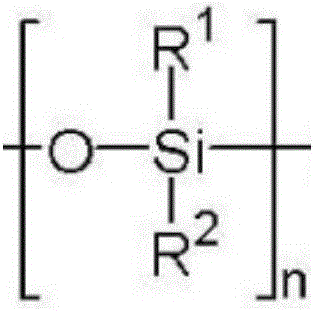

Low-temperature-resistant low-smoke inflaming-retarding light-diffusing polycarbonate composite material

A low-smoke flame-retardant, polycarbonate technology, applied in the field of polymer composite materials, to achieve good low-temperature impact performance, low smoke density, and low smoke density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

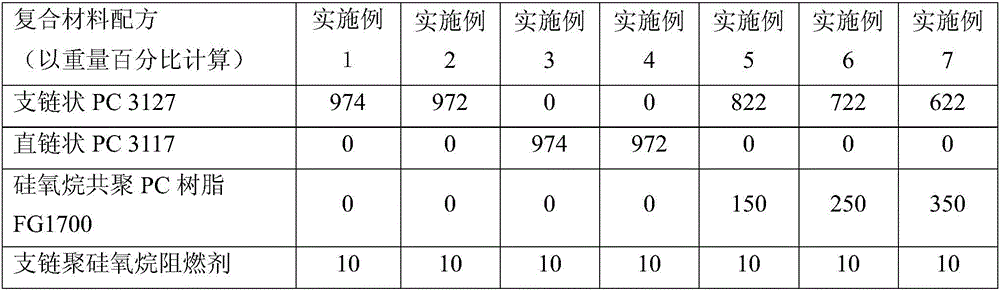

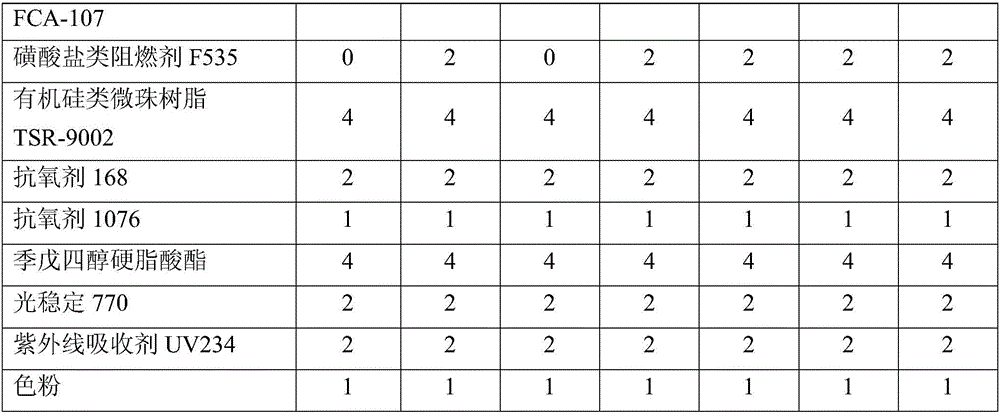

Embodiment 1

[0040] Example 1. Preparation of Low Temperature, Low Smoke, Flame Retardant and Light Diffusion Polycarbonate Composite Material

[0041]The following components in weight percent: 974 parts of branched-chain PC of model 3127, 10 parts of branched polysiloxane flame retardant FCA-107, 4 parts of silicone microbead resin TSR-9002, 2 parts of anti- Oxygen agent 168, 1 part of antioxidant 1076, 4 parts of pentaerythritol stearate, 2 parts of light stabilizer 770, 2 parts of ultraviolet absorber UV234 and 1 part of toner are mixed in a high-speed mixer for 3 minutes, and then mixed at 260-280 Extrude through a twin-screw extruder at ℃, cool and granulate, dry the obtained pellets at 120℃ for 4 hours, and then inject them into standard strips at 260-280℃.

Embodiment 2

[0042] Example 2. Preparation of Low Temperature, Low Smoke, Flame Retardant and Light Diffusion Polycarbonate Composite Material

[0043] The following components in weight percent: 972 parts of branched chain PC of model 3127, 10 parts of branched chain polysiloxane flame retardant FCA-107, 2 parts of sulfonate flame retardant F535, 4 parts of organic silicon Bead-like resin TSR-9002, 2 parts of antioxidant 168, 1 part of antioxidant 1076, 4 parts of pentaerythritol stearate, 2 parts of light stabilized 770, 2 parts of ultraviolet absorber UV234 and 1 part of toner are mixed at high speed Mix in the machine for 3 minutes, then extrude through a twin-screw extruder at 260-280°C, cool, and granulate. The obtained pellets are dried at 120°C for 4 hours and then injection-molded into a standard spline at 260-280°C. have to.

Embodiment 3

[0044] Example 3. Preparation of Low Temperature, Low Smoke, Flame Retardant and Light Diffusion Polycarbonate Composite Material

[0045] The following components will be in weight percentage: 974 parts of linear PC model 3117, 10 parts of branched polysiloxane flame retardant FCA-107, 4 parts of silicone microbead resin TSR-9002, 2 parts of anti Oxygen agent 168, 1 part of antioxidant 1076, 4 parts of pentaerythritol stearate, 2 parts of light stabilizer 770, 2 parts of ultraviolet absorber UV234 and 1 part of toner are mixed in a high-speed mixer for 3 minutes, and then mixed at 260-280 Extrude through a twin-screw extruder, cool, and granulate. The obtained pellets are dried at 120°C for 4 hours and then injection-molded into standard strips at 260-280°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com