Patents

Literature

276results about How to "Good mechanical resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

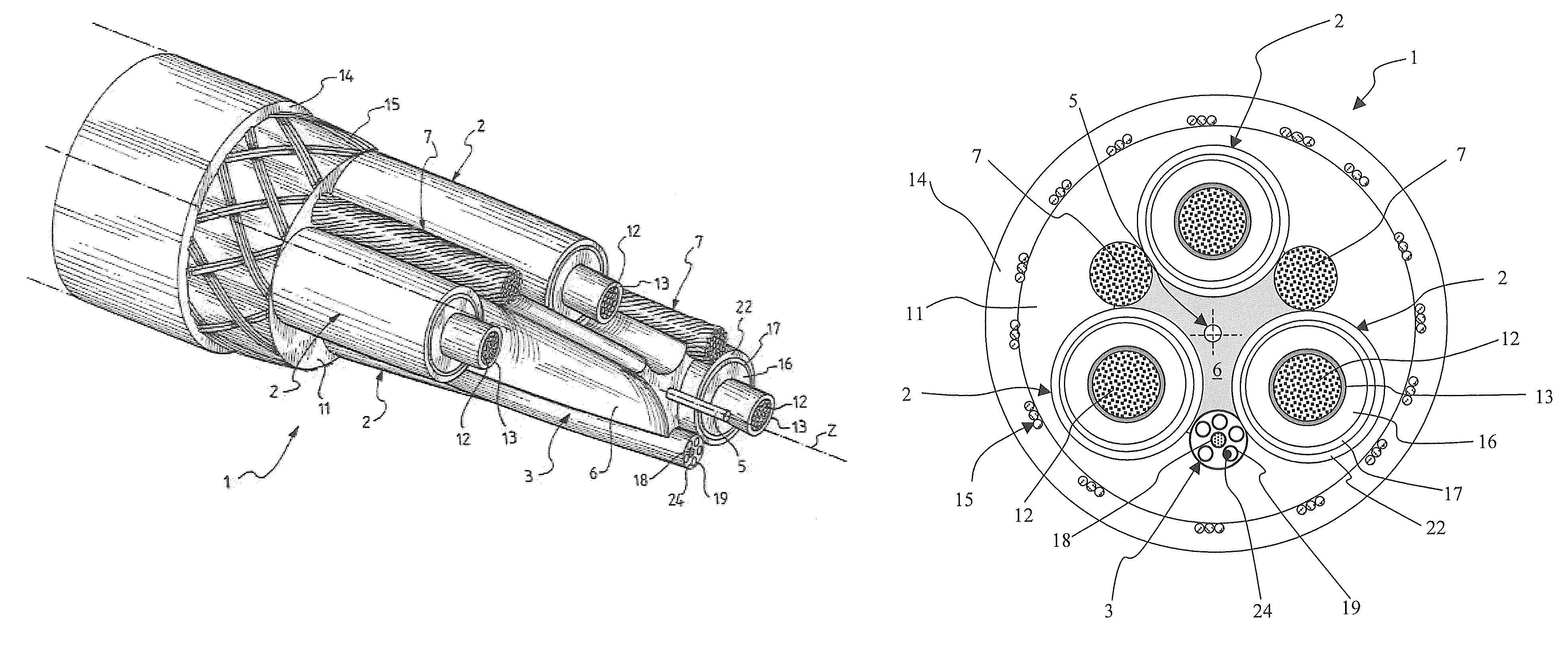

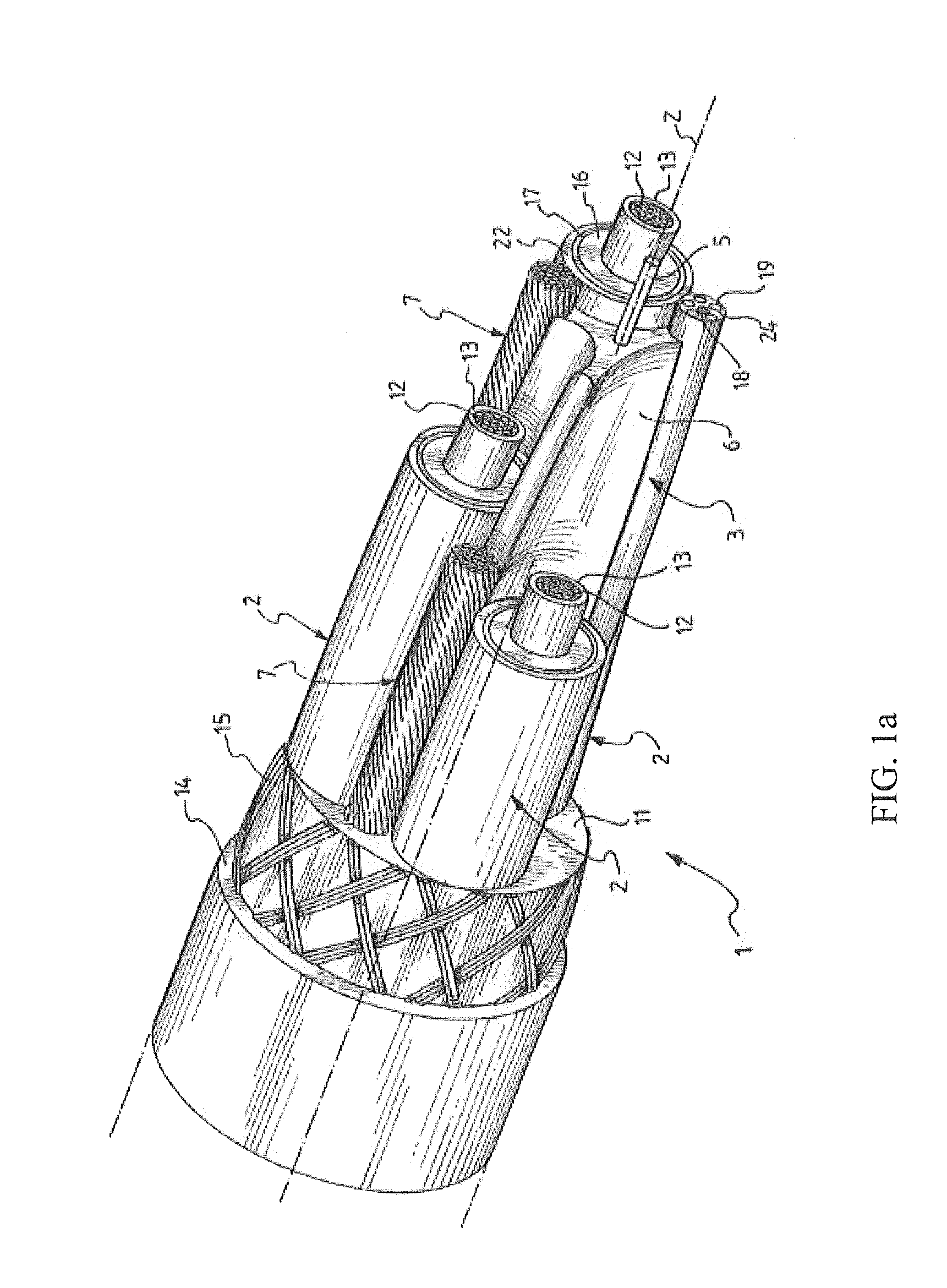

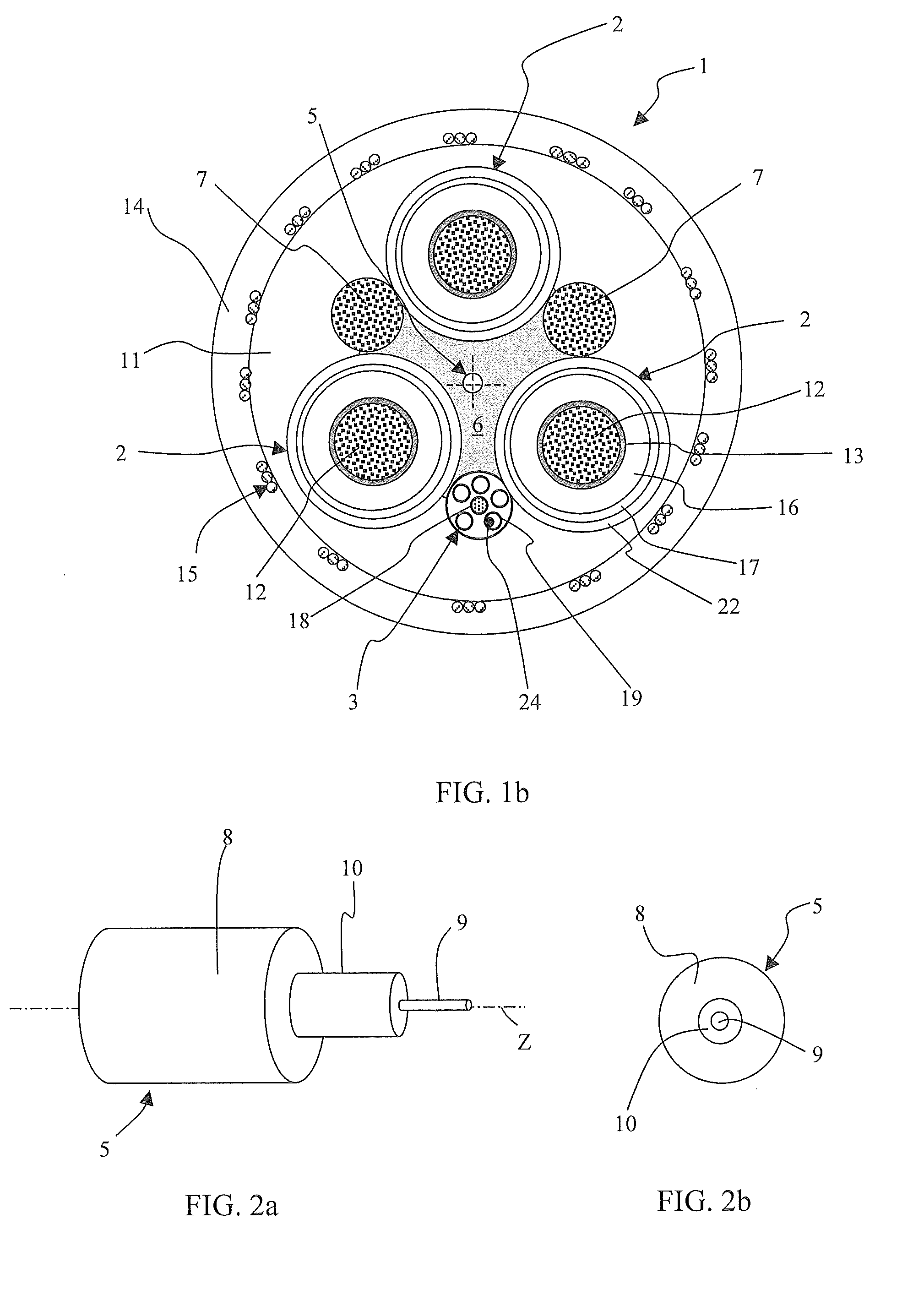

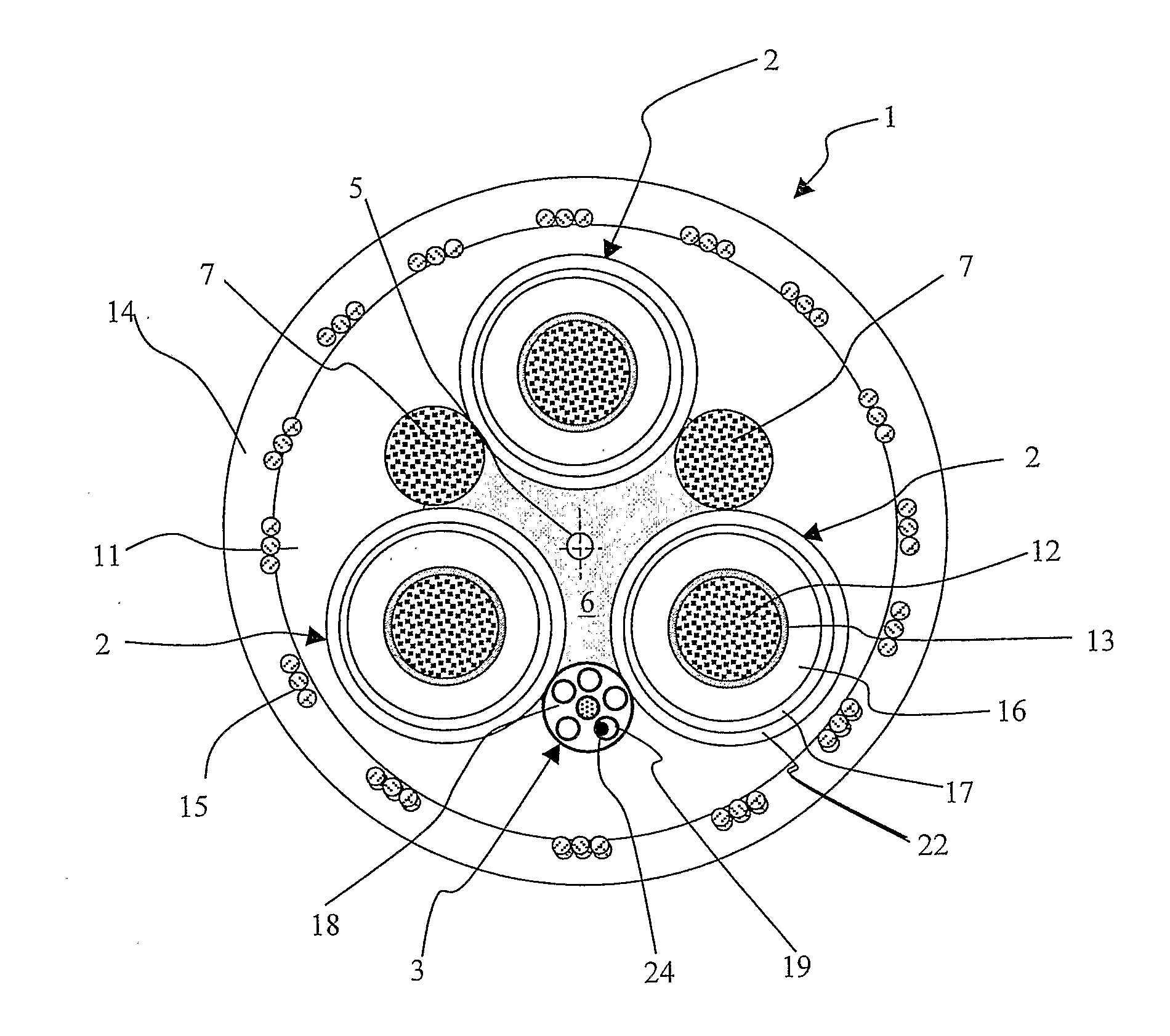

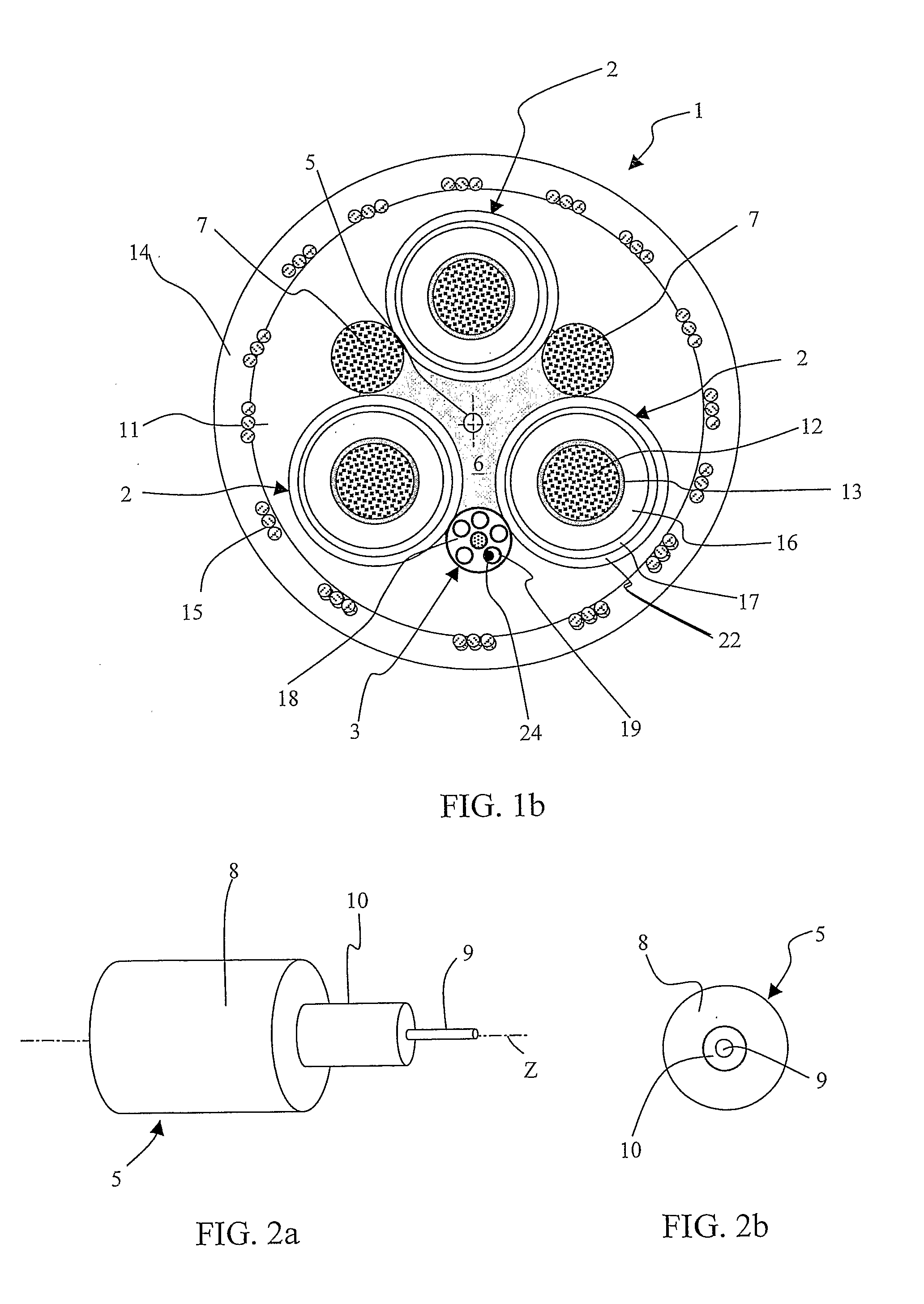

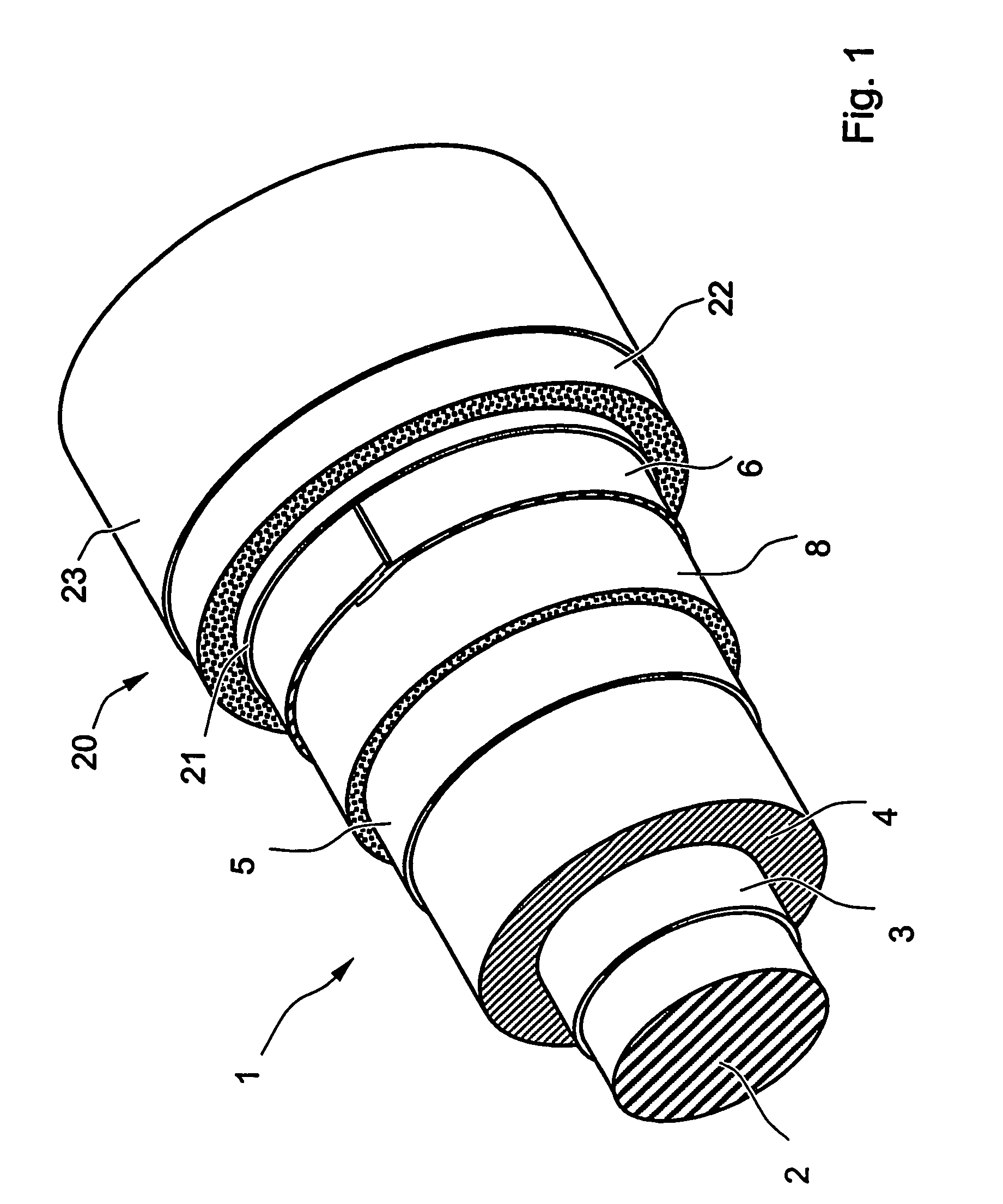

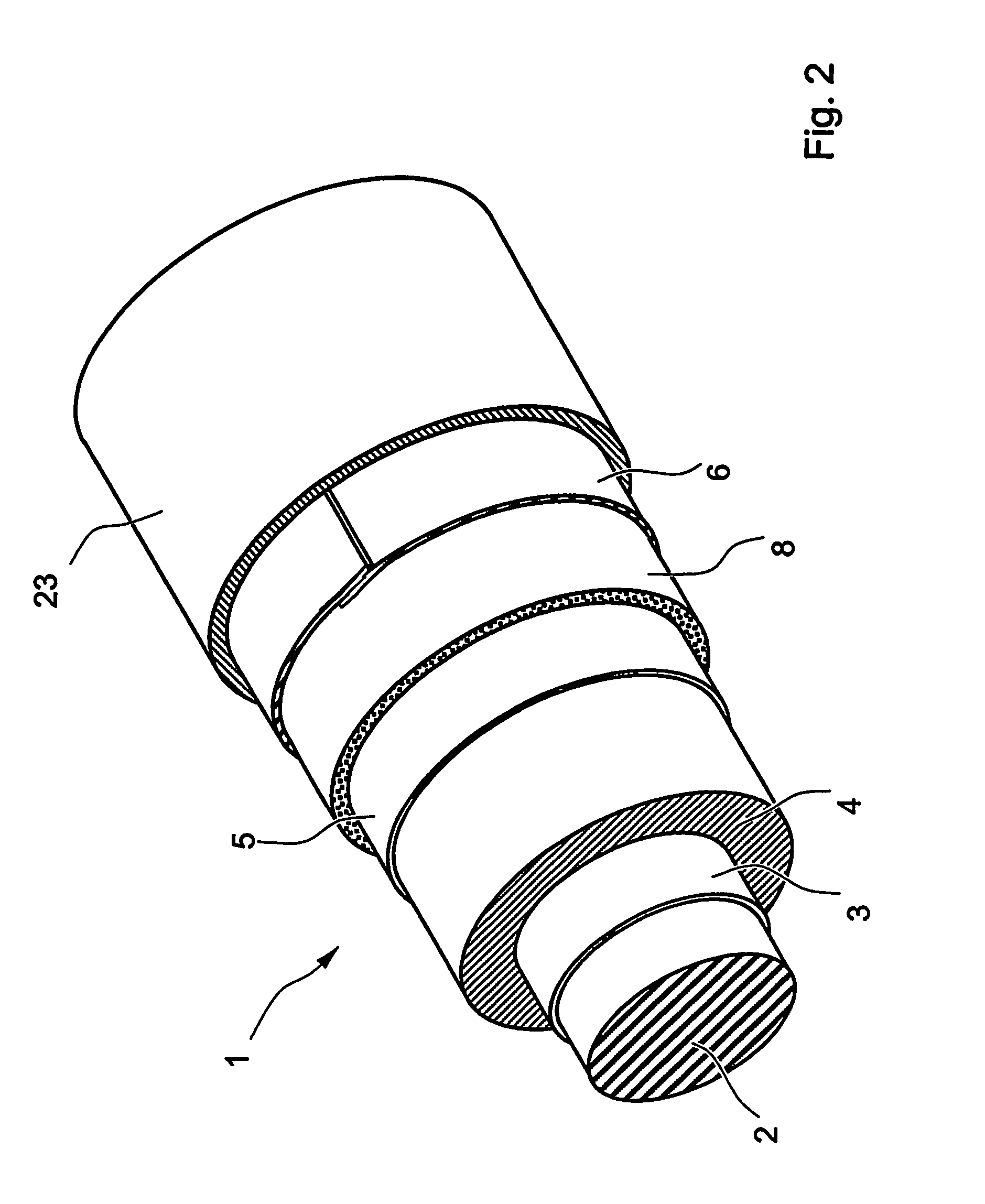

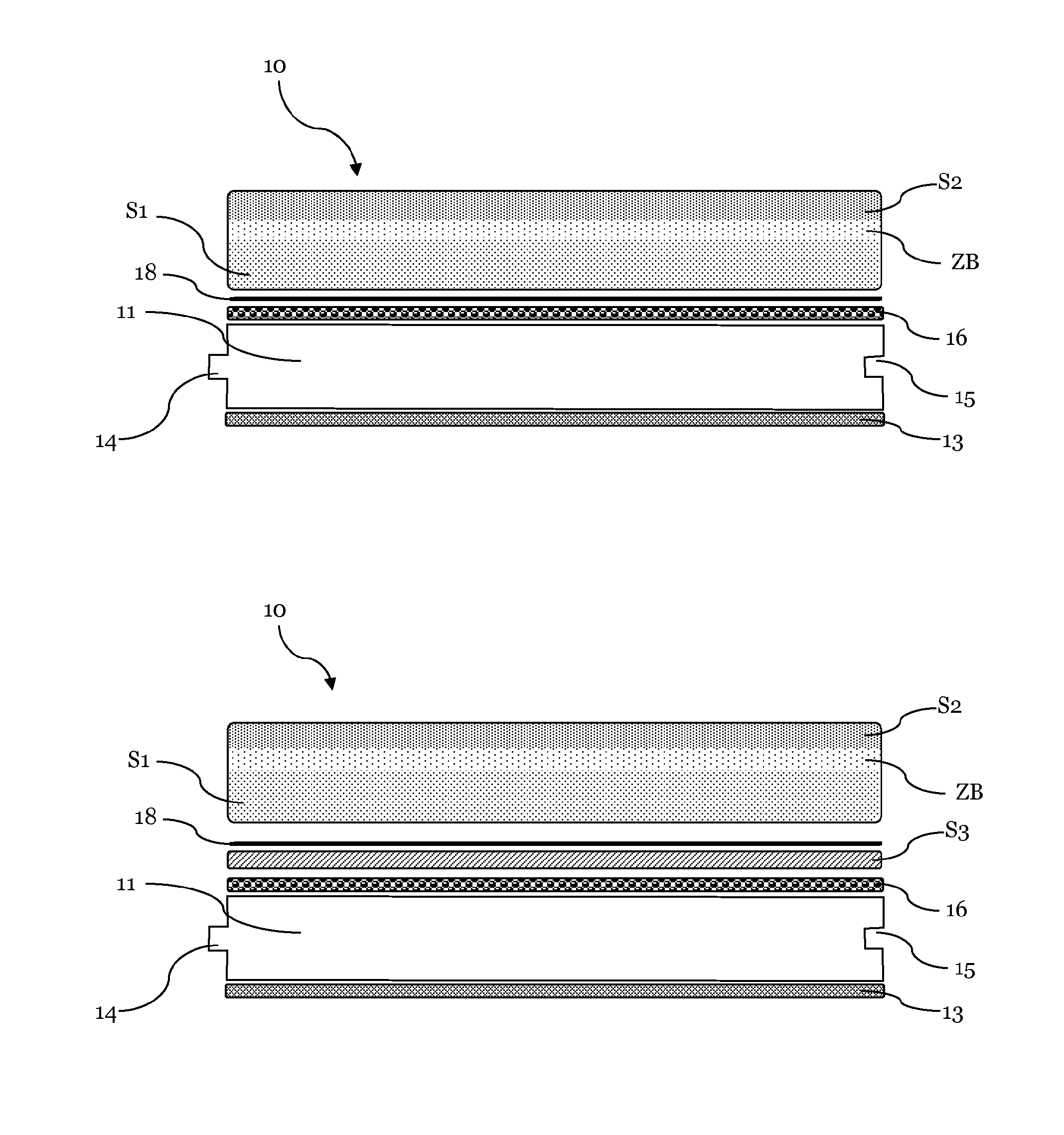

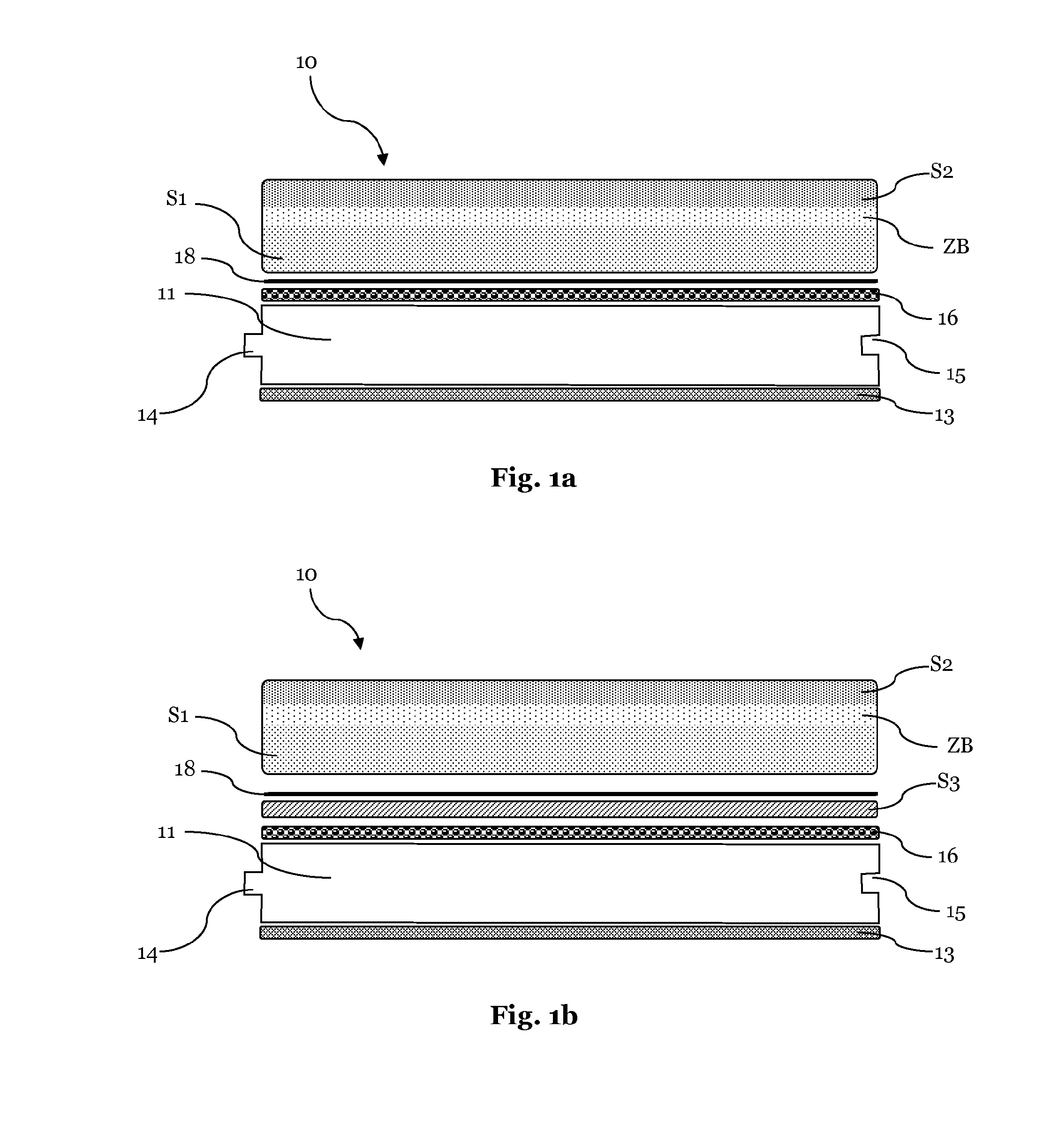

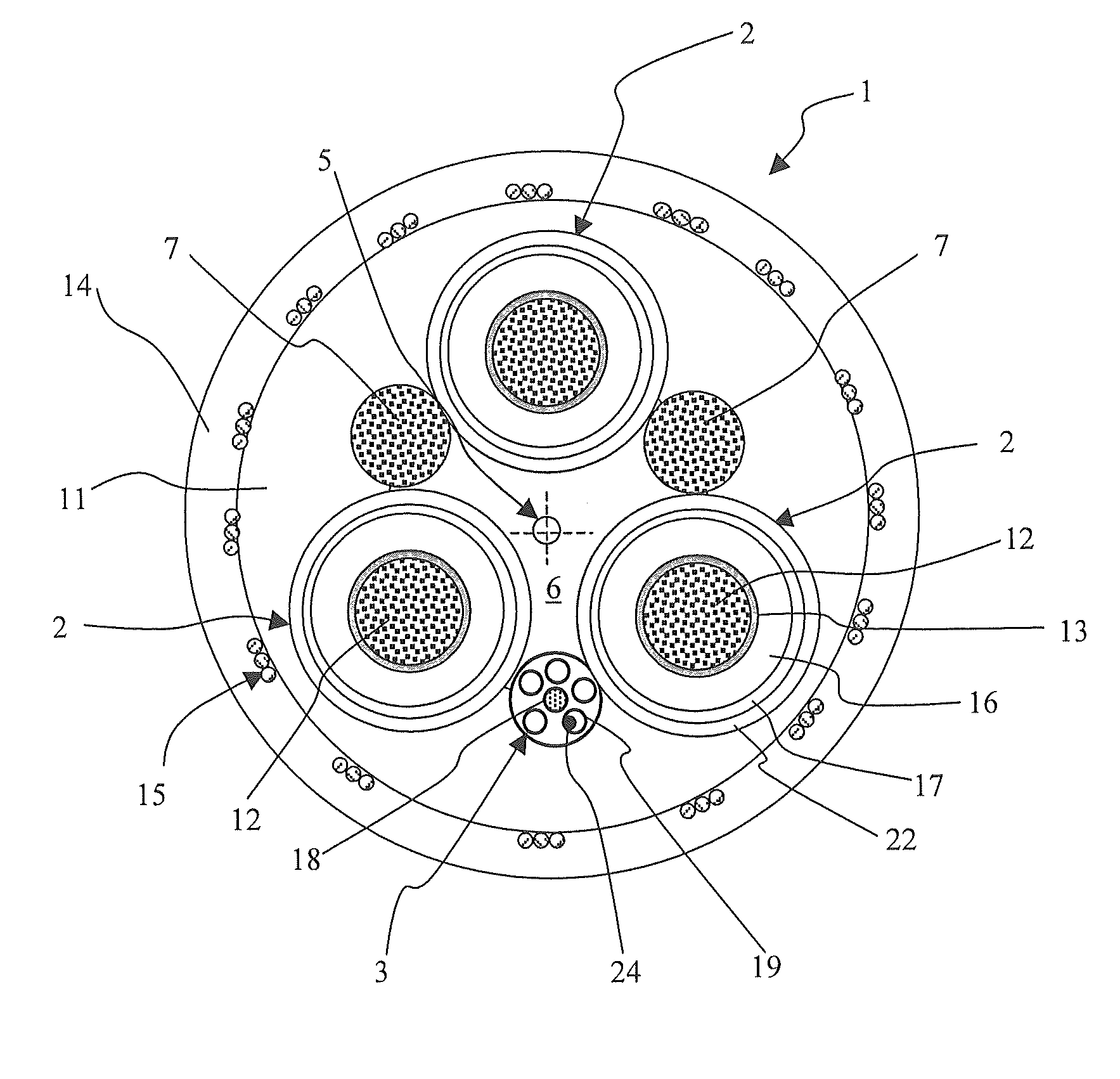

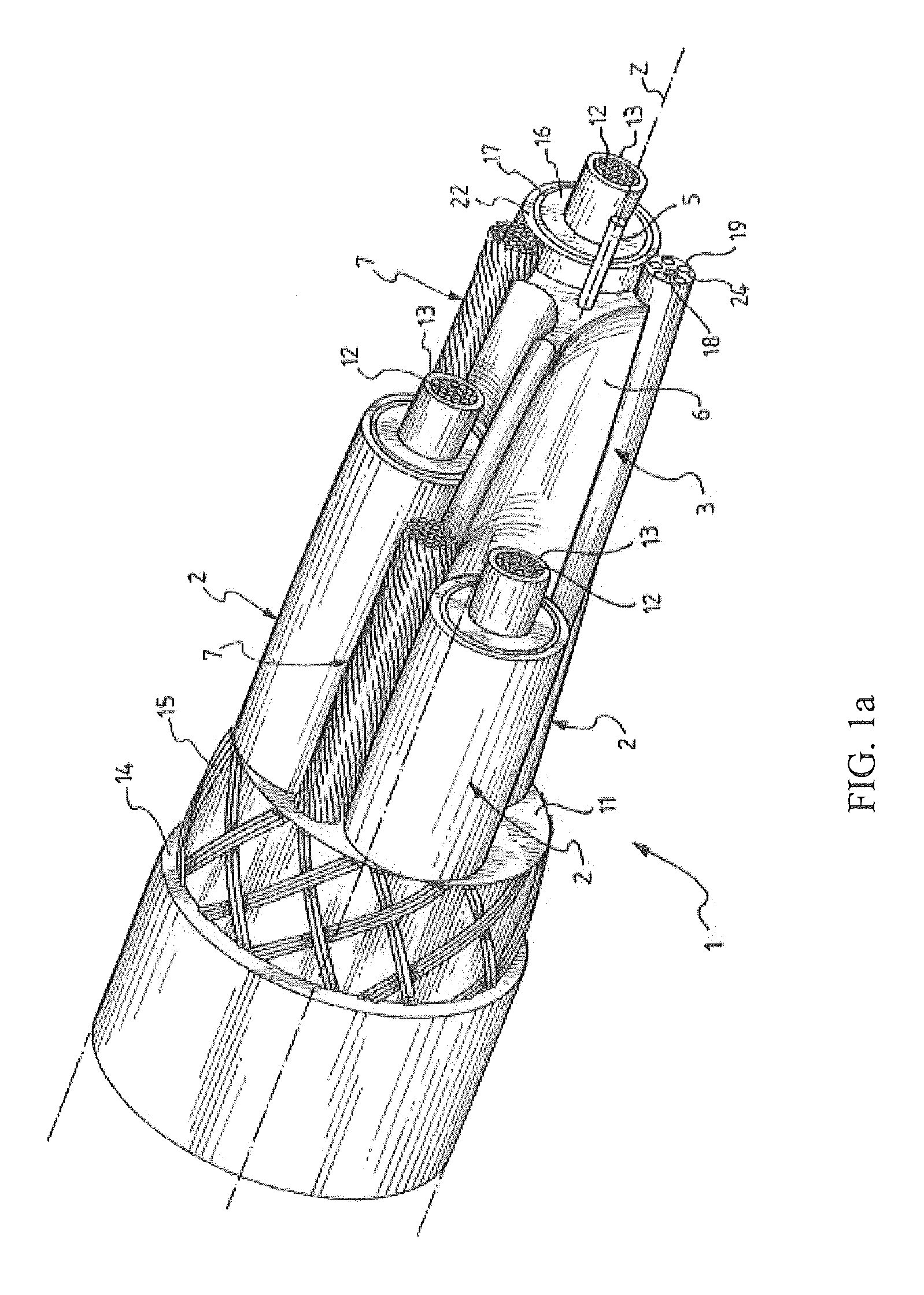

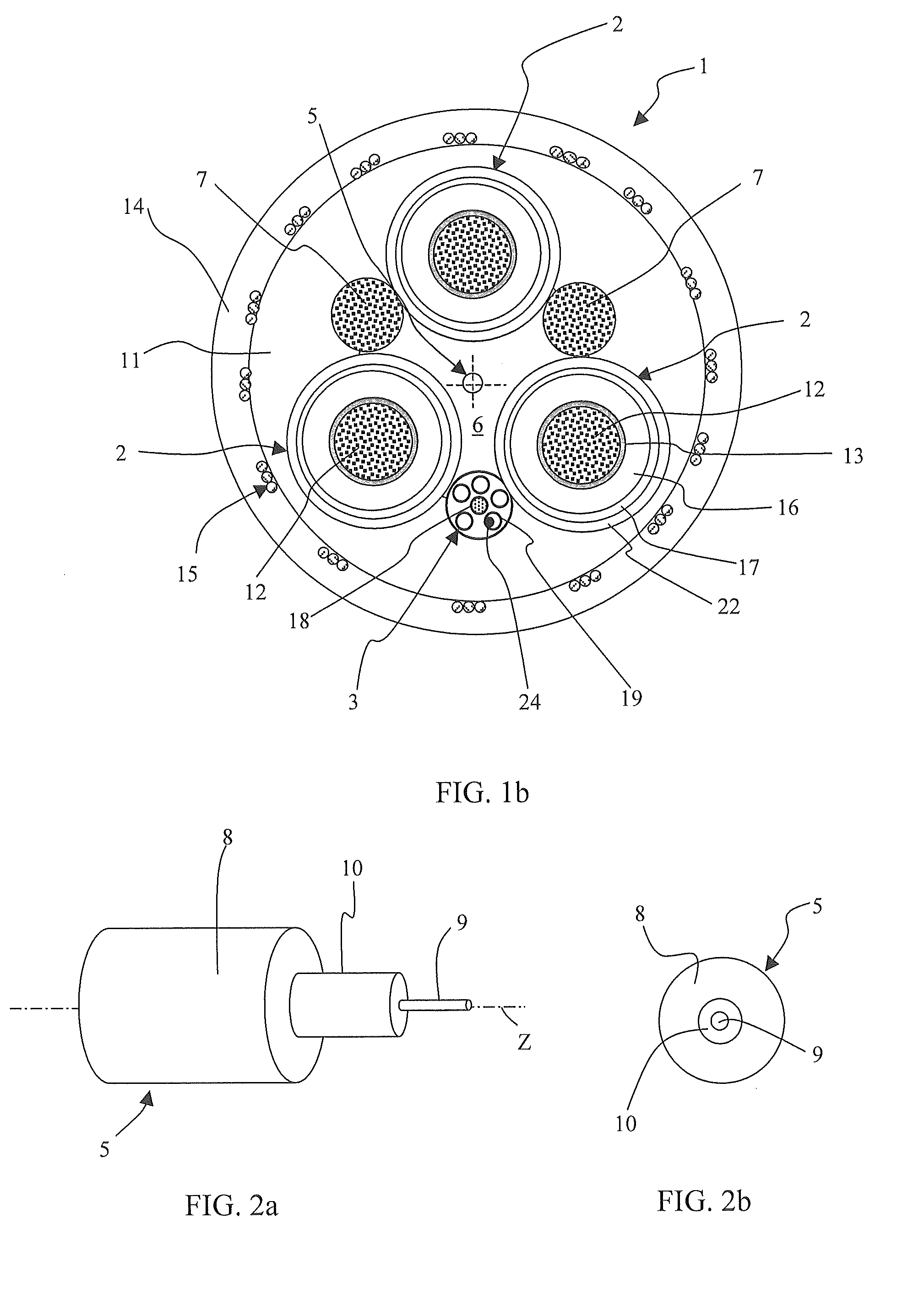

Electric cable with strain sensor and monitoring system and method for detecting strain in at least one electric cable

ActiveUS20120082422A1Effective periodic maintenanceHigh mechanical stressControlForce measurement by measuring optical property variationElectrical conductorMonitoring system

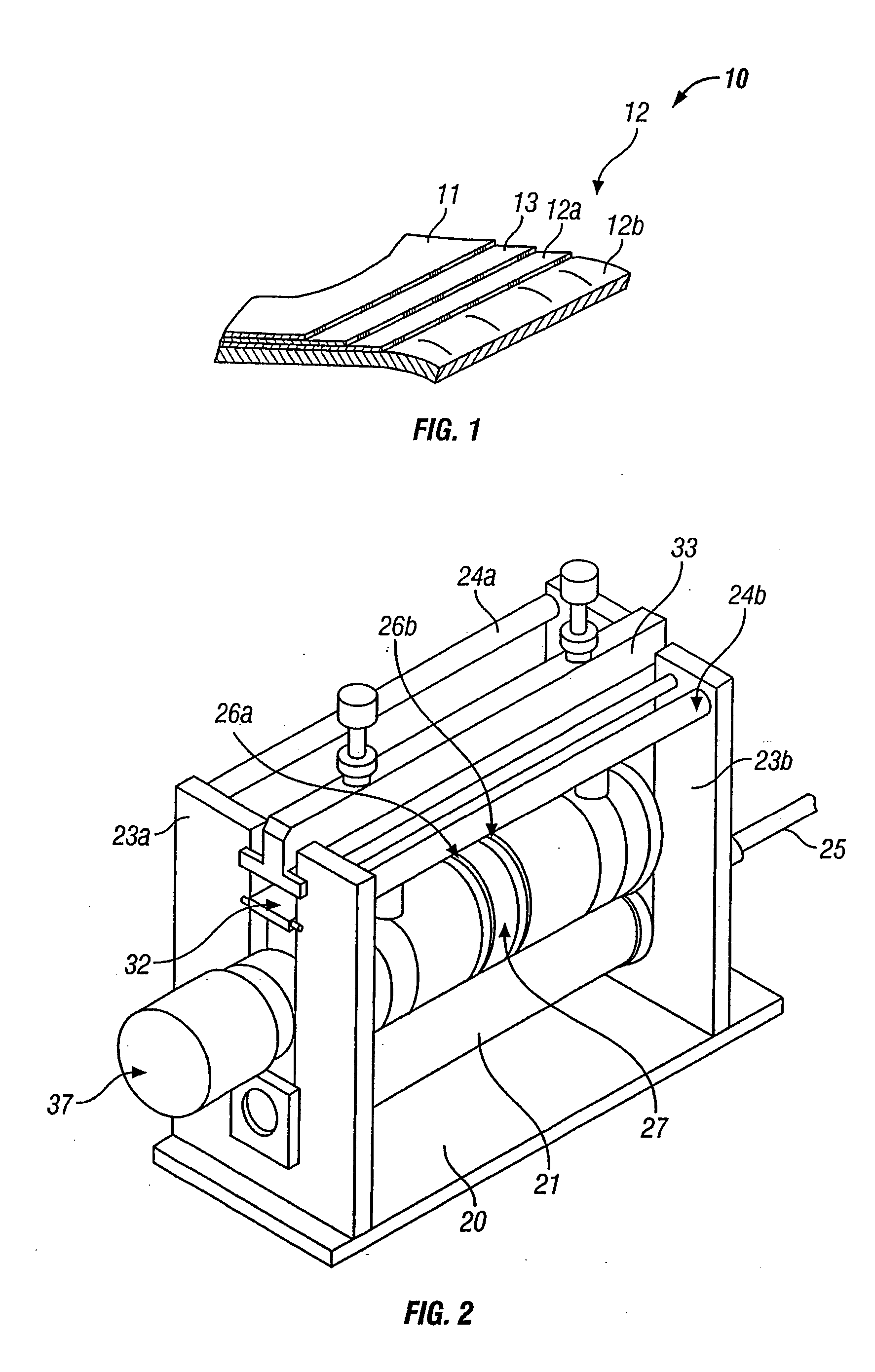

An electric cable includes a strain sensor longitudinally extending along the cable and including a strain optical fibre arranged within a bending neutral region surrounding and including a bending neutral longitudinal axis of the electric cable, and at least two longitudinal structural elements, at least one of the at least two longitudinal structural elements being a core including an electrical conductor, wherein the strain sensor is embedded in a strain-transferring filler mechanically coupling at least one of the at least two longitudinal structural elements with the strain sensor. With the disclosed cable construction, the strain experienced by the at least one of the at least two longitudinal structural elements is transferred to the strain sensor at least in a strained condition. In the preferred embodiments, the electric cable is a heavy-duty cable.

Owner:PRYSMIAN SPA

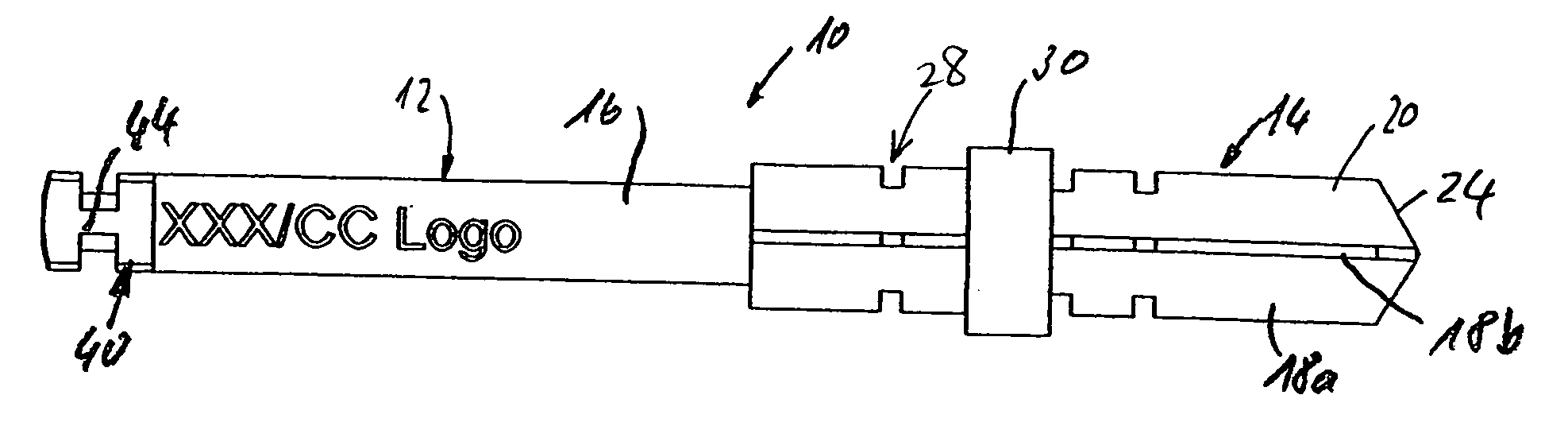

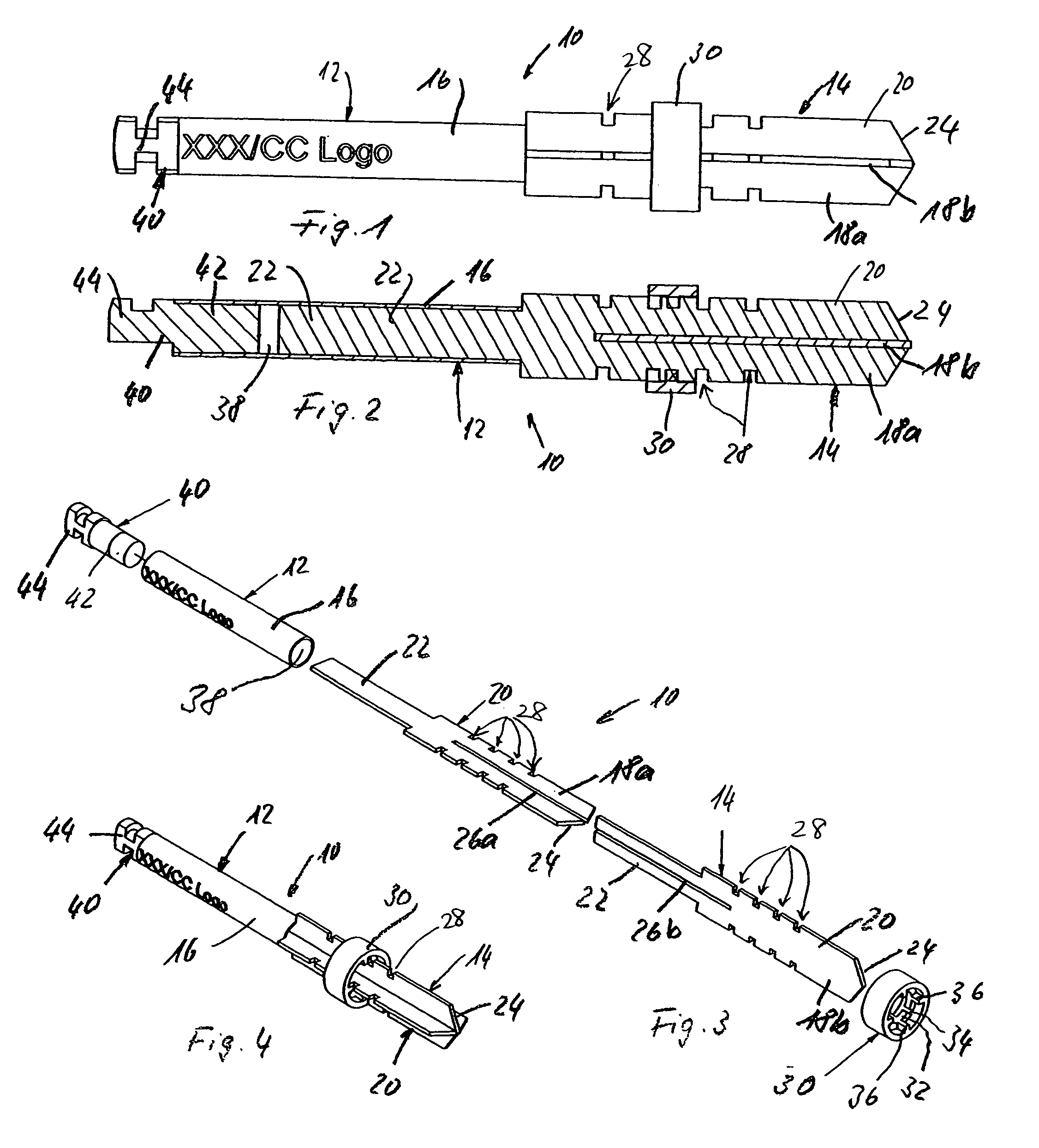

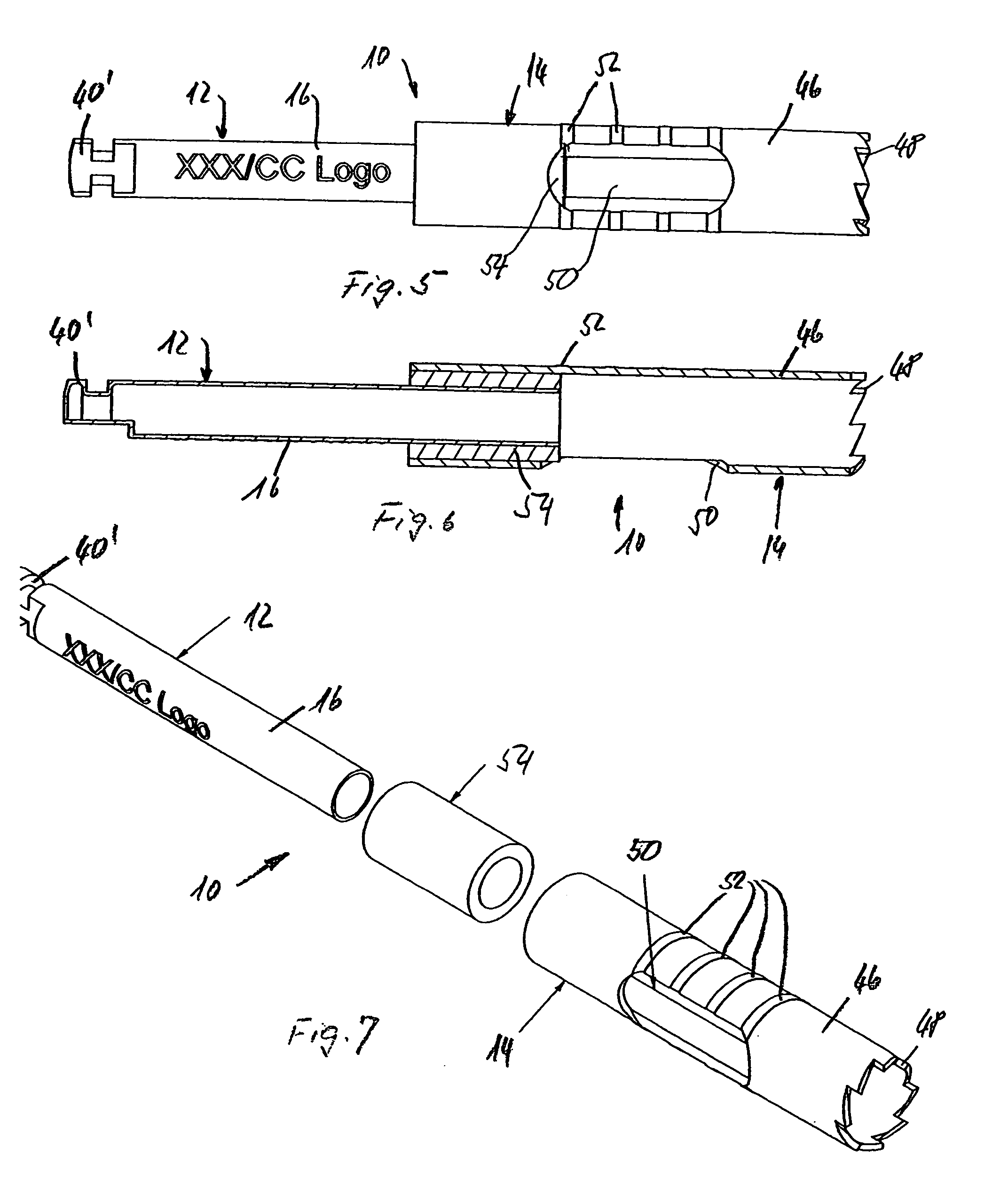

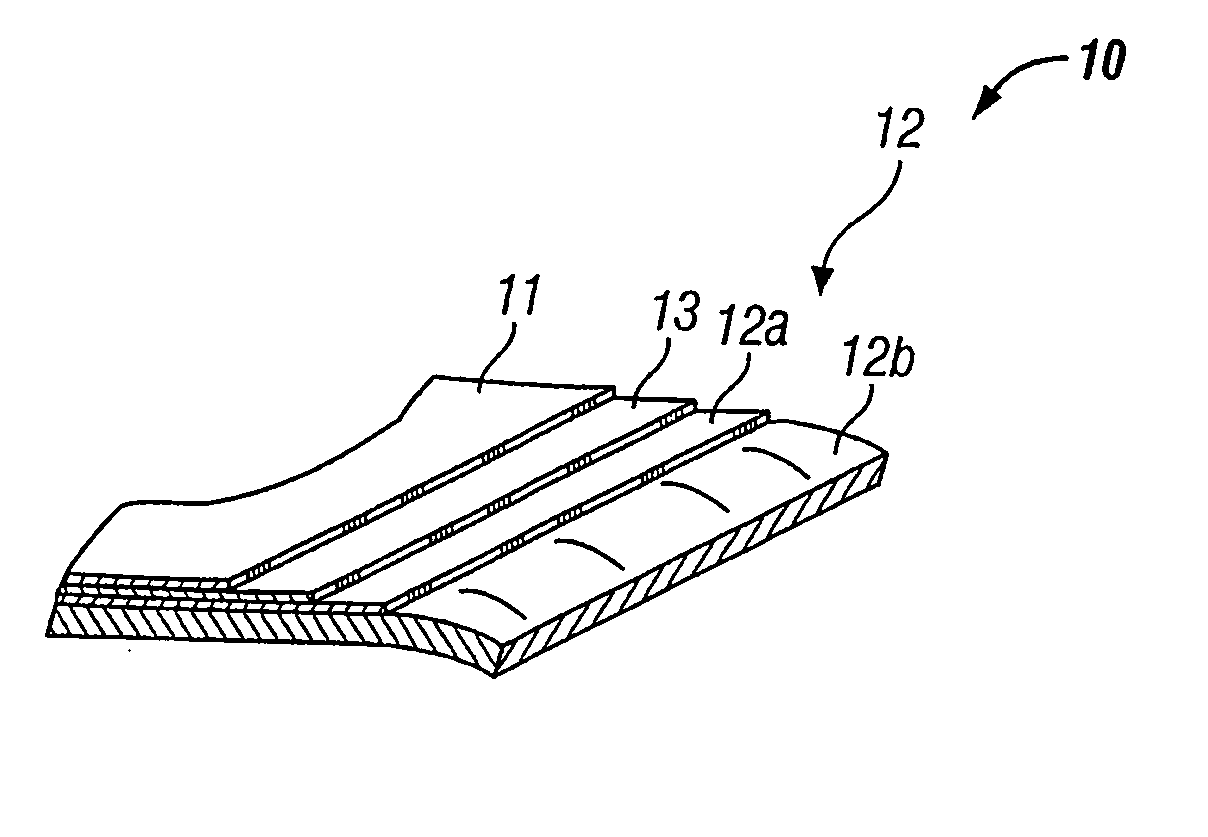

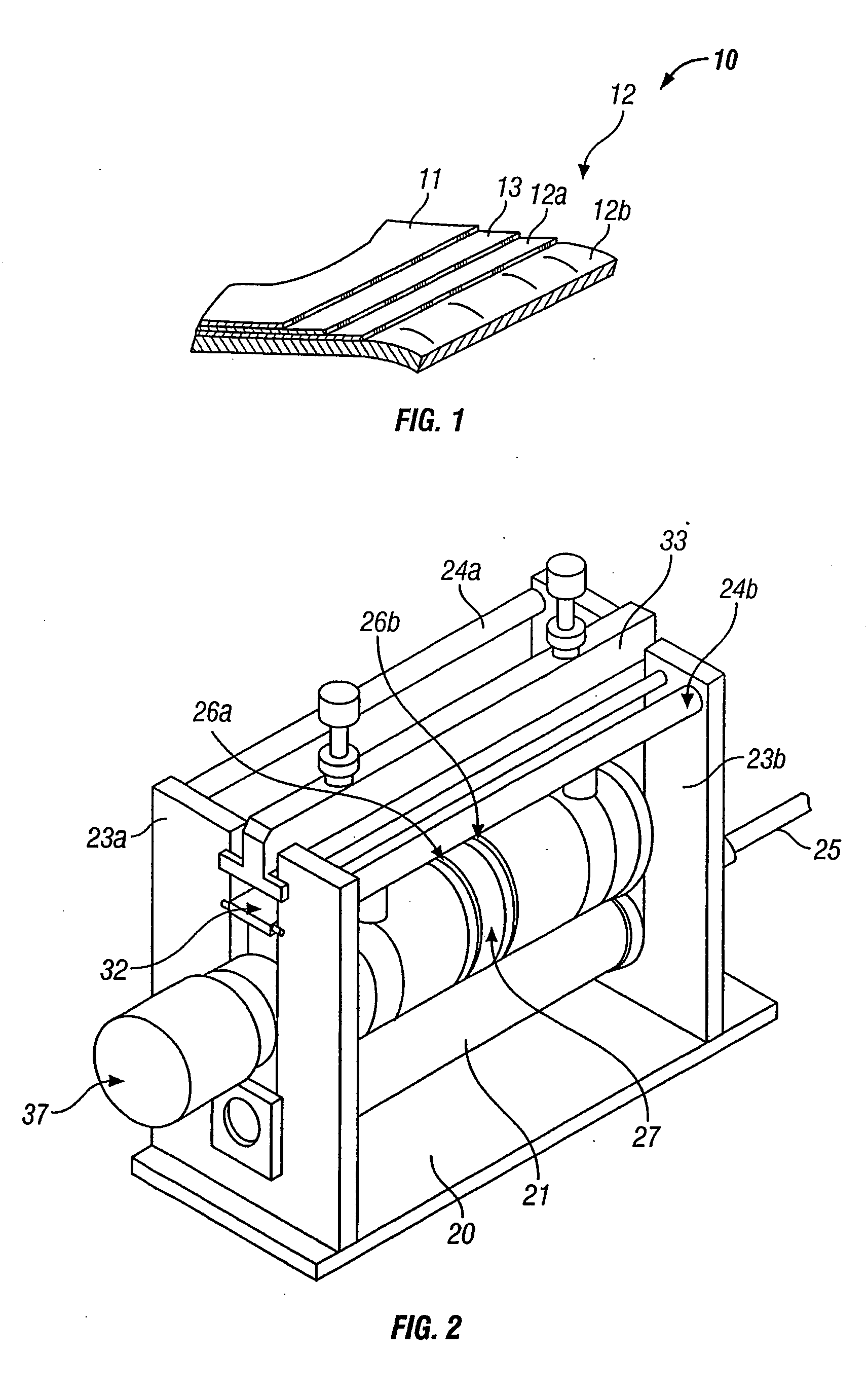

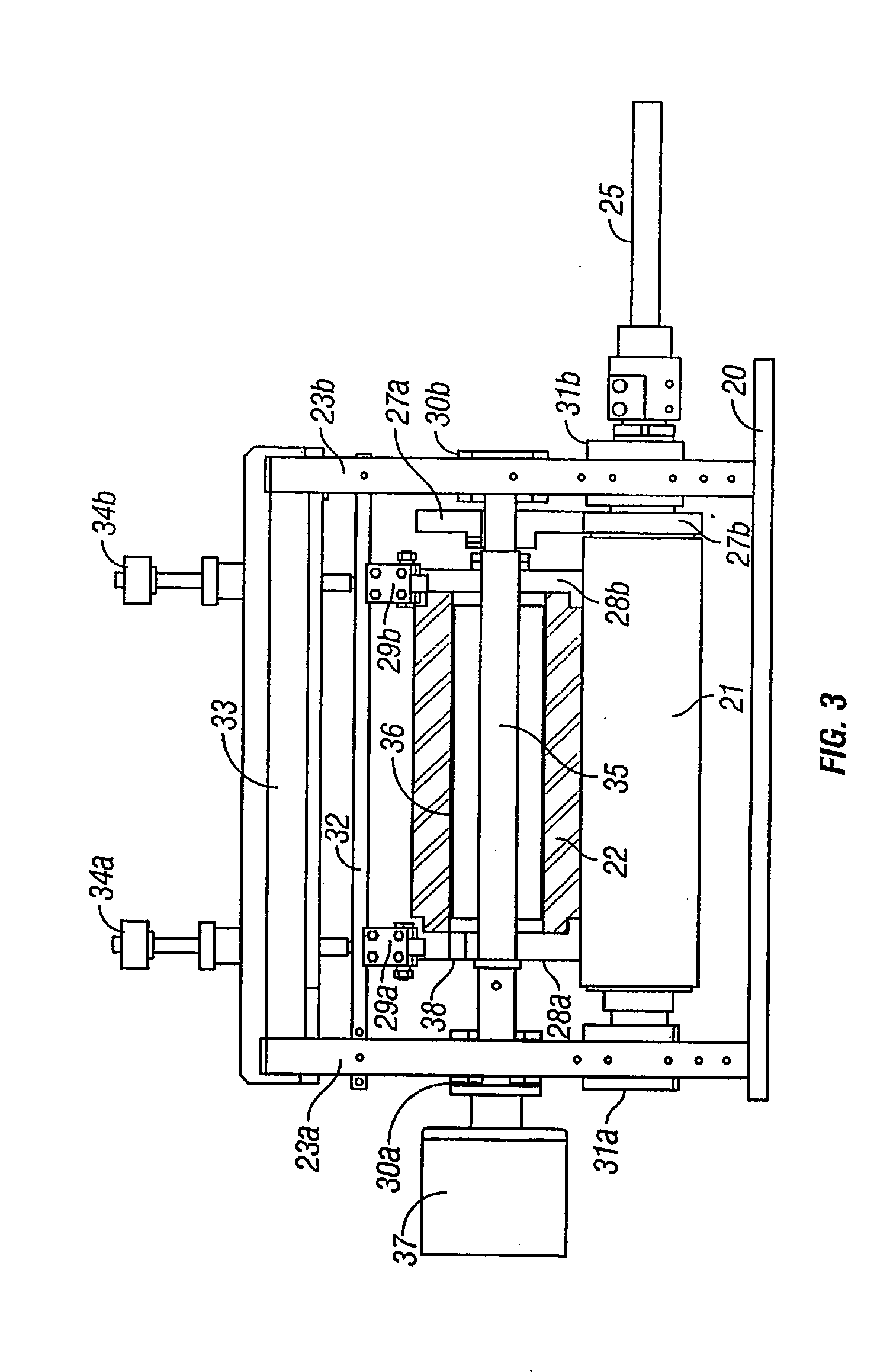

Method for manufacturing disposable rotary cutting tools and disposable rotary tool for dental or medical applications

InactiveUS20060008771A1Low costSafe and reliableDental implantsDrilling/boring measurement devicesEngineeringMedical treatment

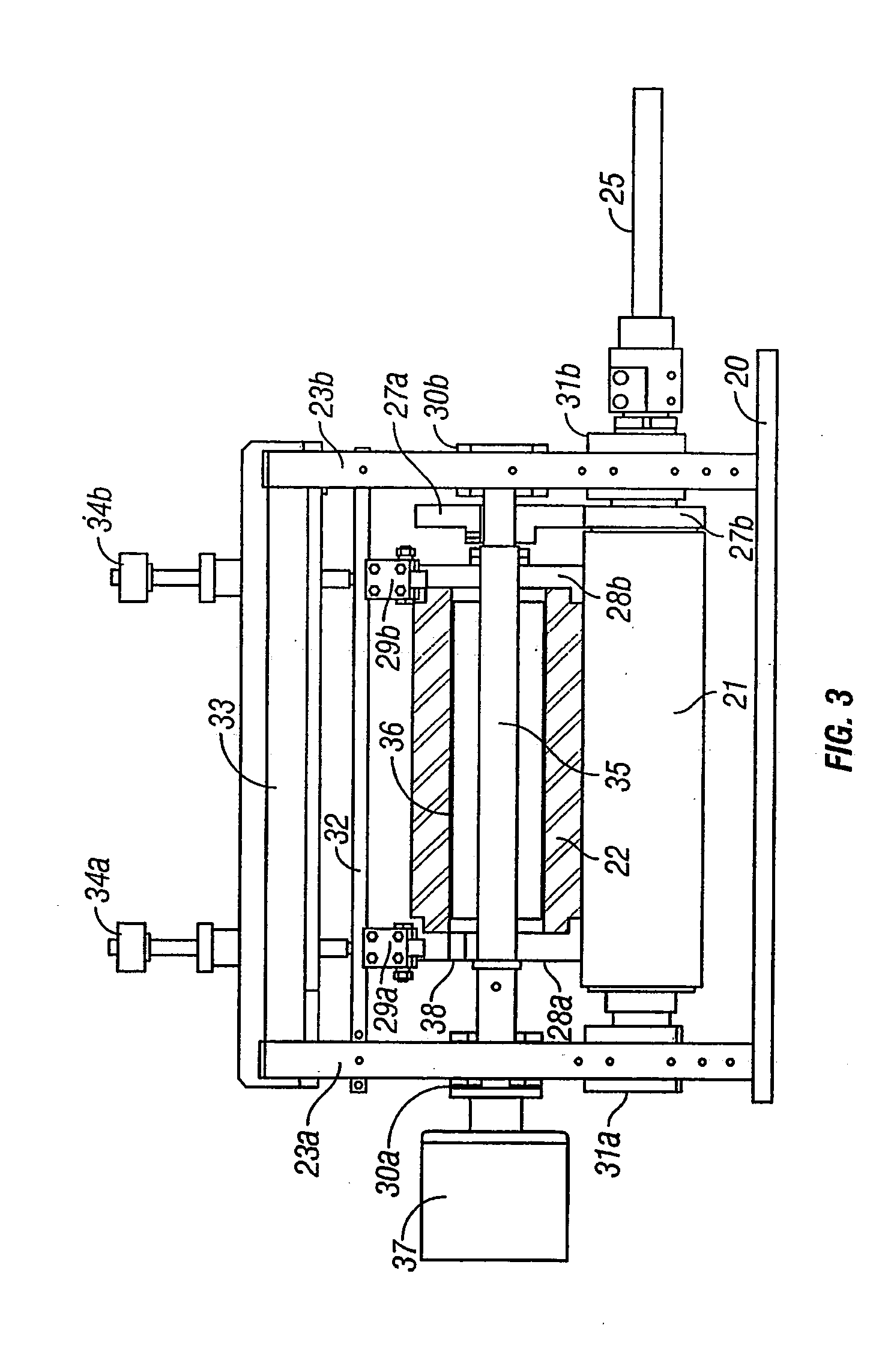

The shank (12) of a disposable rotary cutting tool (10) comprises a pipe section (16) cut from a drawn metal pipe. The tool head (14) is formed from a cut-out (18a, 18b) of a drawn metal sheet or a section of a metal tube by non-cutting machining. The pipe section (16) and the tool head (14) are advantageously attached by force fitting.

Owner:STRAUMANN HLDG AG

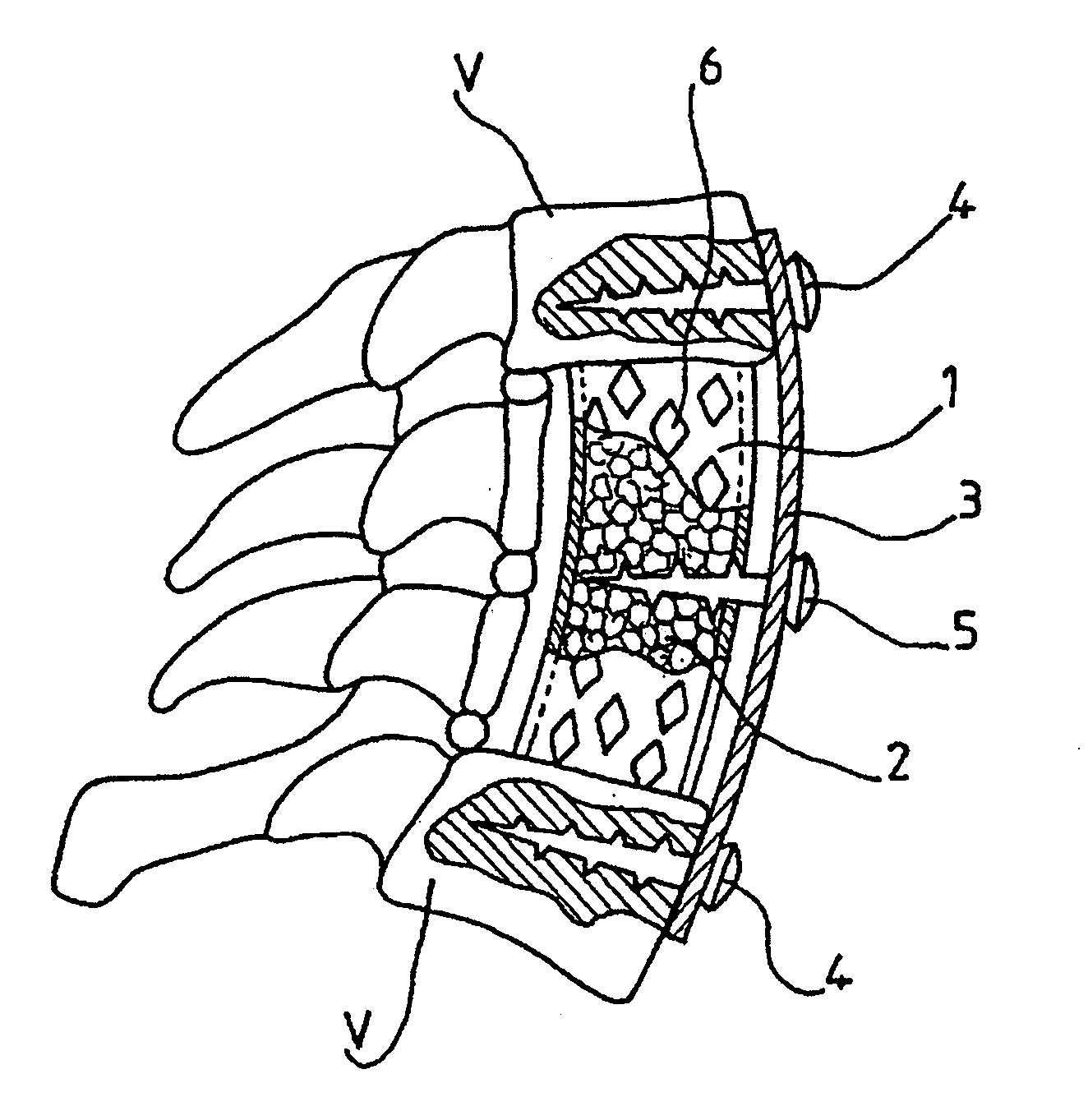

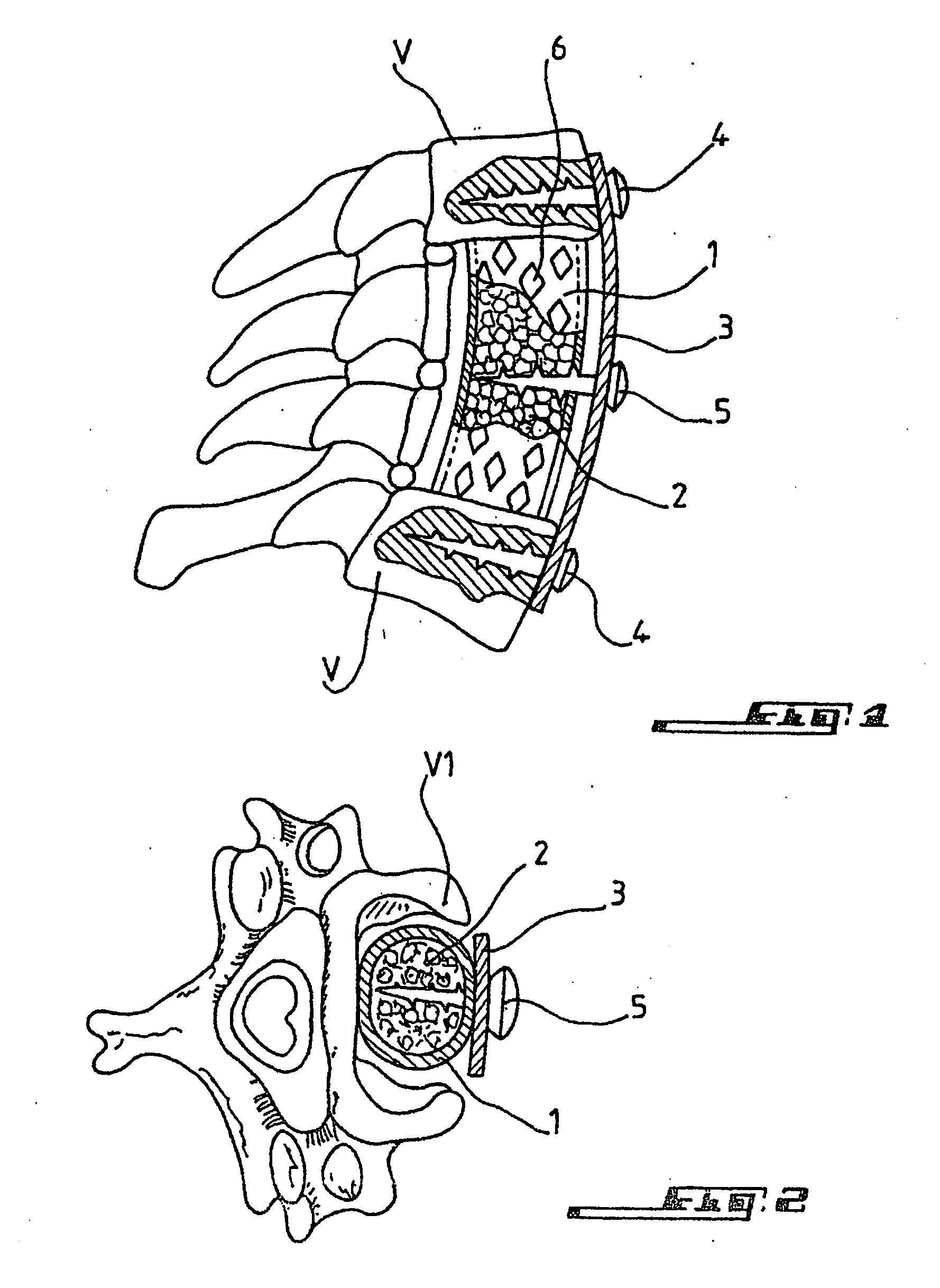

Method for repairing bone

InactiveUS20070073401A1Good mechanical resistanceInternal osteosythesisBone implantBone chamberBiomedical engineering

A method for repairing bone in a bone cavity delimited by healthy bone faces, and from which traumatized bone has been excised, comprises adjusting a flexible, biocompatible mesh fabric tube to fit the bone cavity and contact the healthy bone faces and filling the mesh tube with a bone graft. A bioresorbable coating is applied to the tube to rigidify the tube having been adjusted in shape to fit the bone cavity. The coating seals the mesh against graft movement through the mesh of the tube until the bioresorbable coating has been resorbed. The tube is inserted within the bone cavity and the coating is resorbed to allow the graft to pass from the interior of the tube, through the mesh, to the healthy bone faces.

Owner:COUSIN BIOTECH R L

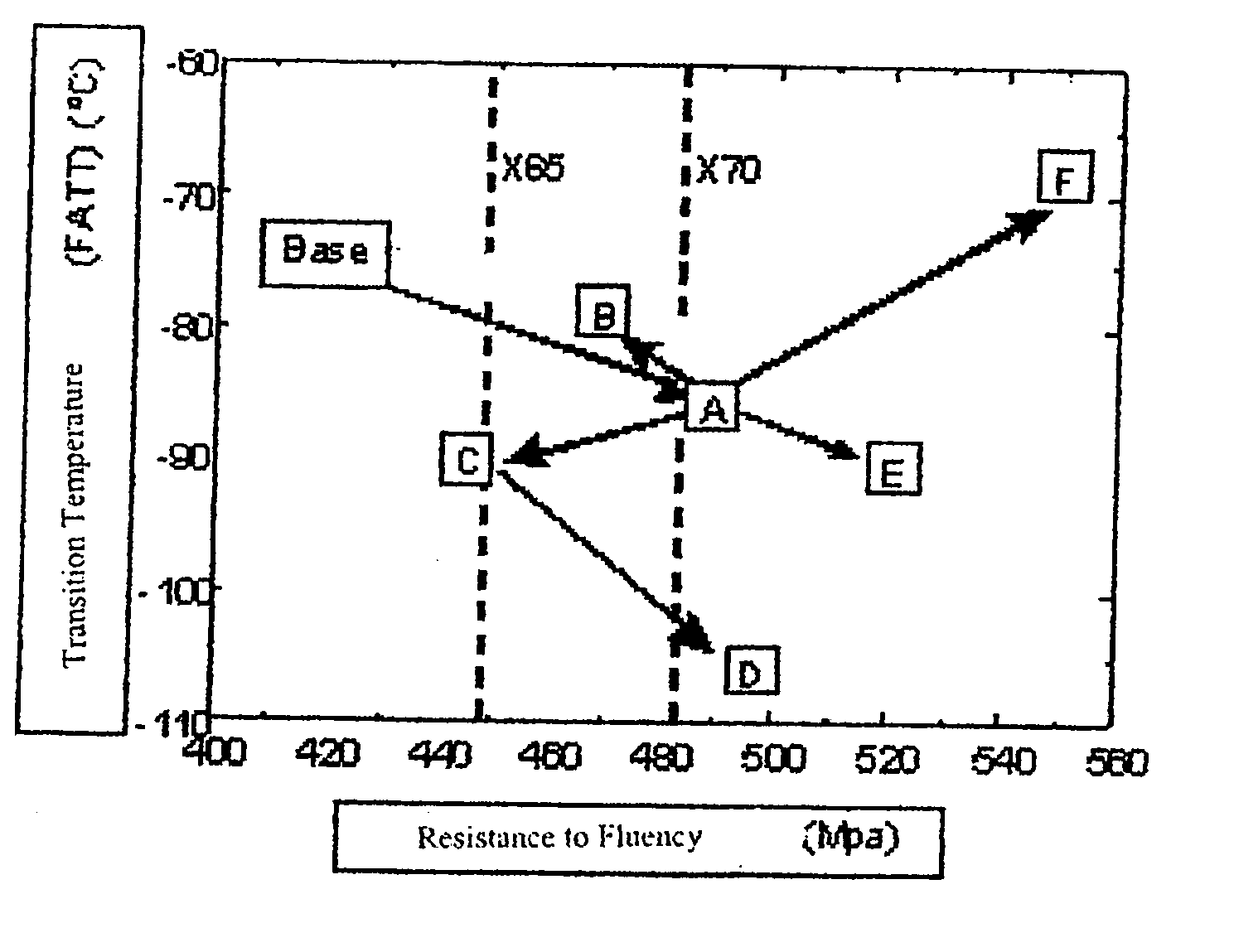

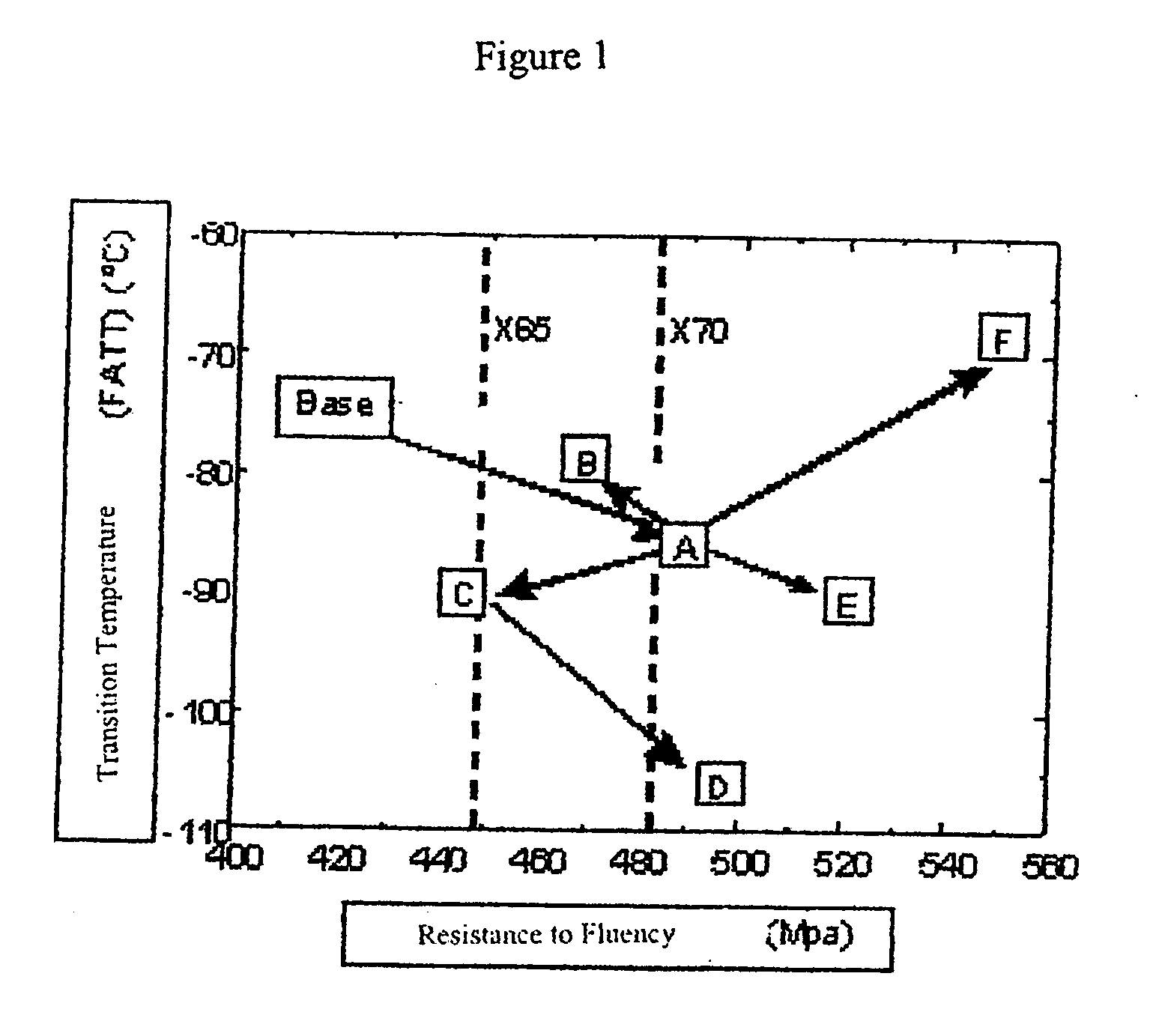

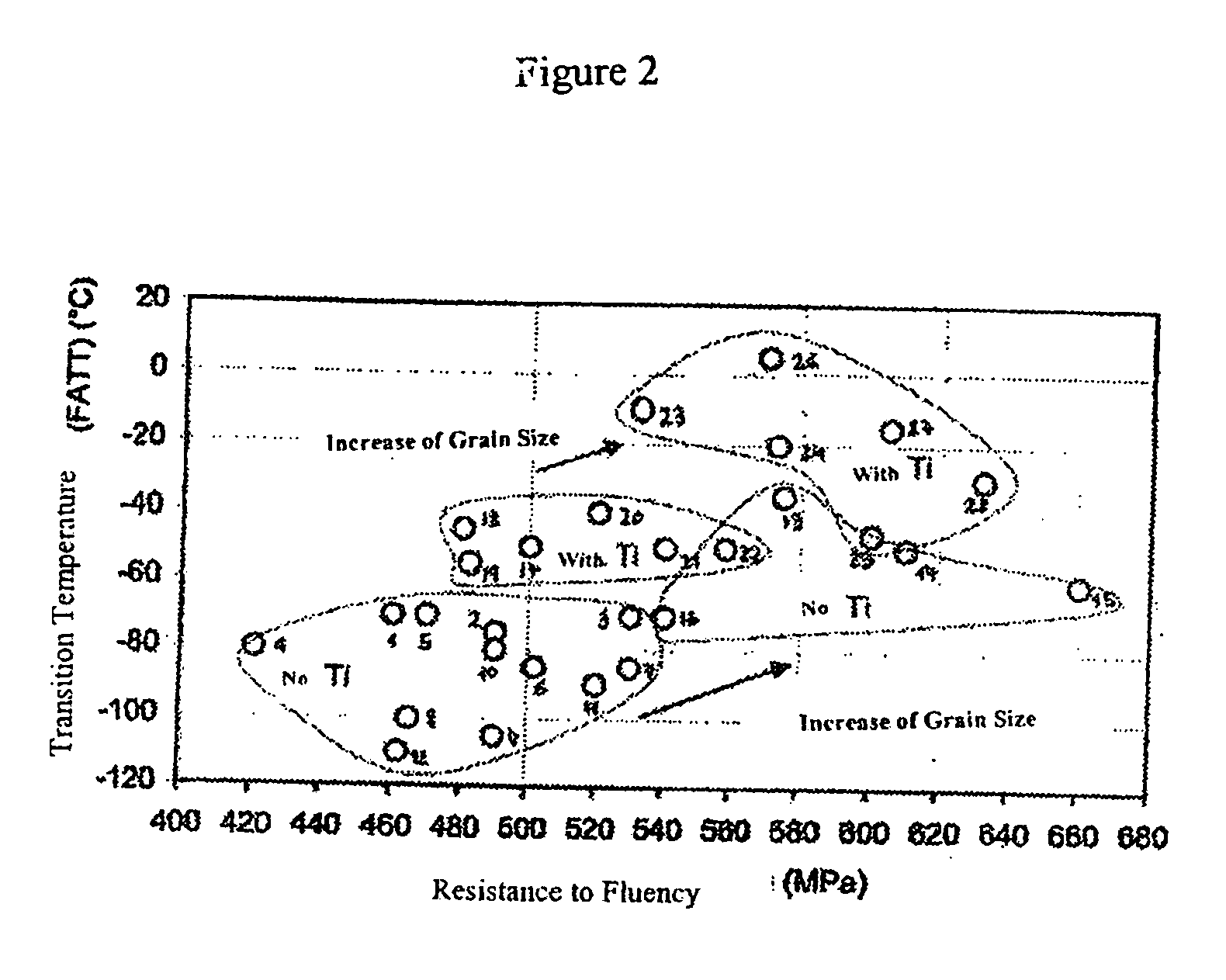

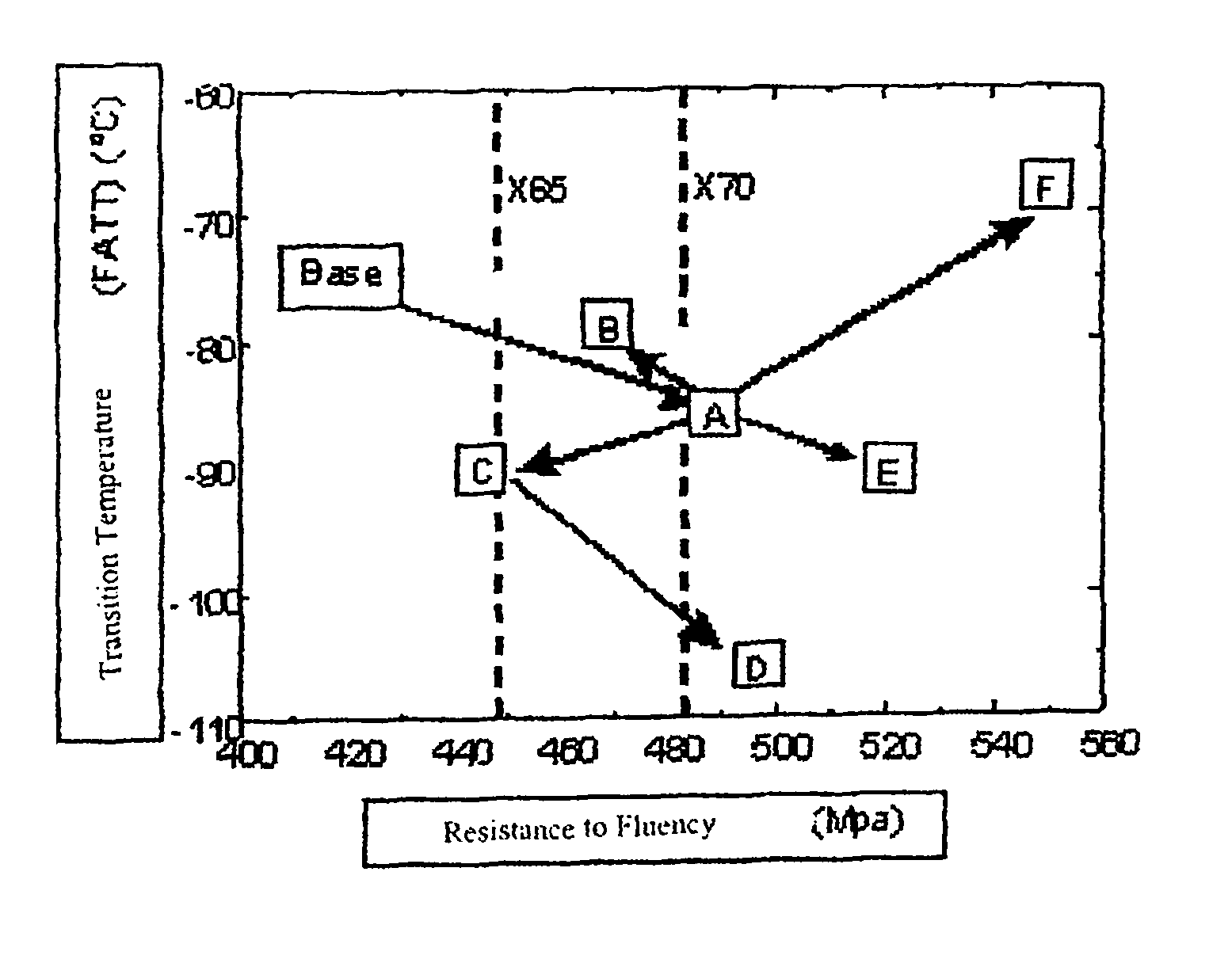

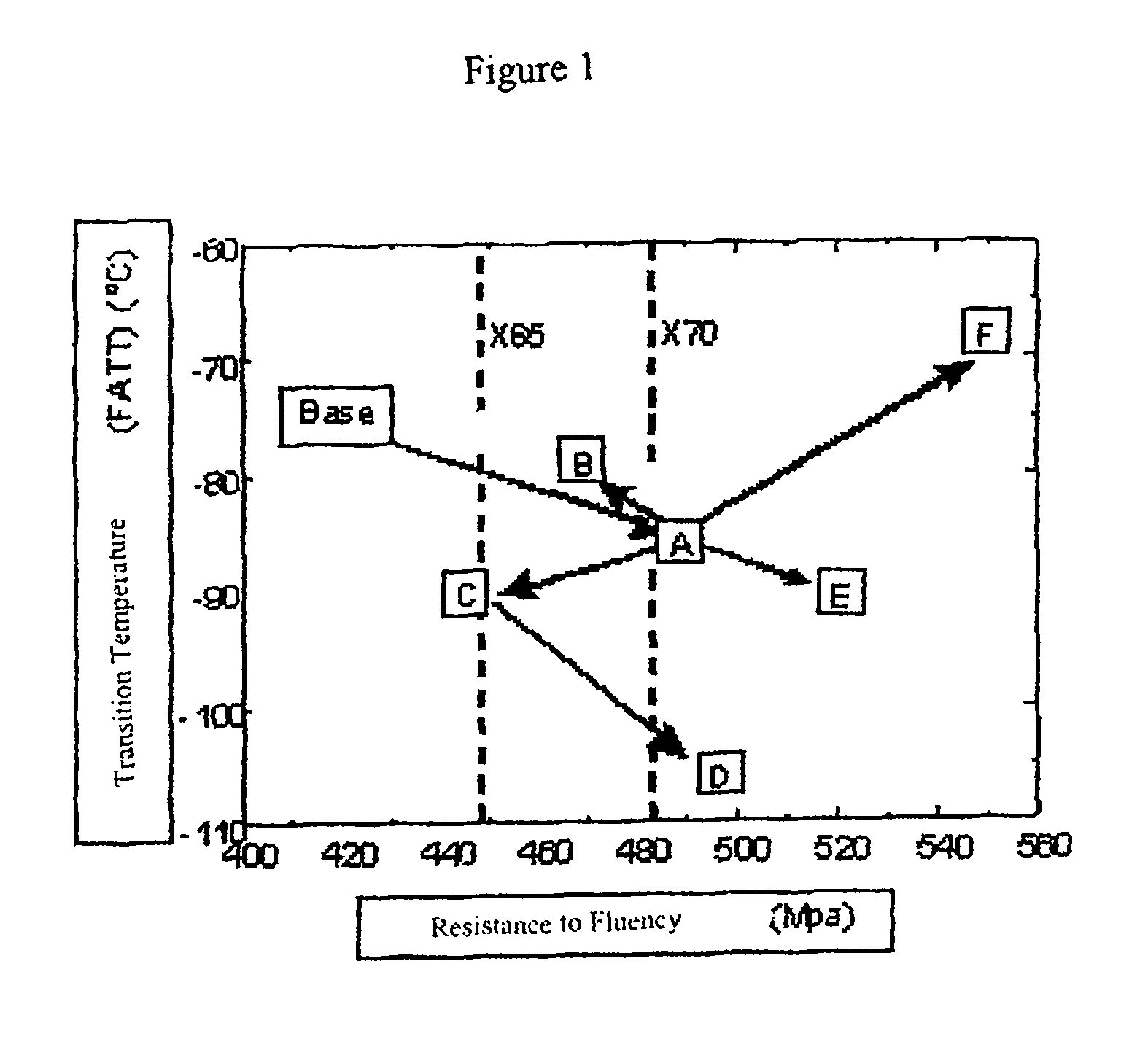

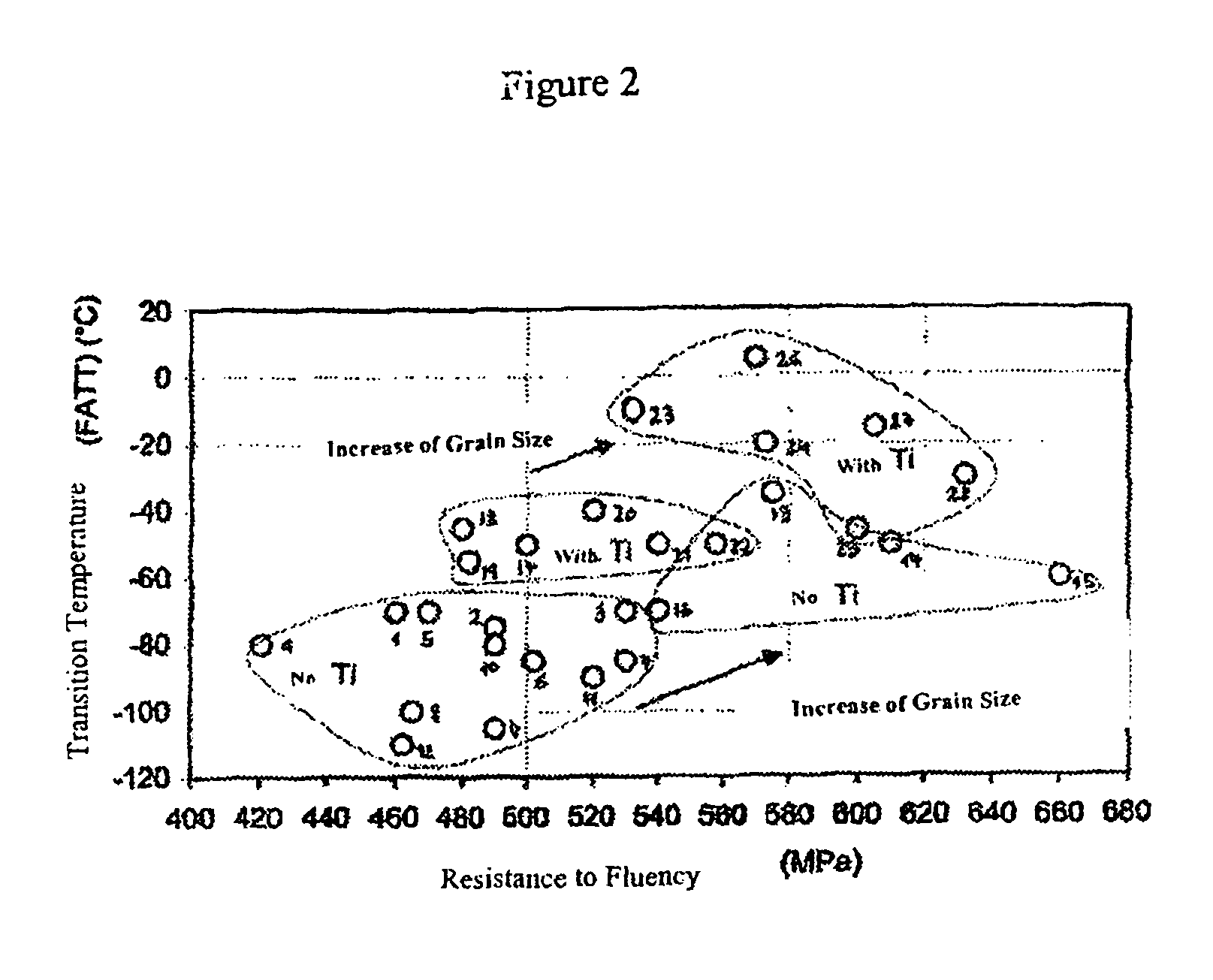

Seamless steel tube which is intended to be used as a guide pipe and production method thereof

ActiveUS20070089813A1High mechanical resistanceHardenability is lowFurnace typesHeat treatment furnacesSteel tubeCorrosion

The present invention pertains to steel with high mechanical resistance at room temperature and up to 130° C., good toughness and good corrosion resistance in the metal base as well as good resistance to cracking in the heat affected zones (HAZ) once the tubing is welded together, and more specifically to heavy gauge seamless steel tubing with high mechanical resistance, good toughness and good corrosion resistance called catenary conduit. The advantages of the present invention with respect to those of the state of technology reside in providing a chemical composition for steel used to manufacture heavy gauge seamless steel tubing with high mechanical resistance, good toughness, good fissure resistance in the HAZ and good corrosion resistance and a process for manufacturing this product. These advantages are obtained by using a composition made up basically of Fe and a specific chemical composition.

Owner:TUBOS DE ACERO DE MEXICO +1

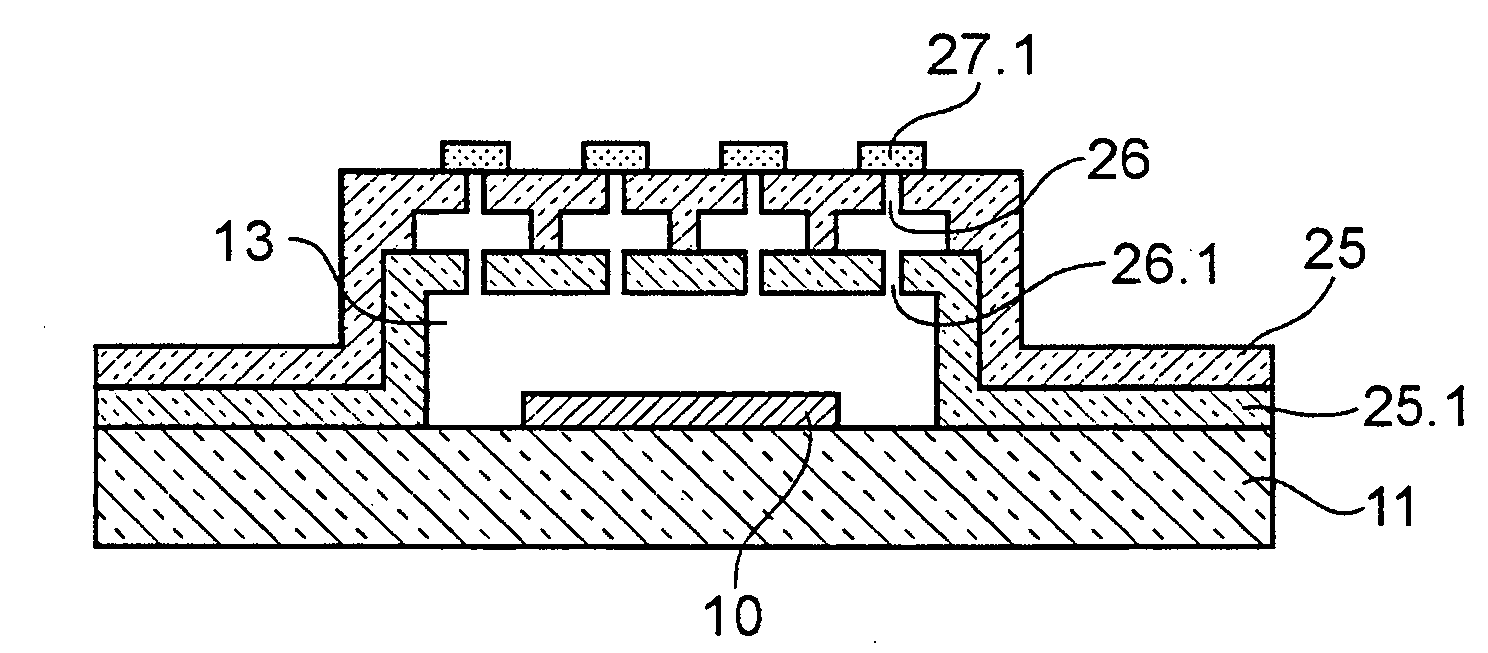

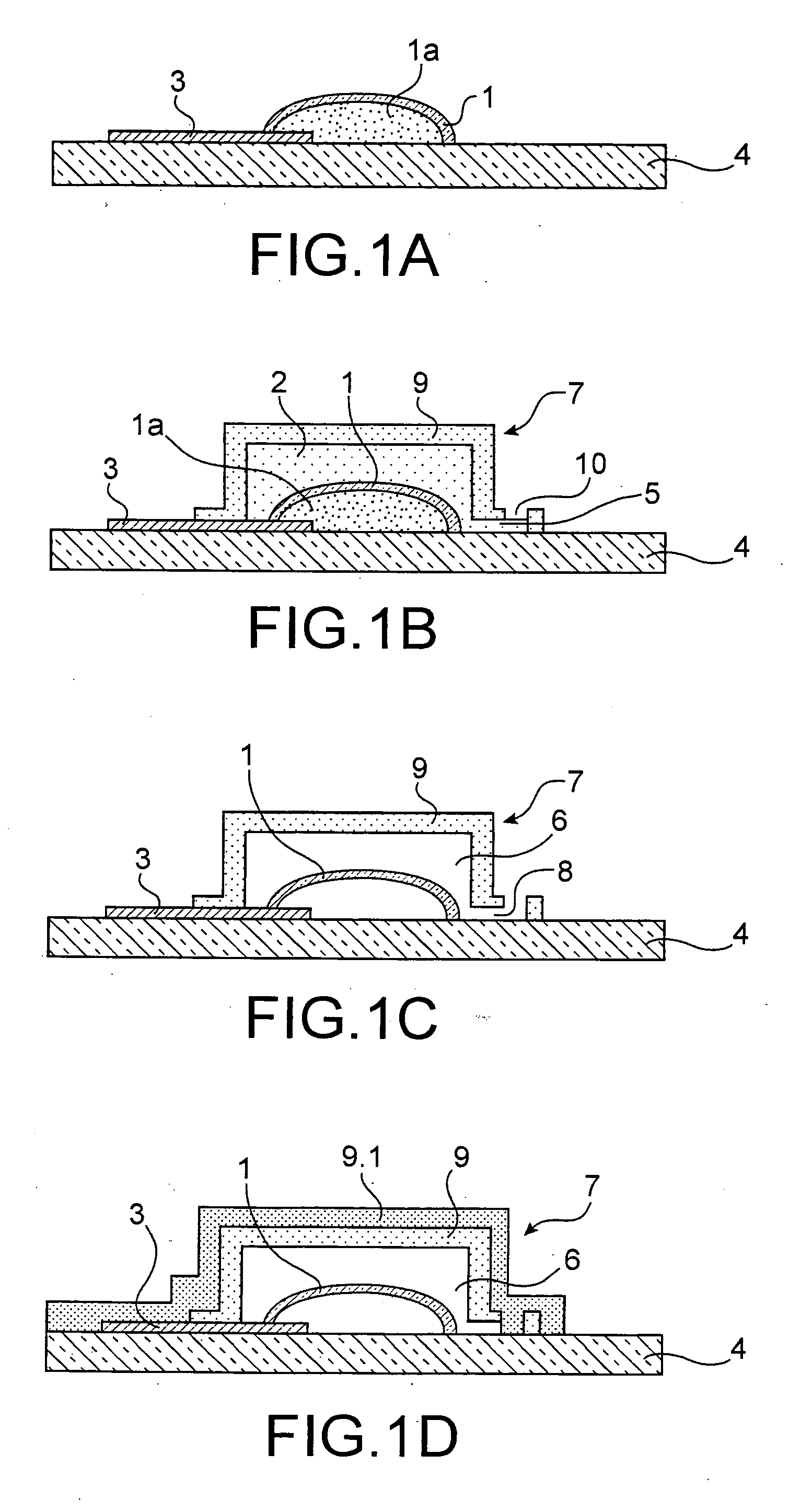

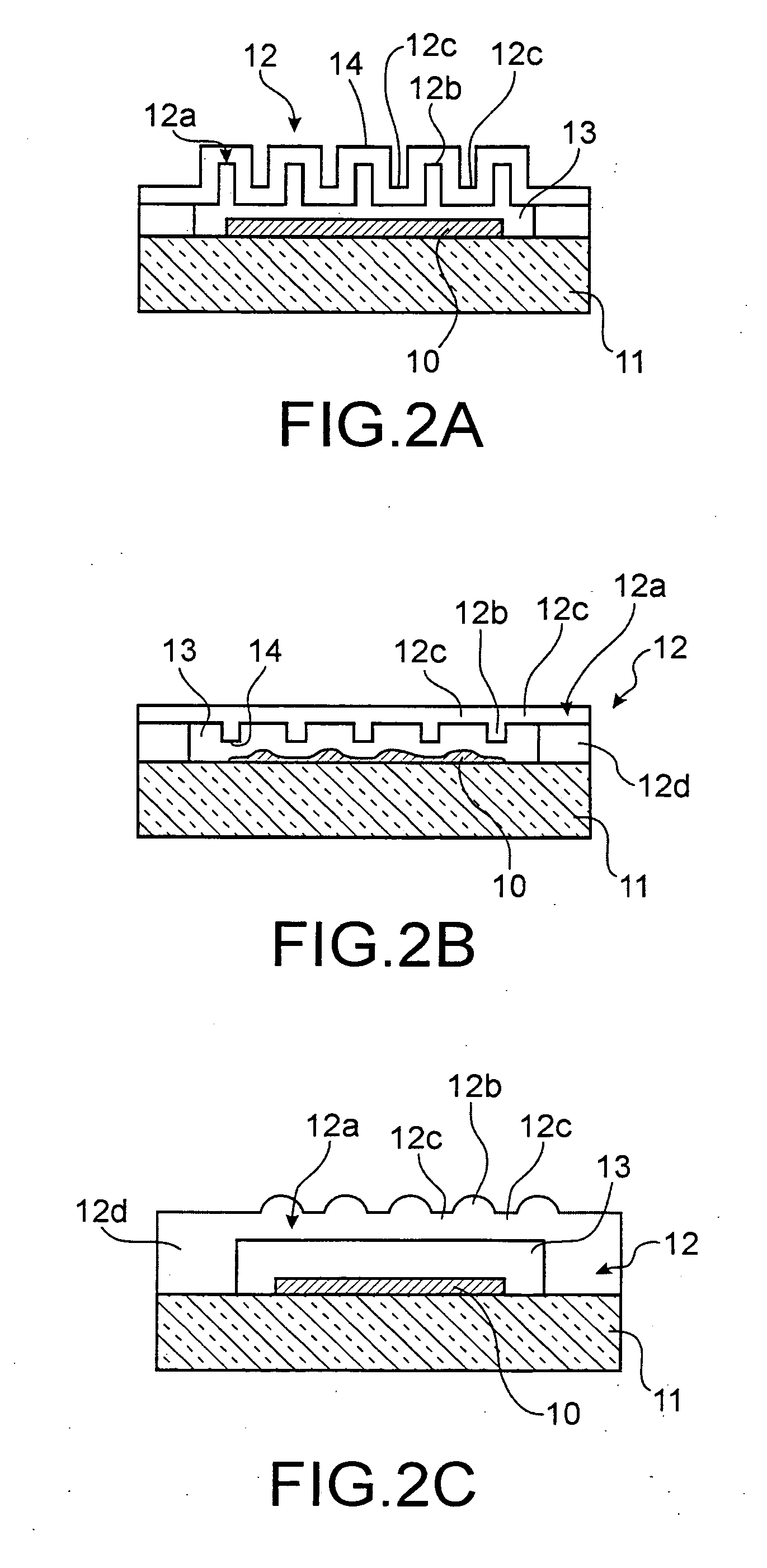

Microcomponent Provided with a Cavity Delimited by a Cap with Enhanced Mechanical Resistance

ActiveUS20090194309A1Easy to manufactureGood mechanical resistanceForming microstructural systemsPrinted circuit manufactureMechanical resistanceMechanical engineering

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

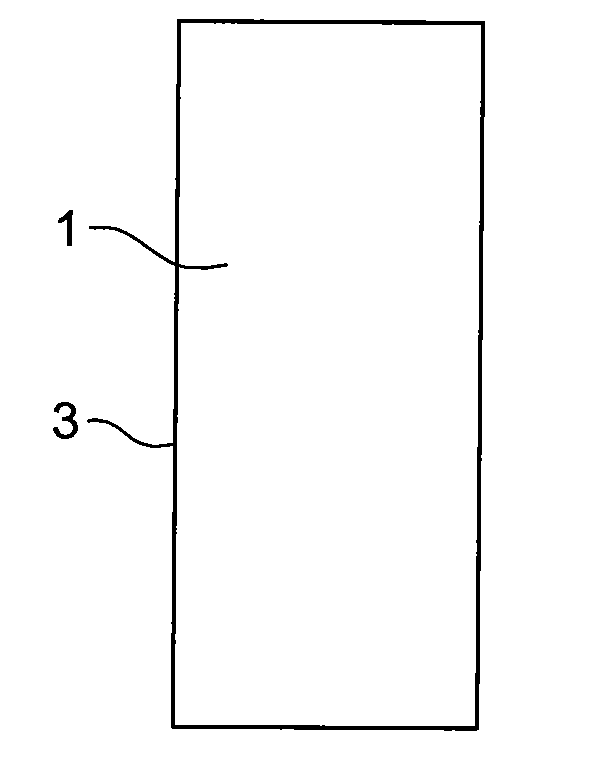

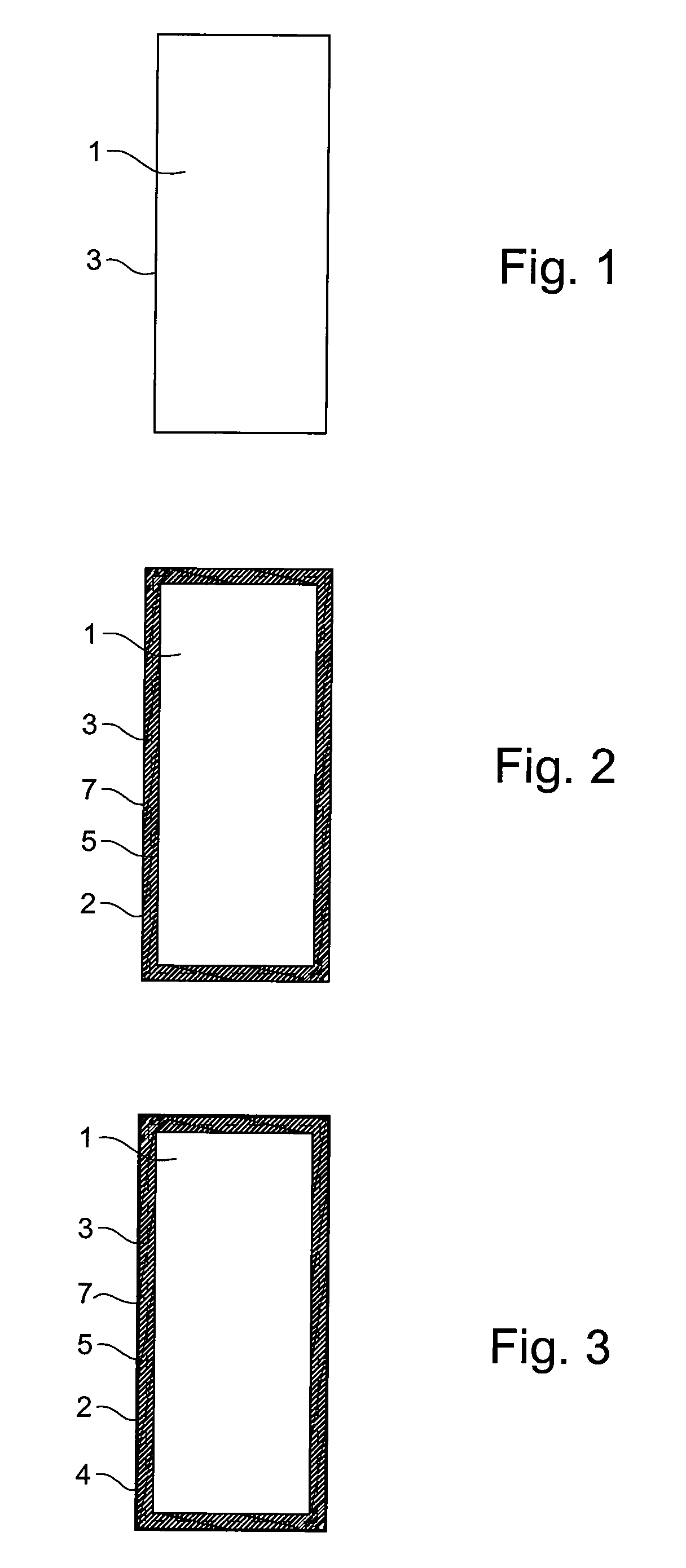

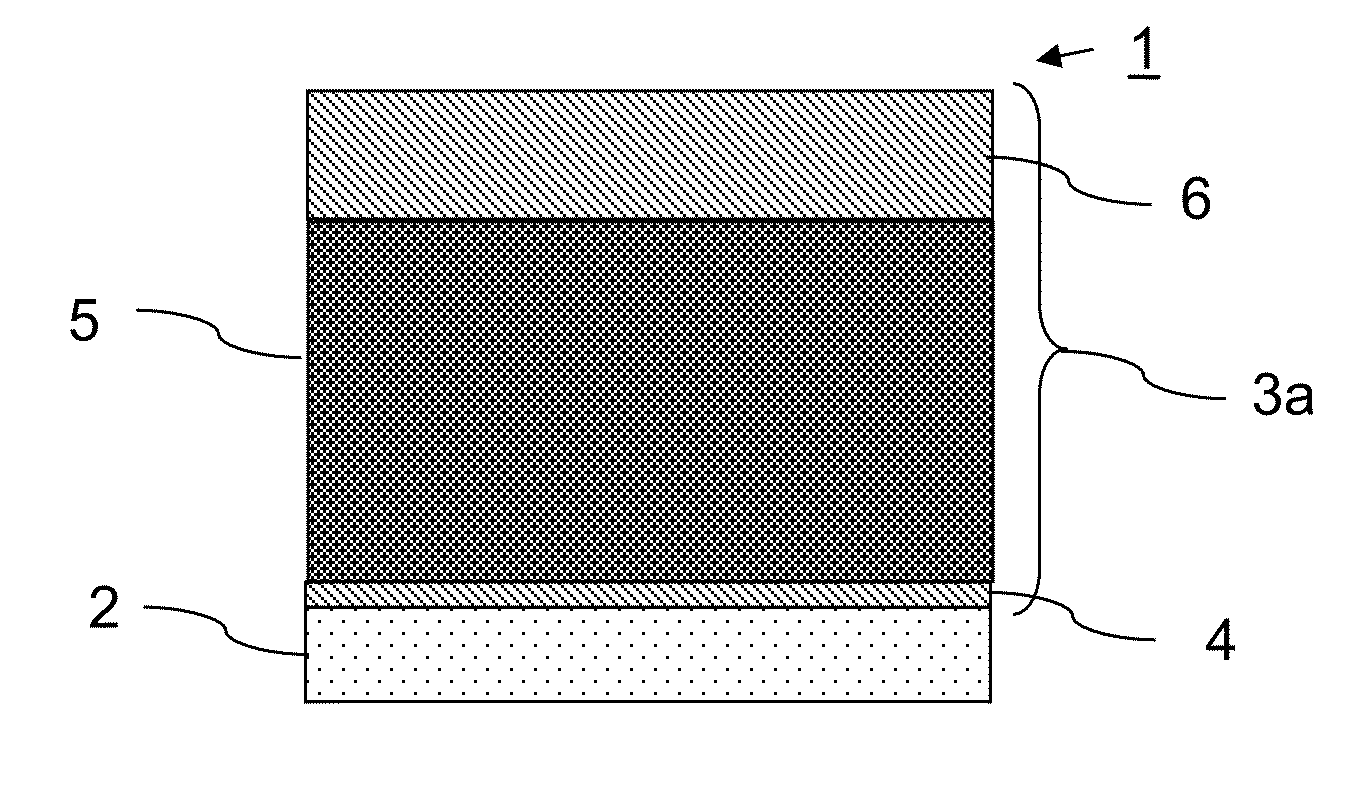

Reinforced micro-mechanical part

ActiveUS20100214880A1Good mechanical resistanceImprove mechanical propertiesGearworksPolycrystalline material growthSilicon dioxideSilicon

The micro-mechanical part, for example a horological movement part, includes a silicon core (1) all or part of the surface (3) of which is coated with a thick amorphous material (2). This material is preferably silicon dioxide and has a thickness which is five times greater than the thickness of native silicon dioxide.

Owner:ETA SA MFG HORLOGERE SUISSE

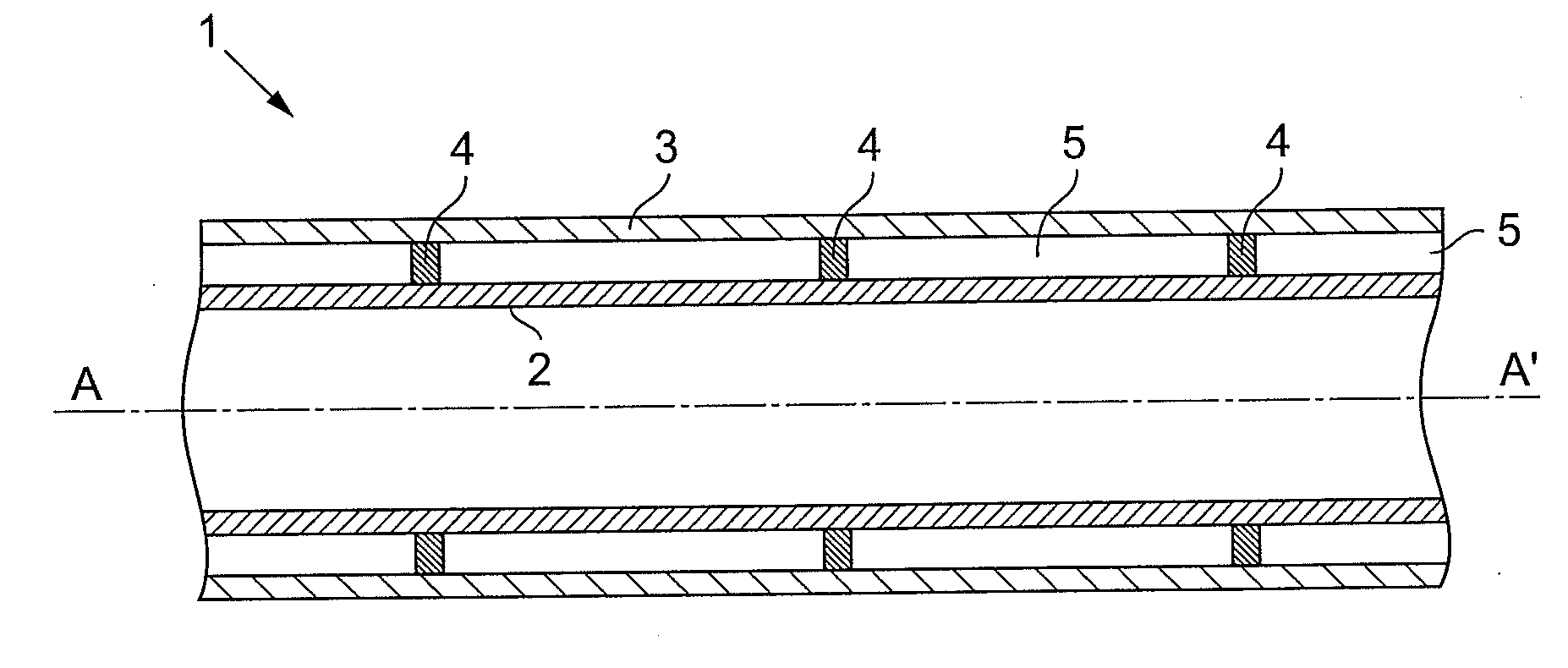

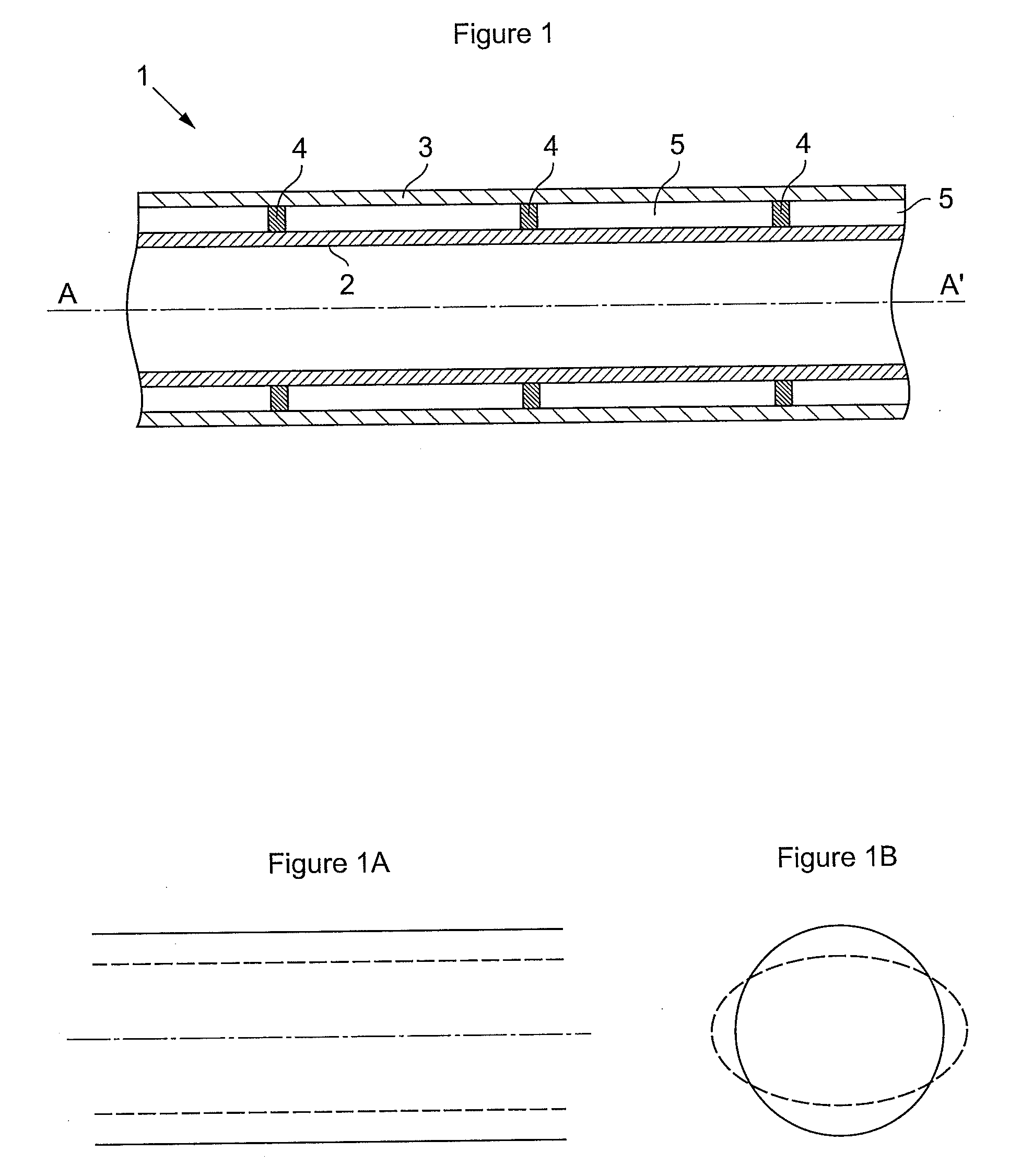

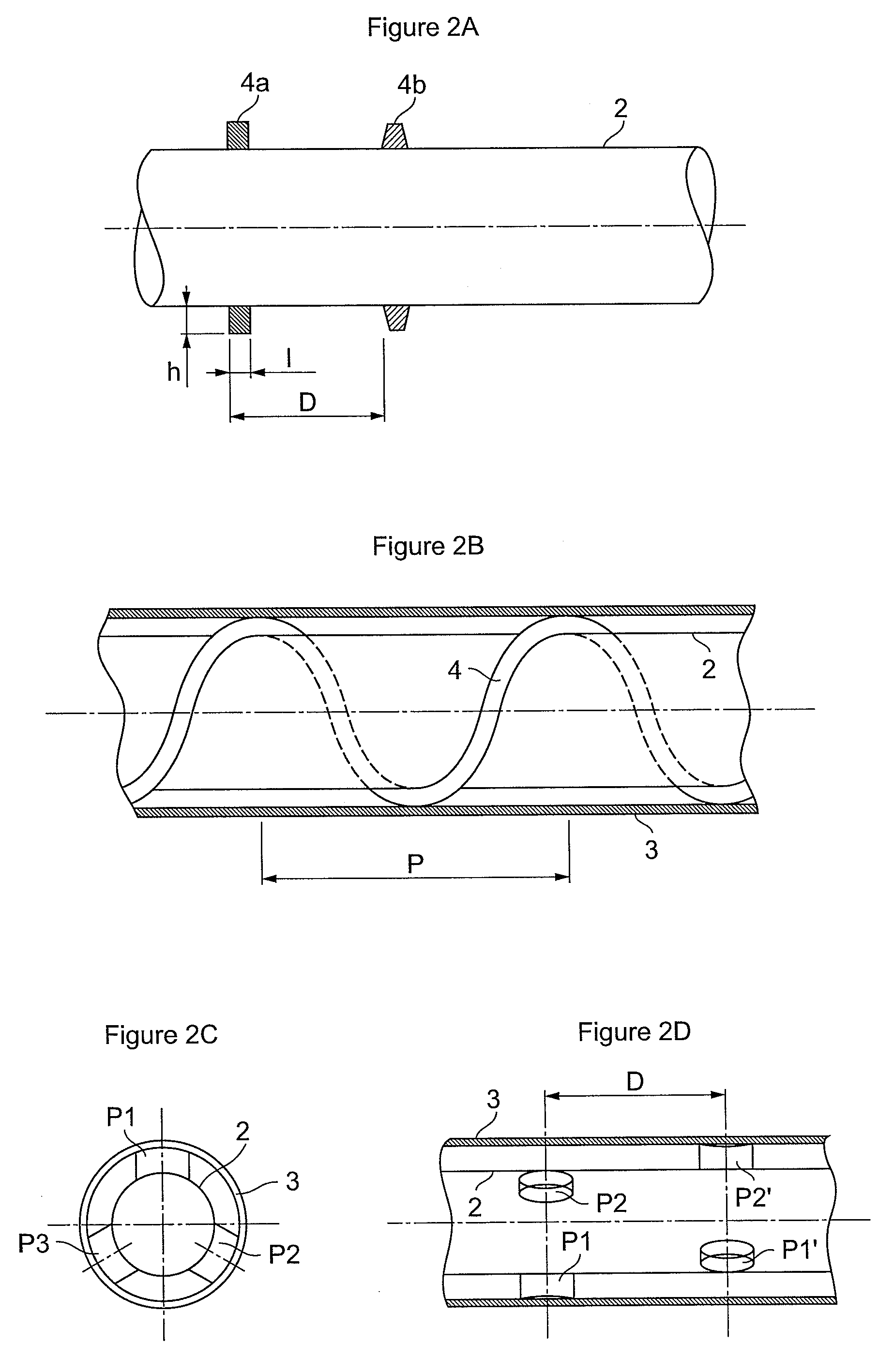

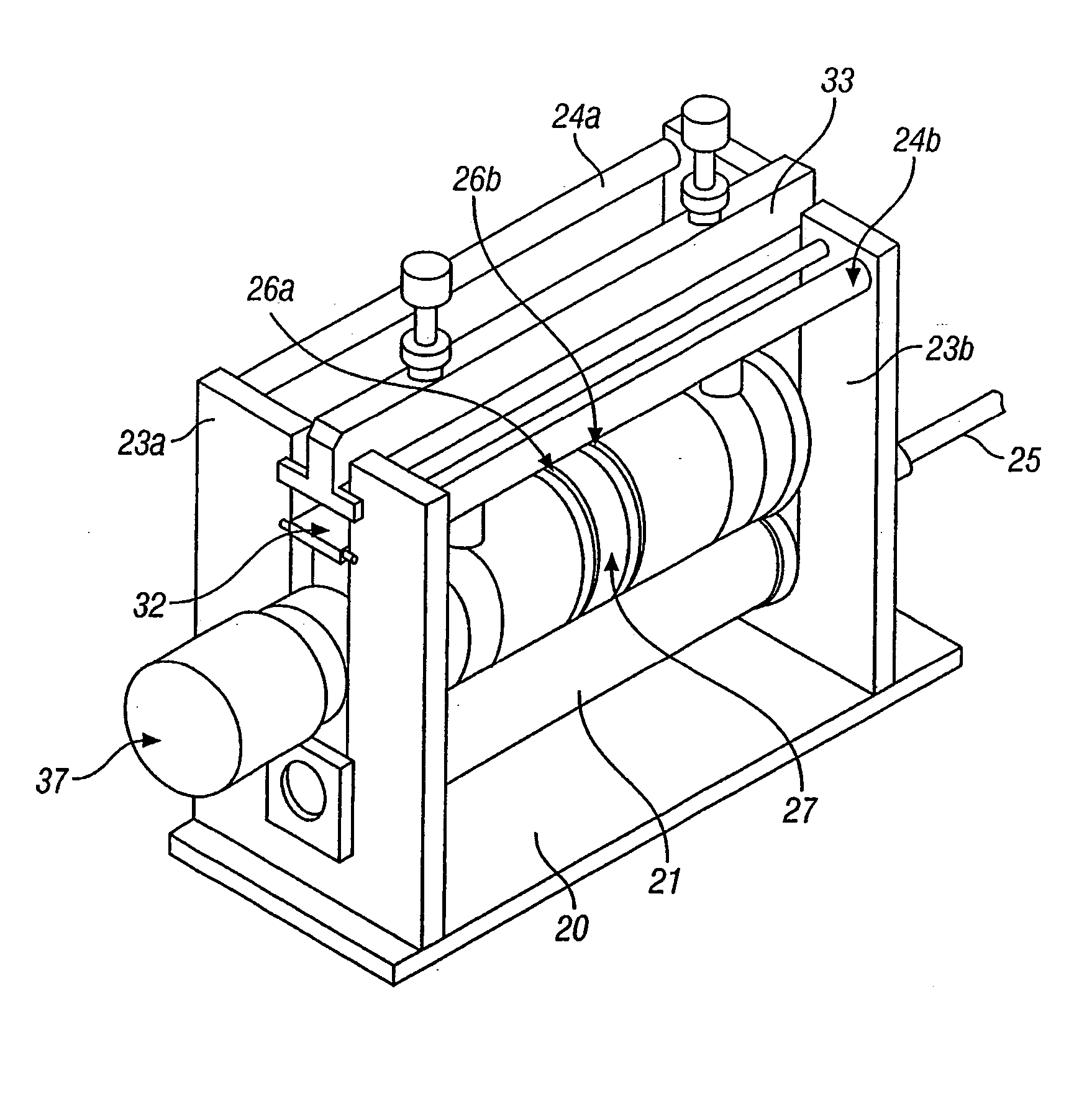

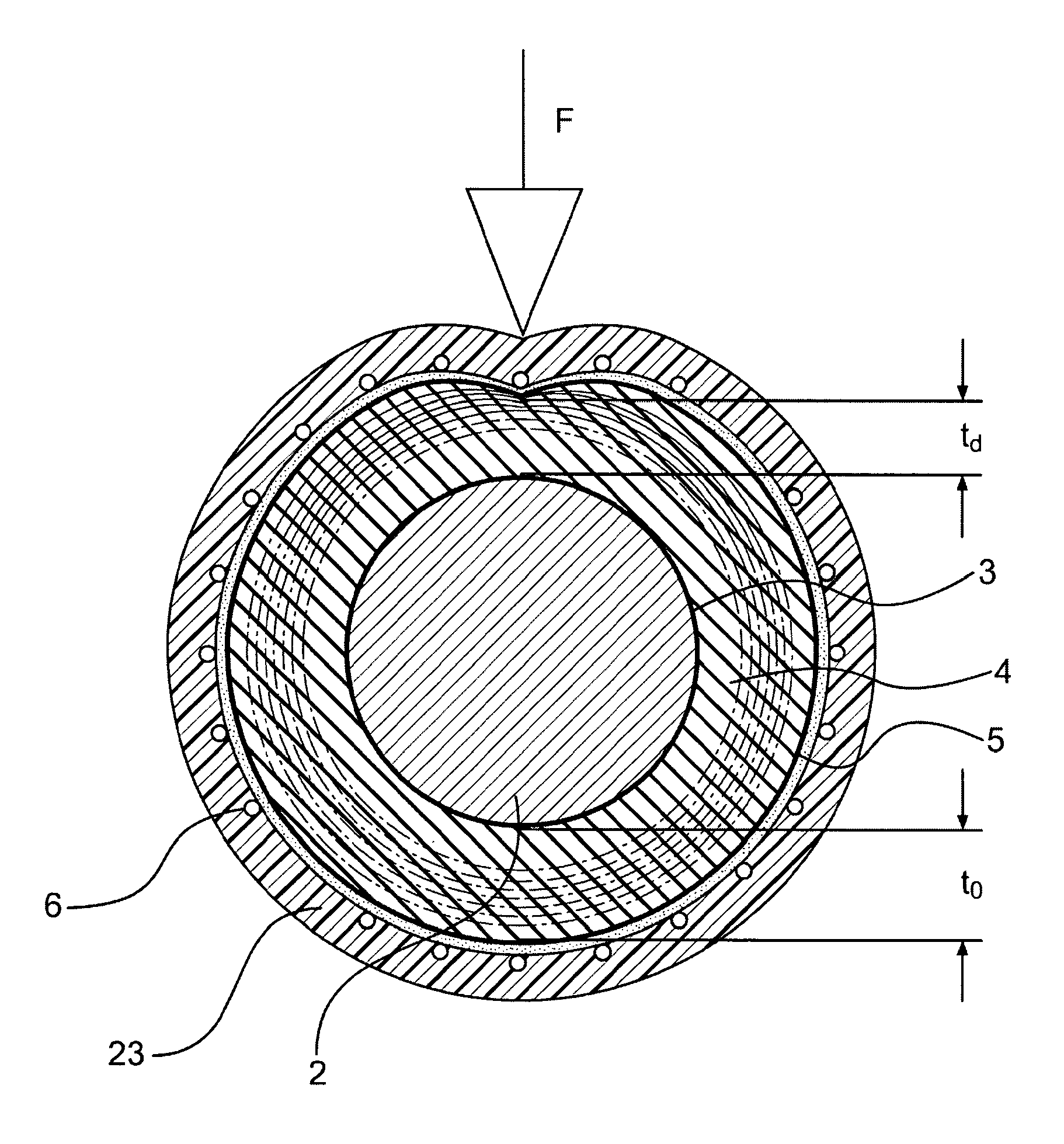

Reinforced double-walled pipe and manufacturing method

InactiveUS20090000681A1Good mechanical resistanceReduce steel thicknessThermal insulationMetal-working apparatusMechanical resistanceDouble-walled pipe

The double-walled pipe comprises a rigid internal tube 2 arranged in a rigid external tube 3, the tubes being separated by an annular space, centering elements holding the internal tube in position in relation to the external tube.External tube 3 withstands alone an external pressure at least above 50 bars.The mechanical resistance of the pipe to the external pressure is reinforced by placing centering elements 4 in contact with internal tube 2 and with external tube 3.

Owner:INST FR DU PETROLE

Apparatus for producing scored lines in a film

InactiveUS20050209076A1Reduce operating costsReduce investmentEnvelopes/bags making machineryMechanical working/deformationBearing surfaceBiomedical engineering

The present invention makes it possible to produce at least one scored line in at least one plastic outer layer of a film. The device of the invention includes bearing surface for the film and at least one projection for forming the scored line by penetration of the projection into the plastic layer when the film is in position against the said bearing surface. The projections may be arranged in the form of ribs on one or more coaxial rollers. The projections may form the scored line by ultrasonic plastic flow, the film being compressed between a sonotrode and the rollers. The invention provides methods using these devices and it also provides films having scored lines, and packages having scored lines.

Owner:MARS INC

Membranes and devices for gas separation

InactiveUS20100071559A1Increase resistanceImprove throughputMembranesSemi-permeable membranesActive phaseChemistry

A membrane includes:a hollow support having a plurality of poresan active phase including a gaz-selective capting material embedded into the pores.

Owner:CENT NAT DE LA RECHERCHE SCI

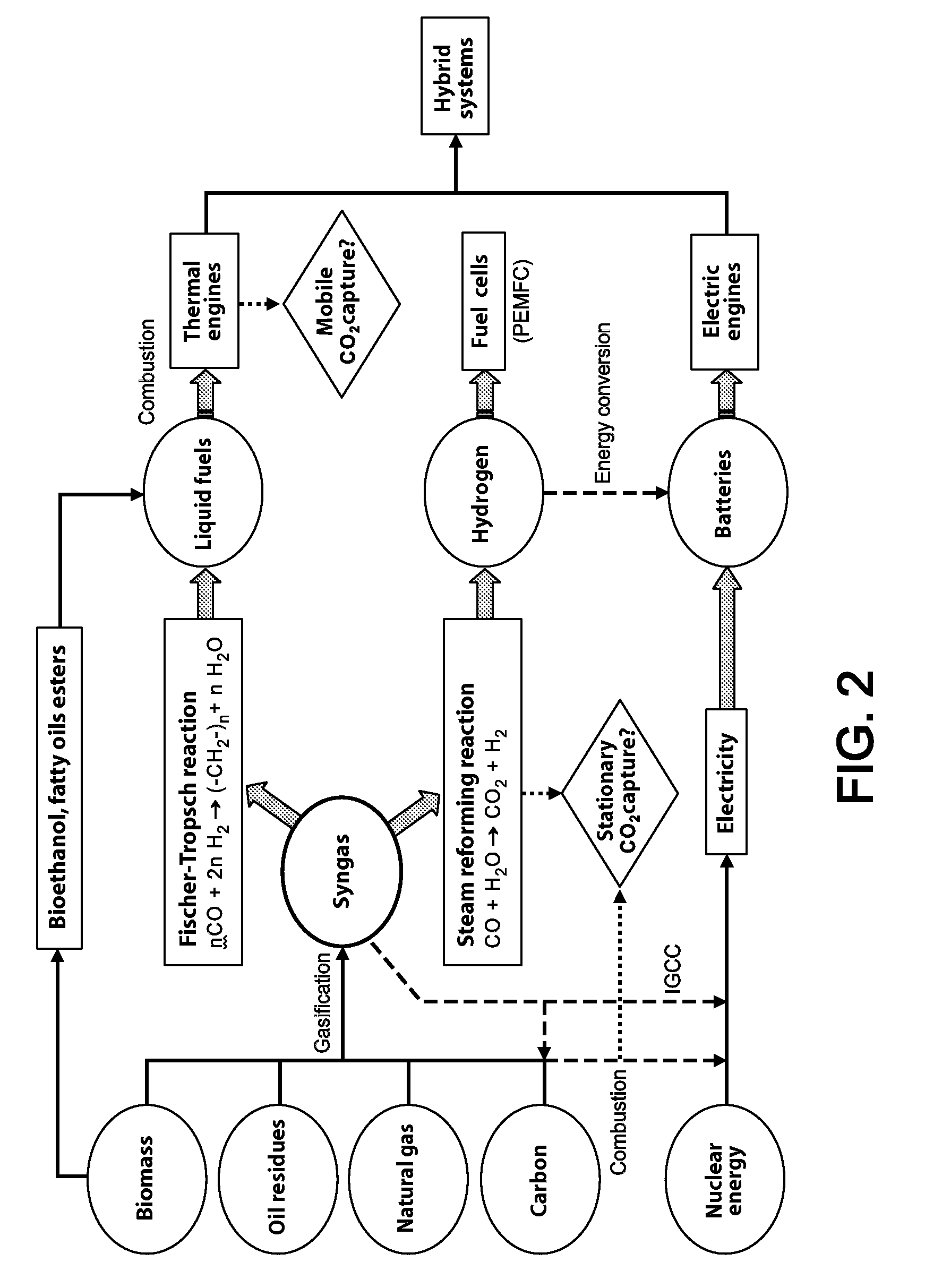

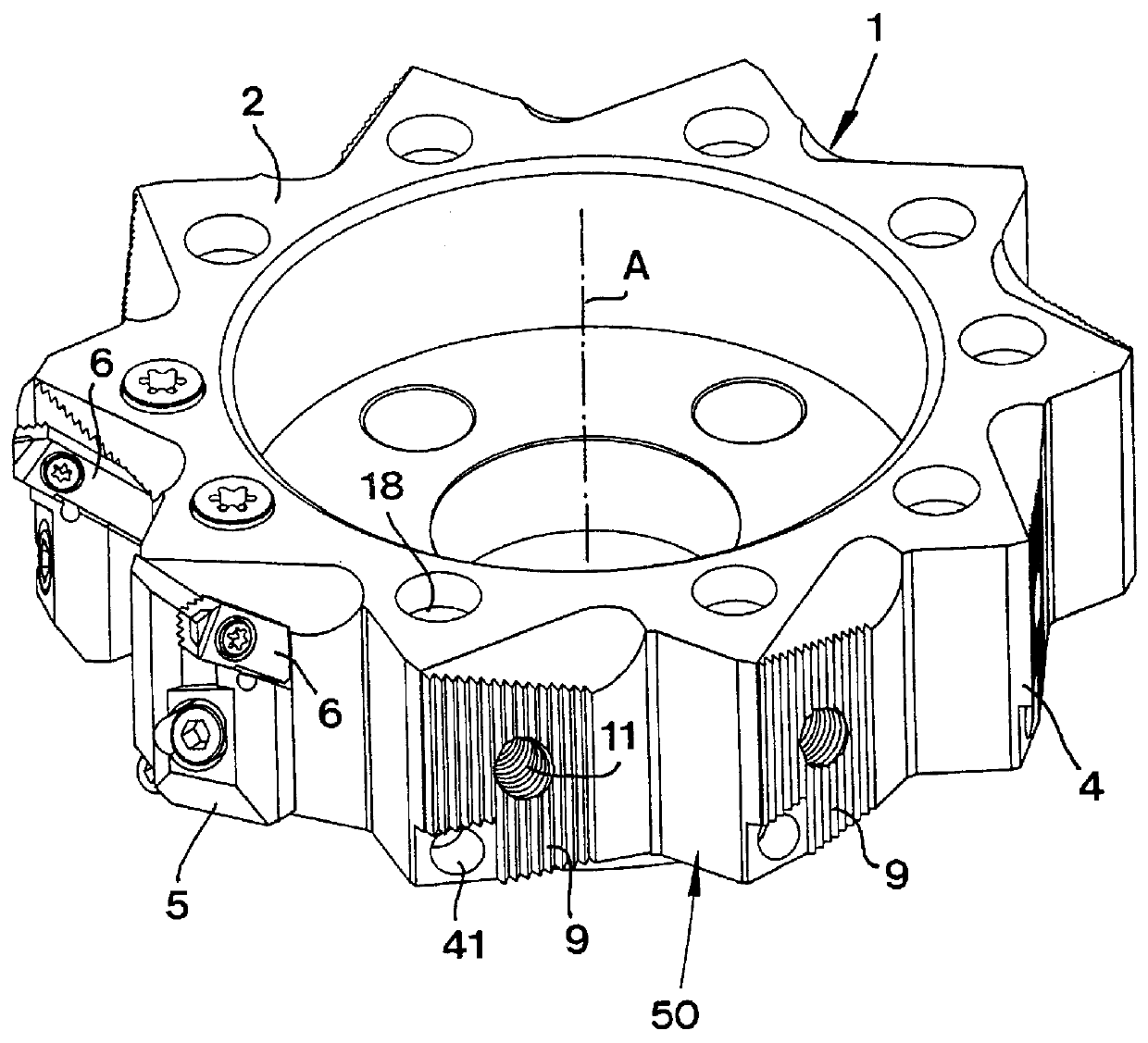

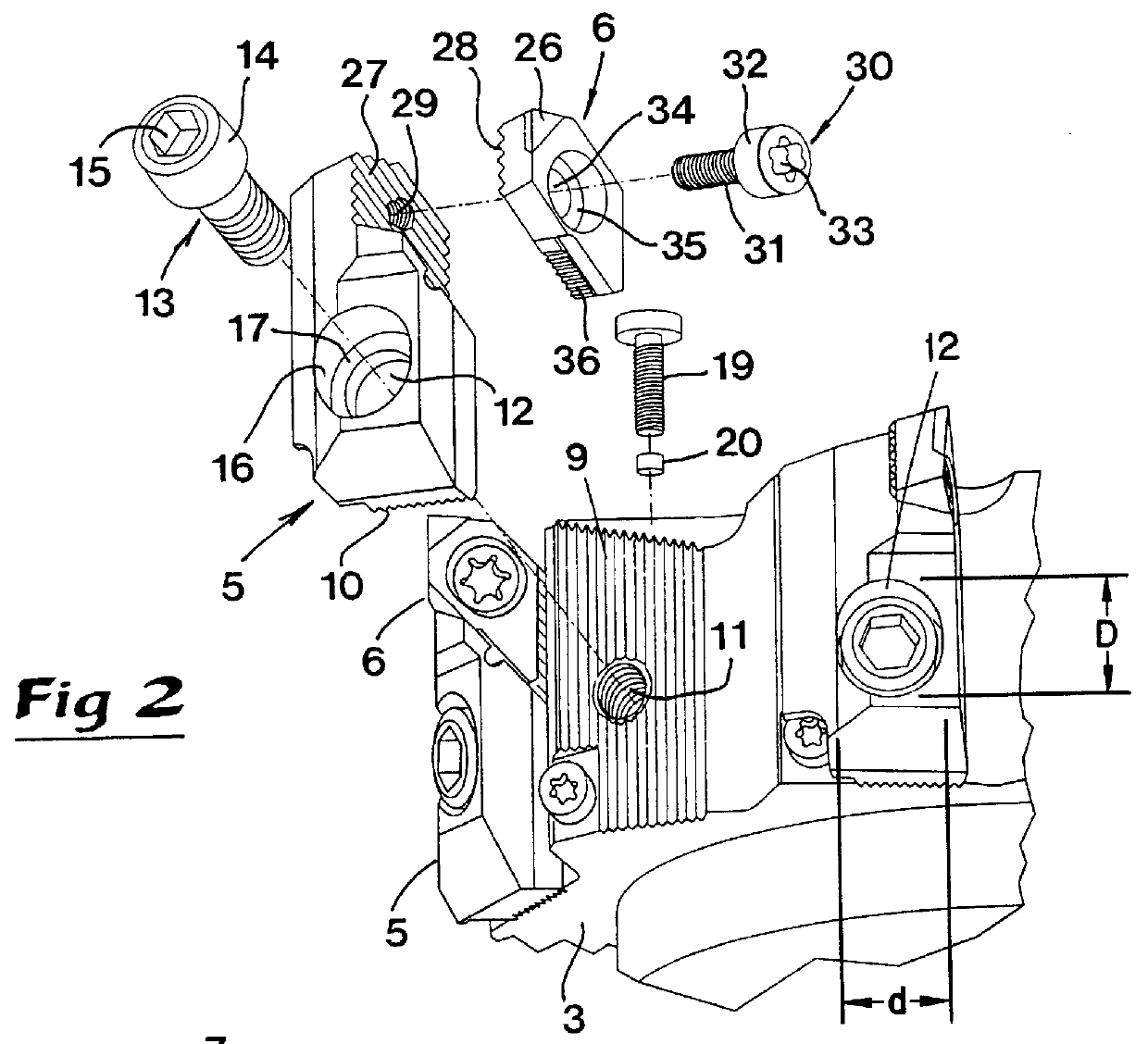

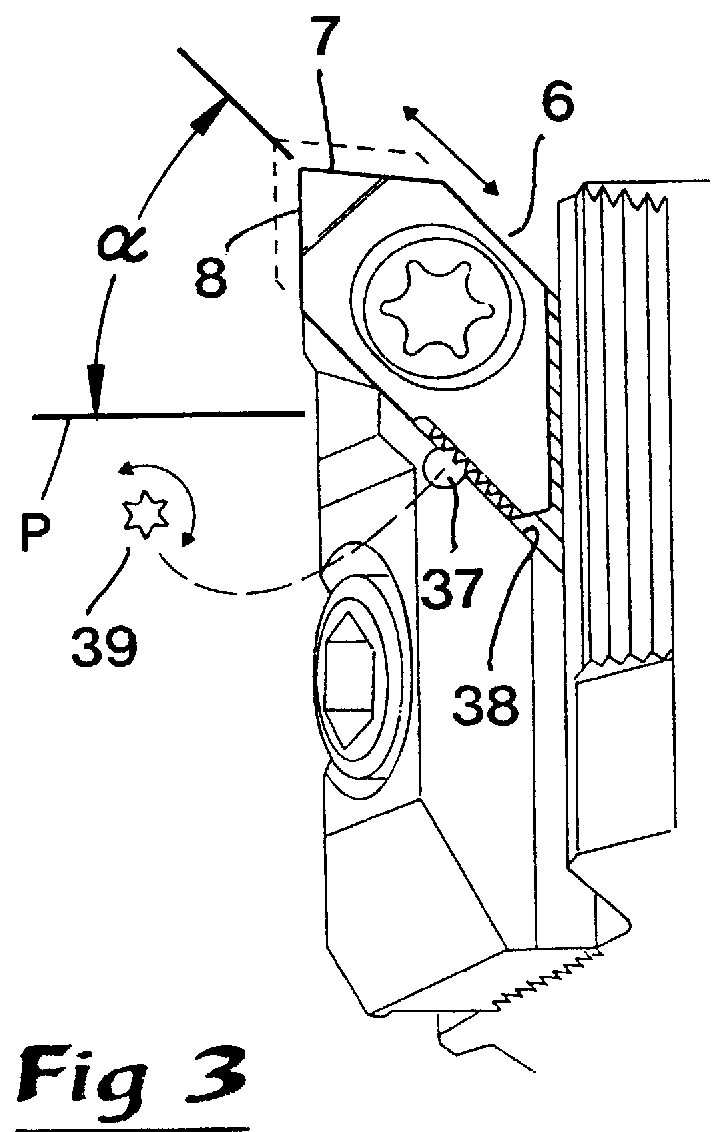

Milling tool having cassette-mounted inserts attached to a rotary supporting body

InactiveUS6086290AIncrease machine speedReduce supportMilling cuttersShaping cuttersEngineeringMechanical engineering

A milling tool includes a rotatable supporting body having detachable cassettes upon which cutting inserts are mounted. The cutting inserts are provided with cutting edges. Two serrated surfaces are provided in order to connect the individual cassette with the supporting body. A first of the two serrated surfaces is located upon the periphery of the supporting body and faces outwards from the supporting body, while the other serrated surface is formed at an inner side of the cassette.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Seamless steel tube which is intended to be used as a guide pipe and production method thereof

ActiveUS8002910B2Good mechanical resistanceImprove toughnessFurnace typesHeat treatment furnacesHeat-affected zoneCrack resistance

The present invention pertains to steel with high mechanical resistance at room temperature and up to 130° C., good toughness and good corrosion resistance in the metal base as well as good resistance to cracking in the heat affected zones (HAZ) once the tubing is welded together, and more specifically to heavy gauge seamless steel tubing with high mechanical resistance, good toughness and good corrosion resistance called catenary conduit. The advantages of the present invention with respect to those of an the state of technology reside in providing a chemical composition for steel used to manufacture heavy gauge seamless steel tubing with high mechanical resistance, good toughness, good fissure resistance in the HAZ and good corrosion resistance and a process for manufacturing this product. These advantages are obtained by using a composition made up basically of Fe and a specific chemical composition.

Owner:TUBOS DE ACERO DE MEXICO +1

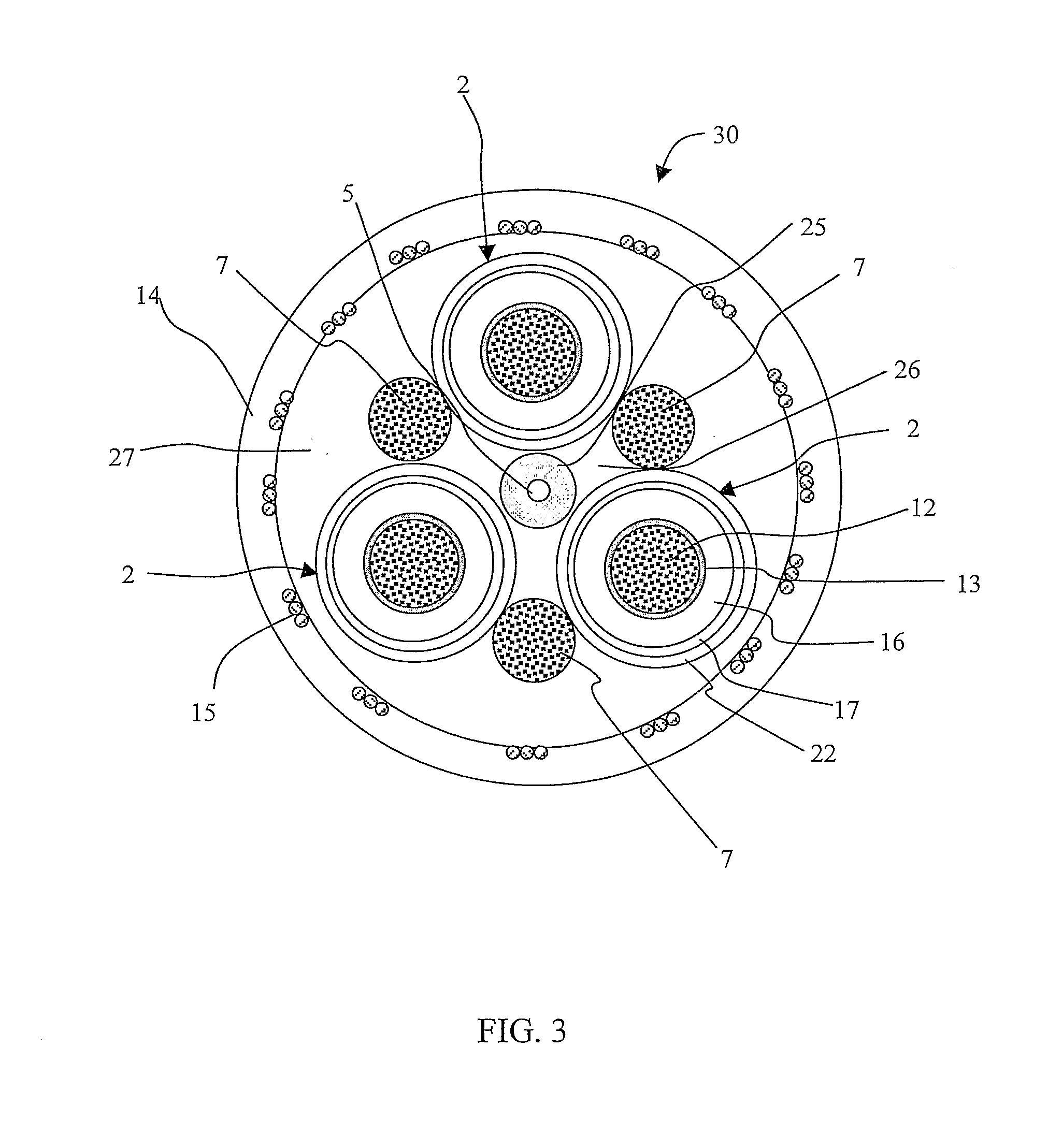

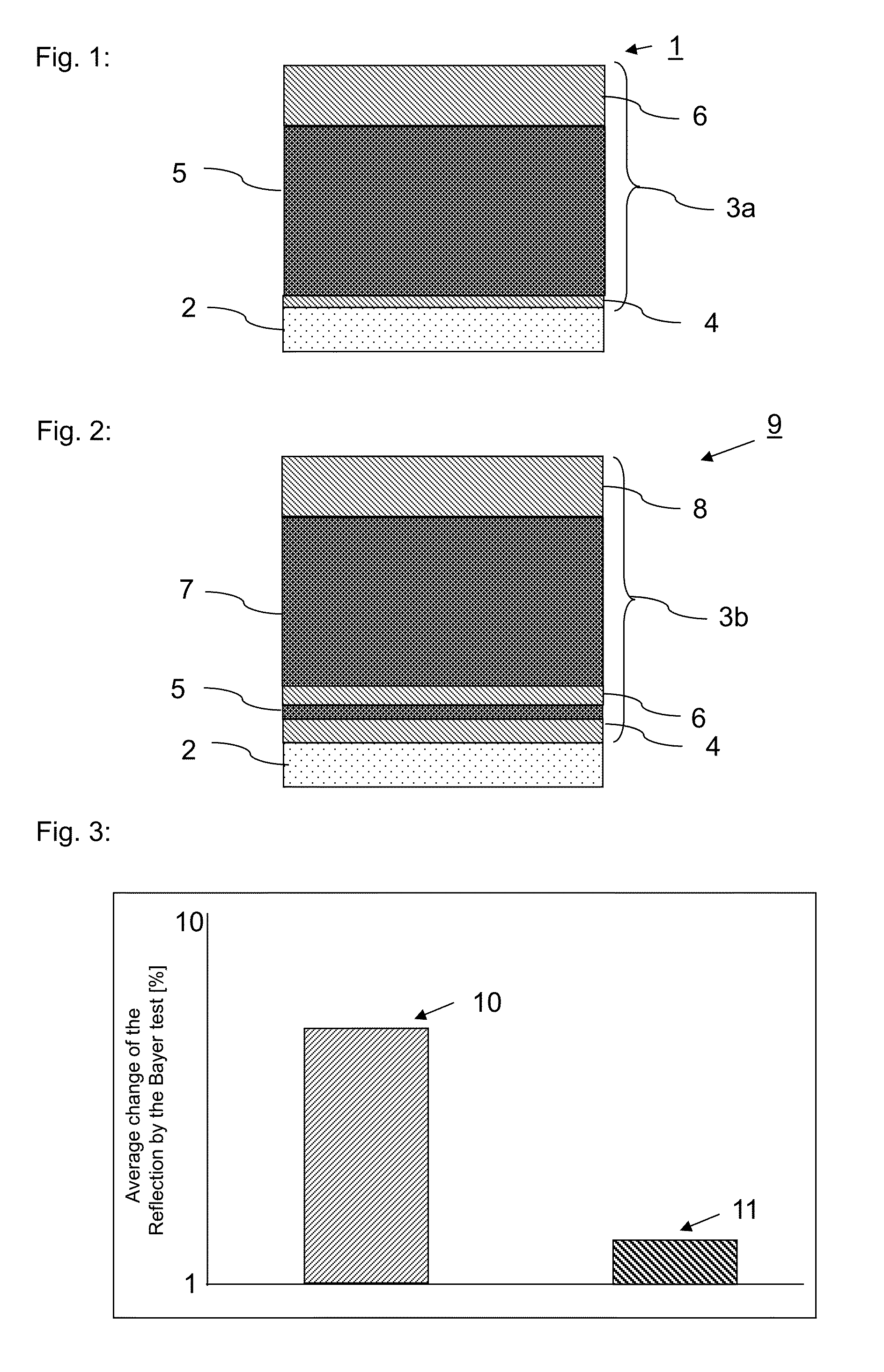

Glass-ceramic which is at least partly provided with a hard material layer

InactiveUS20130209762A1Protected even better and more durablyGood mechanical resistanceLayered productsCoatingsAmorphous phaseThermal expansion

Glass-ceramic is provided that is at least partly provided with a hard material layer to protect against external mechanical influences. The hard material layer contains at least two phases, which are present side by side and are mixed with one another. The at least two phases include at least one nanocrystalline phase and one amorphous phase. The hard material layer has a hardness of at least 26 GPa and a layer thickness of at least 0.5 μm. The hard material layer is chemically resistant in the temperature range from 200° C. to 1000° C. The coefficient of thermal expansion (α) of the glass-ceramic does not differ by more than + / −20% from the coefficient of thermal expansion (α) of the hard material layer.

Owner:SCHOTT AG

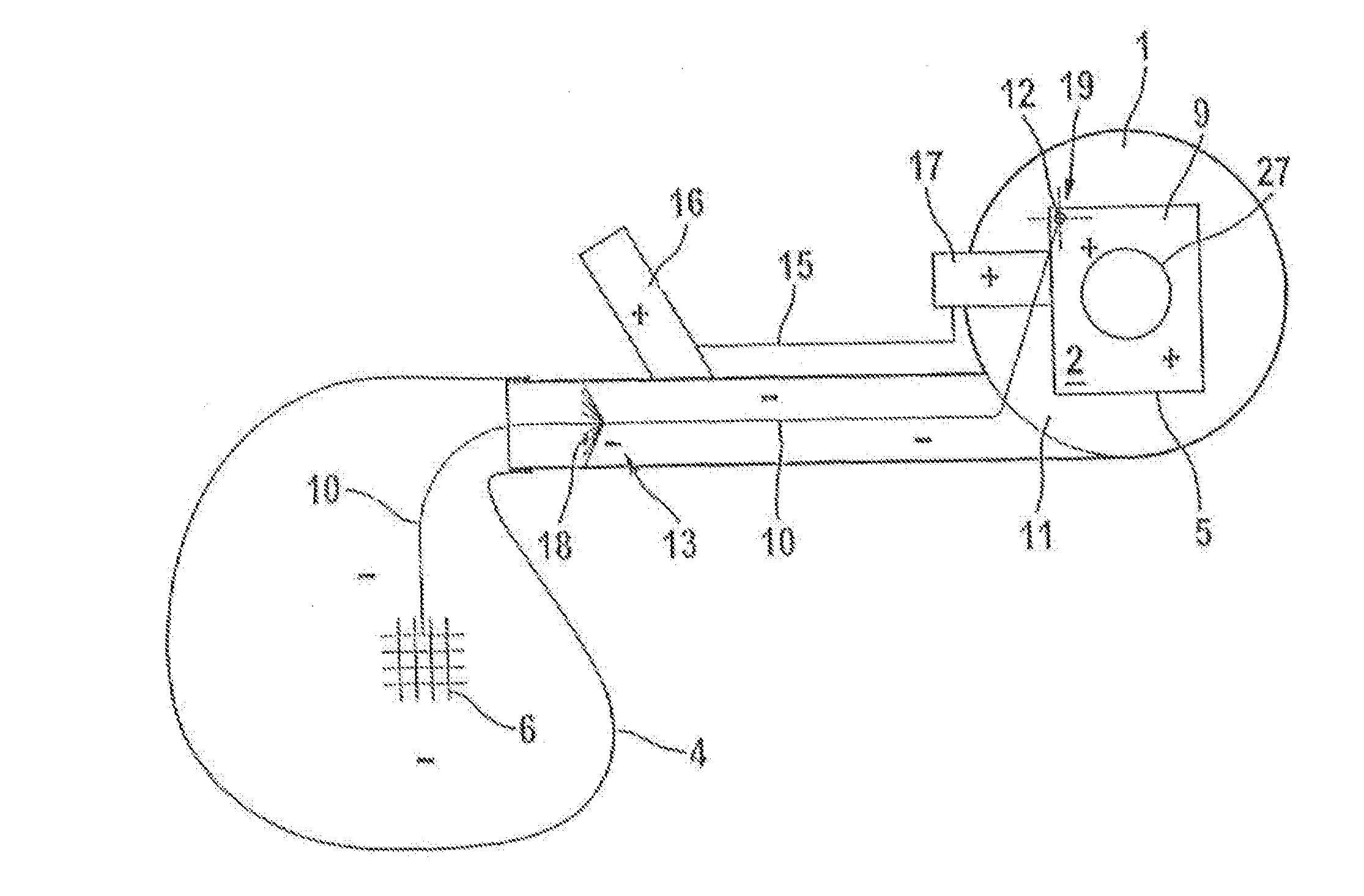

Electric cable with bending sensor and monitoring system and method for detecting bending in at least one electric cable

ActiveUS20120174683A1Effective periodic maintenanceHigh mechanical stressControlForce measurement by measuring optical property variationNon symmetricMonitoring system

A method for monitoring at least the bending strain of at least one electric cable provided with at least one peripheral mechanically non-symmetric strength member is provided.

Owner:PRYSMIAN SPA

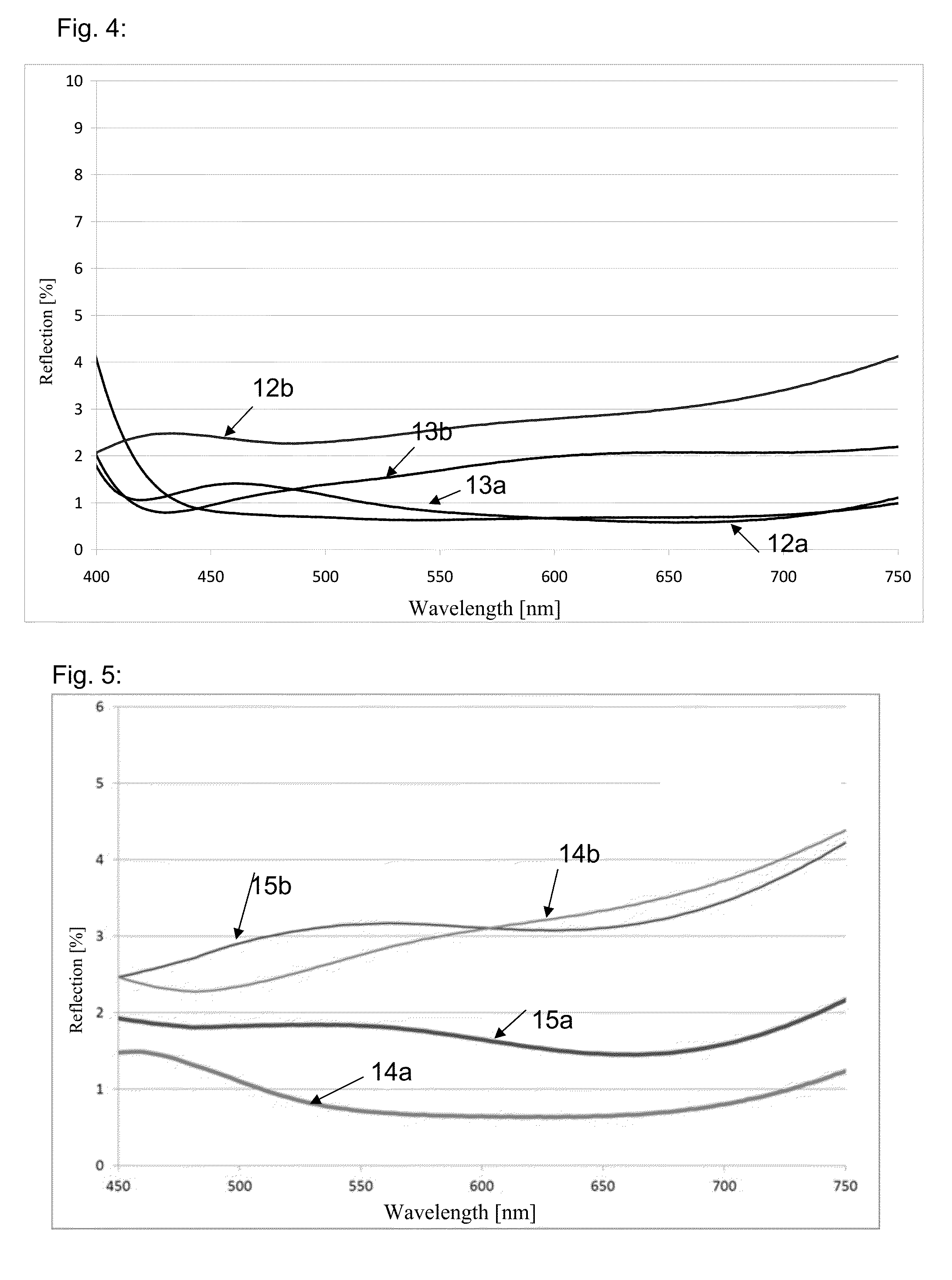

Hard Anti-reflective coatings and manufacturing and use thereof

InactiveUS20150355382A1Crystal formation can be enhancedImprove mechanical propertiesLayered productsVacuum evaporation coatingAnti-reflective coatingCrystal structure

A coated substrate is provided with a scratch-resistant anti-reflective coating. The anti-reflective coating is designed as an optical interference coating that has at least two low refractive index layers and at least one high refractive index layer. The high refractive index layer is a transparent hard material layer and includes crystalline aluminum nitride with a hexagonal crystal structure with a (001) preferred orientation. The low refractive index layers include SiO2. The low refractive index layers and high refractive index layers are arranged alternately.

Owner:SCHOTT AG

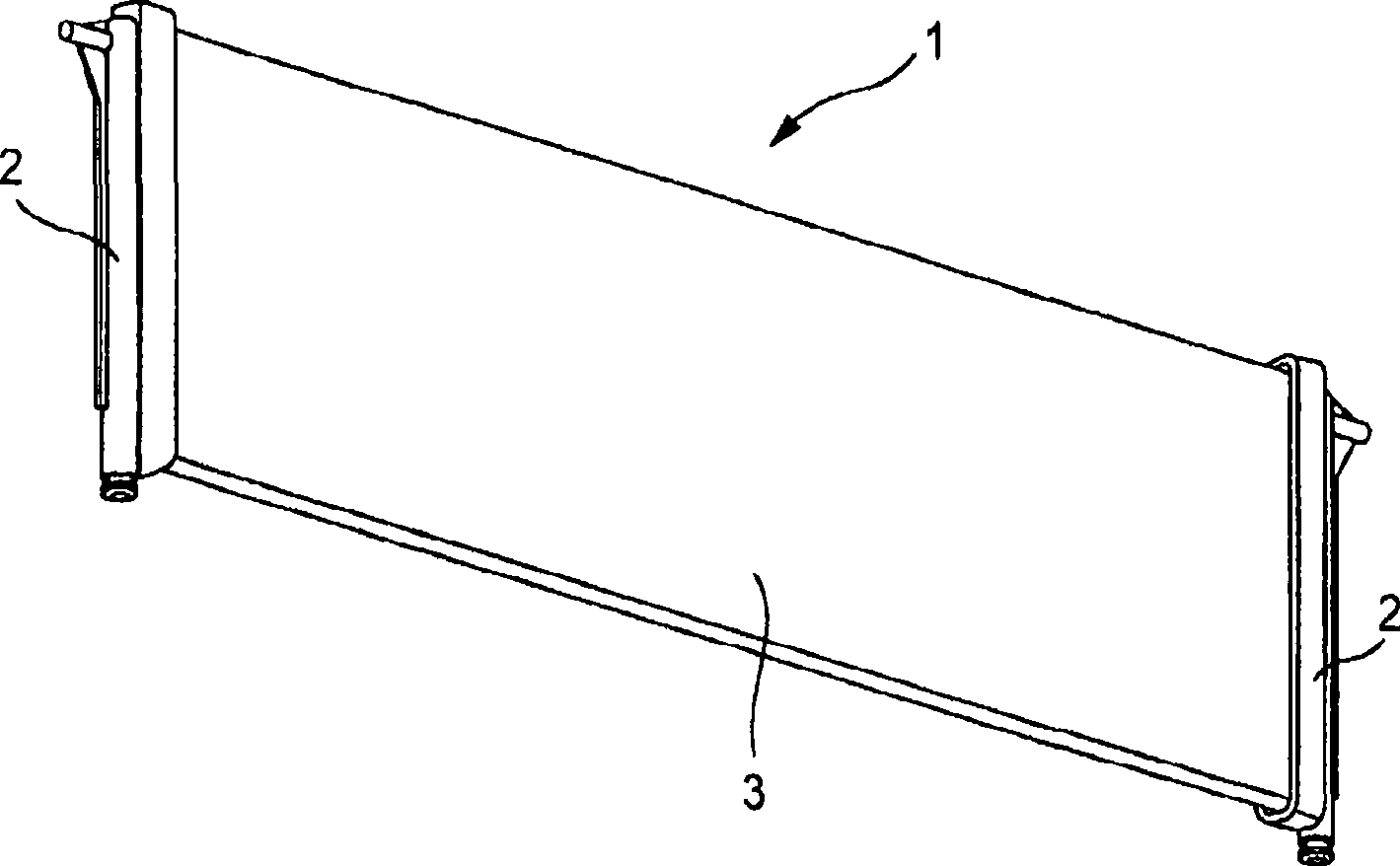

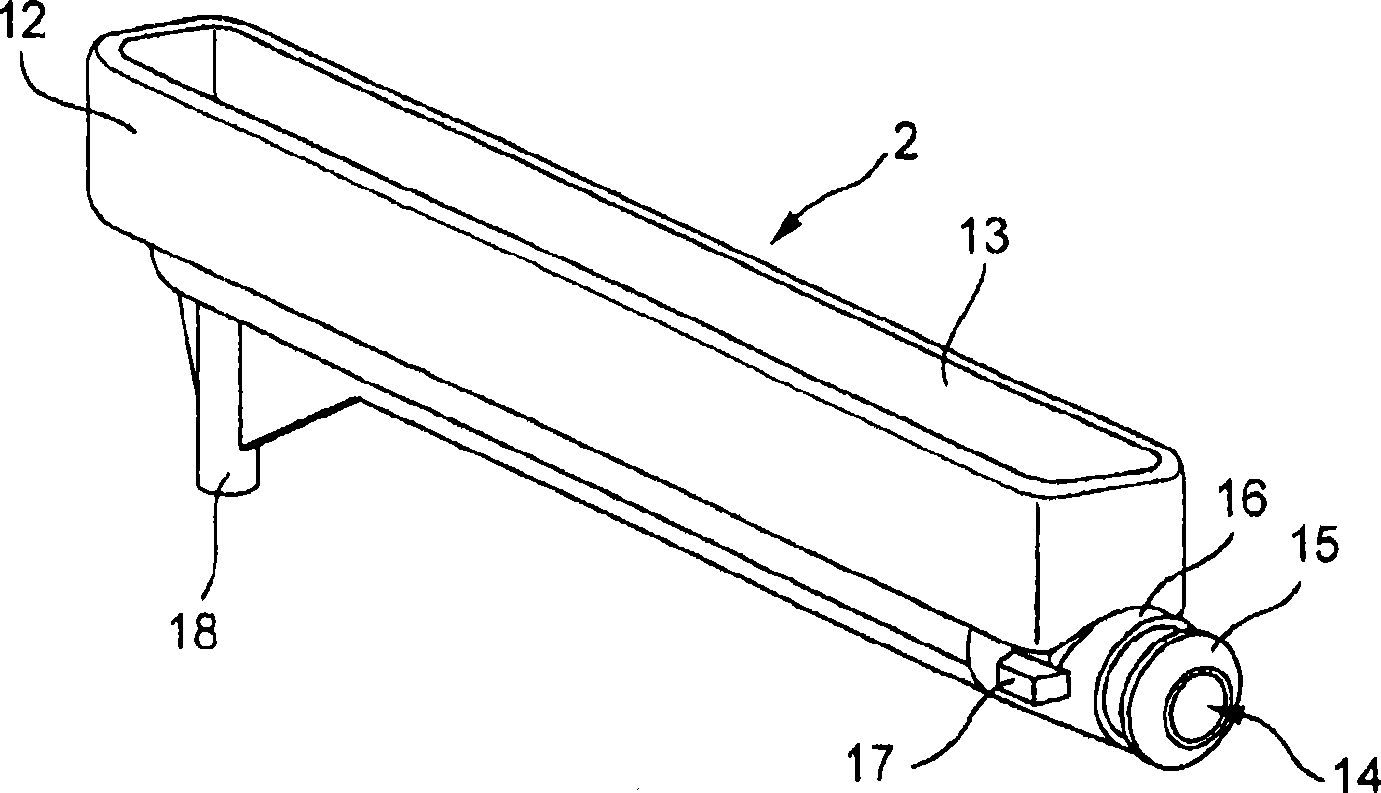

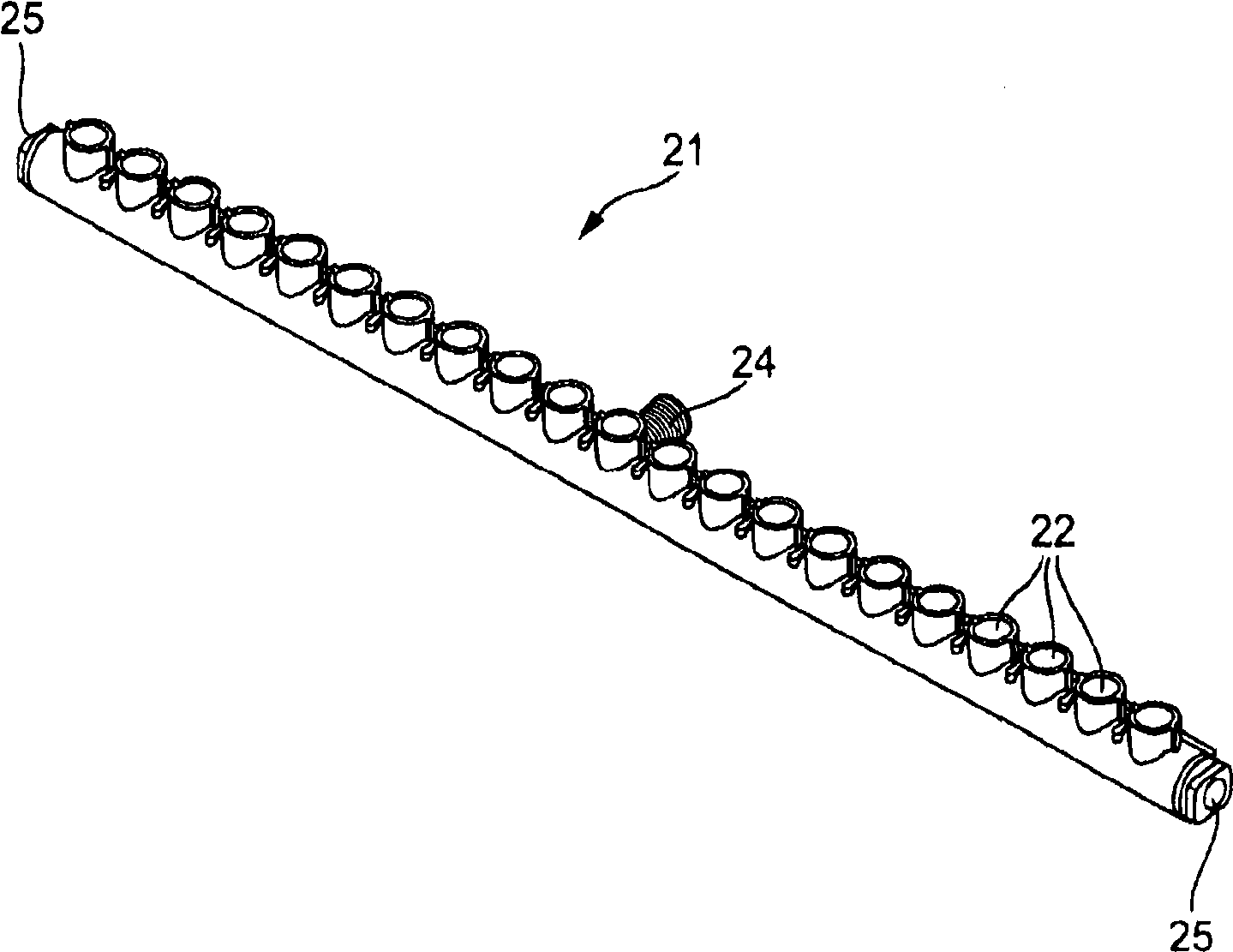

Filter unit for wastewater treatment and production of drinking water

InactiveCN101489653AIncrease productionHigh filter actionMembranesUltrafiltrationFilter systemRetrofitting

A filter unit for sewage treatment and drinking water provision and components which are suitable for the production and the use of such filter units are described. The filter unit has at least one ceramic filter(3) and at least one holder for liquid-tight fixing of the filter in the holder(2), the filter being fixed in the holder by adhesive bonding with the aid of an adhesive. At the same time, the holder is adjusted to the design of the filter, especially to its design as a flat filter. A separate filtrate collecting channel (21)and a holding device (18)for the filter units or other components allow the provision of a finished filter system which is also suitable for retrofitting of already existing plants.

Owner:ITN NANOVATION AG

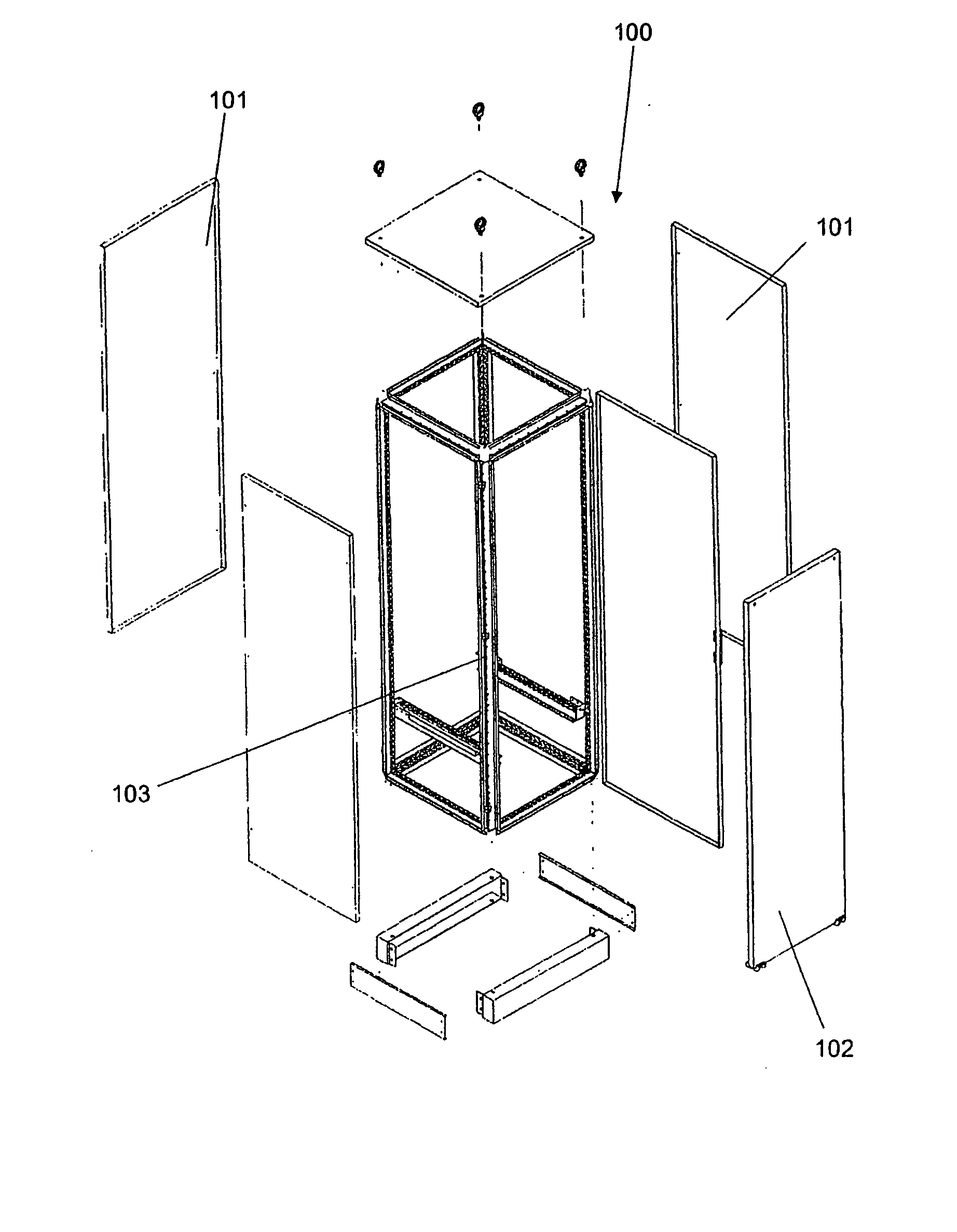

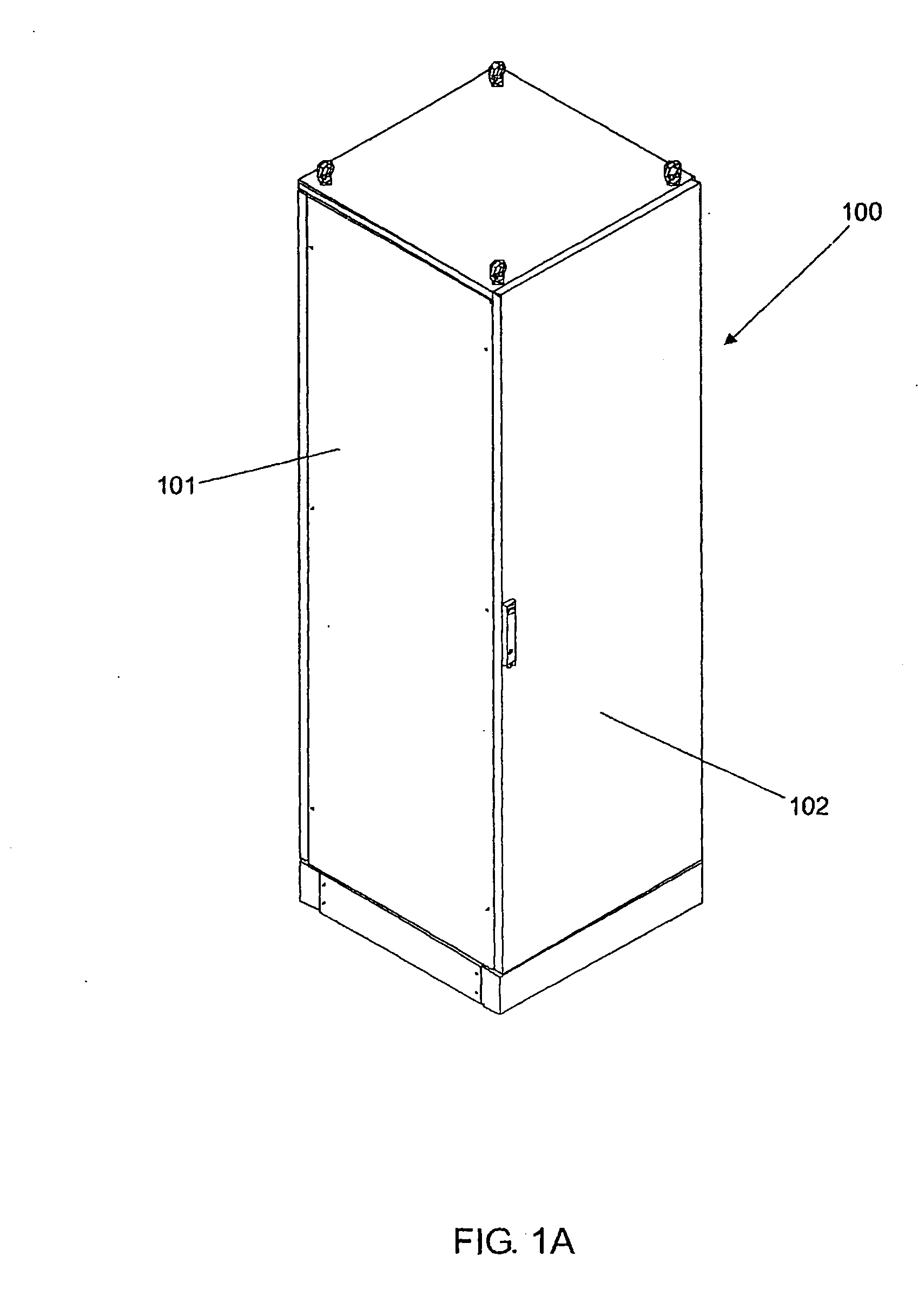

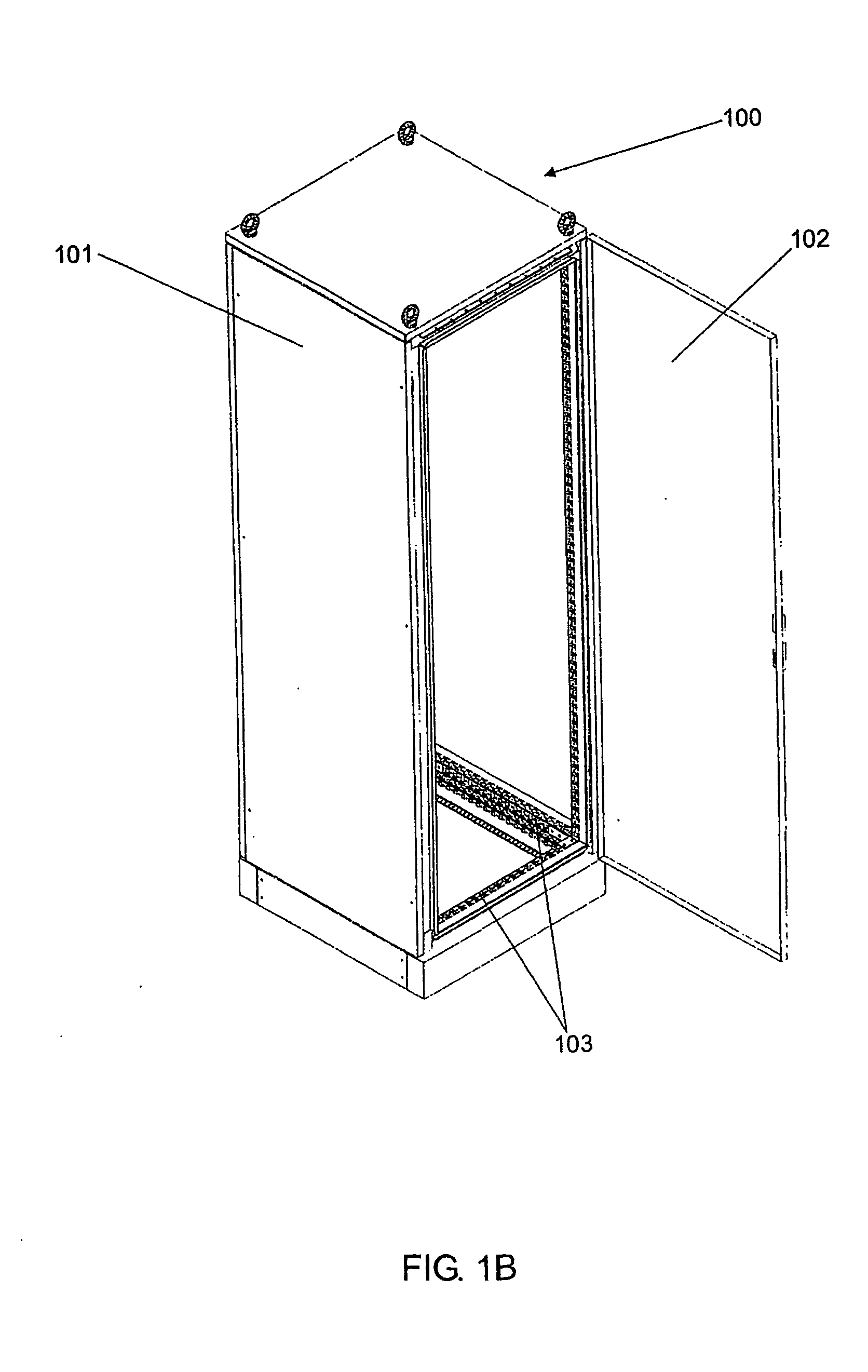

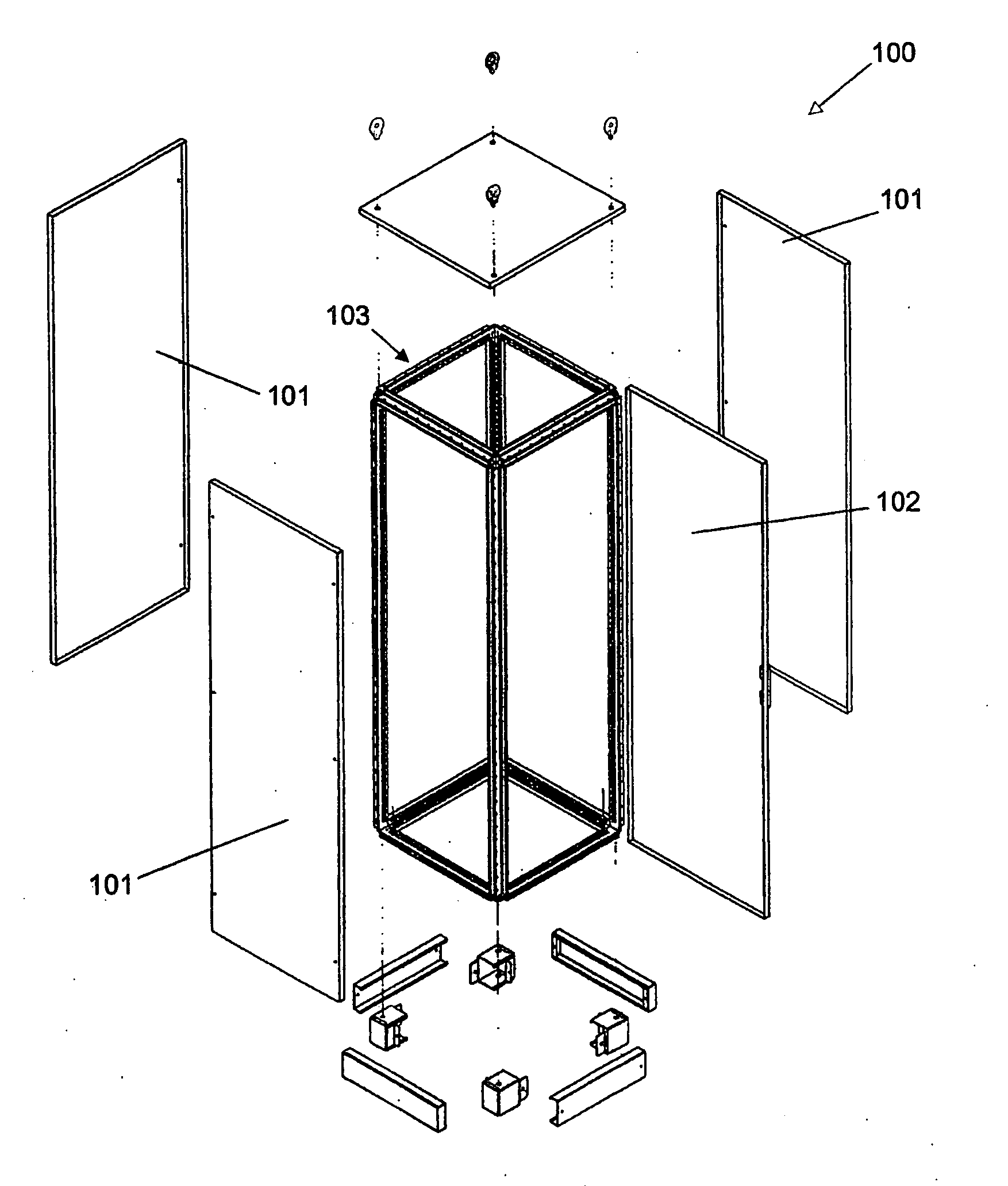

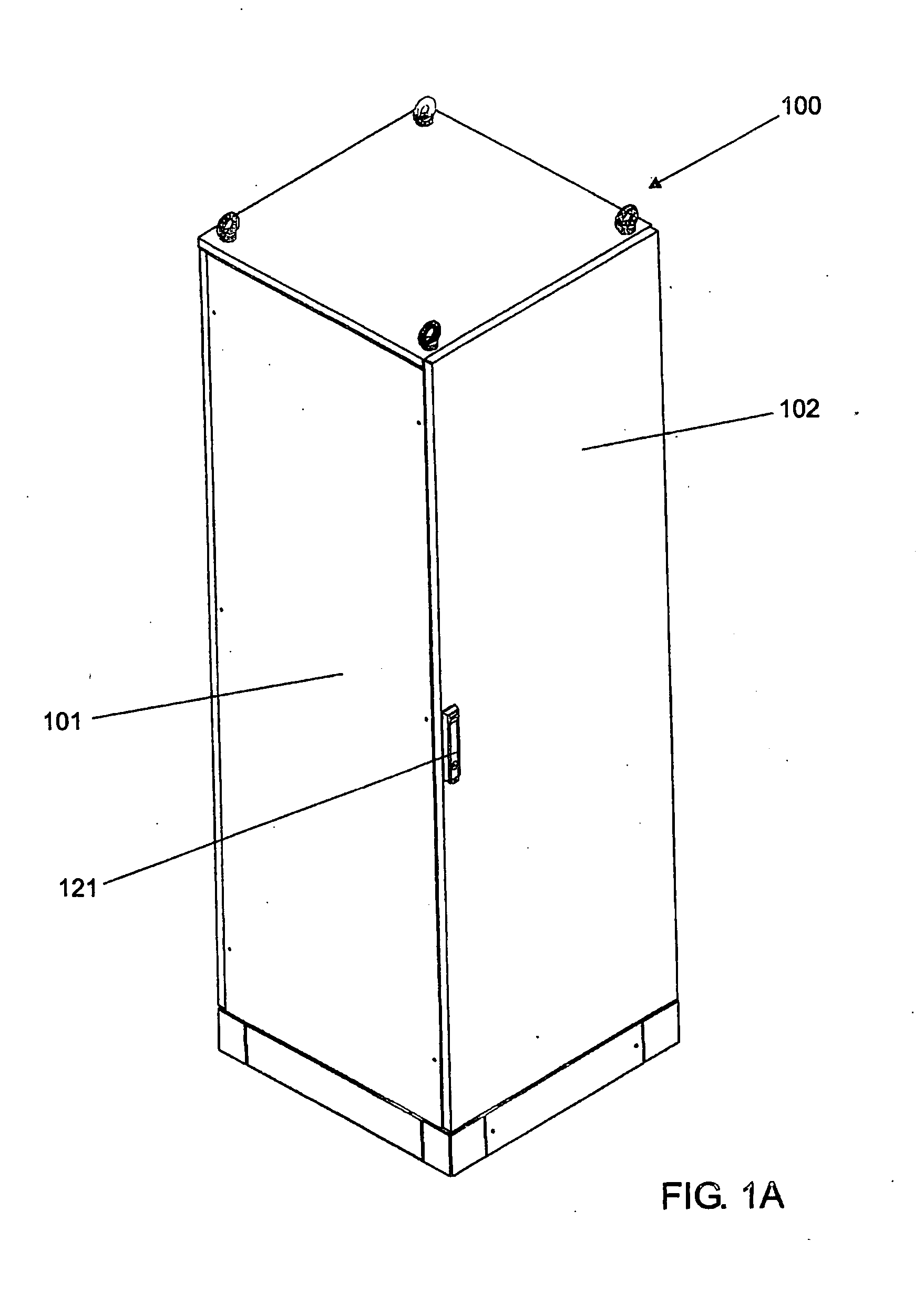

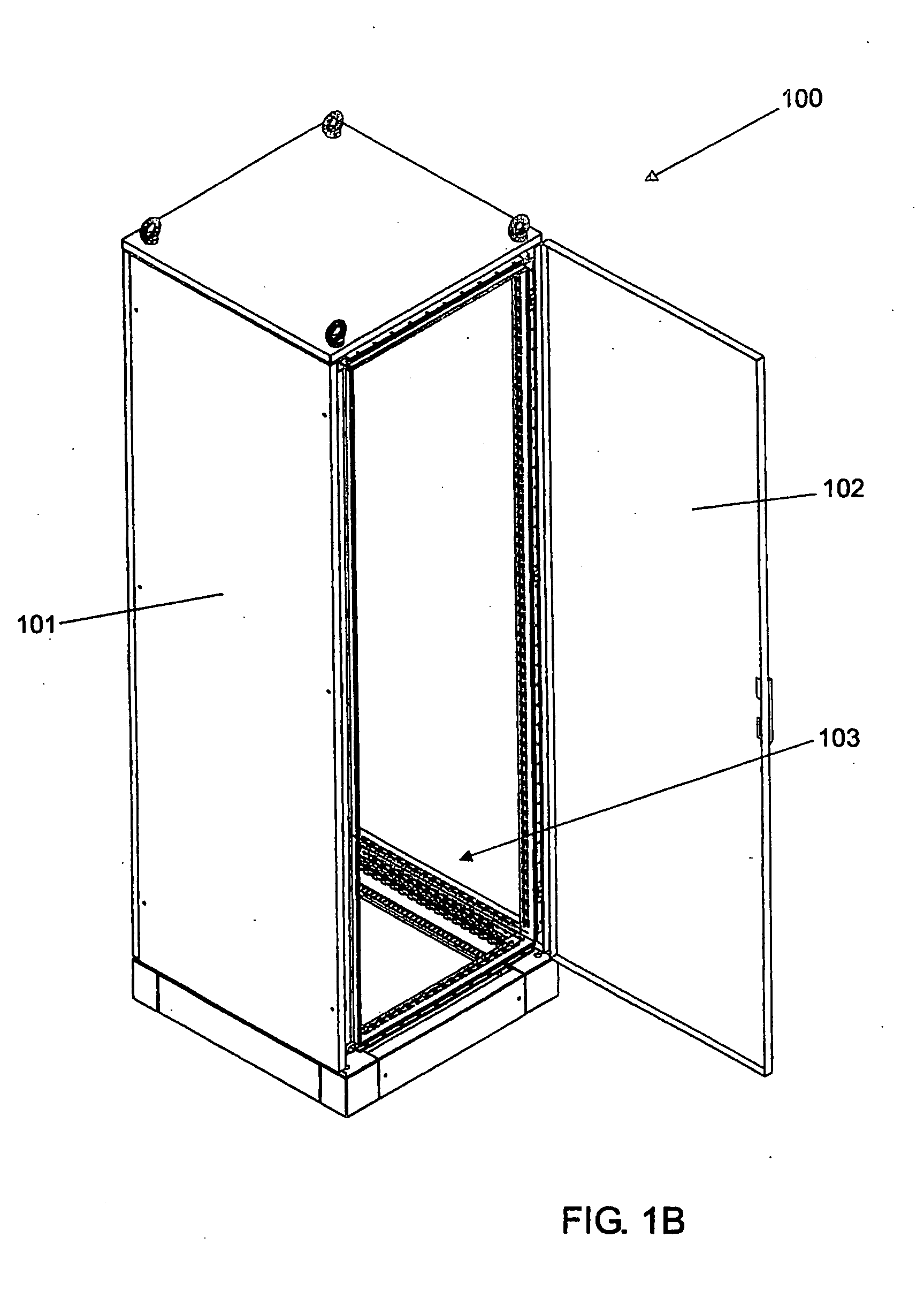

Metallic profile for the composition of structures for the assembly of cabinet/enclosures

InactiveUS20050174020A1Good mechanical resistanceImprove featuresSubstation/switching arrangement casingsRack/frame constructionFolded formDouble wall

Comprehending a profile (104) that, from the outside, constitutes the means of support for the closings and accessories, while on the inside, the same structure configures the struts for the assembly of components and electric and electronic devices, in addition to which this profile (104) presents a cross section with a geometry defined by a central core in the tubular shape with a quadrangular section (105), where the vertex (106) is oriented to the inside of the cabinet (100), while the opposite vertex (107) is oriented to the outside of this cabinet (100), and these two vertexes are formed by single walls, which does not apply to the other two remaining vertexes (108) and (109), which are defined by the junction of the sheet that forms the first two vertexes (106-107) and from this point on, the double walls (110) are extended in a coplanar position in relation to the adjacent walls (106a-106b) of the vertex (106), forming opposite rims (111a 111b), whose ends are perpendicularly folded forming short ends (112) and (113) which, besides being grooved (114), are also distanced in parallel from the adjacent walls (107a-107b) of the vertex (107), whose wall (107a) includes a projection perpendicularly oriented to the outside, configuring a perpendicular rim (115), finalizing the configuration of a profile that permits the assembly of structures (103) which, in turn, receives different closings (101) and doors (102), configuring cabinets / enclosures or boxes (100).

Owner:FRANCISQUINI MELQUISEDEC

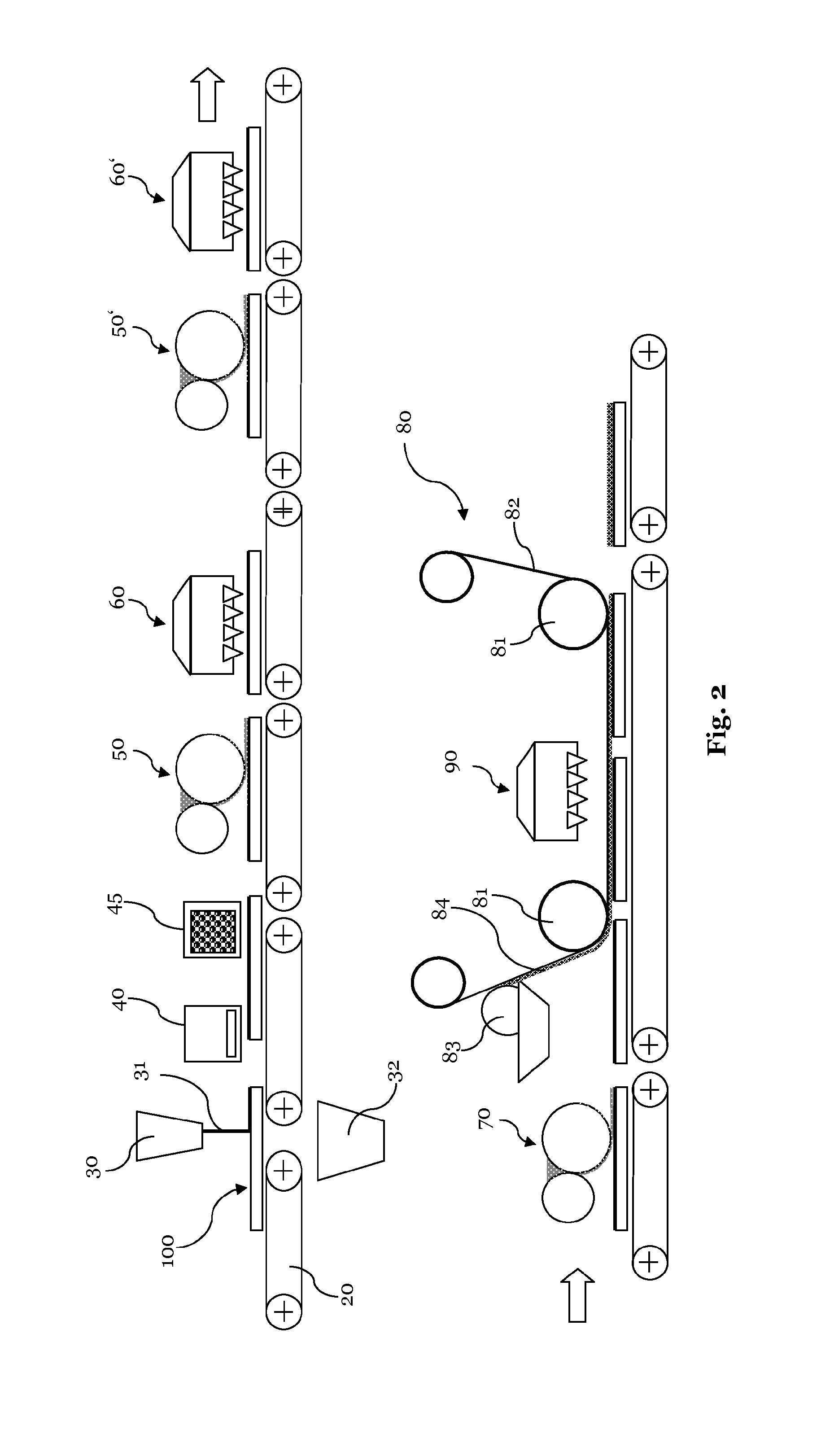

Continuous process for manufacturing electrical cables

InactiveUS7459635B2Increase in costExtended production timeNon-insulated conductorsPlastic/resin/waxes insulatorsElectrical conductorEngineering

A process for manufacturing an electric cable. In particular, the process includes the steps of: a) feeding a conductor at a predetermined feeding speed; b) extruding a thermoplastic insulating layer in a position radially external to the conductor; c) cooling the extruded insulating layer; and d) forming a circumferentially closed metal shield around the extruded insulating layer. The process may be carried out continuously, i.e., the time occurring between the end of the cooling step and the beginning of the shield forming step is inversely proportional to the feeding speed of the conductor.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

Process for the production of phenylalkanes that use a catalyst based on silicated alumina

InactiveUS20050177017A1Good mechanical resistanceImprove spatial resolutionCatalyst activation/preparationHydrocarbonsAlkyl transferArame

The invention relates to a process for the production of at least one compound that is selected from among the 2-, 3-, 4-, 5-, and 6-phenylalkanes by alkylation of an aromatic compound by means of at least one olefin that comprises at least 9 carbon atoms per molecule, in the presence of a catalyst that comprises at least one non-zeolitic substrate with a silicated alumina base that contains an amount of more than 6% by weight and less than or equal to 50% by weight of silica (SiO2) and that exhibits particular characteristics, whereby said process is carried out at a temperature of between 30 and 400° C., a pressure of between 0.1 and 10 MPa, an hourly volumetric flow rate of 0.50 to 200 h−1, and an aromatic compound / olefin molar ratio of between 1:1 and 50:1.

Owner:INST FR DU PETROLE

Improvement to metallic cross sections for the manufacture of housing for electrical panels

InactiveUS20070175648A1Good mechanical resistanceImprove stabilitySubstation/switching arrangement casingsGaseous cathodesElectronic componentMetal

Especially developed for the assembly of structures which are normally used in the most varied of cabinet types, these are also known as electrical panels, which in reality are cabinets with side closing doors to house a very large variety of electrical and electronic components and devices, encompassing a cross section (104) which on its exterior constitutes the means of support for the enclosures and accessories, whilst that on the inside, the same structure configures the uprights for the assembly of the electrical and electronic devices.

Owner:FRANCISQUINI MELQUISEDEC

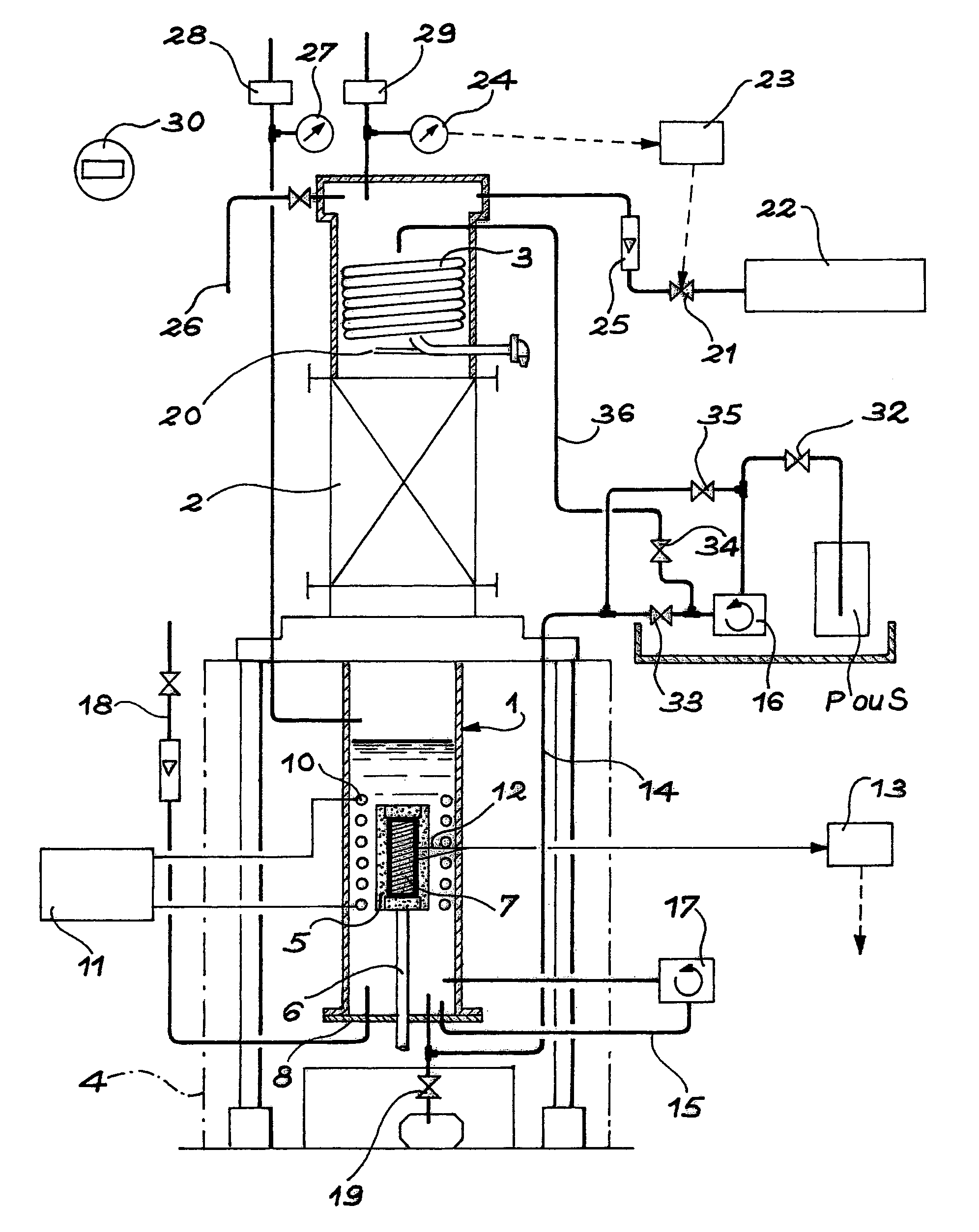

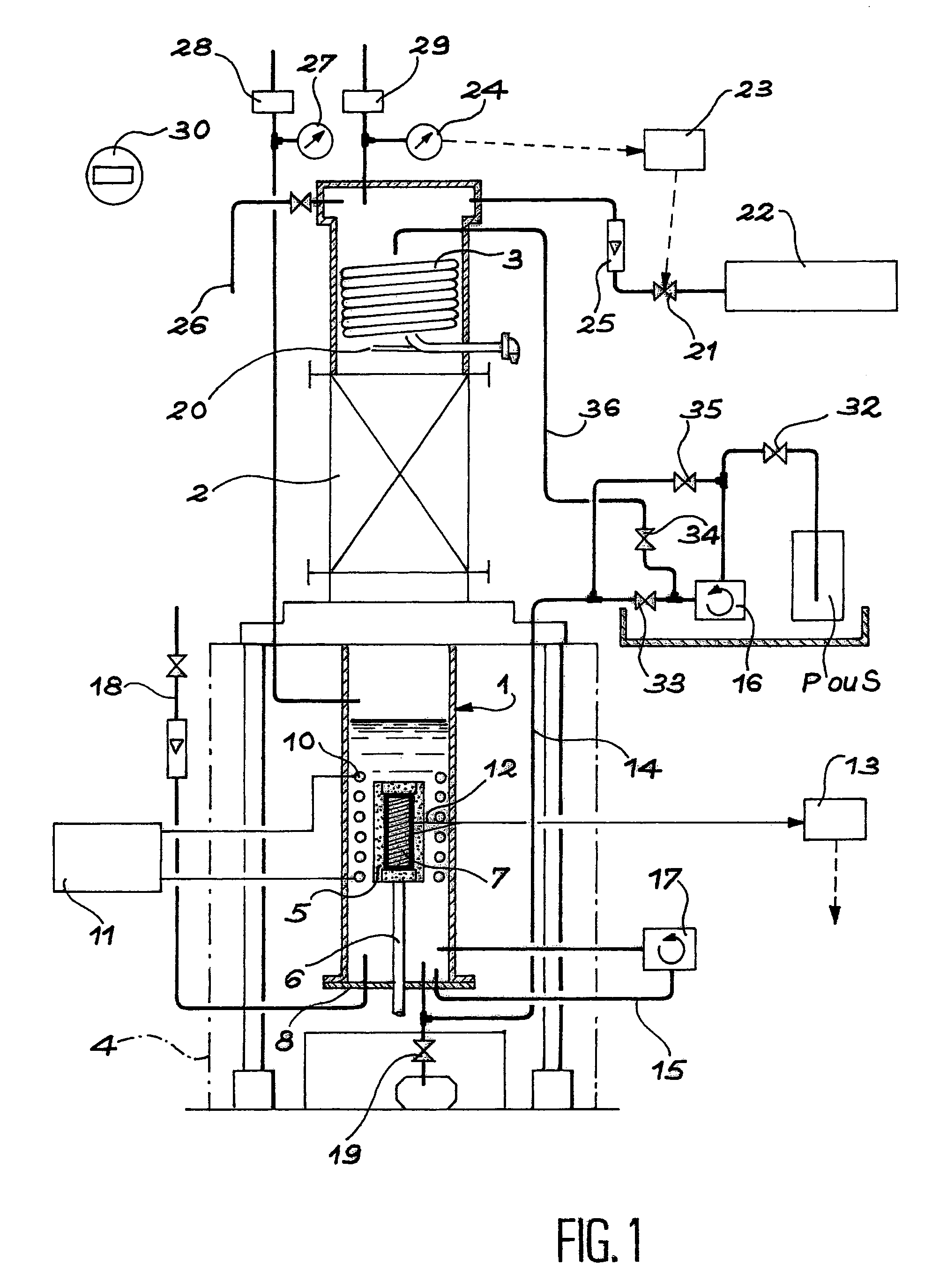

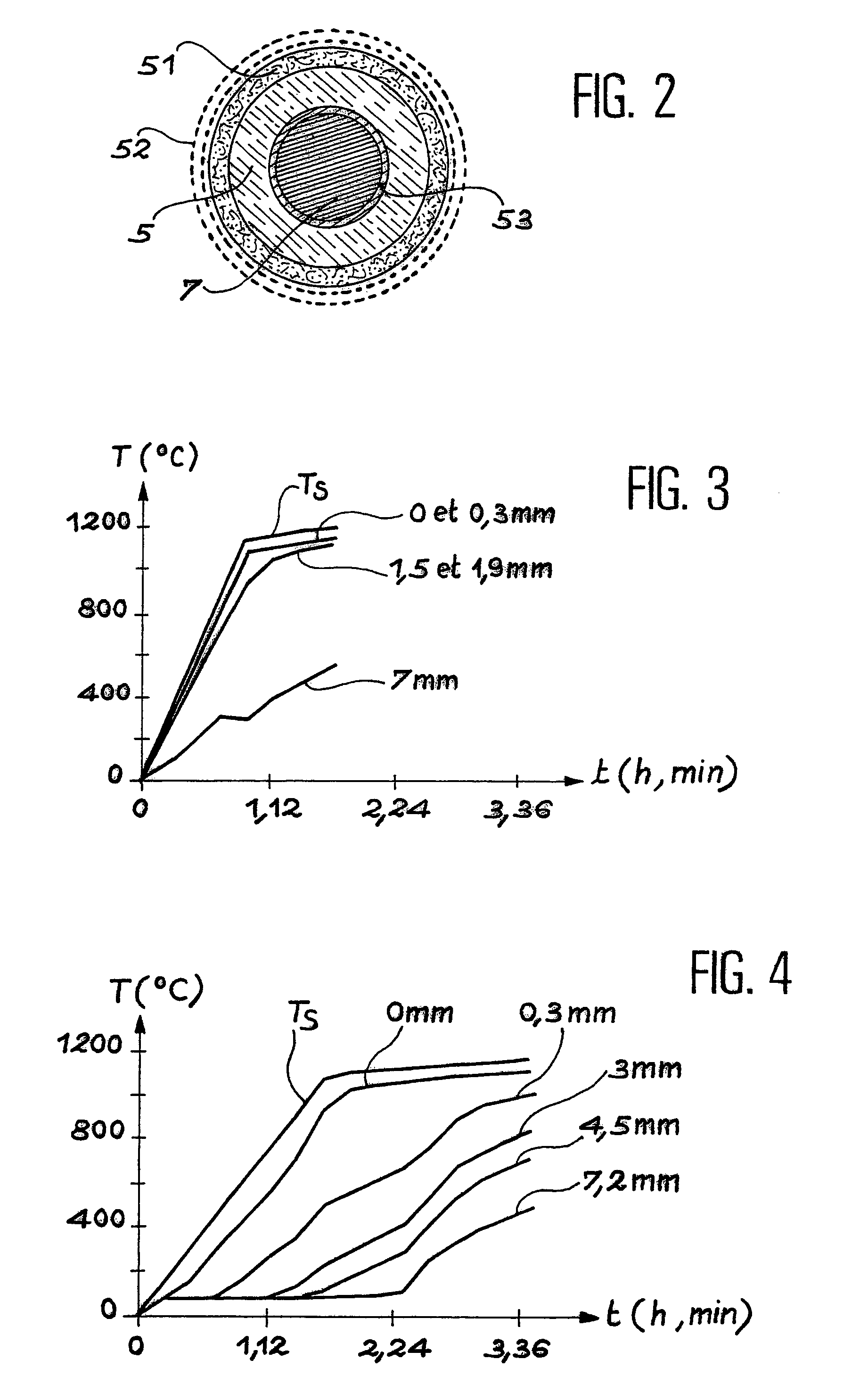

Methods for calefaction densification of a porous structure

InactiveUS6994886B2Good mechanical resistanceImprove thermal insulation performancePretreated surfacesCoatingsDecompositionVaporization

The invention relates to a film-boiling densification method for a porous structure (mixed gas-liquid method) (5) consisting in immersing of the porous structure into a liquid precursor, a hydrocarbon, for example, and heating the system in order to deposit the decomposition product of said liquid precursor, for example carbon, into the pores of the porous structure, characterized in that the flow of the liquid precursor entering the porous structure is reduced, for example by means of a filter (52) made of polytetrafluorethylene surrounding the structure so as to reduce the vaporization phenomenon of the liquid precursor around the porous structure to be densified.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

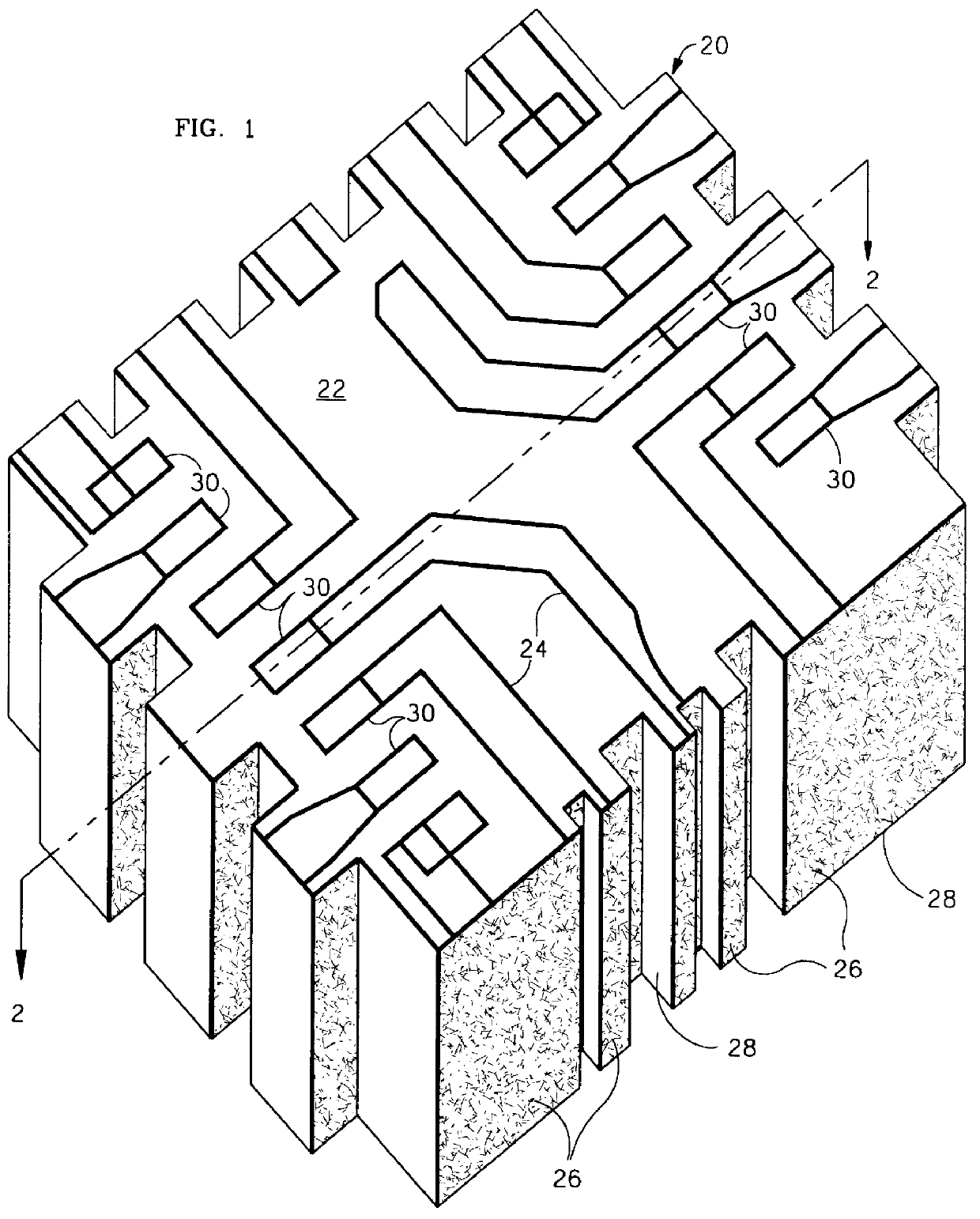

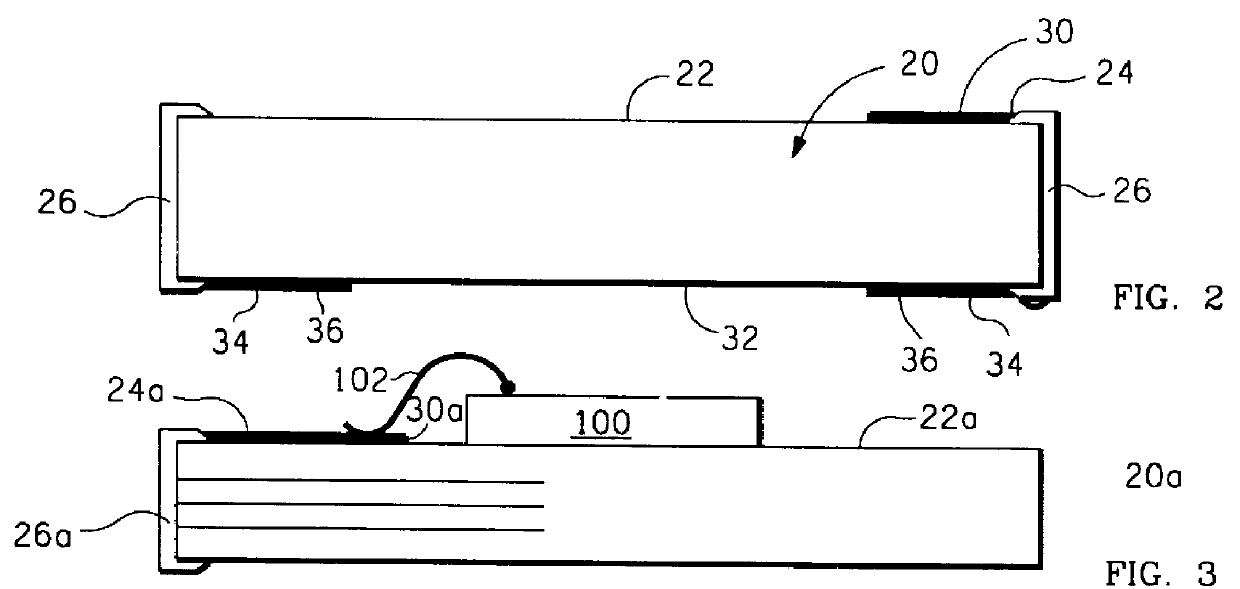

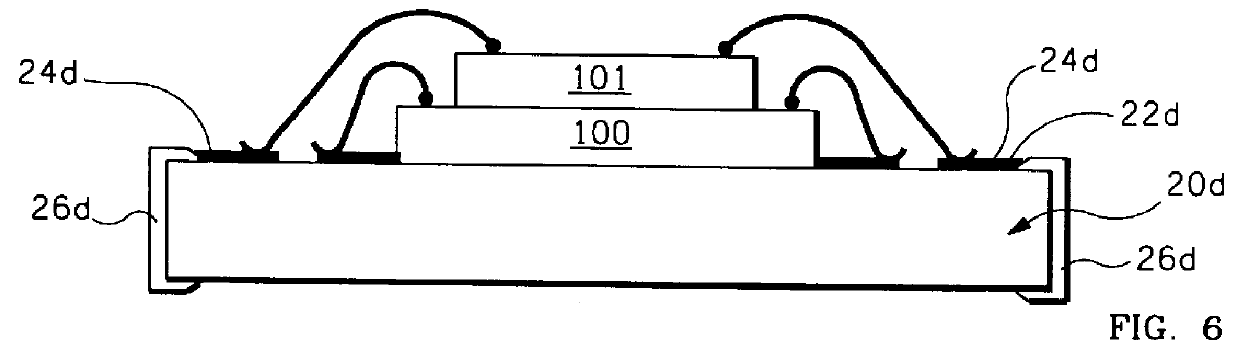

Monolithic integrated multiple electronic components internally interconnected and externally connected by conductive side castellations to the monolith that are of varying width particularly monolithic multiple capacitors

InactiveUS6011684AFirmly connectedSave spaceMultiple fixed capacitorsSemiconductor/solid-state device detailsAudio power amplifierCeramic capacitor

Variable width electrically conductive (i) traces and (ii) pads in the forms of castellations and connecting traces upon the surfaces of volume microminiature electronic components permit variable area electrical interconnection in three dimensions, particularly of monolithic, buried-substrate, multiple ceramic capacitors to integrated circuit receivers and amplifiers to make microminiature hearing aids insertable within the ear canal. A preferred embodiment monolithic multiple capacitor with side, top and bottom surfaces has a number of electrically conductive parallel layers disposed within its body with a conductive trace extending from each layer to be exposed upon a side surface. Metallized bus strips of at least two widths extend along the side surface; relatively thinner bus strips selectively interconnecting the exposed traces to form a plurality of capacitors while the relatively thicker bus strips selectively extend at least some traces to one or more edge(s) of the top and / or bottom surfaces of the body where they may be externally connected, normally to piggy-backed components, by reflow soldering. The different-width metallized bus strips are preferably made by rectangular saw-cut slots in the body at differently spaced intervals, the rectangular saw-cuts forming castellations having a greater depth than width to reduce parasitic capacitance.

Owner:DEVOE ALAN D +1

Easy-to-clean cooking surface and electrical household appliance comprising such a surface

InactiveUS20080081211A1Improved ease of cleaning characteristicReduce adhesionVacuum evaporation coatingSputtering coatingKitchen utensilsAlloy

Owner:SEB SA

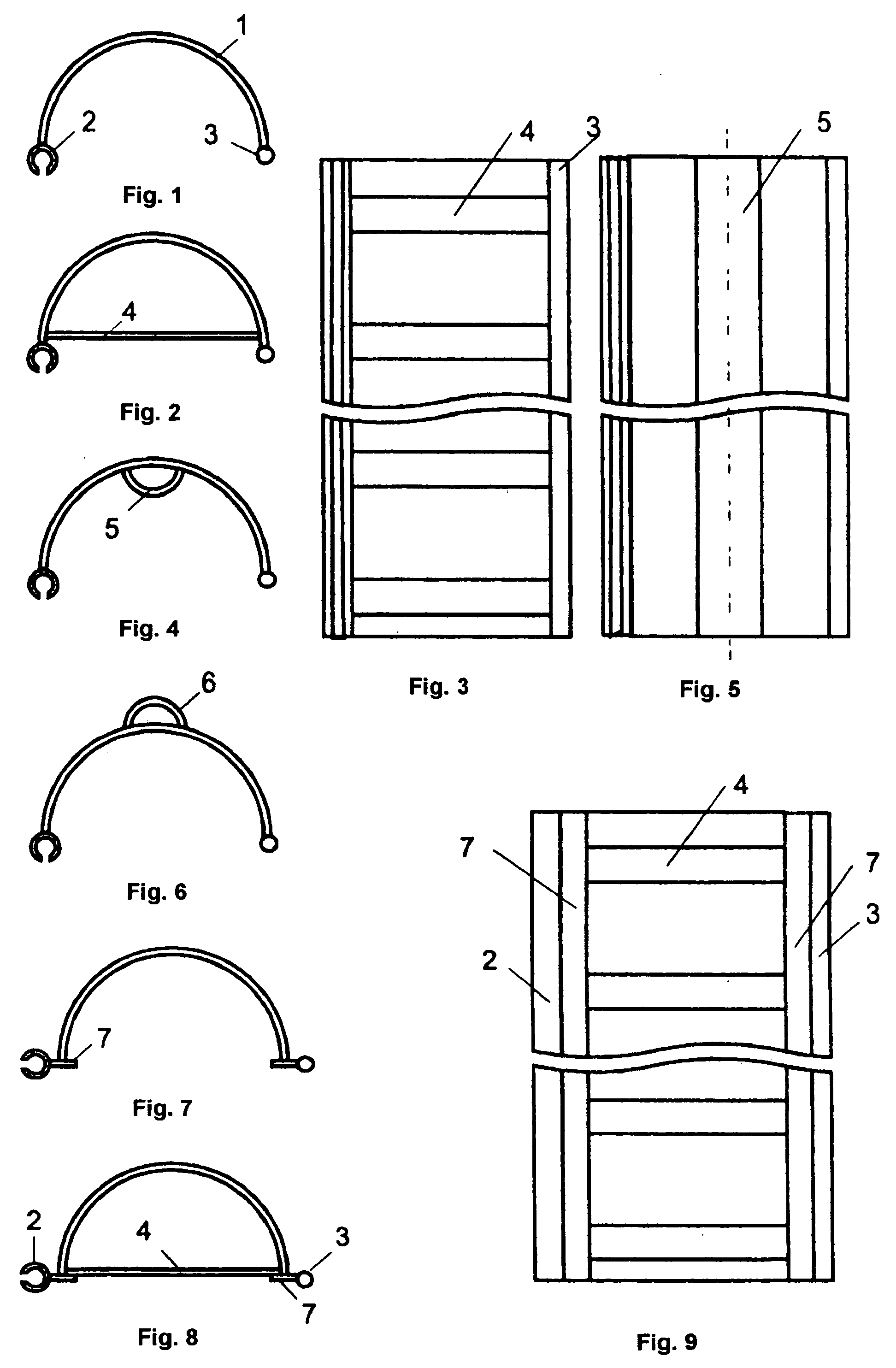

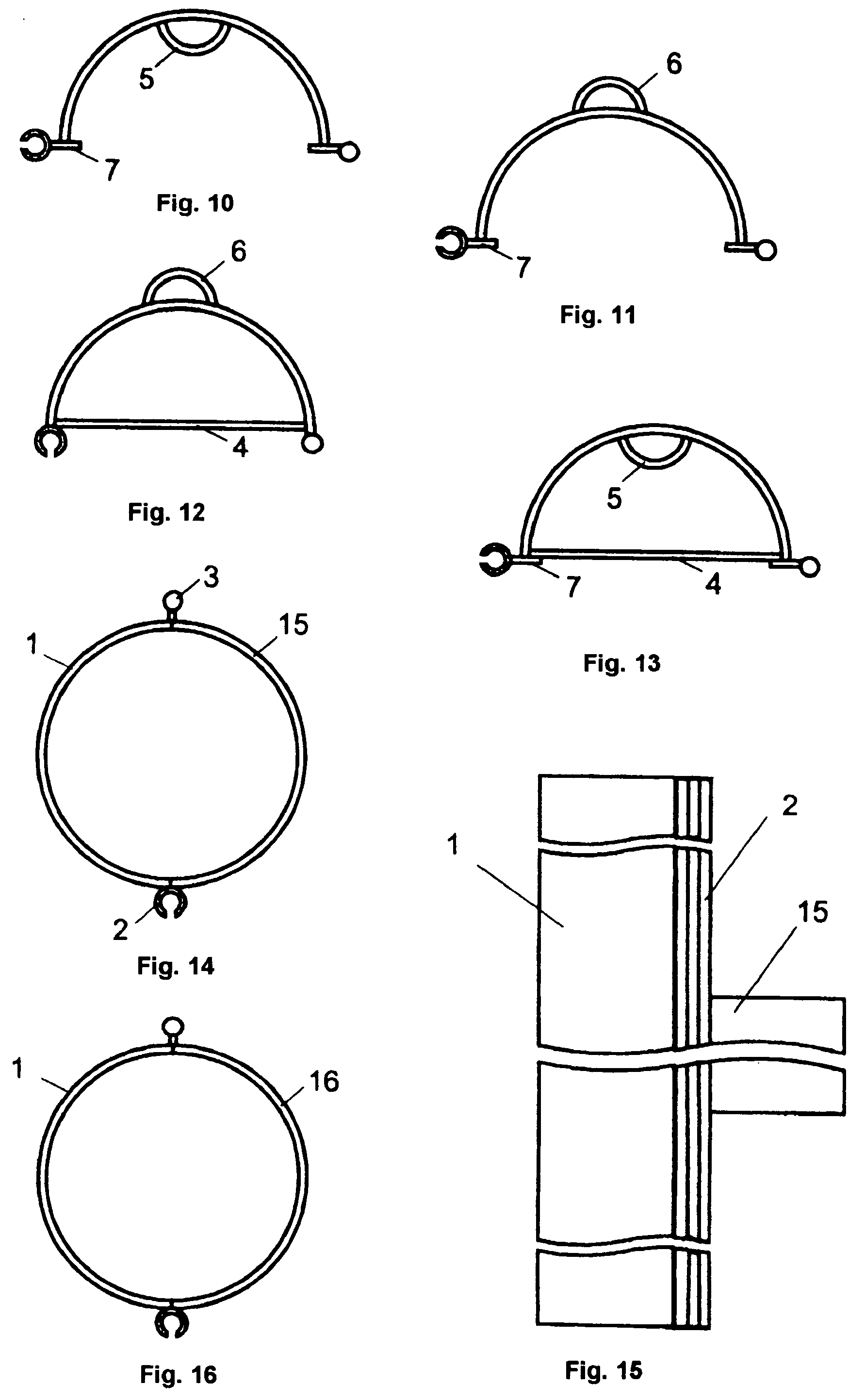

Grooved sheet pile and method for production thereof

InactiveUS20040120775A1Good mechanical resistanceReduce necessityArtificial islandsExcavationsSheet pileCorrosion resistant

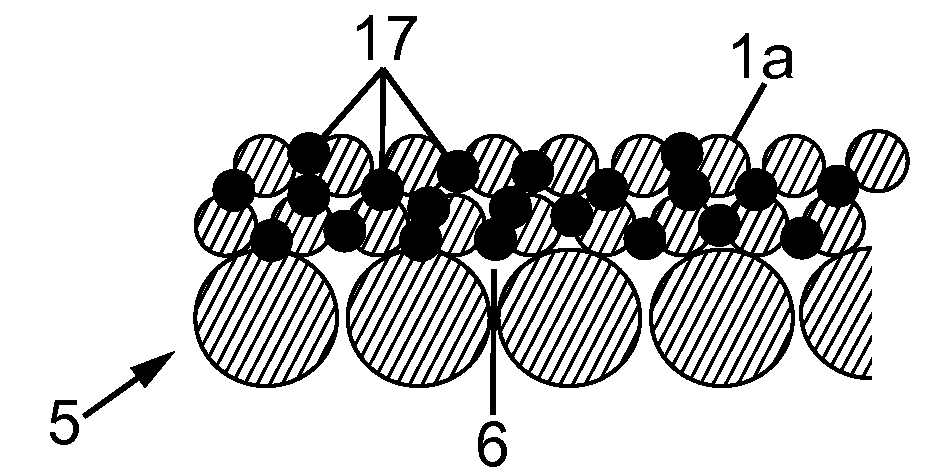

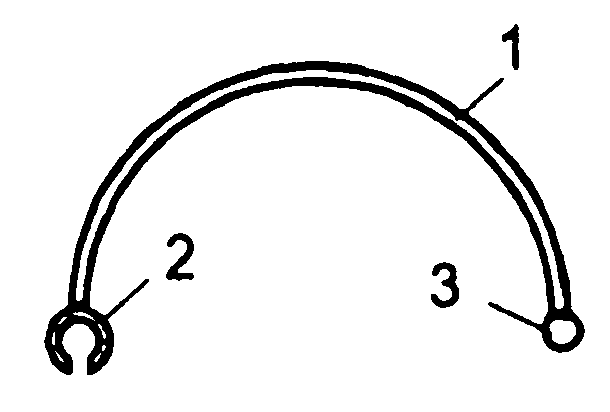

The inventive grooved sheet pile having a though-type body is produced by cutting a cylindrical segment (1) from a round tube along the length thereof, and fixing locking elements (2 and 3) to the side edges of said segment. The segment (1) can be cut together with an annular section (15) of a tube (16) and reinforced by fixing elements (4), an internal (5) or external (6) strap, internal (8 and 9) and / or external (10 and 11) faceplates or stiffening ribs fixed thereto. Said segment can be embodied from sections of cylindrical segments welded to each other. At least one section (18) has an increased thickness or is made of a corrosion-resistant material. In order to produce an enlarged grooved pile, two or more cylindrical segments (1) cut from a tube are used. Said segments are disposed in a parallel position with respect to each other and fixed to each other with the aid of reinforcing elements (12, 13, and 14). The locking elements (2 and 3) are fixed to the lateral side of the thus obtained panel. Said invention makes it possible to simplify the production of the grooved piles and to expand the variability of the design thereof. Said production can be carried out without rolling mills.

Owner:SHEET PILE LLC

Method for producing a directly printed panel

PendingUS20160200092A1Good mechanical resistanceLess economicalCovering/liningsSynthetic resin layered productsHardnessEngineering

The present invention relates to a panel as well as a method for producing a panel, in particular a wall- ceiling- or floor panel. The method according to the invention provides that a layer of liquid radiation curing acrylate with a low Martens hardness is applied on a support layer in a first step. This is followed by an application of an intermediate layer in a second step and thereafter the application of a further layer wet-on-wet, which as a Martens hardness after curing which is larger than the Martens hardness of the first applied layer. The resulting panel has an intermediate layer with an inhomogeneous hardness profile due to the wet-on-wet application which leads to particularly advantageous properties.

Owner:XYLO TECH AG

Apparatus for producing scored lines in a film

InactiveUS20050123724A1Good mechanical resistanceMechanical working/deformationLayered productsBearing surfaceBiomedical engineering

The present invention makes it possible to produce at least one scored line in at least one plastic outer layer of a film. The device of the invention includes bearing surface for the film and at least one projection for forming the scored line by penetration of the projection into the plastic layer when the film is in position against the said bearing surface. The projections may be arranged in the form of ribs on one or more coaxial rollers. The projections may form the scored line by ultrasonic plastic flow, the film being compressed between a sonotrode and the rollers. The invention provides methods using these devices and it also provides films having scored lines, and packages having scored lines.

Owner:MARS INC

Electric cable with strain sensor and monitoring system and method for detecting strain in at least one electric cable

ActiveUS8953915B2Low costAvoid permanent damageControlForce measurement by measuring optical property variationElectrical conductorMonitoring system

An electric cable includes a strain sensor longitudinally extending along the cable and including a strain optical fiber arranged within a bending neutral region surrounding and including a bending neutral longitudinal axis of the electric cable, and at least two longitudinal structural elements, at least one of the at least two longitudinal structural elements being a core including an electrical conductor, wherein the strain sensor is embedded in a strain-transferring filler mechanically coupling at least one of the at least two longitudinal structural elements with the strain sensor. With the disclosed cable construction, the strain experienced by the at least one of the at least two longitudinal structural elements is transferred to the strain sensor at least in a strained condition. In the preferred embodiments, the electric cable is a heavy-duty cable.

Owner:PRYSMIAN SPA

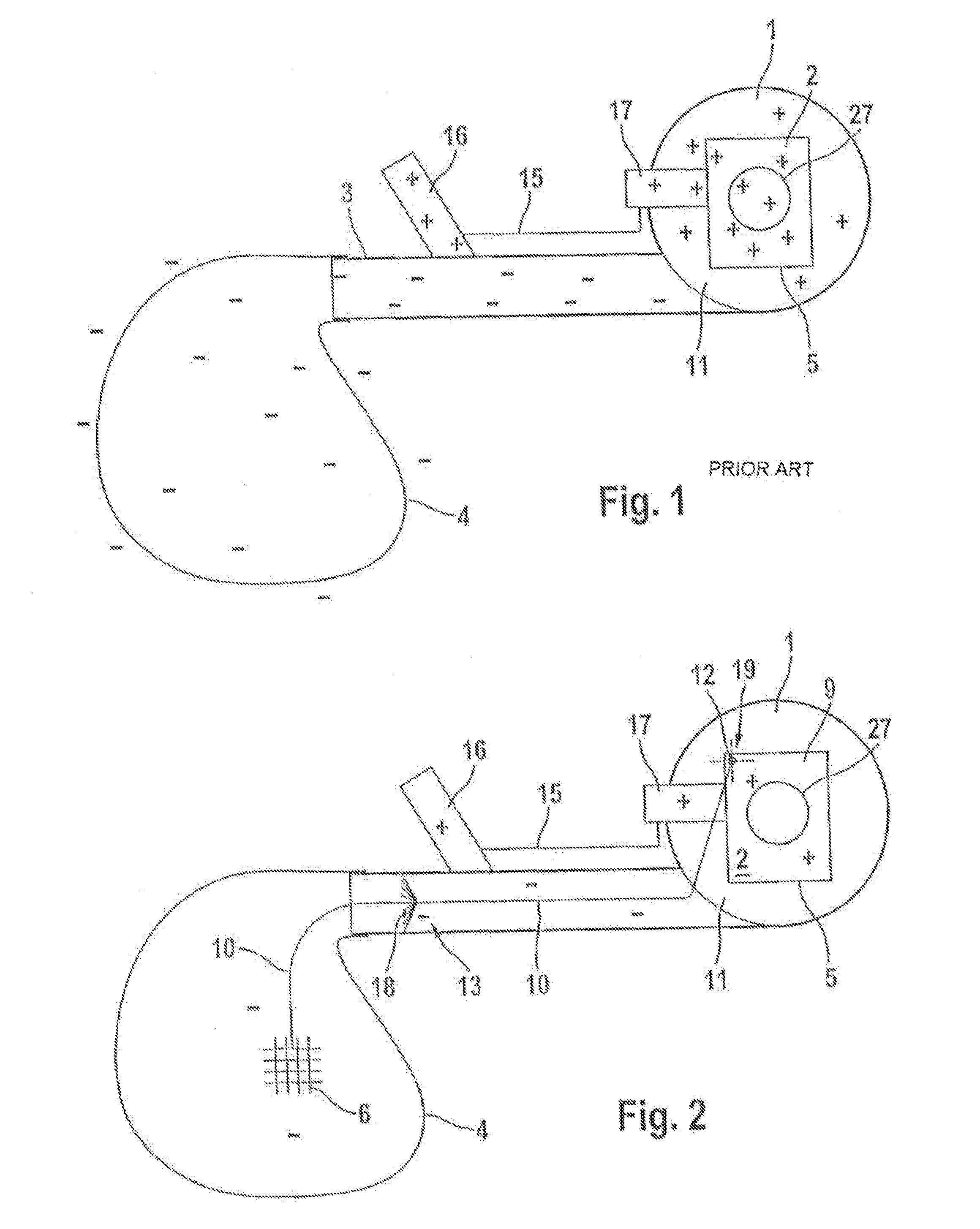

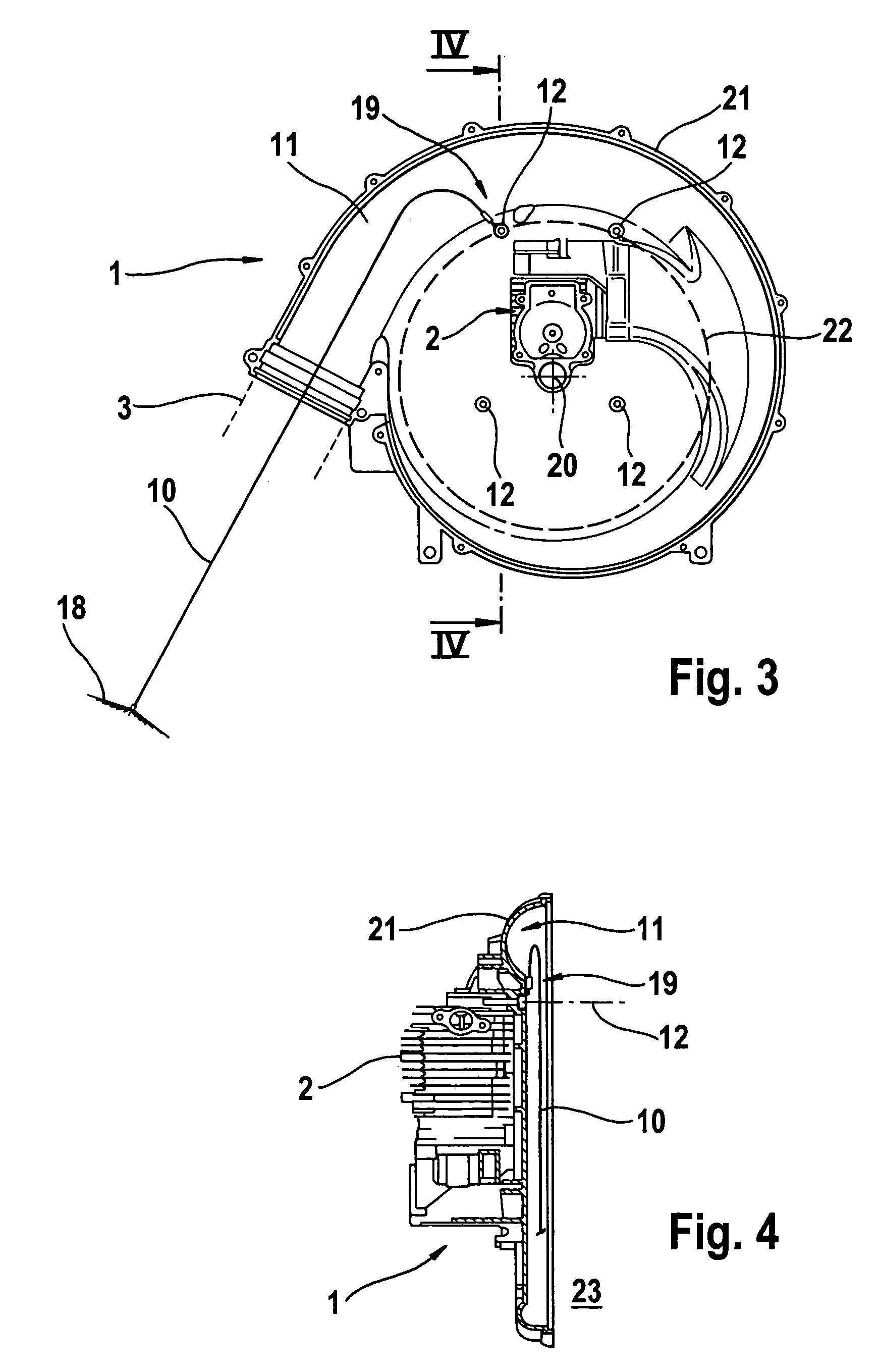

Suction device/blower

InactiveUS7279021B2Potential differenceIncrease contactCombination devicesLiquid degasificationElectricityEngineering

Owner:ANDREAS STIHL AG & CO KG

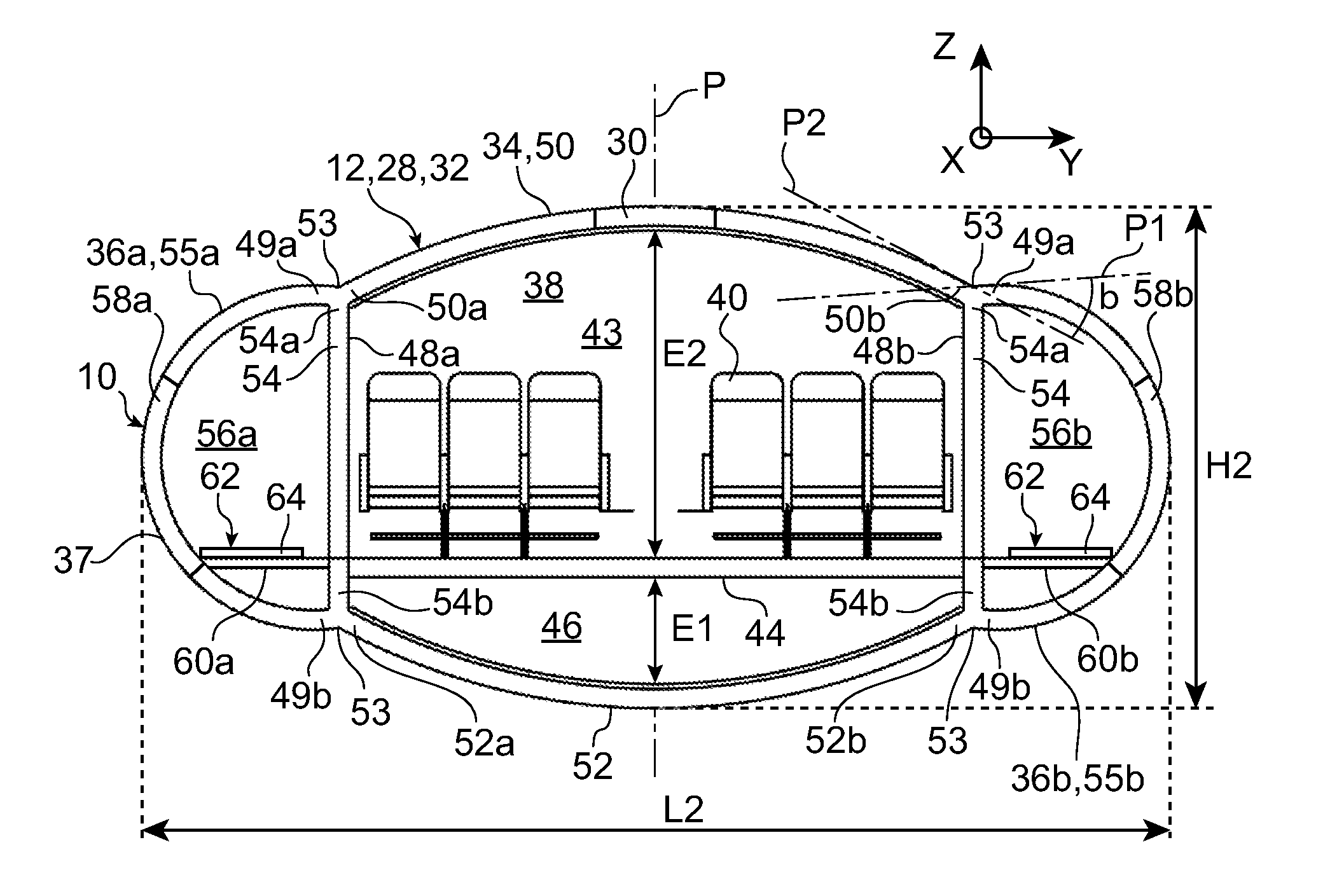

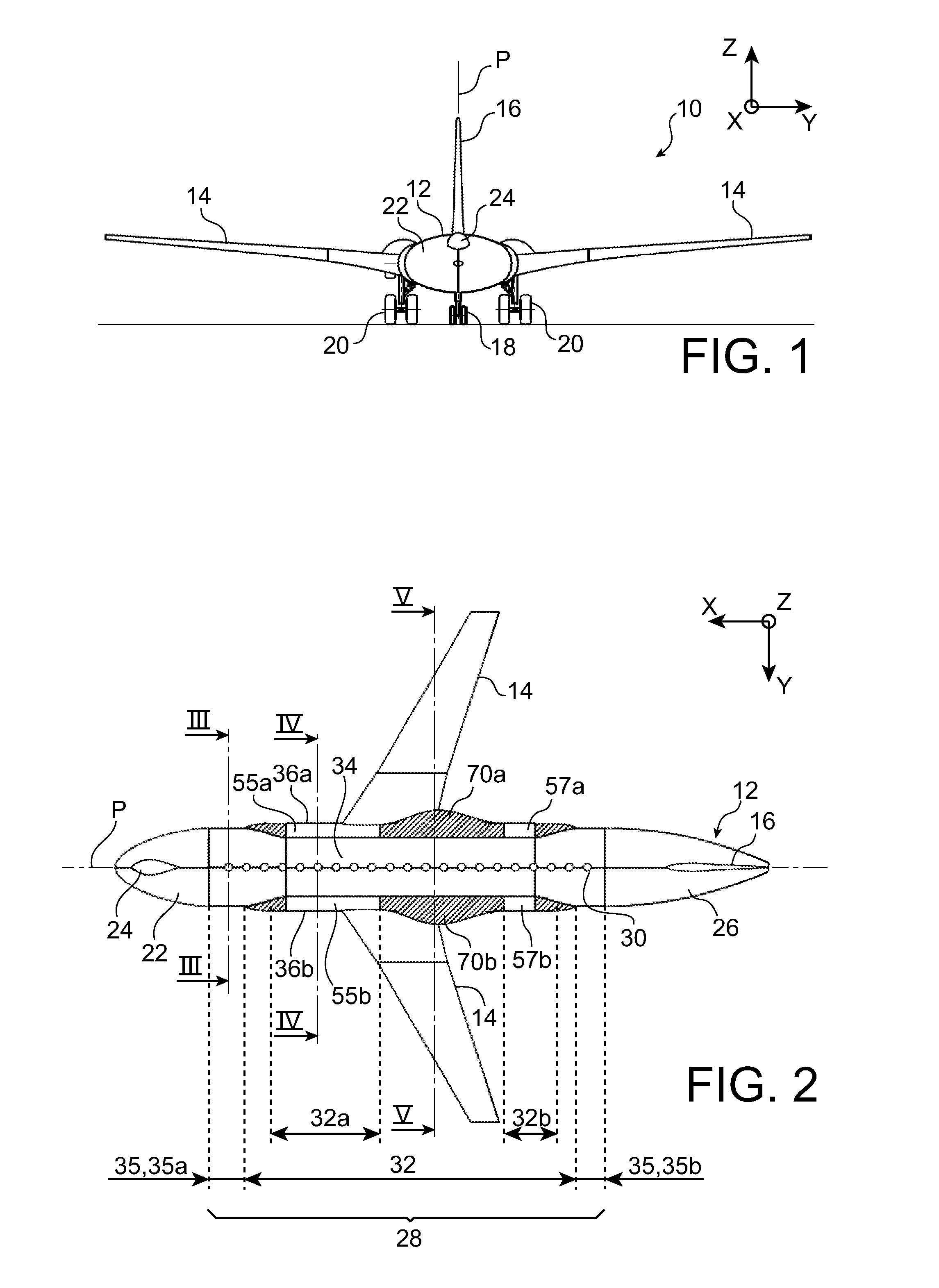

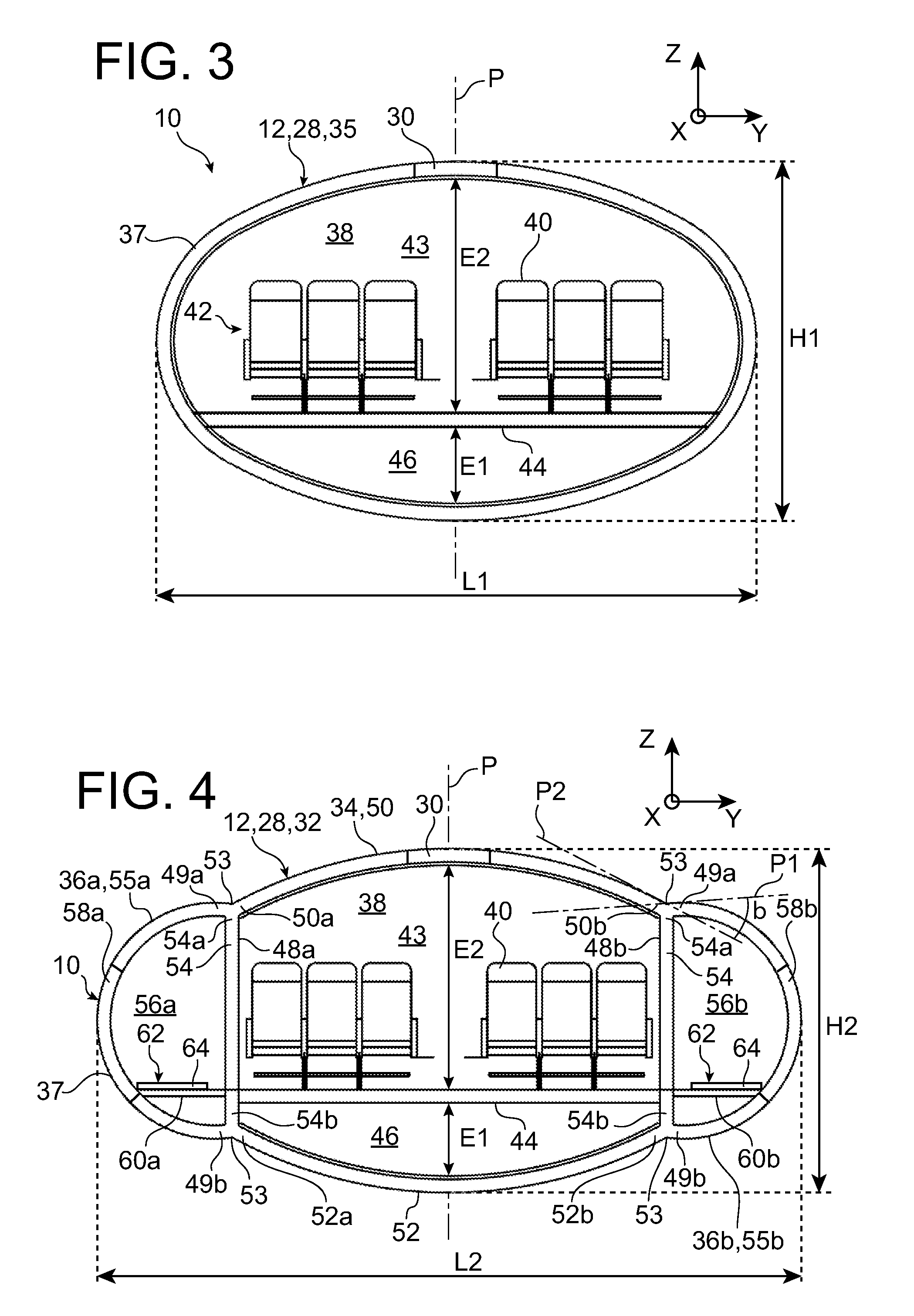

Airplane with a fuselage having side outgrowth delimiting storage spaces

InactiveUS20140175218A1Simple and economical and effectiveReduce internal volumePower plant fuel tanksFreight handlingCarrying capacityFuel tank

An aircraft of which the transversal section of the fuselage is reduced optimally at the price of a reduced carrying capacity of luggage or merchandise but adapted to short- and medium-haul type routes. The fuselage has for this purpose lateral protuberances defining storage areas arranged on either side of a passenger cabin and able to house luggage and / or merchandise, and / or onboard service equipment, and / or removable fuel tanks.

Owner:AIRBUS OPERATIONS (SAS)

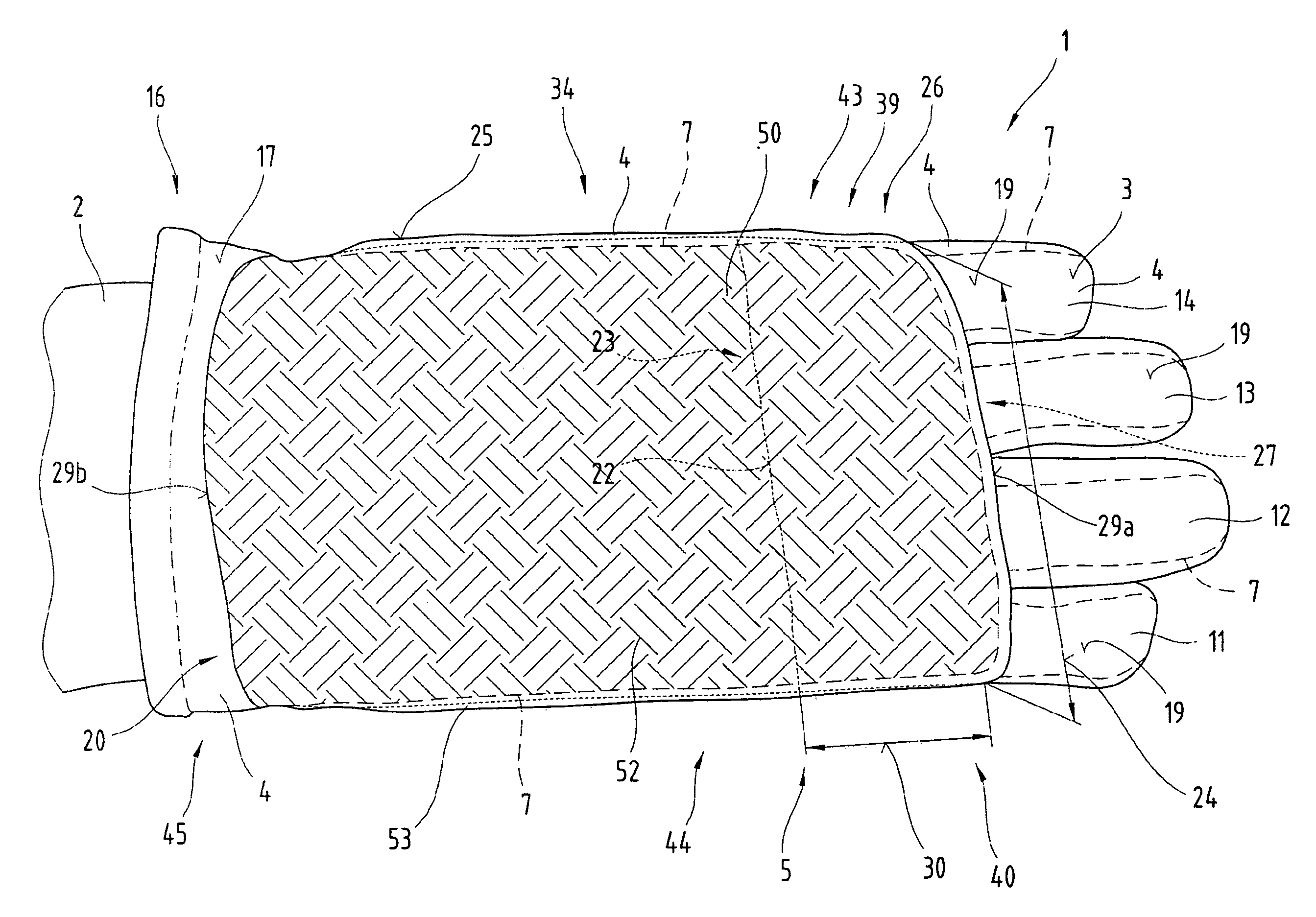

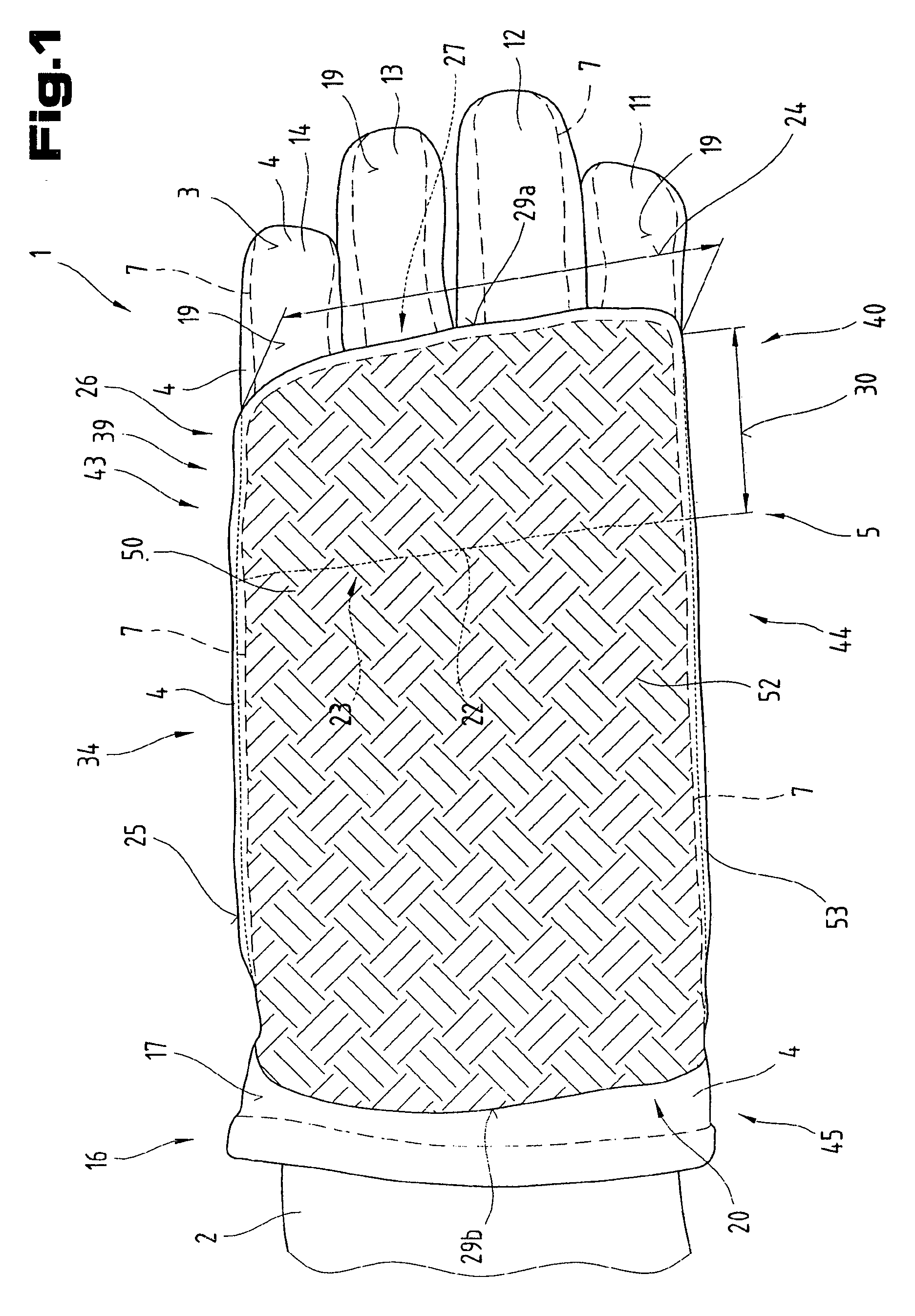

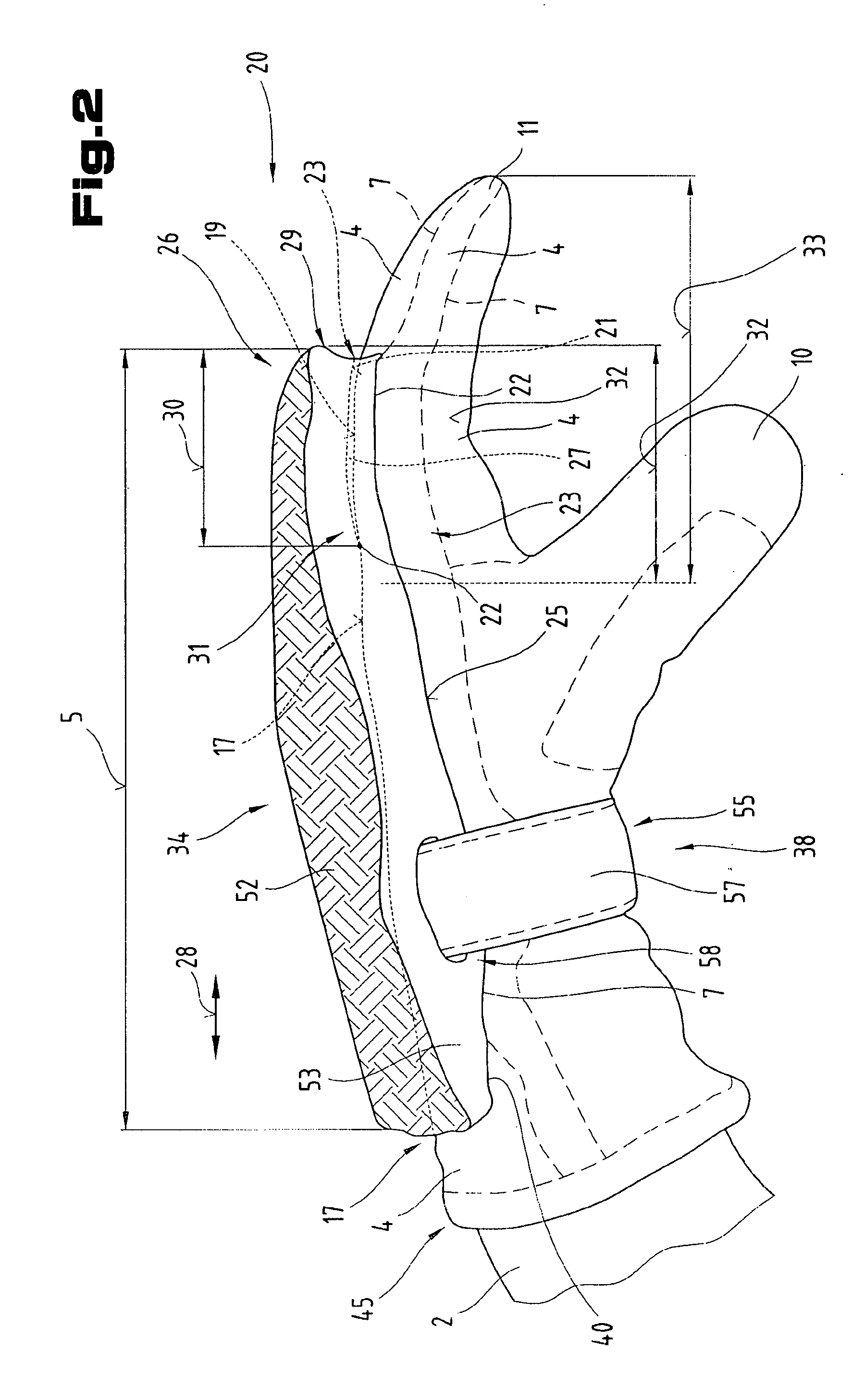

Protective glove

InactiveUS20090126058A1Function increaseUsable stowage spaceGlovesEye treatmentForeign matterEngineering

The invention relates to a protective glove (1) for protecting certain regions of a user's hand (2) against foreign bodies impacting with it such as bullets and / or stabbing or cutting devices, with a lining (4) made from a material that is not or not very resistant to stabs, cuts or incisions and is not bullet-proof, for example a textile fabric, a leather, a laminate or similar, comprising several glove fingers (10 to 14), and a glove top face (17) extends on an external surface (3) of the lining (4) in the region of finger top sides (19) and in a top hand region (15), and a bullet-proof and / or cut or stab inhibiting protective padding (20) is built up on or placed on certain regions of the glove top face (17) starting from a padding bottom face (21) and is attached to the lining (4) at joining points (22), and the protective padding (20) prevents penetration by foreign bodies impacting with it to a glove interior lying underneath it.

Owner:ESKA LEDERHANDSCHUHFAB & CO

Cooling article involving evaporation of water from a polymer absorbent

InactiveUS7048976B2Good mechanical resistanceIncrease the number ofHeat protectionWristbandsCross-linkDesorption

The invention relates to a cooling article comprising a polymer absorbent enclosed within a bag delimited by a collapsible envelope having non-watertight walls, wherein said polymer absorbent is under the form of particles each of which comprises a core of less cross-linked polymer sequences more active in retaining absorbed water and a shell of more cross-linked polymer sequences apt to retard diffusion of water from a particle to another during desorption of absorbed water.

Owner:LOREAL SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com