Patents

Literature

58 results about "Cryogenic engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cryogenic engineering is a sub stream of mechanical engineering dealing with cryogenics, and related very low temperature processes such as air liquefaction, cryogenic engines (for rocket propulsion), cryosurgery. Generally, temperatures below cold come under the purview of cryogenic engineering. Cryogenics may be considered as the recent advancement in the field of refrigeration. Though there is no fixed demarcation as to where refrigeration ends and cryogenics begins even then for general reference temperature below –150c(120k) are considered as cryogenic temperature. The four gases which mainly contribute for cryogenic application and research are (O2-B.P.90K), (N2-B.P.77K), (Helium-B.P.4.2k) & (H2-B.P.20K). The word "cryogenic" is derived from Greek κρύο (cryo) – "cold" + γονική (genic) – "having to do with production".

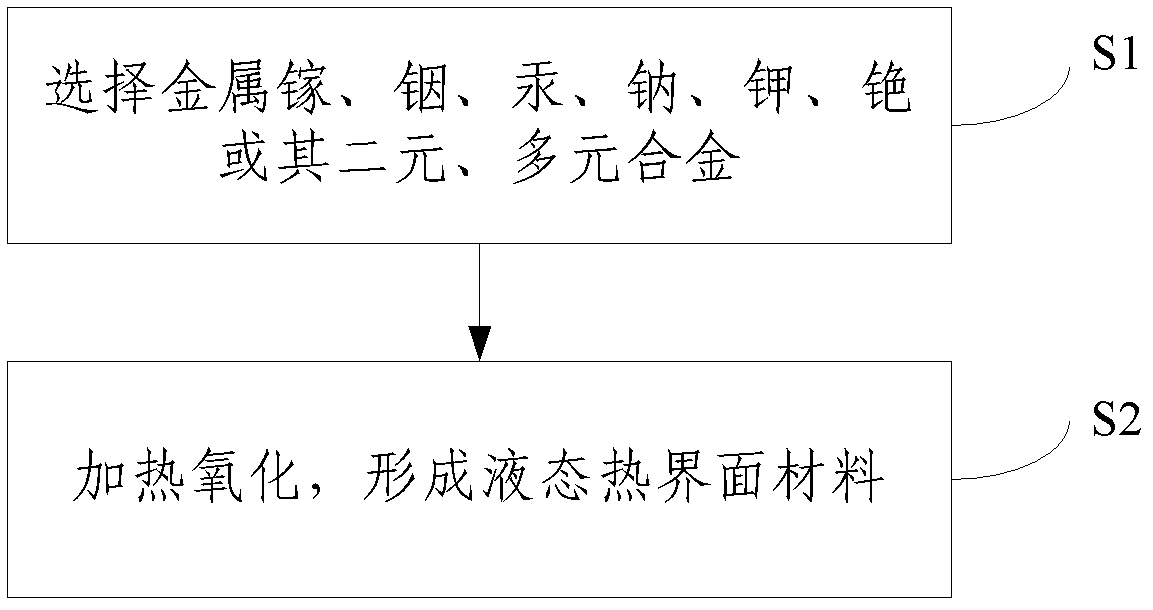

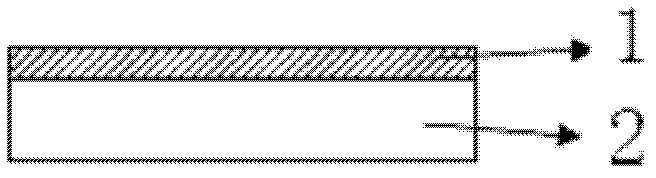

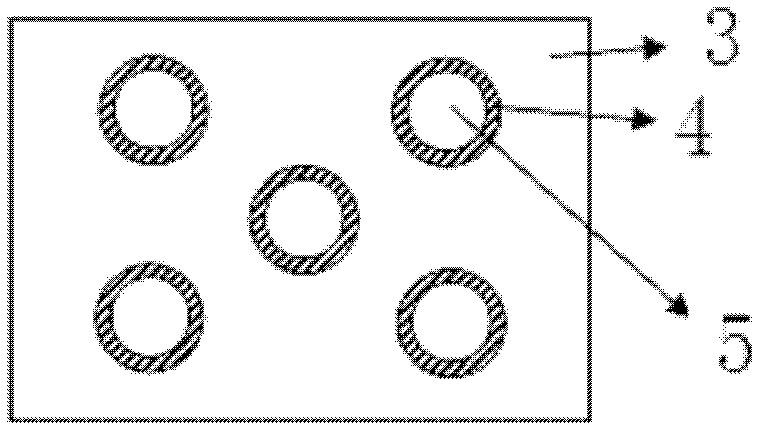

Thermal interface materials and manufacturing method thereof

The invention discloses thermal interface materials and a manufacturing method of the thermal interface materials. The interface materials are formed by means of heating and oxidization of metals such as gallium, indium, mercury, sodium, potassium, cesium or binary alloy and multicomponent alloy of the cesium. The manufacturing method comprises the following steps: selecting metals such as the gallium, the indium, the mercury, the sodium, the potassium, the cesium or the binary alloy and the multicomponent alloy of the cesium, and enabling the metals or the alloy to become liquid and enabling the liquid metals or the alloy to be placed in air or oxygen through heating. By means of placing the metals such as the gallium, the indium, the mercury, the sodium, the potassium, the cesium or the binary alloy and the multicomponent alloy of the cesium in the air and the oxygen to be oxidized to form the thermal interface materials, wettability between metal-based fluid and each interface can be greatly enhanced, thereby requirements of the thermal interface materials can be met. Due to the good thermal and wetting properties, the thermal interface materials can play significant roles in an aspect of electric chip thermal conductivity of the fields such as cryogenic engineering, boosters of computers, satellites and rockets and laser device.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

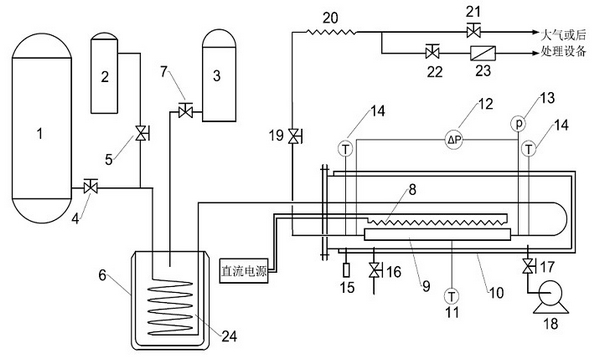

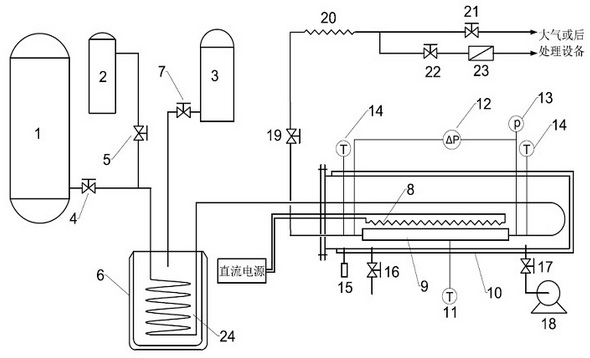

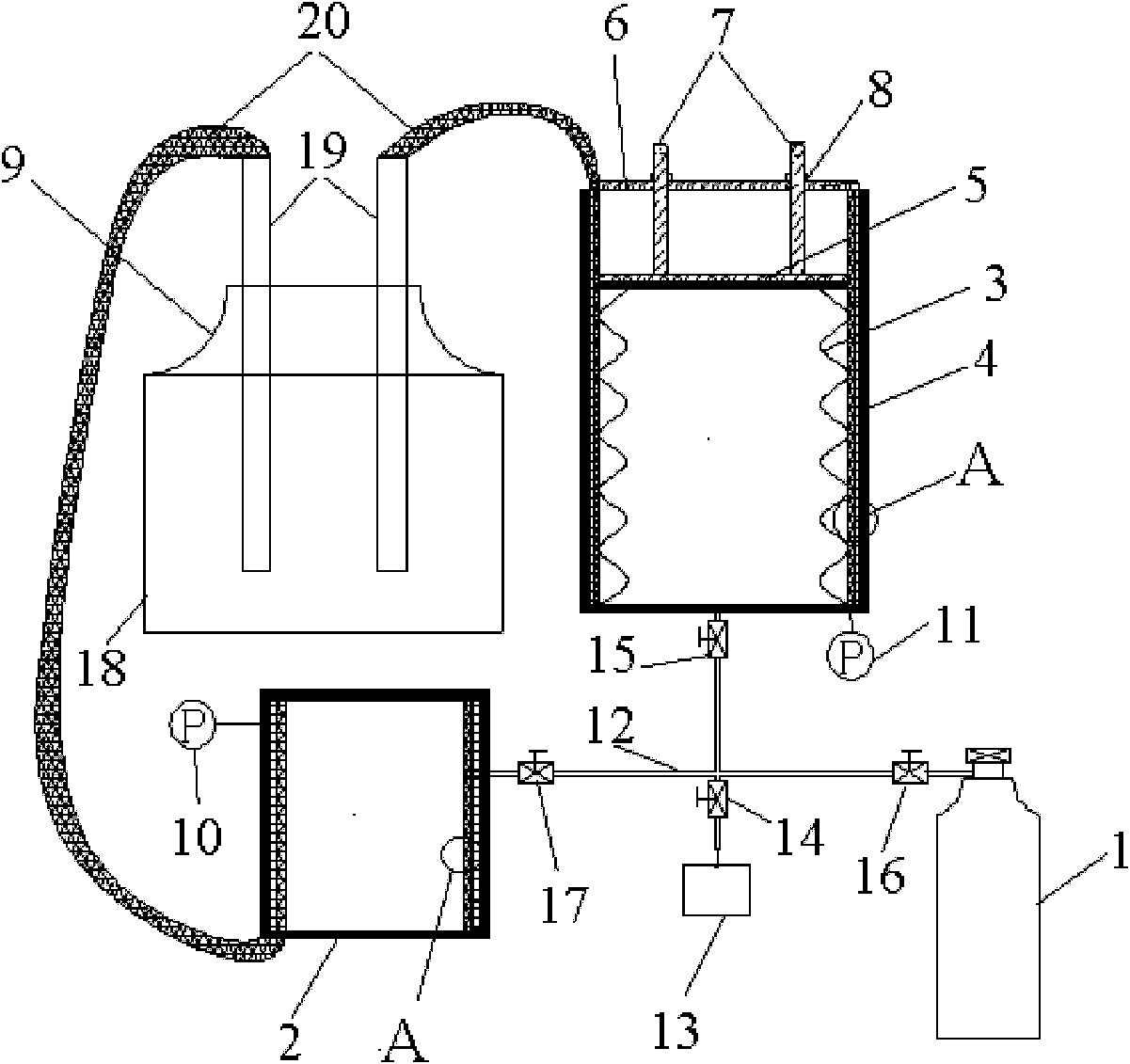

Testing system for researching flow boiling heat transfer character and pressure drop character of cryogenic fluid

InactiveCN102435632AImprove utilization efficiencyImprove securityMaterial heat developmentFlow boiling heat transferCooling coil

The present invention provides a testing system for researching flow boiling heat transfer character and pressure drop character of cryogenic fluid, which belong to the technical field of cryogenic engineering and cryogenic technique. The testing system comprises a cryogenic self-pressurized storage tank, a nitrogen steel cylinder, a liquid nitrogen steel cylinder, a wide-mouth dewar, a cooling coil, an electric heating device, heat exchange equipment to be tested, a test vacuum dewar, a temperature transducer, a pressure transducer, a differential pressure transducer, a vaporizer and a gas flowmeter. The cryogenic self-pressurized storage tank is used as a pressurization device in the testing system and cryogenic fluid is outputted under a certain pressure, which can simplify the testingsystem. The heat exchange equipment to be tested is arranged in the test vacuum dewar for reducing heat loss in the testing. A vacuum valve is arranged in the test vacuum dewar and can be connected to outer high pressure nitrogen for blowing the inner part of the test vacuum dewar when necessary, which can improve the system safety. The testing system has the advantages of less land occupation, small investment, simple control, easy operation, safe, reliable and applicability to various cryogenic fluids including flammable and explosive cryogenic fluids.

Owner:SHANGHAI JIAO TONG UNIV

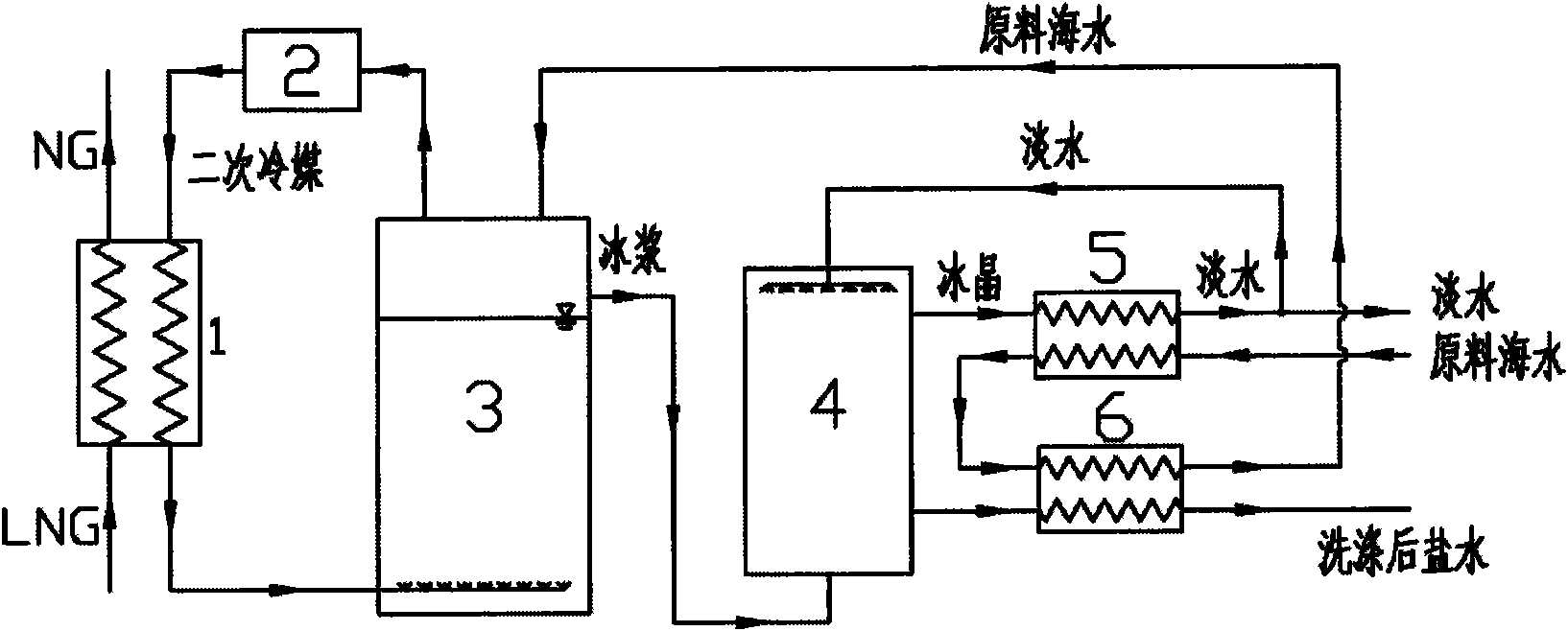

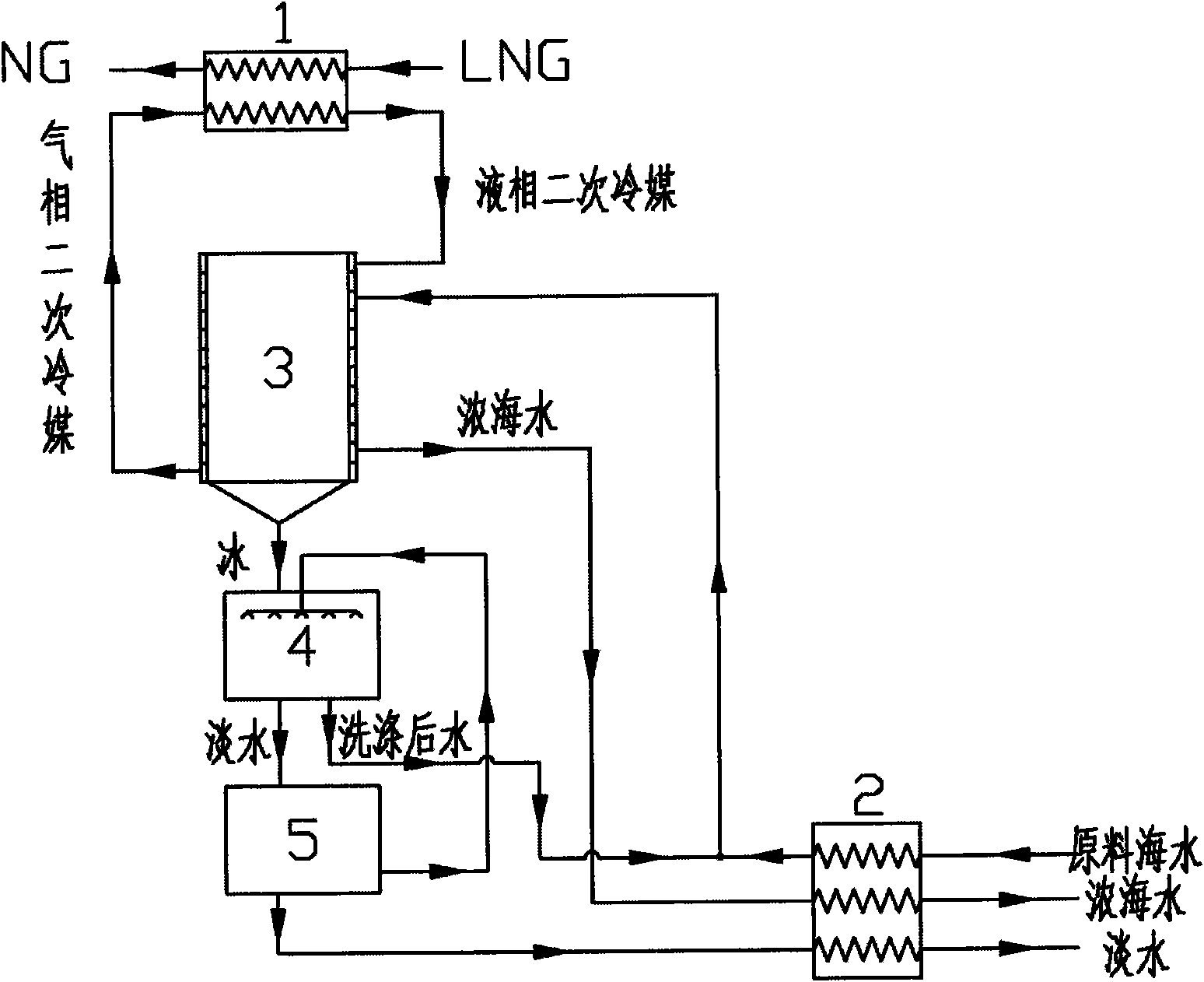

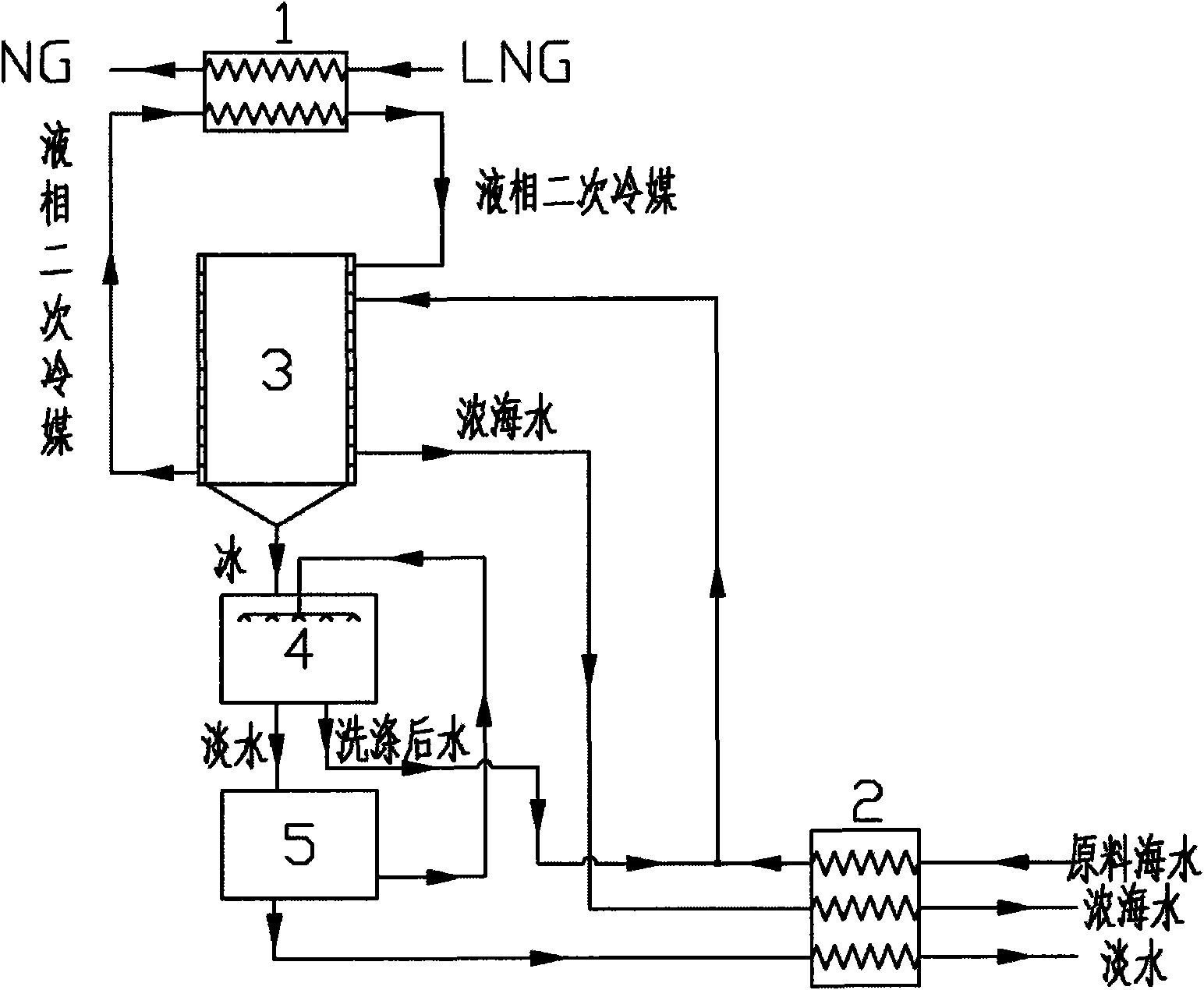

Method for desalting seawater by utilizing cold energy of liquefied natural gas through direct contact refrigeration

InactiveCN101628740AReduce energy consumptionReduce lossesGeneral water supply conservationDomestic cooling apparatusWater insolubleSeawater

The invention relates to a method for desalting seawater by utilizing the cold energy of liquefied natural gas through direct contact refrigeration, belonging to the technical field of refrigeration and cryogenic engineering. Firstly, heat exchange is carried out between the liquefied natural gas and secondary coolant in a heat exchanger, the liquefied natural gas is gasified to absorb heat so as to condense the water-insoluble secondary coolant by reducing the temperature thereof, the condensed secondary coolant is sprayed into a crystallizer to exchange heat with seawater through direct contact, liquid drops of the secondary coolant is evaporated to absorb heat, and therefore seawater around the liquid drops releases heat and is refrigerated into ice crystals. Prepared ice is rinsed in a rinsing tank so as to eliminate salt attached to the surface of the ice and then is led into a melting device to be melted into fresh water. The process recovers a great amount of cold energy accumulated in the liquefied natural gas, dispenses with a high consumption refrigerating unit and can effectively reduce the energy consumption of indirect refrigeration seawater desalination device, the loss of the heat exchange process is low, and the size of the device is small.

Owner:SHANGHAI JIAO TONG UNIV

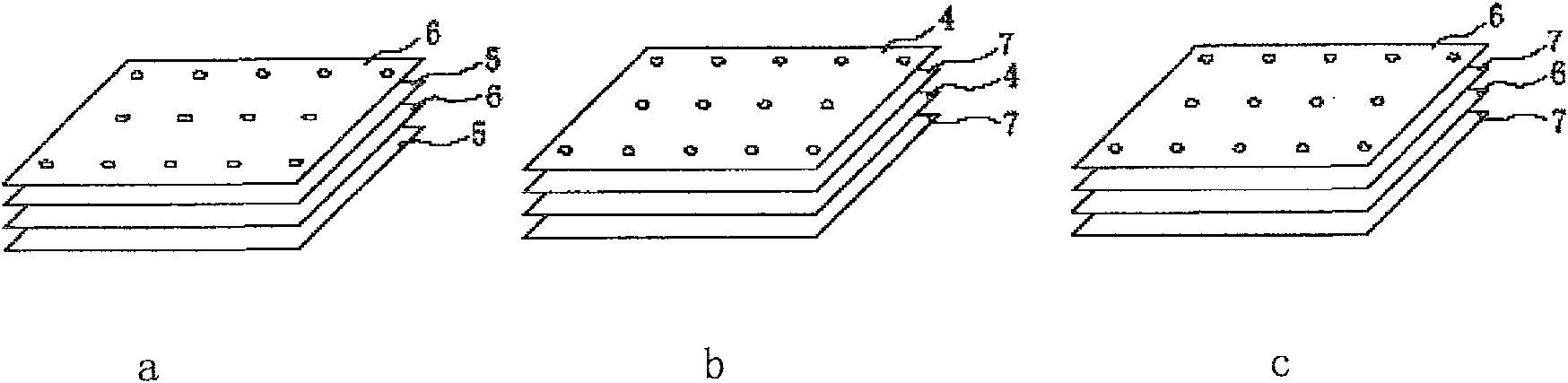

Various material composite fire retardant -type high vacuum multiple layer heat insulation structure

InactiveCN101307857AGuaranteed flame retardant performanceGuaranteed CompatibilityThermal insulationPipe protection by thermal insulationFiberGlass fiber

The invention relates to an inflaming retarding type high vacuum multilayer heat insulation structure combined with multiple materials, which belongs to the cryogenic engineering and cryogenic technical field. The invention comprises a high temperature side combination, a transition combination and a low temperature side combination, wherein the high temperature side combination adopts an alternating combination of the aluminum foil and the glass fiber paper; the transition combination adopts an alternating combination of the double-sided aluminum coated sheet and the glass fiber paper or the aluminum foil and the chemical fiber paper or the double-sided aluminum coated sheet and the chemical fiber paper; and the low temperature side combination adopts a mixed combination of the aluminum foil, the glass fiber paper and the chemical fiber paper. The insulation structure of the invention is characterized in that the whole structure can retard inflaming without exterior inflaming and the low temperature heat-insulating performance is superior to that of the traditional inflaming retarding type heat insulation structure, thereby decreasing the use of the heat insulating materials, lowering the cost of the heat insulating materials, shortening the intervals of the vacuum interlayers, increasing the inner effective volume of the low temperature vessel when the outside dimensions are the same, and contributing to the light weight and the volume maximization of the mobile low temperature accumulating conveyers.The inflaming retarding type high vacuum multilayer heat insulation structure combined with multiple materials has more obvious economic benefit and social benefit in the cryogenic engineering.

Owner:SHANGHAI JIAO TONG UNIV

Desalting method with phase change for indirectly freeze seawater by using of liquefied natural gas refrigeration capacity

InactiveCN101624224AReduce energy consumptionGeneral water supply conservationDomestic cooling apparatusHigh energyEngineering

The invention relates to a desalting method with phase change for indirectly freeze seawater by using liquefied natural gas refrigeration capacity, belonging to the technical field of refrigeration and low-temperature engineering. The liquefied natural gas exchanges heat with a secondary refrigerant in a heat exchanger firstly, the liquefied natural gas absorbs the heat to lead the temperature of the secondary refrigerant to reduce and generate gas-liquid phase change, then the secondary refrigerant enters a crystallizer and indirectly exchanges heat with seawater so as to lead seawater to be frozen to ice on a heat exchanging surface, and simultaneously the secondary refrigerant absorbs heat to be gasified. The prepared ice enters a water tank and melts into fresh water. The recovered liquefied natural gas contains large amount of refrigeration capacity, does not need a high-energy consumption refrigerating unit, and can effectively reduce the energy consumption of a desalting device for indirectly freezing seawater.

Owner:SHANGHAI JIAO TONG UNIV

Method for desalting seawater by utilizing cold energy of liquefied natural gas through phase transition-free indirect refrigeration

InactiveCN101628741AReduce energy consumptionReduce the temperatureDomestic cooling apparatusGeneral water supply conservationEngineeringSeawater

The invention relates to a method for desalting sea water by utilizing the cold energy of liquefied natural gas through phase transition-free indirect refrigeration, belonging to the technical field of refrigeration and cryogenic engineering. Firstly, heat exchange is carried out between the liquefied natural gas and liquefied secondary coolant in a heat exchanger, and the liquefied natural gas is gasified to absorb heat, thereby reducing the temperature of the secondary coolant while maintaining the phase thereof; secondly, the liquid phase secondary coolant enters a crystallizer and indirectly exchanges heat with seawater so as to refrigerate the seawater on the heat exchange surface into ice, and the secondary coolant absorbs heat to raise the temperature and is not gasified. The prepared ice is rinsed in a rinsing tank so as to eliminate salt attached to the surface of the ice and then is led into an ice melting tank to be melted into fresh water. The invention recovers a great amount of cold energy accumulated in the liquefied natural gas, dispenses with a high consumption refrigerating unit, and can effectively reduce the energy consumption of indirect refrigeration seawater desalination device.

Owner:SHANGHAI JIAO TONG UNIV

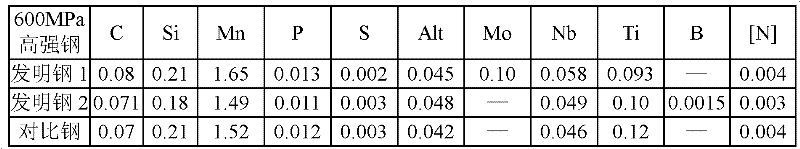

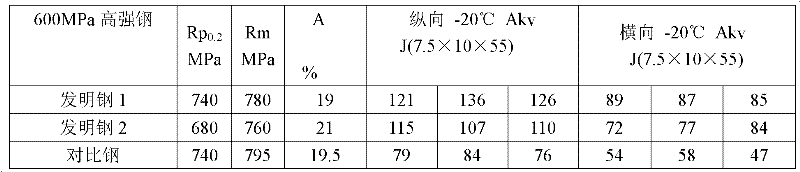

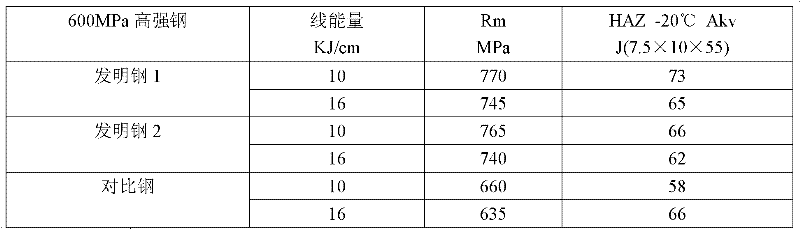

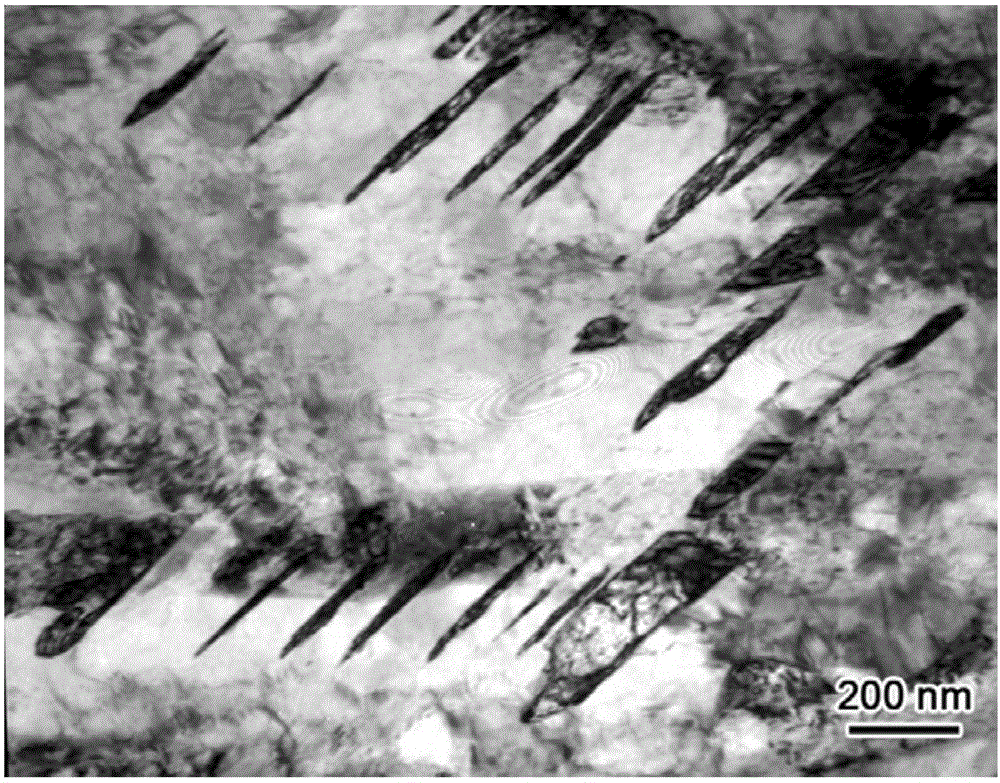

Low-temperature steel for engineering machinery and production method thereof

InactiveCN102409233AImprove high heat input welding performanceImprove toughnessTemperature control deviceHeat-affected zoneMechanical property

The invention relates to low-temperature steel for engineering machinery and a production method thereof. The steel is suitable for higher heat input welding and comprises the following chemical components by weight percent: 0.06-0.08% of C, 0.15-0.25% of Si, 1.6-1.9% of Mn, 0.05-0.07% of Nb, 0-0.30% of Mo, 0-0.0020% of B, 0.08-0.14% of Ti, 0.01-0.06% of Al, not more than 0.02% of P, not more than 0.010% of S, not more than 0.008% of N and the balance of Fe and inevitable impurities. The production method is characterized by controlling the heating temperature, precision rolling inlet temperature, finish rolling temperature, finished cooling temperature and annealing temperature. The material can ensure the transverse universal coiling impact energy at minus 20 DEG C to be more than 47J, and meanwhile, the HAZ (heat affected zone) strength and toughness of the steel plate can meet the mechanical property requirements of the base metal under 20KJ / cm welding property energy.

Owner:SHOUGANG CORPORATION

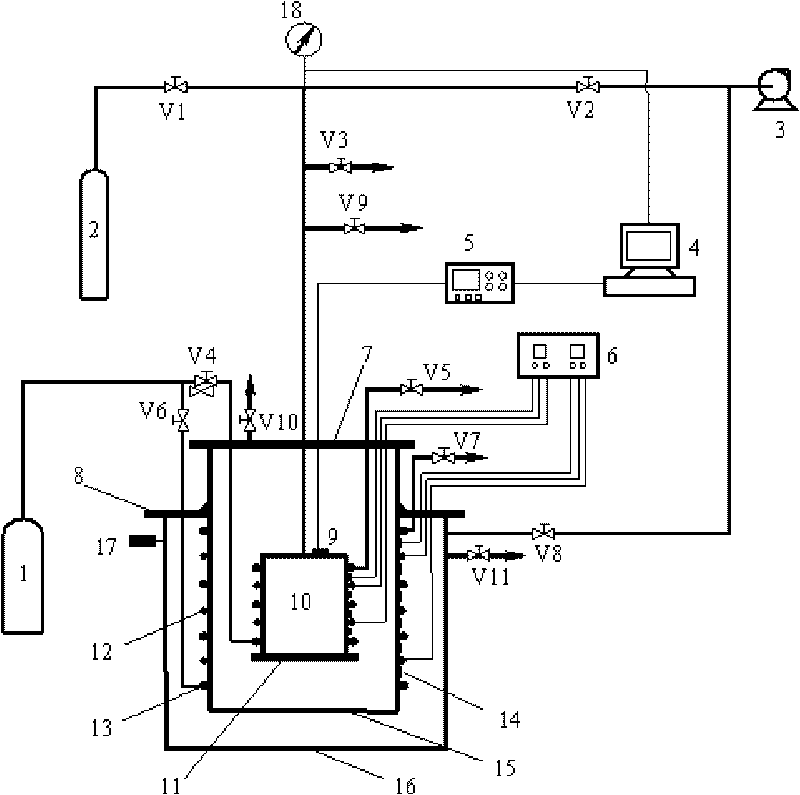

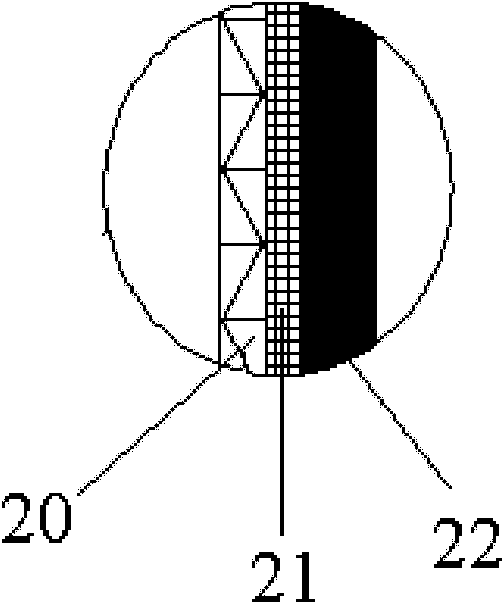

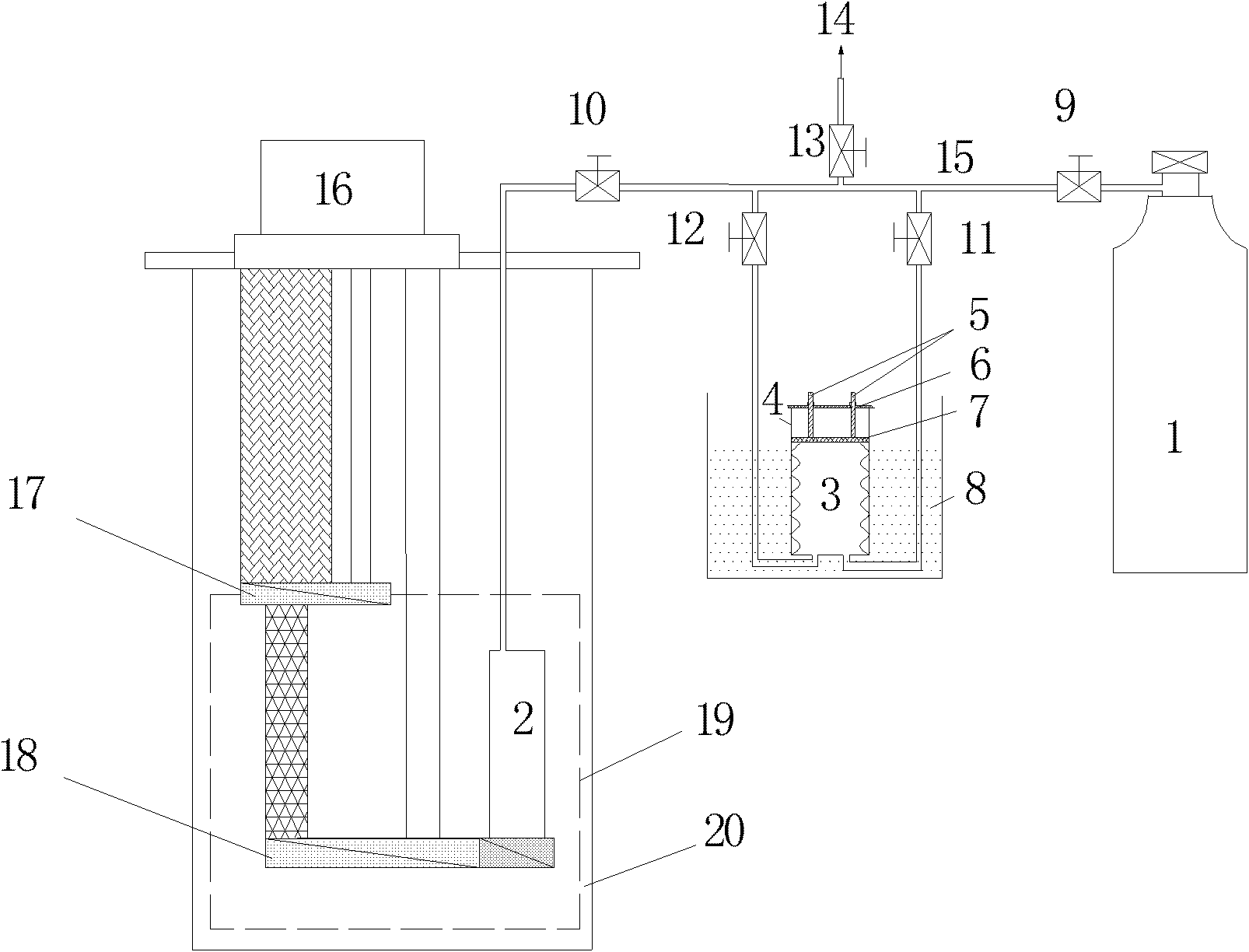

Wide temperature zone hydrogen storage material low temperature hydrogen storage performance testing device

InactiveCN101762435AGuaranteed replacementShorten test timeMaterial analysisGas cylinderData acquisition

The invention relates to wide temperature zone hydrogen storage material low temperature hydrogen storage performance testing device, belonging to the low temperature engineering and low temperature technical field and being applicable to measuring low temperature hydrogen storage performance of multiple hydrogen storage materials in wide temperature zone. The testing device comprises a liquid nitrogen Dewar, a high pressure hydrogen gas cylinder, a vacuum set, a data acquisition computer, a temperature acquiring device, a PID temperature controller, a flange, a platinum resistor, a sample room, a heating wire, a cooling coil, a thermocouple, a Dewar, a vacuum gauge, a pressure sensor and a valve. The testing device takes circulating liquid nitrogen as cooling working medium and combines electrical heating to realize temperature regulation in wide temperature zone. The PID temperature controller regulates heating amount of the heating wire by the temperature signal acquired by the thermocouple. The pressure sensor and temperature acquiring device transmit the acquired data to the data acquisition system. The flange of sample room is arranged at the bottom of the sample room, inner Dewar and outer Dewar flanges are welded into a whole, thus ensuring replacement of sample. The testing device is simple in structure, is easy to manufacture and has better economy.

Owner:SHANGHAI LNG NEW ENERGY TECH

Double effect device being capable of gas boosting, transferring and recycling

InactiveCN101865167AAchieve compressionGuaranteed not to be pollutedFluid-pressure convertersPressure vesselsGas cylinderEngineering

The invention relates to a double effect device being capable of gas boosting, transferring and recycling, which belongs to the technical field of fluid machinery. The device comprises a source gas cylinder, a target gas cylinder, a compressed gas cylinder, a sleeve, a flat plate, a sealing gland, a regulating lever, a displacement restrictor, a refrigerator and a vacuum equipment, wherein the compressed gas cylinder is positioned in the sleeve, and both ends of the compressed gas cylinder are sealed; one end of the compressed gas cylinder is fixed with the bottom of the sleeve, and the otherend is connected with the flat plate; the flat plate is movably arranged in the sleeve; the sealing gland is fixed on the top of the sleeve; the bottom end of the regulating lever is fixed on the flat plate; the top end of the regulating lever is sleeved on the sealing gland, and the top ends o the the regulating lever and the sealing gland are respectively provided with the displacement restrictors; the refrigerator is respectively connected with the target gas cylinder and the sleeve; and the vacuum equipment, the compressed gas cylinder, the source gas cylinder and the target gas cylinder are communicated with each other through ducts. On the basis of the thermodynamic properties of compressible gases, the invention realizes the double effect being capable of boosting, transferring andrecycling for a small amount of special gases by the means of the background art combining cryogenic engineering and deformable metal structure.

Owner:SHANGHAI JIAO TONG UNIV

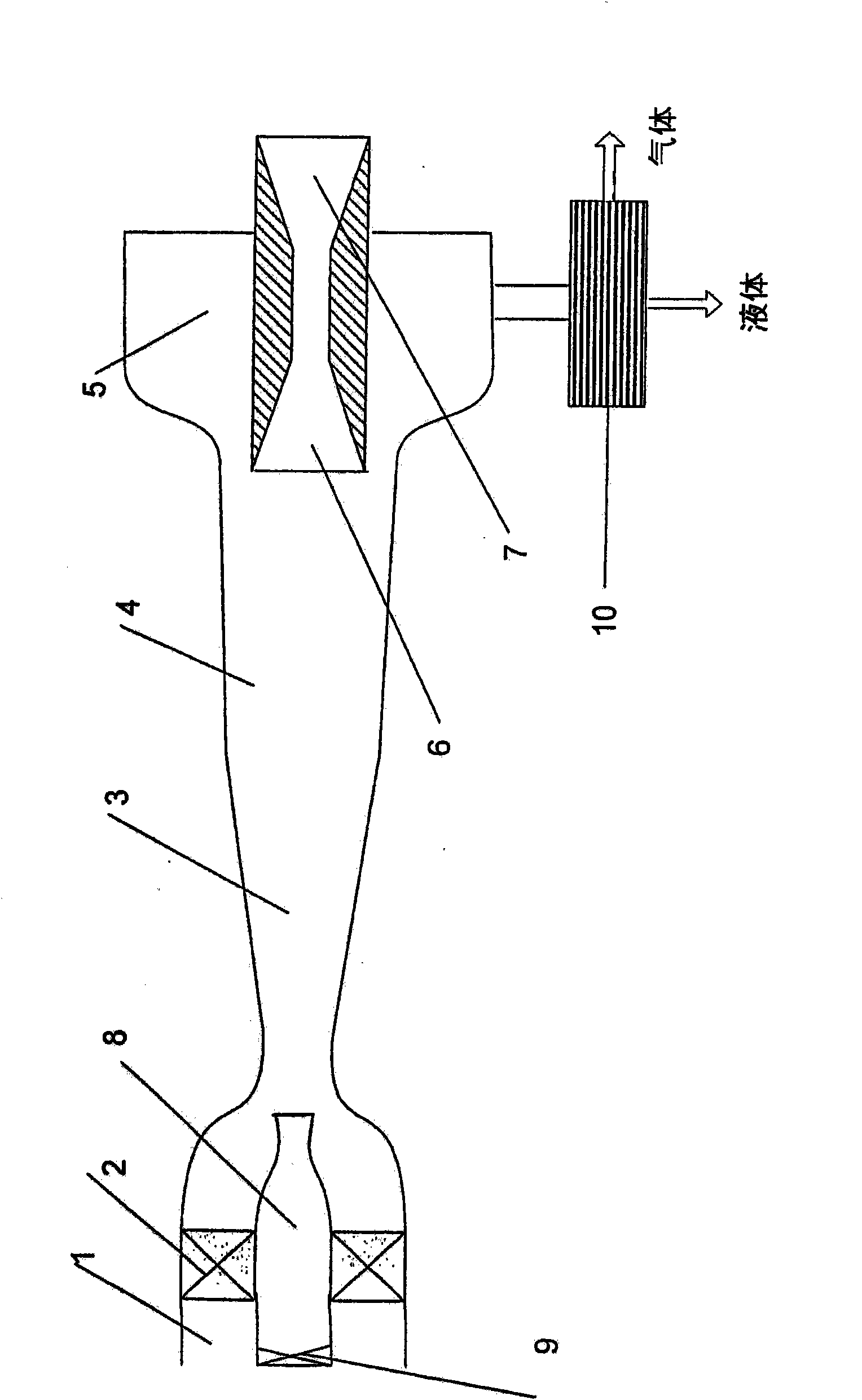

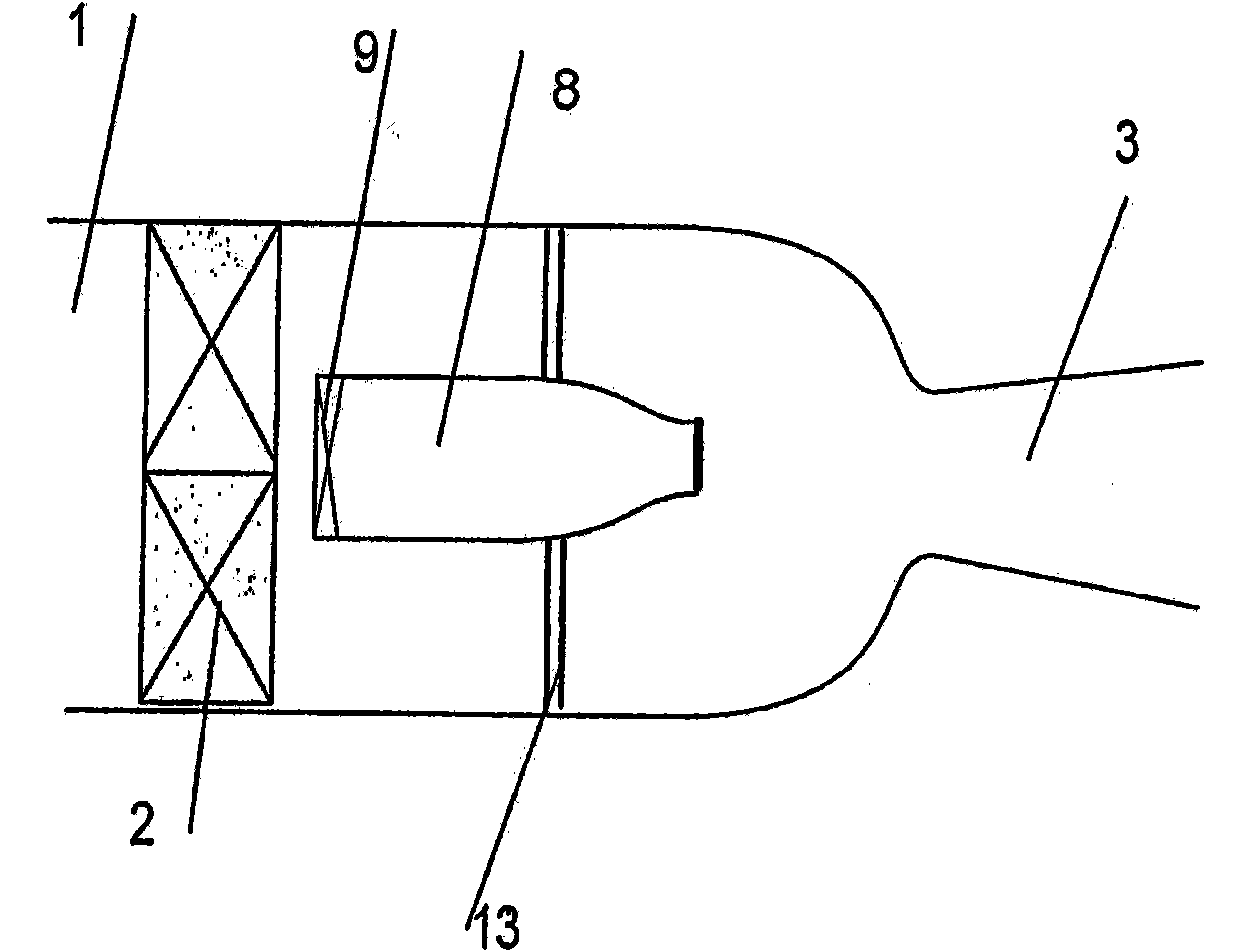

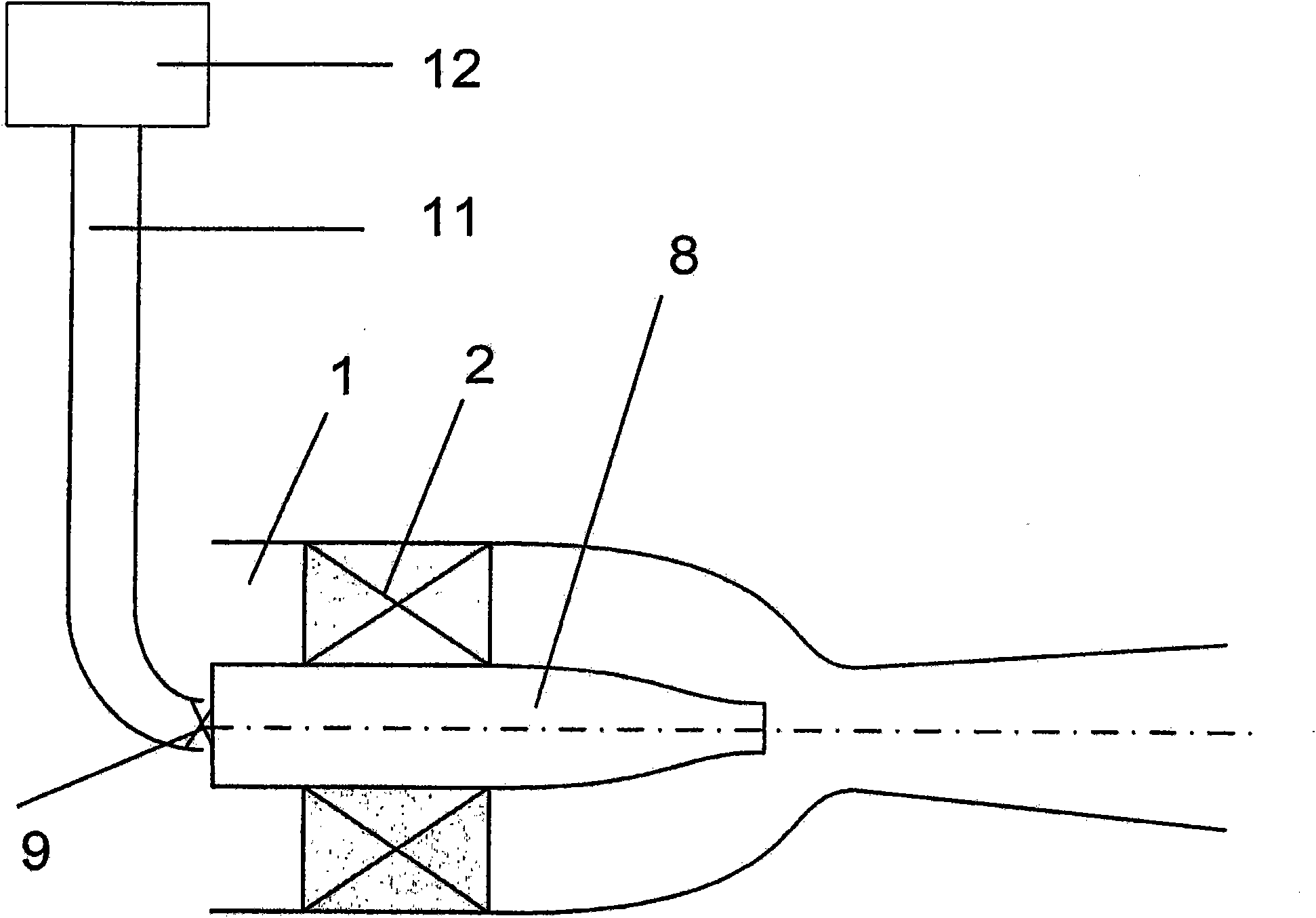

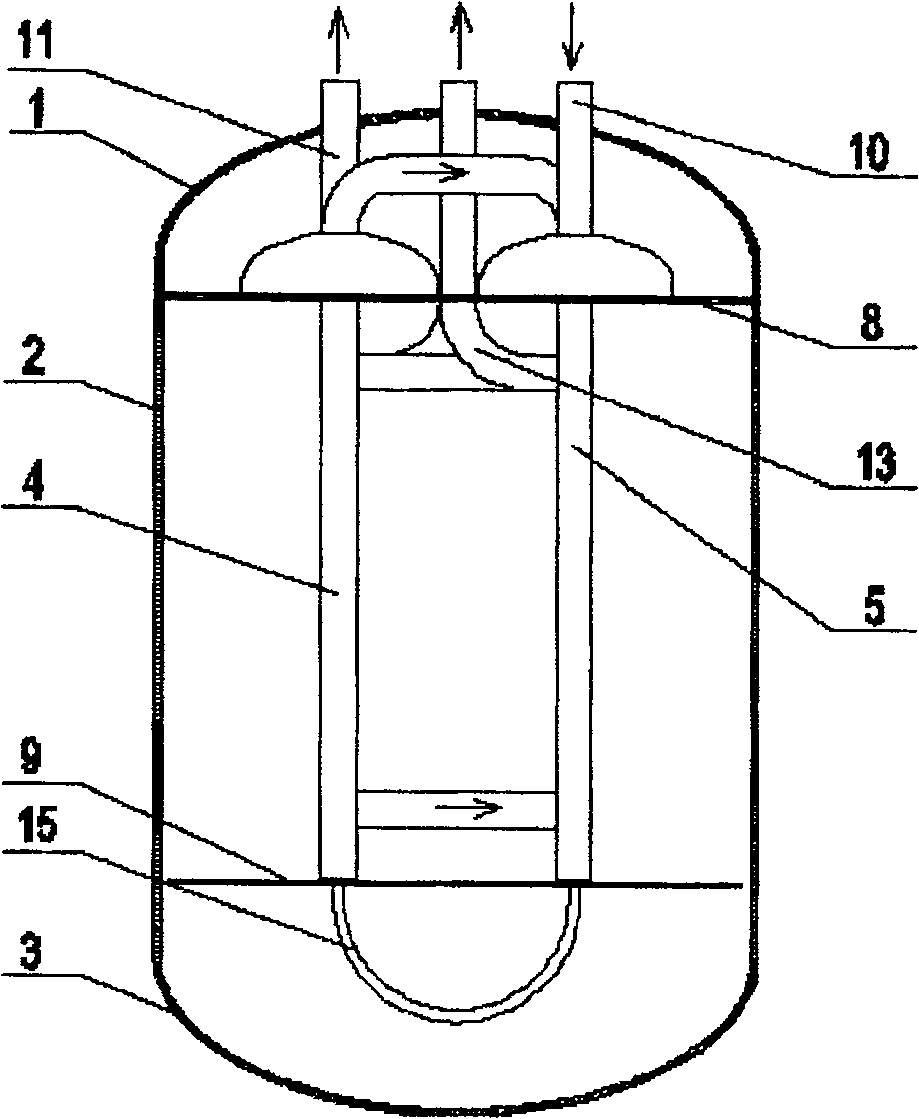

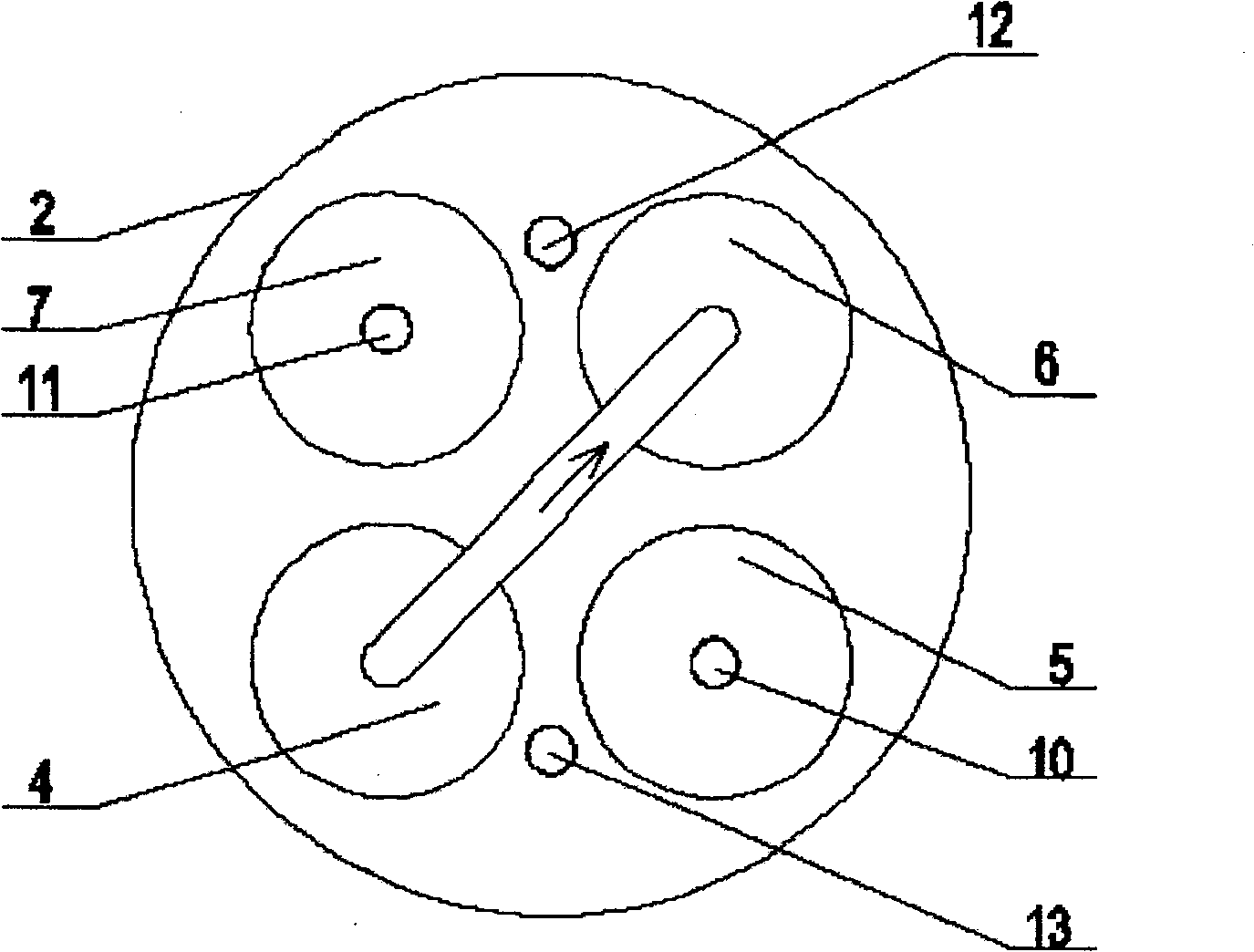

Gas liquefaction and separation device

ActiveCN101828088AReduce pressure differenceImprove equipment efficiencySolidificationVacuum condensationProduct gasEngineering

The invention relates to cryogenic engineering. The inventive device for liquefying and separating gas and for releasing one or more gases from a mixture thereof, comprises, in series axially positioned, a prechamber (1) with gas flow whirling means (2) arranged therein, a subsonic or supersonic nozzle (3) with a working segment (4), which is abutted thereto and to which liquid phase extracting means (5) is connected, and a subsonic diffuser (7) or the combination of a supersonic (6) and the subsonic diffuser (7). The nozzle (3) is designed in such a way that it makes it possible to achieve the ratios, between the inlet and outlet cross-sectional areas and the minimum cross-section thereof, which provides, at the output of the nozzle, a statical pressure and a statical temperature corresponding to the conditions of condensation of gas or target gas mixture components. The length of the working segment (4) is selected according to a condition of forming condensate drops with a size greater than 0.5 mkm and of drifting them, by centrifugal forces, from the axial area of the working segment to the walls of the drop extracting means, and the aperture angle of the working segment (4) is selected such as to maintain the conditions of condensation of the gas or the target components thereof. The device is provided with an additional nozzle (8) arranged in the prechamber. The invention makes it possible to increase the separation efficiency.

Owner:3S GAS TECH LTD

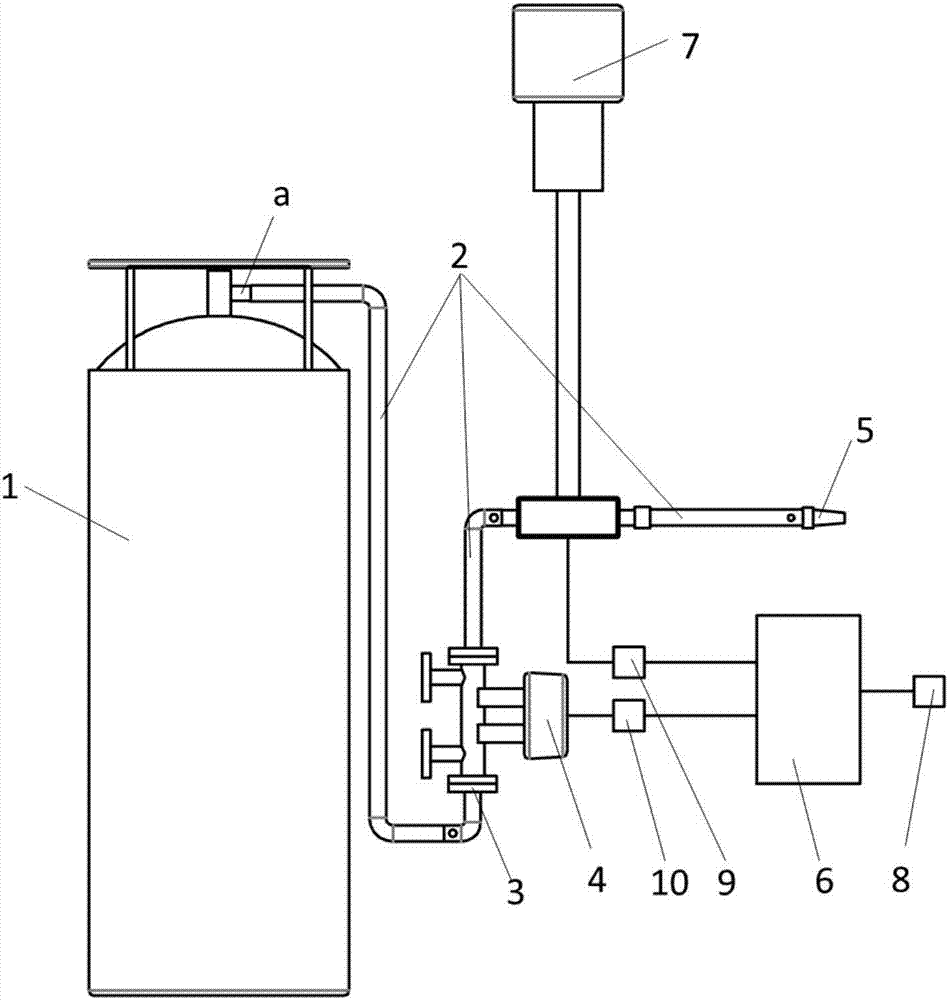

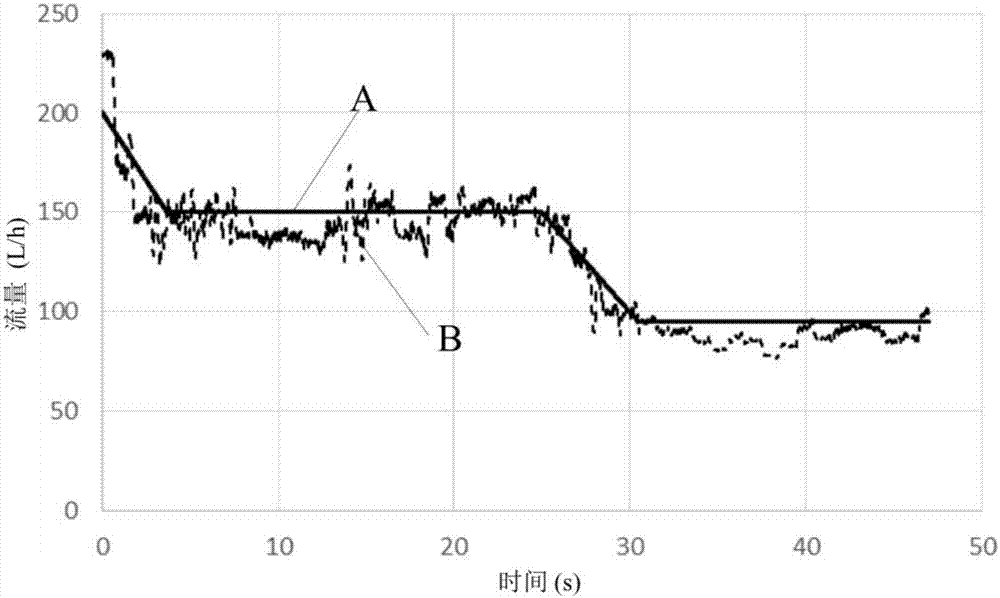

Method for regulating and controlling stable flow of liquid nitrogen jet flow state

InactiveCN107388032ARegulation and stabilityIncrease profitVessel mounting detailsContainer filling methodsJet flowHeat losses

The invention relates to a method for regulating and controlling the stable flow of the liquid nitrogen jet flow state and belongs to the field of cryogenic engineering. According to regulation of the stable flow of the liquid nitrogen jet flow state through the method, a heat insulation pipeline is utilized to reduce heat leakage, the two-phase flow gas mass fraction is regulated and controlled within a certain range, the gasification ratio of liquid nitrogen in the delivering process is decreased, and the stable output result in the allowable range is obtained. The liquid nitrogen delivering flow is monitored in real time, and liquid nitrogen flow regulation and stable output are achieved through a PID regulating and control method. According to the method, cryogenic fluids in cryogenic medium processing are effectively stabilized, regulated and controlled, the dry degree of the liquid nitrogen in pipeline delivering is decreased, and the utilization rate of the fluids during liquid nitrogen ultra-low temperature cutting is increased. A liquid nitrogen delivering device is compact in structure, a vacuum pipeline is adopted, the heat loss in the pipeline is reduced, the liquid nitrogen gasification rate is decreased, the two-phase flow gas mass fraction is decreased, the liquid nitrogen jet flow state is stabilized, and the liquid nitrogen flow is accurately regulated and controlled.

Owner:DALIAN UNIV OF TECH

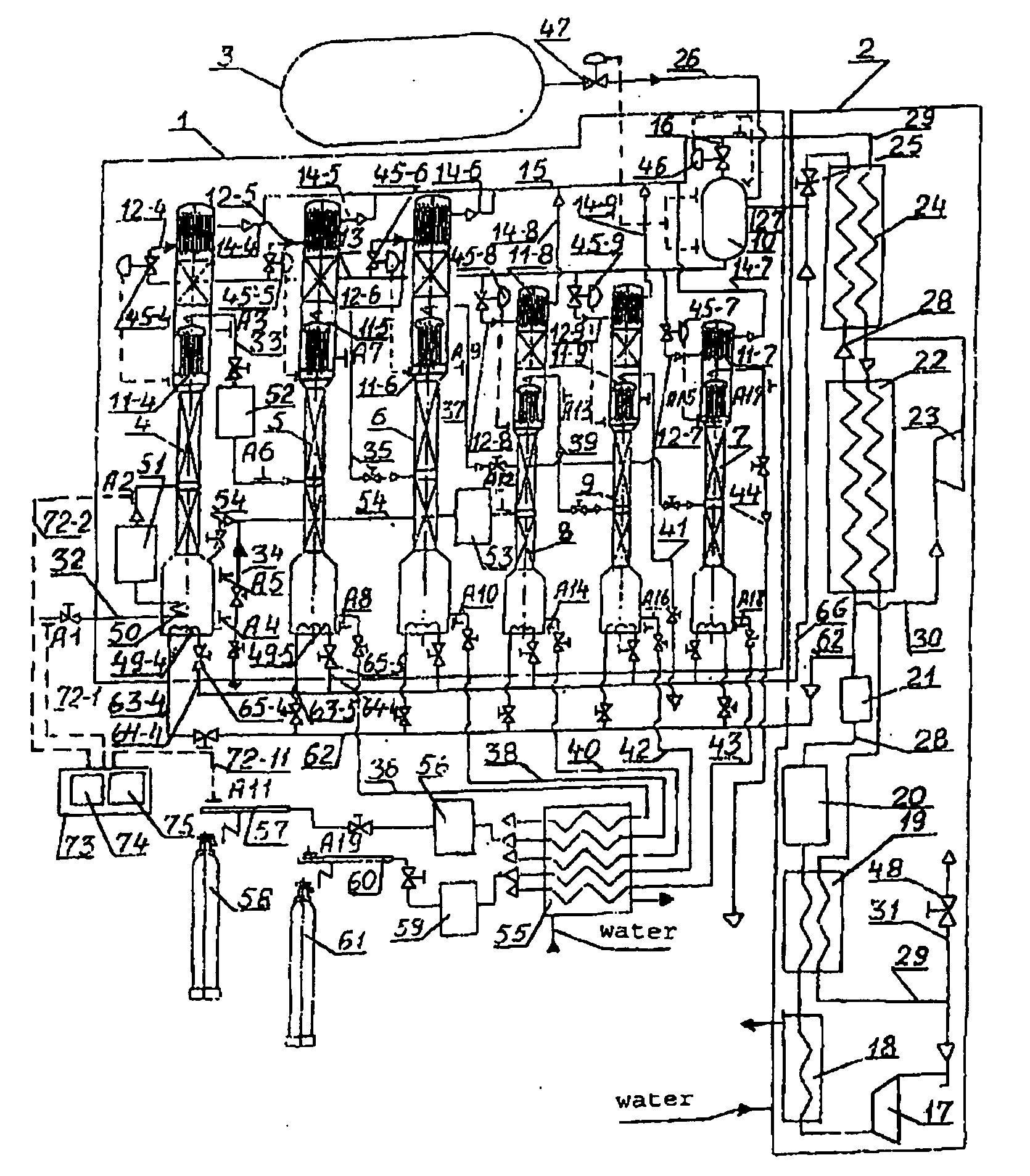

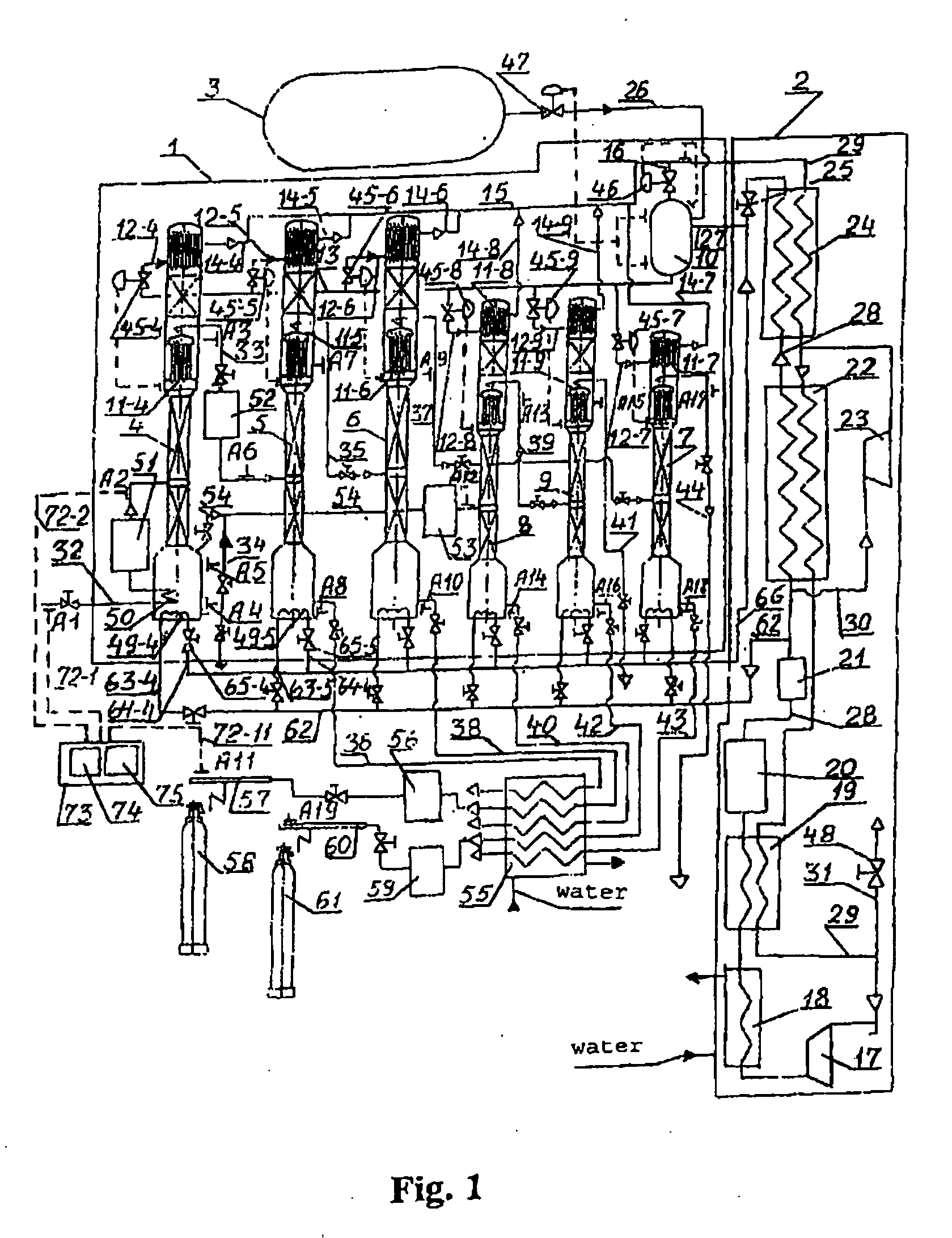

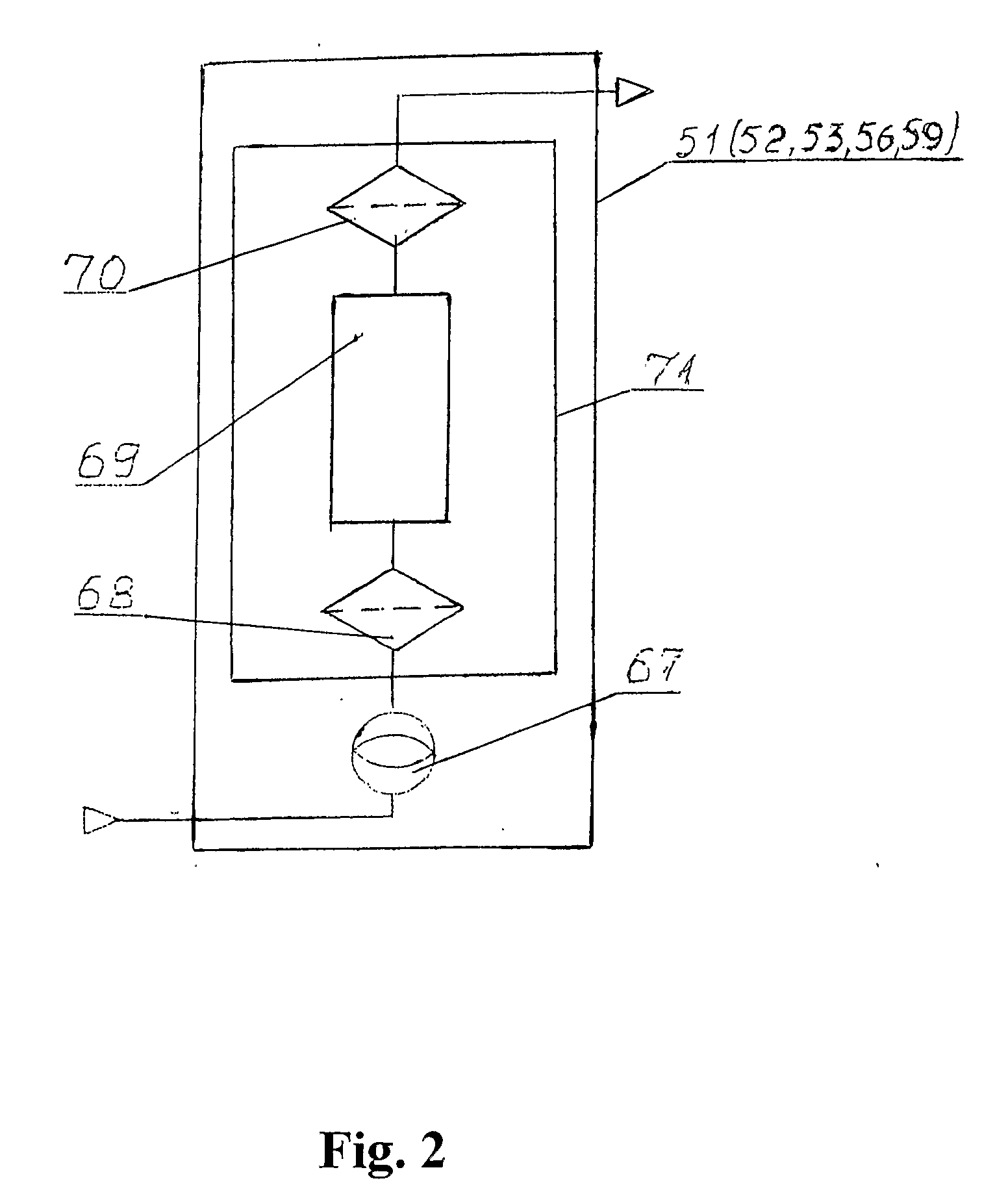

Method for Purifying and Separating a Krypton-Xenon Mixture by Rectification and a Device for Carrying Out Said Method

InactiveUS20090188278A1Increase productivityImprove efficiencySolidificationLiquefactionKryptonFiltration

The invention relates to cryogenic engineering, in particular to purifying krypton-xenon mixture and is usable in the chemical and oil-and-gas industries. The inventive method comprises purifying and separating the mixture in rectification columns, wherein coolant is removed and returned to a cooling cycle, additionally removing radionuclides from krypton and xenon fractions and from krypton and xenon production flows by means of filtration and / or adsorption and / or rectification and / or absorption and / or chemical and / or physicochemical methods in apparatuses for additional removing radionuclides. Balloons for reception of the separated products are certified with respect to radionuclides content and / or activity prior to and after the filling thereof. An installation for carrying out the method is also disclosed, allowing to additionally remove radionuclides from the separated products in such a way that the products can be used, for example, for medical purposes and to increase the cost efficiency of purification and separation processes.

Owner:SAVINOV MIKHAIL JURIEVICH

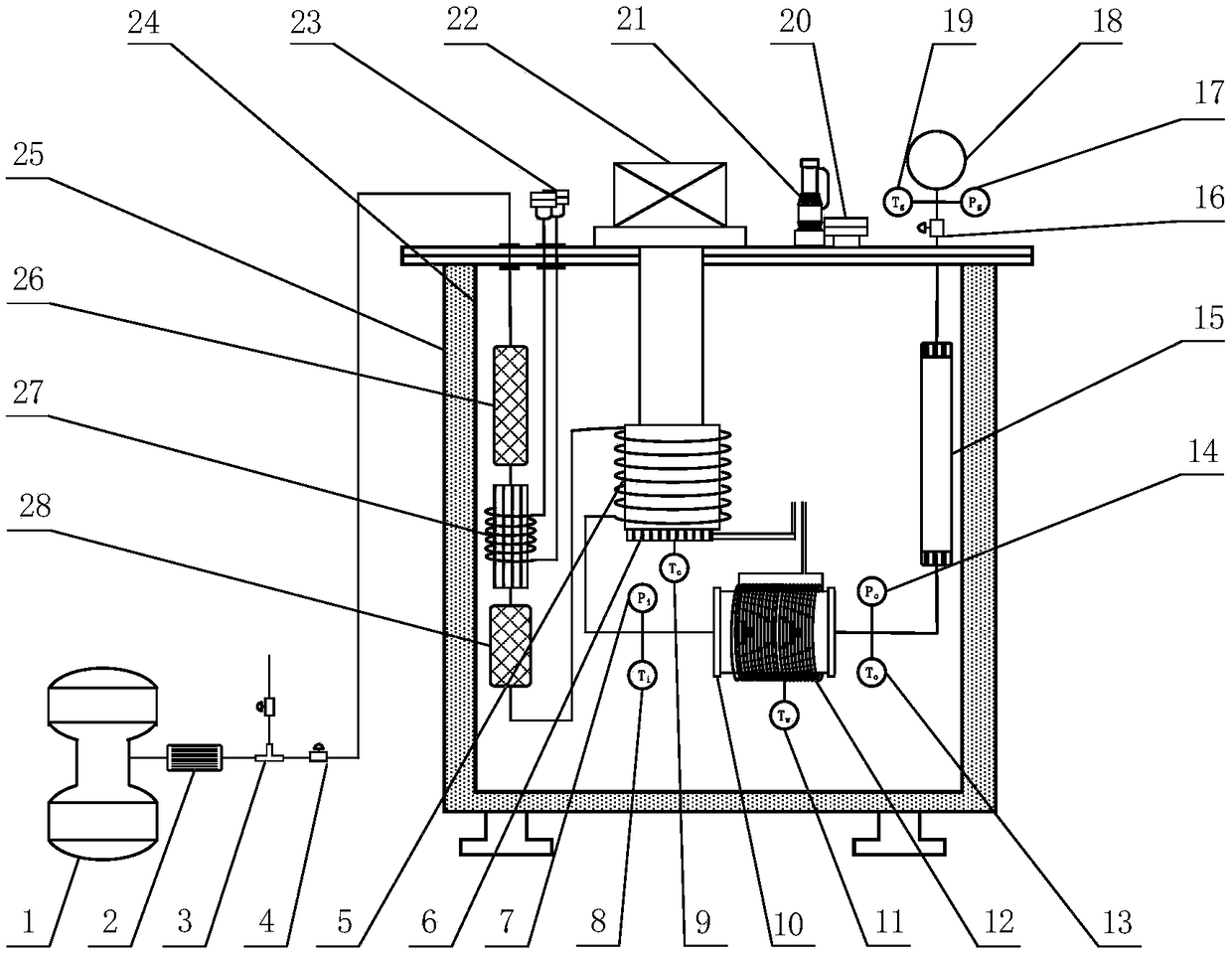

Cryogenic alternating flow heat transfer property testing platform and method

PendingCN109490359AMeasure temperature in real timeMeasure pressure in real timeMaterial heat developmentTemperature controlEngineering

The invention discloses a cryogenic alternating flow heat transfer property testing platform and a method and relates to the field of cryogenic engineering. The testing platform comprises a driving unit, a temperature control unit, a testing unit and a phase modulating unit. By providing a temperature sensor, a pressure sensor and a dynamic pressure sensor to separately measure the temperature andpressure signals in a to-be-tested apparatus in real time under a condition close to the actual operating working condition, basic heat exchange data of the to-be-tested apparatus under different parameters can be acquired, so that design and optimization of the to-be-tested apparatus can be guided effectively.

Owner:ZHEJIANG UNIV

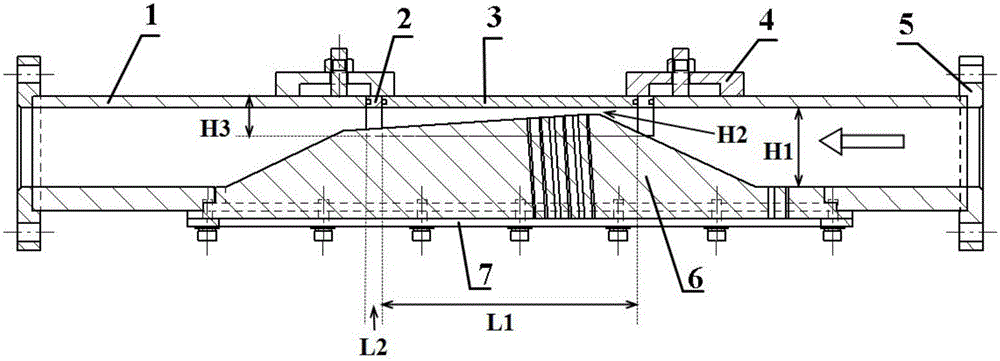

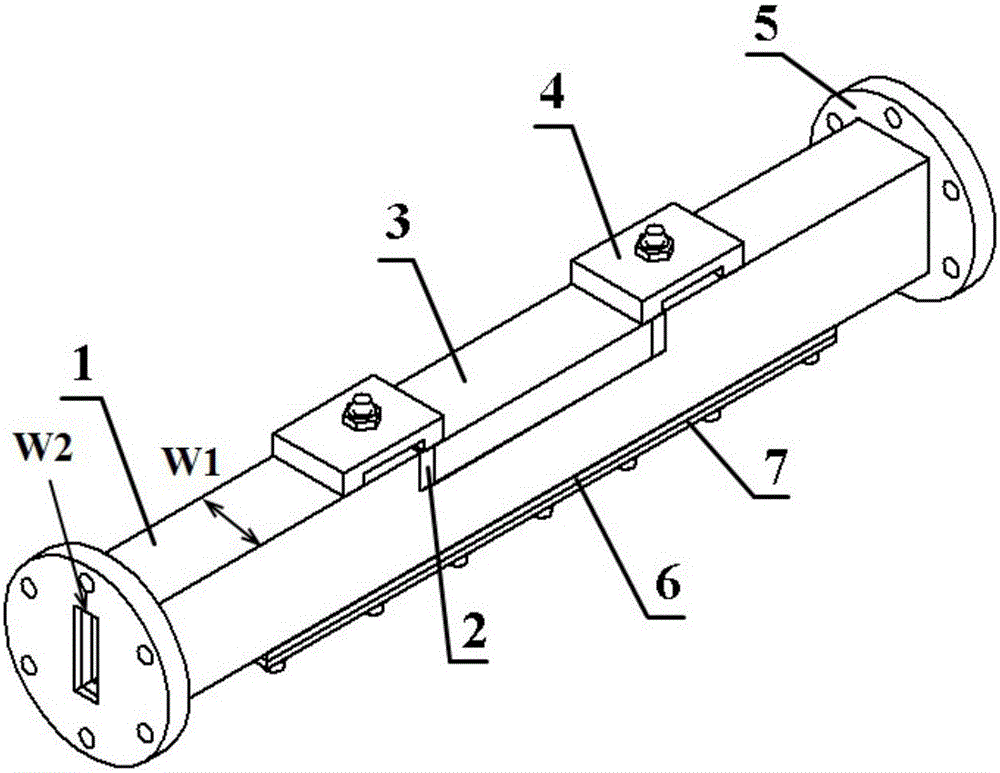

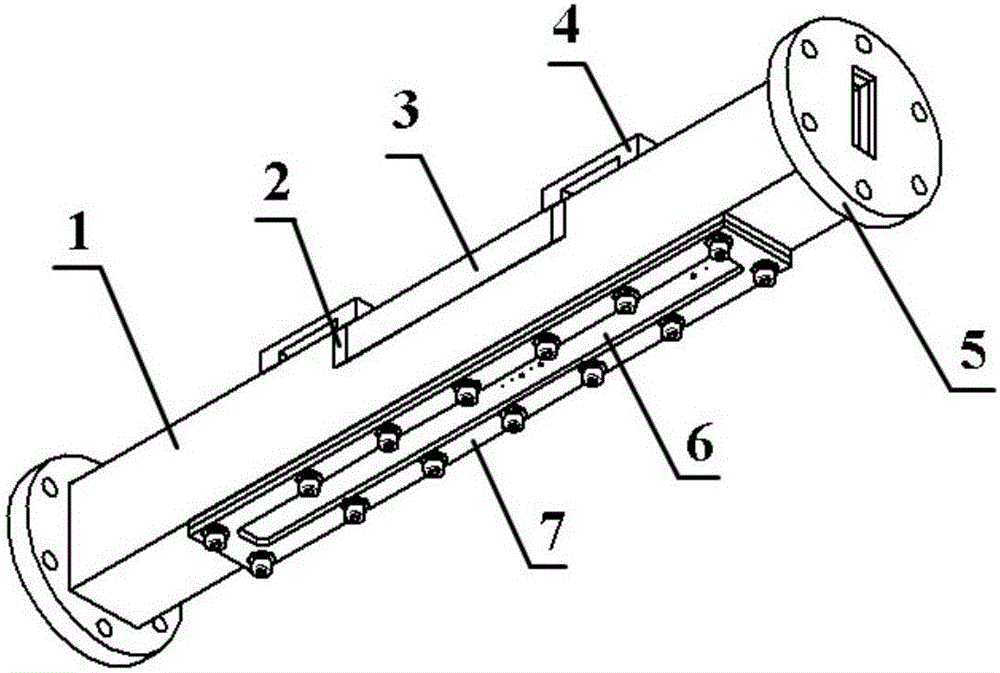

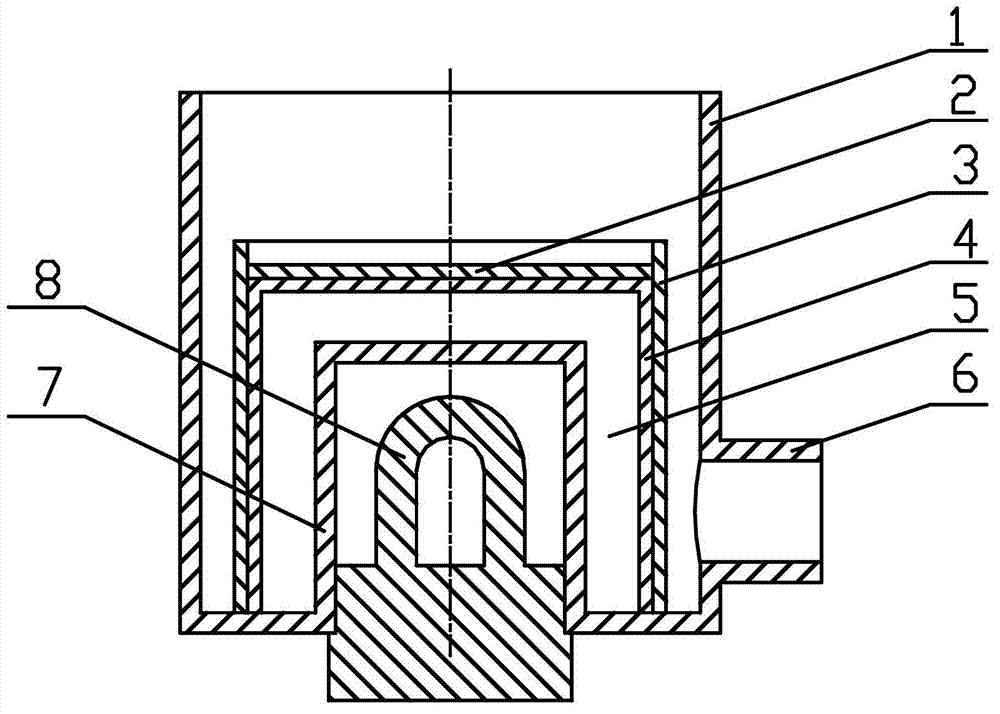

Detachable cryogenic liquid cavitation flow observational test section

InactiveCN106053015ANot easy to damageSimple structureHydrodynamic testingDirect flow property measurementVisual testVisual observation

The invention relates to a detachable cryogenic liquid cavitation flow observational test section, which belongs to the technical field of fluid mechanical engineering, cryogenic engineering and aerospace engineering. The detachable cryogenic liquid cavitation flow observational test section comprises temperature sensors and pressure sensors, wherein the temperature sensors and the pressure sensors are installed on a runner lower panel through installation holes; the runner lower panel is in contact connection with a pipeline inside a basic runner through a notch at the lower part of the basic runner, and is fixedly connected on the basic runner through a pressing gasket; a visual observation window is formed in a notch at the upper part of the basic runner, and two buffer gaskets are installed on both sides of the visual observation window separately; a connecting bayonet is fixedly connected on the basic runner; and both sides of the basic runner are provided with flange plates. The detachable cryogenic liquid cavitation flow observational test section is assembled by adopting a plurality of parts, is simple in structure, has few components, greatly reduces cost when compared with an integrated visual test section made of glass materials entirely, is convenient in detachment and installation, and is not prone to damage during the detachment and installation process.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-efficiency hydrogen removal device in high-vacuum multilayer heat-insulation cryogenic container

InactiveCN102814146AEfficient removalLow costOther chemical processesPressure/vacuum vesselsElectricityGlass fiber

The invention relates to a high-efficiency hydrogen removal device in a high-vacuum multilayer heat-insulation cryogenic container, belonging to the technical field of cryogenic engineering and cryogenic technology. The high-efficiency hydrogen removal device comprises an gas outlet device, a cover mesh, a side mesh, a piece of glass fiber cloth, an adsorption chamber, an gas inlet pipe, an concave base plate, an electric heater and a gas absorbing agent which is the copper oxide powder. The gas inlet pipe and the gas outlet pipe are welded in the corresponding position of the upper part of the outer tank of the cryogenic container; the copper oxide powder is put in the adsorption chamber; when the vacuum degree of the interlayer of the adsorption chamber varies, the copper oxide powder is subjected to chemical reaction with the hydrogen in the vacuum interlayer in the electric heating form to generate copper and water vapor, wherein the water vapor is adsorbed by other gas absorbing agents in the vacuum layer; and the hydrogen in the vacuum interlayer of the cryogenic container is removed effectively so that the vacuum interlayer returns to the high vacuum state. The high-efficiency hydrogen removal device is arranged outside the interlayer of the cryogenic container, can be used for removing the hydrogen in the interlayer effectively to maintain the vacuum degree of the interlayer and has the advantages of low-cost, convenience of installation, long service life and other gas absorbing agent saving.

Owner:SHANGHAI JIAO TONG UNIV

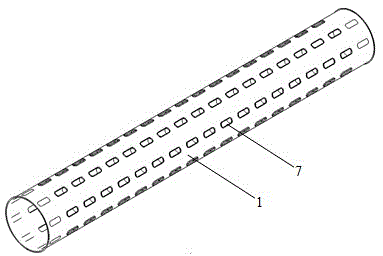

Anti-frosting LNG air-heated nanofluid heat exchange pipe

ActiveCN105651104AMaintain air qualityStable media flowStationary tubular conduit assembliesIce removalSocial benefitsFrost

The invention discloses an anti-frosting LNG air-heated nanofluid heat exchange pipe which comprises an outer heat exchange pipe and an inner heat exchange pipe, wherein the upper parts of the outer heat exchange pipe and the inner heat exchange pipe are fixedly connected through a first hub support; the lower parts of the outer heat exchange pipe and the inner heat exchange pipe are fixedly connected through a second hub support; a capillary heat exchange pipe is arranged between the outer heat exchange pipe and the inner heat exchange pipe; a nanofluid is introduced in the capillary heat exchange pipe; through holes are uniformly distributed in the outer heat exchange pipe; and bulges are arranged on the edges of the through holes. The anti-frosting LNG air-heated nanofluid heat exchange pipe can be widely applied to low-temperature liquid vaporizers and low-temperature storage and transportation equipment self superchargers, the frost can be efficiently removed, the gas supply quality at the outlet of a vaporizer is maintained, and the anti-frosting LNG air-heated nanofluid heat exchange pipe has the advantages of low cost, convenience in mounting and disassembly, and the like, and has remarkable economic benefits and social benefits in cryogenic engineering.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

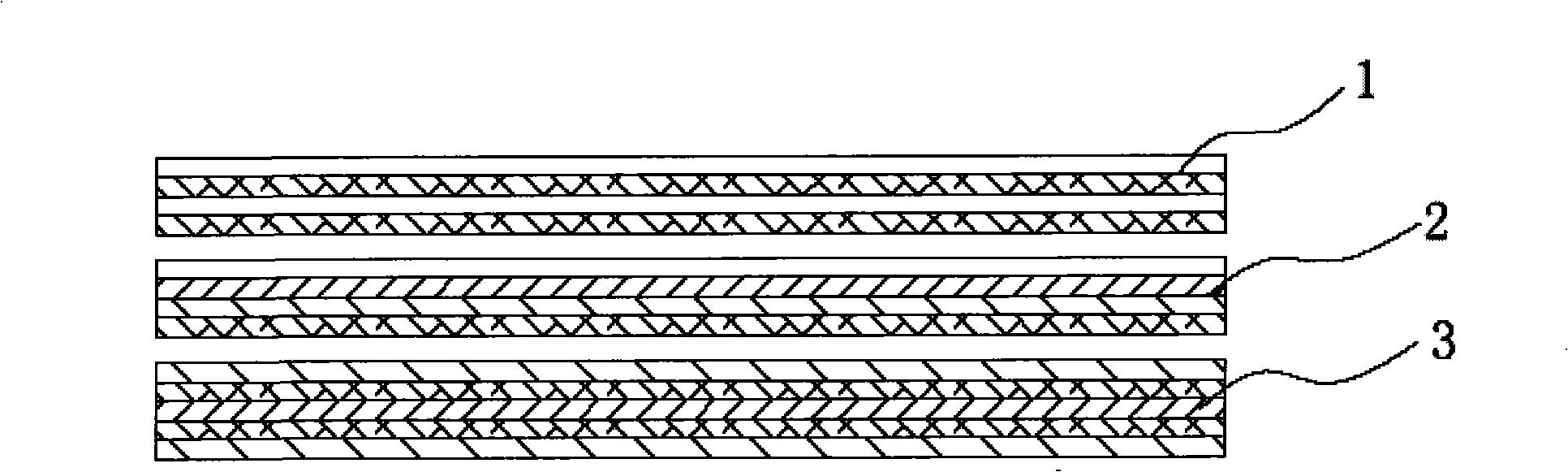

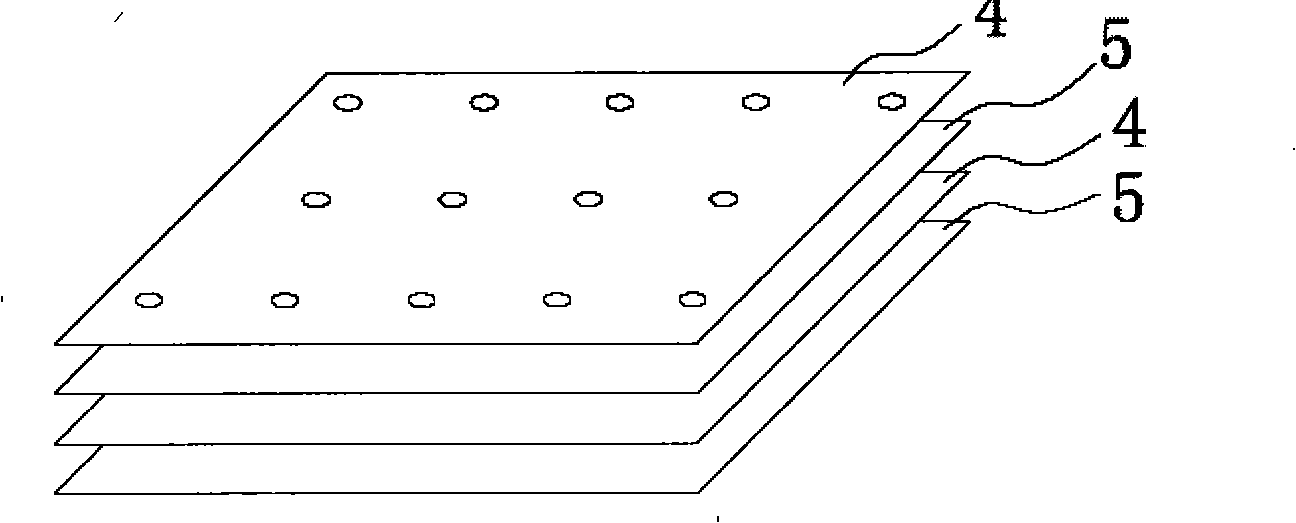

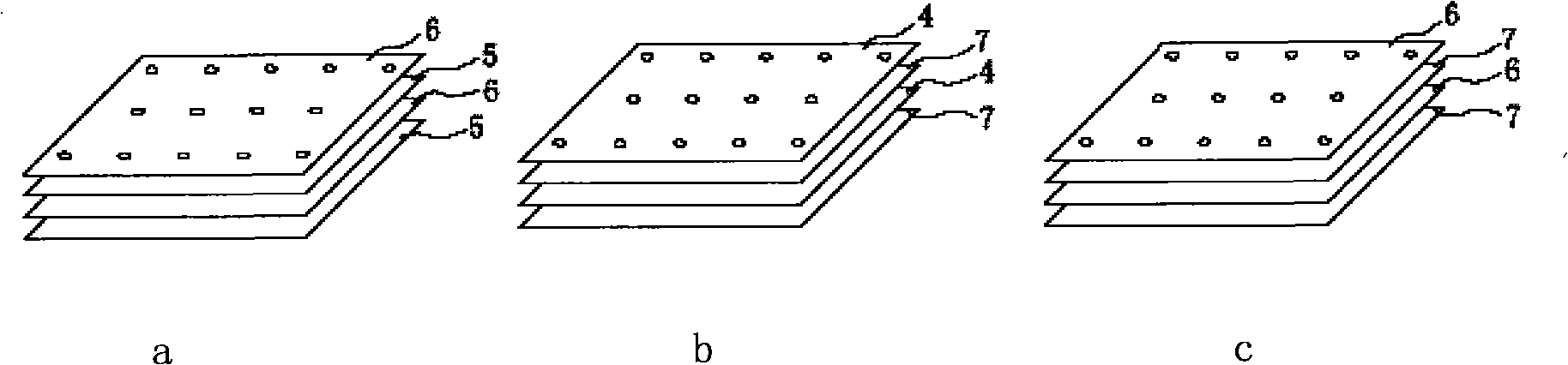

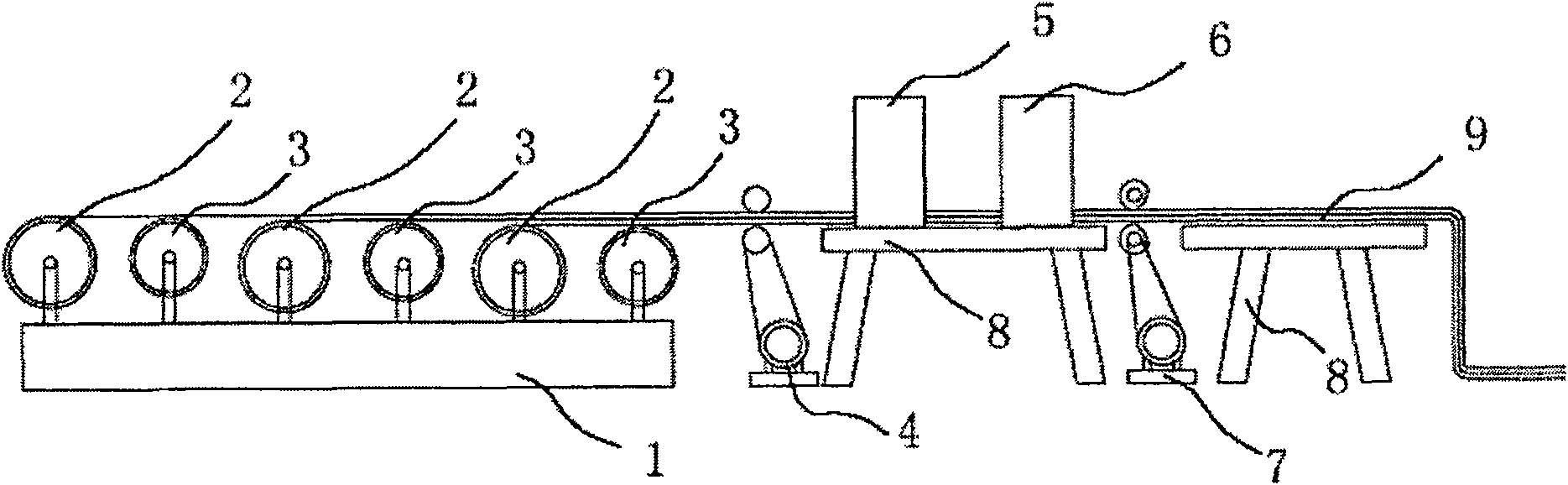

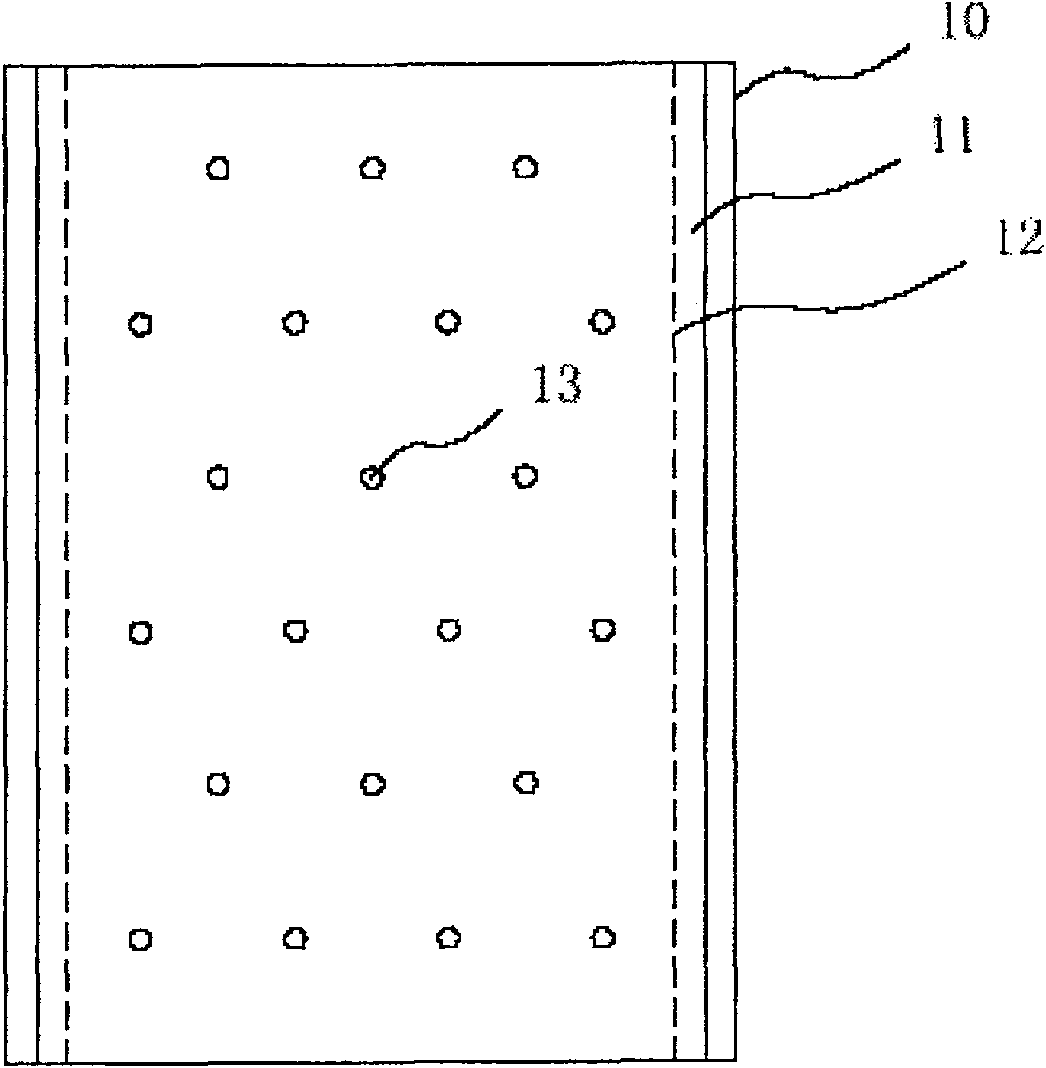

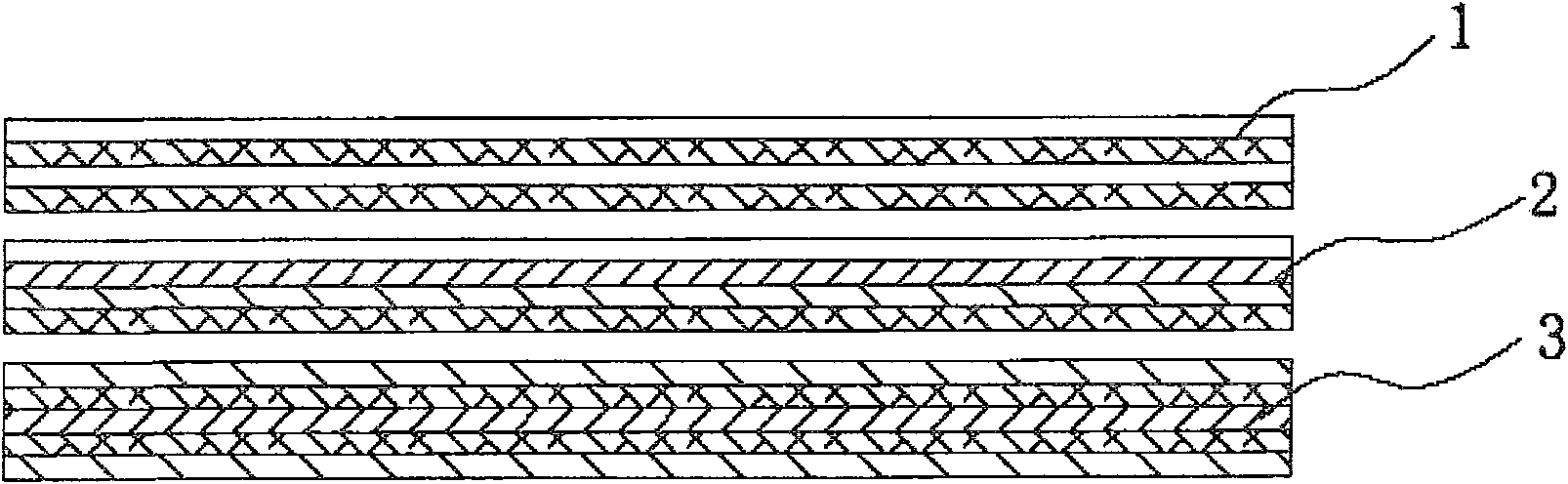

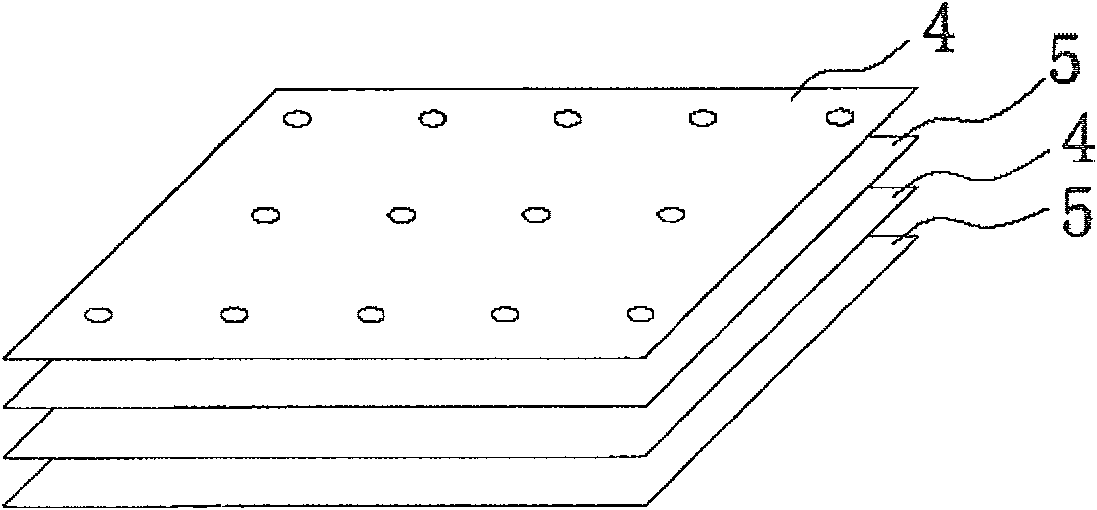

High vacuum multiple layer heat insulation quilt manufacture method

InactiveCN100564986CTo achieve the effect of heat insulationReduce workloadThermal insulationPipe protection by thermal insulationSocial benefitsProduction line

The invention provides a method for making a microvacuum multilayer heat-insulating quilt, belonging to cryogenic engineering and cryogenic technical field. The method comprises the following steps of: preparing a mechanized production line; a plurality of reflecting layers and heat insulating layers is sewed into a quilt by seams after the plurality of reflecting layers and heat insulating layers are alternately combined on the production line according to certain requirements; and the quilt is evenly penetrated to make holes. The microvacuum multilayer heat-insulating quilt made by using the method reduces workloads for winding heat-insulating materials, shortens binding period, guarantees that the heat insulation quilt can not loose during using, and even can improve vacuumizing efficiency and maintain high vacuum degree between interlayer on the premise of a guarantee of excellent and stable heat insulation performance, thereby the method has more advantages of lot manufacturing and producing of cryogenic storage and transportation equipment, and prominent economic benefit and social benefit in cryogenic engineering.

Owner:SHANGHAI JIAOTONG UNIV

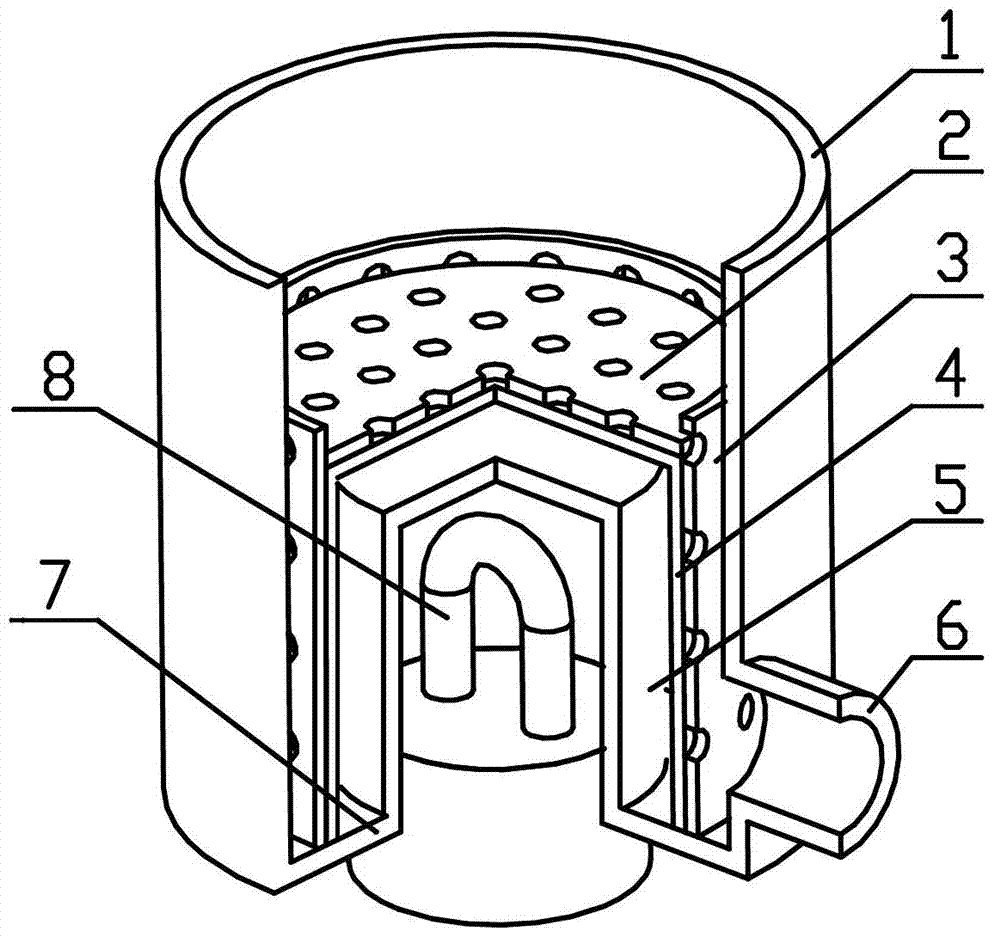

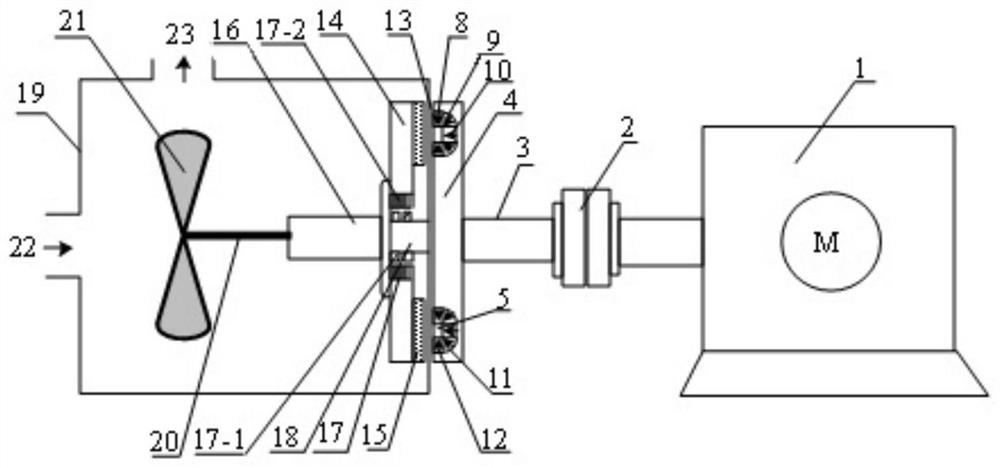

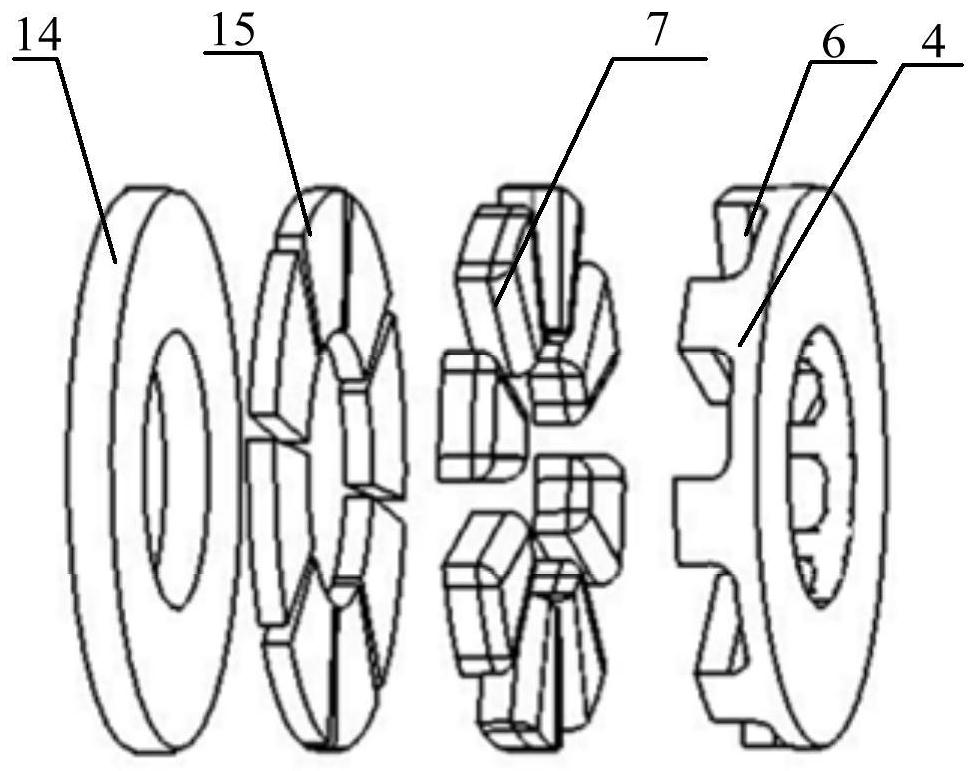

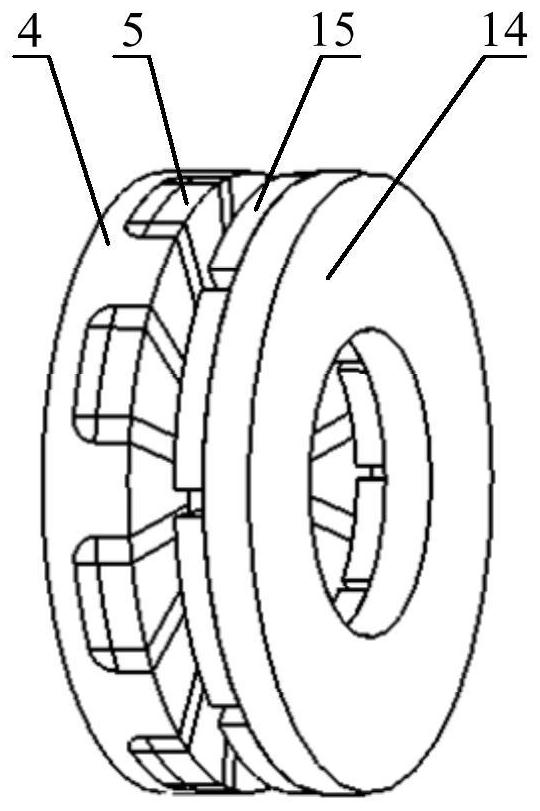

Composite magnetism gathering type permanent magnet-superconducting coupling transmission device for cryopump

PendingCN114710004AReduce axial loadIncrease profitMagnetic circuitMagnetic bearingsPermanent magnet rotorMagnetic tension force

The invention belongs to the field of magnetic coupling transmission in low-temperature engineering, and particularly relates to a composite magnetism gathering type permanent magnet-superconducting coupling transmission device for a low-temperature pump, the low-temperature pump comprises a pump shell, an impeller shaft, an impeller, an input shaft, a permanent magnet rotor yoke, a superconducting rotor yoke and an output shaft, the input shaft and the permanent magnet rotor yoke are arranged on the outer side of the pump shell, and the superconducting rotor yoke and the output shaft are arranged on the inner side of the pump shell; the inner side of the permanent magnet rotor yoke is provided with a plurality of U-shaped grooves internally provided with composite magnetism gathering type U-shaped permanent magnet poles and magnetic conductive iron sheets, a circle of fan-shaped superconducting sheets are arranged on the superconducting rotor yoke at intervals, the permanent magnet poles and the superconducting sheets are correspondingly connected in a non-contact mode at intervals through working air gaps, and the middle of the superconducting rotor yoke is rotationally connected with a suspension component through a radial magnetic suspension bearing. The outer side of the superconducting rotor yoke is fixedly connected with the output shaft. By improving the arrangement mode of the magnetic poles of the permanent magnet disc, leakage flux of the permanent magnet rotor is reduced, and excitation magnetic field distribution is improved; the transmission torque is improved by using the strong capture magnetic field and high current-carrying density of the superconducting sheet, and non-contact torque transmission from a normal temperature end to a low temperature end is realized.

Owner:HENAN POLYTECHNIC UNIV

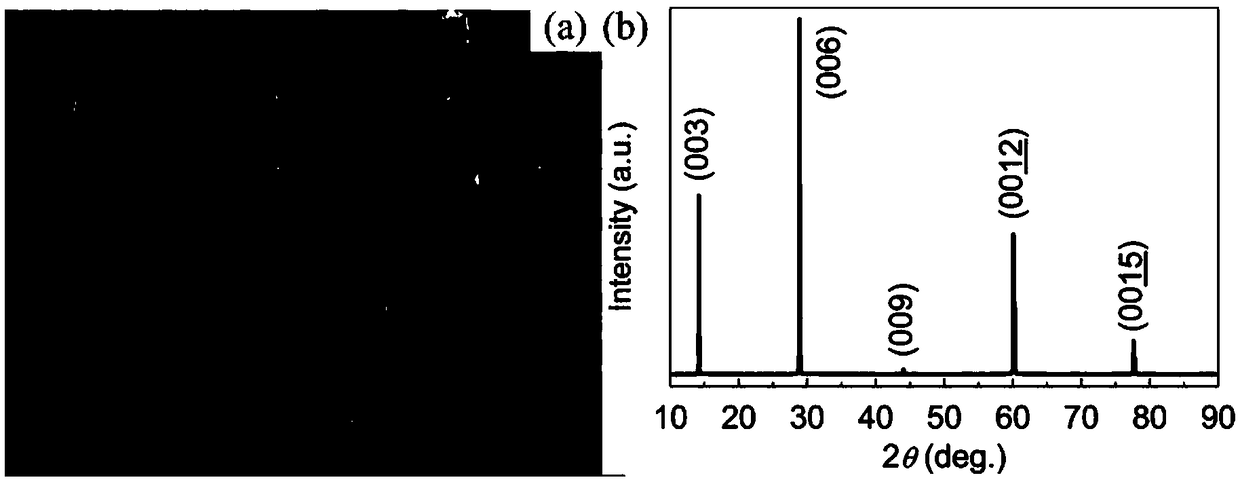

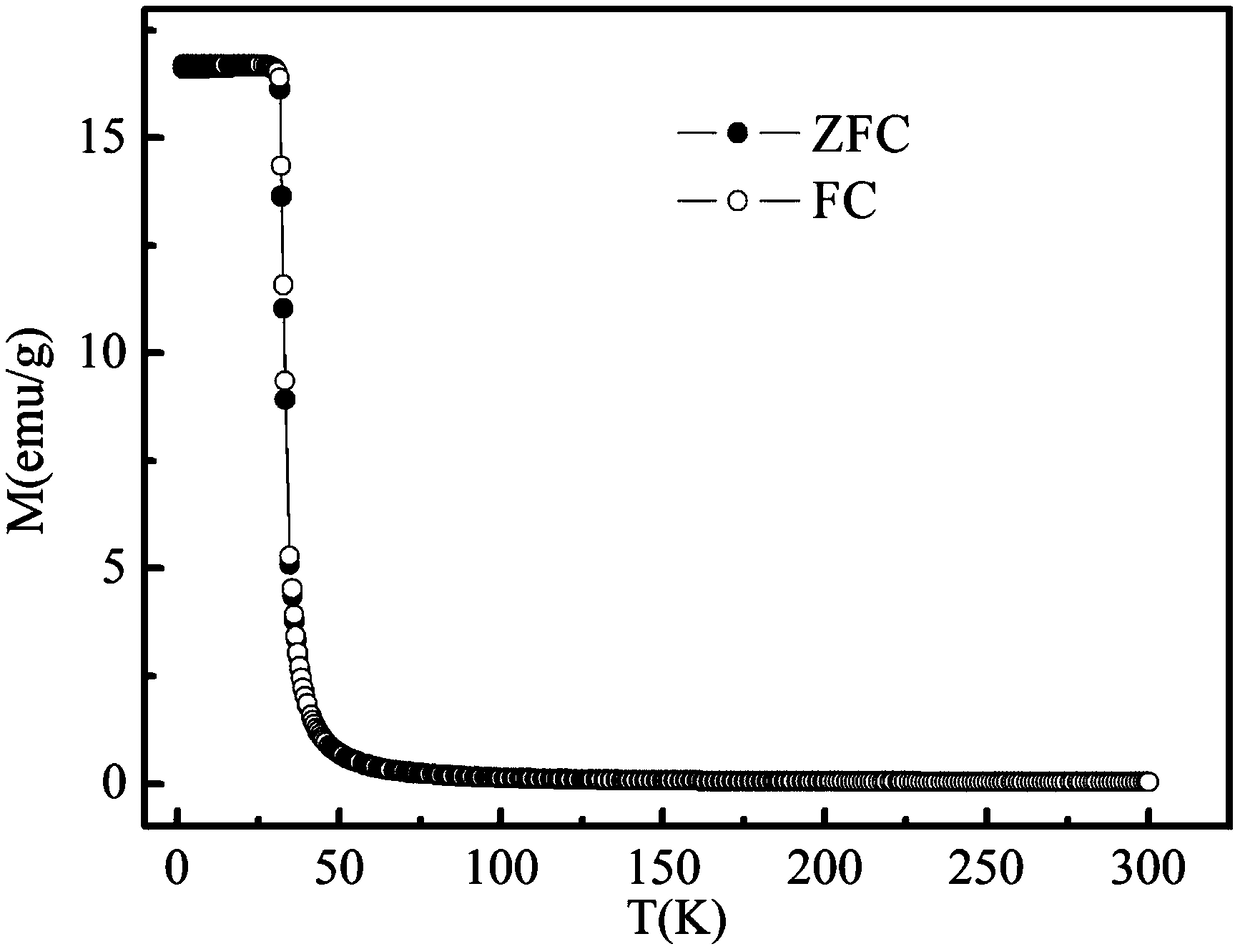

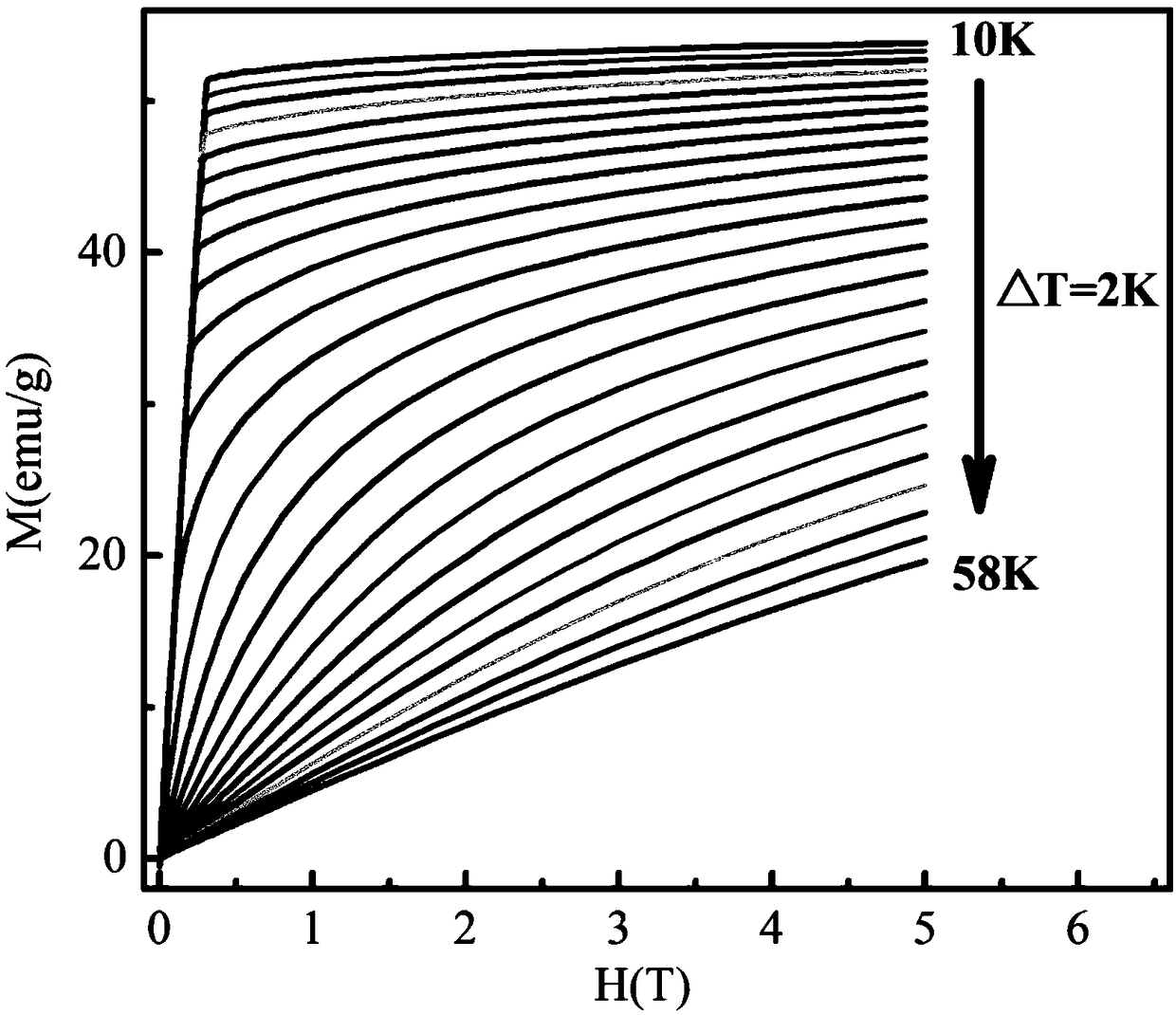

CrBr3 single crystal with magnetocaloric effect and preparation method and application thereof

InactiveCN108754606AEasy to purifySynthesis temperature is lowPolycrystalline material growthInorganic material magnetismGas phaseHigh energy

The invention discloses a CrBr3 single crystal with a magnetocaloric effect and a preparation method and an application thereof, and belongs to the technical field of magnetic refrigeration materials.The preparation method includes placing a CrBr3 polycrystalline raw material into a quartz tube and form high vacuum; placing the quartz tube horizontally placed into a tubular furnace of a second temperature zone, heating a tubular furnace source zone and a growth zone simultaneously and then cooling to the room temperature after the temperature is constant to obtain the CrBr3 single crystal. The preparation method has low synthesis temperature, simple equipment and simple manufacturing process. The gas phase transport process is beneficial to the purification of the material, so that the single crystal has high purity and good quality. The prepared single crystal material has secondary phase transition of ferromagnetic to paramagnetic in 33K, is stable in performance under an applied magnetic field, and has large magnetic entropy change and relative cooling capacity. The preparation parameters are provided for development and application of magnetic refrigeration, and the single crystal can be used in the technical fields of high energy physics, low temperature engineering precision instruments, power industry and the like.

Owner:BEIJING UNIV OF POSTS & TELECOMM

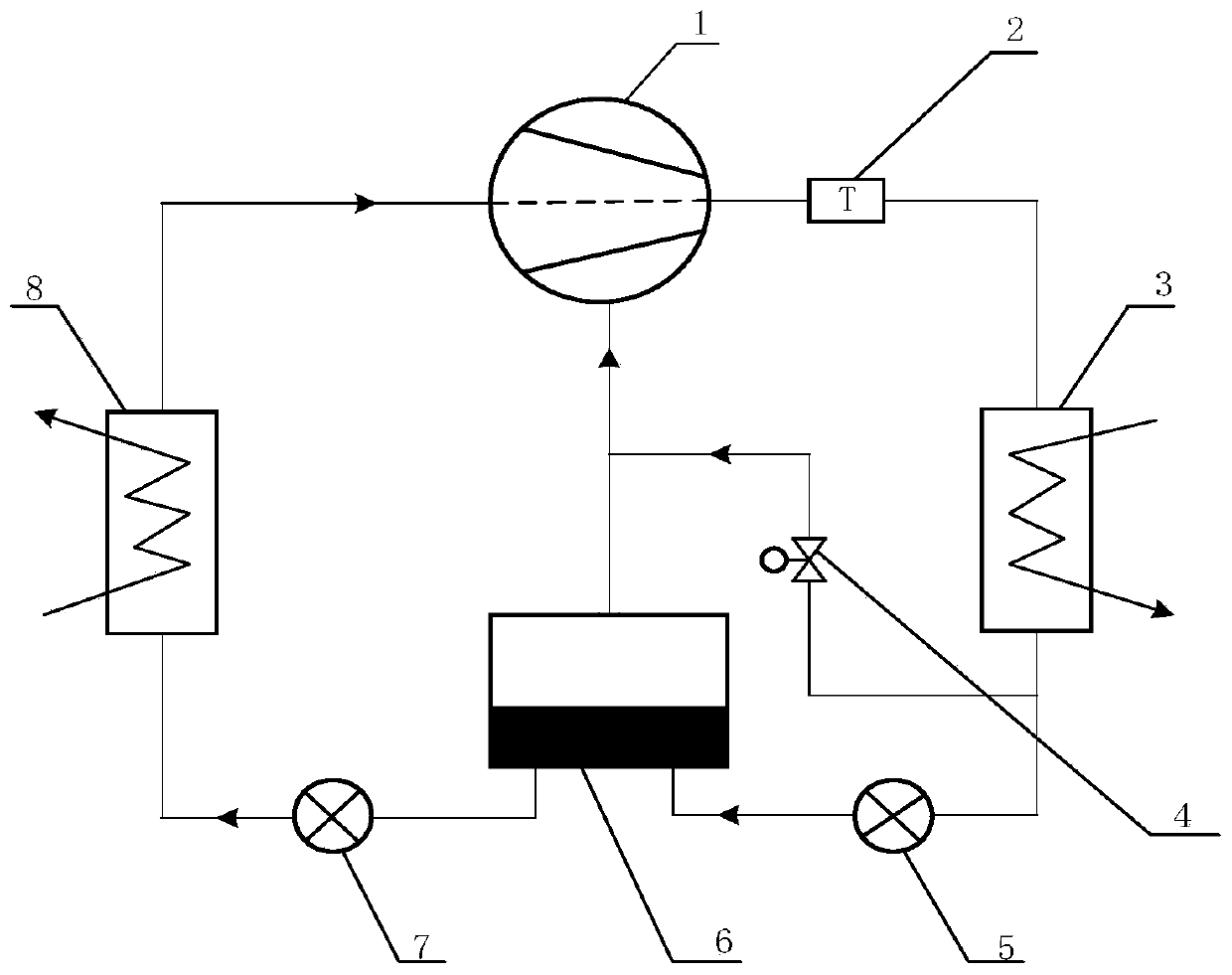

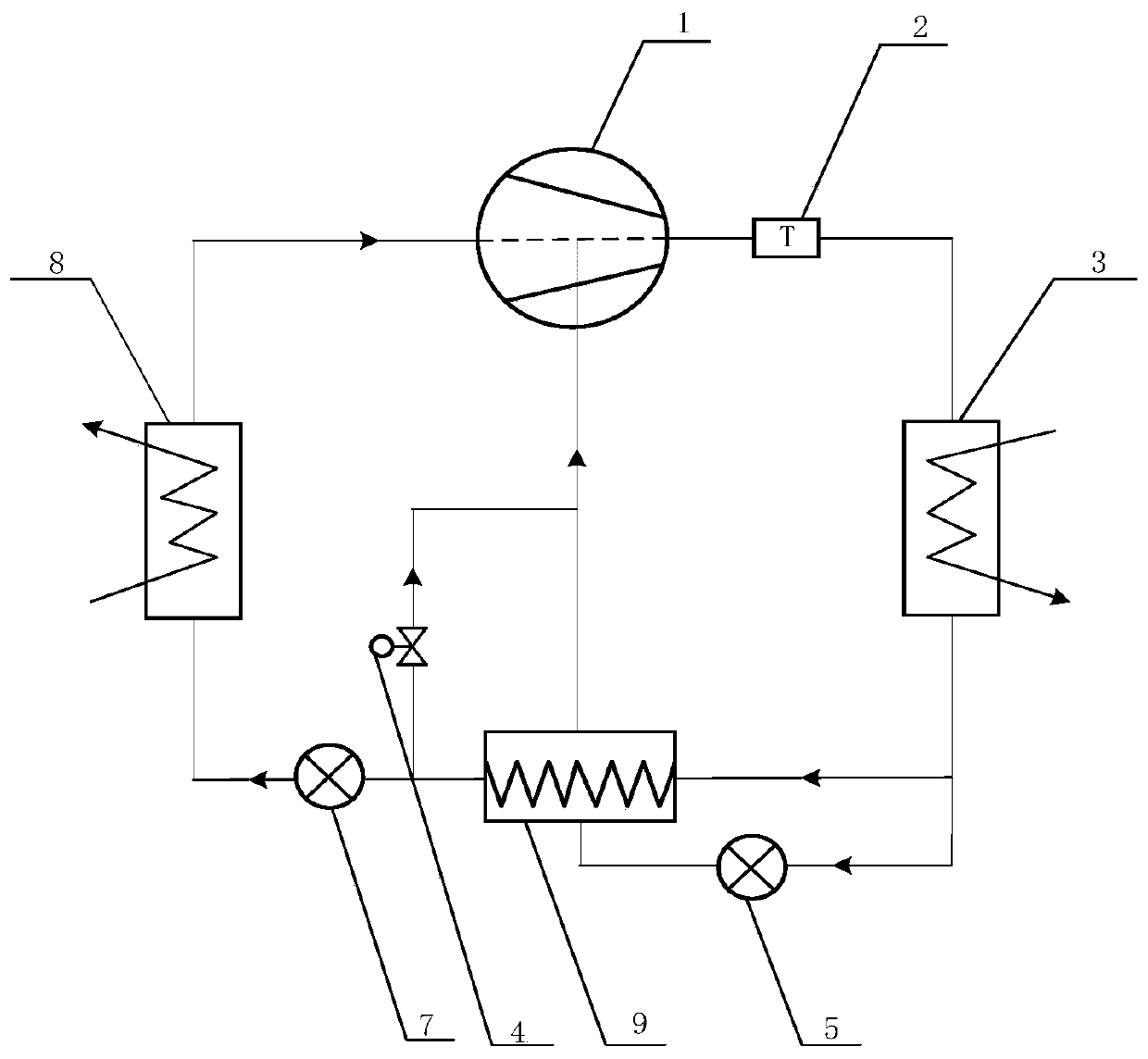

Method for cooperatively cooling high-pressure ratio refrigeration compressor by diverted gas and liquid jointly entering gas supplementing port

InactiveCN111023605AImprove intelligent operationReduce exhaust temperatureMechanical apparatusCompression machines with non-reversible cycleRefrigeration compressorEngineering

The invention discloses a method for cooperatively cooling a high-pressure ratio refrigeration compressor by diverted gas and liquid jointly entering a gas supplementing port, and belongs to the fieldof refrigeration and low-temperature engineering. The method is characterized in that an original economizer system is improved, which means a temperature sensor, a flow regulating valve and a drainage pipeline are additionally arranged, wherein the temperature sensor detects the discharge temperature of the compressor in real time, the injected amount of refrigerant liquid is controlled by adjusting the opening degree of the flow regulating valve, and the injected refrigerant liquid enters the compressor through the gas supplementing port after being mixed with gas in a gas supplementing pipeline, so that the the compressor is prevented form being additionally provided with a liquid supplementing port; and the compressor is supplemented with the gas and the liquid, so that the dischargetemperature can be effectively reduced, and in the case of high pressure ratio, a heat pump / a refrigeration circulation system can still achieve stable and efficient operation. According to the method, the problem that in the case of high pressure ratio, the discharge temperature of the compressor is too high can be solved.

Owner:BEIJING UNIV OF TECH

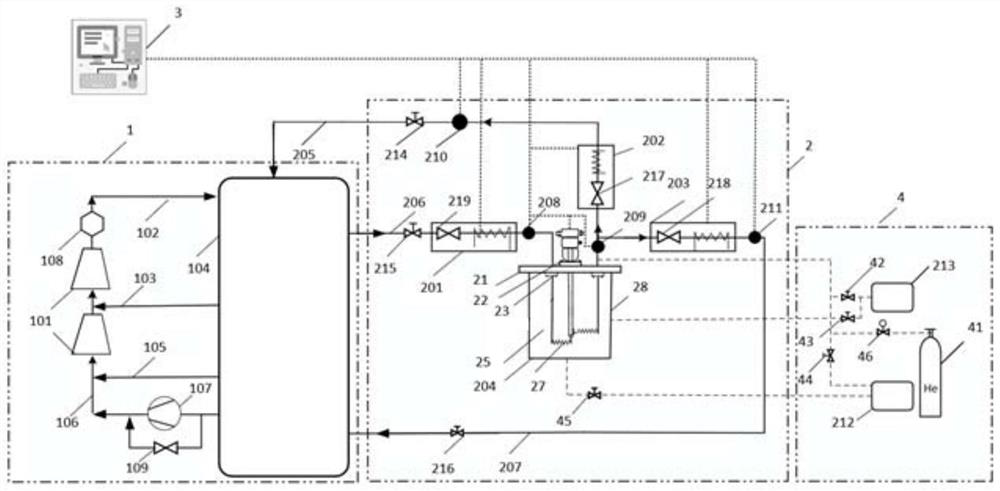

Testing system for low-temperature valve

ActiveCN112649190ANo need to change operating conditionsImprove efficiencyMachine valve testingData acquisitionProcess engineering

The invention belongs to the field of refrigeration and low-temperature engineering, and discloses a testing system for a low-temperature valve. The system comprises a refrigeration unit, a test device, a data acquisition and monitoring unit and a gas evacuation and replacement device; the refrigeration unit is used for providing a low-temperature test working medium for the test device; the gas evacuation and replacement device is used for carrying out gas replacement on a transmission pipeline in the test device; the test device is used for detecting internal and external leakage rates of the low-temperature valve, valve flow characteristics and valve reliability; the data acquisition and monitoring unit is used for displaying and storing experimental data of the test device in the testing process of the low-temperature valve in real time; the refrigeration unit comprises a helium compressor unit, a cold box and a helium transmission pipeline; the helium compressor unit is connected with the cold box through the helium transmission pipeline; the cold box is connected with the test device; the helium compressor unit pressurizes helium and then inputs the helium into the cold box for cooling; and the cold box outputs low-temperature high-pressure helium to the test device. The testing system is suitable for testing low-temperature valves with the temperature range of 2.2-300K and the pressure range of 1bar-20bar.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

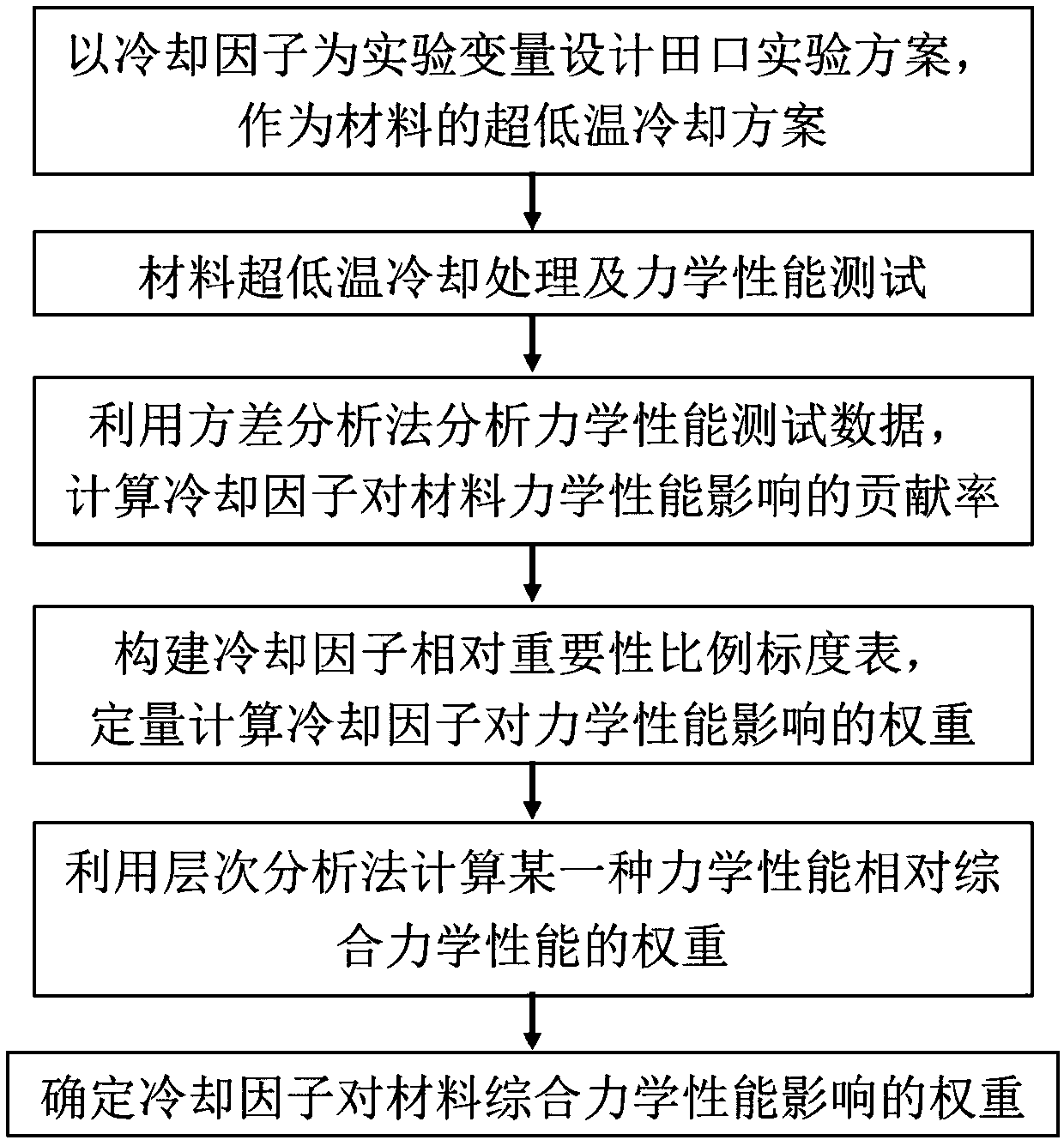

Method for evaluating influence on mechanical property of material by ultralow-temperature cooling

ActiveCN108195707ARealize quantitative evaluationImprove accuracyMaterial strength using tensile/compressive forcesDesign optimisation/simulationEvaluation resultStrength of materials

The invention belongs to the field of low temperature engineering and relates to a method for evaluating the influence on the mechanical property of a material by ultralow-temperature cooling. The method comprises the following steps: designing a Taguchi experiment by taking a cooling factor as an experimental variable, making an ultralow-temperature cooling scheme of a test piece, implementing ultralow-temperature cooling treatment on the test piece according to the scheme and performing mechanical property test; analyzing test data by a variance analysis method and calculating the contribution rate of the cooling factor on the mechanical property influence; constructing a relative importance ratio scale table and quantitatively calculating the weight of the cooling factor on the mechanical property influence by virtue of a level analysis method; calculating the weight that a certain mechanical property of the material accounts for the comprehensive properties; and determining the weight of the cooling factor on the influence on the comprehensive properties of the material so as to represent the influence on the mechanical property of the material by ultralow-temperature cooling.By the method, quantitative analysis on the weight of the cooling factor on the influence on the comprehensive mechanical properties of the material is realized, and the evaluation result is accurateand reliable.

Owner:DALIAN UNIV OF TECH

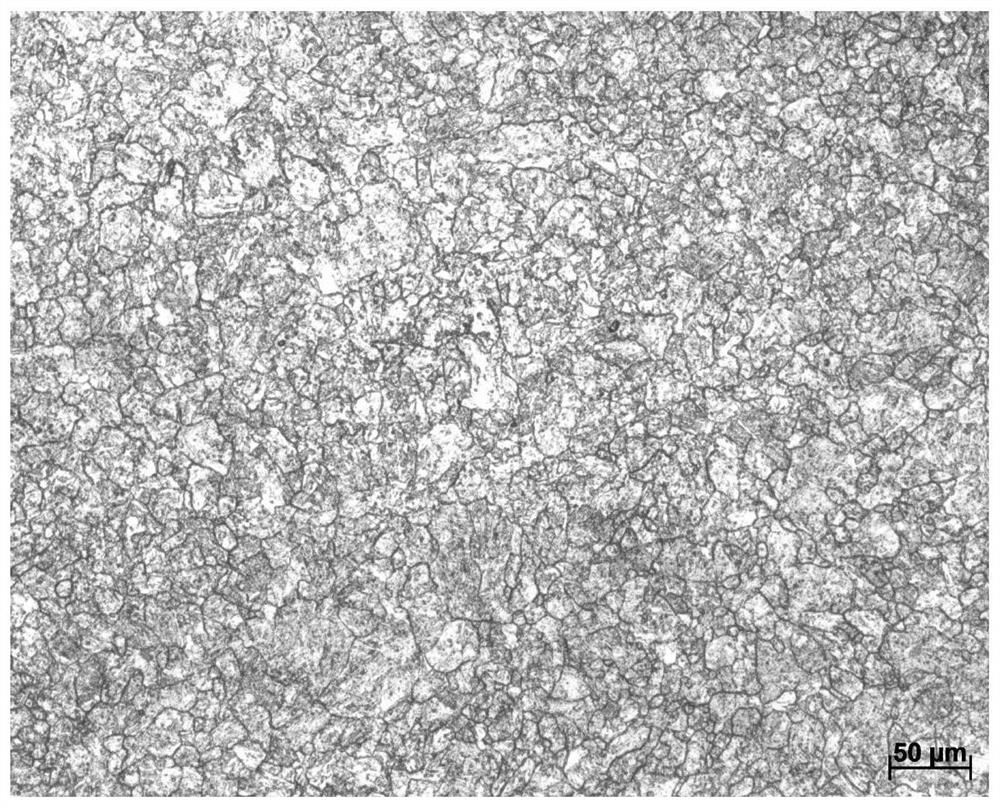

High-strength stainless steel for deep sea cryogenic engineering and manufacturing method of steel

ActiveCN105779901AImprove room temperature strengthImprove low temperature toughnessProcess efficiency improvementFishingImpurity

The invention discloses high-strength stainless steel for deep sea cryogenic engineering and a manufacturing method of the steel, and belongs to the technical field of stainless steel. Chemical components of the stainless steel comprise, by weight percent, smaller than 0.05% of C, 12.2% to 13% of Cr, 8.0% to 8.5% of Ni, 2.1% to 2.5% of Mo, smaller than 0.3% of Al, smaller than 0.0015% of N, smaller than 0.1% of Si, smaller than 0.01% of Mn, smaller than 0.005% of P, smaller than 0.001% of S and the balance Fe and inevitable impurities. The manufacturing method comprises the steps that a vacuum induction furnace and consumable electrode vacuum furnace dual smelting technology is adopted, and after smelting, a steel ingot is subject to annealing, cogging, forging or rolling to form the steel. The steel and the method have the beneficial effects that after heat treatment is carried out, and the steel has the excellent strength and toughness matching performance and excellent salt-fog resistance performance, and is suitable for structural parts, fasteners and the like of deep sea drilling exploitation or fishing equipment.

Owner:CENT IRON & STEEL RES INST

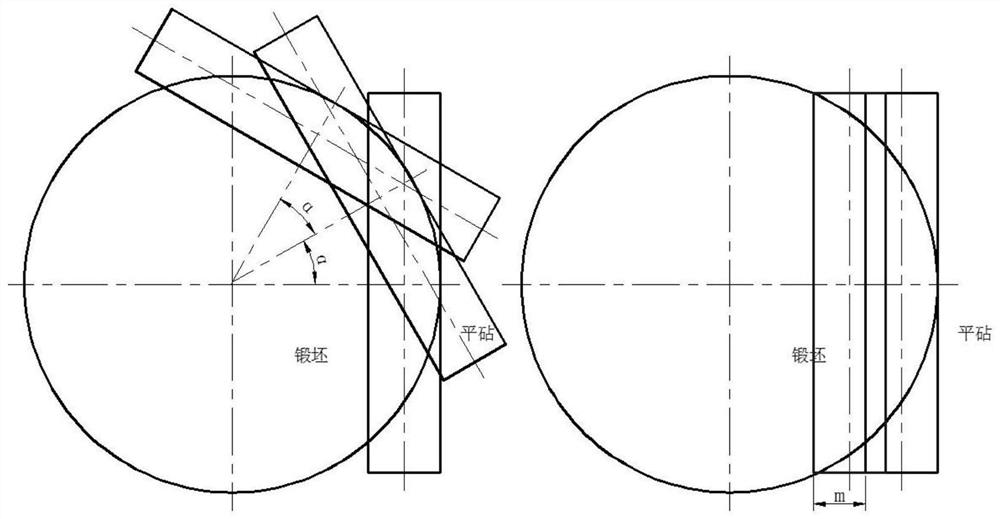

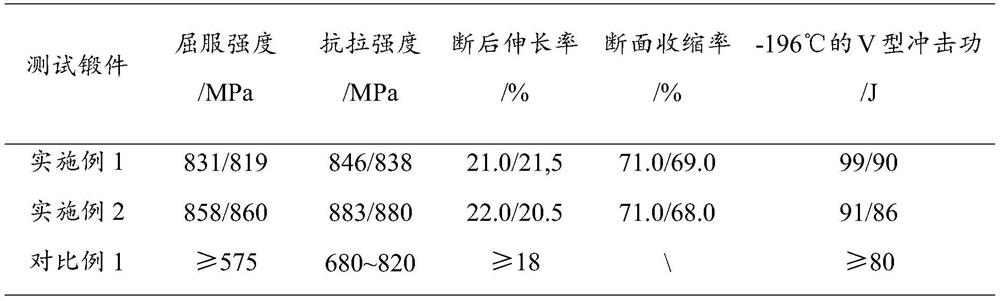

Manufacturing method of 9% Ni steel ultra-large-specification cake-shaped forge piece for ultralow-temperature engineering

ActiveCN112756525AImprove surface plasticityImprove surface qualityMetal-working apparatusPolishingIngot

The invention provides a manufacturing method of a 9% Ni steel ultra-large-specification cake-shaped forge piece for ultralow-temperature engineering, is suitable for manufacturing the 9% Ni steel ultra-large-specification cake-shaped forge piece with the diameter larger than 3000 mm and the thickness larger than 400 mm, and belongs to the technical field of metal hot working. The surface defects of a cylindrical steel ingot are cleaned through polishing, and a crack induction source is eliminated; the surface structure of the steel ingot is broken through stepped heating and pressing treatment, the surface plasticity of the cylindrical steel ingot is improved, the surface quality is improved, and a forging stock with good performance is obtained; and then the forging stock is subjected to three times of upsetting and two times of drawing-out, coarse grains in the forging stock are rapidly refined, a cylindrical blank body with excellent performance is obtained, the structure uniformity of the 9% Ni steel cake-shaped forge piece for the ultralow-temperature engineering is finally guaranteed, and forge piece cracks are avoided. The data of the embodiment show that the grain size of the obtained 9% Ni steel ultra-large-specification cake-shaped forge piece for the ultralow-temperature engineering reaches the level 6 or above, and the 9% Ni steel ultra-large-specification cake-shaped forge piece has extremely excellent room-temperature and low-temperature mechanical properties.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +3

Various material composite fire retardant-type high vacuum multiple layer heat insulation structure

InactiveCN100559052CGuaranteed flame retardant performanceGuaranteed CompatibilityThermal insulationPipe protection by thermal insulationFiberGlass fiber

The invention relates to a flame-retardant high-vacuum multi-layer thermal insulation structure compounded by various materials, which belongs to the field of cryogenic engineering and cryogenic technology. The invention includes high-temperature side combination, transition combination and low-temperature side combination. The high-temperature side combination adopts alternate combination of aluminum foil and glass fiber paper; the transition combination adopts double-sided aluminized film and glass fiber paper, or aluminum foil and chemical fiber paper, or double-sided coated Alternate combination of aluminum film and chemical fiber paper; the combination of double-sided aluminized film, glass fiber paper and chemical fiber paper is used for the low temperature side combination. The heat insulation structure of the present invention is non-combustible outside, the whole structure is flame retardant, and the low temperature heat insulation performance is better than the traditional flame retardant heat insulation structure, so the amount of heat insulation materials can be reduced, the cost of heat insulation materials can be reduced, and the distance between vacuum interlayers can be reduced. The effective volume inside the large cryogenic container is more conducive to the lightweight and volume maximization of mobile cryogenic storage and transportation equipment, and has significant economic and social benefits in cryogenic engineering.

Owner:SHANGHAI JIAO TONG UNIV

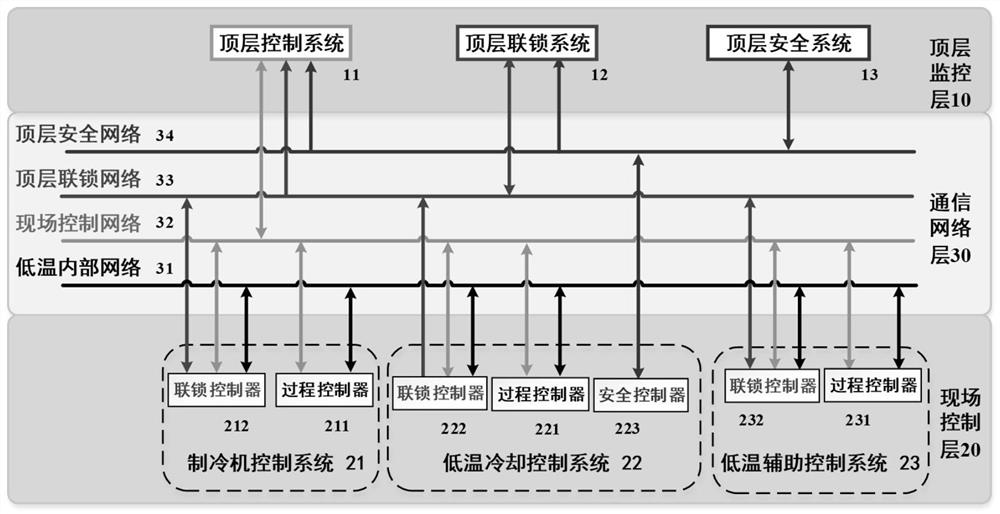

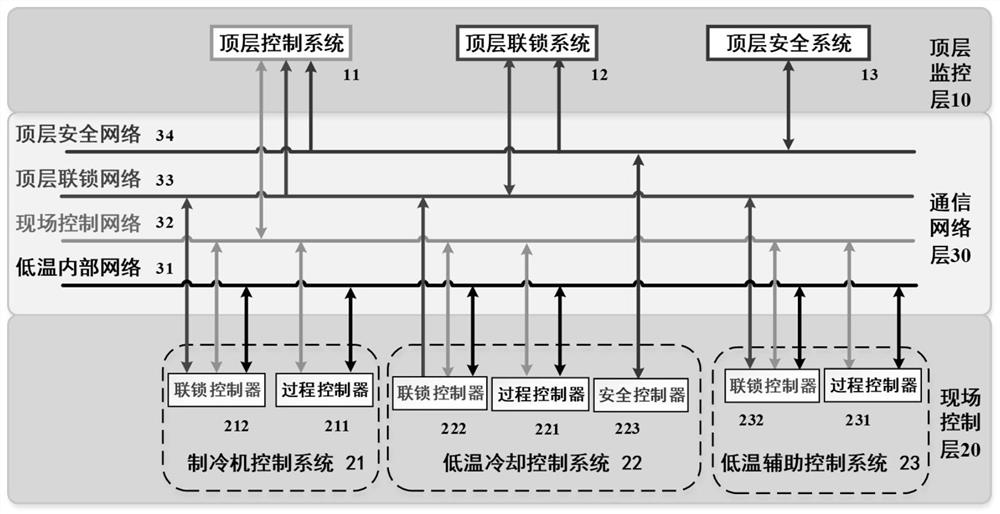

Network System of Helium Cryogenic Control System

ActiveCN112230610BVersatilityMeet operational needsTransmission systemsTotal factory controlTemperature controlControl system

The invention discloses a network system of a helium low-temperature control system, which relates to the technical field of low-temperature engineering. The low-temperature top-level monitoring system of the invention adopts an open management system architecture, the low-temperature field system adopts a general industrial controller, and the low-temperature communication network adopts a mature According to the characteristics of the on-site sub-control system, it is divided into process control, interlock control, safety control, etc. The invention combines the functional characteristics and requirement levels of the helium cryogenic system to formulate risk prevention and control strategies, divide dedicated communication networks, disperse specific tasks, and centralize hierarchical management, which can meet the operating requirements of large and complex helium cryogenic plant-level cryogenic control systems. The network structure of a helium cryogenic control system proposed by the invention has universality and is suitable for industrial process control systems.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

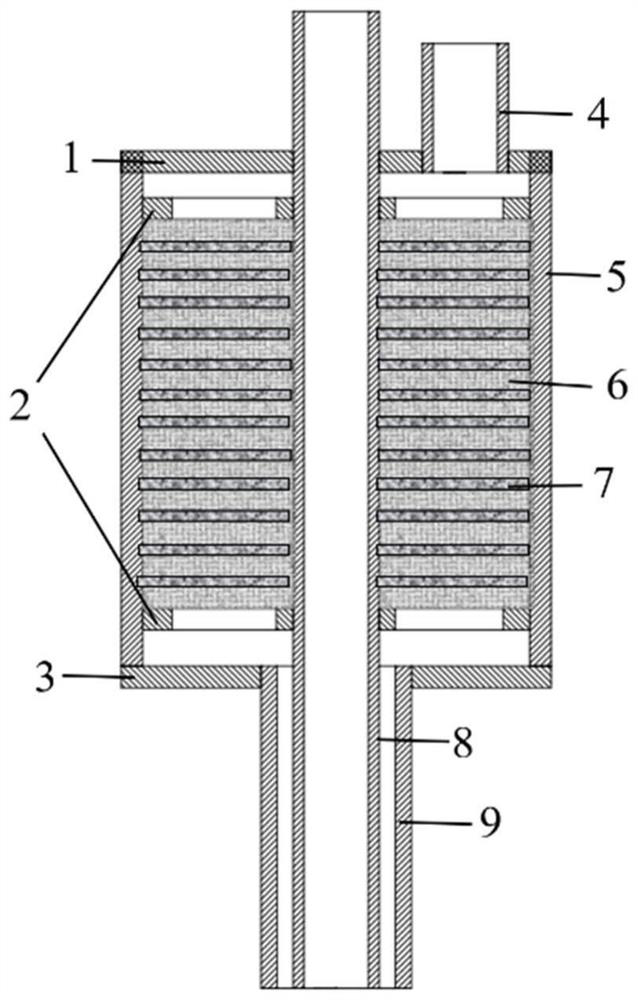

Composite low-temperature negative-pressure dividing wall type heat exchanger for refrigerating machine in extremely low-temperature area

PendingCN114754507AReduce axial heat conduction lossImprove heat transfer efficiencyEvaporators/condensersCompression machinesCopper wireEngineering

The invention relates to the field of refrigeration and low-temperature engineering, and discloses a composite low-temperature negative-pressure dividing wall type heat exchanger for a refrigerating machine in an extremely low-temperature area, which comprises an upper top cover, a baffle, a lower top cover, a high-pressure outlet connecting pipe, a sleeve, a copper wire net, a stainless steel wire net, a pipe-in-pipe heat exchanger inner pipe and a pipe-in-pipe heat exchanger outer pipe. The heat exchanger is applied to a last-stage refrigerating unit of a refrigerating machine in an extremely-low-temperature area, is compact in structure, can be used as an efficient negative-pressure dividing wall type heat exchanger in an extremely-low-temperature gas-liquid two-phase area, and can also be used as a three-way structure for shunting high-pressure fluid and low-pressure fluid of a last-stage pipe double-pipe heat exchanger; the axial heat conduction loss of the last-stage dividing wall type heat exchanger for the refrigerating machine in the extremely-low-temperature area is reduced, the flow speed of low-mass-flow fluid in the extremely-low-temperature area is increased, the heat exchange area of the fluid in a gas-liquid two-phase flow area is increased, and the heat exchange efficiency of the last-stage dividing wall type heat exchanger for the refrigerating machine in the extremely-low-temperature area is improved. And the refrigerating machine has very positive significance in application of the refrigerating machine in special fields such as extremely low temperature areas, aerospace and the like.

Owner:上海铂钺制冷科技有限公司

Network system of helium low-temperature control system

ActiveCN112230610AVersatilityMeet operational needsTransmission systemsTotal factory controlNetworked systemIndustrial engineering

The invention discloses a network system of a helium low-temperature control system, and relates to the technical field of low-temperature engineering. A low-temperature top-layer monitoring system adopts an open management system architecture, a low-temperature field system adopts a universal industrial controller, and a low-temperature communication network adopts a mature industrial communication network; and process control, interlocking control, safety control and the like are divided according to the characteristics of the field sub-control system. According to the invention, a risk prevention and control strategy is formulated by combining the functional characteristics and the requirement levels of the helium low-temperature system, a special communication network is divided, specific tasks are dispersed, centralized hierarchical management is realized, and the operation requirements of a large complex helium low-temperature factory-level low-temperature control system can be met. The network structure of the helium low-temperature control system provided by the invention has universality and is suitable for an industrial process control system.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

High-strength 9% Ni steel for ultra-low temperature engineering fasteners and its preparation method

ActiveCN112647021BImprove purityIncrease gas contentMetal-working apparatusIncreasing energy efficiencyTemperingMetallic materials

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +3

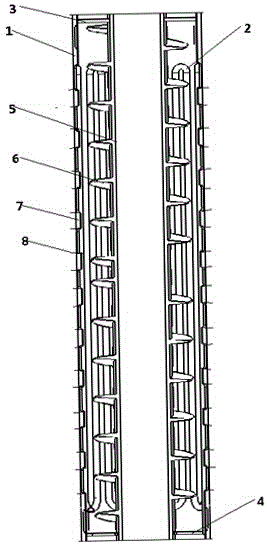

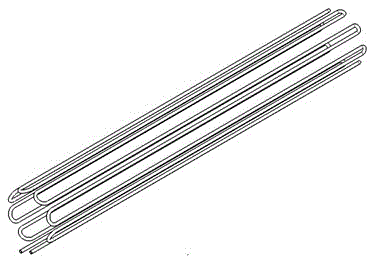

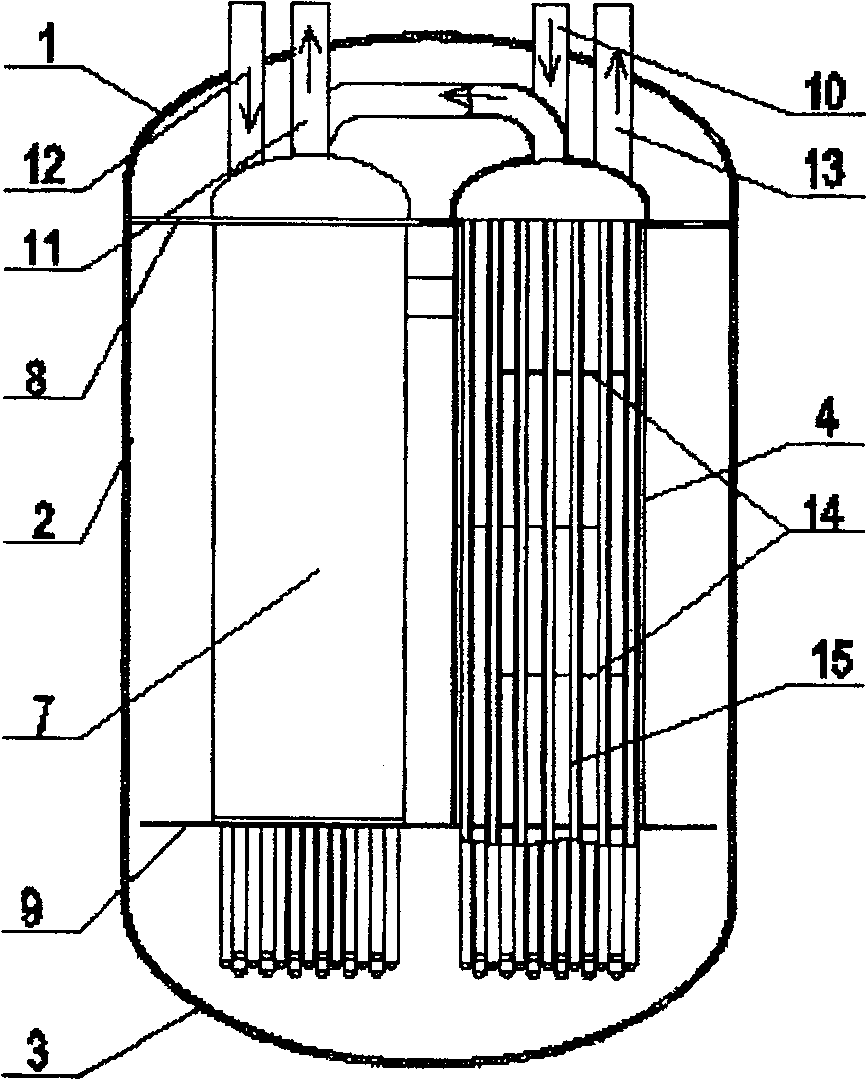

Gas low temperature heat exchanger capable of self eliminating stress and pollution proof

InactiveCN100535571CReduce air permeabilitySmooth inner surfaceStationary tubular conduit assembliesSocial benefitsShell and tube heat exchanger

The gas low-temperature heat exchanger with self-relieving stress and anti-pollution belongs to the field of low-temperature engineering and low-temperature technology. The invention includes a cylinder body of a low-temperature heat exchanger, a lower head of a low-temperature heat exchanger, an upper head of a low-temperature heat exchanger, A, B, C and D four shell-and-tube heat exchangers, tube sheets, support plates, low-temperature heat exchanger tube-side inlet tubes, low-temperature heat exchanger tube-side outlet tubes, low-temperature heat exchanger shell-side inlet tubes and low-temperature heat exchangers Shell-side outlet pipe. The shells of the four shell-and-tube heat exchangers are narrow and rectangular, and the heat exchange tubes are U-shaped heat exchange tubes. The four shell-and-tube heat exchangers are placed in the low-temperature heat exchanger cylinder in a square array and connected in series. . The material used in the low-temperature heat exchanger is OCr18Ni9 / 304, which has low air permeability, smooth inner surface, wear resistance, strong corrosion resistance, and stable performance, preventing gas from being polluted. In addition, at low temperature, the stress generated by the thermal expansion and contraction of the material is considered, so that the stress can be eliminated by itself, and its sealing performance is improved. Finally, the low-temperature heat exchanger has good sealing performance and prevents the gas from being polluted. It has significant economic and social benefits.

Owner:SHANGHAI JIAOTONG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com