Variable-pitch mechanism and pick-up device with variable-pitch function

A technology of a variable pitch mechanism and a pick-up device, applied in the field of automation, can solve problems such as waste of space layout, and achieve the effect of efficient and accurate picking and picking process and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

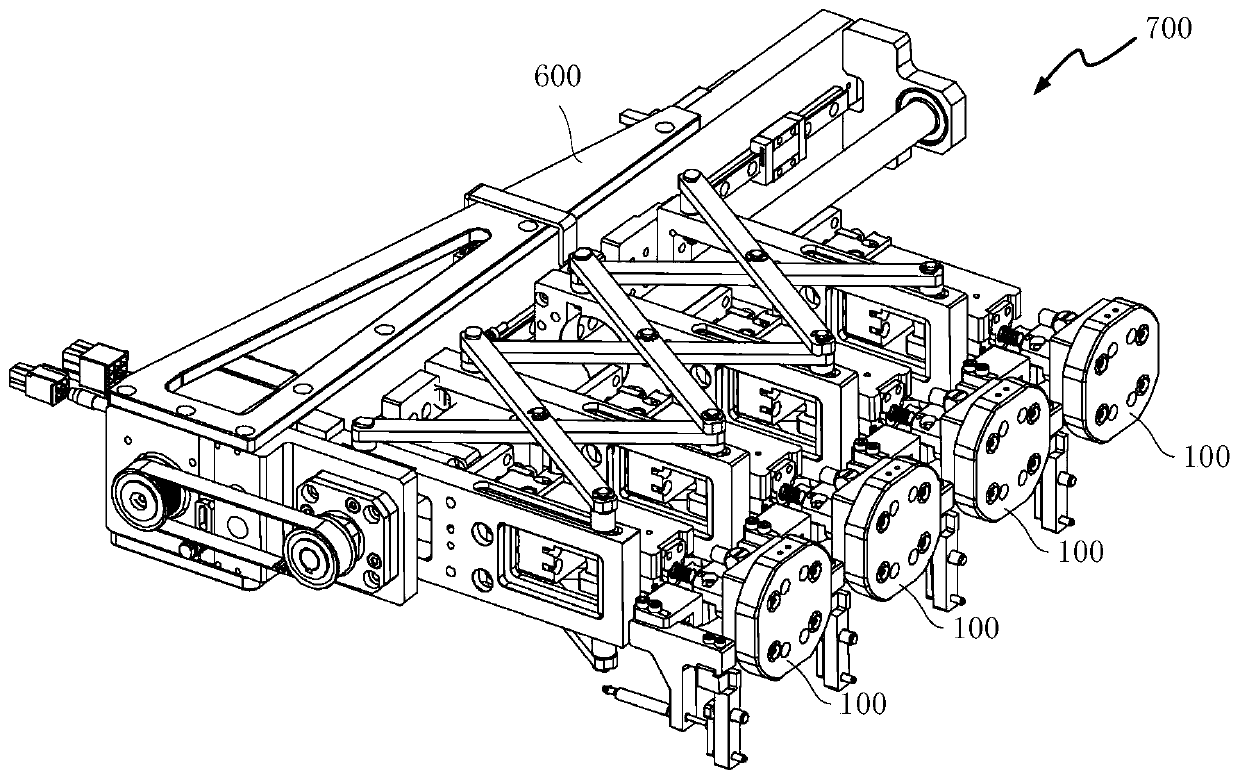

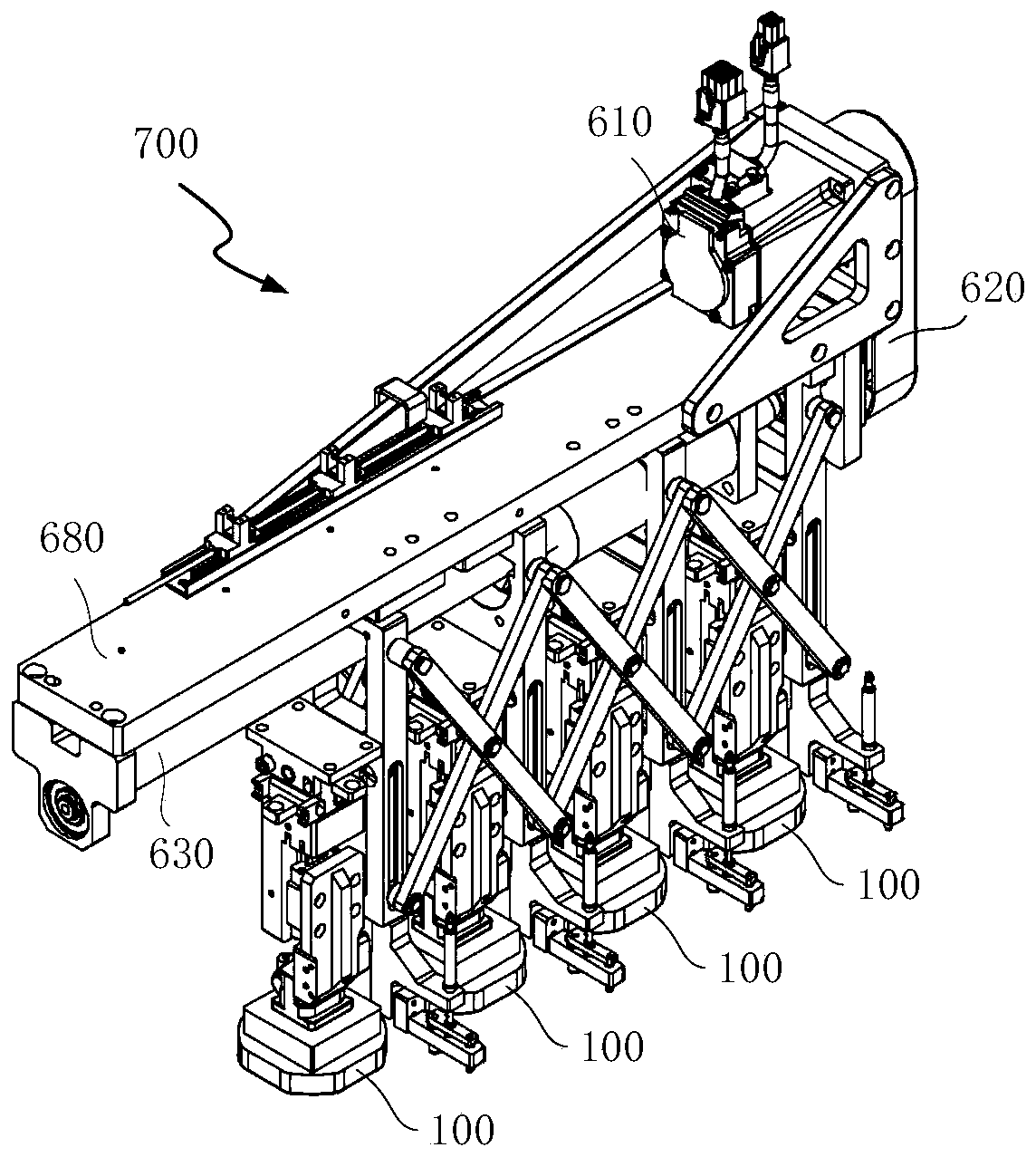

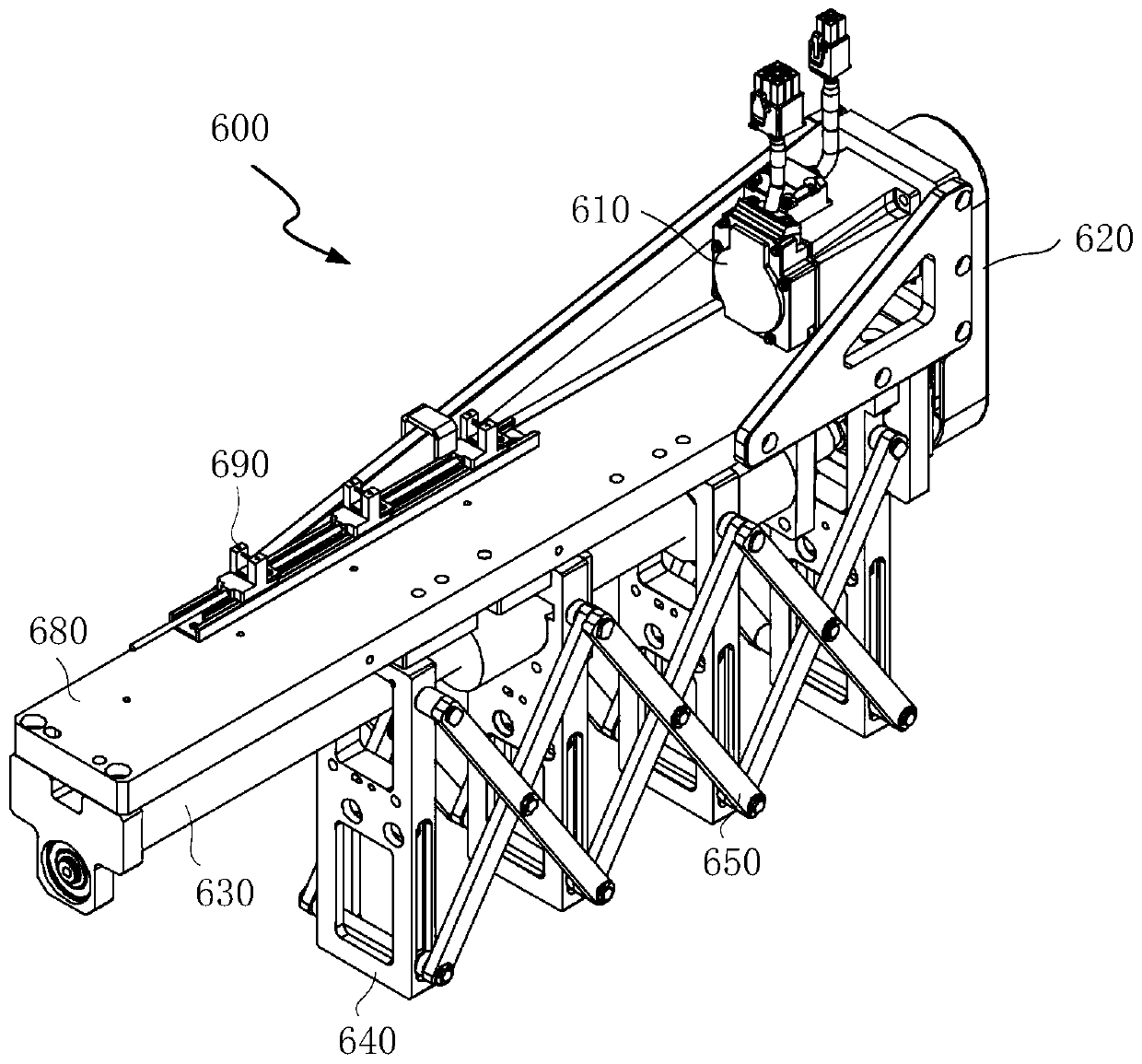

[0048] A variable distance mechanism, such as image 3 , Figure 4 As shown, it includes a variable distance unit body 600 with several pickup units 100 installed; the distance variable unit body 600 includes a variable distance driver 610, a variable distance moving assembly 630, a variable distance fixed plate 640, and a variable distance base frame 680; wherein,

[0049] The variable pitch driver 610 is used to drive the variable pitch moving assembly 630 to move relative to the variable pitch base frame 680;

[0050] The distance-variable base frame 680 is used to form a fixed foundation support; the variable-distance driver 610 and the variable-distance mobile assembly 630 are fixed on the variable-distance base frame 680; several variable-distance fixed plates 640 are fixed on the variable-distance mobile assembly 630; the variable-distance fixed plate 640 is used for fixedly installing the pickup unit 100;

[0051] The variable pitch driver 610 drives the variable pit...

Embodiment 2

[0059] Such as Figure 9 , Figure 10 As shown, the pick-up unit 100 includes a pick-up drive assembly 120, a suction cup assembly 140, and a magnetic attraction assembly 150; wherein,

[0060] Suction cup assembly 140, magnetic attraction assembly 150 are fixedly connected on the movable block 129 of picking up drive assembly 120;

[0061] The suction cup assembly 140 includes several suction cups 144 for absorbing the workpiece to be picked up; the magnetic attraction assembly 150 includes a magnet 151 for absorbing the ferromagnetic part of the workpiece to be picked up;

[0062] Driven by the pickup driving assembly 120 , the suction cup assembly 140 and the magnetic attraction assembly 150 move toward the workpiece to be picked up, so that the suction cup 144 and the magnet 151 respectively pick up different parts of the workpiece to be picked up. In this embodiment, the fast pick-up of the workpiece to be picked is realized by using the combination of vacuum negative p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com