Multifunctional one-furnace multi-strip quick high-efficiency heat treatment production line and process for bimetal strip saw blades

A bimetallic belt, multi-functional technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of inability to achieve fast and efficient production, large production site area, high energy consumption, and achieve increased production capacity, high production capacity, and high guarantee. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

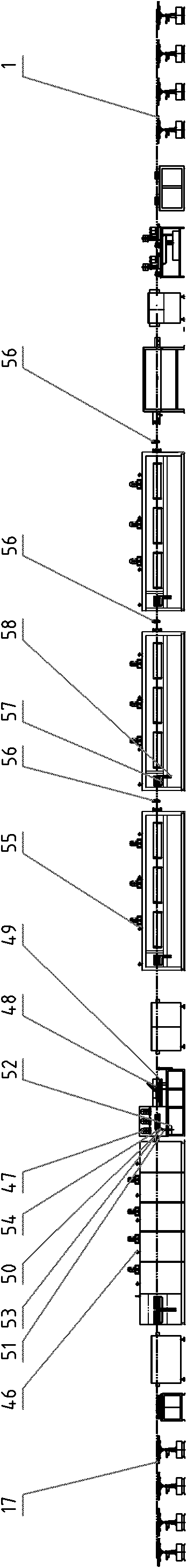

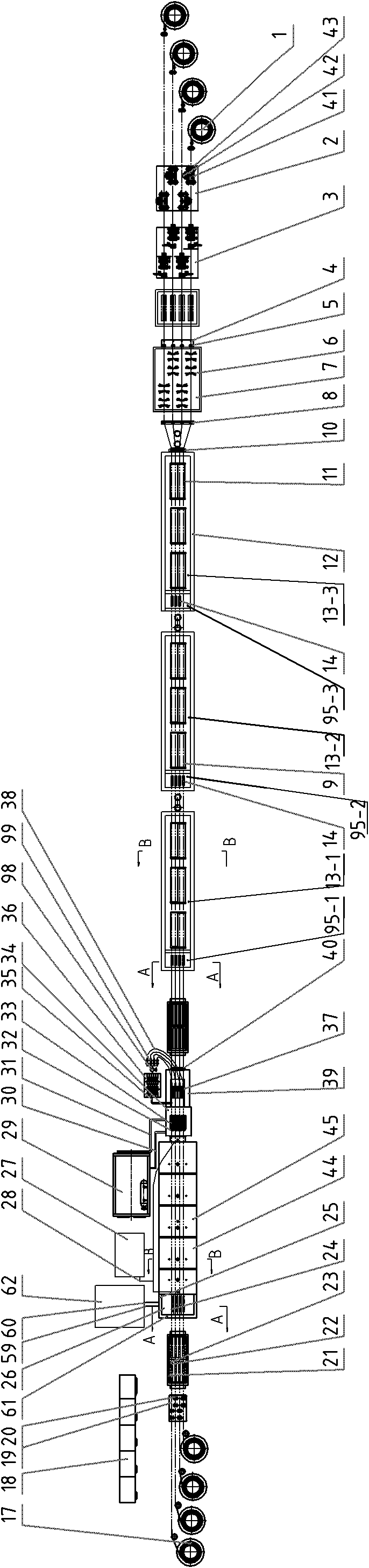

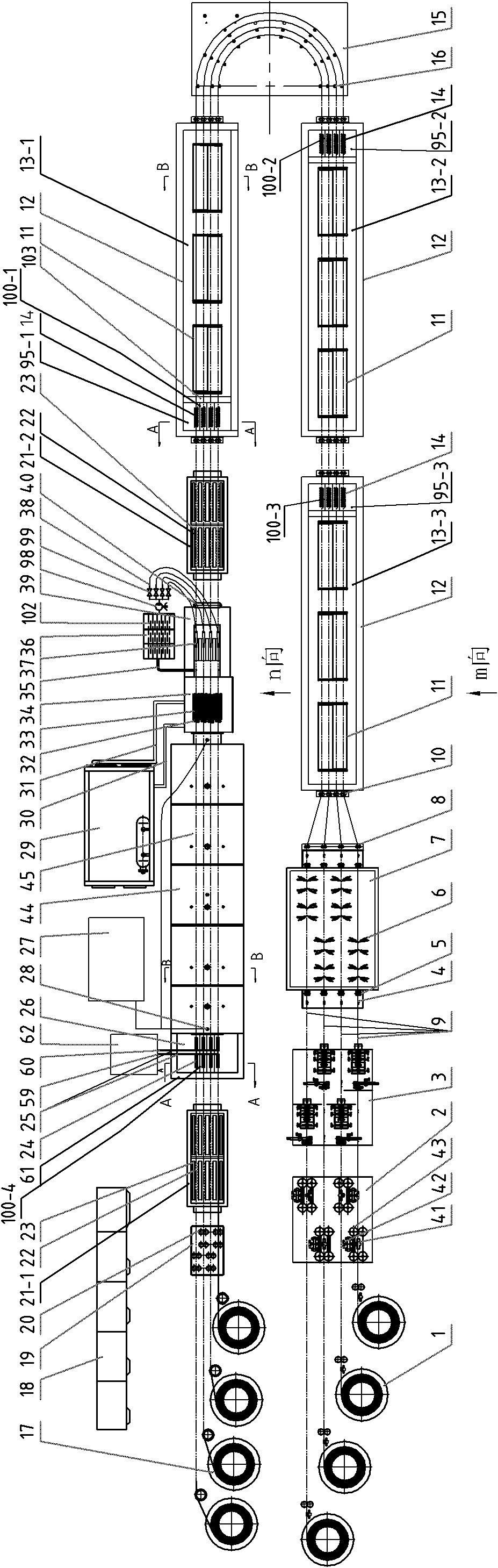

[0038] Specific implementation mode one: as Figure 1-15 As shown, the heat treatment production line for multi-functional, multi-band, fast and high-efficiency bimetallic band saw blades described in this embodiment includes a temperature control system 18, a nitrogen generator 27, and a refrigeration unit 29. N feeding devices 17, induction hardening preheating furnace 26, box type quenching heating furnace 44, composite quenching device 34, oil cooling quenching device 39, first induction tempering preheating furnace 95-1, first box type Tempering furnace 13-1, second induction tempering preheating furnace 95-2, second box type tempering furnace 13-2, third induction tempering preheating furnace 95-3, third box type tempering furnace 13-3, Guide wheel device 8, dry sandblasting machine 7, online marking and oiling equipment 3, output traction device 2 and N receiving devices 1 located at the outlet of the third box-type tempering furnace 13-3; wherein N is a natural number ...

specific Embodiment approach 2

[0054] Specific implementation mode two: as Figure 1-15 As shown, the production line in this embodiment also includes a rotary device 15, and the rotary device 15 is arranged between the first box-type tempering furnace 13, the rotary device 15 and the second induction tempering preheating furnace 95; the saw blade is rotated The device 15 is composed of N sets of guide wheels D16; the N sets of guide wheels D16 are arranged horizontally and fan-shaped; the function of the saw blade turning device is to turn the N saw blades 9, and gradually change the N saw blades 9 running side by side to run in the opposite direction. The saw blade turning device 15 is arranged at the inlet end of the induction tempering preheating furnace 95 of the outlet end of the first box type tempering furnace 13 and the inlet end of the second box type tempering furnace 13; N saw blades 9 after the saw blade turning device 15 The induction tempering preheating furnace 95 at the entrance of the seco...

specific Embodiment approach 3

[0055] Specific implementation mode three: as Figure 6 As shown, the composite cooling device in this embodiment is composed of nitrogen gas, cryogenic quenching device 72 and nitrogen gas, water cooling quenching device 106 . Other components and connections are the same as those in the first embodiment.

[0056] Specific implementation mode four: as figure 2 , image 3 As shown, the dry sandblasting equipment 7 described in this embodiment is used for sandblasting N saw blades 9 at the same time, and 4 to 8 spray guns (8 in the figure) are arranged on both sides of each saw blade 9, and 4 to 8 spray guns are arranged on both sides of each saw blade 9. Symmetrically arranged horizontally, the nozzle of the spray gun faces the side of the saw blade, and the angle and position of the nozzle of the spray gun are adjustable. Other components and connections are the same as those in the first embodiment.

[0057] Specific implementation mode five: as Figure 1-15 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com