Patents

Literature

143results about How to "Alleviate resource constraints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for sharing resources in a wireless communication network

ActiveUS20080095071A1ServeRaise priorityData switching by path configurationWireless communicationVoice communicationDistribution method

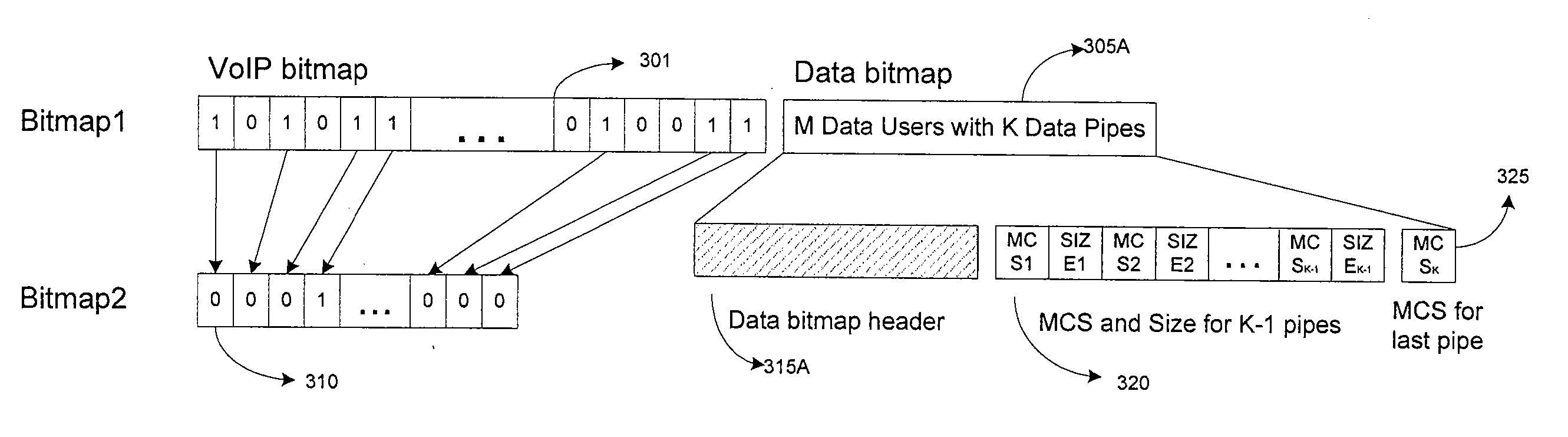

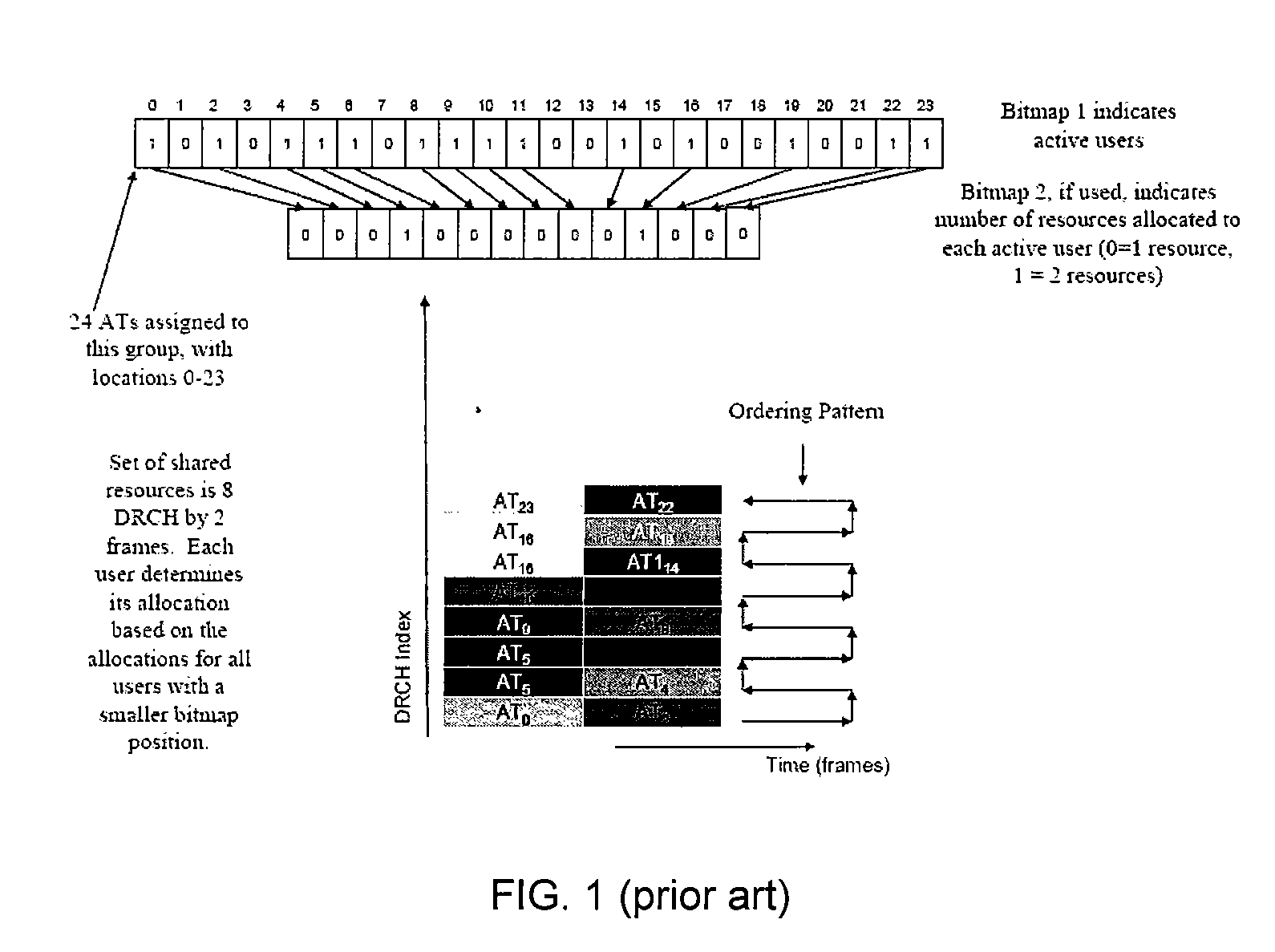

Method and system for sharing resources in a wireless communication network. According to an embodiment, the present invention provides a method for resource allocation. The method includes providing an access node that is configured to provide wireless access for both voice and data services. The method also includes providing at least a first access terminal that is configured to perform at least voice communication through the access node. Additionally, the method includes providing at least a second access terminal that is configured to perform at least data communication through the access node. The method further includes allocating a first portion of communication resources to the first access terminal. The method additionally includes allocating a second portion of communication of resources to the second access terminal. Furthermore, the method includes generating a group resource allocation message, which includes at least a first bitmap and a second bitmap.

Owner:FUTUREWEI TECH INC

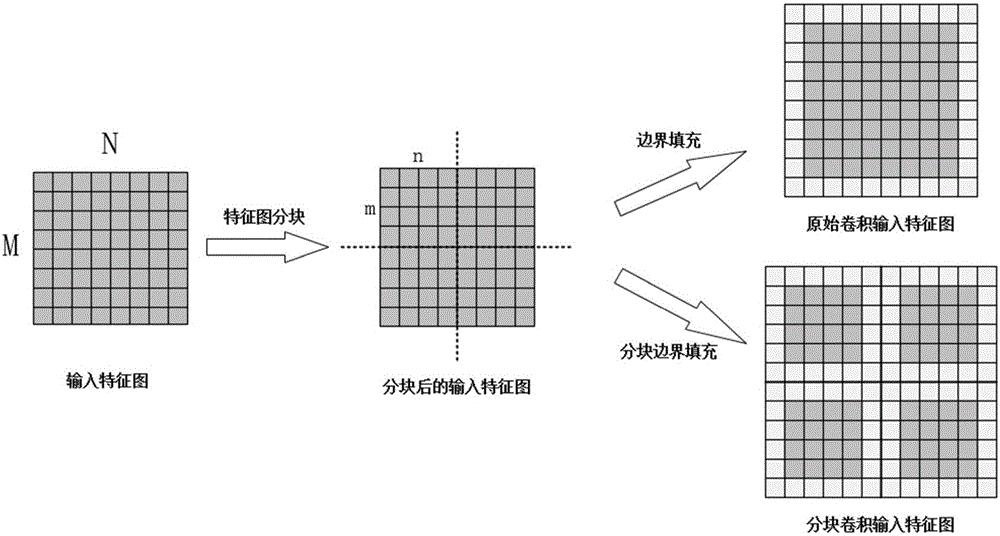

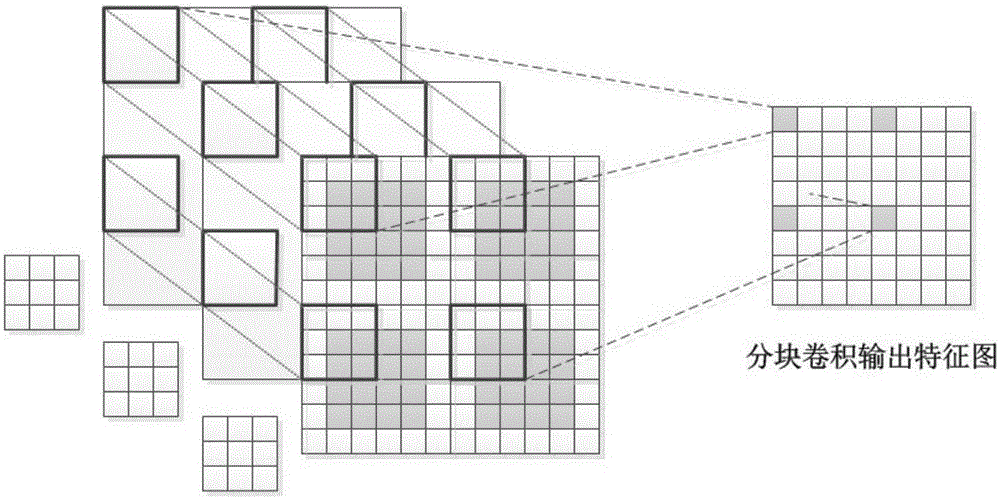

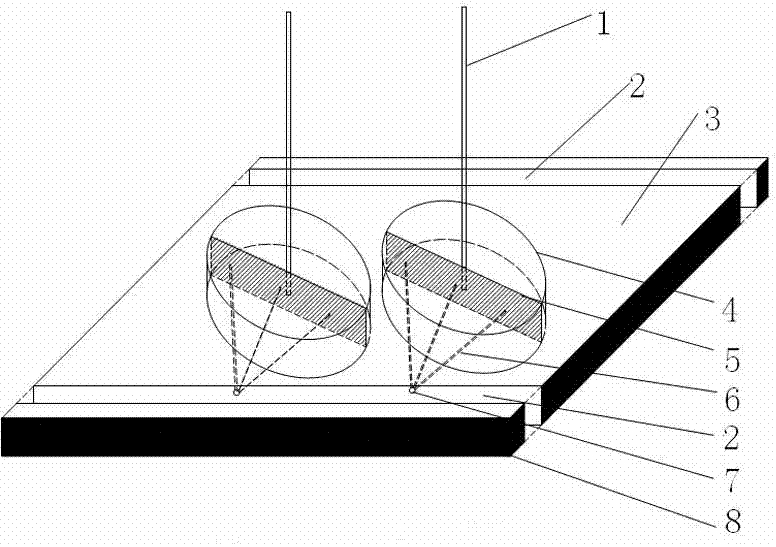

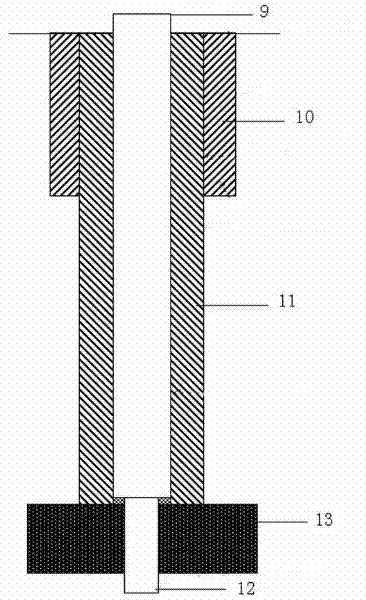

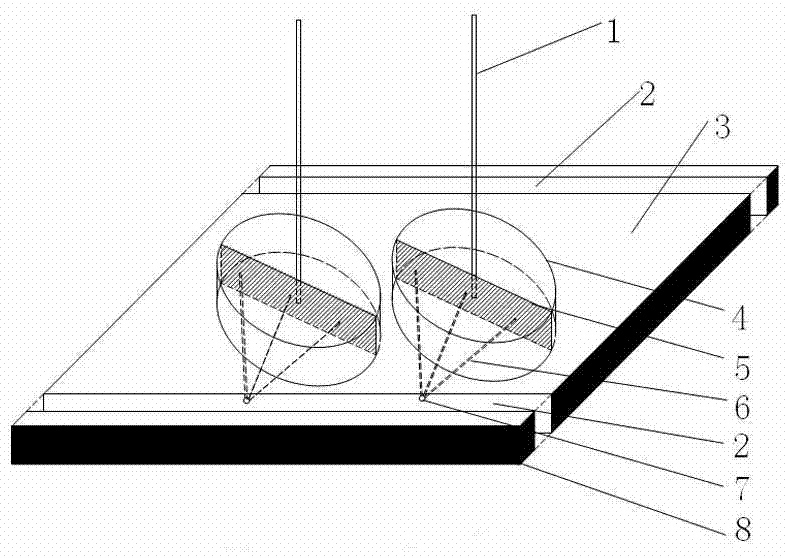

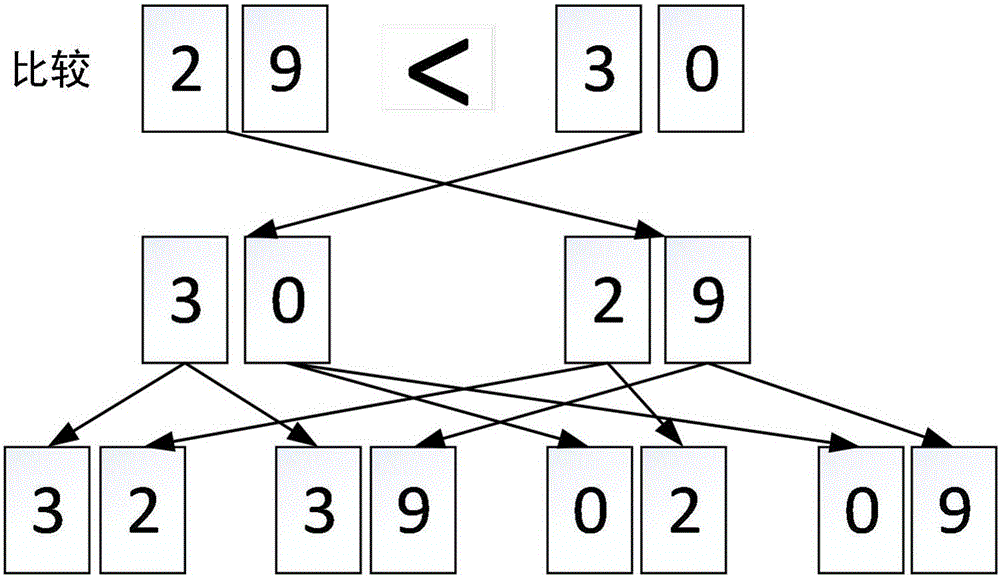

Blocked convolution optimization method and device for convolution neural network

ActiveCN107437110AResource Constraint Issues EliminatedAlleviate resource constraintsNeural architecturesPhysical realisationNerve networkAlgorithm

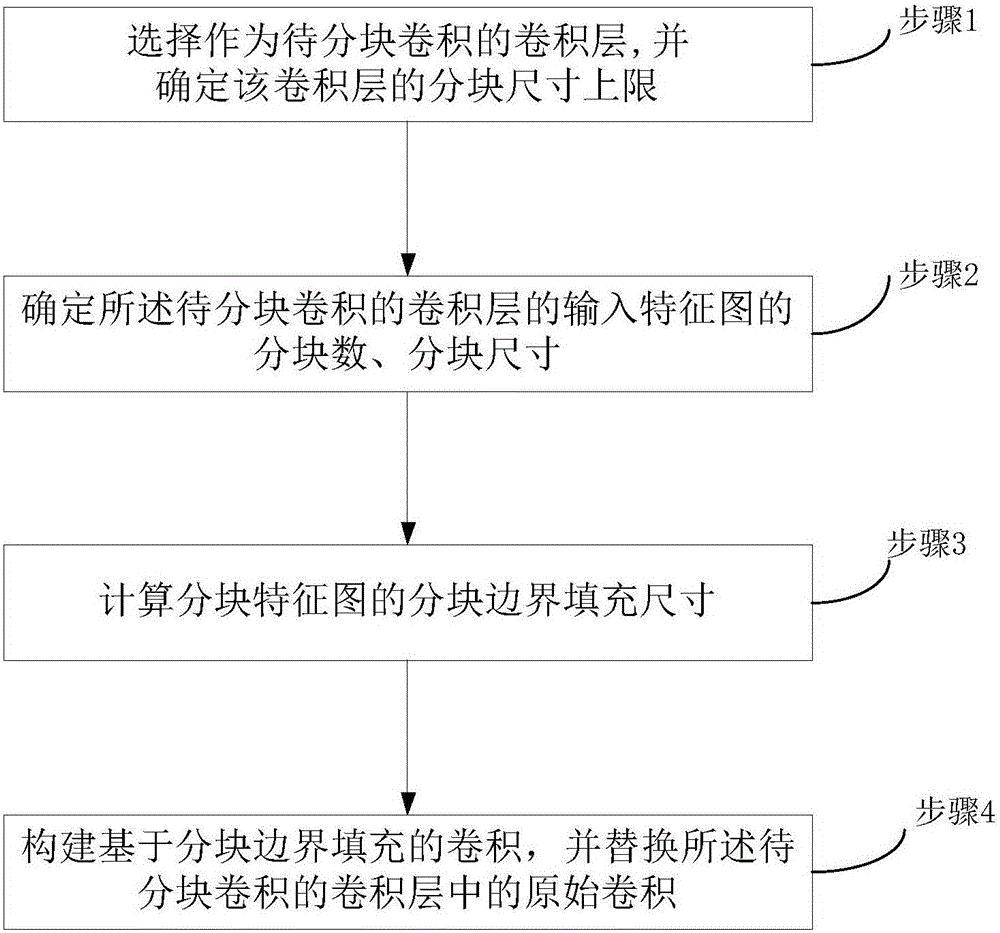

The invention relates to the field of deep neural networks and provides a blocked convolution optimization method and a device for a convolution neural network, so as to solve the bottleneck problem of convolution operation in a hardware processing system in the neural network. The optimization method comprises steps: a to-be-blocked convolution layer is selected, and the upper limit of the block size is determined; according to the upper limit of the block size, a block number and the block size of an input feature map are determined; based on the block number, the block size, the size of a convolution kernel, the size of the input feature map and the filling size of an input feature map boundary, the block boundary filling size of a block feature map is calculated; and based on the block number, the block size and the block boundary filling size, a convolution based on the block boundary filling is built to replace the original convolution. The resource constraint problem of the convolution neural network during operation of an embedded hardware platform is greatly alleviated, the burst length is improved maximally when a memory is read and written, the throughput is improved, the time delay is reduced, and the efficiency is improved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Bacterial speices and method for producing succinic acid by microbial fermentation

InactiveCN1814747AEfficient accumulationAlleviate resource constraintsBacteriaFermentationMicroorganismButanedioic acid

This invention relates to a method for producing succinic acid type culture by animalcule fermentation, especially relating to an animalcule actinobacillus succinogenes SW0580 generating succinic acid by a fermentated sugariness raw material, its preservation number: CGMCC No. 1593 and a method for utilizing said animalcule fermentation to produce succinic acid, in which, said animalcule is the actinobacillus succinogenes separated from the rumen tested and 10-50g / L succinic acid can be produced by anaerobic fermentating 20-100g / L sugariness raw materials.

Owner:JIANGNAN UNIV

Zinc alloy bar extruding process designing and optimizing method

ActiveCN102463268AHigh degree of automationSolving Extrusion Cracking ProblemsConstitutive equationMicrostructure

The invention relates to a zinc alloy bar extruding process designing and optimizing method, which comprises the steps of: obtaining a true-stress and true-strain curve of a zinc alloy by adopting a high-temperature compression and high-temperature tension test; establishing a constitutive equation and an operation drawing of the zinc alloy, carrying out microstructure analysis, researching a thermal deformational behavior, selecting a deformation condition suitable for processing; carrying out finite element numerical simulation, establishing an extrusion forming limit drawing, optimizing an extrusion process window, carrying out thermal extrusion to obtain a zinc alloy bar; and establishing an extrusion test data base, and predicting a relationship between the extrusion process and surface cracking, quality and performance of the extrusion bar by adopting a neutral network. The invention can realize optimal matching of all parameters in a process of extruding the zinc alloy bar, accurate control on the extruding process, and integration of process design, optimization and performance control. The prepared zinc alloy bar has the characteristics of better surface quality, fine and uniform textures, high performance, high pass percent and high production efficiency, is suitable for massive production, and has remarkable economic and social benefits.

Owner:GRIMAT ENG INST CO LTD

Rapid tissue culture method for lycium ruthenicum murr

InactiveCN104719165AReduce stepsImprove tissue culture efficiencyHorticulture methodsPlant tissue cultureBiotechnologyMedicine

The invention discloses a rapid tissue culture method for lycium ruthenicum murr, belonging to the technical field of plant tissue culture. The rapid tissue culture method comprises the following steps: explants sterilization, induction culture, rooting culture, subculture, acclimatization and transplantation. According to the rapid tissue culture method, the rooting culture can be carried out during the subculture, so that the tissue culture is high, the operation is simple and convenient, the period is short, and complete plants can be rapidly acquired; the tissue culture process is not influenced by environmental factors.

Owner:四川天府贝瑞生态农业有限公司

Method for extracting coal seam gas through ground fracturing and underground horizontal drill holes

ActiveCN102493831AImprove permeabilityImprove drilling air permeabilityFluid removalGas removalHydraulic fracturingCoal

The invention relates to a method for developing underground coal seam gas, and provides a method for extracting coal seam gas through ground fracturing and underground horizontal drill holes in order to ensure the safety production of a coal shaft and improve the air permeability of the underground drill holes as well as the extraction efficiency of gas. The method comprises the following steps: 1) shaft placing design; 2) ground shaft drilling, as well as ground construction of vertical drill holes or directional drill holes for a mine in areas with roadways and without construction of underground coal seam gas extraction drill holes; 3) hydraulic fracture, namely, conducting hydraulic sand fracture after well completion so as to form high permeable fracture influenced areas; 4) underground horizontal long drill holes, namely, drilling horizontal directional seam gas extraction holes along a main mineable coal seam to form a horizontal drill hole influenced areas; the horizontal drilling hole influenced area is communicated with the fracture influenced area to realize the coal seam gas extraction. Through adopting the method provided by the invention, the hazard of coal mine gas disaster can be eliminated, and the guarantee degree of safety production of the coal mine can be improved at the same.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

Potassium sulfate and magnesium sulfate fertilizer production process having extrusion prilling step and no drying step

InactiveCN101298393AReduce releaseIncrease profitMagnesium fertilisersPotassium fertilisersIron sulphateBiology

The invention relates to a technique for manufacturing magnesium potassium sulfate fertilizer by extrusion pelleting with no drying, which is characterized by: mixing lemery, anhydrous magnesium sulfate, water retention agent as well as medium elements and microelements according to the weight portions of 46:35:0.6:18.4; transmitting the mixture to a feed hopper after being fully stirred, then packaging the mixture into a finished product by rolling, cutting up, pelleting and sieving; the medium elements and the microelements include: zeolite powder, borax, zinc sulfate, bluestone and green copperas which are uniformly mixed according to the weight portions of 10 to 20: 1 to 3: 1 to 2.5: 0.1 to 1.5 : 0.1 to 1. The invention adopts the technique of extrusion pelleting and is added with a drought control water retention growth promoting agent; the produced multi-element magnesium potassium sulfate water retention fertilizer has the advantages of slow nutrient release, high fertilizer operating factor, easing resource shortage, reducing soil nutrient losing, protecting the underground water environment as well as being safe and environment protective. During the whole manufacture process, no water and no drying processes are educed, thus reducing power consumption and coal consumption during the drying and cooling processes; no contaminations of the three wastes are discharged during the manufacture process.

Owner:郭瑞

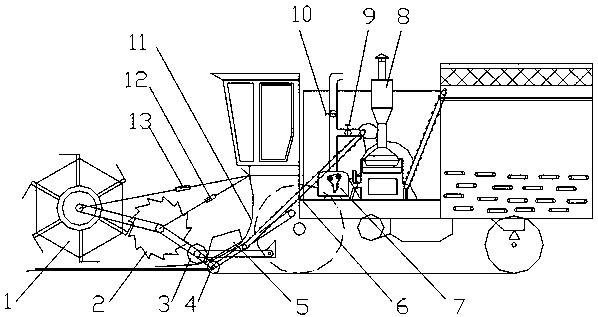

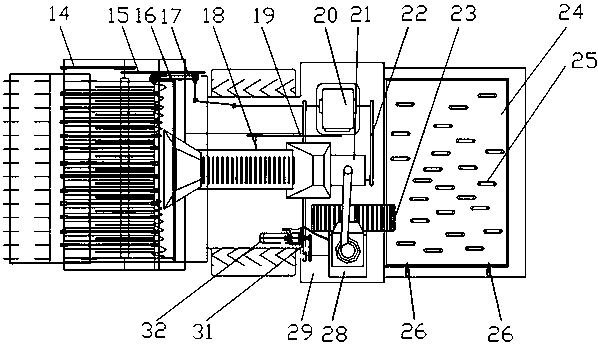

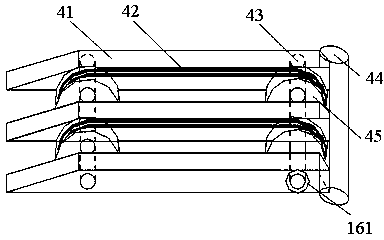

Full-automatic collection, smashing and compact forming combination machine for field waste crop straws

ActiveCN103749964ASolving the collection is labor-intensiveSolve efficiency problemsBiofuelsSolid fuelsPre treatmentAgricultural machinery

The invention discloses a full-automatic collection, smashing and compact forming combination machine for field waste crop straws, and belongs to the technical field of agricultural machineries. According to the full-automatic collection, smashing and compact forming combination machine for field waste crop straws, the problems of great labor cost and low transportation efficiency in collection of the agricultural straws are solved. The full-automatic collection, smashing and compact forming combination machine for the field waste crop straws comprises a front straw automatic picking and preprocessing system, a smashing and compact forming integration system and a biomass particle automatic transportation and temporary storage system, wherein the front straw automatic picking and preprocessing system is suspended on the front side of a walking chassis integrated system frame; the smashing and compact forming integration system and the biomass particle automatic transportation and temporary storage system are mounted on a chassis of the walking chassis integrated system from front to back; the front straw automatic picking and preprocessing system, the smashing and compact forming integration system and the biomass particle automatic transportation and temporary storage system are connected together through a transmission mechanism. The combination machine is applicable to full-automatic collection, smashing and compact forming for the field waste crop straws.

Owner:NORTHEAST FORESTRY UNIVERSITY

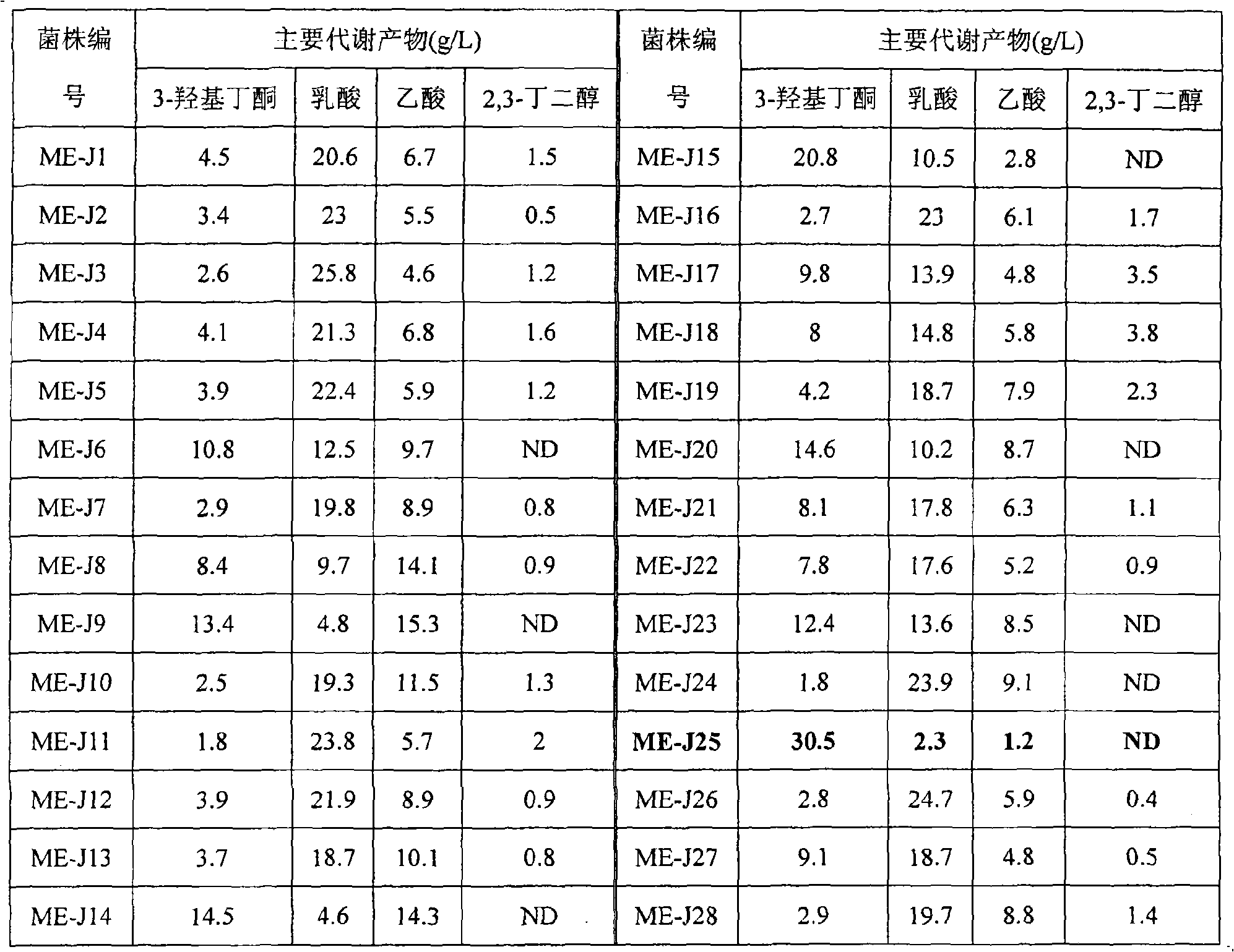

Bacterial strain for preparing 3-hydroxy butanone and uses thereof

InactiveCN101294143AImprove synthesis abilityImprove conversion rateBacteriaMicroorganism based processesHigh concentrationTransformation efficiency

The invention discloses a strain for generating 3-hydroxy butanone and the application thereof, which belong to the field of bioengineering technology. The stain is named as Paenibacillus polymyxa ME-J25 and is preserved in China General Microbiological Culture Collection Center with the preservation number of CGMCC No.2505. The strain can be fermented to generate 3-hydroxy butanone with higher concentration, higher transformation efficiency and extremely low content of the reduced byproduct 2,3-butanediol of 3-hydroxy butanone, and is suitable for industrial production of 3-hydroxy butanone.

Owner:NANJING TECH UNIV

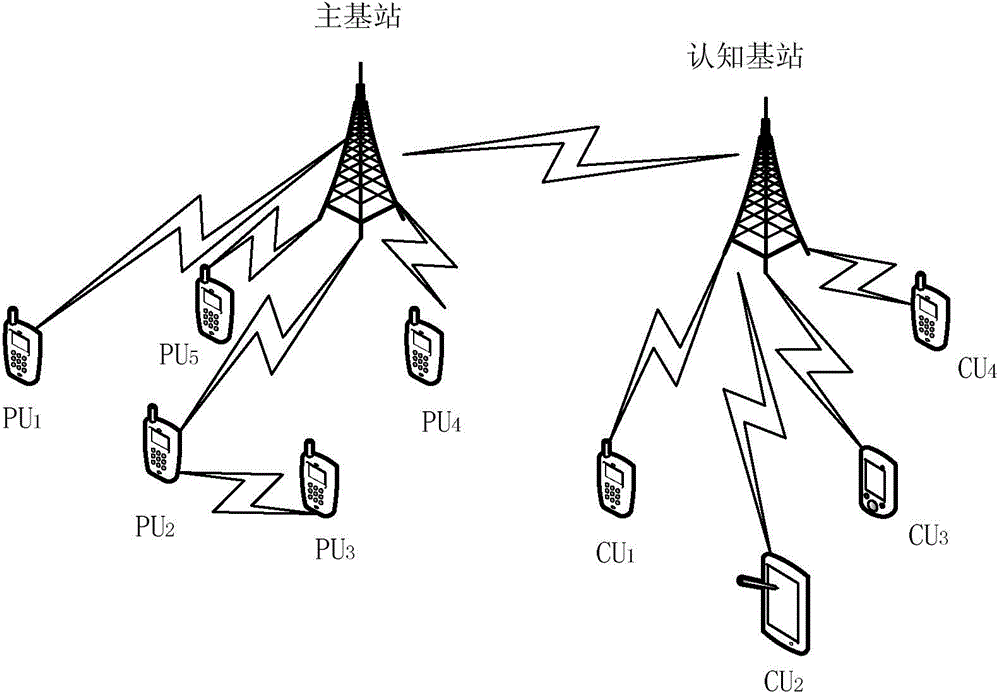

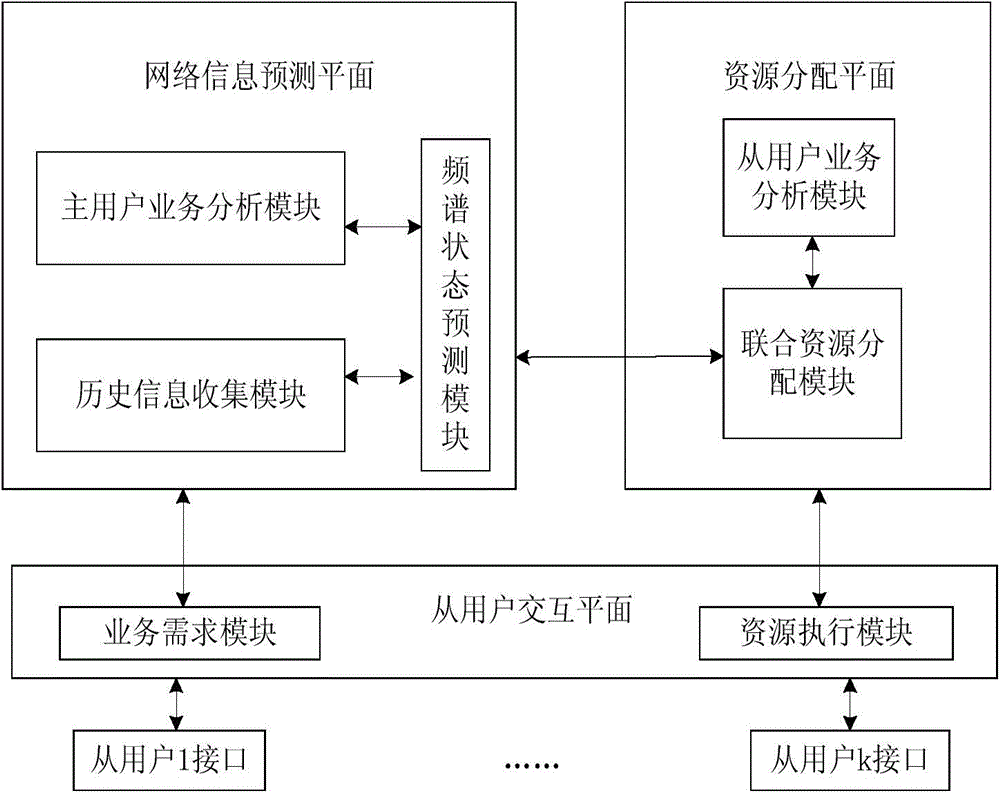

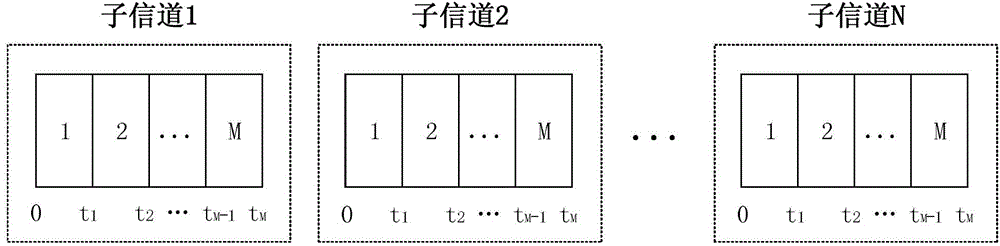

Dynamic cognitive network resource allocating method

ActiveCN104093209AReduce performance degradationJoint resource optimizationHigh level techniquesWireless communicationFrequency spectrumResource allocation

The invention discloses a dynamic cognitive network resource allocating method, and belongs to the technical field of wireless communication. The occupied situation of a master user authorization frequency band is predicted based on master user historical information and service characteristics, a cognitive base station carries out subordinate user frequency spectrum and power joint optimization allocation according to the frequency spectrum prediction information and subordinate user service requirement information, and therefore maximization of the subordinate user joint energy efficiency and minimization of the number of switching times are achieved. According to the method, the occupied state of the cognitive network master user frequency band, the subordinate user service requirement and switching cost caused by frequency band switching are comprehensively taken into consideration, the joint resource allocation is carried out based on a network energy efficiency maximization criterion, and the subordinate user joint energy optimization is achieved while the subordinate user service requirement is guaranteed and the performance drop caused by switching is reduced.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

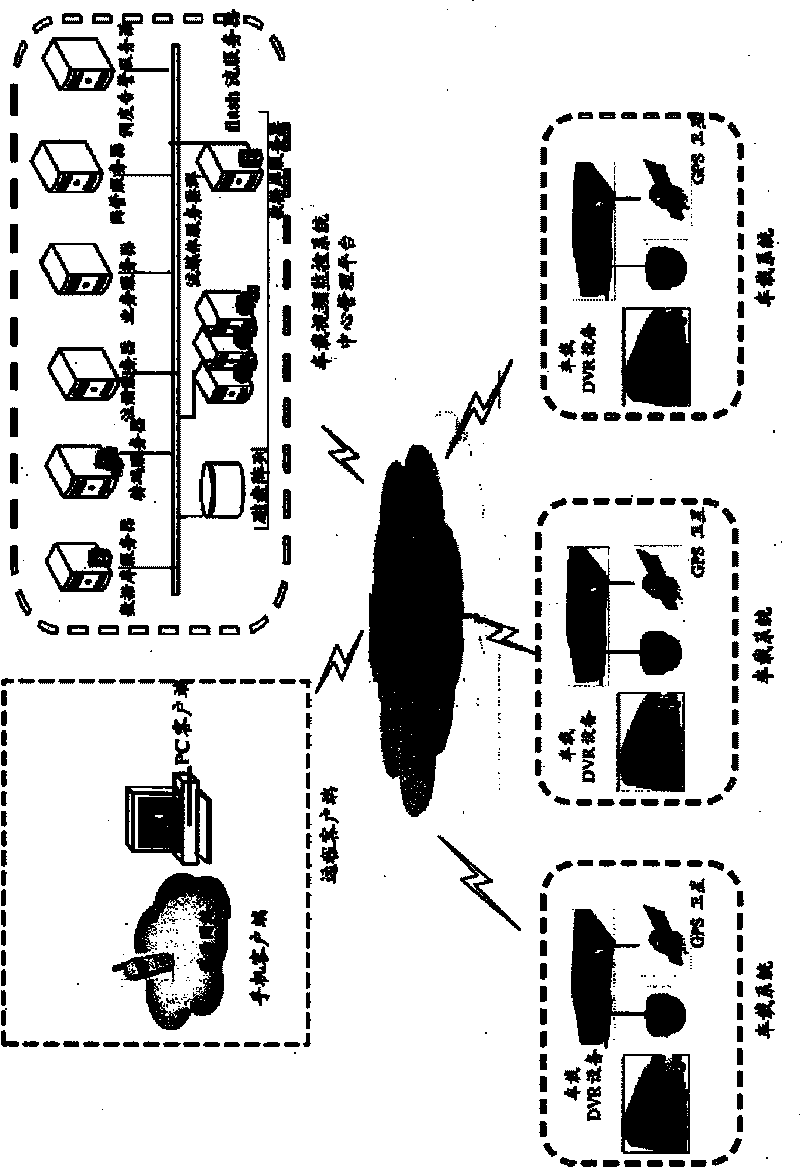

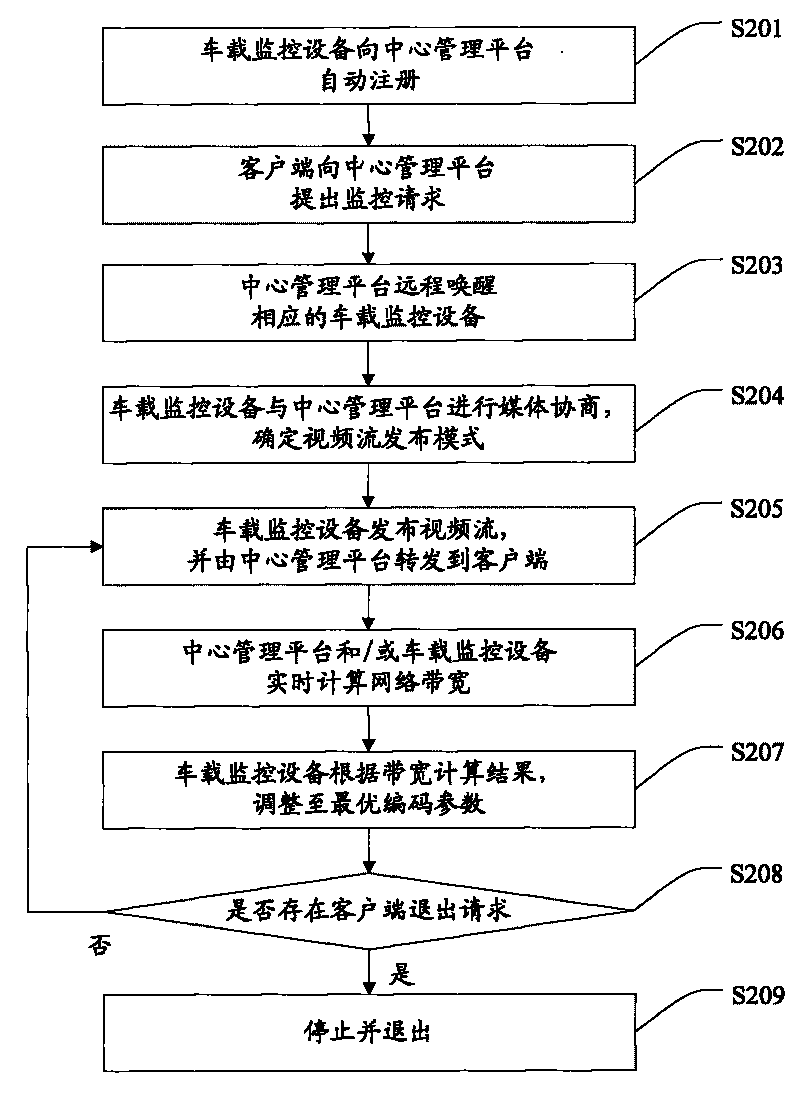

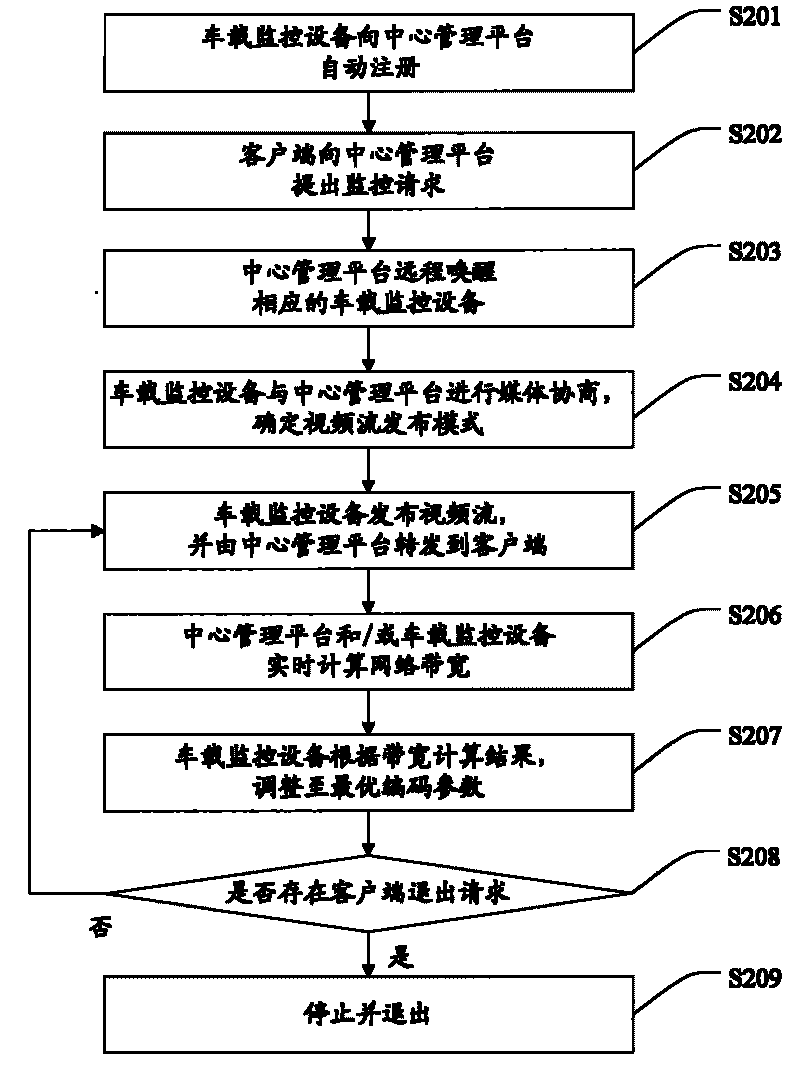

Car video monitoring method based on mobile network

InactiveCN101765001AAlleviate resource constraintsSatisfied with clear monitoringClosed circuit television systemsDigital video signal modificationMobile WebVideo monitoring

The invention discloses a car video monitoring method based on a mobile network, which is applicable to a car video monitoring system including a vehicle-mounted monitoring device, a central management platform, a remote client and a communication network. The monitoring method comprises that according to the monitoring request of the client, the central management platform awakens the corresponding vehicle-mounted monitoring device remotely. After being activated, the vehicle-mounted monitoring device finishes connection and issues video stream. The central management platform transmits the video stream to the client in order to play in real time. The vehicle-mounted monitoring device is remotely awakened and activated by the central management platform and issues the video stream only when the client has request. The inadequate problem of mobile network resources can be relieved greatly.

Owner:GUANGDONG ESHORE TECH

Environment protection type ethanol gasoline

The present invention relates to synthetic gasoline, and is especially one kind of environment protecting ethanol gasoline with less tail gas exhaust and its production process. The production process includes the mixing of ethanol 25 wt%, mixed benzene 35 wt% and 93# gasoline 39.2 wt% at normal temperature and normal pressure; adding multipurpose additive in 0.8 wt% and full mixing; and filtering to eliminate impurity. The multipurpose additive includes ferrocene, liquid paraffin, acetone and 2, 6-ditert butyl-4-cresol(264) in equimolal amount. The present invention has less tail gas pollution, no bad effect on the engine and low production cost.

Owner:肖丽

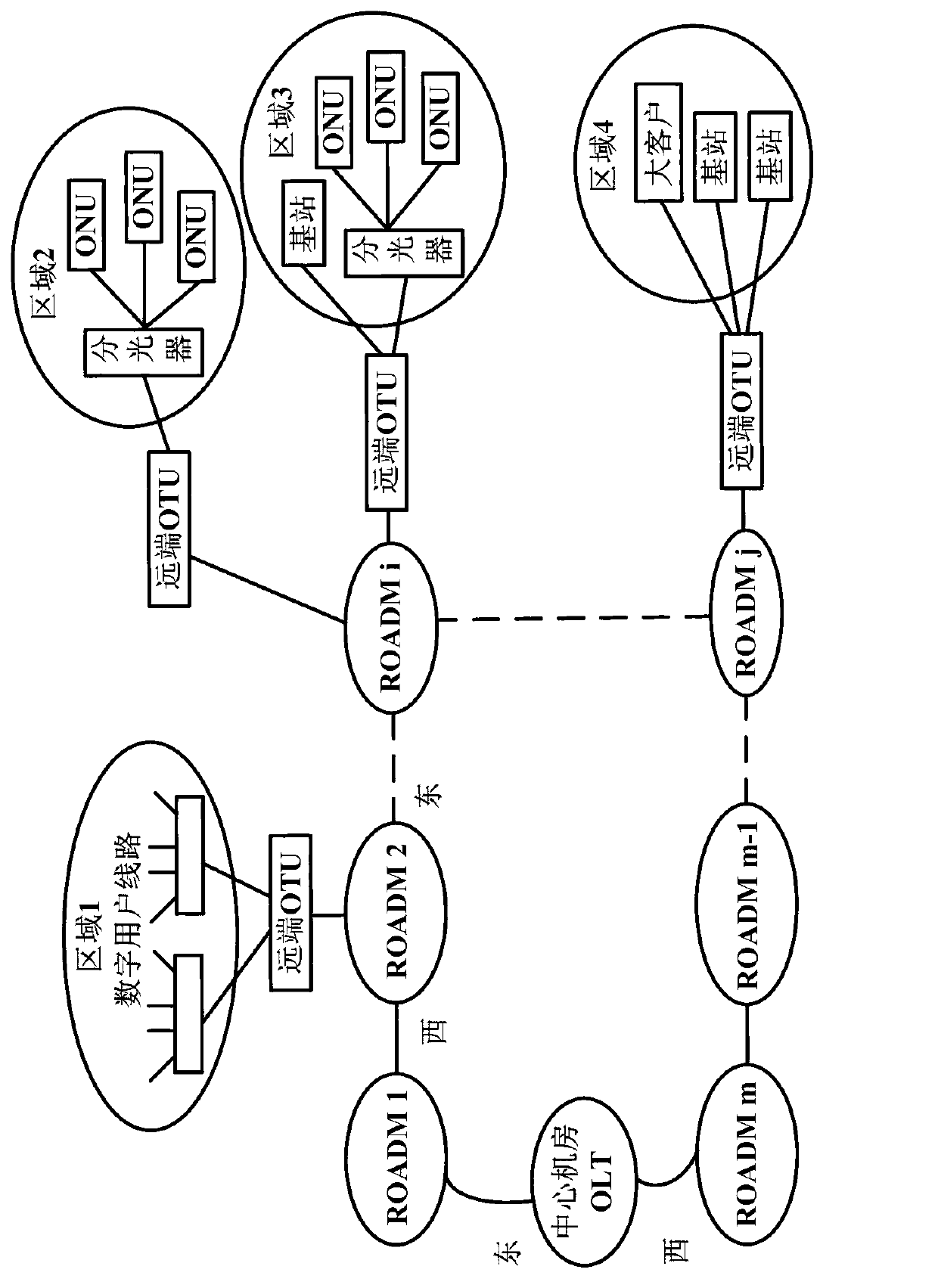

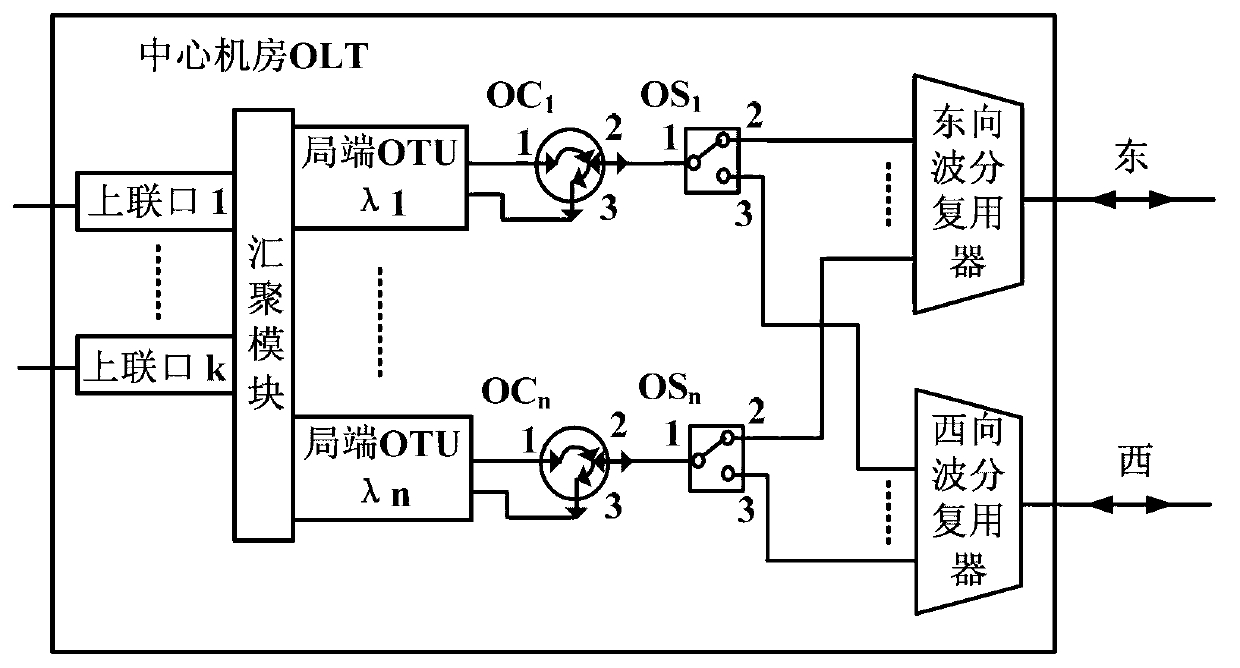

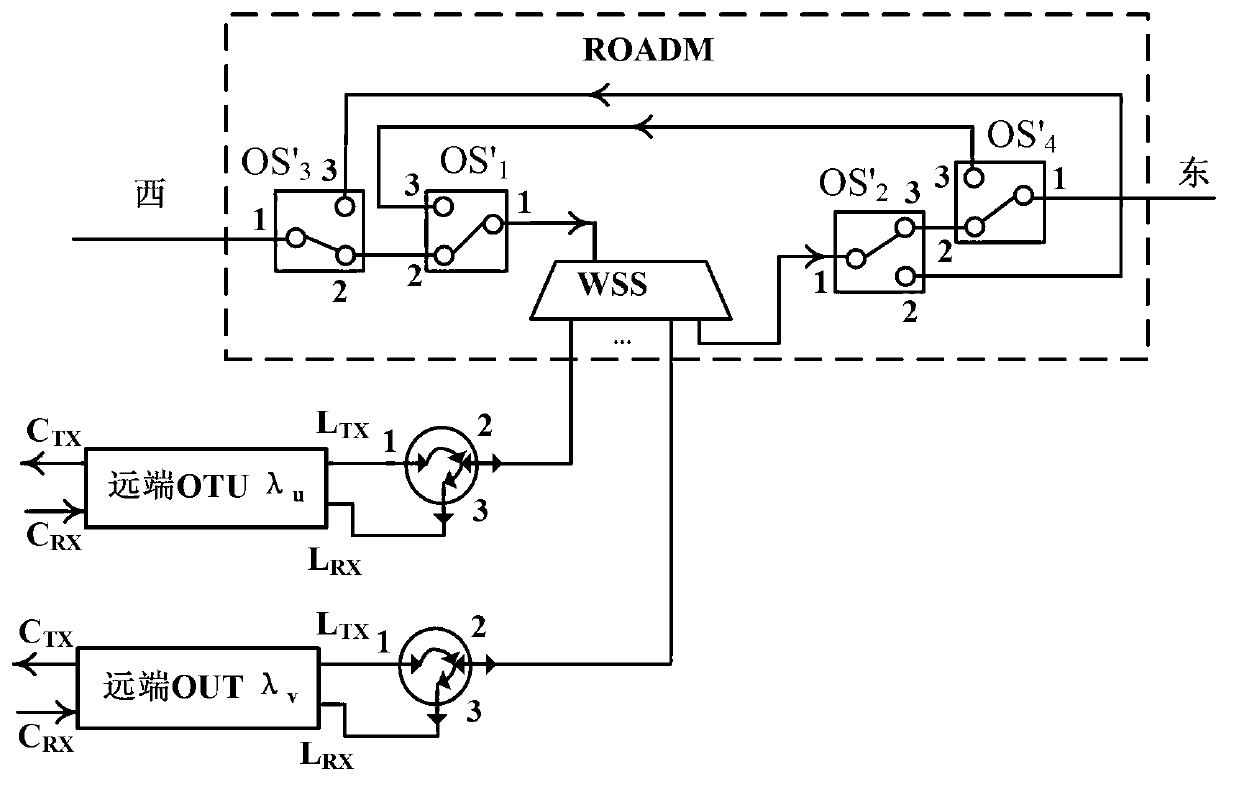

Convergence type metropolitan area wavelength division access network system and accessing method

ActiveCN103281152AMaintain low cost requirementsEasy constructionWavelength-division multiplex systemsData switching networksNetwork ConvergenceAccess network

The invention discloses a convergence type metropolitan area wavelength division access network system and an accessing method, and relates to the field of metropolitan area access. The system comprises an OLT located in a central apparatus room, m ROADM nodes and n far-end OTUs, wherein m and n belong to positive integers, m is larger than or equal to 1, and n is larger than or equal to m. The central apparatus room is a network convergence point, the OLT of the central apparatus room and the m ROADM nodes are sequentially connected through optical fibers to form an annular topological structure, the connecting direction of the m ROADM nodes in an annular topology is expressed in the eastward direction and the westward direction, on the basis of the clockwise direction, the eastward direction of a prior ROADM node is connected with the westward direction of a next ROADM node, only one optical fiber exists between every two adjacent ROADM nodes, and each ROADM node is connected with at least one far-end OTU. All services of a service provider can be accessed through one network, the robustness requirements such as mobile backhaul and a special line for a big customer are met, management is convenient, cost is low, bandwidth is allocated flexibly, capacity is large, and the accessing distance is long.

Owner:WUHAN POST & TELECOMM RES INST CO LTD

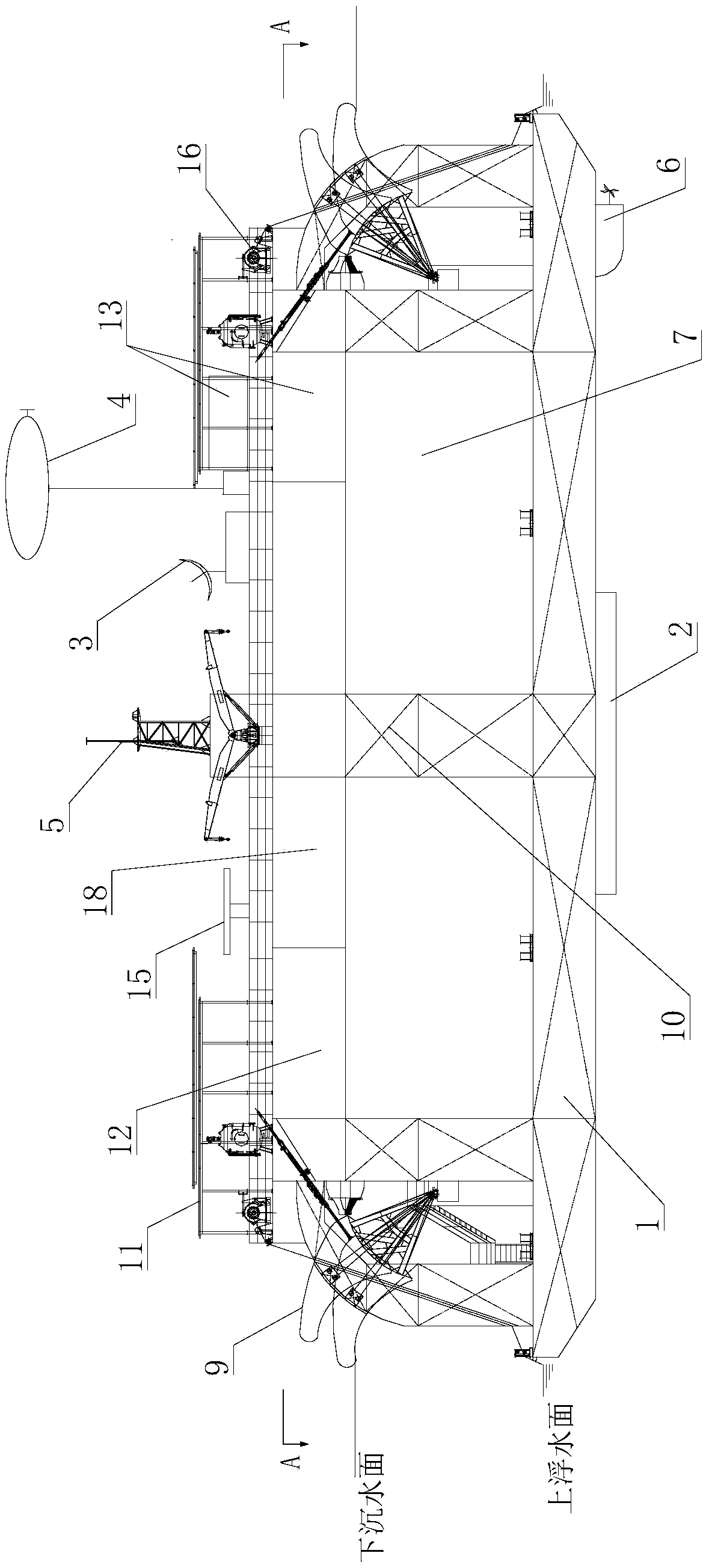

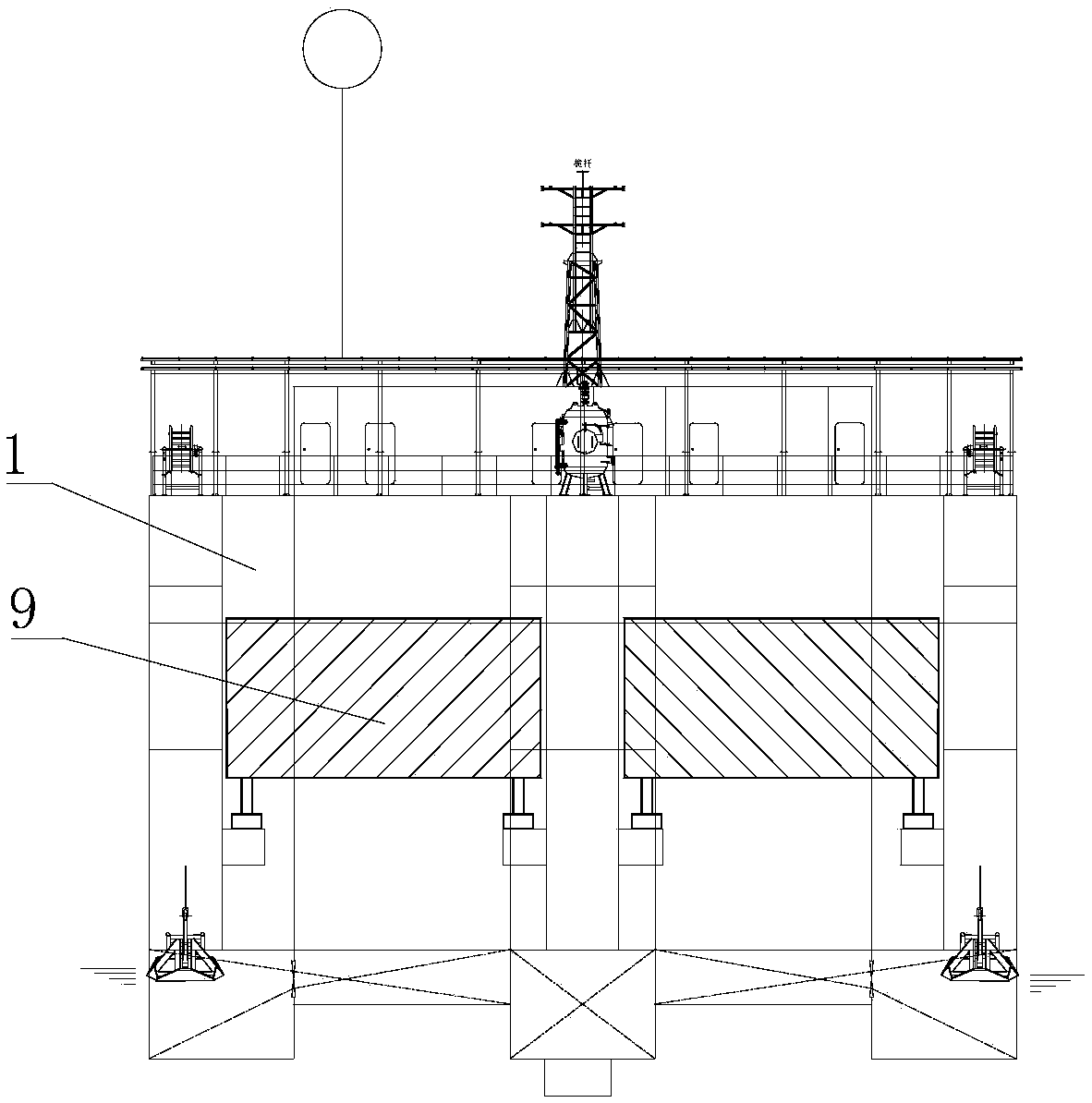

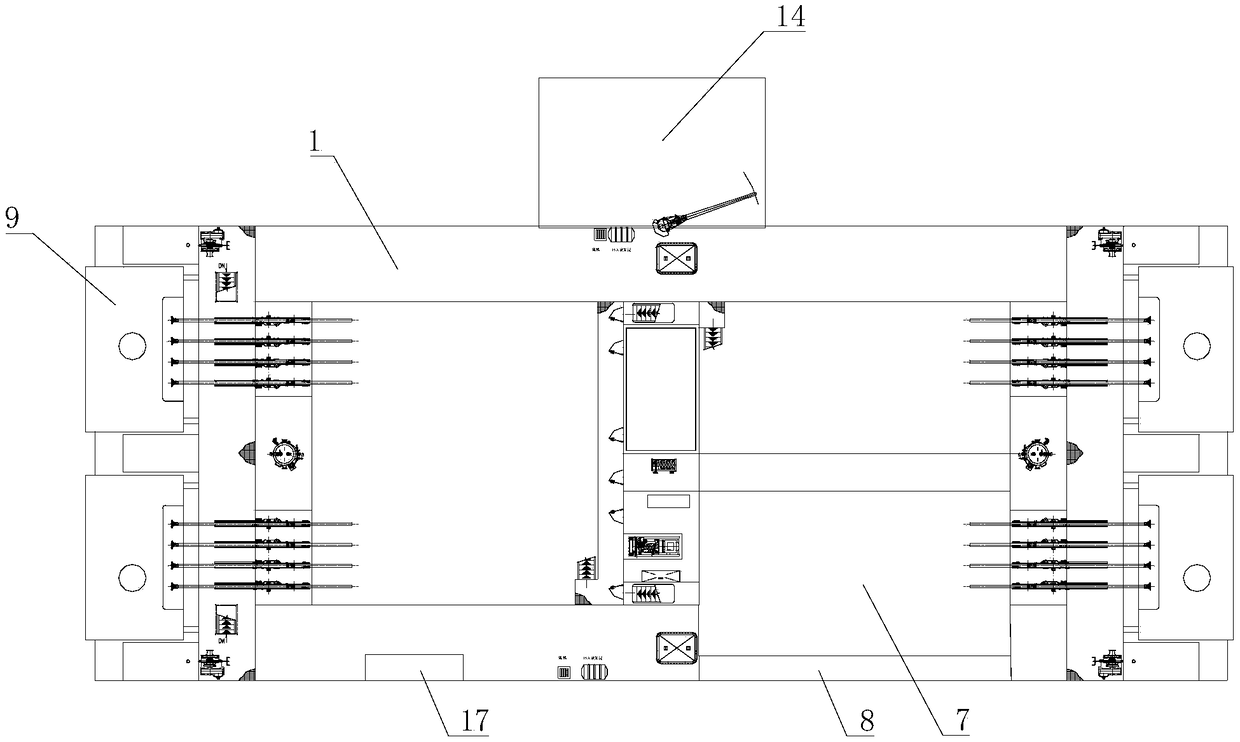

Offshore floating integrated facility platform powered by green energy

InactiveCN109178228ASafe and efficient operationHave experimental conditions for scientific researchWaterborne vesselsVessels for aircraftFresh water organismWaste recycling

The invention discloses an offshore floating integrated facility platform driven by green energy, including a main body of a semi-submersible platform, a sustainable power supply system, an ocean observation system, an integrated test system, a connection system, an ocean communication and relay system, a freshwater system and an organic waste recycling and energy utilization system which are installed on the main body of the semi-submersible platform. The offshore floating integrated facility platform driven by green energy takes the large-scale semi-submersible wave energy power generation platform as a carrier to construct an offshore sustainable power supply system composed of wave energy + solar energy + energy storage + standby diesel generator set, is equipped with seabed, underwater, water surface and sky detection equipment and instruments, and is equipped with general and special equipment to form a complete observation equipment launch, operation, recovery support system, toensure the safety and efficiency of scientific research equipment in a variety of operating conditions; and the offshore floating integrated facility platform driven by green energy is integrated with natural gas hydrate, hydrology, meteorology and other research cabins to form an integrated ocean laboratory, and has open sea test conditions for long-term scientific research.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Manufacturing method for wood-based cotton stalk composite artificial board

InactiveCN105235044AAlleviate resource constraintsReduce manufacturing costDomestic articlesFlat articlesFiberSteam pressure

The invention provides a manufacturing method for a wood-based cotton stalk composite artificial board. The manufacturing method is characterized by comprising the following steps that firstly, cotton stalks are cut off, the water content of the cotton stalks is controlled to be within 15-20%, and then the cotton stalks are cut into small sections 1.5-2.5 cm long; secondly, hot grinding is carried out, particularly, the cotton stalks cut as needed and wood strips are subjected to hot grinding and pulping through two hot grinding machines, and the pulping condition of the cotton stalks is that the steam pressure is 2-5 kg / cm<2>; thirdly, glue is applied and dried, gluing and drying are carried out synchronously after hot grinding, and water-proofing agents are added at the time; the applied glue amount and the applied water-proofing agent number of the cotton stalks are 10-14% and 1-2% respectively, the applied glue amount and the applied water-proofing agent number of wood fibers are 8-12% and 0.5-1% respectively, and the water content of the fibers with glue applied is 8-12% through drying; fourthly, laying is carried out, the dried mixed materials with the glue applied are laid into a board blank with the required thickness; fifthly, hot pressing is carried out, the hot pressing temperature is 140-200 DEG C, the hot pressing pressure is 2.5-4 MPa, and the hot pressing time is 15-30 second / mm; and sixthly, edges are cut, and another kind of fiber board product is formed.

Owner:高云

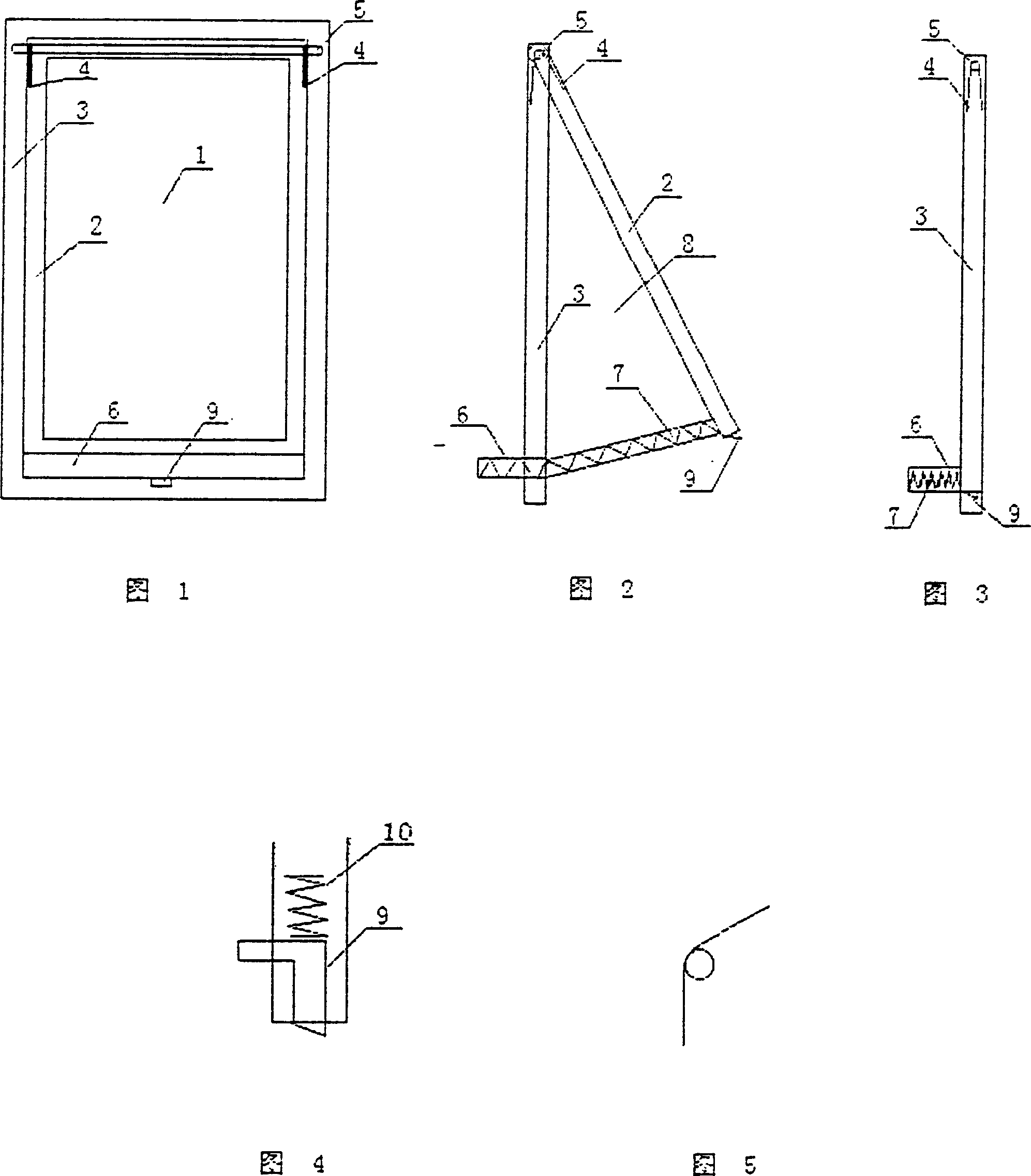

Window capable of preventing wind and filtering dust

InactiveCN101100927AGuaranteed cleanlinessExtended service lifeVentilation arrangementWing fastenersEngineeringFilter window

This is a dust filter window. Upon opening, dust filter web is drawn out from a web box by a spring installed in the window axial. Air goes upward through the web into room. The bolt and bolt spring forms an auto lock. Upon strong wind, wind force push back the spring to make the window automatically closed.

Owner:程新生

Feed for feeding cordyceps sinensis host larvae and method for feeding host larvae

InactiveCN106343276ASolve the problem of artificially cultivated insect sourceAlleviate resource constraintsAnimal feeding stuffAnimal science

The invention provides a feed for feeding cordyceps sinensis host larvae and a method for feeding the host larvae, wherein the feed is prepared from the following food materials: rhizoma polygoni vivipari and ginseng fruit (potentilla anserina). In a plurality of embodiments, the feed is also prepared from potato, sweet potato and carrot which serve as the food materials. The invention also provides a method for preparing the feed and a method for feeding hepiaua larva by adopting the feed. According to the feed and the method provided by the invention, artificial technical links for feeding the hepiaua larva are realized; the feed and the method can be used for artificial scale feed of the bat moth larvae, and generate a huge pushing action on artificial cultivation of cordyceps sinensis, thereby generating huge economic benefits.

Owner:王云

Clean alcohol ether gasoline vehicle fuel

The invention discloses a vehicle fuel of clean alcohol ether gasoline. The vehicle fuel consists of 21 to 66 percent by weight of methanol, 20 to 70 percent by weight of light hydrocarbon, 4 to 8 percent by weight of xylene, 1 to 8 percent by weight of acetone, 0.1 to 4 percent by weight of MTBE, 0.1 to 6 percent by weight of OP-10, 0.1 to 5 percent by weight of Polysorbate-80, 0.01 to 0.5 percent by weight of Sudan-1, 1 to 6 percent by weight of butyl acetate, 1 to 6 percent by weight of butyl alcohol, 0.1 to 1 percent by weight of toluene, 0.1 to 0.5 percent by weight of benzotriazol and 0.1 to 0.8 percent by weight of tetrachloroethylene. The vehicle fuel can solve the problems in the prior art, can reduce the pollution of emissions and improve the security of the fuel.

Owner:赵熙汉 +1

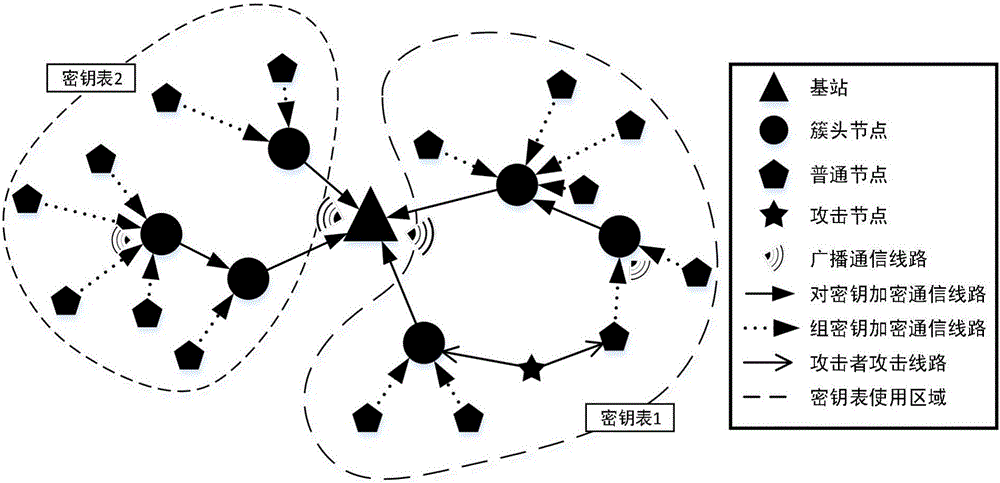

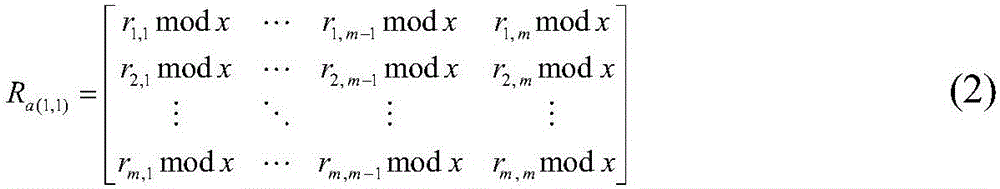

Wireless sensor network key management method based on key table

ActiveCN105933896AAlleviate resource constraintsReduce communication overheadNetwork topologiesSecurity arrangementWireless sensor networkingNetwork attack

The invention relates to a wireless sensor network key management method based on a key table. An N order key table matrix is generated by a random function in a networking stage in a wireless sensor network based on clustering, the order of the key table matrix is voluntarily configured by a network manager, the larger the order is, the higher the strength of the generated key is, and elements in the key table are extracted to serve as key materials to construct a pair key and a group key for node communication, wherein the key table limits the elements in the matrix by modular operation, and the diversity of the generated keys is improved; and the pair key and the group key are updated in a network operation stage. The method specifically comprises the following steps: 1, establishing a pair key material; 2, establishing the pair key; 3, establishing and allocating the group key; 4, updating the pair key; and 5, updating the group key. By adopting the method, the strength of the generated keys is improved, the calculation, storages and communication overheads of the nodes can be reduced, meanwhile the forward / backward safety of the network is guaranteed, and the ability of defending replay attack, forgery attack and other common network attacks are available.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Compound biological pesticide-added fertilizer with efficacy of tobacco quality improvement and preparation method and application of compound biological pesticide-added fertilizer

PendingCN108892562AEffectively control pollutionPollution controlAnimal corpse fertilisersExcrement fertilisersBiotechnologyCamellia oleifera

The invention discloses a compound biological pesticide-added fertilizer with an efficacy of tobacco quality improvement and a preparation method and application of the compound biological pesticide-added fertilizer. The compound biological pesticide-added fertilizer is characterized by being prepared from a composted substrate, a potential of hydrogen regulating agent, a silicon fertilizer and biocontrol factors, wherein a consumption ratio of the composted substrate to the potential of hydrogen regulating agent to the silicon fertilizer is (200-300):(10-15):(1-4), the composted substrate comprises a basic substance and a composted substance in a ratio of (500-800):(1-3). Waste tobaccos and the like are taken as raw materials, then composted strains are added to realize mixed compositingand fermentation, and an appropriate amount of a carbon source, a nitrogen source, the potential of hydrogen regulating agent, the silicon fertilizer and the bicontrol factors are added to obtain thebiological pesticide-added fertilizer which contains camellia oleifera and tobacco active components, the biocontrol factors and metabolites thereof. In addition, functions of improving soil nutrientcirculation, microbial community structure and tobacco quality and prevention and control of tobacco disease and pest damages are achieved, recycling of tobacco waste resources, camellia seed cakes and livestock and poultry excrement is realized, and great benefits are achieved.

Owner:INST OF PLANT PROTECTION SICHUAN ACAD OF AGRI SCI

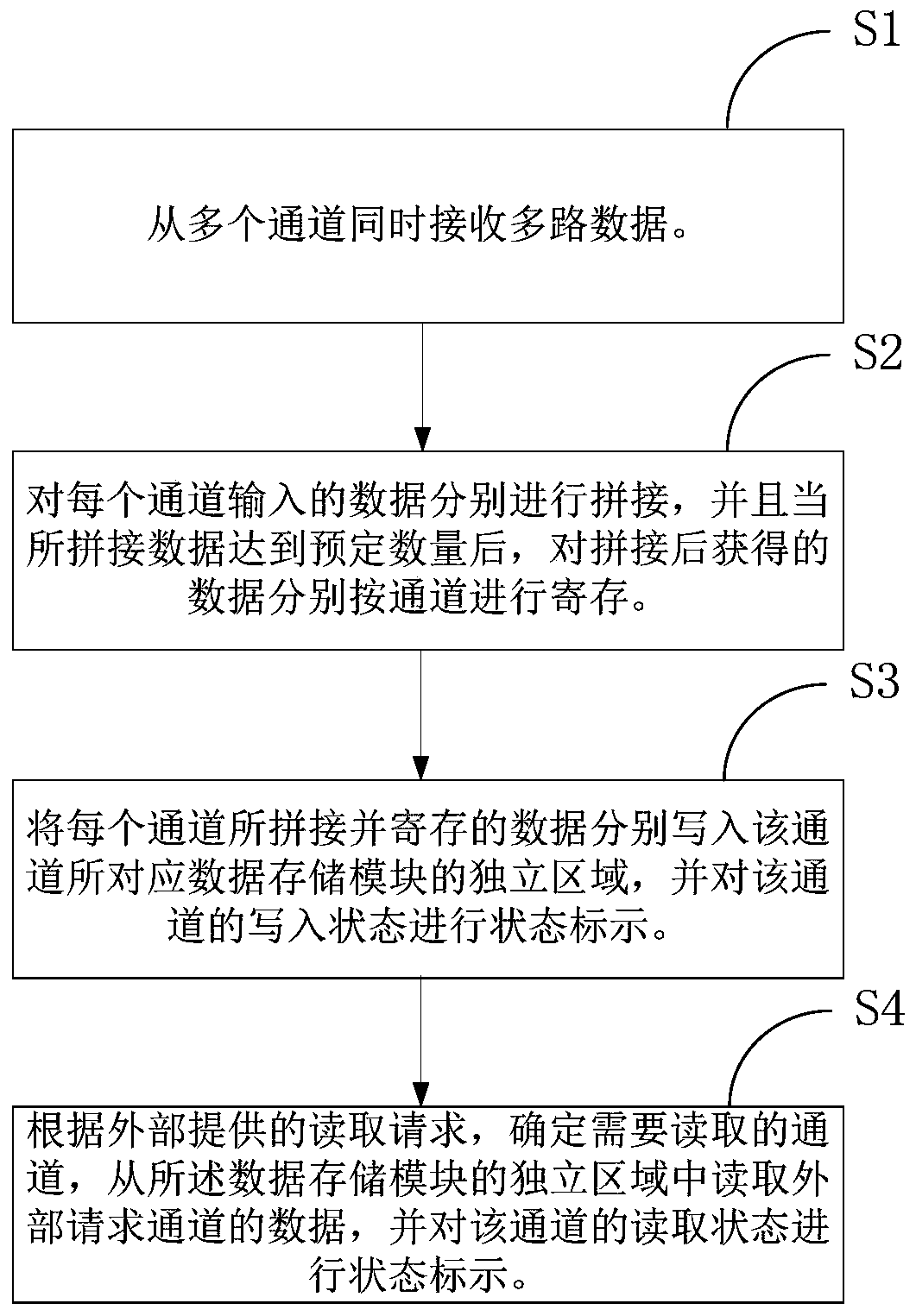

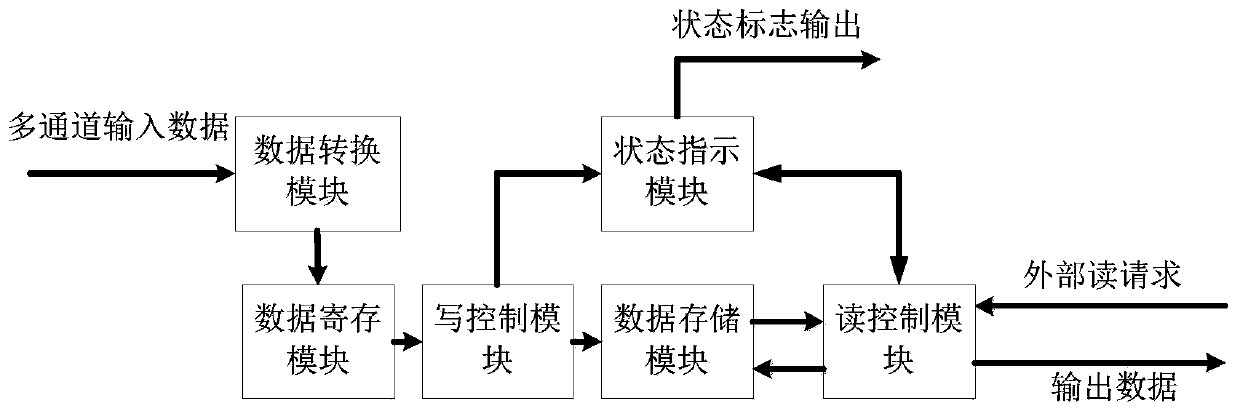

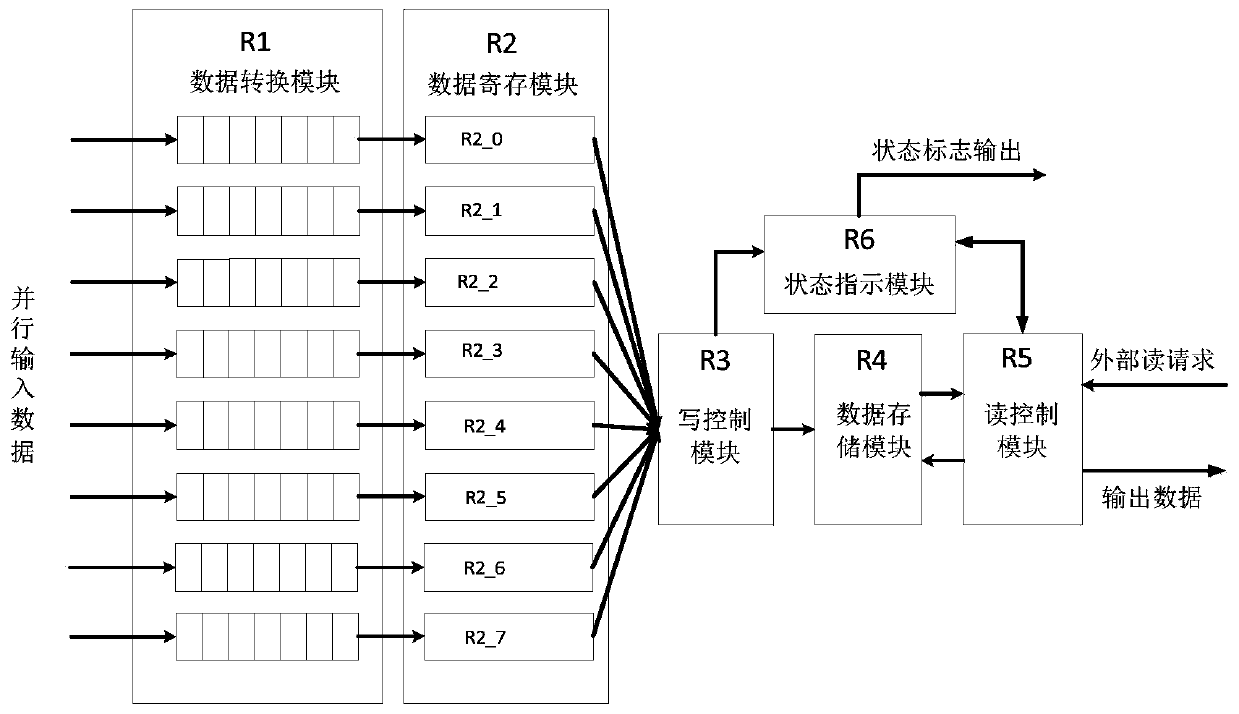

Method and device for writing multi-channel FIFO in parallel

ActiveCN110134366AImprove reading and writing efficiencyGuaranteed independenceMemory adressing/allocation/relocationData conversionData inputComputer science

The invention provides a method for writing multi-channel FIFO in parallel. The method comprises the steps that S1, receiving multi-channel data from multiple channels at the same time; S2, respectively splicing the data input by each channel, and respectively registering the spliced data according to the channels when the spliced data reaches a preset quantity; and S3, dividing the data storage module into a plurality of independent areas according to the number of channels of the plurality of channels, enabling each independent area to correspond to one channel, respectively writing the dataspliced and registered for each channel into the independent area corresponding to the channel, and performing state marking on the writing state of the channel. According to the invention, bit widthconversion of the data is realized outside the RAM in the multi-channel FIFO, and polling and writing are carried out on a plurality of channels by utilizing bit width conversion time, so that read-write interruption caused by accumulation of the data in the processes of splicing, writing and reading is avoided, and the read-write efficiency of the multi-channel FIFO is greatly improved.

Owner:HEFEI UNIV OF TECH

Production method of heat-producing insulating riser sleeve

InactiveCN104209466AEasy to replaceImprove feeding efficiencyFoundry mouldsFoundry coresSocial benefitsEconomic benefits

The invention relates to a production method of a heat-producing insulating riser sleeve. The production method comprises the steps of batching, mixing, modeling, drying, checking and packaging. The novel heat-producing insulating riser sleeve with high-temperature resistance, low heat conduction and high heat production has excellent heat-producing stability reaching up to 1600 DEG C; and compared with a traditional insulating riser sleeve, the developed riser sleeve has greatly improved feeding efficiency, excellently kept production process performance and use performances of the product, has prominent economic benefit and social benefit on such aspects as promotion of material upgrading, remission of resource deficiency, energy conservation, consumption reduction and improvement of user product quality, and has wide market prospect.

Owner:霍山县东胜铸造材料有限公司

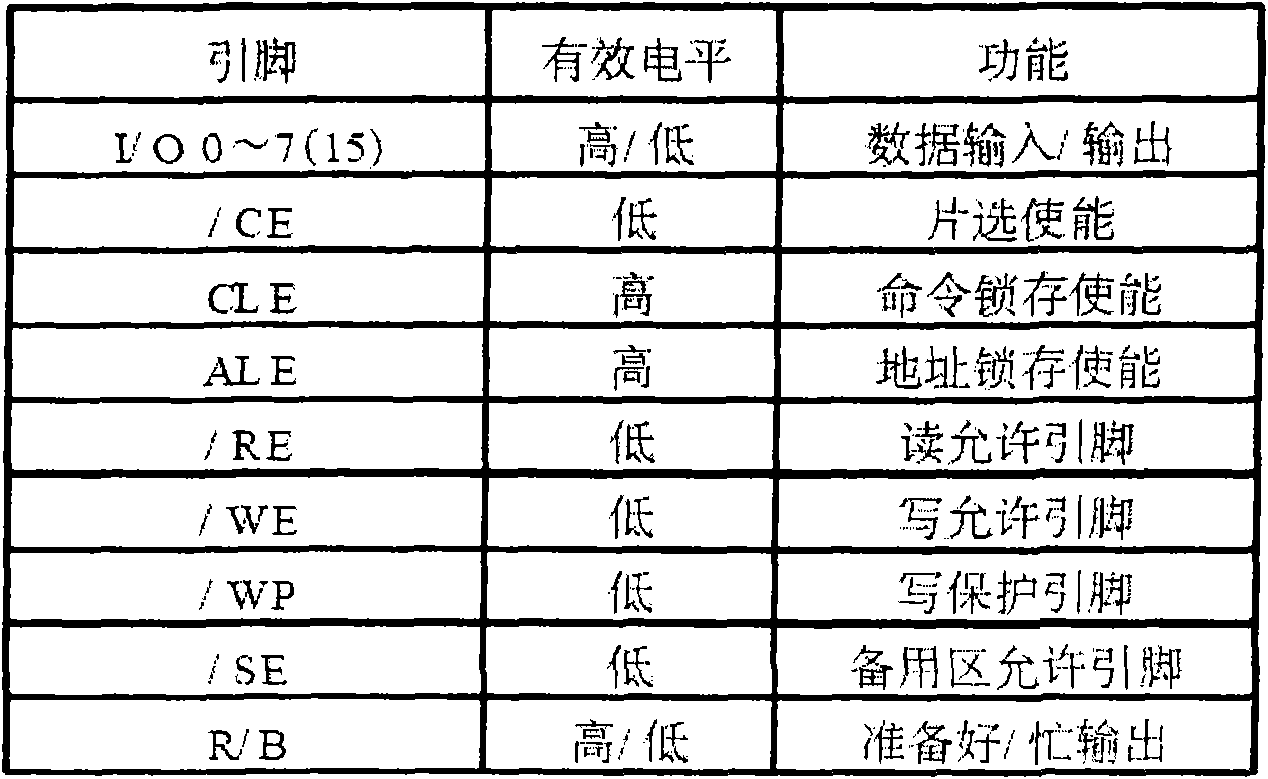

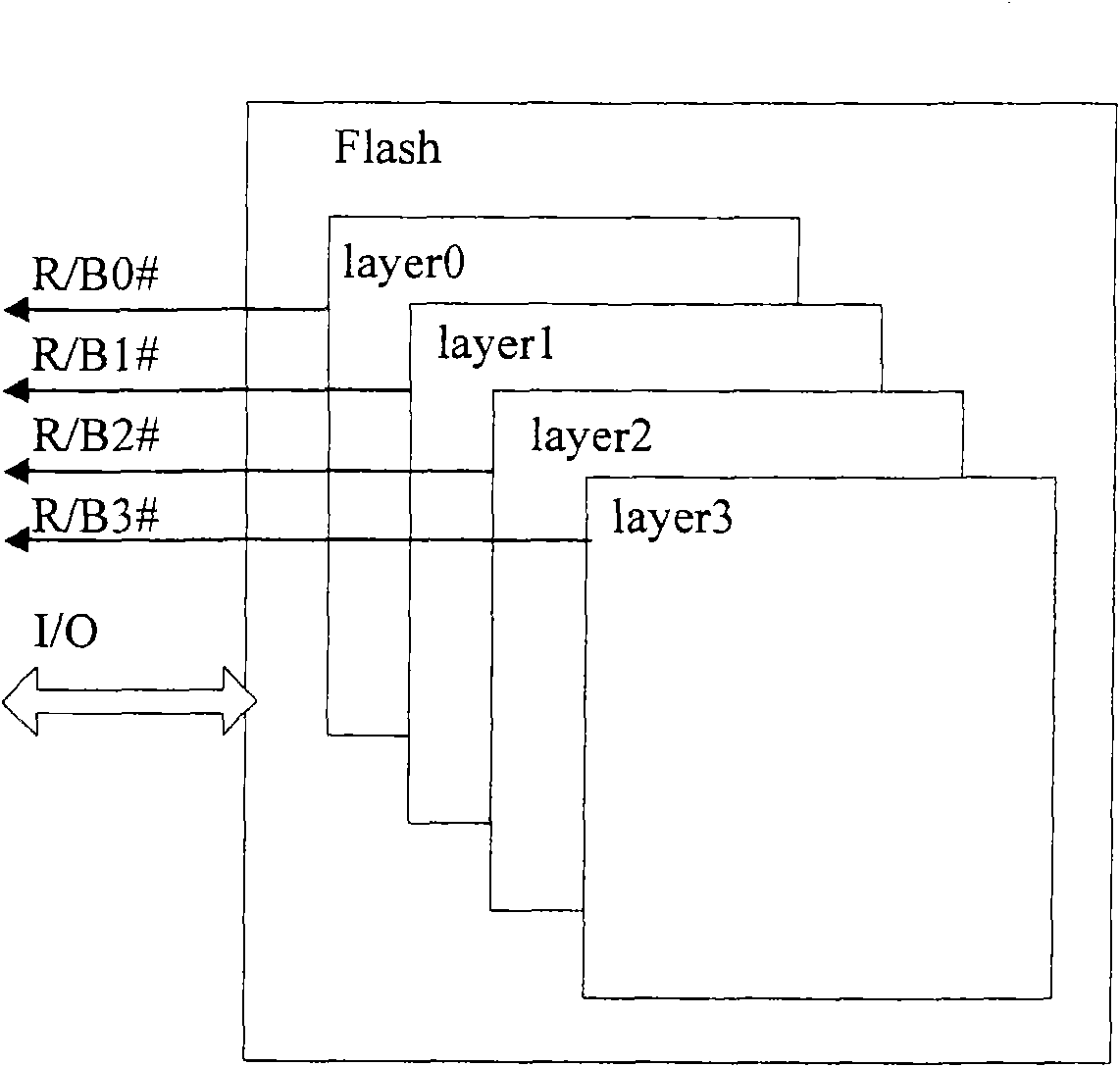

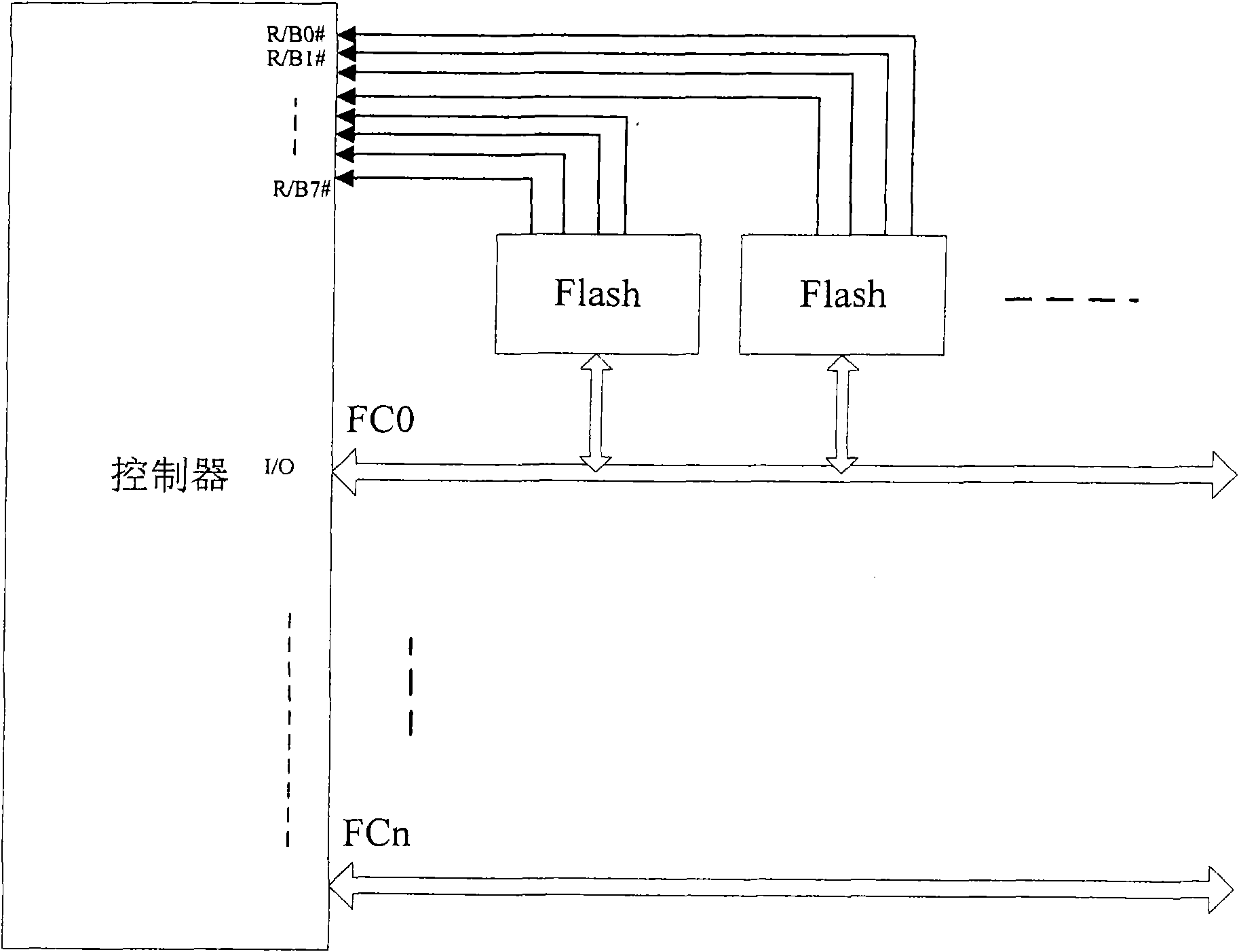

Method, device and system for inquiring state based on Flash

ActiveCN101539895AAlleviate resource constraintsReduce connectionsElectric digital data processingInformation valueStatus register

The embodiment of the invention provides a method, a device and a system for inquiring the state based on Flash; the method comprises the steps of: sending a state inquiry command to the layer in Flash; obtaining the value of I / O bit which corresponds to the state information value of the layer in Flash in a state register of the layer in Flash; and determining the state of the layer in Flash according to the value of the I / O bit. The embodiment of the invention also provides a state sending method based on Flash; the method comprises the steps of: receiving a state inquiry command which is sent by a Flash controller for inquiring the layer state; and feeding back the value of the I / O bit, which corresponds to the state information value of the layer in Flash in the state register of the layer in Flash to the Flash controller. The embodiment of the invention achieves the technical effect of effectively easing the lacked pin resources of the Flash controller.

Owner:HUAWEI TECH CO LTD

Method for preparing high-quality rapeseed protein containing conjugated linoleic acid by multi-strain fermentation

InactiveCN101632411ASolve the problem of high levels of toxic substancesHigh in nutrientsAnimal feeding stuffMicroorganism based processesRapeseedBran

The invention discloses a method for preparing high-quality rapeseed protein containing conjugated linoleic acid by multi-strain mixed fermentation, which belongs to the field of feed resources. The method comprises the following steps: adding bran, carbohydrates, vegetable fat and water to the rapeseed protein; uniformly mixing and stirring the materials and sterilizing the materials; then inoculating a strain culture solution of lactobacillus plantara, bacilli and mould fungi for generating the conjugated linoleic acid to a rapeseed cake (dreg) for fermentation by controlling temperature. The rapeseed protein prepared by the method has a detoxification rate being higher than 85 percent and generates a high-quality protein raw material containing the conjugated linoleic acid, small peptides and amino acids through the fermentation processing of the lactobacillus plantara, the bacilli and the mould fungi, thereby effectively relieving the difficulty of being short of protein feeds of China.

Owner:陈志敏

Core-shell structure phase change material and preparation method thereof

InactiveCN110408366AHigh thermal conductivityPrevent leakageHeat-exchange elementsPhase-change materialSilicone rubber

The invention discloses a core-shell structure phase change material and a preparation method thereof. The core-shell structure phase change material comprises a core layer and a shell layer coating the outside of the core layer, wherein the shell layer comprises a base supporting material and a heat conduction enhancer, and the base supporting material is a high density polyethylene or an addition type liquid silicone rubber; and the core layer comprises a phase change material and the heat conduction enhancer, and the use amount of the heat conduction enhancer in the material of the core layer is 0-95% of the use amount of the phase change material in the core layer. The high density polyethylene or the addition type liquid silicone rubber is used as the base supporting material, and forms the shell layer together with the heat conduction enhance, so the heat conduction property of the core-shell structure phase change material is significantly improved; and a core part is coated with the core layer through the shell layer, so the problem of leakage of the phase change material after liquefaction at a temperature above a phase transformation point is effectively prevented.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA +1

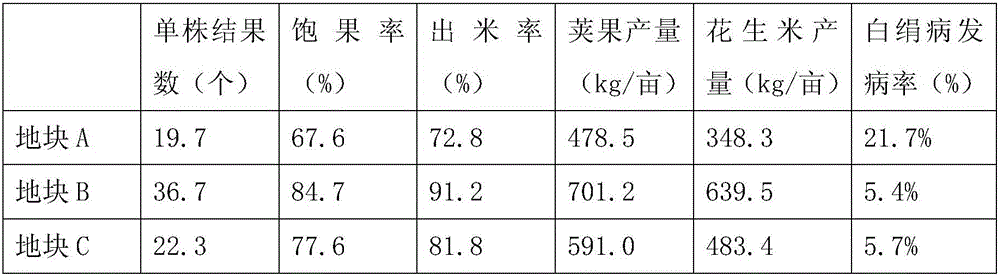

Disease-resistant, drought-resistant and high-yield package fertilizer for peanuts and fertilization method

InactiveCN105777347AIncrease productionImprove immunityBiocideMagnesium fertilisersTrace elementDisease resistant

The invention provides a disease-resistant, drought-resistant and high-yield package fertilizer for peanuts and a fertilization method. The package fertilizer comprises a component resistant to peanut sclerotium blight and a drought-resistant component, wherein the component resistant to peanut sclerotium blight is applied as a basic fertilizer component, and the drought-resistant component is applied as a foliar fertilizer component. A basic fertilizer further comprises a nitrogen-phosphorus-potassium compound fertilizer and medium and trace element fertilizers; a foliar fertilizer further comprises a vigorous growing control and fruit swelling agent for peanuts. The package fertilizer is reasonable in nutrition arrangement, nutrients in the whole growing period of the peanuts can be effectively absorbed and utilized, drought resistance of the peanuts can also be improved, peanut sclerotium blight can also be effectively prevented and controlled, high yield and drought resistance of the peanuts and peanut sclerotium blight prevention and control are integrated, and the effects are remarkable.

Owner:张玉勋

Clean compound diesel oil vehicle fuel

InactiveCN101392204ALow processing energy consumptionReduce pollutionLiquid carbonaceous fuelsDiesel engineMethanol

The invention discloses a vehicle fuel of clean compound diesel. The vehicle fuel consists of 17 to 64 weight percent of methanol, 27 to 70 weight percent of heavy oil, 0.5 to 25 weight percent of xylene, 0.5 to 5 weight percent of acetone, 1.5 to 20 weight percent of butyl alcohol, 0.1 to 0.5 weight percent of toluene, 0.1 to 0.5 weight percent of benzotriazol, 0.1 to 0.5 weight percent of tetrachloroethylene, 0.5 to 5 weight percent of isooctyl nitrate, 0.1 to 4 weight percent of Polysorbate-80, 0.5 to 10 weight percent of No.200 solvent naphtha and 0.5 to 5 weight percent of of butyl acetate. The vehicle fuel of clean compound diesel can substitute the existing diesel to supply power for diesel engine, can solve the more and more serious current problems of high oil price and difficult oiling, has the advantages of low energy consumption and free pollution, and imposes no negative impact on the environment.

Owner:赵熙汉 +1

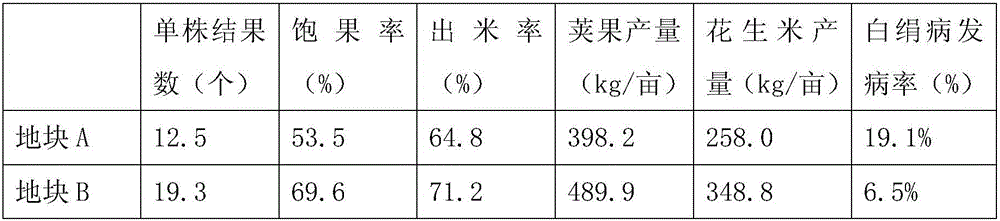

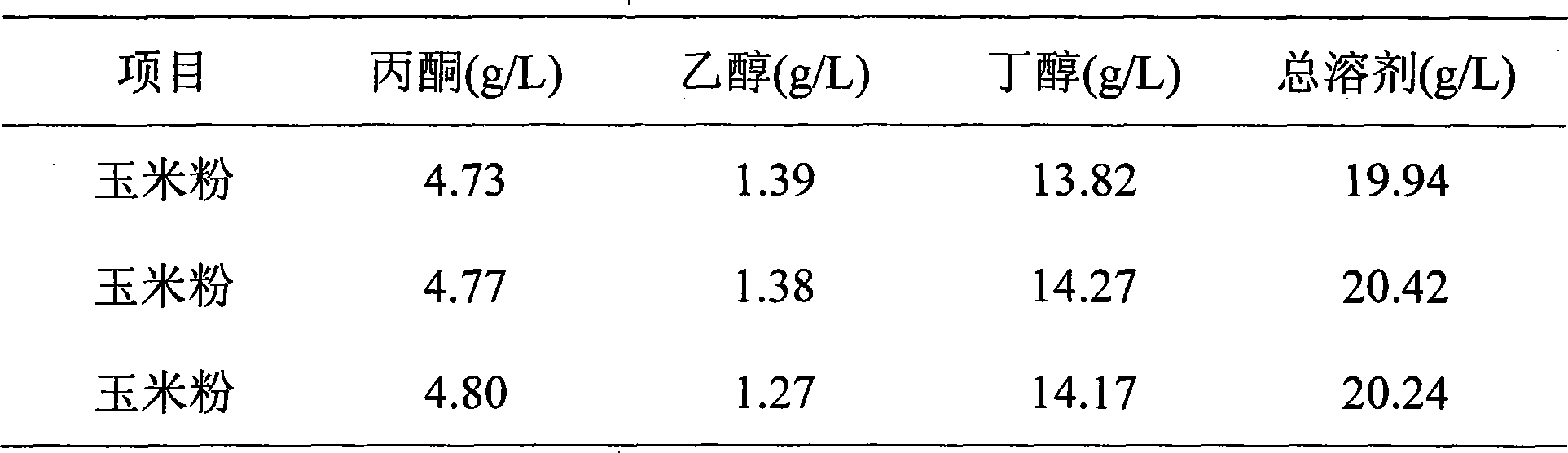

Method for improving yield of acetone, butanol and ethanol produced by fermentation of manioc materials

InactiveCN101250562ALow costAlleviate resource constraintsBiofuelsMicroorganism based processesAlcoholNitrogen source

The invention relates to a method for increasing the productivity of acetone, butyl alcohol and ethanol which are produced through fermenting starchy raw materials. The characteristic of method is to supplement a nitrogen source to the starchy raw materials. The method of the invention solves the problems that the output is low and the cost is high when the starchy raw materials are fermented to produce the acetone, the butyl alcohol and the ethanol since the starchy raw materials can not be effectively utilized by ABE clostridium.

Owner:上海天之冠可再生能源有限公司

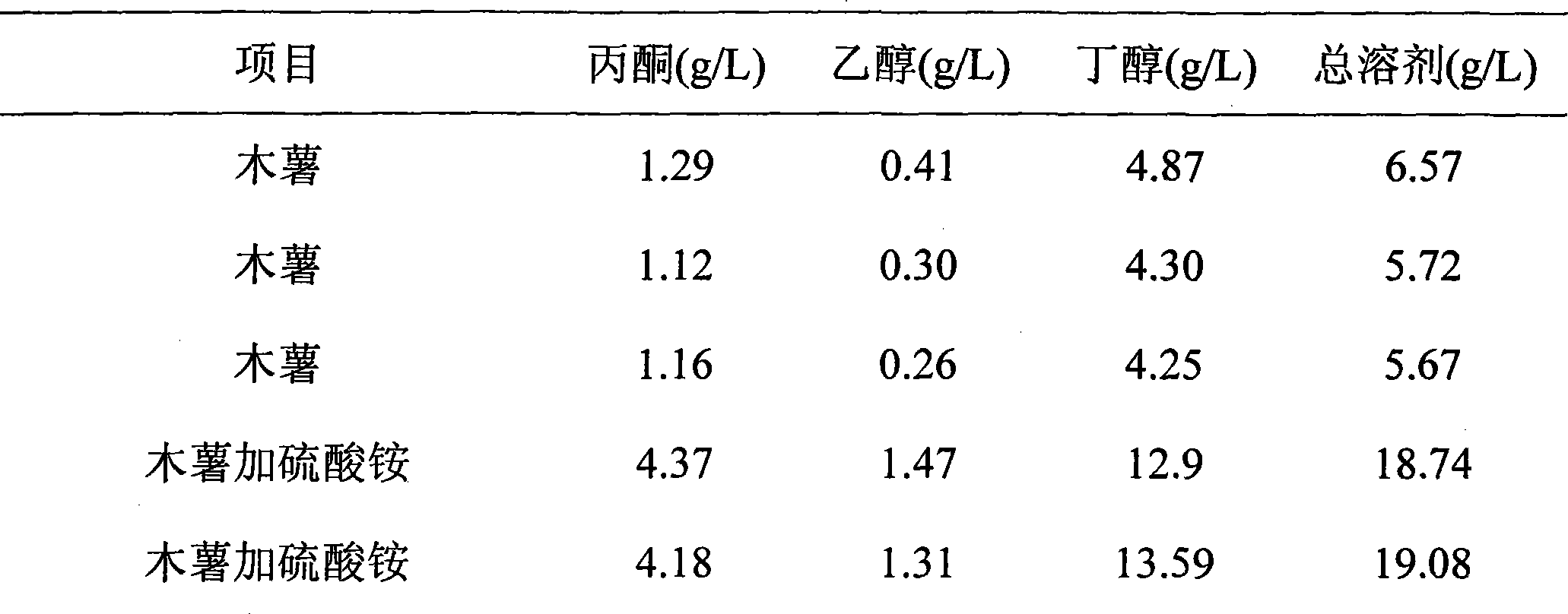

Method for preparing titanium dioxide from high-titanium coal gangue

ActiveCN104477982AIncrease profitEasy to operateSolid waste disposalTitanium dioxideMicrowave ovenDissolution

The invention discloses a method for preparing titanium dioxide from high-titanium coal gangue, and belongs to the technical field of resourceful utilization of coal-series solid wastes. A new technology is provided for resourceful utilization of cal gangue by taking high-titanium coal gangue as a raw material for producing titanium dioxide. The method comprises: mixing sulfuric acid and goal gangue subjected to grinding and sieved by a 80 mesh sieve according to the mass ratio of 1.4-1.6:1, performing acidification reaction in a microwave oven, and performing dissolving and filtering to prepare an acid immersion liquid; performing neutralization, reduction and dilution on the acid immersion liquid, adding sodium carbonate or potassium carbonate to adjust pH to 4.5, separating to obtain a titanium dioxide precursor, performing alkali dissolution on the precursor to obtain crude titanium, dissolving the crude titanium with a diluted acid for removing impurities, filtering to obtain refined hydrated titanium dioxide, and calcining at 800 DEG C to prepare titanium dioxide. The method is capable of extracting aluminium and iron while preparing titanium dioxide, the usage amount and the utilization rate of coal gangue are high, auxiliary materials do not need adding, and the method has the advantages of being simple in production technology, convenient to operate, low in energy consumption, stable in product quality, easy for industrialized production and the like.

Owner:KUNMING UNIV OF SCI & TECH +1

Benzalkonium chloride monomer synthesis technology

ActiveCN106946716AHigh purityLess impuritiesAmino compound purification/separationOrganic compound preparationBenzyl chlorideEthyl acetate

The invention relates to the technical field of fine chemicals, and more specifically relates to a benzalkonium chloride monomer synthesis technology. The synthesis technology comprises the following steps: (1) according to a formula, weighing fatty alkyl dimethyl tertiary amines, benzyl chloride, and ethyl acetate; (2) adding ethyl acetate into a glass lined reactor, pumping fatty alkyl dimethyl tertiary amines and benzyl chloride into a head tank, starting the stirring device of the reactor, dropwise adding fatty alkyl dimethyl tertiary amines and benzyl chloride into the reactor at a room temperature according to a same ratio; (3) heating the reactor to a temperature of 70 to 100 DEG C, and maintaining the temperature to carry out reactions for 7 to 10 hours; (4) starting circulating cooling water to cool the products to the room temperature until crystals are precipitated completely; (5) taking out the crystals, subjecting the crystals to vacuum suction filtration, during the suction filtration process, washing the crystals by ethyl acetate for 2 to 5 times, and saving the filter cakes; and (6) adding ethyl acetate into the filter cakes, carrying out re-crystallization, and after the crystals are completely precipitated, drying the crystals. The production cost is low and the purity of prepared benzalkonium chloride is high.

Owner:广东洛斯特制药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com