Process for recycling papermaking waste residues

A papermaking waste residue and process technology, which is applied in the process field of papermaking waste residue recycling, can solve the problems of polluting the air, backward technology, waste of manpower and material resources, etc., and achieves the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

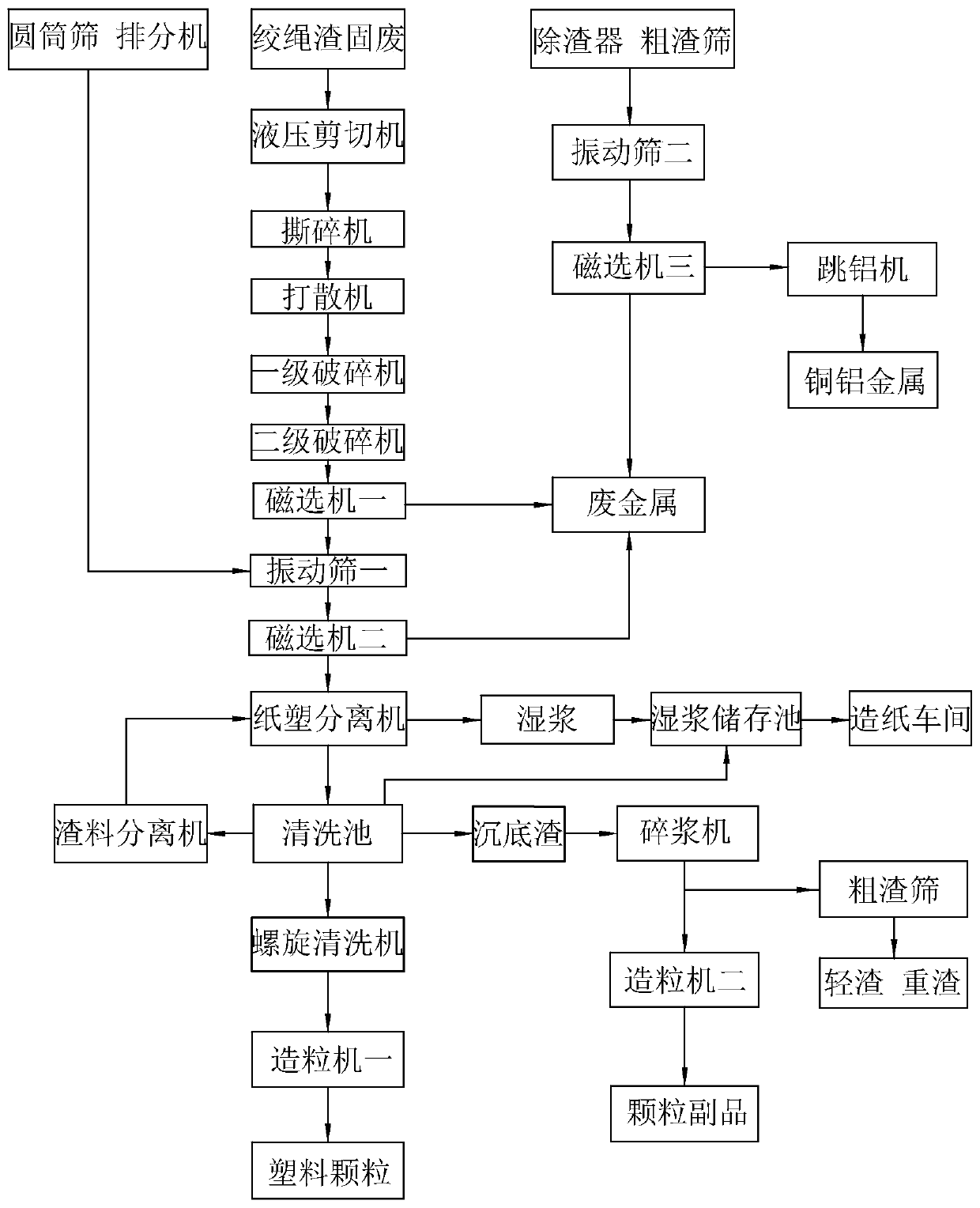

[0032] a. Metal separation: This step includes three sources of raw materials for metal separation, mainly from the solid waste obtained from the treatment of twisted rope slag (annual production capacity of 10,285 tons), through hydraulic shears, shredders, broken up Crusher, primary crusher and magnetic separator 1 initially select some scrap metals, and then pass through vibrating screen 1 and magnetic separator 2 to further select scrap metals; 17,600 tons, which is equivalent to 11,000 tons of dry solid waste) The waste obtained from the treatment will directly enter the vibrating screen 1, and the waste metal will be selected through the magnetic separator 2 (250 tons of metal produced at the slag of the twisted rope, the cylinder screen, the row The metal produced by the extension machine is 460 tons / year); the ton body waste (annual production of 2115 tons) from other sources (treated by the slag remover and the coarse slag screen) is passed through the second vibrating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com