Method for desalting seawater by utilizing cold energy of liquefied natural gas through phase transition-free indirect refrigeration

A technology of liquefied natural gas and no phase change, which is applied in the field of frozen seawater desalination and indirect frozen seawater desalination without phase change, which can solve the problem of high energy consumption and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

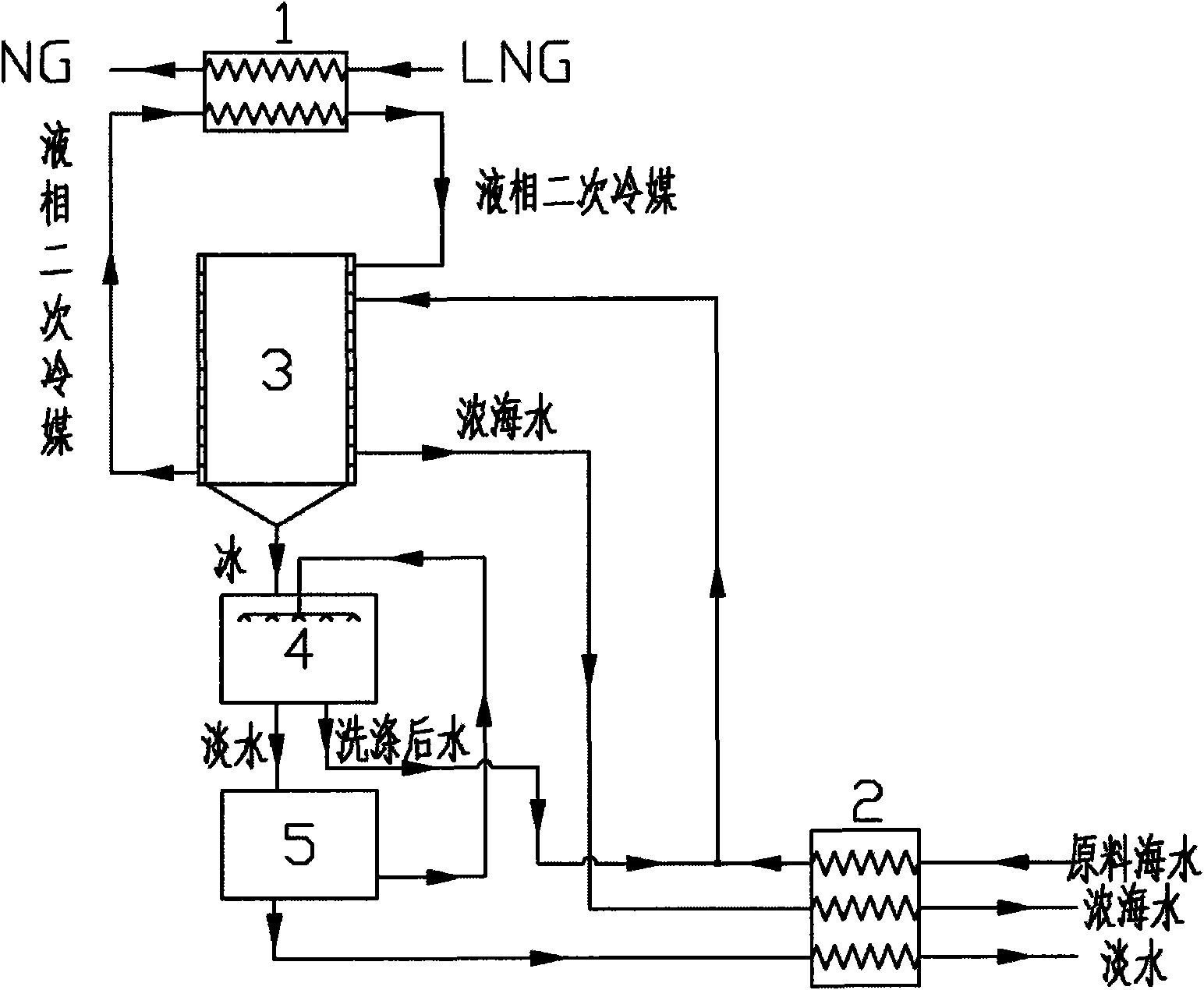

[0015] The specific implementation of the present invention using R410A as the secondary refrigerant will be further described below in conjunction with the accompanying drawings.

[0016] Such as figure 1 Shown, the inventive method comprises the following steps:

[0017] 1. The liquefied natural gas exchanges heat with the liquid-phase secondary refrigerant R410A in the first heat exchanger 1, and the secondary refrigerant R410A releases heat, and the temperature drops without phase change; among them, the secondary refrigerant R410A is in the first heat exchanger 1 The inlet state parameters are -15°C, 0.55MPa, the outlet state parameters are -35°C, 0.5MPa, and the first heat exchanger 1 adopts a plate-fin low-temperature heat exchanger;

[0018] 2. The cooled liquid-phase secondary refrigerant R410A enters the evaporation coil outside the crystallizer 3, and the raw seawater enters the inner side of the crystallizer 3 after being cooled by the second heat exchanger 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com