Piezoelectric ultrasonic vibration absorption picker

A piezoelectric ultrasonic and pick-up technology, which is applied in the direction of fluid, manipulator, chuck, etc. using vibration, can solve the problems of slow suction and exhaust speed, low work efficiency, uneven suction and pick-up force, etc., and achieve uniform suction and grasping force. , reduce energy consumption, high pickup efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

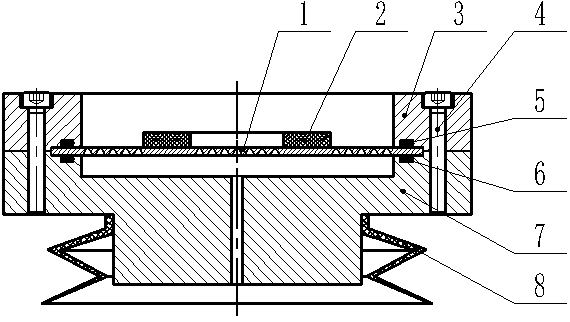

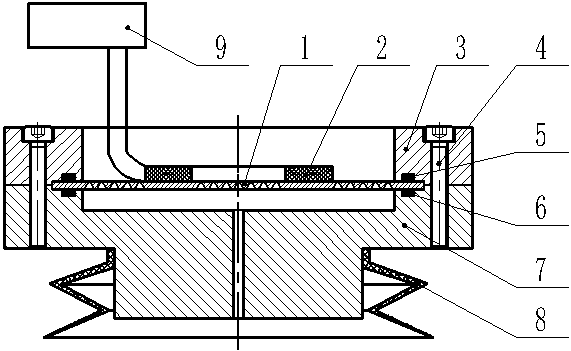

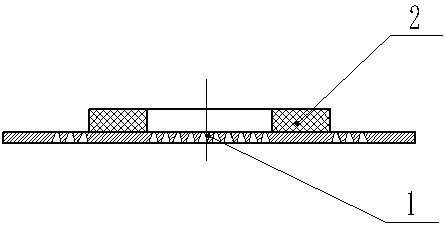

[0026] combine figure 1 Shown, a kind of piezoelectric ultrasonic vibration adsorption pick-up comprises pick-up sucker 8, vibrating plate, pick-up shell 7 and the upper cover plate 3 that is connected on pick-up shell 7 by bolt 4, vibrating plate and pick-up shell The vibration cavity is formed between the bodies 7, and the vibration plate is composed of a vibrating diaphragm 1 and an annular piezoelectric ceramic sheet 2 coaxially bonded. The piezoelectric ceramic sheet 2 is made of PZT-8, with an outer diameter of 16mm, an inner diameter of 8mm, and a thickness of The vibration diaphragm 1 is made of 316L stainless steel, with a thickness of 0.1mm and a diameter of 25mm. The pick-up suction cup 8 is arranged under the pick-up housing 7, and the pick-up suction cup 8 and the vibration chamber are arranged in the pick-up housing 7. The connected channel, with a diameter of 6mm, the lower end of the pickup housing 7 extends into the pick-up suction cup 8, and occupies 85% of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com