Asymmetrical multi-subdivision bearing and manufacture process thereof

A manufacturing process, asymmetric technology, applied in the direction of ball bearings, bearing components, shafts and bearings, can solve the problems of blank and finished product processing and transportation inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

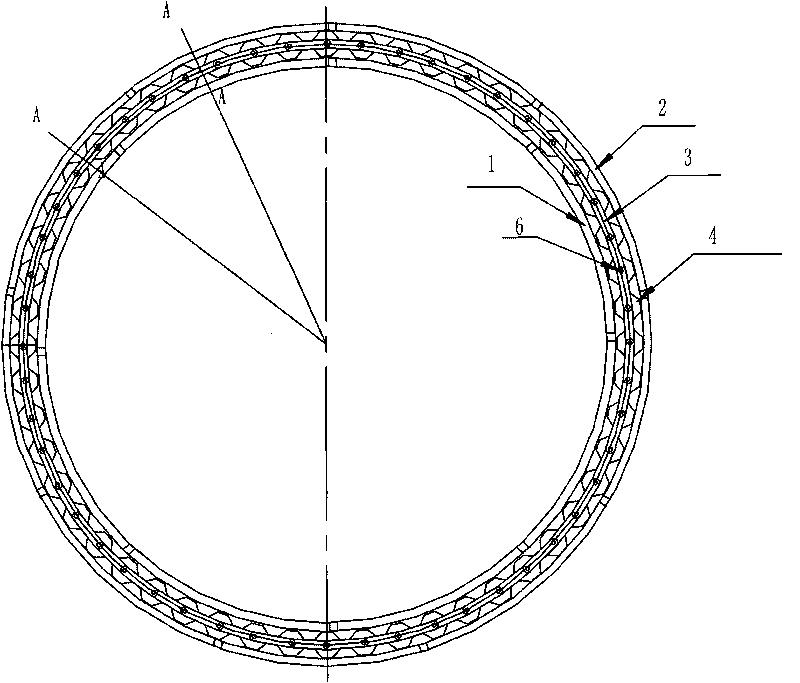

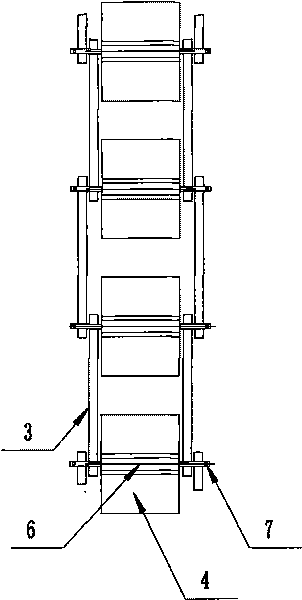

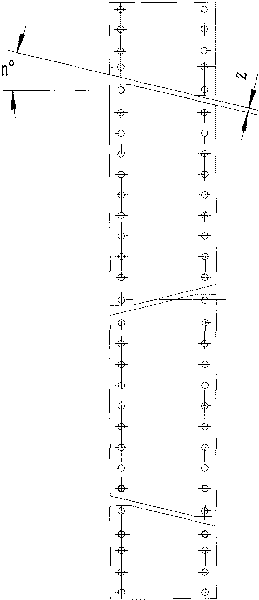

[0022] See figure 1 , figure 2 , image 3 , asymmetric multi-section bearings, composed of cages composed of inner ring 1, outer ring 2, rolling elements 4, chain plates 3, chain shafts 6 and pin shafts 7, rolling elements 4 between inner ring 1 and outer ring 2 Realize the rotation of large machinery and the transmission of radial load. See image 3 , the inner ring 1 and the outer ring 2 are subdivided structures formed by connecting multiple arc-shaped plates 5, and there is a gap of 1.5-0.1 mm between two adjacent arc-shaped plates, and the subdivision method is an asymmetric structure. There is an included angle of 6°~20° between the interface line and the center line of the bearing, which can ensure that the rolling element 4 rolls smoothly over the interface without impact and noise. Due to the angle of the interface, the asymmetric sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com