Patents

Literature

489 results about "Induction hardening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Induction hardening is a type of surface hardening in which a metal part is induction-heated and then quenched. The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction hardening is used to selectively harden areas of a part or assembly without affecting the properties of the part as a whole.

Cold roll for rolling lithium battery guard plate and manufacturing method thereof

ActiveCN103397267AHigh strengthImprove wear resistanceRollsMetal rolling arrangementsInduction hardeningService condition

The invention discloses a cold roll for rolling a lithium battery guard plate and a manufacturing method thereof. The cold roll contains the following chemical components in percentage by mass: 0.7-1.0% of C, 0.2-1.0% of Si, 0.2-0.6% of Mn, no more than 0.02% of P, no more than 0.02% of S, 2.0-4.0% of Cr, 0.2-0.6% of Ni, 0.2-0.8% of Mo, 0.1-0.5% of V and the balance of Fe and inevitable impurities. The manufacturing method of the cold roll comprises the processing steps of electroslag steel ingot fusion casting, roll blank forging, quenching and tempering treatment, induction hardening treatment, cold treatment, final heat treatment, machining and the like. The cold roll disclosed by the invention has high hardness and wear resistance; and under the service condition of the same strength, the service life of the cold roll is prolonged by 45-55% in comparison with the service life of the original common chrome steel cold roll, and the roll body case hardness of the cold roll can be up to 97-105 HSD.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

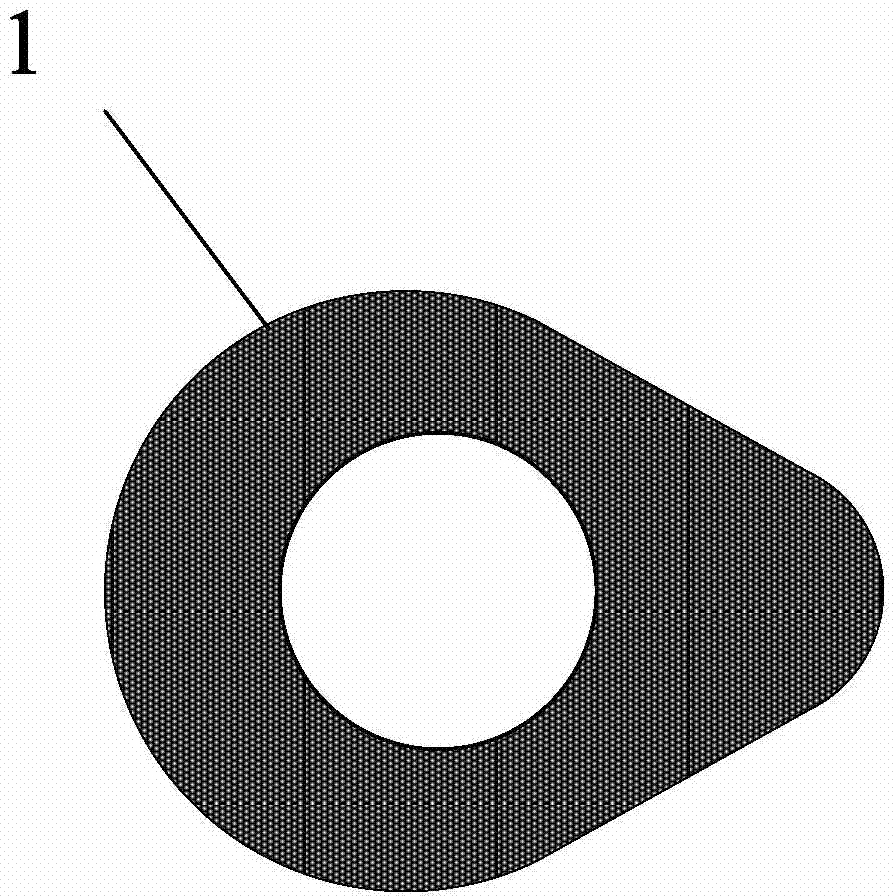

Powder metallurgy compound cam and manufacturing method thereof

InactiveCN104708006AImprove wear resistanceUniform hardness distributionHigh densityInduction hardening

The invention belongs to the technical field of cams, and in particular, relates to a powder metallurgy compound cam and a manufacturing method thereof. The powder metallurgy compound cam consists of a cam piece and a liner with different materials, wherein the cam piece and the liner both comprise outer edges and inner edges, and further comprise base circle parts and peach tip parts; the inner edge of the cam piece and the outer edge of the liner are compounded through metallurgical bonding; and the outer edge of the liner and the inner edge of the cam piece are the same in shape, are both similar to the outer edge of the cam piece in shape, and are both cam-shaped. Blanks of the cam piece and the liner are sintered to obtain the powder metallurgy compound cam. The compound cam is suitable for a mechanically assembled cam shaft; and compared with a conventional powder metallurgy cam or a steel cam, the compound cam can save such procedures as keyway pulling and induction hardening, and has such advantages as high density, good precision of inner hole size, high torque, even hardness distribution of the liner and the cam piece, stress relief and good wear resistance.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +2

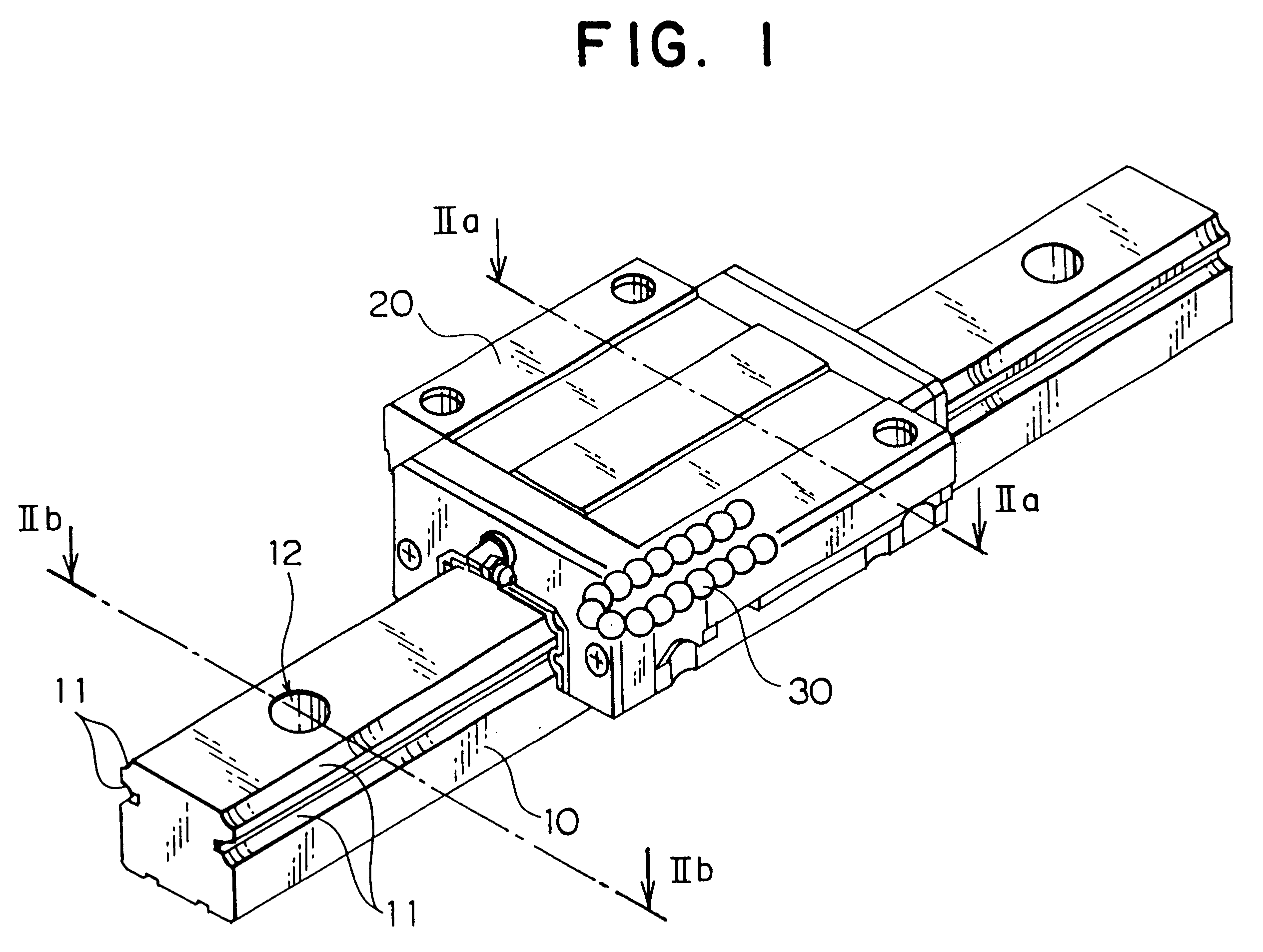

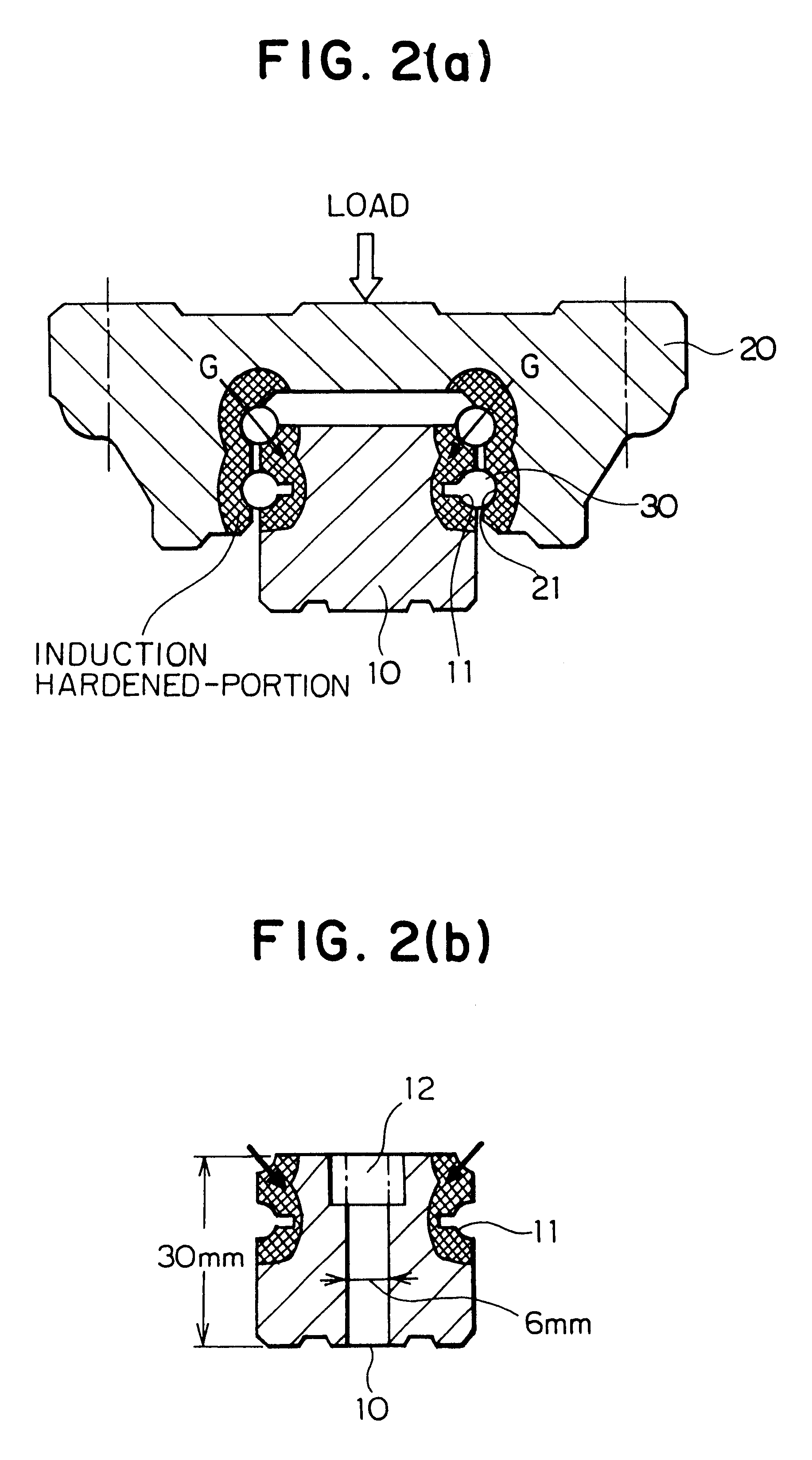

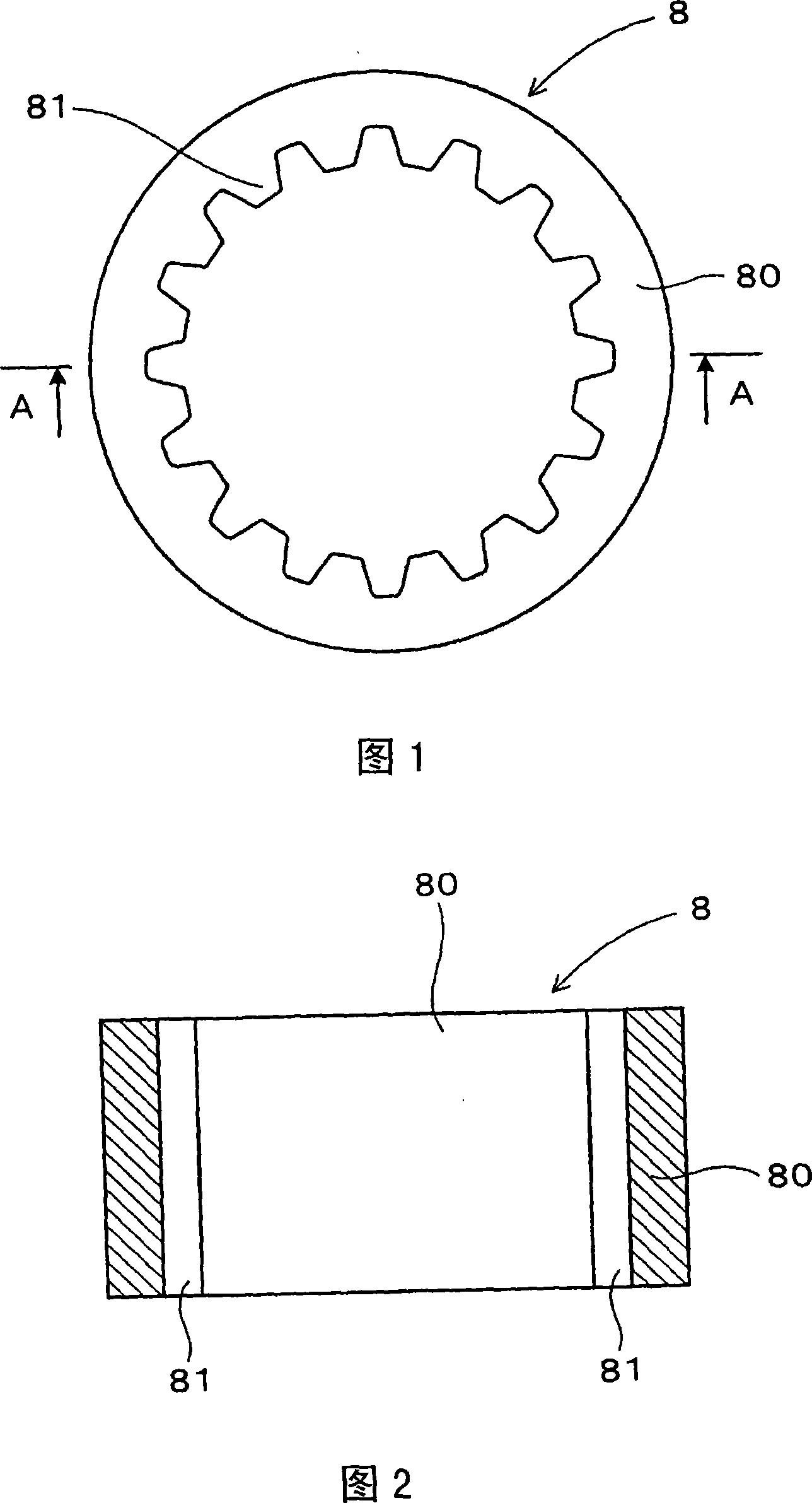

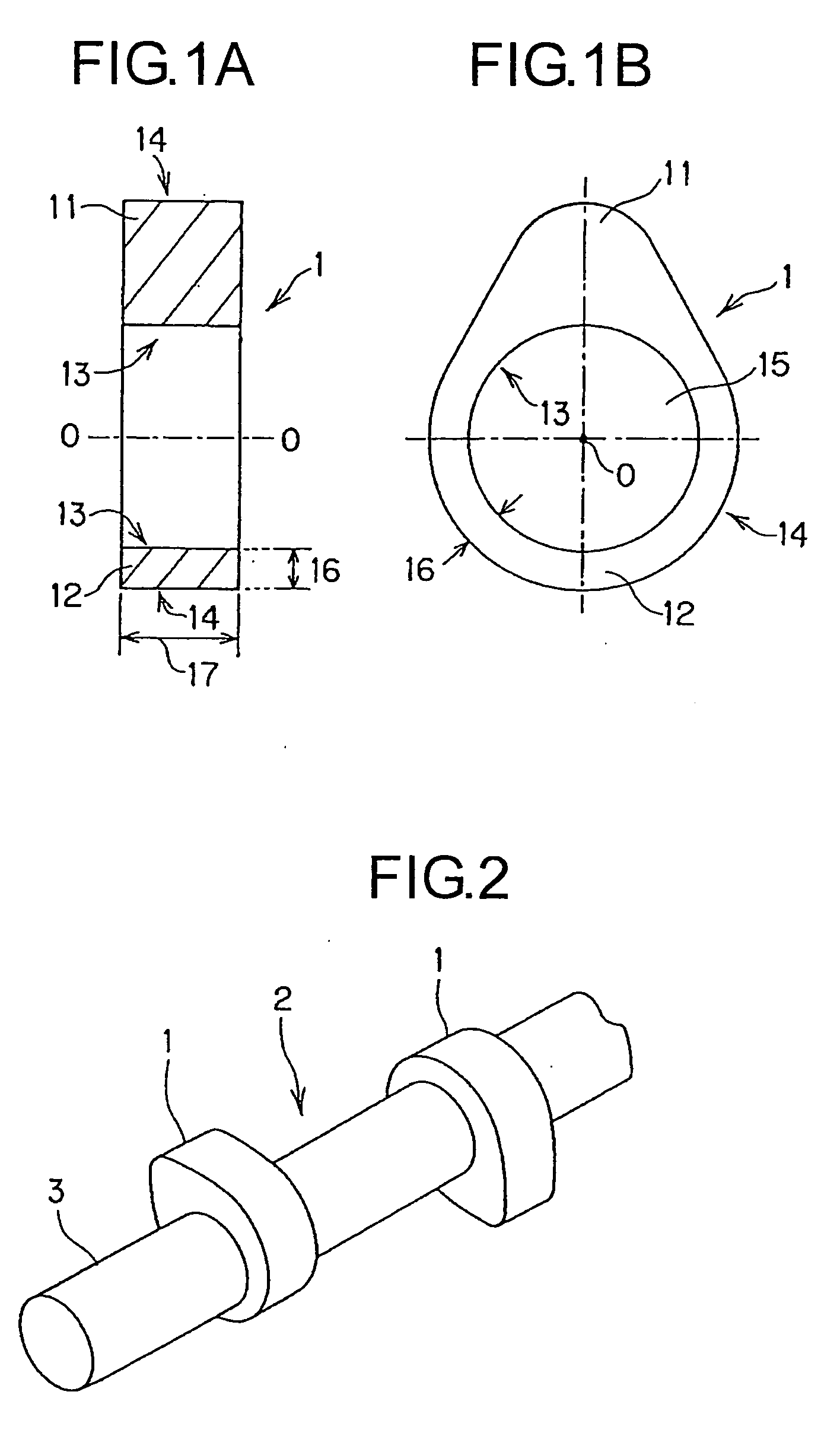

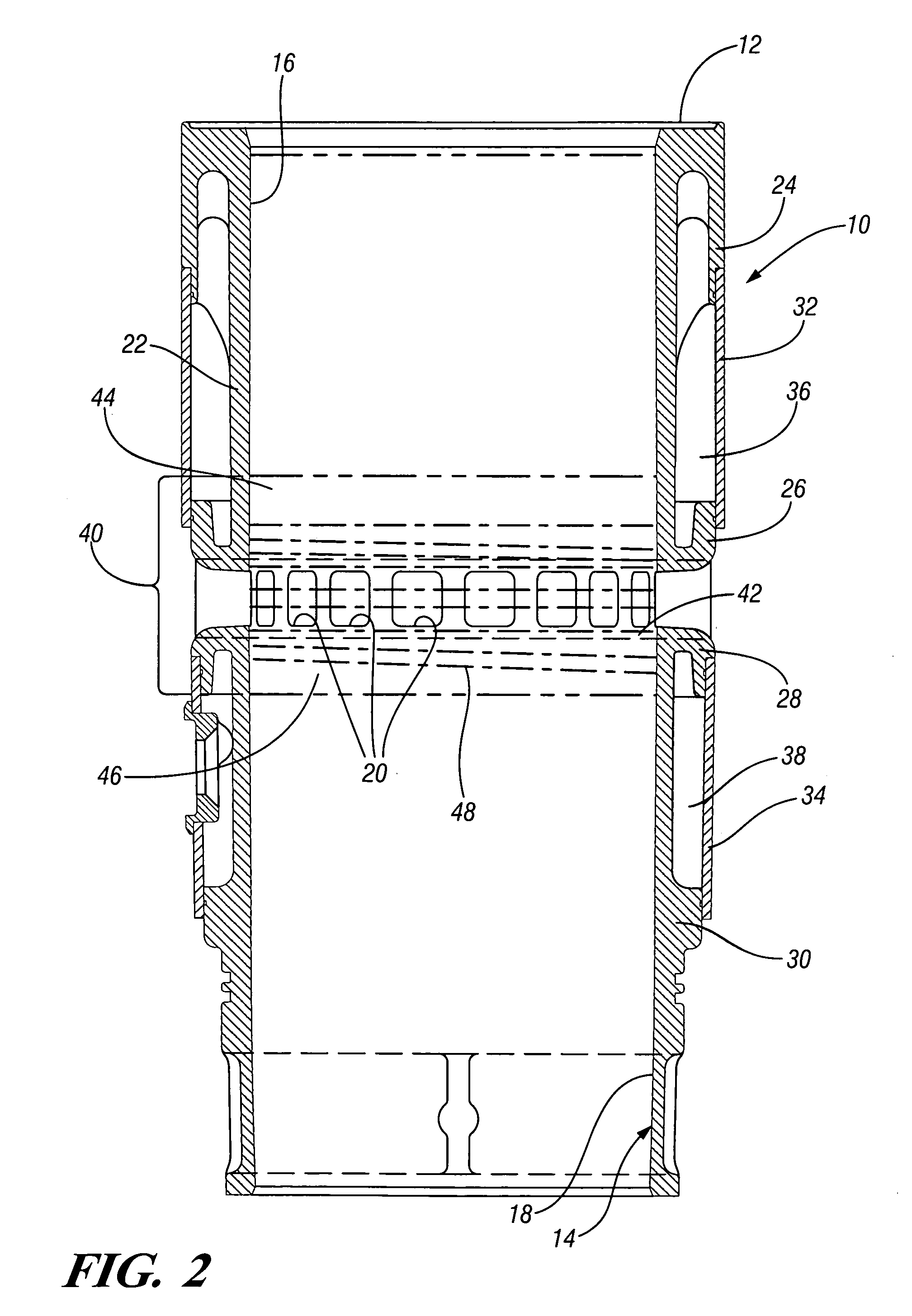

Induction-hardened rolling bearing device

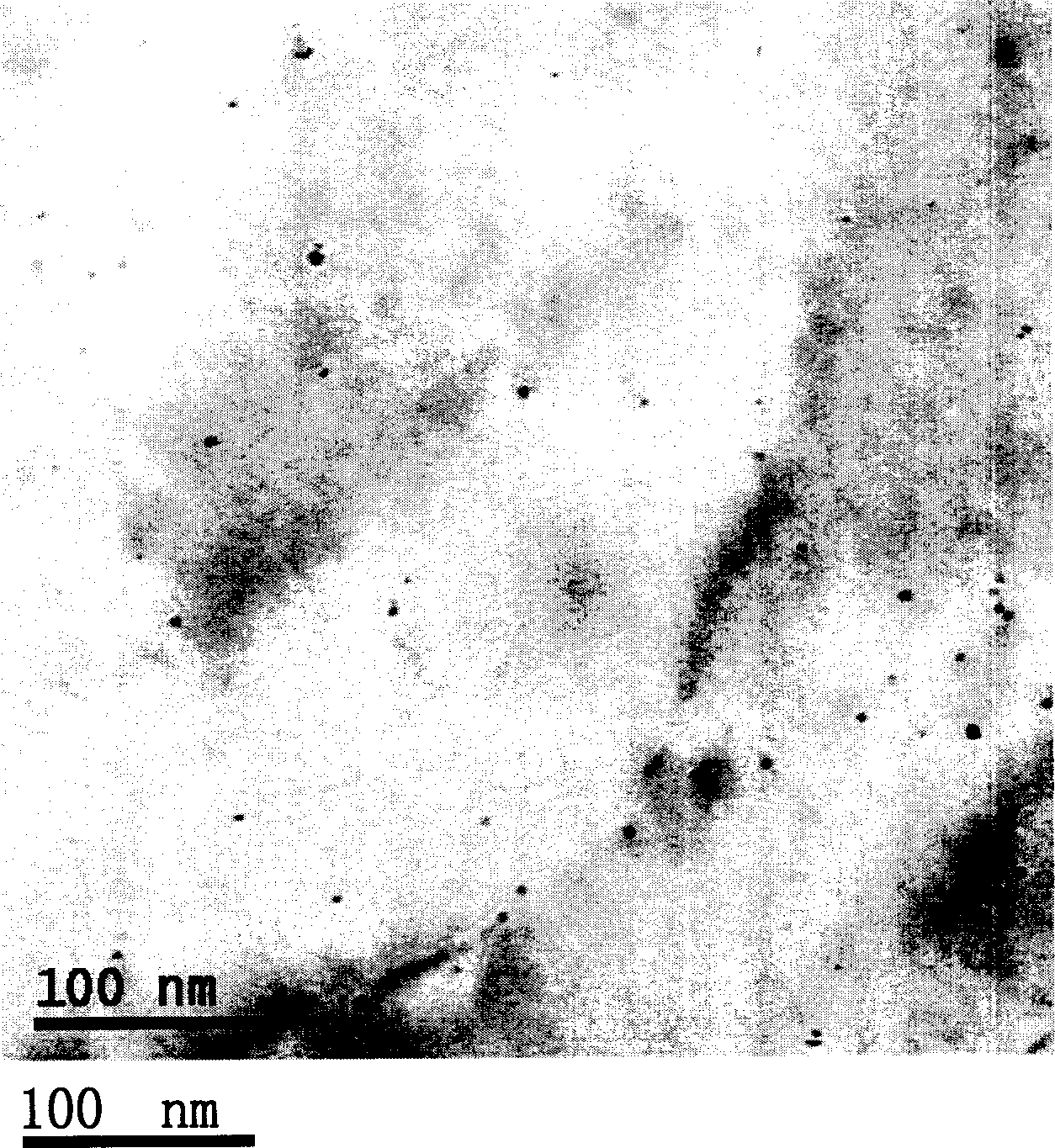

InactiveUS6332714B1Excellent in cold drawabilityEasy to useLinear bearingsBearing componentsCarbideInduction hardening

An induction-hardened rolling bearing device used by disposing rolling elements in a raceway track member, with excellent cold drawability and improved wear resistance and extended service life, in which ingredients of an alloy for the raceway track member contain, from 0.40 to 0.90% of C, from 0.05 to 0.80% of Si, from 0.10 to 2.0% of Mn, from 0.05 to 0.50% of Ti and 0.03% or less of N, on the weight basis, induction hardening is applied at least to the raceway surface of the raceway track member, and Ti carbide and Ti carbonitride each having an average particle diameter of from 5 to 100 nm are dispersed on the surface and in the steels of the raceway track member to make the hardness of the raceway surface to HRC 59 or more.

Owner:NSK LTD +1

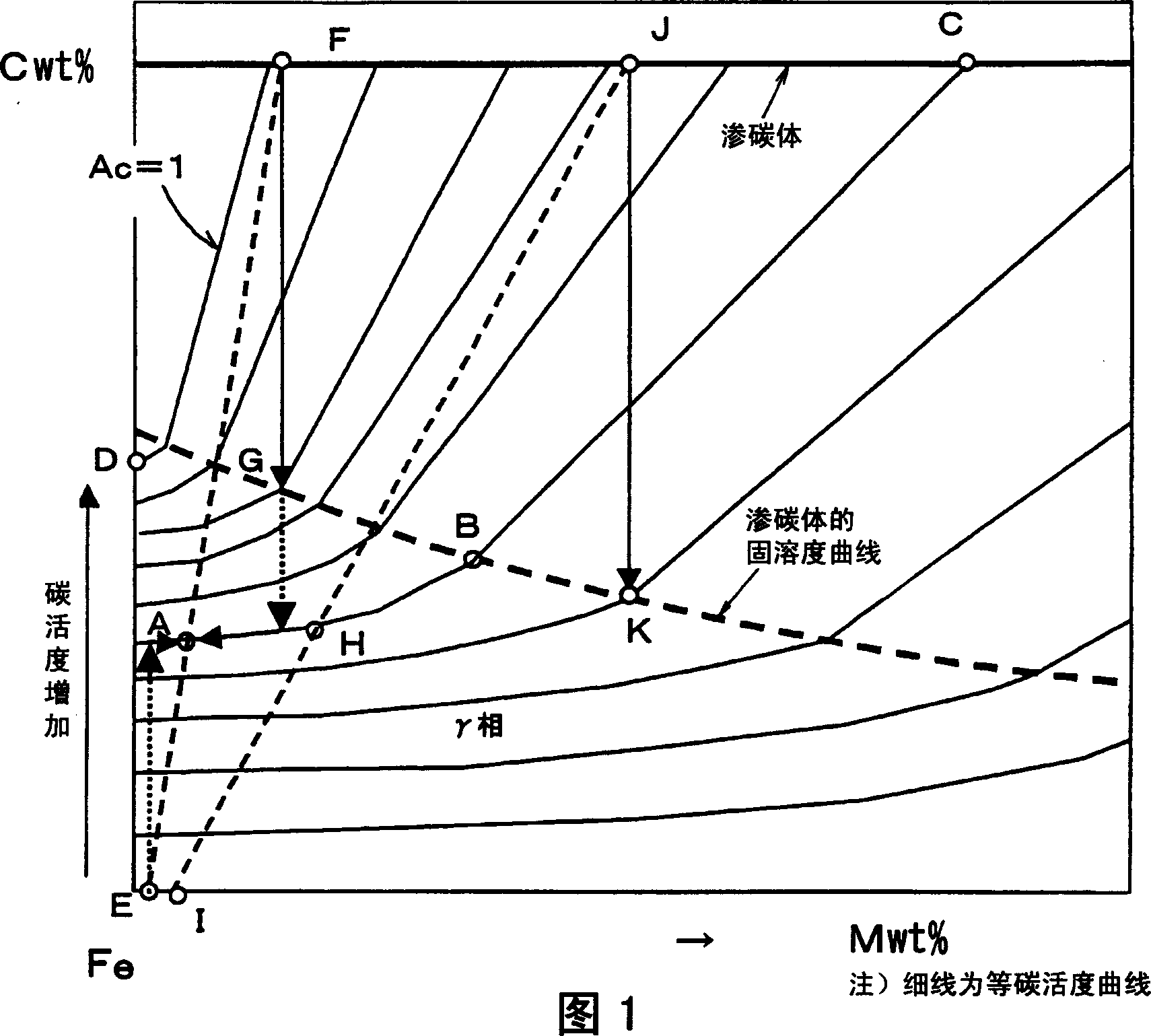

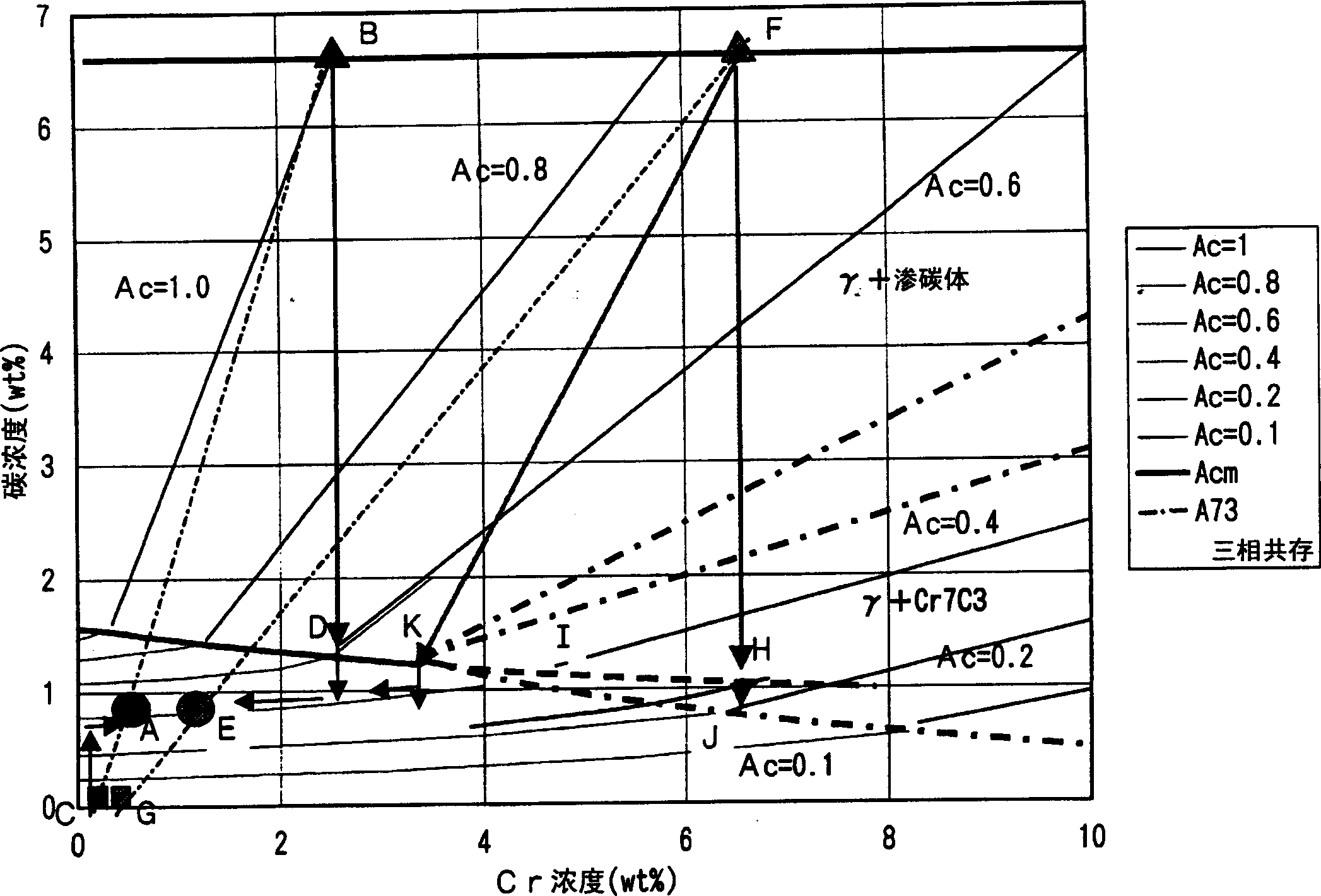

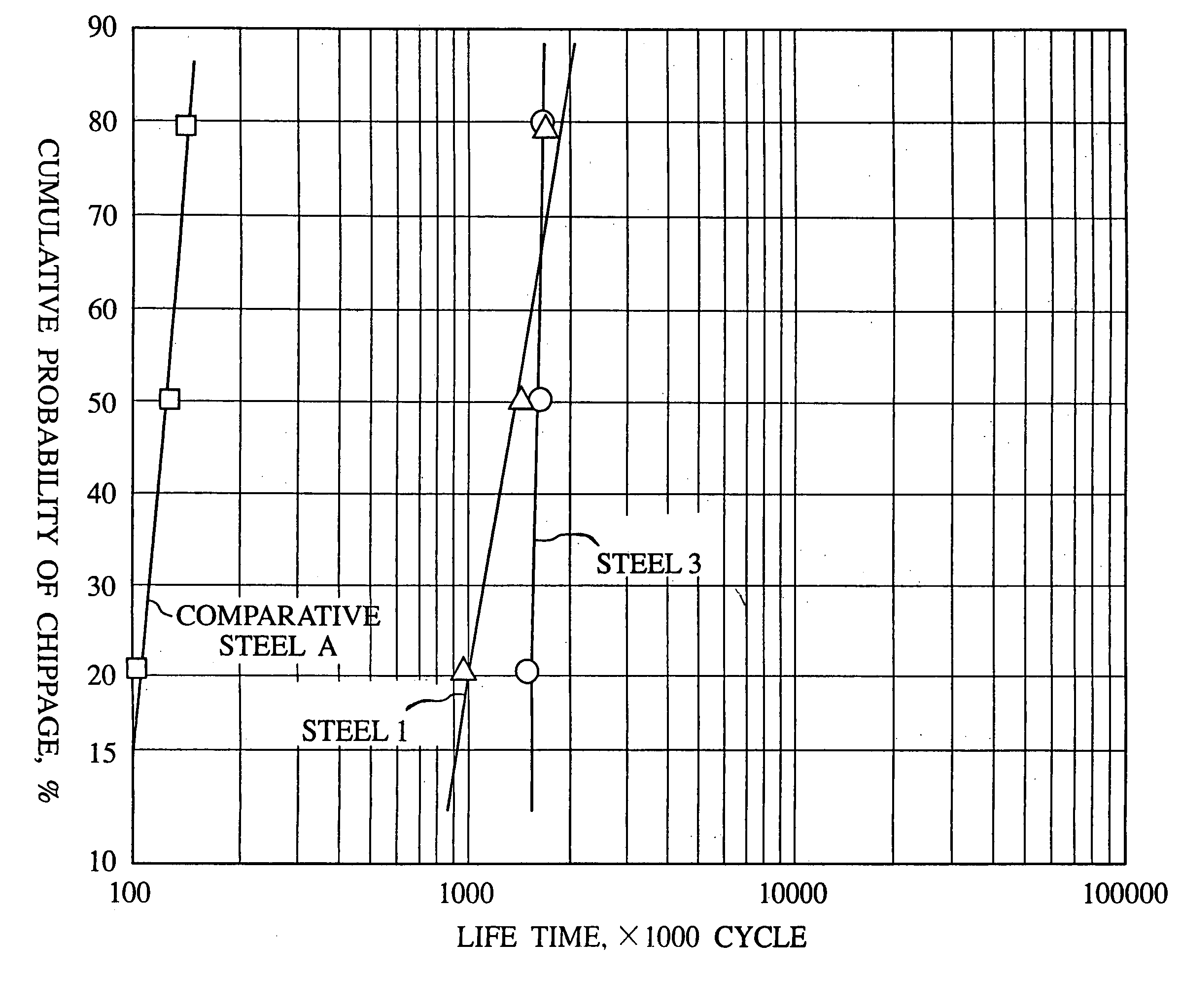

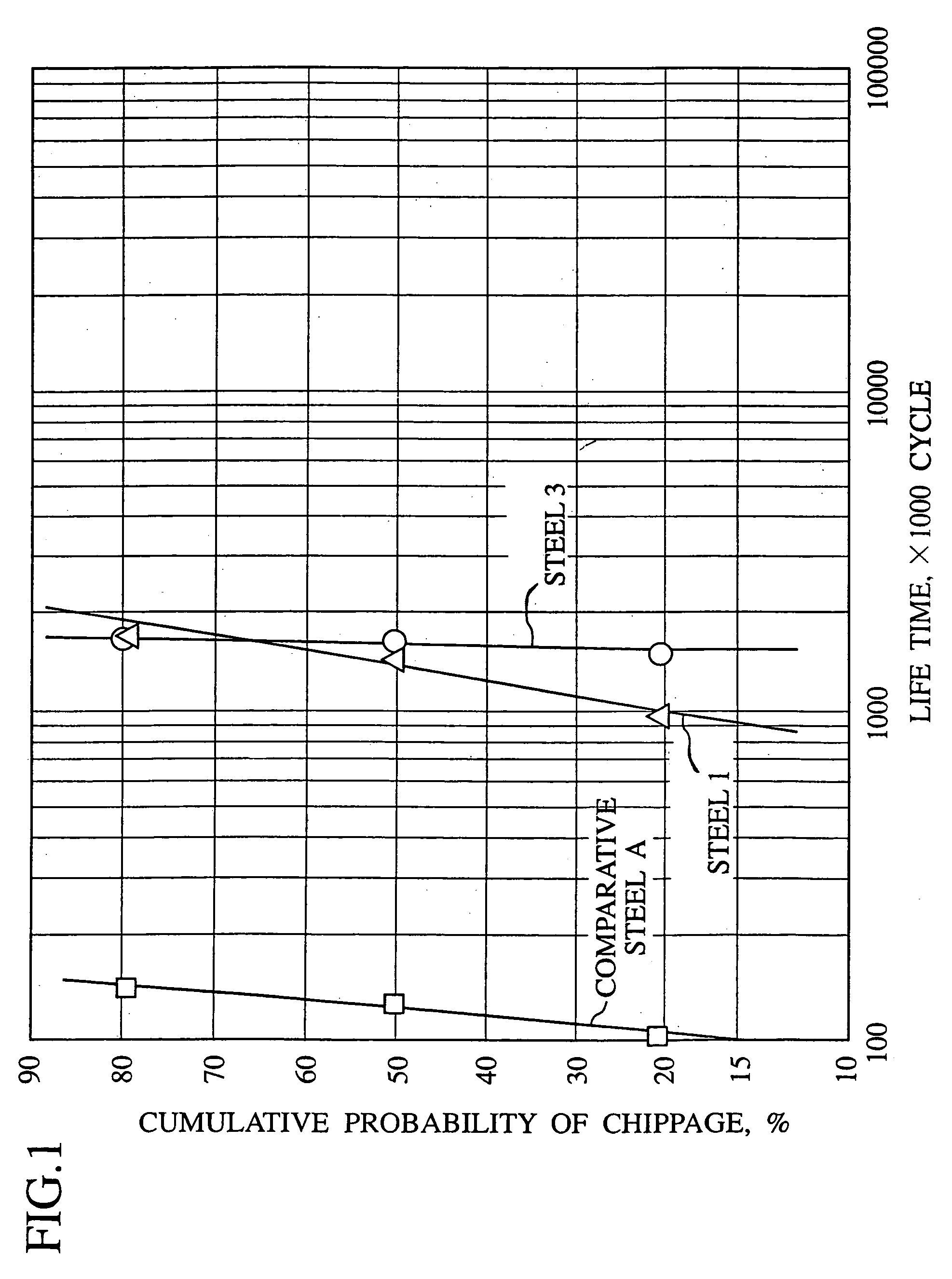

Rolling parts and producing process thereof

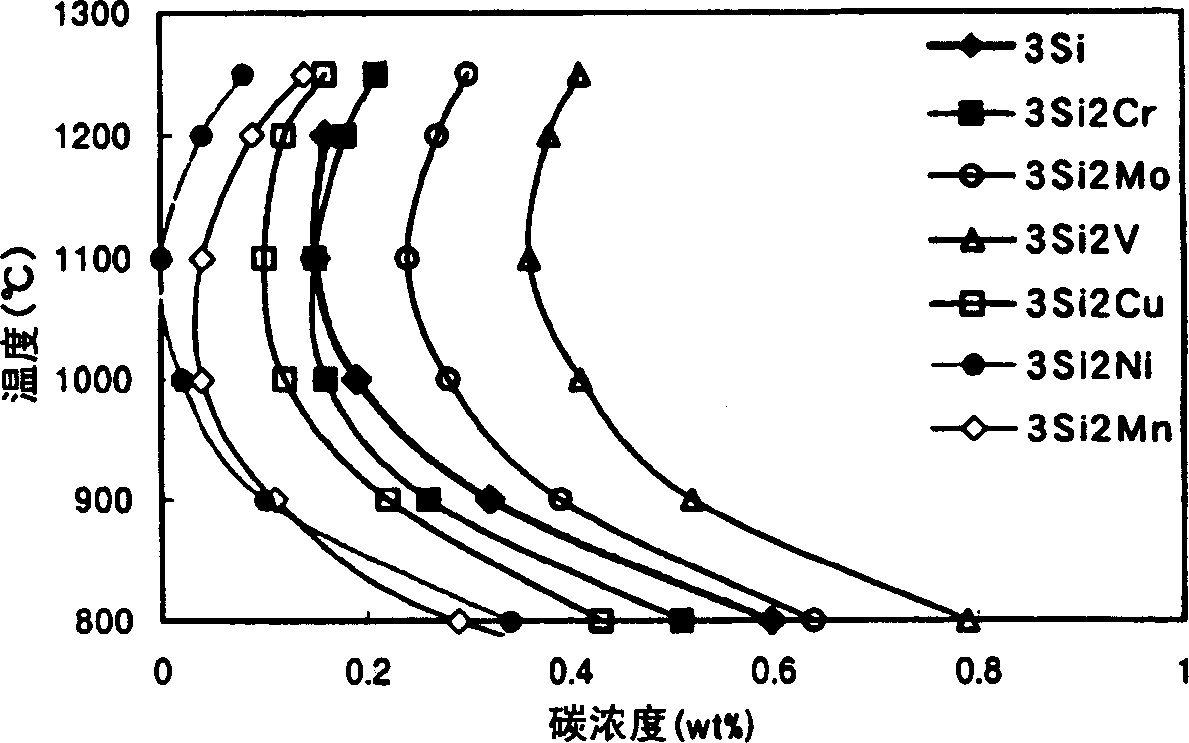

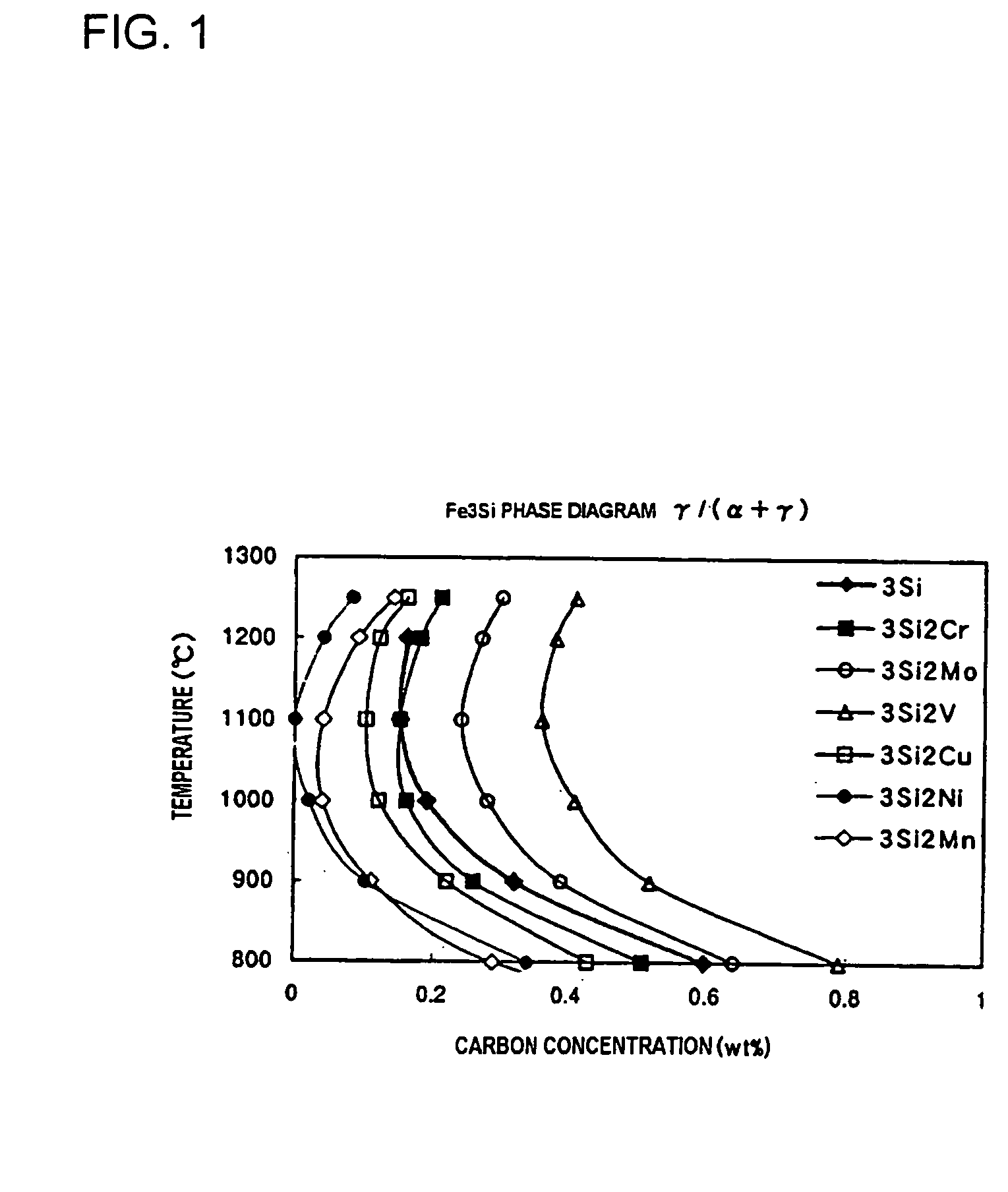

Various inexpensive rolling elements for use under high interface pressure such as induction hardened gears are provided, which have improved seizure resistance at tooth flanks and a temper hardness of HRC 50 or more at 300 DEG C. To this end, a rolling element is made from a steel material which contains at least 0.5 to 1.5 wt % carbon and 0.2 to 2.0 wt % one or more alloy elements selected from V, Ti, Zr, Nb, Ta and Hf; and in which 0.4 to 4.0% by volume one or more compounds selected from the carbides, nitrides and carbonitrides of the above alloy elements and having an average particle diameter of 0.2 to 5 mum are dispersed. In such a rolling element, the soluble carbon concentration of a martensite parent phase of a rolling contact surface layer is adjusted to 0.3 to 0.8 wt %, the martensite parent phase having been subjected to induction hardening and low temperature tempering, and one or more of the above carbides, nitrides and carbonitrides are dispersed in an amount of 0.4 to 4.0% by volume within the martensite parent phase.

Owner:KOMATSU LTD

Carburized induction-hardened component

InactiveCN101184860AIncrease power outputImprove fatigue strengthFurnace typesIncreasing energy efficiencySurface layerHardness

A component is subjected to carburizing treatment and then induction-hardening treatment, and is formed from steel consisting essentially of, by mass, C: minimum 0.08% and under 0.3%; Si: maximum 2.0%; Mn: from 0.2% to 3.0%; P: maximum 0.03%; S: from 0.005% to 0.05%; Ni: maximum 1.5%; Cr: maximum 3.0%; Mo: maximum 1.0%; O: maximum 0.0025%; and N: from 0.005% to 0.03%; and further including either or both of, by mass, Al: from 0.005% to 0.05%, and Ti: from 0.005% to 0.05%; and still further including either or both of, by mass, V: maximum 0.3%, and Nb: maximum 0.3%; and a residual portion includes Fe and unavoidable impurities. The hardness of a surface layer is at least 55 HRC and the hardness of a core part is from 20 to 50 HRC. A metal structure of the core part does not include a martensite structure.

Owner:AISIN AW CO LTD +1

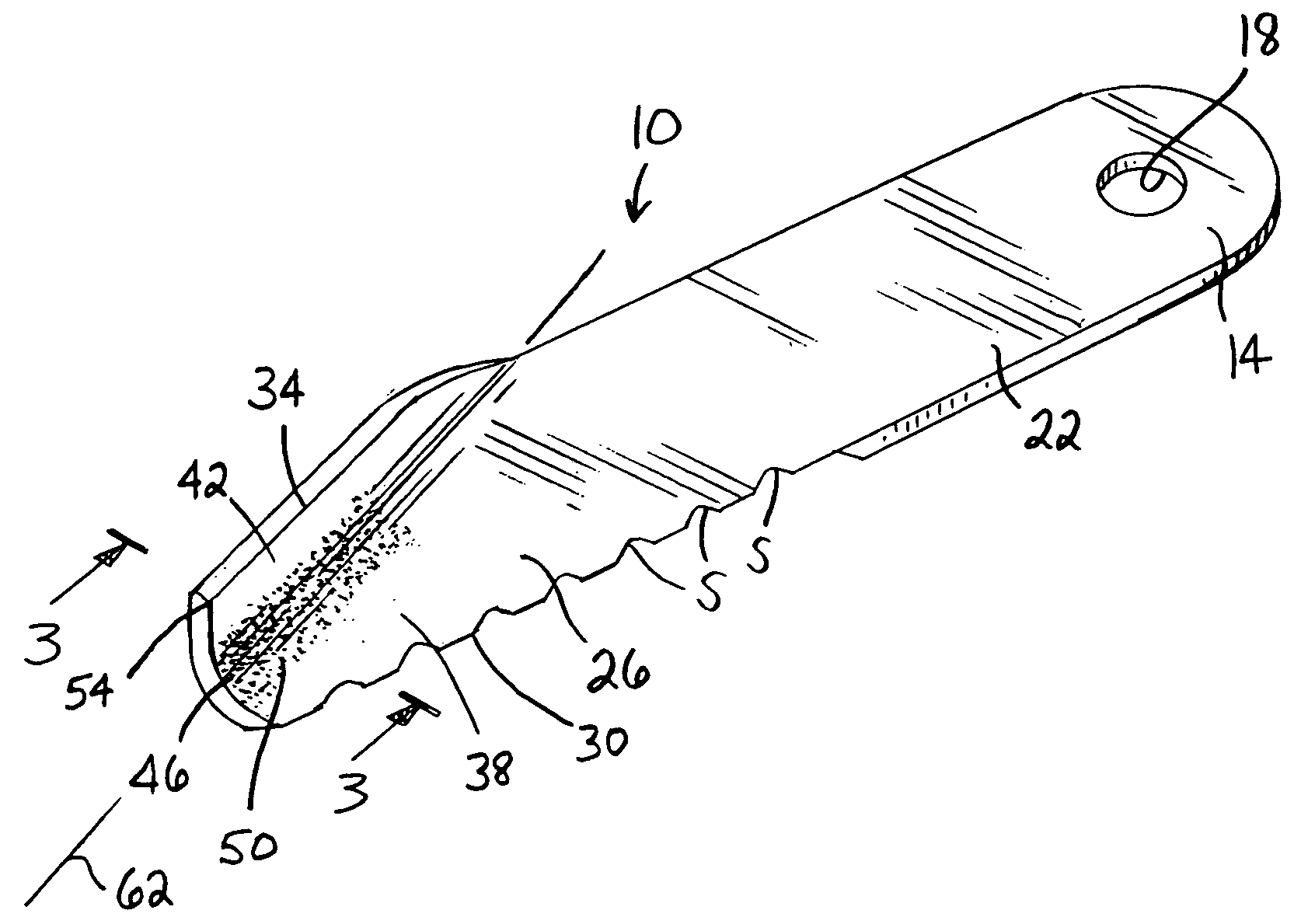

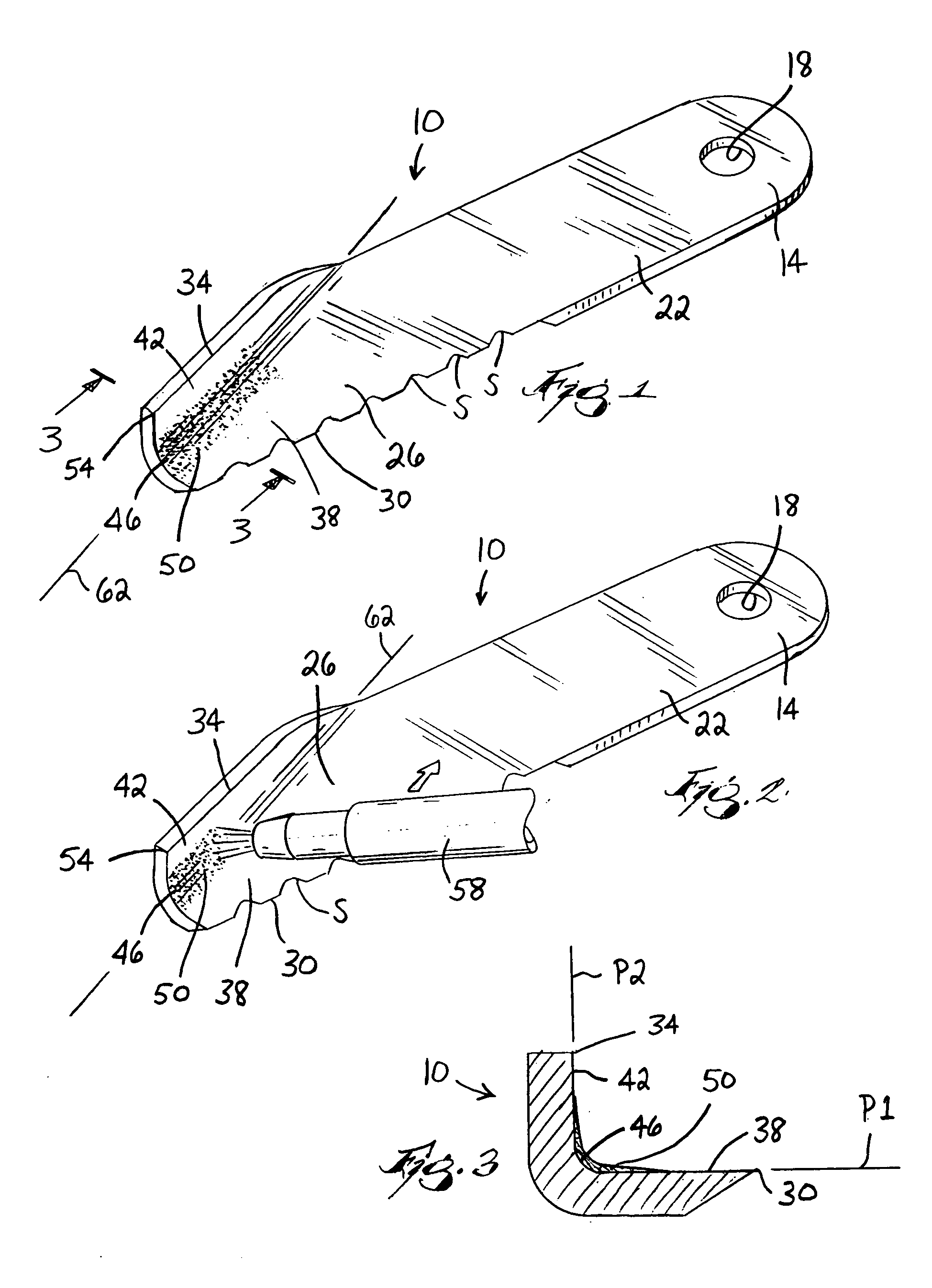

Wear resistant cutting blade

InactiveUS20060213342A1Bent portions of the blade will not be prematurely weakenedMowersCuttersWear resistantEngineering

A cutting blade includes a mounting portion and a working portion located at a distance from the mounting portion. The working portion includes a first surface portion at least partially lying in a first plane, a second surface portion at least partially lying in a second plane that is non-parallel to the first plane, and an intermediate surface portion between the first and second surface portions. At least part of the intermediate surface portion has a wear-resistant property that is substantially different from a wear-resistant property of at least part of the second surface portion. The intermediate surface portion can be treated via thermal spray coating, laser hardening, induction hardening, and other similar surface hardening processes. Additionally, a piece of hardened material can be bonded to the intermediate surface portion. Furthermore, the blade thickness adjacent the intermediate surface portion can be increased.

Owner:FISHER BARTON

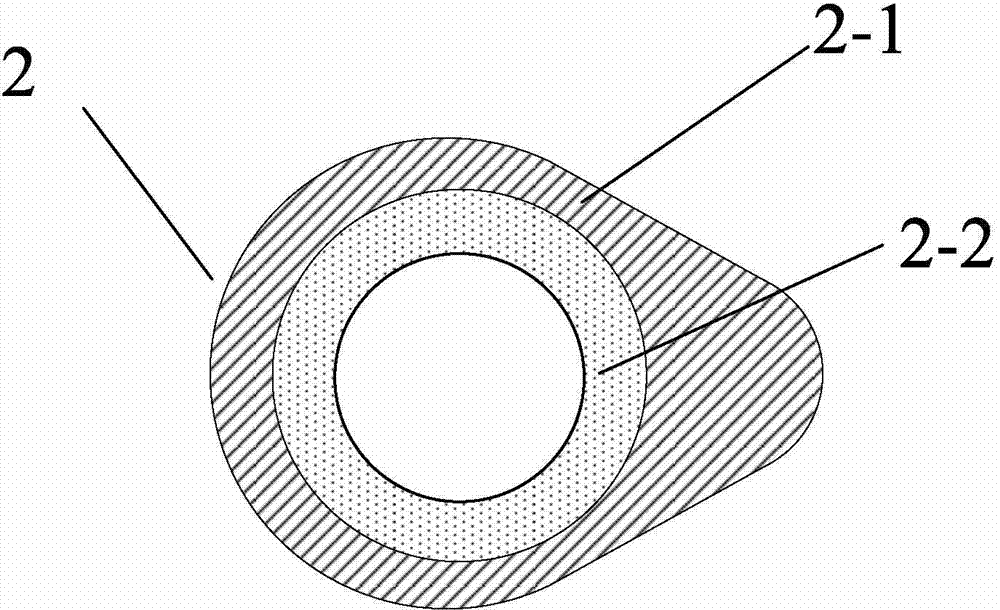

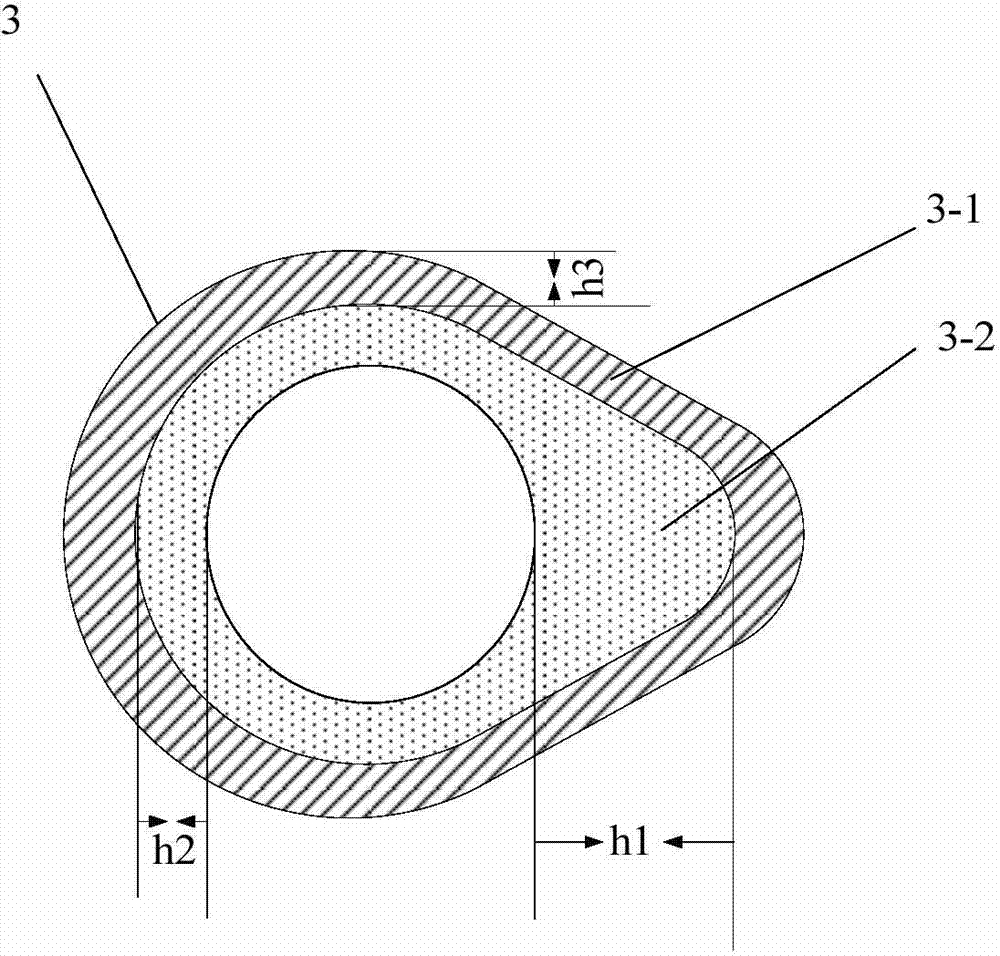

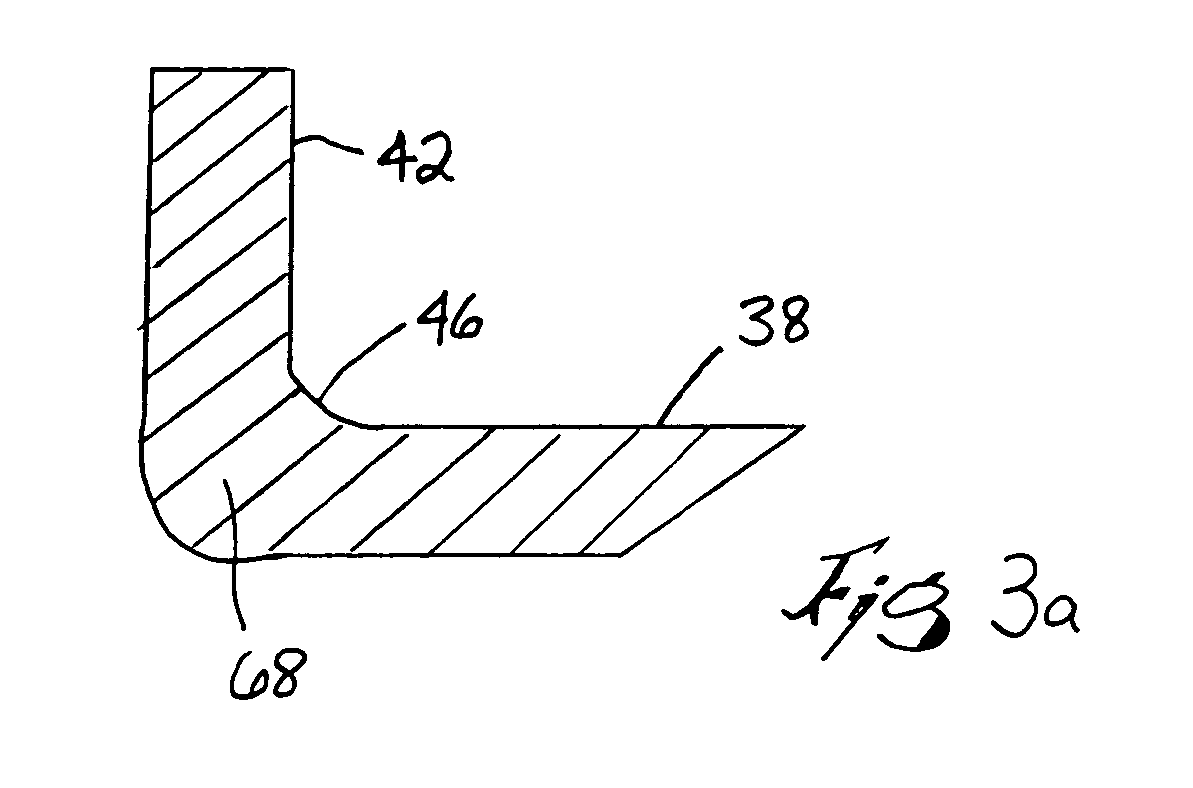

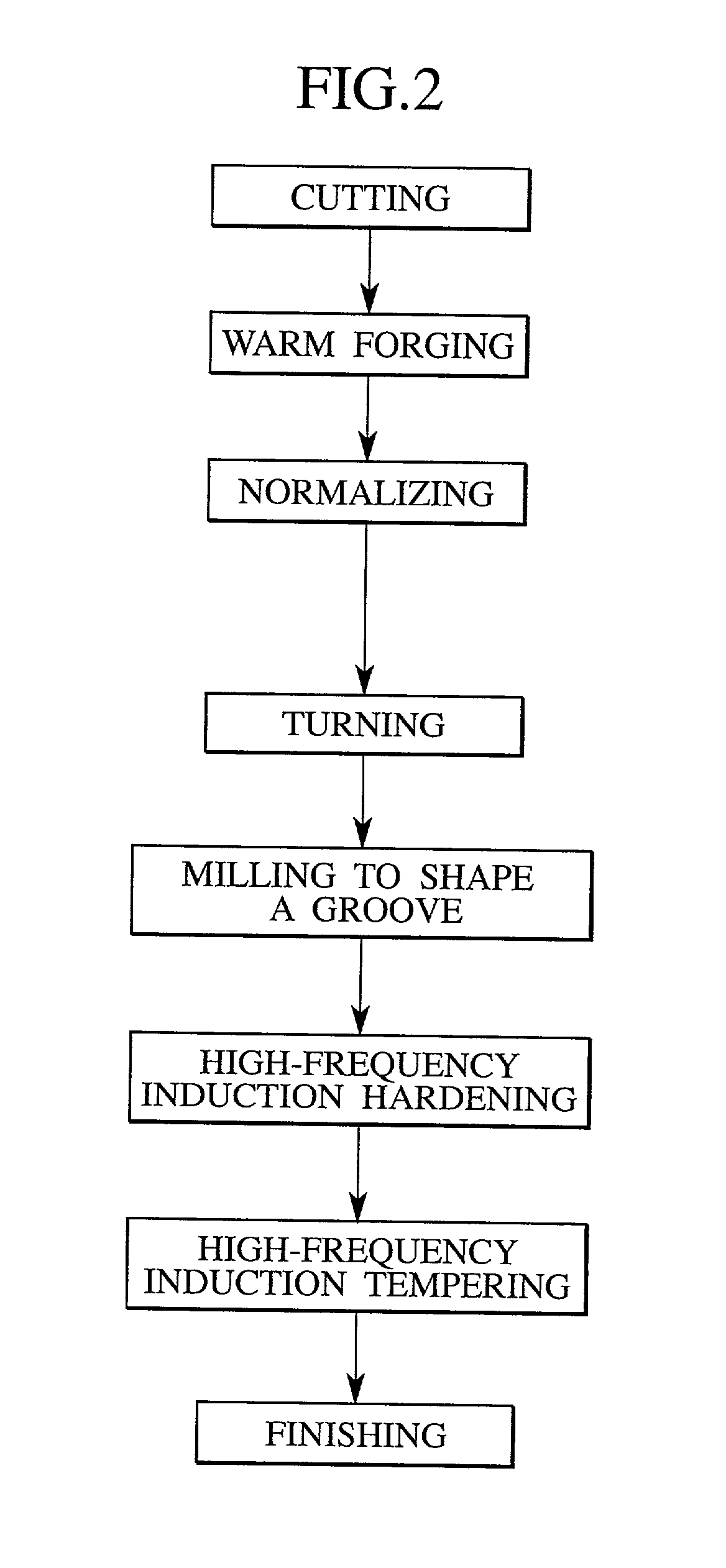

Method of Manufacturing Cam Shaft, Cam Shaft, and Cam Lobe Material Used in the Same

InactiveUS20080276753A1Expand allowanceReduce wall thicknessCamsValve drivesMetallurgyDegrees of freedom

A method of manufacturing a cam shaft that prevents cracks during the joining of a cam lobe to a shaft, and improves the degree of freedom of design of the cam lobe is provided.By a method of manufacturing a cam shaft that after an inner circumferential surface 13 of a cam lobe 1 is subjected to treatment for residual compressive stress addition treatment, the cam lob 1 is joined to a shaft, above problem is solved. It is preferred that the residual compressive stress on the inner circumferential surface 13 of the cam lobe 1 is not less than 100 MPa. In addition, an outer peripheral surface 14 of the cam lobe 1 can be also subjected to treatment for residual compressive stress addition treatment. As the treatment for residual compressive stress addition treatment, shot-peening treatment, induction hardening treatment, barrel polishing treatment, carburizing and quenching treatment or carbonitriding treatment is performed.

Owner:NIPPON PISTONRING CO LTD

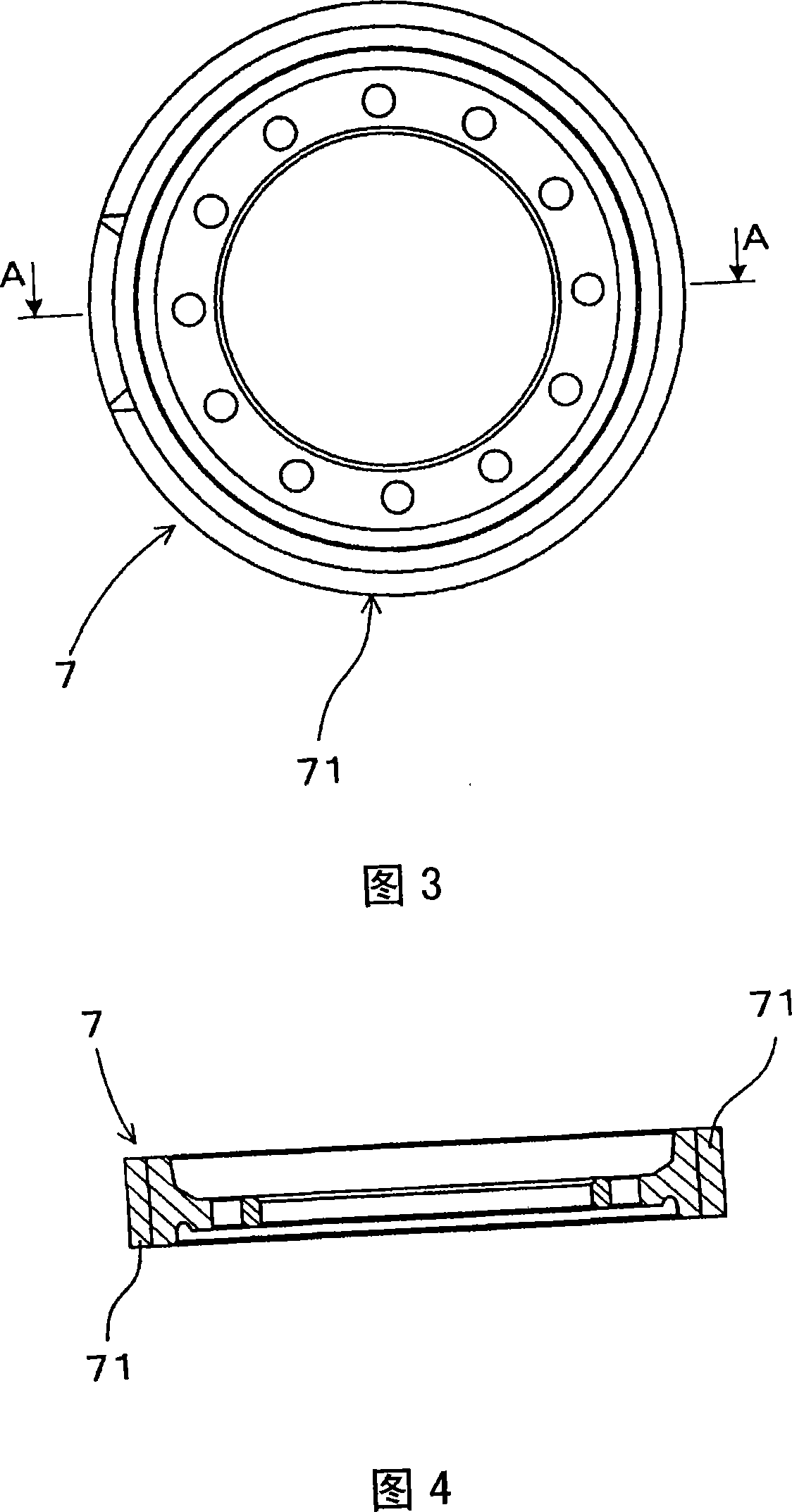

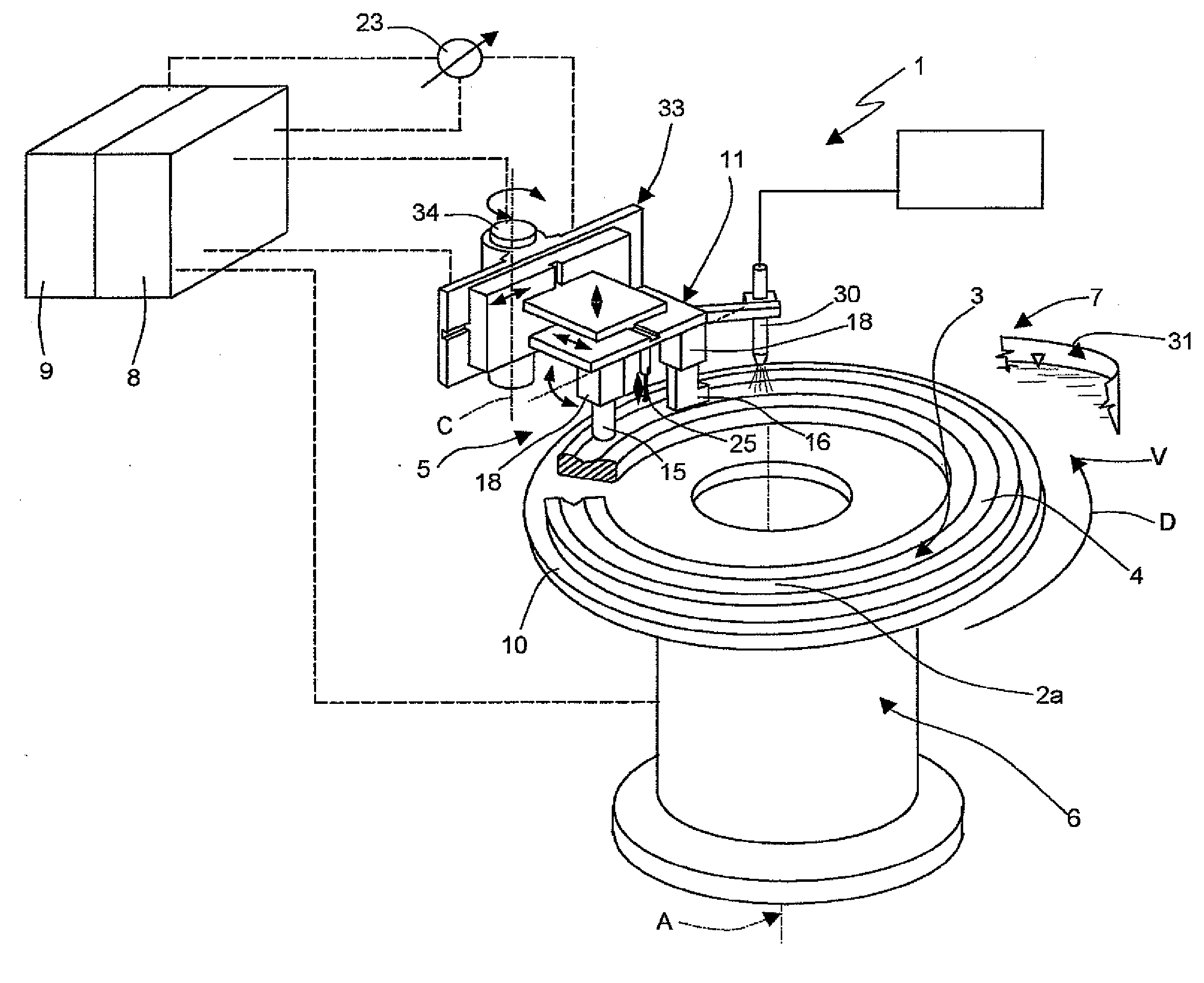

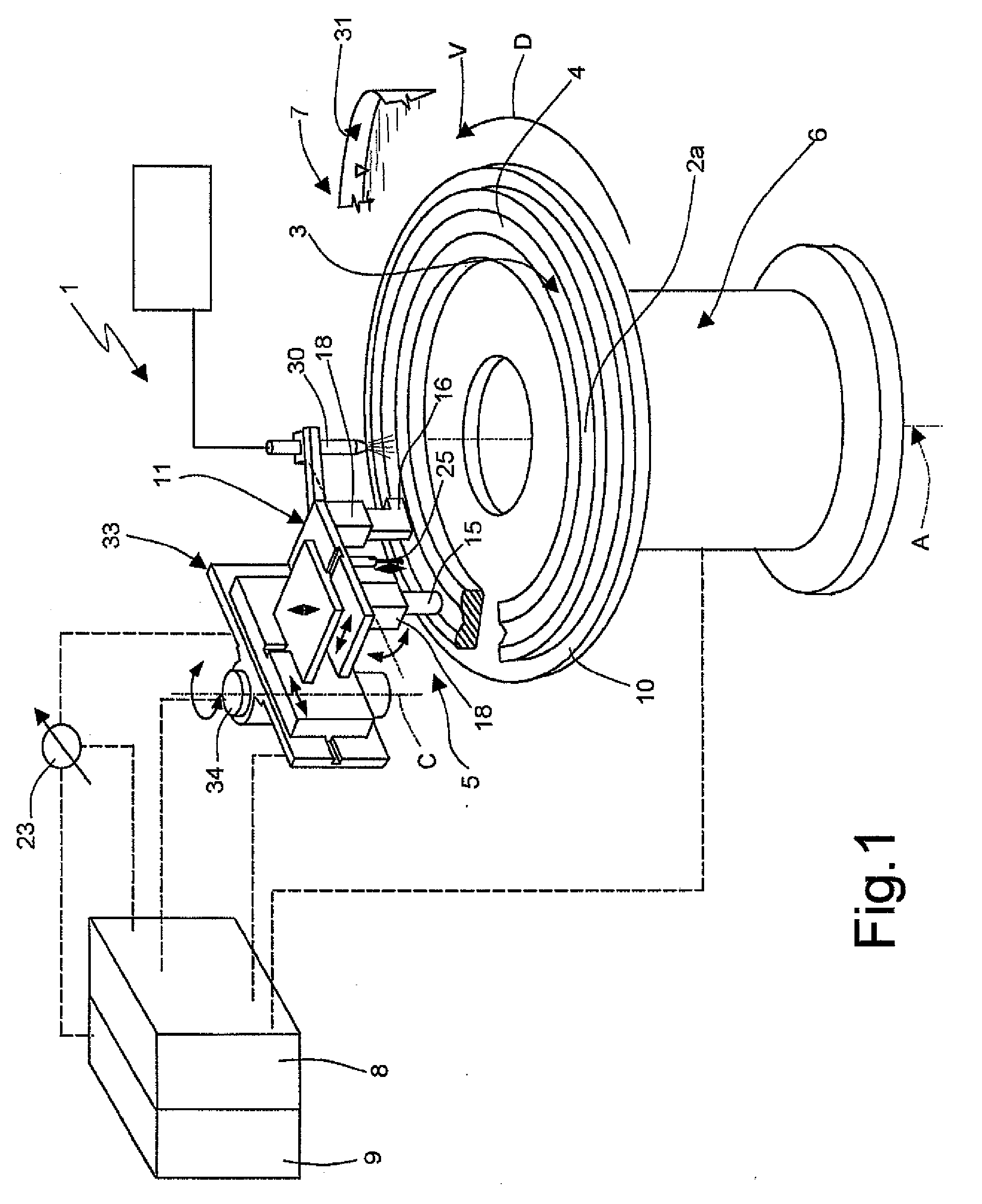

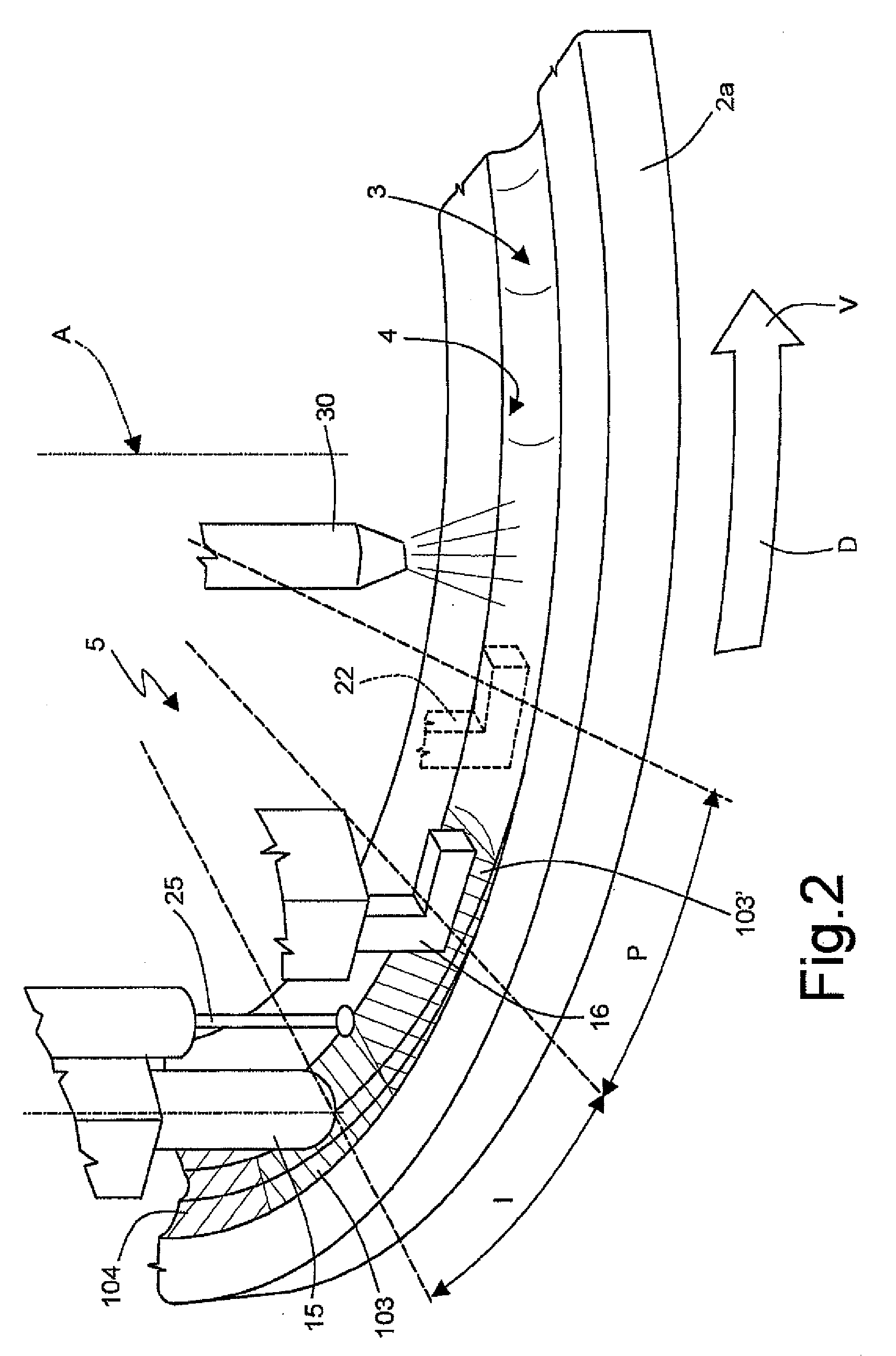

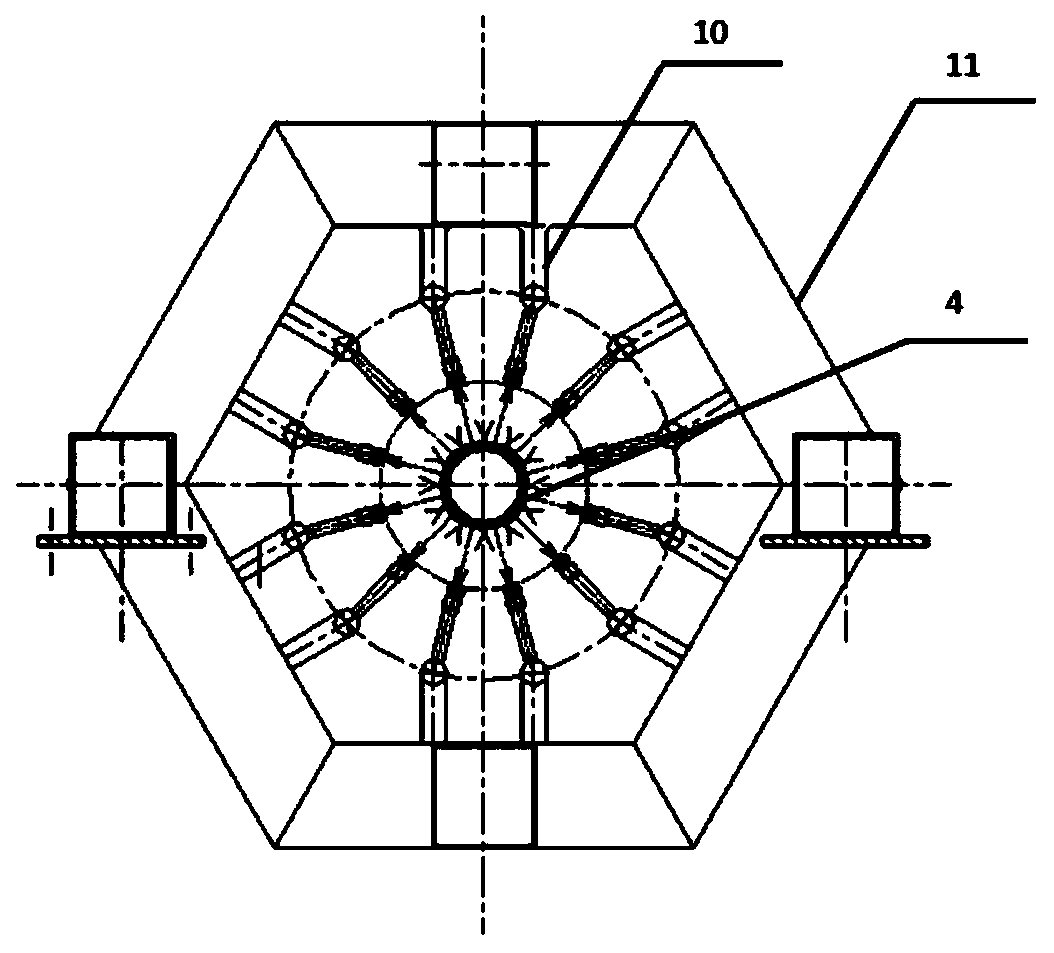

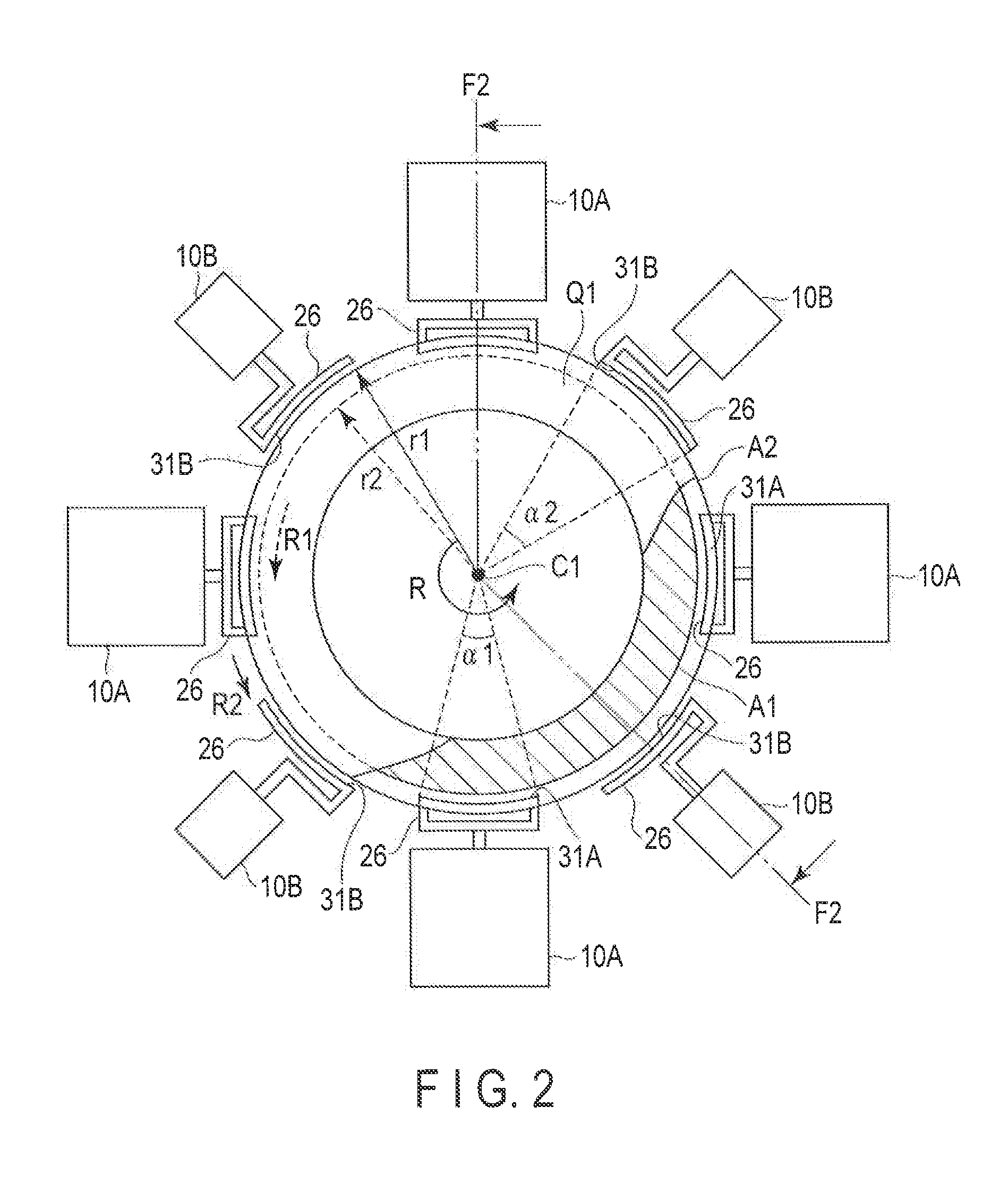

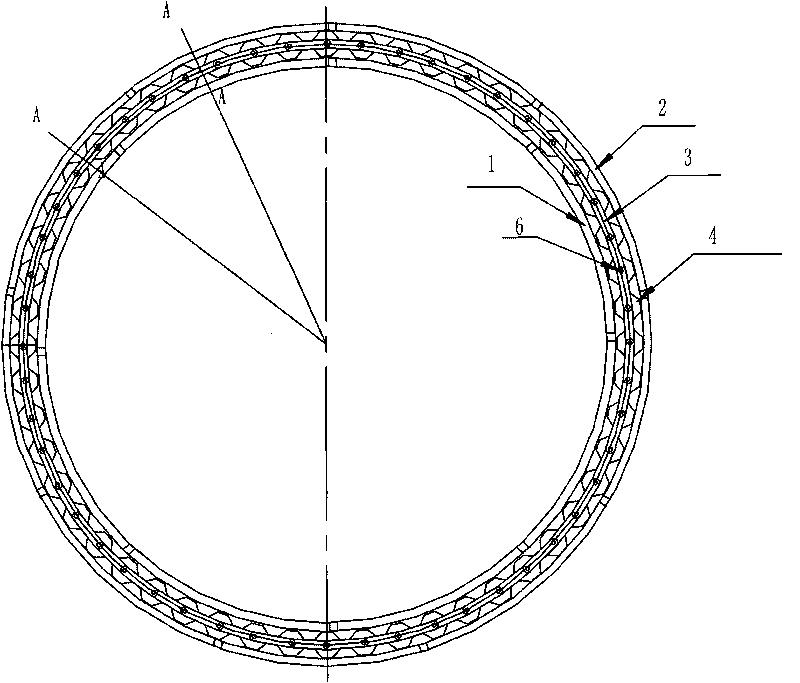

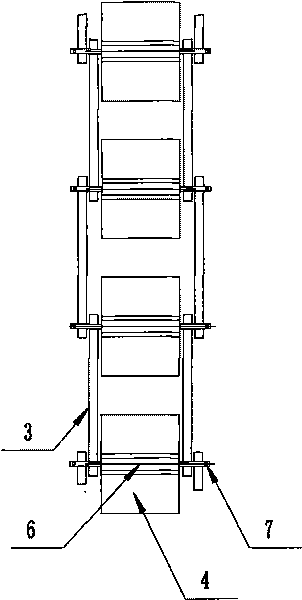

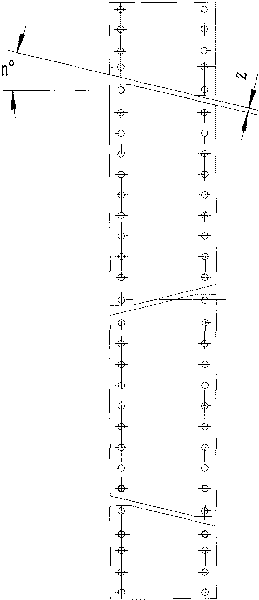

Device and method for performing a localized induction hardening treatment on mechanical components, specifically thrust blocks for large-sized rolling bearings

InactiveUS20100243643A1Increase chanceIncrease heatCoil arrangementsIncreasing energy efficiencyMechanical componentsRolling-element bearing

A device and method for induction hardening rolling tracks of thrust blocks of bearings, according to a required hardening profile. At least two inductors arranged in tandem are used within a track to be hardened, at a predetermined distance from a surface of the track and the thrust block is rotated with respect to the inductors, so as to make them cover the entire track, with a complete 360° turn; the inductors, at least one first pre-heating inductor and one at least heating inductor, are shaped so as to generate a first and a second magnetic fields, respectively, both having flux lines which are perpendicular to each other, and one of the two inductors is mounted on an orientable head so as to be able to arrange the two inductors oriented according to the curvature of the track. The mentioned predetermined distance of the inductors from the track is obtained by using a feeler to accurately detect the geometry of the track and which is introduced between the two inductors and then moved away during the heating steps which are performed sequentially in synchronism with the rotation of the thrust block, and by varying, in a final step, the electric power fed to at least one inductor.

Owner:SAET

High speed steel composite roller heat treatment method

InactiveCN101215628AIncrease productivityReduce energy consumptionFurnace typesHeat treatment furnacesSocial benefitsInduction hardening

A compound rolling heat treatment process of rapid-steel belongs to the steel rolling technology field. The invention comprises conducting annealing treatment for roller with 870-890 DEG C of annealing temperature, warming up for 6-10 hours, proceeding induction quenching on a 50Hz / 250Hz double-frequency quenching machine, preheating the roller before the induction quenching with 280-350 DEG C of preheating temperature for 6-10 hours of preheating warming. The roller is need being rotated and shifted down perpendicularly along axial direction when in quenching heating. The roller is water-cooled fast after heated up, then is conducted the first tempering treatment with 520-560 DEG C, and is insulated tempering for 4-6 hours, and then is cooled down in air. The roller is reheated to 500-540 DEG C to finish the second tempering treatment, and is insulated tempering for 6-8 hours, and is cooled down when the temperature of furnace is cooled smaller than 200 DEG C. The heat treatment technology of the invention treats high speed steel compound rolling, has simple technology, low energy consumption, short production cycle, high rolling strength and excellent use effect, and has excellent economic and social benefits after being popularized and applied.

Owner:BEIJING UNIV OF TECH

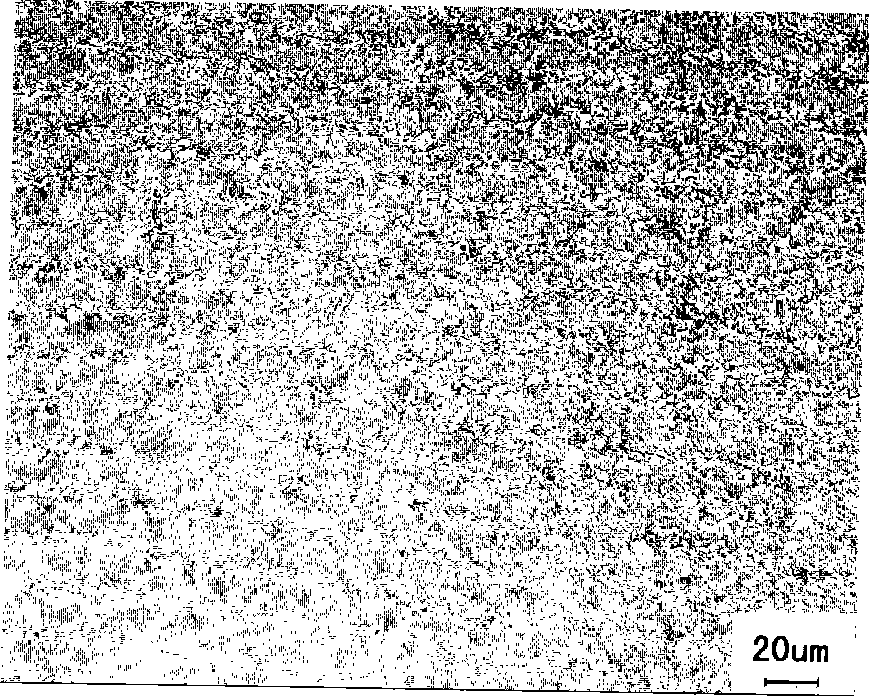

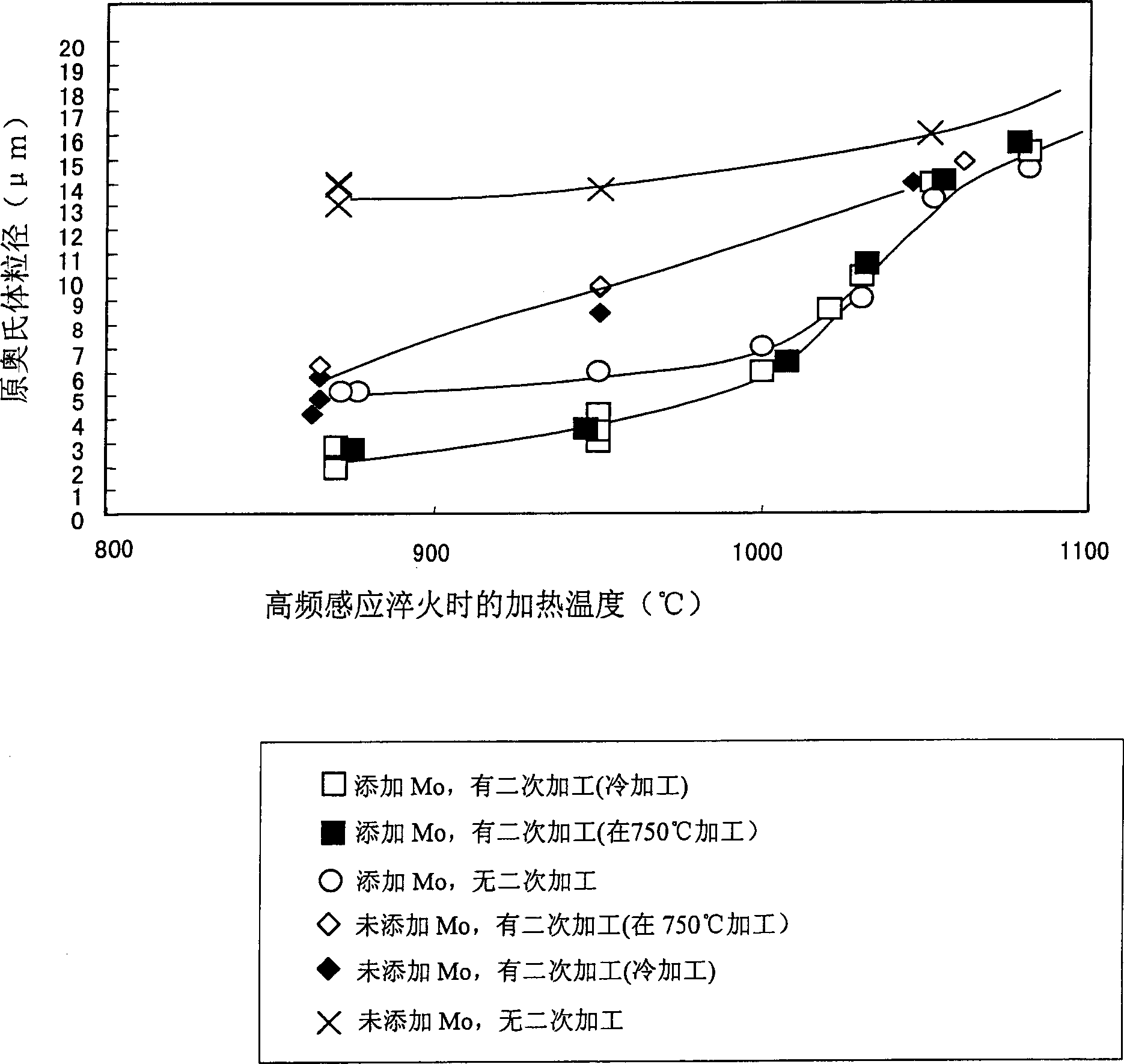

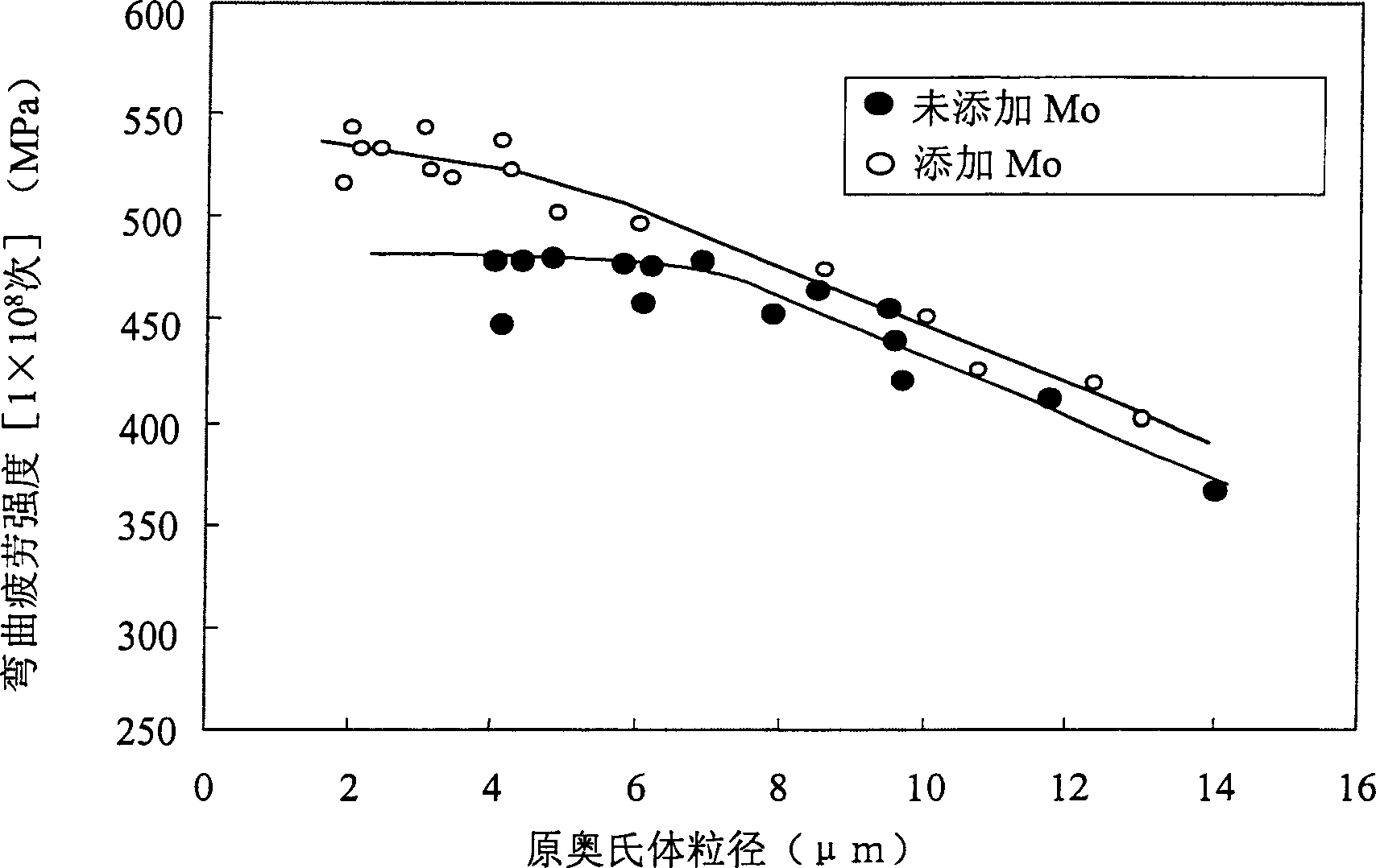

Component for Machine Structure, Method of Producing the Same and Material for Induction Hardening

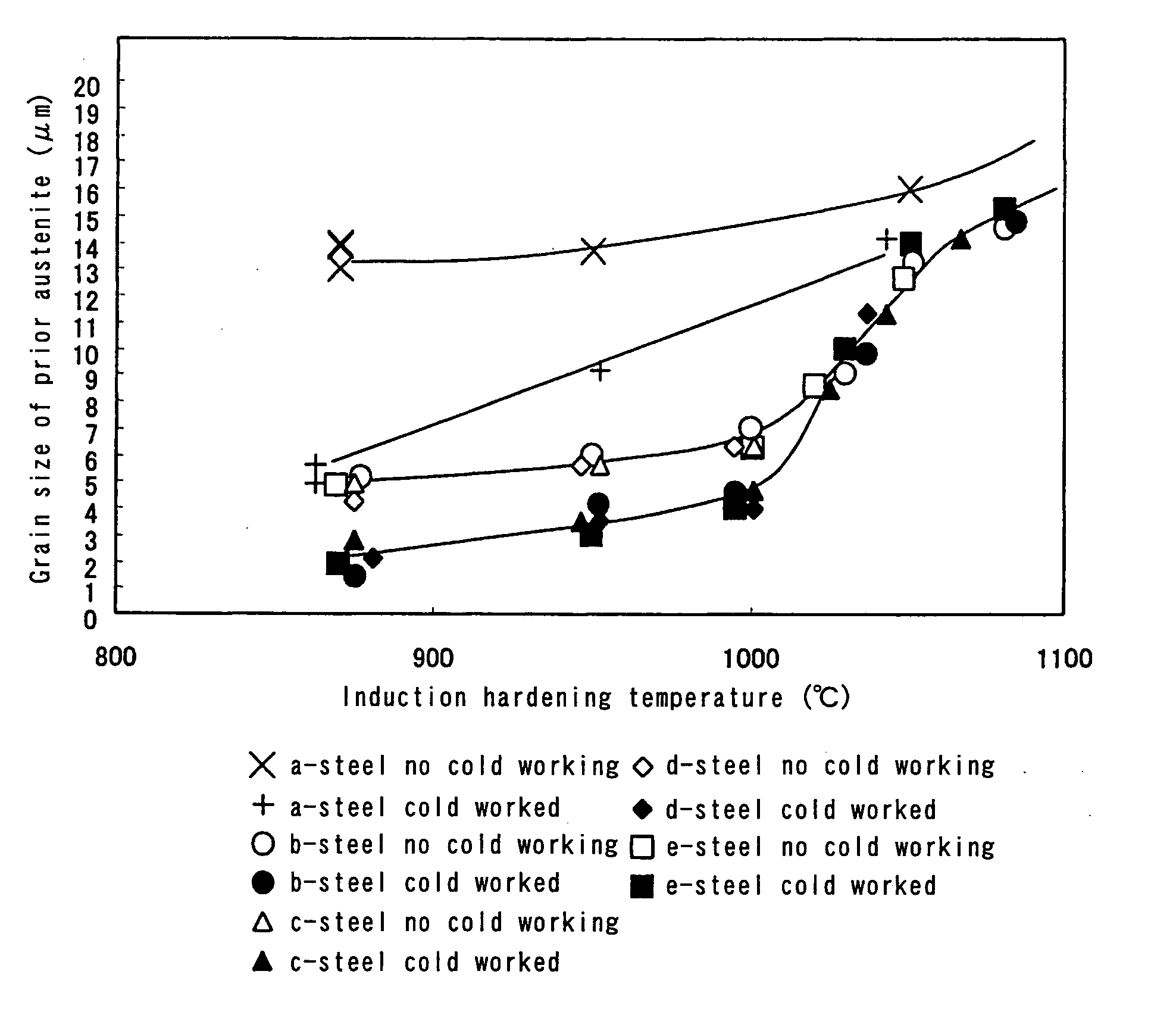

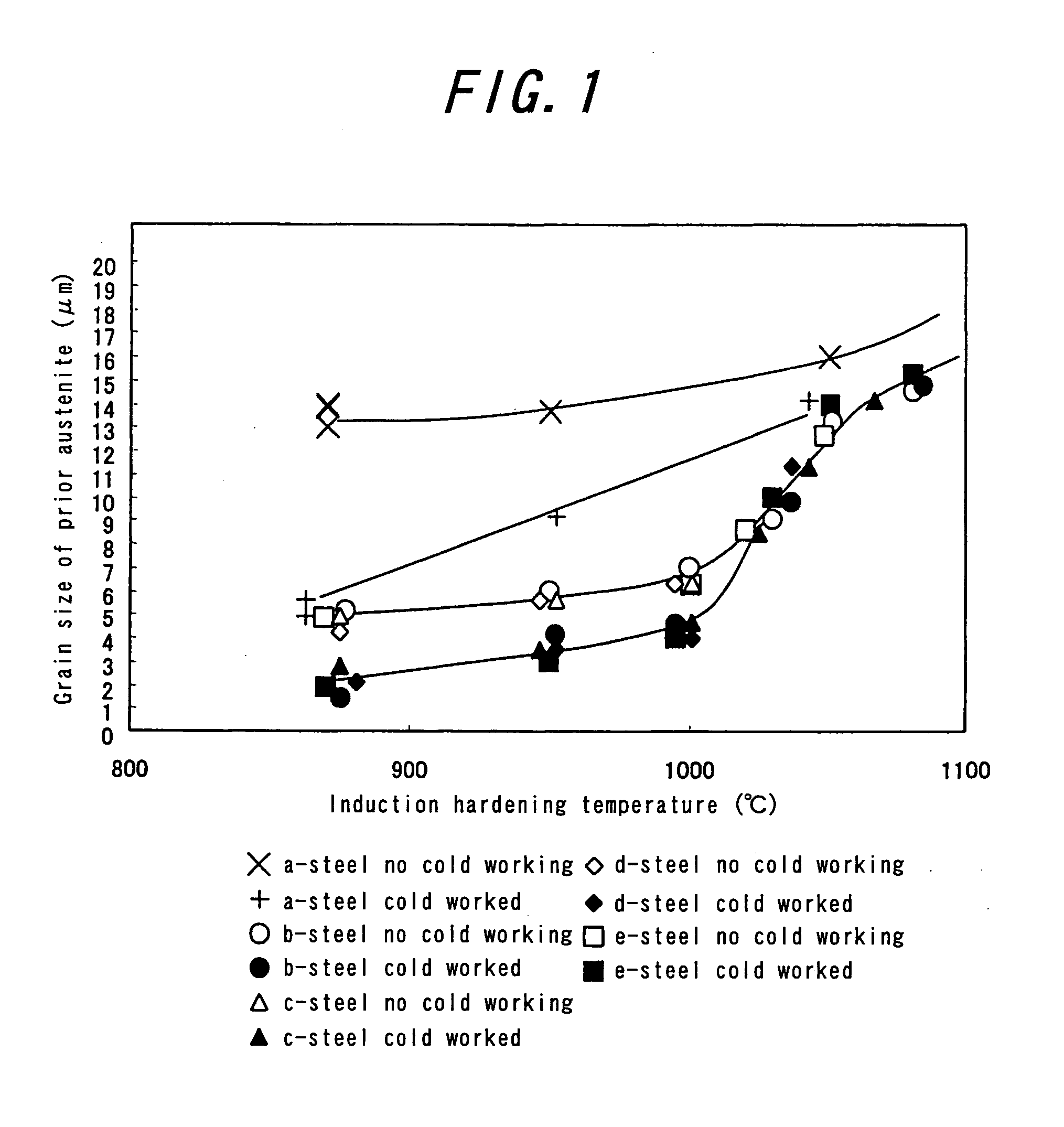

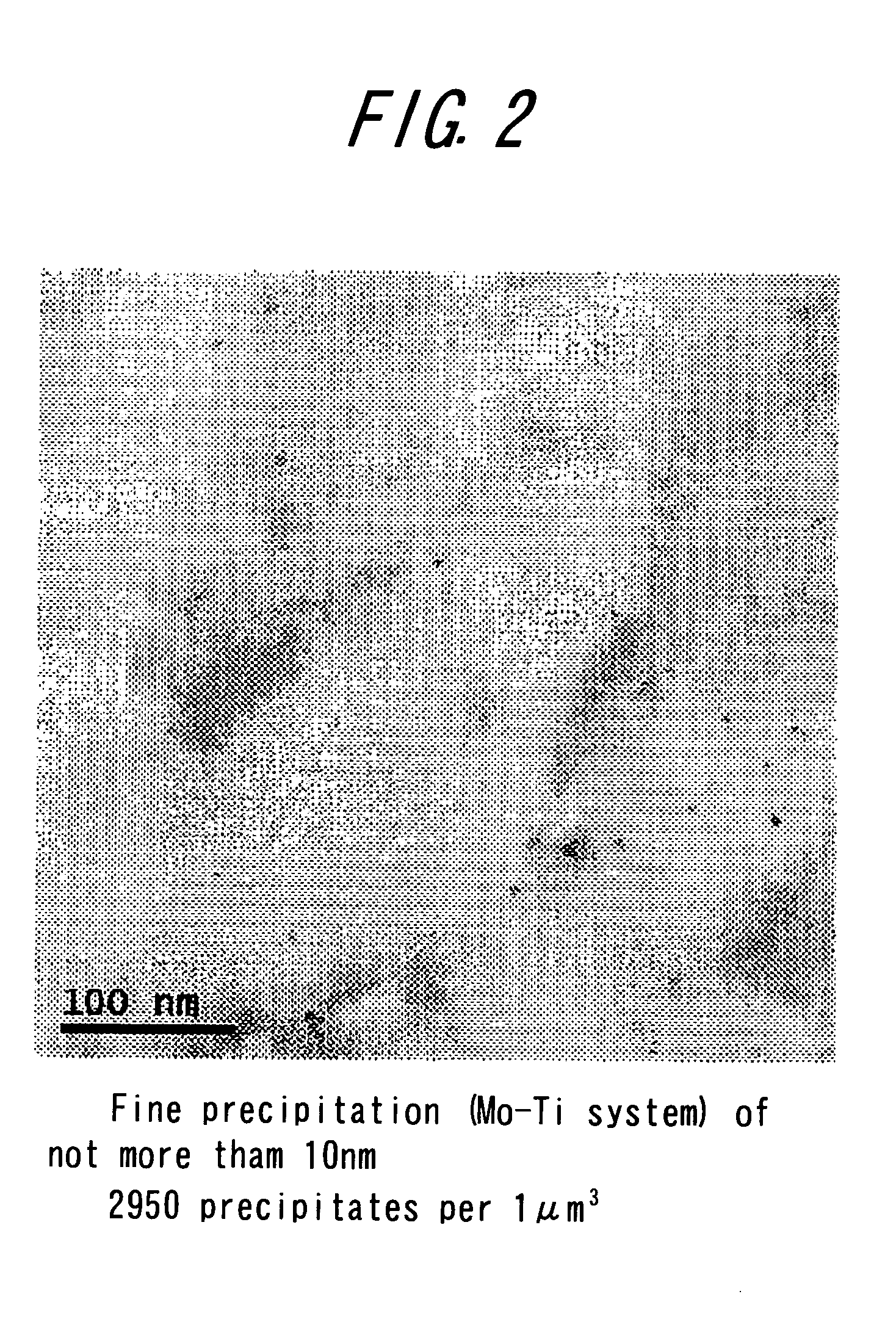

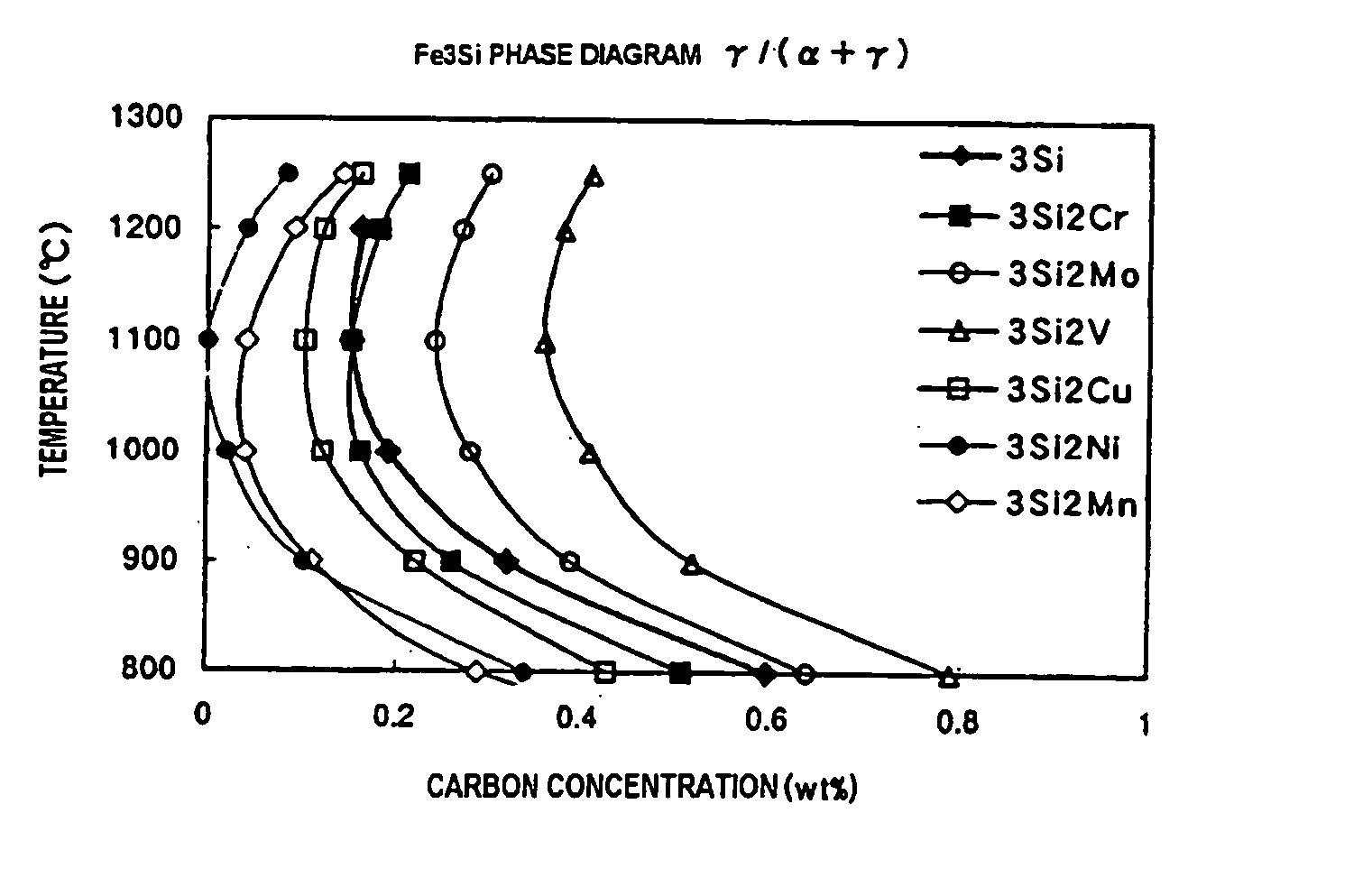

InactiveUS20080247900A1Improve fatigue performanceConsiderable effectIncreasing energy efficiencyAustenite grainHardness

There is provided a component for machine structure having a hardened layer through an induction hardening in at least a part thereof, and more improving fatigue strengths as compared with the conventional ones, in which the hardened layer has a hardness Hv of not less than 750 and an average grain size of prior austenite grains is not more than 7 μm over a full thickness of the hardened layer.

Owner:JFE STEEL CORP

Rolling elements

InactiveUS20050247377A1Improve the immunityHigh contact fatigue strengthSolid state diffusion coatingFurnace typesSurface layerInduction hardening

The pitting resistance of a gear is increased by hardening its tooth flanks through application of carburizing / quenching, bright hardening and induction hardening to a steel material capable of providing significantly improved softening resistance in tempering at a low temperature of 300 to 350° C. To this end, the steel material prepared so as to satisfy the relationship described by: 5≦4.3×Si (wt %)+7.3×Al (wt %)+3.1×V (wt %)+1.5×Mo (wt %)+1.2×Cr (wt %)×(0.45÷C (wt %)) is carburized such that the carbon concentration of its carburized surface layer is adjusted to 0.6 to 0.9 wt %; and the steel material is subjected to quenching and tempering at 300° C. or less subsequently to the carburization process, or alternatively the steel material is once cooled after the carburization process and then subjected to treatments of re-heating hardening and tempering at 300° C. or less so that a hardness of HRC 58 or more is ensured by the tempering process at 300° C.

Owner:KOMATSU LTD

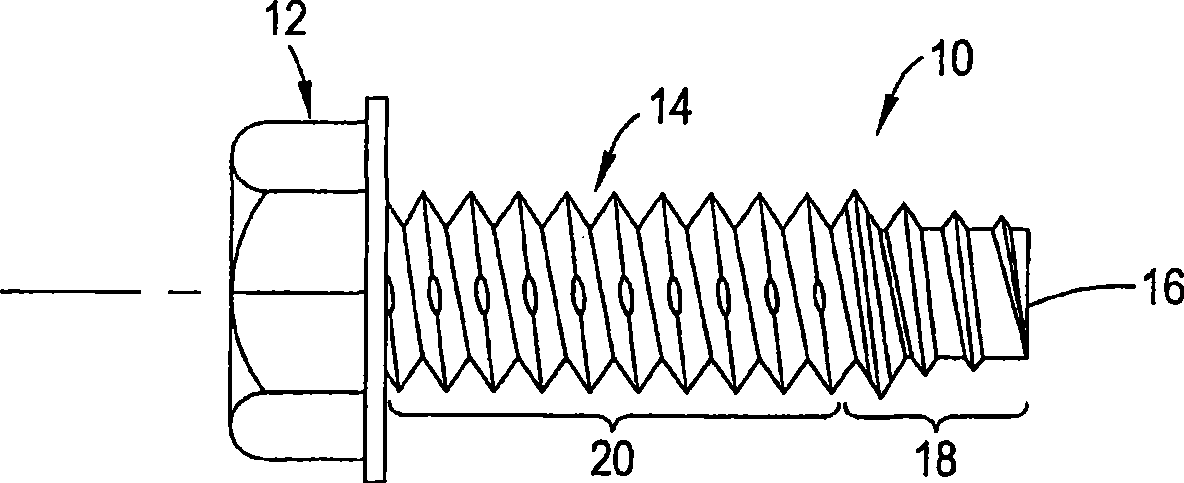

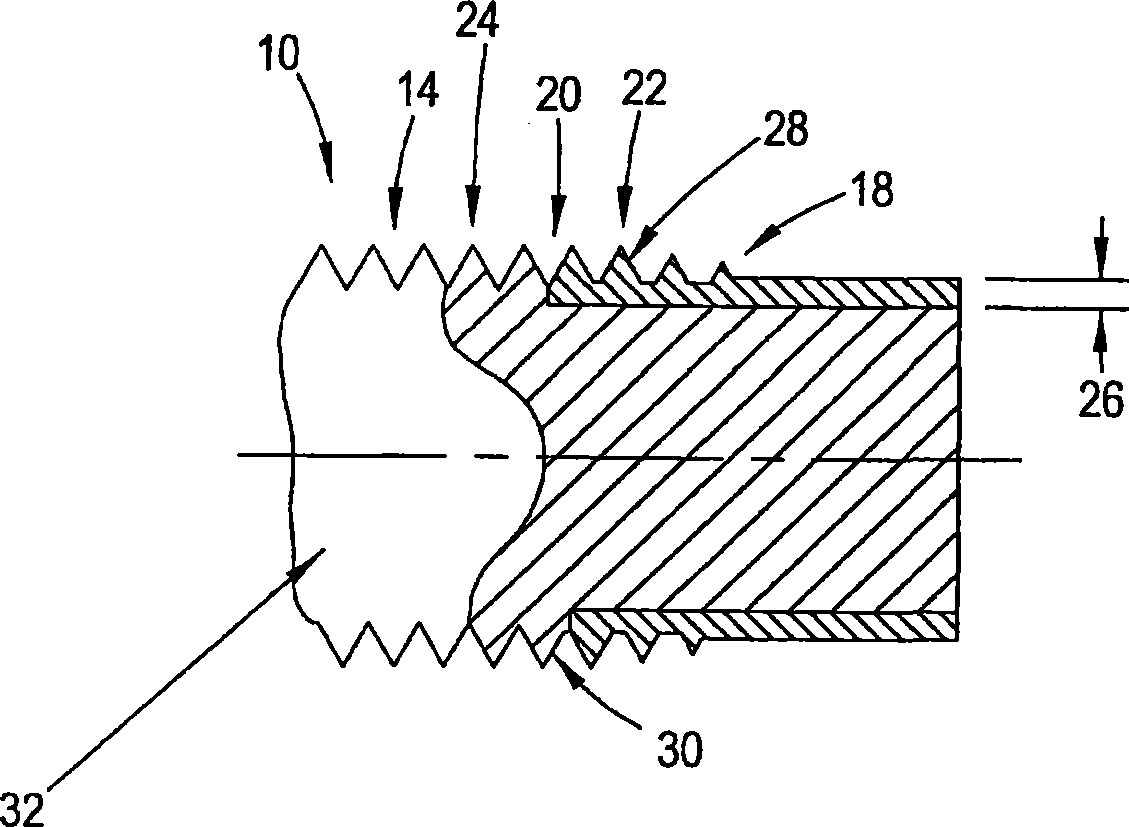

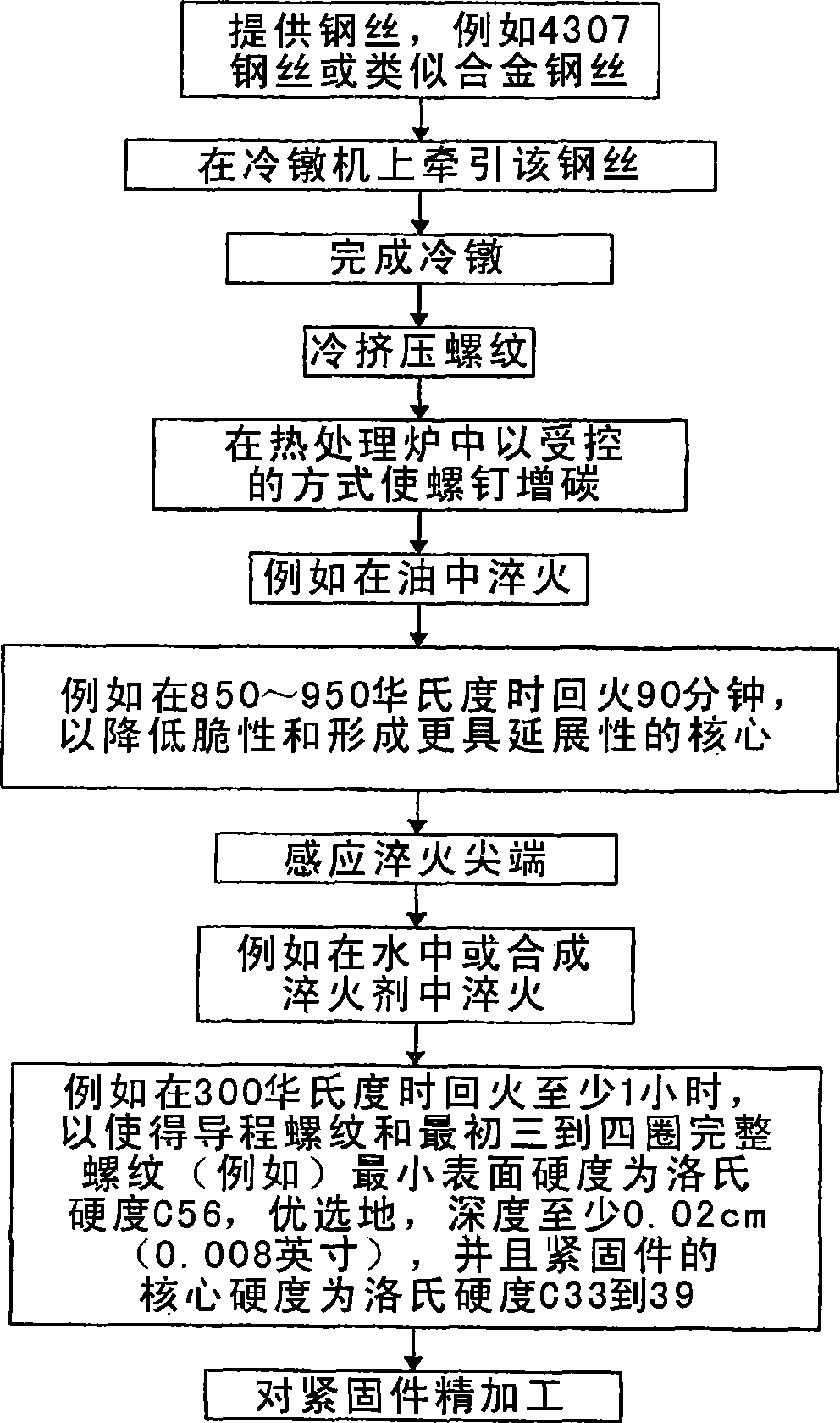

High performance thread forming screw

The invention provides a thread forming screw and a method for forming the same. A thread forming screw having a minimum surface hardness of HRC 56. The screw can form threads in a workpiece having a surface hardness which exceeds HRC 23. A method of surface hardening a screw includes carbon enriching the screw to at least a 0.48% carbon level, and then quenching the screw. Then, the screw is tempered such that the surface hardness does not exceed the core hardness by more than 3 Rockwell C points, and both the surface and core are at a Rockwell C33-C39 hardness. Subsequently, the point is induction hardened, and the screw is quenched again. The screw is again tempered such that the lead threads and the first 3-4 full threads are at a Rockwell C56 minimum hardness, preferably to a depth of at least 0.008 inches, and the core of the fastener is at Rockwell C33-C39 hardness. Finally, a finish is applied.

Owner:ACUMENT INTPROP LLC

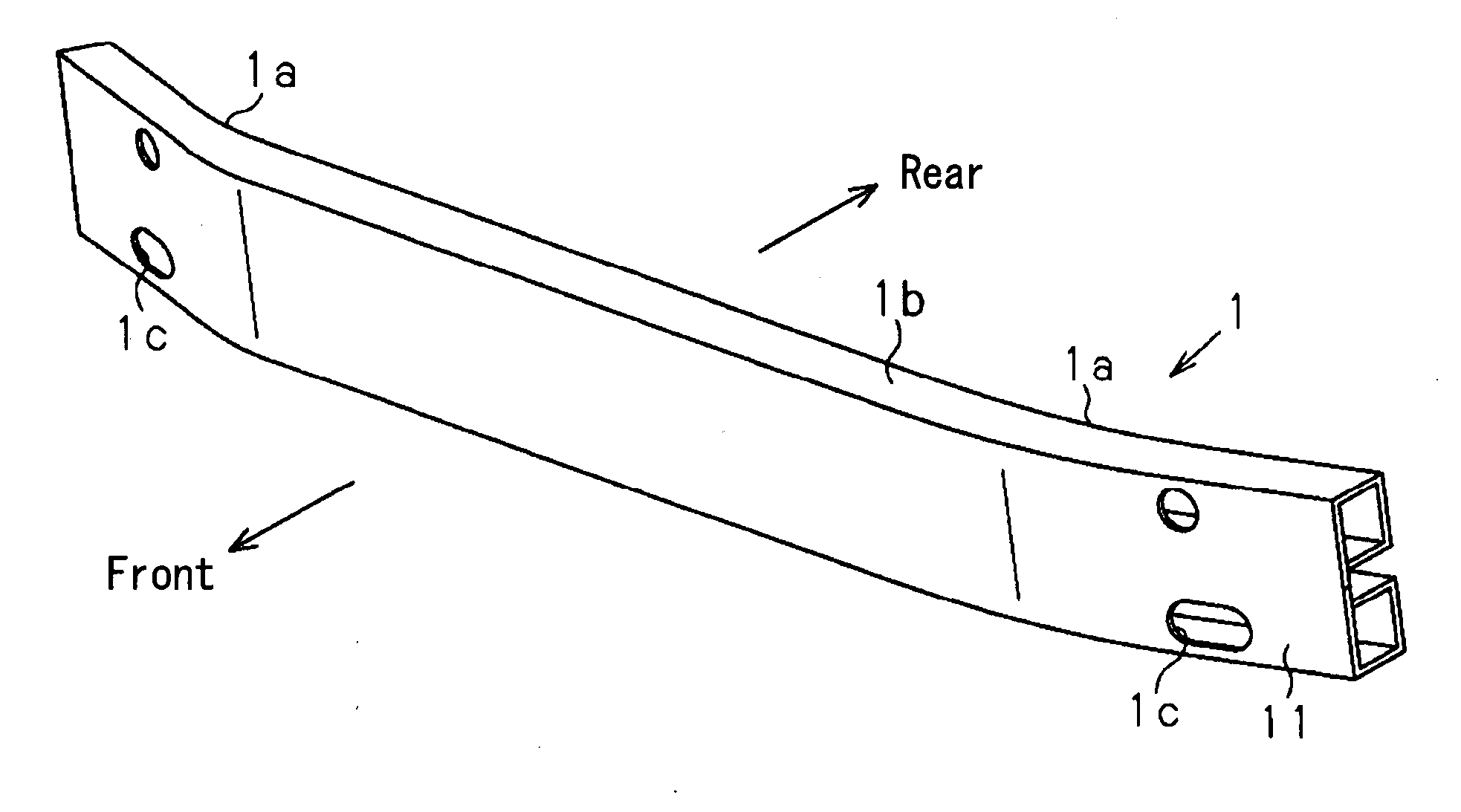

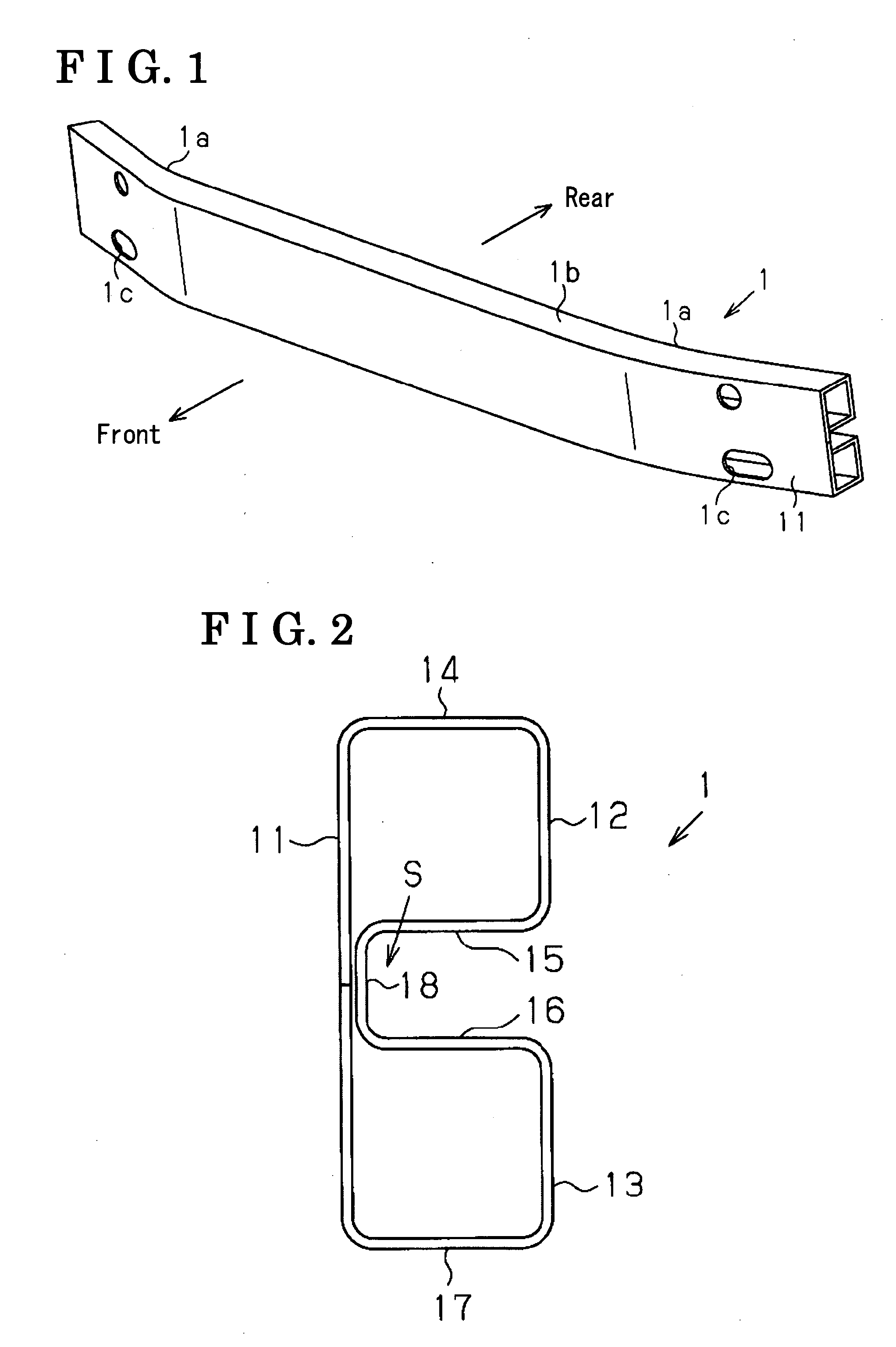

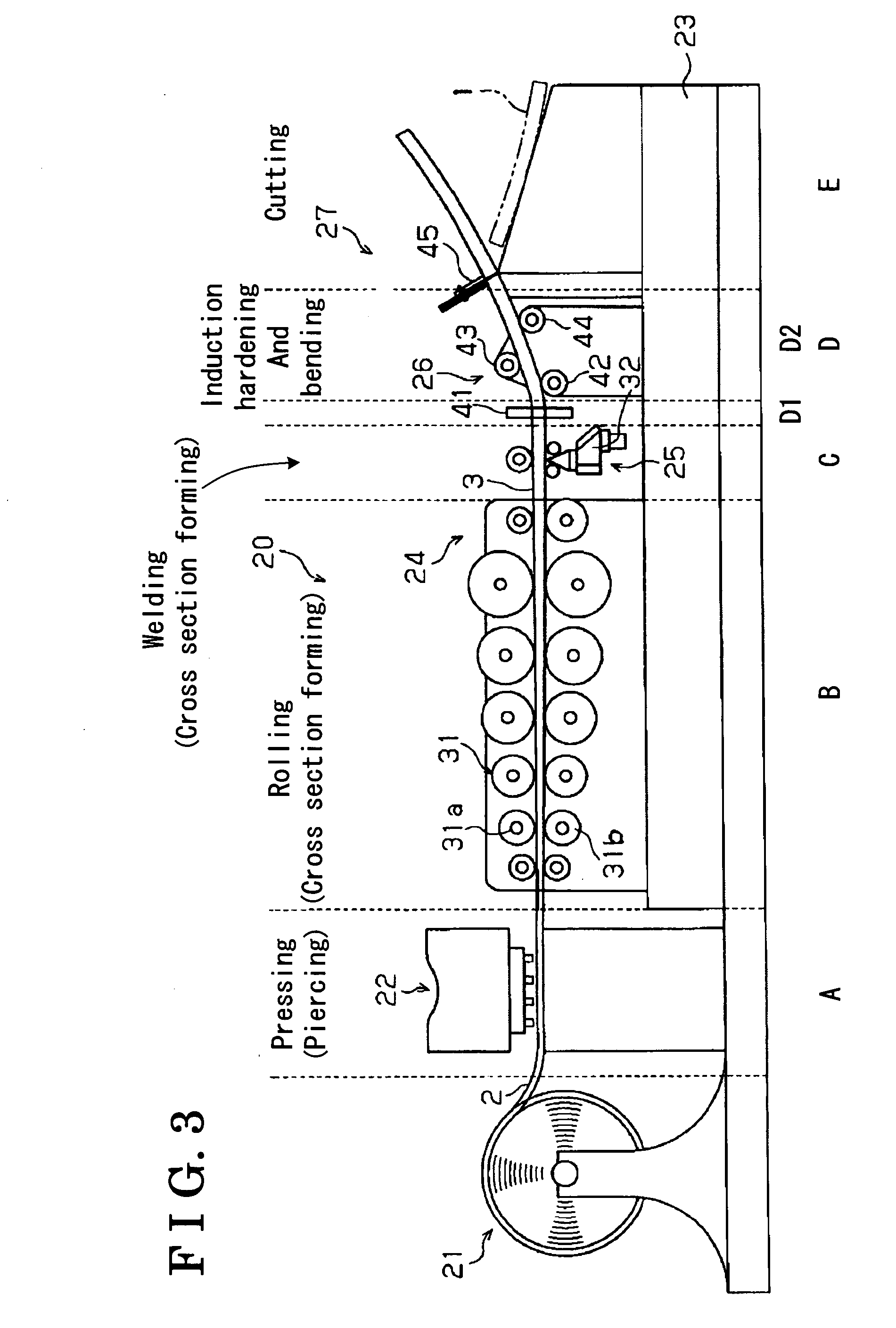

Method for manufacturing impact absorber for vehicle

A method for manufacturing an impact absorber for a vehicle includes a first process for manufacturing a formed body having a constant cross-sectional configuration by performing roll forming on a metal sheet and a second process for manufacturing the impact absorber by performing an induction hardening treatment and a bend forming on the formed body after performing the first process.

Owner:AISIN SEIKI KK +1

Technique for induction heating steel rod tempering heat treatment

InactiveCN101186962ASimple structureStrong process controllabilityFurnace typesHeat treatment furnacesProduction lineInduction hardening

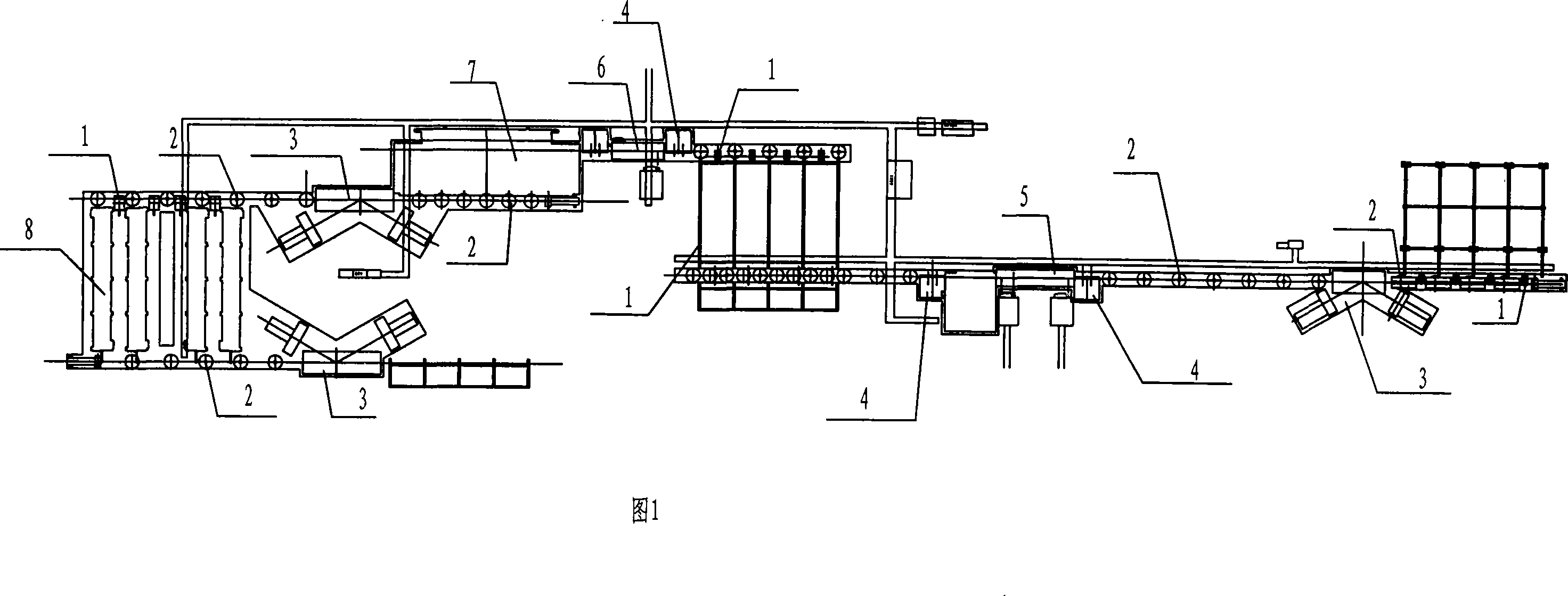

The invention relates to a process for modified heat treatment of induction heating steel rods, which is characterized in that modified process is accomplished on a continuous processing production line of straightening, induction hardening, induction tempering, heat-insulating tempering, and roll cooling of the steel rod. The specific process is straightening, quenching, tempering, cooling and straightening, blanking checking and warehousing. The beneficial effects of the invention are that heat effect of inductive loop is employed to carry on modified heat treatment of rolled steel, which enables the core organization to be evenly tempered sorbite organization, thereby preheating and warming are not needed, the temperature is raised rapidly, and manufacture of long pieces can be achieved via length sizing.

Owner:TIANJIN JINNENG POWER ELECTRONICS

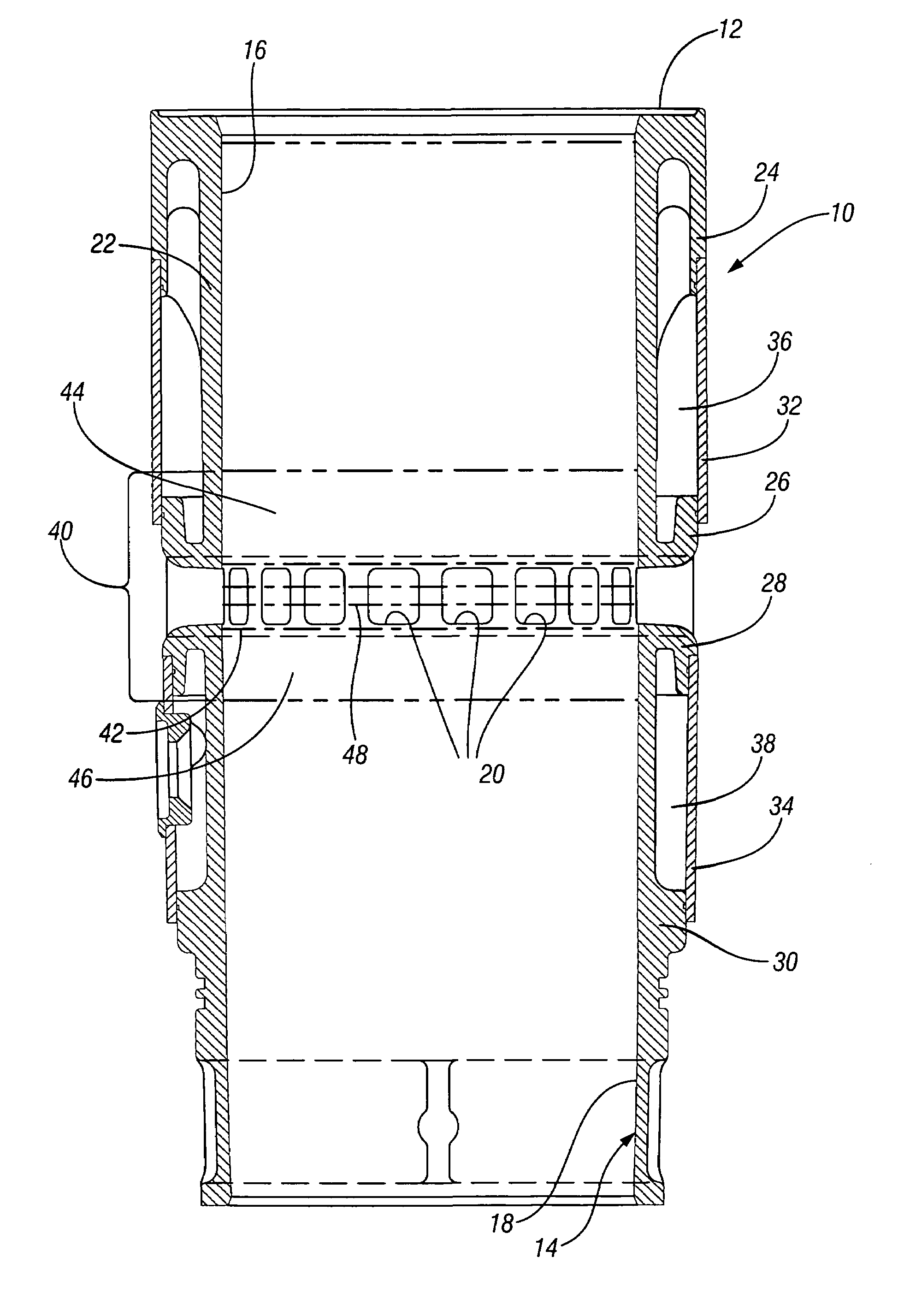

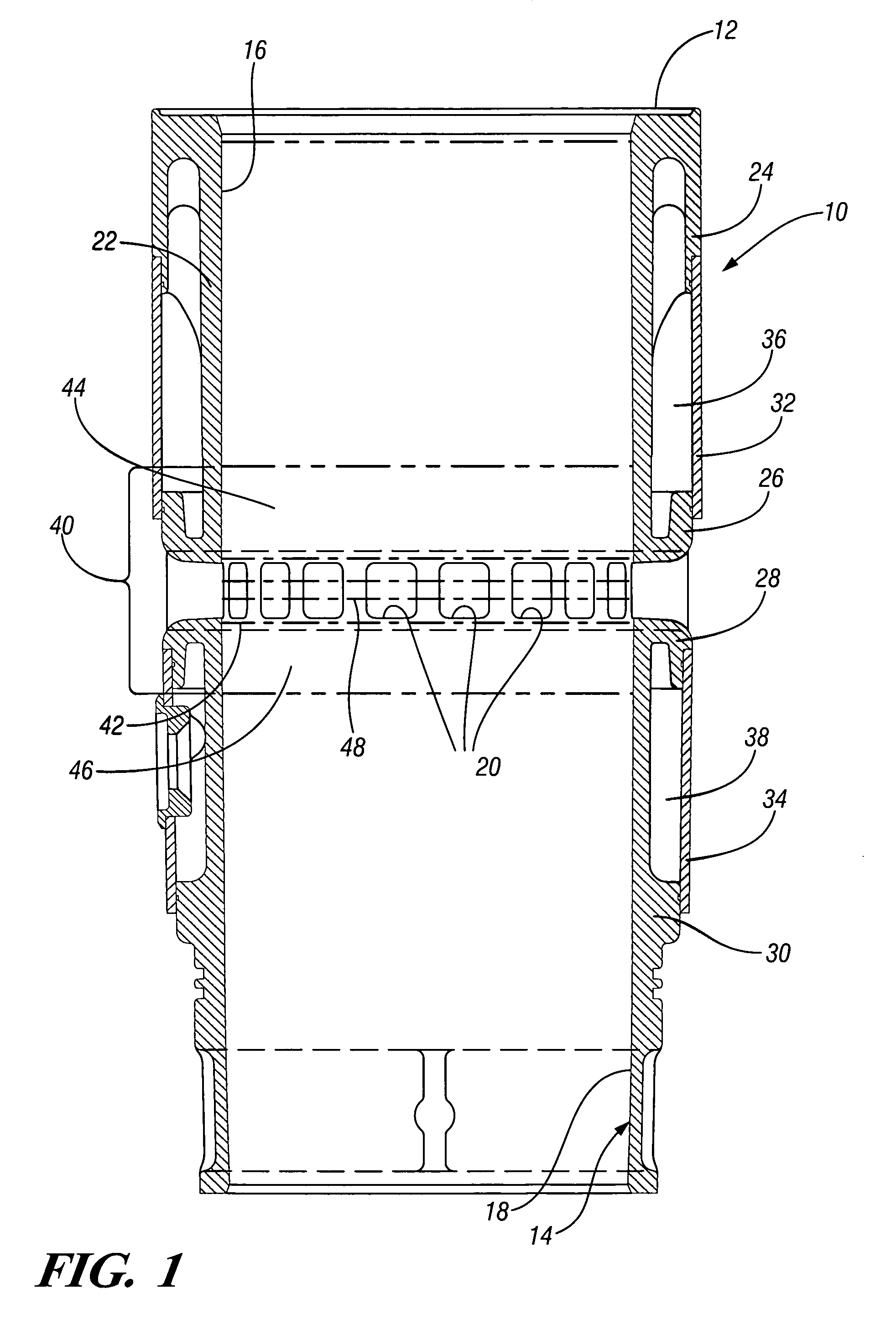

Induction heat treatment method and coil and article treated thereby

InactiveUS20050039830A1Additional componentEasy to controlCoil arrangementsFurnace typesInduction hardeningMaterials science

A method of induction heat treating the outer surface of articles having an irregular surface shape. The method employs an induction coil that provides a non-planar magnetic field that is adapted to the irregular shape of the article, such that distinct sections of the induction coil produce distinct magnetic fields that are adapted to induce currents in, and thereby provide heat to, distinct sections of the outer surface of the article. The method and induction coil are particularly adapted to provide an induction hardening heat treatment for the outer surfaces of the inner races of Rzeppa-type constant velocity joints.

Owner:FORD MOTOR CO

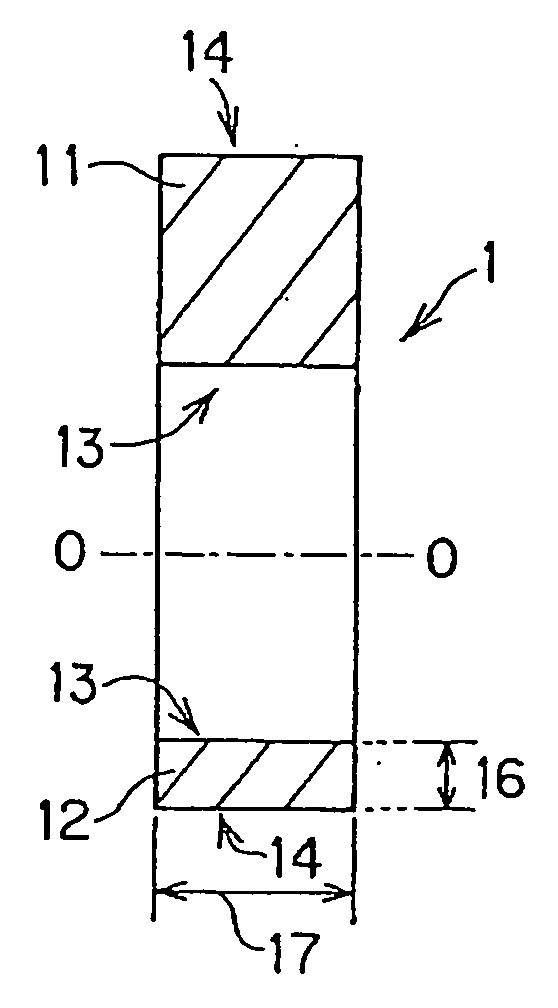

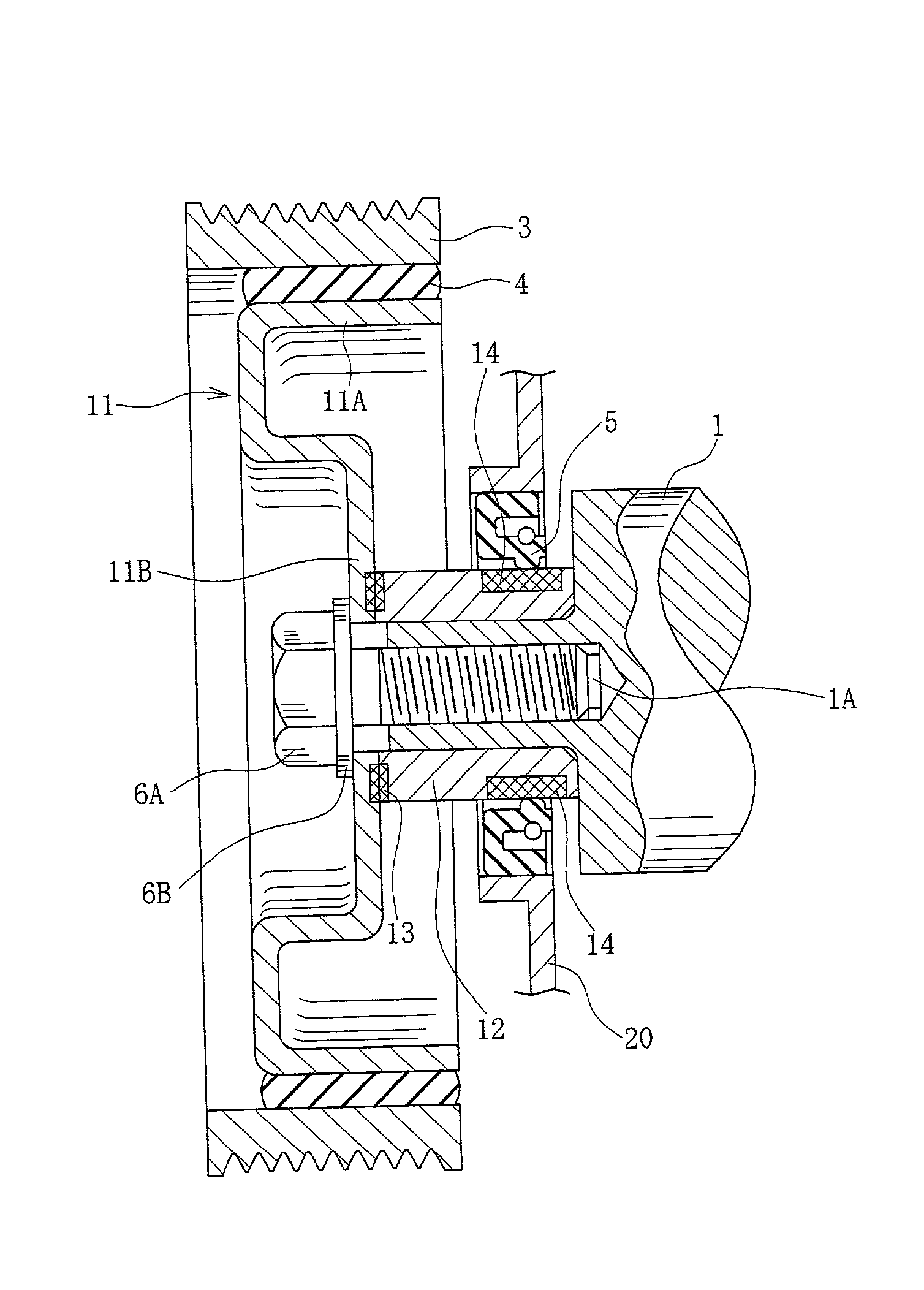

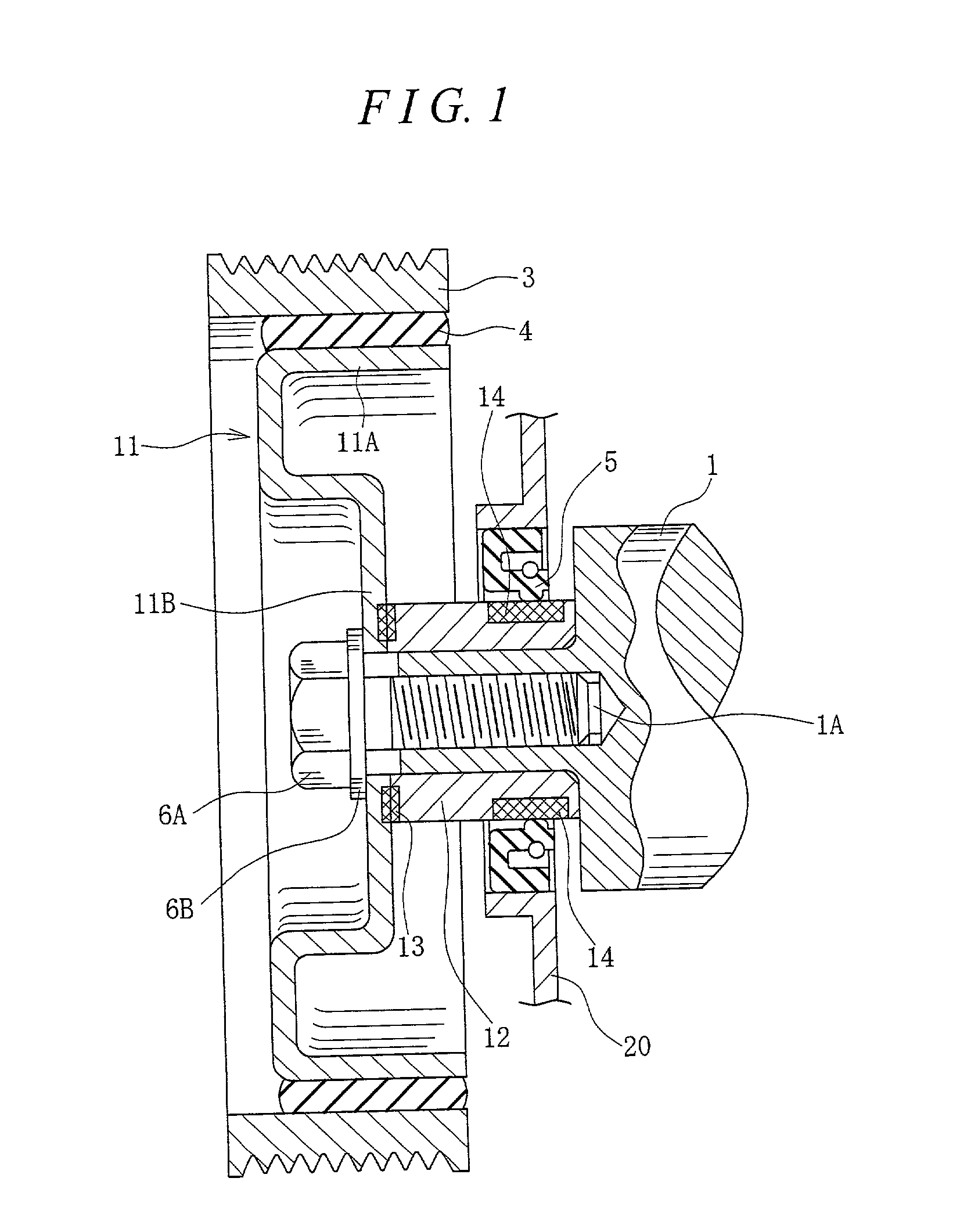

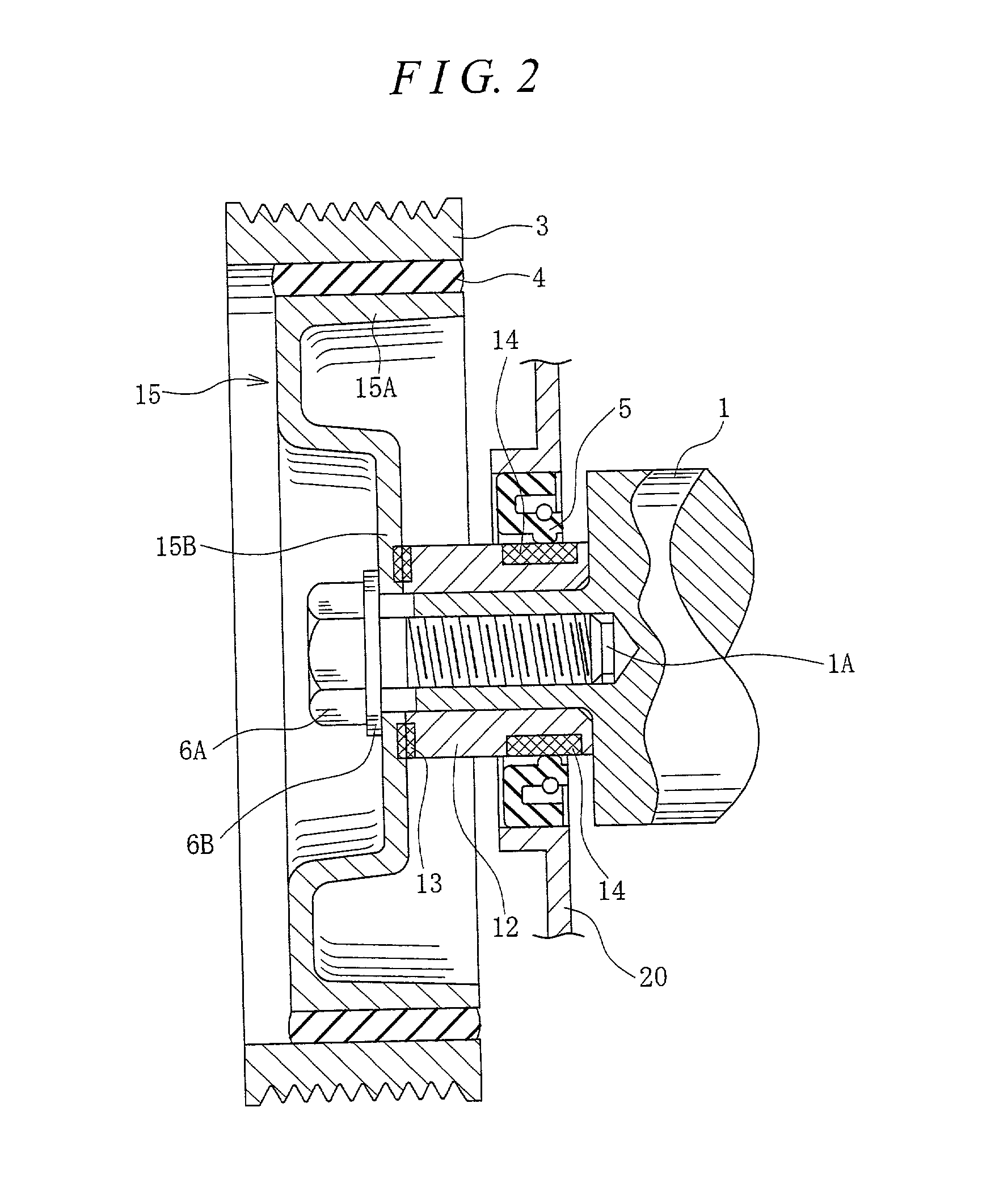

Torsional damper

InactiveUS20020129675A1High strengthIncrease resistanceRotating vibration suppressionSynthetic resin layered productsElastomerEngineering

A torsional damper mounted to a crank shaft of an internal combustion engine has a hub provided with a rim portion and a fixing portion, and a boss welded to the rim portion. A mass body is arranged in an outer side of the rim portion via a cylindrical elastic body. A seal element of an oil seal mounted to an engine assembly makes contact with an outer circumferential surface of the boss. The hub 11 has a carbon equivalent of 0.5% or less, and a boss has a carbon equivalent of 0.5% or less and a carbon content of 0.2% or more. Induction hardening is applied to a portion of the boss with which the oil element makes contact.

Owner:FUKOKU CO LTD

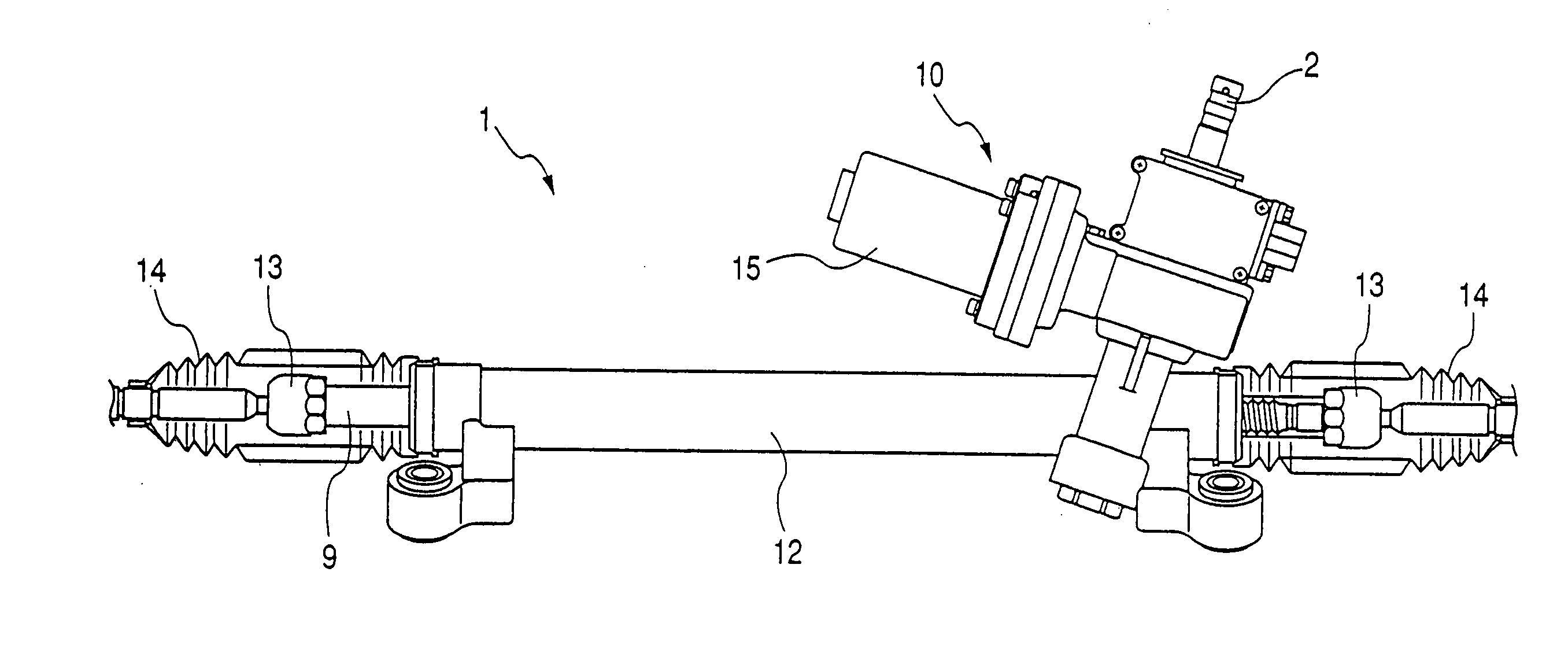

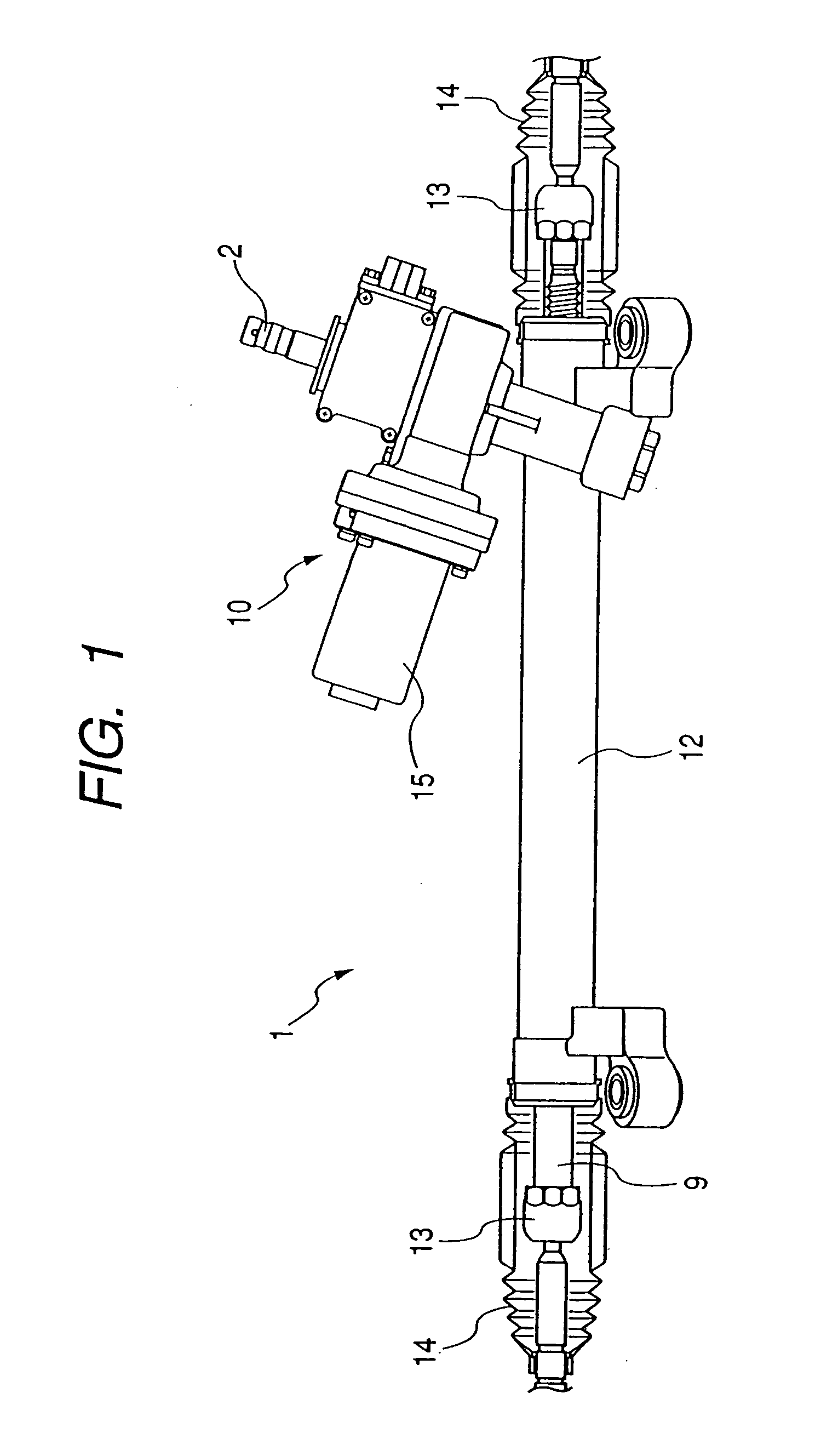

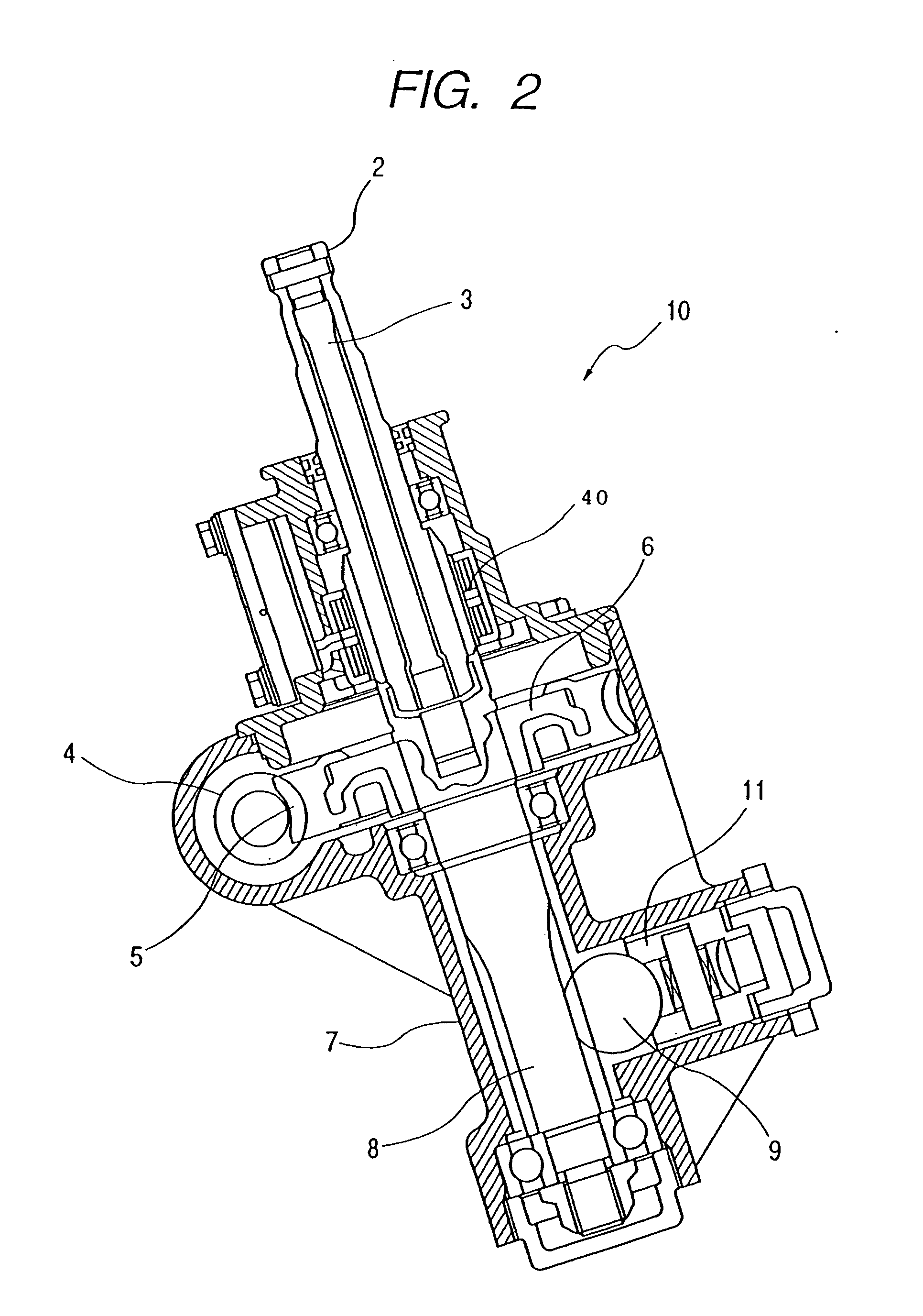

Reduction gear and method and apparatus for manufacturing the reduction gear concerned, and electric power steering system with the reduction gear concerned

InactiveUS20050172744A1Maintain hardnessToothed gearingsPortable liftingElectric power steeringReduction drive

A reduction gear including: a worm wheel, the tooth skin portion of which is at least made of macromolecular composite material, and a worm for meshing with the worm wheel concerned, wherein a tooth surface of the worm has been heat-treated by high-frequency induction hardening.

Owner:NSK LTD +1

High-strength race and method of producing the same

InactiveUS7083688B2High hardnessImprove fatigue performanceBearing componentsFurnace typesSurface fatigueHardness

The high-strength race of the present invention comprises using A steel for a high-strength race comprising the following elements in percentage by weight: C: 0.30 to 0.60%, Si: 0.30 to 1.30%, Mn: 0.5 to 1.5%, B: 0.0050% or less, Cr: 0.1 to 0.5%, Mo: 0.1 to 0.5%, Si+Mo: 0.5 to 1.4%, Ni: 0.02 to 1.0%, the balance of Fe and unavoidable impurities, performing induction hardening to make the race have a surface hardness of 58 HRC or more and further a surface hardness of 52 HRC or more even after the surface is tempered at 300° C. The high-strength race is superior in rotating fatigue properties, anti-surface fatigue strength and productivity by a combination of composition control and induction hardening.

Owner:NISSAN MOTOR CO LTD

Driving shaft processing technique

The invention discloses a driving shaft processing technique. The driving shaft processing technique includes the steps of forging, normalizing, rough turning, finish turning, deep-hole drilling, hobbing, oil-hole drilling, carburizing, induction hardening, external grinding and completion of finished products. Surface hardness and core tenacity of driving shafts produced by the driving shaft processing technique can be improved, and deformation of the driving shafts can be reduced.

Owner:泰州市东方传动技术有限公司

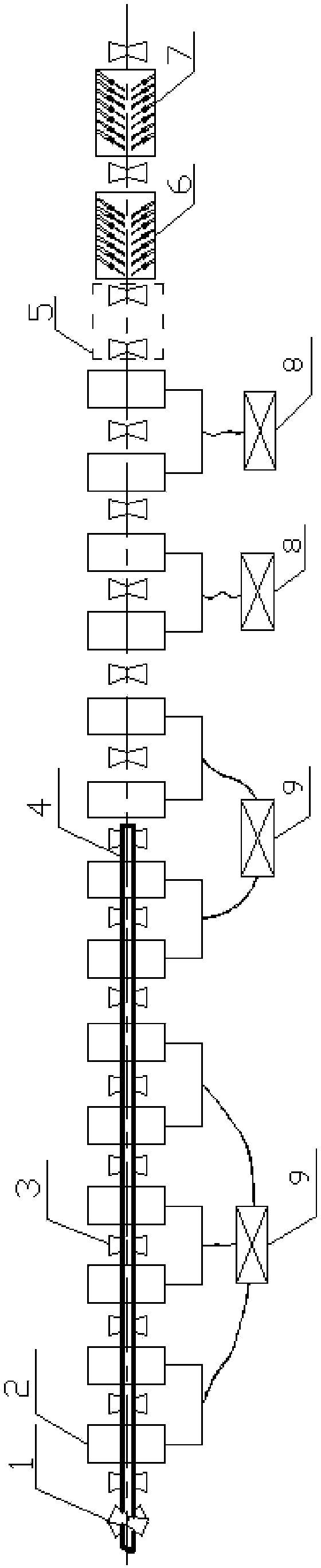

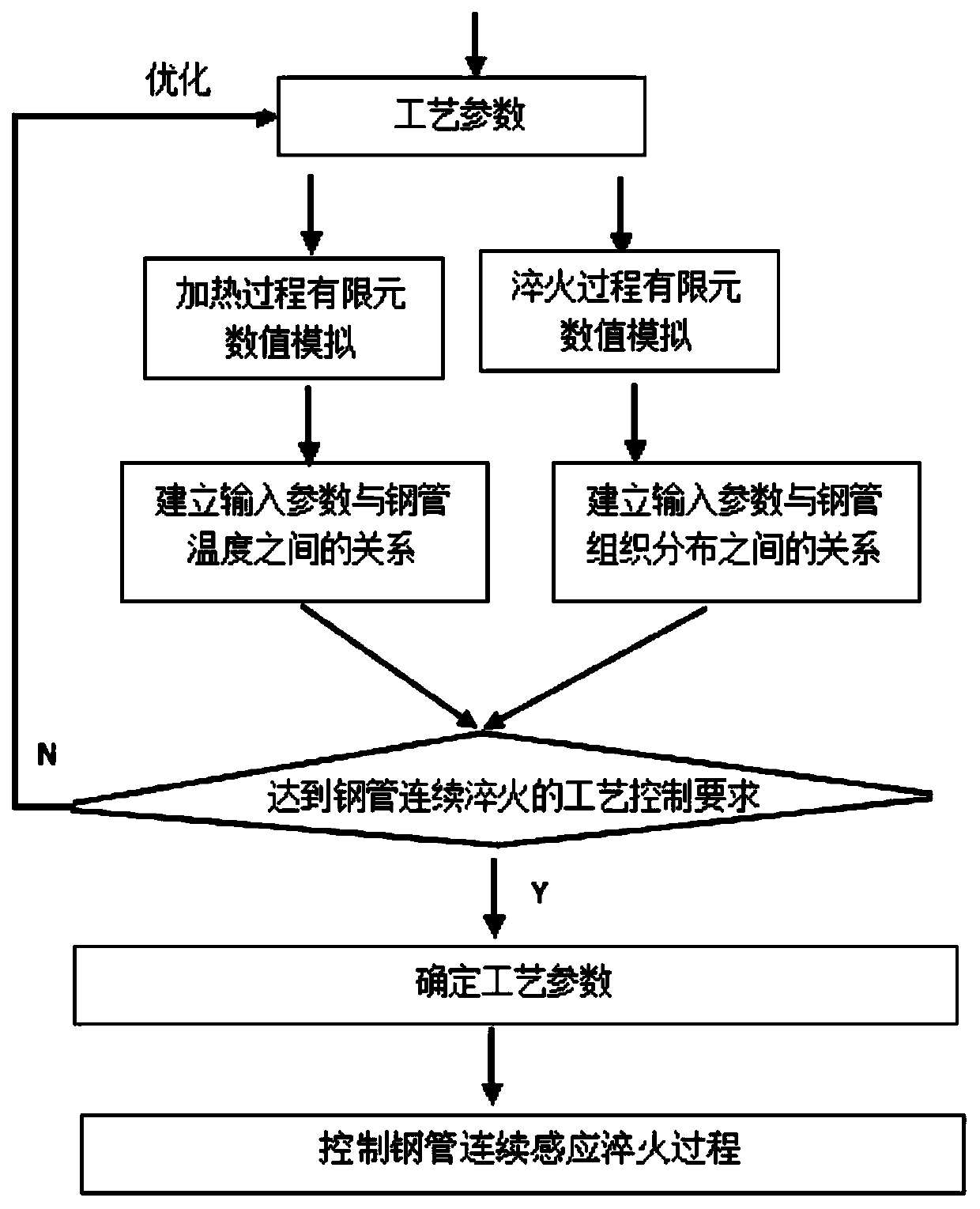

Steel pipe continuous quenching process control method based on numerical simulation

ActiveCN104212969ASmall temperature differenceReduce consumptionIncreasing energy efficiencyFurnace typesElement analysisInduction hardening

The invention relates to a steel pipe continuous quenching process control method based on numerical simulation. The method comprises the following steps that initial technological parameters of the continuous induction quenching process are calculated according to the moving linear speed and quenching cooling water spraying pressure of a steel pipe, and the initial technological parameters comprise a heating process technological parameter and a quenching process technological parameter; finite element analysis is carried out on the steel pipe continuous induction heating process, and the relation between the heating process technological parameter and the internal and external surface temperature of the steel pipe is obtained; finite element analysis is carried out on the steel pipe quenching cooling process, and the relation between the quenching process technological parameter and the steel pipe tissue distribution condition is obtained; according to the process control requirement, the heating process technological parameter and the quenching process technological parameter conforming to the technological control requirement are obtained, and a final steel pipe continuous induction quenching process control parameter is formed; the obtained control parameter is used for controlling the actual steel pipe continuous quenching process. Compared with the prior art, the method has the advantages of reducing energy consumption caused by technological parameter determining through preproduction, improving the working efficiency and the like.

Owner:SHANGHAI JIAO TONG UNIV

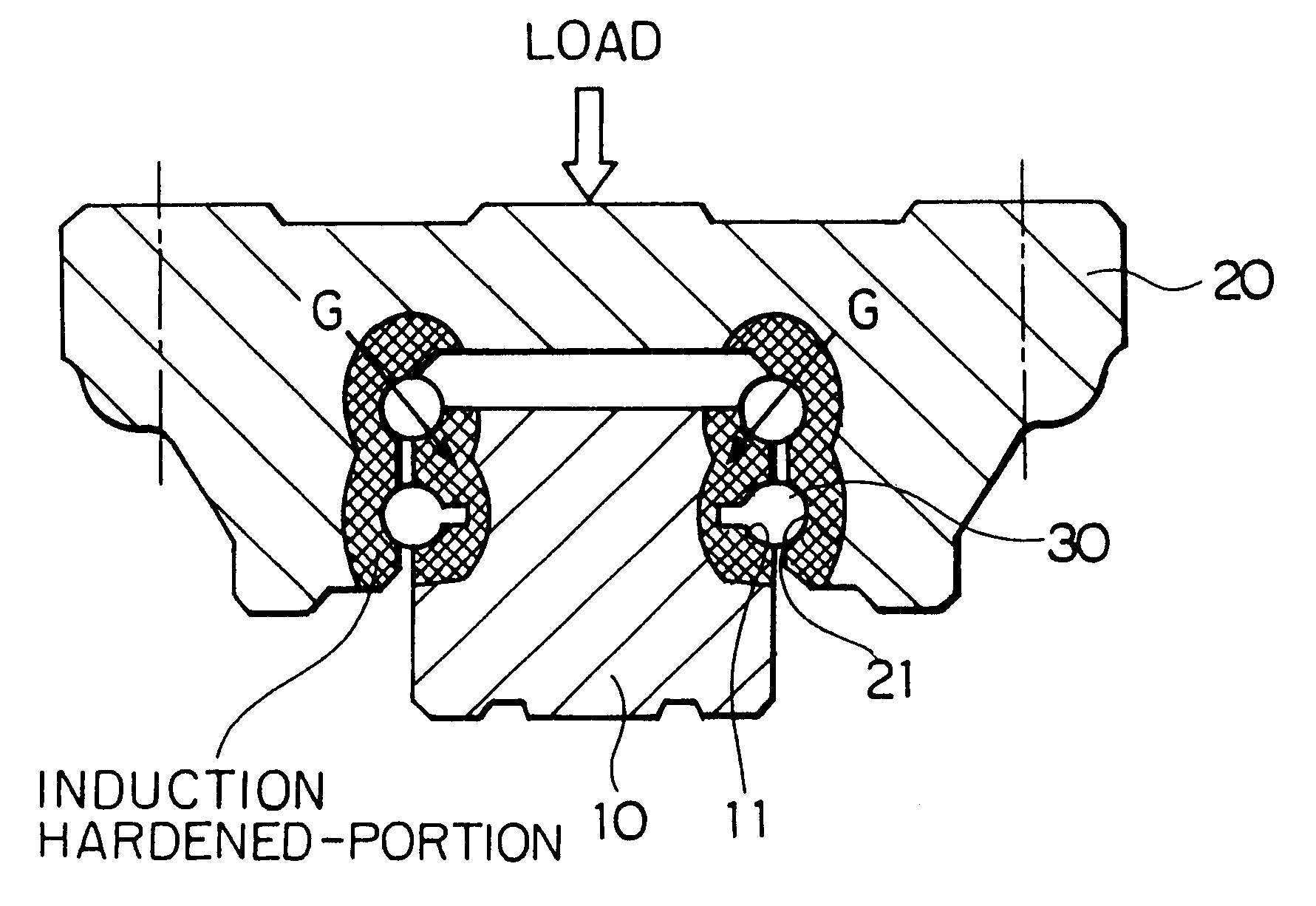

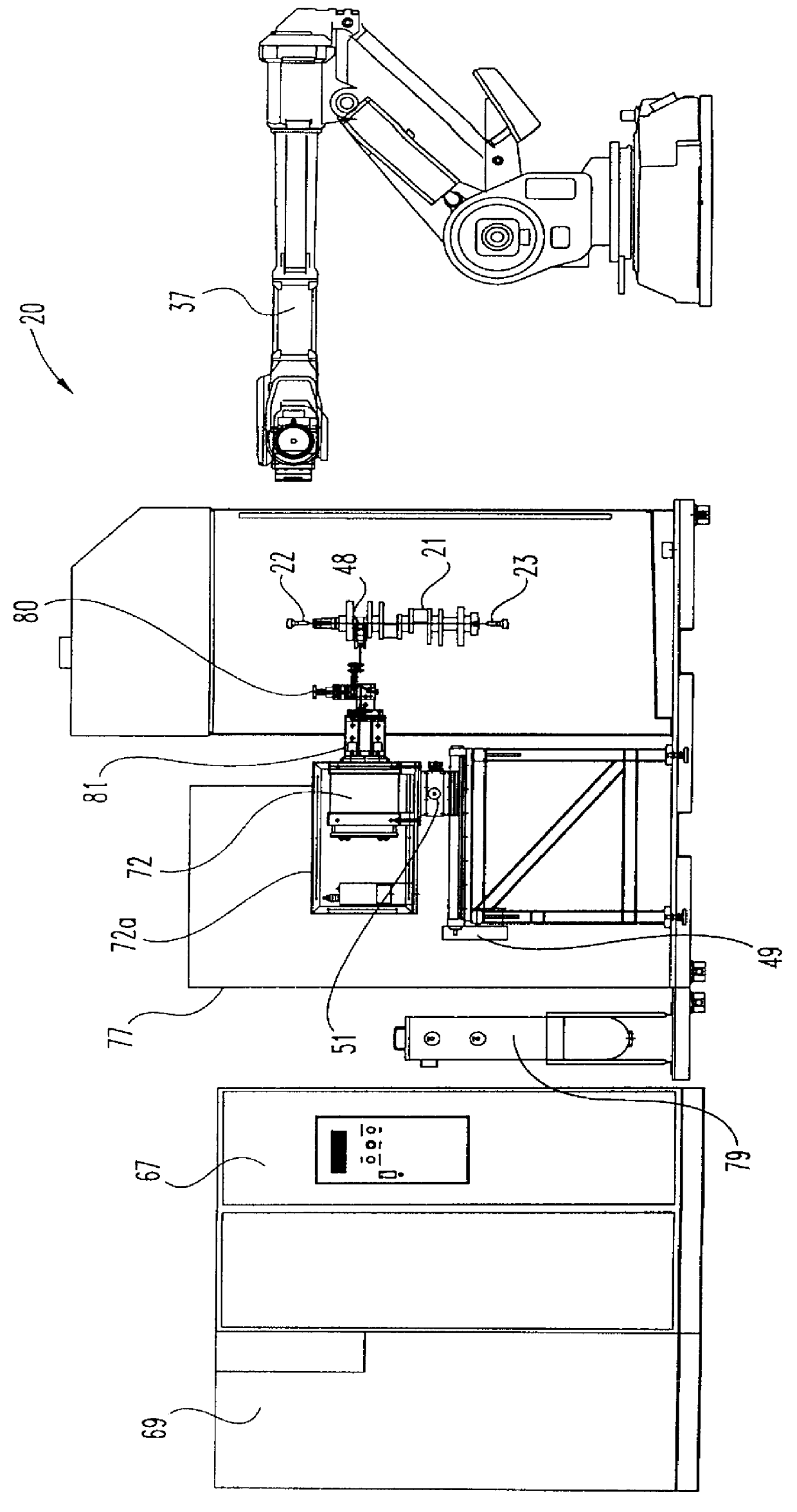

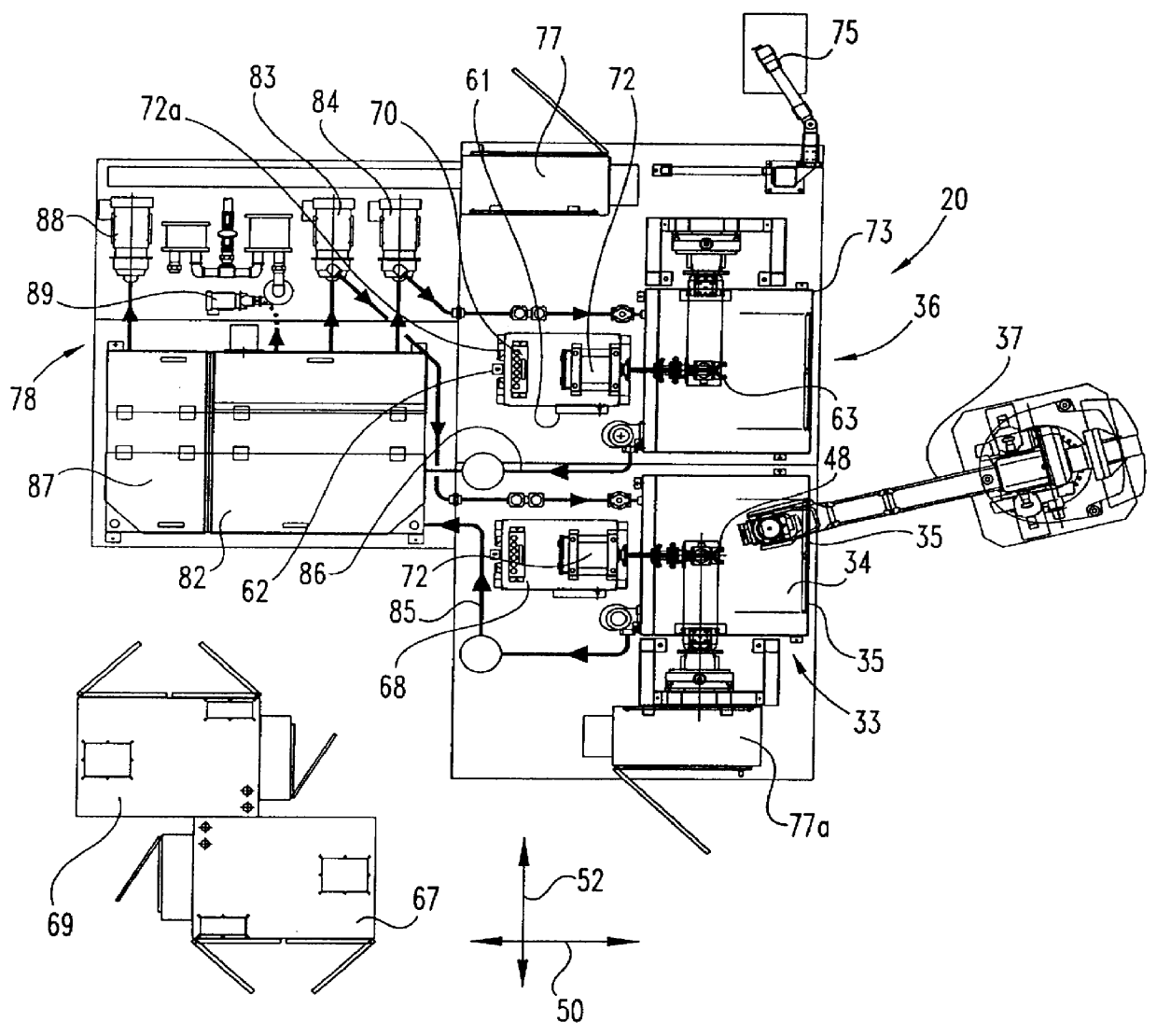

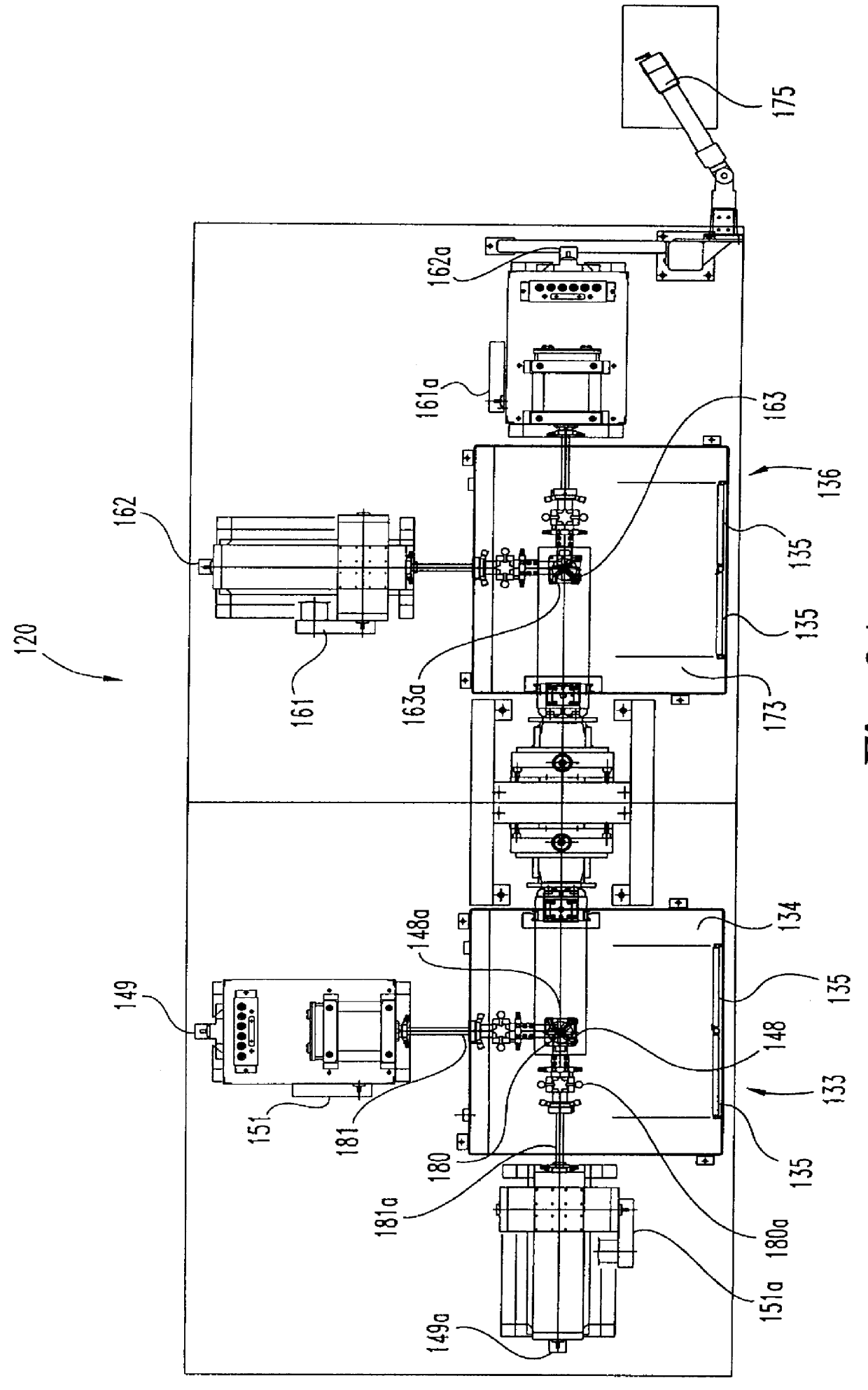

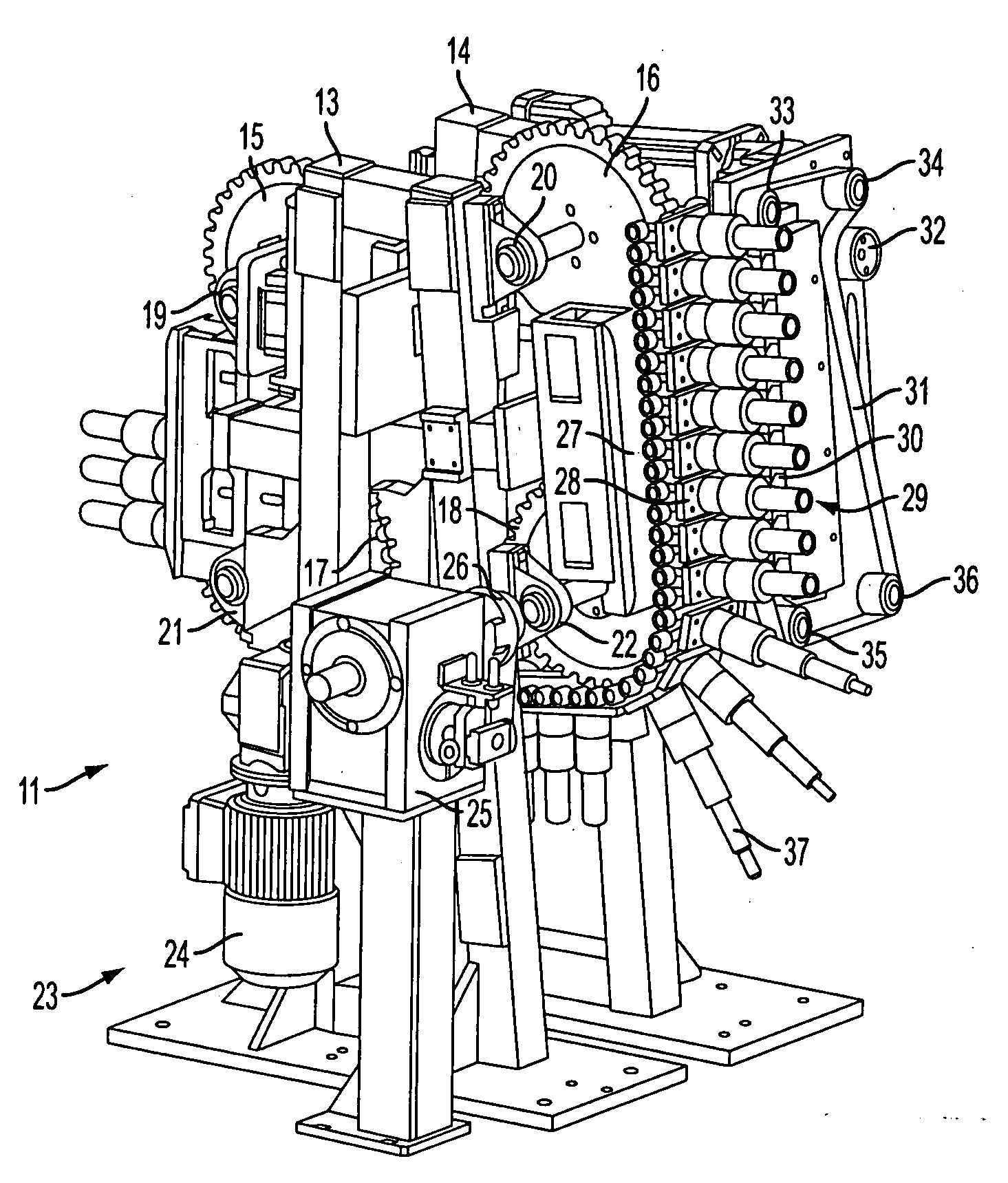

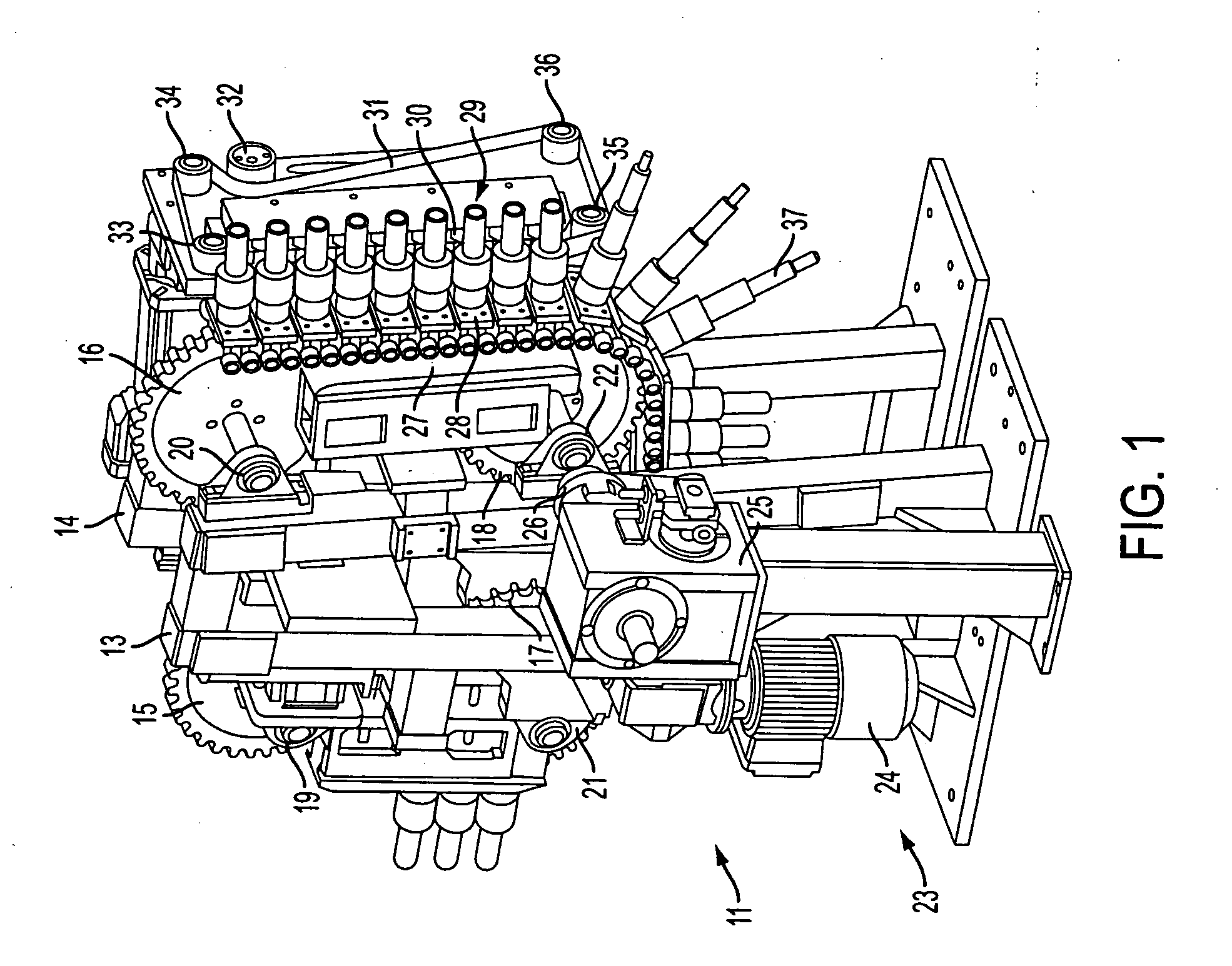

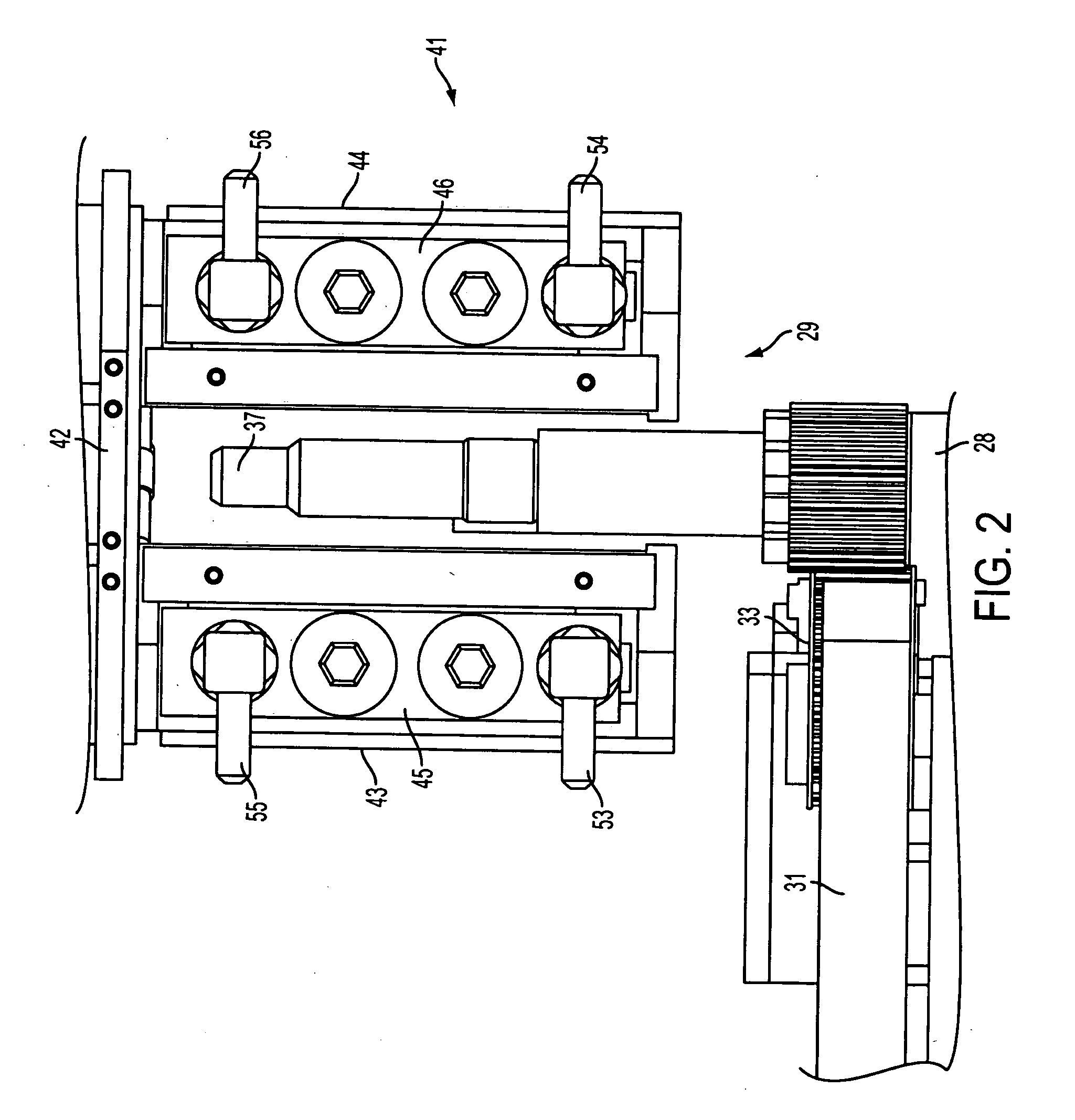

Induction hardening apparatus for a crankshaft

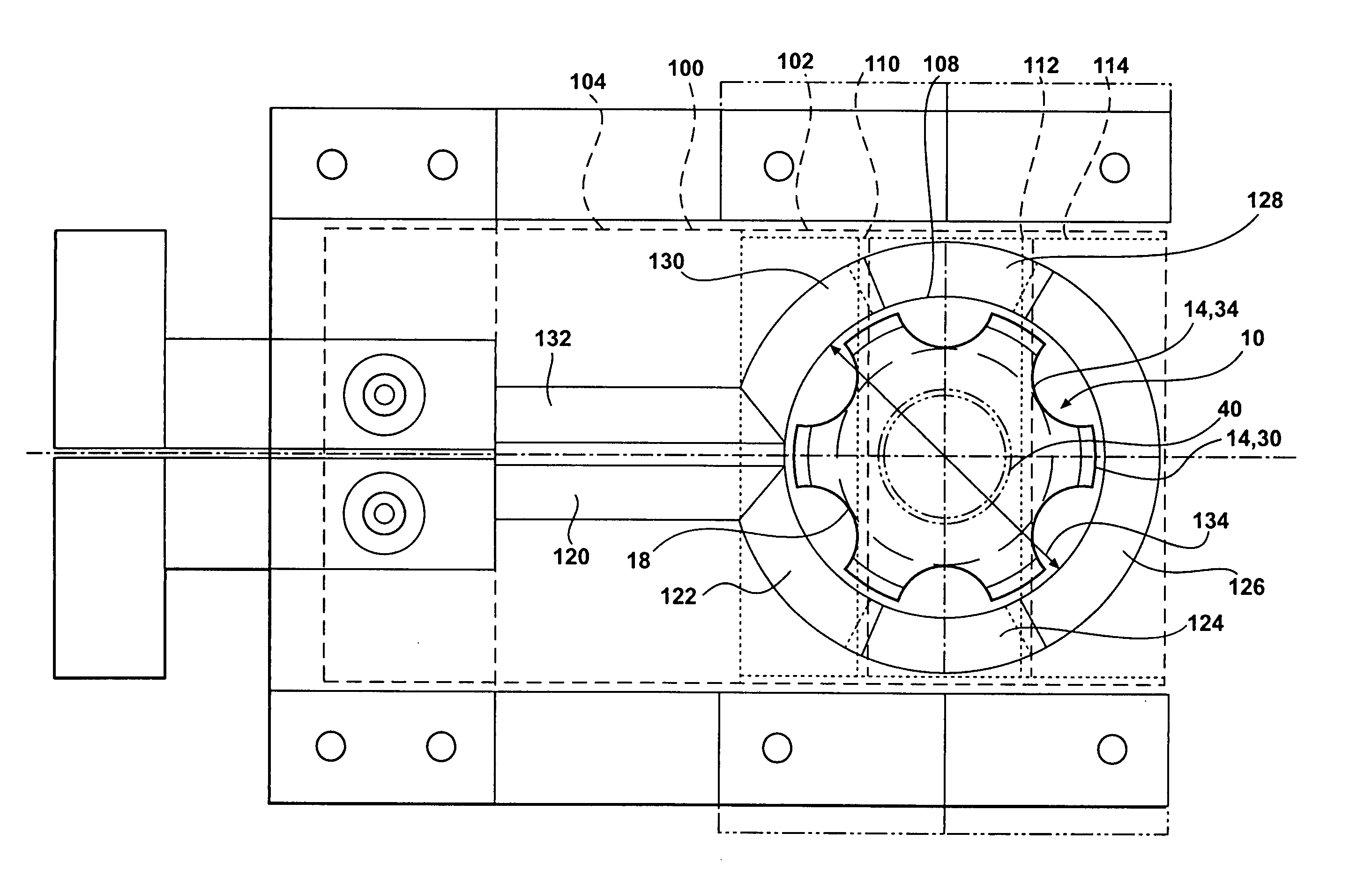

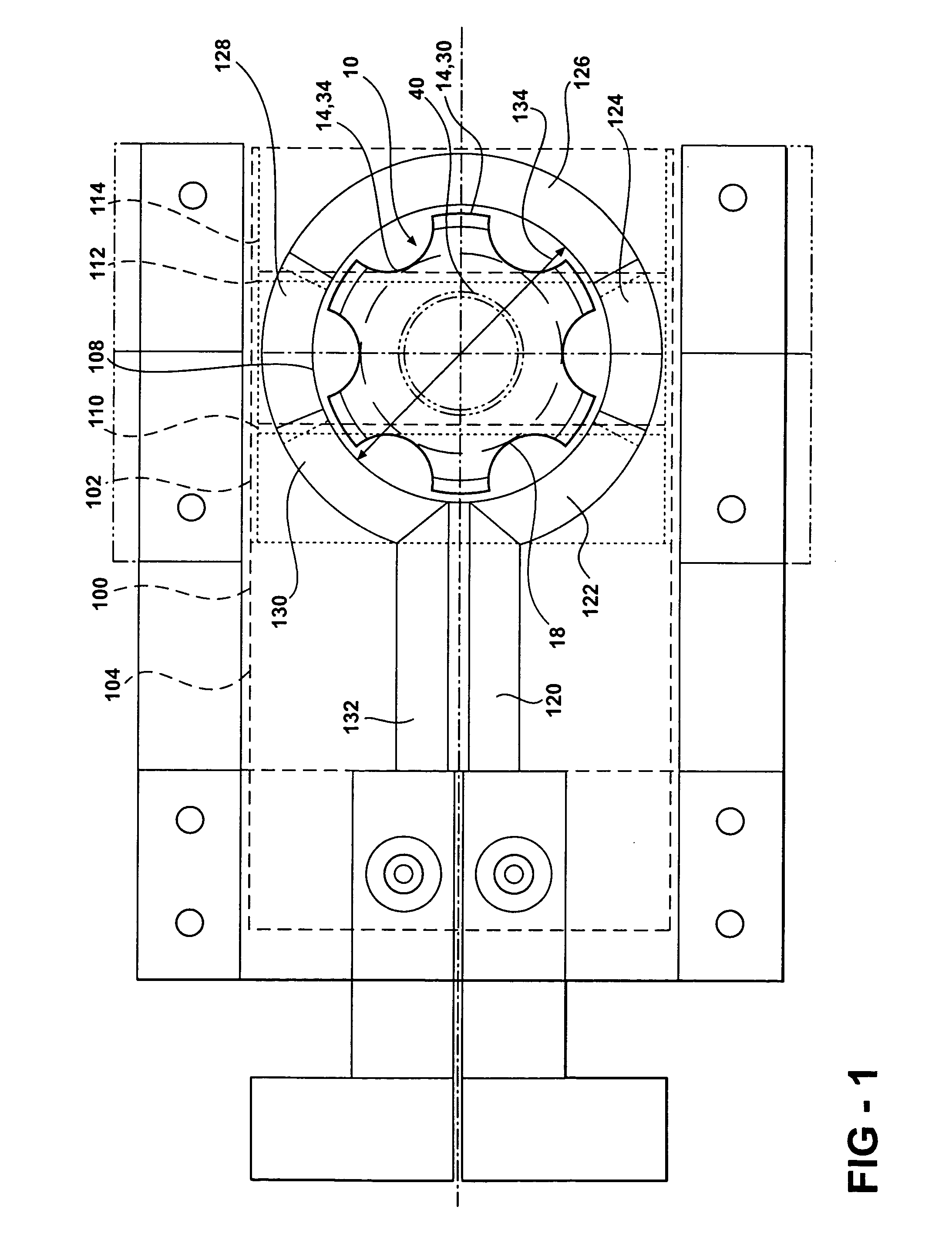

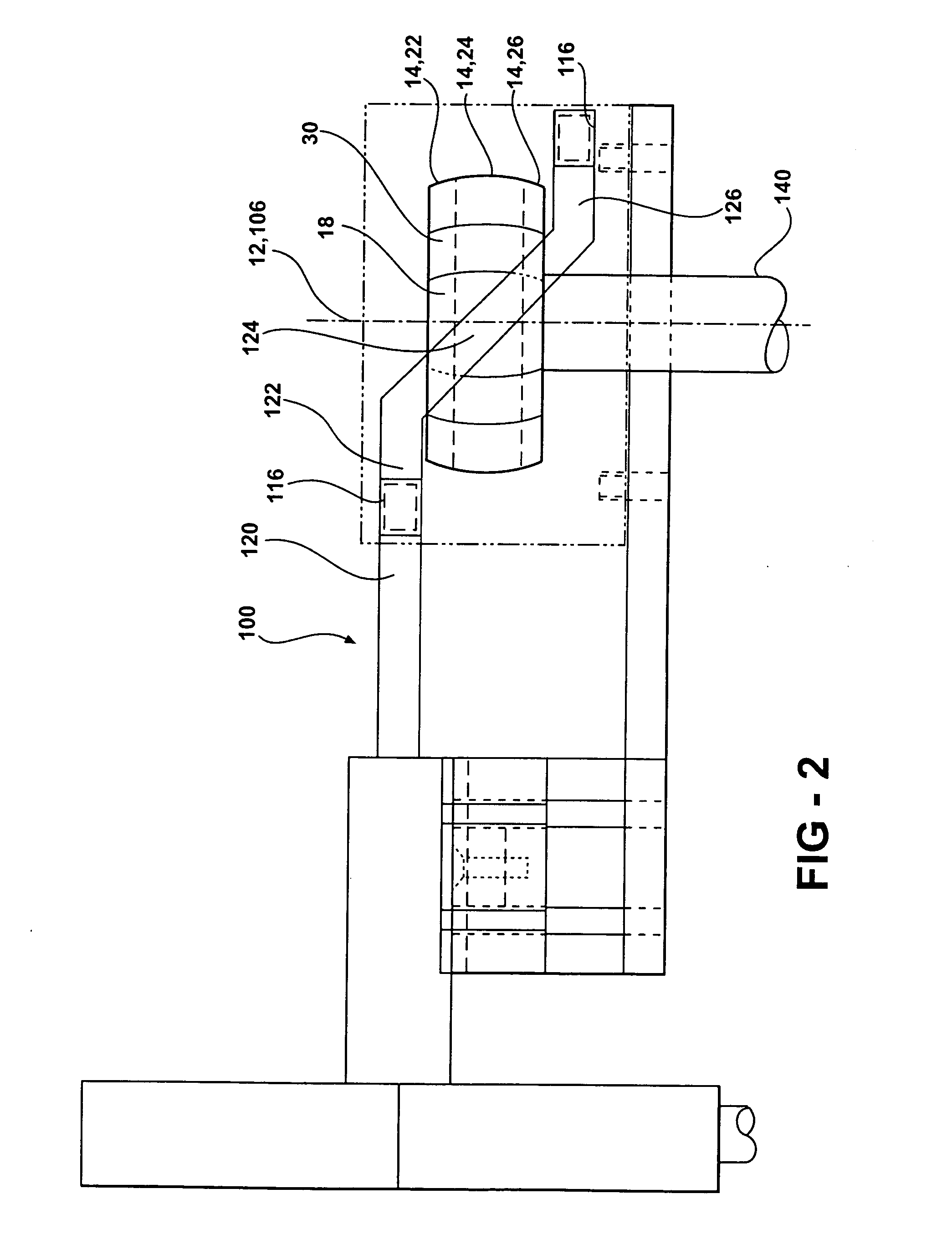

InactiveUS6153865AImproved induction hardening apparatusCoil arrangementsInduction heating apparatusInduction hardeningWorkstation

An induction hardening apparatus for inductively heating and quench hardening a crankshaft includes an arrangement of two workstations similarly configured and a robotic device indexing the crankshaft from a first workstation to a second workstation. The induction hardening apparatus is designed with a single induction coil located at the first workstation for the sequential induction heating and quench hardening of the pins of the crankshaft. At the second workstation, a single induction coil is used for the bearing surfaces of the crankshaft. One feature of the present invention is that the induction coils do not contact the surfaces of the crankshaft which are being inductively heated and quench hardened. Crankshaft dimensions and geometry are prograrmned into servodrive systems which move the corresponding coil in X and Y directions accurately tracing the orbit or path of each pin and each bearing surface. Another feature of the present invention is the use of an offset 180 degree coil which provides improved heating patterns in less time than traditional 90 degree coils.

Owner:CONTOUR HARDENING

Composite microalloyed large-section non-quenched and tempered steel

ActiveCN102199731AHigh strengthImprove fatigue strengthTemperature control deviceMetal rolling arrangementsInduction hardeningUltimate tensile strength

The invention discloses composite microalloyed large-section non-quenched and tempered steel, specifically relates to large-section rolled non-quenched and tempered steel used for a half shaft of an automobile and non-quenched and tempered steel used for a half shaft of an engineering machinery. On one hand, the strength of the large-section non-quenched and tempered steel is increased through increasing C content, and on the other hand, grains are further refined through adding microalloy elements such as Nb, V and Ti, thus maintaining certain toughness while improving strength; in addition,the fatigue strength of the half shaft is improved through employing an induction hardening method, and the hardenability of steel is improved through adding B. The invention effectively solves the use strength requirement of the large-section non-quenched and tempered steel half shaft, guarantees the fatigue life of the half shaft, improves the performance of the half shaft, lowers the cost of the half shafts, saves energy and reduces heat treatment deformation.

Owner:HENAN SUDA ELECTRIC AUTOMOBILE TECH

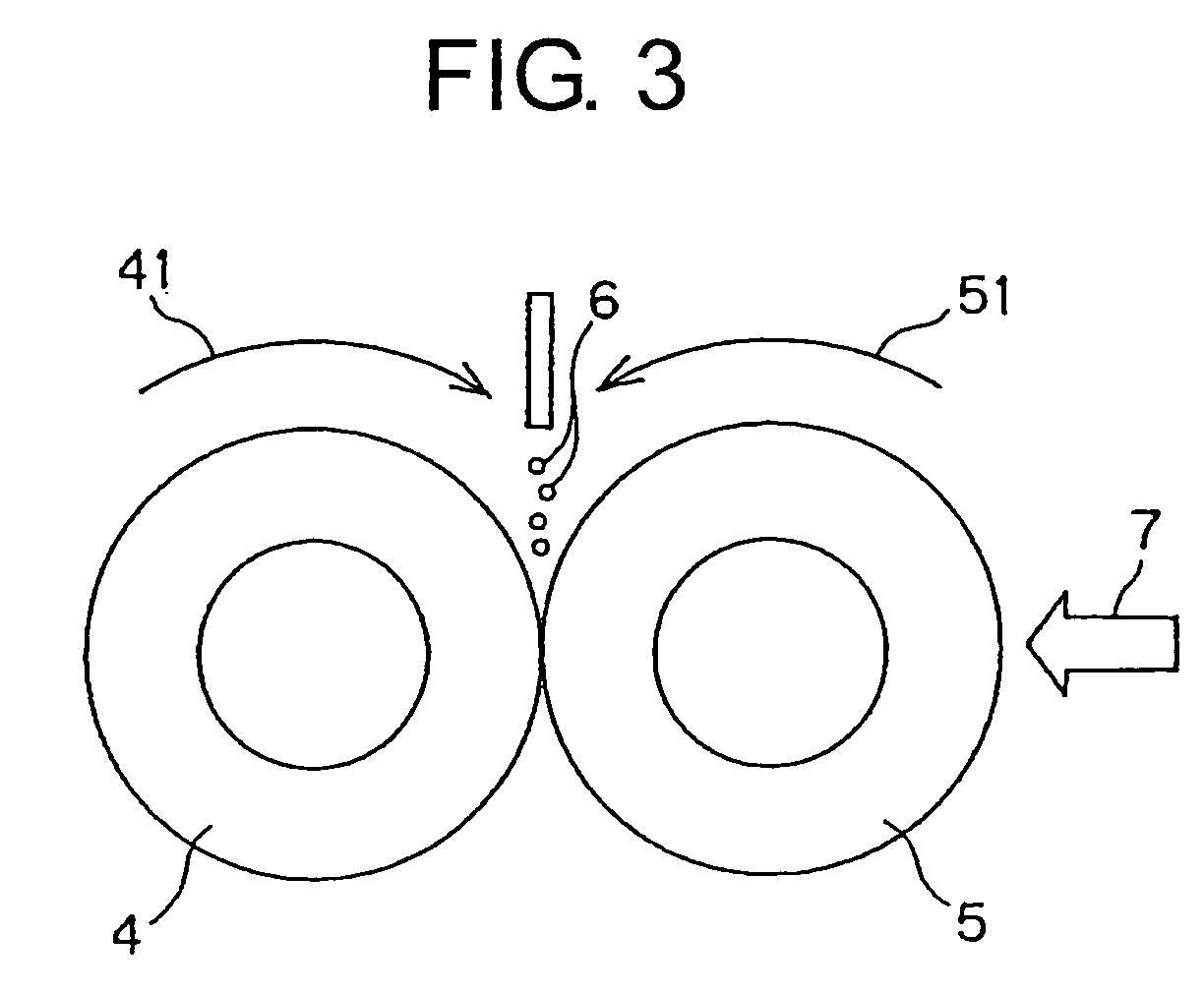

Process of and device for induction-hardening helical springs

InactiveUS20080128057A1Reducing any interfering factorsFurnaces without endless coreIncreasing energy efficiencyCoil springInduction hardening

A process of induction-heating helical springs, more particularly valve springs, for the purpose of carrying out subsequent hardening by quenching and tempering, wherein the helical springs, while being individually fixed and rotatingly driven, are guided through an electro-magnetic alternating field.

Owner:MUHR UND BENNDER KG

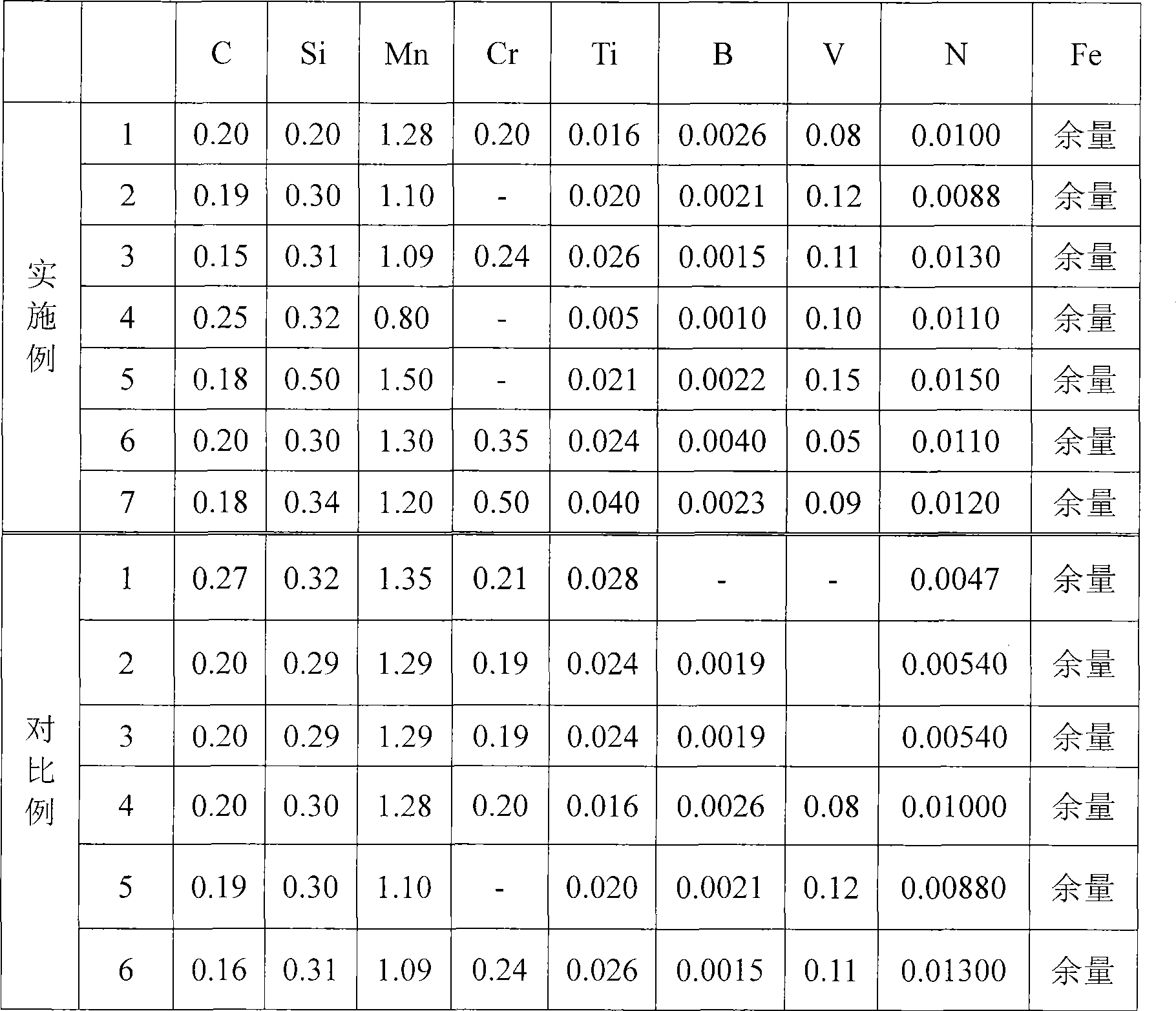

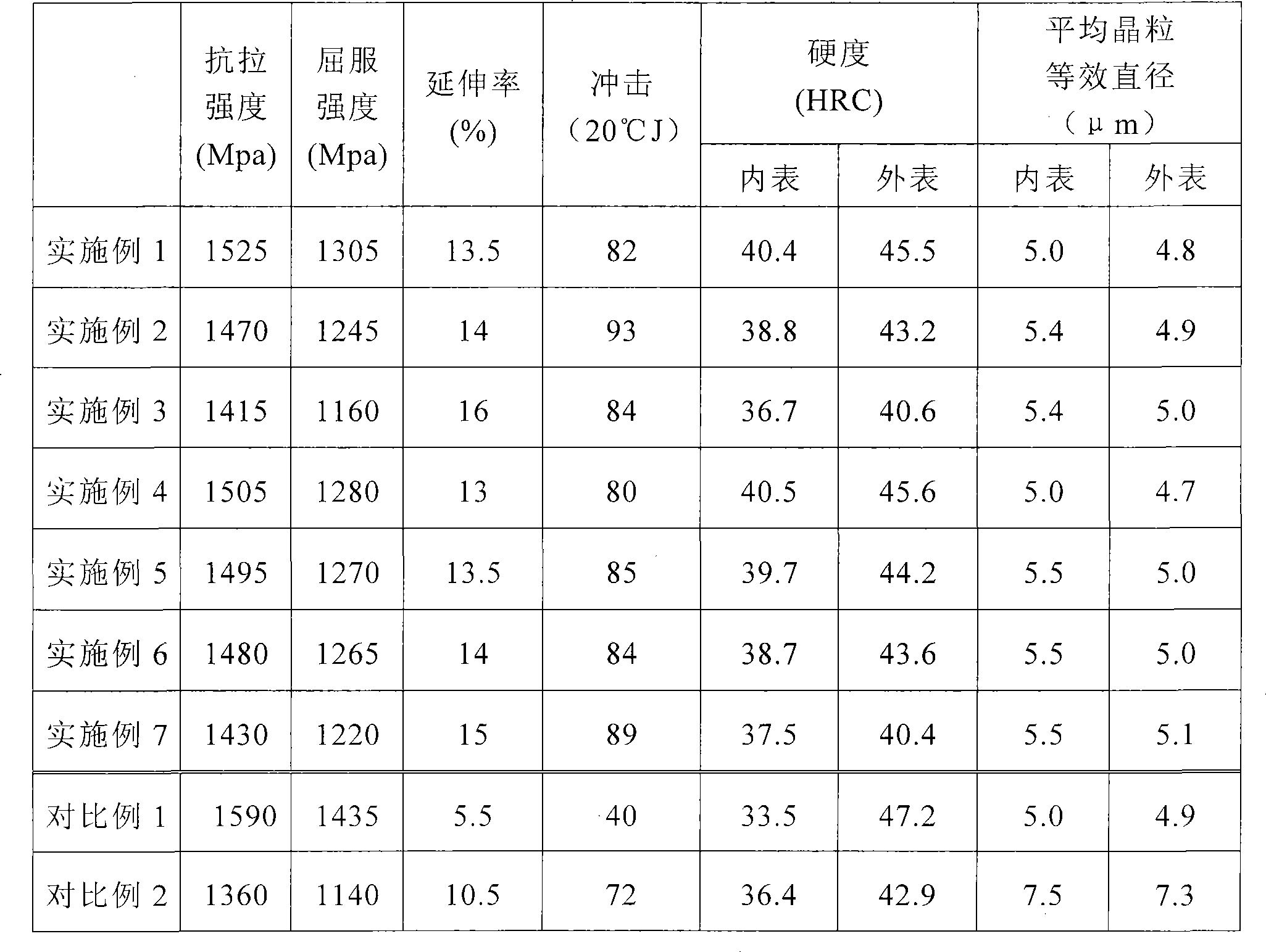

High strength anti-collision pipe for automobile and method of manufacturing the same

ActiveCN101497960AUniform ultrafine grain structureImprove toughnessFurnace typesBumpersInduction hardeningImpurity

The invention relates to a high-strength anti-collision tube used for a car and a manufacturing method thereof, wherein a. the high-strength anti-collision tube comprises the chemical compositions according to percentages by weights of 0.15-0.25 percent of C, 0. 8-1.5 percent of Mn, 0.2-0.5 percent of Si, 0.01-0.04 percent of Ti, 0.001-0.004 percent of B, 0.05-0.15 percent of V, more than 0.008 percent and less than or equal to 0.015 percent of N, and the rest of Fe and unavoidable impurities; b. the manufacturing method comprises the following steps: the chemical compositions are smelted and cast into a steel ingot; c. a steel tube is made by a process of punching plus cold rolling or cold drawing; d. the heat treatment of the processes of normalizing, high-frequency induction hardening and annealing is carried out for the steel tube, wherein the normalizing temperature is 800-900 DEG C, and the normalizing heat-insulation time is 10-40 minutes; the high-frequency induction hardening and heating time is 2-4 seconds, and the hardening and heating temperature is 900-950 DEG C; the annealing temperature is 150-250 DEG C, and the heat insulation time is 0.5-4 hours. The invention can produce the car anti-collision tube with the maximum wall thickness of 2.5mm, not only ensures that the high-frequency induction heating is even, but also fully restricts grains to grow and has the advantages of even superfine crystal organizations, ultrahigh strength, good tenacity, and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

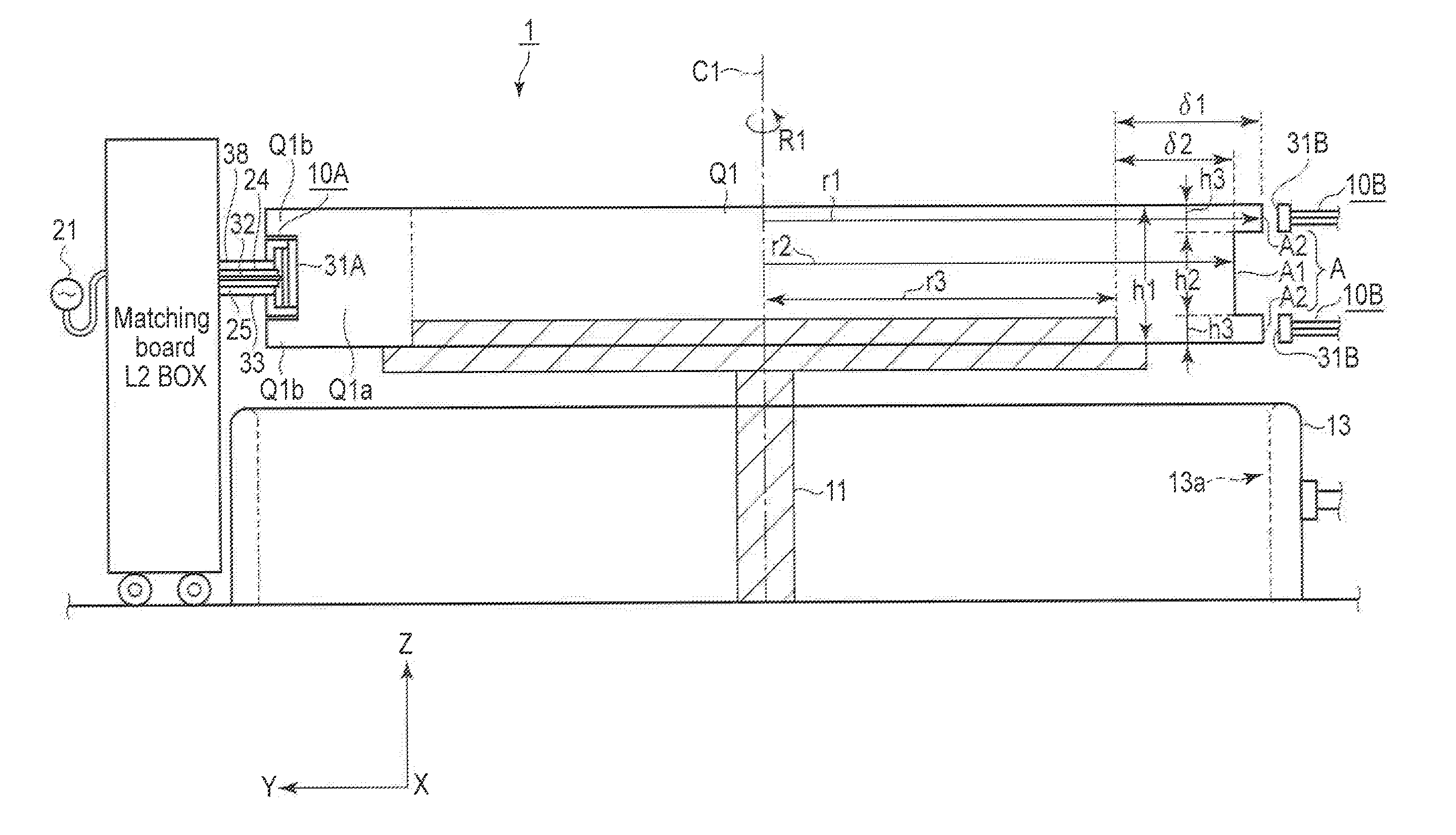

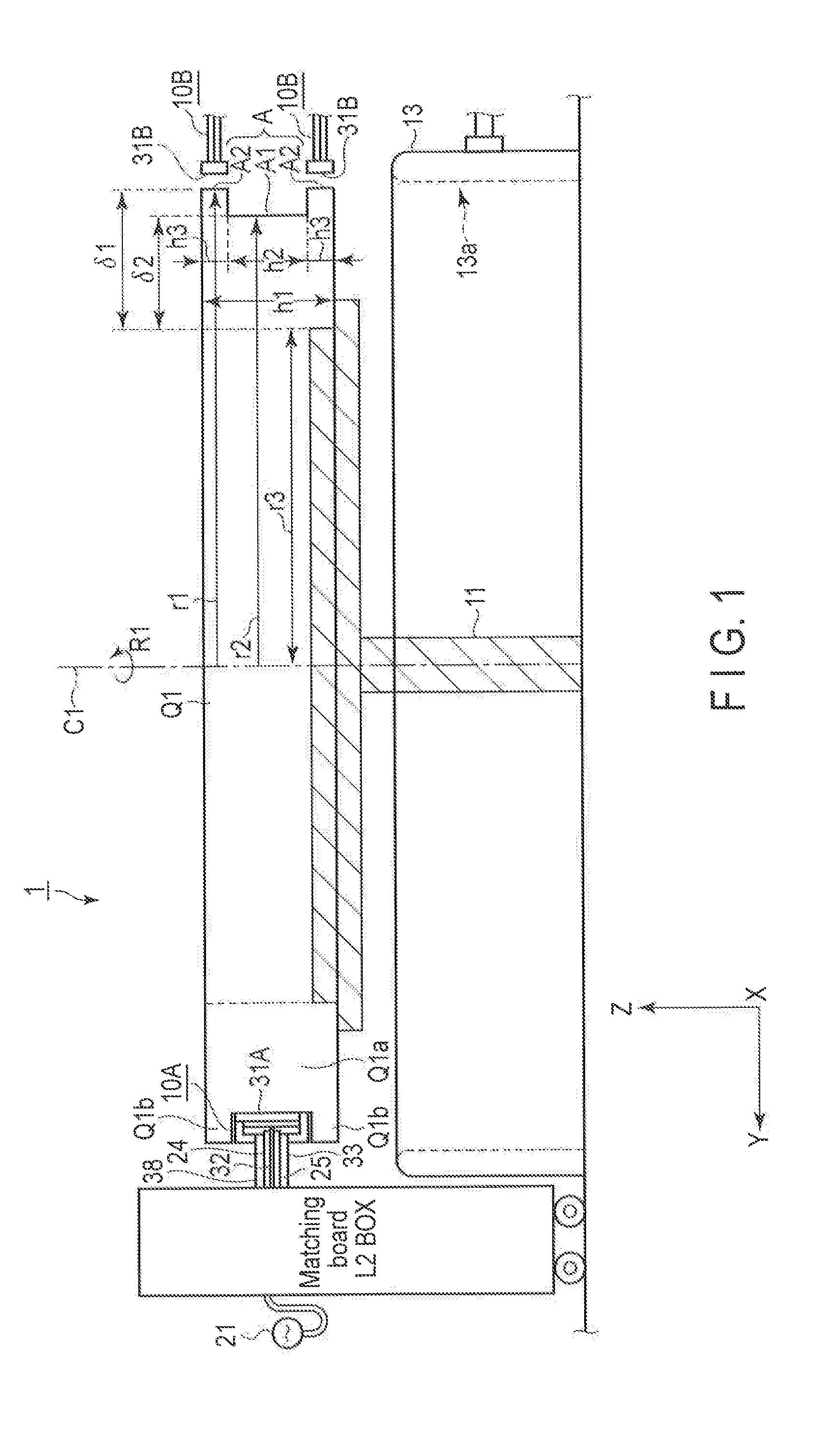

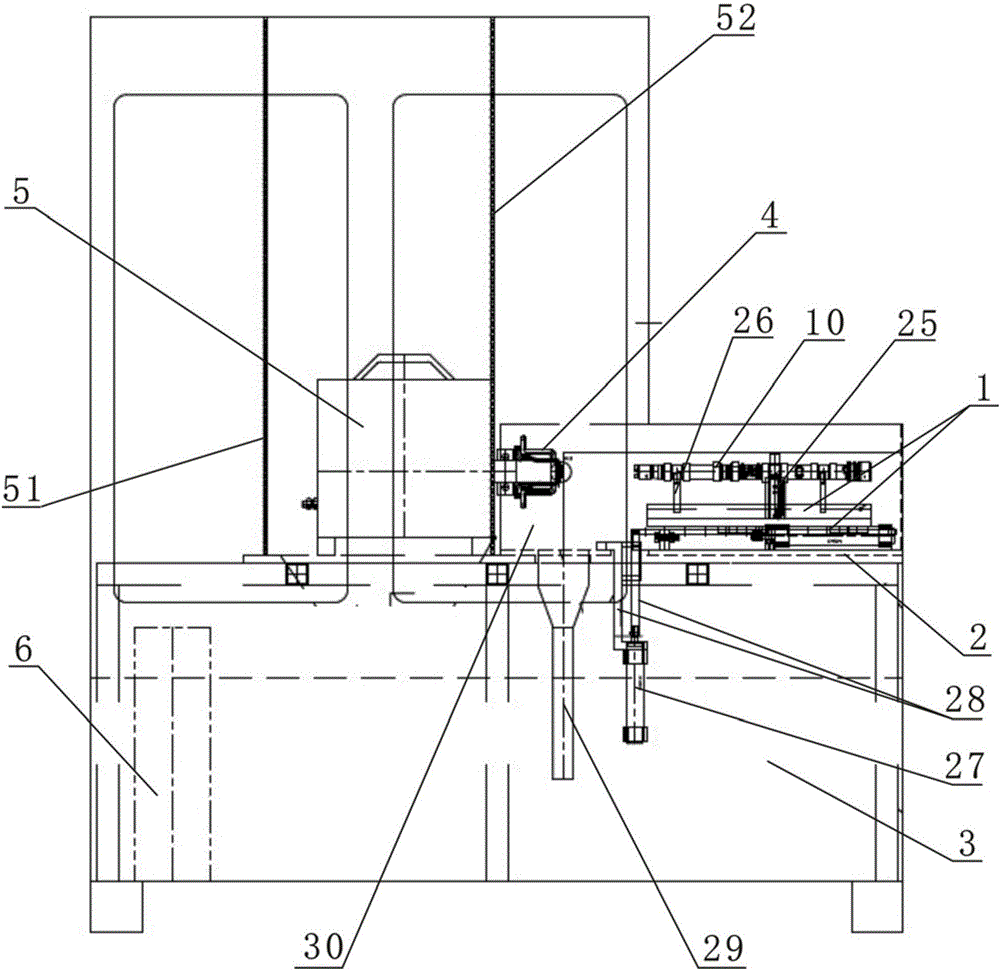

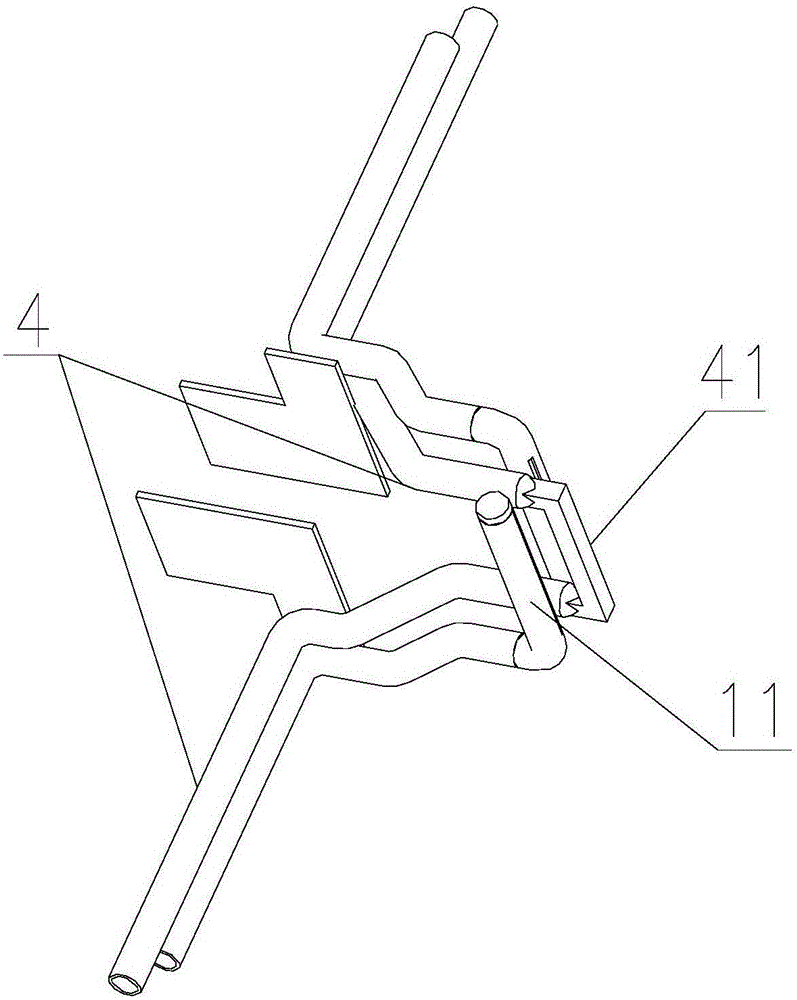

Induction hardening apparatus, induction hardening method, induction heating coil, heat treatment apparatus, and heat treatment method

ActiveUS20120125919A1Easily realizedUnified processingCoil arrangementsFurnace typesElectrical conductorInduction hardening

According to an embodiment, an induction heating coil includes a heating conductor portion which is formed of a conductor member and has a zigzag shape in which a bent portion opened to one side in a first direction and a bent portion opened to the other side in the first direction are alternately continuously arranged in opposite directions along a second direction crossing the first direction.

Owner:NETUREN CO LTD

Steel parts for machine structure, material therefor, and method for manufacture thereof

Steel parts for a machine structure which have a chemical composition in mass % that C: 0.3 to 0.7 %, Si: 0.3 % or less, Mn: 0.2 to 2.0 %, Al: 0.005 to 0.25%, Ti: 0.005 to 0.1 %, Mo: 0.05 to 0.6 %, B: 0.0003 to 0.006 %, S: 0.06 % or less, P: 0.020 % or less, O: 0.0030 % or less and the balance: Fe and inevitable impurities, has a hardened layer formed by induction hardening at least on a part of the surface thereof, wherein the hardened layer has an average old austenite grain diameter of 7 mum or less and it has non-metal inclusions comprising an oxide having a maximum diameter of 15 mum. The above parts exhibit excellent fatigue strength, and thus are suitable for a drive shaft, a constant-velocity universal joint, and the like.

Owner:JFE STEEL CORP

Hot roll for rolling titanium plate and manufacturing method of hot roll

The invention discloses a hot roll for rolling a titanium plate, and a manufacturing method of the hot roll. The hot roll comprises the following chemical constituents in percentage by weight: 0.30-0.50% of C, 0.60-2.00% of Si, 0.20-1.00% of Mn, 4.50-6.00% of Cr, 0.05-0.65% of Ni, 1.00-2.00% of Mo, 0.50-1.50% of V, less than or equal to 0.025% of P, less than or equal to 0.020% of S, and the balance of Fe and unavoidable impurities. The manufacturing method of the hot roll for rolling the titanium plate comprises the processing steps of steel ingot refining, roll blank forging, thermal refining, induction quenching treatment, tempering treatment and the like. Compared with the traditional hot roll made of a Cr3 material, the hot roll is good in abrasive resistance, corrosion resistance and thermal crack resistance, and the service life of the hot roll can be prolonged by above 70%.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Asymmetrical multi-subdivision bearing and manufacture process thereof

InactiveCN101709741ASolve processabilitySolve shipping problemsBall bearingsBearing componentsState of artEngineering

The invention relates to the field of large-size pivoting support products, in particular to an asymmetrical multi-subdivision bearing and a manufacture process thereof. The asymmetrical multi-subdivision bearing is characterized in that an inner ring and an outer ring are of asymmetrical subdivision structures formed by connecting a plurality of sections of arc plates; the inner ring and the outer ring spliced by the arc plates respectively form closed round roller paths, and a retaining frame is arranged between the roller paths; rollers are uniformly and non-uniformly arranged on the retaining frame; and a rolling body drives the retaining frame to do rotary motions. The processing process of the inner ring, the outer ring and flanges comprises the following steps of: (1) forging and annealing; (2) carrying out machining, roll curving and stabilizing treatment; (3) tempering and shaping; (4) preliminarily working; (5) carrying out induction hardening on a working surface; and (6) finishing. Compared with the prior art, the invention effectively solves the problems of relevant links of processing, transport, assembly, maintenance, and the like of large-size bearings.

Owner:鞍山钢铁轴承有限公司

Quenching system and method applied to workpiece induction quenching

ActiveCN105734228AEasy to operateCompact structureIncreasing energy efficiencyFurnace typesTransformerLiquid water

The invention discloses a quenching system and method applied to workpiece induction quenching. The quenching system comprises a sliding component, a quenching bracket, a water receiving tank, an induction coil heating device, a transformer, a quenching liquid water tank, a cooling water tank and a refrigeration industrial air conditioner, wherein the induction coil heating device is electrically connected with the transformer; a quenching liquid spray pipe is arranged on the sliding component; the water receiving tank is arranged below the quenching bracket; a submersible pump is arranged in the water receiving tank; the cooling water tank is mounted in the quenching liquid water tank; and a backflow copper pipe is mounted in a quenching liquid cooling work cavity below the cooling water tank. In the invention, induction quenching heating of a workpiece is realized through the induction coil heating device, the sliding component can perform sliding switch of the workpiece between two step positions of induction heating and quenching cooling, and the operation is more convenient and quicker; and moreover, high-temperature quenching liquid and high-temperature cooling water can be subjected to cooling heat exchange treatment at the same time, a refrigeration industrial air conditioner and a set of cooling system are shared, and therefore, the equipment is compact in structure and convenient to mount on a production line.

Owner:MIANYANG BRILLIANCE RUIAN AUTOMOTIVE COMPONENTS

Ported engine cylinder liner with selectively laser-hardened and induction-hardened bore

Owner:ELECTRO-MOTIVE DIESEL

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com