Steel parts for machine structure, material therefor, and method for manufacture thereof

A structural and mechanical technology, applied in the field of steel parts for mechanical construction, which can solve the problems of not fully meeting the latest requirements of fatigue strength

Inactive Publication Date: 2006-07-19

JFE STEEL CORP

View PDF2 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] However, as in the case above, the latest requirements for fatigue strength cannot be fully met by the above components

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0103] 100 kg each of No. 1-18 steels having the compositions shown in Table 1 were melted, and then forged under the hot working conditions shown in Table 2, thereby forming No. 1-22 bar-shaped steel materials with a diameter of 160 mm. In this step, the end temperature of the thermal processing is set to 700° C. or higher.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

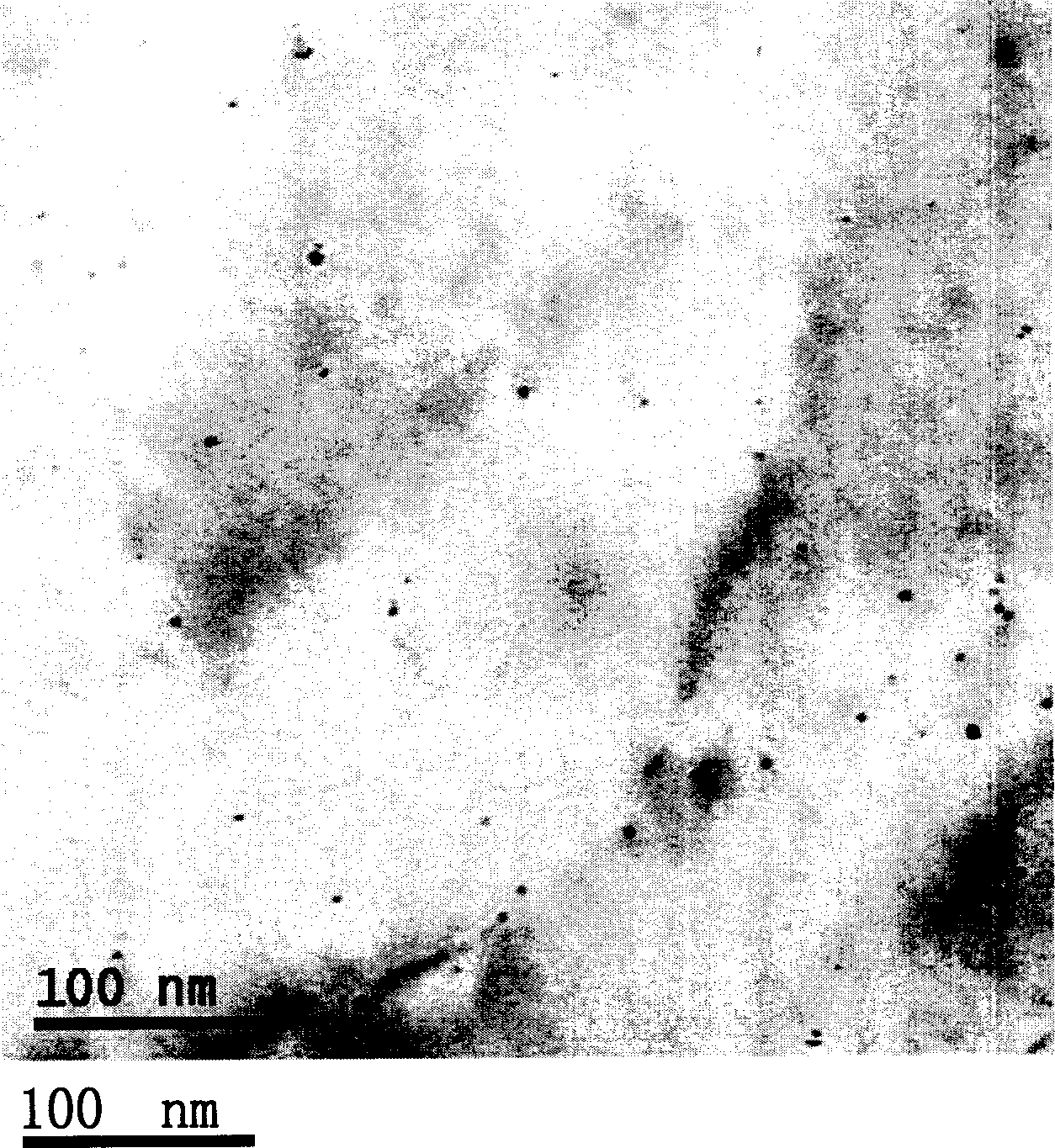

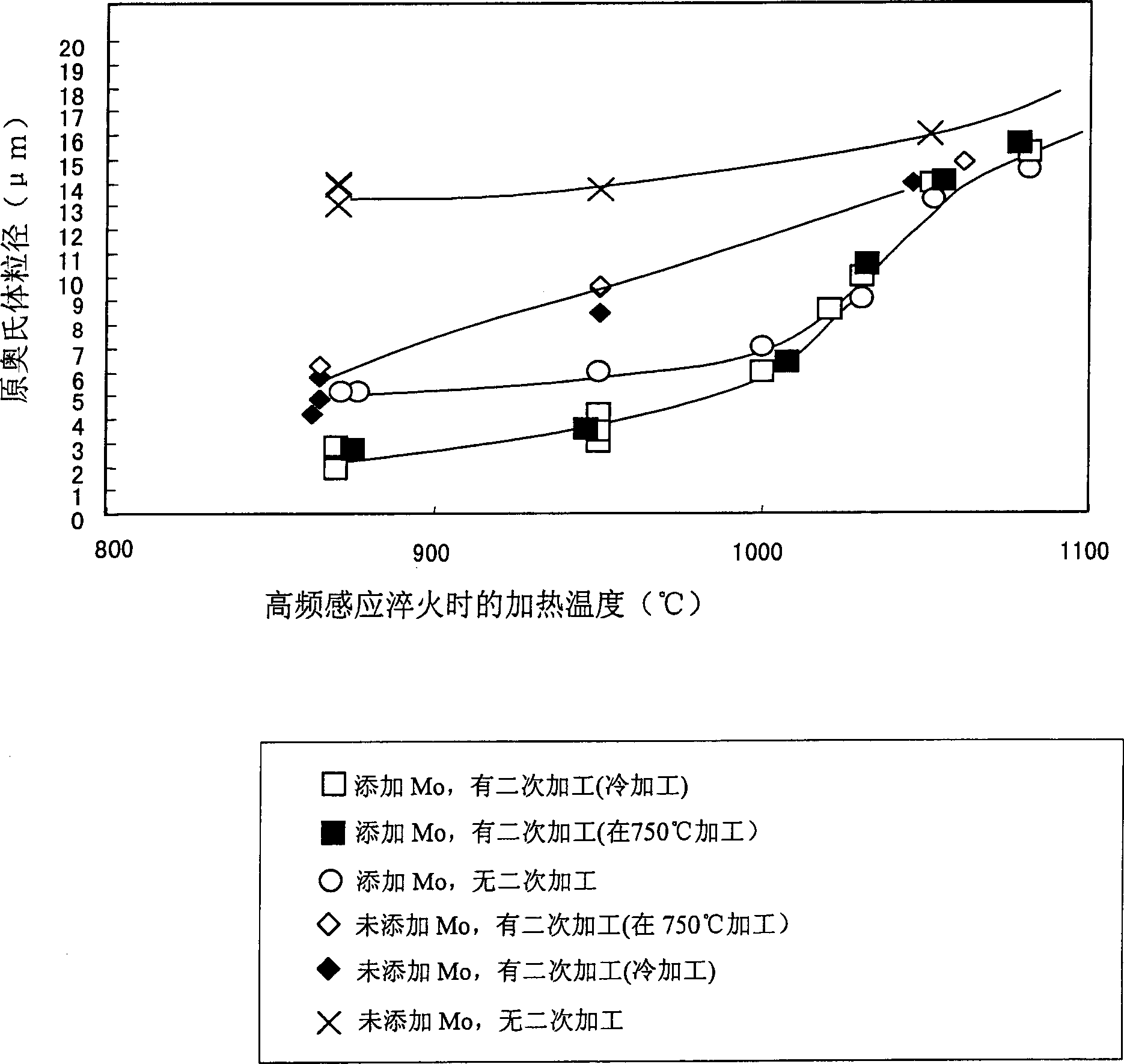

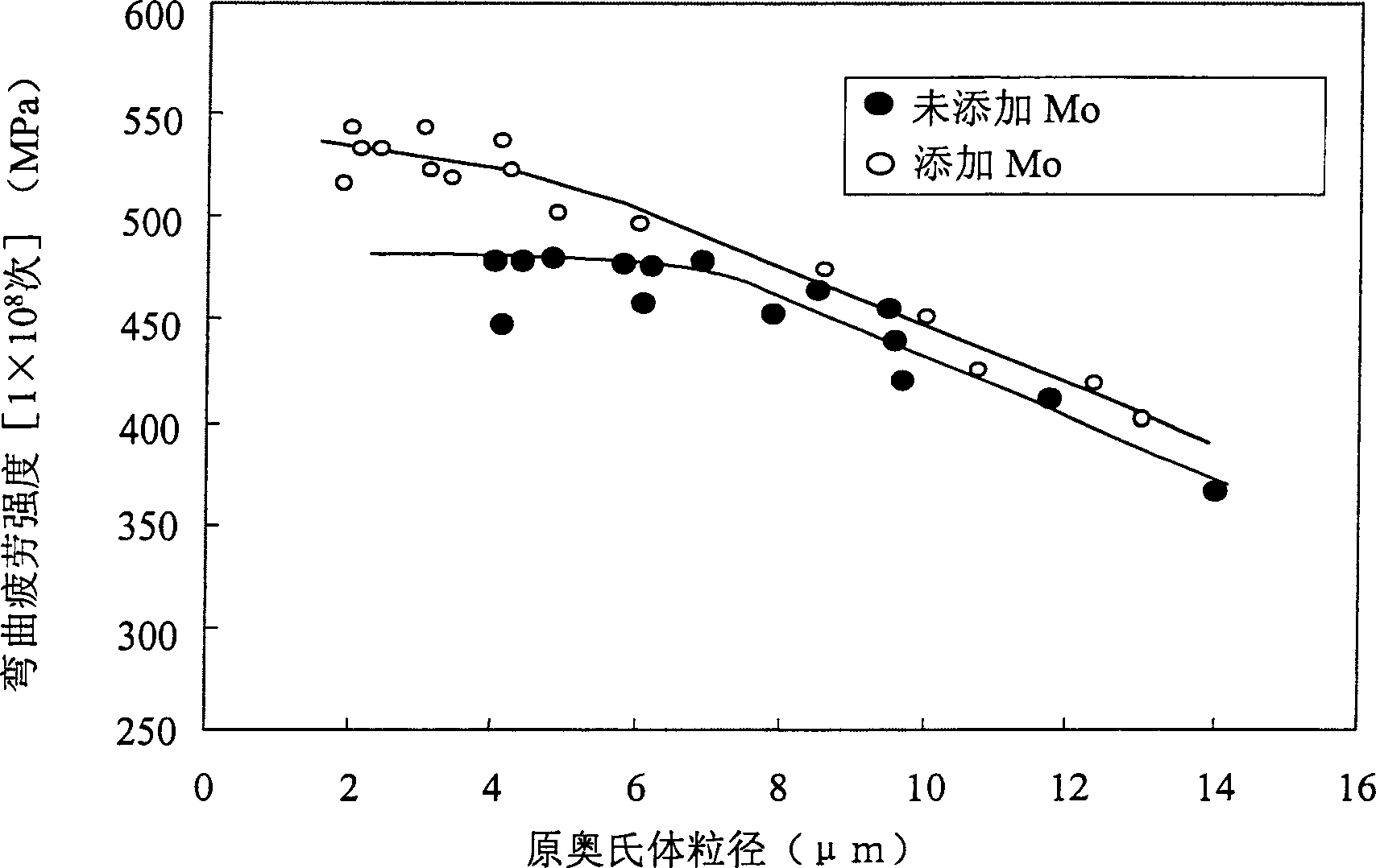

Steel parts for a machine structure which have a chemical composition in mass % that C: 0.3 to 0.7 %, Si: 0.3 % or less, Mn: 0.2 to 2.0 %, Al: 0.005 to 0.25%, Ti: 0.005 to 0.1 %, Mo: 0.05 to 0.6 %, B: 0.0003 to 0.006 %, S: 0.06 % or less, P: 0.020 % or less, O: 0.0030 % or less and the balance: Fe and inevitable impurities, has a hardened layer formed by induction hardening at least on a part of the surface thereof, wherein the hardened layer has an average old austenite grain diameter of 7 mum or less and it has non-metal inclusions comprising an oxide having a maximum diameter of 15 mum. The above parts exhibit excellent fatigue strength, and thus are suitable for a drive shaft, a constant-velocity universal joint, and the like.

Description

technical field [0001] The present invention relates to a steel part for mechanical construction, such as an automobile drive shaft or a constant velocity joint, which has a hardened layer formed on its surface by induction hardening, and to a raw material for the steel part and to the production of the steel part Manufacturing method. Background technique [0002] Hitherto, for parts for mechanical construction such as automobile drive shafts or constant velocity joints, hot-rolled steel bars were subjected to hot forging, cutting, cold forging, etc. Fatigue strength, such as torsional fatigue strength, bending fatigue strength, and sliding and rolling contact fatigue strength, which is an important performance of the machine structural member, is imparted to the above-treated member for machine structural use. [0003] In recent years, along with the increasing demand for reducing the weight of automobile parts due to environmental problems, further improvement in the fat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/00C21D8/00C21D9/28C21D1/10

CPCC22C38/14C21D9/28C22C38/02C22C38/12C22C38/04C22C38/08C21D1/10Y02P10/25

Inventor 林透大森靖浩黑泽伸隆松崎明博丰冈高明山田克美

Owner JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com