Patents

Literature

104results about How to "Rapid quenching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma synthesis of nanopowders

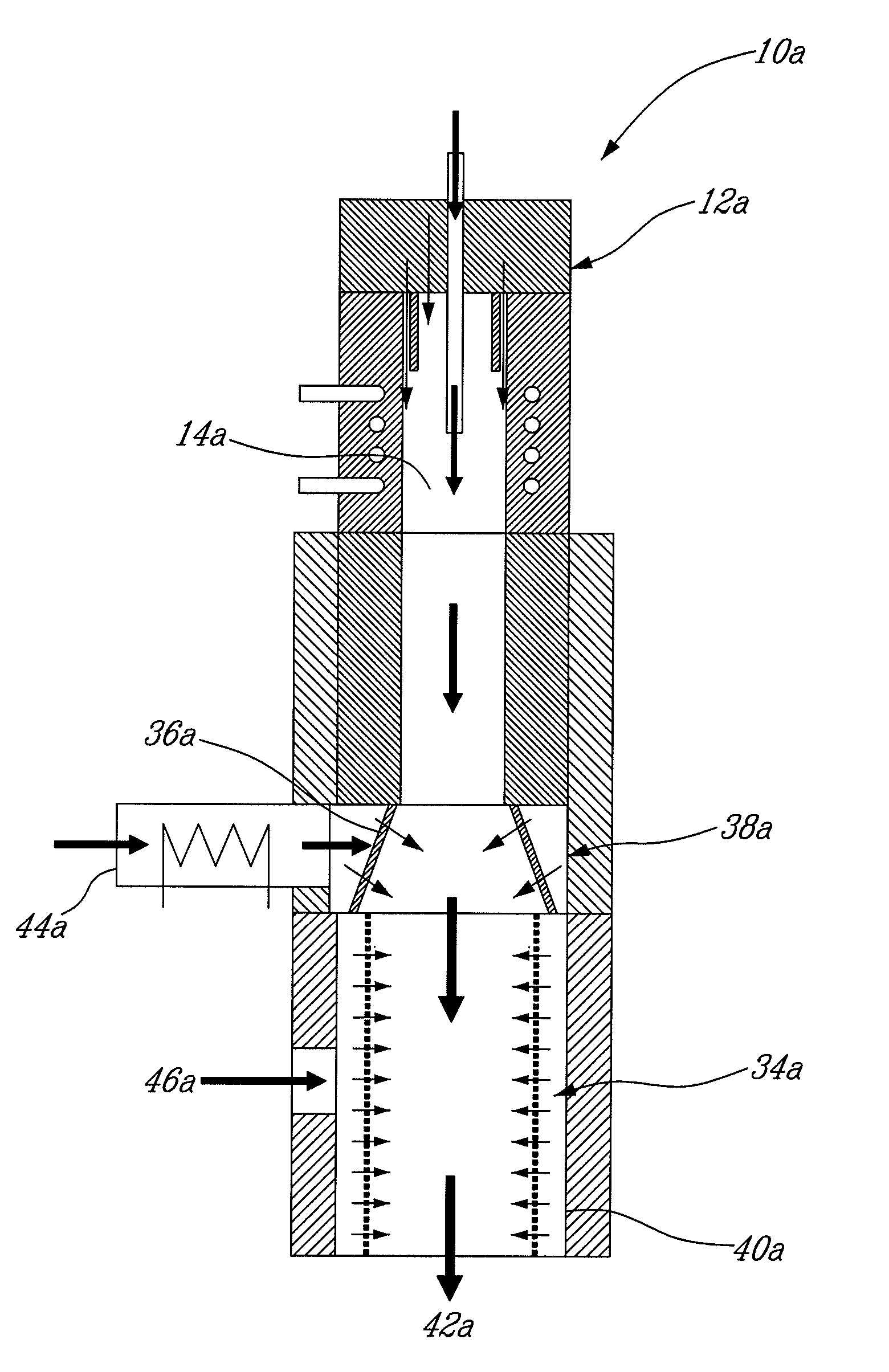

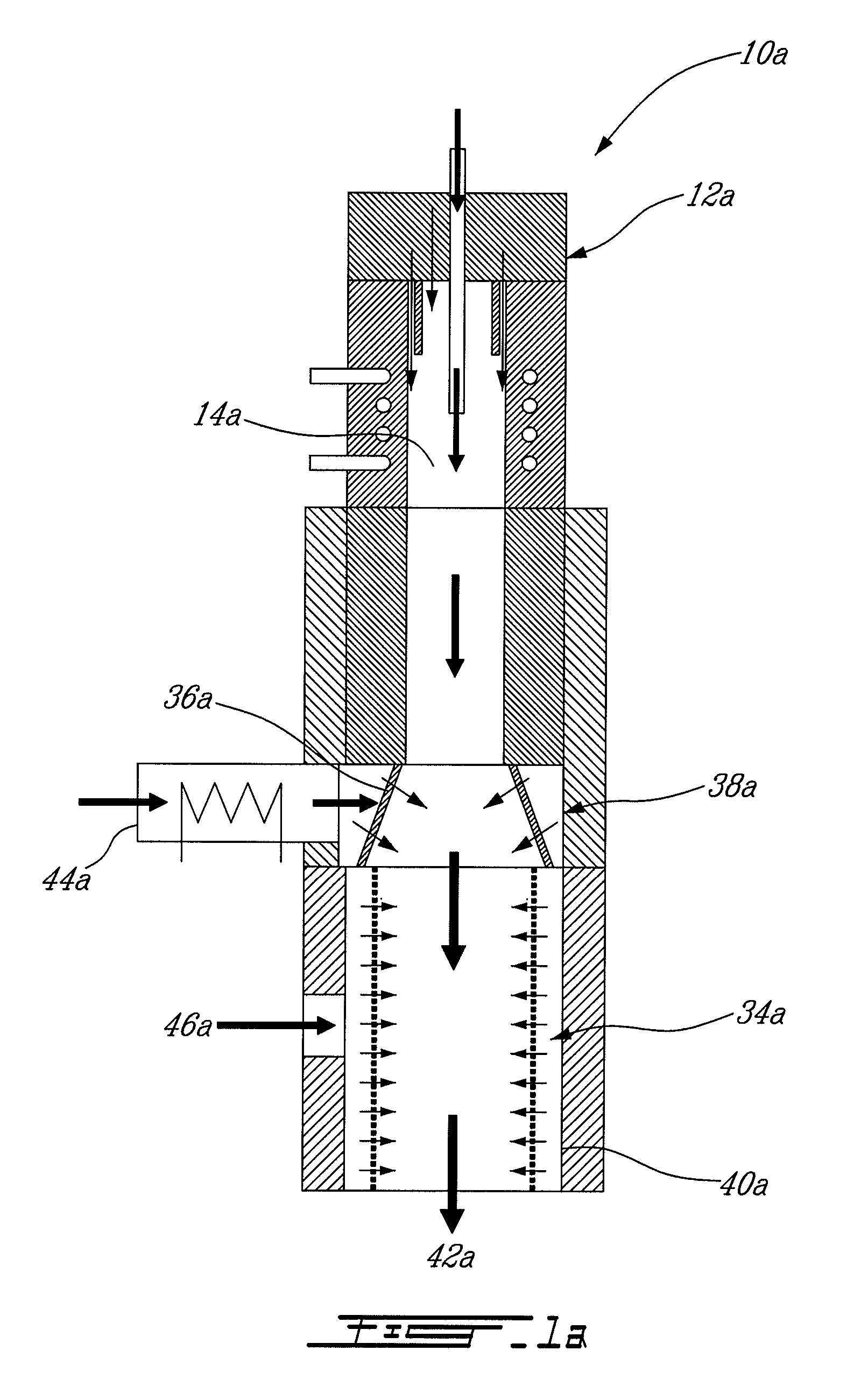

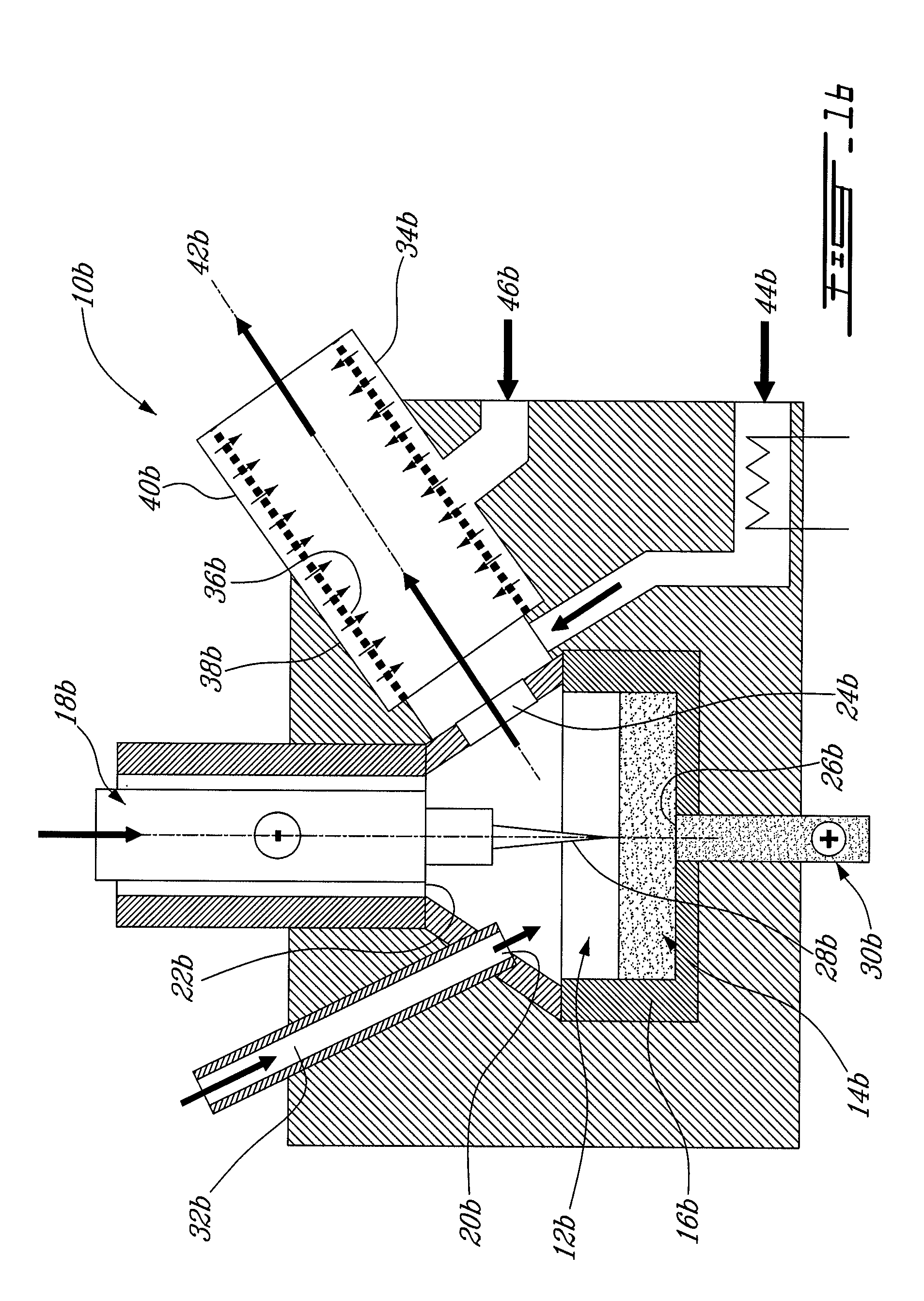

ActiveUS20070221635A1Improve scalabilityReduce the possibilityArc welding apparatusPlasma techniquePlasma flowQuenching

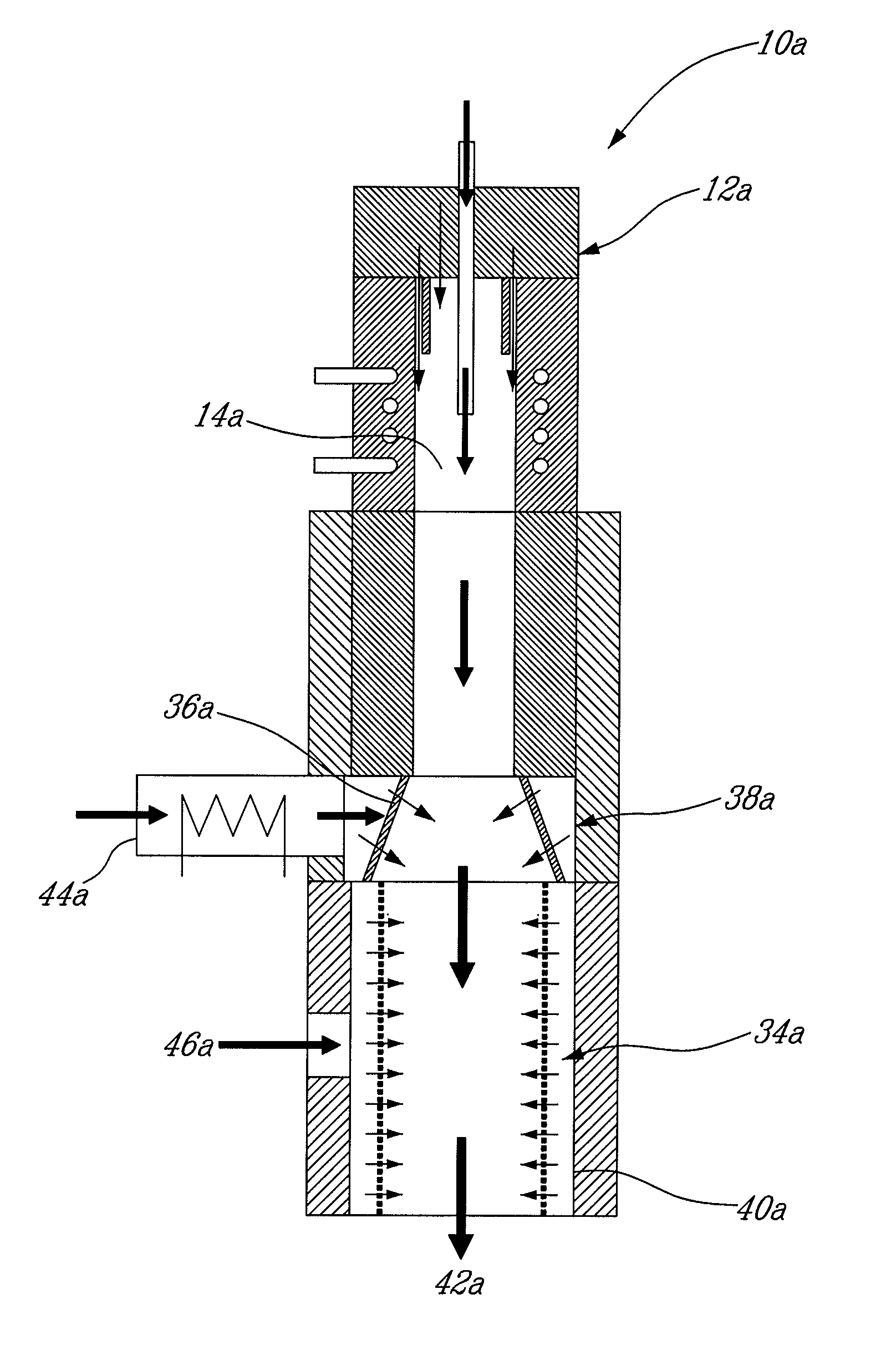

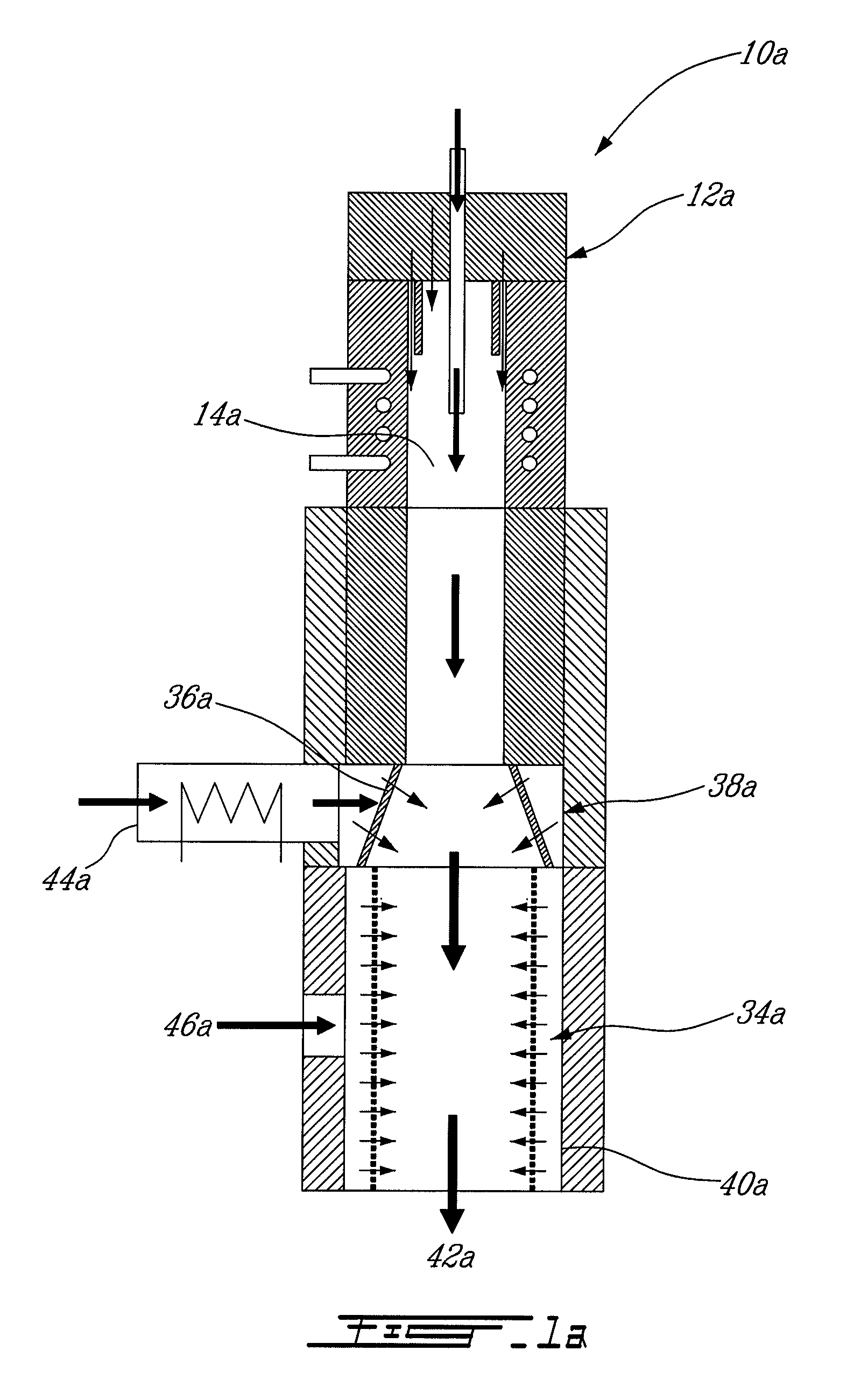

A process and apparatus for preparing a nanopowder are presented. The process comprises feeding a reactant material into a plasma reactor in which is generated a plasma flow having a temperature sufficiently high to vaporize the material; transporting the vapour by means of the plasma flow into a quenching zone; injecting a preheated quench gas into the plasma flow in the quenching zone to form a renewable gaseous condensation front; and forming a nanopowder at the interface between the renewable controlled temperature gaseous condensation front and the plasma flow.

Owner:TEKNA PLASMA SYST INC

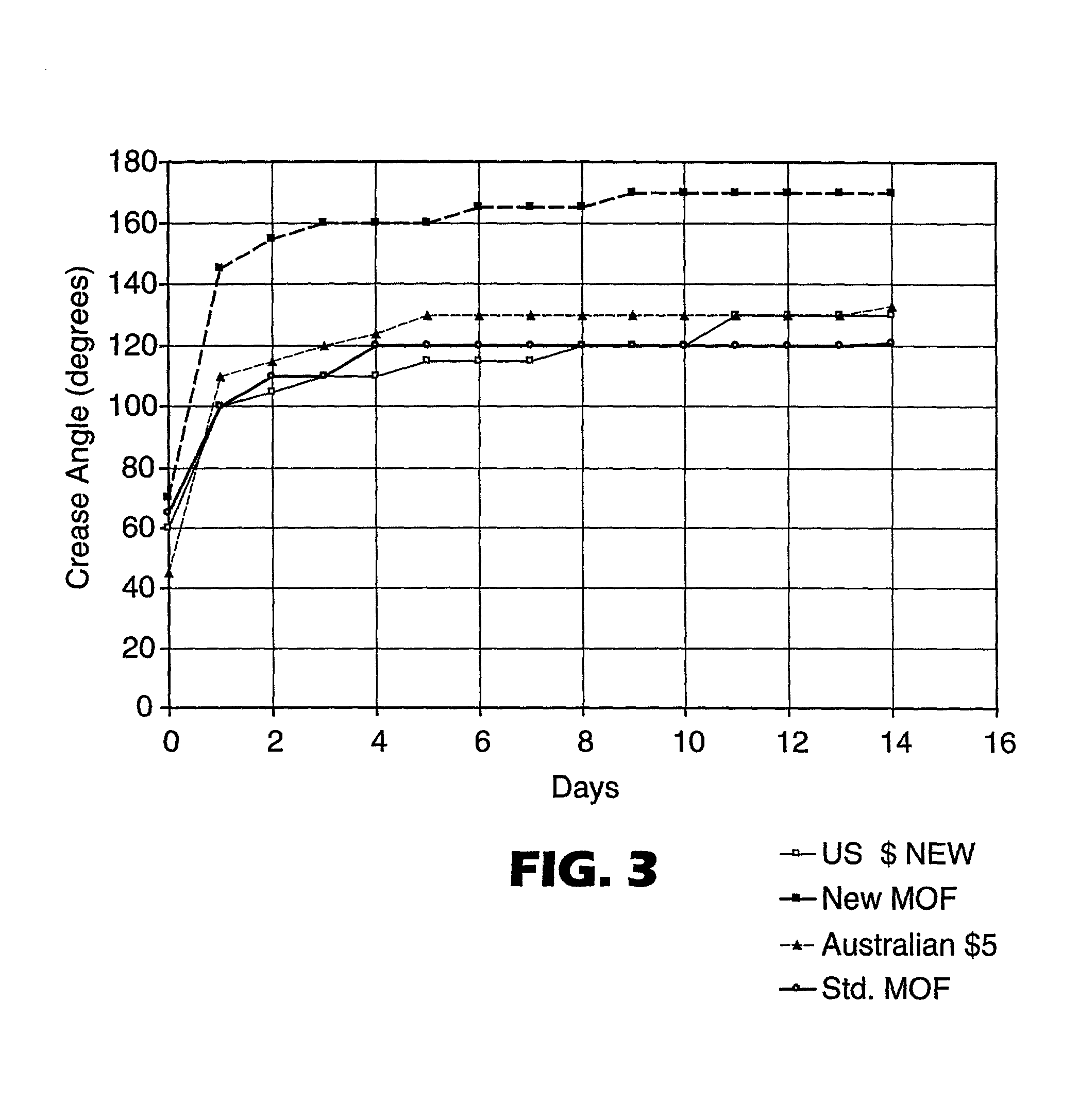

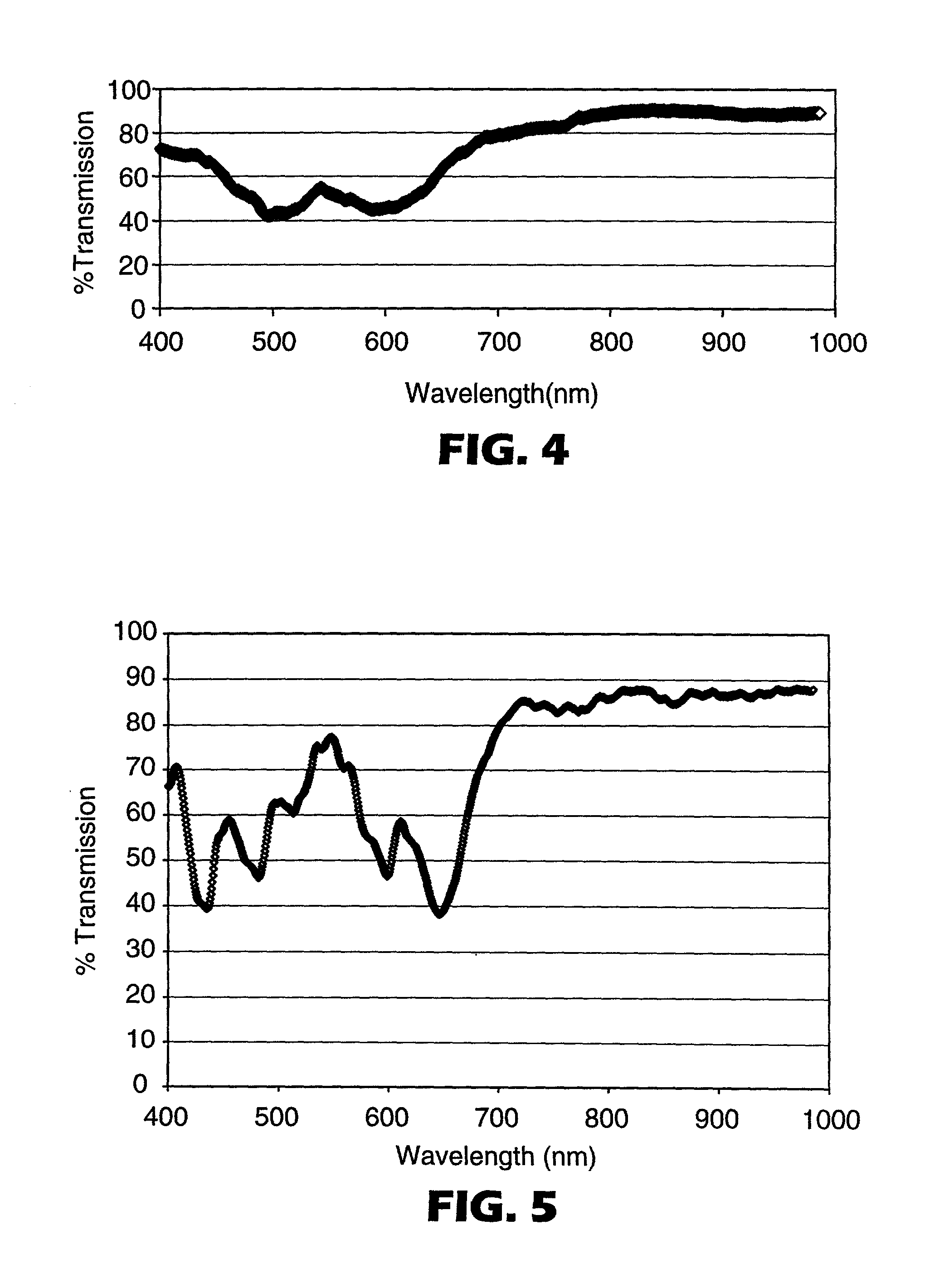

Low Tg multilayer optical films

InactiveUS20030072931A1Fine creaseExcellent crumple recoveryLayered productsPolarising elementsThermoplasticPliability

Multilayer optical films are comprised of materials with glass transition temperatures below room temperature (<30° C.). The high refractive index polymers are unique in that they exhibit mechanical properties similar to other low Tg semi-crystalline polymers, yet have significant birefringence (>0.05) when strain induced oriented. Novel combinations of comonomers for thermoplastics control the rate of crystallinity for improved processability and flexibility, giving the films crease and crumple recovery advantages.

Owner:3M INNOVATIVE PROPERTIES CO

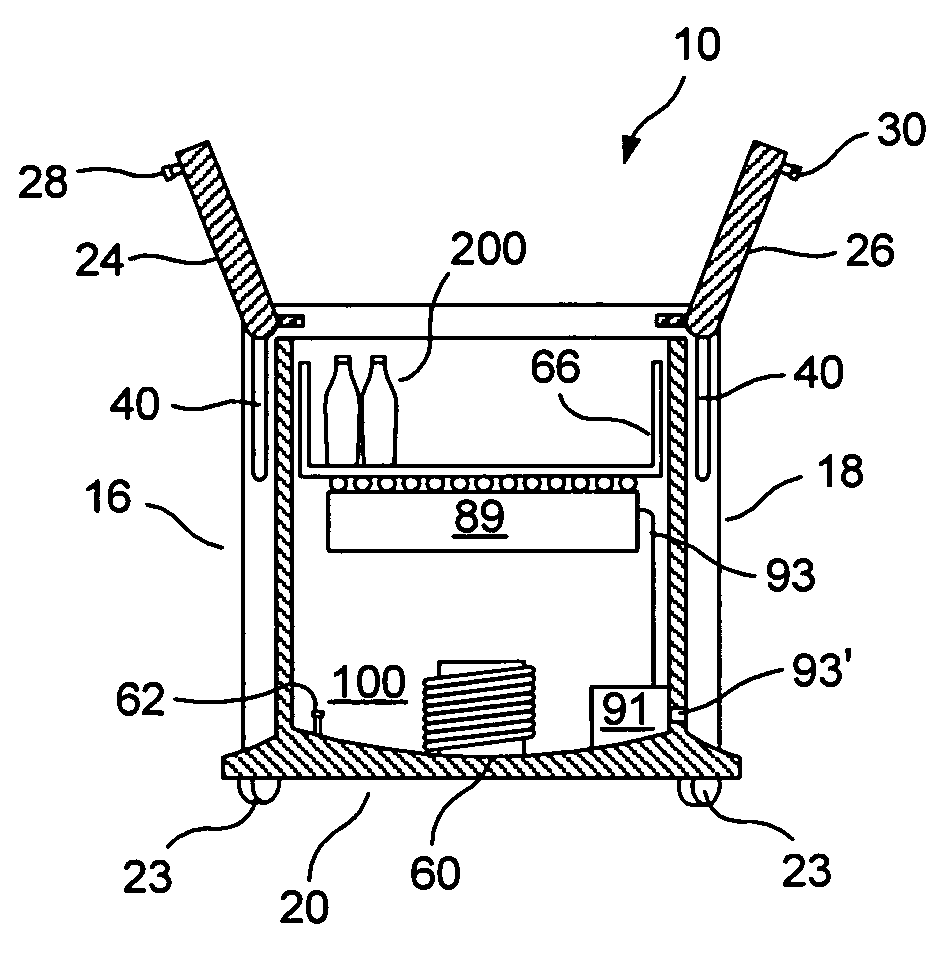

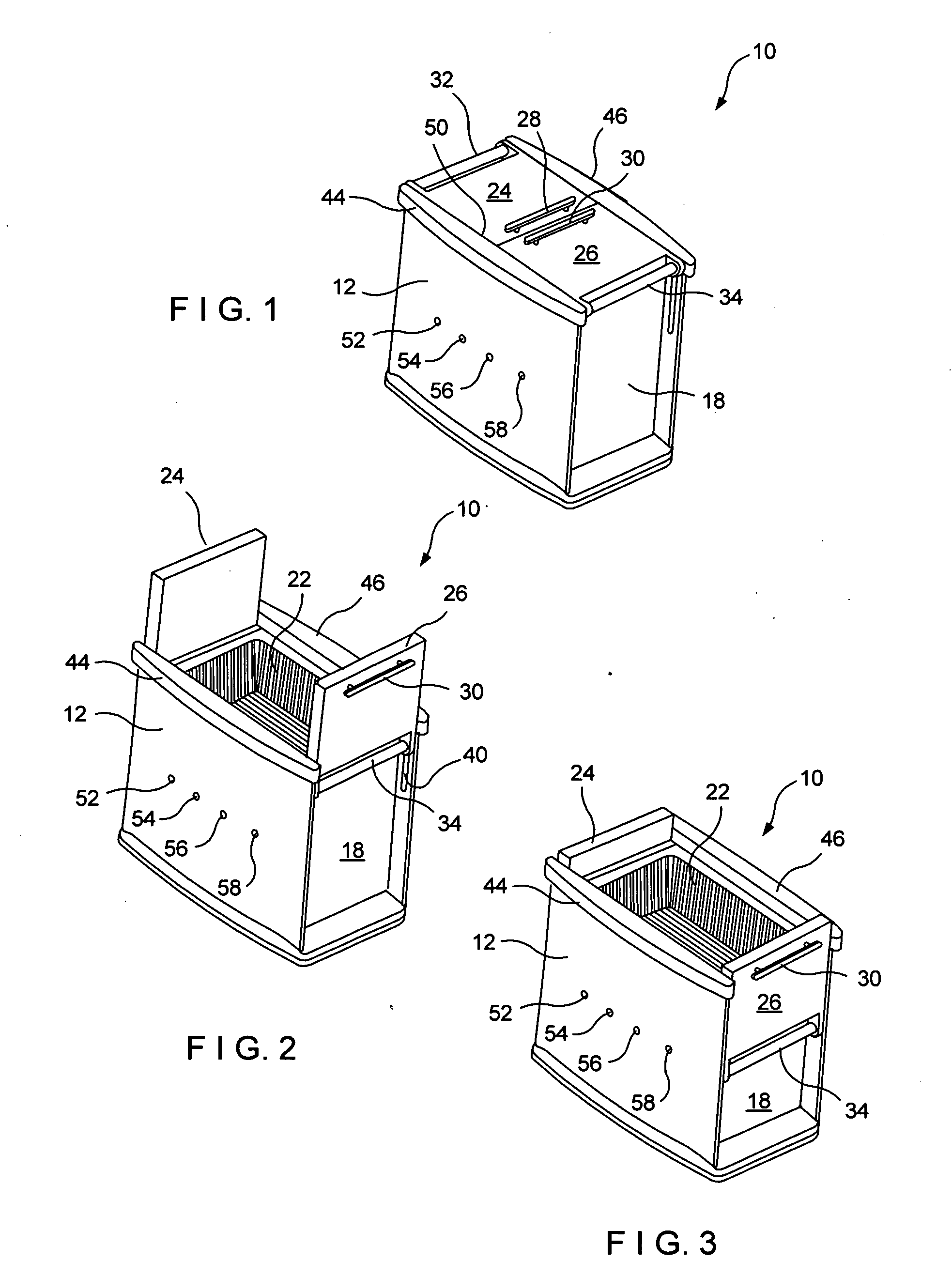

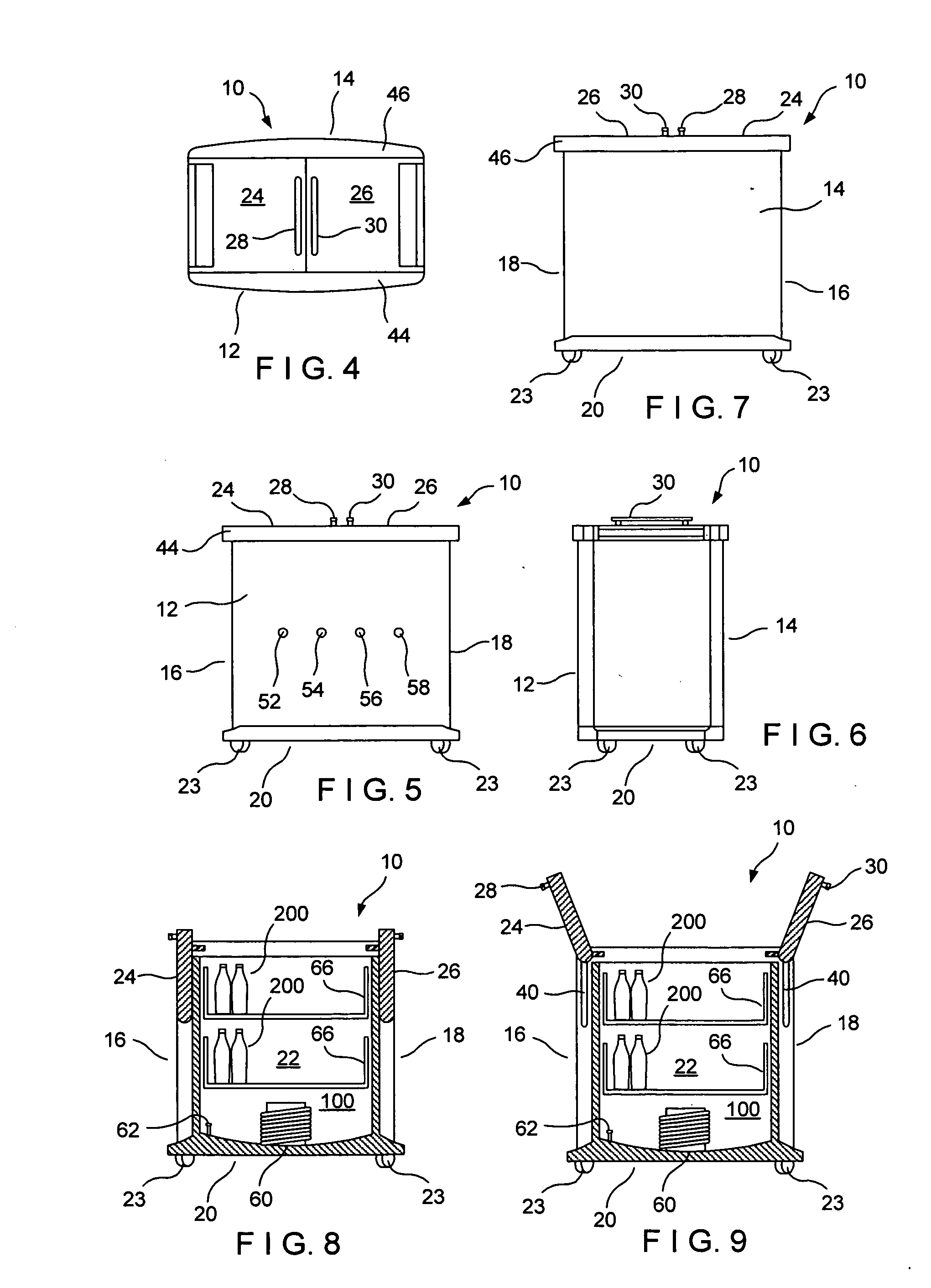

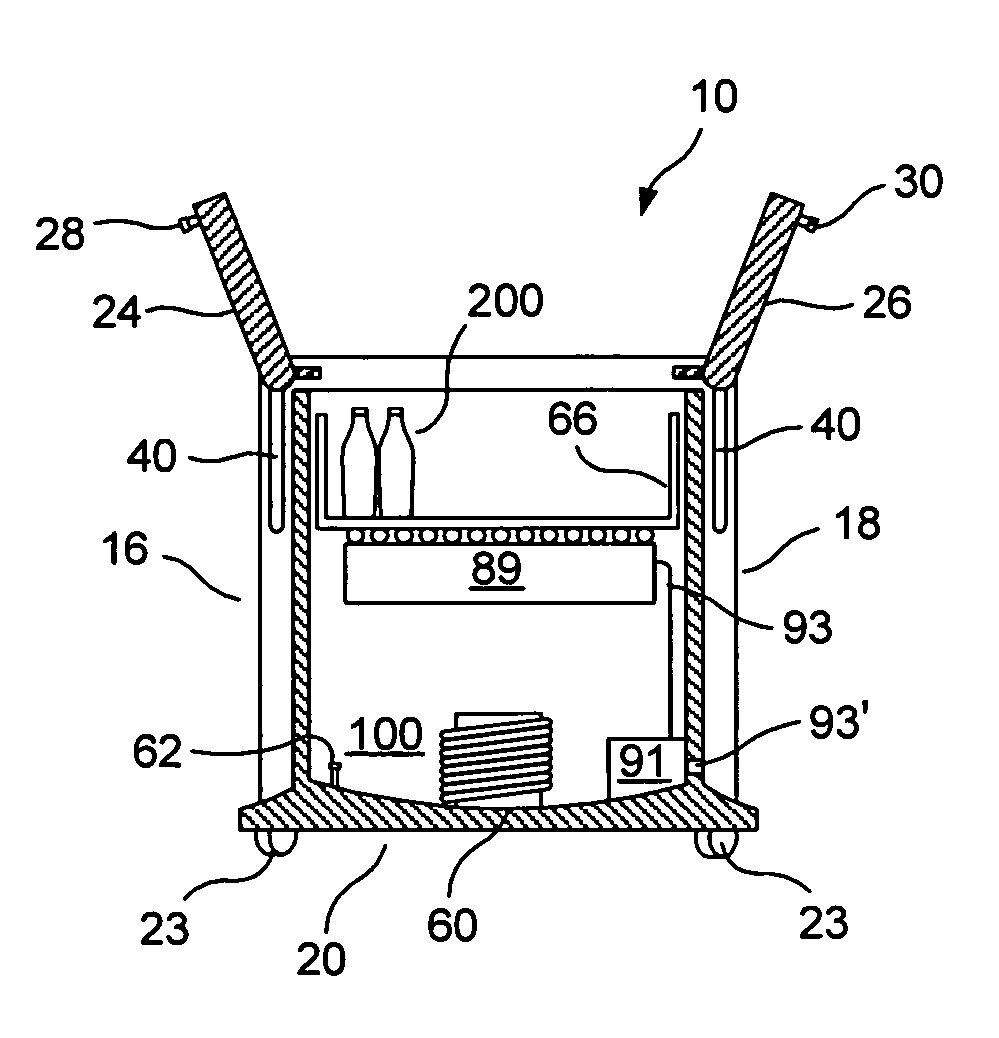

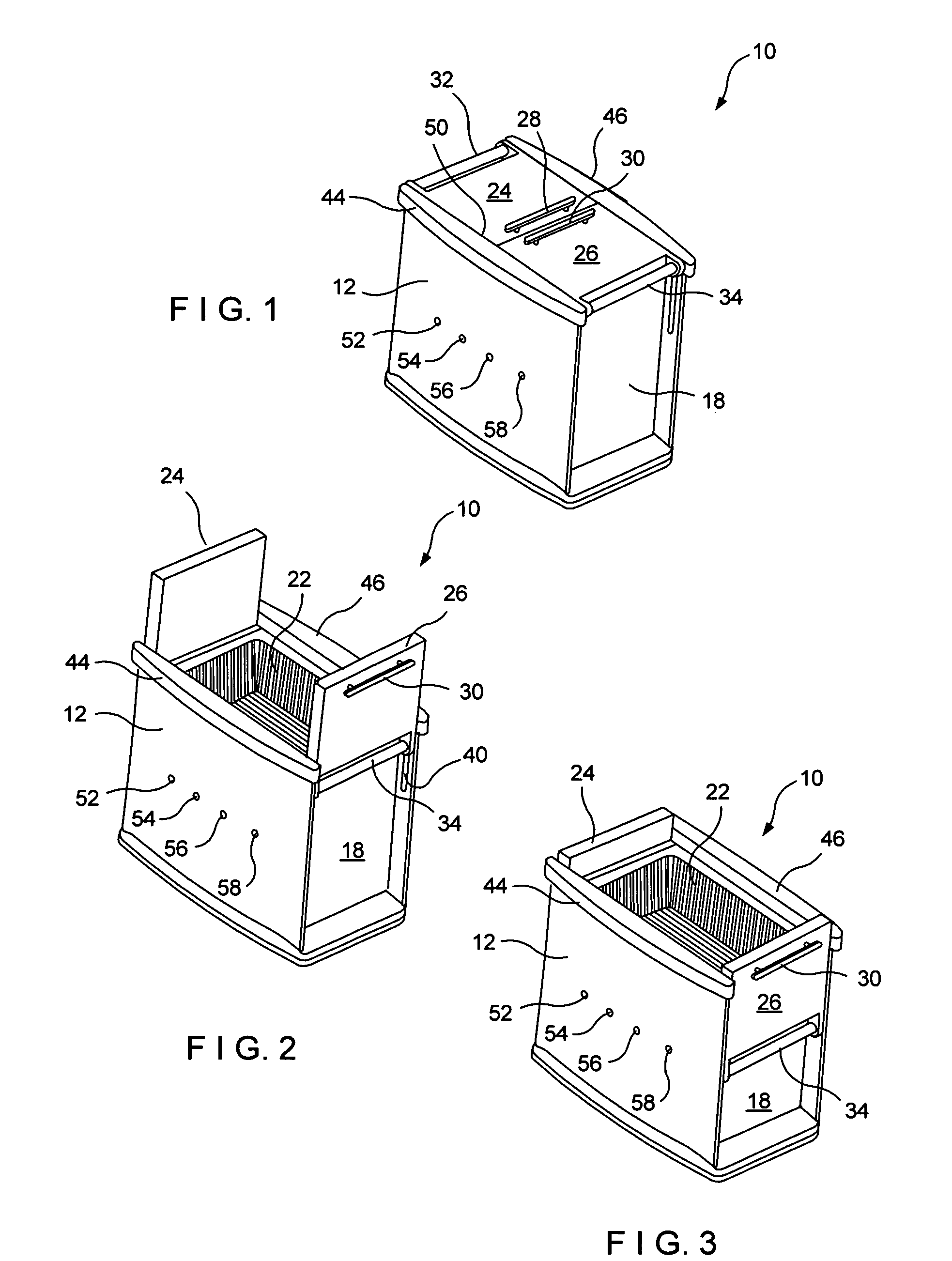

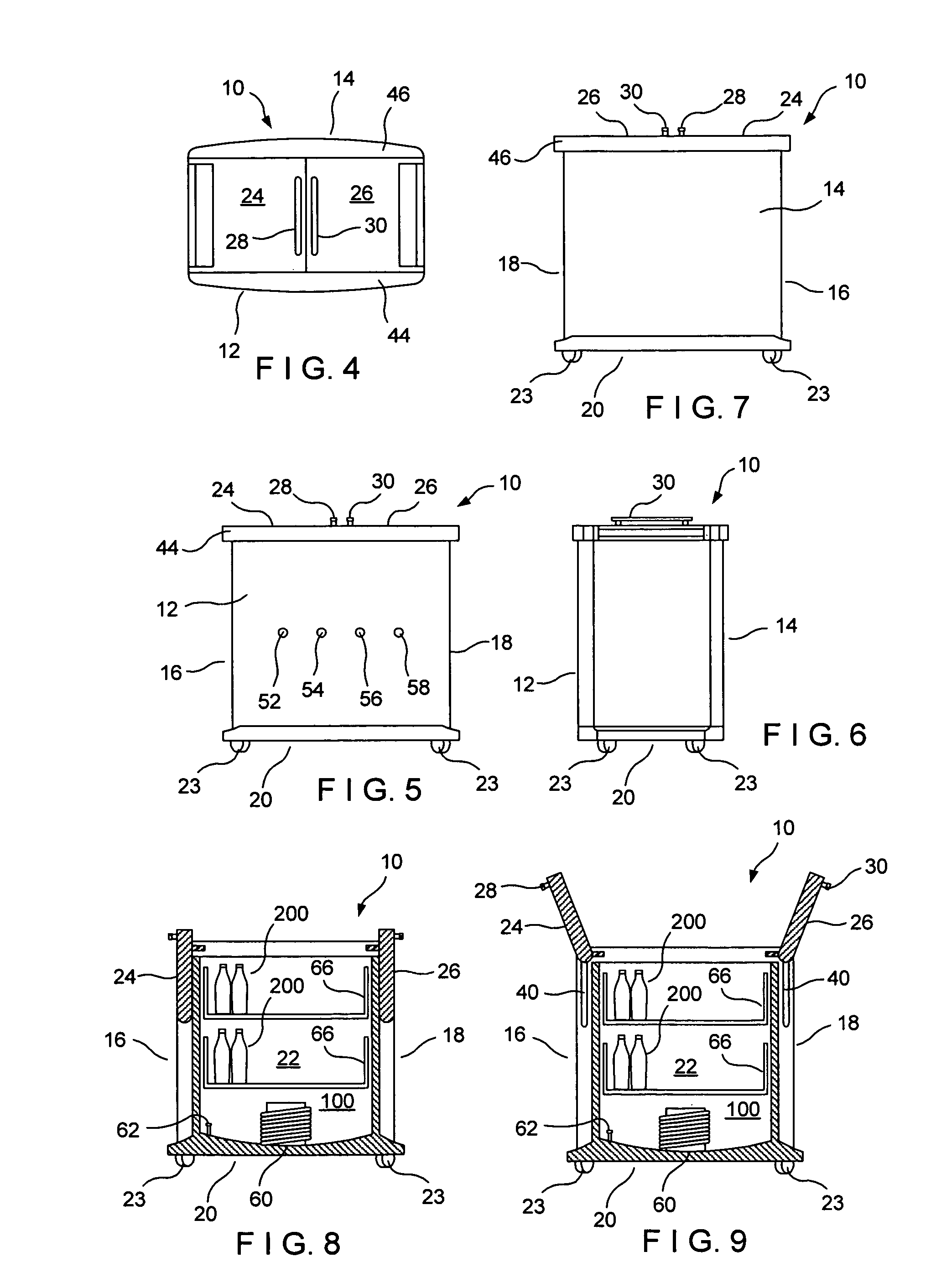

Refrigerated chest for rapidly quenching beverages and visually identifying when such beverages reach target temperature

InactiveUS20100251755A1Fast coolingFast quenchingLighting and heating apparatusCooling fluid circulationSaline waterSalt water

The cooling chest for rapidly quenching beverages includes a quench tray for holding containers of beverage. The quench tray is lowered into salt-water or other cooling liquid which is cooled by a refrigeration unit. A processing device determines the temperature of the beverages within the containers within the quench tray and further activates a mechanism for removing the quench tray from the water or cooling liquid when the desired temperature is reached. The processing device can also activate the mechanism for removing the quench tray from the water or cooling liquid when the upper lid or access doors are opened.

Owner:LAUCHNOR JOHN C

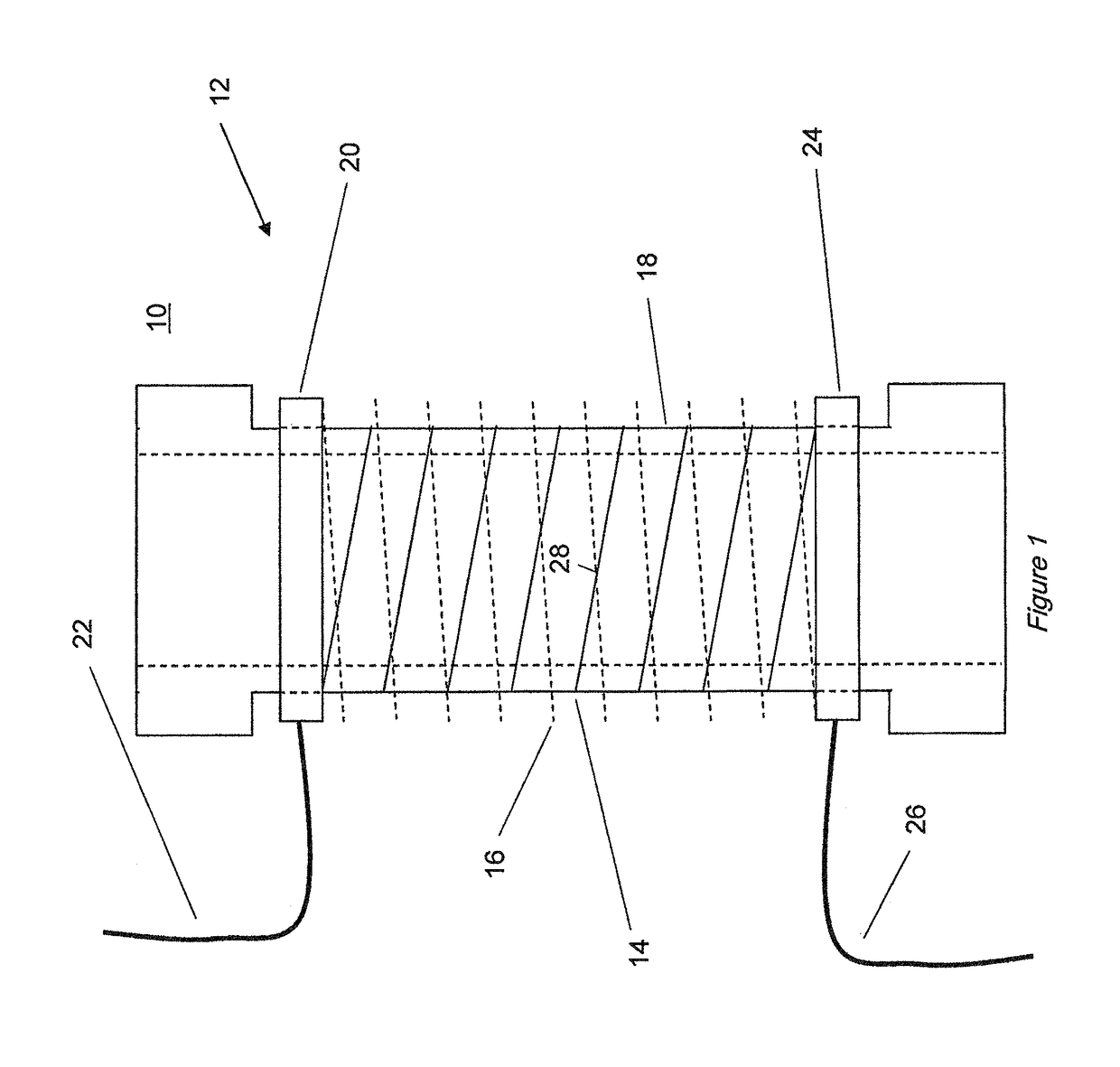

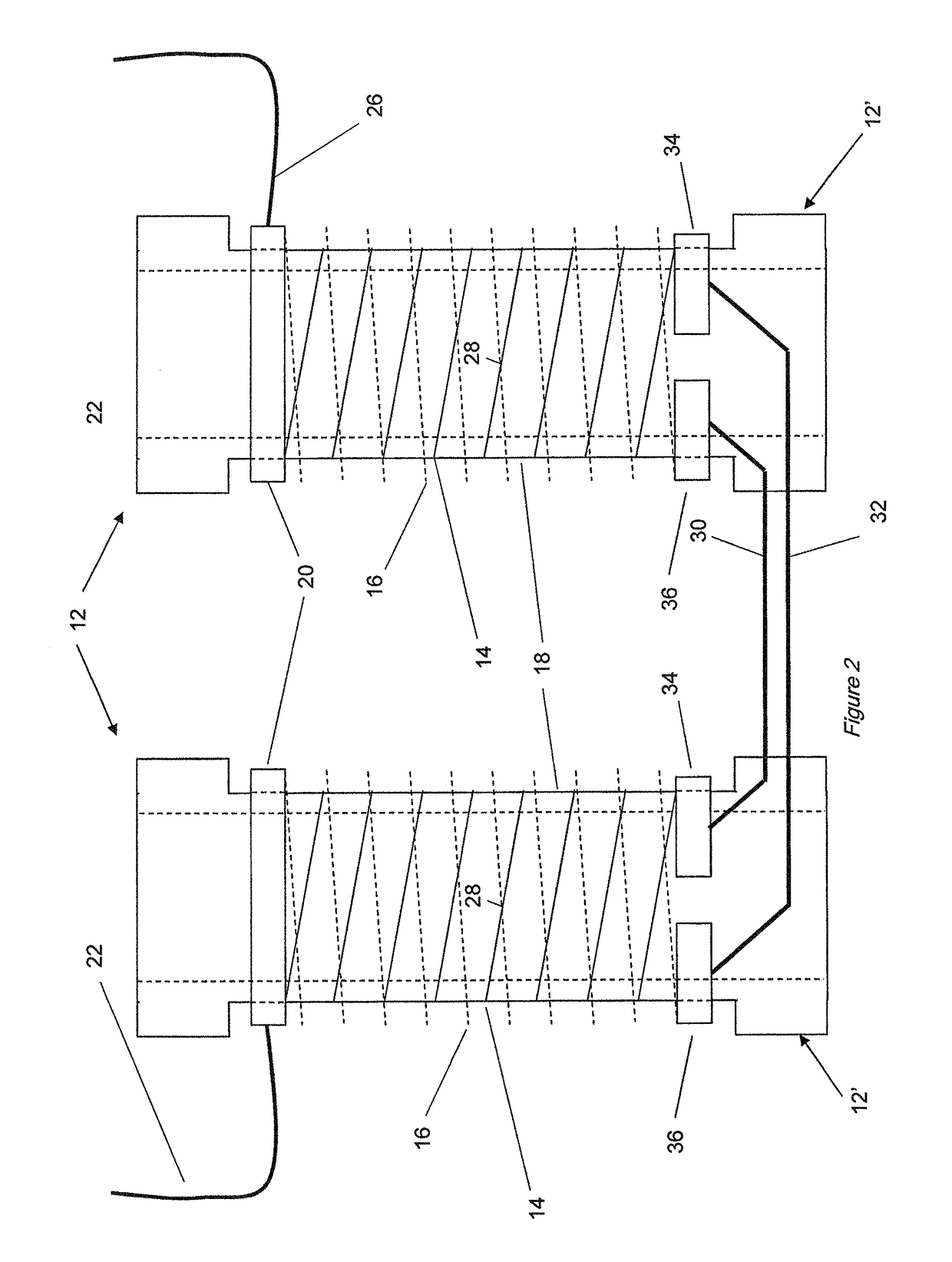

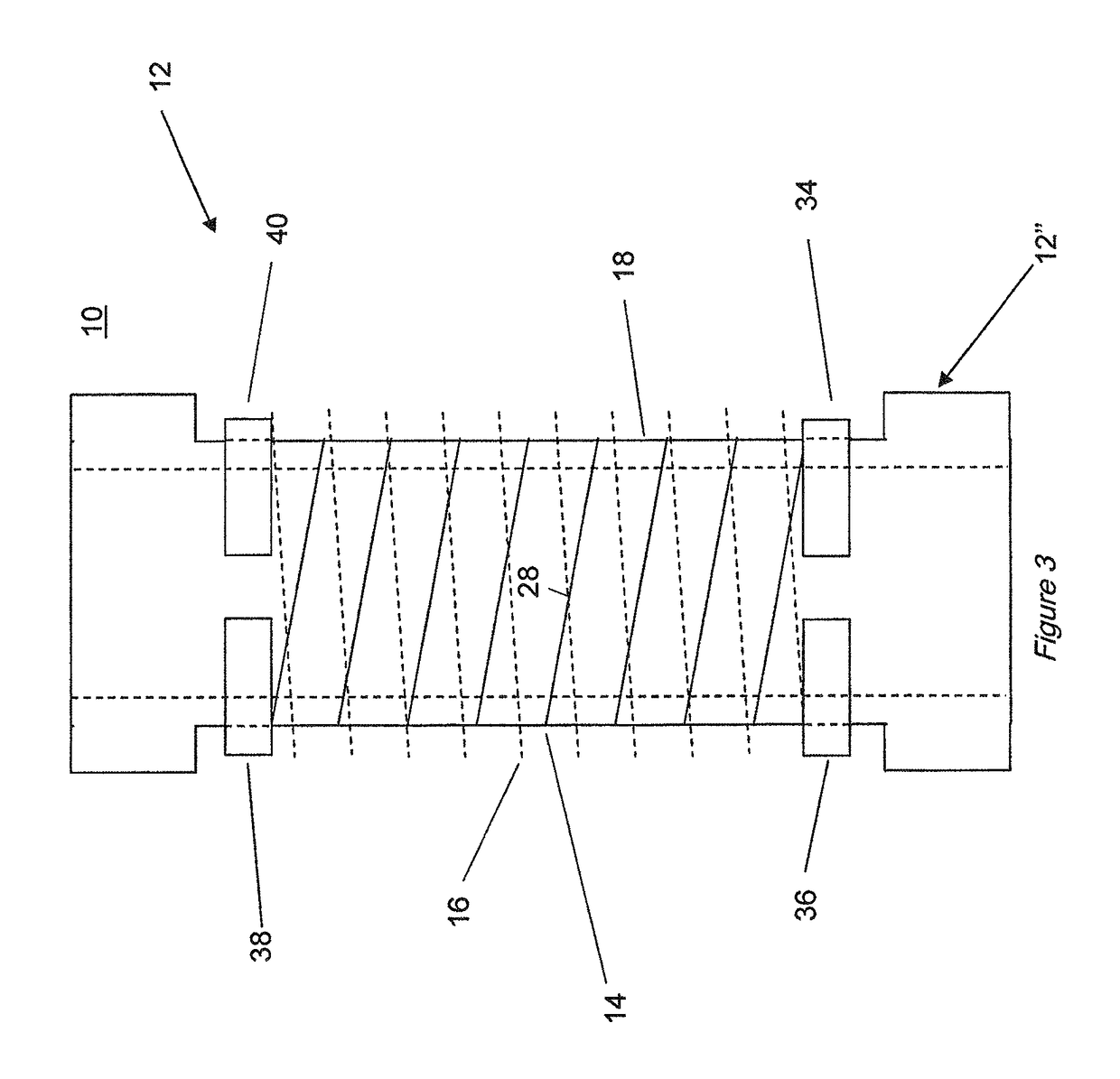

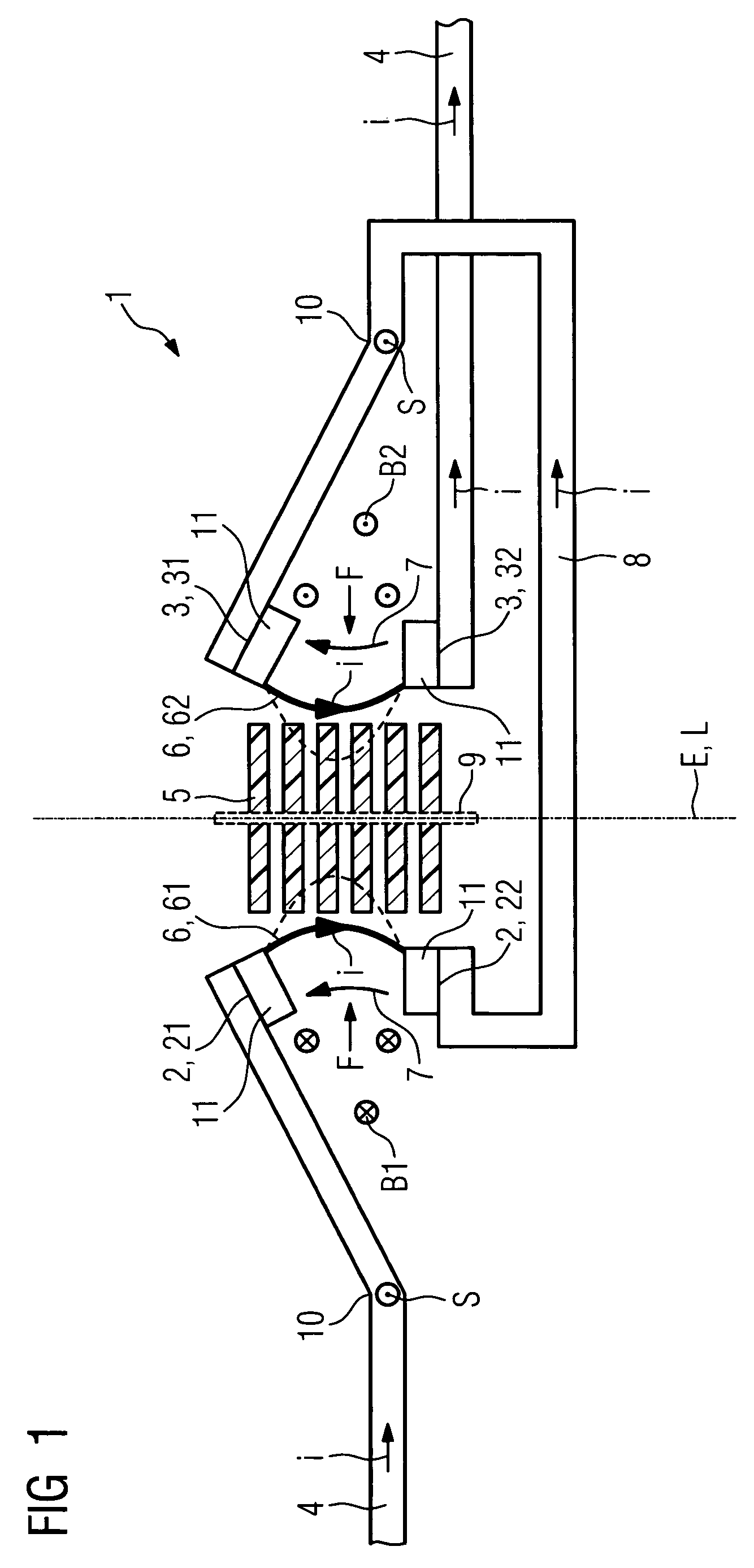

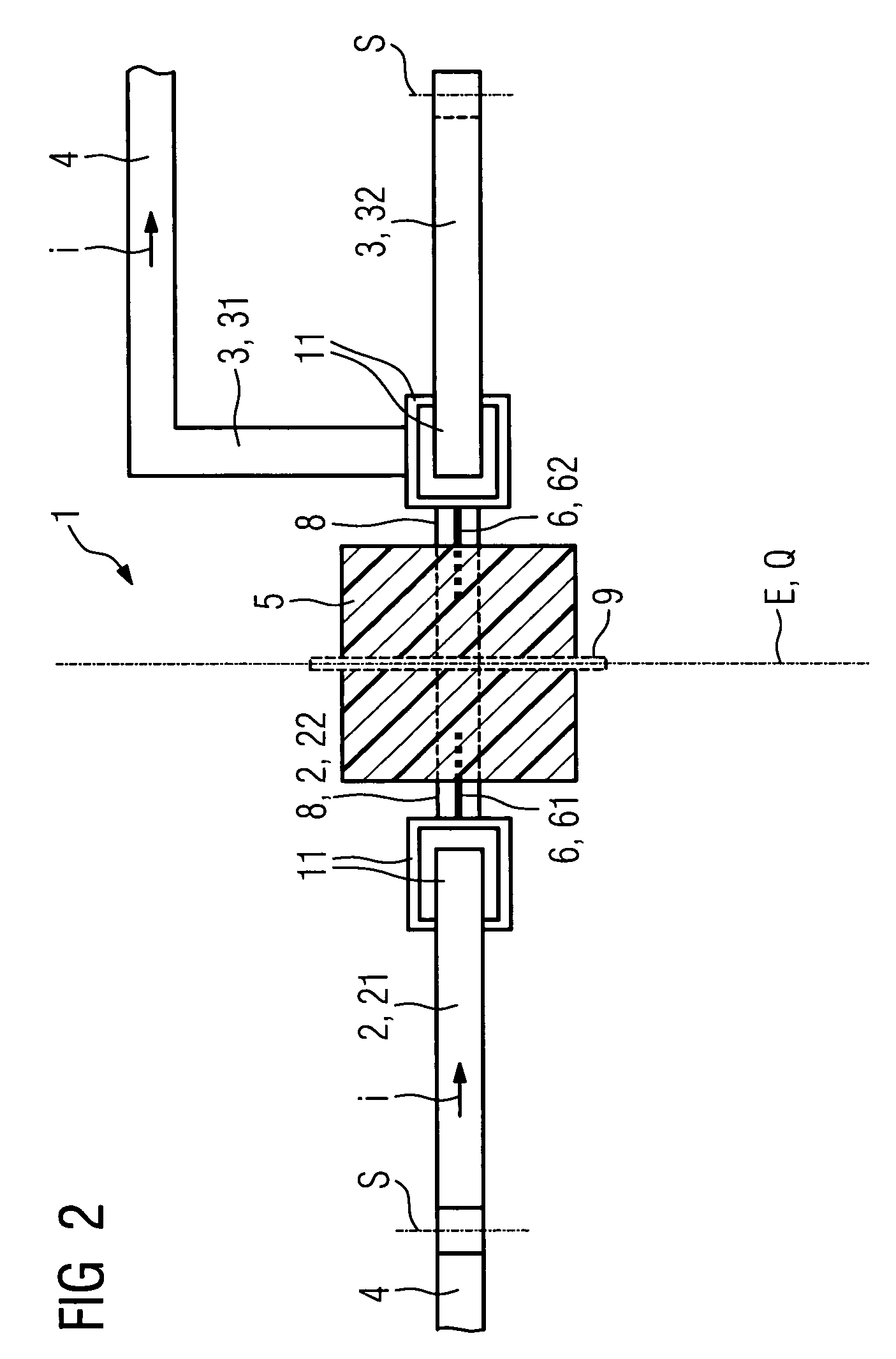

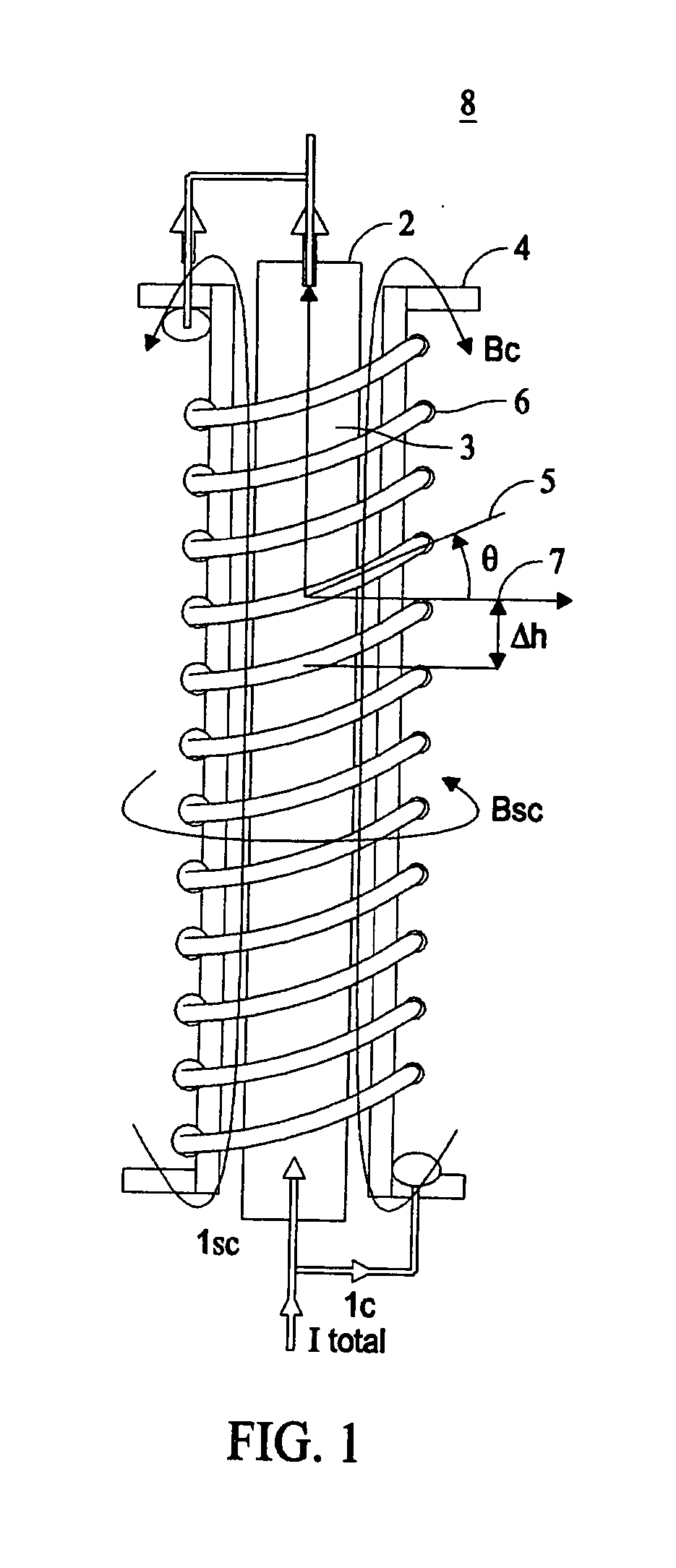

Device for a current limiter and a current limiter comprising said device

ActiveUS10186858B2Rapid and even transitionHigh proportionSuperconducting magnets/coilsNormal-superconductive switchable devicesSuperconducting fault current limitersEngineering

A device (10) for a current limiter is described, the device (10) comprising: at least one coil assembly (12) adapted to carry a current, the coil assembly (12) comprising: a first coil (14), comprising a first superconducting element, adapted to carry a first portion of said current, and a second coil (16), comprising a second superconducting element, adapted to carry a second portion of said current, wherein said first and second coils (14, 16) are arranged such that, when said first and second superconducting elements are each in a superconducting state and said coil assembly (12) carries said current, a magnetic field generated by said first portion of said current in said first coil (14) is substantially cancelled by a magnetic field generated by said second portion of said current in said second coil (16); and wherein said device is adapted such that, in use, the first superconducting element carries a higher proportion of said current than the second superconducting element. The device may be used in a superconducting fault current limiter to provide a low inductance during normal operation and a rapid and even quench under fault current conditions.

Owner:ROLLS ROYCE PLC

High strength Al-Mg-Zn-Si alloy for welded structures and brazing application

InactiveUS6302973B1Improve corrosion resistanceHigh strengthWelding/cutting media/materialsSoldering mediaMagnesiumZinc

Aluminium-magnesium-zinc-silicon alloy, preferably in the form of a plate or a sheet or an extrusion, having the following composition in weight percent: Mg 0.5-1.5; Zn 0.1-3.8; Si 0.05-1.5; Mn 0.2-0.8; Zr 0.05-0.25; Cr 0.3 max.; Cu<0.3; Fe 0.5 max.; Ag 0.4 max.; Ti 0.2 max.; balance Al and inevitable impurities.

Owner:HOOGOVENS ALUMINIUM PROFILTECHNIK GMBH +1

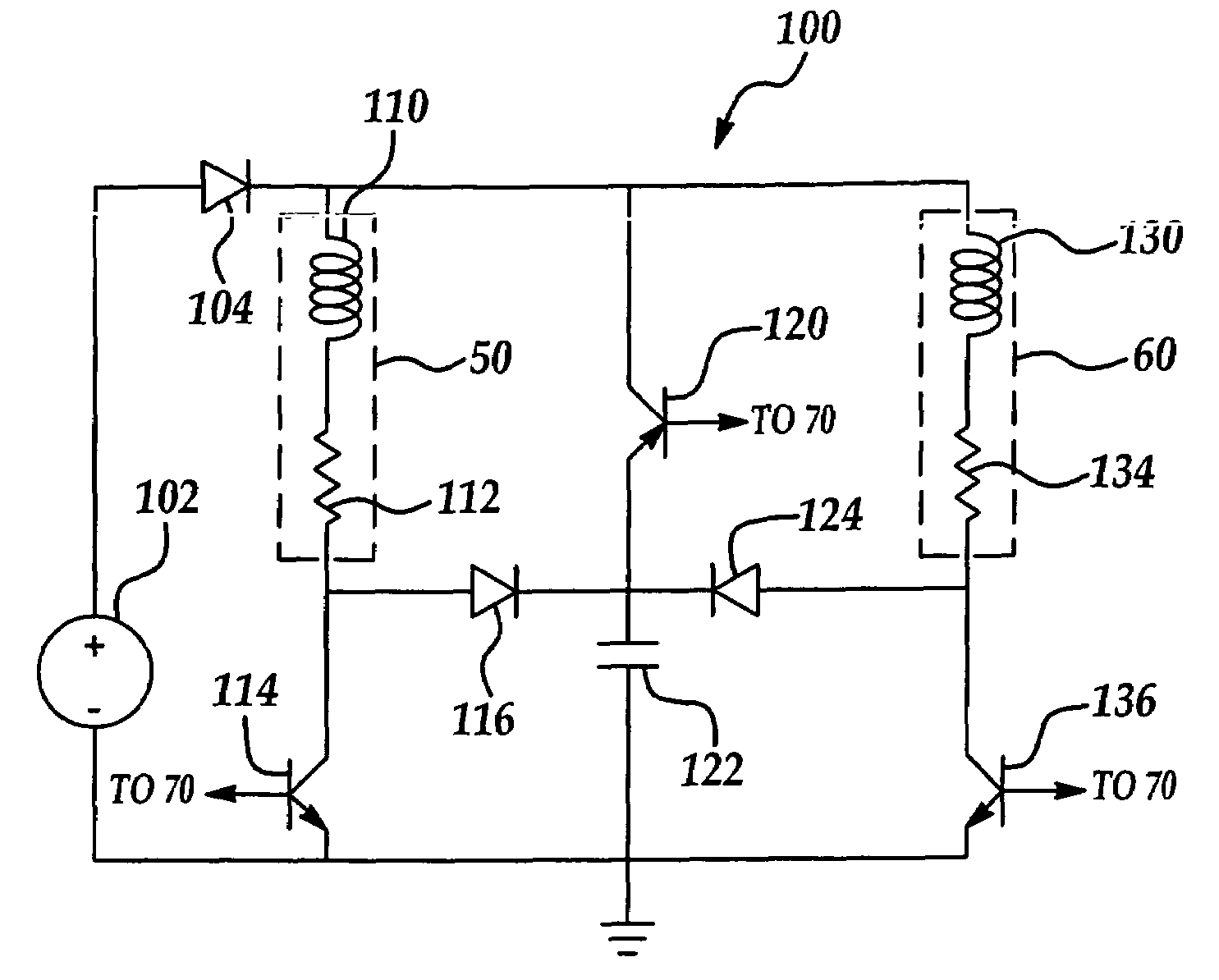

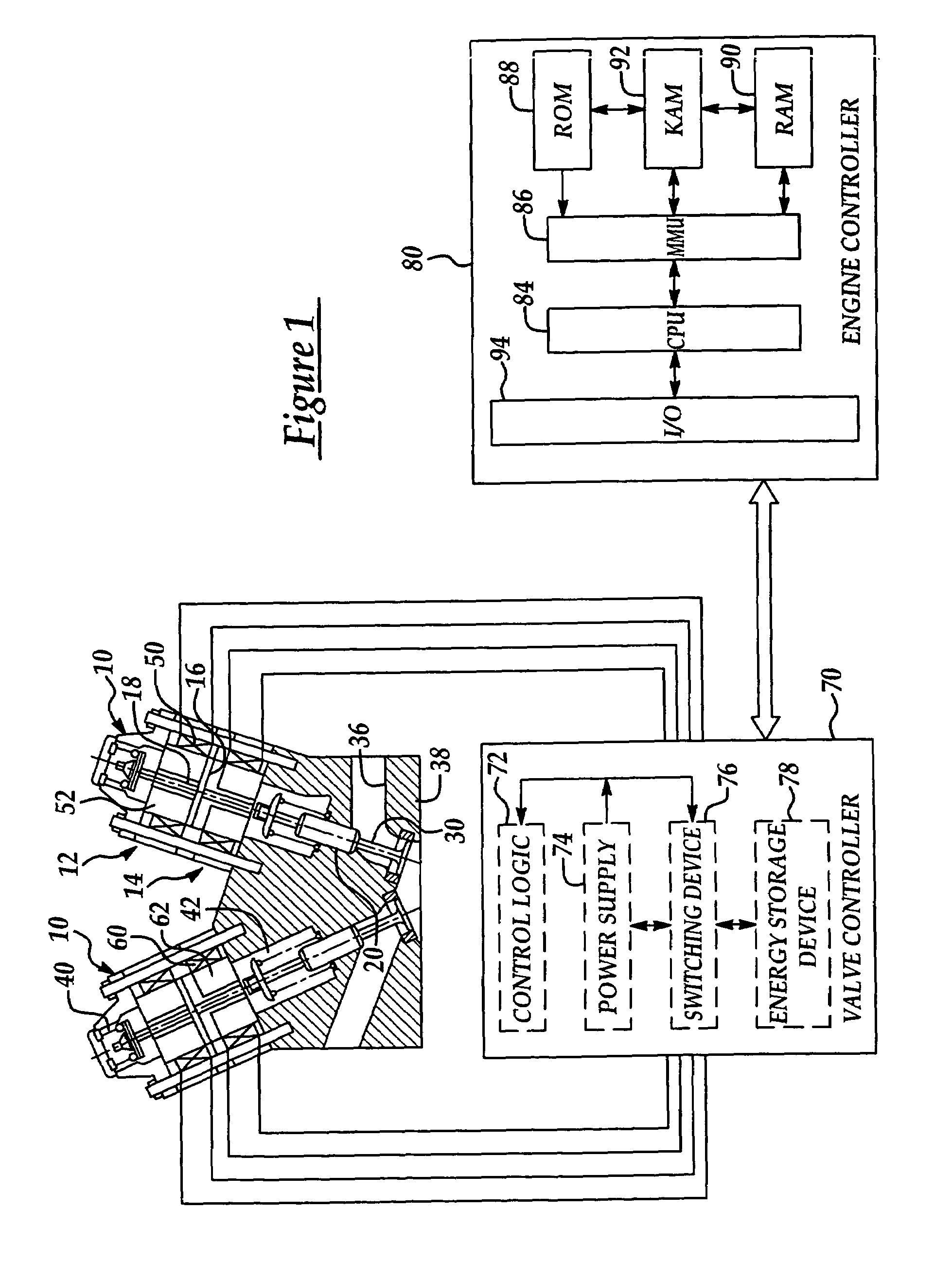

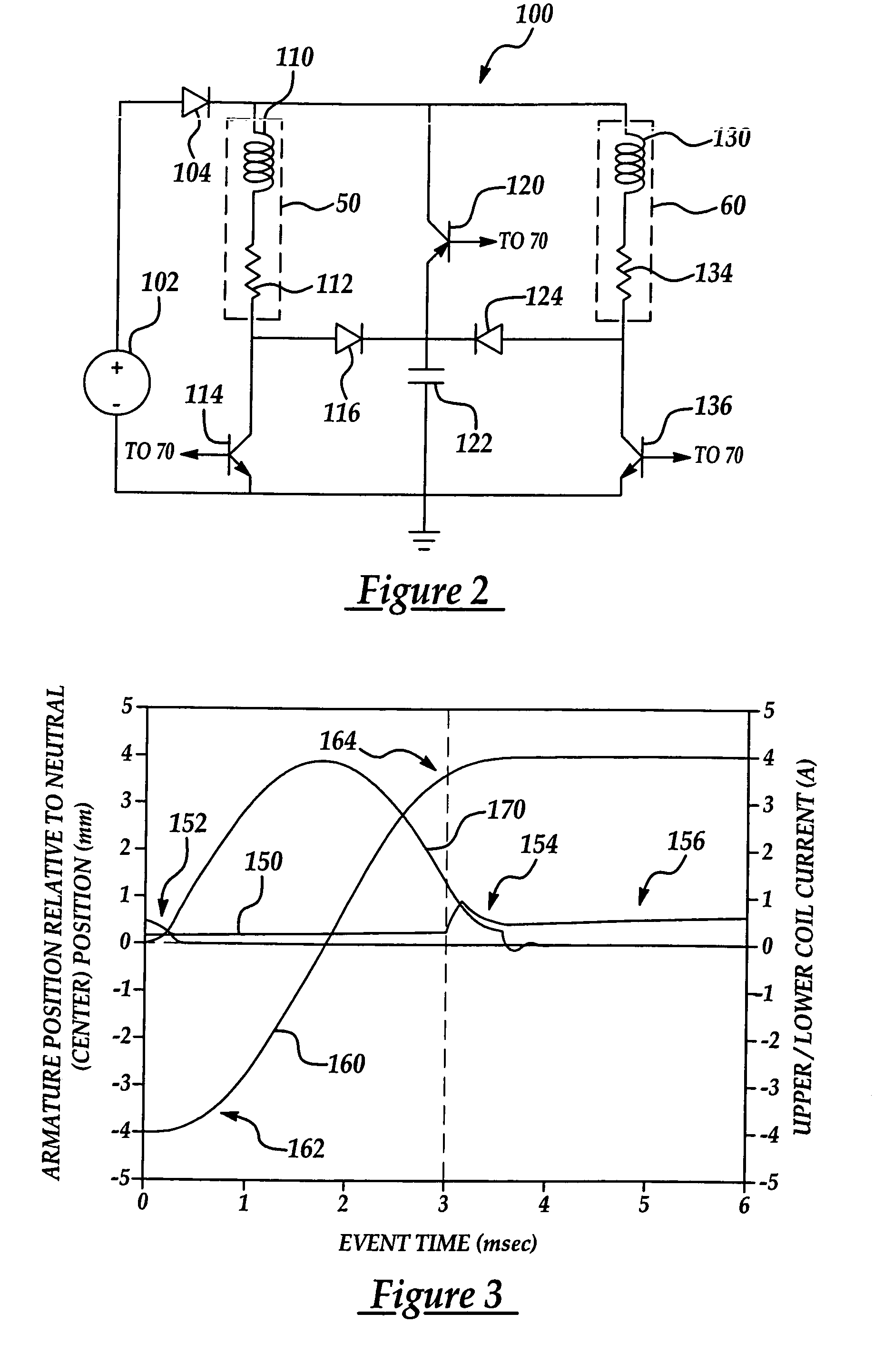

Electromagnetic valve actuation

ActiveUS6948461B1Loss of forceRapidly quench the coil currentOperating means/releasing devices for valvesElectric switchesCombustion chamberControl system

A system and method for controlling an internal combustion engine provide valve actuation that selectively couples an energy storage device to a launching coil to recover energy stored in the magnetic field and valve spring of the launching coil, decouples the energy storage device during a valve opening or closing event to control energy supplied to the catching coil, and couples the energy storage device to the catching coil to transfer energy from the storage device to the catching coil to provide a repeatable soft landing. A nonlinear feedback controller incorporates a feedforward system with an observer to control the rate of energy into the magnetic field of the catching coil while compensating for system losses and work to overcome gas forces within the combustion chamber. Feedback linearization techniques improve stability of the control system.

Owner:FORD GLOBAL TECH LLC

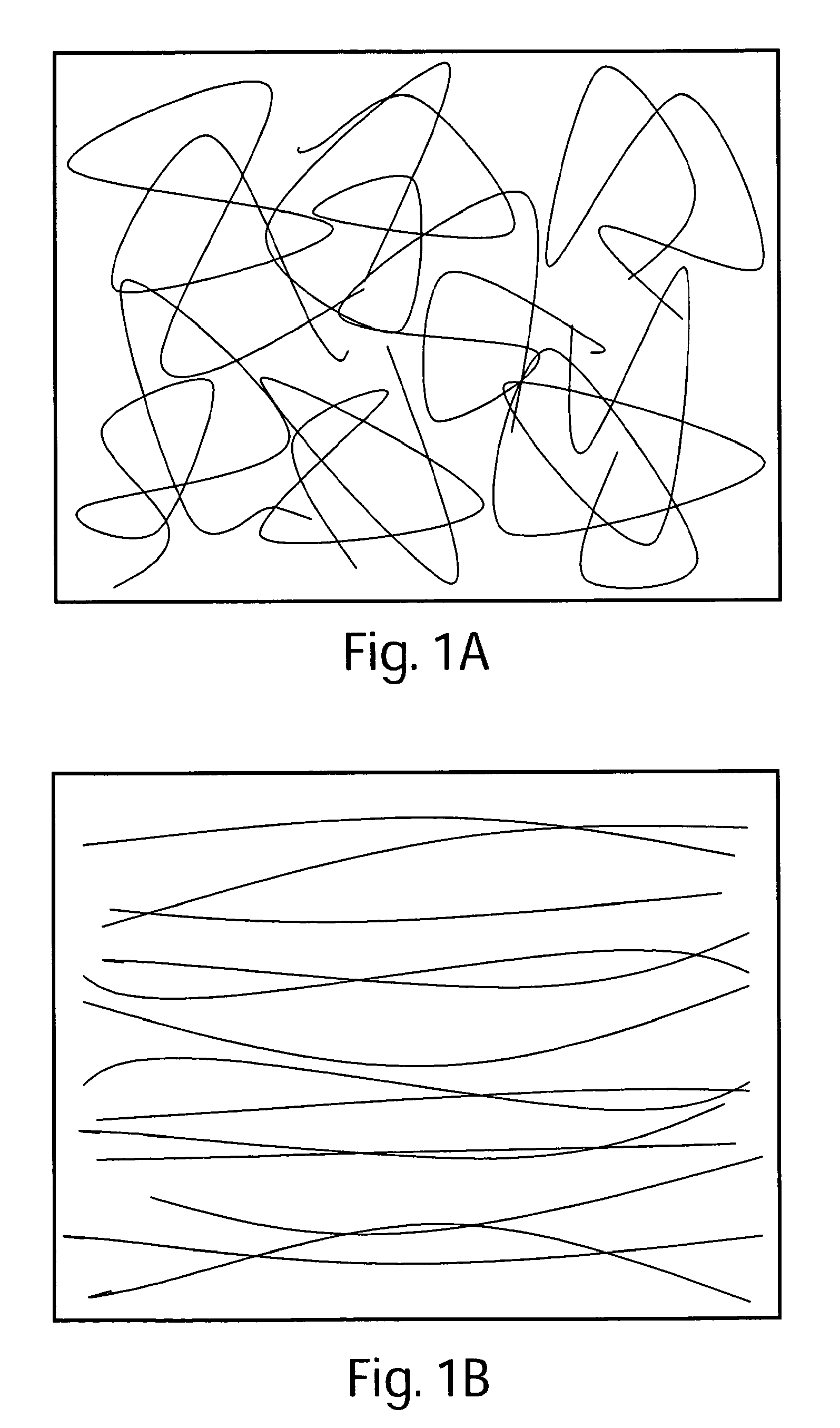

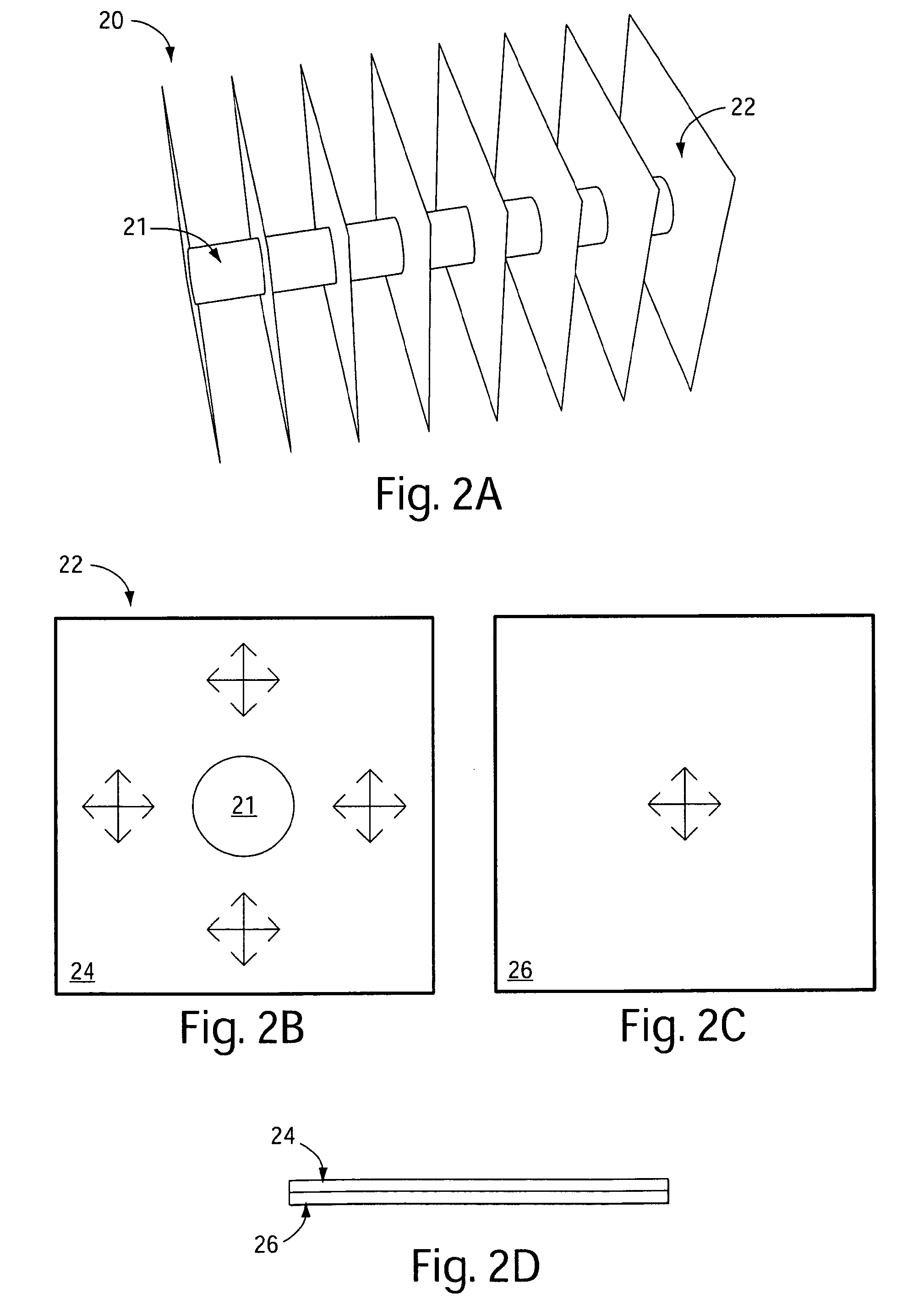

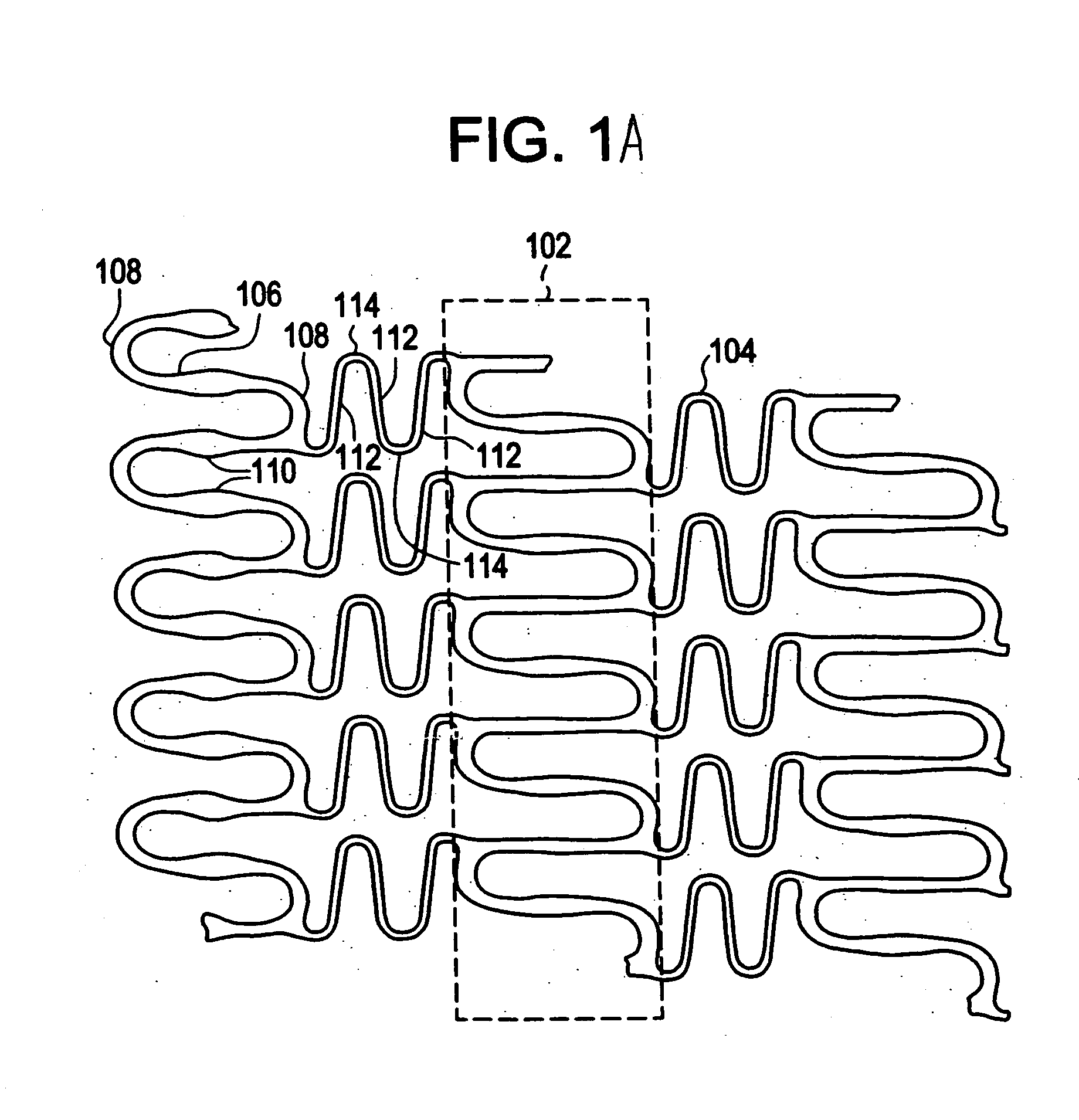

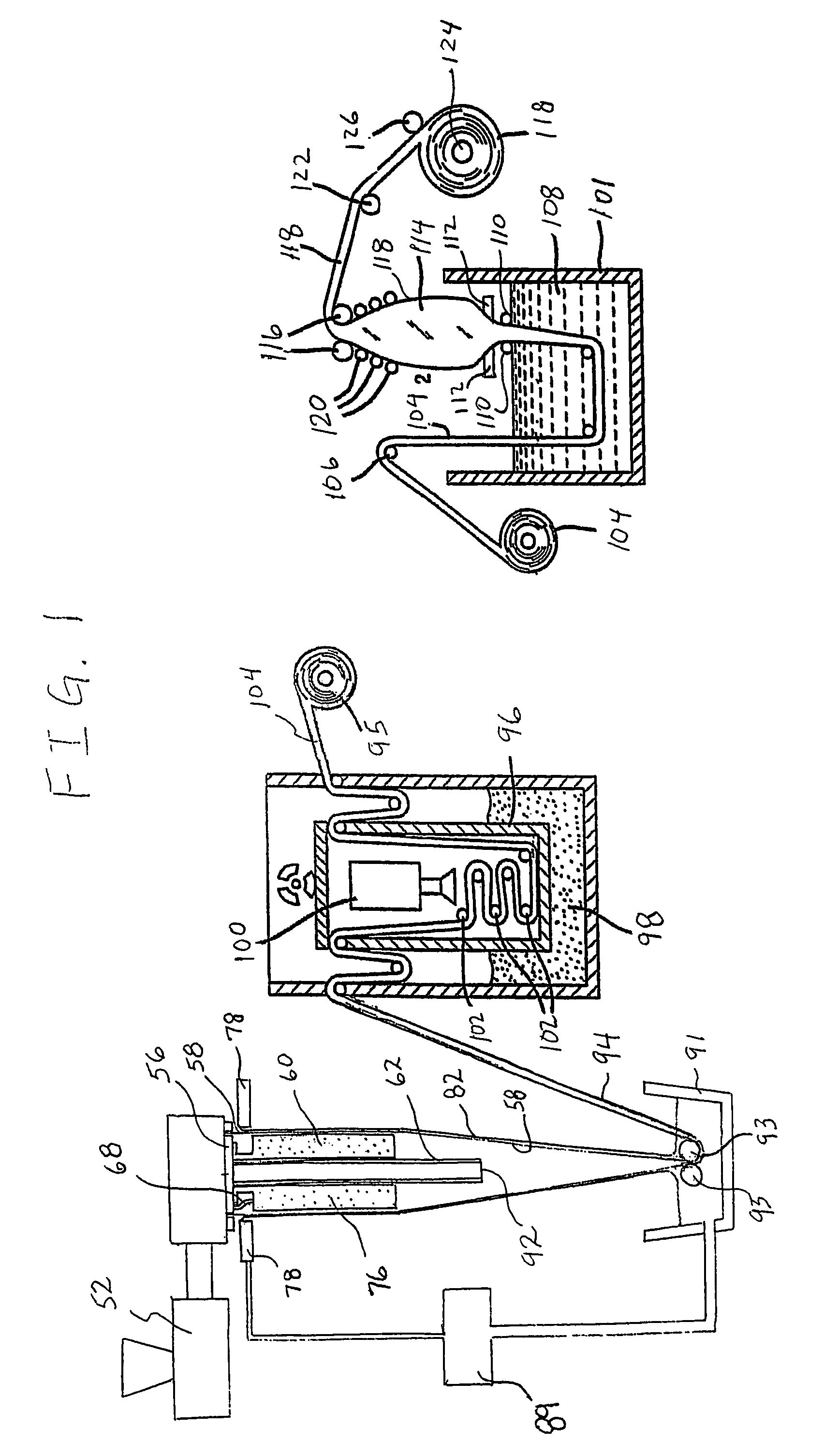

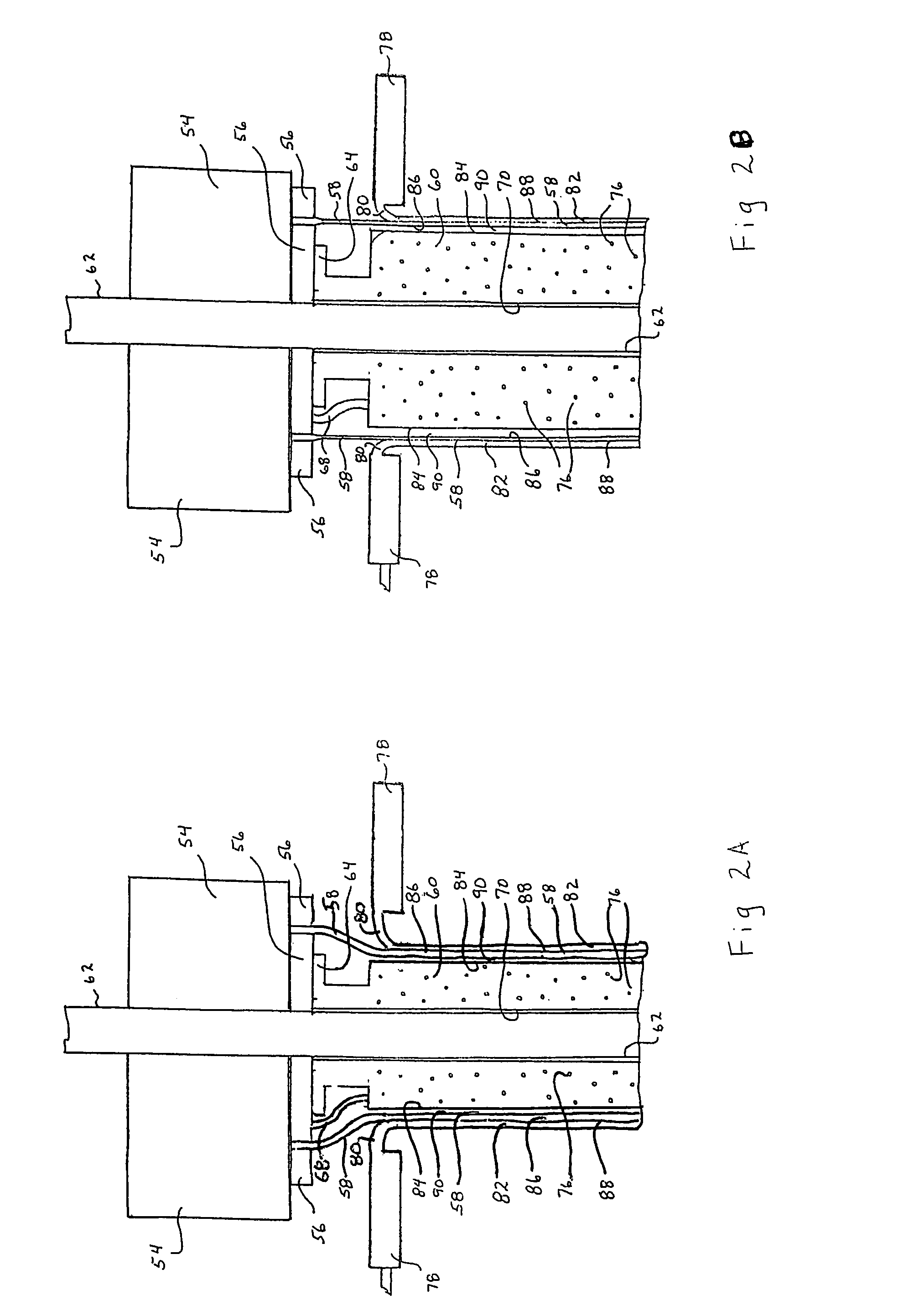

Polymer sheets and other bodies having oriented chains and method and apparatus for producing same

ActiveUS20100301258A1Rapid quenchingSynthetic resin layered productsPretreated surfacesPolymer sciencePolymer

that are made up of oriented polymer chains are provided. Chains of polymer may be oriented or substantially aligned in one or more directions exhibiting enhanced thermal conductivity along the direction of orientation. Orientation of polymers within sheets may lead to a wide range of thermally relevant applications.

Owner:MASSACHUSETTS INST OF TECH

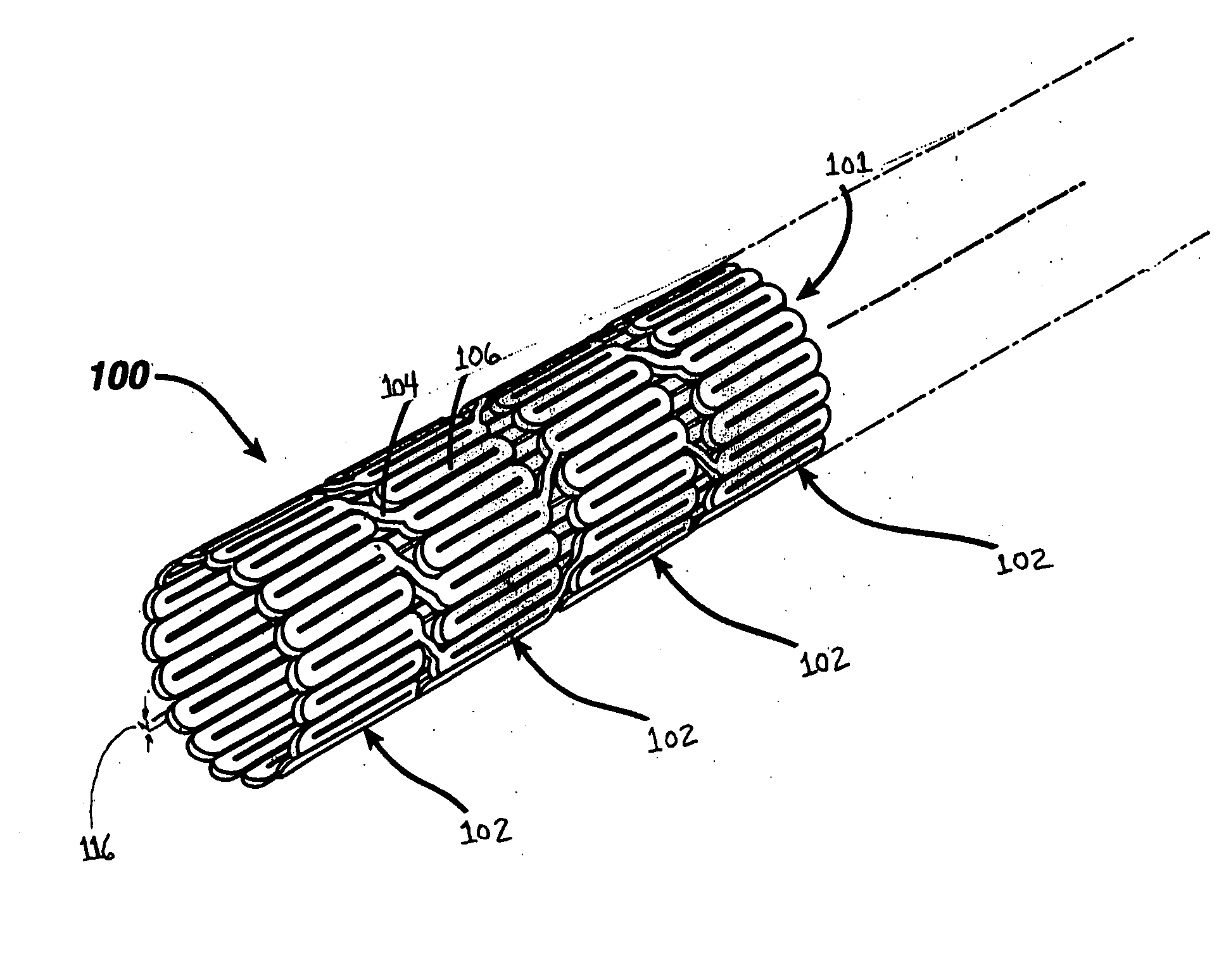

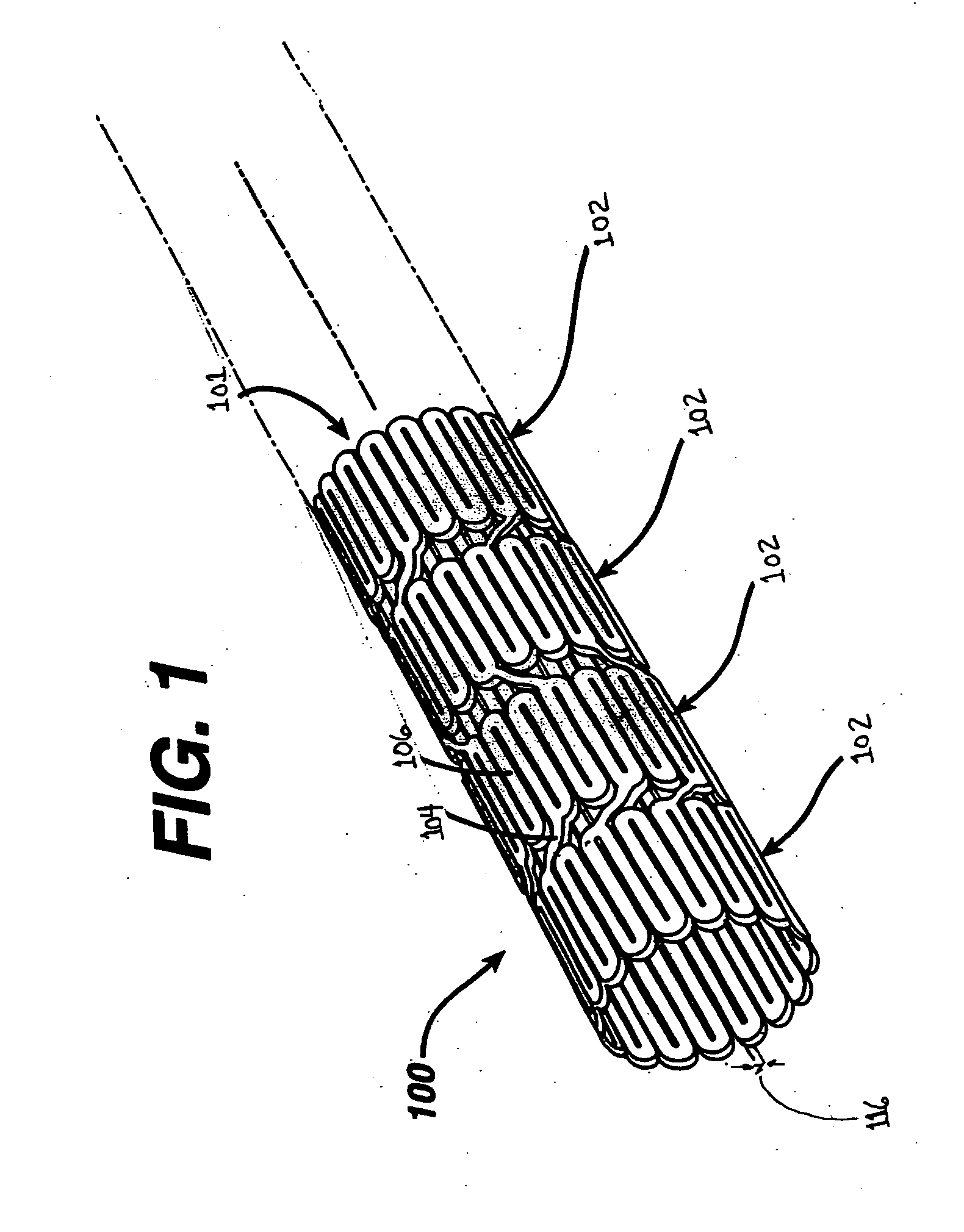

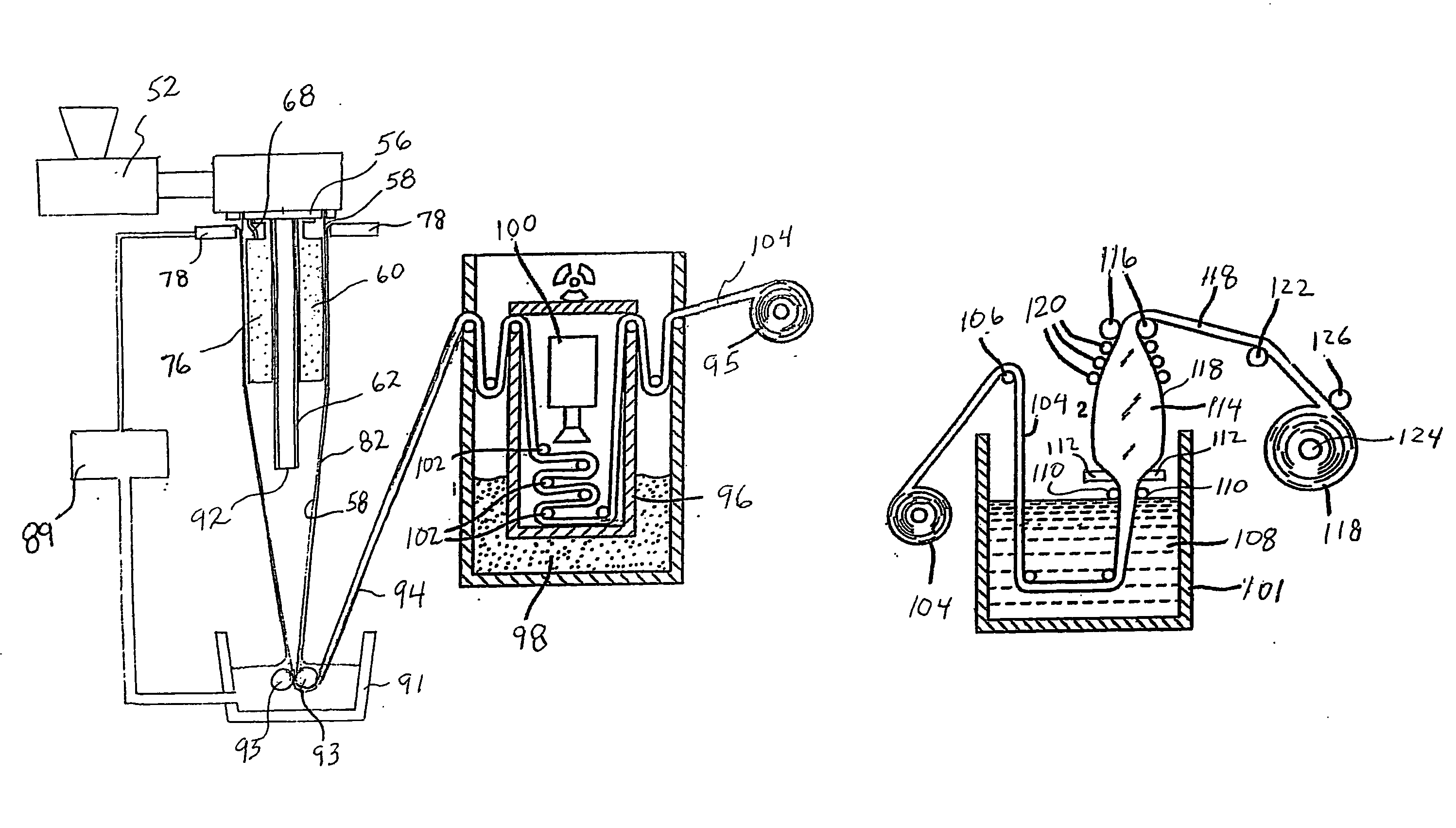

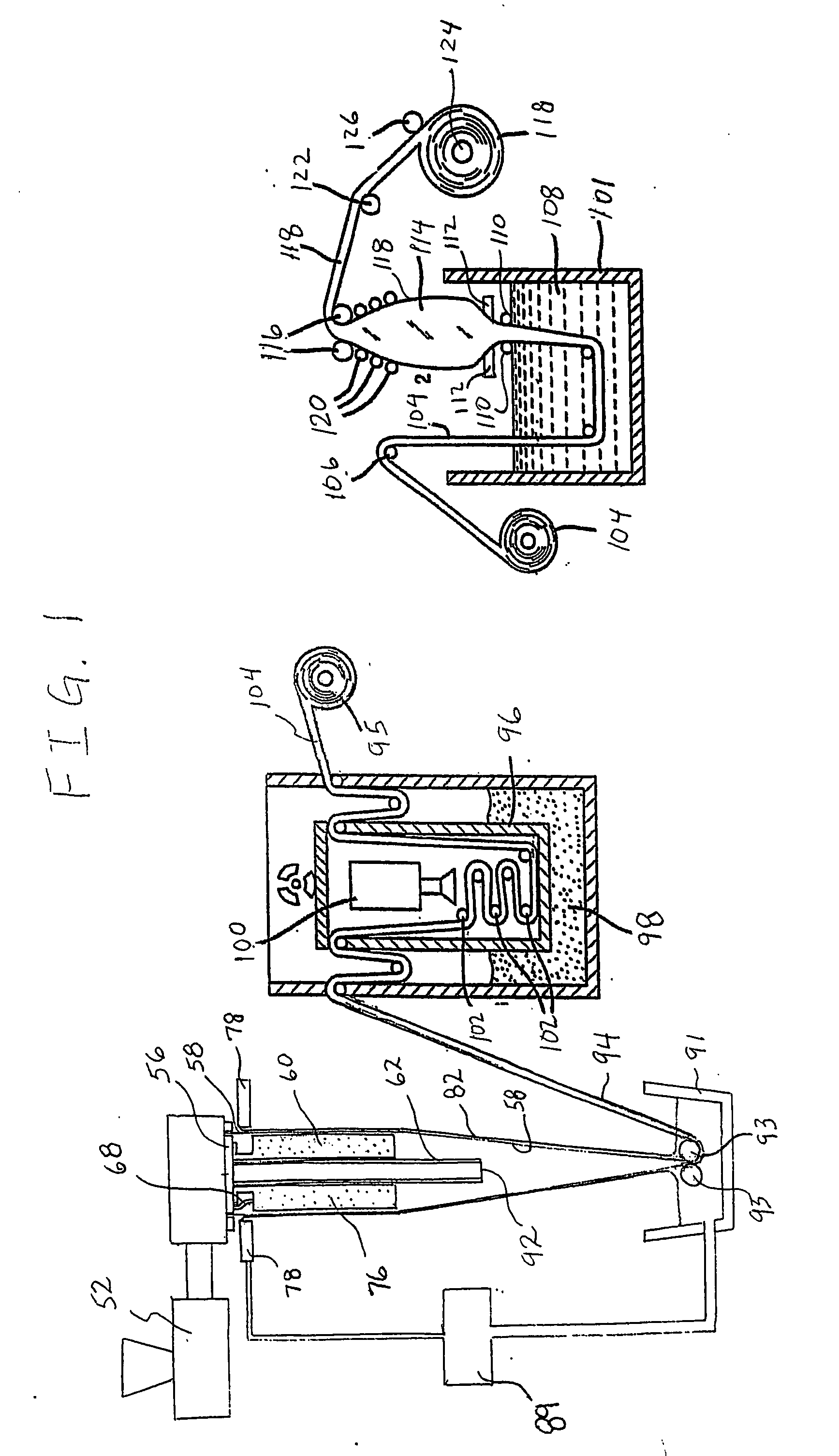

Method and apparatus for making polymeric drug delivery devices having differing morphological structures

InactiveUS20080169582A1Wide rangeEasy to manufactureWood working apparatusDomestic articlesAnatomical conduitPlasticizer

A polymeric medical device is constructed from bioabsorbable polymers. The device is constructed from a tube comprised of at least one polymer. The polymer is treated at pre-determined heating and cooling temperatures to obtain a desired morphology. The morphology or arrangement of the polymeric structure ensures that the device maintains its shape characteristics to ensure proper modeling of the vessel. In particular, the crystallinity of the polymeric structure is adjusted so as to resist recoil. The device can also contain a therapeutic agent dispersed throughout the structure or coated on the structure in such a manner as to elute the therapeutic agent when implanted in an anatomical conduit. The device can also be constructed from a blend of polymers and other agents such as plasticizers.

Owner:CORDIS CORP

Premium Quality Refrigerated Vegetable Products and Methods of Making Them

InactiveUS20130183420A1Obstruct passageIncrease storage spaceMilk preservationFruits/vegetable preservation by heatingMedicineAdditive ingredient

The disclosure relates to methods of treating whole, cut, or other processed botanical ingredient(s) in a manner that reduces the load of viable food-contaminating organisms (human or other animal pathogens and food spoilage organisms), preferably without substantially altering one or more of the organoleptic properties of the ingredient(s). The method includes subjecting a botanical foodstuff to a high pressure processing (HPP) treatment and to aseptically sealing the foodstuff within a package that contains a microbistat. Such treatments improve the storage stability of the foodstuff and preferably do not significantly alter one or more organoleptic properties of the botanical ingredient(s). Packaged foodstuffs treated as described herein exhibit beneficial properties, such as retention of taste, appearance, and texture and extended shelf life, relative to non-treated foodstuffs.

Owner:DEL MONTE FOODS

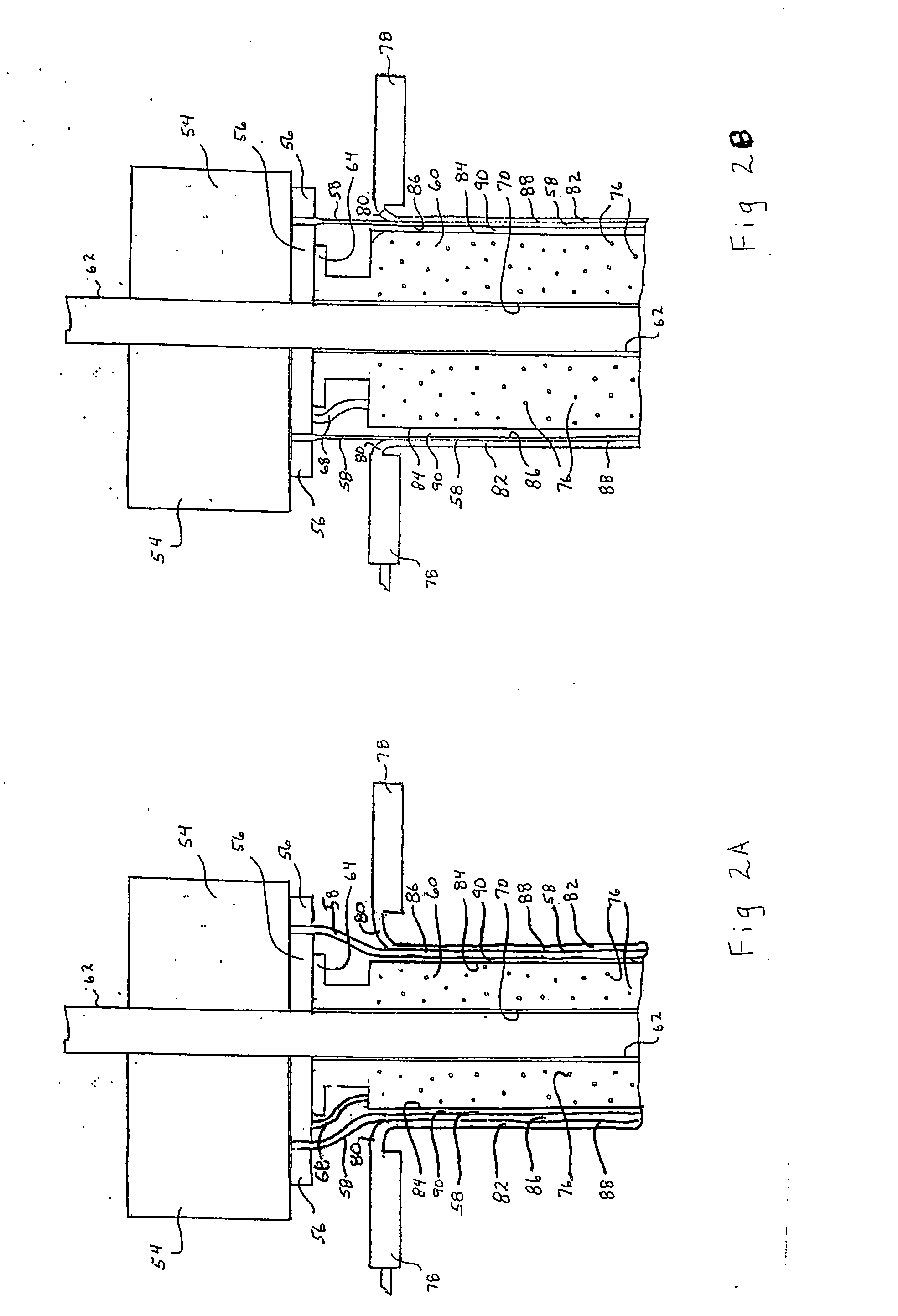

Shrink film containing semi-crystalline polyamide and process for making same

ActiveUS20080182053A1Precise positioningGood optical performanceWrappers shrinkageShrinkage connectionsPolyamideSolid-state

A multilayer, heat-shrinkable film contains at least one semi-crystalline polyamide selected from the group consisting of polyamide 6, polyamide 66, polyamide 6 / 66, and polyamide 6 / 12. The film may have a total semi-crystalline polyamide content of at least 35 volume percent, based on total film volume, and a total free shrink at 185° F. of at least 35 percent. The film may have an FTIR Transmission Absorbance A1199 / A1170 ratio of up to 1.65. The film may be a retortable film, capable of being used in a process for preparing a retorted packaged product. A process for making a heat-shrinkable annular film containing the semi-crystalline polyamide comprises extruding an annular extrudate downward from an annular die, quenching the annular extrudate by applying a quenching liquid to the annular extrudate, reheating the extrudate to an orientation temperature, and orienting the reheated annular extrudate while the reheated annular extrudate is in the solid state, the orientation being carried out with a total orientation factor of at least 2, to produce a film having a total free shrink at 185° F. of at least 10 percent.

Owner:CRYOVAC INC

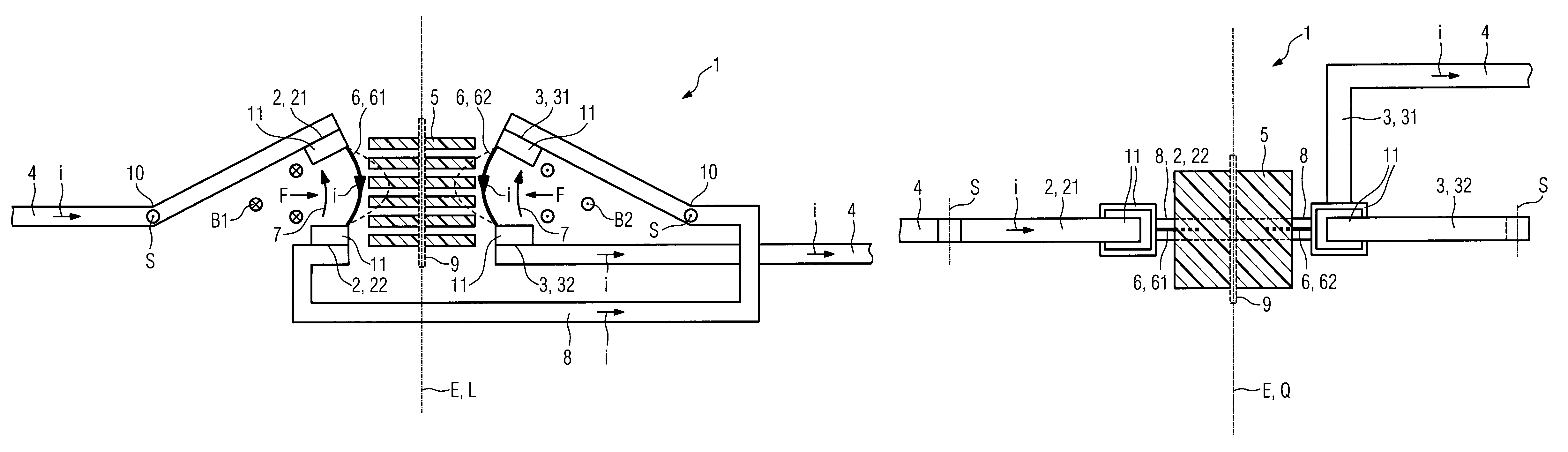

Switching device, in particular a power switching device, having two pairs of series-connected switching contacts for interrupting a conducting path

InactiveUS7902948B2Open fastMinimal air gapCircuit-breaking switches for excess currentsHigh-tension/heavy-dress switchesPower switchingEngineering

A switching device, in particular a power switching device, has two pairs of series-connected switching contacts for interrupting a conducting path and at least one quenching packet, disposed near the pairs of switching contacts, for quenching the arcs occurring when the conducting path opens. The pairs of switching contacts are arranged such that their opening paths are substantially mutually parallel or antiparallel. The pairs of switching contacts are connected in series such that the same current flowing in both arcs flows spatially in the same direction. The quenching packet is disposed in the area between the opening paths.

Owner:SIEMENS AG

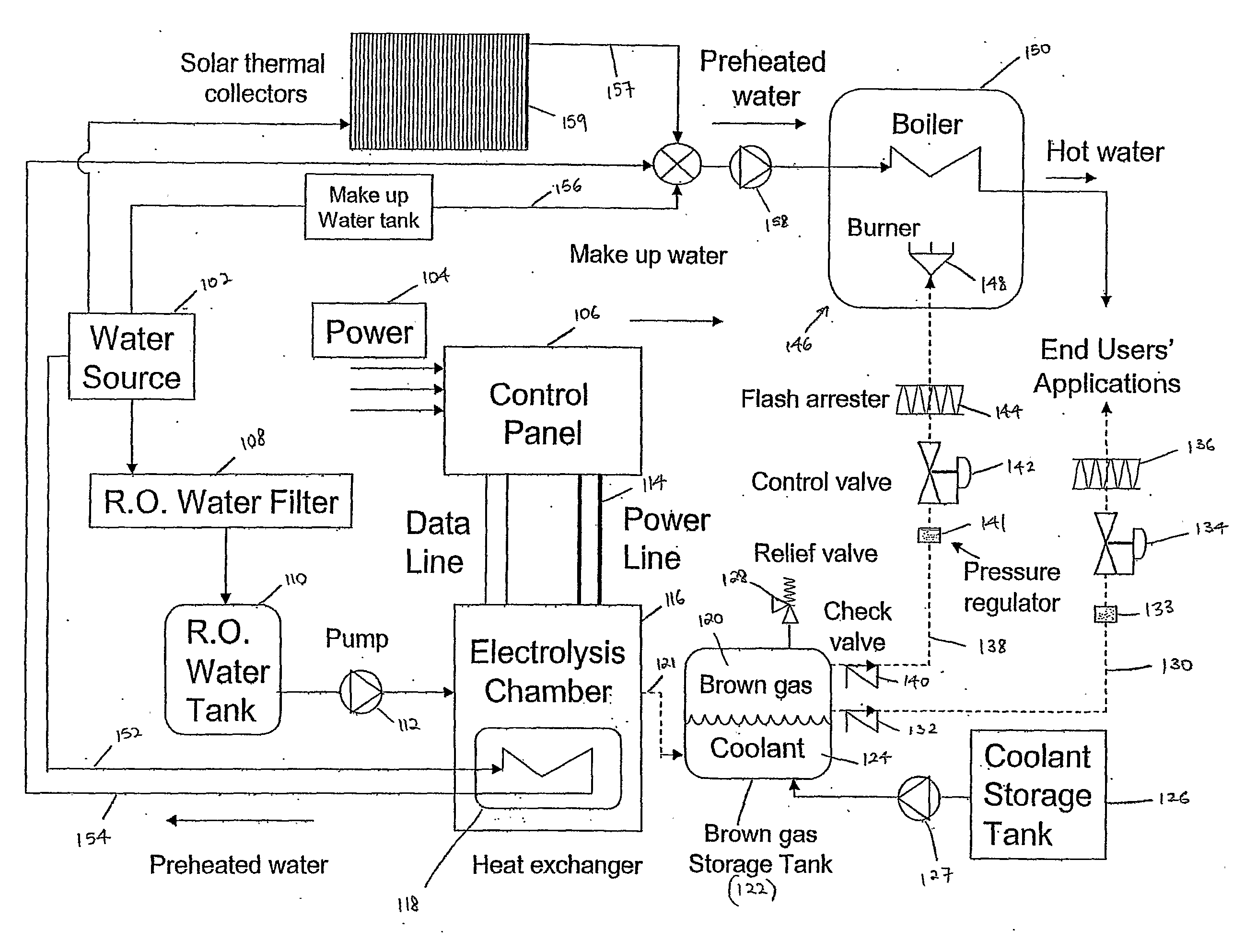

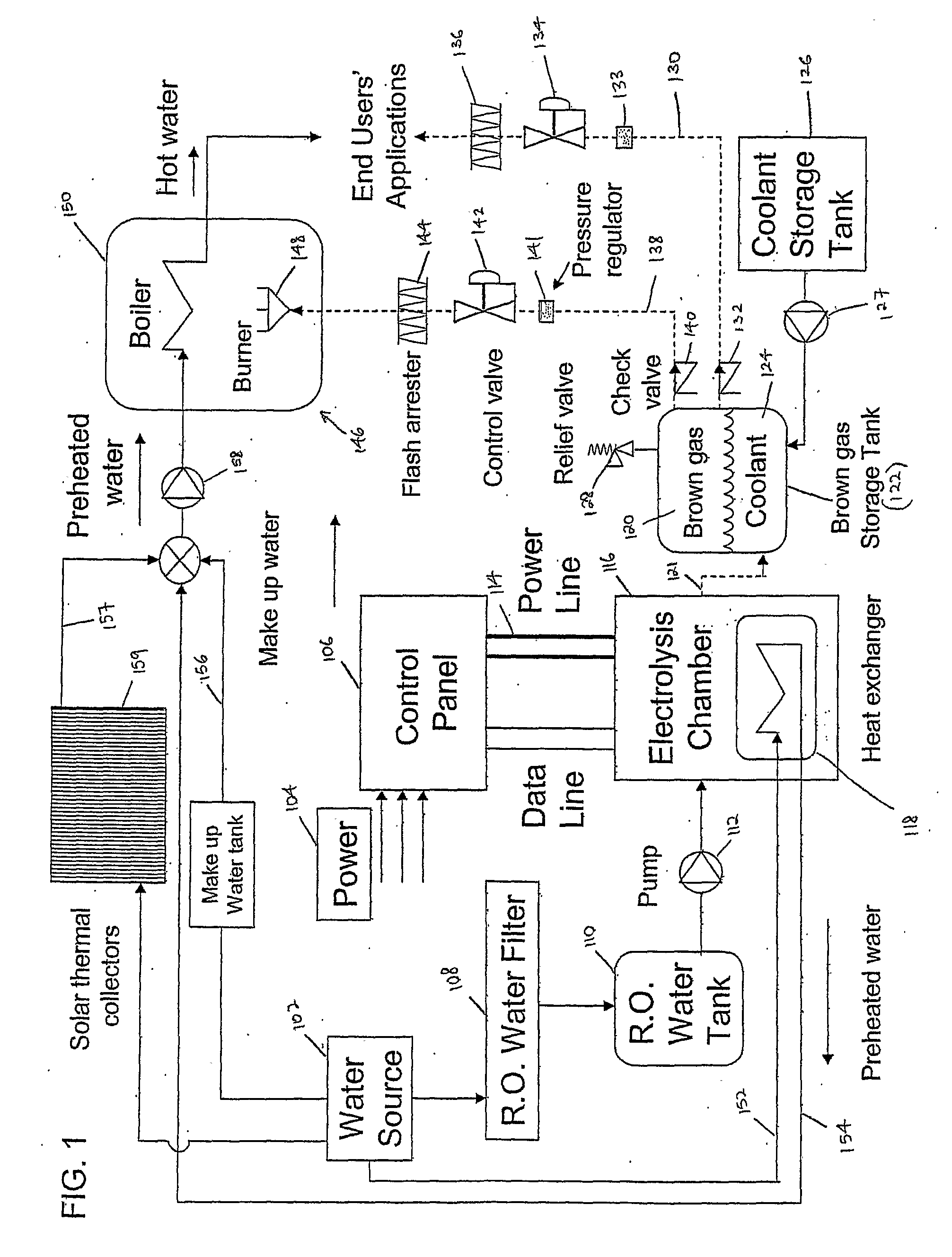

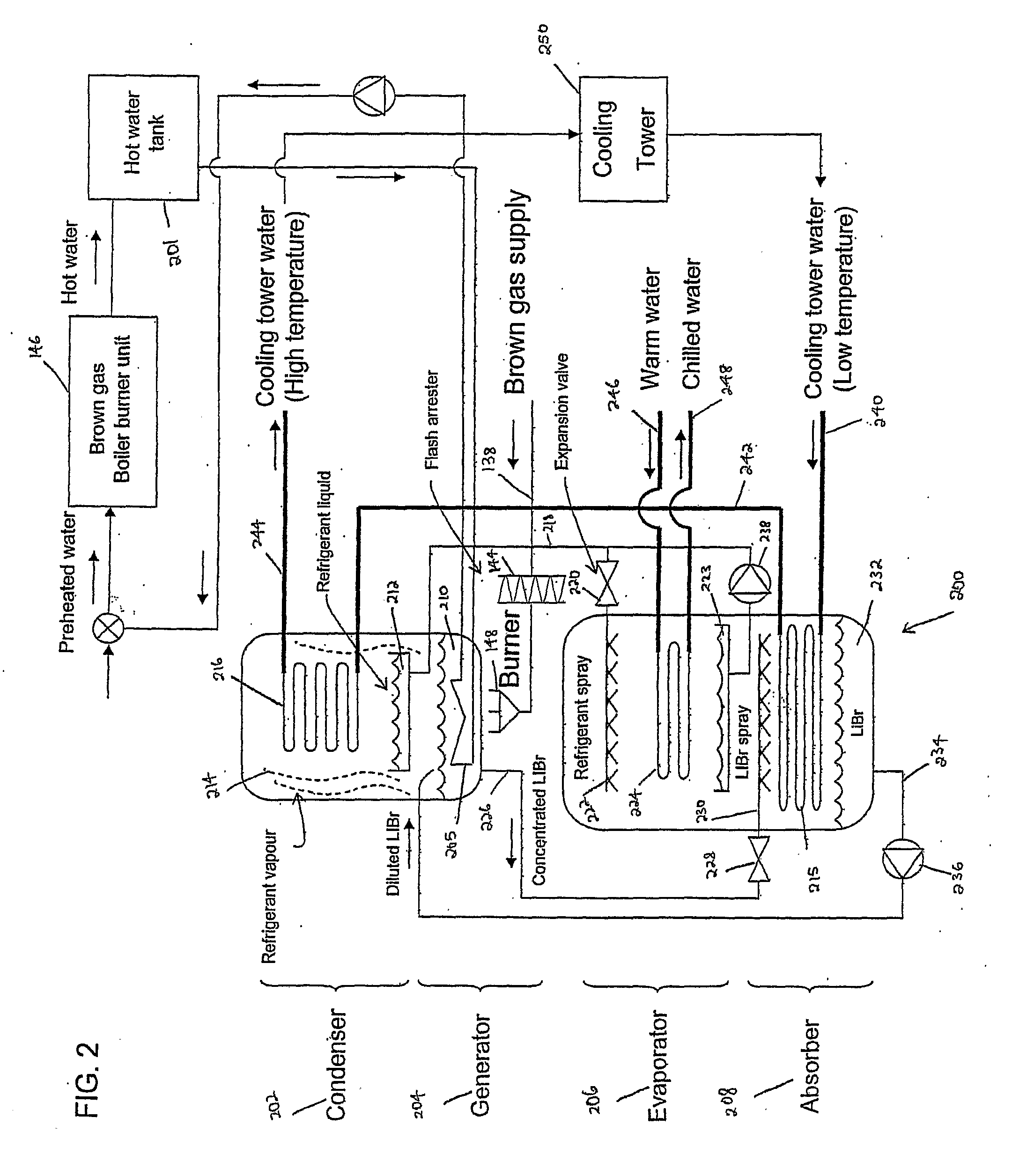

System for generating brown gas and uses thereof

InactiveUS20100206248A1Rapid quenchingIncrease volumeBurnersElectrolysis componentsElectricityProduct gas

A system for the generation, storage and use of Brown's gas comprising at least one Brown's gas generator, in communication with an electricity supply and water supply; at least one first storage chamber, in fluid communication with the generator, for storing the Brown's gas generated from said generator; and Brown's gas application means in communication with said at least one first storage chamber, wherein said generator and first storage chamber are located proximate the Brown's gas application means. For example, the Brown's gas may be used for the production of hot water, for the production of chilled water and as fuel in an incineration unit.

Owner:MOK SIONG CHEAK STEVEN

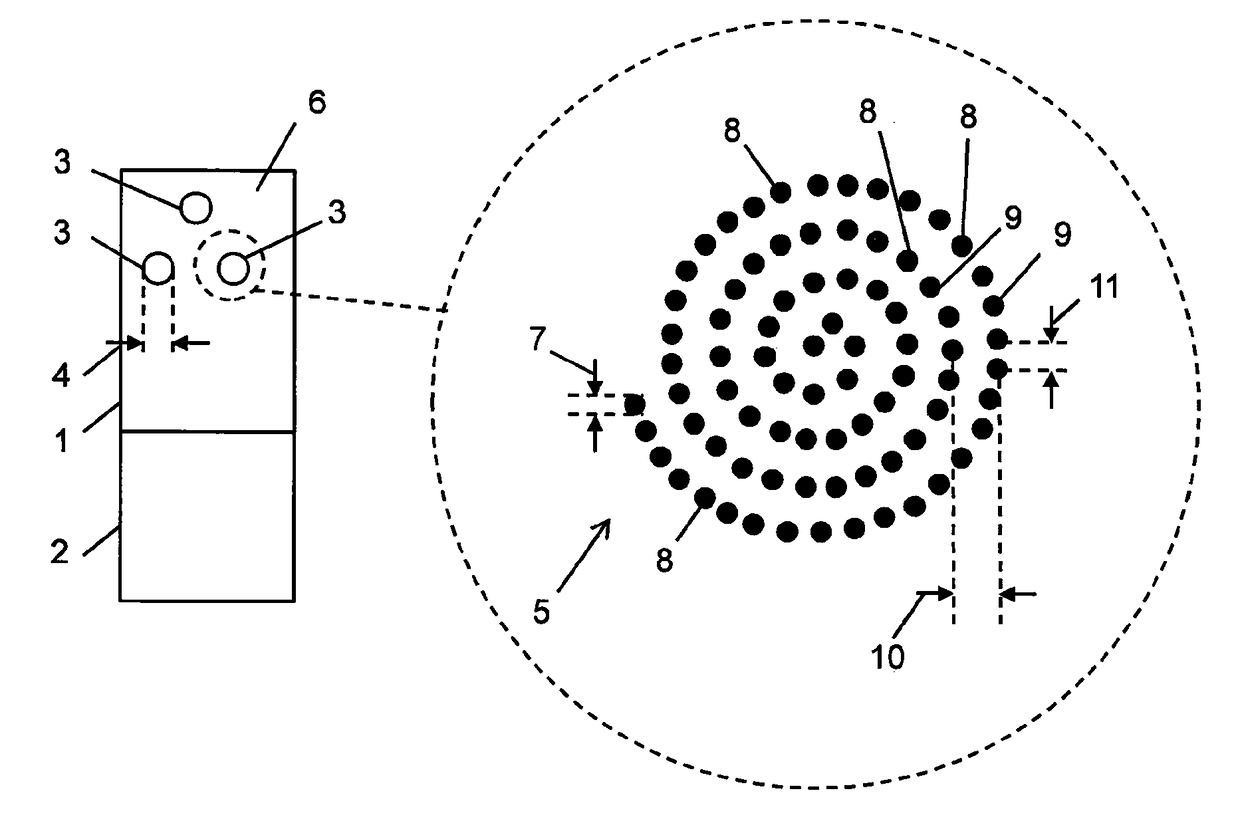

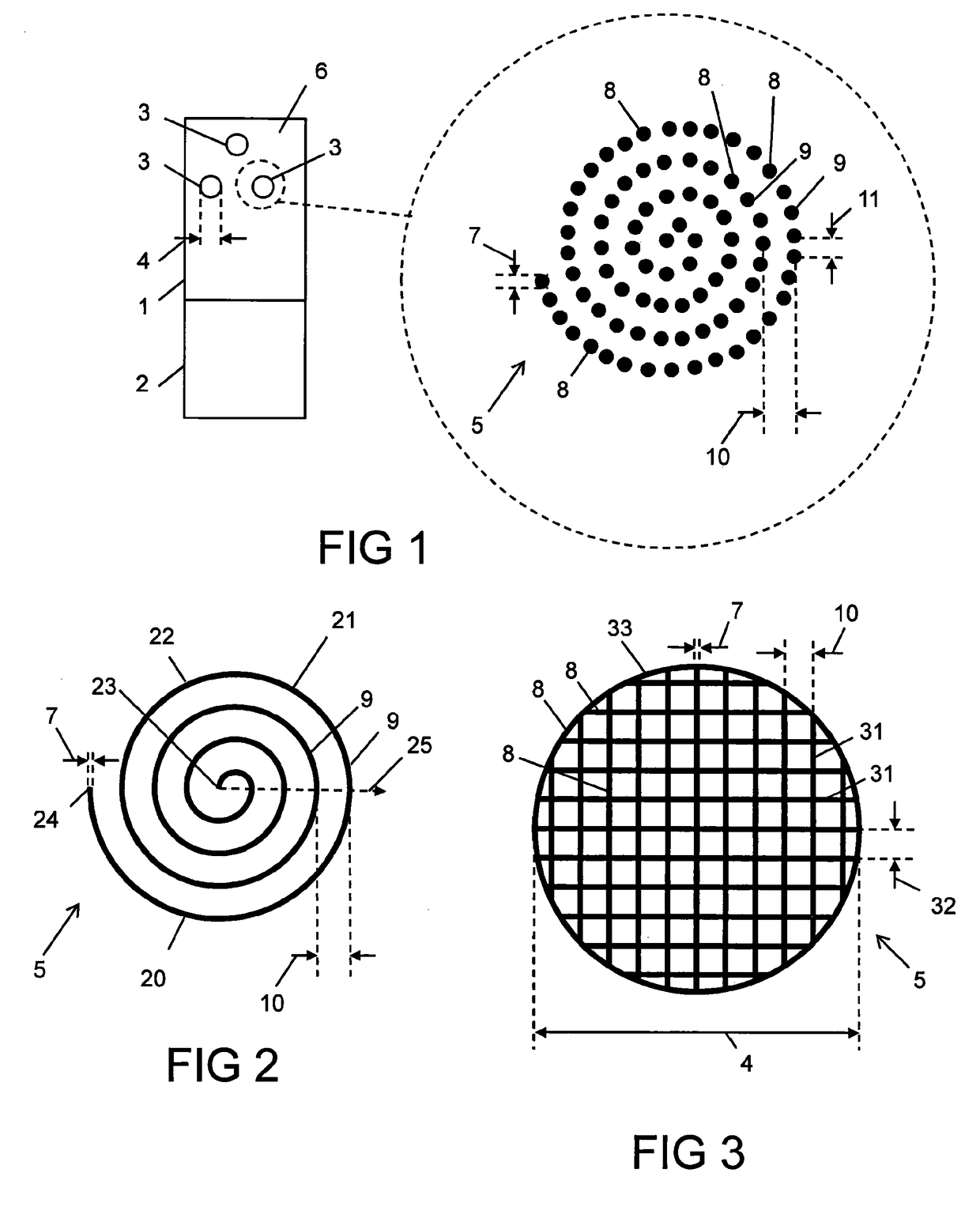

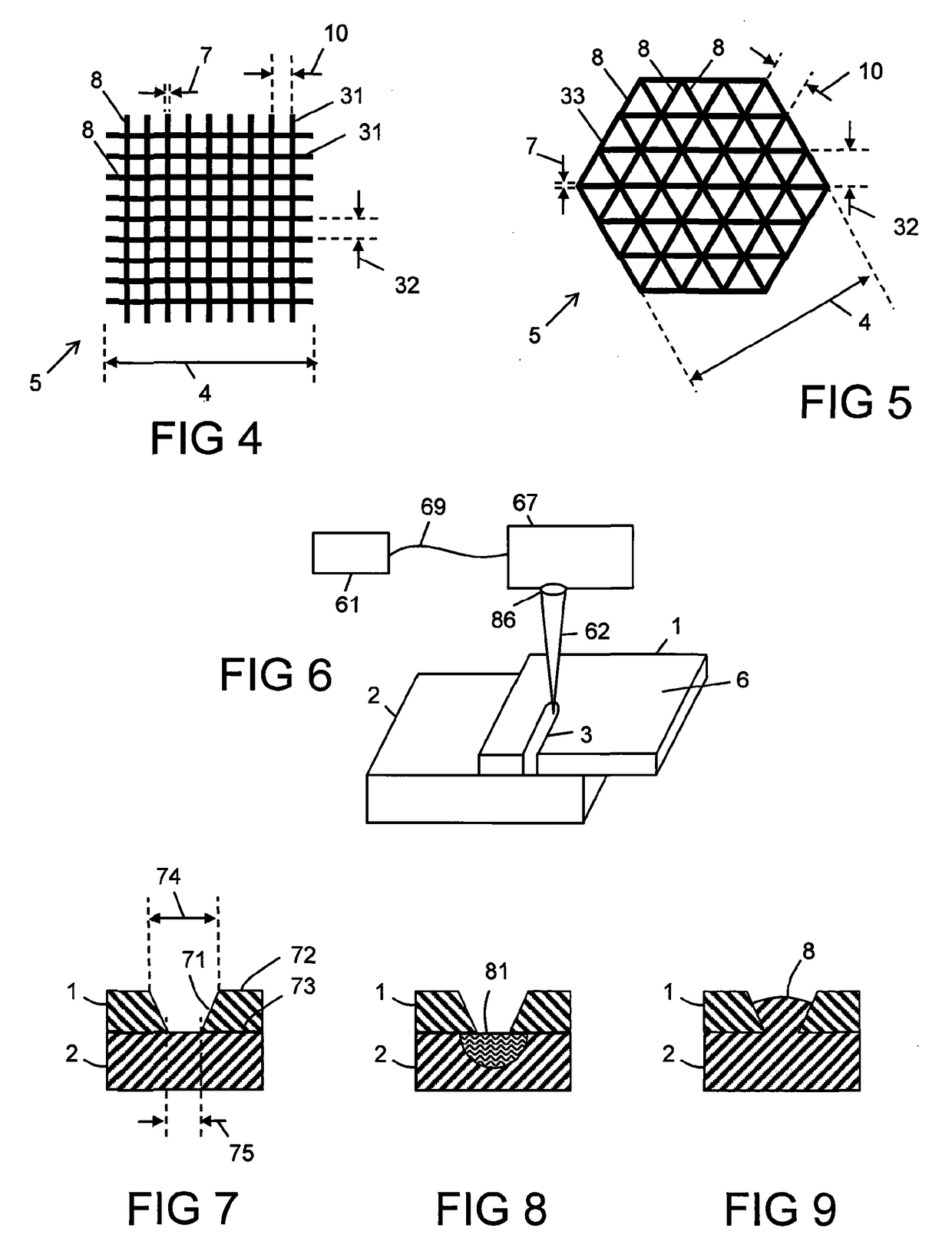

A Weld

PendingUS20180045232A1Improve surface smoothnessHigh densitySheet joiningLaser beam welding apparatusMetallic materialsMetal

A weld (3) between a first material (1) and a second material (2), the first material (1) being a first metallic material, and the second material (2) being a second metallic material, the weld (3) has a width (4) between 0.5 mm and 7 mm, the weld (3) comprises at least one microweld (8), the microweld (8) forms a welding pattern (5) defined parallel to a surface (6) of the first material (1), and the microweld (8) has a characteristic feature size (7) of between 20 μm and 400 um.

Owner:SPI LASERS UK

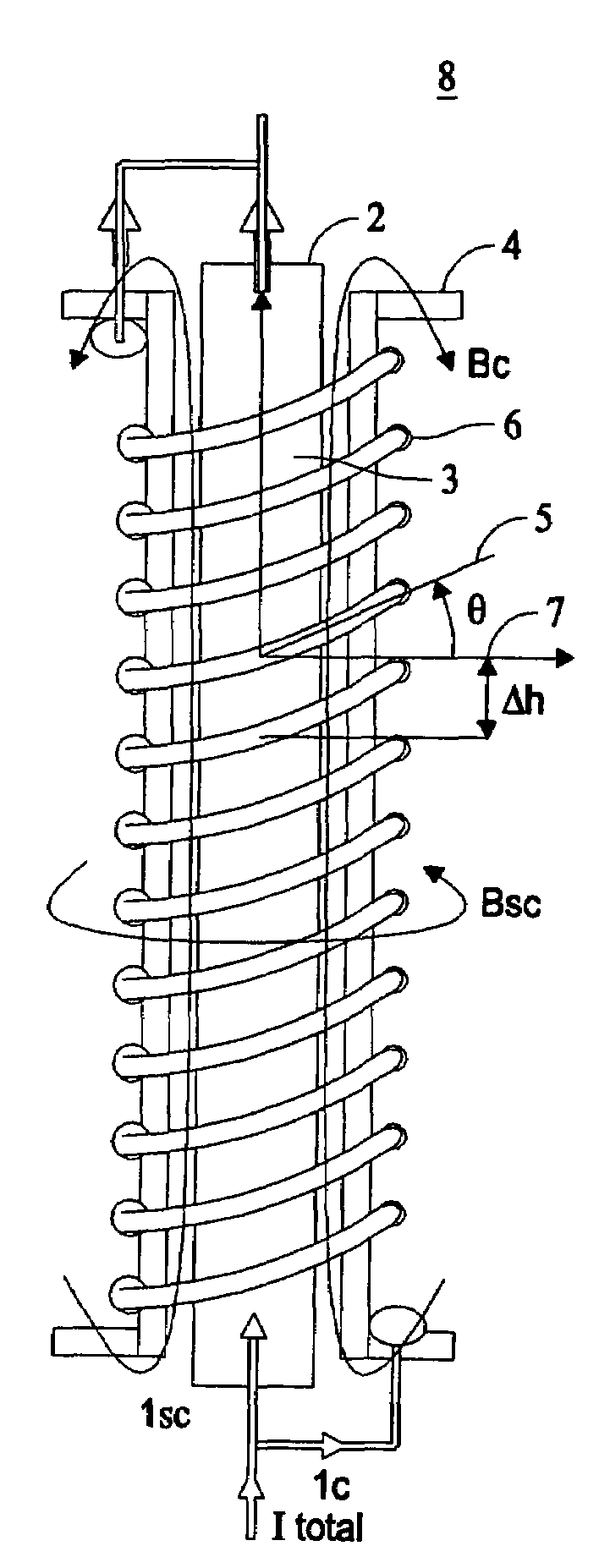

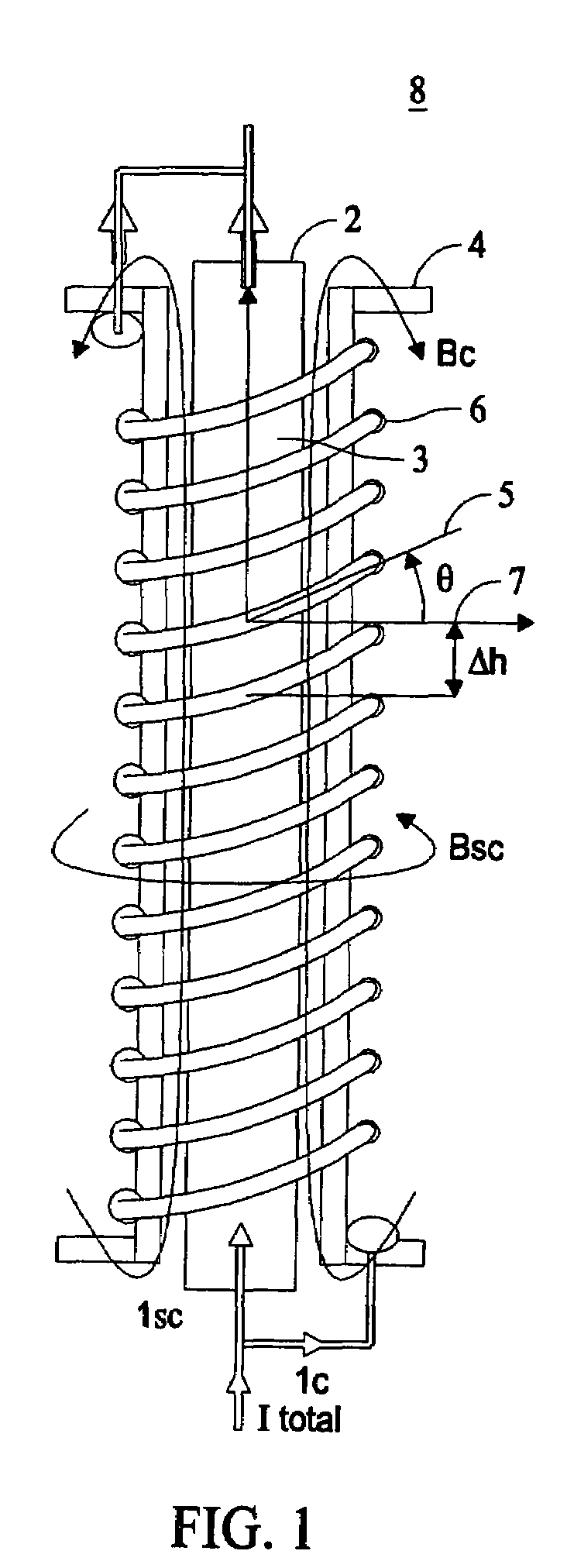

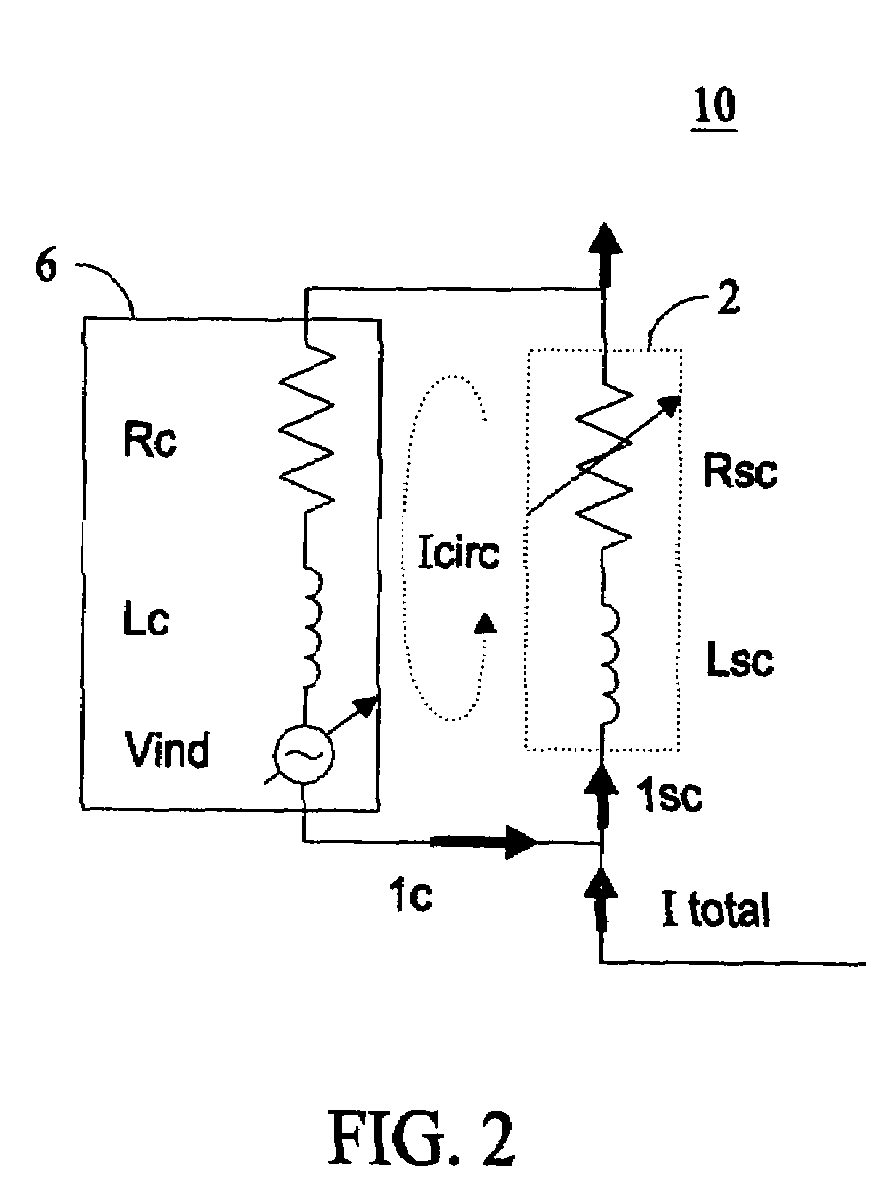

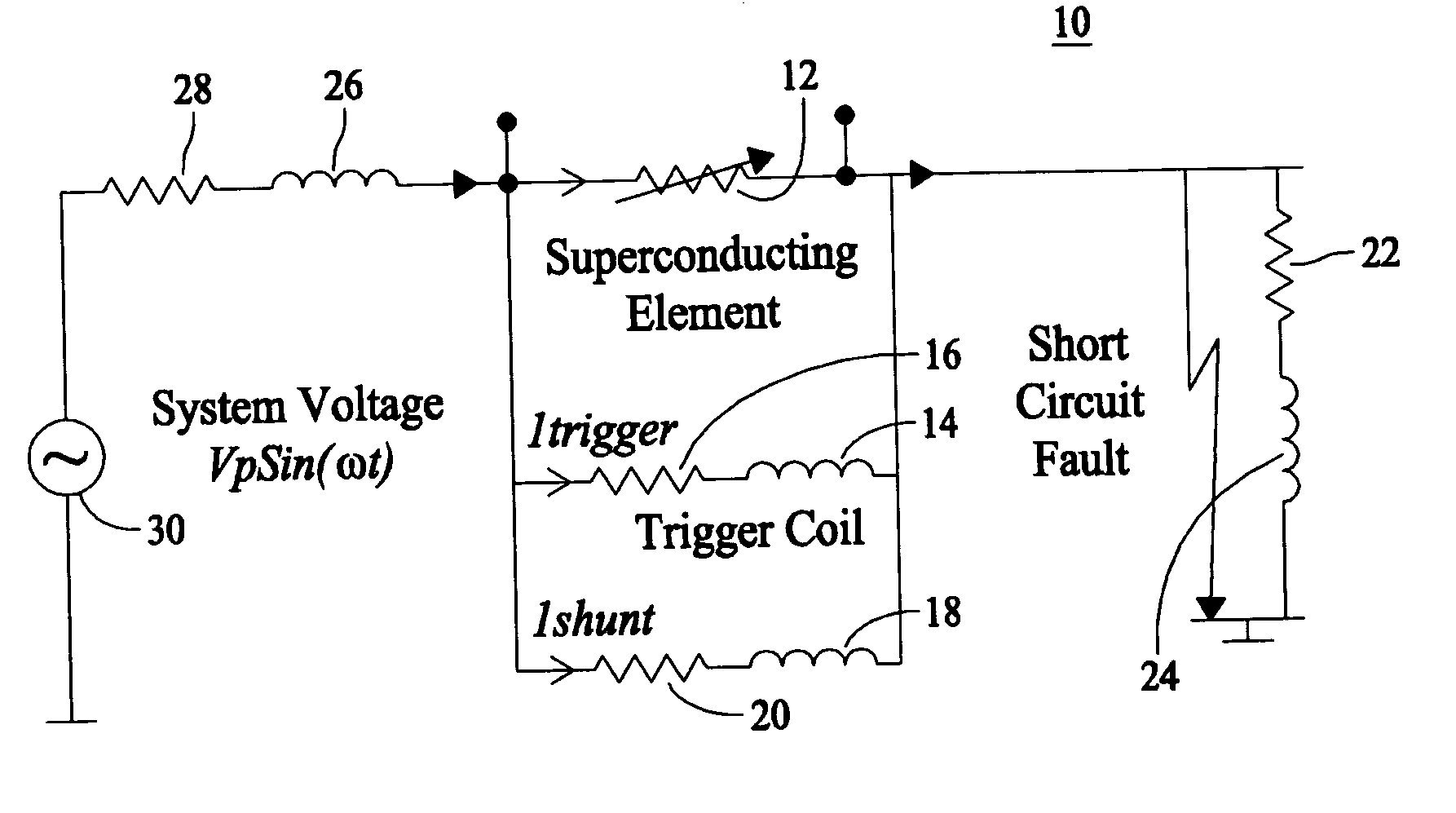

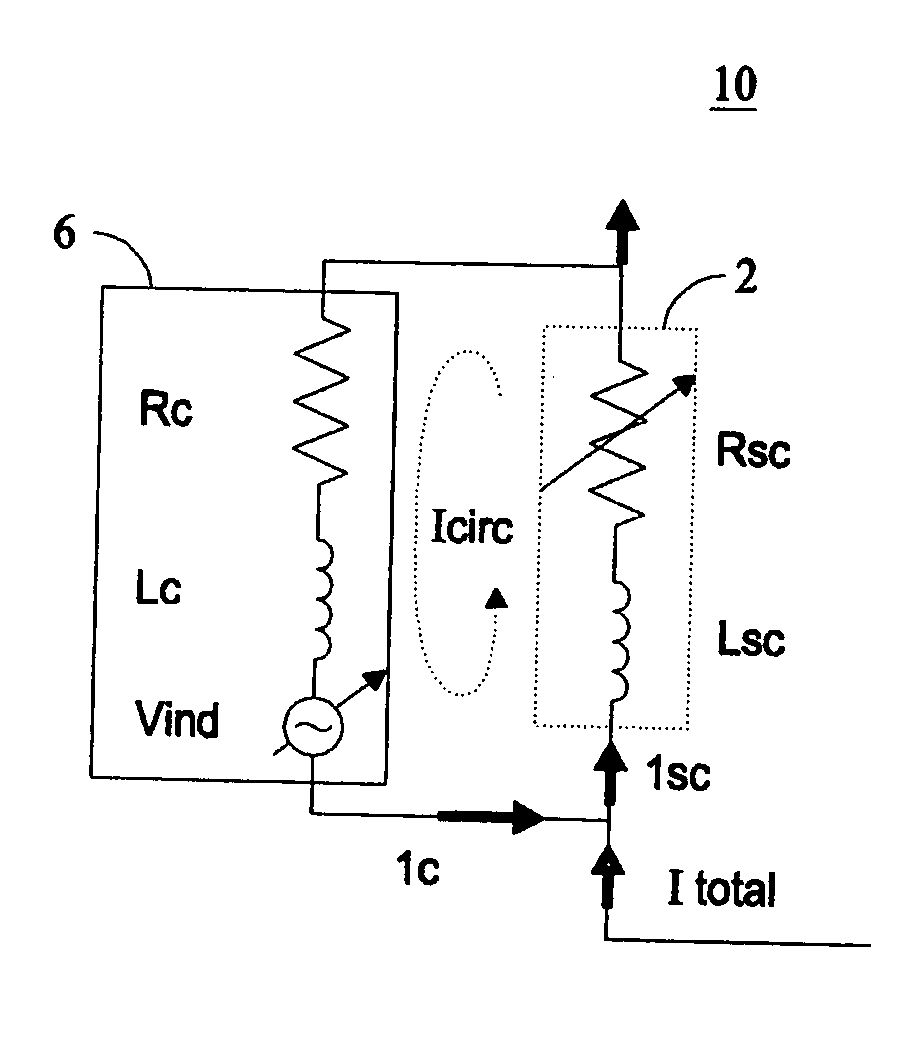

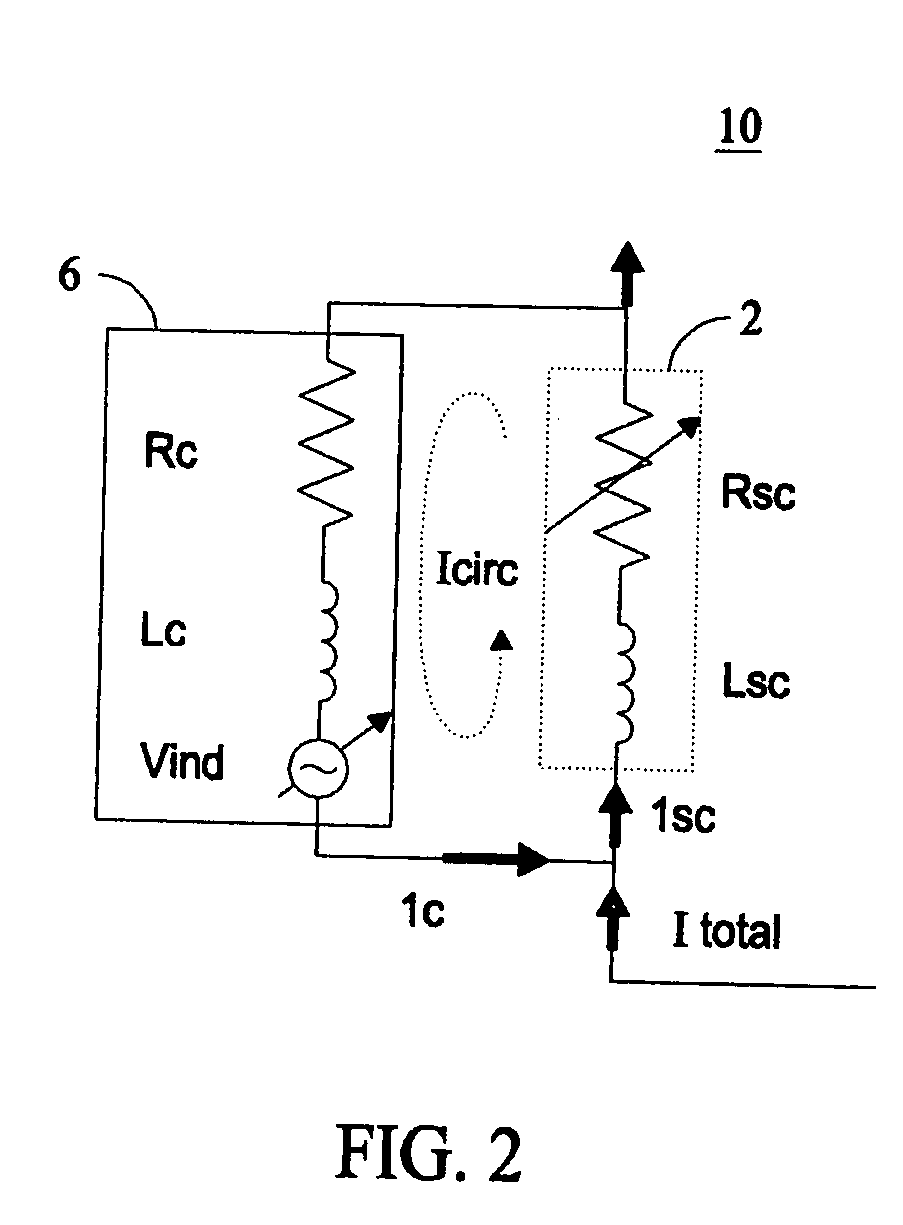

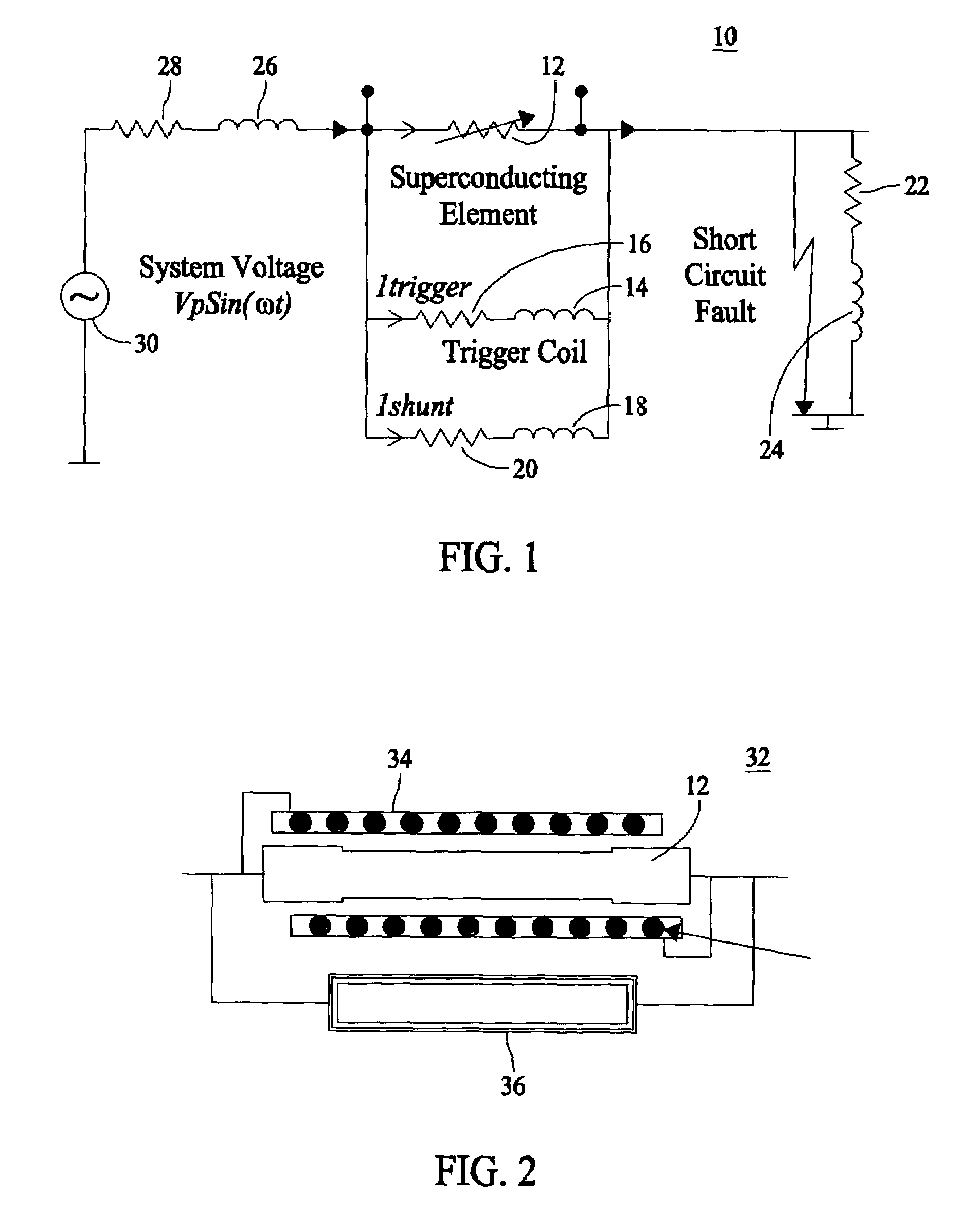

Superconducting FCL using a combined inducted magnetic field trigger and shunt coil

InactiveUS7283339B2Increase speedReduce creationMagnetsMagnetic materialsShunt impedanceHigh temperature superconducting

A single trigger / shunt coil is utilized for combined induced magnetic field triggering and shunt impedance. The single coil connected in parallel with the high temperature superconducting element, is designed to generate a circulating current in the parallel circuit during normal operation to aid triggering the high temperature superconducting element to quench in the event of a fault. The circulating current is generated by an induced voltage in the coil, when the system current flows through the high temperature superconducting element.

Owner:SUPERPOWER INC

Shrink film containing semi-crystalline polyamide and process for making same

ActiveUS7687123B2Easy to convertPrecise positioningWrappers shrinkageSynthetic resin layered productsPolyamideAbsorbance

A multilayer, heat-shrinkable film contains at least one semi-crystalline polyamide selected from the group consisting of polyamide 6, polyamide 66, polyamide 6 / 66, and polyamide 6 / 12. The film may have a total semi-crystalline polyamide content of at least 35 volume percent, based on total film volume, and a total free shrink at 185° F. of at least 35 percent. The film may have an FTIR Transmission Absorbance A1199 / A1170 ratio of up to 1.65. The film may be a retortable film, capable of being used in a process for preparing a retorted packaged product. A process for making a heat-shrinkable annular film containing the semi-crystalline polyamide comprises extruding an annular extrudate downward from an annular die, quenching the annular extrudate by applying a quenching liquid to the annular extrudate, reheating the extrudate to an orientation temperature, and orienting the reheated annular extrudate while the reheated annular extrudate is in the solid state, the orientation being carried out with a total orientation factor of at least 2, to produce a film having a total free shrink at 185° F. of at least 10 percent.

Owner:CRYOVAC ILLC

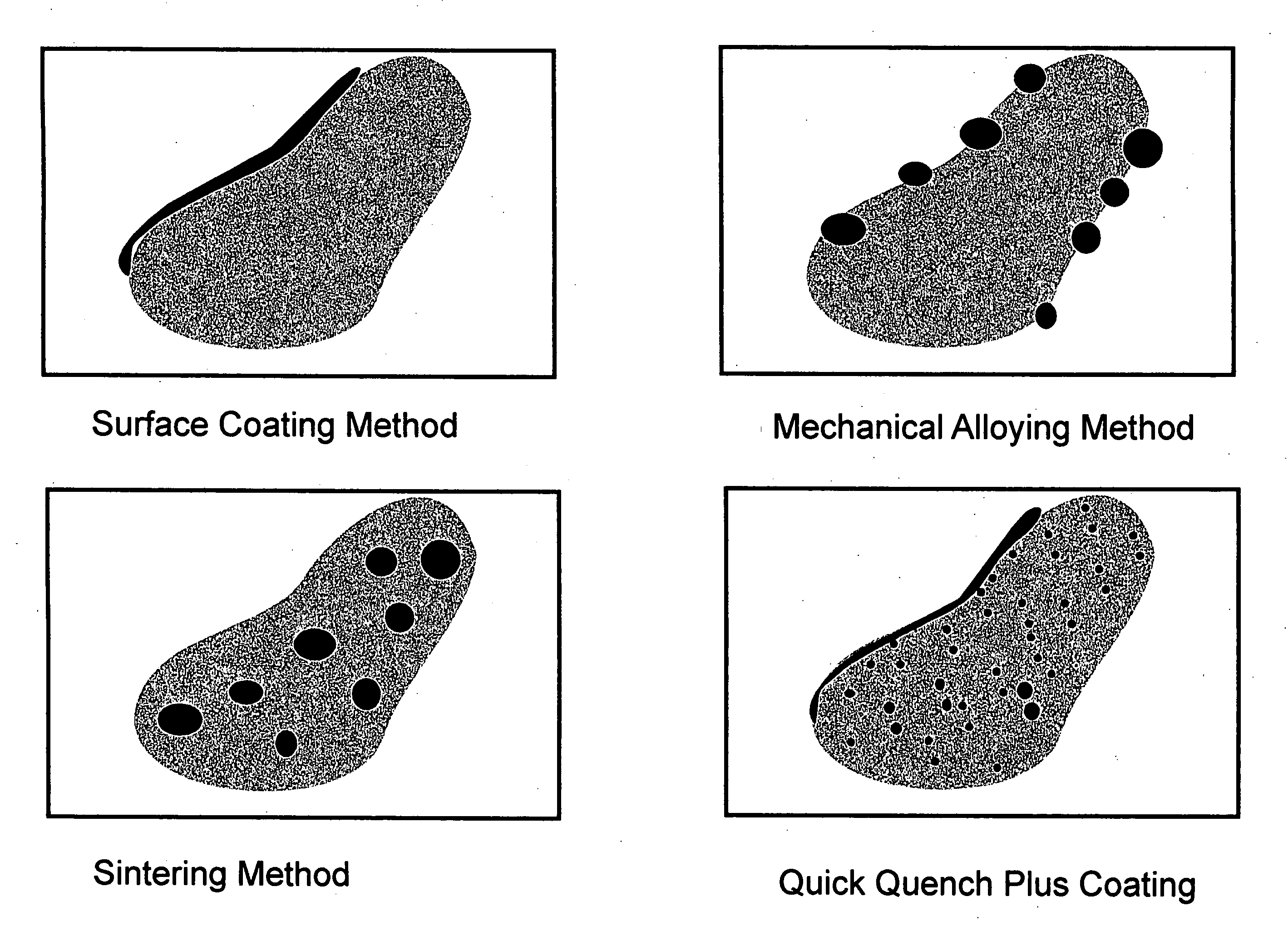

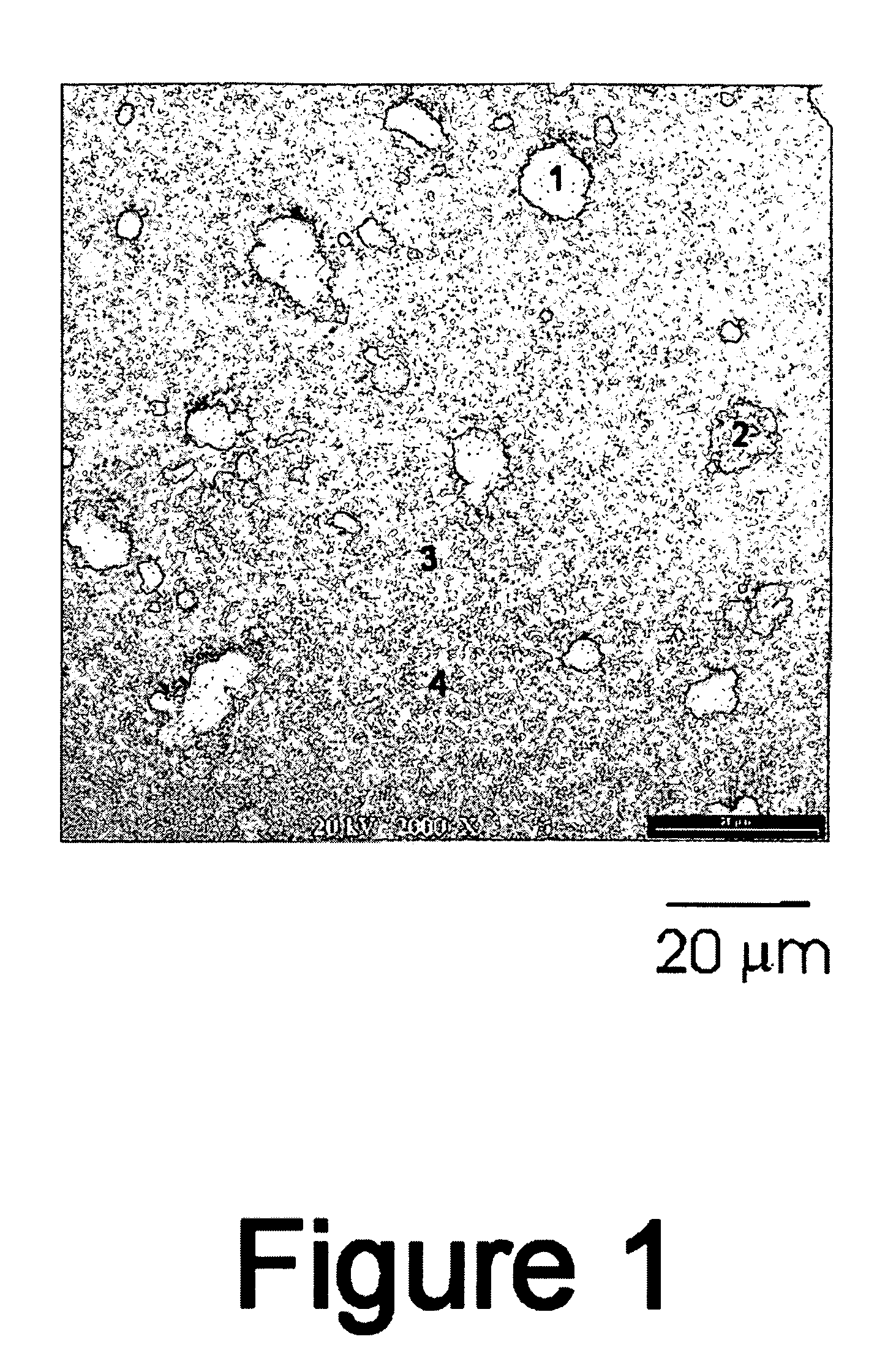

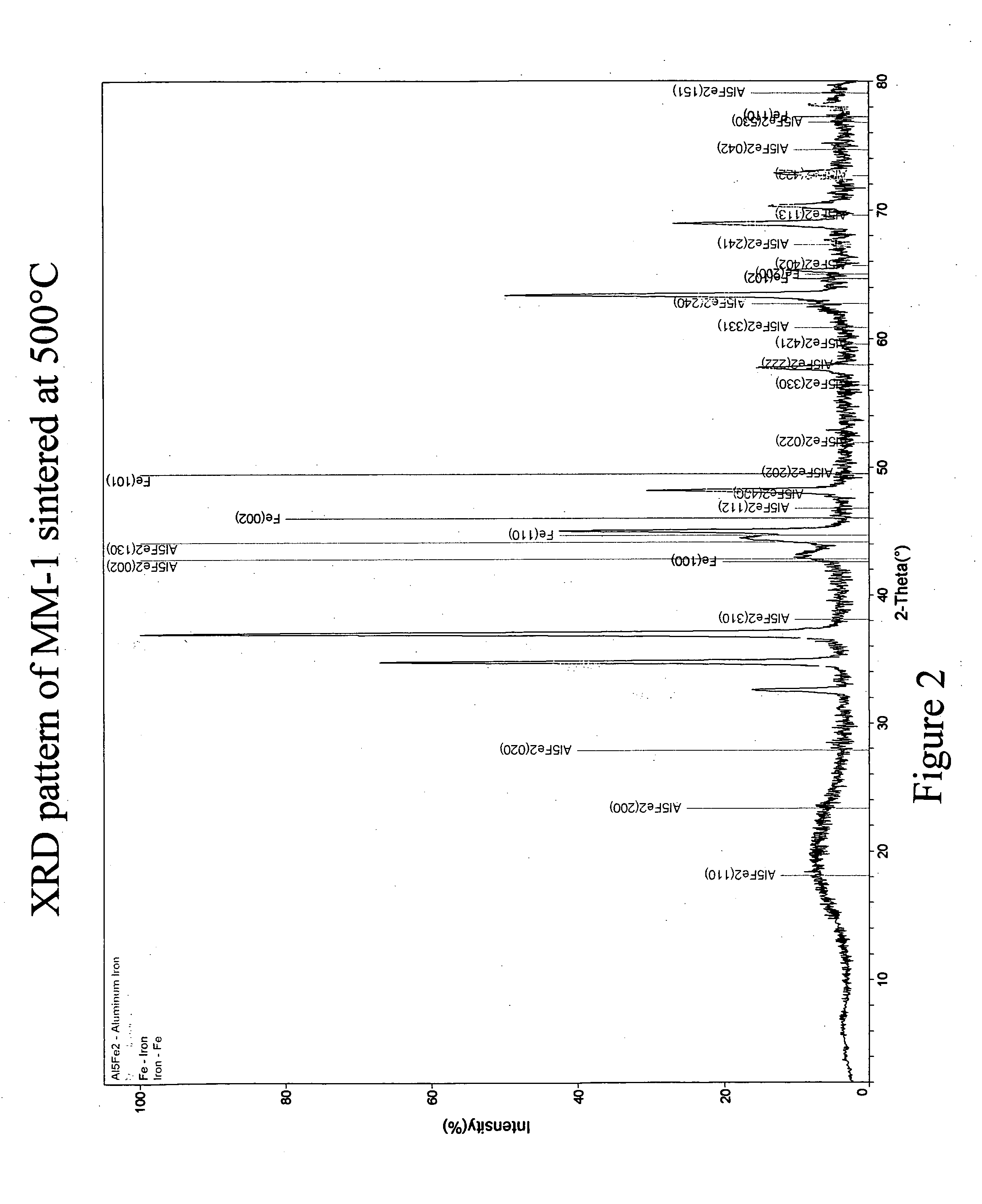

Catalyzed hydrogen desorption in Mg-based hydrogen storage material and methods for production thereof

InactiveUS20050126663A1Rapid quenchingHydrogenCatalyst activation/preparationMagnesiumMaterials science

A magnesium-based hydrogen storage material including magnesium or a magnesium-based hydrogen storage alloy and a hydrogen desorption catalyst which is insoluble in said magnesium-based hydrogen storage alloy and is in the form of: 1) discrete dispersed regions of catalytic material in the bulk of said magnesium or magnesium-based hydrogen storage alloy; 2) discrete dispersed regions on the surface of particles of said magnesium or magnesium-based hydrogen storage alloy; 3) a continuous or semi-continuous layer of catalytic material on the surface of said magnesium or magnesium-based hydrogen storage alloy which is in bulk or particulate form; or 4) combinations thereof. Methods of producing the material are also disclosed.

Owner:TEXACO OVONIC HYDROGEN SYST LLC

Refrigerated chest for rapidly quenching beverages and visually identifying when such beverages reach target temperature

InactiveUS8161769B2Rapid cooling and quenchingRapid quenchingLighting and heating apparatusCooling fluid circulationSalt waterEngineering

The cooling chest for rapidly quenching beverages includes a quench tray for holding containers of beverage. The quench tray is lowered into salt-water or other cooling liquid which is cooled by a refrigeration unit. A processing device determines the temperature of the beverages within the containers within the quench tray and further activates a mechanism for removing the quench tray from the water or cooling liquid when the desired temperature is reached. The processing device can also activate the mechanism for removing the quench tray from the water or cooling liquid when the upper lid or access doors are opened.

Owner:LAUCHNOR JOHN C

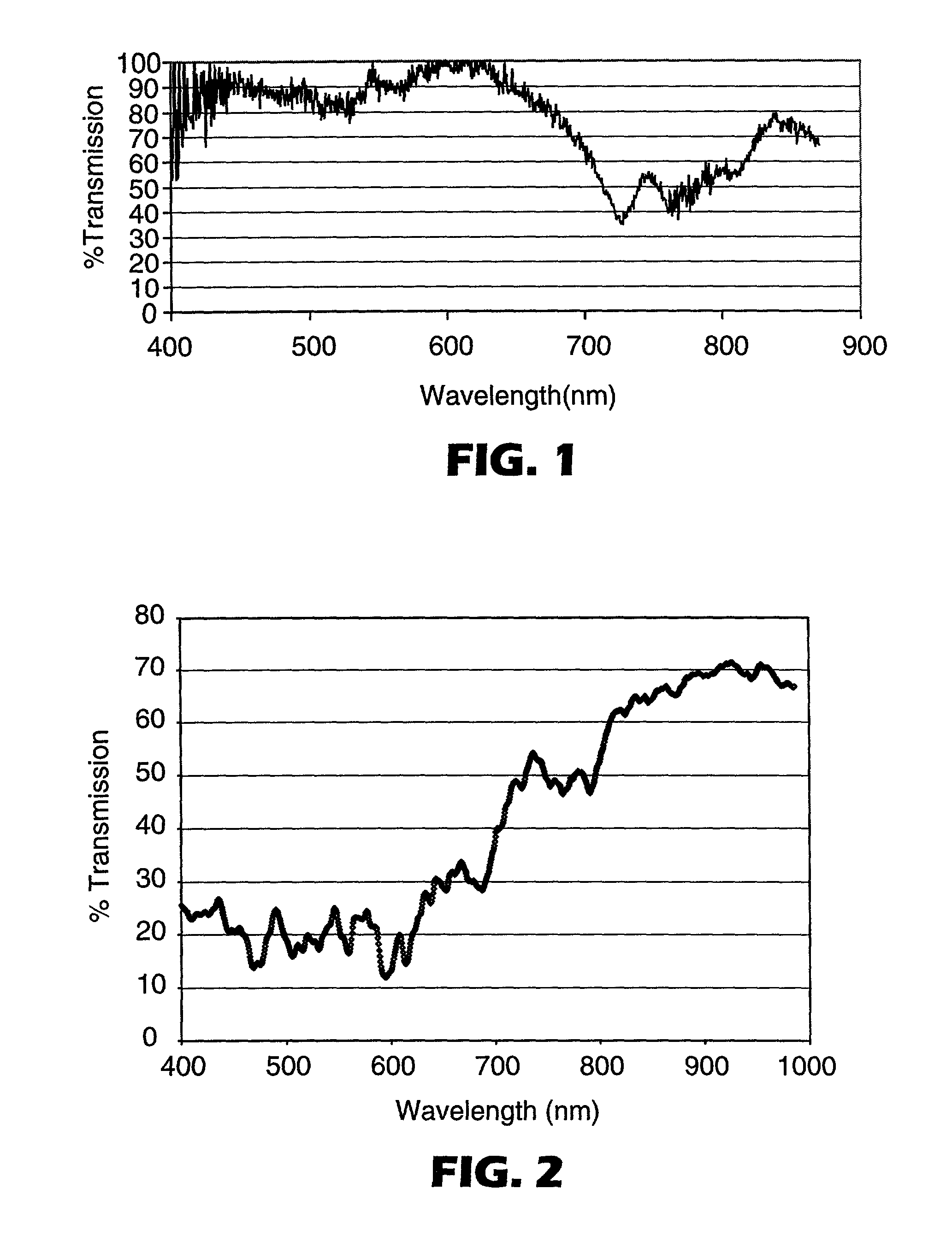

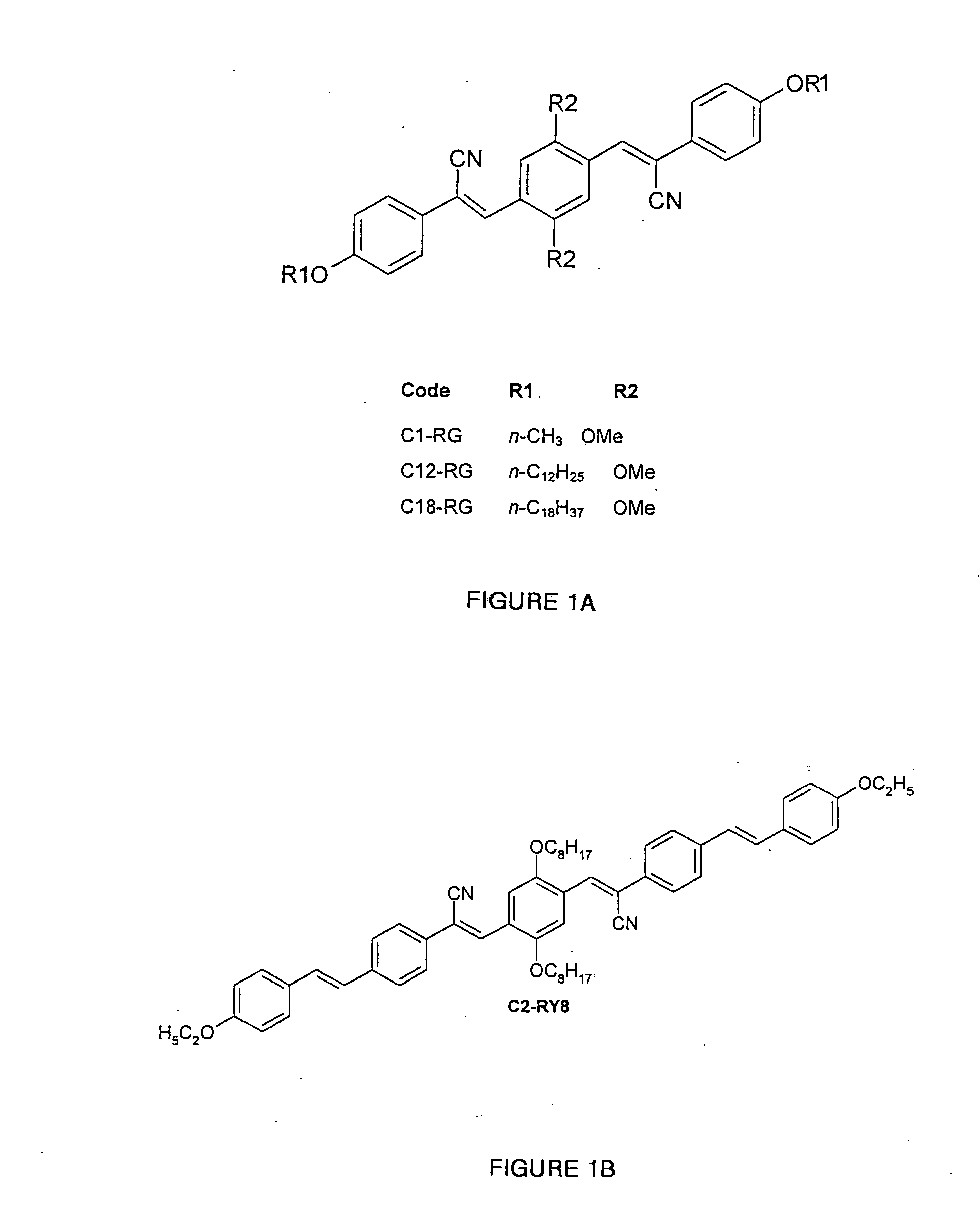

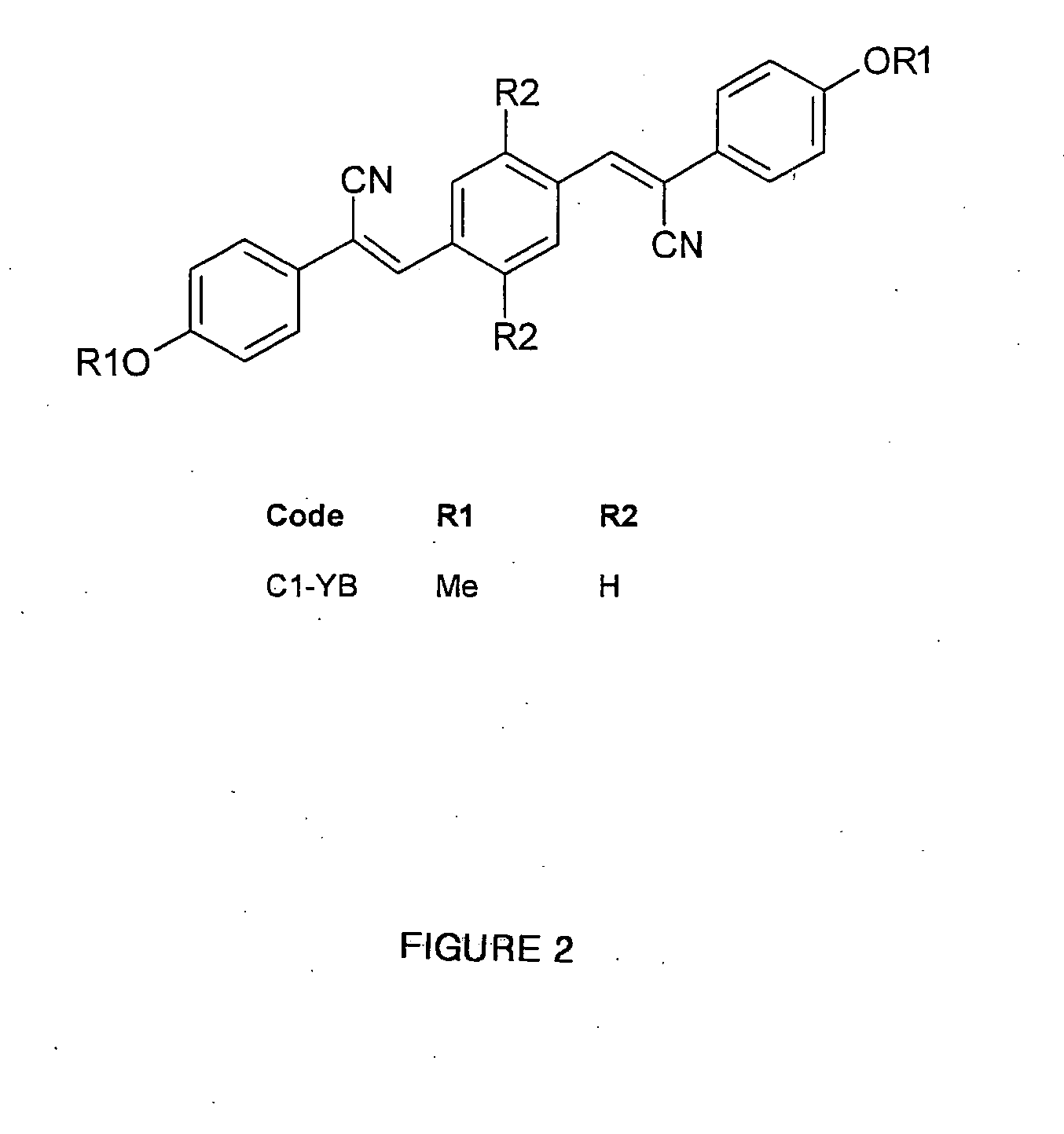

Time-temperature indicators

InactiveUS20070158624A1Reduce manufacturing costEasy to measureDiffusing elementsCamera filtersEngineeringColor changes

Time temperature indicators are disclosed which comprise at least one carrier material and one aggregachromic indicator dye and which respond to the combined effects of temperature and time with an easily measurable, time-temperature dependent, irreversible, color change. The invention also discloses to methods to produce such time-temperature indicators and materials therefore. Also, the devices disclose methods for determining the time / temperature history.

Owner:CASE WESTERN RESERVE UNIV

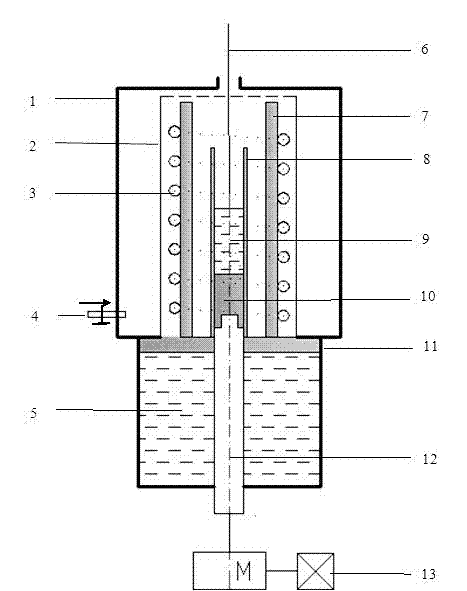

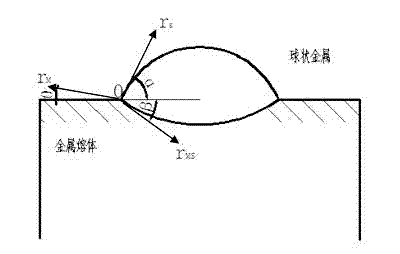

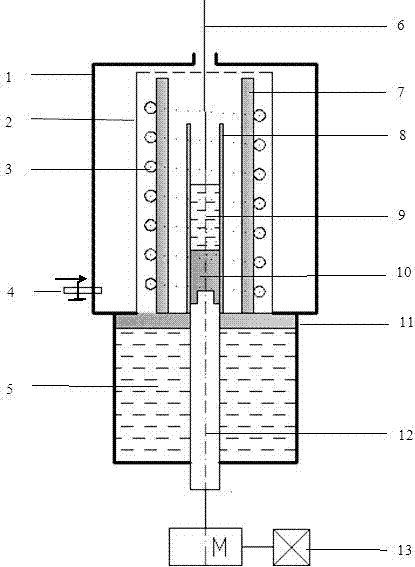

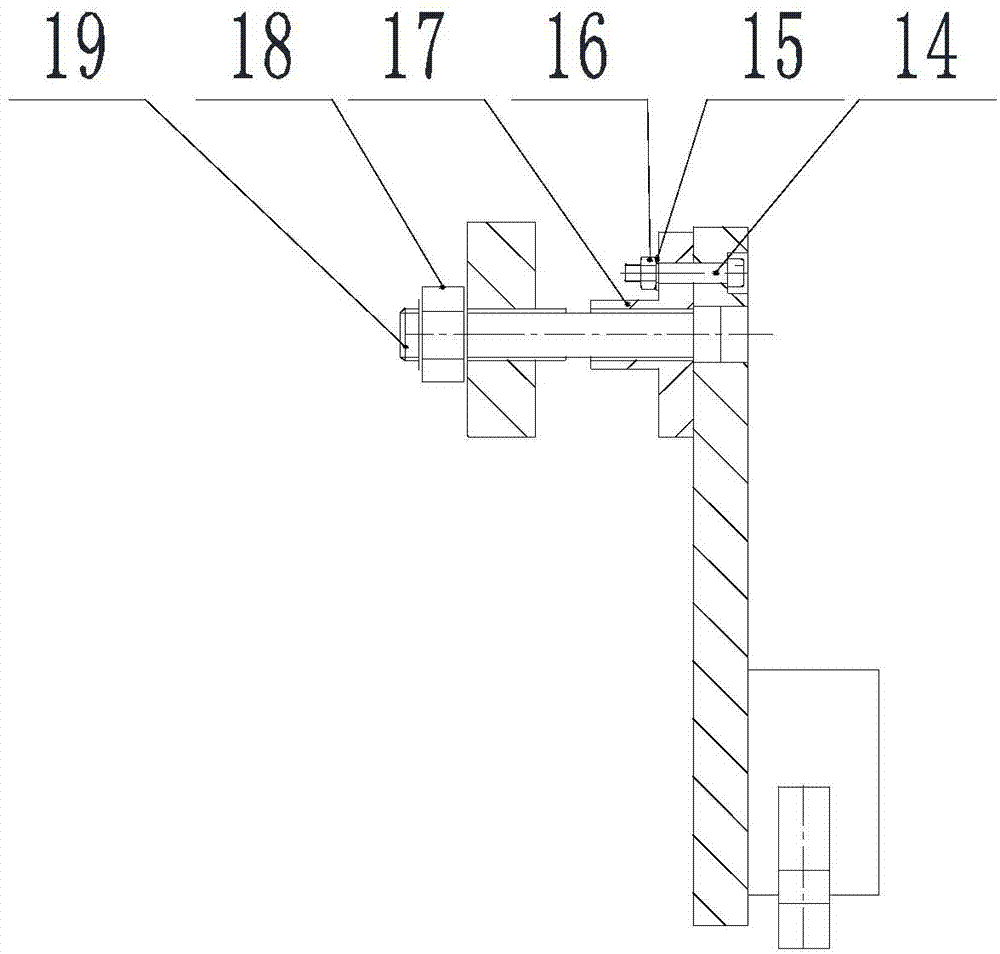

Method and device for determining material solid/liquid interfacial energy by experiment

The invention relates to a method and a device for determining material solid / liquid interfacial energy by experiment, and belongs to the field of solidification technology in material preparation. The invention is characterized by comprising the following steps that: A, a metal ingot is cut into a cylindrical bar with a proper size through a wire cutting machine; the cylindrical bar is cleaned up and dried by a blow drier; the dried cylindrical bar is placed into a suited alundum tube and is fixed on a draw bar; the draw bar with the dried cylindrical bar as a sample, a cooling tank and a servo motor are assembled well; and a position of the sample in a heating system is adjusted by the draw bar and it is ensured that a part of the sample bar is melted well; B, argon as protective gas isfed into the heating system; after 20 minutes, the heating system is started, when a temperature in a furnace of the heating system rises to an objective temperature, the temperature in the furnace is kept for a period of time to ensure the stabilization of heat flow in the furnace; C, a metal globular solid which is congener with the sample is placed on the surface of the molten sample from the upper portion of the device; when the surface of the metal globular solid is infiltrated with the molten sample, a servo drawing system is started; the sample is pulled down fast and enters into the cooling tank to be quenched and thus a feature of a solid / liquid interface is maintained; and a contact angle value is obtained by a direct measure and is substituted into an interfacial tension balance formula and interfacial energy is calculated out by the formula. The present device realizes a core idea that a feature of a solid / liquid interface of a sample at a high temperature is maintained byfast quenching.

Owner:SHANGHAI UNIV

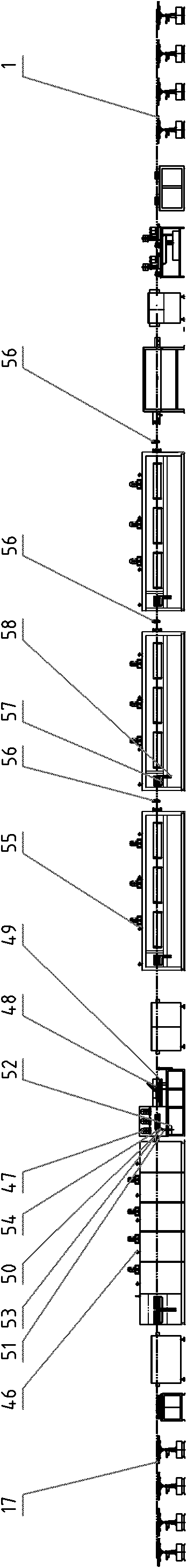

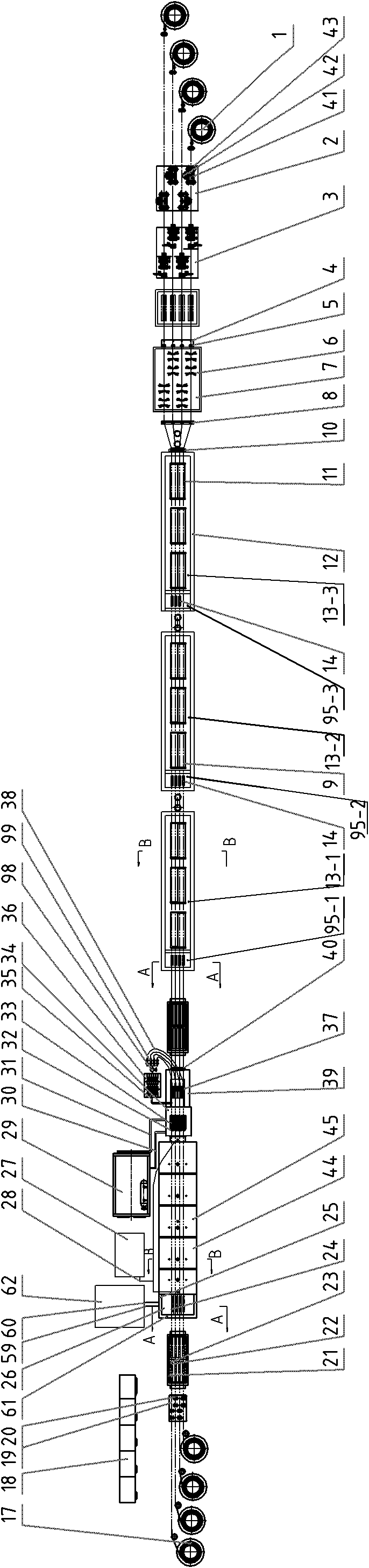

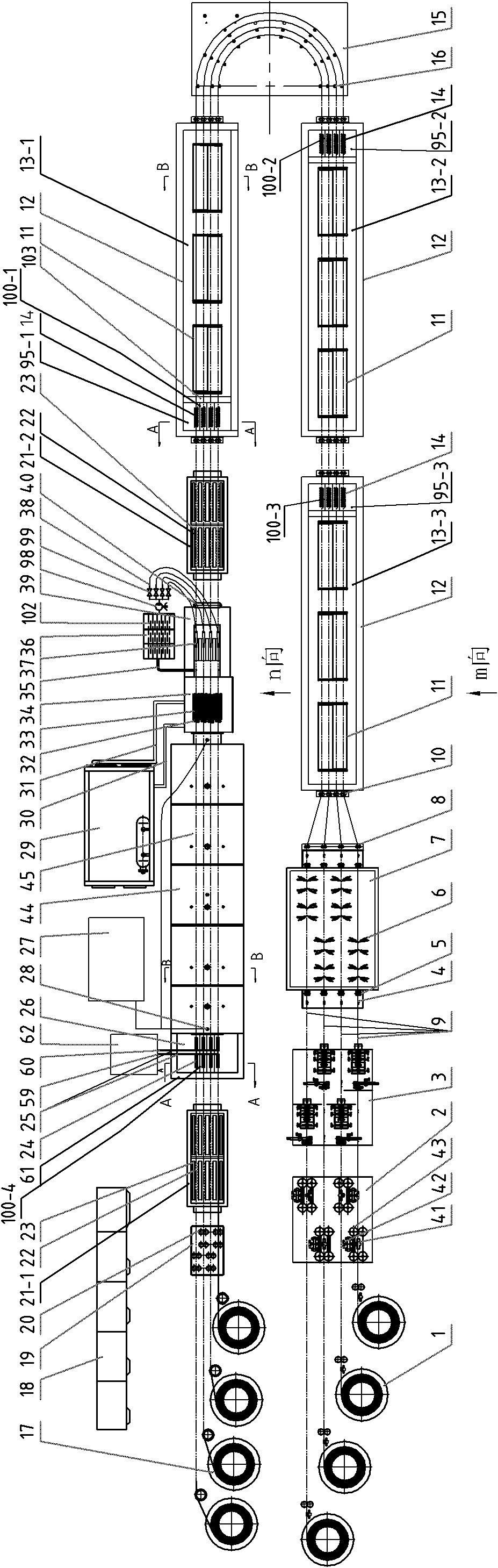

Multifunctional one-furnace multi-strip quick high-efficiency heat treatment production line and process for bimetal strip saw blades

InactiveCN102534169AImprove efficiencyIncrease production capacityFurnace typesHeat treatment furnacesMultiple functionLarge capacity

The invention discloses a multifunctional one-furnace multi-strip quick high-efficiency heat treatment production line and a process for bimetal strip saw blades, and relates to a heat treatment production line and a quenching process for bimetal strip saw blades. By the production line and the process, a technology for heating and cooling the saw blades quickly is implemented, the saw blades have high quality, and high efficiency, high capacity, low input, low cost and low energy consumption are achieved. Quick step quenching is performed by a deep cooling, water cooling, air cooling and nitrogen composite cooling process, so that the high efficiency and high capacity of production and the high quality of the saw blades can be ensured; and all process equipment is integrated into one production line, all processes such as quenching, tempering, sand blasting, cleaning, drying, marking, oiling, straightening and the like are finished on one production line, and a plurality of band saw blades of various specifications can be produced on one production line simultaneously. After the production line is implemented, the capacity of the saw blades is improved by about 3 times, the quality of products is improved by about 30 percent, energy such as electricity, water, oil, gas and the like is saved by over 200 percent, project investment is saved by over 200 percent, plant and land are saved by over 150 percent, production cost is reduced by over 50 percent, and the contradiction and technical bottleneck problem of conventionally exchanging quality for yield and exchanging high input for high capacity for years are radically solved.

Owner:曹玉贵

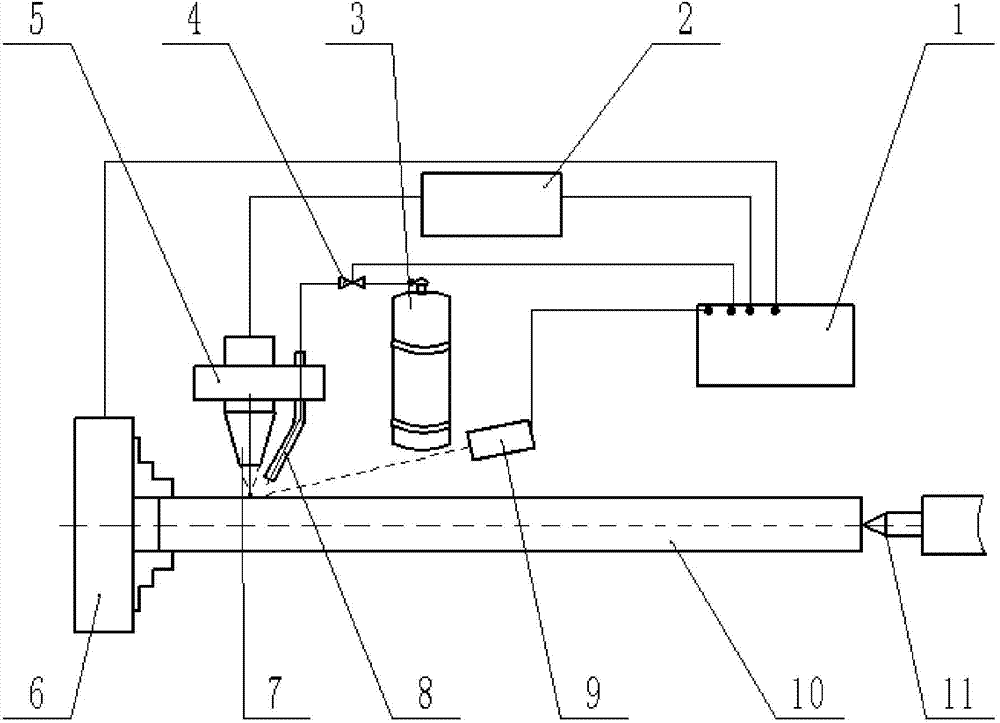

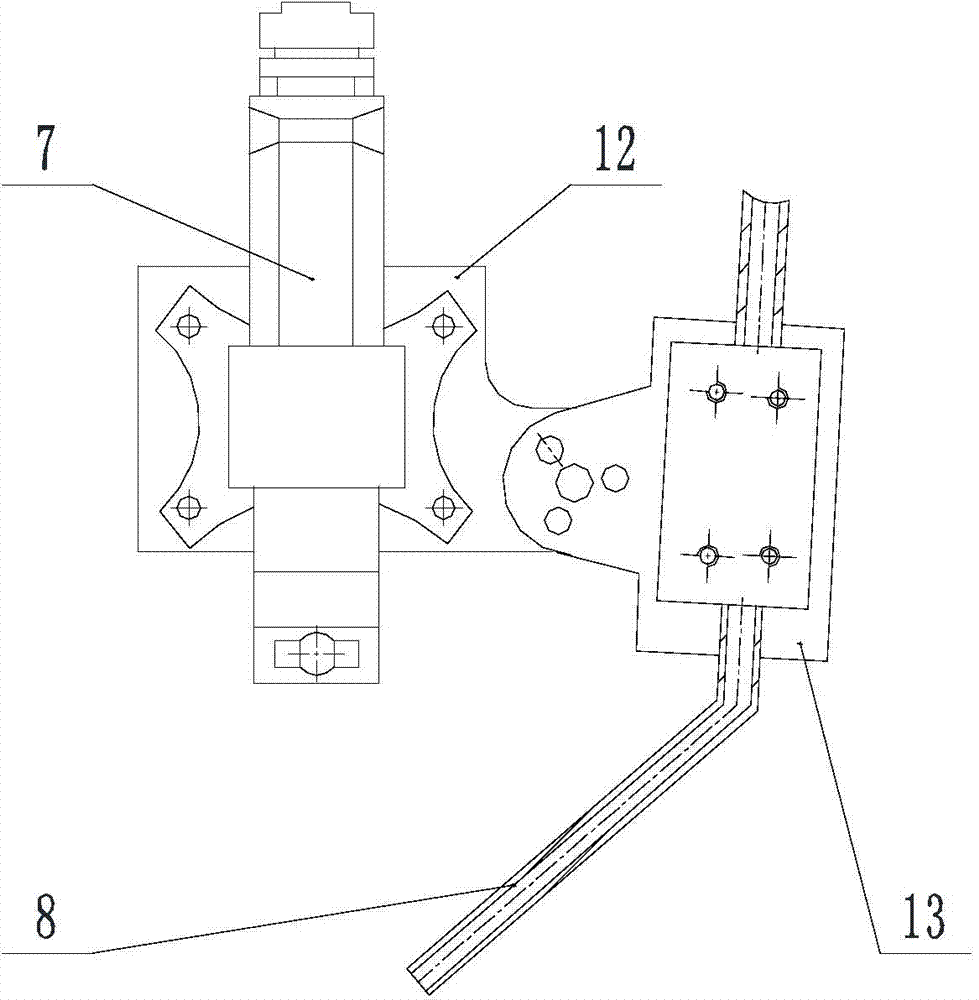

Quick quenching device and method for shaft parts

InactiveCN104775011ATemperature monitoringWon't soften the problemFurnace typesHeat treatment furnacesLaser quenchingLiquid nitrogen cooling

The invention discloses a quick quenching device and method for shaft parts. The quick quenching device for shaft parts is provided with a temperature monitoring device, a laser device, a liquid nitrogen cooling system, a workpiece clamp and a connecting plate assembly, wherein the connecting plate assembly is provided with a manipulator connecting plate, a connecting component and a spray nozzle connecting plate, a laser head is installed on the manipulator connecting plate, and a liquid nitrogen spray nozzle is installed on the spray nozzle connecting plate and is connected with a liquid nitrogen cooling system control valve through an air delivery pipe. The workpiece clamp is arranged under the connecting plate assembly and is provided with a chuck, a tip and a control system for controlling rotation of the chuck, and a workpiece is arranged between the chuck and the tip. The temperature monitoring device is arranged on one side of the connecting plate assembly and is used for monitoring the temperature of a laser quenching zone on the workpiece. By the adoption of the quick quenching device and method for shaft parts, the automation degree of surface laser strengthening of large shafts can be improved, working efficiency can be improved, shaft surface strengthening and near-net shaping can be also achieved, additional machining is not needed basically, and working procedures and cost are saved.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

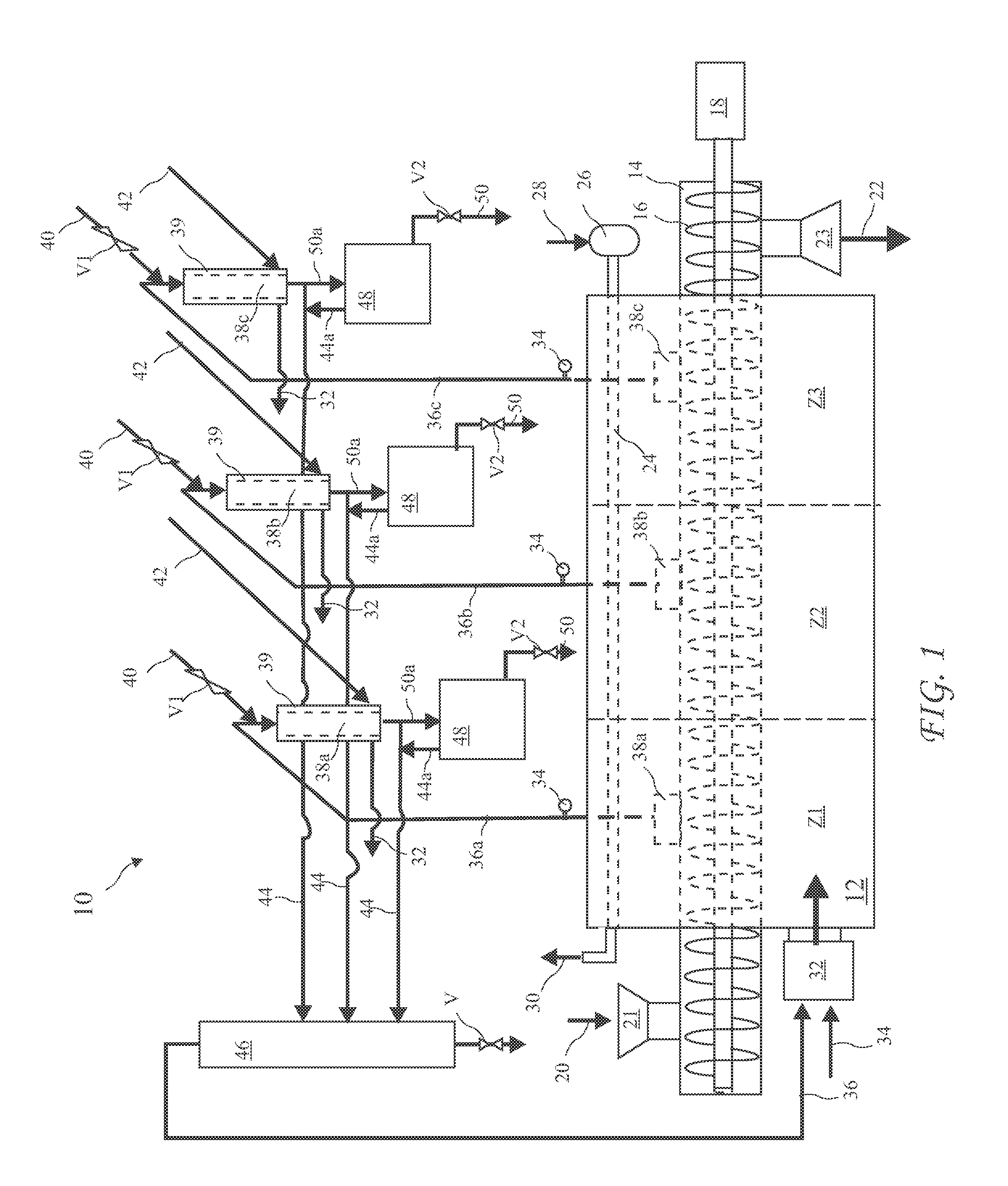

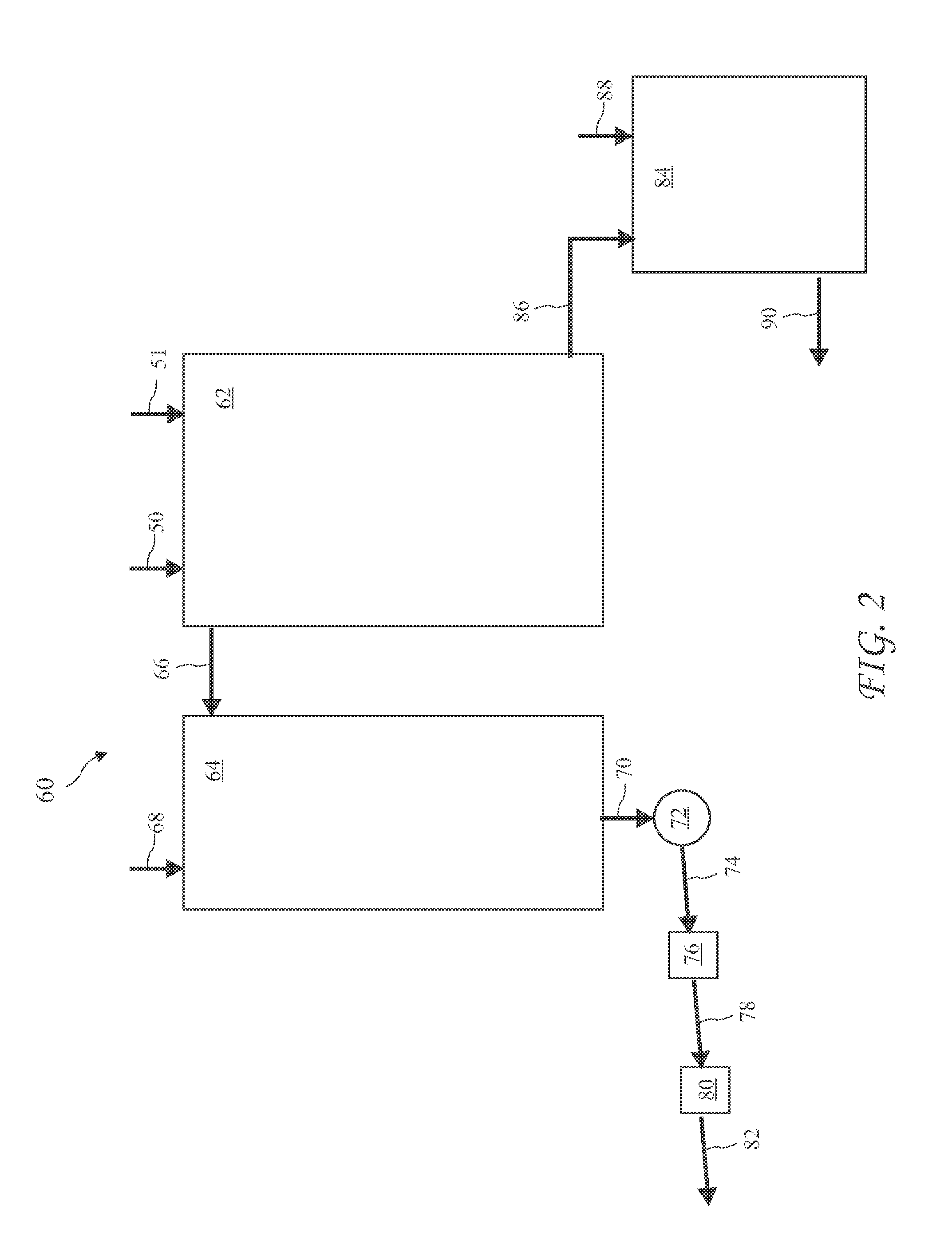

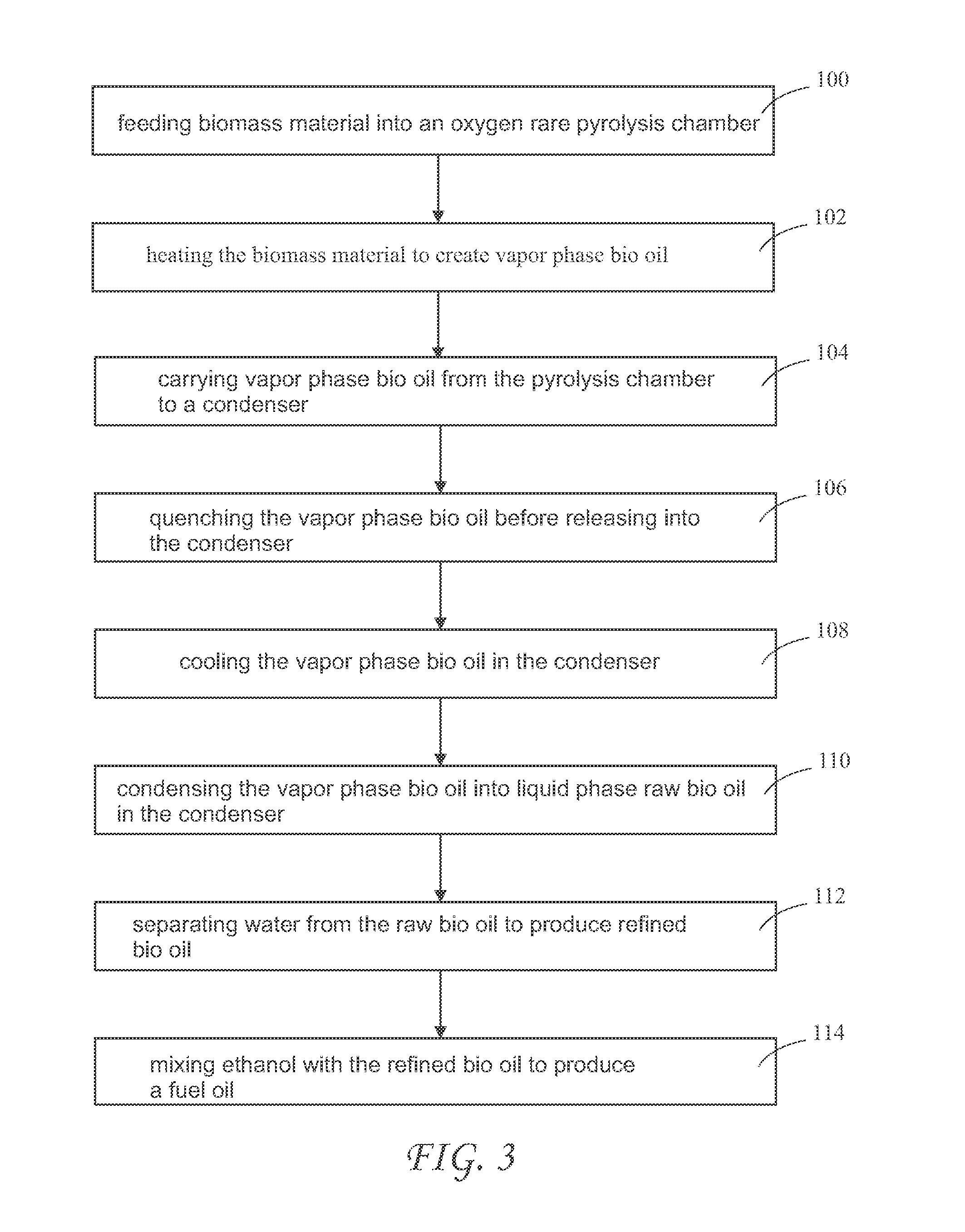

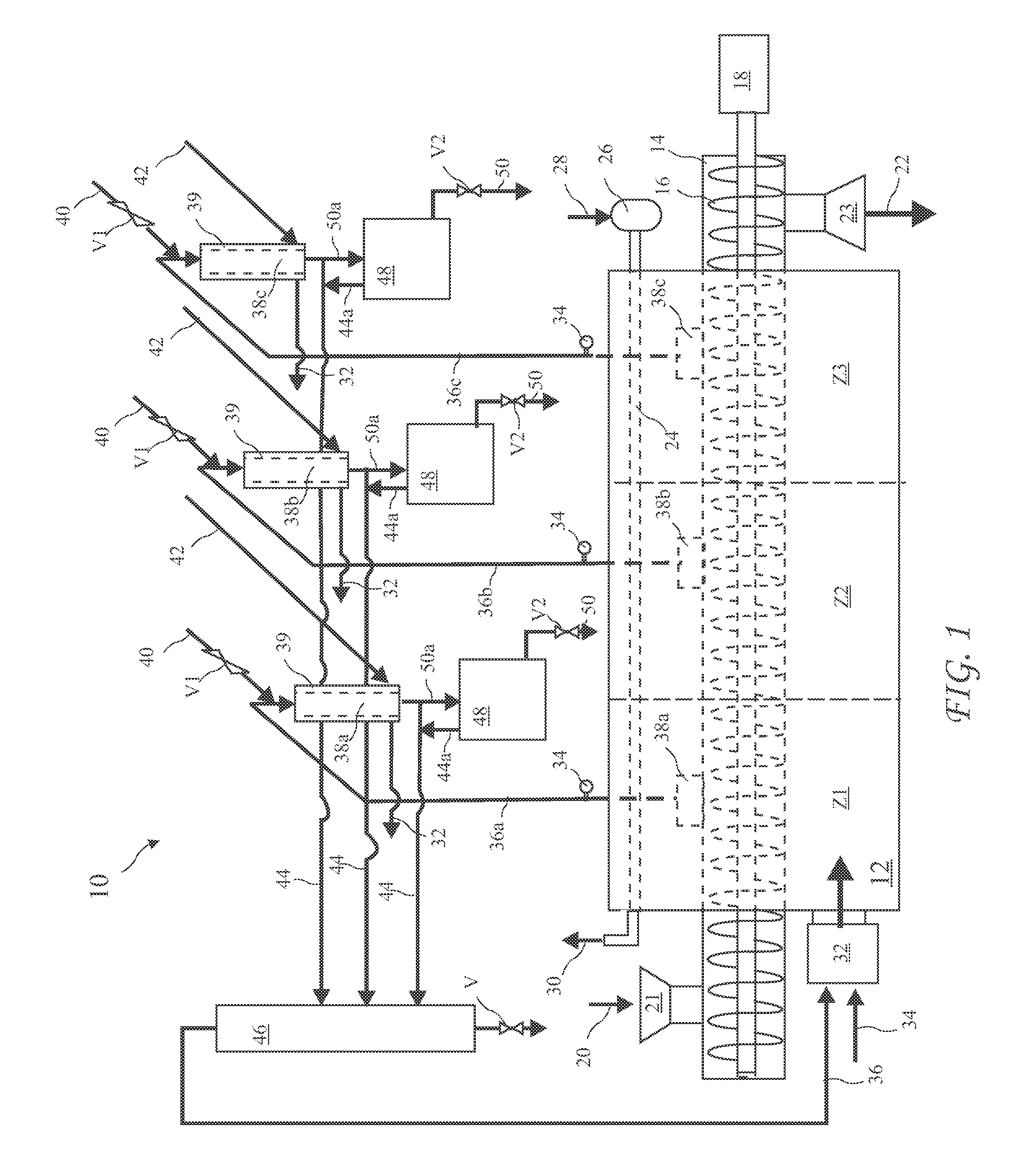

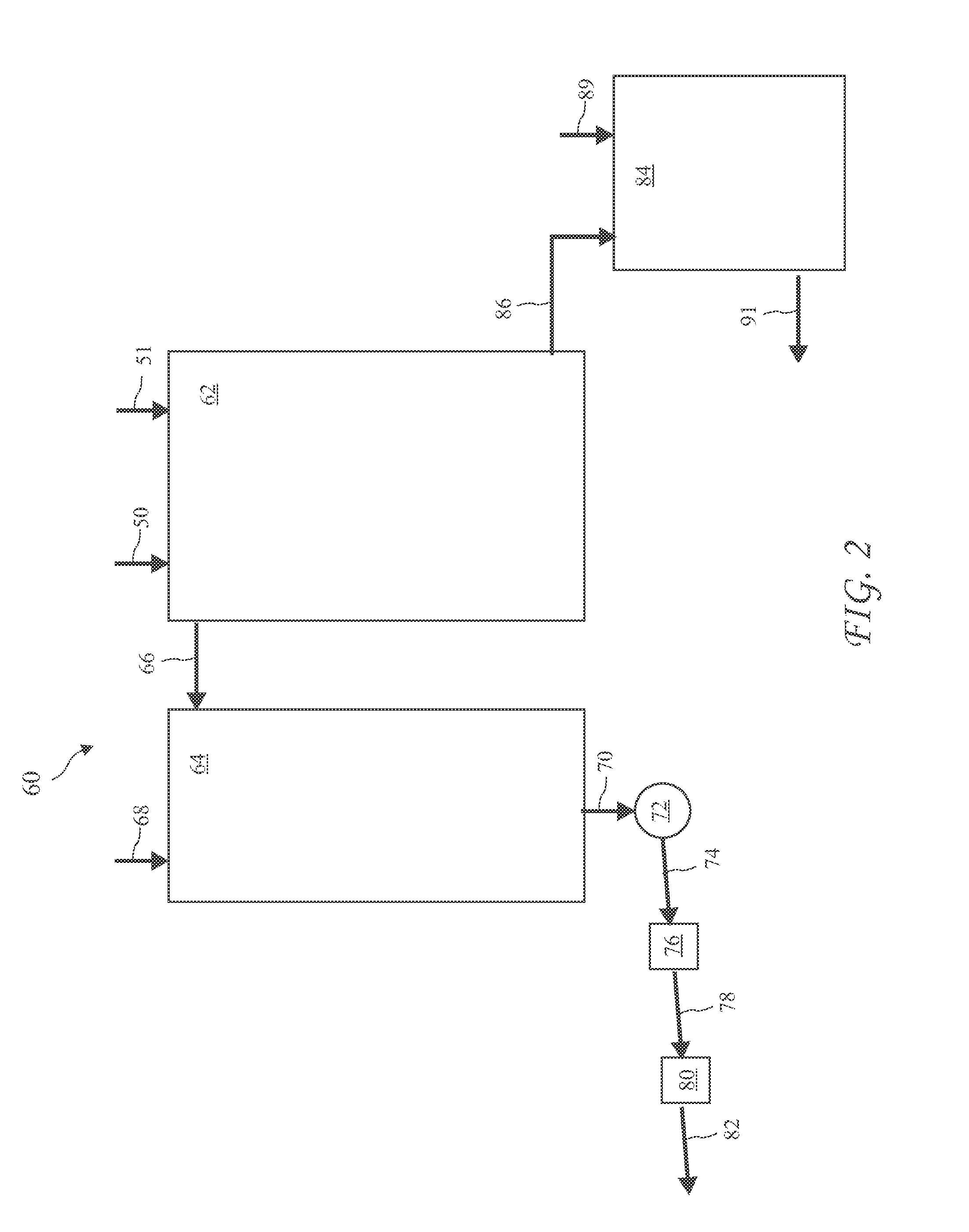

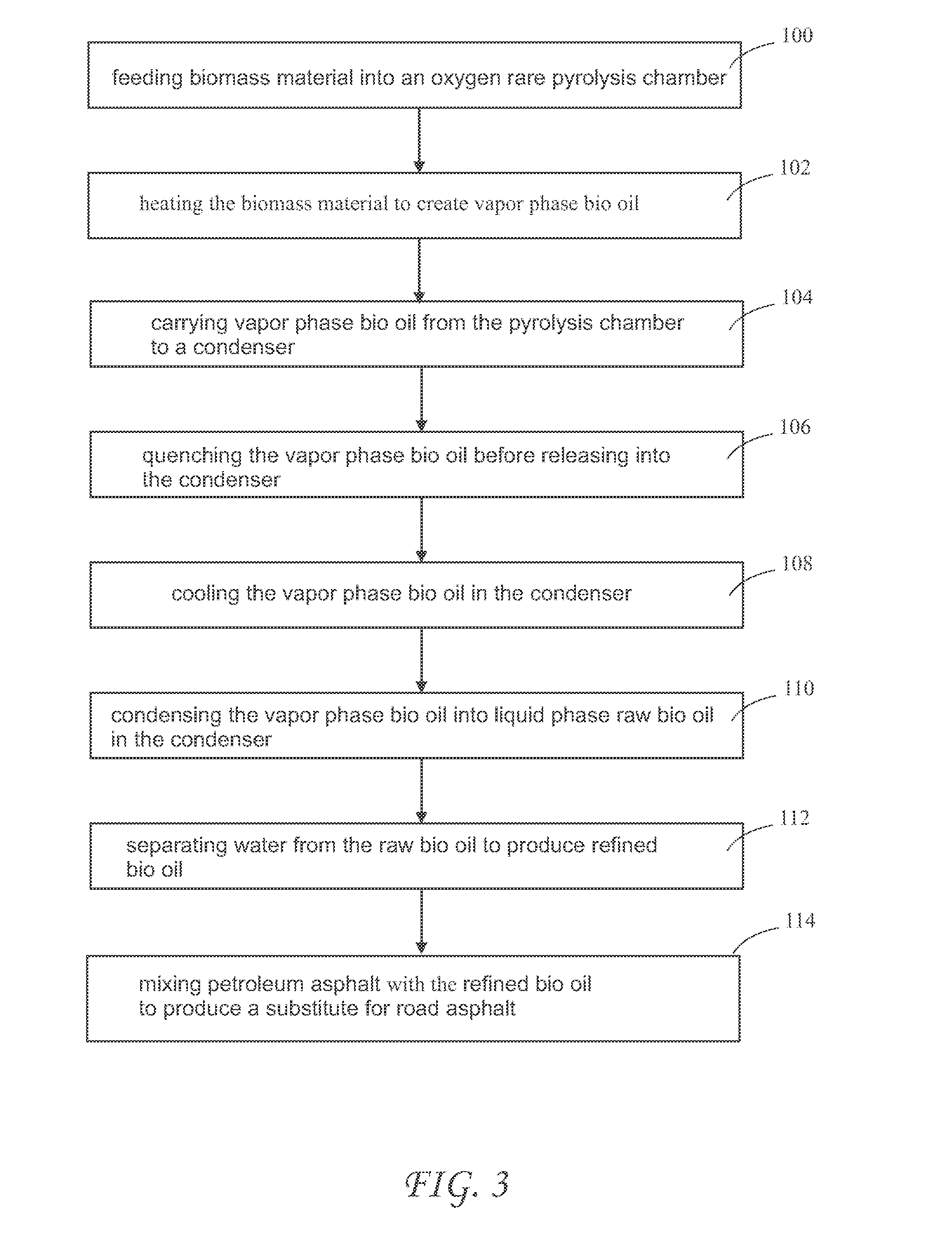

Biomass Bio Oil Upgrade Method

A bio oil pyrolysis and conditioning system produces a useful fuel oil. The pyrolysis system includes an auger carrying biomass feed material though an oxygen rare pyrolysis chamber. Vapor phase bio oil is collected at three locations along the length of the pyrolysis chamber and carried from the pyrolysis chamber to condensers and quenched by a water spray before release into the condensers. The water also serving as a solvent to reduce pH in the liquid phase raw bio oil. The raw bio oil is carried to a conditioning system where the raw bio oil resides in a separation tank where the water separates and is removed producing refined bio oil. Ethanol is mixed with the refined bio oil to provide the fuel oil.

Owner:KARR GRP OF COMPANY

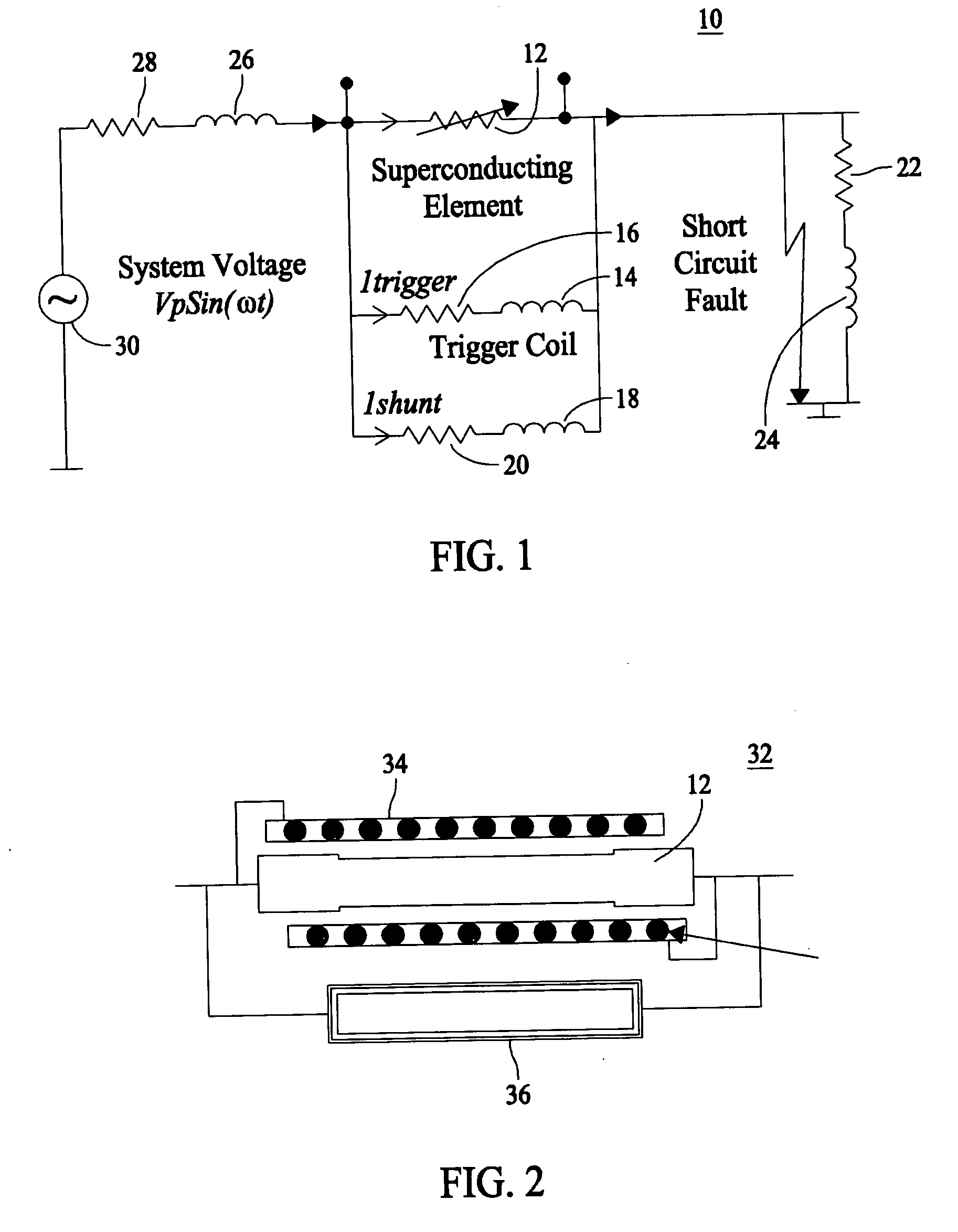

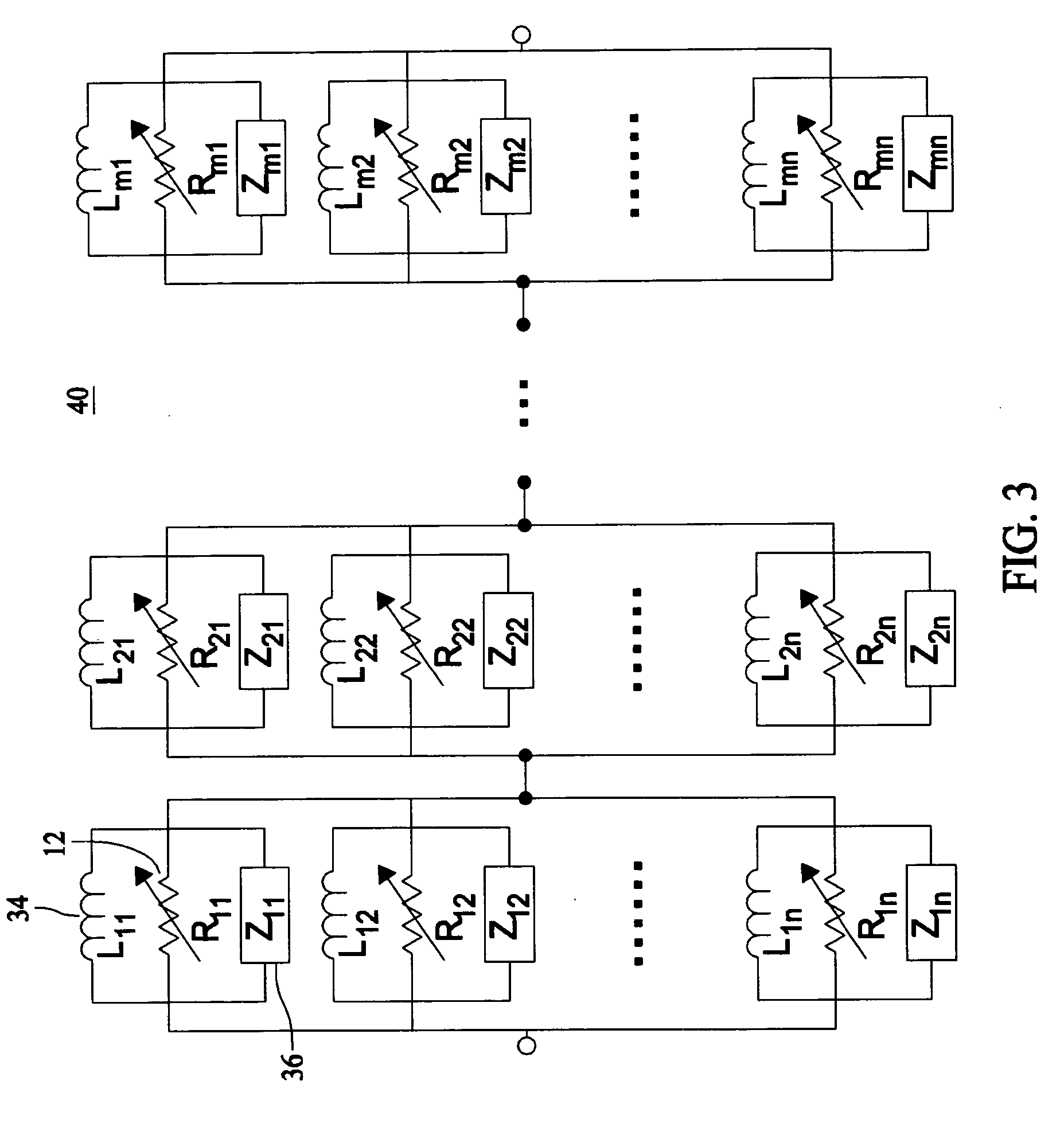

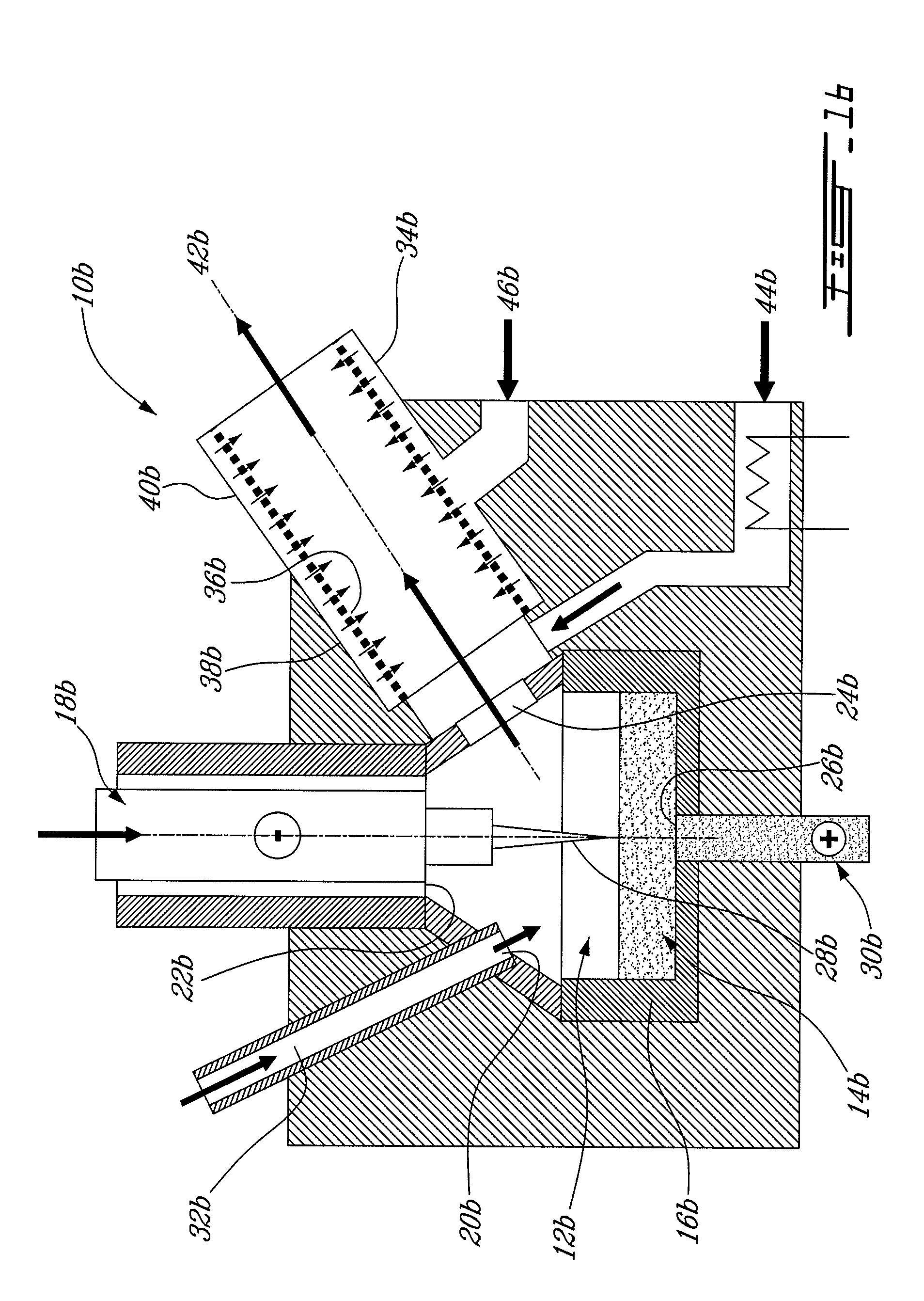

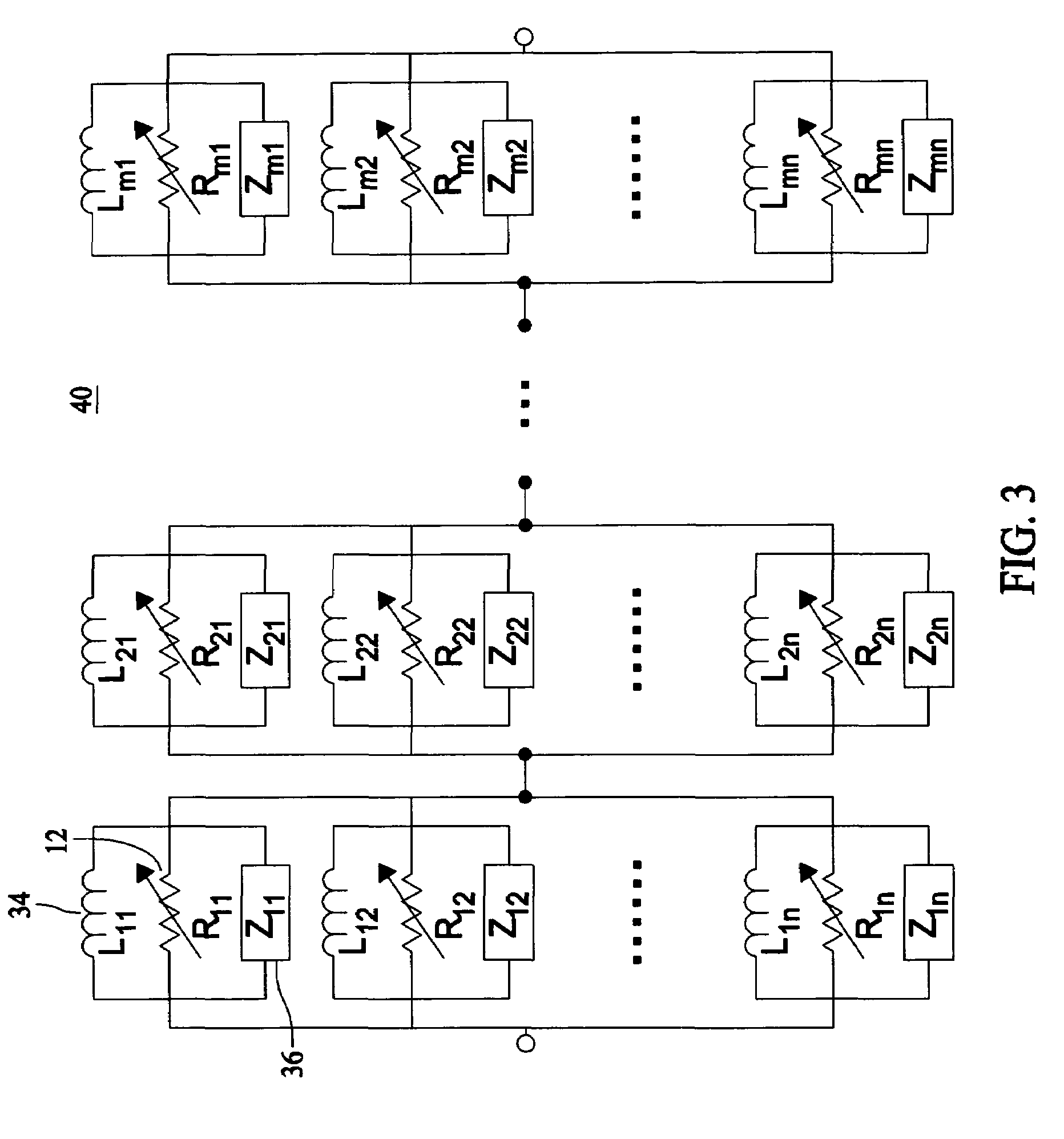

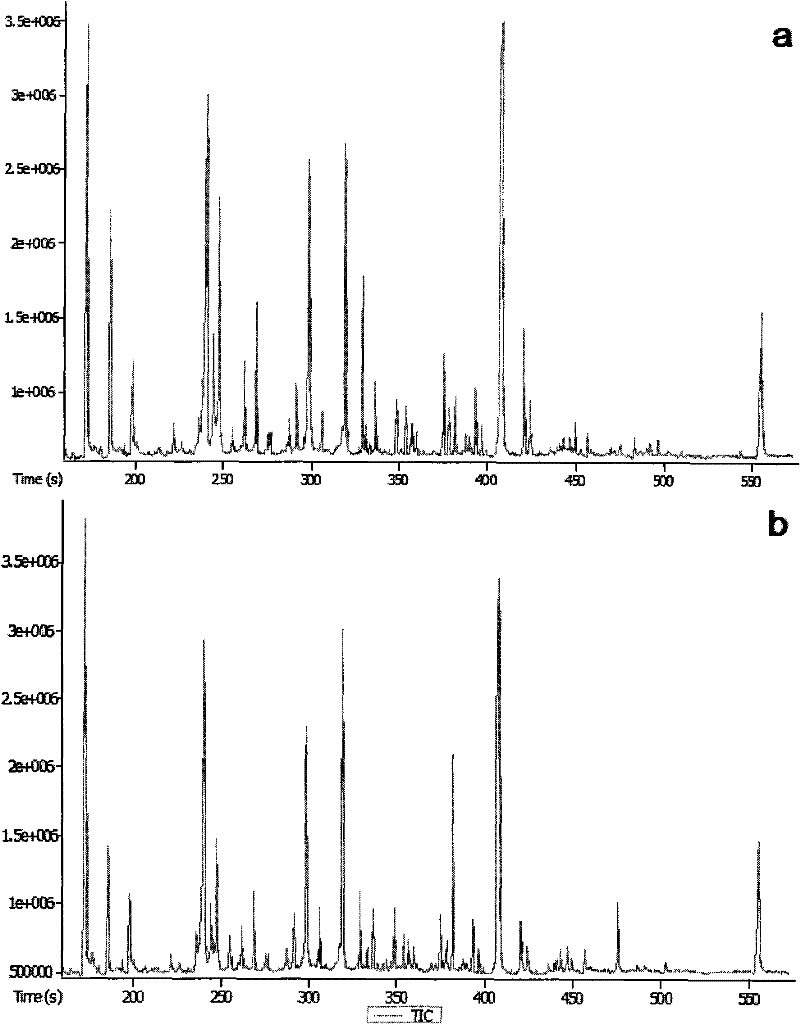

Self-triggering superconducting fault current limiter

InactiveUS20060221517A1Rapid quenchingIncrease flexibilityEmergency protective arrangements for automatic disconnectionEmergency protective arrangements for limiting excess voltage/currentElectrical resistance and conductanceElectricity

A modular and scaleable Matrix Fault Current Limiter (MFCL) that functions as a “variable impedance” device in an electric power network, using components made of superconducting and non-superconducting electrically conductive materials. The matrix fault current limiter comprises a fault current limiter module that includes a superconductor which is electrically coupled in parallel with a trigger coil, wherein the trigger coil is magnetically coupled to the superconductor. The current surge doing a fault within the electrical power network will cause the superconductor to transition to its resistive state and also generate a uniform magnetic field in the trigger coil and simultaneously limit the voltage developed across the superconductor. This results in fast and uniform quenching of the superconductors, significantly reduces the burnout risk associated with non-uniformity often exitsting within the volume of superconductor materials. The fault current limiter modules may be electrically coupled together to form various “n” (rows)דm” (columns) matrix configurations.

Owner:SUPERPOWER INC

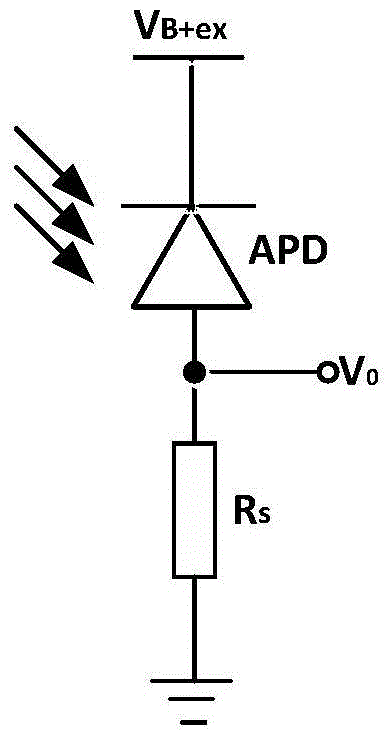

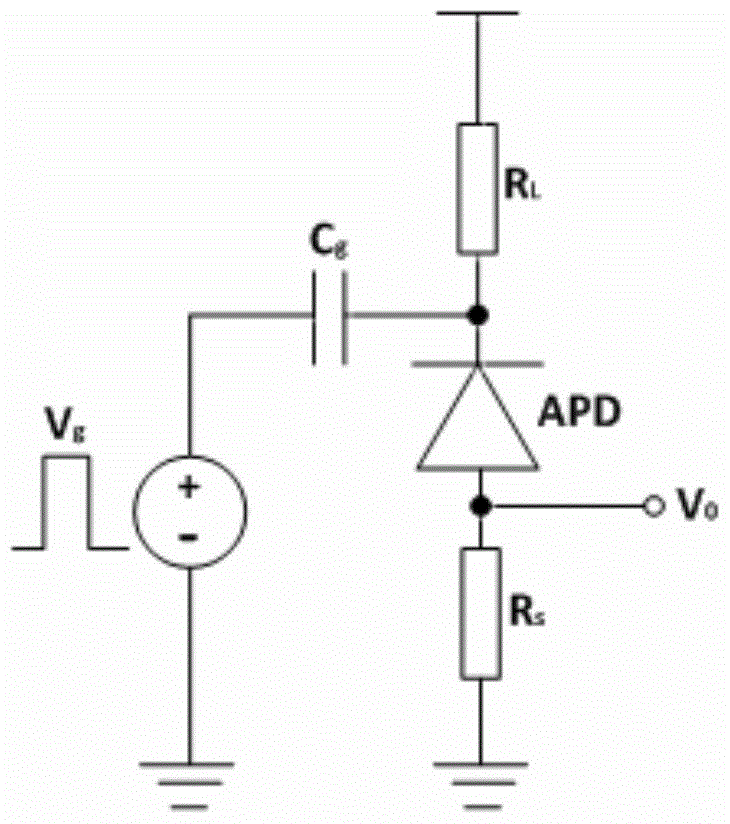

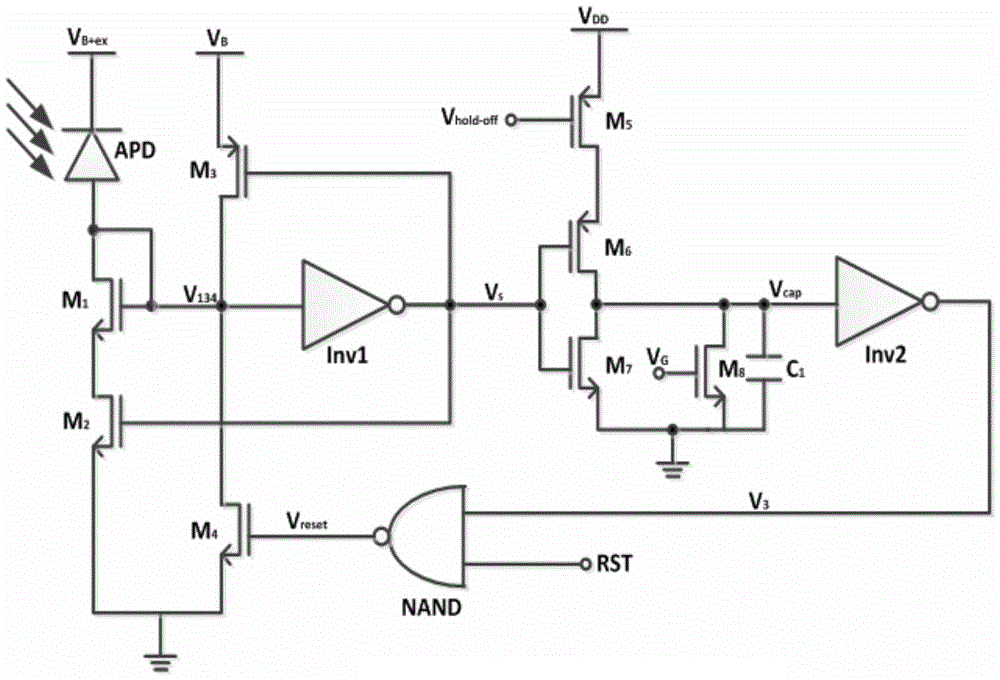

Active quenching circuit used for APD detector in Geiger mode

The invention discloses an active quenching circuit used for an APD detector in a Geiger mode, and the circuit comprises an nmos tube M1, an nmos tube M2, a pmos tube M3, an nmos tube M4, a pmos tube M5, a pmos tube M6, an nmos tube M7, an nmos tube M8, a capacitor C1, a phase inverter Inv1, a phase inverter Inv2, and an NAND gate NAND. A drain electrode of the nmos tube M1 is connected with the anode of the APD detector, and the cathode of the APD detector is connected with a biasing reversal high-voltage VB+ex. The subnanosecond-level active quenching and quick resetting of the APD detector or an APD array are achieved through a feedback structure, and the quenching time is at a subnanosecond level. The maximum hold-off time is 5ns, and can be adjusted automatically according to the actual condition. The whole circuit structure is simple and compact, is small in area, is low in power consumption, is high in speed, is suitable for the quenching of a single or pixel-level APD detector, and reliably guarantees that the APD detector achieves the random continuous detection and the service life of a device is prolonged.

Owner:TIANJIN UNIV

Superconducting FCL using a combined inducted magnetic field trigger and shunt coil

InactiveUS20060274458A1Less complexImprove equipment reliabilityNormal-superconductive switchable devicesEmergency protective arrangements for limiting excess voltage/currentShunt impedanceHigh temperature superconducting

A single trigger / shunt coil is utilized for combined induced magnetic field triggering and shunt impedance. The single coil connected in parallel with the high temperature superconducting element, is designed to generate a circulating current in the parallel circuit during normal operation to aid triggering the high temperature superconducting element to quench in the event of a fault. The circulating current is generated by an induced voltage in the coil, when the system current flows through the high temperature superconducting element.

Owner:SUPERPOWER INC

Biomass Bio Oil Upgrade Method

A bio oil pyrolysis and conditioning system produces a useful road asphalt. The pyrolysis system includes an auger carrying biomass feed material though an oxygen rare pyrolysis chamber. Vapor phase bio oil is collected at three locations along the length of the pyrolysis chamber and carried from the pyrolysis chamber to condensers and quenched by a water spray before release into the condensers. The water also serving as a solvent to reduce pH in the liquid phase raw bio oil. The raw bio oil is carried to a conditioning system where the raw bio oil resides in a separation tank where the water separates and is removed producing refined bio oil. The refined bio oil is mixed with an equal or greater amount of petroleum asphalt to obtain a substitute for road asphalt.

Owner:KARR GRP OF COMPANY

Plasma synthesis of nanopowders

ActiveUS8859931B2Improve scalabilityReduce the possibilityBoron/boridesNitrogen-metal/silicon/boron binary compoundsPlasma flowNanometre

A process and apparatus for preparing a nanopowder are presented. The process comprises feeding a reactant material into a plasma reactor in which is generated a plasma flow having a temperature sufficiently high to vaporize the material; transporting the vapor with the plasma flow into a quenching zone; injecting a preheated quench gas into the plasma flow in the quenching zone to form a renewable gaseous condensation front; and forming a nanopowder at the interface between the renewable controlled temperature gaseous condensation front and the plasma flow.

Owner:TEKNA PLASMA SYST INC

Self-triggering superconducting fault current limiter

InactiveUS7440244B2Rapid quenchingIncrease flexibilityEmergency protective arrangements for automatic disconnectionEmergency protective arrangements for limiting excess voltage/currentConductive materialsQuenching

A modular and scaleable Matrix Fault Current Limiter (MFCL) that functions as a “variable impedance” device in an electric power network, using components made of superconducting and non-superconducting electrically conductive materials. The matrix fault current limiter comprises a fault current limiter module that includes a superconductor which is electrically coupled in parallel with a trigger coil, wherein the trigger coil is magnetically coupled to the superconductor. The current surge doing a fault within the electrical power network will cause the superconductor to transition to its resistive state and also generate a uniform magnetic field in the trigger coil and simultaneously limit the voltage developed across the superconductor. This results in fast and uniform quenching of the superconductors, significantly reduces the burnout risk associated with non-uniformity often existing within the volume of superconductor materials. The fault current limiter modules may be electrically coupled together to form various “n” (rows)דm” (columns) matrix configurations.

Owner:SUPERPOWER INC

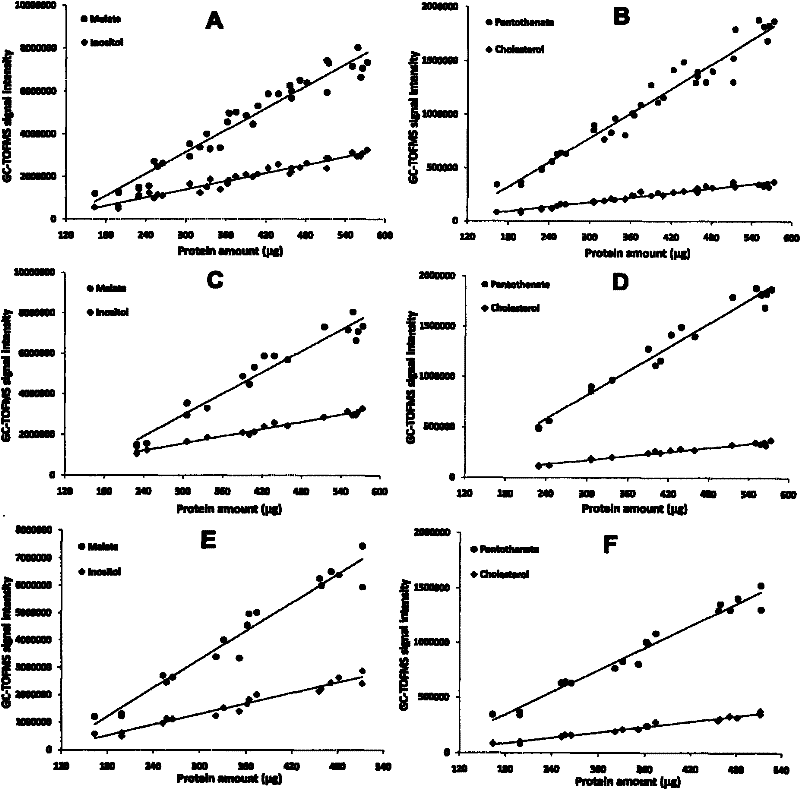

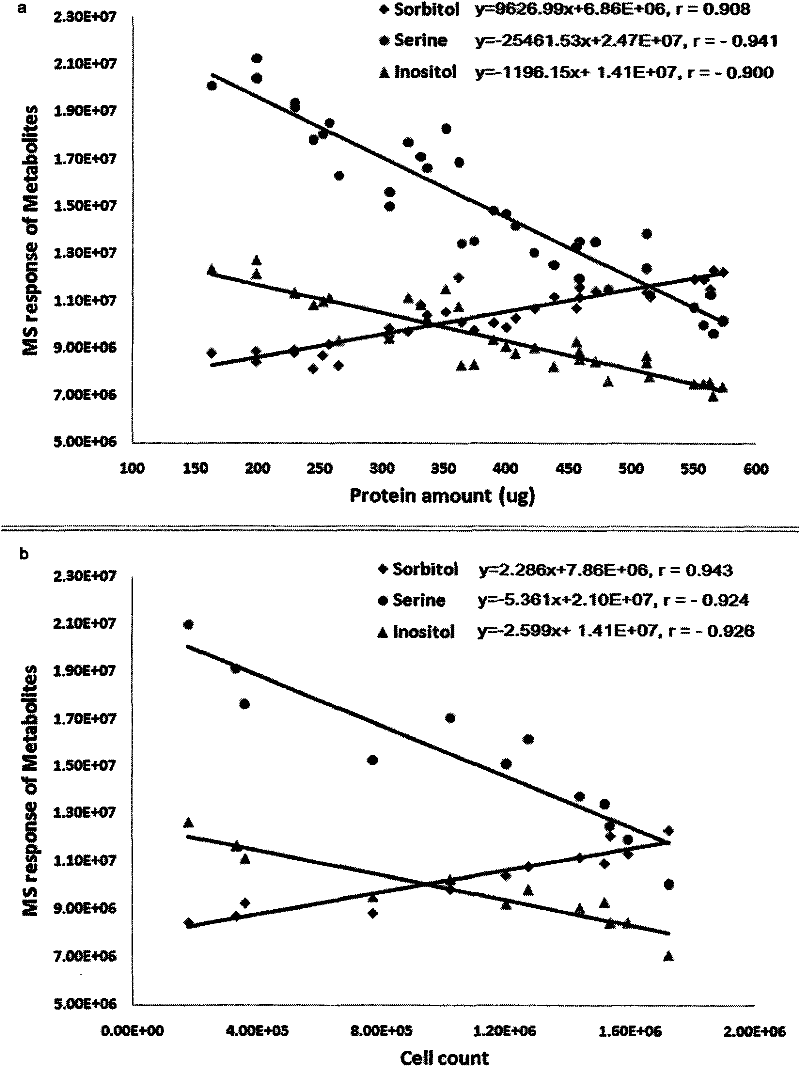

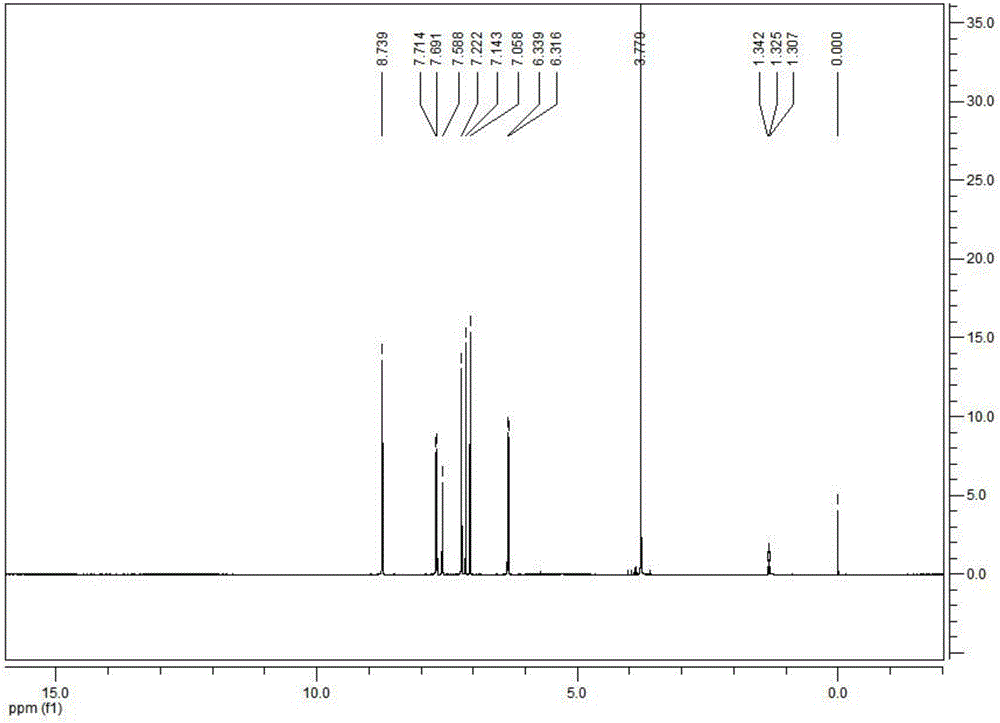

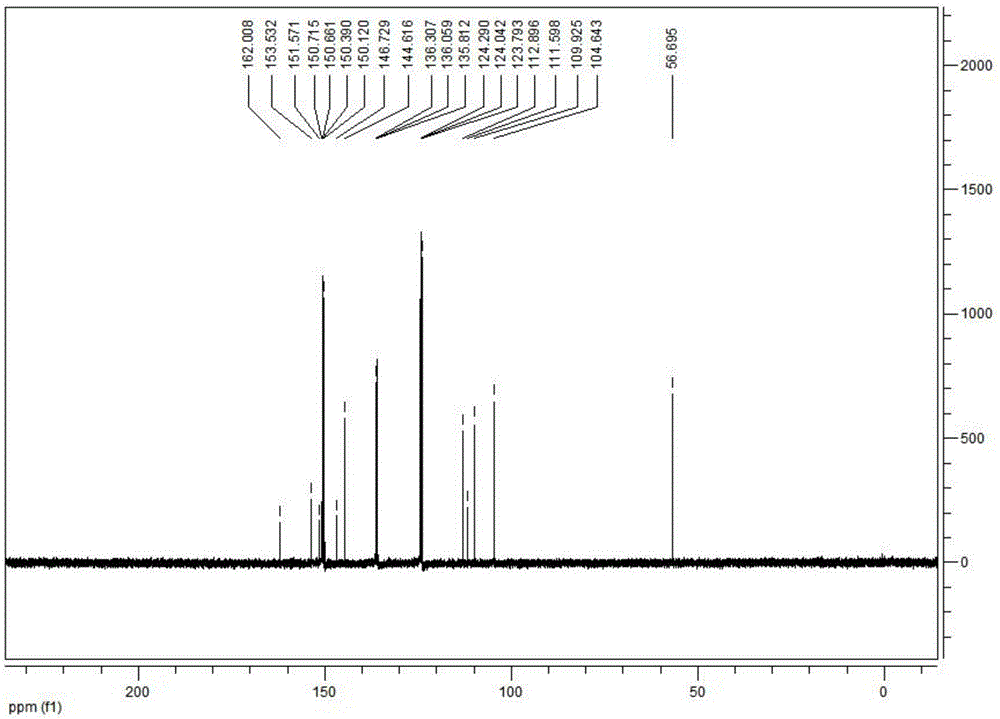

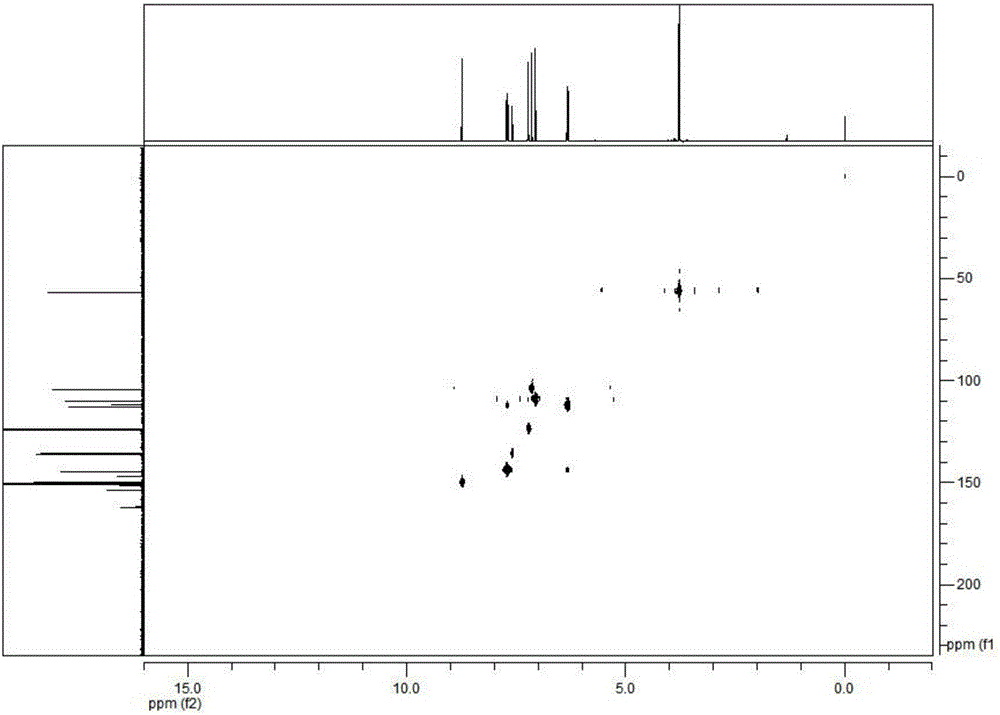

New method for performing data correction by using cell metabolite relative content as cell number index

InactiveCN102175809AEfficient collectionEfficient metabolic quenchingComponent separationMicrobiological testing/measurementMass spectrometryCell metabolite

The invention discloses a new method for performing data correction by using cell metabolite relative content as cell number index. The new method is characterized by comprising the steps of: realizing the fast quenching of biochemical metabolism in cells by using a simple sample pre-processing method; efficiently extracting small molecule metabolites by an optimized extraction solvent; and roundly and half quantitatively measuring the small molecule compounds in a biological sample by a metabonomics method based on measuring technology like mass spectrum, nuclear magnetic resonance and the like so as to identify a quantitative index of symbolic metabolites in cells to be as the cell number, and regarding the quantitative index as a weight factor to perform data correction. Compared with the quantitative index of the prior cell number, the method is simple, fast and with good repeatability; additional experimental working and the error caused by the additional working are reduced; the accuracy and reliability of experiment result are improved; the difficulty for relatively quantifying the number of in vitro cultured cells is solved; a new displacing method is supplied for cell metabonomics and relevant researches; and the method can be widely used in the relevant researches in the field of cell molecular biology.

Owner:CHINA PHARM UNIV

Method for extracting scopoletin compounds from tobacco

InactiveCN106749143AHarm reductionRapid quenchingOrganic chemistryTobacco treatmentDissolutionFood flavor

The invention discloses a method for extracting scopoletin compounds from tobacco. The method is characterized by comprising the following steps of preparing tobacco extracts; performing water dissolution on the tobacco extracts; then, performing extraction; eluting the extraction liquid in a macroporous resin chromatographic column by ethyl alcohol; after eluant is collected, performing reduced pressure concentration; then, performing capillary tube sampling thin-layer chromatography; merging the eluant with the similar ingredients; performing reduced pressure concentration until the materials are dry so that a tobacco polar extract is obtained; merging samples showing brownish black spots by a thin-layer chromatography method; performing reduced pressure concentration; obtaining coarse extracts; uniformly stirring the coarse extracts and silica gel; using a positive phase silica gel column for separation and elution; by using the thin-layer chromatography method, merging flavor matters according to different Rf values in accordance with different polarities to obtain fine extracts; performing positive phase column chromatography on the fine extracts; performing elution; segmenting TLC detection into five parts from A to E; performing reverse phase silica gel column chromatography on the section B; then, feeding the sample to a half preparation chromatography system for separation; under each chromatography condition, maintaining the time for 7.23 minutes; and performing separation to obtain the monomeric compound.

Owner:GUIZHOU TOBACCO SCI RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com