Rolling contact fatigue testing machine of roller component

A rolling contact fatigue and testing machine technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., to achieve the effect of strong practicability, convenient operation, and reasonable and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

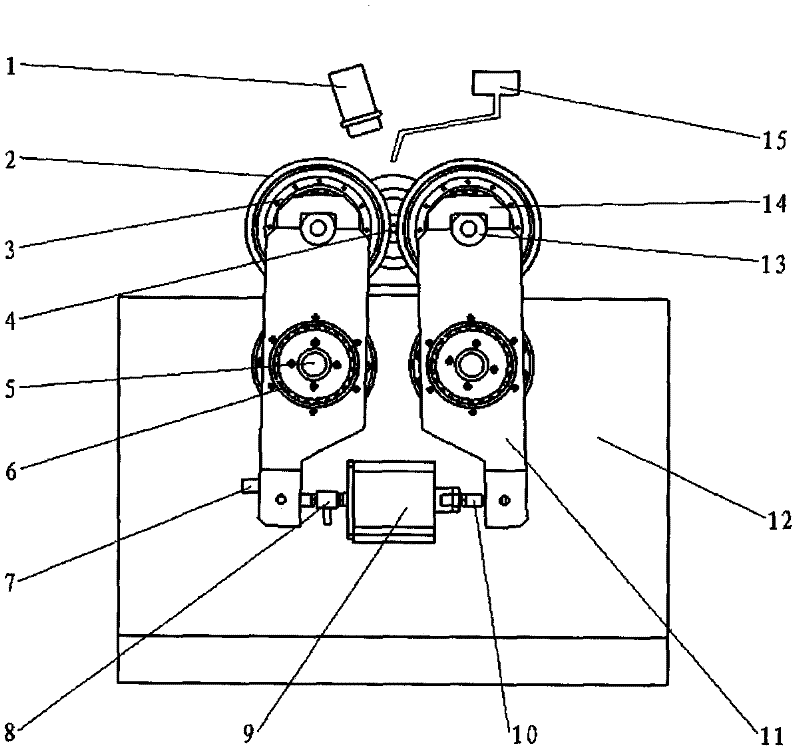

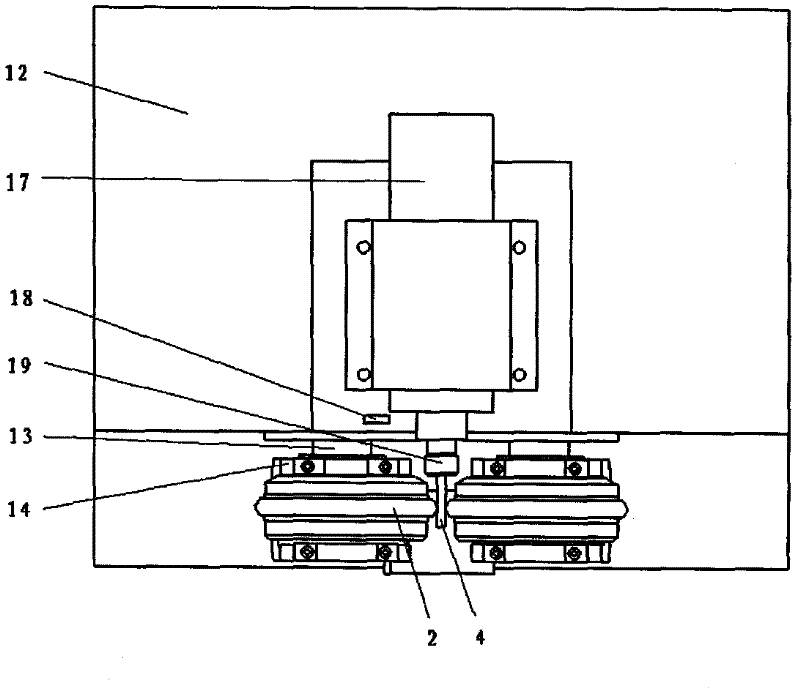

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

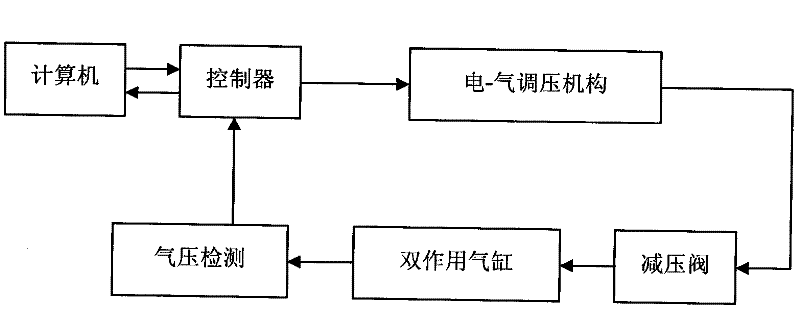

[0016] See attached Figure 1~3 As shown, this kind of roller element rolling contact fatigue testing machine mainly includes a base 12, an air spindle 17, an idler 2, a swing arm 11, a double-acting cylinder 9 and an air pressure adjustment system, and is characterized in that: on the side of the base 12 On the vertical plane, two swing arms 11 are vertically arranged side by side through the support bearings 6 on the two support shafts 5, and the center position of the swing arms 11 is sleeved on the support bearing 6 as the center of rotation. The upper end is equipped with an idler 2, and the central axis of the idler 2 is perpendicular to the side of the base 12. The installation structure of the idler 2 is: both idler 2 are mounted on the idler shaft 13 that is fitted with precision bearings 3, and the idler shaft 13 passes through The pressure pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com