Various material composite fire retardant -type high vacuum multiple layer heat insulation structure

A multi-layer heat insulation and high vacuum technology, which is applied in the direction of layered products, heat exchange equipment, metal layered products, etc., can solve the flame retardancy of the heat insulation structure, and various reflective materials and intervals Objects and other issues, to achieve the effect of reducing spacing, reducing consumption, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

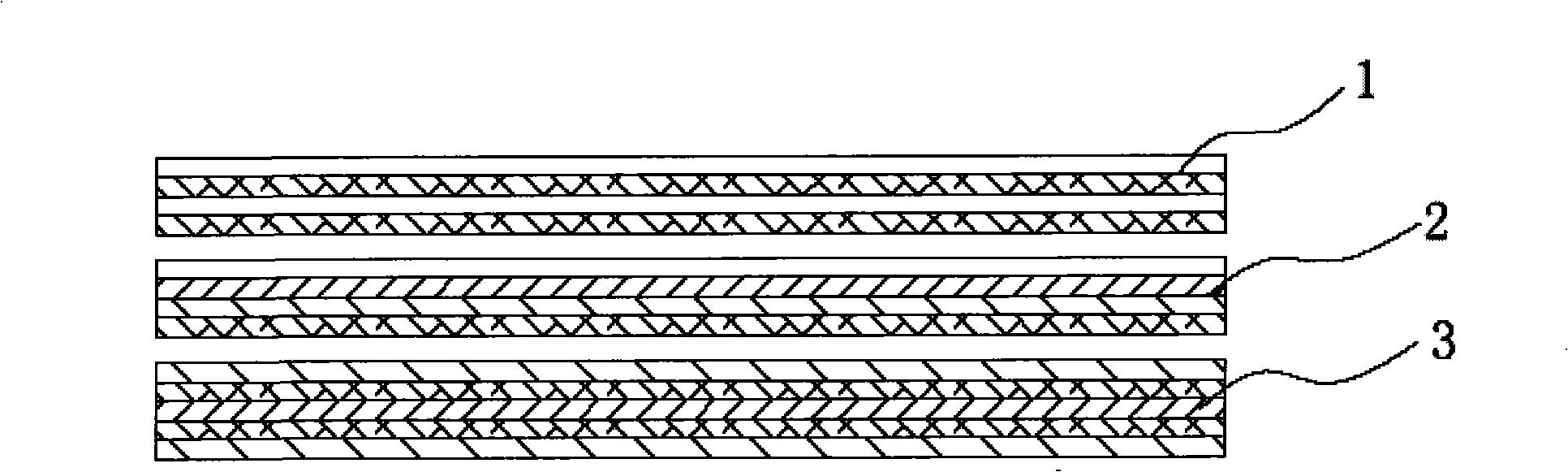

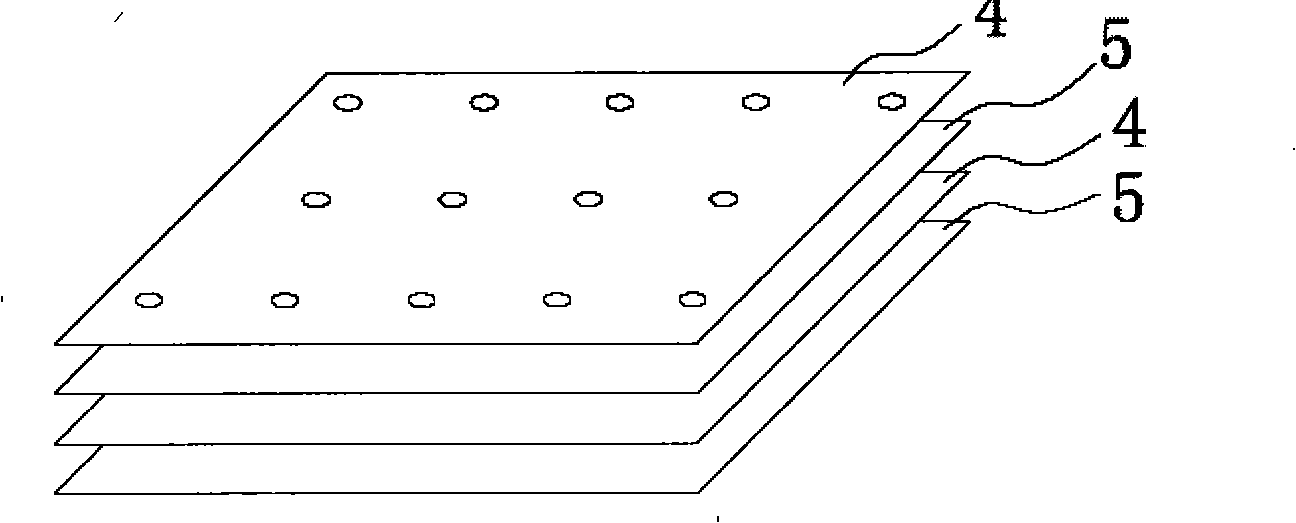

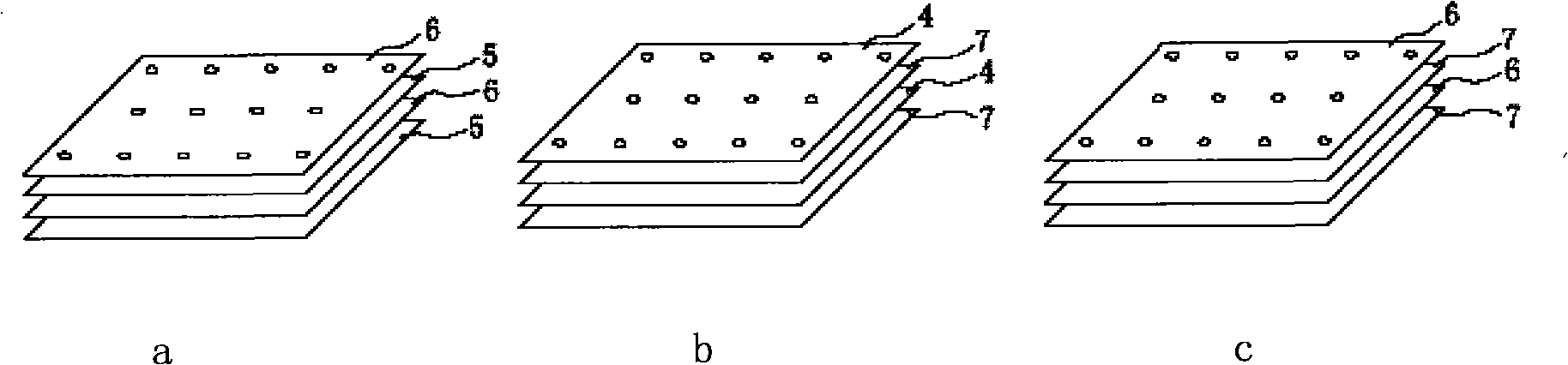

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the multi-material composite flame-retardant high-vacuum multi-layer insulation structure of the present invention includes: high-temperature side combination 1, transition combination 2 and low-temperature side combination 3, which are sequentially coated on the outside of the heat-insulating low-temperature shell from outside to inside, The high-temperature side combination 1 is close to the external environment, the low-temperature side combination 3 is close to the heat-insulated low-temperature shell, and the transition combination 2 is sandwiched between them.

[0024] Combination 1 on the high temperature side consists of no less than 5 layers of aluminum foil 4 and glass fiber paper 5 with the same number of layers alternately, wherein the width of glass fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com