Boron-containing waste liquid cement curing formula and curing method

A technology of concentrated waste liquid and cement solidification, which is applied in the fields of radioactive purification and nuclear engineering, can solve the problems of low waste containment rate and high nuclide leaching rate, and achieve the goal of reducing radionuclide leaching rate and meeting the requirements of automatic loading and unloading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

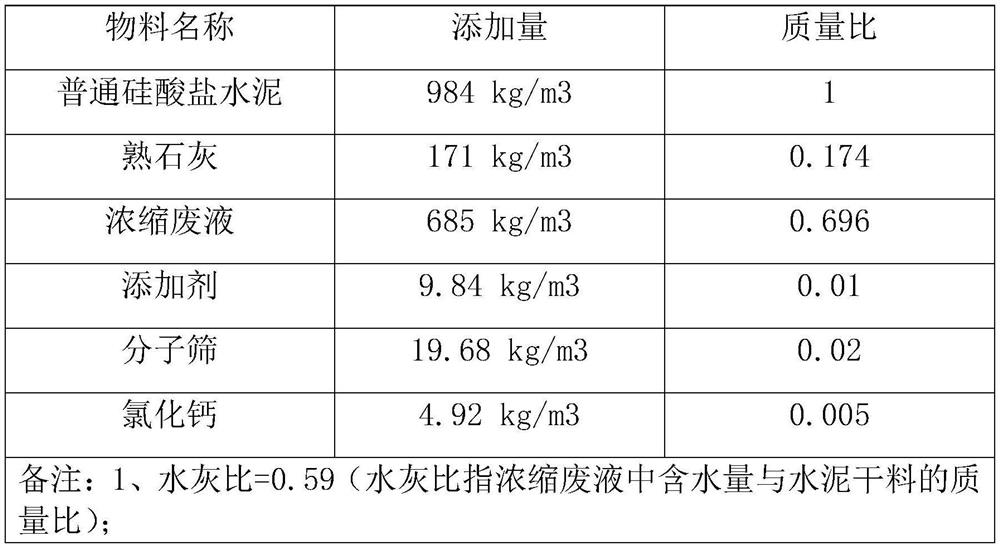

Embodiment 1

[0044] A boron-containing concentrated waste liquid cement solidification formula, comprising ordinary Portland cement, lime, additives, molecular sieves, concentrated waste liquid and calcium chloride, the ordinary Portland cement, lime, concentrated waste liquid, additives, molecular sieves and The mass ratio of calcium chloride is 1:0.174:0.696:0.01:0.02:0.005.

[0045] The strength grade of the ordinary Portland cement is 42.5, 3-day compressive strength ≥ 17Mpa, 28-day compressive strength ≥ 42.5Mpa, 3-day flexural strength ≥ 3.5Mpa, 28-day flexural strength ≥ 6.5Mpa.

[0046] The ordinary Portland cement comprises the following components in weight percentage: 80%-95% of Portland cement clinker doped with gypsum, and the balance is active materials such as slag, pozzolan, fly ash and limestone.

[0047] The Ca(OH)2 purity in the slaked lime is more than or equal to 95%.

[0048] The additive is a water reducer, the water reducer is Glenium C333, and the added amount of ...

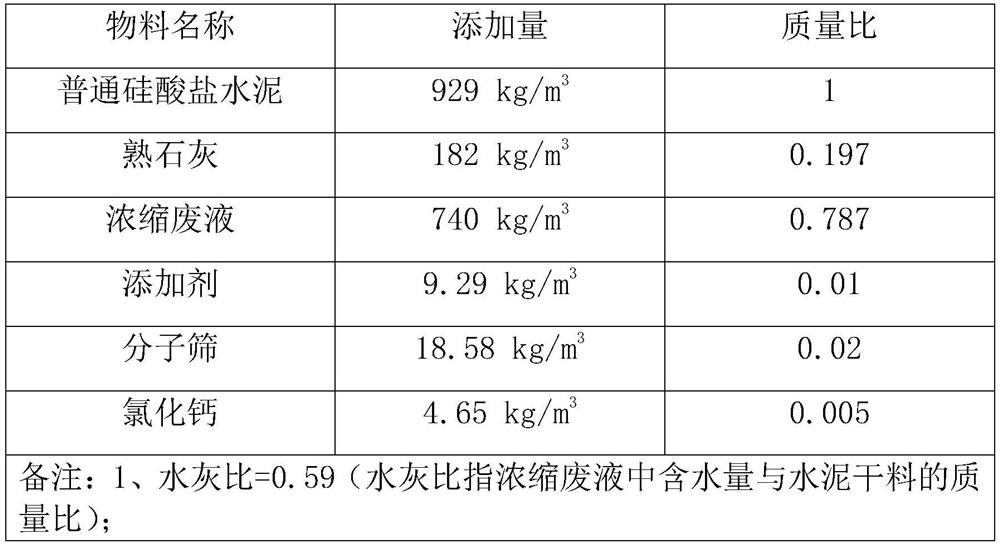

Embodiment 2

[0058] A boron-containing concentrated waste liquid cement solidification formula, comprising ordinary Portland cement, lime, additives, molecular sieves, concentrated waste liquid and calcium chloride, the ordinary Portland cement, lime, concentrated waste liquid, additives, molecular sieves and The mass ratio of calcium chloride is 1:0.194:0.787:0.01:0.02:0.005.

[0059] The strength grade of the ordinary Portland cement is 42.5, 3-day compressive strength ≥ 17Mpa, 28-day compressive strength ≥ 42.5Mpa, 3-day flexural strength ≥ 3.5Mpa, 28-day flexural strength ≥ 6.5Mpa.

[0060] The ordinary Portland cement comprises the following components in weight percentage: 80%-95% of Portland cement clinker doped with gypsum, and the balance is active materials such as slag, pozzolan, fly ash and limestone.

[0061] The Ca(OH)2 purity in the slaked lime is more than or equal to 95%.

[0062] The additive is a water reducer, the water reducer is Glenium C333, and the added amount of ...

Embodiment 3

[0072] The boron-containing concentrated waste liquid cement solidification formula of Example 1 is subjected to laboratory cold test verification and thermal test verification to verify whether the formula performance meets GB14569.1 "Performance Requirements for Low and Medium Level Radioactive Waste Solidified Body-Cement Solidified Body" and GB7023 "Long-term leaching test of solidified radioactive waste" requirements.

[0073] 1. Properties of cement slurry: The cement slurry in Example 1 has moderate consistency, low fluidity, and no bleeding after 1 hour.

[0074] 2. Compressive strength: The 28-day compressive strength of the cement solidified body sample should not be less than 7MPa. In this experiment, the cement solidified body of Example 1 was used for the compressive strength test, and the experimental results showed that its 28-day compressive strength was 32.1-43.2 MPa, with an average of 38.5 MPa, meeting the standard requirements.

[0075] 3. Immersion resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com