Railroad rail steels resistant to rolling contact fatigue

a technology of railroad rails and steels, applied in the field of railroad rail steels, can solve the problems of rails being often prematurely retired from service, rails eventually wear out, and a large amount of thermo-mechanical deterioration, and achieve the effect of reducing the amount of non-metallic inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

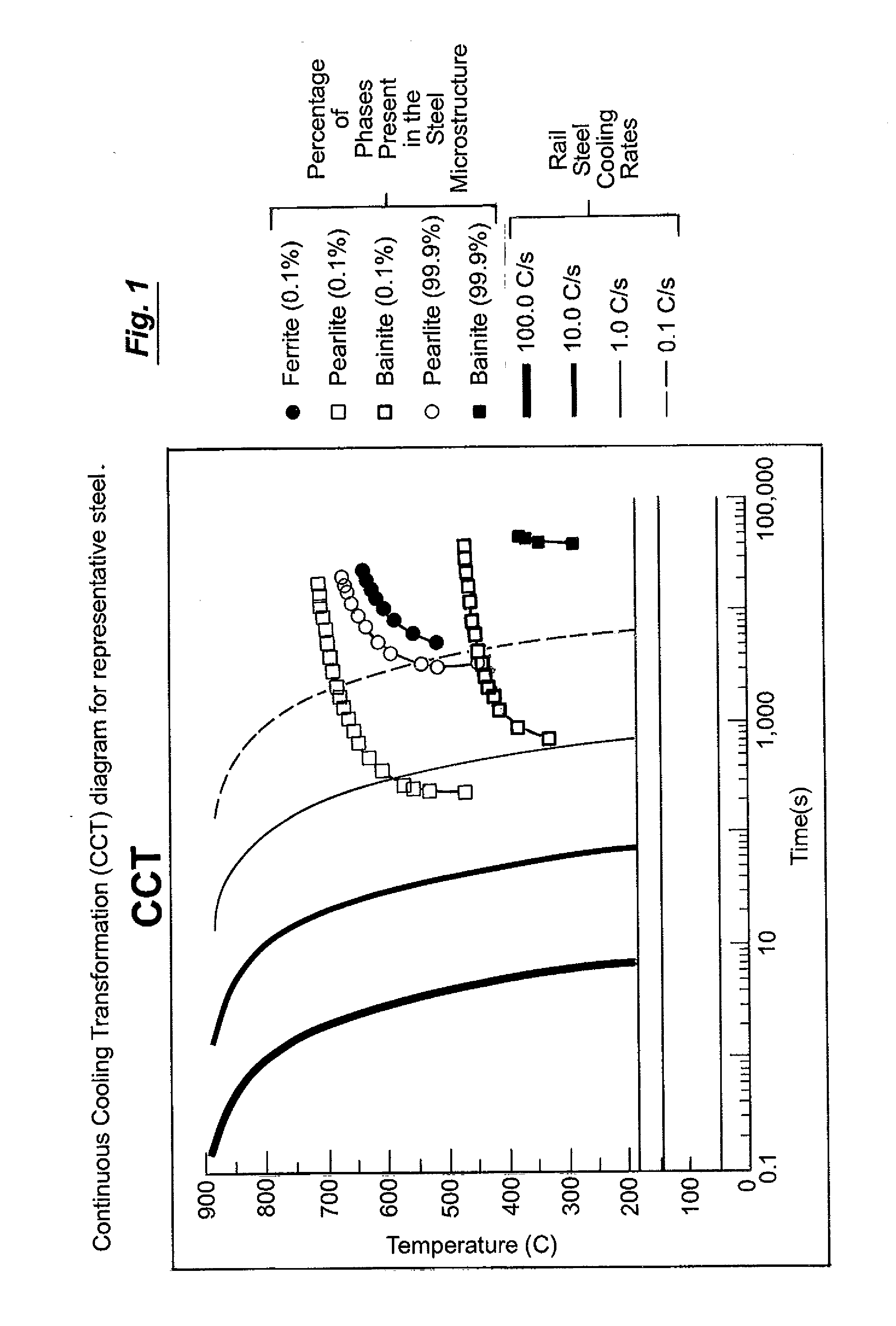

[0056]Applicants have found that the presence of the previously described alloying elements, in the concentrations given, are especially significant factors in imparting rolling contact fatigue occurrence in the railroad rails at the contact zone between the rolling wheel and the rail head surface. Another key point with respect to these steel formulations is that a pearlitic transformation of such steels takes place at relatively long coil hold times, see for example the continuous cooling transformation (CCT) diagram depicted in FIG. 1. It illustrates a representative cooling practice used to cool down applicants' steel after bloom rolling. The cooling can be continuous, or it can be arrested at a certain temperature and then the rail can be held at a temperature between 600 and 700° C. in order to allow a full pearlitic transformation to take place in the rail. Once the pearlitic transformation is completed the rails can be cooled down naturally to reach the room temperature.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com