Patents

Literature

126results about How to "Quick pick up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Garbage classification method, device and system

ActiveCN105173482AConvenient statisticsQuick StatisticsRefuse receptaclesClassification methodsOperating system

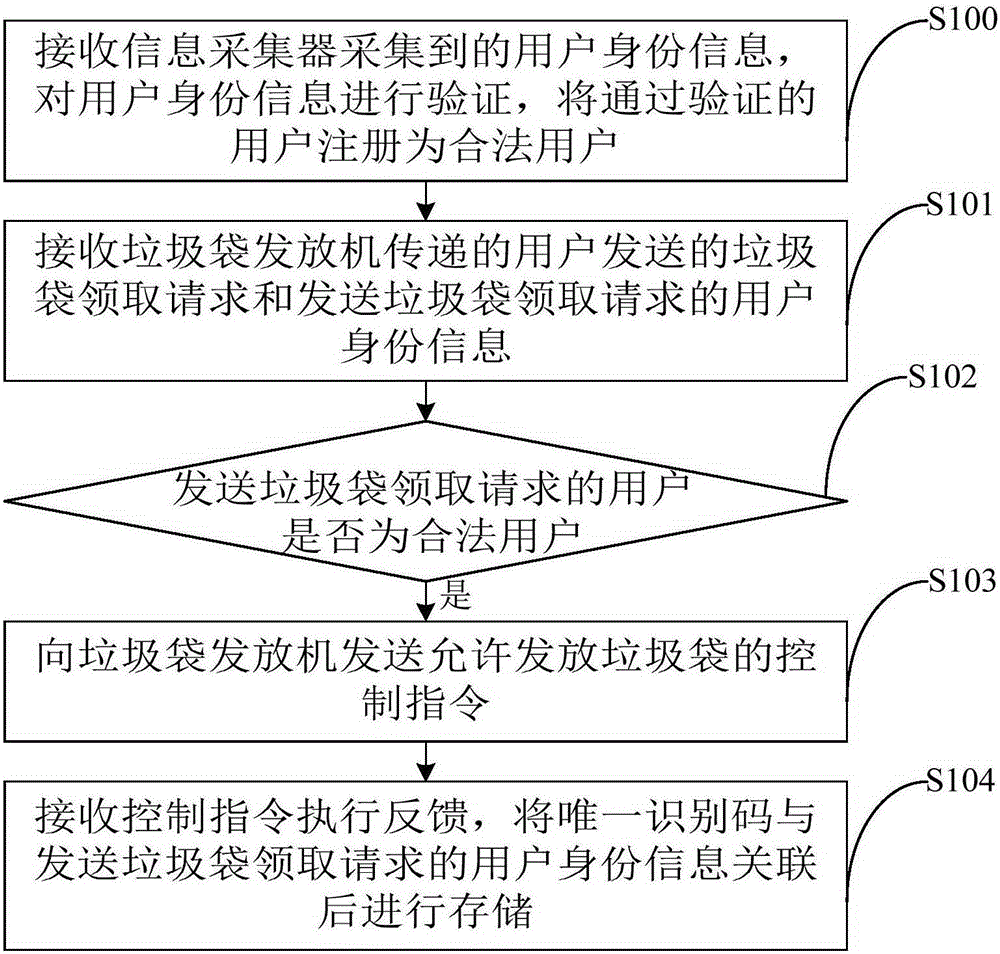

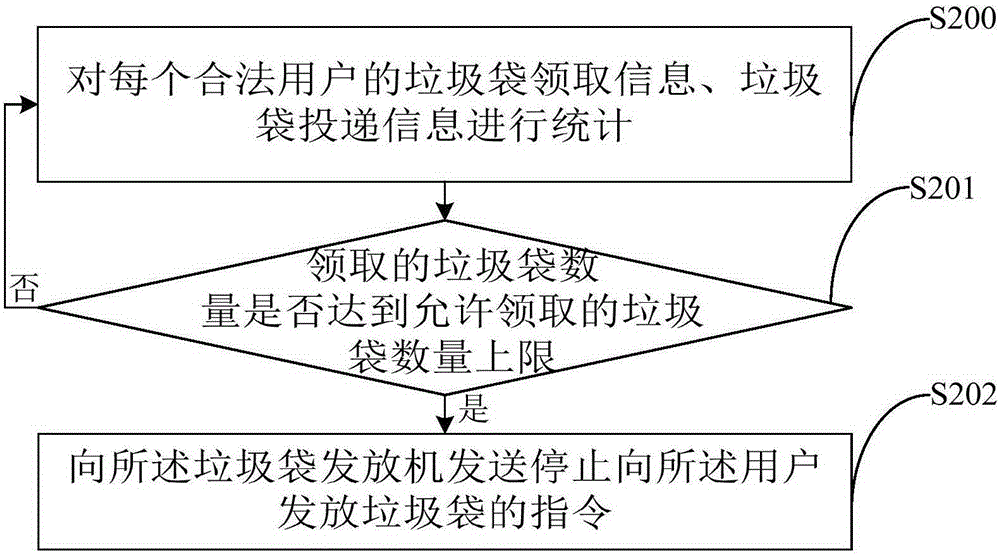

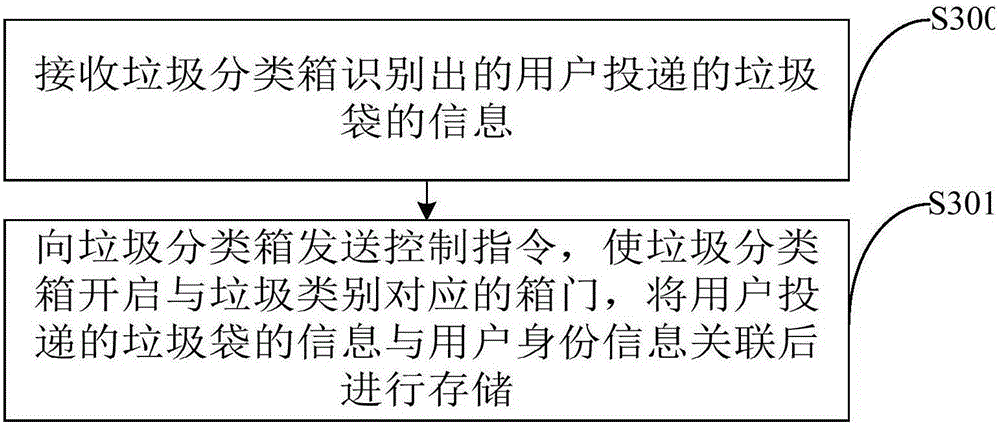

The embodiment of the invention provides a garbage classification method, device and system. The problem that the garbage classification effect needs to be improved in the prior art is solved. The garbage classification method includes the steps that identity information of a user is verified and the user passing the verification is registered as a legal user; a garbage bag acquisition request sent by the user and the identity information of the user sending the garbage bag acquisition request are received; whether the user sending the garbage bag acquisition request is a legal user or not is judged, if yes, a garbage bag issuing permission control instruction is sent to a garbage bag issuing machine, and the garbage bag issuing machine issues garbage bags with class labels to the legal user; and control instruction execution feedback sent by the garbage bag issuing machine is received and a unique identification code is correlated with the identity information of the user sending the garbage bag acquisition request and then stored. By the utilization of the garbage classification method, device and system, user garbage classification convenience can be remarkably improved, implementation is convenient, and application and popularization are easy.

Owner:蒋曙

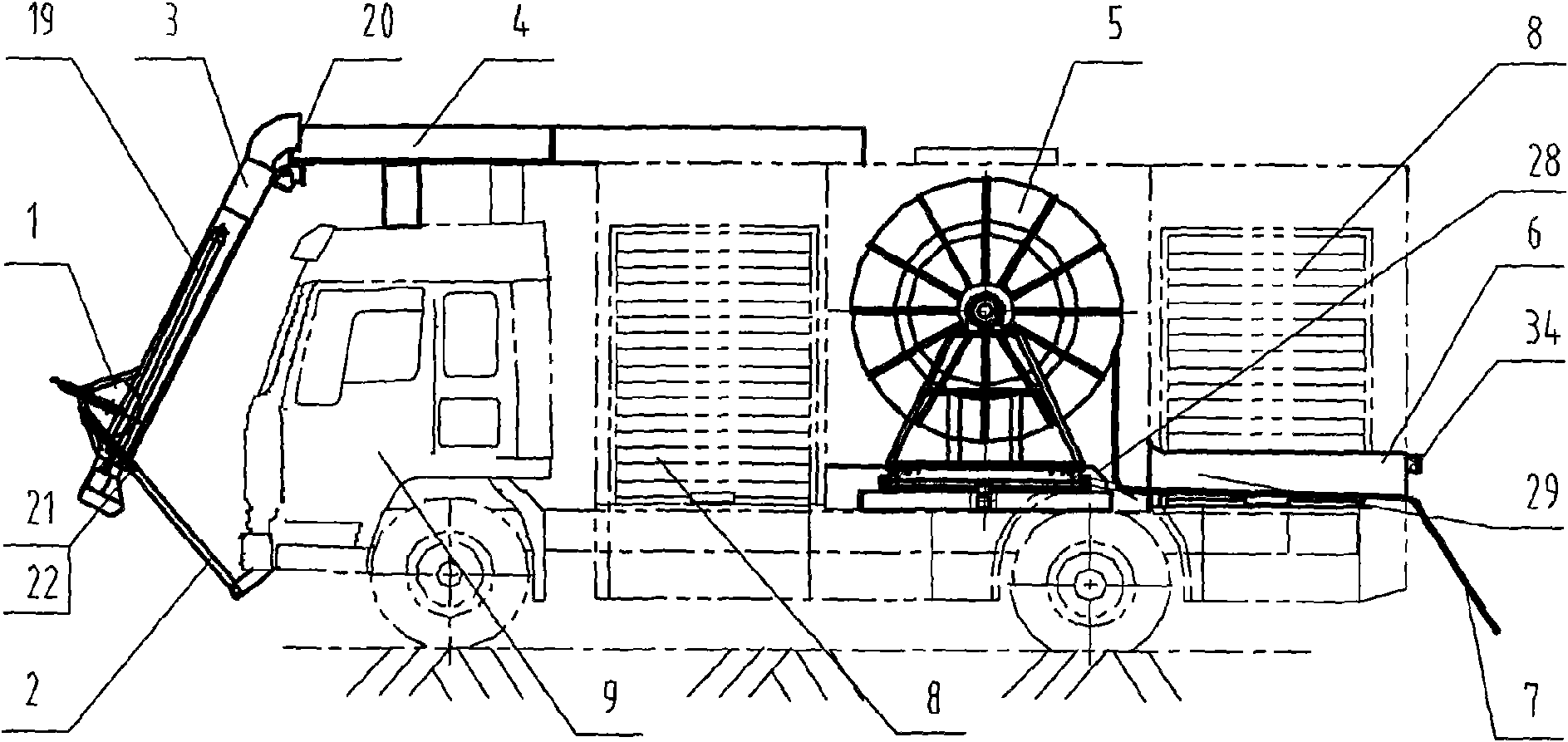

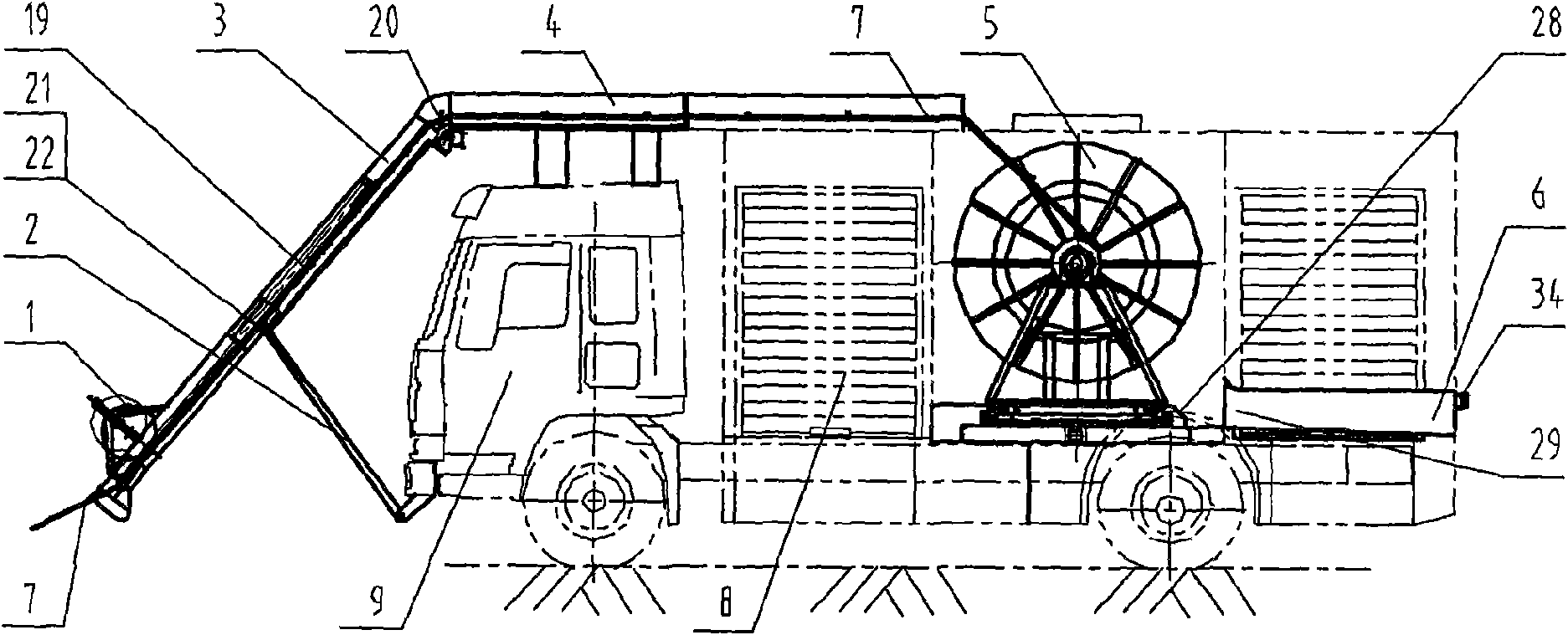

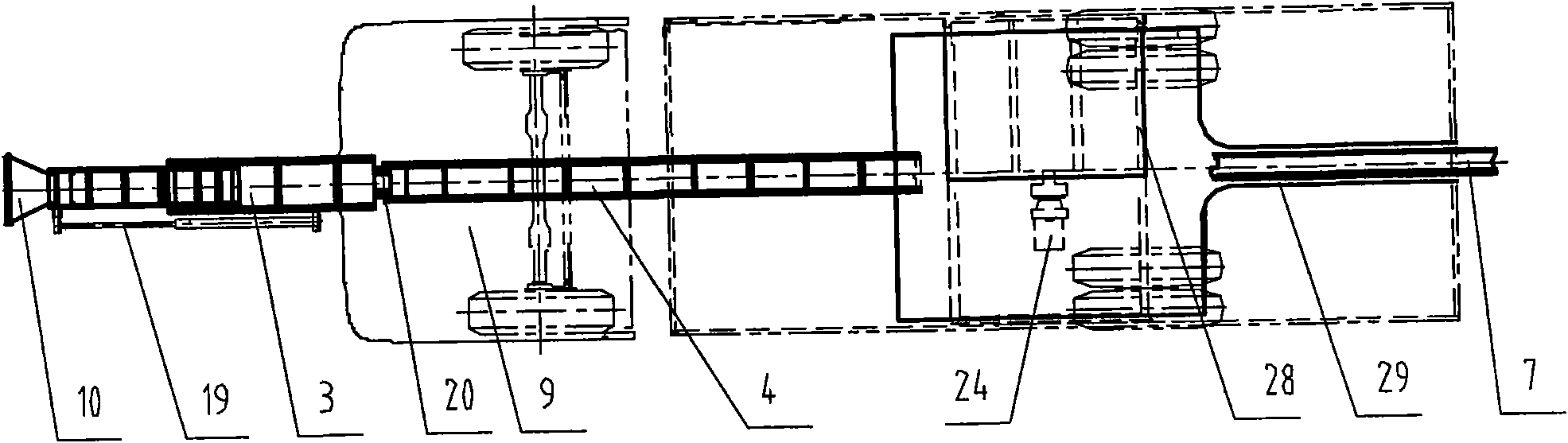

Fire service equipment vehicle with fire-hose laying and picking device

A fire service equipment vehicle with a fire-hose laying and picking device comprises a vehicle body (9) and is characterized in that a reel device (5) which can collect and release water hoses is arranged on the middle rear part of the vehicle body (9); the front part of the reel device is provided with an upper chute (4) and a lower chute (3) which are connected together by an articulating structure (20), and a picker (1) which is arranged on the front end part of the lower chute, extrudes and shapes the water hoses; and a laying device (6) which sends the water hoses out is arranged on the rear part of the reel device. The implementation of the invention can realize the fast and long distance laying and picking of the water hoses which are jointly controlled by machinery, electricity and liquid, solves the problem of getting water from water sources far from fire disaster fields; afterwards, the water hoses can be taken back to the fire service equipment vehicle with less effort by depending the fire-hose laying and picking device.

Owner:ZHENGZHOU YUTONG HEAVY IND

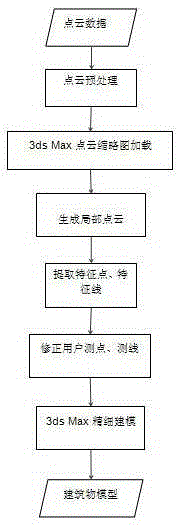

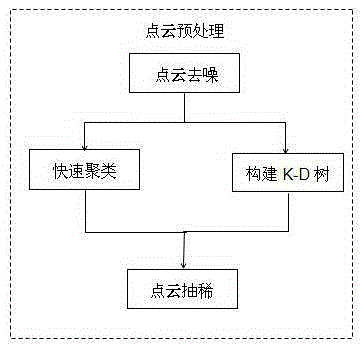

3ds Max fast and precise three-dimensional modeling method and system based on point cloud

The invention provides a 3ds Max fast and precise three-dimensional modeling method and system based on point cloud. The method comprises the following steps: preprocessing point cloud, comprising carrying out point cloud denoising on point cloud data obtained by an airborne or vehicle-mounted laser radar at first, carrying out fast clustering, constructing a K-D tree, and carrying out point cloud thinning; providing a thumbnail of all point cloud according to the central point of each clustered category based on 3ds Max; generating local point cloud, when a user selects a building corner, obtaining neighborhood point cloud through the K-D tree of the belonging category, using a corner extraction algorithm to extract all corners from the neighborhood point cloud to serve as feature points, carrying out plane fitting on the point cloud data in the neighborhood point cloud to obtain a planar intersecting line, and using the planar intersecting line as a feature line; correcting a measurement point of the user according to the feature points, when the user carries out line measurement, searching a contour line of a drawn building to correct the line measurement of the user; and modeling according to the building contour based on 3ds Max.

Owner:WUHAN UNIV

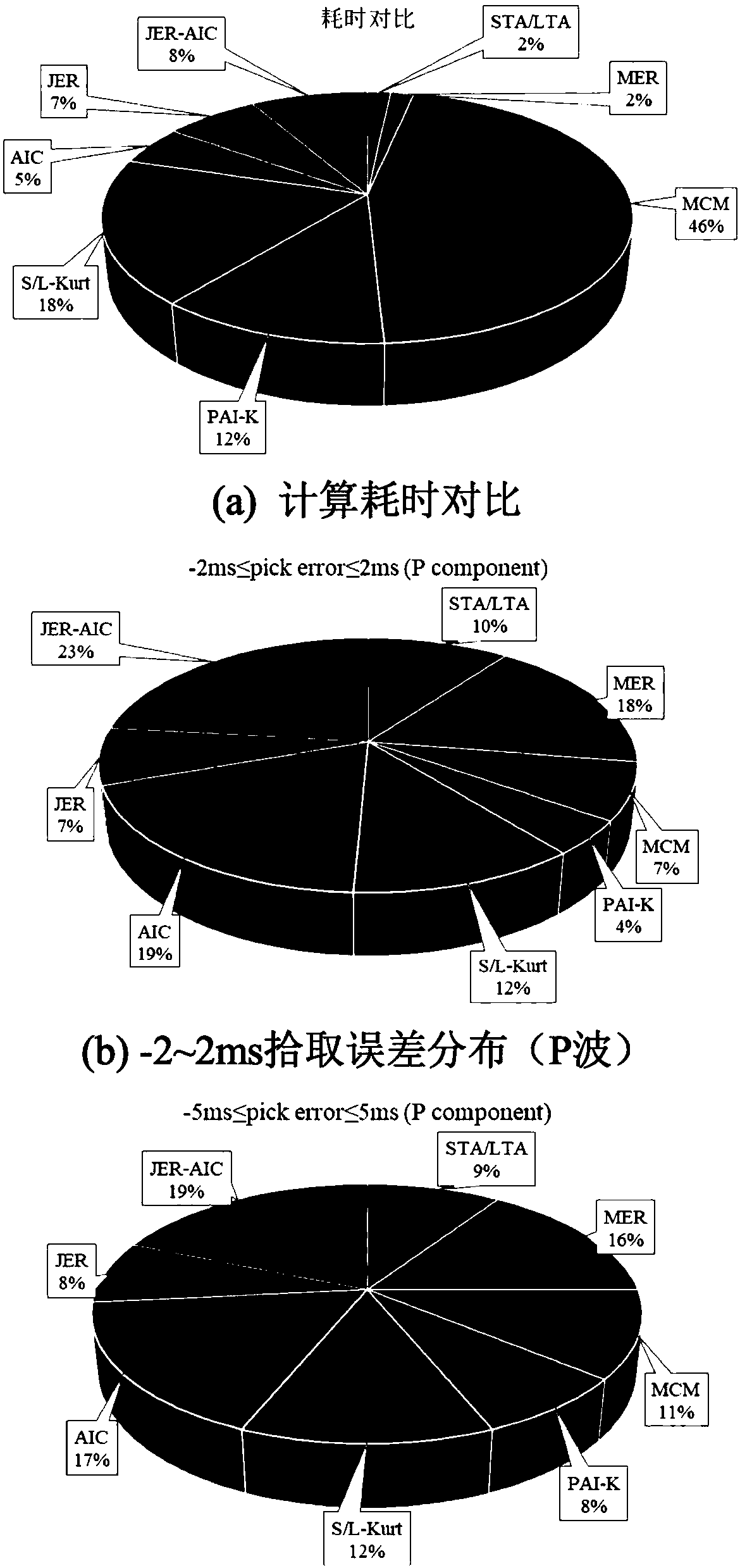

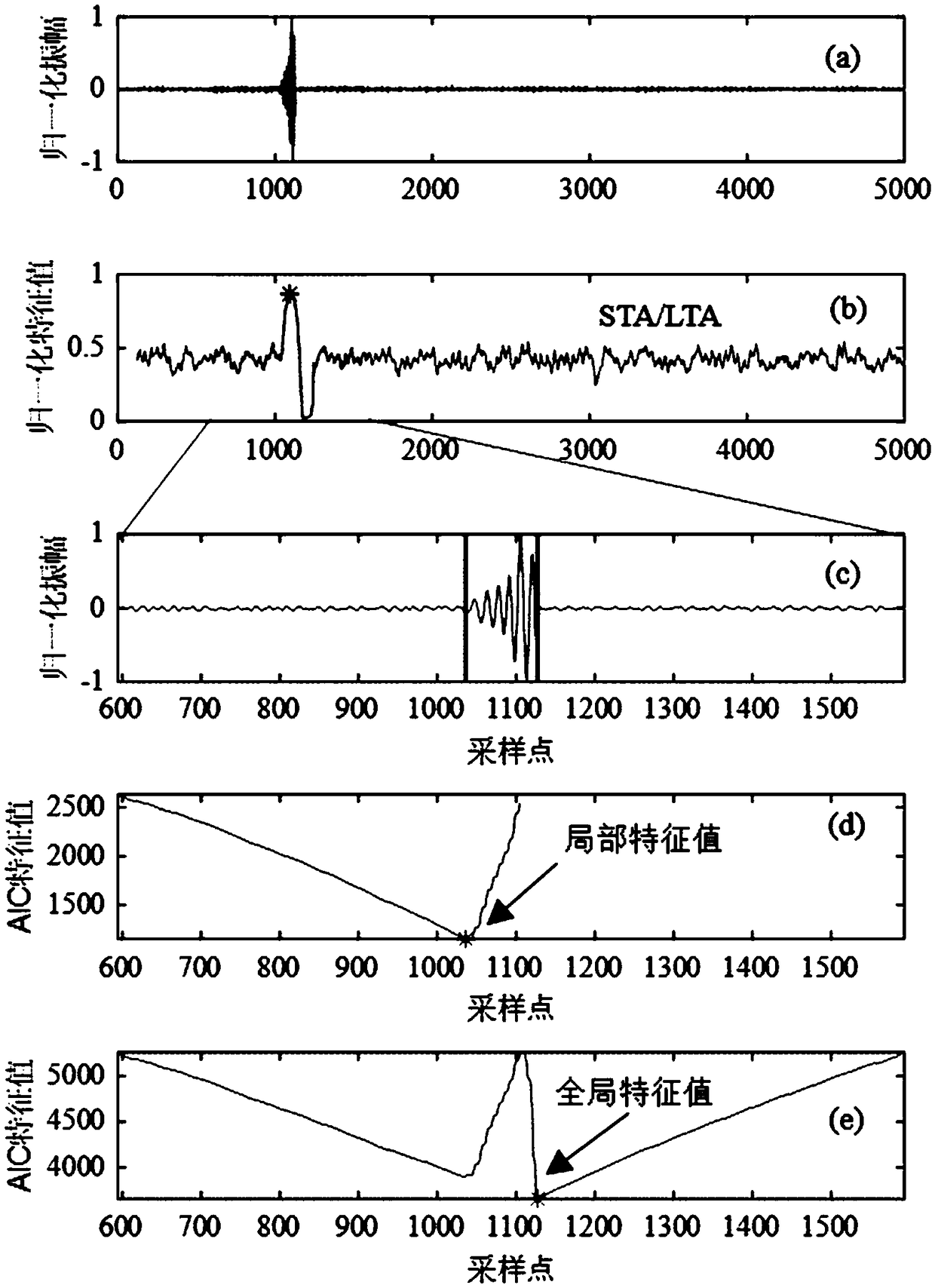

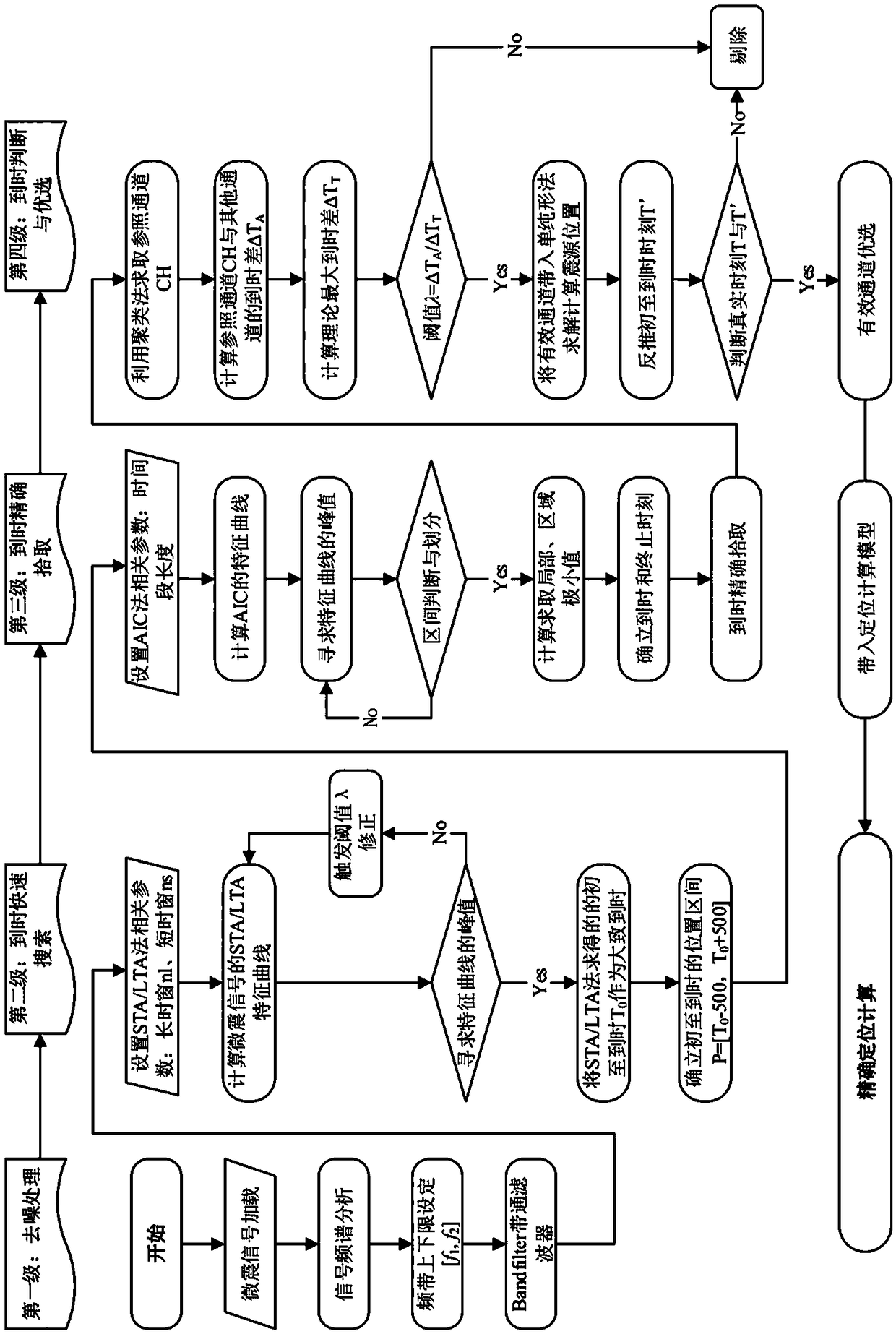

Automatic grading picking and optimizing method of micro-seismic wave shape first arrival time

The invention discloses an automatic grading picking and optimizing method of micro-seismic wave shape first arrival times. The method comprises four steps of noise reduction processing-arrival time rapid searching-arrival time accurate picking-arrival time judging and optimizing, specifically, the noise reduction processing is carried out on original signals by using a MATLAB build-in Butterworthband-pass 10-200 Hz filter; peak points in the signals are rapidly judged by using a peak judgmental method, then each 500 sampling point is pushed and moved to the left and right by using the peak points, then a first arrival time position is preliminarily established by using a STA / LTA method; first arrival time accurate picking selects two methods of AIC algorithm and MER algorithm, a first arrival time position of a micro-seismic wave shape is established; and a judging and optimizing process of an effective channel is summarized as three steps such as clustering analysis picking reference channel is carried out, time difference removing invalid channel is carried and envelope curve judging presenting error channel is carried out. The automatic grading picking and optimizing method ofthe micro-seismic wave shape first arrival time can rapidly and accurately pick the first arrival time of the micro-seismic signals, and can automatically judge and remove the channel with larger interference or error.

Owner:NORTH CHINA INST OF SCI & TECH

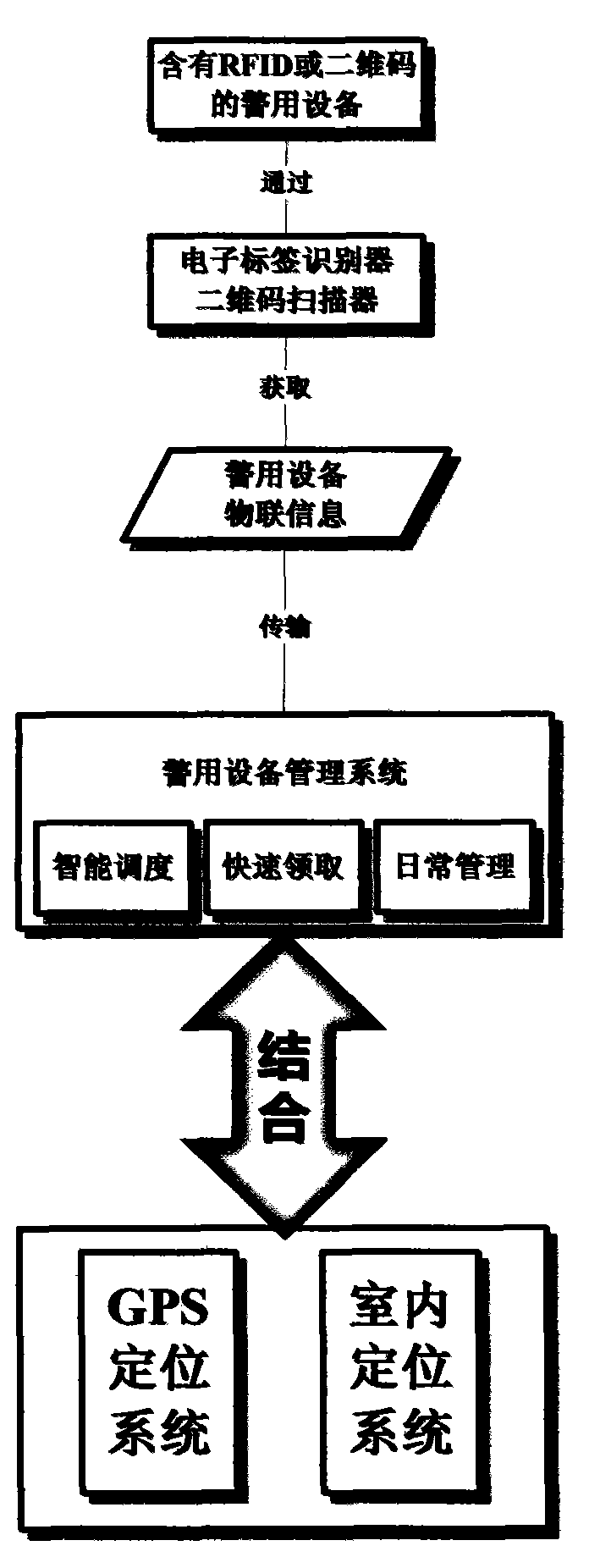

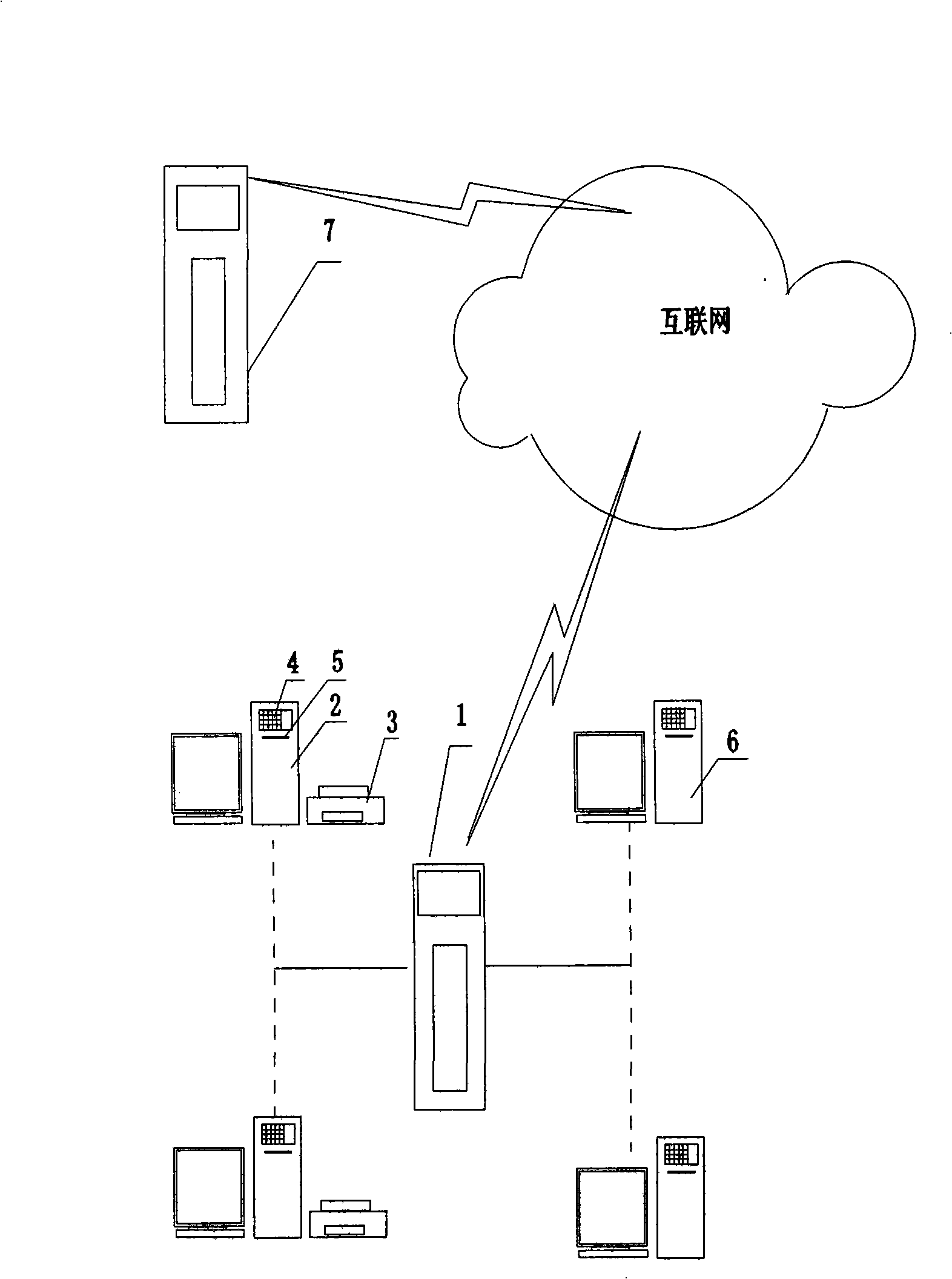

Police device management method based on internet of things

InactiveCN103825920AMeet the needs of fast scheduling and disposal resourcesSpeed up distributionTransmissionElectronic taggingThe Internet

Disclosed is a police device management method based on internet of things. The method includes: (1) establishing a police device management system which is deployed in a three-layer framework including a sensing layer, a network layer and an application layer and clients; (2) according to the situation, equipping police devices with internet-of-things sensing devices including electronic labels, sensors, two-dimension codes and mobile terminals; (3) reading basic information of devices equipped with the sensing devices to the police-device management system through the internet-of-things sensing devices respectively; (4) after the information of the police devices is input into the system, users accessing different applications of the system through the clients of the alarm device management system.

Owner:CHINA CHANGFENG SCI TECH IND GROUPCORP

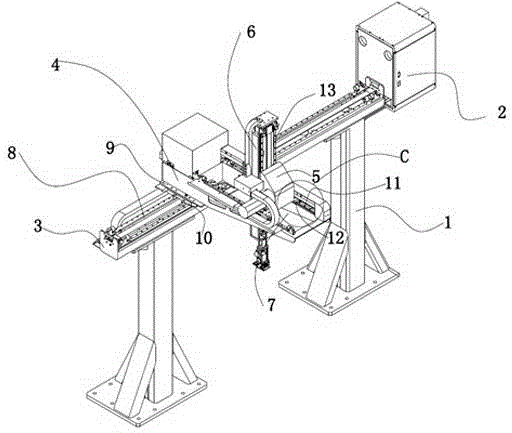

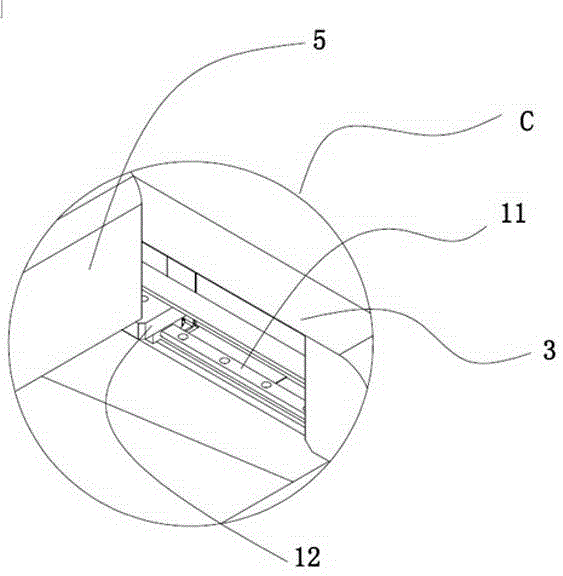

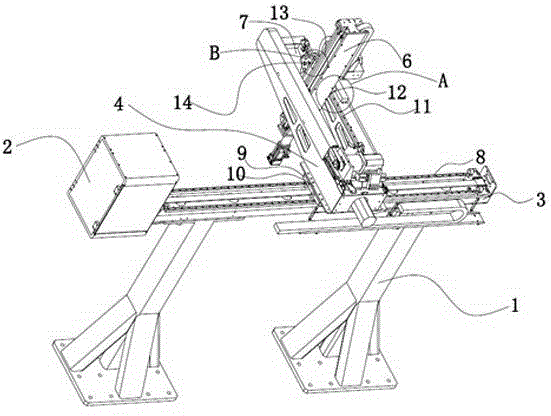

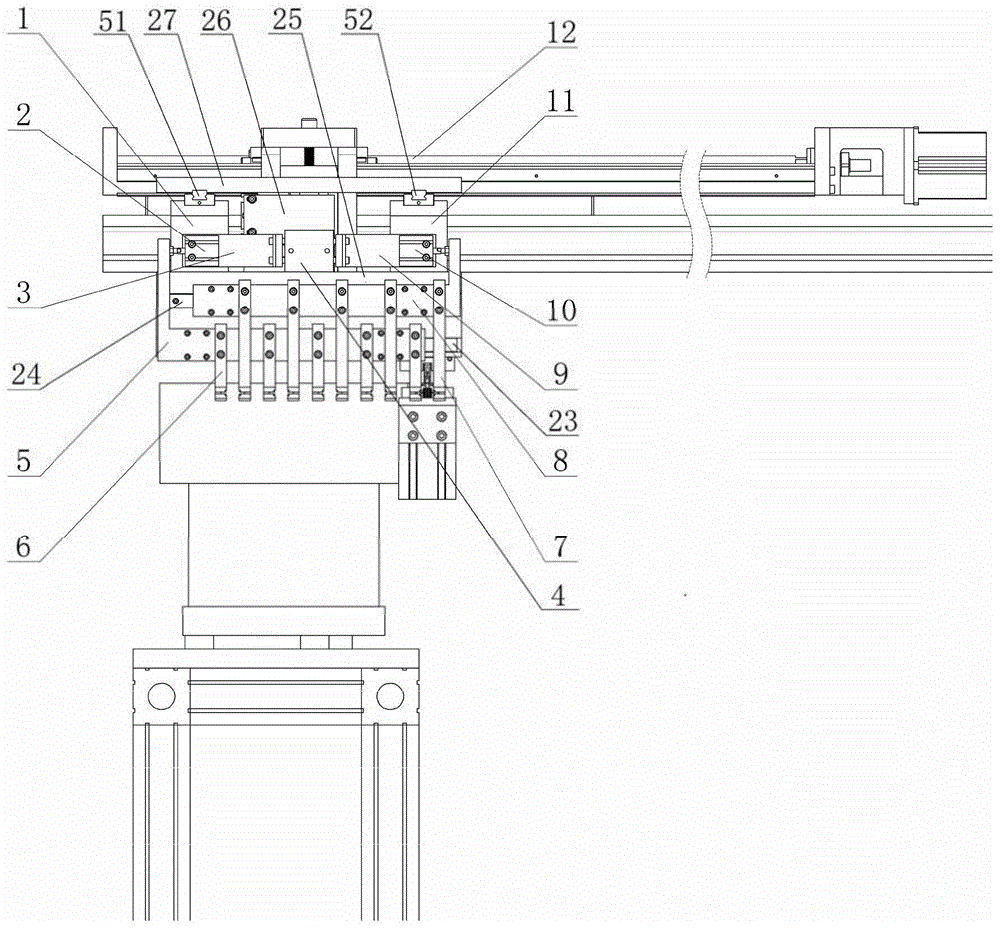

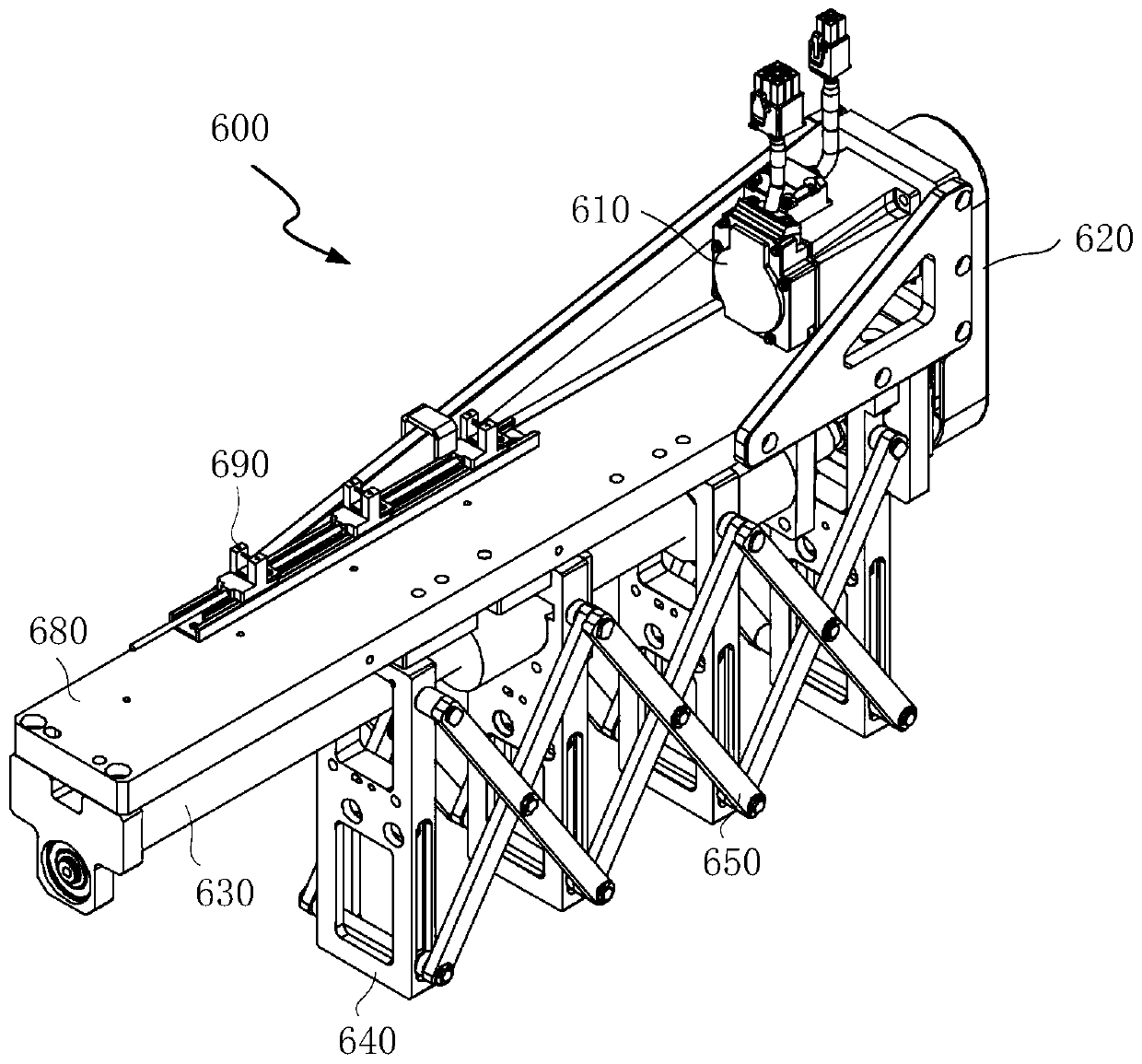

Triaxial truss type high-speed servo robot

InactiveCN104669239AReduce weightMove quicklyProgramme-controlled manipulatorEngineeringElectric control

The invention discloses a triaxial truss type high-speed servo robot. The triaxial truss type high-speed servo robot comprises a machine base, an electric control box, a slide gun barrel, a drawing beam, an arm bracket and an arm beam; the electric control box is arranged at one side of the slide gun barrel, and the slide gun barrel is erected on the machine base; the drawing beam is erected on the slide gun barrel, and the drawing beam is repeatedly glided along the length direction of the slide gun barrel; the drawing beam is a reversed-right-trapezoid shaped structure, and one end of the drawing beam closing to the middle of a trapezoid waist part is a hollow form; the arm beam is crossed through the hollow part of the drawing beam and vertically erected on the drawing beam through the arm bracket, and the arm bracket is repeatedly glided along the length direction of the drawing beam; meanwhile, the arm beam is vertically glided in turn along the arm bracket. By reducing the structure and weight of the drawing beam, the drawing beam can be rapidly moved on the slide gun barrel; meanwhile, the arm beam is vertically erected at the hollow place of the drawing beam, so that the space occupancy ratio is reduced, and thereby the rapid material picking is realized, the picking cycle is short, and the working efficiency of an injection molding machine is improved.

Owner:徐建

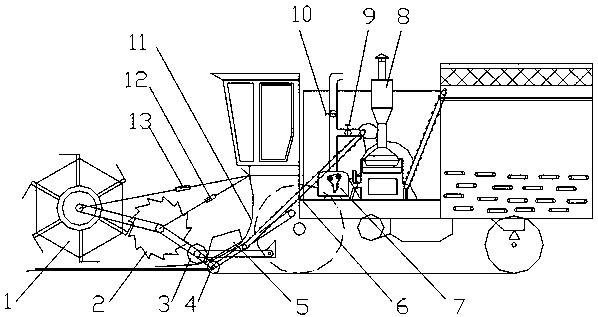

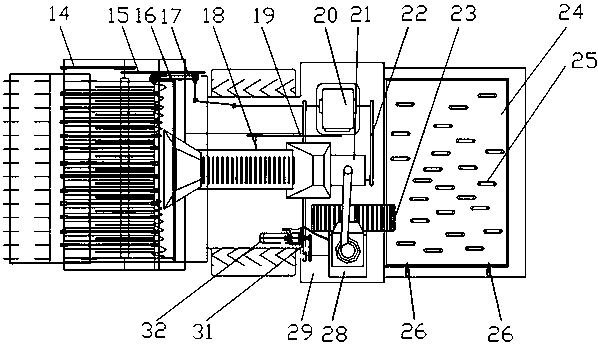

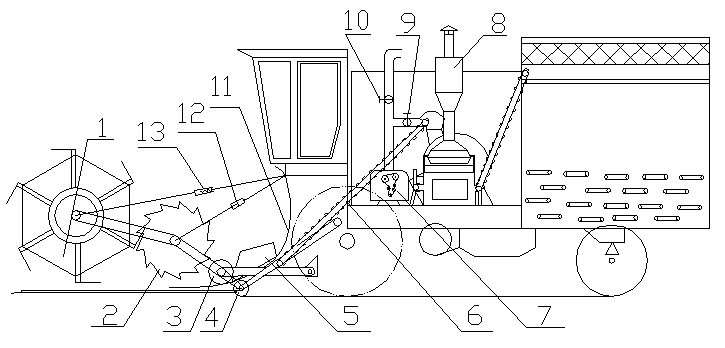

Full-automatic collection, smashing and compact forming combination machine for field waste crop straws

ActiveCN103749964ASolving the collection is labor-intensiveSolve efficiency problemsBiofuelsSolid fuelsPre treatmentAgricultural machinery

The invention discloses a full-automatic collection, smashing and compact forming combination machine for field waste crop straws, and belongs to the technical field of agricultural machineries. According to the full-automatic collection, smashing and compact forming combination machine for field waste crop straws, the problems of great labor cost and low transportation efficiency in collection of the agricultural straws are solved. The full-automatic collection, smashing and compact forming combination machine for the field waste crop straws comprises a front straw automatic picking and preprocessing system, a smashing and compact forming integration system and a biomass particle automatic transportation and temporary storage system, wherein the front straw automatic picking and preprocessing system is suspended on the front side of a walking chassis integrated system frame; the smashing and compact forming integration system and the biomass particle automatic transportation and temporary storage system are mounted on a chassis of the walking chassis integrated system from front to back; the front straw automatic picking and preprocessing system, the smashing and compact forming integration system and the biomass particle automatic transportation and temporary storage system are connected together through a transmission mechanism. The combination machine is applicable to full-automatic collection, smashing and compact forming for the field waste crop straws.

Owner:NORTHEAST FORESTRY UNIVERSITY

Versatile card hospital diagnosis management system

InactiveCN101299264AOptimize service processReduce workloadData processing applicationsCo-operative working arrangementsCyber operationsThe Internet

The present invention provides a card hospital diagnosis management system, whose structure is composed of a system data storage server, information enquiry computer terminals, and diagnosis and treatment check computer terminals, wherein, the system data storage server is provided in the hospital system, the information enquiry computer terminals with card reader and printer are mounded in the allure, and computer terminals with card reader are mounted in every out-patient clinic and inspection departments; every computer terminals are connected with the system data storage server through wired or wireless mode to form a local area network; and the system data storage server is connected with to the server of the network operation company through internet. Compared with the prior technology, the card hospital diagnosis management system optimizes the flow of hospital services, reduces the workload of the out-patient departments and inspection departments, improved work efficiency, improves the patients' right to know, and will bring more social and economic benefits to hospitals.

Owner:曹莹莹

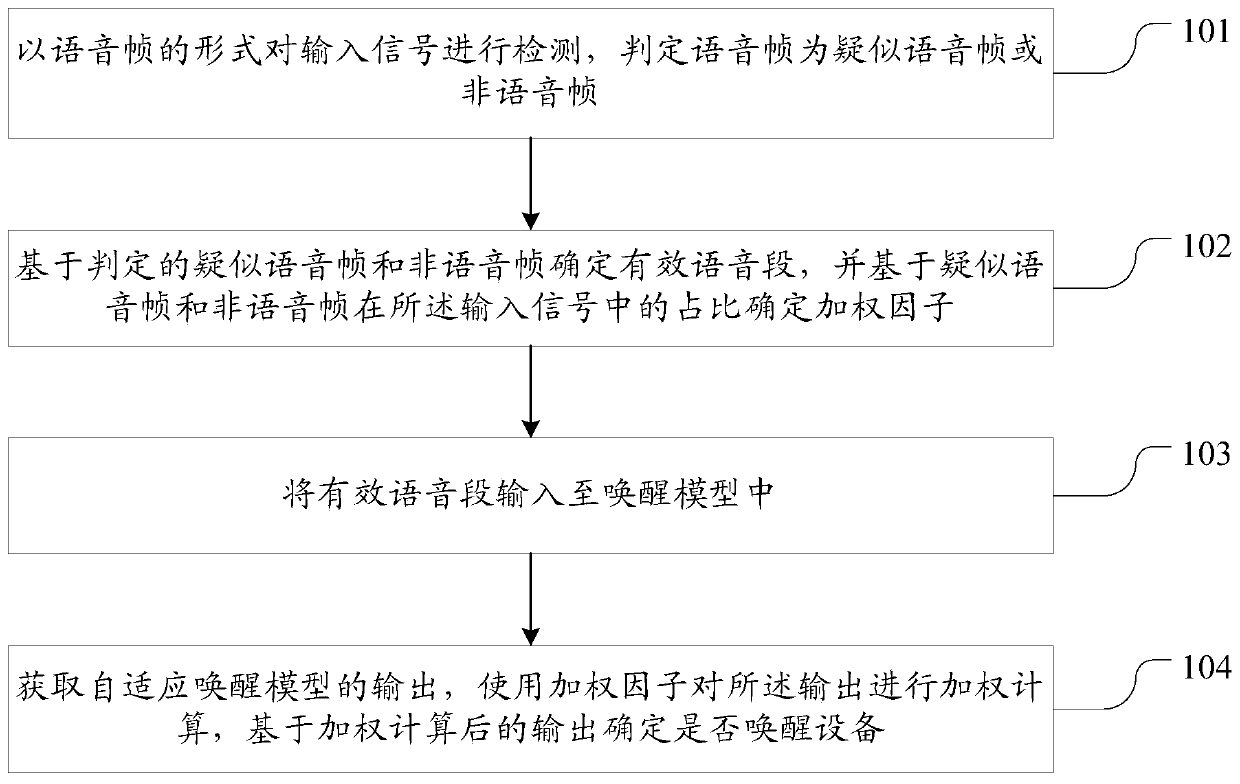

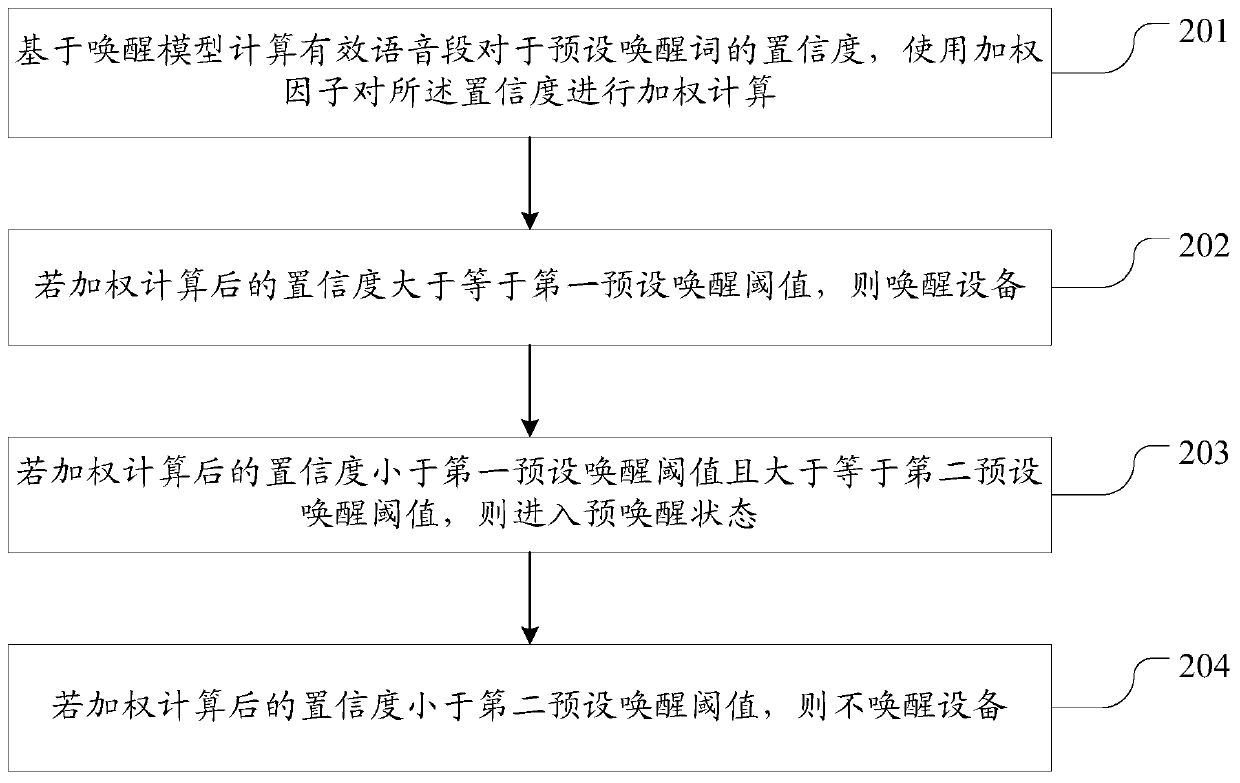

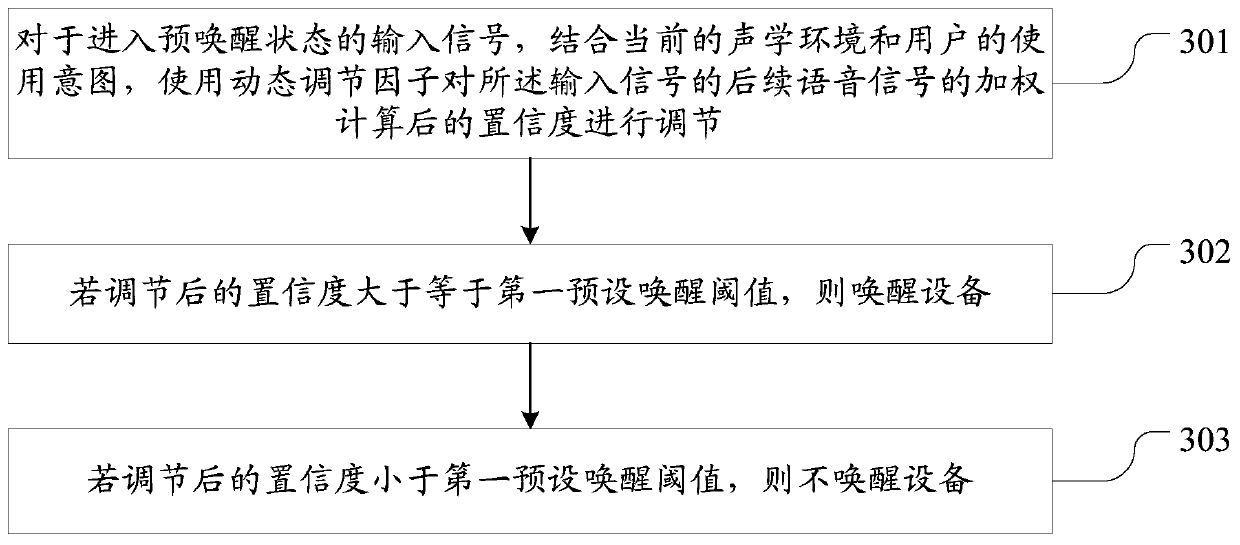

Voice awakening performance improvement method and device

ActiveCN110473539ASuppress false wakeupQuick pick upSpeech recognitionNeural network learningFalse awakening

The invention discloses a voice awakening performance improvement method and device. The voice awakening performance improvement method comprises the following steps of detecting an input signal in avoice frame form, and judging whether the voice frame is a suspected voice frame or a non-voice frame; determining an effective voice segment based on the determined suspected voice frame and the non-voice frame, and determining a weighting factor based on the ratio of the suspected voice frame and the non-voice frame in the input signal; inputting the effective voice section into an awakening model, wherein the awakening model is a multi-classification model obtained after supervised depth neural network learning is carried out on collected awakening word positive example samples and non-awakening word negative example samples; and acquiring the output of the adaptive awakening model, carrying out weighted calculation on the output by using the weighting factor, and determining whether the equipment is awakened or not based on output after weighing calculation. According to the scheme provided by the invention, the false awakening rate of a noise scene can be effectively inhibited, and further, the awakening rate for a specific user can be improved in a targeted manner.

Owner:AISPEECH CO LTD

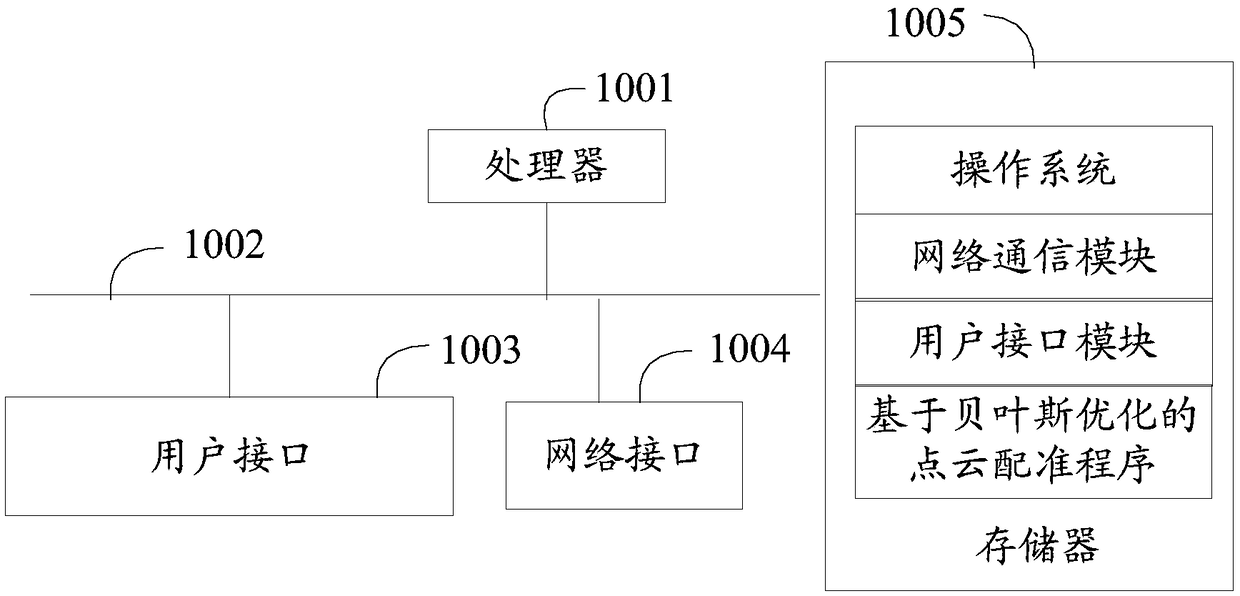

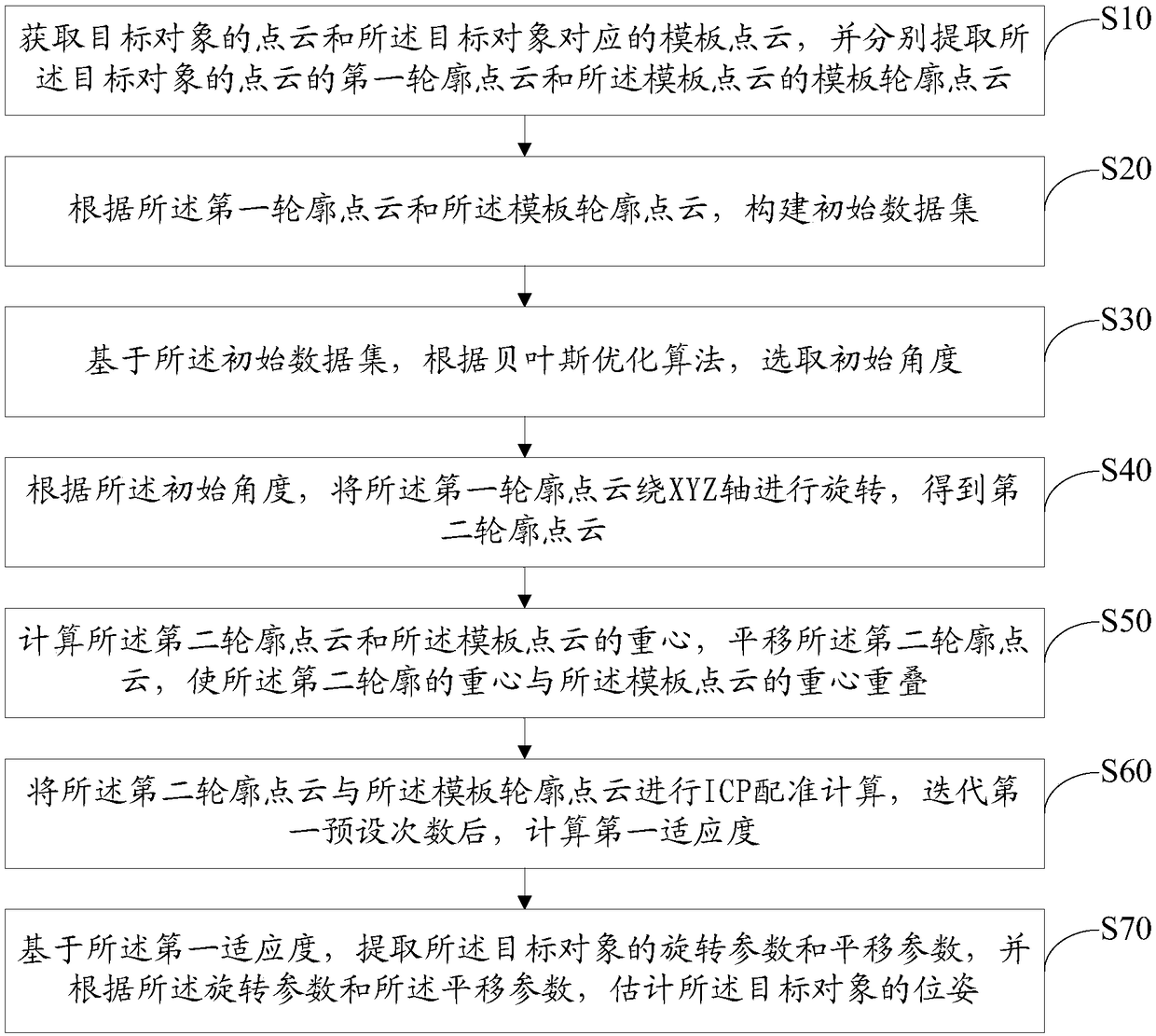

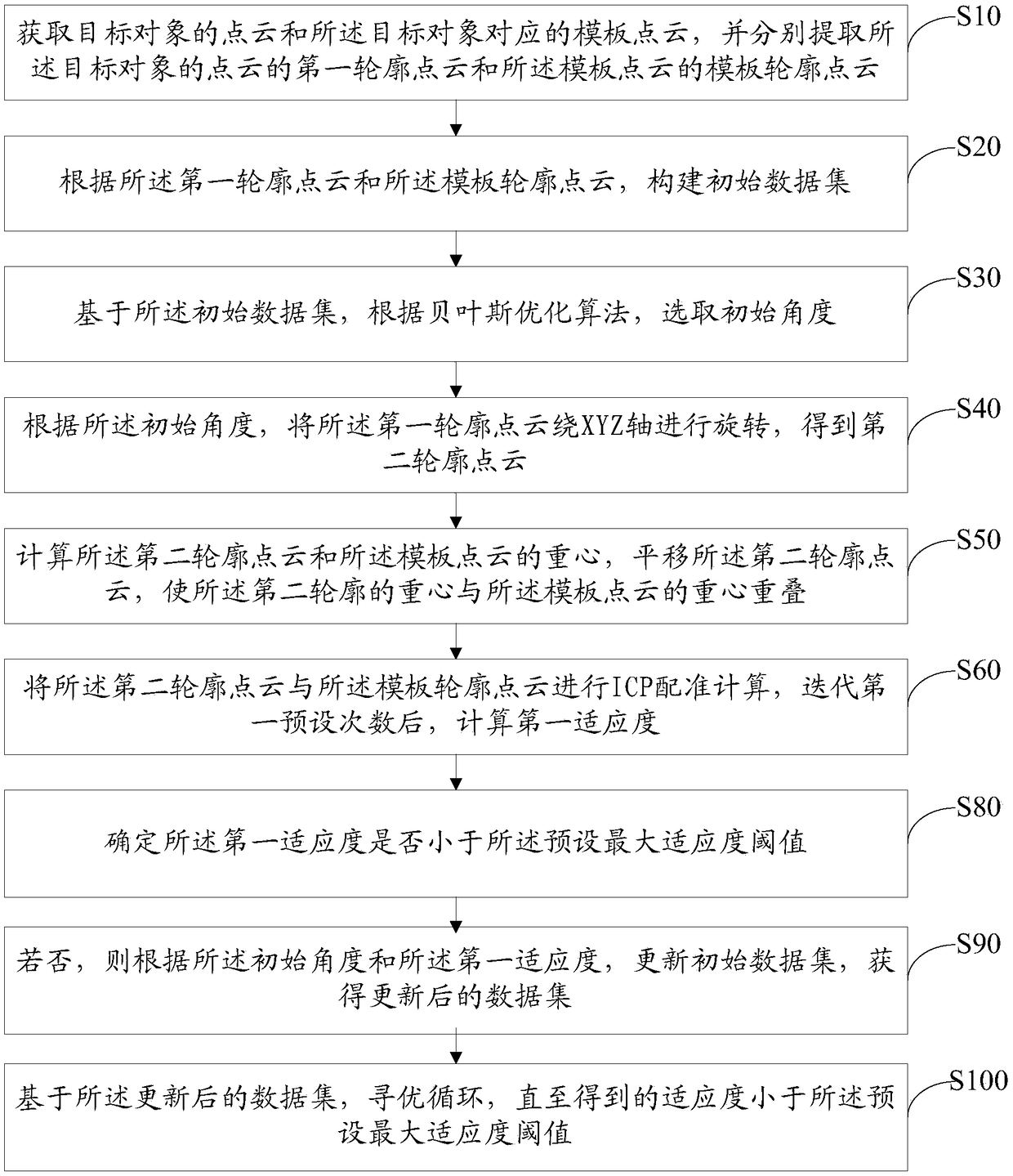

Point cloud registration method, system and readable storage medium based on bayesian optimization

The invention discloses a point cloud registration method based on Bayesian optimization, a system and a readable storage medium. The method comprises the following steps: obtaining a contour point cloud of a target object and a template contour point cloud; Build the initial data set; According to the Bayesian optimization algorithm, the initial angle is selected. According to the initial angle,the contour point cloud is rotated and translated to obtain a new contour point cloud. The new contour point cloud and the template contour point cloud are registered by ICP, and the fitness is obtained. And extracting a rotation parameter and a translation parameter of the target object based on the first fitness to estimate a pose of the target object. The invention utilizes the contour point cloud of the target object to carry out registration and optimization based on the Bayesian optimization algorithm, and finds out the relatively optimized initial position and posture of the target object, so that the robot adjusts the picking action according to the initial position and posture, and quickly completes the picking of the target object.

Owner:深圳一步智造科技有限公司

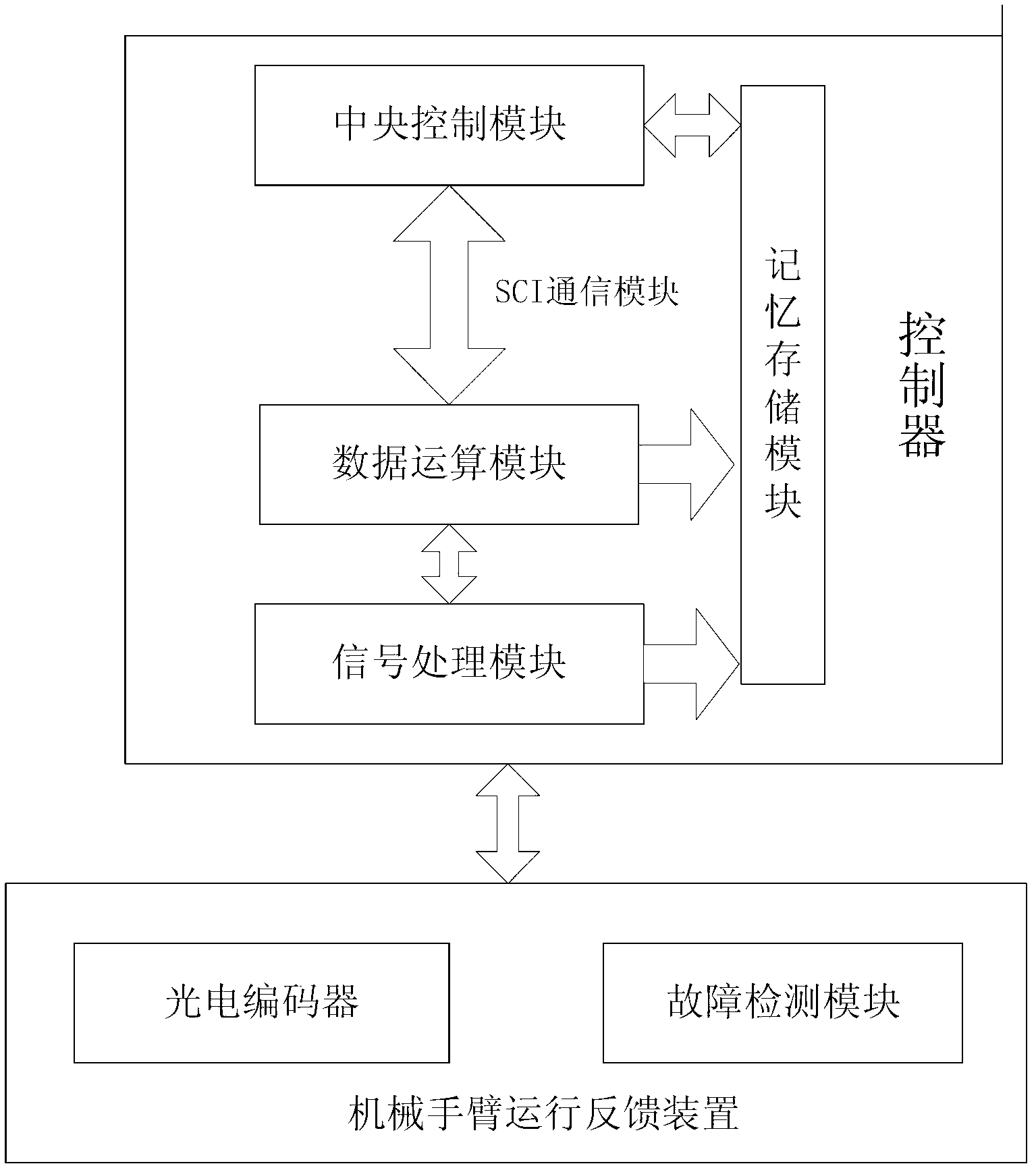

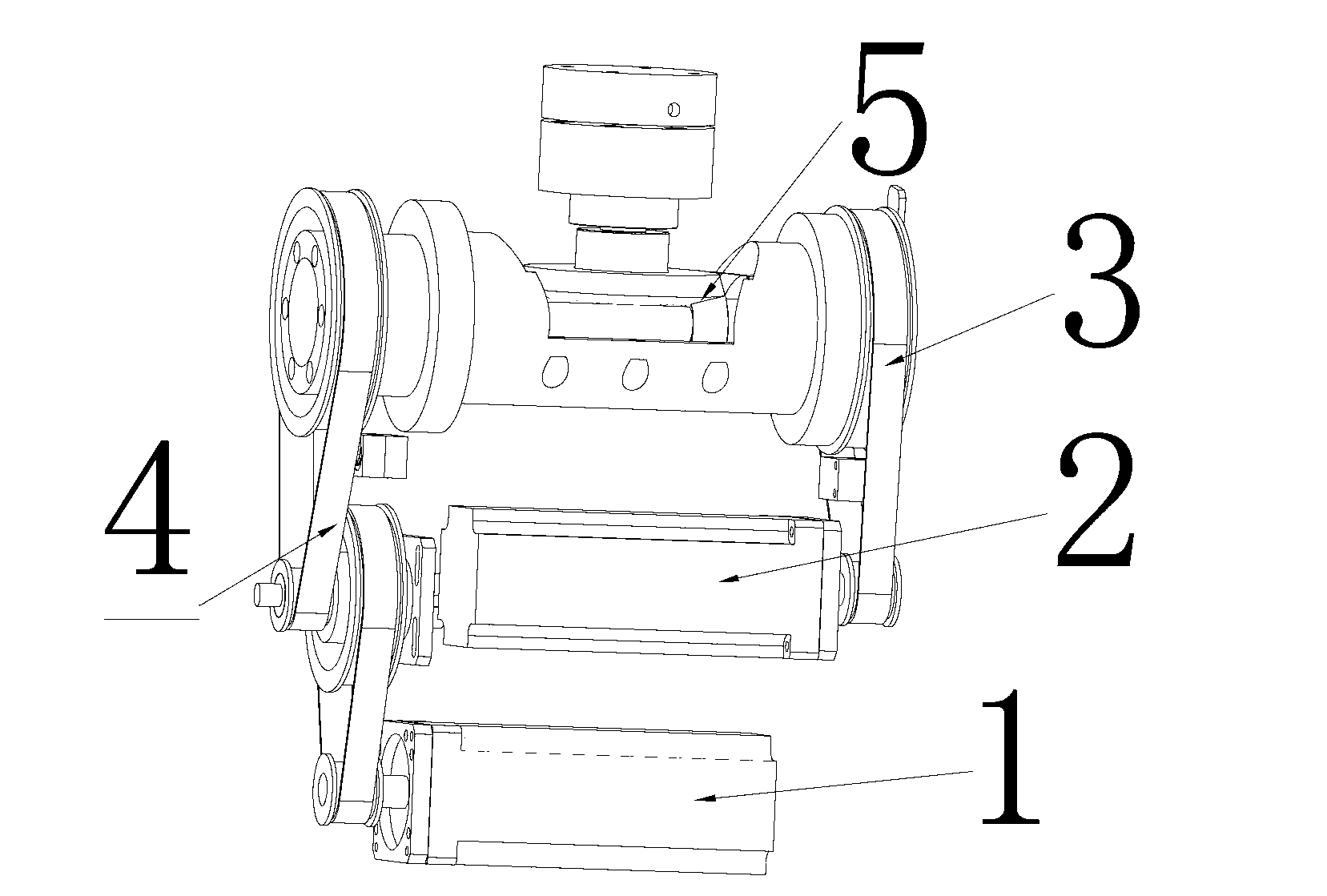

Preparation method of five-axis numerical control mechanical arm and five-axis numerical control mechanical arm

ActiveCN103056879AEfficient extractionQuick pick upProgramme-controlled manipulatorNumerical controlRobotic arm

The utility model discloses a preparation method of five-axis numerical control mechanical arm. The method comprises the following steps of:(1) arranging a mechanical arm body, arranging an X-axis arm, a Y-axis arm and a Z-axis arm on X axis, Y-axis, Z-axis and utilizing a servo motor to drive the X-axis arm, Y-axis arm and Z-axis arm to shift to move; (2) arranging controlling device and operation feedback device of mechanical arm on the mechanical arm body and connecting the controlling device and the operation feedback device of mechanical arm by CAN control bus; (3) arranging a B,C axis-motion mechanism, which rotates 180DEG on the B axis, and 360DEG on the C axis under the driven of the servo motor, on the end portion of the Z-axis arm; (4) arranging central control module, data computing module, memory storage module and signal processing module which are sequentially connected inside the control device. The utility model also discloses a five-axis numerical control mechanical arm which can apply the method of five-axis numerical control mechanical arm.

Owner:DONGGUAN ALFA AUTOMATION TECH CO LTD

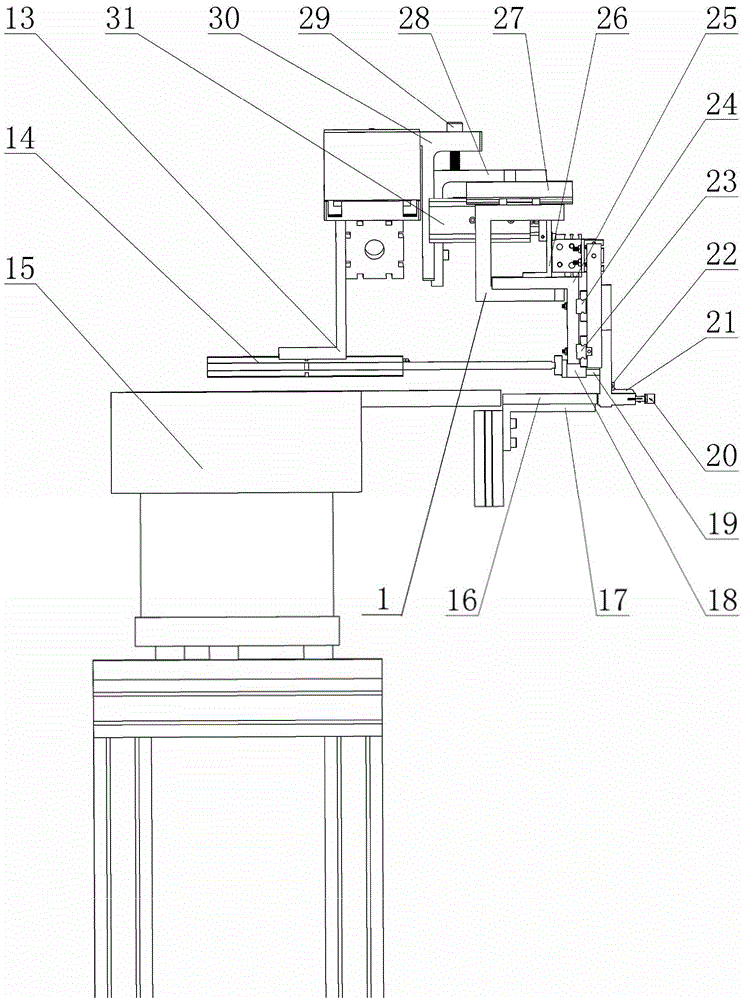

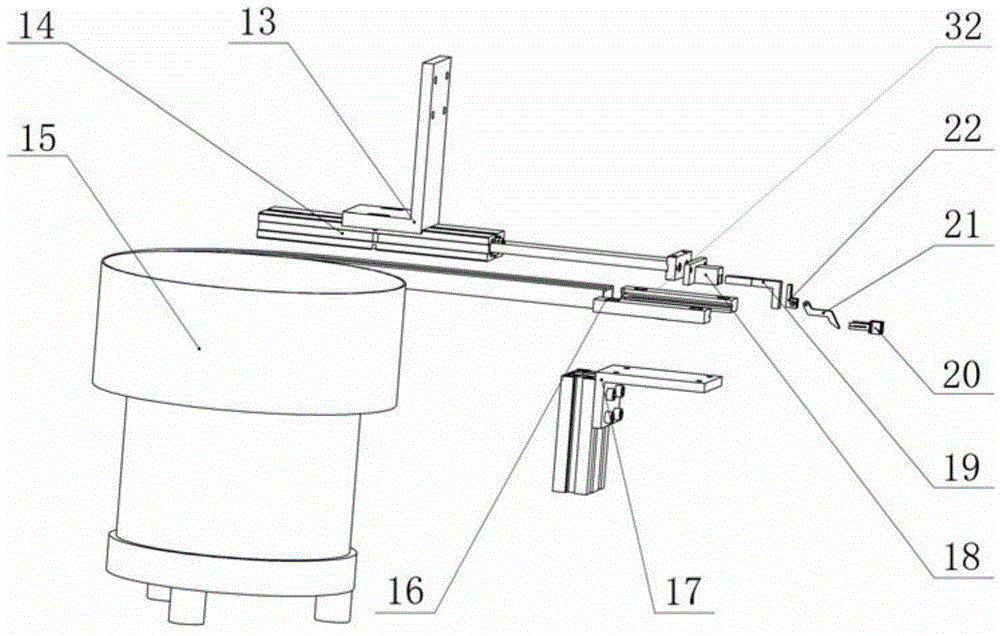

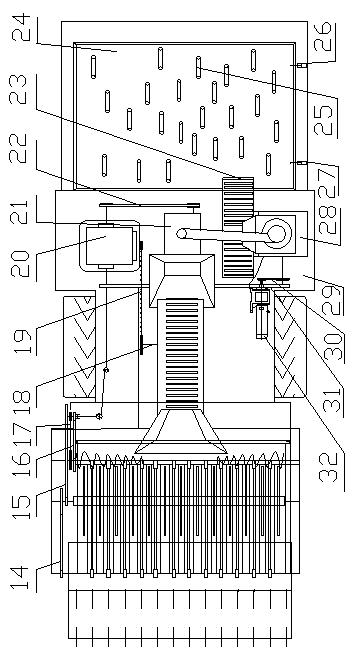

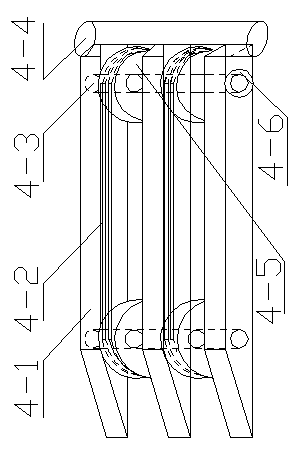

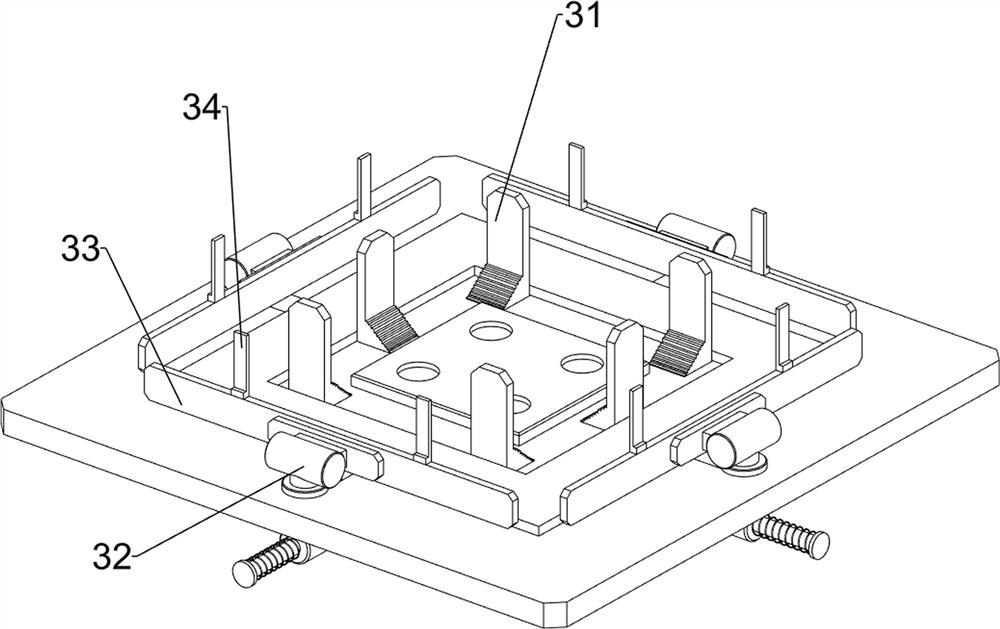

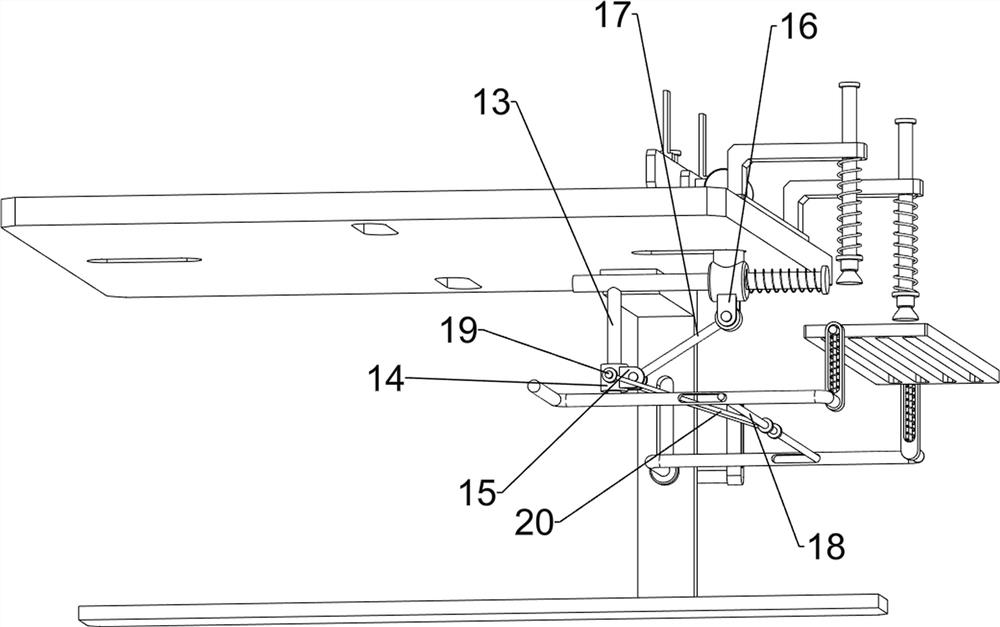

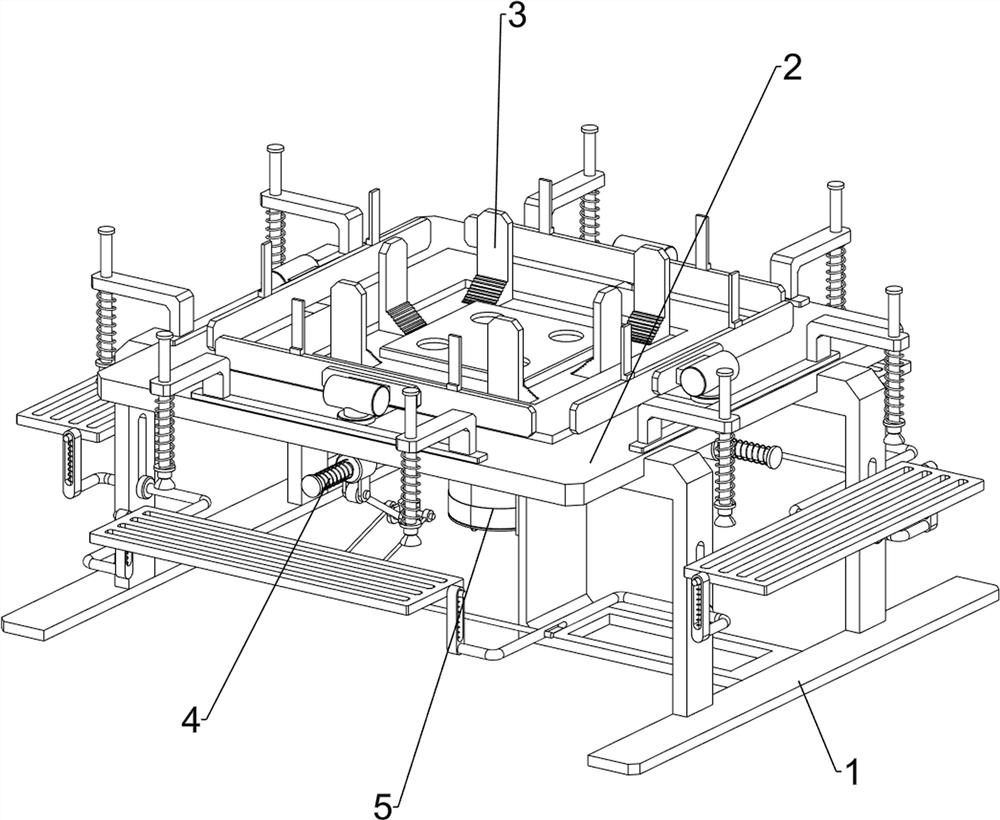

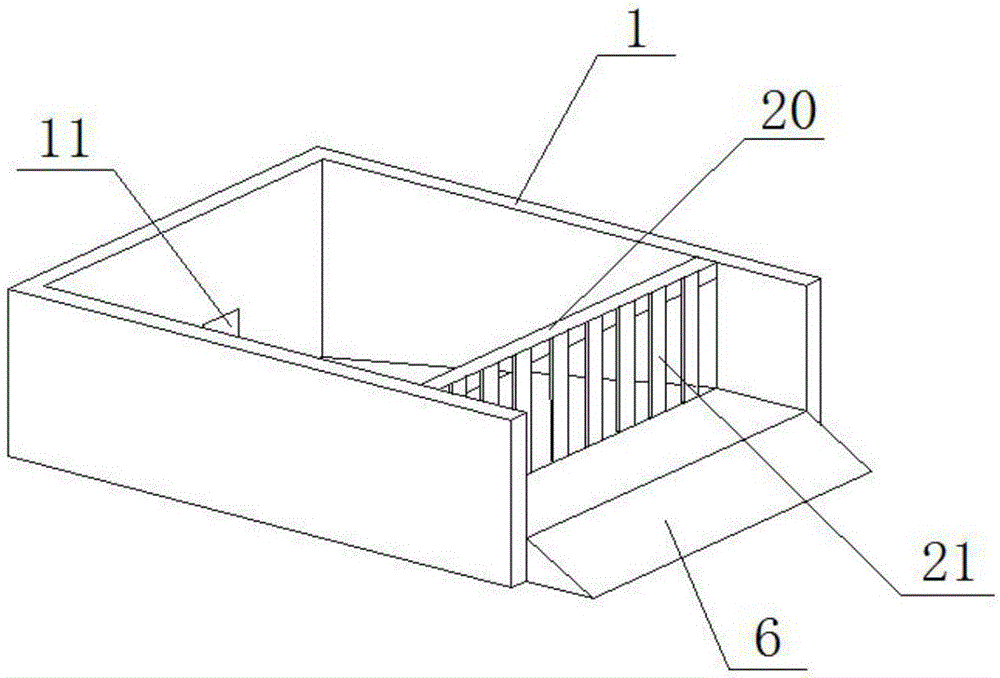

Whole-row automatic conveying device of grafting clamp

The invention relates to the technical field of agricultural machinery and especially relates to a whole-row automatic conveying device of a grafting clamp. The whole-row automatic conveying device of the grafting clamp comprises a grafting clamp conveying table, a grafting clamp ordering vibration disk (15), a clamp feeding air cylinder (14), a clamp feeding slide groove (16), a pushing air cylinder (31) of the grafting clamp conveying table and a horizontal movable mechanism (12) of a grafting clamp conveying table. The whole-row automatic conveying device of the grafting clamp provided by the invention can automatically convey a row of five grafting clamps in one operational circulation and fix a row of five grafted seedlings simultaneously. The whole-row automatic conveying device of the grafting clamp realizes rapid picking and conveying of the grafting clamps and fixes the whole row of grafted seedlings and increases working efficiency in the conveying of the grafting clamps of an automatic grating device and fixation of the grafted seedlings, so that working efficiency of grafting operation is increased, and labor force is saved.

Owner:CHINA AGRI UNIV

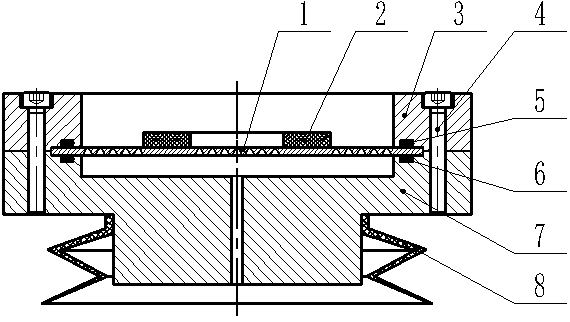

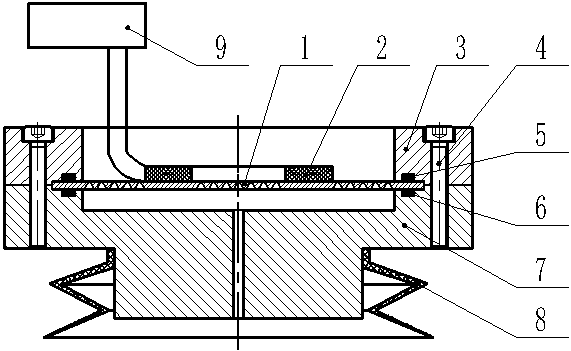

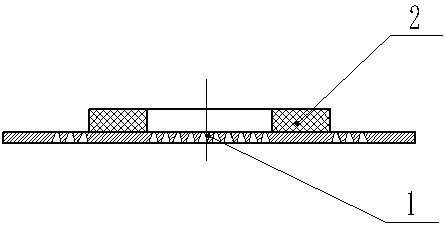

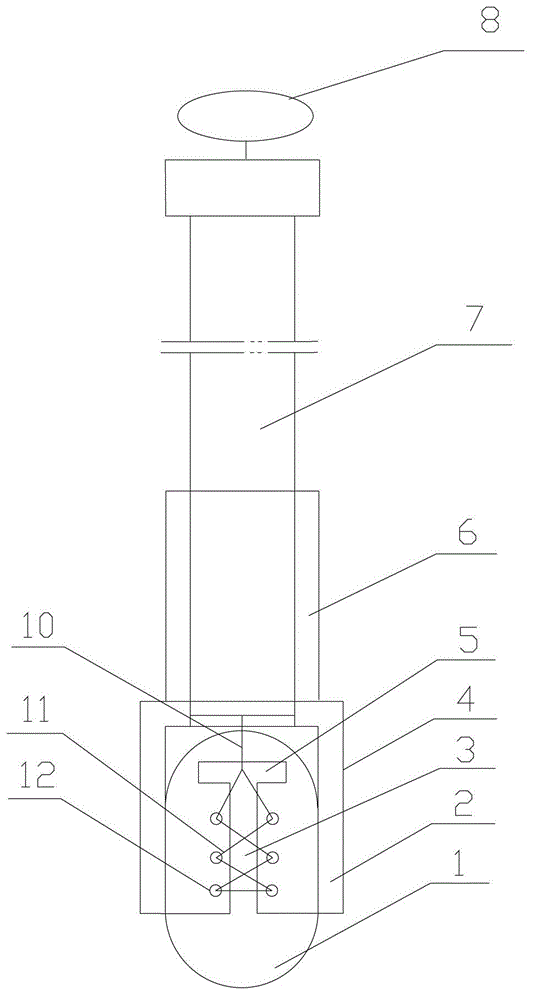

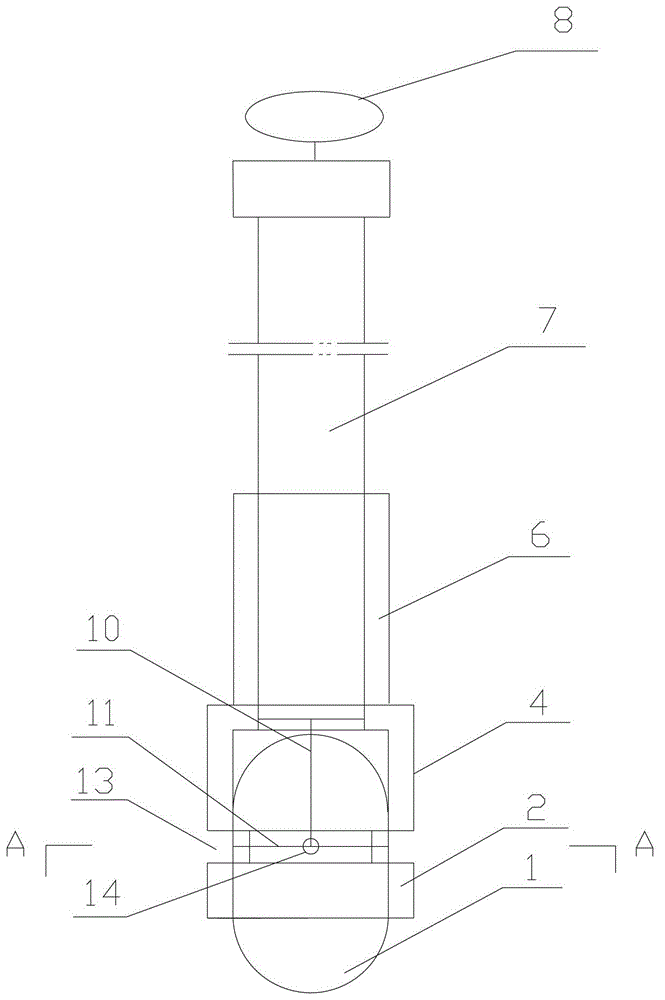

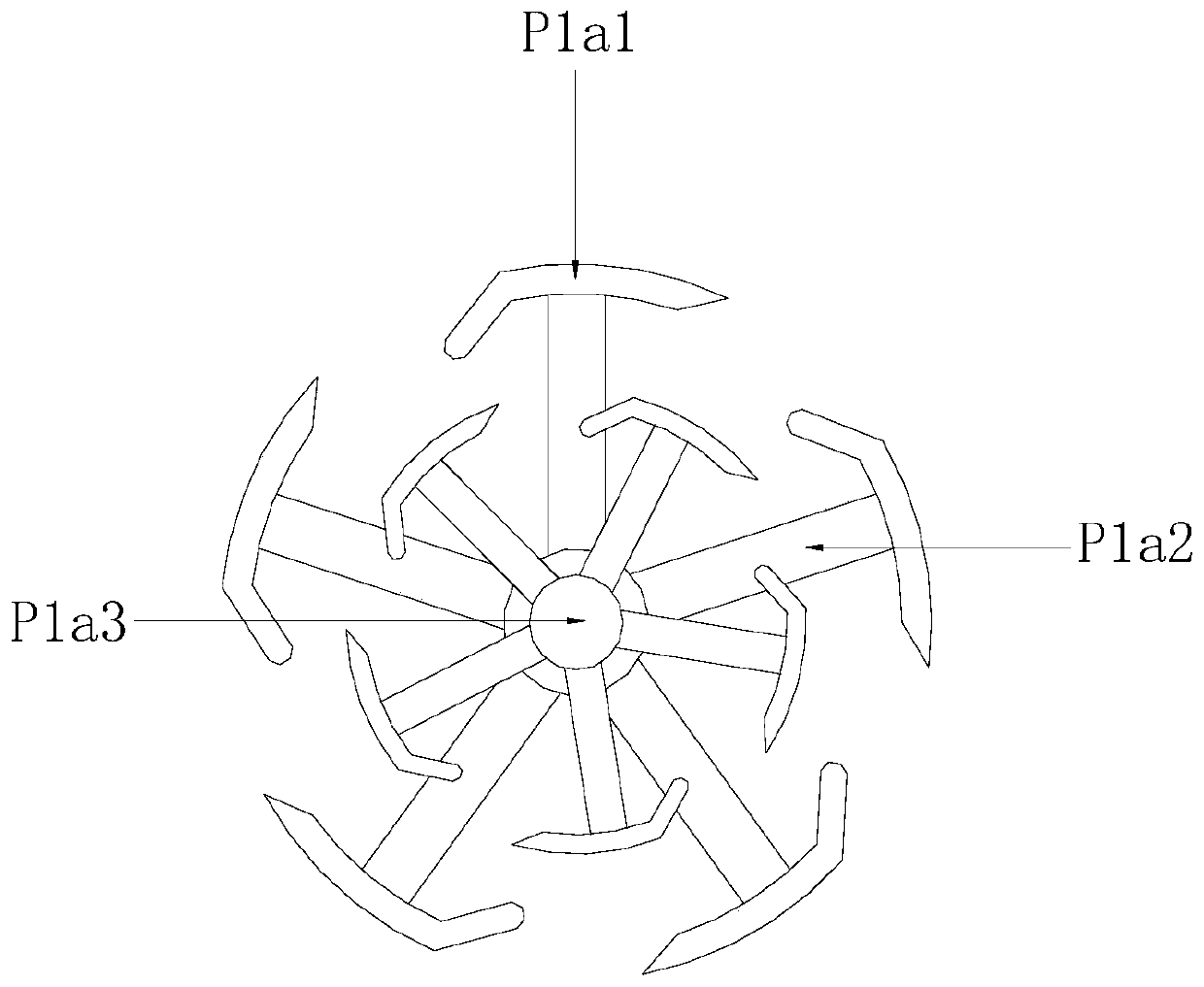

Piezoelectric ultrasonic vibration absorption picker

InactiveCN103192402AEasy to controlSimple structureGripping headsMechanical vibrations separationUltrasonic vibrationAtmosphere

The invention discloses a piezoelectric ultrasonic vibration absorption picker which comprises a picking sucker (8), a vibrating plate, a picker shell (7) and an upper cover plate (3). The upper cover plate (3) is connected onto the picker shell (7) by bolts (4), a vibrating cavity is formed between the vibrating plate and the picker shell (7), a vibrating diaphragm (1) and an annular piezoelectric ceramic plate (2) are coaxially adhered with each other to form the vibrating plate, conical holes are uniformly distributed in a middle circular area and a peripheral annular area, which are not in contact with the annular piezoelectric ceramic plate (2), the upper cover plate (3) and the picker shell (7), of the vibrating diaphragm (1), large ends of the conical holes face the vibrating cavity, small ends of the conical holes face the external atmosphere, the picking sucker (8) is arranged on the lower side of the picker shell (7), a channel is arranged in the picker shell (7), the picking sucker (8) can be communicated with the vibrating cavity via the channel, and the lower end of the picker shell (7) extends into the picking sucker (8) and occupies 60-90% of the internal volume of the picking sucker (8).

Owner:SUZHOU UNIV OF SCI & TECH

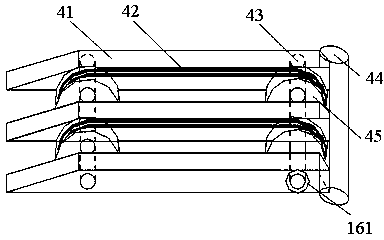

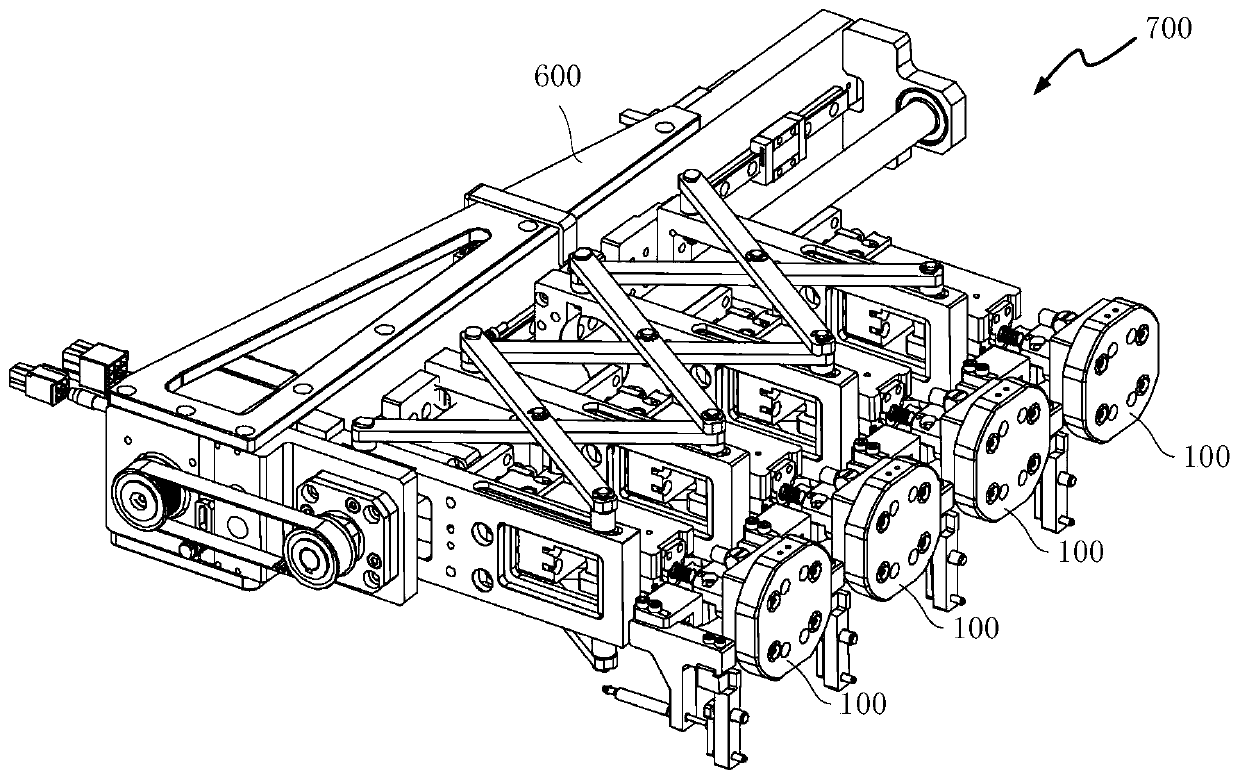

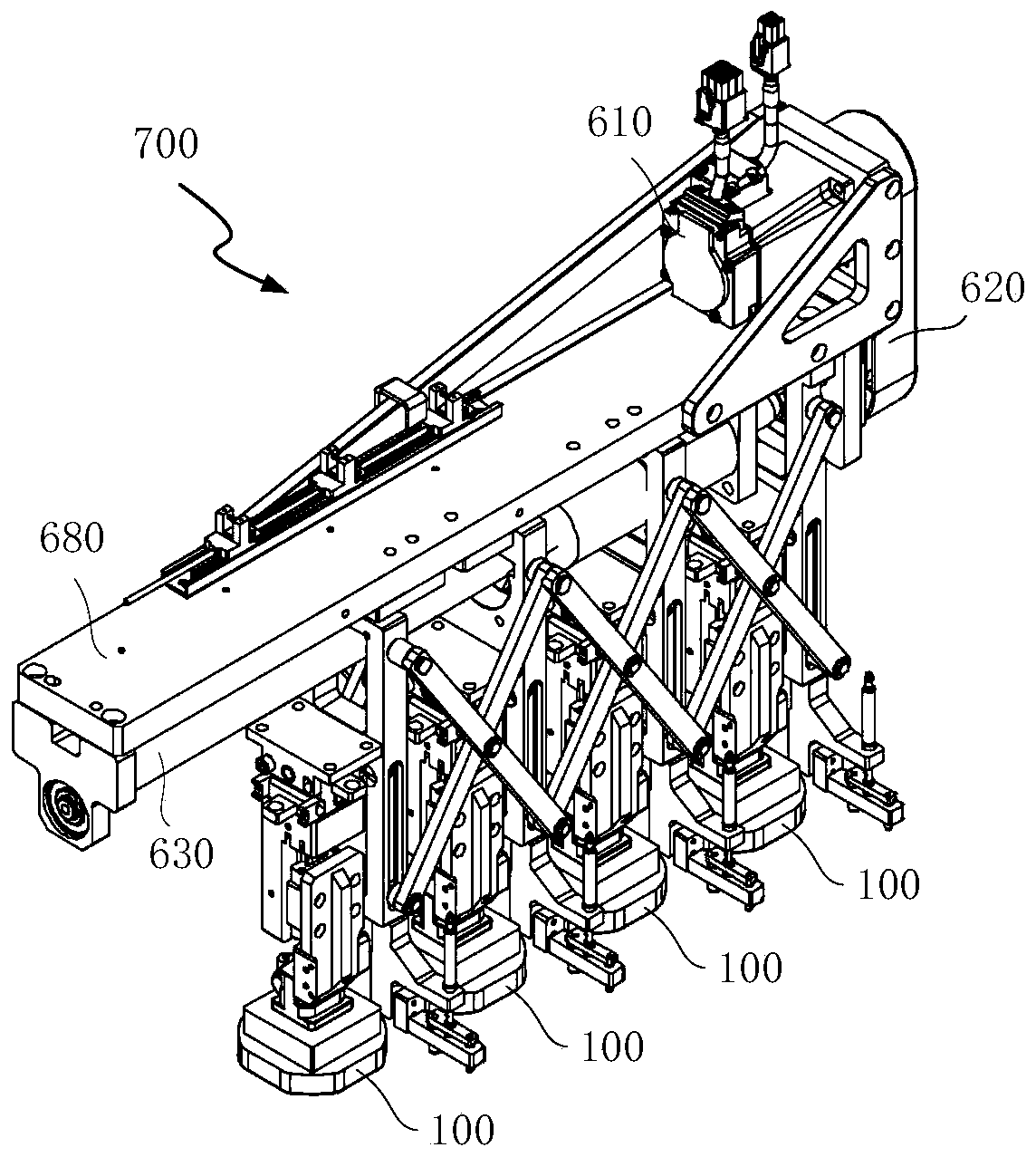

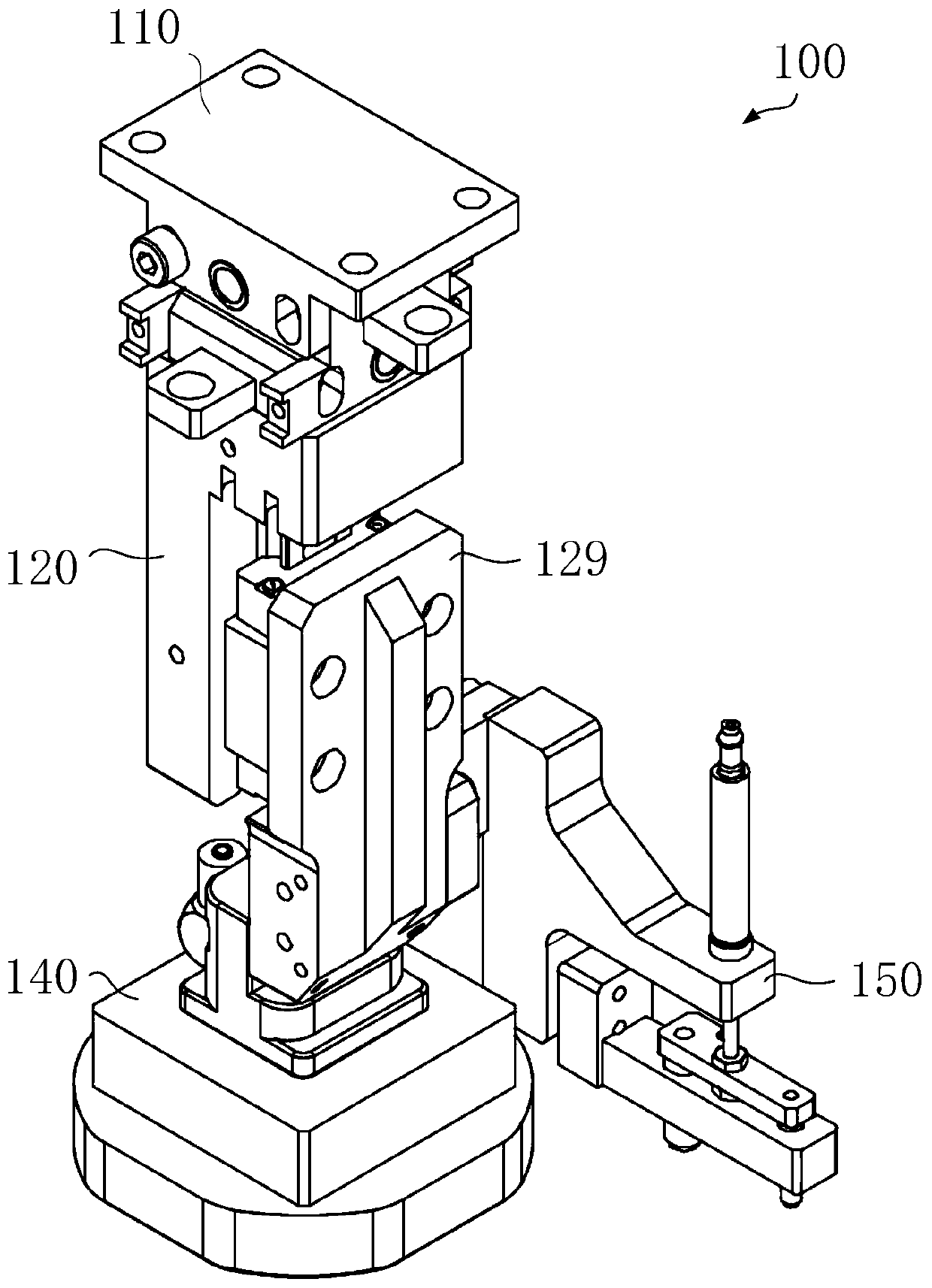

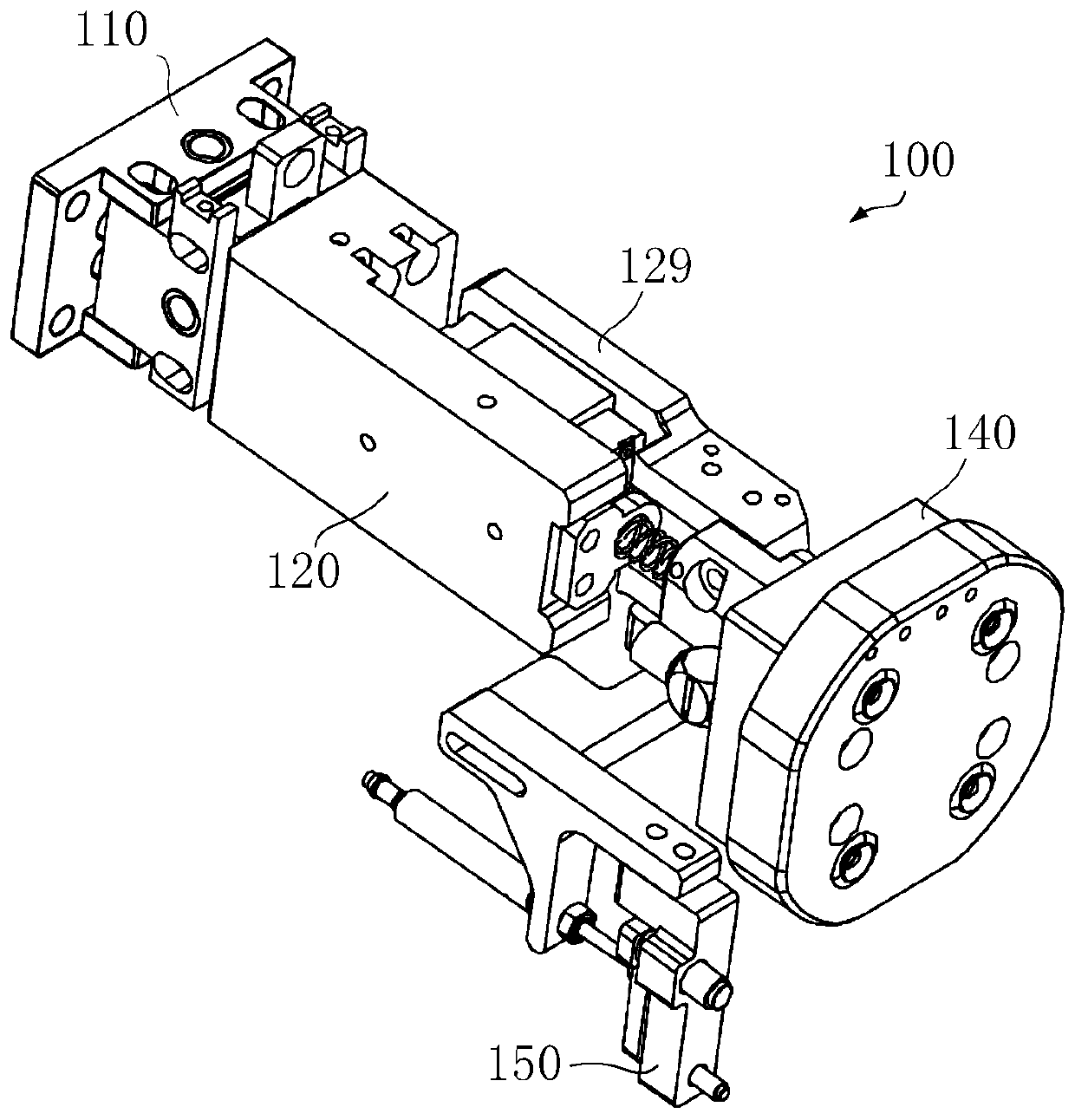

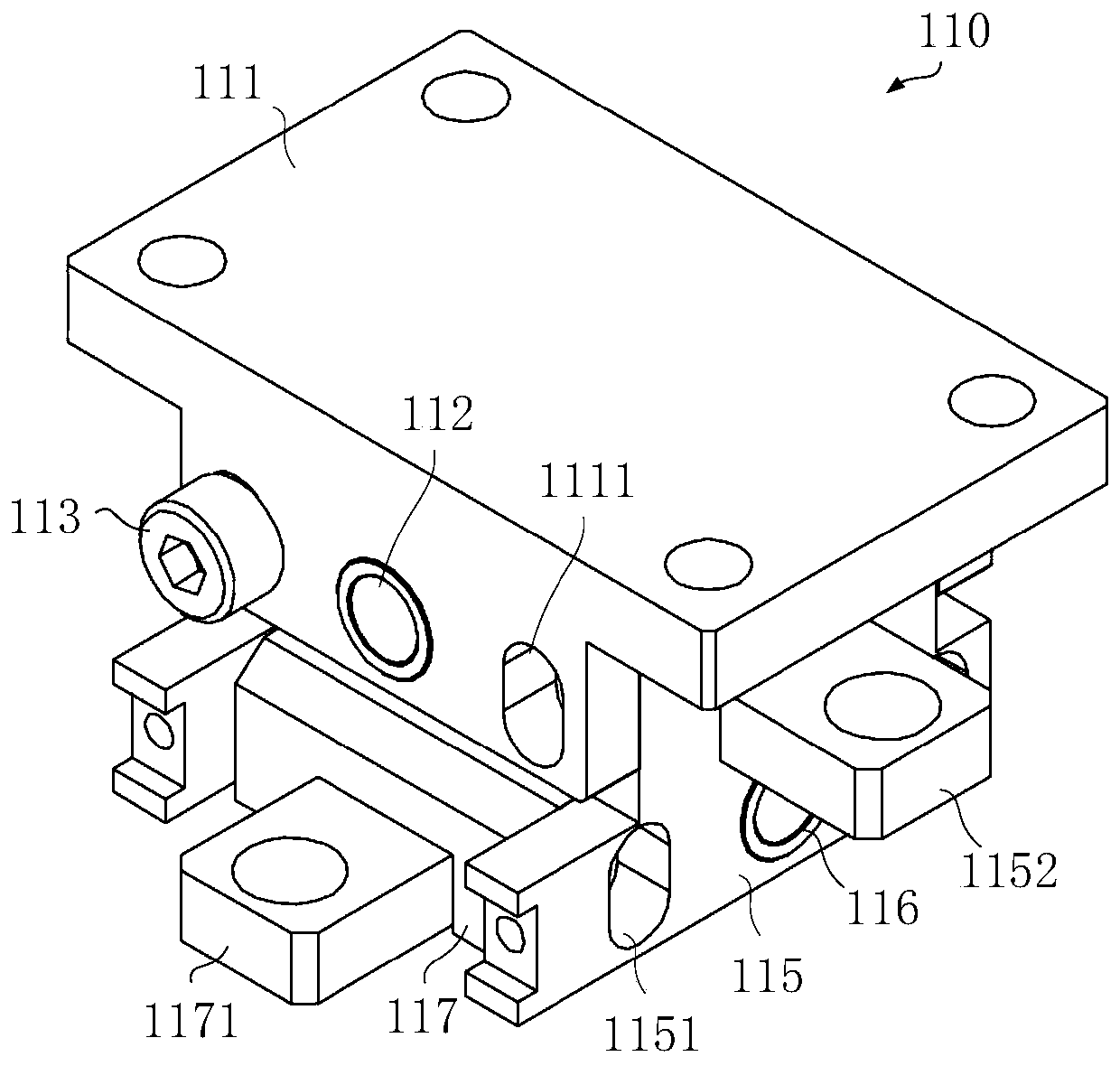

Variable-pitch mechanism and pick-up device with variable-pitch function

PendingCN110436191AMeet the requirements of automatic loading and unloadingSolve the problem of spacing transformationConveyor partsEngineeringElectrical and Electronics engineering

The invention provides a variable-pitch mechanism. The variable-pitch mechanism comprises a variable-pitch unit body provided with a plurality of pick-up units; the variable-pitch unit body comprisesa variable-pitch driver, a variable-pitch movable assembly, variable-pitch fixed plates and a variable-pitch base frame; and the variable-pitch driver drives the variable-pitch movable assembly to move, so that the distance between every two adjacent variable-pitch fixed plates becomes larger or reduced. The invention further relates to a pick-up device with a pitch-variable function. According tothe variable-pitch mechanism, automatic switching of the distances between two adjacent pick-up units is realized through structural design; meanwhile, vacuum negative pressure and magnetic attraction are combined to achieve rapid pickup of to-be-picked workpieces; the device is ingenious in structure, reasonable in design and capable of solving the problem of spacing changing of different stations of the multiple pick-up structures; and meanwhile, the pick-up process is efficient and accurate, the pick-up clamping force is continuously adjustable, and the automatic feeding and discharging requirements of the workpieces are met.

Owner:BOZHON PRECISION IND TECH CO LTD

Full-automatic collection, smashing and compact forming combination machine for field waste crop straws

InactiveCN103271229AQuick pick upImprove the economyBiofuelsSolid fuelsAgricultural engineeringAgricultural science

The invention discloses a full-automatic collection, smashing and compact forming combination machine for field waste crop straws. At the present, the waste straws in farmlands can be only collected by workers because no special mechanical equipment is provided; however, in the busy autumn harvest season, farmers are busy in harvest preferentially and hardly have time to collect the straws. The full-automatic collection, smashing and compact forming combination machine for the field waste crop straws comprises a front-mounted straw automatic picking and pretreating system with an oil cylinder and a traveling base plate integration system, wherein the oil cylinder (12) is connected with a tined wheel (1); the tined wheel is connected with a cutting saw web wheel (2); the cutting saw web wheel is connected with a conveying auger (3); and the conveying auger is connected with a soil shaking and short-distance quick conveying mechanism (4) and a material inlet (5). The full-automatic collection, smashing and compact forming combination machine is used for collecting, smashing and pressing the field waste crop straws.

Owner:NORTHEAST FORESTRY UNIVERSITY

Order processing method and device, server and nonvolatile storage medium

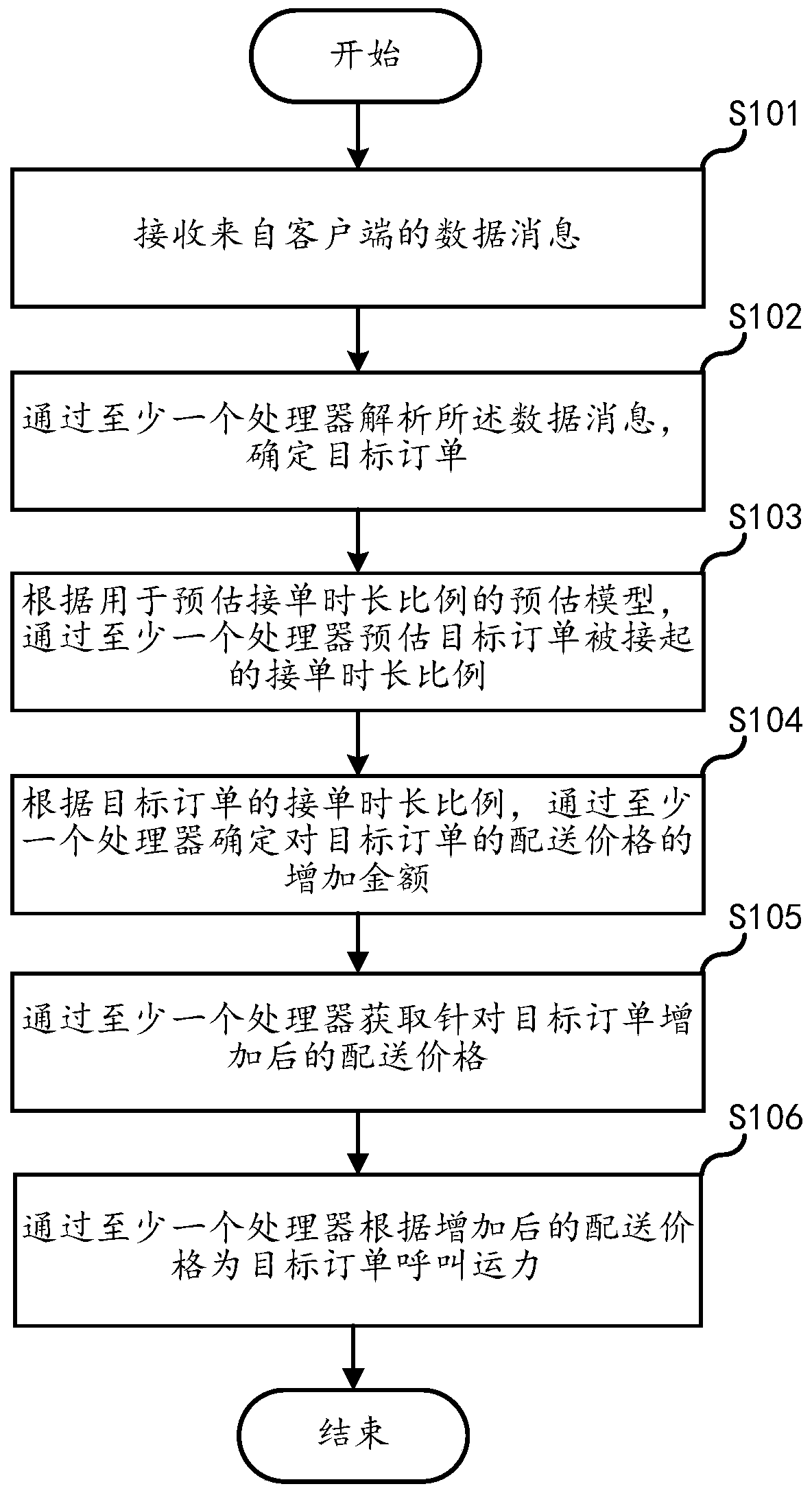

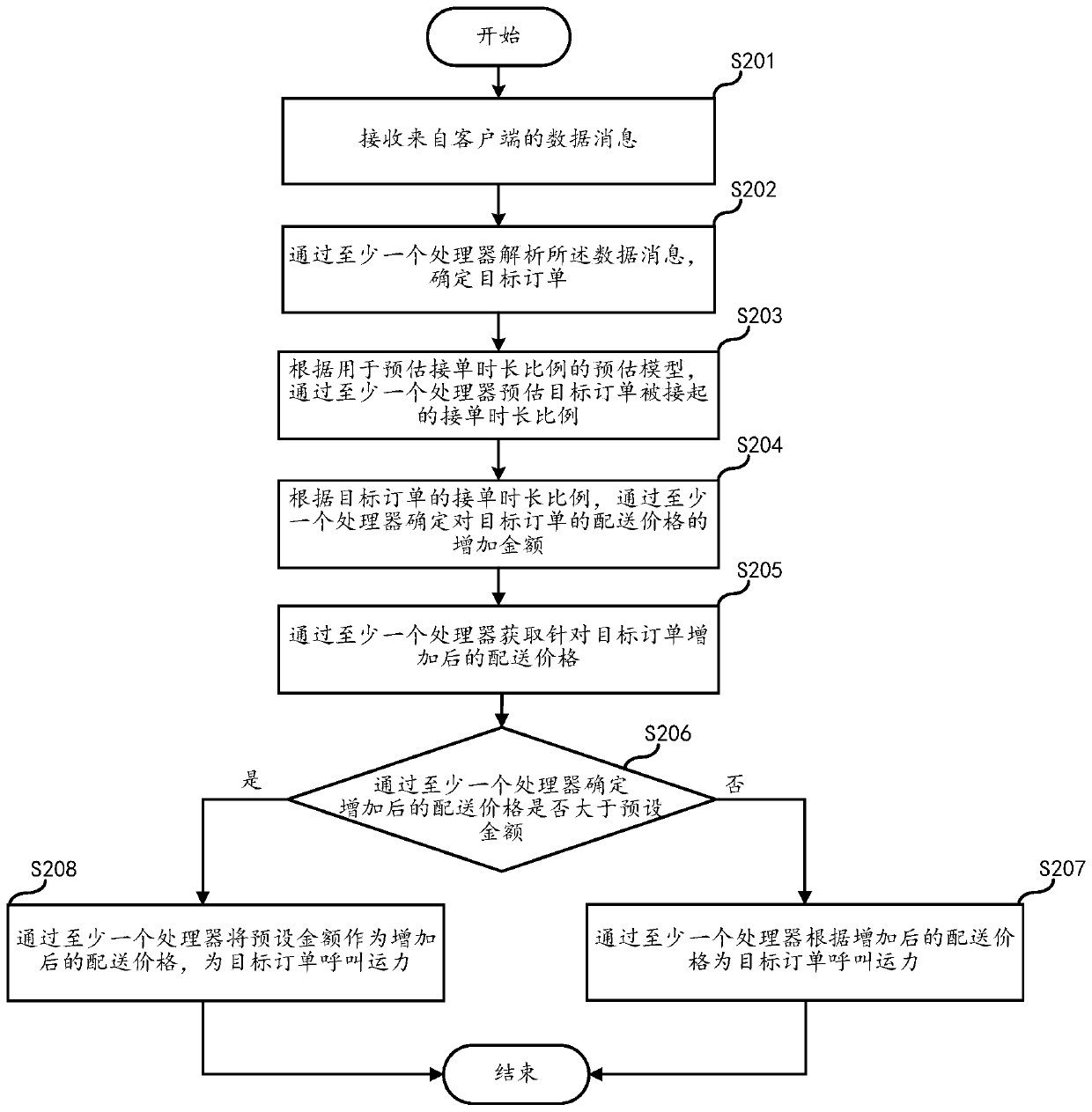

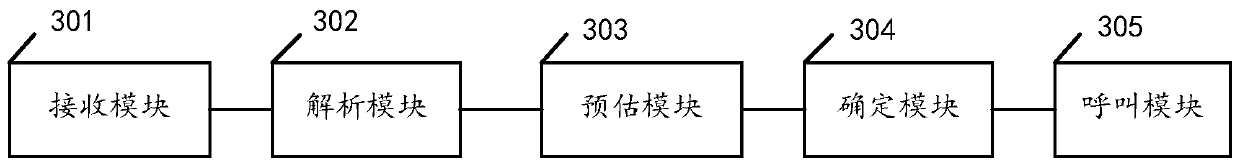

PendingCN111127154AIncrease pick-up speedReduce processingBuying/selling/leasing transactionsLogisticsInformation processingEngineering

The embodiment of the invention relates to the technical field of information processing, and discloses an order processing method and device, a server and a nonvolatile storage medium. The order processing method comprises the steps of analyzing a data message from a client to determine a target order; according to an estimation model used for estimating an order receiving duration proportion, estimating the order receiving duration proportion of the target order being received; wherein the pre-estimation model is obtained by taking pre-collected historical characteristic data of an order asa training sample and carrying out offline training through a machine learning framework; determining an increase amount of the delivery price of the target order according to the order receiving duration ratio of the target order; obtaining an increased delivery price for the target order, and calling transport capacity for the target order according to the increased delivery price. Pricing can be completed rapidly and reasonably, so that the target order can be received rapidly, the processing duration of the target order is shortened, the order quantity processed by the server within the unit duration is increased, and the order processing efficiency of the server can be improved on the whole.

Owner:RAJAX NETWORK &TECHNOLOGY (SHANGHAI) CO LTD

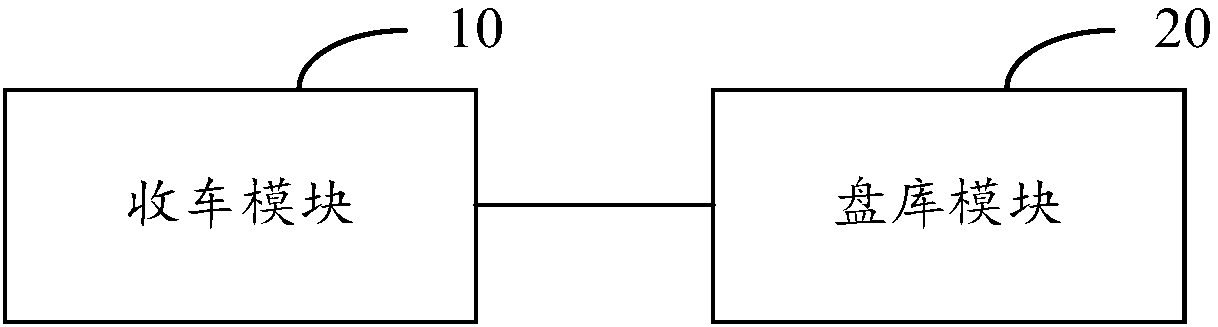

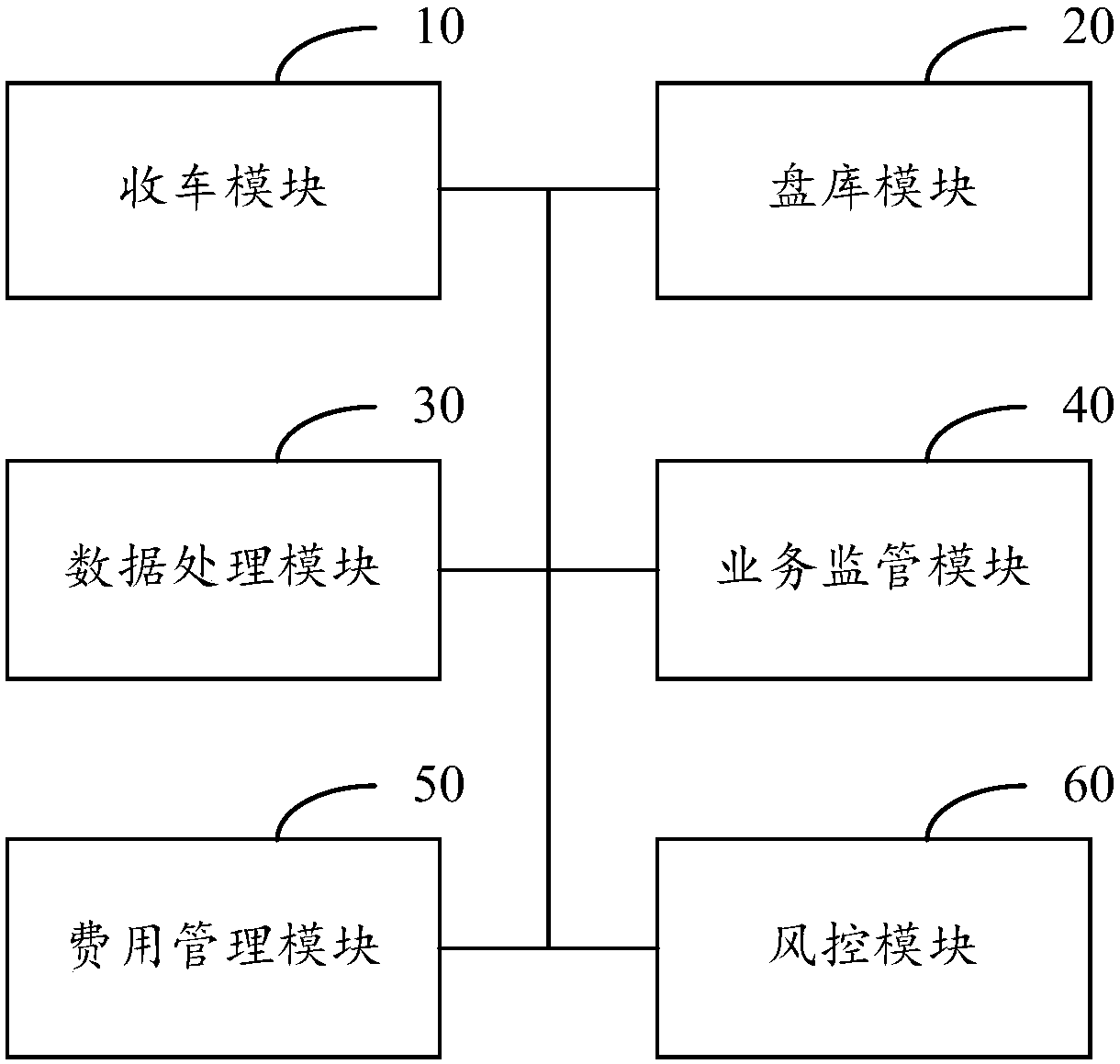

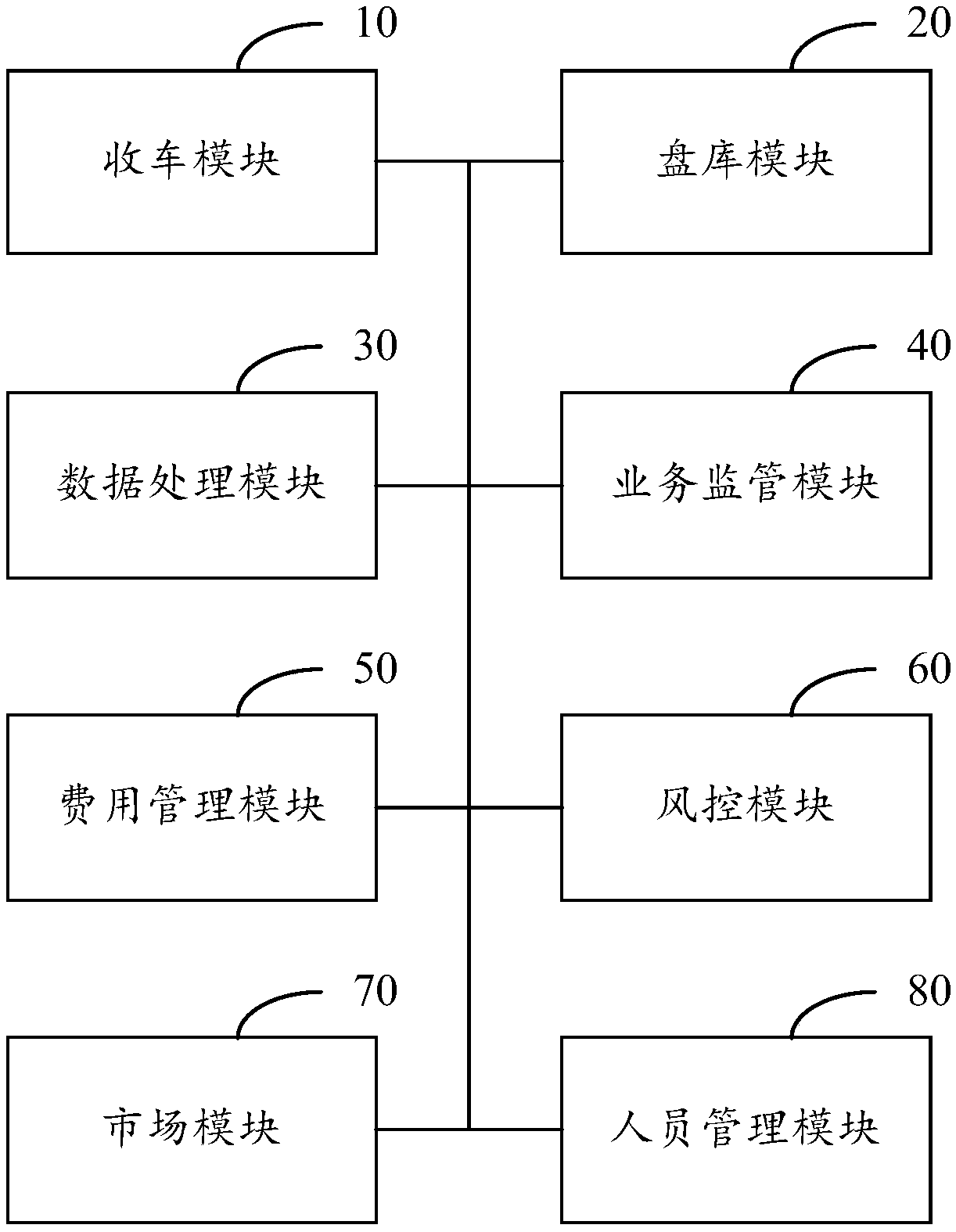

Automobile supervisory system

InactiveCN108280495AAccelerateImprove efficiencyCo-operative working arrangementsLogisticsEngineeringAlarm message

The invention provides an automobile supervisory system. The automobile supervisory system comprises a vehicle collecting module, used for getting first VIN code information to multiple vehicles to becollected and first label information of RFID labels installed on the vehicles to be collected, and binding the first VIN code information and the first label information; a stocktaking module, usedfor generating a stocktaking detailed list according to a binding relation between the first VIN code information and the first label information, and getting second label information of the RFID labels installed on the vehicles to be stock-taken, while the second label information is matched with the stocktaking detailed list, determining that the state of the vehicles to be stock-taken is normal, and while the second label information is not matched with the stocktaking detailed list, generating an alarm message. The automobile supervisory system is capable of, through binding a VIN code andthe label information, rapidly completing the vehicle collection. The speed is rapid, and the efficiency is high. In addition, through binding the VIN code and the label information, the double guarantee can be performed, so errors are not easily generated in a vehicle collecting process, and a stocktaking process is safer and standardized.

Owner:长久金孚企业管理咨询(深圳)有限公司

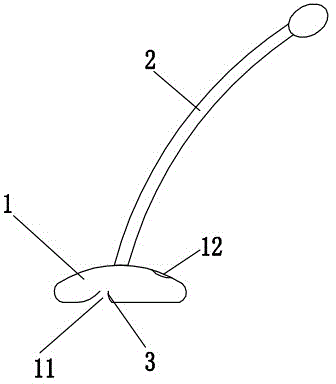

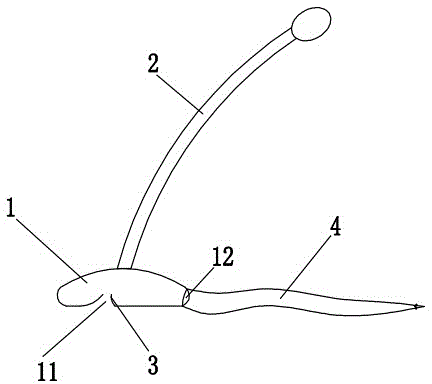

Capsule endoscope feeding device

InactiveCN102871635AReliable releaseCompact structureSurgeryEndoradiosondesCapsule EndoscopesBiomedical engineering

A capsule endoscope feeding device comprises a gastroscope tube, a connection sleeve, a fixing wire and a control wire, wherein the small end of the connection sleeve is arranged on the gastroscope tube, the inner diameter of the larger end is slightly larger than the outer diameter of a capsule endoscope, the length of the connection sleeve is two thirds of the length of the capsule endoscope, and the capsule endoscope is arranged in the large end; the fixing wire is arranged on the large end of the connection sleeve to fix the capsule endoscope; and the control wire penetrates through the gastroscope tube to be connected with the fixing wire. According to the capsule endoscope feeding device, the capsule endoscope left in the alimentary canal or the stomach can be conveniently and quickly taken and fed into the duodenum; for a patient having difficulty in swallowing the capsule endoscope, the capsule endoscope outside the body can be quickly fed into the duodenum; the capsule endoscope feeding device can release the capsule endoscope reliably, is compact in structure and low in manufacture cost, and can be used for the existing universal capsule endoscope.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Pick-up mechanism for workpiece loading and unloading

PendingCN110436190AMeet the requirements of automatic loading and unloadingQuick pick upConveyor partsEngineeringDISC assembly

The invention provides a pick-up mechanism for workpiece loading and unloading. The mechanism comprises a pick-up unit body, wherein the pick-up unit body comprises a first drive assembly, a sucking disc assembly and a magnetic attraction assembly, and the sucking disc assembly and the magnetic attraction assembly are fixedly connected to a movable block of the first drive assembly; the sucking disc assembly comprises a plurality of sucking discs for adsorbing a to-be-picked-up workpiece; the magnetic attraction assembly comprises magnets for adsorbing the ferromagnetic portion of the to-be-picked-up workpiece ; and driven by the first drive assembly, the sucking disc assembly and the magnetic attraction assembly move towards the to-be-picked-up workpiece so as to correspondingly pick up different parts of the to-be-picked-up workpiece. The pick-up mechanism for workpiece loading and unloading has the advantages of being ingenious in structure and reasonable in design; vacuum negativepressure and magnetic attraction are jointly adopted, so that fast pickup for the to-be-picked-up workpiece is achieved, thus solving the problem of fast pickup for an irregular workpiece; and meanwhile, the pick-up process is efficient and accurate, and pick-up clamping force can be continuously adjusted, thus meeting the requirements of automatic workpiece loading and unloading.

Owner:BOZHON PRECISION IND TECH CO LTD

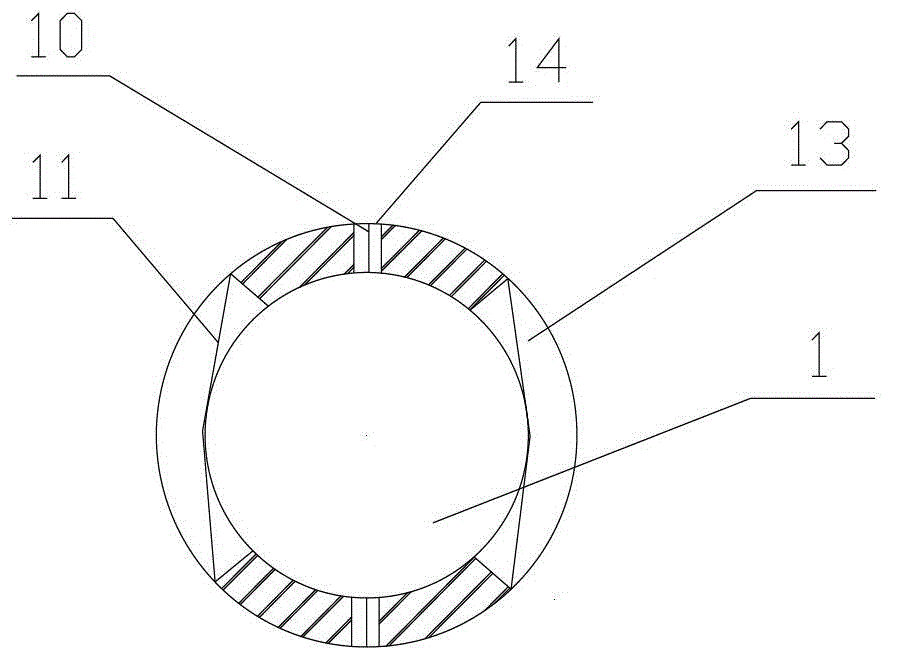

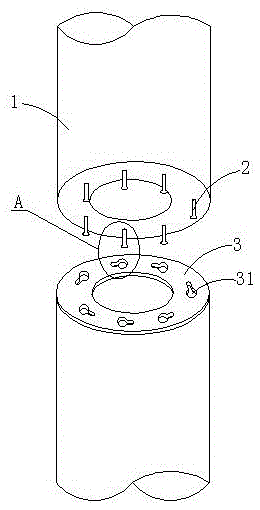

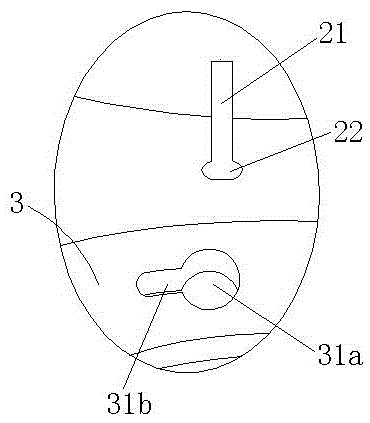

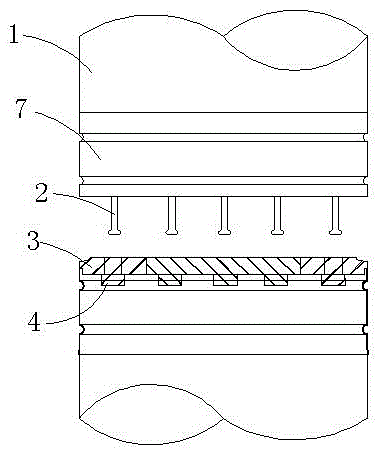

Foundation treatment pile and pile splicing method thereof

InactiveCN105484258AFully consider the force characteristicsReduce physical hazardsBulkheads/pilesBuilding constructionLoad bearing

The invention discloses a foundation treatment pile and a pile splicing method thereof. The foundation treatment pile comprises a pile body formed by sequentially connecting precast single piles, a connecting head is arranged at one end of each precast single pile, each connecting head comprises a rod body axially arranged and an expansion head at the external end of the rod body, and the diameter of the expansion head is larger than that of the rod body; an end plate is fixed at the other end of each precast single pile, connecting holes matched with the connecting heads are formed in the end plates, the connecting holes comprise communicated rib inserting holes and rib sliding holes adopting long-strip-shaped structures, the diameters of the rib inserting holes are larger than the diameters of the expansion heads, and the widths of the rib sliding holes are larger than the diameters of the rod bodies and smaller than the diameters of the expansion heads; by adopting the mechanical connection way that the connecting heads are matched with the connecting holes, on-site quick pile splicing is achieved, and the foundation treatment pile provided by the invention has the advantages that the structure is simple, the construction efficiency is high, the cost is low, and the load bearing capability of the pile is strong.

Owner:ZHONGCHUN GAOKE PILE IND

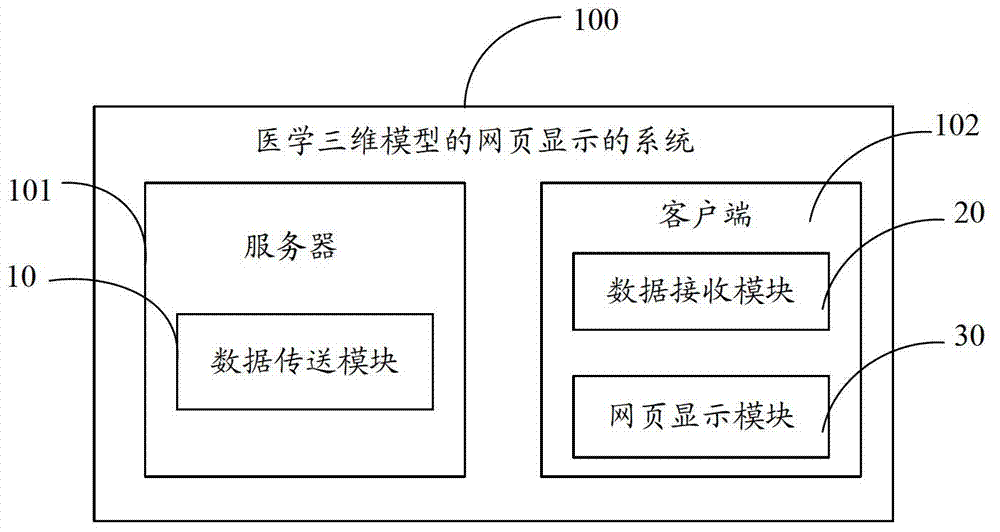

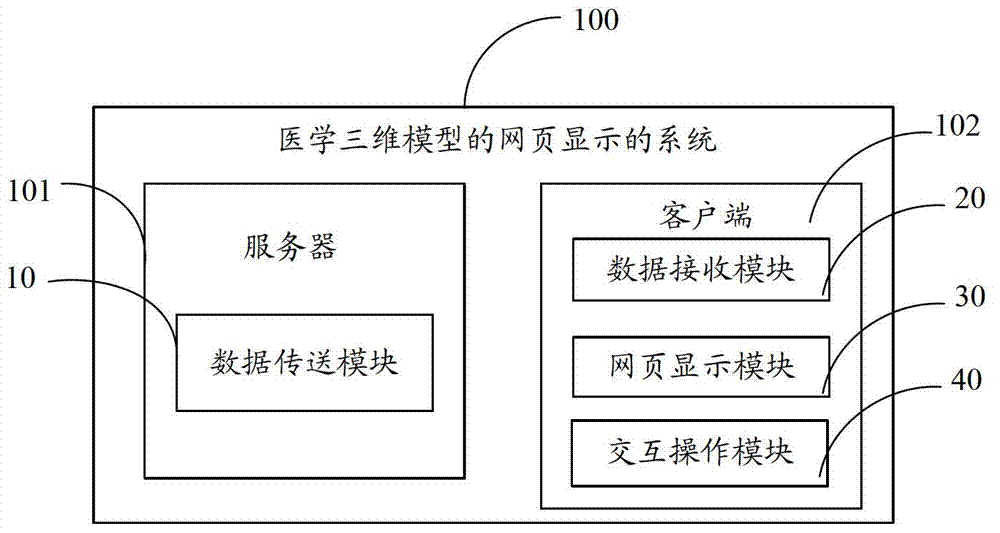

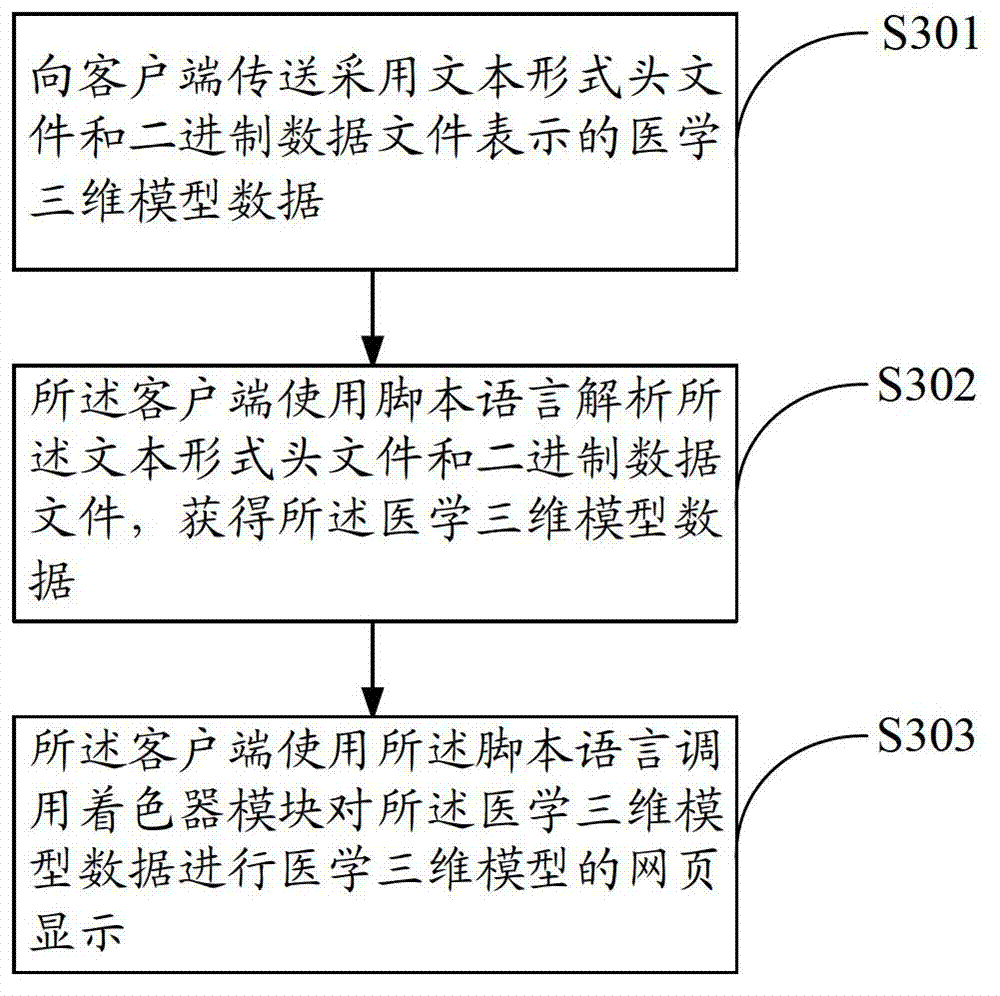

Method for webpage displaying of three-dimensional medical model and system thereof

ActiveCN102880454AImprove network transmissionImprove efficiencyTransmissionSpecific program execution arrangementsScripting languageWeb page

The invention is suitable for the technical field of three-dimensional medical model application, and provides a method for webpage displaying of a three-dimensional medical model, and a system thereof. The method comprises the steps as follows: A, three-dimensional medical model data shown by a txt header file and a binary data file is transmitted to a client; B, the client analyzes the text header file and the binary data file by utilizing a scripting language to obtain the three-dimensional medical data; and C, the client utilizes the scripting language to call a shader module to display the webpage of the three-dimensional medical model on the three-dimensional medical model data. Therefore, the network transmission speed of the three-dimensional medical model data is increased, and the efficiency of the webpage displaying of the three-dimensional medical model is improved with the adoption of the method and the system.

Owner:SHENZHEN YORATAL DMIT

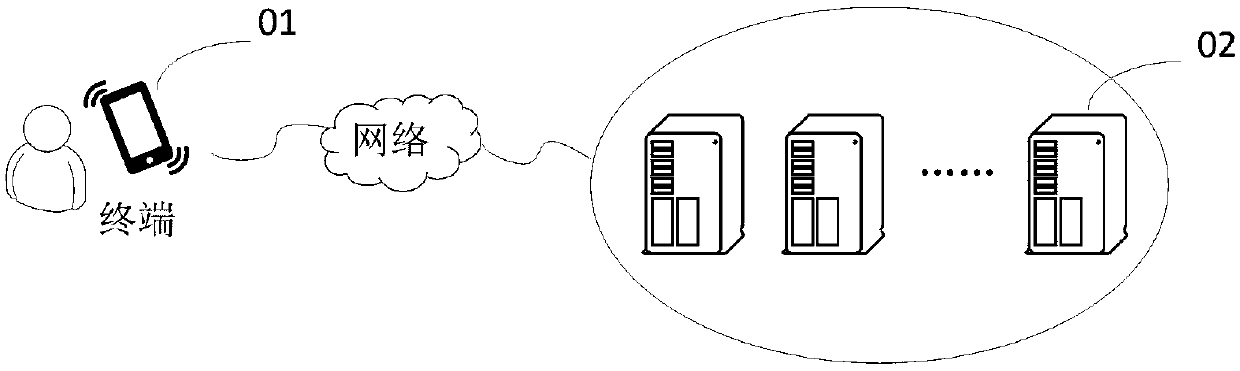

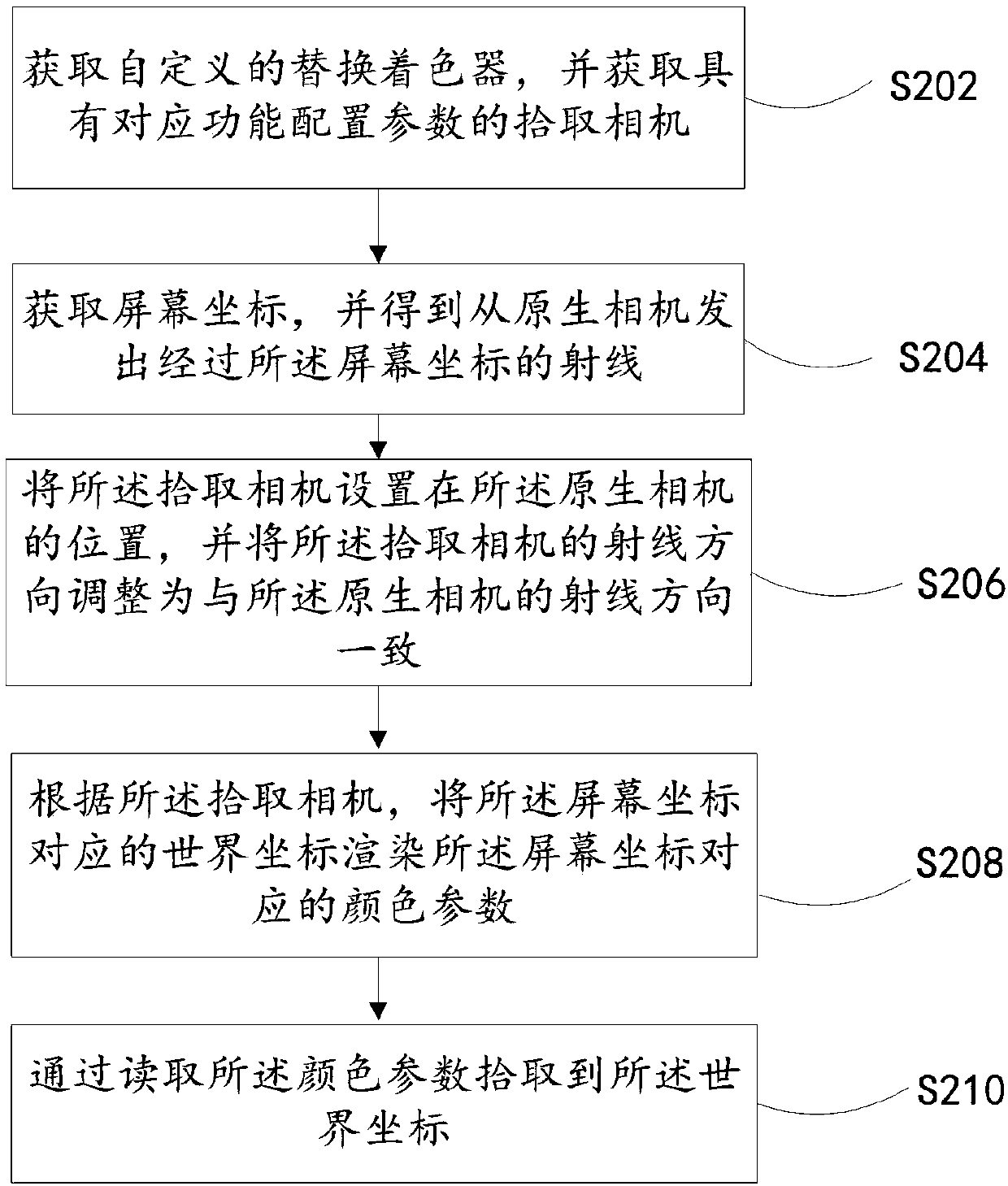

Method and device for picking coordinates, equipment and storage medium

The invention discloses a method and device for picking coordinates, equipment and a storage medium. The method includes the steps of obtaining a user-defined replaced shader and a picking camera withcorresponding functional configuration parameters; obtaining screen coordinates and rays which are emitted by a holo camera and pass by the screen coordinates; setting the picking camera on the position of the holo camera and adjusting the ray direction of the picking camera to be identical to that of the holo camera; according to the picking camera, conducting rendering on world coordinates corresponding to the screen coordinates according to color parameters corresponding to the screen coordinates; reading the color parameters to pick the work coordinates. The device is simple in implementation mode and stable in performance. The implementation process is efficient, and the coordinates can be picked quickly.

Owner:友谊时光科技股份有限公司

Automatic lamination device of distribution transformer

ActiveCN112786305AImprove work efficiencyEasy to replaceInductances/transformers/magnets manufactureDistribution transformerClassical mechanics

The invention relates to an automatic lamination device, and especially relates to an automatic lamination device for a distribution transformer. The invention provides the automatic lamination device for the distribution transformer, which can be used for automatically laminating and reducing a large amount of manpower. The automatic lamination device for the distribution transformer comprises: a bottom plate provided with a first supporting plate; a limiting mechanism arranged on the first supporting plate; a transmission mechanism arranged at the bottom of the first supporting plate; and a driving mechanism arranged on the bottom plate, wherein the driving mechanism is matched with the transmission mechanism. The driving mechanism rotates to drive the transmission mechanism to rotate, and the transmission mechanism rotates to drive the limiting mechanism to slide oppositely to stack the iron cores.

Owner:晋中益电变压器有限公司

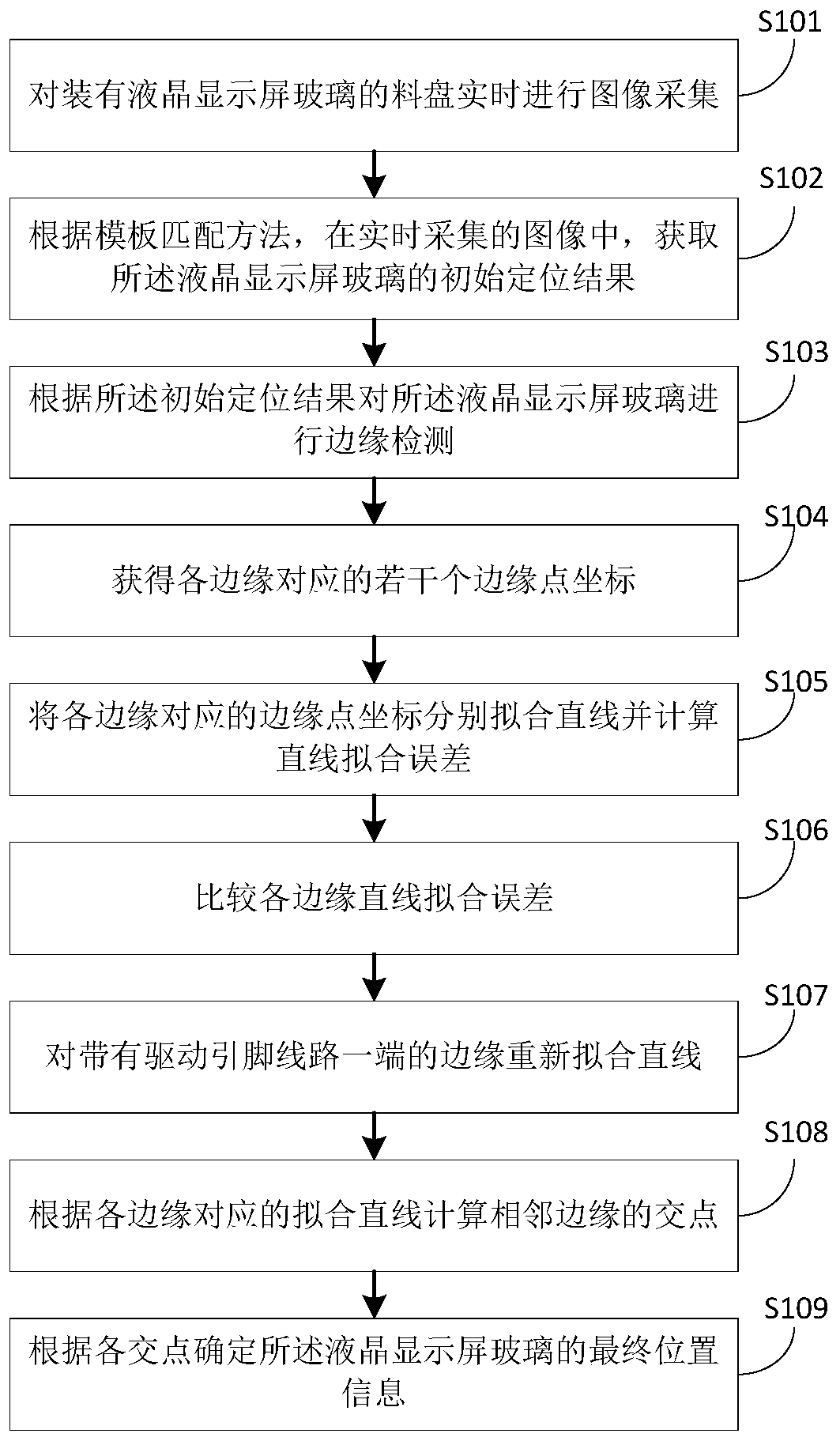

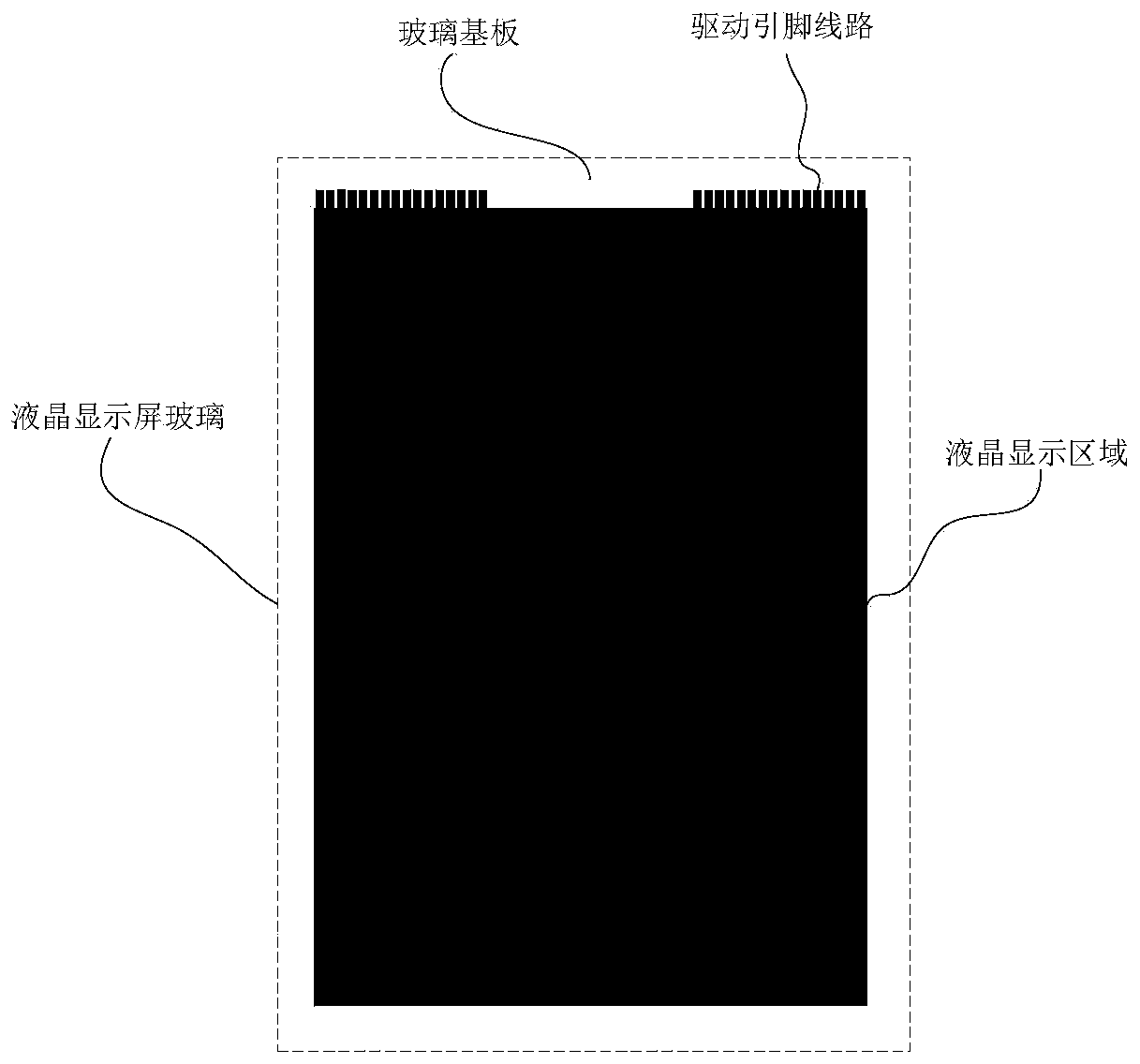

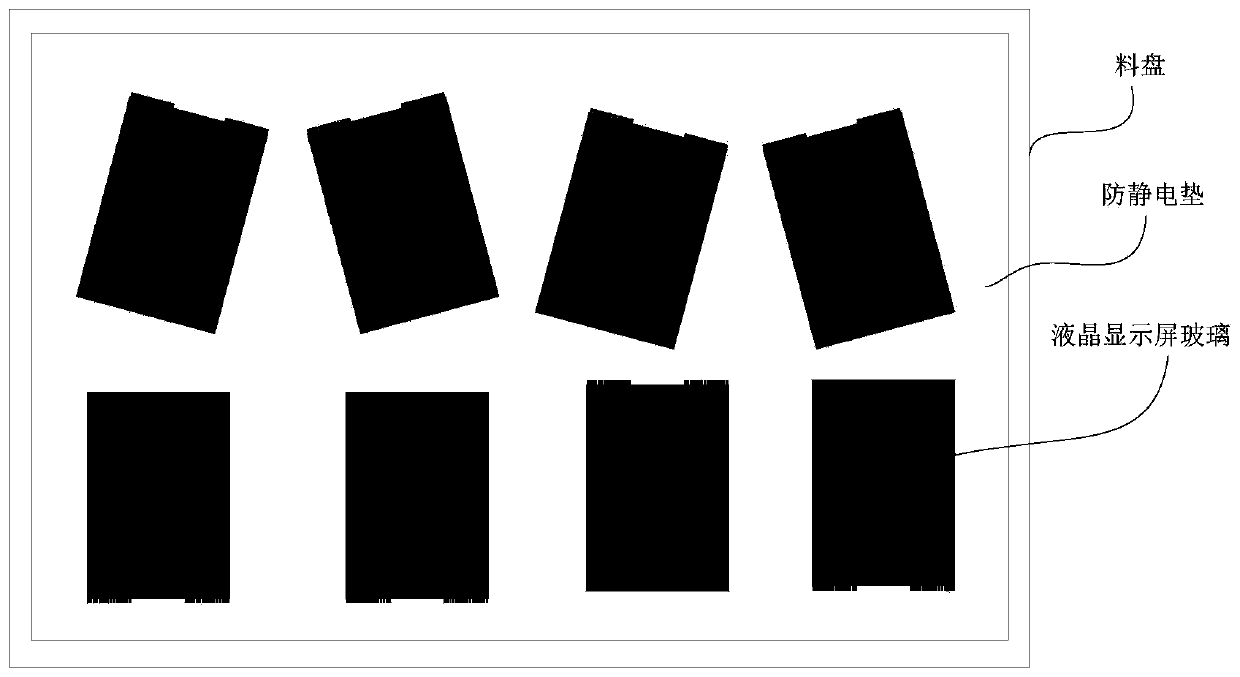

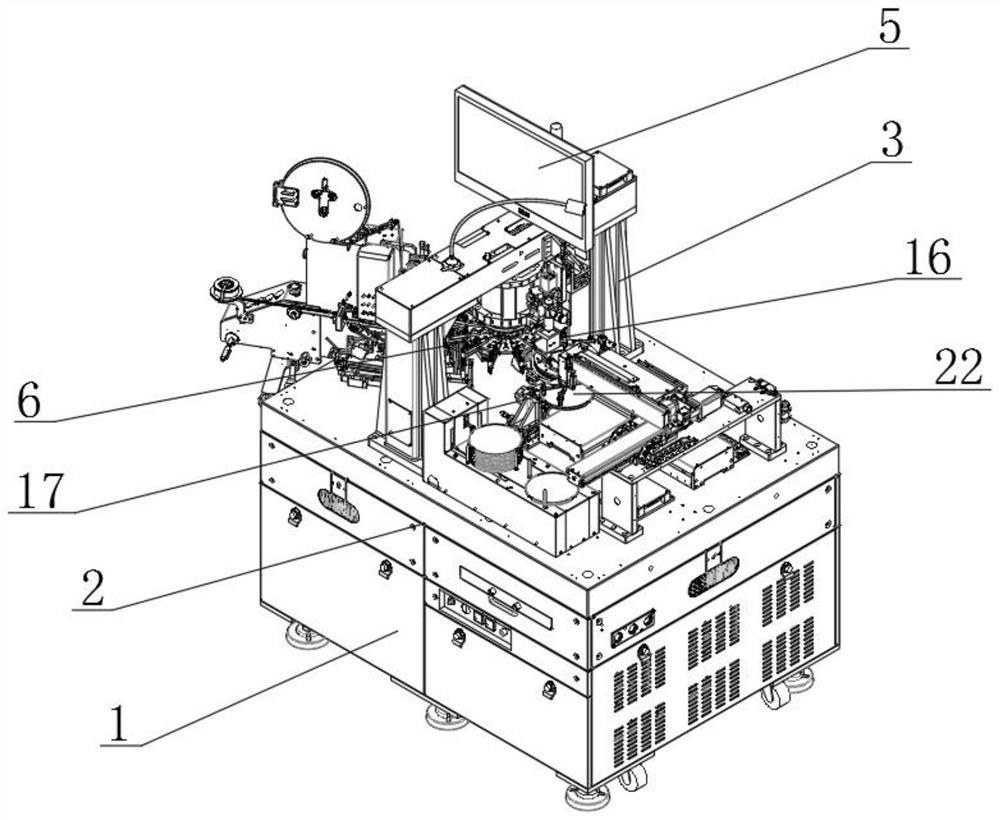

Liquid crystal display glass positioning and picking method and system and visual processing system

ActiveCN110281240AQuick pick upPick up accuratelyProgramme-controlled manipulatorImage analysisTemplate matchingLiquid-crystal display

The invention discloses a liquid crystal display glass positioning and picking method and system and a visual processing system. A robot is adopted for grabbing liquid crystal display glass; a corresponding imaging system is designed according to the characteristics of the liquid crystal display glass and a material disc; and a liquid crystal display glass image positioning method is provided according to the actual imaging characteristic of the liquid crystal display glass. Firstly, a template matching method is adopted for obtaining a liquid crystal display glass initial positioning result in an image, then the edge points on all the edges of the liquid crystal display glass are detected, and finally the position and angle of the liquid crystal display glass are calculated according to the edge points on each edge. The position and angle of the liquid crystal display glass can be fast and precisely positioned even though the liquid crystal display glass is arbitrarily placed in the material disc; then the visual processing system cooperates with a robot controller, the position and angle information for precisely positioning the liquid crystal display glass is converted into the axle position of robot picking, and therefore the robot can pick the product fast, accurately and stably.

Owner:北京博视智动技术有限公司

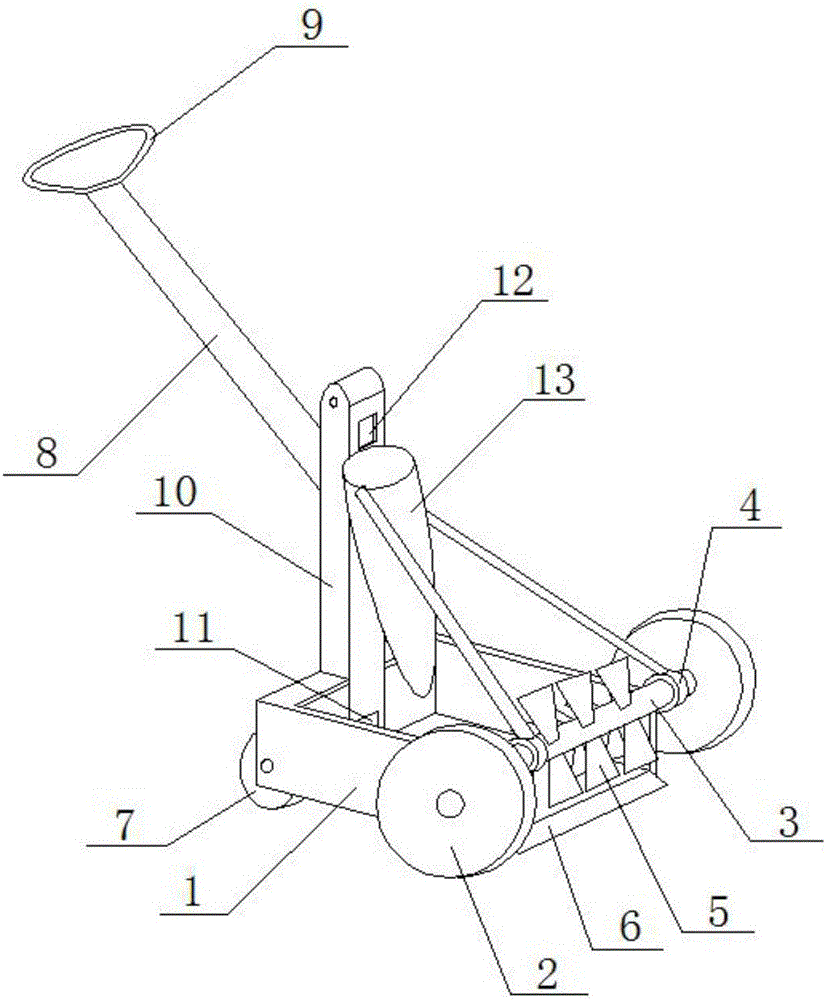

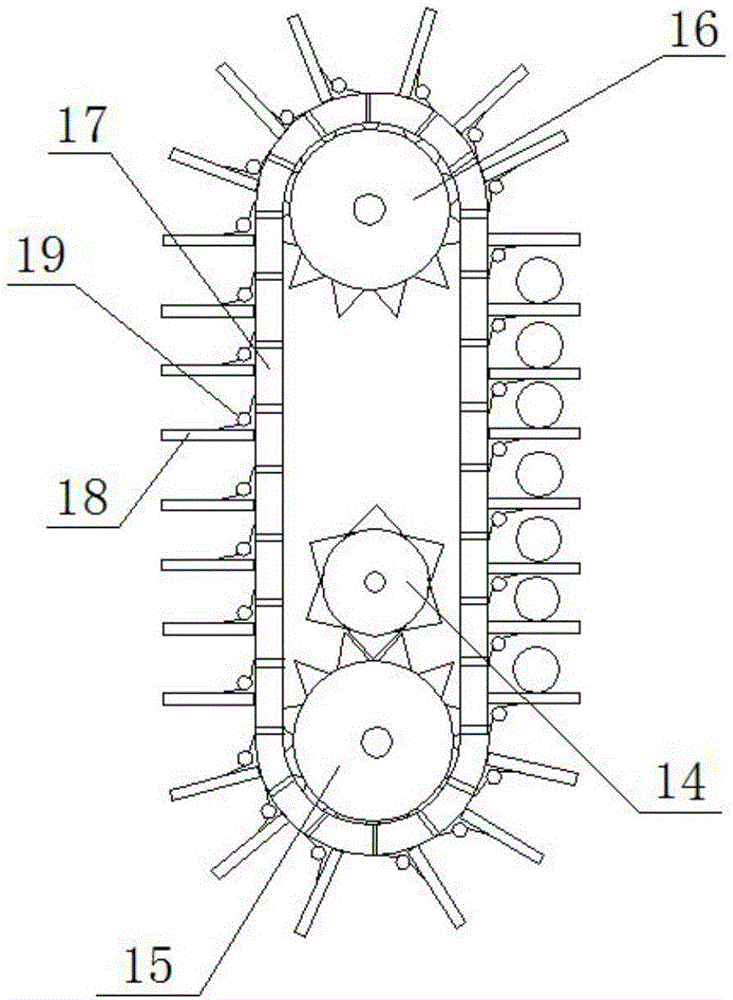

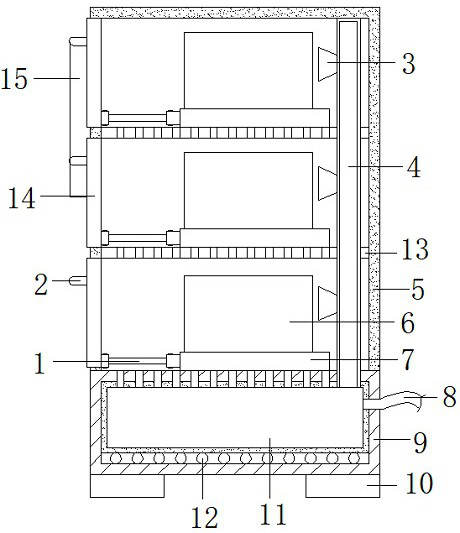

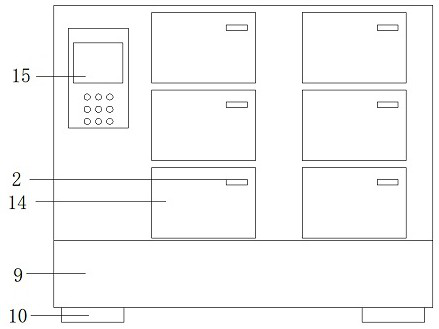

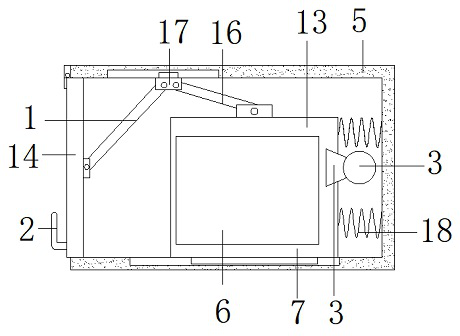

Rapid batch ball picking-up device applied to table tennis training base

InactiveCN106581965ARealize pick-up and transferEasy to operateBall sportsRacket sportsTransfer mechanismTennis ball

The invention discloses a rapid batch ball picking-up device applied to a table tennis training base. The device comprises a moving mechanism, a ball scraping mechanism, a transfer mechanism and a collection bag, wherein the moving mechanism comprises a collection tank, two front wheels, two rear wheels and a push frame; the collection tank is of a box-shaped structure of which the front end is open; two bearings are arranged at the front end of the collection tank; a connecting shaft penetrates through the two bearings; the two front wheels are respectively fixed at two ends of the connecting shaft; the two rear wheels are fixed on the rear lower side of the collection tank; the push frame is fixed above the collection tank; the transfer mechanism comprises a sleeve, and a ball inlet and a ball outlet which are respectively formed in the lower part and the upper part of the sleeve; the collection bag is arranged at the ball outlet; and a lifting structure used for lifting table tennis balls from bottom to top is arranged in the sleeve. With the adoption of the above structure, the ball picking-up operation can be efficient, the table tennis balls can be collected into the collection bag from the ground without bending down, and the balls can be uninterruptedly picked up basically.

Owner:GUANGZHOU KAIYAO ASSET MANAGEMENT CO LTD

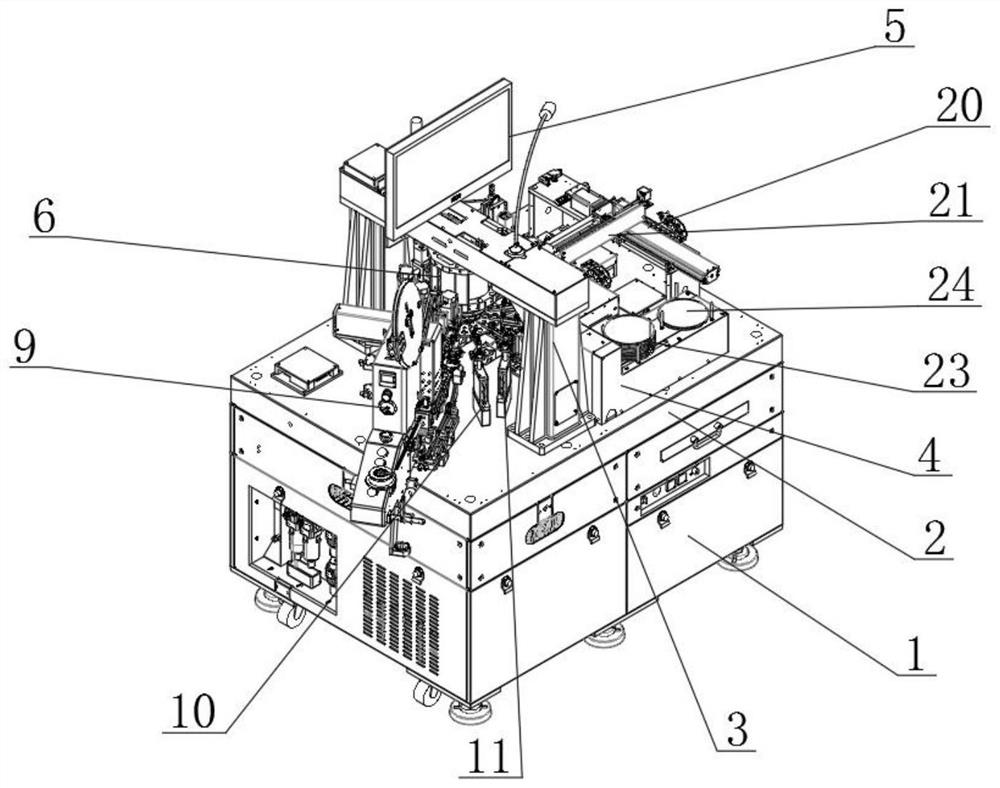

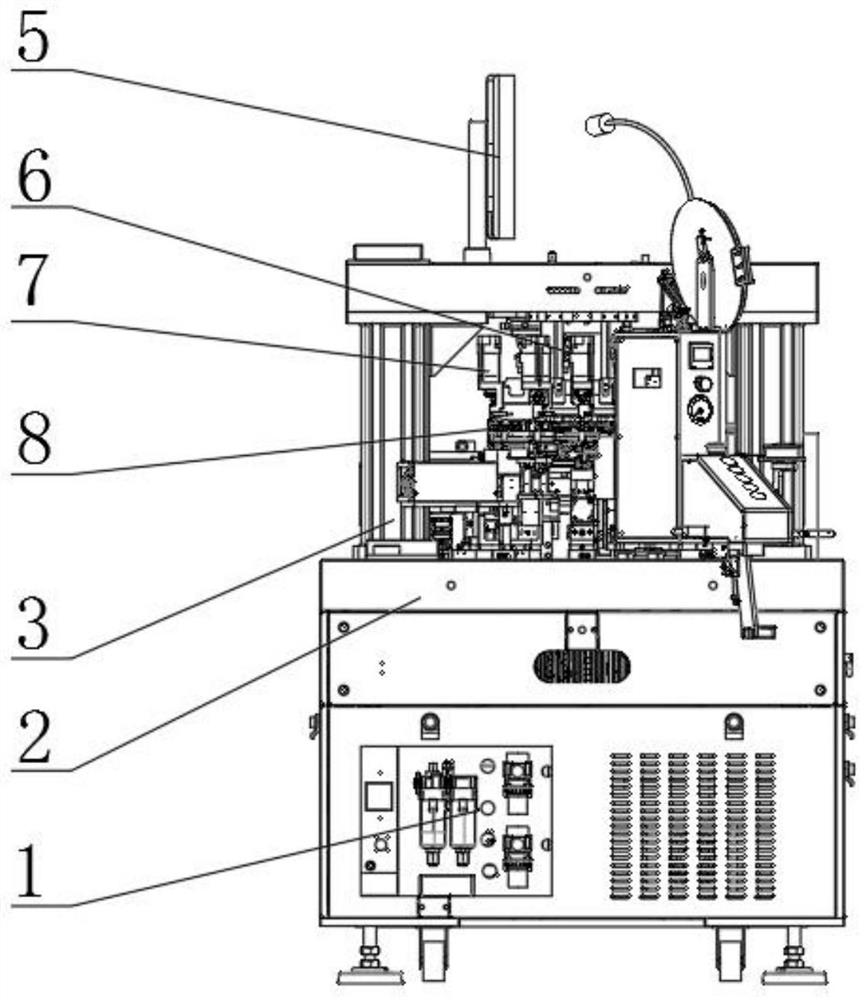

Wafer chip product testing and braiding equipment and processing method thereof

PendingCN112820683AHigh-speed spatial location transferPrecise spatial position transferSemiconductor/solid-state device manufacturingConveyor partsProduct testingWafer

The invention discloses wafer chip product testing and braiding equipment and a processing method thereof. The wafer chip product testing and braiding equipment comprises an equipment electric box cabinet used for providing power supply power for the whole equipment. The equipment electric box cabinet comprises a workbench and a gantry vertical arm mechanism, and the bottom end of the gantry vertical arm mechanism is connected to the surfaces of the two sides of the workbench through bolts, and the gantry vertical arm mechanism is used for fixing a vacuum turret module movably arranged at the bottom end of the gantry vertical arm mechanism, and the wafer disc lifting mechanism is arranged on the side, away from the gantry vertical arm mechanism, of the surface of the workbench. According to the invention, the wafer feeding system, the vacuum turret system and the chip closing processing system are reasonably arranged and formed, and through close cooperation of the wafer feeding system, the vacuum turret system and the chip closing processing system, high-speed, accurate and reliable spatial position transfer of wafer chip products can be carried out on the same equipment, rapid picking and testing of the wafer chip products from a wafer blue film are realized. The problems of dark cracks, scratches, damages and the like on wafer chip products in the process are avoided, manpower is saved, and the production efficiency is improved.

Owner:NORTECH AUTOMATION SHENZHEN CO LTD

Device for picking up ball

InactiveCN104689536AReasonable structural designEasy pick upBall sportsMechanical engineeringEngineering

Owner:陈仕兰

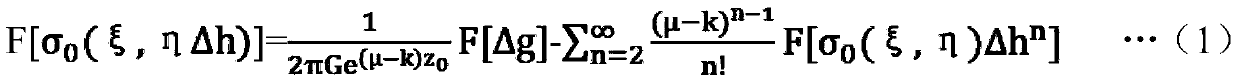

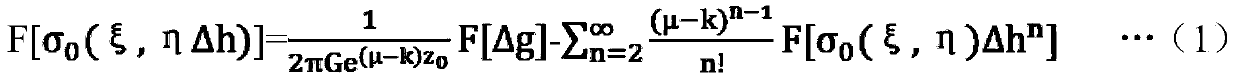

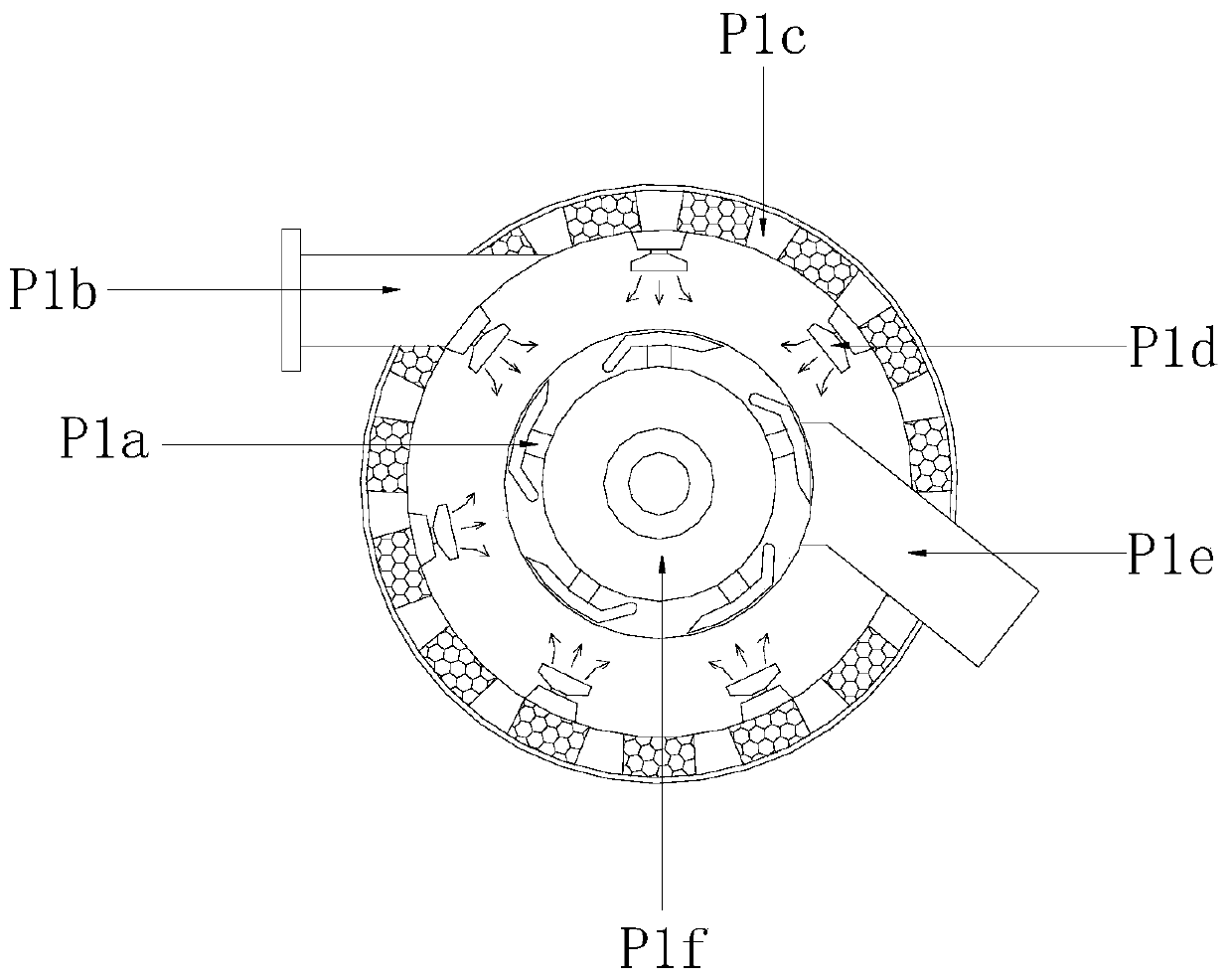

Method for picking up underground deep structure information

ActiveCN111045098AEasy to operateImprove effectivenessGravitational wave measurementUranium mineGravity anomaly

The invention belongs to the technical field of uranium mine geophysical exploration, and particularly relates to a method for picking up underground deep structure information. The method comprises the following steps of: acquiring precise longitude and latitude coordinates and elevation data of measuring points in a uranium resource exploration region of a basin; selecting a small scale to deploy a measuring net in the basin exploration region, and carrying out high-precision gravity measurement in the region to obtain gravity data; performing density measurement on a rock specimen in the collection and investigation region; carrying out elevation correction, Bouguer gravity anomaly correction and latitude correction on the gravity data to obtain gravity anomaly delta g values of the measuring points, carrying out edge expansion processing, and performing gridding processing on all the smoothed delta g values to obtain a Bouguer gravity anomaly grid and the like; and analyzing and interpreting the residual map in combination with the rock stratum density data in the step 3, and extracting the change features of the deep structure information in the region.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

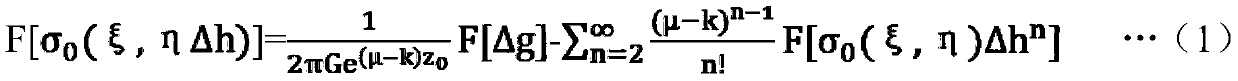

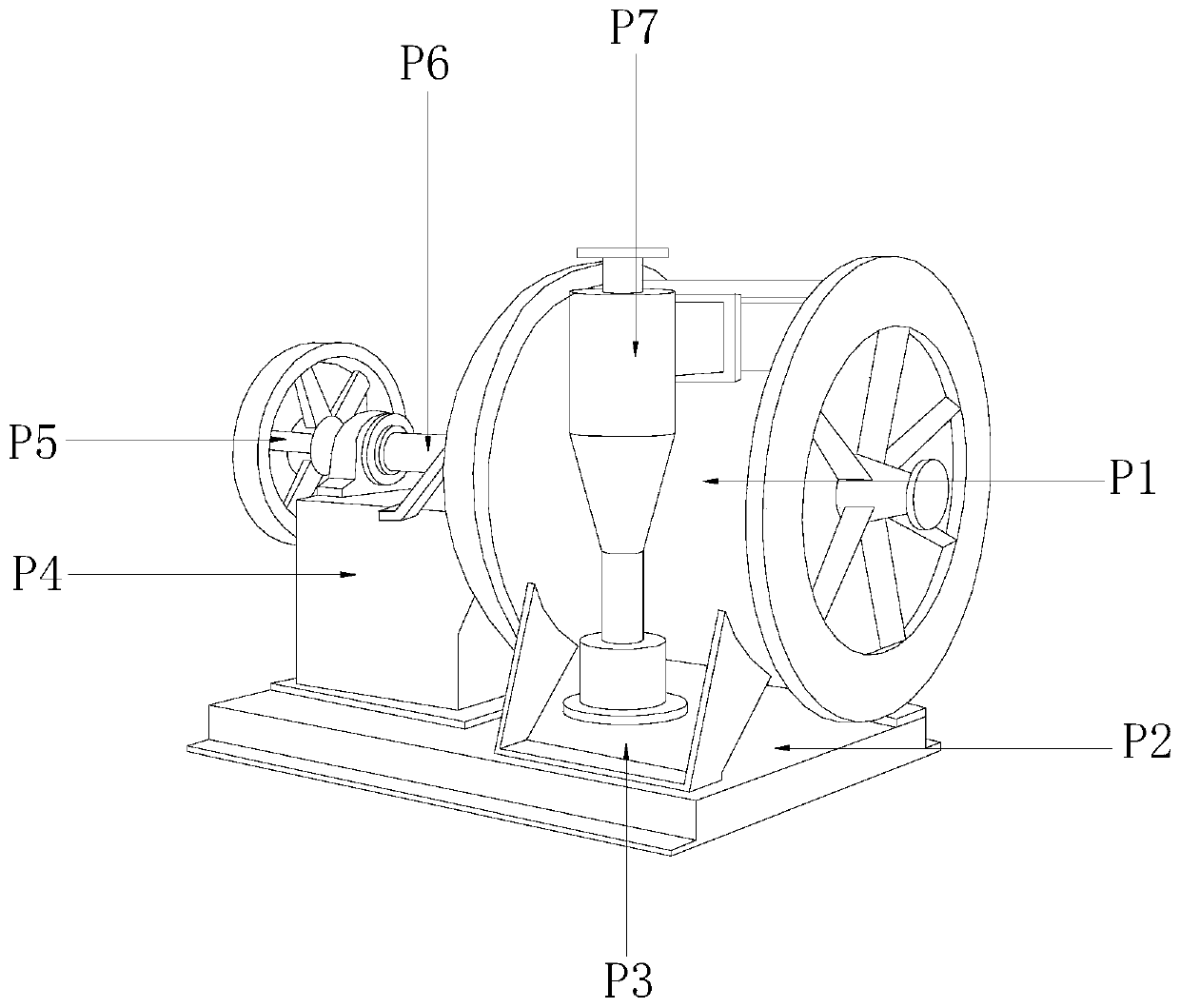

Sanitary pad fiber separation device by utilizing leading, absorbing and scraping principle

ActiveCN110479740AConvenient scattered collectionAchieve disruptionTransportation and packagingSolid waste disposalEngineeringFiber

The invention discloses a sanitary pad fiber separation device by utilizing a leading, absorbing and scraping principle. The sanitary pad fiber separation device structurally comprises a separation bin, a fixing base, positioning support legs, a control host, a belt wheel, a driving shaft and a crushing mechanism, wherein the bottom of the separation bin is buckled at the right end of the top of the fixing base through the positioning support legs; and the control host is arranged at the left end of the top of the fixing base. According to the sanitary pad fiber separation device, heavy substances are diffused outside under the driving of water flow stirring and are absorbed by a side scraping net and then guided out of a heavy substance discharge pipe; a pressurization mechanism in the separation bin is capable of disturbing and controlling the water pressure in the middle through a water wave plate while performing flow stirring, so that the light substances are quickly picked up bya guide assembly; and the light substances picked up by a fiber scraping piece are shifted inward by a progressive frame, so that the absorption efficiency of an absorption opening is greatly improved, and the loss of fiber is avoided.

Owner:西藏瑞华资本管理有限公司

Take-out placement cabinet with heat preservation function for catering

PendingCN112545215ASolve functionSolve the problem of inconvenient pickupFurniture partsCabinetsProcess engineeringHeat conservation

Owner:湖南杨家大院餐饮文化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com