Perforating device for stainless steel product manufacturing and machining

A punching device, stainless steel technology, used in positioning devices, feeding devices, manufacturing tools, etc., can solve the problems of time-consuming and laborious hole position accuracy, affecting the final quality of the product, and large vibration amplitude of the drilling machine, achieving stability and safety. Improve, improve the efficiency and quality of production and processing, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

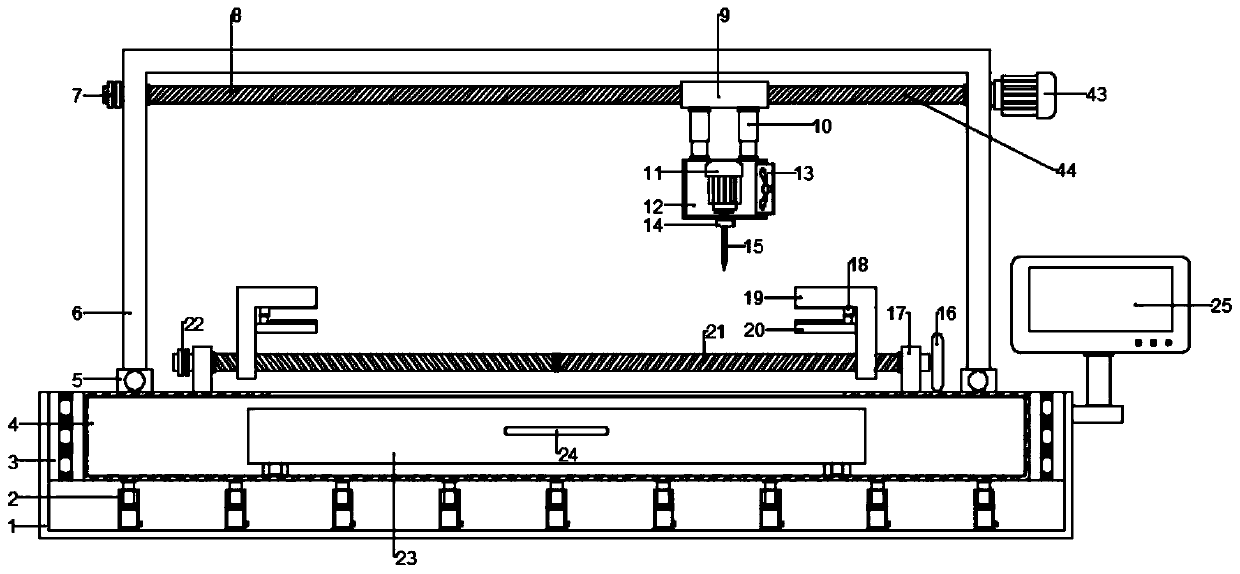

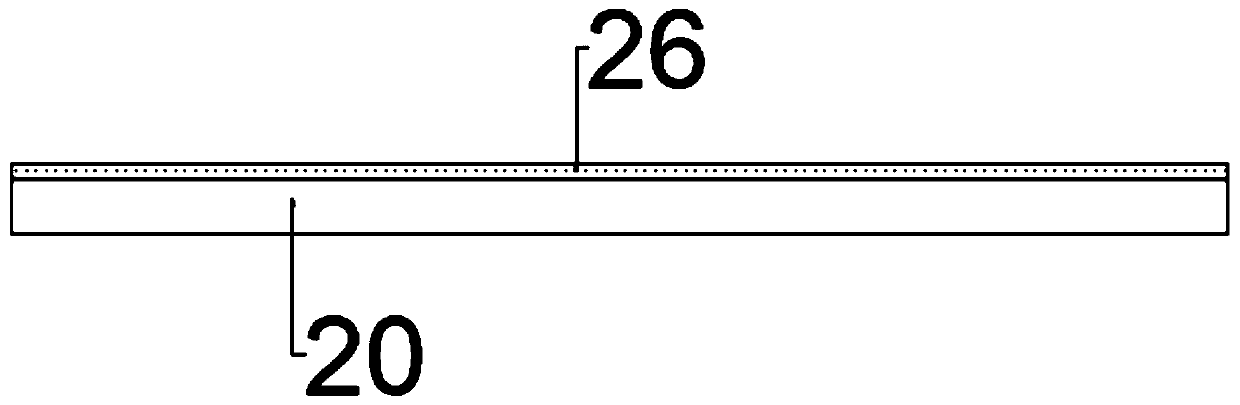

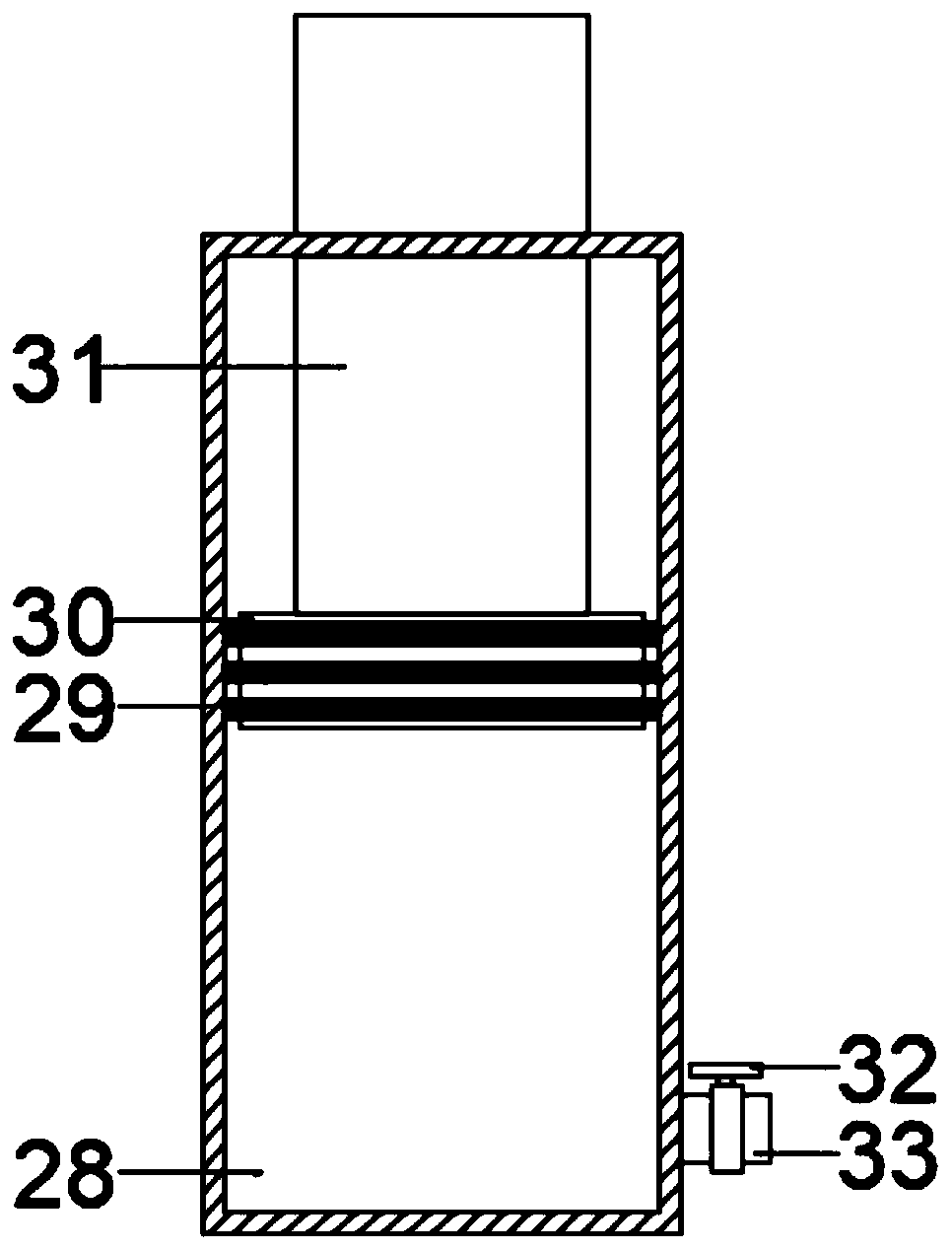

[0027] see Figure 1-5 , in an embodiment of the present invention, a punching device for production and processing of stainless steel products, comprising a U-shaped base 1, a mounting table 4 and a U-shaped plate 6, the mounting table 4 is arranged in the U-shaped base 1, and the U-shaped base 1 A plurality of air cylinder assemblies 2 are uniformly arranged at the bottom of the inner cavity, and the upper ends of the air cylinder assemblies 2 are fixedly connected to the bottom of the installation platform 4. The air cylinder assembly 2 includes an inflatable cylinder 28 and a vertical rod 31, and the vertical rod 31 is slidably inserted into the inflatable cylinder 28 Above, one end of the vertical rod 31 located in the inflator 28 is fixedly connected with a movable block 30, and the side wall of the movable block 30 is provided with a plurality of channels from top to bottom for sealing between the movable block 30 and the bottom of the inner cavity of the inflatable cyli...

Embodiment 2

[0037] see Figure 6 The difference between the embodiment of the present invention and embodiment 1 is that, further, in order to facilitate the movement of the device, the bottom of the U-shaped base 1 is symmetrically provided with a plurality of moving wheels 45, and each moving wheel 45 is provided with a brake. Stop assembly, the staff can move this device easily and conveniently by moving wheel 45.

[0038] The working principle of the present invention is: when the present invention is in use, first rotate the rotary handle 16 according to the size of the stainless steel plate to adjust the distance between the two L-shaped plates 19, then put the stainless steel plate on the two clamping plates 20, and then Start a plurality of second telescopic rods 18 to shrink at the same time to fix the stainless steel plate, then control the longitudinal braking assembly 5 and the lateral braking assembly 44 through the control panel 25 to position the drilling position of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com