Heat-conducting high-temperature nylon composite material and preparation method thereof

A technology of nylon composite materials and heat-conducting fillers, applied in the field of heat-conducting high-temperature nylon composite materials and their preparation, to achieve good heat-conducting effects and high flame-retardant grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below.

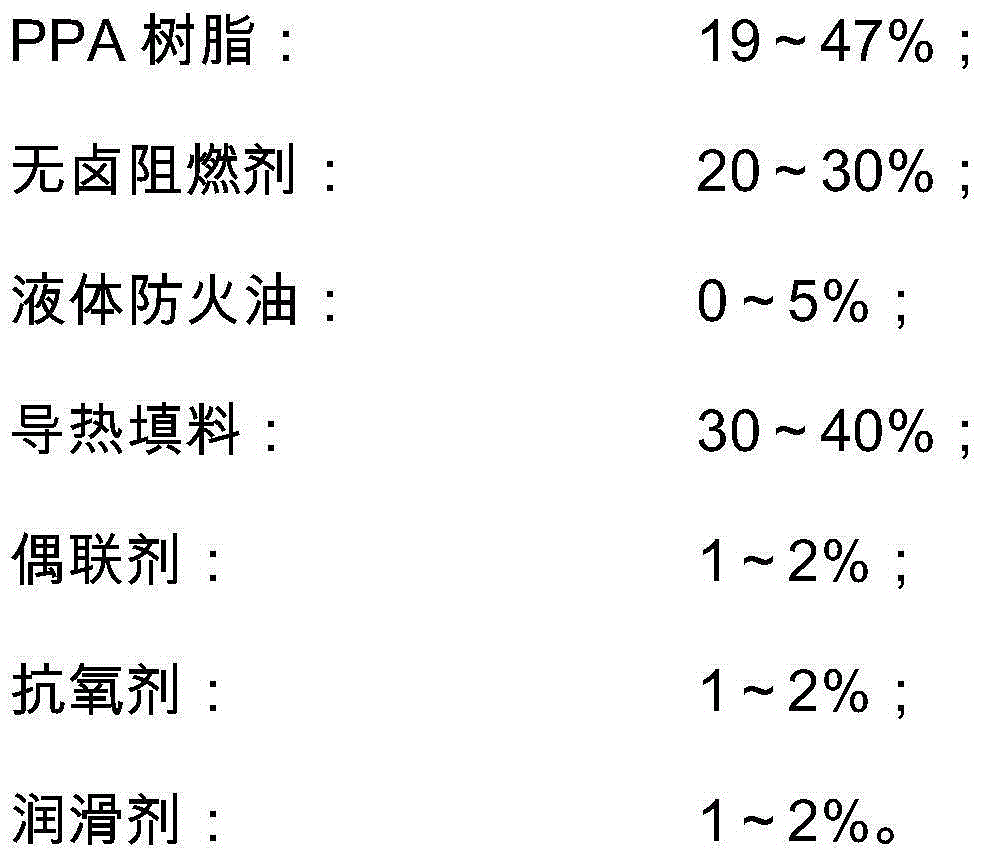

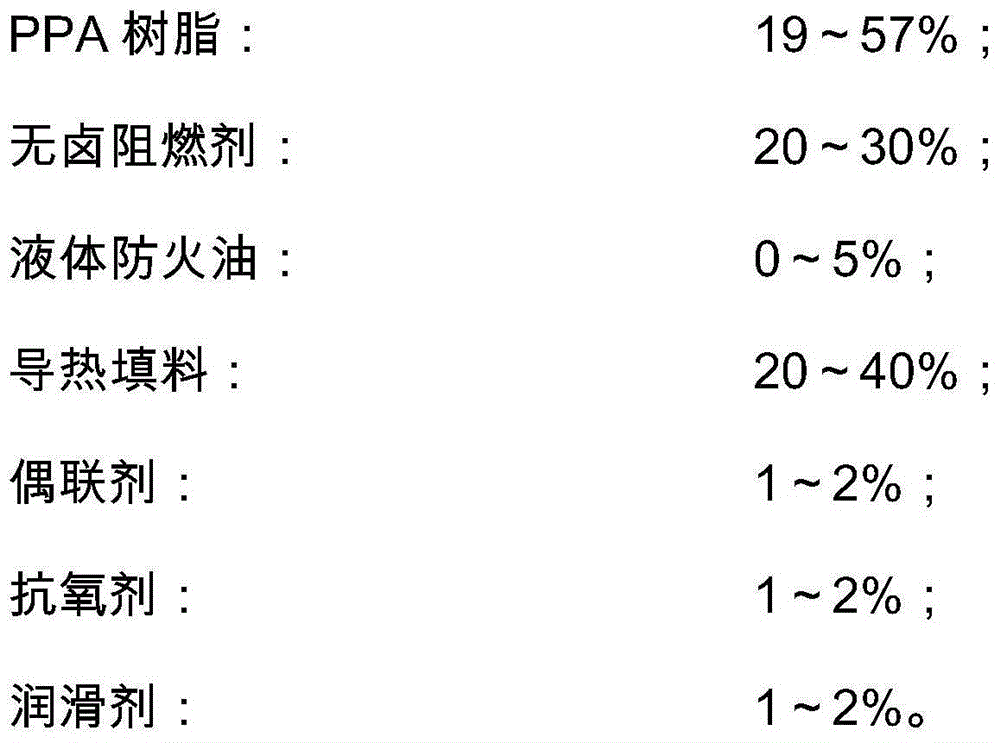

[0025] The halogen-free flame-retardant and heat-conducting high-temperature nylon compound of the embodiment of the present invention consists of the following components in parts by mass (parts by weight):

[0026]

[0027] In the following examples,

[0028] The PPA resin is preferably polyphthalamide, a medium-low viscosity resin with a melting point above 310°C and a viscosity between 2.4 and 2.7mpa.s, namely Solvay's 6000 series.

[0029] The magnesium hydroxide of Shenzhen Jinhaohui Mining Development Co., Ltd. is selected as the halogen-free flame retardant, and the specification is JLH-QD2. Magnesium hydroxide has a large heat absorption due to its decomposition and produces H2O, which can isolate the air. After its decomposition, the oxide is a high-temperature resistant substance, so it can not only play a role in flame retardancy, but also does not p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com