polished is placed in the V-shaped groove of the V-shaped block 11, and the pressure plate 10 is placed on the outer surface, and the pressure plate 10 and the V-shaped block 11 are fixed on the lower end of the steel sheet 2 by screws 9.

[0042] For valve core parts, the technical status before electrolyte-plasma polishing is: 0.01mm process margin is left on the outer circle, the cylindricity of the outer circle is <0.005mm, and the polishing process parameters are: polishing solution concentration 2%; polishing temperature 80 ℃; the polishing time is 5 minutes, and the actual measurement after polishing: the outer contour of the part is evenly blunted R≈0.1, and the tiny burrs on the outer surface are completely removed.

[0043]After measuring the part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com