Steel rail with excellent contact fatigue performance and production method thereof

A contact fatigue and rail technology, applied in the field of rails, can solve the problems of low rolling contact fatigue resistance of rails, peeling off blocks, and high alloying cost, and achieve the effect of good rolling contact fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

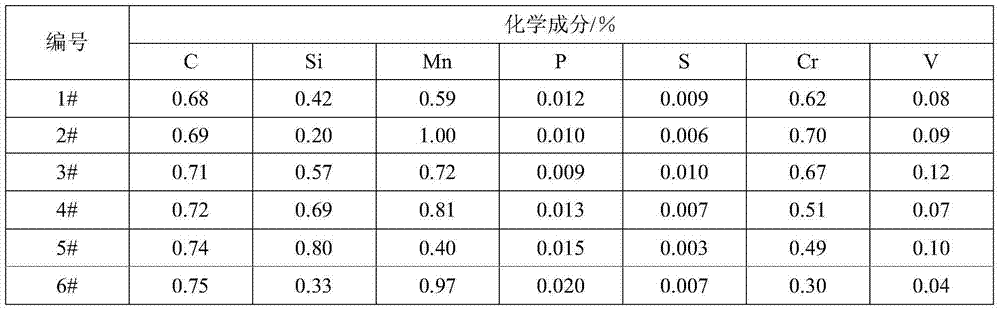

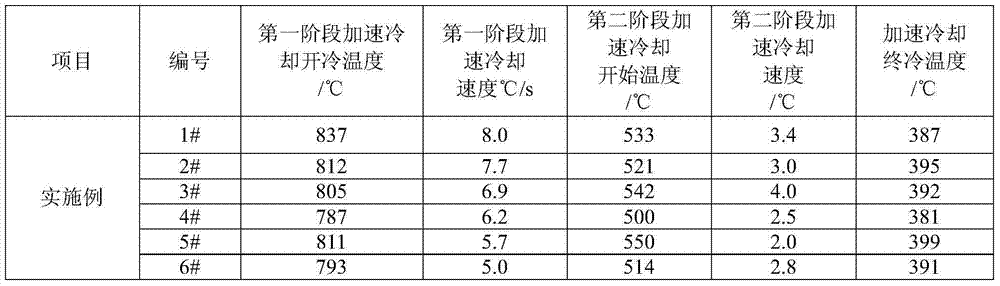

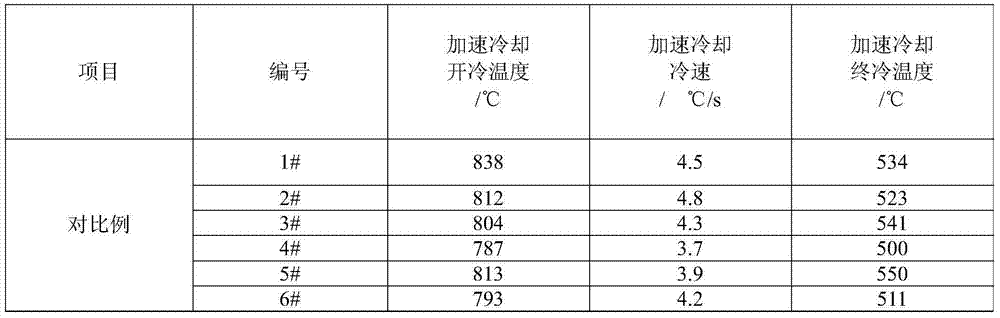

[0012] The steel rail of the present invention adopts the following chemical composition: 0.68%-0.75%C, 0.20-0.80%Si, 0.40%-1.00%Mn, 0.30%-0.70%Cr, 0.04%-0.12%V, S content≤0.010%, P content ≤0.020%, the balance is Fe and unavoidable impurities. The molten steel containing the above components is smelted in a converter or an electric furnace without aluminum deoxidation. After LF refining, the S content in the steel is reduced. After RH vacuum treatment or VD treatment, the composition is fine-tuned to the target range, and at the same time, the H, O, and N in the steel are further reduced. Content: The molten steel is continuously cast into 250mm×250mm-450mm×450mm cross-section steel billets, then cooled into a heating furnace, heated to 1200-1300°C and held for a certain period of time, and then released from the furnace, after dephosphorization by high-pressure water, it is rolled by universal method or pass method Made into 50-75kg / m required section rail.

[0013] The tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com