Patents

Literature

108results about How to "Improve the quality of production and processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

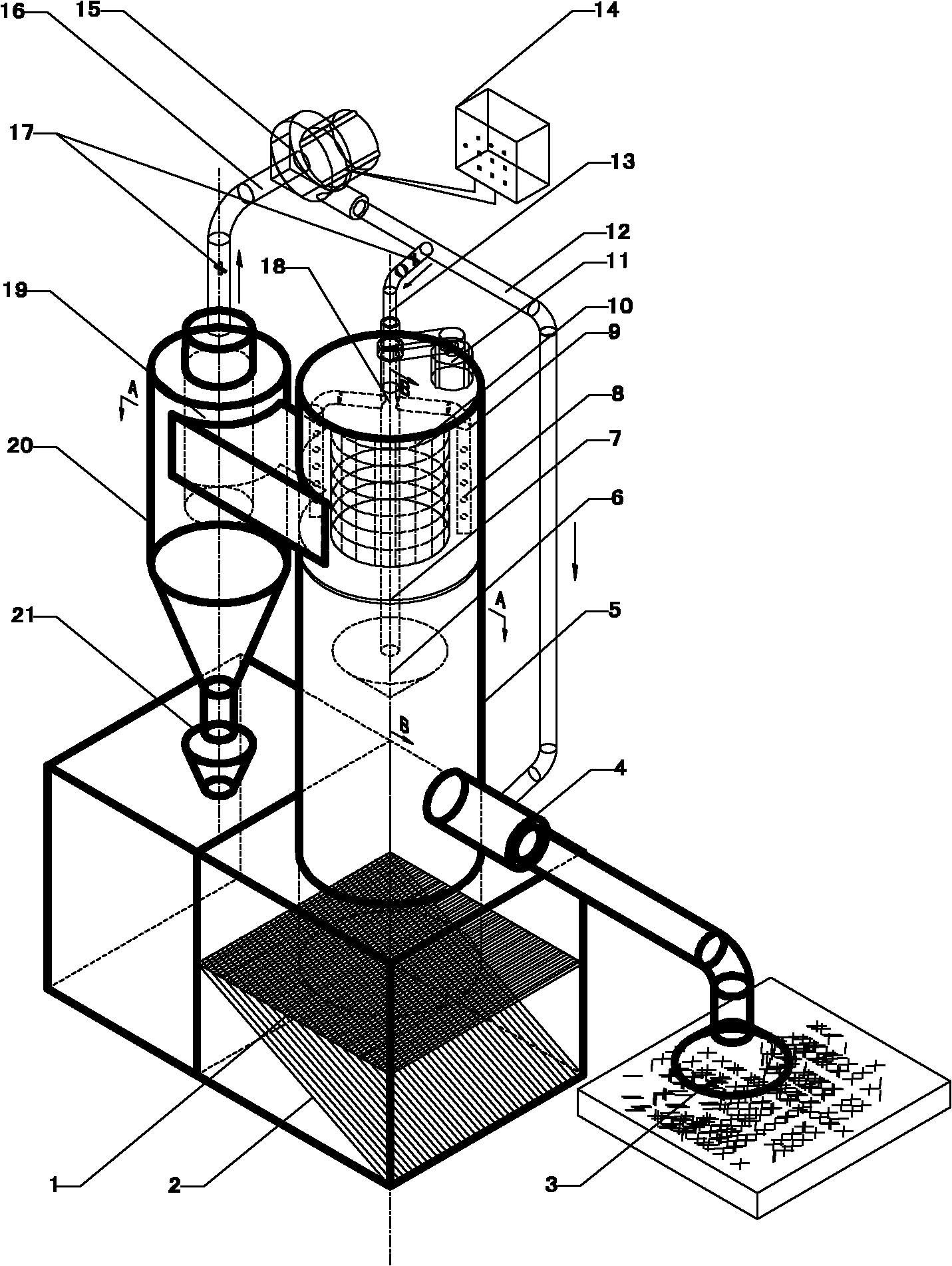

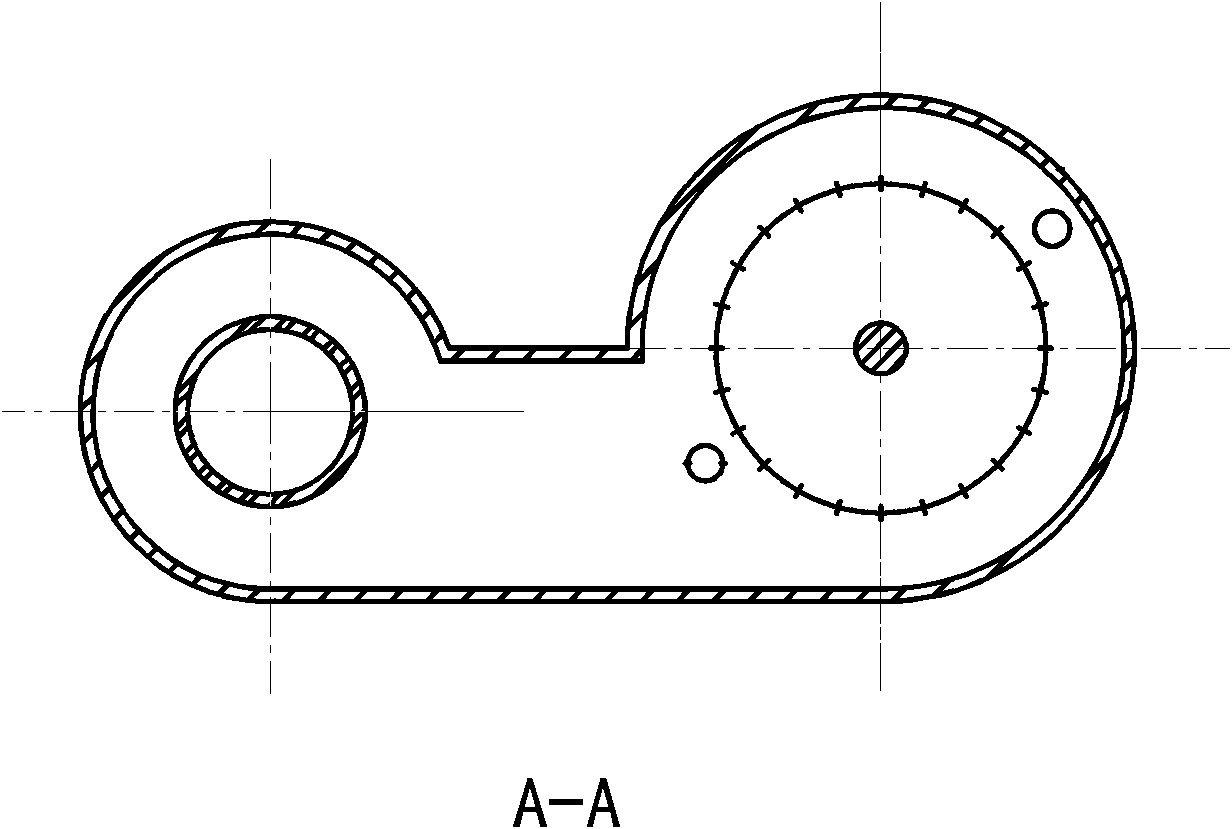

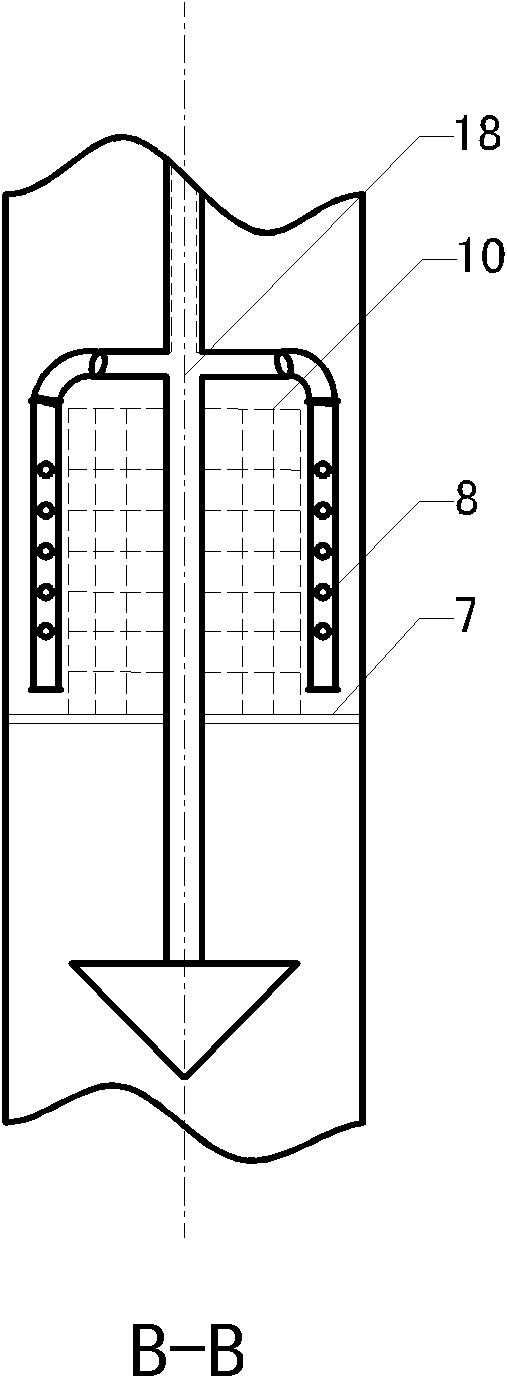

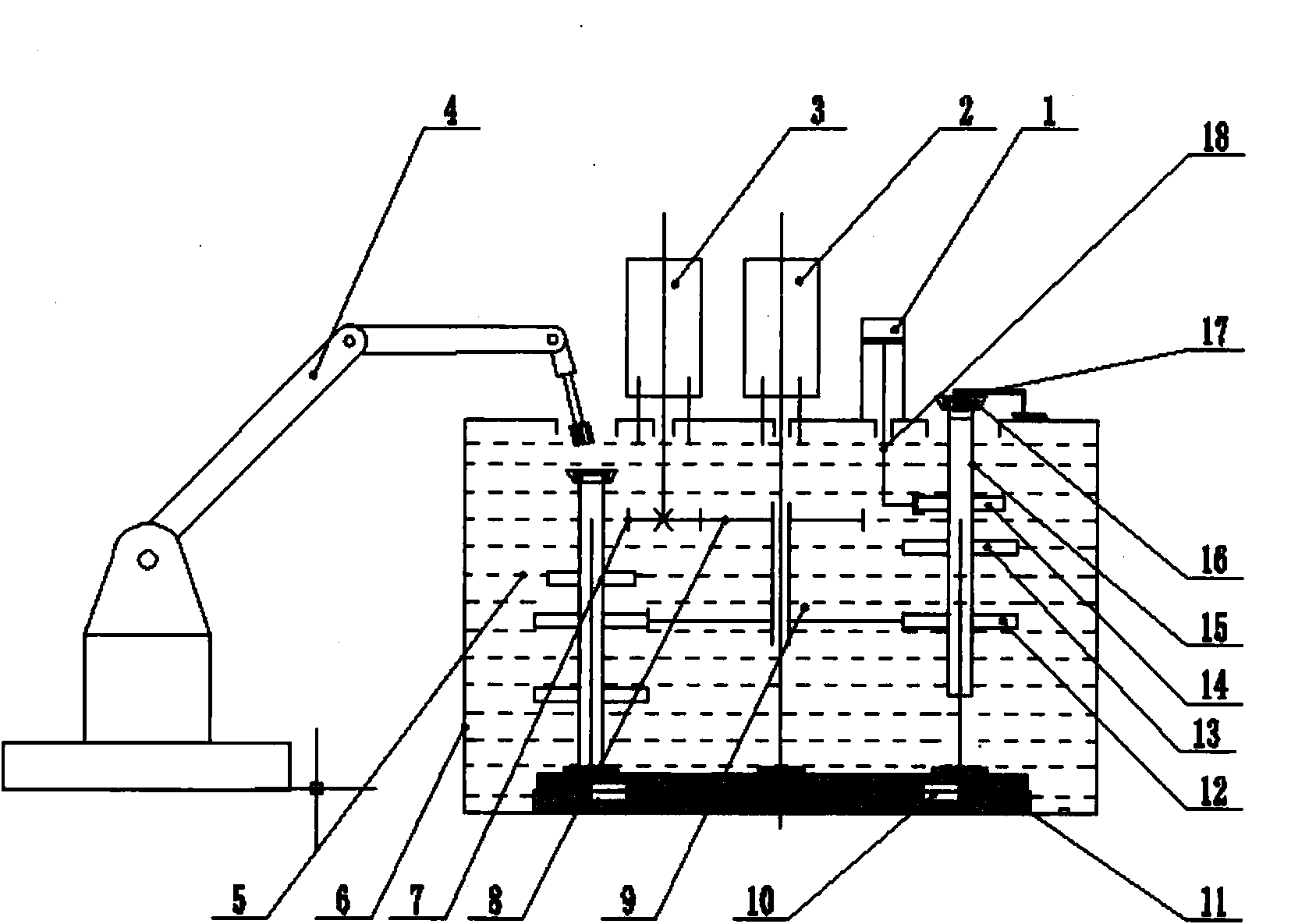

Combined cyclone separation/collection device and method for separating and collecting pollen

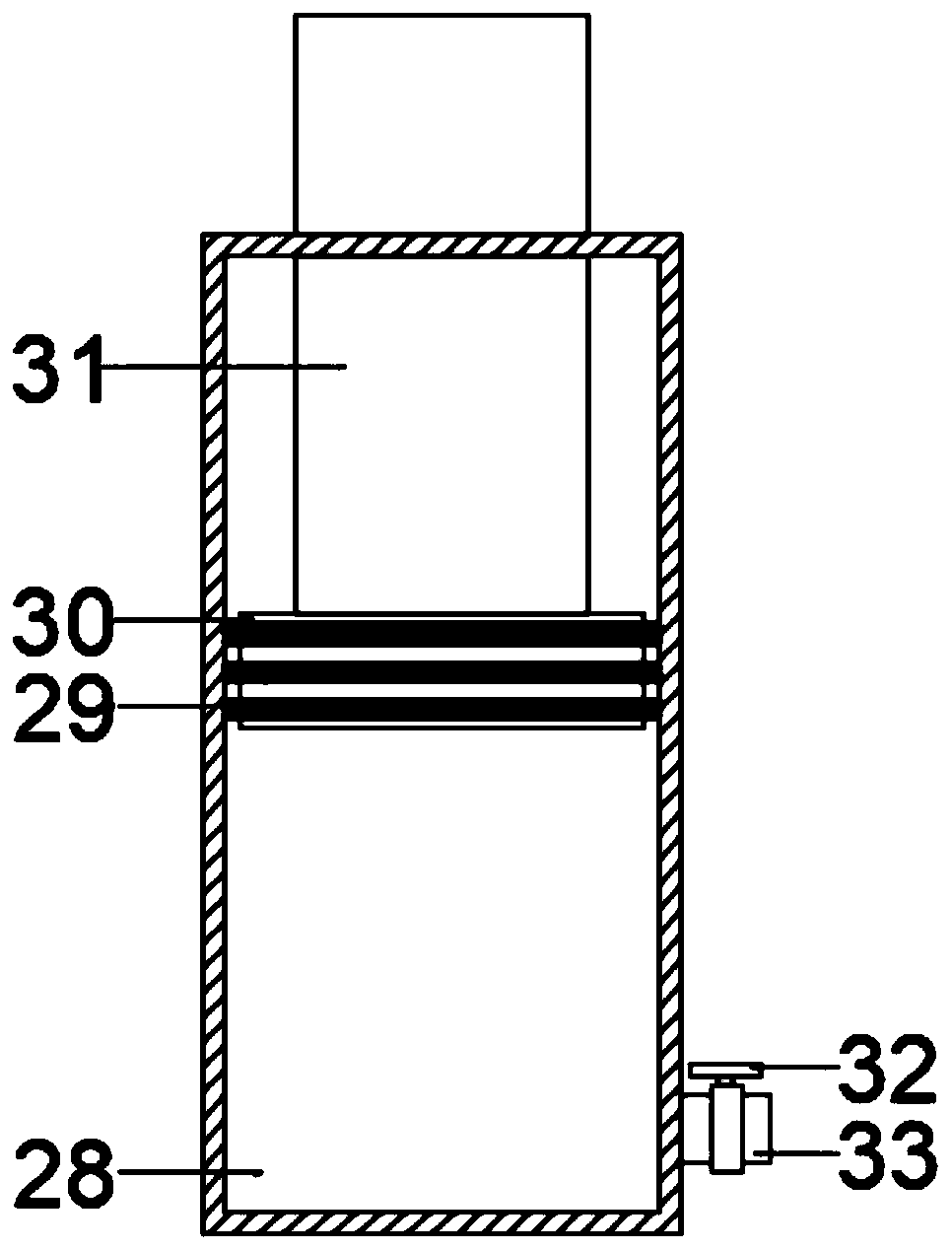

The invention discloses a combined cyclone separation / collection device and a method for separating and collecting pollen based on the device. The device comprises a cylindrical settling chamber and a double-cylinder cyclone. The cylindrical settling chamber is down communicated with an umbrella-type taker. The sidewalls of the top of the cylindrical settling chamber are communicated with the outer cylinder of the cyclone. An air duct is arranged outside the cylindrical settling chamber, and is communicated with the cylindrical settling chamber and the inner cylinder of the cyclone, respectively. Besides, the air duct is connected to an external variable frequency fan. A cylinder screen, a reflecting cone and a three-way air blowback pipe are arranged in the inner space of the cylindrical settling chamber. The rotating central shaft of the reflecting cone rotates through connection with an external variable speed motor. A stripper plate and a discharge chute are arranged on the bottom of the cylindrical settling chamber. Furthermore, a pollen collecting chamber is arranged on the bottom of the double-cylinder cyclone. The method comprises the following steps of: suctioning dust-containing pollen by means of an airflow, and filtering the dust-containing pollen; performing separation in the cylindrical settling chamber; and collecting the pollen in the cyclone, and purifying the dust-containing airflow for recycling. The device and the method of the invention are capable of effectively improving the pollen separation / extraction efficiency and preventing dispersion of pollen, and suitable for being popularized and used.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

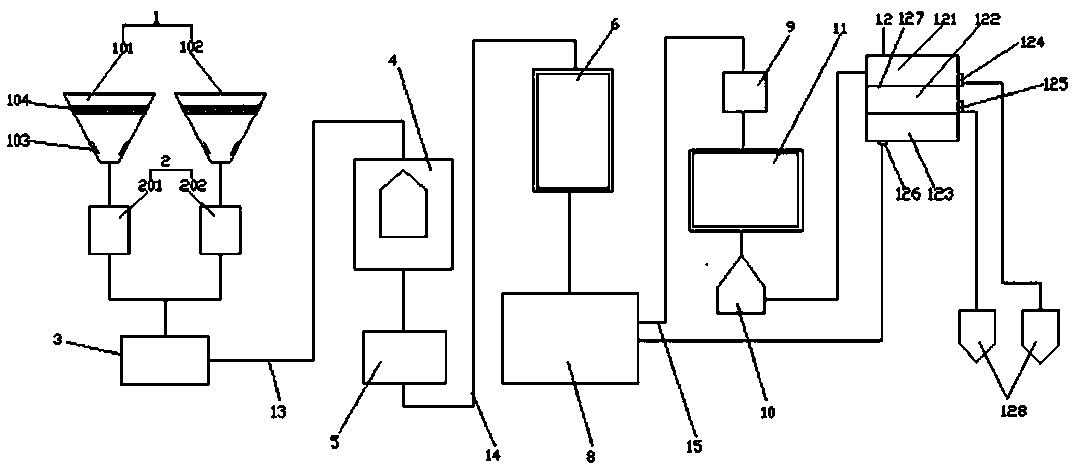

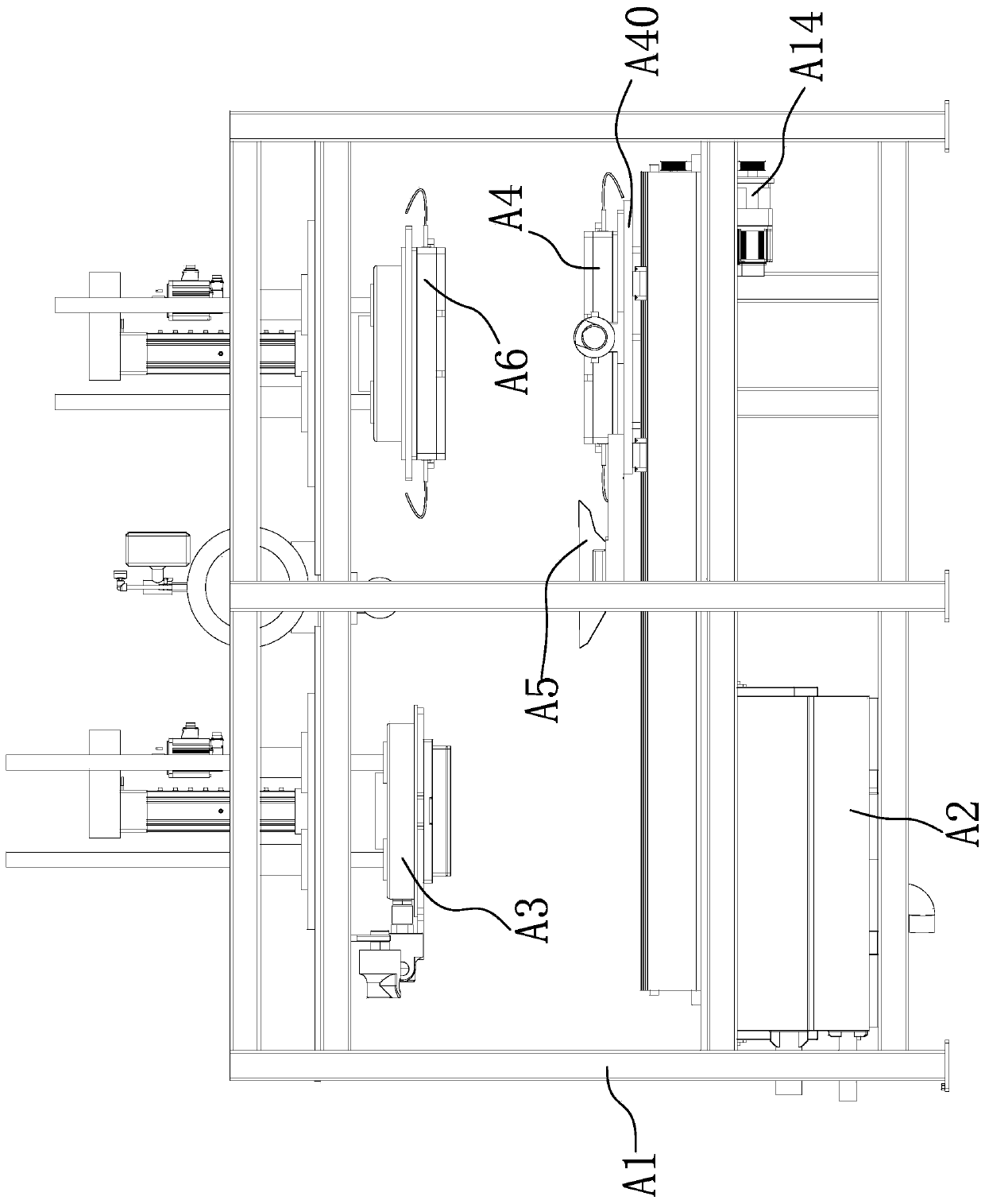

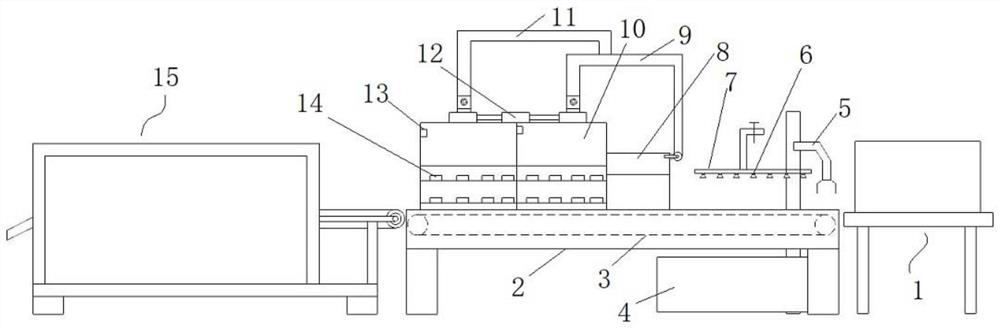

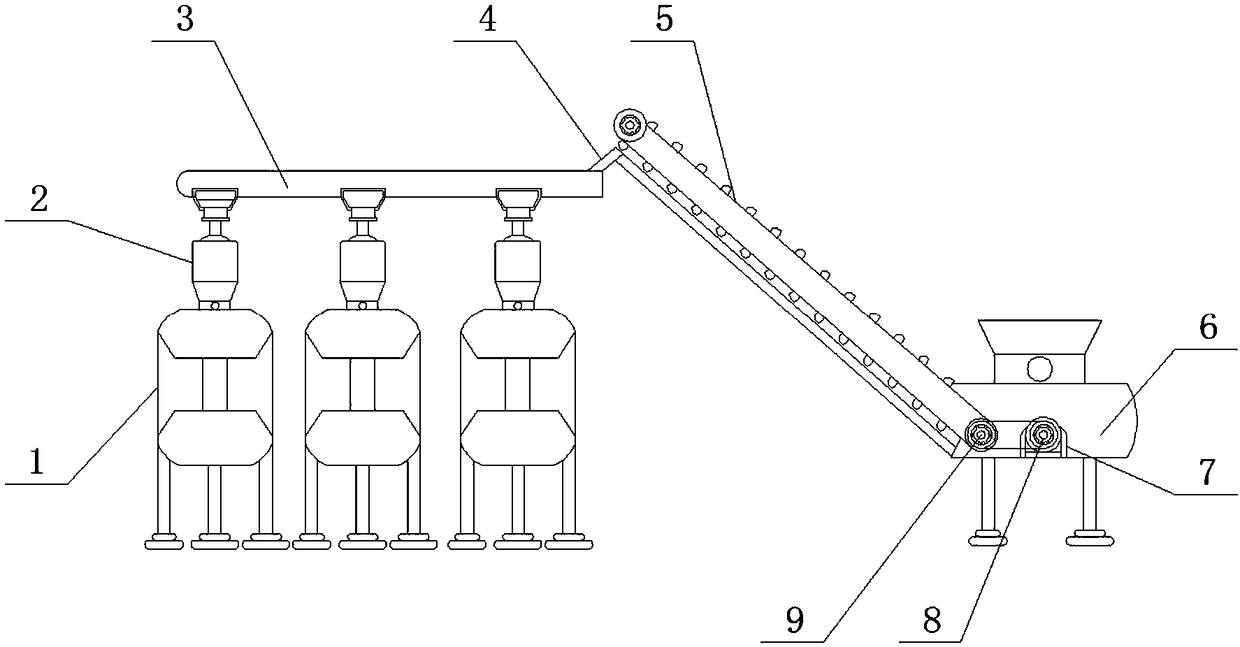

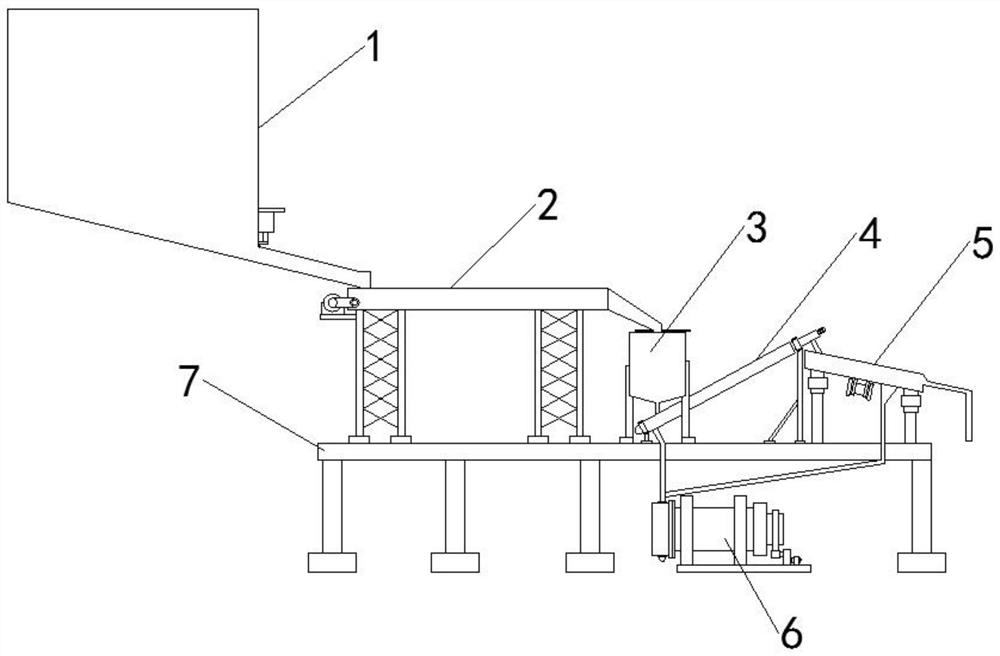

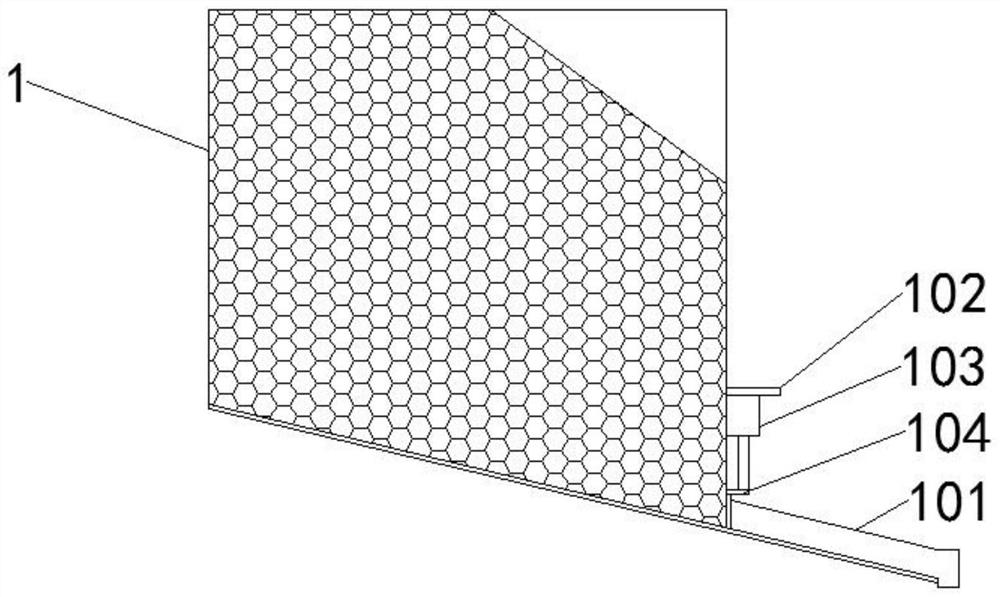

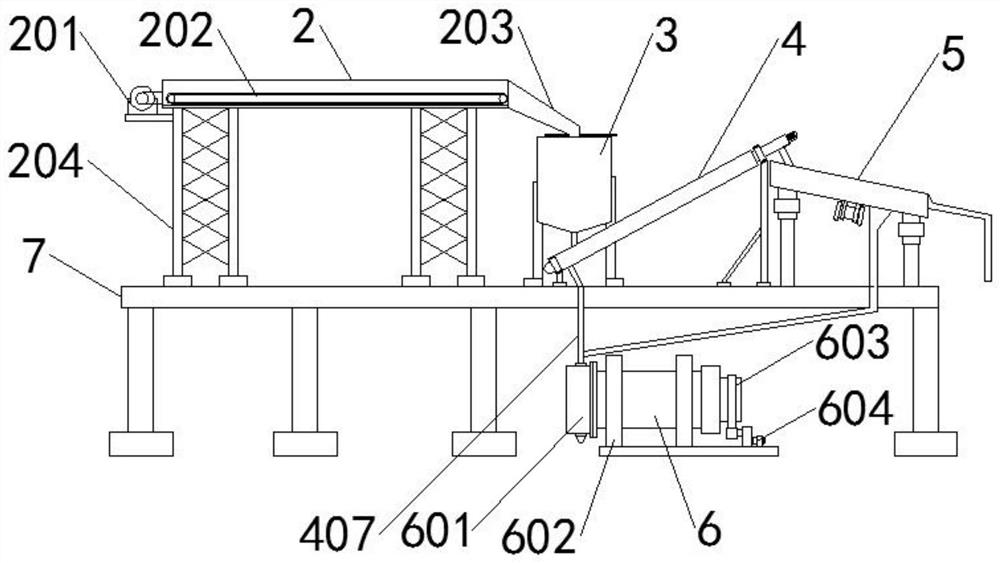

Granulated feed producing and processing equipment and method

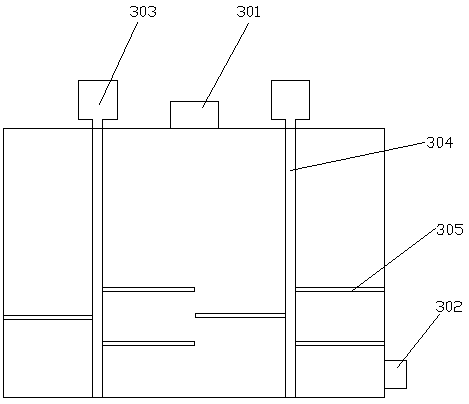

PendingCN109480319AMessy layoutHigh energy consumptionFeeding-stuffProcess equipmentProcess engineering

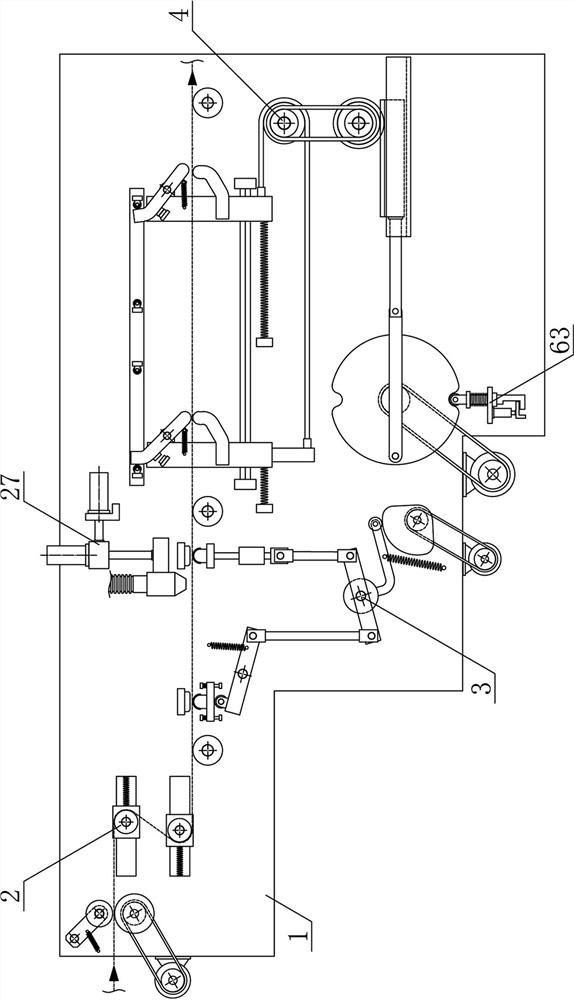

The invention relates to granulated feed producing and processing equipment and method. The granulated feed producing and processing equipment comprises a raw material receiving system, a crushing system, a mixing machine, a granulating system and a quantitative packaging system, wherein the raw material receiving system comprises a feeding device, a dosing device, a stirring barrel, an impurity removing device and a dust removing device; the crushing system comprises a crusher and an ozone generating device; the granulating system comprises a conditioning device, a granulator and a cooler; and the quantitative packaging system comprises a sorting machine and a quantitative packaging mechanism. Through adoption of the granulated feed producing and processing equipment disclosed by the invention, the defects that in the prior art, a set of perfect feed producing and processing equipment does not exist, most conventional equipment has single equipment working procedure, the equipment layout is in disorder, the energy consumption is high, the production process is complex, the production efficiency is low, and the product quality cannot be guaranteed, are solved; and the granulated feed producing and processing equipment disclosed by the invention is high in automation degree, simple in structure, high in production efficiency and low in cost, and can produce multi-grade products,and the grade quality is high.

Owner:韶关正邦农牧科技有限公司

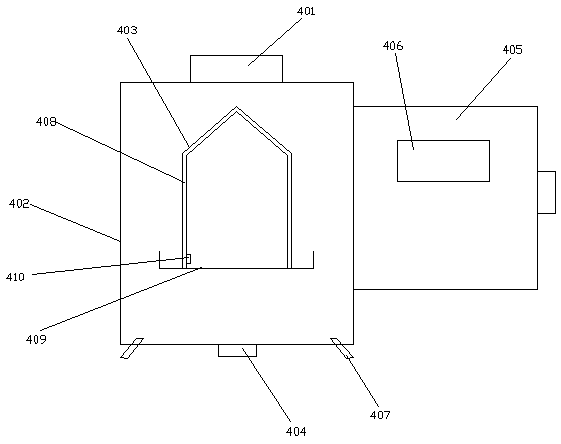

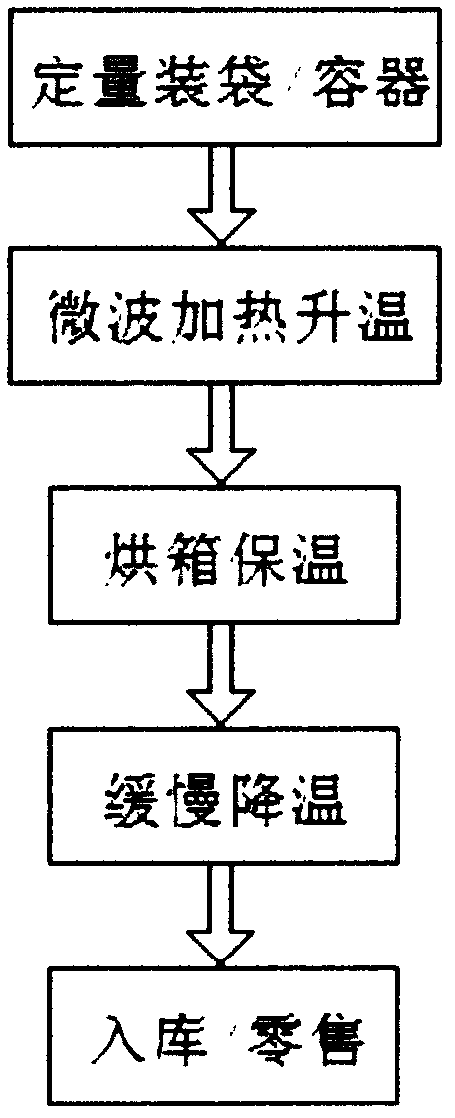

Microwave pest killing method for grain products such as rice, beans, wheat

InactiveCN102986864AAchieve pest controlComplete production processSeed preservation by heatingCold airAgricultural science

The invention discloses a microwave pest killing method for grain products such as rice, beans, wheat and the like for grain raw material or processed grain, which is applicable to the grain products before being put in storage or taken out of storage. The microwave pest killing method for grain comprises the following steps: (1) quantitatively putting the grain product into a pored packing bag or nonmetal container; (2) uniformly heating to 40-70 DEG C in a box-type or tunnel-type industrial microwave oven; (3) setting temperature to 50-70 DEG C in a tunnel-type thermal insulation oven, and keeping the temperature for 3-15 minutes; (4) slowly reducing the temperature of the container or the packing bag to below 40 DEG C in a cooling channel in a cold air environment; and (5) storing the product or selling at retail. The method disclosed by the invention is a pure physical pest killing technology, and can completely kill the adults, larvae and eggs in the grains of rice and beans while maintaining the original quality and flavor of the grain products such as rice, beans, wheat and the like.

Owner:SHANGHAI MAIFENG MICROWAVE EQUIP

Alpha linolenic acid cryogenic separation and purification method

InactiveCN102030629AChange concentrationComplete production processFatty acids production/refiningCarboxylic compound separation/purificationNemorensic acidAlpha-Linolenic acid

The invention discloses an alpha linolenic acid cryogenic separation and purification method, comprising the steps of: uniformly mixing oil rich in alpha linolenic acid and acetone or a methanol solvent according to a volume ratio of 1:(3-6), placing a container containing the mixed solution in an environment at (-30)-(-60) DEG C for refrigeration, separating and removing crystals at low temperature when the temperature reaches (-30)-(-60) DEG C, and desolventizing the solution to remove the solvent accounting for 20-30% of the total volume; repeating the steps of refrigeration, crystal removal and desolventization for 3-5 times for separating and removing the crystals; and after circularly removing the crystals for 3-5 times, repeating the steps of refrigeration and crystal removal once again when the volume ratio of the alpha linolenic acid to the solvent reaches 1:(2-3), and desolventizing the finally obtained mixed solution to obtain the alpha linolenic acid. The method is a pure physical cryogenic separation technology and can improve product quality and yield stability, and the concentration of the obtained alpha linolenic acid is above 80%.

Owner:SHANGHAI MAIFENG MICROWAVE EQUIP

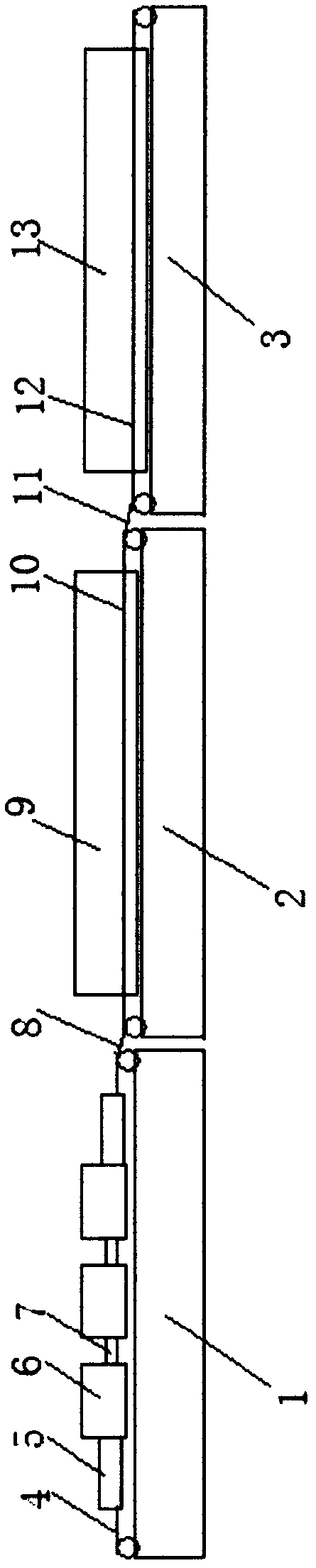

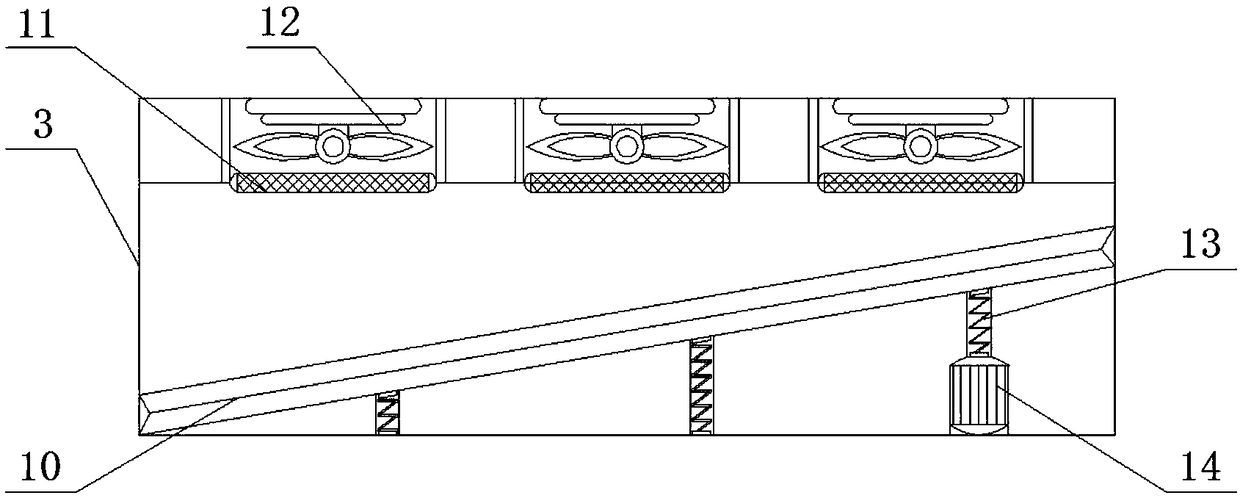

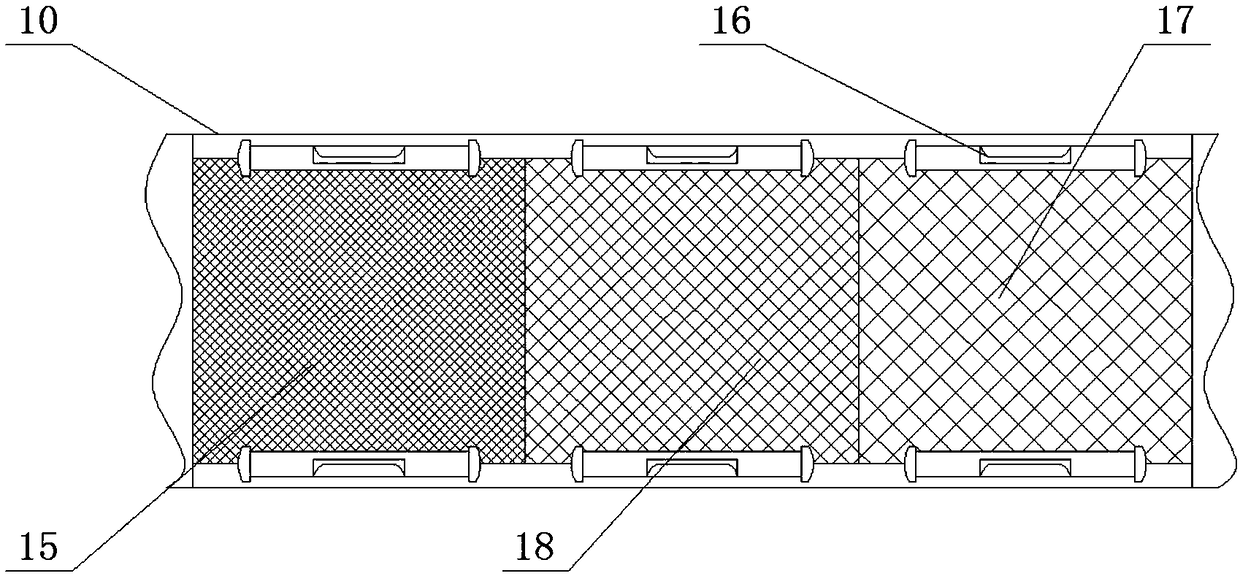

Conveying and impurity suction device for melt-blown cloth production

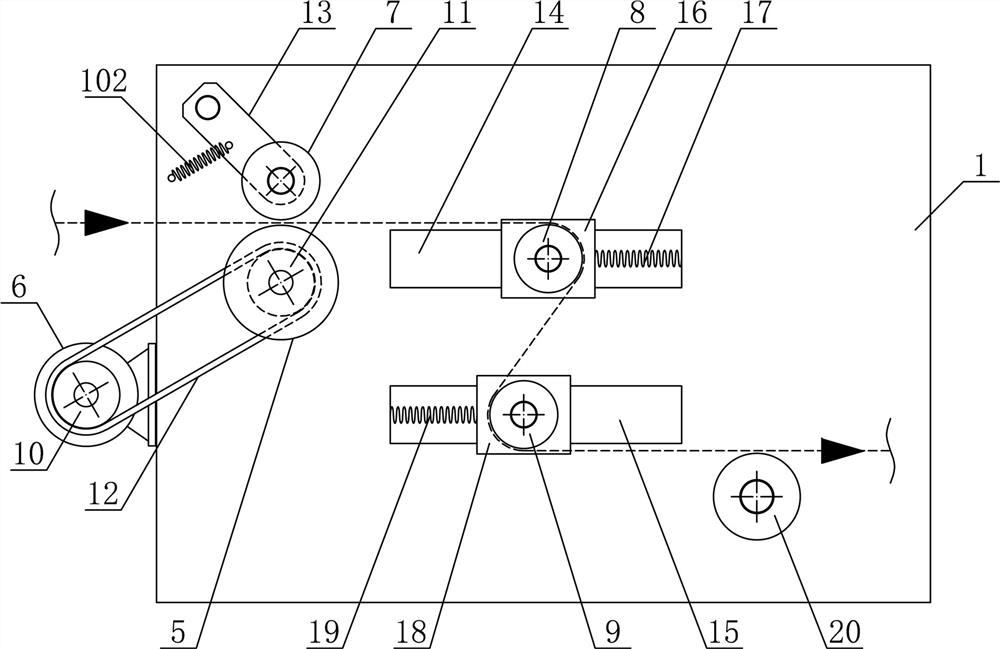

ActiveCN111826920ASmooth and smooth pressing and fixingPress and fix evenlyMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention discloses a conveying and impurity suction device for melt-blown cloth production, and belongs to the field of melt-blown cloth production equipment. A melt-blown cloth pressing rotary roller is arranged on the upper side of a cloth feeding and conveying rotary roller, a front material guide rotating roller and a rear material guide rotating roller are rotationally connected to a cloth conveying machining bracket in sequence, a front positioning cloth pressing plate is fixedly arranged on the upper side of a front lifting guide plate, a rear positioning cloth pressing plate is fixedly arranged on the upper side of a rear lifting guide plate, a cloth discharging and conveying rotary roller is rotationally connected to the cloth conveying machining bracket on one side of the rear material guide rotating roller, a lifting material guide rotating roller is rotationally connected to a lifting reciprocating guide plate, a reciprocating impurity suction material pipe is arrangedbetween the front positioning cloth pressing plate and the rear positioning cloth pressing plate, and an impurity suction connecting hose is arranged in the middle of the upper side of the reciprocating impurity suction material pipe in a communicating mode. The conveying and impurity suction device for melt-blown cloth production is reasonable in structural design, melt-blown cloth can be pressed and fixed intermittently, efficiently and stably in the conveying process, then the melt-blown cloth can be subjected to segmented impurity suction machining conveniently and smoothly, the automation degree of melt-blown cloth production and machining is improved, and the requirements of production and use are met.

Owner:桐乡市中瑞环保科技有限公司

Medical mask machine capable of automatic packaging

ActiveCN111674612AImprove the limit effectGuarantee processing qualityPackagingArticle feedersEconomic benefitsProduction quality

The invention discloses a medical mask machine capable of automatic packaging. The machine comprises a transportation platform, a packaging processing platform, a packaging machine body, and a transportation belt. The arrangement of a limiting block and a limiting drum can realize a good limiting effect on a mask to be packaged, and ensure that no position deflection of the mask occurs in the conveying process, thereby guaranteeing the processing quality of the mask. Through the arrangement of a push rod, a fixed circular groove and a first spring pin, the position of the limiting drum can beadjusted, so position limiting can be realized based on the actual size of the mask, the application range is widened and benefits of application are increased. Through the arrangement of a compactingdevice, after the mask to be packaged is wrapped by a paper film, on the one hand, the mask can be duly compacted, the paper film is attached to the mask, i.e., extra space between the mask and the paper film is squeezed out, waste of the paper film is prevented, and economic benefits are improved, and on the other hand, tidiness of mask packaging is improved, the aesthetic property after packaging is guaranteed, and processing production quality is therefore improved.

Owner:滕春根

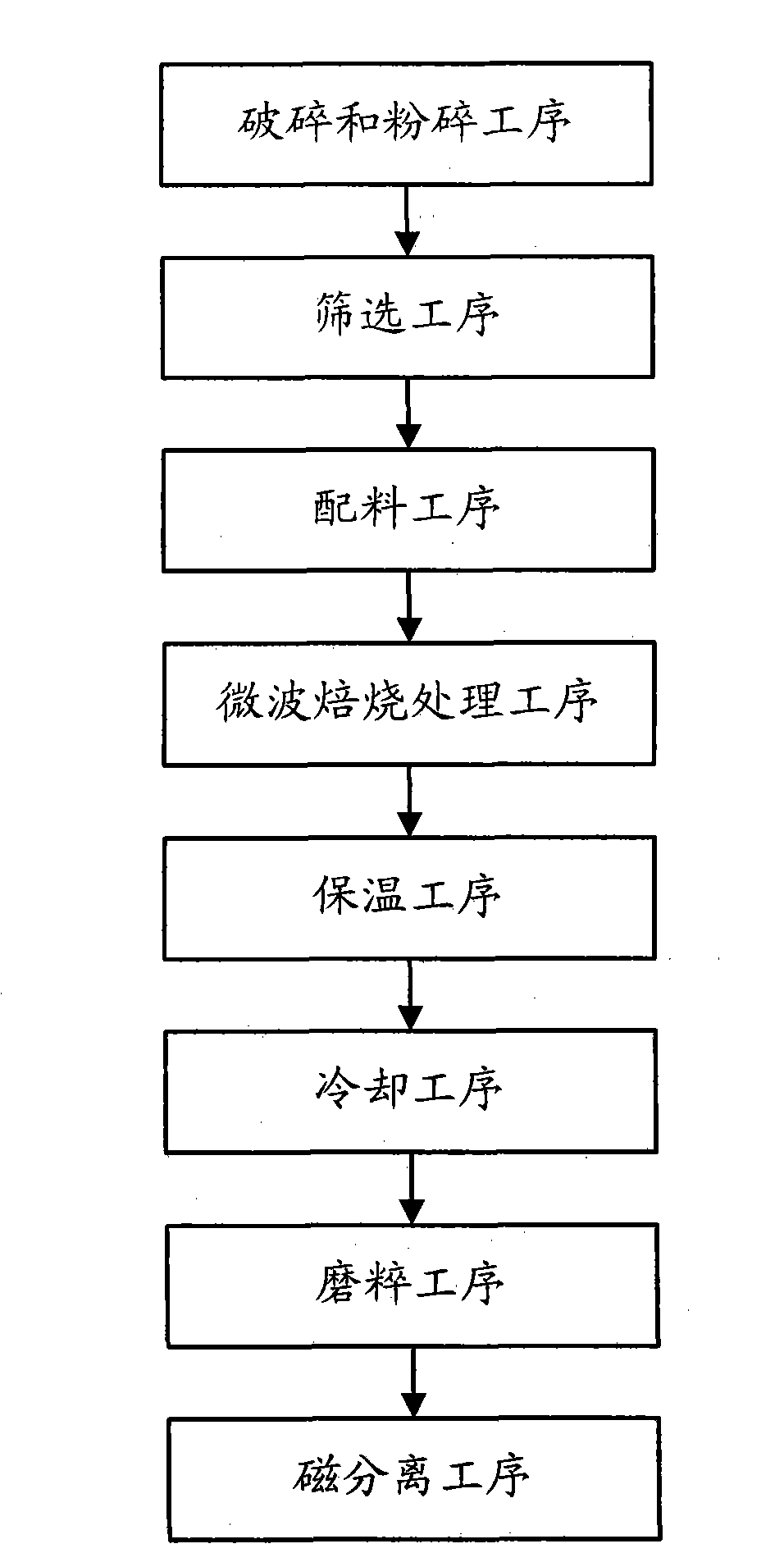

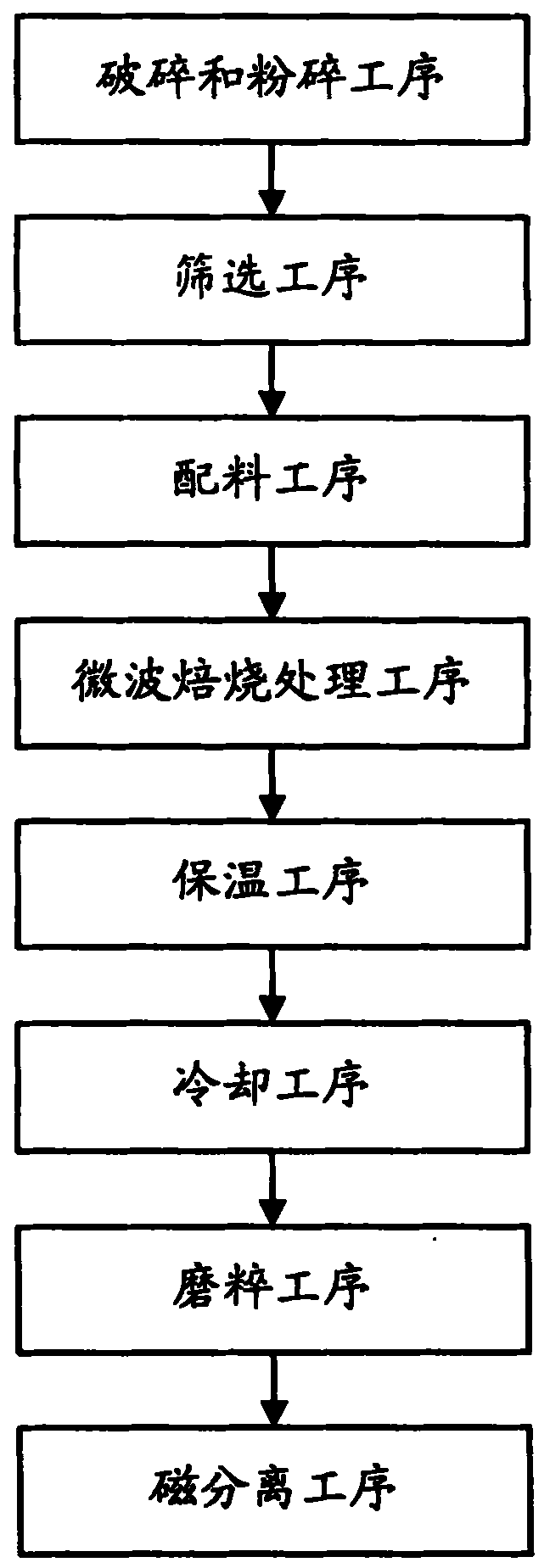

Method for converting natural non-magnetic iron ore into magnetite

InactiveCN102168170AIncrease profitComplete production processSievingScreeningMicrowave methodMagnetite

The invention discloses a method for converting natural non-magnetic iron ore into magnetite by a microwave method, and particularly relates to a method for converting non-magnetic iron ore such as natural limonite, hematite and siderite into the magnetite through processes of crushing, smashing, sieving, mixing, microwave roasting treatment, heat preservation, cooling, grinding, magnetic separation and the like. In the method, the production process is intact, the mechanization degree is high, production processing cycle is shortened, production processing speed is improved, the conversion rate of a magnetite powder product is high, and the continuous production can be realized; and the device simultaneously has the characteristics of energy conservation and high efficiency, and can improve the quality of products and the stability of the yield.

Owner:SHANGHAI MAIFENG MICROWAVE EQUIP

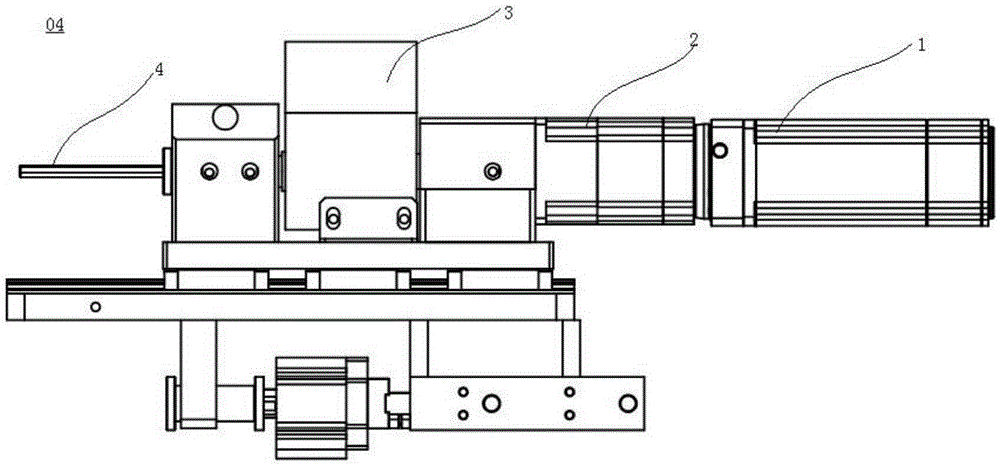

Intelligent torque driving control mechanism and intelligent screw assembling machine adopting intelligent torque driving control mechanism

InactiveCN105414942AGuaranteed assembly qualityQuality assuranceMetal working apparatusReducerControl theory

The invention discloses an intelligent torque driving control mechanism. The intelligent torque driving control mechanism comprises a servo motor, a speed reducer and a controller used for monitoring output torque values of the servo motor. The speed reducer is connected with the servo motor, the controller is connected with the speed reducer, and the controller comprises the torque output end which is connected with the outside.

Owner:周盈玉

Stamping die for part production

ActiveCN110394398APrevent copper damageImprove stamping qualityOther manufacturing equipments/toolsStamping processEngineering

The invention relates to the field of stamping dies for part production, in particular to a stamping die for part production. The stamping die comprises a plurality of maintenance plates, a shell, a discharging structure, an electric hydraulic cylinder, a stamping structure, a transmission structure, a rolling-out structure, a guide structure and a cutting structure. The stamping structure is connected to the electric hydraulic cylinder, then the stamping structure can be driven through the electric hydraulic cylinder to stamp on copper plates step by step conveniently, then the situation thatcopper plates are damaged in the stamping process is effectively prevented, meanwhile, after the stamping structure finishes stamping, stamped parts are driven through extrusion force to be separatedfrom the stamping structure conveniently, and then the stamping quality and the stamping efficiency are greatly improved; the rolling-out structure is arranged inside the shell, then the copper plates can be rolled out through the rolling-out structure conveniently, meanwhile, the transmission structure is connected to the rolling-out structure, and then rolling and stamping are synchronous; andthe guide structure is fixed on the shell, then the copper plates with different thicknesses and different widths can be guided conveniently, and the situation that the copper plates shift, so that the production and machining quality of the copper plates is influenced is avoided.

Owner:唐山华舜科技股份有限公司

Electric polishing machine tool

InactiveCN105195832AExtended working hoursHigh degree of automationGear-cutting machinesGear teethEconomic benefitsOutput device

The invention relates to an electric polishing machine tool, comprising a main body, a bearing rotary frame, a bearing, a following wheel, a rotary belt, a machining box, support desk legs, a stabilizing seat, a large power generator, an electric energy output device, a motor box, a transmission line, an intelligent positioning device, a rotary speed wheel supporting frame and a main rotary speed wheel; the bearing is provided with the following wheel of which the upper side is provided with the rotary belt; the large power generator is arranged in the main body; the right side of the large power generator is connected with the electric energy output device; the motor box is connected with the electric energy output device by the transmission line; the intelligent positioning device is arranged at the lower side of the motor box; the main rotary speed wheel is arranged at the left side of the rotary speed wheel supporting wheel. The novel electric polishing machine tool is higher in automatic degree, saves massive labor and material resource and is suitable for batch production of multiple parts, the machining production efficiency and gear quality are improved and economic benefits are increased.

Owner:TIANJIN JUXINGXIANGHAI MACHINERY CO LTD

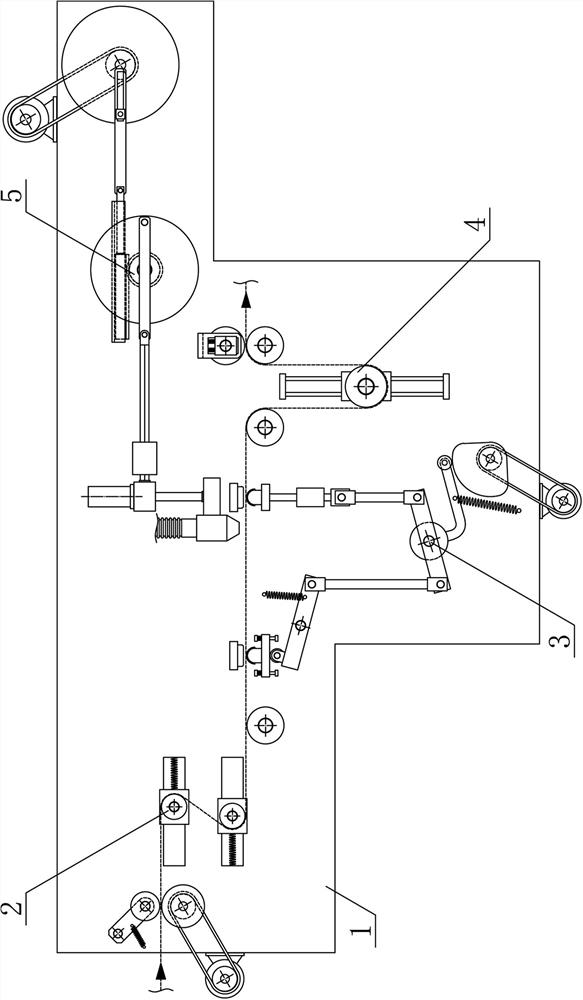

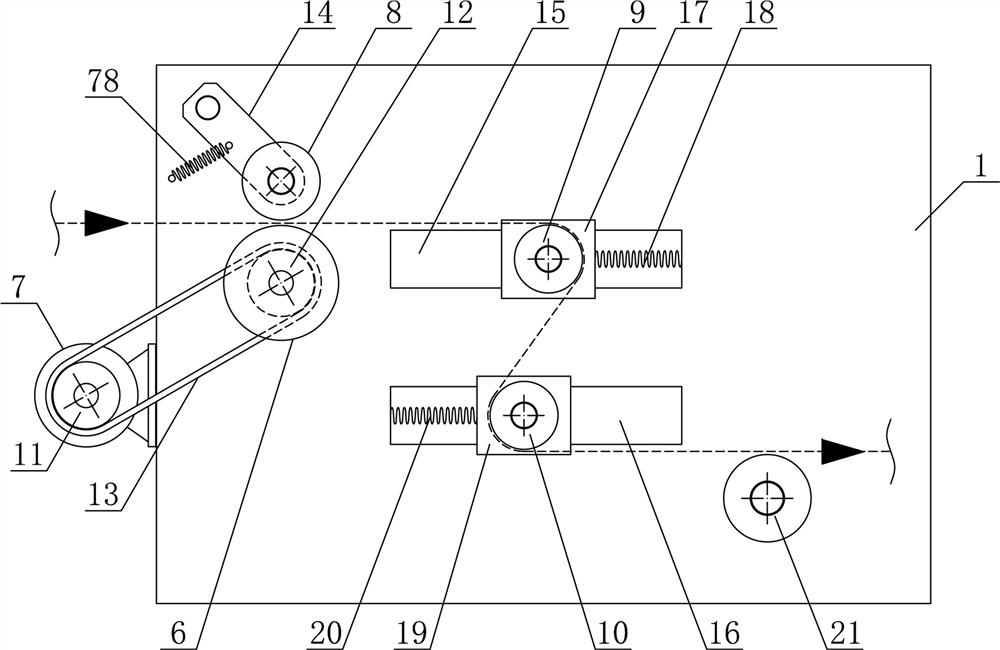

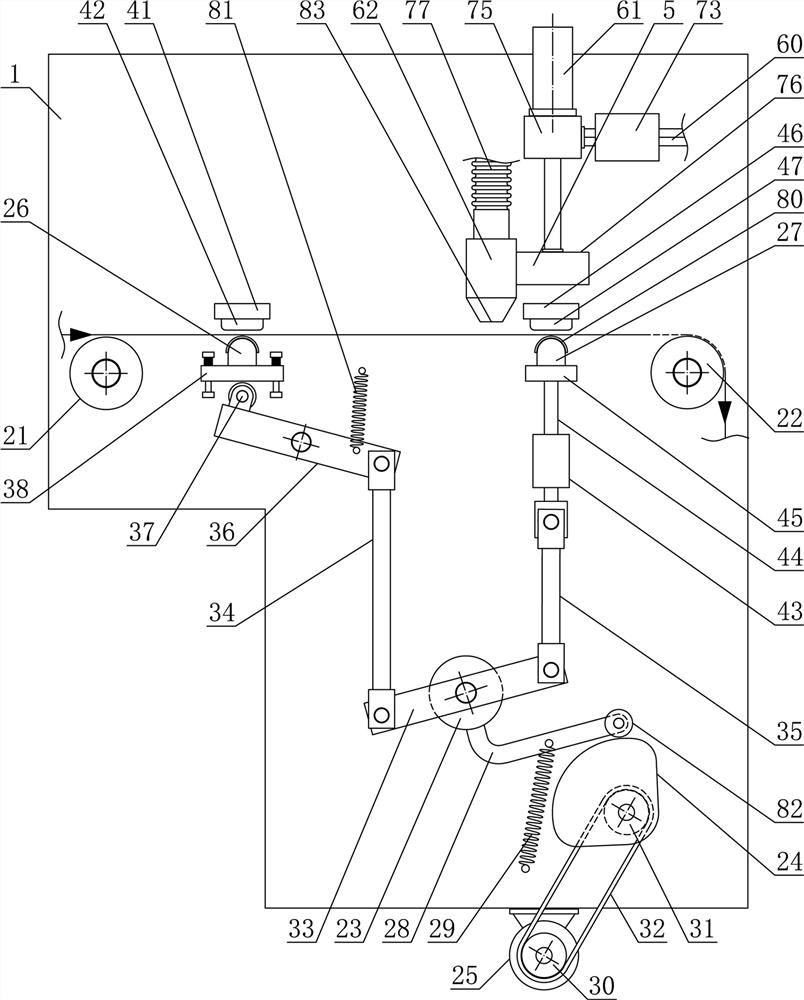

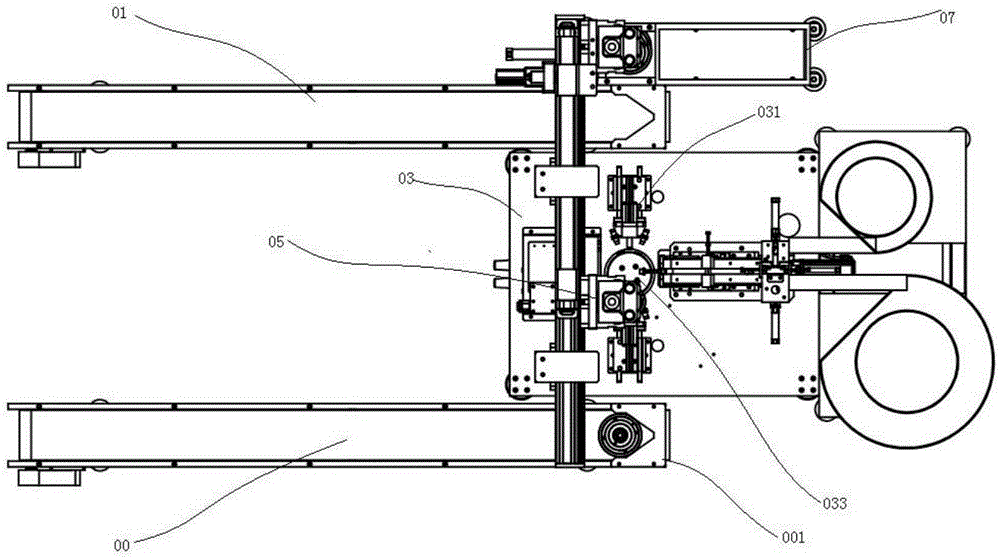

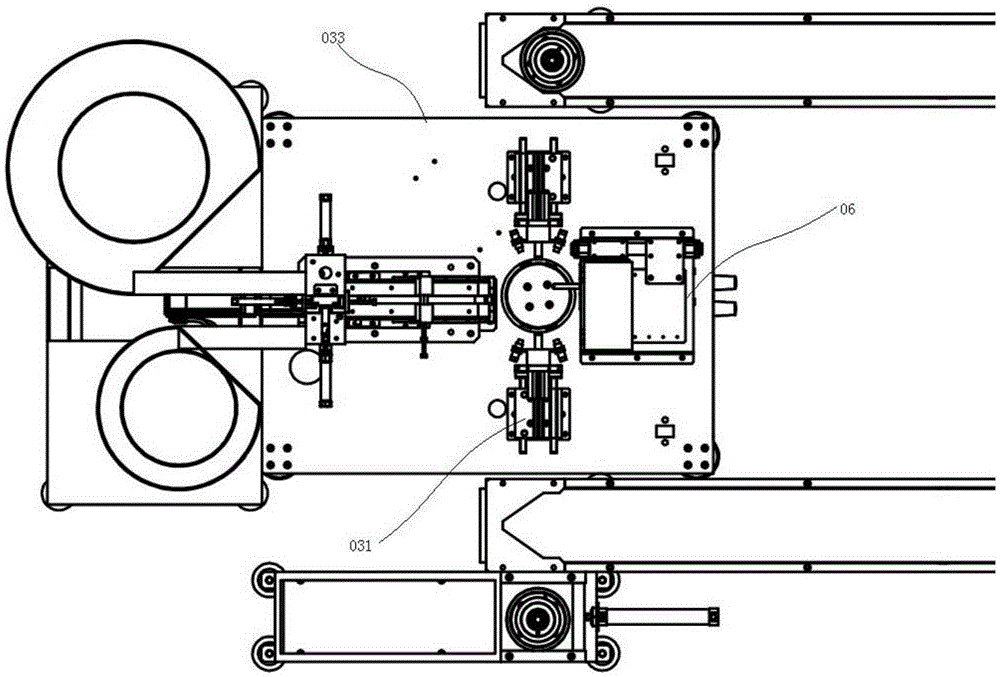

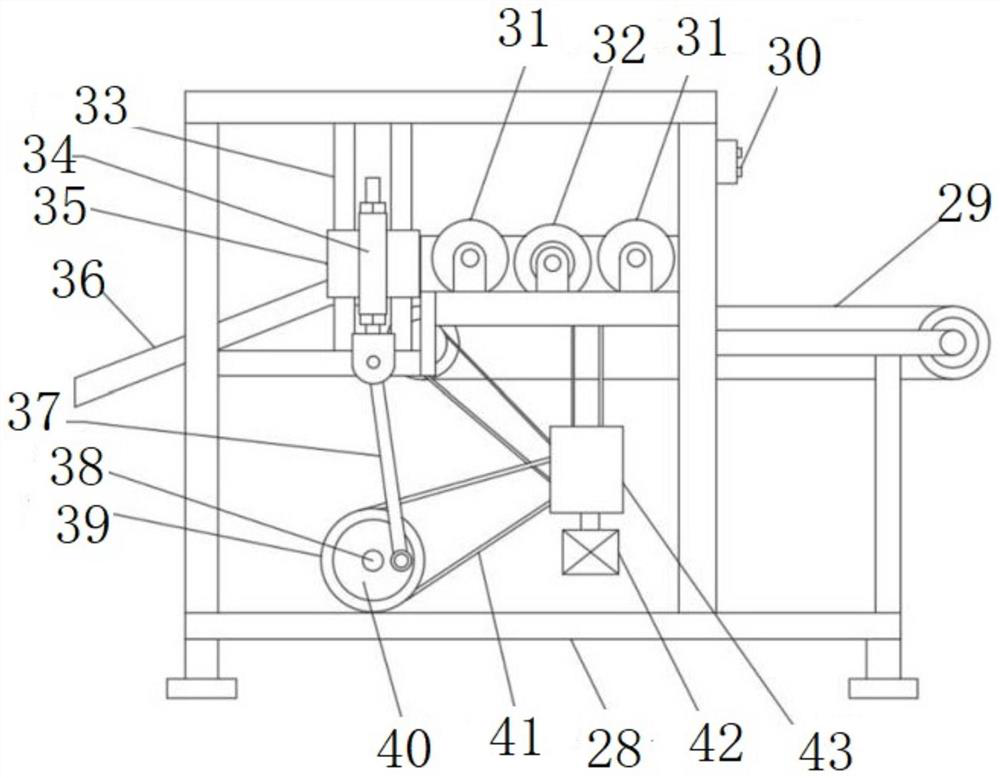

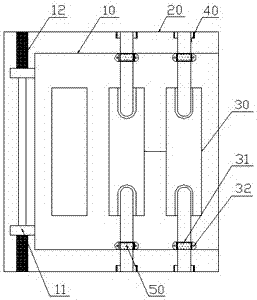

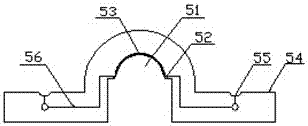

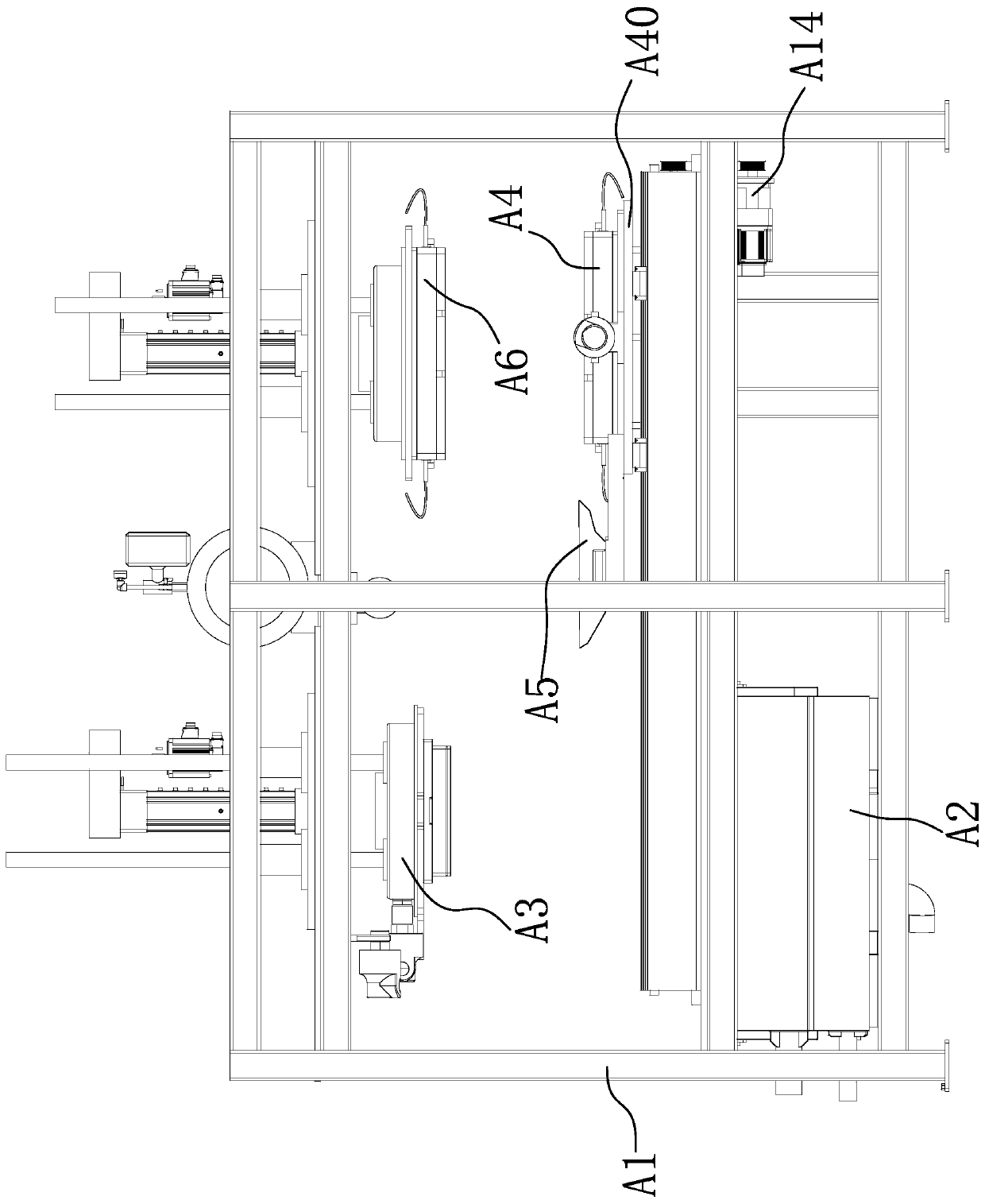

Double-station die cutting equipment for machining printed label roll

PendingCN108214669AIncrease productivityImprove the quality of production and processingMetal working apparatusAnnular cutterEngineering

The invention discloses double-station die cutting equipment for machining a printed label roll. The equipment comprises a machine frame with a conveying platform, wherein one end of the conveying platform is a feeding end, the other end of the conveying platform is a discharging end, and the conveying platform is provided with two die cutting lower dies arranged at intervals; a die cutting upperdie is arranged above each die cutting lower die, a hard substrate is arranged on the upper surface of each die cutting lower die, and the upper surfaces of the hard substrates are flush with the upper surface of the conveying platform; annular cutters are arranged in the center areas of the lower surfaces of the die cutting upper dies, flexible buffering pads are further arranged on the lower surfaces of the die cutting upper dies, annular groove bodies for allowing the annular cutters to be inserted are formed in the flexible buffering pads, and the thickness of each flexible buffering pad is larger than the thickness of each annular cutter in the vertical direction; and at least one negative pressure cavity is arranged in the conveying platform, a plurality of vertical adsorption smallholes communicating with the negative pressure cavities are formed in the upper surface of the conveying platform, and a monitoring device used for monitoring the positions of labels on the label rollis arranged on the conveying platform.

Owner:QIANDA NEW MATERIAL CO LTD

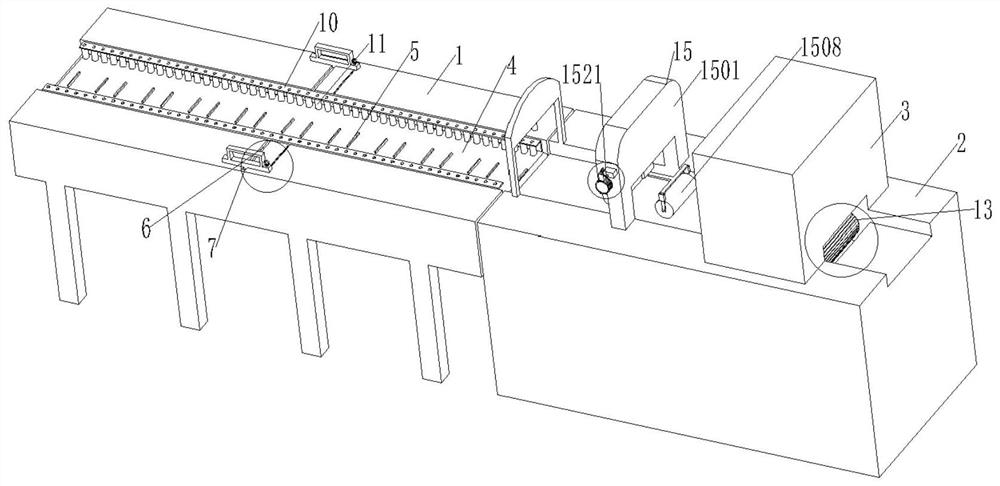

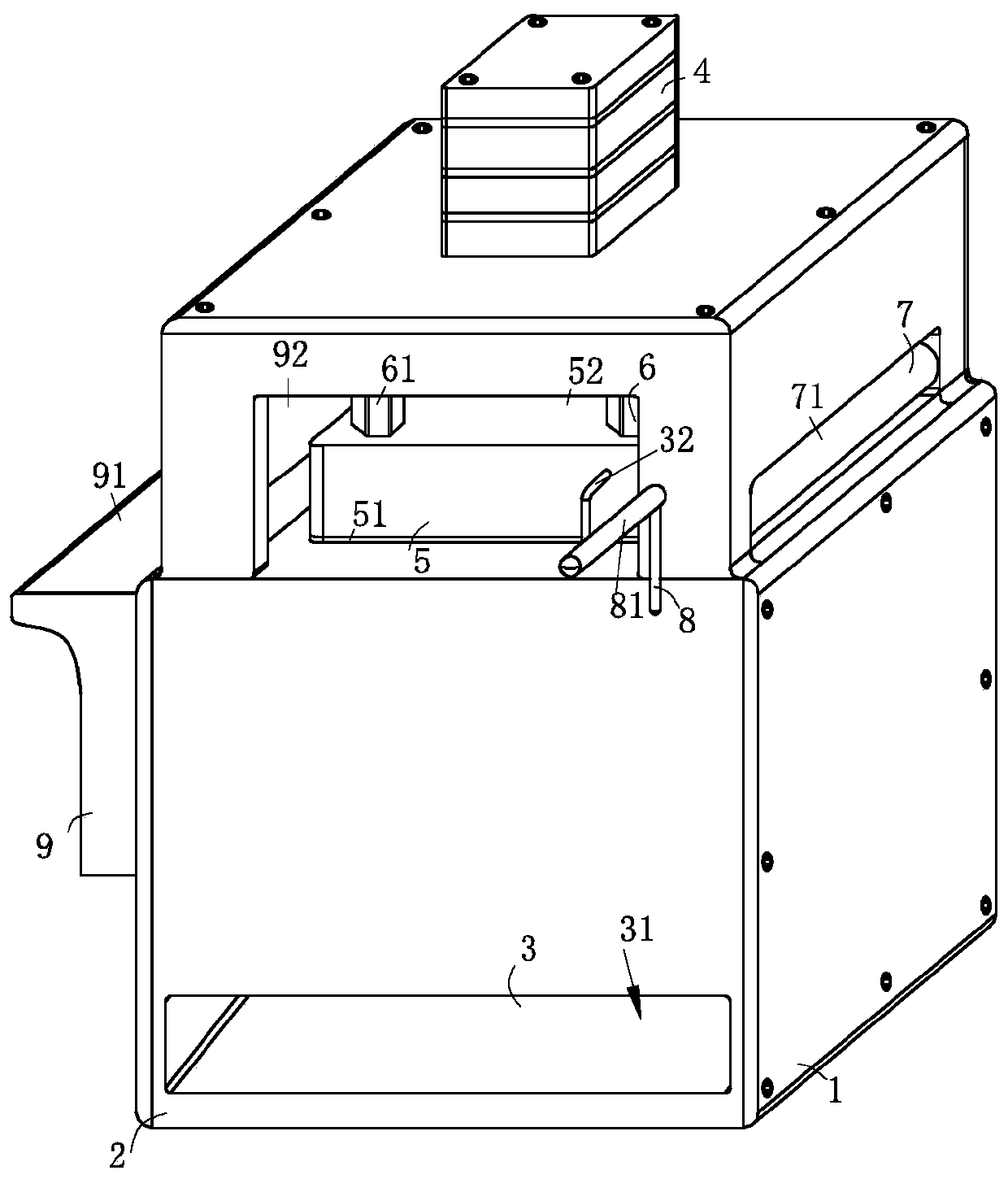

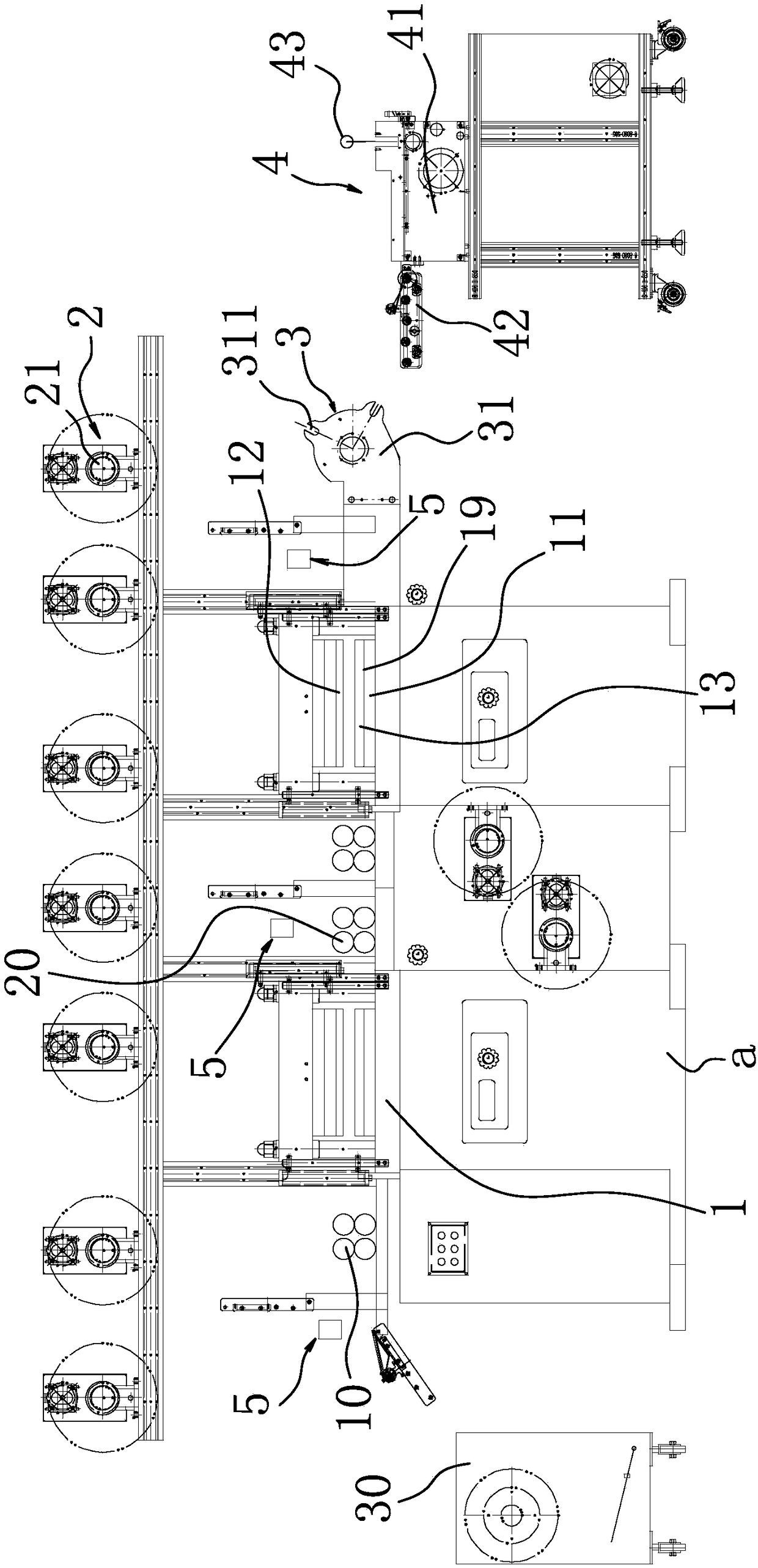

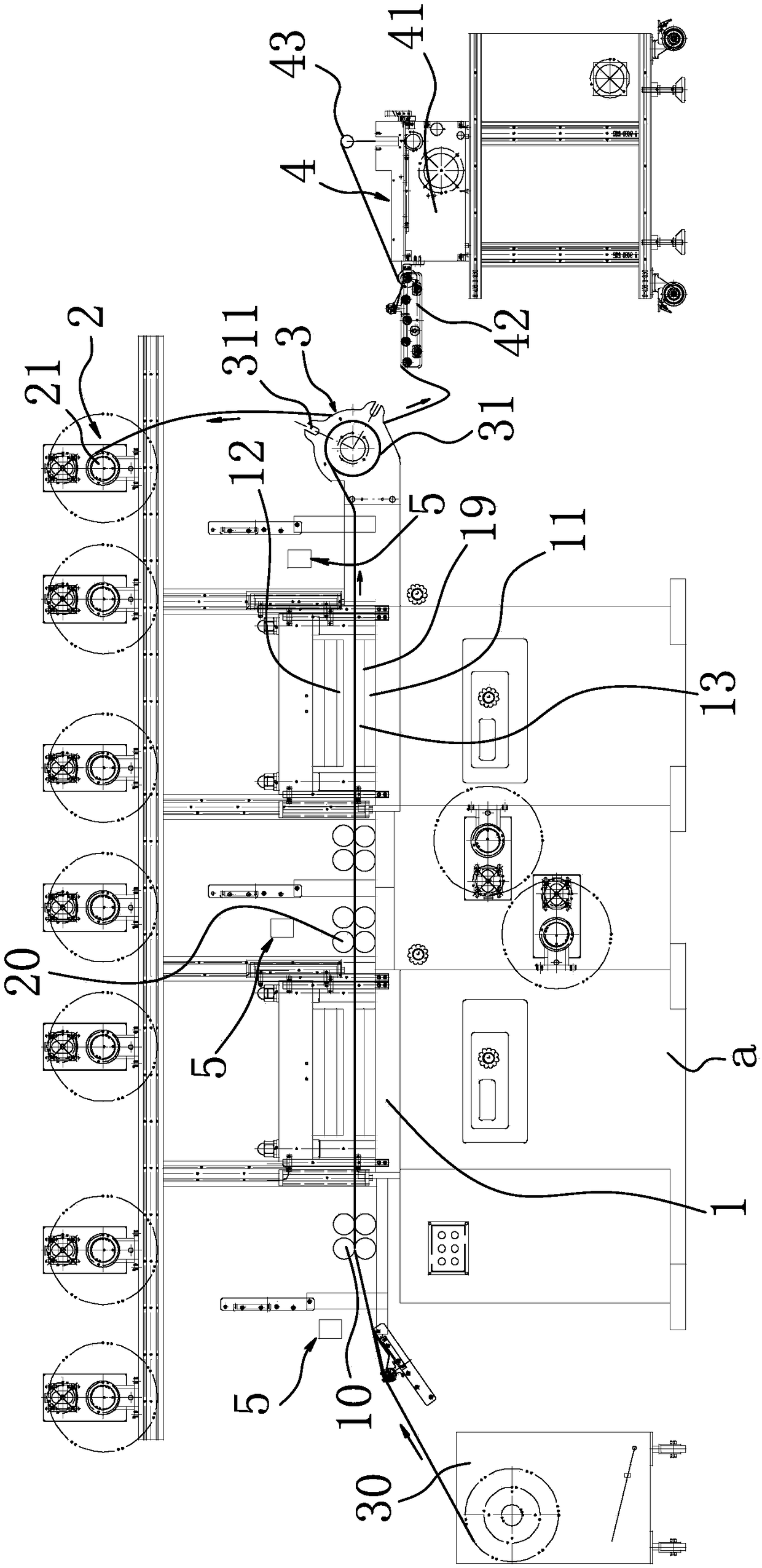

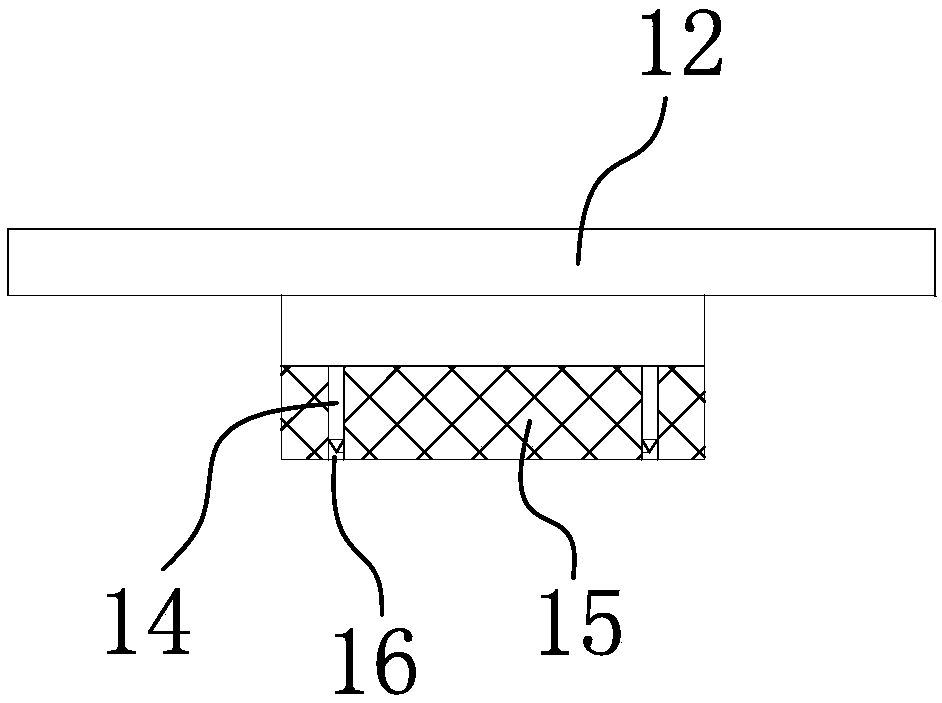

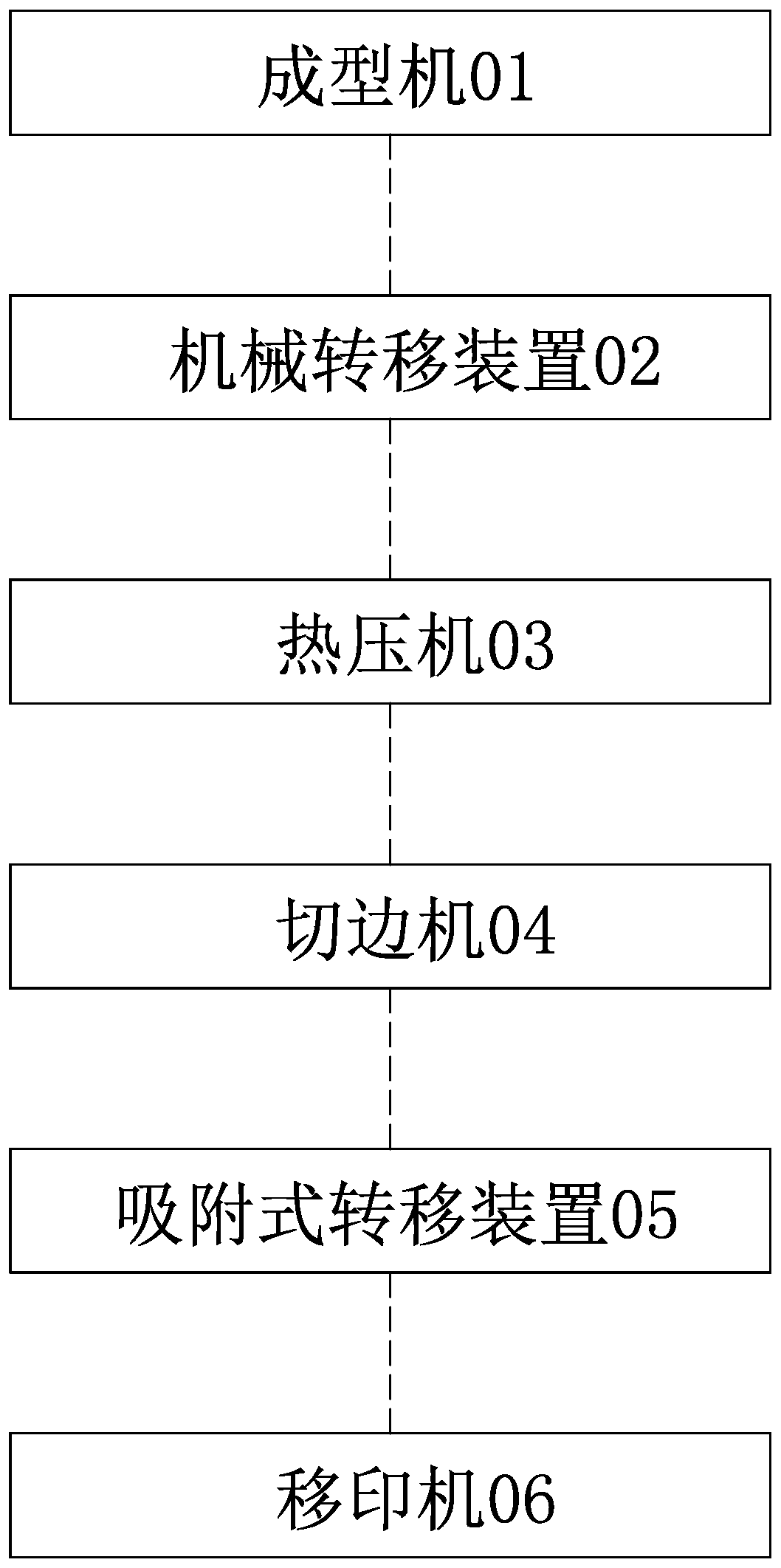

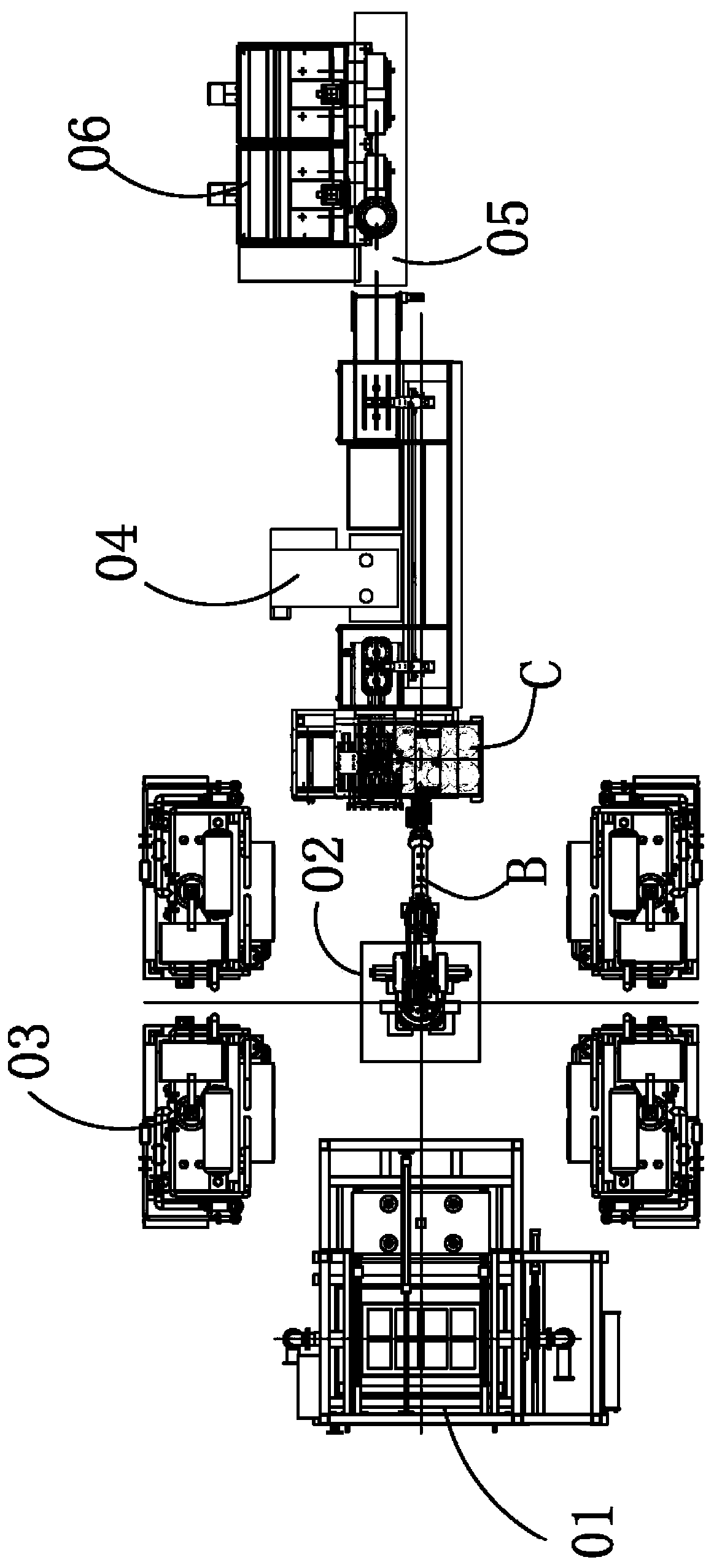

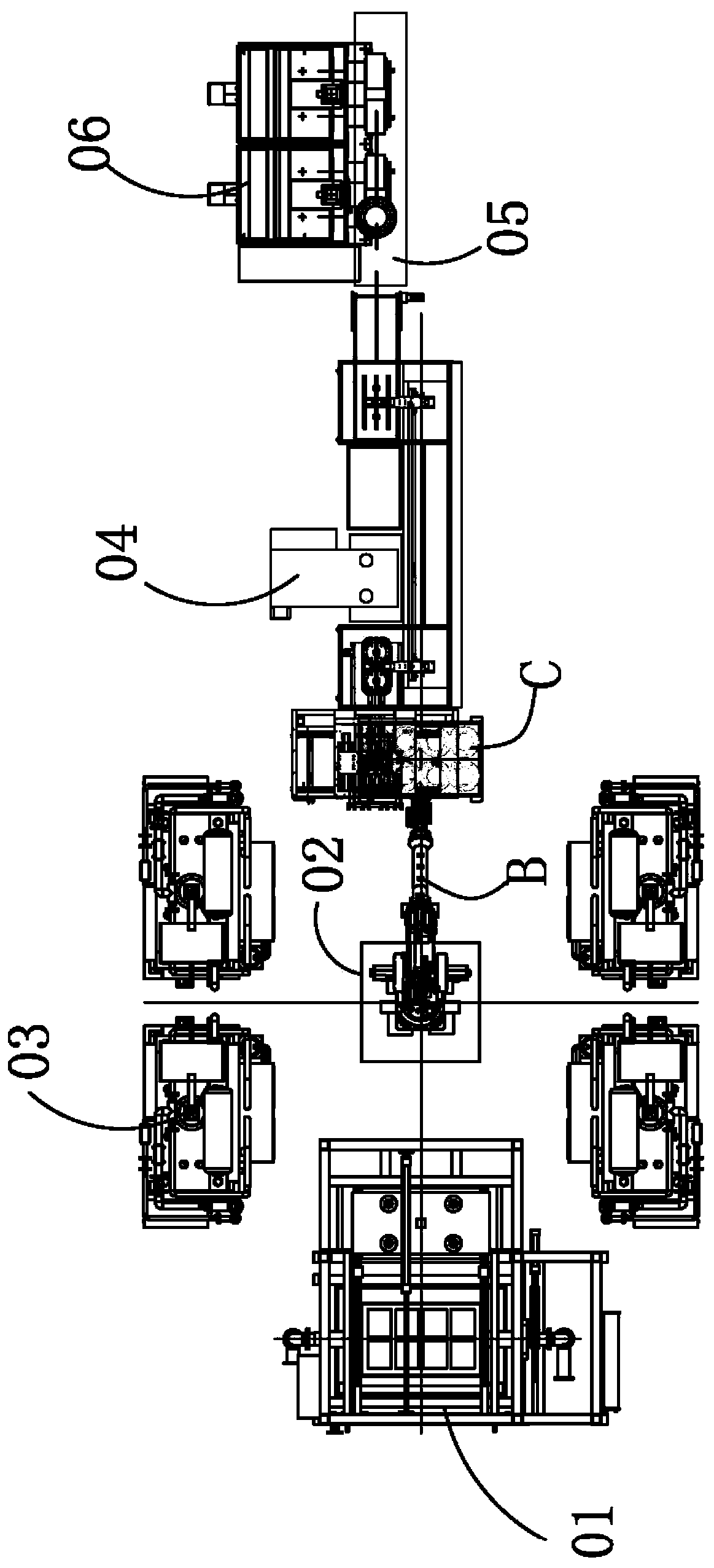

Paper product processing production line with heating and edge cutting functions

PendingCN111287022AImprove the quality of production and processingMeet production requirementsTextiles and paperMolding machineProcess engineering

The invention relates to a paper product processing production line with heating and edge cutting functions. The technical problem that an existing production line is low in machining efficiency is solved. The paper product processing production line comprises at least one forming machine which is a suck-back pulp forming machine used for extruding or forming pulp; at least one mechanical transferdevice which is used for taking and transferring paper product blanks formed by the forming machine; at least one hot press to which the obtained paper product blanks are transferred and released through the mechanical transfer device, with the hot press performing overheat pressing on the paper product blanks; and an edge cutting machine, wherein the mechanical transfer device takes, transfers and releases the paper product blanks subjected to hot pressing to the edge cutting machine, and the edge cutting machine cuts off residual edges of the paper product blanks. The paper product processing production line has the advantage that the production and processing efficiency is improved.

Owner:ZHEJIANG SHURCON MFG

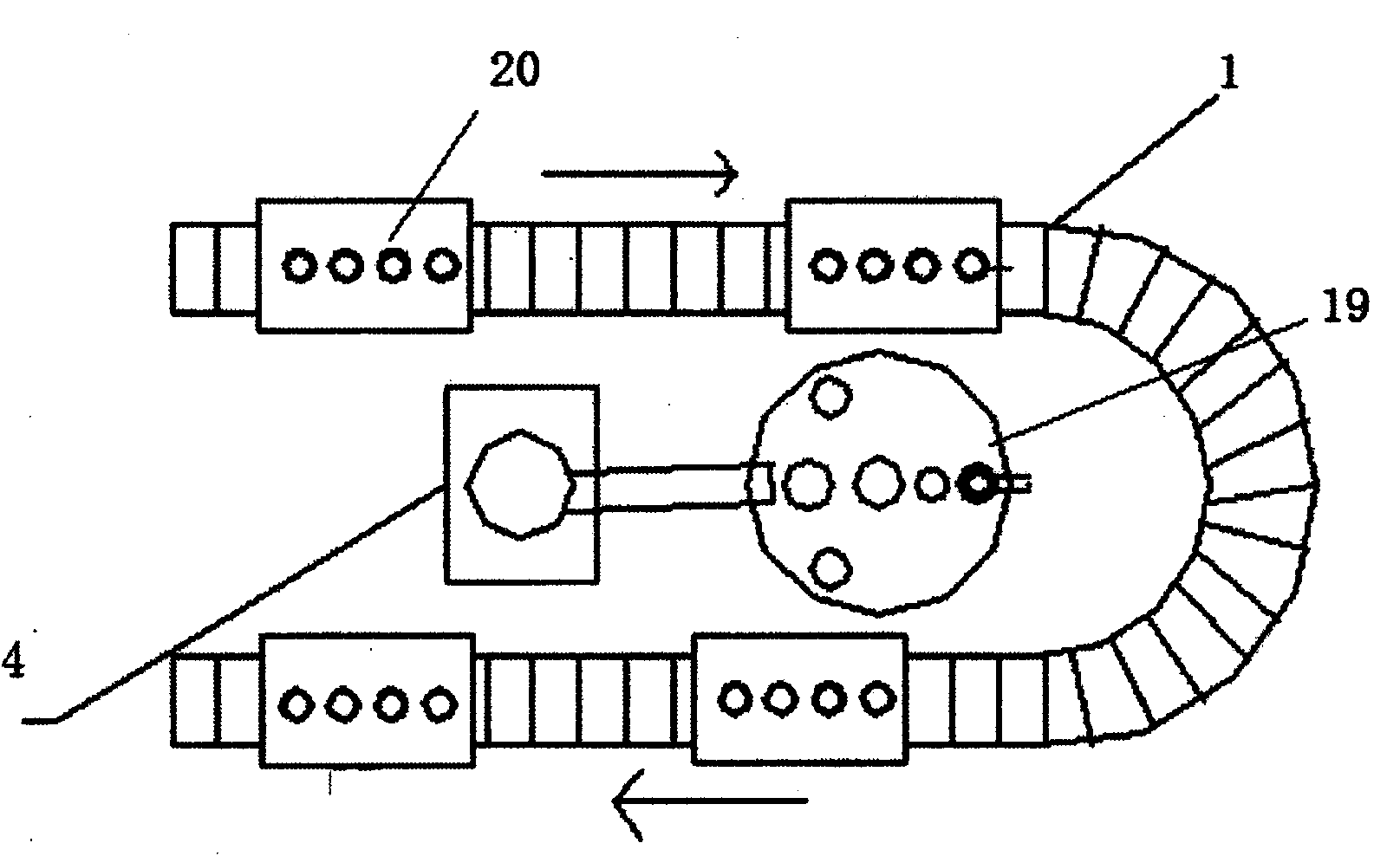

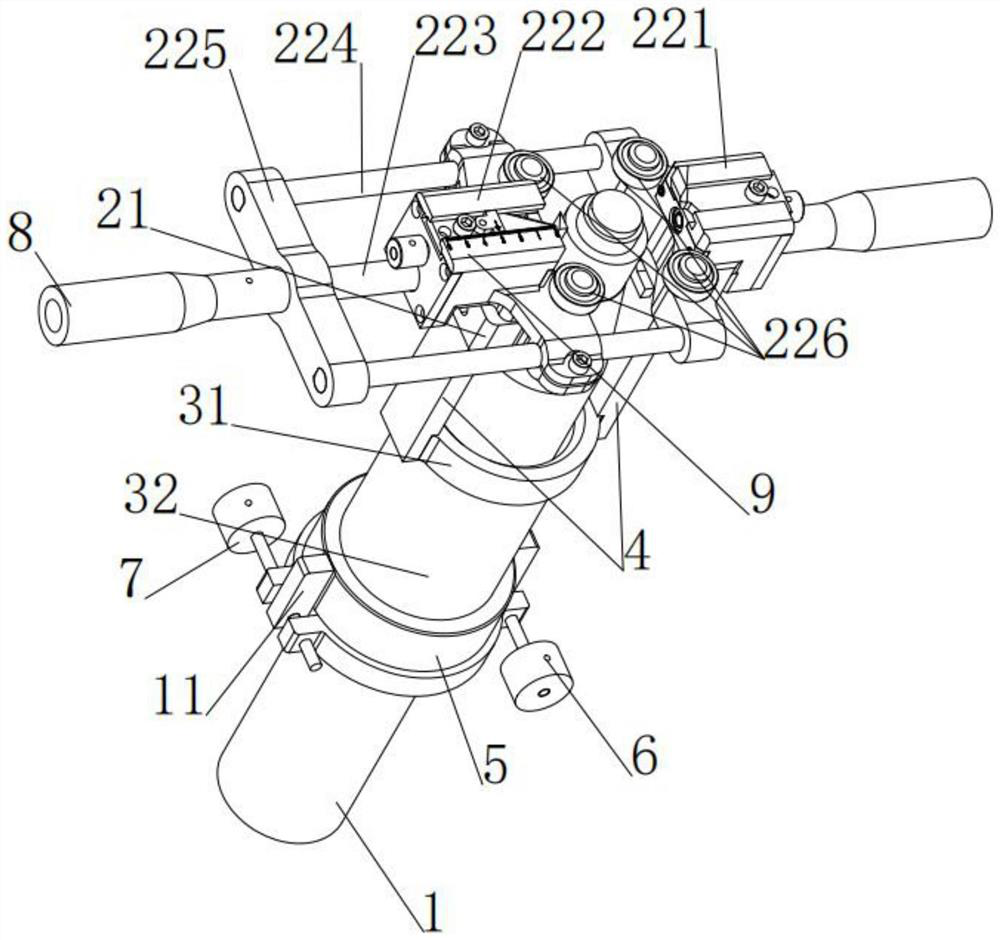

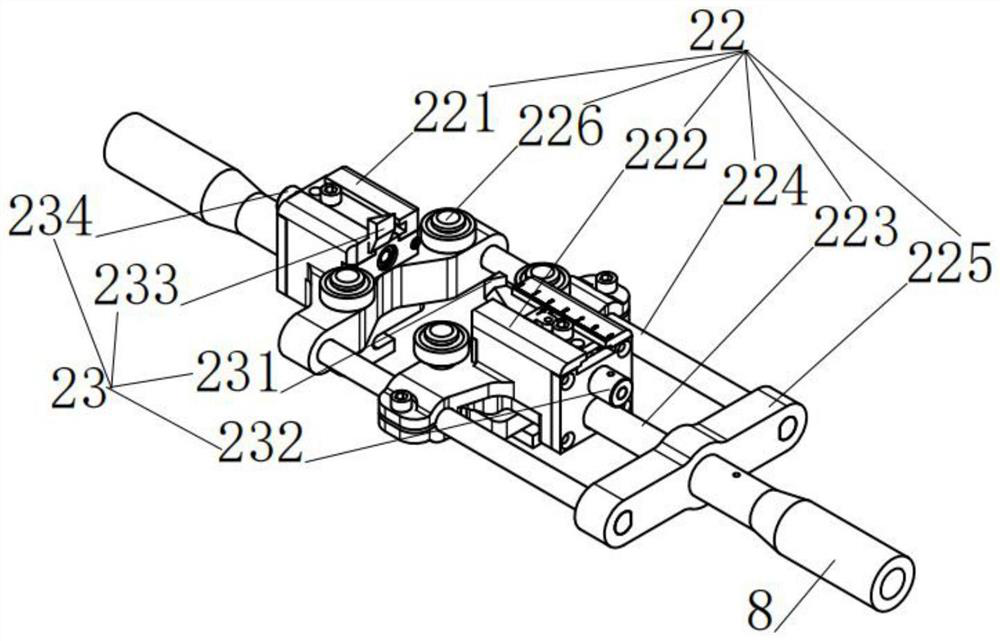

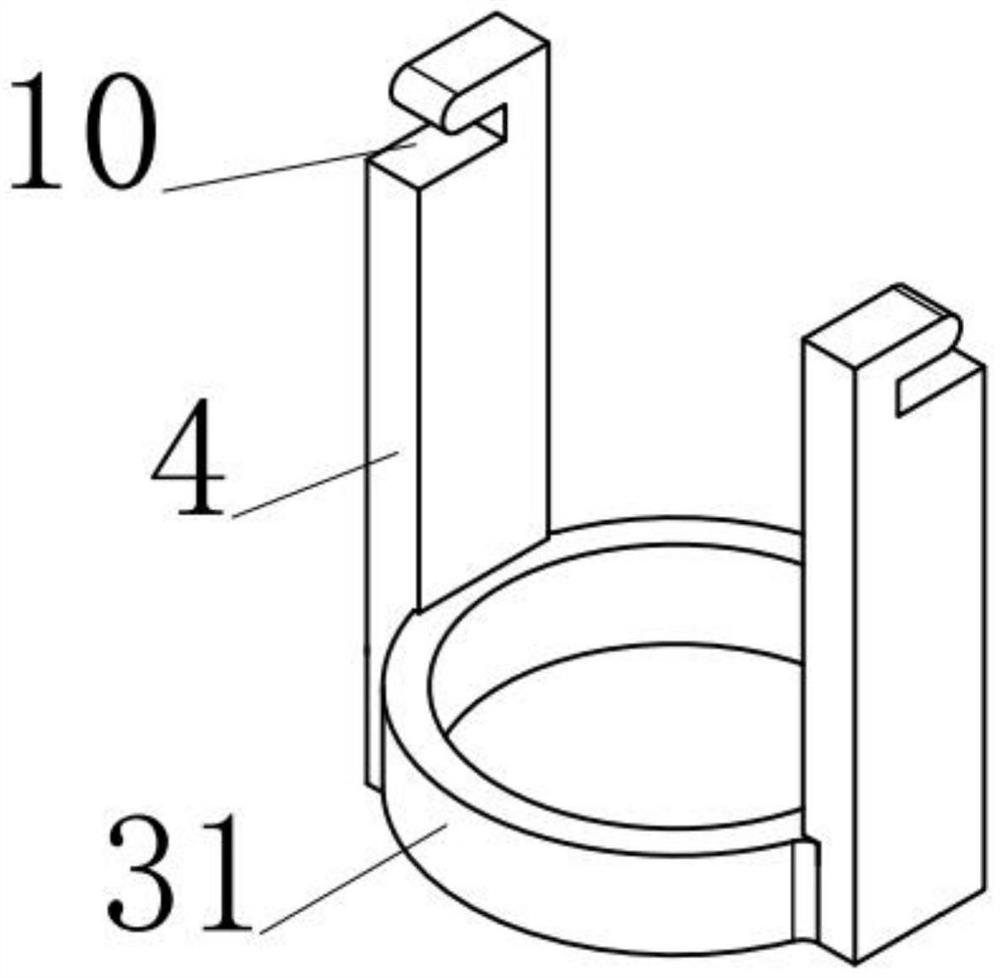

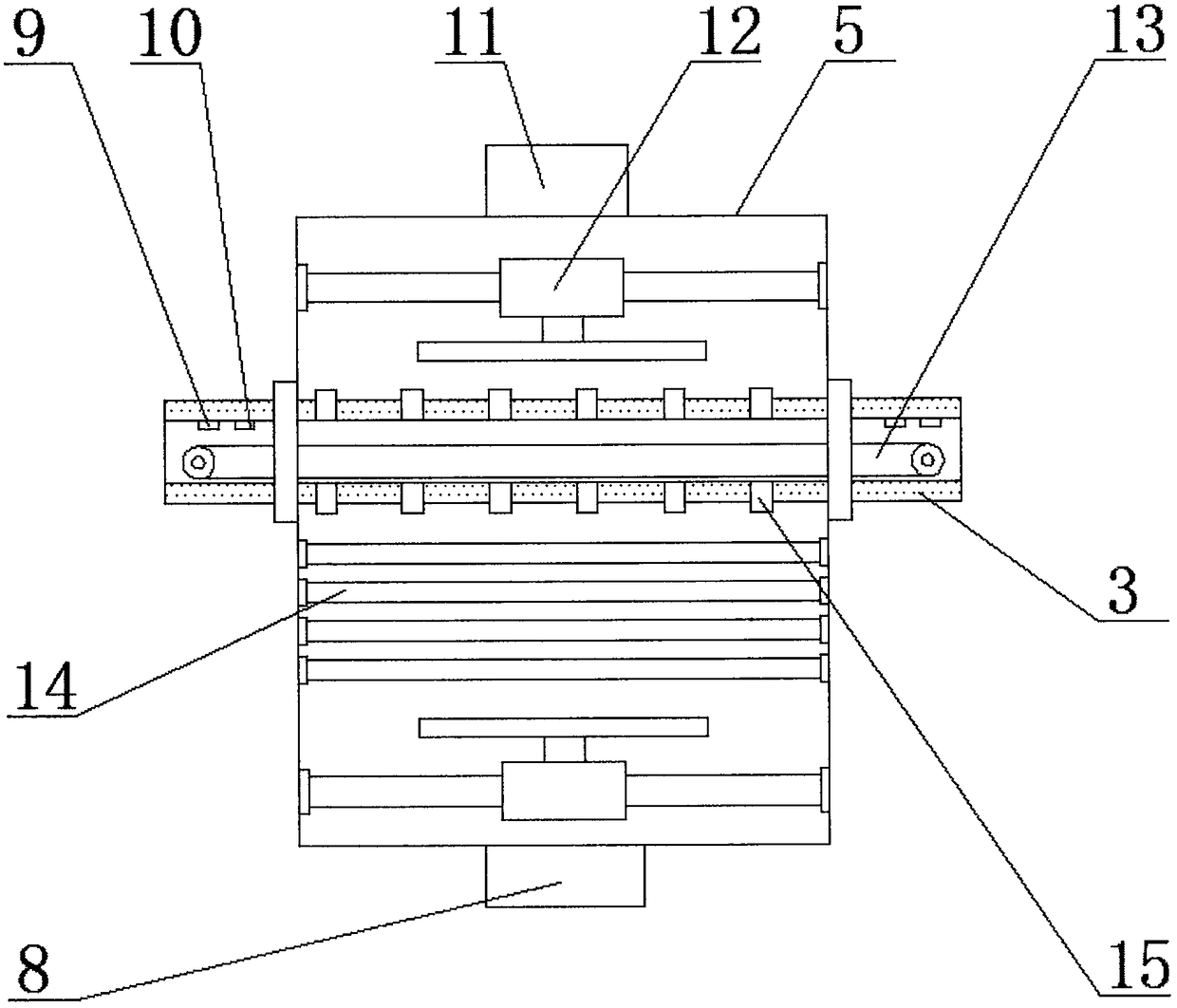

Bearing ring and sleeve part automatic quenching machine based on robot control

InactiveCN103937954ASmooth rotationUniform quenchingFurnace typesHeat treatment process controlFlexible manufacturing systemButt joint

The invention relates to a bearing ring and sleeve part automatic quenching machine based on robot control. The quenching machine is characterized by comprising an RGV (Rail Guided Vehicle) automatic guiding transport trolley system, a robot, quenching equipment and control sub-system, wherein a to-be-processed part is placed on an RGV trolley of the RGV automatic guiding transport trolley system to automatically transport the to-be-processed part; the robot grasps the to-be-processed part on the RGV trolley and puts the to-be-processed part in the quenching equipment and control sub-system to heat and quench the to-be-processed part; and then, the robot takes the quenched part from the quenching equipment and control sub-system on the RGV trolley. The invention provides a bearing inner and outer ring automatic quenching system which not only can save the cost, but also can further improve the efficiency and the quenching quality and is in butt joint and integrated with the flexible manufacturing systems of the enterprise.

Owner:DONGHUA UNIV

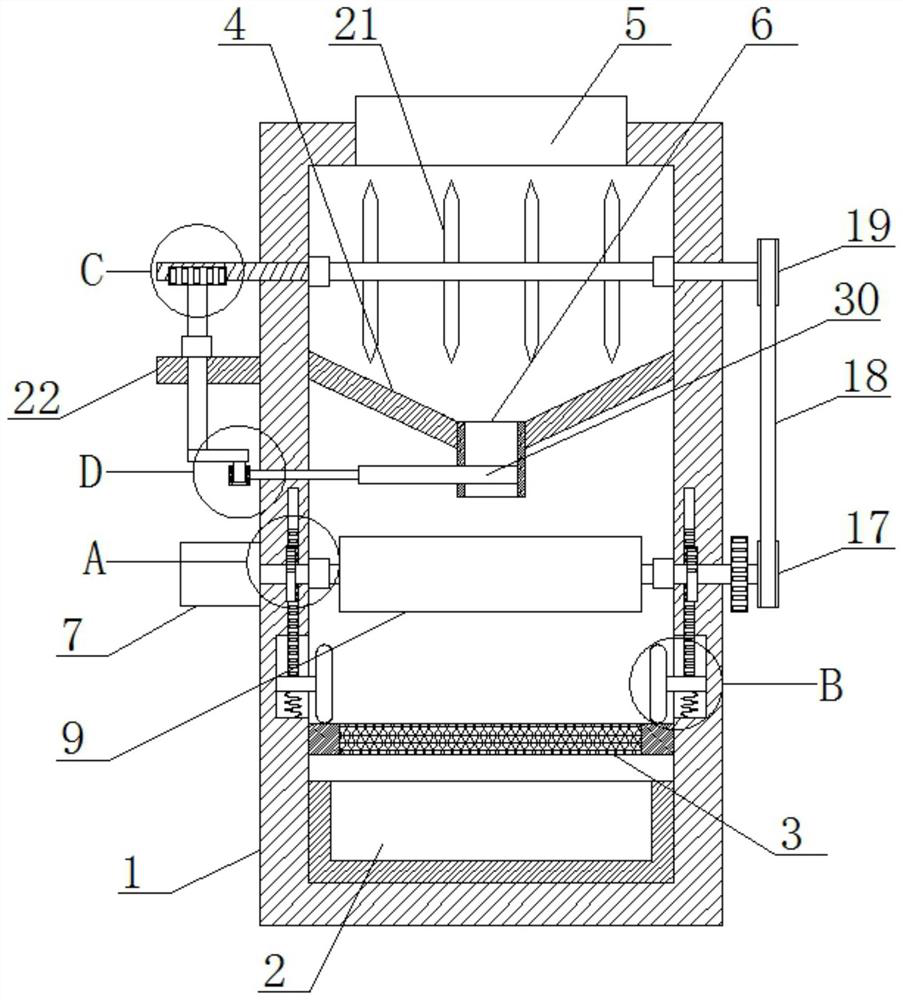

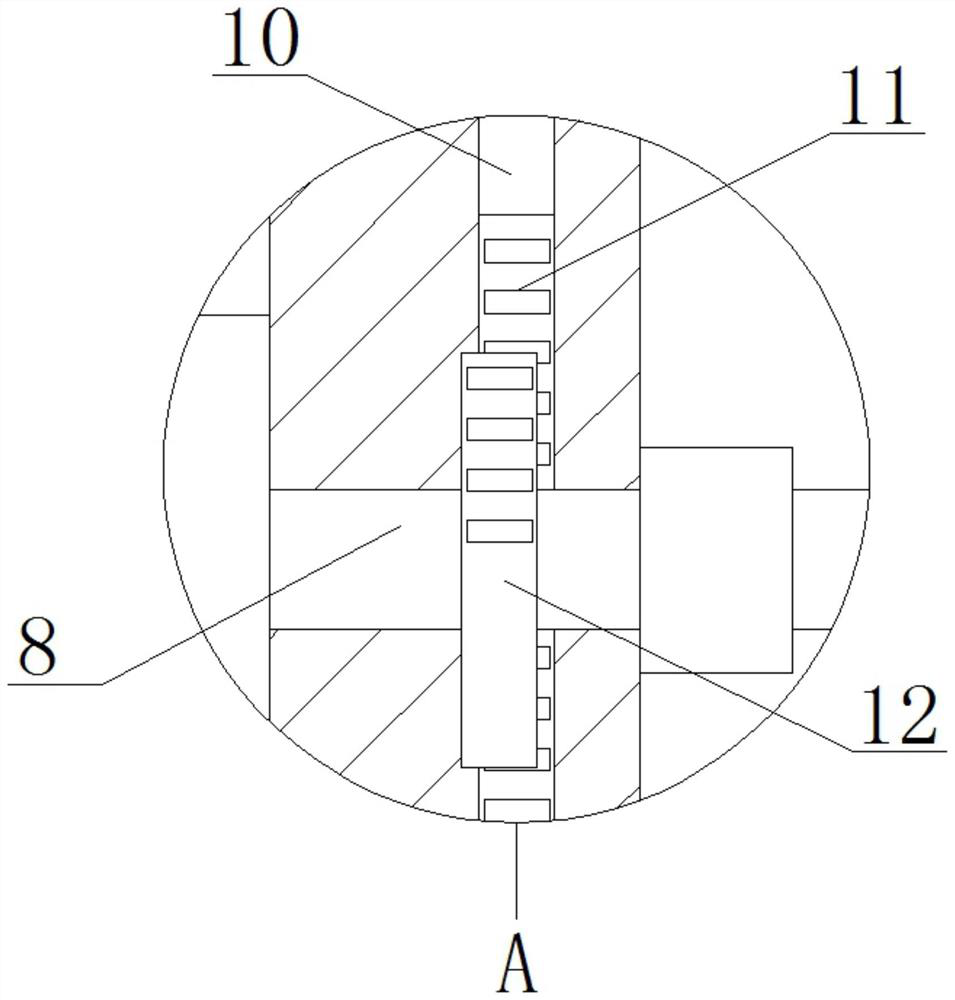

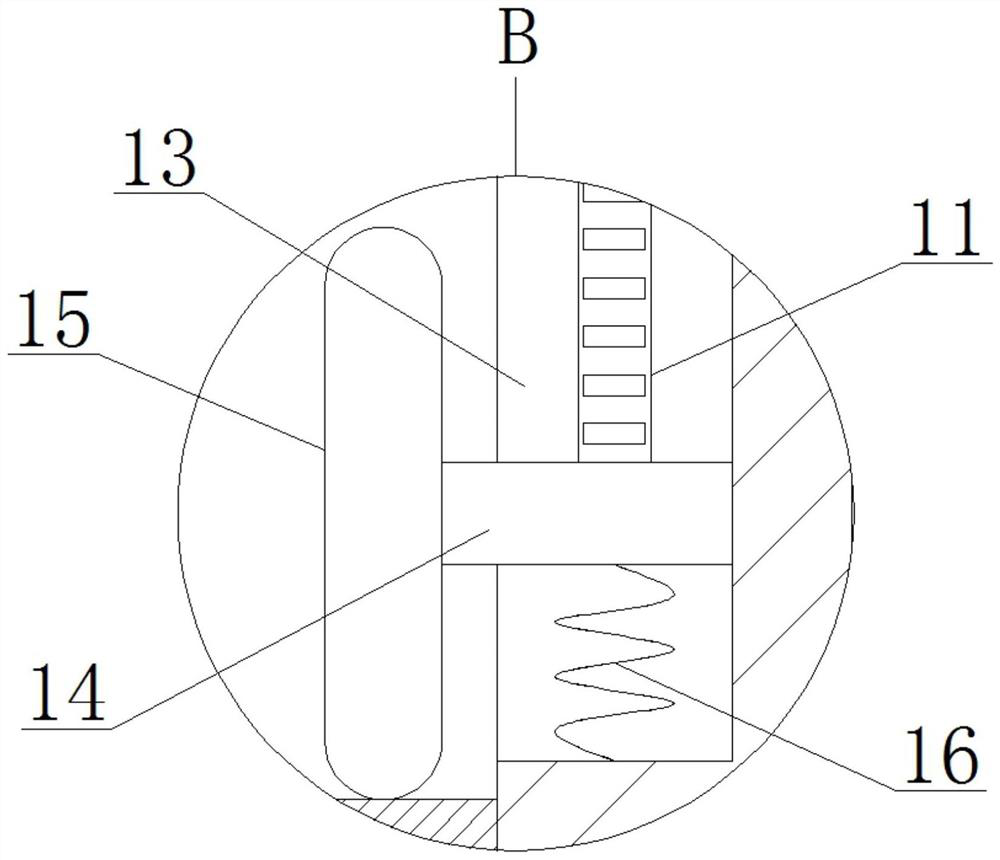

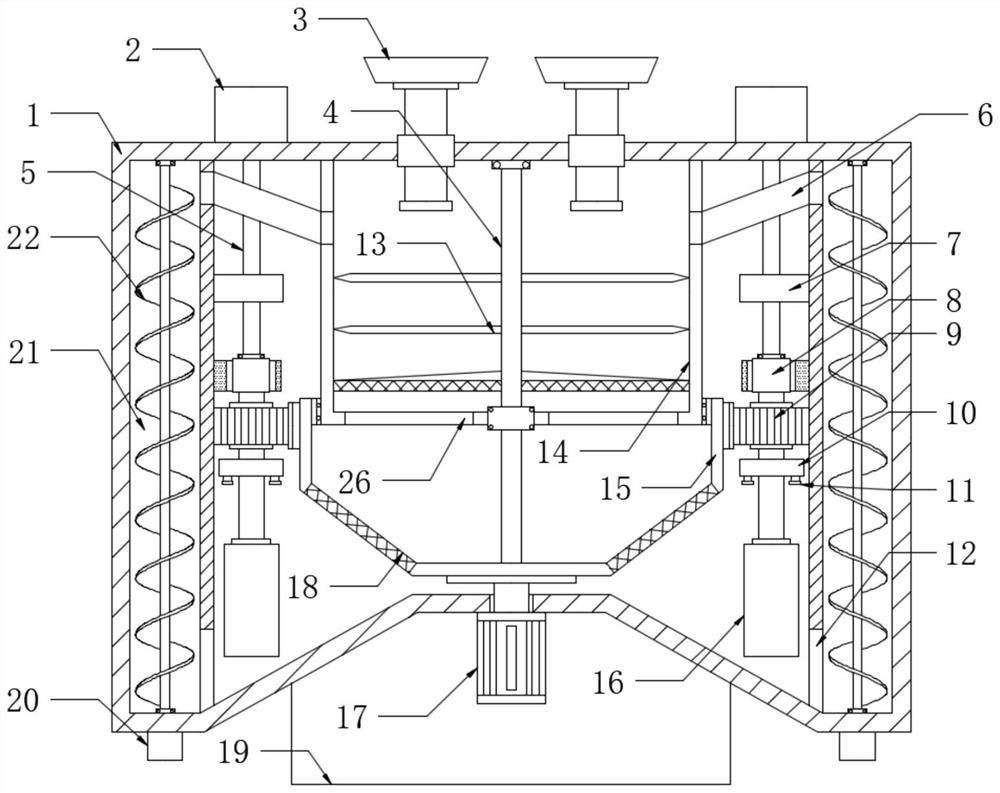

Crushing and grinding device for medicine production

The invention belongs to the field of medicine production and processing, particularly relates to a crushing and grinding device for medicine production, and aims to solve the problem that the medicine production and processing quality is reduced due to the fact that materials are not convenient to fully crush and grind in the process of crushing and grinding the materials by an existing crushing and grinding device. According to the solution, the crushing and grinding device for medicine production comprises a shell, a feed inlet is formed in the top of the shell, a collecting box is placed on the inner wall of the bottom of the shell, a sieve plate is fixedly installed in the shell, a funnel is fixedly installed in the shell, a discharge outlet is formed in the bottom of the funnel, the two sides of the shell are each provided with two symmetrical first through holes, the same first rotating shaft is rotationally installed in the two first through holes in each side, and the two first rotating shafts are fixedly sleeved with grinding rollers. According to the crushing and grinding device for medicine production, in the process of crushing and grinding materials, the materials can be fully crushed and ground conveniently, so that the medicine production and processing quality is improved, and the crushing and grinding device is simple in structure and convenient to use.

Owner:王维庭

Eucommia ulmoides processing device and method

InactiveCN113288928AIncrease the number ofImprove the efficiency of kneading and pokingDrying solid materials with heatDrying machines with progressive movementsBiotechnologyBiochemical engineering

The invention provides an eucommia ulmoides processing device and method. The processing device comprises a rubbing mechanism used for applying force to eucommia ulmoides and rubbing the eucommia ulmoides, a conveying mechanism used for conveying the rubbed eucommia ulmoides, a cleaning mechanism used for cleaning the eucommia ulmoides at the feeding end of the conveying mechanism, a drying mechanism used for drying the eucommia ulmoides cleaned by the cleaning mechanism, and a dicing mechanism used for dicing the dried eucommia ulmoides. The production line processing of rubbing, cleaning and drying machine dicing of eucommia ulmoides can be achieved. The production and processing efficiency and quality are improved.

Owner:怀化林泉药业有限公司 +1

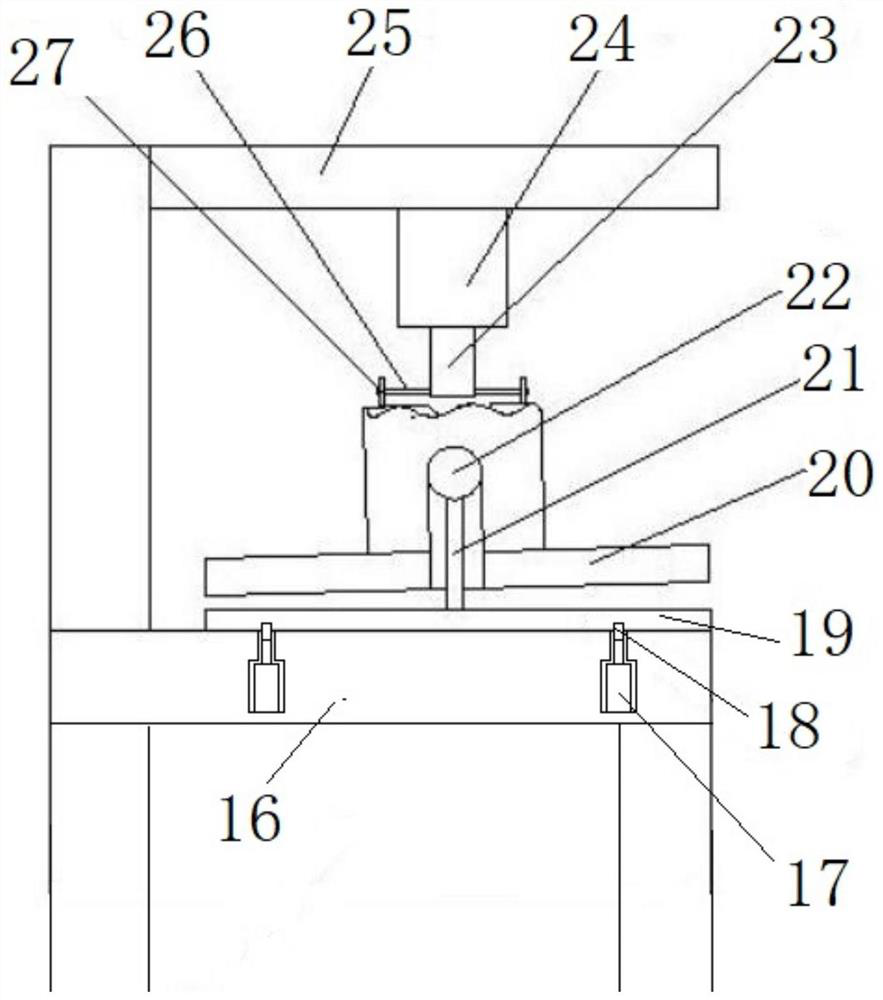

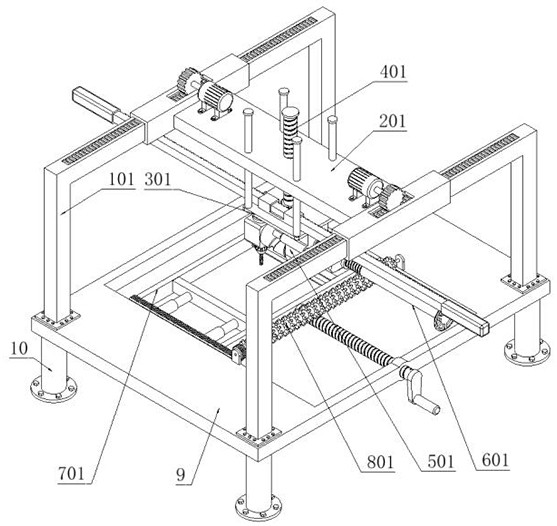

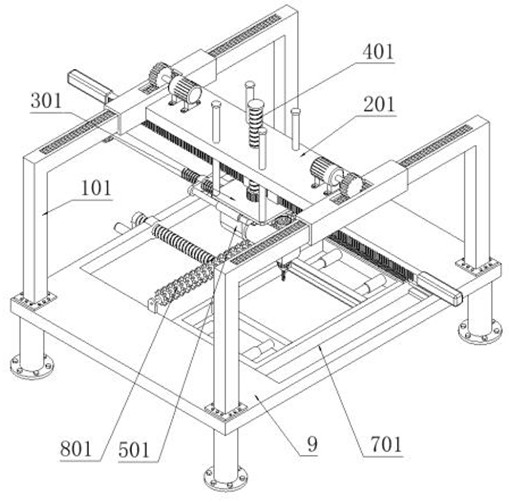

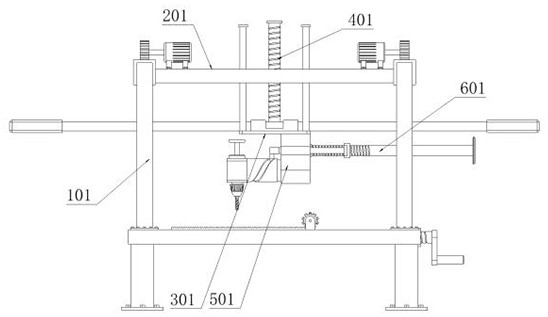

Perforating device for stainless steel product manufacturing and machining

InactiveCN111482631AImprove production and processing efficiencyImprove the quality of production and processingFeeding apparatusPositioning apparatusStructural engineeringMachining

The invention discloses a perforating device for stainless steel product manufacturing and machining. The device comprises a U-shaped base, an installing table and a U-shaped plate. The installing table is arranged inside the U-shaped base. A plurality of air pressure cylinder assemblies are evenly arranged at the bottom of the inner cavity of the U-shaped base. The upper ends of the air pressurecylinder assemblies are all fixedly connected to the bottom of the installing table. A damping cushion plate assembly is arranged between the left side wall of the installing table and the inner wallof the U-shaped base, and a damping cushion plate assembly is arranged between the right side wall of the installing table and the inner wall of the U-shaped base, a longitudinal braking assembly is arranged on the installing table, the U-shaped plate is arranged on the longitudinal braking assembly, a transverse braking assembly is arranged on the U-shaped plate, a movable base is arranged on thetransverse braking assembly, an installing box is arranged below the movable base, the bottom of the installing box is rotationally provided with a fastening base for clamping and fixing a drill botthrough a bearing, and a clamping unit is arranged on the installing table. The device is provided with the clamping unit for clamping and fixing a stainless steel plate, precise perforating can be performed while time and labor are saved, the good damping performance is further achieved, and the stability and safety are greatly improved.

Owner:SUZHOU SAISHUOLA STAINLESS STEEL PROD CO LTD

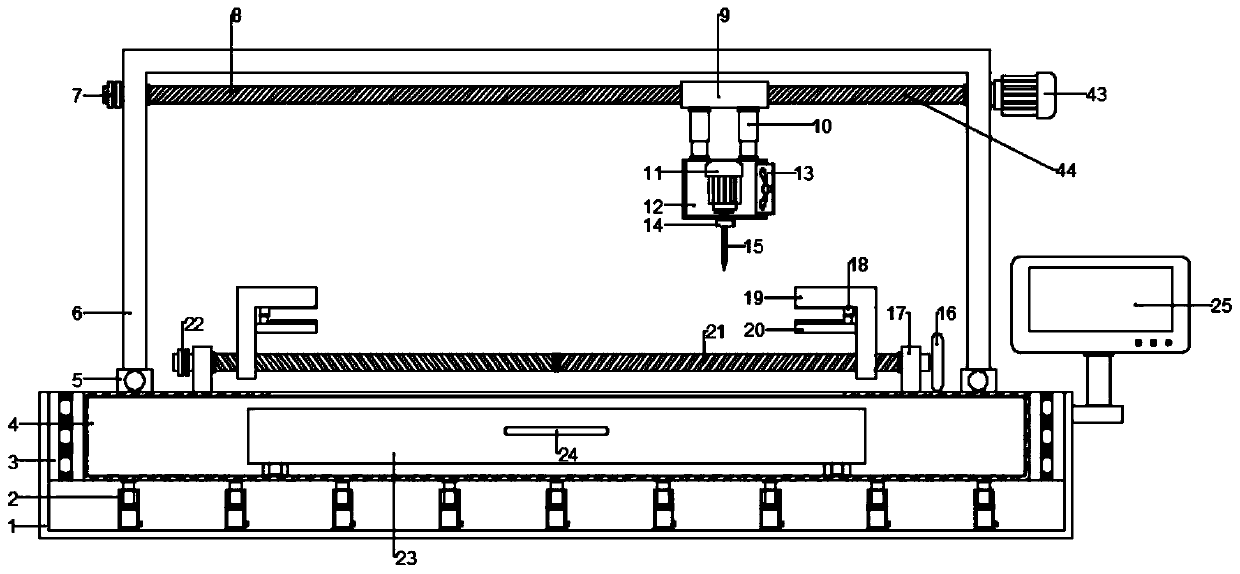

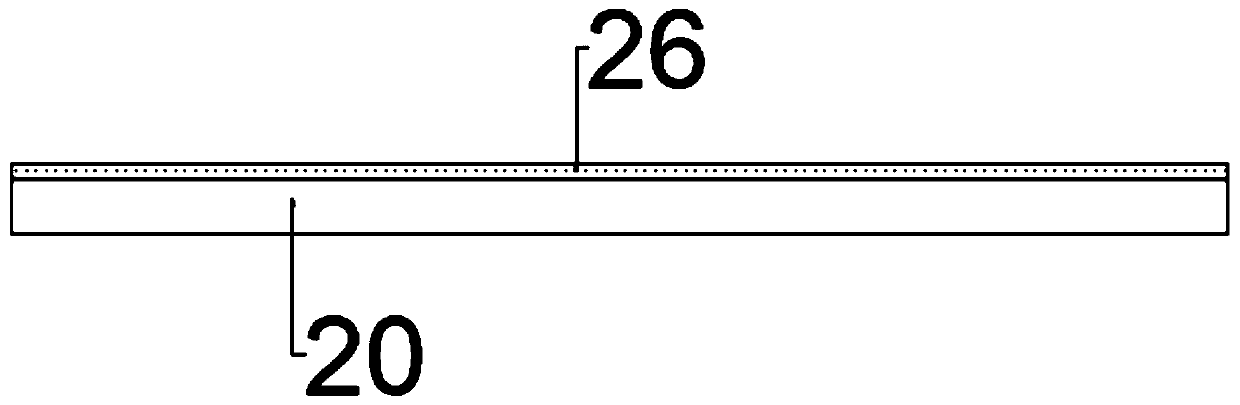

Melt-blown cloth conveying and processing device

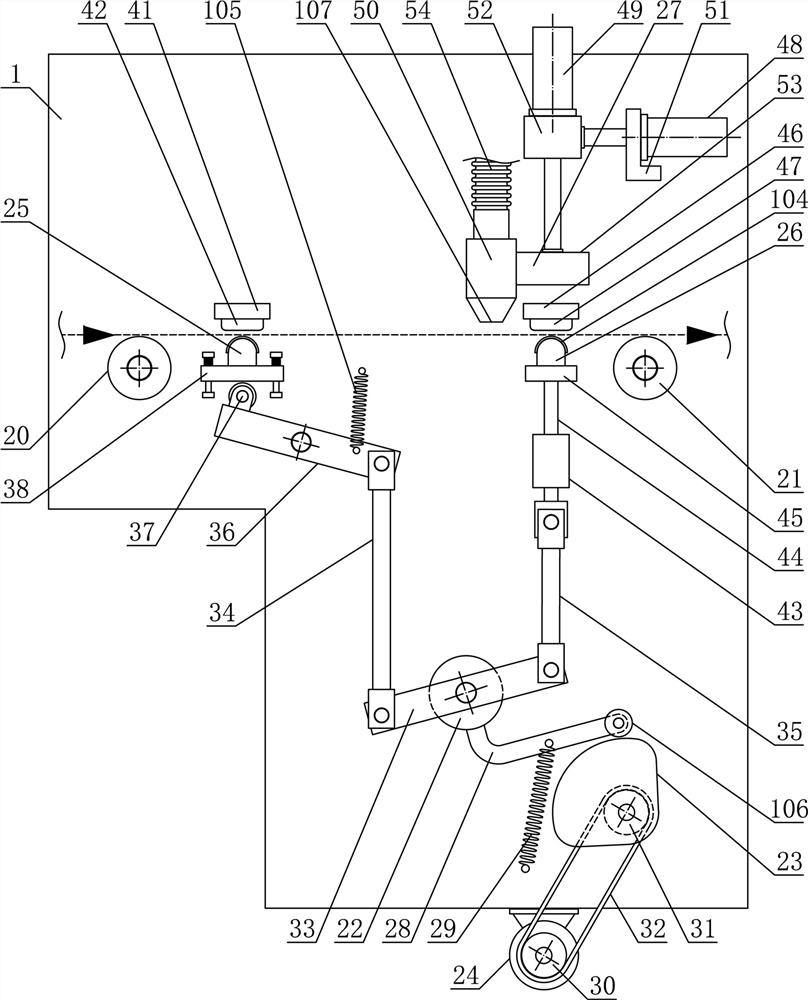

ActiveCN111824828ASwing smoothly and convenientlySufficient and efficient suctionWebs handlingEngineeringMechanical engineering

The invention discloses a melt-blown cloth conveying and processing device, and belongs to the field of melt-blown cloth production equipment. The melt-blown cloth conveying and processing device is characterized in that a cloth feeding and guiding mechanism, a cloth pressing and impurity sucking mechanism and a cloth pulling and conveying mechanism are sequentially arranged on a cloth conveying and processing support; a melt-blown cloth pressing rotary roller is arranged on the upper side of a cloth feeding and conveying rotary roller, a front positioning cloth pressing plate is arranged on the upper side of a front lifting guide plate, and a rear positioning cloth pressing plate is arranged on the upper side of a rear lifting guide plate; a reciprocating and impurity sucking mechanism isarranged on the part, on the upper sides of the front positioning cloth pressing plate and the rear positioning cloth pressing plate, of the cloth conveying and processing support; and a front clothpulling guide plate and a rear cloth pulling guide plate are arranged on the two sides of a reciprocating cloth pulling guide rod, and a disc positioning mechanism is arranged on the part, on the lower side of a cloth pulling rotating disc, of the cloth conveying and processing support in the radial direction of the cloth pulling rotating disc. The melt-blown cloth conveying and processing deviceis reasonable in structural design, melt-blown cloth can be efficiently, conveniently and sequentially pulled and conveyed in a segmented mode, the melt-blown cloth can be stably and smoothly subjected to segmented impurity sucking processing in the melt-blown cloth conveying process, the automation degree of melt-blown cloth production and processing is improved, and the requirements of production and use are met.

Owner:桐乡市中瑞环保科技有限公司

Cleaning device for semiconductor product production and processing

InactiveCN111744874AReasonable structure and layout of the deviceEasy to operateDrying gas arrangementsCleaning using toolsProcess engineeringManufacturing engineering

The invention discloses a cleaning device for semiconductor production and processing. The cleaning device comprises a bearing base, a cleaning unit and a liquid filtering unit. The cleaning unit andthe liquid filtering unit are both arranged on the bearing base. The cleaning unit comprises a cleaning tank and a scrubbing assembly. The scrubbing assembly is arranged in the cleaning tank. The cleaning device is reasonable in structure layout, easy to operate, convenient to use, capable of realizing mechanized cleaning of semiconductors and good in cleaning effect, has the rapid drying function, greatly improves the production and processing efficiency and quality of the semiconductors and has the great practicality.

Owner:顾骏

Plastic particle loader with screening function

InactiveCN108327122AImprove the quality of production and processingEfficient screeningSievingScreeningDrive wheelEngineering

The invention discloses a plastic particle loader with a screening function; the plastic particle loader includes a loading machine, a screen and first mesh plates. The bottom end of the loading machine is provided with a feeding trough, the feeding trough is fixedly connected with the loading machine, and the bottom end of the interior of the feeding trough is provided with a motor; the motor isfixedly connected with the feeding trough, and the front end of the motor is provided with a drive wheel; the drive wheel is in transmission connection with the motor, and the left side of the drive wheel is provided with a driven wheel. Through three different-specification mesh plates on the screen, and with cooperation of a vibration force produced by energized operation of the vibrating motor,plastic particle raw materials and impurities are effectively screened, and convenience is provided for a user to use; through arrangement of a heating pipe and a draught fan, and through energized operation of the heating pipe and the draught fan, hot gas flow is generated, water on the surface of plastic particles is dried, adhesion and caking of the raw materials are avoided, normal use of thenext process of the raw materials is ensured, and the quality of the production and processing of the plastic particles is improved.

Owner:海宁市鑫航塑料制品有限公司

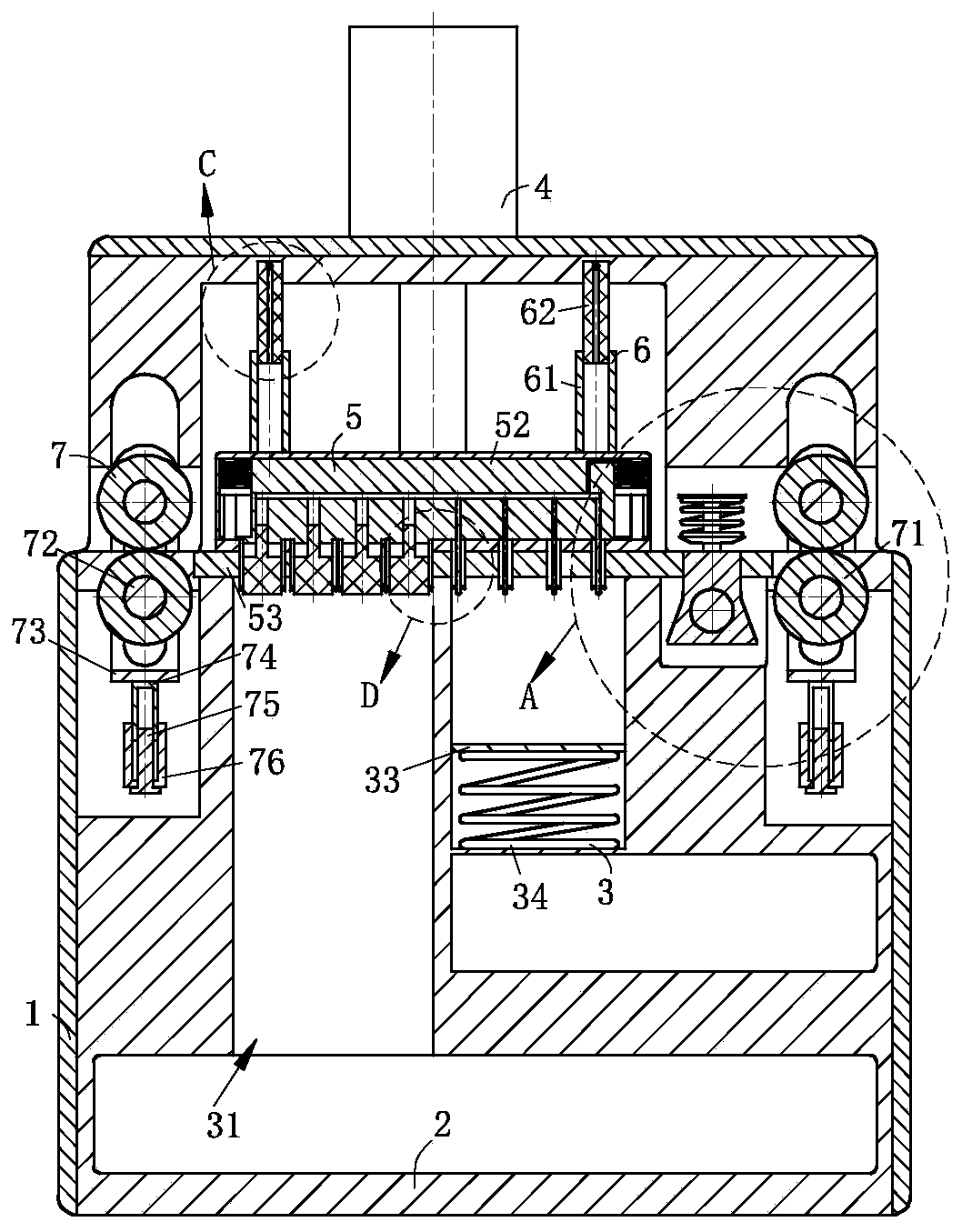

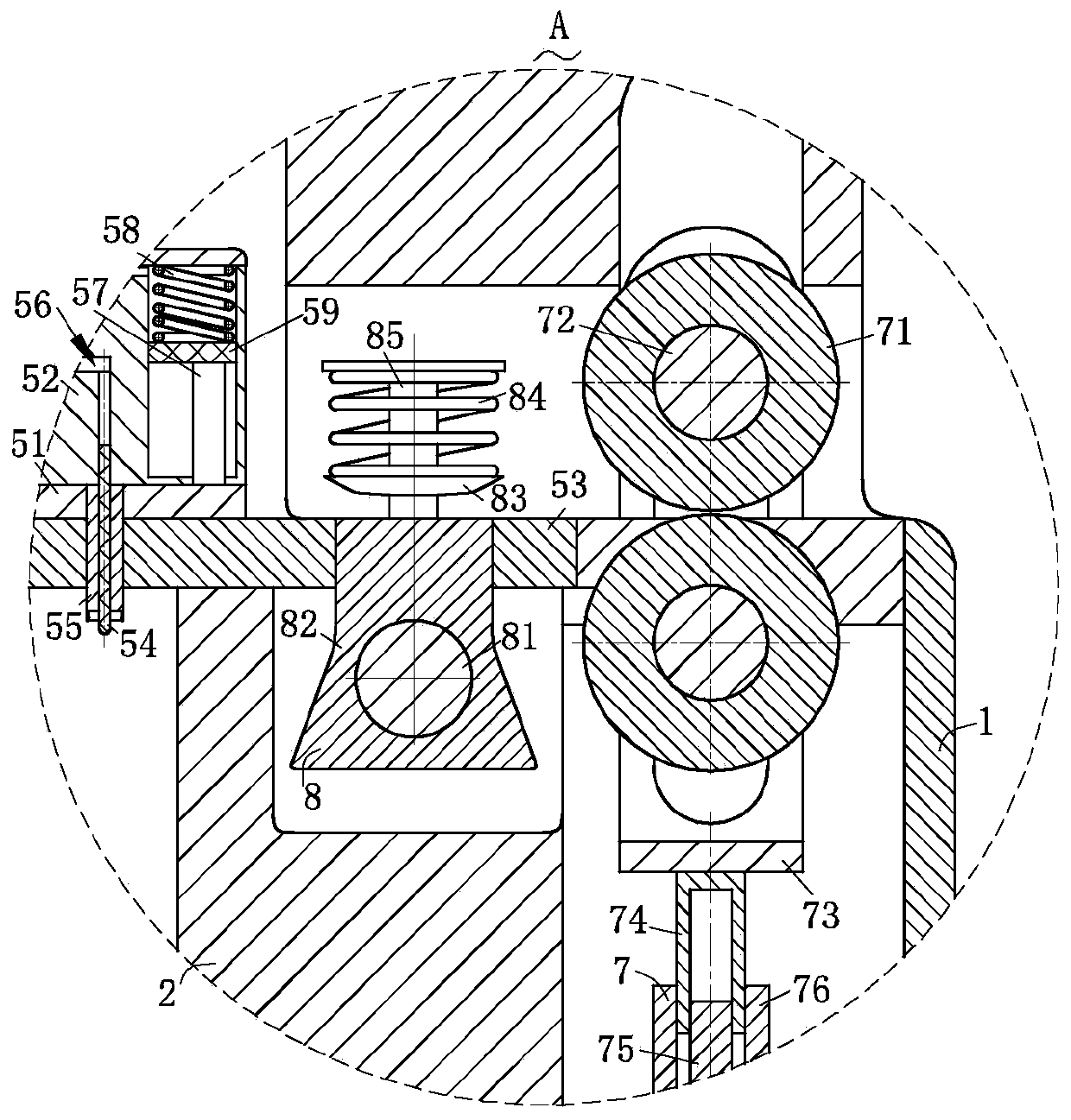

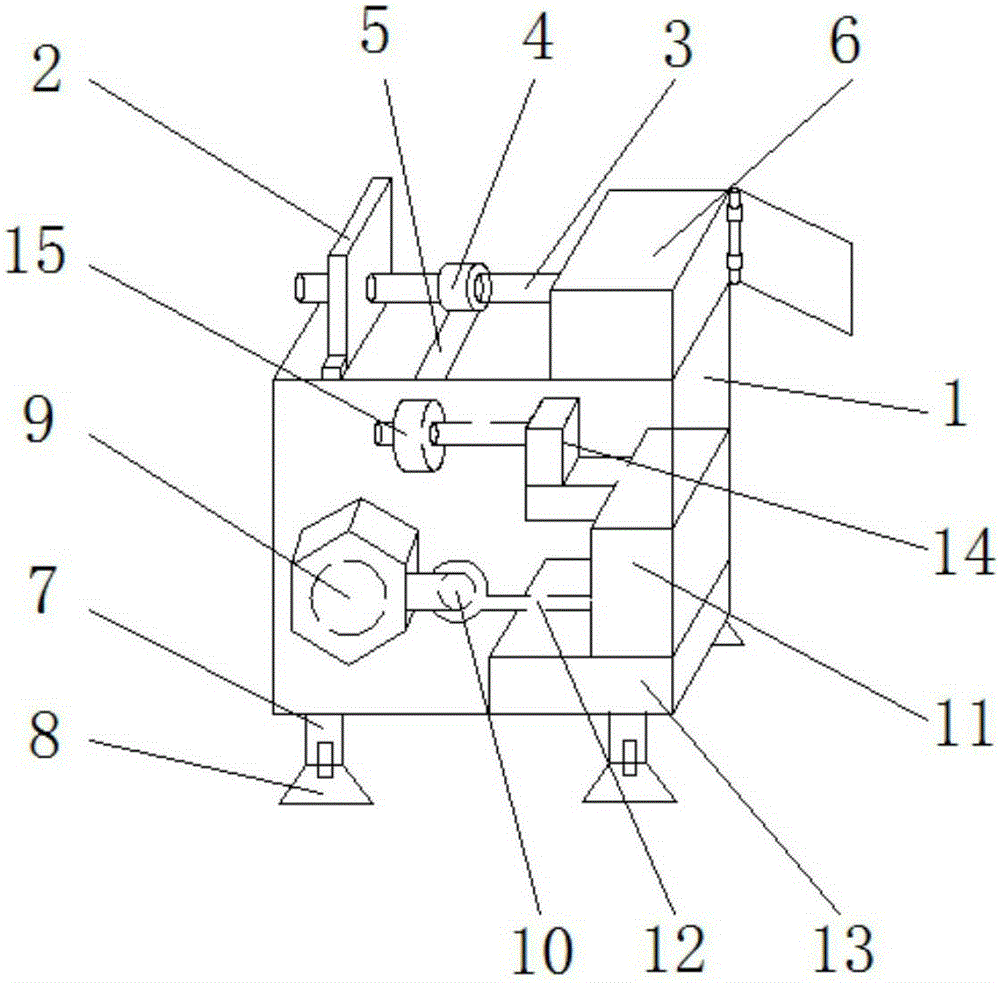

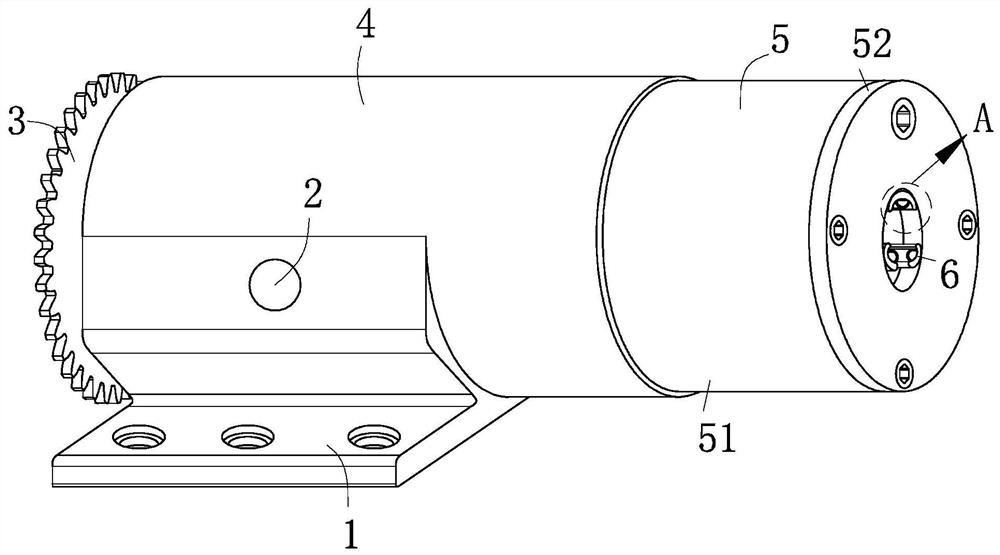

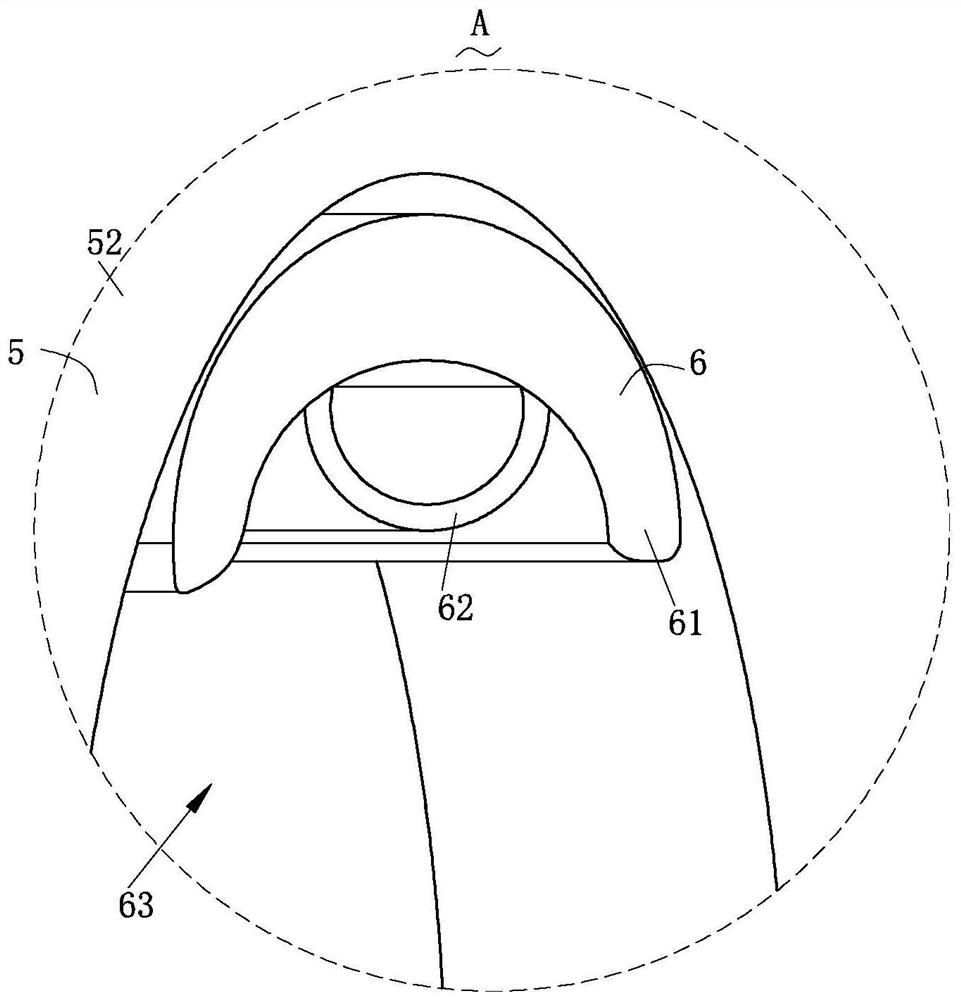

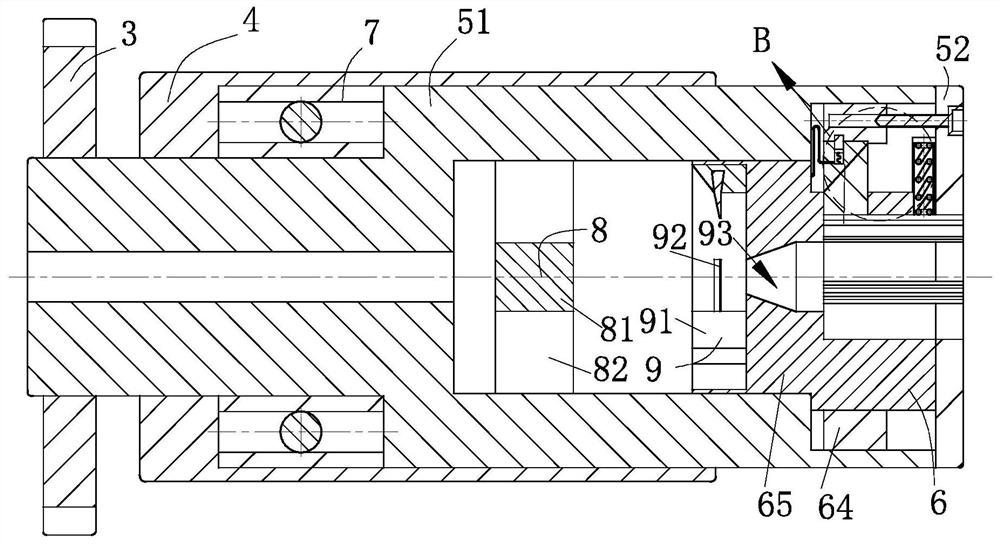

A grease lubricated spindle

ActiveCN110340384BSpeed up circulationImprove the quality of production and processingLarge fixed membersMaintainance and safety accessoriesGear wheelElectric machinery

The invention relates to the field of grease lubrication spindles, in particular to a grease lubrication spindle. The grease lubrication spindle comprises a base, a rubber plug, a gear, a sleeve, a spindle structure, a clamping structure, a bearing, a dust cleaning structure and a limiting structure. A driving ring and a stop block are fixed through the limiting structure. The driving ring is limited through centrifugal force generated during rotating of the spindle structure and the stable state of the limiting structure. When the spindle structure stops emergently, the limiting structure drives the driving ring to be separated from the stop block under the inertia effect so that the clamping structure cannot clamp a workpiece, the spindle structure can rotate continuously, and then the situation that a cutting tool and a motor of the cutting tool are damaged due to emergent stop of the spindle structure is effectively prevented. Through the dust cleaning structure, the limiting structure is more stable under the condition of normal rotation of the spindle structure. The limiting structure disperses air flow to effectively prevent the situation that cut scraps are splashed due toexcessive wind power caused by high-speed rotation of the spindle structure. Accordingly, the dust cleaning quality is greatly improved.

Owner:安徽航睿电子科技有限公司

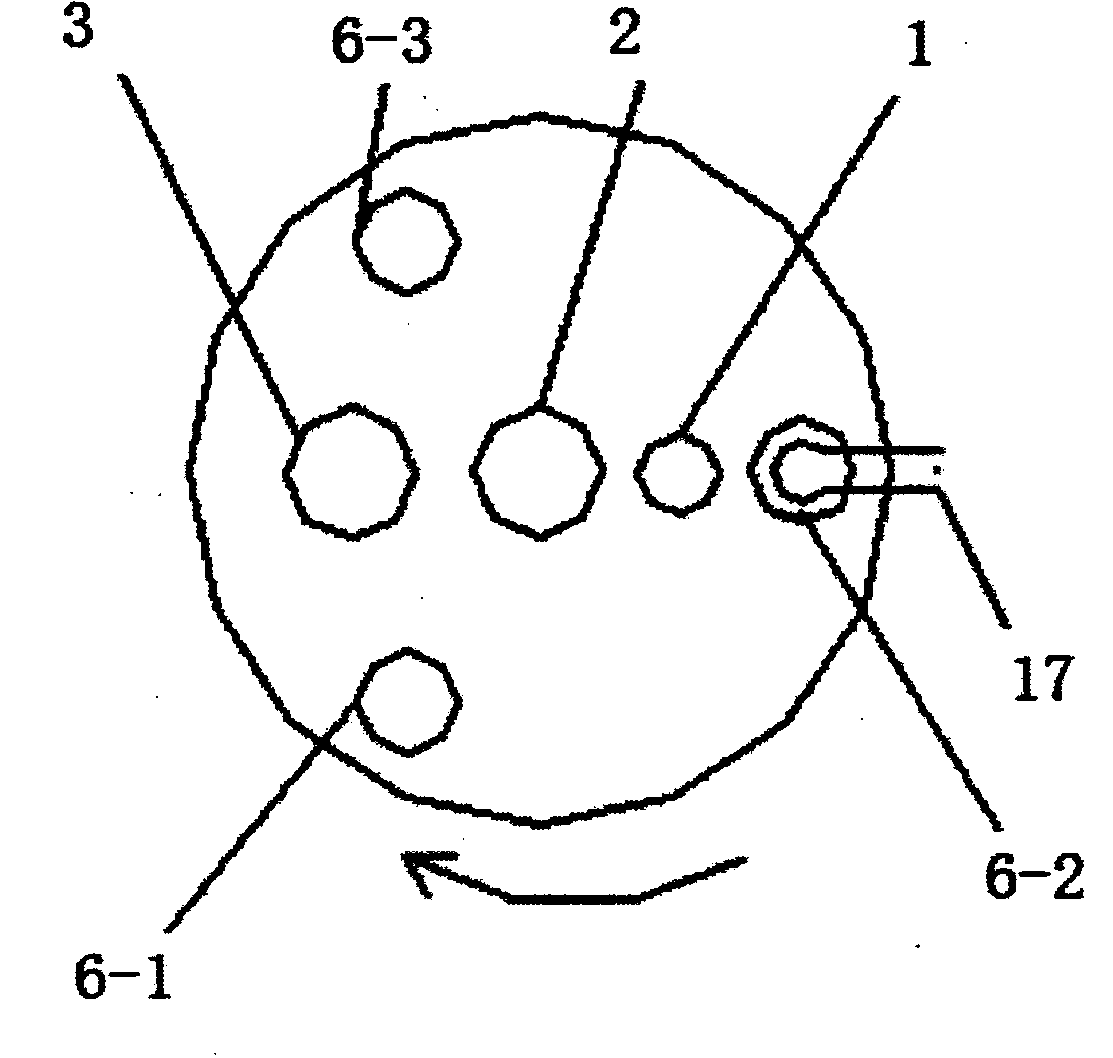

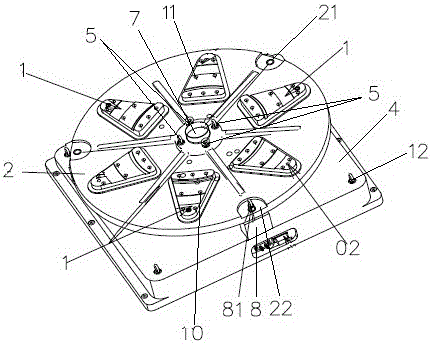

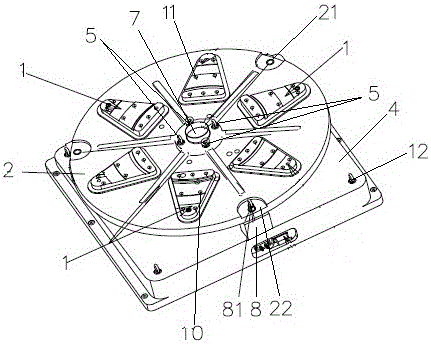

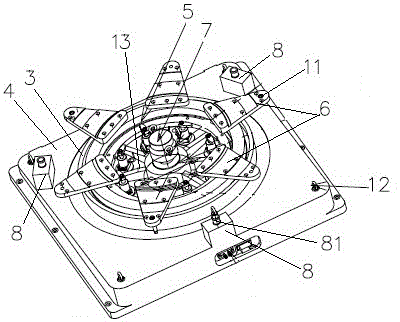

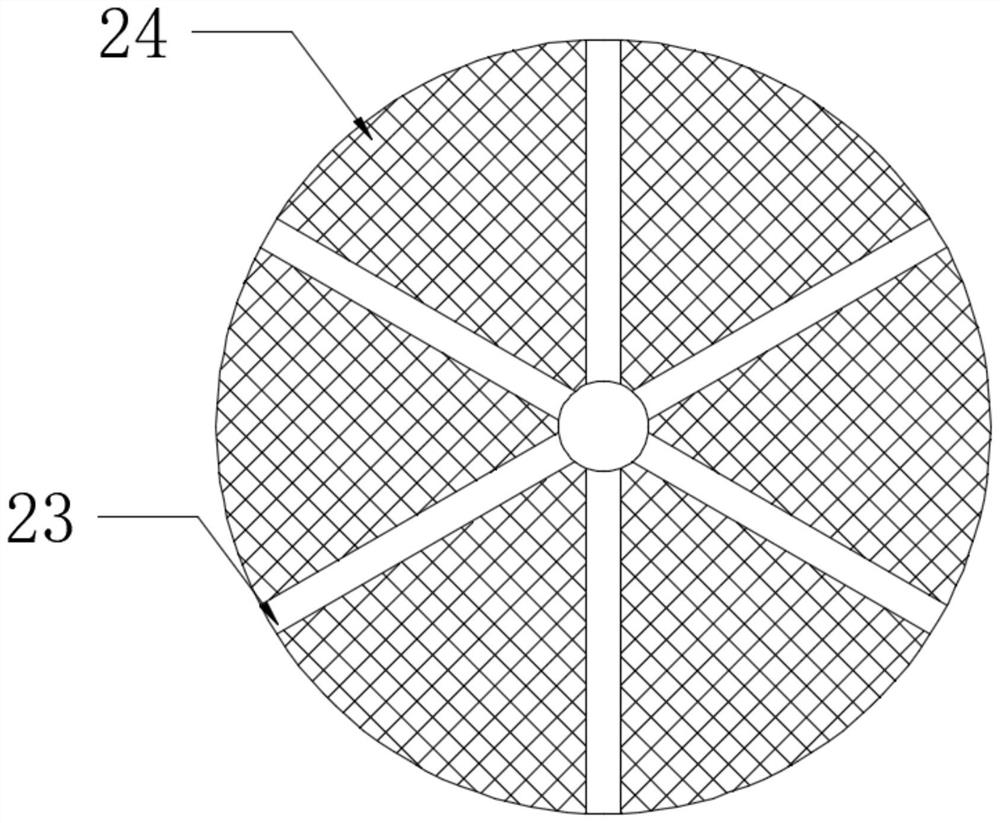

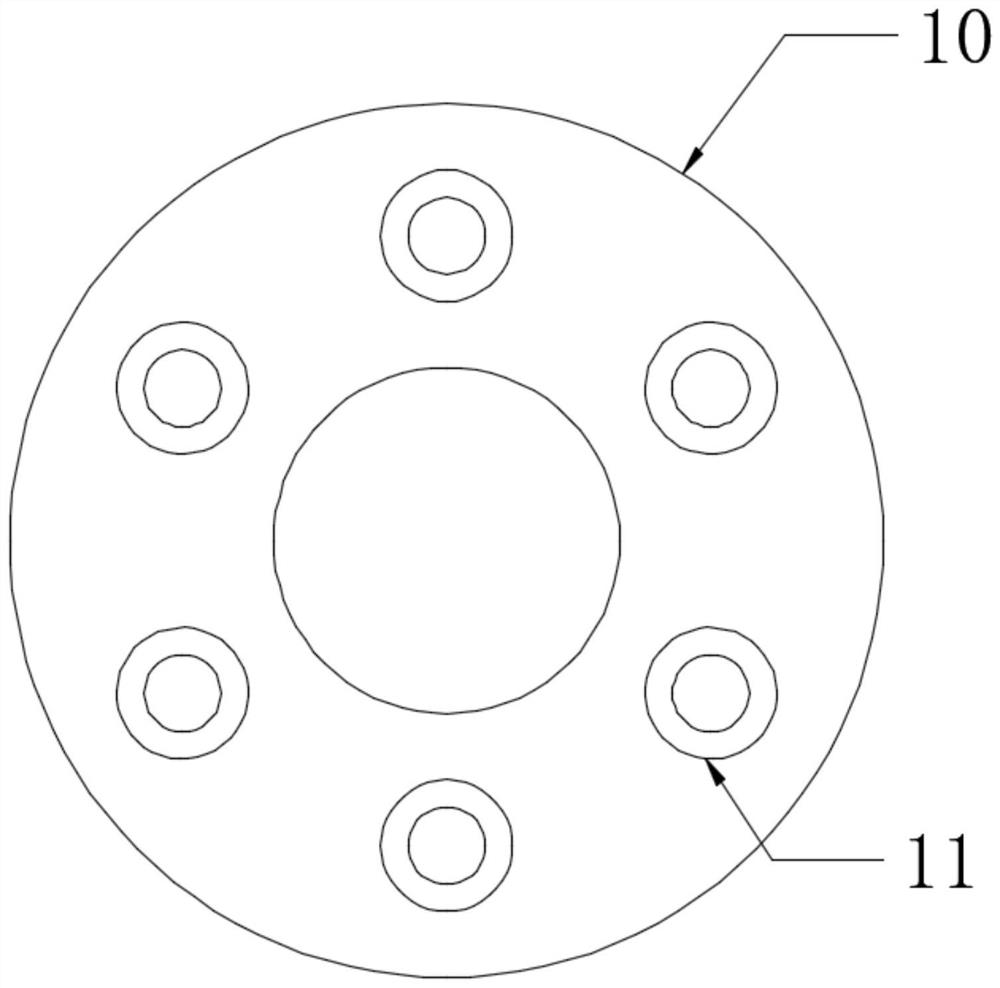

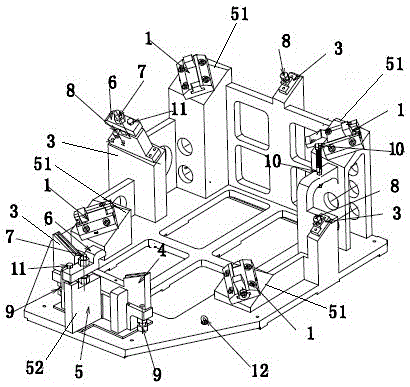

Clamp for disc-shaped large casting multi-hole and multi-plane finish machining

ActiveCN104999295AGuaranteed StrengthGuaranteed stiffnessWork holdersPositioning apparatusEngineeringMachining

The invention discloses a clamp for disc-shaped large casting multi-hole and multi-plane finish machining. The clamp comprises an annular boss arranged on a base. A clamping disc is obliquely connected to the top of the annular boss through a rotating shaft. A plurality of lower positioning pieces are arranged between the clamping disc and the annular boss and fixedly connected to the annular boss. A plurality of upper positioning pieces are connected to the top of the clamping disc. The upper positioning pieces and the lower positioning pieces are arranged in the circumferential direction of the clamping disc respectively. Each upper positioning piece and the corresponding lower positioning piece are provided with a plurality of corresponding connecting holes. Products to be machined penetrate through the connecting holes in the upper and lower positioning pieces through a plurality of connecting pieces to be connected and fixed. The portion, close to the rotating shaft, of the clamping disc is provided with a plurality of clamping devices. The clamp is simple in structure, low in cost and high in clamping stability, collision and damage phenomena caused by repeated clamping are reduced, and machining efficiency and product machining quality are improved.

Owner:ANHUI YONGCHENG MACHINERY

Fixture for multi-hole and multi-plane finishing of disc-shaped large castings

ActiveCN104999295BImprove stabilitySimple structureWork holdersPositioning apparatusEngineeringMachining

The invention discloses a clamp for disc-shaped large casting multi-hole and multi-plane finish machining. The clamp comprises an annular boss arranged on a base. A clamping disc is obliquely connected to the top of the annular boss through a rotating shaft. A plurality of lower positioning pieces are arranged between the clamping disc and the annular boss and fixedly connected to the annular boss. A plurality of upper positioning pieces are connected to the top of the clamping disc. The upper positioning pieces and the lower positioning pieces are arranged in the circumferential direction of the clamping disc respectively. Each upper positioning piece and the corresponding lower positioning piece are provided with a plurality of corresponding connecting holes. Products to be machined penetrate through the connecting holes in the upper and lower positioning pieces through a plurality of connecting pieces to be connected and fixed. The portion, close to the rotating shaft, of the clamping disc is provided with a plurality of clamping devices. The clamp is simple in structure, low in cost and high in clamping stability, collision and damage phenomena caused by repeated clamping are reduced, and machining efficiency and product machining quality are improved.

Owner:ANHUI YONGCHENG MACHINERY

Adhesive glue preparation stirring device for synthetic paper production

InactiveCN113457539AImprove the quality of production and processingImprove the mixing effectMixersAdhesive gluePaper production

The invention discloses an adhesive glue preparation stirring device for synthetic paper production, and relates to the technical field of synthetic paper production and processing equipment. The adhesive glue preparation stirring device comprises a stirring box, a stirring assembly, a centrifugal assembly, a heating assembly and a circulating assembly; the stirring assembly includes a mixing chamber and multiple groups of stirring components arranged in the mixing chamber, the mixing chamber is fixedly mounted in the stirring box, the stirring component is used for preliminarily stirring raw material glue in the mixing chamber, feeding pipes are oppositely arranged on the two sides of the top of the mixing chamber, a driving component rotates to preliminarily stir the glue raw material, the preliminarily stirred glue falls into the centrifugal barrel, the centrifugal barrel is driven to rotate at a high speed, under the action of centrifugal force, internal glue is thrown out and falls to the circulating assembly, and the circulating assembly circularly conveys the glue into the mixing chamber to be repeatedly stirred again, so that the stirring effect is effectively improved, and the production and processing quality of synthetic paper is improved.

Owner:阜阳市尤美新材料科技有限公司

Combined type feeding device used in gravel production

InactiveCN113019547AEasy to transportEasy for preliminary screeningSievingScreeningElectric machineryVibration motor

The invention discloses a combined type feeding device used in gravel production, and belongs to the technical field of gravel production feeding equipment. According to the technical scheme, the combined type feeding device is characterized by comprising a supporting base, wherein a hopper is arranged above the left side of the supporting base, a feeding frame, a crushing cavity, a feeding barrel and a vibrating screen are sequentially arranged above the supporting base from left to right, a gravel washing machine is arranged below a supporting base, the crushing cavity is used for crushing processing, crushed gravel is completely separated from silt solidified on the gravel, a feeding motor is started, a spiral shaft rotates, the feeding barrel conveniently conveys the crushed gravel to the position above the vibrating screen to be screened, screening holes penetrate through the outer side wall of the feeding barrel, when the gravel is rotationally conveyed in the feeding barrel, the silt is screened out of the feeding barrel, preliminary screening of the gravel is facilitated, a vibration motor is started, screening operation of the gravel is facilitated, the purpose that the gravel and the silt are completely screened is achieved, and therefore, the production and processing quality of the gravel is improved.

Owner:甘肃建投矿业有限公司

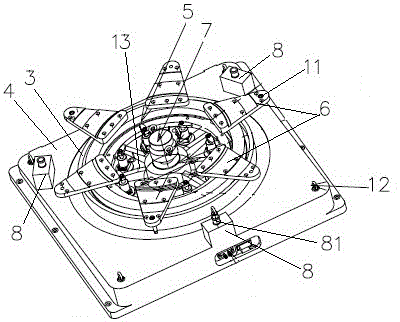

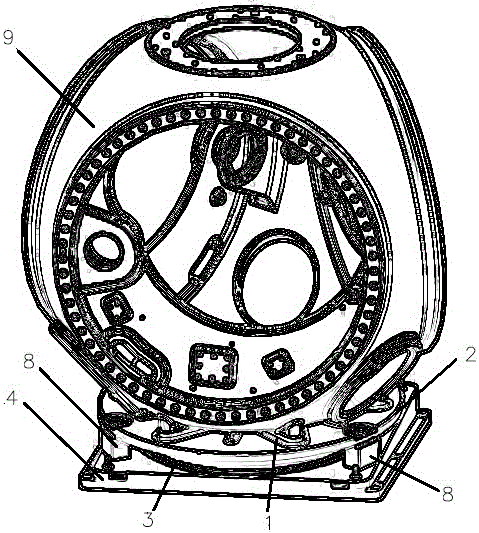

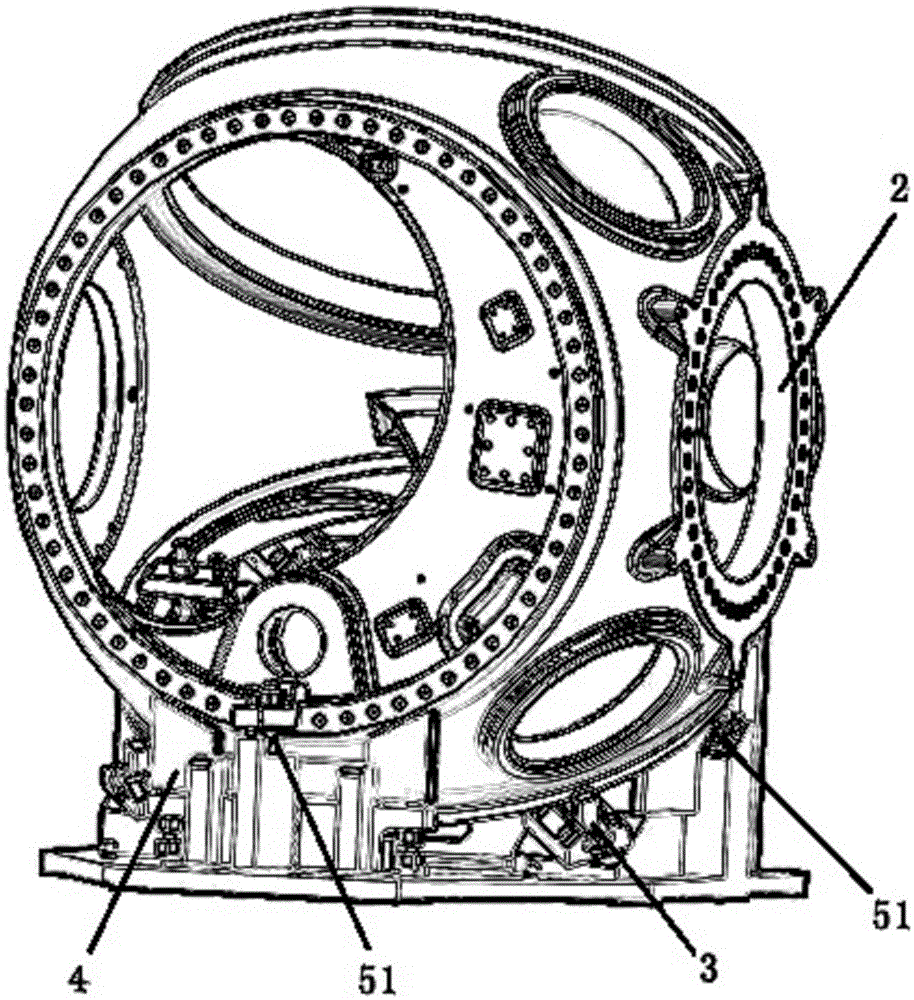

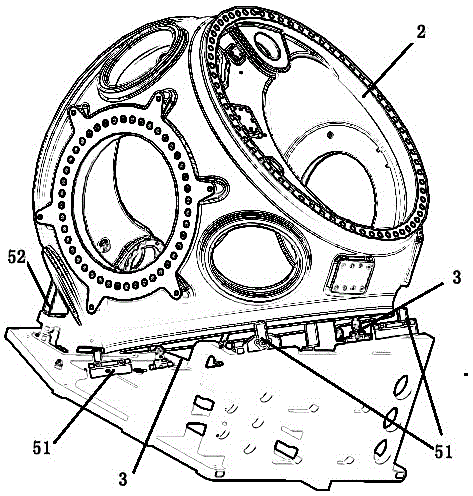

Clamp for large spherical casting multi-hole multi-plane same-direction machining

ActiveCN105058097AAdjust the positioning angleAdjuster displacementPositioning apparatusMetal-working holdersEngineeringSpherical shaped

The invention discloses a clamp for large spherical casting multi-hole multi-plane same-direction machining. The clamp comprises a V-shaped supporting body arranged on a framework, and at least three angle supports arranged between supporting bases and end supporting bases in a staggered manner. The V-shaped supporting body comprises at least two sets of symmetric supporting bases and end supporting bases, wherein the end supporting bases are arranged on the symmetry axis of the two sets of symmetrically-arranged supporting bases and located at one ends of the supporting bases. The end supporting bases and the supporting bases are each provided with a clamping pawl. Each angle support is provided with a supporting nail. The clamp is simple in structure, low in cost and high in clamping stability. The integral strength and rigidity of the clamp are guaranteed, and the phenomenon of cutter vibration generated during cutting of a to-be-machined large spherical casting or other large spherical components is avoided. The smoothness of workpiece machining surfaces and the precision of machining sizes are improved, and the production machining quality of products is improved.

Owner:ANHUI YONGCHENG MACHINERY

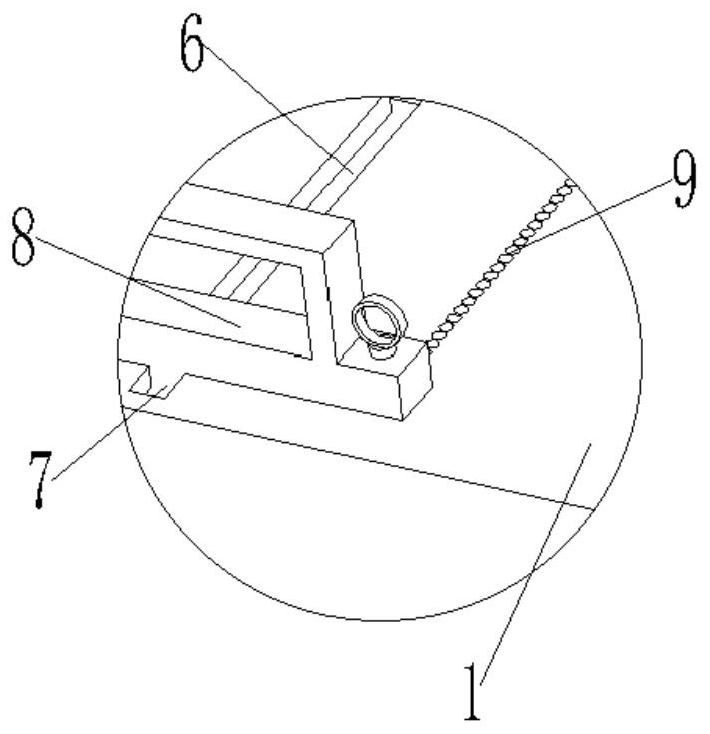

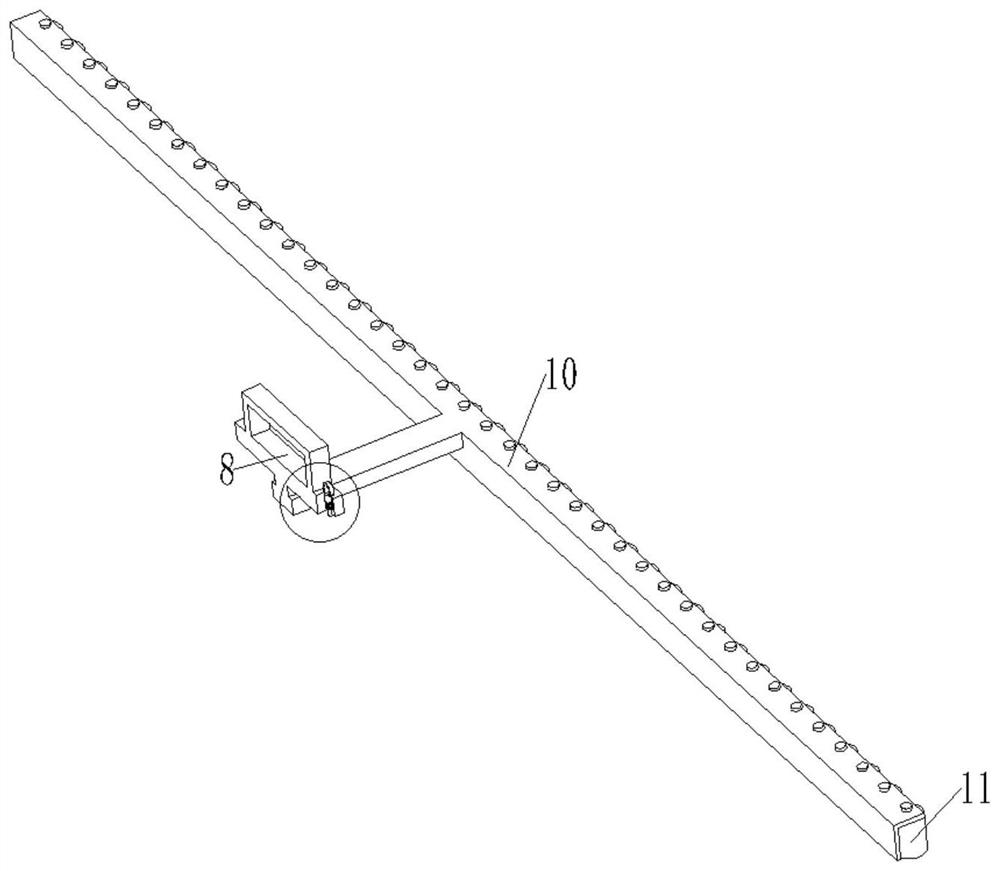

Stripping and cutting device capable of accurately controlling stripping and cutting depth of cable insulation layer

PendingCN114825198AImprove the quality of production and processingAvoid damageApparatus for removing/armouring cablesApparatus for joining/termination cablesPower cableInsulation layer

The invention relates to the technical field of power cable installation construction and power cable operation and maintenance tools, and discloses a stripping and cutting device capable of accurately controlling the stripping and cutting depth of a cable insulation layer, the stripping and cutting device comprises a stripping and cutting mechanism used for stripping and cutting a cable, and one side of the stripping and cutting mechanism is provided with a radial depth control mechanism matched with the stripping and cutting mechanism. The stripping and cutting mechanism comprises a nut connecting seat, a nut connecting rod is movably connected to the nut connecting seat, the radial depth control mechanism comprises an inner threaded sleeve and an outer threaded sleeve, the end, away from the nut connecting seat, of the nut connecting rod is in bolted connection with the inner threaded sleeve, the inner threaded sleeve is in threaded connection with the outer threaded sleeve, and the outer threaded sleeve is in threaded connection with the nut connecting seat. The end, away from the inner thread sleeve, of the outer thread sleeve is sleeved with an outer thread sleeve fixing base, the outer thread sleeve fixing base is provided with a forward adjusting screw and a reverse adjusting screw, and the manufacturing and machining quality of the cable connector in actual work is improved.

Owner:广西新南润电力科技有限公司 +1

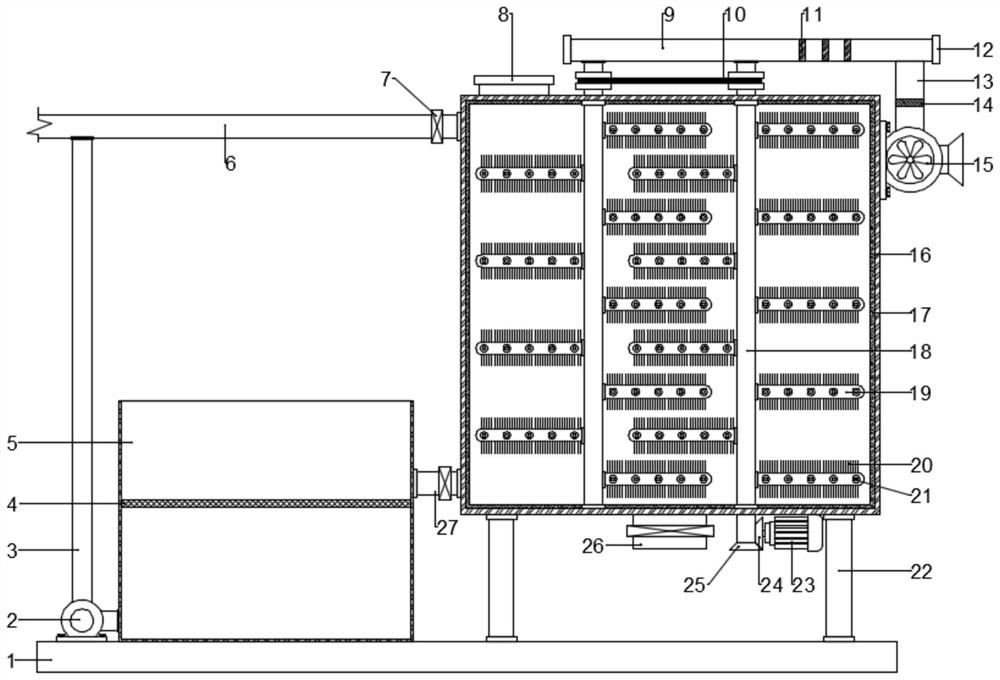

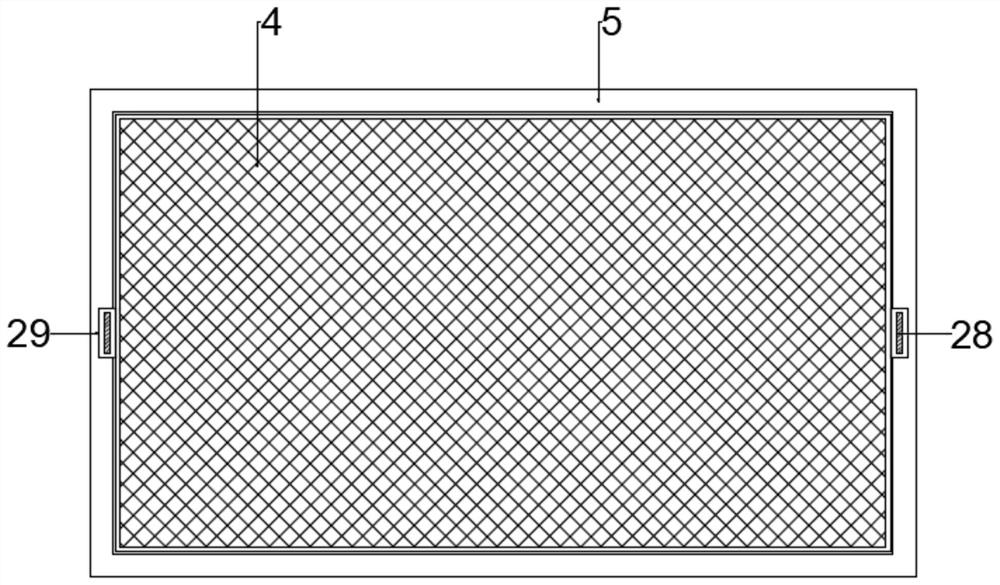

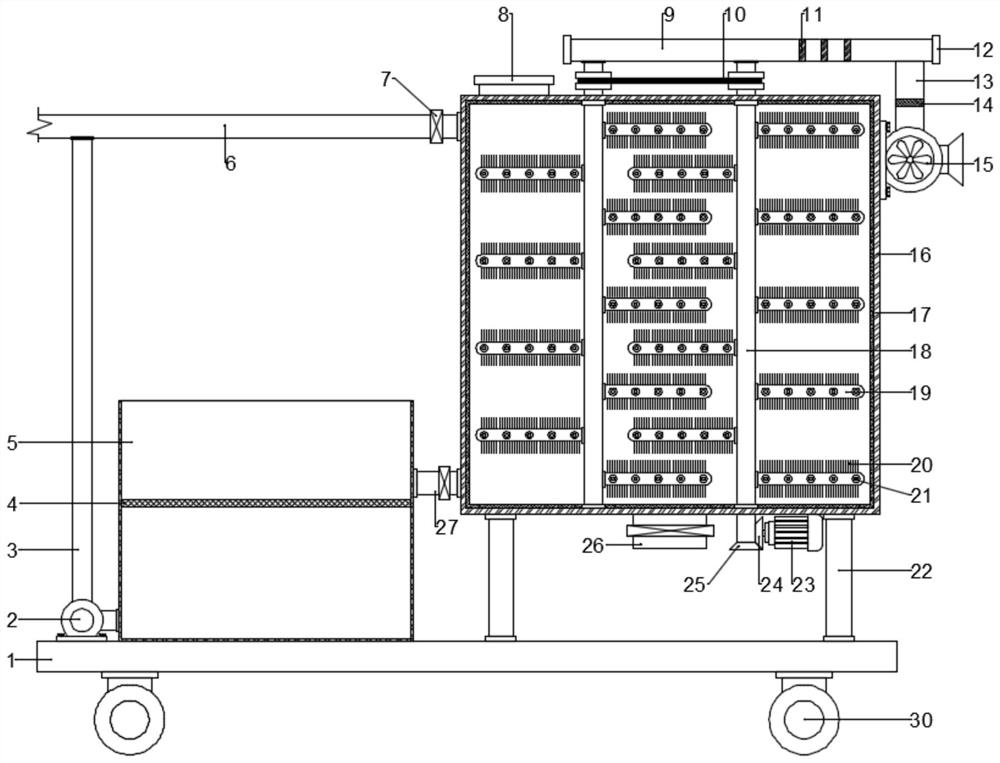

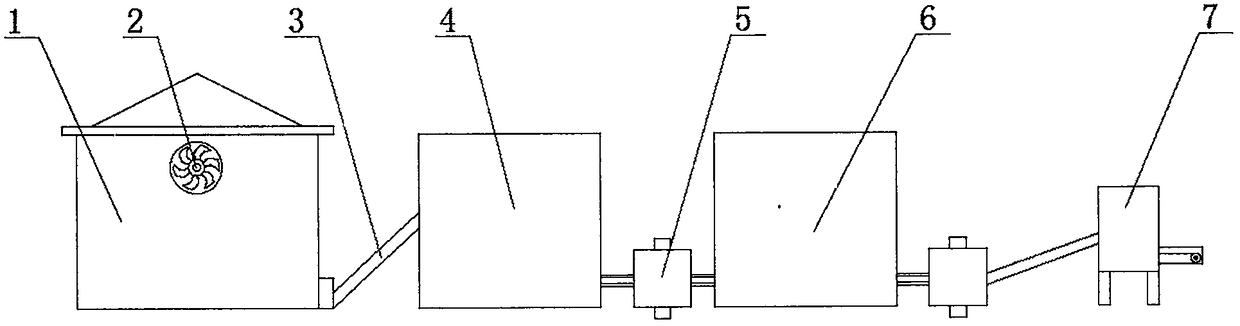

High-efficiency dehumidification device special for grain processing

InactiveCN108077419AReal-time detection of temperatureAvoid damageSeed preservation by dryingEngineeringAir exchange

The invention discloses a high-efficiency dehumidification device special for grain processing. The high-efficiency dehumidification device includes a raw grain granary, an air exchange fan is arranged above the front surface of the raw grain granary, a first production workshop is arranged on the right side of the air exchange fan, a conveying pipeline is arranged at the connection part of the first production workshop and the raw grain granary, a drying dehumidifier is arranged on the right side of the first production workshop, and temperature monitors are arranged at the internal parts ofthe two ends of the drying dehumidifier, and are near the conveying pipeline. The right sides of the temperature monitors are equipped with humidity monitors. The temperature monitors are respectivelyinstalled on the two ends of the drying dehumidifier to facilitate the real-time detection of the temperature before and after grain processing to avoid the problem of excessive temperature damage tograins; the humidity monitors facilitates the detection of the humidity of the grains, so that the dryness of the grains is maximumly increased without damage to the quality of the grains; the raw grain granary facilitates separated ventilation of raw grains in separate warehouse to avoid mixing of the raw grains and semi-finished grains.

Owner:林万九

Multipurpose plate precision machining device

ActiveCN113635159AControl processing strengthPreventing Oversanding ProblemsGrinding carriagesFeeding apparatusRotational axisEngineering

The invention provides a multipurpose plate precision machining device. The multipurpose plate precision machining device comprises two sets of supporting parts. A mounting plate is fixedly connected with the bottoms of the two groups of supporting parts; mounting legs are fixedly connected to four corners of the bottom of the mounting plate; operation devices slidably sleeve the two groups of supporting parts, and the operation devices are slidably connected with floating devices; the operation devices are in threaded connection with a driving part; machining devices are fixedly connected to the bottoms of the floating devices, and pushing parts are slidably connected with the machining devices; and a fixing part is slidably connected to the mounting plate, a cleaning part is connected to the mounting plate in a rotating shaft mode, rotating switching of the machining sets can be achieved by adopting the mode that a machining shaft frame is rotationally connected with a rotating shaft, meanwhile, a threaded groove is formed in the rotating shaft, pushing of ball heads on the pushing parts is matched, different machining modes of the machining sets can be replaced more conveniently, and the production and machining efficiency is greatly improved.

Owner:JIANGSU TANG BASE BUILDING MATERIALS TECH GRP CO LTD

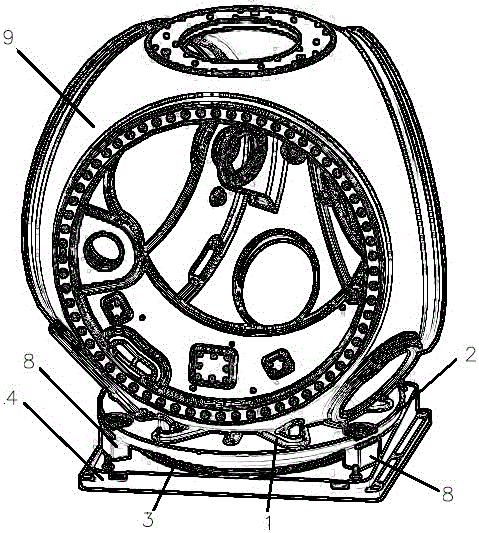

Core box structure for manufacturing integrated sand core of diesel engine

ActiveCN107052237AImprove the quality of production and processingAvoid cokingFoundry moulding apparatusEngineeringDiesel engine

The invention discloses a core box structure for manufacturing an integrated sand core of a diesel engine. The core box structure for manufacturing the integrated sand core of the diesel engine comprises a core box body. A supporting seat body is arranged on the outer side of the core box body. A supporting block is further arranged on the outer side wall of the core box body. The supporting block is provided with a supporting shaft in a penetrated manner, and the supporting shaft is used for being connected with the supporting seat body and the core box body. The core box body is further provided with a sand core mechanism. The two ends of the sand core mechanism are provided with supporting rotary shafts. Rotating grooves are arranged at the supporting rotary shafts and the edges of the core box body. Each rotating groove is provided with a connecting flange which is used in cooperation with the rotating groove. A seal connecting piece is arranged between each rotating groove and the corresponding connecting flange. The core box structure for manufacturing the integrated sand core of the diesel engine protects the core box against the sand leaking phenomenon and the coking phenomenon through the improvement on the structure of the core box, normal operation of equipment is guaranteed, the overall production and machining quality of the diesel engine is improved, the service life of the equipment is prolonged, and actual use requirements are met.

Owner:ANHUI QUANCHAI TIANHE MACHINERY

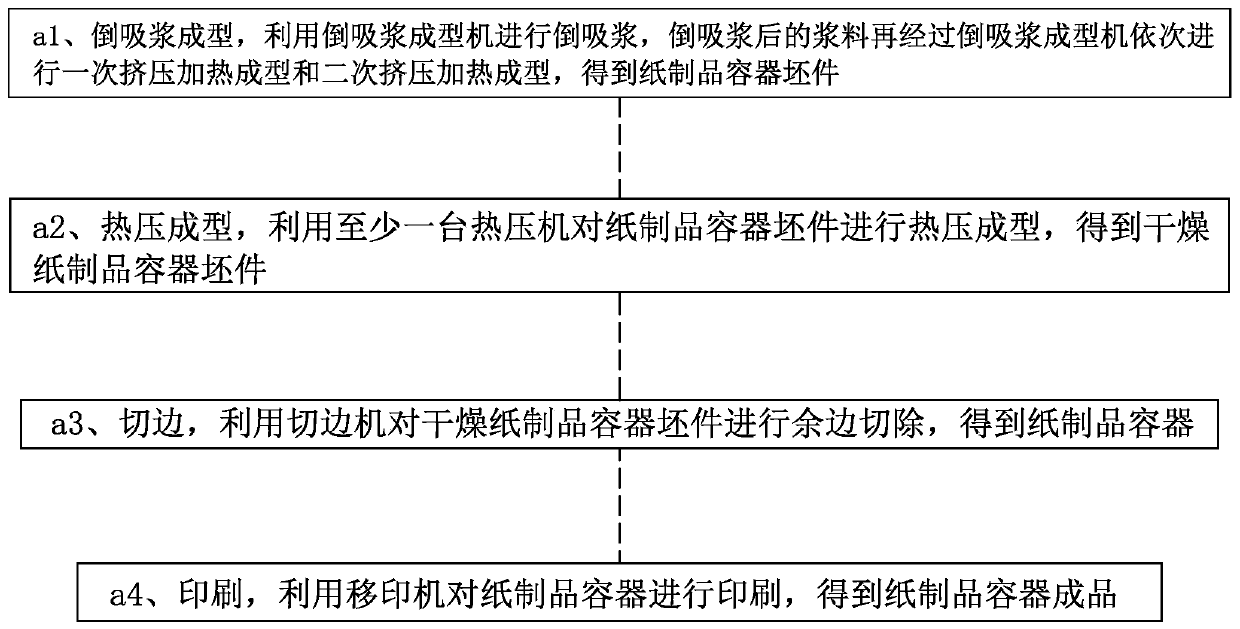

Paper product container processing method

ActiveCN111395051AImprove the quality of production and processingMeet production requirementsTextiles and paperMetal working apparatusPad printingMolding machine

A paper product container processing method comprises the following steps: a1, suck-back pulp forming is conducted, specifically, pulp suck-back is carried out by using a suck-back pulp forming machine, and pulp subjected to pulp suck-back is sequentially subjected to primary extrusion heating forming and secondary extrusion heating forming by using the suck-back pulp forming machine, so that a paper product container blank is obtained; a2, hot press molding is conducted, specifically, at least one hot press is used for conducting hot press molding on the paper product container blank, and a dry paper product container blank is obtained; a3, edge cutting is conducted, specifically, residual edges of the dried paper product container blank are cut off through an edge cutting machine, and apaper product container is obtained; and a4, printing is conducted, specifically, the paper product container is printed by using a pad printing machine to obtain a finished product of the paper product container.

Owner:ZHEJIANG SHURCON MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com