Full-automatic collection, smashing and compact forming combination machine for field waste crop straws

A crop straw, fully automatic technology, applied in the field of agricultural machinery, can solve problems such as labor consumption and low transportation efficiency, and achieve the effects of reducing environmental pressure, promoting economy, and alleviating resource constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

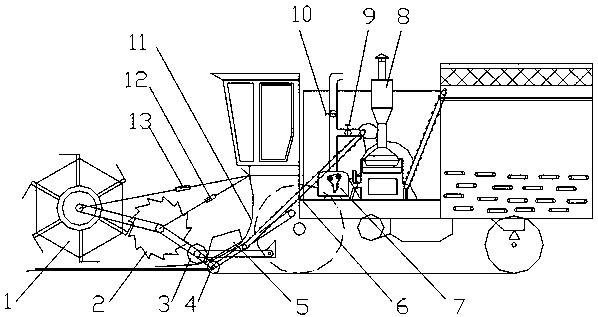

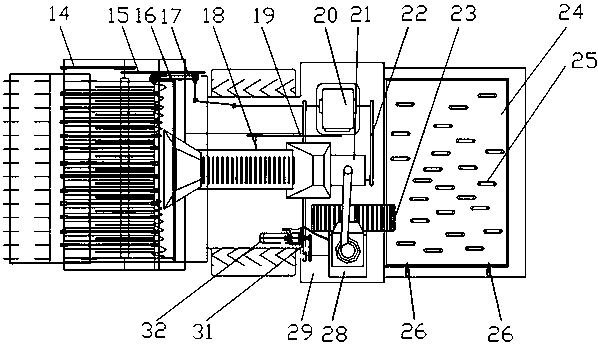

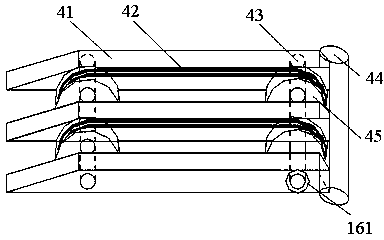

[0041] Specific implementation method: the fully automatic collecting, pulverizing and compacting forming machine for waste crop straw in the field in this embodiment includes a front-mounted straw automatic picking and pretreatment system, an integrated system for pulverizing and compacting molding, an automatic conveying temporary storage system for biomass particles and a walking system. Chassis integration system, the front-mounted straw automatic picking and pretreatment system is suspended on the front side of the frame of the walking chassis integration system, the crushing and compacting integrated system and the biomass particle automatic conveying and temporary storage system are installed on the walking chassis from front to back On the chassis of the integrated system, the front-mounted straw automatic picking and pretreatment system, the crushing and compacting integrated system and the biomass particle automatic conveying temporary storage system are connected toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com