Patents

Literature

137 results about "Rolling contact fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High strength bainitic steel rail and heat treatment process thereof

ActiveCN103160736AImprove wear resistanceImprove impact toughnessFurnace typesHeat treatment furnacesImpurityHeat treated

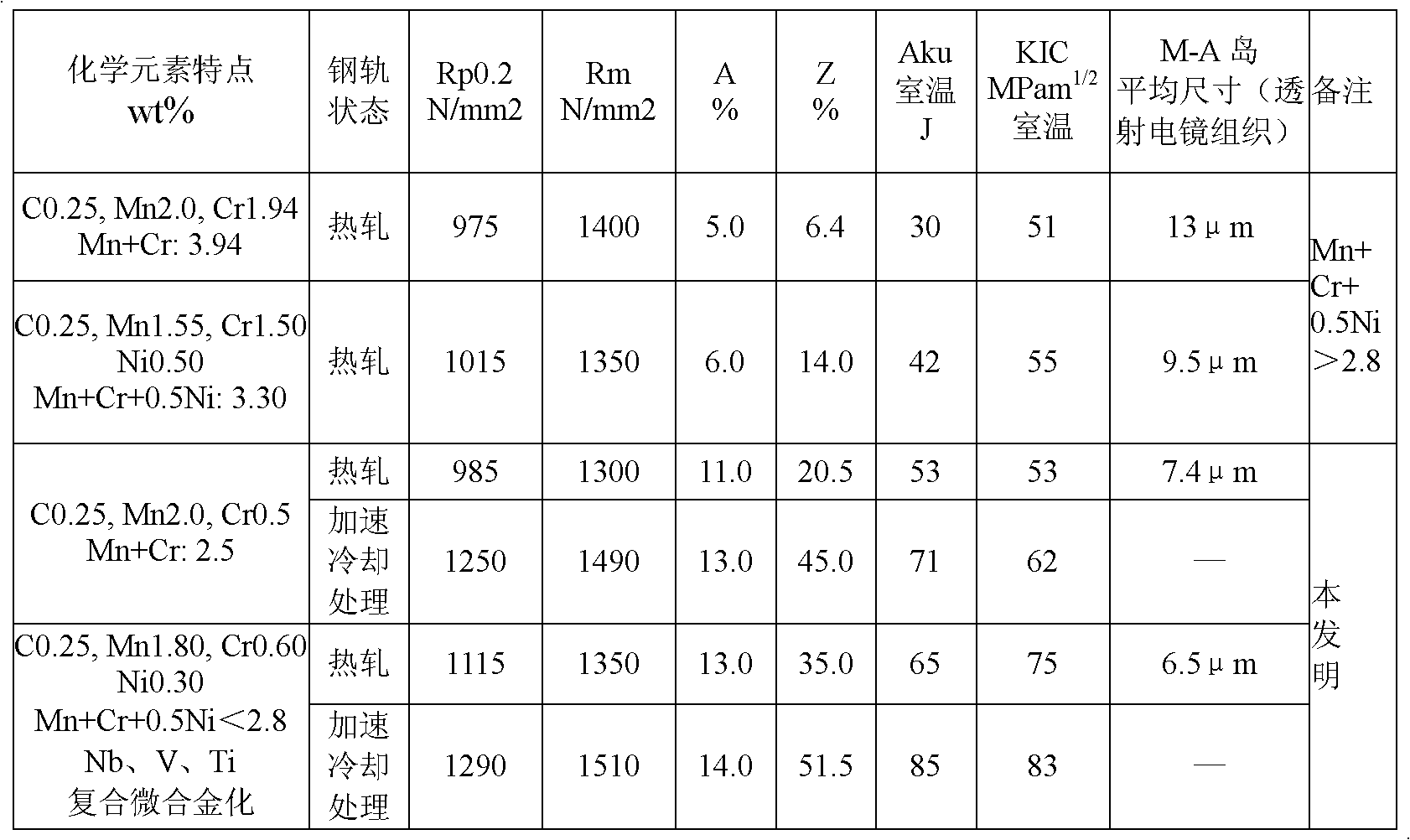

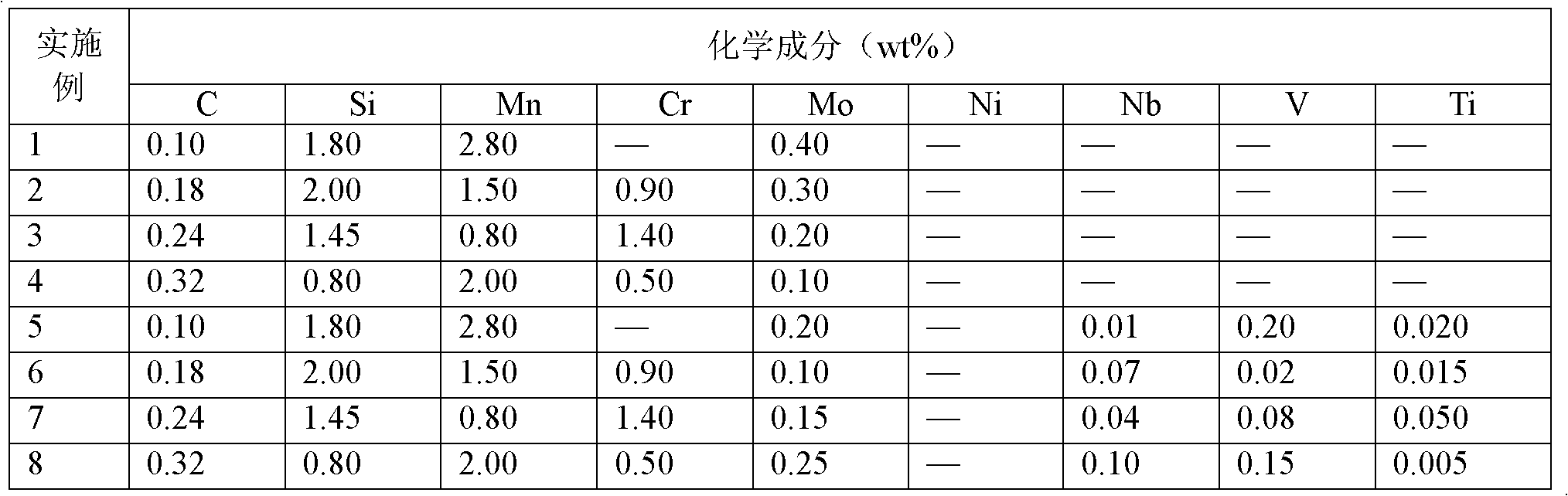

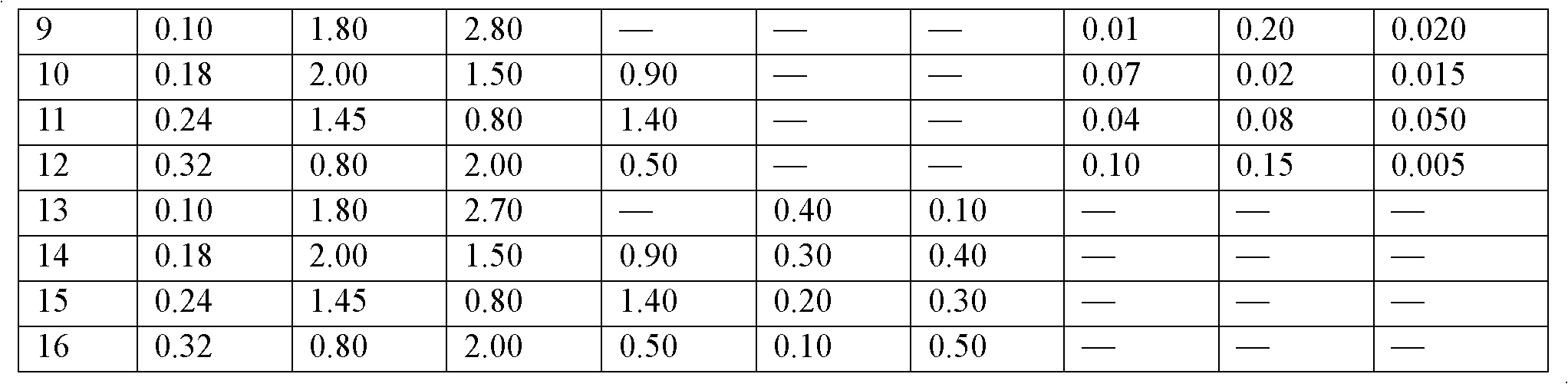

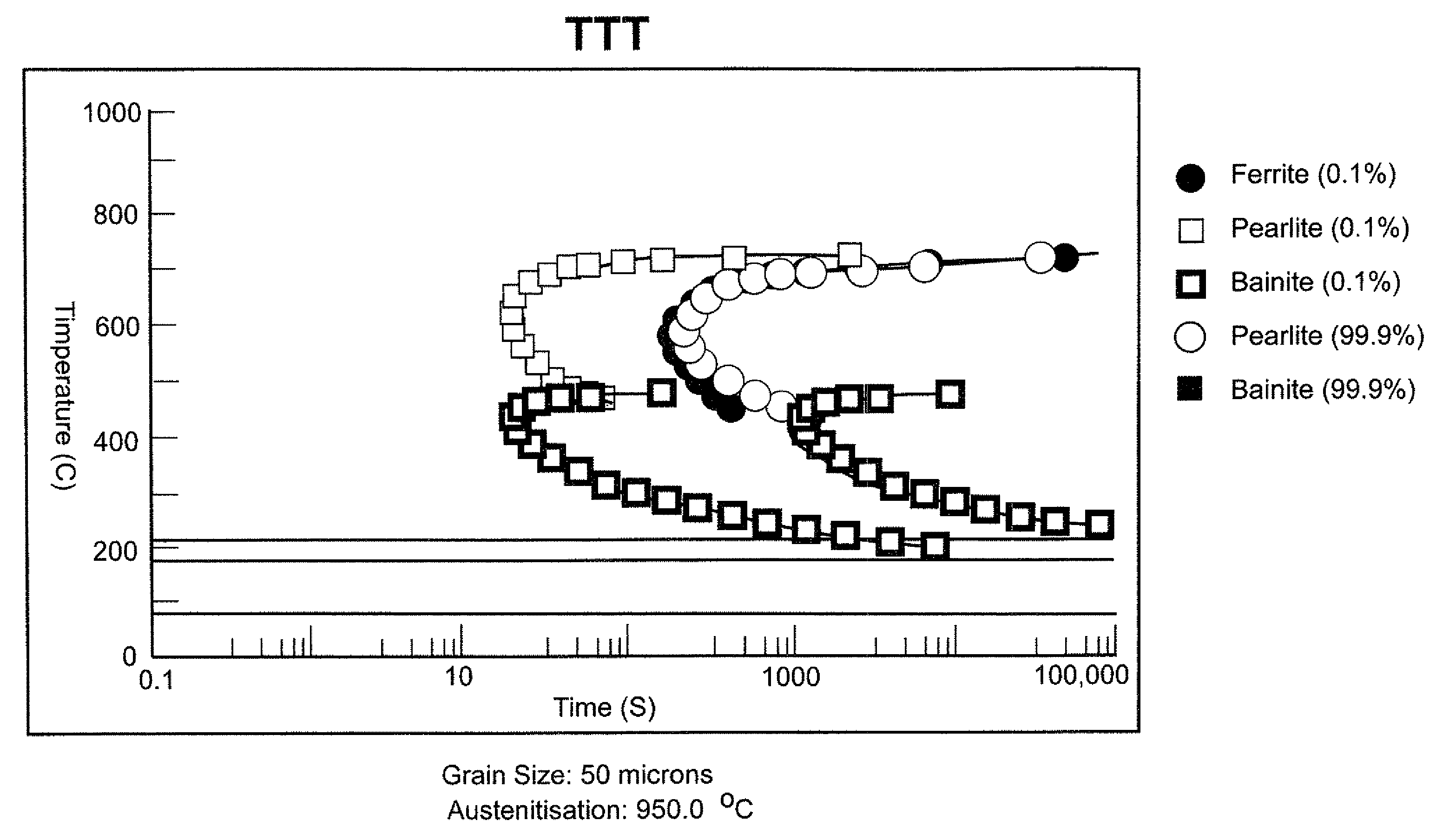

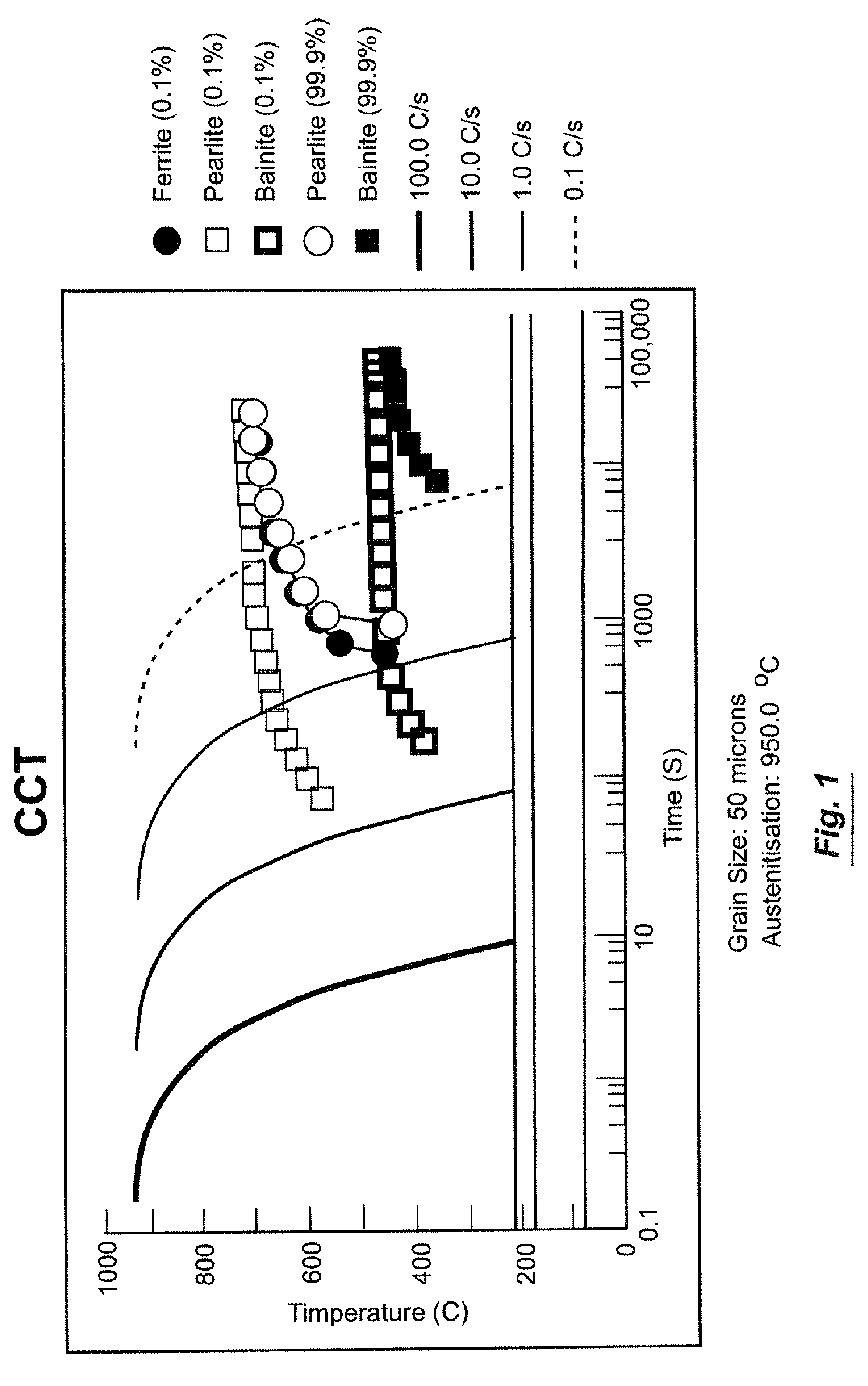

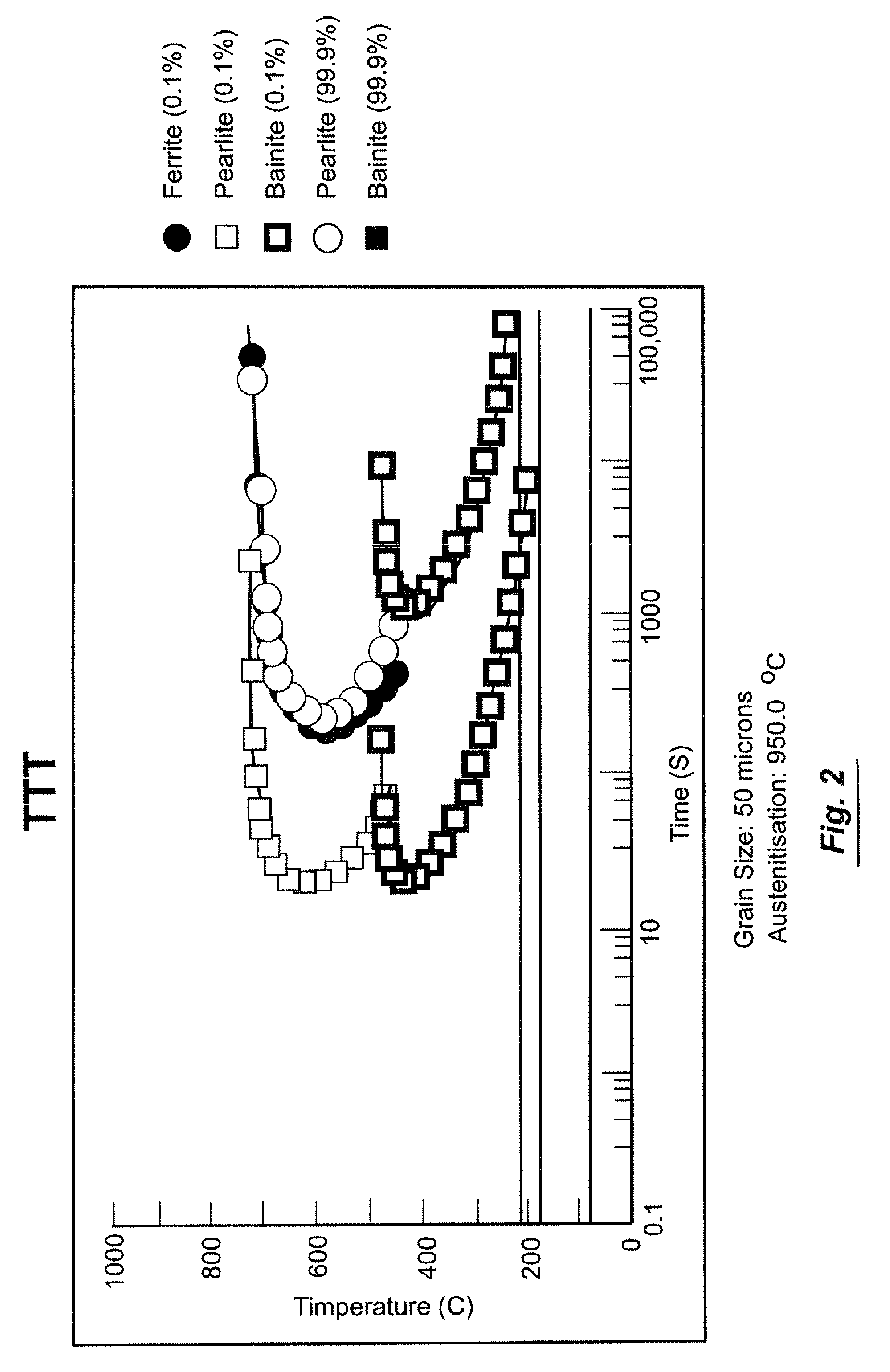

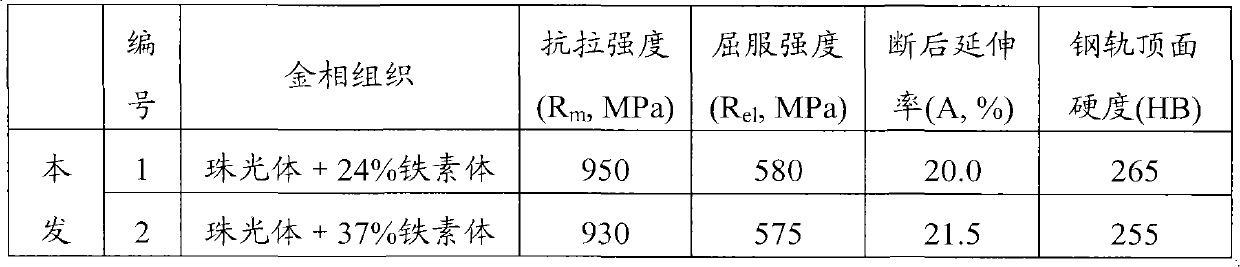

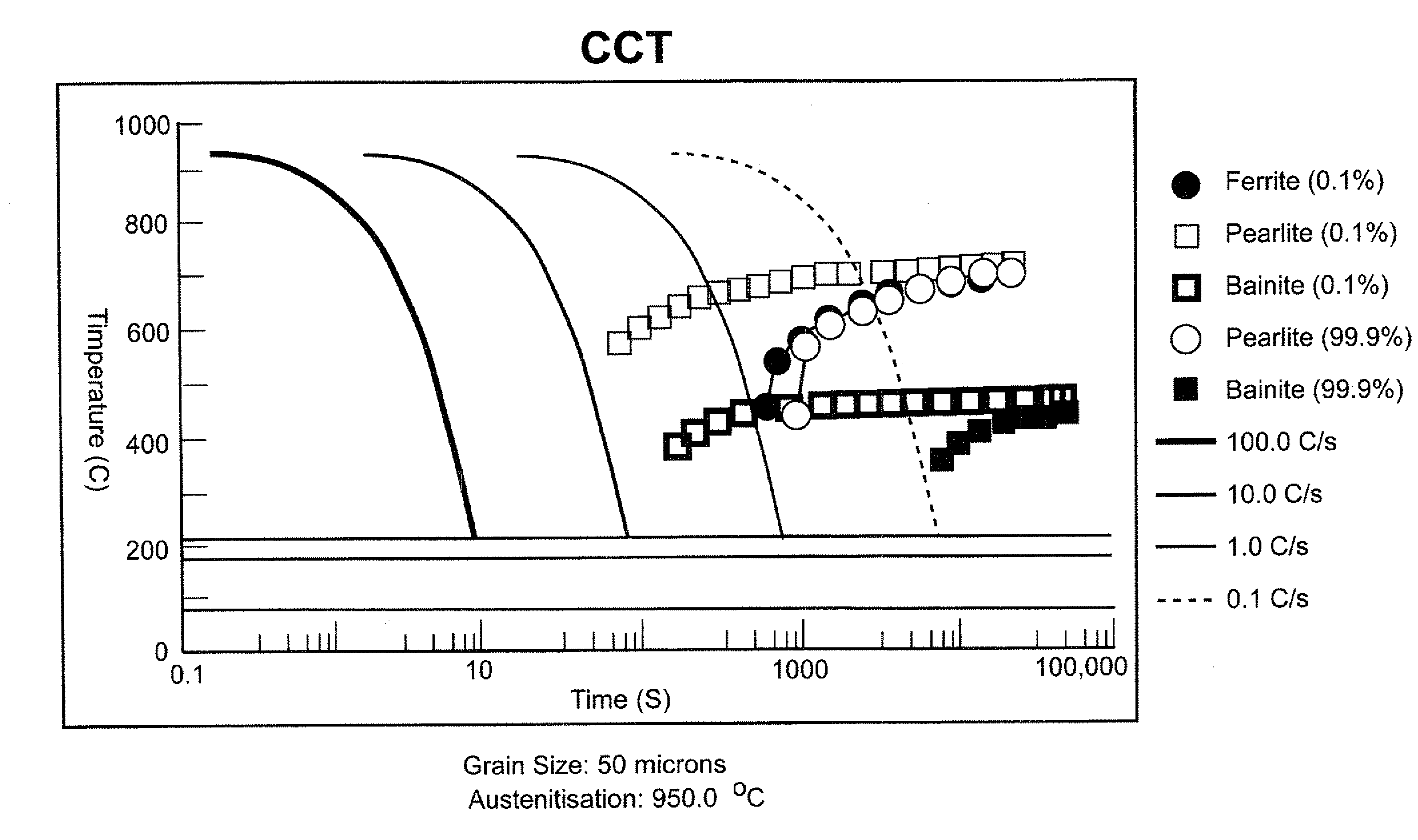

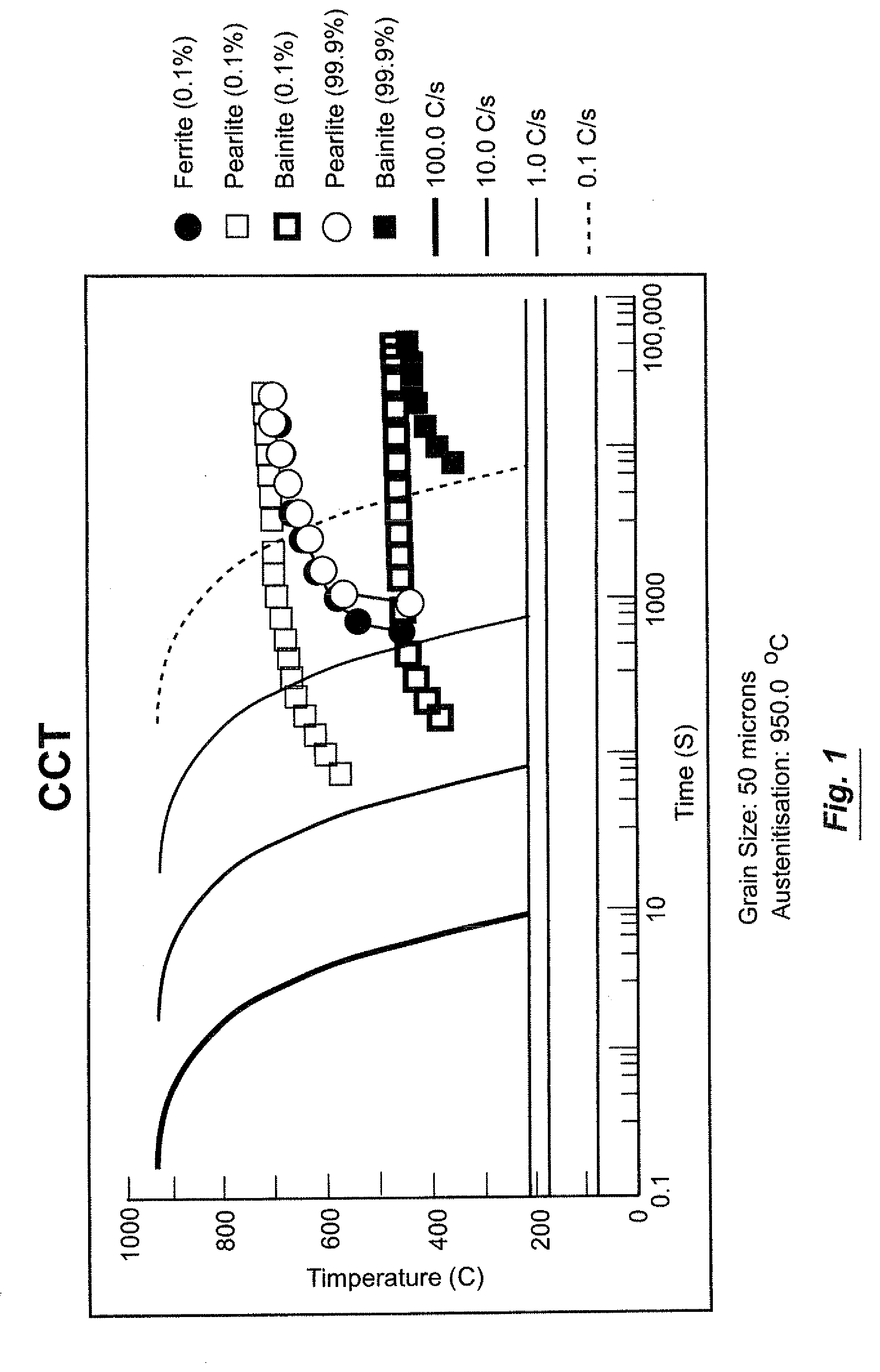

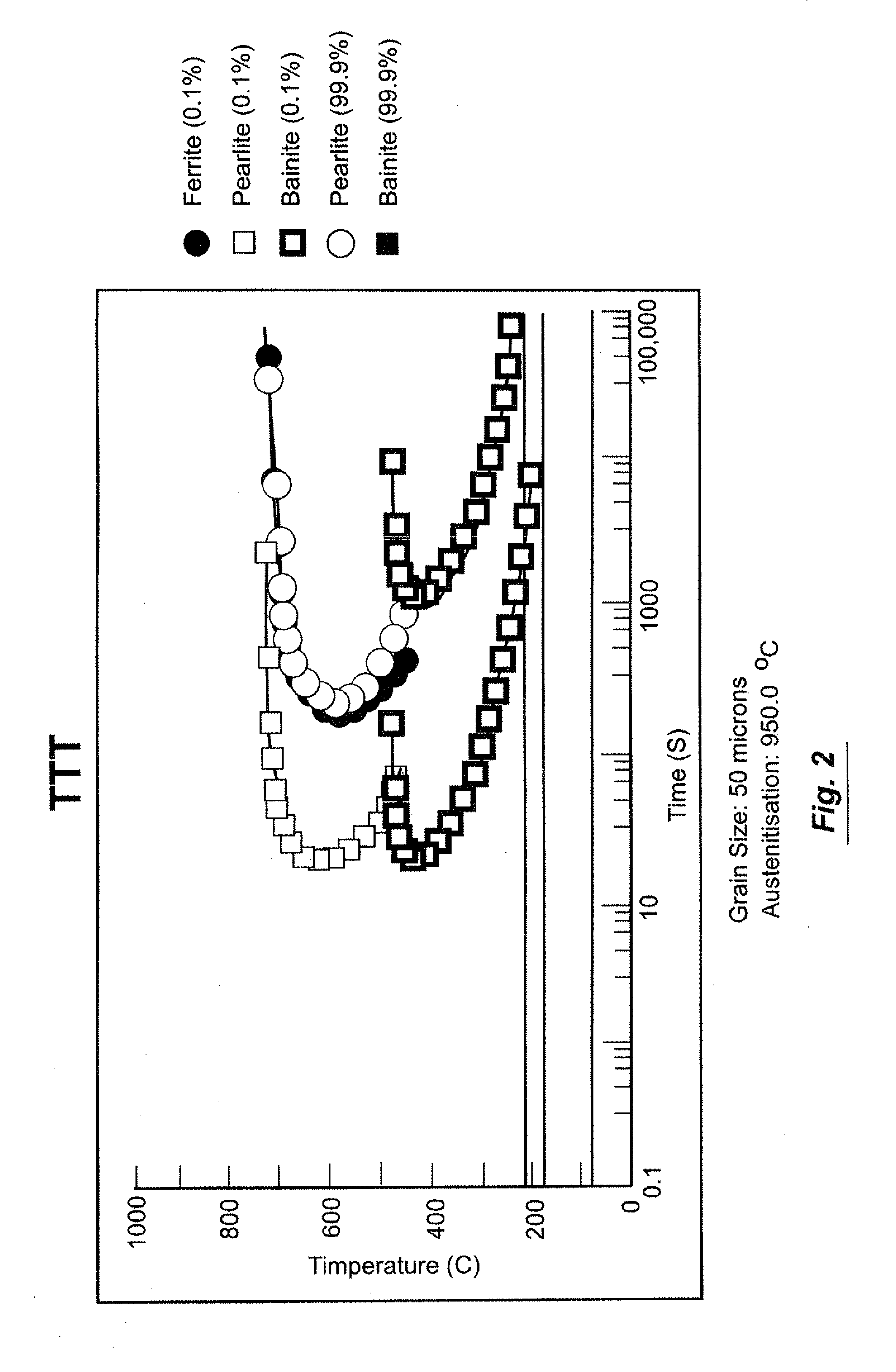

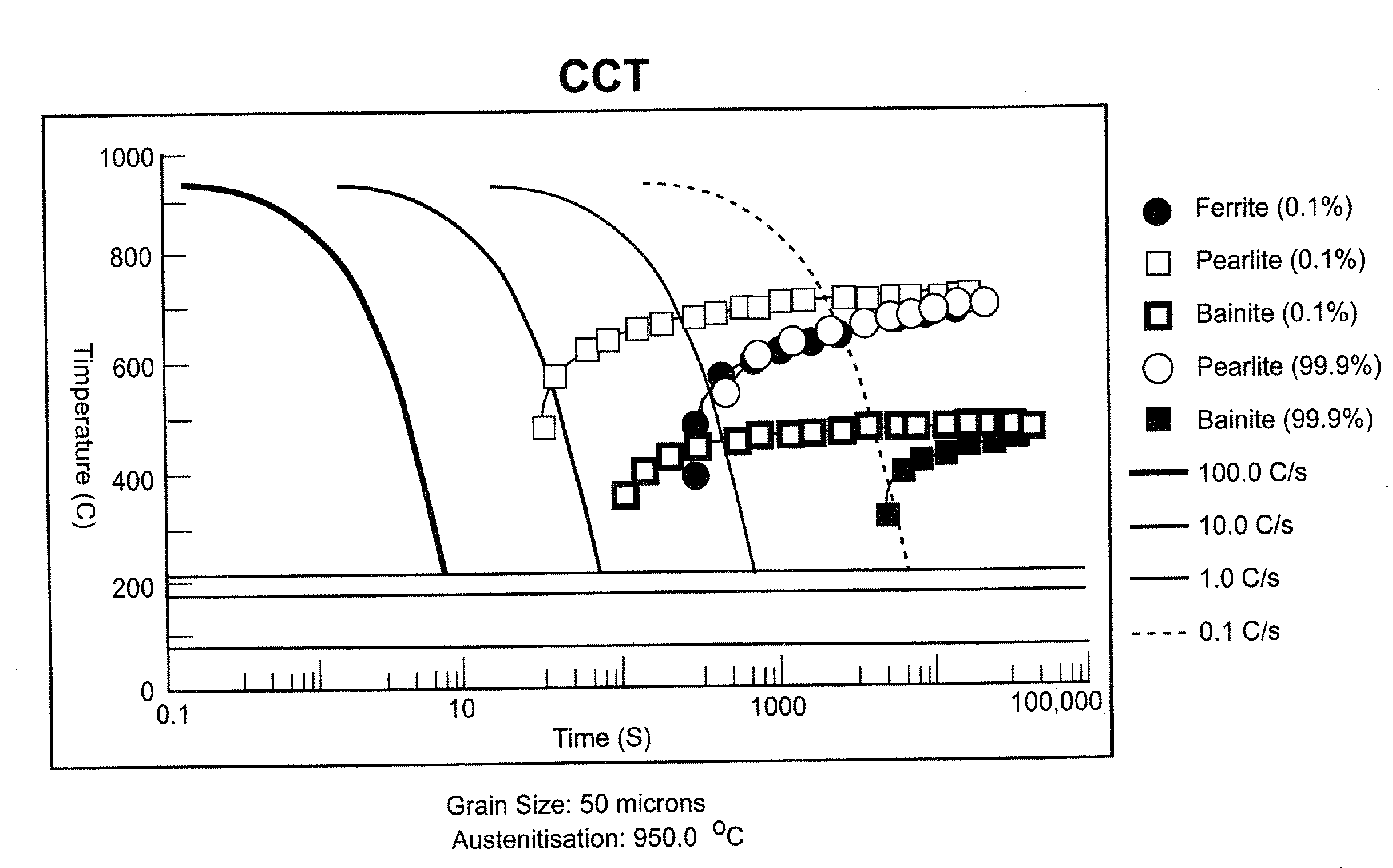

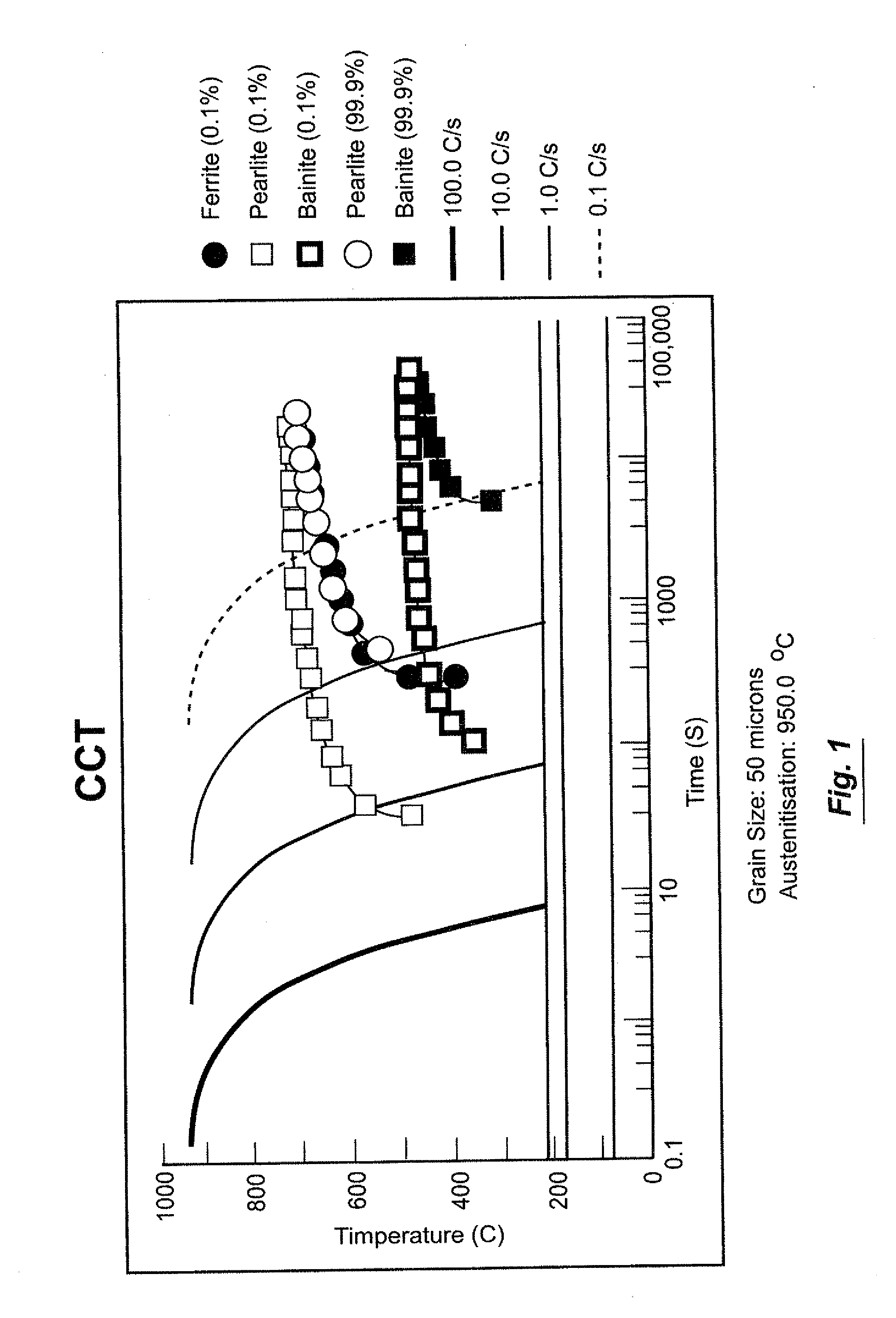

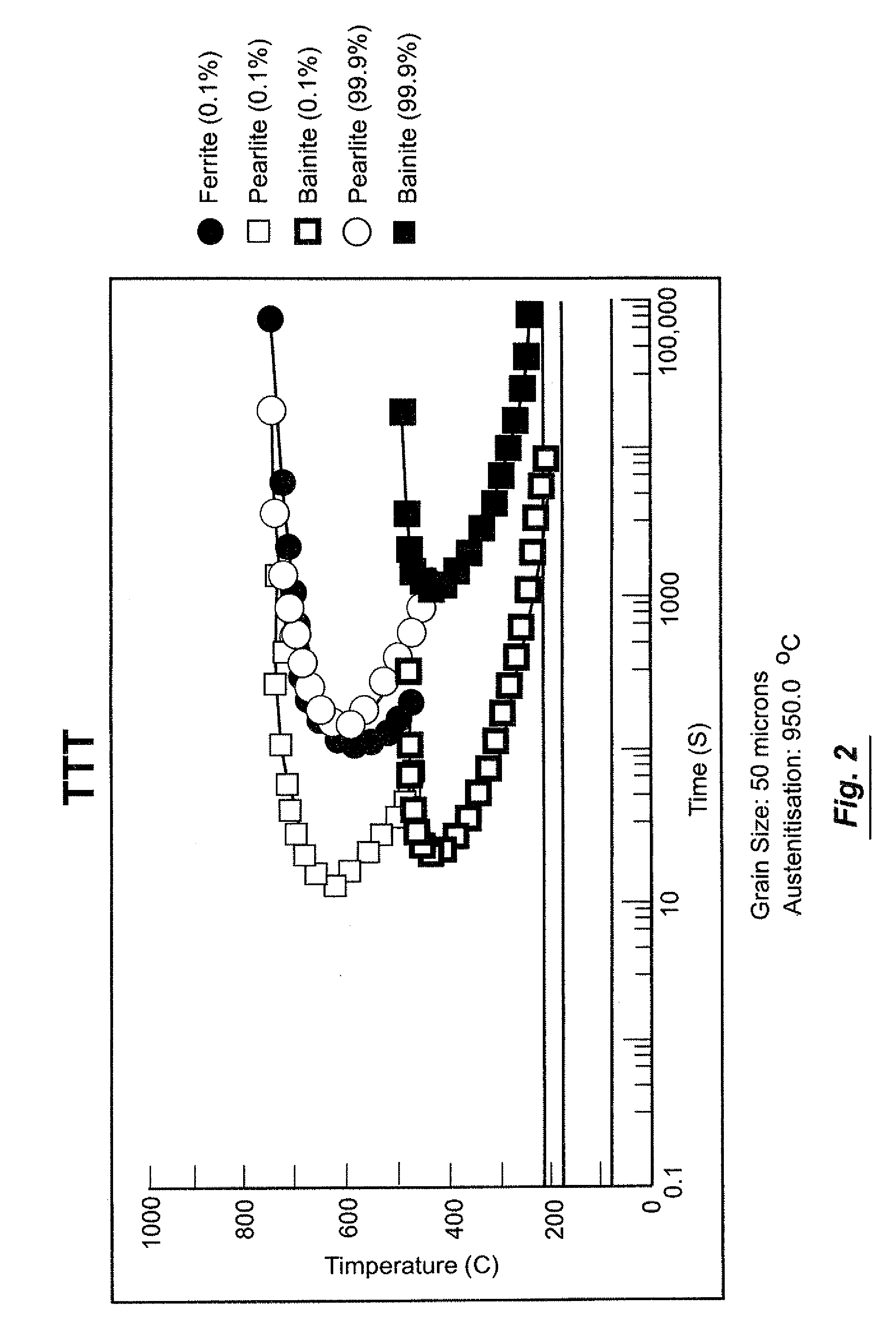

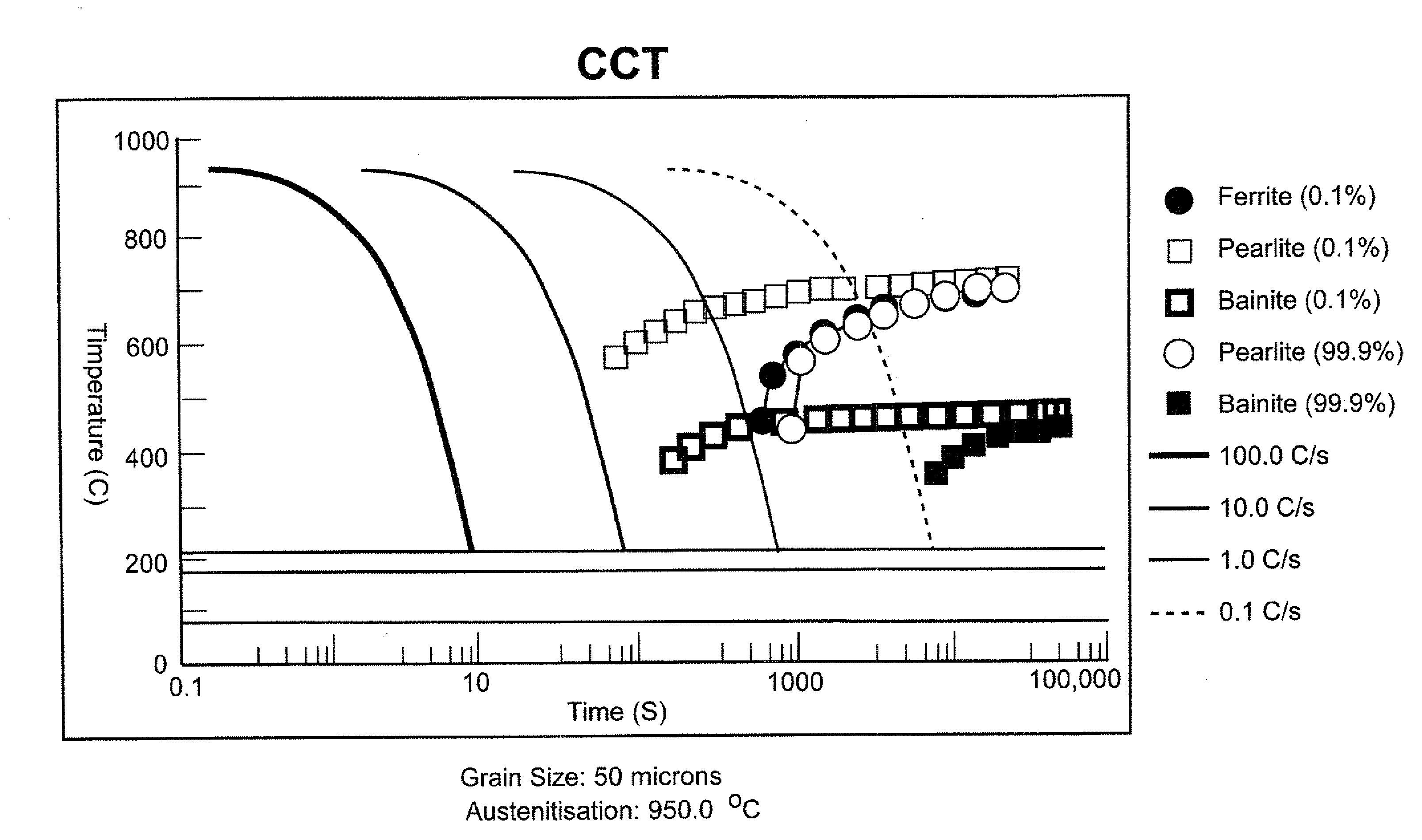

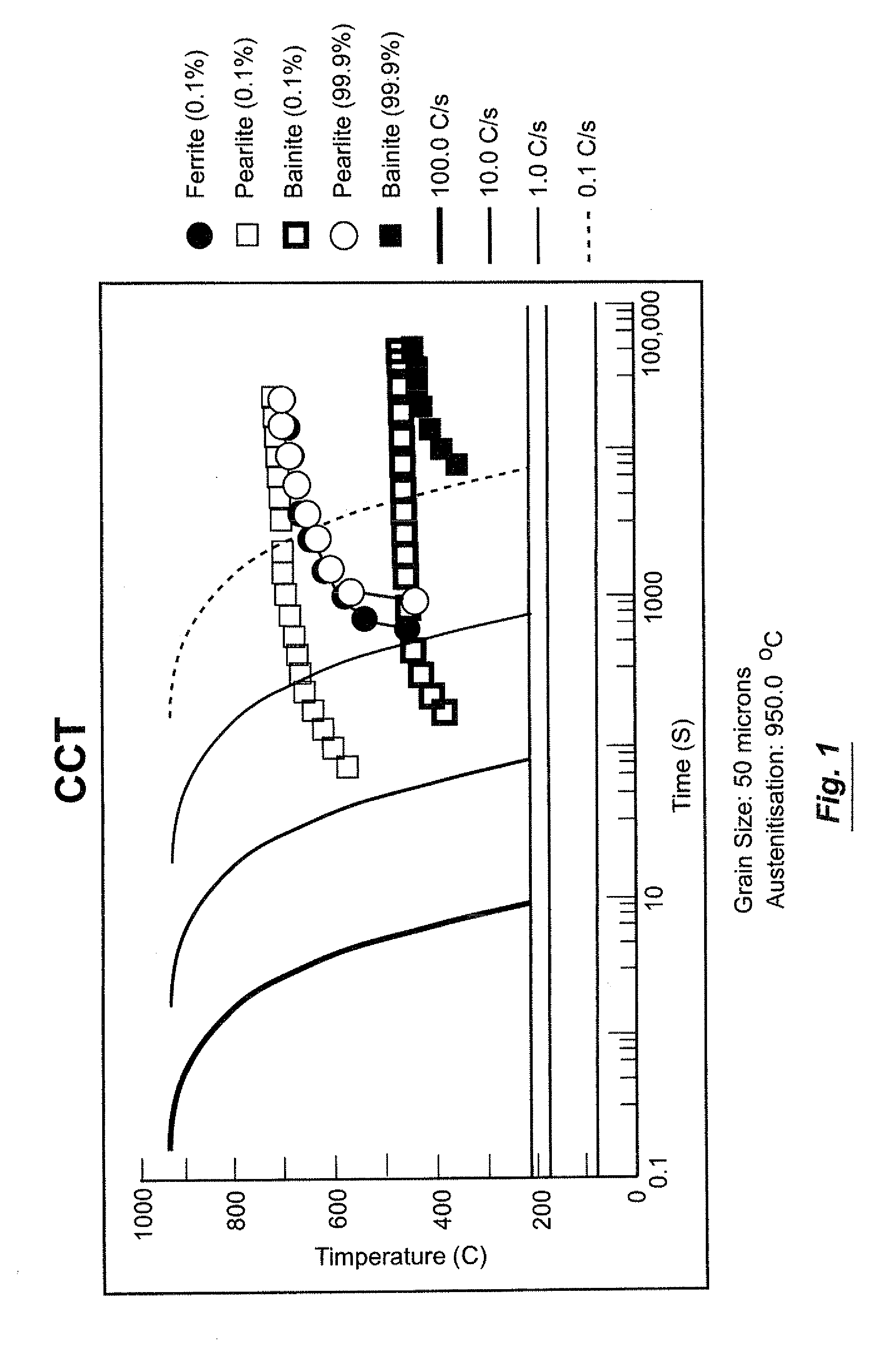

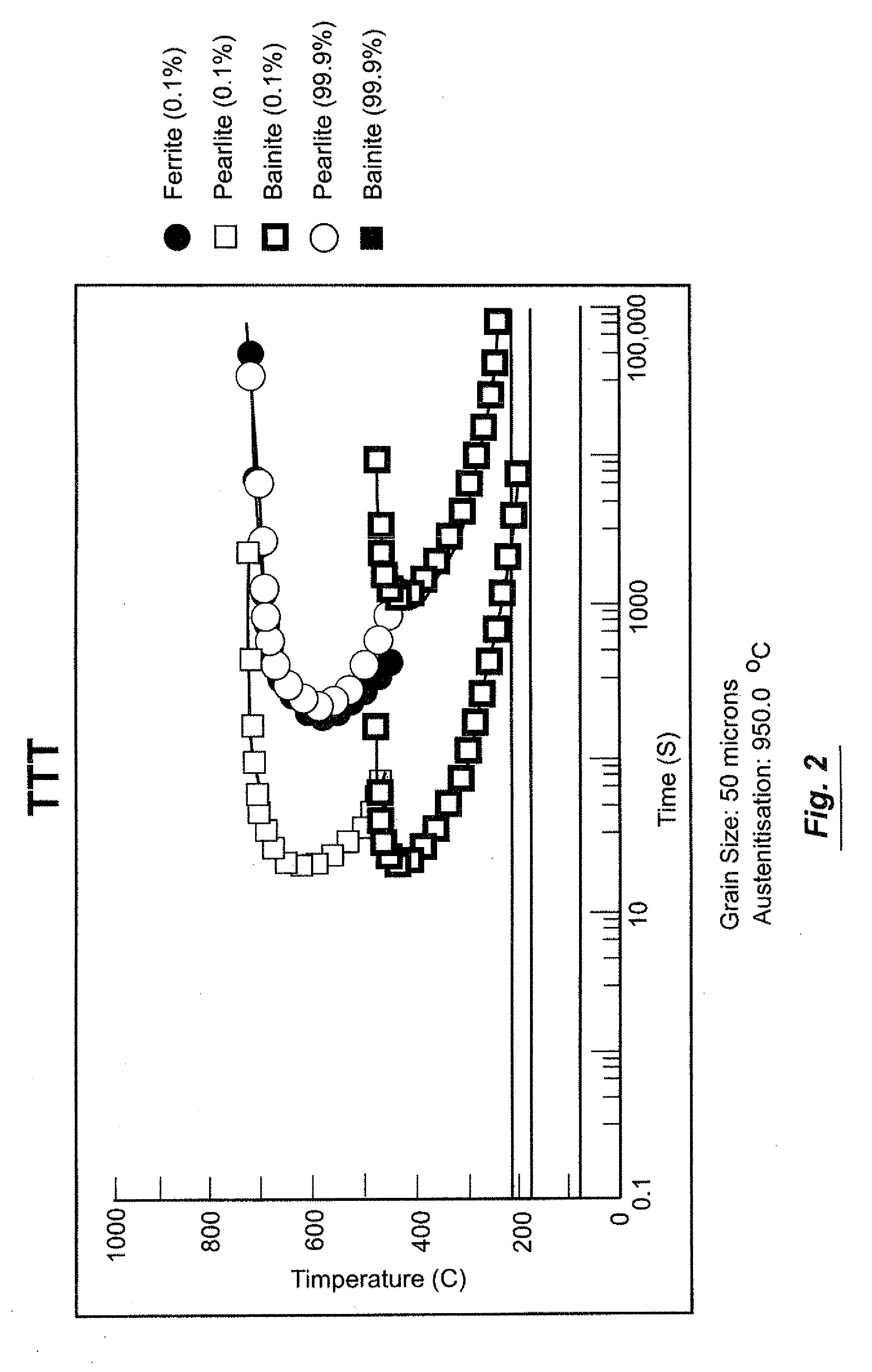

The invention provides a high strength bainitic steel rail and a heat treatment process thereof. The steel rail comprises the following chemical compositions by weight percentage: 0.10%-0.32% of C, 0.80%-2.00% of Si, 0.80%-2.80% of Mn, Cr less than 1.50%, 0.10%-0.40% of Mo, 0-0.5% of Ni, wherein Mn, Cr and Ni satisfy the relation of: Mn+Cr+0.5Ni<=2.8%, and the balance of Fe and unavoidable impurities. The process is as below: conducting hot rolling on the steel rail or air cooling on the steel rail to room temperature, then reheating to 850-1000 DEG C for austenization; cooling the steel rail head to 620-570 DEG C with a cooling rate of 0.3-15 DEG C / s; when the temperature is lower than 620-570 DEG C, cooling to 350-200 DEG C with a cooling rate of 0.5-5 DEG C / s; and then conducting air cooling to room temperature. The invention avoids generation of excessive unstable thick M-A islands in granular bainite during air cooling to room temperature in hot rolling, reduces the risk of straightening fracture (or delayed fracture)of hot-rolled steel rail, and improves the adaptability of steel production process. The steel rail has tensile strength higher than 1400MPa, and realizes optimum matching of strength, toughness and ductility, and excellent rolling contact fatigue resistance and wear resistance.

Owner:ANGANG STEEL CO LTD

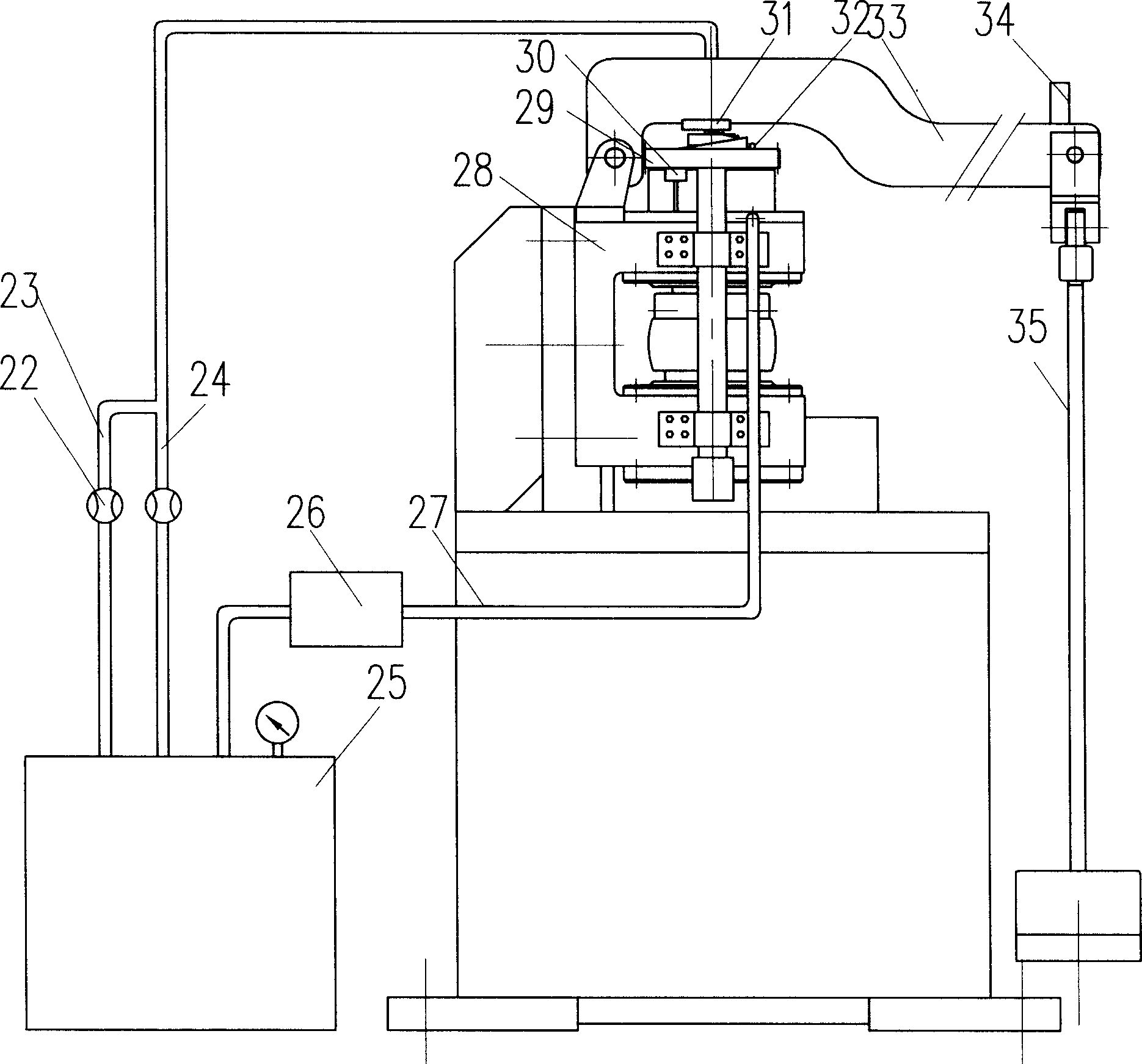

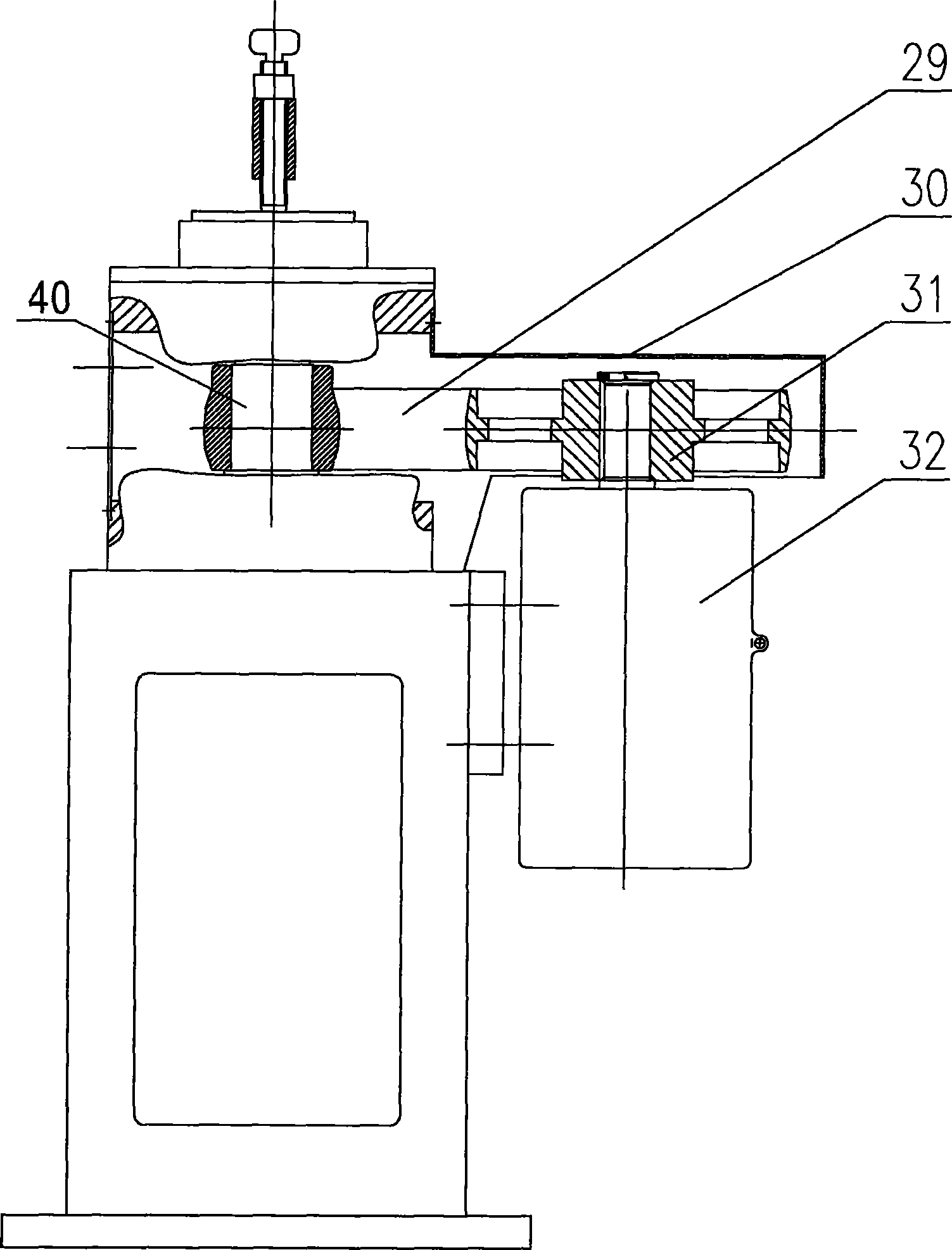

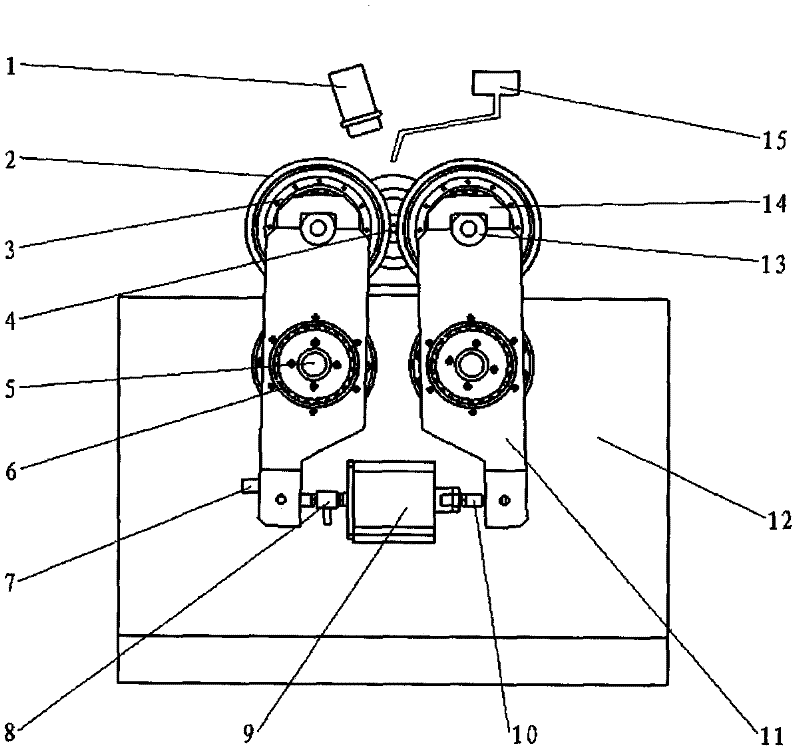

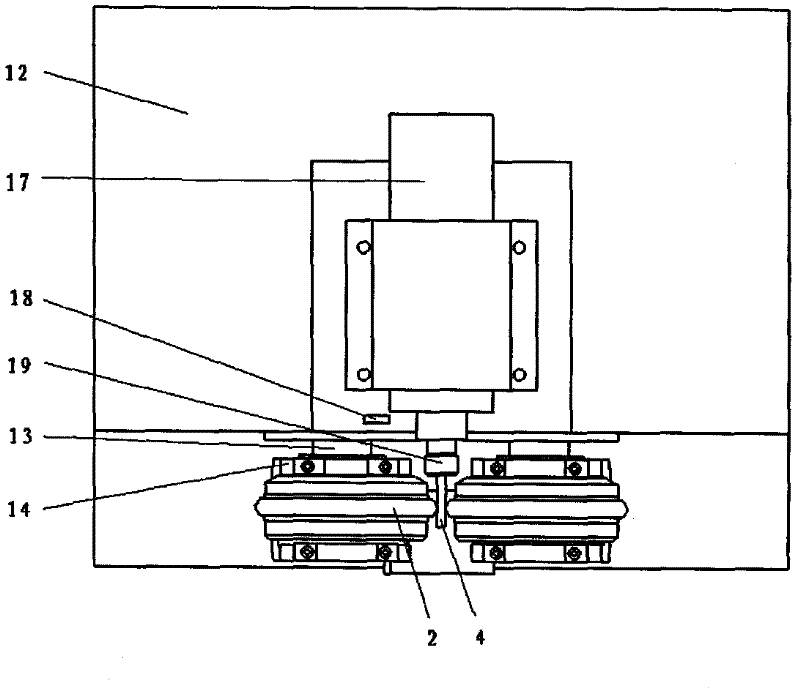

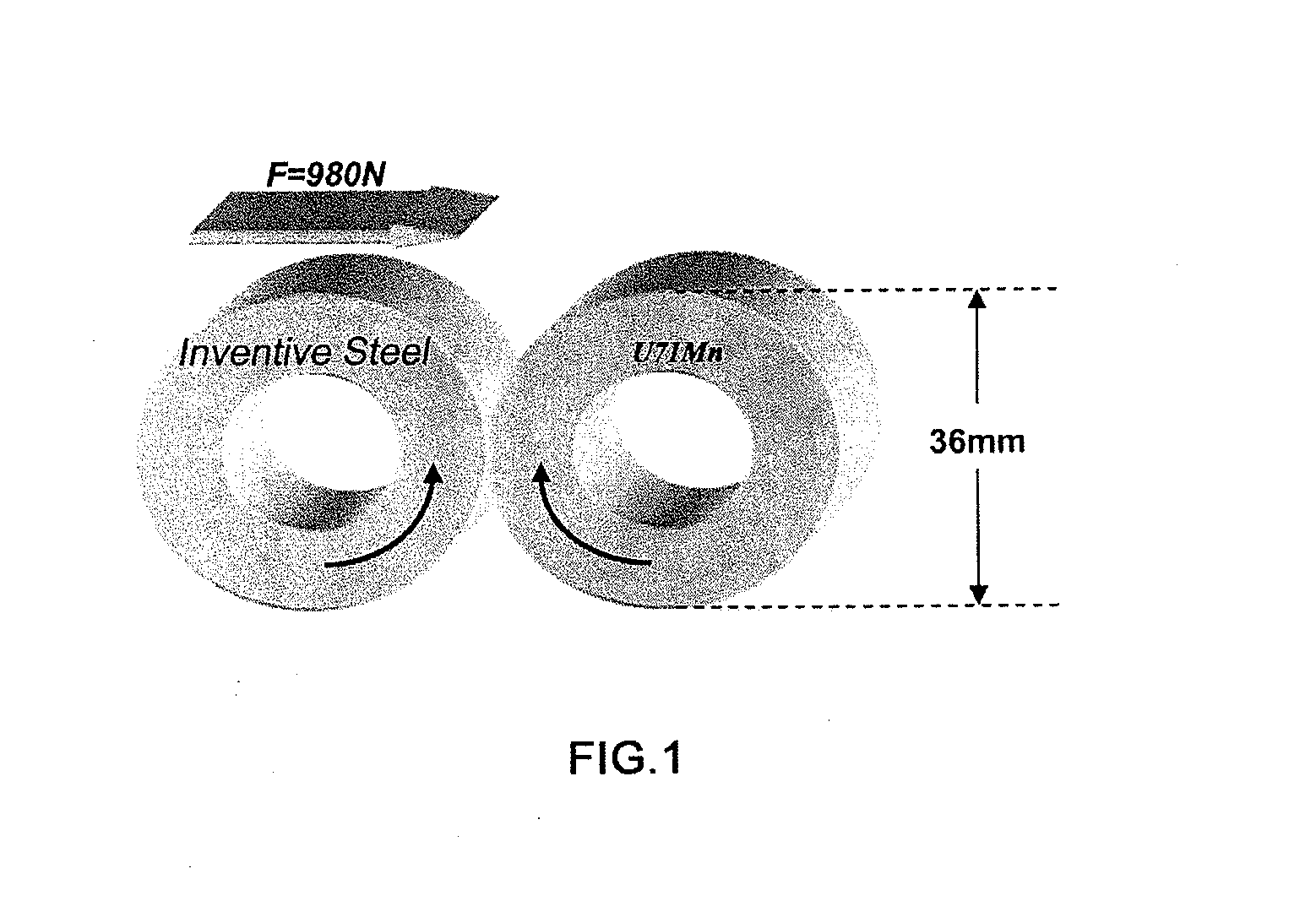

Work condition analogue rolling contact fatigue tester

InactiveCN1715869AReduce the numberReduce fatigue test timeMachine bearings testingUsing mechanical meansTemperature controlInterference fit

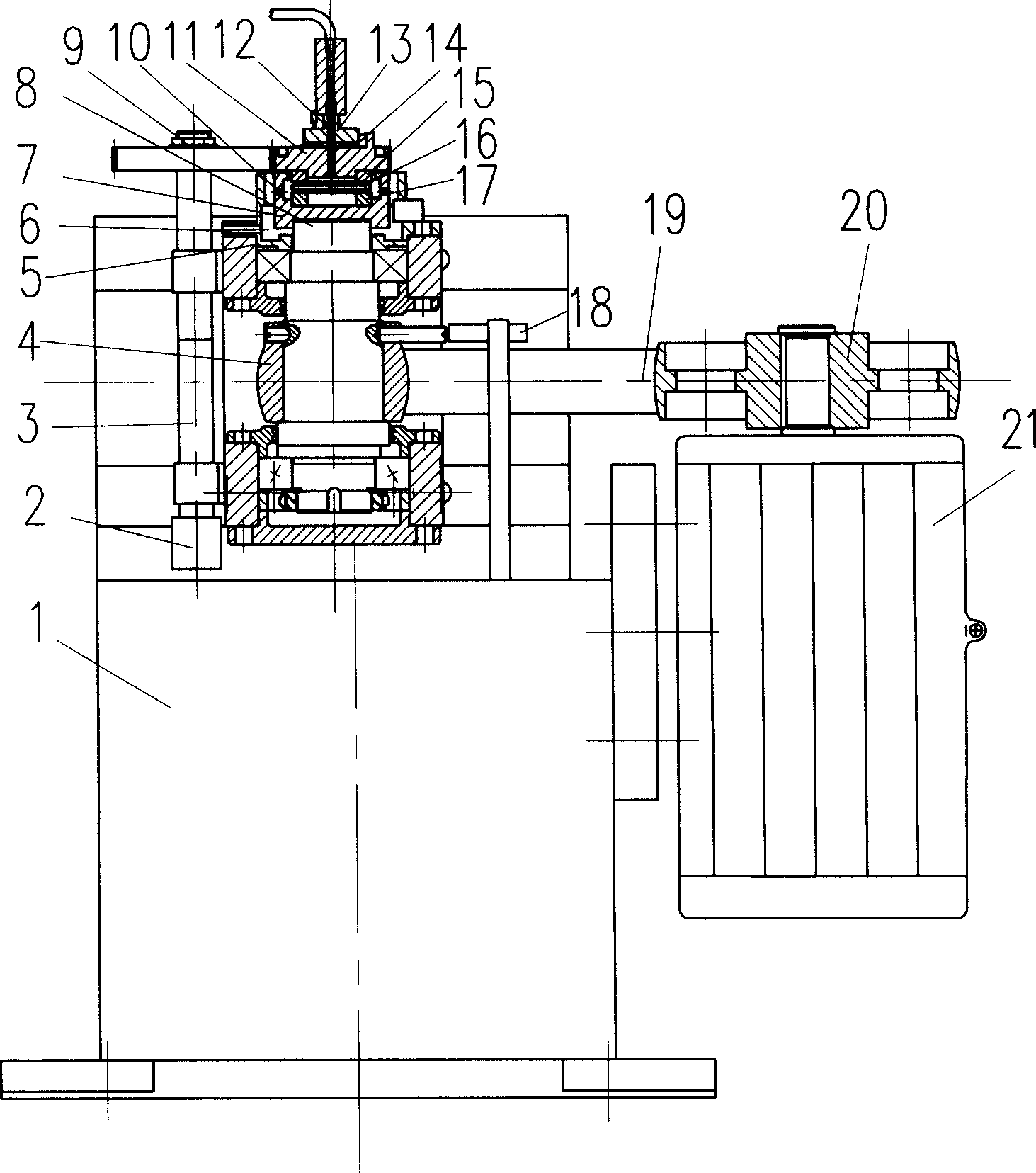

The on-line work condition simulating rolling contact fatigue tester includes driving device, loading device, testing device and signal collecting device, and has temperature controlling cavity sleeved on the driving shaft, lower test cavity end interference fitted to the end of the driving shaft and set inside the temperature controlling cavity, test cavity with upper test sample, rolling part, lower test sample, abruptly stopping cam on the upper test sample, and rolling pin thrust bearing on the abruptly stopping cam and matching the pressure block below the loading lever. The present invention can simulate the contact fatigue, friction and wear process of friction pair with or without surface coating for relevant detection, and the instantaneous failure state may be kept by means of abrupt stopping unit.

Owner:YANSHAN UNIV

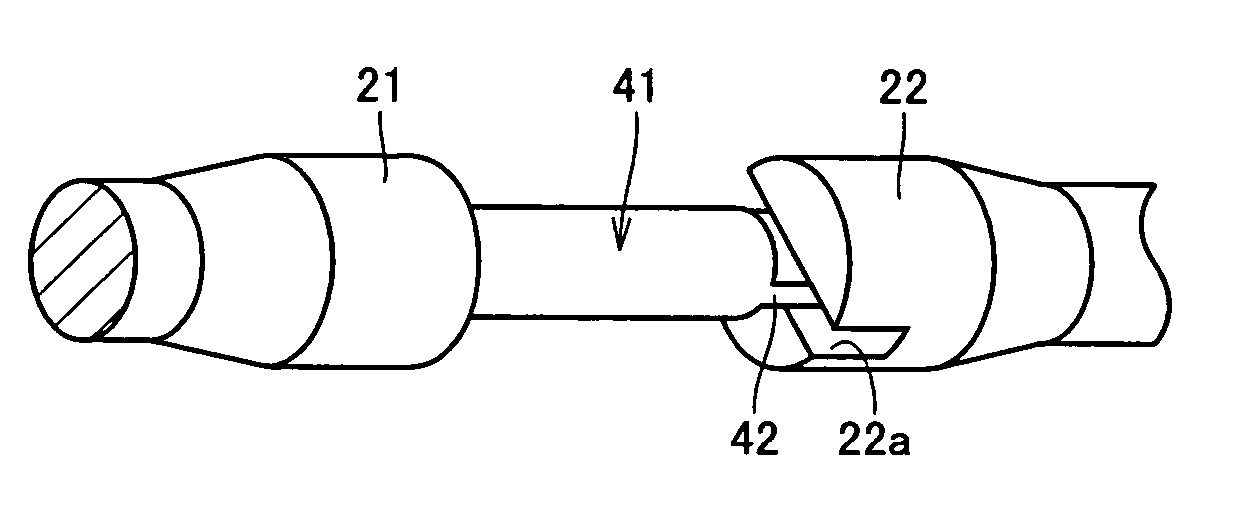

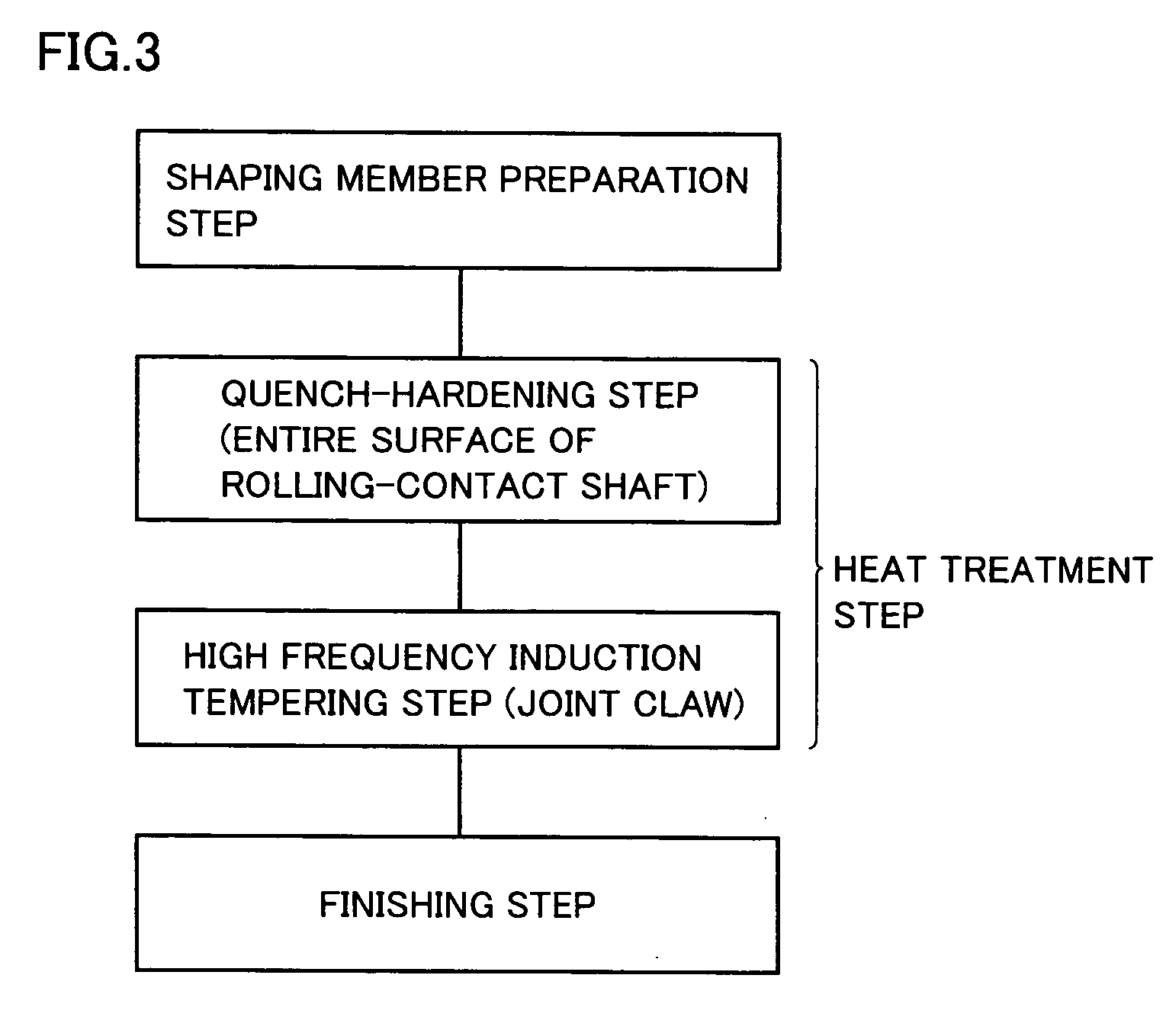

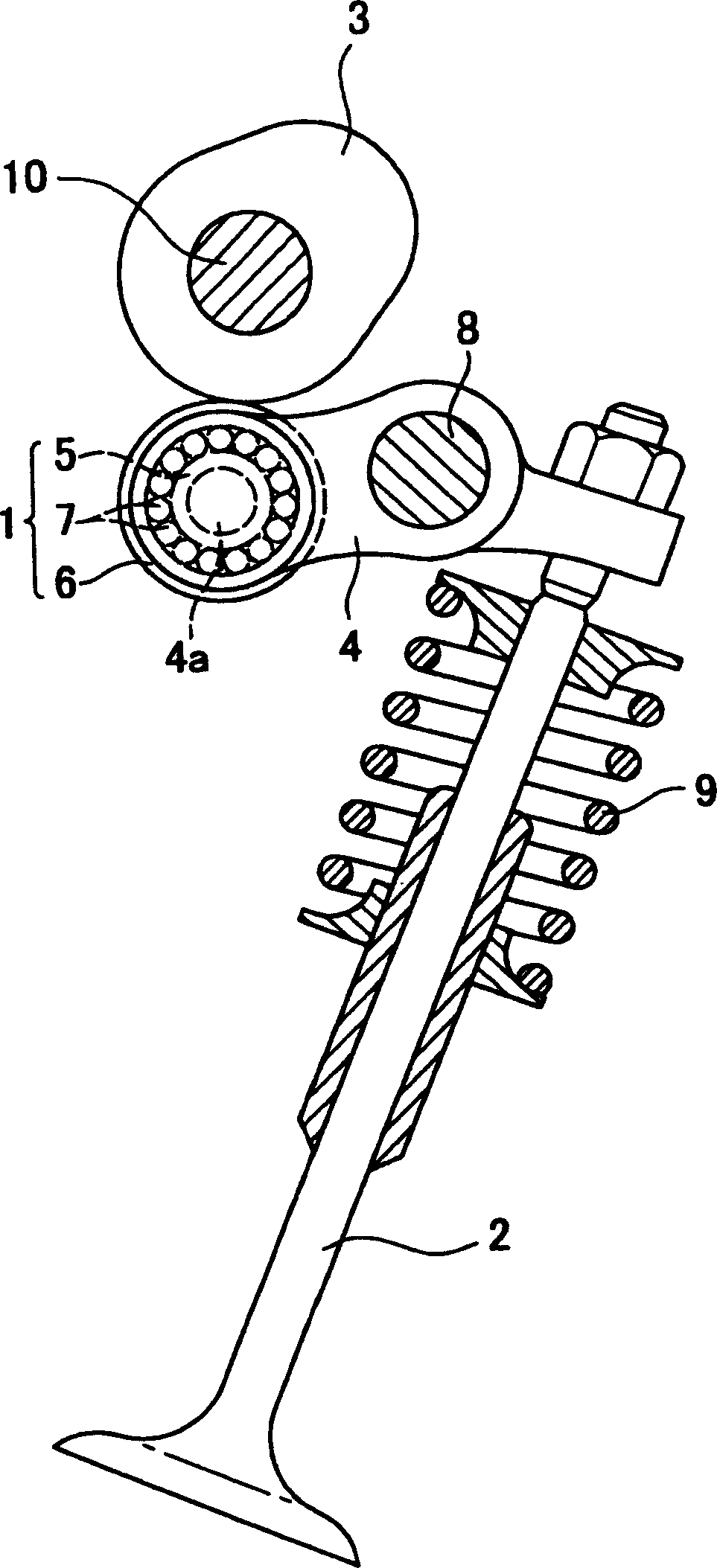

Rolling-contact shaft with joint claw

ActiveUS20070034301A1Improve contact fatigue lifeShaftsBearing componentsEngineeringMechanical engineering

A steel-made rolling-contact shaft with a joint claw improved in both the rolling contact fatigue life at the raceway and the static fracture strength (torsional strength) at the claw includes a joint claw at one end, and has a portion of the outer cylindrical surface functioning as a raceway of a needle roller qualified as a rolling element of a needle bearing. The joint claw is subjected to tempering by induction heating. A nitrogen-enriched layer is formed at the surface layer of the rolling-contact shaft with a joint claw. The grain size number of austenite grains in the nitrogen-enriched layer exceeds number 10. The hydrogen content of the rolling-contact shaft with ajoint claw is not more than 0.5 ppm.

Owner:NTN CORP

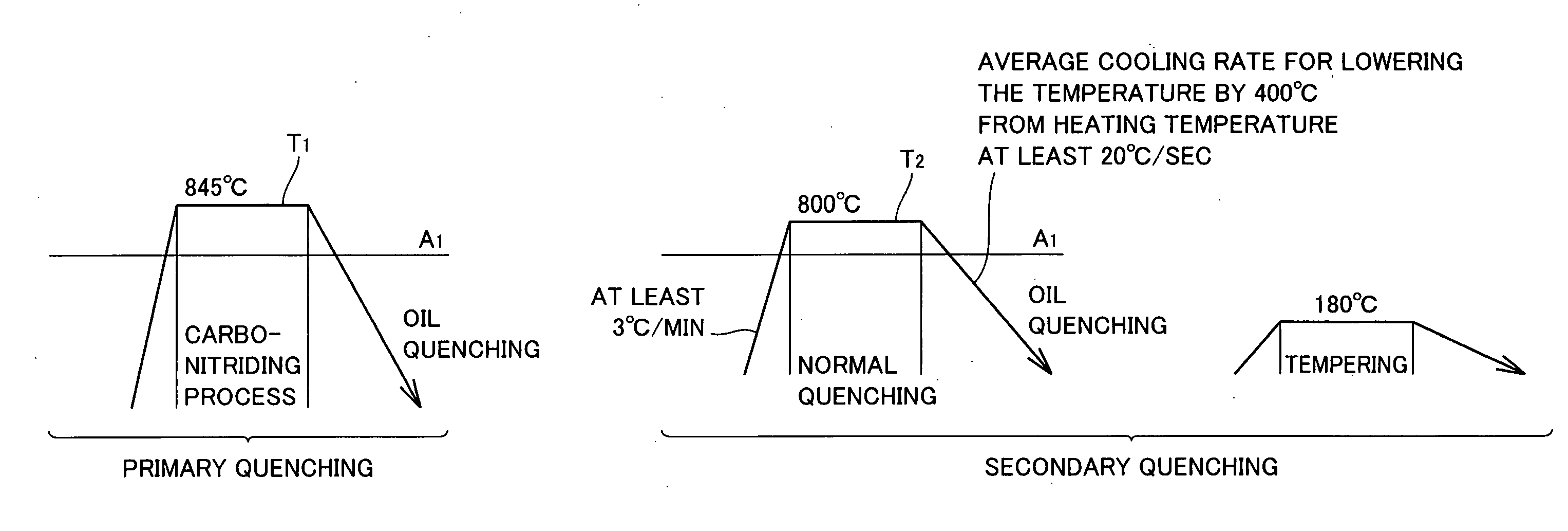

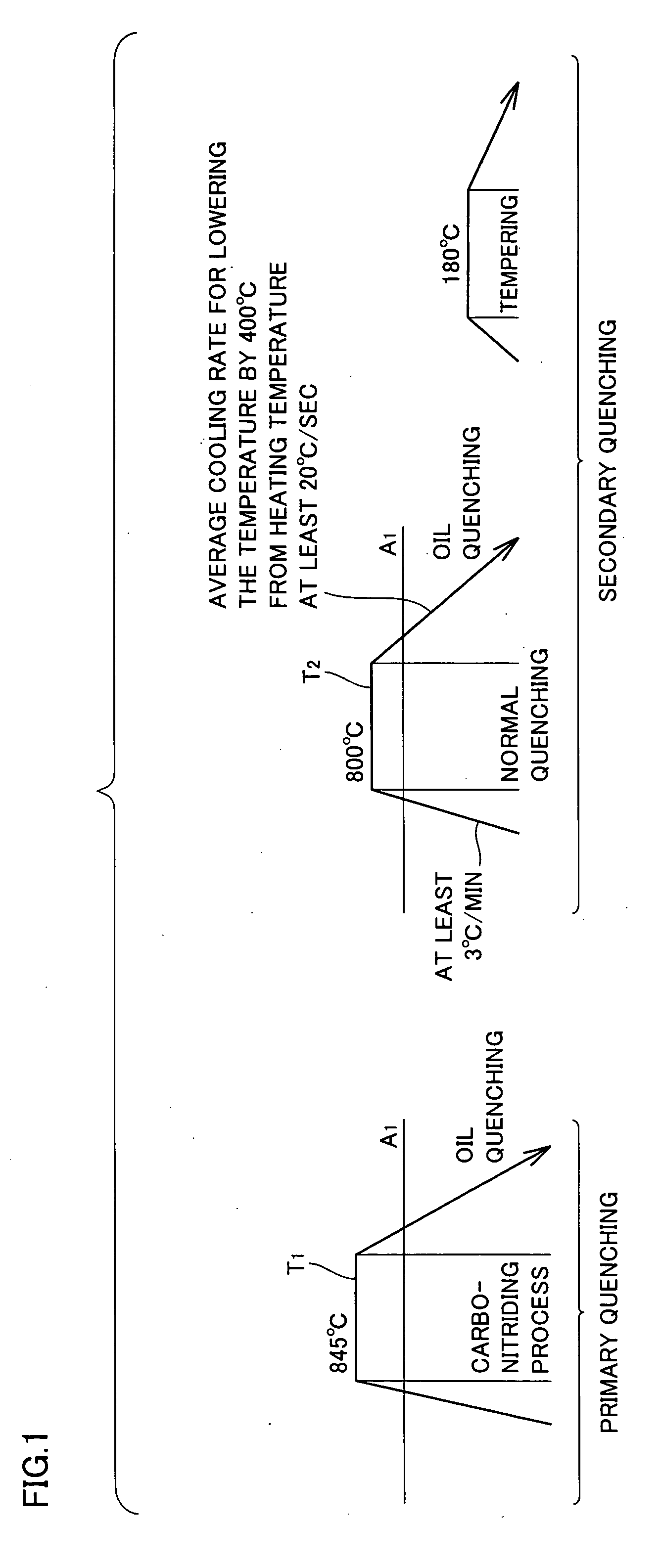

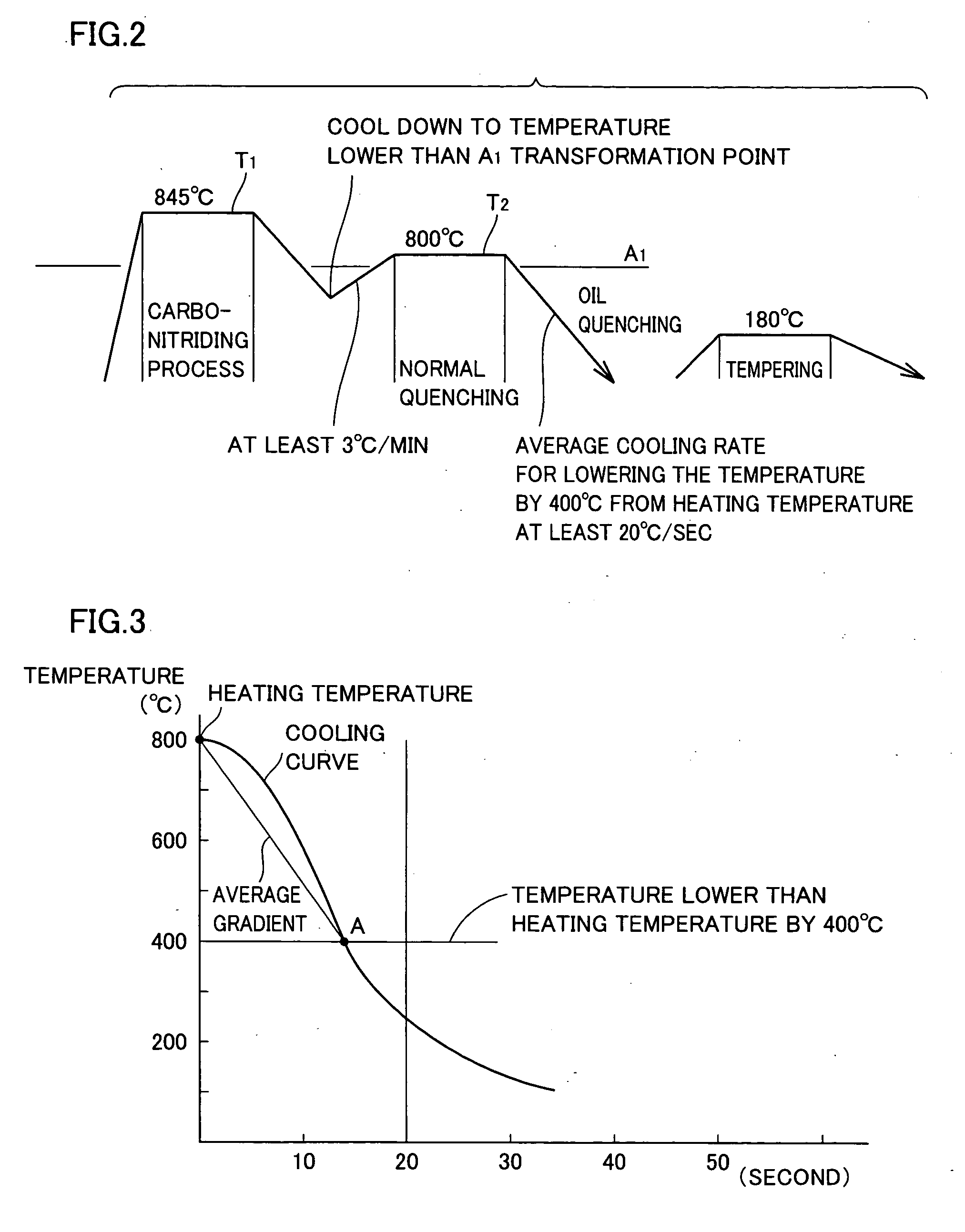

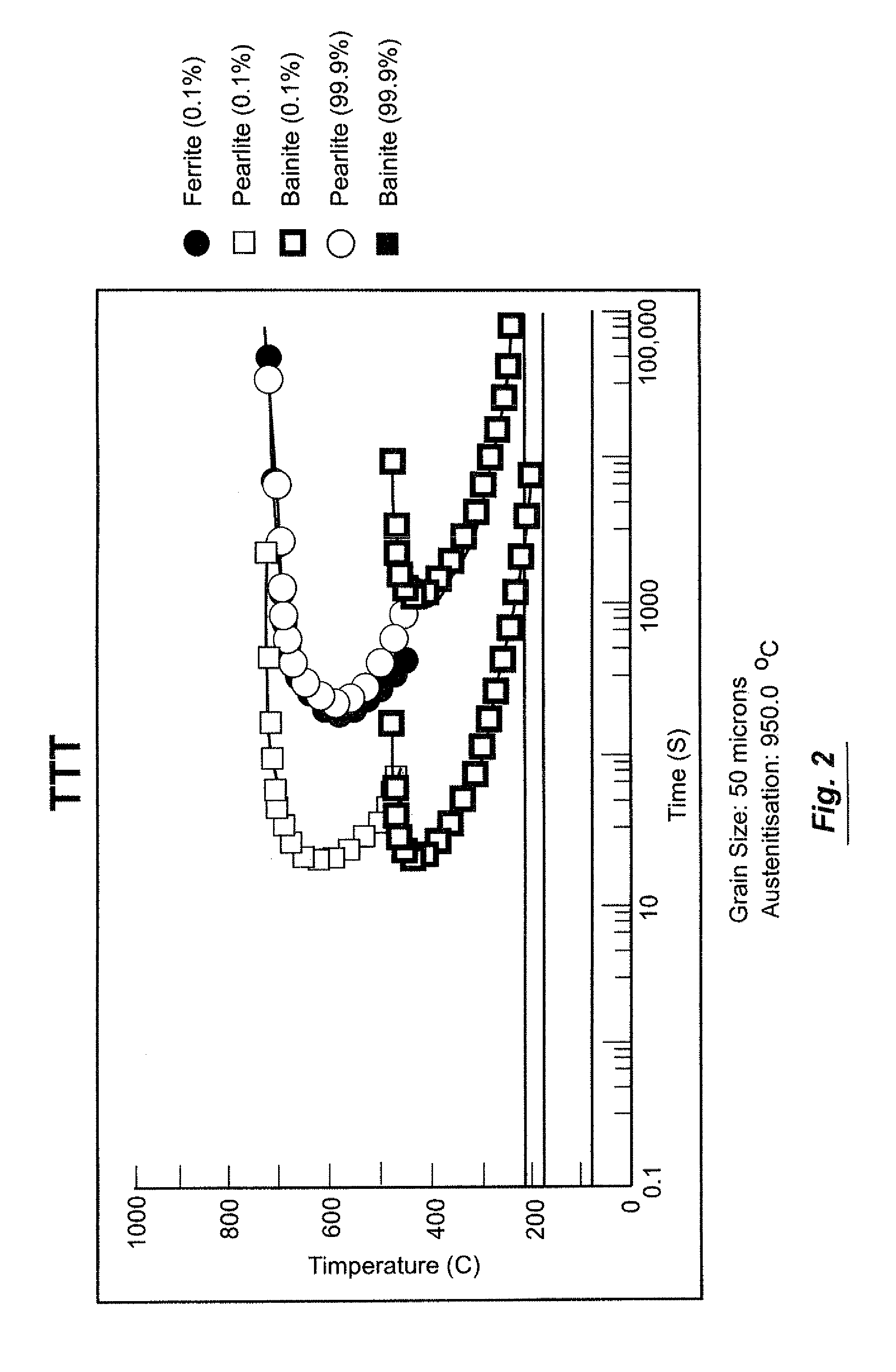

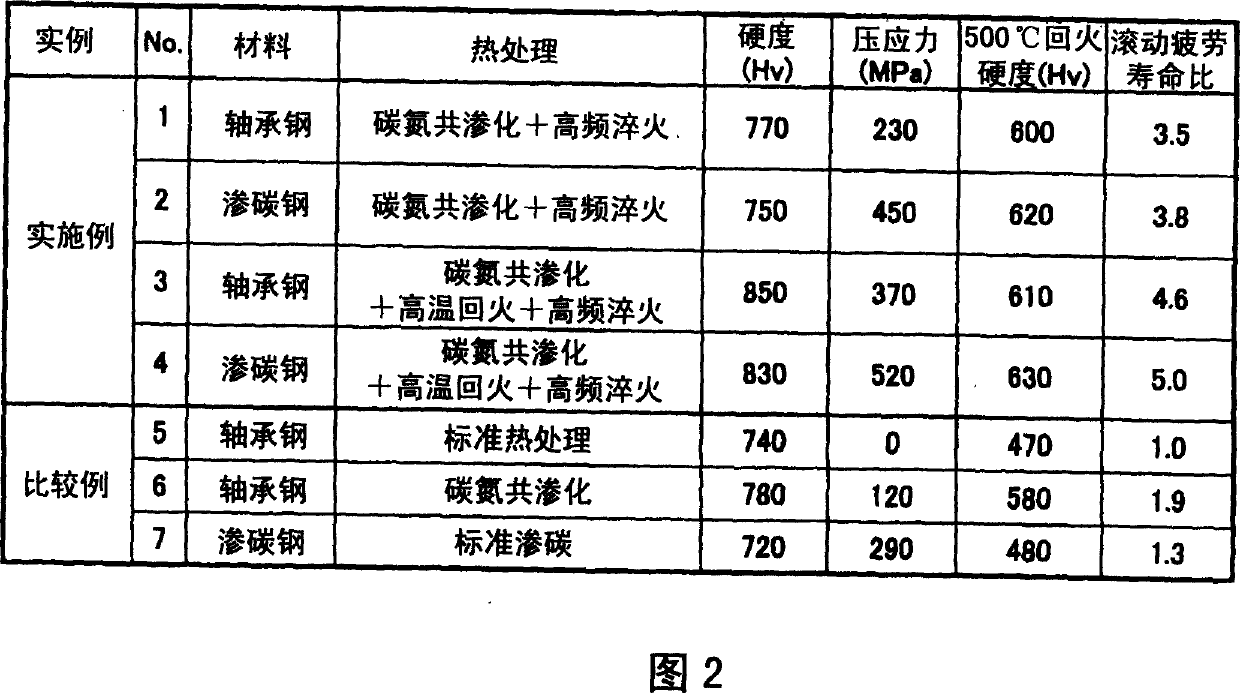

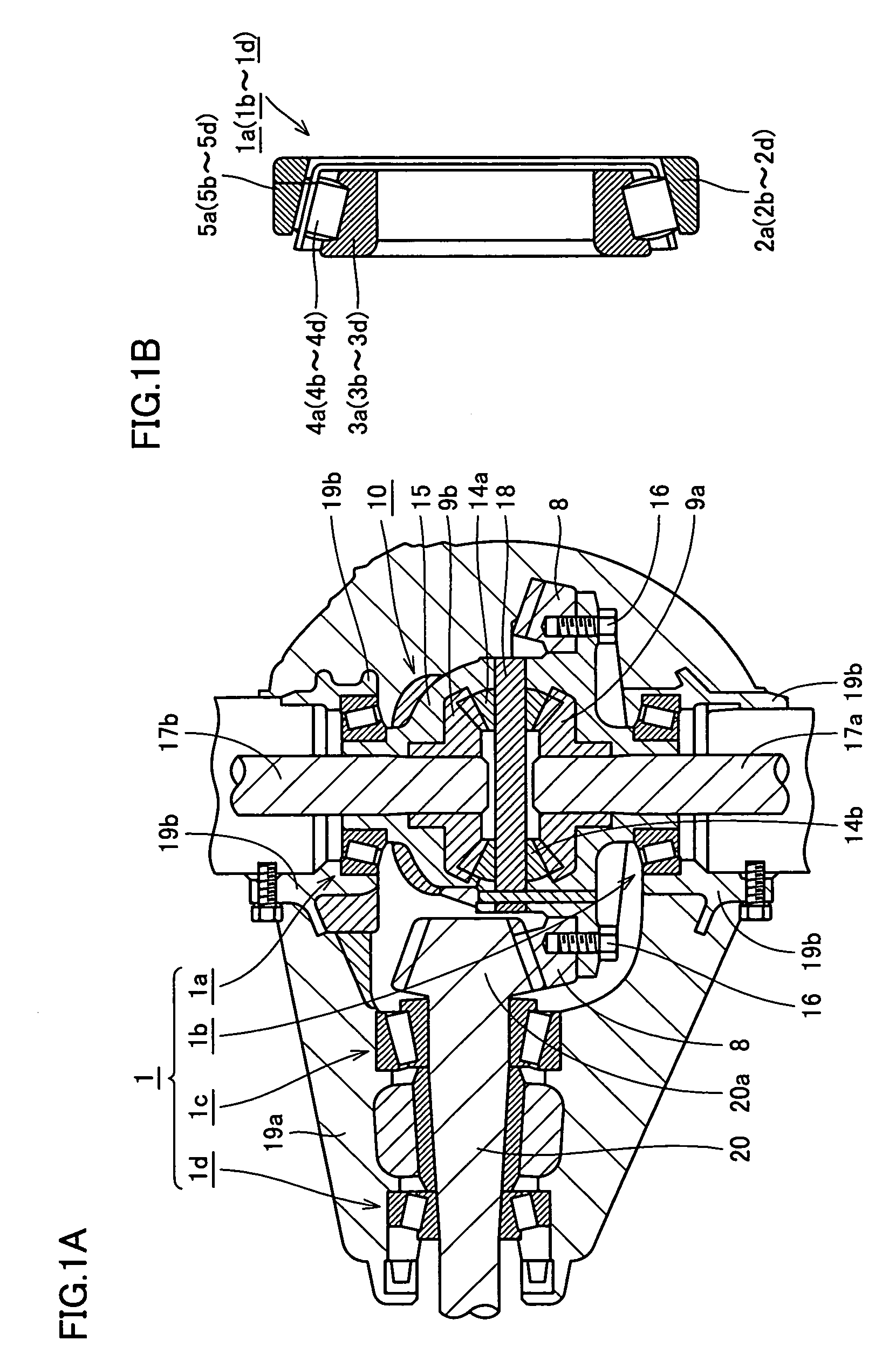

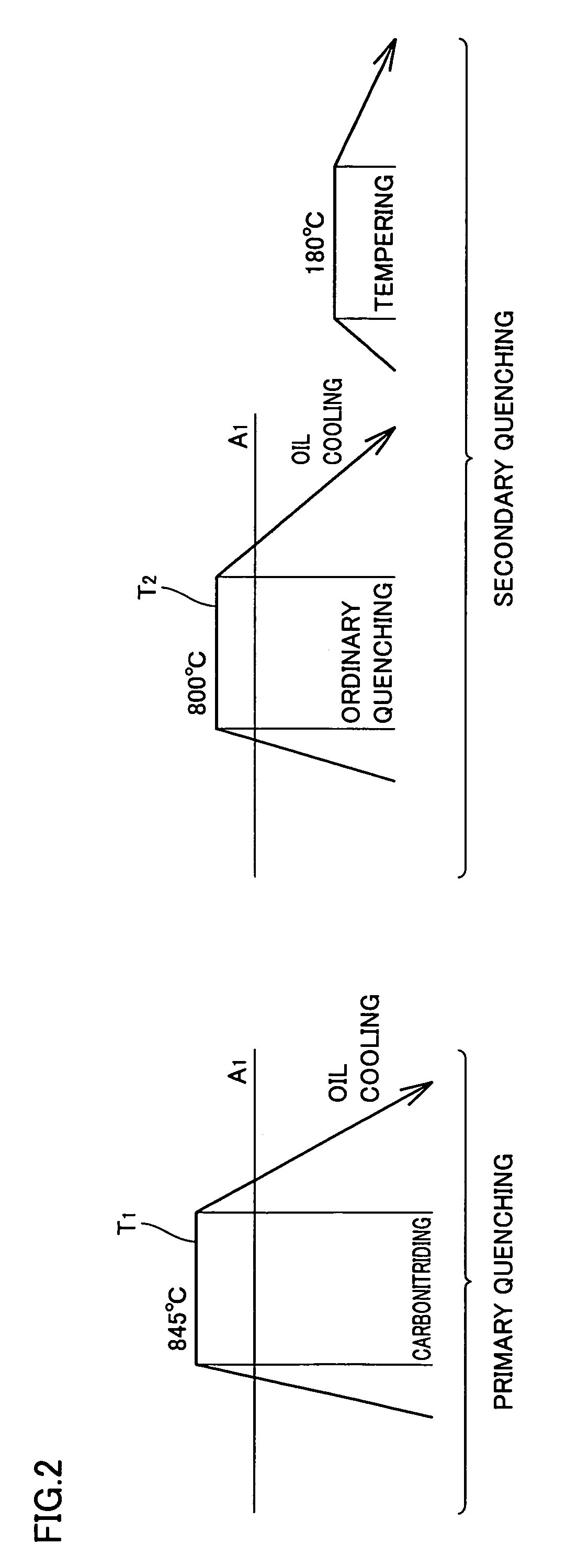

Bearing's component, heat treatment method thereof, heat treatment apparatus, and rolling bearing

ActiveUS20050045247A1Improve cracking strengthReduced long-term dimensional variation rateShaftsBearing componentsRolling contact fatigueUltimate tensile strength

Obtain a bearing's component, a heat treatment method thereof, and a rolling bearing having a long life against rolling contact fatigue and high anti-crack strength, and suppressed long-term dimensional variation rate. The bearing's component is carbonitrided at a carbonitriding temperature higher than an A1 transformation point of steel for the bearing's component and then cooled to a temperature lower than the A1 transformation point, and subsequently, using a heat treatment apparatus that successively moves and heats each individual bearing's component, reheated to a range of quenching temperature of no less than the A1 transformation point and less than the carbonitriding temperature to be quenched.

Owner:NTN CORP

High-impact-toughness steel rail and production method thereof

ActiveCN104480390AGood toughness matchImprove fatigue performanceFurnace typesQuenching agentsChemical compositionRolling contact fatigue

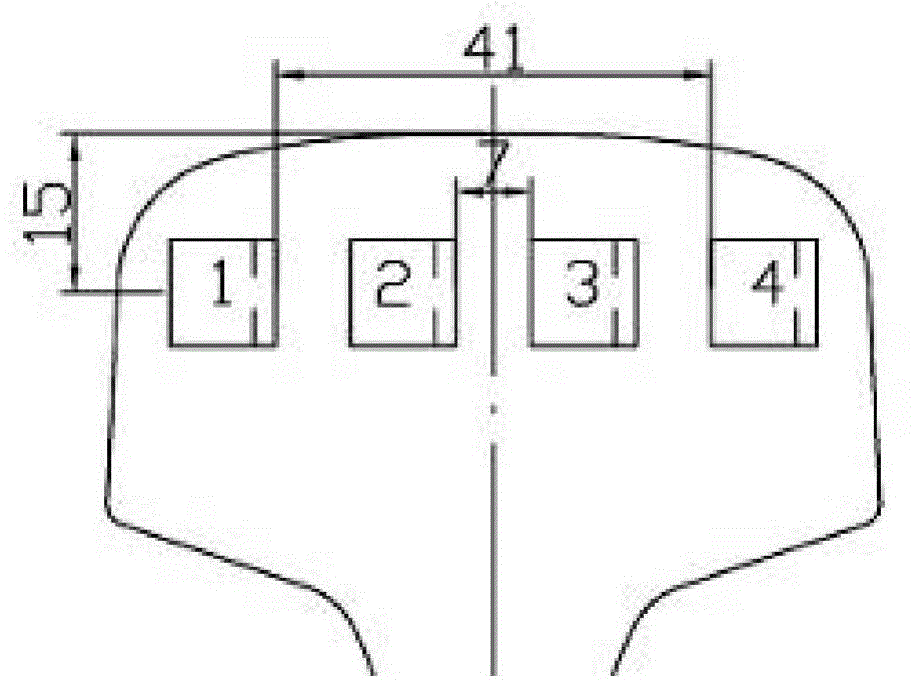

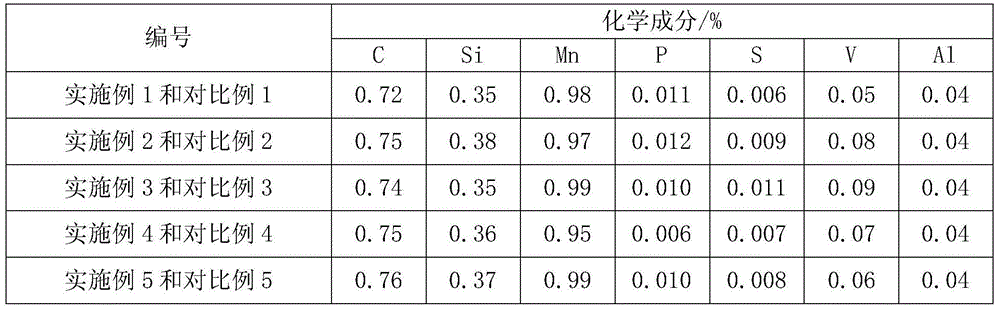

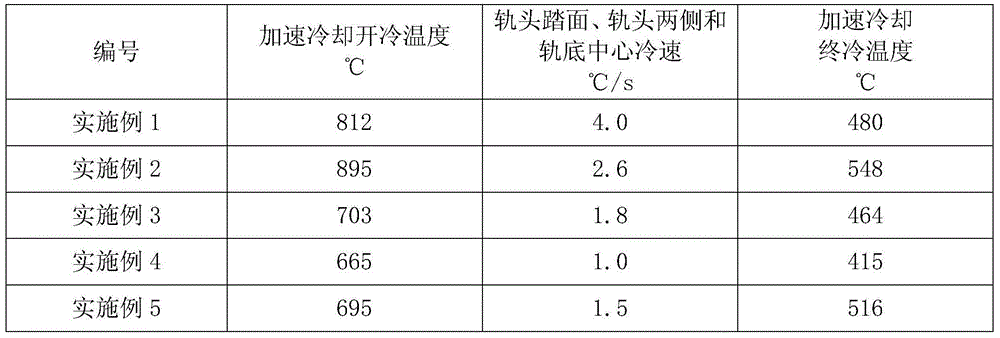

The invention relates to a high-impact-toughness steel rail and a production method of the high-impact-toughness steel rail, and belongs to the field of steel rail material production technologies. The technical aim of providing the high-impact-toughness steel rail is achieved. The high-impact-toughness steel rail is a pearlite steel rail, the interlamellar spacing ranges from 0.05 micron to 0.09 micron, and normal temperature ballistic work ranges from 30 J to 35 J. The steel rail comprises the chemical components: 0.71-0.82 percent of C, 0.25-0.45 percent of Si, 0.75-1.05 percent of Mn, 0.03-0.15 percent of V, no more than 0.030 percent of P, no more than 0.035 percent of S, no more than 0.020 percent of Al and the balance Fe and unavoidable impurities. The rail head U-type impact toughness of the steel rail manufactured through the method can be more than 30 J, tensile strength is larger than 1.300 MPa, the steel rail has good strength and toughness matching, the rolling contact fatigue property and wear-resisting property in the use process are good, and the high-impact-toughness steel rail is suitable for being used as steel rails for railways in high and cold areas.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Forged (rolled) abrasive austenic permanganic steel and its manufacture

A method for forging abrasive austenic high-manganese steel is carried out by smelting by electric furnace to obtain purified steel liquid with low phosphor and sulfur content, pouring into steel ingot, solid-solution heat treating, forging with temperature between 900-1180 degree and heating speed<300 degree / h, solid-solution treating by forged tailed heat, re-heating to austenic temperature, normal solid-solution treating as forger final heat treatment to obtain single-phase austenic tissue. The austenic high-manganese steel consists of C 1.0-1.3 wt%, Mn 10.0-13.0 wt%, Si<0.5 wt%, S<0.01 wt%, P,0.01 wt%, modifier 0.2-0.6 wt% and Fe residues. sigmab>=1000 MPa, sigmas>=600 MPa, delta5>=30%, aKU>=250J / cm 2. It has better impact, wear and roller contact fatigue resistances.

Owner:YANSHAN UNIV

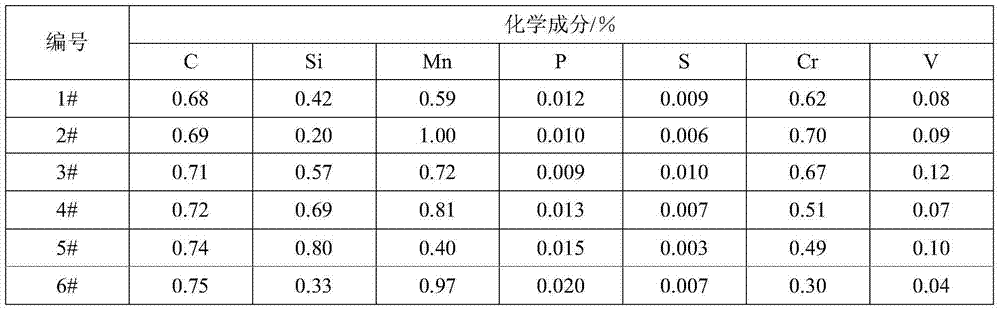

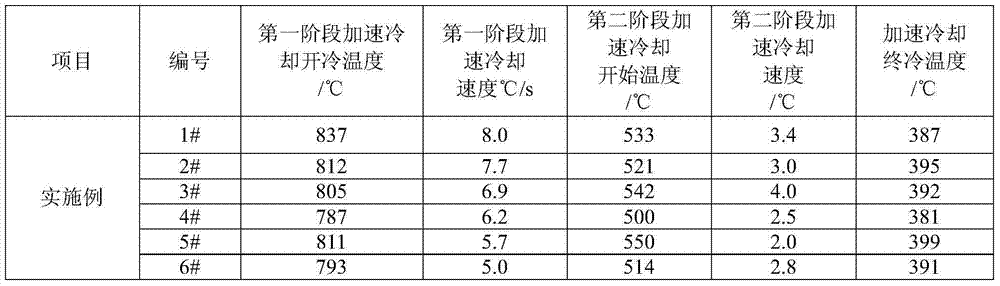

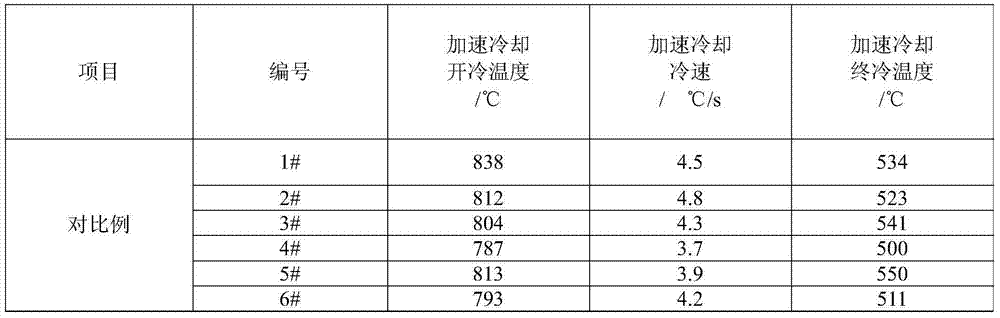

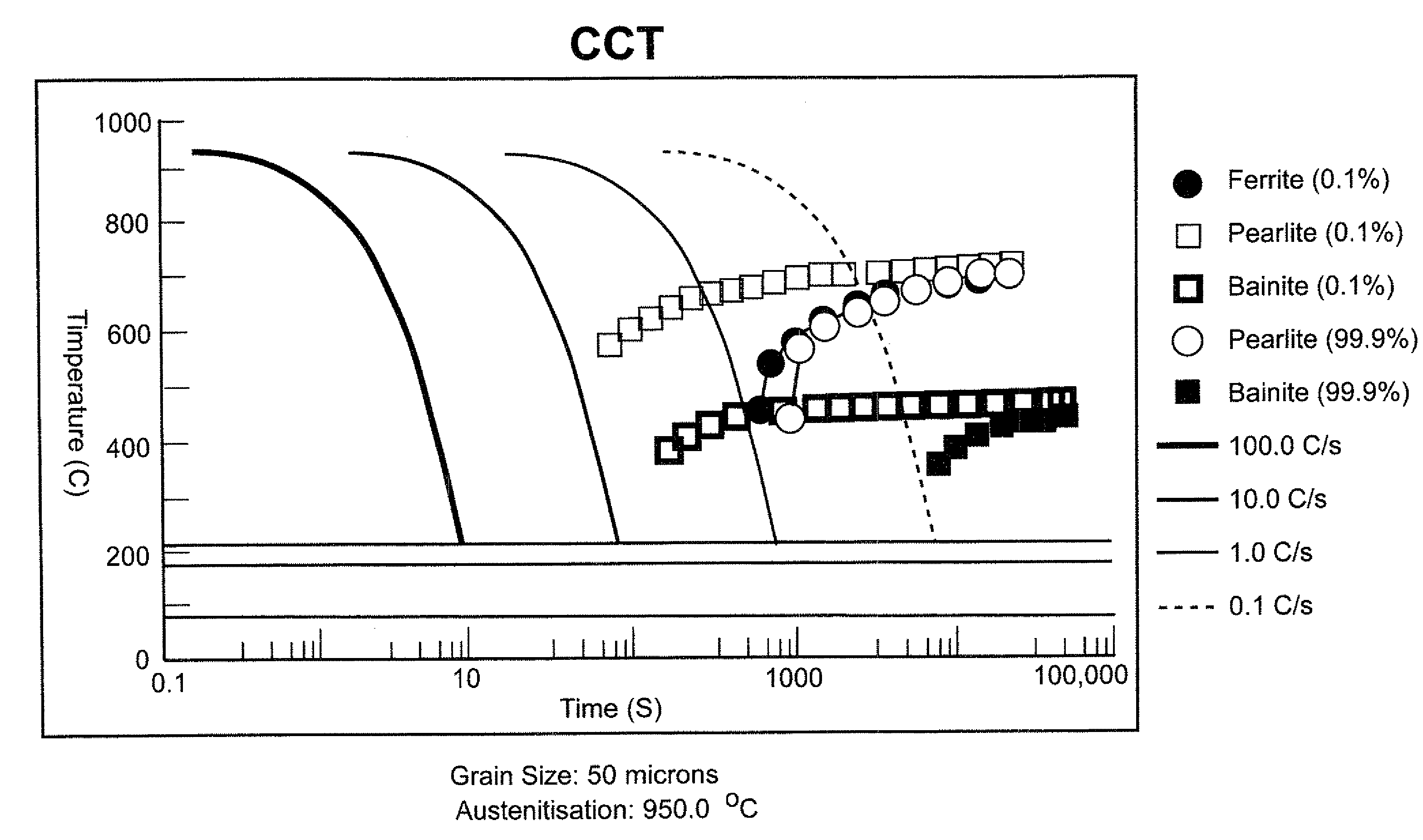

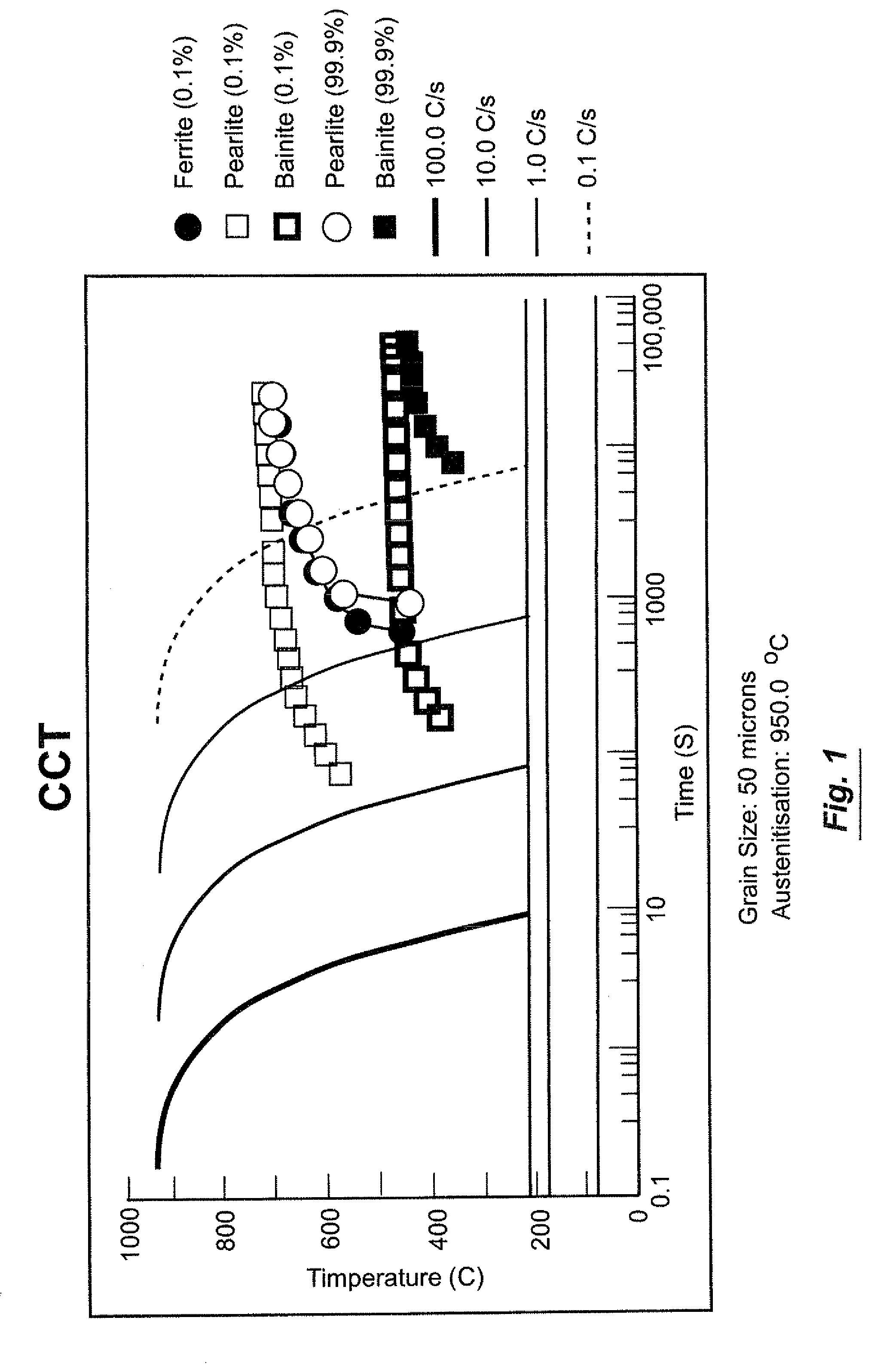

Steel rail with excellent contact fatigue performance and production method thereof

The invention relates to a steel rail with excellent contact fatigue performance and a production method thereof. The steel rail with excellent contact fatigue performance comprises the following elements in percentage by weight: 0.68-0.75% of C, 0.2-0.8% of Si, 0.4%-1% of Mn, 0.3%-0.7 % of Cr, 0.04%-0.12% of V, less than or equal to 0.01% of S, less than or equal to 0.02% of P and the balance of Fe and inevitable impurities. The production method comprises the following steps of carrying out LF refining and RH vacuum treatment in a converter to obtain a square billet, rolling the square billet to form a steel rail of which the cross section is 50-75kg / m, and carrying out accelerated cooling on the rail head part by using the waste heat of the steel rail and adopting a water spray mixed gas with a cooling speed of 5-8 DEG C / s; and when the temperature of the surface of the rail head is cooled to 500-550 DEG C, continuously cooling the rail head by virtue of compressed air with a cooling rate of 2-4 DEG C / s until the temperature of the surface of the rail head is cooled to below 400 DEG C, stopping the accelerated cooling and carrying out air-cooling to room temperature. According to the steel rail disclosed by the invention, the interlamellar spacing in pearlite colonies located at a position from the steel rail head tread to 20mm beneath is 0.07-0.1mu m, the tensile strength of the steel rail is greater than or equal to 1200MPa, the elongation of the steel rail is greater than or equal to 12% and the steel rail has excellent rolling contact fatigue resistance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Railroad wheel steels having improved resistance to rolling contact fatigue

Steels having a pearlitic structure and containing 0.65 to 0.80 weight percent carbon, 0.90 to 1.10 weight percent silicon, 0.85 to 1.15 weight percent manganese, 0.001 to 0.030 weight percent phosphorus, 0.009 to 0.013 weight percent niobium, 0.05 to 0.15 nickel, 0.20 to 0.30 weight percent molybdenum, 0.10 to 0.30 weight percent vanadium and 0.005 to 0.040 weight percent sulfur with the remainder of said steel being iron and incidental impurities, can be used to make railway wheels that are particularly resistant to rolling contact fatigue and, hence, shelling.

Owner:TRANSPORTATION TECH CENT

Rolling bearing

Owner:NTN CORP

Railroad wheel steels having improved resistance to rolling contact fatigue

Steels having a pearlitic structure and containing 0.65 to 0.80 weight percent carbon, 0.90 to 1.10 weight percent silicon, 0.85 to 1.15 weight percent manganese, 0.001 to 0.030 weight percent phosphorus, 0.009 to 0.013 weight percent niobium, 0.05 to 0.15 nickel, 0.20 to 0.30 weight percent molybdenum, 0.10 to 0.30 weight percent vanadium and 0.005 to 0.040 weight percent sulfur with the remainder of said steel being iron and incidental impurities, can be used to make railway wheels that are particularly resistant to rolling contact fatigue and, hence, shelling.

Owner:TRANSPORTATION TECH CENT

Steel rail used for high-speed and quasi-high speed railways and manufacturing method thereof

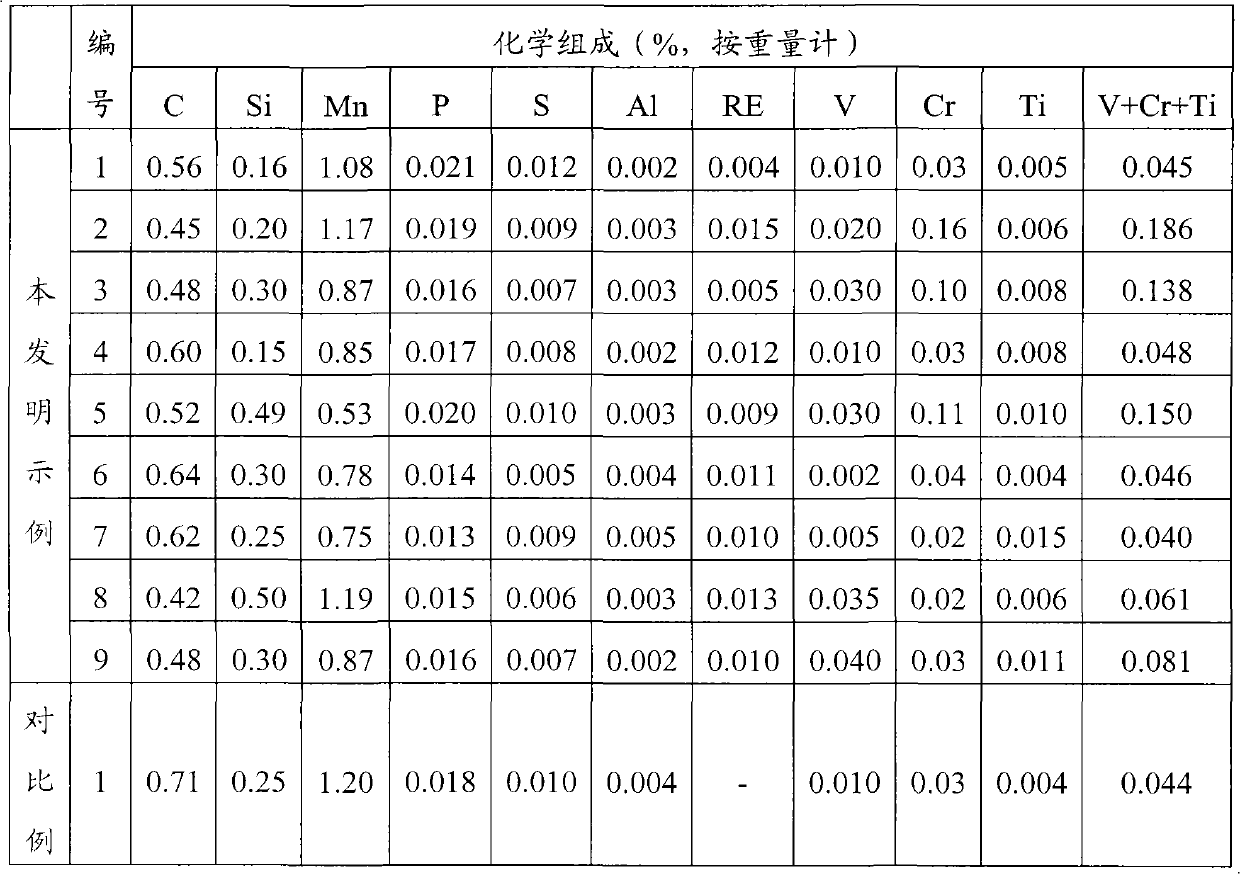

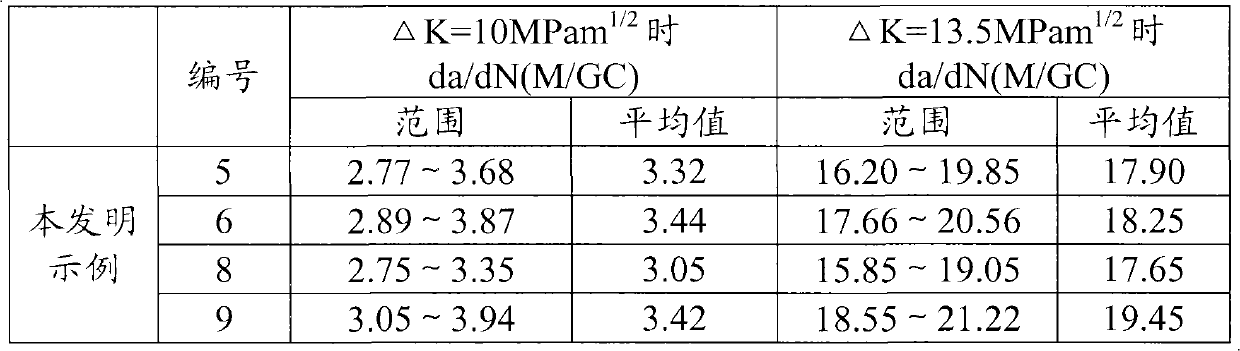

ActiveCN101921950AImprove toughnessHigh yield strengthRailsFurnace typesRare-earth elementChemical composition

The invention discloses a steel rail used for high-speed and quasi-high speed railways and a manufacturing method thereof. The method comprises: reducing carbon content and utilizing a mode of controlled cooling after rolling to manufacture the steel rail with favorable rolling contact fatigue performance. The steel rail comprises the following chemical compositions by weight percent: 0.40%-0.64% of C, 0.10%-1.00% of Si, 0.305-1.50% of Mn, less than or equal to 0.025% of S, less than or equal to 0.005% of Al, greater than 0% and less than or equal to 0.05% of rare-earth elements, greater than 0% and less than or equal to 0.20% of at least one of V, Cr and Ti and the balance of Fe and inevitable impurities. The steel rail manufactured by the method of the invention maintains the strength and hardness of the existing steel rail of the high-speed railways, and simultaneously has improved plasticity and yield strength; and the energy value needed for initiation and expansion of fatigue microcracks formed on the surface of the steel rail is improved, thus the rolling contact fatigue performance of the steel rail can be improved under the same condition, and finally the service life and transportation safety of the steel rail are improved.

Owner:PANZHIHUA IRON AND STEEL +1

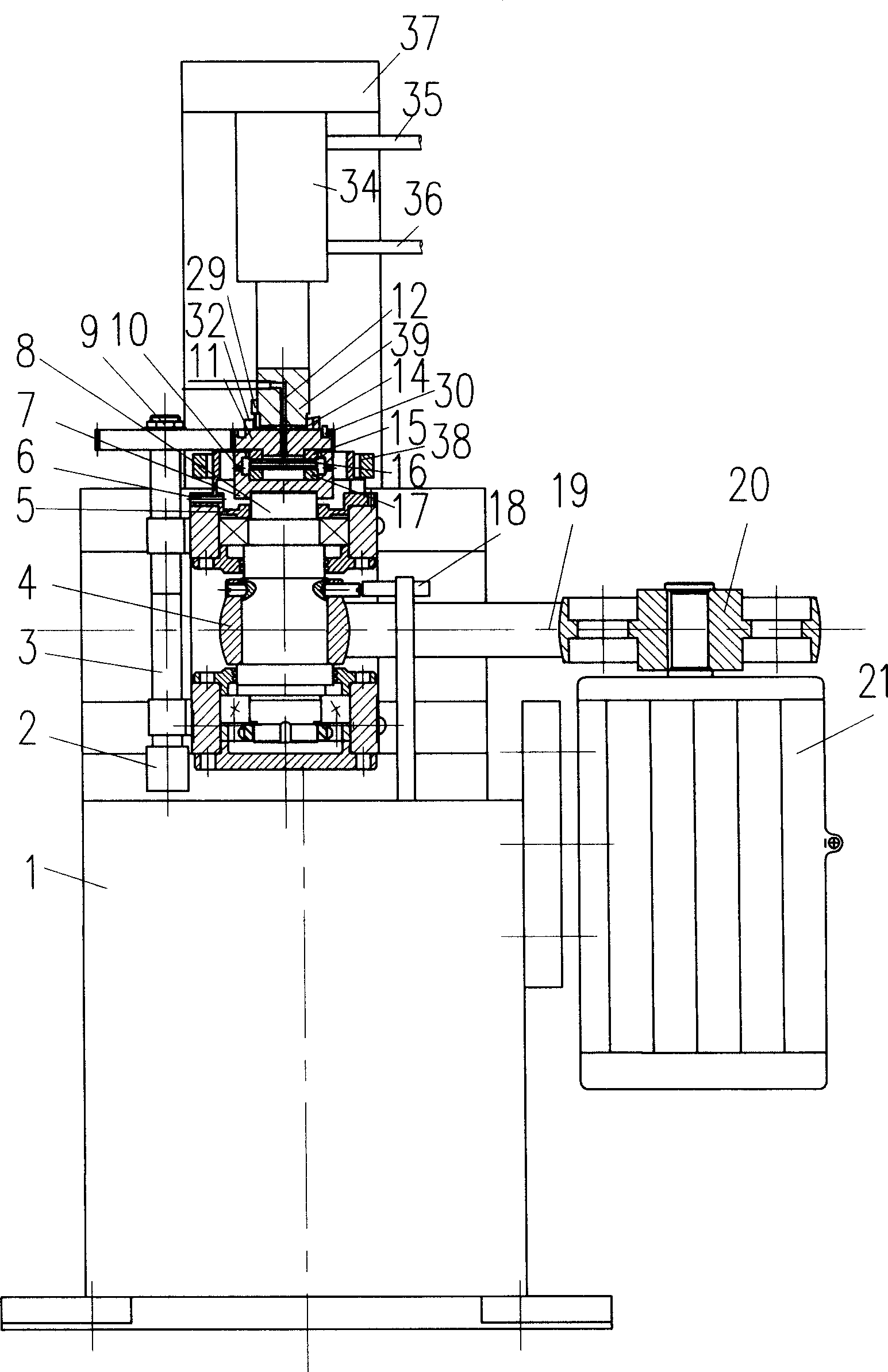

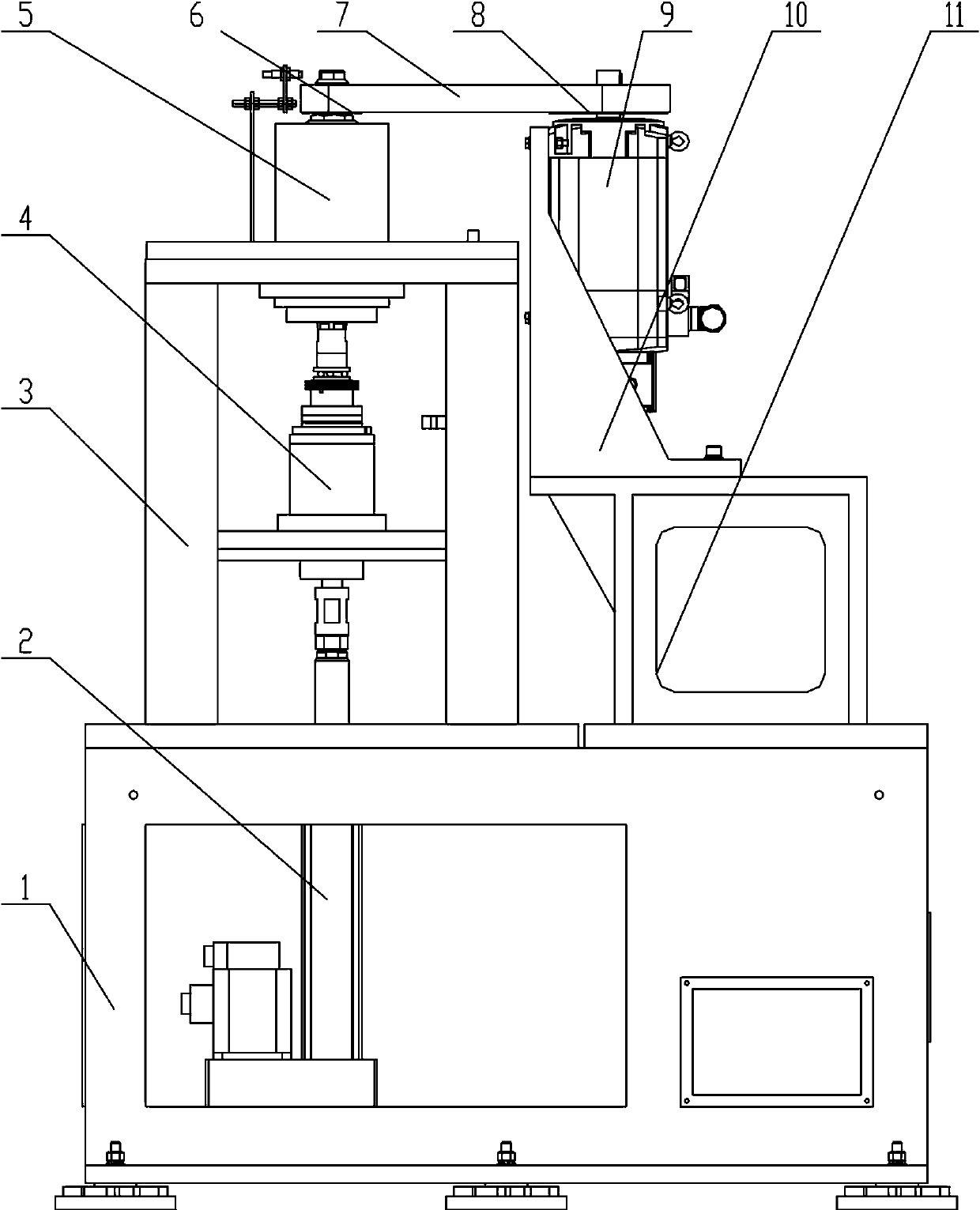

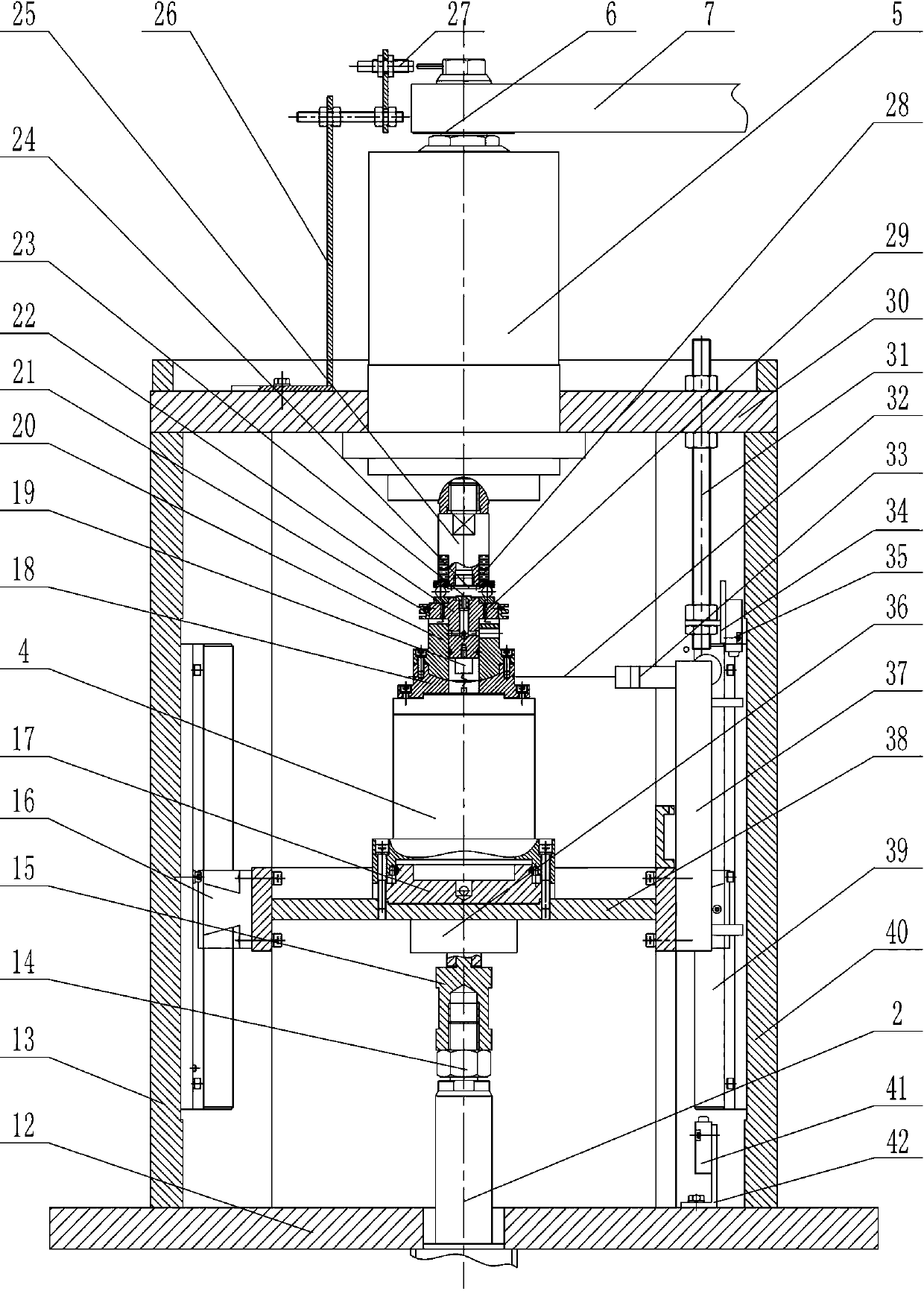

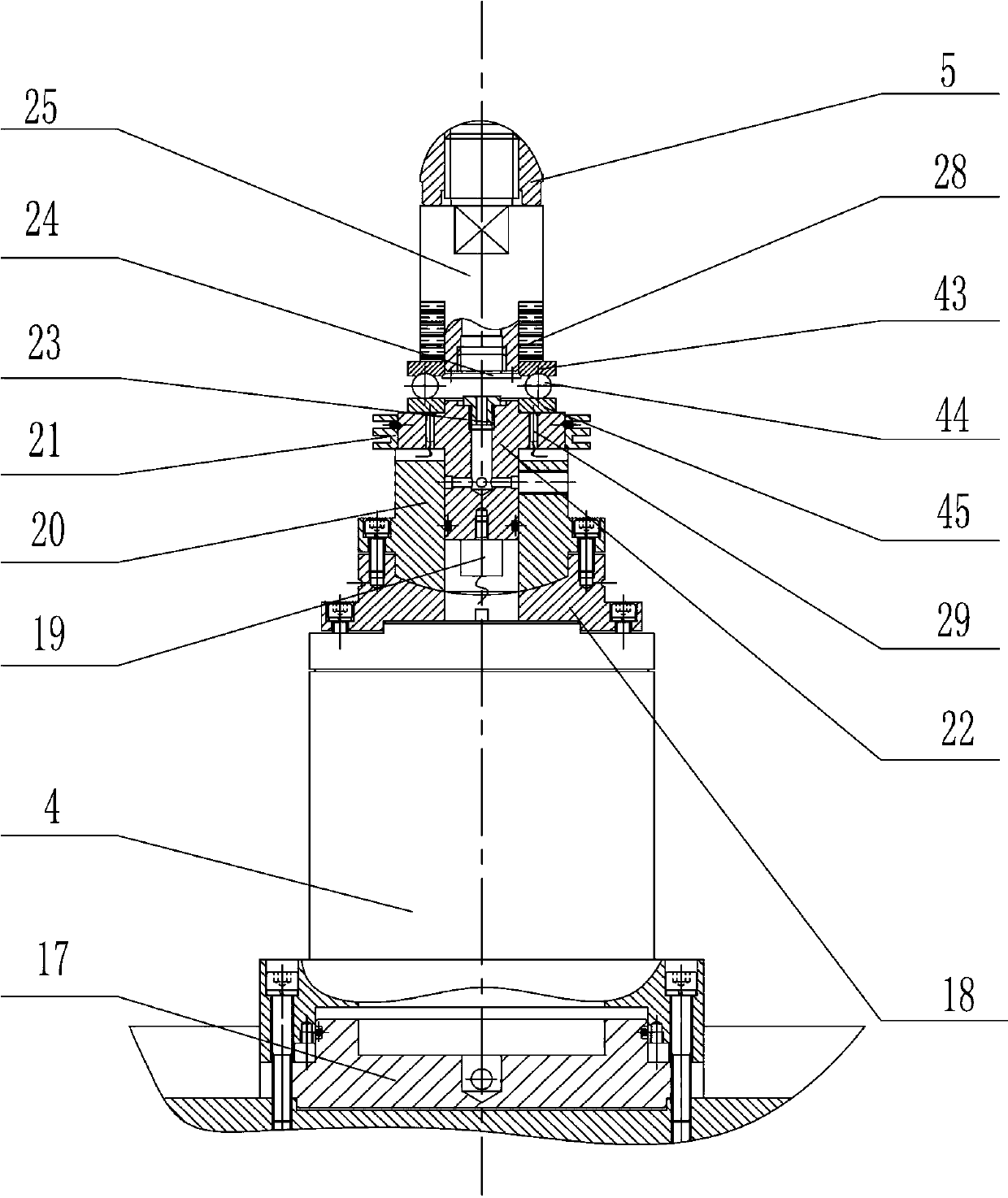

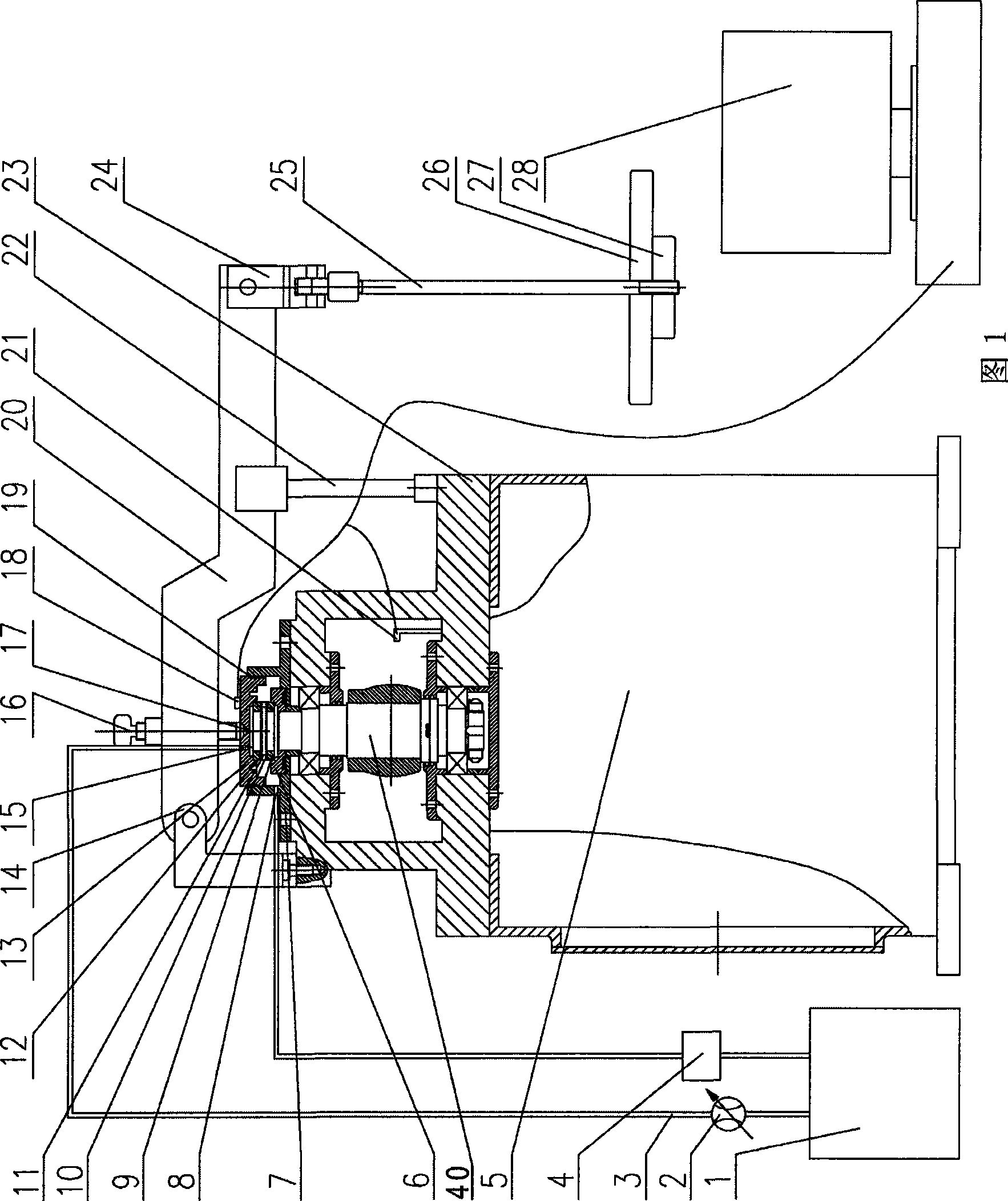

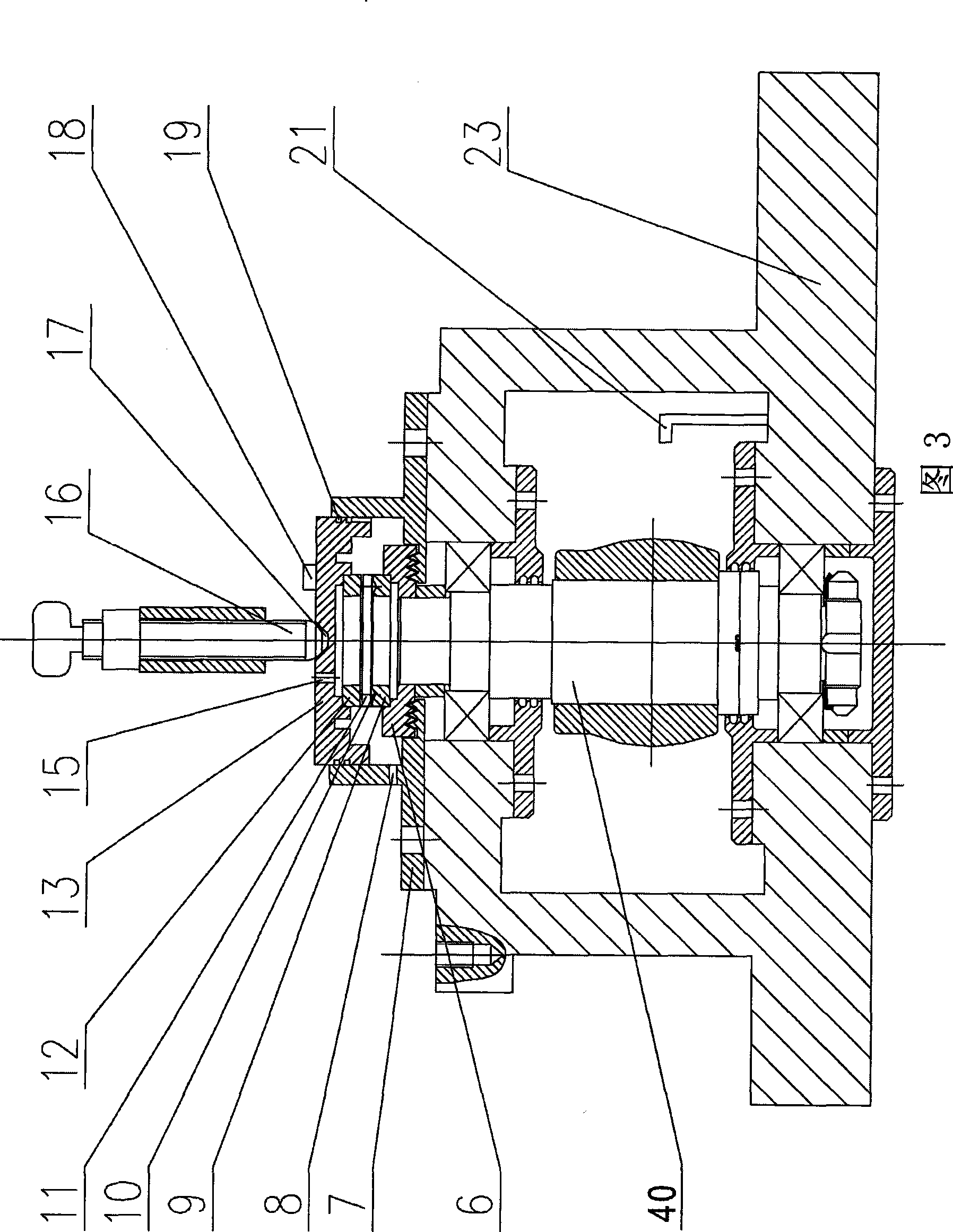

High-speed rolling contact fatigue testing machine

InactiveCN103344553AUse cleanEasy to controlUsing mechanical meansMaterial analysisRolling contact fatigueEngineering

The invention discloses a high-speed rolling contact fatigue testing machine. The high-speed rolling contact fatigue testing machine is characterized in that a driving pulley (6) arranged on the upper end of the output shaft of a servo motor (9) is in transmission connection with a driven pulley (8) arranged on the upper end of a static pressure main shaft (5), and the static pressure main shaft (5) is fixed on an upper beam (30) arranged on a rack (3); a servo electric cylinder (2) is connected with a pressure sensor (36) fixed on the lower surface of a moving beam through a connecting piece (15) of the pressure sensor; the upper end of a hydraulic supporting platform (4) is fixed on a sphere base lower part (18), a lower test specimen base (21) is connected with a sphere base upper part (20), and the lower test specimen base (21) is connected with a test specimen base ring (45) in a clearance fit mode. The high-speed rolling contact fatigue testing machine provided by the invention has the advantages that the rolling contact of a bearing material under a high speed and heavy load working condition is simulated, the key parameter of rolling contact fatigue of a testing material can realize accurate detection, and finally, the data support is provided for evaluating the rolling contact fatigue property of the bearing material.

Owner:YANSHAN UNIV

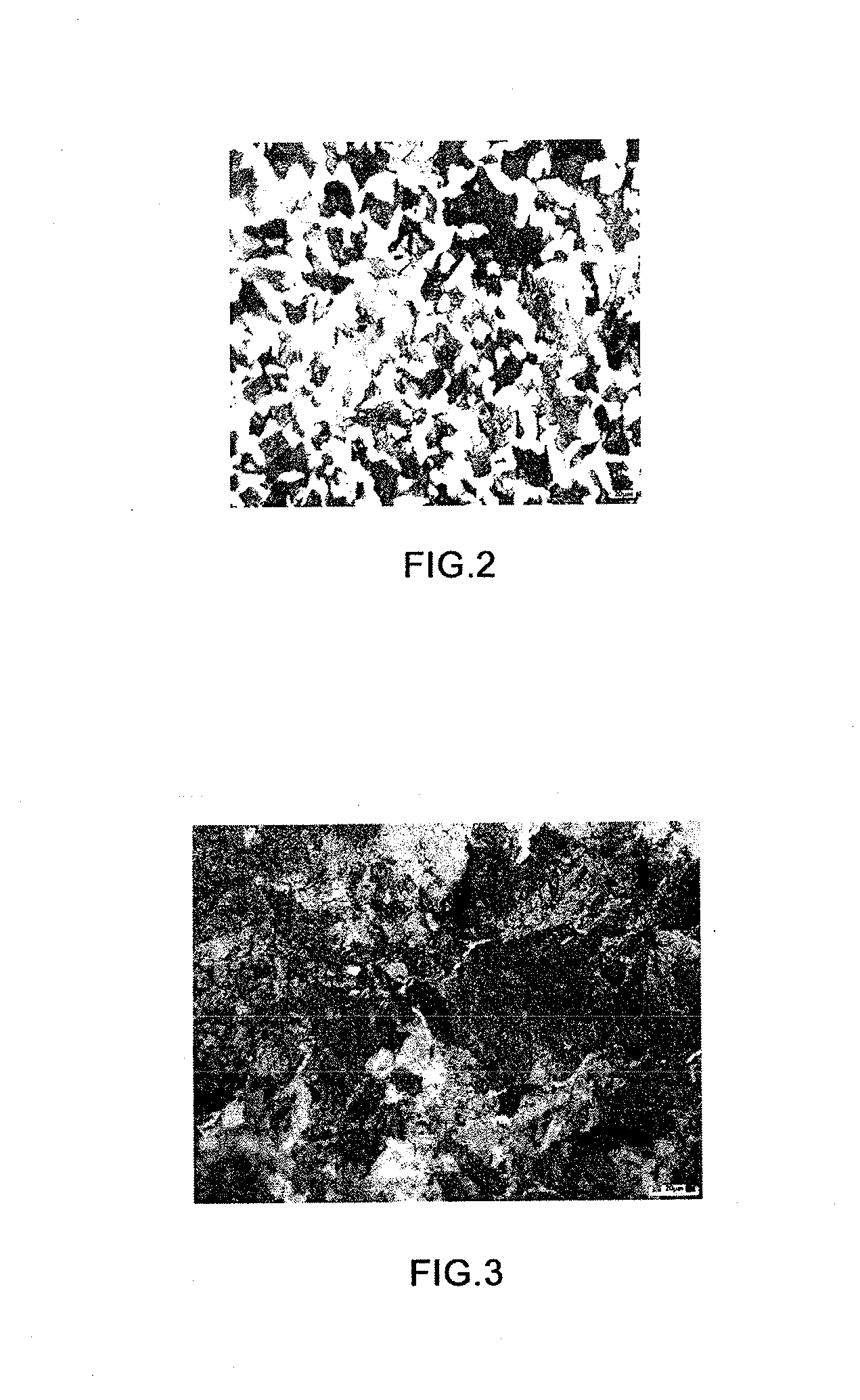

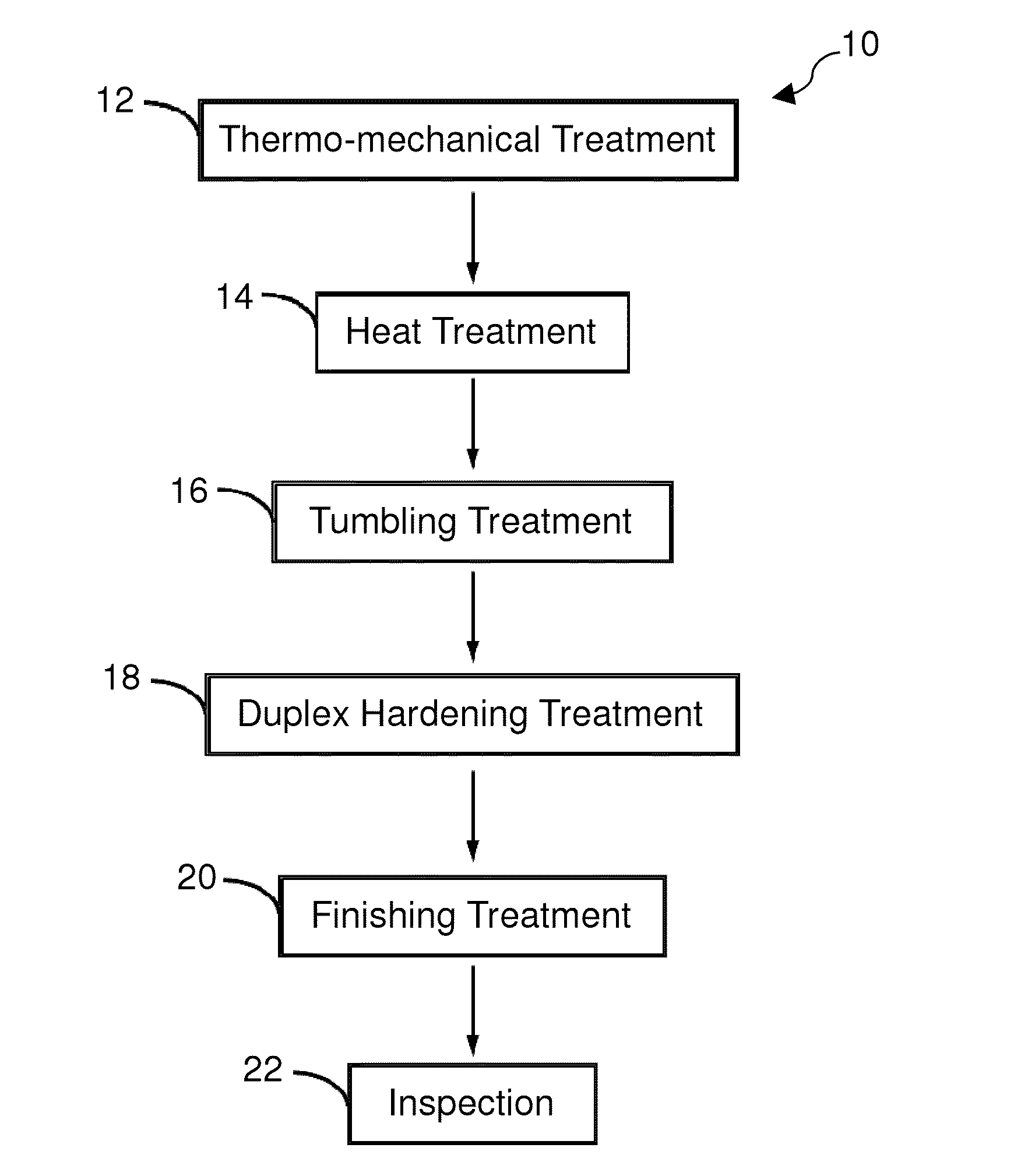

Internal high hardness type pearlitic rail with excellent wear resistance, rolling contact fatigue resistance, and delayed fracture property and method for producing same

ActiveCN101743334AImprove wear resistanceExcellent resistance to fatigue damageFurnace typesMetal rolling arrangementsFatigue damageSurface layer

An internal high hardness type pearlitic rail has a composition containing 0.73% to 0.85% by mass C, 0.5% to 0.75% by mass Si, 0.3% to 1.0% by mass Mn, 0.035% by mass or less P, 0.0005% to 0.012% by mass S, 0.2% to 1.3% by mass Cr, 0.005% to 0.12% by mass V, 0.0015% to 0.0060% by mass N, and the balance being Fe and incidental impurities, wherein the value of ¢% Mn! / ¢% Cr! is greater than or equal to 0.3 and less than 1.0, where ¢% Mn! represents the Mn content, and ¢% Cr! represents the Cr content, and the value of ¢% V! / ¢% N! is in the range of 8.0 to 30.0, where ¢% V! represents the V content, and ¢% N! represents the N content, and wherein the internal hardness of a rail head is defined by the Vickers hardness of a portion located from a surface layer of the rail head to a depth of at least 25 mm and is greater than or equal to 380 Hv and less than 480 Hv.

Owner:JFE STEEL CORP

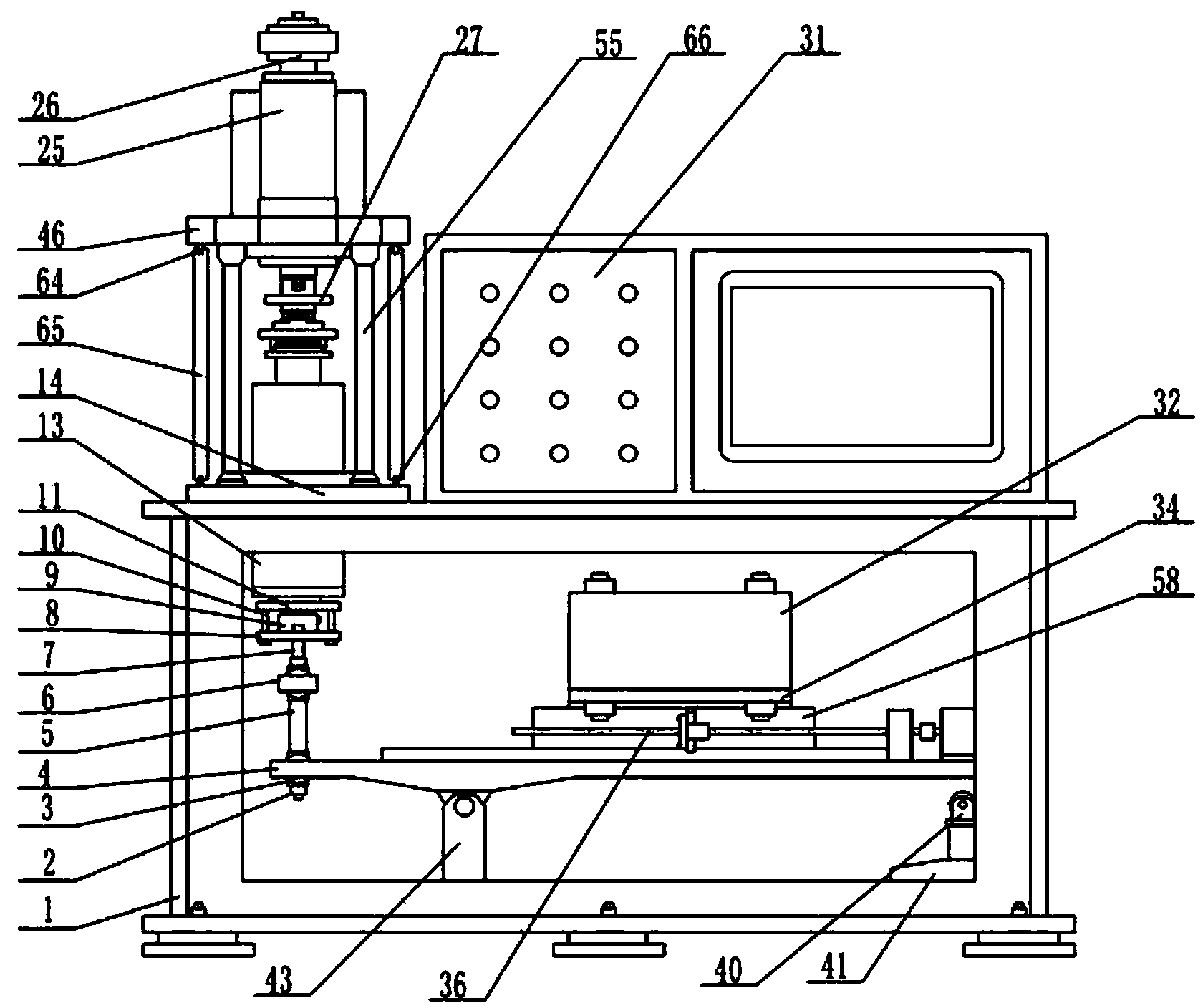

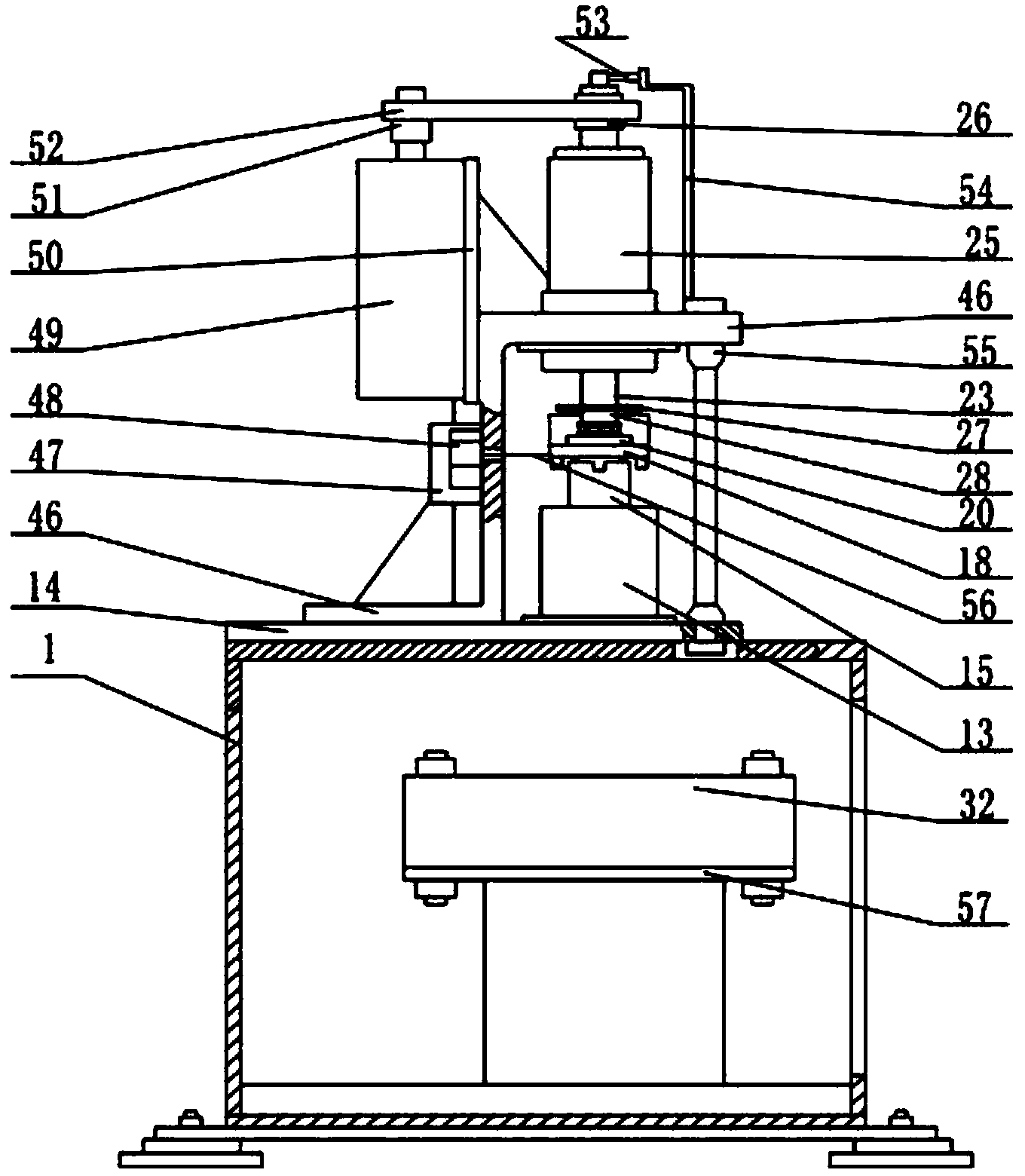

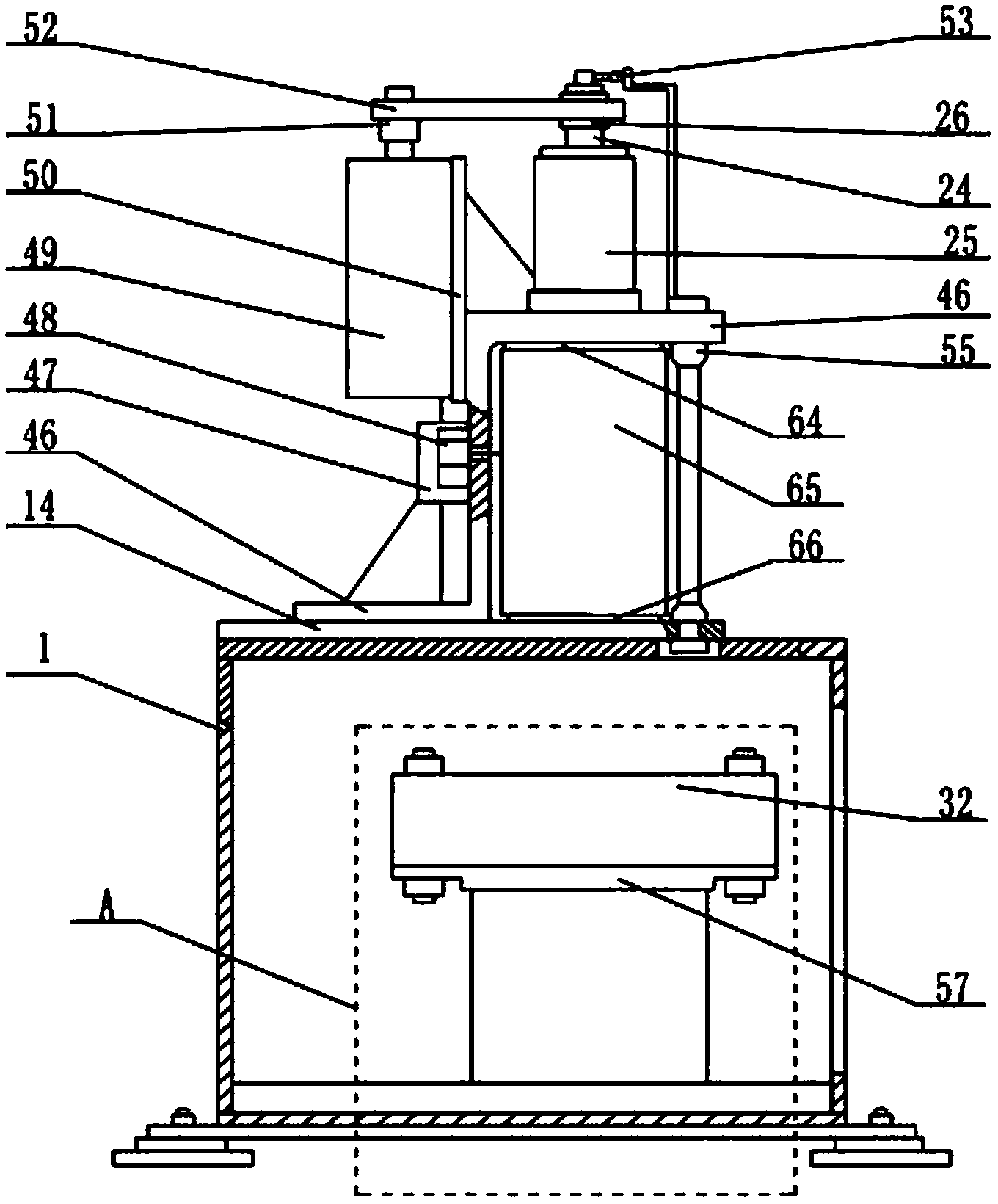

Lever power-driven loading type rolling contact fatigue test machine

InactiveCN104019989ASave electricityLow costMachine bearings testingUsing mechanical meansEngineeringLubrication

The invention discloses a lever power-driven loading type rolling contact fatigue test machine which comprises a machine body, a loading system, a transmission system, a lubrication system and an information acquisition control system. The lever power-driven loading type rolling contact fatigue test machine is characterized in that the loading system comprises a stepping motor, a ball screw, a weight, a weight tray, a jack fixing frame and a power-driven jack. The output shaft of the stepping motor is connected with the ball screw through a plum coupling, the power-driven jack is arranged in the jack fixing frame, the weight is mounted on the weight tray and controlled by the stepping motor to move on a lever, and loads are loaded to a test piece automatically through the self weight of the weight and the principle of lever amplification. The lever power-driven loading type rolling contact fatigue test machine can implement loading of variable loads on a bearing and detect key parameters of contact fatigue of materials, energy and electricity are saved, cost is lowered, and economic benefits are increased.

Owner:YANSHAN UNIV

Coatings rolling contact fatigue tester

InactiveCN101393096ASimple structureEasy to operateUsing mechanical meansInvestigating abrasion/wear resistanceRolling contact fatigueControl system

The invention relates to a coat rolling contact endurance testing machine, which comprises a tester, a loading mechanism, a driving mechanism, a lubrication system, and an information acquisition and control system. The coat rolling contact endurance testing machine has a simple structure, convenient operation and high reliability; in addition, because the testing machine is provided with a plurality of rolling elements, the testing machine has a plurality of contact points and can realize a high efficient test; besides; and through detecting vibration signals and monitoring the surface condition of the coat or a fraction pair, when micro-cracks are generated, the testing machine can pause the test and save the failure moment.

Owner:EAST CHINA UNIV OF SCI & TECH

High-carbon chromium bearing part surface peening thermal treatment method

The invention relates to a heat treatment method, in particular to a high-carbon chrome bearing part surface intensified heat treatment method. The heat treatment method adopts the following steps: firstly, carbonitriding treatment: at the temperature of 830 to 850 DEG C, through adding 0.95 to 1.2C percent of carbon potential and 0.2 to 0.4m<3> / h of ammonia gas, a GCr15 bearing part is carbonitrided for 6 to 8 hours and then oil quenching is performed; secondly, high temperature tempering: at the temperature of 580 DEG C with the tolerance of 10 DEG C, high temperature tempering is implemented for 1.5 to 2.5 hours, and the bearing part is discharged from the furnace and air-cooled; thirdly, at the temperature of 820 DEG C with the tolerance of 10 DEG C, in the protective atmosphere of 0.95 to 1.2C percent of carbon potential and 0.2 to 0.4m<3> / h of ammonia gas, and the conventional secondary high temperature tempering is carried out. The invention has the advantages that a penetrating layer of 0.4 to 0.65mm can be achieved on the part surface through the method, in the obtained carbon nitrogen compound, the residual austenite amount is not less than 20 percent, the carbon nitrogen compound has 12 to 13 grade ultra fine grain size, the particle is difficult to differentiate under the optical microscope of 500 times, and the wear resistance and the anti-rolling contact fatigue lifetime of the bearing under the polluted lubrication environment are enhanced.

Owner:WANXIANG +1

Steel material with excellent rolling fatigue life and method of producing the same

InactiveUS20060081314A1Excellent rolling contact fatigue lifeImprove bearing lifeBearing componentsBearingsAustenite grainRolling contact fatigue

Provided are a steel having excellent rolling contact fatigue life and the manufacturing method thereof. The steel consists essentially of 0.7 to 1.1% C, 0.2 to 2.0% Si, 0.4 to 2.5% Mn, 1.6 to 4.0% Cr, 0.1% or more and less than 0.5% Mo, 0.010 to 0.050% Al, bymass, and balance of Fe and inevitable impurities, is treated by quenching and tempering, has residual cementite grain sizes ranging from 0.05 to 1.5 μm, and has prior-austenite grain sizes of 30 μm or smaller. When the steel is used to bearing steel, the bearing life extends even under service in more severe environments.

Owner:JTEKT CORP +1

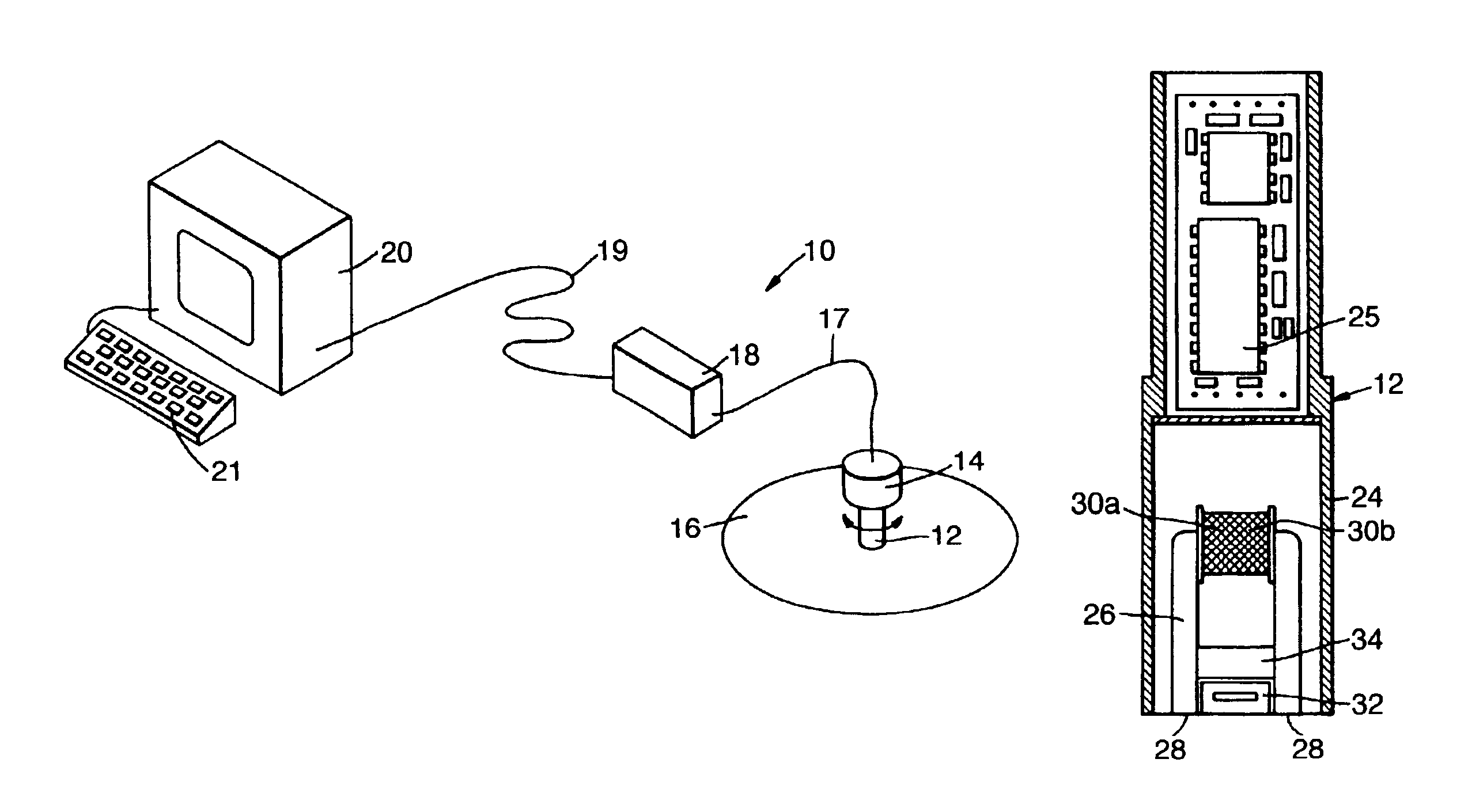

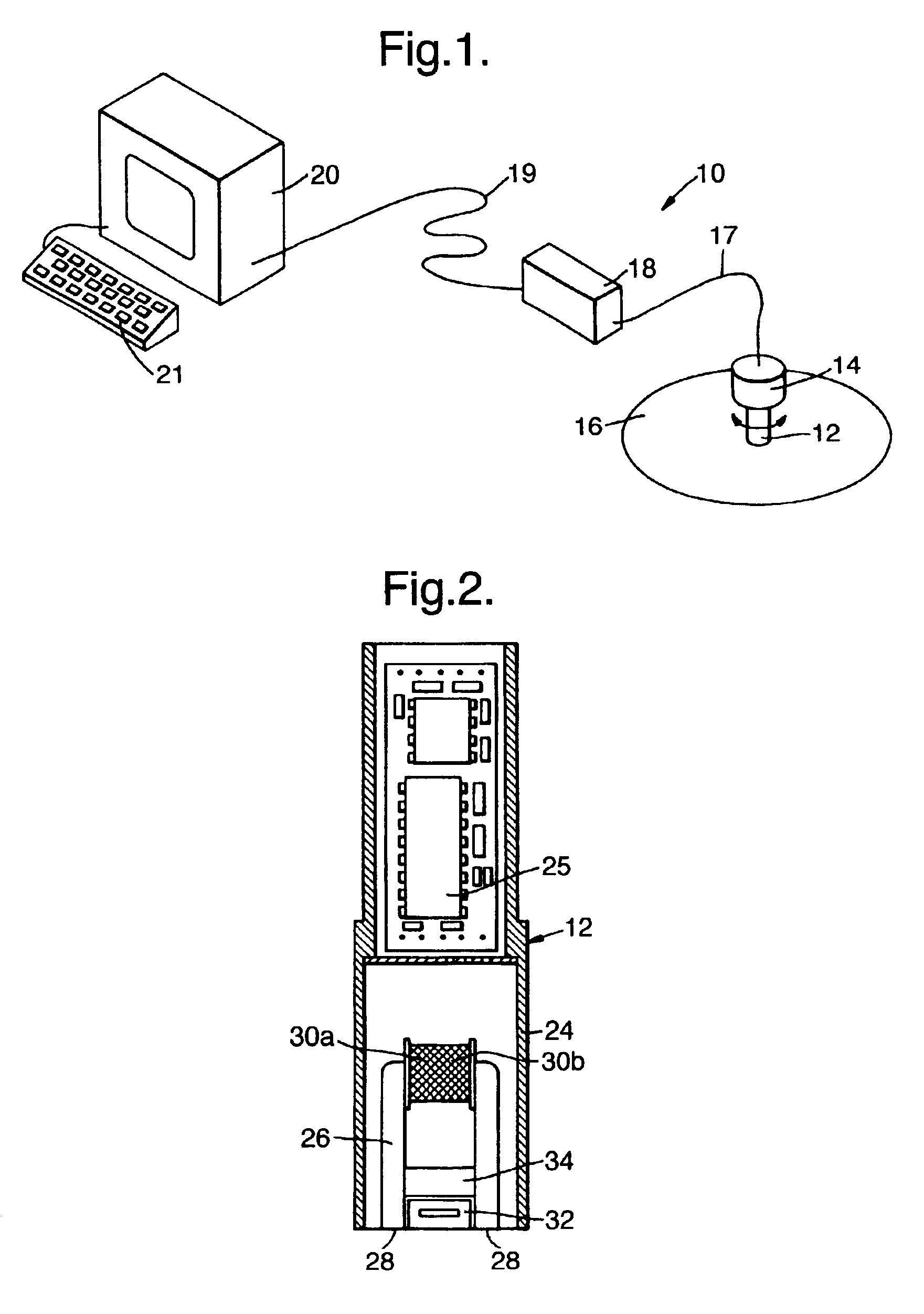

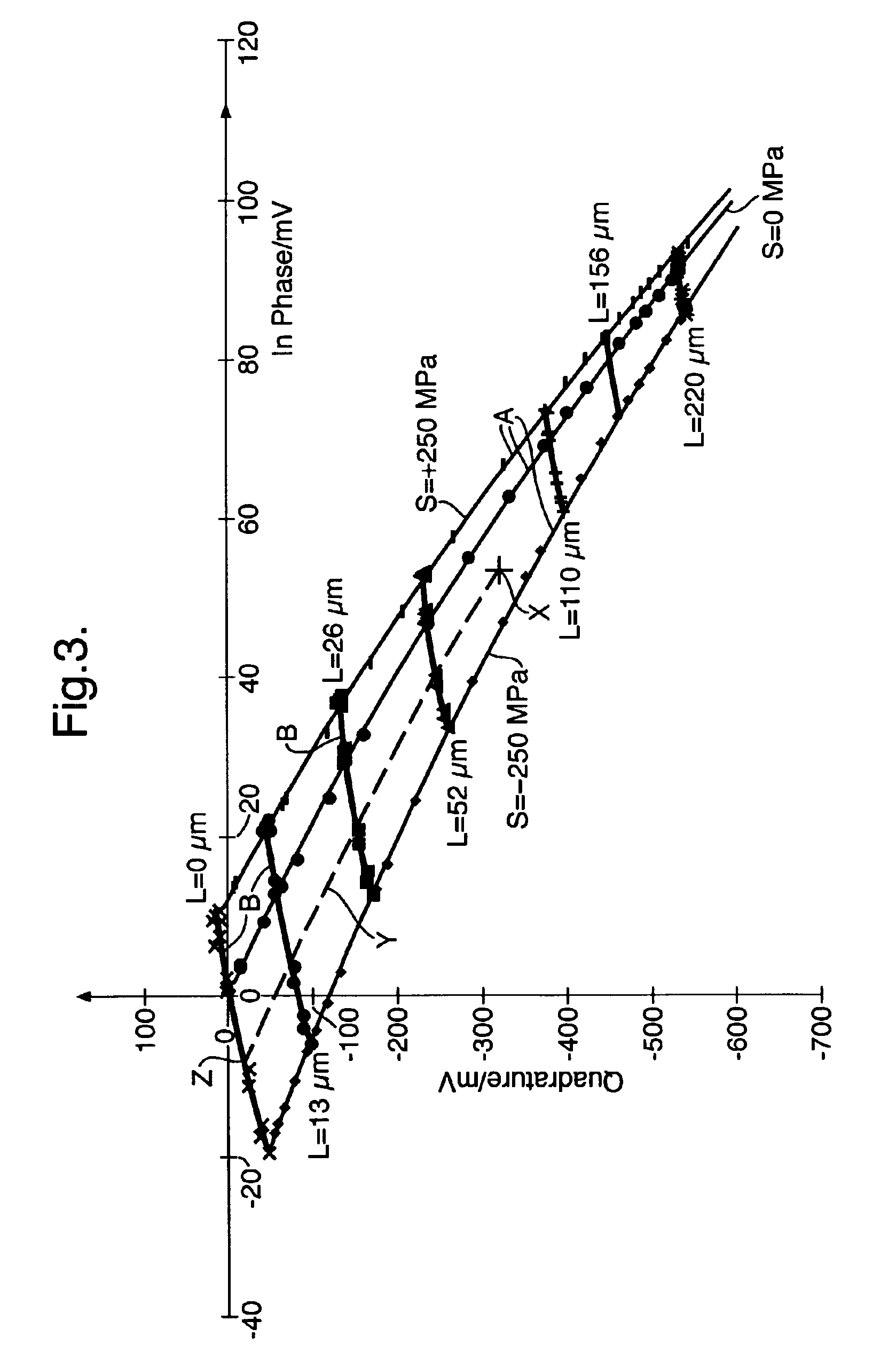

Detection of rolling contact fatigue

InactiveUS6964202B2Accurate representationAccurately determineAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsSurface stressRolling contact fatigue

The onset of rolling contact fatigue in an object may be detected by measuring the residual stresses in the surface of the object, and monitoring changes in their magnitude or their direction. The values of residual stresses in the surface are those averaged over a depth that may be in the range say 0.1 mm to 8.0 mm, for example about 2.5 mm. For ferromagnetic objects such as rails, the method may utilize an electromagnetic probe. Prior to rolling contact fatigue the surface stresses are compressive, and the onset of rolling contact fatigue may be characterized by a marked decrease of the stress in the generally transverse direction.

Owner:BAKER HUGHES ENERGY TECH UK LTD

Railroad wheel steels having improved resistance to rolling contact fatigue

Steels having a pearlitic structure and containing 0.65 to 0.80 weight percent carbon, 0.90 to 1.10 weight percent silicon, 0.85 to 1.15 weight percent manganese, 0.001 to 0.030 weight percent phosphorus, 0.009 to 0.013 weight percent niobium, 0.05 to 0.15 nickel, 0.20 to 0.30 weight percent molybdenum, 0.10 to 0.30 weight percent vanadium and 0.005 to 0.040 weight percent sulfur with the remainder of said steel being iron and incidental impurities, can be used to make railway wheels that are particularly resistant to rolling contact fatigue and, hence, shelling.

Owner:TRANSPORTATION TECH CENT

Railroad rail steels resistant to rolling contact fatigue

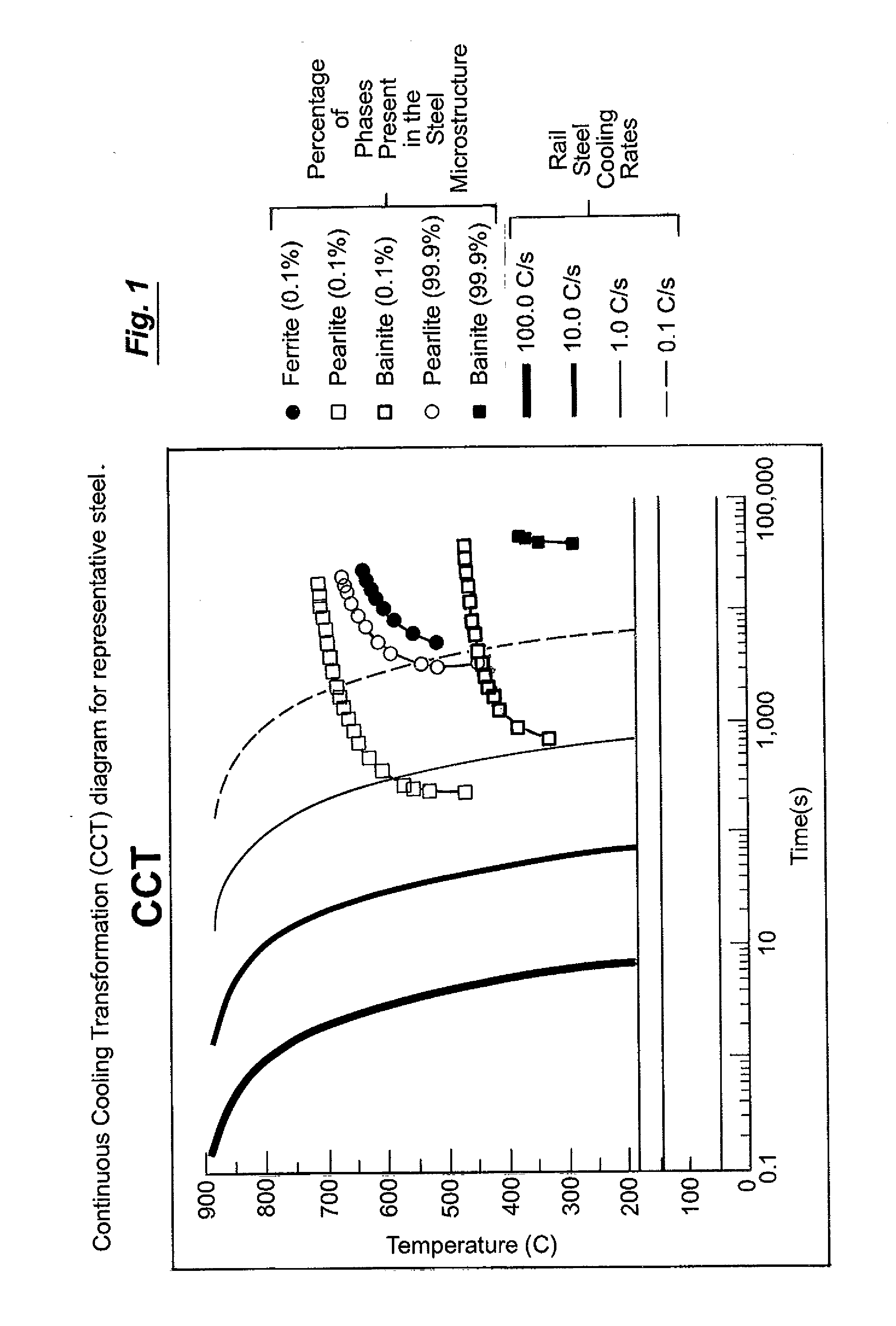

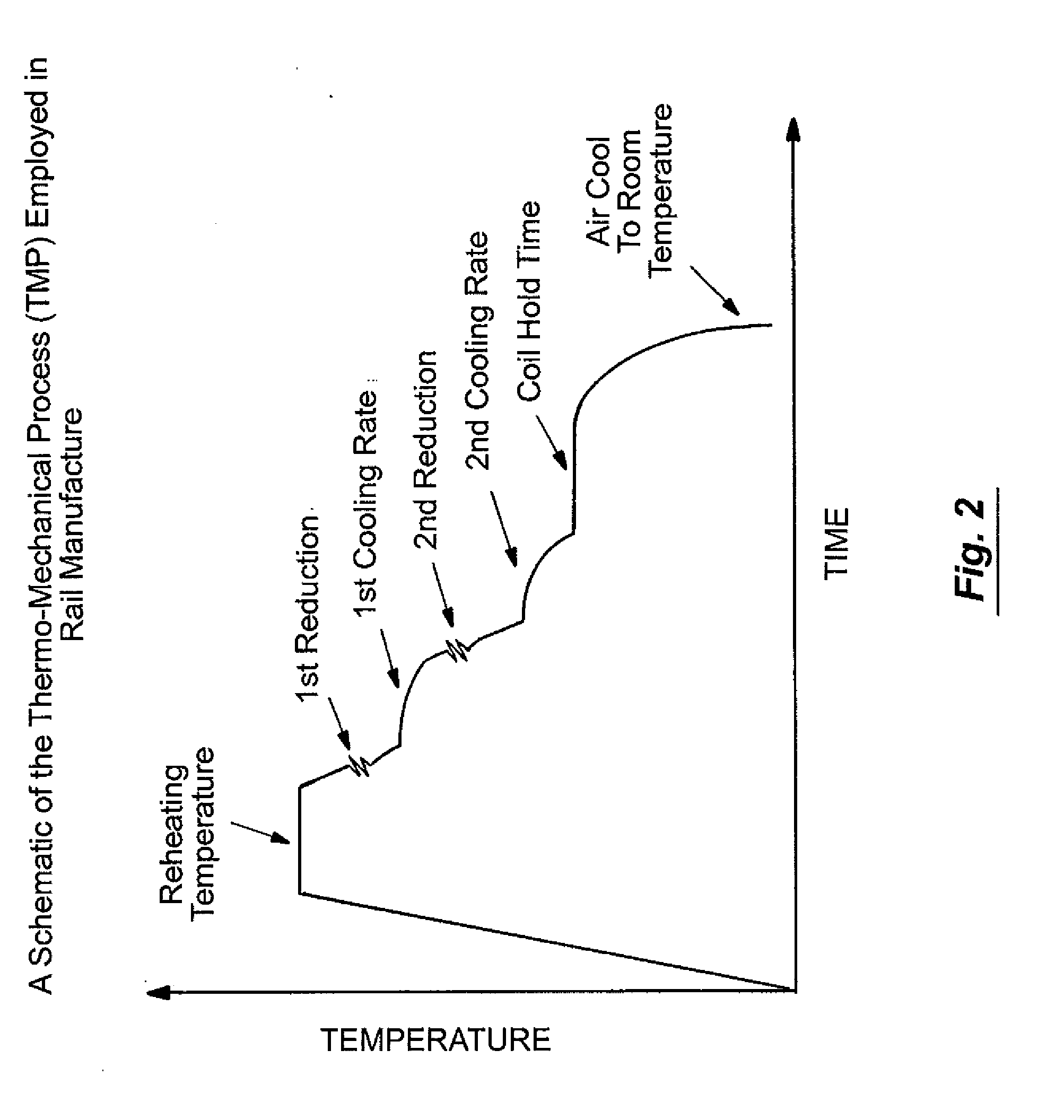

InactiveUS20110189047A1Reduce the amount requiredReduce the cross-sectional areaFurnace typesHeat treatment furnacesNiobiumManganese

Railroad rail steels having a pearlitic structure and containing 0.720 to 0.860 wt % carbon; 1.000 to 1.280 wt % manganese; 0.450 to 1.000 wt % silicon; 0.010 to 0.100 wt % copper; 0.150 to 0.280 wt % chromium; 0.0010 to 0.0500 wt % aluminum; 0.050 to 0.120 wt % nickel; 0.100 to 0.260 wt % molybdenum; 0.100 to 0.210 wt % vanadium; 0.0010 to 0.0065 wt % nitrogen; 0.0010 to 0.0080 wt % phosphorus; 0.0010 to 0.0040 wt % sulfur; and 0.0100 to 0.0350 wt % niobium with the remainder of said steel being iron, can be used to make railway rails that are particularly resistant to rolling contact fatigue and, hence, shelling.

Owner:TRANSPORTATION TECH CENT

Wear resistant and anti-fatigue surfacing electrode

InactiveCN101274395AArc blowing force is largeLarge melting coefficientWelding/cutting media/materialsSoldering mediaWear resistantRare earth

The invention discloses a wear resistant and fatigue resistant surfacing welding electrode which has an H08Mn or H08MnA welding wire as a welding core and is characterized by the components of the electrode coating of the electrode by weight percent: 10 to 20 percent of marble, 5 to 10 percent of fluorite, 2 to 4 percent of quartz, 5 to 10 percent of titanium ore, 2 to 4 percent of chalkstone, 10 to 25 percent of nitrided ferrochromium, 20 to 30 percent of metal manganese, 10 to 20 percent of nitrided ferromanganese, 5 to 10 percent of ferrotungsten and 1 to 3 percent of rare earth ferromagnesian alloy; and also is characterized by using sodium silicate as a binder. The chemical components of the melting cladding layer material of the surfacing welding comprise 15 to 17 wt percent of Mn, 4 to 6 wt percent of Cr, 2 to 4 wt percent of W, 0.08 to 0.20 wt percent of N, 0.2 to 0.4 percent of C, small amount of Re, less than 0.1 wt percent of impurities and the rest is iron. When using the electrode for the surfacing welding, a DC welding machine is adopted and the electrode is used as a cathode. The obtained cladding layer of the surfacing welding is a single-phase austenite structure with the rigidity of 220 to 260HB and has excellent capability of processing rigidification and excellent performances of rolling contact fatigue resistance and wear resistance, and can obviously lengthen the service life of wearing and fatigue parts after repairing.

Owner:YANSHAN UNIV

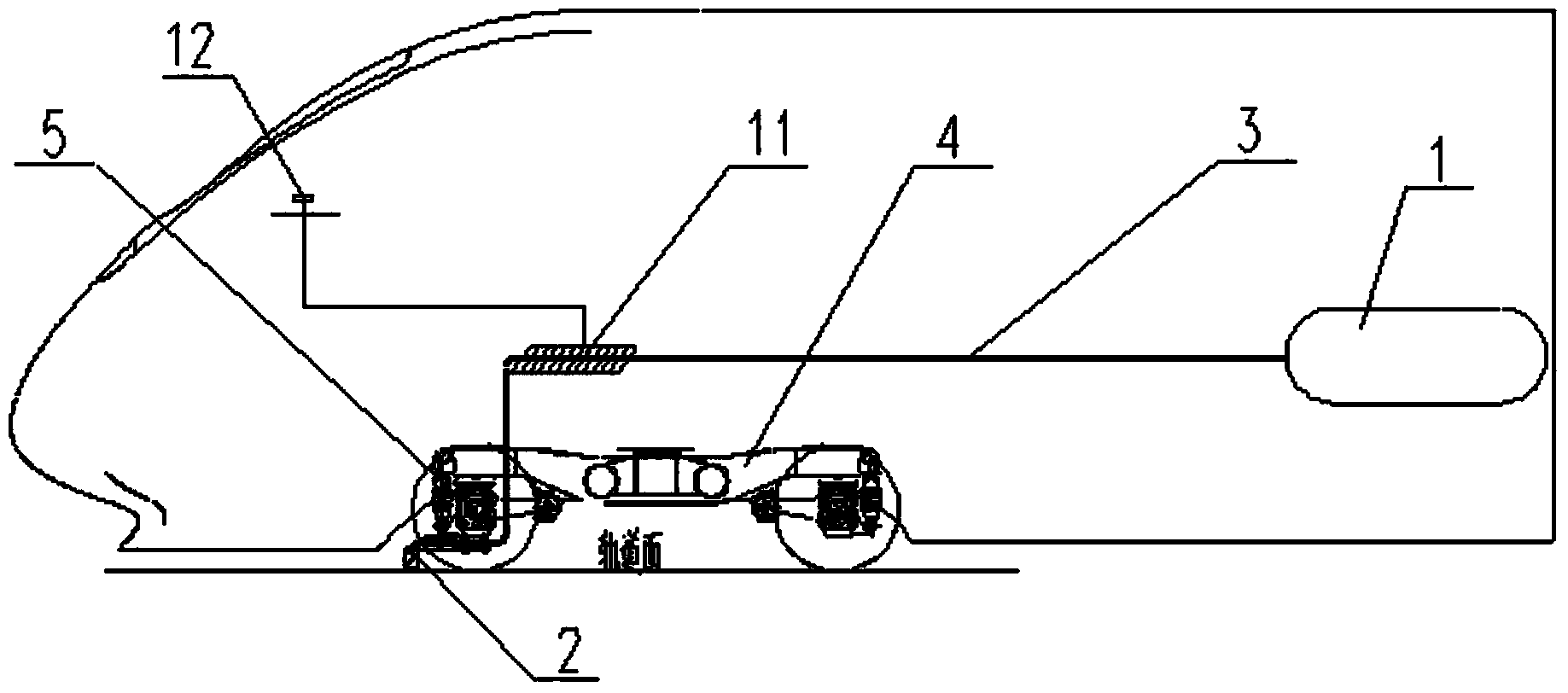

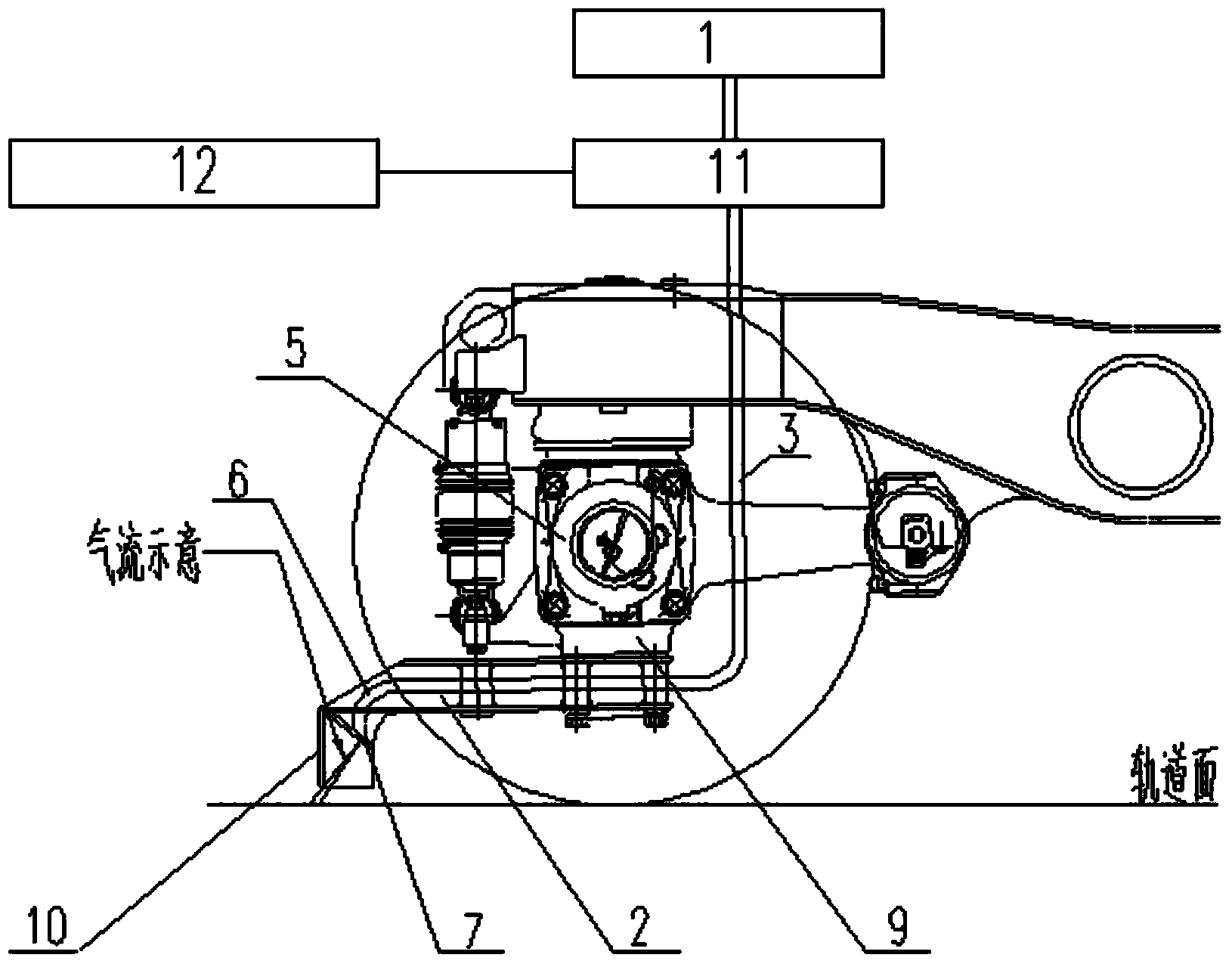

Obstacle removing method and obstacle removing device for railway vehicle

InactiveCN104386086AWon't wear outNo wear partsRailway wheel guards/bumpersForeign matterRolling contact fatigue

The invention relates to an obstacle removing method and an obstacle removing device for a railway vehicle. Compressed air is blown to a rail in front of wheels by an air supply source to remove obstacles on the rail. The method and the device use high-pressure gas for removing the obstacles, have the advantages of zero wearing part, zero rail abrasion, zero need of periodic replacement, convenience for maintenance and cost reduction, can remove tinier foreign matters on the rail, heat and dry the rail, reduce the wheel rolling contact fatigue source, and prolong the service life of the wheels and the rail, and are specifically suitable for the railway vehicle running in high-cold and high-sand wind environments.

Owner:CRRC QINGDAO SIFANG CO LTD

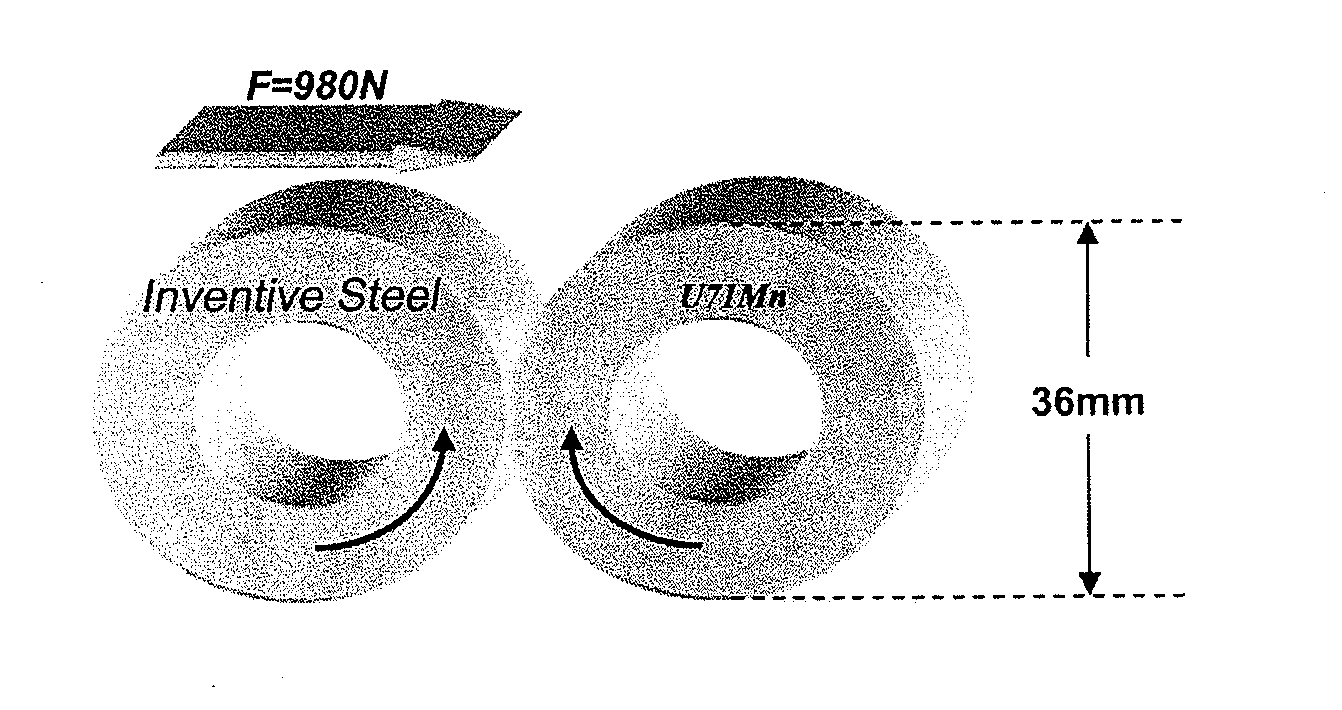

Railroad steels having improved resistance to rolling contact fatigue

Steels having a pearlitic structure and containing 0.6 to 0.8 wt. % carbon; 0.70 to 1.00 wt. % silicon and 0.8 to 1.2 wt. % manganese can be further alloyed with chromium, molybdenum, vanadium, niobium and / or copper and used to make railway wheels, railway rims and railway rails that are particularly resistant to rolling contact fatigue and, hence, shelling.

Owner:TRANSPORTATION TECH CENT

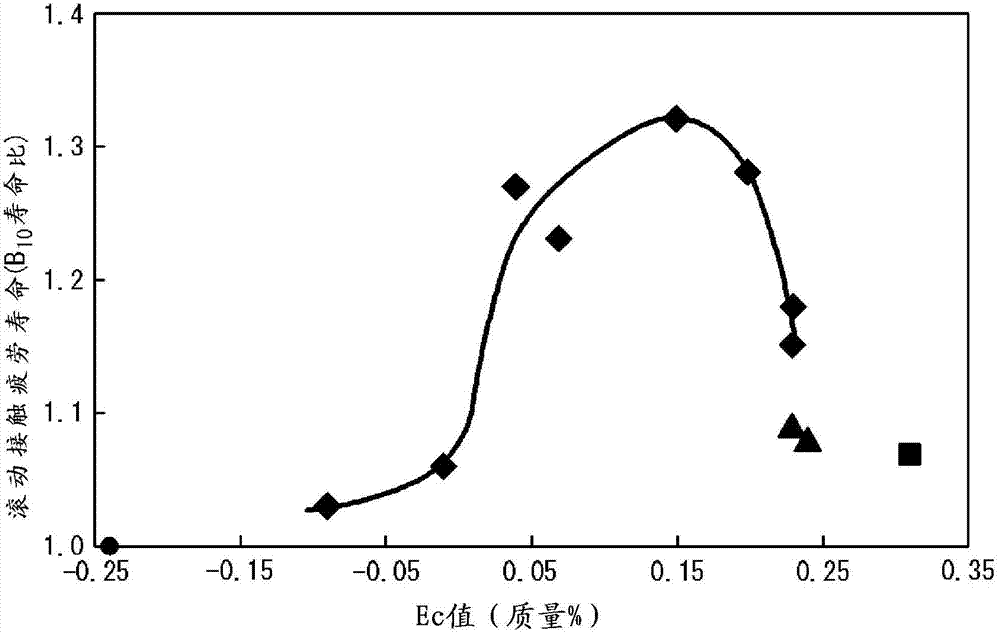

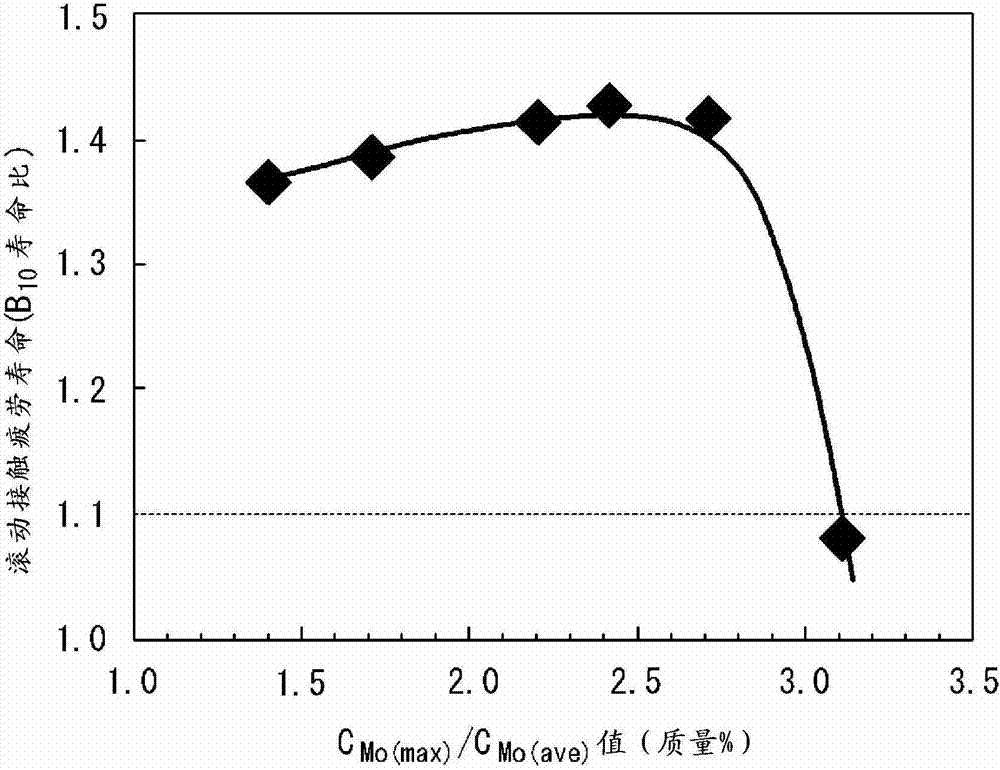

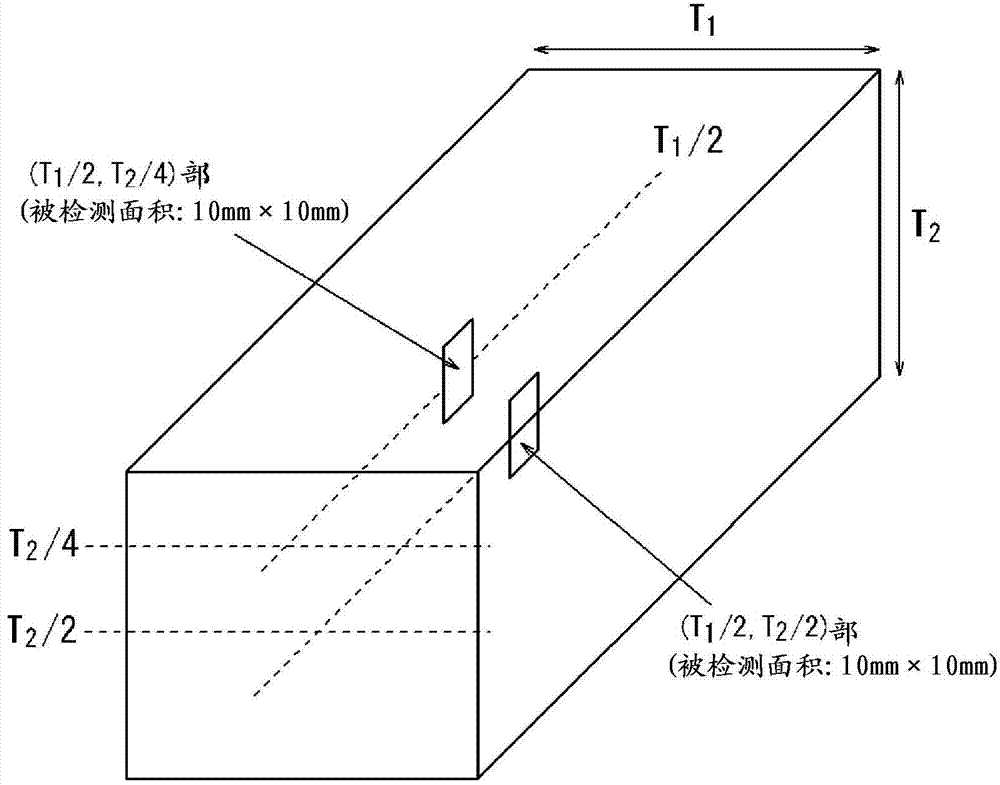

Bearing steel and ingot material for bearing having excellent rolling contact fatigue life characteristics and method for manufacturing the same

ActiveCN103168112AStable manufacturingYouNai Rolling Contact Fatigue Life CharacteristicsFurnace typesHeat treatment furnacesRolling contact fatigueCarbide

The present invention has a component composition which comprises 0.56 to 0.70 mass% of C, 0.15 mass% or more but less than 0.50 mass% of Si, 0.60 to 1.50 mass% of Mn, 0.50 to 1.10 mass% of Cr, 0.05 to 0.5 mass% of Mo, 0.025 mass% or less of P, 0.025 mass% or less of S, 0.005 to 0.500 mass% of Al, 0.0015 mass% or less of O, 0.0030 to 0.015 mass% of N, and residual Fe and inevitable impurities as the balance, and which has an eutectic carbide generation index (Ec) that is 0<Ec=0.25 and an Mo segregation degree that is 2.8 or less.

Owner:JFE STEEL CORP +1

Railroad wheel steels having improved resistance to rolling contact fatigue

Steels having a pearlitic structure and containing 0.65 to 0.80 weight percent carbon, 0.90 to 1.10 weight percent silicon, 0.85 to 1.15 weight percent manganese, 0.001 to 0.030 weight percent phosphorus, 0.009 to weight percent niobium, 0.05 to 0.15 nickel, 0.20 to 0.30 weight percent molybdenum, 0.10 to 0.30 weight percent vanadium and 0.005 to 0.040 weight percent sulfur with the remainder of said steel being iron and incidental impurities, can be used to make railway wheels that are particularly resistant to rolling contact fatigue and, hence, shelling.

Owner:TRANSPORTATION TECH CENT

Rolling contact fatigue testing machine of roller component

InactiveCN102494963AImprove efficiencySimple structureMaterial strength using repeated/pulsating forcesVertical planeRolling contact fatigue

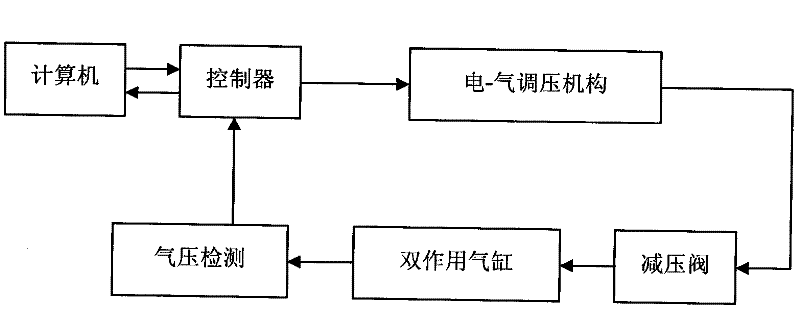

The invention relates to a rolling contact fatigue testing machine of a roller component, which comprises an air spindle, a base, left and right idle pulleys, swing arms, a double-purpose cylinder, an automatic pneumatic control system and the like; the two swing arms are vertically arranged in the vertical plane of the base through a bearing; a large-diameter idle pulley is installed on the upper end of each swing arm; the lower end of each swing arm is connected with the cylinder and a force sensor through a spherical coupler at a rod end; the pressure of the cylinder can be changed according to a given program through a pressure adjusting system under the control of a computer and then is applied on the roller component through the level actions of the swing arms; and the roller component rotates at high speed along the air spindle through a high-precision spring fixture. The rolling contact fatigue testing machine disclosed by the invention is simple in structure, convenient for operation and strong in practicability and is capable of completing a fatigue effect experiment in a determined area on the surface of a test piece with variable load under a given cycle period rapidly and effectively in a low-cost manner.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

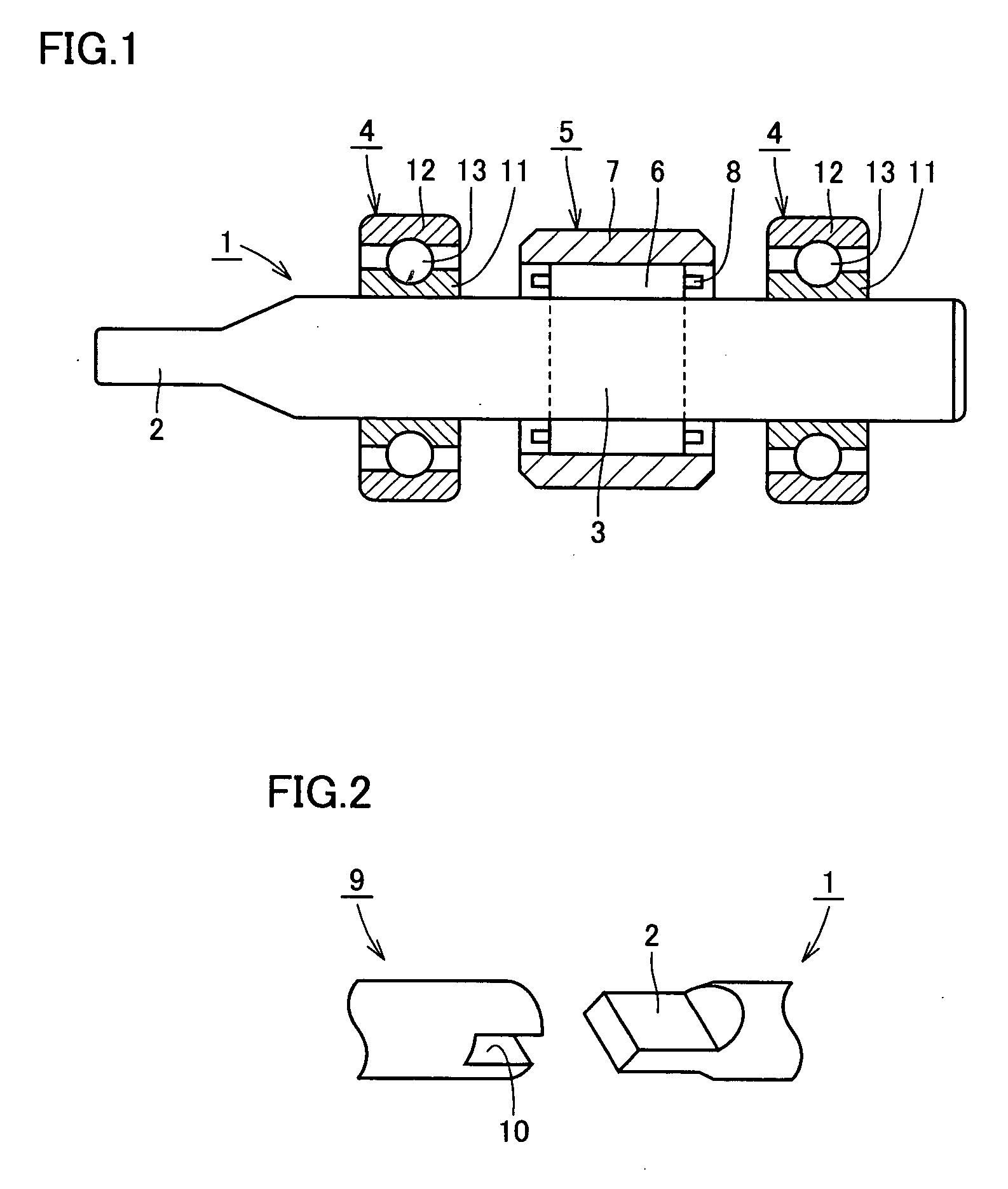

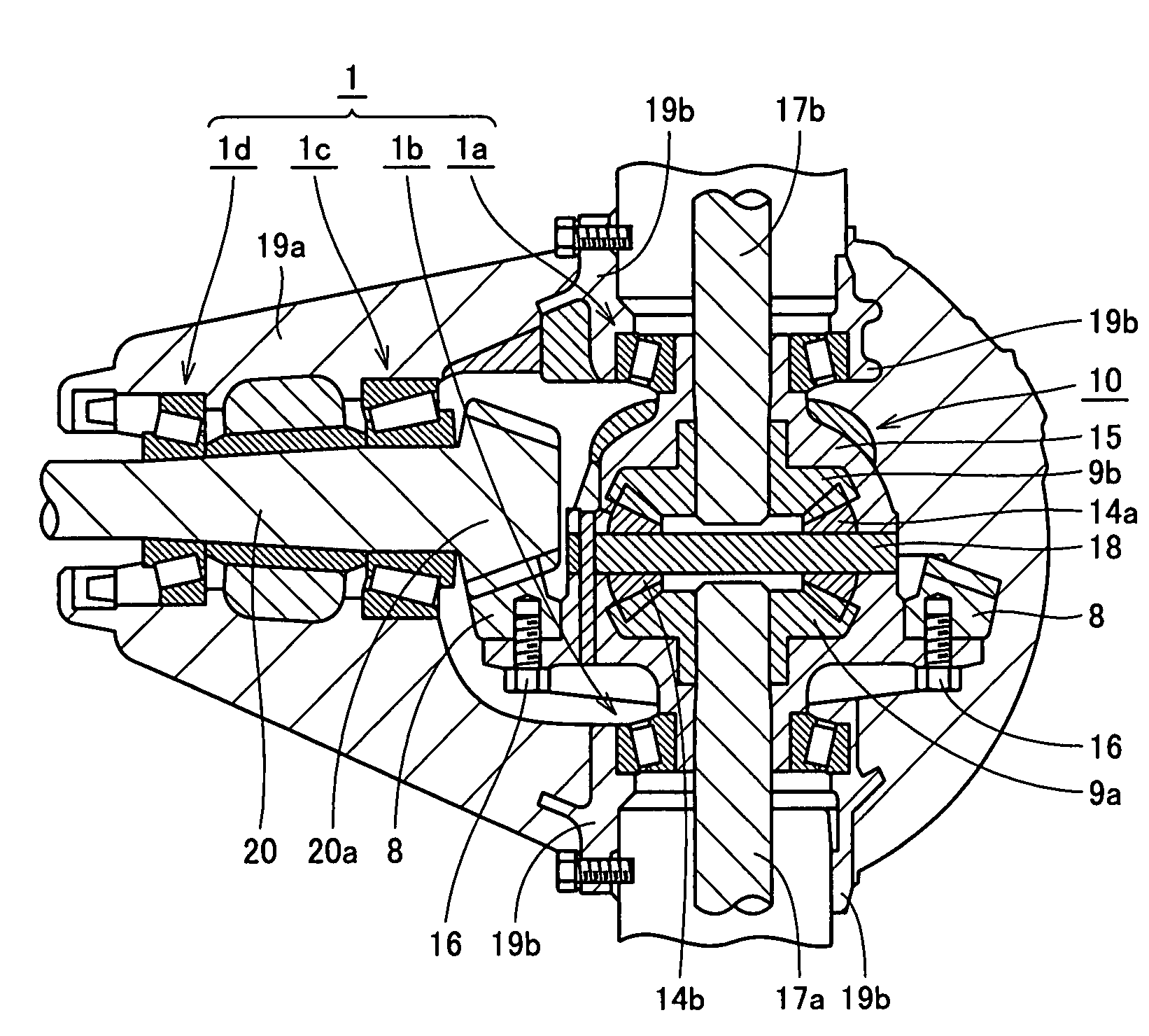

Differential support structure, differential's component, method of manufacturing differential support structure, and method of manufacturing differential's component

ActiveUS7334943B2Improve fatigue lifeImprove fatigueShaftsBearing componentsAustenite grainRolling contact fatigue

A structure supporting a differential rotatably includes an inner ring arranged at the differential, an outer ring arranged at an external peripheral portion formed to surround the differential, and a tapered roller rolling between the inner ring and the outer ring. At least any one of the inner ring, the outer ring and the tapered roller has a carbo-nitrided layer and provides an austenite grain number falling within a range exceeding 10. Thus the structure can be provided with increased anti-crack strength and dimensional stability, and increased rolling contact fatigue life.

Owner:NTN CORP

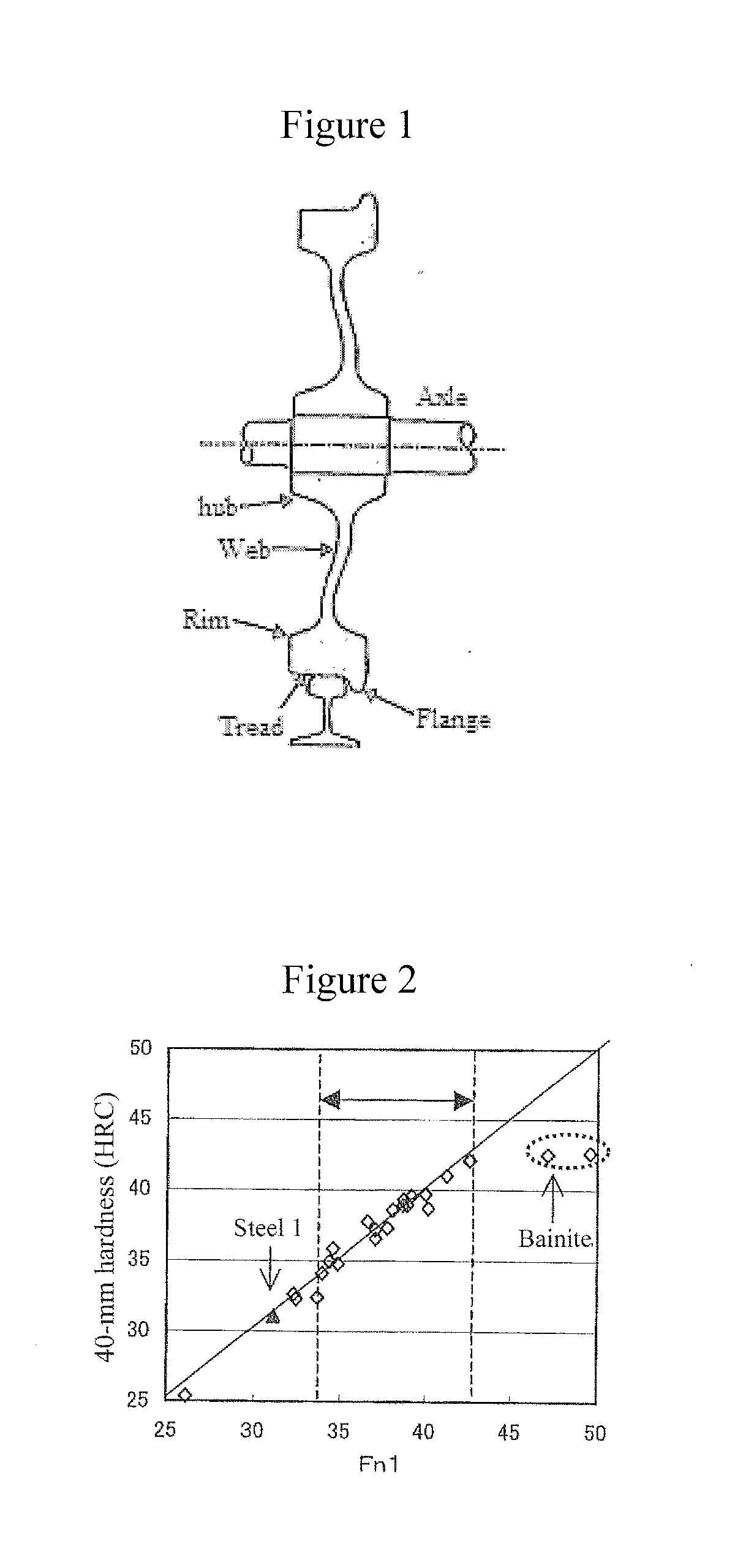

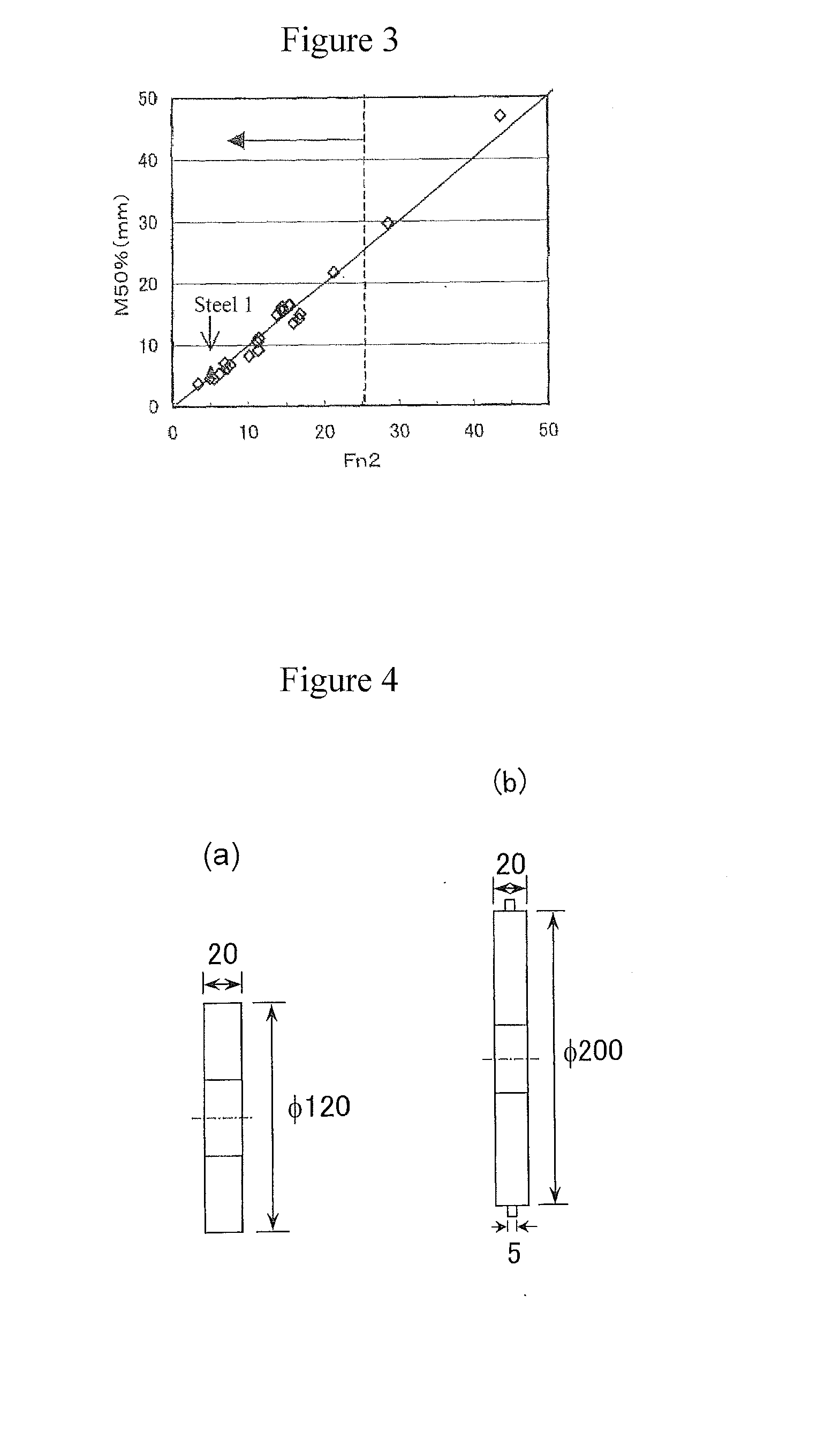

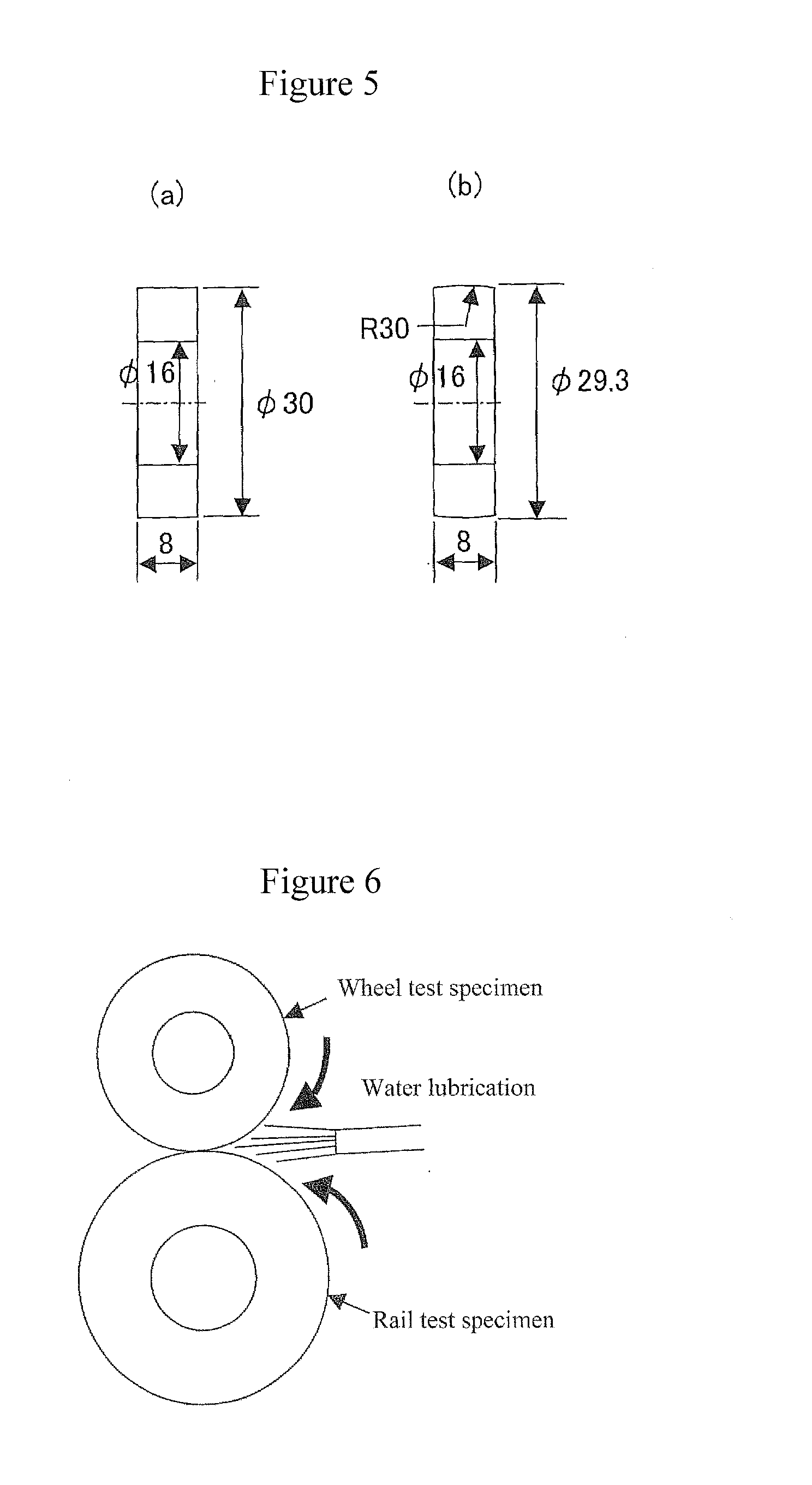

Steel for wheel

InactiveUS20130243640A1Improve balanceIncrease running distanceRail-engaging wheelsFurnace typesRolling contact fatigueChemical composition

There is provided steel for wheel having a chemical composition consisting of, by mass percent, C: 0.65 to 0.84%, Si: 0.02 to 1.00%, Mn: 0.50 to 1.90%, Cr: 0.02 to 0.50%, V: 0.02 to 0.20%, and S: 0.04% or less, in which 34≦2.7+29.5×C+2.9×Si+6.9×Mn+10.8×Cr+30.3×Mo+44.3×V≦43, and 0.76×exp(0.05×C)×exp(1.35×Si)×exp(0.38×Mn)×exp(0.77×Cr)×exp(3.0×Mo)×exp(4.6×V)25, the balance being Fe and impurities, and the impurities containing P: 0.05% or less, Cu: 0.20% or less, and Ni: 0.20% or less. This steel for wheel is excellent in balance between the wear resistance, rolling contact fatigue resistance and the spalling resistance, and can give a long life to the wheel.

Owner:NIPPON STEEL CORP

Steel rail for high speed and quasi-high speed railways and method of manufacturing the same

InactiveUS20130193223A1Excellent rolling contact fatigue propertyToughnessRailsMetal rolling stand detailsRare-earth elementRolling contact fatigue

The present discloses a steel rail for high speed and quasi-high speed railways and a manufacturing method thereof. The steel rail having a superior rolling contact fatigue property can be obtained by reducing content of carbon in conjunction with controlled cooling after rolling. The steel rail includes 0.40-0.64% by weight of C, 0.10-1.00% by weight of Si, 0.30-1.50% by weight of Mn, less than or equal to 0.025% by weight of P, less than or equal to 0.025% by weight of S, less than or equal to 0.005% by weight of Al, more than 0 and less than or equal to 0.05% by weight of a rare earth element, more than 0 and less than or equal to 0.20% by weight of at least one of V, Cr, and Ti, and a remainder of Fe and inevitable impurities. The steel rail manufactured according to the method of the present invention maintains the strength and hardness of the existing steel rail for the high speed railways, while enhancing the toughness, plasticity and yield strength, and an energy value required for initiating and expanding microcracks formed at the surface of the steel rail due to fatigue is increased, and thus under the same conditions, the rolling contact fatigue property of the steel rail can be improved, thereby finally improving the service lifetime and the transportation safety of the steel rail.

Owner:PANZHIHUA IRON AND STEEL +1

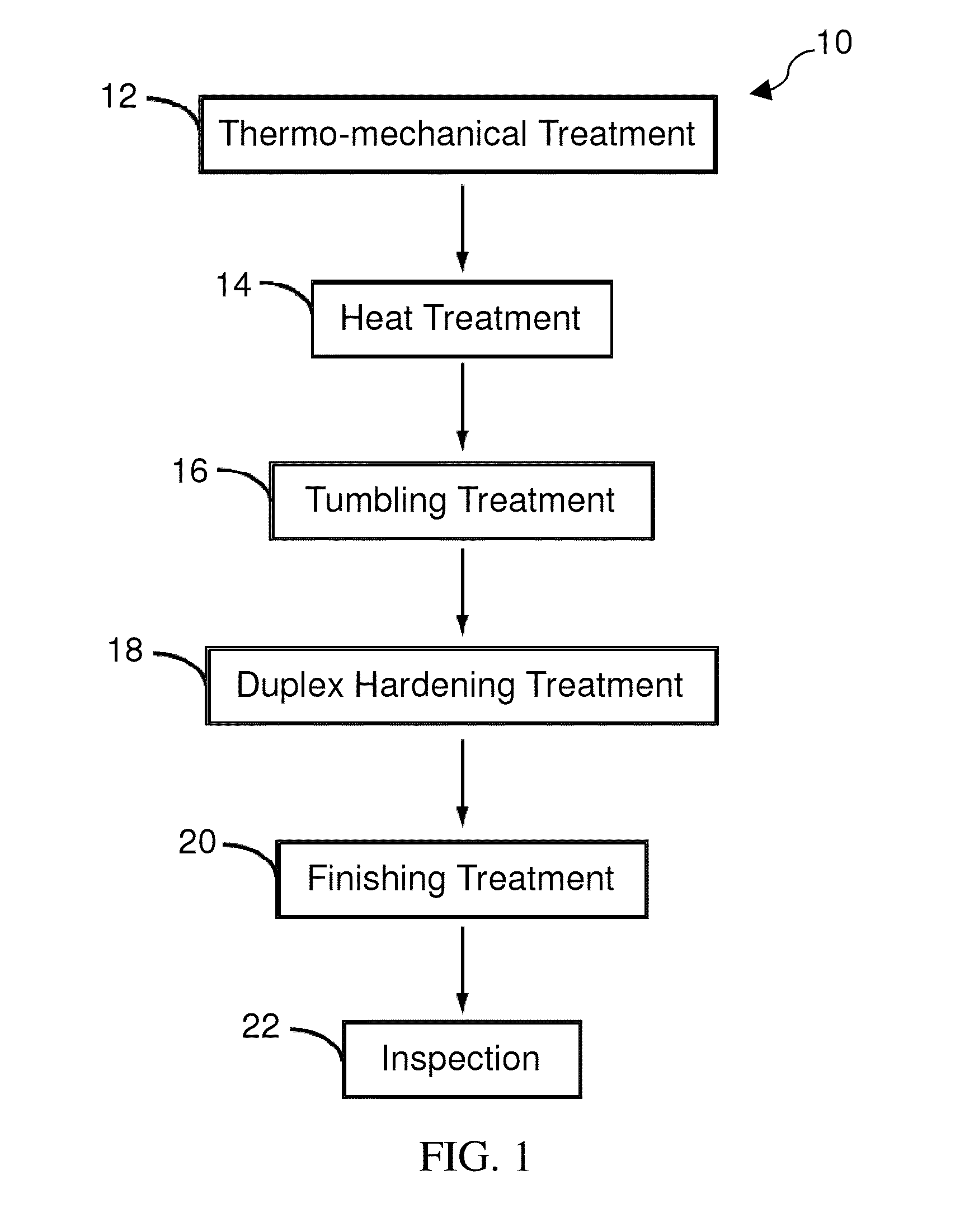

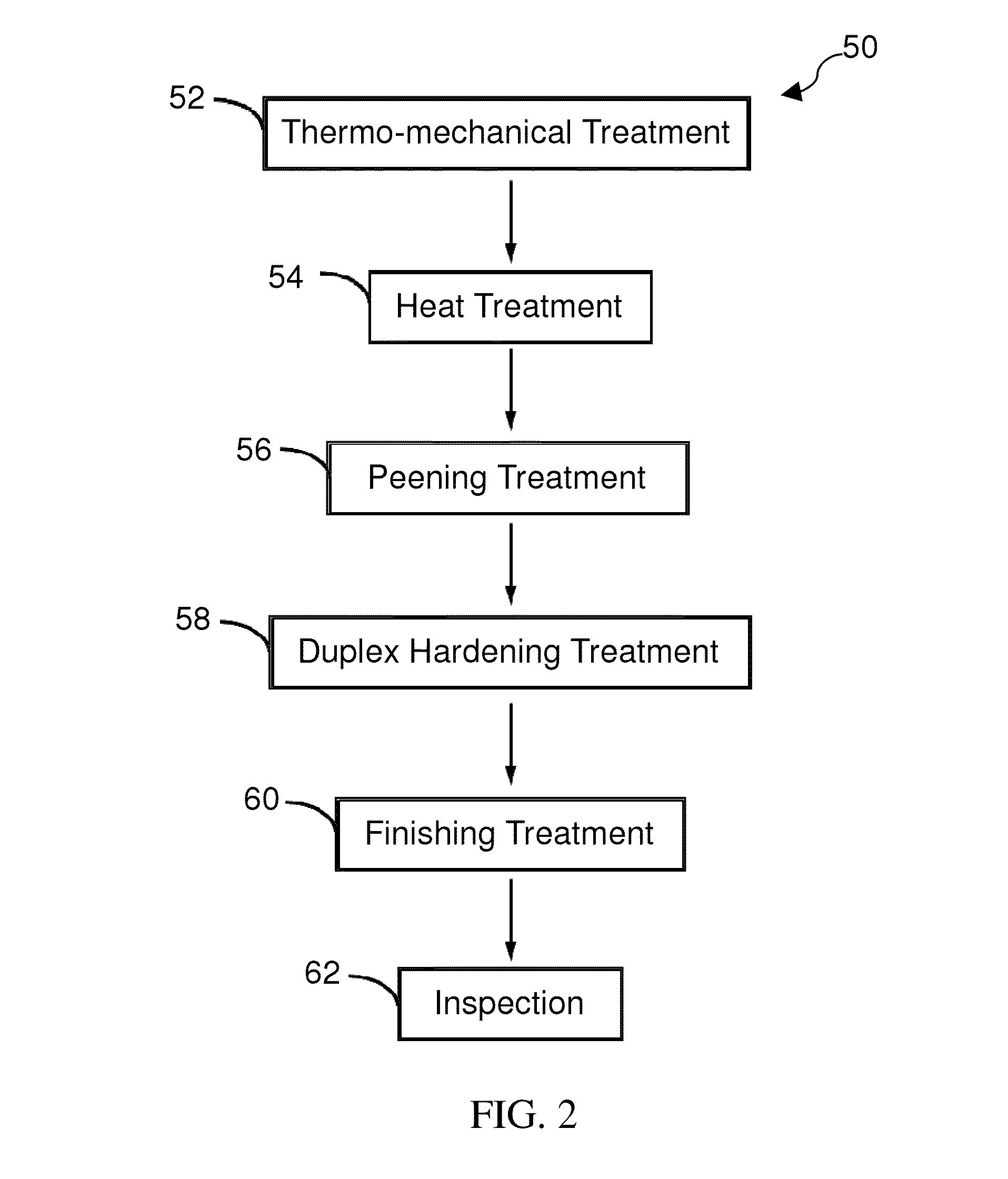

Manufacturing Process for Aerospace Bearing Rolling Elements

ActiveUS20130306194A1Improved rolling contact fatigue/endurance limitUltra-high compressive surface residual stressSolid state diffusion coatingFurnace typesShear stressRolling contact fatigue

A method of treating bearing rolling elements or bearing rings after a hardening and temper heat treatment is disclosed. The method may include treating the bearing rolling elements in a tumbling treatment and then in a duplex hardening treatment. The method may include treating the bearing rings in a peening treatment and then in a duplex hardening treatment. The duplex hardening treatment may also include at least one sequential process segment consisting of subjecting the bearing rolling element & rings to a nitriding process to increase the surface hardness and compressive residual stress. The combined two-step process produces a deep surface / sub-surface residual stress greater than the depth of the maximum operating von-Mises shear stress along with an ultra-hard surface with high magnitude of compressive residual stress. In so doing, the bearing ring and rolling elements will have significantly enhanced rolling contact fatigue resistance and resistance to surface imperfections and debris.

Owner:RAYTHEON TECH CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com