High-speed rolling contact fatigue testing machine

A technology of contact fatigue and high-speed rolling, which is applied in the field of testing machines, can solve the problems that affect the accuracy of the test results of the test progress, affect the test results of the friction torque of the sample, and cannot realize continuous loading. Small, low-noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

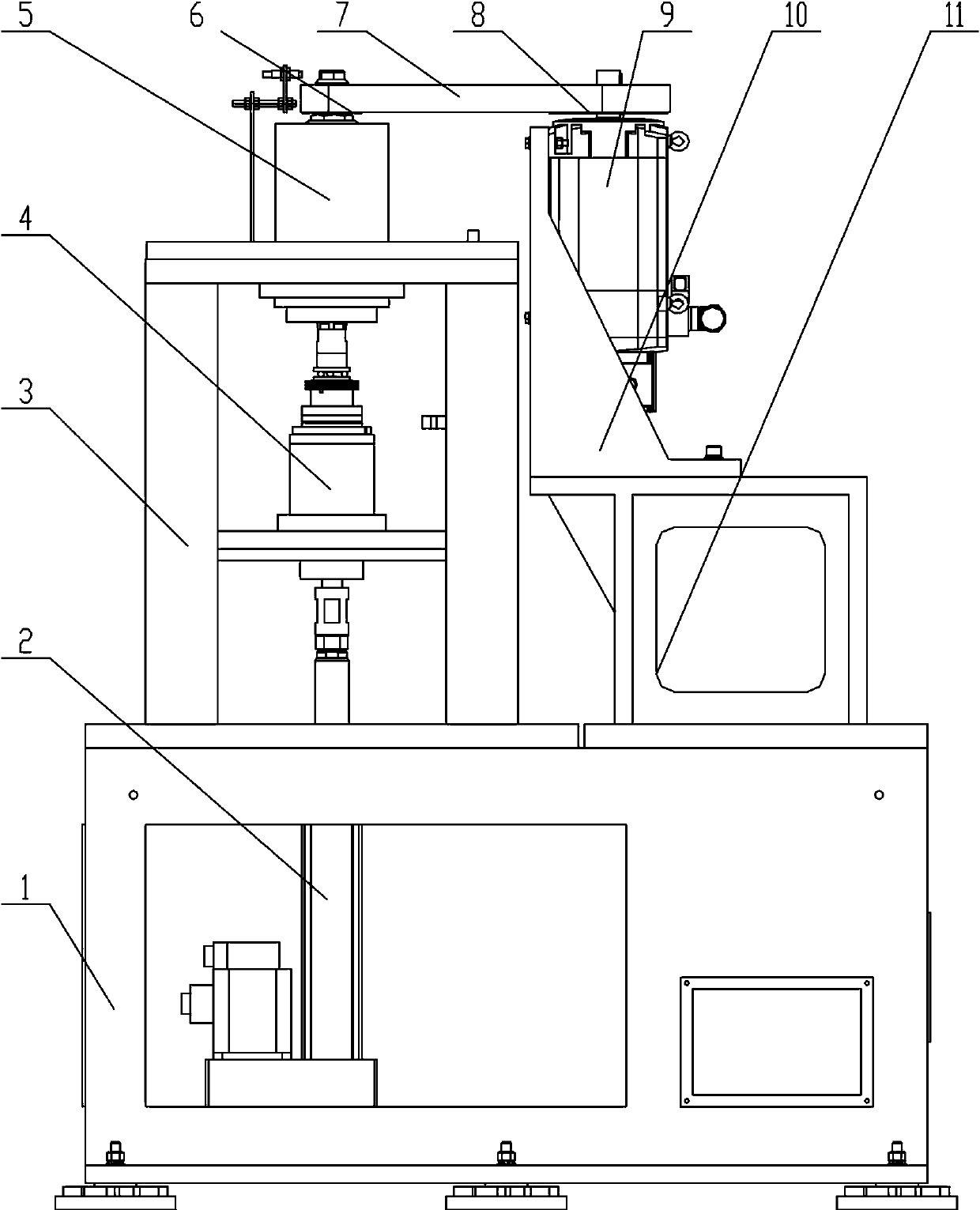

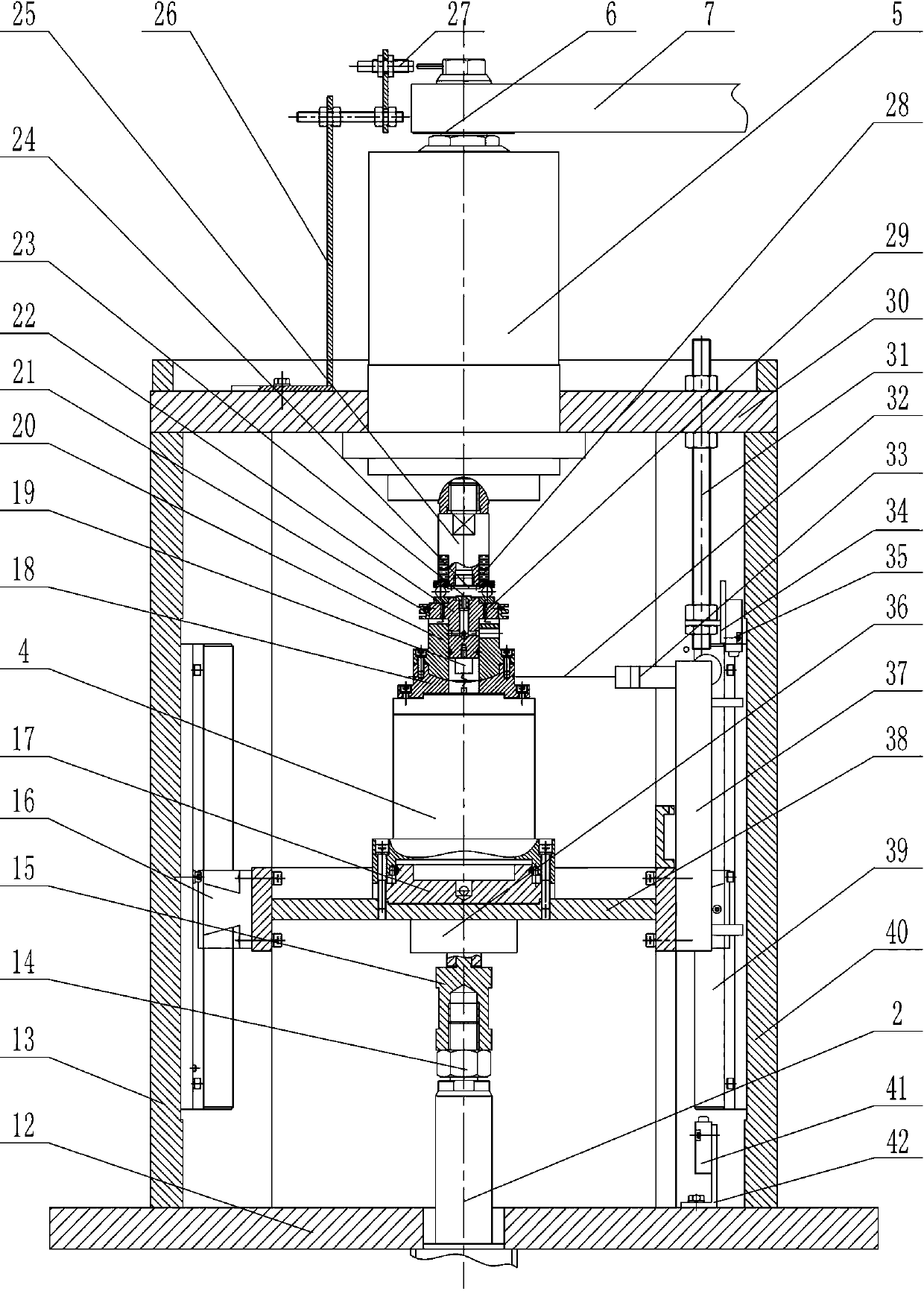

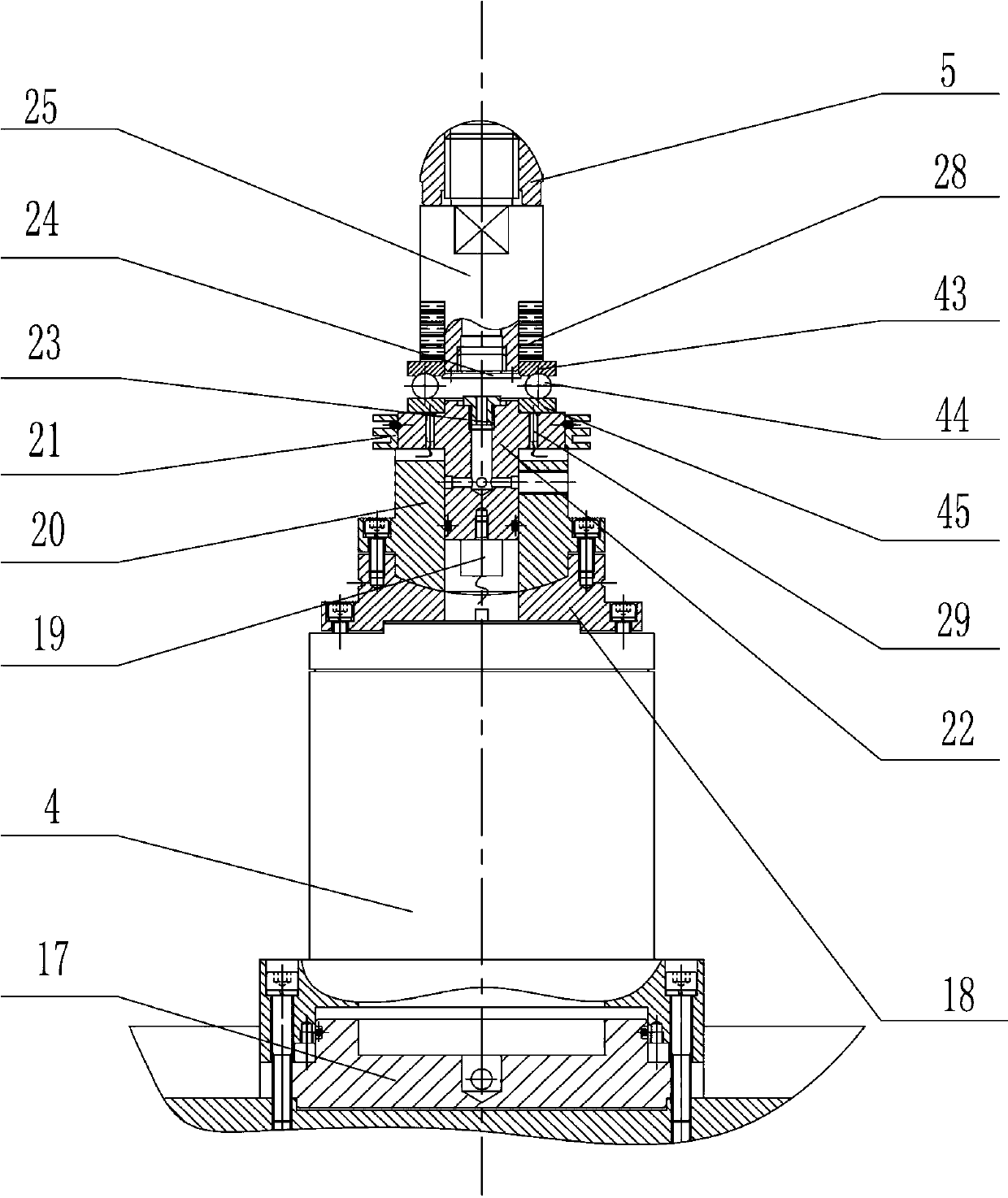

[0022] figure 1 , figure 2 It is a structural schematic diagram of the high-speed rolling contact fatigue testing machine disclosed by the present invention. The frame 3 and the independent motor base 11 are fixed on the base 1, and the motor support 10 is installed on the independent motor base 11. Servomotor 9 is installed on the side of motor support 10, driving pulley 6 is installed on the output shaft of servomotor 9 by taper sleeve, and servomotor 9 is fixed on static pressure main shaft 5 upper ends by driving pulley 6, ribbed belt 7 and Driven belt pulley 8 drive connections. The static pressure main shaft 5 is fixed on the upper beam 30 of the frame 3 through the end flange. The upper end of the transmission mandrel 25 is connected with the lower end of the static pressure main shaft 5 through threads, the inner ring of the ceramic heat insulating sleeve 28 is connected with the transmission mandrel 25 through clearance fit, and the shaft ring 43 of the thrust bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com