Patents

Literature

220results about How to "High flame retardant grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen-free flame-retardant PBT and preparation thereof

The invention discloses a halogen-free flame-retardant PBT which is prepared by the following components according to the percent by weight: 30-70 percent of PBT resin, 0-50 percent of alkali-free glass fiber, 13-35 percent of halogen-free flame retardant, 0-20 percent of toughening agent, 0.5-1 percent of acid absorption agent, 0.5 percent of antioxidant, 0.5-5 percent of colorant and 0.5-1 percent of processing aid. Low-valent organic phosphate flame retardant or the compound of the lower-valent organic phosphate flame retardant and melamine polyphosphate is taken as the halogen-free flamen retardant of the halogen-free flame-retardant PBT, and the acid absorption agent, the toughening agent, the antioxidant and the processing aid are added to the halogen-free flame retardant, thereby the halogen-free flame-retardant PBT which has good flame-retardant effect, high flame-retardant grade, different colors, high mechanical strength and good thermal stability is prepared. The method for preparing the halogen-free flame-retardant PBT has the advantages of easy operation.

Owner:KINGFA SCI & TECH CO LTD +1

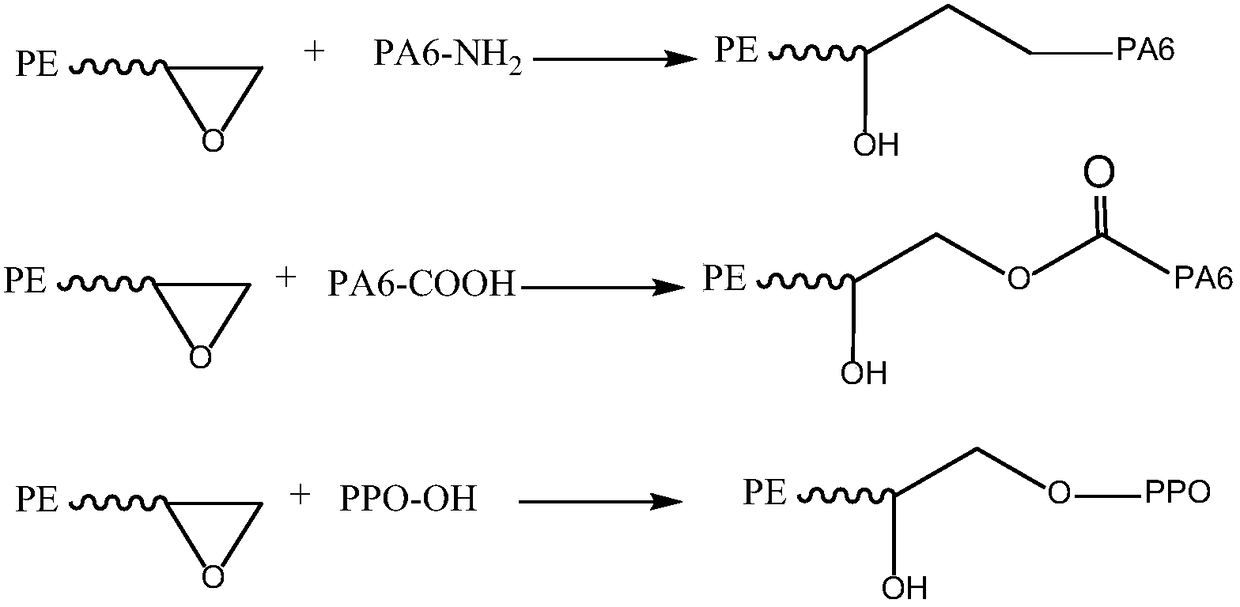

Halogen-free flame retardant thermoplastic elastomer cable material and preparation method thereof

InactiveCN104530626ANo significant change in electrical propertiesGood compatibilityRubber insulatorsPlastic/resin/waxes insulatorsElastomerPolymer science

The invention belongs to the technical field of polymer materials and relates to a halogen-free flame retardant thermoplastic elastomer cable material. The halogen-free flame retardant thermoplastic elastomer cable material is characterized by comprising the following raw materials in parts by weight: 20-60 parts of a styrene type elastomer, 20-60 parts of polyphenyl ether resin, 10-40 parts of polyolefin, 10-50 parts of a polyolefin type elastomer, 10-50 parts of a plasticizer, 20-60 parts of a complex phosphorus-nitrogen flame retardant, 1-5 parts of a lubricating agent, 0.1-1 part of an antioxidant and 0.1-1 part of an anti-ultraviolet absorbent. The invention further discloses a preparation method of the cable material. The cable material disclosed by the invention has the characteristics of excellent processing performance, high flame-retardant grade, no toxicity, light density, good anti-tear performance, good acid and alkali resistance, good weather resistance and the like, as well as particularly prominent water resistance and anti-cracking performance. After high-temperature and high-humidity long-term aging, the cable material has no precipitate, the excellent mechanical and physical properties are kept, and the electrical properties do not change obviously.

Owner:JIANGSU ZHONGLI GRP CO LTD

High-flame-resistance high-strength high-reflection polycarbonate material as well as preparation method thereof and application thereof

ActiveCN105968771AImprove flame retardant propertiesGood light shading reflection functionMass ratioHigh intensity

The invention discloses a high-flame-resistance high-strength high-reflection polycarbonate material which is prepared from the following raw materials in percentage by mass: 10-75% of polycarbonate, 0.05-10% of a flame retardant, 0.1-0.8% of an anti-dropping agent, 25-75% of light-reflecting master batches, 1-10% of a toughening agent, 0.2-1% of an ultraviolet resistant agent, 0.2-1% of an antioxidant and 0.2-5% of a lubricant, wherein the light-reflecting master batches consist of a light reflecting agent, a coupling agent, polycarbonate and auxiliaries in a mass ratio being 40 to (7.5 to 17.5) to (37 to 57) to (0.1 to 5). The material has a good light shielding and reflecting function, high flame resistance, and good mechanical property. The invention further discloses a preparation method and application for the high-flame-resistance high-strength high-reflection polycarbonate material. The high-flame-resistance high-strength high-reflection polycarbonate material can be used for preparing a light reflecting piece, and is especially suitable for preparing an LED (light-emitting diode) lamp reflecting cover.

Owner:中广核瑞胜发(厦门)新材料有限公司

Glass fiber reinforced halogen-free flame-retardant PA66 and preparation thereof

The invention discloses a glass fiber reinforced halogen free flame retardation PA66 material and a preparation method thereof. The glass fiber reinforced halogen free flame retardation PA66 comprises the following components by weight percentage: 36 to 60 percent of PA66 resin, 15 to 50 percent of non-alkali glass fiber, 12 to 25 percent of halogen free flame retardant, 0.5 to 1 percent of borate, 0.5 percent of antioxidant and 0.5 to 1 percent of processing additive. The glass fiber reinforced halogen free flame retardation PA66 has high flame retardation grade which reaches vertical firing (0.8mm)FV-0, excellent mechanical properties: a tensile strength reaching 145MPa, bending strength reaching 215MPa and cantilever notch impact strength reaching 12kj / m for a 30 percent glass fiber reinforced product and good thermal endurance: heat distortion temperature (1.82MPa) reaching 250 DEG C. The borates are added to improve the thermal stability, and consequently the end product has excellent thermal stability property. The preparation method for the glass fiber reinforced halogen free flame retardation PA66 material has the advantage of simple operation.

Owner:KINGFA SCI & TECH CO LTD +1

Flame-retardant composite material with easy dyeing and laser marking and preparation method thereof

The invention provides a composition for preparing halogen-free environmentally-friendly flame-retardant nylon 66 composite materials with glass fibre reinforcement, easy dyeing and laser marking. The composition is prepared from the following components by weight: 30-60 parts of nylon, 20-40 parts of alkali-free arsenic-free chopped glass fibre, 15-30 parts of halogen-free flame retardant, 3-8 parts of synergistic coloured flame-retardant auxiliary, 0.2-1 parts of laser marking auxiliary and 1-2 parts of other auxiliaries. The environment-friendly halogen-free flame retardance of the product reaches the level of UL94V0 and accords with the Rohs requirement of EU. The composition has excellent colouring capability, is suitable for various laser marking and clear in the marks without fading and has excellent overall performance in the glass fibre reinforcement.

Owner:NANJING JULONG SCI&TECH CO LTD

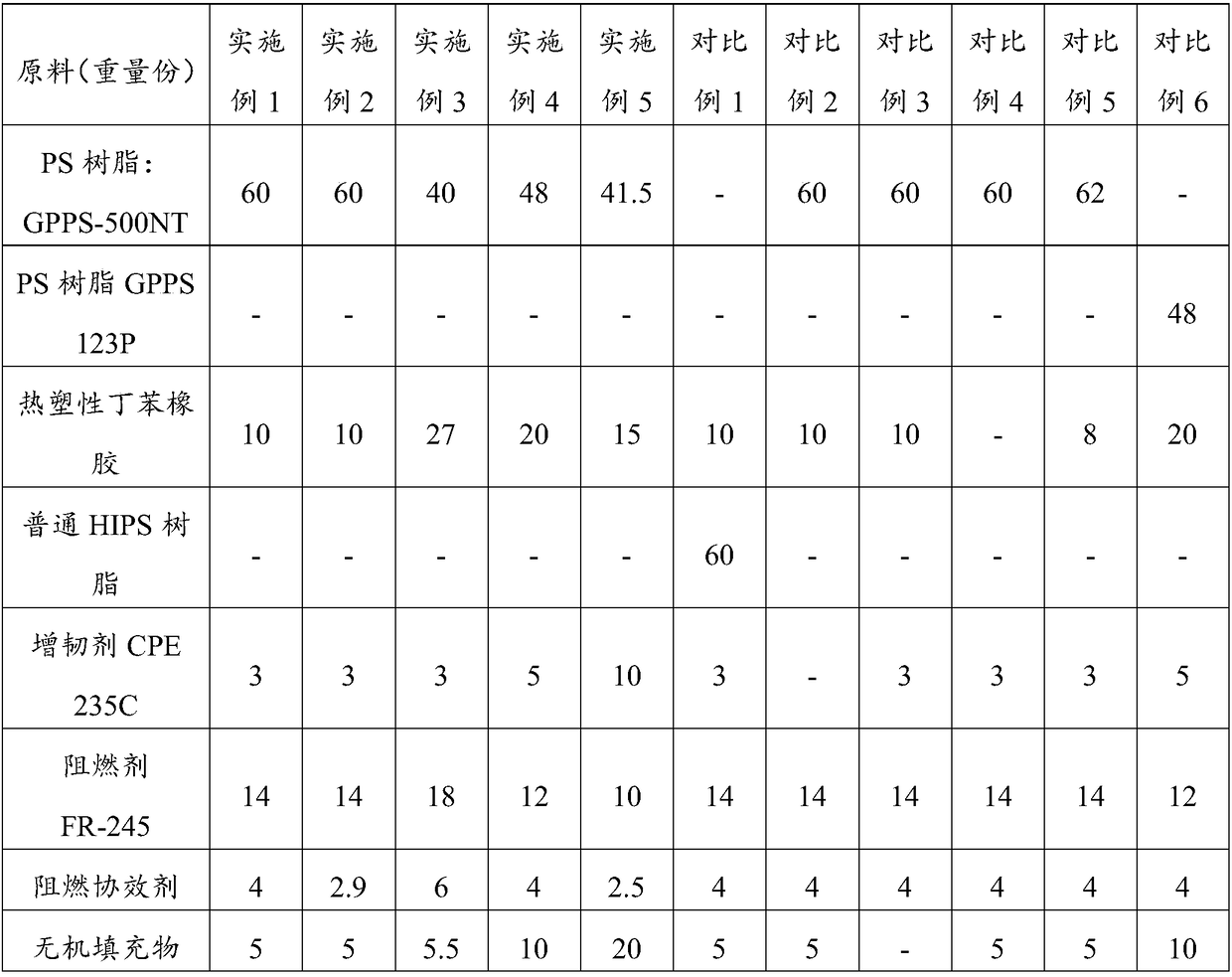

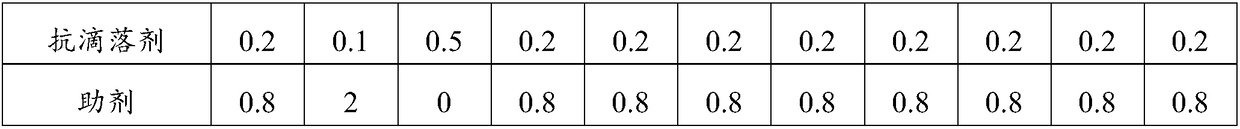

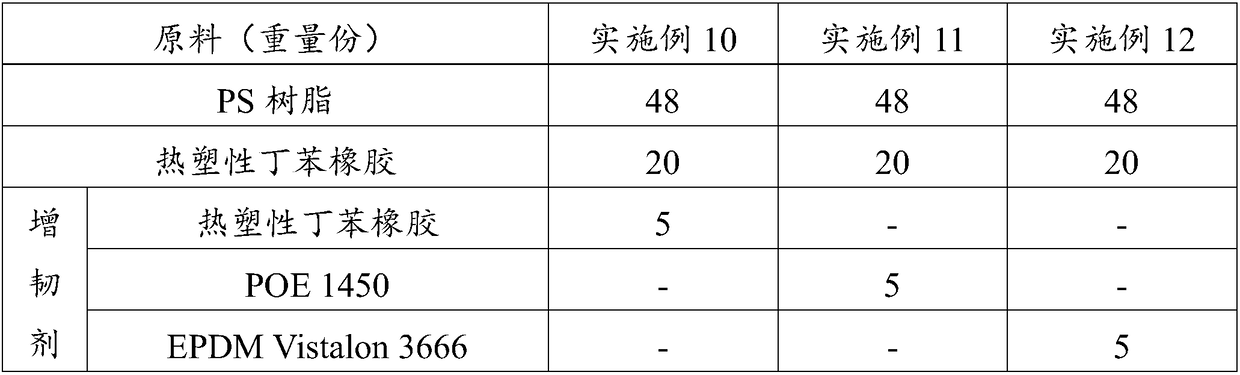

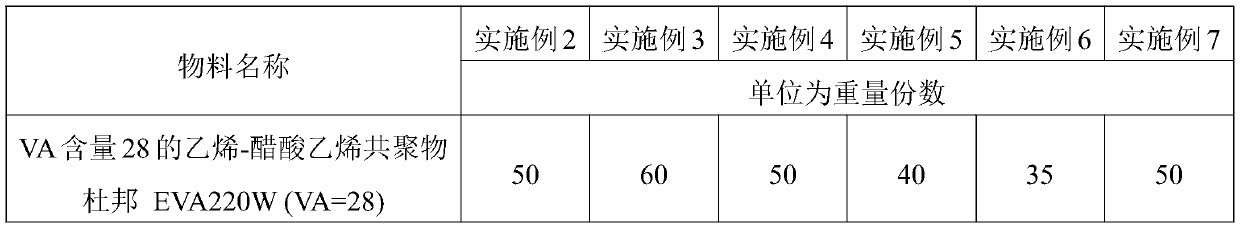

HIPS composite material with high flammability

ActiveCN109503970AHigh flame retardant gradeImprove performanceUltimate tensile strengthFire retardant

The invention discloses a HIPS composite material with high flammability. The HIPS composite material comprises the following components in parts by weight: 40-60 parts of PS resin, 10-27 parts of thermoplastic butadiene styrene rubber, 3-10 parts of flexibilizer, 10-18 parts of fire retardant, 2.5-6 parts of flame retardant synergist, 5-20 parts of inorganic filler, 0.1-0.5 part of anti-drippingagent and 0-2 parts of auxiliaries; weight-average molecular weight of PS resin is more than or equal to 15*104g / mol; melt flow rate MFR is 3-6g / 10min. The HIPS composite material with high flammability disclosed by the invention has the following advantages: 1) high flame retardant level (maximal level can reach up to 2.0mm 5VA level); 2) excellent overall performance and balanced strength and notch impact property; 3) low cost and capability of substituting high-flammability ABS in some situations; 4) good appearance and wide processing window.

Owner:江苏金发再生资源有限公司

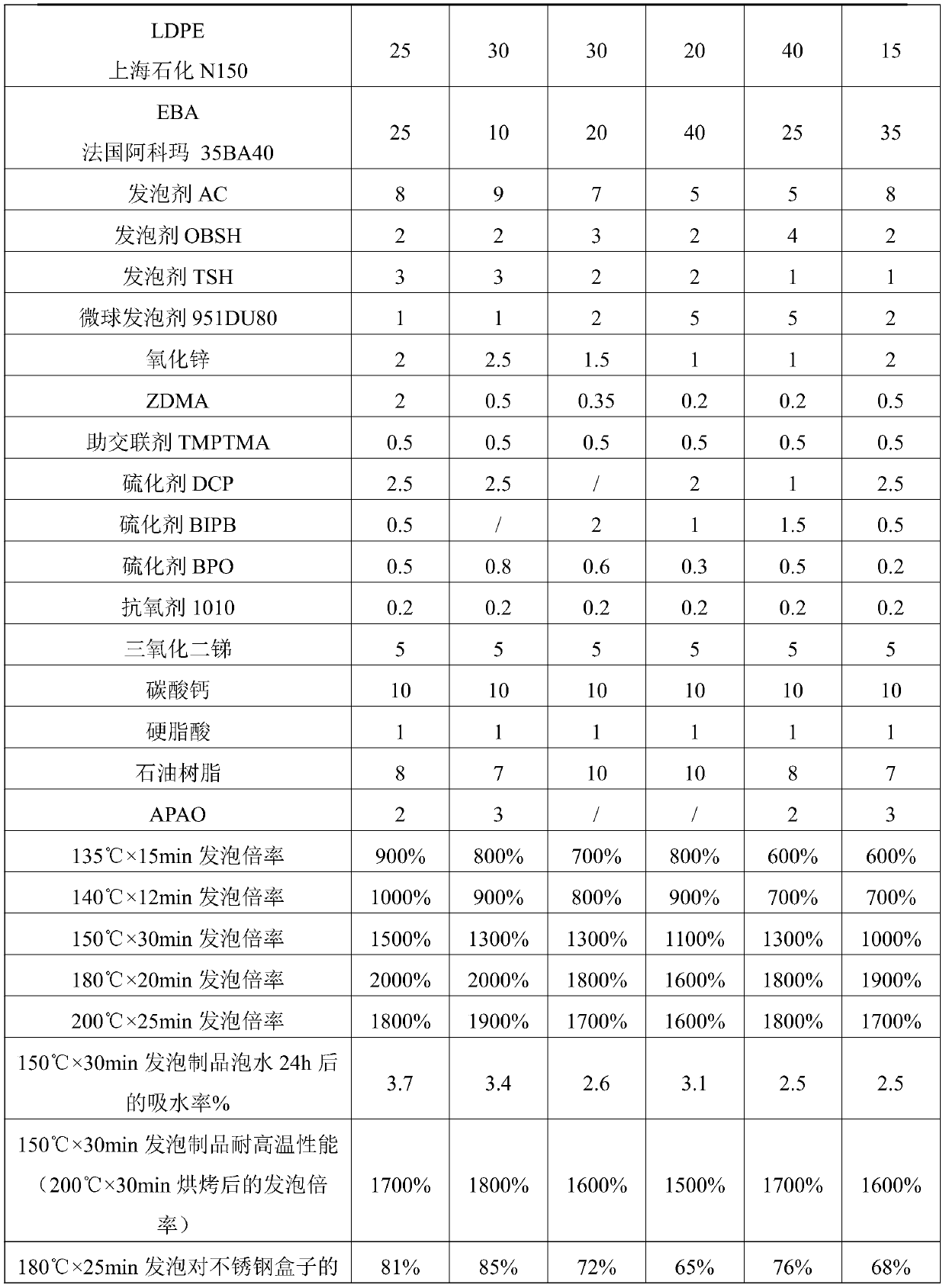

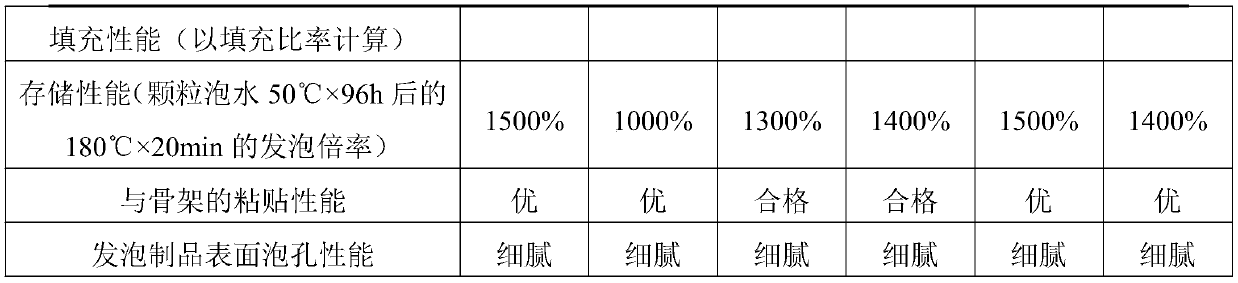

Low-temperature automobile expansion adhesive and preparation method thereof

ActiveCN110684486AHigh foaming ratioNot prone to collapse and shrinkage problemsNon-macromolecular adhesive additivesMacromolecular adhesive additivesVulcanizationFoaming agent

The invention discloses a low-temperature automobile expansion adhesive. The low-temperature automobile expansion adhesive is made of the following raw materials in parts by weight: 100 parts of a polymer, 3-5 parts of a peroxide vulcanization agent, 0.5-3 parts of a vulcanization auxiliary agent, 5-15 parts of a foaming agent, 0.5-8 parts of a foaming activator, 1-10 parts of a filler, 2-15 partsof a tackifier, 0.5-3 parts of a lubricant, 0-2 parts of an antioxidant, and 0-10 parts of a flame retardant. According to the low-temperature automobile expansion adhesive, the raw material composition is carefully chosen, the content of each raw material is optimized, and the prepared low-temperature automobile expansion adhesive has high foaming ratio and small product density, and can fill large cavities. The expansion adhesive has high bonding strength with an ABS framework member. The expansion adhesive has good high-temperature baking stability. The expansion adhesive after foaming isnot easy to collapse and shrink. The low-temperature foaming performance and high-temperature foaming ratio are well balanced. The storage stability is good, the product quality is stable, and a storage period is relatively long.

Owner:浙江杰上杰新材料股份有限公司

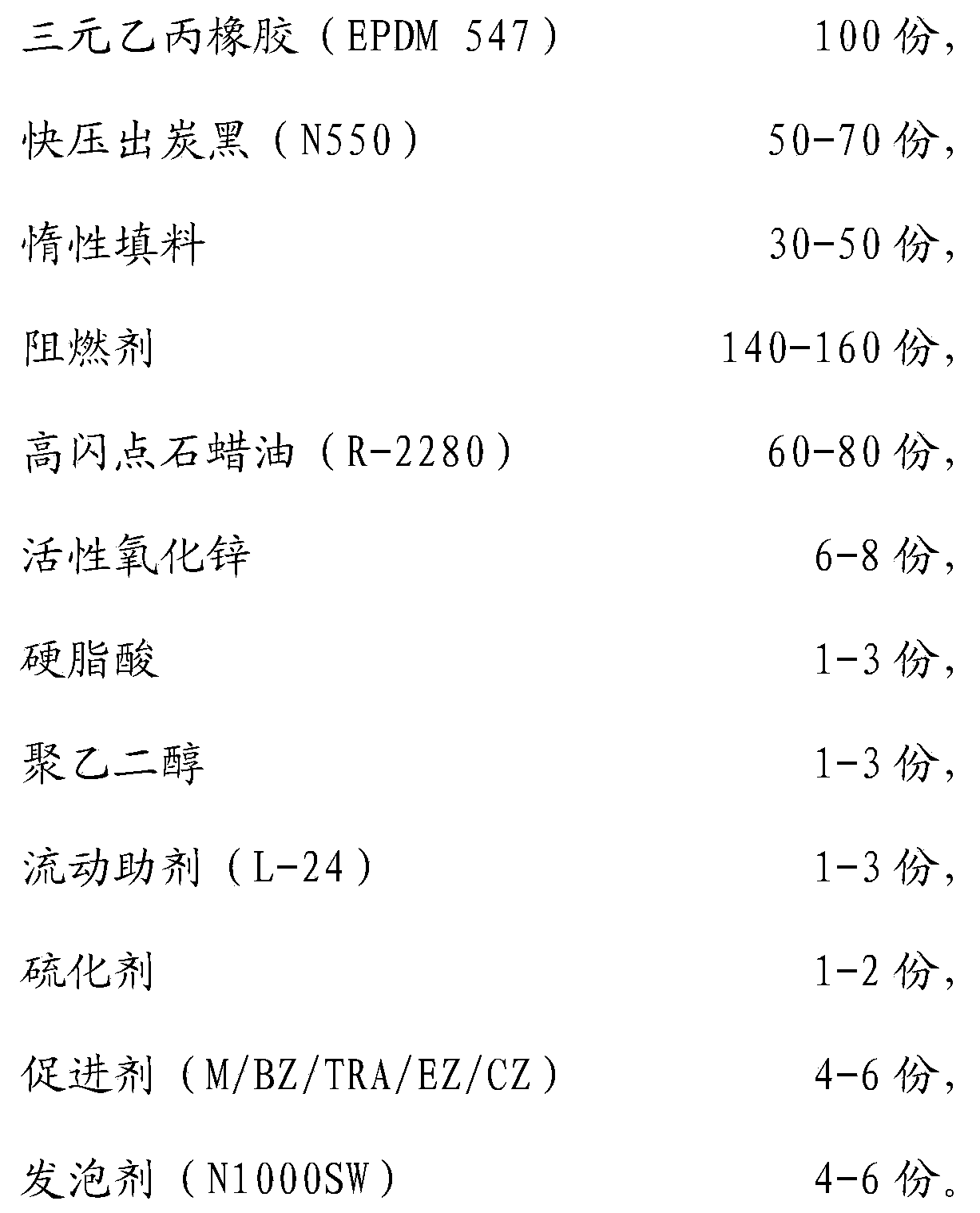

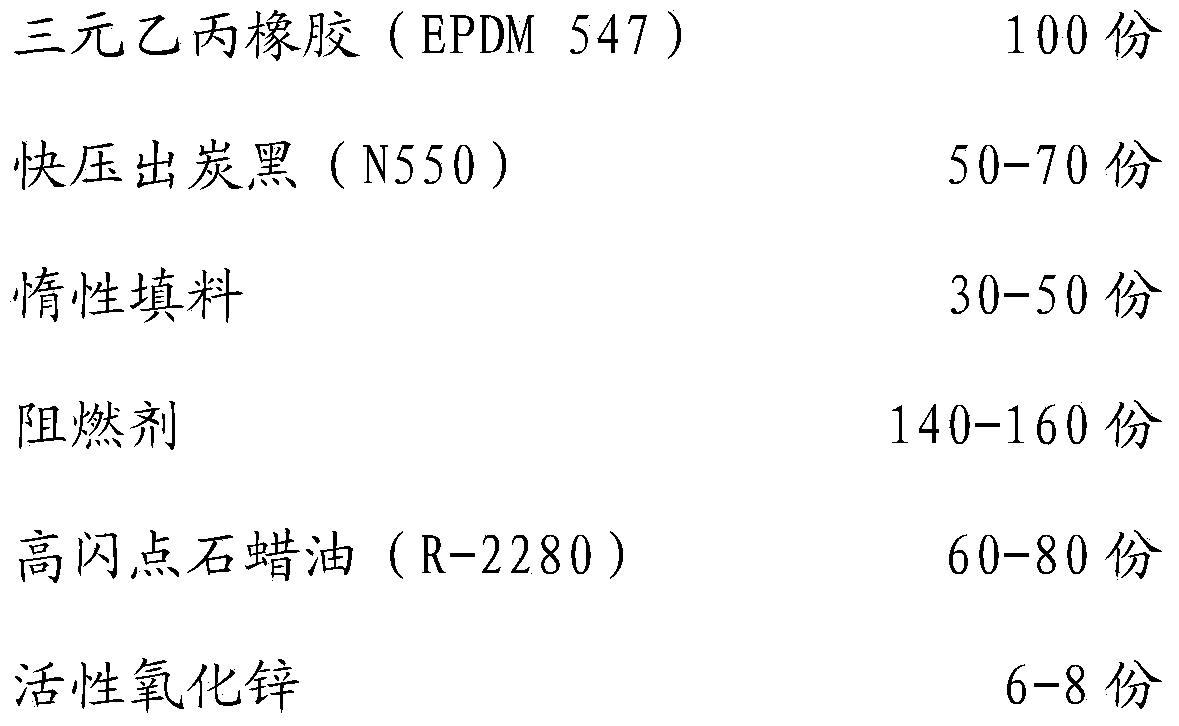

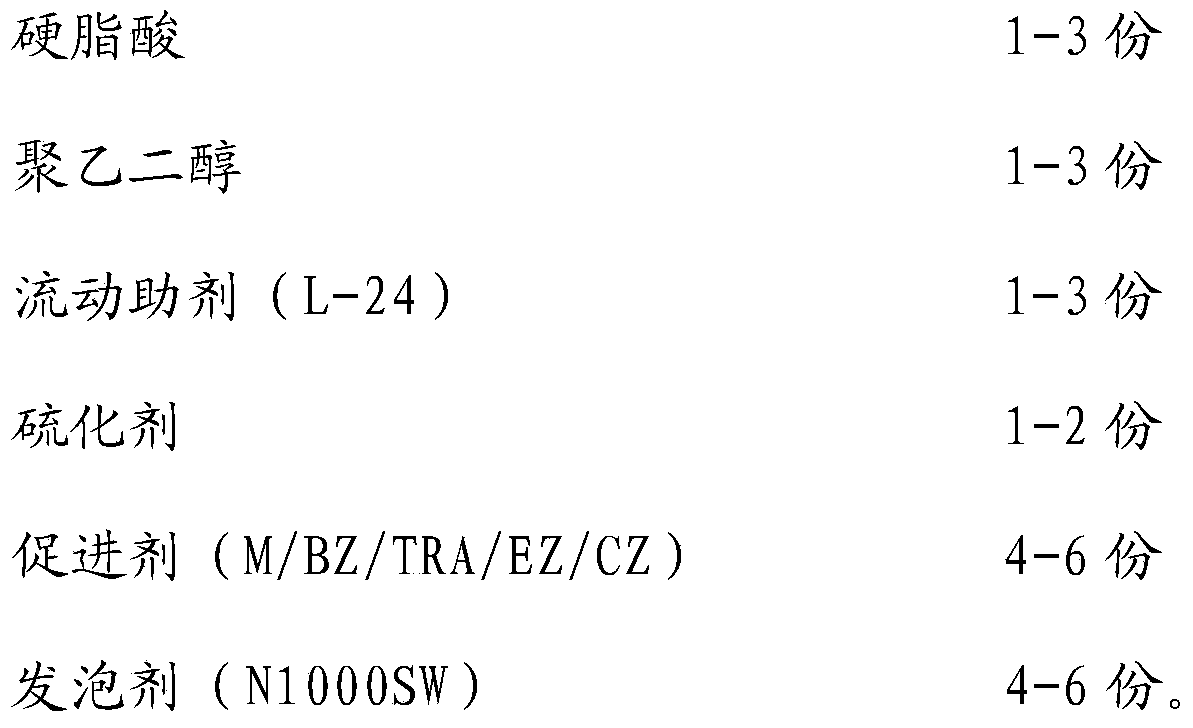

EPDM flame-retardant sponge sealing strip for high-speed rail

The invention discloses an EPDM flame-retardant sponge sealing strip for a high-speed rail. The EPDM flame-retardant sponge sealing strip comprises the following components in parts by mass: 100 parts of high-ENB-content EPDM (ethylene propylene diene monomer), 50 to 70 parts of fast extruding furnace black, 30 to 50 parts of inert filler, 140 to 160 parts of flame-retardant agent, 60 to 80 parts of high-flash-point paraffin oil, 1 to 2 parts of anti-aging agent TMQ, 6 to 8 parts of activated zinc oxide, 1 to 3 parts of stearic acid, 1 to 3 parts of polyethylene glycol, 1 to 3 parts of flow additive, 1 to 2 parts of vulcanizing agent, 4 to 6 parts of accelerant and 4 to 6 parts of foaming agent. By adopting the flame-retardant sponge formula, a better material performance can be obtained, the density is 0.5 to 0.6 g / cm<3>, the flame-retardant grade reaches a burning-resisting grade, and the requirement of the high-speed rail sponge sealing strip on light weight and flame retardant property can be met.

Owner:TIANJIN XINZHONGHE RUBBER IND

Thin-wall high-CTI-value flame-retardant polycarbonate blend and preparation method thereof

The invention relates to the technical field of alloy materials and discloses a thin-wall high-CTI-value flame-retardant polycarbonate blend and a preparation method thereof. Compared with the prior art, a phosphonitrile flame retardant is added into the raw material formula of the preparation method, so that on one hand, the drawbacks that the thermal distortion temperature and flexibility of polycarbonate are substantially decreased due to the addition of an organic phosphate flame retardant in the prior art can be effectively overcome, and the heat resistance and tenacity of a polycarbonatecomposition is effectively improved; and on the other hand, the phosphonitrile flame retardant with effective nitrogen and phosphorus amounts has very good flame-retardant effect, the flame-retardantlevel of the polycarbonate composition can be effectively increased, and meanwhile, the electric leakage marking resistance of the polycarbonate composition can be greatly improved by virtue of the phosphonitrile flame retardant.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

Foaming body and preparation method thereof

The invention provides a foaming body, which is a heteropical mixture formed by a high foaming material and a low foaming material, wherein the low foaming material comprises 100 parts of a matrix resin, 10-30 parts of a foaming agent and 10-100 parts of a flame retardant body; the high foaming material comprises 46-380 parts of a matrix resin and 5-160 parts of a foaming agent; and the melting point of the matrix resin in the high foaming material is higher than that of the matrix resin in the low foaming material. In the invention, the foaming body comprises the high foaming material and the low foaming material, the high foaming material is dispersed into the low foaming material in the form of small particles, and high foaming particles are foamed at a high foaming rate while the low foaming material is foamed at a relatively low foaming rate during expansion foaming of the foaming body, so that the overall foaming rate of the foaming body can be increased.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

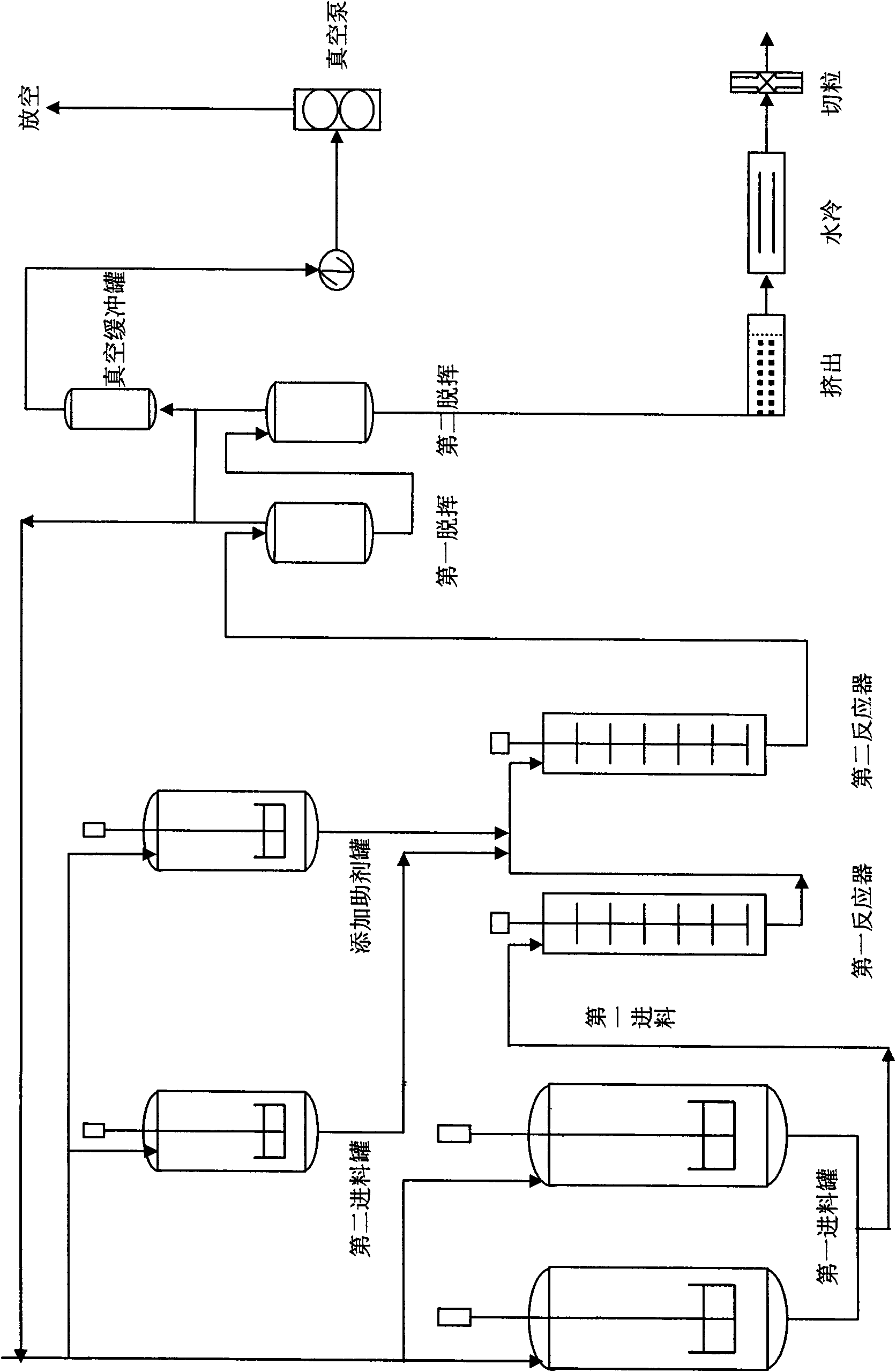

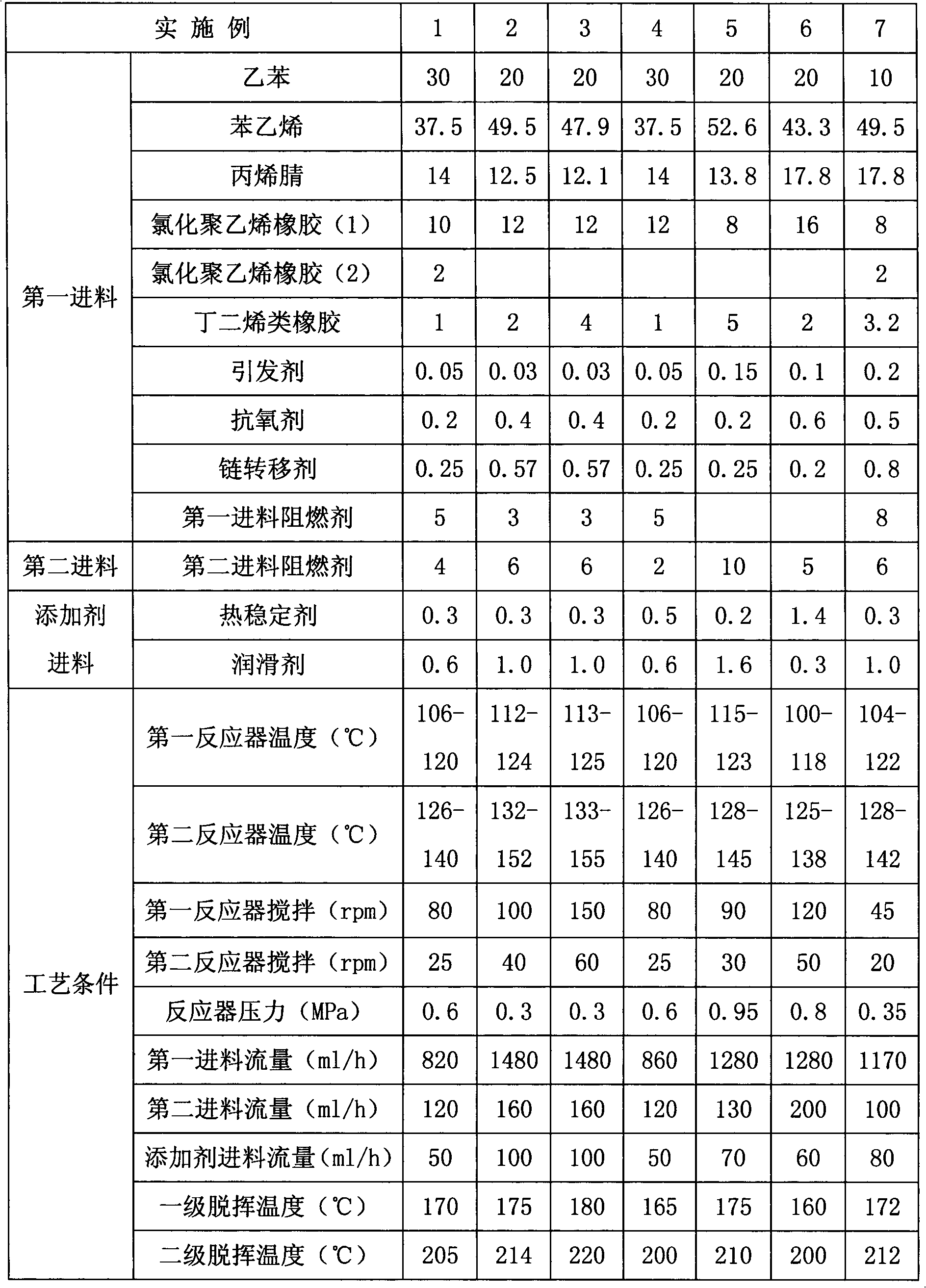

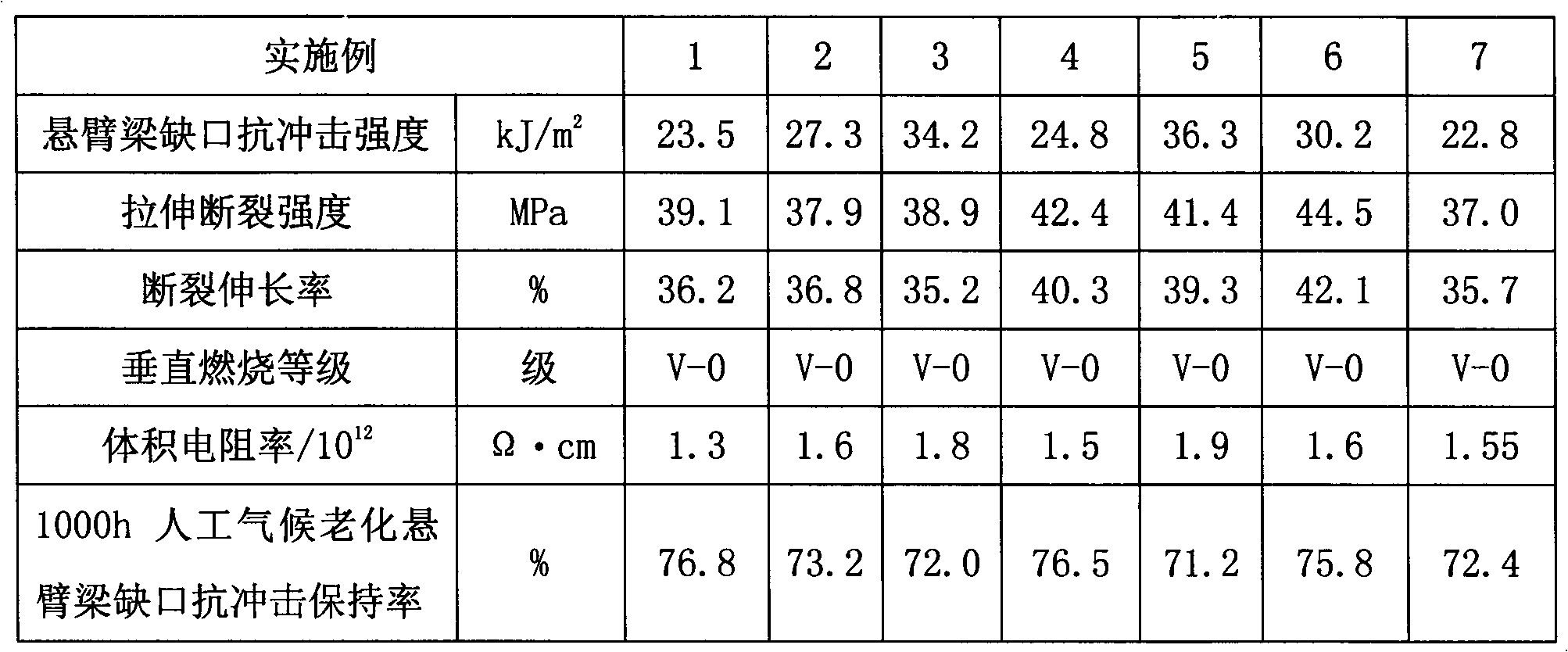

Method for preparing continuous bulk of flame retardant and highly impact resistant acrylonitrile-chlorinated polyethylene-styrene resin

A method for preparing a continuous bulk of a flame retardant and highly impact resistant acrylonitrile-chlorinated polyethylene-styrene resin comprises the following steps: dissolving chlorinated polyethylene rubbers, butadiene rubbers, flame retardants and auxiliaries into a mixture of mono alkyl ethylene aromatic monomers and unsaturated nitrile monomers to be involved in polymerization reaction as first feed solution, mixing the first feed solution with second feed, containing the same or different flame retardants, of mixed solution of aromatic hydrocarbon and with additive feed, containing heat stabilizers and lubricants, of the mixed solution of aromatic hydrocarbon, and then continuously carrying out polymerization reaction. The resin prepared by the method of the invention has high notch impact strength, high flame retardant rating, superior comprehensive performance and excellent antistatic performance and weather resistance. The volume resistivity can reach 2.0*10<12> and below, and the notch impact strength retention rate can reach 70% and above under the condition of artificial weathering for more than 1000h; therefore, the resin can be on a par with the ASA resins famous for weather resistance.

Owner:ZHEJIANG OCEANKING DEVELOPMENT CO LTD

High-flame retardation chemically-crosslinked polyethylene foamed material and preparation method thereof

The invention discloses a high-flame retardation chemically-crosslinked polyethylene foamed material. The material is prepared from the following components by weight: 48 to 52.5% of a foaming agent master batch, 11 to 14% of a cross-linking agent master batch, 20 to 23% of a fire retardant master batch, 10 to 12.5% of low density polyethylene and 2 to 5% of a magnesium hydroxide master batch, wherein the foaming agent master batch is prepared by mixing the low density polyethylene and a foaming agent, the cross-linking agent master batch is prepared by mixing the low density polyethylene and a cross-linking agent, the fire retardant master batch is prepared by mixing the low density polyethylene and a fire retardant, and the magnesium hydroxide master batch is prepared by mixing the low density polyethylene and magnesium hydroxide. The invention has the following advantages: the prepared chemically-crosslinked polyethylene foamed material has a high flame retardation grade, reaching Grade B1 and has fine and compact surface foam pores.

Owner:宁波辉门科技有限公司

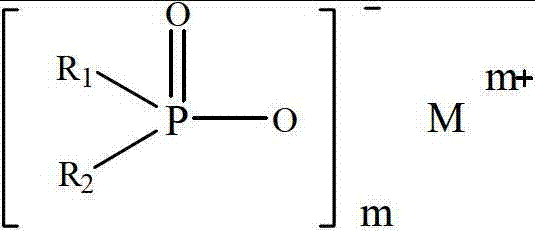

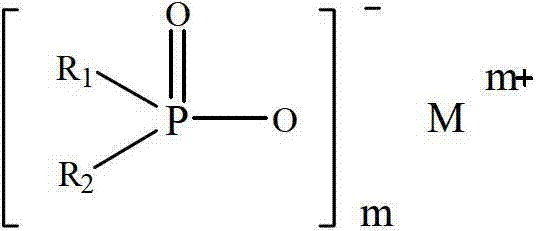

Flame retardant polyolefin and preparation method and product thereof

ActiveCN103113649AHigh flame retardant efficiencyHigh flame retardant gradePolyolefinPolymer science

The invention discloses flame retardant polyolefin and a preparation method and a product thereof. The flame retardant polyolefin comprises the following components in parts by weight: 100 parts of polyolefin resin, 5-64 parts of flame retardant, 1-60 parts of flame retardant synergist, 0-50 parts of additive, 0-100 parts of stuffing and 0-10 parts of other assistants. The sum of the flame retardant and the flame retardant synergist in parts by weight is 25-65 parts. The flame retardant synergist is ammonium salt containing at least one NH<4+>. The other additives are charring agents and / or stabilizers. According to the invention, through reasonable selection of the flame retardant synergist, the flame retardant efficiency of hypophosphite or alkyl hypophosphite flame retardant can be greatly improved in polyolefin resin, and the use amount of the hypophosphite or alkyl hypophosphite flame retardant in polyolefin resin can be greatly reduced, so that polyolefin resin can reach a high flame retardant level on the condition that the addition of the flame retardant is low.

Owner:KINGFA SCI & TECH CO LTD +1

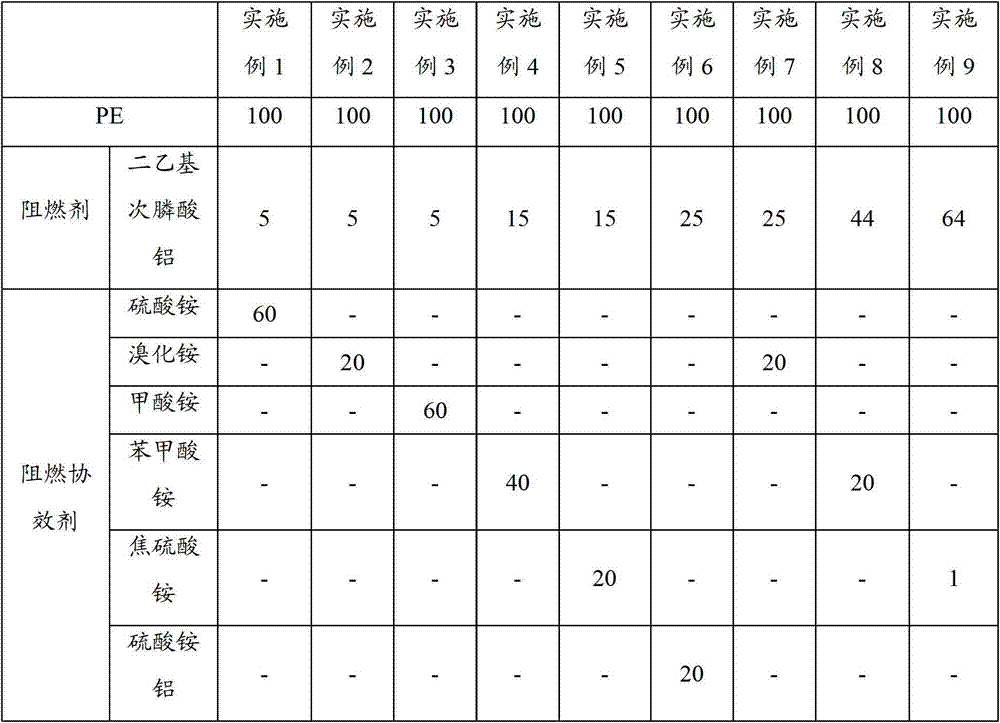

Phosphorus-containing polyether plasticizer and flame-retardant single-component silane modified sealant, and preparation methods and application thereof

ActiveCN110511369AGood compatibilityHigh flame retardant gradeNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceSilanes

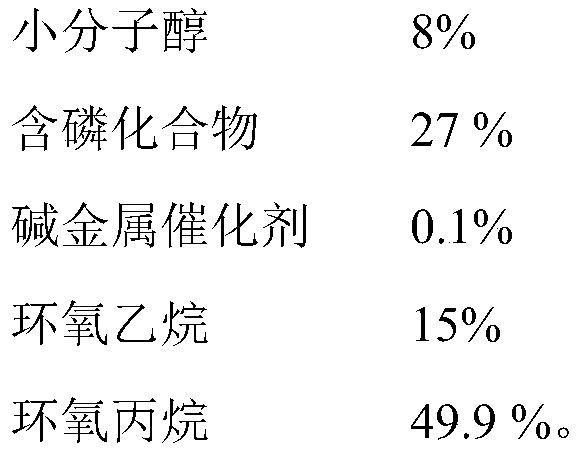

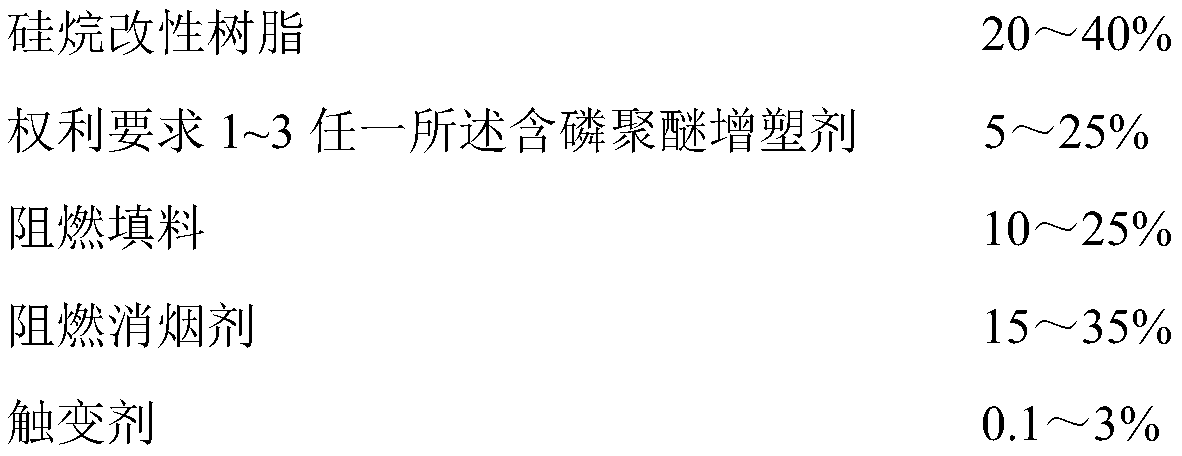

The invention relates to a phosphorus-containing polyether plasticizer and a flame-retardant single-component silane modified sealant, and preparation methods and application thereof. The phosphorus-containing polyether plasticizer is composed of the following components in percentage by mass: 1 to 10% of small molecular alcohol, 18 to 34% of a phosphorus-containing compound, 0.1 to 0.3% of an alkali metal catalyst, 10 to 20% of ethylene oxide, and 37.9 to 50% of propylene oxide. The phosphorus-containing polyether plasticizer provided by the invention has chain segments similar to the main chain structures of a silane modified sealant, and has good compatibility with silane modified resin; meanwhile, the phosphorus-containing polyether plasticizer can be cooperatively used with a flame-retardant filler and a flame-retardant smoke suppressor for synergistic flame retardance, so a flame retardance grade is improved, and smoke density and smoke toxicity are reduced. The sealant preparedfrom the phosphorus-containing polyether plasticizer, silane modified resin and the like has the advantages of lower smoke density, low smoke toxicity, low VOC content, excellent mechanical propertiesand bonding properties, and a flame retardant grade of 94V-0 grade, and meet the use requirements on sealants for rail transit.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

Housing material for electronic equipment and preparation method thereof

The invention discloses a housing material for electronic equipment and a preparation method thereof and relates to the field of electronic equipment materials. The housing material comprises polyvinyl chloride having polymerization degree of 600, thermoplastic polyurethane, modified chopped carbon fiber, polycarbonate, maleic anhydride grafted polypropylene, polymethacrylimide, nano silica, polyamide wax, diphenylamine, calcium-zinc composite stabilizer, an antioxidant, an anti-ultraviolet agent, a foaming agent, and a foam stabilizer. The preparation method of the housing material comprises: drying the materials; conveying part of the materials into an injection molding machine for melting; adding the rest materials after melting; pouring through the injection molding machine, cooling, opening a mold to take a product. The housing material is simple and convenient to prepare and low in cost; the finished housing material has high flame-retardant level and high mechanical strength, can have certain weakening and shielding functions for electromagnetic irradiation generated by electronic equipment, and is suitable for popularization and application.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

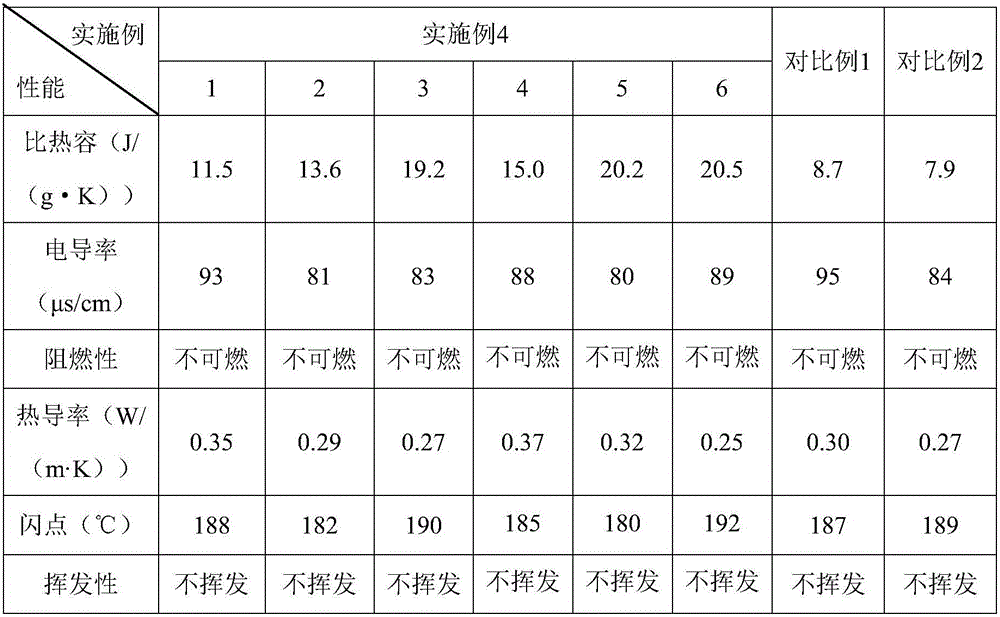

Cooling liquid for battery constant temperature control and preparation method thereof

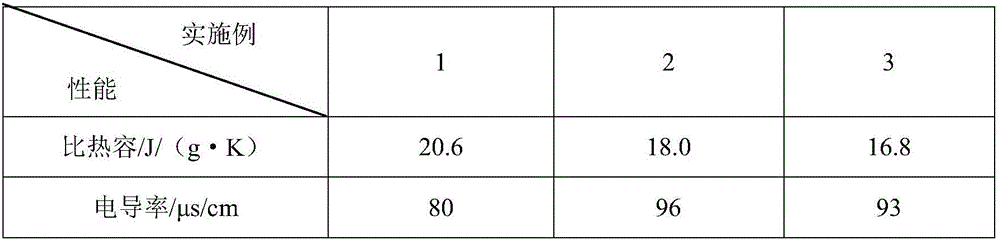

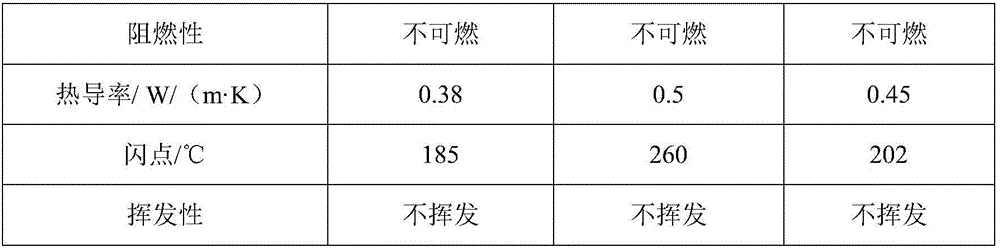

ActiveCN106785222AHigh flame retardant gradeImprove thermal conductivitySecondary cellsSolventPhase-change material

The invention discloses cooling liquid for battery constant temperature control and a preparation method thereof. The cooling liquid is prepared from 16 to 50 percent of phase-change materials, 3 to 15 percent of emulsifying agents, 1 to 10 percent of additive assistants and 30 to 60 percent of solvents. The preparation method comprises the following steps that the temperature of the phase-change materials is raised to 70 to 80 DEG C; stirring is started to 2000 to 6000rpm; the emulsifying agents are added and are uniformly stirred; then, the additive assistants are added and stirred; finally, the solvents are added; accelerated stirring is performed to reach 4000 to 6000rpm; sufficient homogeneous emulsification is performed; the cooling liquid is obtained. Compared with the traditional cooling liquid, the cooling liquid has the advantages of high heat capacity, low electrical conductivity, high flame retardant stage, high heat conductivity, high flash point and low volatility; the storage of heat energy of a battery module is realized through the phase-change materials; the technical requirement of constant temperature control is met; meanwhile, during the preparation, a high-speed dispersion emulsification technology is combined with a phase change technology; the heat capacity, the flame retardant performance and the anti-electrolytic chemical reaction of the cooling liquid are optimized.

Owner:JIANGSU LOPALTECH

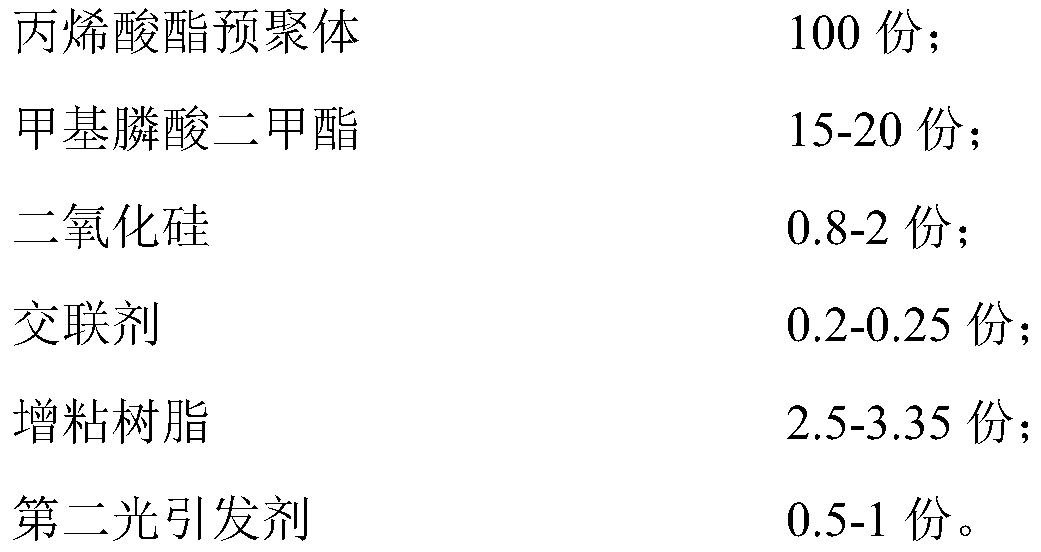

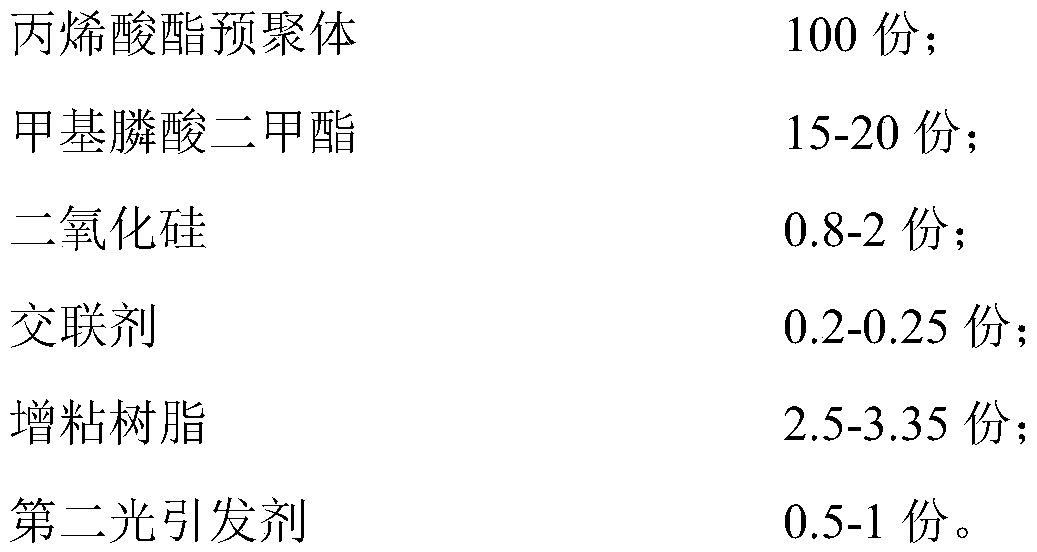

Halogen-free flame-retardant UV-cured acrylate pressure-sensitive adhesive and pressure-sensitive adhesive tape, and preparation method thereof

ActiveCN110655872AImprove flame retardant performanceImprove adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceDimethyl methylphosphonate

The invention discloses a halogen-free flame-retardant UV-cured acrylate pressure-sensitive adhesive and a pressure-sensitive adhesive tape, and a preparation method thereof. The halogen-free flame-retardant UV-cured acrylate pressure-sensitive adhesive comprises the following raw materials in parts by weight: 100 parts of an acrylate prepolymer, 15 to 20 parts of dimethyl methylphosphonate, 0.8 to 2 parts of silicon dioxide, 0.2 to 0.25 part of a cross-linking agent, 2.5 to 3.35 parts of tackifying resin, and 0.5 to 1 part of a second photoinitiator. The pressure-sensitive adhesive tape formed by the halogen-free flame-retardant UV-cured acrylate pressure-sensitive adhesive is good in flame-retardant effect, excellent in pressure-sensitive adhesive property and wide in application range.

Owner:湖南省和祥润新材料有限公司

Flame-retardant heat-resisting silicone rubber and preparation method thereof

InactiveCN107513273AMeet the use requirementsImprove flame retardant performancePolymer scienceSilanes

The invention discloses the manufacture of a silicone rubber material, and particularly discloses flame-retardant heat-resisting silicone rubber and a preparation method thereof. The flame-retardant heat-resisting silicone rubber is prepared from the following raw materials in parts by weight: 100 parts of raw rubber with the vinyl molar content of 0.12%, 30 to 50 parts of fumed silica, 3 to 6 parts of dimethoxydimethylsilane, 3 to 6 parts of hydroxyl silicone oil, 0.2 to 0.6 part of vinyl trimethoxy silane, 0.2 to 0.4 part of stearic acid 1801, 1 to 10 parts of zinc oxide, 20 to 30 parts of decabromodiphenyl ethane and 1 to 2 parts of cerium oxide. After adopting the formula and the method, raw materials are reasonably selected and matched, a special preparation method is used and the parameters are strictly controlled in a preparation process, so that a prepared product has good flame retardant property after being detected practically, meanwhile, has better high temperature resistance, hardness, strength and processability, and fully meets the use requirement of a high-temperature-resistant flame-retardant cable.

Owner:JIANGSU TIANCHEN NEW MATERIALS

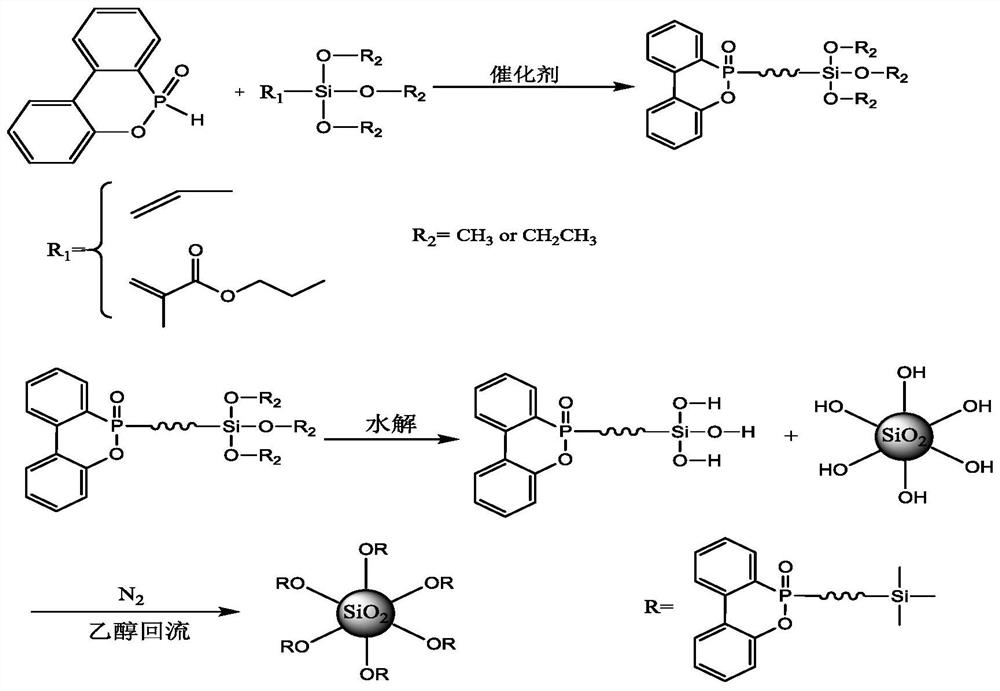

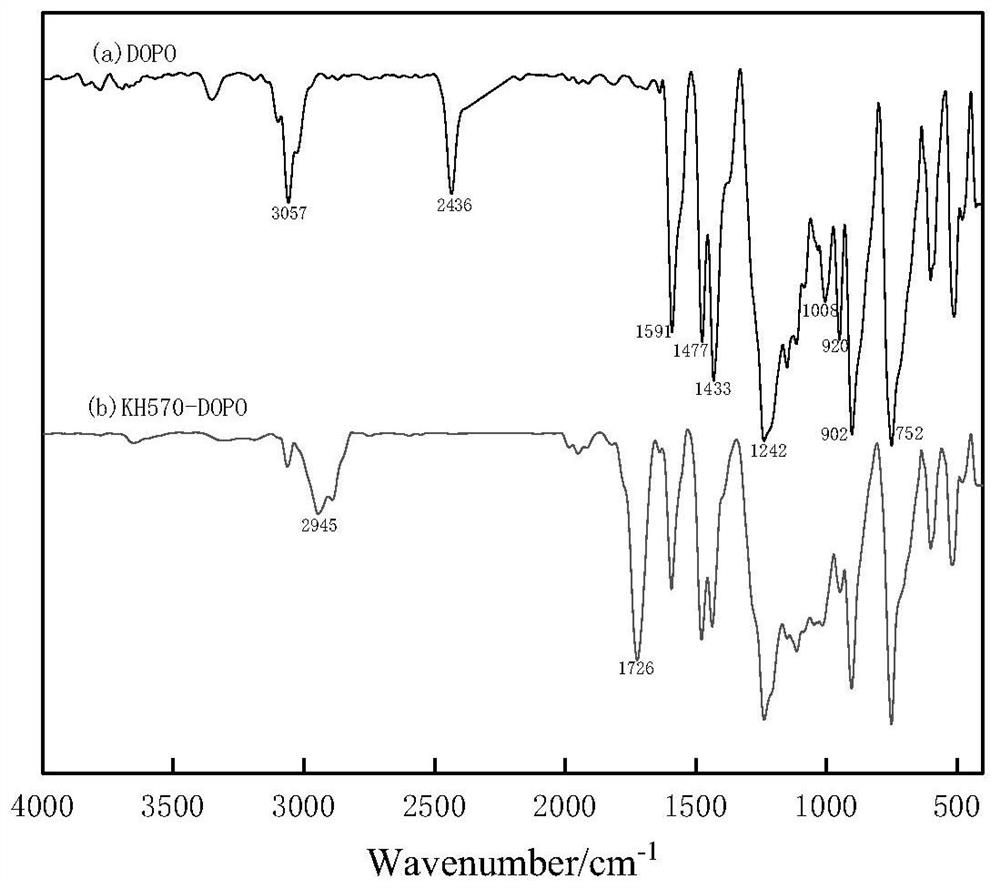

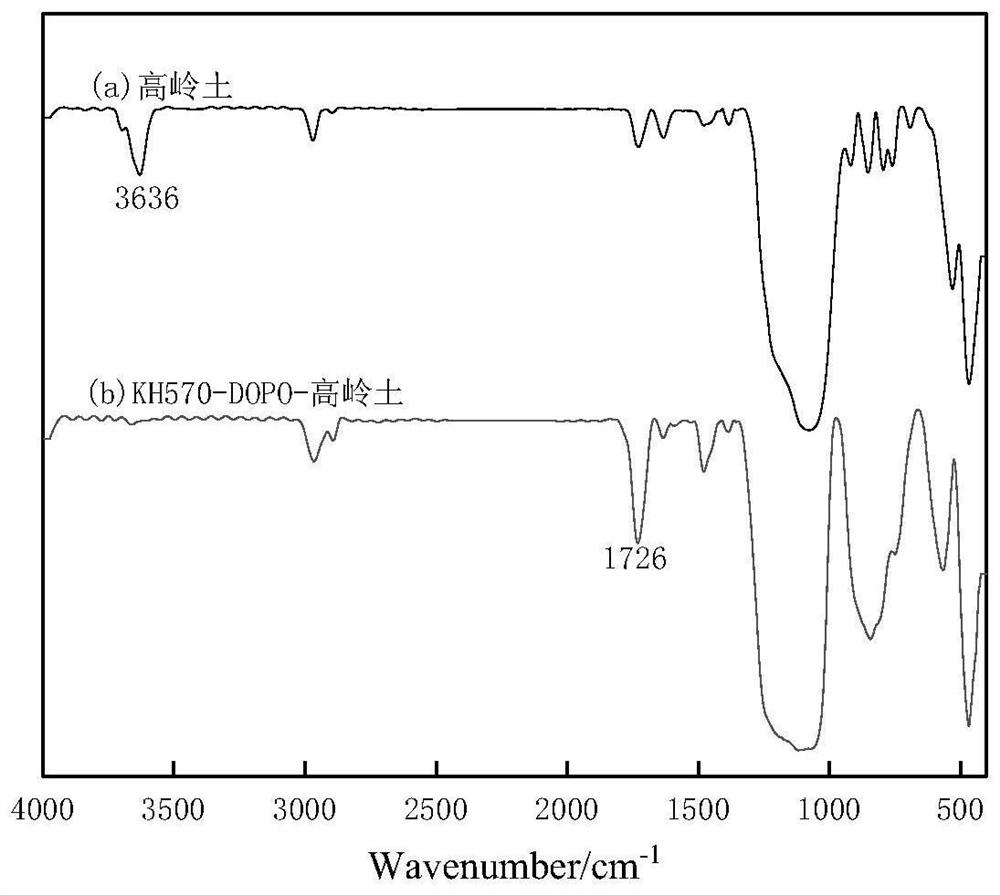

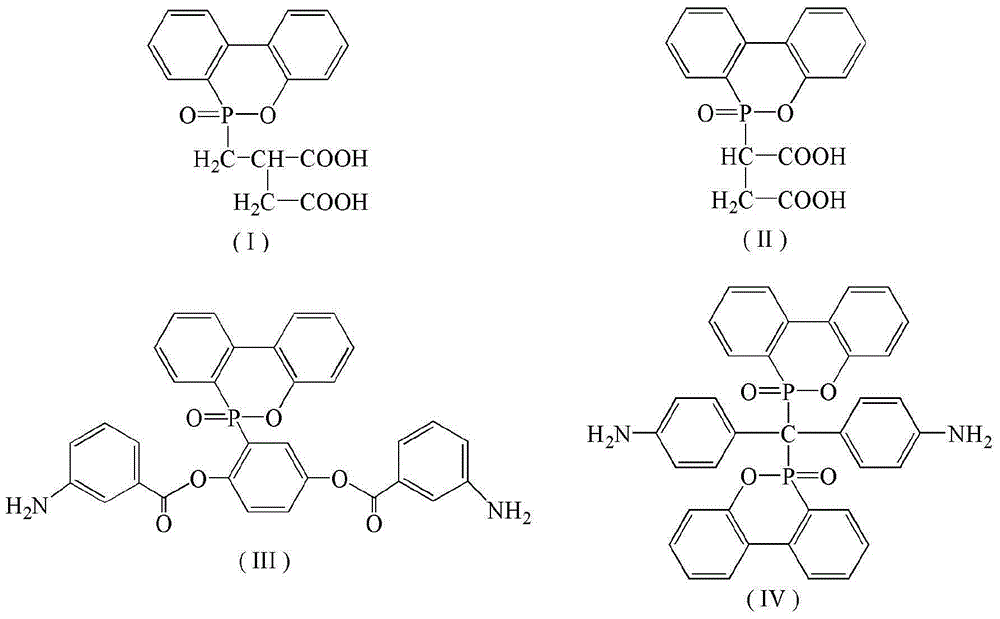

DOPO-based silicon-phosphorus synergistic flame retardant as well as preparation method and application thereof

PendingCN111793090AImprove flame retardant performanceHigh flame retardant gradeGroup 5/15 element organic compoundsSilane couplingFree-radical addition

The invention belongs to the technical field of flame retardants, and particularly discloses a DOPO-based silicon-phosphorus synergistic flame retardant. The raw materials comprise the following components: 1.0 to 3.0 parts of DOPO; 1.5 to 3.0 parts of a silane coupling agent, 0.075 to 0.180 part of a catalyst, 100.0 to 200.0 parts of a solvent, 1.0 to 3.0 parts of inorganic clay, 0.1 to 0.2 partof a pH regulator, 3.0 to 4.0 parts of deionized water, 57.0 to 76.0 parts of an alcohol compound and 1.0 to 2.0 parts of an auxiliary flame retardant. The preparation method comprises the following steps: carrying out free radical addition reaction on DOPO and a silane coupling agent to obtain a flame-retardant intermediate, and adding a catalyst to accelerate the reaction; then hydrolyzing to obtain a silanol group, carrying out dehydration combination on the silanol group and hydroxyl on inorganic clay, and supplementing with an auxiliary flame retardant to obtain the DOPO-based silicon-phosphorus synergistic flame retardant. The invention also discloses an application of the DOPO-based silicon-phosphorus synergistic flame retardant in preparation of flame-retardant modified epoxy resin.

Owner:SHAANXI UNIV OF SCI & TECH

Glass fiber reinforced polycarbonate composite material with flame-retarding mobility and thermal endurance, and product thereof

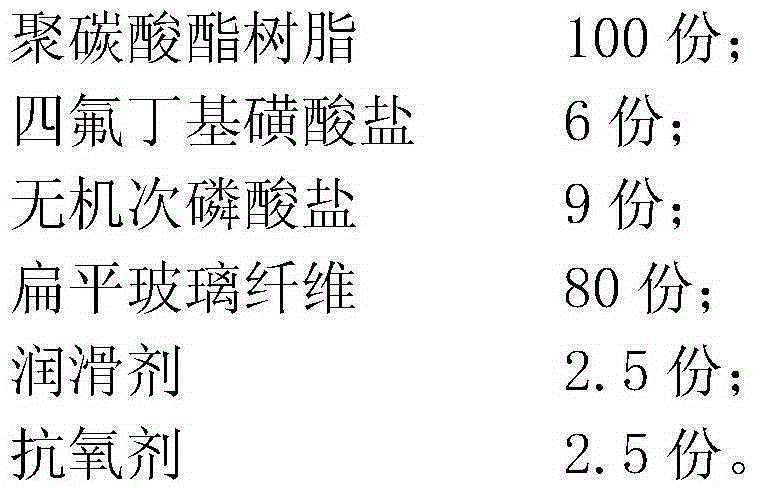

The invention belongs to the technical field of high polymer material, and particularly relates to a glass fiber reinforced polycarbonate composite material with flame-retarding mobility and thermal endurance, and a product thereof. The composite material is prepared from, by weight, 100 parts of polycarbonate resin, 20-150 parts of glass fiber, 2-30 parts of flame retardant, and 2-10 parts of lubricant. Through adding a certain amount of glass fiber, flame retardant and lubricant in the polycarbonate resin, the glass fiber reinforced polycarbonate composite material with flame-retarding mobility and thermal endurance, and the product thereof can acquire composite materials and products with high flame retarding grade; the flame retarding grade can reach 0.5 mmV-O grade; besides, the composite material has excellent mobility and thermal endurance.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Flexible decorative wood veneer

InactiveCN103753900AHigh flame retardant gradeAvoid damageSpecial ornamental structuresWood layered productsWood veneerSurface layer

The invention provides a flexible decorative wood veneer which is high in flame retardant property and can be bent at a large angle. The flexible decorative wood veneer adopts a multilayer structure, wherein the surface layer is a wood veneer layer, the middle layer is a metal thin film, and the bottom layer is kraft paper; a non-woven cloth layer is arranged between the surface layer and the middle layer; an adhesive layer or a film adhesive layer is arranged between every two layers. Non-woven cloth is used for preventing the wood veneer from being damaged or torn away; the wood veneer with the non-woven cloth is extremely high in flexibility and stability; therefore, when the wood veneer is produced into different products through other machines, problems can be avoided. The wood veneer can be attached to the surface, with any curvature, of furniture, and wood chips cannot be broken, so that a plenty of wood materials are saved, the wood veneer is convenient to process, the processing time can be saved, and the cost is reduced.

Owner:冯桔红

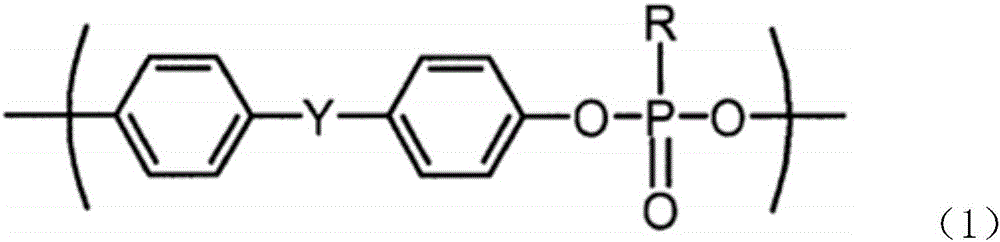

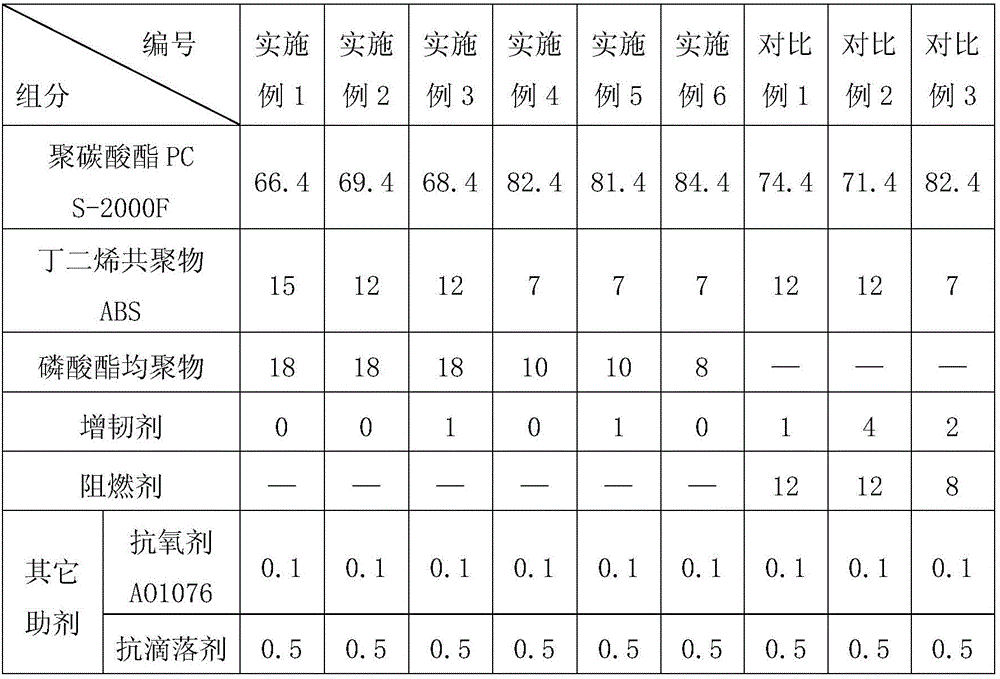

High-heat resistance and high-toughness polycarbonate composition and preparation method thereof

ActiveCN106084717AImprove flame retardant performanceOvercome the heat distortion temperaturePhosphateHeat resistance

The invention discloses a high-heat resistance and high-toughness polycarbonate composition and a preparation method thereof. The composition comprises, by weight, 60-90 parts of polycarbonate, 1-20 parts of a butadiene copolymer, 5-25 parts of a phosphate ester homopolymer, 0-8 parts of a flexibilizer and 0-9.6 parts of other assistants, and the quantity sum of weight parts of all above components is 100. Compared with the prior art, the preparation method has the following advantages: addition of the phosphate ester homopolymer to the raw material formula well overcomes an abuse that present organophosphate flame retardant greatly reduces the heat deformation temperature and the toughness of polycarbonate, effectively improves the heat resistance and the toughness of the polycarbonate composition, has a very good flame retardation effect, and effectively improves the flame retardation grade of the polycarbonate composition; and the phosphate ester homopolymer has extremely good compatibility with polycarbonate, has no plasticizing effect on alloy, and obviously improves the heat resistance of the polycarbonate composition without influencing the flame retardation grade or the toughness of the polycarbonate composition.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

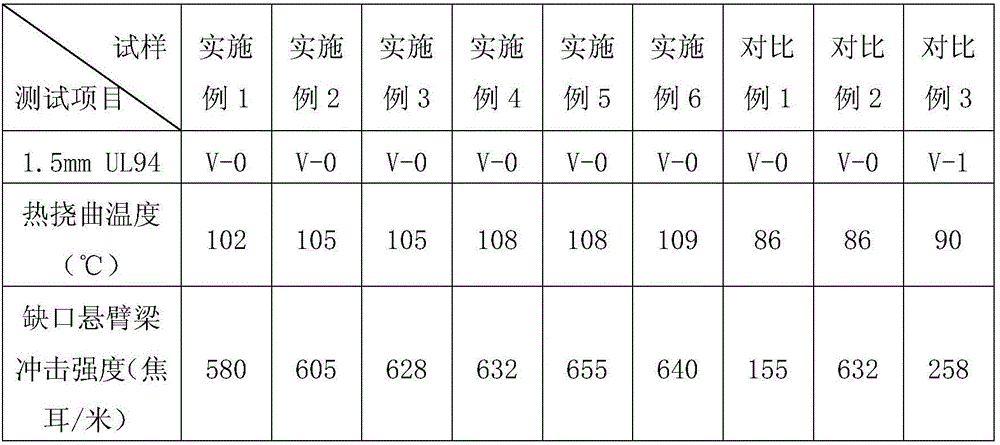

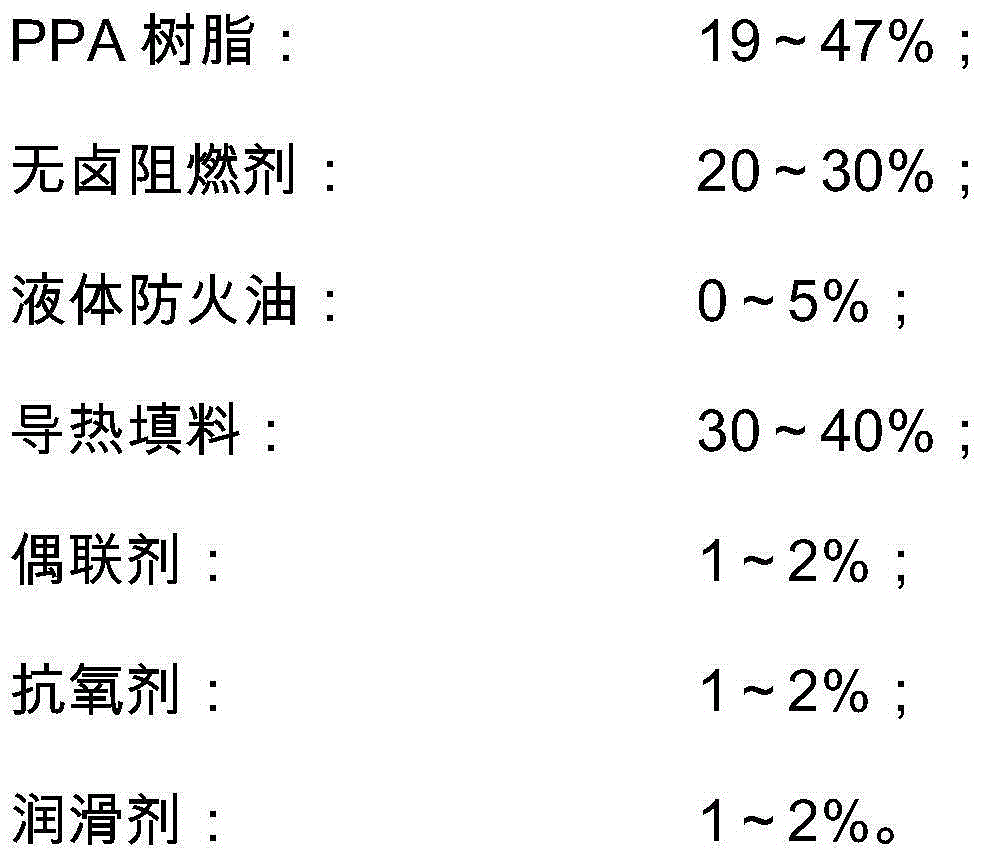

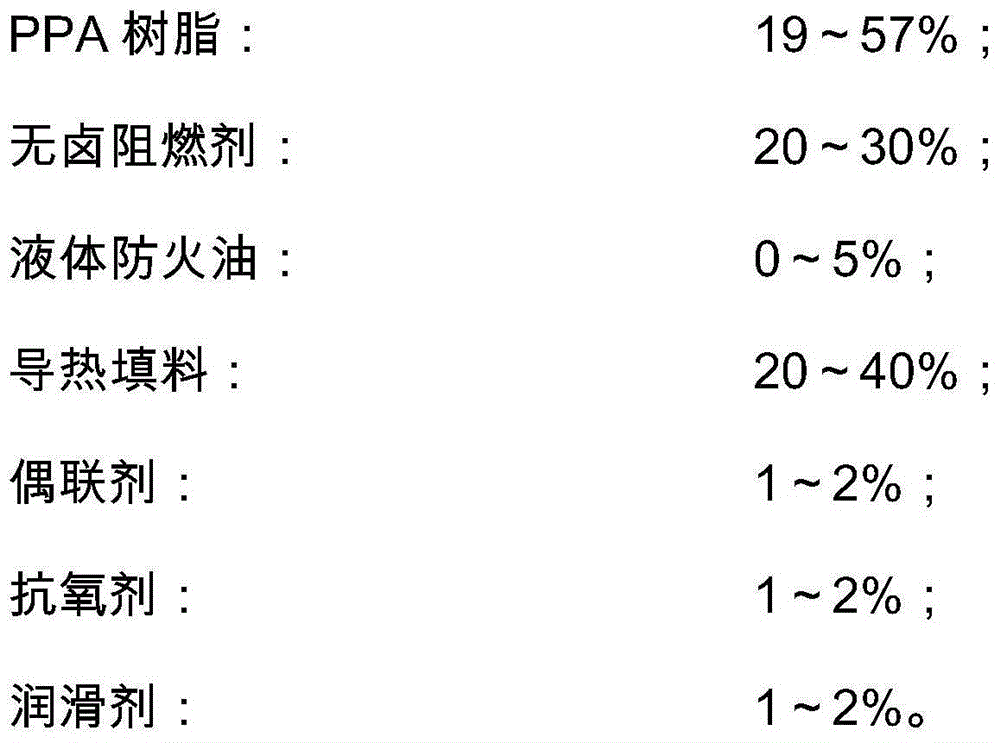

Heat-conducting high-temperature nylon composite material and preparation method thereof

The invention discloses a heat-conducting high-temperature nylon composite material and a preparation method thereof. The heat-conducting high-temperature nylon composite material is composed of, by mass, 19-47% of PPA resin, 20-30% of halogen-free flame retardants, 0-5% of liquid fireproofing oil, 30-40% of heat-conducting packing, 1-2% of coupling agents, 1-2% of antioxidants and 1-2% of lubricating agents. The nylon composite material is good in heat-conducting effect and high in flame retardant grade and can meet the non-halogen requirements of flame retardant materials in the European Union standard.

Owner:DONGGUAN HUAYING NEW MATERIAL CO LTD

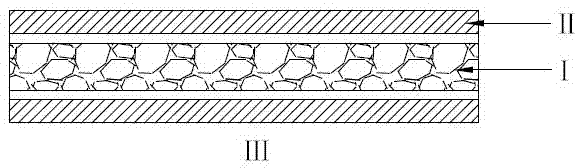

Halogen-free flame-retardant resin matrix sandwich structure body and preparation method thereof

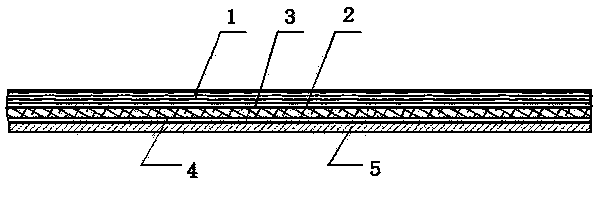

ActiveCN103753905AHigh flame retardant gradeReduce volatilitySynthetic resin layered productsLaminationFiberPolymer science

The invention discloses a halogen-free flame-retardant resin matrix sandwich structure body. The halogen-free flame-retardant resin matrix sandwich structure body is composed of a core material (I) and resin matrix fiber reinforced body materials (II) which are configured on the upper surface and / or the lower surface of the core material (I), wherein the core material (I) is composed of materials with clearances; the core material has the specific gravity of 0.03-2.0, and has the thickness of 0.1-5.0mm, and is composed of a foaming body with clearances or modified thermoplastic resin matrix fiber reinforced materials; a thermoplastic resin matrix and a long fiber form a clearance structure by crossing fiber wet resin. The halogen-free flame-retardant resin matrix sandwich structure body prepared by the invention achieve the flame-retardant level as high as UL94-V0, and is high in weather resistance, high in ultraviolet irradiation resistance, light in weight, thin in thickness, high in rigidity, simple in process, and mainly applied to surface structure plates of the 3C industry, the household appliance industry, relevant crates and the like.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV +1

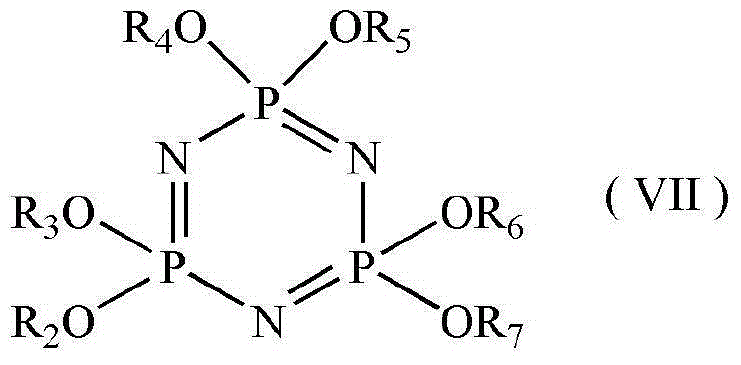

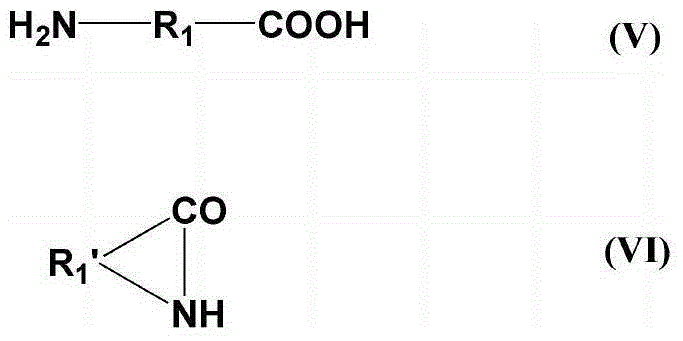

Branched modifier and corresponding flame retardant nylon resin

ActiveCN105017525APolymerization conditions are mildIncrease reaction rateGroup 5/15 element organic compoundsHalogenCombustion

The invention discloses a branched modifier having the structure shown in the formula (VII), wherein R2-R7 are the same or different and are independently hydrocarbonyl or substituted hydrocarbonyl containing 1-20 carbon atoms, the substituted hydrocarbonyl is hydrocarbonyl containing terminated carboxyl or terminated amino, and at least one of R2-R7 is substituted hydrocarbonyl containing terminated carboxyl or terminated amino. The invention also provides a flame retardant nylon resin, a reactive flame retardant and diamine or dicarboxylic acid form a salt with equal mole ratio, the obtained salt solution is mixed with a nylon polymeric monomer and the branched modifier, and then a polycondensation reaction is carried out to obtain the flame retardant nylon resin. The flame retardant nylon resin has the characteristics of no halogen, environmental protection, no dripping during combustion, high flame retardant efficiency, high flame retardant grade, permanent flame retardancy and no migration.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

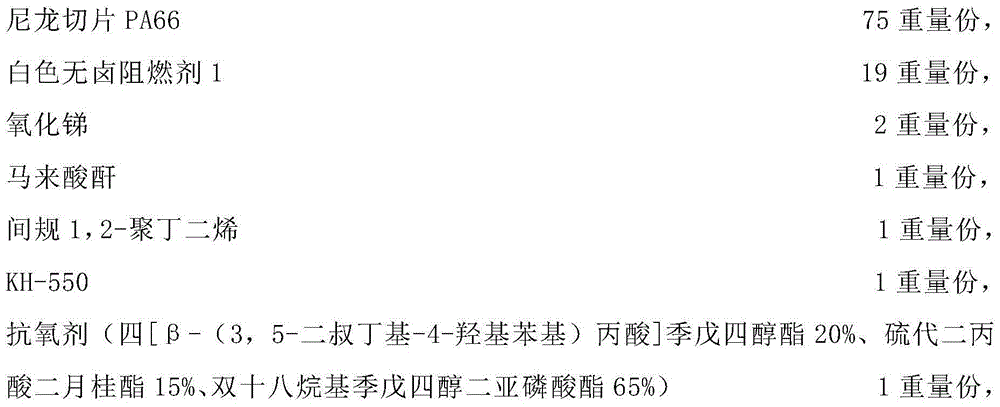

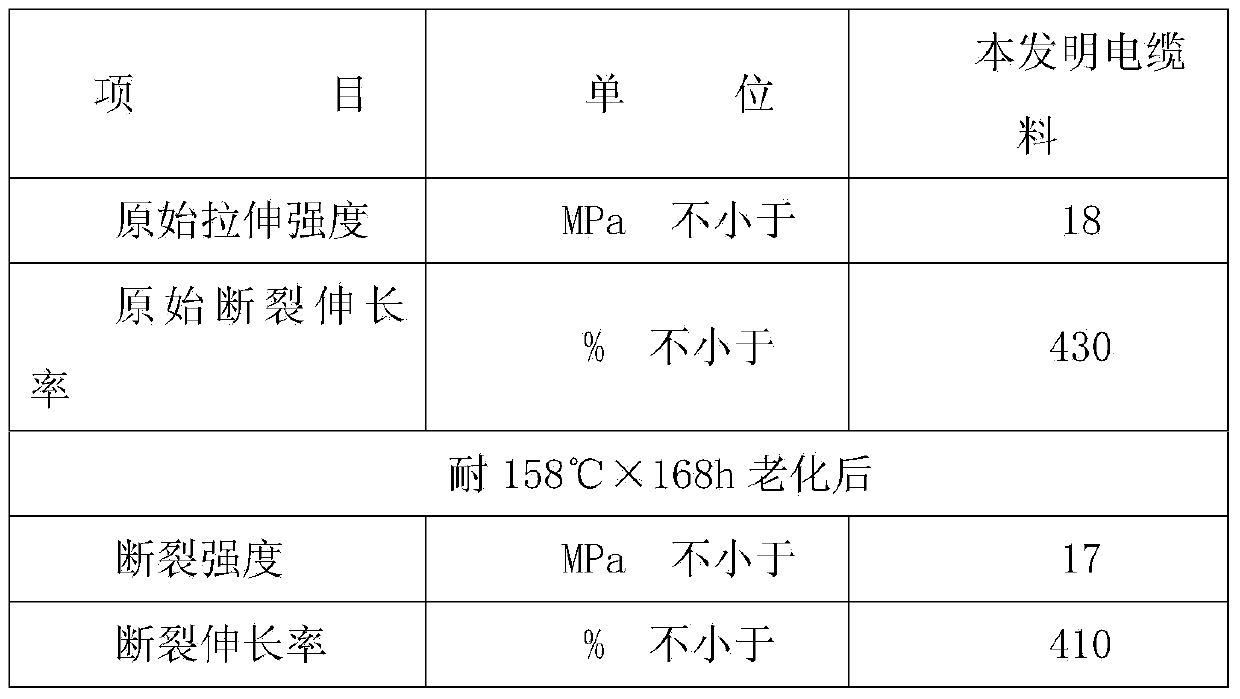

Preparation method of unenhanced halogen-free flame retardant nylon 66

The invention relates to a preparation method of an unenhanced halogen-free flame retardant nylon 66, and belongs to the technical field of flame retardant engineering plastics. The method comprises the following steps: synthesizing a halogen-free flame retardant; preparing raw materials according to the following proportions: 65-85 parts by weight of nylon 66 sliced sections, 8-20 parts of self-synthesized halogen-free flame retardant, 1-5 parts of auxiliary flame retardant, 0-2.5 parts of compatilizer, 0.5-2 parts of flexibilizer, 0.5-1.5 parts of silane coupling agent, 1-4 parts of antioxygen; adding the materials into a high-speed mixing machine to uniformly mix; melting and extruding; feeding a mixture into a double-screw extruder for melting, blending and extruding; bracing; water-cooling; and chopping and drying to obtain the flame retardant nylon 66. The prepared flame retardant nylon is high in flame retardance, high in toughness, high in abrasion resistance, high in electric performance, high in heat resistant performance and the like; based on a complex synergistic effect of the self-synthesizing flame retardant and the auxiliary flame retardant, a good and stable effect can be realized, and the preparation method can be widely suitable for the fields of automobiles, mechanical industries, electronic appliances, precise instruments and the like.

Owner:BEIJING CO FOUND HIGH TECH INCUBATOR

High inflaming retarding polyolefin cable insulating material and preparation method thereof

InactiveCN103724748AHigh tensile strengthImprove heat resistanceInsulated cablesInsulatorsElastomerCross-link

The invention discloses a high inflaming retarding polyolefin cable insulating material which is characterized by comprising the following raw materials in parts by weight: 40-45 parts of polyolefin elastomer resin, 14-18 parts of EVA, 12-15 parts of polyethylene, 10-12 parts of aluminium hydroxide, 2-3 parts of a silane coupling agent KH550, 1-2 parts of a cross-linking agent TAC, 4-6 parts of polyvinyl acetate, 2-3 parts of dibutyltin dilaurate, 2-3 parts of triethoxyvinylsilane, 1-2 parts of isocyanate, 1-2 parts of tungsten boride, 1-2 parts of ricinoleic acid, 16-18 parts of triethyl O-acetylcitrate, 5-8 parts of tributyl citrate and 6-8 parts of an addition agent. The high inflaming retarding polyolefin cable insulating material provided by the invention is high in tensile strength, has better heat resistance and processability, and improves the flame retardant rating. The preparation method of the high inflaming retarding polyolefin cable insulating material is reasonable in design and simple and convenient to operate.

Owner:WUHU JIACHENG ELECTRONICS TECH

Novel organic silicon cladded black phosphorus flame retardant as well as preparation method and application thereof

The invention discloses a novel organic silicon cladded black phosphorus flame retardant. The novel organic silicon cladded black phosphorus flame retardant is obtained by cladding black phosphorus with organic silicon in an aprotic polar solvent or a polar proton solvent under the protection of inert gas. A micron-grade or nano-grade flame-retarding raw material such as the black phosphorus or low-dimension black phosphorus is creatively subjected to organic silicon cladding and dispersion in the aprotic polar solvent or the polar proton solvent to prepare the micron-grade or nano-grade novelflame retardant; the novel flame retardant can improve various mechanical properties of a base material and can improve the flame-retarding grade of the material very well. According to the flame retardant disclosed by the invention, the micron-grade or nano-grade black phosphorus is cladded by the organic silicon and synergistic flame-retarding effects of the micron-grade or nano-grade black phosphorus and the organic silicon are combined, so that the flame retardant is dispersed into a base body of the material in a nano-grade manner; the flame-retarding performance of the material can be improved and the various mechanical properties of the material also can be improved; an application field of the flame retardant is expanded.

Owner:HUNAN UNIV OF TECH

Epoxy resin adhesive and preparation method thereof

InactiveCN104152090ALow toxicityWide ratioNon-macromolecular adhesive additivesEpoxy resin adhesivesFire retardantResin adhesive

The invention relates to an epoxy resin adhesive. The epoxy resin adhesive comprises the following raw materials in percentage by mass: 25-66% of silicon micropowder, 10-45% of a toughening agent, 10-30% of bisphenol A type epoxy resin, 1.5-3.5% of a flame retardant, 0.05-0.5% of carbon black, 1.5-4% of phenolic aldehyde epoxy resin, 1.4-4% of dicyandiamide, 2.5-5.6% of a thixotropic agent and 1.5-3.6% of an accelerant. The epoxy resin adhesive has the advantages of low toxicity, volatility effect, wide blending ratio, strong bonding force, good toughness and high flame retardant level which can reach V-0. The preparation method of the epoxy resin adhesive comprises the following processing steps of weighting, roasting, dispersing, mixing, pressing, mixing, pressing, vacuumizing, sampling, inspecting and packaging. The preparation method has the advantages of simple process, convenience in operation and high yield and suitable for large-scale popularization and application.

Owner:HUIZHOU QIANGDA ELECTRONICS

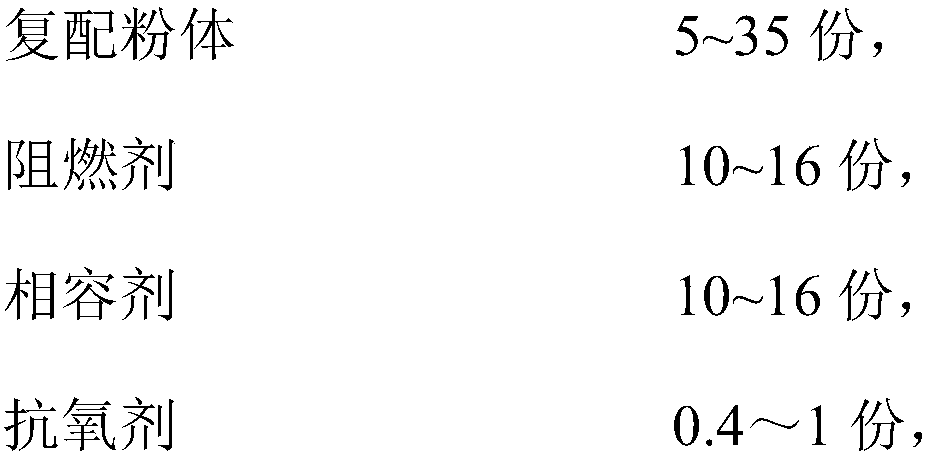

Fire-retardant and heat-resistant PPO (poly-p-phenylene oxide) alloy and preparation method thereof

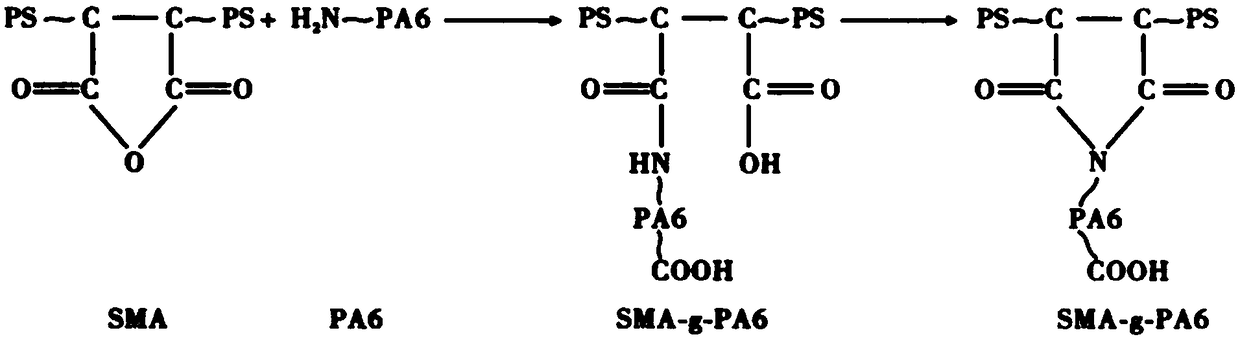

The invention relates to a fire-retardant and heat-resistant PPO alloy. The fire-retardant and heat-resistant PPO is prepared from raw materials including, by weight part, 55-85 parts of PPO resin, 15-45 parts of PA6 (polyamide 6) resin, 5-35 parts of compound powder, 10-16 parts of fire-retardant agent, 10-16 parts of compatilizer and 0.4-1 part of antioxidant agent, wherein the total weight partoccupied by the PPO resin and the PA6 resin is 100 parts, and the compound powder is formed by premixing barium sulfate, talcum powder, glass fiber powder and silane coupling agent KH550. The fire-retardant and heat-resistant PPO achieves a fire-retardant grade of UL94-5VA and meanwhile is high in heat resistance and tenacity.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com