Flame retardant polyolefin and preparation method and product thereof

A technology of polyolefin and polyolefin resin, applied in the field of flame retardant polyolefin and its preparation, can solve the problems of low flame retardant efficiency, limited degree of synergy, increase the cost of flame retardant composition, etc., and achieve high flame retardant grade, The effect of improving flame retardant efficiency and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

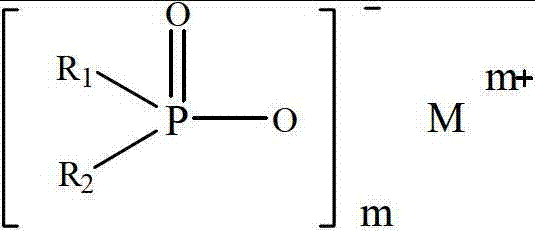

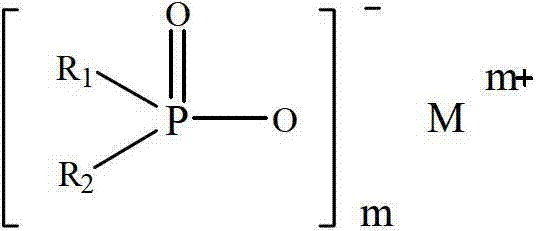

Method used

Image

Examples

Embodiment 1~18

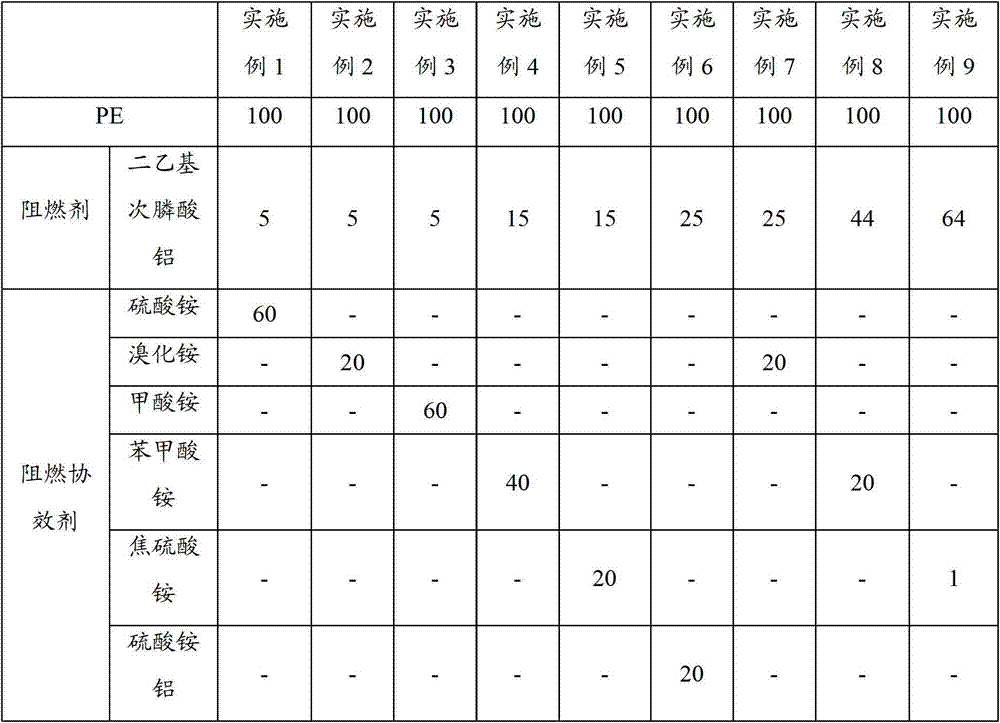

[0078] Embodiment 1~18 and comparative example 1~6

[0079] According to the proportions recorded in Tables 1 to 3, the components were uniformly mixed, and extruded at 160-230°C to prepare the flame-retardant polyolefins of Examples 1-18 and Comparative Examples 1-12. The test results of its flame retardancy and processability are shown in Table 4.

[0080] Table 1

[0081]

[0082] Table 2

[0083]

[0084]

[0085] table 3

[0086]

[0087] Table 4

[0088]

[0089] The performance test of embodiment 1~18 and comparative example 1~12 is as shown in table 5:

[0090] table 5

[0091]

[0092]

[0093] It can be seen from the results in Table 5 that when the existing MCA / MPP is used as a flame retardant synergist, the flame retardant effect is not good. It can be seen from Table 5 that the flame retardant polyolefin described in the present invention can achieve a high flame retardant effect with a small amount of flame retardant added through reaso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com