Parcel sorting method and system

A sorting system and package technology, applied in the field of intelligence and logistics automation, can solve the problems of poor separation effect, poor effect, uneven spacing between packages, etc., to achieve precise separation of packages, improve efficiency and accuracy, and high separation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

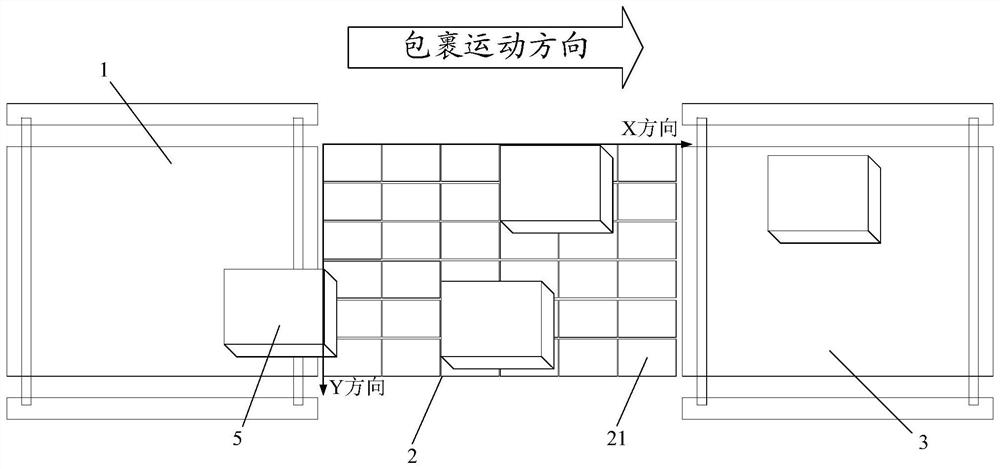

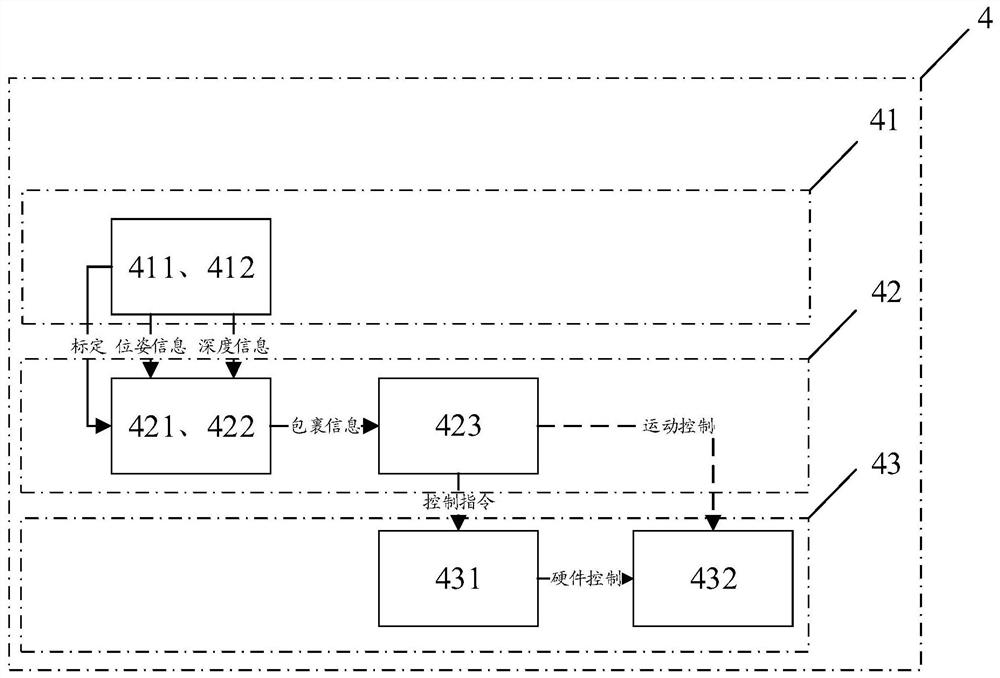

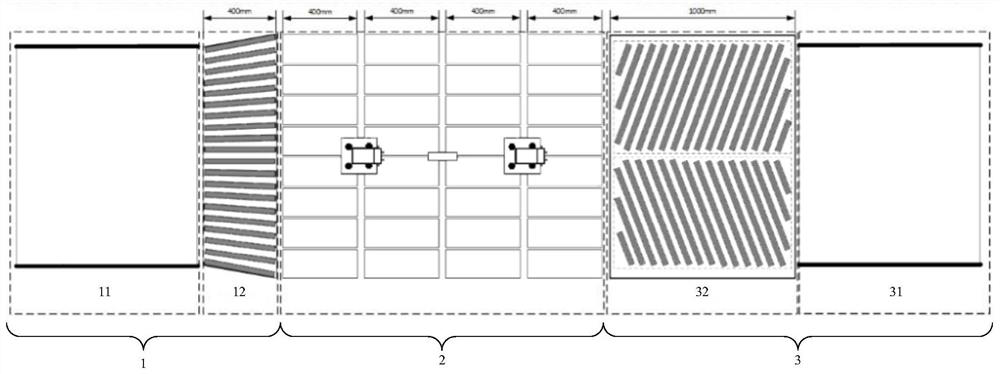

[0109] Such as Figure 1 to Figure 3 As shown, Embodiment 1 of the present application discloses a package sorting system. The package sorting system includes: the package sorting system includes an input conveyor 1 , a separator 2 , an output conveyor 3 and a control device 4 arranged in sequence. The separator 2 has a plurality of transfer modules 21, the input conveyor 1 transfers a plurality of parcels 5 to the separator 2, and the separator 2 uses a plurality of transfer modules 21 to separate and sort each parcel 5 and transfer to the output conveyor Machine 3.

[0110] Wherein, the input conveyor 1 can preferably include an input conveyor belt 11 and a dispersion roller 12, and the dispersion roller 12 is arranged between the input conveyor belt 11 and the input end of the separator 2, and the output conveyor 3 can preferably include an output conveyor belt 31 and centering rollers 32. The centering roller 32 is arranged between the output conveyor belt 31 and the outp...

Embodiment 2

[0133] Such as Figure 7As shown, Embodiment 2 of the present application discloses a parcel sorting method, which is applied to the parcel sorting system of Embodiment 1 of the present application. The parcel sorting system includes an input conveyor 1, a separator 2, an output Conveyor 3 and control device 4. The input conveyor 1 is arranged at the input end of the separator 2 , and the output conveyor 3 is arranged at the output end of the separator 2 . The control device 4 is used to control the input conveyor 1, the separator 2 and the output conveyor 3. The separator 2 has a plurality of conveying modules 21. The input conveyor 1 transmits a plurality of parcels 5 to the separator 2. The separator 2 uses A plurality of delivery modules 21 separate and sort each package 5 and deliver it to the output conveyor 3 .

[0134] The parcel sorting method disclosed in Embodiment 1 of the present application is used to implement the parcel sorting method in Embodiment 2 of the p...

Embodiment 3

[0192] Such as Figure 16 As shown, Embodiment 3 of the present application discloses a parcel sorting method, which is applied to a parcel sorting system. The parcel sorting system includes an input conveyor 1, a separator 2, an output conveyor 3 and a control device 4 arranged in sequence. The control device 4 is used to control the input conveyor 1, the separator 2 and the output conveyor 3. The separator 2 has a plurality of conveying modules 21. The input conveyor 1 transmits a plurality of parcels 5 to the separator 2. The separator 2 uses A plurality of delivery modules 21 separate and sort each package 5 and deliver it to the output conveyor 3 .

[0193] The parcel sorting method disclosed in Embodiment 1 of the present application is used to implement the parcel sorting method in Embodiment 3 of the present application. The package sorting method mainly includes the following steps:

[0194] Step1: Turn on the control device and parcel sorting system;

[0195] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com