Patents

Literature

177 results about "Polyphthalamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

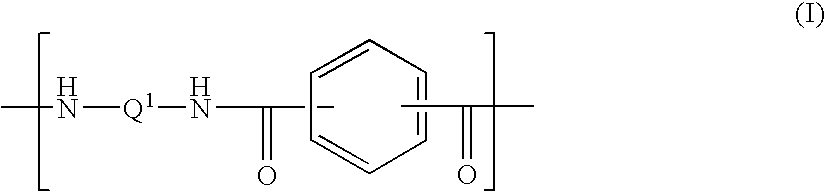

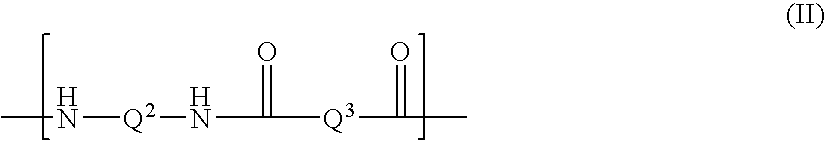

Polyphthalamide (aka. PPA, High Performance Polyamide) is a subset of thermoplastic synthetic resins in the polyamide (nylon) family defined as when 55% or more moles of the carboxylic acid portion of the repeating unit in the polymer chain is composed of a combination of terephthalic (TPA) and isophthalic (IPA) acids. The substitution of aliphatic diacids by aromatic diacids in the polymer backbone increases the melting point, glass transition temperature, chemical resistance and stiffness.

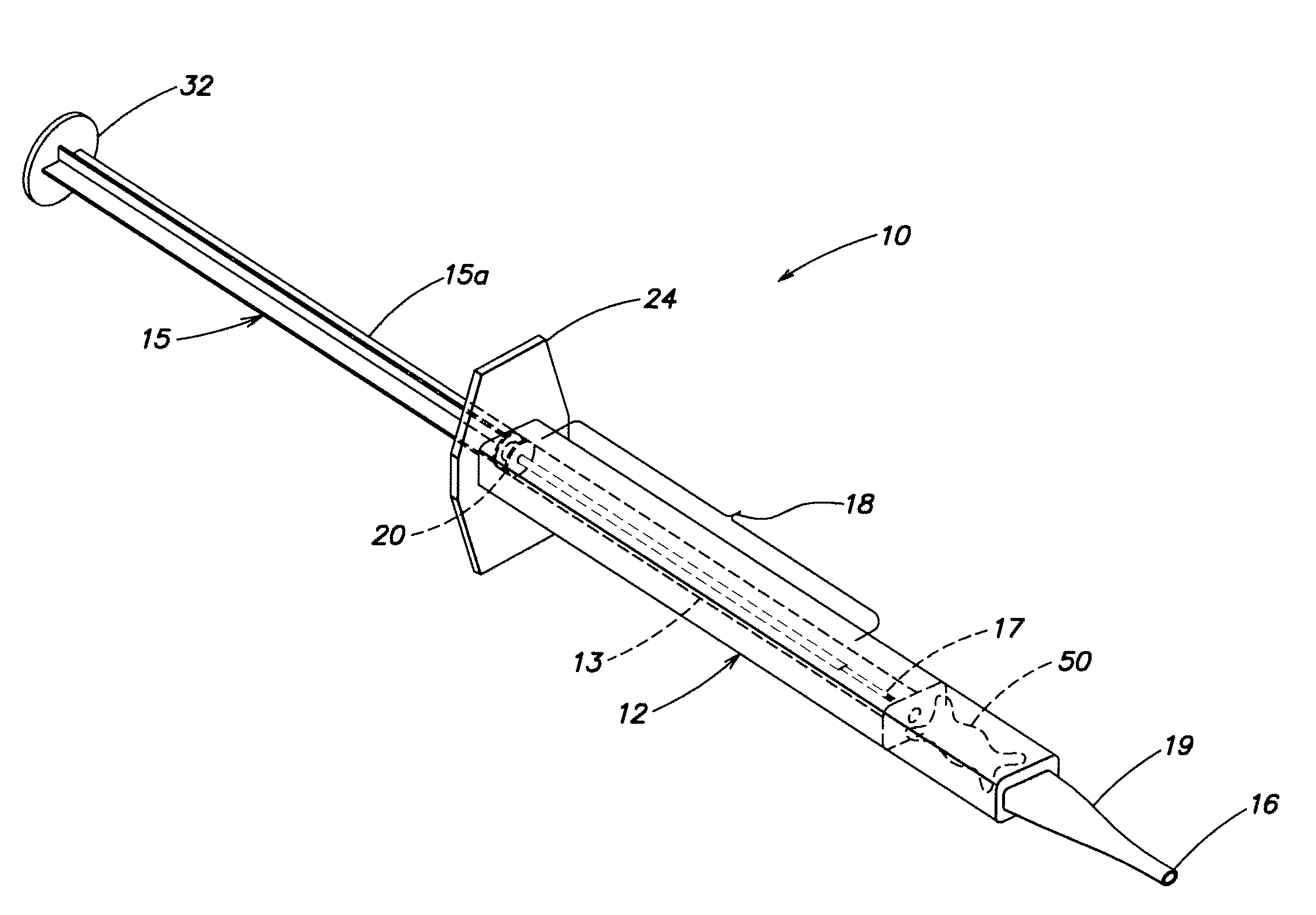

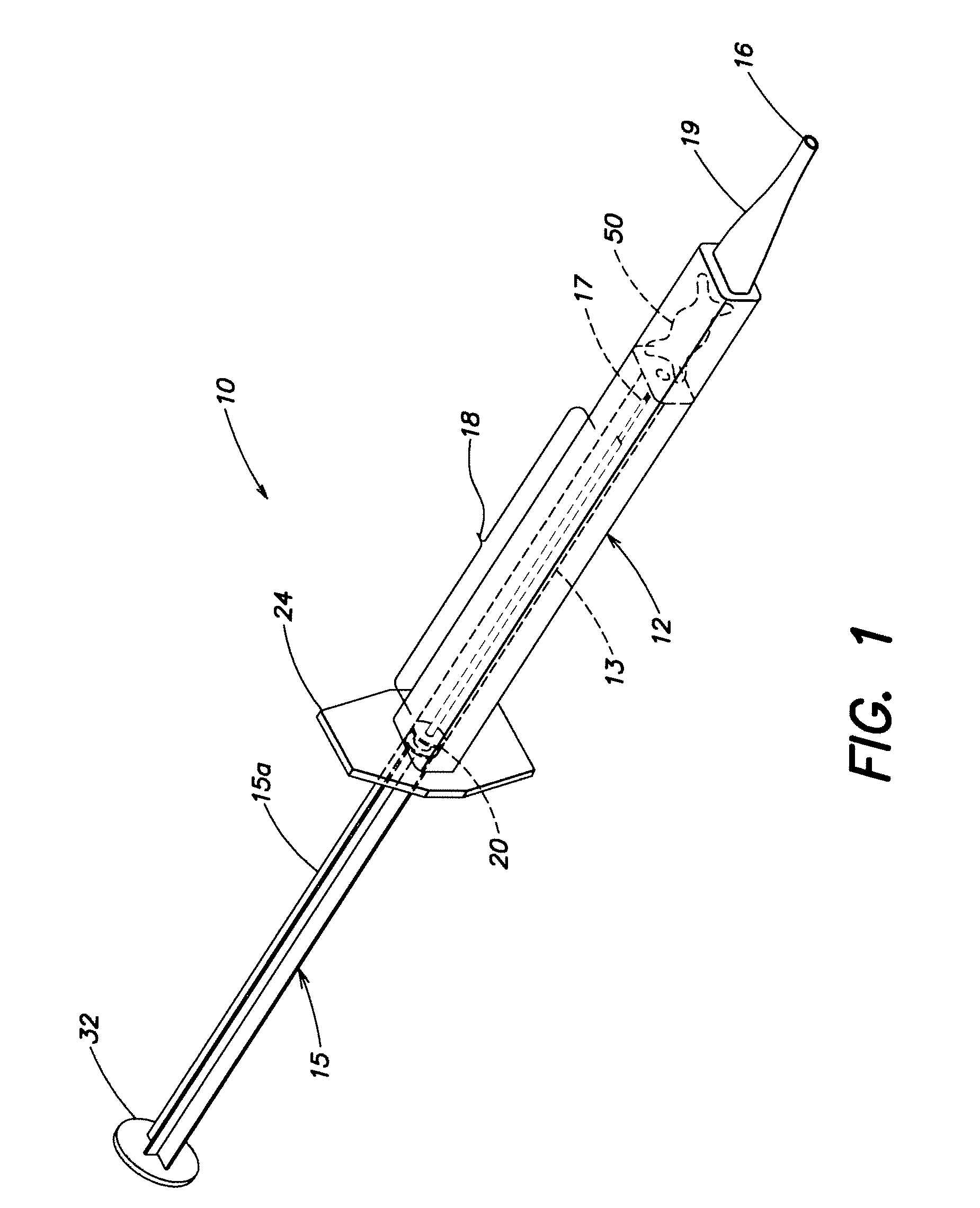

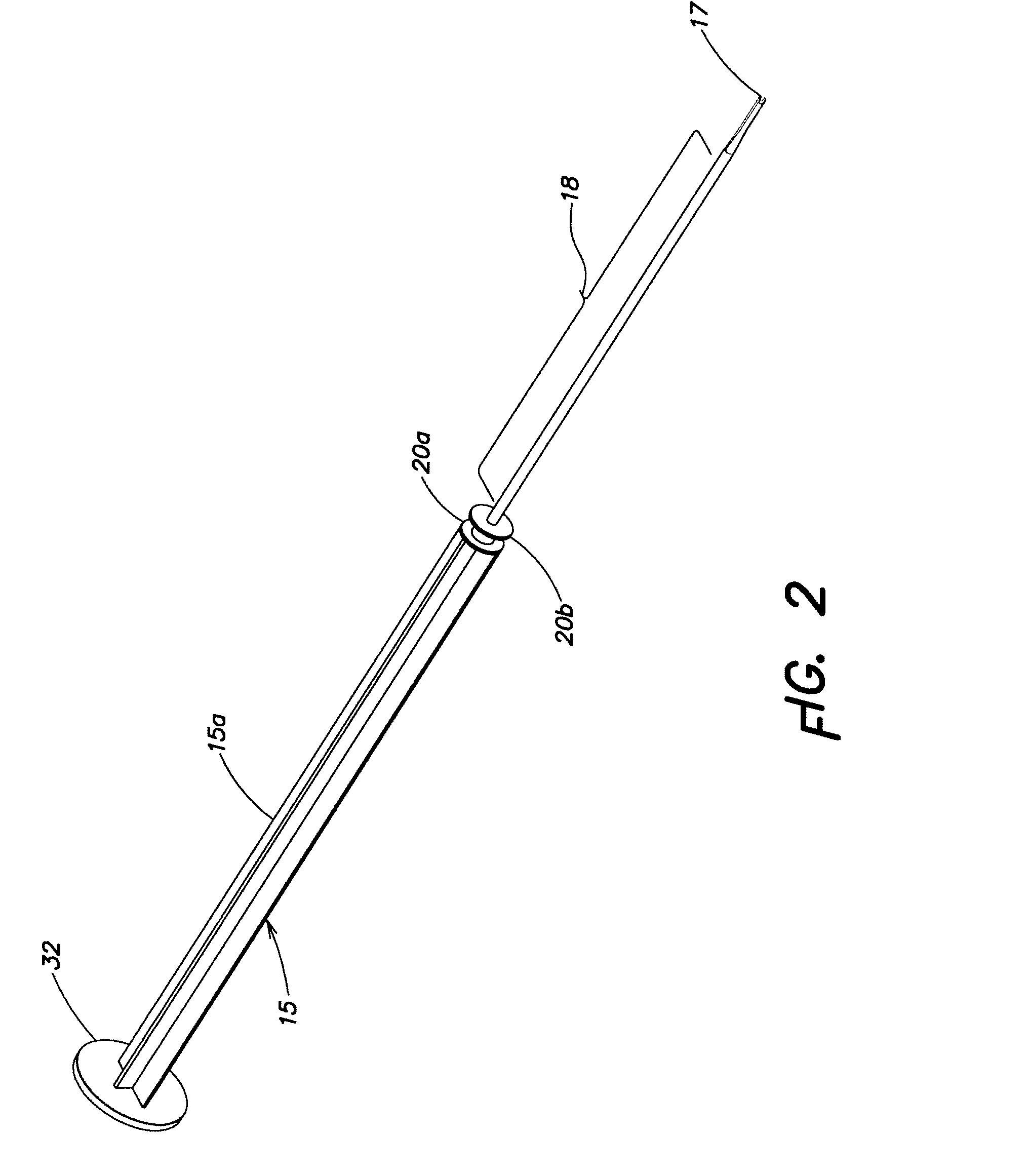

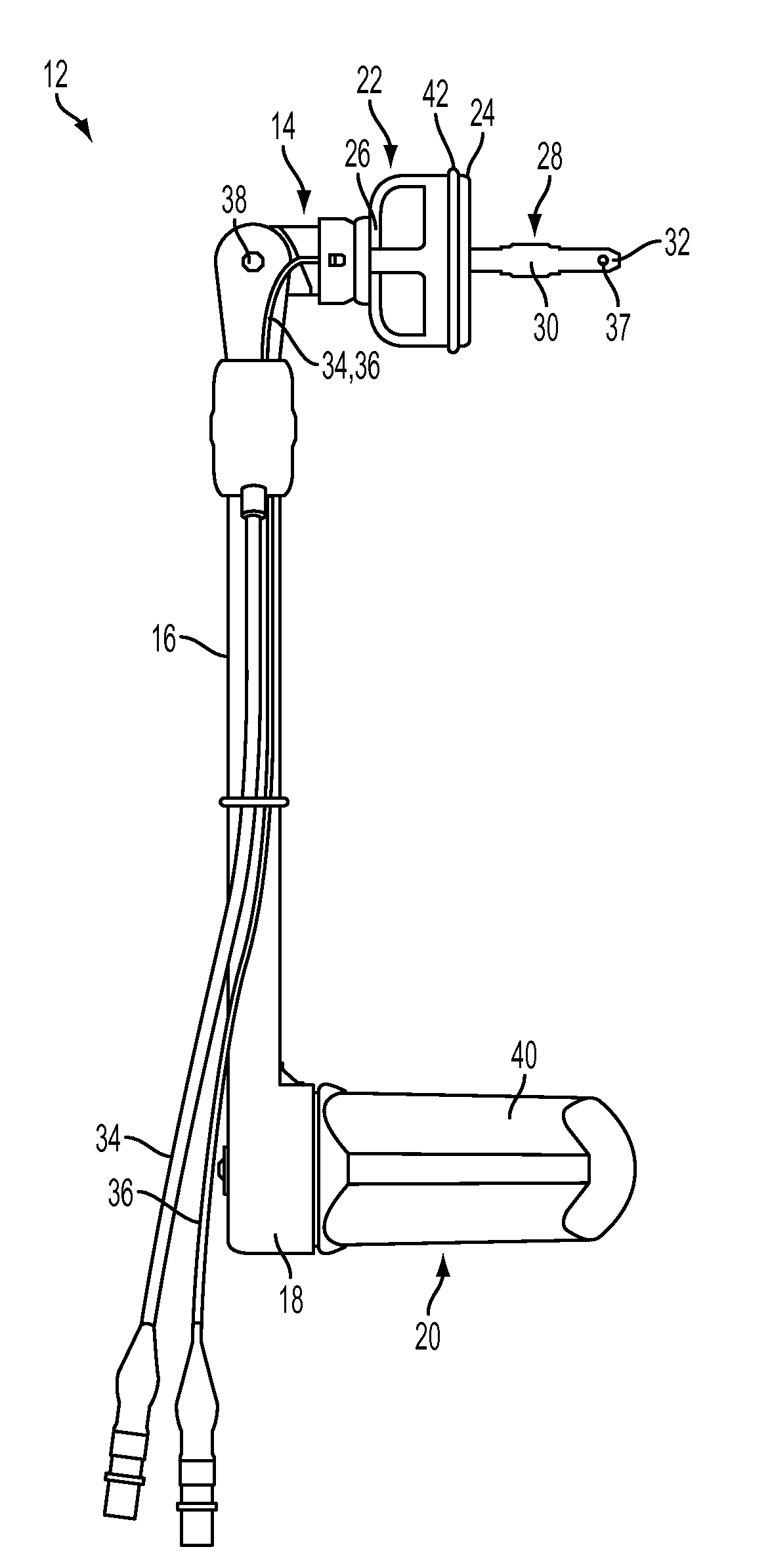

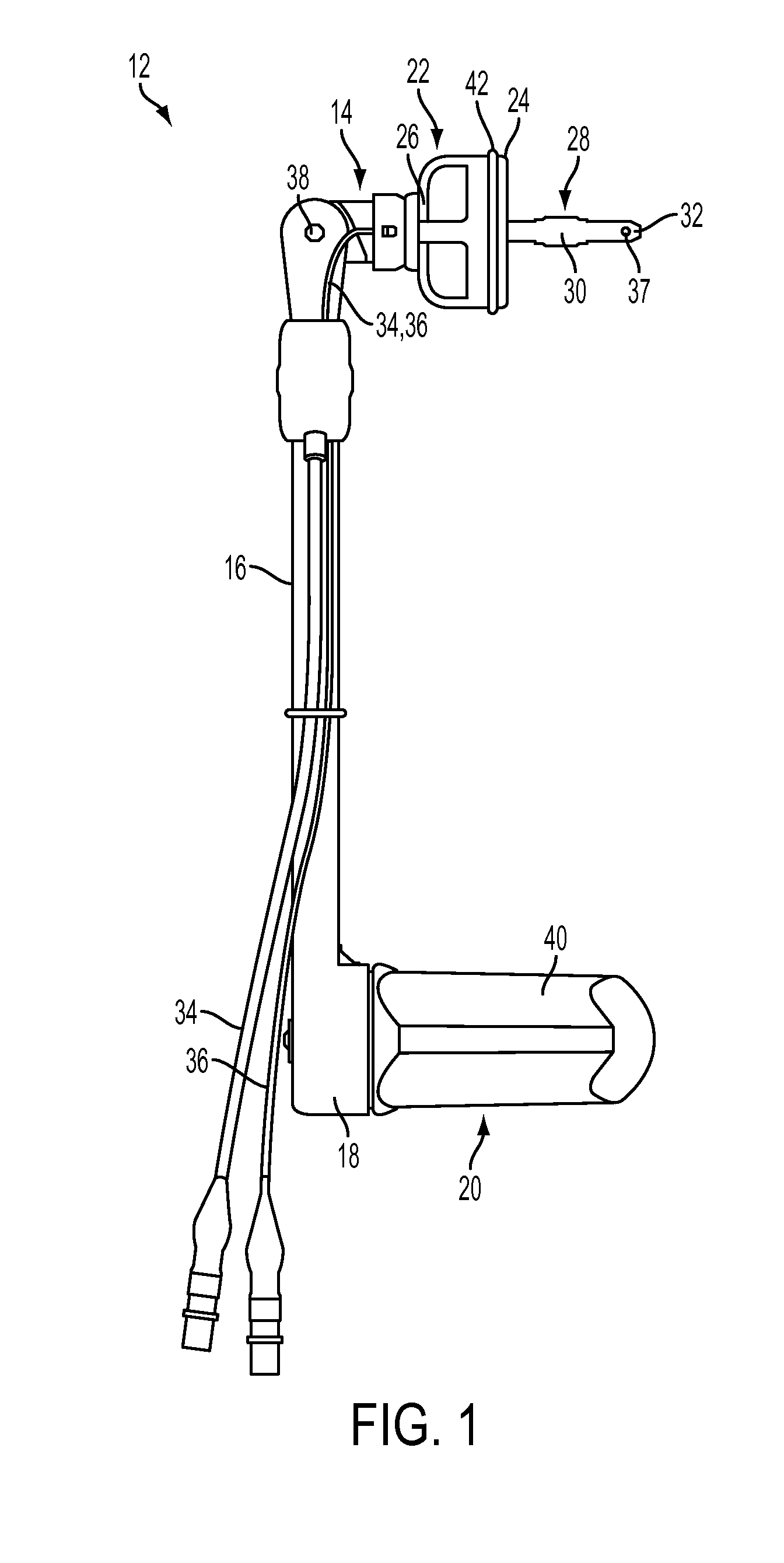

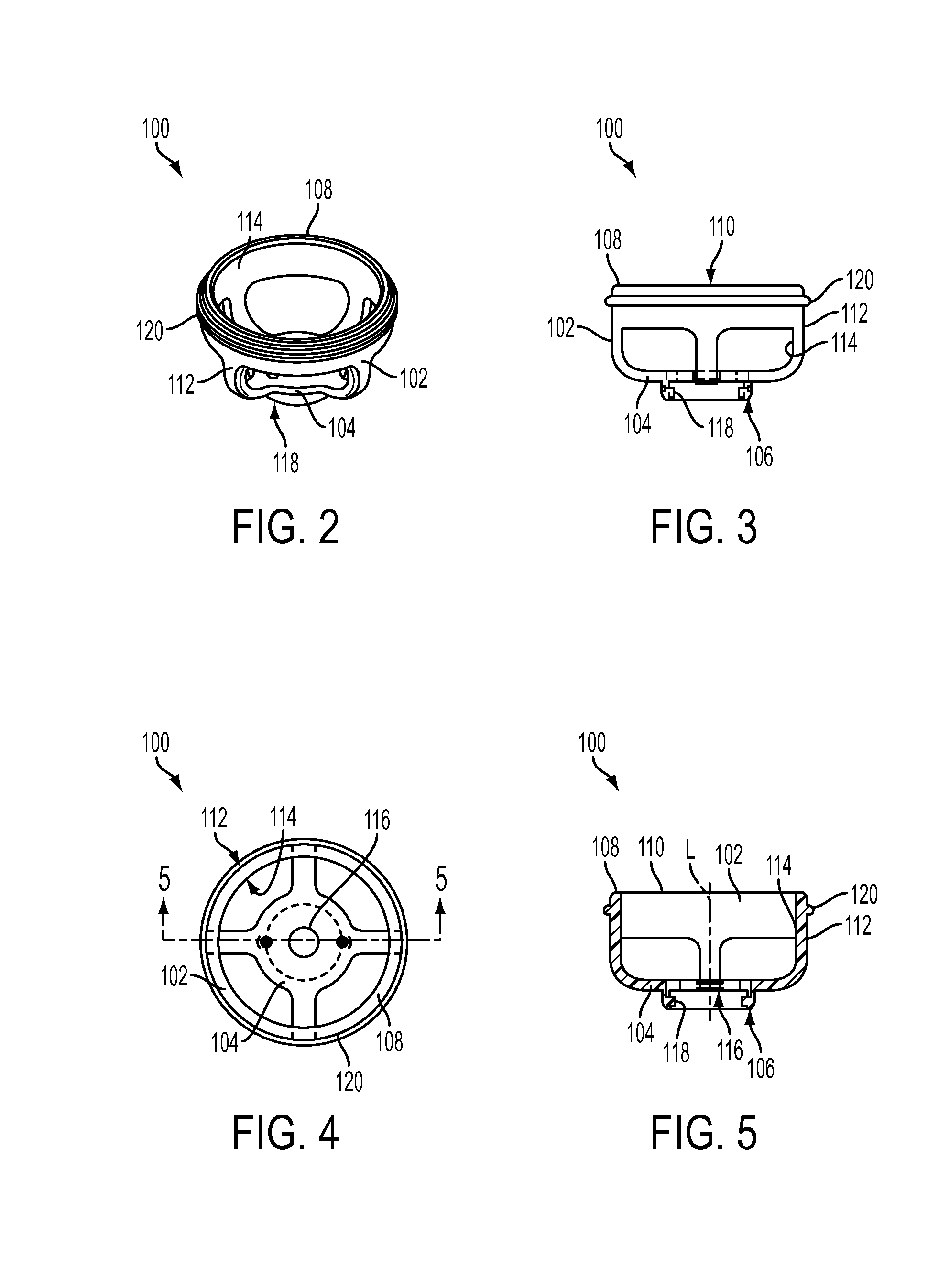

Intraocular Lens Inserter Plunger

InactiveUS20080027461A1Precise deliveryReduce deliveryEye surgeryIntraocular lensPolytetramethylene terephthalatePolyphthalamide

An IOL injector, comprising an injector body; and a plunger. The plunger comprises a shaft comprising a moldable material having a flexural modulus greater than 600 thousand psi, and a plunger tip. The moldable material may have a flexural modulus greater than 750 thousand psi or greater than 1 million psi. The plunger shaft may comprise, for example, Polybutylene Terephthalate (PBT), Polyphthalamide (PPA) or liquid crystal polymer (LCP).

Owner:BAUSCH & LOMB INC

High temperature nylon PPA reinforcing material and preparation method thereof

The invention discloses a high temperature nylon PPA reinforcing material and a preparation method thereof. The high temperature nylon PPA reinforcing material comprises the following components in part by weight: 30 to 50 parts of polyphthalamide, 8 to 20 parts of polyamide, 10 to 15 parts of main fire retardant, 3 to 5 parts of assistant fire retardant, 30 to 45 parts of filling reinforcing agent, 0.2 to 0.6 part of antioxidant, 0.2 to 0.8 part of lubricant, and 0.3 to 0.6 part of nucleating agent. The invention overcomes the defects of lower liquidity and difficult processing of the PPA because a polyamide material is introduced; the polyamide material has the characteristics of high liquidity and similar molecular structure, and can be well fused with the PPA material, so that the liquidity is improved, the processing temperature is greatly reduced, and the processing procedure is simplified; and a modified material with excellent performance after being reinforced by a glass fiber is equal to foreign brand materials, and plays a role in laying the foundation for domestic volume production and future quantity demand in the domestic market.

Owner:徐东

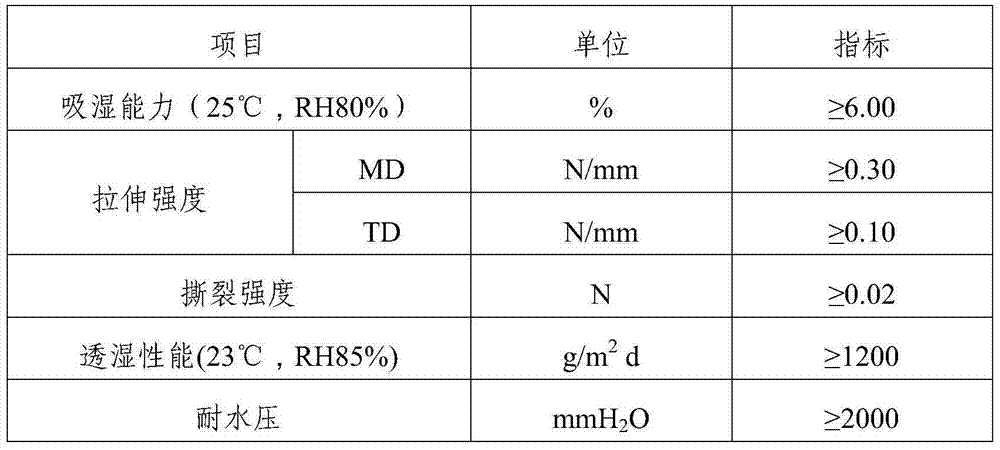

Water resistible and breathable plastic film with drying function as well as preparation method and application thereof

InactiveCN103571013AWith moisture absorption functionDoes not affect breathabilitySynthetic resin layered productsMetal layered productsSodium BentoniteMoisture absorption

The invention provides a water resistible and breathable plastic film with a drying function. The plastic film is prepared from the following raw materials in parts by weight: 40-80 parts of macromolecule plastic, 20-60 parts of an adsorbent and 1-5 parts of an auxiliary material, wherein the macromolecule plastic is at least one of polyethylene, polypropylene, thermoplastic elastomer and the like; the adsorbent is selected at least one of silica gel, montmorillonite, bentonite, molecular sieve, calcium carbonate, titanium dioxide and the like; the auxiliary material is selected from at least one of macromolecule wax, modified polyphthalamide, calcium stearate and the like. The plastic film adopts a plastic film (bidirectional or unidirectional) tension technique, and the adsorbent with the drying function is added into the raw material formula for manufacturing a water resistible and breathable film, so that a material has a certain moisture absorption function under the condition that the air permeability of the material is not affected.

Owner:昆山威胜干燥剂研发中心有限公司

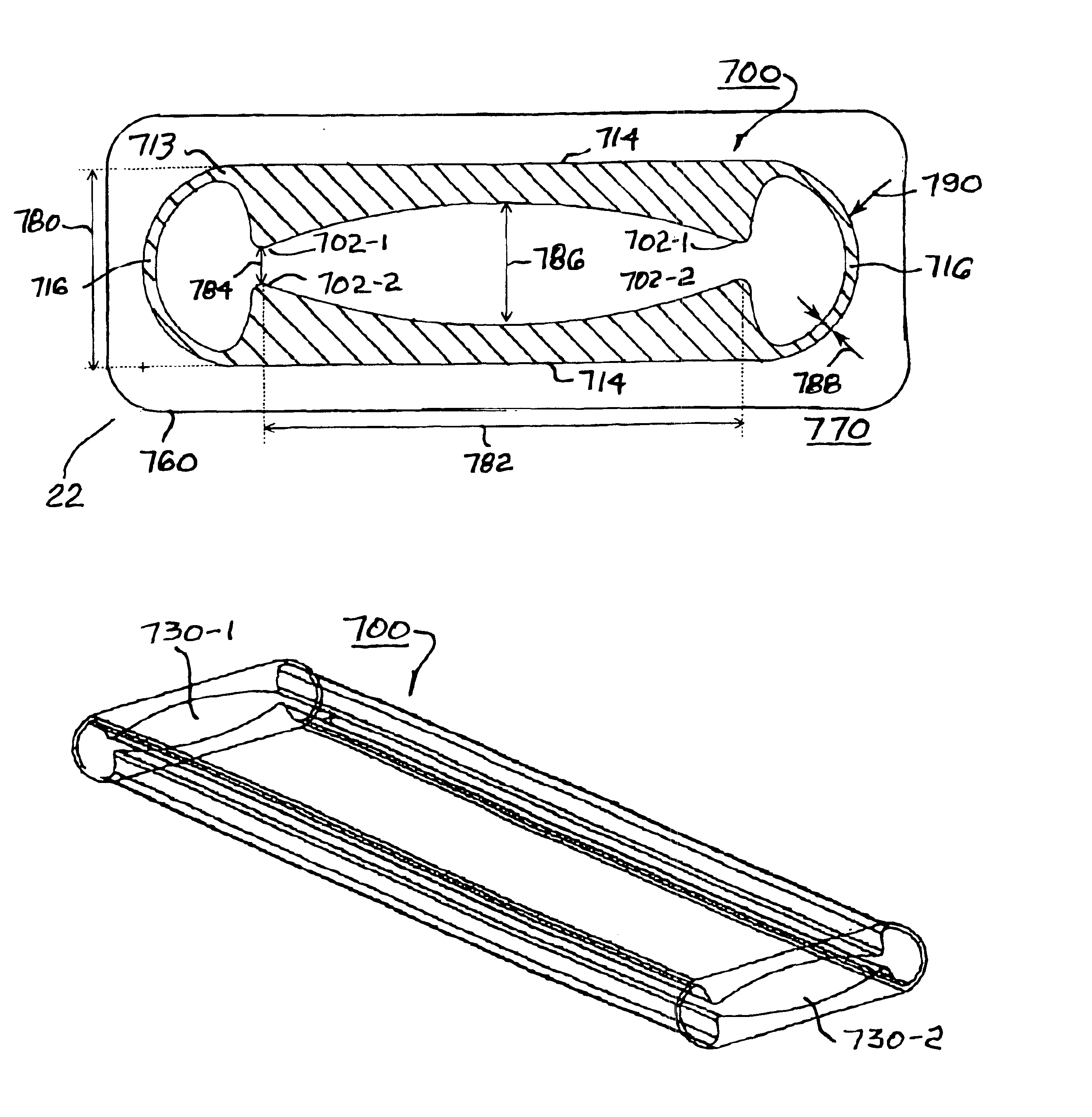

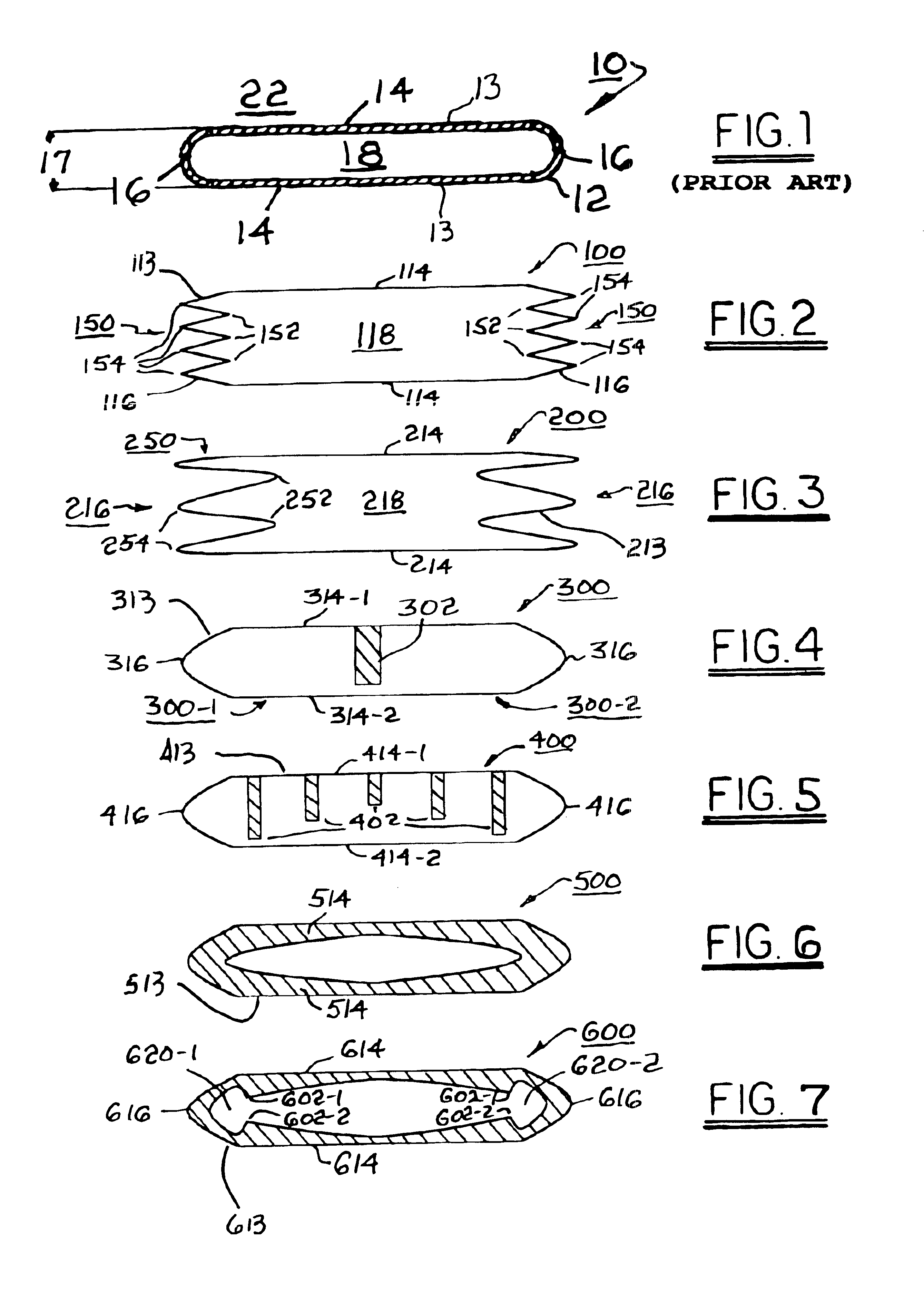

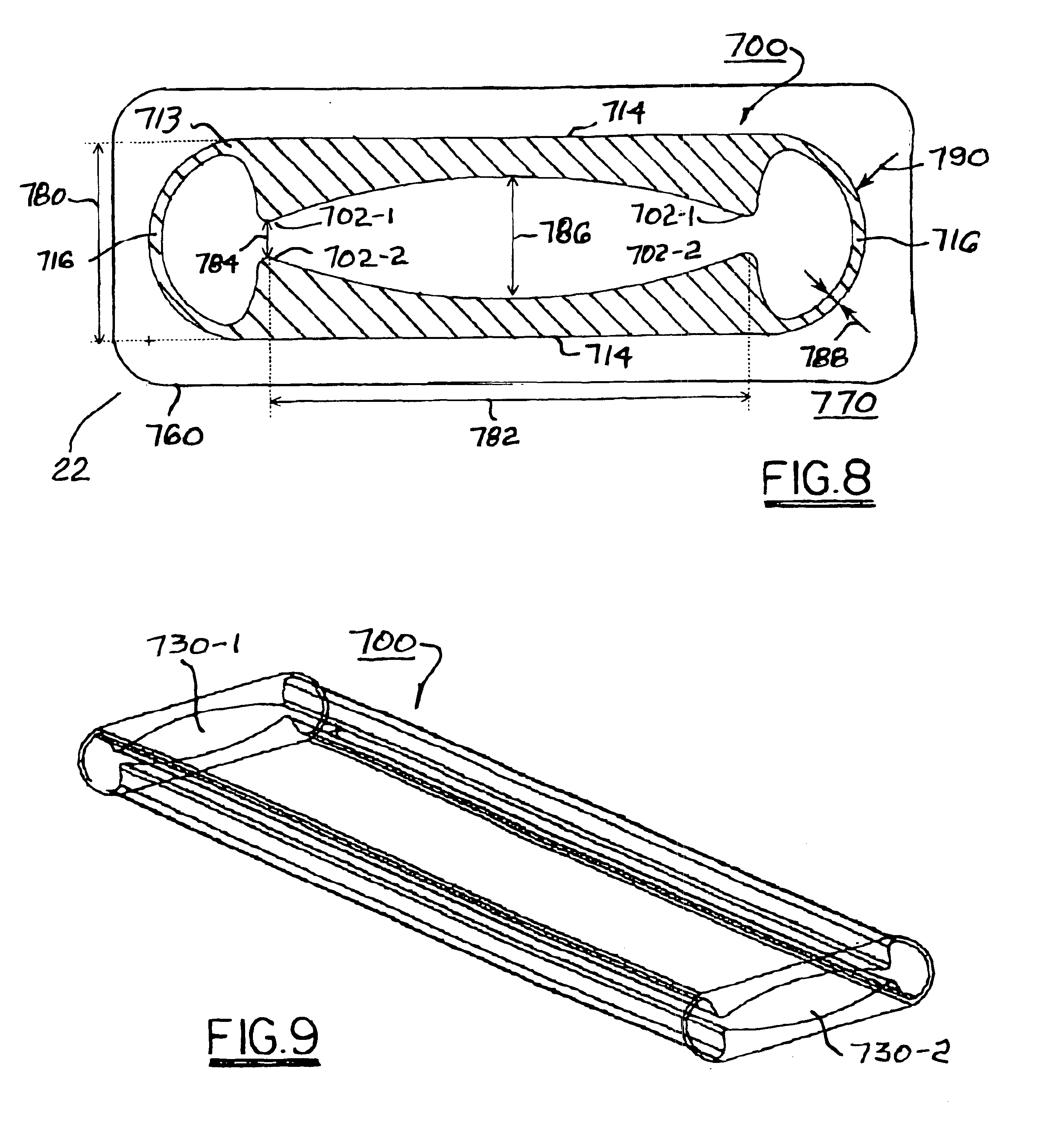

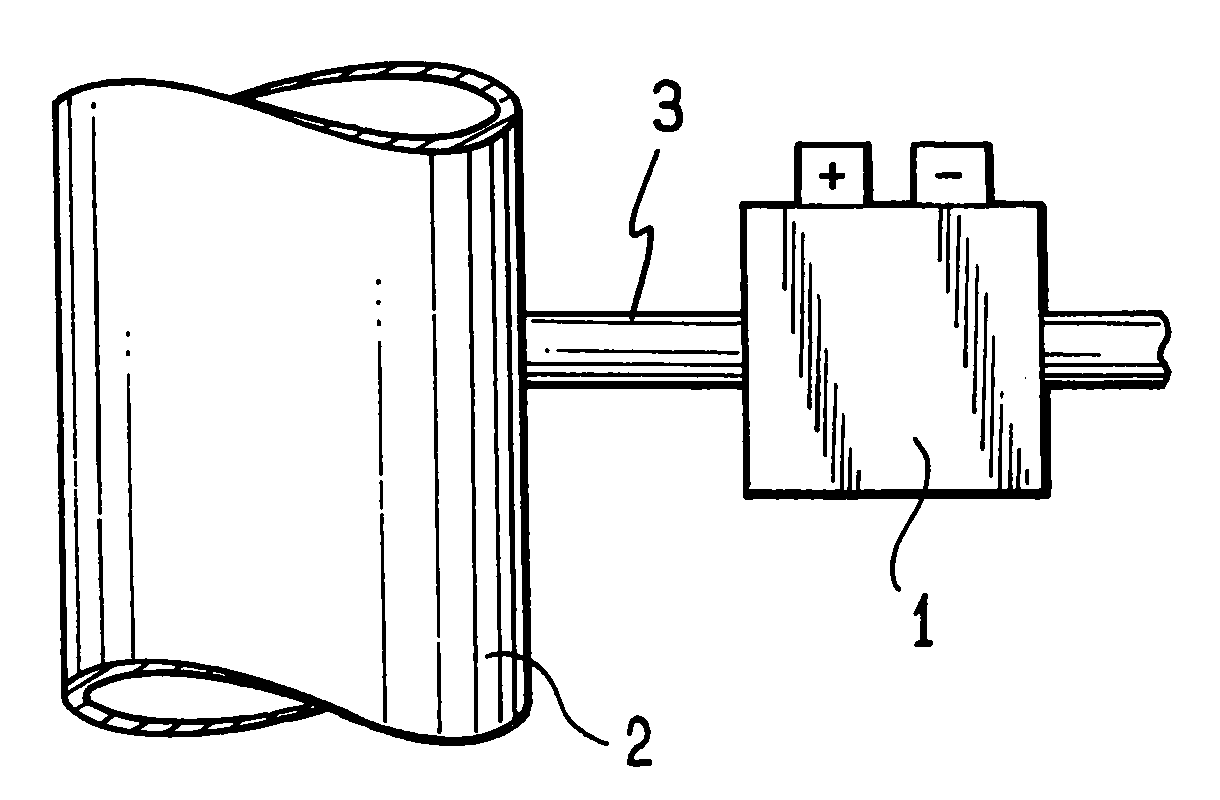

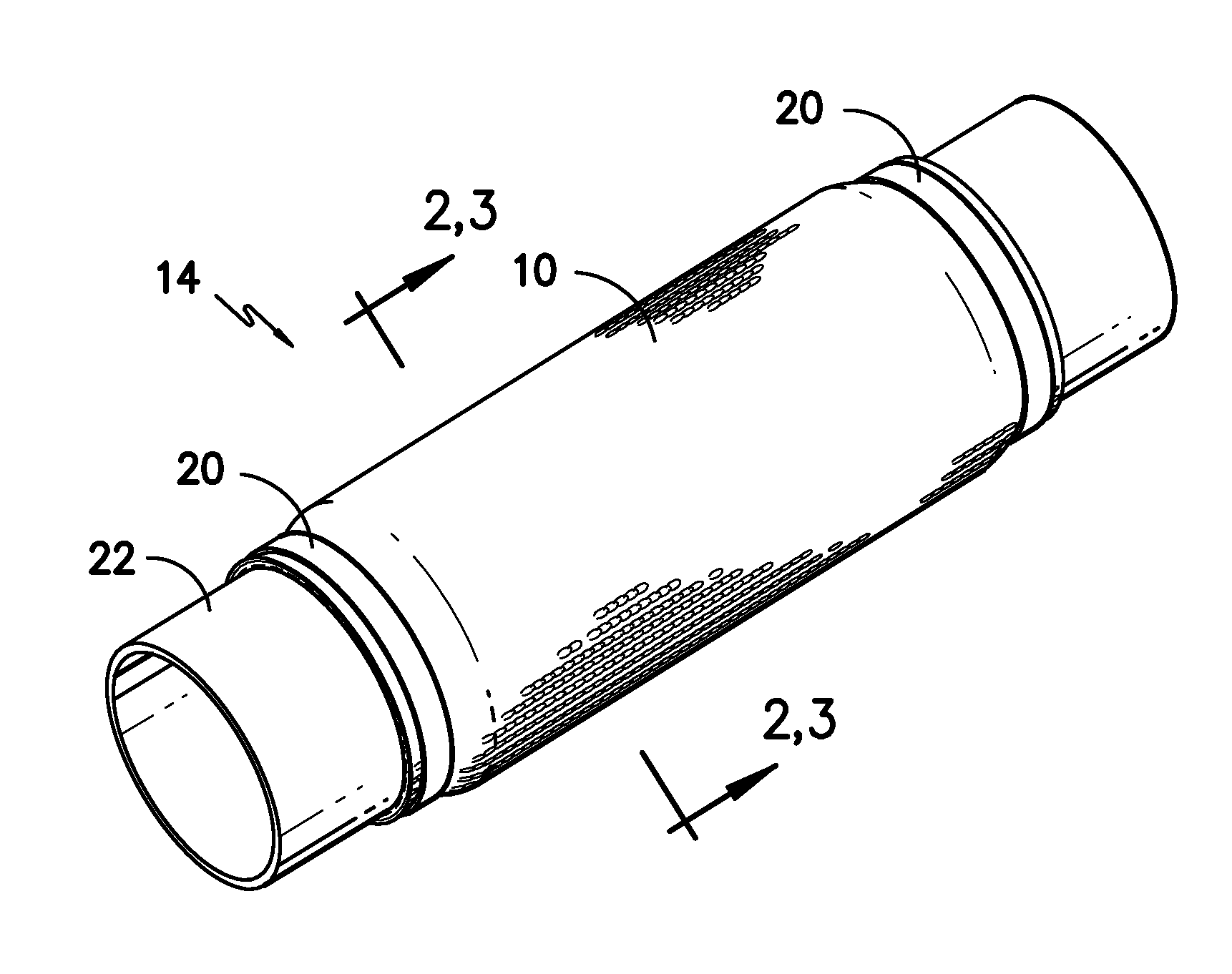

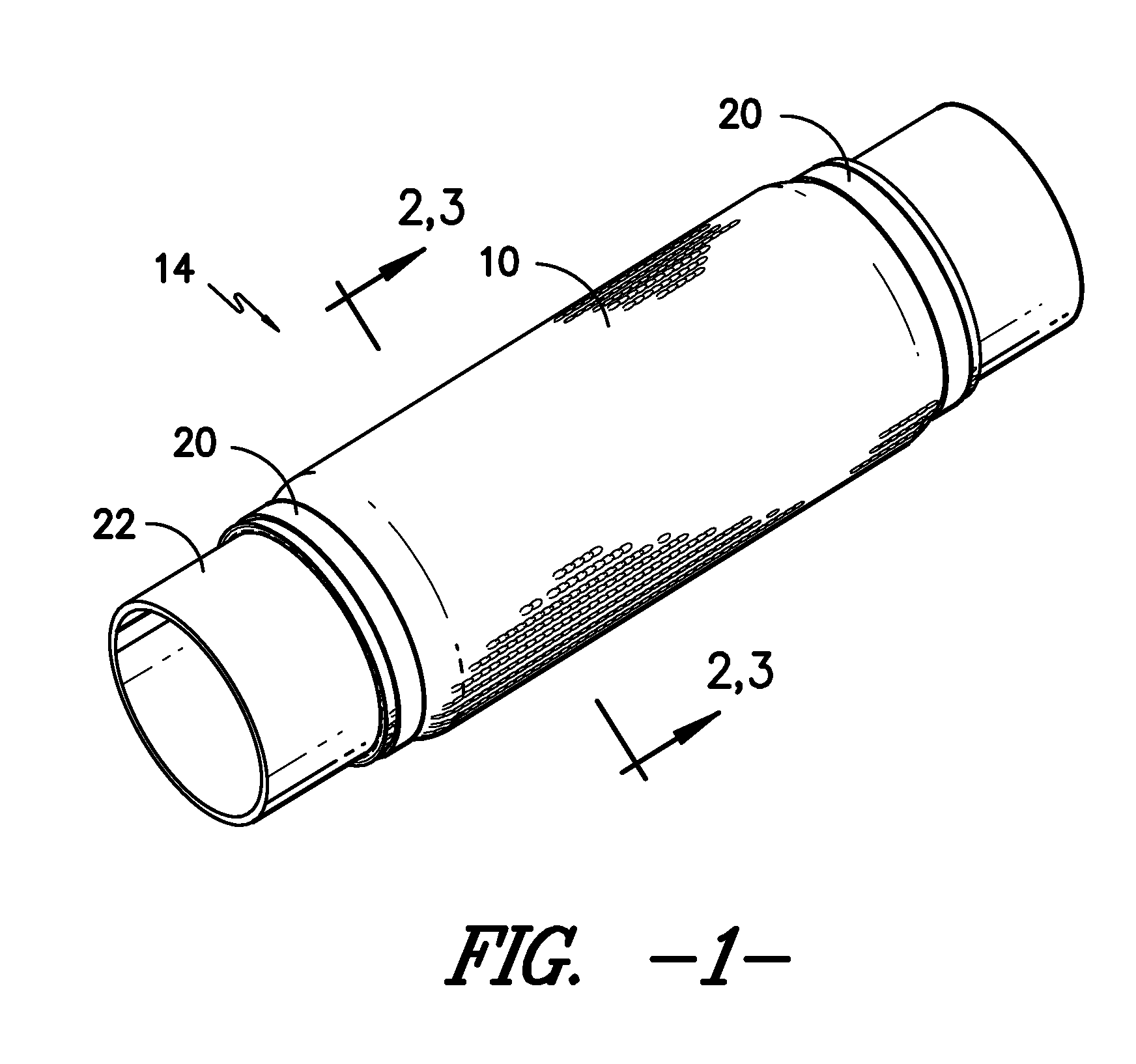

Variable stiffness fuel rail pulse damper having extended dynamic range

InactiveUS6901914B1Increase stiffnessMinimizing resultant stressLow-pressure fuel injectionPipe elementsVariable stiffnessPolyetherimide

A fluid pulse damper having increased dynamic range and sensitivity, being especially useful in suppressing pulsations in the fuel supply rail of an internal combustion engine. The damper is a longitudinal gas-filled plastic pillow having walls formed by opposed flexible short sides and opposed flexible long sides, and includes at least one internal self-contact element, and preferably a plurality of such elements. As the short sides flex, the elements make contact internally, shifting the damper into a different compression regime and extending the pressure / response over an increased range of pressures. A feature of some embodiments is that the inner surface within the contact elements is shifted into tension after the elements make contact, thereby stiffening the damper and increasing the damper's resistance to further deformation. The damper is formed of a plastic such as ultra-high molecular weight polyethylenes, high flow polyetherimides, or tubing grade polyphthalamides.

Owner:DELPHI TECH INC

Colpotomy cup-like structure and intrauterine manipulator including same

A cup-like structure for engaging a cervix of a patient includes a rim, and includes a base defining an aperture through which one or more tubular members of a uterine manipulator may extend into the uterus. The cup-like structure is made from one or more of a polyphthalamide (PPA) material and a polyetheretherketone (PEEK) material. A uterine manipulator including a cup-like structure is also disclosed.

Owner:CLINICAL INNOVATIONS LLC

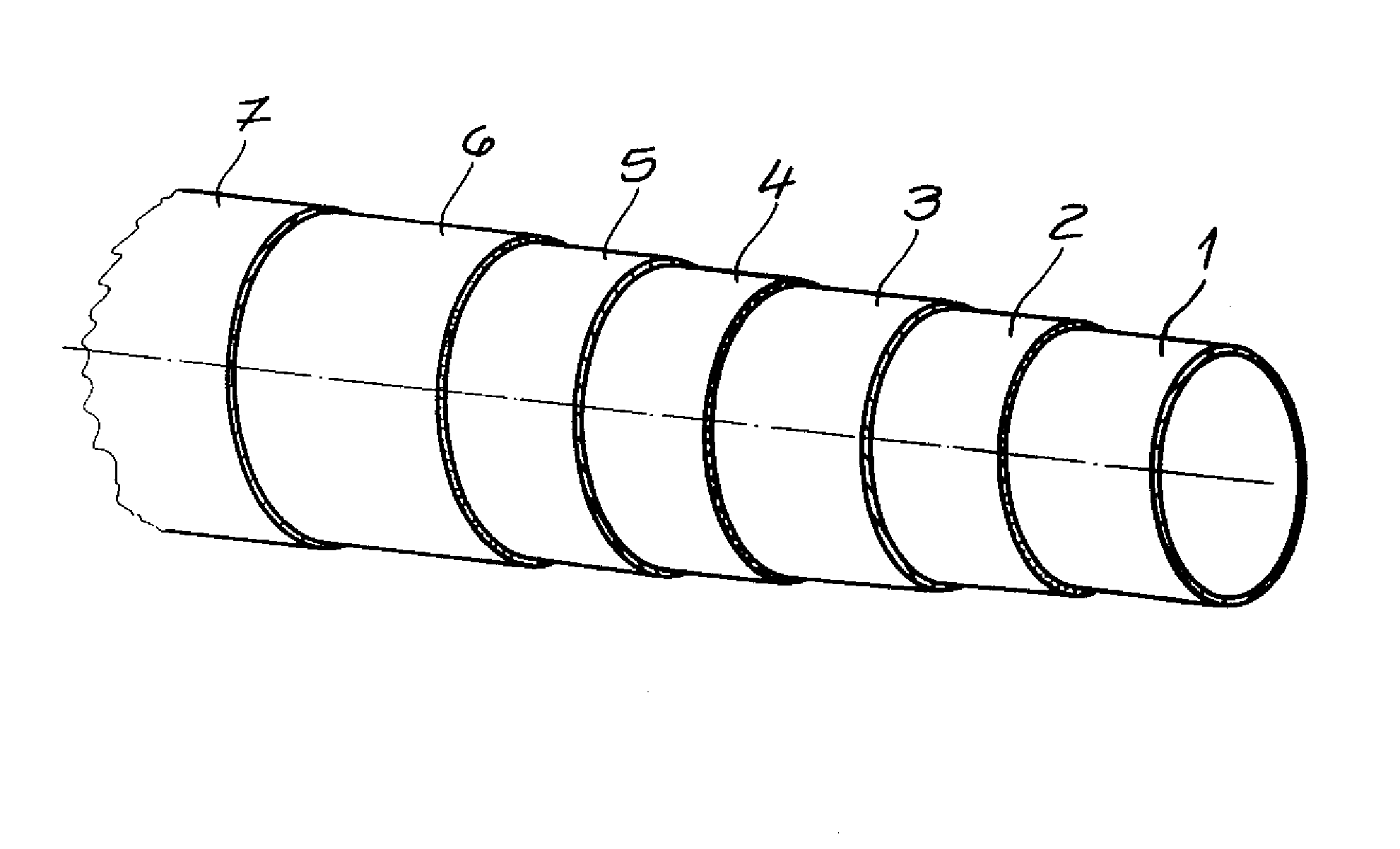

Fluoropolymer/evoh/ppa multilayer pipe for conveying hydrogen and a fuel cell electricity production assembly including such a pipe

InactiveUS20100035116A1Improve the immunityImprove temperature performanceReactant parameters controlFinal product manufactureElectricityFuel cells

A pipe having: a layer of fluoropolymer; an intermediate layer of ethylene and vinyl alcohol copolymer; and an outer layer of polyphthalamide. An electricity production assembly is provided using a fuel cell and including such a pipe.

Owner:NOBEL PLASTIQUES

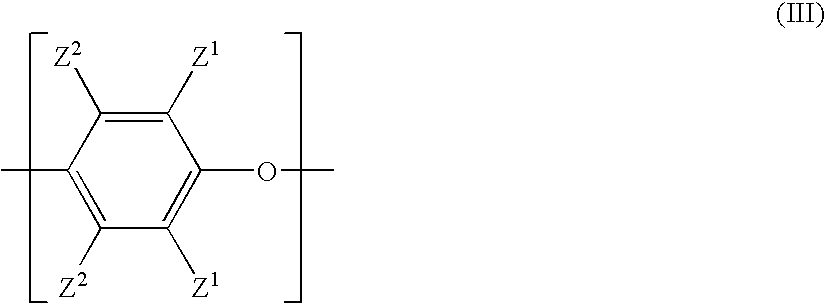

Flame resistant polyphthalamide/poly(arylene ether) composition

Disclosed herein is a flame resistant composition comprising a compatibilized blend of a polyphthalamide and a poly(arylene ether); and a phosphinate, wherein the composition is substantially free of linear aliphatic polyamides.

Owner:SHPP GLOBAL TECH BV

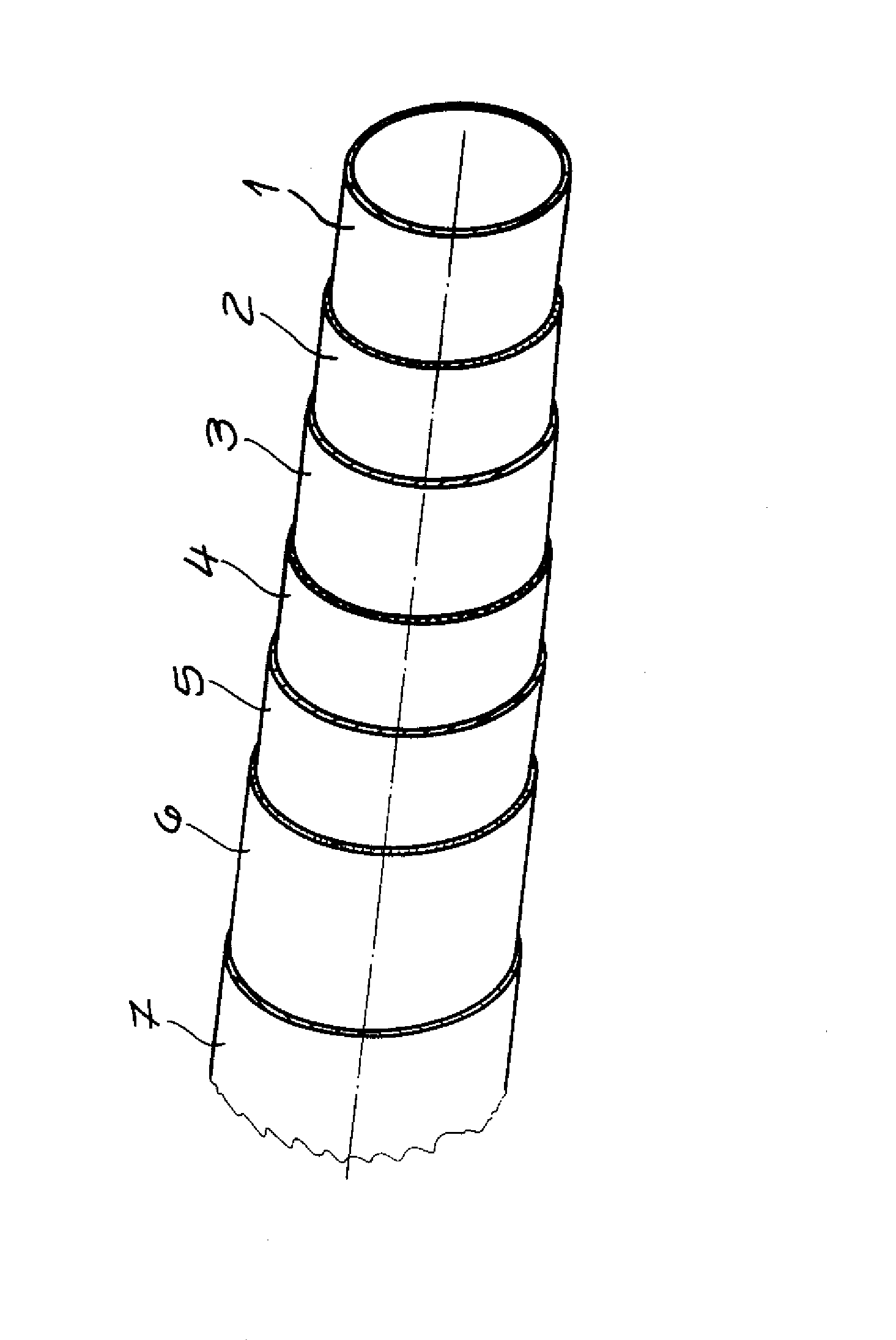

Multi-Layered Fuel Feed Pipe

ActiveUS20140246111A1Reduce penetrationGood mechanical resistanceSynthetic resin layered productsMachines/enginesPolyphthalamidePolybutylene

Multi-layered fuel feed pipe, wherein the feed pipe comprises at least five layers with the following layer structure from the inside to the outside: an innermost layer consisting of at least one polymer from the group “polyamide, fluoropolymer, polyphenylene sulfide, polybutylene naphthalate”, a first support layer consisting of polyamide, a barrier layer, a second support layer consisting of polyamide, an outer layer consisting of at least one polymer from the group “polyamide, polyphenylene sulfide, polyphthalamide”.

Owner:TI AUTOMOTIVE FULDABRUCK

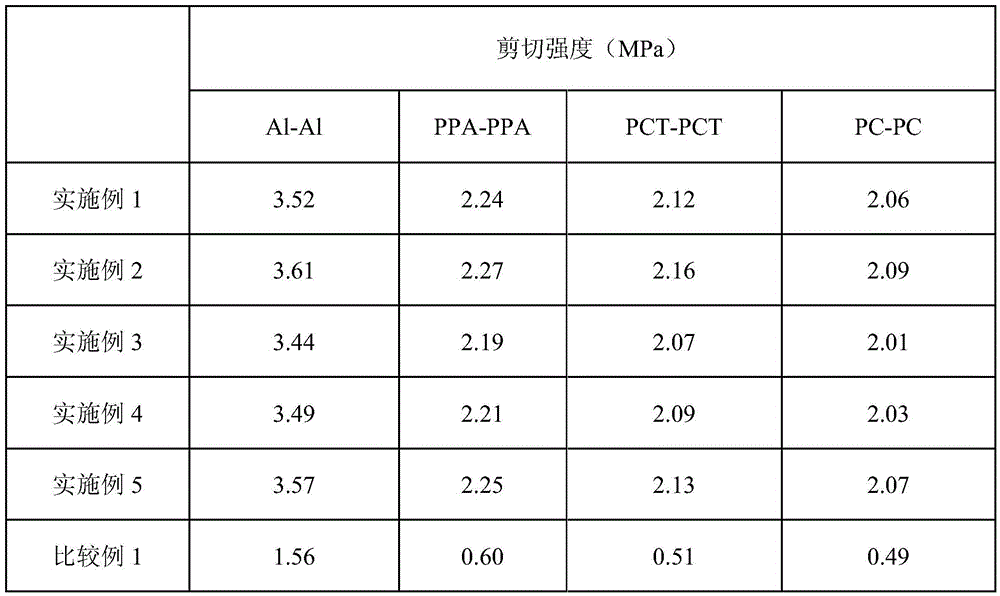

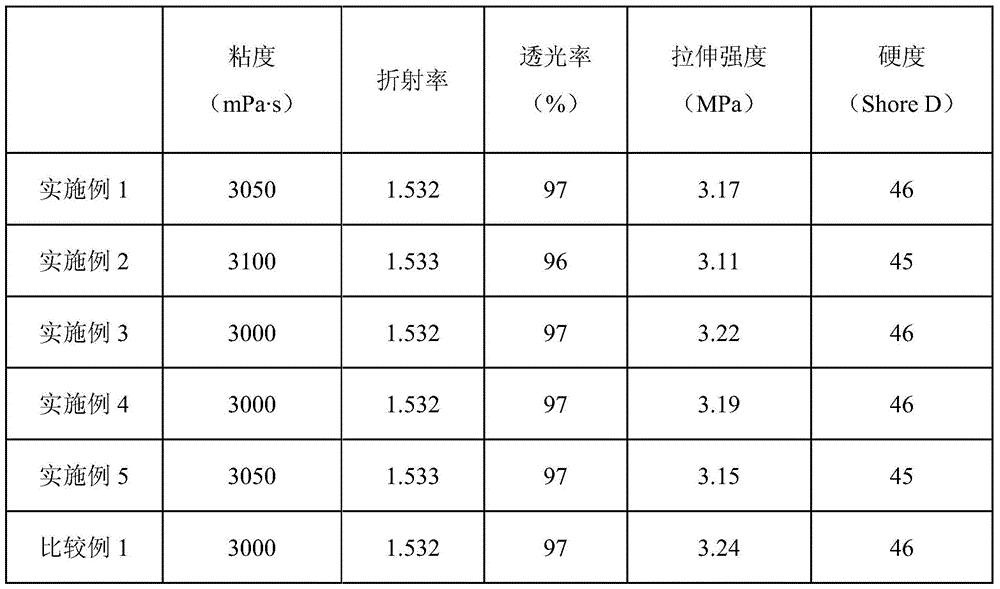

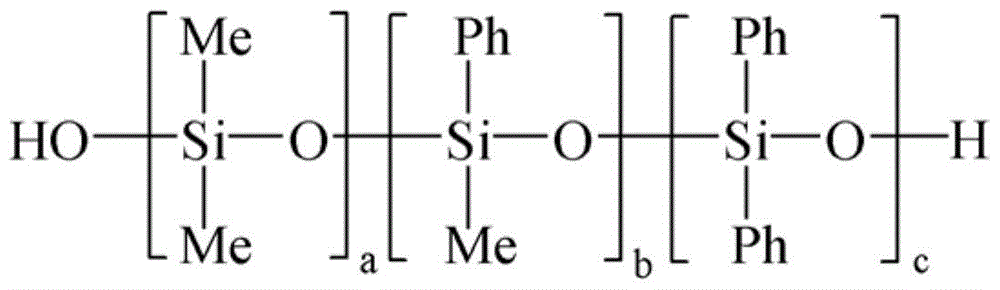

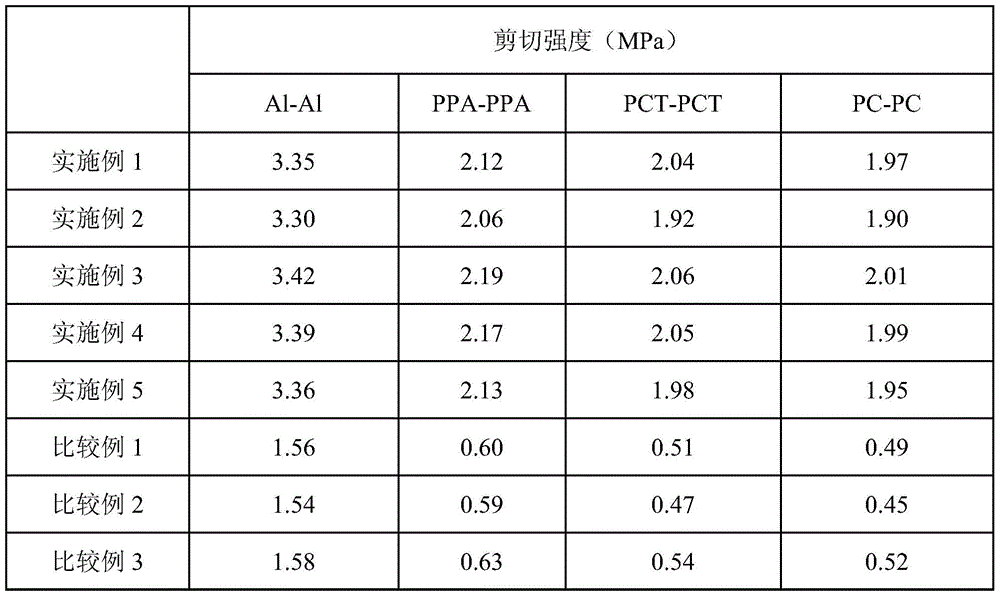

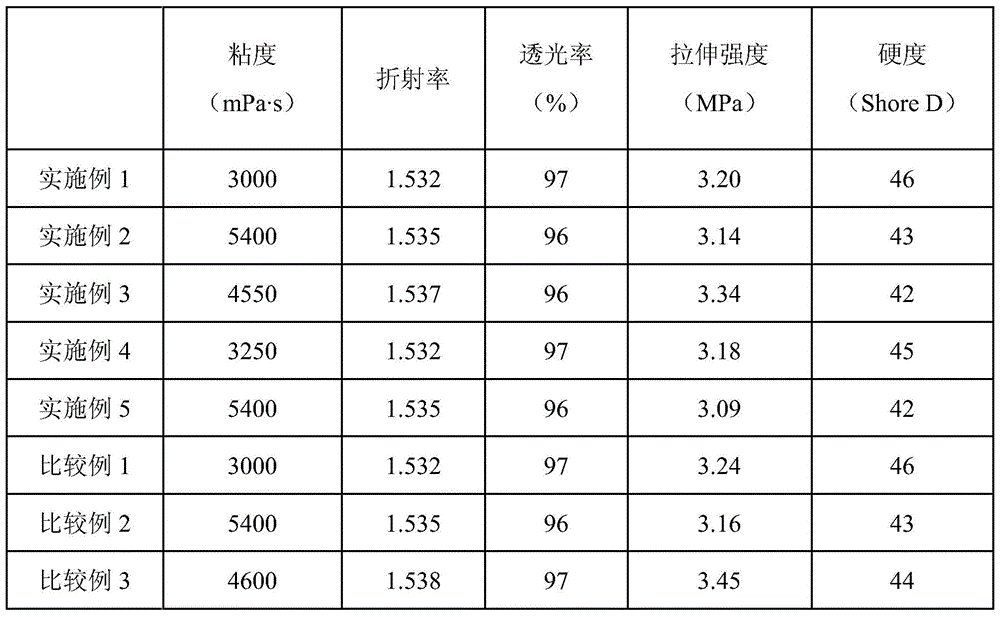

Organic boron silicon adhesion promoter with high refractive index as well as preparation method and application of organic boron silicon adhesion promoter

ActiveCN105524282AHigh refractive indexAvoid the disadvantage of easy to open loopMacromolecular adhesive additivesEpoxySilanes

The invention discloses an organic boron silicon adhesion promoter with a high refractive index as well as a preparation method and an application of the organic boron silicon adhesion promoter. The preparation method comprises steps as follows: diphenylsilanediol, epoxy silane, ester silane, borate and a solvent are uniformly stirred at the room temperature, a titanate catalyst is added, a mixture reacts for 4-14 h at the reaction temperature controlled in a range from 25 DEG C to 60 DEG C and continuously reacts for 2-6 h at the vacuum degree controlled in a range from 0.05 MPa to 0.098 MPa and at the temperature controlled in a range from 60 DEG C to 140 DEG C, and the organic boron silicon adhesion promoter with the high refractive index is prepared. The prepared adhesion promoter can not only remarkably improve the adhesion performance of high-refractive-index addition type silica gel for LED packaging, but also has the high refractive index and good compatibility with the silica gel, particularly has a remarkable function for improvement of the adhesion performance of plastic base materials such as polyphthalamide, polyethylene terephthalate, 1,4-cyclohexanedimethanol terephthalate, polycarbonate and the like and can be expected to be widely applied to the field of LED device packaging.

Owner:SOUTH CHINA UNIV OF TECH

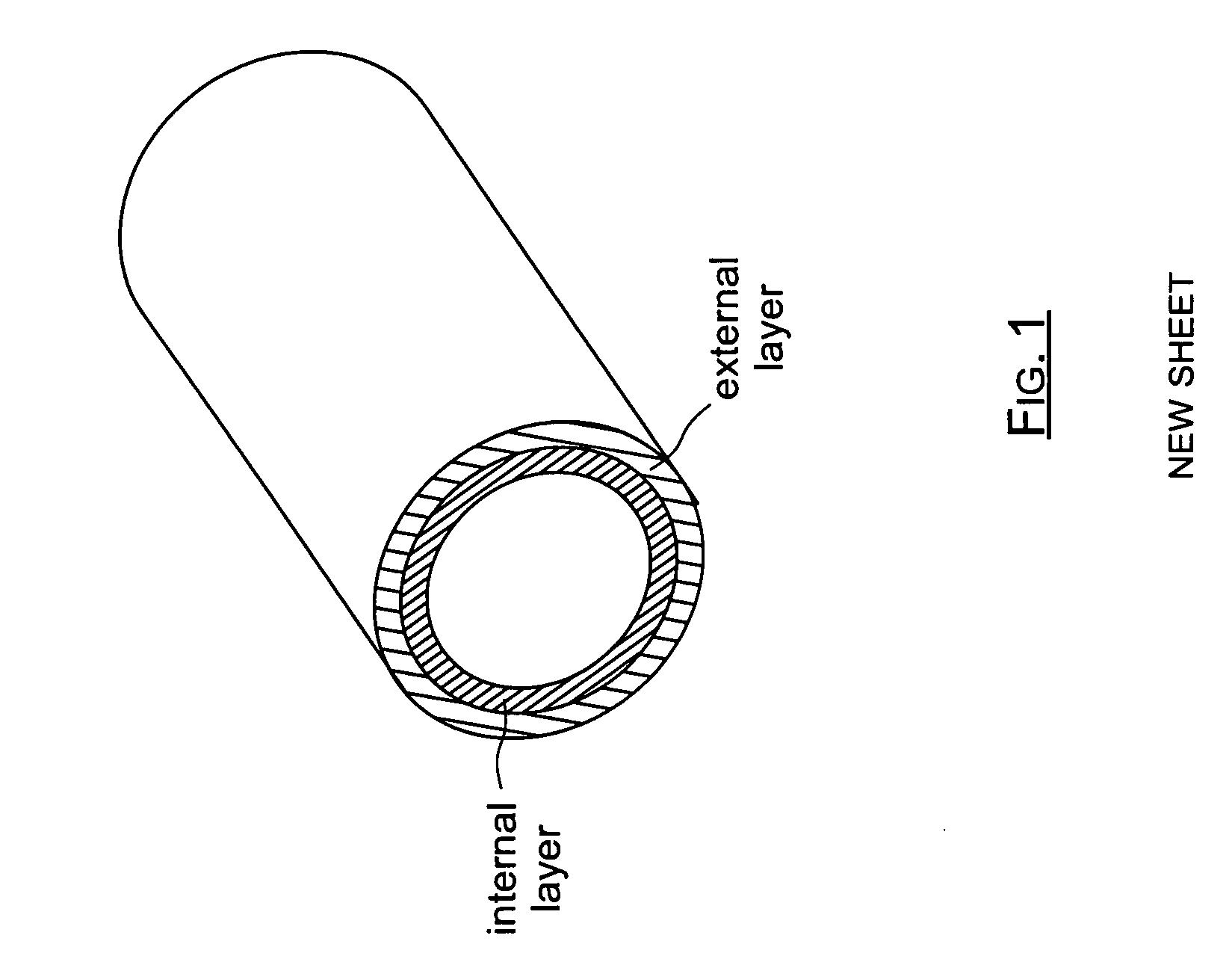

Tube for transporting a fluid in an automobile

InactiveUS20030192612A1Well formedImpairing functionLayered productsFlexible pipesPolyphthalamideEngineering

A multilayer tube comprising at least an inner layer, an intermediate layer, and an outer layer, wherein the intermediate layer is formed by a polyphthalamide.

Owner:NOBEL PLASTIQUES

Antibacterial master batch and preparation method of antibacterial master batch, antibacterial artificial grass and preparation method of antibacterial artificial grass

ActiveCN104558776AGuaranteed antimicrobial propertiesHigh tensile strengthMonocomponent polyolefin artificial filamentArtifical filament manufactureMasterbatchLow-density polyethylene

The invention discloses an antibacterial master batch, a preparation method of the master batch, antibacterial artificial grass and a preparation method of the artificial grass. The antibacterial master batch is prepared by the step of performing double screw co-extrusion on the following components in percentage by weight: 20-30 percent of low-density polyethylene, 30-40 percent of an antibacterial material, 10-20 percent of a plasticizer, 10-20 percent of acetone and 10-20 percent of polyphthalamide (PPA). The method for preparing the antibacterial artificial grass comprises the following steps: adding the antibacterial master batch disclosed by the invention into a matrix resin, mixing, extruding, stretching, setting, dropping and twisting. The antibacterial material, the low-density polyethylene and PPA are co-extruded to process the antibacterial master batch, so that the tensile strength, deflection and other performances of the artificial grass can be improved; and moreover, the antibacterial artificial grass disclosed by the invention is subjected to hot extrusion in a spinning screw, so that the antibacterial master batch and the matrix resin are fused and therefore the antibacterial artificial grass has resistance and good processability.

Owner:GUANGZHOU AOSHENG ARTIFICIAL STRAW CO LTD

Ppa/fluoropolymer pipe

InactiveUS20080083469A1Good protection against external aggressionAvoid contamination of fluidSynthetic resin layered productsFlexible pipesPolyphthalamideEngineering

A pipe for transporting fluid in motor vehicles, such as fuel or oil under high tempature and pressure, comprises one layer constituted for the most part of polyphthalamide (PPA) and one layer constituted for the most part of fluoropoloymer. The pipe has a thickness formed mainly by the thickness of the polyphthalamide layer, the thickness of the polyphthalamide layer being five to ten times greater than the thickness of the fluoropolymer layer. The polyphthalamide layer can be directly in contact with the fluoropolymer and a bonding layer of polyamide can also be present between these two main layers.

Owner:NOBEL PLASTIQUES

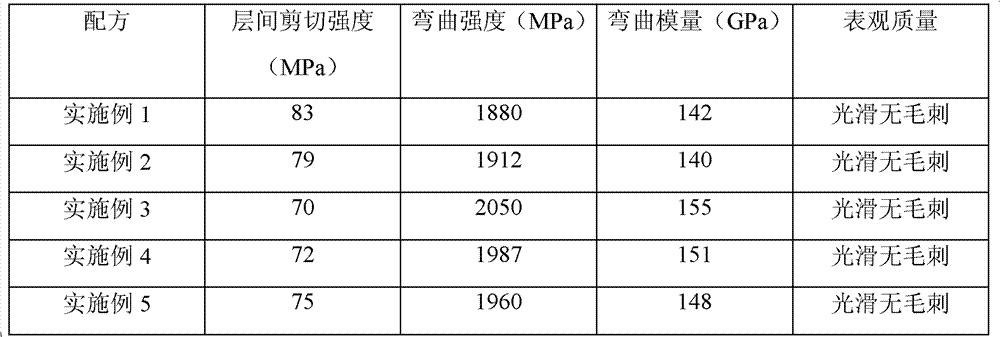

Modified pultrusion composite material and preparation method thereof

InactiveCN103360727AReduce production fluctuationsShorten the production cyclePolyphthalamideFluorine containing

The invention belongs to the scientific and technical field of composite materials, and discloses a modified pultrusion composite material and a preparation method thereof. The material is prepared from the following components in parts by weight: 100 parts of resin, 10-200 parts of a diluter, 0-80 parts of a filler, 0.1-2 parts of an initiator, 0.1-2 parts of a lubricant, 0.1-1 parts of a release agent and 200-1200 parts of inorganic fiber. Compared with the prior art, a fluorine-containing processing agent PPA (Polyphthalamide) is primarily used in the pultrusion composite material in the invention, so that pultrusion composite material can be effectively reduced, and the production period can be shortened. The fluorine-containing processing agent PPA is wide in application and good in effect in production of the pultrusion composite material, and part of the release agent can be replaced, and the content of the filler can be increased, so that the cost is effectively lowered.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Organosilicon bonding promoter for LED packaging high-refractive-index addition-type silica gel and preparation method and application of organosilicon bonding promoter

InactiveCN105713201AAvoid the disadvantage of easy to open loopGood adhesionMacromolecular adhesive additivesEpoxyPolymer science

The invention discloses an organosilicon bonding promoter for LED packaging high-refractive-index addition-type silica gel and a preparation method and application of the organosilicon bonding promoter.According to the preparation method, an organosilicon compound containing hydroxyl and phenyl, epoxy silane, ester silane and a solvent are stirred to be uniform at room temperature, a titanate catalyst is added, a reaction is performed at the temperature of 25-60 DEG C for 6-15 h and continued at the vacuum degree of 0.05-0.098 MPa and the temperature of 60-140 DEG C for 2-6 h, and then the high-refractive-index organosilicon bonding promoter containing epoxy and ester is prepared.The prepared bonding promoter is high in refractive index, compatibility with the LED packaging high-refractive-index addition-type silica gel is good, the bonding performance, particularly with polyphthalamide, poly-1,4-cyclohexylene dimethylene terephthalate and polycarbonate, of the silica gel can be remarkably improved, and the promoter can be widely applied to the field of LED device packaging.

Owner:SOUTH CHINA UNIV OF TECH

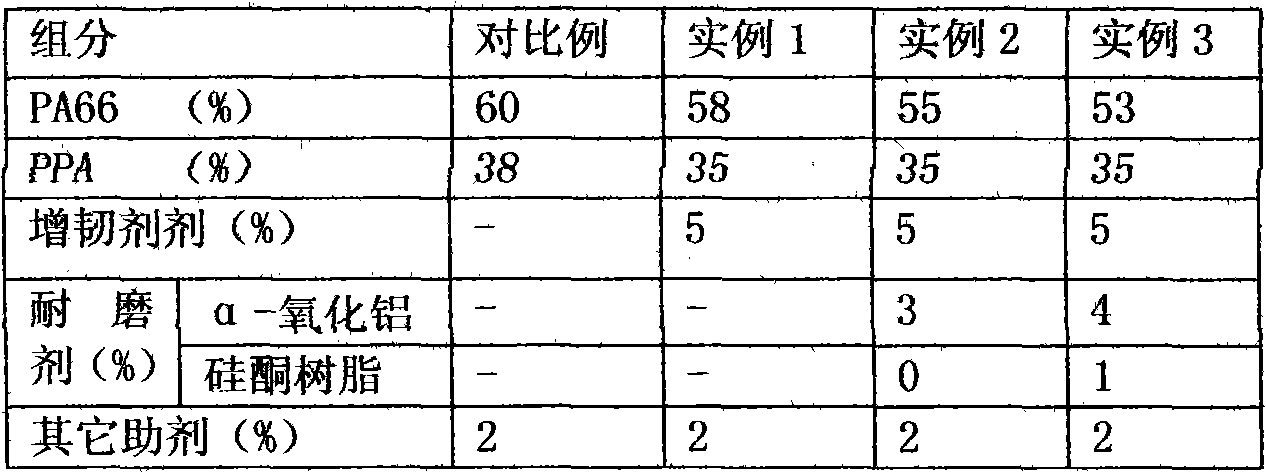

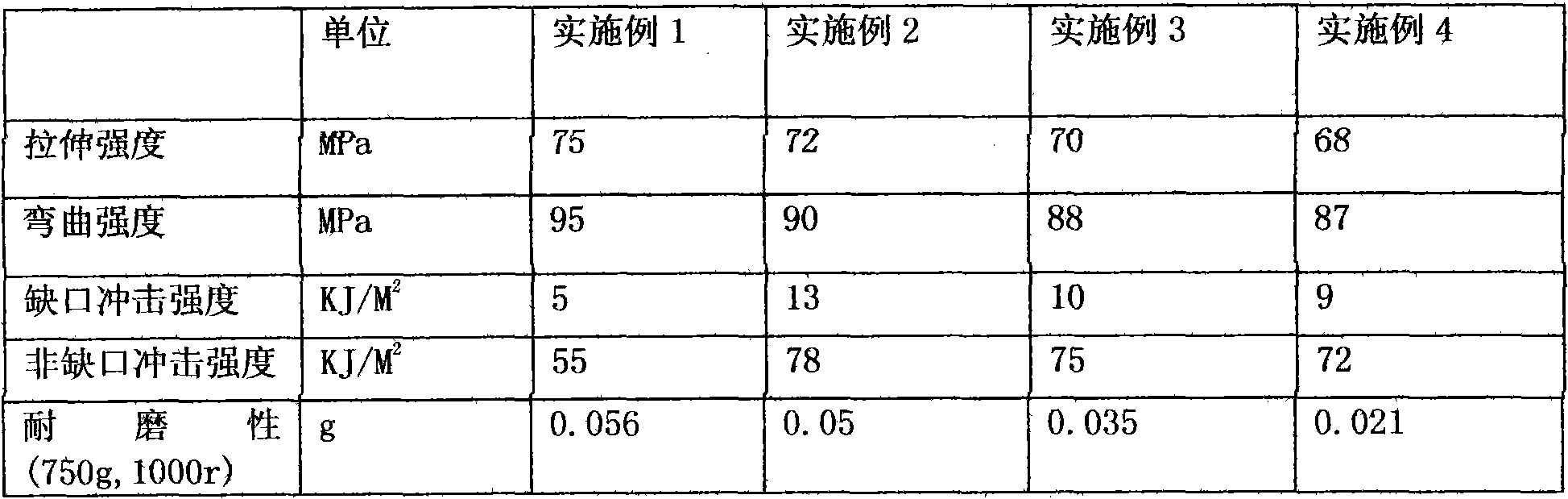

Preparation and application of high-wear-resistance modified nylon composition

The invention discloses preparation and application of a high-wear-resistance modified nylon composition. The high-wear-resistance modified nylon composition comprises the following components in percentage by weight: 30-70 parts of PA66 (Polyamide) resin, 20-50 parts of PPA (Polyphthalamide) resin, 4-8 parts of toughening agent, 4-7 parts of wear-resisting agent and 2-5 parts of other auxiliary agents. The material has wide application in the fields of automobiles, machinery and the like and has an obvious advantage of substituting metal in the aspects of a wear-resistant shaft bushing, a slip sheet and the like. A preparation method for the high-wear-resistance modified nylon composition comprises the following process steps of: uniformly mixing the raw materials according to a proportion; adding into a double-screw extruder; and controlling the temperature at 250-330 DEG C for granulation to obtain the high-wear-resistance modified nylon composition. The high-wear-resistance modified nylon composition with superior comprehensive performance is prepared.

Owner:BEIJING SHOUSU NEW MATERIAL TECH

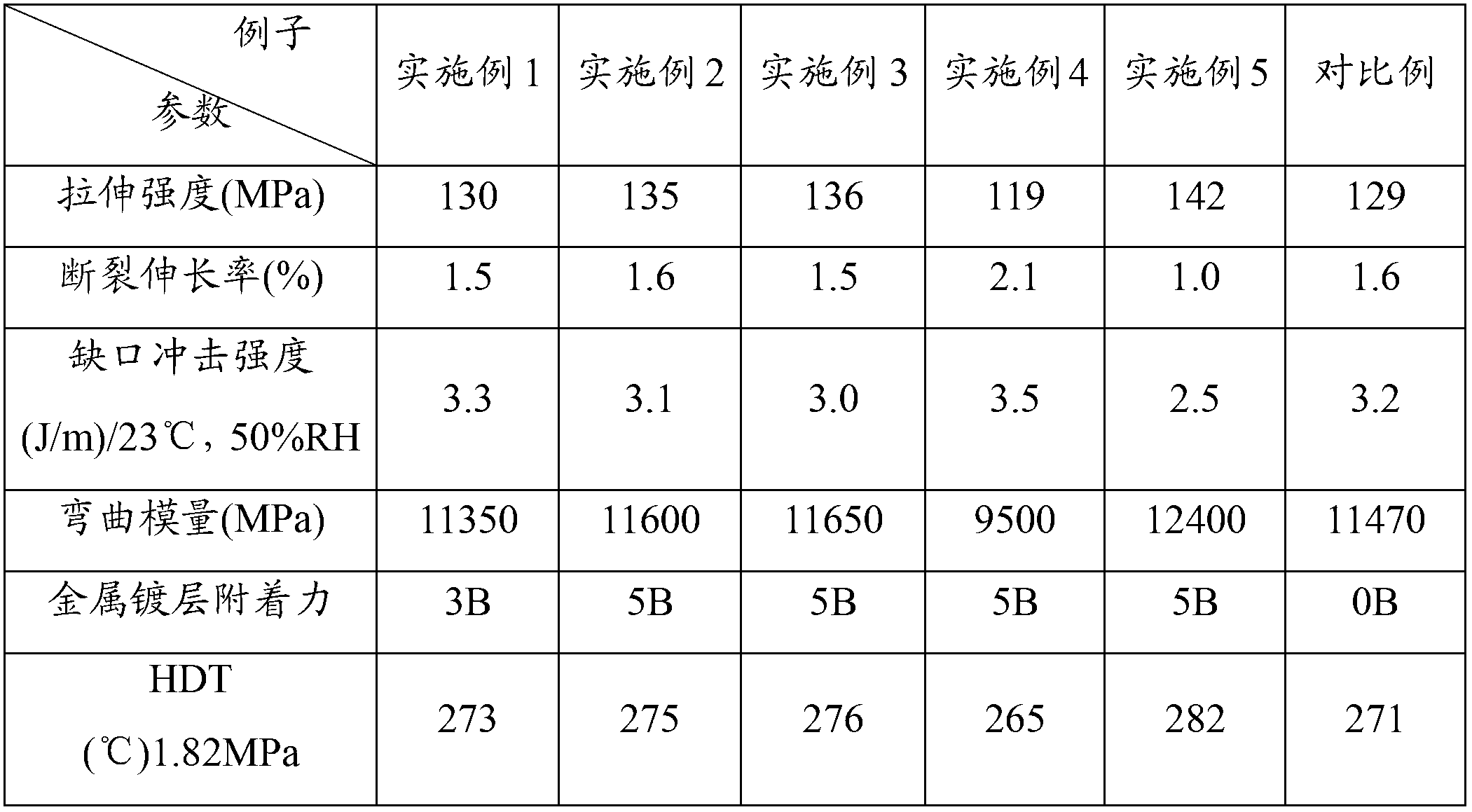

Polyphthalamide composite material and preparation method thereof

The invention relates to a polyphthalamide composite material and a preparation method thereof. The polyphthalamide composite material comprises the following raw materials in part by weight: 27.4 to 88.85 parts of polyphthalamide, 1 to 20 parts of thermotropic liquid crystalline polymer, 10 to 50 parts of glass fiber, 0.05 to 0.6 part of antioxidant and 0 to 2 parts of lubricant. The method comprises the following steps of: S1, weighing the polyphthalamide, the thermotropic liquid crystalline polymer, the antioxidant and the lubricant in proportion and mixing the raw materials for a period of time; and S2, adding the mixed raw materials into a double-screw extruder, adding the glass fiber into the mixture in proportion in a laterally feeding mode, fusing, extruding and pelletizing the mixture. The polyphthalamide composite material and the preparation method have the advantages of effectively reducing melt viscosity during processing, increasing melt flow rate, further improving material processing performance, lowering the fracture rate of the glass fiber and improving the mechanical property and thermal property of the composite material.

Owner:SHENZHEN KEJU NEW MATERIAL

Flame retardant reinforced polyphthalamide composite material and preparation method thereof

The invention discloses a flame retardant reinforced polyphthalamide composite material and a preparation method thereof. The flame retardant reinforced polyphthalamide composite material comprises the following raw materials in parts by weight: 22.1-55.8 parts of polyphthalamide, 1-18 parts of thermotriopic liquid crystalline polymer, 20-45 parts of glass fibers, 14-18 parts of flame retardant, 0.1-0.6 part of antioxidant and 0.3-1 part of lubricant. By introducing TLCP (Thermotriopic Liquid Crystalline Polymer) into a glass fiber reinforced flame retardant PPA (Phenlypropanolamine) system, the flame retardant reinforced polyphthalamide composite material can lower the viscosity of a blend melt, improve the fluidity of the composite materials, enhance the stability of the flame retardant system, the comprehensive properties of the materials and the moulding processing performance of the flame retardant system, save the moulding processing energy consumption, lower the product cost and has wider application prospect in the electronic and electrical field, the mechanical engineering field and the like.

Owner:SHENZHEN KEJU NEW MATERIAL

High-performance anti-static PET composite material

InactiveCN104945865AImprove heat resistanceImprove antistatic performancePolyethylene terephthalate glycolCyclodextrin

The invention provides a high-performance anti-static PET composite material which is prepared from the following raw materials in parts by weight: 20-26 parts of PET resin, 8-14 parts of nano zinc oxide, 1-4 parts of linoleic acid, 6-10 parts of polyacrylamide, 2.5-4 parts of cyclodextrin, 7-9 parts of polyethylene terephthalate, 0.15-0.2 part of an antioxidant, 4-7 parts of polyphthalamide, 8-11 parts of titanium dioxide, 8-12 parts of glass fibers, 4-7 parts of montmorillonite, 3-6 parts of a flame retardant, 4-9 parts of an antistatic agent and 0.5-0.8 part of a heat stabilizer. The high-performance anti-static PET composite material has the beneficial effects of very good heat resistance and antistatic property, is improved in bending property and impact property, and has good whether resistance and chemical resistance stability; and the operation process is simple and easy to implement.

Owner:QINGDAO JINGSHITONG PRECISION MACHINERY MFG

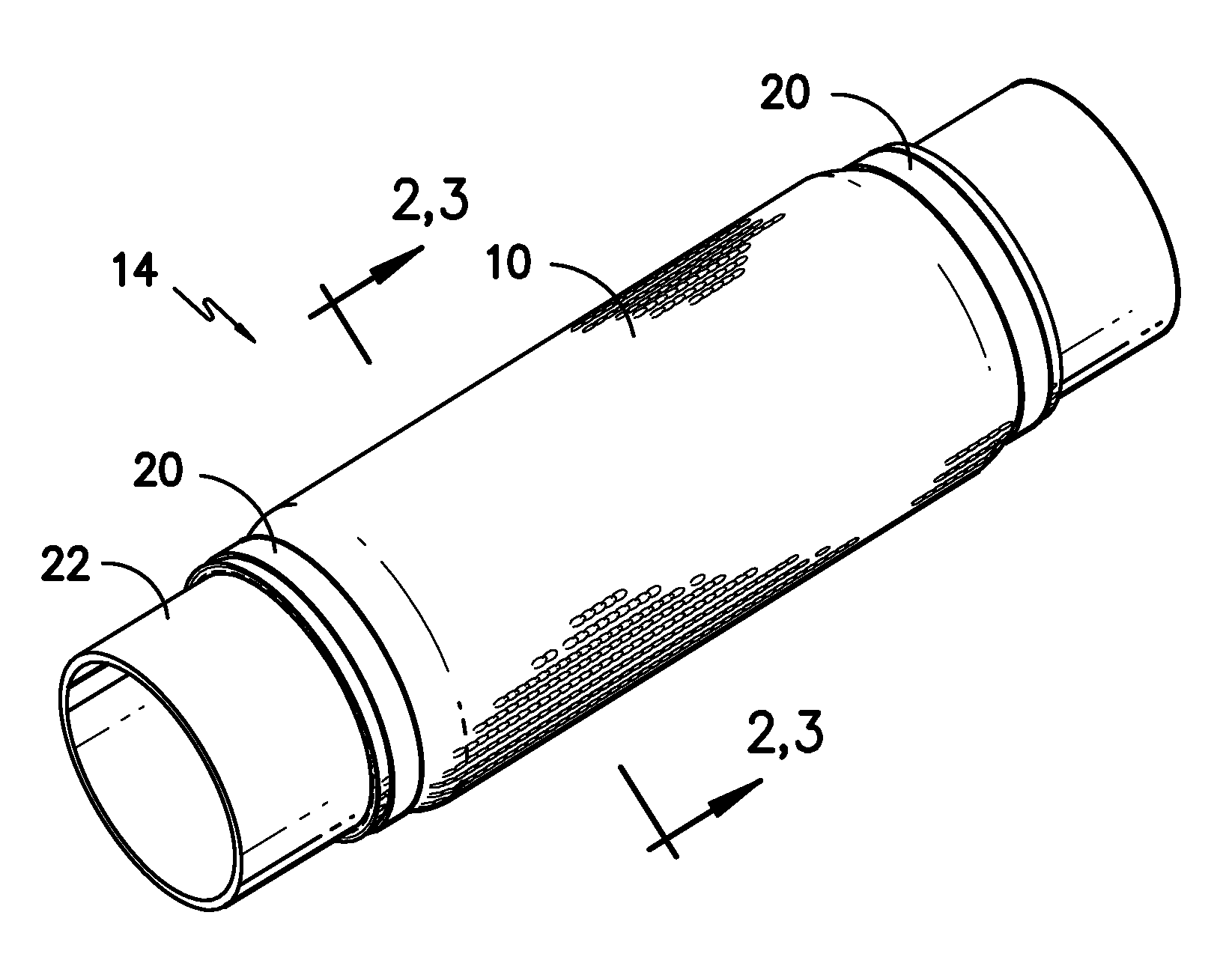

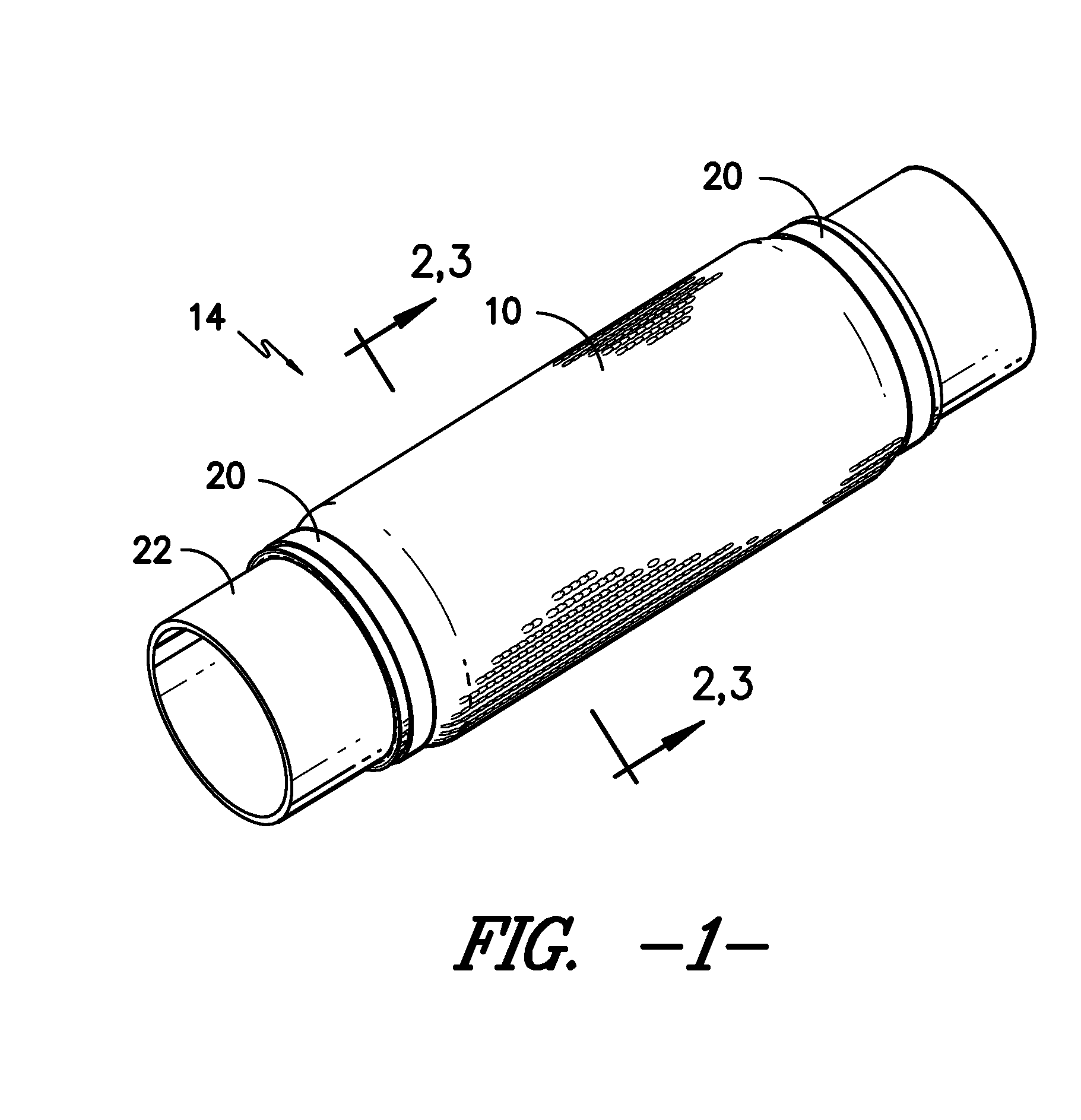

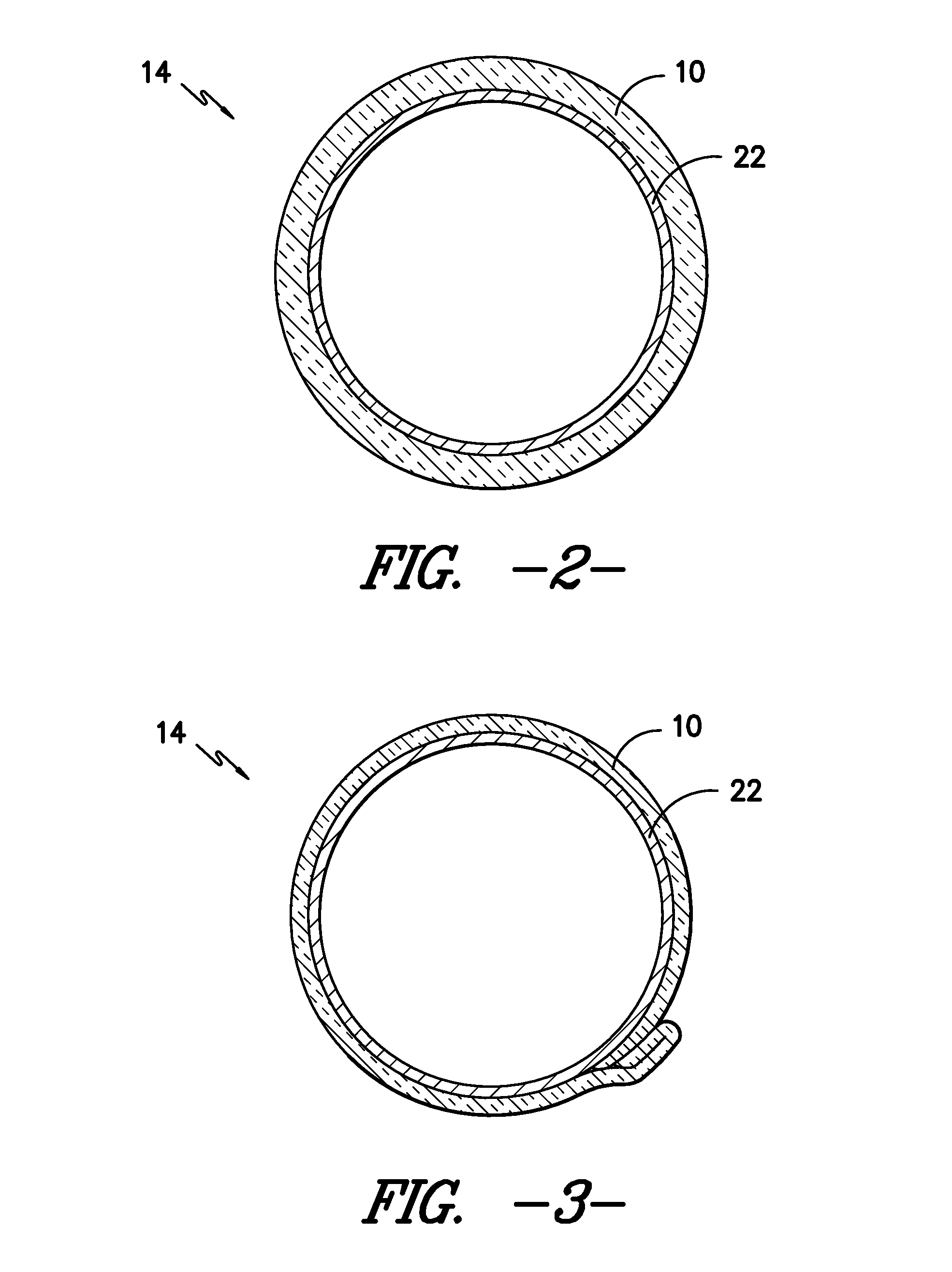

Heat curable composite textile

A heat curable, circular knitted fabric includes reinforcing and meltable resin fibers that can be cured to form a more rigid material form. In one embodiment, the fabric includes a core spun yarn, wherein the core may be made from glass, carbon, basalt, aramid or metal. The wrap surrounding the core may include resin type fibers such as Poly(p-phenylene sulfide) PPS, Polyetherimide (PEI), Polyether ether ketone (PEEK), Polysulfone (PES), Polyphthalamide (PPA), nylon, polyester, or polypropylene.

Owner:NELSON GLOBAL PROD INC

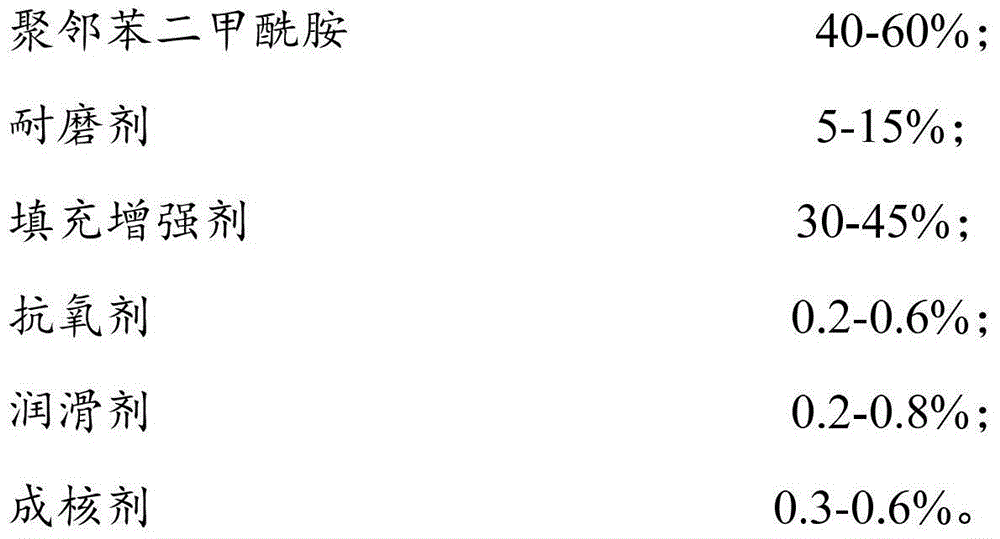

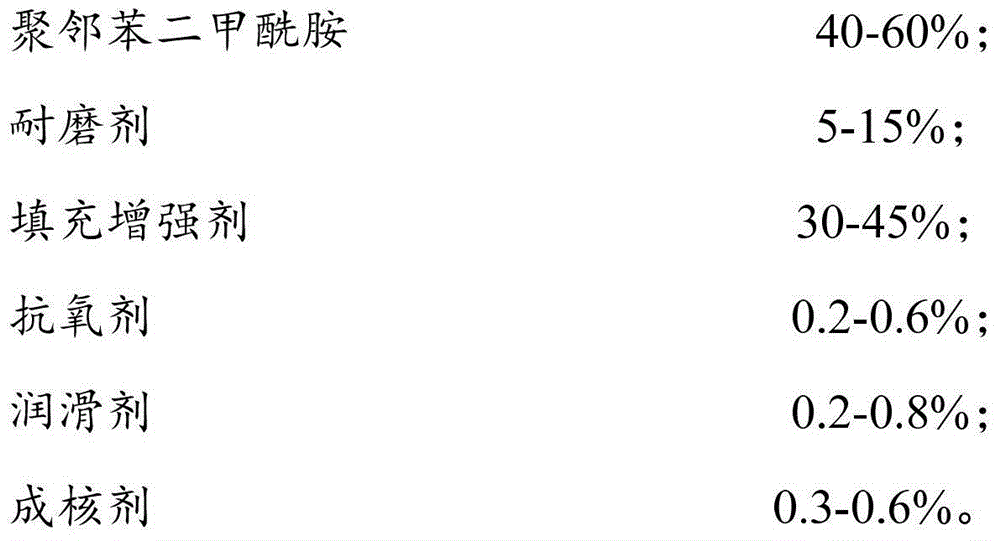

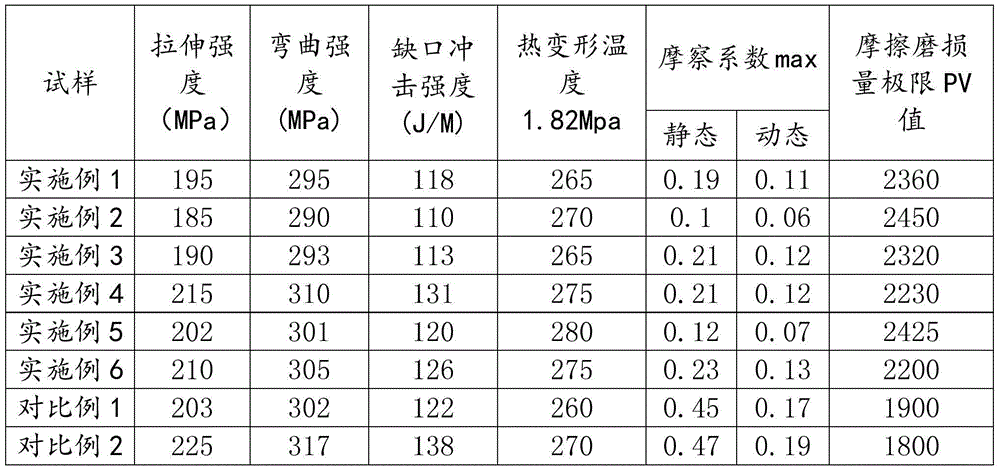

Polyphthalamide (PPA) composite material with high temperature resistance and abrasion resistance and preparation method of PPA composite material

The invention is applicable to the field of high molecular materials and provides a polyphthalamide (PPA) composite material with high temperature resistance and abrasion resistance and a preparation method of the PPA composite material. The PPA composite material with high temperature resistance and abrasion resistance comprises the following raw material components in percentage by mass: 40-60% of PPA, 5-15% of an abrasion-resistant agent, 30-45% of a filling and reinforcing agent, 0.2-0.6% of an antioxidant, 0.2-0.8% of a lubricating agent and 0.3-0.6% of a nucleating agent. The preparation method of the PPA composite material with high temperature resistance and abrasion resistance comprises the following steps: sorting, mixing in a mixer, putting the obtained mixture into a double-screw extruder, carrying out melt extrusion, and pelletizing. The PPA composite material with high temperature resistance and abrasion resistance has the advantages that the abrasion-resistant agent is introduced into PPA, so that abrasion resistance and self-lubricating property of PPA are improved, and glass fibers are adopted for carrying out enhancement processing, and thus a modified composite material with excellent performance is obtained, mechanical properties and heat resistance and abrasion resistance properties are guaranteed, and the PPA composite material with high temperature resistance and abrasion resistance can be applied to a transmission part under high temperature condition.

Owner:ANHUI KEJU NEW MATERIALS

Heat curable composite textile

A heat curable, circular knitted fabric includes reinforcing and meltable resin fibers that can be cured to form a more rigid material form. In one embodiment, the fabric includes a core spun yarn, wherein the core may be made from glass, carbon, basalt, aramid or metal. The wrap surrounding the core may include resin type fibers such as Poly(p-phenylene sulfide) PPS, Polyetherimide (PEI), Polyether ether ketone (PEEK), Polysulfone (PES), Polyphthalamide (PPA), nylon, polyester, or polypropylene.

Owner:NELSON GLOBAL PROD

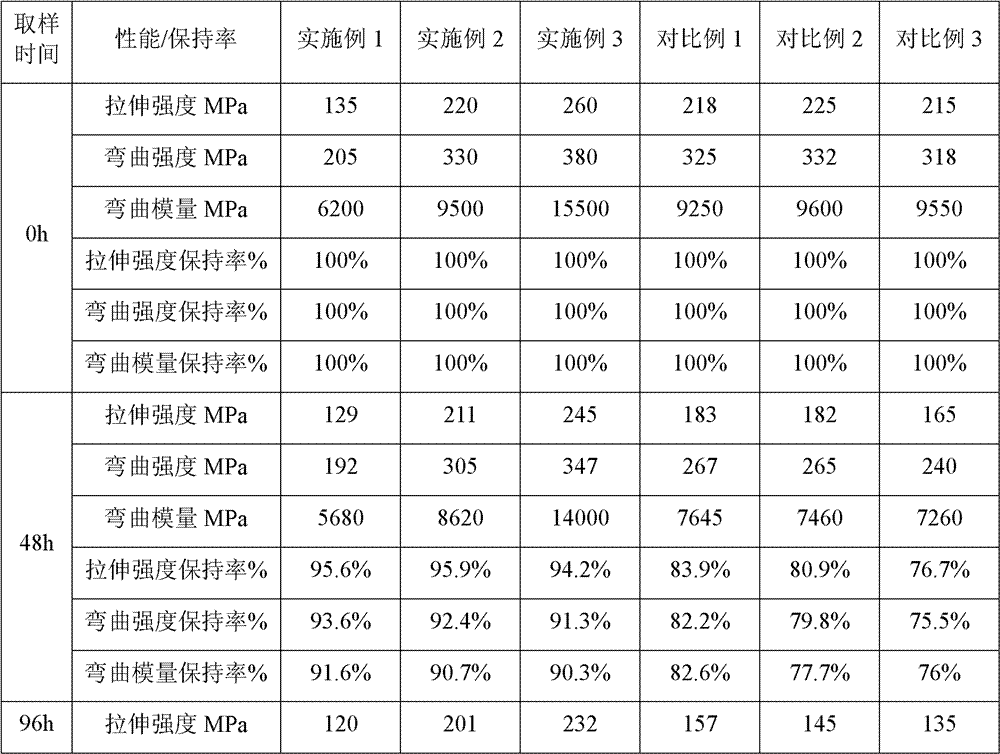

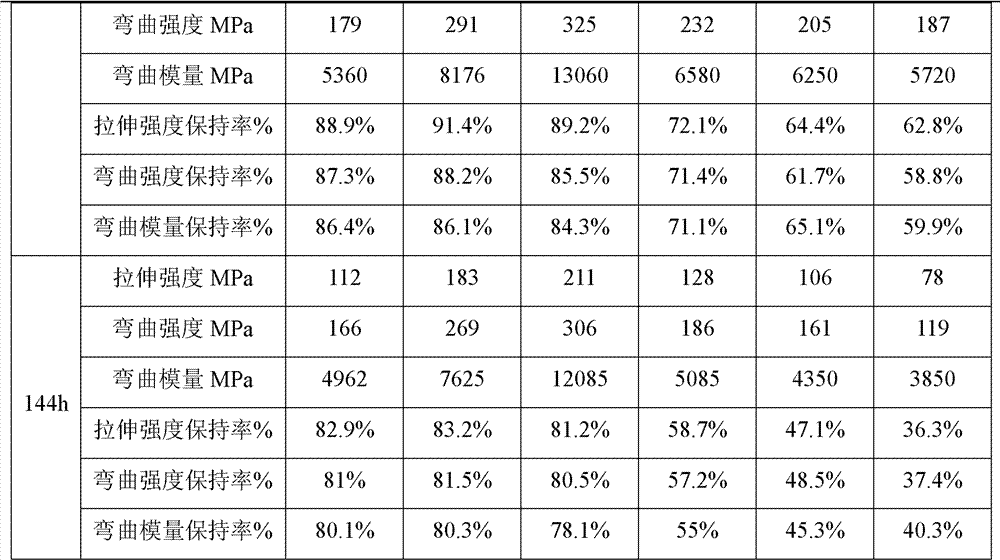

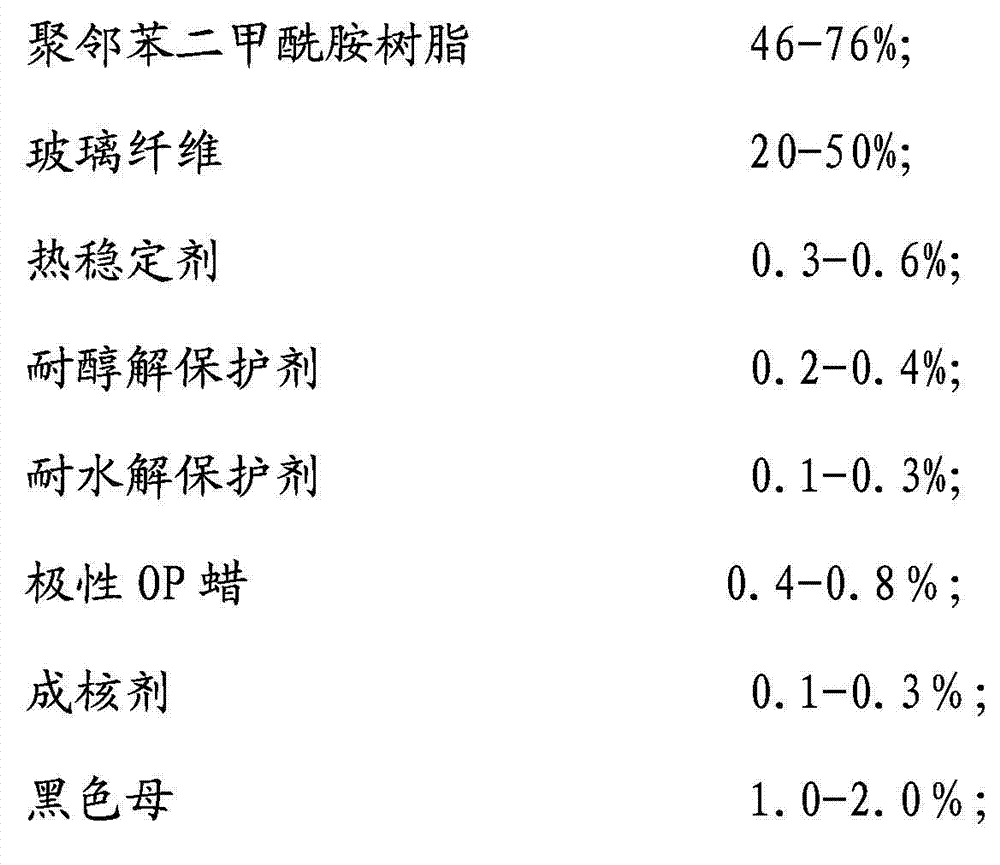

Hydrolysis-resistance alcoholysis-resistance glass fiber reinforced PPA (phenyl-propanolamine) material and preparation method thereof

The invention discloses a hydrolysis-resistance alcoholysis-resistance glass fiber reinforced PPA (phenyl-propanolamine) material and a preparation method thereof. The hydrolysis-resistance alcoholysis-resistance glass fiber reinforced PPA material consists of the following components in percentage by weight: 46 to 76 percent of polyphthalamide resin, 20 to 50 percent of glass fibers, 0.3 to 0.6 percent of heat stabilizer, 0.2 to 0.4 percent of alcoholysis-resistance protective agent, 0.1 to 0.3 percent of hydrolysis-resistance protective agent, 0.4 to 0.8 percent of polarity OP (oxidized polyethlene) wax, 0.1 to 0.3 percent of nucleating agent and 1.0 to 2.0 percent of black color masterbatch. The reinforced PPA material disclosed by the invention not only has excellent mechanical property, but also has excellent hydrolysis-resistance and alcoholysis-resistance characteristics. When the hydrolysis-resistance alcoholysis-resistance glass fiber reinforced PPA material is soaked in hot water and ethylene glycol solution for a long time, over 80 percent of mechanical property can be kept. The hydrolysis-resistance alcoholysis-resistance glass fiber reinforced PPA material can be widely used in the automobile industry and other fileds. When the hydrolysis-resistance alcoholysis-resistance glass fiber reinforced PPA material is used for manufacturing parts which are in contact withwater and antifreezing solution for a long time, not only can the manufacturing cost of the parts be reduced, but also the weights of the parts can be greatly reduced.

Owner:徐东

High-refraction-index boron-containing organic silicon tackifier and preparation method thereof

ActiveCN109824903AStrong electron-withdrawingGood adhesionMacromolecular adhesive additivesFiltrationRefractive index

The invention belongs to the field of organic silicon rubber additives and particularly relates to a high-refraction-index boron-containing organic silicon tackifier and a preparation method thereof.The tackifier is high in silicon rubber compatibility, catalyst poisoning is avoided, boron atoms can be attracted by electron cloud on phenyl in PPA (polyphthalamide) serving as an adhered base material, and adhesion between silicon rubber and PPA is improved. A preparation process is simple, high repeatability and controllability are realized, an adopted catalyst can be easily removed through reduced-pressure suction filtration, reaction conditions are mild, consumption of organic solvents in a reaction process is avoided, and industrialization can be easily realized. By changing of reactionconditions and a reactant ratio, viscosity of the organic silicon tackifier is reduced to 56.8-73.6mPa s while the refraction index is up to 1.5078-1.5203, and the organic silicon tackifier is suitable for high-refraction-index addition type organic silicon rubber.

Owner:SOUTH CHINA UNIV OF TECH

Laser formed polyphthalamide composition and preparation method thereof

The invention discloses a laser formed polyphthalamide composition and a preparation method thereof. The laser formed polyphthalamide composition comprises the following raw materials in parts by weight: 30-75 parts by polyphthalamide, 3-15 parts of inorganic pigment, 0.3 part of nucleating agent, 20-40 parts of glass fiber, 0.5 part of lubricating agent, 0.2 part of hindered phenol antioxidant and 0.2 part of phosphite ester antioxidant. The laser formed polyphthalamide composition provided by the invention can be used in a laser direct forming technology, has high resistance and excellent mechanical property, is applicable to a reflow soldering process, is environmental-friendly and nontoxic, is low in cost, and is simple in machining process.

Owner:SINOPLAST NEW MATERIAL

Composite material of polyphthalamide (PPA) and polyphenylene sulfide (PPS) and preparation method thereof

InactiveCN102241885AImprove flame retardant performanceImprove heat resistancePolyphthalamidePolymer science

The invention belongs to the technical field of macromolecular materials, and particularly, discloses a composite material of PPA and PPS and a preparation method thereof. The PPA and the PPS, which are used as main raw materials, are modified under a melting state in combination with a filling enhancer, a lubricating agent, an antioxidant and a coupling agent. The filling enhancer is added to improve the mechanical and thermal properties of the composite material, the lubricating agent is added to improve the processability of the composite material, the antioxidant is added to improve the stability of the PPA during processing, and the coupling agent is added to reinforce the bonding between the filling enhancer and matrix resin.

Owner:SHENZHEN KEJU NEW MATERIAL

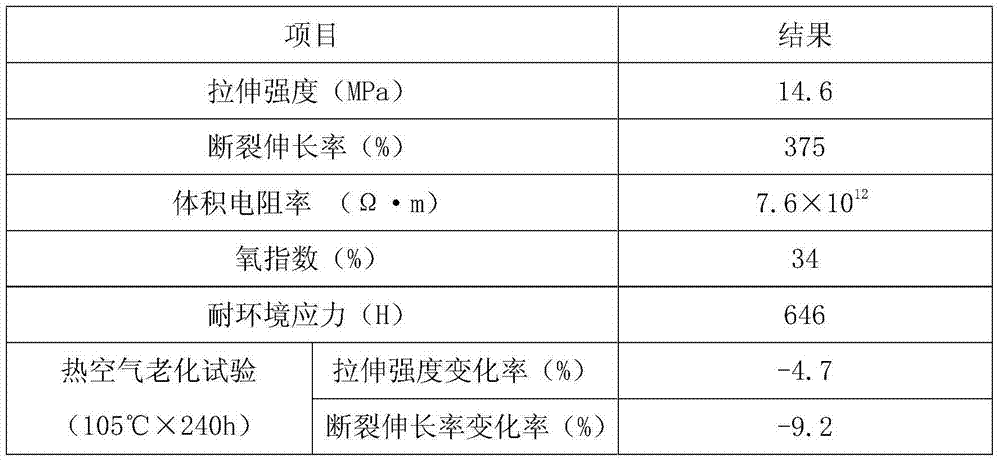

Environmental stress crack-resistant polyethylene sheath material for power wire and preparation method thereof

InactiveCN103540008AGood environmental stress cracking resistanceGood high and low temperature resistancePlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethyleneLead phosphate

The invention discloses an environmental stress crack-resistant polyethylene sheath material for a power wire and a preparation method thereof. The environmental stress crack-resistant polyethylene sheath material is prepared from the following substances in parts by weight: 80-100 parts of linear low-density polyethylene, 15-20 parts of polystyrene resin, 10-15 parts of polyphthalamide, 4-8 parts of dimethyl silicon oil, 2-3 parts of dibasic lead phosphate, 1-2 parts of calcium stearate, 1-2 parts of zinc stearate, 0.5-1 part of antioxidant 1010, 1-2 parts of antioxidant 168, 2-4 parts of ethylene distearate amide, 4-6 parts of chlorinated paraffin and 3-5 parts of pine tar. The sheath material has the advantages of excellent environmental stress crack resistance, high-low temperature resistance, acid-base resistance, salt mist resistance, ozone aging resistance, ultraviolet radiation resistance, abrasive resistance and tensile strength, is capable of working normally in a working environment at a temperature ranging from 60 DEG C below zero to 105 DEG C, is non-deformable and non-cracking in long-time use, is safe and reliable and is applicable to internal and external sheathes of overhead power wires in the outdoor.

Owner:天长市富达电子科技股份有限公司

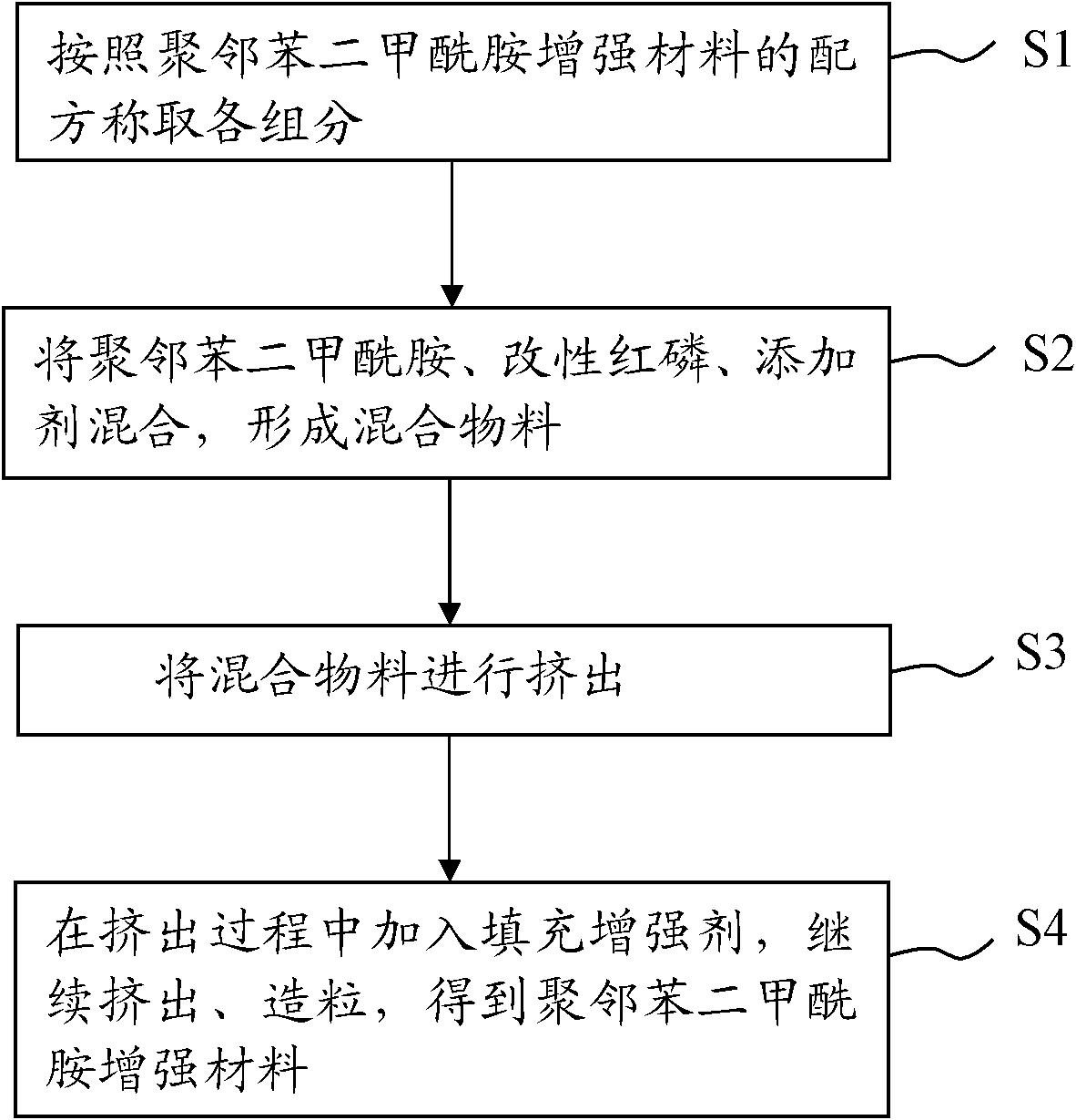

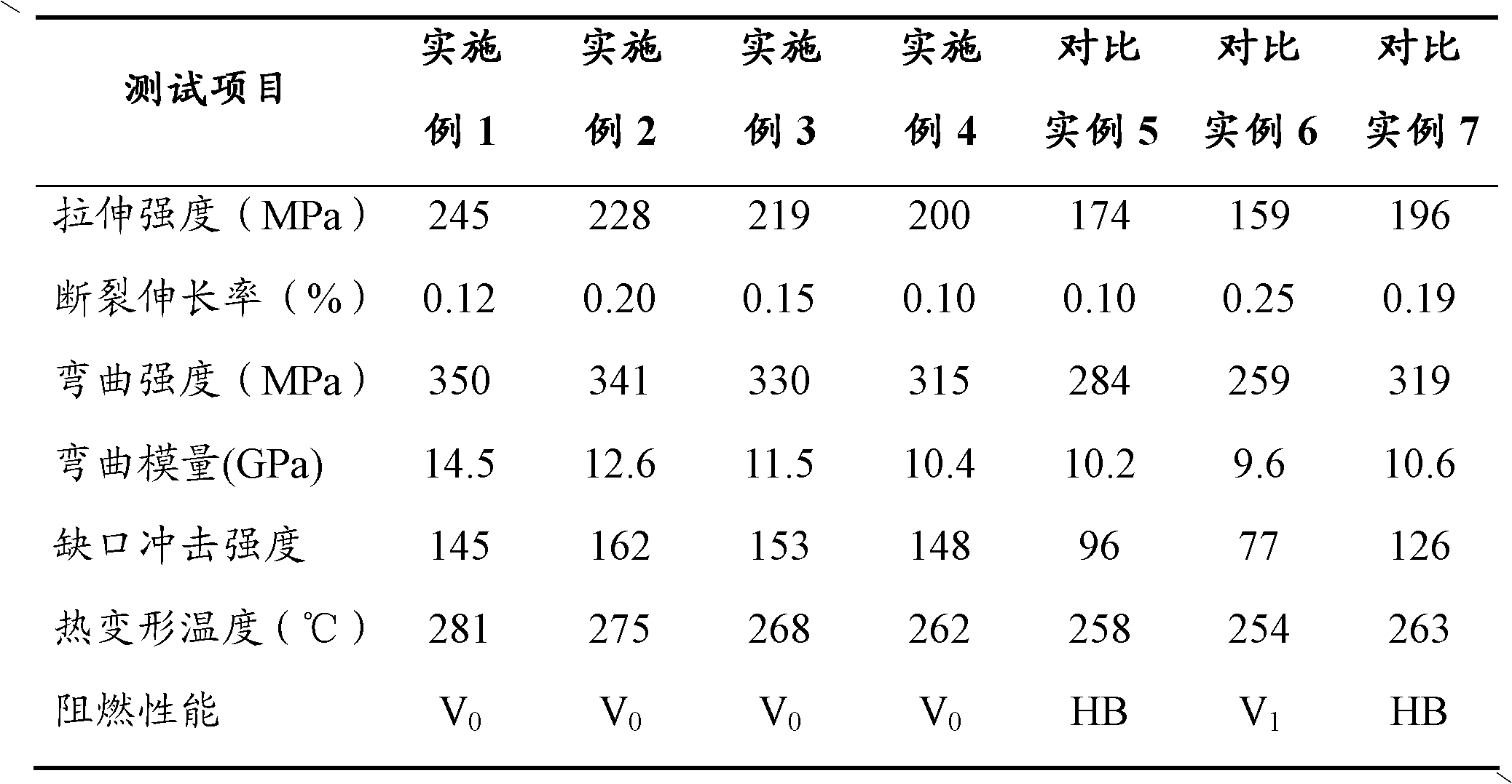

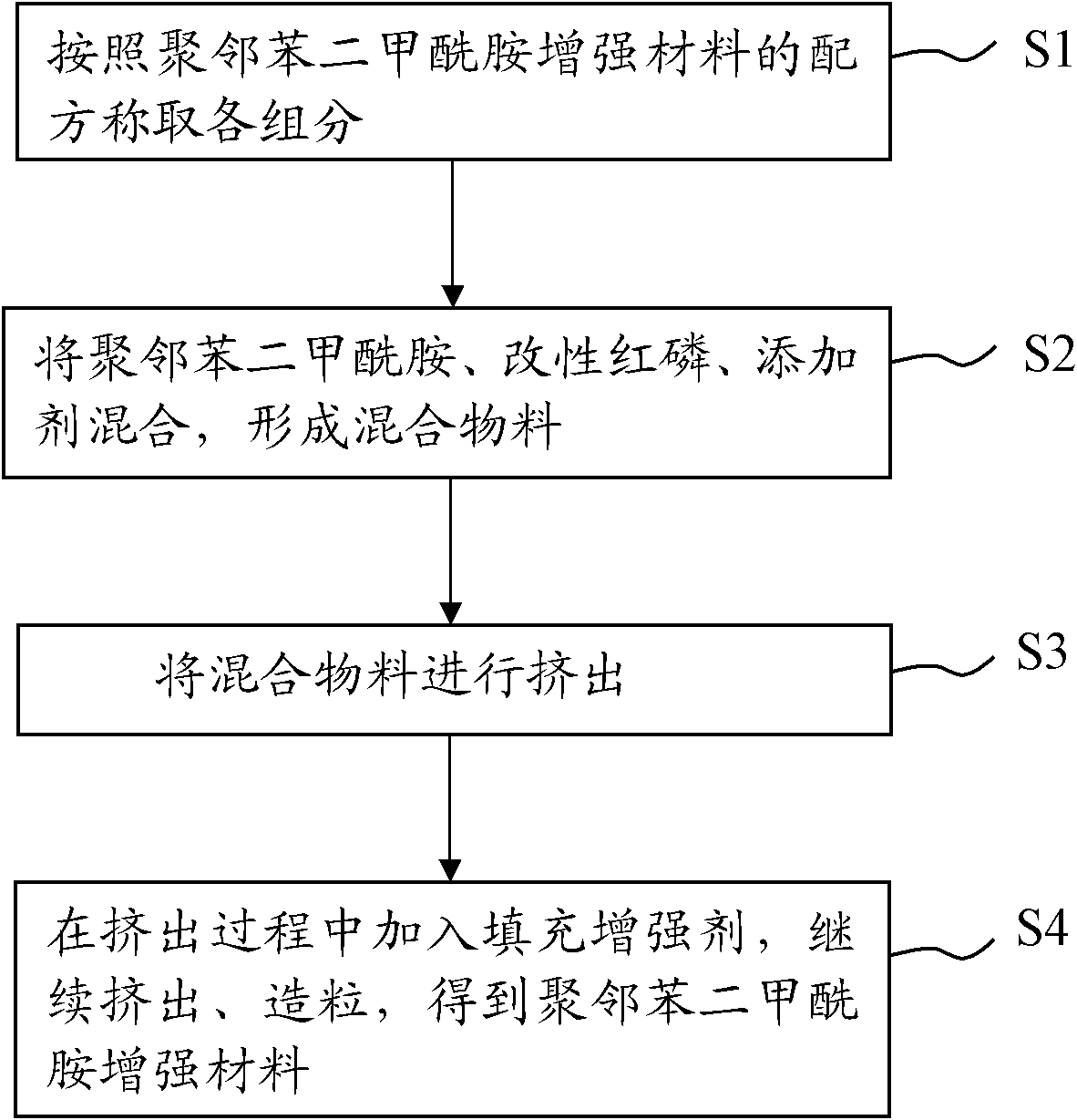

Polyphthalamide reinforced material and preparation method thereof

InactiveCN102134393AImprove flame retardant performanceHigh tensile strengthPigment treatment with organosilicon compoundsPolyphthalamideUltimate tensile strength

The invention discloses a polyphthalamide reinforced material and a preparation method thereof. The polyphthalamide reinforced material comprises the following formula components in percentage by mass: 48 to 58 percent of polyphthalamide, 6 to 15 percent of modified red phosphorus, 35 to 45 percent of filler intensifier and 1 to 2 percent of additive. The polyphthalamide reinforced material disclosed by the invention tales polyphthalamide as a basic component, and as the polyphthalamide acts with the modified red phosphorus, the filler intensifier, the additive and other components in an extrusion process, the polyphthalamide reinforced material has high flame-retarding performance and mechanical properties such as tensile strength and impact strength. Meanwhile, the production cost of the polyphthalamide reinforced material is low. The preparation method of the polyphthalamide reinforced material comprises: mixing the components according to a formula; and performing segmental feeding and extrusion. The preparation method adopts a simple process, and is low in cost and suitable for industrial production.

Owner:SHENZHEN KEJU NEW MATERIAL

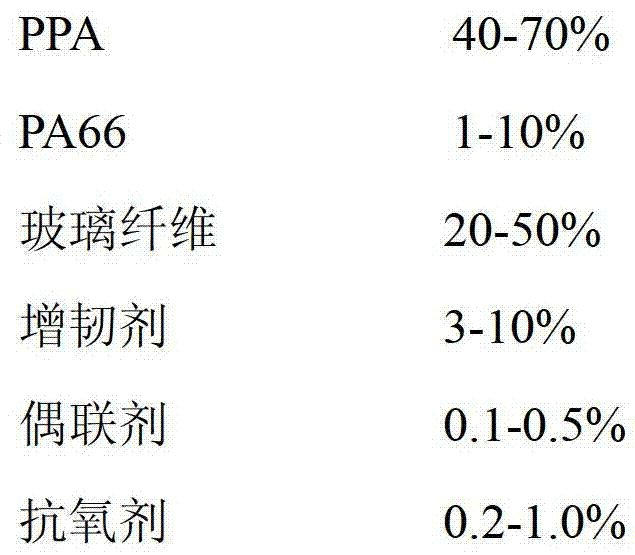

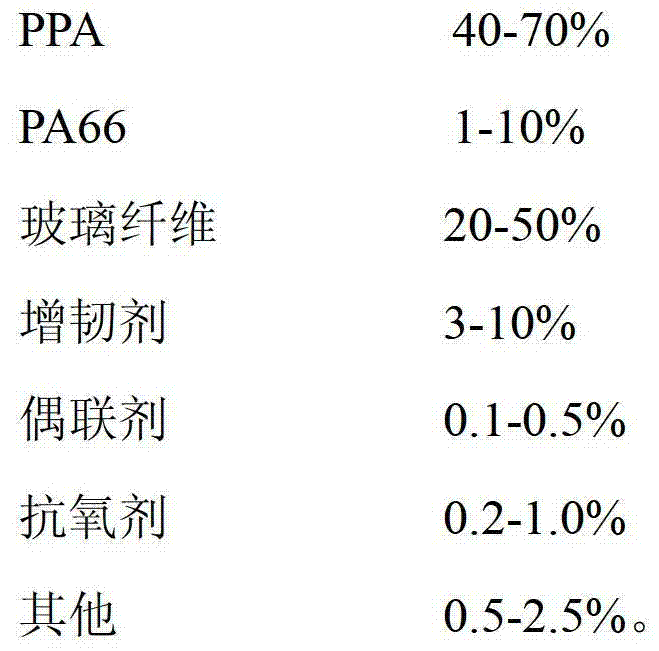

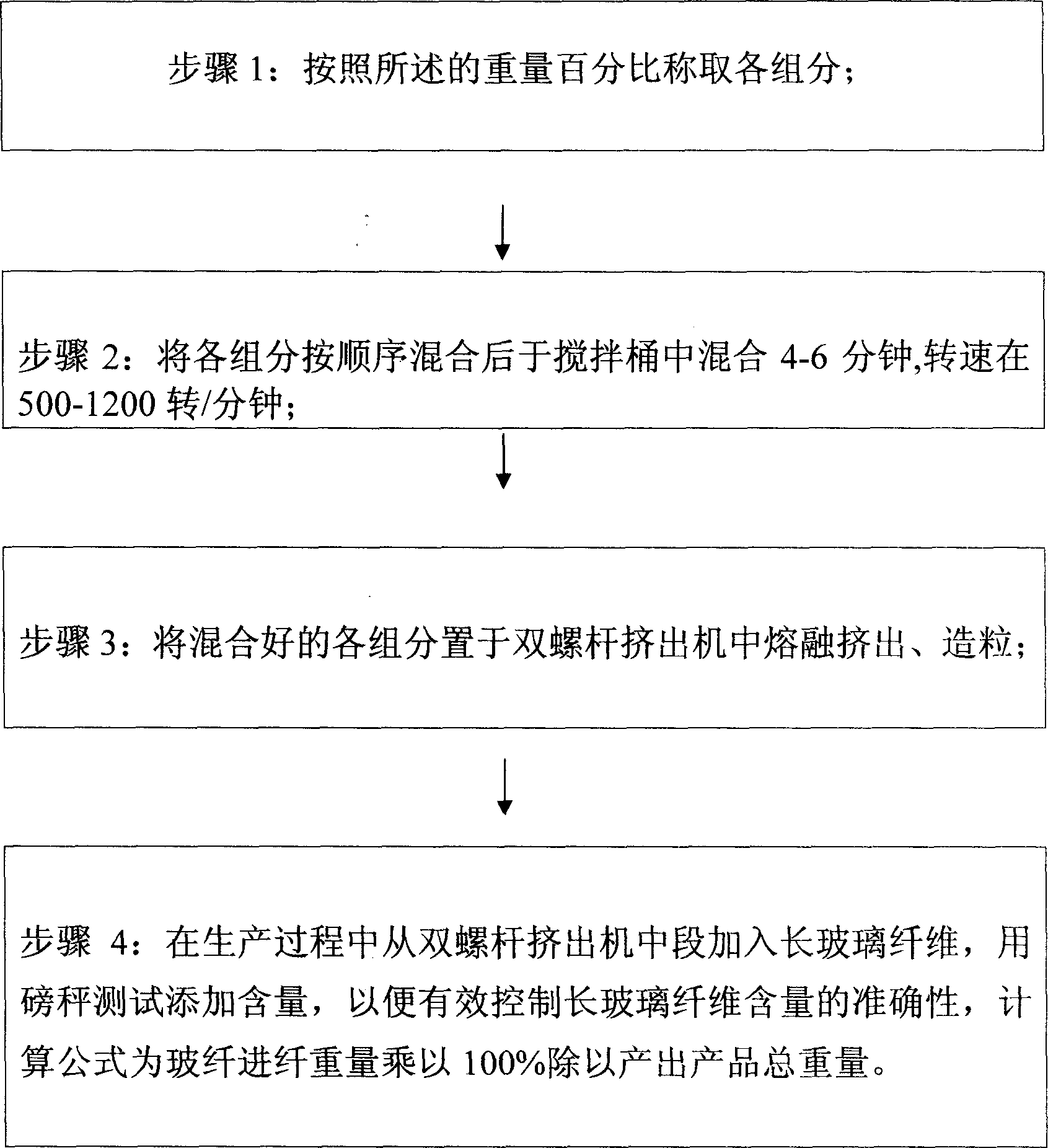

High-temperature-resistant nylon composite material and preparation method thereof

InactiveCN103160120AImprove heat resistanceImprove impact resistanceGlass fiberHeat deflection temperature

The invention relates to a high-temperature-resistant nylon composite material and a preparation method thereof. The high-temperature-resistant nylon composite material comprises, by weight percentage, 40-70% of polyphthalamide (PPA), 1-10% of polyamide 66 (PA66), 20-50% of glass fibers, 3-10% of toughening agents, 0.1-0.5% of coupling agents, 0.2-1.0% of antioxygen, and 0.5-2.5% of the balance. The preparation method comprises the PPA, the PA66 and other raw materials are put into a mixer to be mixed for 10-20 minutes, pre-mixed materials are extruded through an extruder, stretched into strips, water-cooled through a water tank, blow-dried, and dragged to a stock cutter to finish grain cutting, and then the high-temperature-resistant nylon composite material is obtained. The heat deflection temperature of the high-temperature-resistant nylon composite material can achieve more than 290 DEG C, and the high-temperature-resistant nylon composite material has better heat resistance than common high-temperature-resistant nylon achieving 280 DEG C. In addition, impact resistance is good, impact strength can achieve 15kJ / m<2>, and the high-temperature-resistant nylon composite material is simple in manufacturing process and low in cost, and has good application prospects.

Owner:宁波锦地工程塑料有限公司

Poly (hexanediamine adipate) and polyphthalamide fiber-adding alloy and preparation method thereof

InactiveCN101099821AReduce processing costsImprove surface qualityReptile material medical ingredientsDermatological disorderFiberGlass fiber

The invention is concerned with alloy with fibre made of poly(hexamethylene adipamide) and phthalamide phthalic diamide. It relates to 36.15 to 46.15 percent of poly (hexamethylene adipamide), 20 to 30 percent of phthalamide phthalic diamide (PPA), 30 to 33 percent of long fiberglas, 0.1 to 0.2 percent of lubricant and 0.1 to 0.3 percent of antioxidant in weight proportion. This also shows the preparation method of the said alloy. This product and method can improve the surface quality and control the cost of material and product, and it is fit for the high demand of heat resisting, such as engine accessory, dynamoelectric tool shell, inside and outside parts of electrical apparatus with and details of cars.

Owner:SHENZHEN KEJU NEW MATERIAL

High-molecular plastic particles for cable and preparation method for high-molecular plastic particles

InactiveCN104927171AHigh tensile strengthHigh elongation at breakPlastic/resin/waxes insulatorsLow-density polyethyleneDibutyl tin dilaurate

The invention discloses high-molecular plastic particles for a cable and a preparation method for the high-molecular plastic particles. The plastic particles comprise the following components in parts by weight: 25-35 parts of low density polyethylene, 6-13 parts of silane crosslinked polyethylene, 12-20 parts of chloroprene rubber, 4-7 parts of polyphthalamide, 3-9 parts of polyhydroxybenzoate, 1.5-4.5 parts of alpha-n-butyl cyanoacrylate, 2.5-5.5 parts of dibutyltin dilaurate, 2-5 parts of tributyl borate and 2-5 parts of dioctyl phthalate. The preparation method comprises the following steps of: (1) uniformly mixing the materials in a high speed mixer for later use; (2) then extruding the mixed materials which are uniformly mixed by a twin-screw extruder; and (3) granulating the materials which are extruded by the twin-screw extruder to prepare the high-molecular plastic particles for the cable. The prepared high-molecular plastic particles for the cable are suitable for a cable sheath material.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com