Patents

Literature

106results about How to "Uniform quenching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

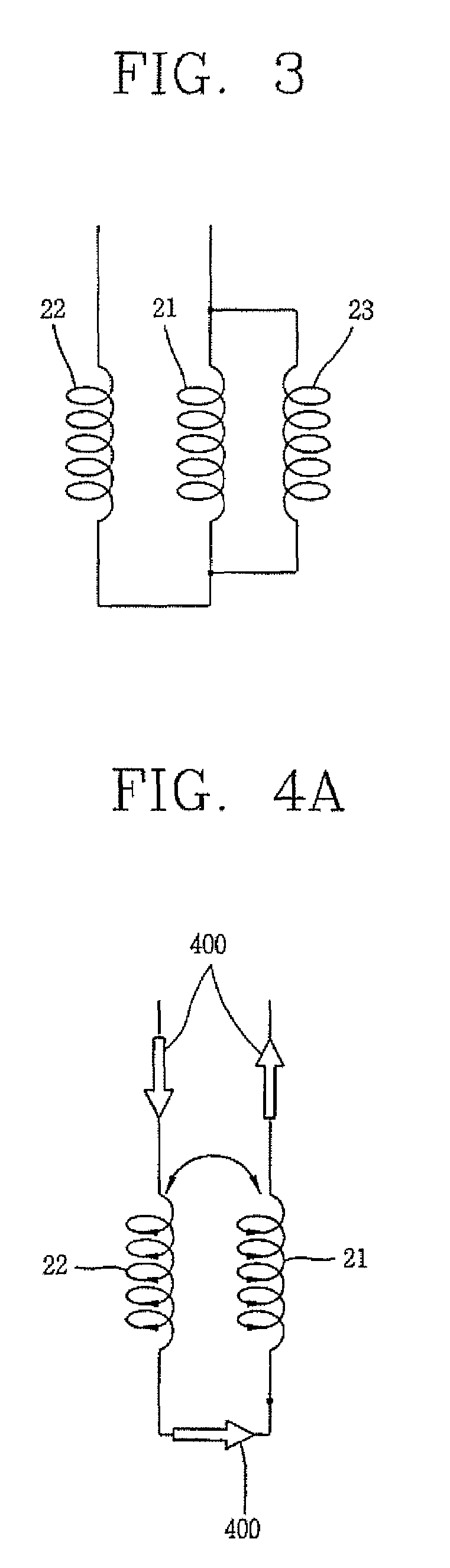

Resistive superconducting fault current limiter

ActiveUS7558030B2Total current dropImprove toleranceSuperconductors/hyperconductorsEmergency protective arrangements for limiting excess voltage/currentElectrical resistance and conductanceElectrical conductor

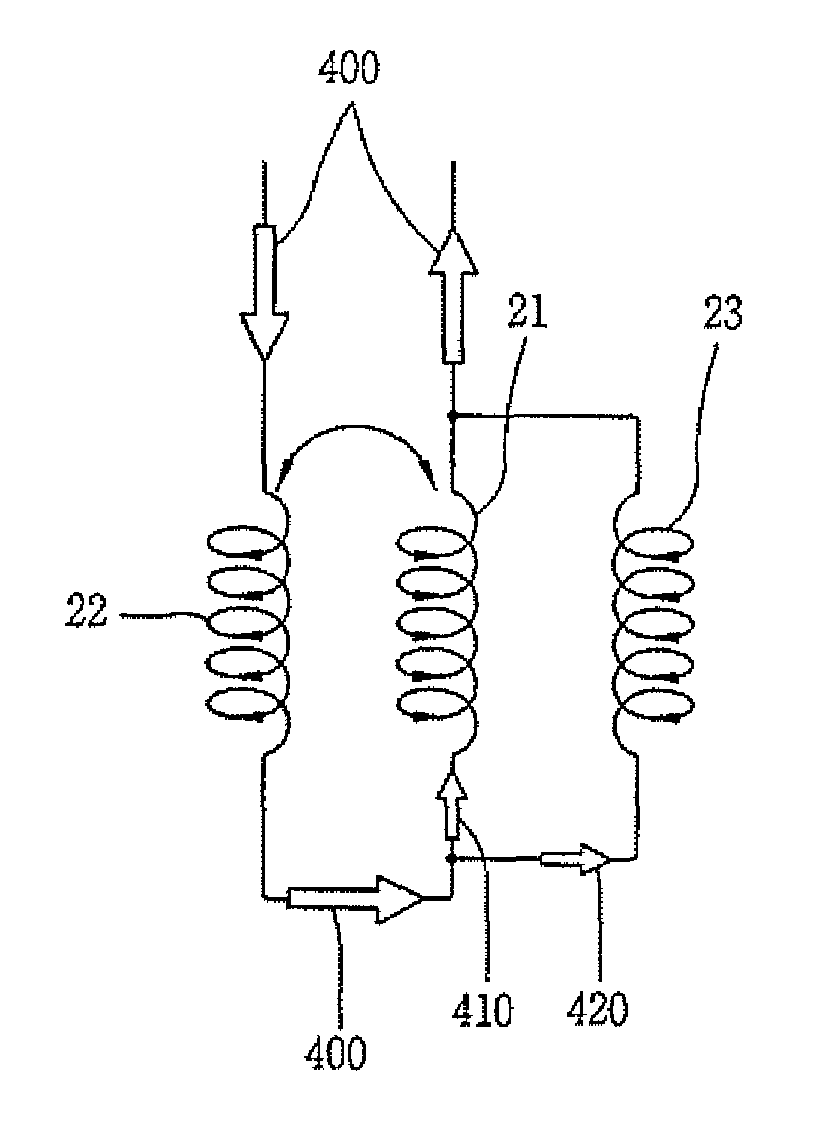

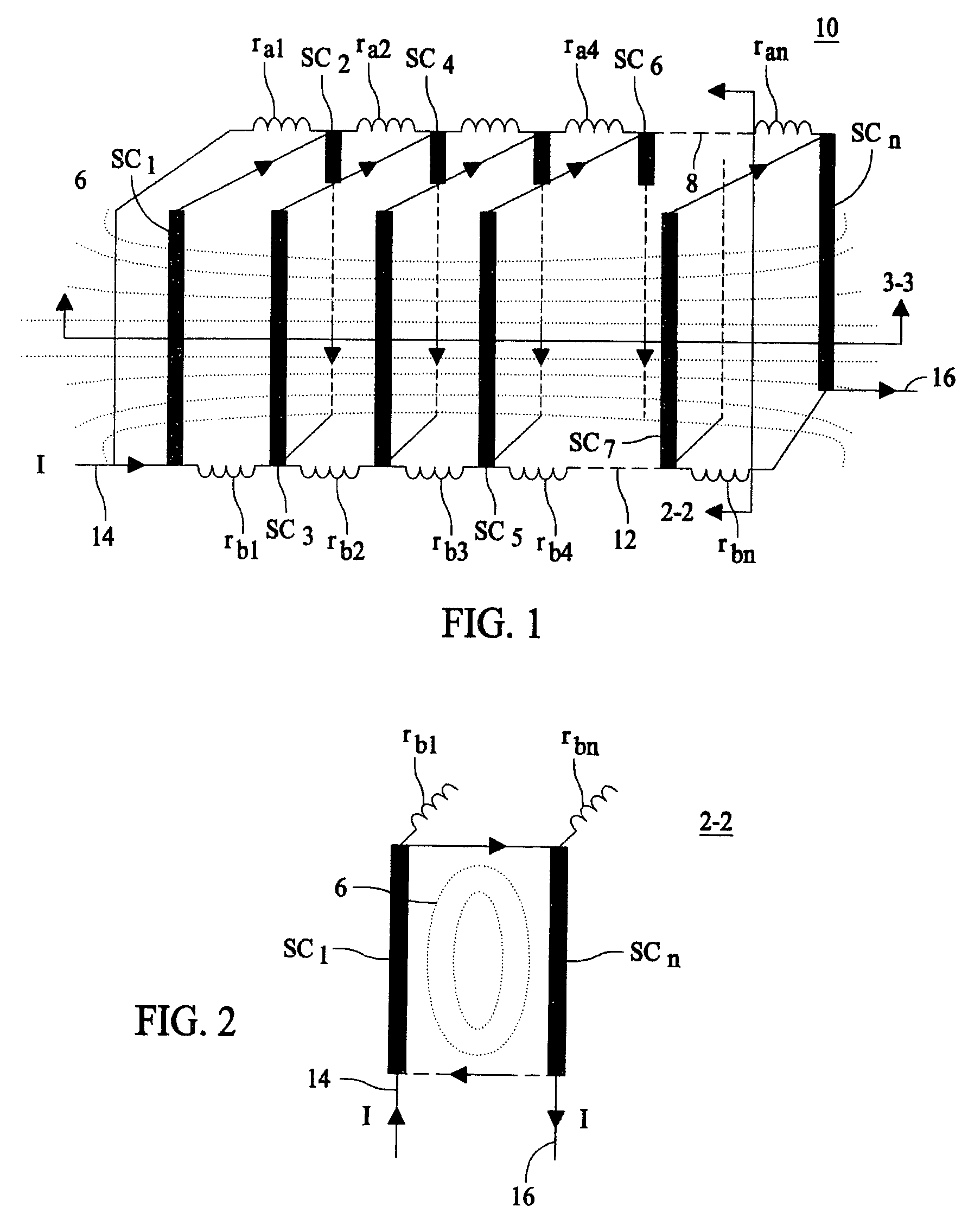

A resistive superconducting fault current limiter comprises: a superconducting limiter element which is in a superconductive state in the event of a normal current occurrence, and which is in a normal conductive state having a predetermined resistance when a fault current larger than a predetermined threshold current value flows; a superconducting serial coil serially connected to the superconducting limiter element so as to face each other so that a current loss can be minimized accordingly as currents flow in opposite directions thus to cancel magnetic fields, and having a threshold current value greater than the threshold current value of the superconducting limiter element by a predetermined ratio; and a normal conductor parallel coil connected to the superconducting limiter element in parallel and having a predetermined resistance smaller than the resistance of the superconducting limiter element when a fault current occurs, for preventing the superconducting limiter element from being overheated by dividing a current flowing through the superconducting limiter element and for uniformly quenching the superconducting limiter element by generating a magnetic field when a fault current occurs

Owner:LS IND SYETEMS CO LTD

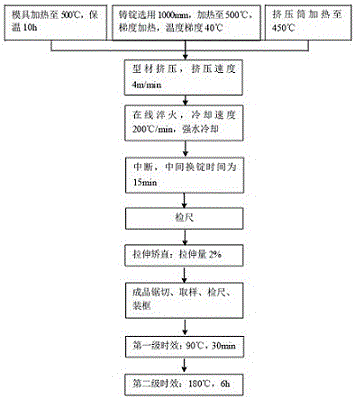

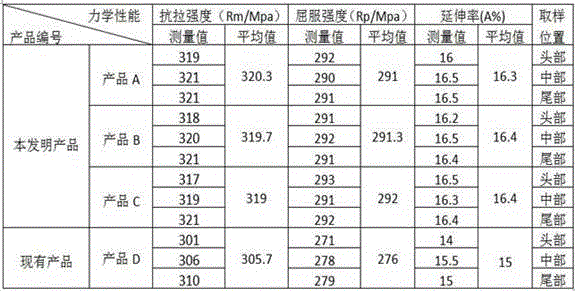

Al-Mg-Si aluminum alloy and extrusion method for sectional bar of Al-Mg-Si aluminum alloy

The invention discloses an Al-Mg-Si aluminum alloy and an extrusion method for a sectional bar of the Al-Mg-Si aluminum alloy. The Al-Mg-Si aluminum alloy comprises, by weight percent, 0.9%-1.25% of Mg, 0.5%-0.9% of Si, 0.2%-0.42% of Cu, smaller than or equal to 0.6% of Fe and 0.07%-0.35% of Cr and further comprises one or more elements of smaller than or equal to 0.15% of Mn, smaller than or equal to 0.22% of Zn, smaller than or equal to 0.15% of Ti, smaller than or equal to 0.05% of V, smaller than or equal to 0.5% of Hf, smaller than or equal to 0.25% of Sc, smaller than or equal to 1.0% of Ag and the balance Al. The aluminum alloy with the high mechanical performance is obtained by optimizing alloy components, the content of the alloy components and the sectional bar extrusion technology, and the production efficiency is effectively improved. The problems that in the prior art, conventional aluminum for transportation is low in strength and poor in ductility, the control range of the sectional bar extrusion technology link is wide, stability is poor, online quenching control difficulty is large, quenching uniformity is poor, and the production efficiency is low are solved.

Owner:广西南南铝加工有限公司

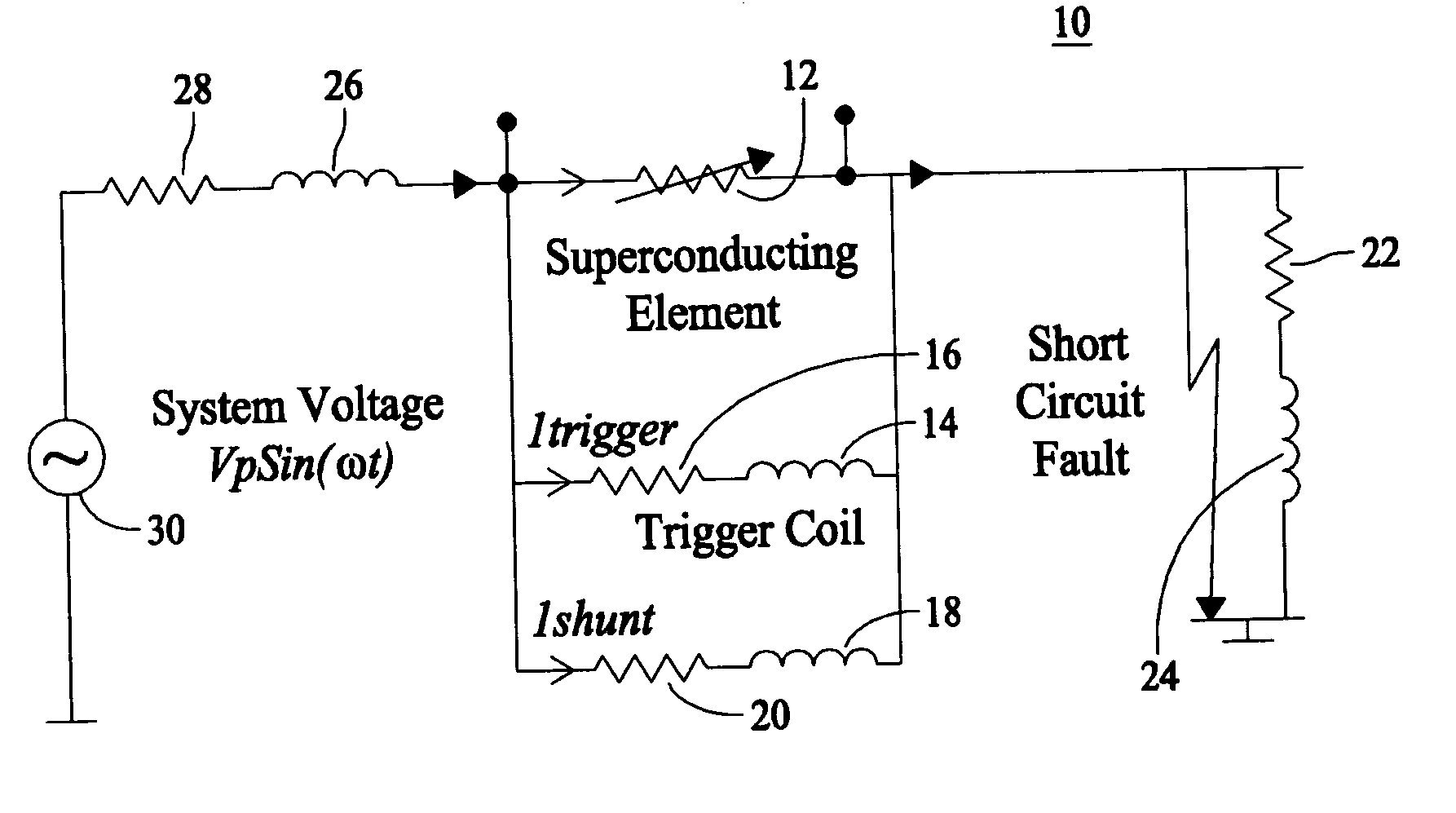

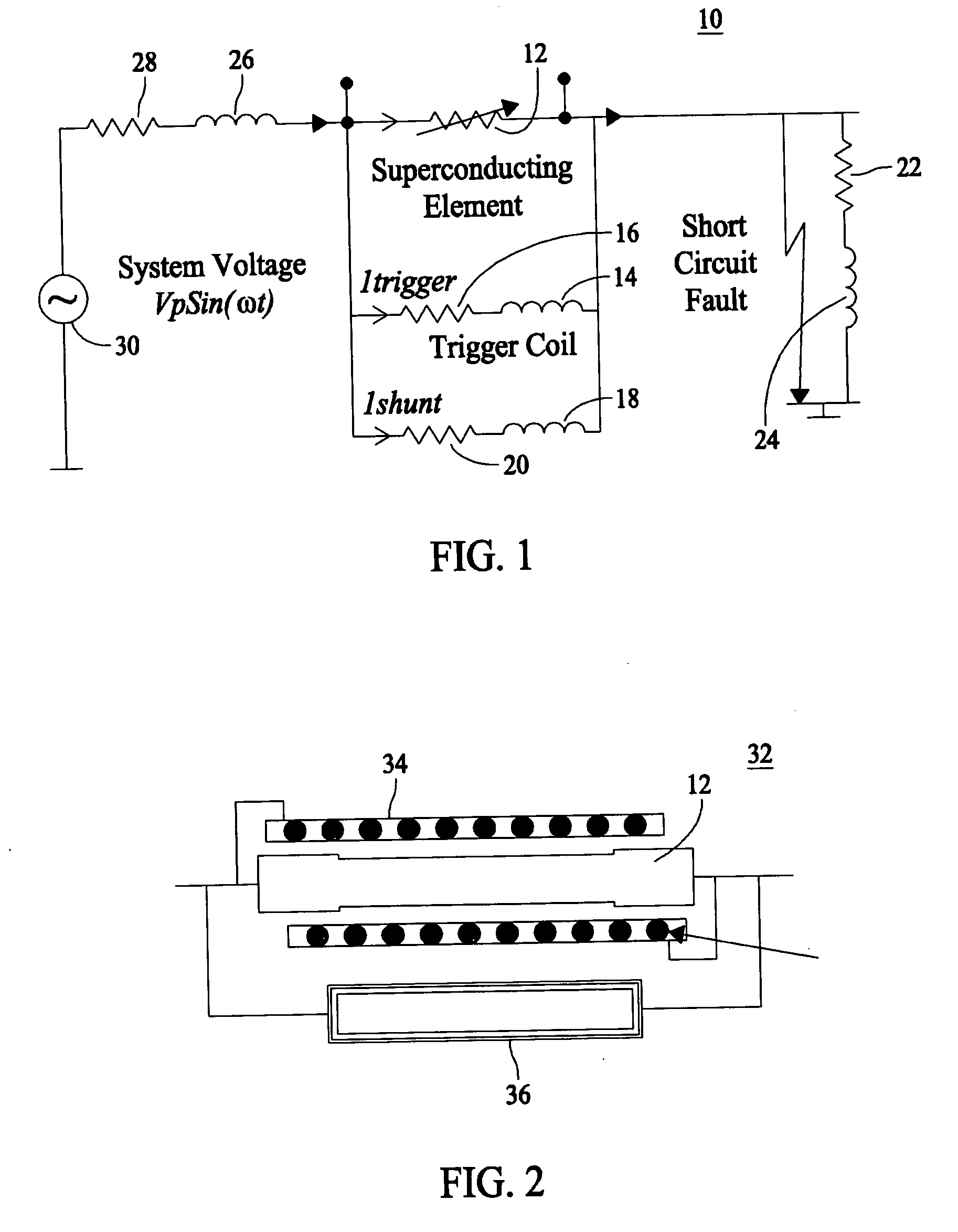

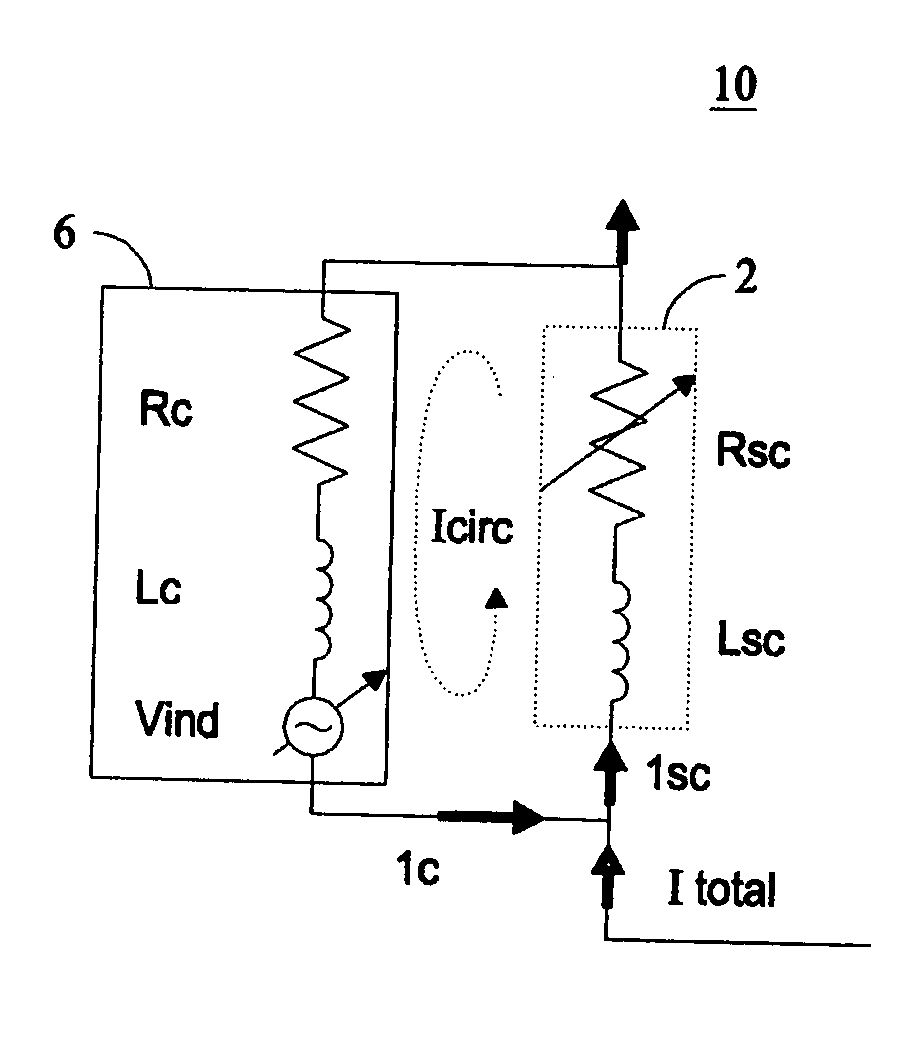

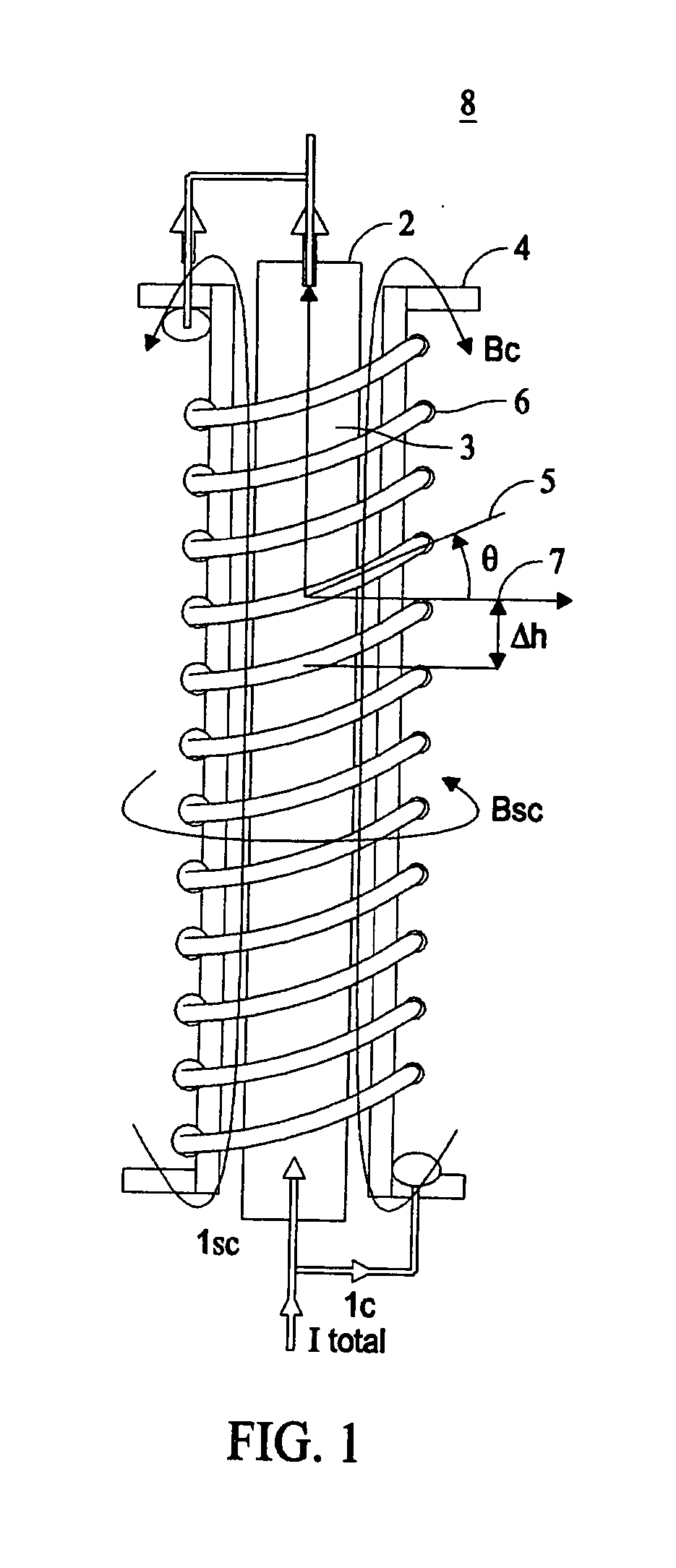

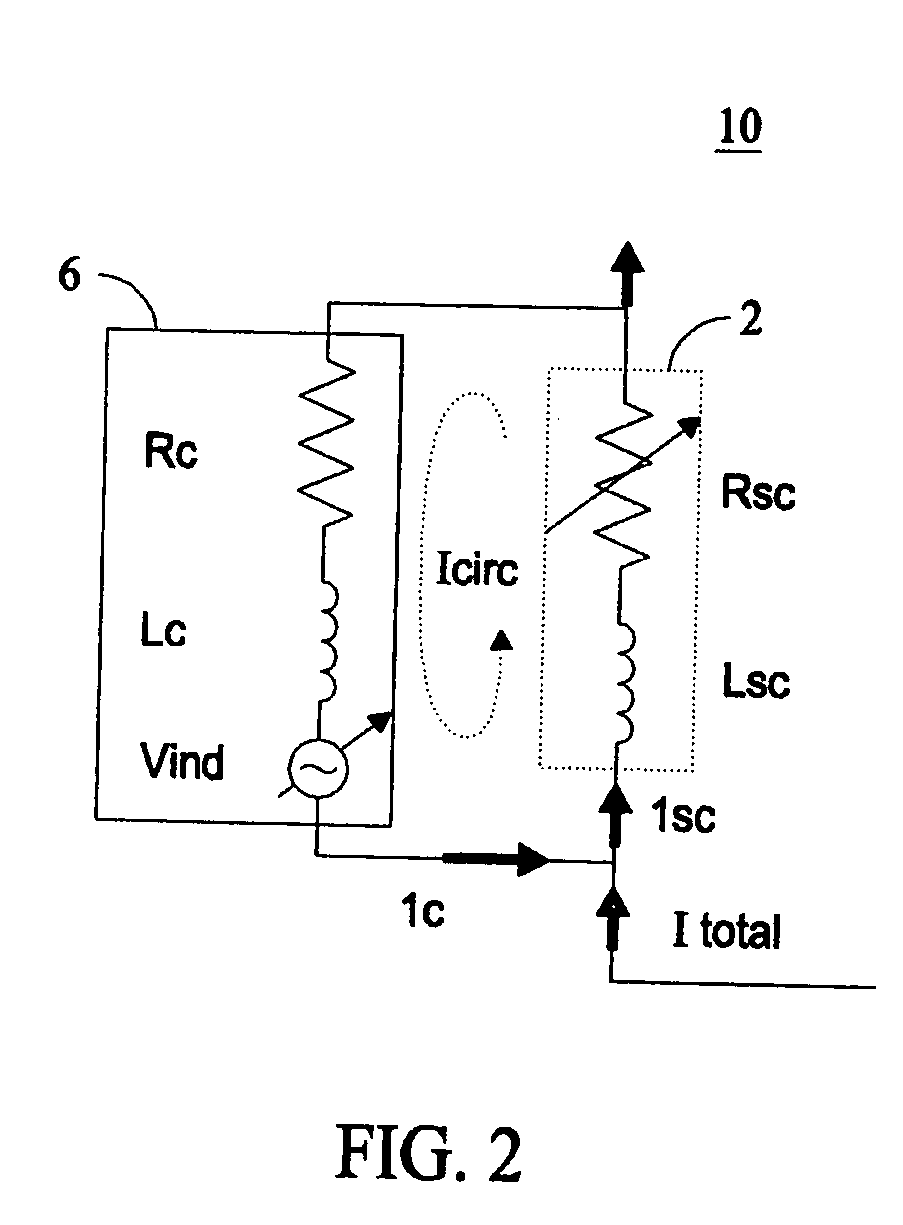

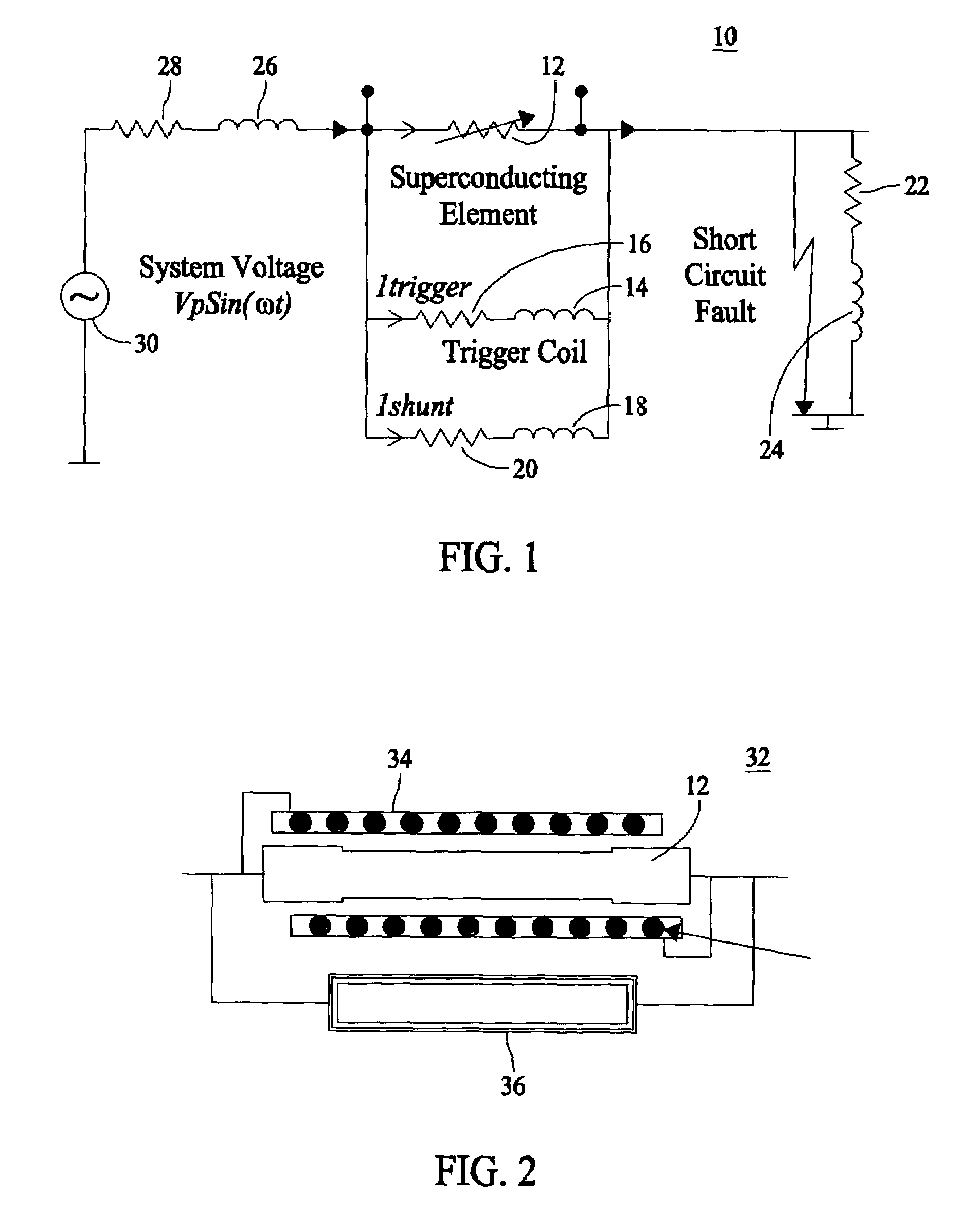

Superconducting FCL using a combined inducted magnetic field trigger and shunt coil

InactiveUS7283339B2Increase speedReduce creationMagnetsMagnetic materialsShunt impedanceHigh temperature superconducting

A single trigger / shunt coil is utilized for combined induced magnetic field triggering and shunt impedance. The single coil connected in parallel with the high temperature superconducting element, is designed to generate a circulating current in the parallel circuit during normal operation to aid triggering the high temperature superconducting element to quench in the event of a fault. The circulating current is generated by an induced voltage in the coil, when the system current flows through the high temperature superconducting element.

Owner:SUPERPOWER INC

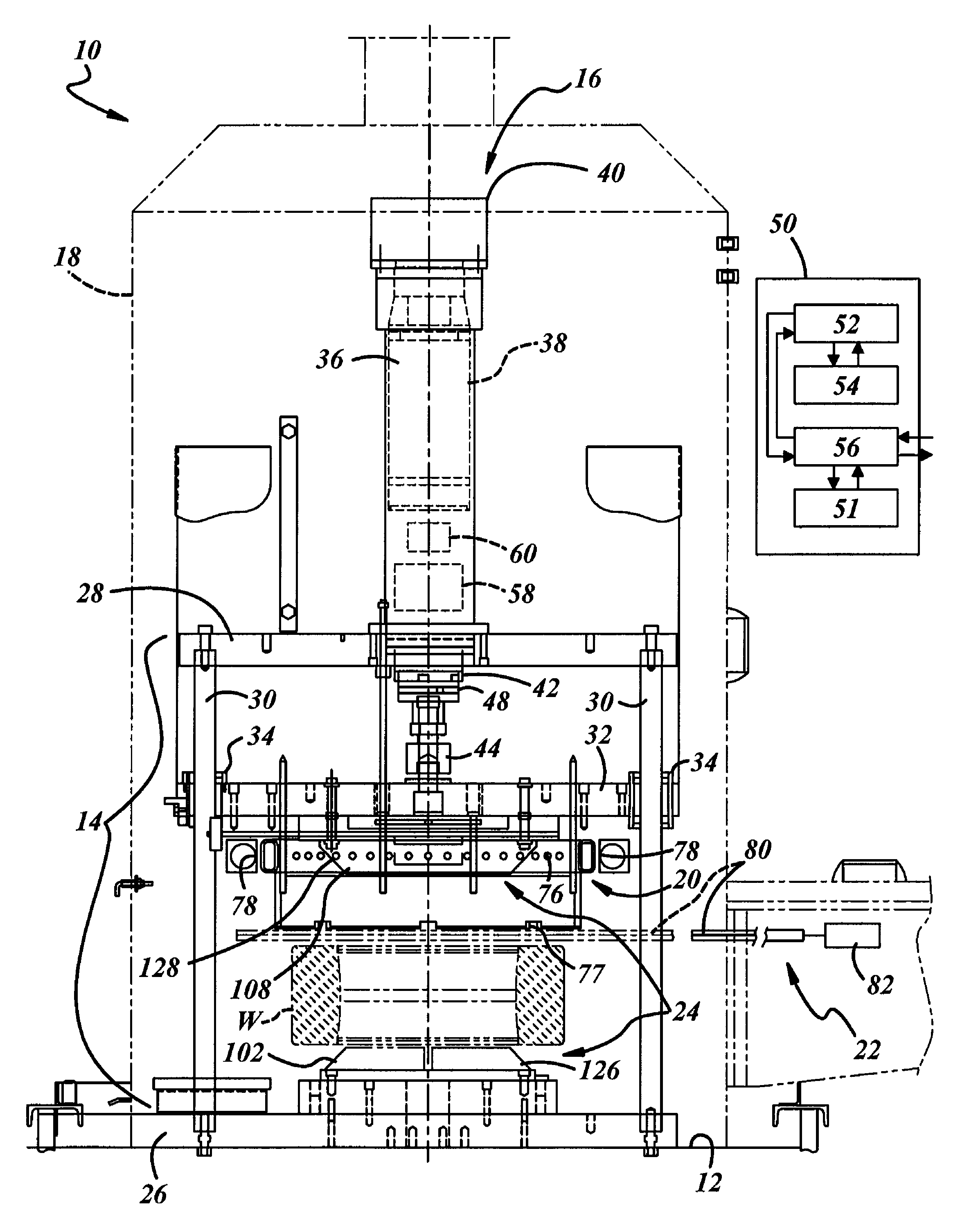

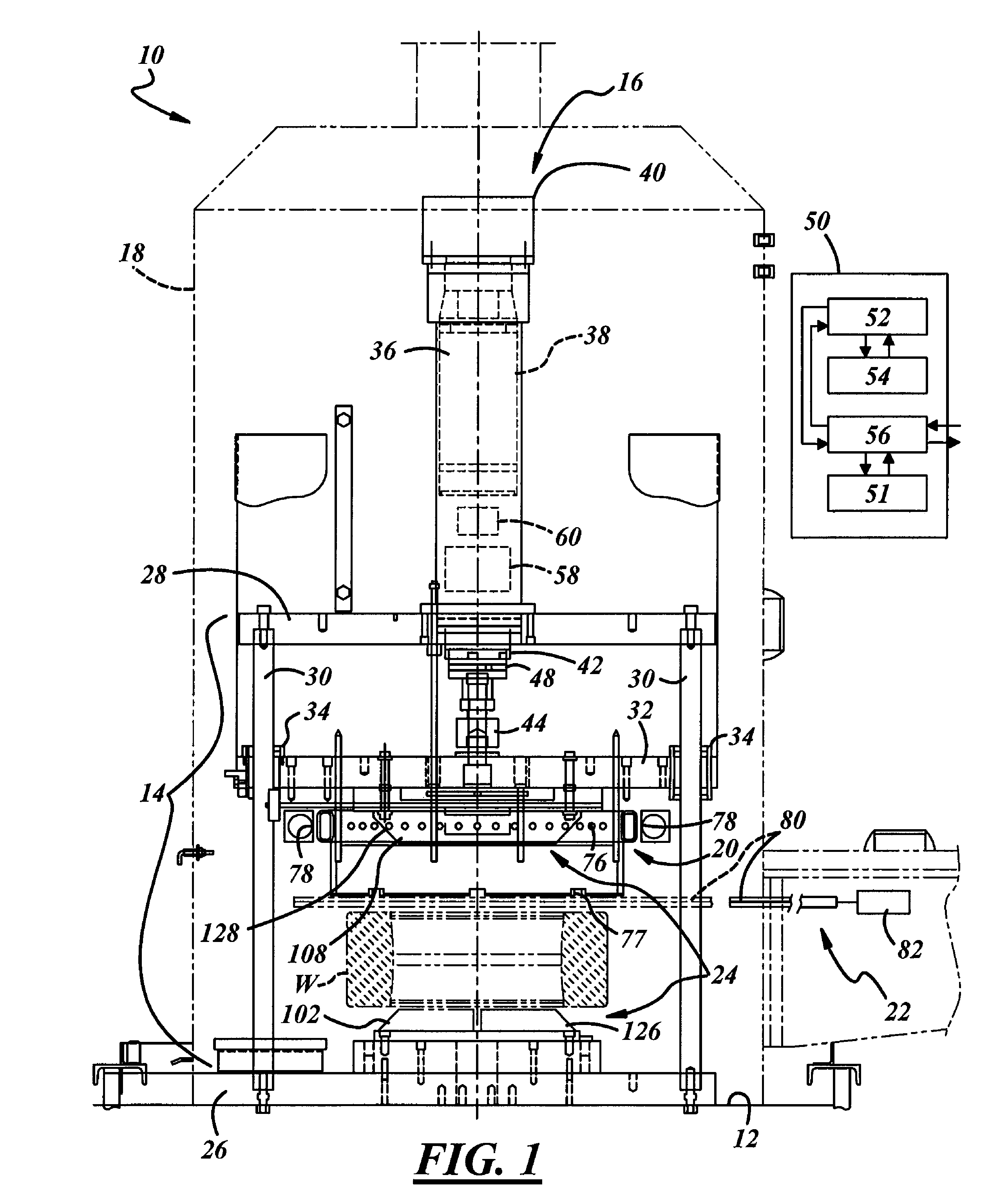

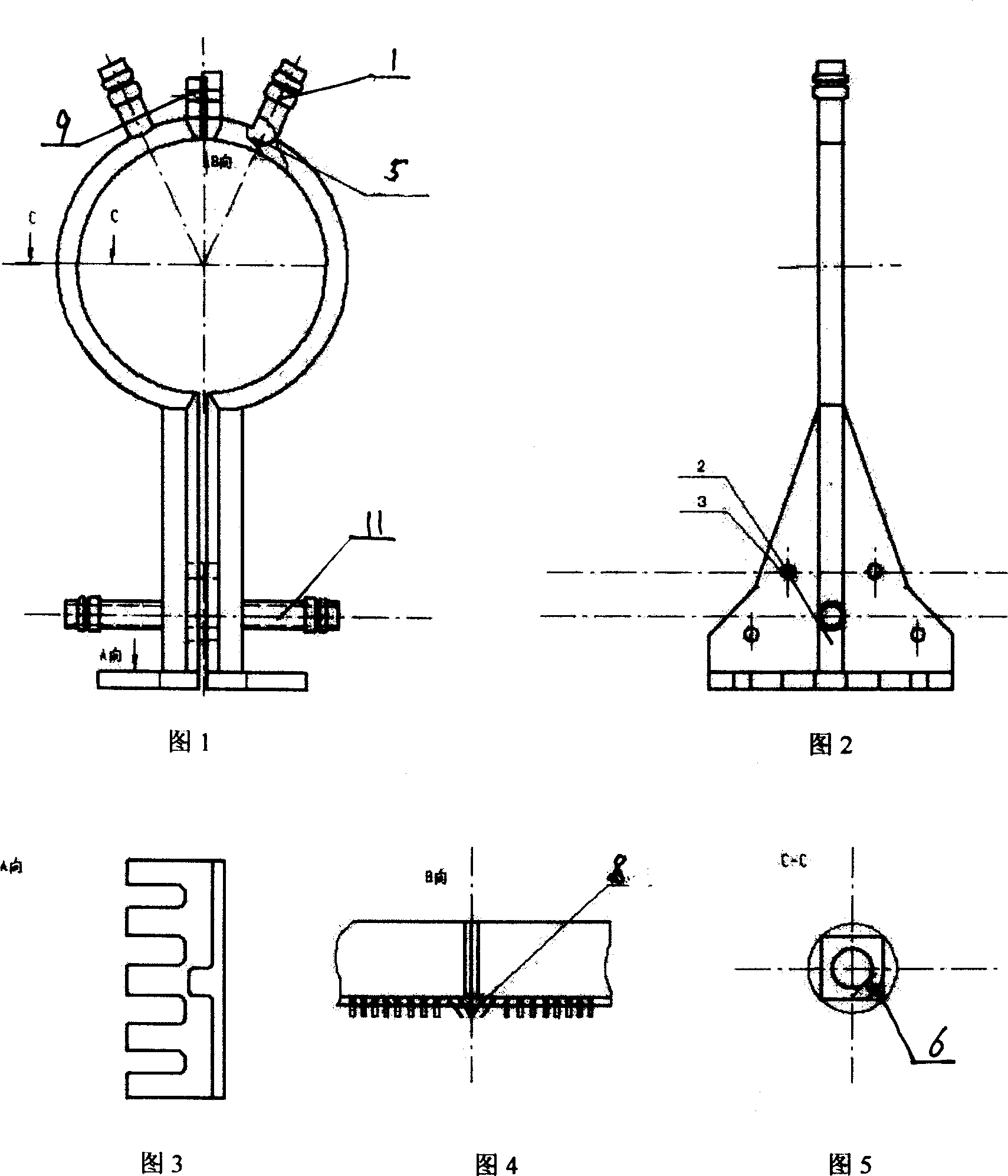

Quenching methods and apparatus

InactiveUS8034285B2Uniform quenchingReduce distortion problemsBearing componentsFurnace typesQuenchingMaterials science

One or more of the following quenching methods and apparatus: a quenching press for quenching a steel ring, a method of quenching a steel ring, a corresponding set of quenching dies for quenching steel rings, a die handling tool and related method to lift the corresponding set of quenching dies, and a die handling apparatus to load and unload dies to a quenching press.

Owner:STERLING ENG & MFG

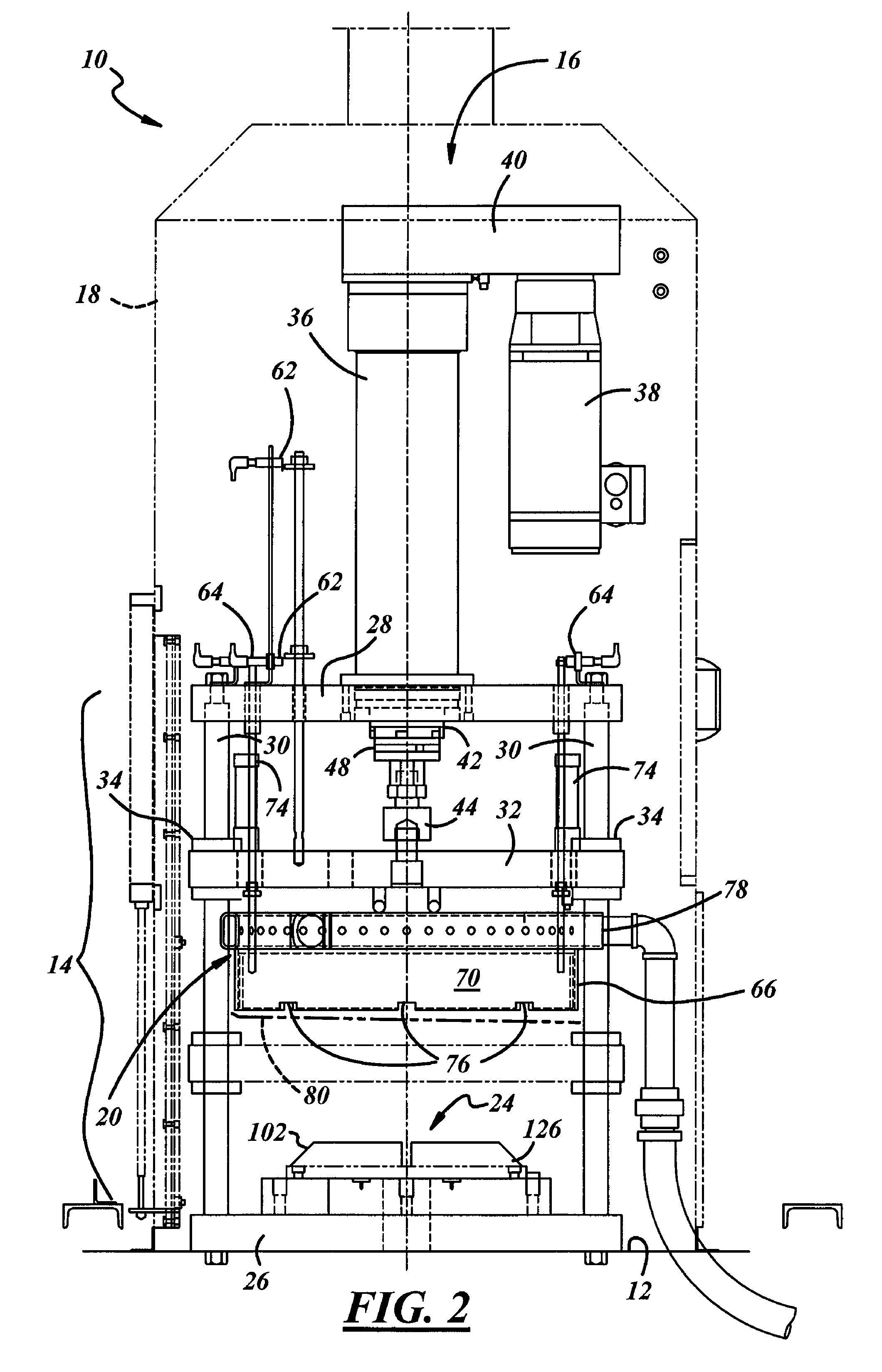

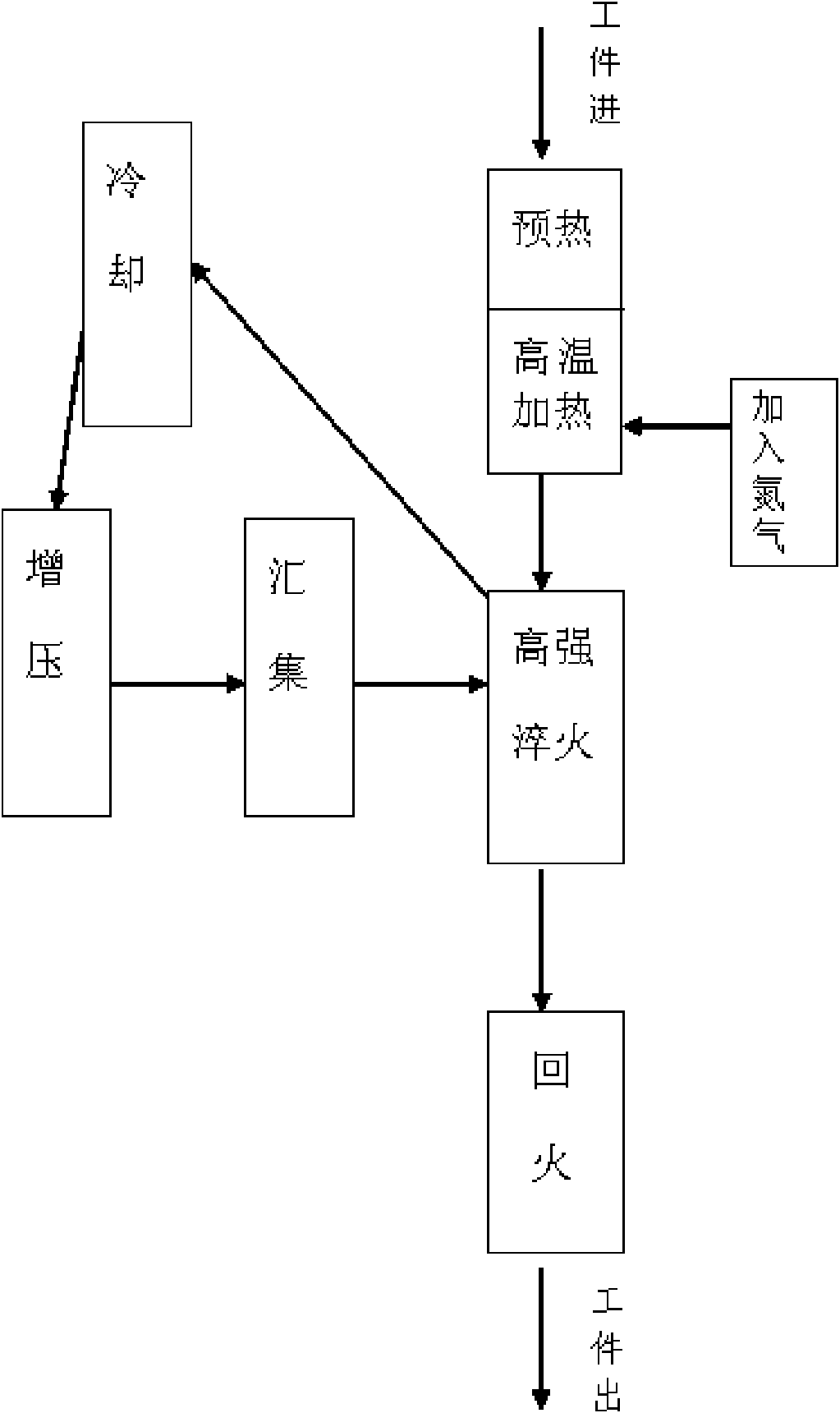

Heating processing technology for wear-resistant cutting board

ActiveCN101570819AHigh strengthIncrease productivityFurnace typesQuenching agentsQuenchingWear resistant

The invention relates to a heating processing technology of a wear-resistant cutting board, in which a shaped wear-resistant cutting board workpiece is preheated, heated under high temperature, and then is subjected to high-strength quenching and tempering. The technology comprises the following steps: A. preheating: the preheating temperature is 450-550 DEG C, and the preheating time is 0.5-1.125min / mm; B. high temperature heating: the temperature is 870-890 DEG C, and the holding time is 0.5-1.125min / mm; C. high-strength quenching: whole spray water time of high-strength quenching is 70-700 seconds, and time in intensified spray is 15-20 seconds; D. tempering: low temperature tempering is carried out, followed by air cooling to room temperature; high pressure cooling water used in the invention is recyclable. The invention has the advantages of making full use of reasonable heating processing technology under the premise of ensuring fine property of the wear-resistant cutting board, improving production efficiency and saving energy consumption, thus lowering production cost of the wear-resistant cutting board.

Owner:LIUZHOU JINMAO MACHINERY

100-260 mm-thick tempering-state prehardened plastic mold steel plate and manufacturing method thereof

ActiveCN107177796AImprove organizationImprove the quality of flaw detectionSheet steelChemical composition

The invention relates to a 100-260 mm-thick tempering-state prehardened plastic mold steel plate. The steel plate has the following chemical components in percentage by mass: 0.35-0.45 of C, 0.20-0.50 of Si, 0.60-1.00 of Mn, 1.00-2.50 of Cr, 0.20-0.50 of Mo, 0.04-0.15 of V+Ti, 0.01-0.04 of Als, 0.015 or less of P, 0.005 or less of S, and the balance of Fe and inevitable impurities; the steel plate is uniform in performance; the overall hardness difference is not more than 2.0 HRC; and the steel plate reaches NB / T47013.3 plate part I grade requirements by ultrasonic detection. The overall hardness difference is not more than 2.0 HRC; the steel plate reaches NB / T47013.3 plate part I grade requirements by ultrasonic detection; and the total inclusion grade is not higher than 2.5. The chemical components of the mold steel plate are simplified; the improvement is performed from the production process angle; the difference of the steel plate in the thickness direction is reduced; and in particular, the section hardness uniformity is improved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

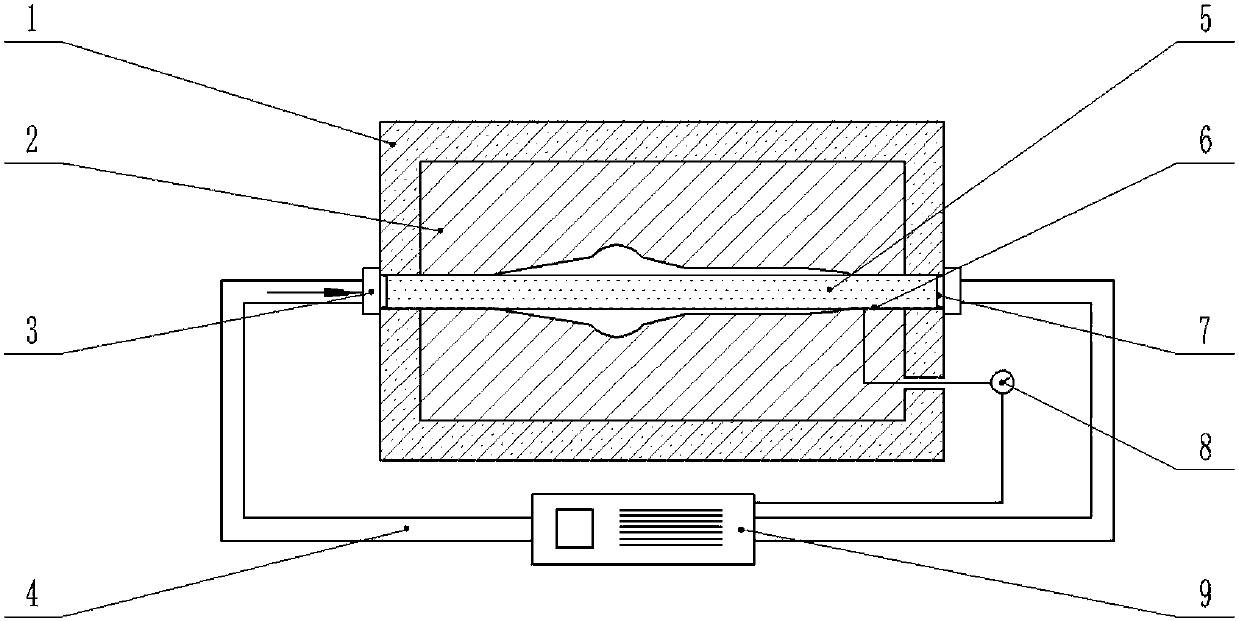

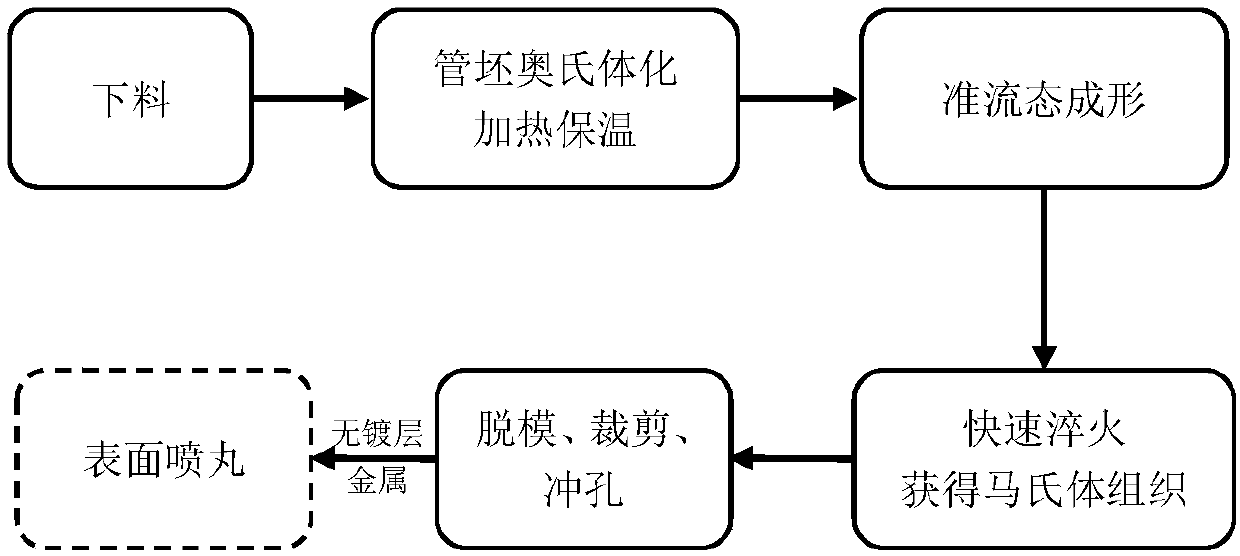

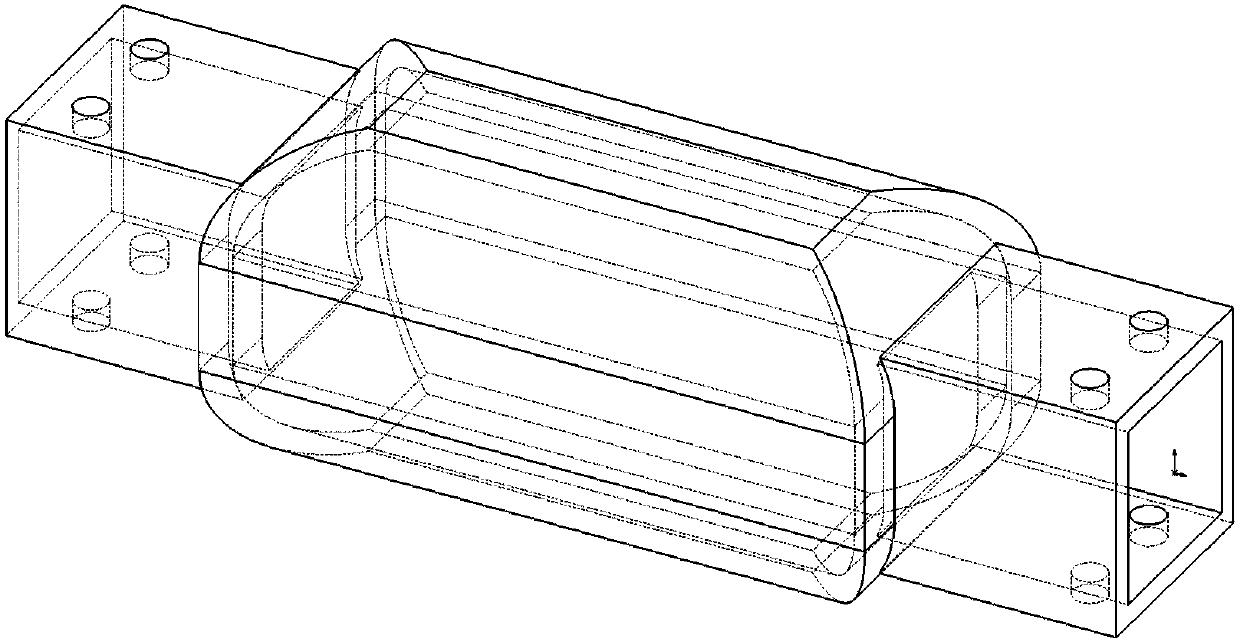

Quasi-flow-state rapid forming method for martensitic steel complicated tubular structure

ActiveCN107626767ASolve forming technical problemsMeet the urgent needs of the applicationFurnace typesHeat treatment furnacesPunchingMartensite

The invention discloses a quasi-flow-state rapid forming method and device for a martensitic steel complicated tubular structure, and belongs to the technical field of advanced manufacturing of metalcomplicated structures. The quasi-flow-state rapid forming method for the martensitic steel complicated tubular structure comprises the following steps: heating a tube until complete austenitizing isimplemented, then rapidly transferring the tube into a die, and carrying out die closing; after die closing is finished, rapidly filling a tube blank with a ceramic quasi-flow-state medium, and then pushing a propelling punch to enable a part, which is not subjected to die closing, of the tube to swell after filling is finished; and after complete die closing is finished, filling the tube with cooling water, and adjusting flow speed to enable a structure to be converted into martensite completely. After a forming process is finished, a final structure is obtained by operations such as cutting,punching and shot blasting. The quasi-flow-state medium is used for swelling of an inner wall, huge risks caused by gas swelling can be reduced, and the fatigue life is prolonged; and moreover, in the forming process, the thinning ratio of a tube wall is reduced, and the forming precision of the tube is high. The quasi-flow-state rapid forming method has good adaptability for forming of a key tubular structure of special equipment, and has high engineering application value.

Owner:NANJING INST OF TECH

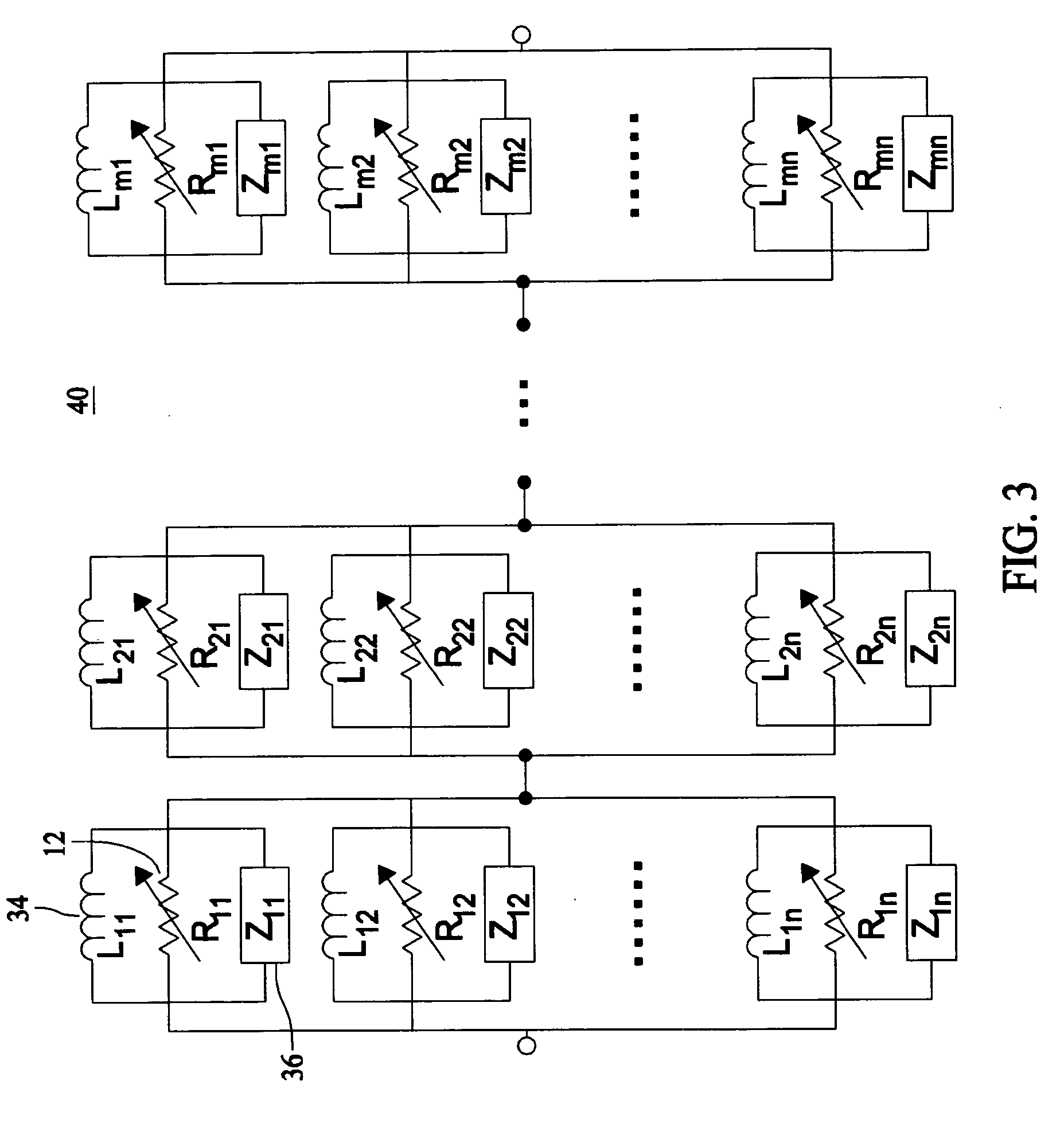

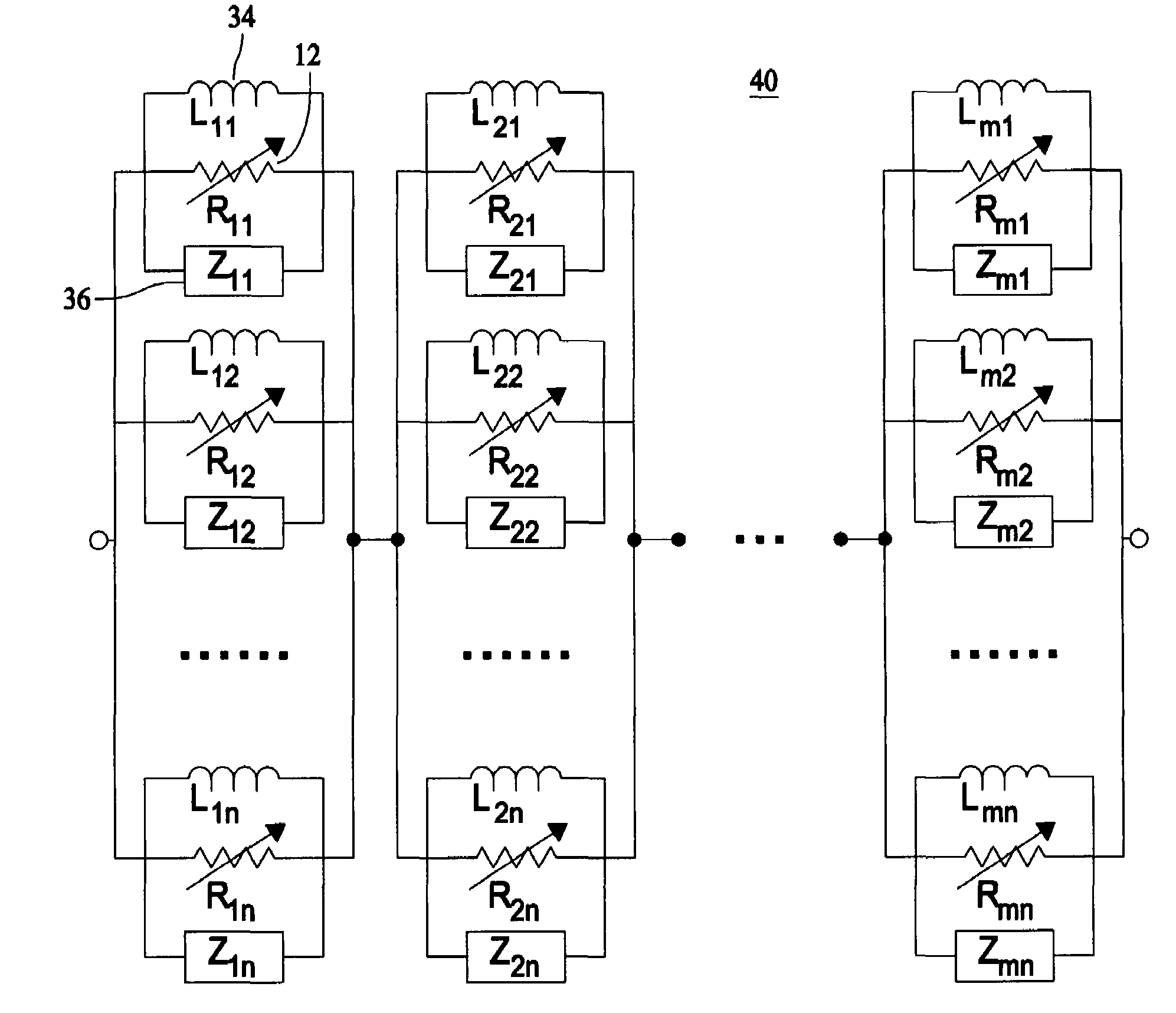

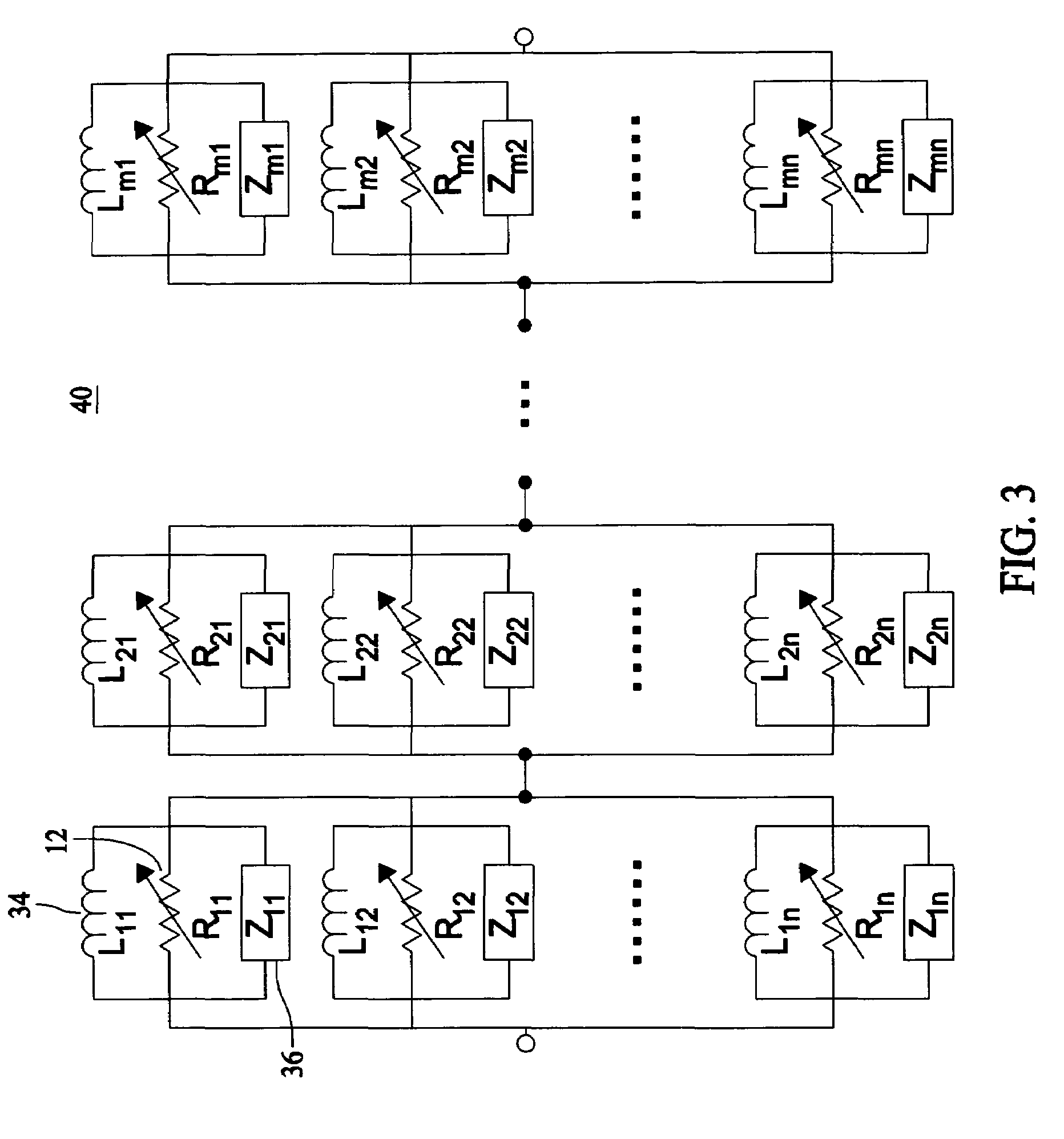

Self-triggering superconducting fault current limiter

InactiveUS20060221517A1Rapid quenchingIncrease flexibilityEmergency protective arrangements for automatic disconnectionEmergency protective arrangements for limiting excess voltage/currentElectrical resistance and conductanceElectricity

A modular and scaleable Matrix Fault Current Limiter (MFCL) that functions as a “variable impedance” device in an electric power network, using components made of superconducting and non-superconducting electrically conductive materials. The matrix fault current limiter comprises a fault current limiter module that includes a superconductor which is electrically coupled in parallel with a trigger coil, wherein the trigger coil is magnetically coupled to the superconductor. The current surge doing a fault within the electrical power network will cause the superconductor to transition to its resistive state and also generate a uniform magnetic field in the trigger coil and simultaneously limit the voltage developed across the superconductor. This results in fast and uniform quenching of the superconductors, significantly reduces the burnout risk associated with non-uniformity often exitsting within the volume of superconductor materials. The fault current limiter modules may be electrically coupled together to form various “n” (rows)דm” (columns) matrix configurations.

Owner:SUPERPOWER INC

Surface hardening treatment method for large-power low-speed diesel engine piston bar

ActiveCN101148688AHigh heating and quenching efficiencyImprove quenching efficiencyFurnace typesIncreasing energy efficiencyMicro structureLow speed

The surface hardening treatment process for piston rod of great power low speed diesel engine includes continuous surface heating to 900-940 deg.c in an intermediate frequency inducing heater of the quenching apparatus, quenching through spraying water, tempering through heating to 200-270 deg.c, and rotating the piston rod while heating in the inducing heater and spraying water. The present invention has high quenching efficiency, environment friendship, homogeneous heating and quenching, and capacity of reaching required surface hardness, quench hardened layer depth and micro structure.

Owner:DALIAN MARINE DIESEL

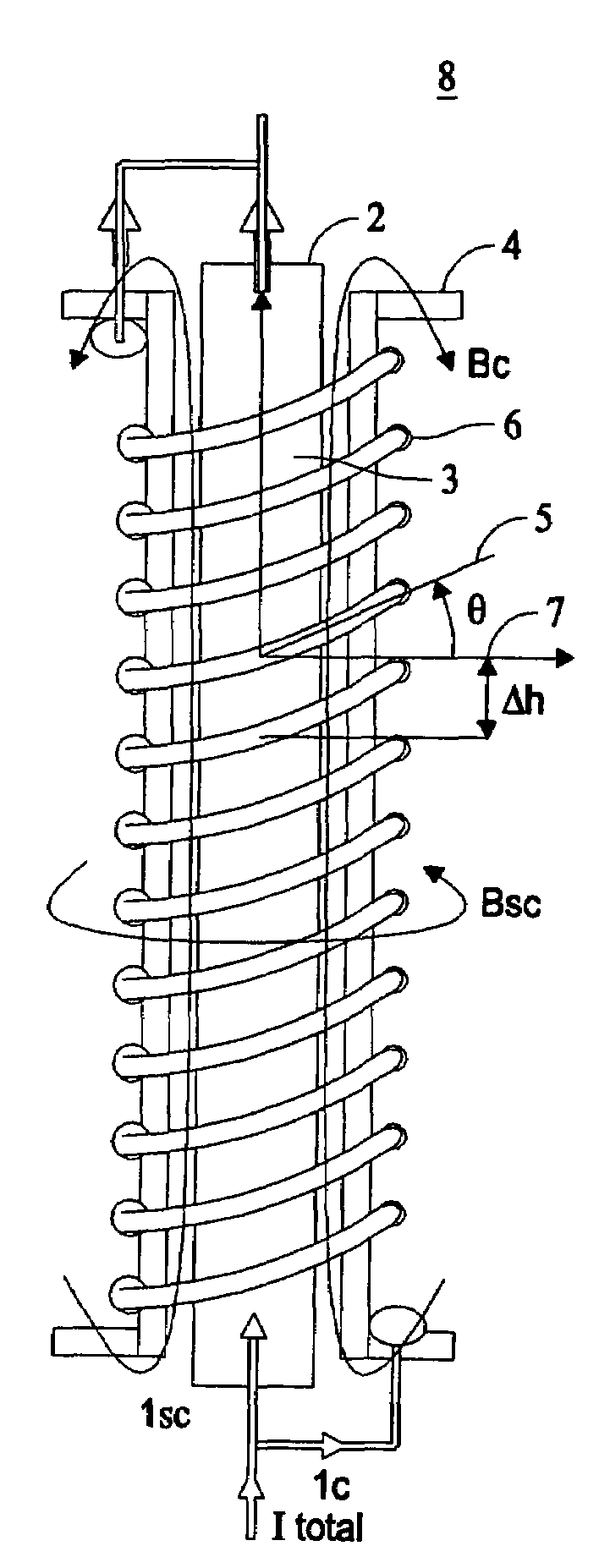

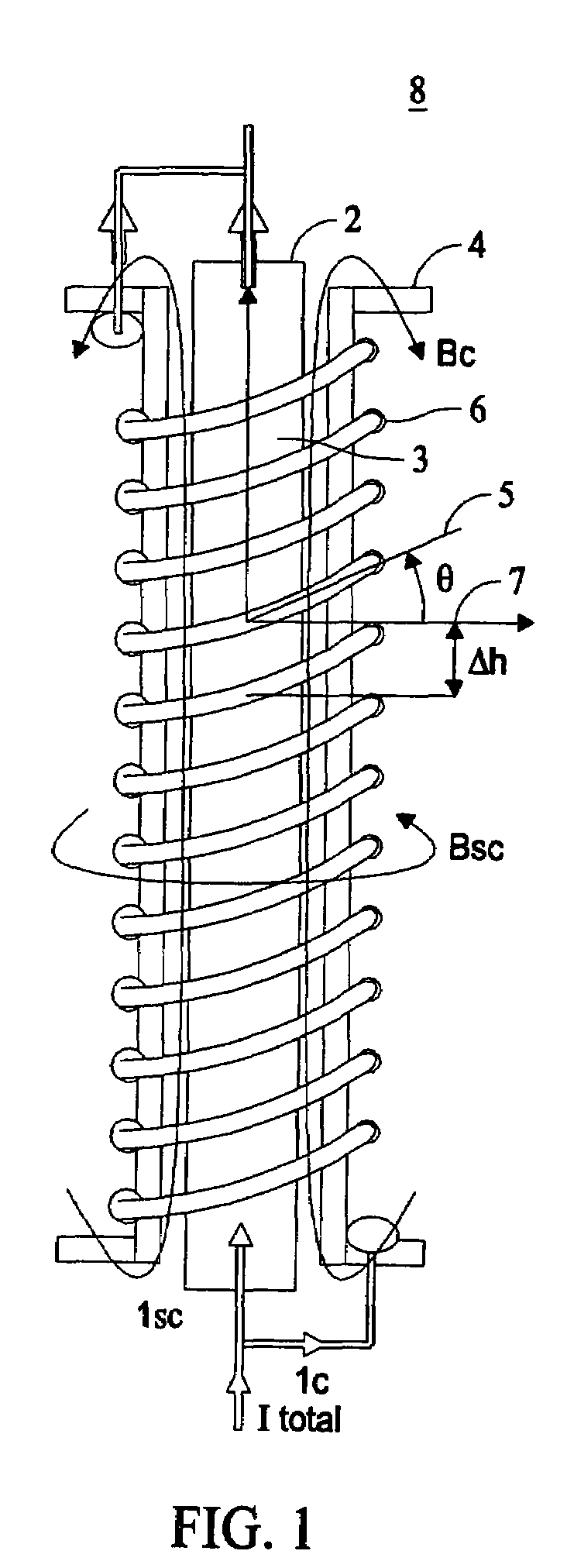

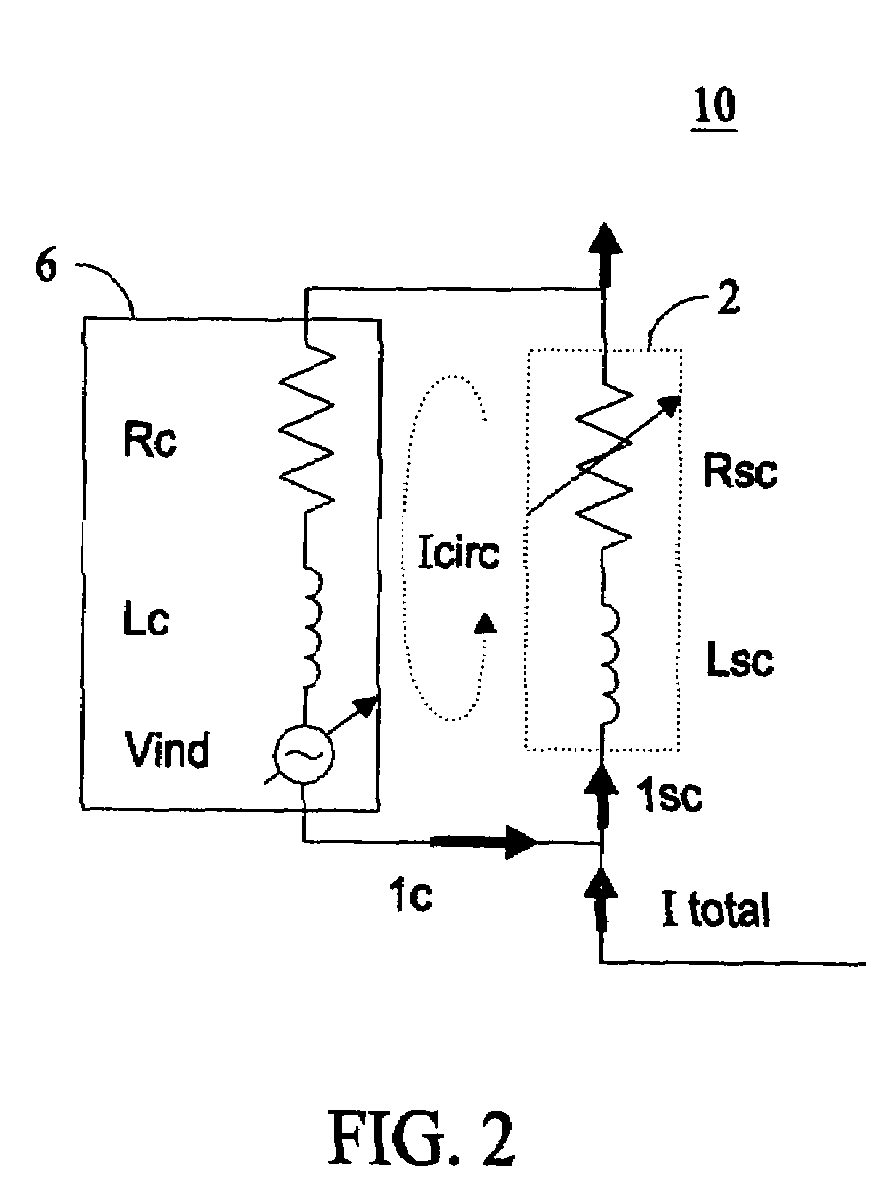

Superconducting FCL using a combined inducted magnetic field trigger and shunt coil

InactiveUS20060274458A1Less complexImprove equipment reliabilityNormal-superconductive switchable devicesEmergency protective arrangements for limiting excess voltage/currentShunt impedanceHigh temperature superconducting

A single trigger / shunt coil is utilized for combined induced magnetic field triggering and shunt impedance. The single coil connected in parallel with the high temperature superconducting element, is designed to generate a circulating current in the parallel circuit during normal operation to aid triggering the high temperature superconducting element to quench in the event of a fault. The circulating current is generated by an induced voltage in the coil, when the system current flows through the high temperature superconducting element.

Owner:SUPERPOWER INC

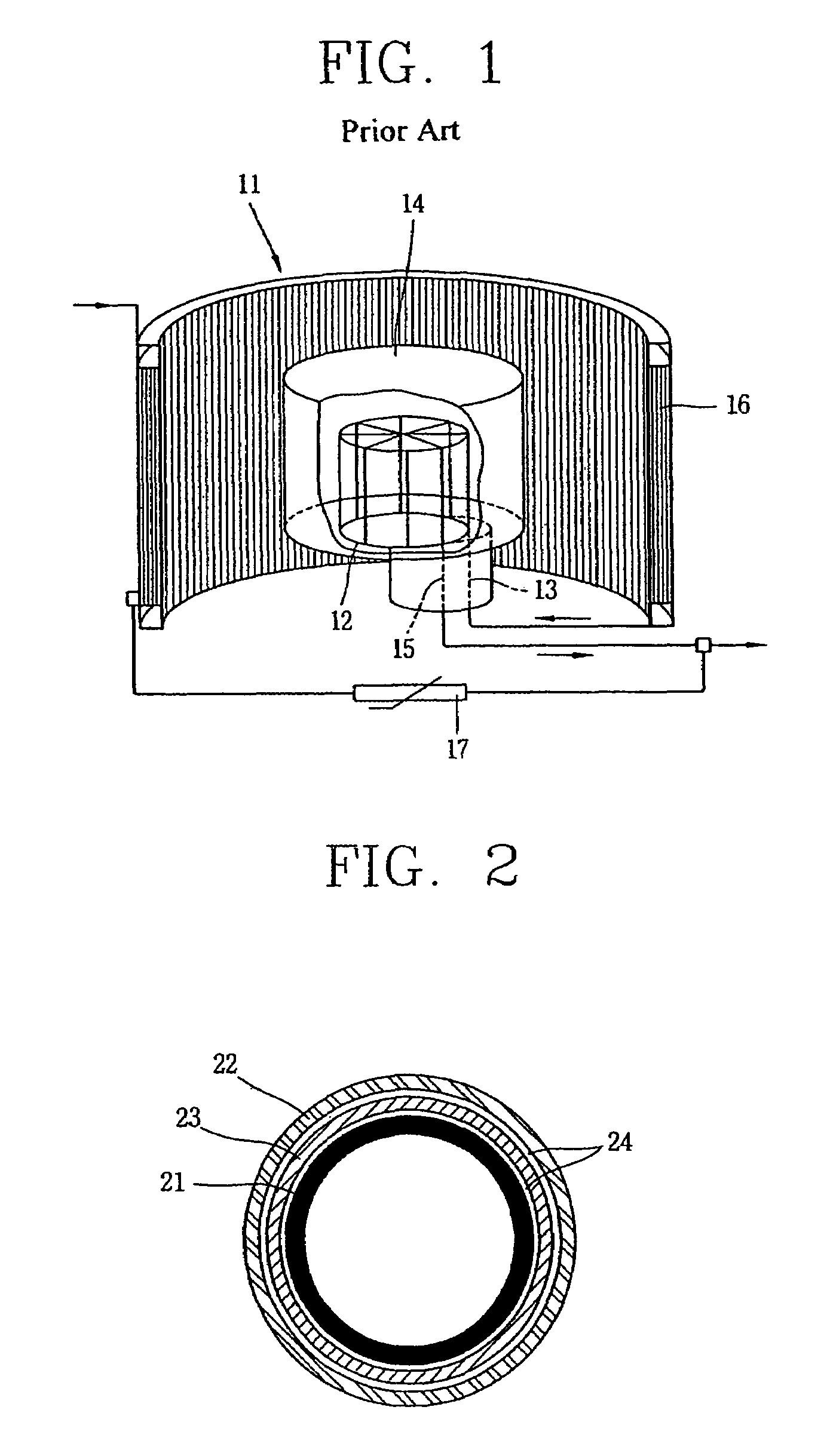

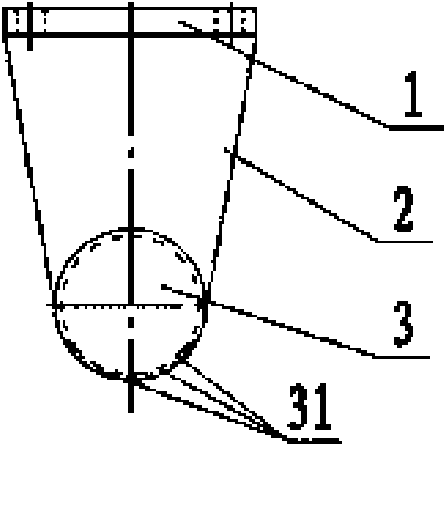

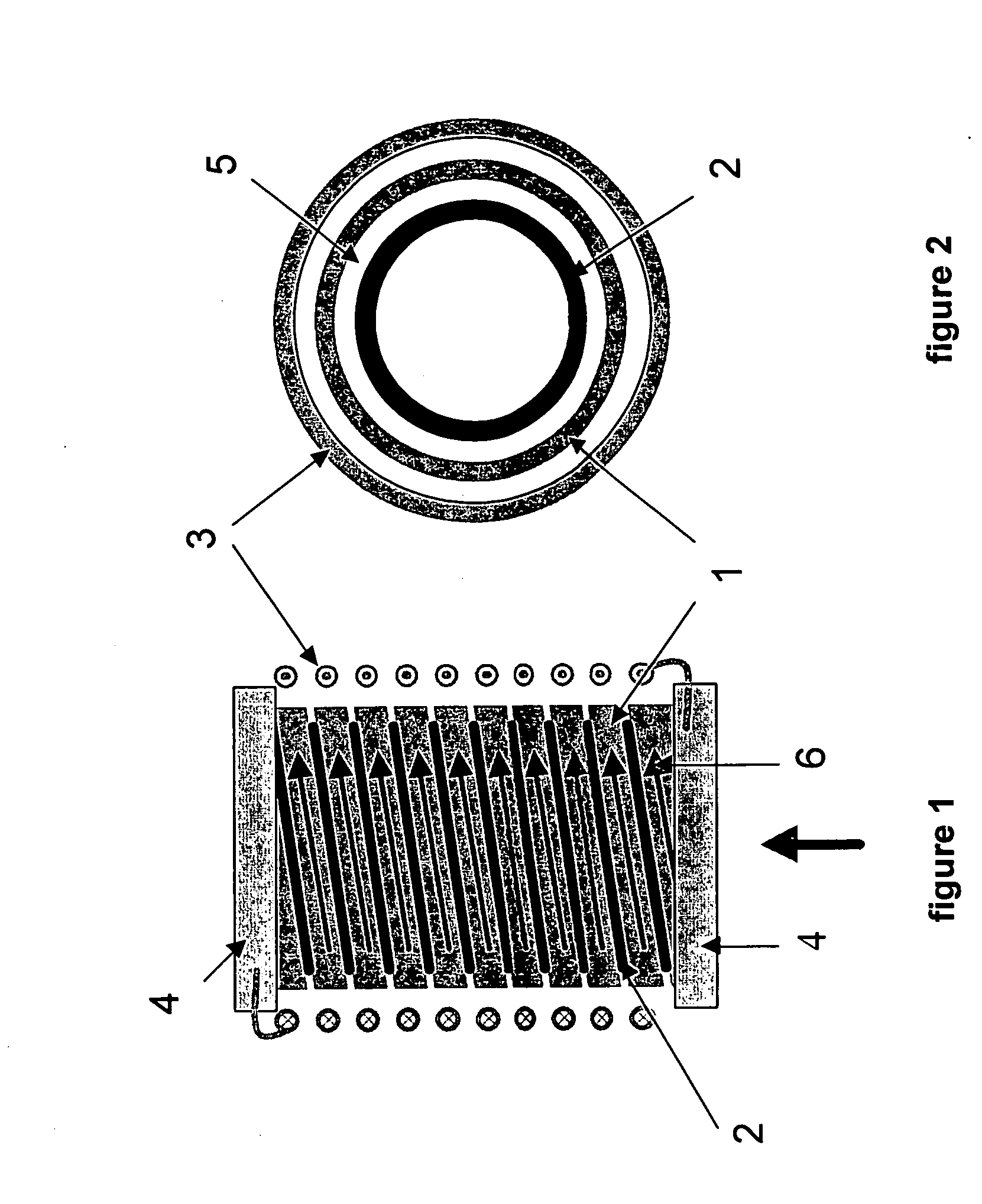

Compact superconducting current limiting component in coil configuration with low inductance

InactiveUS20060217269A1Easily insulateSimpler and cheapSuperconductors/hyperconductorsSemiconductor/solid-state device detailsSelf triggeringHollow cylinder

The present invention is directed to a superconducting current limiting component, particularly to a ceramic high temperature superconducting current limiting component which is self triggering, comprising a coil (1) made of ceramic high temperature superconductor material, wherein around the outer surface of the coil (1) made of ceramic high temperature superconductor material a second coil (3) is applied as a shunt and, preferably, wherein the coil (1) made of ceramic high temperature superconductor material is applied onto a hollow cylindrical body (2) made of a ceramic high temperature superconductor material.

Owner:NEXANS

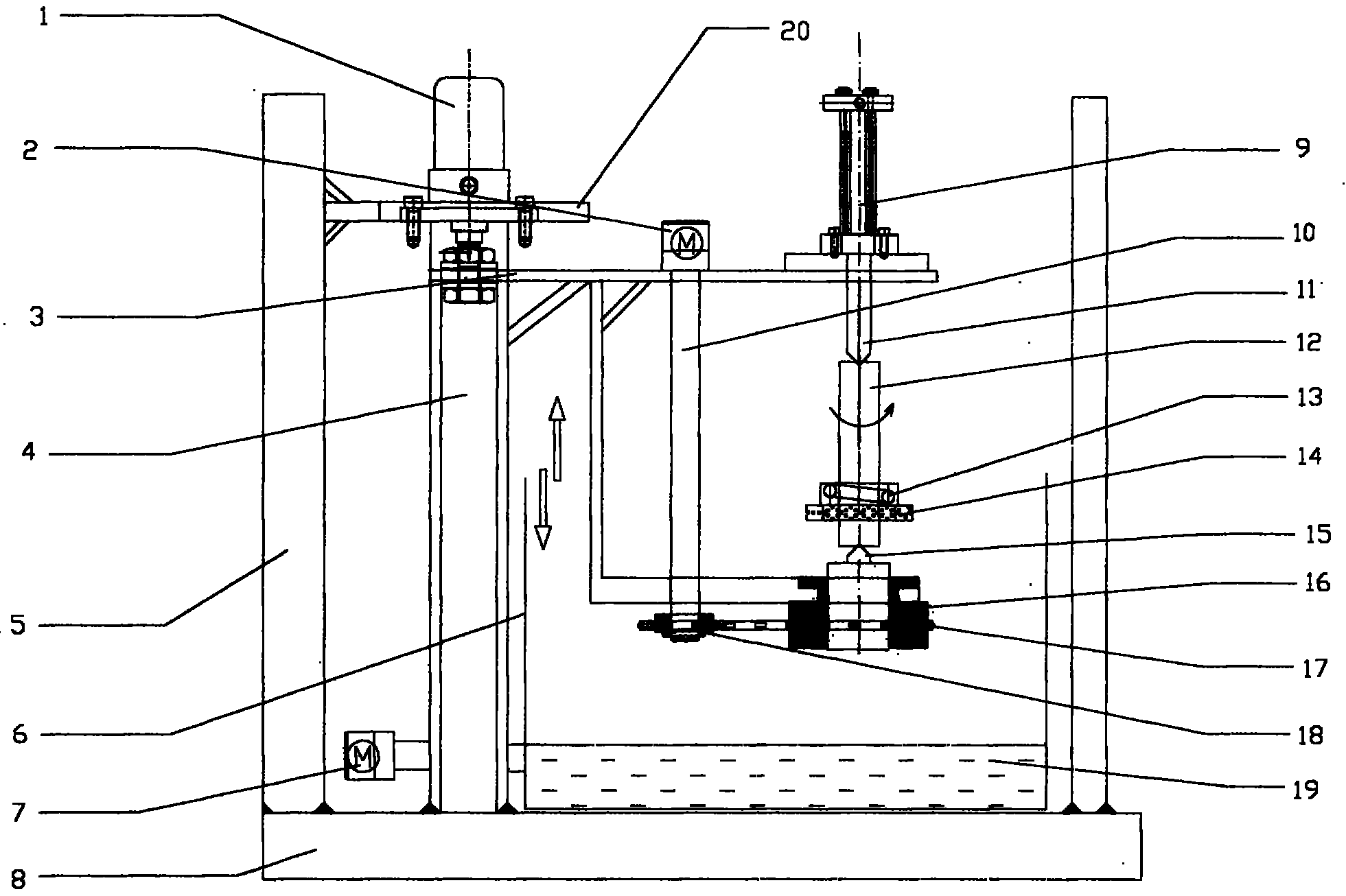

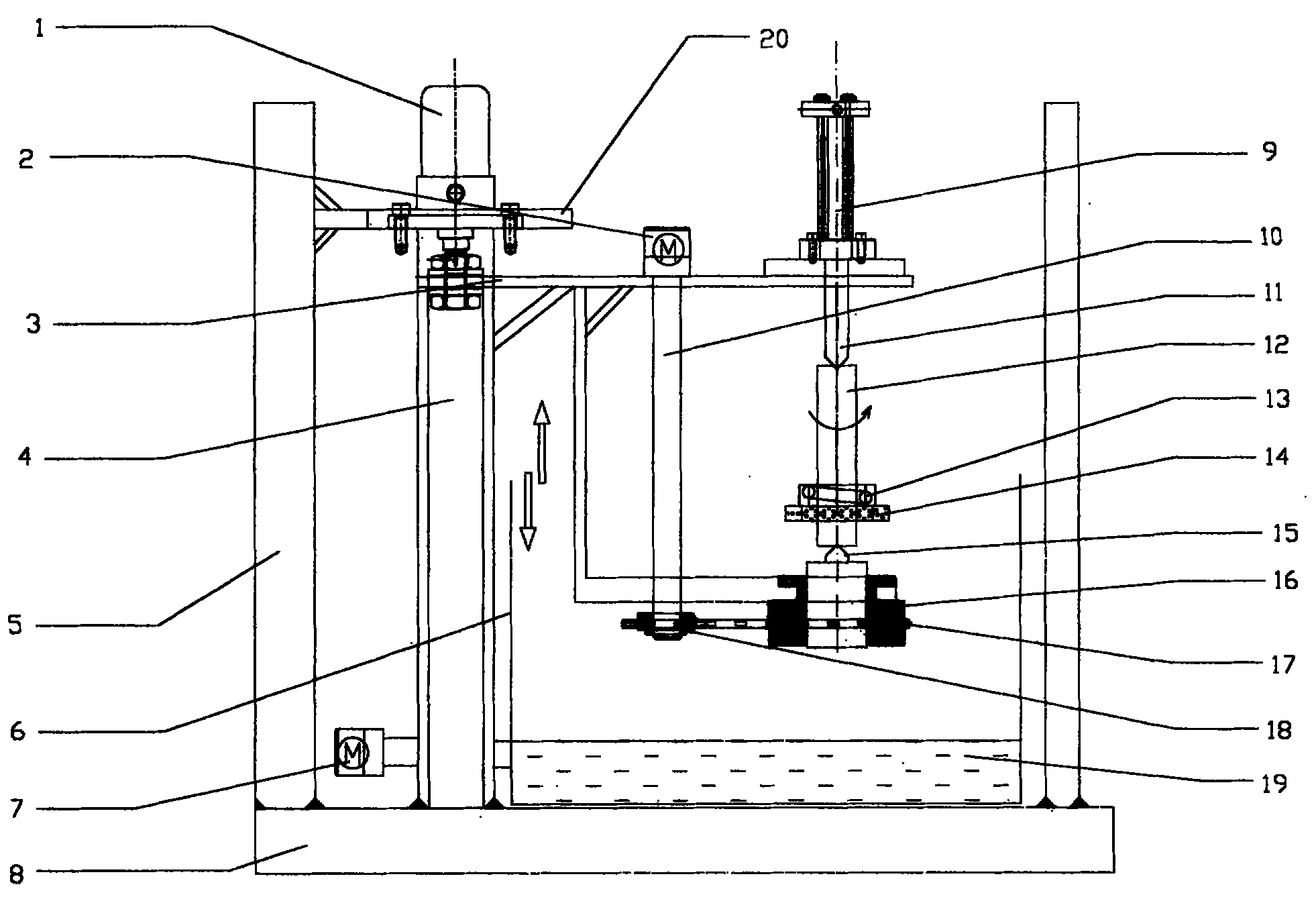

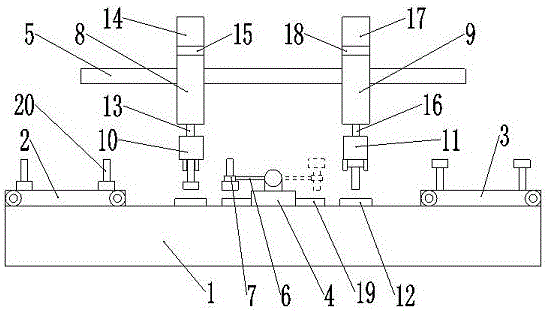

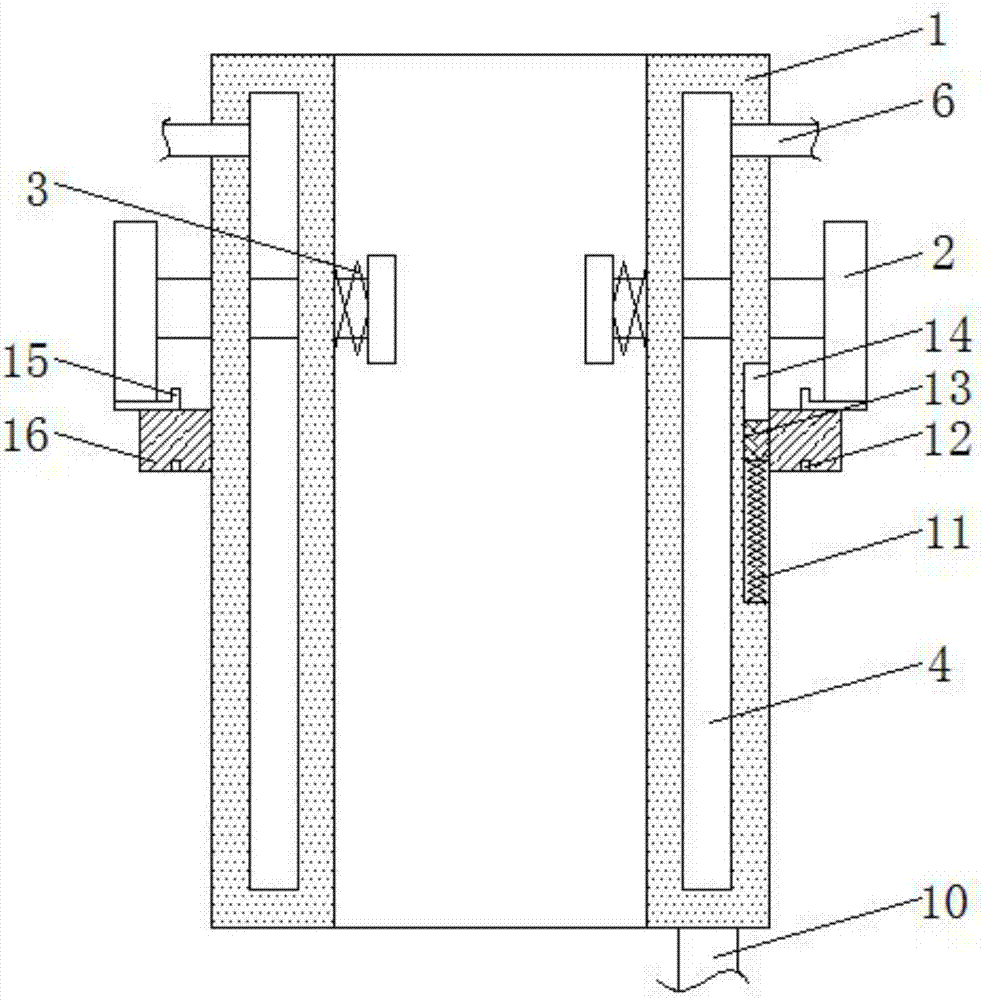

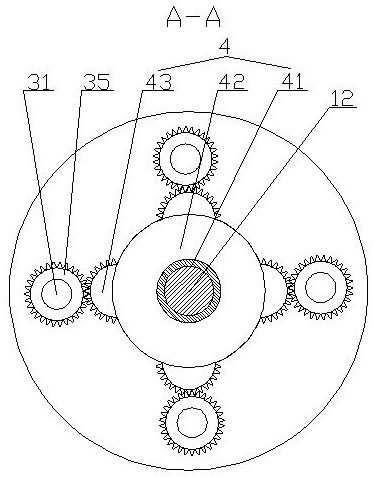

High-frequency surface quenching machine

ActiveCN101892364AUniform quenchingEasy to assemble and disassembleIncreasing energy efficiencyQuenching devicesDrive shaftHardness

The invention discloses a high-frequency surface quenching machine and relates to a processing and heat treatment device. The high-frequency surface quenching machine comprises a base, a support, a self-rotating motor, a high frequency machine and a water tank, and is characterized in that a lifting lead screw is arranged on the base, a lifting motor is arranged on the lifting lead screw, the lifting motor can control a lifting sliding plate to slide on the lifting lead screw, a material-jacking cylinder and the self-rotating motor are arranged above the lifting sliding plate, the lower end of the material-jacking cylinder is connected with an upper tip, the self-rotating cylinder is connected with a transmission shaft, a small belt wheel is arranged at the bottom end of the transmission shaft, the small belt wheel is connected with a big belt wheel through a belt, a lower tip is arranged above the big belt wheel, and a water spray head and a high-frequency heating coil are arranged between the upper tip and the lower tip. The high-frequency surface quenching machine can solve the problem of non-uniform quenching hardness of the surface of a workpiece of the high-frequency surface quenching machine in the prior art, has low cost and convenient use and can ensure the uniform quenching of the surface of the workpiece.

Owner:JOUDER PRECISION INDAL KUSN

Self-triggering superconducting fault current limiter

InactiveUS7440244B2Rapid quenchingIncrease flexibilityEmergency protective arrangements for automatic disconnectionEmergency protective arrangements for limiting excess voltage/currentConductive materialsQuenching

A modular and scaleable Matrix Fault Current Limiter (MFCL) that functions as a “variable impedance” device in an electric power network, using components made of superconducting and non-superconducting electrically conductive materials. The matrix fault current limiter comprises a fault current limiter module that includes a superconductor which is electrically coupled in parallel with a trigger coil, wherein the trigger coil is magnetically coupled to the superconductor. The current surge doing a fault within the electrical power network will cause the superconductor to transition to its resistive state and also generate a uniform magnetic field in the trigger coil and simultaneously limit the voltage developed across the superconductor. This results in fast and uniform quenching of the superconductors, significantly reduces the burnout risk associated with non-uniformity often existing within the volume of superconductor materials. The fault current limiter modules may be electrically coupled together to form various “n” (rows)דm” (columns) matrix configurations.

Owner:SUPERPOWER INC

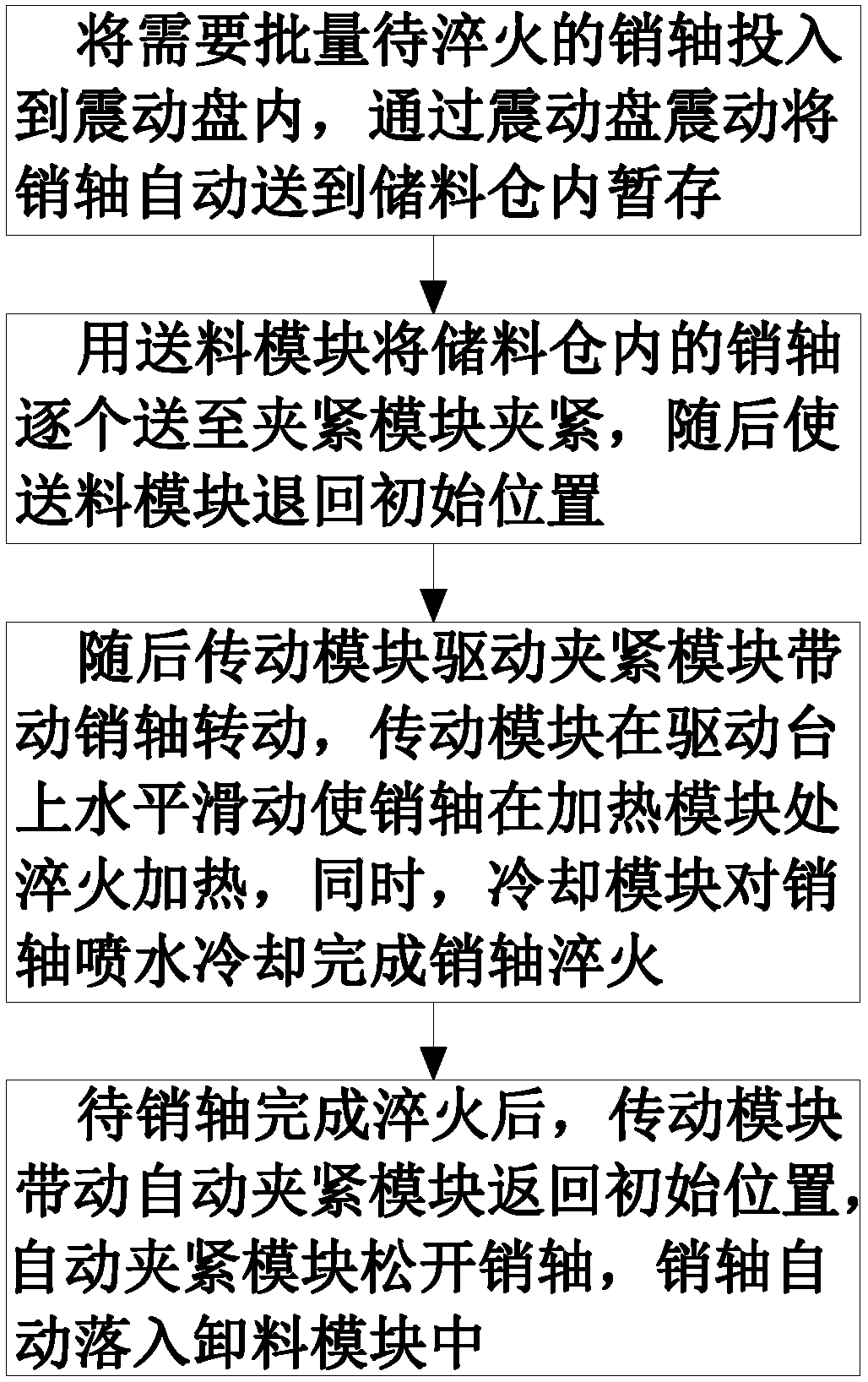

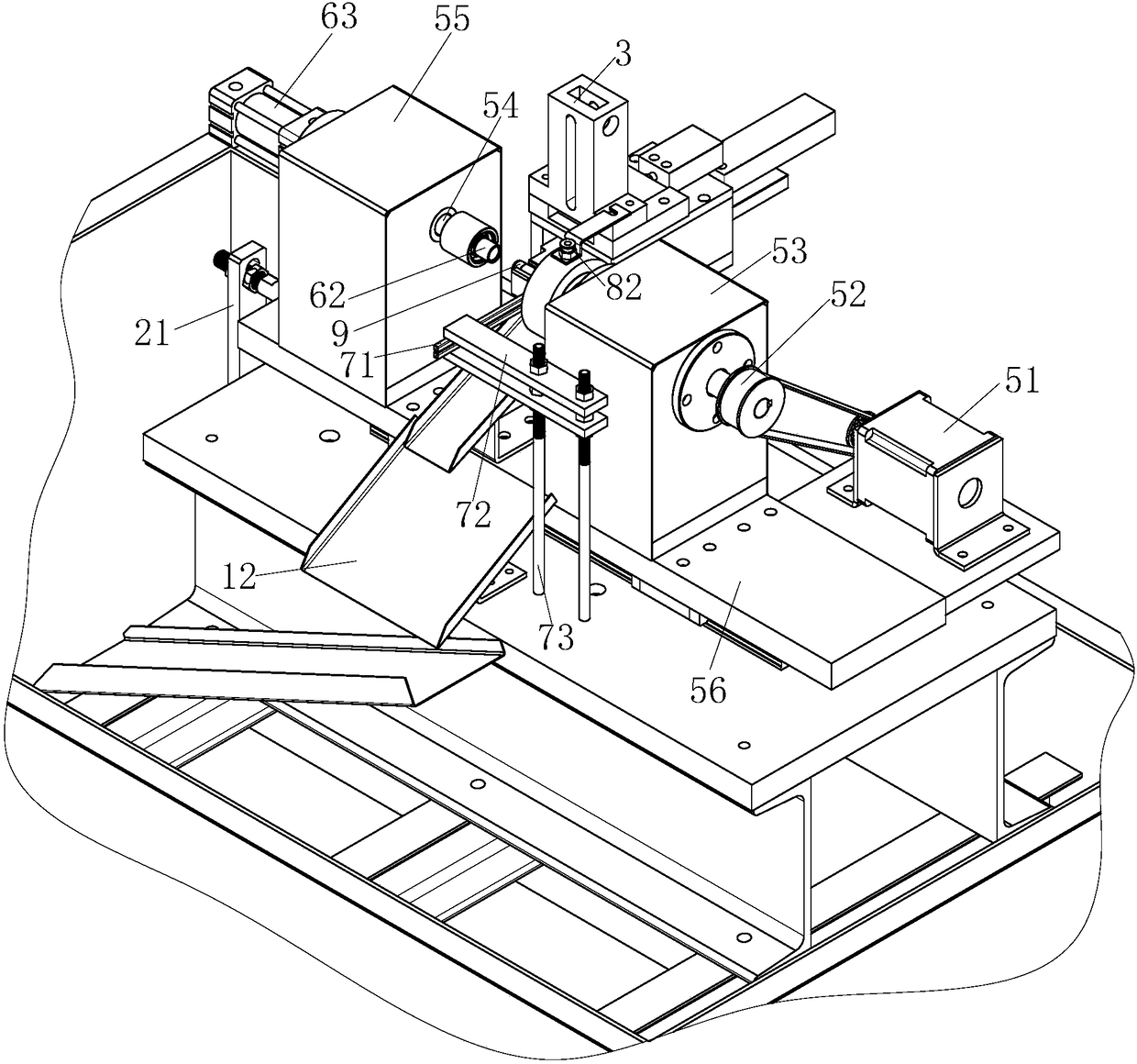

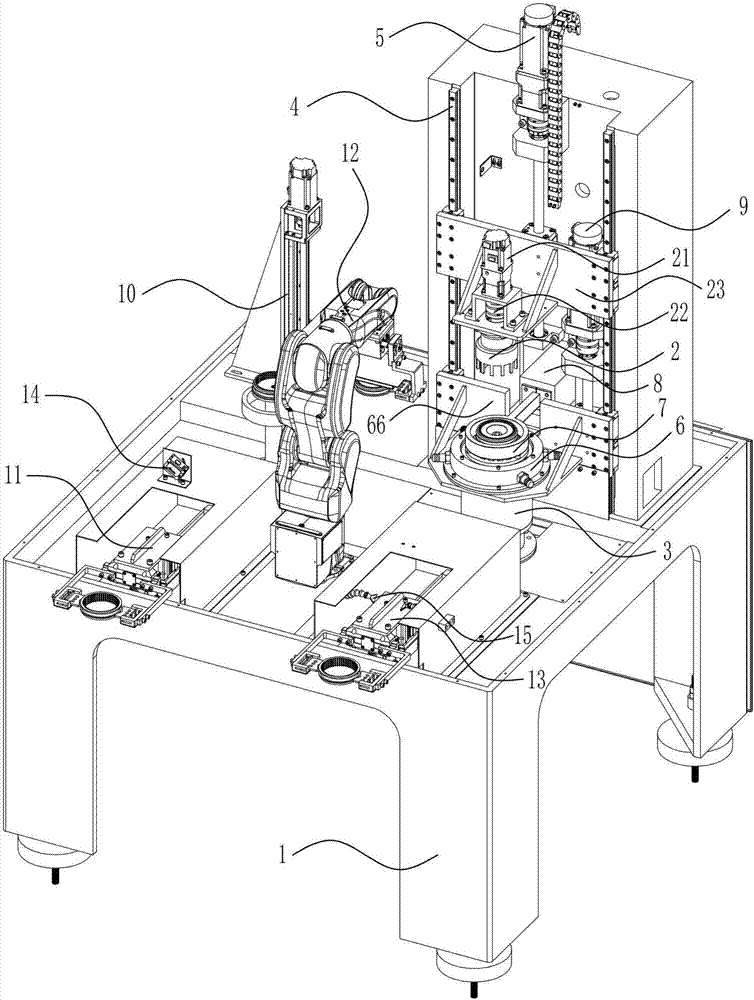

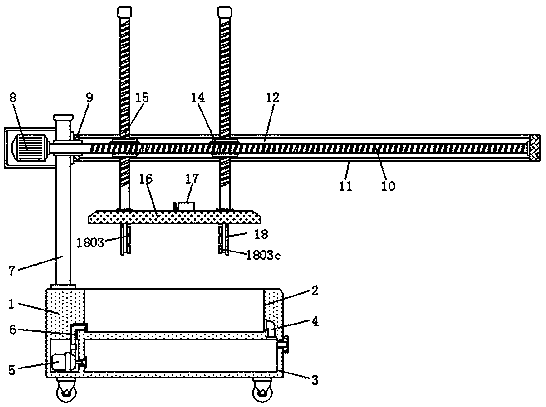

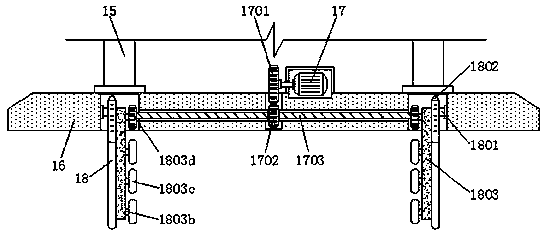

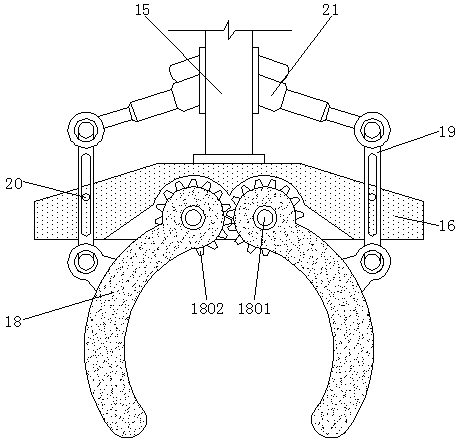

Automatic quenching machine tool

ActiveCN105821188AImprove quenching effectImprove quenching qualityFurnace typesHeat treatment furnacesQuenchingManipulator

The invention discloses an automatic quenching machine tool comprising a machine tool main body, wherein the machine tool main body is provided with a servo system. The automatic quenching machine tool is characterized in that a feeding device is arranged at the left side of the machine tool main body; a discharging device is arranged at the right side of the machine tool main body; a turnover seat controlled by the servo system is arranged in the middle of the machine tool main body; a beam is arranged right above the machine tool main body; the turnover seat is provided with a rotating arm by which turnover manipulators are educed; the beam is provided with a left sliding seat and a right sliding seat which are controlled by the servo system; the lower end of the left sliding seat is provided with a left manipulator adapted to the feeding device; the lower end of the right sliding seat is provided with a right manipulator adapted to the discharging device; and the machine tool main body is provided with a quenching system adapted to the left manipulator and the right manipulator. The automatic quenching machine tool has the very remarkable beneficial effects of high work efficiency, automatic double-station quenching of workpieces, good quenching effect and quality and wide application range.

Owner:WONH IND

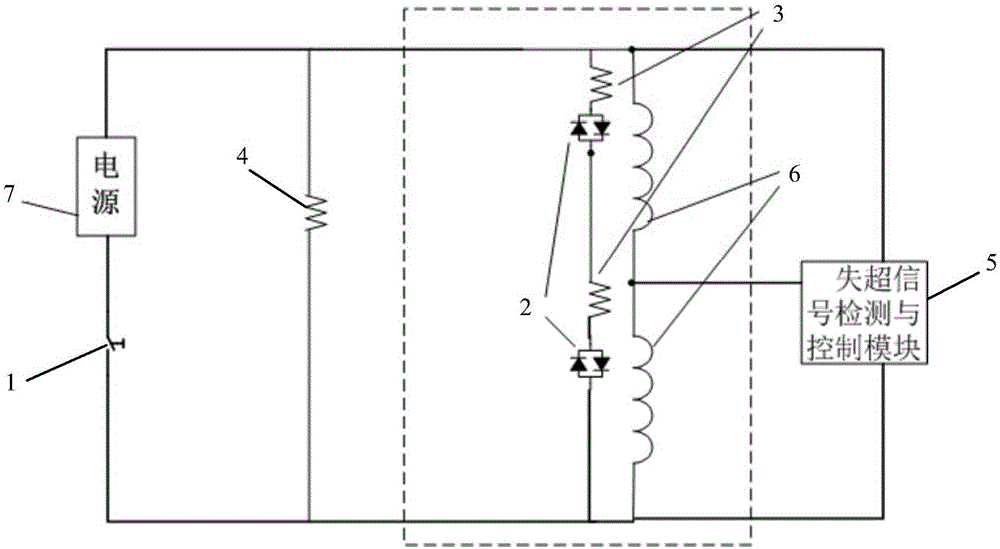

Quench protection method based on internal protection and external protection for 230 MeV superconducting cyclotron superconducting coil

ActiveCN106356813AReduce the maximum temperature riseUniform quenchingEmergency protective circuit arrangementsSuperconductor elements usageElectrical resistance and conductanceComputer module

The invention relates to a quench protection method based on internal protection and external protection for a 230 MeV superconducting cyclotron superconducting coil; a connection line for a superconducting exciting coil and a power supply is provided with a quench protection control switch, two ends of the superconducting exciting coil are connected with external protection resistors, the superconducting exciting coil is also parallelly connected with an internal protection cold diode set, the internal protection cold diode set is connected with a quench heater, and a quench signal detection and control module is connected respectively with the superconducting exiting coil and the quench protection control switch. According to the method, the internal protection cold diode set is used to clamp coil quench voltage, so that the problem that the sole use of a large external protection resistance coil leads to excessively high quench voltage is solved; the coil is evenly quenched by using the embedded heater, and highest temperature rise in the superconducting coil is decreased; chances for the cyclotron superconducting exciting coil to damage upon quenching may be greatly slimmed.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

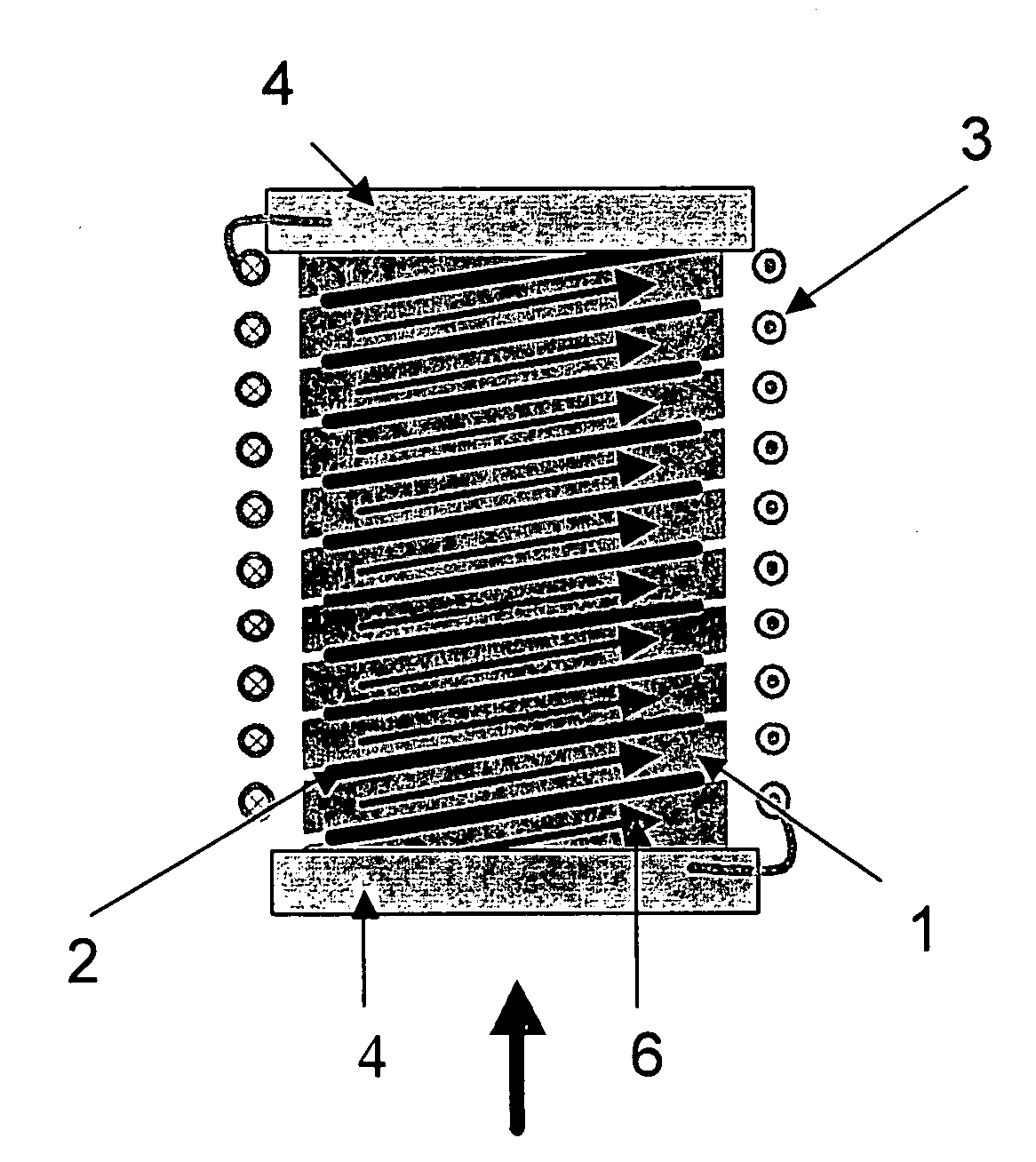

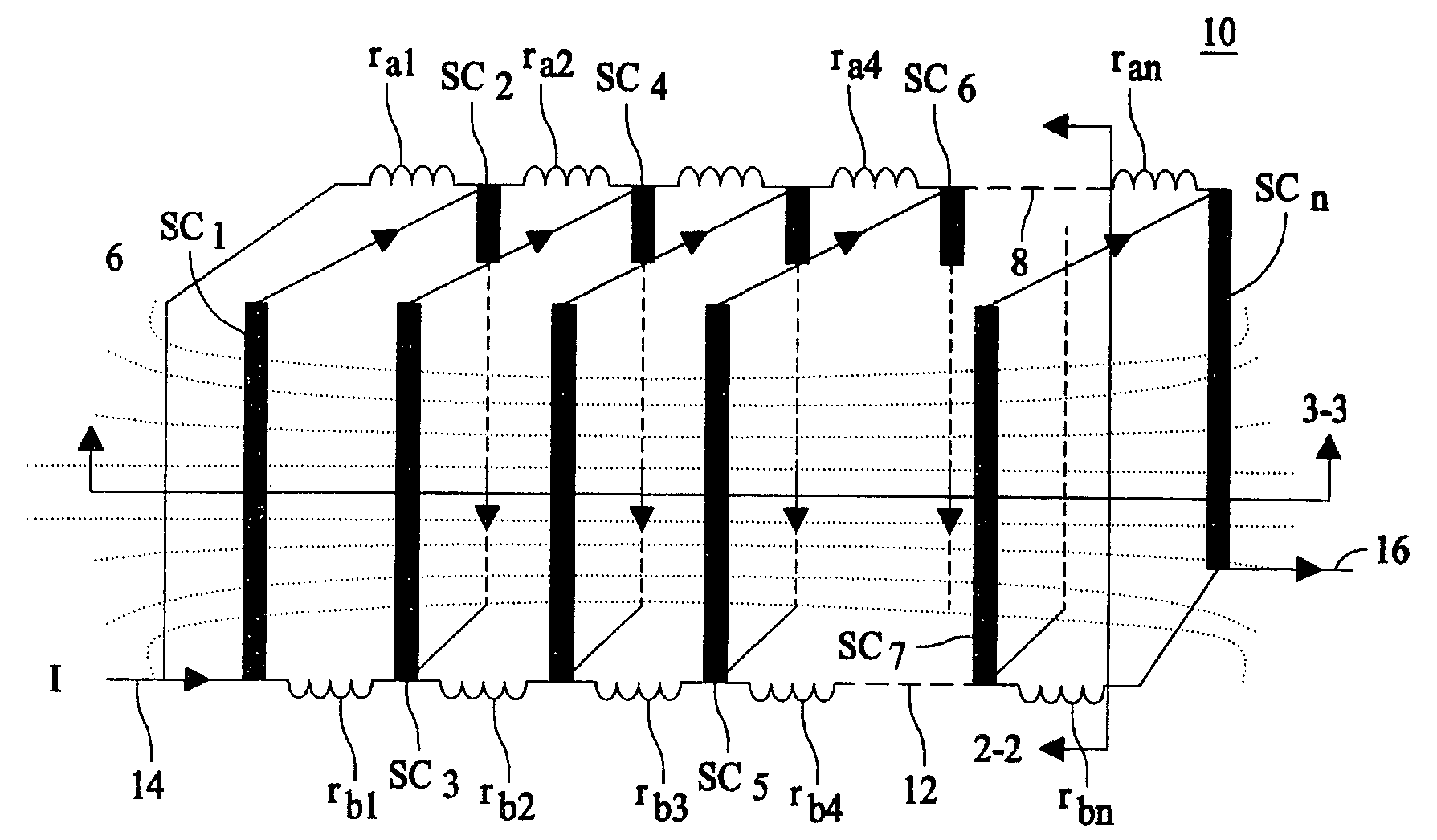

Self field triggered superconducting fault current limiter

InactiveUS20060279388A1Improve equipment reliabilityIncreased complexityMagnetsMagnetic materialsElectrical conductorSuperconducting fault current limiters

A superconducting fault current limiter array with a plurality of superconductor elements arranged in a meanding array having an even number of supconductors parallel to each other and arranged in a plane that is parallel to an odd number of the plurality of superconductors, where the odd number of supconductors are parallel to each other and arranged in a plane that is parallel to the even number of the plurality of superconductors, when viewed from a top view. The even number of superconductors are coupled at the upper end to the upper end of the odd number of superconductors. A plurality of lower shunt coils each coupled to the lower end of each of the even number of superconductors and a plurality of upper shunt coils each coupled to the upper end of each of the odd number of superconductors so as to generate a generally orthoganal uniform magnetic field during quenching using only the magenetic field generated by the superconductors.

Owner:SUPERPOWER INC

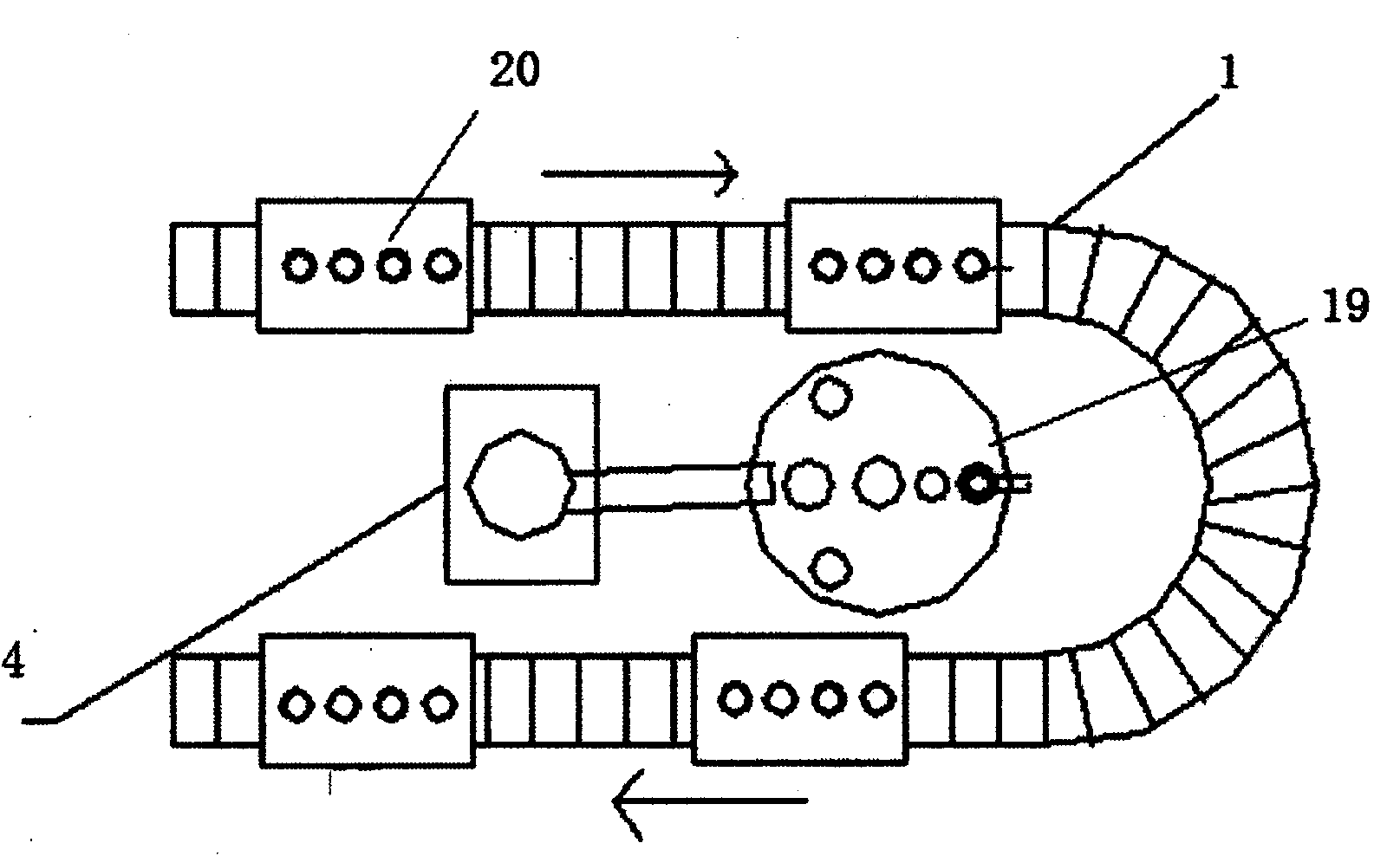

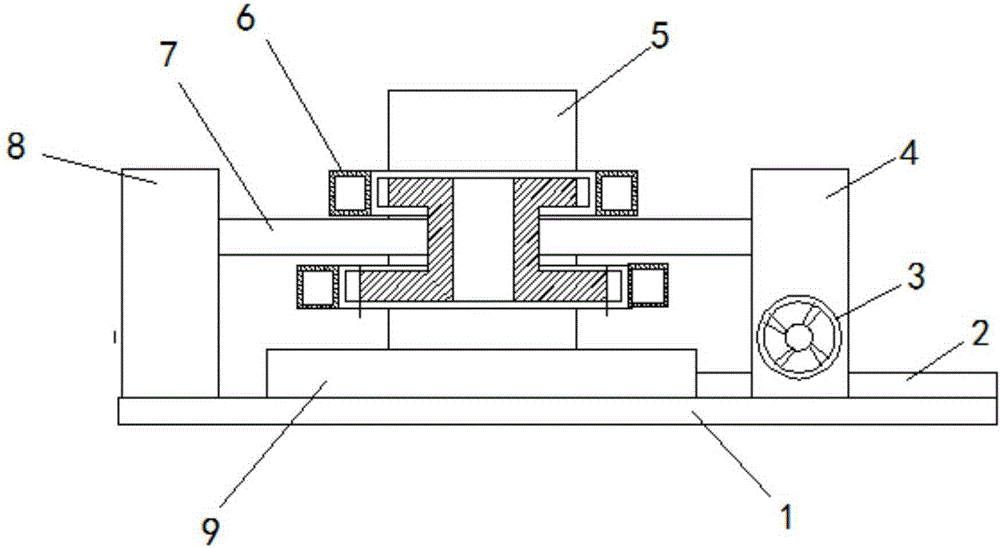

Pin shaft quenching method

ActiveCN108531704AImprove quenching efficiencyContinuous and stable deliveryIncreasing energy efficiencyFurnace typesQuenchingHeat treated

The invention relates to the technical field of pin shaft heat treatment, in particular to a pin shaft quenching method. The pin shaft quenching method comprises the following steps that to-be-quenched pin shafts are put into a storage bin to be temporarily stored, the pin shafts in the storage bin are fed to a clamping module to be clamped one by one through a feeding module, and then the feedingmodule returns back to the initial position; and a transmission module drives the clamping module to drive the pin shafts to rotate, the transmission module horizontally slides on a driving platformto enable the pin shafts to be quenched and heated at a heating module, at the same time, a cooling module sprays water to cool the pin shafts, pin shaft quenching is completed, the transmission module drives the automatic clamping module to return to the initial position, the automatic clamping module loosens the pin shafts, and the pin shafts automatically fall into a discharging module. According to the pin shaft quenching method, the pin shaft quenching method is improved through an automatic induction pin shaft quenching machine, therefore, full automation is achieved in the pin shaft quenching process, manual operation is not needed, and the pin shaft quenching efficiency and the pin shaft overall quality are improved.

Owner:ANHUI JIXI HUISHAN CHAIN TRANSMISSION

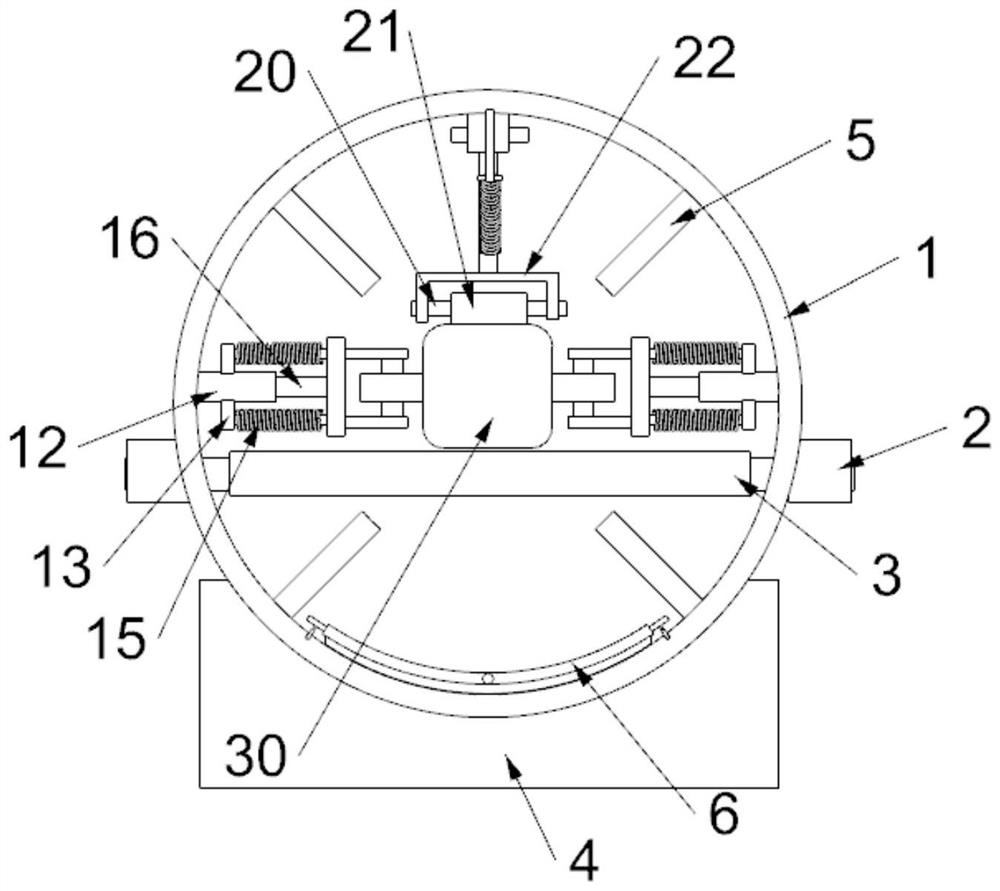

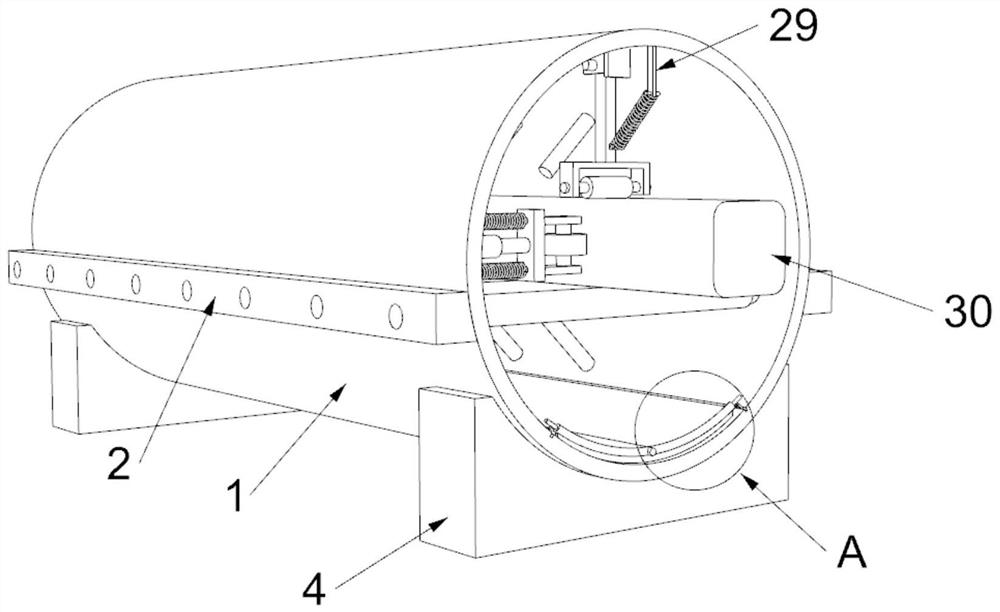

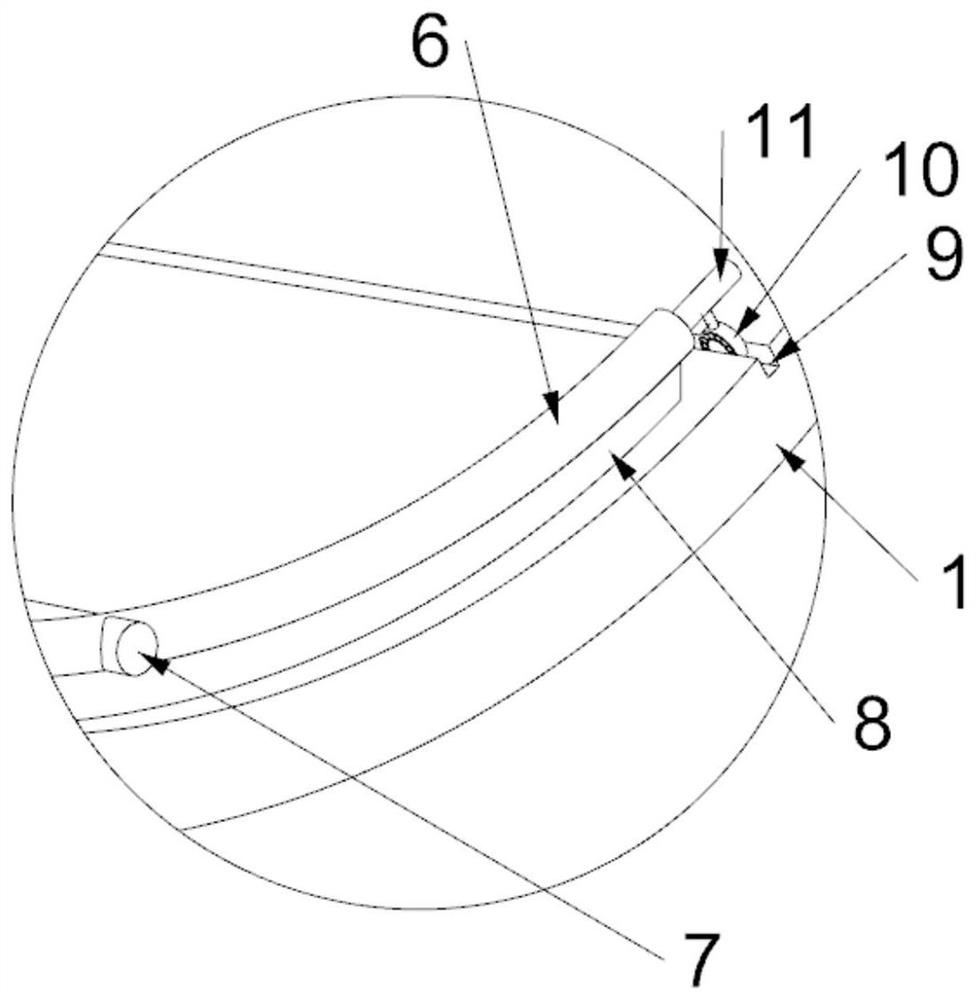

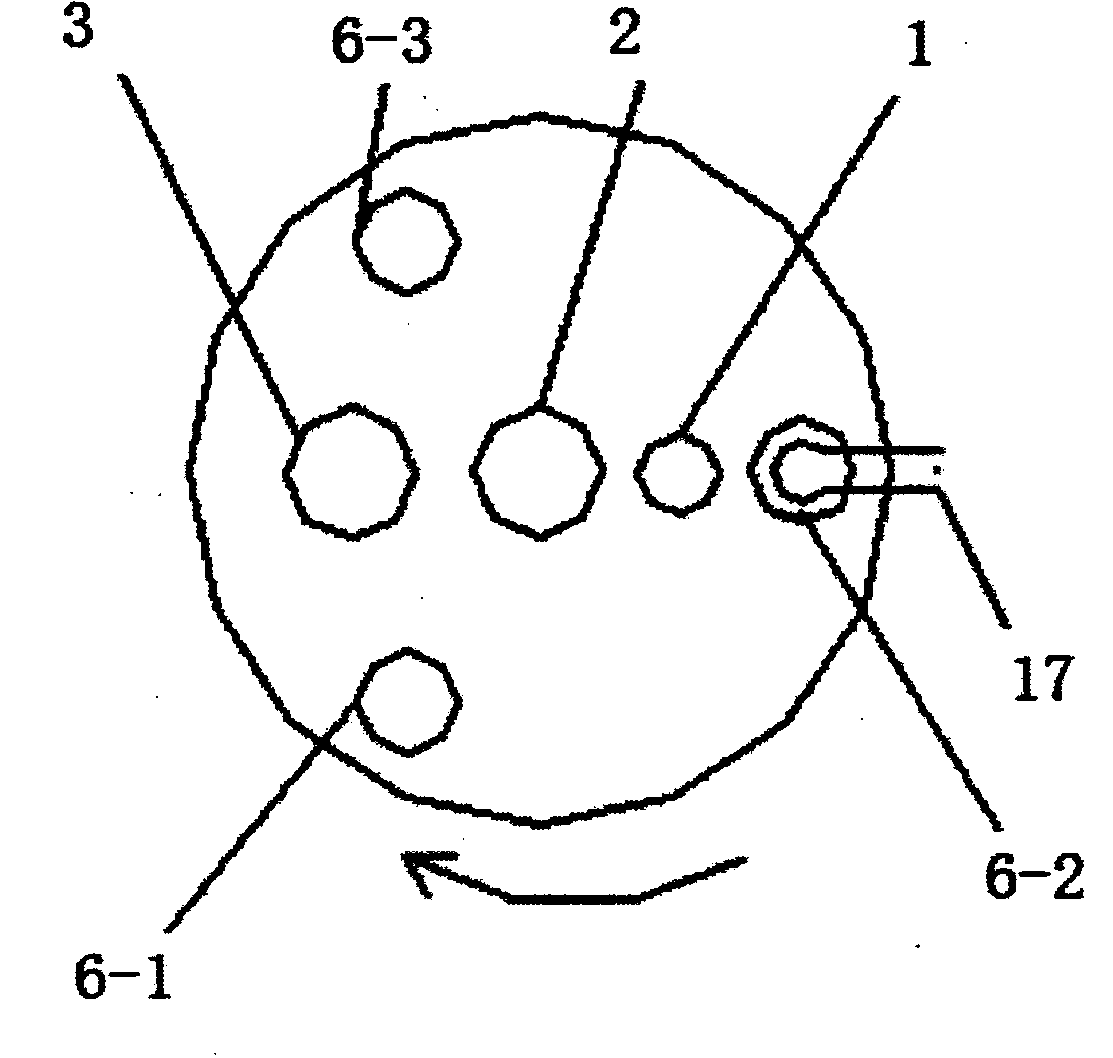

Copper alloy casting surface strengthening quenching device

InactiveCN112853240AUniform quenchingMitigate safety and health impactsProcess efficiency improvementQuenching devicesMetal debrisWater spray

The invention discloses a copper alloy casting surface strengthening quenching device. The copper alloy casting surface strengthening quenching device comprises a quenching device body, a guide roller is installed in the interior of the quenching device body and installed on a guide roller frame, a copper alloy casting is placed on the guide roller, the guide roller frame is welded to the outer wall of the quenching device body, water spraying guns are installed on the inner wall of the quenching device body, a metal debris cleaning device is installed at the lower end of the interior of the quenching device body, and an auxiliary clamping device and an auxiliary pressing device are arranged on the guide roller. The water spraying guns are installed in the interior of the quenching device body and are arranged in the interior of the quenching device body in a circular array mode, so that the copper alloy casting is more uniform in the quenching process, and meanwhile, the adopted quenching device body is cylindrical, and therefore the influence of heat radiation on the safety and health of operators can be effectively relieved.

Owner:刘雪飞

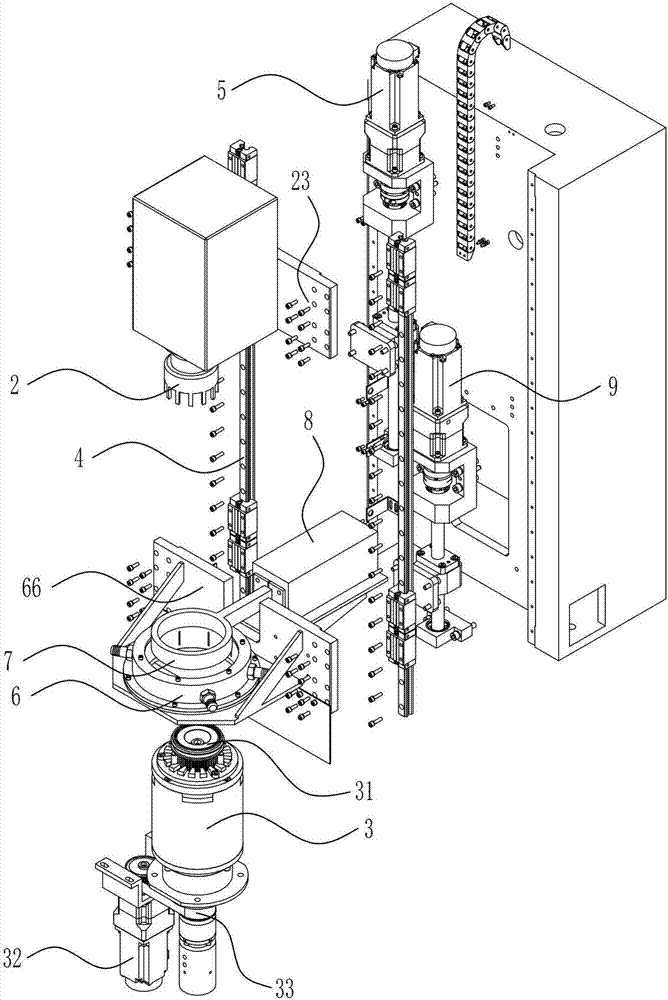

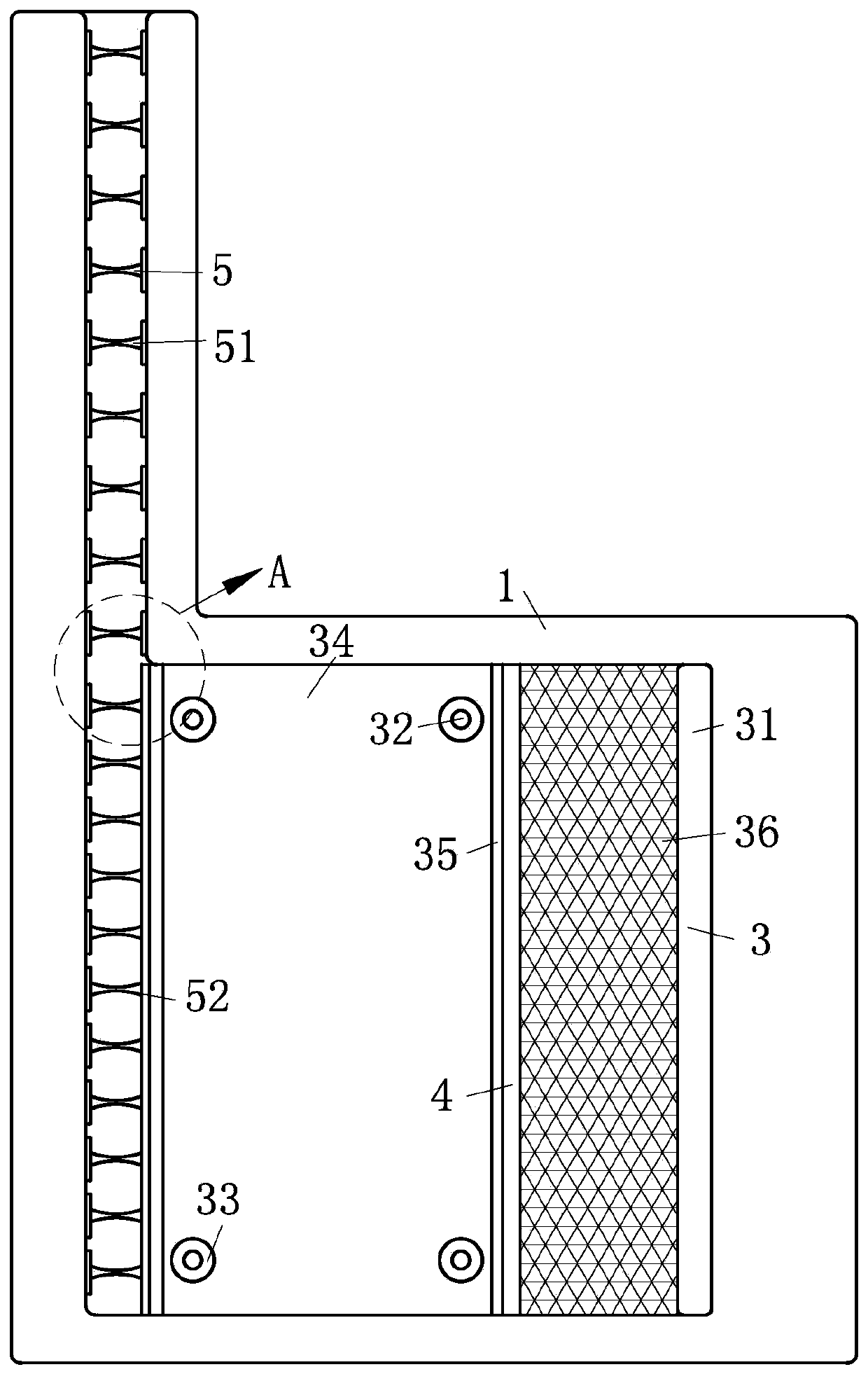

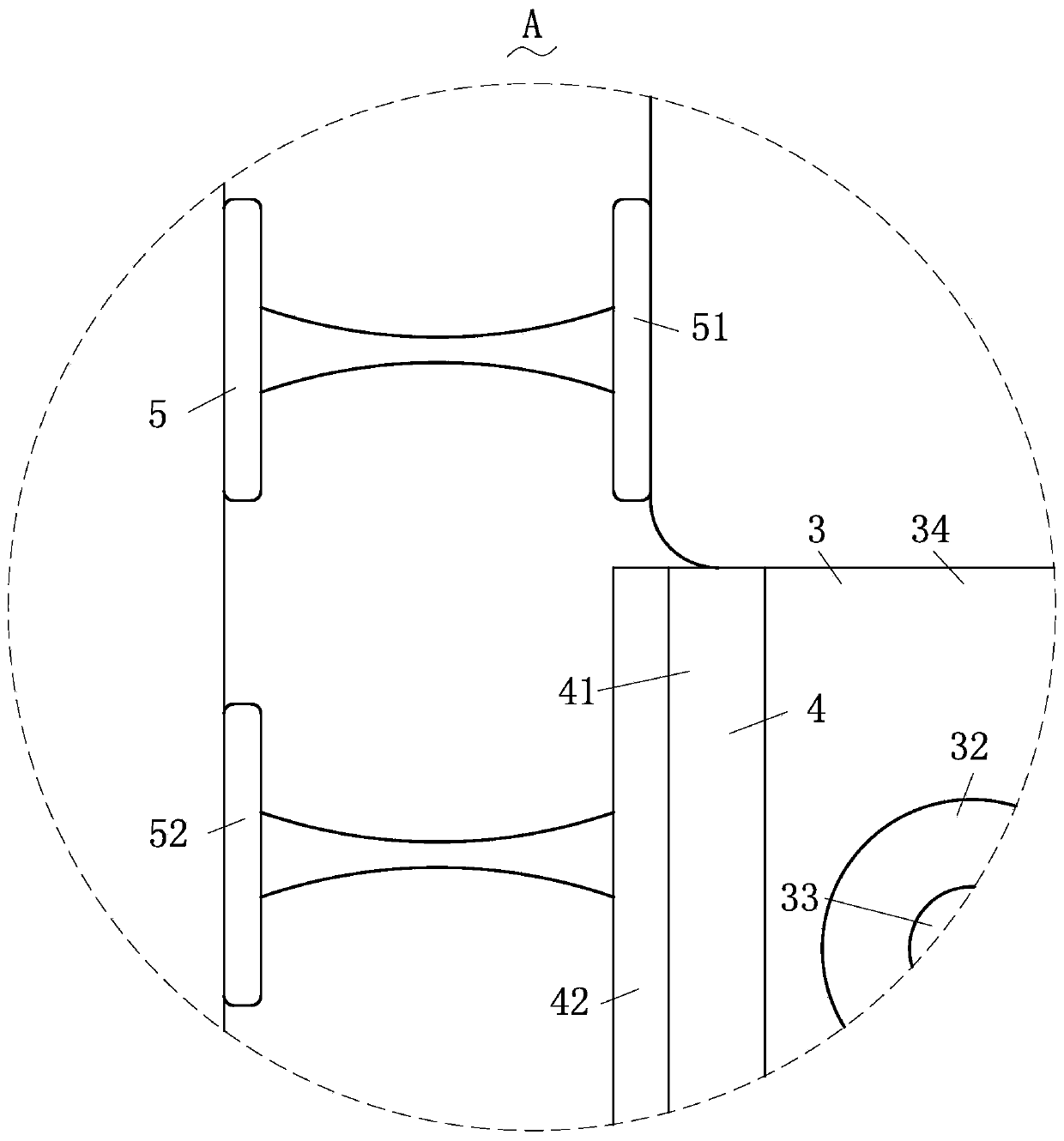

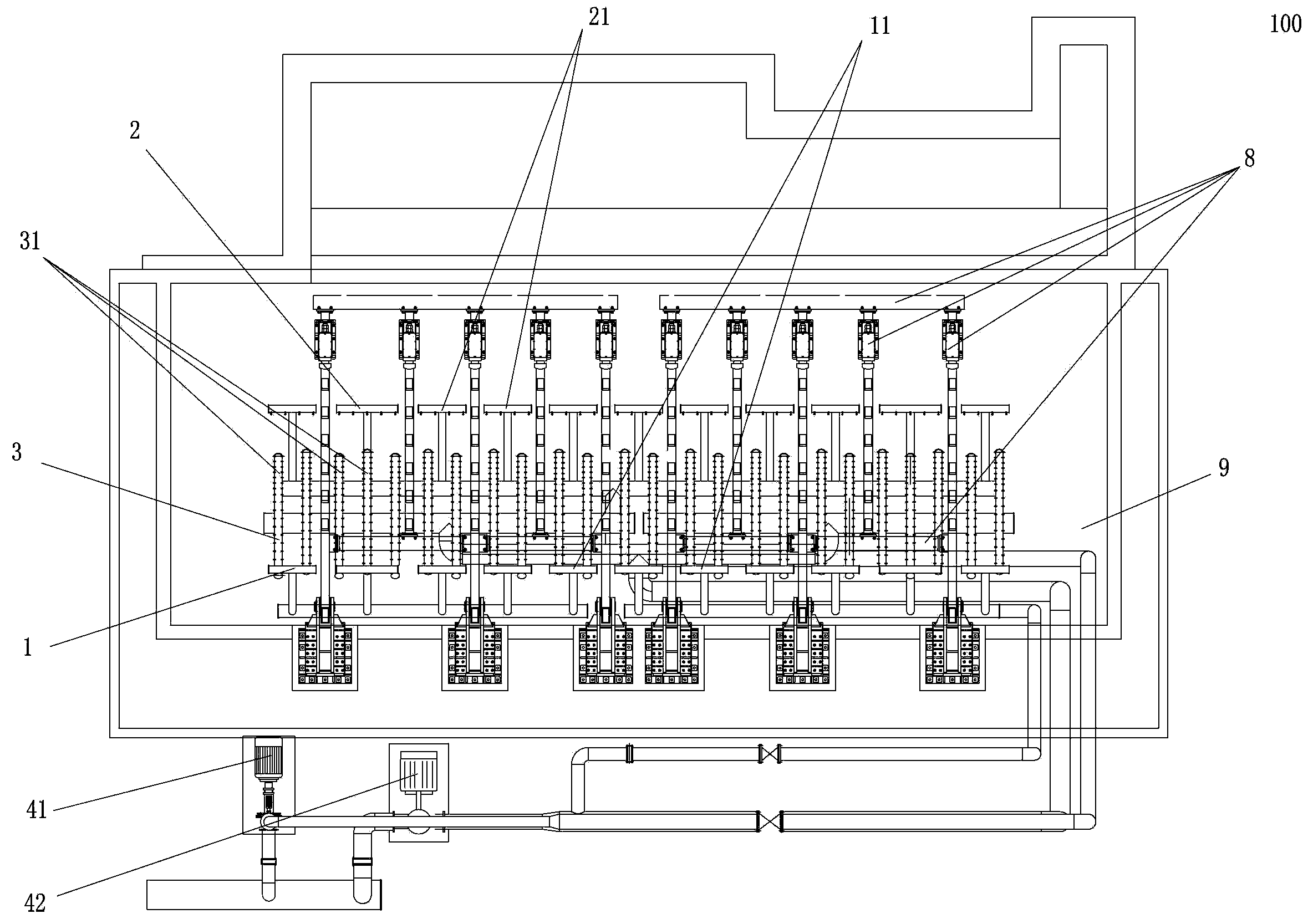

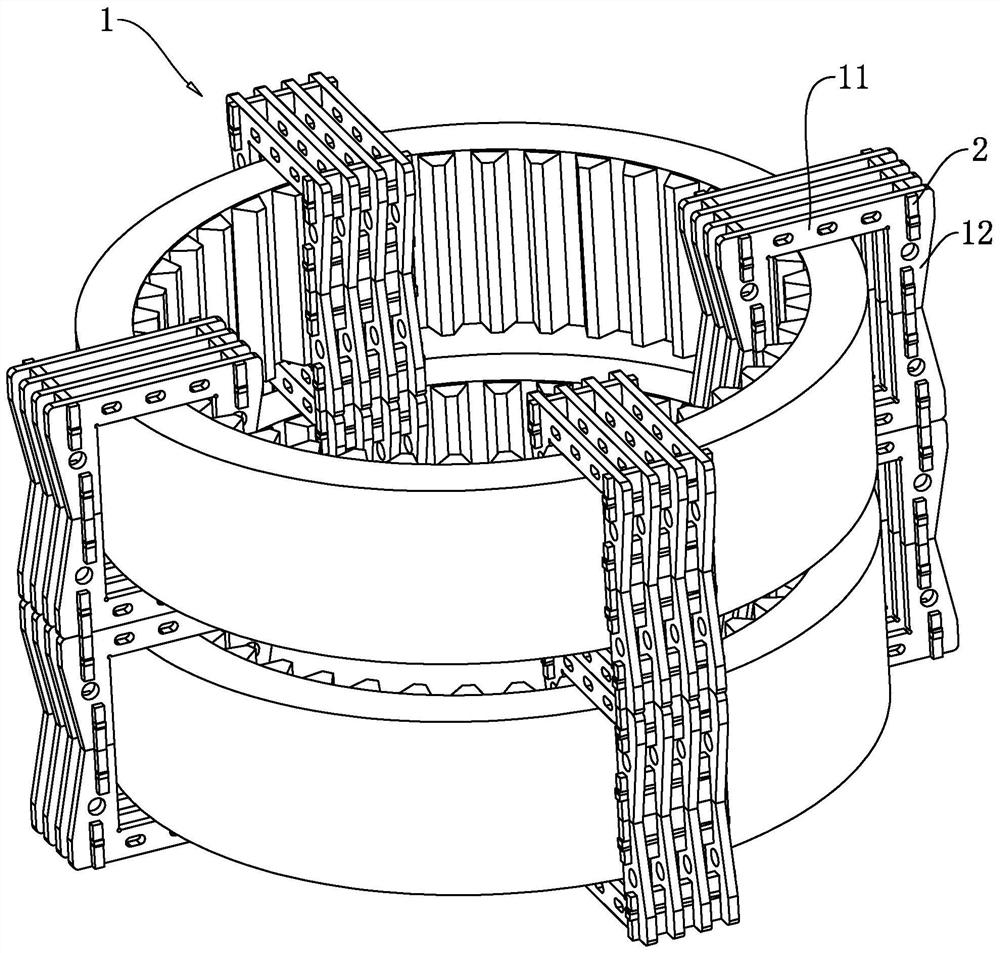

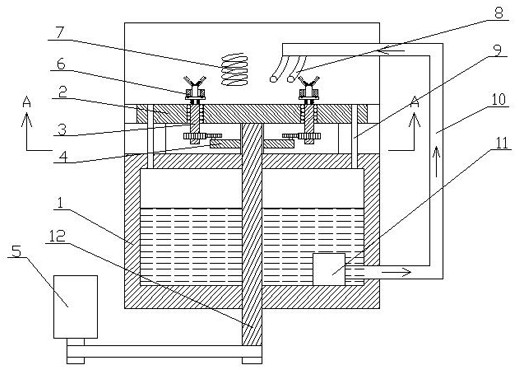

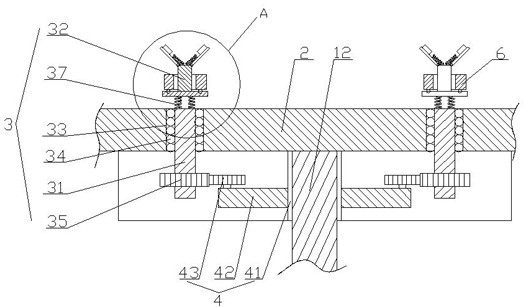

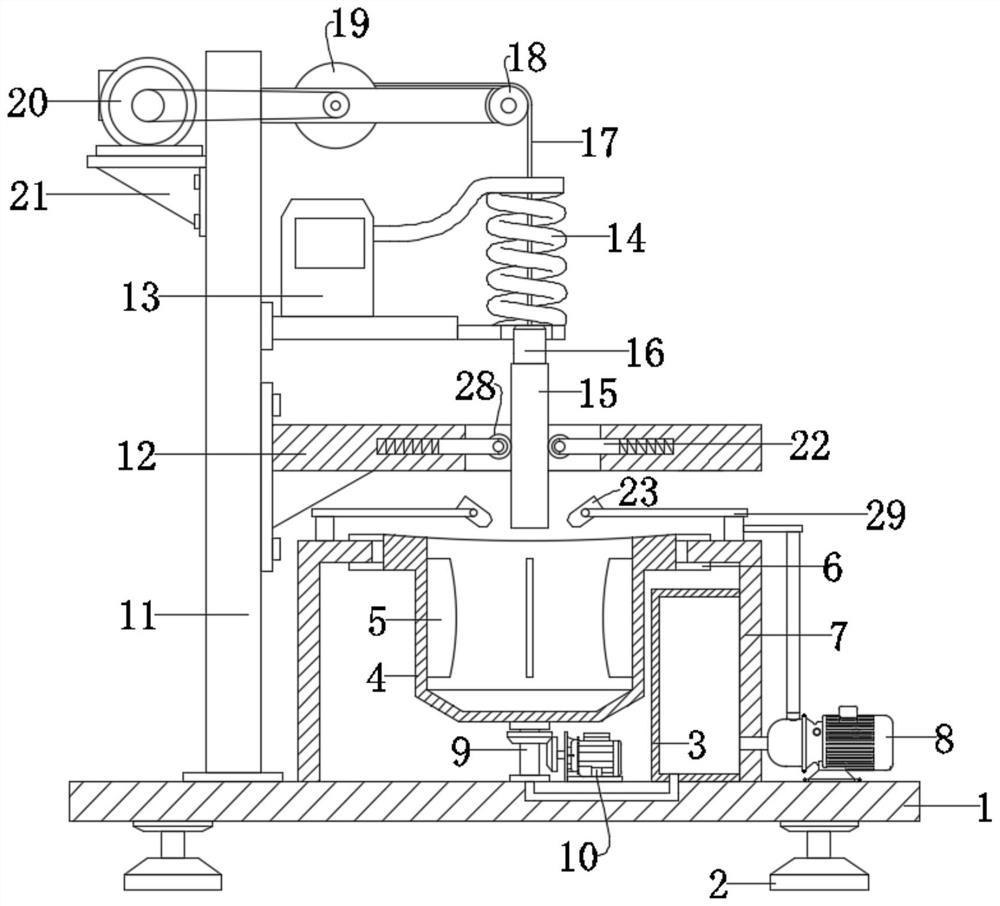

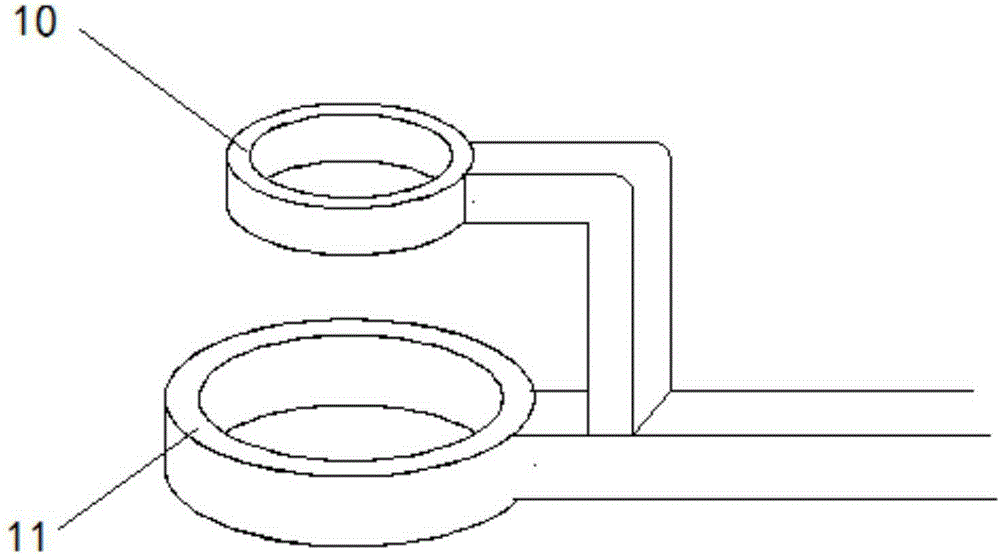

Pressure quenching and tempering integrated machine tool for thin-wall annular parts

InactiveCN106987697AFully contactedUniform quenchingFurnace typesHeat treatment furnacesQuenchingInductor

The invention relates to a press quenching machine tool, in particular to an integrated press quenching and tempering machine tool for thin-walled annular parts; Fire machine tool, the machine tool can realize the effect of small wear of the parts on the mandrel, perfect waterproof measures, and automatic loading and unloading; the machine tool includes upper mold, lower mold, upper mold lifting assembly, liquid spray ring, liquid spray ring slider, return The fire heating sensor and the liquid spray ring lifting assembly, etc.; the lower mold, the upper mold lifting assembly and the liquid spray ring lifting assembly are all installed on the frame, the liquid spray ring slider is connected with the liquid spray ring lifting assembly, and the liquid spray ring slider A liquid spray ring and a tempering heating sensor are installed on it; the present invention overcomes the shortcomings of the existing machine tool that the shape-limited mandrel is severely worn after the parts are quenched, and the quenching and tempering must be processed separately, and achieves integrated heating and quenching. Integrate with the tempering process, the wear of the mandrel is small, and the effect of automatic loading and unloading is perfect with waterproof measures.

Owner:GANZHOU QUNXING ROBOT

Feeding device of deformed steel bar quenching device with uniform quenching function

ActiveCN111020168ALess work for workersEasy to moveFurnace typesCleaning using toolsSteel barMechanical engineering

The invention relates to the field of deformed steel bar production, in particular to a feeding device of a deformed steel bar quenching device with a uniform quenching function. The feeding device comprises a base, a collecting mechanism, a pushing mechanism, a first conveying mechanism, a second conveying mechanism and a cleaning mechanism. The pushing mechanism is fixedly mounted on the base; and the pushing mechanism pushes deformed steel bars, and the pushing mechanism facilitates separation of the deformed steel bars with different diameters, so that multiple deformed steel bars are conveniently added at a time, and the deformed steel bars are pushed one by one through the pushing mechanism, the work of workers is reduced, trouble and labor are saved, continuous movement of the deformed steel bars is facilitated, feeding coherence is facilitated, and utilization of heat resources is facilitated. The first conveying mechanism is installed on the base, and the second conveying mechanism is installed on the base, so that the first conveying mechanism and the second conveying mechanism are conveniently used for conveying the deformed steel bars, the deformed steel bars can be continuously conveyed one by one, continuous and uniform quenching of the deformed steel bars is facilitated, trouble and labor are saved, and the efficiency is improved.

Owner:湖北立晋钢铁集团有限公司

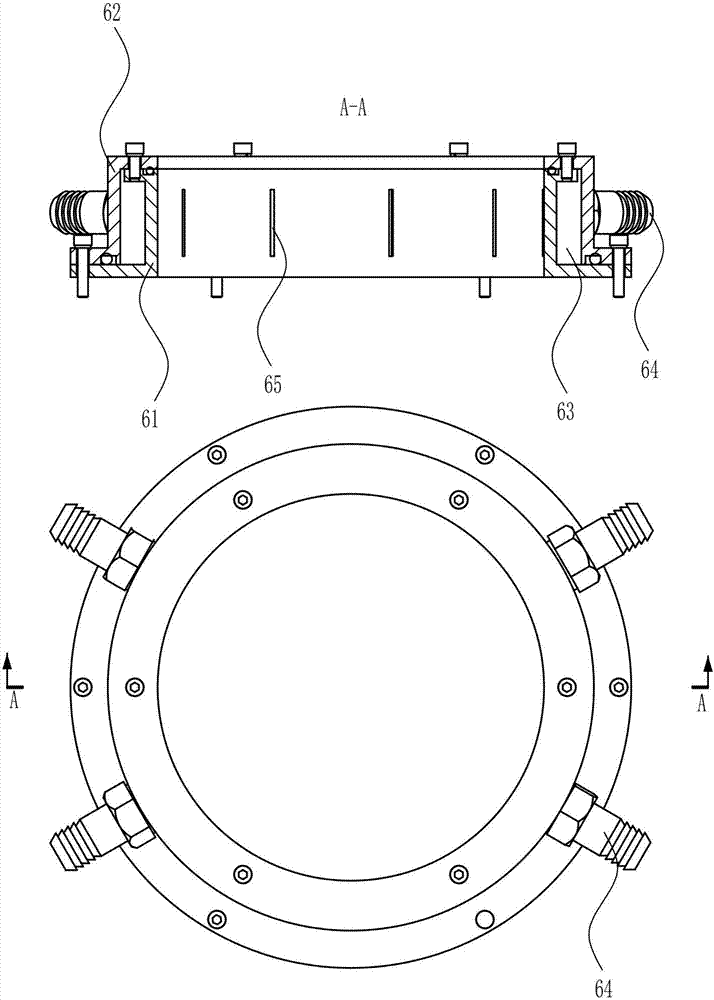

Shaft type quenching induction coil with clamping function

ActiveCN107058682AWith clamping functionEffectively fixedIncreasing energy efficiencyQuenching devicesWater coolingBlock match

The invention discloses a shaft type quenching induction coil with a clamping function. The shaft type quenching induction coil comprises an induction coil body, a cavity is formed in the induction coil body, the outer side face of the induction coil body is fixedly communicated with a water inlet pipe and a water draining pipe, the water inlet pipe and the water draining pipe are communicated with the cavity, a water stop valve is arranged on the draining pipe, one side face of the induction coil body is fixedly connected with a connecting line, the induction coil body is sleeved with a limiting ring, a groove formed in a ring manner is formed in one side face of the limiting ring, and a clamping block matched with the clamping groove is fixedly connected to the inner side wall of the limiting ring. According to the shaft type quenching induction coil with the clamping function, a workpiece can be effectively fixed, workpiece loosening can be effectively avoided, direct contact between the workpiece and the induction coil is effectively avoided, the stability is good, quenching is uniform, the workpiece can be effectively subject to water cooling, the workpiece can be effectively prevented from being damaged by burning, heating efficiency is high, and product quality is effectively ensured.

Owner:浙江诺珥新材料有限公司

Quenching device capable of facilitating clamping and quenching of hardware materials

ActiveCN109112272AConvenient clamping and quenchingEasy to rotate and scrollFurnace typesHeat treatment furnacesLiquid storage tankQuenching

The invention discloses a quenching device capable of facilitating clamping and quenching of hardware materials. The device comprises a quenching box, a micro water pump, a mounting plate, a servo motor, a linkage rod and a driving cylinder, wherein the quenching box is provided with a quenching bath, a connecting pipe is arranged at the right side of the quenching bath, and the quenching bath isconnected with a liquid storage tank by means of the connecting pipe; the micro water pump is connected with the left side of the liquid storage tank, and the liquid storage tank and the micro water pump are both positioned inside the quenching box; the linkage rod is positioned at the outer side a clamping device, and is connected with a mounting cover by means of a connecting rod; the linkage rod is connected with the driving cylinder, and the driving cylinder is positioned at the outer side of an adjusting rod. The quenching device capable of facilitating clamping and quenching of hardwarematerials facilitates the automatic clamping of the cylindrical hardware materials by using the clamping device, thus avoiding the high temperature damage to workers; a pushing device conveniently drives the hardware materials to rotate and roll in cooling liquid, so that the uniform quenching of the hardware materials is facilitated.

Owner:YANCHENG NUOWEITE ELECTROMECHANICAL TECH

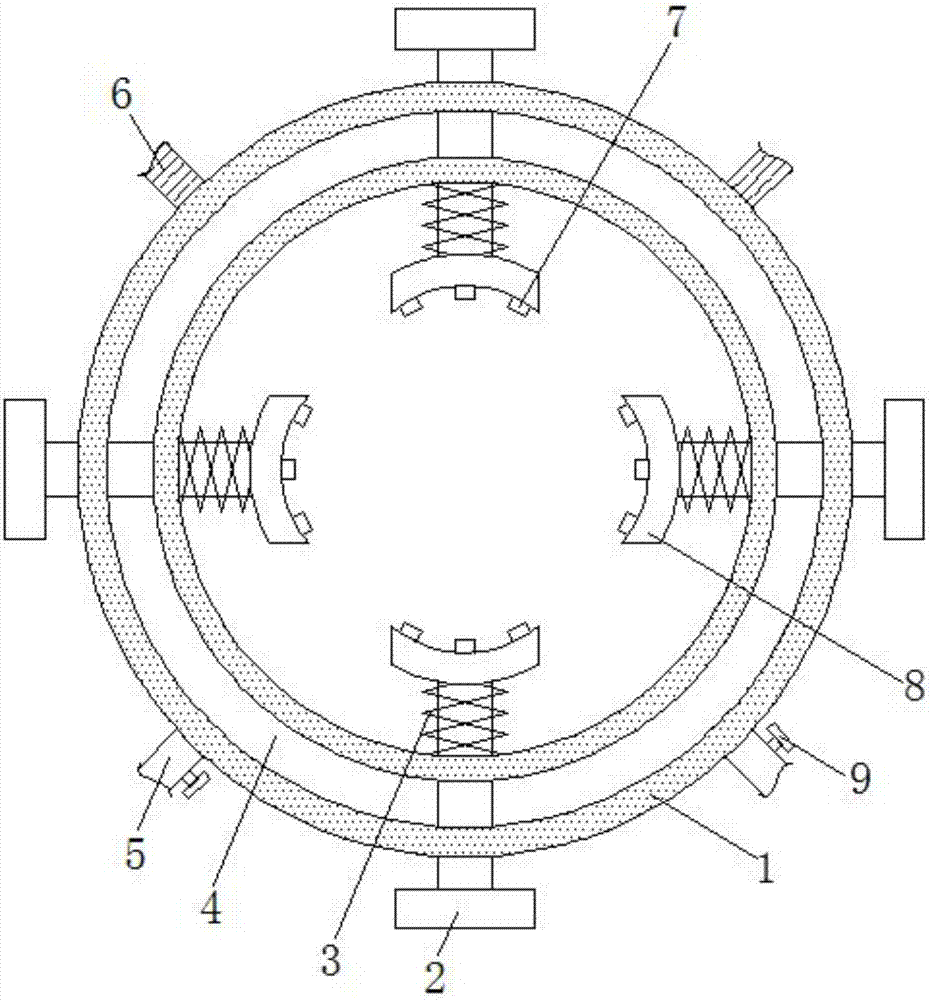

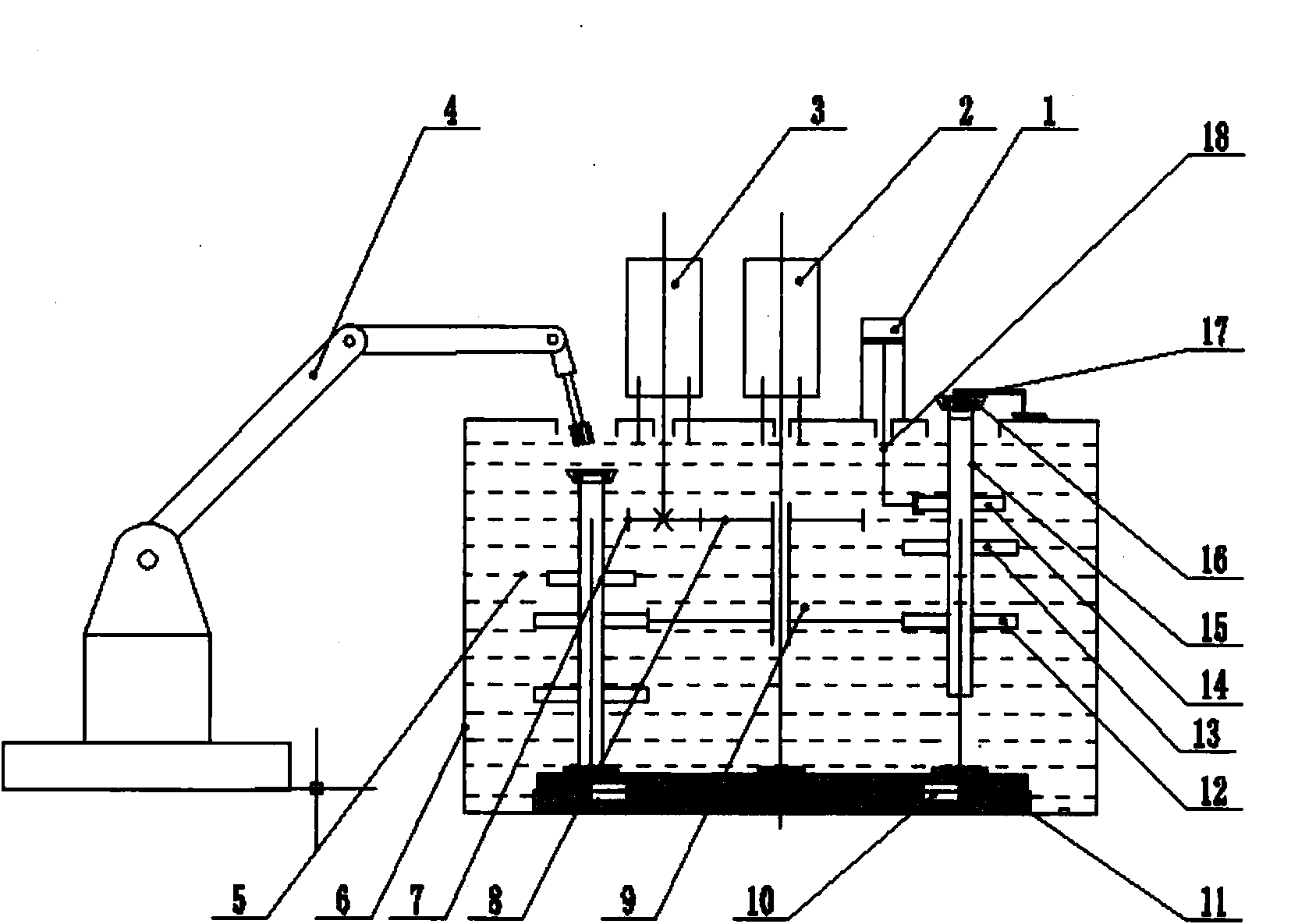

Bearing ring and sleeve part automatic quenching machine based on robot control

InactiveCN103937954ASmooth rotationUniform quenchingFurnace typesHeat treatment process controlFlexible manufacturing systemButt joint

The invention relates to a bearing ring and sleeve part automatic quenching machine based on robot control. The quenching machine is characterized by comprising an RGV (Rail Guided Vehicle) automatic guiding transport trolley system, a robot, quenching equipment and control sub-system, wherein a to-be-processed part is placed on an RGV trolley of the RGV automatic guiding transport trolley system to automatically transport the to-be-processed part; the robot grasps the to-be-processed part on the RGV trolley and puts the to-be-processed part in the quenching equipment and control sub-system to heat and quench the to-be-processed part; and then, the robot takes the quenched part from the quenching equipment and control sub-system on the RGV trolley. The invention provides a bearing inner and outer ring automatic quenching system which not only can save the cost, but also can further improve the efficiency and the quenching quality and is in butt joint and integrated with the flexible manufacturing systems of the enterprise.

Owner:DONGHUA UNIV

Heat treatment induction hardening technique for sprocket wheel

InactiveCN106011438ANo pollution in the processHigh hardnessIncreasing energy efficiencyFurnace typesEconomic benefitsInduction hardening

The invention discloses a heat treatment induction hardening technique for a sprocket wheel. The heat treatment induction hardening technique adopts the following technical steps of inspecting; cleaning and drying; hardening; cleaning and drying; tempering; detecting and performing rust-resisting treatment. According to the heat treatment induction hardening technique, the technique is simple, environmental protection without pollution in the whole process is realized, the hardness, the strength and wear resistance of the sprocket wheel can be effectively improved, and the service life of the sprocket wheel is prolonged; in the hardening step, an HX-200 medium is adopted to cool, and a workpiece is enabled to be uniformly hardened; a uniform diaphragm is formed on the surface of metal, so that the workpiece is effectively protected from being cracked; and the carried quantity is little, the hardened workpiece does not need to be cleaned, and the medium does not need to be discharged. The heat treatment induction hardening technique is suitable for various materials; the adjustment for the concentration is avoided, so that the production cost is reduced; and energy is saved, so that environmental pollution is reduced, and economic benefits are increased.

Owner:XINGHUA DONGHUA GEAR

Workpiece quenching equipment and process thereof

InactiveCN110283989AAvoid bump marksHigh strengthHeat treatment process controlQuenching devicesHardnessHot liquids

The invention discloses workpiece quenching equipment and a process thereof. The workpiece quenching equipment comprises a quenching pond. A quenching liquid box is arranged above the quenching pond, a fixed shaft is arranged below a partition plate, two rotating rods are movably arranged on the fixed shaft, a driving gear is fixedly arranged at the center of one of the rotating rods, and the center of a driven bevel gear is fixedly connected to a bevel gear base through a transmission rod; the quenching pond communicates to a hot liquid box through a communicating pipe I, and the hot liquid box communicates to a cold liquid box through a communicating pie II; the hot liquid box communicates to the quenching liquid box through water return pipe I, and the cold liquid box communicates to the quenching liquid box through a water return pipe II. The invention provides the workpiece quenching equipment which can achieve a quenching effect of quickly cooling the workpiece at a high temperature and slowly cooling the workpiece at a low temperature, meets the latest research conclusion and improves the strength and hardness of the workpiece effectively. The invention also discloses the process based on the workpiece quenching equipment. The process is simple to operate, good in product quality and quite worth being popularized.

Owner:BENGBU COLLEGE

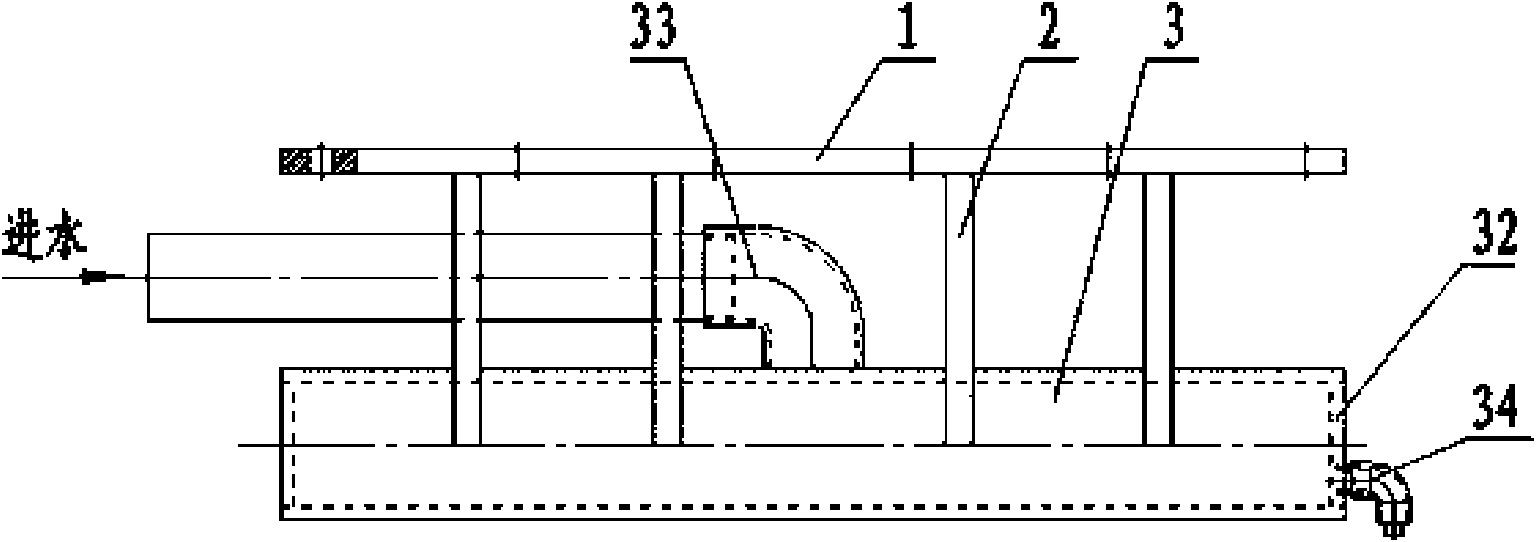

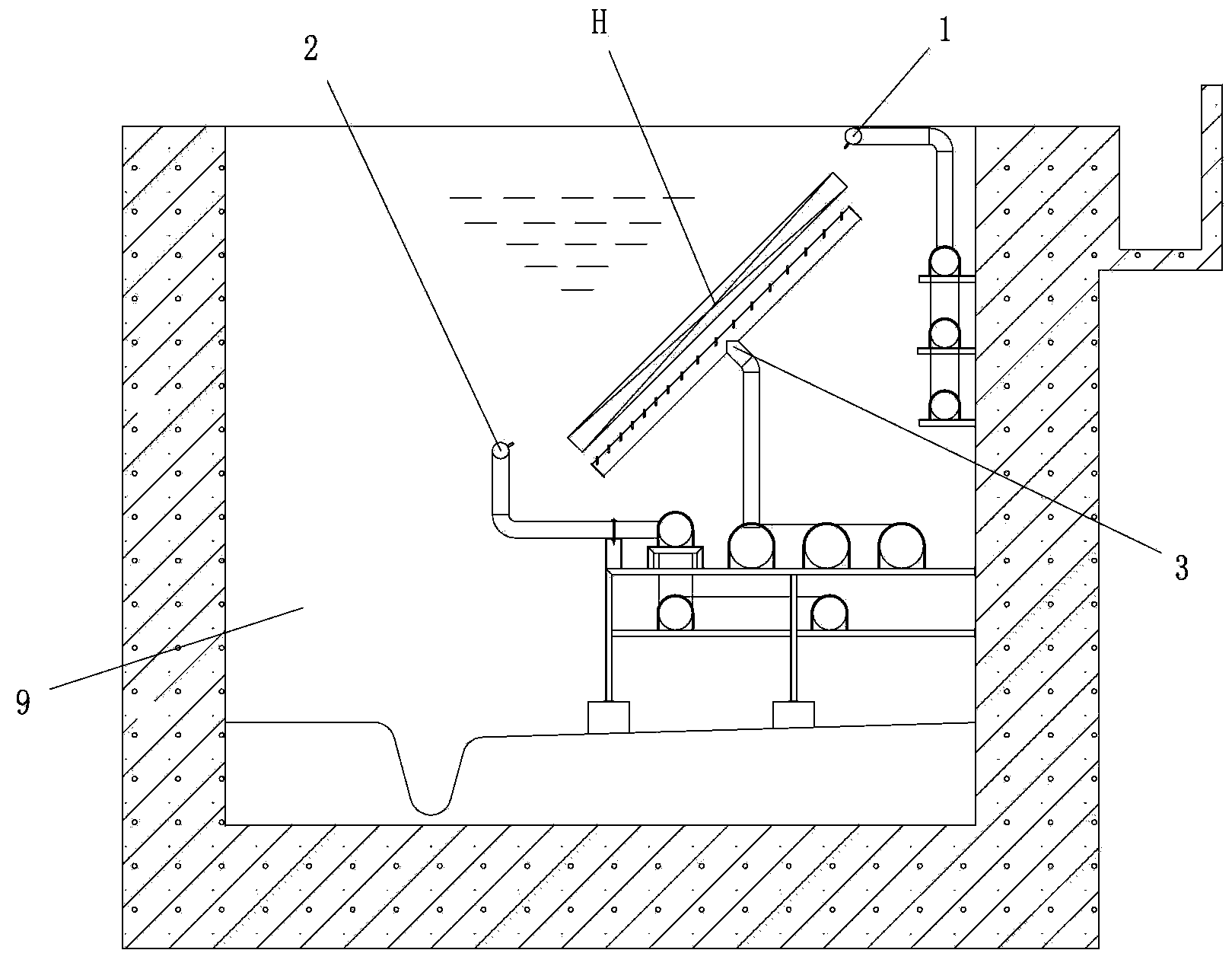

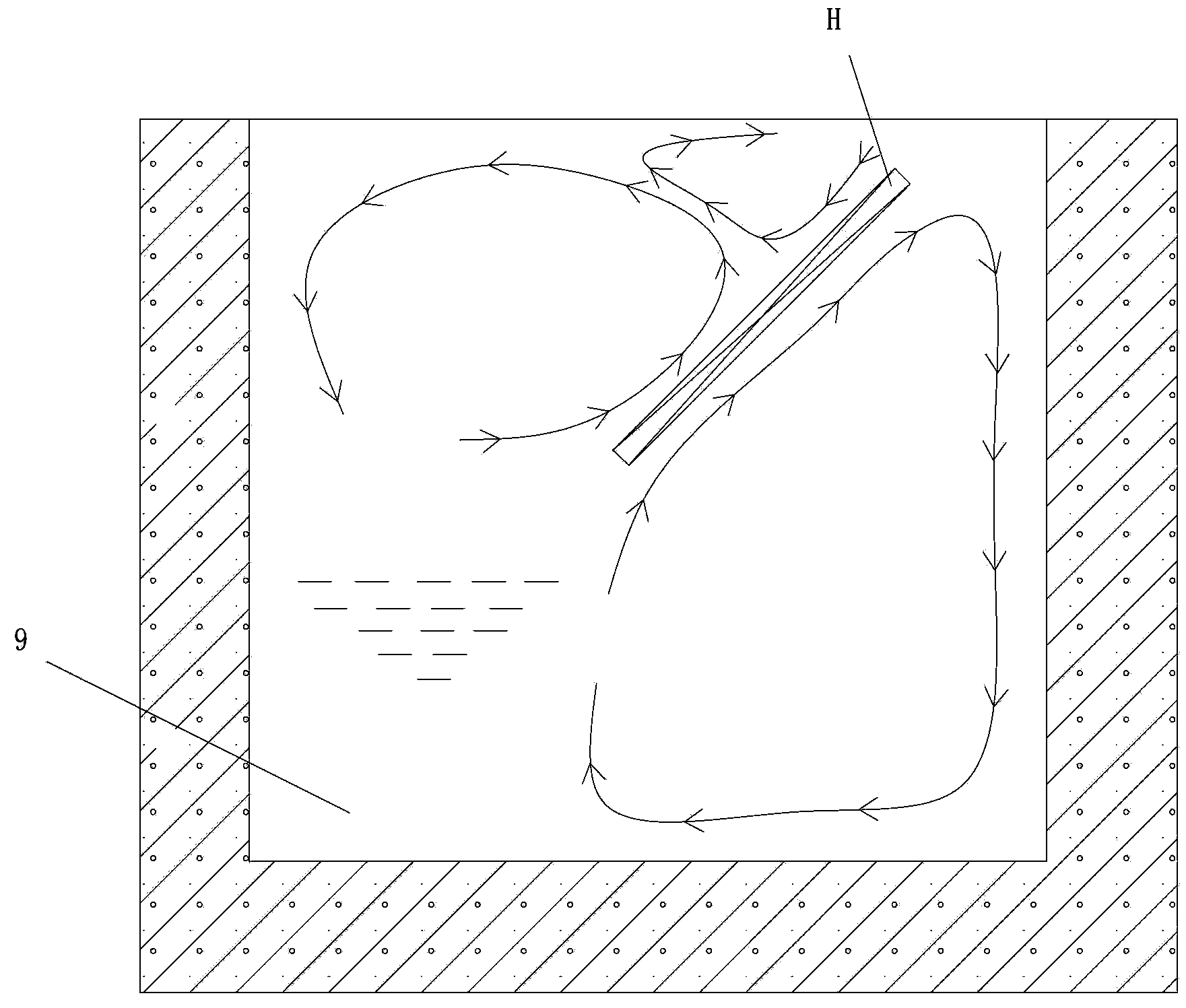

Water cooling system for steel plate quenching apparatus

InactiveCN103436670AUniform quenchingImprove quenching qualityFurnace typesHeat treatment furnacesQuenchingWater spray

The invention provides a water cooling system for a steel plate quenching apparatus. The water cooling system is composed of a first water spraying device, a second water spraying device and a third water spraying device all arranged in a quenching tank, wherein the first water spraying device is arranged above the top of the upper surface of a steel plate at an inclined quenching position and composed of a plurality of first nozzles arranged at intervals along the edge of the top of the steel plate upper surface, the second water spraying device is arranged above the bottom of the upper surface of the steel plate at the inclined quenching position and composed of a plurality of second nozzles arranged at intervals along the edge of the bottom of the steel plate upper surface, and the third water spraying device is arranged below the lower surface of the steel plate at the inclined quenching position and composed of a plurality of third nozzles horizontally or vertically arranged at intervals along the steel plate lower surface. The water cooling system can take away considerable bubbles generated on the surface of the steel plate through washing in a short time, so quenching of the steel plate is more uniform, and quality defects of the quenched steel plate caused by different local cooling rates are avoided.

Owner:CERI PHOENIX INDAL FURNACE CO TD +1

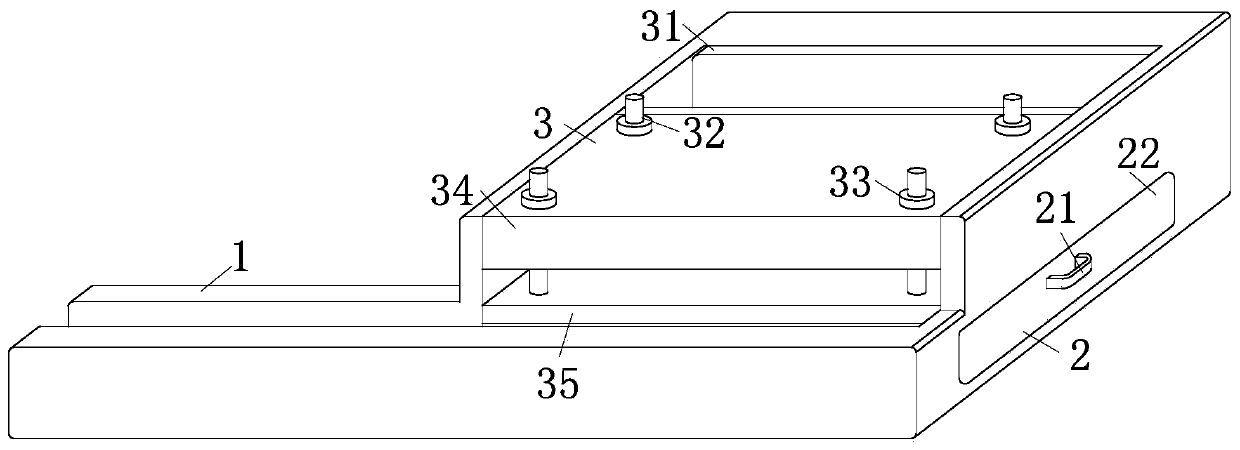

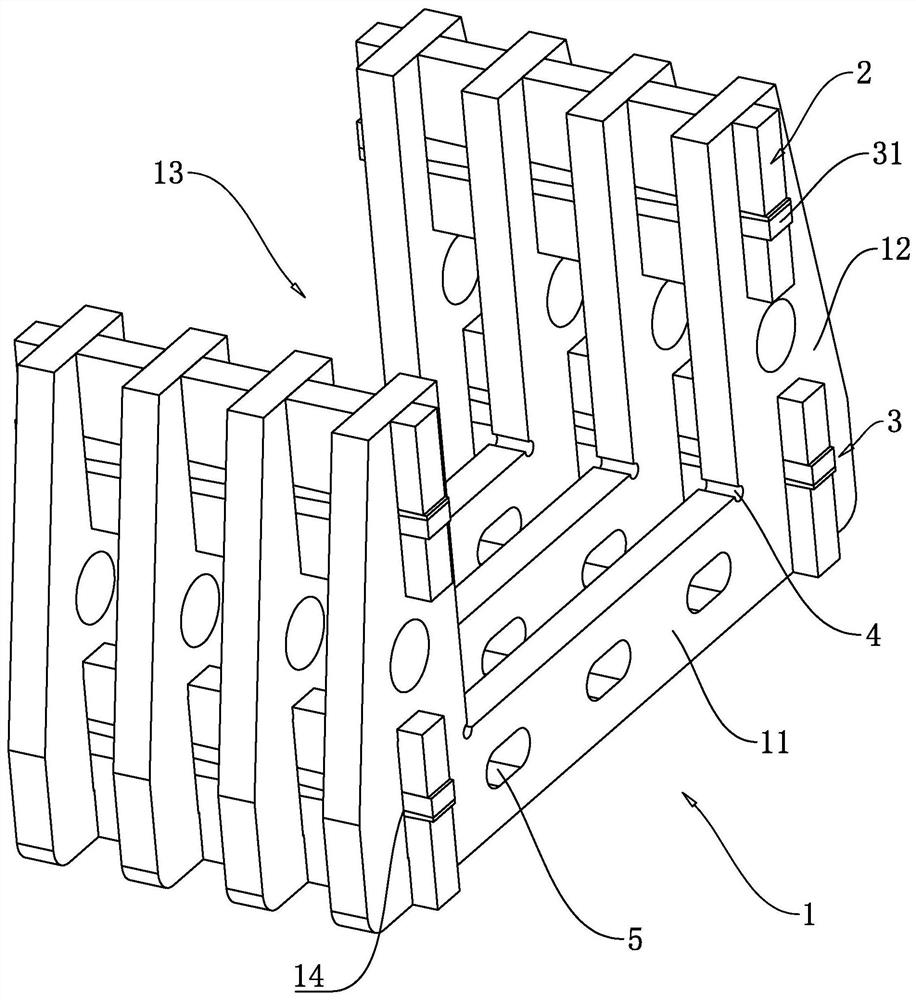

Assembly type cushion for heat treatment of ring workpieces

PendingCN112126769AExtended service lifeNot easy to loosenFurnace typesHeat treatment furnacesEngineeringHeat stress

The invention relates to an assembly type cushion for heat treatment of ring workpieces, and belongs to the technical field of heat treatment auxiliary tools. The assembly type cushion comprises a plurality of supporting plates arranged side by side, wherein each supporting plate comprises a supporting base and supporting stand columns fixed to the two ends of the supporting base; a containing space is formed between the supporting base and the supporting stand columns; assembly holes are formed in the supporting stand columns; and at least one rib plate used for connecting the plurality of supporting plates is inserted in the assembly holes. The supporting plates are arranged in an assembly type, heat stress is not likely to be generated at the joints of the supporting stand columns and the supporting bases, the tearing phenomenon at the joints of the supporting stand columns and the supporting bases is reduced, and therefore the service life of the supporting plates is prolonged.

Owner:溧阳市永恒热处理有限公司

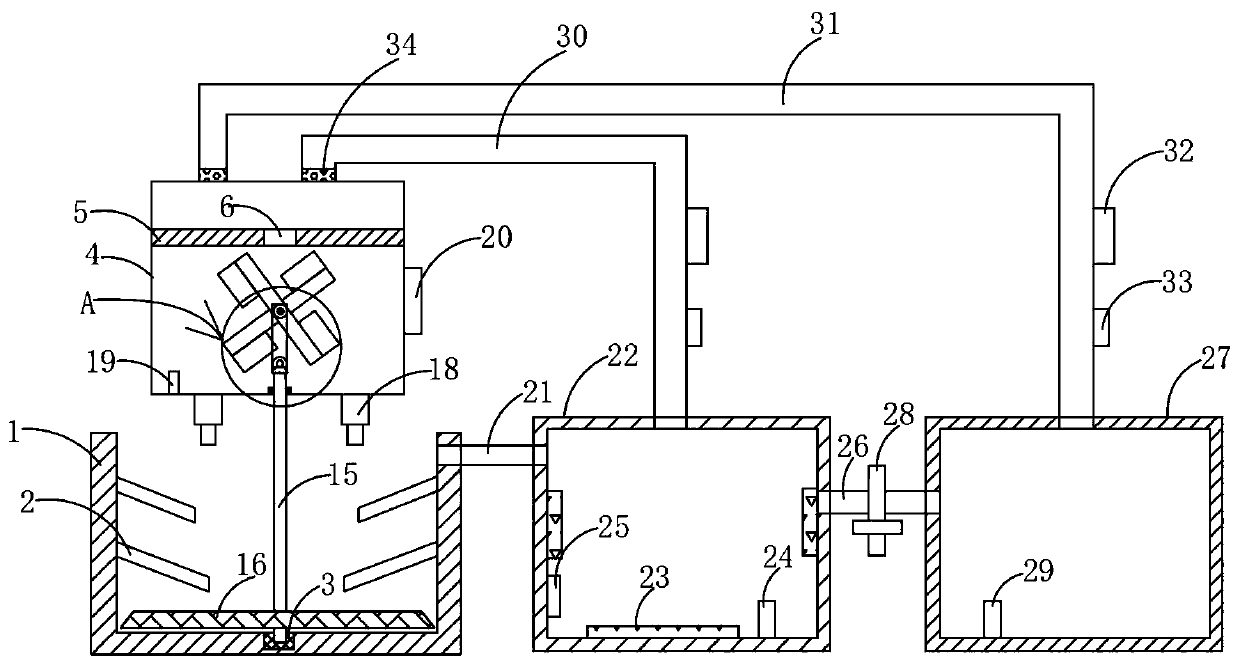

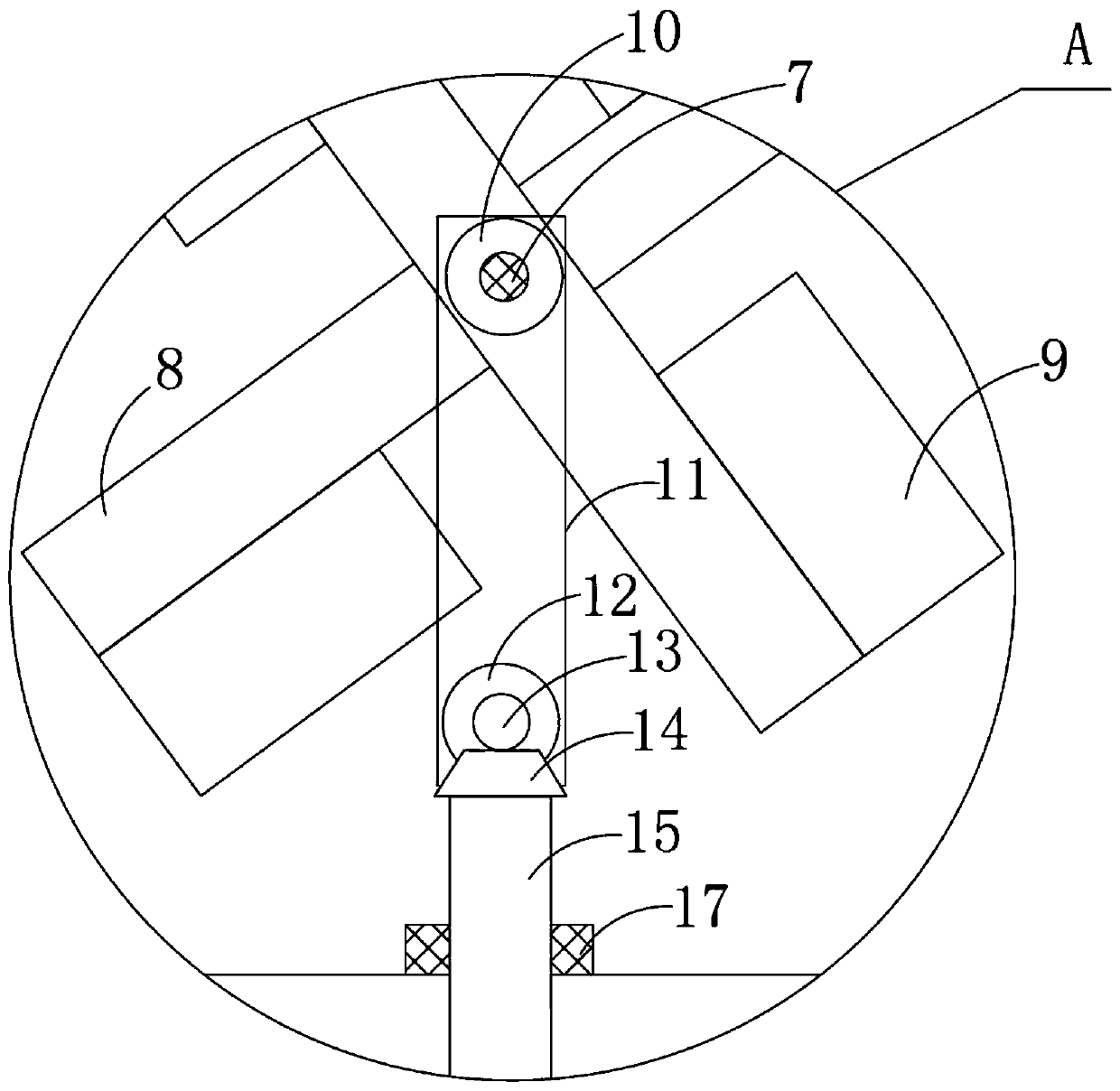

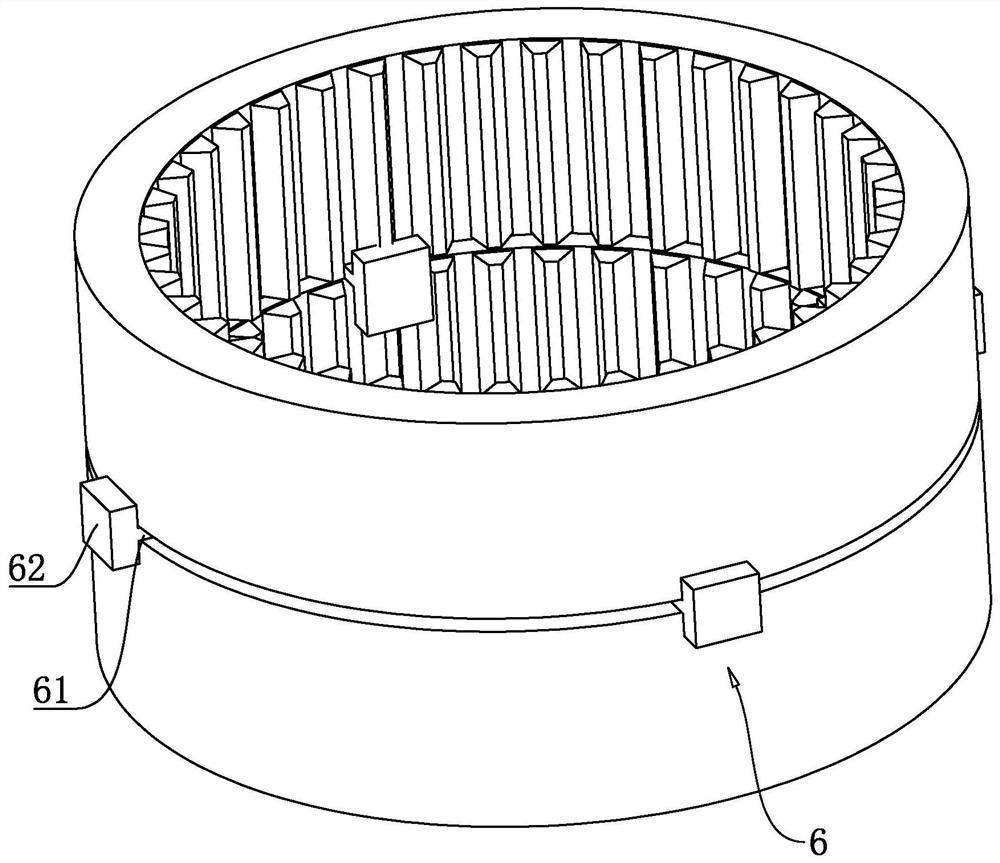

Quenching system for realizing uniform quenching of gears

PendingCN112831644AUniform quenchingEnsure consistencyFurnace typesIncreasing energy efficiencyGear wheelElectric machinery

The invention relates to a quenching system for realizing uniform quenching of gears. The quenching system comprises a quenching box, a rotary disc is arranged above the quenching box, a plurality of clamping mechanisms are arranged on the rotary disc, a rotary shaft longitudinally penetrating through the quenching box is arranged at the lower end of the rotary disc, the lower end of the rotary shaft protrudes out of the quenching box, the rotary shaft rotates through a motor, and gear workpieces are arranged on the clamping mechanisms in a sleeving mode. The rotary shaft is provided with a transmission mechanism, the clamping mechanisms rotate relative to the transmission mechanism along with rotation of the rotating disc so as to achieve auto-rotation on the rotating disc, the quenching box is provided with an induction copper pipe, the position, close to the induction copper pipe, of the quenching box is provided with a cooling liquid spraying pipe, and the rotating disc is provided with a plurality of flow holes allowing cooling liquid to flow into the quenching box. The cooling liquid spraying pipe communicates with the quenching box through a pipeline, and a water pump enabling cooling liquid to flow to the cooling liquid spraying pipe is arranged in the quenching box. The quenching system for realizing uniform quenching of gears has the following advantages that circumferential rotation of the gear workpieces in the vertical direction is guaranteed during quenching, and the ends and the outer circumferences of the gear workpieces are uniformly quenched.

Owner:NANTONG ZHONGLV GEAR CO LTD

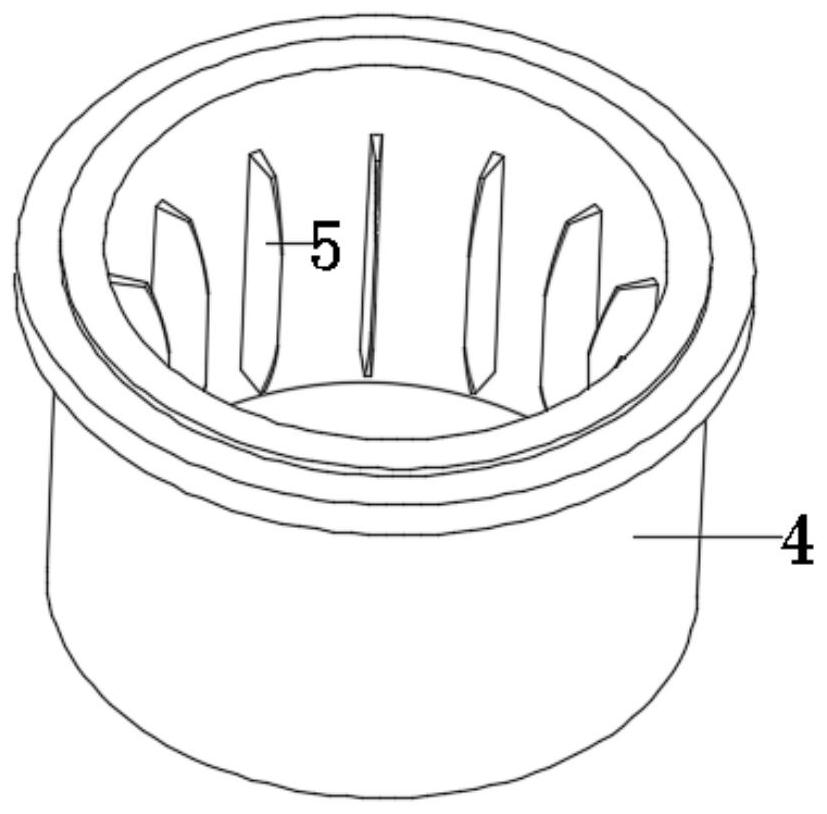

Heat treatment device for machine tool spindle production

InactiveCN112430724AEasy to useUniform quenchingFurnace typesHeat treatment furnacesBlade plateWater storage

The invention discloses a heat treatment device for machine tool spindle production. The heat treatment device comprises a bottom plate, a spindle and a quenching box. A round hole is formed in the center position of a support. The side edge of the quenching box is fixedly connected with a clamping block. The clamping block is arranged on the edge of the round hole. The quenching box can rotate along the support. A positioning assembly is arranged on a carrier plate. A heating device is arranged above the carrier plate. According to the device, a plurality of blade plates are fixedly connectedto the inner wall of the quenching box, and therefore when the quenching box rotates, the blade plates further drive quenching liquid in a box body to rotate, during spindle quenching, the rotary quenching liquid acts on the spindle, the single-layer cross section of the spindle is quenched uniformly, and the actual quenching effect of the spindle is further improved. Meanwhile, the quenching liquid enters a water storage tank through a pipeline through a water pump and then enters an atomization sprayer to be sprayed to the spindle, the heated spindle is pretreated, and good application prospects are achieved.

Owner:汪斯宏

Dual-ring double quenching device for duplicate gear

InactiveCN105936957ASynchronous heatingImprove efficiencyFurnace typesIncreasing energy efficiencyTransformerEngineering

The invention discloses a dual-ring double quenching device for a duplicate gear. The device comprises a worktable and a potential device; the workbench is provided with a sliding rod, a fixed support rod and a material box. The upper ends of the fixed support rod and a movable support rod are provided with a fixed arm; the sliding rod is provided with the movable support rod; the inside of the potential device is provided with an induction coil transformer and a control module; the upper end of the exterior of the potential device is provided with a double-ring sensor; and the double-ring sensor comprises a small induction coil and a large induction coil; and the lower part of the movable support rod is provided with a swing wheel. The dual-ring double quenching device for the duplicate gear uses the fixed arm to fix the duplicate gear in the double-ring sensor; the swing wheel swings to fasten the duplicate gear, and at this time, the potential device energizes the double-ring sensor, so as to heat the large and small gears of the duplicate gear; after quenching, the potential device is cut off, a rocking handle is rocked to keep the fixed arm on the movable support plate away from the duplicate gear; and the duplicate gear falls into the material box for a next procedure.

Owner:QIJIANG XIANGHE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com