Patents

Literature

180 results about "Cold test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term “cold test” typically refers to any kind of test performed using colder than average temperatures to determine certain characteristics of an object or material. One common usage is to determine the hardiness of seeds that are likely to be planted in cold weather.

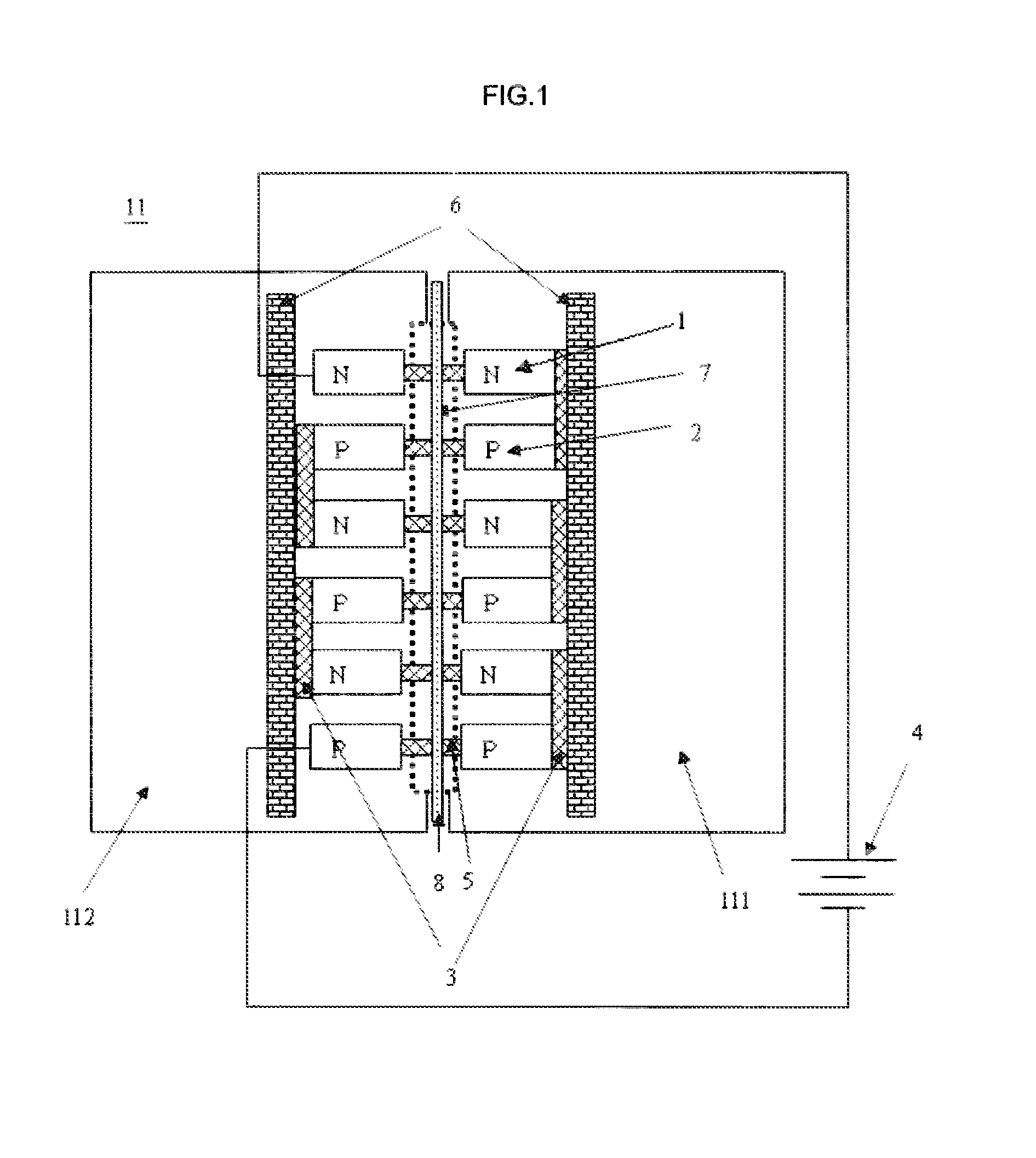

Deep level transient spectroscopy technology based ionizing radiation damage defect detecting method for bipolar devices

InactiveCN103868973AMaterial analysis by electric/magnetic meansFull width at half maximumDeep level

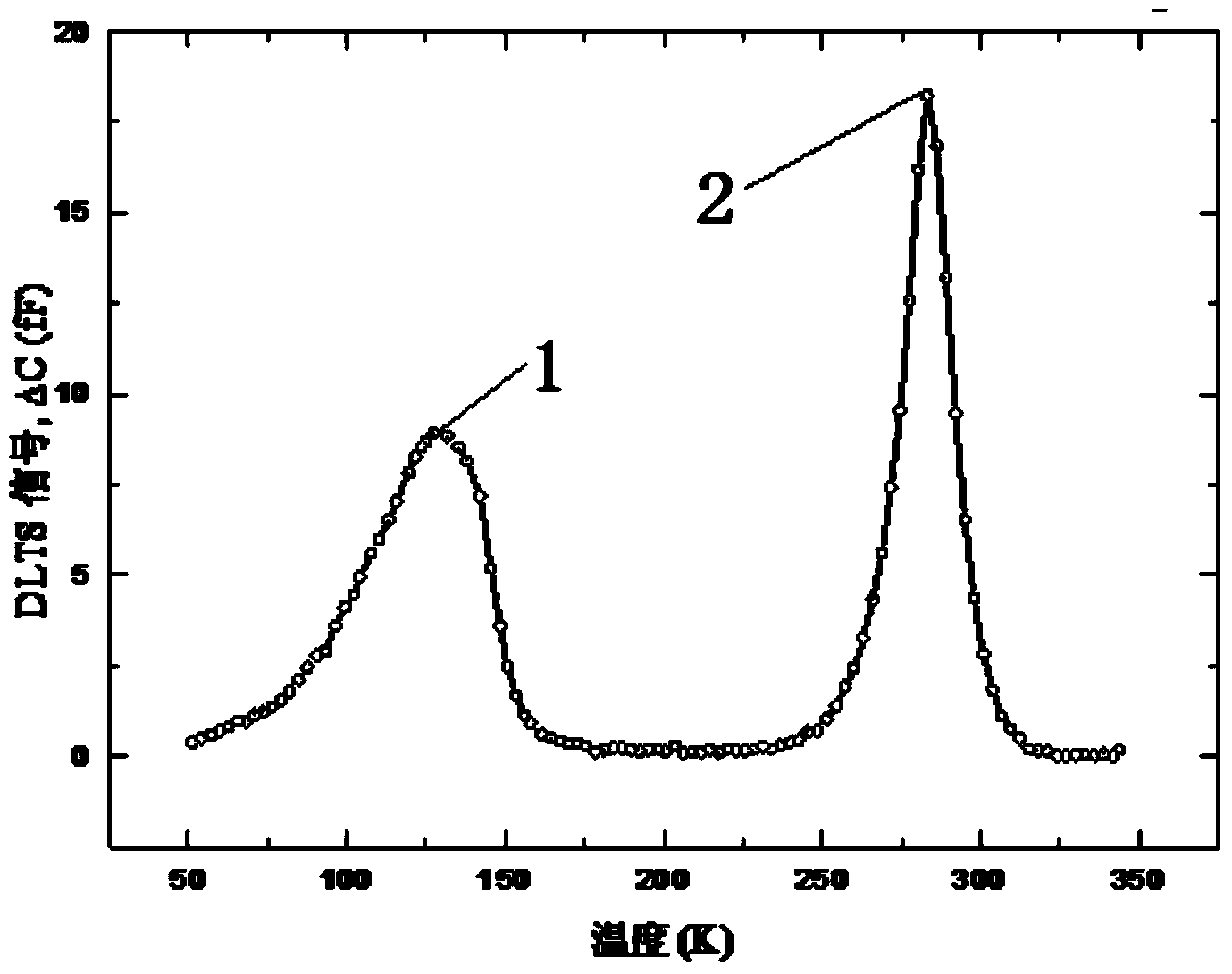

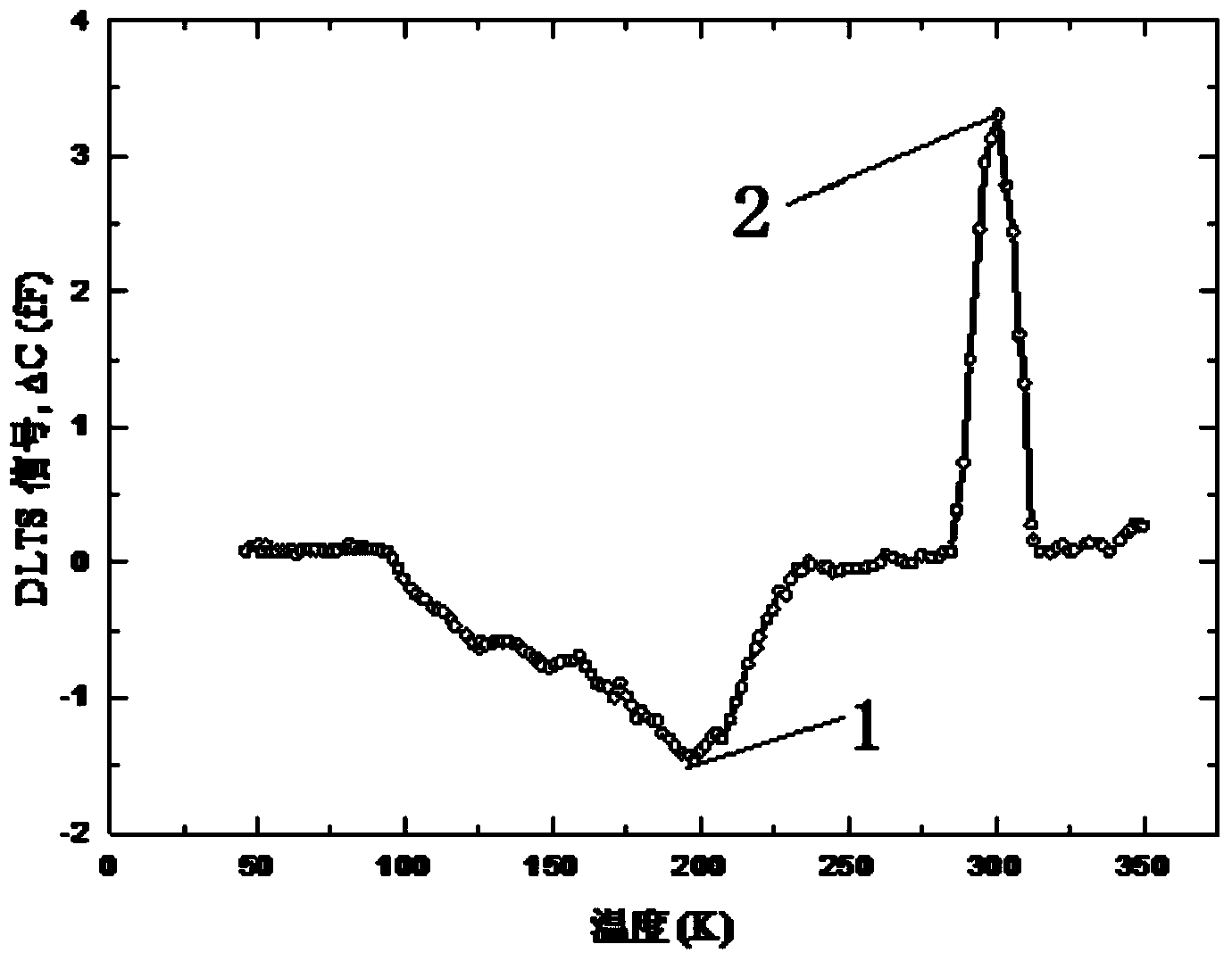

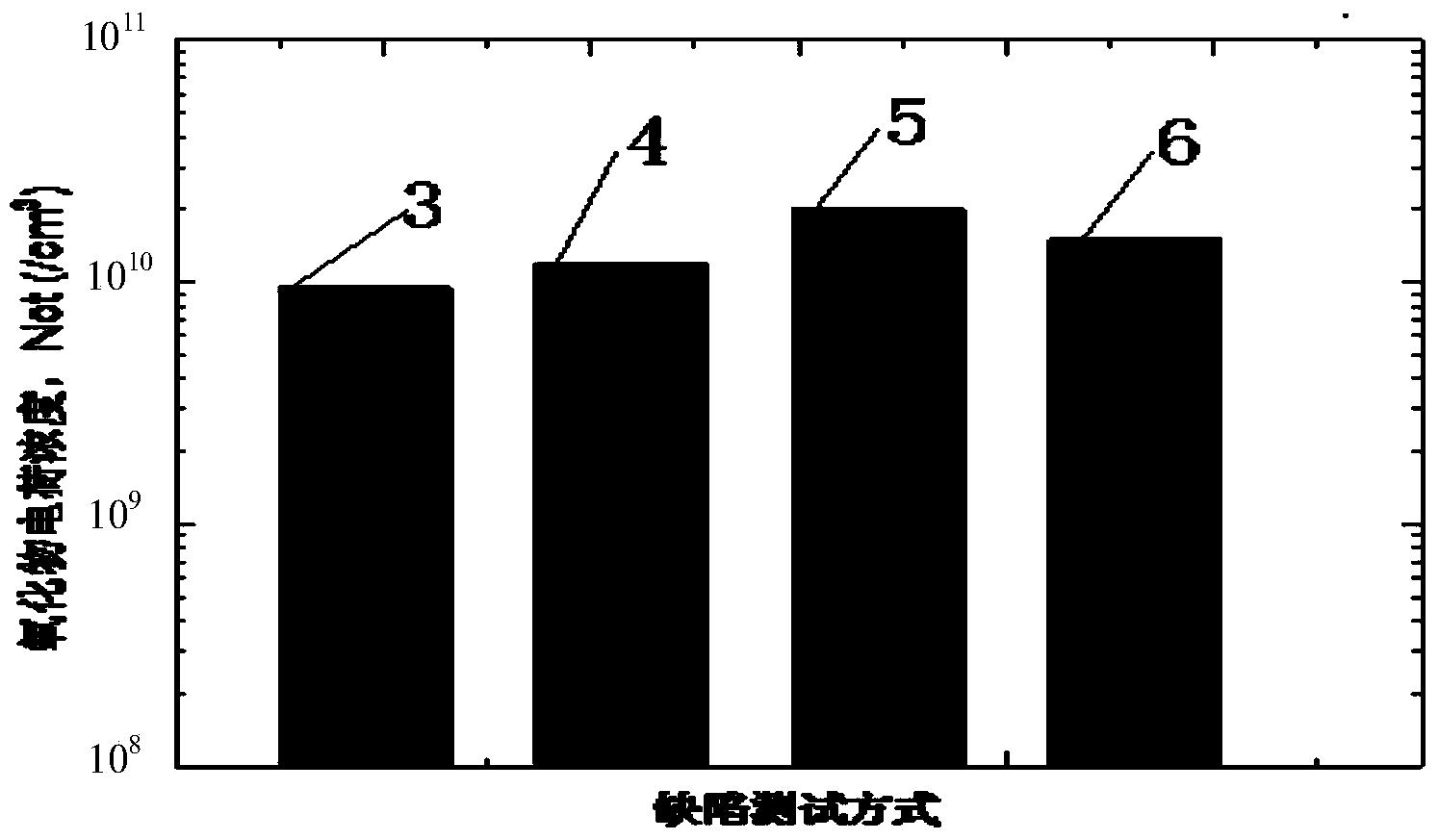

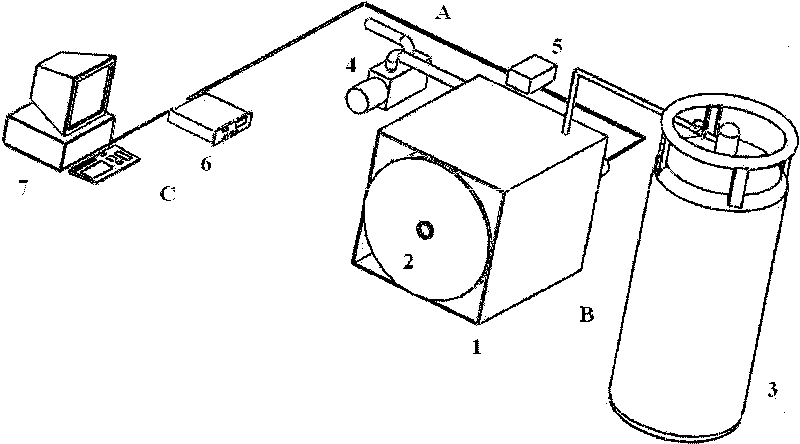

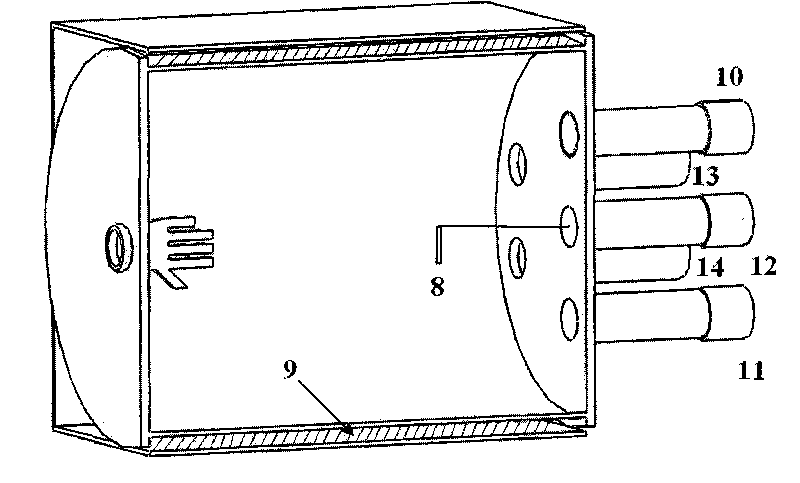

The invention relates to a deep level transient spectroscopy technology based ionizing radiation damage defect detecting method for bipolar devices, belonging to the field of electronic technology. The method is used for solving the problem that the ionizing radiation damage defect of the existing bipolar transistor is difficult to quantify. The method comprises the following steps: firstly, installing a bipolar device on a low temperature testing table of a deep level transient spectrometer and connecting the base electrode and the collector electrode of the bipolar device with a high test connector and a lower test connector of the deep level transient spectrometer respectively, wherein the bipolar device and the low temperature testing table of the deep level transient spectrometer must be connected tightly; secondly, setting the test parameters, wherein the parameters include reverse bias voltage VR, impulse voltage VP, test period TW, pulse width TP and the temperature scanning range; and obtaining oxide charge, as well as temperature, peak height and full width at half maximum of the peak, corresponding to interface-state DLTS (deep level transient spectroscopy) signal peak; and finally, acquiring the ionizing radiation damage defect of the bipolar device according to the temperature, the peak height and the full width at half maximum of the peak, corresponding to the interface-state DLTS signal peak. The method can be applied to the defect detecting field.

Owner:HARBIN INST OF TECH

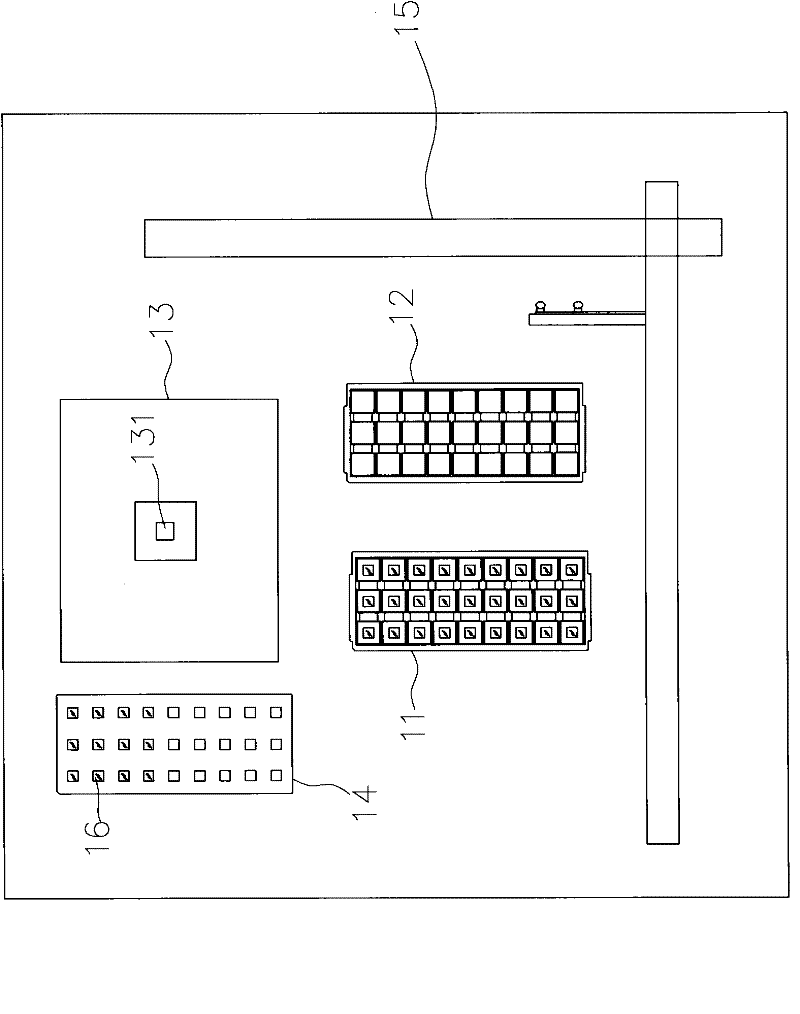

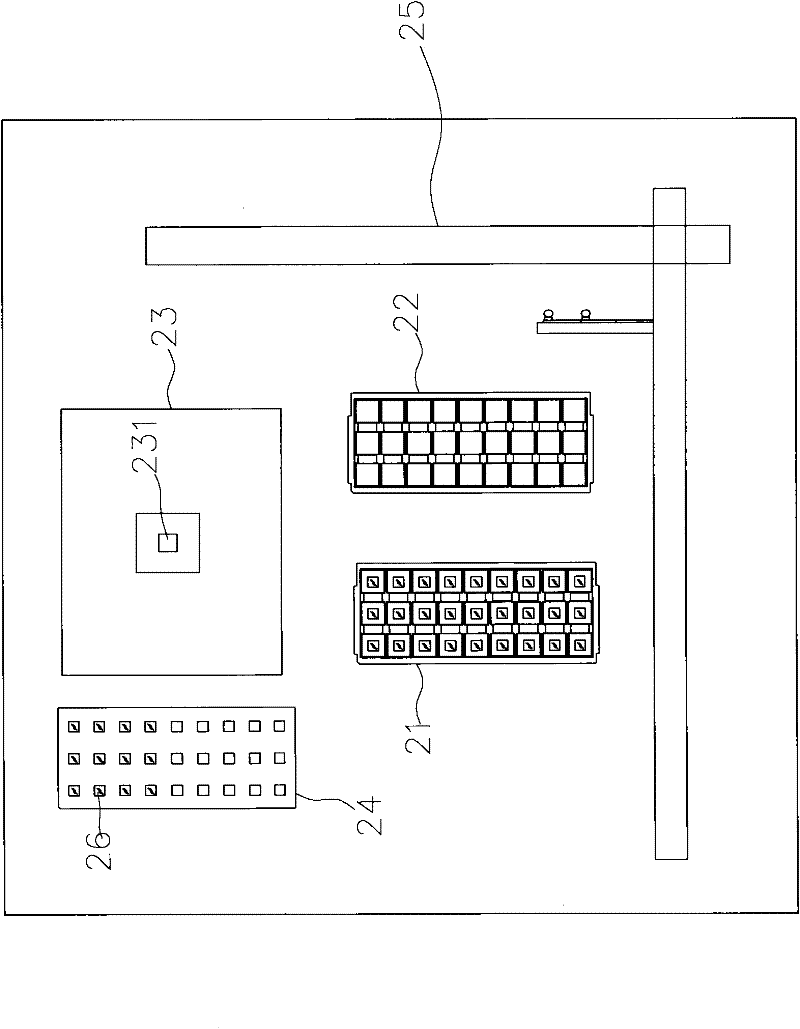

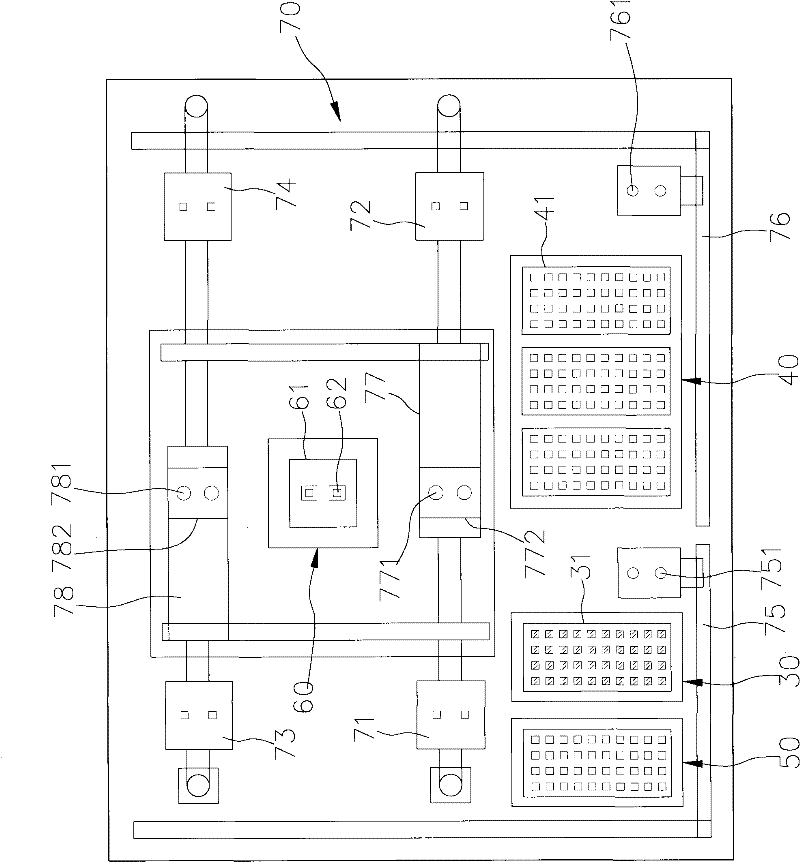

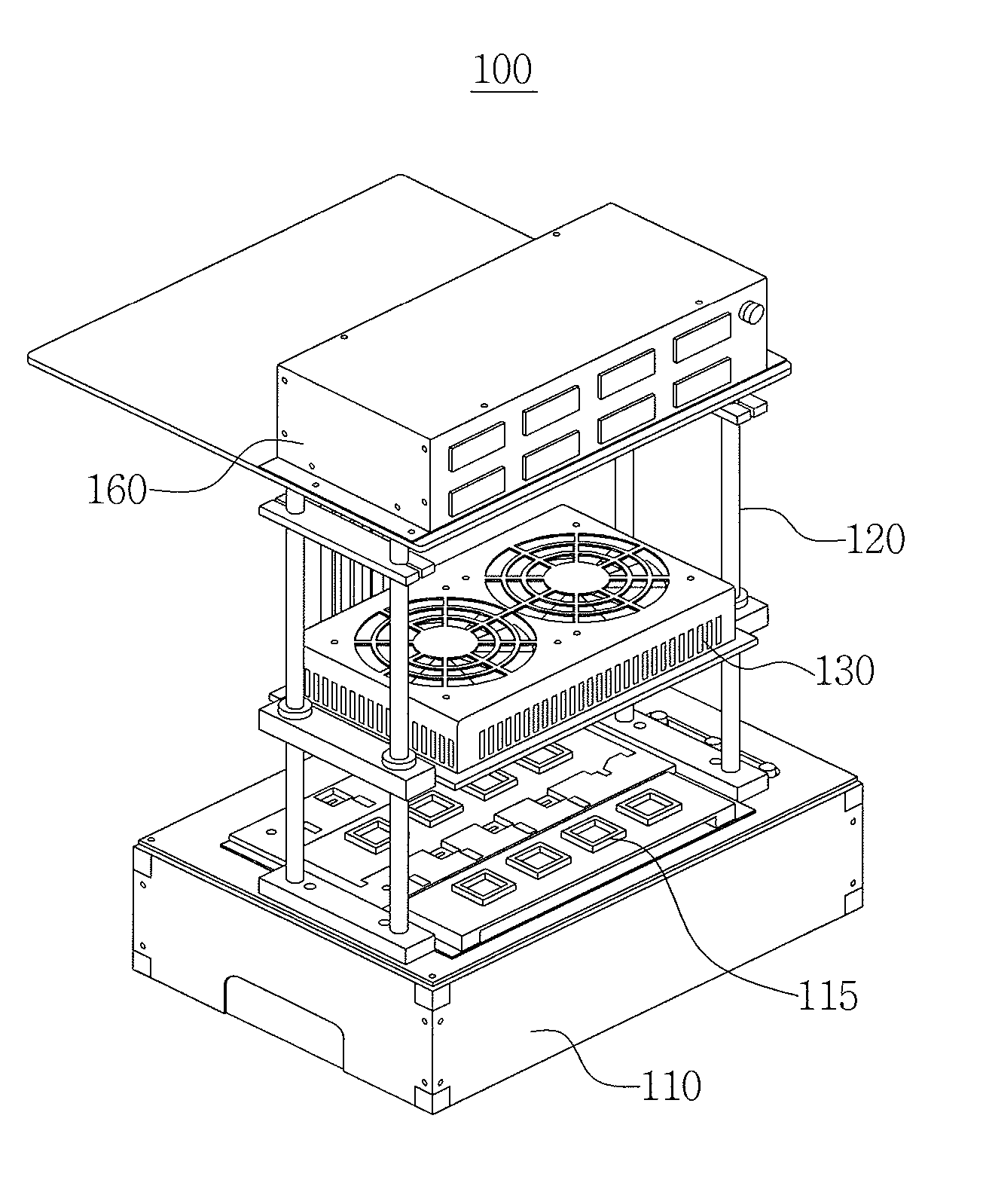

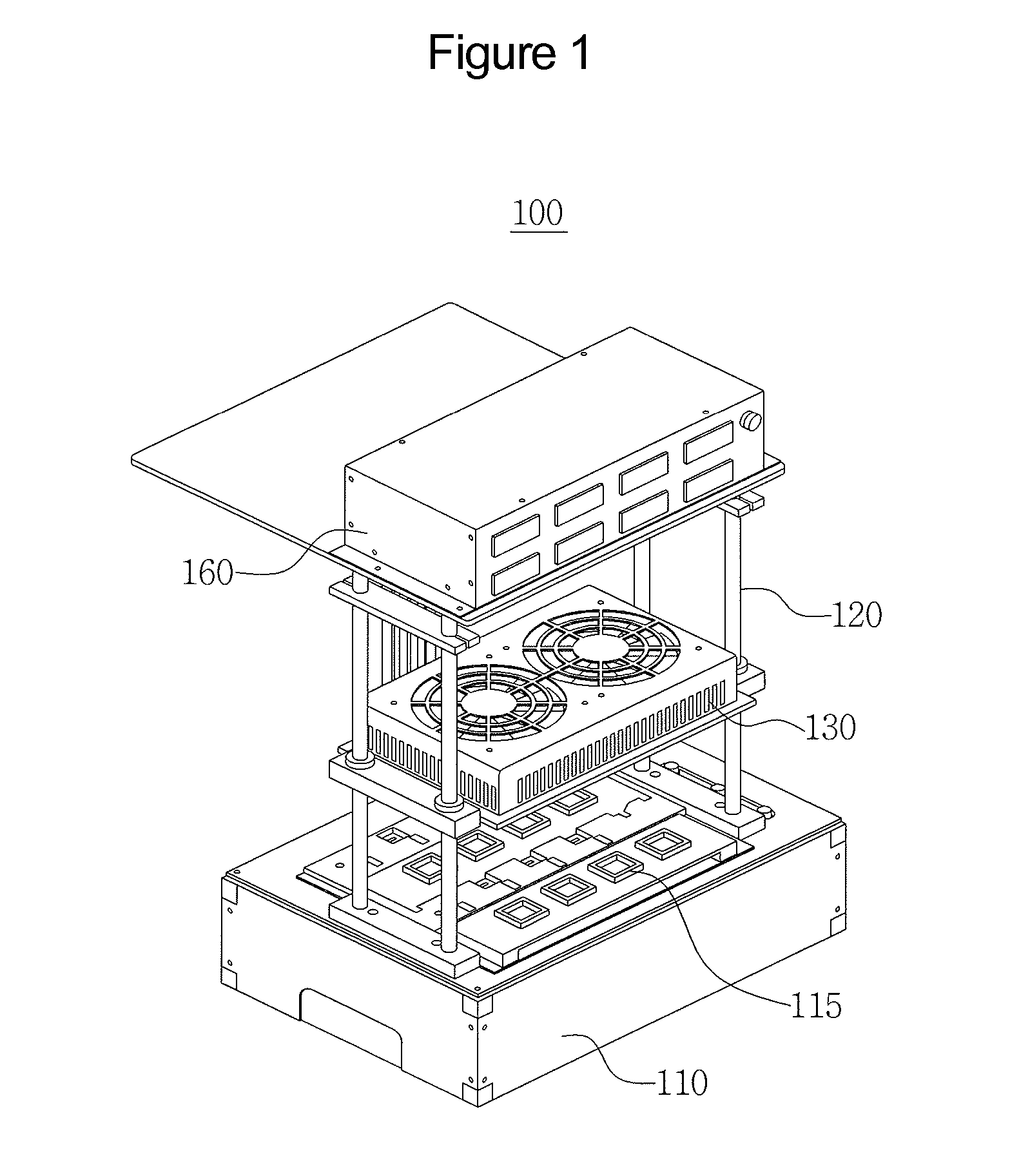

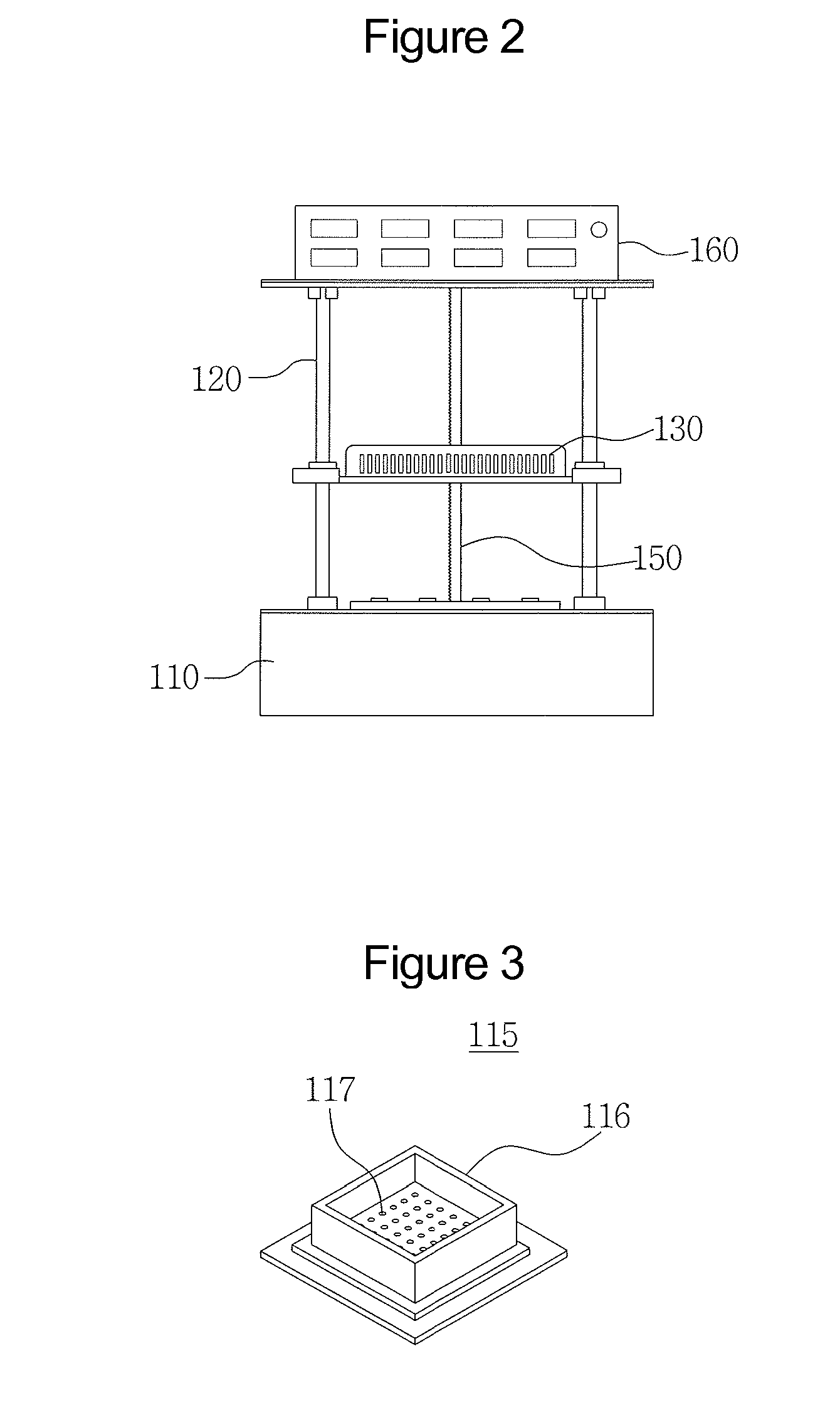

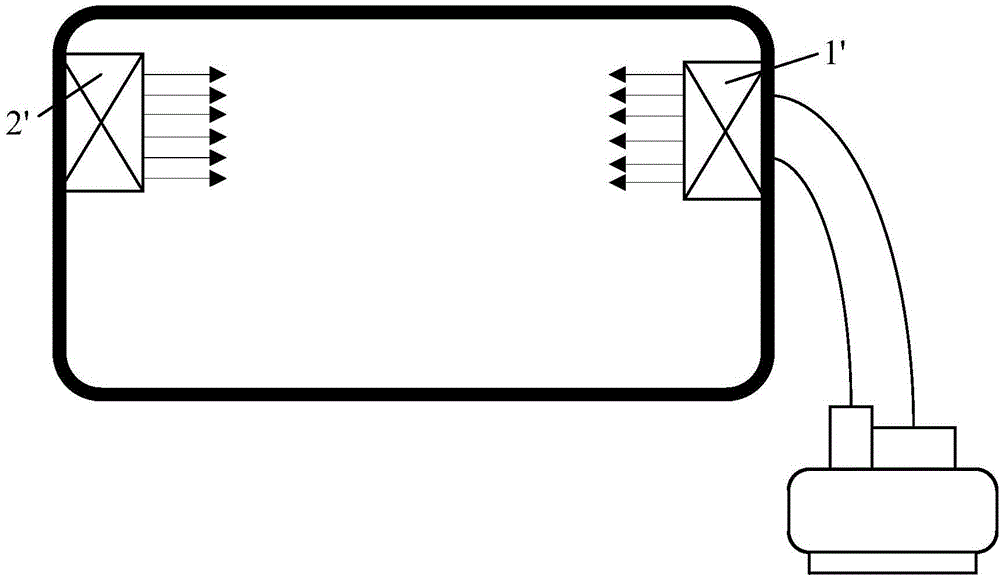

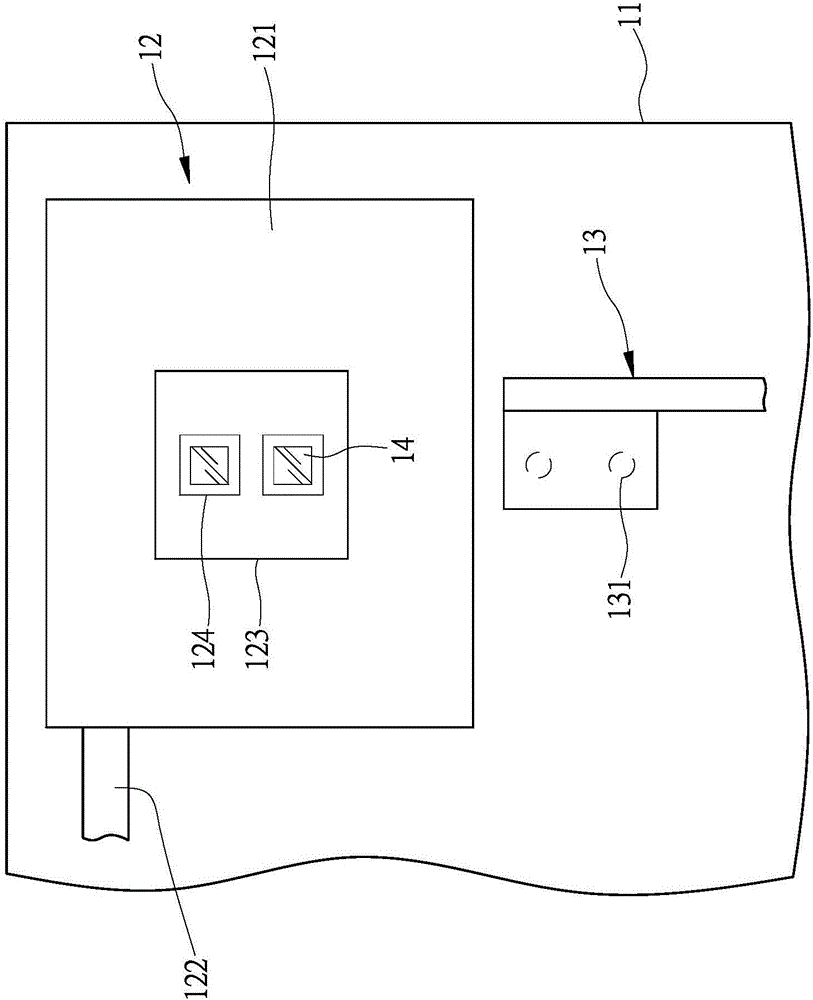

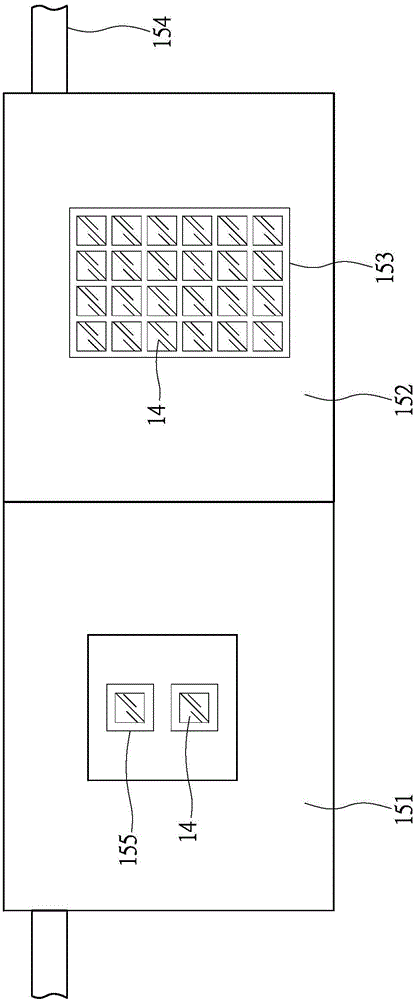

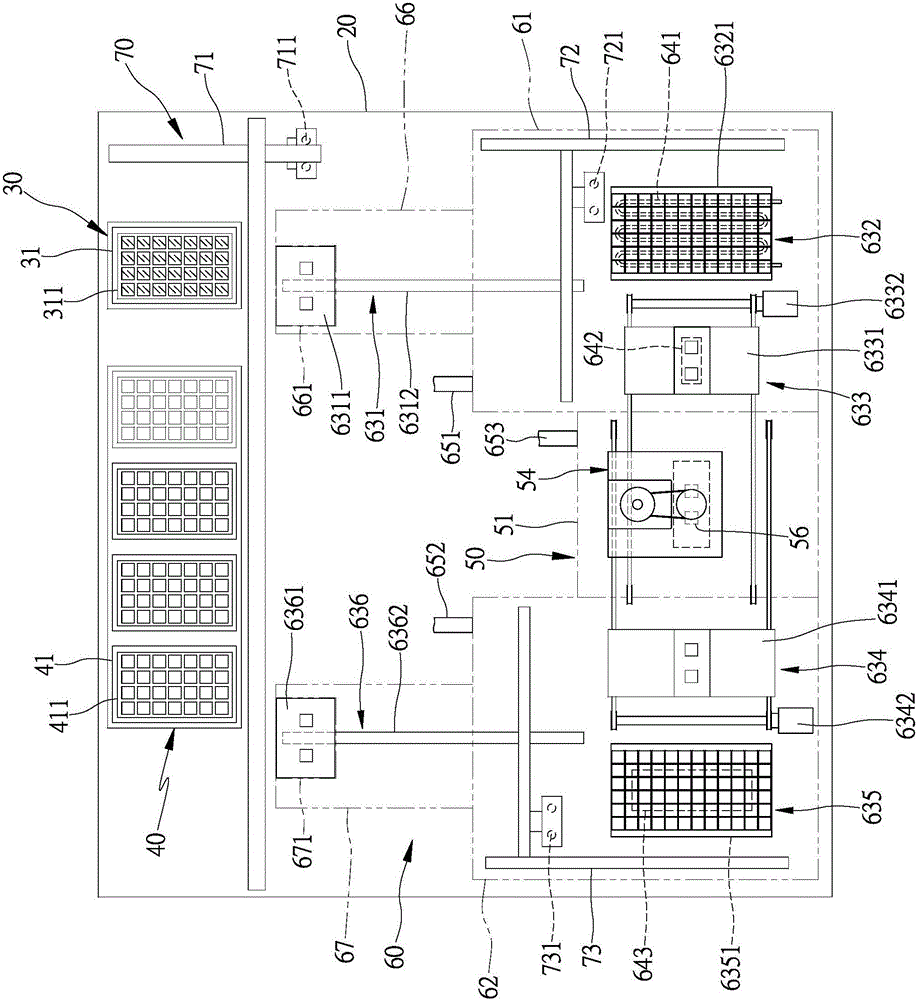

Electronic component test sorter that can perform cold/hot tests

An electronic component testing and sorting machine that can perform cold test / hot test. The machine is equipped with a feeding device, a receiving device, a testing device and a conveying device. The feeding device accommodates multiple electronic components to be tested. The receiving device is to accommodate a number of different grades of electronic components that have been tested. The testing device is equipped with a test seat for testing electronic components. Arm and the first and second crimping arms of the two crimping arms are used to transport the electronic components to be tested / completed, and a pre-heater is installed above the crimping devices of the first and second crimping arms. The thermostat can change the pre-cooling / preheating electronic components to be tested according to the operating temperature of the cold test / hot test, so that the electronic components can continue to perform the thermal test after the cold test is performed in the test socket; thus, it can Make electronic components perform cold test / hot test operations consistently on the same equipment, so as to achieve the practical benefits of improving test productivity and reducing equipment costs.

Owner:HON TECH INC

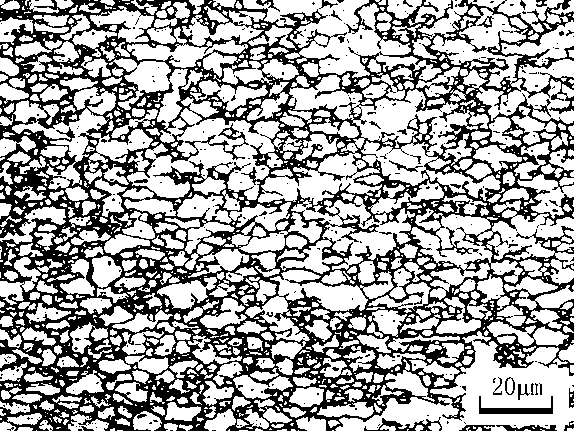

Steel for 300MPa-grade automobile structural part and production method for steel

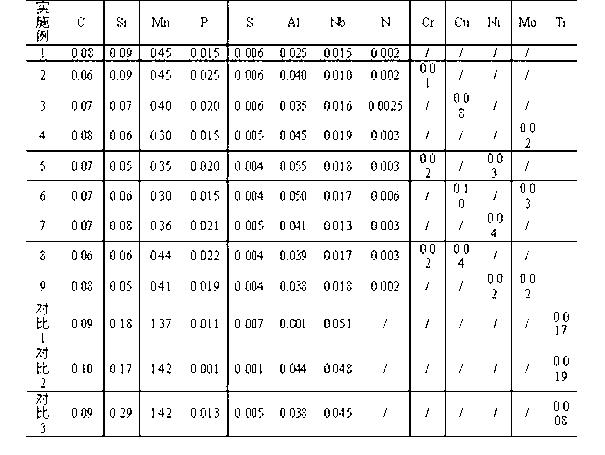

The invention relates to steel for a 300MPa-grade automobile structural part and a production method for the steel. The steel comprises the following main components in percentage by weight: 0.06-0.08 percent of C, 0.05-0.09 percent of Si, 0.30-0.45 percent of Mn, 0.025-0.055 percent of Al, 0.015-0.025 percent of P, less than or equal to 0.006 percent of S, 0.010-0.019 percent of Nb, less than or equal to 0.006 percent of N and the balance of Fe and impurities. The production method comprises the production steps of molten iron desulfurization, converter smelting, ladle argon blowing, continuous casting, heating of a casting blank, hot rolling, winding, conventional pickling, cold rolling, continuous operation and flattening for later use. The production method disclosed by the invention has the advantages of short process flow, lower energy consumption and stable mechanical property; and in addition, on the premise that the yield strength of 300-340MPa and the tensile strength of 390-445MPa are met, the elongation percentage is not lower than 31 percent, the plastic strain ratio r is 1.45-1.80, a strain hardening index n is 0.16-0.20, a wide-cold test bending is 180 degrees and a bending diameter d is equal to 0; and in a metallographic structure, an equiaxed ferrite is 85-90 percent and a granular pearlite is 10-15 percent.

Owner:武汉钢铁有限公司

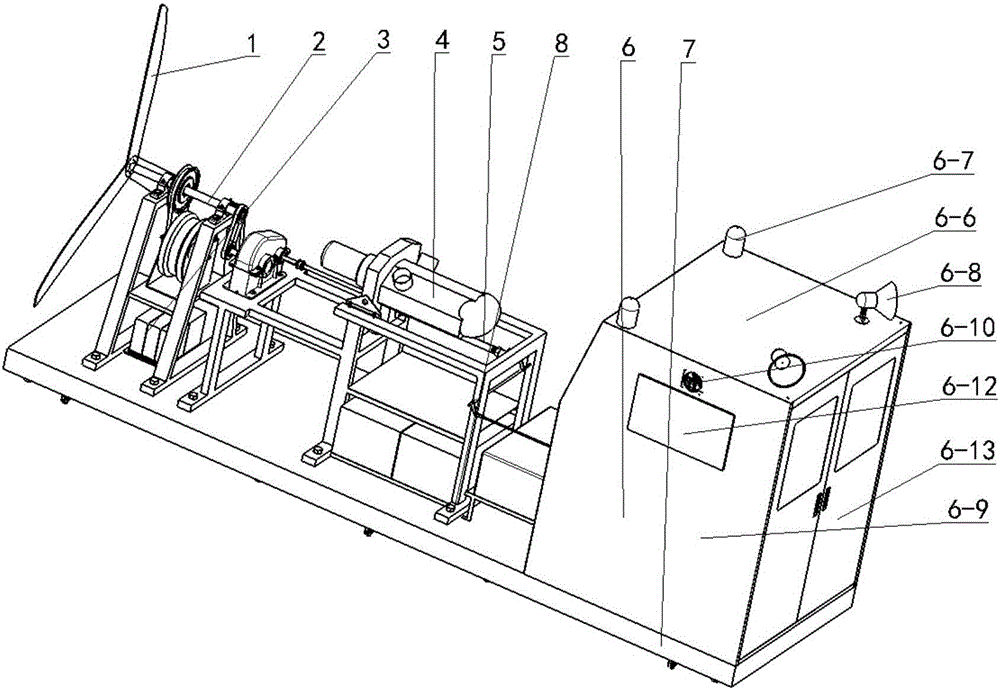

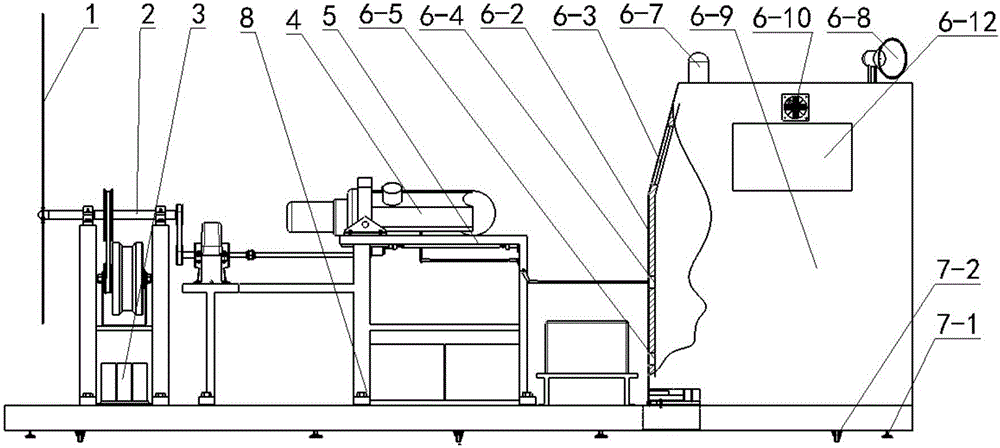

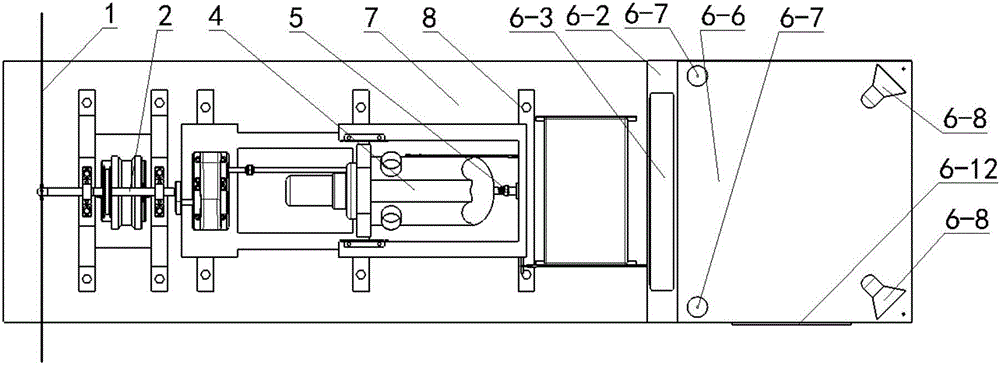

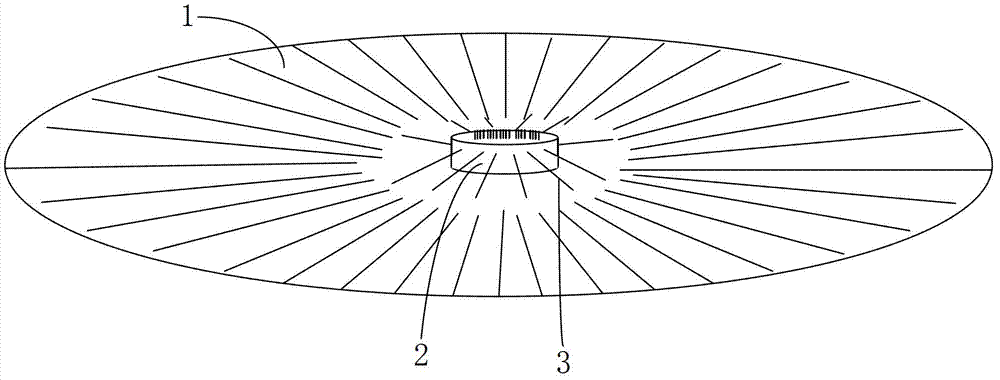

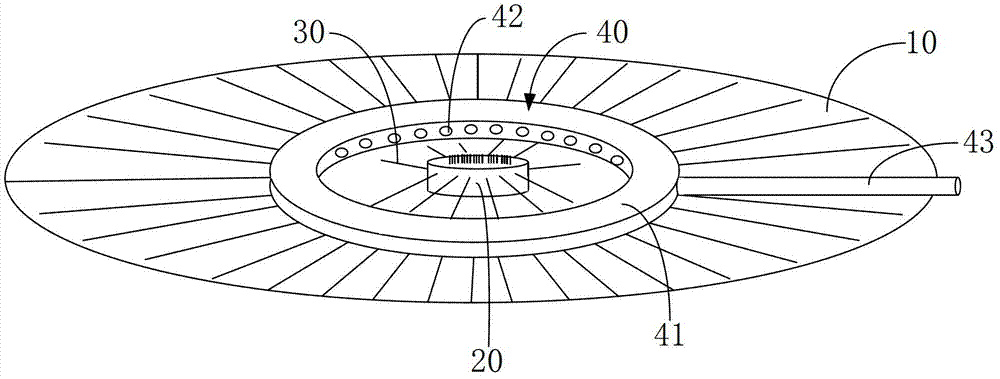

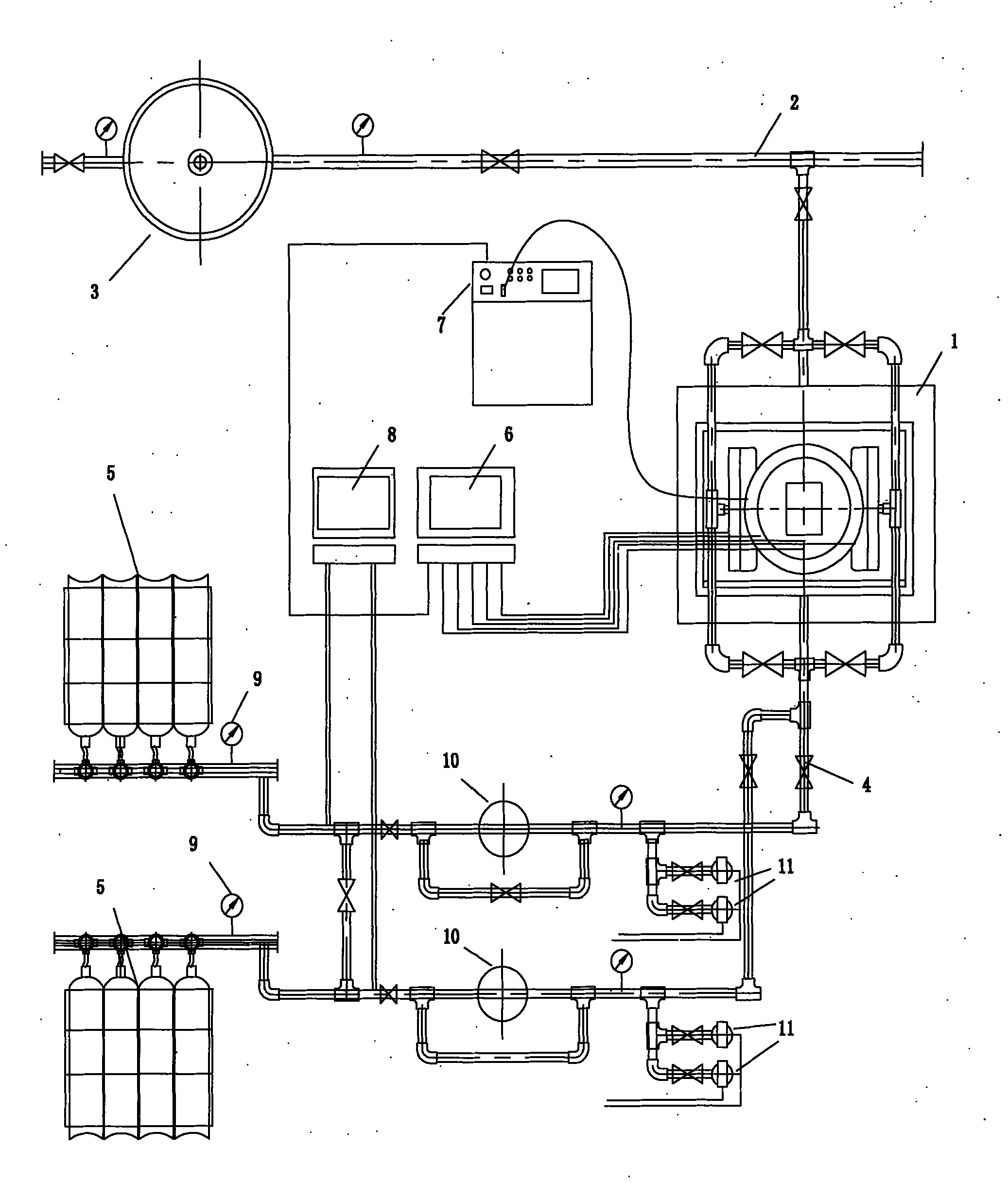

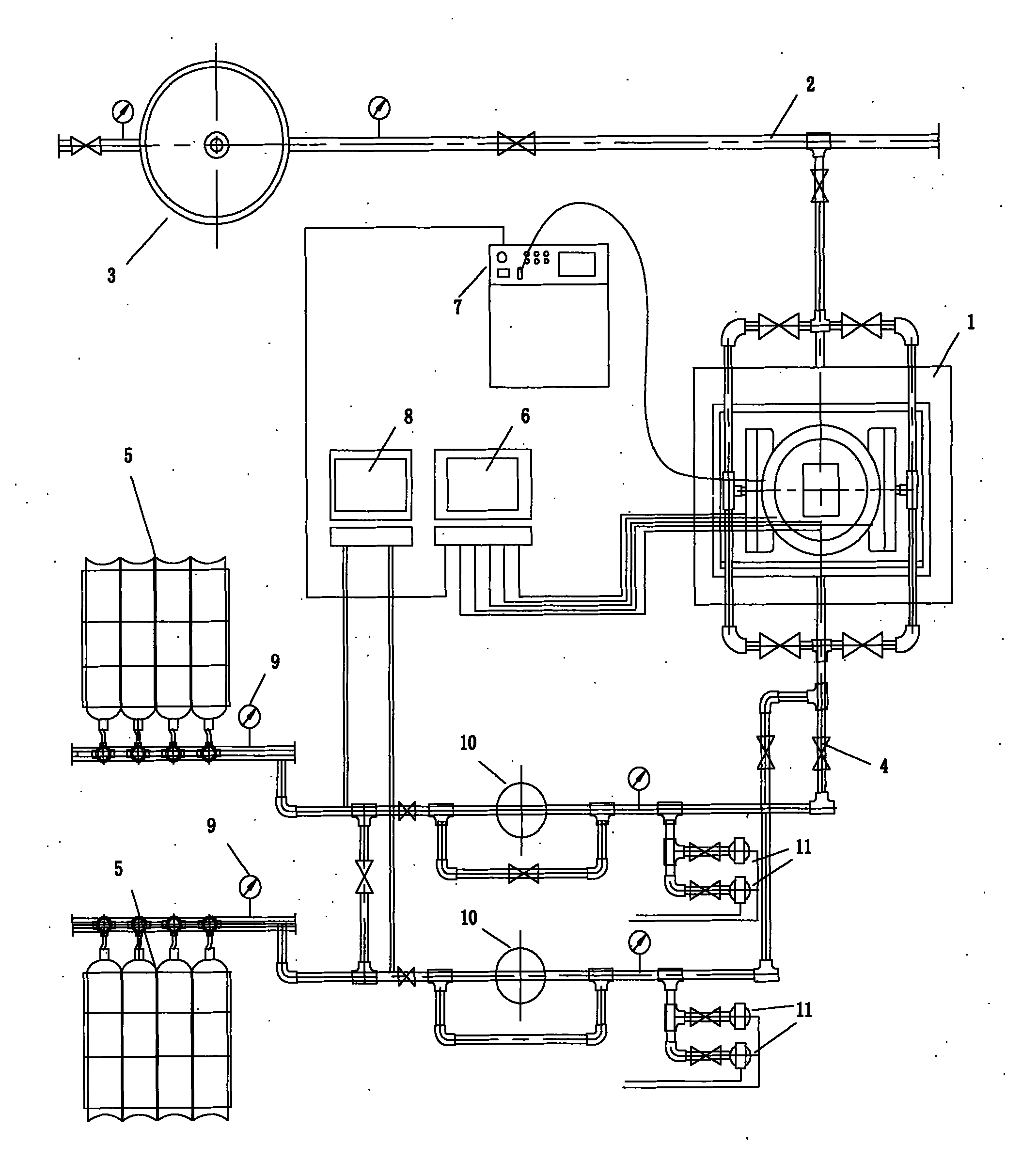

Turbo shaft engine test bench for aviation

PendingCN106840683ASmooth transmissionMeet teaching needsEngine testingEducational modelsAviationControl system

The invention provides a turbo shaft engine test bench for aviation, and aims at overcoming the defects that the turbo shaft engine test bench in the prior art is poor in stability, low in locating accuracy and low in security, only has one transmission mode, the problem of test run of a turbo shaft engine for aviation under the condition of the load cannot be solved. The turbo shaft engine test bench is characterized by comprising a drive system, a control system, an engine, a support structure and a control room, wherein a four-point locating support structure of the engine is formed by front and back two locating lugs, a horizontal locating support shaft and a vertical locating support shaft; and an integrated console integrating control, display and data processing is arranged in the control room. The turbo shaft engine test bench has the beneficial effects that the turbo shaft engine test bench is provided with the load, is high in locating support accuracy and high in vibration resistance; vertical output is changed into axial output by the drive system; the transmission is stable and the occupied space is small; miniaturization of the turbo shaft engine test bench for aviation is achieved; the turbo shaft engine test bench has three modes of hot test run, cold test run and simulated test run; the teaching efficiency is improved; the security during test run is ensured; abrasion of the engine is reduced; and the teaching cost is reduced.

Owner:KUNSHAN HANGLI AIRBORNE EQUIP

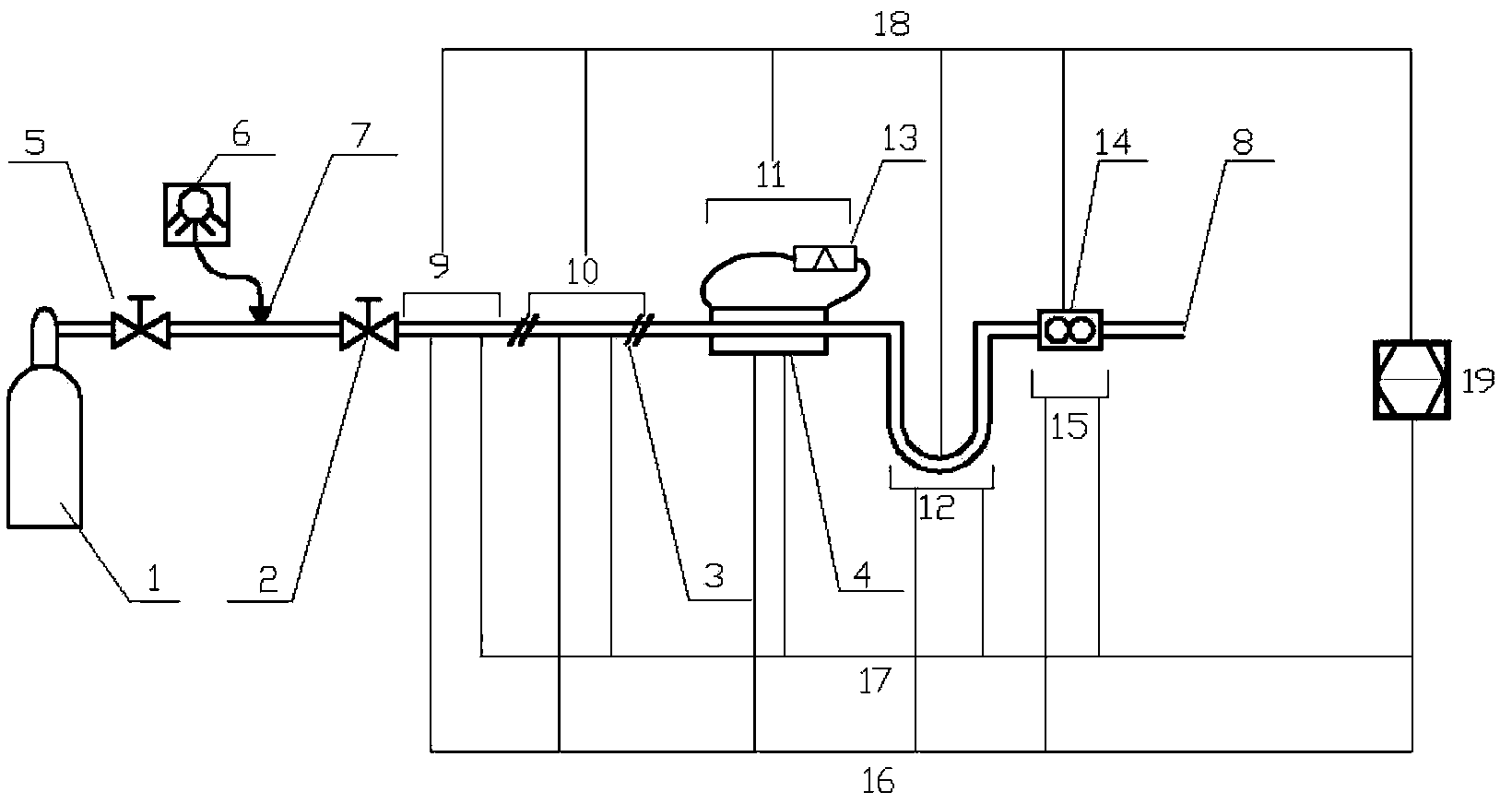

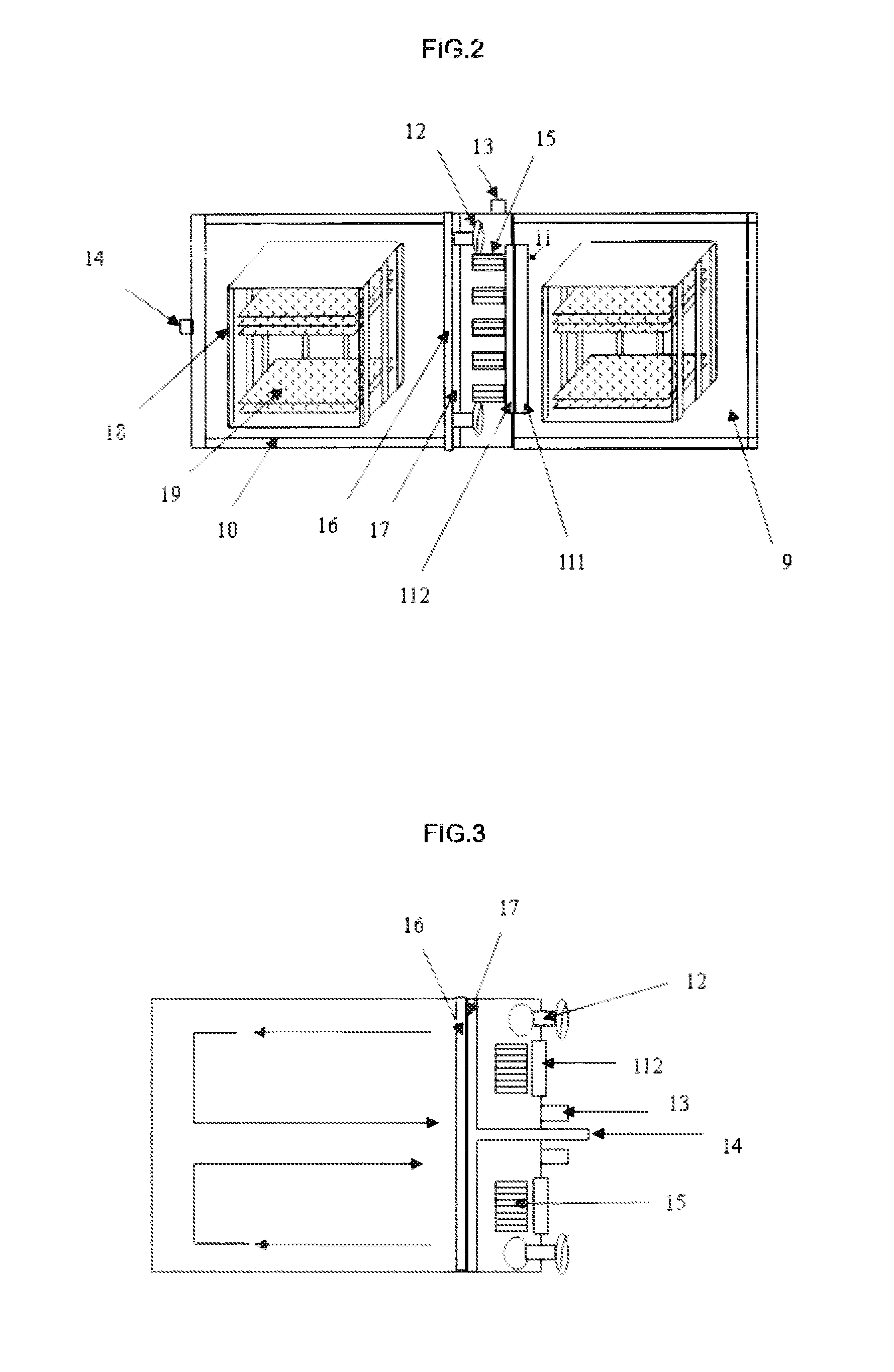

Natural gas pipeline hydrate simulated generation test method and device

The invention discloses a natural gas pipeline hydrate simulated generation test method and device. The test method comprises the steps of sweeping air retained in pipes at a pressure drop test pipe section (9), a rough pipe wall test pipe section (10), a low-temperature test pipe section (11), an elbow test pipe section (12) and a flowmeter test pipe section (15); adjusting the temperature of the low-temperature test pipe section (11) to the appointed temperature, and injecting liquid water into the pressure drop test pipe section (9) in the form of vaporific micro droplets; observing the hydrate generation situation of all the test pipe sections and the change situations of temperature and pressure of all the test pipe sections, and recording the time, flow and pressure data when hydrates appear, grow and block; and analyzing environmental factors and required conditions for natural gas hydrate generation according to the natural gas hydrate generation situation combined with the temperature and pressure data so as to determine a key pipe section easily causing natural gas hydrate generation. The natural gas pipeline hydrate simulated generation test method is easy to operate; various measurement measures are supplied, and measured data are close to an actual pipeline conveying environment.

Owner:PIPECHINA SOUTH CHINA CO

Hot/cold test equipment for NAND flash memory with dehumidifying function

InactiveUS20130133339A1Prevent moistureElectronic circuit testingMachines using electric/magnetic effectsCold testThermoelectric element

Disclosed herein is hot / cold test equipment for a Nand Flash Memory. The test equipment includes a mounting unit that contains the Nand Flash Memory together with a socket to test whether the memory is defective or not, a chamber provided above the mounting unit and moving up and down to come into contact with the socket and thereby provide a target temperature, and a temperature display displaying the target temperature. The chamber includes a block inserted into the socket, a thermoelectric element seated on an upper portion of the block, a water jacket seated on an upper portion of the thermoelectric element and circulating cooling water therein, and a cooling fan provided in the water jacket to blow air downwards, with a discharge hole being formed on a lower surface of the block to discharge nitrogen gas.

Owner:ENC TECH

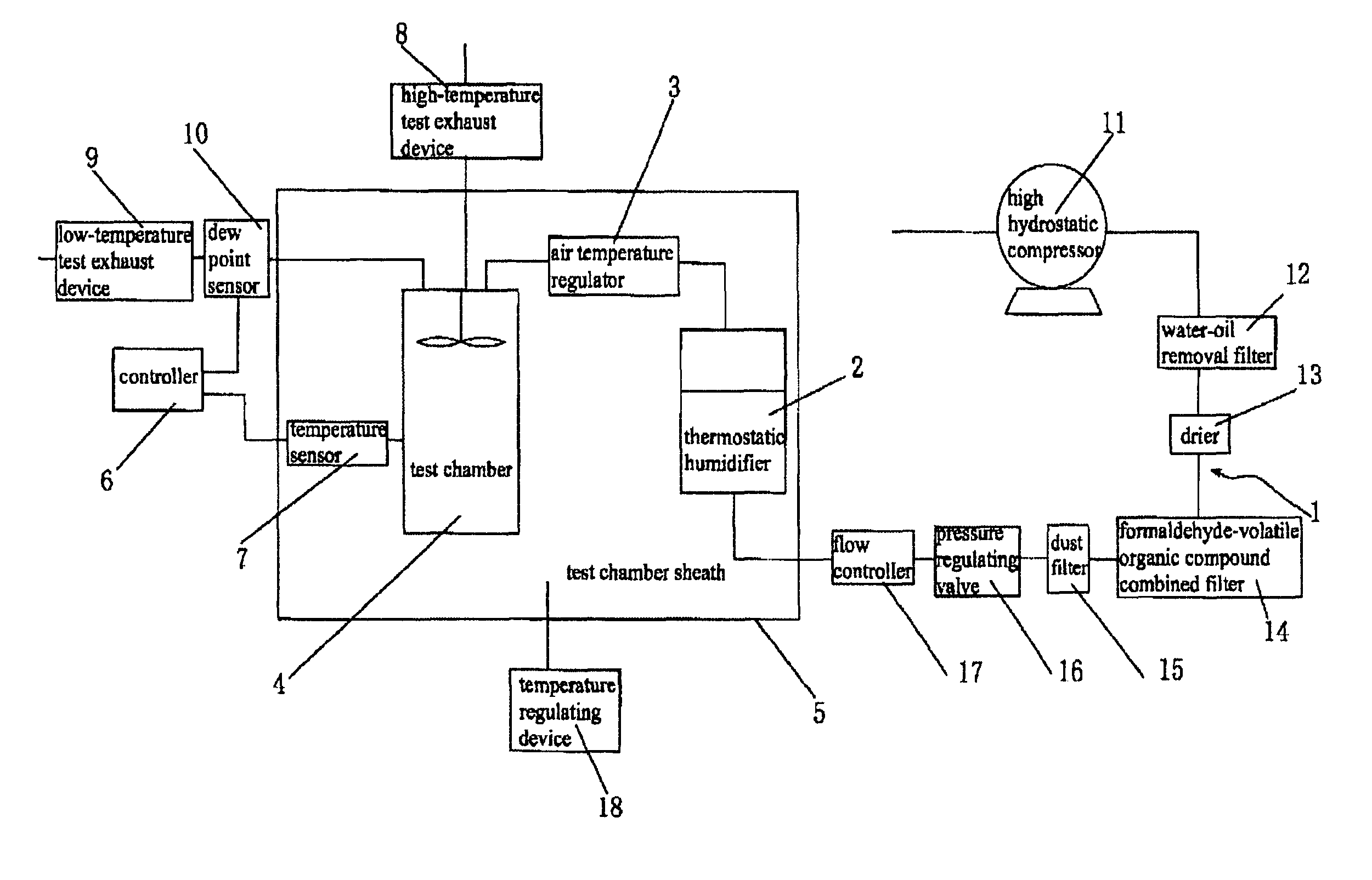

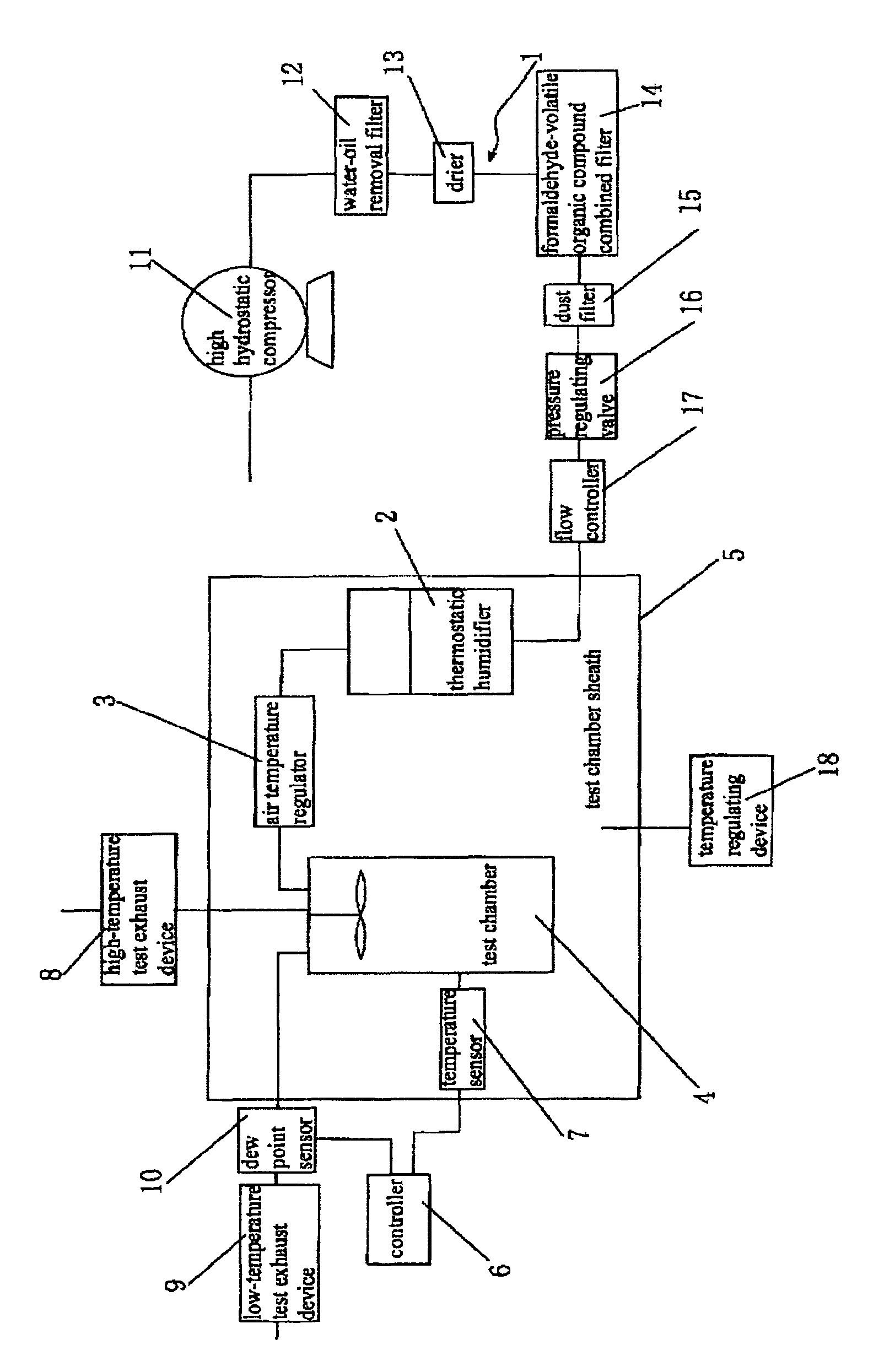

Detection system and humidity detection method for detecting volatile organic compound

Detection system and humidity detection method for detecting volatile organic compound comprises a device for introducing clean air and a controller, wherein the device for introducing clean air is connected with a test chamber; a test chamber sheath is sleeved outside the test chamber; the test chamber is provided with a temperature sensor for detecting the temperature in the test chamber, a high-temperature test exhaust device is connected with a high-temperature exhaust pipeline of the test chamber, and a low-temperature test exhaust device is connected with a low-temperature exhaust pipeline of the test chamber; a pipeline connecting the test chamber with the low-temperature test exhaust device is also provided with a dew point sensor for detecting dew point of the air in the low-temperature exhaust pipeline; and the temperature sensor and the dew point sensor are connected with the controller.

Owner:DONGGUAN CITY SIMPLEWELL TECH

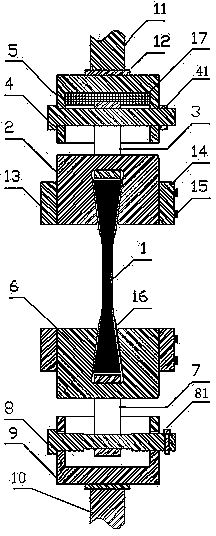

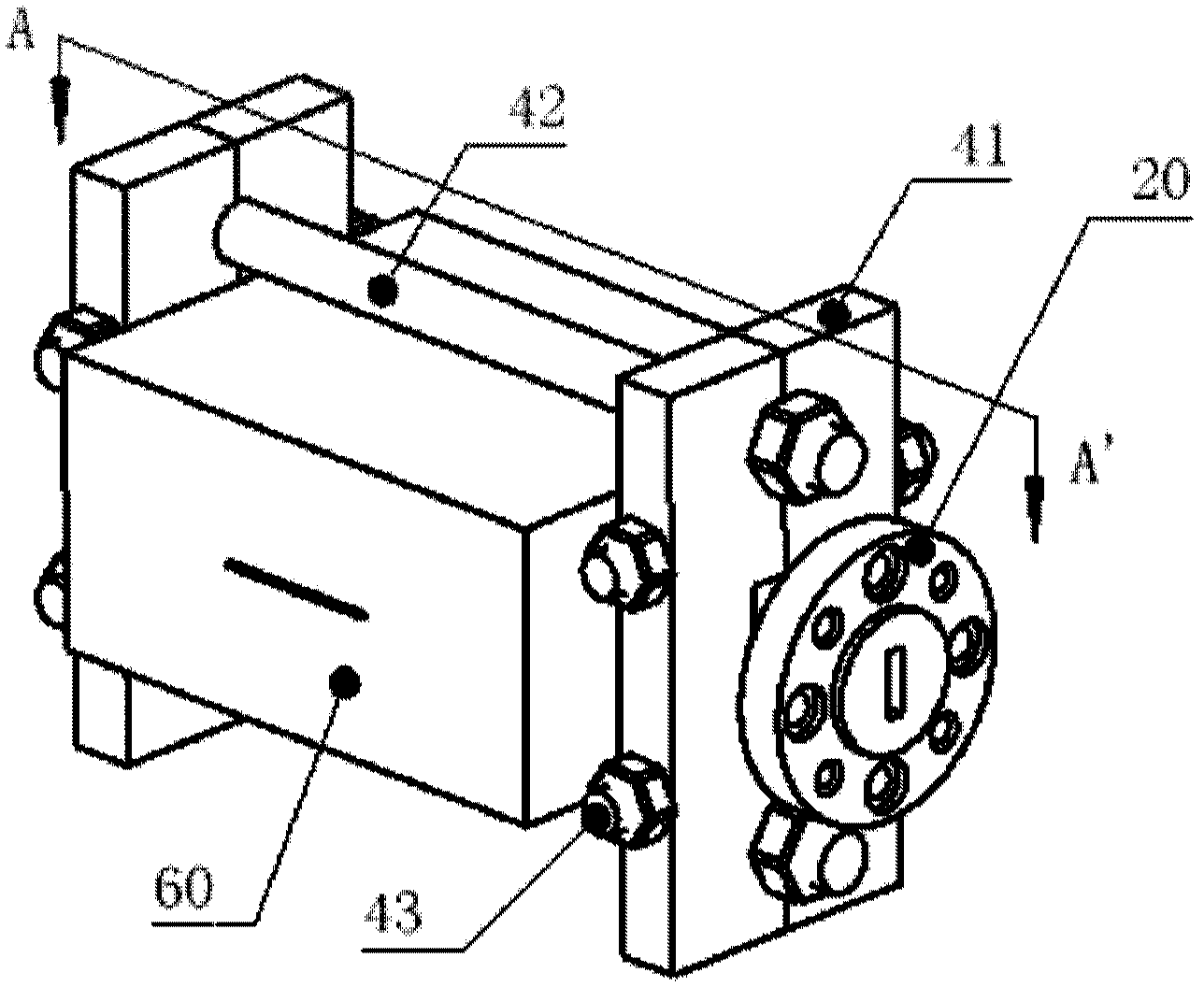

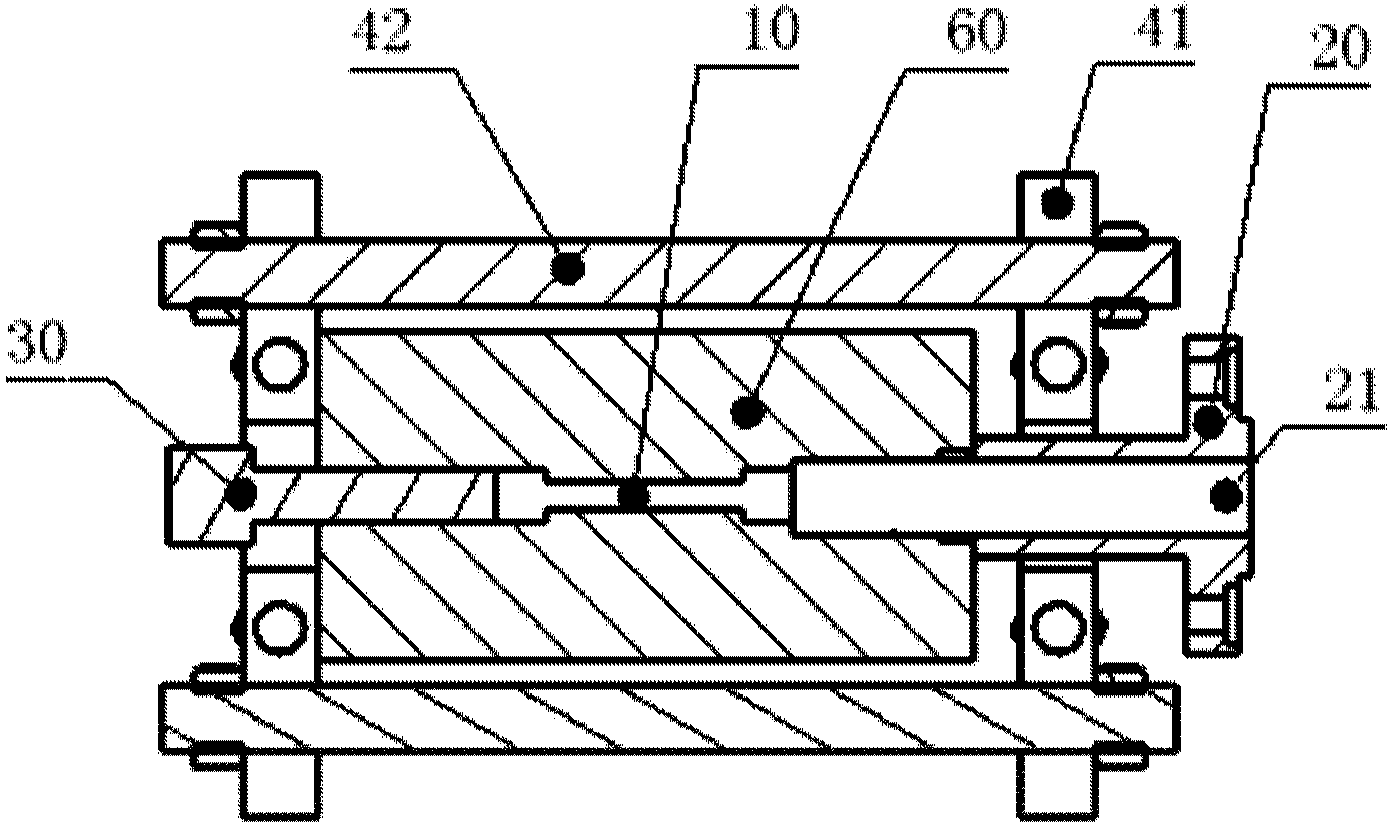

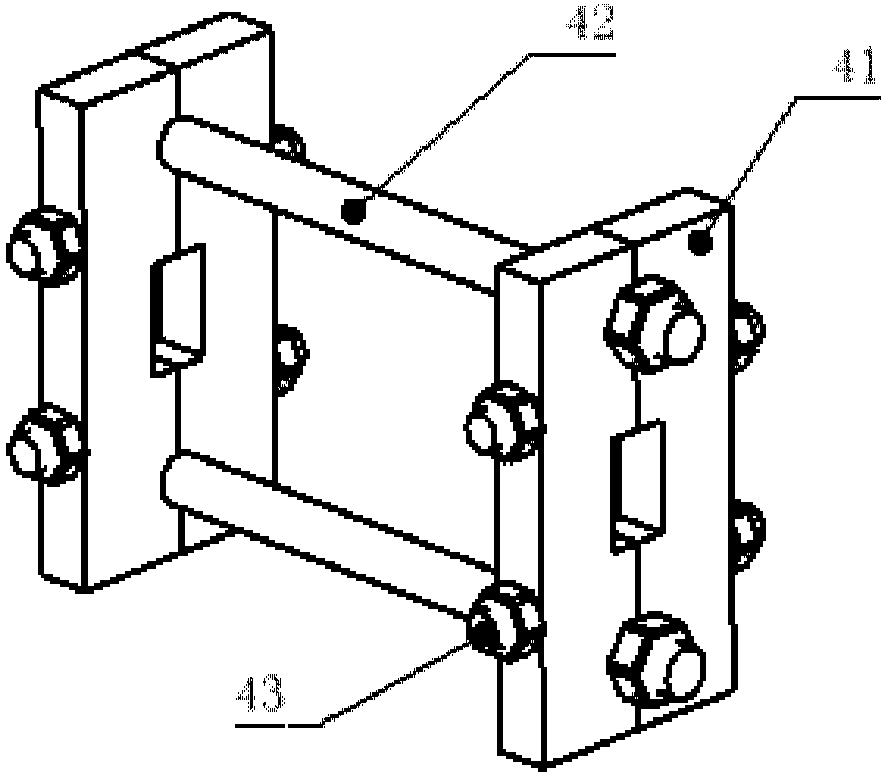

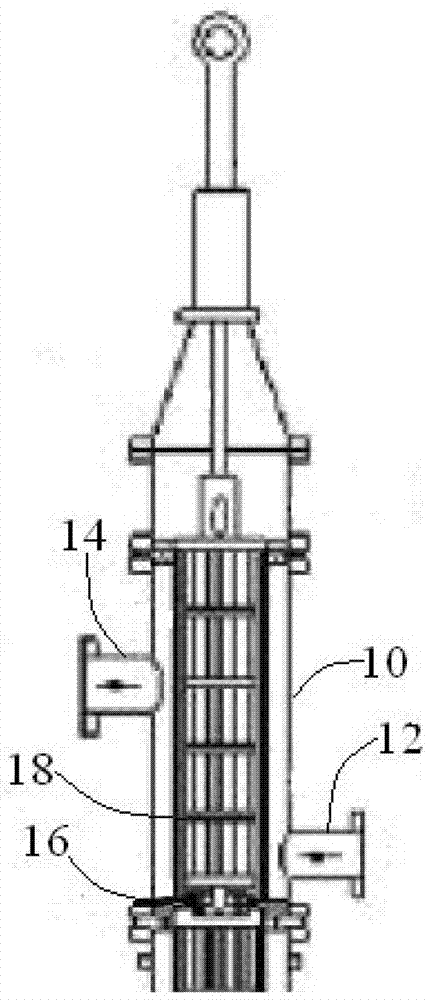

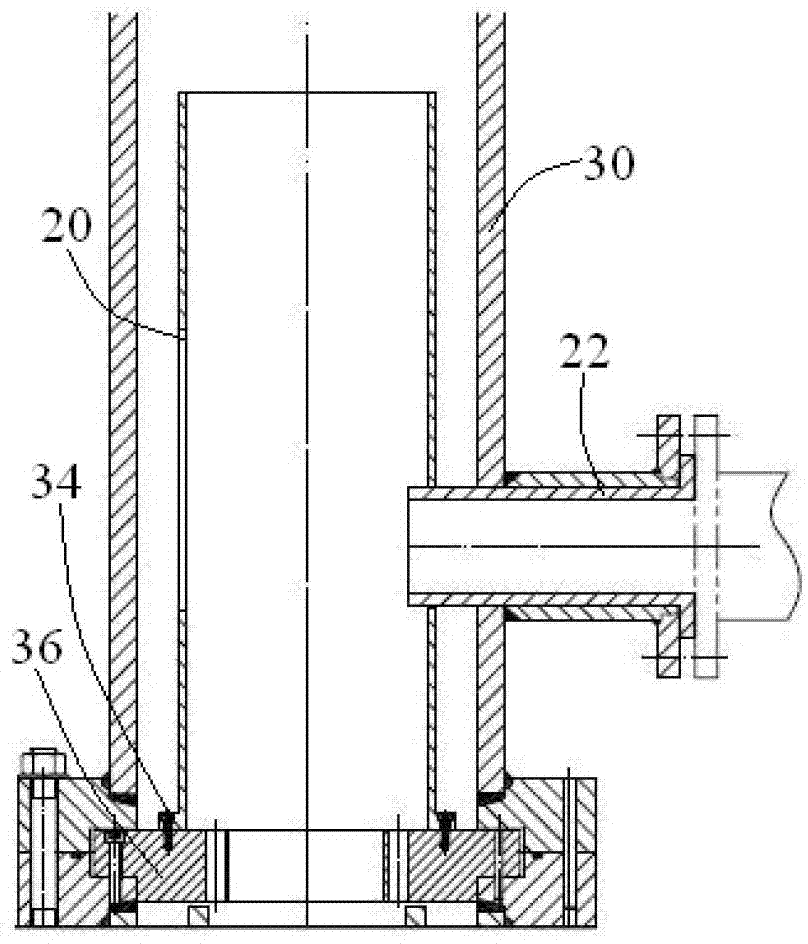

Clamping mechanism of testing device for direct tensile strength of fragile material

InactiveCN104330304ANot distortedNot subject to bendingMaterial strength using tensile/compressive forcesCold testUltimate tensile strength

The invention discloses a clamping mechanism of a testing device for the direct tensile strength of a fragile material. The clamping mechanism comprises an upper clamping component and a lower clamping component, wherein the upper clamping component comprises an upper wedge-shaped clamp (2) which is hung on an upper cylindrical pin (4) of an upper cylinder (5) through an upper circular ring (3), the upper cylindrical pin (4) is mounted on a pin hole of the upper cylinder (5), and the upper cylinder (5) is connected with an upper pulling rod (11); the lower clamping component comprises a lower wedge-shaped clamp (6) which is connected to a lower cylindrical pin (8) of a lower cylinder (9) through a lower circular ring (7), the lower cylindrical pin (8) is mounted on a pin hole of the lower cylinder (9), and the lower cylinder (9) is connected with a lower pulling rod (10) of a testing machine. The clamping mechanism has the advantages that a test piece is prevented from being bent and distorted in the direct tensile process of the fragile material, and the clamping of the wedge-shaped clamps to the test piece is improved; the clamping mechanism is applicable to indoor temperature testing, high temperature testing and low temperature temperature.

Owner:CHONGQING UNIV

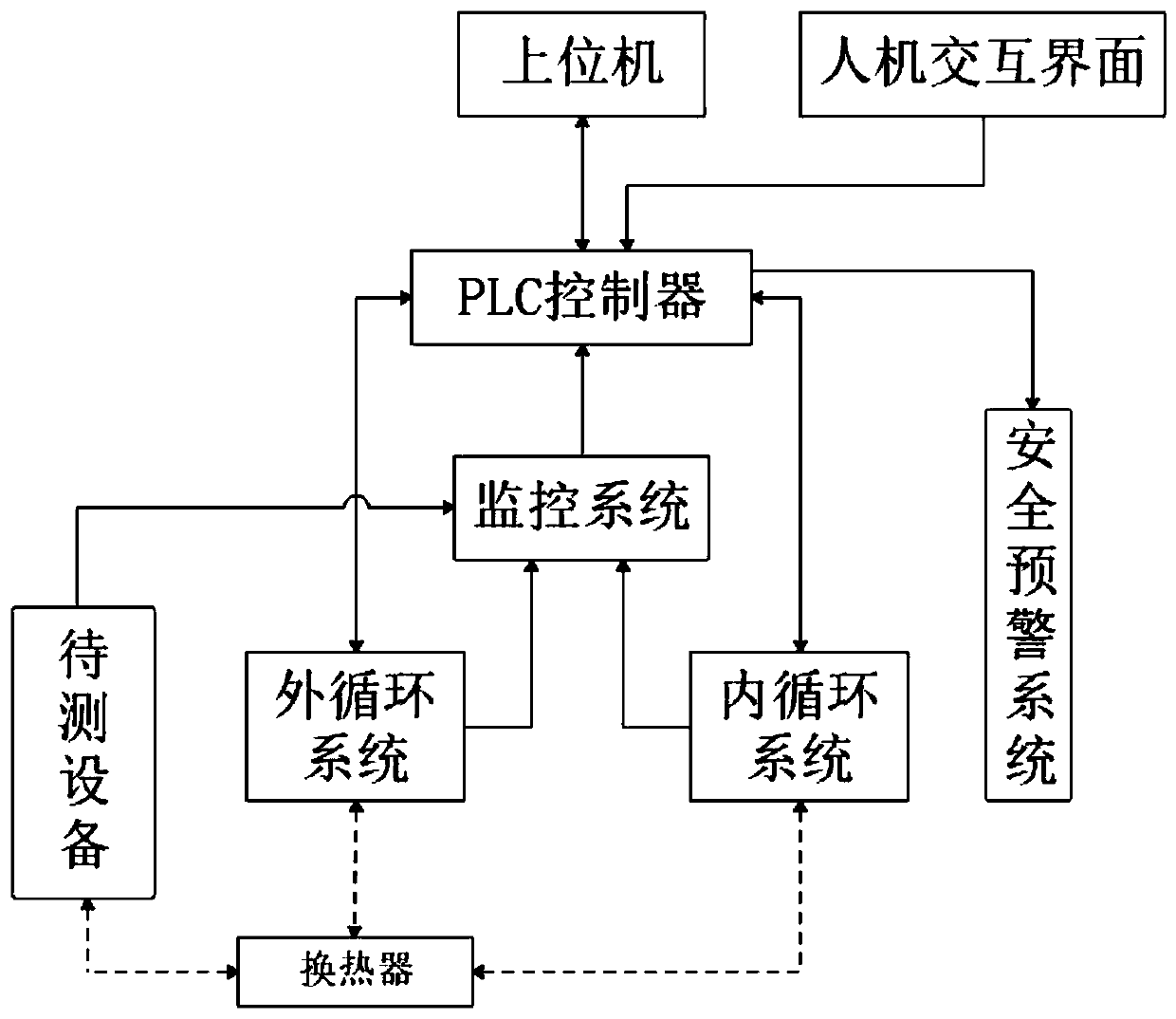

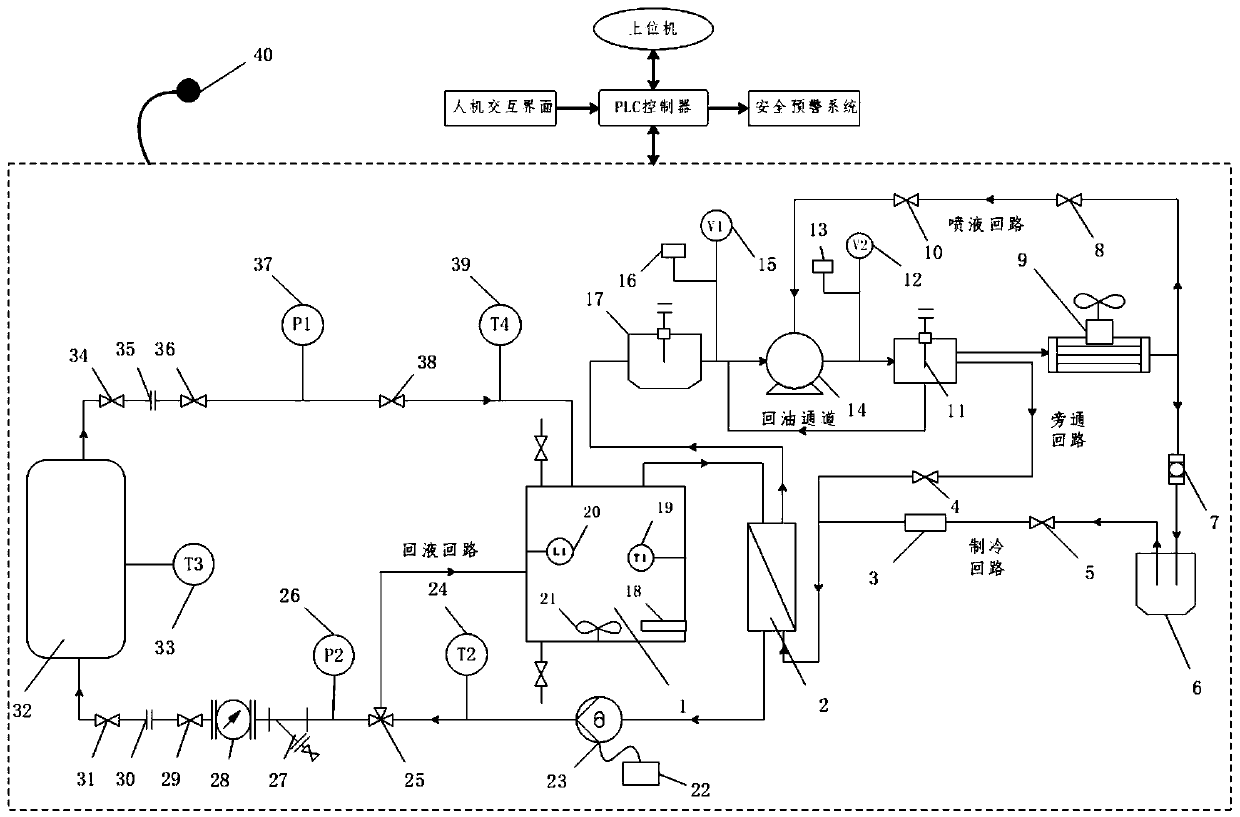

High-and-low-temperature cycle performance testing device for several kinds of devices

InactiveCN109960298ALower water supply temperaturePrecise temperature control effectTemperature control using digital meansAuxillary controllers with auxillary heating devicesTemperature controlCold test

The invention discloses a high-and-low-temperature cycle performance testing device for several kinds of devices. The testing device comprises an outer circulation system, an inner circulation systemand a control system. The outer circulation system and the inner circulation system share one heat exchanger; and a refrigerant circulation passage and a circulation liquid circulation passage are arranged in the heat exchanger. The outer circulation system includes a circulation liquid tank, a three-way valve, and a heat exchange tube that is sleeved on to-be-tested equipment; the outlet of the circulation liquid tank is connected to an inlet of the circulation liquid circulation passage of the heat exchanger; a first inlet of the circulation liquid tank is connected to a first port of the three-way valve and a second inlet of the circulation liquid tank is connected to the heat exchange tube; a second port of the three-way valve is connected to the outlet of the circulation liquid circulation passage of the heat exchanger; and a third port of the three-way valve is connected to the heat exchange tube. According to the high-and-low-temperature cycle performance testing device, the temperature control is carried out precisely; the temperature is stable; the real working conditions can be simulated; and the high-and-low-temperature cycle performance testing device is suitable for high-and-low temperature testing of various devices.

Owner:WUHAN UNIV OF TECH

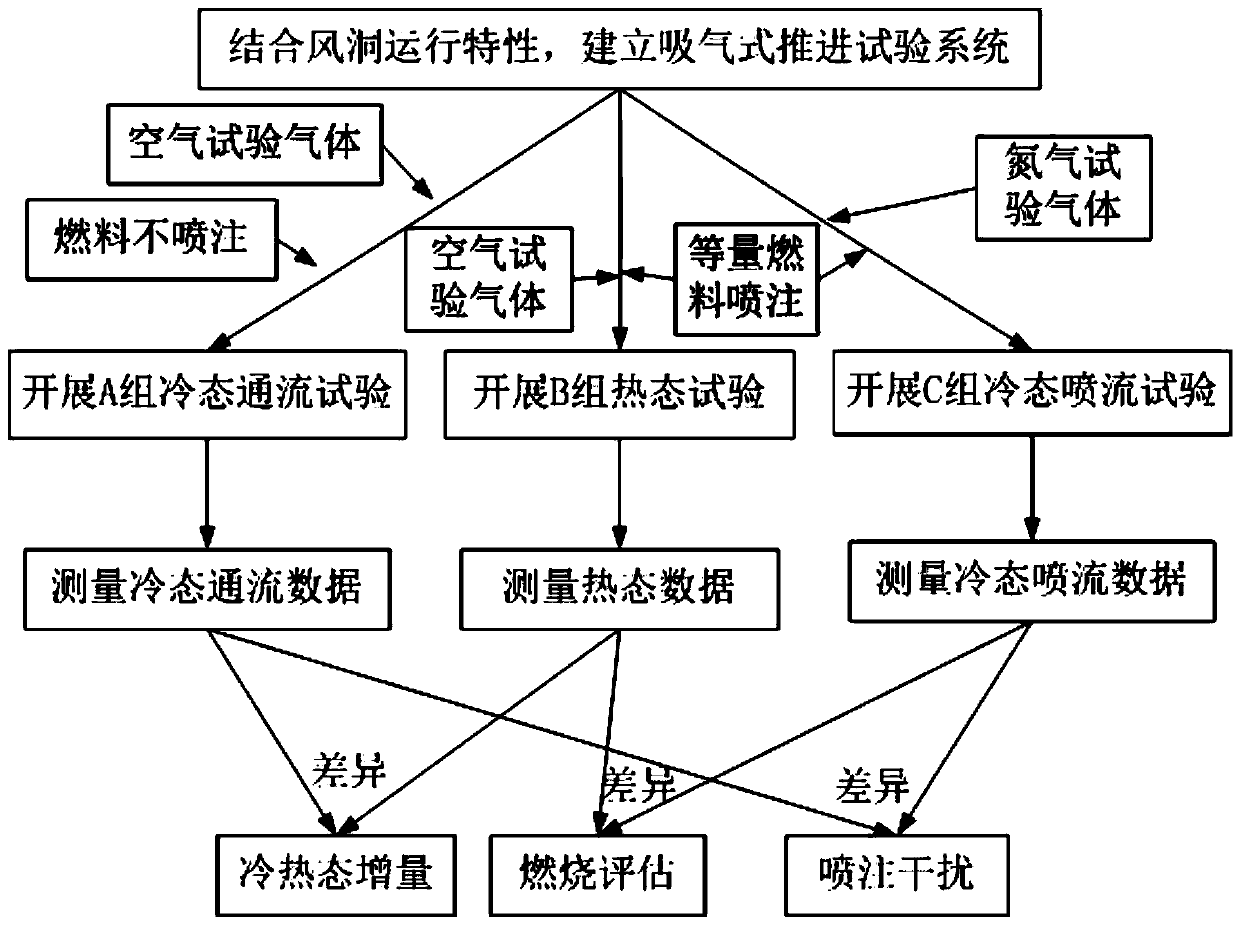

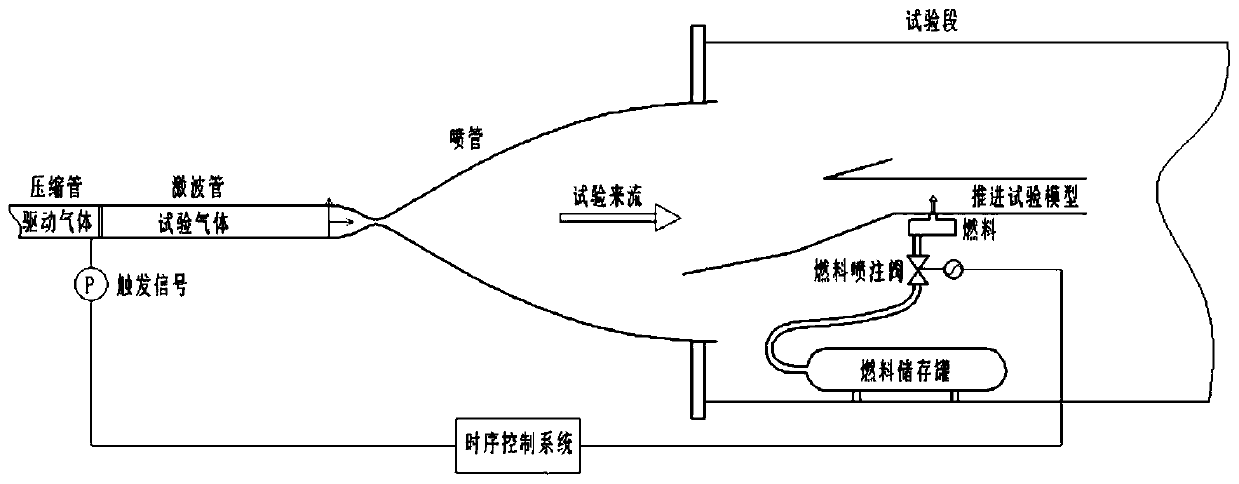

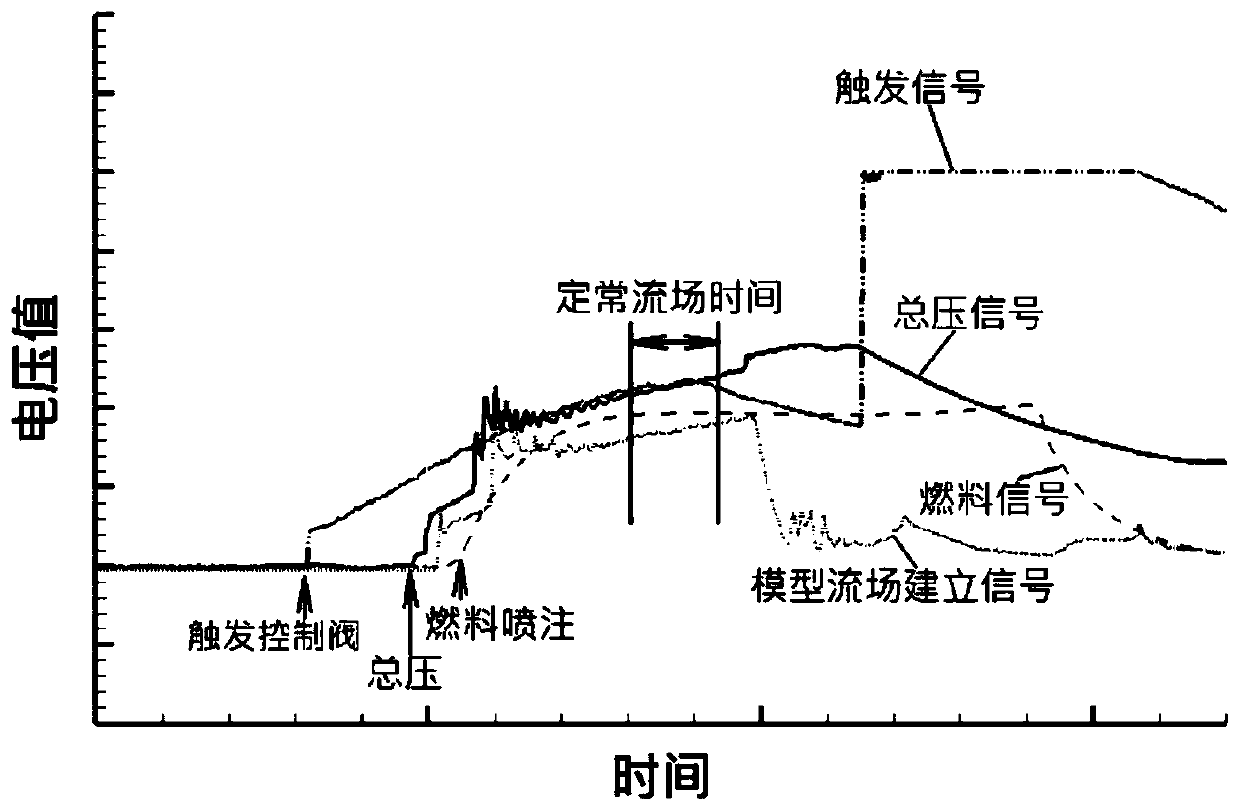

Aspirating type propulsion test simulation method based on high-temperature pulse wind tunnel

InactiveCN109883646ASolve the acquisition problemSolve the problem of air-breathing propulsion test data acquisitionGas-turbine engine testingAerodynamic testingIncremental testCold test

The invention discloses an aspirating type propulsion test simulation method based on a high-temperature pulse wind tunnel. The aspirating type propulsion test simulation method based on the high-temperature pulse wind tunnel comprises the following steps that (1) an aspirating type propulsion test system is established; (2) an A group cold test is conducted, and test data of non-fuel spouting columns and air incoming flow are measured; (3) a B group cold test is conducted, and the test data of the non-fuel spouting columns and the air incoming flow are measured; (4) a C group cold jet test isconducted, and cold jet test data flown from flue spouting and nitrogen flow are measured; (5) the differences of A, B, and C test data are compared, sprouting influence, burning characteristic and colt and hot performance analyses are completed, and stimulation on aspirating type propulsion is realized. According to the aspirating type propulsion test simulation method based on the high-temperature pulse wind tunnel, through sprouting control of fuel and replacement of test gas, three groups of control test stimulation methods A, B and C are formed, the burning characteristic of the aspirating type propulsion test can be judged, performance incremental test data of cold and hot performances can be obtained, and the aspirating type propulsion test simulation method can further be used forthe fuel sprout disturbance characteristic analysis of the aspirating type propulsion test.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

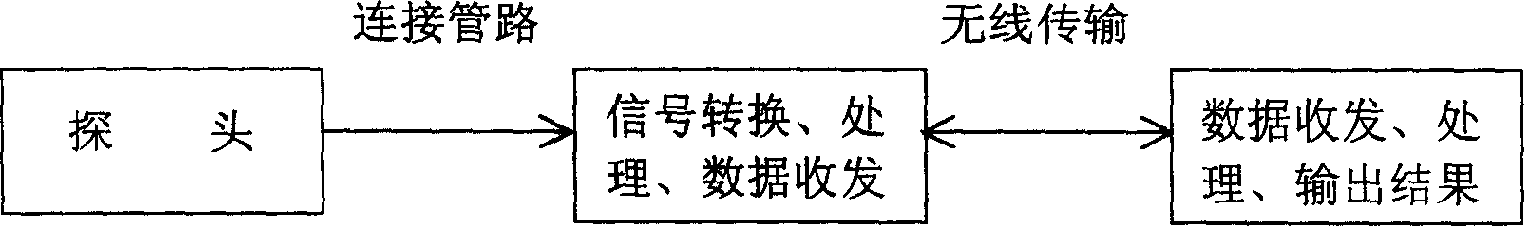

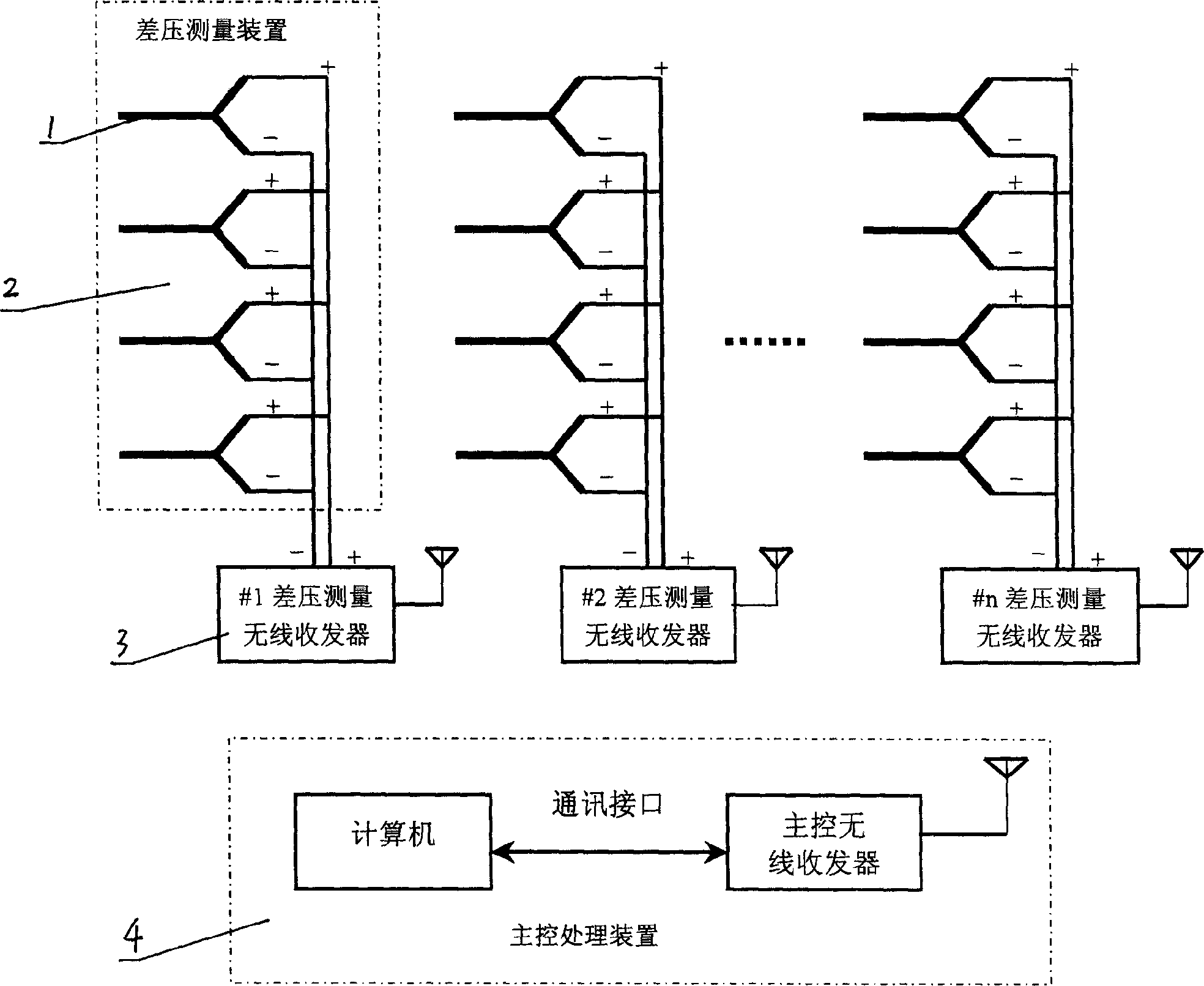

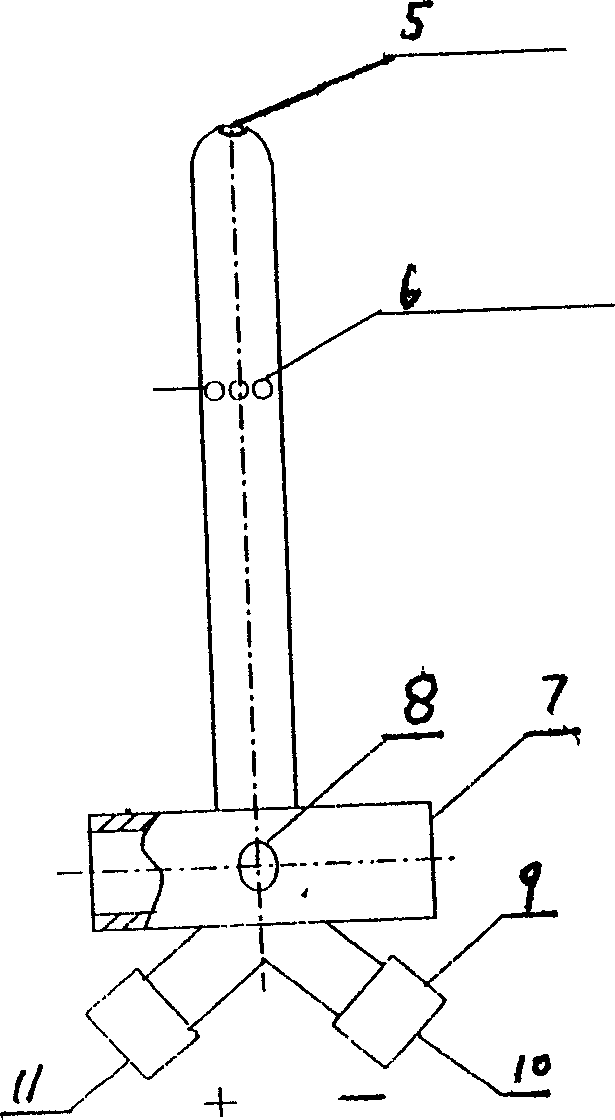

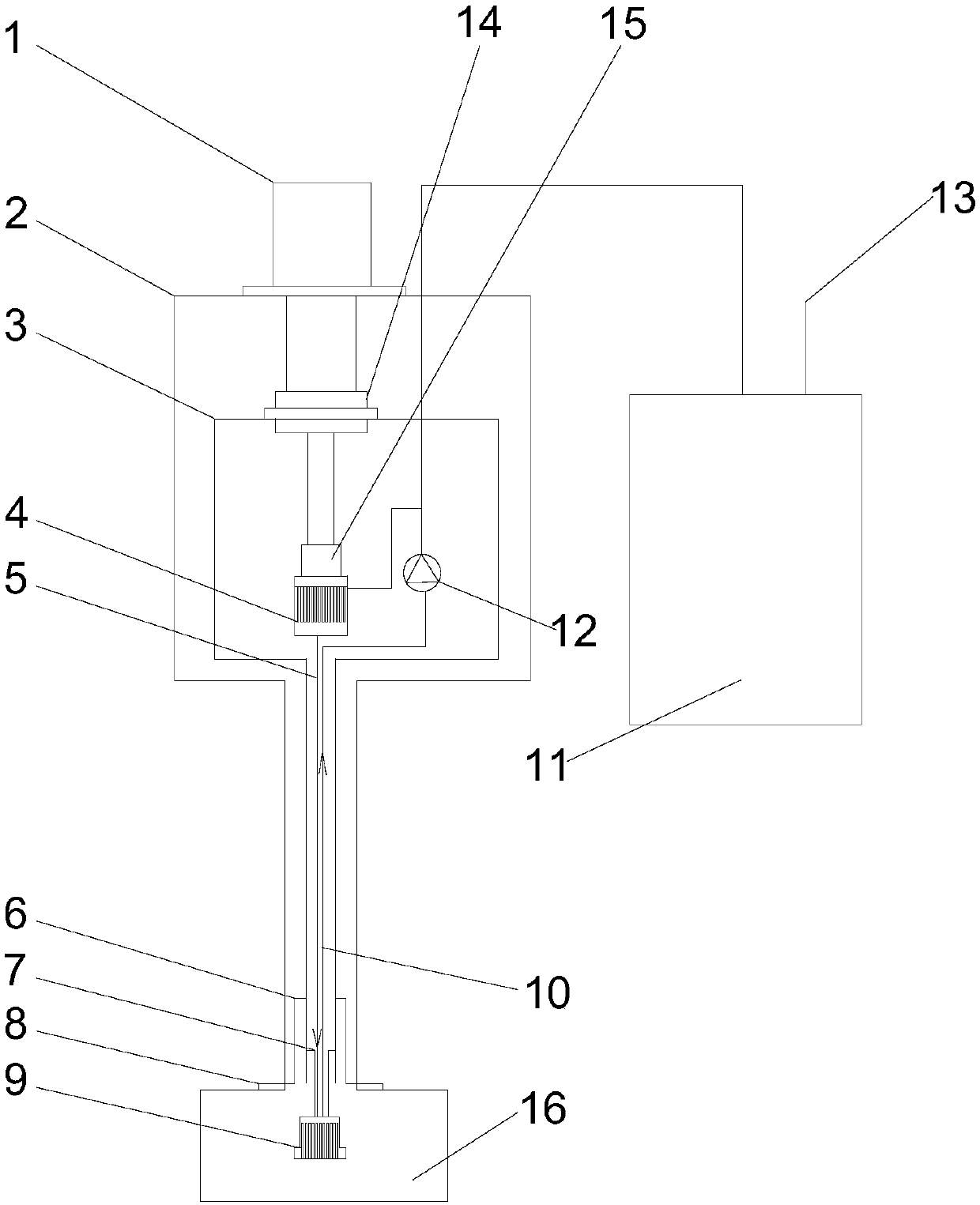

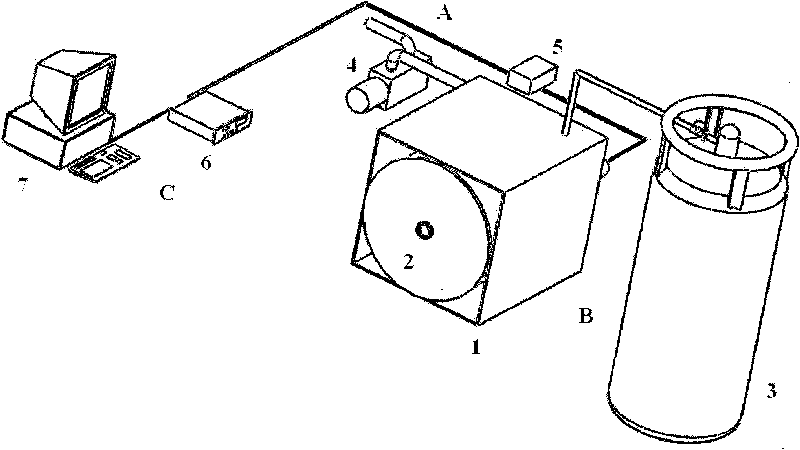

Automatic test system for cold test of boiler and test method thereof

InactiveCN1558204AEasy to installThe measurement layout is reasonableCombustion regulationMaterial analysisTransceiverEngineering

The present invention discloses one kind of automatic boiler cold state test system and method. Several wind speed measuring probes are fixed via fixtures in measurement positions of the burner exit to measure accurate wind pressure signals, which are averaged in multi-channel pipeline, converted into electric signal in the pressure difference converter, converted in A / D converter into digital quantity and processed in microprocessor; the processed data are sent via pressure difference radio transceiver to main controlling radio transceiver and fed to computer via the communication interface for further processing to obtain the measurement results. The present invention has the advantages of simple installation, accurate data, fast measurement, etc.

Owner:徐州发电厂

Quality measurement method of solar photovoltaic cable

InactiveCN102539247ATest air agingTest performanceWeather/light/corrosion resistanceResistance/reactance/impedenceCold testEngineering

The invention discloses a quality testing method of a solar photovoltaic cable. The quality testing method comprises the following testing steps of: 1, placing the solar photovoltaic cable in a place with the environment conditions that the temperature is 90 DEG C and the humidity is 85%, carrying out air thermal aging test for 1000h, and after the test is finished, when the maximal change rate of the strength / elongation of the solar photovoltaic cable does not exceed + / -30%, judging the solar photovoltaic cable to be qualified in the test and carrying out a next testing step; and 2, placing the solar photovoltaic cable in a low-temperature refrigerating cabinet at -40+ / -2 DEG C, carrying out a low-temperature test for 16 hours, and after the test is finished, when the solar photovoltaic cable has no cracks, judging the solar photovoltaic cable is qualified in the test and carrying a next testing step. The method disclosed by the invention is reasonable, the actual service environment of the solar photovoltaic cable is used during testing, so that the actual quality condition of the solar photovoltaic cable can be tested effectively, the actual service life of the solar photovoltaic cable can be measured, the quality problems are reduced, and the method has extensive popularization and application values.

Owner:广东优科检测认证有限公司

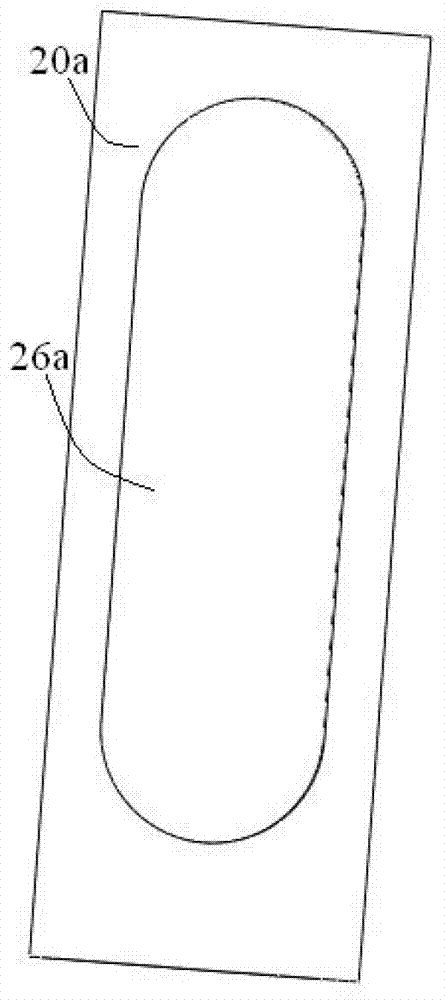

Device and method for performing cold test on intermediate resonant cavity of small-size sheet beam klystron

InactiveCN104062499AReduce usageRealize cold testFrequency measurement arrangementKlystronResonant cavity

The invention provides a device and a method for performing cold test on an intermediate resonant cavity of a small-size sheet beam klystron. According to the device, the two sides of an intermediate resonant cavity are provided with through holes communicated with the two sides of a resonant cavity body. The device comprises a tuning pin, a test output flange and a vector network analyzer. The narrow end of the tuning pin is inserted into the through hole on the first side of the intermediate resonant cavity to form a cavity wall of the intermediate resonant cavity, and the wide end of the tuning pin is connected with a stepper motor. The test output flange is fixed to the second side of the resonant cavity body, the first side of the test output flange is a rectangular step, is inserted into the second side of the resonant cavity body and is sunk to the bottom, the center of the test output flange is provided with a waveguide hole which has the same size with the cross section of the through hole on the second side of the intermediate resonant cavity, and a first side of the waveguide hole is aligned at the intermediate resonant cavity. A test port of the vector network analyzer is connected to the first side of the waveguide hole in the center of the test output flange. The cold test device of the invention has the advantages of simple structure, small size, low cost and light weight, can be used for testing the tuning characteristics of the intermediate resonant cavity, and has broad application prospects.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

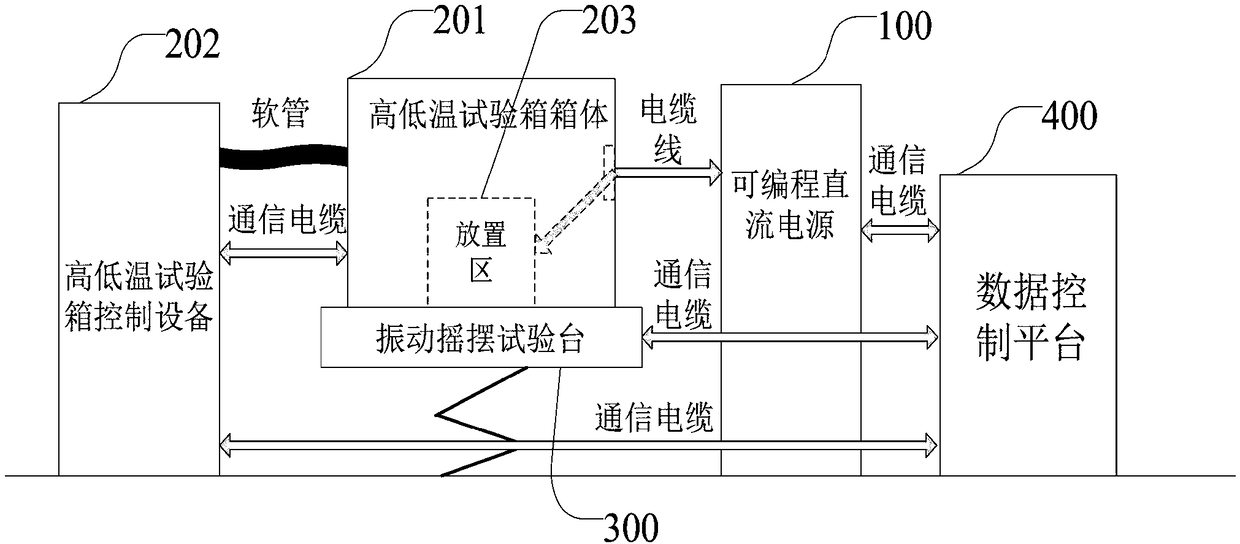

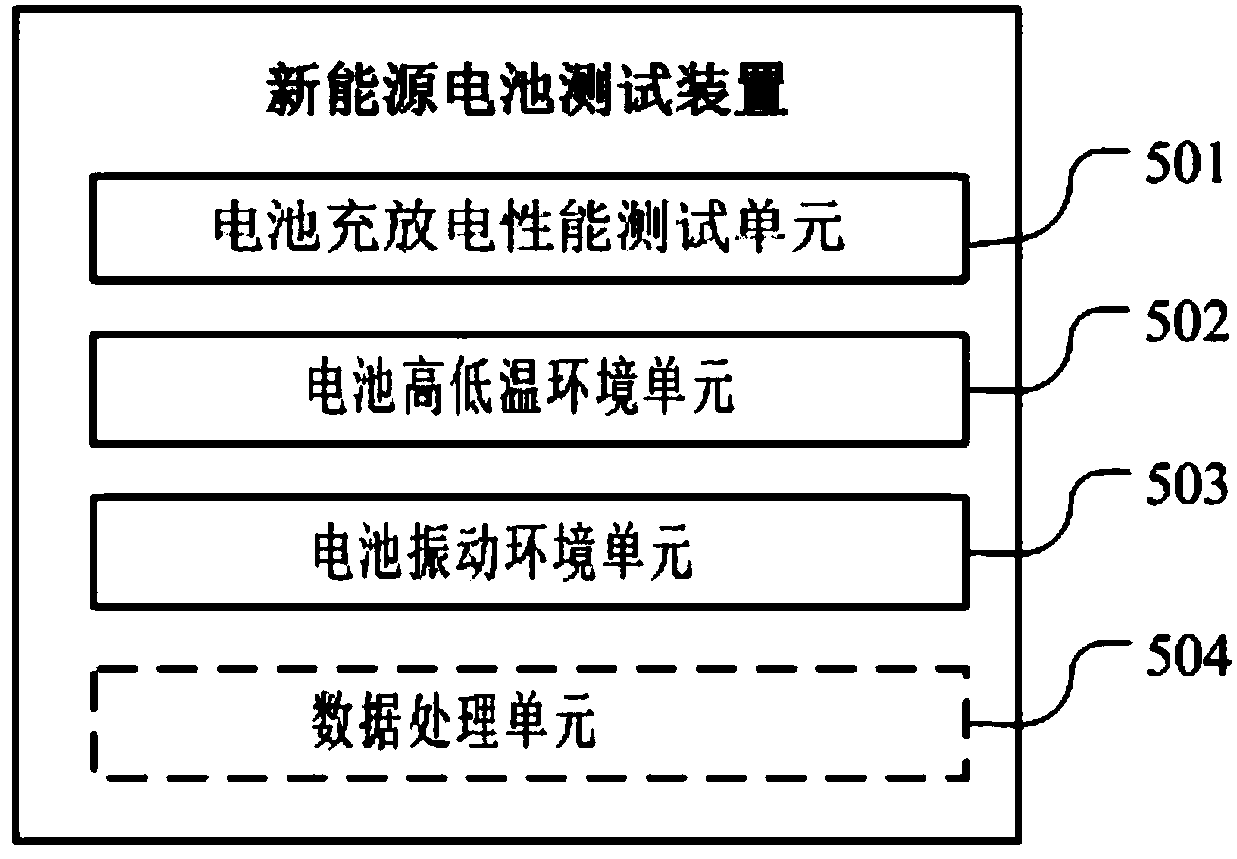

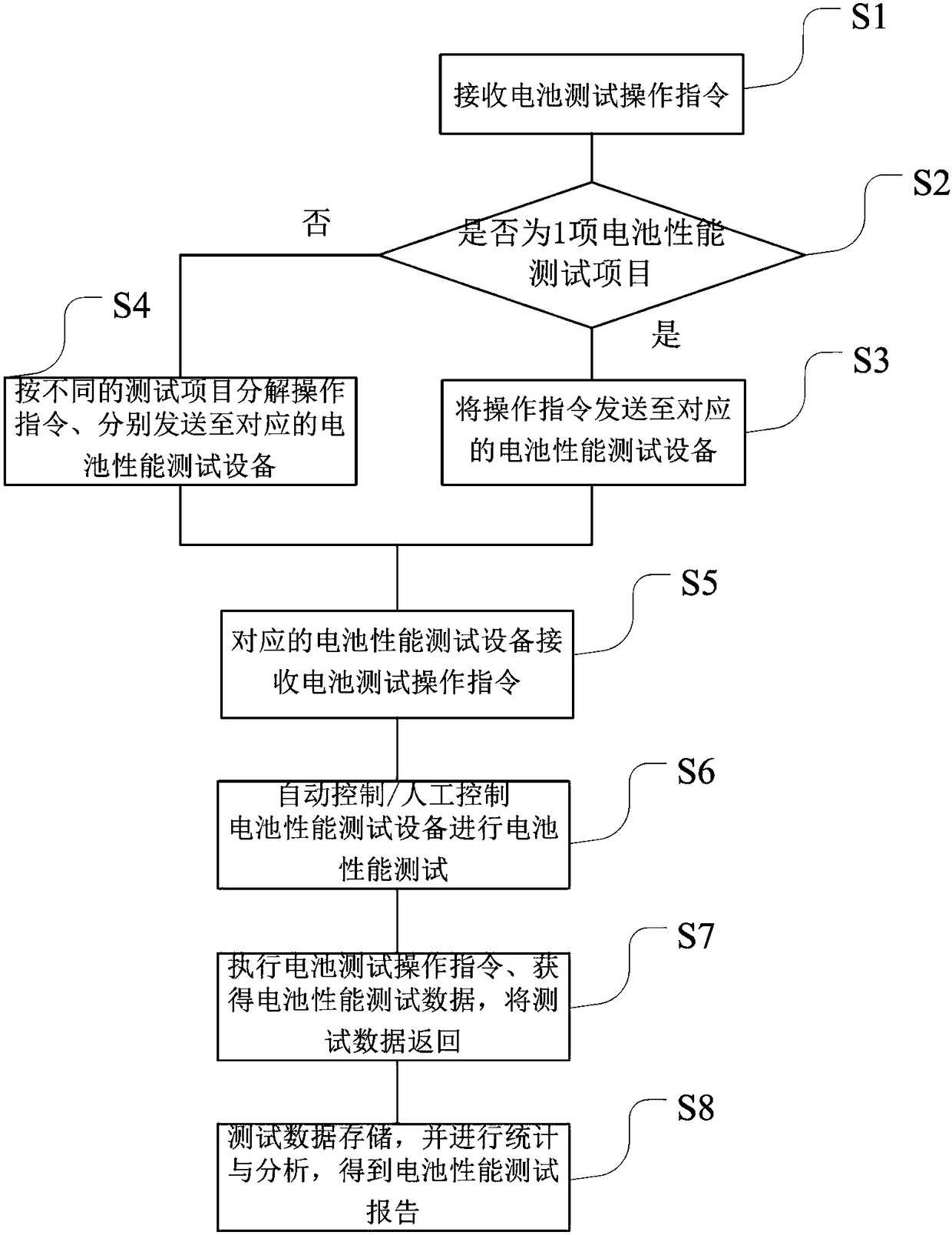

New energy battery test system, device and method

PendingCN108318826AIncrease profitMeet the requirements of environmental test conditionsElectrical testingVibration testingData controlNew energy

The invention relates to a new energy battery test system, device and method, and belongs to the technical field of new energy battery test. The new energy battery test system comprises a programmableDC power supply, a high / low temperature test box, a vibration-swing test bench and a data control platform in communication connection with different test equipment; via the system, charging / discharging performance test, high / low temperature test and vibration test can be carried out on a new energy battery in the temperature and humidity environment (the extreme temperature and humidity) and thevibration-swing environment at the same time; and the digital control platform controls test of single battery performance or composite test multiple battery performances remotely, completely automatic processing is realized, a test result is rapider, a test result is more accurate and reliable, and the operation process is simplified greatly.

Owner:青岛海洋电气设备检测有限公司

Using method of multi-circulation warm-stamping equipment

InactiveCN102590261ACompetent Reliability Accelerated Testing RequirementsMaterial thermal analysisGreenhouseCold test

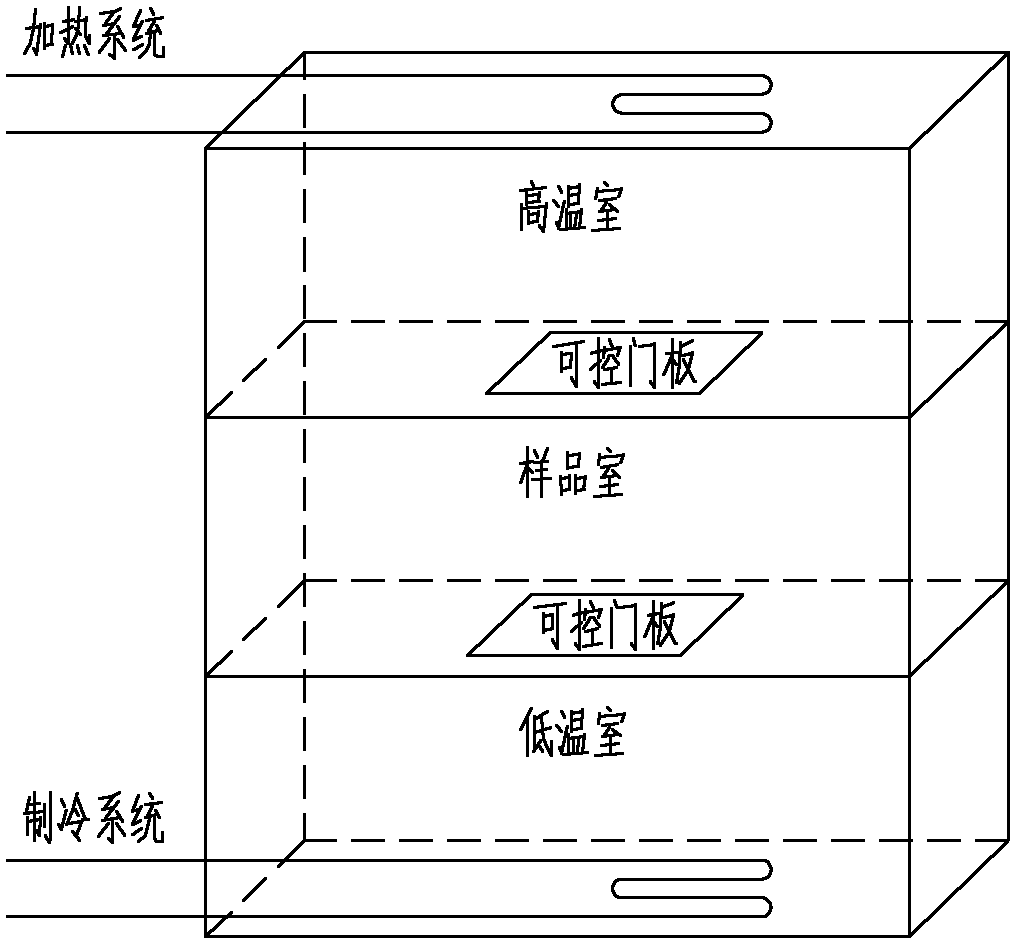

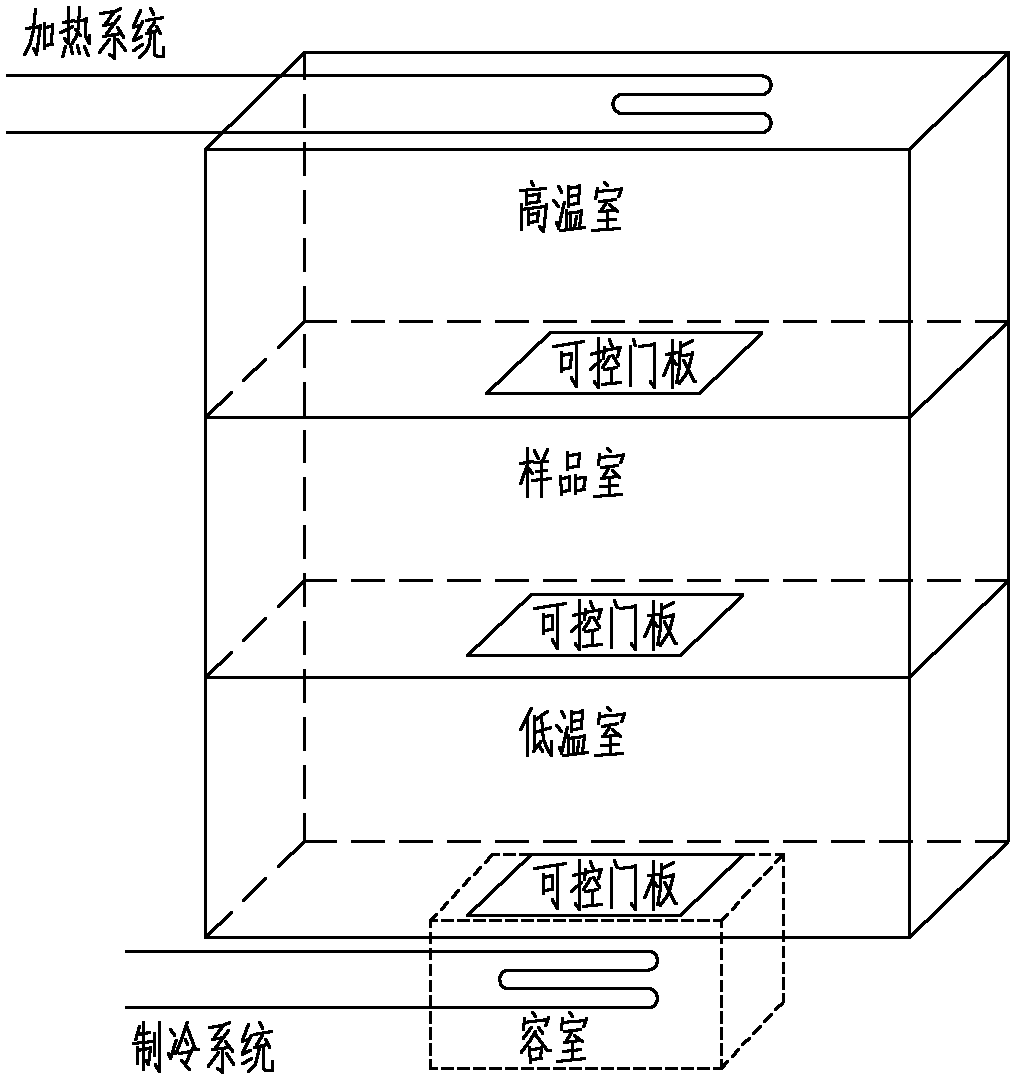

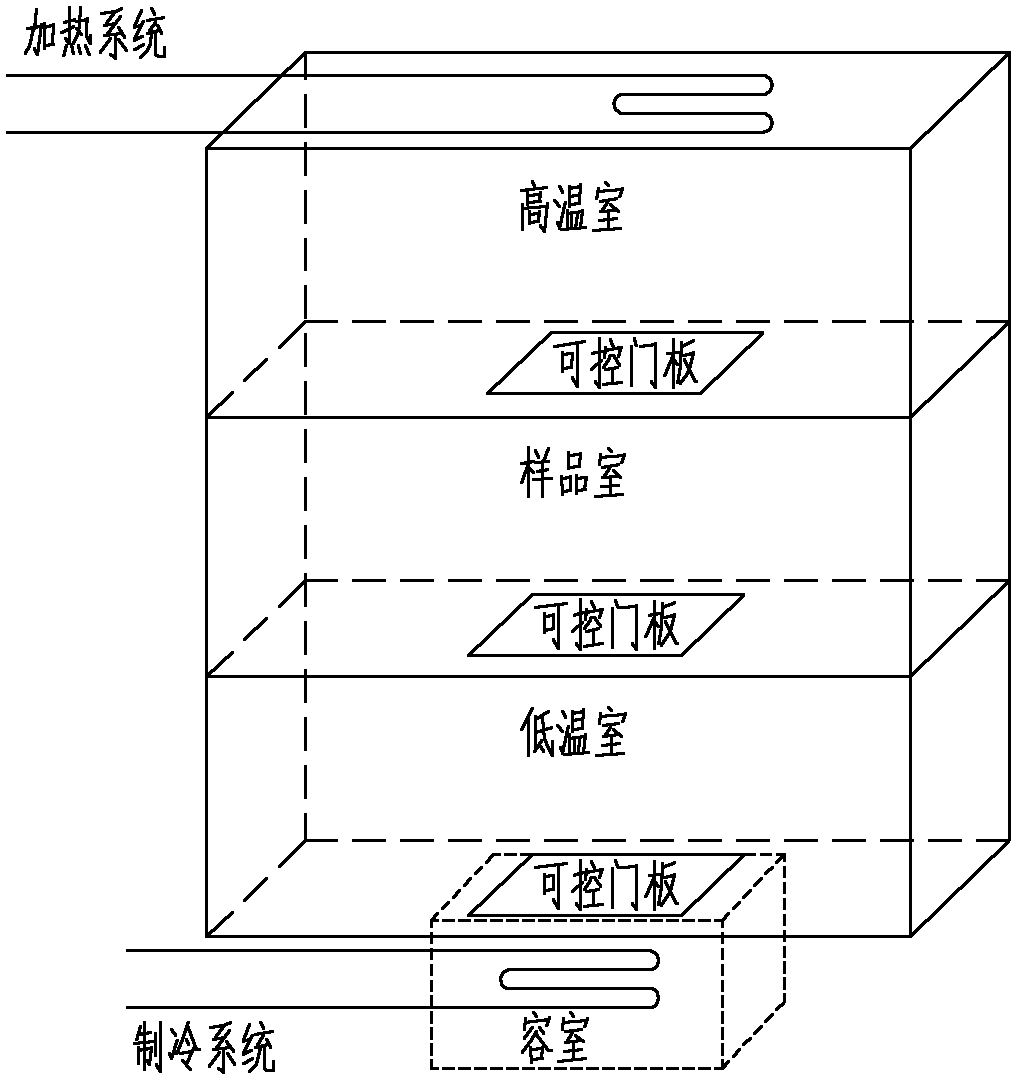

The invention relates to a using method of multi-circulation warm-stamping equipment; the warm-stamping equipment comprises a high temperature chamber, a sample chamber and a low temperature chamber, which are sequentially connected, wherein a controllable door plate is arranged between the high temperature chamber and the sample chamber and between the sample chamber and the low temperature chamber respectively, the high temperature chamber is connected with a heating system, a containing chamber which can contain a condenser is arranged below the low temperature chamber and is connected with a refrigerating system, and another controllable door plate is arranged between the low temperature chamber and the containing chamber. The using method of the warm-stamping equipment is as follows: when a sample to be measured is in a high temperature testing phase, closing the controllable door plate between the low temperature chamber and the containing chamber, performing heating, defrosting, air drawing-off and dried air replenishing on the containing chamber; when the sample to be measured is in a low temperature testing, closing the heating system in advance, starting the refrigerating system and opening the controllable door plate between the low temperature chamber and the containing chamber; and in the method, continuous 80-time circular operation can be performed and the requirement of reliability accelerated test of photovoltaic modules can be met.

Owner:TRINA SOLAR CO LTD

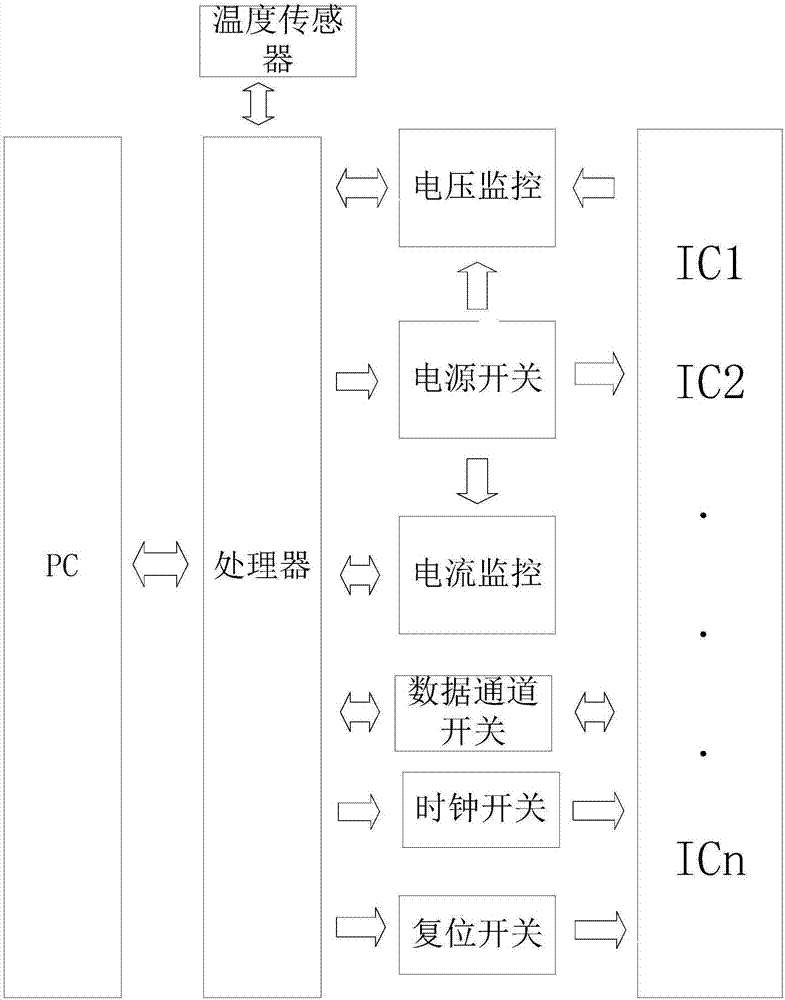

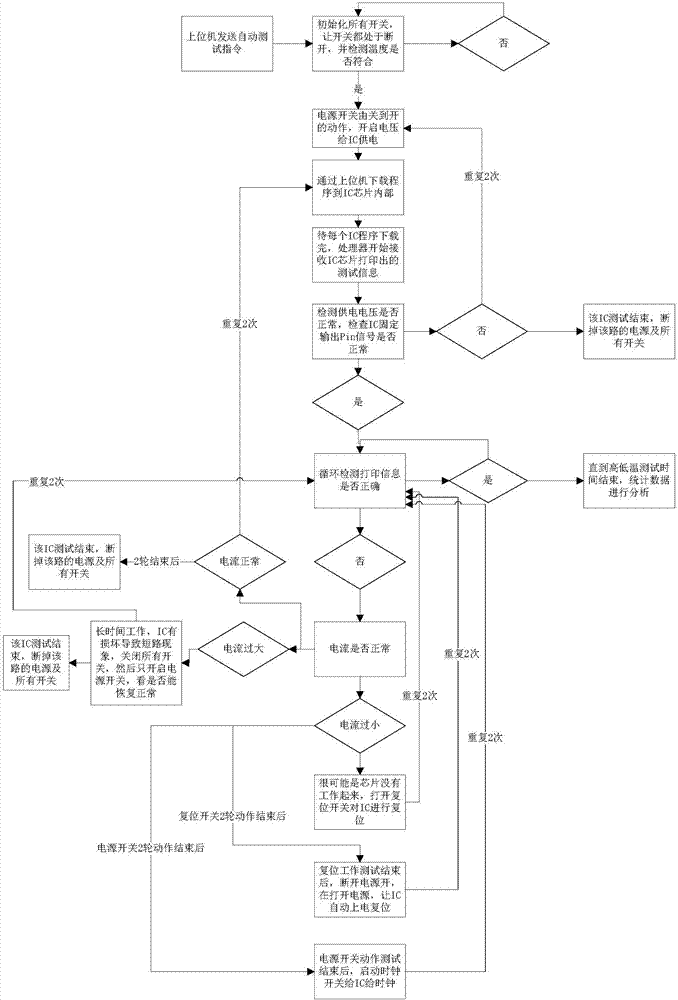

High and low temperature test device for IC testing

The invention relates to a high and low temperature test device for IC testing, so that technical problems that abnormity elimination and correction can not be carried out on a single abnormal integrated circuit while a high-and-low-temperature box is not opened and the power of the integrated circuit that can not be corrected or has been tested can not be cut off completely to enter a silence state in the prior art can be solved. The test device is composed an upper computer, a hardware circuit connected with the upper computer, and a plurality of ICs connected with the hardware circuit. The hardware circuit includes a processor, a power supply module, a current monitoring module, a voltage monitoring module and a switch module, wherein the power supply module, the current monitoring module, the voltage monitoring module and the switch module are connected with the processor. Therefore, the problems can be solved well. The test device can be applied to the industrial IC production.

Owner:张家港市欧微自动化研发有限公司

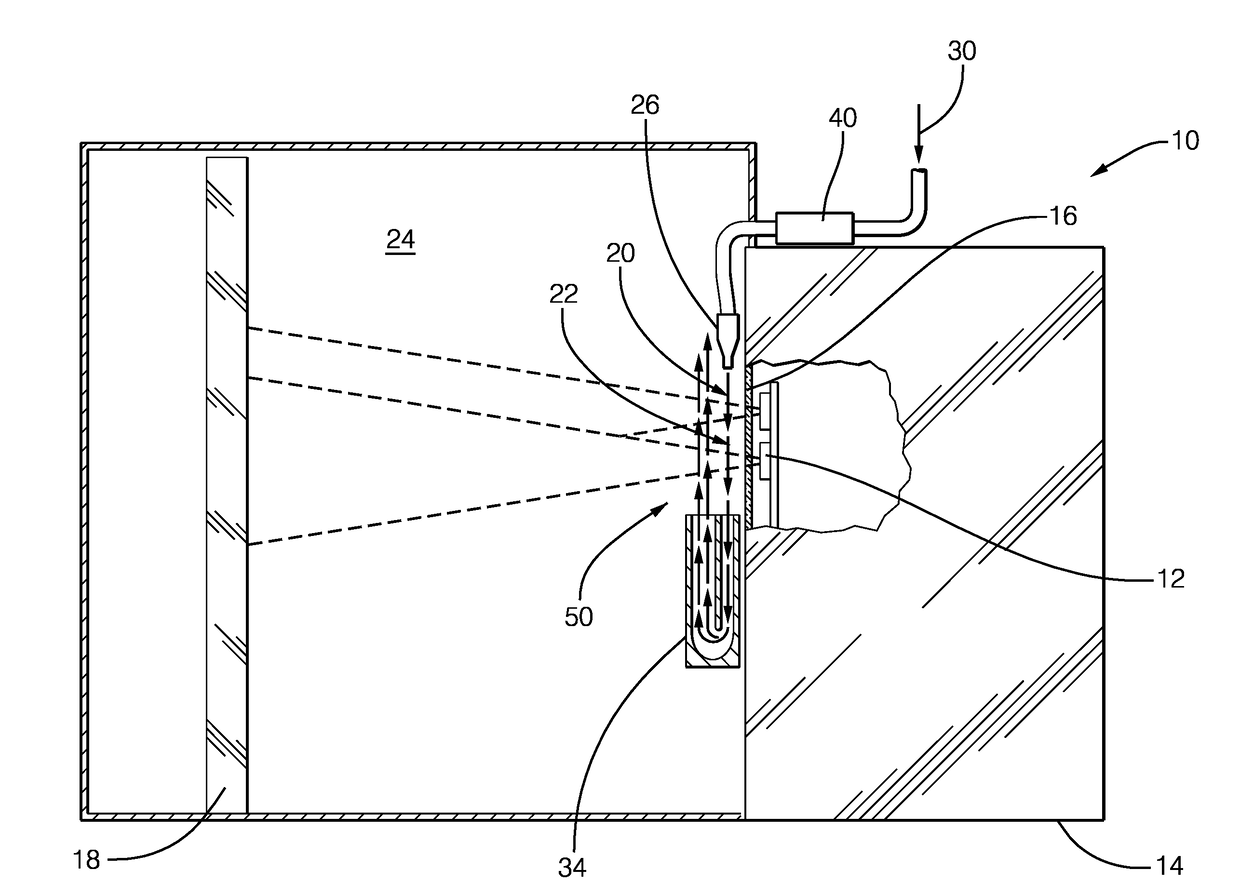

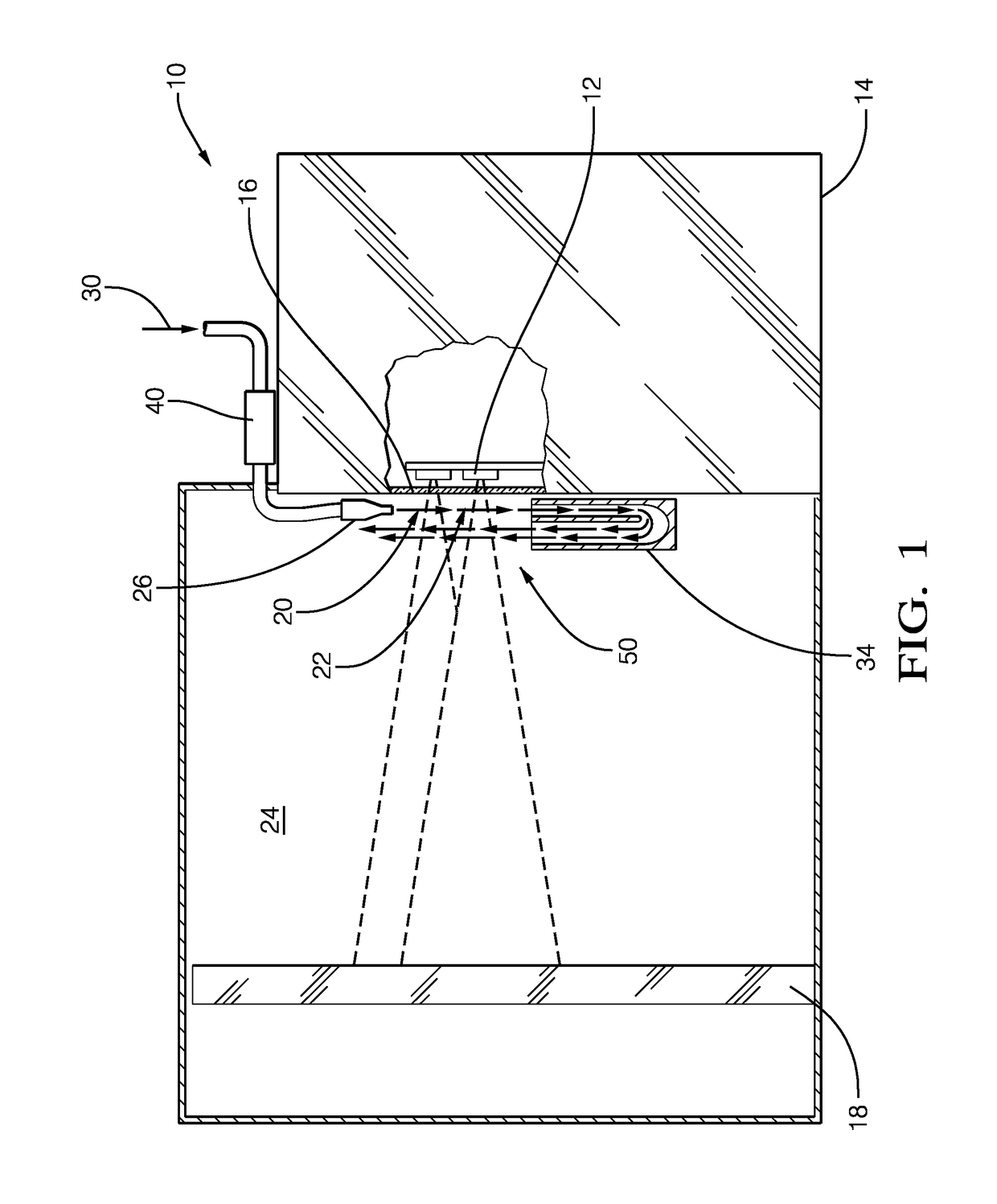

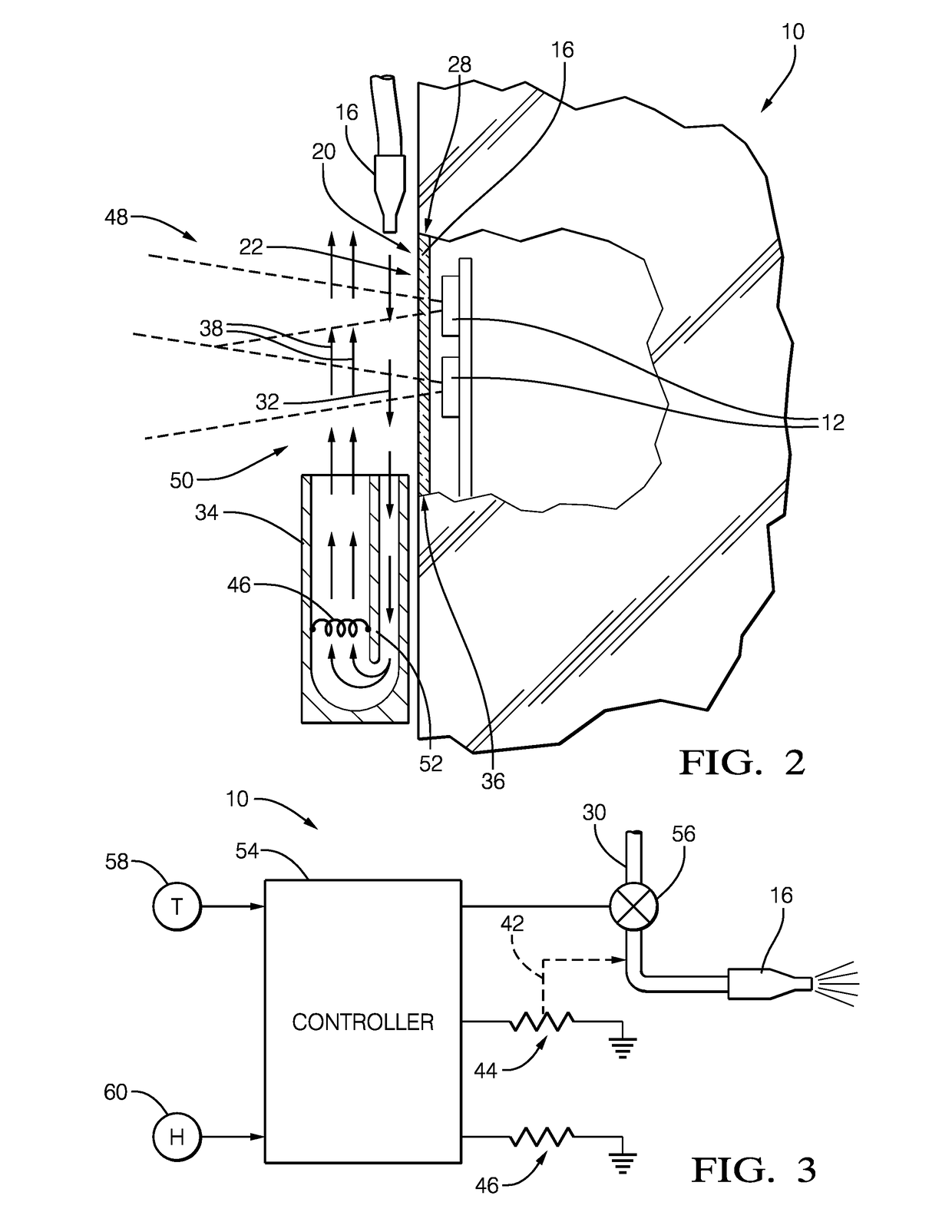

Bi-Directional Air-Curtain For Cold Testing A Camera

A cold-test system for testing a camera at a cold temperature includes a test-chamber with a window, a nozzle, and a recirculator. The window is installed in the test-chamber so the camera is provided with a view of a test-target outside of the test-chamber. The nozzle is located proximate to a first edge of the window. The nozzle is configured to direct air from an air-source in a first direction and adjacent to an outside-surface of the window. The recirculator is located proximate to a second edge of the window opposite the first edge. The recirculator is configured to receive the air moving in the first direction and re-direct that air in a second direction opposite the first direction and adjacent to the air moving in the first direction opposite the window. The nozzle and the recirculator cooperate to form a bi-directional air-curtain proximate to the outside-surface.

Owner:APTIV TECH LTD

Device for high and low temperature shock tests

InactiveCN104931375AReduce electricity demandReduce shockElectrical testingStructural/machines measurementElectricityCold test

The invention provides a device for high and low temperature shock tests. The device comprises a shell and partition plates arranged in the shell. The shell is divided by the partition plates into a first cavity, a second cavity and a third cavity, wherein the first cavity is used for conducting a high-temperature test on a product to be tested, the second cavity is used for conducting a low-temperature test on a product to be tested, and the third cavity is used for stopping heat exchange between the first cavity and the second cavity. By the adoption of the technical scheme, rapid testing of the product to be tested is achieved, the investment cost can be reduced, and the electricity consumption of a test device can be reduced.

Owner:HEFEI HUALING CO LTD +1

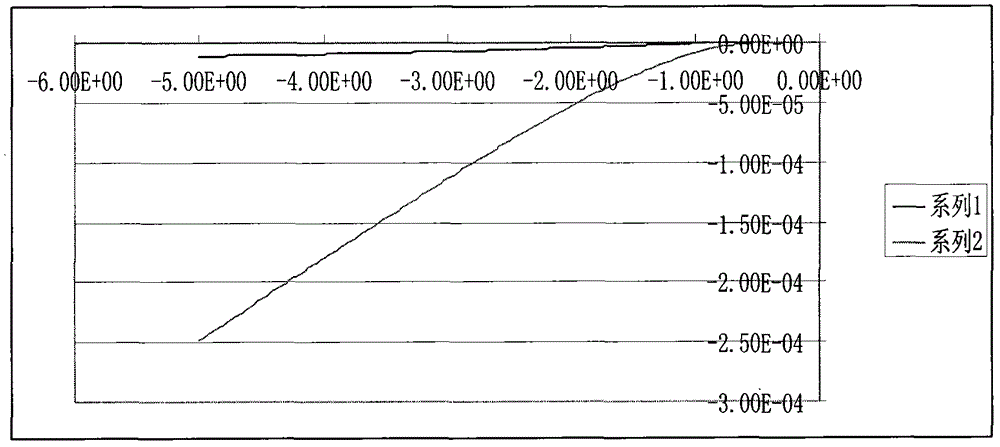

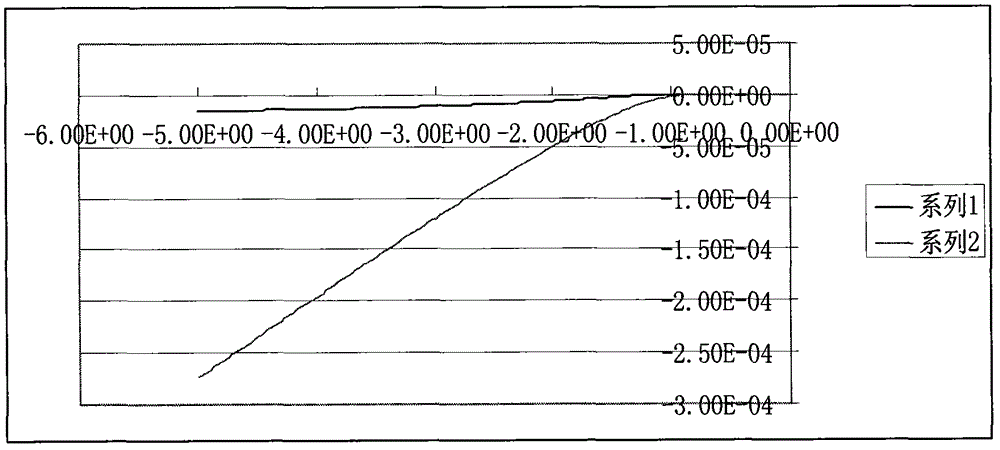

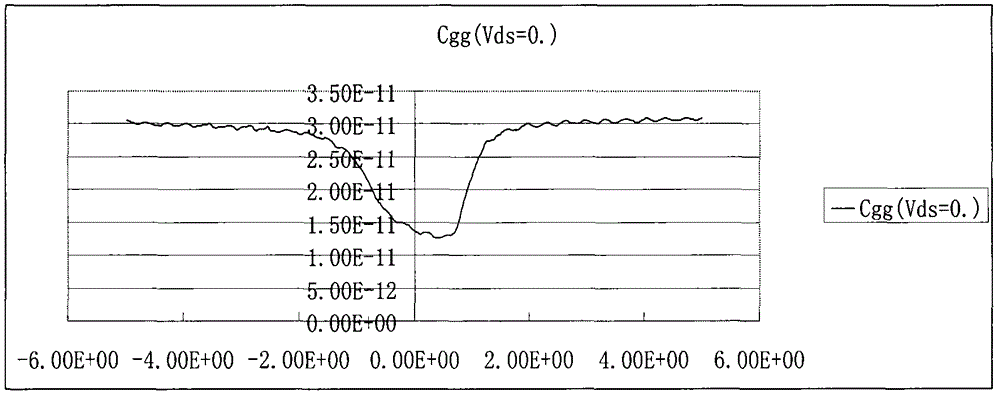

Low-temperature CMOS (Complementary Metal-Oxide-Semiconductor Transistor) modeling method

The invention discloses a CMOS (Complementary Metal-Oxide-Semiconductor Transistor) modeling method at a low temperature of being lower than 77 K. The method takes a BSIM3 (Berkeley Short-channel isolated gate field effect transistor Model 3) as a base; a model parameter with the pertinence is respectively selected from a BSIM3 model according to a physical definition that the model parameter is changed along the temperature and a counting expression correction term is added; an initial value of a correction coefficient is determined according to a test result; the initial value of the correction coefficient is substituted into the BSIM3 model; and the model parameter is debugged and simulated. The model parameter needing to be tested comprises Vgs-Id, Cgg-Vgs, Vds-Id, Cgc-Vgs, a high resistance HR and a low-temperature 77-K property of a poly1 resistor. BsimPro software is used for substituting a low-temperature test parameter result to enable a simulation curve to be accurately close to an actual low-temperature test property curve, more simply and rapidly finish the modeling of an MOS (Metal-Oxide-Semiconductor Transistor) transistor at the low temperature of 77 K and improve the low-temperature design capability of a special integrated circuit.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Cross flow testing apparatus and method for cold test on drive wires of nuclear power plants

The invention discloses a cross flow testing apparatus and method for a cold test on drive wires of nuclear power plants. The testing apparatus comprises a cross flow limiter, a cross flow inlet connecting tube and an outlet connecting tube, wherein the cross flow limiter is removably arranged between an upper barrel of a pressure vessel and a control rod guide cylinder, and the cross flow inlet connecting tube after passing through the upper barrel of the pressure vessel extends to the inside of the cross flow limiter. According to the device and the method, through arranging the removable cross flow limiter between the upper barrel of the pressure vessel and the control rod guide cylinder, the cross flow limiter relatively conforms to actual situations; through replacing the cross flow limiters which are different in structures, the influence of the cross flow limiter on the rod falling time of a control rod assembly can be determined according to different needs, thereby enabling an operation of optimizing a drive wire design by test results to be possible.

Owner:中广核工程有限公司 +1

Compatible probe card capable of being used in high temperature test and low temperature test

InactiveCN103091522AImprove compatibilityLow costElectrical measurement instrument detailsElectrical testingProbe cardCold test

The invention relates to a compatible probe card capable of being used in a high temperature test and a low temperature test. The compatible probe card comprises a substrate, a base seat and a probe. The base seat is fixed on the substrate, the probe is fixed on the base seat, one end of the probe is communicated with a circuit on the substrate, and the other end of the probe contacts with a wafer. A cooling device is further arranged on the substrate. The cooling device comprises a shell body. An air inlet and an air outlet are formed in the shell body. The air inlet is connected to a cool air source and the air outlet corresponds to the positions of the base seat and the probe. Due to the fact that the cooling device is arranged on the substrate, when the high temperature test is implemented, cool air flows in from the air inlet to cool the base seat and the probe, and when the low temperature test is implemented, the cool air source is switched off, and the test is implemented normally. Therefore, compatibility of the high temperature test and the low temperature test is realized, and smooth running of a wafer test is guaranteed.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

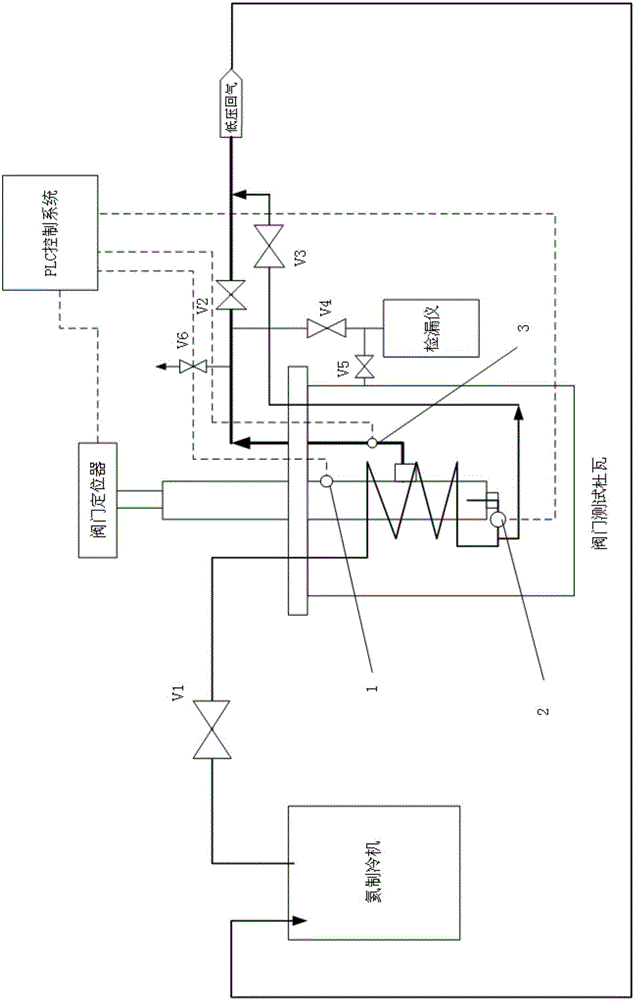

Low-temperature valve property testing device

InactiveCN106768687AAutomate operationImprove work efficiencyDetection of fluid at leakage pointCold testBottle

The invention discloses a low-temperature valve property testing device. The low-temperature valve property testing device comprises a Dewar bottle, wherein a low-temperature liquid delivery tube is wound on a valve rod of a low-temperature valve to be tested from top to bottom; the low-temperature liquid delivery tube is divided into two channels before entering a valve inlet; one channel is directly connected with an output pipe opening of an upper sealing flange and returns to a low-pressure air return pipeline of a refrigerator; a stop valve is mounted on an outlet of the pipeline; the other channel is connected with a low-temperature valve inlet, is connected with another output pipe opening of the upper sealing flange via a low-temperature valve outlet, and returns to the low-pressure air return pipeline of the refrigerator through the stop valve; meanwhile, the pipeline is connected with a helium mass spectrometer leak detector via a flange through a stop valve; and low-temperature thermometers are respectively mounted on the valve rod of the valve to be tested, the valve inlet and the valve outlet. The whole low-temperature testing system is operated automatically, the working efficiency is improved, repeatability and accuracy of operation are high, meanwhile, online storage and history viewing of data are realized, and data analysis and operation optimization are facilitated.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

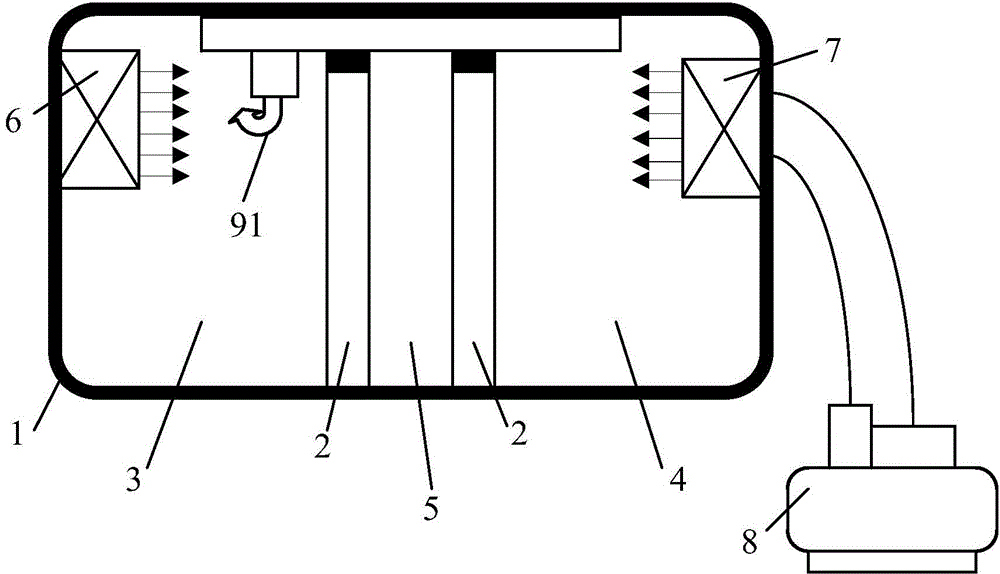

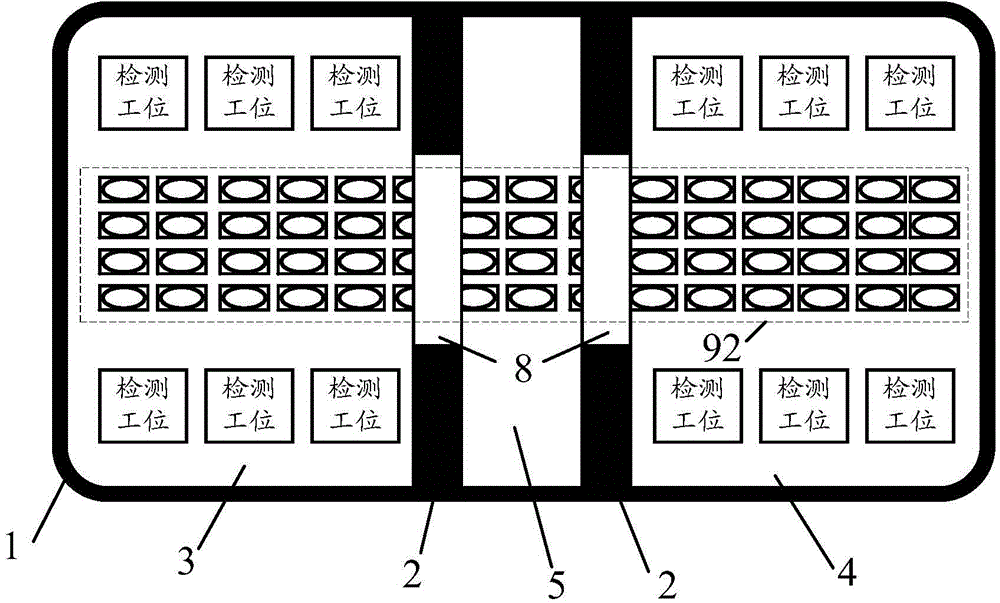

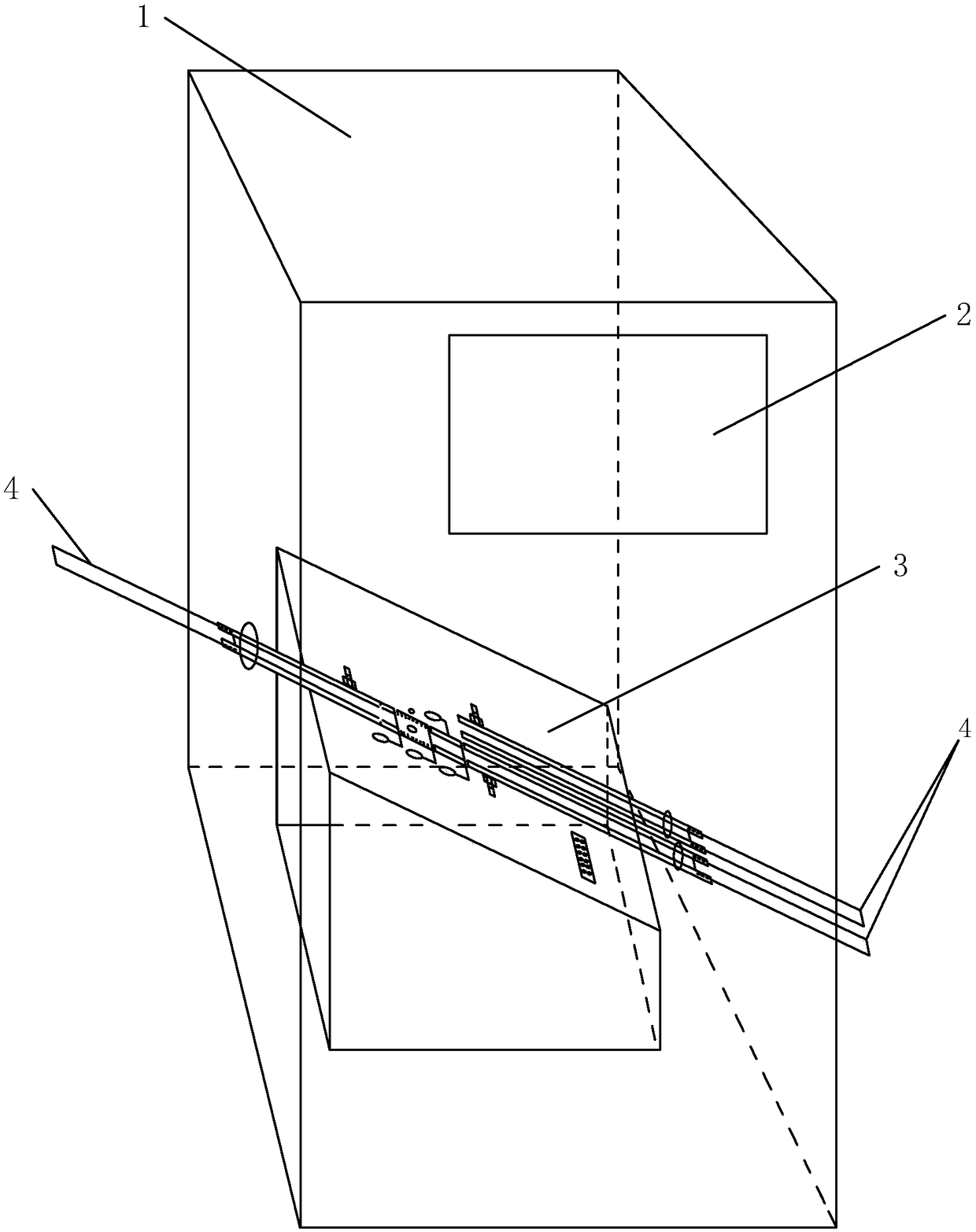

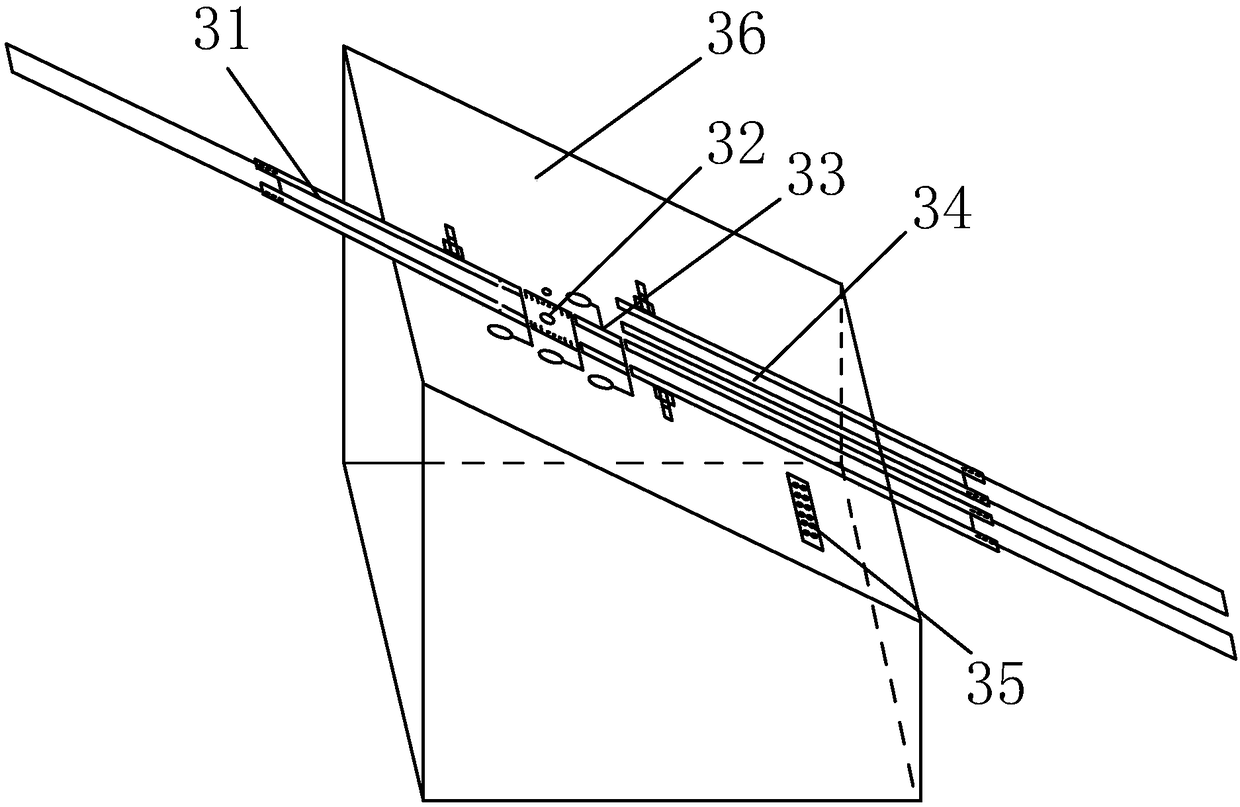

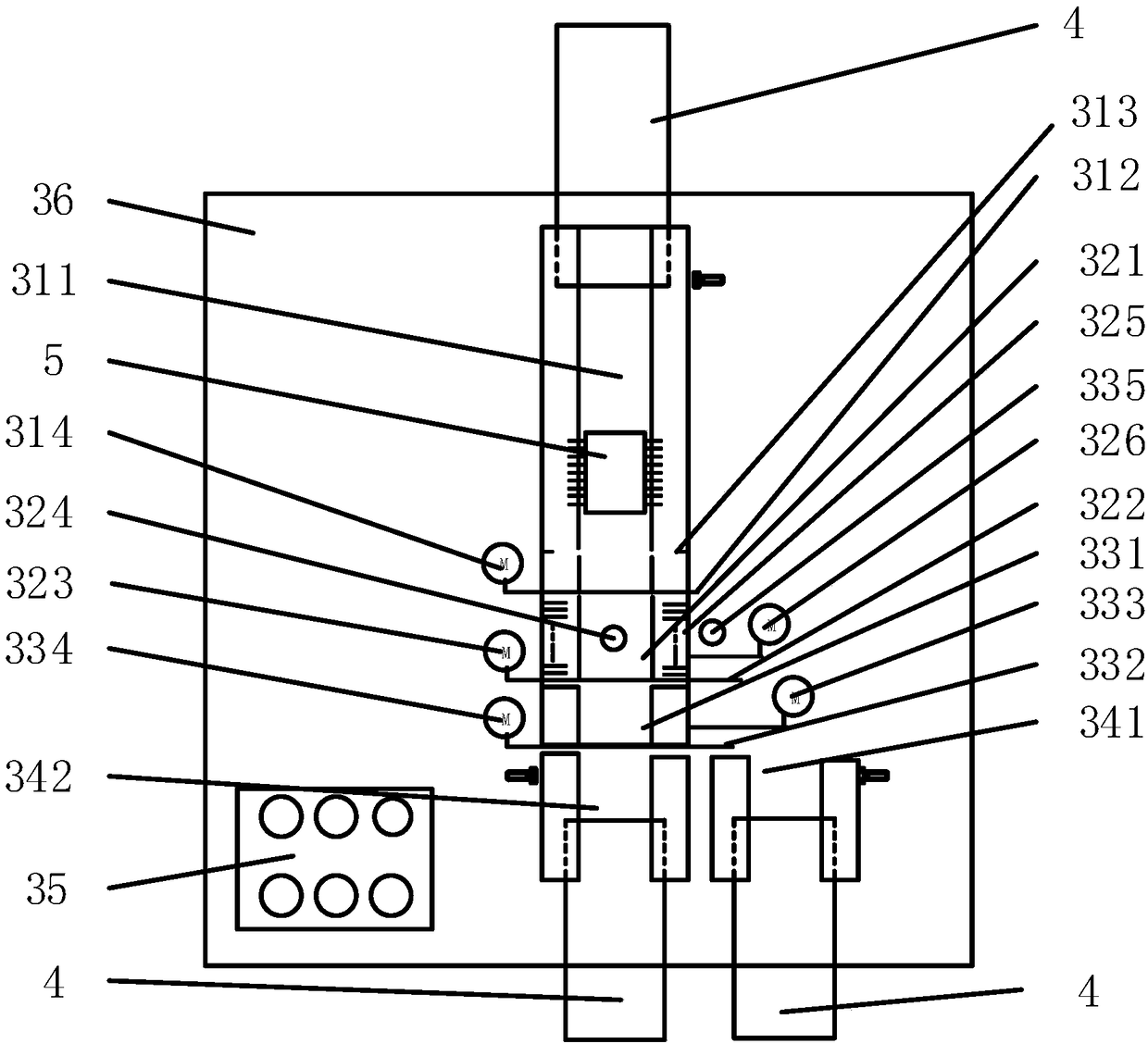

High and low temperature test device of integrated circuit

InactiveCN108152704ASave time for high and low temperature testingElectronic circuit testingTemperature stressCold test

The invention discloses a high and low temperature test device of an integrated circuit, and belongs to the technical field of circuit test. The test device comprises an integrated circuit fixing device and an integrated circuit test system, the integrated circuit fixing device is arranged in a high and low temperature casing, the integrated circuit test system connected with the integrated circuit fixing device so that the integrated circuit fixing device is controlled to send a test chip in and out and temperature stress test is carried out on the test chip, and the integrated circuit fixingdevice comprises a charging mechanism, a test mechanism, a sorting mechanism and a discharging mechanism. The high and low temperature test device of the integrated circuit has the advantages that batch of integrated circuit chips can be tested needless of opening the high and low temperature casing when the test chips are tested, high and low temperature test time of IC is reduced greatly, and high and low temperature electrical performance of the multiple and even batch of IC can be tested under the condition that the high and low temperature casing is not opened.

Owner:NINGBO XINLU COMM TECH CO LTD

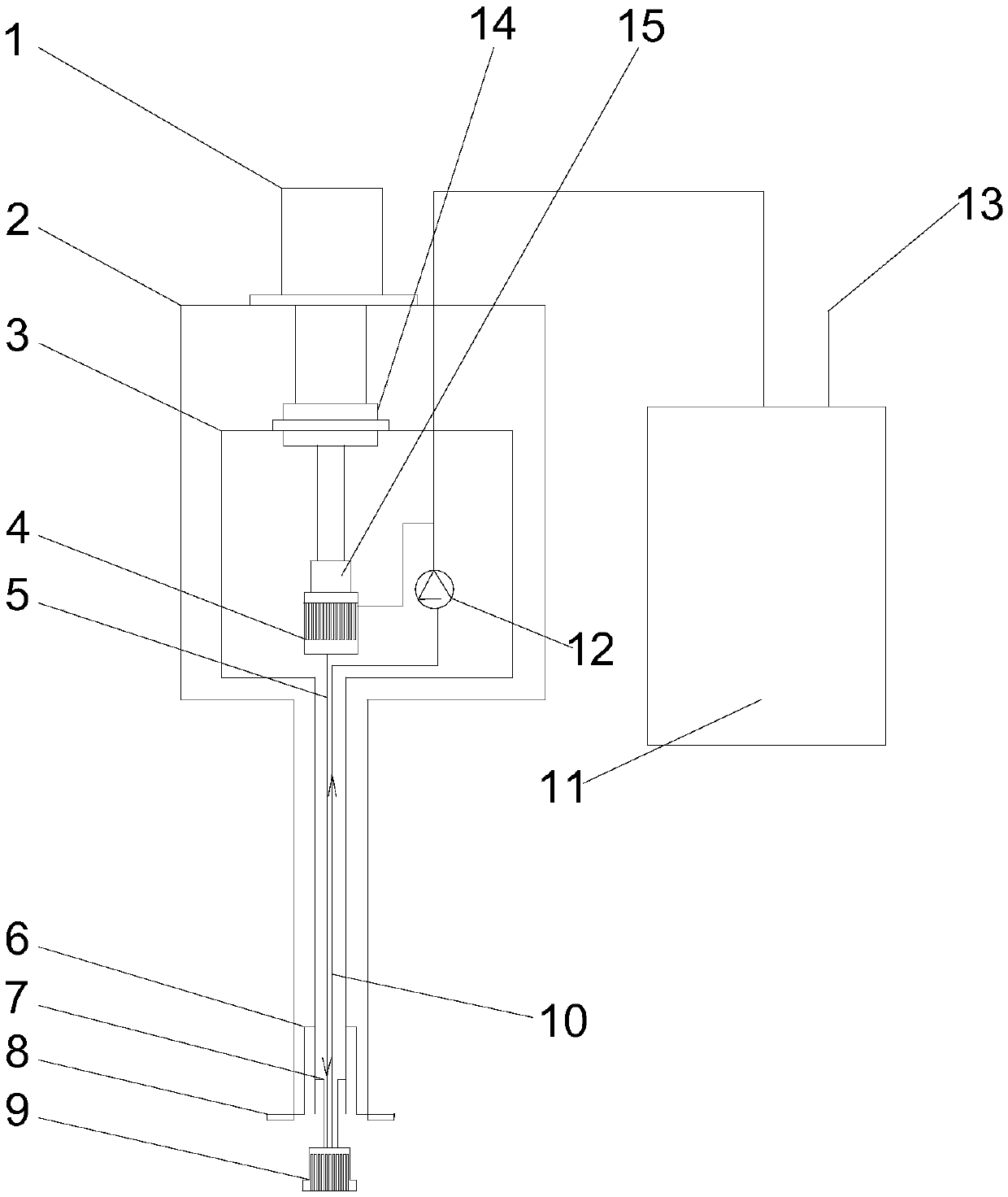

Long-distance cold transfer device based on small cryogenic refrigerator

ActiveCN107727481AReduce convective heat transferSmall low convection heat transferPreparing sample for investigationCompression machinesCold testCold shield

The invention provides a long-distance cold transfer device based on a small cryogenic refrigerator. The device comprises a vacuum chamber and the cryogenic refrigerator fixedly arranged in the vacuumchamber, the lower end of the vacuum chamber is in detachable sealing connection with a test chamber for containing a sample to be tested, a cold shield is arranged in the vacuum chamber, the lower part of the small cryogenic refrigerator is inserted to the cold shield, a first heat exchanger is fixedly arranged at the lower end of the small cryogenic refrigerator, a second heat exchanger capableof exchanging heat with the sample to be tested is arranged in the test chamber, the first heat exchanger and the second heat exchanger are connected by a circulating pipeline, and the circulating pipeline is positioned in the cold shield. The device can meet the installation requirements of a test space, makes the low temperature test of the sample easy, and has a application range.

Owner:TSINGHUA UNIV

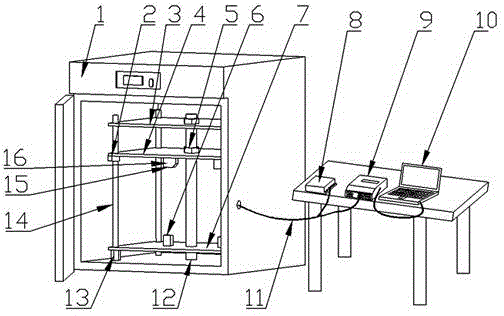

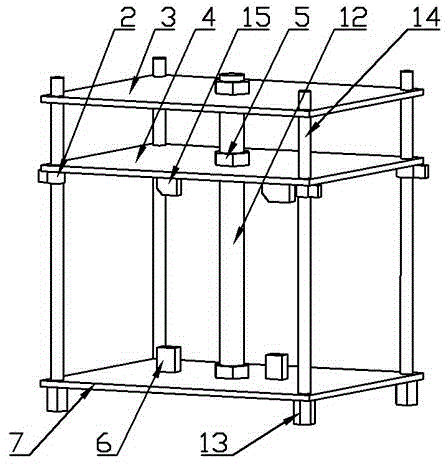

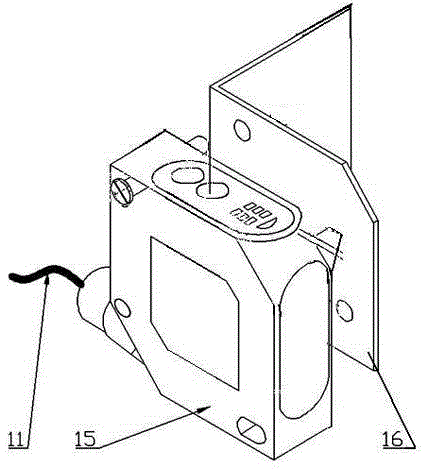

Low-temperature calibration device of laser displacement sensor

InactiveCN104596427AEasy to use and flexibleAvoid Cumulative ErrorsUsing optical meansCold testLaptop

The invention relates to a low-temperature calibration device of a laser displacement sensor. The low-temperature calibration device of the laser displacement sensor is characterized in that four leveling nuts are mounted at the bottoms of four support columns, support screws are provided with threads, the nuts sleeve the support screws respectively and are arranged on a sensor fixing plate, the sensor fixing plate is fixed to the four support columns through clamps, the laser displacement sensor below the sensor fixing plate is fixed through a fixing frame and screws, a direct current switch power supply is connected to the laser displacement sensor through a wire, a data acquisition instrument is connected to a laptop through a wire, the data acquisition instrument and the laser displacement sensor are connected to the direct current switch power supply through a wire, and a gauge block is arranged below a support, on the plate and under the laser displacement sensor. The low-temperature calibration device of the laser displacement sensor enables the laser displacement sensor to be used in a permafrost deformation test and can calibrate the laser displacement sensor at a low temperature to verify indicators, such as performance and accuracy of the laser displacement sensor used in the low-temperature permafrost deformation test.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

Low temperature test device

InactiveCN101806662AWindows of kindnessFriendly operationMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesEngineeringBottle

The invention relates to a test device for producing an ultralow temperature liquefied natural gas valve, in particular to a low temperature test device. The low temperature test device comprises a low temperature groove. One end of the low temperature groove is connected with a liquid nitrogen storage tank through a pipeline, the other end is connected with a nitrogen group bottle through a pipeline, and the low temperature groove is also respectively connected with an electric control unit and a helium leak detector through a line. compared with the prior art, the low temperature test device can obtain optimal data to enhance the mechanical property of the valve, prolong the service life of the valve, stabilize the size, improve the uniformity and reduce the deformation and has the advantages of high test accuracy, wide test range, high test automation degree and the like.

Owner:方存正

Electronic component test equipment

InactiveCN106290991AAvoid condensationShorten pre-cooling operation timeElectrical testingMeasurement instrument housingTemperature controlCold test

The invention provides electronic component test equipment, which comprises a feeding device, a receiving device, an environment control device, a test device, a moving device and a central control device. The moving device is used for taking electronic components to be tested from the feeding device and moving the electronic components to the environment control device through a material moving mechanism. The environment control device comprises at least one temporary placing area, a bearing mechanism, a temperature control mechanism and an anti-condensation mechanism. The bearing mechanism is arranged in the temporary placing area, and is used for allowing the material moving mechanism to place the electronic components to be tested with a bearer. The test device is used for taking out the pre-cooled electronic components to be tested from the bearer of the environment control device through a pickup mechanism, moving the electronic components to be tested to a test room, and placing the electronic components to be tested on a tester to carry out cold test work; and after cold test is finished, the material moving mechanism of the moving device moves the tested electronic components to the receiving device for collection. The environment control device is utilized to pre-cool the electronic components to be tested in a direct and forced manner, thereby reducing precooling work time, preventing condensation of the electronic components to ensure test qualified rate, and improving test production efficiency.

Owner:HON PRECISION INC

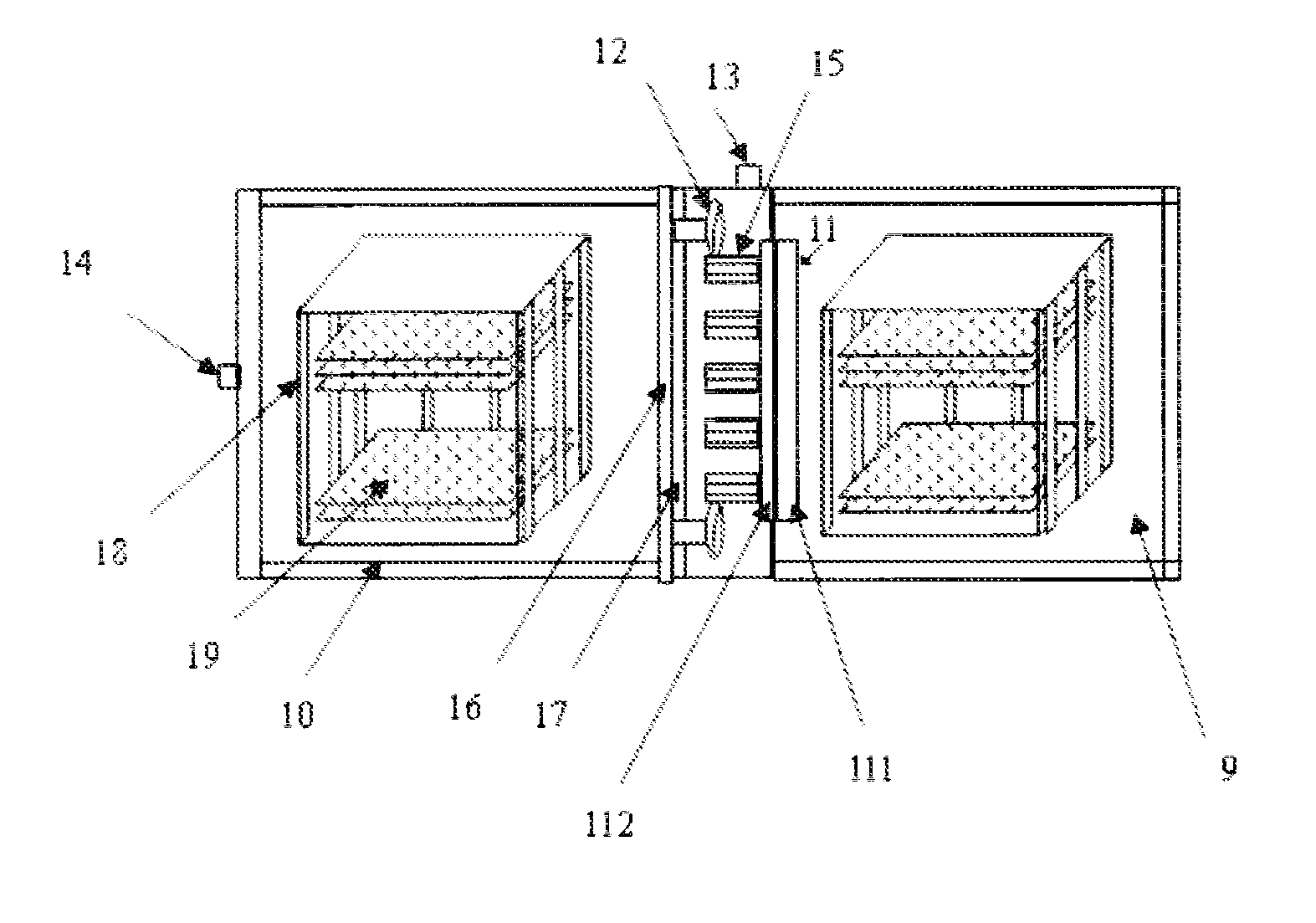

High and low temperature test equipment

ActiveUS20140153609A1Improve thermal uniformityEnergy efficiencyWeather/light/corrosion resistanceStatic indicating devicesCold testEngineering

The invention relates to the technical field of LDC fabrication and specifically to a high and low temperature test equipment. The high and low temperature test equipment comprises a housing, and further comprises a partition disposed in the interior of the housing. The partition divides the interior of the housing into a plurality of chambers and is provided with a Peltier effect sheet. The Peltier effect sheet is used for, when it is powered-on, cooling at least one of the chambers and meanwhile heating at least one chamber other than the at least one of the chambers. The high and low temperature test equipment may cool and heat at the same time in an efficient, power conserving way and have uniform heating function.

Owner:BOE TECH GRP CO LTD +1

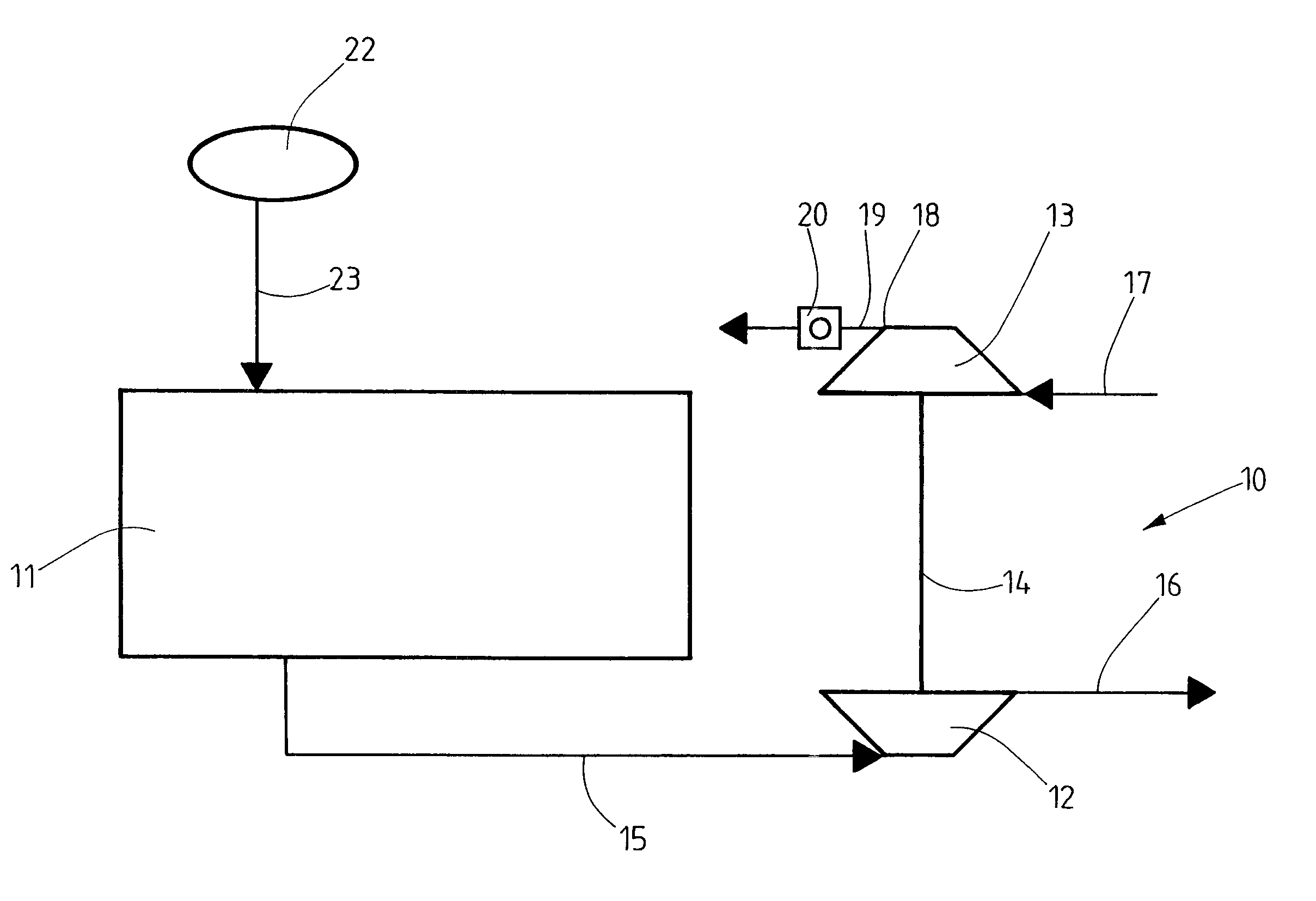

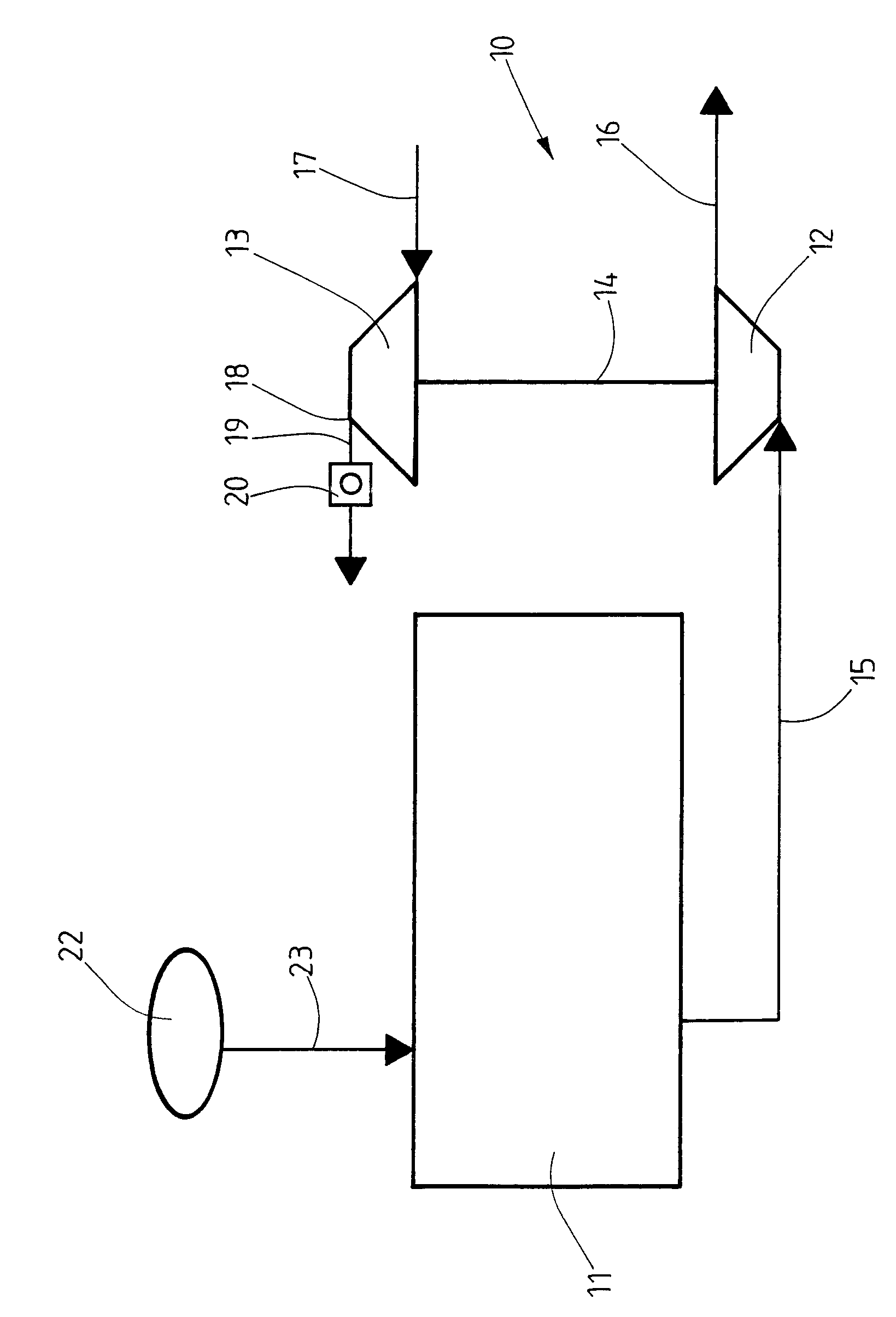

Method for the testing of exhaust gas turbochargers

InactiveUS7278302B2Increase pressureFavorably carry-outMachine part testingGas-turbine engine testingTurbochargerCold test

The method according to the invention provides for an internal combustion engine (11) driven in trailing mode to generate compressed air for driving the turbine (12) of the exhaust-gas turbocharger (10) to be tested. It is thereby possible to carry out the cold testing of the exhaust-gas turbocharger (10) together with that internal combustion engine (11) with which the exhaust-gas turbocharger (10) is subsequently operated. Furthermore, there is provision, in the method, for throttling the air on the delivery side of the compressor (13). The compressor (13) can thereby be operated under load in the turbine characteristic diagram during the cold test. Thus, further measurement quantities can be determined which make it possible to determine the characteristic of the exhaust-gas turbocharger (10) to be tested in the cold test.

Owner:JOHANN A KRAUSE MASCHFAB GMBH & CO

Operational capacity test device of low-temperature pressure gloves

InactiveCN101750227AMaterial strength using tensile/compressive forcesStructural/machines measurementDifferential pressureLiquid nitrogen cooling

The invention relates to an operational capacity test device of a pair of low-temperature pressure gloves, comprising a vacuum system, a refrigerating system and a temperature measuring system. The operational capacity test device is characterized in that the vacuum system comprises a vacuum pump and a piezoresistive vacuum gauge; the refrigerating system comprises a pressure Dewar flask and a low-temperature pressure chamber; the temperature measuring system comprises a temperature sensor, a logging device and a computer; wherein air in the low-temperature chamber is extracted by the vacuum pump so as to realize differential pressure inside and outside the gloves; a low-temperature environment of the low-temperature pressure chamber is realized by liquid-nitrogen cooling in the pressure Dewar flask; the temperature measuring system is used for acquiring, monitoring at the real time, recording temperature values of all temperature-measuring points and ensuring that the measuring temperature reaches technical requirements. The operational capacity test device can not only satisfy pressure and visual requirements on a normal-temperature pressure test device, but also provide a low-temperature test environment from the normal temperature to -100 DEG C according to test requirements, realize the low-temperature pressure two-factor environment and carry out the operational capacitytest on the gloves under the pressure condition.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com