Patents

Literature

201results about How to "Accurate control precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

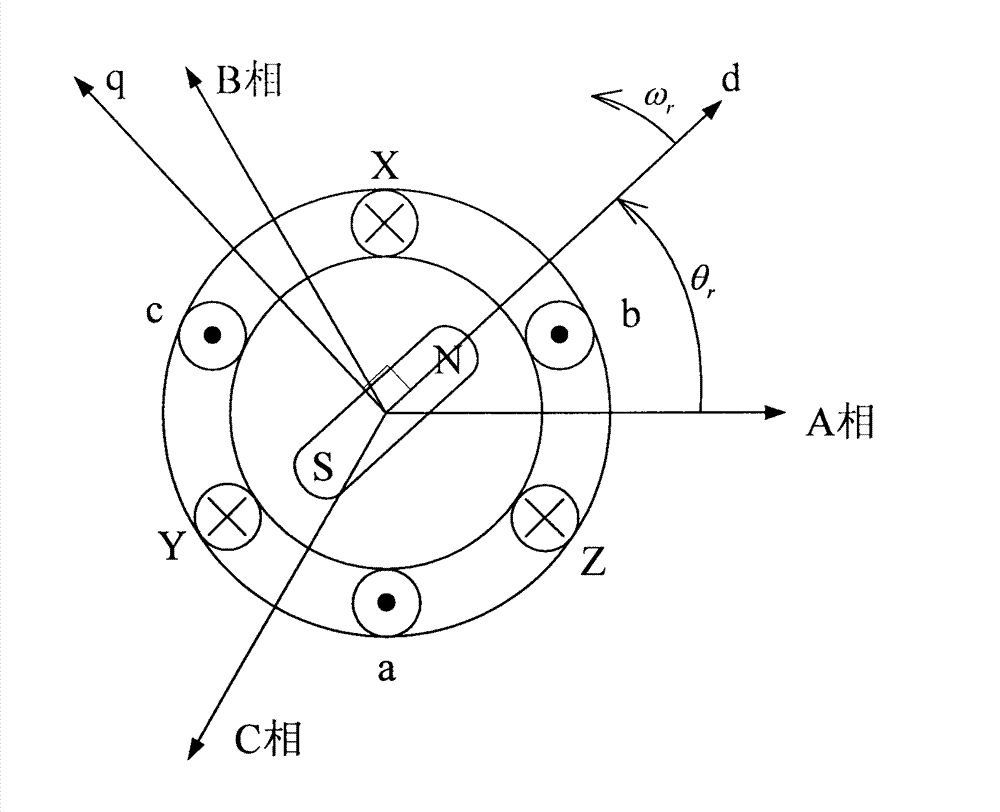

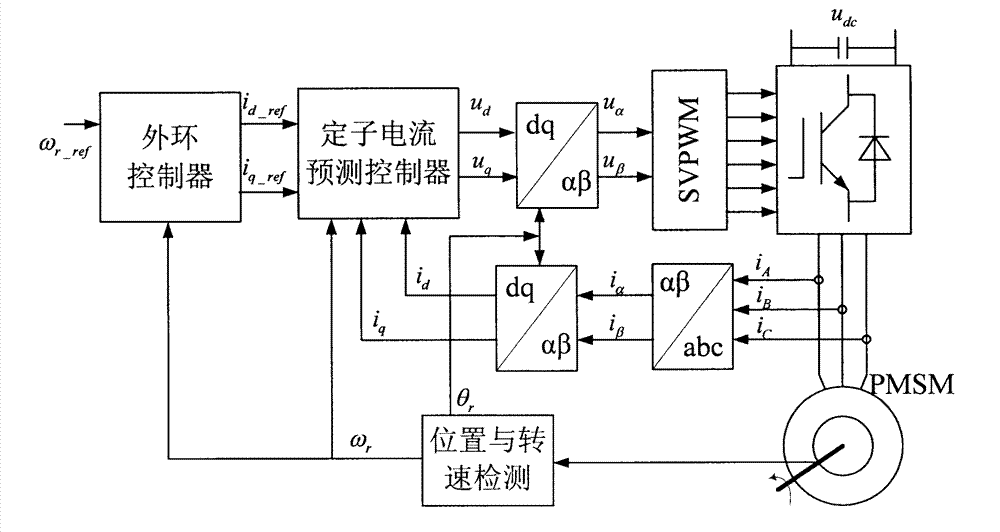

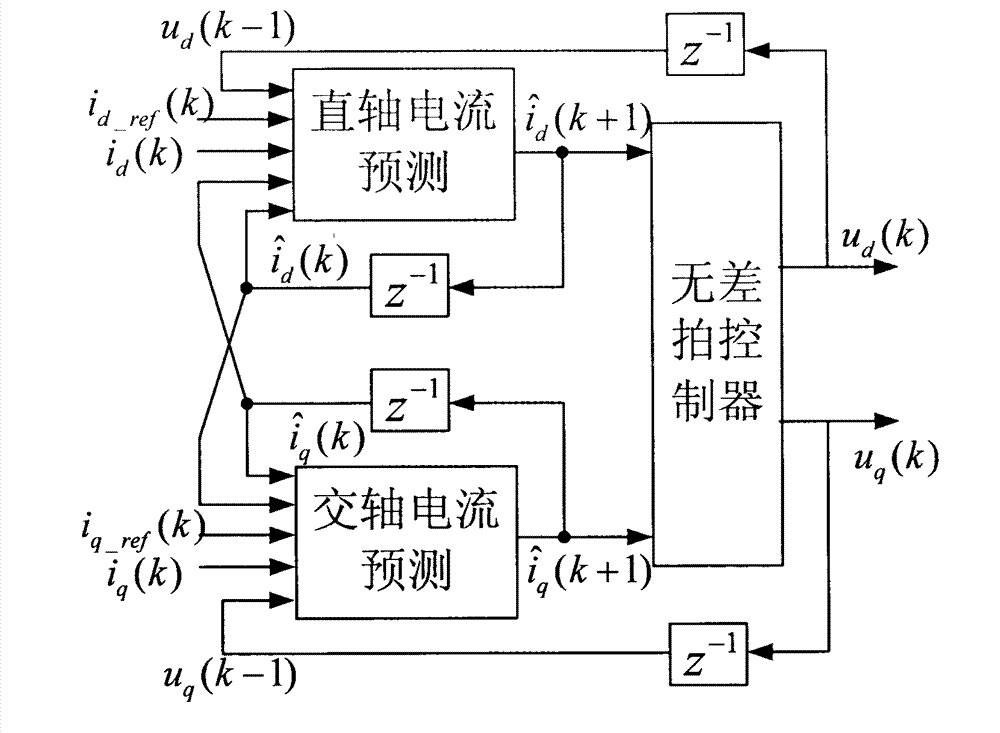

Current predictive control method of permanent magnet synchronous motor

InactiveCN102904520AFast startShorten the timeElectronic commutation motor controlAC motor controlStator voltageControl signal

The invention relates to a current predictive control method of a permanent magnet synchronous motor, which belongs to the electric control field. The dynamic response speed and the control accuracy for the stator current control of the permanent magnet synchronous motor are improved through stator current prediction and deadbeat control, and the system delaying is compensated, so that the noise and the torque ripple of the motor in operation are reduced. The method comprises the steps as follows: obtaining a three phase stator current signal, and the electrical angle and the electrical angular speed of the motor rotor through the technologies of sensor sampling and a photoelectric coded disc or position sensorless detection; carrying out Clarke transformation and Park transformation on the stator current signal to obtain the stator current in a synchronous revolution dq coordinate system; substituting the obtained stator current signal in the dq coordinate system into a control equation of a current predictive controller of the permanent magnet synchronous motor, carrying out deadbeat control according to the given value of the obtained stator current in the dq coordinate system in an outer ring controller to obtain a stator voltage vector in the dq coordinate system; carrying out Park inverse transformation on the obtained stator voltage vector in the dq coordinate system, to obtain a pulse-width modulation (PWM) control signal of an inverter by a space vector pulse width modulation (SVPWM) method, controlling the stator current through the inverter, and then implementing the current predictive control over the permanent magnet synchronous motor.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

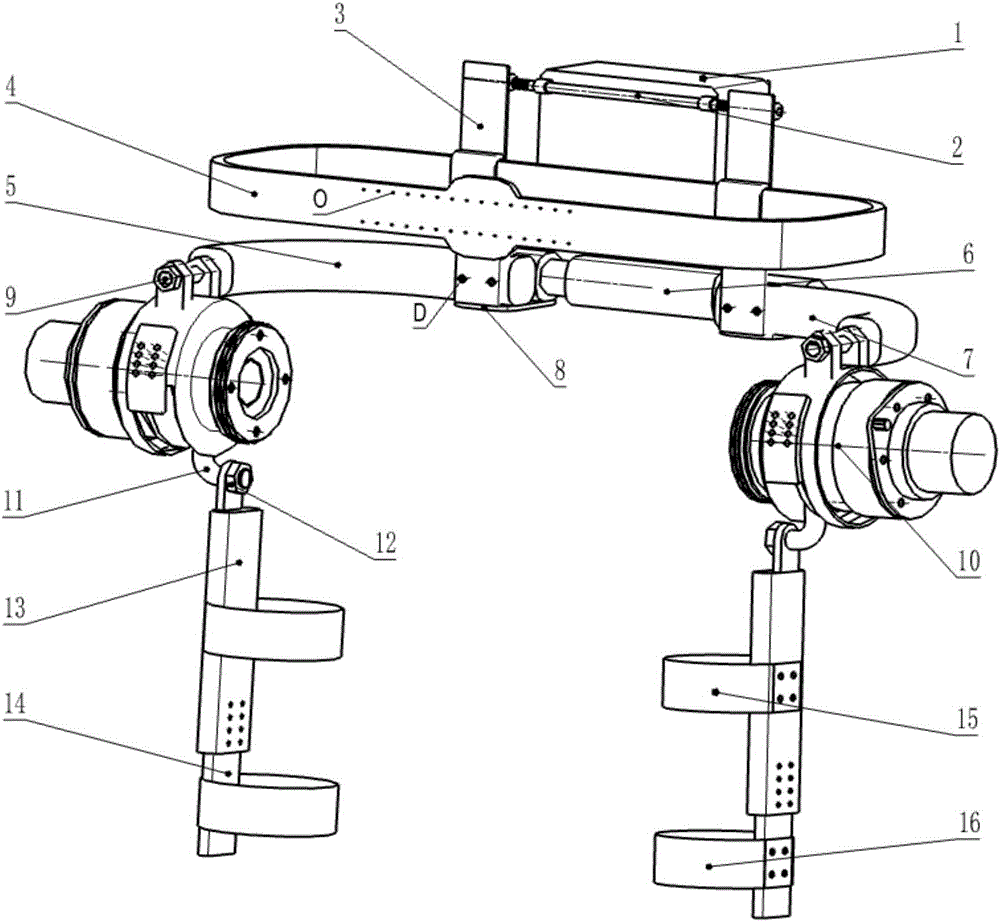

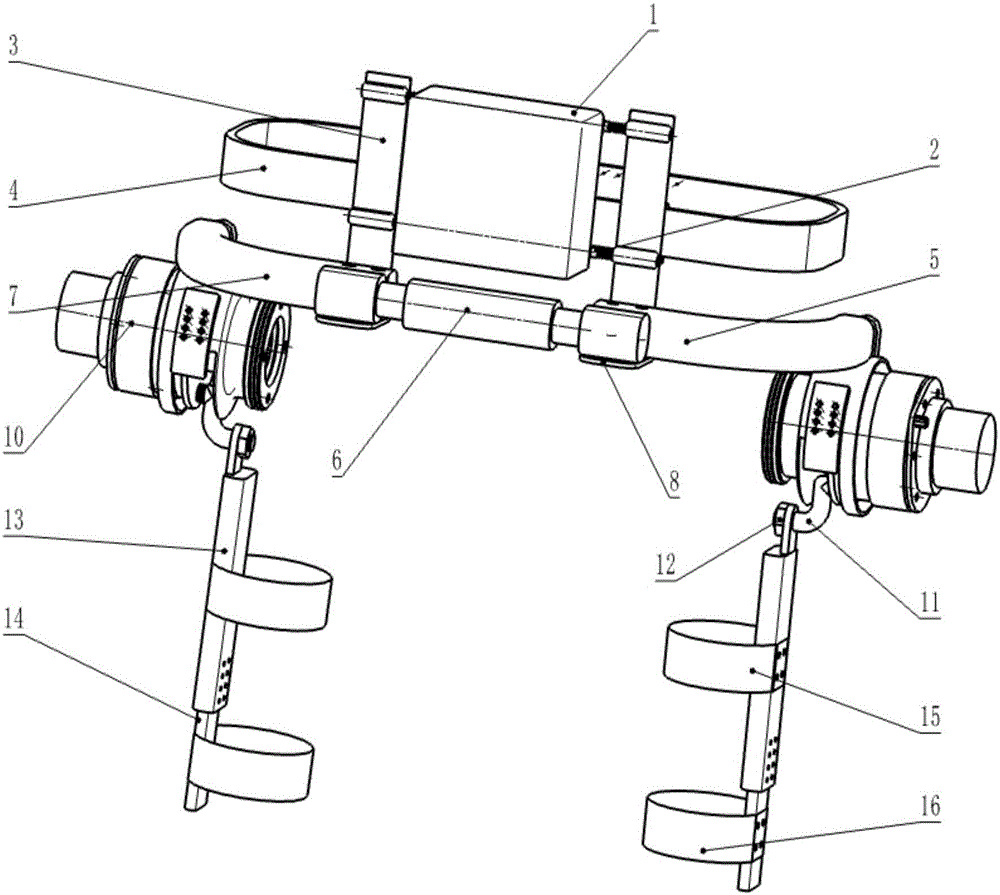

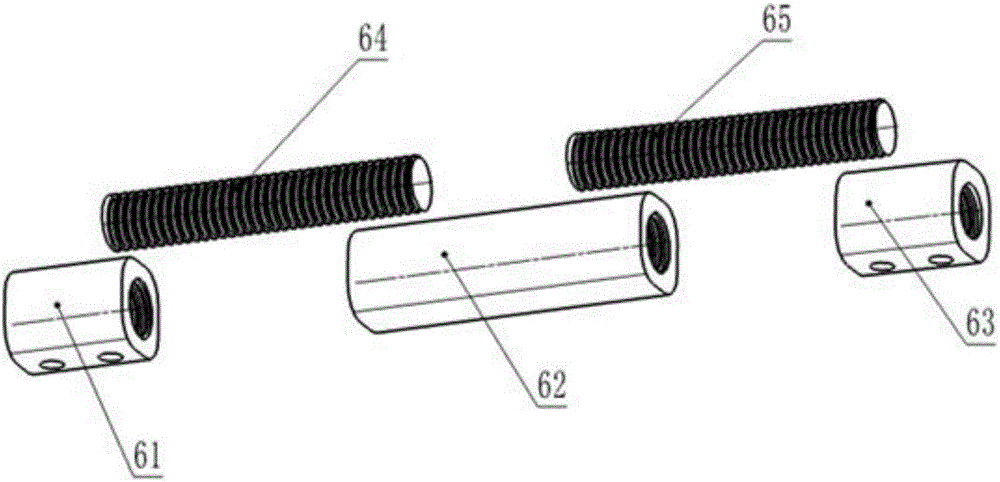

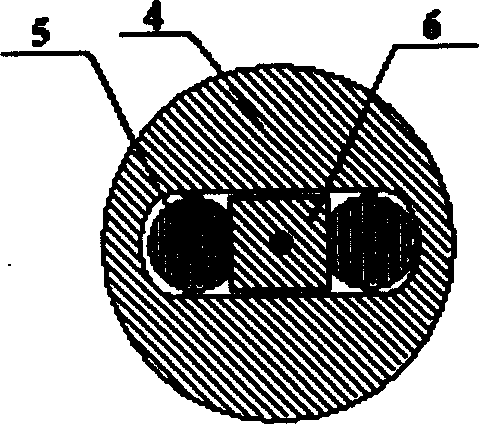

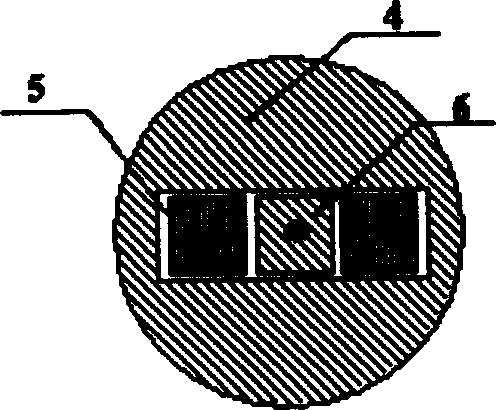

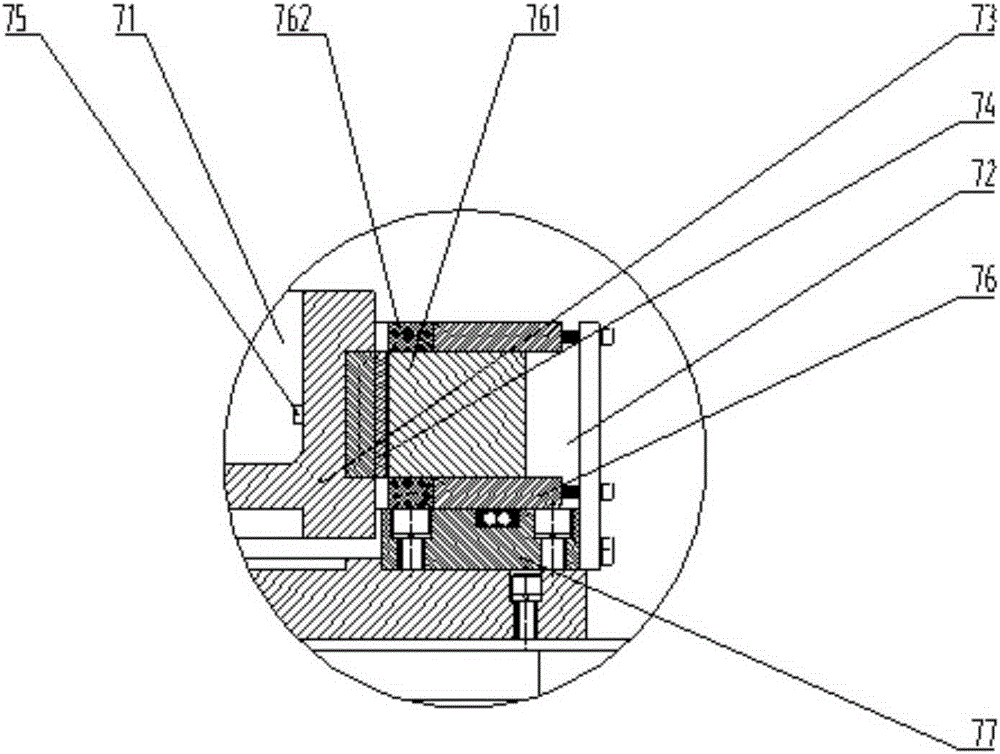

Portable hip joint assisting mechanism

InactiveCN106142056ASuitable for everyday wearAccurate control precisionProgramme-controlled manipulatorThighMotor drive

The invention provides a portable hip joint assisting mechanism. A left waist support and a right waist support are the same in structure, i.e., both of an L-shaped structure. One ends of the left waist support and the right waist support are fixedly connected to two sides of a waist adjusting mechanism by means of connecting flanges. Two back support plates are fastened and connected to side surfaces of the left waist support and the right waist support by means of screws, and both perpendicular to the waist supports. Two support connecting rods arranged in parallel up and down are in threaded connection with the back support plates. A control box is suspended to the support connecting rods. A waist belt passes through sleeve holes in the middle portions of the back support plates. Hip driving mechanisms are located at lower sides of the waist supports and in threaded connection with the other ends of the left waist support and the right waist support by means of connecting shafts. A joint execution mechanism is formed by a first thigh connecting rod, a second thigh connecting rod, a first thigh binding band and a second thigh binding band. The portable hip joint assisting mechanism provides a motor-driven hip joint assisting mechanism for providing extra torque with the requirements of simple structure, low weight, safety and controllability and high practical and economical values on the mechanism.

Owner:JIANGSU UNIV

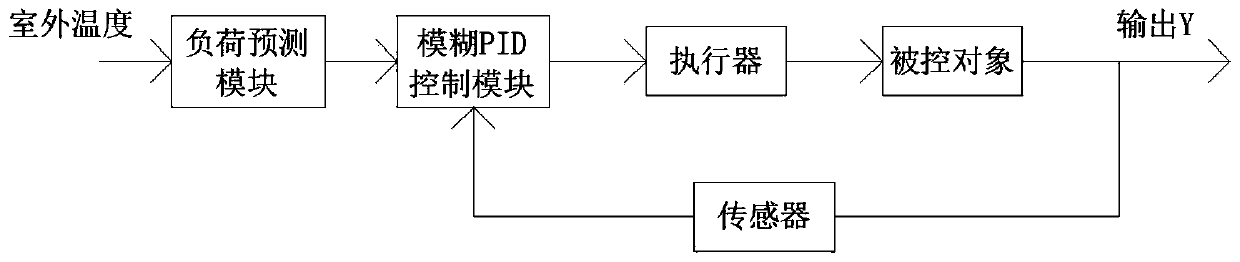

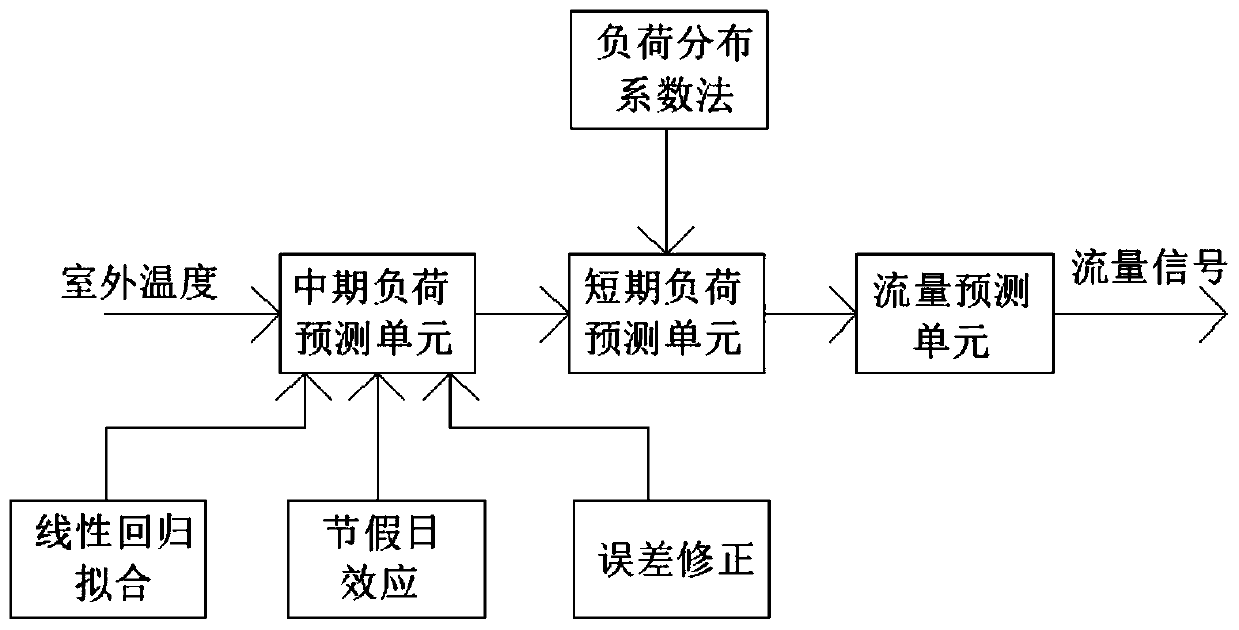

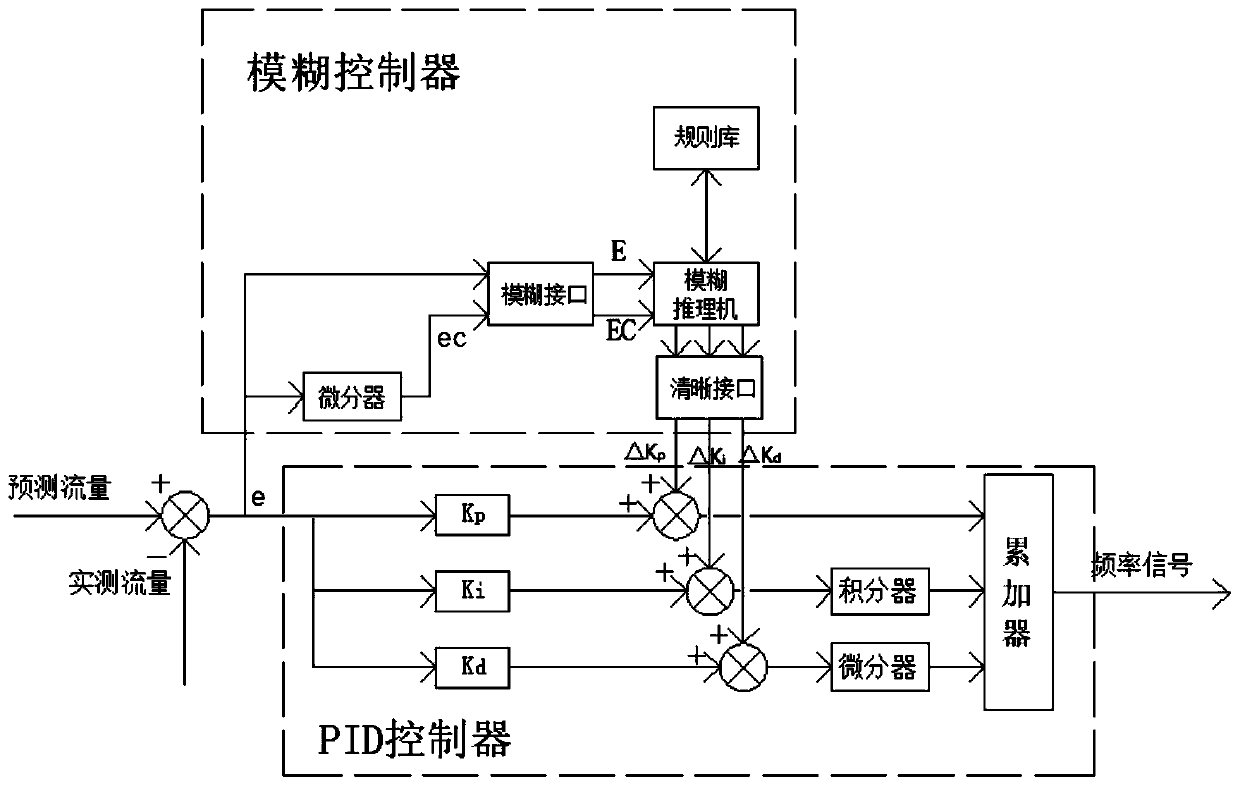

Refrigeration house temperature feedforward-fuzzy control system based on dynamic load variation and control method

ActiveCN109708258AAccurate predictionImprove controlMechanical apparatusSpace heating and ventilation safety systemsFrequency changerTraffic prediction

The invention discloses a central air conditioning fuzzy PID control system based on load prediction control. The system comprises a load prediction module, a fuzzy PID control module, an executor, acontrolled object and a sensor. The load prediction module is composed of three load prediction units including the medium-term load prediction unit, the short-term load prediction unit and the flow prediction unit. A load prediction controller calculates the required chilled water flow of a current chilled water system according to history operating data and an outdoor temperature, then the required frequency of a chilled water pump is calculated by means of the intelligent fuzzy PID control system, finally, the rotating speed of the water pump is changed through a water pump frequency changer, variable flow control of central air conditioning chilled water is completed, and therefore, the system has the energy-saving benefit. By means of the refrigeration house temperature feedforward-fuzzy control system based on dynamic load variation and the control method, the phenomena that temperature control through a traditional central air conditioning system chilled water control scheme lags, and the control precision is not high are avoided, early response of a flow control system is achieved, and the performance of a central air conditioning system is guaranteed.

Owner:NANJING DARSY ENERGY TECH CO LTD

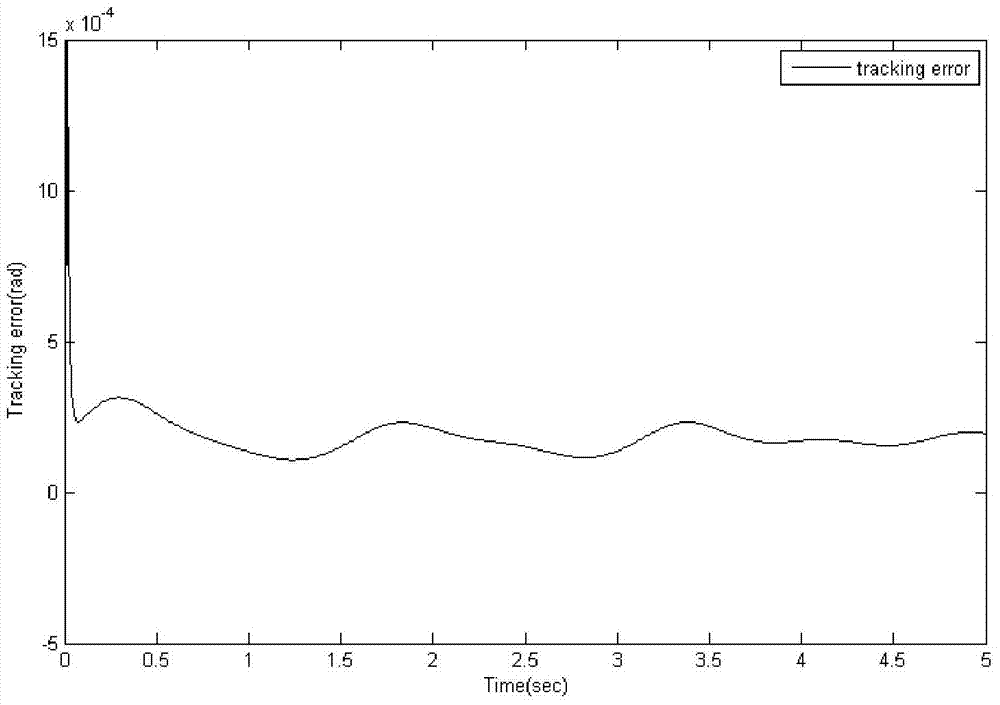

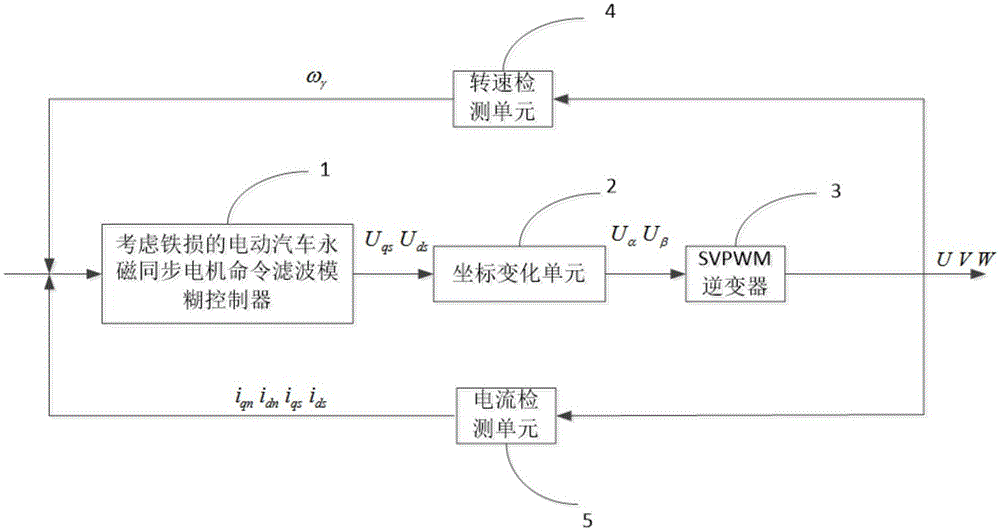

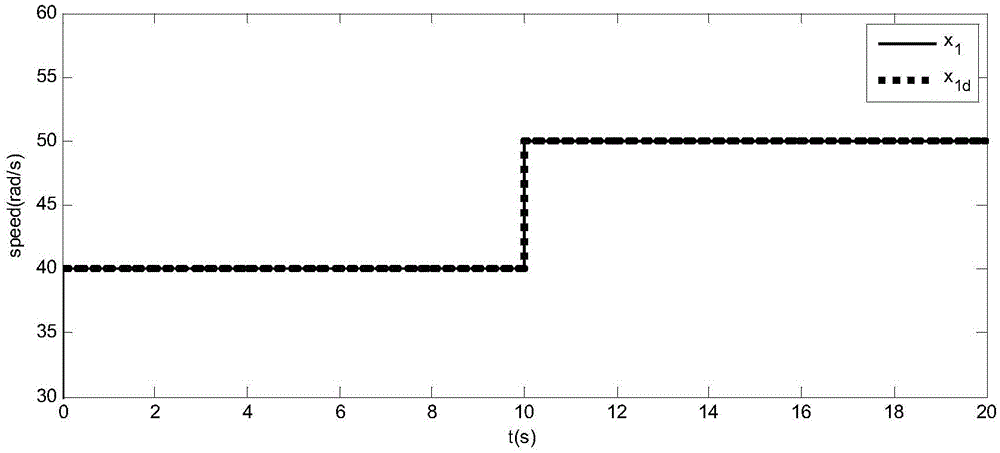

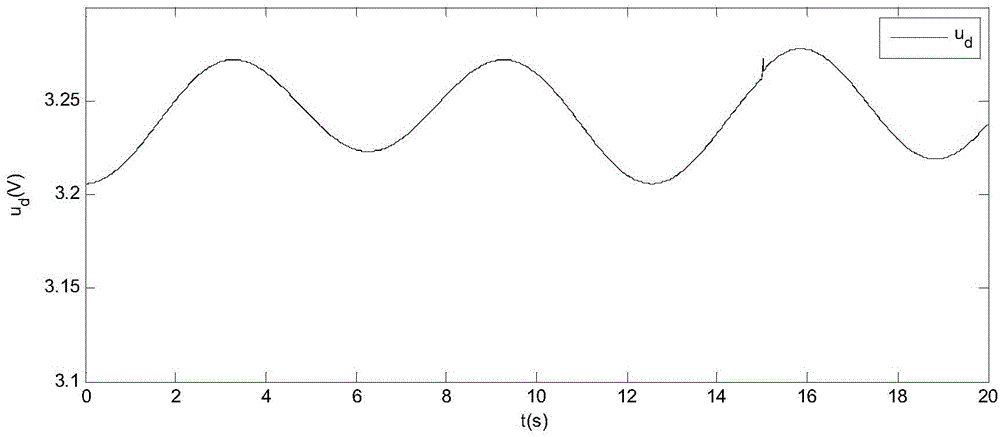

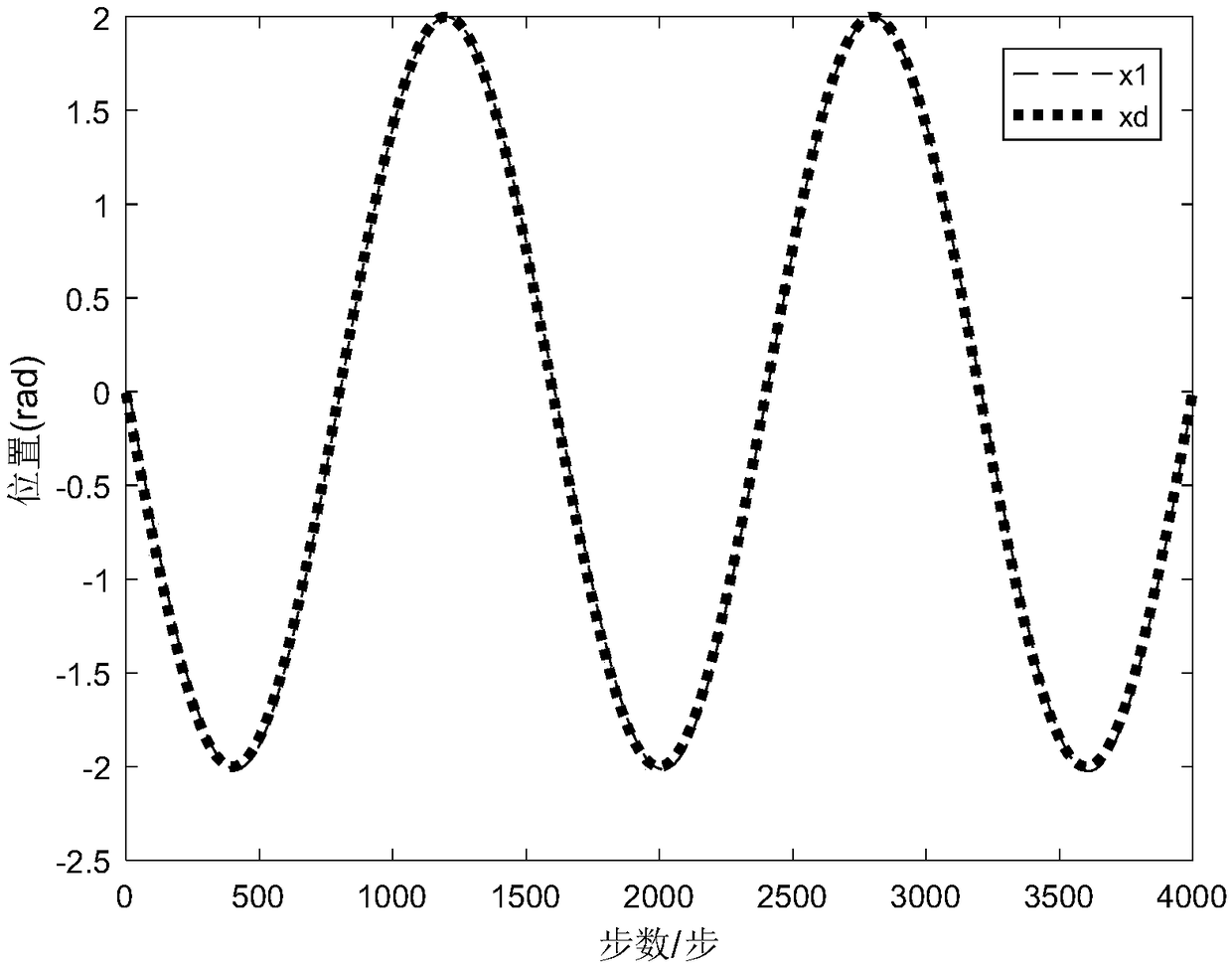

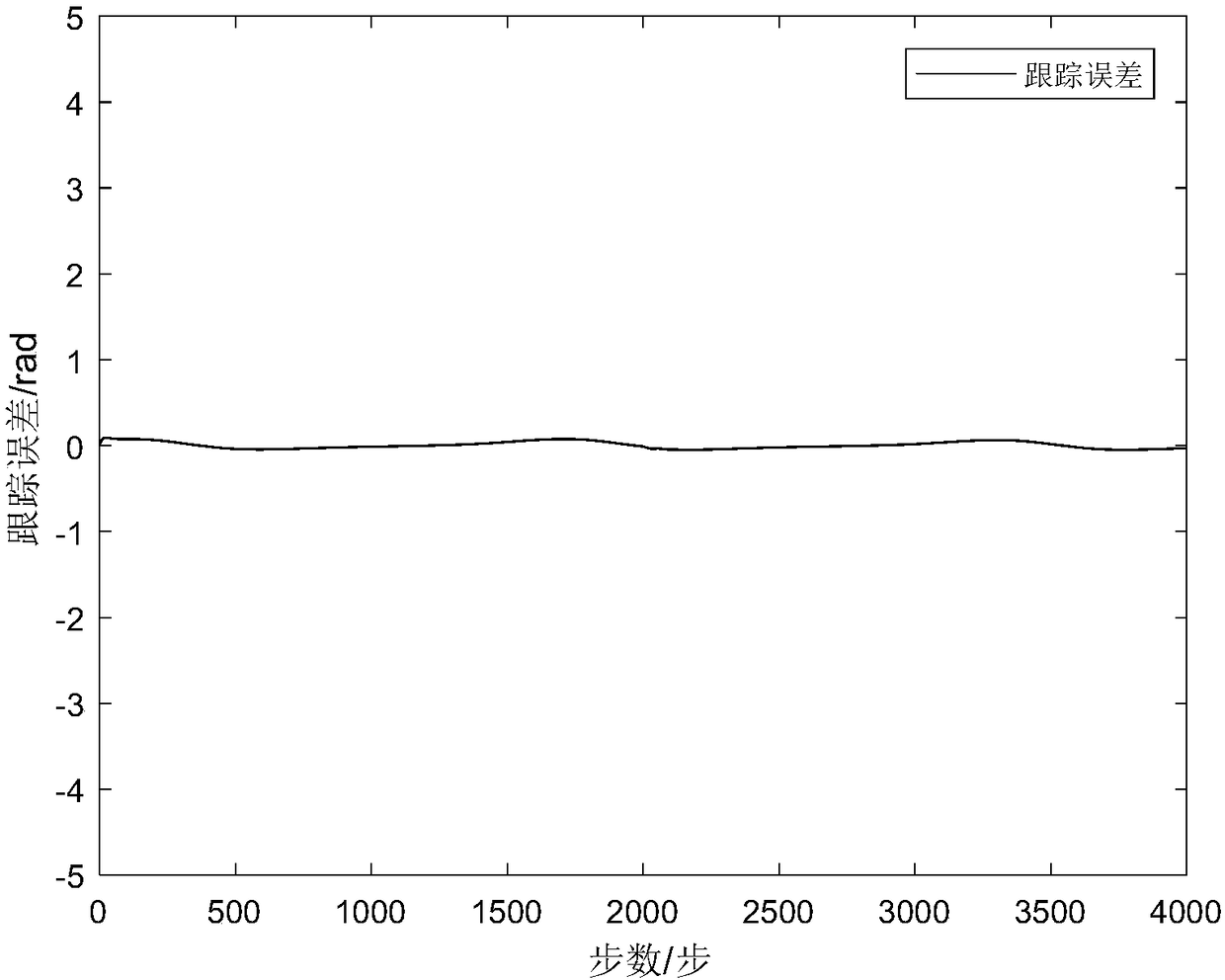

Control method of driving system of permanent magnet synchronous motor of electrical automobile considering iron loss

InactiveCN103701371ASolve the problem of position tracking controlSolving Nonlinear Control ProblemsElectronic commutatorsBacksteppingSynchronous motor

The invention discloses a control method of a driving system of a permanent magnet synchronous motor of an electrical automobile considering iron loss, and provides a control method of a driving system of a permanent magnetic synchronous motor considering iron loss based on a self-adaptive fuzzy backstepping method, which solves the non-linear problem of the power driving and control system of the motor of the electrical automobile, enables the motor to quickly reach the stable running state and is more suitable for the control objects requiring quick dynamic response, such as the driving system of the electrical automobile. The control rules u[d] and u[q] only adopt one self-adaptive parameter theta, so as to reduce the calculation amount. The method has the advantages that the problem of position tracking and control of the permanent magnet synchronous motor considering the iron loss under the conditions of orienting to the site and having undetermined parameter and load torque disturbance is solved; the fuzzy logic system is used for approximating to the unknown non-linear item, and the self-adaptive fuzzy backstepping method is used for enabling the tracking error to approximate to 0; the more accurate control precision is reached, and the ideal position tracking and control effect is ensured.

Owner:QINGDAO UNIV

Coater scraper apparatus

ActiveCN103350055AMake sure the thicknessEnsure flatnessLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to a coater scraper apparatus. The apparatus comprises a scraper rack connected to a coater frame, a scarper having a cutting edge corresponding the coating roller of a coater is press-fitted on the scraper rack through a scraper press plate, a scraper rack adjusting shaft paralleling to the scraper rack is movably arranged on the coater frame in a penetrating mode, the scraper rack is connected with the scraper rack adjusting shaft and rotate around the scraper rack adjusting shaft, an adjusting worm gear is fixedly connected with the scraper rack adjusting shaft in a penetrating mode, the coater frame supports an adjusting worm having a driving cooperation with the adjusting worm gear, and the adjusting worm is connected with a hand wheel. The coater scraper apparatus accurately controls the adjustment between the scraper and the coating roller by adopting the scraper rack rotatablely far from or close to the coating roller and combining the scraper adjusting seat and a trimming cylinder, so the apparatus has the advantages of simple and compact structure, convenient and accurate adjustment, and effective ensure of the thickness of a glue solution on the coating roller for the uniform adjustment, and is suitable for the use of various different specification coating rollers and coating thicknesses.

Owner:泰兴联创绝缘材料有限公司

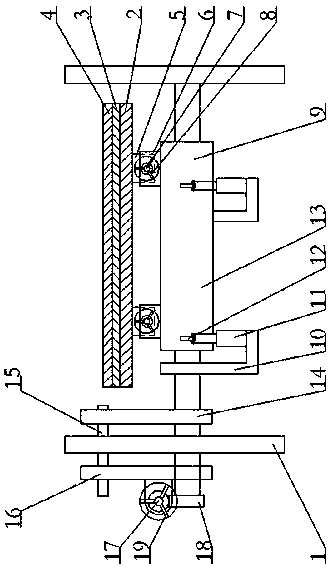

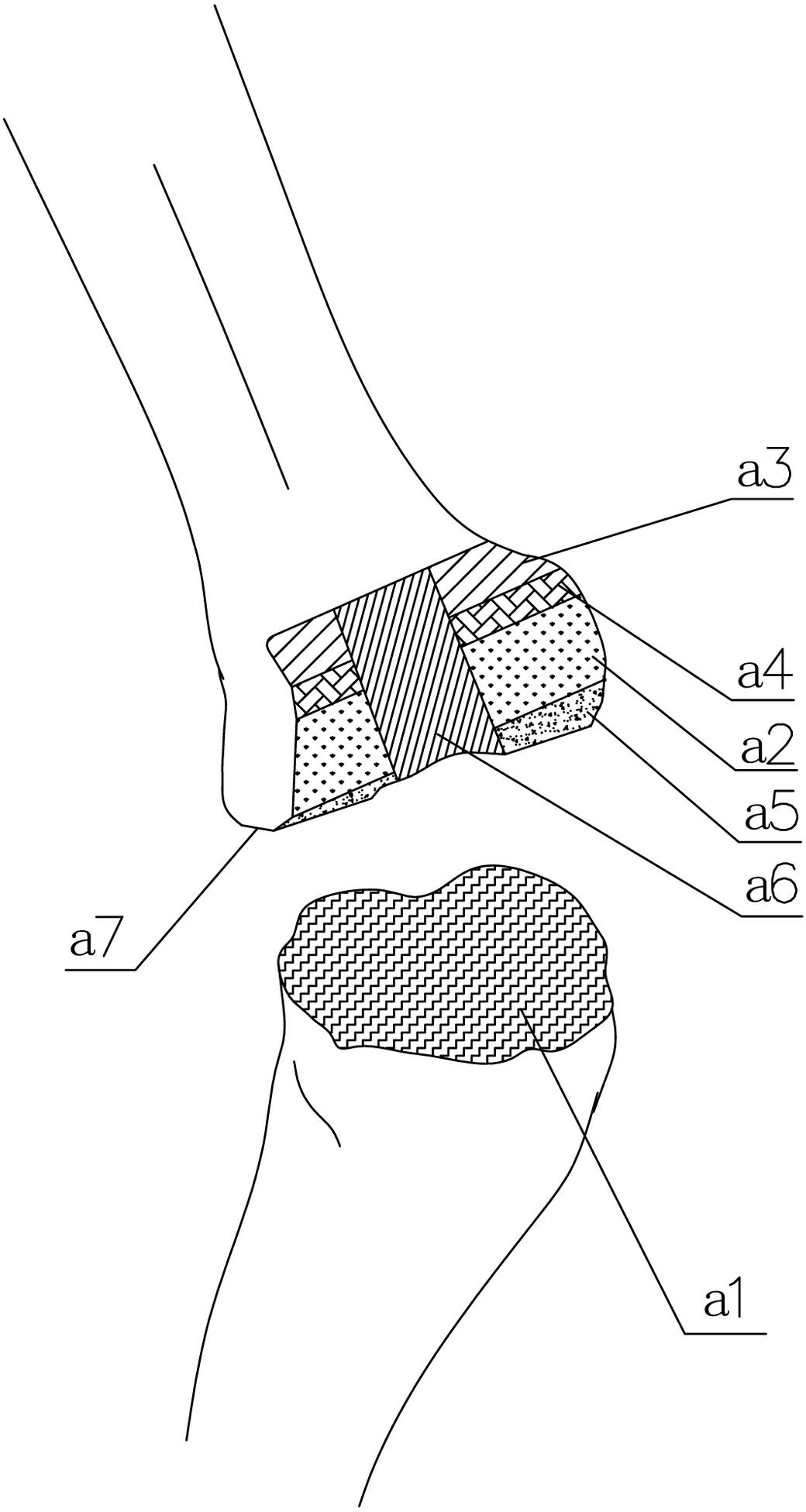

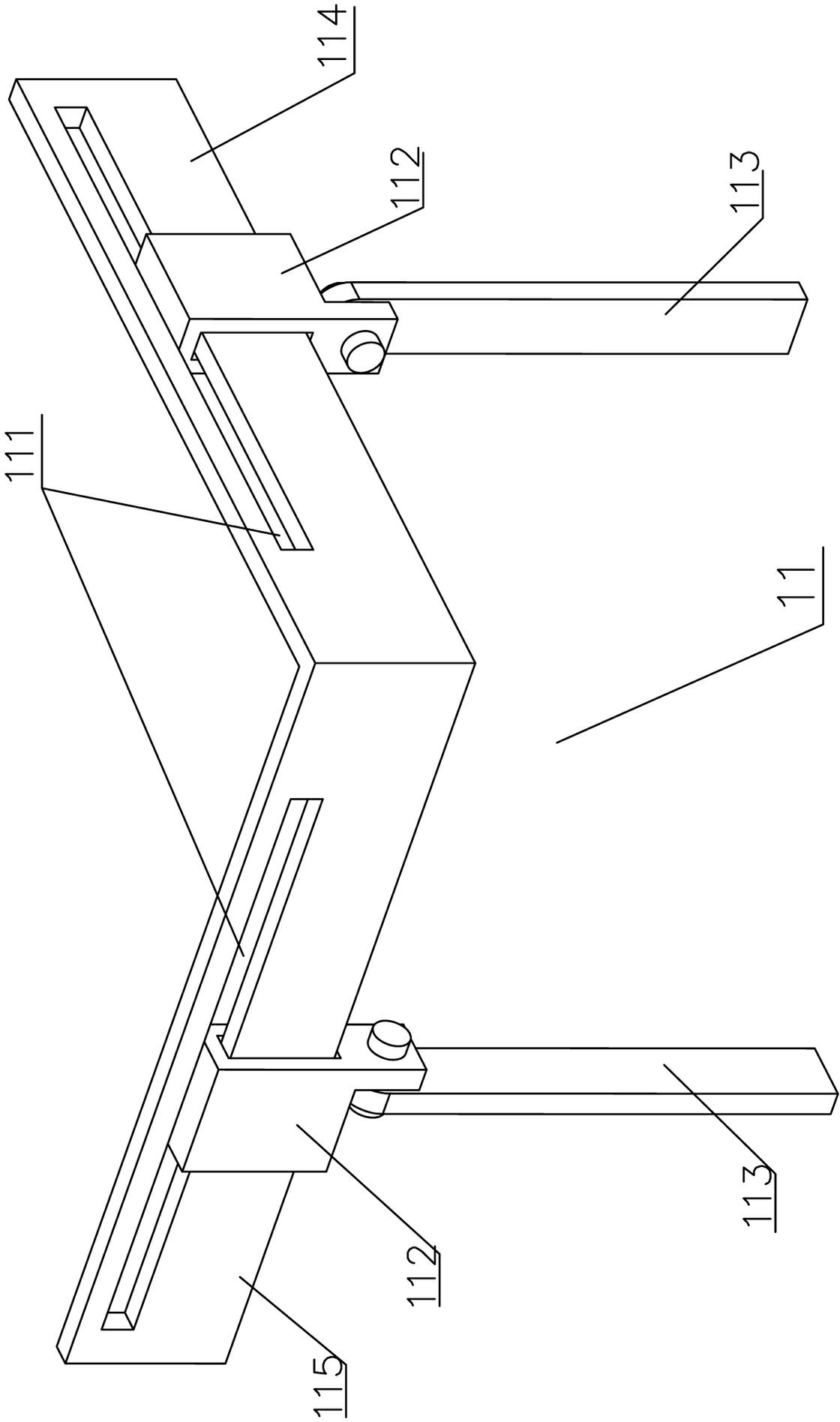

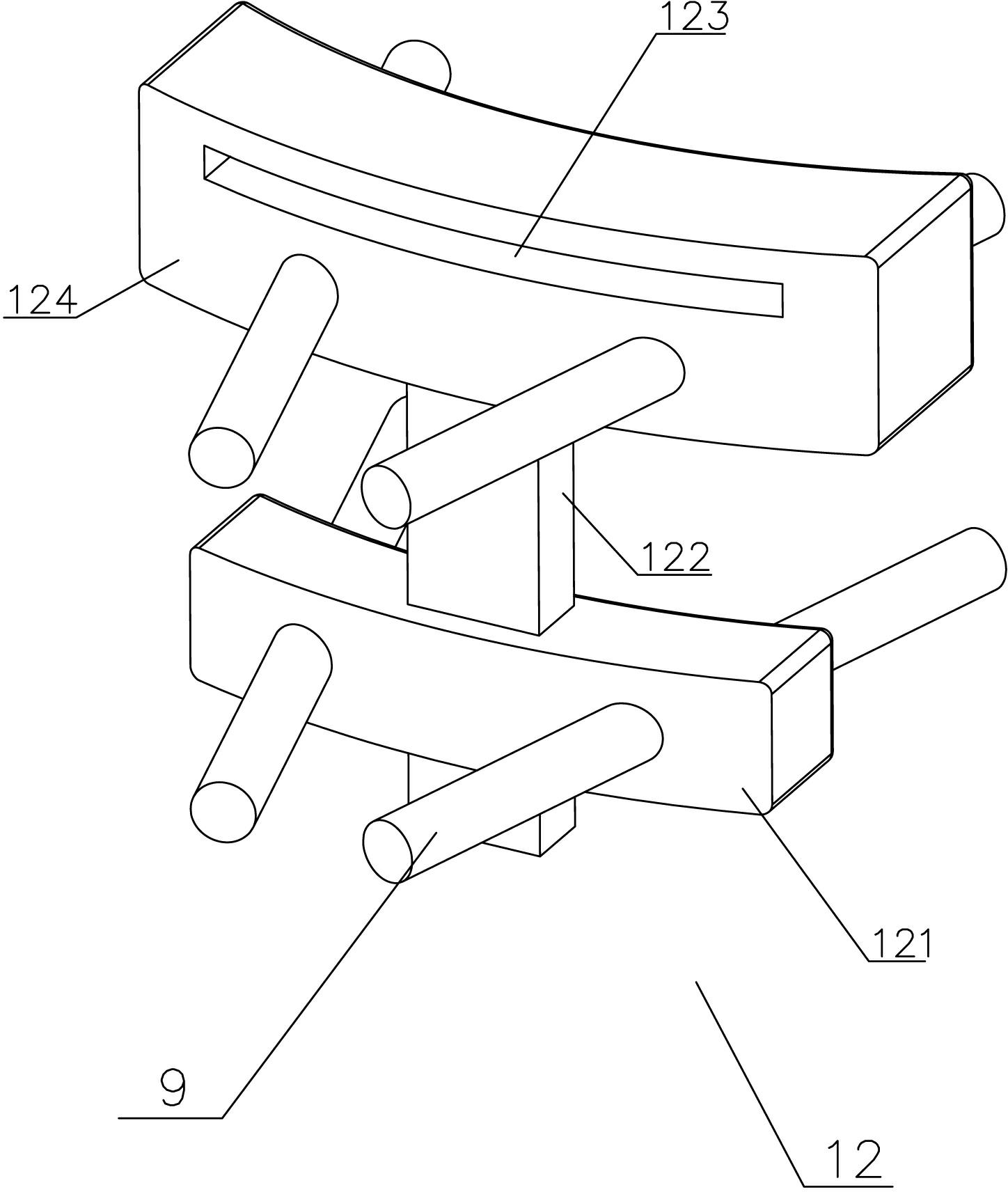

Positioning and bone-cutting system used for minimally invasive artificial knee joint replacement

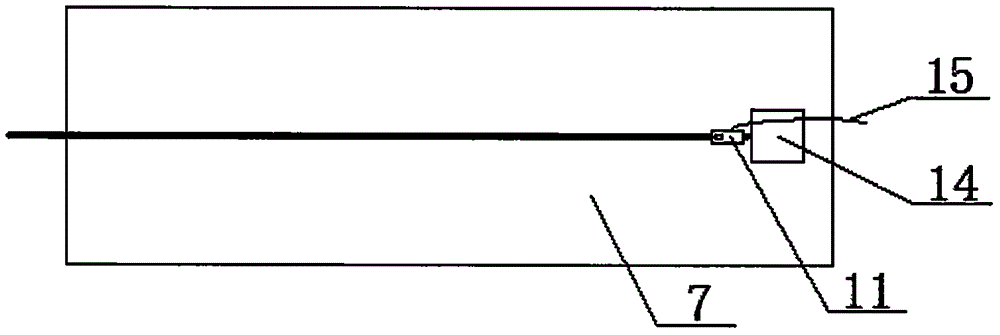

InactiveCN102113910AReduced volume of osteotomy instrumentsImprove performanceDiagnosticsSurgical sawsOrthodonticsPositioning system

The invention discloses a positioning and bone-cutting system used for minimally invasive artificial knee joint replacement, which comprises a positioning sub-system and bone-cutting sub-system, wherein the positioning sub-system comprises a plurality of reference modules and a positioning barrier module coupled with the reference modules; the bone-cutting sub-system comprises a plurality of bone-cutting drills, a plurality of bone-cutting saws, a patella trimming drill used for trimming a patella and a bone cut section trimming drill used for trimming a bone cut section; and the bone-cutting drills and the bone-cutting saws are limited by the positioning barrier module during the operation. In the positioning and bone-cutting system used for the minimally invasive artificial knee joint replacement, the positioning sub-system and the bone-cutting sub-system cooperate to accurately control the bone-cutting precision and the bone-cutting depth, reduce the wound area and protect the soft tissues. The positioning and bone-cutting system used for the minimally invasive artificial knee joint replacement has a simple structure, is easy to use, achieves the effect of rapidly and accurately positioning and cutting the bone, and can be widely applied to minimally invasive artificial knee joint replacement.

Owner:徐栋梁 +1

Electric car permanent magnet synchronous motor command filtering fuzzy control method taking iron loss into account

ActiveCN105024609AStrong ability to resist load disturbanceSolve the problem of speed tracking controlElectronic commutation motor controlVector control systemsPermanent magnet synchronous motorElectric cars

The invention discloses an electric car permanent magnet synchronous motor command filtering fuzzy control method taking iron loss into account. According to the fuzzy control method, a command filtering technology is introduced in a traditional back-stepping design method, error caused by filtering is reduced by introduction of compensation signals, and a problem of 'calculation explosion' caused by continuous derivation in the traditional back-stepping control is overcome successfully. In the control method provided by the invention, a fuzzy logic system is used for approaching a nonlinear function in the system, a command filtering back-stepping technology and a fuzzy self-adaptive method are combined together to form a fuzzy self-adaptive speed controller; after being regulated by the control method provided by the invention, a motor can quickly run in a steady state, and the control method is more suitable for a control object needing fast dynamic response, such as an electric car drive system; simulation result shows that, with the control method provided by the invention, influence caused by inaccuracy of parameters can be overcome, ideal control effect is guaranteed beneficially, and fast and steady response to revolving speed is realized.

Owner:QINGDAO UNIV

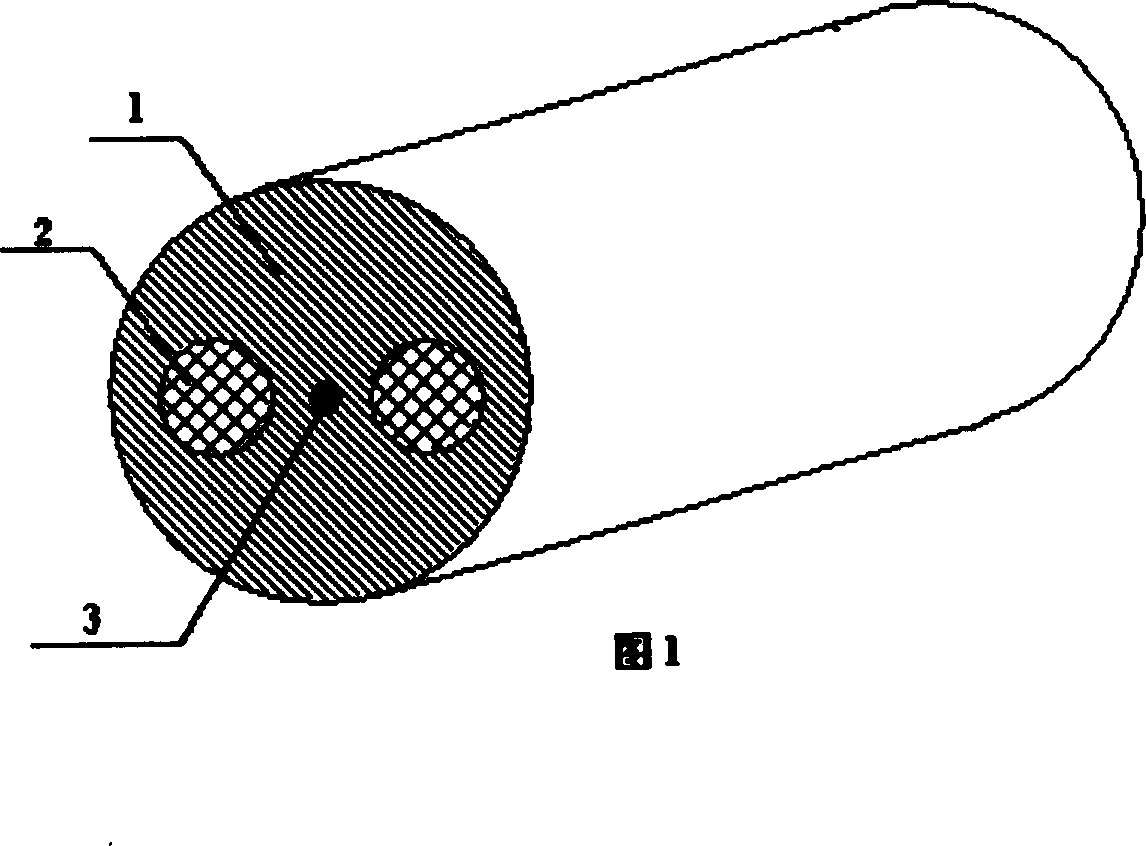

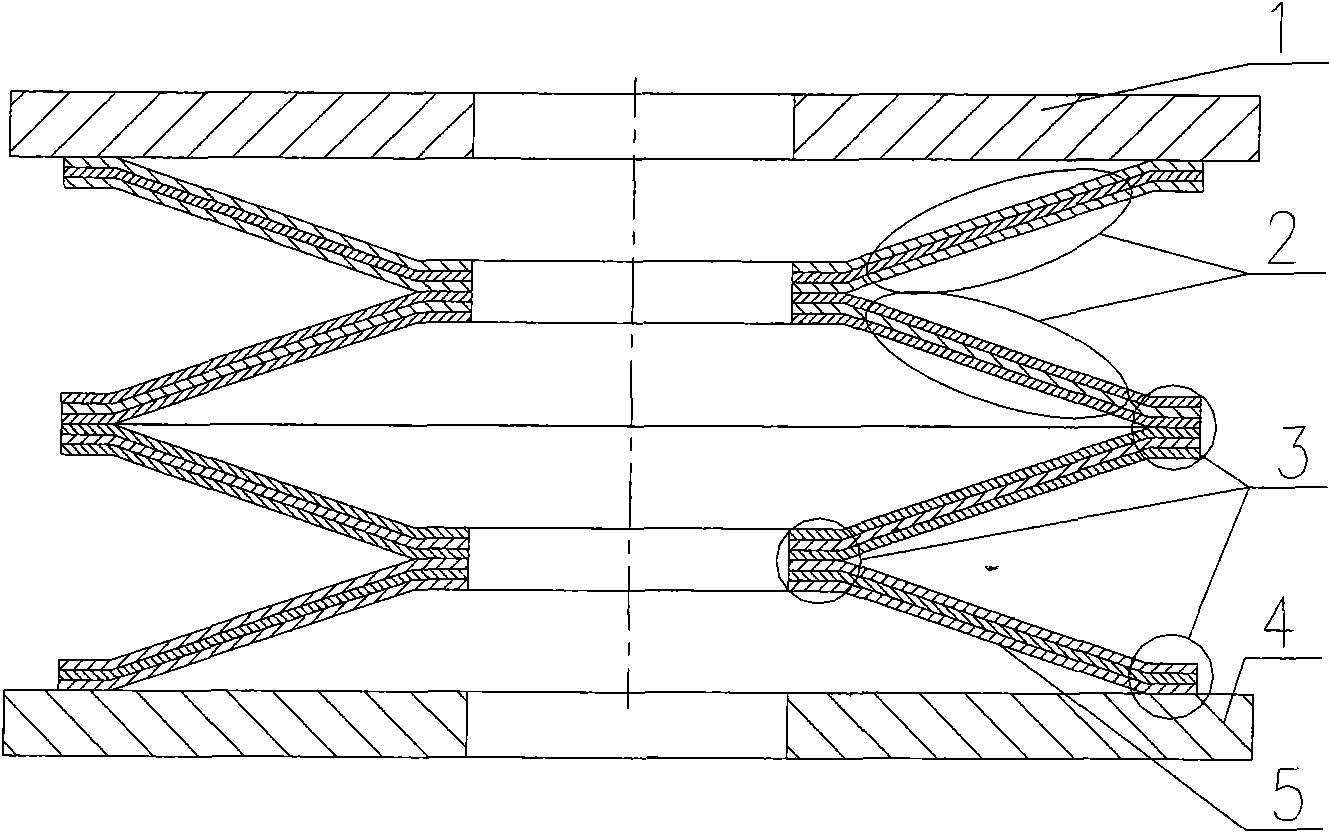

Method for producing polarization maintaining optical fibre

ActiveCN1557754AReduce processing stressReduce residual stressGlass making apparatusOptical light guidesPolarization-maintaining optical fiberEngineering

The making process of circular polarization maintaining fiber includes deposition process to make core rod and stress rod with preserved coating, machining mechanically the matched sides of the core rod and the stress rod to reach the matching interval requirement, machining mechanically the inner hole of quartz casing for fitting the combined cross section of the core rod and the stress rod, setting the machined core rod and stress rod into the quartz casing for matching tightly to constitute prefabricated rod for circular polarization maintaining fiber, drawing, cleaning, and re-drawing to form fiber. The making process has high precision, high product quality and powerful adaptability, and is suitable for mass producing circular polarization maintaining fiber product.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

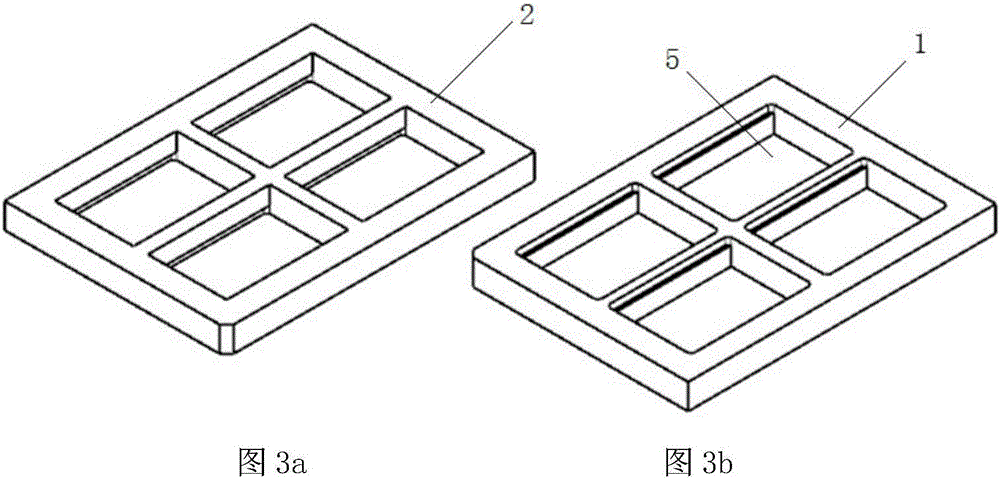

Glass heating graphite mold and production method thereof

ActiveCN106746526AImprove molding qualityGood for mass productionGlass reforming apparatusGlass productionGraphiteMaterials science

The invention discloses a glass heating graphite mold and a production method thereof. The mold comprises a front mold and a rear mold, wherein the front mold comprises a front mold base and a front mold core made of a graphite material; the rear mold comprises a rear mold base and a rear mold core made of the graphite material; a cavity matched with the front mold core is formed in the front mold base; the front mold core is arranged in the cavity of the front mold base; a cavity matched with the rear mold core is formed in the rear mold base; the rear mold core is arranged in the cavity of the rear mold base; intermediate areas of opposite surfaces of the front mold core and the rear mold core are three dimensional curved surfaces suitable for processing to obtain hot bending glass during mold closing; edge areas of the opposite surfaces of the front mold core and the rear mold core are respectively provided with a plurality of supporting insert via holes; supporting inserts are arranged in the supporting insert via holes; when the mold is closed, the supporting inserts, which are oppositely arranged, on the front mold core and the rear mold core, make contact with one another, so that the effects of positioning and supporting the mold cores are realized, and the pressures of the mold cores are borne. According to the glass heating graphite mold disclosed by the invention, large-scale mass production is easily realized while the molding quality of the graphite mold is improved.

Owner:DONGGUAN HUAQING OPTICAL TECH

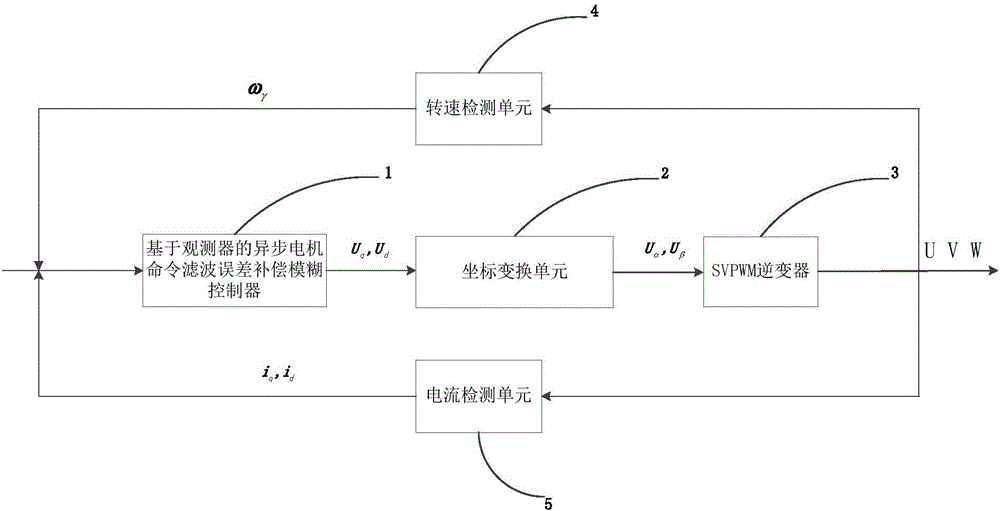

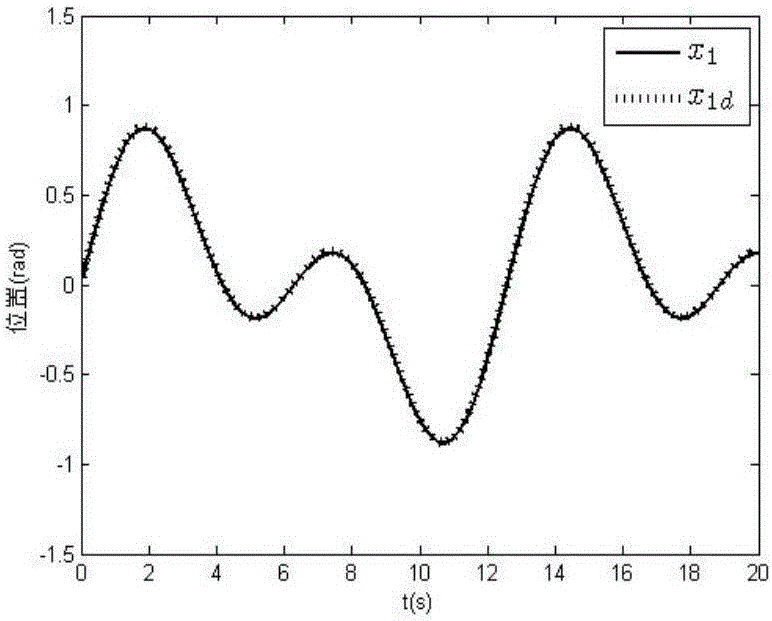

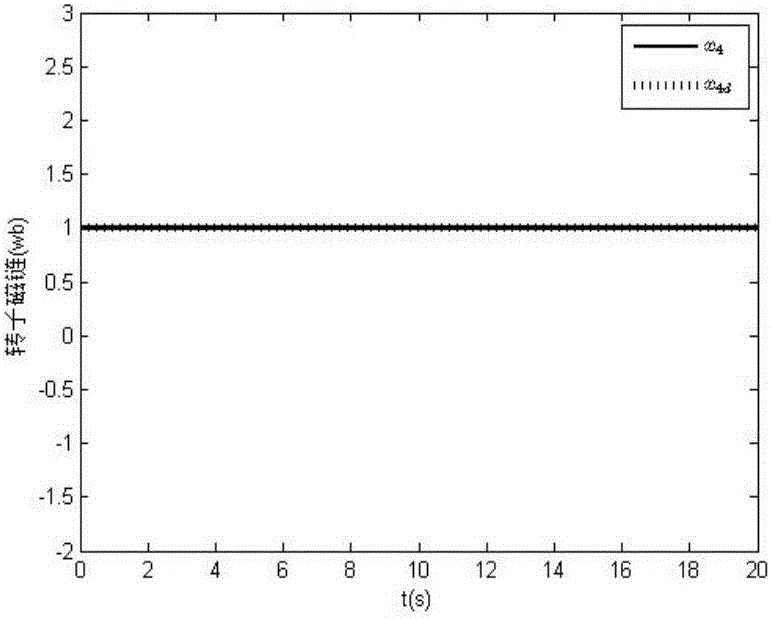

Observer-based command filtering error compensation fuzzy control method of induction motor

ActiveCN106788052ASolve the problem of position tracking controlSolving Nonlinear Control ProblemsElectronic commutation motor controlVector control systemsBacksteppingAdaptive method

The invention discloses an observer-based command filtering error compensation fuzzy control method of an induction motor. Aiming at the problem of non-linearity existing in a driving and control system of the induction motor, a command filtering technology is introduced to a traditional backstepping design method; and meanwhile, by an error compensation mechanism, an error caused by filtering is reduced, so that the control accuracy is improved, and the problem of calculation explosion caused by continuous derivation in traditional backstepping control is successfully solved. According to the method, the rotor angular speed of the induction motor is estimated by a dimension reduction observer; meanwhile, a fuzzy logic system approaches to a non-linear function in the motor driving system, and the command filtering backstepping technology is combined with an adaptive method to construct a controller; after regulation by the method, the motor running can rapidly reach a stable state; and a simulation result shows that by the method, the influence of parameter inaccuracy can be solved, an ideal control effect is favorably ensured, and the rapid and stable response to a rotation speed is achieved.

Owner:QINGDAO UNIV

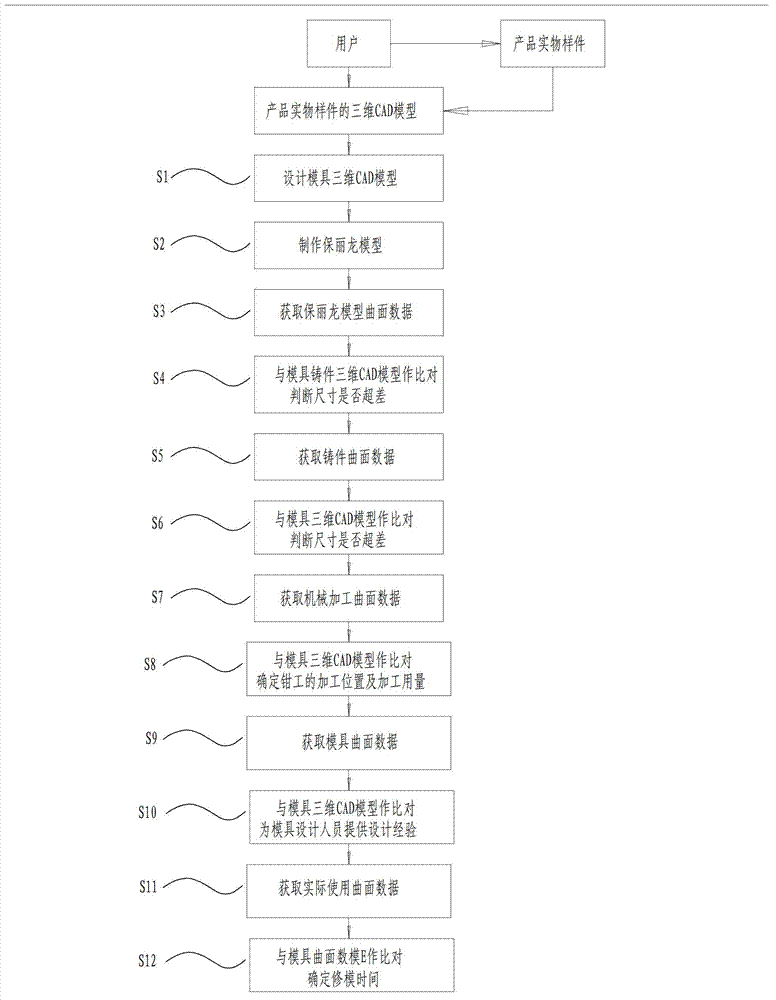

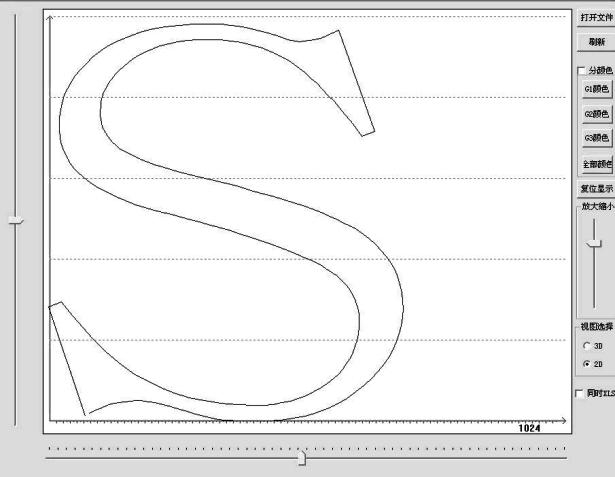

Control method of full-life periodical processing precision of mould

ActiveCN102728729AImprove manufacturing precisionHigh precisionShaping toolsSpecial data processing applicationsComputer Aided DesignComputer science

The invention discloses a control method of full-life periodical processing precision of a mould, and relates to a processing control method of the mould. The control method comprises the following steps of: S1, designing a three-dimensional CAD (Computer-Aided Design) mode of the mould; S2, manufacturing a Styrofoam mode; S3, acquiring the curved surface data of the Styrofoam mode; S4, comparing with the three-dimensional CAD mode of the mould cast piece to judge whether the size is out of tolerance; S5, acquiring the curved surface data of the cast piece; S6, comparing with the three-dimensional CAD mode of the mould to judge whether the size is out of tolerance; S7, acquiring the mechanical processing curved surface data; S8, comparing with the three-dimensional CAD mode of the mould to determine the processing position and the processing quantity of a tongman; S9, acquiring the curved surface data of the mould; S10, comparing with the three-dimensional CAD mode of the mould to provide the design experience for the mould designers; S11, acquiring the actual used curved surface data; and S12, comparing with the curved surface digifax E of the mould to determine the time for modifying the mould. The control method can improve the manufacture precision of the mould and can reduce the manufacturing time of the mould, so that the control method is especially applied to the mould by which the metal plates are directly manufactured as covers.

Owner:柳州市鑫鼎科技有限公司

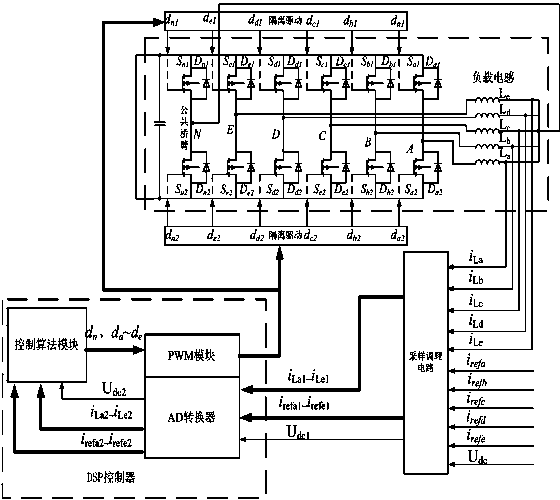

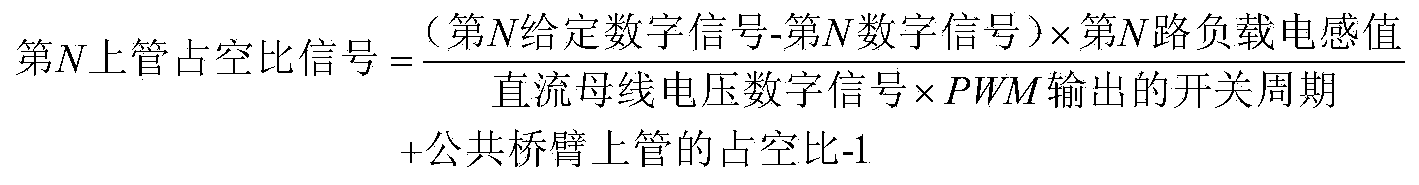

Digital single-cycle control method for multiplexed-output magnetic bearing switch power amplifier

ActiveCN103825480AImprove anti-disturbance abilityFast dynamic responseAc-dc conversionBearingsMagnetic bearingControl signal

The invention discloses a digital single-cycle control method for a multiplexed-output magnetic bearing switch power amplifier. According to the method, the duty ratio of a public bridge arm power device is fixed, only bus voltages, N paths of inductive currents and N paths of given current signals need to be sampled, and the PWM control signals of the power devices of N loaded bridge arms can be obtained through a digital controller in a computing mode. According to the digital single-cycle control method, a public bridge arm does not need to be controlled independently, the digital control structure of the switch power amplifier can be effectively simplifier, few DSP chip resources are occupied, the real-time computing capacity is improved, the changes of the currents with different polarities of N paths of output currents can be met at the same time, the complete decoupling control over the N paths of output currents is achieved, control precision is high, dynamic responses are good, arithmetic speed is high, implementation is simple, and high economic value and practical value are achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

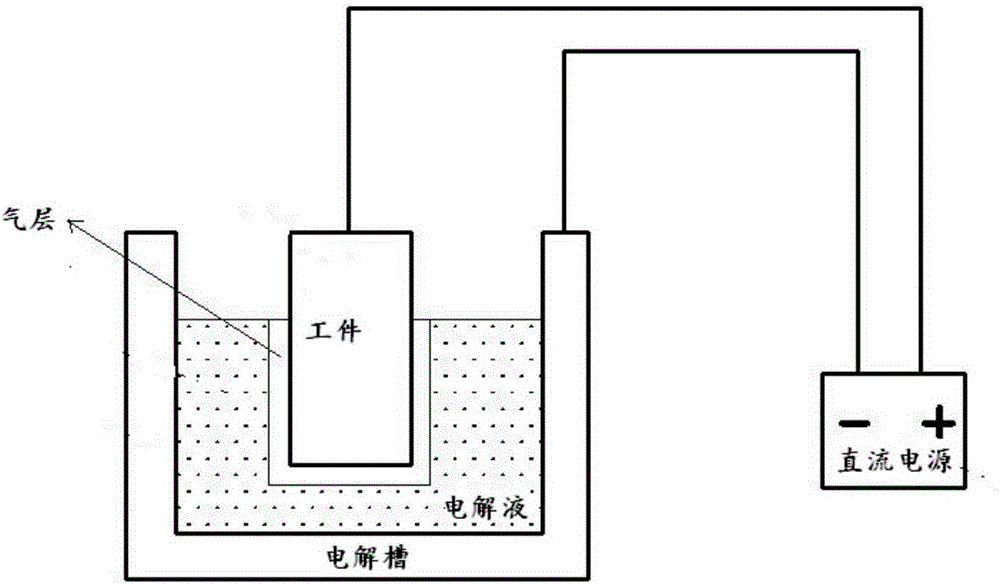

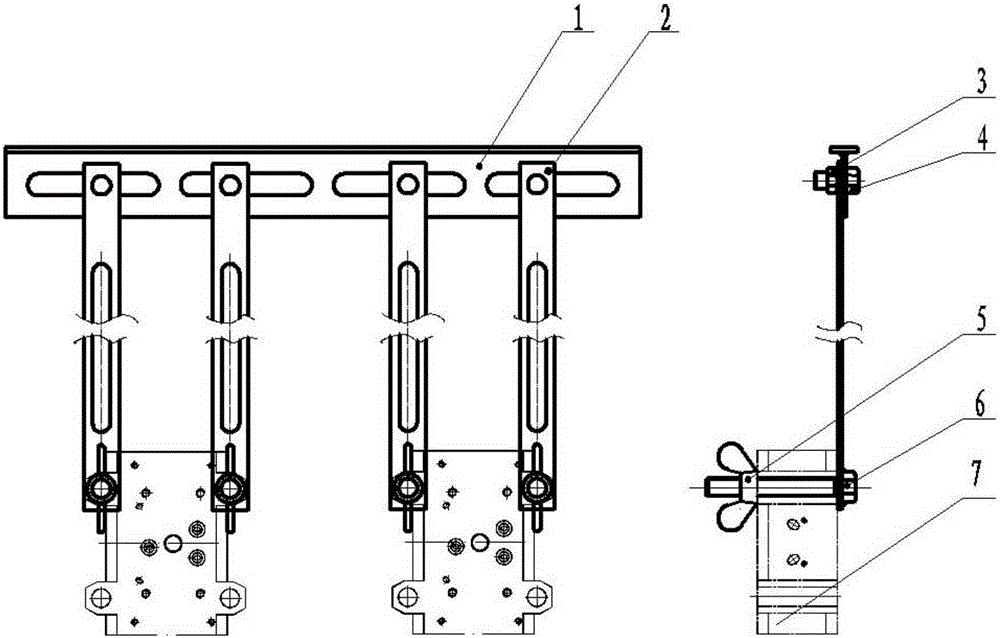

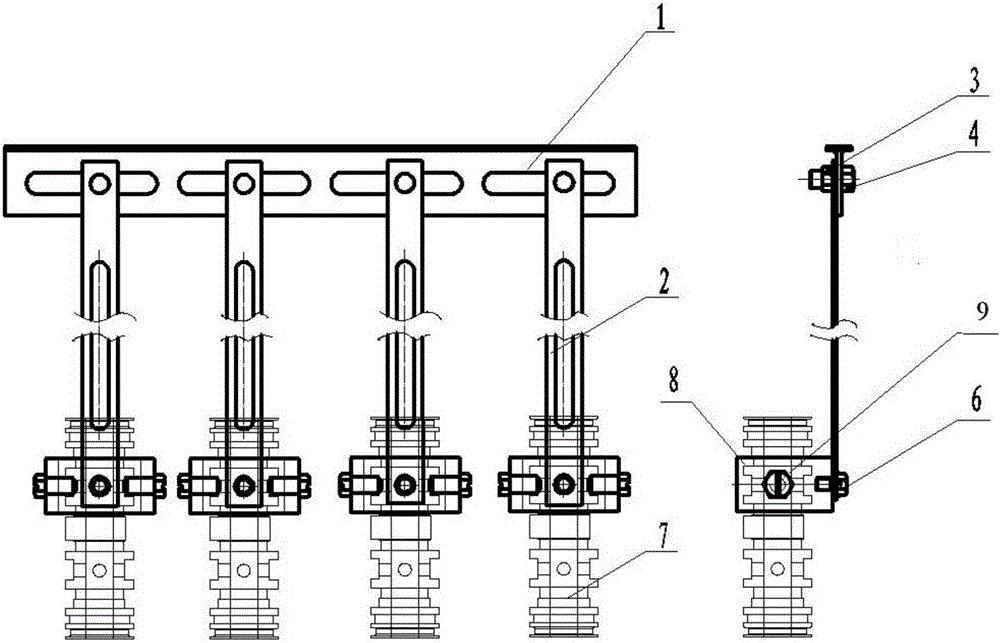

Electrolyte-plasma polishing technique for stainless steel precise structural part

InactiveCN105220218AImprove the finishSolve the existence of tiny glitchesDirect currentAmmonium sulfate

The invention discloses an electrolyte-plasma polishing technique for a stainless steel precise structural part. The electrolyte-plasma polishing technique for the stainless steel precise structural part comprises the following steps that (1) 0.01-0.03 mm technological allowance is set before the stainless steel precise structural part is polished; (2) the stainless steel precise structural part is installed on a special polishing tool, the tool comprises an insertion plate and steel sheets, a plurality of sliding grooves are formed in the insertion plate, one steel sheet is installed in each sliding groove, the steel sheets can slide horizontally along the sliding grooves, the structural part to be polished is fixedly arranged at the lower ends of the steel sheets, the clamping surface of the tool makes close contact with the surface of the structural part, and ablation of the surface of the part caused by abnormal discharging is prevented; (3) ammonium sulfate polishing liquid with the concentration being 2%-4% is added into an electrolytic bath, and the temperature of the polishing liquid is controlled between 80 DEG C and 95 DEG C; and (4) the structural part which is clamped through the tool in the step (2) is placed in the polishing liquid in the step (3), and polishing is conducted through direct currents for 2-10 min.

Owner:北京实验工厂有限责任公司 +1

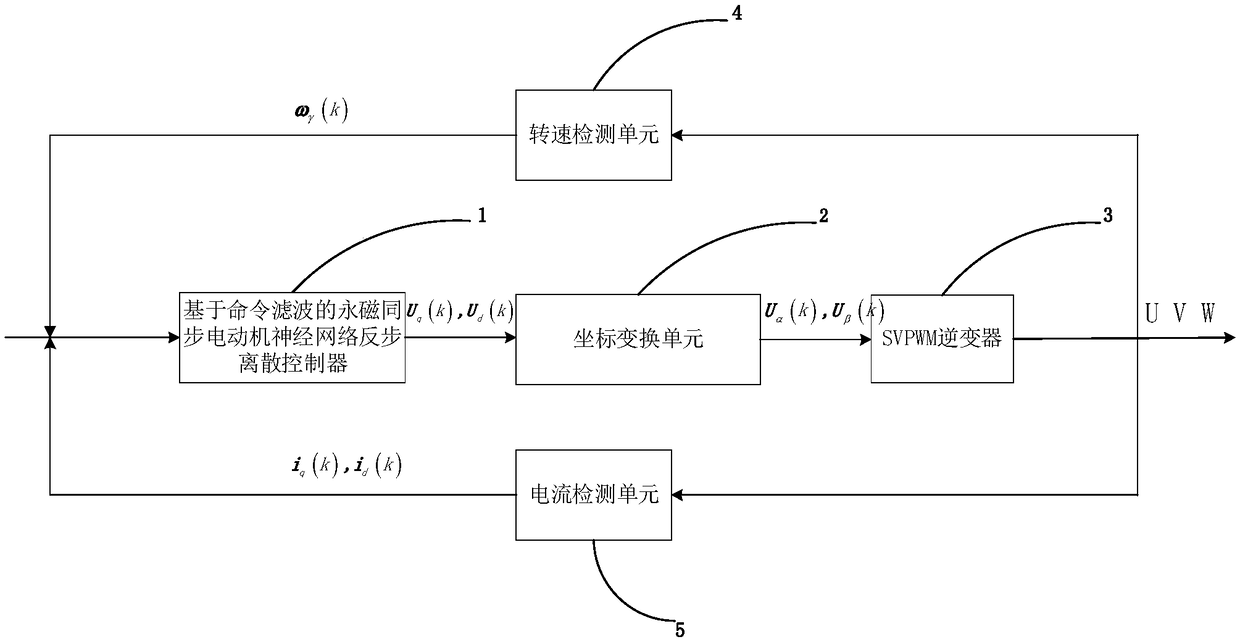

Command filtering-based synchronous motor neural network back-stepping discrete control method

ActiveCN108964545AImprove stabilityImprove realizabilityElectronic commutation motor controlElectric motor controlSynchronous motorController design

The invention discloses a command filtering-based synchronous motor neural network back-stepping discrete control method. In order to solve the problem that a permanent magnet synchronous motor has many variables and strong coupling, and is easily affected by external load and motor related parameter changes, a neural network adaptive controller is designed based on a command filtering technologyand the principle of a back-stepping method; the neural network technology is used to approximate unknown nonlinear terms; the adaptive back-stepping method is applied to the design of the controller;and the command filtering technology is used to solve the problem of computation explosion. According to the method of the invention, complete controller design which is absent in a traditional method is supplemented, so that Lyapunov stability analysis is improved; after being subjected to the control and adjustment of the controller, the operation of a motor can quickly reach a steady state, sothat the motor is more suitable for a control object requiring fast dynamic response; and simulation results show that the novel controller overcomes the influence of parameter inaccuracy, ensures anideal control effect, and achieves the fast and stable tracking of a position.

Owner:QINGDAO UNIV

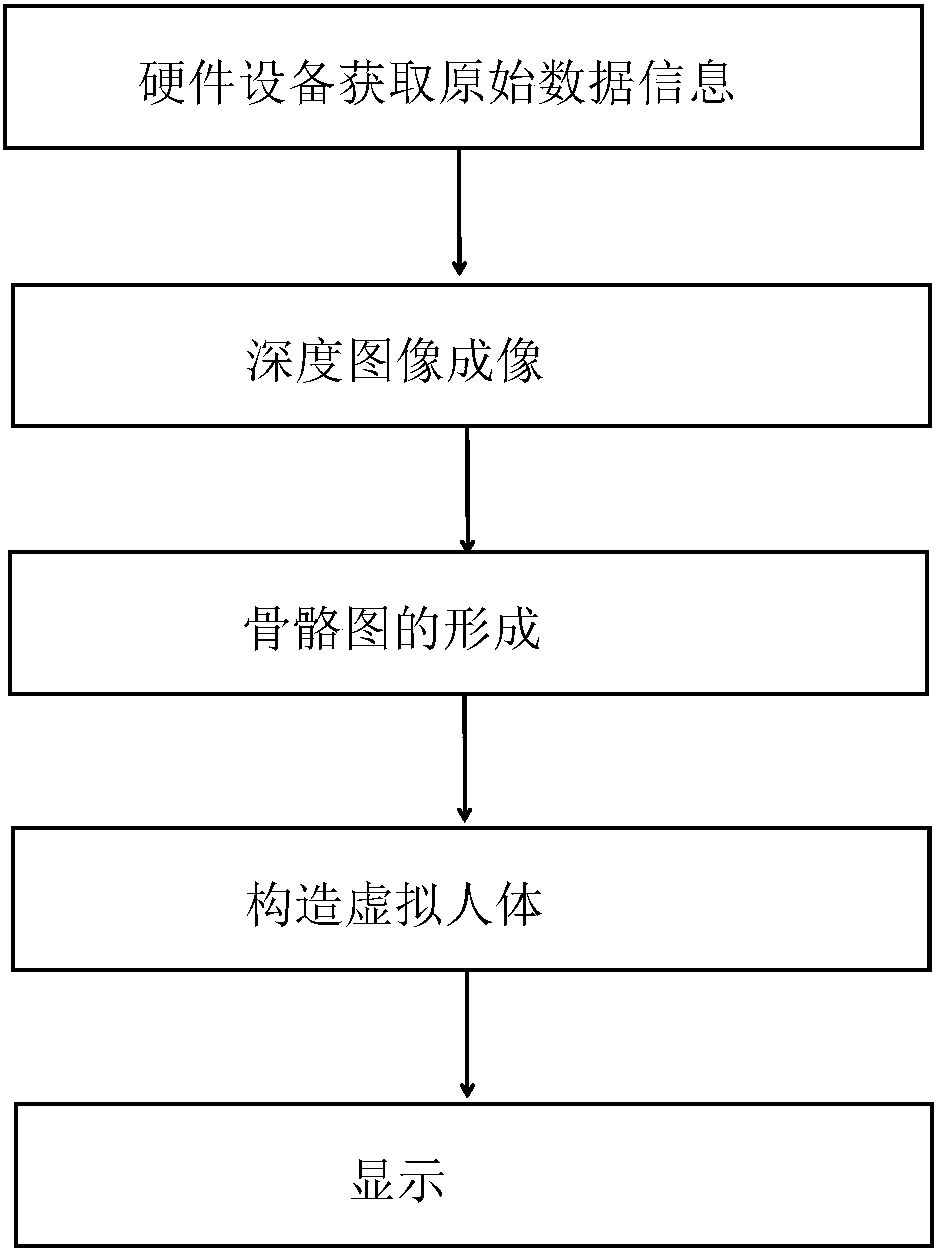

Human body image recognition method

InactiveCN110457980AHigh screen requirementsAccurate control precisionCharacter and pattern recognitionSpeech recognitionHuman bodyData stream

The invention discloses a human body image recognition method, and the method achieves the recognition of a human body image through the following steps: S1, enabling hardware equipment to carry out the skeleton tracking, identity recognition and voice recognition of a human body, and provides the obtained original data information which comprises a depth data stream, a color video stream and original audio data; s2, performing depth image imaging according to the data information acquired by the hardware equipment; s3, forming a skeleton map: distinguishing a human body from a background environment from the depth image, further identifying articulation points of the human body, and identifying human skeletons; s4, constructing a virtual human body: constructing muscles after human skeletons are identified; and S5, transmitting the constructed virtual human body data with bones and muscles to a computer, and projecting the virtual human body data to a display through the computer. According to the invention, real-time dynamic capture and dynamic judgment are realized, so that some schemes with relatively high picture requirements and accurate control precision are realized.

Owner:上海梓琰信息科技有限公司

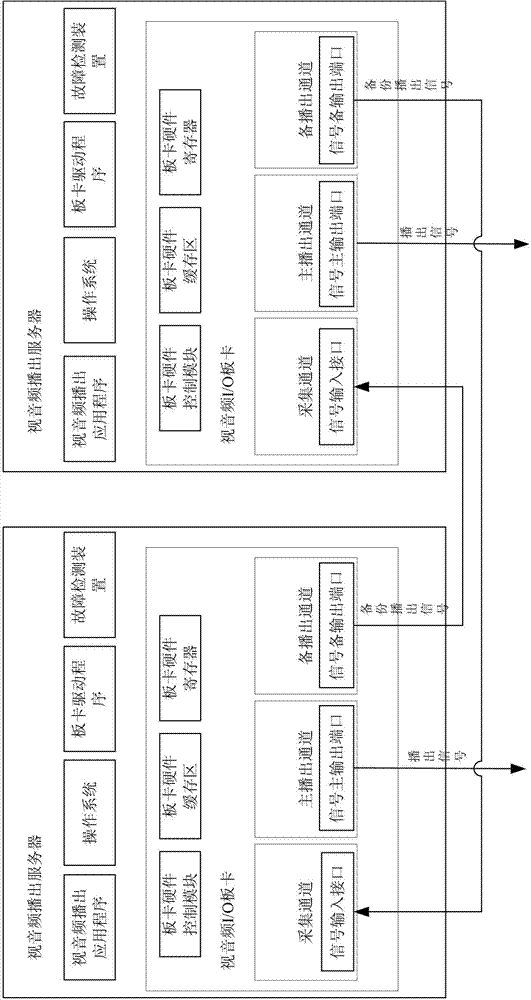

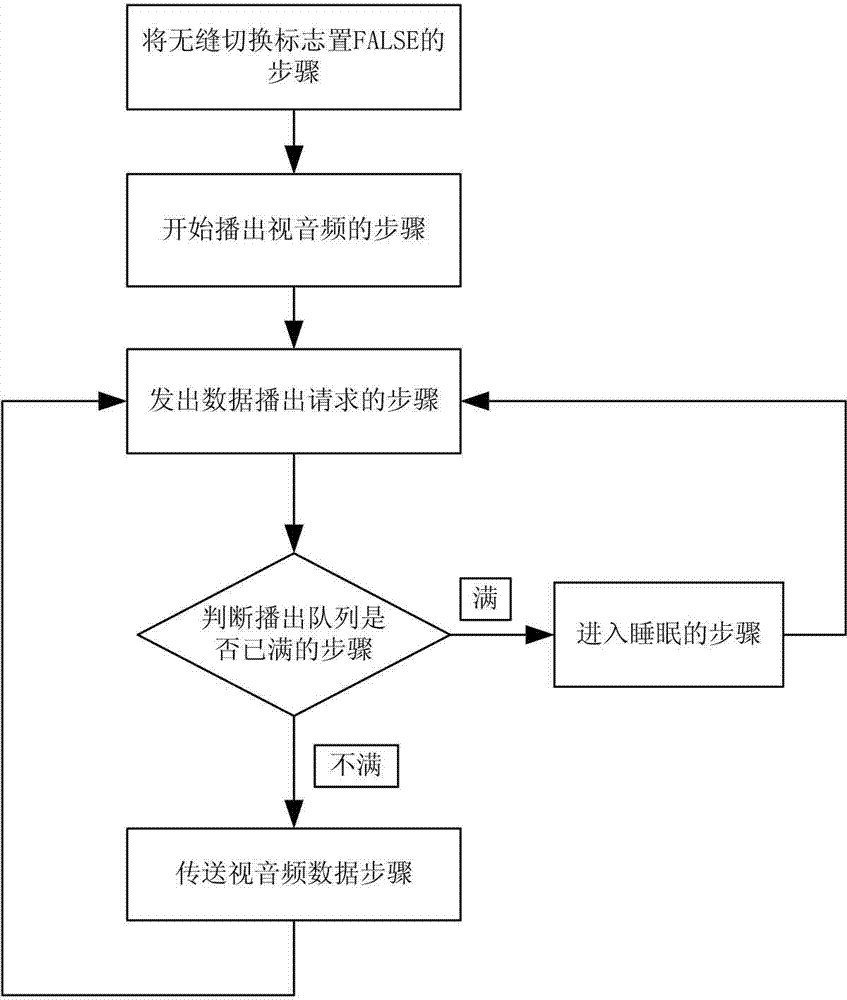

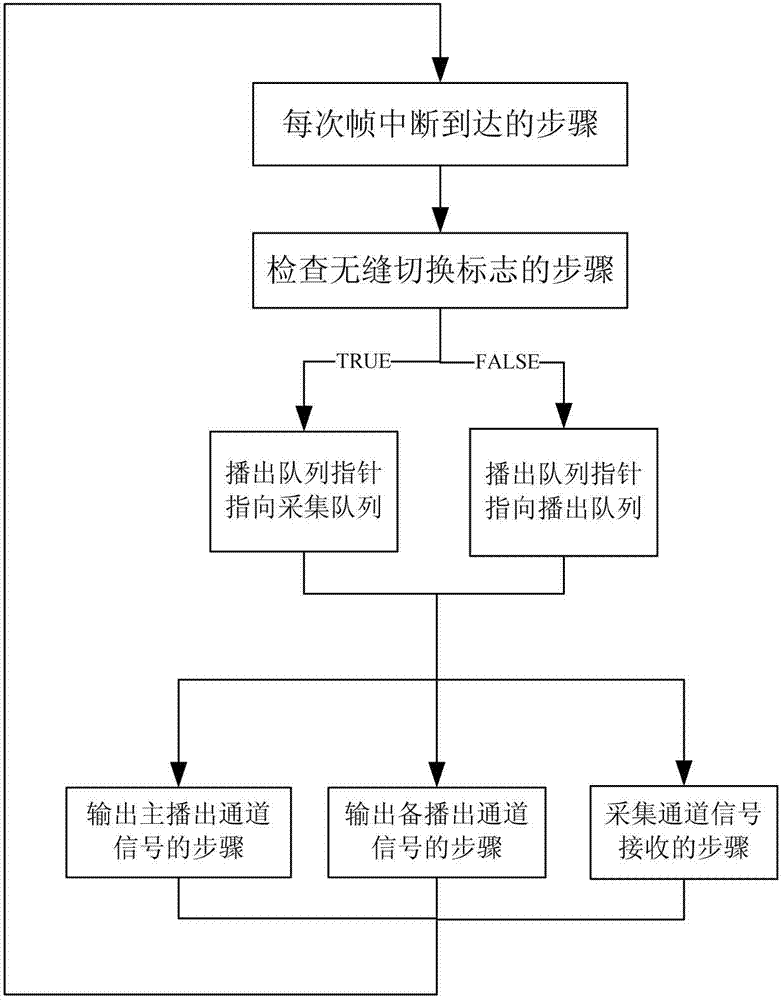

Seamless switching system and method for ensuring normal broadcast of audio frequency

ActiveCN103686196AAccurate control precisionNo green screenSelective content distributionInput/outputAudio frequency

The invention relates to a seamless switching system and a seamless switching method for ensuring normal broadcast of audio. The seamless switching system for ensuring the normal broadcast of audio comprises two video and audio broadcast servers, wherein the video and audio broadcast server comprises a video and audio I / O (Input / Output) board card, a board card drive program, a fault detecting device, an operating system and a video and audio broadcast application program; the video and audio I / O board card comprises a board card hardware buffer cache, a board card hardware register, a board card hardware control module, a signal input interface, a signal main output port and a signal spare output port. According to the seamless switching system and the seamless switching method for ensuring normal broadcast of audio, the switching is performed in video frames, the accuracy of switching frame can be accurately controlled, when in switching period, the signal is broadcasted without appearance of green screen and flickering, repeated frames or frame skipping does not appear, and thus the seamless switching of the spare broadcast signal when a fault appears is achieved.

Owner:BEIJING DAYANG TECH DEV

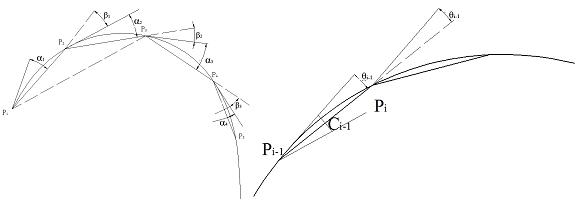

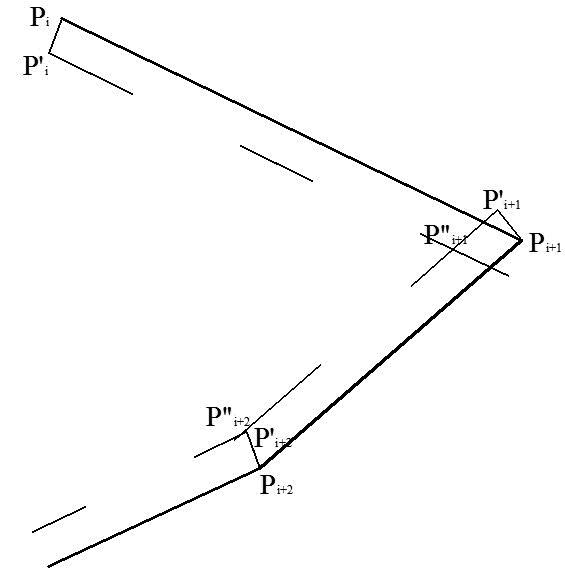

Method for estimating error in numerical control processing

InactiveCN102540977AAccurately reflect the processing qualityAccurate control precisionProgramme controlComputer controlProcessing accuracyBack calculation

The invention provides a method for estimating an error in numerical control processing, and the method can be used for solving the problems in an existing error estimation method. On the basis of the original method, the method provided by the invention comprises the following steps of: firstly determining a unit tangent vector of each point according to a cutter center track obtained by an NC code guided out from CAM (Computer Aided Manufacturing) software; then combining the cutter radius, cutter center coordinates and the determined tangent vector of each point to perform back calculation, thus obtaining a practicable curvilinear path of processing; and finally calculating an arch height error according to the practical curvilinear path obtained through calculation. According to the method provided by the invention, the error is estimated according to the practicable curvilinear path, thus the processing precision can be judged more accurately, the processing quality is improved, and a visual and effective reference basis is provided for selection of technological parameters of a complex curved surface finishing process.

Owner:SHANGHAI UNIV

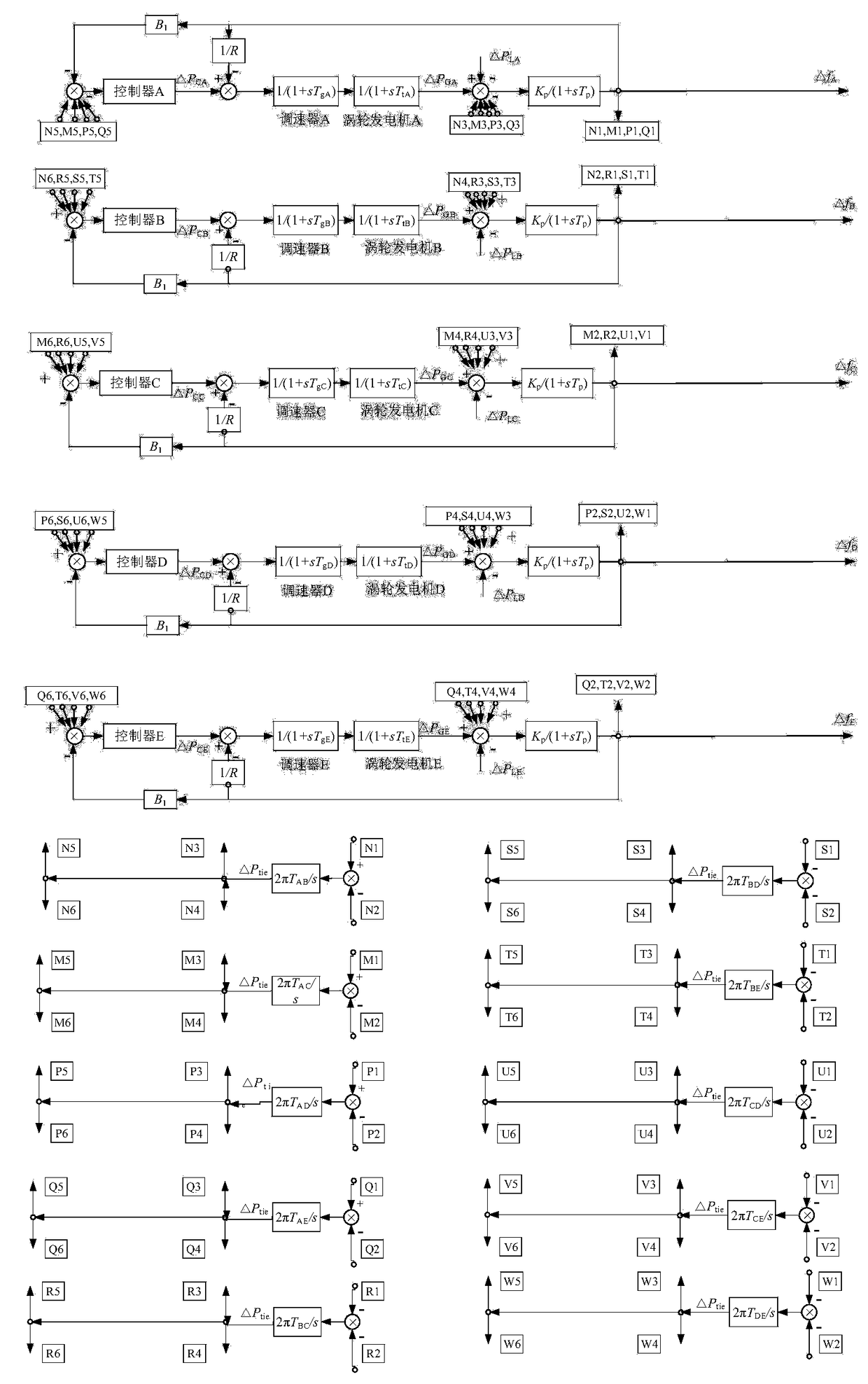

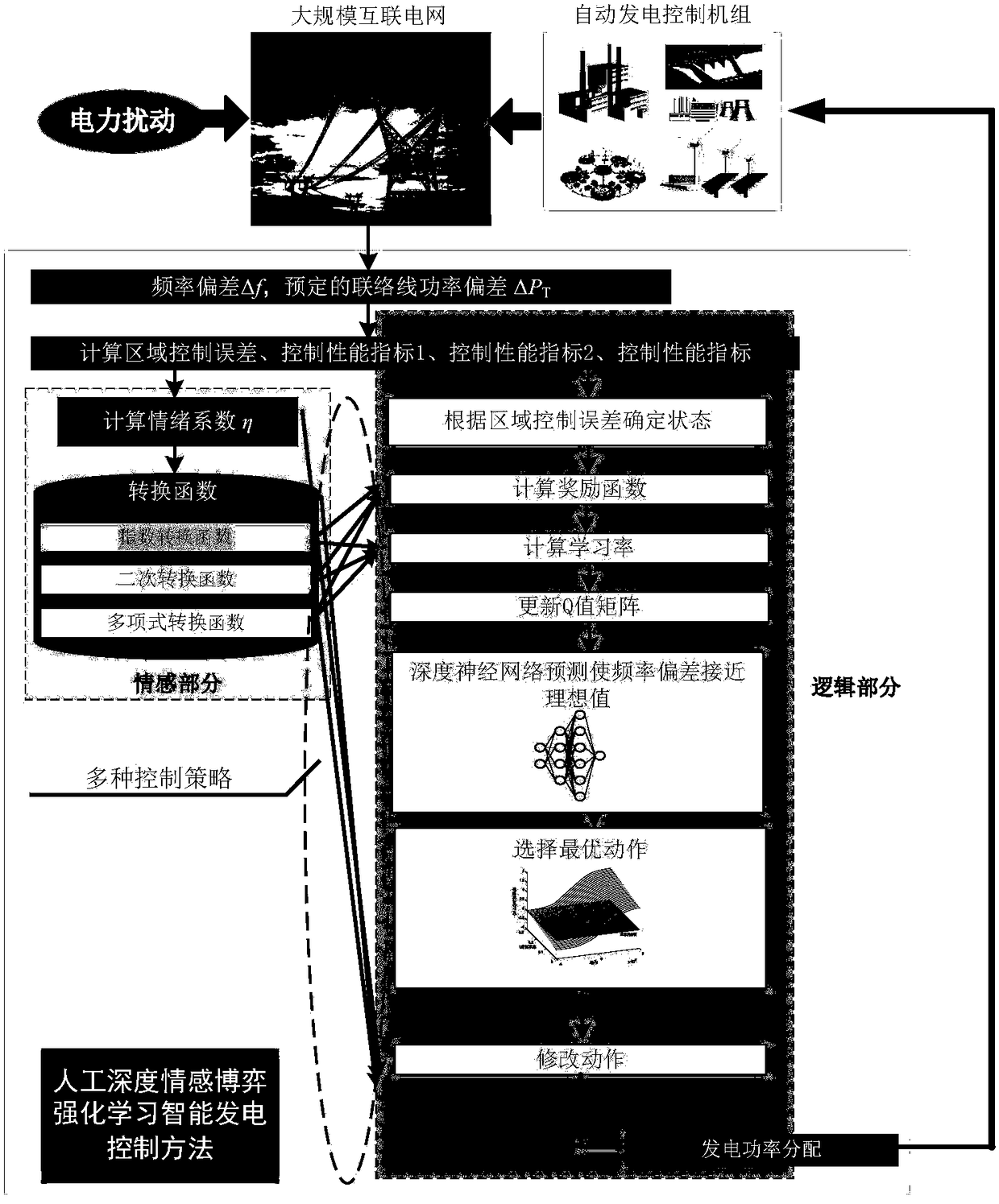

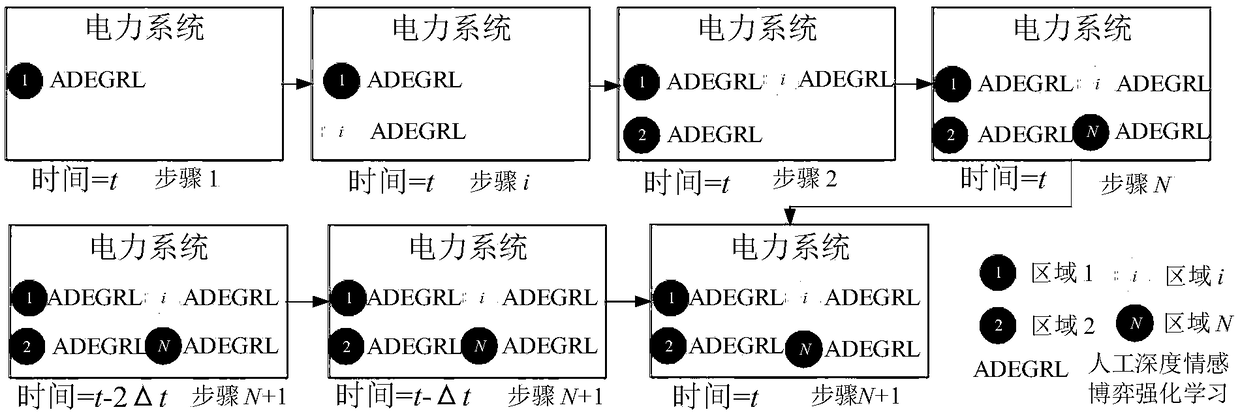

Intelligent power generation control method for artificial deep emotional game reinforcement learning

InactiveCN109494766AImprove continuityImprove active controlPower oscillations reduction/preventionAlgorithmReinforcement learning algorithm

The invention provides an intelligent power generation control method for artificial deep emotional game reinforcement learning. The combines an artificial emotional reinforcement learning algorithm with a deep reinforcement learning algorithm and is used for intelligent power generation control. The method combines artificial emotion in artificial intelligence, reinforcement learning, a deep neural network algorithm and a game theory. The artificial deep emotional reinforcement learning algorithm integrates the deep neural network and the artificial emotion into a reinforcement learning framework. The deep neural network is configured to improve the probability update strategy of traditional reinforcement learning. The artificial emotion quantifies the power generation system informationby an emotional quantization function to update the learning rate, the discount factor, and the output action value of the traditional reinforcement learning. The method takes a frequency deviation and an area control error as inputs, and takes a power command of a generator set as an output. The intelligent power generation control method for artificial deep emotional game reinforcement learningis effective, feasible, robust and rapid.

Owner:GUANGXI UNIV

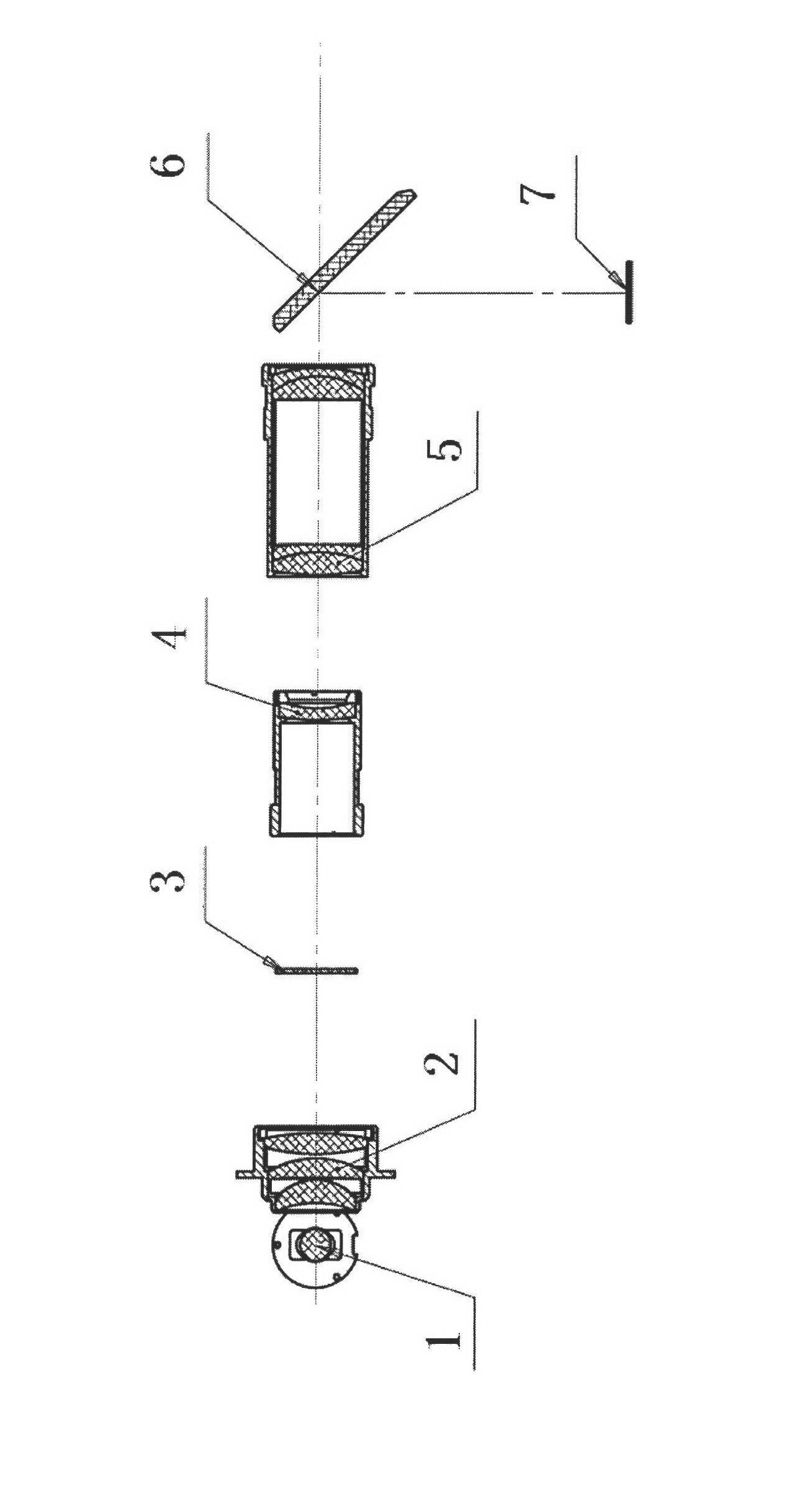

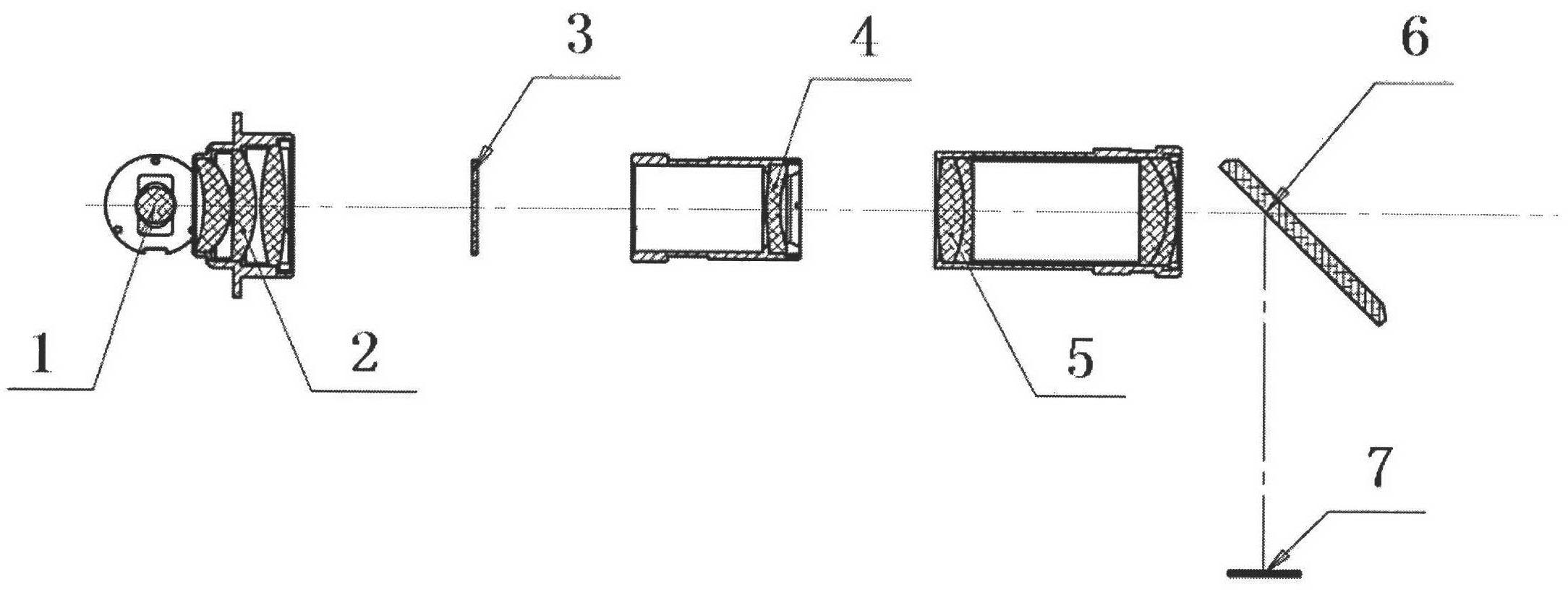

Ocular anterior segment detection and illumination system

InactiveCN102499632AAchieve regulationTo achieve the effect of observation lightingLighting device detailsOthalmoscopesCorneal curvatureImaging quality

The invention discloses an ocular anterior segment detection and illumination system, comprising a light source as well as a light condensing mirror, a R, G and B (red, green and blue) three-color liquid crystal sheet unit or a digital light processor (DLP), a lower projecting mirror group and a reflecting mirror, which are sequentially distributed in an emerging direction of light rays of a light source, wherein the light condensing mirror and the lower projecting mirror group are coaxially arranged, and a liquid crystal sheet or a digital micromirror unit is connected with a control unit. The control unit comprises a computer system, preferentially, the computer system is also connected with at least one control device of a game control rod, a mouse and a keyboard. The ocular anterior segment illumination system is simple in structure, easy to control, has high stable property and high image quality and can achieve new functions for data measurement such as measurement of corneal topography, corneal curvature and the like.

Owner:沈激

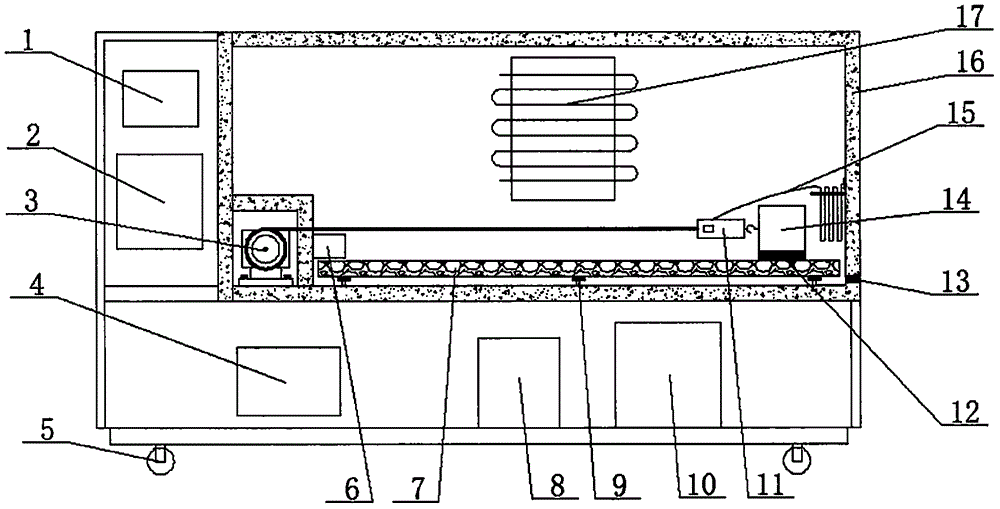

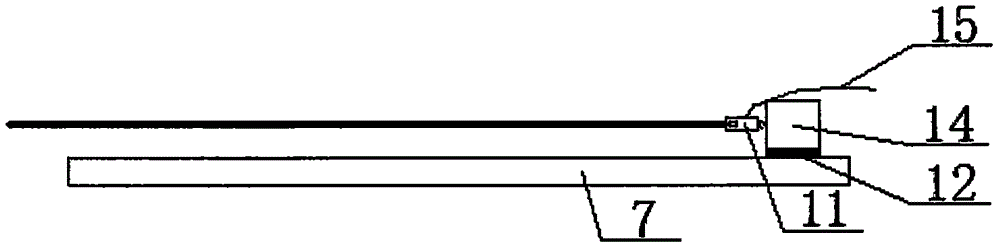

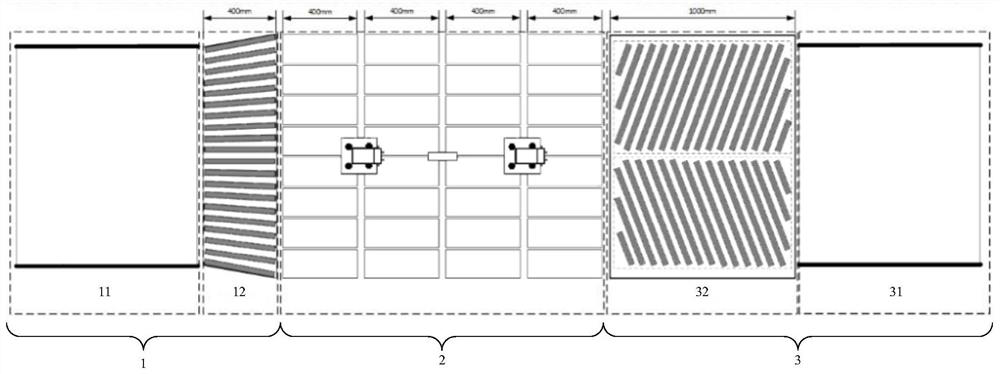

Testing device and testing method for measuring road surface friction attenuation rate of snow-melting agent under low-temperature environment

ActiveCN105823725AThe test results are meaningfulSignificance of test resultsUsing mechanical meansMaterial analysisUltrasound attenuationSnow melting

The invention provides a testing device and testing method for measuring the road surface friction attenuation rate of a snow-melting agent under the low-temperature environment .The testing device is composed of a testing box and a road surface friction coefficient measuring device .The road surface friction attenuation rate of the snow-melting agent under the low-temperature environment is measured by building a road surface testing table and controlling the temperature in the testing box .The testing device is used in the testing method .The method includes the three steps of test preparation, measurement and result sorting .Testing results obtained through the testing device and the testing method are accurate, stable and reliable and can truly reflect changes of anti-slip performance of a road surface after the snow-melting agent is used, advantages are remarkable, and the preferential road snow-melting agent plays an important role in improving road driving safety and reducing traffic accidents.

Owner:SHANDONG JIAOTONG UNIV

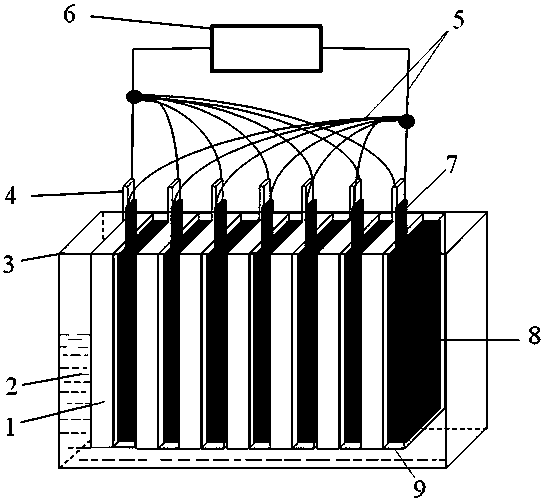

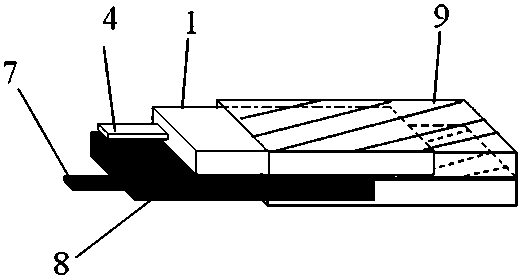

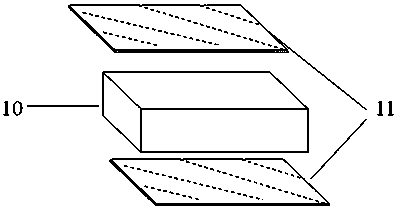

A method and device for pre-lithiation of negative pole piece of lithium ion battery

The invention provides a pre-lithiation method and device for negative pole pieces of a lithium-ion battery. The method comprises the steps as follows: firstly, the negative pole pieces and metal lithium pieces are sequentially immersed into an electrolyte at intervals in an inert atmosphere condition; the negative pole pieces correspond to the metal lithium pieces one by one but are not in contact with the metal lithium pieces; the negative pole pieces and the metal lithium pieces are connected with a positive electrode and a negative electrode of a power supply through leads respectively; the negative pole pieces are charged; the charging current is 0.05-2.0C; and the negative pole pieces are taken out and dried to obtain the pre-lithiated negative pole pieces. According to the pre-lithiation method and device, 'wet pre-lithiation' is adopted; the cost is low; the production security is high; the pole pieces can be evenly pre-lithiated; and the first efficiency and the energy density of the battery are improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

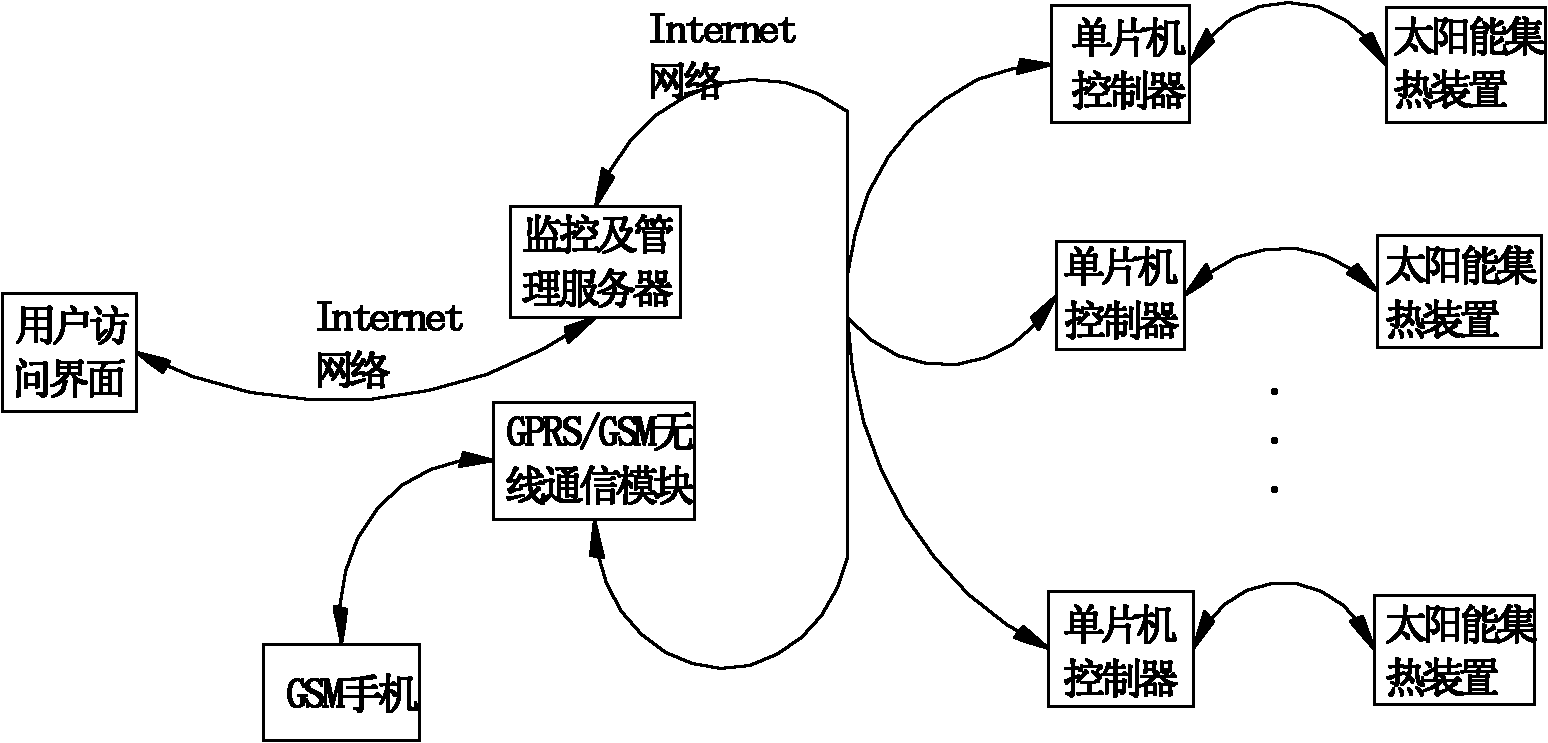

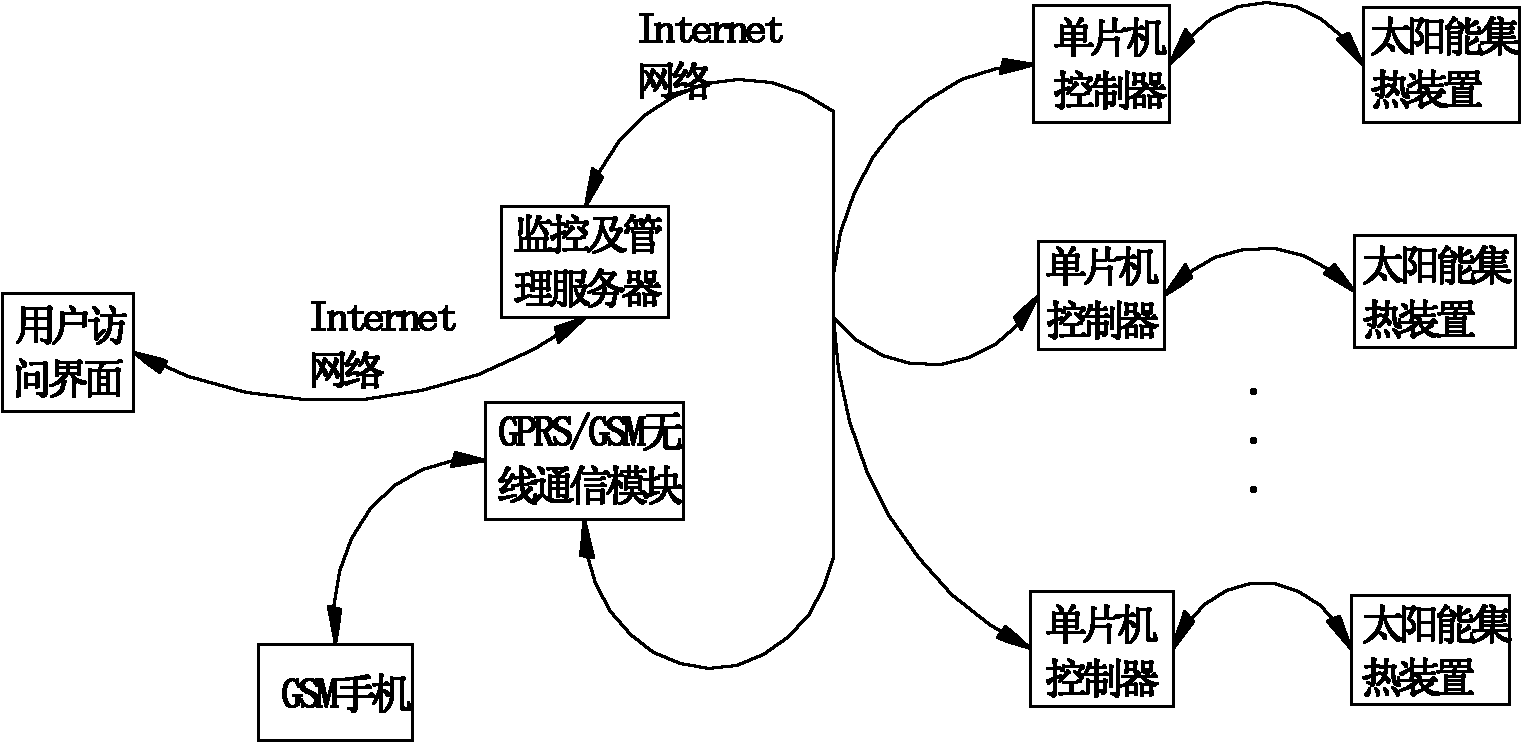

Control device for solar heat-collecting project

InactiveCN102155803AReduce communication frequencyReduce possessionSolar heat devicesTransmissionEngineeringAutomation

The invention discloses a control device for a solar heat-collecting project, which comprises a plurality of solar heat-collecting devices, wherein each solar heat-collecting device is respectively configured with a single chip controller and further comprises a master monitor-management server and a user access platform; the master monitor-management server is in series connection with a network exchanger, and the network exchanger is in communication connection with each single chip controller through the Internet network; the user access platform is in series connection with a gateway router, and the gateway router is interacted with the master monitor-management server through the Internet network; the master monitor-management server comprises a network controller, a webpage information publisher and a water heater parameter monitor; and therefore, the internet is used by the control device to perform centralized single-wire remote monitor on the solar heat-collecting device installed in large area through the webpage, the degree of automation is high and the operation is convenient.

Owner:NANTONG UNIVERSITY +1

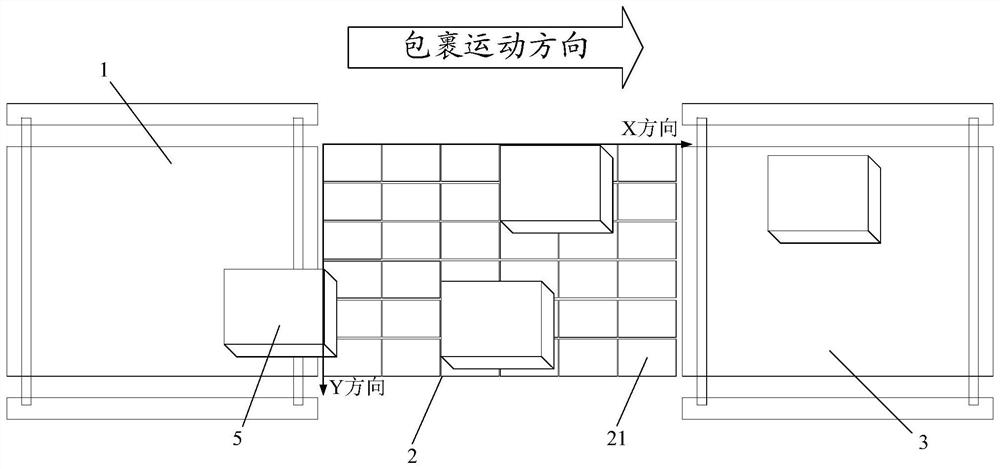

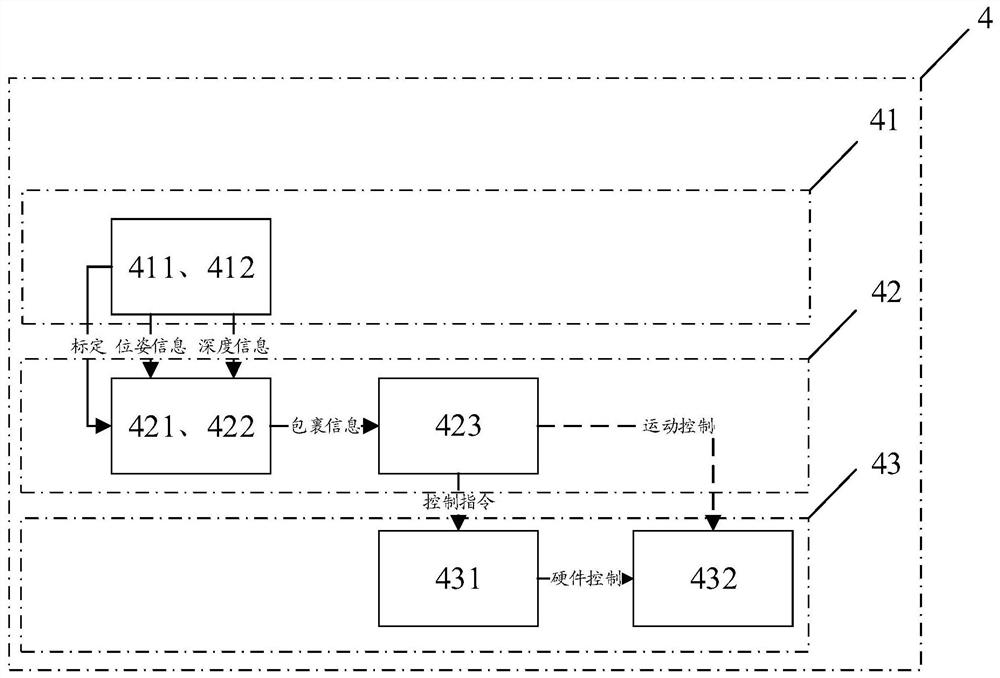

Parcel sorting method and system

ActiveCN111921873AOrdered outputHigh separation precisionSortingLogistics managementProcess engineering

The embodiment of the invention discloses a parcel sorting method and system. Parcels are positioned based on a visual imaging system to obtain imaging information of the parcels, then the coordinaterange correspondingly to each parcel is obtained through the data processing of a control device, according to the location distribution of each parcel on a separator, an appropriate scheduling strategy is used combined with the performance of the separator, and finally the scheduling strategy is sent to the control device to separate the parcels. The method is more accurate in control accuracy and processing throughout than a traditional way through the visual system, and it is not necessary to control the position situation of the parcels flowing into a first conveyor belt in advance by human intervention; and meanwhile the distribution labor cost of a current logistics company in the sorting process can be saved, after the integration of the whole device, the maintenance and improvementin the later stage are also convenient, and the degree of automation of the logistics can be improved.

Owner:HANGZHOU HIKROBOT TECH CO LTD

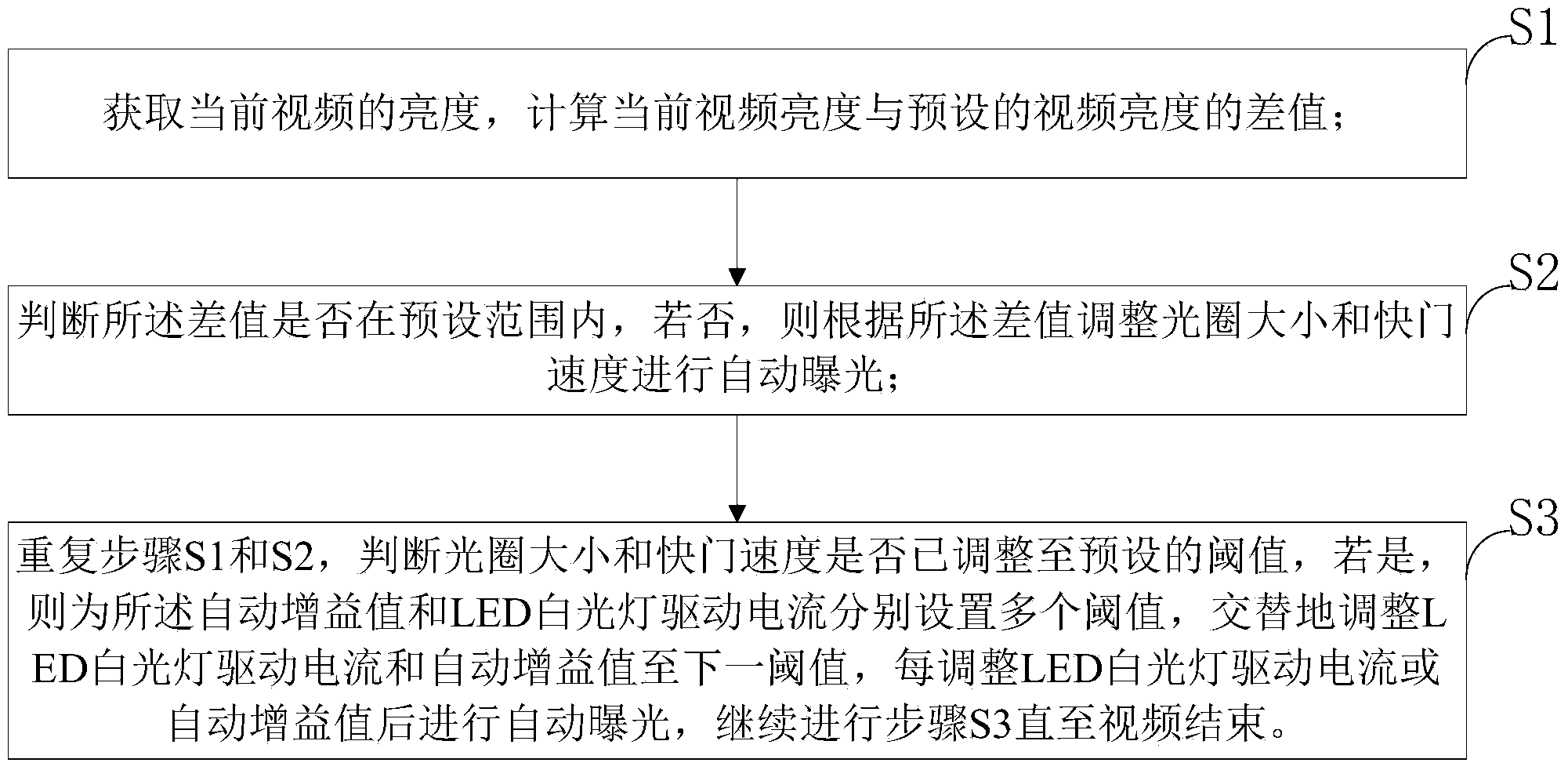

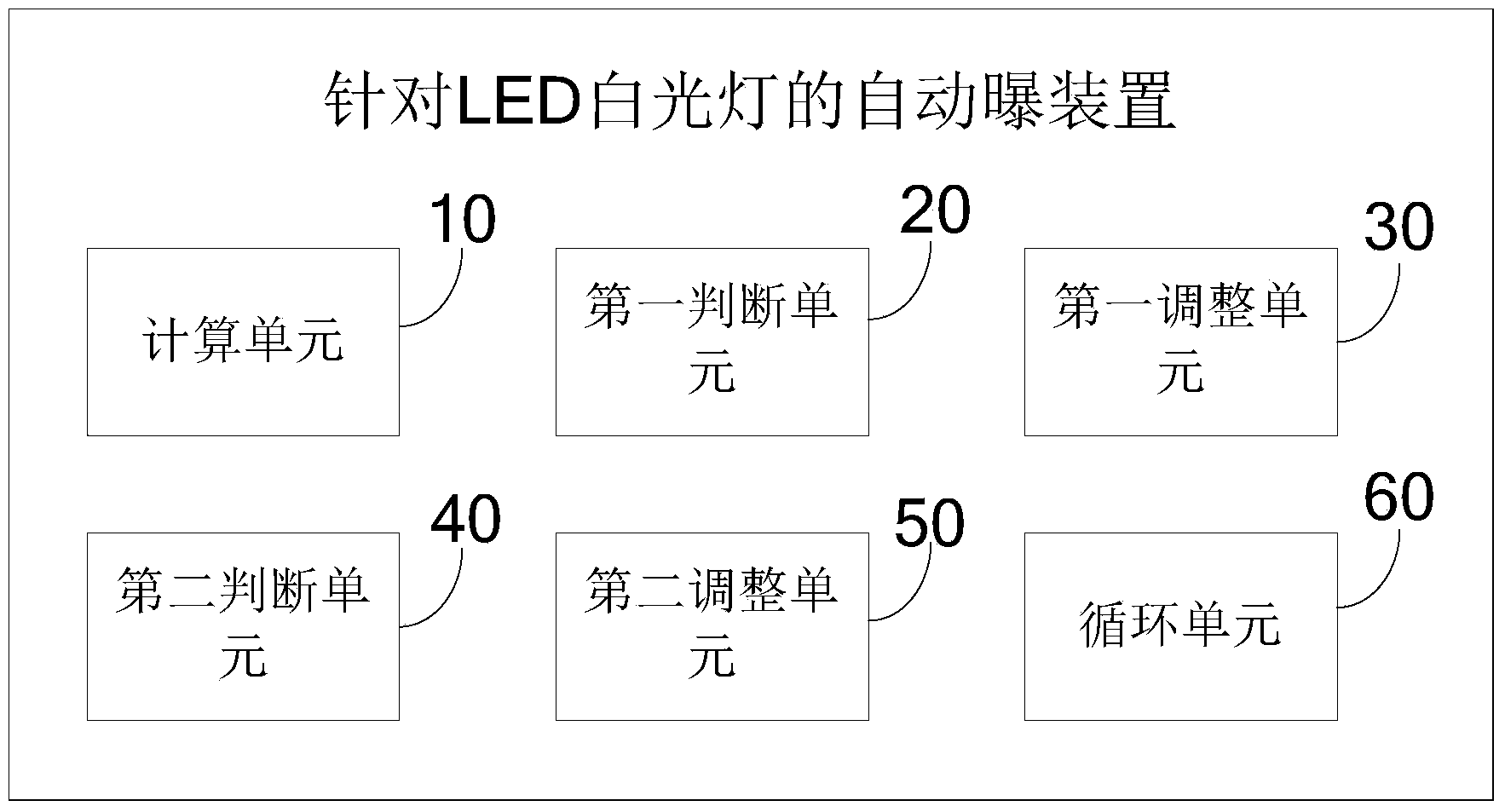

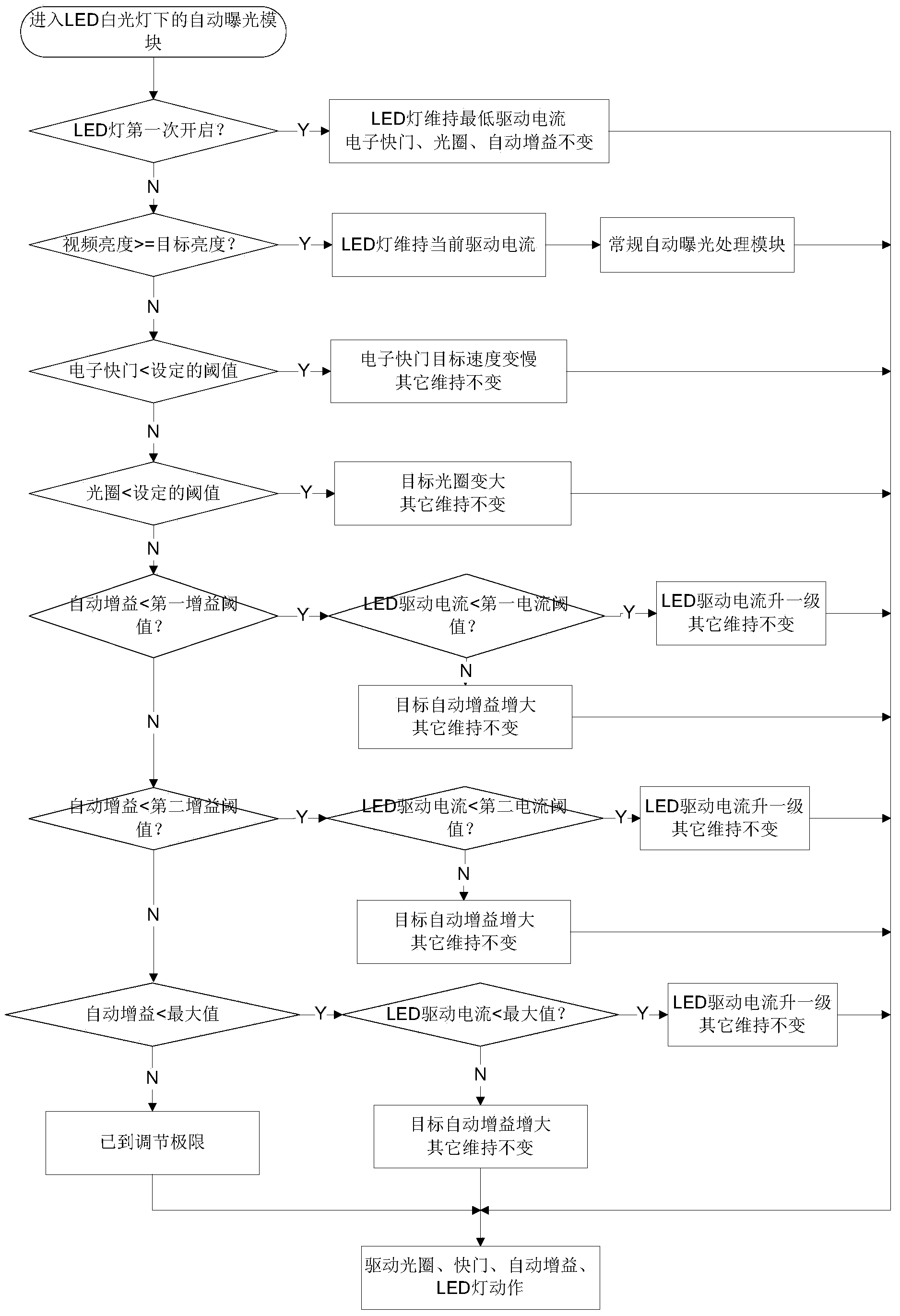

Automatic exposure method and device for LED white-light source

ActiveCN103973992AQuality assuranceReduce power consumptionTelevision system detailsColor television detailsDriving currentShutter speed

The invention discloses an automatic exposure method for an LED white-light source. The method includes the steps that first, the brightness of a current video is acquired, and the difference value between the brightness of the current video and preset video brightness is calculated; second, whether the difference value is within a preset range is judged, and if not, the f-number and the shutter speed are adjusted according to the difference value so that automatic exposure can be performed; third, the first step and the second step are executed again, whether the f-number and the shutter speed are adjusted to preset threshold values is judged, if yes, the driving current and an automatic gain value of the LED white-light source are adjusted alternately till the next threshold value is achieved, automatic exposure is performed after the driving current or the automatic gain value of the LED white-light source is adjusted every time, and the third step is continued till the video ends. The invention further discloses an automatic exposure device for the LED white-light source. Due to the method and devoice, the control accuracy of automatic exposure is more accurate, and the quality effect of the video is effectively guaranteed.

Owner:SHENZHEN INFINOVA

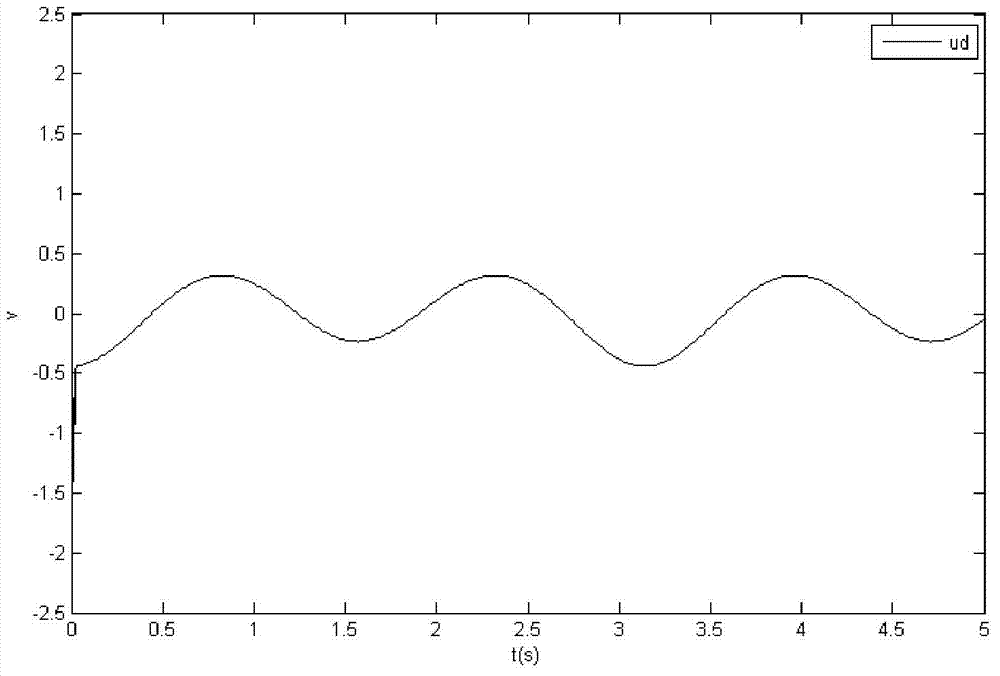

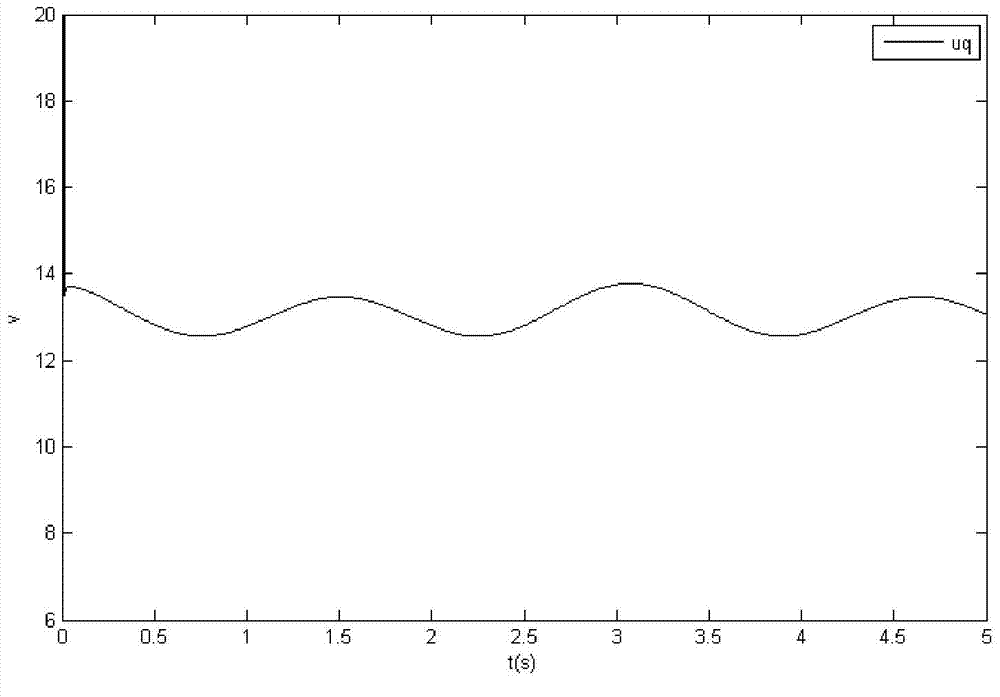

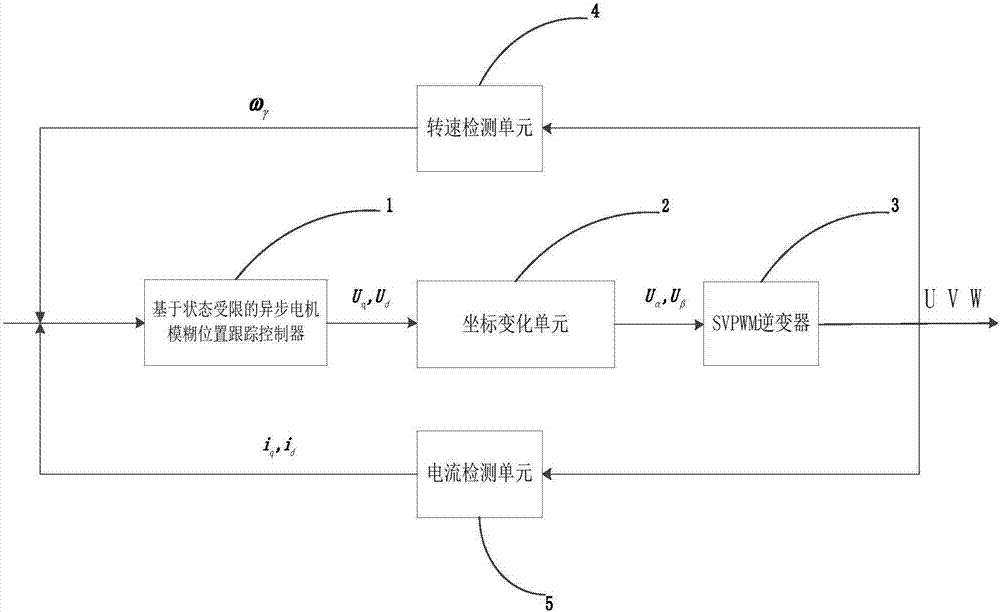

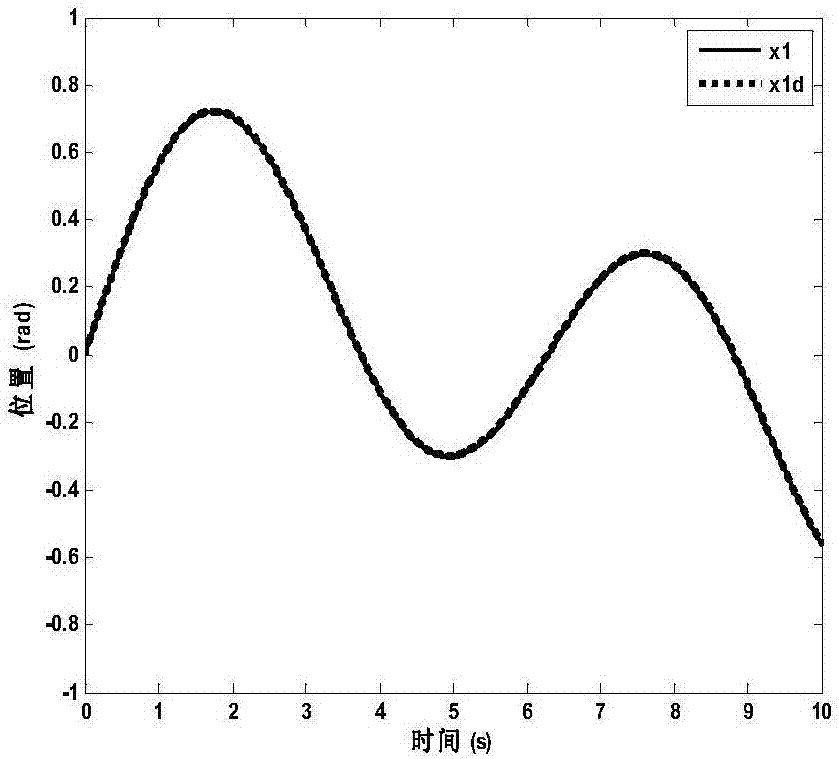

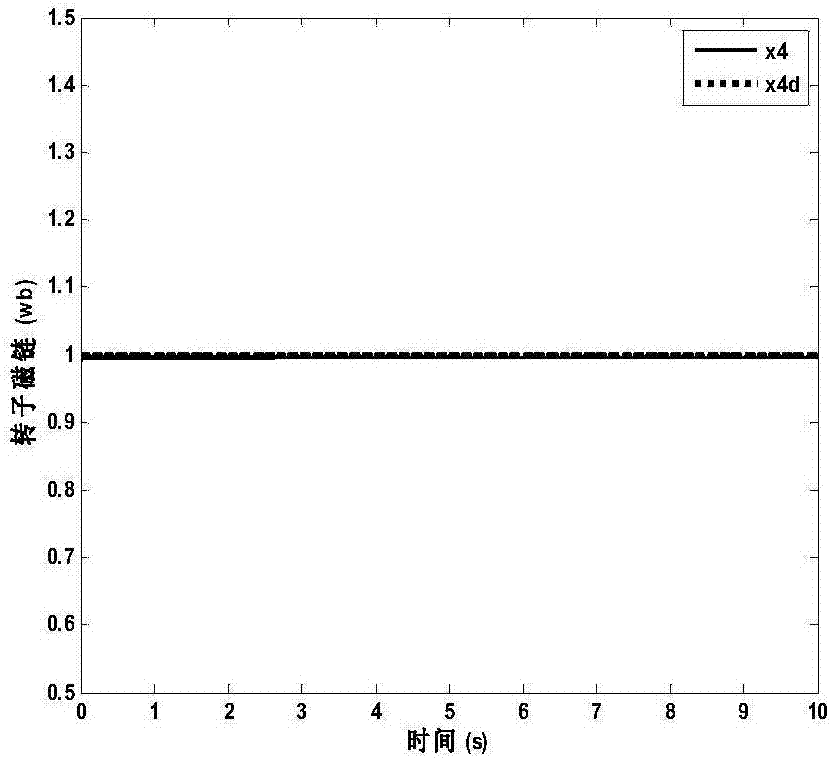

State constraint based asynchronous motor fuzzy position tracking control method

ActiveCN107276471ASolving Nonlinear Control ProblemsReduce mistakesElectronic commutation motor controlVector control systemsLiapunov functionFuzzy adaptive

The invention belongs to the technical field of asynchronous motor position tracking control, and specifically discloses a state constraint based asynchronous motor fuzzy position tracking control method. The method is characterized in that state variables and controlled variables of a motor system are constrained based on a Barrier Lyapunov function in allusion to control accuracy requirements for an asynchronous motor and a nonlinear problem in a driving system, a fuzzy logic system is utilized at the same time to approach to a nonlinear function in the system at the same time, and a fuzzy adaptive position tracking controller is built. According to the method, a tracking error of the system can be ensured to converge to a small enough neighborhood of the origin, simulation results show that the new control method ensures each state variable of the motor to be within a constraint space of the system, and controller input ud and controlled input uq are stabilized within a bounded region. The method disclosed by the invention realizes fast and effective response for asynchronous motor position tracking control.

Owner:QINGDAO UNIV

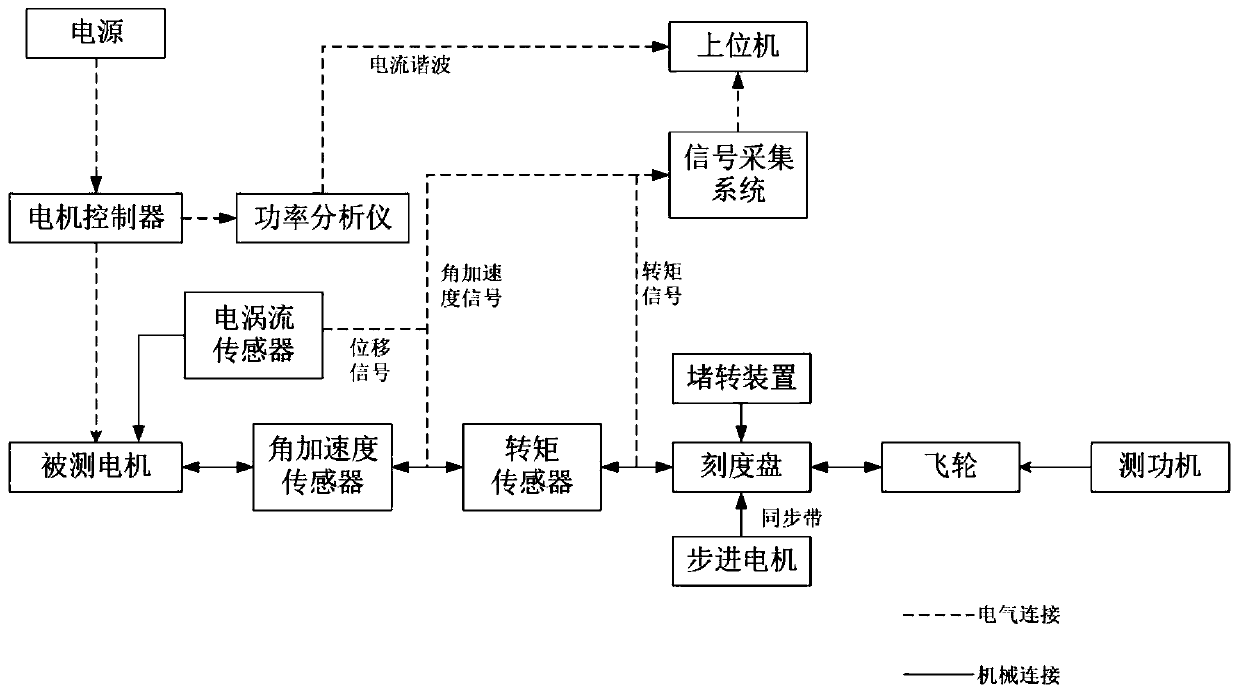

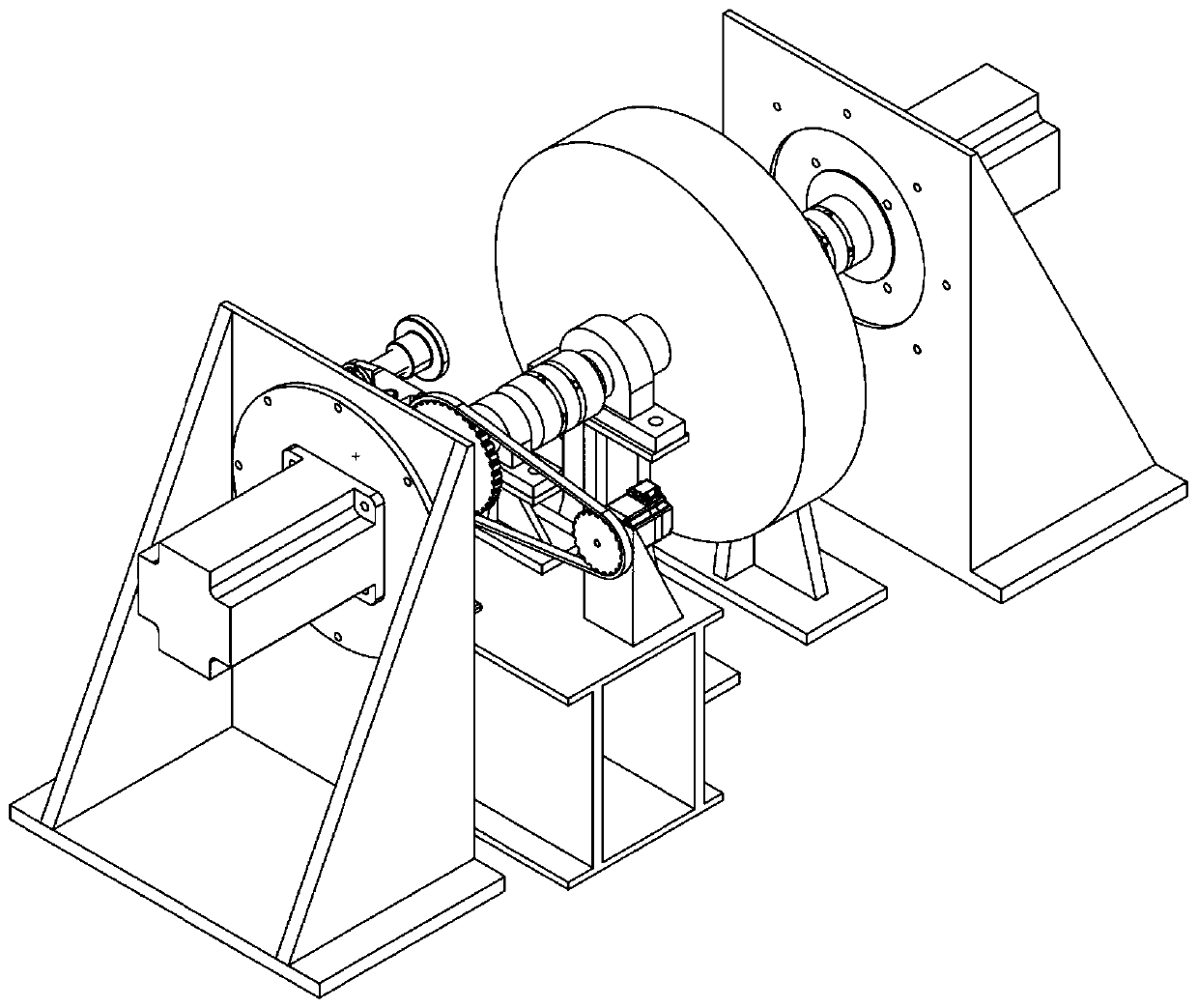

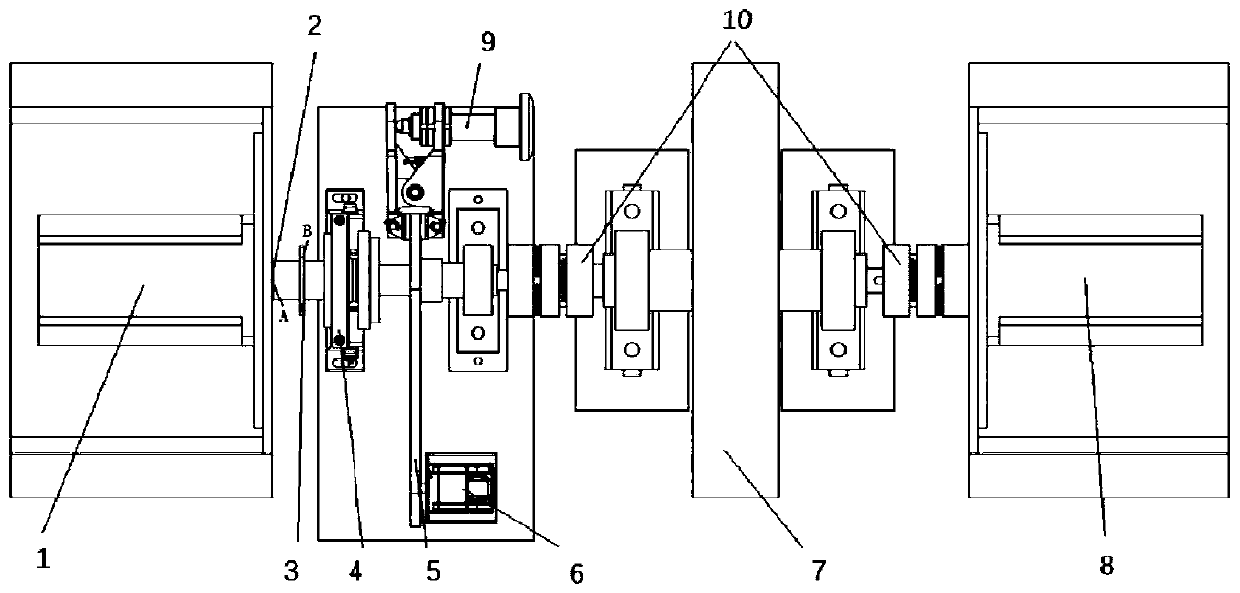

Motor torque ripple test bench and test method

ActiveCN111380635ADirect test of torque fluctuationDirect measurement of cogging torque fluctuationsWork measurementTorque measurementElectric machineCoupling

The invention relates to a motor torque ripple test bench and a test method, a synchronous belt transmission structure is arranged, and the precision of the rotation position of a rotor is accuratelycontrolled through a large belt wheel. Through multi-position stalling, the torque ripple condition of the rotor in one cycle can be obtained; a torque sensor is used in a low-frequency region, and anangular acceleration sensor is used in a high-frequency region, so the measurement range of cogging torque is expanded; the method is suitable for measuring the cogging torque of the full-frequency region of the motor. According to the test bench, the locked-rotor and inertia loading are combined, the torque ripple condition of the motor in a rotation period can be represented through a locked-rotor method on one test bench, and the cogging torque ripple condition of the motor can also be directly tested. And the torque ripple influence of the dynamometer can be reduced as much as possible through the large-inertia flywheel. In addition, the elastic coupling is adopted to eliminate the influence of coaxiality, the eccentricity and vibration in the transmission chain on the sensor side, and the sensor is prevented from being damaged due to vibration.

Owner:SHENZHEN XILIN ELECTRICAL TECH

Diffusion welding multilayer structure diaphragm capsule

The invention is a diffusion welding multilayer structure diaphragm capsule, belonging to the field of diaphragm capsule manufacturing. By adopting the methods of diffusion welding, machining and shaping, the manufacturing of diaphragm capsule in the invention can be realized. The main procedures include thin wall blank preparation, surface cleaning, surface modified treatment, welding-stopping treatment, diffusion welding, machining, shaping and the like. Compared with the multilayer structure diaphragm capsule manufactured by other methods, the multilayer structure diaphragm capsule manufactured by the invention has the advantages of fine fatigue property (above 1 million times), strong pressurization performance, adjustable rigidity, high compression ratio (higher than 80%), capability of micromation of inner holes, high precision of geometric dimensions, strong destabilization resistance, precise and controllable weldingline profile, adjustable width of weldingline and the like. By using the invention, the diaphragm capsule in the shape of circle, square and other shapes can be manufactured, and can serve as a compensation element of displacement and angle in hydraulic, barometric, transferring pipeline installation, an elastic compensation element and a pore damping element as well as a measuring element for a manometer and an altimeter; besides, the diaphragm capsule can be also used as a heat transferring finned tube for air conditioning, refrigeration and other devices as well as a metal capsule of separating gas or liquid for an accumulator and a storage box. The invention can provide multilayer structure diaphragm capsule products with fine performance for related industries.

Owner:北京智创联合科技股份有限公司

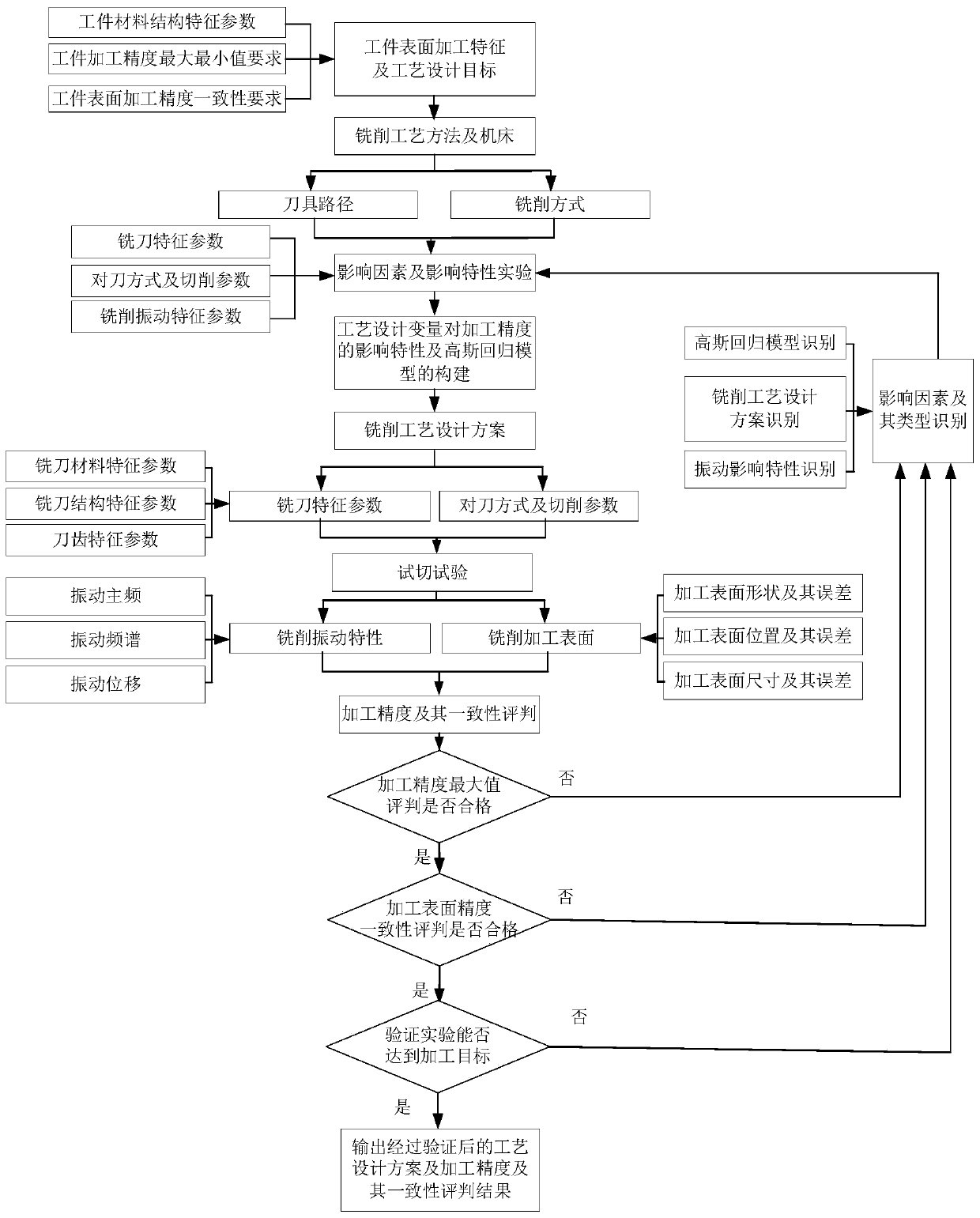

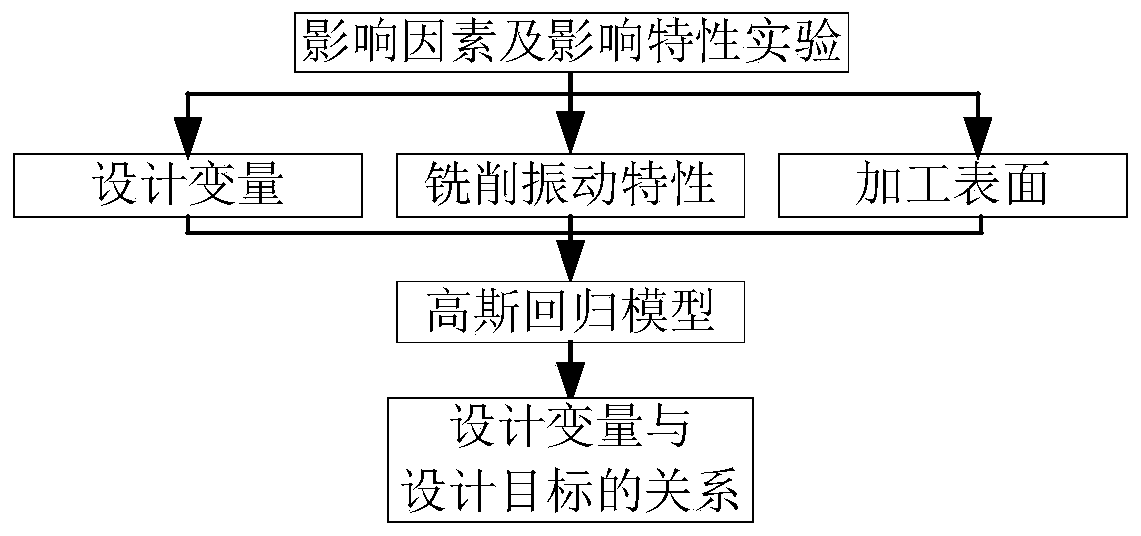

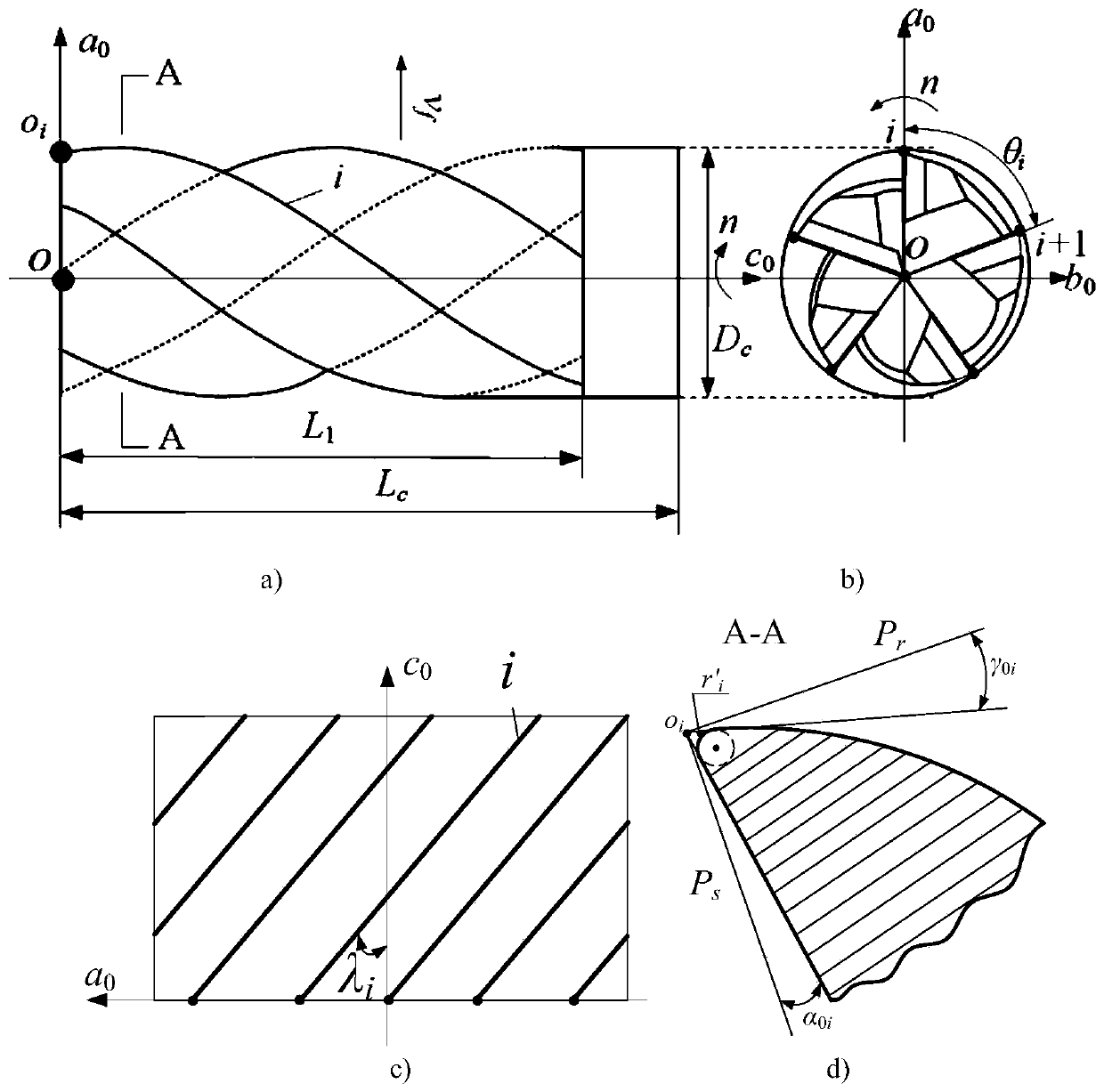

Process design method for milling precision consistency

ActiveCN110222454AImprove consistencyAccurate control precisionGeometric CADDesign optimisation/simulationGrey correlation analysisProcess dynamics

The invention discloses a process design method for milling precision consistency, and belongs to the technical field of milling cutters. Due to the fact that in the prior art, design indexes are incomplete, targets are unclear, accurate control over error distribution of the machined surface cannot be achieved, and the milling process design method is improved aiming at the problems. According tothe method, evaluation indexes of processing precision evaluation are increased, and precise control of processing error distribution is realized. The method comprises: designing a milling vibrationtest, extracting vibration test data, carrying out whole-process dynamic detection on milling vibration, and analyzing the milling vibration and the machining precision by using an improved grey correlation analysis algorithm; and analyzing the dynamic change of each parameter of the precision of the machined surface along with the cutting stroke through a grey correlation algorithm. According tothe process design method, the optimization design, the dynamic design and the collaborative design are comprehensively applied, the original process design method is optimized through the evaluationmethod for the precision consistency of the machined surface, and the machining precision and the consistency level of the machining precision are improved.

Owner:HARBIN UNIV OF SCI & TECH

Numerical control electric screw press driven by permanent magnet synchronous linear servo motor

InactiveCN105312467AEasy maintenanceReduce energy consumptionForging press drivesPress ramLinear motionPermanent magnet synchronous motor

The invention discloses a numerical control electric screw press driven by a permanent magnet synchronous linear servo motor. The numerical control electric screw press comprises a machine body, a machine body guide rail, a sliding block hammer, a copper nut, a main screw, the permanent magnet synchronous linear servo motor and a numerical control system, wherein the upper end of the machine body is fixedly provided with a cross beam; the machine body guide rail is fixed to the machine body; the sliding block hammer is located at the lower portion of the cross beam and can slide on the machine body guide rail; the copper nut is fixed to the sliding block hammer, and one end of the main screw and the copper nut form a screw pair to drive the sliding block hammer to conduct linear motion; the permanent magnet synchronous linear servo motor is arranged on the top of the cross beam and comprises a flywheel rotor and a stator assembly which is fixed to the top of the cross beam, and the other end of the main screw is fixed to the rotating axis of the flywheel rotor. The numerical control electric screw press has the characteristics of being convenient to maintain, low in energy consumption and noise, higher in control precision and safety performance, and the like.

Owner:HUBEI FUSHENG FORGING MACHINE

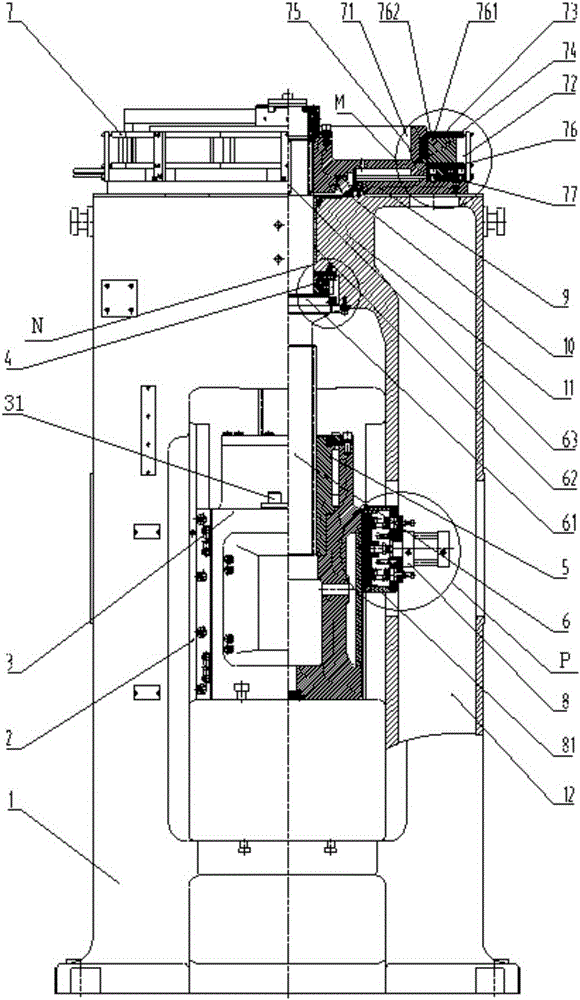

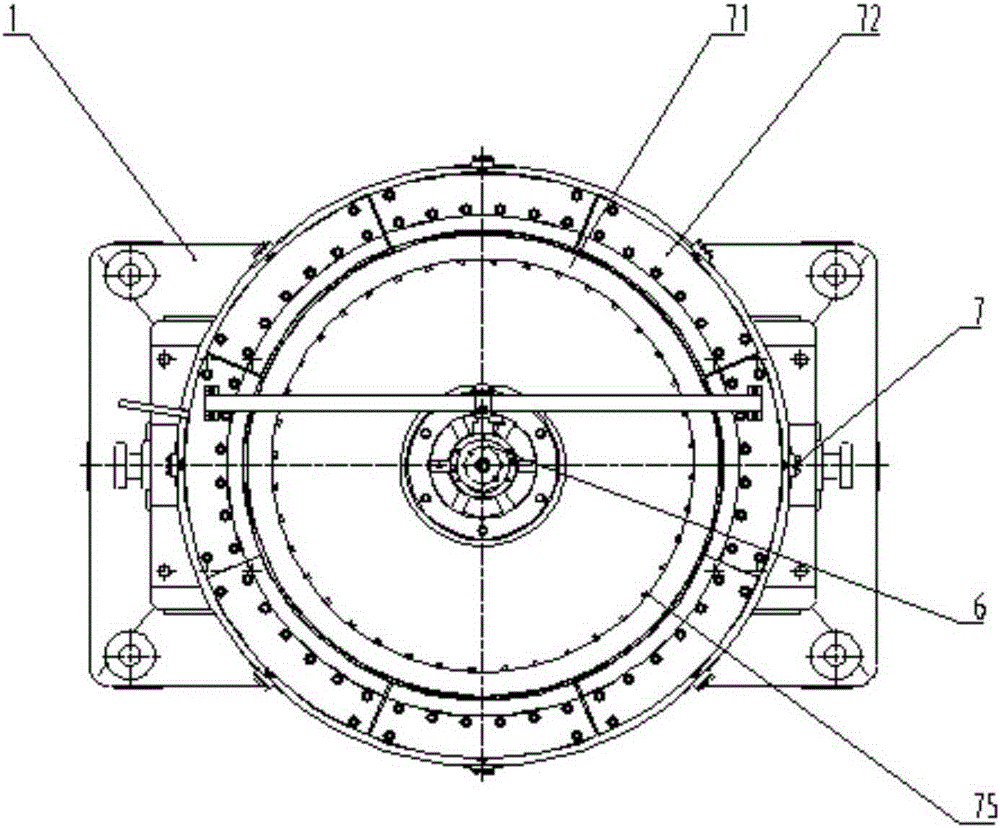

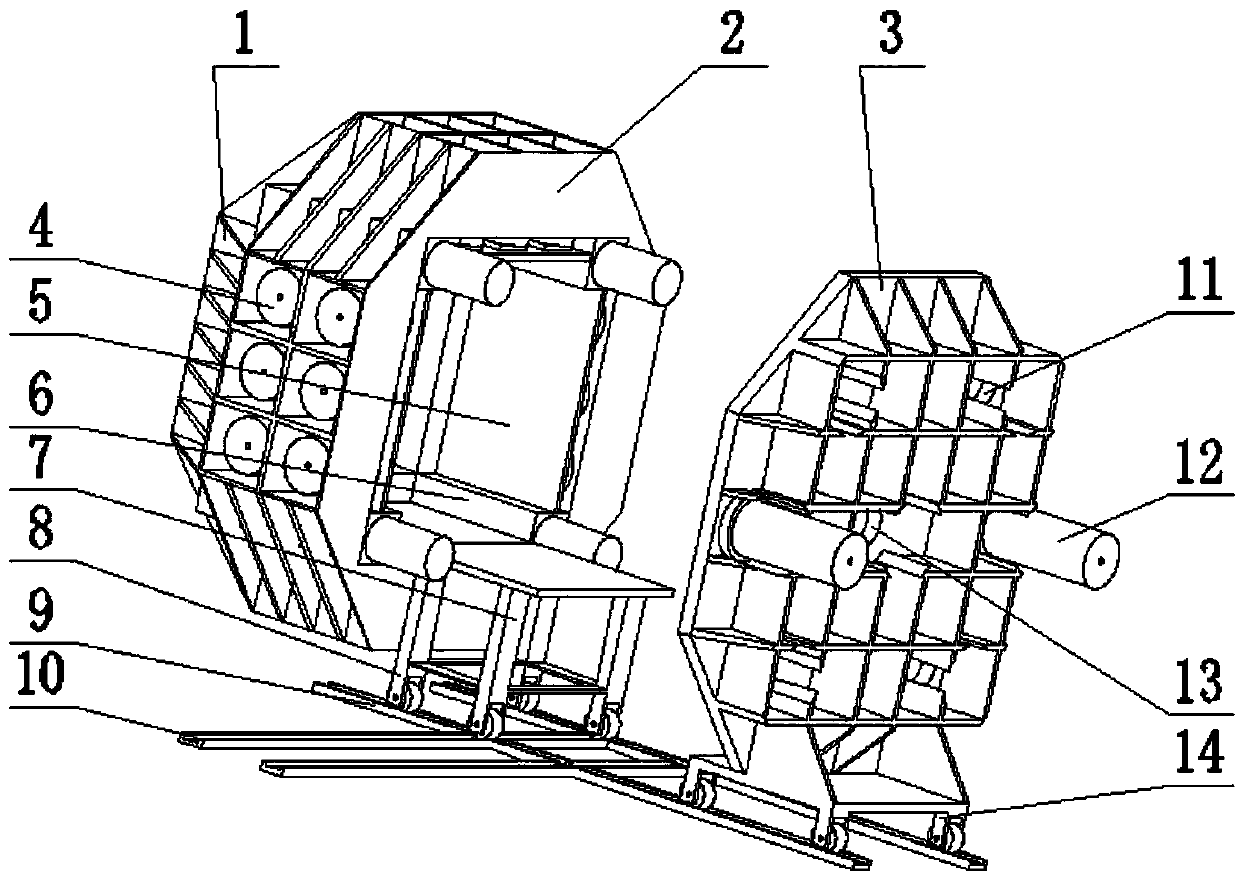

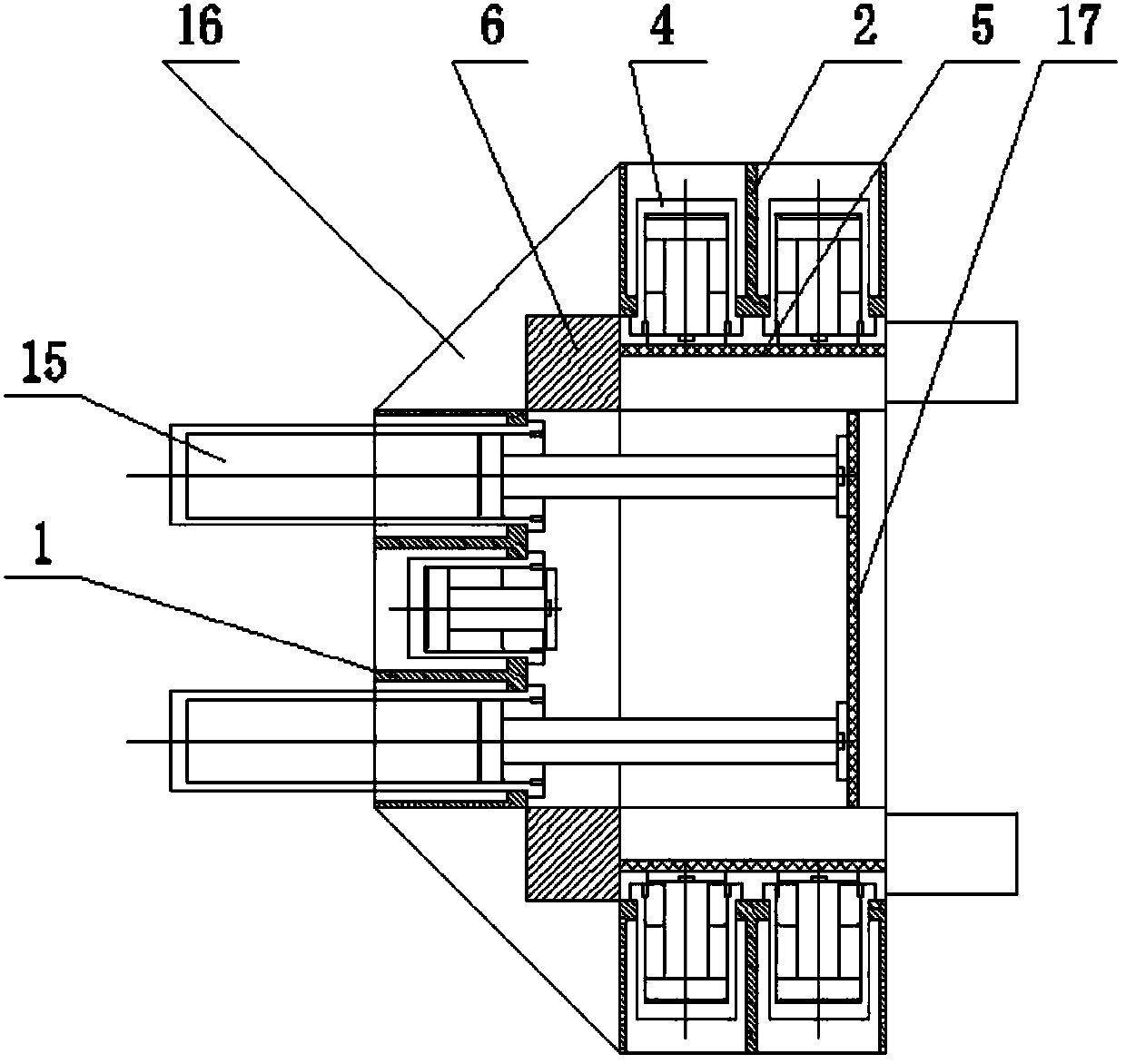

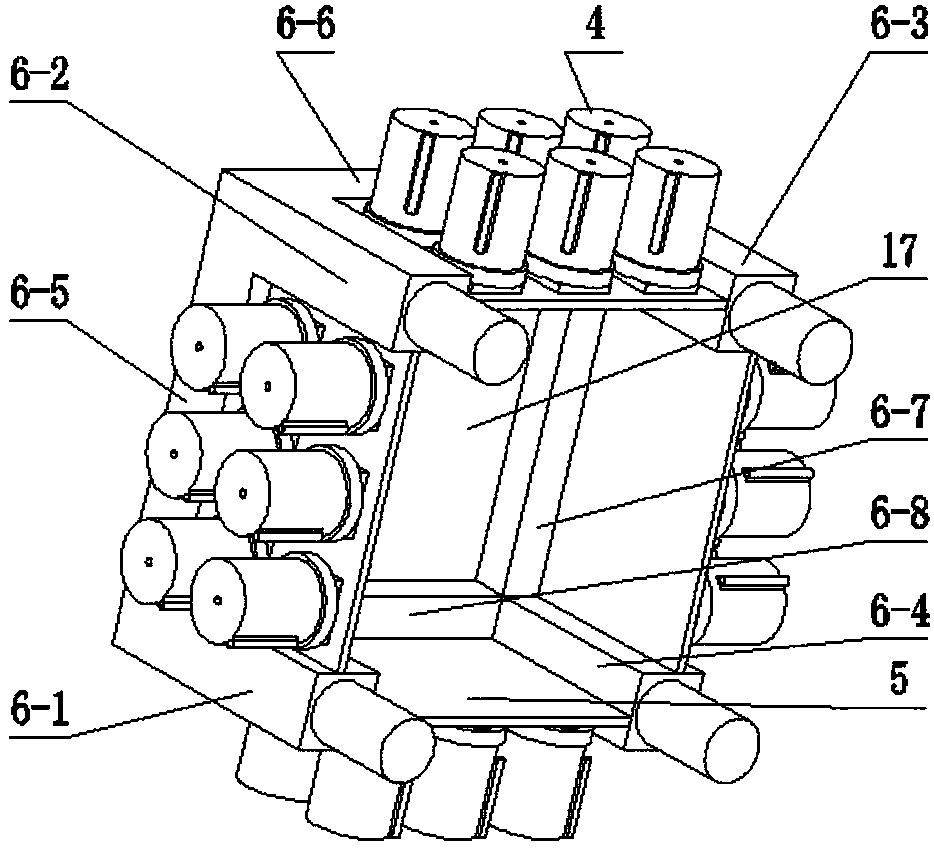

True triaxial multifunctional large deep mine laneway model testing machine

PendingCN107621415AAchieve excavationRealize monitoringMaterial strength using tensile/compressive forcesSurface stressControl system

The invention relates to a true triaxial multifunctional large deep mine laneway model testing machine, which comprises a doughnut shape-like framework system, a hydraulic loading and pressure preserving system, a control system, a pressure water system, an equipment base system and a model dismounting system. The true triaxial multifunctional large deep mine laneway model testing machine is characterized in that the doughnut shape-like framework system is a full sealing structure and can perform the true triaxial five-face and three-directional loading, provide higher model surface stress, preserve high pressure for a long time and carry out the water-yield pressure preserving test. The true triaxial multifunctional large deep mine laneway model testing machine is applicable to multiple scientific studies of the deep mine laneway, and achieve the simulation tests of mutual influences of excavation, supporting, tunneling, water inrush, and high floor pressure, and others of the underground laneway project; the testing machine has the advantages of being compact and simple in structure, convenient to operate, and environment-friendly and energy-saving.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com