Free-piston pulse tube refrigerator using all-carbon aerogel regenerative filler

A pulse tube refrigerator, carbon aerogel technology, applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of decreased specific heat capacity, only existence, and reduced efficiency of deep and low temperature regenerators, and achieve refrigeration. High efficiency, good stability, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

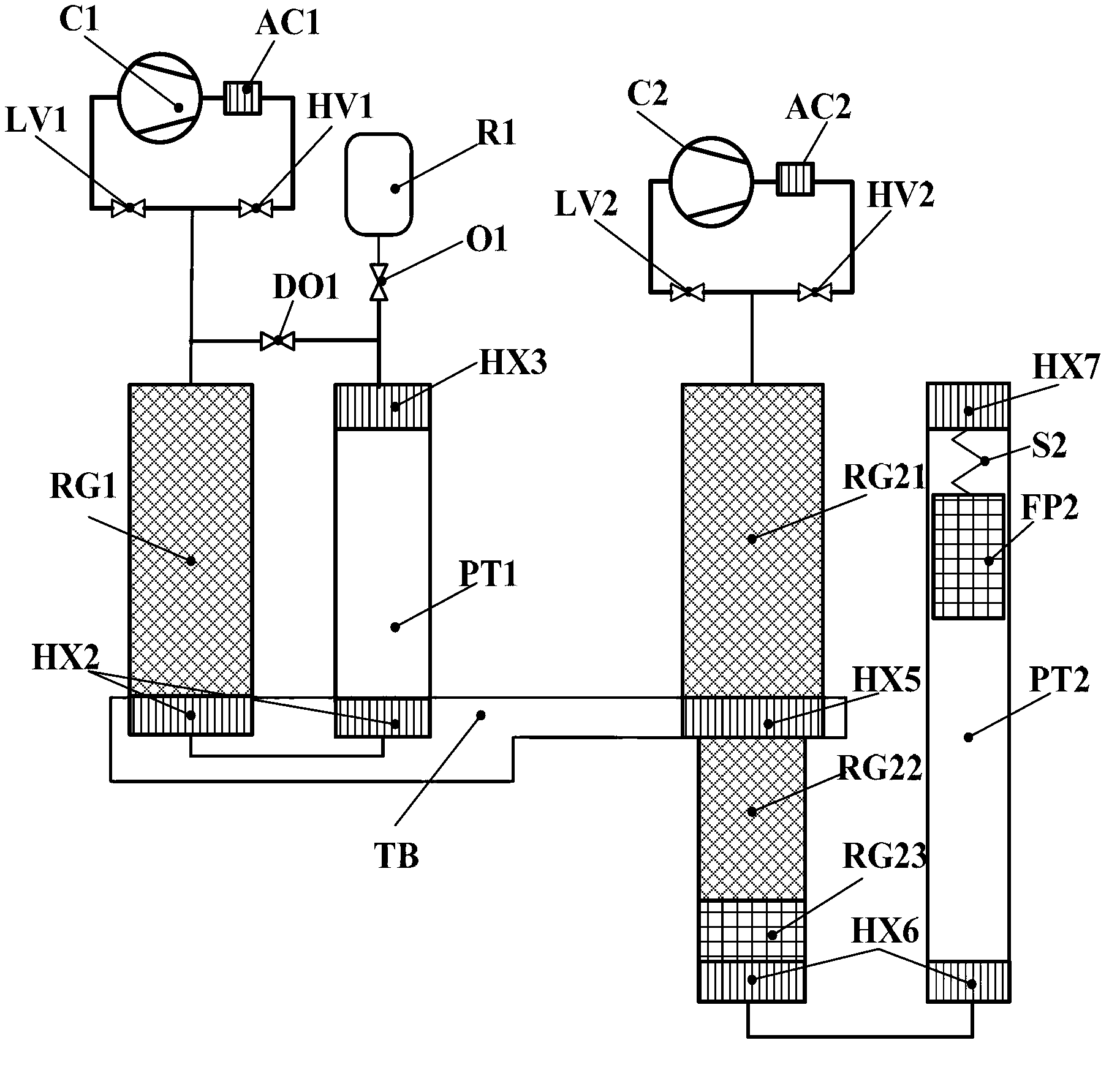

[0051] refer to figure 1 , a free-piston pulse tube refrigerator using all-carbon airgel regenerative filler, including two pulse tube refrigerator units thermally coupled by a thermal bridge TB, which are the first-stage precooling pulse tube refrigerator unit and The second-stage low-temperature pulse tube refrigerator unit: the first-stage pre-cooling pulse tube refrigerator unit consists of the first-stage compressor C1, the first-stage aftercooler AC1, the first-stage compressor low-pressure control valve LV1, the first-stage Compressor high pressure control valve HV1, first stage regenerator RG1, first stage cold end heat exchanger HX2, first stage pulse tube PT1, first stage pulse tube hot end heat exchanger HX3 and first stage phase modulation mechanism Composition, the first-stage phase modulation mechanism includes the first-stage two-way inlet valve DO1, the first-stage orifice valve O1, and the first-stage gas storage R1; the second-stage low-temperature pulse tub...

Embodiment 2

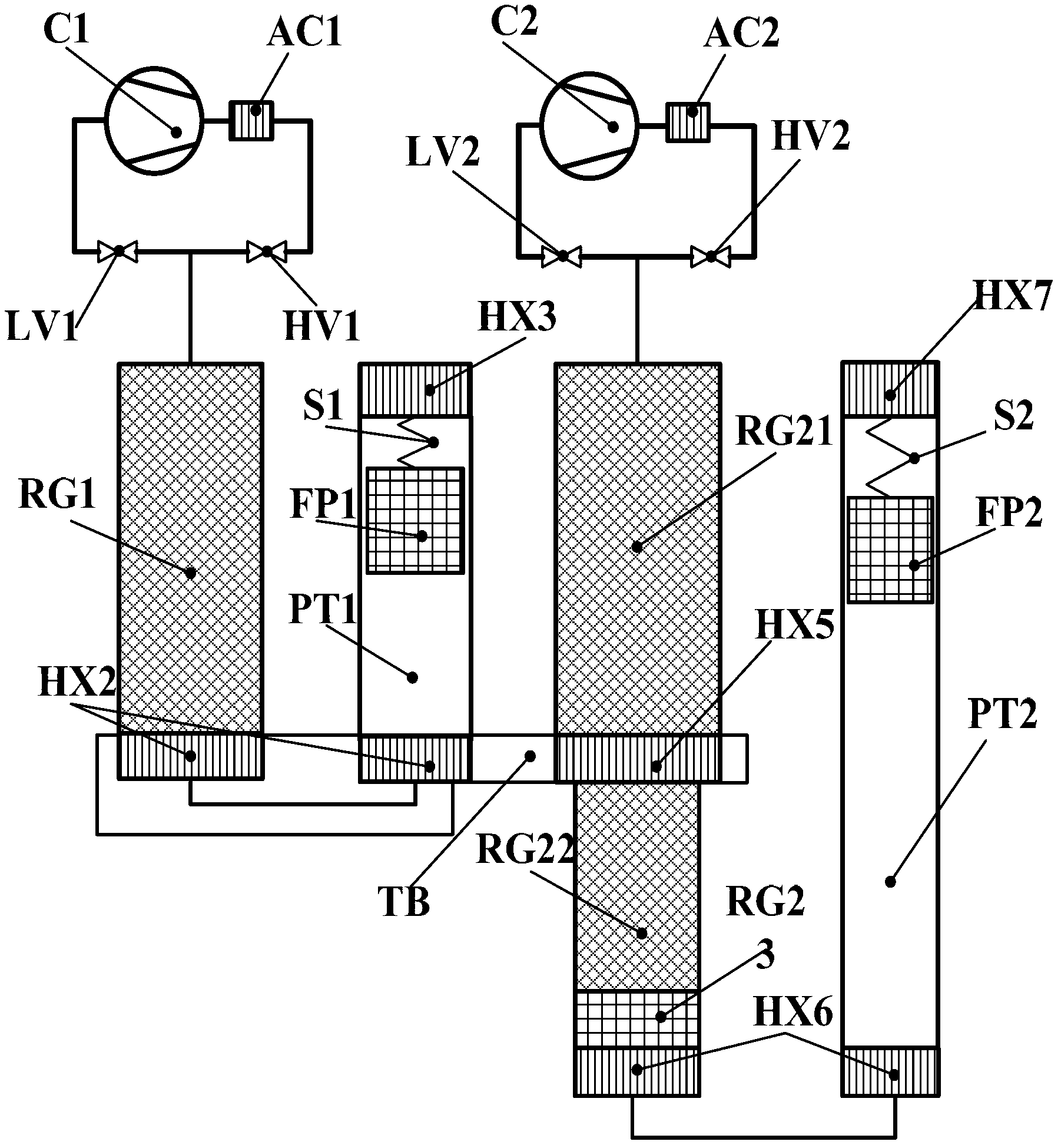

[0059] refer to figure 2 , a free-piston pulse tube refrigerator using all-carbon airgel regenerative filler, its structure is similar to the free-piston pulse tube refrigerator shown in Example 1, the difference from Example 1 is that the first stage precooling The first-stage free piston FP1 is arranged in the first-stage pulse tube PT1 in the pulse tube refrigerator unit, and the first-stage free piston FP1 is connected with the hot end heat exchanger HX7 of the first pulse tube through the first-stage spring S1. The first-stage free piston FP1 is composed of the first-stage airgel column and fits with the first-stage vessel PT1. The first-stage airgel column is cylindrical, and the length is 1 / 3- 1 / 2. At the same time, the first-stage phase adjustment mechanism in the first-stage precooling pulse tube refrigerator unit is omitted.

[0060] The specific connection relationship is as follows: the first-stage compressor C1, the first-stage aftercooler AC1, the first-stage ...

Embodiment 3

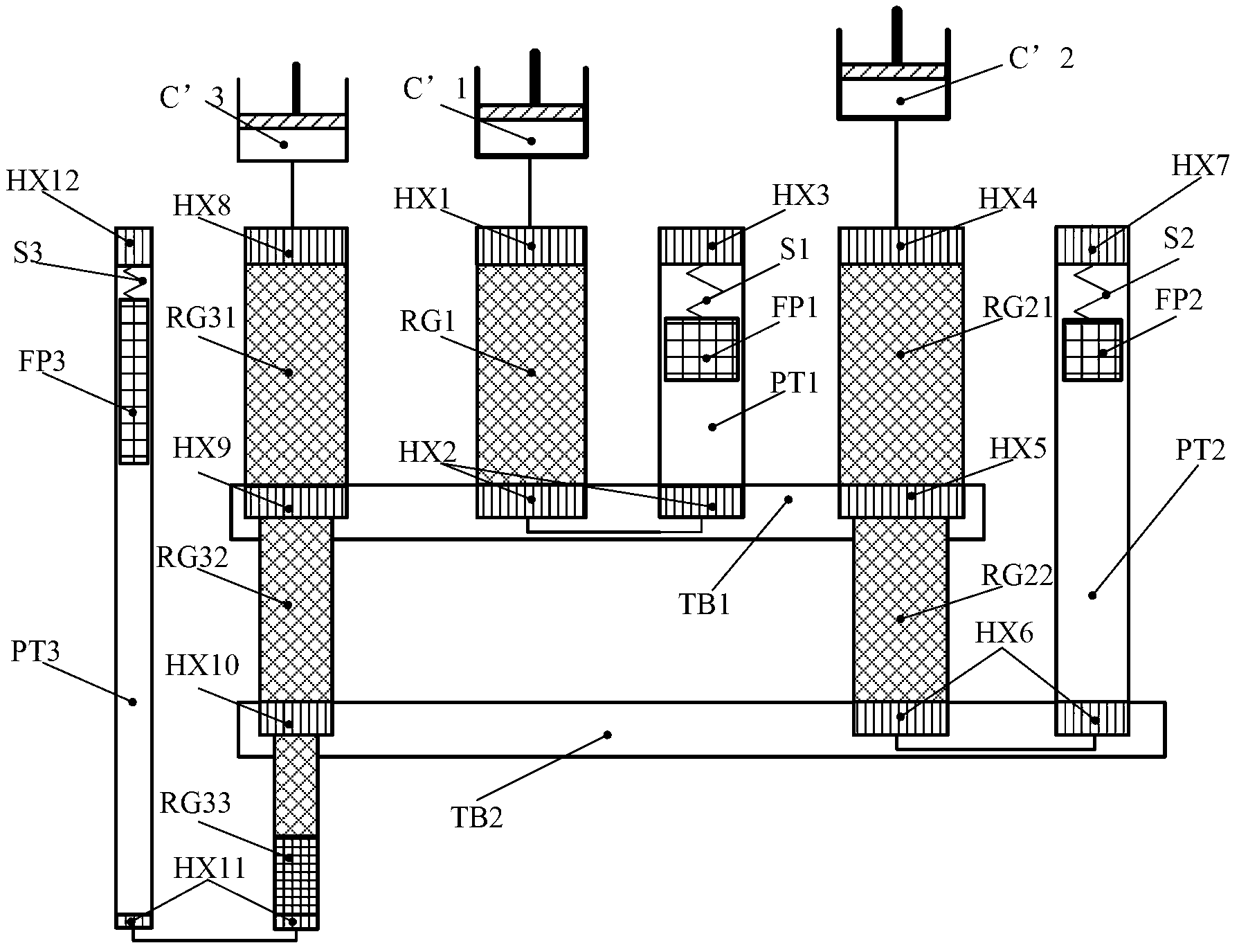

[0063] refer to image 3 , a free-piston pulse tube refrigerator using all-carbon airgel regenerative filler, including a first-stage precooling pulse tube refrigerator unit thermally coupled by a first-stage heat bridge TB1 and a second-stage heat bridge TB2, The second-stage low-temperature pulse tube refrigerator unit and the third-stage low-temperature pulse tube refrigerator unit; the first-stage precooling pulse tube refrigerator unit is composed of the first-stage linear compressor C'1 and the first-stage heat exchanger Heater HX1, first-stage regenerator RG1, first-stage cold-end heat exchanger HX2, first-stage pulse tube PT1, first-stage free piston FP1, first-stage spring S1, and first-stage pulse tube hot-end exchanger Heater HX3; the second-stage low-temperature pulse tube refrigerator unit consists of the second-stage linear compressor C'2, the second-stage regenerator hot-end heat exchanger HX4, the second-stage pre-cooling section regenerator RG21, the second-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com