Patents

Literature

69results about How to "Realize energy utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of producing biogas through high-solid two-phase three-stage anaerobic digestion by using perishable organic wastes

ActiveCN101805753AAvoid cloggingIncrease concentrationWaste based fuelFermentationAcetic acidOrganic acid

The invention provides a method for producing biogas through high-solid two-phase three-stage anaerobic digestion by using perishable organic wastes, which comprises the following steps: the perishable organic wastes are hydrolyzed in a hydrolysis acidogenic reactor, and a mixture obtained after hydrolysis is acidified to generate a large number of organic acid products with low molecular weight; the bottom of the hydrolysis acidogenic reactor is communicated with the bottom of a methanogenic reactor through a circulation pump and a pipeline; the top of the methanogenic reactor is communicated with the top of the hydrolysis acidogenic reactor; and the acetic acid producing reaction is carried out in the methanogenic reactor and the methane producing reaction is continuously carried out. The invention can separate the hydrolysis acidogenic process from the acetic acid and methane producing process in the anaerobic digestion process so as to prevent organic acids generated by the perishable organic wastes from inhibiting methanogenesis. The device has simple processing procedure, low cost, easy maintenance and stable and reliable performance, is suitable for anaerobic digestion treatment of various perishable organic wastes, and has highly efficient and stable biogas production capacity of the perishable organic wastes through the anaerobic digestion.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

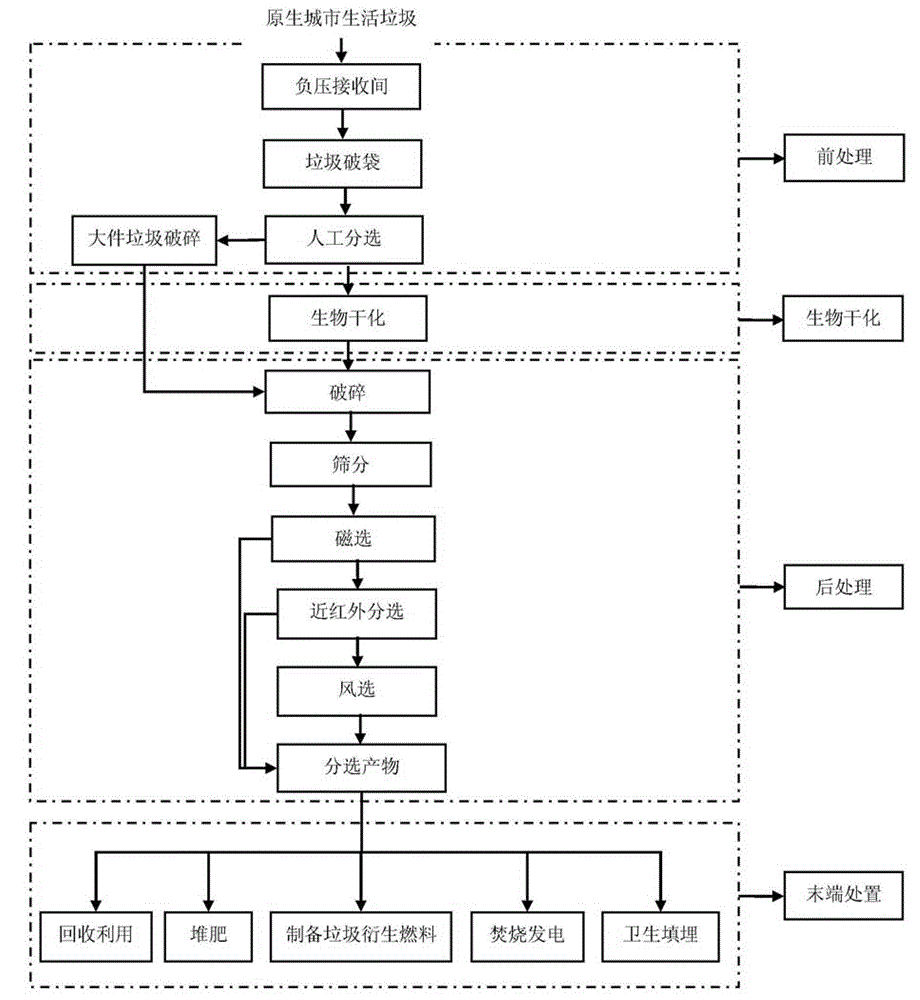

Bio-drying-based domestic refuse treatment method

The invention provides a bio-drying-based domestic refuse treatment method. The method comprises the following steps: (1), pre-treatment: feeding domestic refuses into a negative-pressure receiving room to break bags and manually select; performing innocent treatment on selected harmful refuses which have potential pollution threats to the soil and the underground water, and crushing selected large-size refuses in a large-size refuse crusher, wherein the crushed large-size refuses are treated in a step (3), residual domestic refuses are treated in a step (2), and the air change rate of the negative-pressure receiving room is five to seven times per hour; (2), bio-drying: feeding the residual domestic refuses treated in the step (1) into a bio-drying storehouse, stacking to form a refuse dump body, and covering the refuse dump body with a selective semi-permeable membrane; (3), post-treatment: sequentially performing mechanical crushing, drum screen screening, magnetic separation, near-infrared separation and air separation on the dried products obtained in the step (2) and large-sized refuses crushed in the step (1); (4), tail end treatment: respectively recovering and utilizing according to property difference of products selected according to the step (3).

Owner:BEIJING GEOENVIRON ENG & TECH

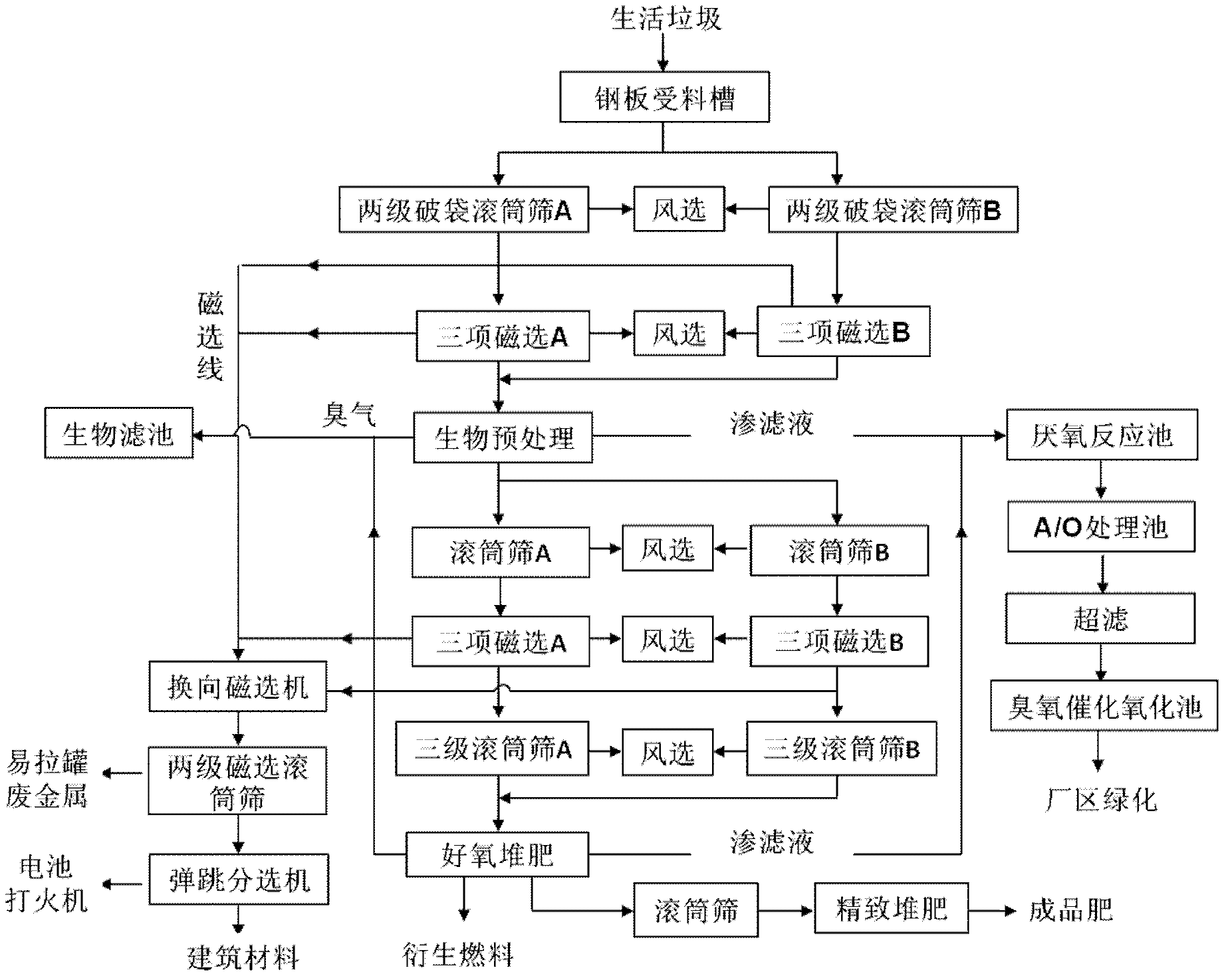

Method for comprehensive treatment of household refuses and secondary pollution control

ActiveCN103008326ACompact layoutReasonable configurationBio-organic fraction processingWaste processingRefuse-derived fuelUnit device

The invention provides a method for comprehensive treatment of household refuses and secondary pollution control. The method comprises the following procedures of: 1) coarse separation of the household refuses; 2) pretreatment of the household refuses; 3) fine separation of the household refuses; 4) aerobic composting of the household refuses; 5) biological organic fertilizer preparation; 6) fabrication of refuse derived fuels; and 7) secondary pollution control. The method employs parallel dual-separation lines which are compact in arrangement; each functional unit device is rational in configuration, easy to operate and mechanically control; the sorting efficiency and the energy source recovery effect are obviously improved; and minimization, harmless treatment, recycling and energy conversion of the household refuses can be realized.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

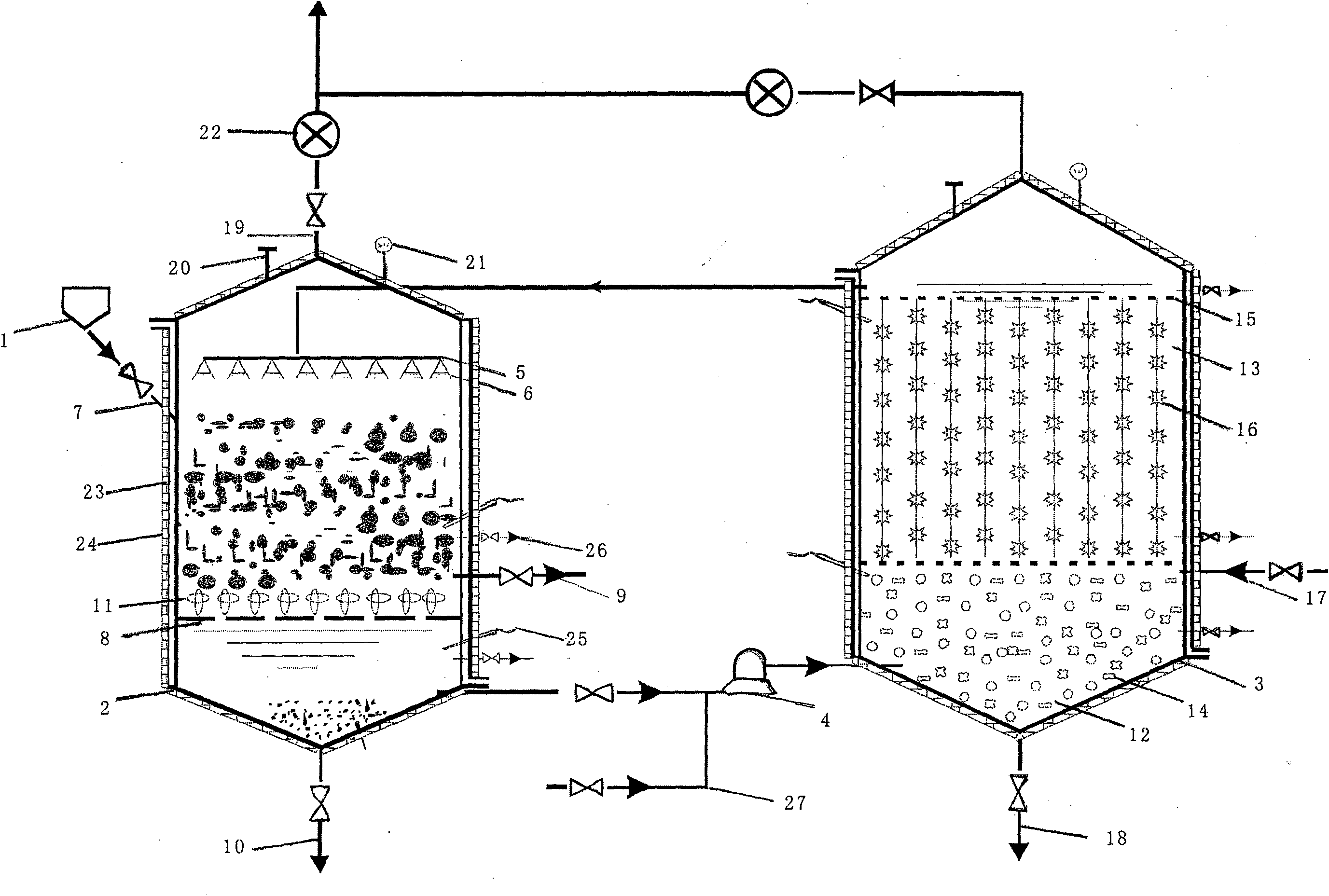

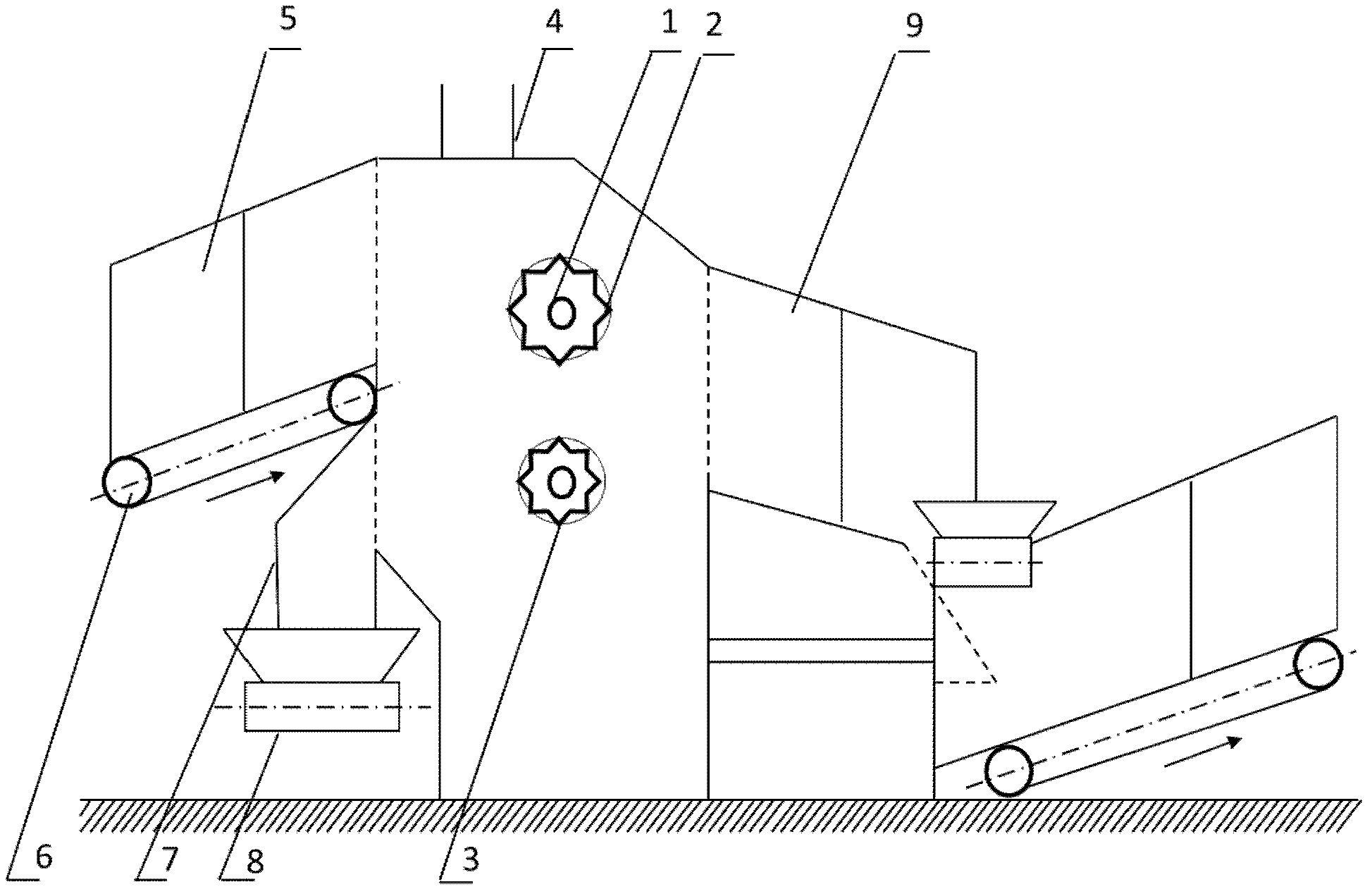

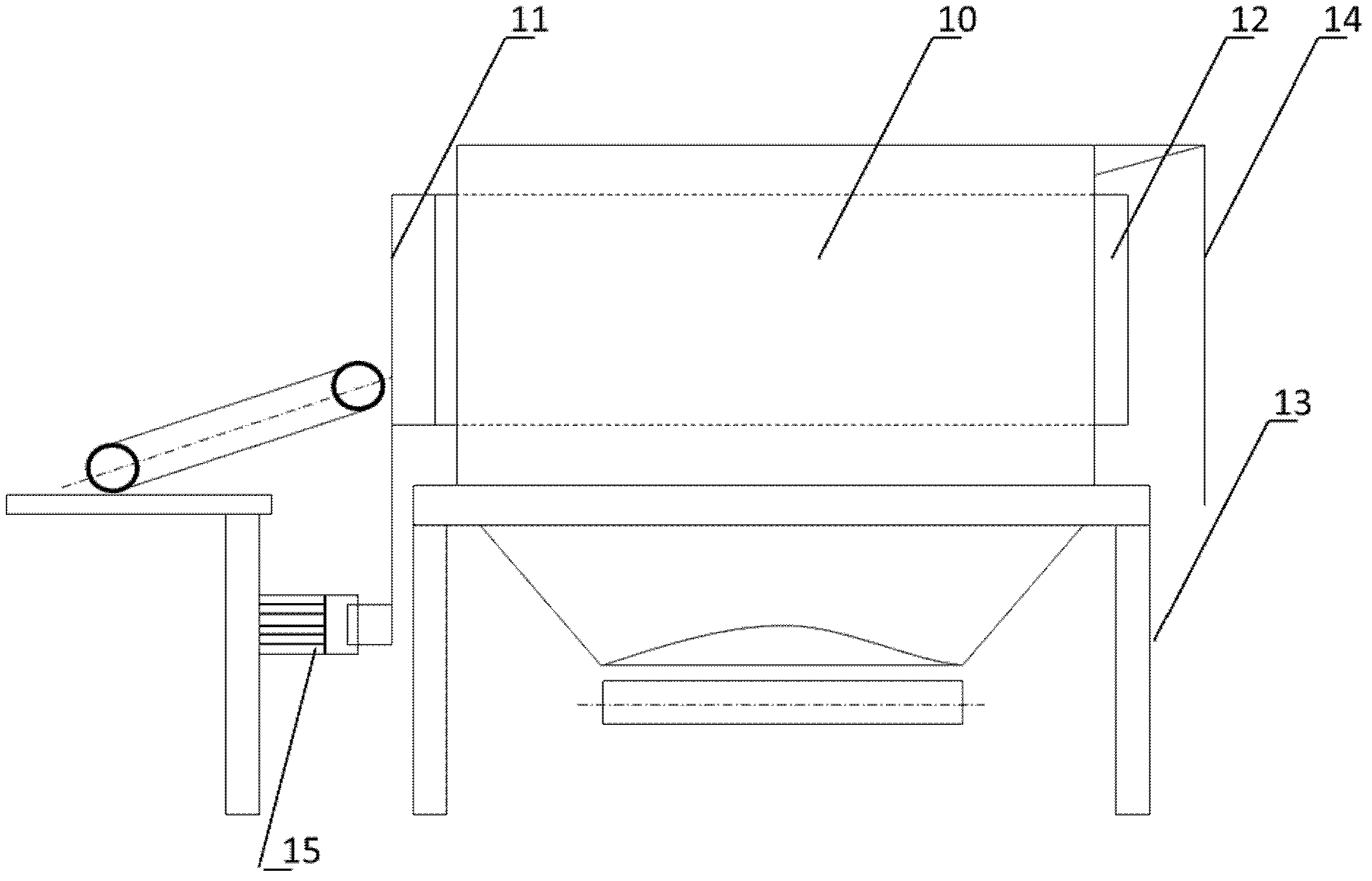

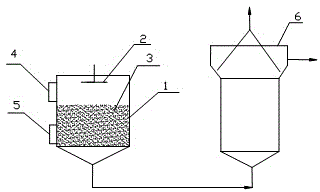

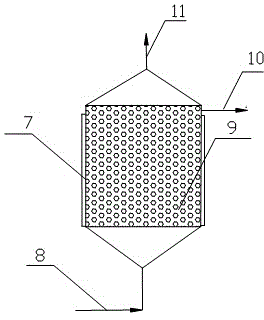

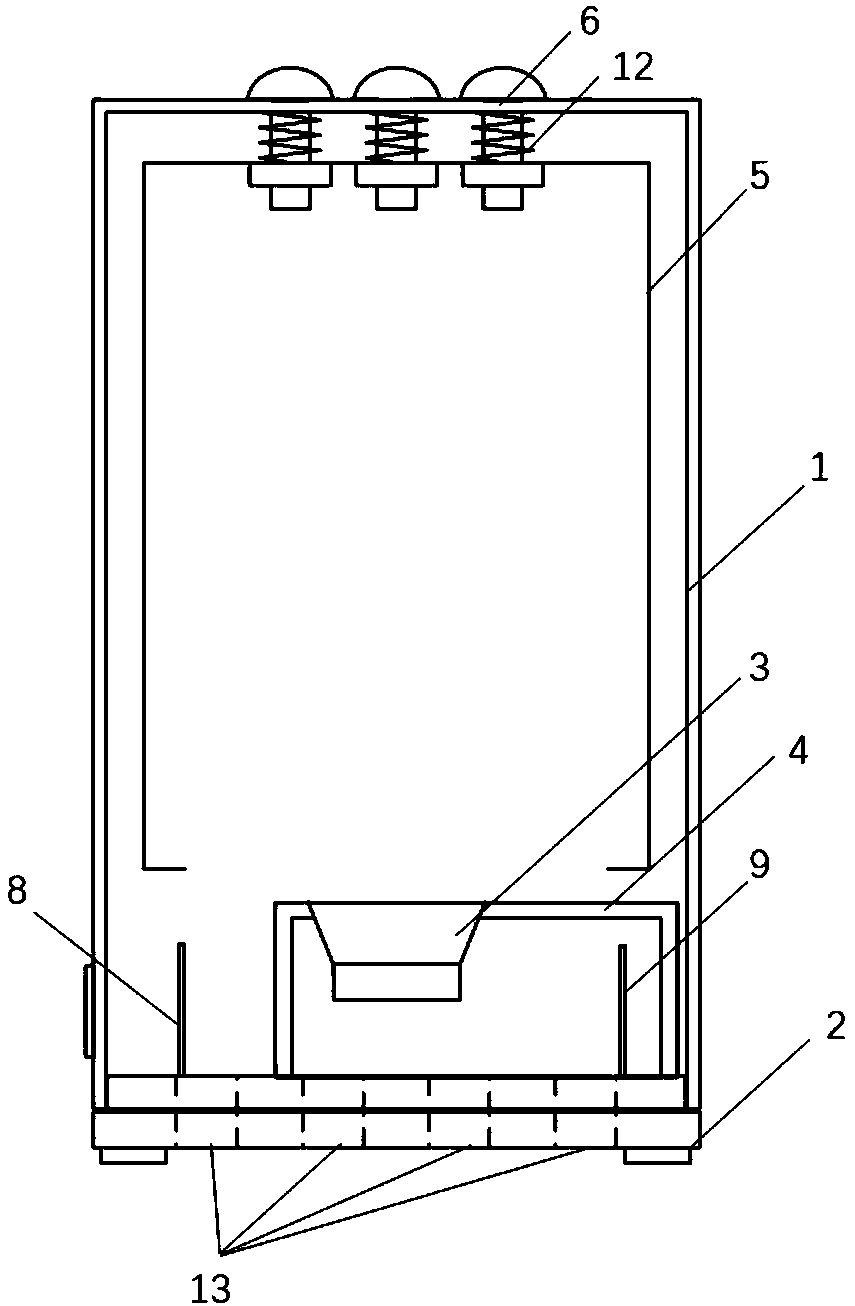

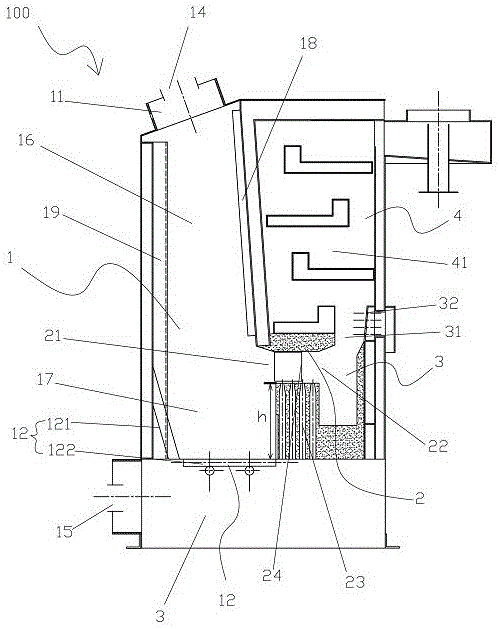

Device for producing biogas by two-phase three-section anaerobic digestion of high solids of perishable organic wastes

ActiveCN101812401ARealize self-circulationImprove abilitiesBioreactor/fermenter combinationsBiological substance pretreatmentsFiberMethane production

The invention provides a device for producing biogas by two-phase three-section anaerobic digestion of high solids of perishable organic wastes. The device comprises a hydrolysis acid-production reactor and a methane-production reactor, wherein the two reactors are connected with each other, and the bottoms of the reactors are communicated through a circulating pump and a pipe; the hydrolysis acid-production reactor is a solid infiltration bed reactor, the top is provided with a water distributor and a spray header, the middle-upper part is provided with a feeding port, the middle-lower part is provided with a perforated plate and a discharging port, the bottom is provided with a residue-discharging port, and infiltration fillers are arranged on the upper surface of the perforated plate; and the methane-production reactor consists of a filter filler bed and a fiber filler bed, wherein the filter filler bed is arranged on the lower part of the methane-production reactor, the filter filler bed is arranged on the upper part of the methane-production reactor, filter fillers are arranged in the filter bed, a fiber filler frame is arranged in the fiber filler bed, and the fiber filler frame is wound by fiber fillers. The device has the advantages of simple processing procedures, low cost, easy maintenance, stable and reliable performance and suitability for the anaerobic digestion treatment of various perishable organic wastes, and has the capability of producing the biogas in high efficiency and stably by the anaerobic digestion of perishable organic wastes.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

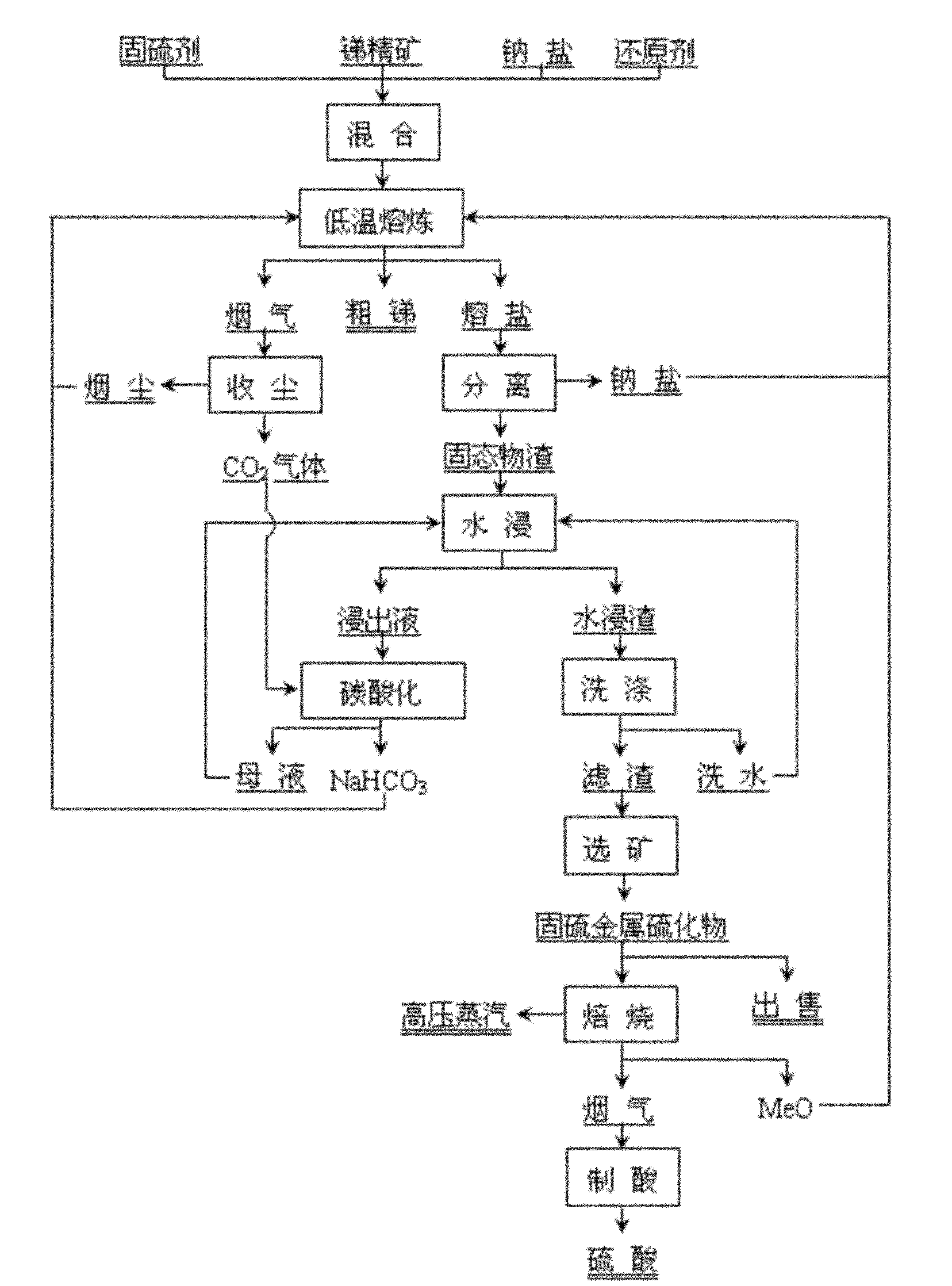

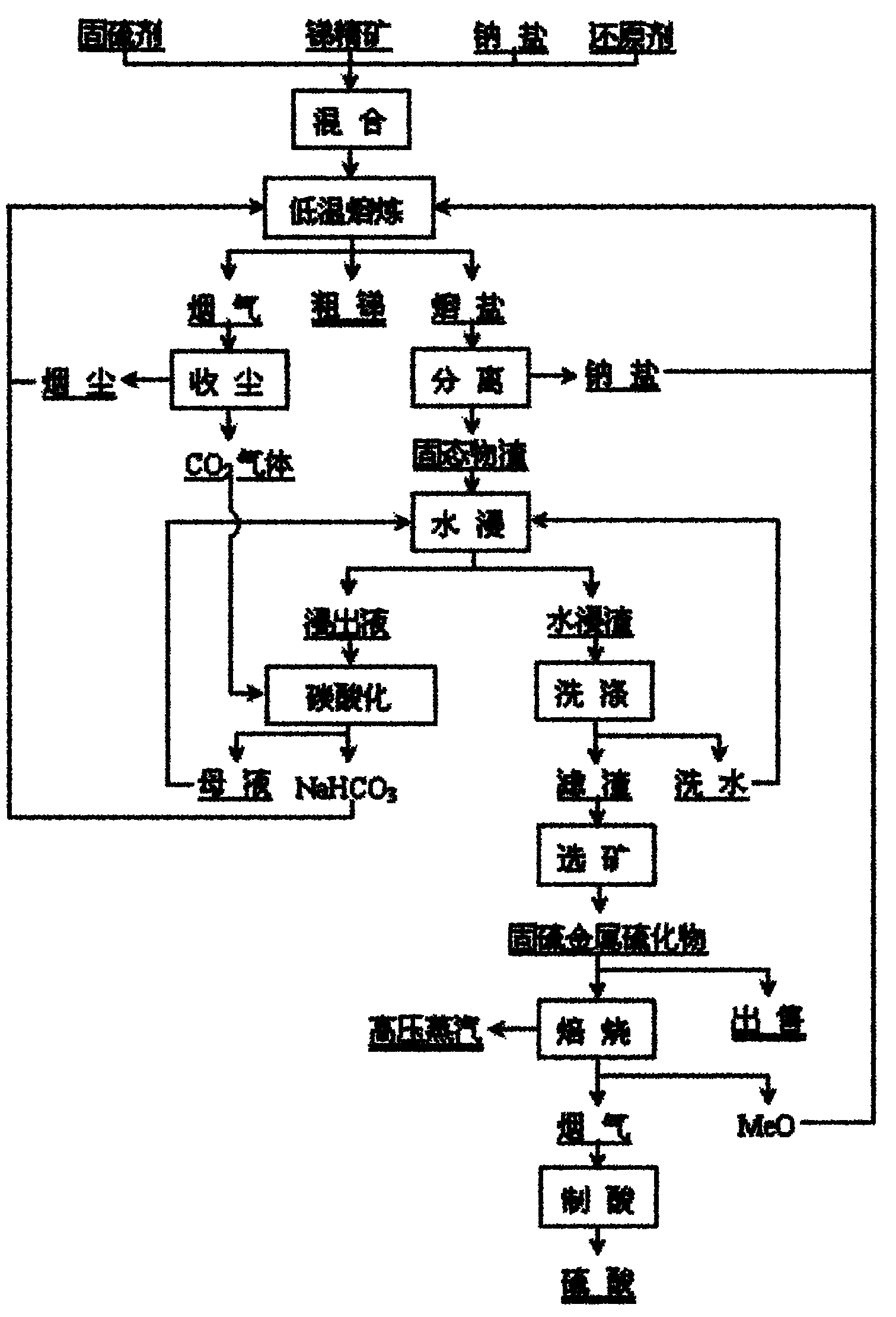

Clean metallurgical method for low-temperature molten salt of antimony

InactiveCN101914693ALower the smelting temperatureImprove direct yieldProcess efficiency improvementSlagSulfide

The invention discloses a clean metallurgical method for low-temperature molten salt of antimony, and belongs to the metallurgical field of non-ferrous metals. The method is characterized by comprising the following steps of: performing reductive sulfur-fixing melting on antimony concentrate and oxide of metal with higher sulfur affinity compared with the antimony in low-temperature inert molten salt to generate liquid metal antimony and sulfur-fixed metal sulfide, and forming molten salt slag by using the sulfur-fixed metal sulfide and non-reacted substances as solid substances; and separating most inert molten salt from the solid substances and then thermally returning the most inert molten salt to the melting process, regenerating NaHCO3 for recycling by using the molten salt slag through a 'water leaching-carbonated precipitation' process, reclaiming the sulfur-fixed metal sulfide concentrate for selling from the leached residue by ore dressing, or performing roasting desulfuration on the leached residue for heat energy utilization and smoke acid making, and returning oxide roasting sand serving as a sulfur-fixing agent to the melting process. The method greatly reduces the antimony melting temperature, produces the crude antimony at one step, realizes reclamation of sulfur and energy utilization of sulfide, thoroughly eliminates environmental pollution of low-concentration SO2 smoke at the same time of simplifying the flow, reducing the cost and greatly improving the direct yield of the antimony, and has the advantages of low carbon, cleanness and high efficiency.

Owner:CENT SOUTH UNIV

System and process for comprehensive utilization of oil shale destructive distillation and semicoke gasification

InactiveCN103923677ARealize energy utilizationReduce pollutionLiquid hydrocarbon mixture productionSpecial form destructive distillationHeat carrierWater vapor

The invention discloses a system for comprehensive utilization of oil shale destructive distillation and semicoke gasification, which comprises a destructive distillation furnace, an oil shale bin, an oil storage tank, an oil-gas separator, a gas heater, a gasification fuel bin, a combustible gas tank, a heater, a gasification furnace and a conveyer device. According to the invention, by using a process for comprehensive utilization of oil shale destructive distillation and semicoke gasification by using the system, semicoke generated by destructive distillation and powdered oil shale are subjected to gasification reaction to generate combustible gas, a part of combustible gas can be used as a fuel to be introduced into the gas heater to heat a heat carrier gas used in the destructive distillation furnace, high-temperature solid residues generated in the gasification furnace are discharged into a heat exchanger to heat cold water into hot water or vapor. According to the invention, the semicoke generated by oil shale destructive distillation is gasified to be recycled, and thus the addition benefits in an oil shale destructive distillation process is increased, heat pollution and chemical pollution of shale residues are reduced, and energy source utilization rate is improved.

Owner:SHANGHAI JIAO TONG UNIV

Procedures of thermal treatment for wet wastes, production residues or other residues

InactiveCN101349429AAchieve separationRealize energy utilizationBiofuelsSpecial form destructive distillationCombustion chamberGas phase

The invention relates to a heat treating method for damp garbage, producing surplus and other residual matters containing natural and / or synthetic organic compositions. The invention provides a mechanical multistage garbage heat treating method used in combination with the traditional conventional fuel combustion type generating equipment while a material flows and energy flows are exchanged between the two equipments for saving conventional fuel. In the invention, the coarse bulky maters with average grain size above 200 mm are pre-comminuted by mechanical means; the pre-comminuted fine bulky matters with average grain size below 200mm and are moisture content above 20wt% are dewatered mechanically; the mechanically dewatered matters are dried to residual moisture content below 10wt% in a separated drying device by steam; the dried matters are pyrolyzed in a separated device under the temperature of 250 to 650 degrees centigrade into solid phase (cokes) and gas phase (pyrolyzed gas); the pyrolyzed gas is burned in a multiple aperture burner and the generated hot gas is inputted into the combustion chamber of the generating equipment used for solid fuel in hot blast manner.

Owner:克劳斯-迪特尔·孔泽 +3

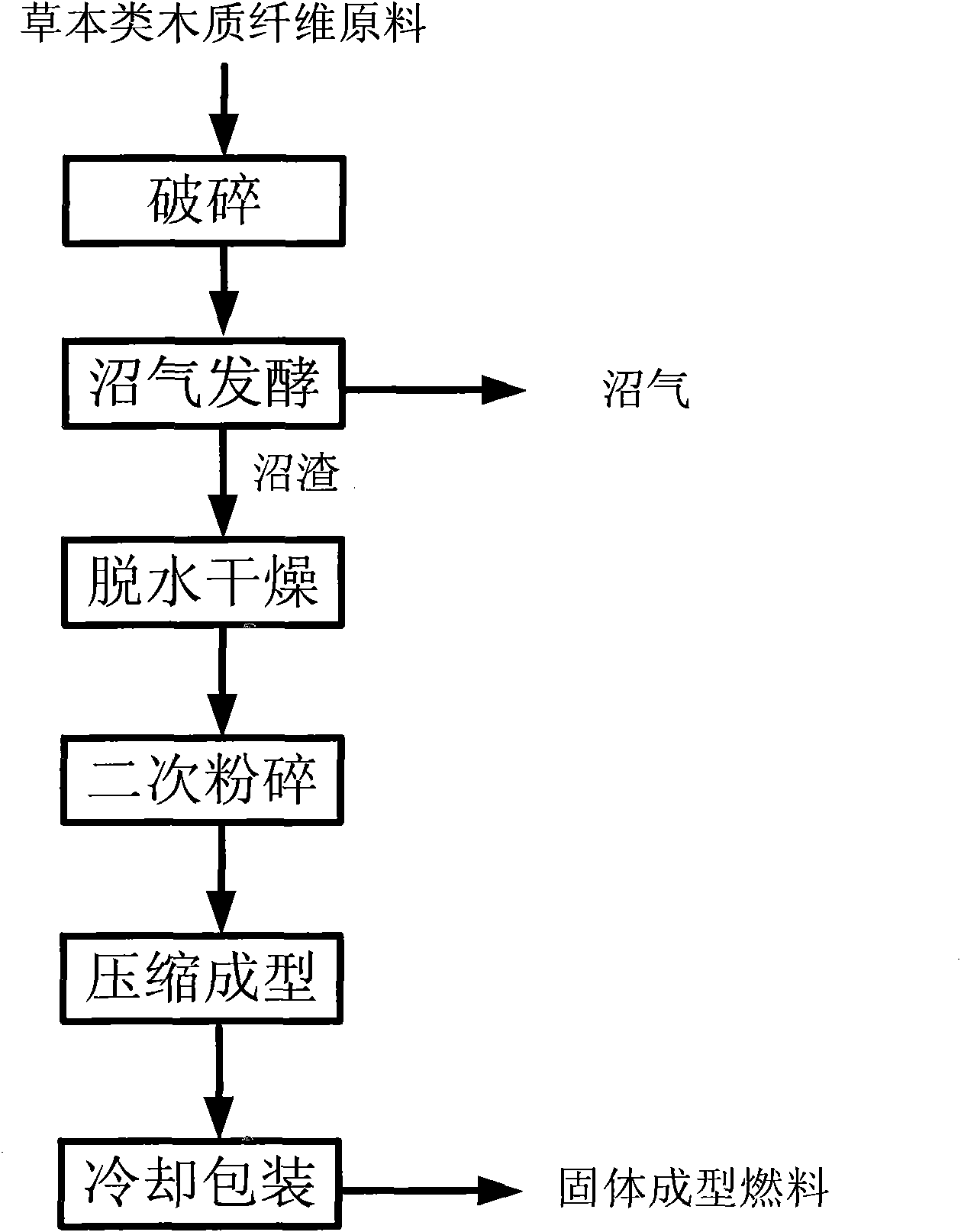

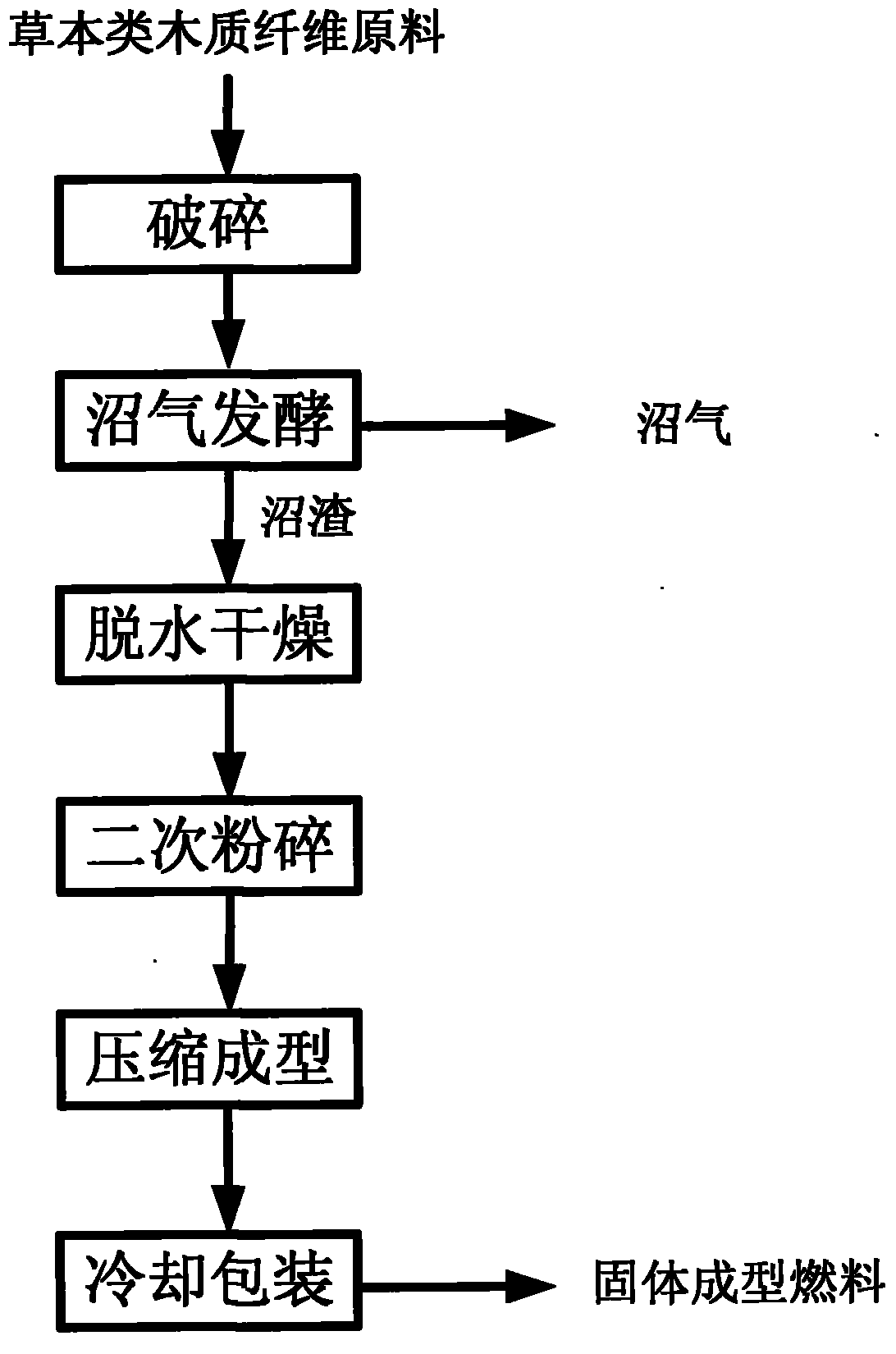

Method for coproducing methane and solid formed fuel by using herbaceous wood fiber as raw material

ActiveCN102061314ARealize energy utilizationImprove economic efficiencyBiofuelsSolid fuelsWater contentChemistry

The invention provides a method for coproducing methane and solid formed fuel by using herbaceous wood fibers as a raw material. The method comprises the following steps of: (1) material crushing: reducing the particle size of the herbaceous wood fiber raw material to be below 40 mm; (2) methane fermentation: controlling the solid concentration of methane fermentation to be 20%-40%; (3) methane residue drying, which ensures the water content of the dried methane residues is 6%-20%; (4) secondary crushing: performing the secondary crushing for the dried methane residues to ensure that the particle size is less than 5 mm; (5) compression forming; and (6) cooling and packaging. The method solves the problem of the disposition of the methane residues, realizes full energy utilization of resources and improves the economic benefit of straw utilization.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

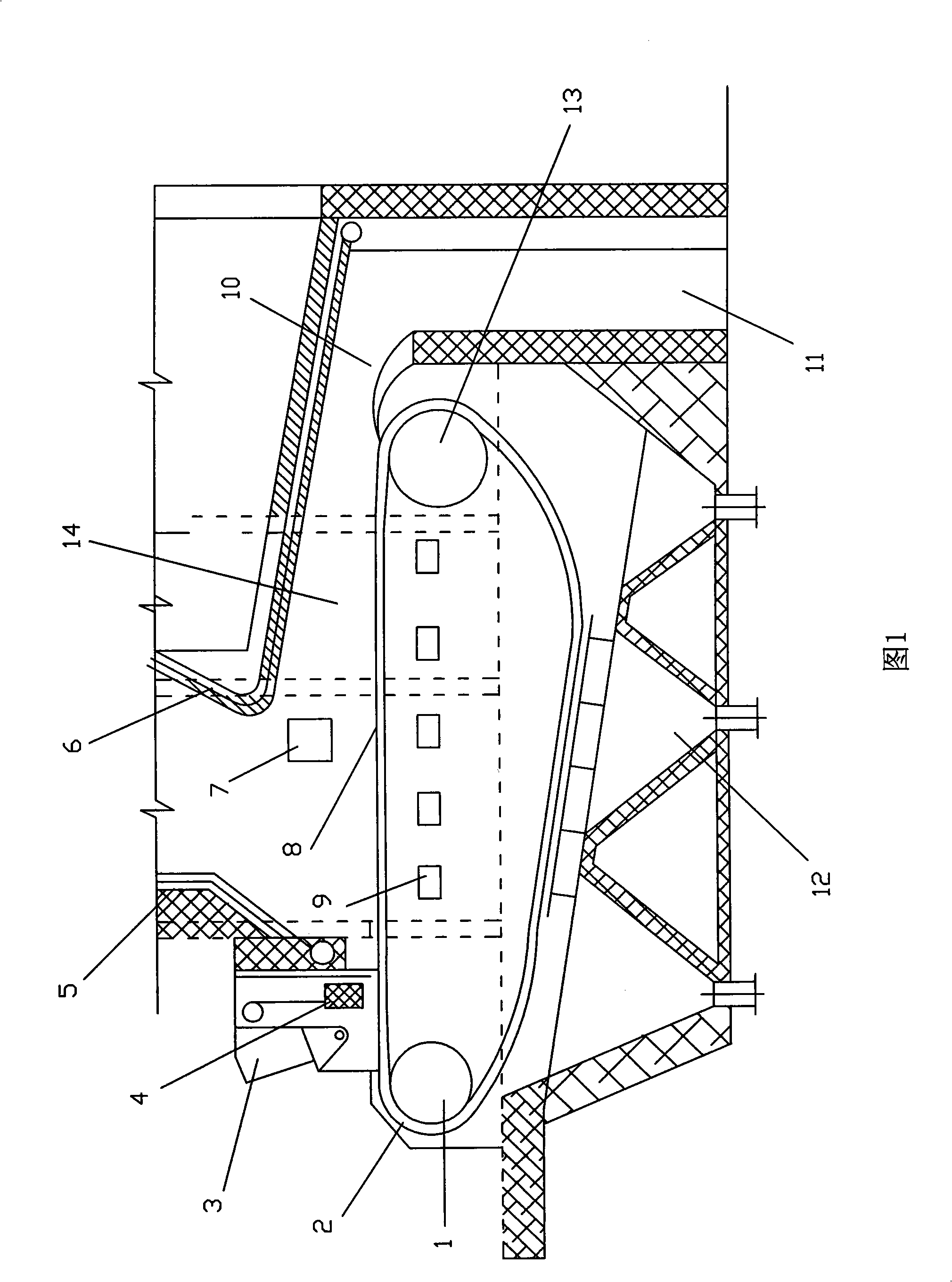

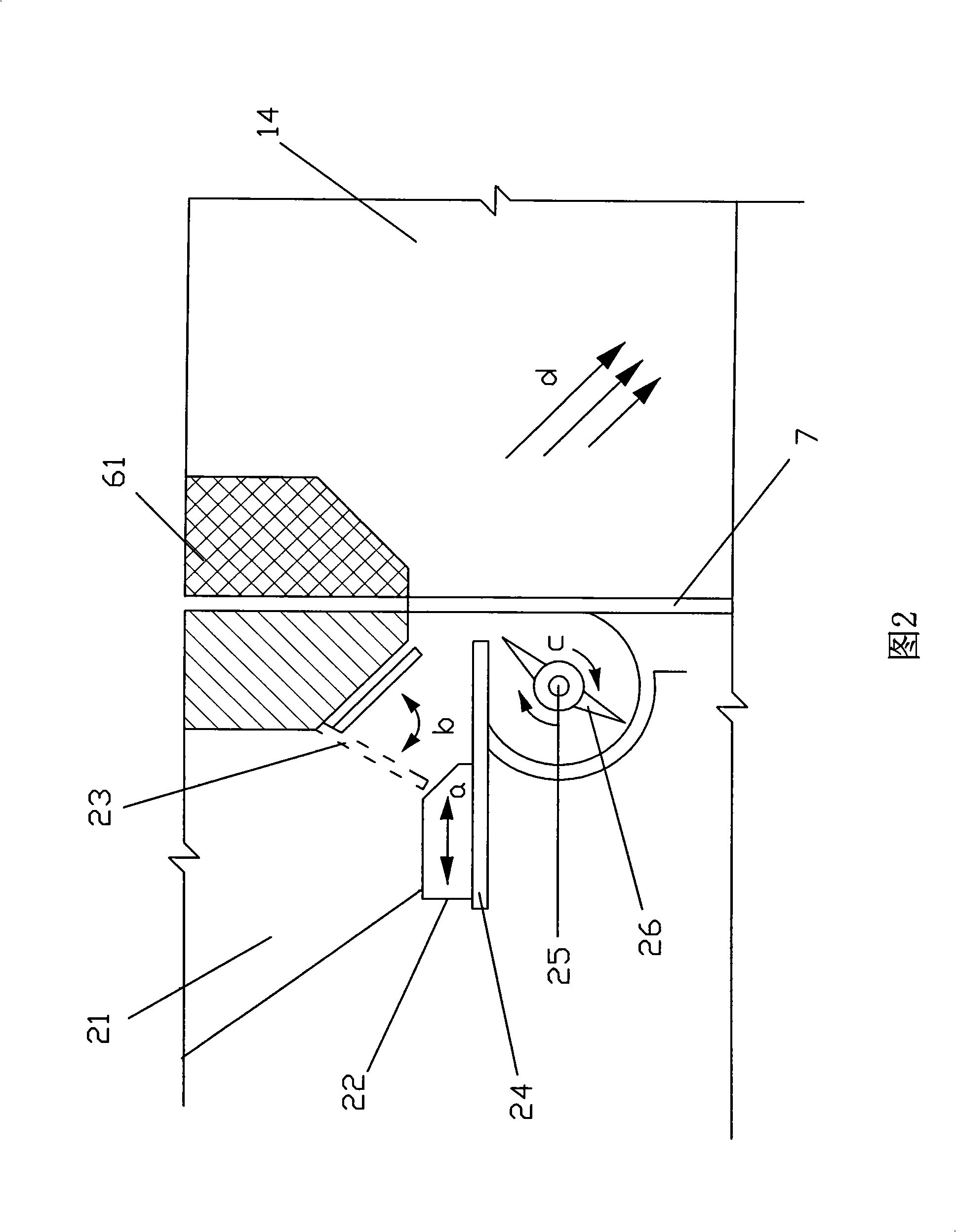

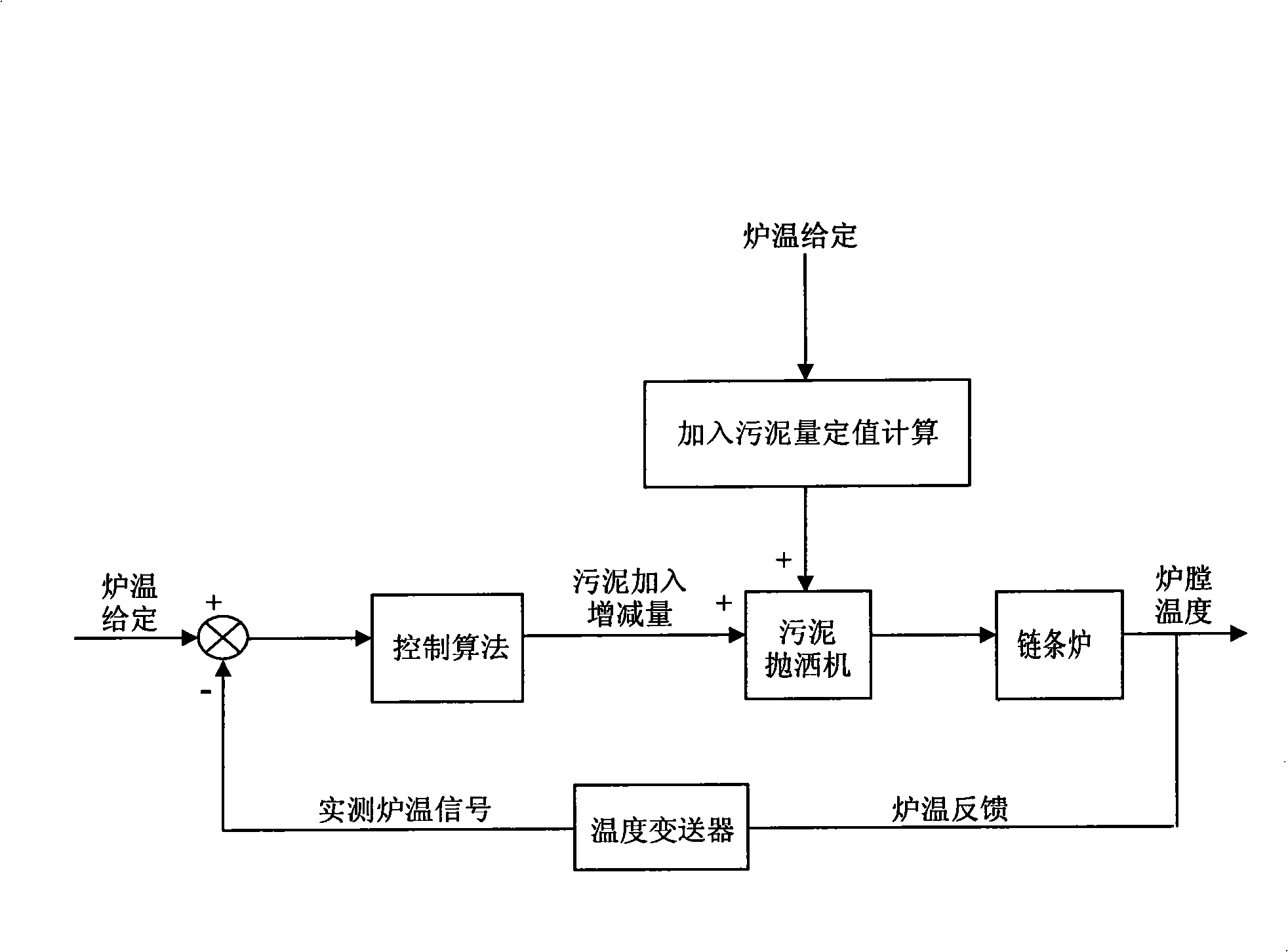

Method for burning sludge of chain furnace

InactiveCN101324337AEasy to control the amount addedHigh thermal efficiencyIncinerator apparatusHeating furnaceDewatered sludge

The invention discloses a method for burning sludge in chain grate. A sludge feeding port is arranged on rear arch on the side surface of the chain grate used in the method; and coal and sludge are respectively added into the furnace of the chain grate. The method comprises following steps: adding the coal into the grates of the chain grate through a coal valve from a coal scuttle in front of the chain grate; preheating, drying, and burning the coal sequentially along with the movement of the grates of the chain grate; uniformly adding the squeezed and dewatered sludge alone from the sludge feeding port into the chain grate, wherein the sludge falls onto the grates in a position in the vicinity to the rear arch at 1 / 2 to 3 / 4 the tail section of the furnace of the chain grate; and igniting and burning the sludge added in the position by the temperature of the tail section of the furnace of the chain grate when the coal burning is substantially ended, wherein the added amount of the sludge is calculated and adjusted in real time according to the heat value of the coal and the temperature when the added amount is stabilized. The chain grate can ensure complete burning of coal when used for burning various kinds of sludge with heat energy utilization value, thus effectively utilizing the heat value of the sludge and improving the heat efficiency of the chain grate.

Owner:ZHEJIANG HUAZHANG TECH

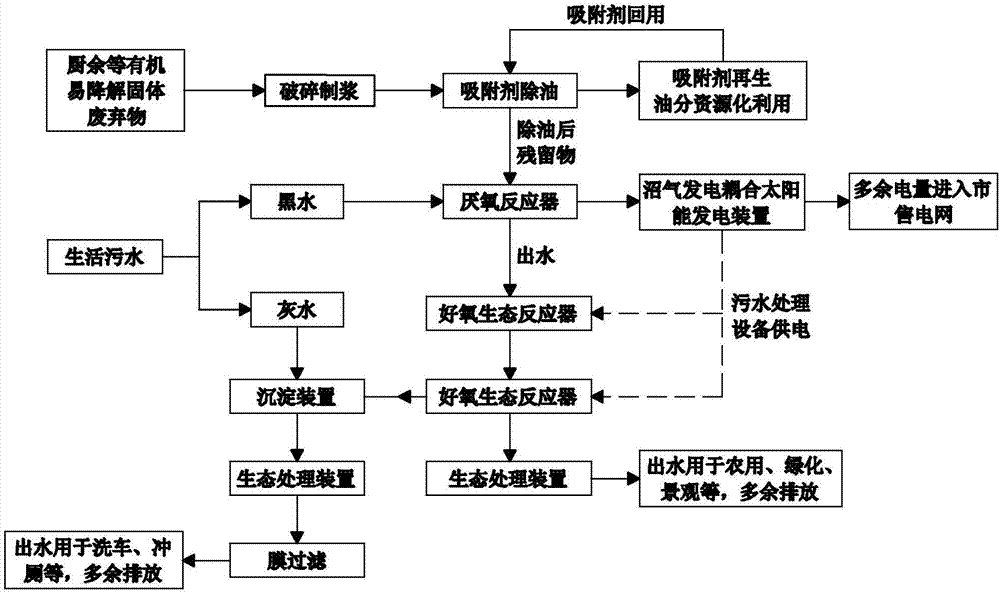

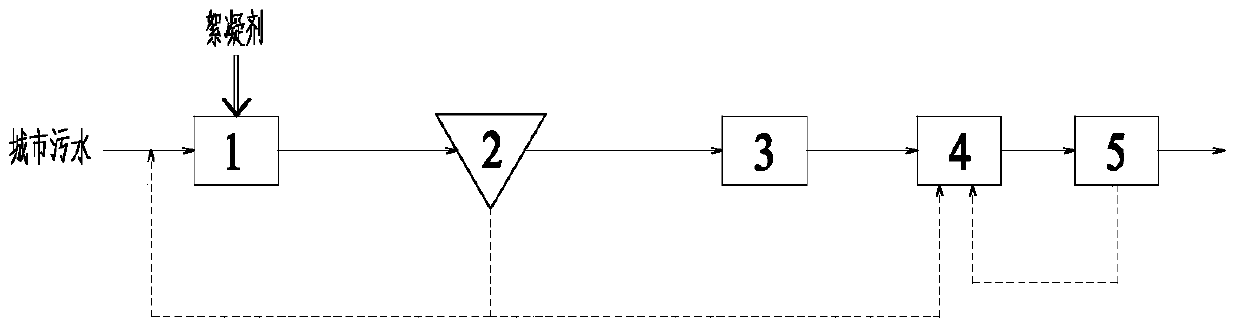

Treatment method for domestic sewage and organic solid wastes

ActiveCN106957130ARealize energy utilizationRealize the reuse of water resourcesBio-organic fraction processingSolid waste disposalSewageSlurry

The invention relates to the field of environmental engineering and particularly relates to a method for treating domestic sewage and organic and degradable solid wastes. According to the technical scheme, the treatment method for the domestic sewage and the organic solid wastes is characterized by comprising the following steps of (1) collecting the organic and degradable solid wastes, carrying out crushing treatment and adding water to adjust to prepare slurry of which the moisture content is greater than 50%; (2) separating black water from grey water, mixing the black water and the slurry obtained in the step (1) and entering the mixture into a first ecological treatment device or / and a precipitation device after passing through an anaerobic reactor, an aerobic bioreactor and an aerobic ecological reactor; and (3) entering the grey water into the precipitation device in the step (2) and then entering a second ecological treatment device for purification. By adopting the scheme, the treatment method for the domestic sewage and the organic and degradable solid wastes capable of treating the degradable organic wastes and the domestic sewage at the same time is provided.

Owner:WENZHOU UNIVERSITY

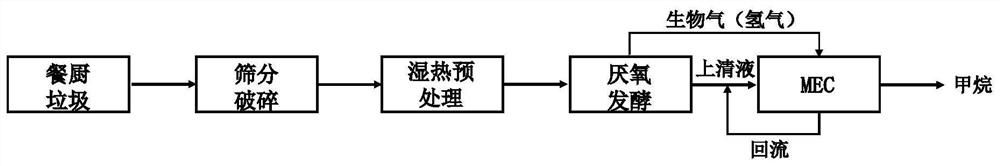

Method for producing methane by microbial electrocatalysis enhanced organic waste

InactiveCN112680481AImprove methanation efficiencyReduce carbon emissionsWaste based fuelFermentationChemistryFermentation broth

The invention discloses a method for synergistically enhancing methane production from food waste by anaerobic fermentation and microbial electrocatalysis. The method comprises the following steps of (1) conducting anaerobic fermentation, crushing organic garbage to prepare slurry, and adding the slurry into an anaerobic fermentation reactor in an intermittent feeding manner to carry out acid-producing hydrogen-producing fermentation; (2) starting a methanogenesis phase reactor, namely enriching electroactive microorganisms and starting the methanogenesis phase reactor by taking granular sludge as an inoculum, a mixed acid as a culture solution and a single-chamber microbial electrolysis cell as the methanogenesis phase reactor; (3) carrying out solid-liquid separation on a fermentation broth obtained in the (1), adjusting the pH value of the fermentation broth to 6.0-8.0 by using a supernatant, pumping the fermentation broth into the methanogenesis phase reactor successfully started in the (2), injecting biogas generated by fermentation in the (1) into the methanogenesis phase reactor, keeping the headspace hydrogen partial pressure of the reactor lower than 1.0 bar, and converting hydrogen and carbon dioxide in the biogas into the methane at a cathode. The methanogenesis phase reactor operates in an internal reflux mode.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

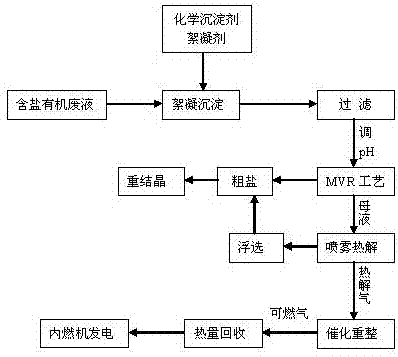

Salt-containing organic effluent treatment method

InactiveCN106865858AReduce corrosionReduce energy consumptionSludge treatment by pyrolysisTreatment involving filtrationLiquid wasteCatalytic reforming

The invention relates to a salt-containing organic effluent comprehensive treatment method, and belongs to the technical field of effluent treatment. The salt-containing organic effluent comprehensive treatment method comprises following steps: in pretreatment, a chemical precipitation agent is used for removing impurities, and a flocculating agent is used for clarification so as to ensure no suspended matter is left, and the pH value is adjusted to an appropriate value; MVR evaporative desalination is carried out so as to enrich organic matters in raw water; an obtained mother liquor is subjected to spraying pyrolysis so as to separate salts from organic matters in the mother liquor; a gas product obtained via pyrolysis is subjected to catalytic reforming so as to obtain flammable gas such as CO and H2; the flammable gas is subjected to heat energy recycling, and is delivered into an internal combustion engine for electricity generation and realize energy and resource utilization of effluent.

Owner:JIANGSU LEKE ENERGY SAVING TECH CO LTD

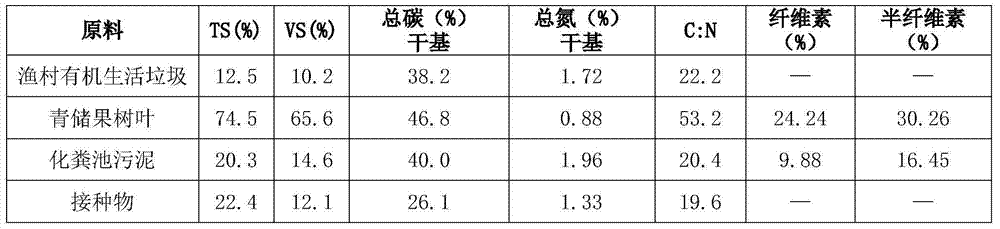

Method suitable for anaerobic dry fermentation of organic household refuses in fishing villages in Jiaodong peninsular region

InactiveCN104498578ARapid development of tourismSolve the problems of excessive production and random discharge of environmental pollutionMicroorganism based processesWaste based fuelDecompositionFishing village

The invention relates to a method suitable for anaerobic dry fermentation of organic household refuses in fishing villages in Jiaodong peninsular region. The method comprises the following steps: mixing the organic household refuses generated in fishing villages in the peninsular region with sludge in a septic tank and the stored fruit tree leaves, wherein the organic household refuses comprise leftovers, internal organs of aquatic products, fish bones of kitchen wastes, various seafood shells, melon shells, vegetable leaves, tealeaf residues, fish-prawn-crab, outdated items of food and excrements in the breeding industry, adding biogas residues fermented in a normal gas production biogas digester over a month after solid-liquid separation to serve as an inoculum, and performing combined anaerobic fermentation to generate biogas. The limitation of single material fermentation is avoided, the organic household refuses in the fishing villages in the Jiaodong peninsular region and other solid wastes are recycled, and decomposition of the organic household refuses is accelerated by virtue of the sludge in the septic tank and the stored fruit tree leaves, so that biogas production is normally started, fermentation-induced biogas production is promoted, the gas production amount is large, and central gas supply of residents and restaurants in the fishing villages can be realized.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Single-stage low-switch-stress and low-output-ripple LED drive circuit

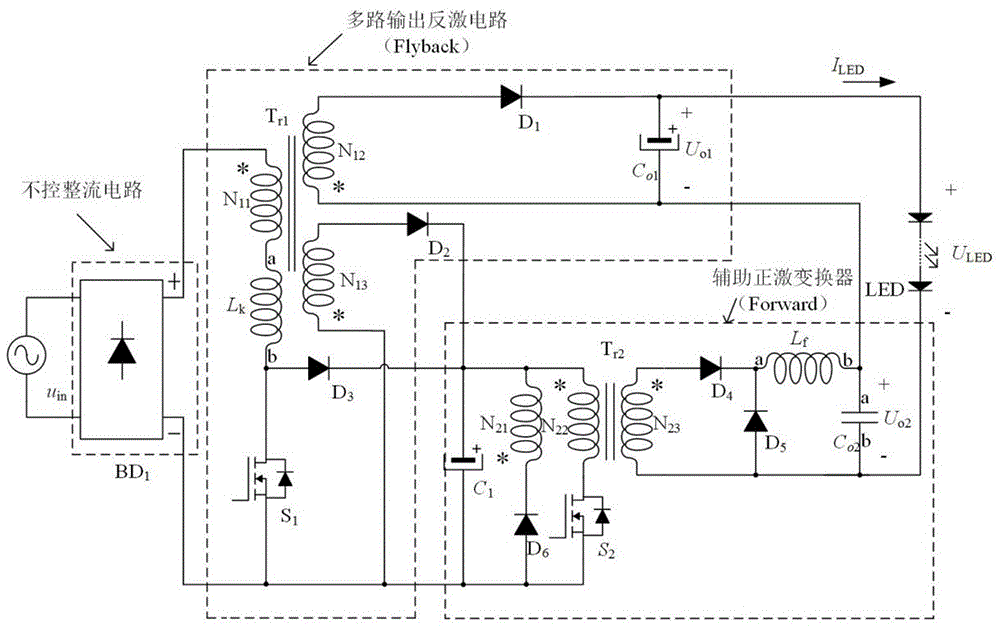

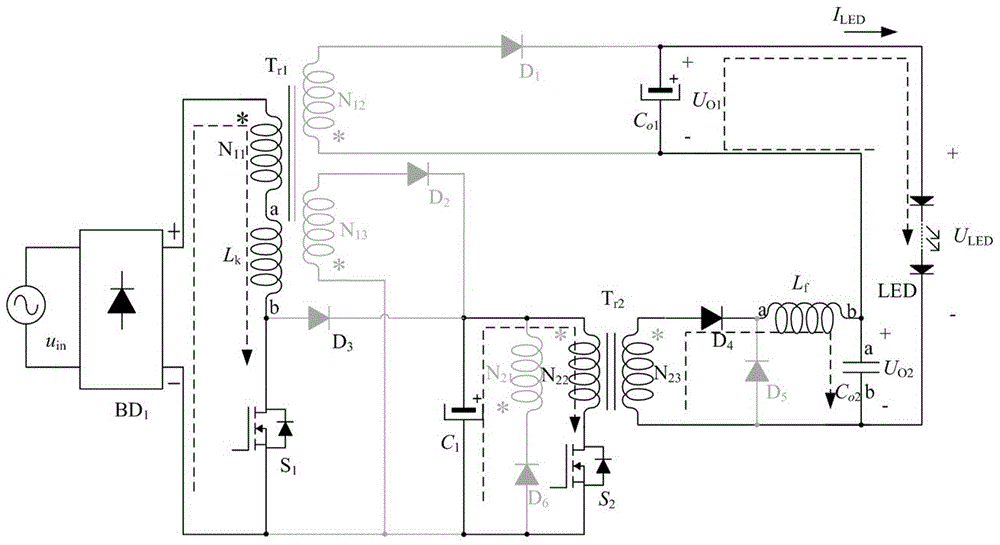

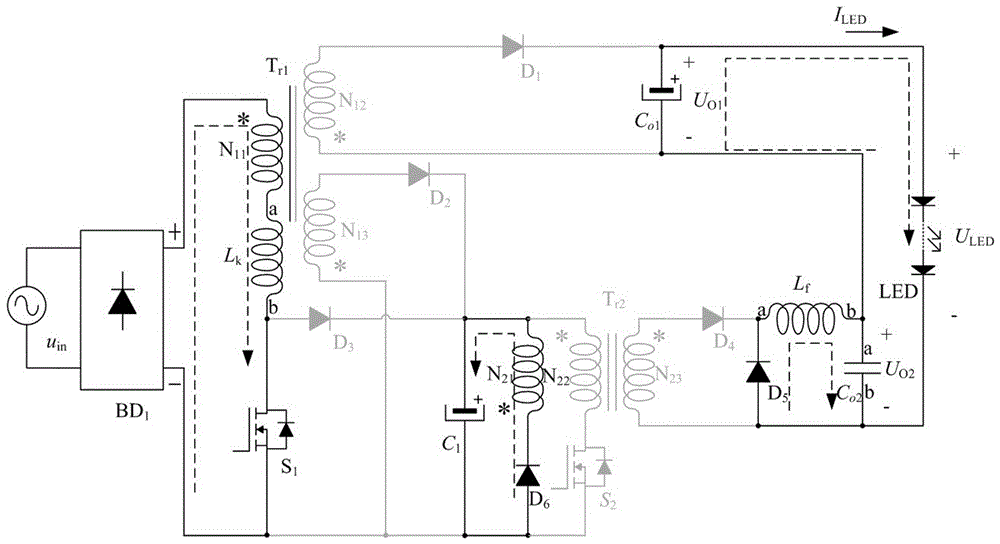

InactiveCN106535400AReduce voltage stressRealize energy utilizationElectrical apparatusElectroluminescent light sourcesLow voltageAlternating current

The invention relates to a single-stage low-switch-stress and low-output-ripple LED drive circuit comprising an input alternating-current power supply uin, a diode rectifier bridge BD1, a main transformer Tr1, an auxiliary transformer Tr2, a first power MOS switch tube S1, a second power MOS switch tube S2, a first power diode D1, a second power diode D2, a third power diode D3, a fourth power diode D4, a fifth power diode D5, a sixth power diode D6, an electrolytic capacitor C1, a first output capacitor Co1, a second output capacitor Co2, an output filter inductor Lf, and an LED lamp load. The LED drive circuit based on combination of a single-stage AC-DC converter Flyback and an auxiliary converter Forward is constructed, so that high-efficiency, low-voltage-stress, low-output-ripple, and constant current output functions are realized.

Owner:FUZHOU UNIV

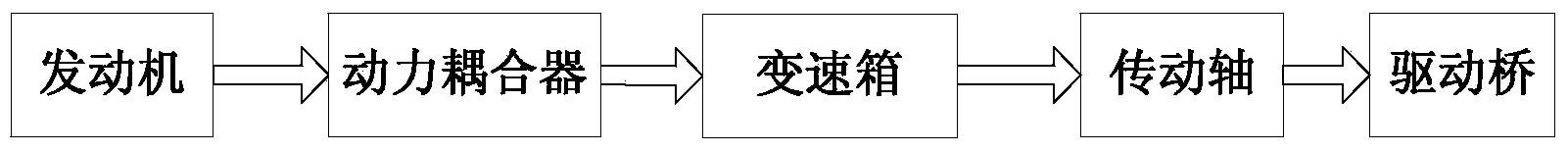

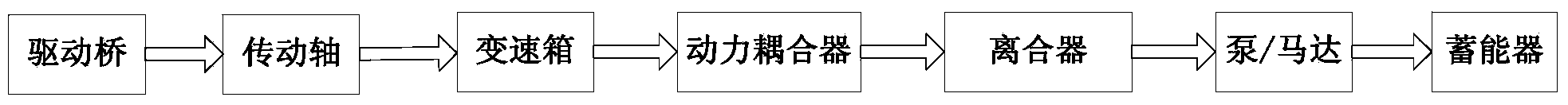

Braking energy recycling system, braking energy recycling method and crane

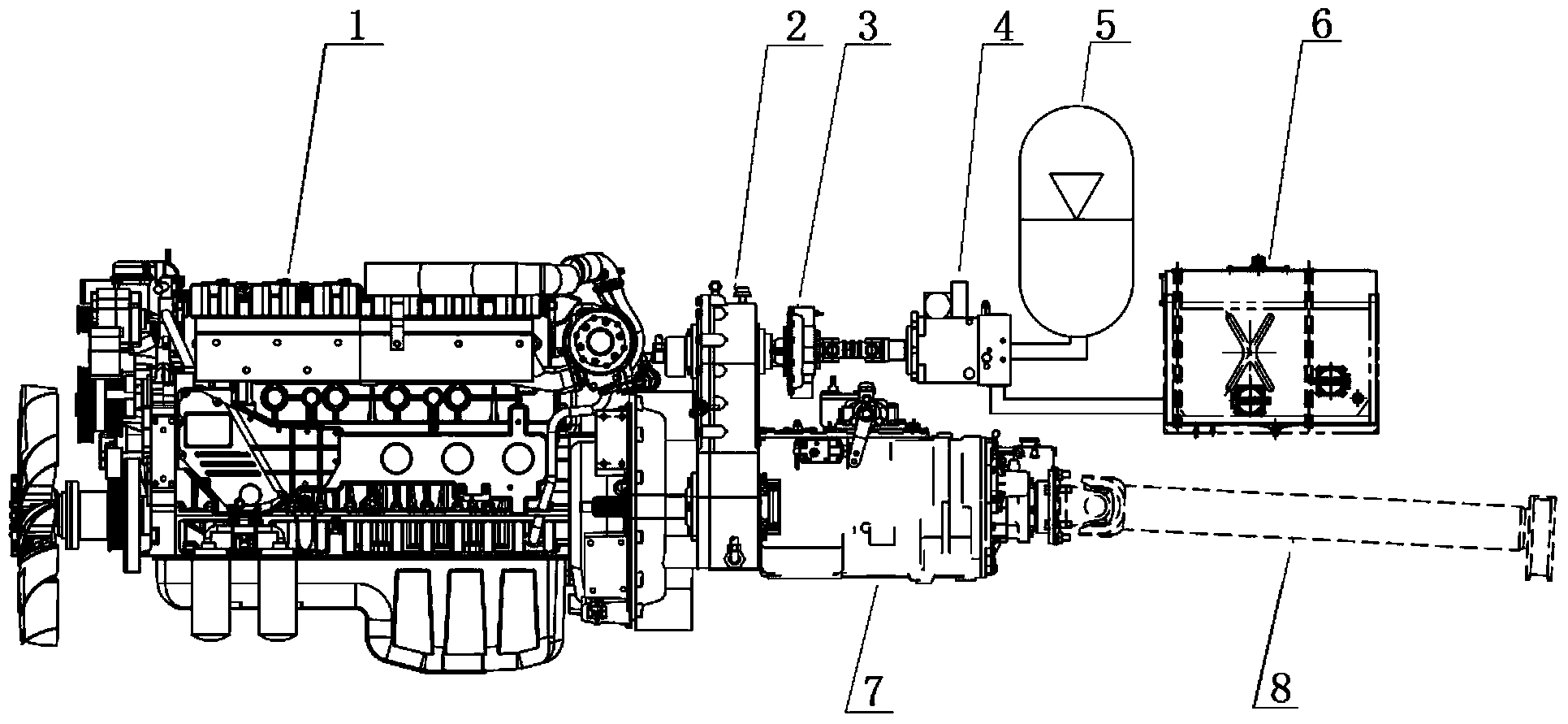

InactiveCN104385915ARealize energy utilizationImprove fuel economyAuxillary drivesPower performanceClutch

The invention relates to a braking energy recycling system, a braking energy recycling method and a crane, wherein the braking energy recycling system comprises an engine, a power coupler connected with the engine, and a clutch and a gearbox in parallel connection with the power coupler. The clutch is connected with a hydraulic pump / motor; the hydraulic pump / motor is in parallel connection with an energy accumulator and a hydraulic oil tank; and the gearbox is connected with a transmission mechanism. In the braking process, braking mechanical energy is converted to hydraulic energy by the transmission mechanism, the gearbox, the power coupler, the clutch and the hydraulic pump / motor, and the hydraulic energy is stored in the energy accumulator to realize the braking energy recovery; and in the starting, accelerating and climbing processes, the energy stored in the energy accumulator is converted into the mechanical energy by the hydraulic pump / motor, and the mechanical energy drives the whole vehicle to move through the transmission of the gearbox, thereby satisfying the power requirements and realizing the energy utilization. The system can effectively recycle the energy generated in the braking process and thus improve the whole machine fuel economy and the whole machine power performance and braking performance.

Owner:XUZHOU HEAVY MASCH CO LTD

Method for producing biogas from fruit and vegetable wastes

ActiveCN104673841AReduce generationMeeting water needsWaste based fuelFermentationCelluloseMethanation

The invention discloses a method for producing biogas from fruit and vegetable wastes. The method is characterized by comprising the following steps: (1) raw material pretreatment: grinding the fruit and vegetable wastes in a ball grinder to damage the difficultly degraded cellulose structure, releasing the bound water in the raw material and the intracellular water and the intracellular matter in the plant cell, and finally putting the obtained pasty effluent in a storage tank to store; (2) solid-liquid separation and coupling: performing solid-liquid separation on the pasty effluent to obtain a fruit and vegetable juice and a solid residue, wherein the fruit and vegetable juice comprises plenty of soluble carbohydrates (mainly comprising monosaccharide and polysaccharide) and easily biodegradable components for methanation processing; the solid residue is mainly rich in cellulose content; acid liquor containing plenty of volatile organic acids is obtained through a high-solid-concentration hydrolysis acid production reaction, a proper substrate is provided for the methane production process, and then the two-phase anaerobic system has a high gas production performance.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

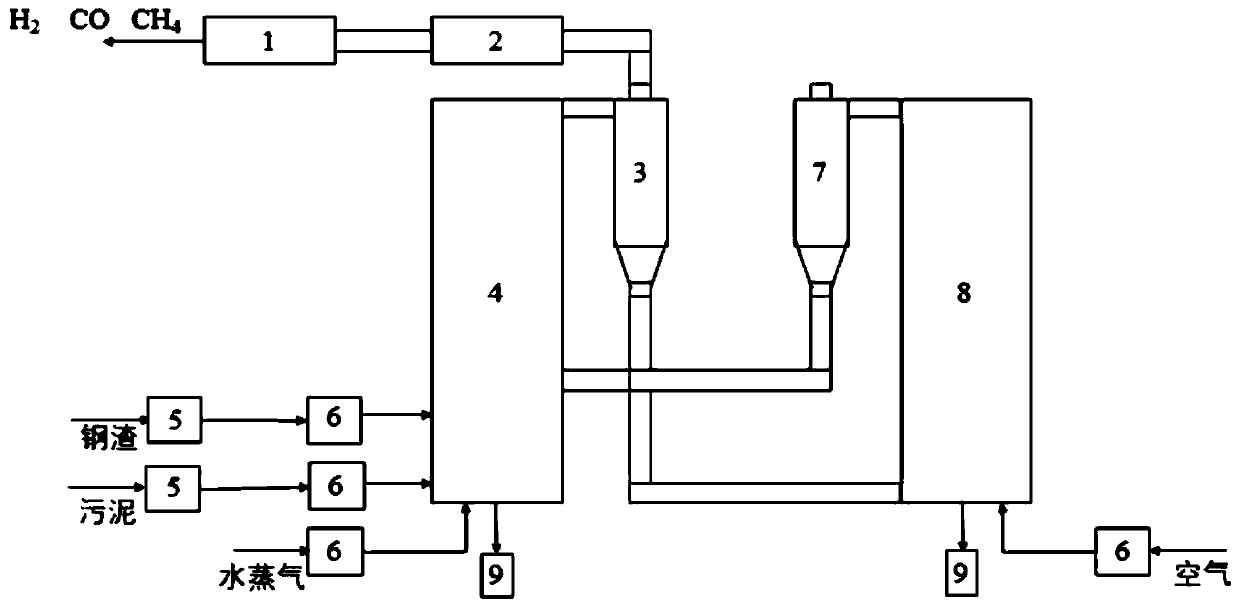

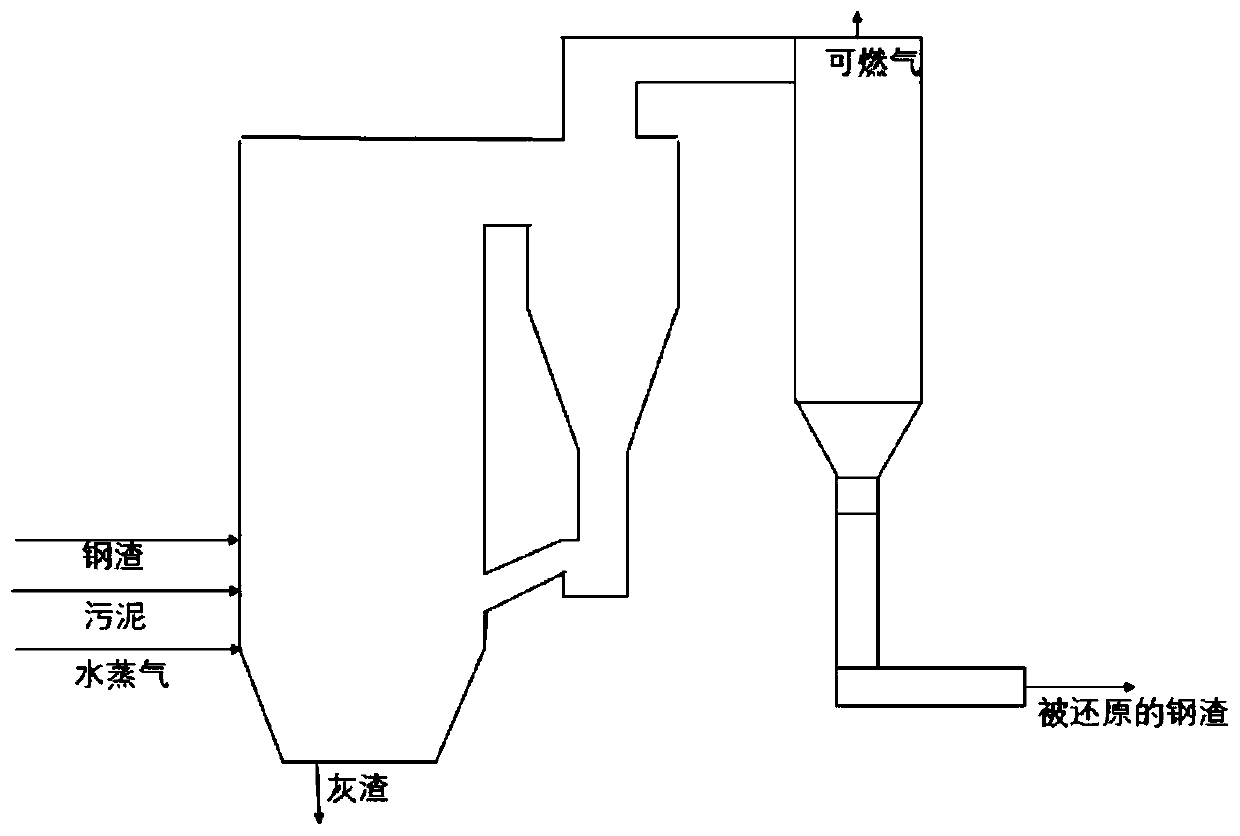

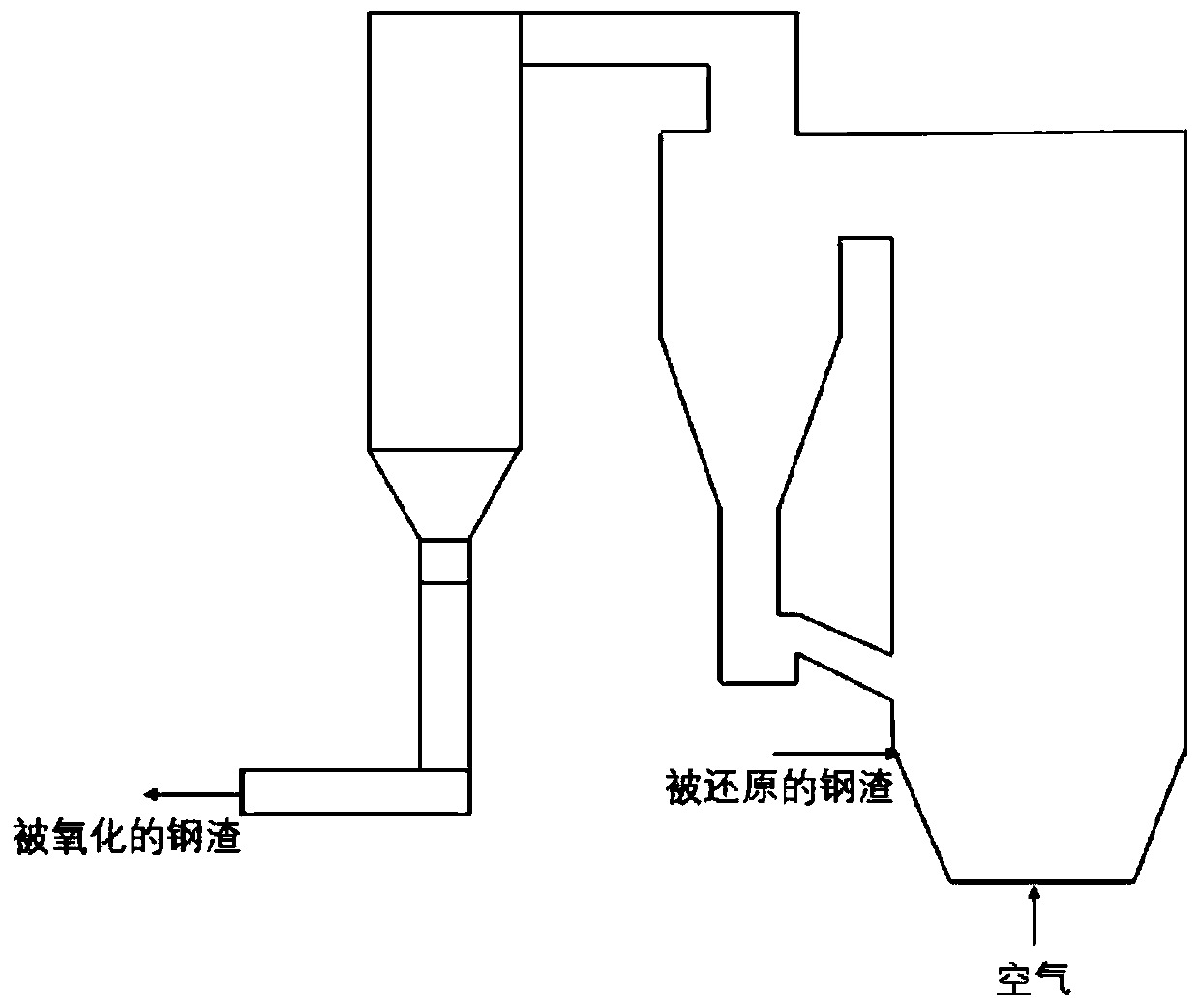

Sludge chemical chain gasification system based on steel slag oxygen carrier and process

PendingCN110342770AReduce pollutionRealize energy utilizationSludge treatmentSpecific water treatment objectivesVolume reductionCompound (substance)

The invention discloses a sludge chemical chain gasification system based on a steel slag oxygen carrier and a process. The system comprises a combustible gas collection device, a filtering device, amain cyclone separator, a main fluidized bed, a grinding machine, an air blower, a secondary bed cyclone separator, a secondary fluidized bed and an ash hopper. Compared with the prior art, the systemviews from practical problems that city sludge and steel slag of the steel industry are hard to treat at present, is based on the idea of "treating wastes with wastes", and develops a sludge chemicalchain gasification technique based on the a steel slag oxygen carrier, and through the research, volume reduction and amount reduction of sludge and steel slag are facilitated, meanwhile, heat valuesin the sludge can be recycled, and energy utilization of the sludge can be achieved. Compared with a conventional sludge treatment technique, the system is capable of remarkably lowering the operation cost, reducing pollutant emission in the production process, and has good social, economic and environment-friendly benefits.

Owner:HENAN UNIV OF URBAN CONSTR

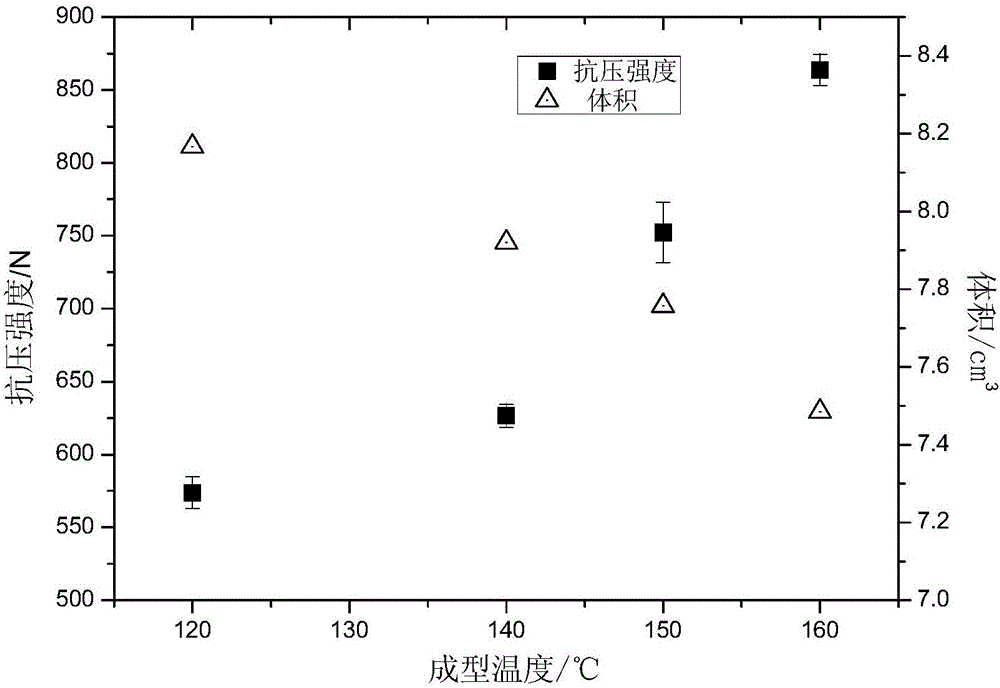

Briquette coal binder, biomass briquette and preparation method thereof

InactiveCN109652156AImprove molding rateImprove thermal stabilityBiofuelsSolid fuelsResource utilizationMaterials science

The invention relates to the technical field of briquettes, and relates to a briquette binder, preparation method of a briquette binder, a biomass briquette and a preparation method of the biomass briquette, the briquette binder is prepared by the following steps: crushing biomass raw materials, and treating the biomass raw material i by adopting a hot-dissolving extraction method to obtain the briquette coal binder. The method disclosed by the invention mainly uses agricultural and forestry wastes such as wheat straws, pine wood chips, cotton straws, corn straws, rice straws and the like as the biomass raw materials, and prepares the biomass briquette by virtue of a hot press molding process; the biomass briquette prepared by the method disclosed by the invention is high in forming rate,the heat stability is good, the drop strength index is excellent, the ignition point is low, compressive strength is high, heat value is high, the production process is simple in operation and high infeasibility, the raw materials are wide in source and low in price, the biomass resources such as agriculture and forestry wastes can be effectively utilized, contribution is made to environmental protection, and resource utilization and energy utilization of biomass such as the agriculture and forestry wastes are realized, so that low-rank coal can be cleaned and efficiently utilized.

Owner:XINJIANG UNIVERSITY

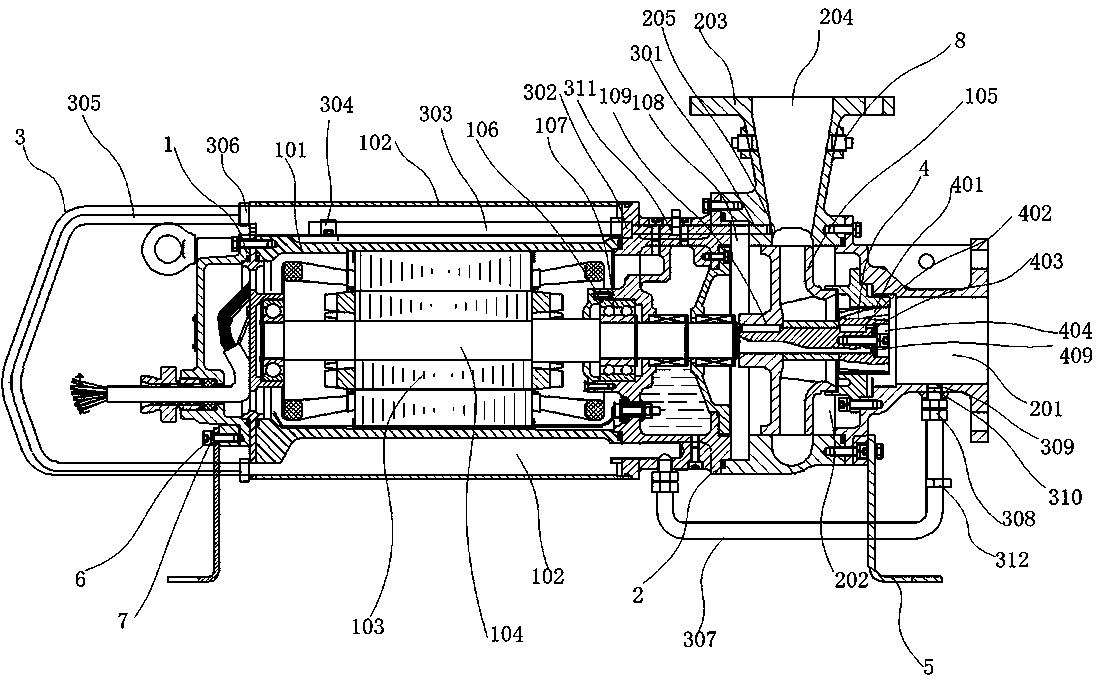

Bedroom cold water pump

ActiveCN109812422ARapid coolingAvoid failureSpecific fluid pumpsPump componentsClamp connectionEngineering

The invention discloses a bedroom cold water pump comprising a motor part assembly, a volute assembly, a circulating cooling filter assembly and a cutting assembly. One part of water of a sewage outlet of a water outlet base of the volute assembly is introduced into a cooling sealing cavity in the motor part assembly through the circulating cooling filter assembly, sewage is used for circularly cooling a motor in a motor sealing cavity, energy utilization of resources is achieved, and the motor can be rapidly cooled. The cutting assembly is arranged in the volute assembly, arc tool slots are arranged on the two sides of the bottom end of a cutting tool bit in a mirror image mode, the rotary cutting efficiency of the two ends of the cutting tool bit can be improved through the arc tool slots, hard impurities can be rapidly cut, and the cutting effect is good. A thread protruding ring is in clamped connection with the interior of a ring-hook-shaped avoiding groove and is fixed through aconnection bolt, and connection firmness between the cutting tool bit and a cutting port ring part can be effectively ensured. By means of up-down matching arrangement of the cutting tool bit and thecutting port ring part, impurities are not likely to be clamped in the cutting assembly to caused faults and damage.

Owner:TAIZHOU TAIFENG PUMP IND

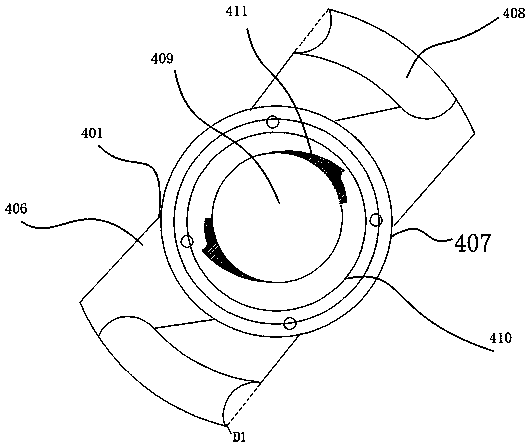

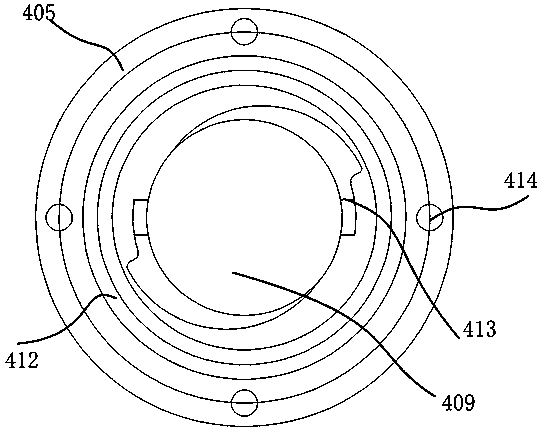

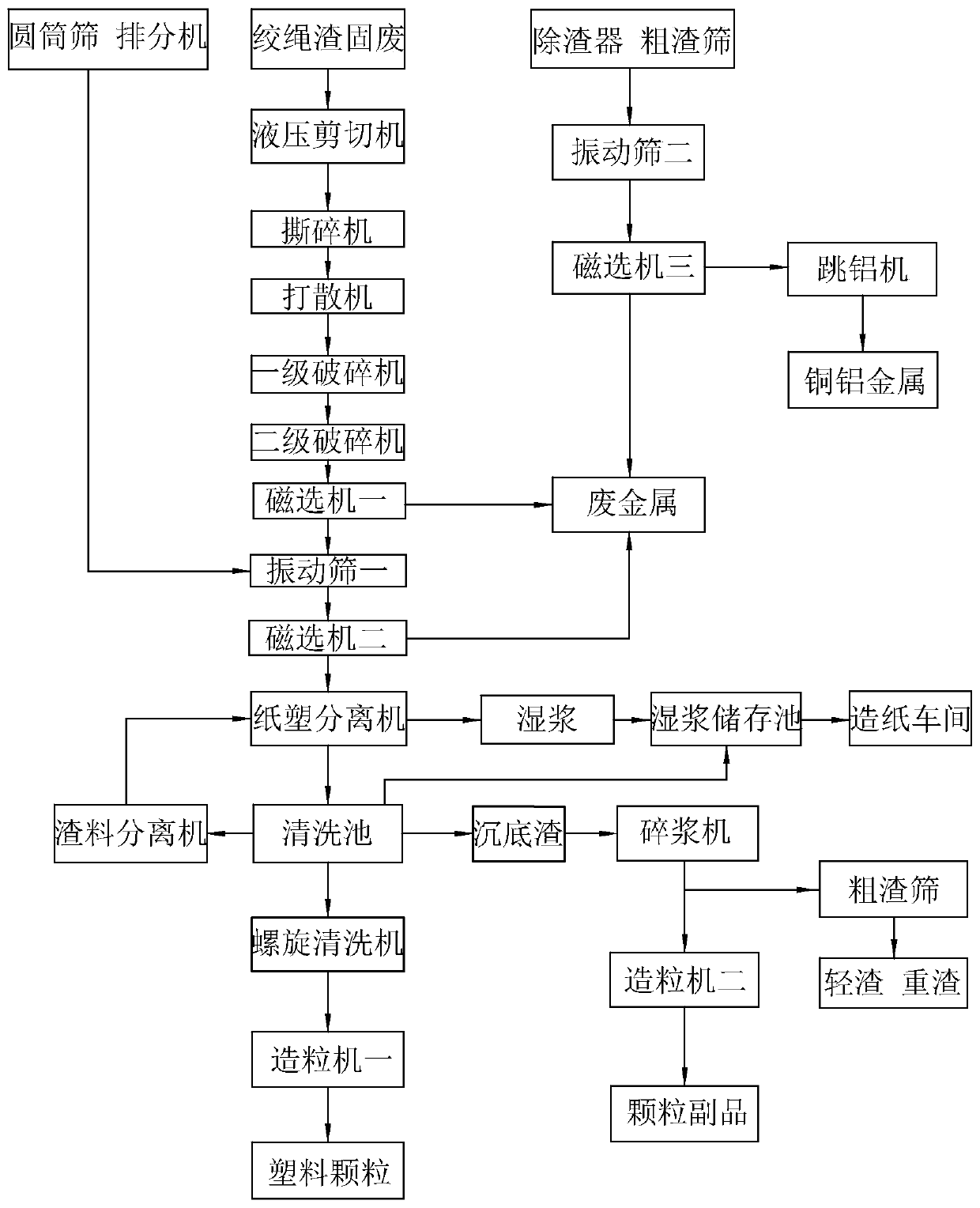

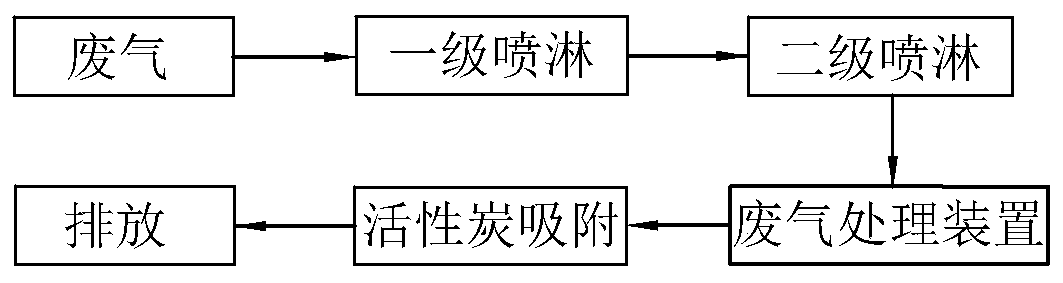

Process for recycling papermaking waste residues

InactiveCN111361056AImprove recycling efficiencyEnvironmental complianceSolid waste disposalPlastic recyclingSlagExhaust fumes

The invention discloses a process for recycling papermaking waste residues. The process comprises the steps of firstly, removing metal in solid waste from twisted rope slag, a cylinder sieve, a slag discharge centrifuge, a residue remover and a rough residue sieve, and then conducting paper-plastic separation on the remaining waste residues in the solid waste obtained from the twisted rope, the cylinder sieve and the slag discharge centrifuge, wherein wet pulp obtained through separation is recycled to a papermaking workshop, obtained plastic fragments are used for manufacturing plastic particles, and meanwhile, exhaust gas generated in the production process is also treated. According to the process, harmless and energy-oriented comprehensive utilization of solid waste is achieved, the advanced clean production process is adopted, secondary pollution is unlikely to occur in the production process, thus harmless and energy-oriented comprehensive utilization of the papermaking waste residues is achieved, and thus waste materials are changed into things of value.

Owner:ZHONGTIAN PAPER

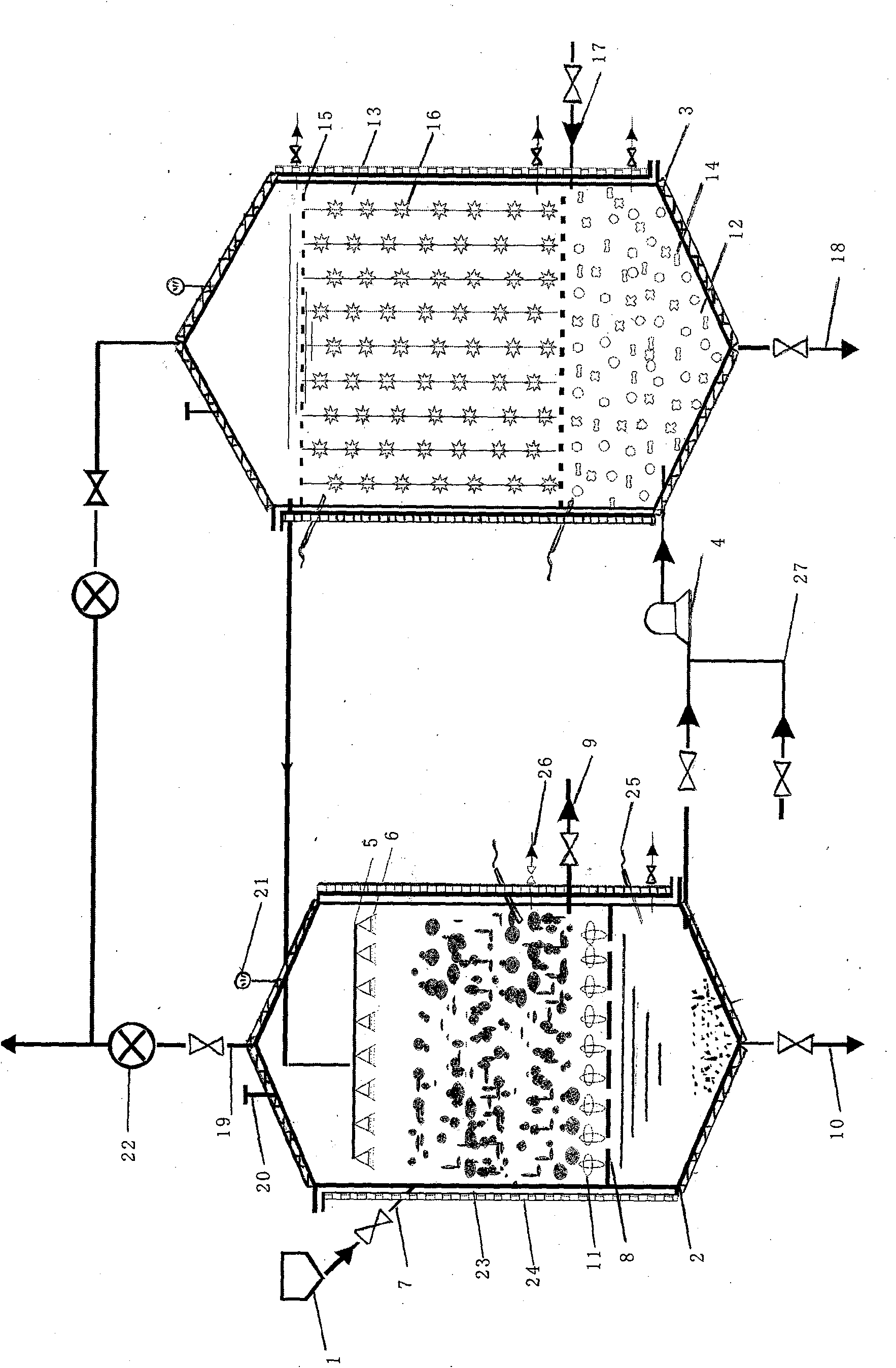

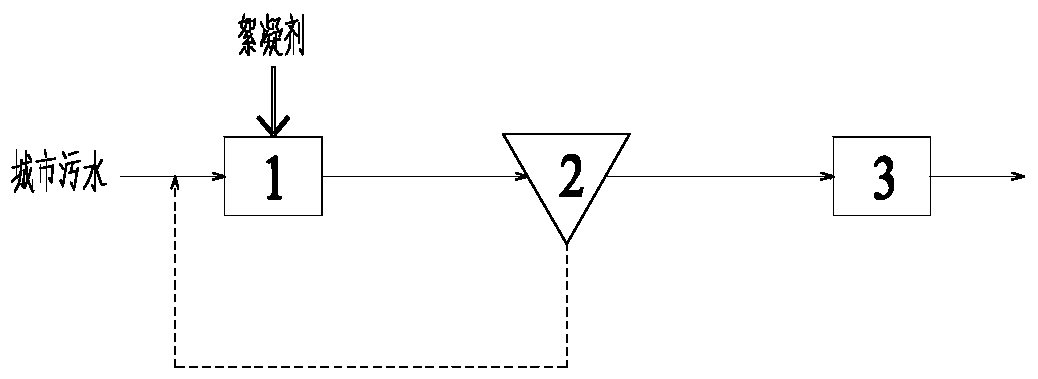

A high-standard nitrogen and phosphorus removal system for urban sewage without additional carbon sources

ActiveCN105366889BAvoid the disadvantages of unstable operation of the anaerobic ammonium oxidation processSimple processTreatment using aerobic processesTreatment with anaerobic digestion processesSludgeWater quality

The present invention relates to a high-standard urban sewage nitrogen and phosphorus removal system without external carbon sources. Urban sewage is fed into an urban sewage water inlet of a chemical-biological flocculation reaction tank; flocculant is fed into a flocculant adding port of the chemical-biological flocculation reaction tank; a drainage port of the chemical-biological flocculation reaction tank is connected with a water inlet of a sedimentation tank by a pipe; a drainage port of the sedimentation tank is connected with a water inlet of a mainstream anammox reaction tank by a pipe; a drainage port of the mainstream anammox reaction tank is connected to a drainage pipeline; and a sludge discharge port of the sedimentation tank is connected into the urban sewage water inlet of the chemical-biological flocculation reaction tank by a pipe. According to the system provided by the present invention, an anammox process and a traditional process are integrated organically, the drawback that in the case of a large amount of water flow and significant fluctuations of water quality, quantity and environmental conditions, the anammox process runs unstably is avoided; nitrogen removal efficiency is high; and the external carbon sources are not required even if the carbon nitrogen ratio is low.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

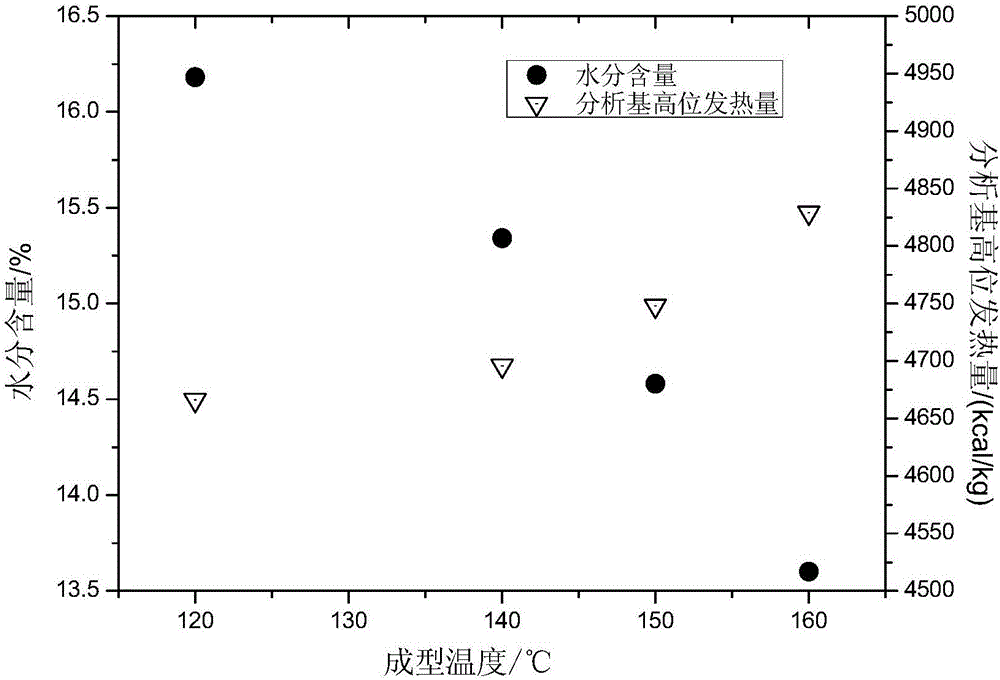

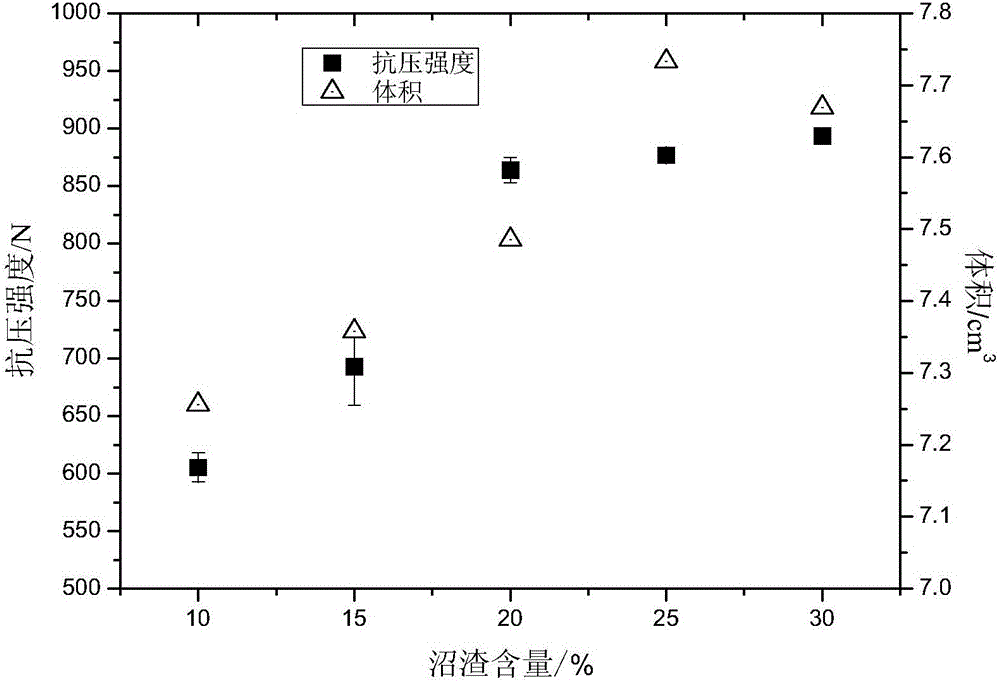

Straw biogas residue biomass coal briquette and preparation method thereof

InactiveCN106701233AReduce moistureReduce energy consumption and equipment lossBiofuelsSolid fuelsWater contentBiomass

The invention provides a straw biogas residue biomass coal briquette and a preparation method thereof. The method comprises the following steps: firstly, carrying out anaerobic fermentation on crushed straws to obtain biogas residues, and crushing the dried biogas residue after drying; secondly, uniformly mixing the crushed biogas residues obtained in the first step with lignite, and carrying out hot press molding on a mixture to obtain the straw biogas residue biomass coal briquette. According to the straw biogas residue biomass coal briquette provided by the invention, the biomass coal briquette is prepared by compression molding of the mixture of the crushed biogas residues and the lignite; the water content of the lignite can be reduced, and energy consumption and equipment loss in the processing process can be effectively reduced; moreover, no binder needs to be added in the preparation process. The straw biogas residue biomass coal briquette prepared by the preparation method has the advantages of higher compressive strength, fall strength and water immersion strength, higher analysis basic heating value, lower water content and no dispersion after being immersed into water for 24 hours.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

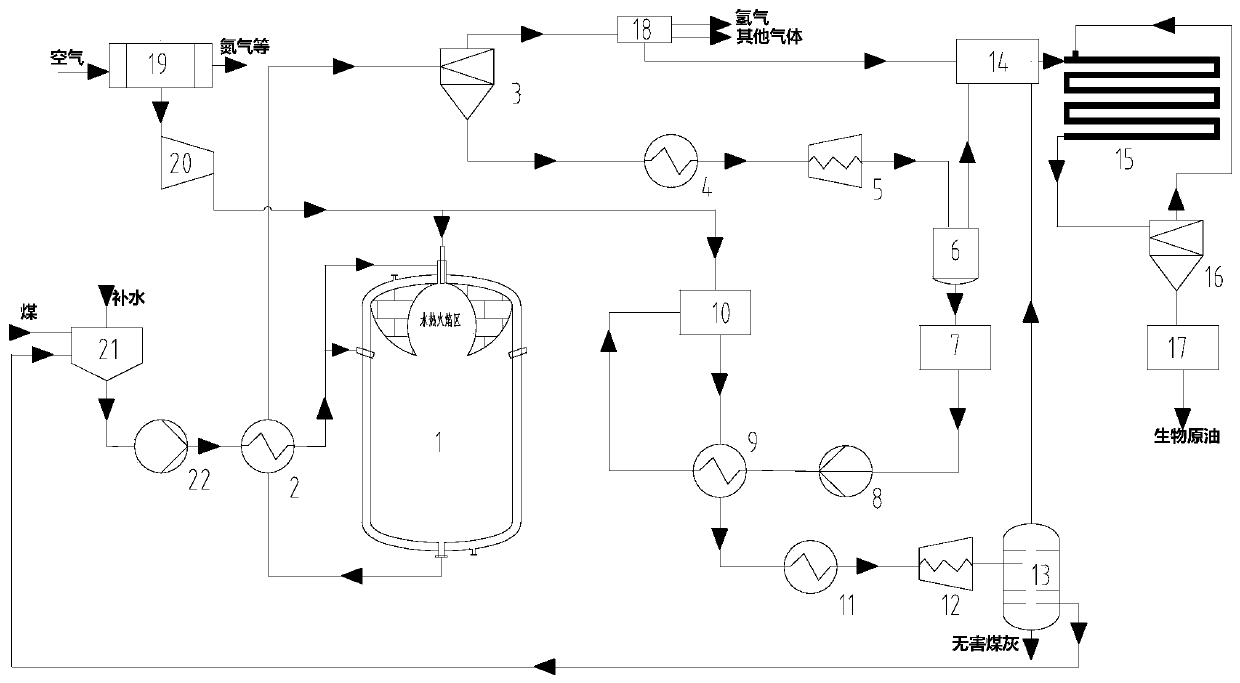

Energy utilization system and method of using carbon-based energy to perform supercritical water gasification to produce hydrogen and CO2

PendingCN111205894AGood yieldHarmlessBioreactor/fermenter combinationsBiological substance pretreatmentsThermodynamicsCombustion

The invention discloses an energy utilization system and method of using carbon-based energy to perform supercritical water gasification to produce hydrogen and CO2. The method comprises the followingsteps: (1) a main reaction process: using the heat of the reaction product of the supercritical water gasification for producing hydrogen to preheat materials; separating to obtain CO2 and a liquid-phase product, regulating the temperature and the pressure of the liquid-phase product, performing a supercritical water oxidation reaction, preheating the liquid-phase product subjected to temperatureand pressure regulation by the heat of the product of the supercritical water oxidation reaction, reducing the pressure, performing three-phase separation, separating to obtain CO2 and a liquid-phaseproduct, and returning the liquid-phase product to prepare coal slurry; (2) energization and carbon-fixing process, utilizing CO2 obtained in the main reaction process to carry out a microalgae carbon-fixing reaction to produce biological crude oil; (3) oxidant supplying process: supplying oxygen to the supercritical water gasification reaction and the supercritical water oxidation reaction; and(4) material supplying process: preparing coal slurry, and supplying materials to the main reaction process. The supercritical hydrothermal combustion technology, the supercritical water gasificationtechnology and the supercritical water oxidation technology are coupled into a whole, and high-value clean conversion and utilization of coal in the whole process are achieved.

Owner:XI AN JIAOTONG UNIV

Acoustic resonance generation device

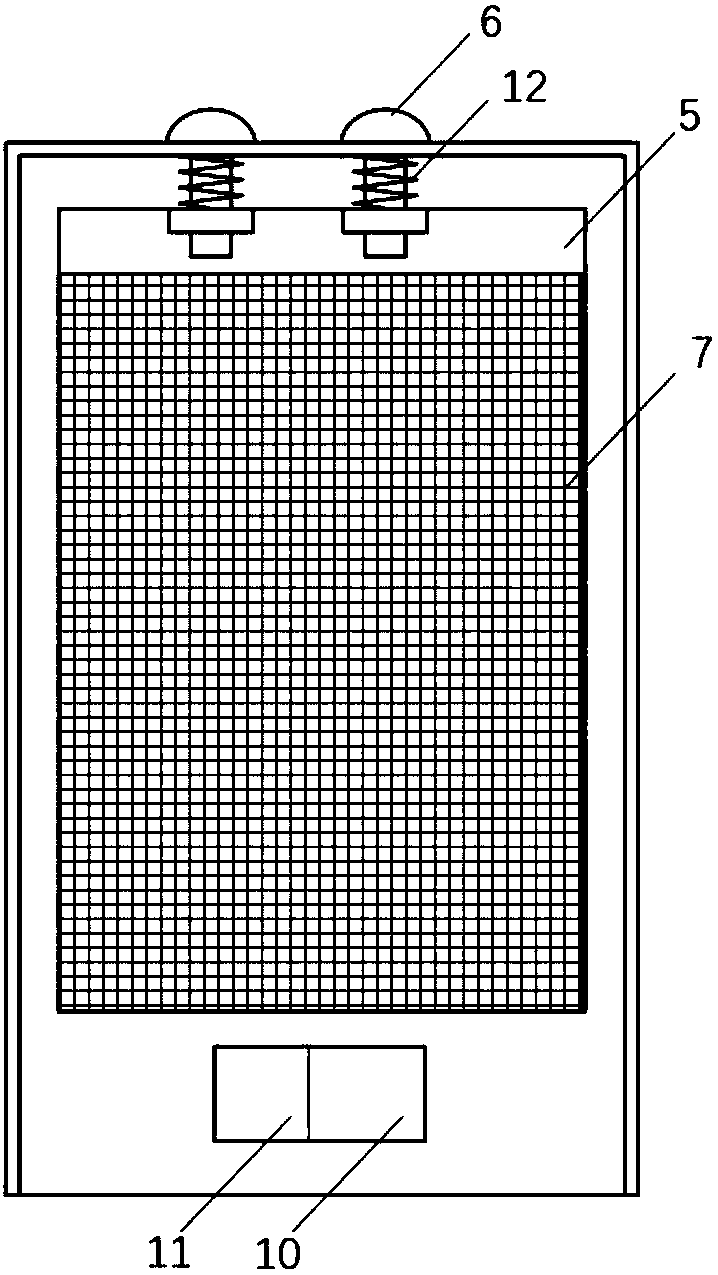

PendingCN108282726ARealize energy utilizationWay to achieveElectrical transducersLoudspeakersAcoustic energyAcoustic wave

The invention discloses an acoustic resonance generation device. The acoustic resonance generation device comprises an outer shell, a base, a loudspeaker, an enclosed sound box frame, a Helmholtz acoustic resonator, a bolt, a ceramic generation module, a rectifying output circuit, an audio driving circuit, an input panel and an output panel, wherein the base is covered with the outer shell; the loudspeaker is fixed to the base through the enclosed sound box frame; the Helmholtz acoustic resonator is suspended above the loudspeaker through the bolt; the ceramic generation module is attached toan outer surface of the Helmholtz acoustic resonator; and the rectifying output circuit and the audio driving circuit are arranged on the base. Through adoption of the acoustic resonance generation device provided by the invention, a corresponding larger-mass resonator is excited to vibrate with small acoustic energy according to the acoustic resonance principle, and the vibration potential energyof the resonator is converted into electric energy, thereby realizing a novel energy utilization and conversion manner, and providing continual power support for production and life.

Owner:杨进

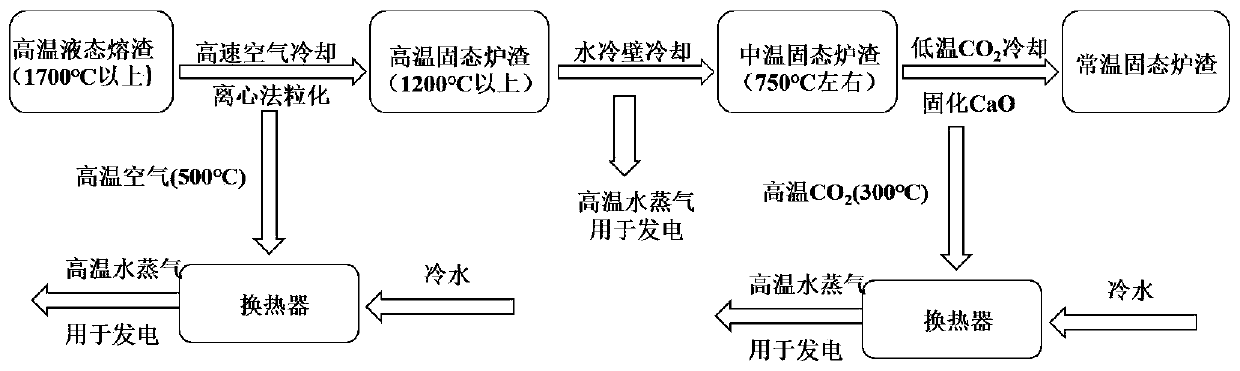

High-temperature liquid slag granulation and waste heat recovery method

InactiveCN111100957ATake advantage ofFully consider the use ofRecycling and recovery technologiesProcess efficiency improvementThermodynamicsWater vapor

The invention discloses a high-temperature liquid slag granulation and waste heat recovery method. Low-temperature air, water and low-temperature carbon dioxide are sequentially selected as heat exchange media, and a three-stage three-medium method is adopted for achieving heat exchange with high-temperature liquid slag to obtain normal-temperature solid slag and heat exchange media absorbing heat. The high-temperature liquid slag granulation and waste heat recovery method specifically comprises the steps that the low-temperature air is adopted to cool slag droplets formed after the high-temperature liquid slag is crushed to form high-temperature solid slag and high-temperature air; the water is adopted to cool the high-temperature solid slag to obtain medium-temperature solid slag and high-temperature water vapor; and countercurrent heat exchange is carried out between the low-temperature carbon dioxide and medium-temperature solid slag to obtain normal-temperature solid slag and high-temperature carbon dioxide. According to the split slag comprehensive utilization method combining centrifugal granulation and three-stage heat exchange, the water does not directly make contact withthe slag, the energy and resource properties of the hot slag are sufficiently considered, through multi-step cooling, the heat in the hot slag can be fully utilized, the low-temperature and high-temperature slag which can be used as raw materials for new plates and building floors can be obtained, and great significance is achieved for practice and popularization.

Owner:PEKING UNIV

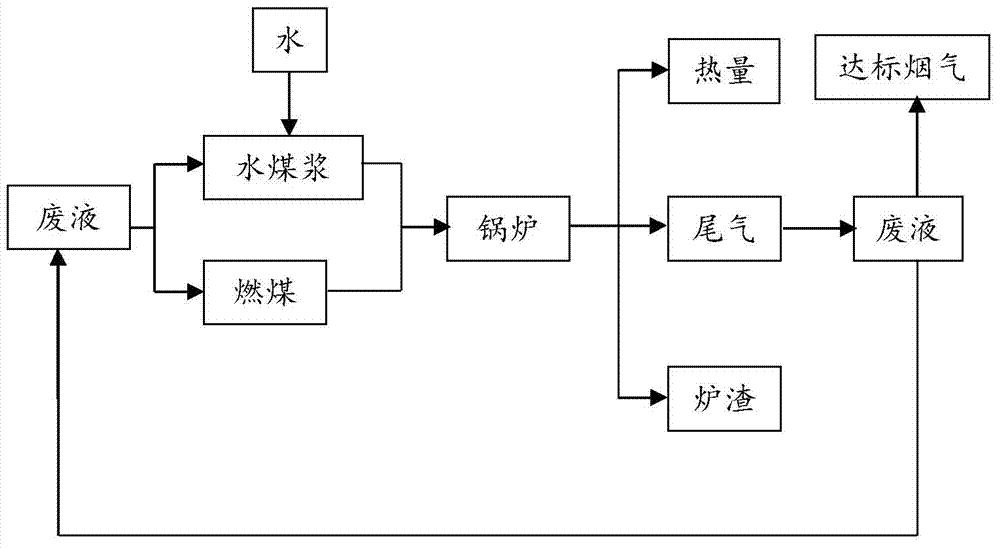

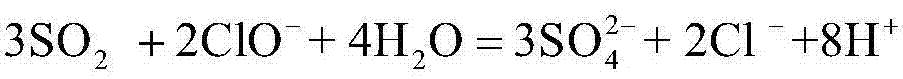

Novel efficient flue gas desulfurization agent and method for treating desulfurization agent

InactiveCN104722186AEmission reductionAlleviate the pressure of pollution prevention and controlDispersed particle separationLiquid carbonaceous fuelsLiquid wasteCombustion

The invention provides flue gas desulfurization (FGD), refers to desulfurization of gas generated by combustion and belongs to tail management flue gas desulfurization. An FGD method technology is relatively developed; even if the desulfurization rate can be up to 90%, the process is complicated and the operation cost is high, and byproducts are difficult to treat. More flue gas desulfurization methods, including a wet method, a dry method and a semi-dry method, exist. Separated waste liquid obtained by carrying out alkali treatment on straws is used, and the waste liquid is used for the flue gas desulfurization and then is mixed with coal powder to form coal slurry to be used as fuel which is completely utilized. On the one hand, residual alkali, alkali lignin and lignin sulfonate in the waste liquid, and SO2 in flue gas are reacted to form a stable structure, and sulfur generated by combusting coal is removed; on the other hand, the residual alkali and oxides are separated from the waste liquid and are reacted with sulfur in the coal to be oxidized into stable sulfate ions, so that the sulfur fixation effect is realized.

Owner:QINGDAO UNIV OF SCI & TECH

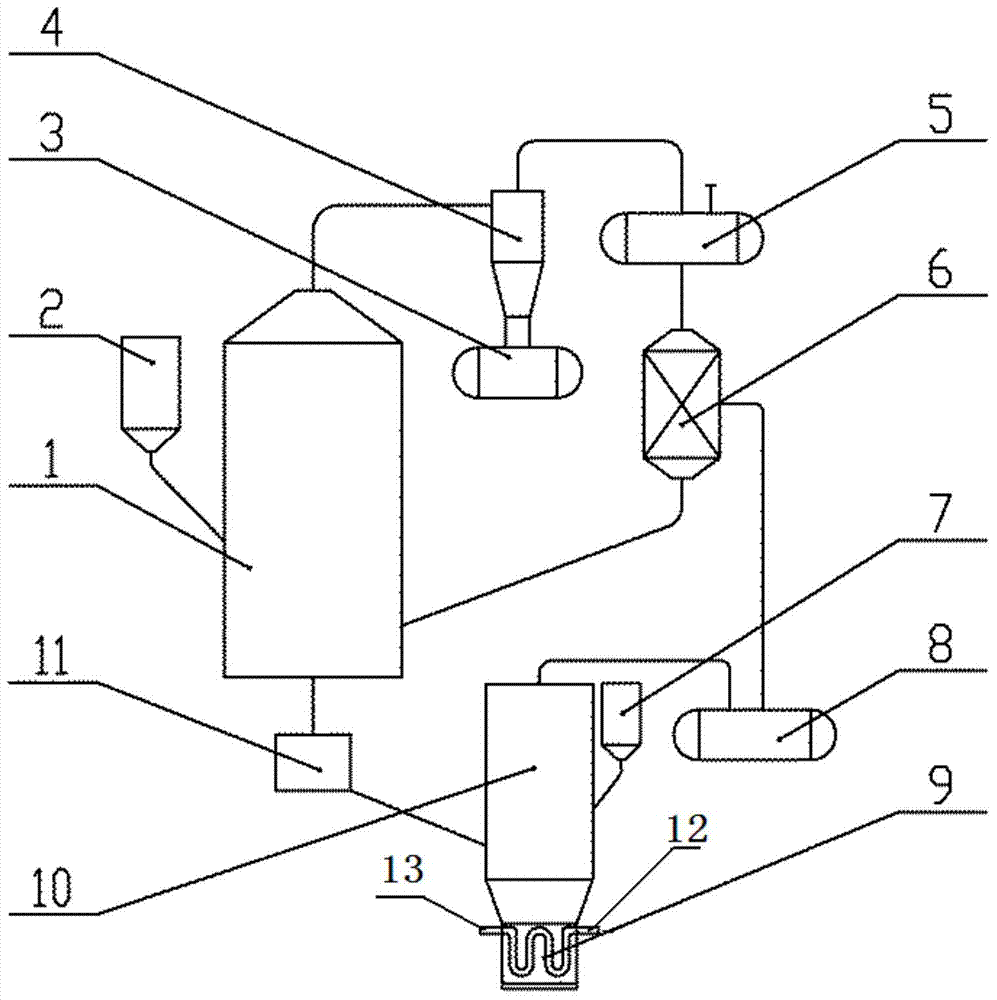

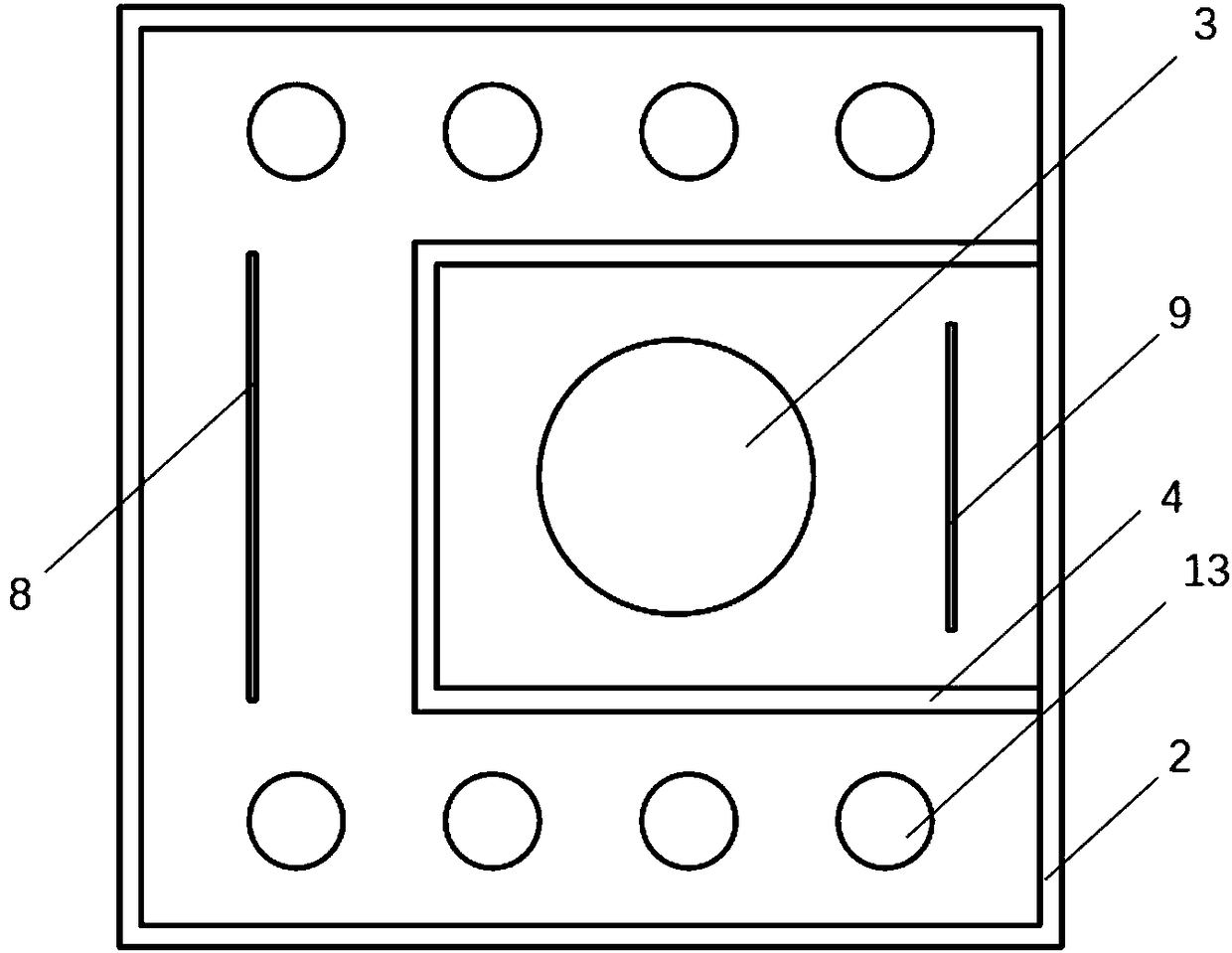

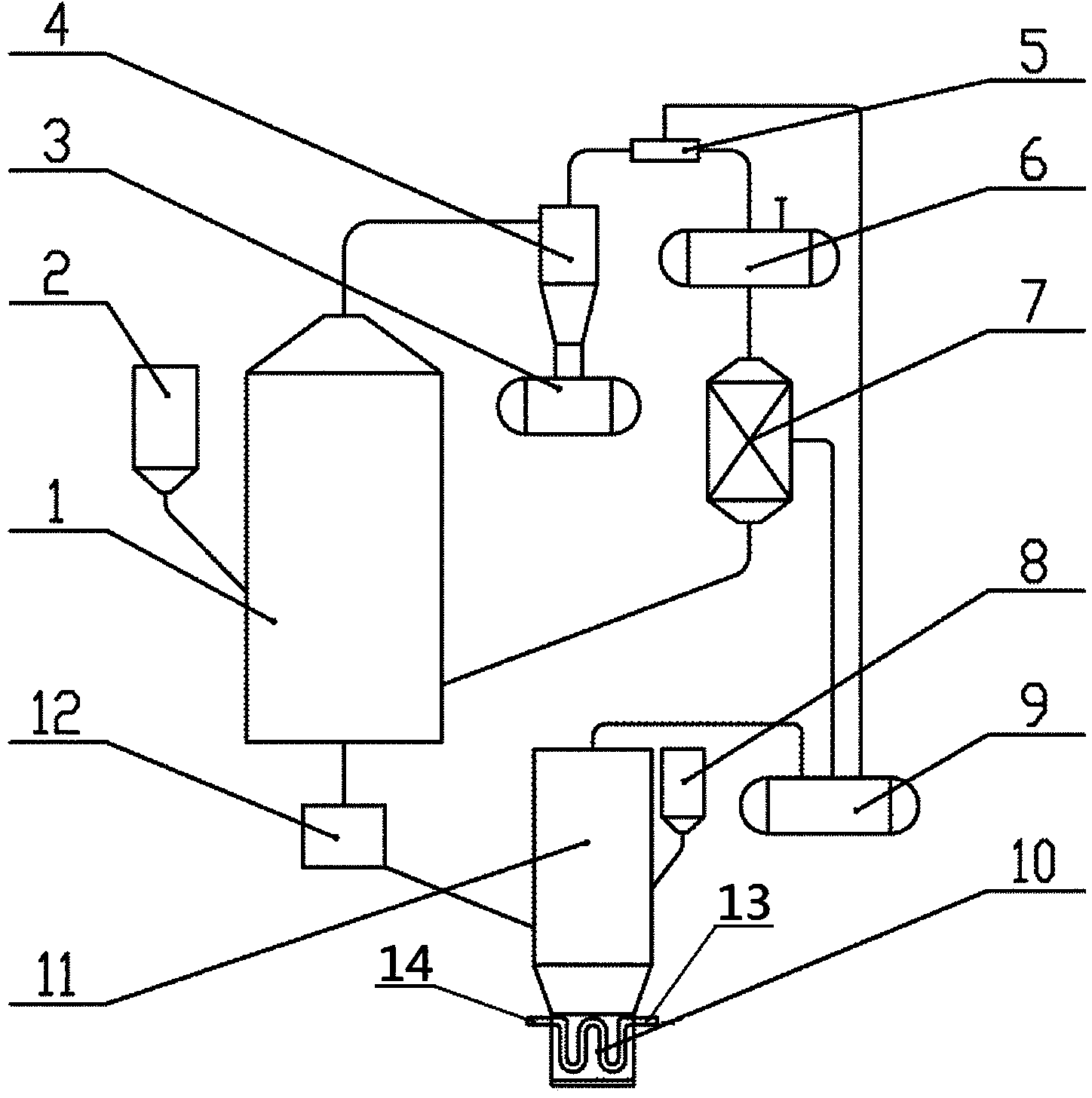

System and process for producing oil by hydrotorting oil shale under increased pressure

InactiveCN103911169ARealize energy utilizationReduce pollutionSpecial form destructive distillationHydrogenGas heater

The invention discloses a system for producing oil by hydrotorting oil shale under increased pressure. The system comprises a dry distillation furnace (1), an oil shale stock bin (2), an oil storage tank (3), an oil-gas separator (4), a hydrogen separator (5), a hydrogen-rich gas tank (6), a gas heater (7), a vaporized fuel cabin (8), a combustible gas tank (9), a heat exchanger (10), a gasification furnace (11) and a conveying device (12). In a process for producing oil by hydrotorting oil shale under increased pressure by using the system, gas produced by dry distillation is separated through the hydrogen separator, produced hydrogen-rich gas is returned into the dry distillation furnace after being heated by the gas heater, and produced dehydrogenated gas and combustible gas produced by gasification in the gasification furnace are introduced into the gas heater as fuels. Oil shale particles are produced into oil through dry distillation in a hydrogen-rich atmosphere, so that organic matters are prevented from being carbonized due to lack of hydrogen, and the oil yield of the oil shale is increased; the dehydrogenated gas and the combustible gas are introduced into the gas heater as fuels, so that the energy utilization ratio is increased.

Owner:SHANGHAI JIAO TONG UNIV

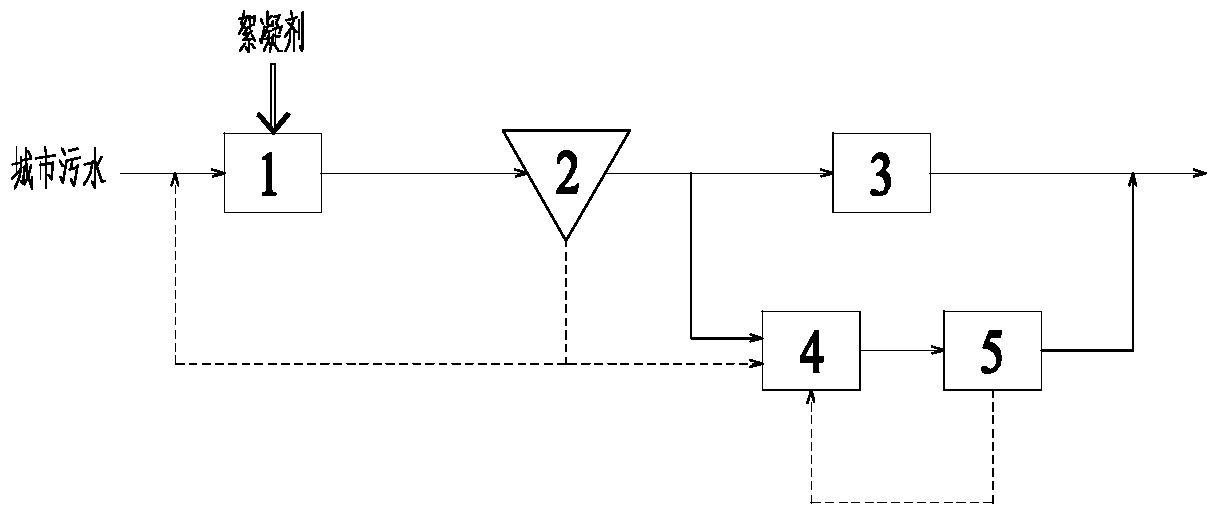

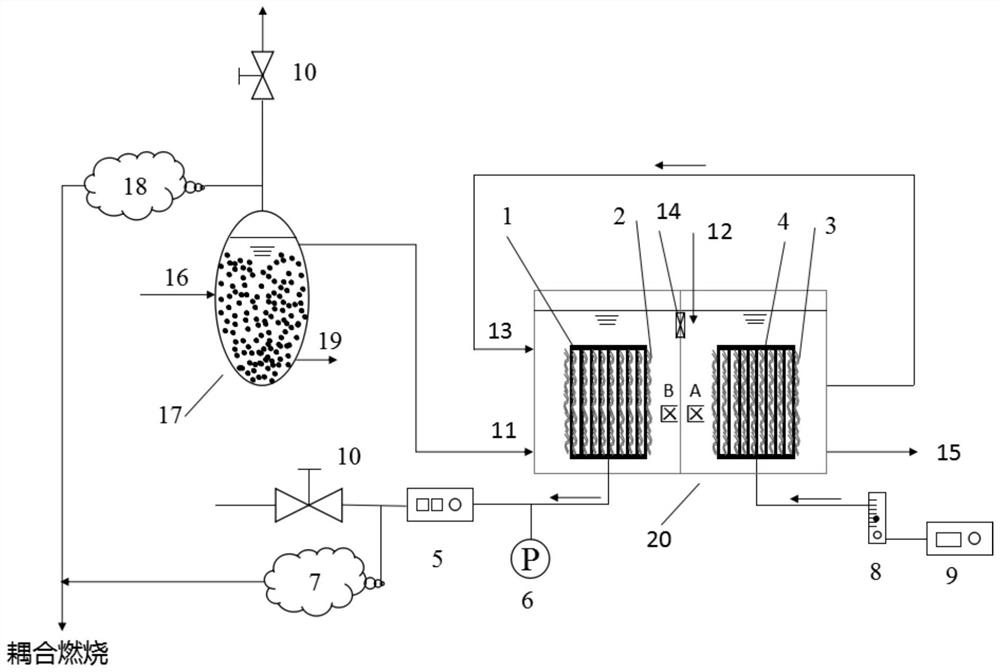

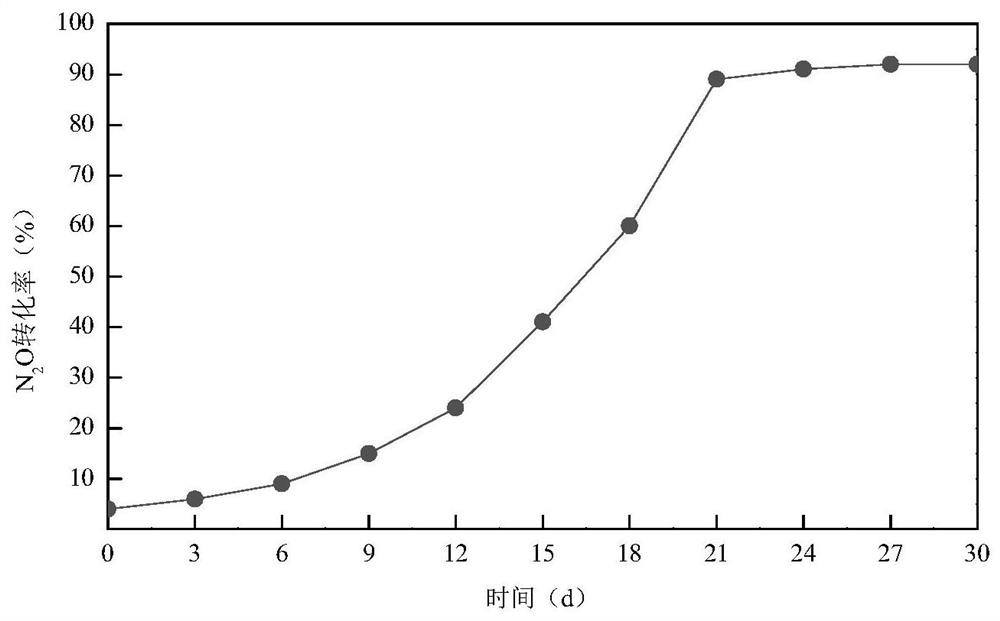

Device and method for recycling nitrogen in sewage treatment plant

ActiveCN112321112AHigh application potentialIncrease spaceWater contaminantsBiological sludge treatmentBiofilmAmmoniacal nitrogen

The invention discloses a device and a method for recycling nitrogen in a sewage treatment plant, the device comprises an anaerobic digester and an integrated biofilm reactor, the anaerobic digester is respectively communicated with a residual sludge water inlet pipe, a sludge digestion liquid pipeline and a methane collecting device, the sludge digestion liquid pipeline is communicated with the integrated biofilm reactor, and the integrated biofilm reactor is divided into an area A and an area B; each of the area A and the area B is respectively provided with a gas-liquid separation membranewhicha nitrosation biofilm is attached to andgrows on and a modified gas-liquid separation membrane which a denitrification biofilm is attached to and grows on , andthe area A and the area B are respectively communicated with an air pump and an N2O a collection device; and the area A converts ammonia nitrogen in the sludge digestion liquid into nitrite nitrogen, and the area B converts nitrite into N2O and collects the N2O, so that the conversion rate of the N2O is higher than 90%. And the generated N2O and the anaerobic digester product methane are subjected to coupled combustion, so that thecombustion heat value can be increased by 37%, thereby implementing the energy utilization of the nitrogen in the sewage treatment plant.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Solid fuel burning stove

InactiveCN106524132AEfficient and clean combustionAvoid black smokeSolid fuel combustionCombustion apparatusCombustion chamberSolid fuel

The invention provides a solid fuel burning stove which comprises a solid sequential burning chamber (1), a heat storage channel (2) and a gas state burning chamber (3). A heat storage channel inlet (21) is formed in the position, higher than a grate (12), of one side of the lower portion of the solid sequential burning chamber, and therefore a reversal-burning area (16) is formed above the heat storage channel inlet (21) of the fuel solid sequential burning chamber, a burning area (17) is formed below the heat storage channel inlet (21) of the solid sequential burning chamber, and a solid-gas separation area is formed at the heat storage channel inlet (21). Air inlet holes (23) are formed in the peripheral wall of the heat storage channel. By adoption of the solid fuel burning stove, cleaning and efficient burning of all kinds of solid fuels can be achieved.

Owner:杨德山

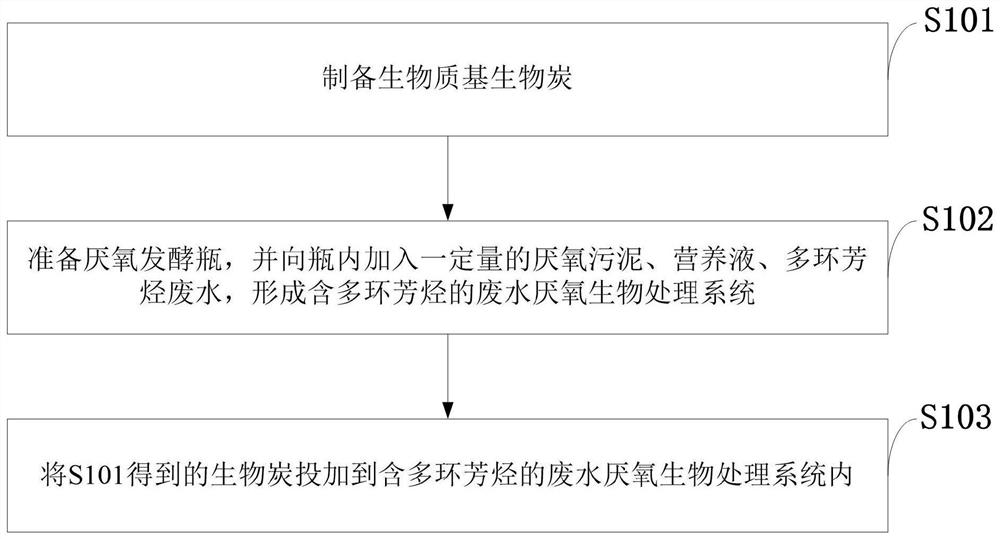

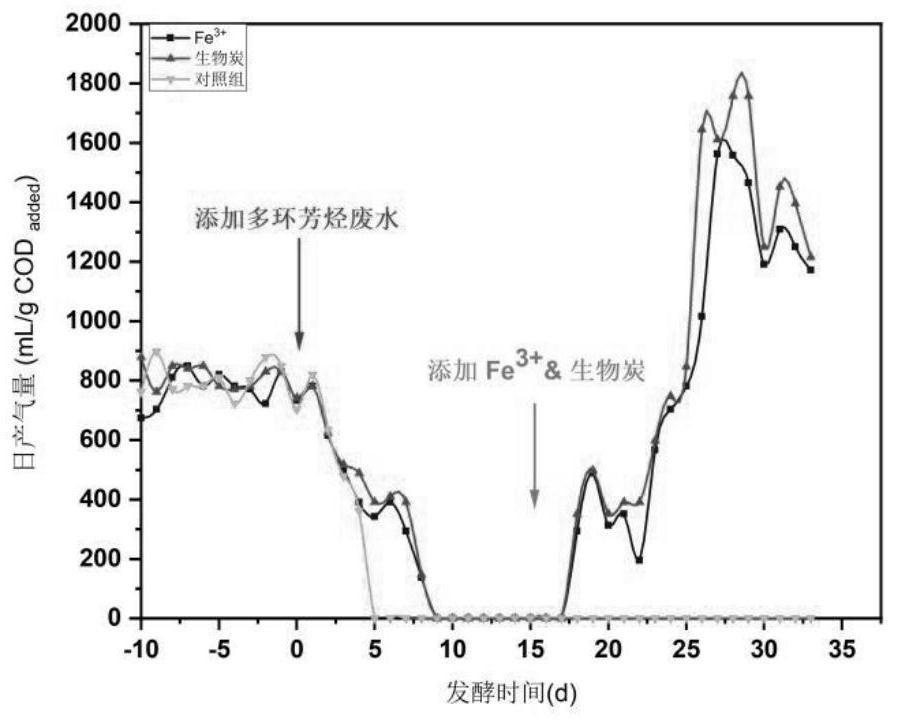

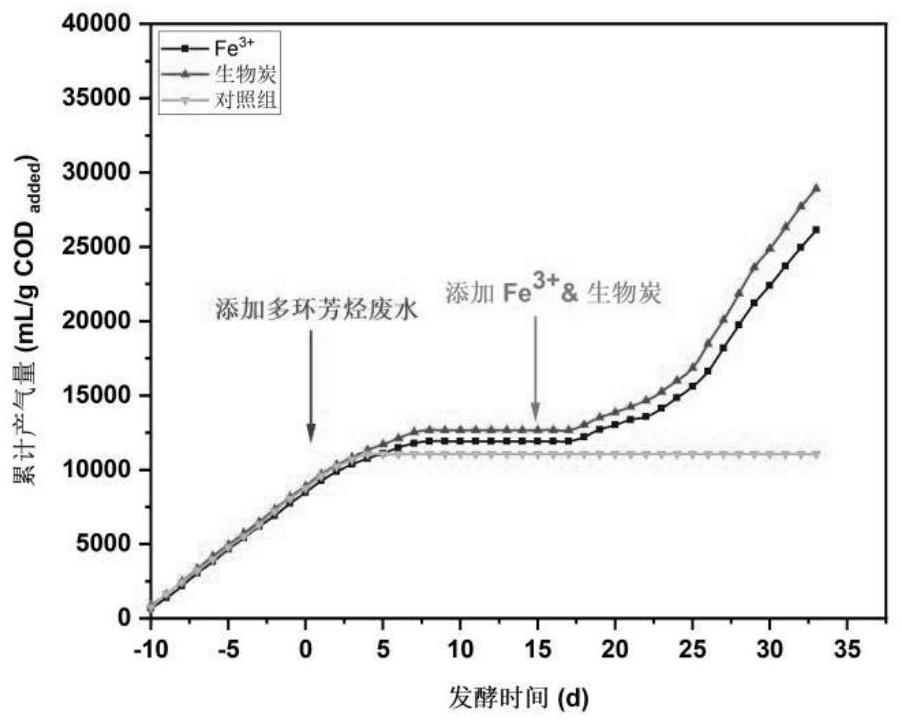

Method for promoting anaerobic degradation of polycyclic aromatic hydrocarbons in wastewater by using biochar

PendingCN114772721ACreativePromote efficient degradationWater contaminantsTreatment with anaerobic digestion processesNutrient solutionAnaeromicrobium sediminis

The invention belongs to the technical field of environmental engineering, and discloses a method for promoting anaerobic degradation of polycyclic aromatic hydrocarbon in wastewater by using biochar, which comprises the following steps: preparing biomass-based biochar; the method comprises the following steps: preparing an anaerobic fermentation bottle, and adding a certain amount of anaerobic sludge, a nutrient solution and polycyclic aromatic hydrocarbon wastewater into the bottle to form a polycyclic aromatic hydrocarbon-containing wastewater anaerobic biological treatment system; and adding the prepared biochar into a polycyclic aromatic hydrocarbon-containing wastewater anaerobic biological treatment system. According to the method, the self-made biochar is added into the wastewater anaerobic degradation system containing the polycyclic aromatic hydrocarbons, and the biotoxicity of the wastewater containing the polycyclic aromatic hydrocarbons can be remarkably reduced through the adsorption and promotion effects of the biochar, so that the adaptation of anaerobic microorganisms to the environment is accelerated, the system can be quickly started, organic pollutants such as the polycyclic aromatic hydrocarbons can be degraded, and the pollution to the environment is reduced. Moreover, oxygen-containing functional groups on the surface of the biochar may excite direct transfer of electrons among groups, so that the anaerobic degradation efficiency of the polycyclic aromatic hydrocarbon is improved, and the degradation of the polycyclic aromatic hydrocarbon and the anaerobic methane production process are promoted at the same time.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com