Patents

Literature

75 results about "Temperature pulse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A normal human body temperature should measure 98.6 F, according to Medline Plus, a service of the National Library of Medicine. Medline Plus also states a normal pulse should be 60 to 100 beats per minute for adults. Each beat of the human heart circulates blood through the vessels, carrying oxygen and nutrients to the rest of the body.

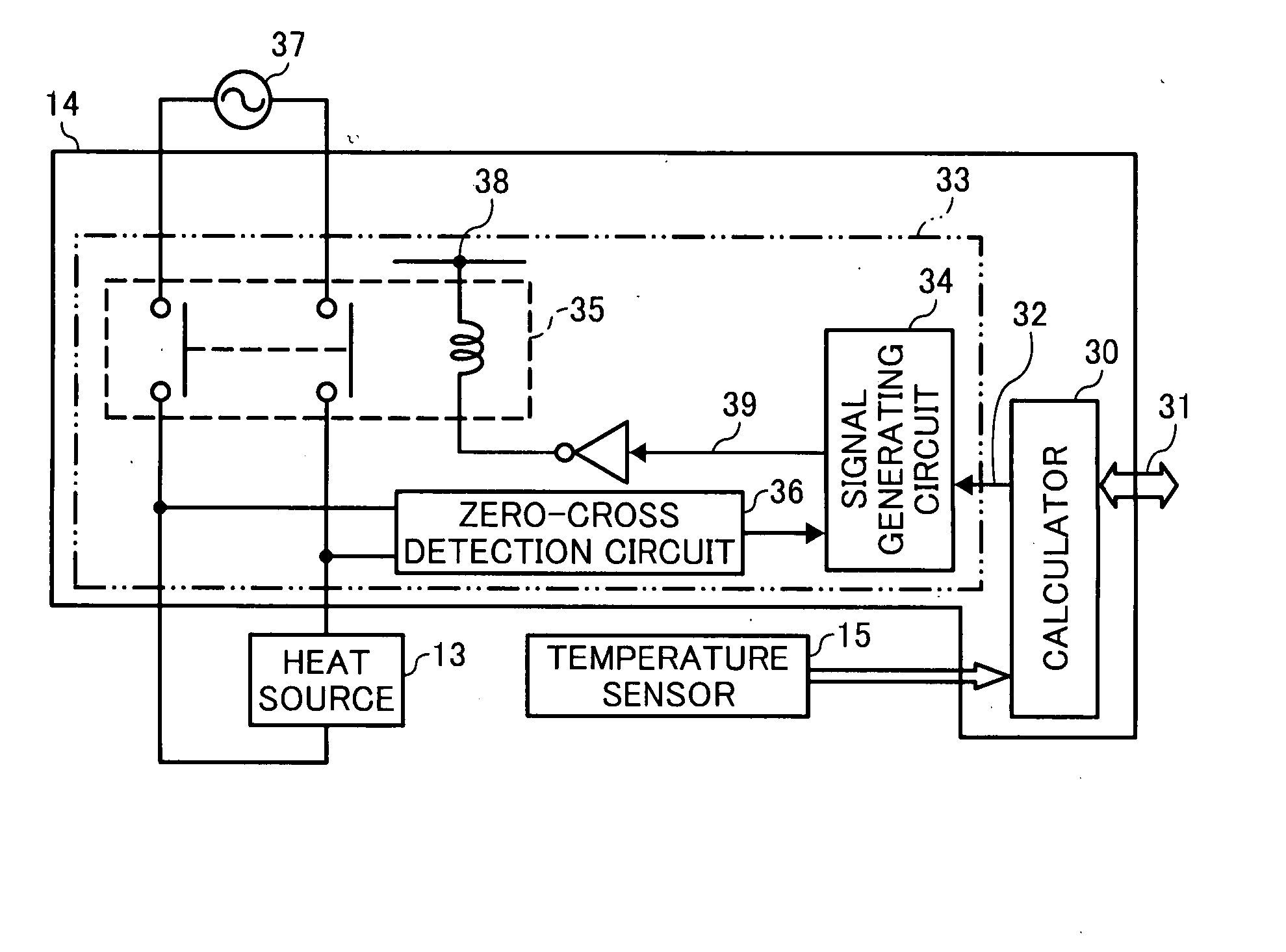

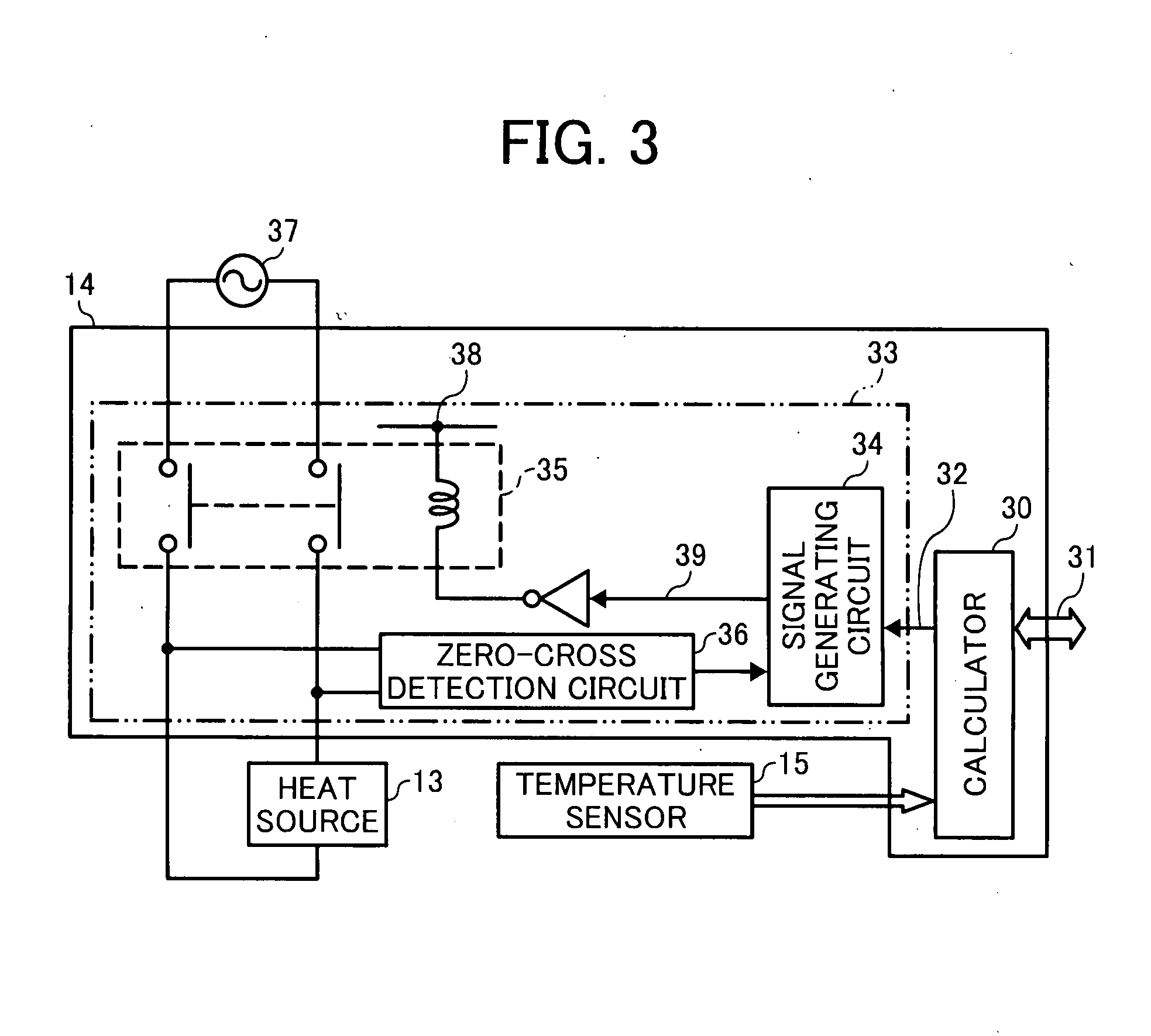

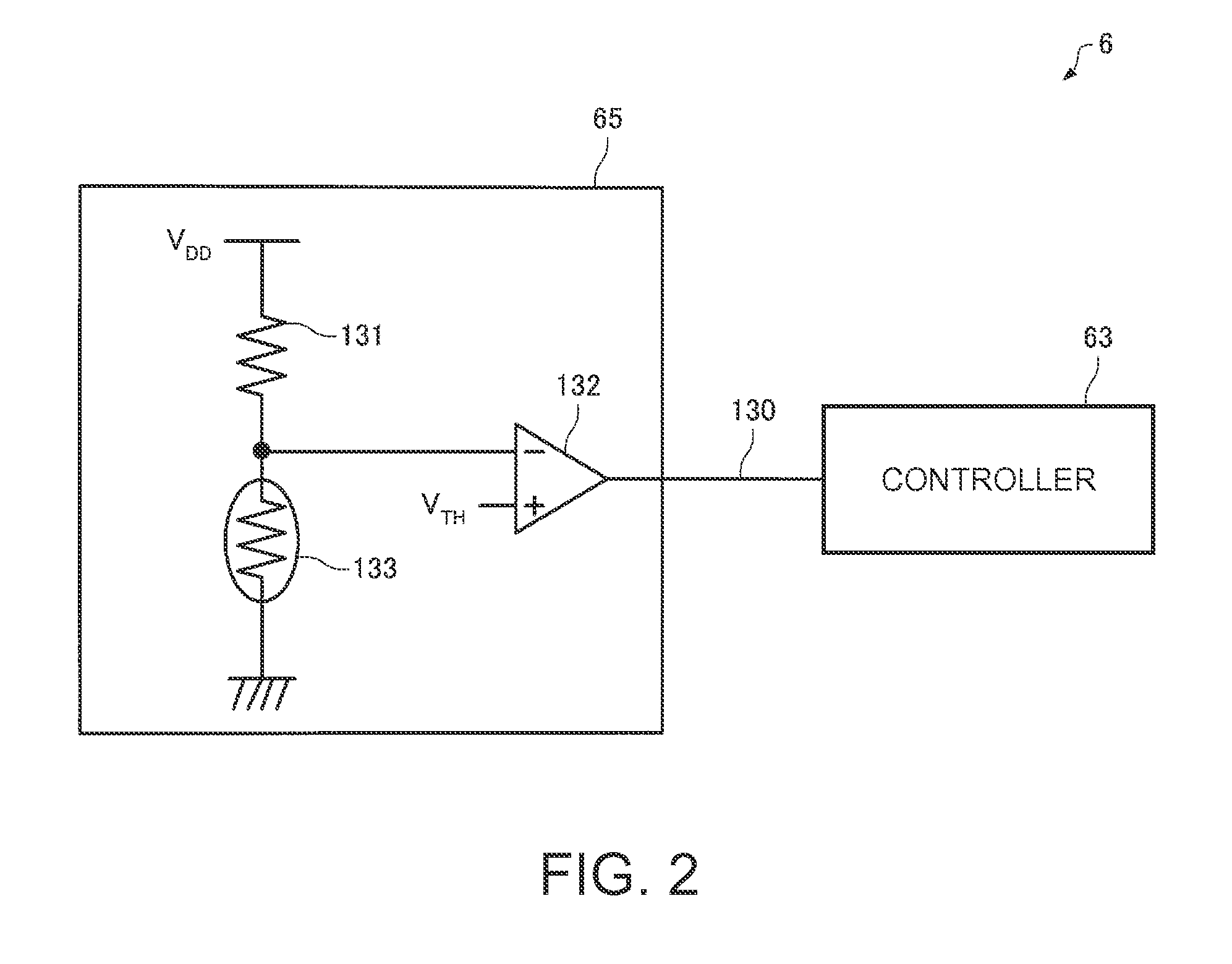

Fixing device, and method and device for heating control used in the same

InactiveUS20080044196A1Drive stabilityReduce errorsTemperature control using analogue comparing deviceElectrographic process apparatusHeat controlAlternating current

A fixing device includes a pair of rotating members, a heater, a detector, a calculator, a pulse width modulation circuit, and a controller. In at least one embodiment, the pair of rotating members is configured to fix a toner image on a recording medium. The heater is configured to heat at least one of the pair of rotating members to a process temperature when driven with an alternating current. The detector is configured to detect the process temperature. The calculator is configured to calculate an amount of heat to adjust the process temperature to a reference temperature. The pulse width modulation circuit is configured to generate a drive signal having a pulse width modulation cycle divided into first and second off times and an on time inserted therebetween. The controller is configured to control operation of the heater according to the drive signal.

Owner:RICOH KK

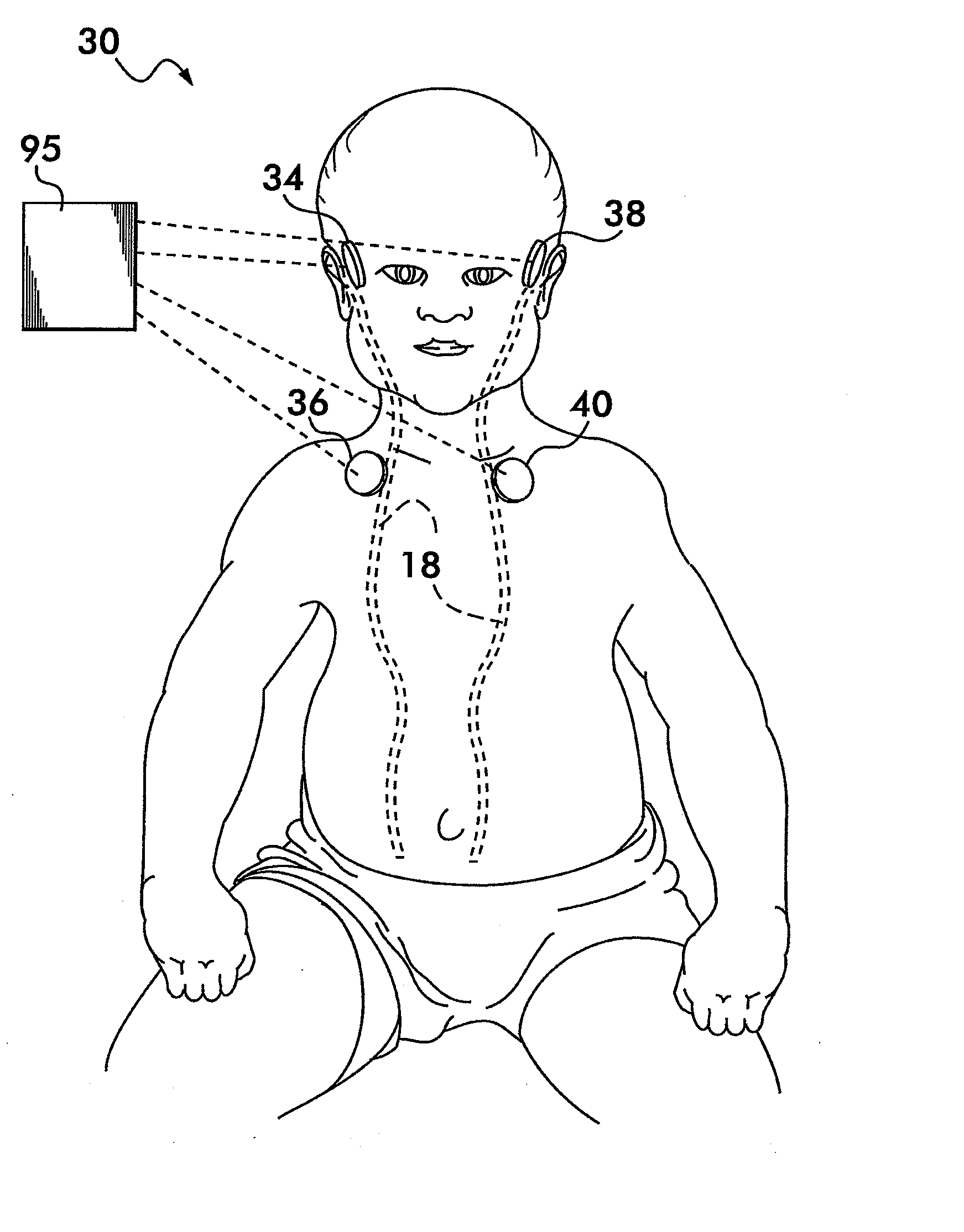

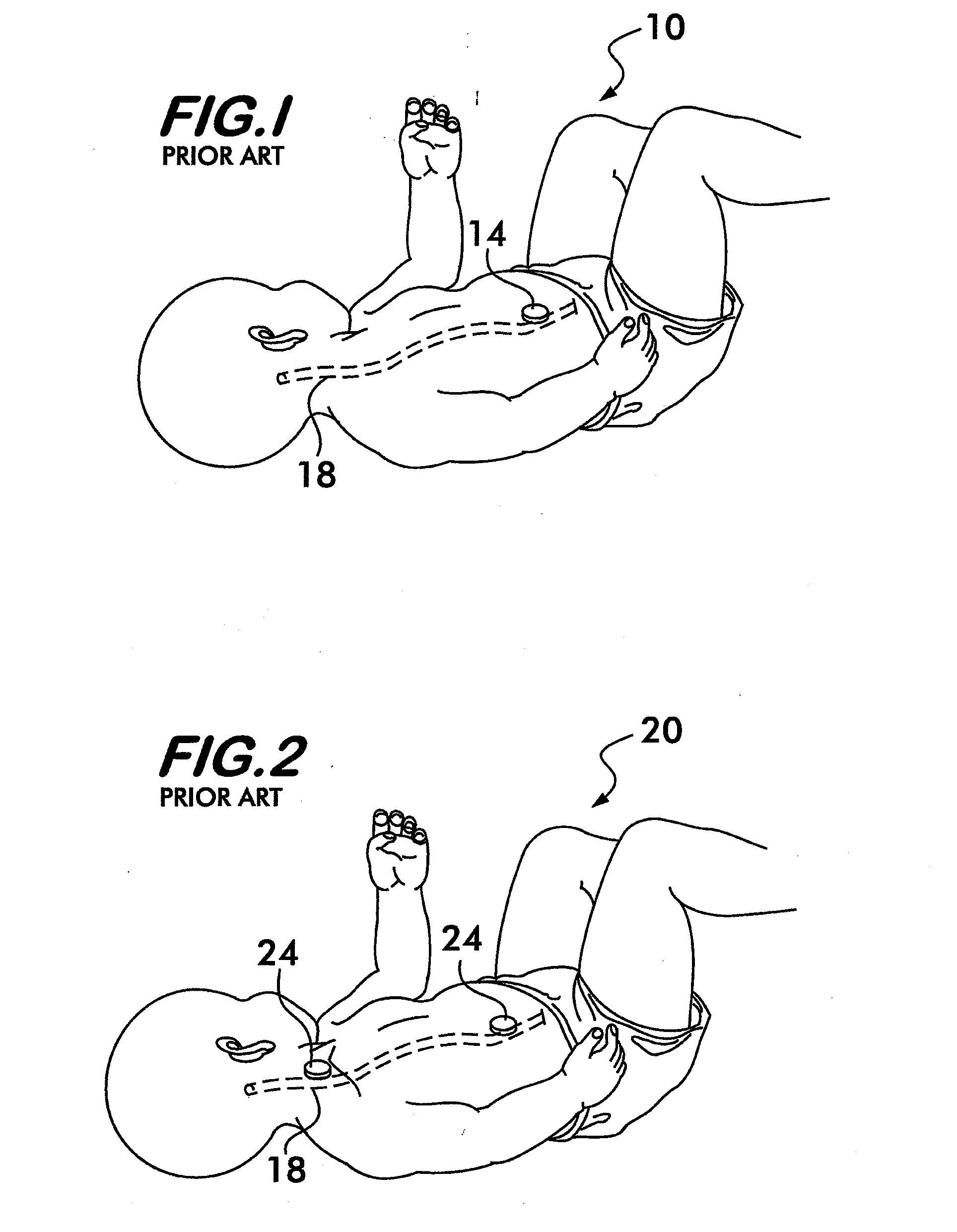

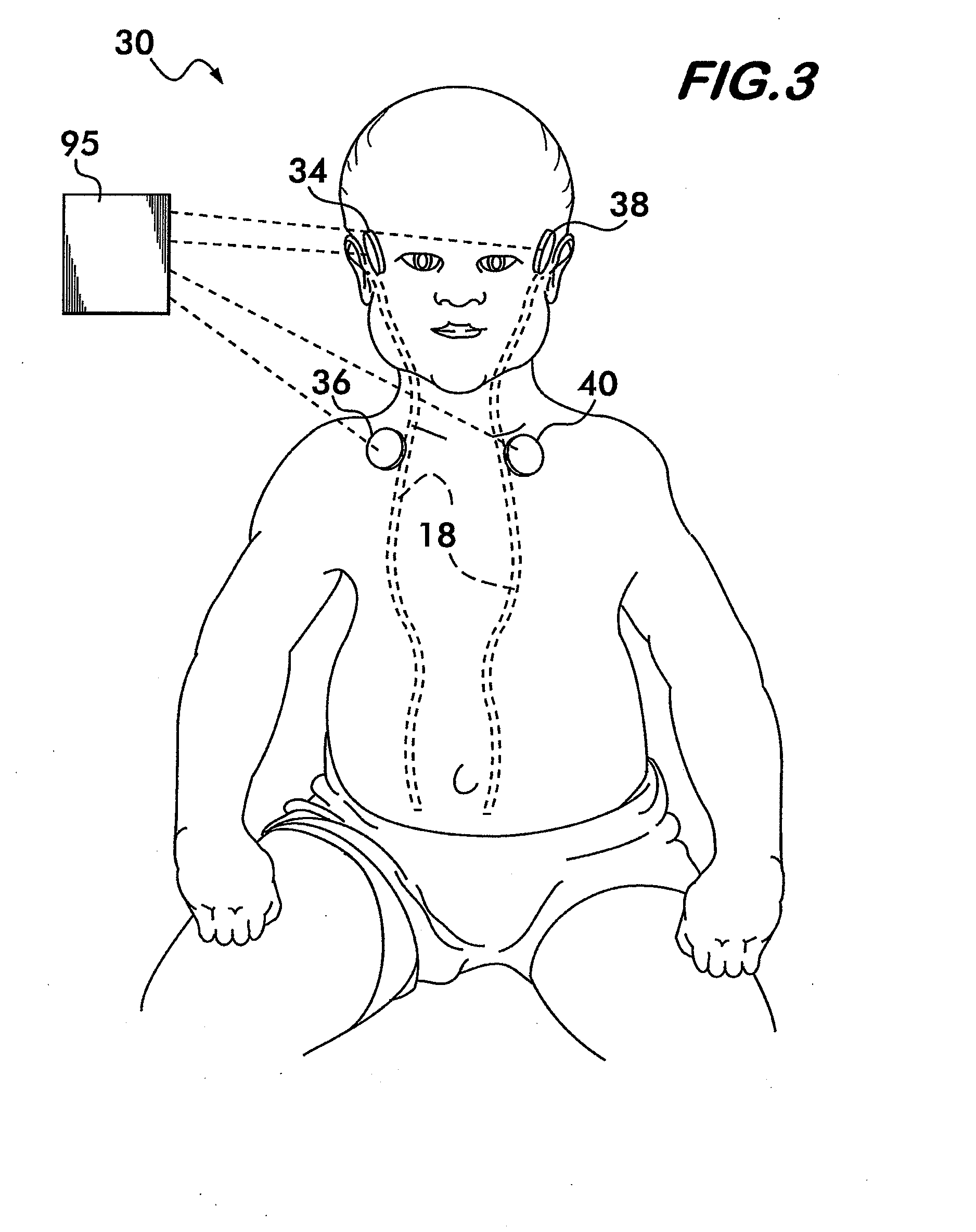

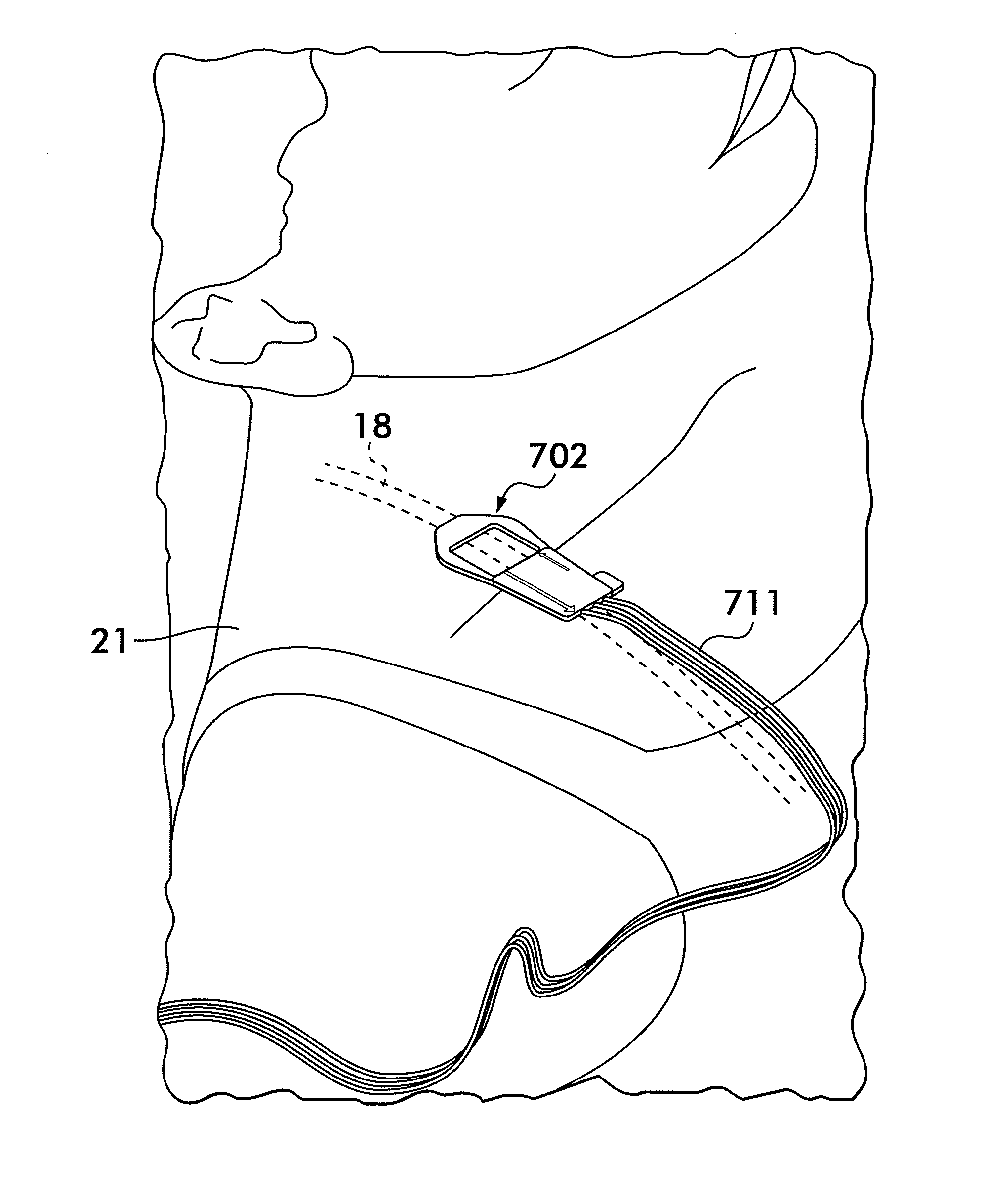

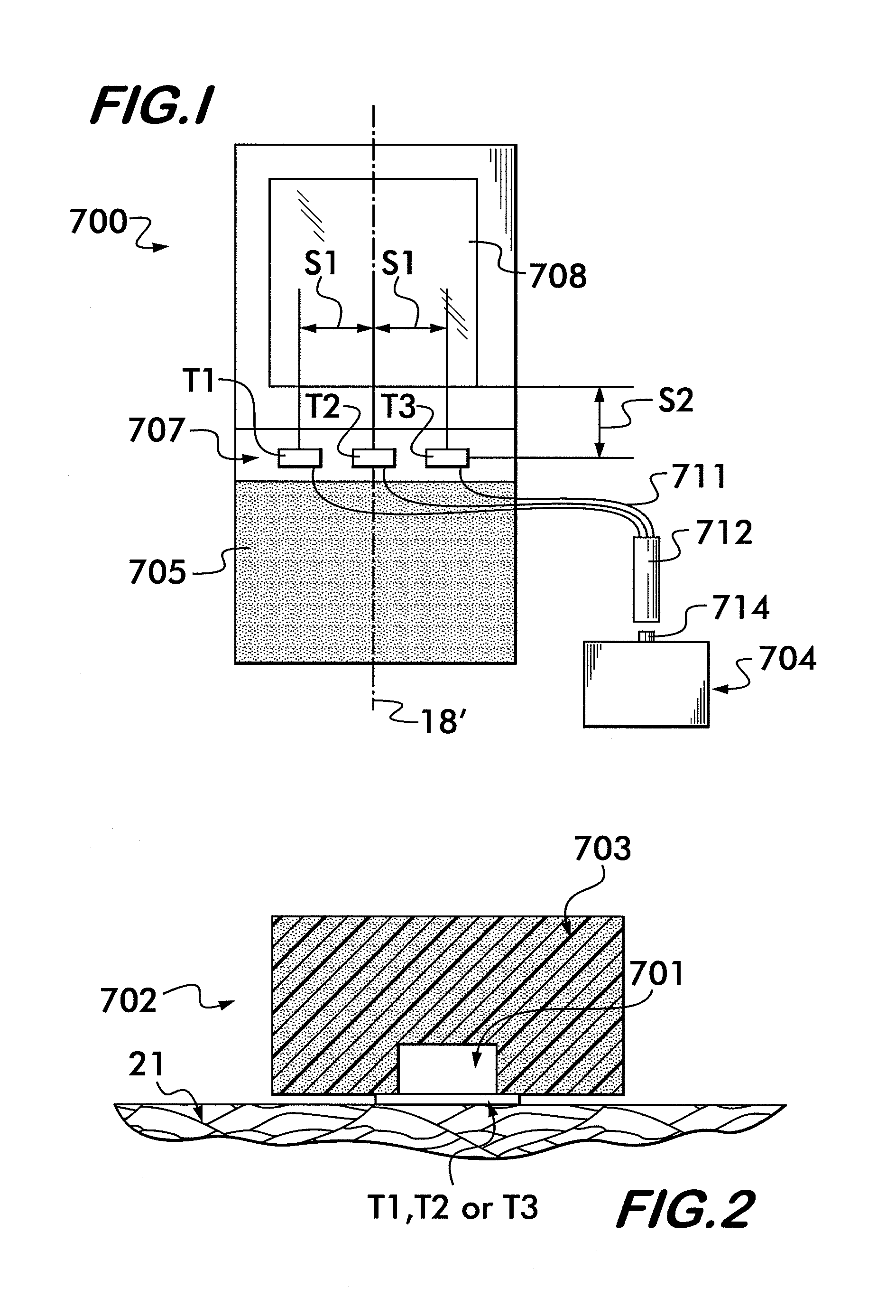

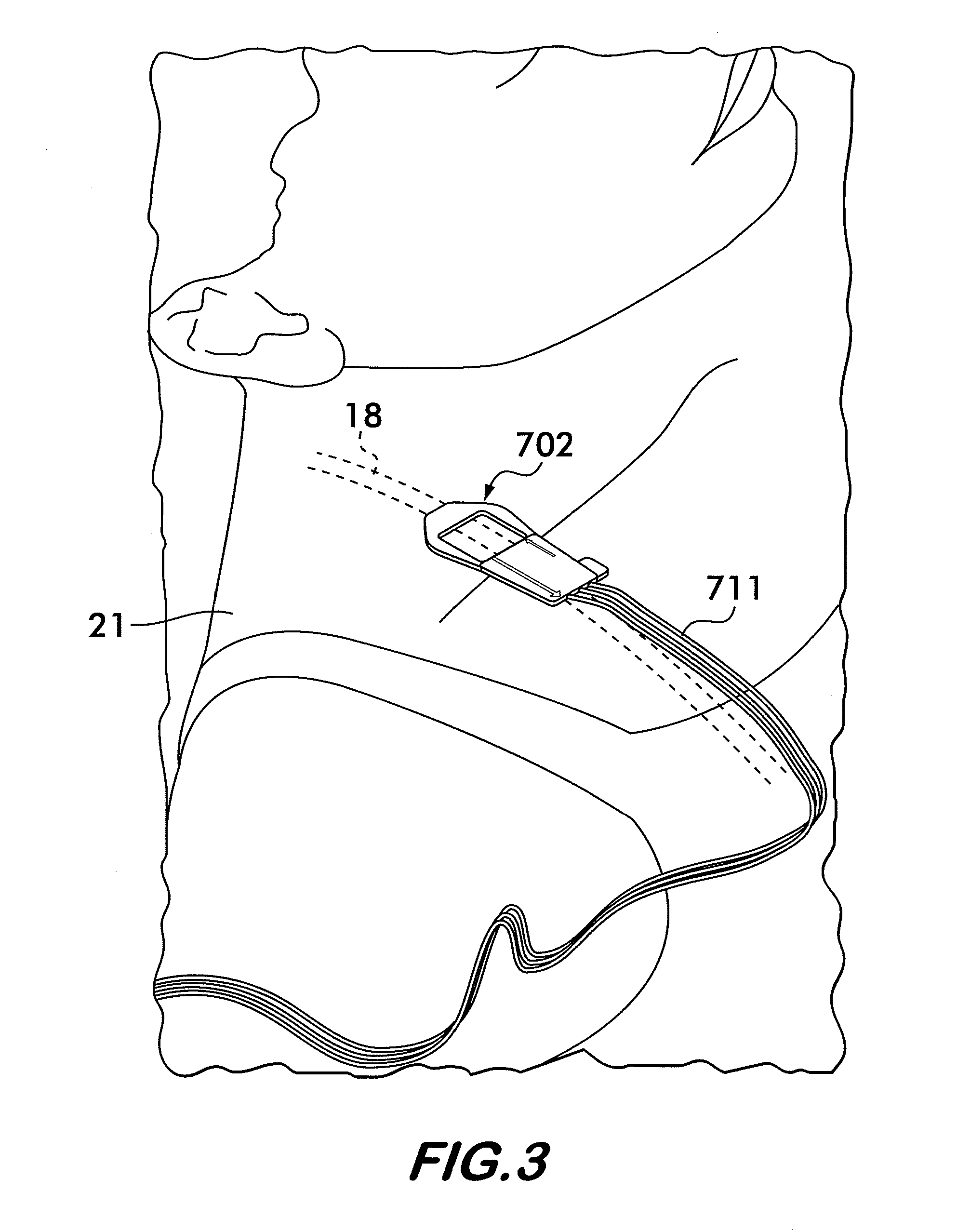

Cerebrospinal Fluid Evaluation Systems

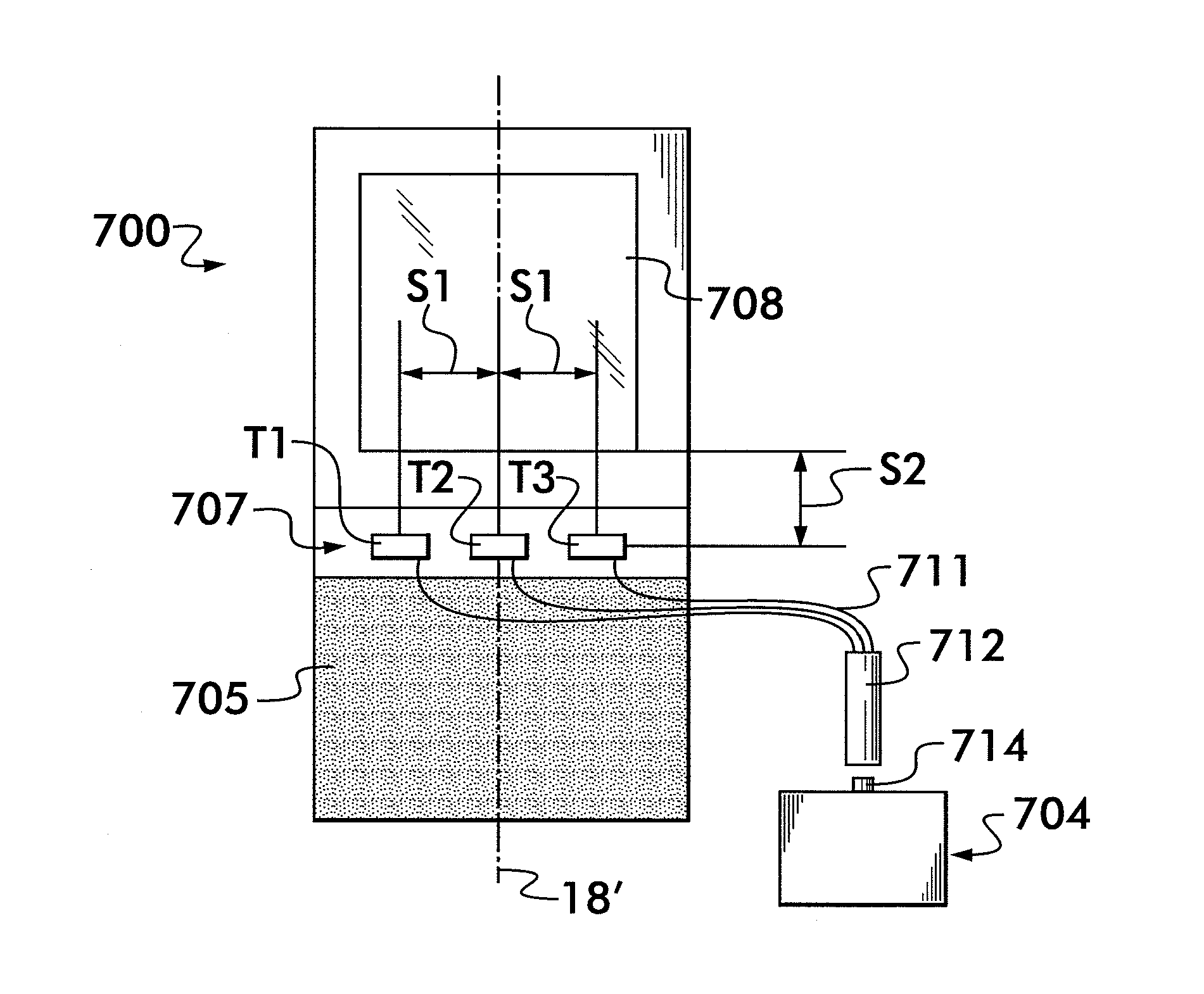

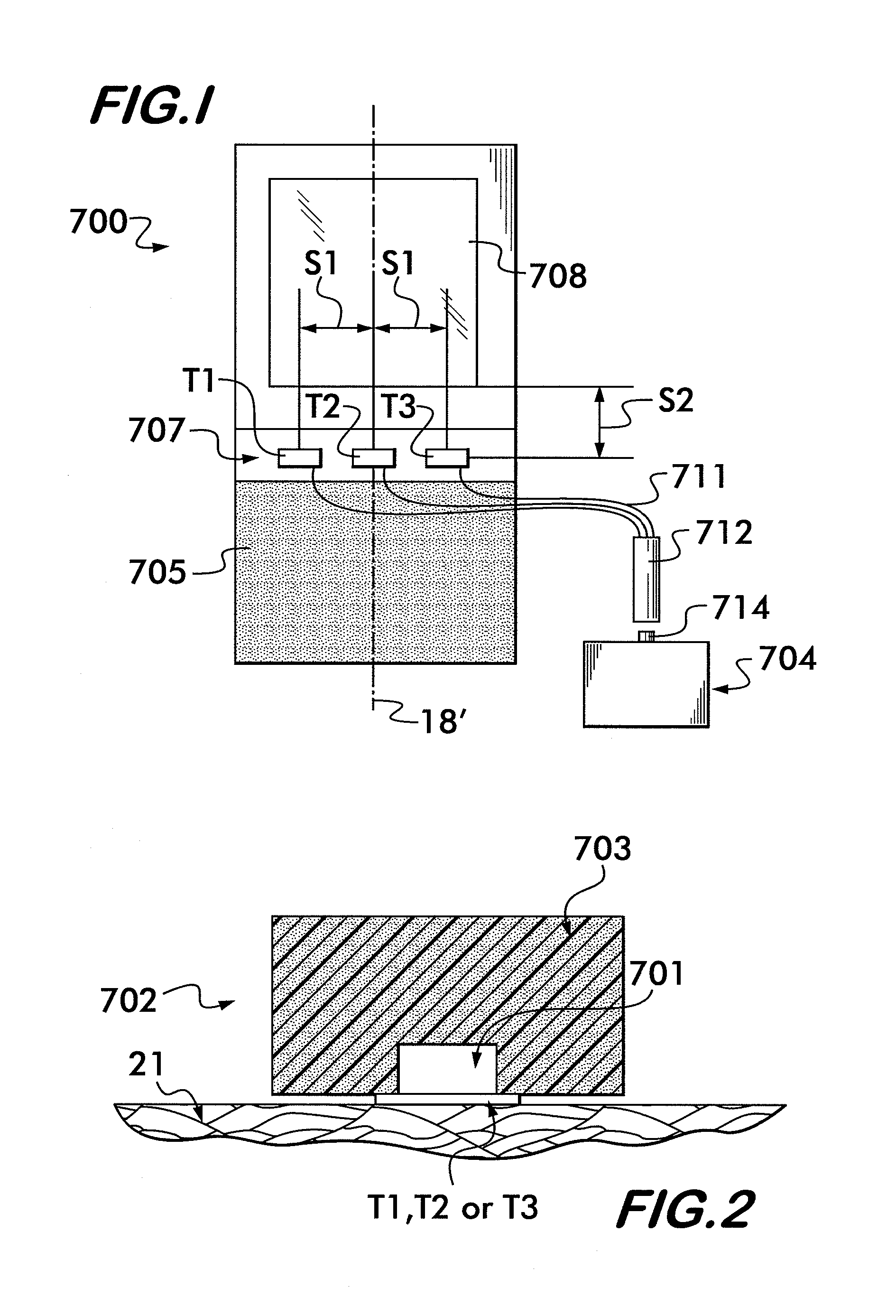

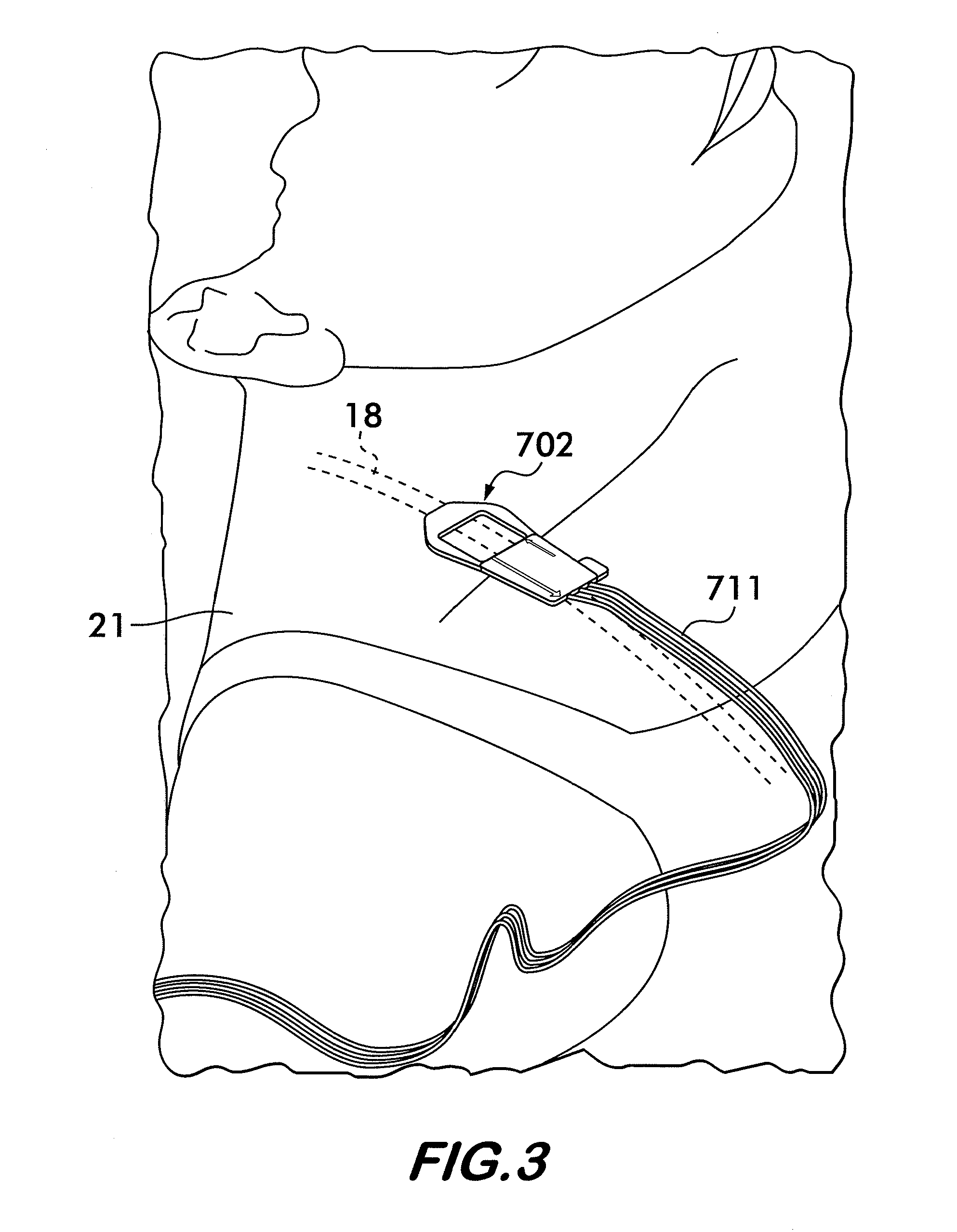

Methods and devices for testing for the presence, absence and / or rate of flow in a shunt tubing implanted under the skin by using a measurement pad having a plurality of temperature sensor configurations, or by using other temperature sensor arrangements, or by using a temperature sensitive material, which are positioned over, or in the vicinity of, the CSF shunt in substantially an upstream and downstream orientation. A temperature source, e.g., a cooling agent, is then applied at a predetermined location with respect to the measurement pad that is insulated from the temperature sensors, or to the temperature sensitive material. The movement of this temperature “pulse” is detected by the temperature sensors, or temperature sensitive material, via the shunt tubing as the CSF carries the temperature pulse while a control sensor detects the pulse via convection through the skin. The temperature data from these sensors are provided to a CSF analyzer that subtracts the control sensor data from each of the other sensors for determining a CSF shunt flow status or flow rate. A reader is used to optically or electrically detect the changes in the temperature sensitive material for determining a CSF shunt flow status or flow rate.

Owner:NEURO DIAGNOSTIC DEVICES

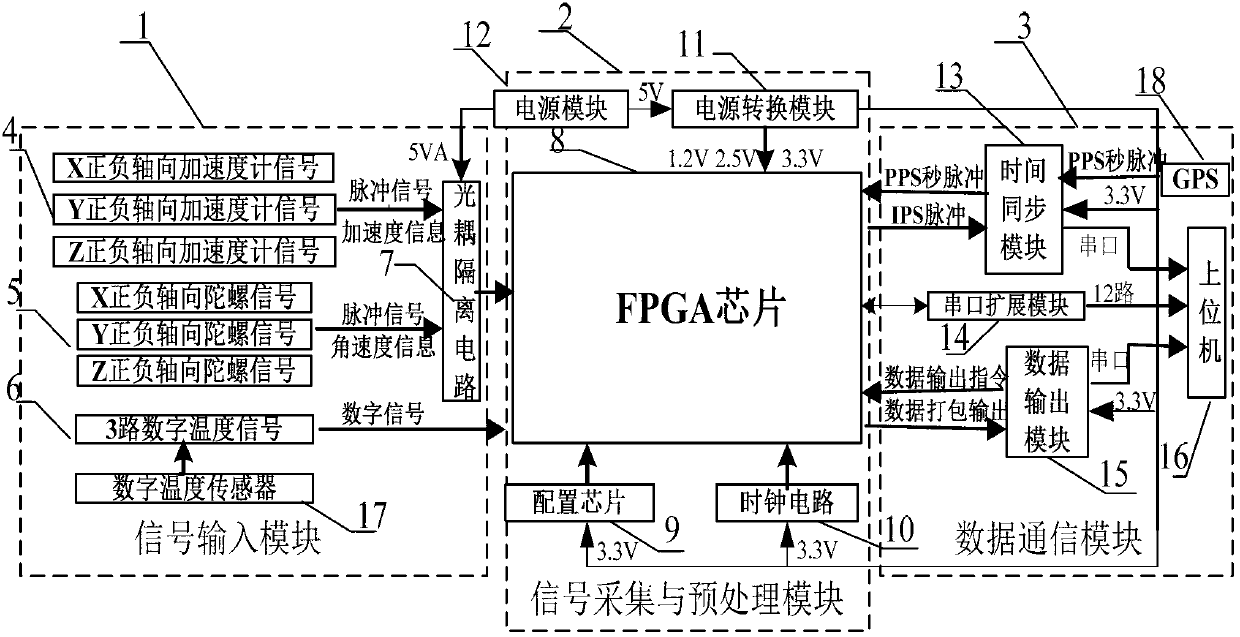

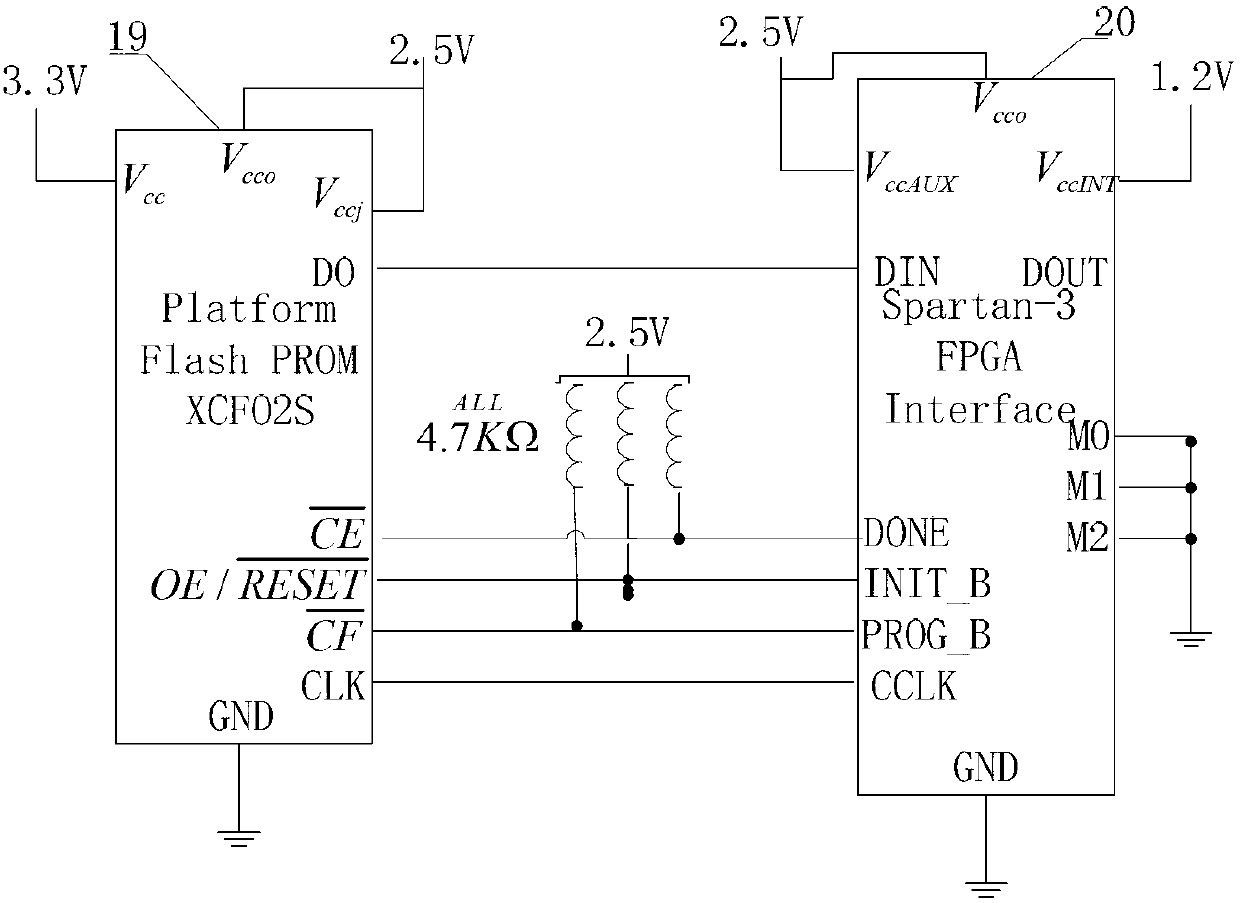

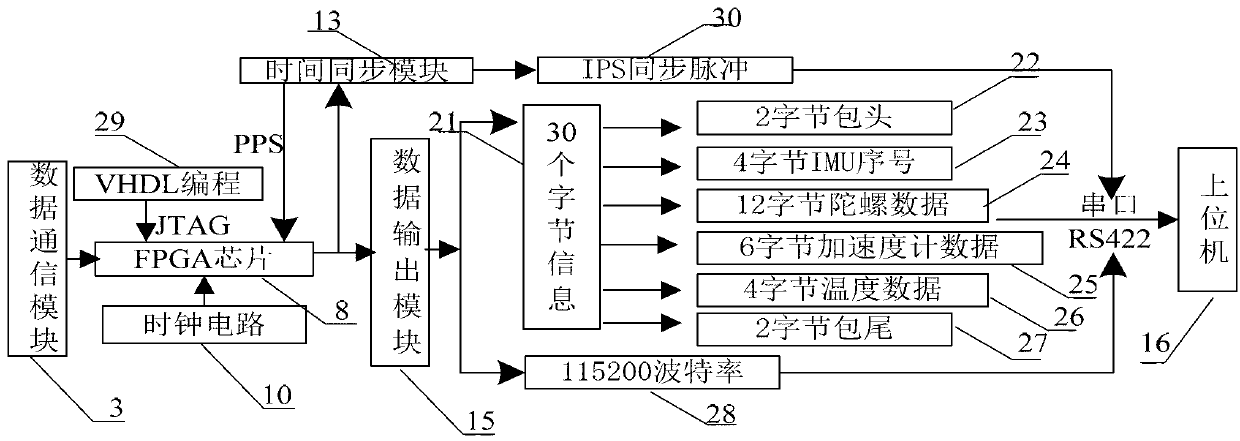

Optical fiber IMU (inertial measurement unit) data collecting system for unmanned aerial vehicle electric power routing inspection

InactiveCN103279058AReduce size and weightReduce power consumptionProgramme controlComputer controlAccelerometerData acquisition

The invention relates to an optical fiber IMU (inertial measurement unit) data collecting system for unmanned aerial vehicle electric power routing inspection. The optical fiber IMU data collecting system comprises a signal input module, a signal collection and preprocessing module and a data communication interface module, wherein the signal input module comprises three paths of accelerometer pulse signals, three paths of gyro pulse signals and three paths of digital temperature signals, and the signals are sent to an FPGA (field programmable gate array) by an optical coupling circuit in an isolated way. The signal collection and preprocessing module is realized by an FPGA chip and a peripheral configuration circuit of the FPGA chip, in addition, the gyro, accelerometer and temperature pulse signals are received in a parallel way, and the smoothening and the preprocessing of data are completed. The data communication module realizes the communication with a host machine through a serial port RS422, on one hand, the data is packed to be sent to a host machine to be resolved or stored, on the other hand, the time synchronization between an IMU and a GPS (global positioning system) is realized, and the reliability of the data is ensured. The invention realizes the light small universal data collection system with high reliability, and important practical significance can be realized on the integrated research and development of the electric power line routing inspection system based on an unmanned aerial vehicle.

Owner:BEIHANG UNIV

Cerebrospinal fluid evaluation system having thermal flow and flow rate measurement pad using a plurality of control sensors

A method and device for testing for the presence, absence and / or rate of flow in a shunt tubing implanted under the skin by using a measurement pad having a plurality of temperature sensors, one of which is aligned with the shunt and the other sensors being symmetrically displaced on either side of the first temperature sensor in a direction transverse to the shunt tubing. These “outer” temperature sensors act as control temperature sensors. A temperature source, e.g., a cooling agent, positioned within an insulated enclosure, is then applied at a predetermined location on the measurement pad that is insulated from the temperature sensors. The movement of this temperature “pulse” is detected by the shunt-aligned temperature sensor via the shunt tubing as the CSF carries the temperature pulse while the control sensors detect the pulse via convection through the skin. The temperature data from these sensors are provided to a CSF analyzer that determines a CSF shunt flow status or flow rate.

Owner:NEURO DIAGNOSTIC DEVICES

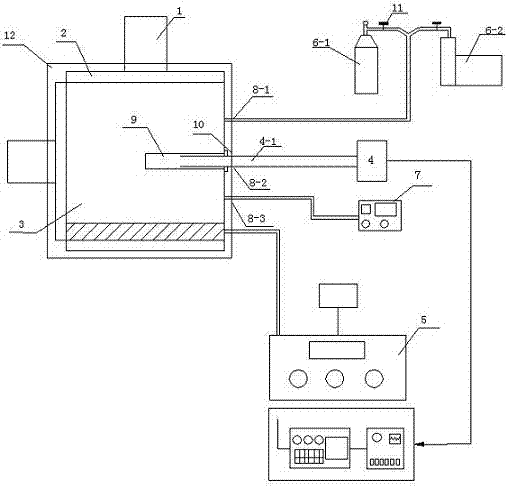

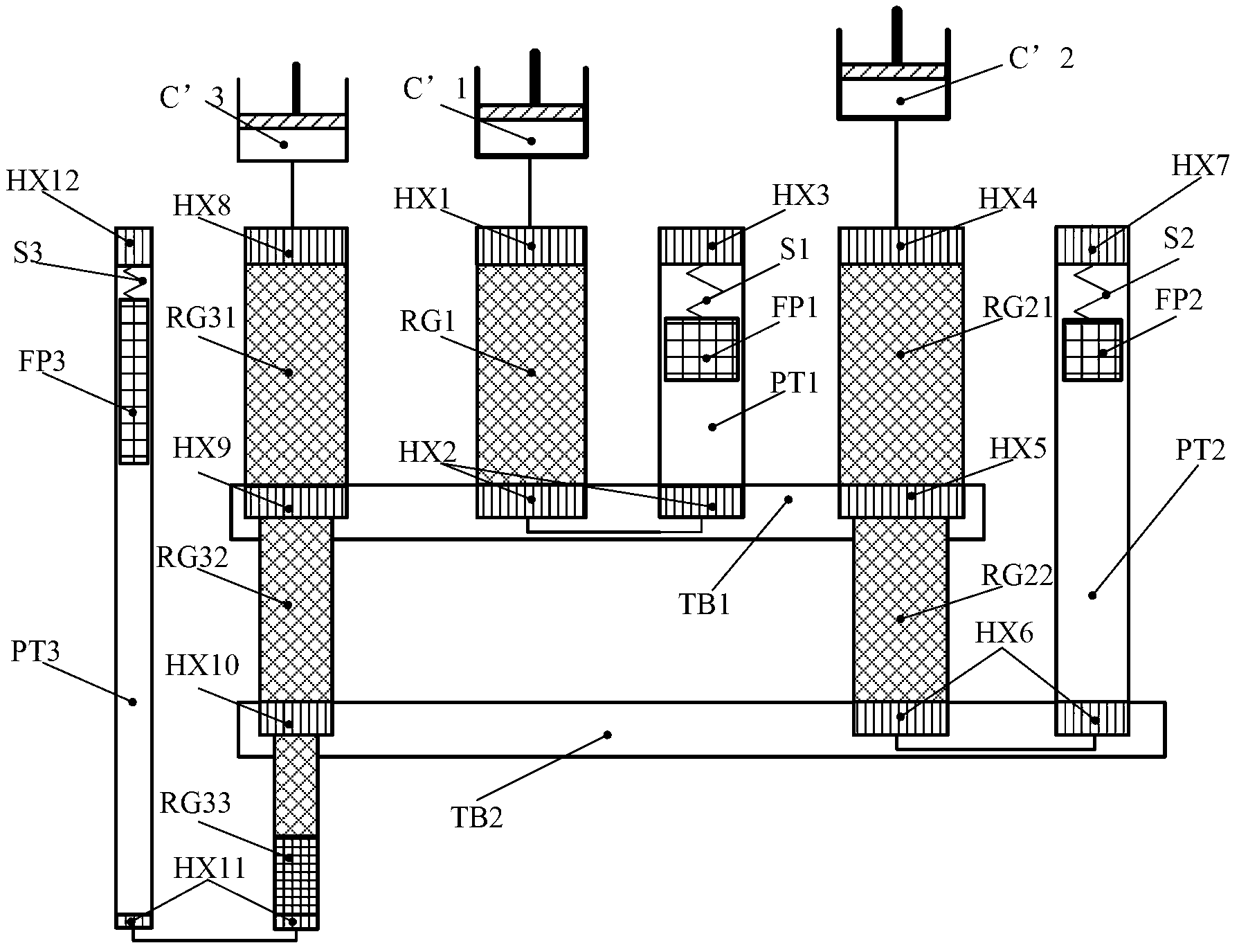

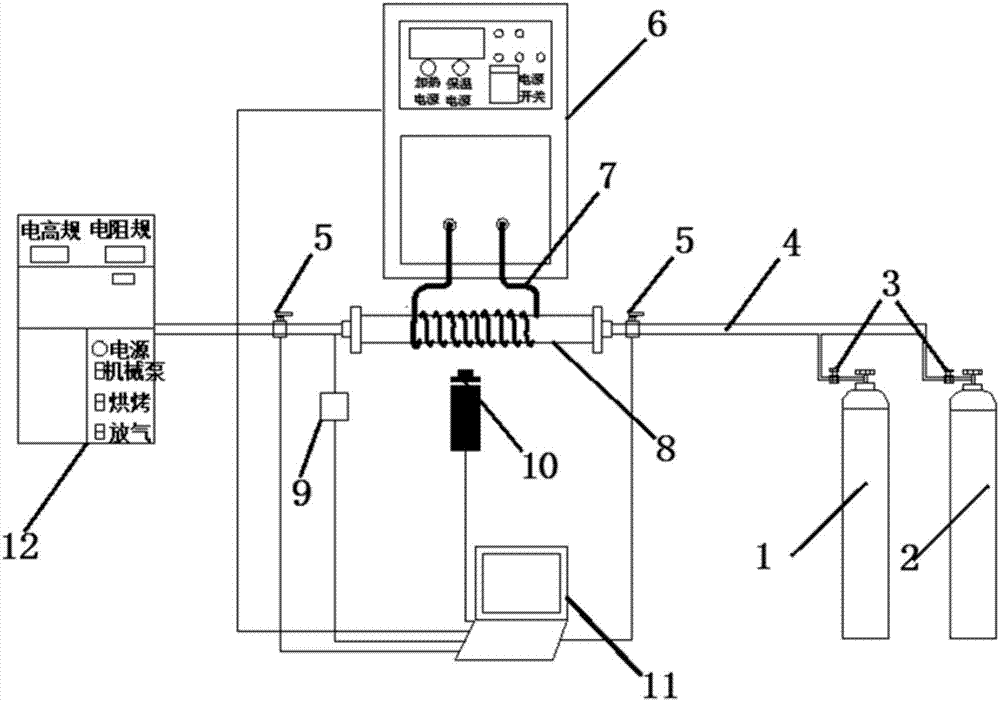

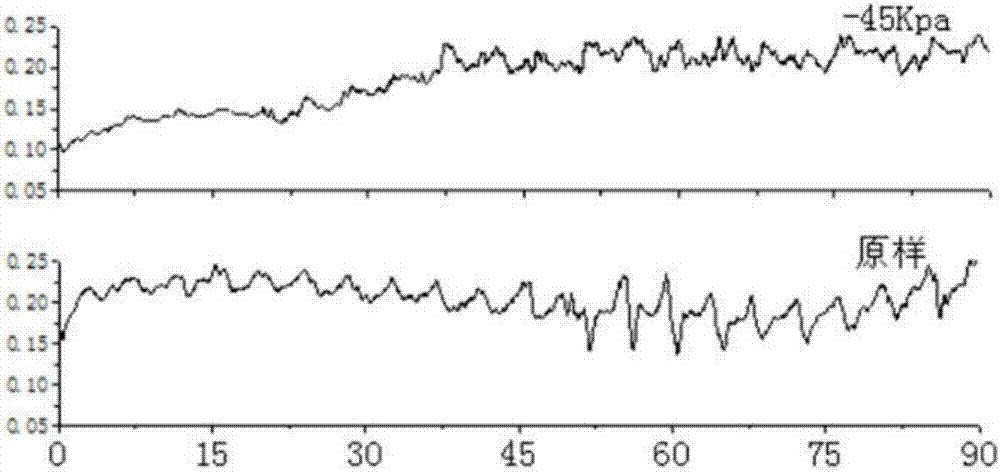

Experimental simulation device and simulation method for temperature-pressure pulse composite cracked coal

ActiveCN107462472AEasy to operateEasy to installMaterial strength using tensile/compressive forcesDesorptionGas cylinder

The invention discloses an experimental simulation device and an experimental simulation method for temperature-pressure pulse composite cracked coal. The device comprises a closed three-shaft pressurizing device, a temperature-pressure pulse composite cracking device, a vacuumizing and gas inflation device and a monitoring device, wherein the temperature-pressure pulse composite cracking device comprises a temperature pulse generation device and a high pressure pulse water pump, the vacuumizing and gas inflation device comprises a vacuumizing pump and an gas injection bottle and is connected with coal via a three-way valve; the closed three-shaft pressurizing device comprises a coal sample tank, pressure plates are arranged on three inner side surfaces of the coal sample tank, and a pushing rod is perpendicularly arranged on the outer side of each pressure plate; the monitoring device comprises a gas concentration monitoring probe, a camera probe with a light source and an electric wire; a cubic groove in the coal sample tank is connected with the coal sample in the closed three-shaft pressurizing device. According to the device and the method provided by the invention, gas adsorption capacity is reduced and gas desorption is promoted by using temperature and pressure pulses by simulating pressure and gas occurrence situations around an underground coal seam; operation is simple, installation and arrangement are felicitated, and production cost is reduced.

Owner:TAIYUAN UNIV OF TECH

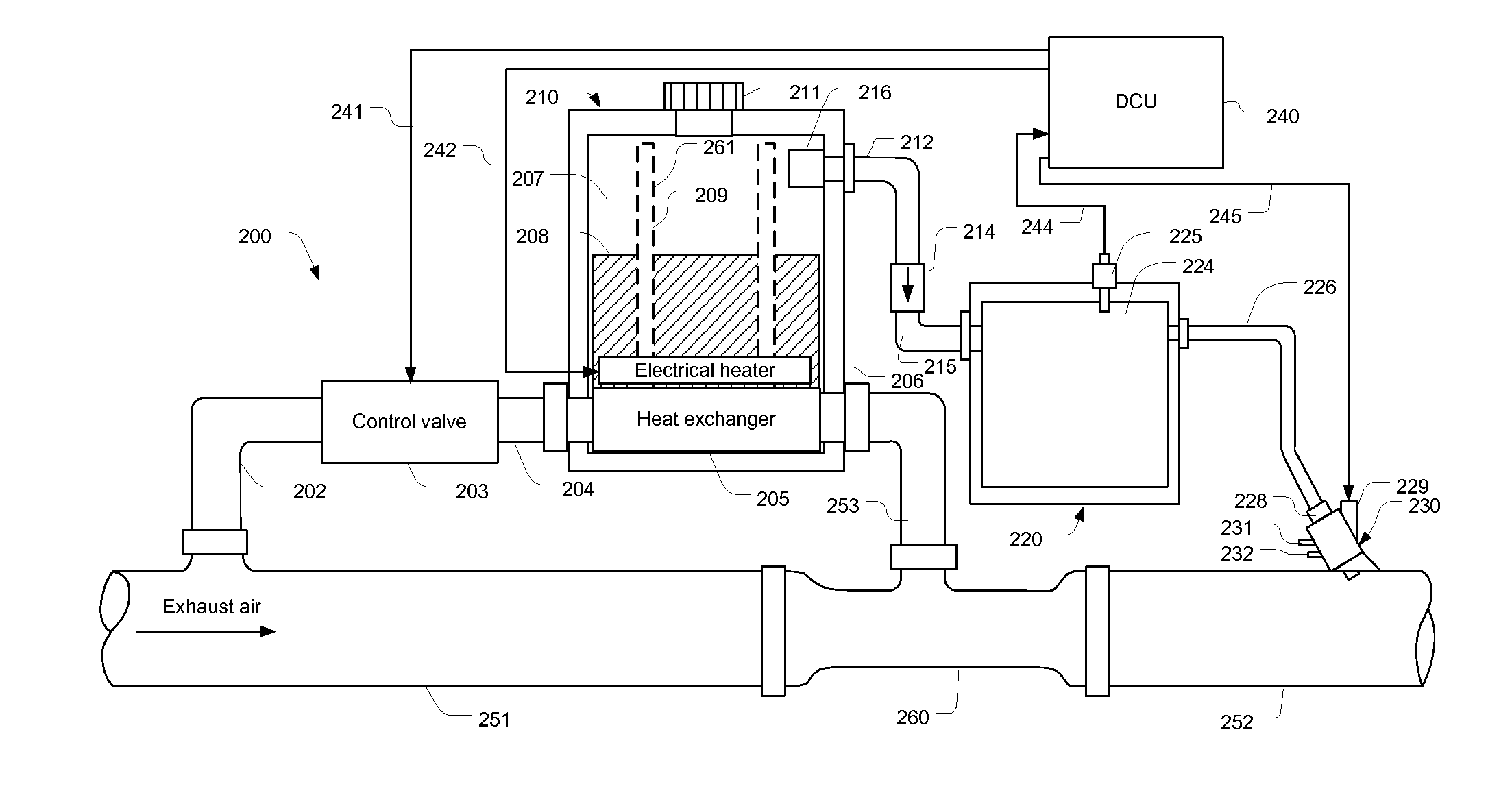

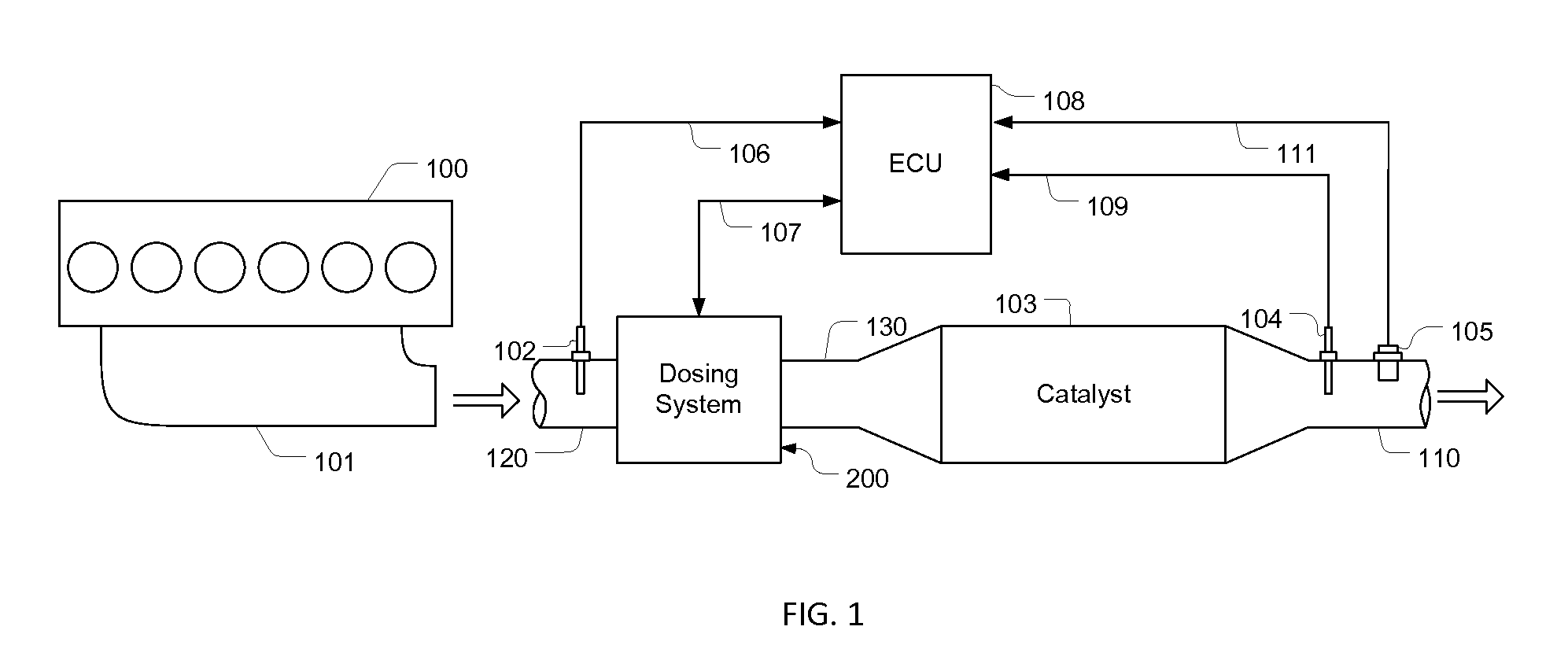

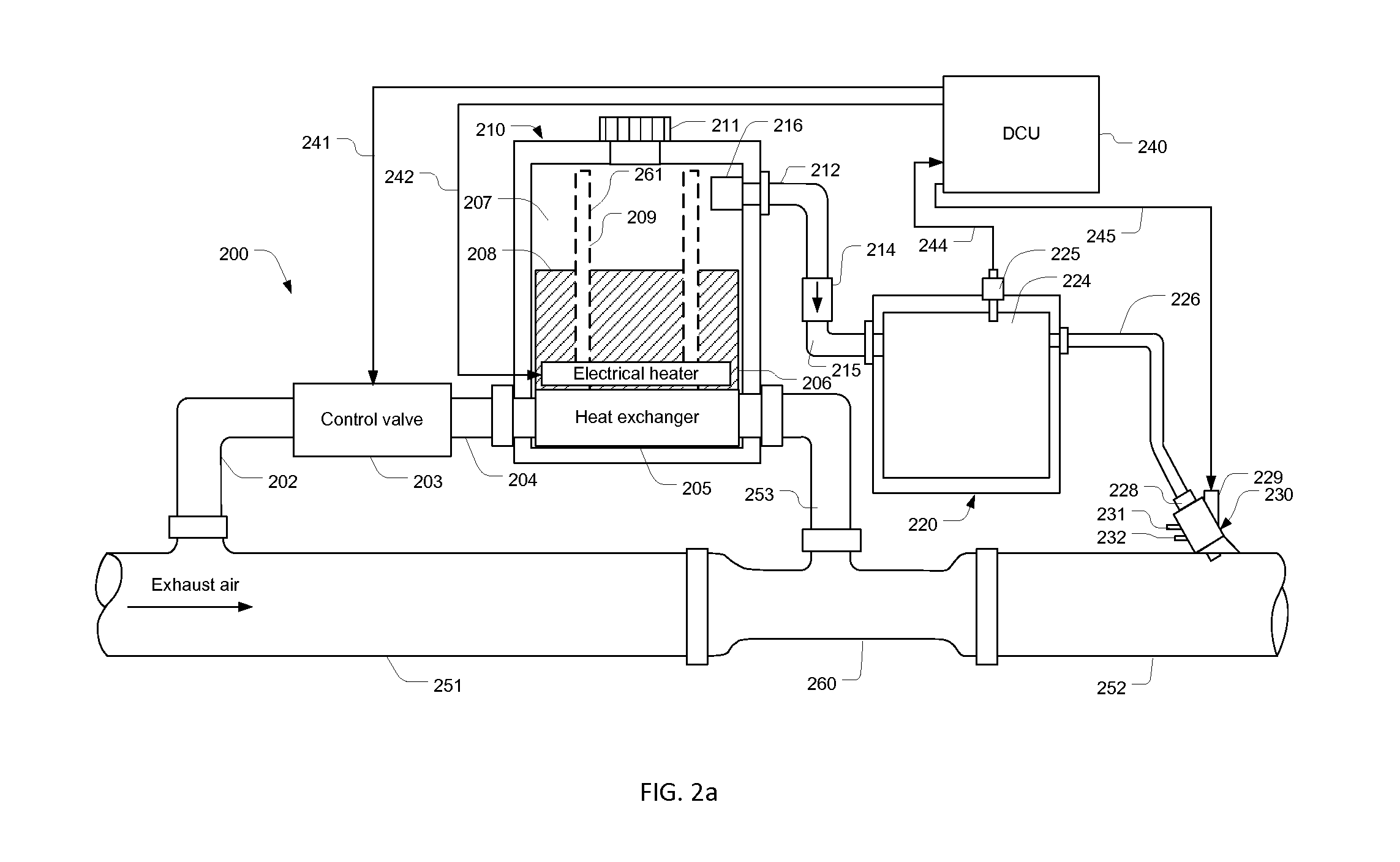

Ammonia Generating and Delivery Apparatus

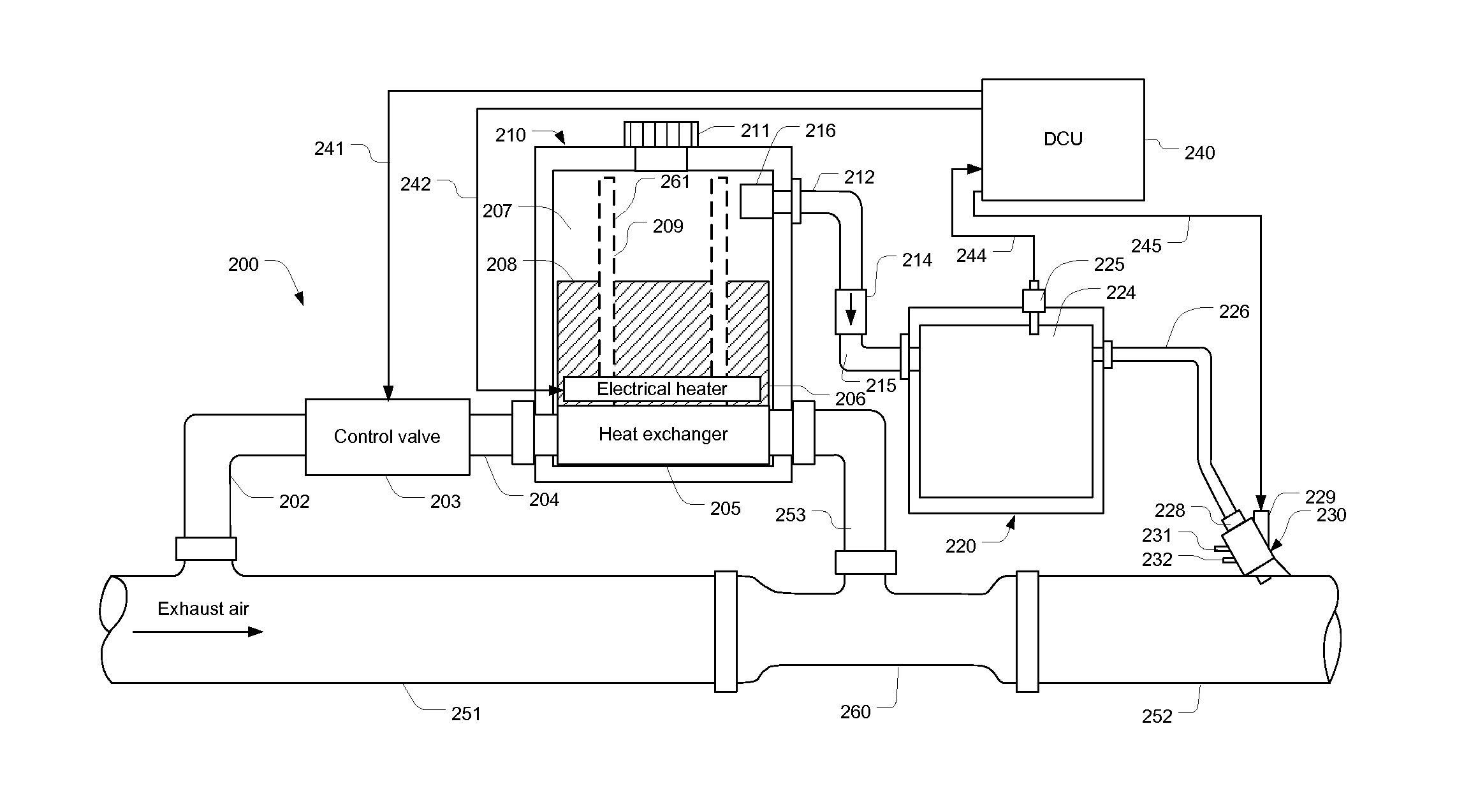

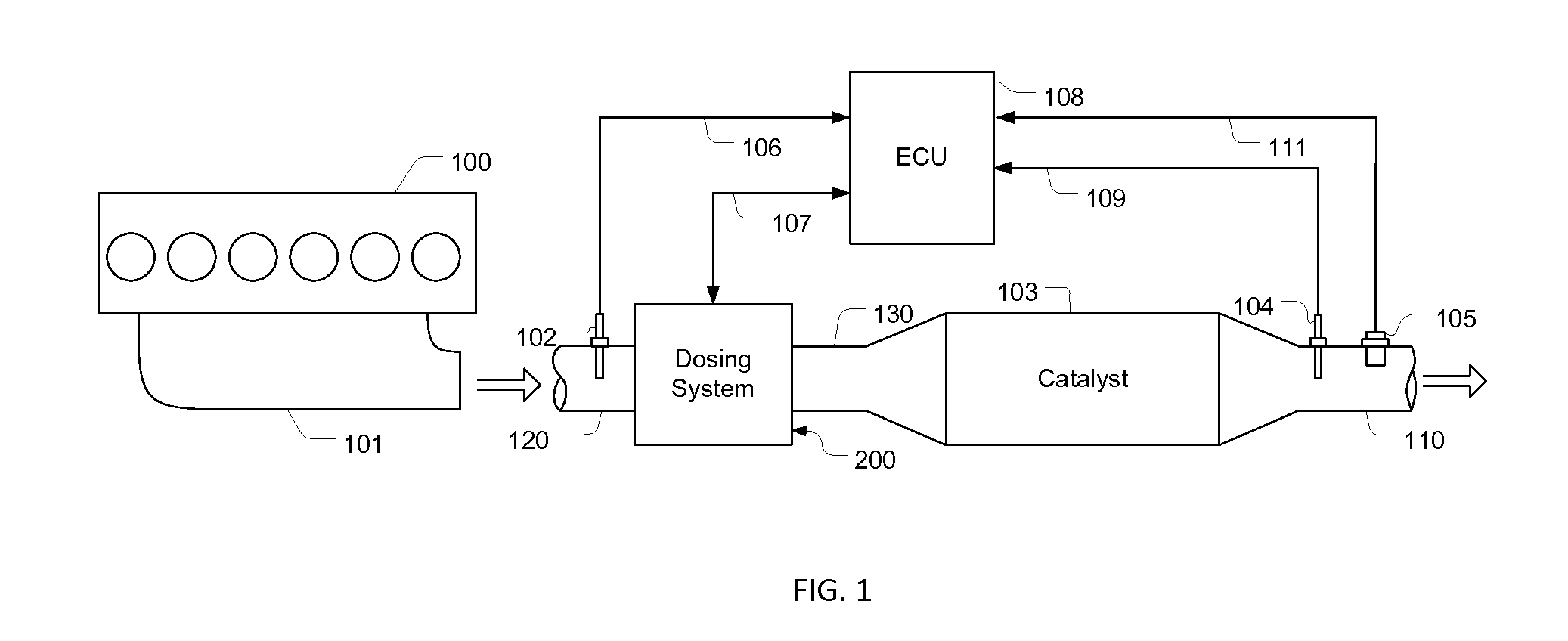

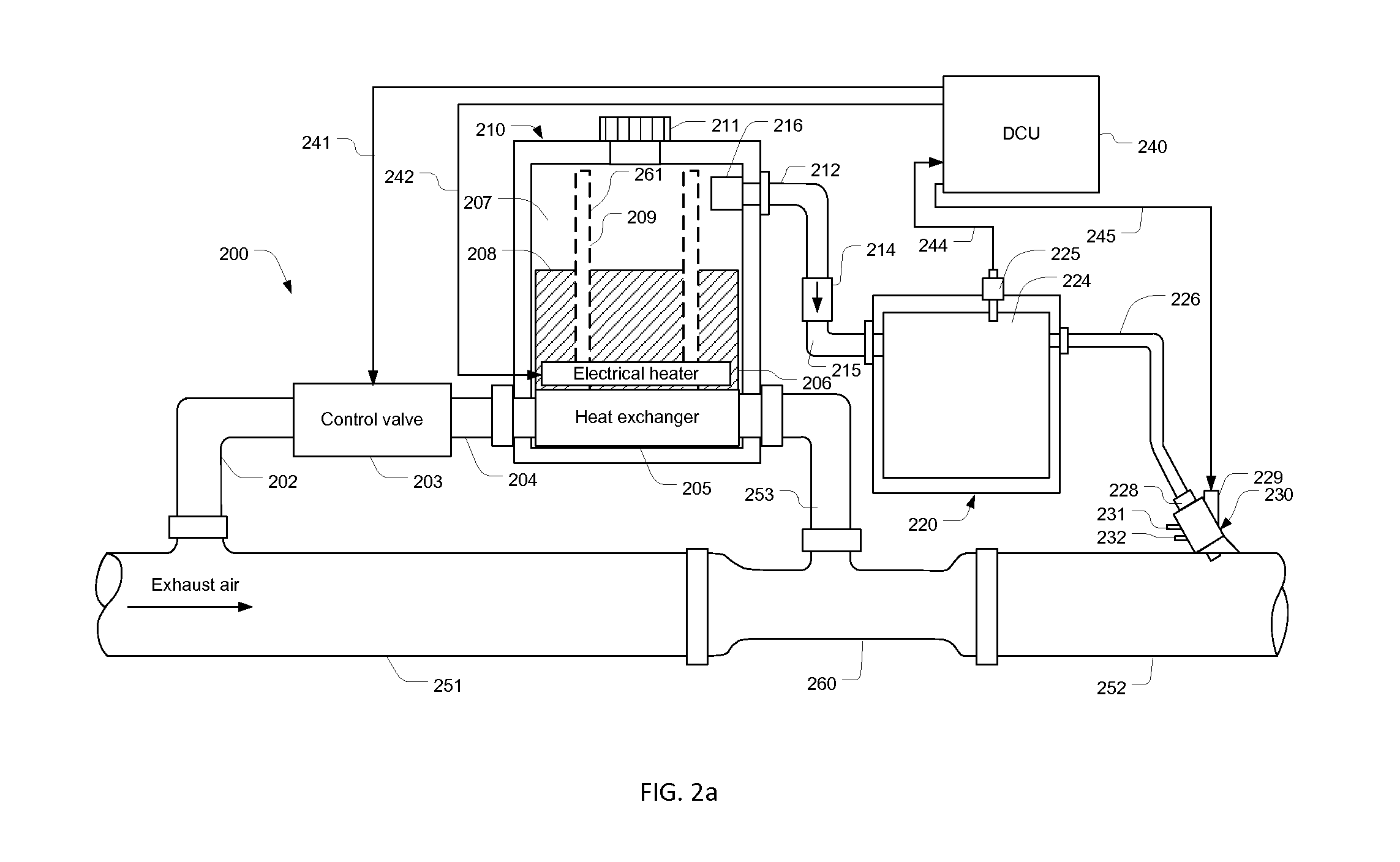

ActiveUS20140286829A1Easy to adjustEasy to controlOperating means/releasing devices for valvesInternal combustion piston enginesThree stageEngineering

An ammonia generating and delivery apparatus generating ammonia by heating a precursor material with a heating device controlled by a temperature pulse controller which receives commands from a pressure controller, and delivering ammonia with a flow rate controlled by a three-stage PWM controller. The temperature pulse controller is used in a first feedback loop to create a temperature pulse sequence at a surface of the heating device. A pressure controller in a second feedback loop provides duty-cycle commands to the temperature pulse controller, while in delivering ammonia, effects of pressure variation to delivery accuracy are compensated in the three-stage PWM controller, which includes a flow-rate feedback loop. The ammonia generating and delivery apparatus can also include two containers, in which the precursor material in one container is charged and discharged according to the capability of the other container in generating ammonia.

Owner:QI BAOHUA

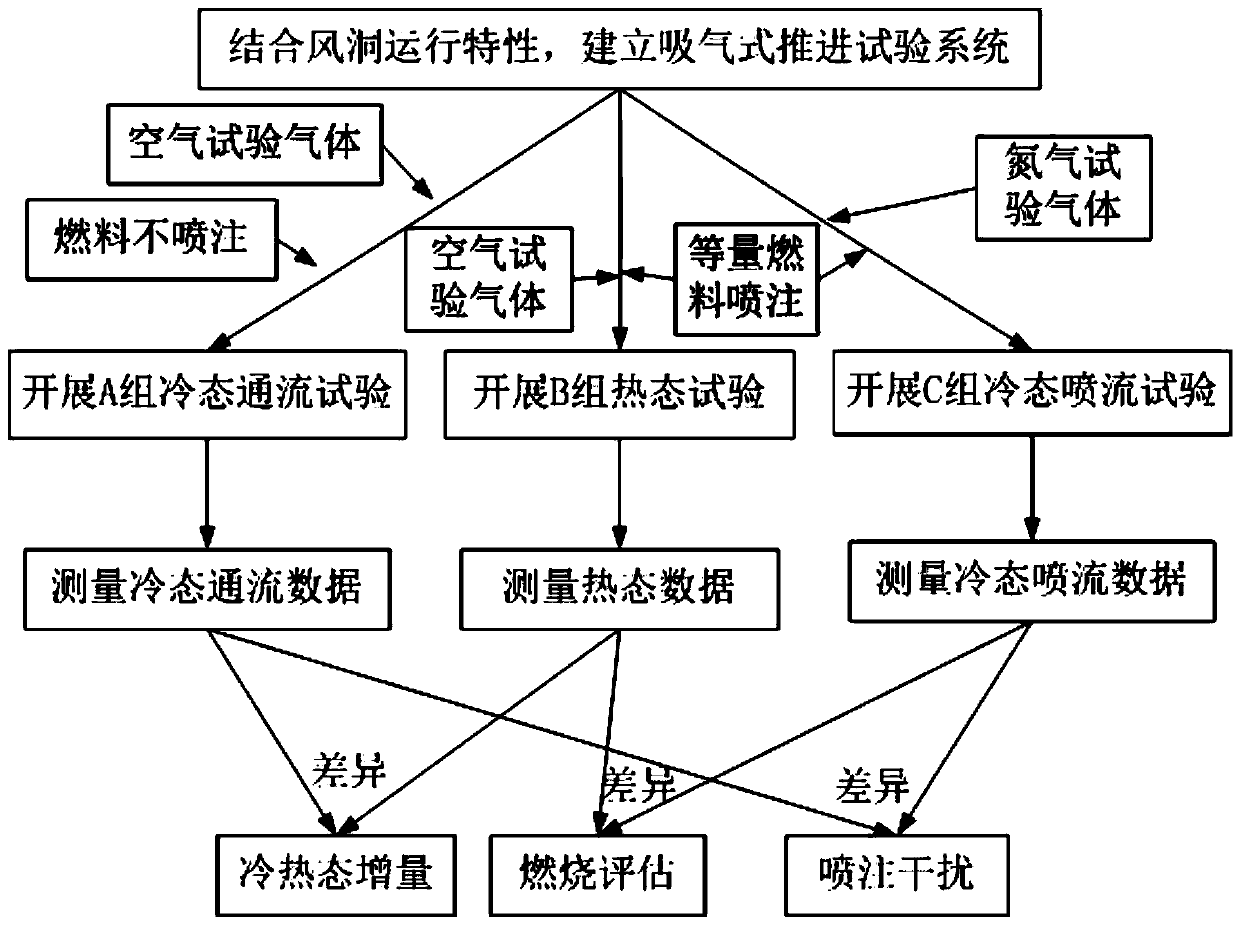

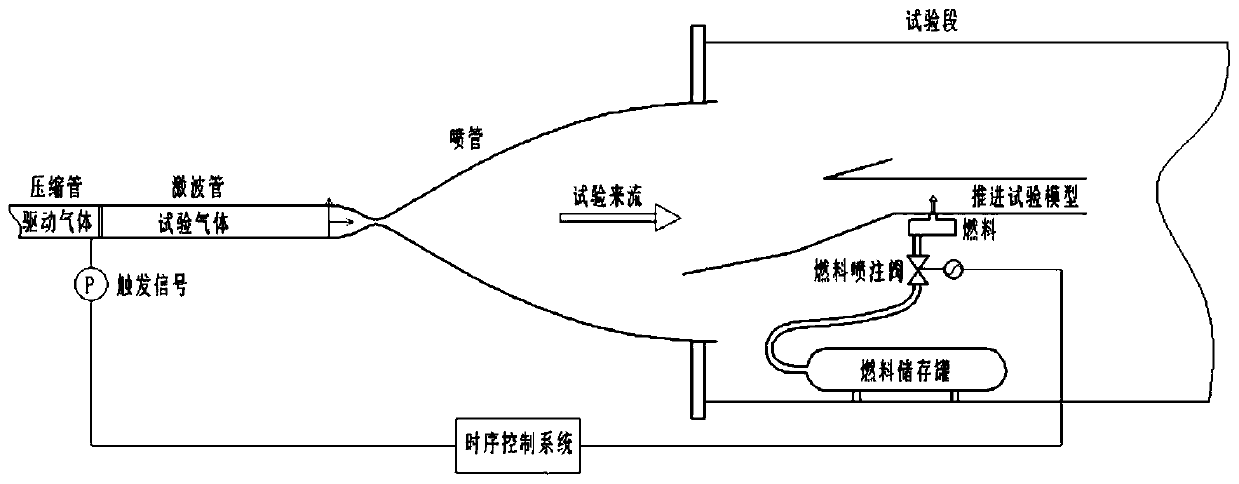

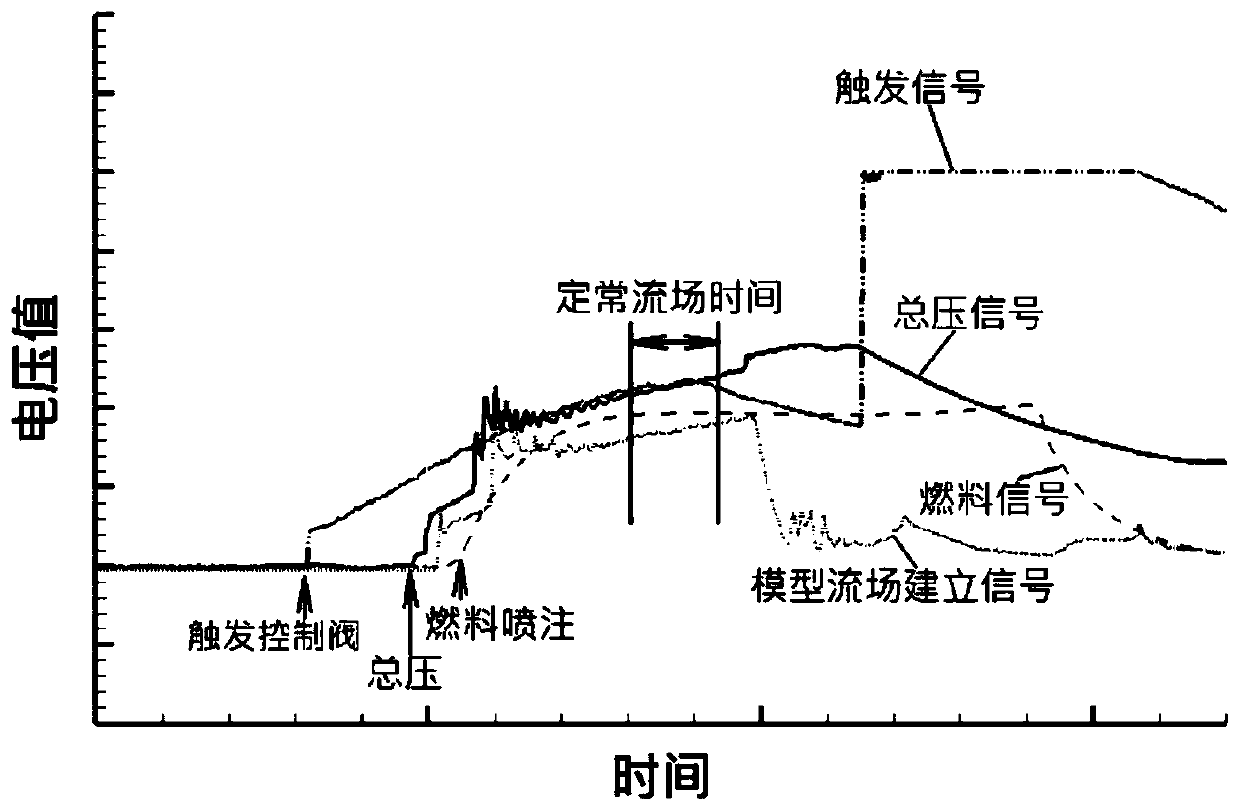

Aspirating type propulsion test simulation method based on high-temperature pulse wind tunnel

InactiveCN109883646ASolve the acquisition problemSolve the problem of air-breathing propulsion test data acquisitionGas-turbine engine testingAerodynamic testingIncremental testCold test

The invention discloses an aspirating type propulsion test simulation method based on a high-temperature pulse wind tunnel. The aspirating type propulsion test simulation method based on the high-temperature pulse wind tunnel comprises the following steps that (1) an aspirating type propulsion test system is established; (2) an A group cold test is conducted, and test data of non-fuel spouting columns and air incoming flow are measured; (3) a B group cold test is conducted, and the test data of the non-fuel spouting columns and the air incoming flow are measured; (4) a C group cold jet test isconducted, and cold jet test data flown from flue spouting and nitrogen flow are measured; (5) the differences of A, B, and C test data are compared, sprouting influence, burning characteristic and colt and hot performance analyses are completed, and stimulation on aspirating type propulsion is realized. According to the aspirating type propulsion test simulation method based on the high-temperature pulse wind tunnel, through sprouting control of fuel and replacement of test gas, three groups of control test stimulation methods A, B and C are formed, the burning characteristic of the aspirating type propulsion test can be judged, performance incremental test data of cold and hot performances can be obtained, and the aspirating type propulsion test simulation method can further be used forthe fuel sprout disturbance characteristic analysis of the aspirating type propulsion test.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

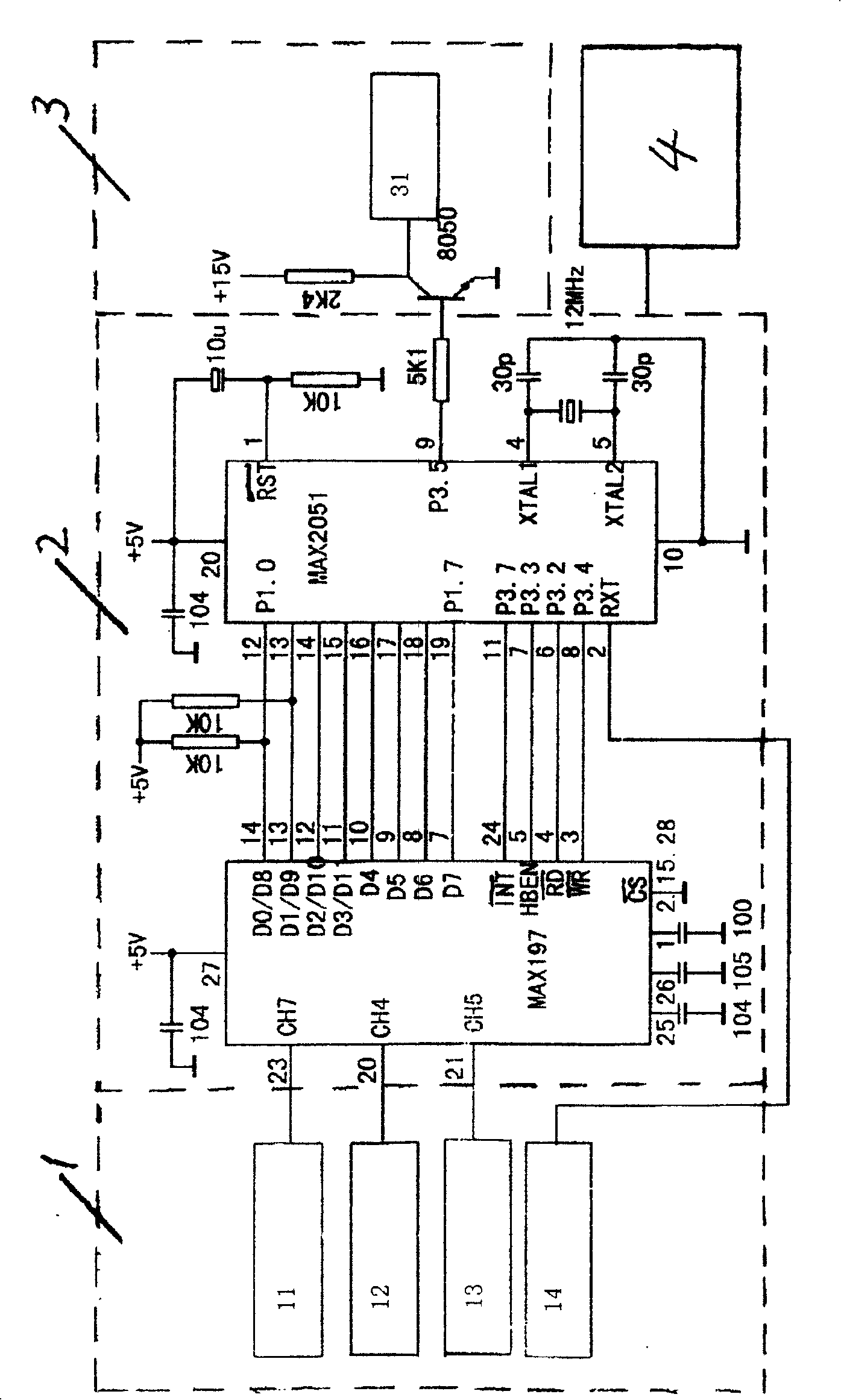

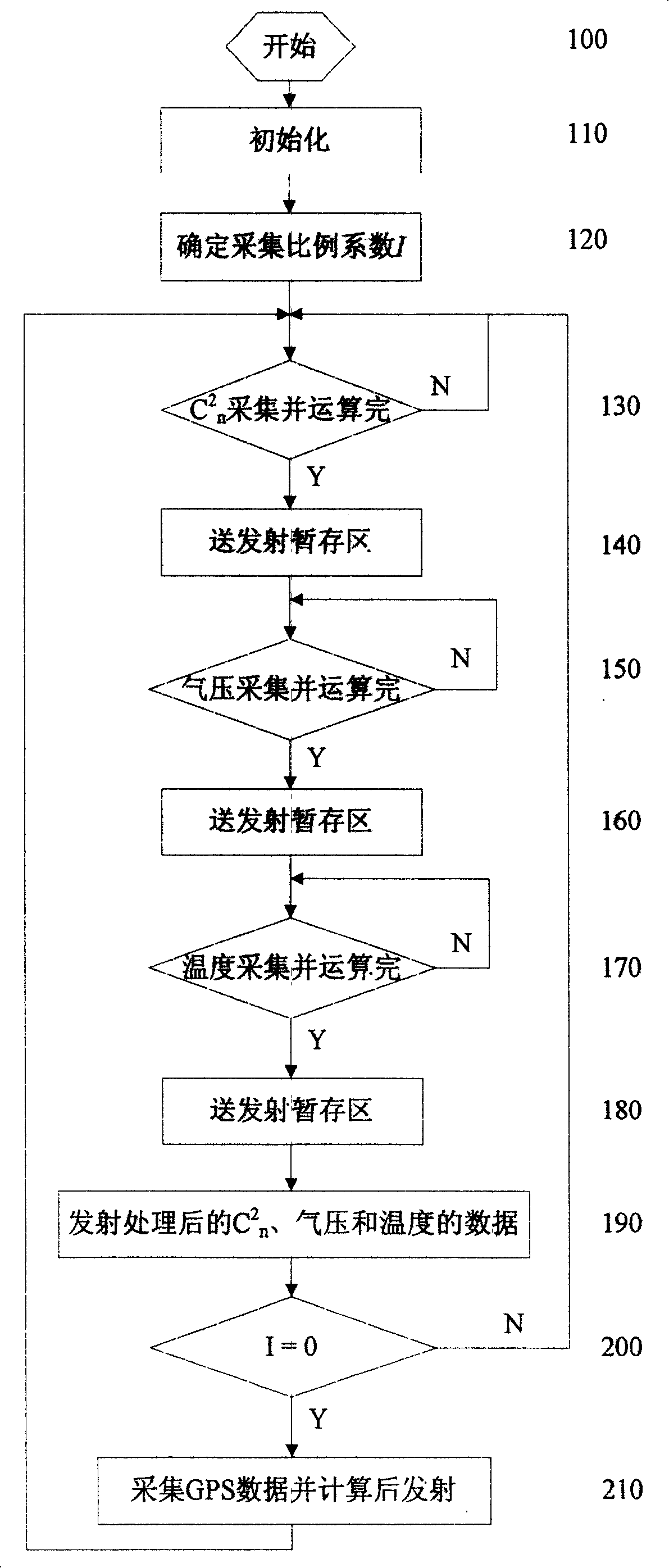

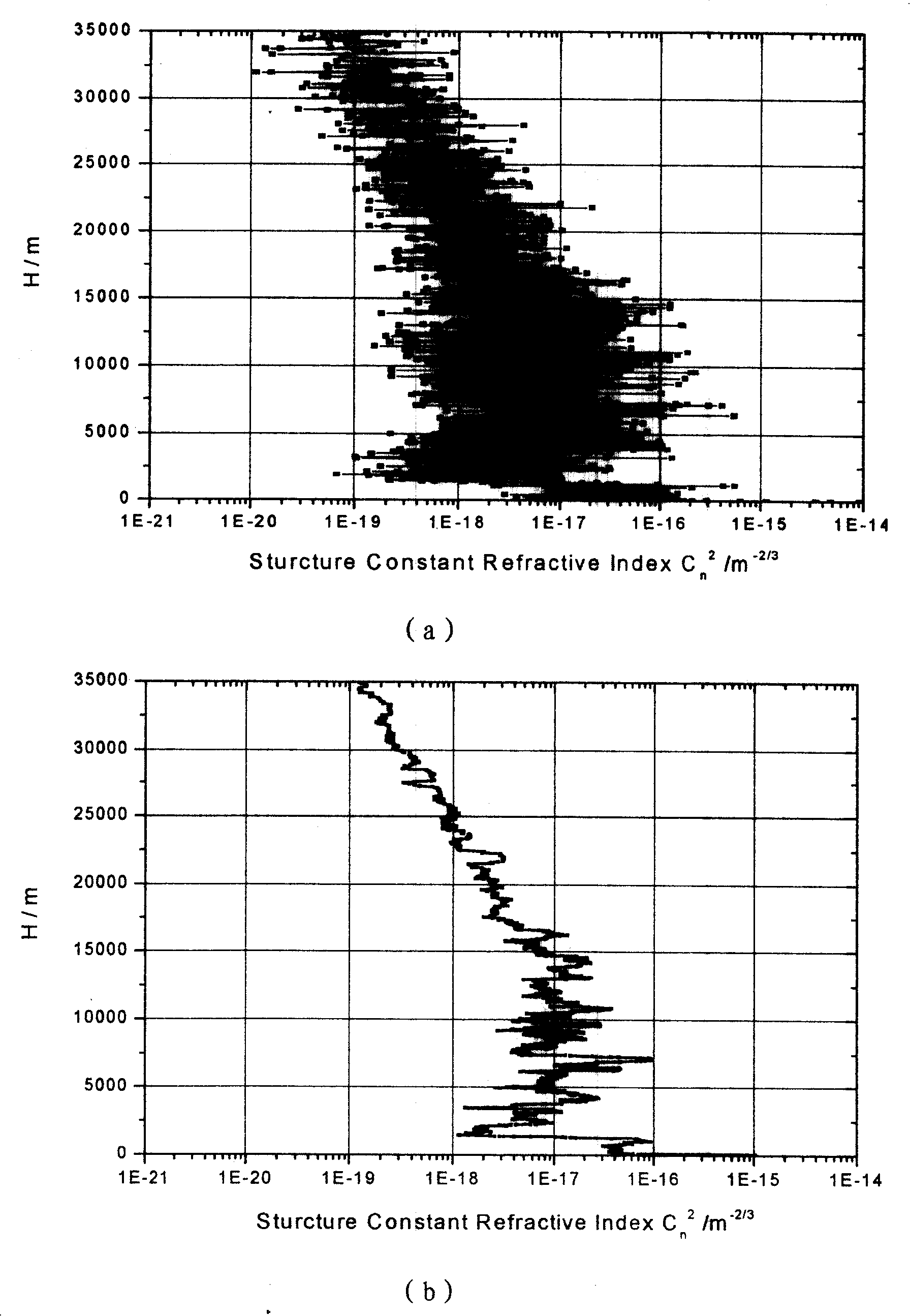

GPSGPS Multifunctional turbulent current sonde and its measurement method

InactiveCN101191840AFunction increaseImprove practicalityBeacon systems using radio wavesPosition fixationMicrocontrollerMeasurement point

The invention discloses a GPS multifunction turbulence radiosnode and a measurement method thereof. The radiosonde comprises a sensing part (1) including a temperature pulse sensor (11), a Barometric pressure sensor (12), an atmospheric temperature sensor (13) and a GPS sensor (14), a signal converting part (2) including an analog-to-digital converter MAX197 and a singlechip AT89C2051, a transmitting part (3) including a lever translator and a transmitter (31), and a power supply (4), all of which are used to convert electric signals output by the sensors into digital signals, and calculate, analyze, code and transmit the digital signals. The method comprises the following steps of: receiving the signal output by the sensors and outputting digital signals; particularly setting time slice for acquiring the output of the sensors and acquisition frequency and determining the acquisition proportionality coefficient of the sensors according to the acquired sensor; and processing and coding the data converted into digital signals and transmitting the data converted into digital signals to the transmitting part to be transmitted. The invention can accurately position and measure the atmosphere turbulence and wind direction and speed at the measurement points.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

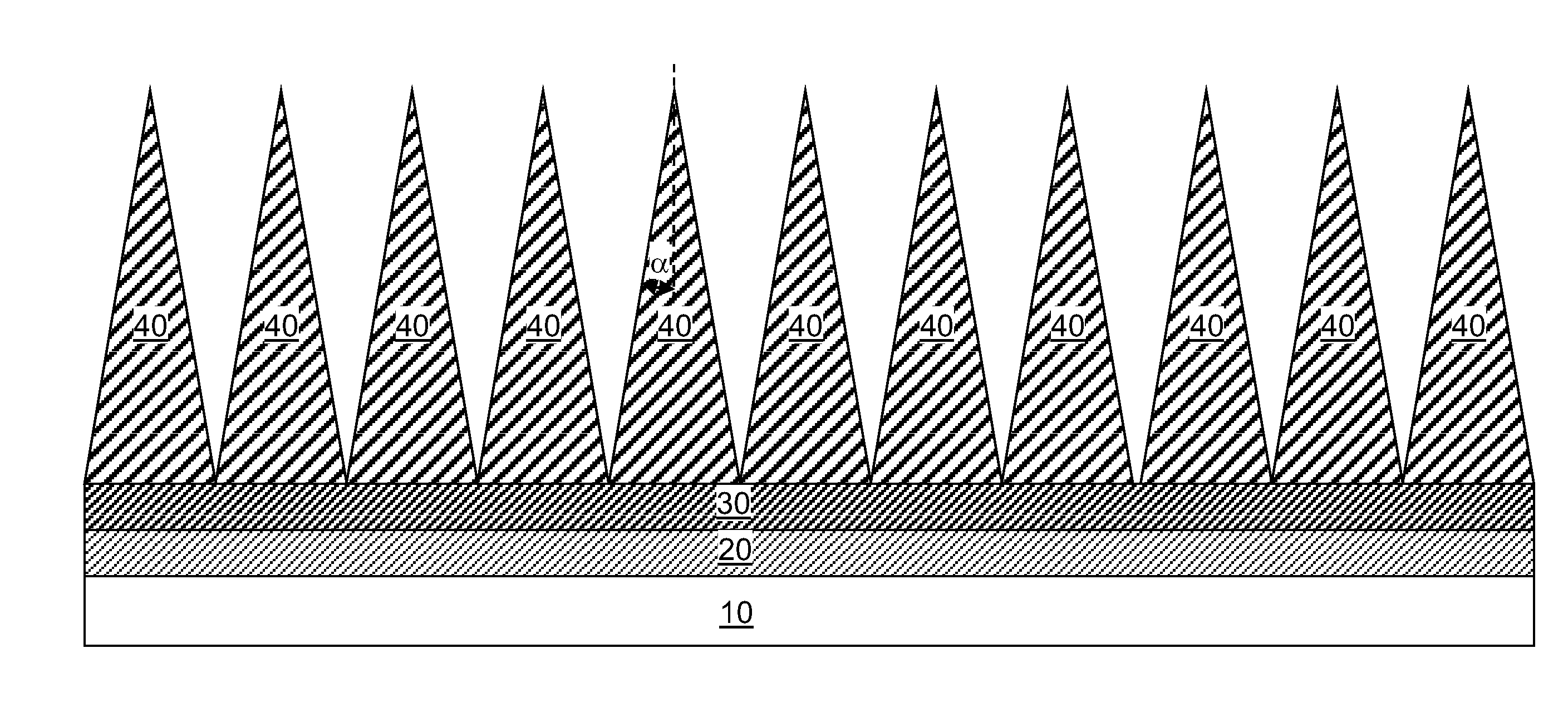

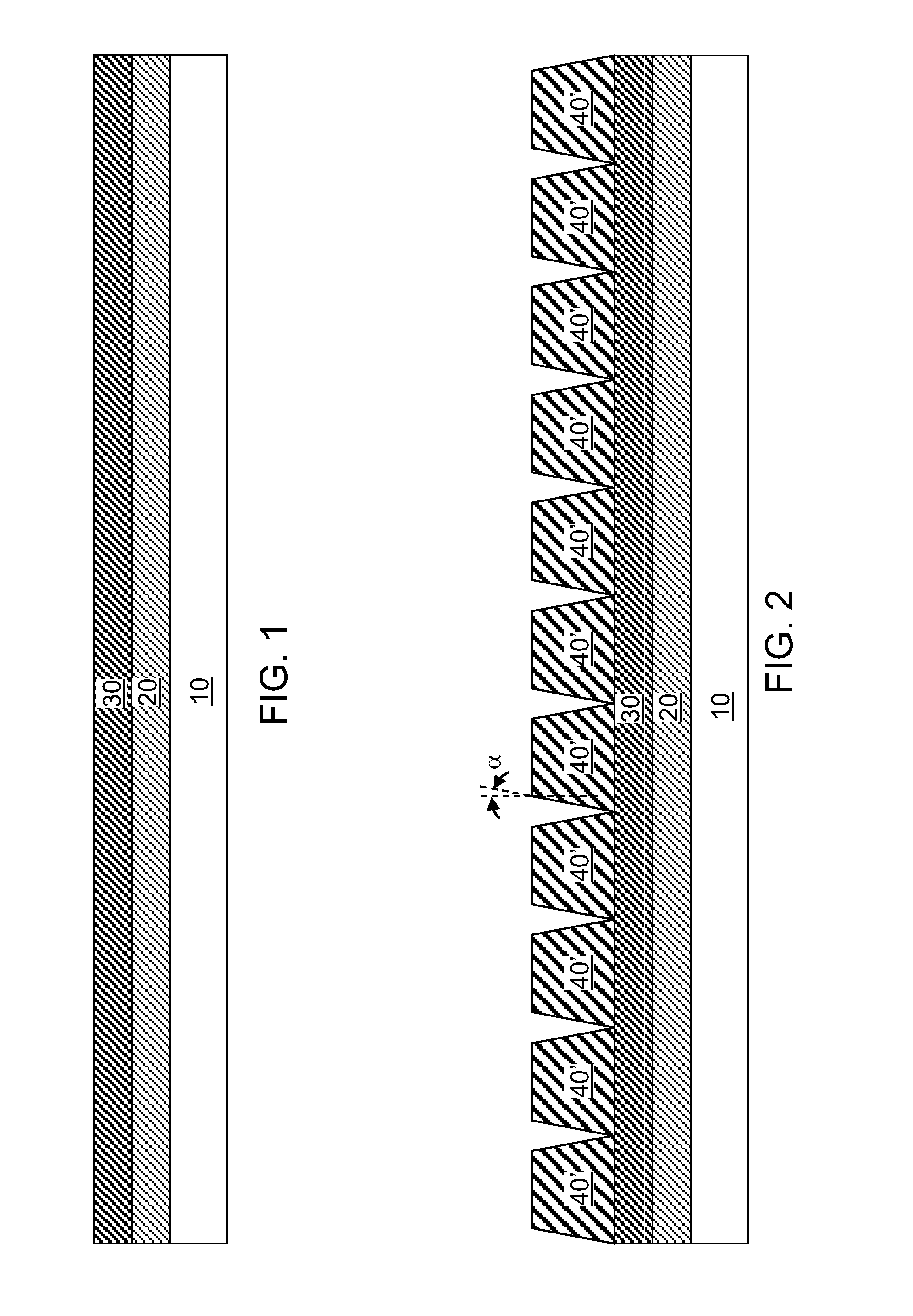

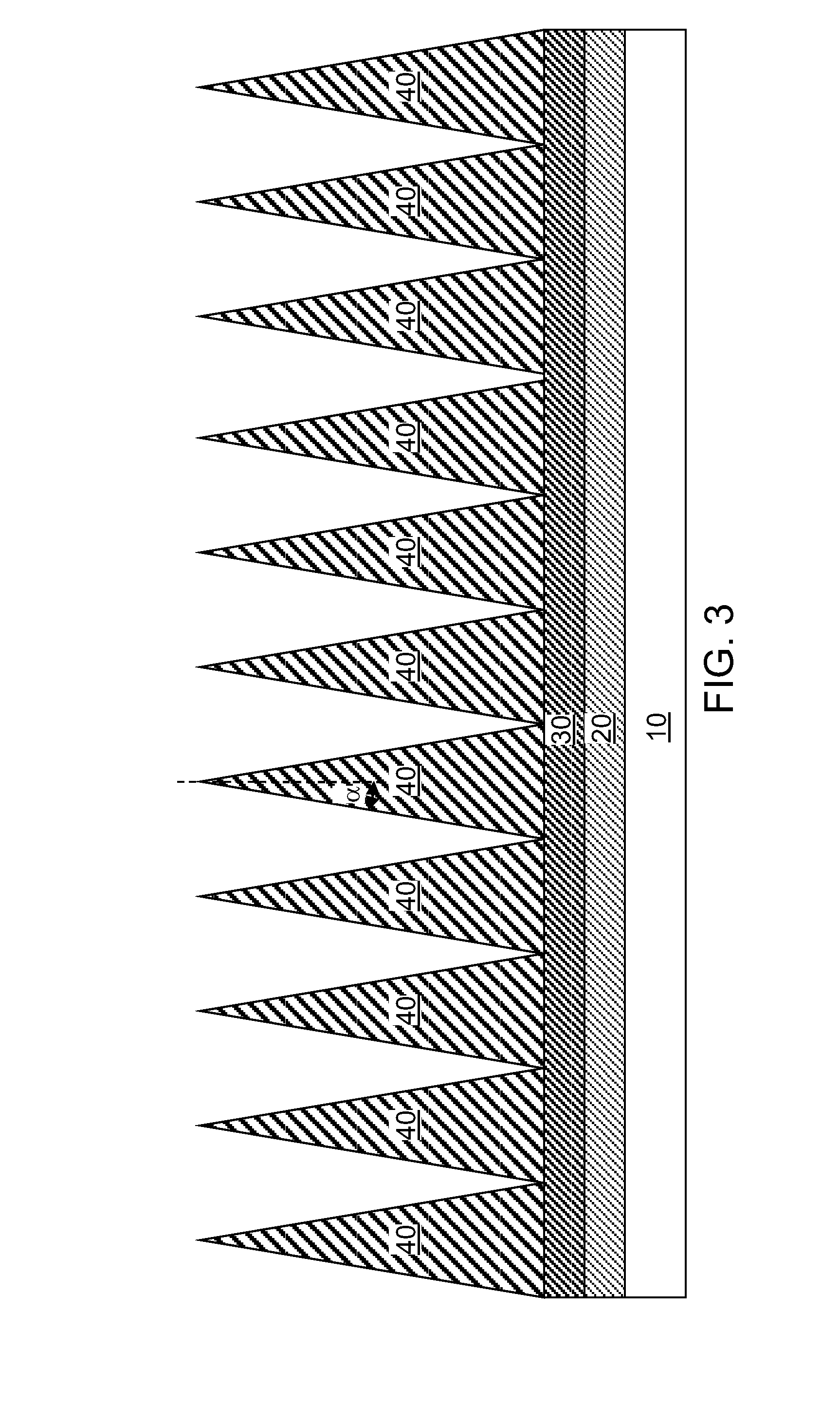

Nanocone-based photovoltaic solar cells

InactiveUS20120255599A1Efficient collectionMinimizing interfacial defectsSemiconductor/solid-state device manufacturingPhotovoltaic energy generationSemiconductor materialsSolar light

A photovoltaic structure including a nanocone-based three-dimensional interdigitated p-n junction is provided in the present invention. The three-dimensional p-n junction is at the interface between n-type oxide semiconductor nanocones and a p-type semiconductor material that functions as a matrix embedding the nanocones. The nanocone-based three-dimensional p-n junction allows efficient minority carriers being extracted from photo-absorber and crossing across the p-n junction, and generates completely-depleted regions throughout the nanocones and the matrix around the nanocones for efficient charge collection. Further, the bandgap energies of the p-doped semiconductor material can be tuned to match the solar light spectrum by mixing related elements. Further, the high temperature pulses can be used to remove defects in the junction interfaces and sintering nanoparticle matrix.

Owner:UT BATTELLE LLC

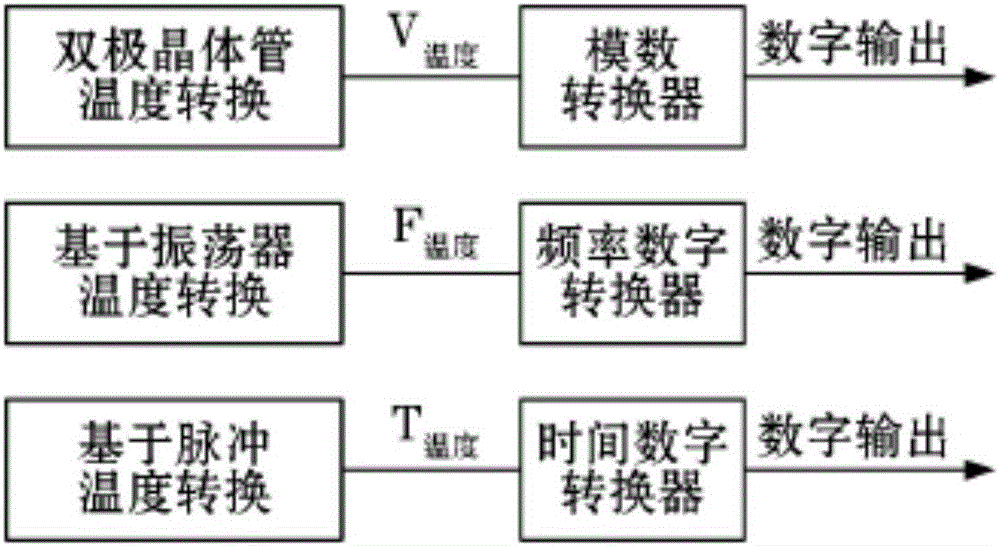

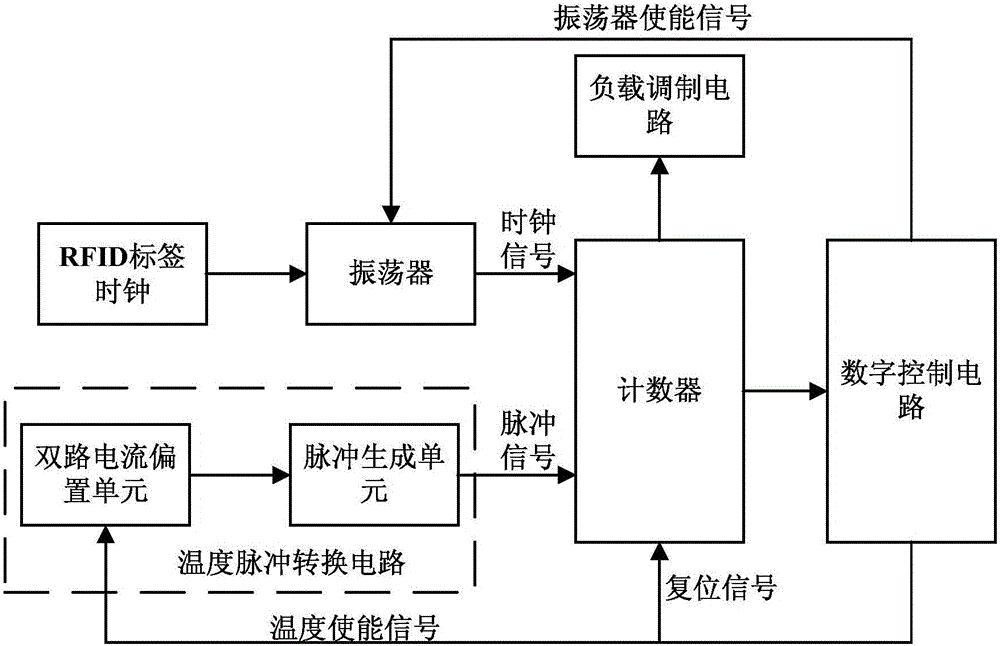

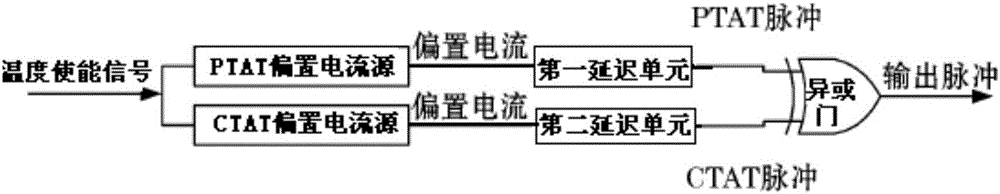

Temperature sensor integrated in RFID tag

PendingCN106017730AOvercome the few flawsReduce areaThermometer applicationsRecord carriers used with machinesHemt circuitsEngineering

The invention discloses a temperature sensor integrated in an RFID tag. The temperature sensor comprises a temperature pulse conversion circuit, a counter, an oscillator, an RFID tag clock, a digital control circuit and a load modulation circuit; the counter, the oscillator, the RFID tag clock, the digital control circuit and the load modulation circuit are all common module circuits between the temperature sensor and other modules; the output end of the RFID tag clock is connected with the input end of the digital control circuit through the oscillator and the counter sequentially; the output end of the temperature pulse conversion circuit is connected with the enabling end of the counter; the output ends of the digital control circuit are connected with the reset end of the counter, the temperature enabling end of the temperature pulse conversion circuit and the enabling end of the oscillator; and one output end of the counter is connected with the input end of the load modulation circuit. The temperature sensor of the invention has the advantages of small chip area, low power consumption and low cost, and can be widely applied to the RFID technology field.

Owner:GUANGZHOU SYSUR MICROELECTRONICS

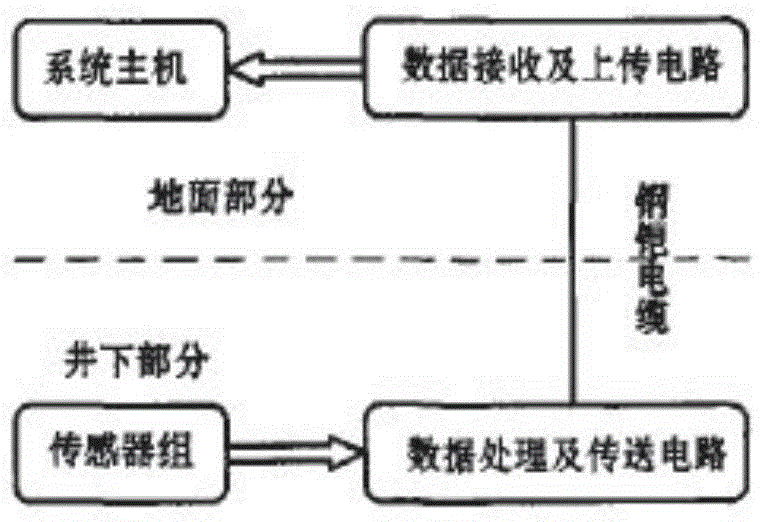

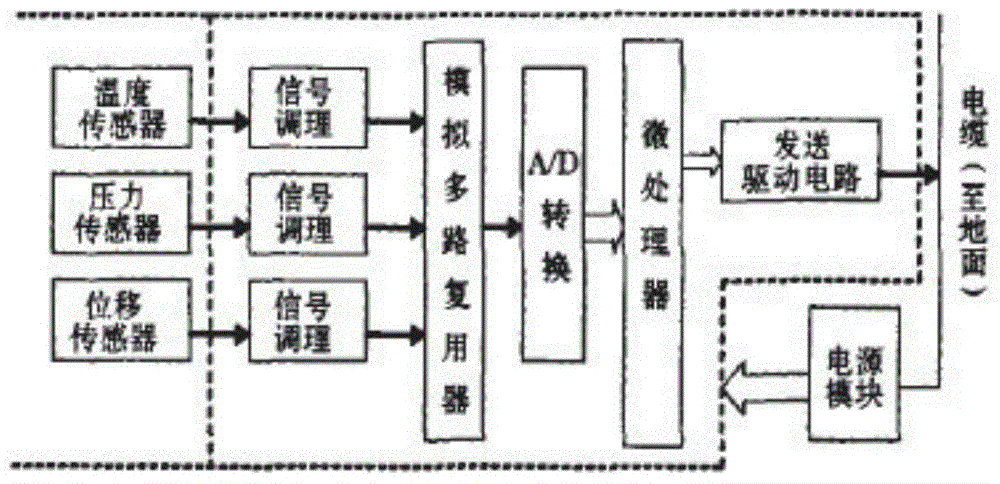

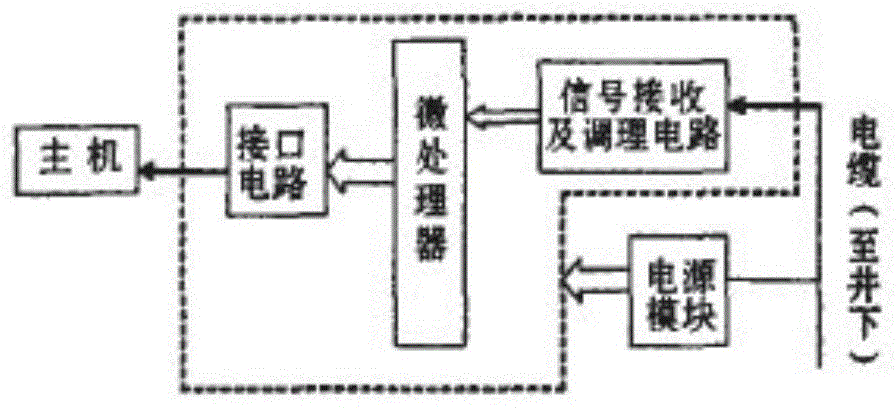

Intelligent well underground data collecting system based on high-temperature single-chip microcomputer

InactiveCN104632199APressure real-time monitoringStable jobSurveyConstructionsAlternating currentLine driver

The invention discloses an intelligent well underground data collecting system based on a high-temperature single-chip microcomputer. The intelligent well underground data collecting system is composed of an underground part and a ground part which are connected through a single-core steel armor cable. The underground part is composed of a sensor set and a data processing and transmitting circuit. The ground part is composed of a data receiver uploading circuit and a system host. 220V alternating current is remotely transmitted to the underground part to be supplied from the ground through the cable. The sensor set comprises a temperature sensor, a pressure sensor and a displacement sensor. Signals of the sensor set are converted into voltage signals after being conditioned, a simulation multiplexer HT506 is utilized for carrying out selective collection, the signals are converted through an A / D converter HT574 and then are transmitted to a microprocessor HT83C51, an HJ389 high-temperature pulse composite signal lone-line driver is adopted as a drive circuit to transmit the signals to the cable, an HJ388 pulse signal preprocessing module in the data receiver uploading circuit carries out signal conditioning on the transmitted underground signals, and the processed signals are transmitted to the microprocessor single-chip microcomputer and then transmitted to the host through an interface circuit MAX232. The pressure, the temperature and the valve displacement are monitored in real time, and long-term stable working under the high temperature environment of 175 DEG C can be achieved.

Owner:成都亿友科技有限公司

Ammonia generating and delivery apparatus

ActiveUS8980181B2Easy to adjustEasy to controlInternal combustion piston enginesExhaust apparatusThree stageEngineering

An ammonia generating and delivery apparatus generating ammonia by heating a precursor material with a heating device controlled by a temperature pulse controller which receives commands from a pressure controller, and delivering ammonia with a flow rate controlled by a three-stage PWM controller. The temperature pulse controller is used in a first feedback loop to create a temperature pulse sequence at a surface of the heating device. A pressure controller in a second feedback loop provides duty-cycle commands to the temperature pulse controller, while in delivering ammonia, effects of pressure variation to delivery accuracy are compensated in the three-stage PWM controller, which includes a flow-rate feedback loop. The ammonia generating and delivery apparatus can also include two containers, in which the precursor material in one container is charged and discharged according to the capability of the other container in generating ammonia.

Owner:QI BAOHUA

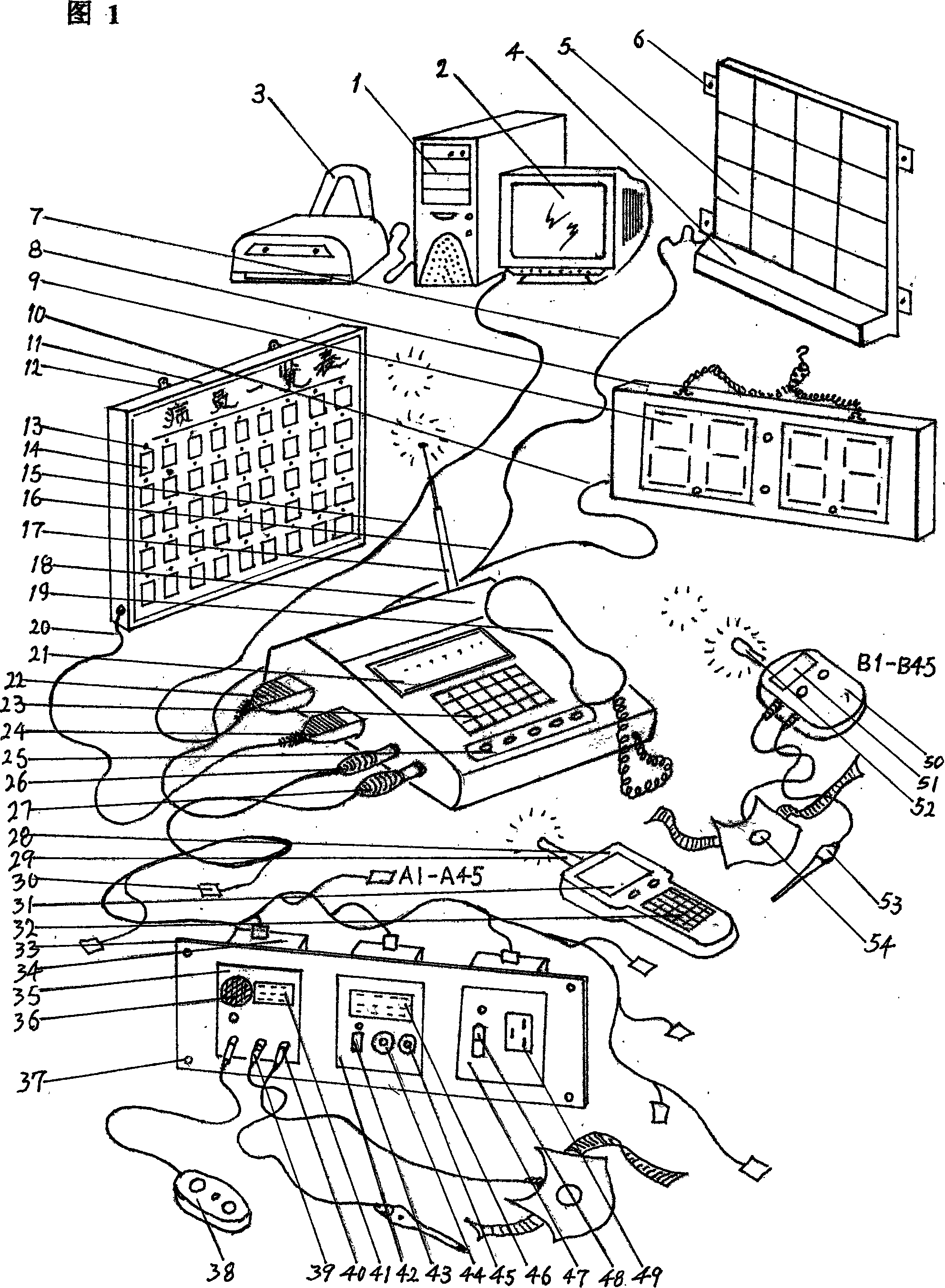

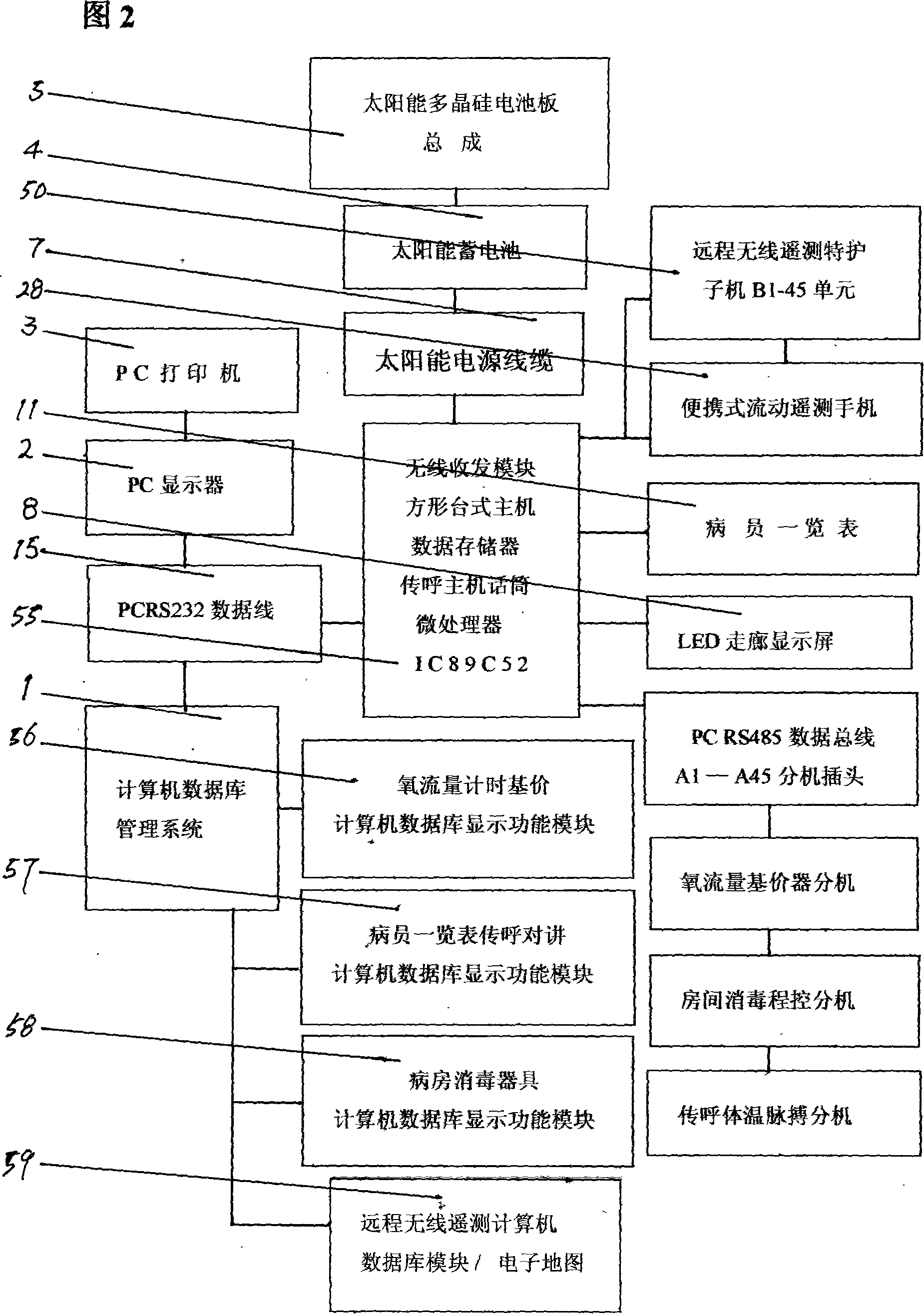

Solar energy remote communication network body temperature monitoring PC database management system

InactiveCN101149869AReduce labor intensityMaintain physical and mental healthTransmission systemsDiagnostic recording/measuringStructure of Management InformationSolar cell

The solar remote communication network body-temperature monitoring PC database management system comprises a computer database management system, a solar cell plate assembly, a patient list, a square desk-type host computer, RS232 data wire connection plug, a host computer RS485 data bus, a portable mobile remote-monitoring hand-set, a built-in body-temperature pulse paging sub-machine, an oxygen-flow timed basic-price storage sub-machine, a room disinfector program-controlled sub-machine, a portable wire-less body-temperature-pulse remote-monitoringGPS tracing-monitoring special-nursing sub-machine B1-B45 unit for a patient. Advantage: simple and convenient use.

Owner:赵增友

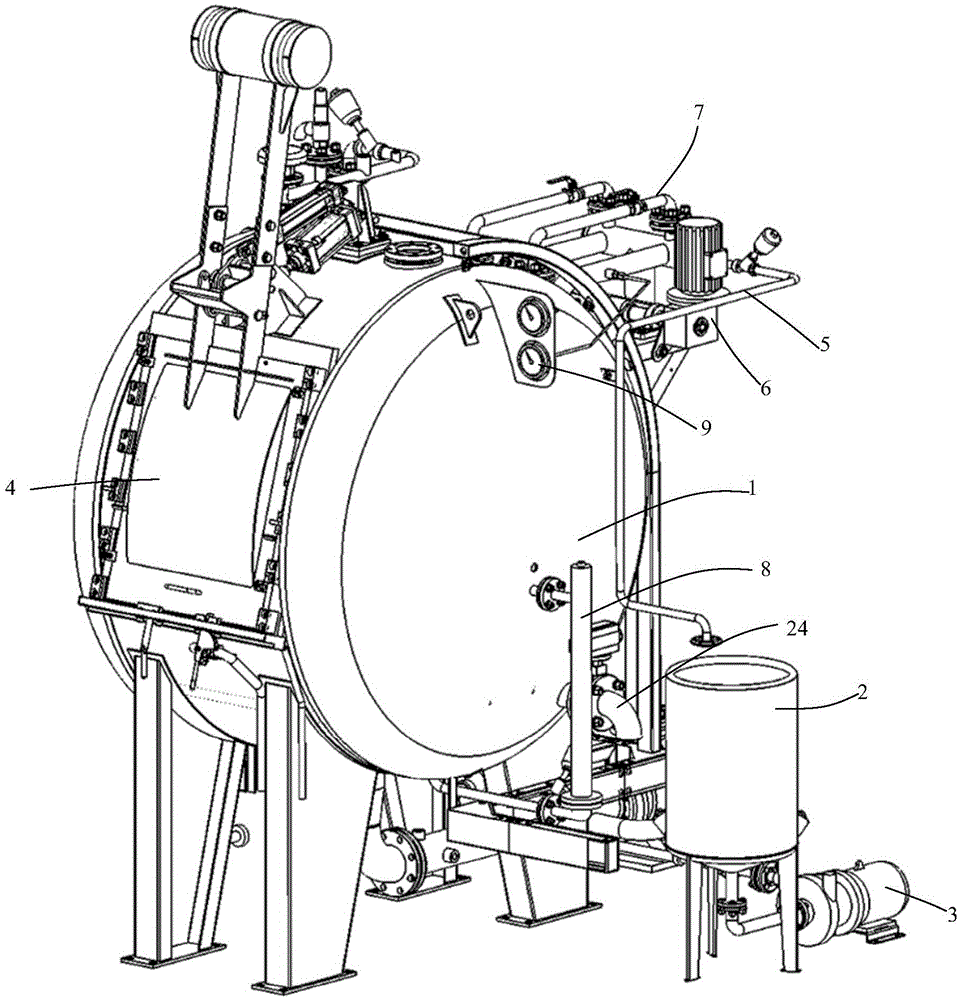

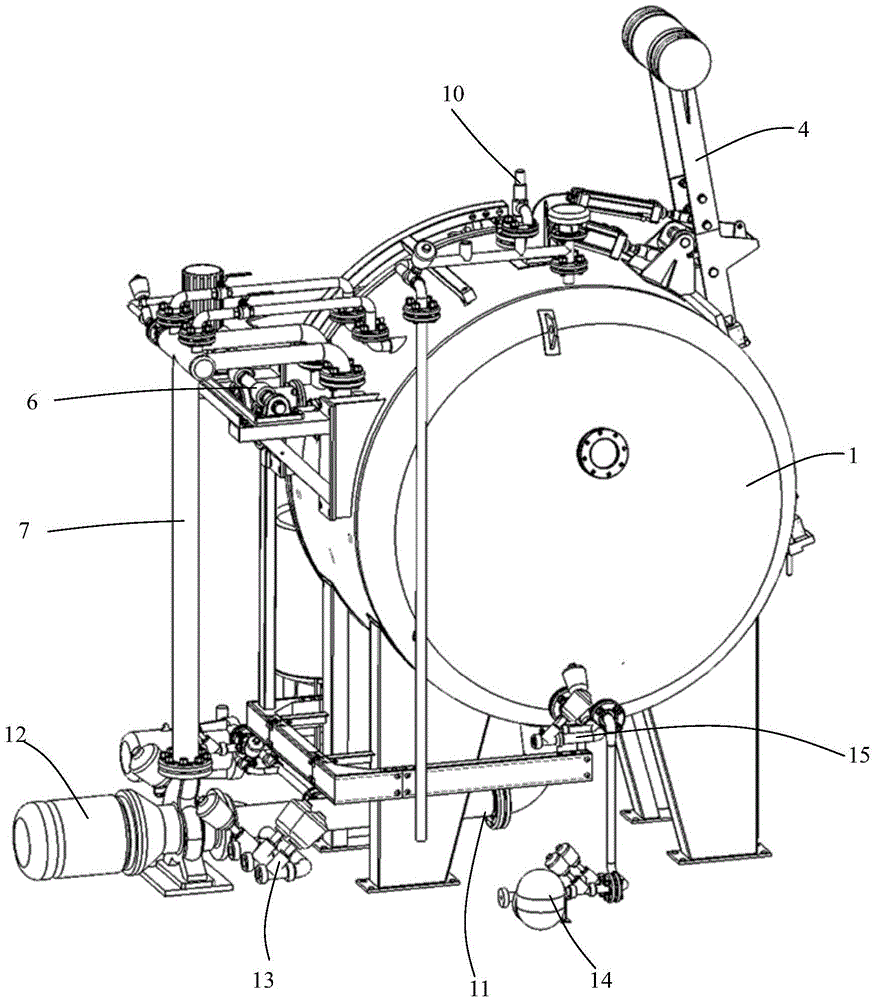

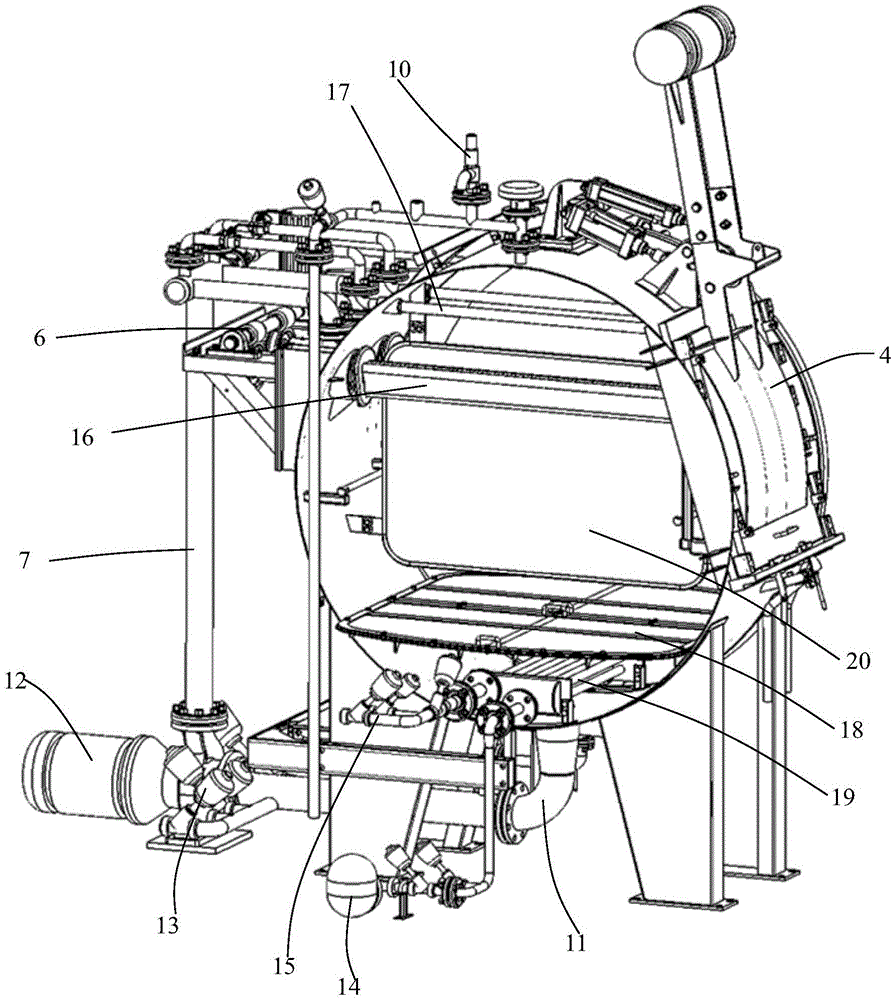

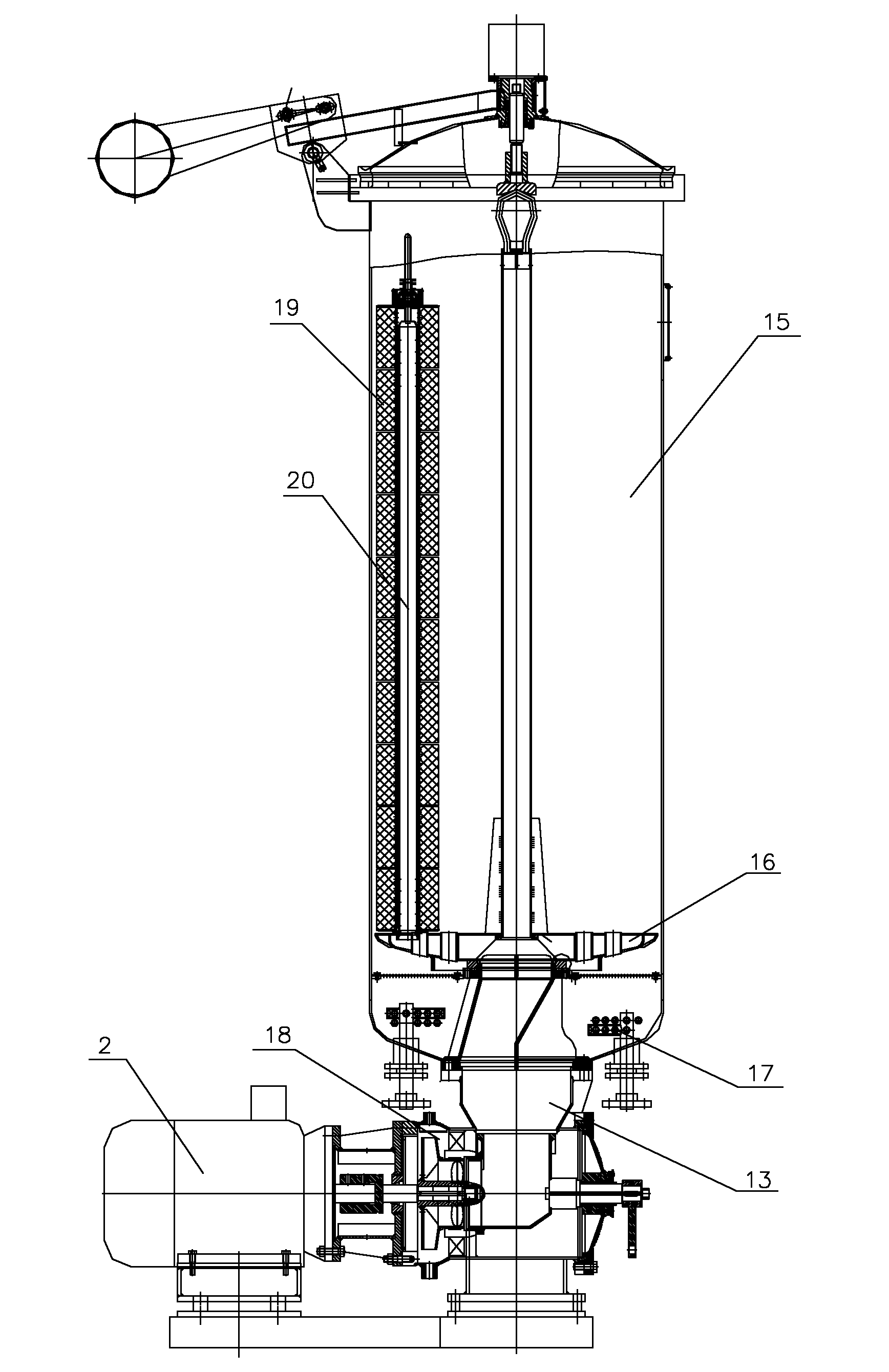

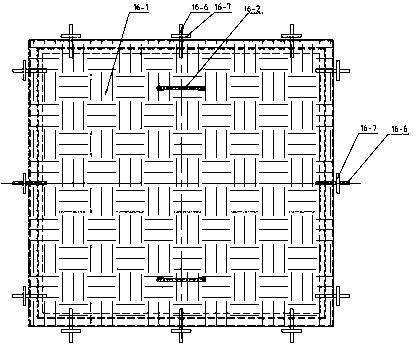

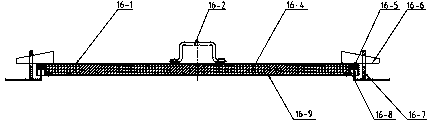

Low-bath-ratio high-temperature pulse type jet dyeing machine

ActiveCN105603654AControl flowControl pressureTextile treatment containersTextile treatment machine arrangementsSocial benefitsJet flow

The invention provides a low-bath-ratio high-temperature pulse type jet dyeing machine. The jet dyeing machine mainly comprises a main cylinder, an auxiliary cylinder, a liquid adding pump, a cylinder cover assembly, an auxiliary cylinder liquid return pipe, a movement system, a dye flow dividing pipe, a liquid level meter, a pressure meter, a decompression valve, a main cylinder liquid return pipe, a main pump, an adding valve set, a steam trap assembly, a coiled pipe steam inlet, a star-shaped spraying pipe, a sprinkler spraying pipe, a filter screen, a heat exchanger, a partition board, a spraying pipe support, a center pipe, a transmission shaft and other parts. According to the pulse type high-temperature jet dyeing machine, spray dyeing is conducted on fabric from the upper direction and the lower direction by means of the star-shaped spraying pipe and the sprinkler spraying pipe, and dyeing uniformity can be effectively improved. A central control system controls the jet flow and pressure of dye liquid according to properties of the fabric and fabric winding thickness, and accordingly dyeing quality can be effectively controlled. The jet dyeing machine can obviously save auxiliaries and dye, reduces waste liquid discharge, and has extremely remarkable economic and social benefits.

Owner:高勋绿色智能装备(广州)有限公司

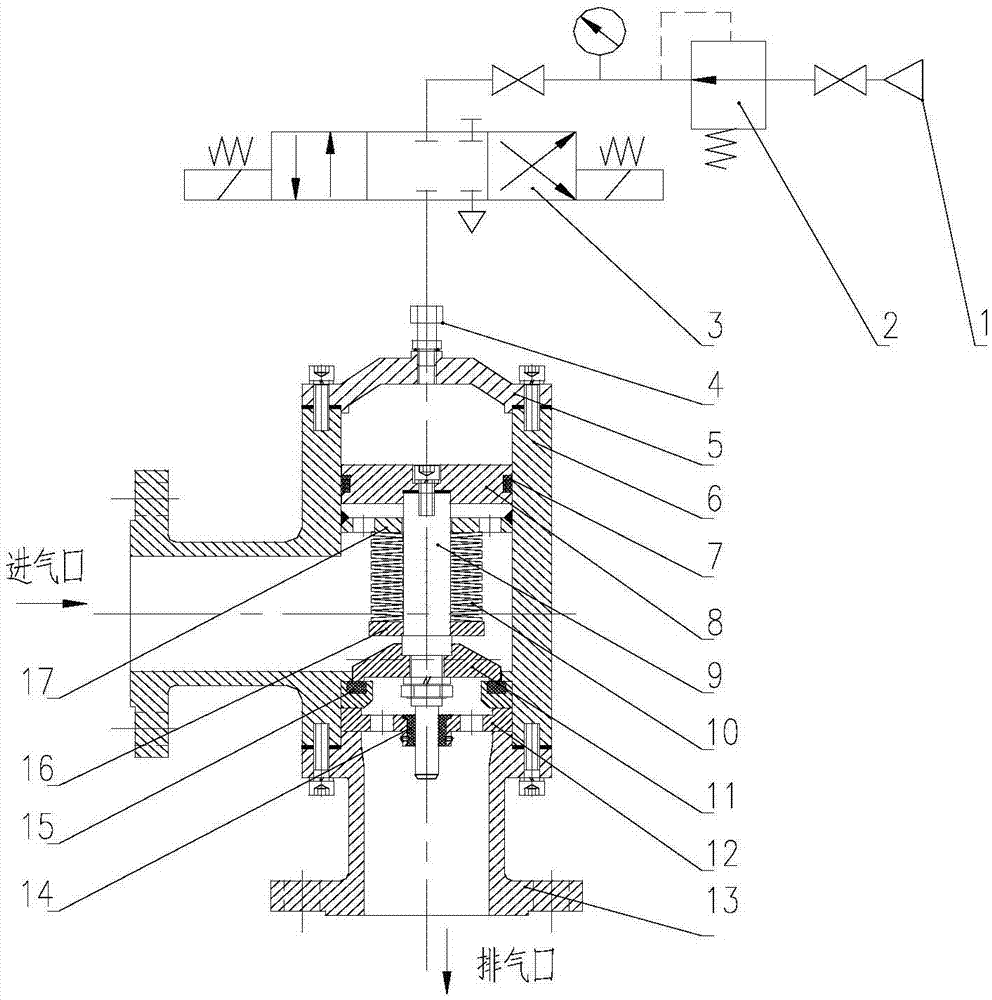

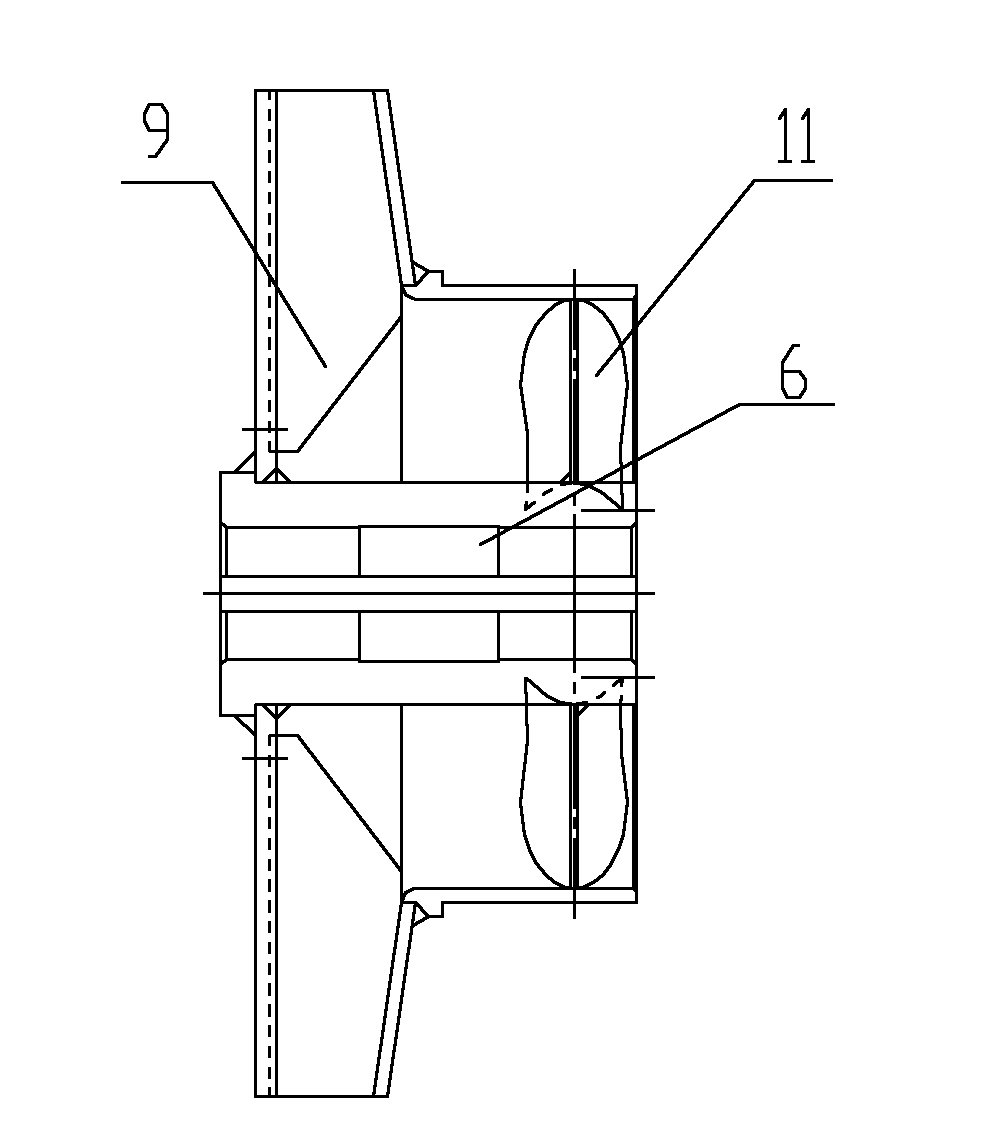

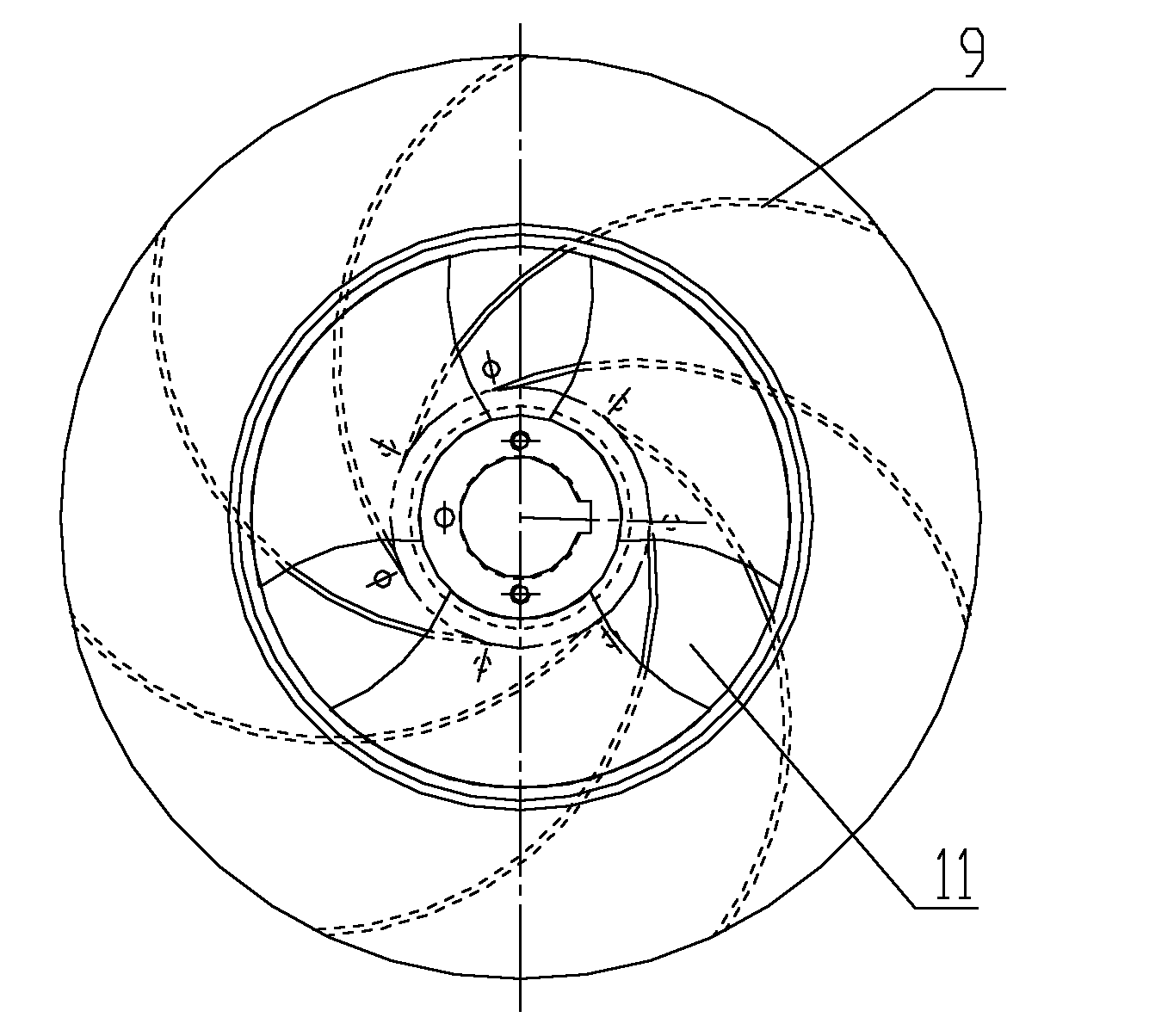

Separation type gas-control high-temperature pulse valve

InactiveCN105443770AReduce the impactSimple structureOperating means/releasing devices for valvesDispersed particle filtrationGas pipelineTemperature pulse

The invention provides a separation type gas-control high-temperature pulse valve which is composed of a solenoid electric valve and a pulse valve body. The pulse valve body comprises a valve body, a piston assembly and a sealing assembly. The valve body is provided with an injected gas inlet, an injected gas outlet and a control port. The gas control port is connected with the solenoid electric valve through a gas pipeline. The injected gas outlet is opposite to the gas control port. The piston assembly is located in the valve body and comprises a piston rod. One end of the piston rod is connected with a piston, and the other end of the piston rod is connected with one side of a gland. The sealing assembly is located in the valve body and comprises a sealing ring. The piston is located between the gas control port and a supporting plate. The piston rod penetrates the supporting plate. The other side of the gland is the injected gas outlet. The sealing ring seals the portion between the gland and the injected gas outlet. The injected gas inlet is located between the gland and the supporting plate. According to the separation type gas-control high-temperature pulse valve, the spraying and blowing work is achieved by alternately attaching the contact face of the gland to the contact face of the sealing ring and separating the contact face of the gland from the contact face of the sealing ring, the process is controlled through reciprocating movement of the piston assembly, the influence on the solenoid electric valve by heat conduction is weakened, and the reliability of work is improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

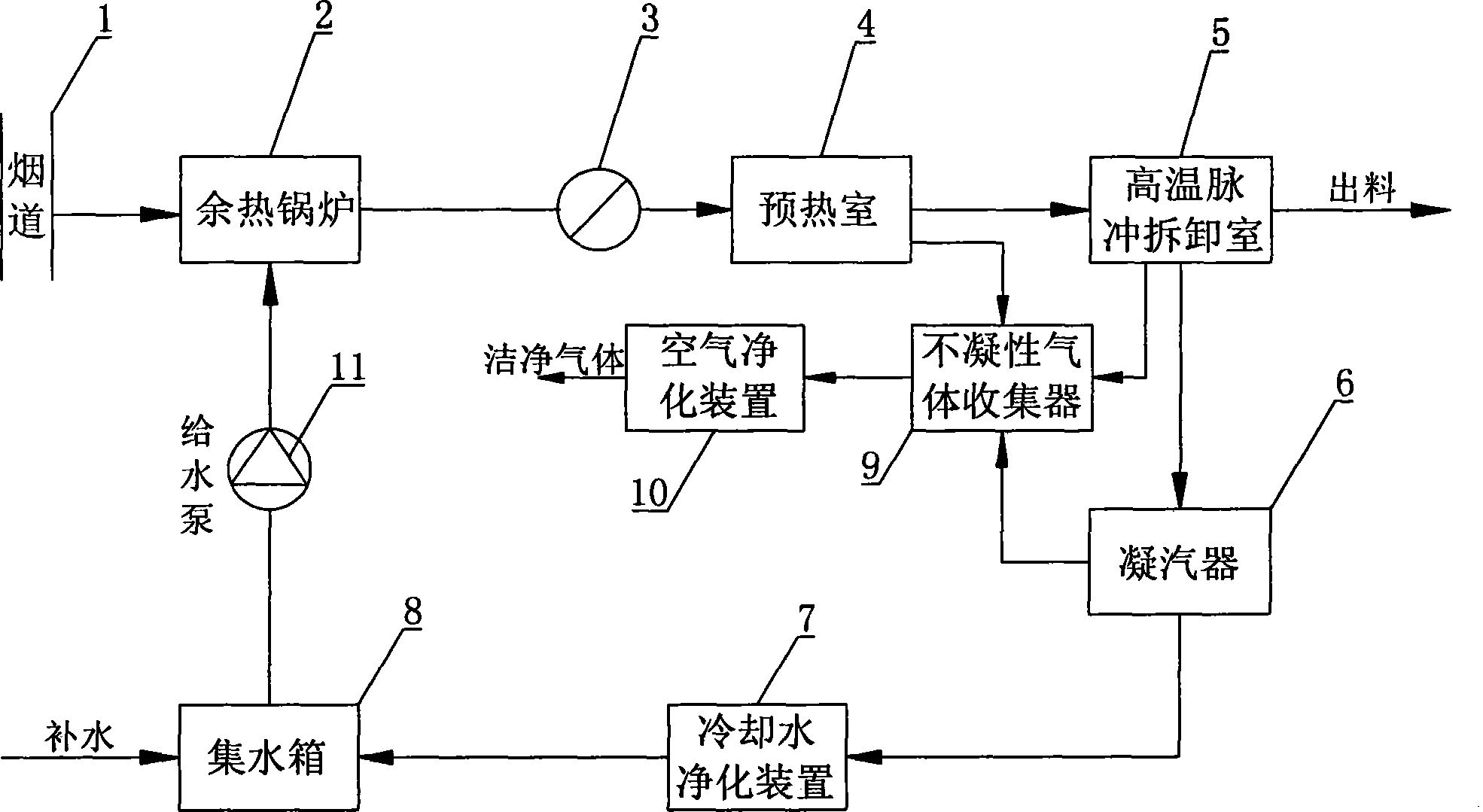

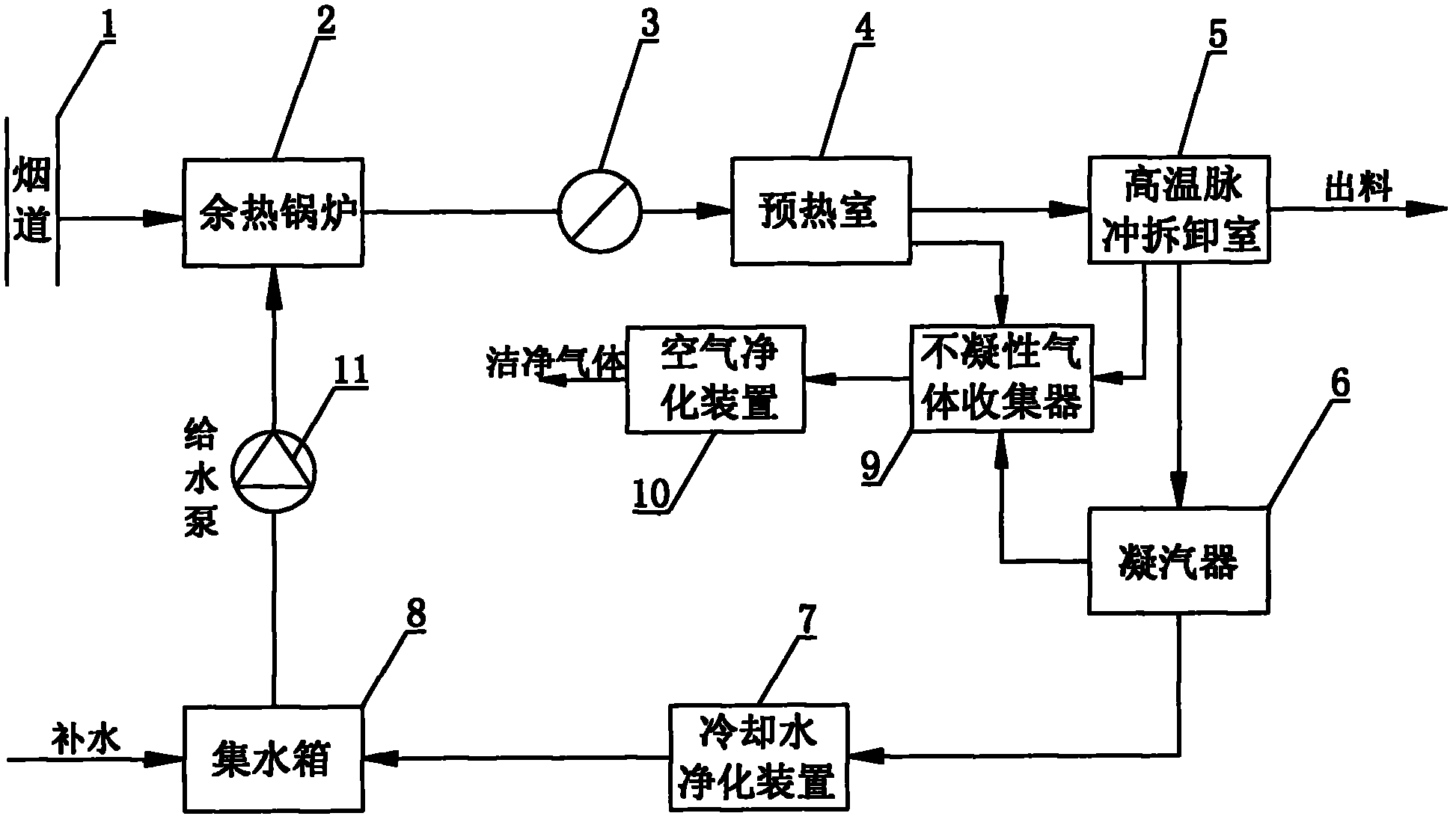

Method for automatic disassembly and recovery of waste printed circuit boards by using industrial waste heat

InactiveCN102284471AEasy to separateEffective sorting and recyclingSolid waste disposalElectronic waste recyclingLower gradeProduct gas

The invention discloses a method for automatically dismantling and recovering electronic components on waste printed circuit boards by using industrial waste heat. It uses industrial waste heat to prepare low-grade superheated steam through the waste heat boiler, and then uses the superheated steam as the heat source and power to realize the automatic disassembly of waste printed circuit board electronic components through high-temperature pulse injection of superheated steam; the superheated steam after work is condensed After the device is properly treated, it is returned to the waste heat boiler for recycling; the gas generated during operation is collected by a non-condensable gas collection device, and then directly discharged after proper treatment. The invention proposes to use the superheated steam prepared by industrial waste heat as the heat source and power to realize the automatic disassembly and recovery of waste printed circuit board electronic components, and at the same time realize the resource utilization of industrial waste heat and waste printed circuit boards, which conforms to the principle of green, low-carbon and environmental protection, and has the advantages of Significant socio-economic and environmental benefits.

Owner:SOUTHWEAT UNIV OF SCI & TECH

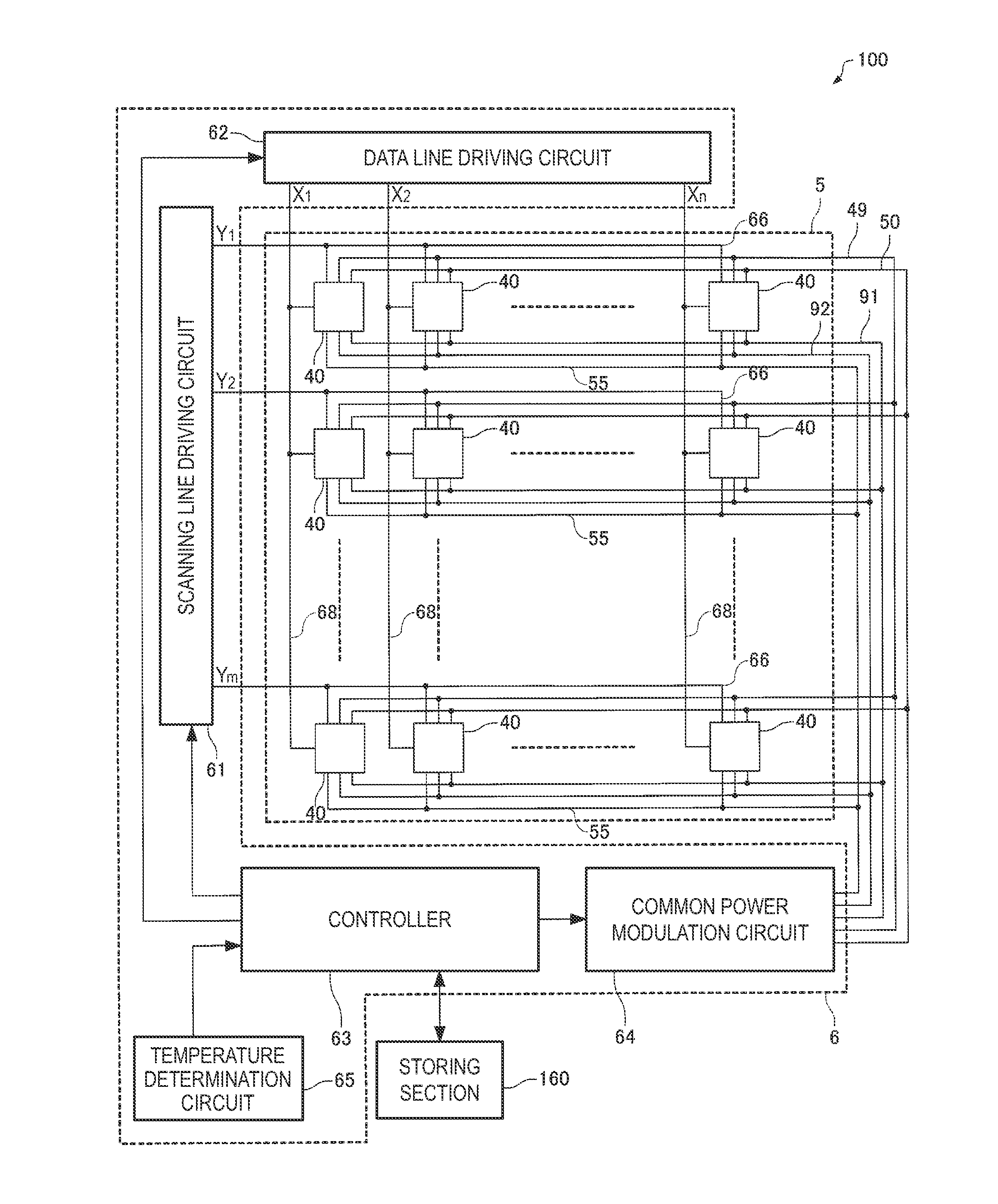

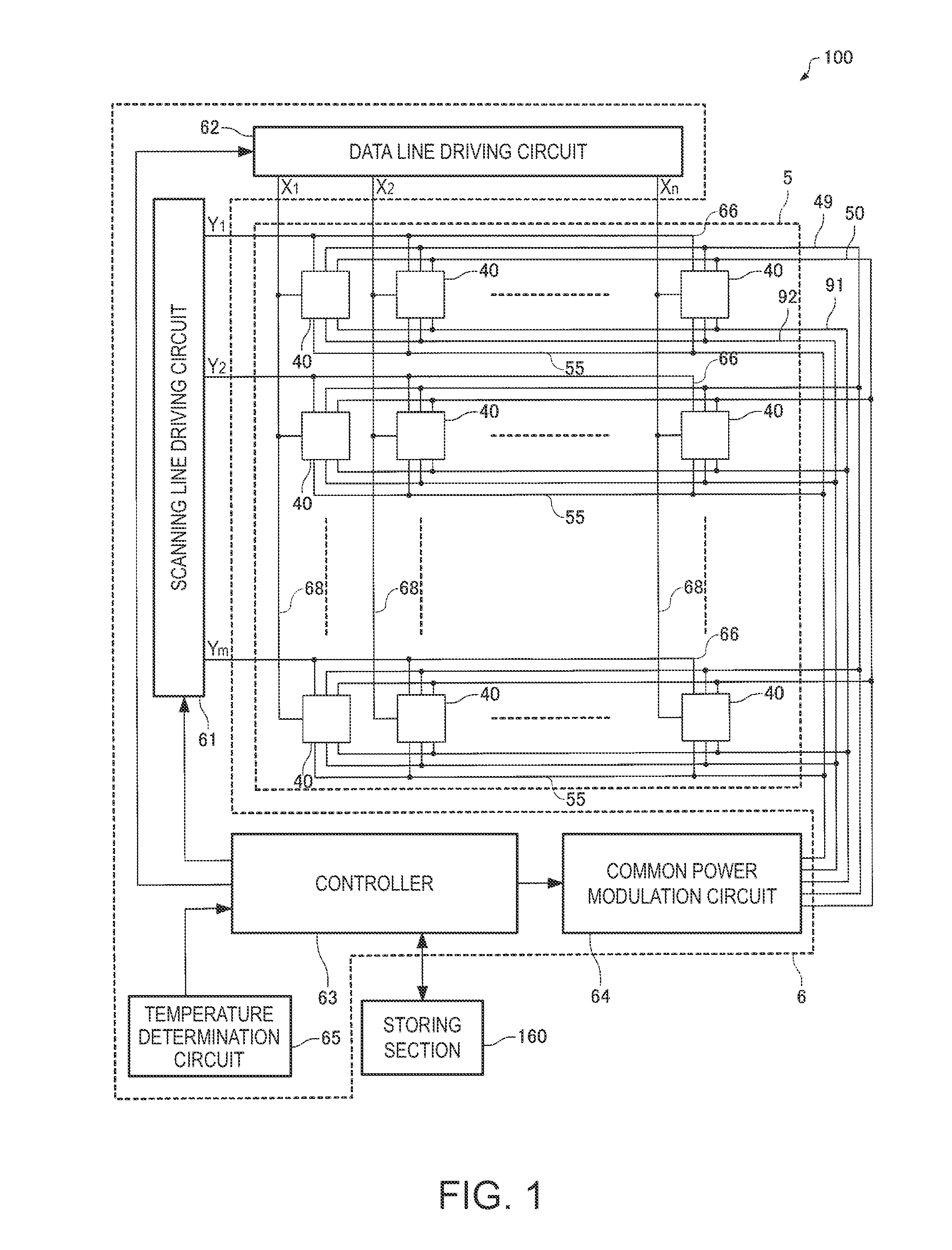

Driving Method of Electrophoretic Display Device, Electrophoretic Display Device and Electronic Apparatus

InactiveUS20120139891A1Suppress flickerCathode-ray tube indicatorsInput/output processes for data processingElectrophoresisDisplay device

An image rewriting process of rewriting an image displayed by applying any one of a first electric potential or a second electric potential to each of a plurality of pixel electrodes and by moving electrophoretic particles by an electric field generated between the pixel electrodes and a common electrode includes a temperature determining process, and includes a first pulse application process which uses the driving pulse signal with the pulse width being a first width, a low temperature pulse application process, and a second pulse application process which uses the driving pulse signal with the pulse width being a second width, performed at the end. The low temperature pulse application process uses the driving pulse signal with the pulse width being the first width.

Owner:SEIKO EPSON CORP

High-temperature pulse flow yarn dyeing machine with ultra low bath ratio and control method thereof

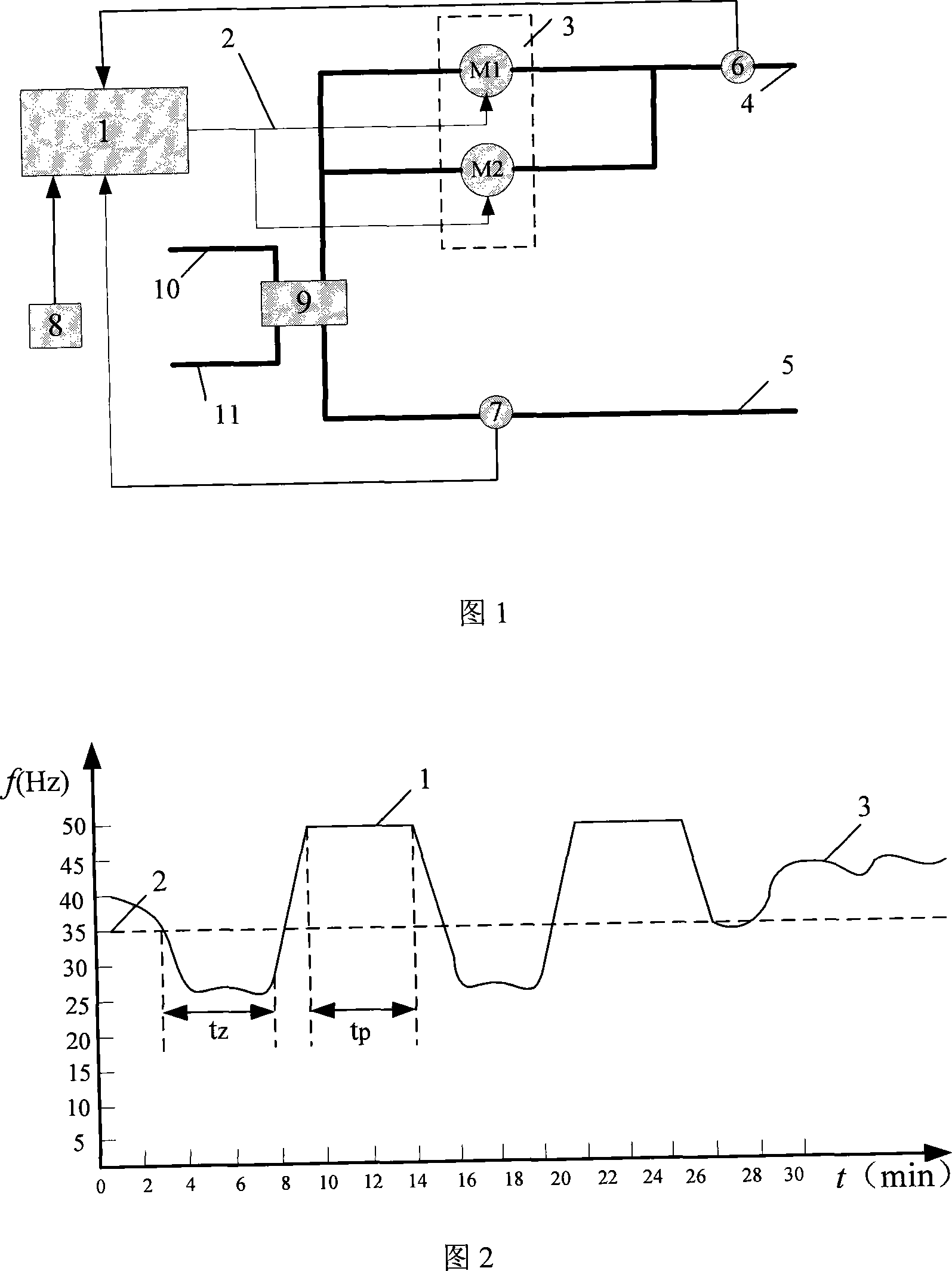

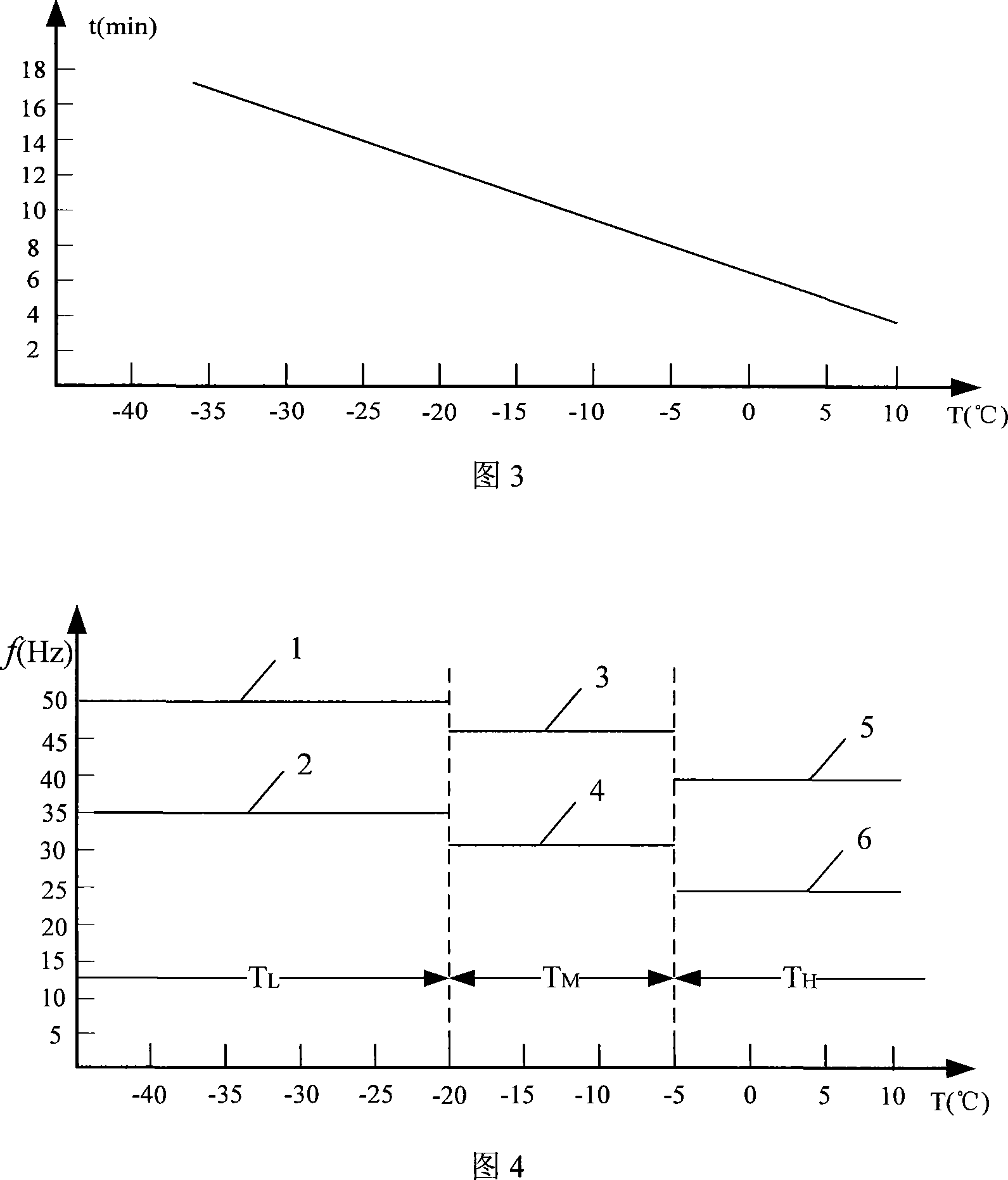

InactiveCN102140743AIncrease exchange frequencyQuick responseTextile treatment machine arrangementsTextile/flexible product manufactureYarnThree level

The invention discloses a high-temperature pulse flow yarn dyeing machine with an ultra low bath ratio and a control method thereof. The yarn dyeing machine comprises a dye vat, a creel, a heat exchange coiler, an adaptive water level monitoring device, a variable frequency motor, a three-level vane pump with an ultra low bath ratio and a dyeing computer. The method comprises the following steps: a time pulse generator in the dyeing computer gives out pulse flow data to a variable frequency motor controller to control the revolving rate of the variable frequency motor according to the set technological process; the variable frequency motor drives the three-level vane pump with an ultra low bath ratio to output dyeing flow in pulse flow type fluctuation; the output dyeing flow carries out adaptive adjustment according to an ideal reference model in the dyeing computer; the adaptive water level monitoring device gives out water-level reference identification information; and according to the information, a water level regulator and the variable frequency motor controller respectively regulate the water level and the variable frequency motor to reach the water level and the pulse flow required by the set technological process. The pulse flow dyeing technology in the invention conforms to the requirement of the minimum consumption of four factors, namely, water, energy, accessory ingredient and time for economical dyeing of ecological environment protection.

Owner:高勋绿色智能装备(广州)有限公司

Winter-heating water circulating pump energy-saving control method

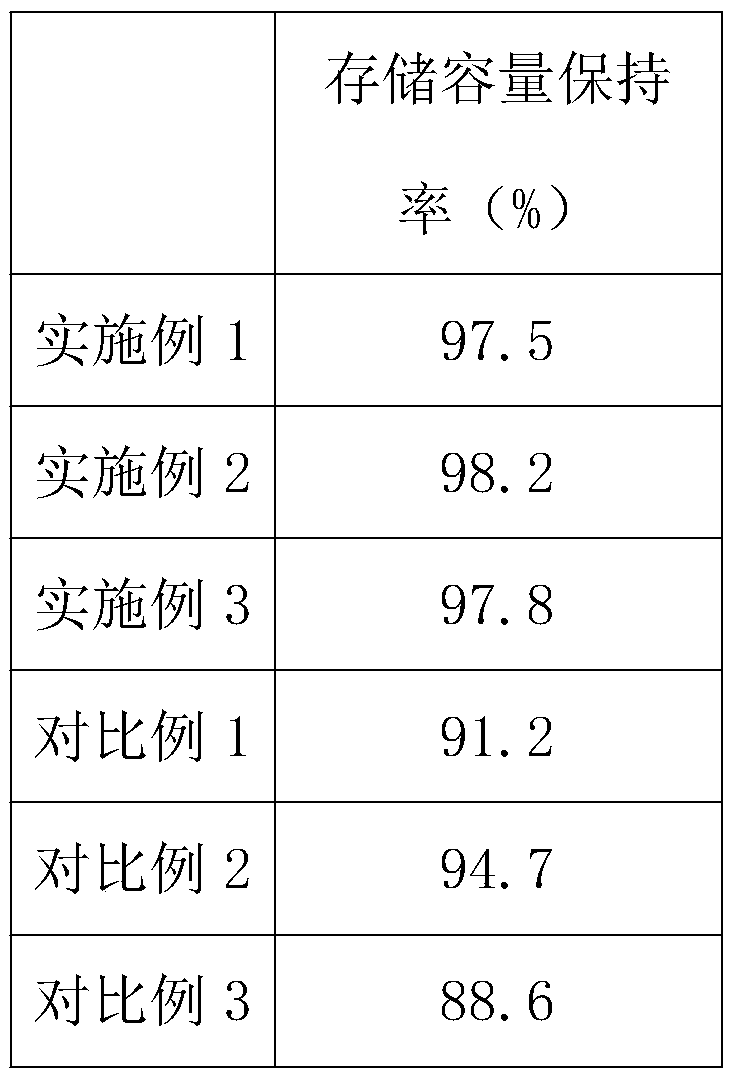

InactiveCN101070974APrevent freezing and crackingLarge space for energy savingLighting and heating apparatusSpace heating and ventilation detailsFrost crackAtmospheric temperature

The invention belongs to the field of electronics and control technology, specifically relates to a control method for saving energy in water circulating pump in winter. Its specific steps are that preinstall turning frequency, turning delay, the minimum and maximum limit of different temperatures pulse frequency. According to the range of temperature between outlet pipe and return pipe the energy-saving control cabinet adopts the PID algorithm to adjust pump operation frequency, when the pump operating frequency is lower than the turning frequency and the break over delay, and then pump operation frequency will be adjusted to the temperature maximum pulse frequency, and maintain a maximum delay time; pump operation frequency is higher than turning frequency and then adjusting by PID regulator; If the pump operating frequency below the turning frequency after adjustment, returning to the steps at the beginning of re-operation; if operation frequency higher than the break over frequency, entered the PID regulator. The invention adopts pulse working to prevent the water pump electricity motor works in the lower frequency limit for long hours, which cause the pipeline freezing and frost cracking because the end of pipeline can't bear under lower temperature long time and couldn't achieve consumer need. To the PWM technology application, the heating temperature is able to adjust heating temperature real-time in accordance with outdoor free air temperature.

Owner:上海联达节能科技股份有限公司

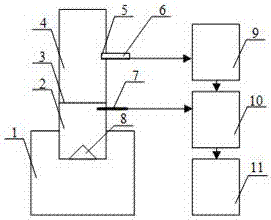

Long-term storage method of lithium ion battery

ActiveCN110534829AImprove solubilityFully activatedElectrolyte/reactants regenerationSecondary cells charging/dischargingEngineeringBiological activation

The invention provides a long-term storage method of a lithium ion battery. The lithium ion battery can be stored for a long time by using the storage method provided by the invention, and the batterycapacity retention rate is high after storage. The storage method provided by the invention comprises the steps that the battery is discharged at predetermined intervals; high-temperature pulse current activation is carried out near the discharge cut-off voltage, and low-temperature large-current activation is carried out within a predetermined voltage range; and constant voltage activation is carried out near the charge cut-off voltage. According to the invention, during the activation process, different activation steps are carried out with different temperature ranges, which can maximize the effect of activation and improve the capacity retention rate of the battery.

Owner:泰州纳新新能源科技有限公司

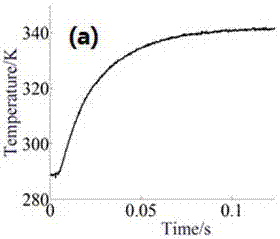

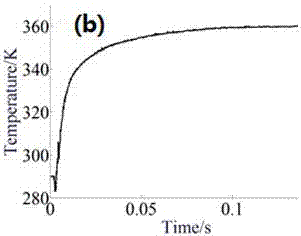

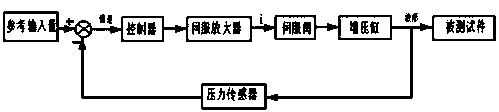

System and method for fast response thermocouple dynamic characteristic calibration based on miniature detonation field

ActiveCN107101749AFast Dynamic CalibrationFast Response Dynamic CalibrationThermometer testing/calibrationDetonationData acquisition

The present invention discloses a system and method for fast response thermocouple dynamic characteristic calibration based on a miniature detonation field. A lot of gas is generated at the moment of self-reaction substance thermal decomposition, a diaphragm is burst to generate high-temperature and high-pressure detonation air flow as a basis, and high-slope temperature pulse signals with a certain width are provided as a fast response thermocouple calibration excitation source to realize dynamic characteristic calibration. The experiment system corresponding to the method comprises a heating and temperature control system, a fire blast field, a diaphragm, a fire blast experimental section, a thermocouple to be calibrated, a thermocouple fixed support, a pressure sensor, a test sample, an amplification circuit, a data collection card and a computer. The system and method for fast response thermocouple dynamic characteristic calibration based on the miniature detonation field can realize dynamic characteristic calibration of the ten-millisecond grade rapid response thermocouple.

Owner:CHINA JILIANG UNIV

Cerebrospinal fluid evaluation system having thermal flow and flow rate measurement pad using a plurality of control sensors

Owner:NEURO DIAGNOSTIC DEVICES

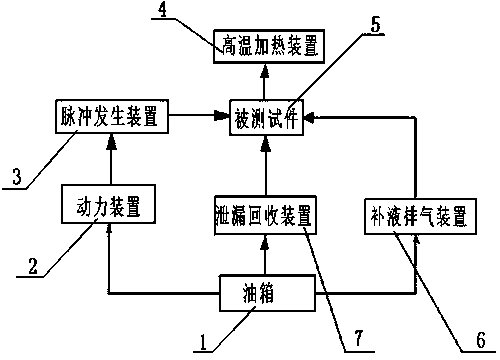

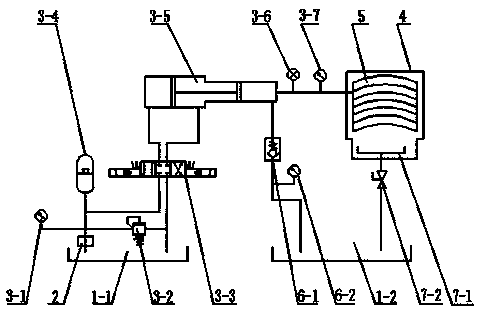

High-temperature pulse test system for hydraulic hose

InactiveCN109030251APrevent regurgitationImprove cleanlinessMaterial strength using repeated/pulsating forcesPulse testEngineering

Owner:HARBIN UNIV OF SCI & TECH

High-temperature resisting and soundproofing anti-skidding door cover for high-temperature pulse bag type dust collector

InactiveCN102908842AIncrease temperatureOvercoming the slippery defectDispersed particle filtrationEngineeringHot Temperature

The invention relates to a high-temperature resisting and soundproofing anti-skidding door cover for a high-temperature pulse bag type dust collector. The high-temperature-resisting and soundproofing anti-skidding door cover comprises a cover plate with a side overturned, and sealing strips arranged around the cover; the cover plate is formed by anti-skidding patterned steel; high-temperature resisting and heat insulating soundproofing cottons are positioned in the cover plate; internal baffle plates are arranged around the high-temperature resisting and heat insulating silencing cottons, and form a sealing groove together with the overturned side of the cover plate; a high-temperature resisting sealing strip is arranged in the sealing groove; and high-temperature resisting and soundproofing microvoid plates are arranged at the bottoms of the high-temperature resisting and heat insulating soundproofing cottons. According to the high-temperature resisting and soundproofing anti-skidding door cover, the cover plate is formed by the anti-skidding patterned steel, so that the shortcoming that the upper part of the cover plate is slippery in rain and snowfall weather can be overcome; the high-temperature resisting and heat insulating soundproofing cottons are positioned in the cover plate, so that the cover plate can be effectively prevented from meeting excessively high temperature; and the high-temperature resisting and soundproofing microvoid plates are also arranged at the bottoms of the high-temperature resisting and heat insulating soundproofing cottons, thus the shortcoming that high noise is generated during pulse jetting can be effectively overcome.

Owner:江苏南方机械有限公司

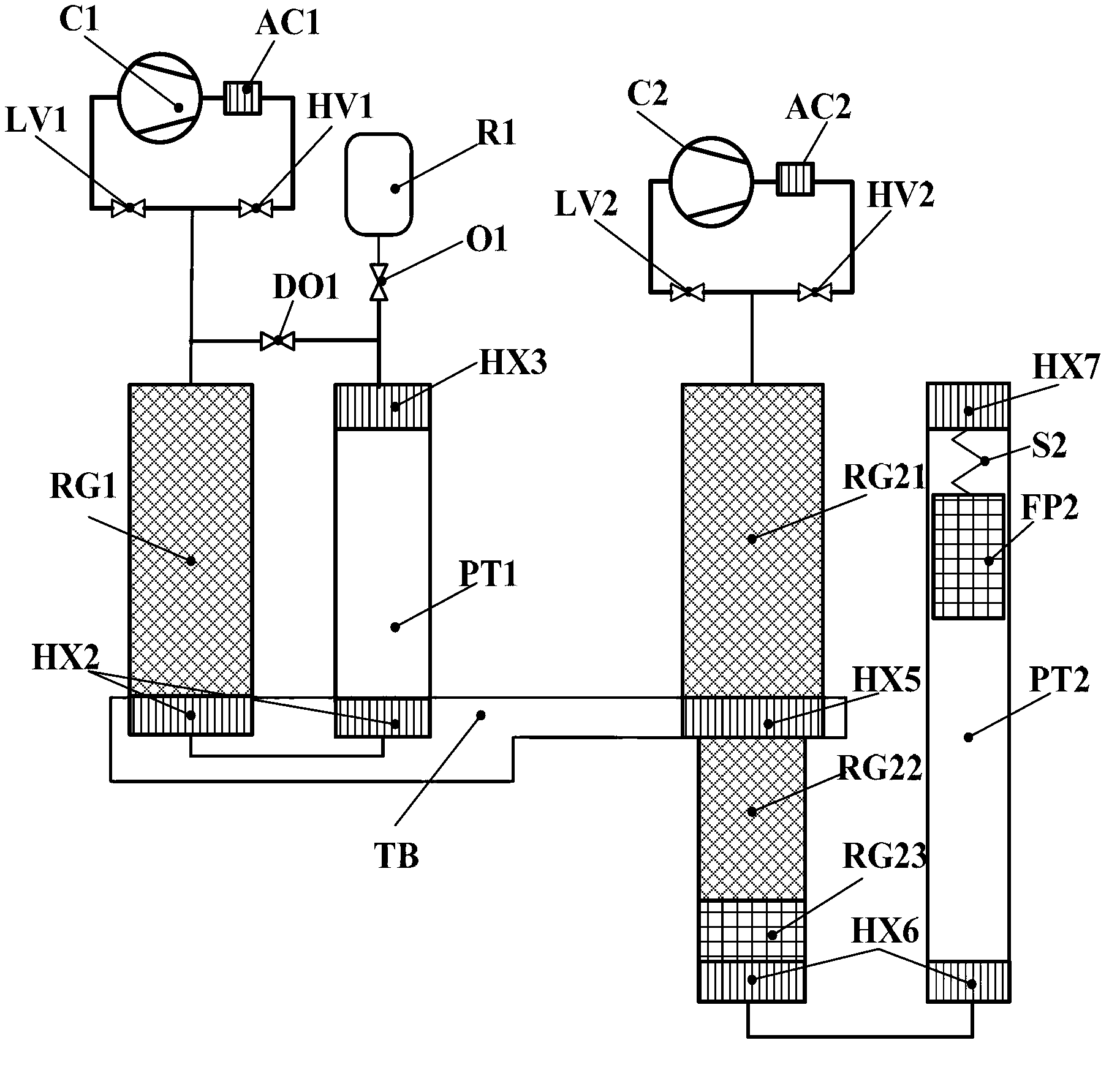

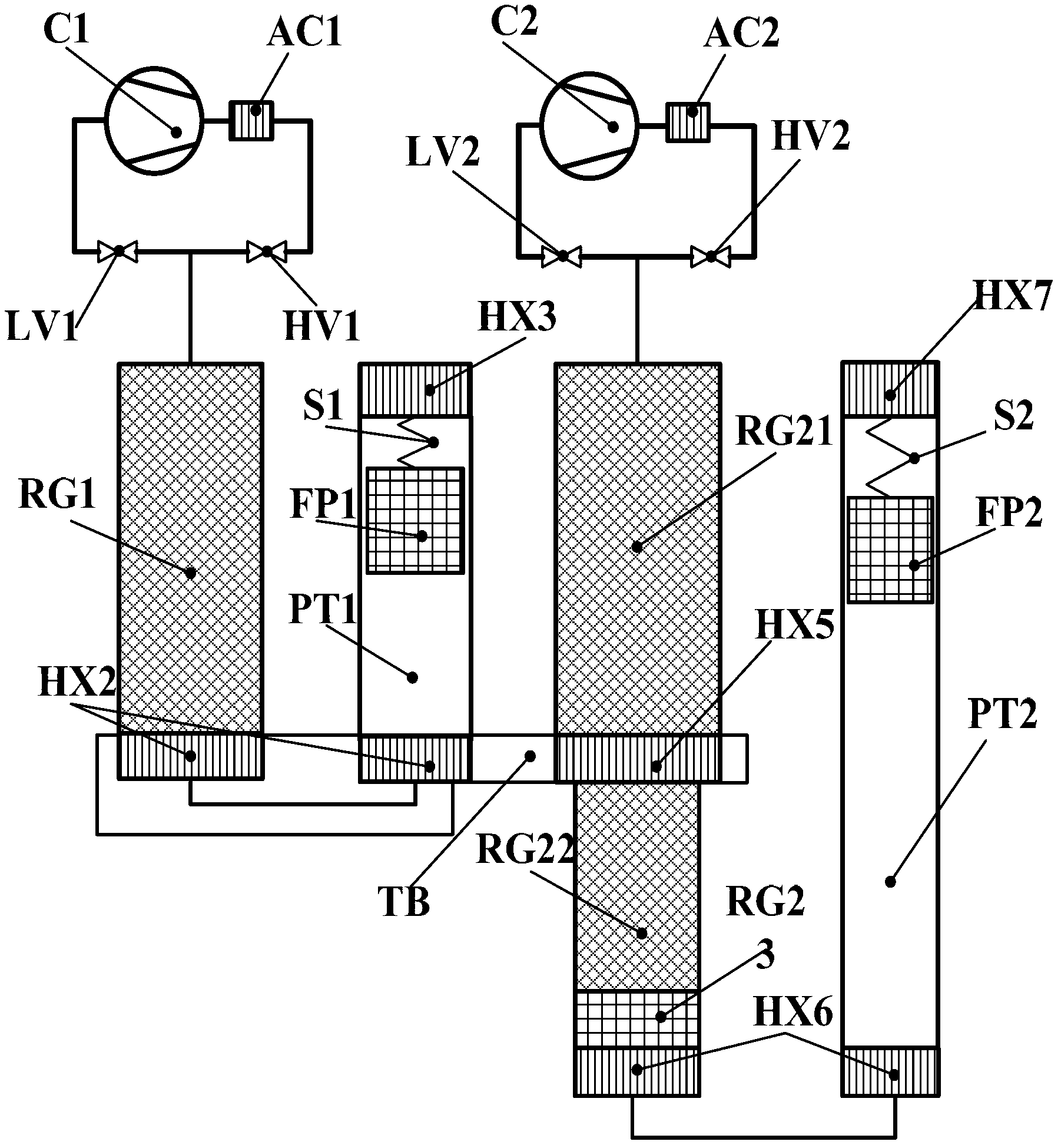

Free-piston pulse tube refrigerator using all-carbon aerogel regenerative filler

ActiveCN103267383AHigh volume specific heat capacityImprove performanceCompression machinesPorosityThermal bridge

The invention discloses a free-piston pulse tube refrigerator using all-carbon aerogel regenerative filler. The free-piston pulse tube refrigerator comprises a plurality of pulse tube refrigerator units coupled through a thermal bridge. At least one of the pulse tube refrigerator tubes comprises a compressor, a regenerator, a cold-end heat exchanger, a pulse tube and a pulse tube hot-end heat exchanger, wherein the parts are connected in sequence, a free piston system comprising a spring and a free piston is disposed in the pulse tube, the free piston is connected with the pulse tube hot-end heat exchanger through the spring, and the free piston is made of an aerogel column which is in hermetic fit with the pulse tube. The low temperature end of the regenerator of the lowermost-temperature pulse tube refrigerator unit among the pulse tube refrigerator units is filled with an all-carbon aerogel layer. The all-carbon aerogel layers more than 95% in porosity and high in adsorptive capacity are filled in the regenerators of the pulse tube refrigerator, the free pistons of the pule tube refrigerator are made of aerogel material, and accordingly efficient cryogenic refrigeration is achieved.

Owner:ZHEJIANG UNIV

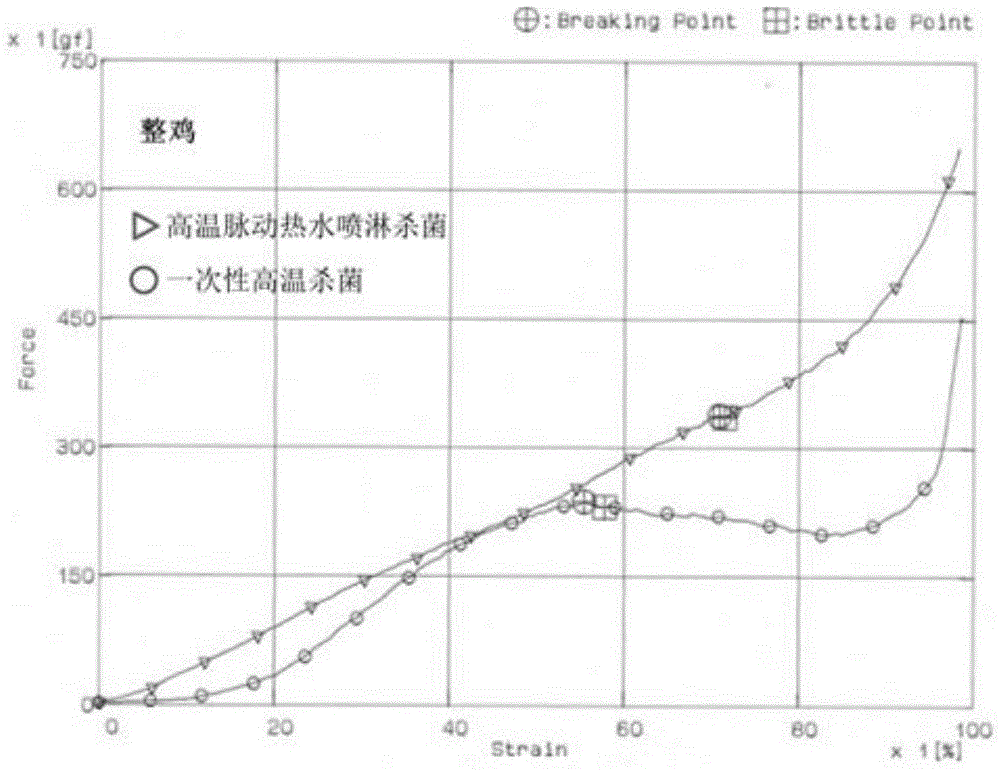

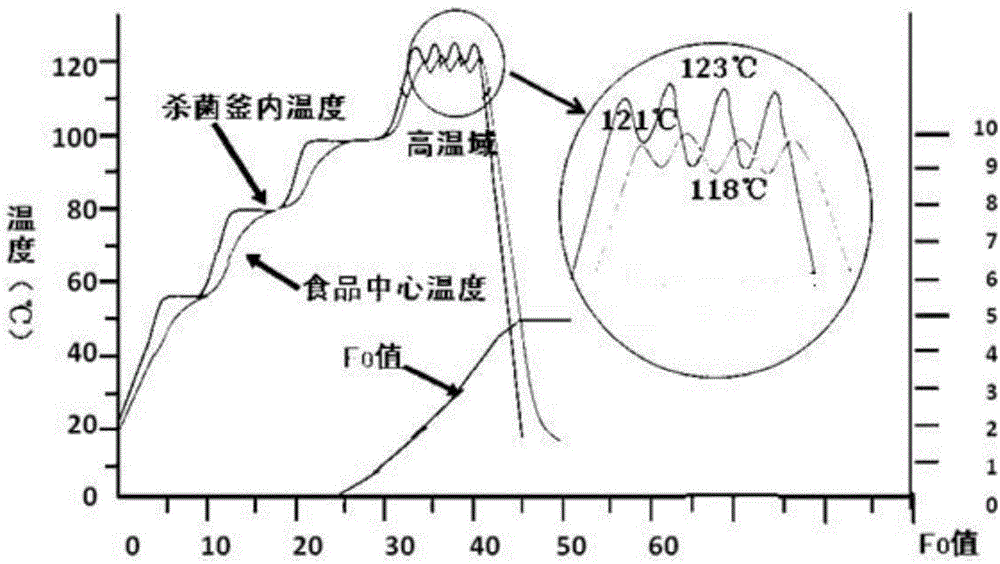

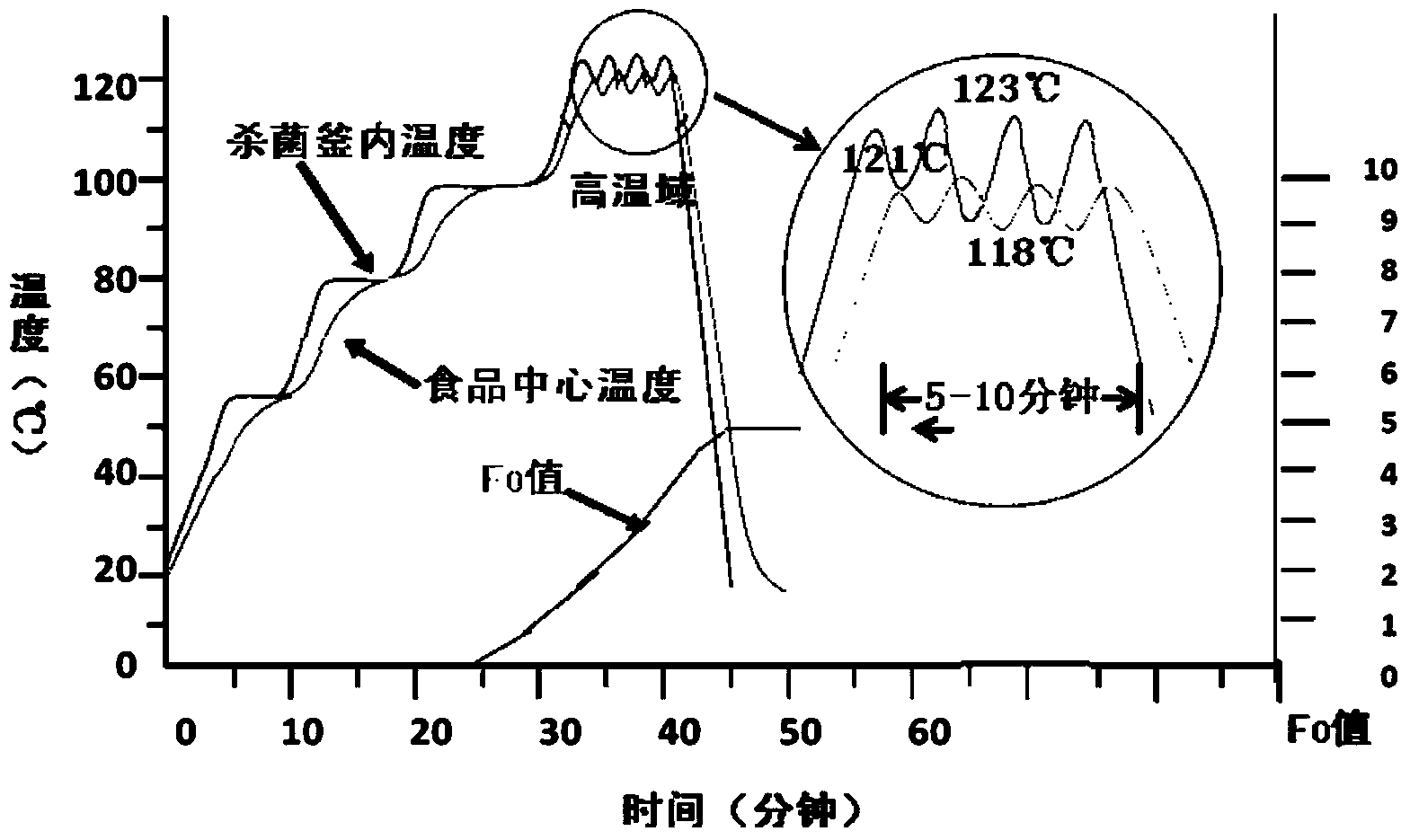

High-temperature pulsed hot water spraying sterilizing method

ActiveCN104146317AThe shape and nutritional composition do not changeFast heating and coolingFood preservationEngineeringPressure balance

The invention provides a pulsed temperature variable sterilizing manner. According to a F0 sterilization technology theory and a principle that microorganisms are easily and rapidly killed due to rapid temperature fluctuation in a high-temperature state and based on a hot water spraying system and multi-grade temperature rise of a temperature-pressure balance system, hot water is adjusted by a steam valve with an opening degree with free and micro adjustment and a heat exchanger when the central temperature of a food reaches a relatively high temperature region, rapid pulsed temperature variation in a hot water spraying device kettle is accurately controlled, the temperature is continuously varied for many times to form a pulsed temperature variable curve, and microorganisms are subjected to cyclical rapid instant temperature variation in a high-temperature region so that the aim of rapidly killing microorganisms is achieved.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

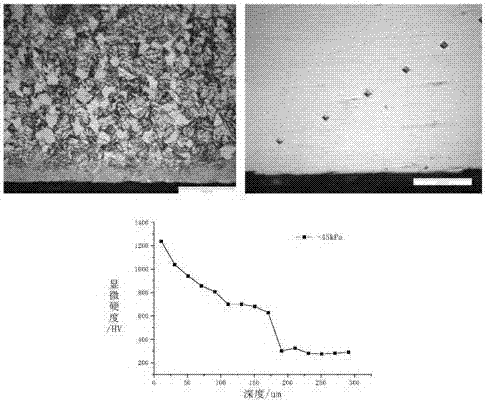

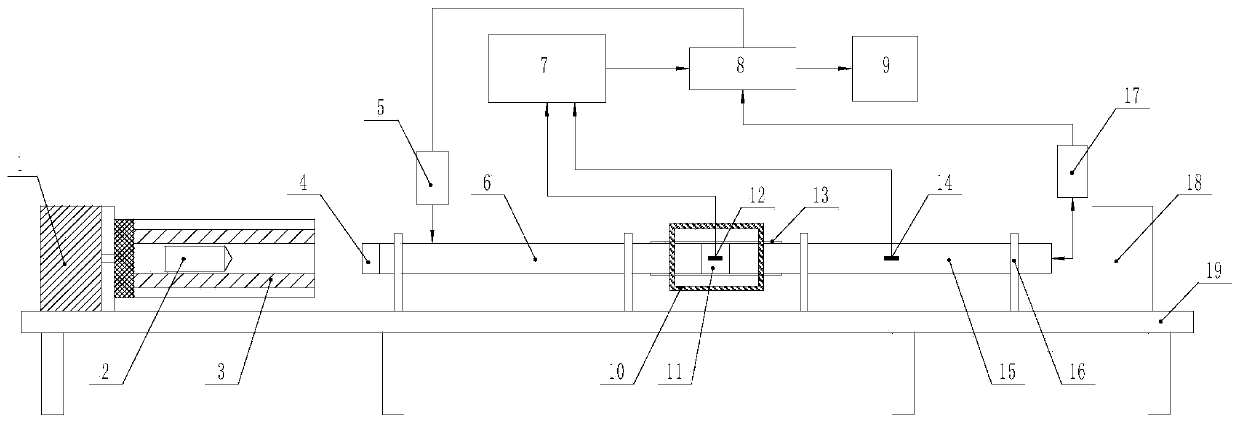

Dual-pulse quick nitriding method and device based on induction heating

PendingCN106868445AHigh vibration frequencyIncrease vibration amplitudeSolid state diffusion coatingControl systemDual pulse

The invention discloses a dual-pulse quick nitriding method and device based on induction heating. A workpiece in a vacuum tube is subjected to quick heating and nitriding through a high-frequency power supply; the surface temperature of the workpiece and the pressure of nitriding gas in the vacuum tube are monitored through an infrared temperature detector and a pressure sensor; and a control system is used for controlling the workpiece to make pulse cycle within the set temperature range or be stabilized at the set temperature through a temperature signal, and controlling the pressure in the tube to present rectangular pulse change through a pressure signal. The dual-pulse quick nitriding method and device based on induction heating have the advantages that temperature pulses improve the vibration frequency and amplitude of surface atoms, pressure pulses improve the quantity of active nitrogen atoms in media, nitriding of nitrogen atoms is accelerated finally on the condition of dual pulses, and quick nitriding of metal is achieved.

Owner:GUIZHOU NORMAL UNIVERSITY

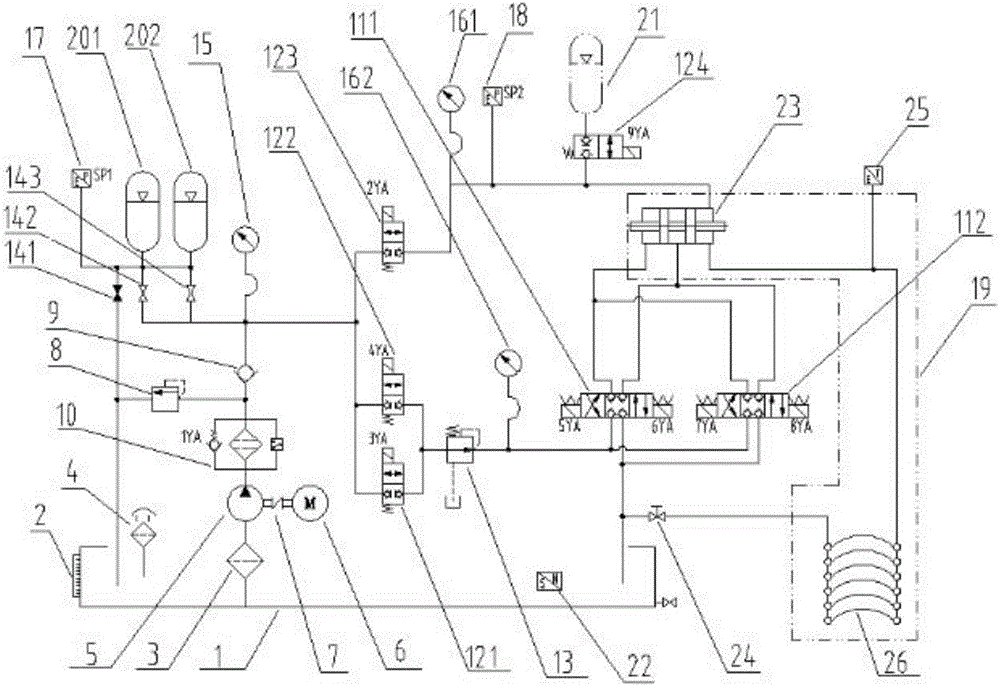

Comprehensive testing system for high-temperature pulse of steering power hose of motor vehicle

ActiveCN105716963AAvoid a series of problems caused by direct chargingSave energyMaterial strength using tensile/compressive forcesCombined testFuel tank

The invention discloses a comprehensive testing system for high-temperature pulse of a steering power hose of a motor vehicle, which is high in integration level, adjustable in pressure pulse curve and extremely low in energy consumption. The comprehensive testing system comprises an oil tank and a bracket device arranged at one side of the oil tank, wherein the measured hose is fixed on the bracket device. The comprehensive testing system is characterized by comprising a hydraulic power loop, a control loop and a high-temperature pulse loop. The comprehensive testing system disclosed by the invention has the advantages that on principle selection of the hydraulic control system, an accumulator-pressurizing mode is adopted for pressurizing the measured hose; and compared with the general principle that a motor pump set is directly adopted for pressurizing the measured hose, the energy is greatly saved and the testing cost is effectively reduced.

Owner:中机寰宇认证检验股份有限公司

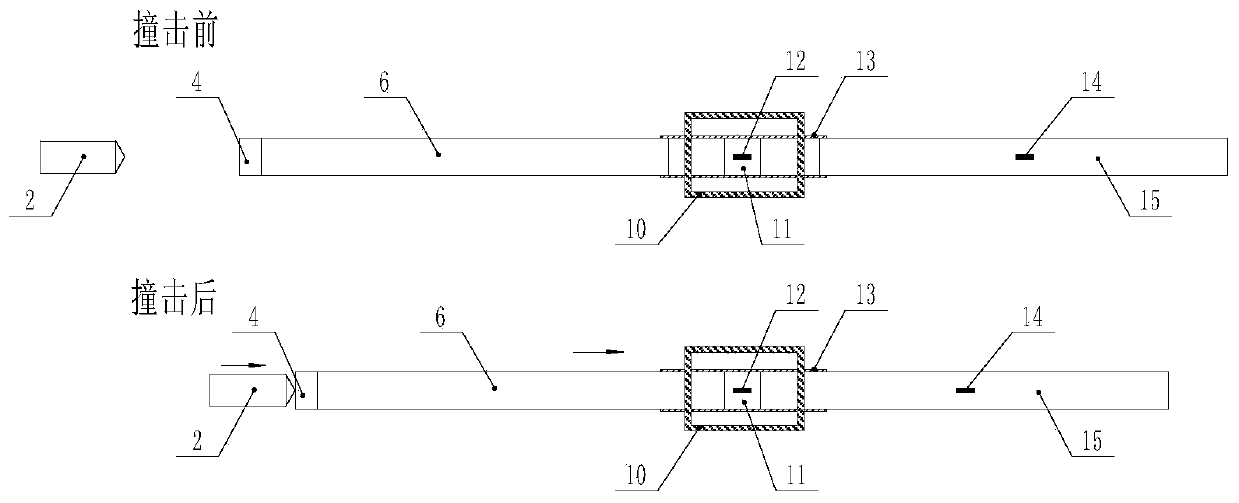

High-temperature pulse dynamic strain calibration device

ActiveCN111551463AImpulse Dynamic Strain ImplementationSolve the speed problemStrength propertiesStrain energyEngineering

The invention discloses a high-temperature pulse dynamic strain calibration device, and belongs to the technical field of strain measurement and testing. The device is mainly composed of a dynamic strain excitation system, a high-temperature environment test system, a calibrated strain measurement system, a laser measurement system and a base support. The projectile body accelerated by the pushingof the compressed gas impacts the incident rod at a high speed to generate the pulse strain as a dynamic strain excitation source, that is, the pulse strain is generated based on a double-Hopkinson separation rod impact mode, so that the pulse strain within a large range and lasting time can be realized. According to the invention, a strain value measured by the laser Doppler measurement system is used as a standard value, and a high-temperature environment test system is combined to adopt a local semi-closed heating scheme, so that strain dynamic calibration at a high temperature is realized. According to the invention, strain measurement calibration is expanded from static characteristics to dynamic characteristics, and strain dynamic calibration in normal-temperature and high-temperature environments can be realized at the same time.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

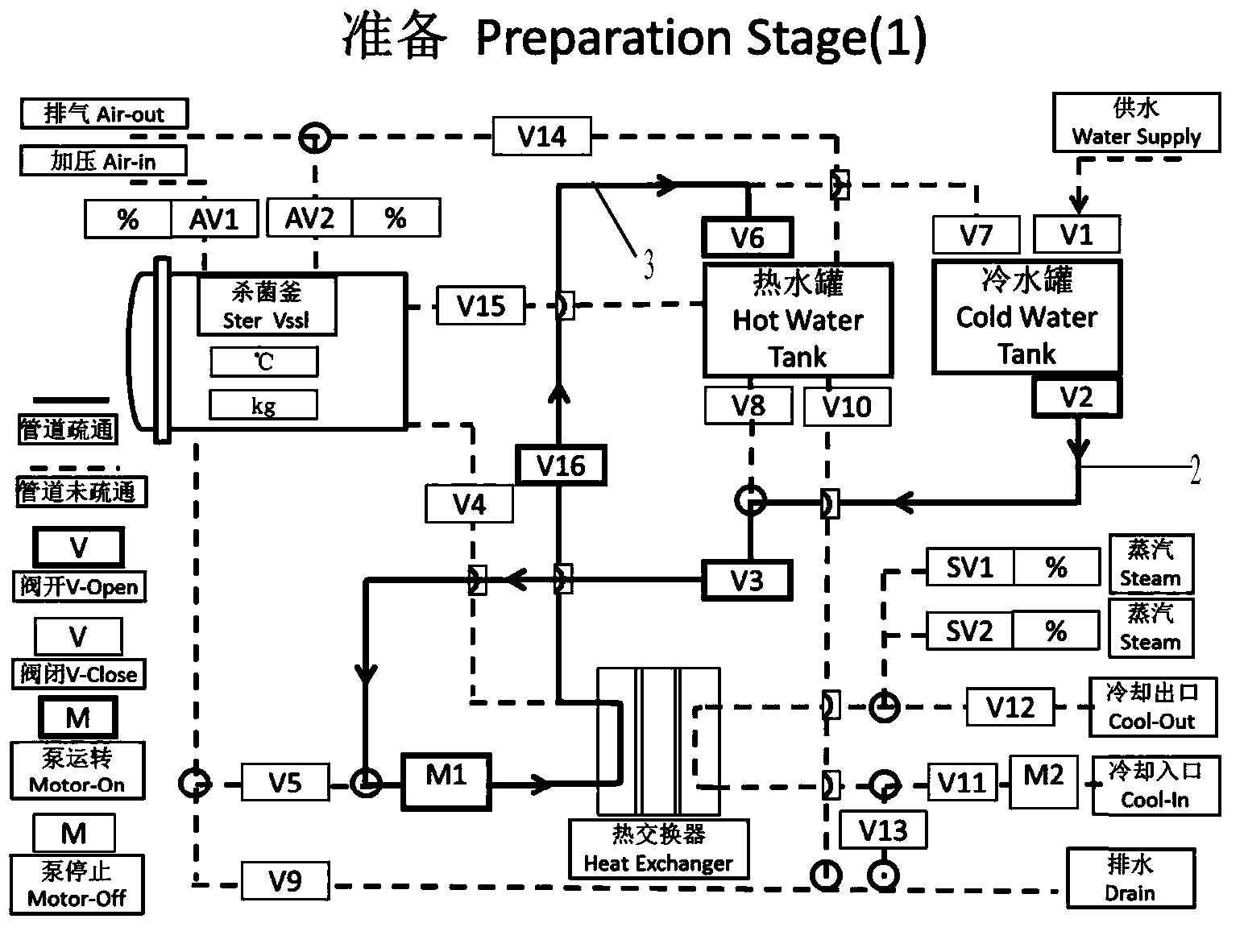

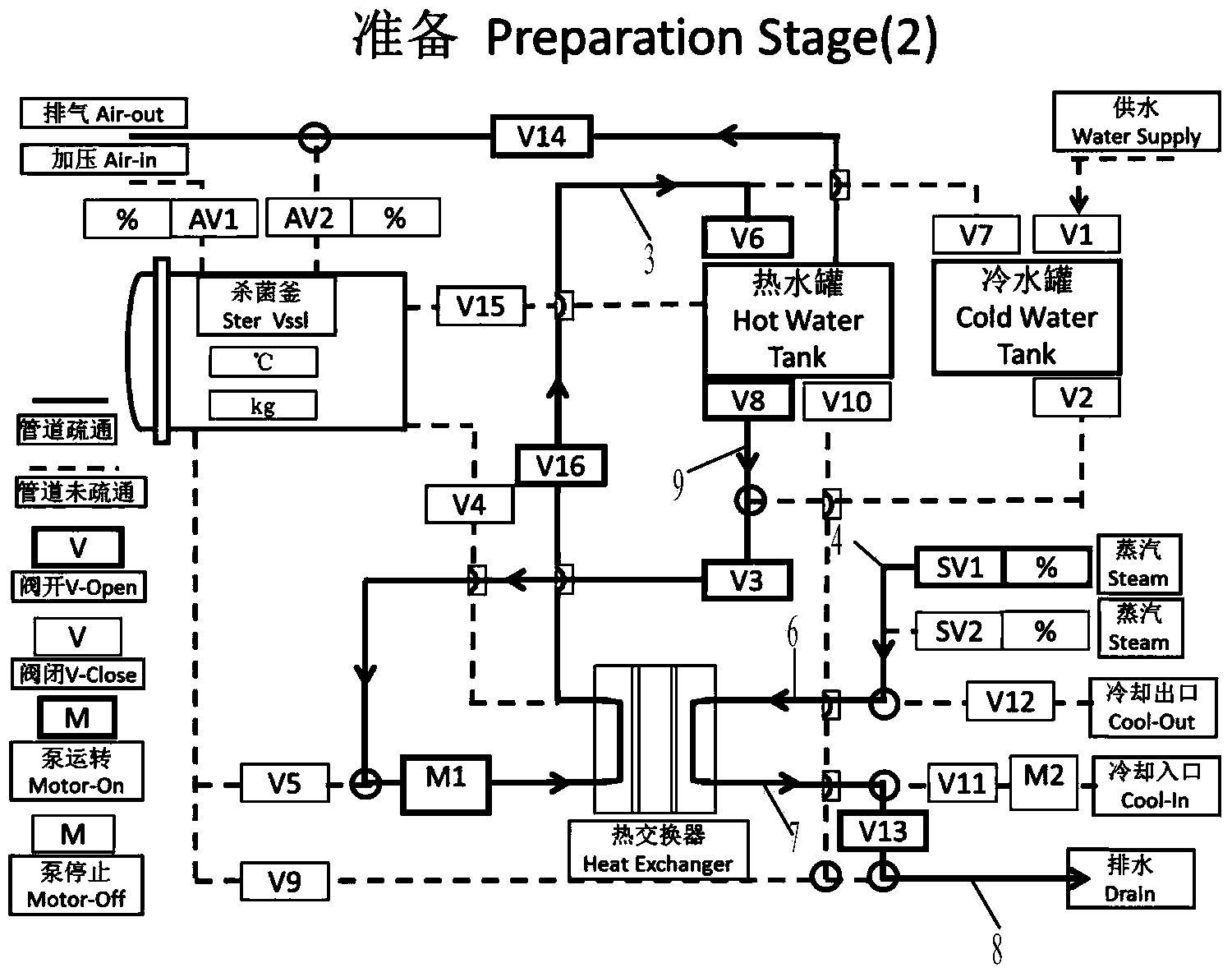

Sterilizing device sprinkling high-temperature pulse hot water

The invention relates to a sterilizing device sprinkling high-temperature pulse hot water. The sterilizing device comprises a sterilizing reactor, a hot water tank, a steam pipeline, a heat exchanger, a temperature sensor, a circulating pump and a controller, wherein an exhaust port, a water inlet and a water outlet are formed in the sterilizing reactor, and the water outlet and the water inlet of the sterilizing reactor are connected with a first pipeline; the hot water tank is connected with the water inlet of the sterilizing reactor through a second pipeline; steam converted by hot water in the circulating process enters the steam pipeline; the first pipeline, the second pipeline and the steam pipeline are respectively connected with the heat exchanger; the temperatures of the sterilizing reactor and the hot water tank are sensed by the temperature sensor; the circulating pump is connected with the first pipeline and the second pipeline and provides the hot water in the pipeline with flowing power; the controller is electrically connected with a valve of the first pipeline, a valve of the second pipeline, a valve of the steam pipeline, the circulating pump and the temperature sensor. Microorganisms can encounter with multiple rapid instant temperature cyclic variation processes in a high-temperature region, so that the purpose of rapidly killing the microorganisms is achieved.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com