Patents

Literature

59results about "Reverberatory furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

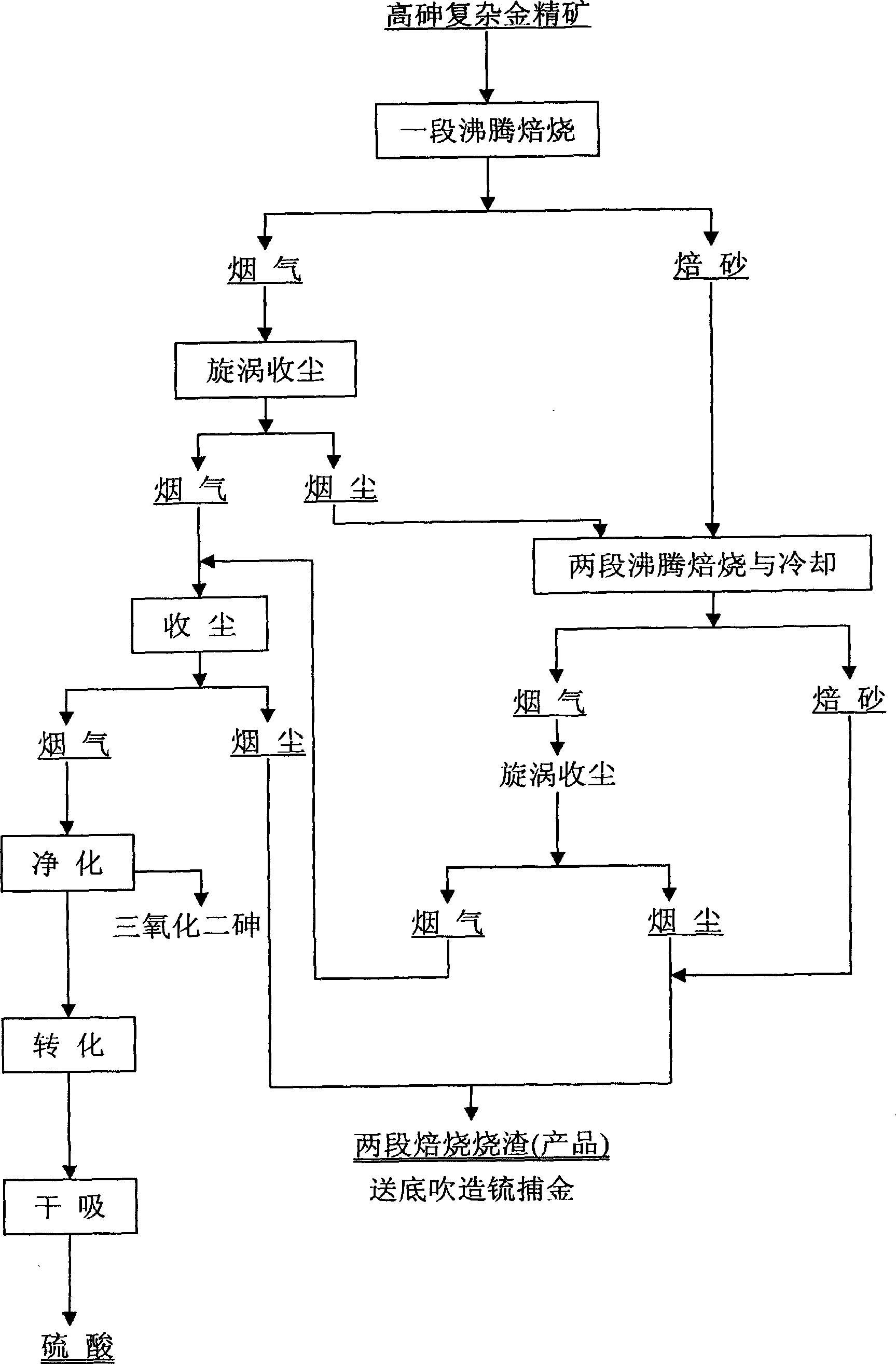

Method for extracting high arsenic complicated golden ore concentrate multielement

ActiveCN101519731AImprove recycling efficiencyReduce low altitude pollutionPhotography auxillary processesReverberatory furnaceElectrolysisMaterials science

The invention discloses a method for extracting high arsenic complicated golden ore concentrate multielement. The method comprises the following steps that: the multielement complicated golden ore concentrate with extra-high arsenic is subjected to the roast dearsenification technique treatment, part of sulfur in the multielement high arsenic golden ore concentrate converted into sulfur dioxide and the arsenic converted into arsenic trioxide enter flue gas which is subjected to dust and arsenic collection, and then enter an acid making system to produce sulphuric acid; the multielement smelting slag and multielement low arsenic golden ore concentrate obtained by roast dearsenification, return products and flux are mixed to obtain copper matte regulus, and the like by adopting oxygen enrichment bottom blowing matte smelting gold collecting process to carry out the smelting process; the copper matte regulus is subjected to converting and refining to cast an anode plate which is sent to an electrolysis system to obtain an electrolytic copper product by refining; anode mud generated through electrolysis is sent to a noble metal refine system to produce gold and sliver, and the like; smelting slag and converting slag are subjected to floatation treatment to obtain copper and iron ore concentrate; and the generated gangue belongs to harmless slag and can be used. The method has the characteristics of wide range of the raw material application, high synthesized recovery efficiency of valuable element, and obvious economic and environment benefits.

Owner:SHANDONG HUMON SMELTING

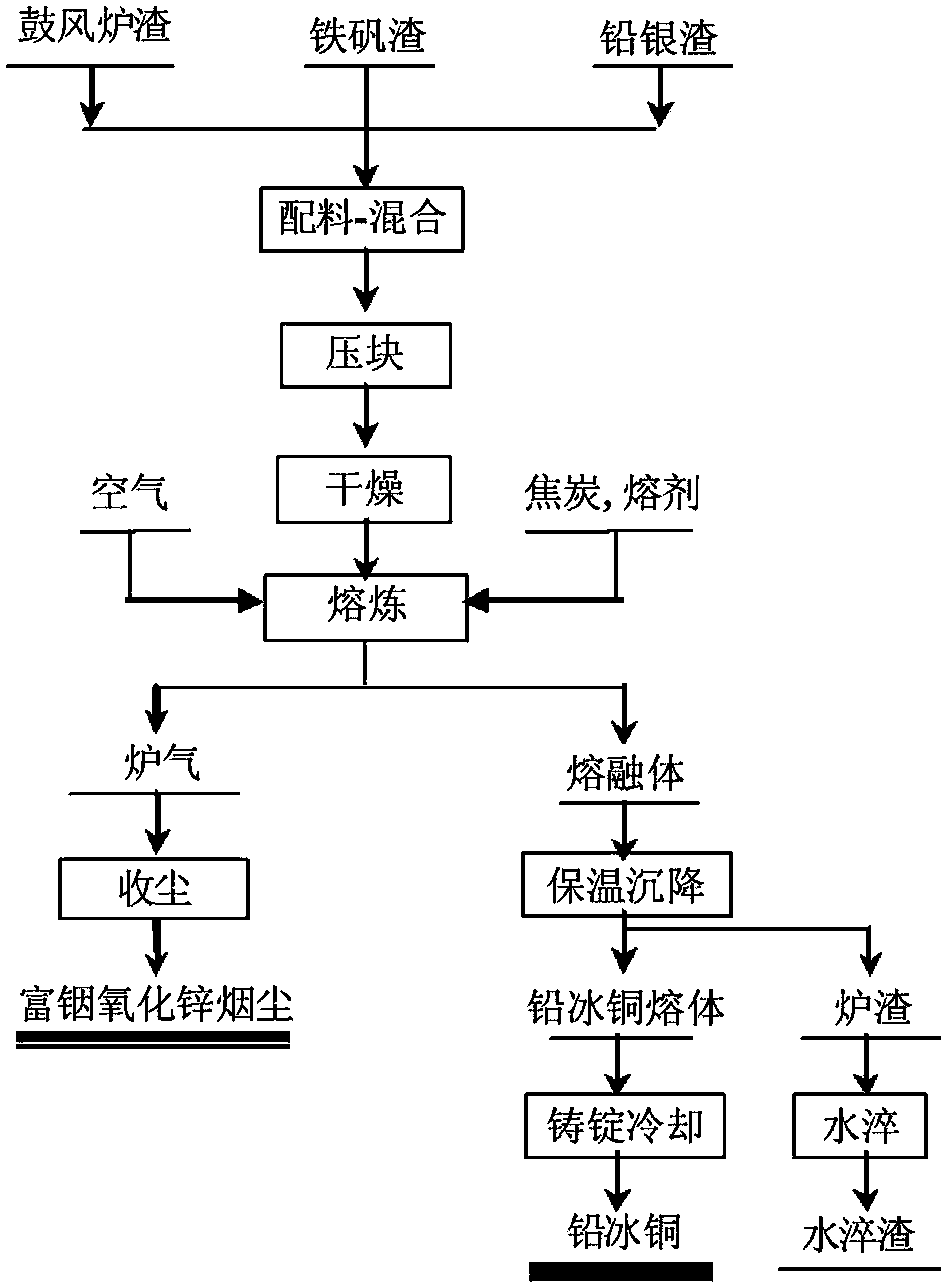

Method for comprehensively recovering valuable metals from zinc smelting slag

InactiveCN103710544AAchieving simultaneous enrichmentAchieve recyclingReverberatory furnaceBlast furnace detailsChemical industryIndium

The invention relates to a method for comprehensively recovering valuable metals from zinc smelting slag, belonging to the technical fields of metallurgy and chemical industry. The method comprises the following steps: proportioning blast furnace slag, iron alum slag and lead silver slag in a mass ratio of (1-2):(2-4):1, mixing, briquetting and drying; smelting the briquette, coke and a fluxing agent in a mass ratio of (4-8):(0.5-2):1 in a matting furnace at 1050-1400 DEG C; collecting dust from matting furnace gas to obtain indium-rich zinc oxide smoke dust; and settling the fused mass while keeping temperature at 1000-1400 DEG C to obtain lead copper matte and harmless furnace slag. The method implements synchronous enrichment and recovery of valuable elements in the zinc smelting slag by the one-step smelting process, and has the characteristics of simple technical process, high comprehensive recovery rate of valuable metals, high cleanness and high efficiency.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

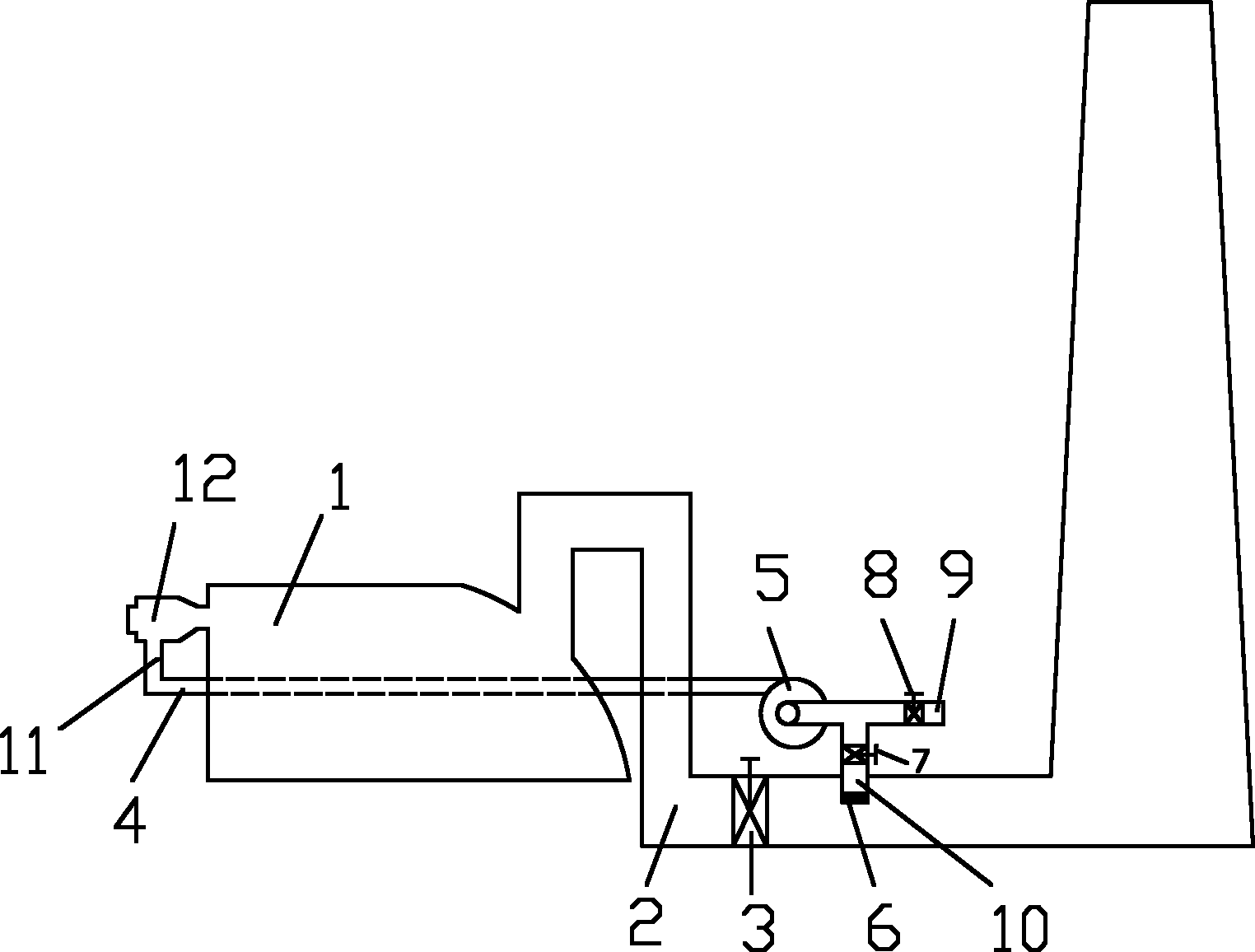

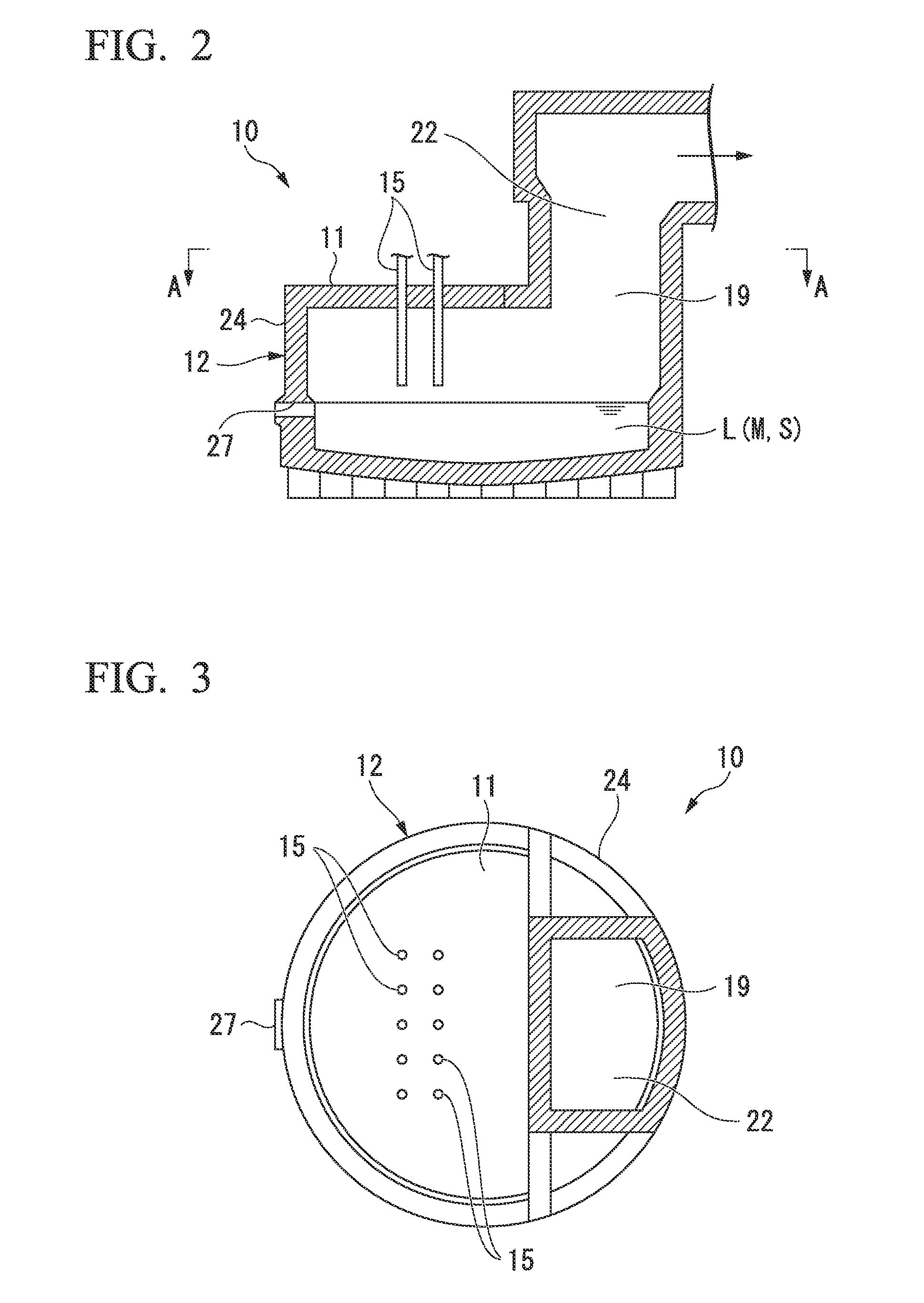

Method and device for smelting recycled copper in reverberator

InactiveCN102061396AReduce oxygen contentFacilitate control of burning rateReverberatory furnaceCombustorCombustion

The invention discloses a method and device for smelting recycled copper in a reverberator. With the method, partial high-temperature fumes of the reverberator are directly mixed with combustion-supporting air to form a combustion-supporting gas with high temperature and low oxygen concentration, thereby improving the uniformity of temperature distribution in the reverberator, reducing local high temperature and reducing the burning loss of metal. The horizontal section of a flue gate of the reverberator is connected with a fume backflow pipe, a high temperature fan and a bypass cool air pipe to transmit a part of high temperature fume exhausted from the reverberator to a burner so that high air temperature and low oxygen concentration combustion is implemented in the reverberator and the fume backflow content accounts for 30% to 50% of the total volume of the fume in the reverberator. The method provided by the invention has the advantages of high metal recovery rate and high heat efficiency, and the device has the advantages of simple structure and reliable performance.

Owner:CENT SOUTH UNIV

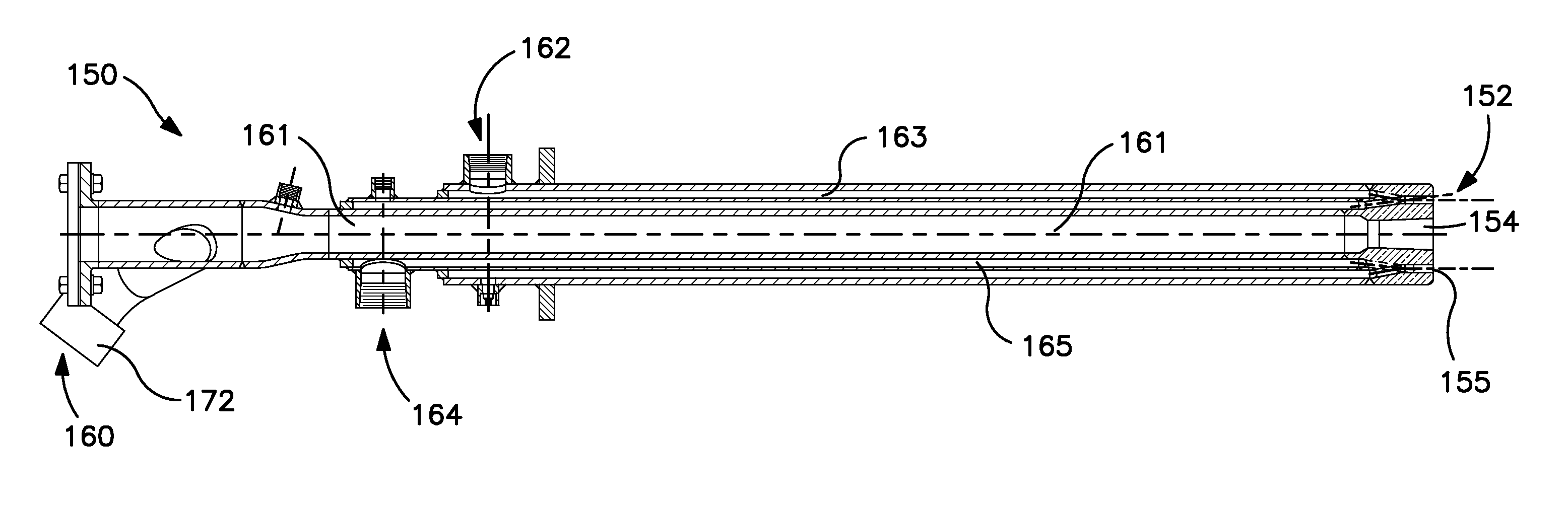

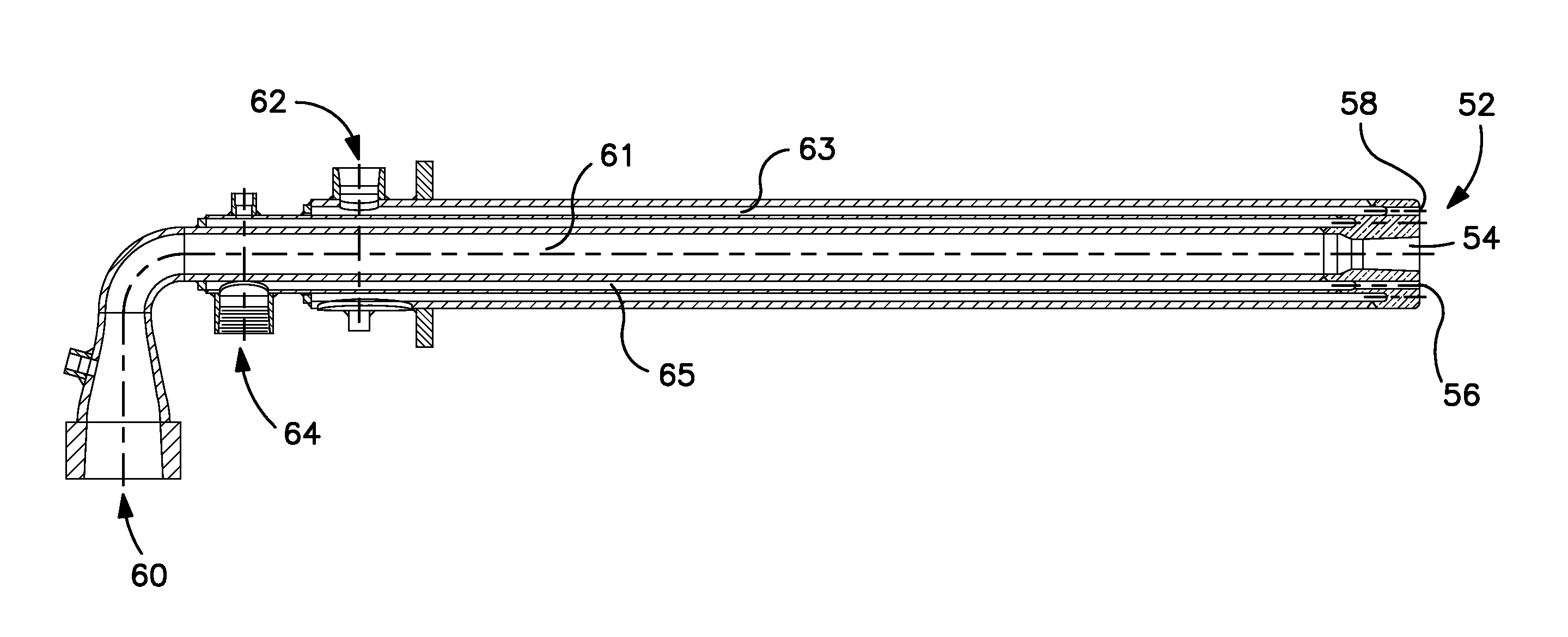

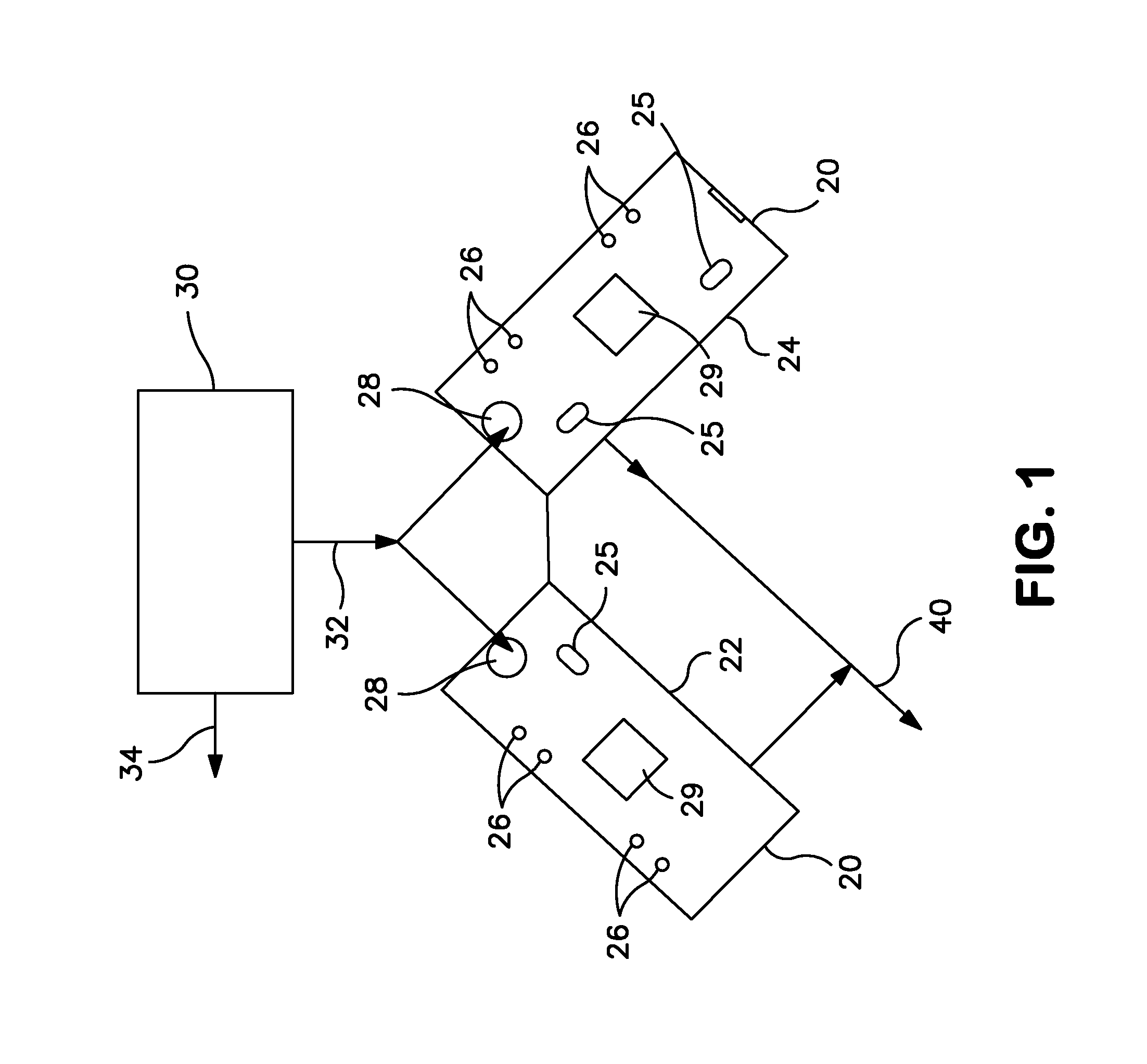

Copper anode refining system and method

A method and system for the copper anode refining is provided in which coherent jet technology is employed to heat the molten blister copper and / or melt scrap copper charges using a melting flame, oxidize the sulfur in the molten blister copper, and reduce the oxygen in the molten blister copper using top-blown coherent jet gas streams from one or more multi-functional, coherent jet lance assemblies. The present system and method employs a microprocessor-based controller operatively controlling the flow of an oxygen-containing gas, an inert gas, a reducing agent and a fuel to the coherent jet lance. The disclosed copper anode refining system and method greatly improves copper production while lowering oxidation / reduction cycle times and minimizing NOx emissions.

Owner:PRAXAIR TECH INC

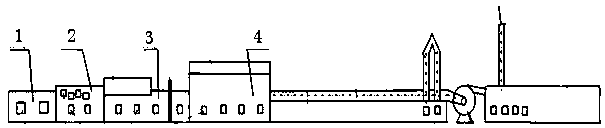

Copper bar continuous casting and tandem rolling production method

InactiveCN101642775AFully oxidizedImprove quality and efficiencyTemperature control deviceReverberatory furnaceLiquid copperIngot

The invention relates to a copper bar continuous casting and tandem rolling production method which comprises the steps: adding copper raw material into a reflecting furnace with the temperature of 1145 DEG C at the speed of 8t / h; after that, filling air for 30min for oxidation when the temperature of copper reaches 1150-1170 DEG C; using timber to deoxidate liquid copper for 1.5-2h at the temperature of 1200-1250 DEG C; under the condition of 1120-1130 DEG C, outputting copper and casting; after the crystallizing the copper and producing ingots at 850-880 DEG C, rolling copper bars at the rotating speed 1200r / min-1320r / min of a rolling mill. The method can control the temperature in the production process of copper bar continuous casting and tandem rolling, and improves the product quality and the production efficiency.

Owner:嘉兴市龙泉铜业有限公司

Machining technology for low-oxygen bright copper bar

InactiveCN107304463AImprove reduction efficiencyReduce consumptionMetal rolling stand detailsReverberatory furnaceCopperLow oxygen

The invention discloses a machining technology for a low-oxygen bright copper bar and belongs to the technical field of copper machining. The machining technology includes the following steps that firstly, scrap copper is subjected to sorting treatment, the treated scrap copper is thrown into a reflecting furnace to be subjected to be heated and melted, low-temperature slagging-off is conducted, then the temperature is increased to 1300 DEG C or above, and high-temperature oxidization is conducted; and after oxidization is over, poling work can be conducted, and finally the bright copper bar is formed through continuous casting and rolling. The machining technology has the beneficial effects of being high in efficiency, capable of saving energy, uniform in product performance, stable in quality and the like.

Owner:TANGYIN COUNTY TIANHAI CARBON

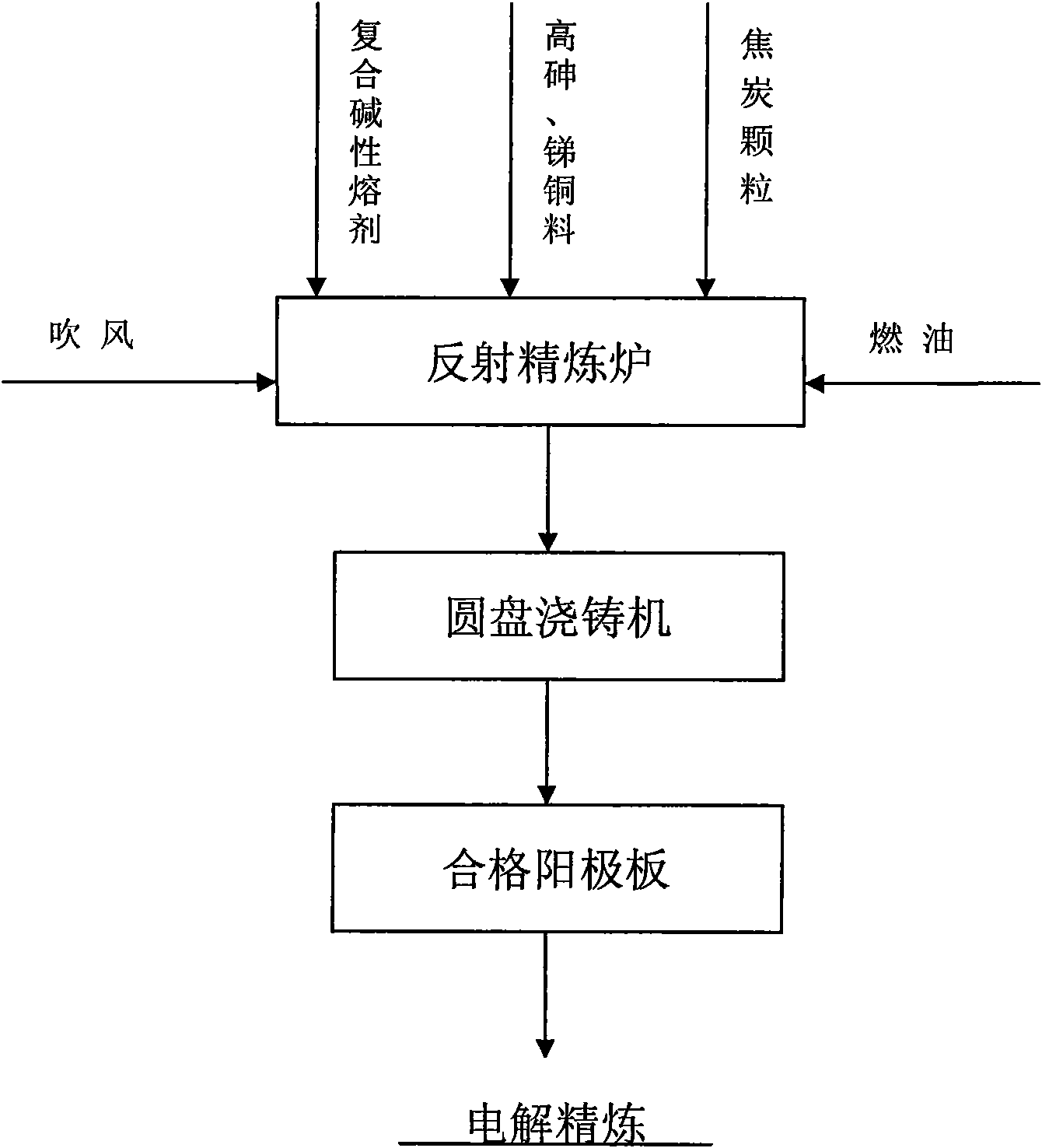

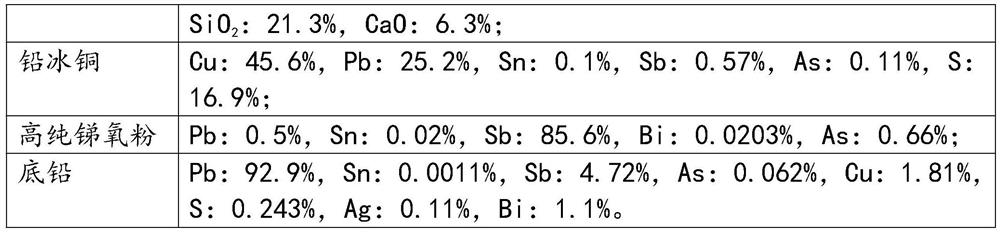

Reverberatory furnace pyrorefining method of crude copper with high arsenic and antimony

InactiveCN101654744ABroaden source channelsAlleviate resource constraintsReverberatory furnaceRedoxReverberatory furnace

The invention relates to a reverberatory furnace pyrorefining method of crude copper with high arsenic and antimony which is a pyrorefining method combining melting, redox volatilizing and composite alkaline fusing agent slagging together. When refining the crude copper with high content of arsenic, antimony and other impurities in the reverberatory furnace, the process comprises the following steps: firstly performing fusion volatilization and redox volatilization and slagging with composite alkaline fusing agent to realize multiple stage purification. The invention has the advantage of simple process, high production efficiency and the like.

Owner:DONGYING FANGYUAN NONFERROUS METALS

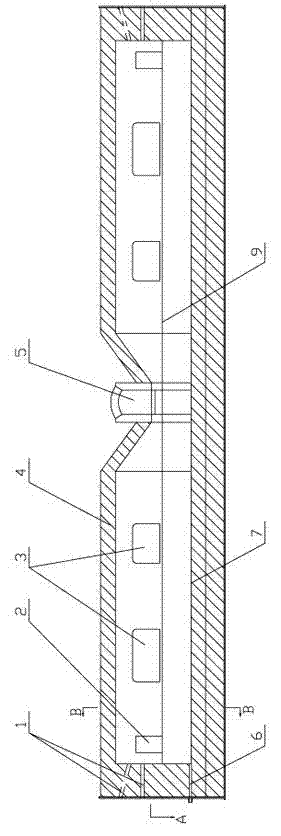

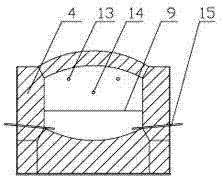

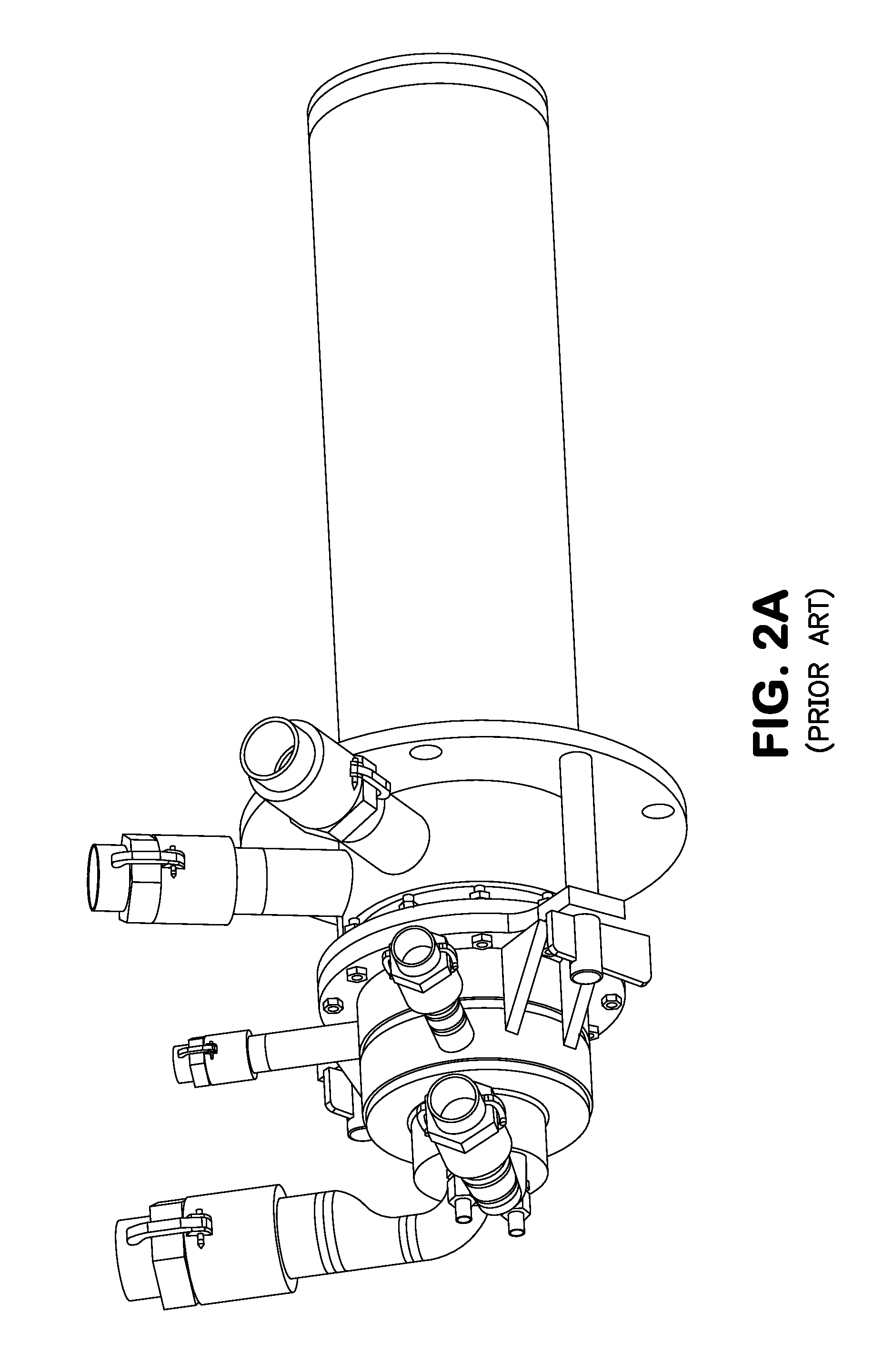

Novel high-grade miscellaneous copper refining furnace system

ActiveCN104232929AReasonable and ingenious structural designLow investment costReverberatory furnaceBrickSlag

The invention discloses a novel high-grade miscellaneous copper refining furnace system which comprises a furnace body and an auxiliary system, wherein the furnace body is formed by butting and combining furnace tails of two fixed type refining reflection furnaces; two groups of combustion openings are symmetrically formed in the left end and the right end of the furnace body and are correspondingly provided with combustion systems and oxygen and gas supply systems; a high-grade copper outlet and a low-grade copper outlet are formed in one end of the furnace body and both adopt water cooling type structures; each copper outlet is correspondingly provided with a cooling water circulating system; a smoke discharging opening is formed in the middle of the furnace body; a material feeding working door is arranged on the furnace wall on one side of the furnace body; a reducing pipe is also arranged on each material feeding working door; each reducing pipe is externally connected with a reduced coal-based powder quantitative control device; three slag discharging openings are also formed in the furnace wall; sizing bricks are symmetrically mounted at the lower part of the furnace wall on two sides of the upper part of the furnace bottom; ventilating pipe structures are mounted on the sizing bricks. The novel high-grade miscellaneous copper refining furnace system is ingenious in structural design, integrates the advantages of three existing refining furnaces, and not only lowers the investment cost, but also is relatively energy-saving and environment-friendly.

Owner:大冶有色金属集团控股有限公司 +1

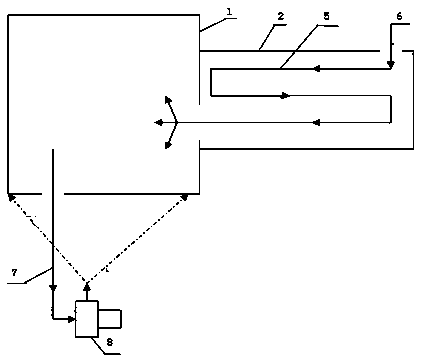

Method for preparing high-grade zinc oxide by utilizing cast iron dust

The invention relates to a production line, mechanical equipment and a technique method for preparing high-grade zinc oxide by utilizing cast iron dust. The method for making the high-grade zinc oxide by utilizing the cast iron dust is characterized in that the traditional Webster furnace production line is modified, a cyclone dust collector of a unique structure is combined with a multi-stage cyclone dust collector to substitute part of cooling pipes of a Webster furnace, the cyclone dust collector as well as a fixed exhaust pipe and a movable exhaust pipe divided by an exhaust pipe cause the length of the exhaust pipe to be adjustable, the length of the exhaust pipe is adjusted by virtue of three sets of lead screws and nuts which are uniformly distributed, the lead screws are fixed on the movable exhaust pipe, and the nuts are fixed on the upper surface of the cyclone dust collector; a cooling water jacket is additionally arranged outside, so that separating and settling effects are achieved, and a cooling effect of a cooling pipe is also achieved. According to the method for making the high-grade zinc oxide by utilizing the cast iron dust, the cast iron dust is utilized, the high-grade zinc oxide is prepared according to a production technology process comprising briquetting, reducing, oxidizing, cooling, separating, settling, cooling and dust collecting, the content of zinc oxide is more than 98% and is increased by more than 10% compared with that of the zinc oxide produced by the traditional Webster furnace production line, the whiteness of the zinc oxide is also greatly improved, and the whiteness of the zinc oxide can be 93.

Owner:HEZHANG LINGXUAN ENVIRONMENTAL PROTECTION TECH CO LTD

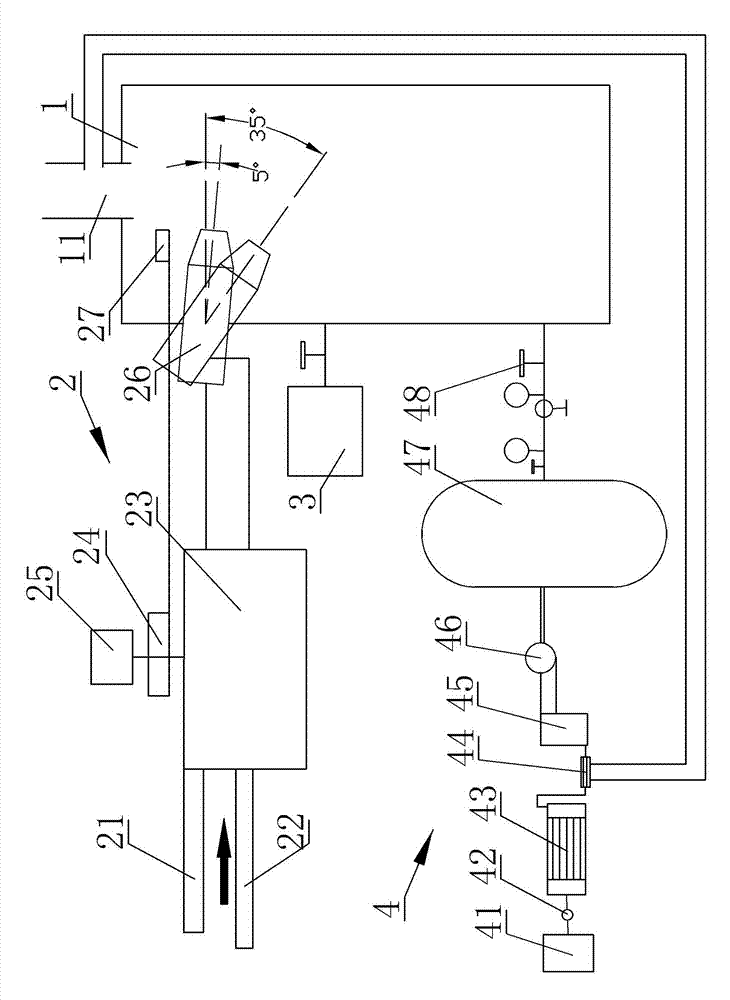

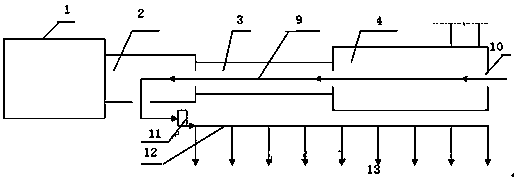

Low-cost equipment energy-saving smelting method for low-grade copper raw materials

InactiveCN104342563AObvious superiorityImprove energy savingReverberatory furnaceProcess efficiency improvementCombustorLower grade

The invention relates to a low-cost equipment energy-saving smelting method for low-grade copper raw materials, and belongs to the technical field of copper processing. The exiting shaft furnace and oxidation reduction furnace cannot be used for smelting low-grade copper. The method has the advantages that a shaft furnace burner is controlled to form circulation high-temperature gas flow, the temperature of the circulation high-temperature gas flow and the temperature of a capped heat insulation chute are controlled, the gas property, the smoke dust flowing and the copper molten liquid flowing of a shaft furnace and an oxidation reduction furnace are controlled, and the continuous energy-saving smelting of anode plates from the low-grade copper raw materials by the low-cost equipment is realized.

Owner:NINGBO UNIV

Preparation process of low-oxygen copper rods

ActiveCN108950237ALow costIncrease productivityReverberatory furnaceProcess efficiency improvementMetallurgyLog reduction

The invention provides a preparation process of low-oxygen copper rods, and belongs to the technical field of copper rod production. The preparation process of the low-oxygen copper rods comprises thesteps of feeding, melting, oxidation and decontamination, reduction, continuous casting and continuous rolling; in the reduction step, natural gas is used for reduction; the pressure of the natural gas is controlled within 0.35-0.45 MPa, and the flow is controlled within 90-120 m3 / h; the reduction time is 1-2 h; and when the natural gas is introduced, an exhaust fan is used for controlling the air pressure in a furnace within 0.01-0.03 MPa. The preparation process of the low-oxygen copper rods has the following beneficial effects: the method of cooperating the natural gas reduction with the furnace internal air pressure control is adopted to replace the log reduction, so that the production efficiency is greatly improved, the environment is protected, the process is simple and easy to control, meanwhile, the product quality is high, and the large-scale popularization and application are facilitated; and such recovered materials as waste copper are used as raw materials, so that the energy is saved.

Owner:朱军良

Production process for low-oxygen copper bars

The invention discloses a production process for low-oxygen copper bars. The production process comprises the following steps of: (1) refining copper liquid; (2) adding a purification flux into the copper liquid obtained in the step (1), and conveying the copper liquid into a holding furnace which is full of nitrogen; (3) straightening a low-oxygen copper bar; (4) continuously extruding the copperbar; (5) after the extrusion, cooling and drying the low-oxygen copper bar through a vacuum antioxidant tube and a cooling trough; and (6) rapidly and uniformly coating wax on the surface of the copper bar, and packaging the copper bar to obtain a high-density oxygen-free copper bar. The production process for low-oxygen copper bars has two effects of impurity removal and gas removal, so that thepurity of copper is increased, the purity of copper materials is improved, the oxygen content of the copper materials is greatly reduced, and the electric conductivity is high.

Owner:安徽润藤电缆材料科技有限公司

Smelting method for separating Cu, Zn and Co from each other

InactiveCN1382814AEasy to separateHigh recovery rateReverberatory furnaceBlast furnace detailsSlagSulfur

A smelting method for separating Cu, Zn and Co from the ore material containing Cu (10-50%), Zn (10-40%) and Co (0.2-2%) features that after the said ore material is pretreated from removing harmful impurities or sintered for removing sulfur, it is molten in blass furnace by selective reduction. As a result, the copper in coarse copper mode is discharged, the zinc in zinc oxide is collected from chimny, and the cobalt in slag mode is recovered. Its advantages are high separation effect and metal recovery rate.

Owner:史汉祥

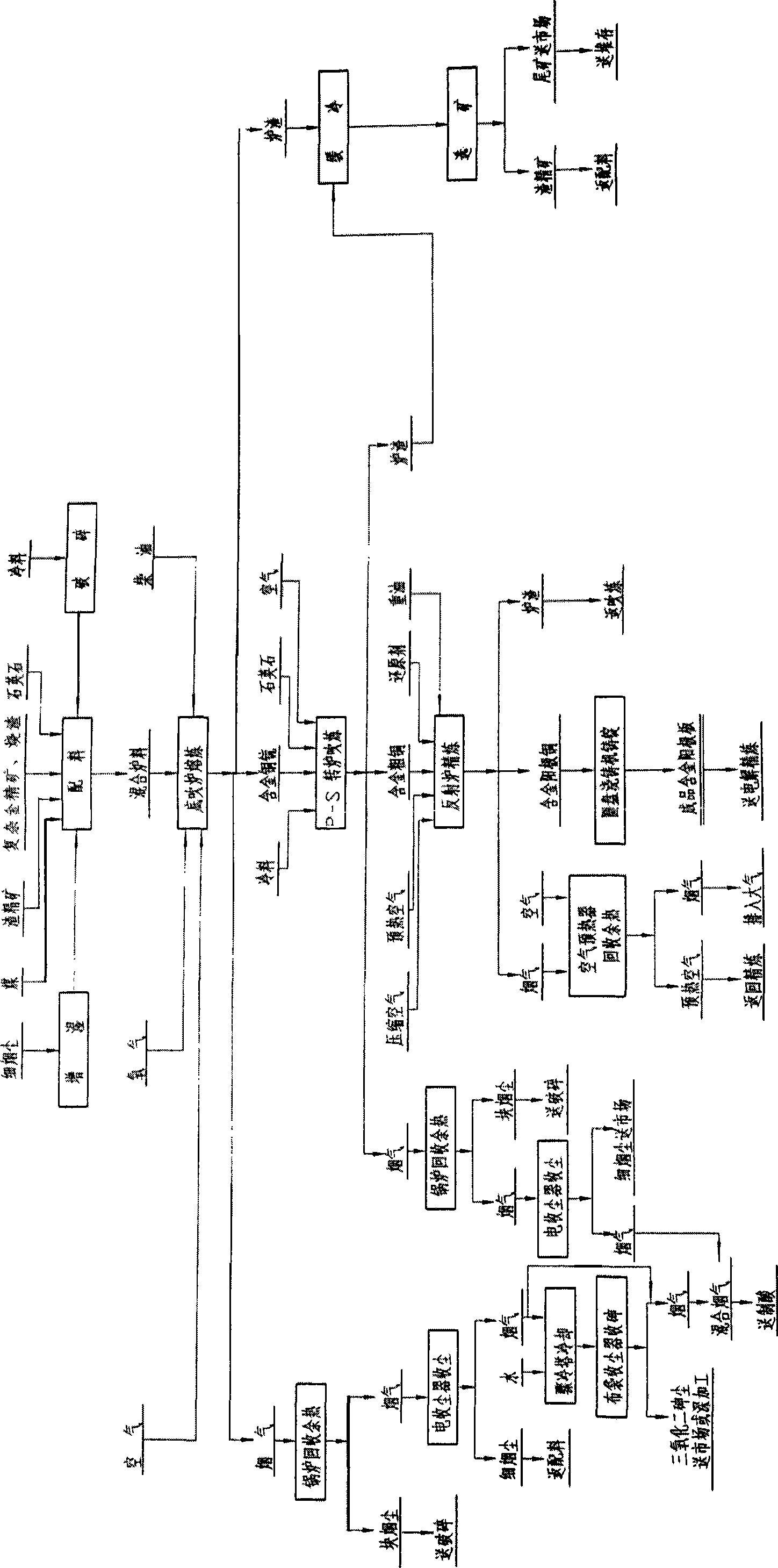

Production technology of refined copper

InactiveCN108315566AImprove smelting efficiencyCompact process designPhotography auxillary processesReverberatory furnaceElectrolysisImpurity

The invention discloses a production technology of refined copper. The technology comprises the following steps: selecting copper concentrate; continuously feeding the produced molten matte into a converter; converting to obtain coarse copper; arranging electrolytic baths; arranging linings of the electrolytic baths; connecting the electrolytic baths in series in a copper electrolyzing workshop; arranging an anode plate, a cathode plate and an electricity conducting rod; charging direct current to the electrolytic baths; dissolving copper in a Cu<2+> form under the effect of the direct currentafter electrons on an anode are lost; dissolving out the Cu<2+> in a copper metal form after electrons are supplied to a cathode; recovering anode slime containing precious metal, selenium, telluriumand other rare metals as a byproduct in copper electrolyzing; extracting and cleaning base metal impurities which gradually accumulate in electrolyte in regular period; removing copper sheets from the baths; and washing the copper sheets with water. According to the production technology of the refined copper, the processes are compact; the refined copper smelting efficiency is improved; and moreover, the energy consumption is reduced.

Owner:张家港市佰坤物资有限公司

Method for refining bismuth from bismuth oxide slag

InactiveCN107937724AImprove extraction efficiencyImprove refining effectReverberatory furnaceProcess efficiency improvementDistillationSlag

The invention discloses a method for refining bismuth from bismuth oxide slag. The method comprises grinding treatment for the bismuth oxide slag, dechloridation treatment, copper-bismuth separation treatment, distillation silver removal, lead removal treatment and waste treatment. The method comprises the following steps: step 1, carrying out grinding treatment for the bismuth oxide slag; step 2,carrying out dechloridation treatment; step 3, carrying out copper-bismuth separation treatment; step 4, carrying out distillation silver removal; step 5, carrying out lead removal treatment; and step 6, carrying out waste treatment. The step of the grinding treatment for the bismuth oxide slag is designed before extracting refined bismuth from the bismuth oxide slag, crushing treatment can be carried out on bismuth oxide, the refining efficiency for the bismuth oxide slag can be increased, and then heating treatment is carried out for preheating raw materials, so that on one hand, the heating time length of the subsequent steps can be increased, and on the other hand, the refining effect of a whole refining process can be improved; and the waste treatment is designed in the last step ofextracting refined bismuth in the bismuth oxide slag, and the impurities of the refined bismuth can be sieved out through a filter sieve, so that the purity of the refined bismuth is improved.

Owner:贵溪三元金属有限公司

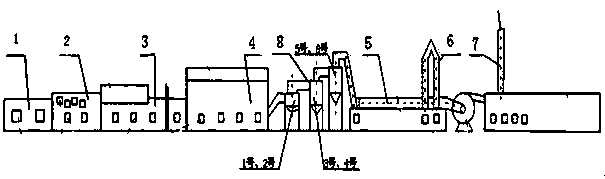

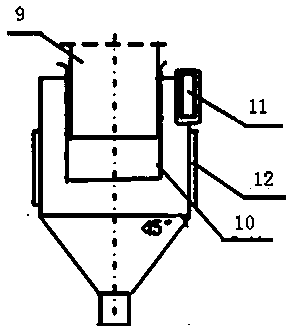

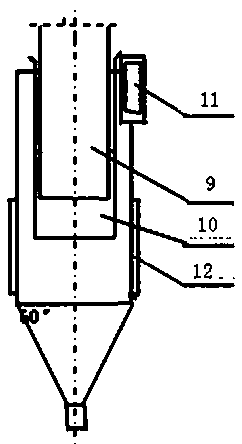

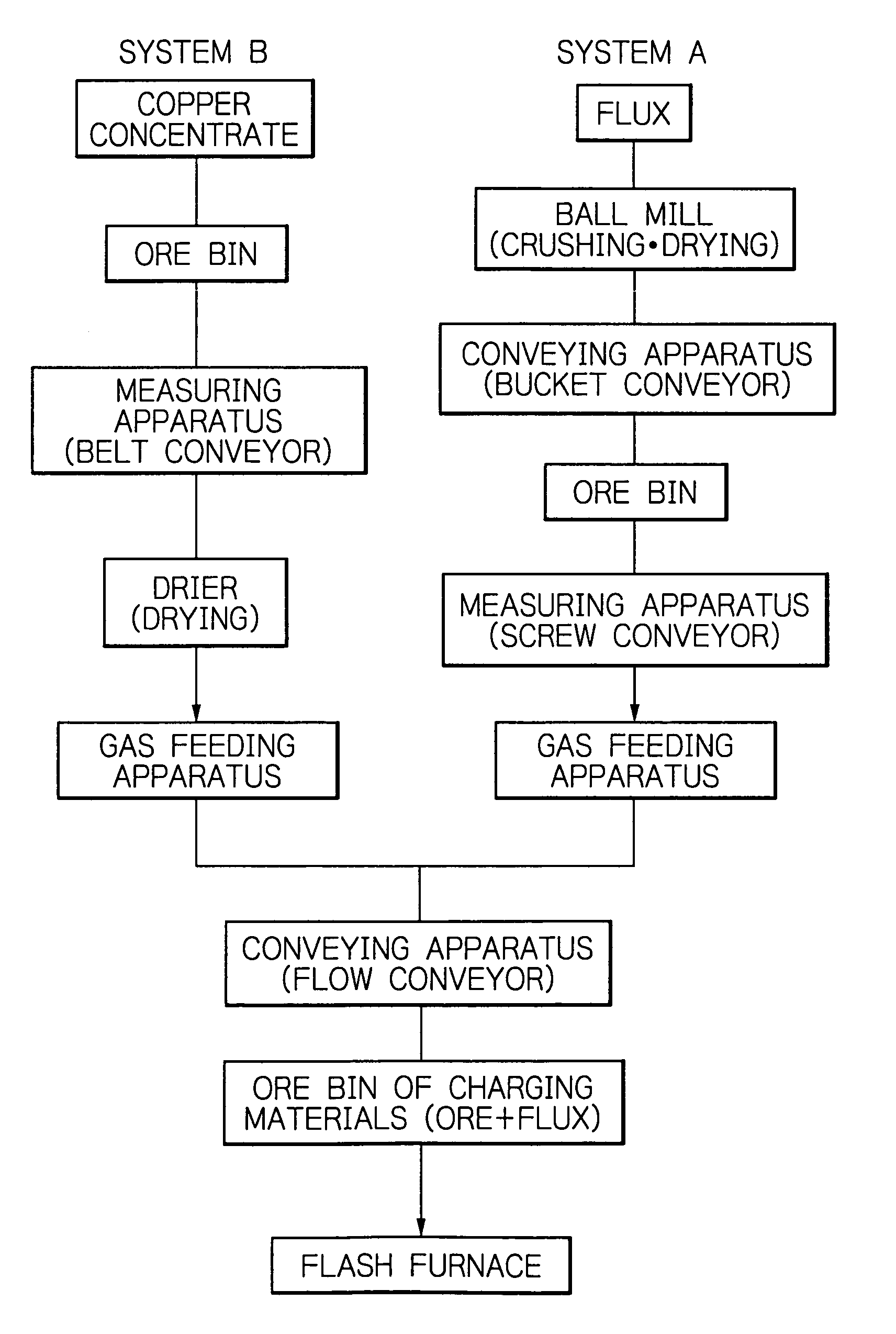

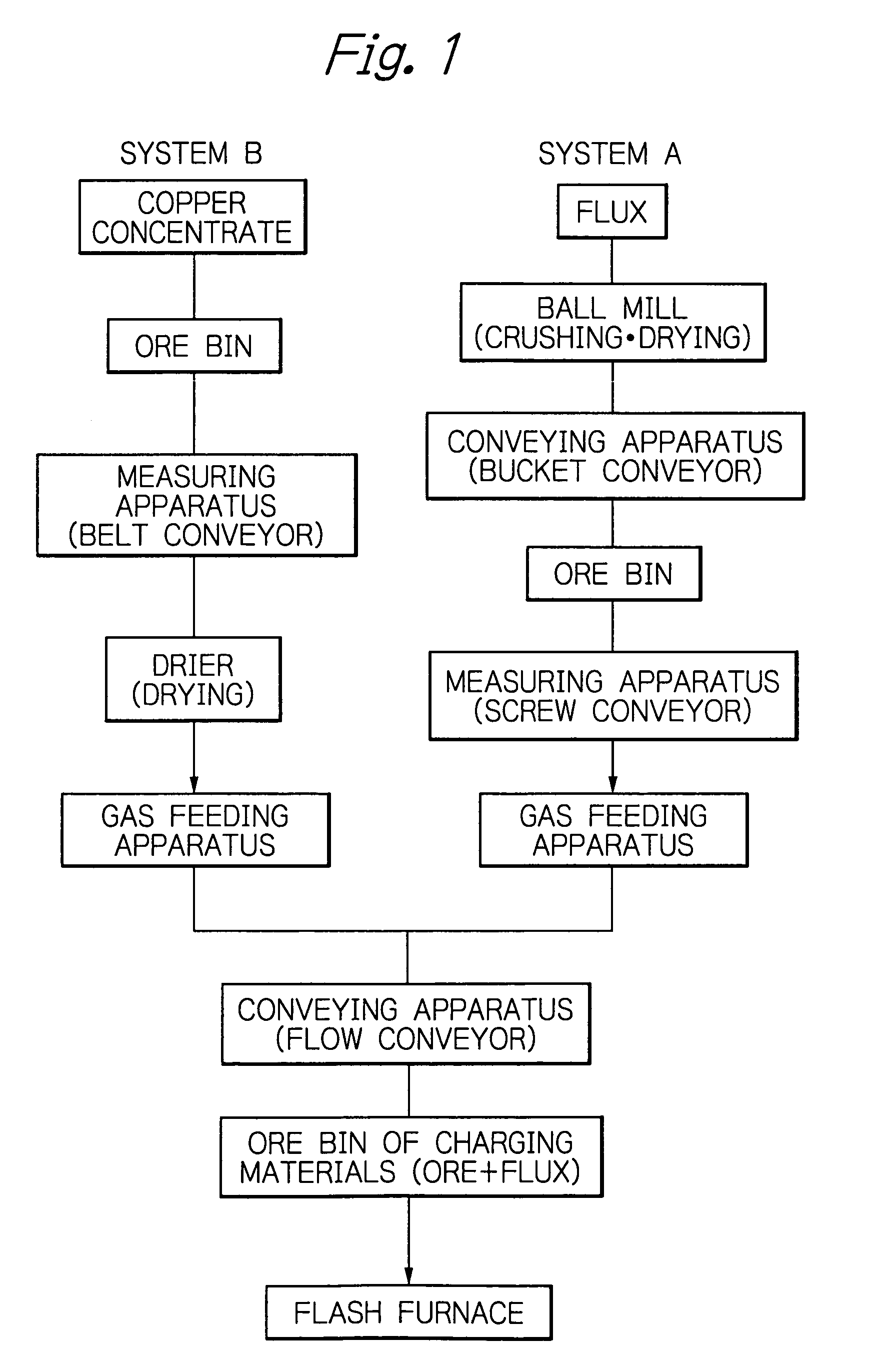

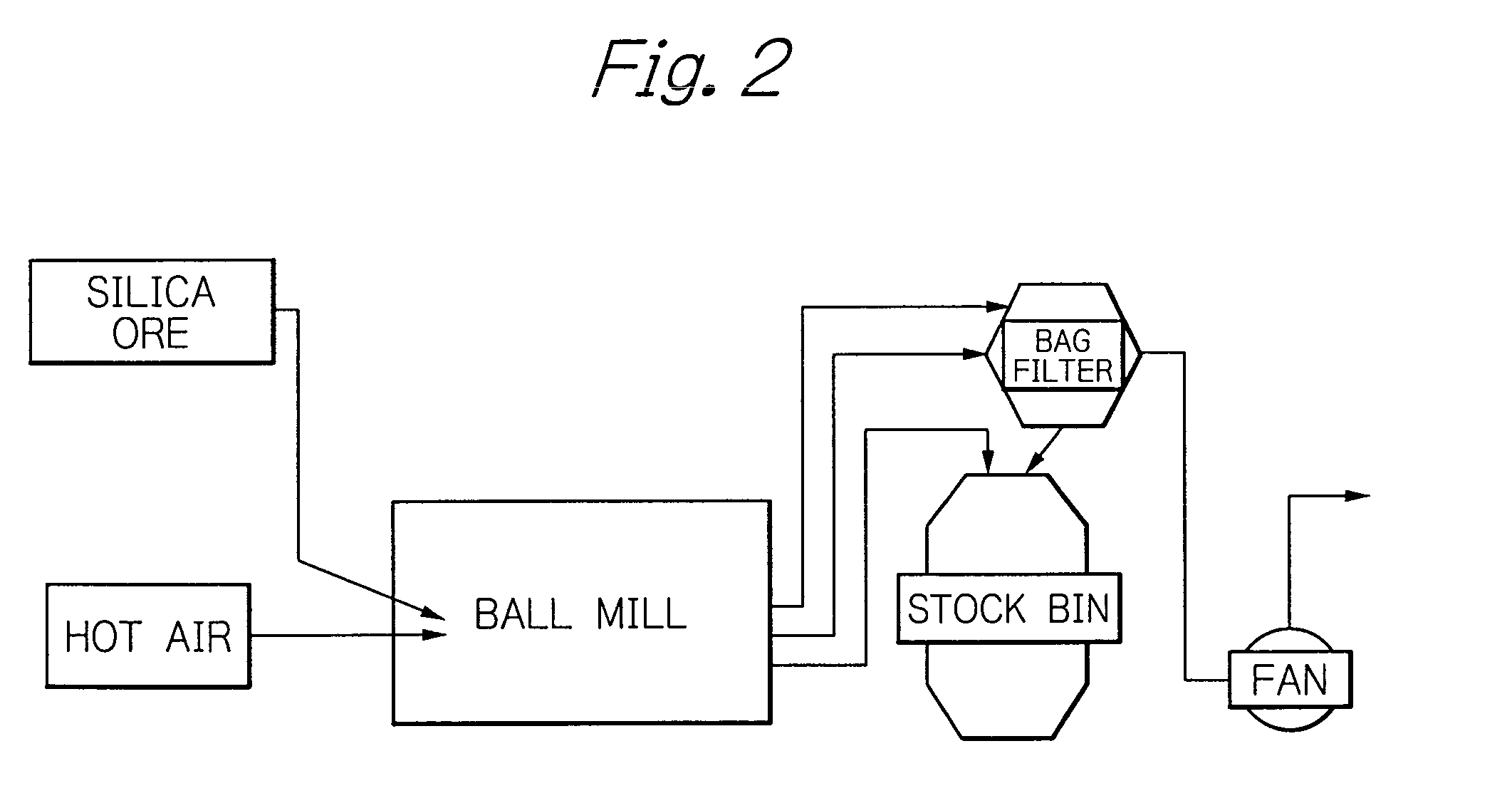

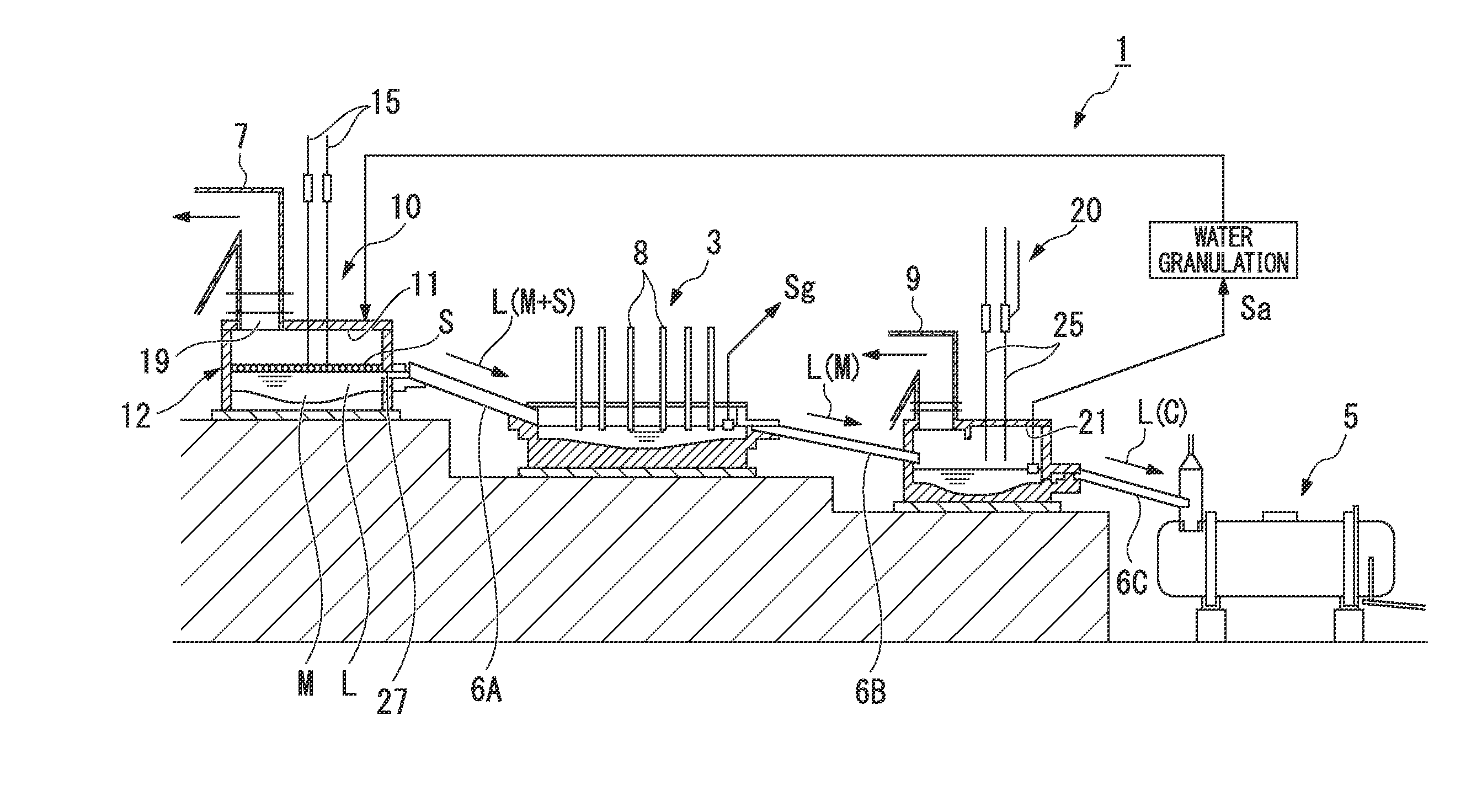

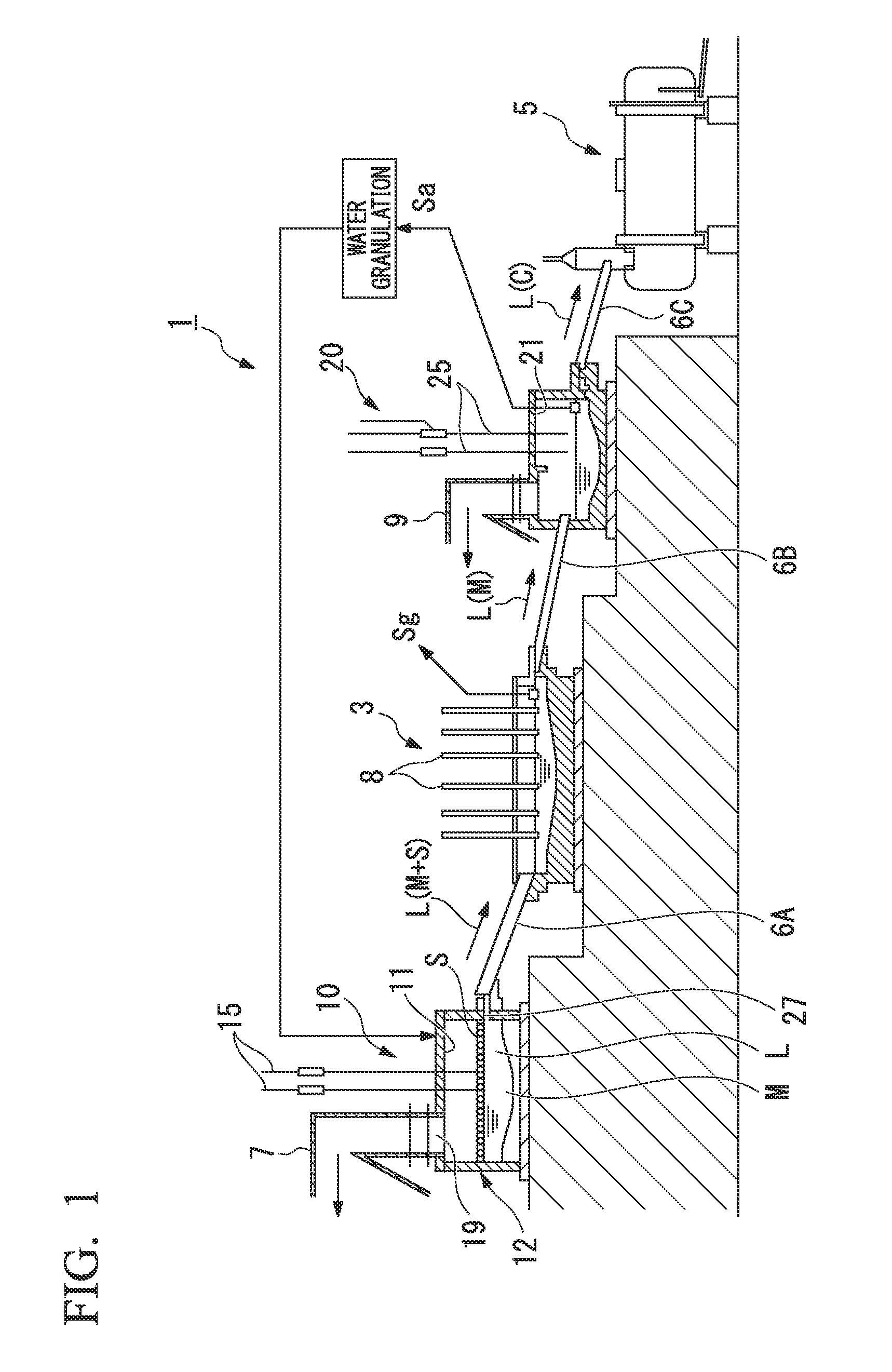

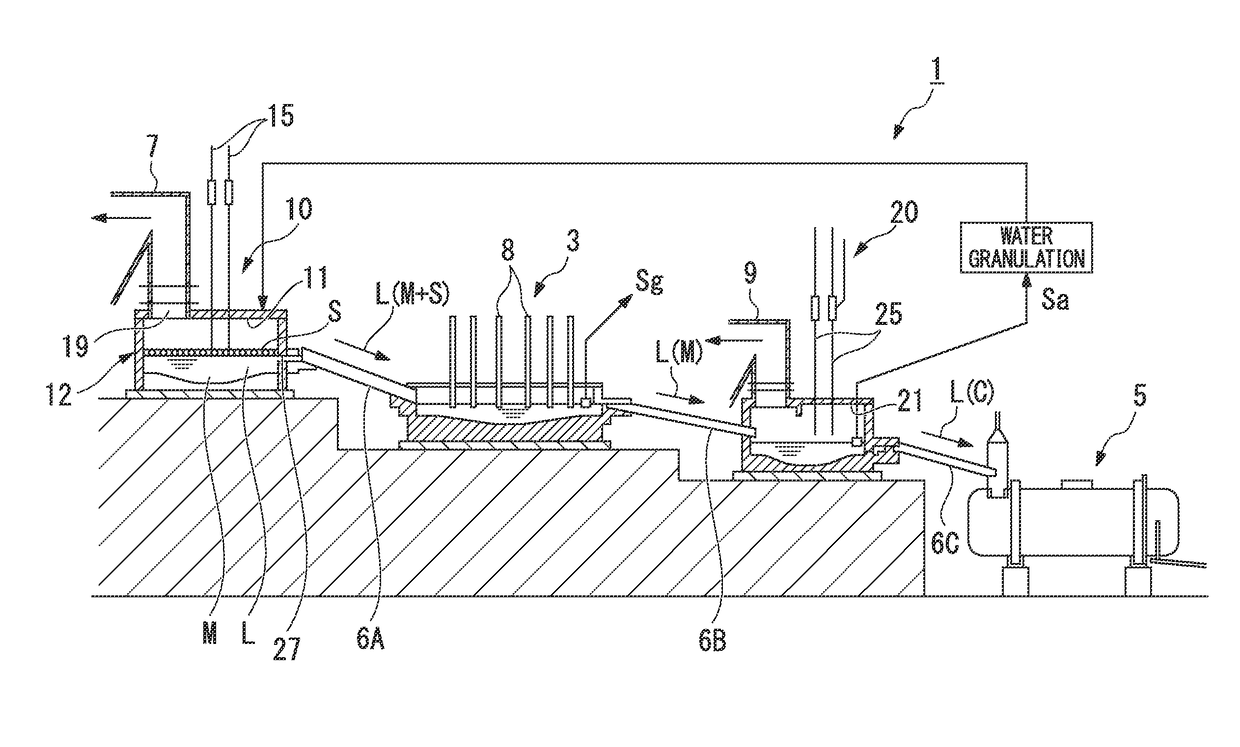

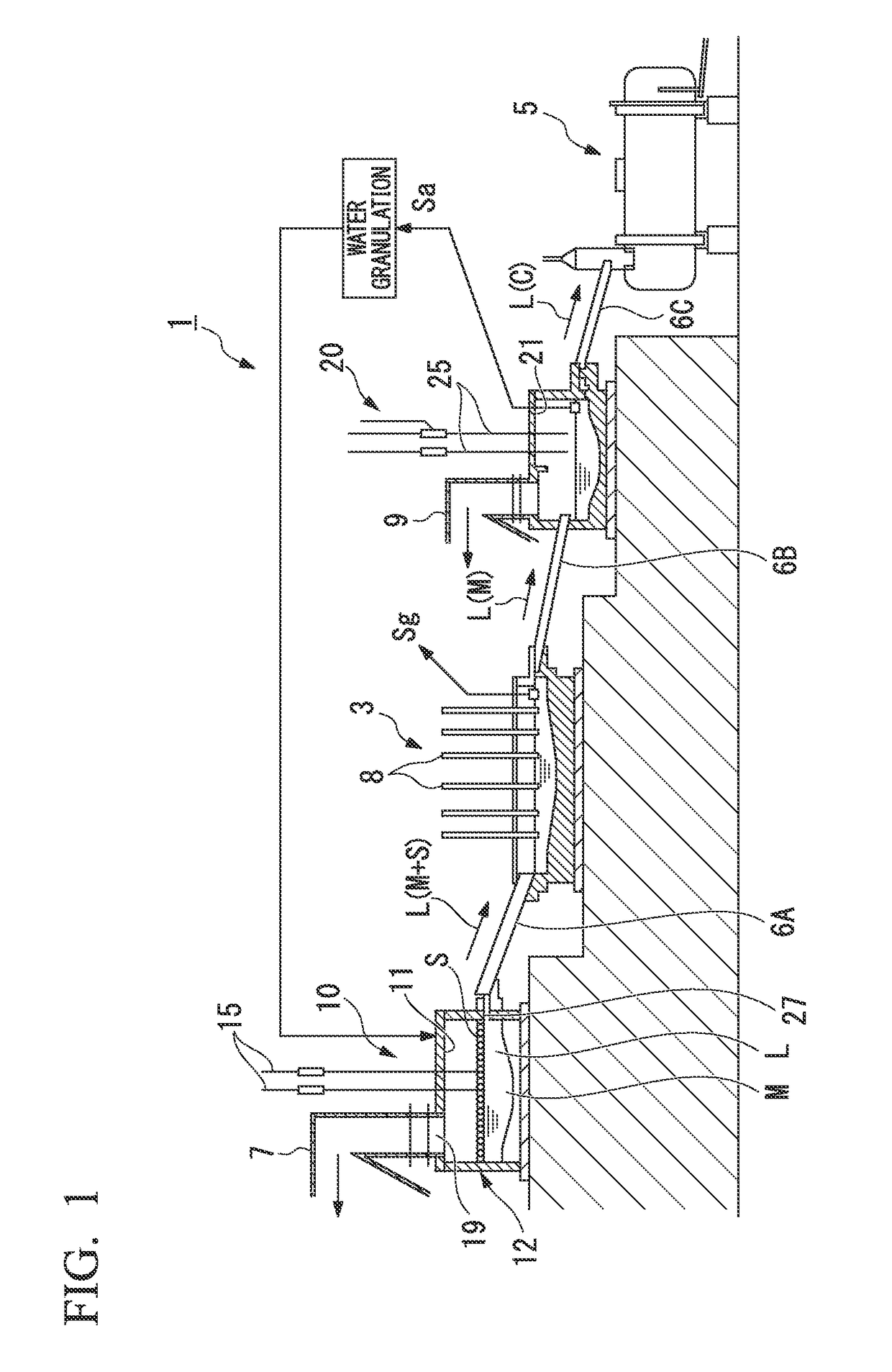

Method of operating non-ferrous smelting plant

ActiveUS7776133B2Increase productionIncrease volumeReverberatory furnaceGrain treatmentsNon-ferrous extractive metallurgyCopper

Owner:JX NIPPON MINING & METALS CORP

Copper anode refining system and method

Owner:PRAXAIR TECH INC

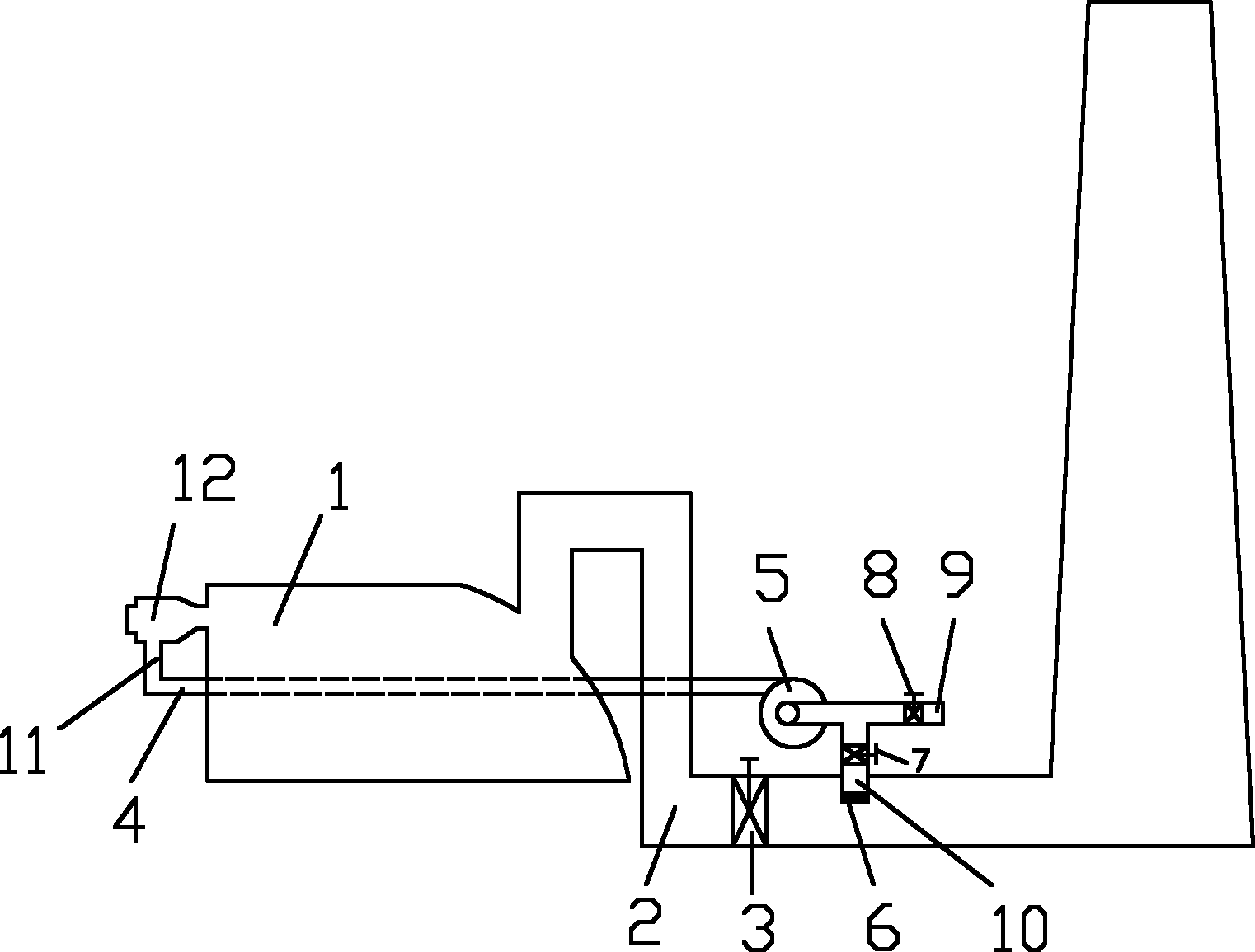

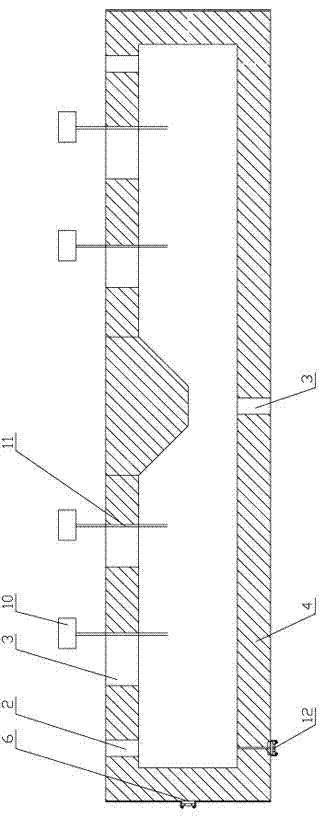

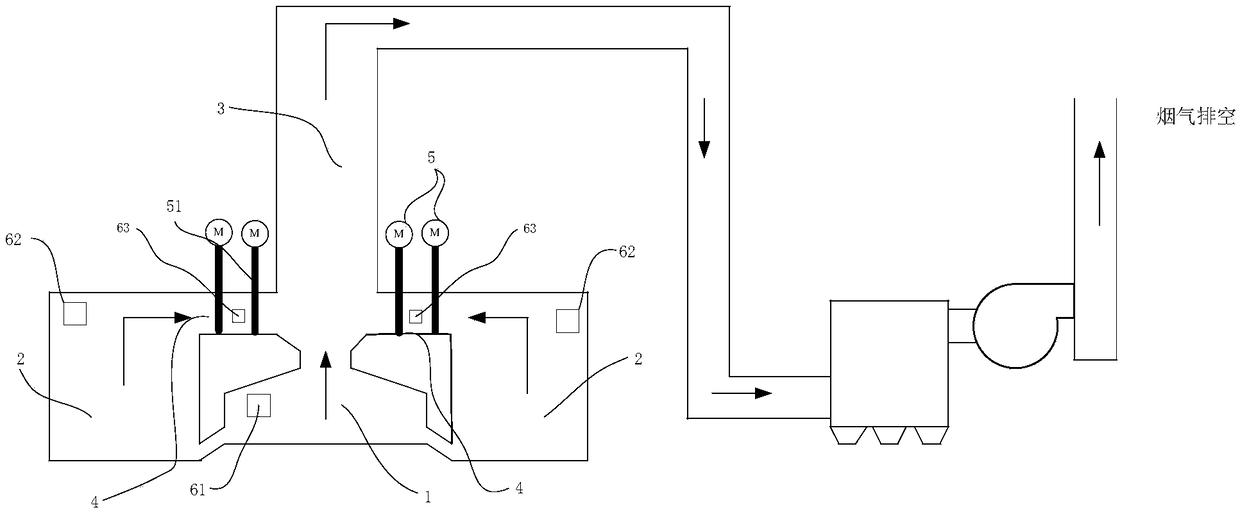

Purple mixed copper smelting and oxidation-reduction system

ActiveCN103526043ASave man hoursIncrease excess oxygenReverberatory furnaceProcess efficiency improvementReverberatory furnaceGas cooler

The invention discloses a purple mixed copper smelting and oxidation-reduction system which comprises a reverberatory furnace body. A flame combustion device and a reduction device are arranged on the reverberatory furnace body, the flame combustion device comprises a fuel feeding pipeline, a combustion improver feeding pipeline and a combustor arranged on the reverberatory furnace body, and the reduction device comprises a reduction control system connected with the reverberatory furnace body. The flame combustion device further comprises a control valve set, a PLC, a computer operating screen and a material sensor, the reduction device further comprises a methyl alcohol feeding box, a feed pump, a smoke waste heat decomposer, a decomposed gas cooler, a decomposed gas molecule absorber, a compression system and a gas storage tank, and the methyl alcohol feeding box, the feed pump, the smoke waste heat decomposer, the decomposed gas cooler, the decomposed gas molecule absorber, the compression system and the gas storage tank are communicated in sequence. The purple mixed copper smelting and oxidation-reduction system is simple in structure, strong in practicality and especially suitable for a purple mixed copper reverberatory furnace.

Owner:湖南金龙国际铜业有限公司

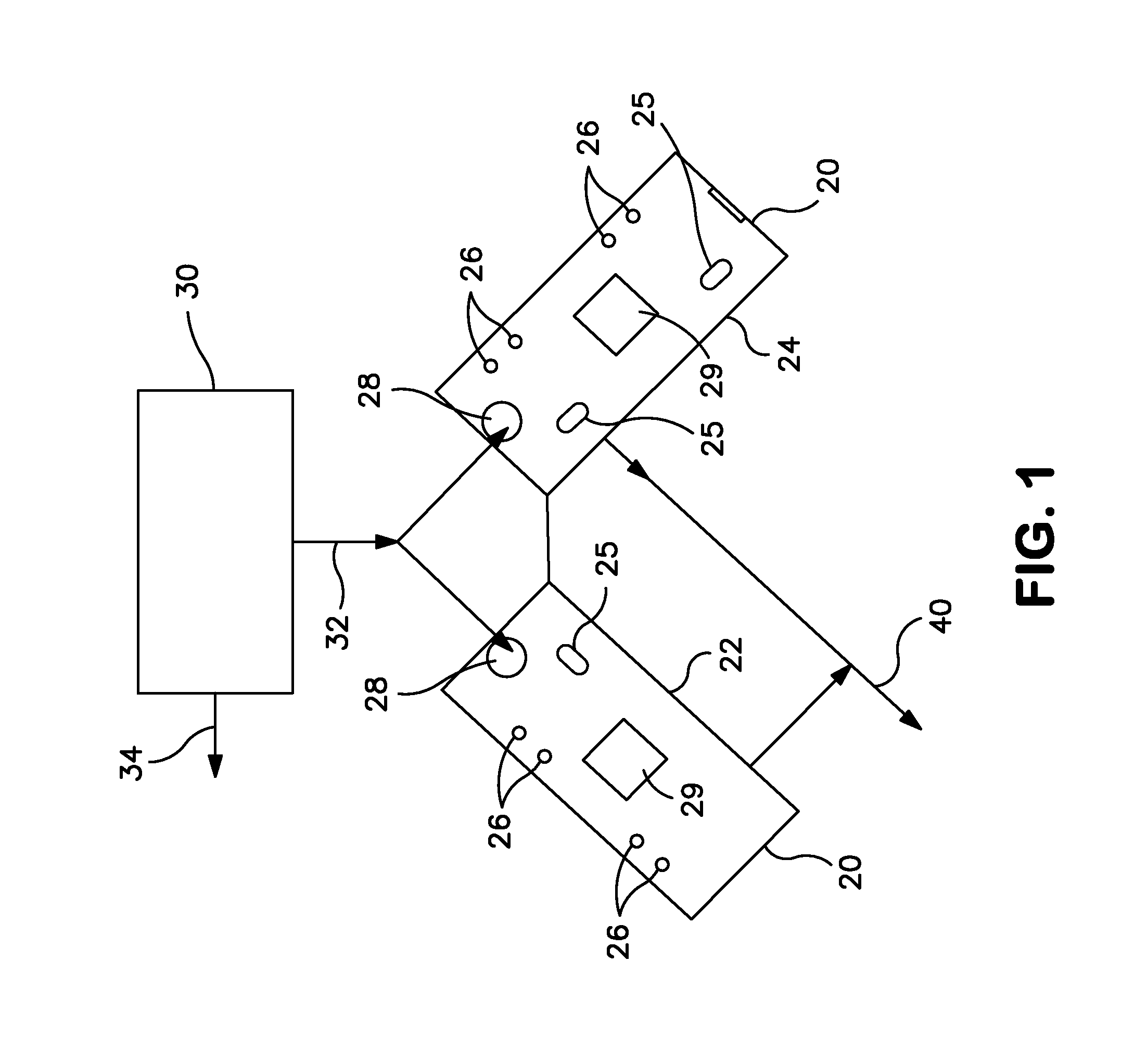

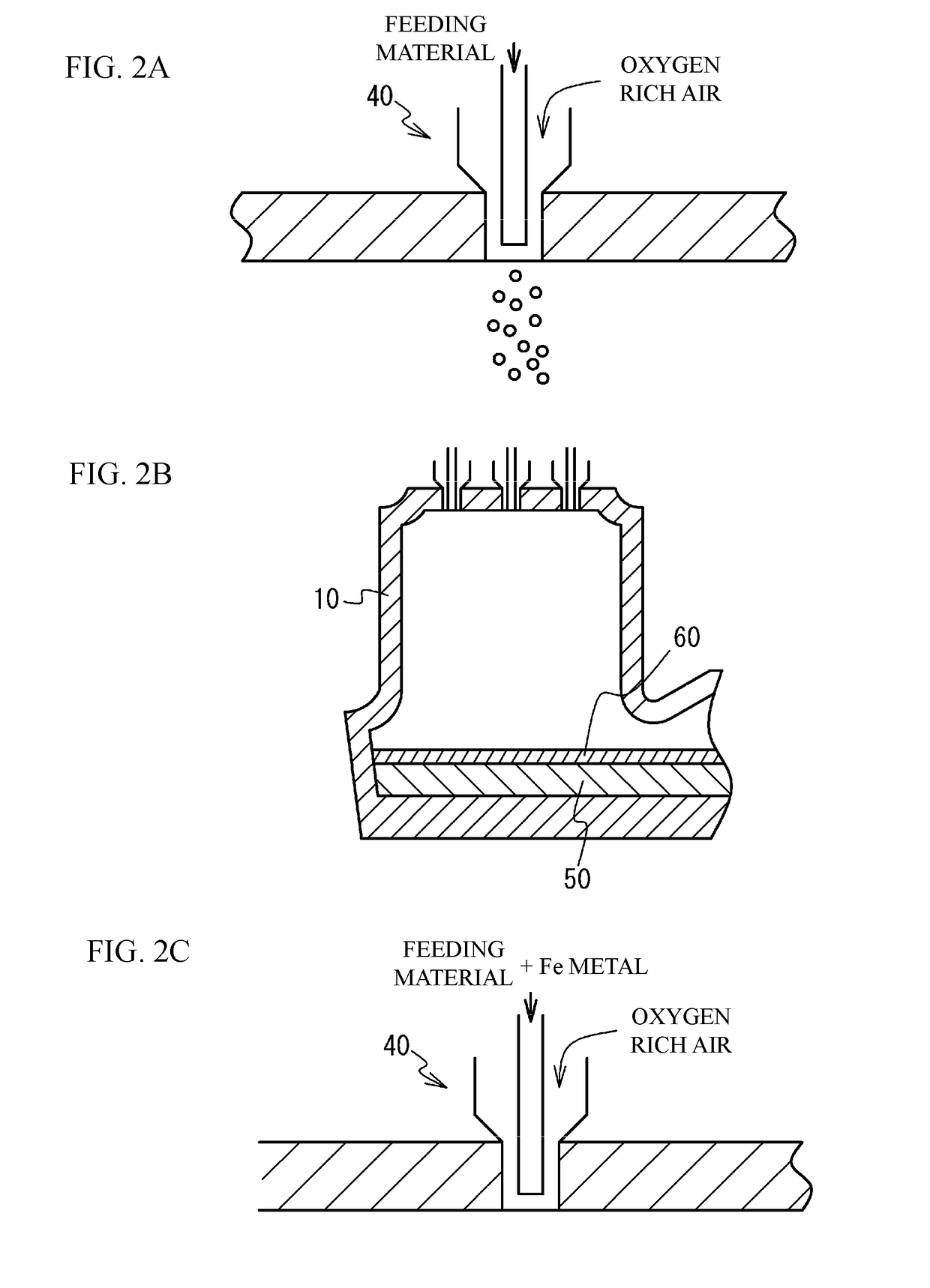

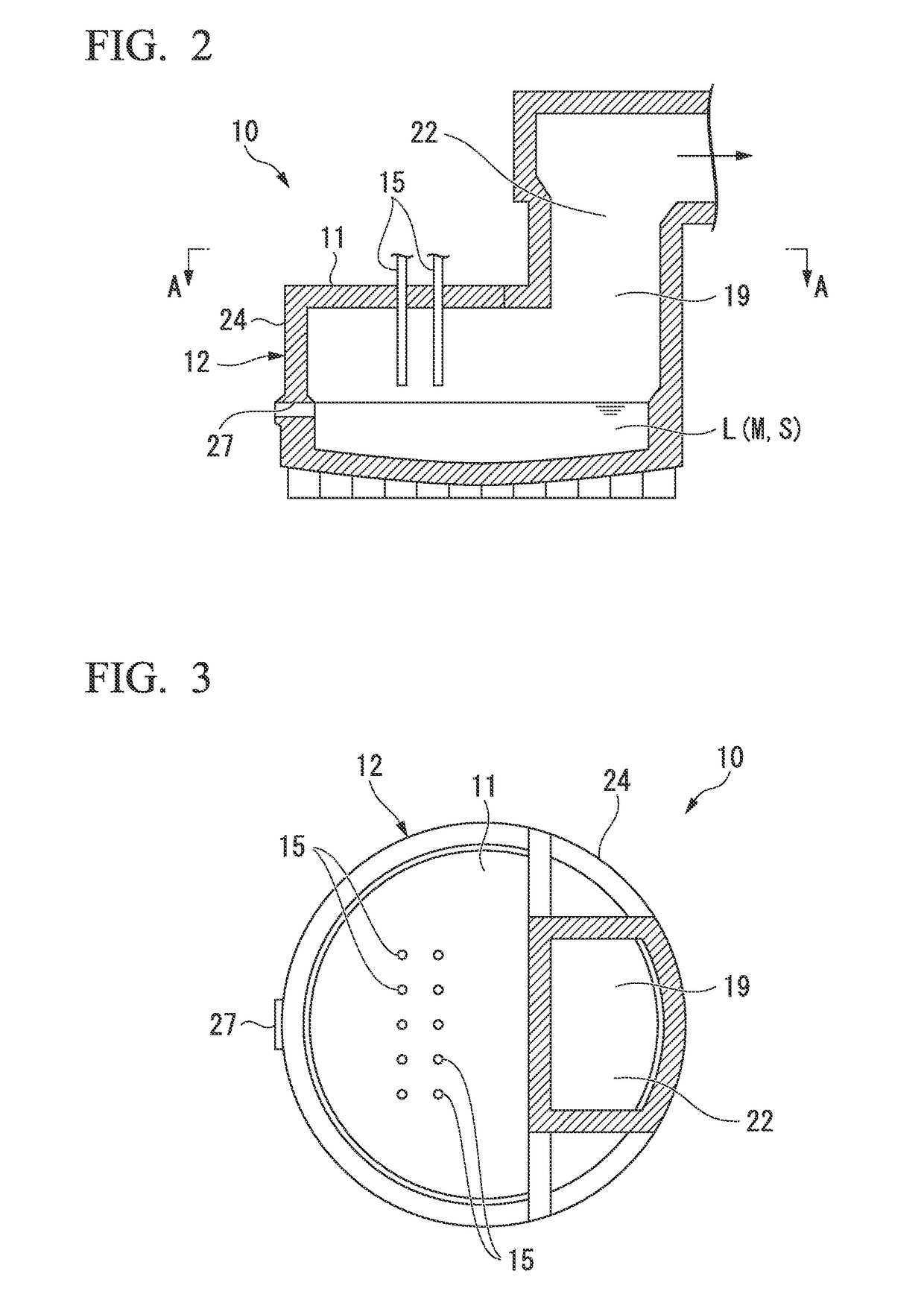

Method for treating combustible material and installation

ActiveUS20150176102A1Reduce materialEasy to handleTransportation and packagingReverberatory furnaceNonferrous metalOxygen

A method for treating combustible material of the present invention includes providing a pipe opened to a molten substance surface above the molten substance surface of molten substance stored in a furnace body for smelting nonferrous metals, and blowing combustible material containing valuable metals and oxygen-enriched air into the molten substance surface of the molten substance from the pipe.

Owner:MITSUBISHI MATERIALS CORP

Method for reducing coal consumption by comprehensively and circularly utilizing waste heat of Webster furnace

ActiveCN103411438ASolve the icingImprove efficiencyCombustion processReverberatory furnacePhysical chemistryEngineering

Owner:HEZHANG LINGXUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Carbide dispersed, strengthened copper alloy

InactiveUS20020007878A1Evenly dispersedGood effectReverberatory furnaceShaft furnaceChromium carbideMolybdenum carbide

A carbide dispersed, strengthened copper alloy includes copper as a major constituent, carbide particles, and a dispersing agent. The carbide particles consist of one or more carbides selected from chromium carbide, tungsten carbide, molybdenum carbide, and tantalum carbide. The dispersing agent consists of one or more elements selected from magnesium, chromium, silicon, and aluminum.

Owner:YAZAKI CORP

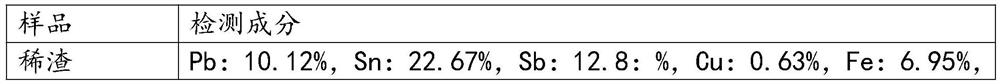

Method for producing raw copper from matte converting water quenching slag by adopting reverberatory smelting

InactiveCN105177303AEasy to makeReverberatory furnaceProcess efficiency improvementMaterials preparationGranularity

The invention provides a method for producing raw copper from matte converting water quenching slag by adopting reverberatory smelting. The method comprises the following steps: carrying out water quenching on top-blown furnace matte converting slag containing 14-22% of copper and 32-48% of iron, then adding the slag into a reverberatory, adding 1-3% of matte converting slag and reducing coal of which the particle size is 1-20mm, and carrying out reduction smelting at the temperature of 1200-1250 DEG C so as to obtain raw copper in which the copper content is greater than or equal to 95% and reverberatory slag in which the copper content is less than 2%. By adopting the method provided by the invention, the direct recovery rate of copper is greater than 90%. The converting slag after water quenching does not need to be specially prepared and only needs to be blended with a right amount of reducing agent to be smelted in the reverberatory, so that the material preparation is simple.

Owner:YUNNAN TIN

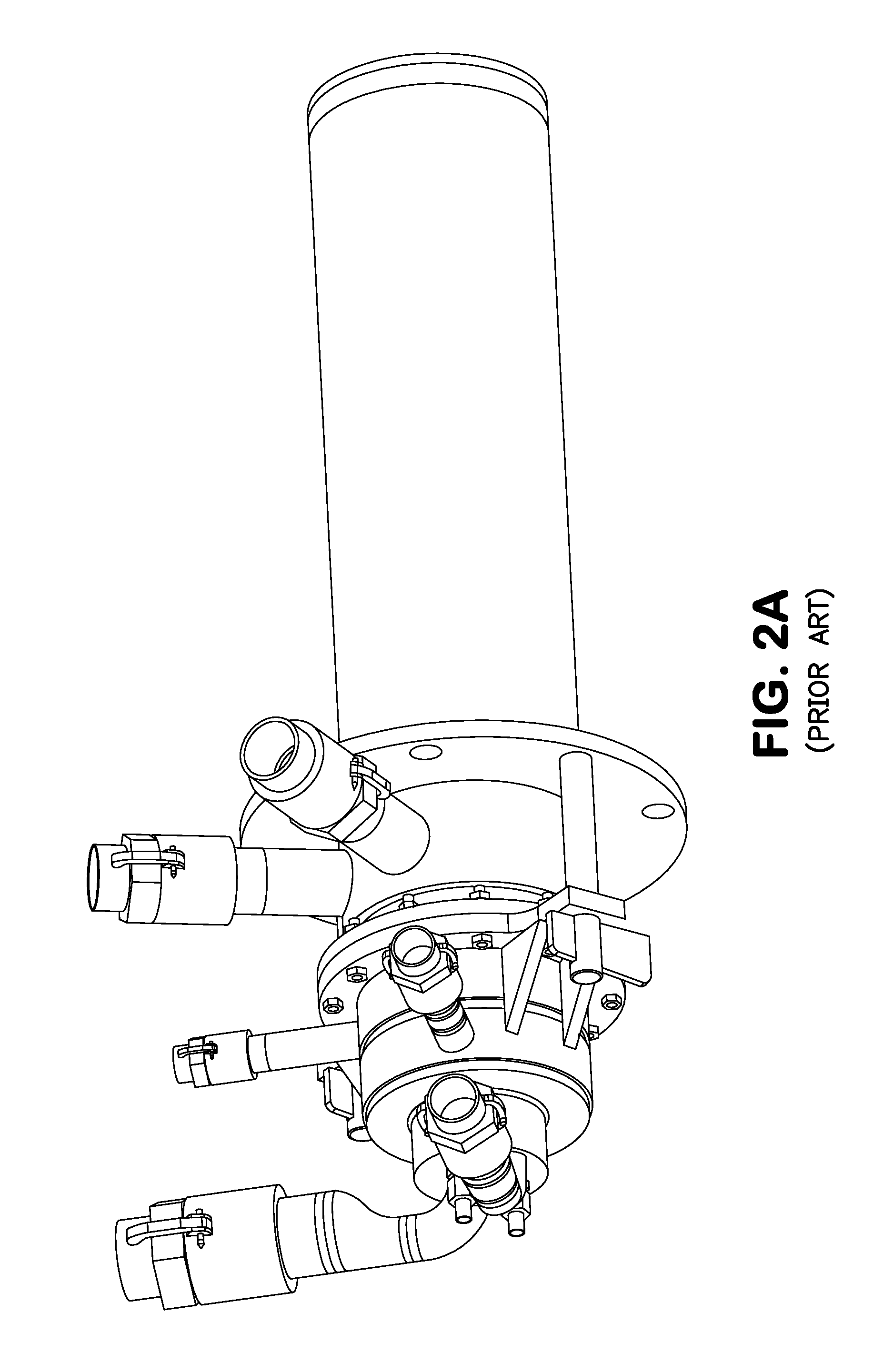

Blow pipe for copper smelting furnace and manufacturing method thereof

ActiveCN101907402AHigh strengthExtended service lifeReverberatory furnaceCharge manipulationCombustionThermal shock

The invention discloses a blow pipe for a copper smelting furnace and a manufacturing method thereof. In the blow pipe, one side of a metal pipe is sleeved on one side of a fire-resistant pipe; the sleeved part is sealed by fire clay; a non-fire-resistant pipe is the metal pipe; and the fire-resistant pipe contains the following raw materials in part by mass: 55 to 65 parts of alumina, 20 to 25 parts of magnesia, 10 to 15 parts of active magnesia powder, 2 to 3 parts of zirconia micro powder, 2 to 4 parts of plasticizing agent, and 7 to 9 parts of binding agent. The blow pipe for the copper smelting furnace has the advantages of high-temperature resistance, thermal shock resistance, high strength, resistance to corrosion of gases such as SO2 and the like, resistance to scouring and vibration of copper slag and high-speed combustion-gas flow and corrosion of molten slag, and long service life.

Owner:广州工业投资控股集团有限公司

A kind of waste purple miscellaneous copper refining agent and its preparation method and application

ActiveCN110527860BImprove the effect of impurity removalImprove corrosion resistanceReverberatory furnaceProcess efficiency improvementCombustionReverberatory furnace

Owner:四川博鑫铜业有限公司

High-quality low-oxygen copper rod and preparation method thereof

PendingCN113936842ALarge contact surfaceAffect the stability of useSingle bars/rods/wires/strips conductorsReverberatory furnaceCopperLow oxygen

The invention belongs to the technical field of copper rod preparation and relates to a high-quality low-oxygen copper rod and a preparation method thereof. The invention mainly aims at the problems that an existing copper rod is poor in connection stability, complex in preparation process, high in cost, low in quality and the like. According to the technical schemes, the high-quality low-oxygen copper rod includes a copper rod body, a connecting groove is formed in a center shaft at one end of the copper rod body, and a connecting column is arranged at one end of the copper rod body. The invention further provides a preparation method of the high-quality low-oxygen copper rod. The preparation method comprises the following steps that: 1, raw materials are treated; 2, c copper liquid is casted and crystallized; 3,machining a copper casting blank; and 4, a low-oxygen copper rod is obtained. According to the prepared low-oxygen copper rod connector, the connecting face is enlarged, the connecting stability of the copper rod is improved, the conductivity and tensile strength of the low-oxygen copper rod are improved, the oxygen content in the copper rod is reduced, the tensile strength and the conductivity of the low-oxygen copper rod are improved, waste copper is utilized, the production cost is reduced, resources are saved, and the low-oxygen copper rod is suitable for application and popularization.

Owner:天大铜业(天长)有限公司

Method for preparing aluminum and white copper alloy by utilizing recovery of waste lithium battery

InactiveCN110016564AHigh puritySimple processReverberatory furnaceProcess efficiency improvementCupronickelSlag

The invention provides a method for preparing an aluminum and white copper alloy by utilizing the recovery of a waste lithium battery. The method comprises the following steps: the waste lithium battery is crushed, and active material powder and mixed particles containing copper and aluminum are separated out; the separated-out mixed particles containing copper and aluminum are put into a screening machine, and a copper-rich material is screened out; the screened-out copper-rich material is put into a refining reverberatory furnace of 1250-1350 DEG C for being molten; then, an auxiliary reducing agent and a flux are added into a molten product; an alloy semi-finished product is obtained after stirring and slag dredging for a certain period of time; according to the value of deviation between the mass contents of all metal elements in the alloy semi-finished product and those of all metal elements required for the preparation of the aluminum and white copper alloy, corresponding pure metal is added into the alloy semi-finished product; and the aluminum and white copper alloy is formed through refining, stirring, slag dredging and casting in the refining reverberatory furnace. The method provided by the invention has the beneficial effects that the process is simple and novel, the product purity is high, and the pollution is relatively low.

Owner:先进储能材料国家工程研究中心有限责任公司

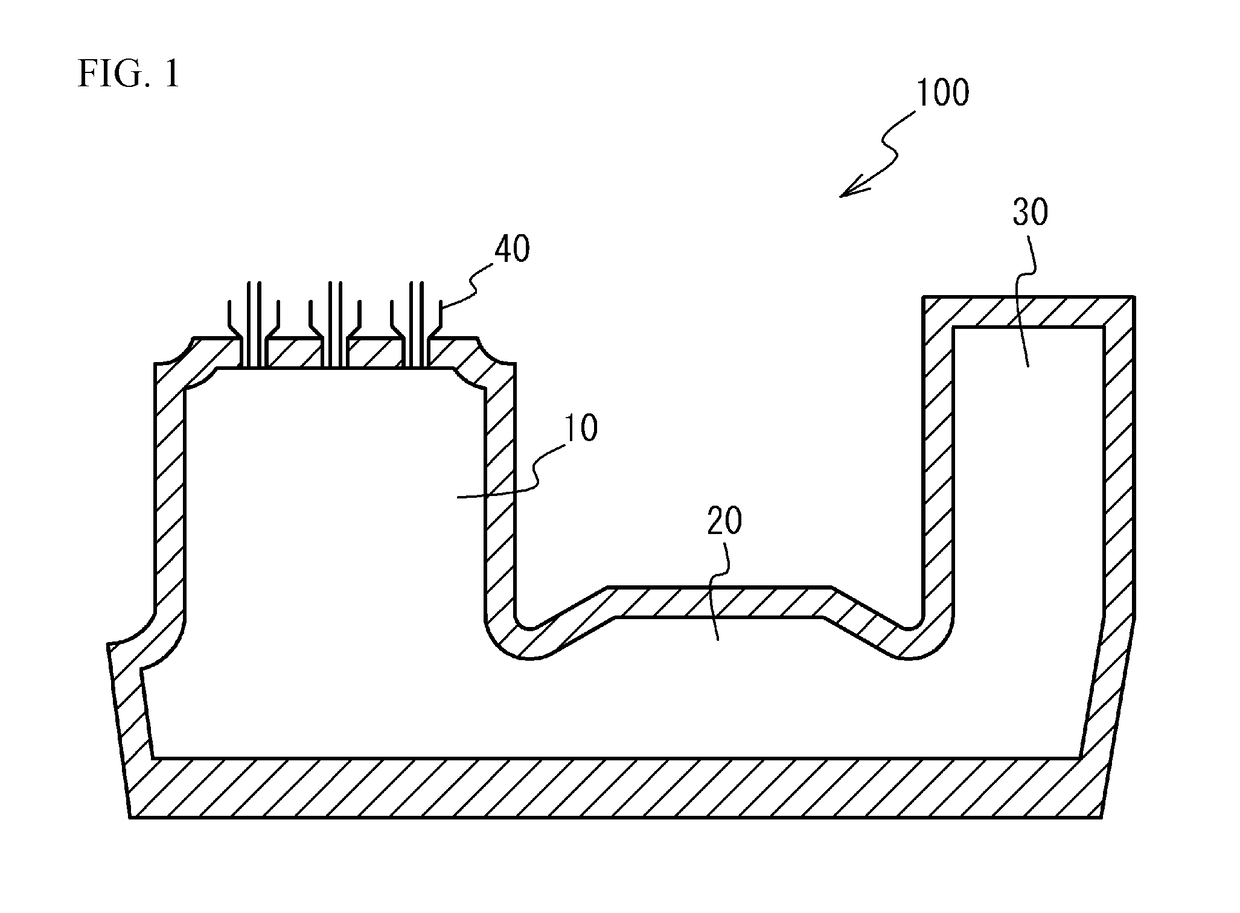

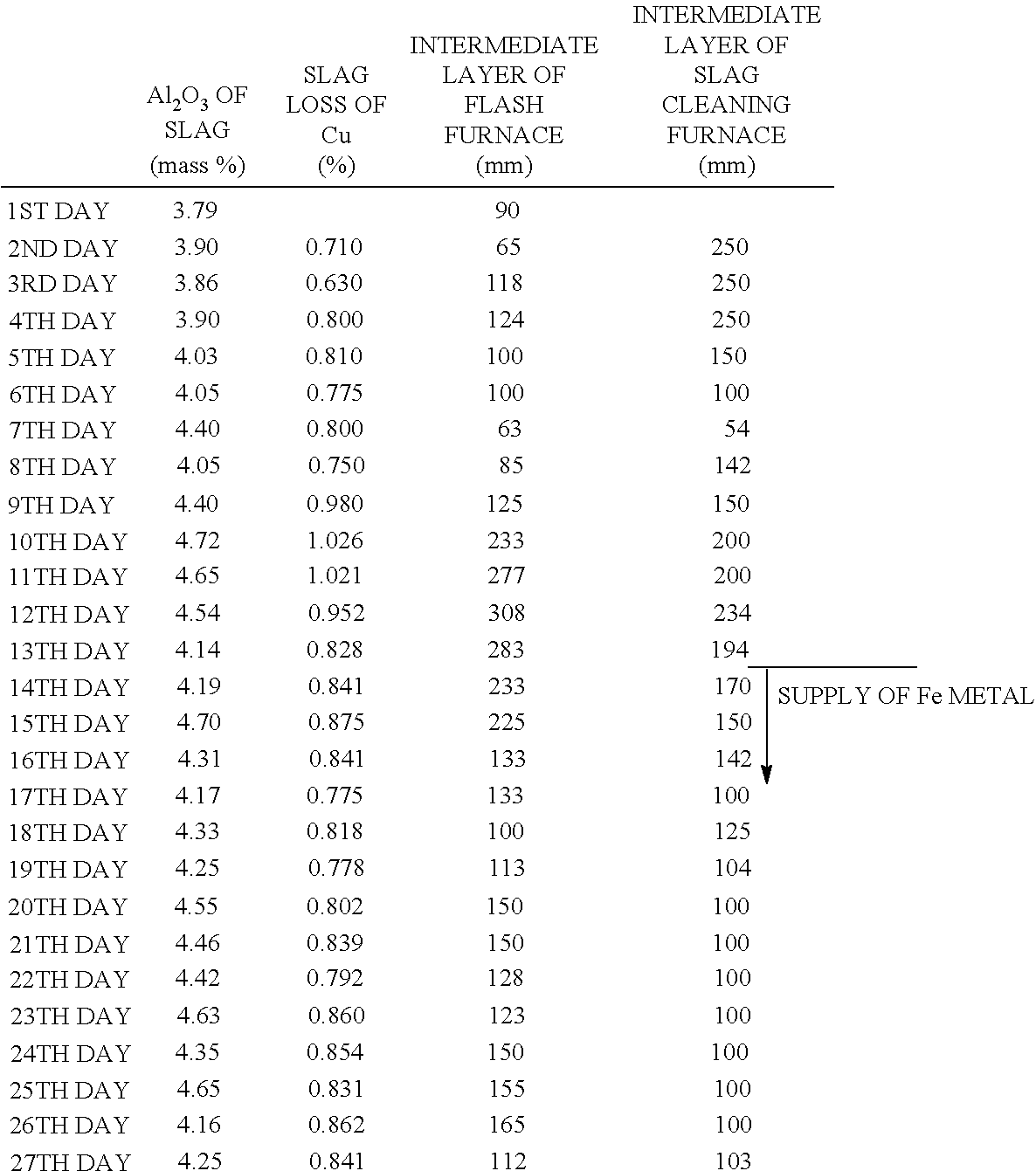

Operation method of copper smelting furnace

ActiveUS20180347009A1Suppress slag lossSuppress a slag lossReverberatory furnaceProcess efficiency improvementCopperMaterials science

An operation method of a copper-smelting furnace is characterized by including supplying an Fe metal source into a copper-smelting furnace together with a feeding material including copper concentrate and a flux, the copper concentrate including Al, the Fe metal source including an Fe metal of 40 mass % to 100 mass %.

Owner:PAN PACIFIC COPPER CO LTD

Method for treating combustible material and installation

ActiveUS9745643B2Effectively used for heatingReduce materialTransportation and packagingSolid waste disposalNonferrous metalIndustrial engineering

A method for treating combustible material of the present invention includes providing a pipe opened to a molten substance surface above the molten substance surface of molten substance stored in a furnace body for smelting nonferrous metals, and blowing combustible material containing valuable metals and oxygen-enriched air into the molten substance surface of the molten substance from the pipe.

Owner:MITSUBISHI MATERIALS CORP

Preparation method and use method of copper dross smelting slag former

InactiveCN114561549AImprove resource recovery efficiencyExtended service lifeOther chemical processesOrganic compound preparationChemical industryResource recovery

The invention relates to the technical field of metallurgy and chemical industry, in particular to a preparation method and a use method of a slagging agent for smelting copper dross, which are used for solving the problems that the use amount of the slagging agent is large, the resource recovery rate in a smelting solution is low and the recovery cost is high because the existing slagging agent cannot fully react with the smelting solution. Copper dross is added into a reverberatory furnace to be heated and smelted, then anode slime is added, after the copper dross and the anode slime are smelted, a slag former is added for a reduction reaction, meanwhile, stirring is conducted, liquid-state thin slag is kept, after reduction is finished, standing precipitation is conducted, and upper-layer thin slag, middle-layer lead copper matte and lower-layer high-antimony lead liquid are discharged; according to the using method, molten copper dross and anode slime are reduced through the slag former, smelting sticky slag and non-molten slag are converted into thin slag with good fluidity, tin, copper and high-antimony lead in the copper dross can be recycled in a classified mode through one-time smelting, the copper dross resource recycling efficiency is greatly improved, the service life of a reverberatory furnace is prolonged, and the production cost is reduced. The comprehensive recovery cost of the secondary lead is reduced.

Owner:ANHUI NARADA RENEWABLE RESOURCE TECH CO LTD

A method for controlling pressure in a refining furnace

InactiveCN106148727BReduced prior knowledge requirementsReduce energy consumptionReverberatory furnaceAdaptive controlCombustionMain channel

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com