Patents

Literature

33results about How to "High "toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-Strength Steel Sheet with Excellent Low Temperature Toughness and Manufacturing Method Thereof

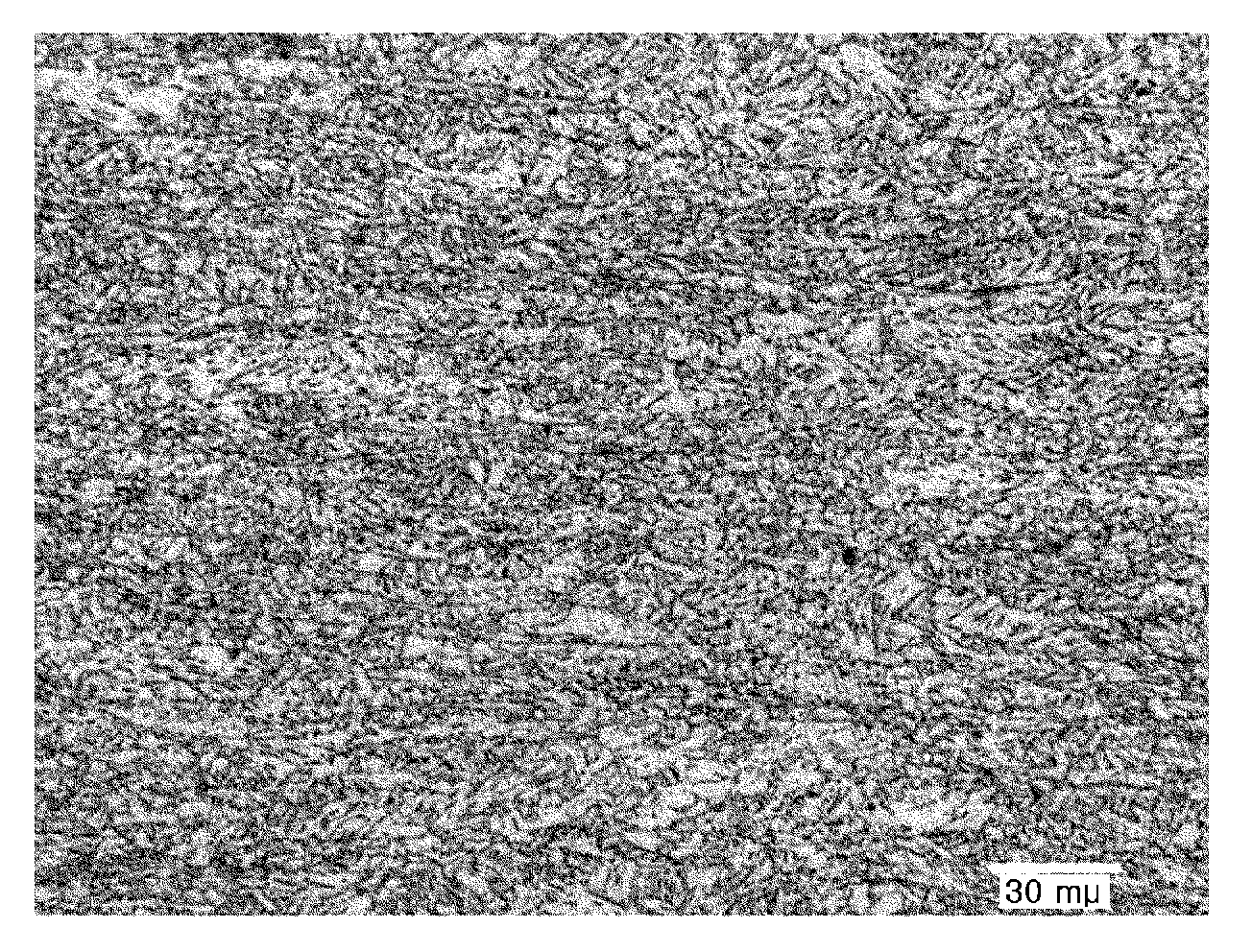

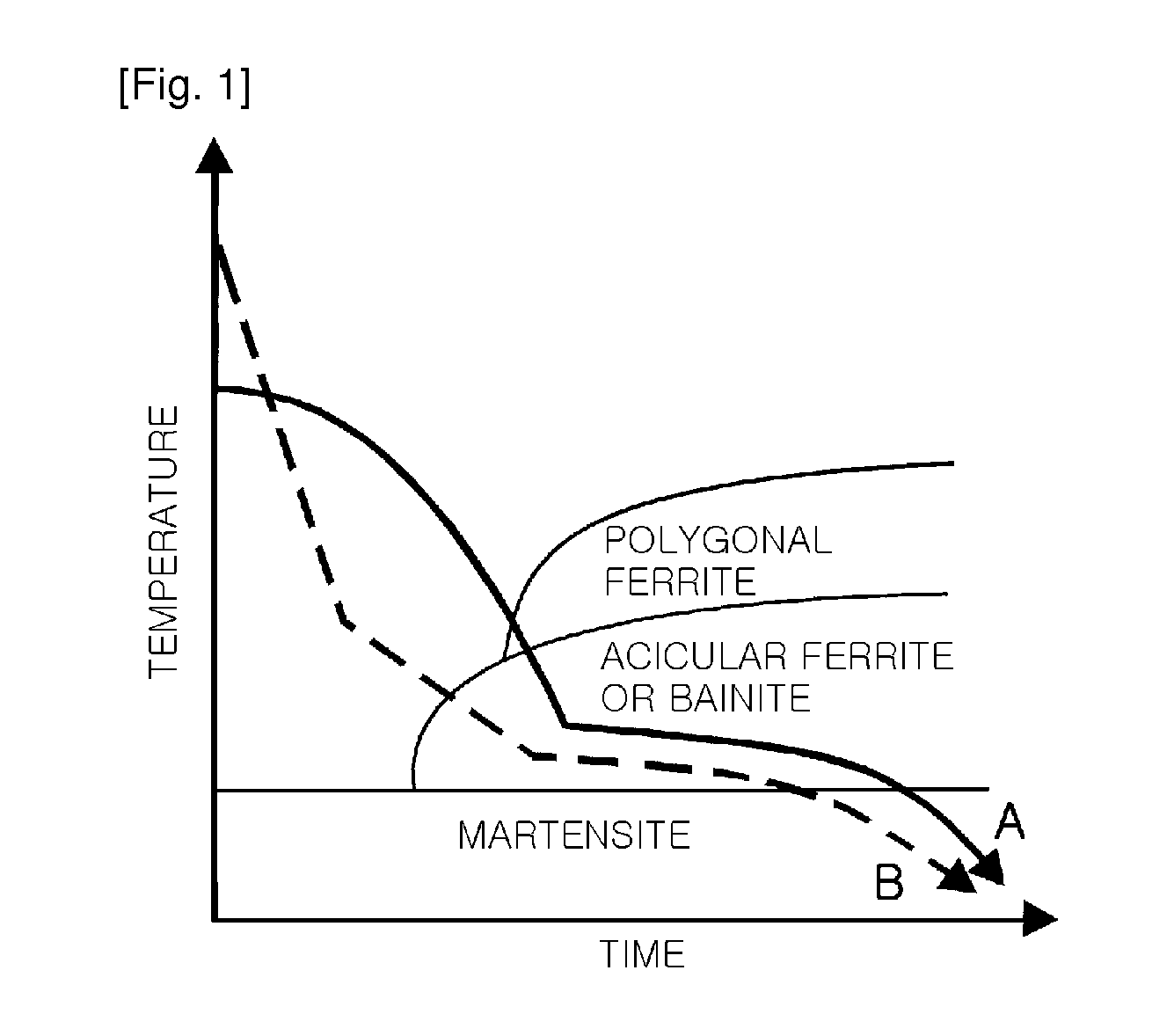

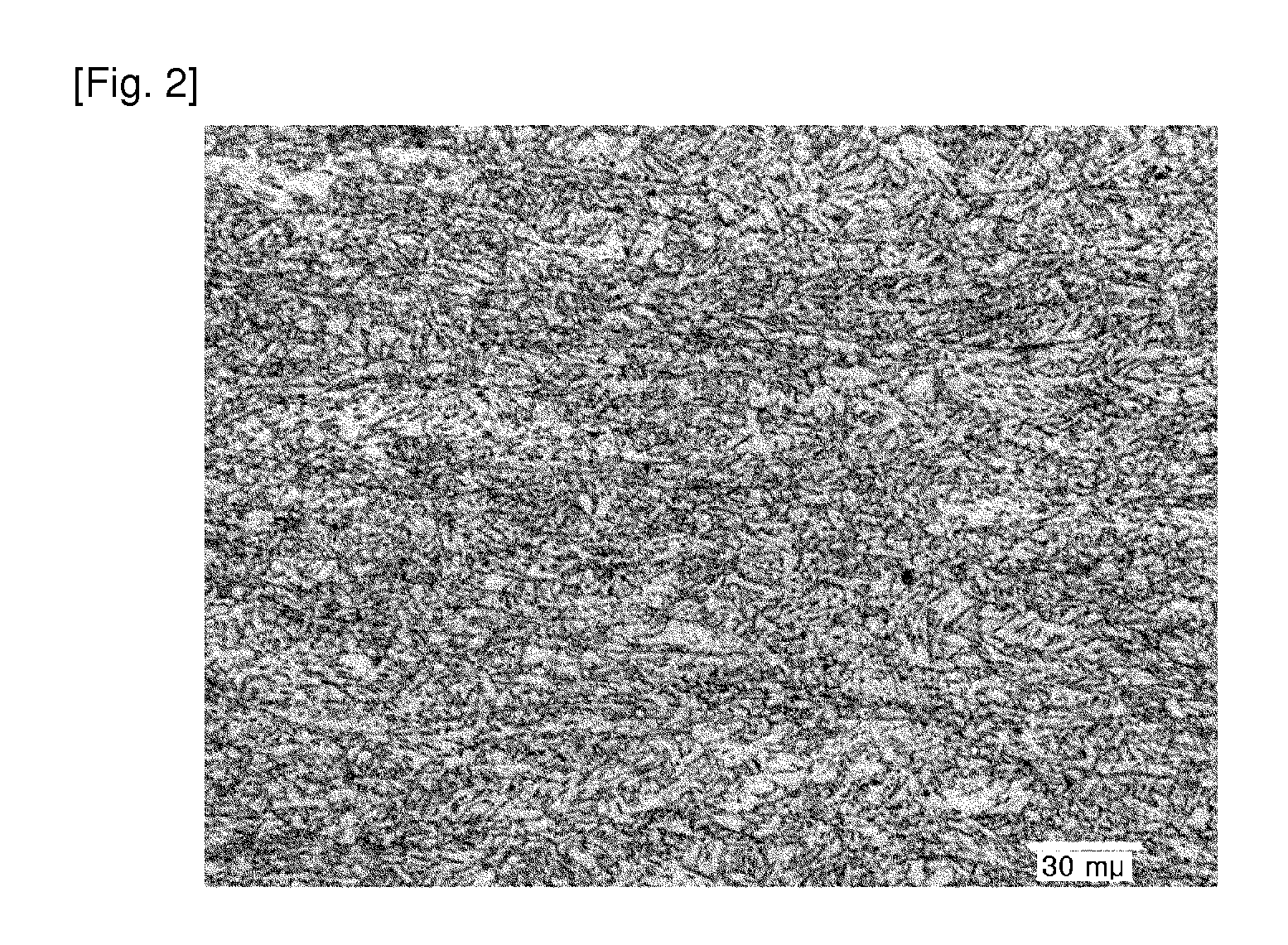

There is provided a high-strength steel plate having acicular ferrite and bainite as a main microstructure and an austenite / martensite (M & A) as a second phase under the control of a cooling rate above the austenite transformation temperature. The high-strength steel plate comprises: carbon (C): 0.03 to 0.10 wt %, silicon (Si): 0.1 to 0.4 wt %, manganese (Mn): 1.8 wt % or less, nickel (Ni): 1.0 wt % or less, titanium (Ti): 0.005 to 0.03 wt %, niobium (Nb): 0.02 to 0.10 wt %, aluminum (Al): 0.01 to 0.05 wt %, calcium (Ca): 0.006 wt % or less, nitrogen (N): 0.001 to 0.006 wt %, phosphorus (P): 0.02 wt % or less, sulfur (S): 0.005 wt % or less, and the balance of iron (Fe) and other inevitable impurities. The method for manufacturing a high-strength steel plate may be useful to economically and effectively manufacture a high strength steel, which is able to secure excellent properties such as high strength and high toughness since the acicular ferrite and bainite may be effectively formed without adding expensive elements such as molybdenum (Mo).

Owner:POSCO

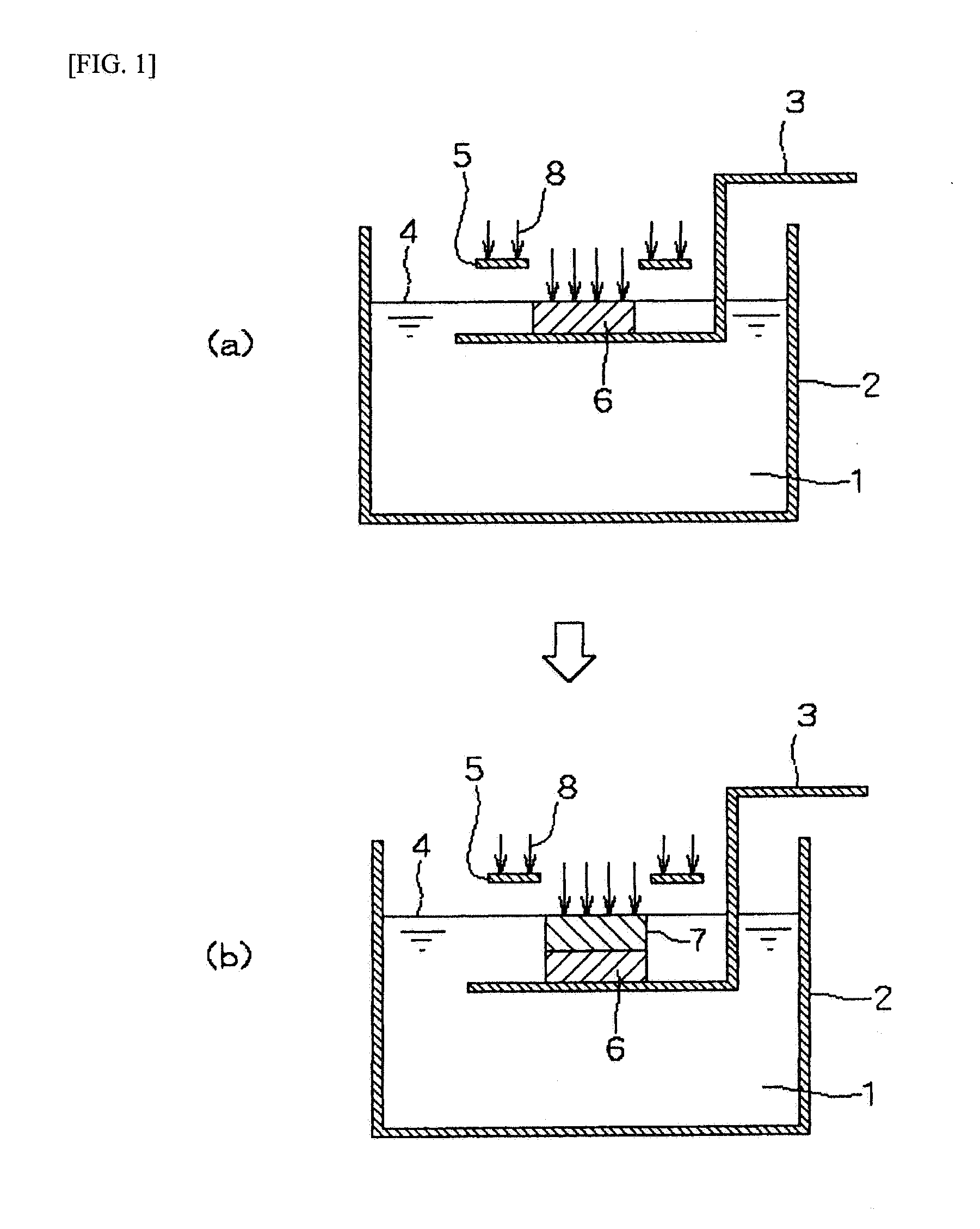

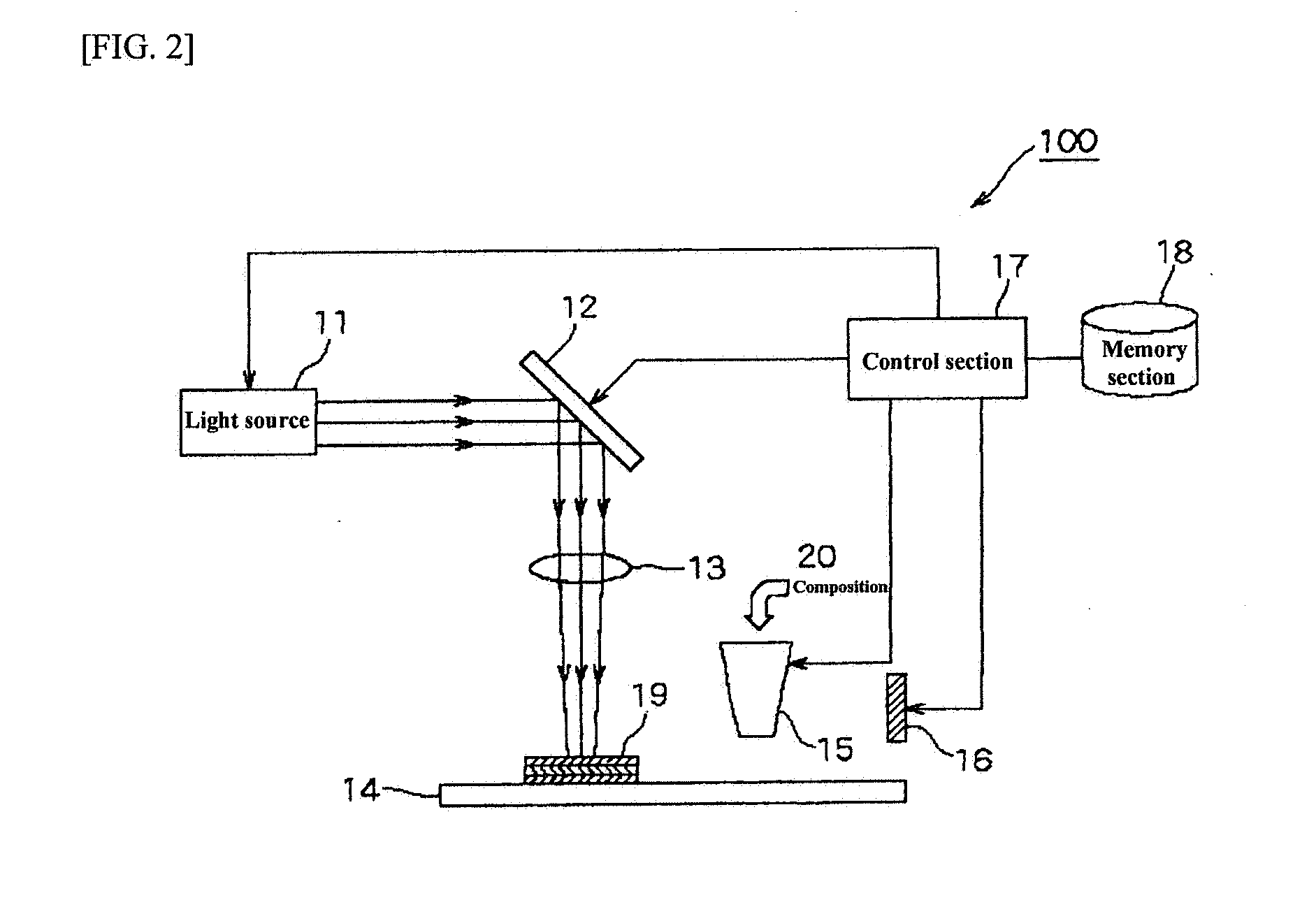

Stereolithography resin compositions and three-dimensional objects made therefrom

InactiveUS20100227941A1High toughnessHigh rigidityAdditive manufacturing apparatusOrganic chemistryPhotoinitiatorPolymer chemistry

A photocurable resin composition for three-dimensional photofabrication operations, including stereolithography, comprising (A) a cationically polymerizable compound having two or more bisphenol structures and one or more hydroxyl groups, (B) a cationically polymerizable compound other than the component (A), (C) a cationic photoinitiator, (D) a radically polymerizable compound, (E) a radical photoinitiator, and (F) multilayer polymer particles having a core and a shell layer, the shell layer containing functional group-modified rubber polymer particles having at least one reactive functional group.

Owner:DSM IP ASSETS BV +2

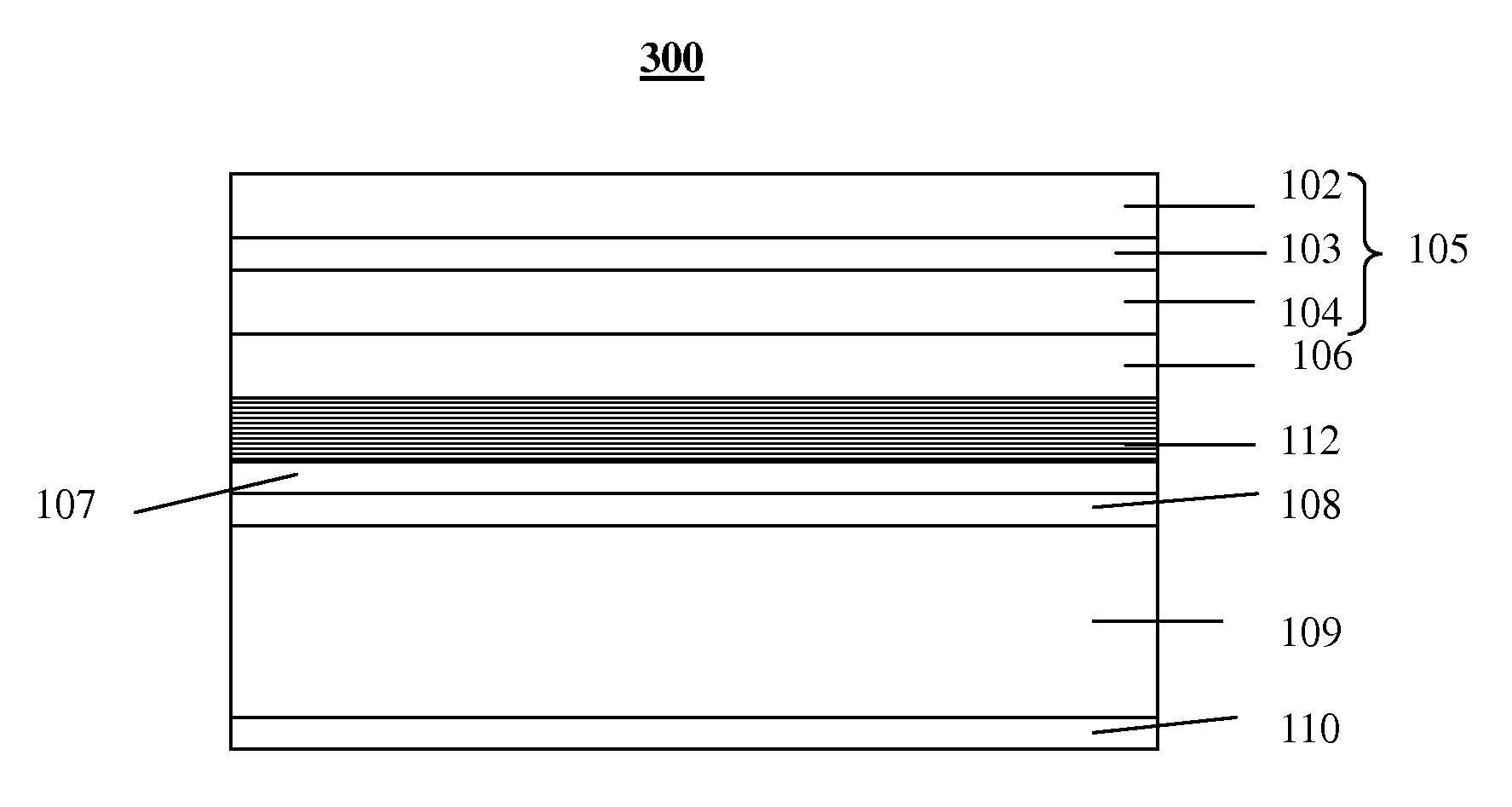

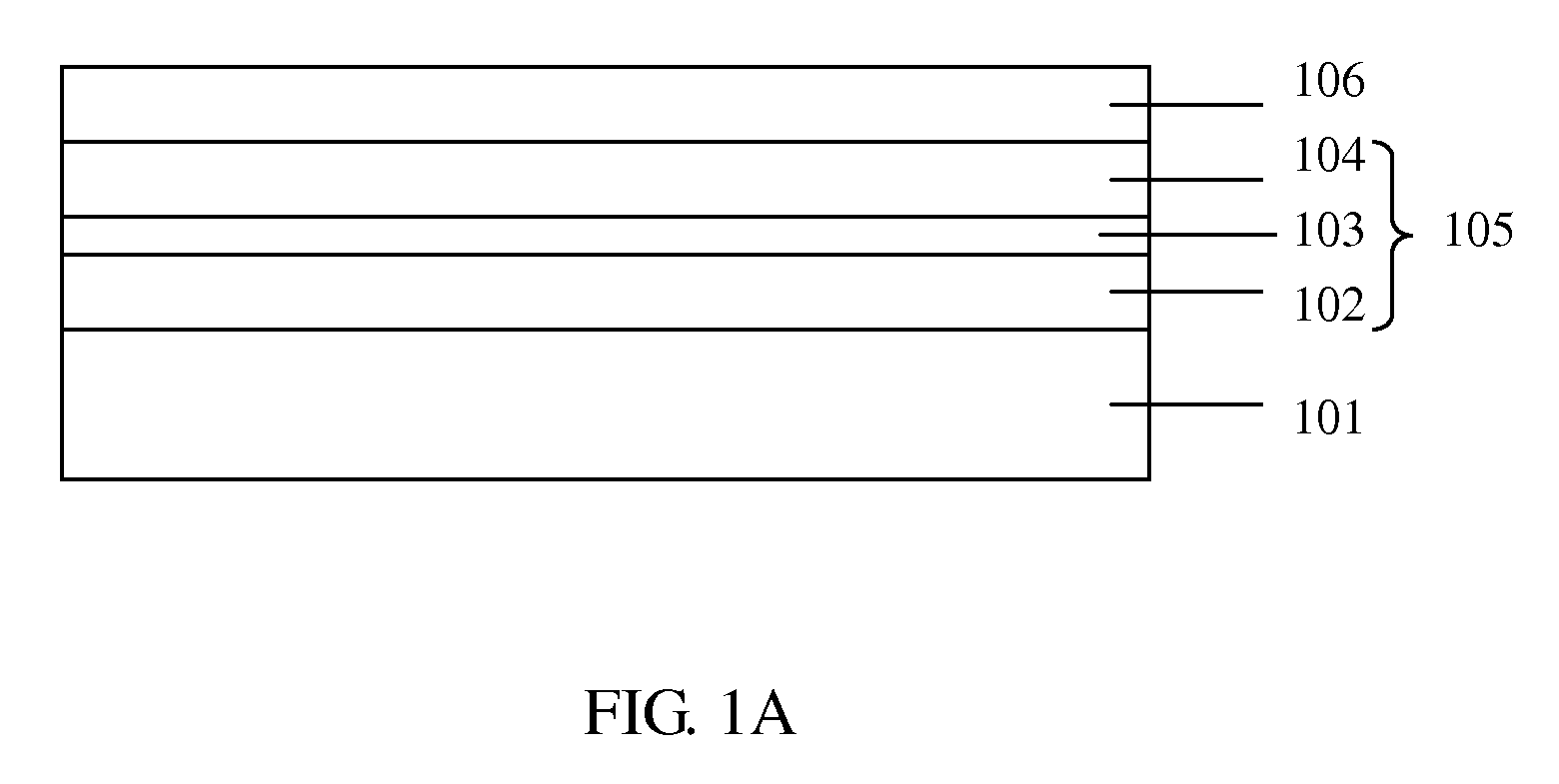

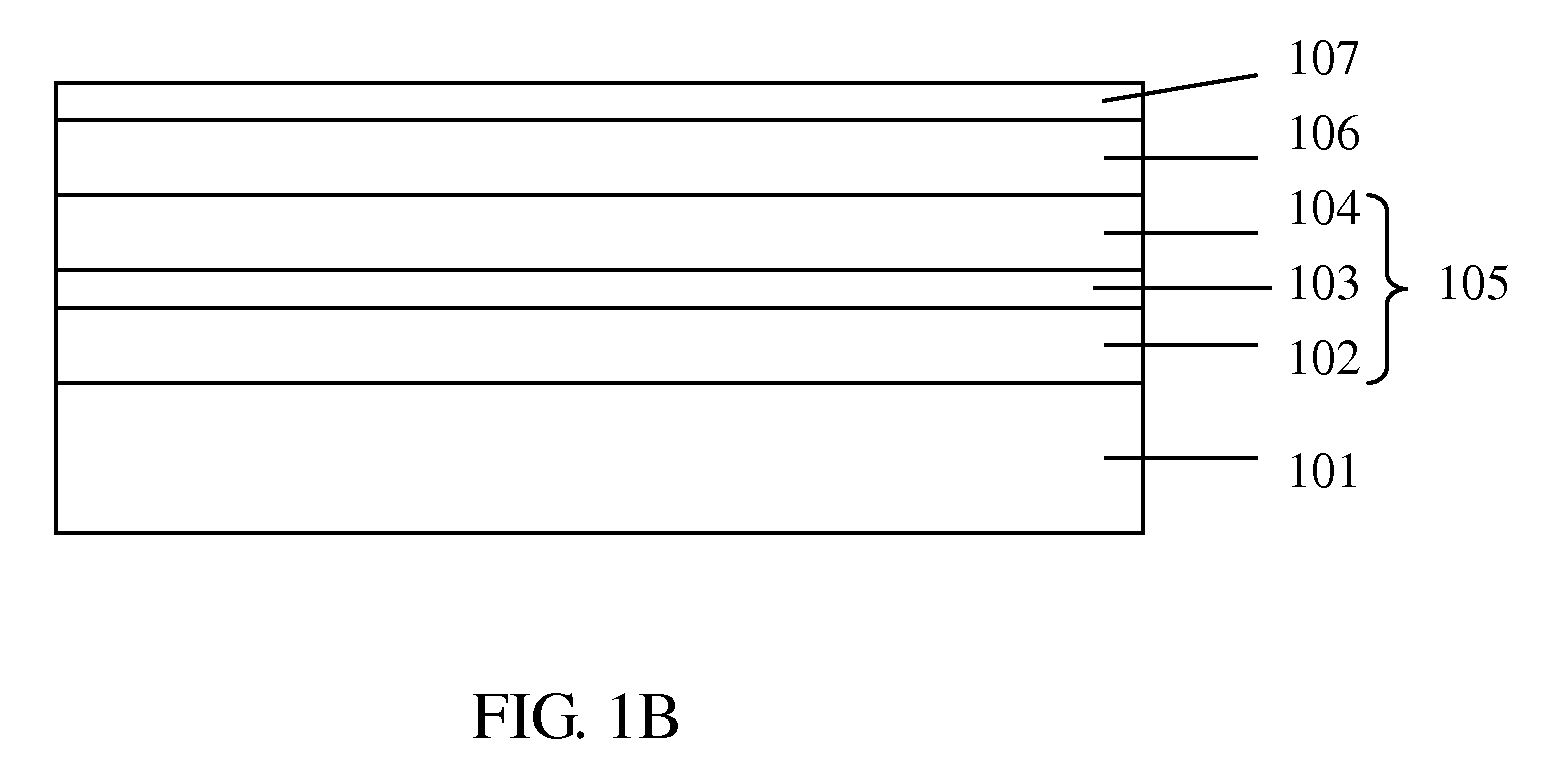

Light-emitting device containing a composite electroplated substrate

InactiveUS20100025714A1High strengthHigh toughnessSemiconductor devicesElectroplatingProtection layer

The application is related to a method of forming a substrate of a light-emitting diode by composite electroplating. The application illustrates a light-emitting diode comprising the following elements: a light-emitting epitaxy structure, a reflective layer disposed on the light-emitting epitaxy structure, a seed layer disposed on the reflective layer, a composite electroplating substrate disposed on the seed layer by composite electroplating, and a protection layer disposed on the composite electroplating substrate.

Owner:EPISTAR CORP

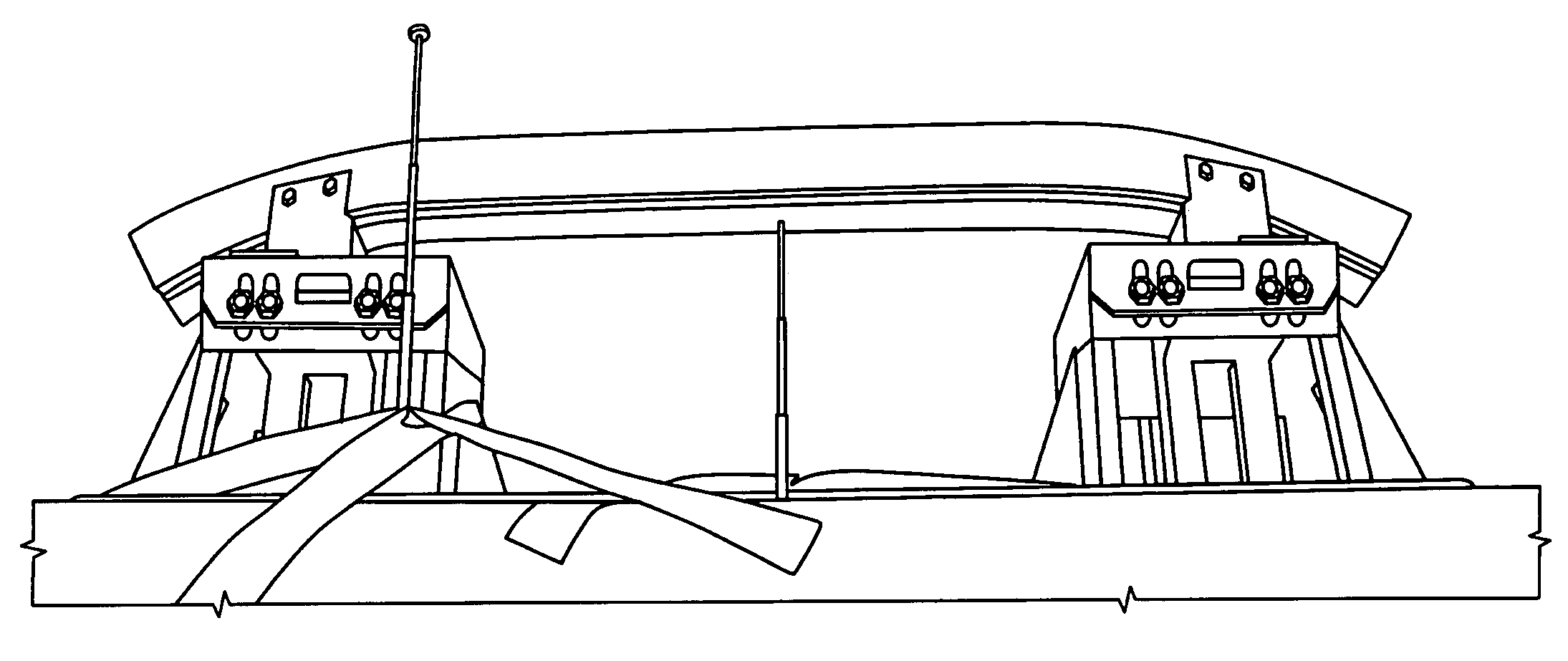

High-strength and high-toughness aluminum alloy material for bumper beam and method for manufacturing the same

The present invention discloses a high strength and high toughness aluminum alloy for a bumper beam and a method for manufacturing the same. The method includes: casting into a billet an aluminum alloy which comprises aluminum as a principal element, silicon (Si) of 0.1 wt. % or less, ferrum (Fe) of 0.2 wt. % or less, copper of 0.45 wt. % to 0.60 wt. %, manganese (Mn) of 0.1 wt. % to 0.20 wt. %, magnesium (Mg) of 1.3 wt. % to 1.5 wt. %, chromium (Cr) of 0.1 wt. % or less, zinc of 4.5 wt. % to 5.1 wt. %, titanium (Ti) of 0.04 wt. % or less, zirconium (Zr) of 0.08 wt. % to 0.12 wt. %, and inevitable impurities of 0.15 wt. % or less; extruding the billet into a predetermined form to form an extrusion; performing a solid-solutionization process to quench the extrusion; subjecting the extrusion to an artificial age-hardening which is performed at a temperature of about 120° C. for 24 hours; and subjecting the extrusion an over age-hardening which is performed at a temperature of about 170° C. to 185° C. for 1 hour to 3 hours.

Owner:HYUNDAI MOTOR CO LTD

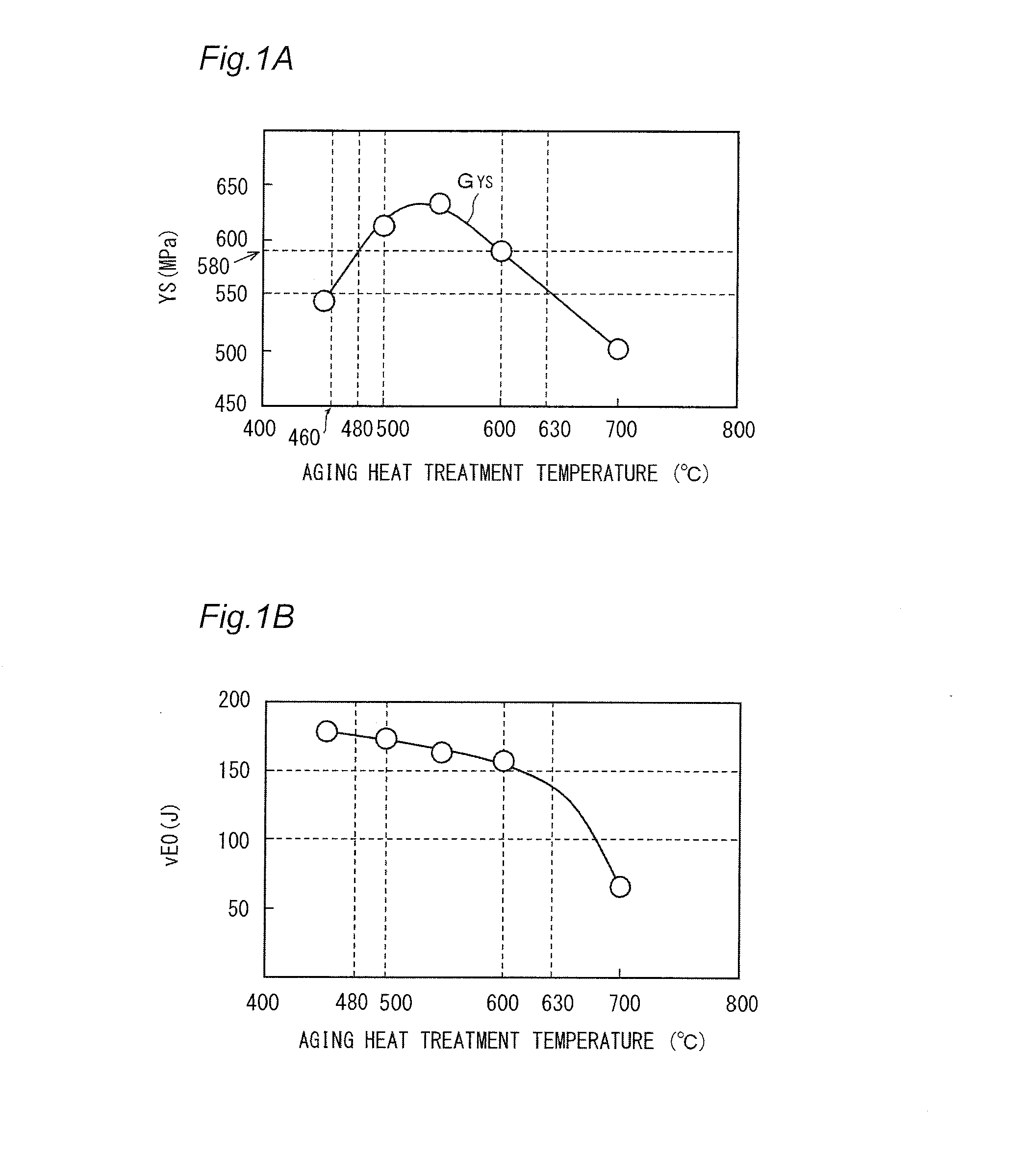

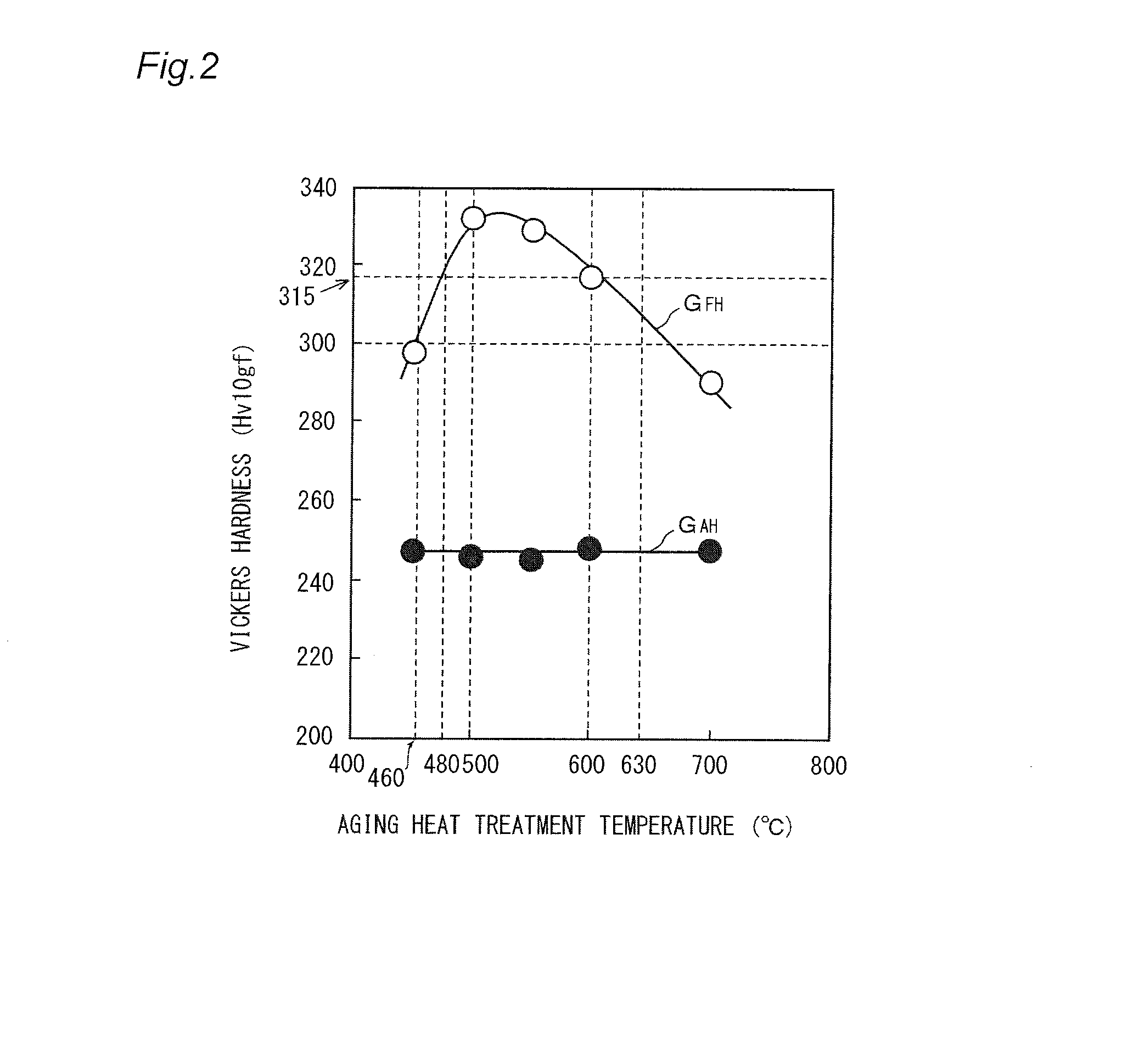

Duplex stainless steel and production method therefor

Provided is a duplex stainless steel having a high strength and a high toughness. A stainless steel according to the present invention includes: a chemical composition containing, in mass percent, C: at most 0.030%, Si: 0.20 to 1.00%, Mn: at most 8.00%, P: at most 0.040%, S: at most 0.0100%, Cu: more than 2.00% and at most 4.00%, Ni: 4.00 to 8.00%, Cr: 20.0 to 30.0%, Mo: at least 0.50% and less than 2.00%, N: 0.100 to 0.350%, and sol. Al: at most 0.040%, the balance being Fe and impurities; and a structure, wherein a rate of ferrite in the structure is 30 to 70%, and a hardness of the ferrite in the structure is at least 300 Hv10gf.

Owner:NIPPON STEEL CORP

Heat treatment method for obtaining high-toughness and high-damage-tolerance dual-phase titanium alloy

ActiveCN113249667AImprove toughnessImproved damage tolerance performanceDamage toleranceTitanium alloy

The invention discloses a heat treatment method for obtaining a high-toughness and high-damage-tolerance double-phase titanium alloy. The heat treatment method comprises the following steps of high-temperature annealing treatment, specifically, keeping the temperature for 0.1-2 hours at T1 temperature, reasonably controlling the cooling speed, preferably, controlling the temperature range from T1 to T-200 DEG C to be 2-50 DEG C / s, controlling the value range of T1 between Tbeta10 DEG C and T, controlling the value range of T between Tbeta10 DEG C and T, controlling the value range of T between Tbeta10 DEG C and T, wherein T is the beta transformation temperature of the double-phase titanium alloy. According to the method, the toughness and the damage tolerance performance of the double-phase titanium alloy are improved by controlling the heat treatment temperature and the cooling speed. The method can be used for the two-phase titanium alloy with two structures under the room temperature conditions of TC11, TA15, TC4, TC17, TC18 and the like, is not limited by the original manufacturing process of the titanium alloy, and is suitable for forge pieces, castings, welding pieces and additive manufacturing pieces of the two-phase titanium alloy.

Owner:北京煜鼎增材制造研究院股份有限公司

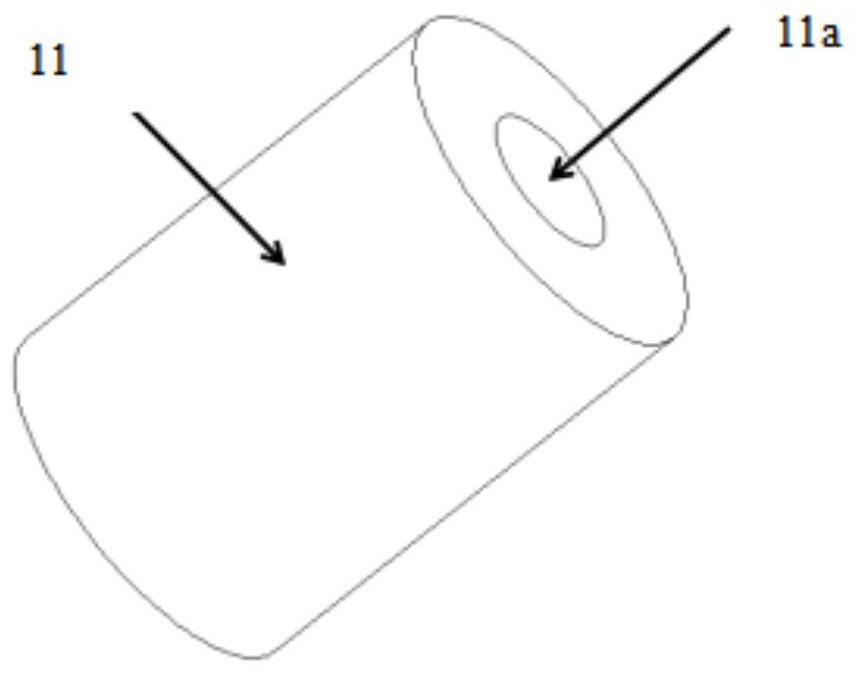

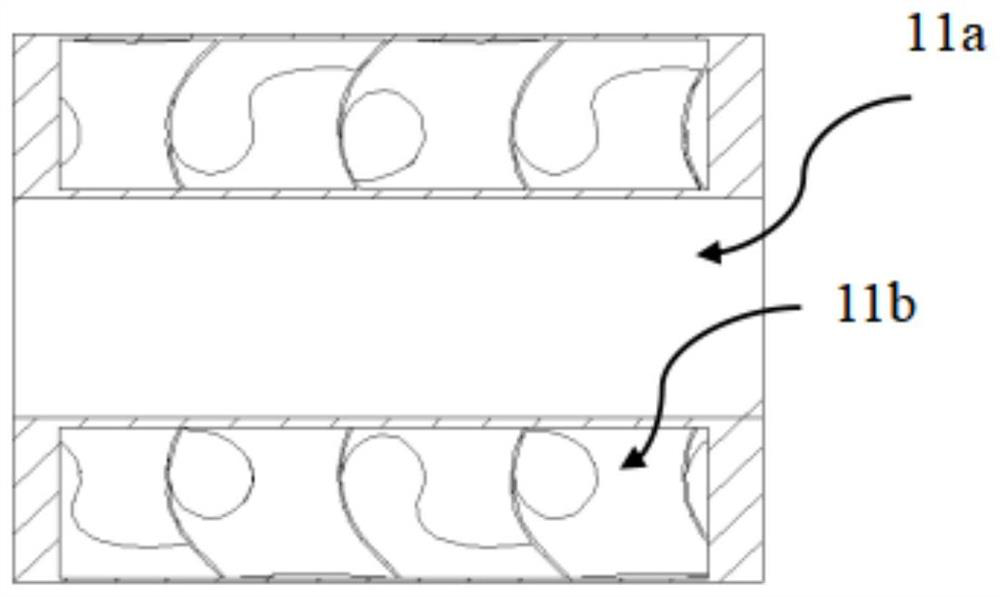

Method and device for perforating a non-woven fabric by means of hydrodynamic needling

ActiveCN103813890AIncreased durabilityHigh toughnessNeedling machinesMetal working apparatusWoven fabricEngineering

Owner:TRUTZSCHLER NONWOVENS

Thermosetting Resin Composition and Semiconductor Sealing Medium

ActiveUS20090258992A1Low resin viscosityHigh toughnessSemiconductor/solid-state device detailsSolid-state devicesComposite materialResin composite

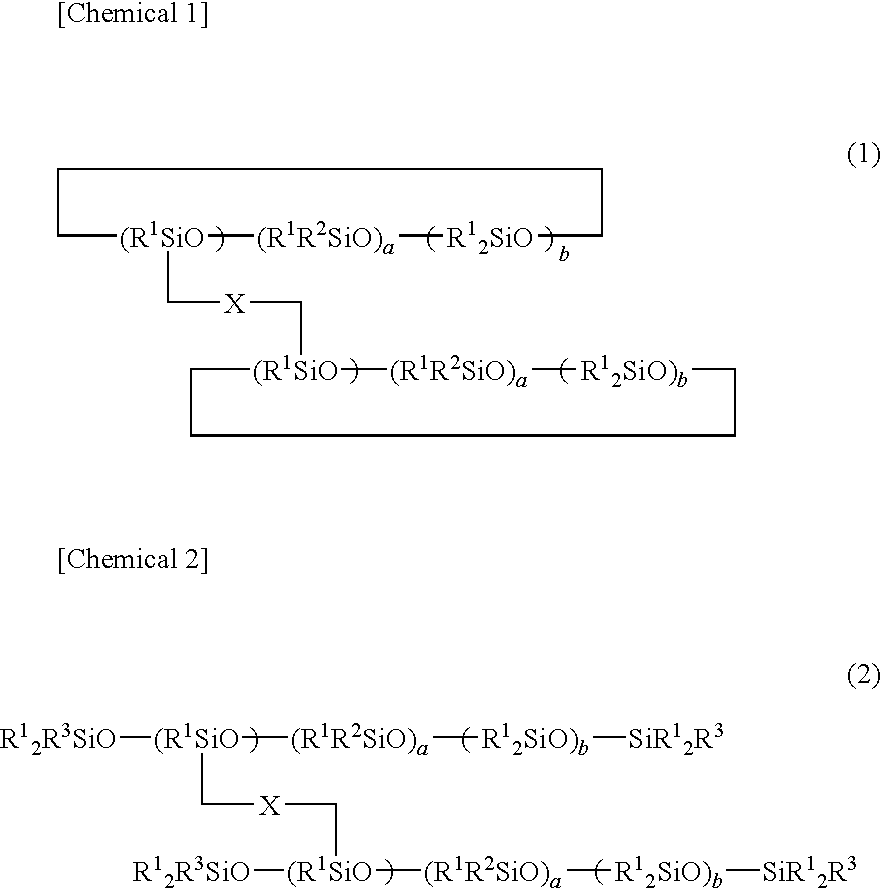

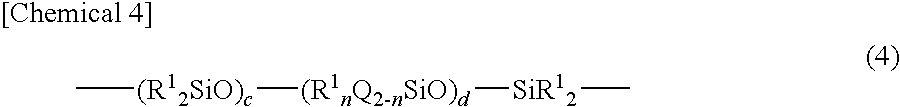

A thermosetting resin compositing having an essential component (A) organopolysiloxane containing a compound represented by following general formula (1) or (2) and optical semiconductor peripheral material using the composition. [Herein, in the formulas, R1 independently represents a substituted or non-substituted monovalent hydrocarbon radical with the carbon number of 1 to 10, R2 represents an epoxy group-containing organic group, R3 represents R1 or R2, a independently represents an integer of 2 or more, b independently represents an integer of 0 or more, X represents general formula (3) , Y represents a bivalent hydrocarbon radical with the carbon number of 1 to 6, Z represents following formula (4), R1 in the formula independently represents a substituted or non-substituted monovalent hydrocarbon radical with the carbon number of 1 to 10, and c represents an integer of 0 or more.]

Owner:ASAHI KASEI CHEM CORP

Steel plate with low yield-tensile ratio and high toughness and method of manufacturing the same

ActiveUS20140144556A1Low yield-tensile ratioHigh toughnessFurnace typesHeat treatment furnacesSteel platesLower yield

A steel plate with a low yield ratio and high toughness. The steel plate comprises components of, by weight: C (0.05-0.08%), Si (0.15-0.30%), Mn (1.55-1.85%), P (less than or equal to 0.015%), S (less than or equal to 0.005%), Al (0.015-0.04%), Nb (0.015-0.025%), Ti (0.01-0.02%), Cr (0.20-0.40%), Mo (0.18-0.30%), N (less than or equal to 0.006%), O (less than or equal to 0.004%), Ca (0.0015-0.0050%), and Ni (less than or equal to 0.40%), a ratio of Ca to S being greater than or equal to 1.5, and the residual being Fe and inevitable impurities.

Owner:BAOSHAN IRON & STEEL CO LTD

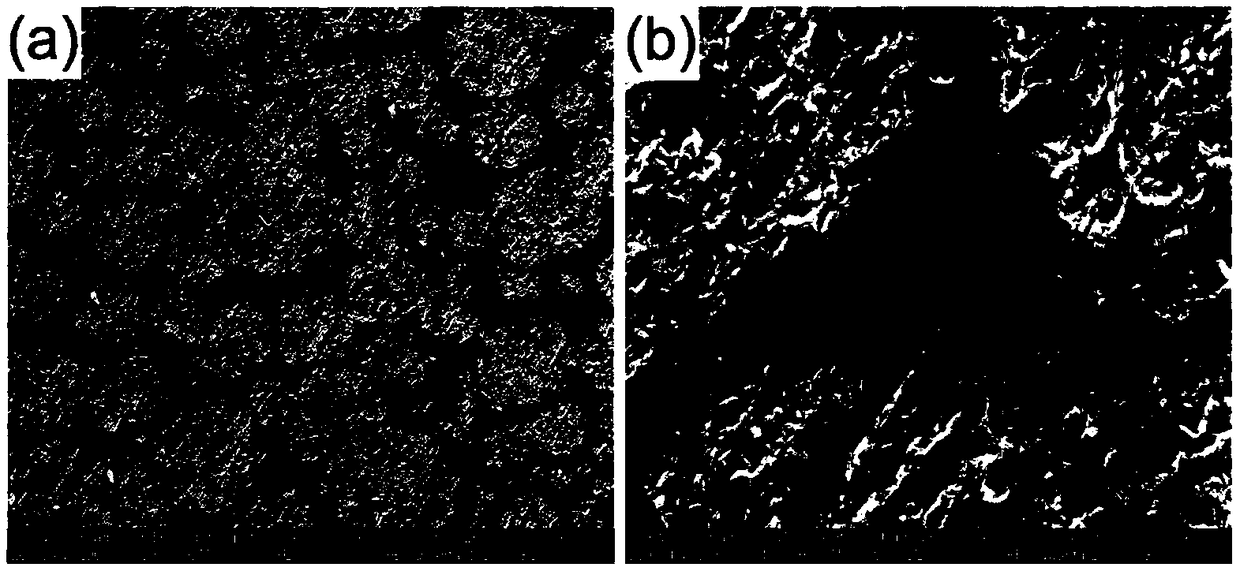

Si3N4 foam ceramic reinforced aluminum-based composite material and preparation method and application thereof

The invention discloses a Si3N4 foam ceramic reinforced aluminum-based composite material and a preparation method and an application thereof. The composite material comprises an aluminum matrix and Si3N4 foam ceramic; and the Si3N4 foam ceramic comprises a Si3N4 foam ceramic skeleton and columnar beta Si3N4 crystal grains which grow on the hole wall of the Si3N4 foam ceramic skeleton in situ, thealuminum matrix uniformly fills pores of the Si3N4 foam ceramic skeleton, and the columnar beta Si3N4 crystal grains are coated with the aluminum matrix. The preparation method of the composite material comprises the following steps that liquid metal aluminum is pressed into the pores of the Si3N4 foam ceramic skeleton by adopting a vacuum air pressure infiltration process so as to obtain the Si3N4 foam ceramic reinforced aluminum-based composite material. The Si3N4 foam ceramic reinforced aluminum-based composite material has the advantages of being good in toughness and erosion resistance,good in mechanical processing performance and the like. The preparation method is simple in process and suitable for batch production.

Owner:NAT UNIV OF DEFENSE TECH

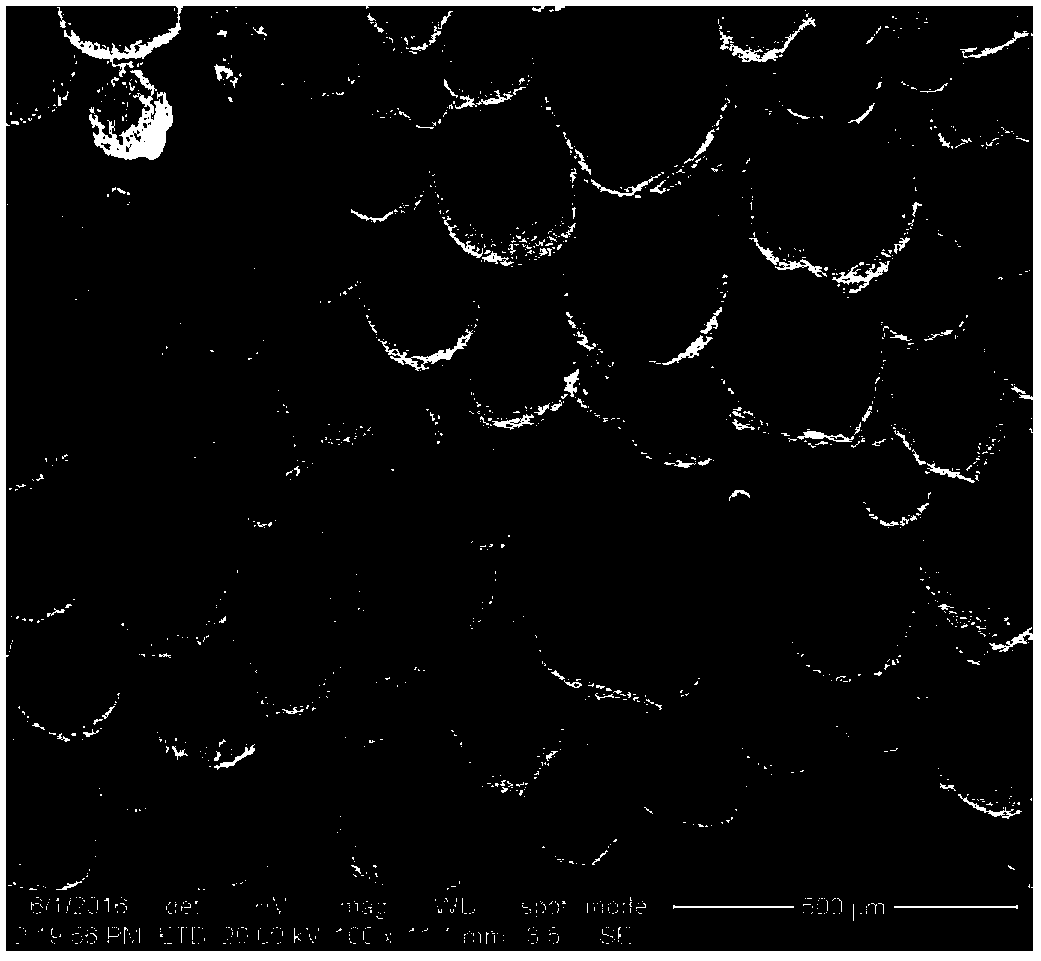

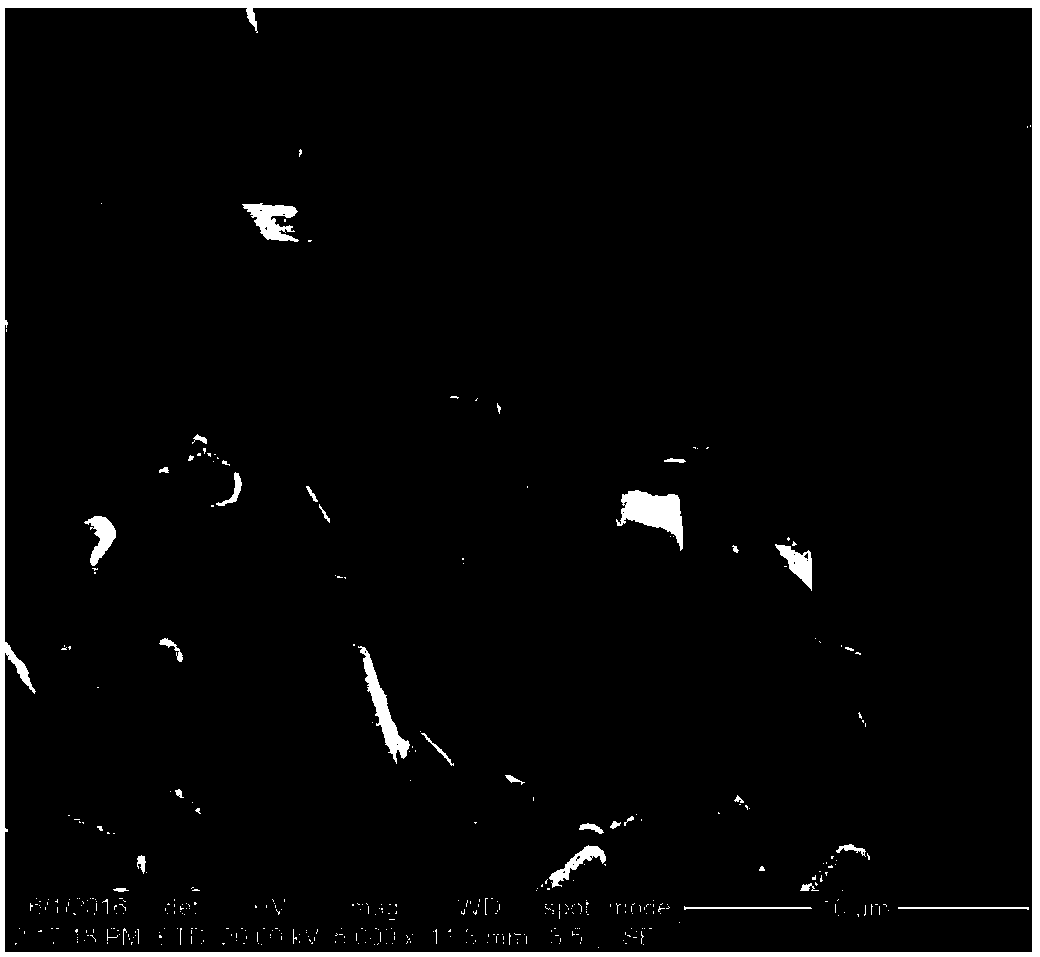

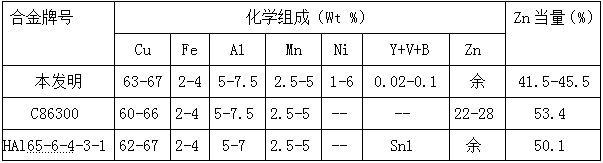

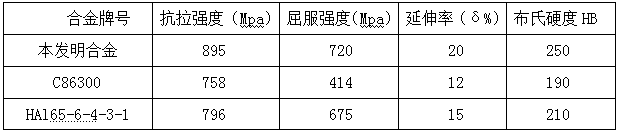

High-strength toughness aluminum brass alloy and manufacturing method thereof

The invention relates to a high-strength toughness aluminum brass alloy and a manufacturing method of the high-strength toughness aluminum brass alloy. The chemical composition of the alloy comprises,by weight, 63-68% of copper, 2-4% of iron, 5-7.5% of aluminum, 2.5-5% of manganese, 1-6% of nickel 0.02-0.1% of yttrium, vanadium and boron, and the balance zinc (containing other inevitable impurities with the content smaller than or equal to 0.5%). Aluminum and copper are added in sequence for alloy smelting, it is ensured that the amount ratio of copper to aluminum is smaller than or equal to2, heating smelting is carried out, the density of the alloy liquid formed by copper and aluminum is smaller than or equal to 7g / cm<3>, in this way, aluminum film covering protection is achieved, manganese can be conveniently immersed in the alloy melt for melting, copper-manganese alloy is formed at first, iron dissolving is added after the temperature is increased, and hard brittle iron-rich particles are reduced or eliminated. An alloy casting has high hardness, has high strength, high hardness, high ductility and good wear resistance, and is widely applied to parts such as bearings, shaftsleeves, thrust nuts and the like which are difficult to lubricate and replace.

Owner:TIANJIN SANTIAOSHI NONFERROUS METAL FOUNDRY

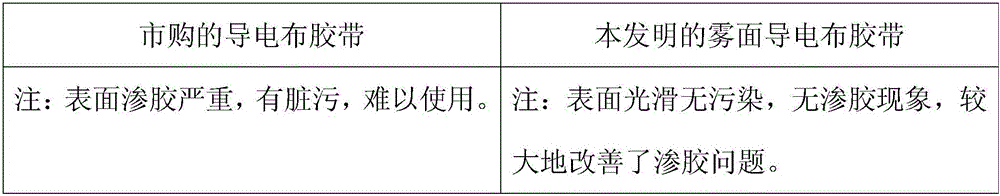

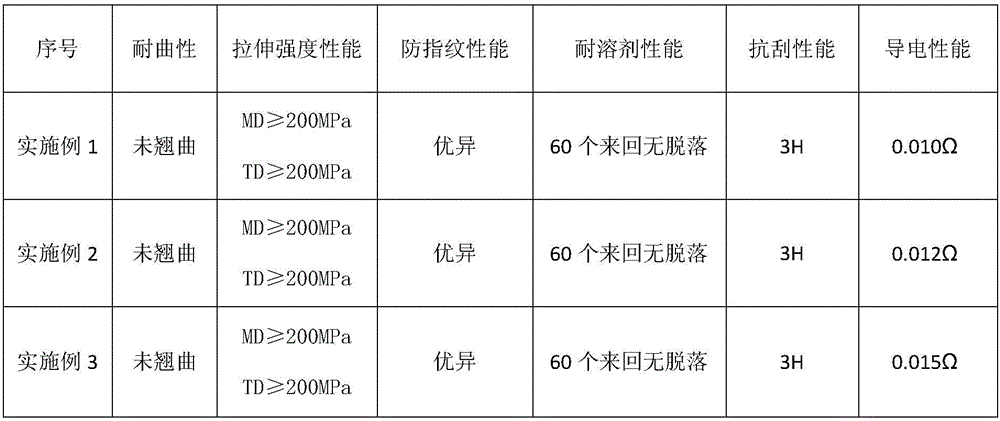

Non-bright, anti-fingerprint and scraping-resistant single-side adhesive tape for conductive fabric and preparation method

InactiveCN105754512AOptimize structureHigh toughnessNon-macromolecular adhesive additivesFilm/foil adhesivesPolyurethane adhesiveElectrically conductive

The invention discloses a non-bright, anti-fingerprint and scraping-resistant single-side adhesive tape for conductive fabric and a preparation method and belongs to the technical field of electromagnetic wave shielding. The conductive fabric material is subjected to special processing, a polyurethane adhesive film is applied to the surface of the conductive fabric material, and then an ink processing layer and a functional coating are applied. The original material structure is changed, the toughness of the material is enhanced, so that the tensile strength of the product is improved, and the surface has the anti-fingerprint, scraping-resistant and solvent-resistant functions. The working efficiency of a user can be increased, and the fraction defective of the product is reduced; the adhesive tape has good electrical properties, physical properties and market application prospect; besides, the preparation method is simple in process and easy to operate and facilitates industrial popularization and application.

Owner:江苏伊诺尔新材料科技有限公司

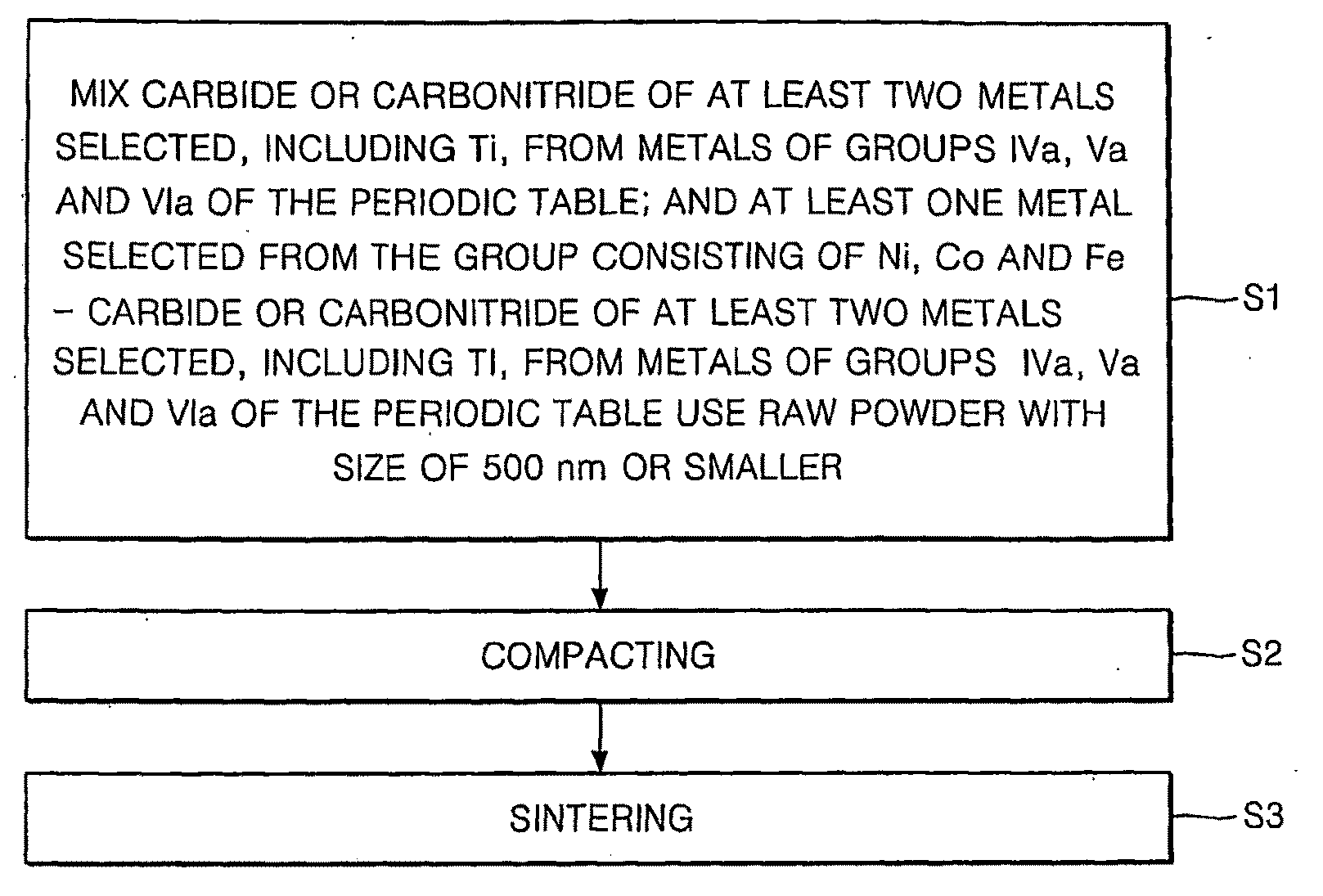

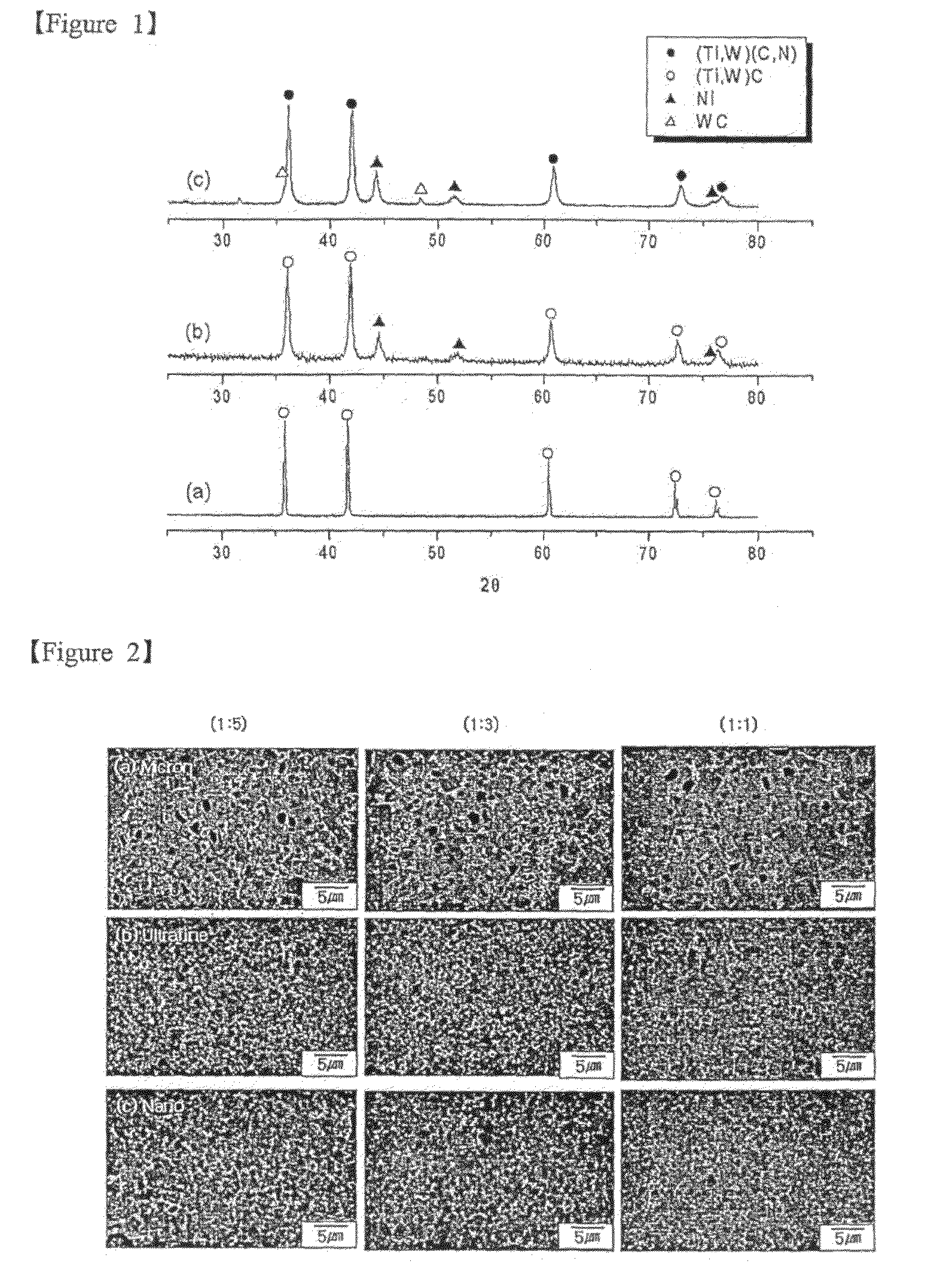

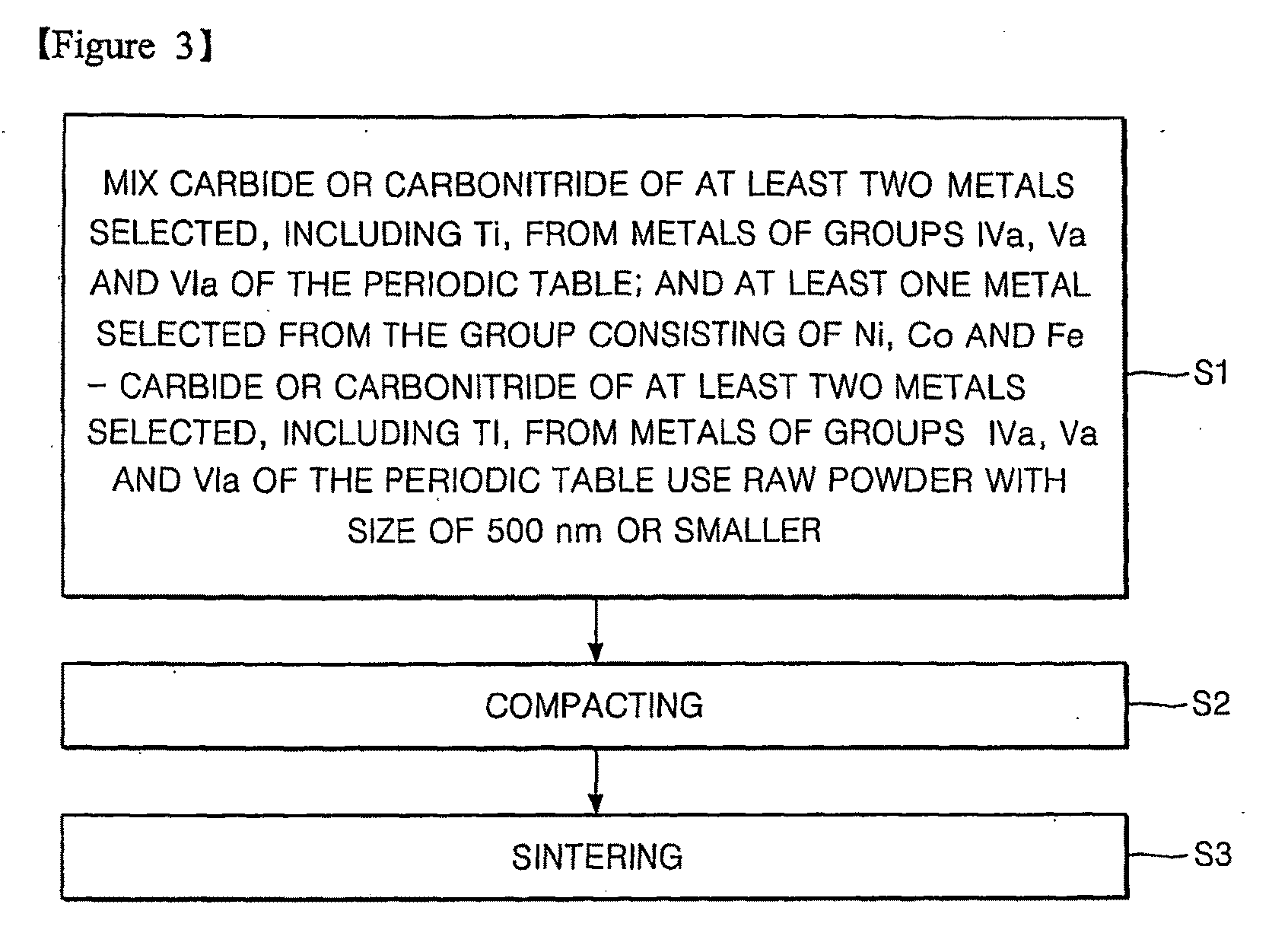

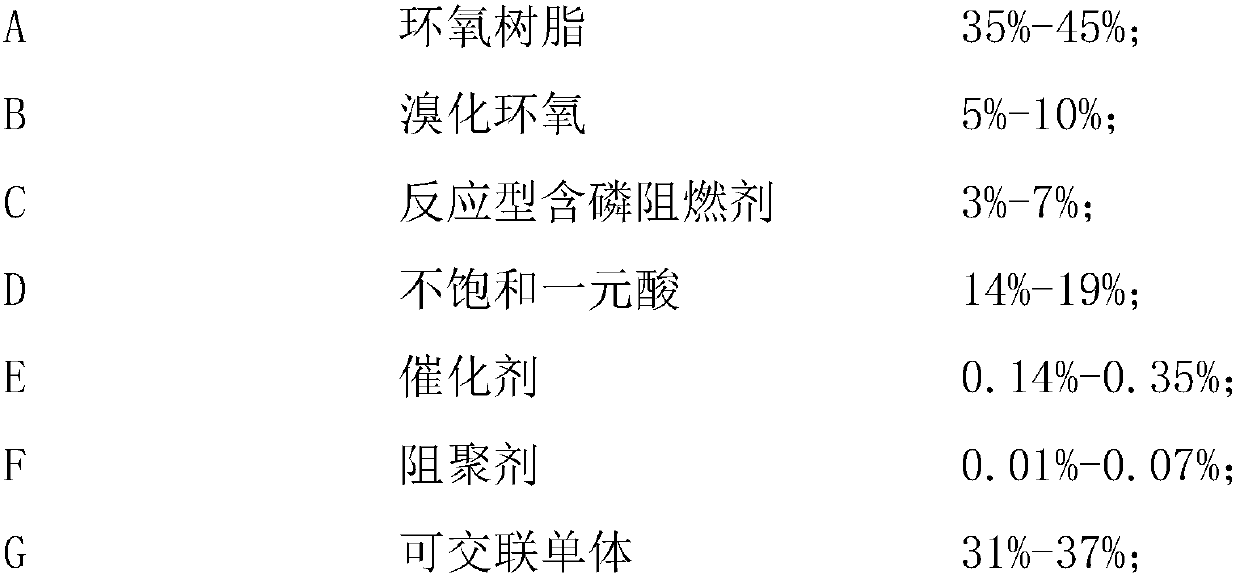

Mixed powder and sintered body, mixed cermet powder and cermet, and fabrication methods thereof

ActiveUS20100184582A1Improve toughnessHigh toughnessNitrogen compoundsTransportation and packagingCermetMixed metal

A mixed powder and a sintered body obtained by sintering the mixed powder. The mixed powder includes a solid-solution powder with complete solid-solution phase. The solid-solution powder includes a carbide or a carbonitride of at least two metals selected, including Ti, from metals of Groups IVa, Va and VIa of the periodic table, or a mixture thereof. A mixed cermet powder and a cermet obtained by sintering the mixed cermet powder are also disclosed. The mixed cermet powder includes at least a cermet powder with complete solid-solution phase. The cermet powder includes a carbide or a carbonitride of at least two metals selected, including Ti, from metals of Groups IVa, Va and VIa of the periodic table, or a mixture thereof, and at least one metal selected from the group consisting of Ni, Co and Fe. Also disclosed are a sintered body and a fabrication method of a cermet.

Owner:SEOUL NAT UNIV R&DB FOUND

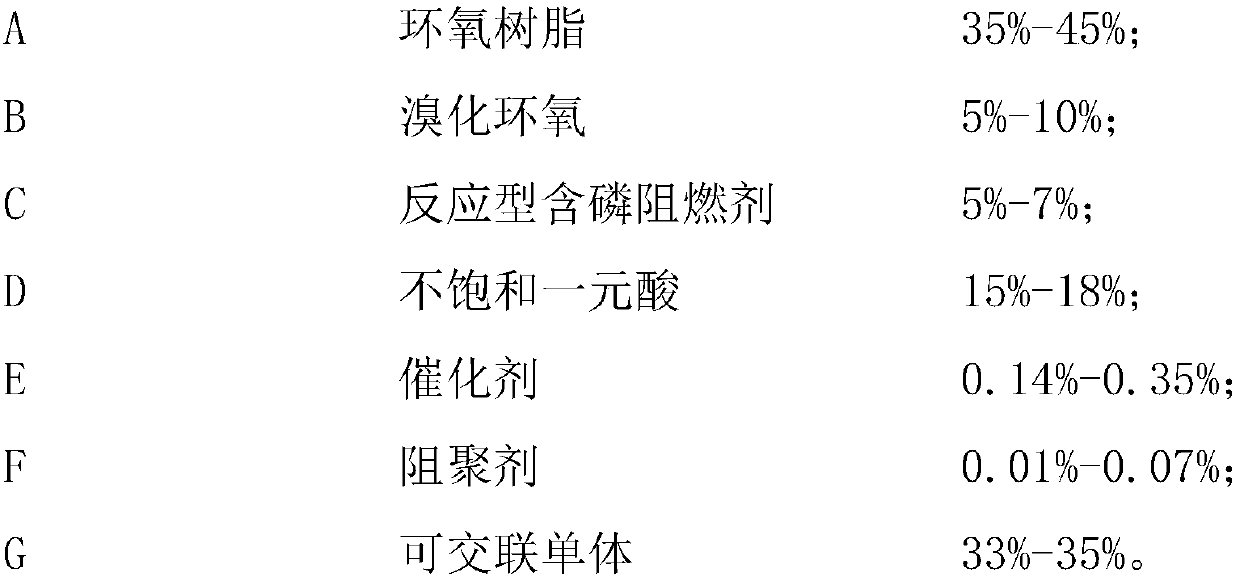

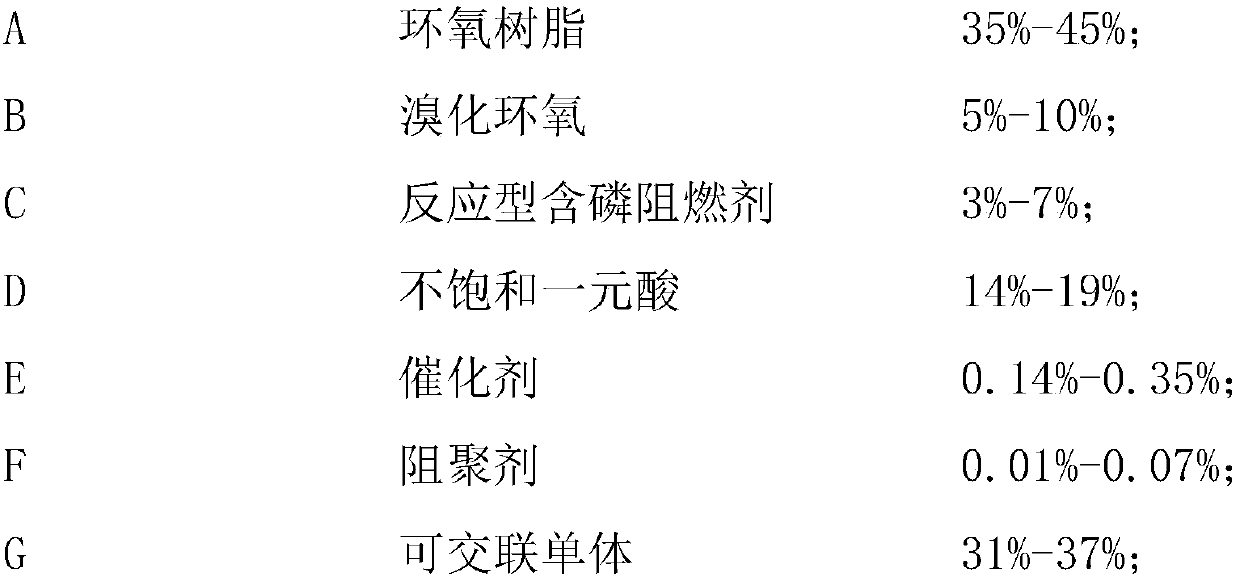

Reactive type flame-retardant vinyl ester resin having synergistic effect and preparation method thereof

InactiveCN107759749AImprove flame retardant performanceHigh flame retardant efficiencyEpoxyPhosphonium

The invention relates to reactive type flame-retardant vinyl ester resin having a synergistic effect and a preparation method thereof, and belongs to the technical field of vinyl ester resin. The reactive type flame-retardant vinyl ester resin is prepared by carrying out a series of reactions on substances such as epoxy resin, a reactive type phosphonium-containing flame retardant agent, unsaturated monacid, a catalyst, a polymerization inhibitor and a crosslinkable monomer. According to the reactive type flame-retardant vinyl ester resin and the preparation method of the reactive type flame-retardant vinyl ester resin disclosed by the invention, reactive type phosphorus as well as bromine and nitrogen elements which can carry out synergism with the reactive type phosphorus are introducedinto the vinyl ester resin, so that the flame-retardance efficiency is greatly improved; under a condition of the same addition amount, compared with conventional added type flame-retardant and single-element reactive type vinyl ester resin, the reactive type flame-retardant vinyl ester resin has the characteristics of high flame retardance efficiency, stable performance and low addition amount, and can be applied to the field requiring higher flame retardance performance; in addition, the resin is moderate in viscosity and good in construction performance, and can be widely applied to a variety of operation processes such as hand lay-up, ejection and roller coating. The resin also has the performance of high corrosion resistance, high heat resistance and high toughness of the vinyl esterresin and high flame retardant performance of reactive type flame-retardant vinyl ester resin.

Owner:CHANGZHOU HUAKE POLYMERS

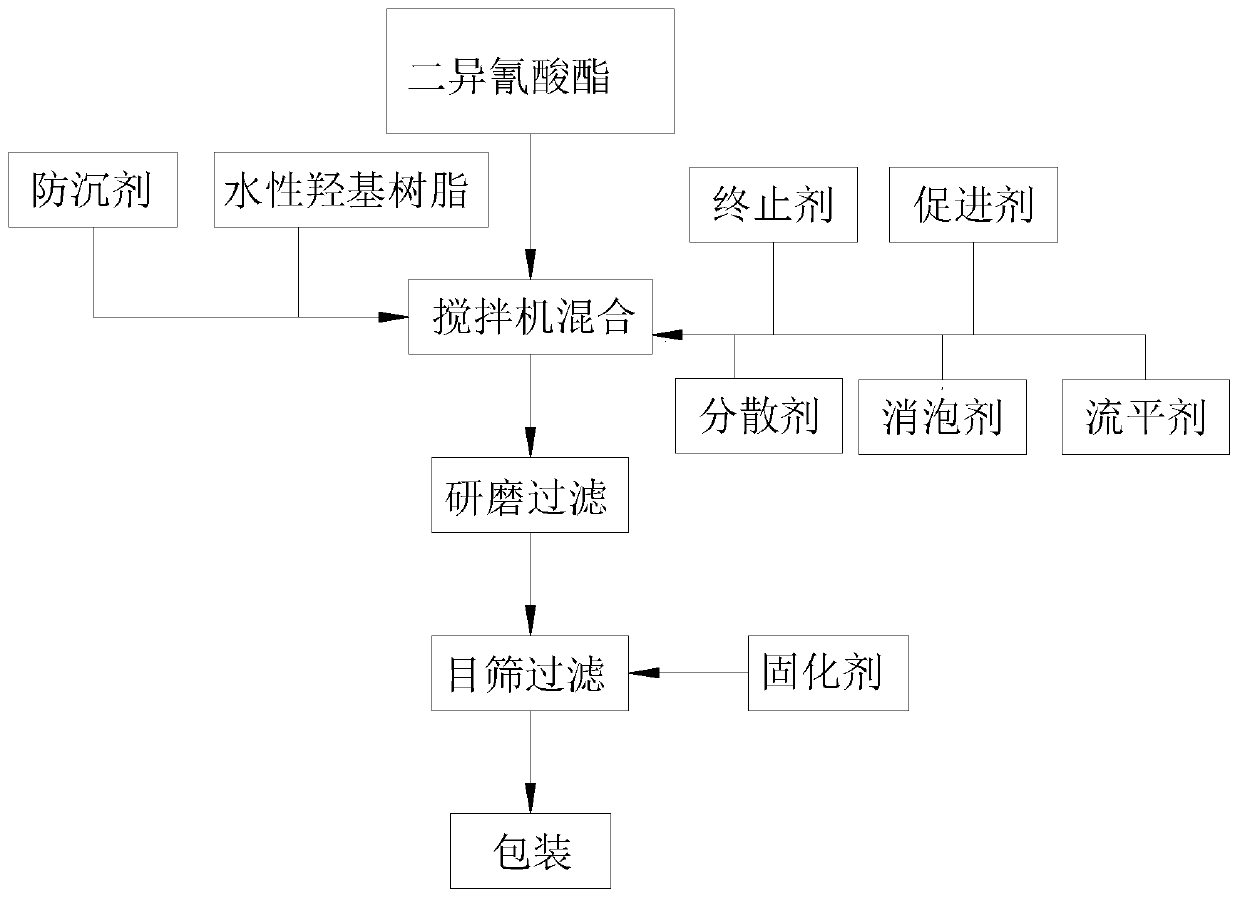

Easily-to-cure waterproof polyurethane wood lacquer and preparation method thereof

The invention discloses an easy-to-cure waterproof polyurethane wood lacquer and a preparation method thereof, and belongs to the technical field of wood lacquer; the easy-to-cure waterproof polyurethane wood lacquer comprises a main lacquer and a curing agent, and the weight ratio of the main lacquer to the curing agent is 100: 7, wherein the main lacquer is prepared from the following componentsin percentage by mass: diisocyanate, water-based hydroxyl resin, an accelerant, a terminating agent, an anti-settling agent, a dispersing agent, an antifoaming agent and a leveling agent; said components are proportioned according to the following mass ratio; the water-based epoxy takes water as a solvent and a diluent; the effect is that the water-based hydroxyl resin achieves the effects of improving the compactness and preventing water; besides, the gel waterproof layer formed by the curing agent improves the mixed waterproof function, and after the diisocyanate forms a film and the effective components act, the cured complex forms a waterproof crystal, so that the waterproof effect is achieved, high wear resistance and impact resistance are achieved, a coating film cannot be softenedafter being heated, the hot spot resistance is extremely high, and the freshness is continuously excellent.

Owner:安徽名士达新材料有限公司

Green and environment-friendly high-toughness building material and preparation method thereof

The invention belongs to the technical field of building materials and provides a green and environment-friendly high-toughness building material and a preparation method thereof. A formula of the building material comprises the following components: portland cement, blast-furnace slag, aluminum silicate fiber cotton, calcium sulfonate, modified wollastonite, polyester fibers, color master batch,a water reducing agent, a toughening agent and a flame retardant. The building material prepared from the components through a reasonable content ratio can overcome the disadvantages that concrete haslow tensile strength and poor toughness, the crack width is difficult to control after cracking and the like; early cracking of the concrete is prevented and the toughness is improved.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

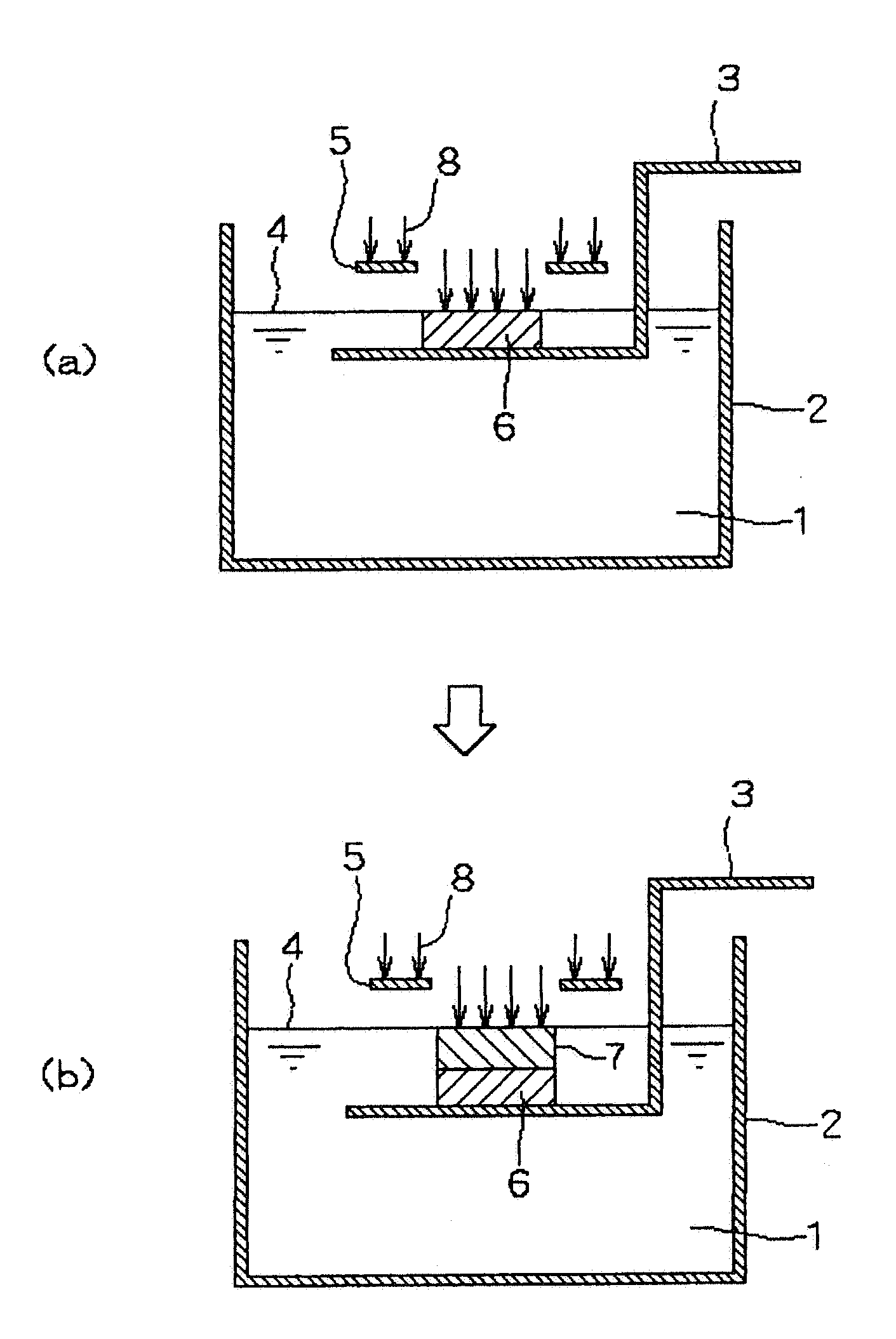

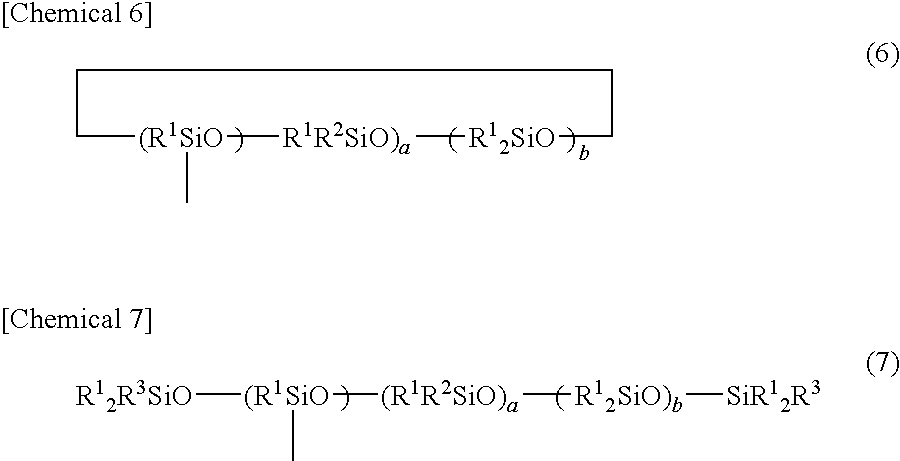

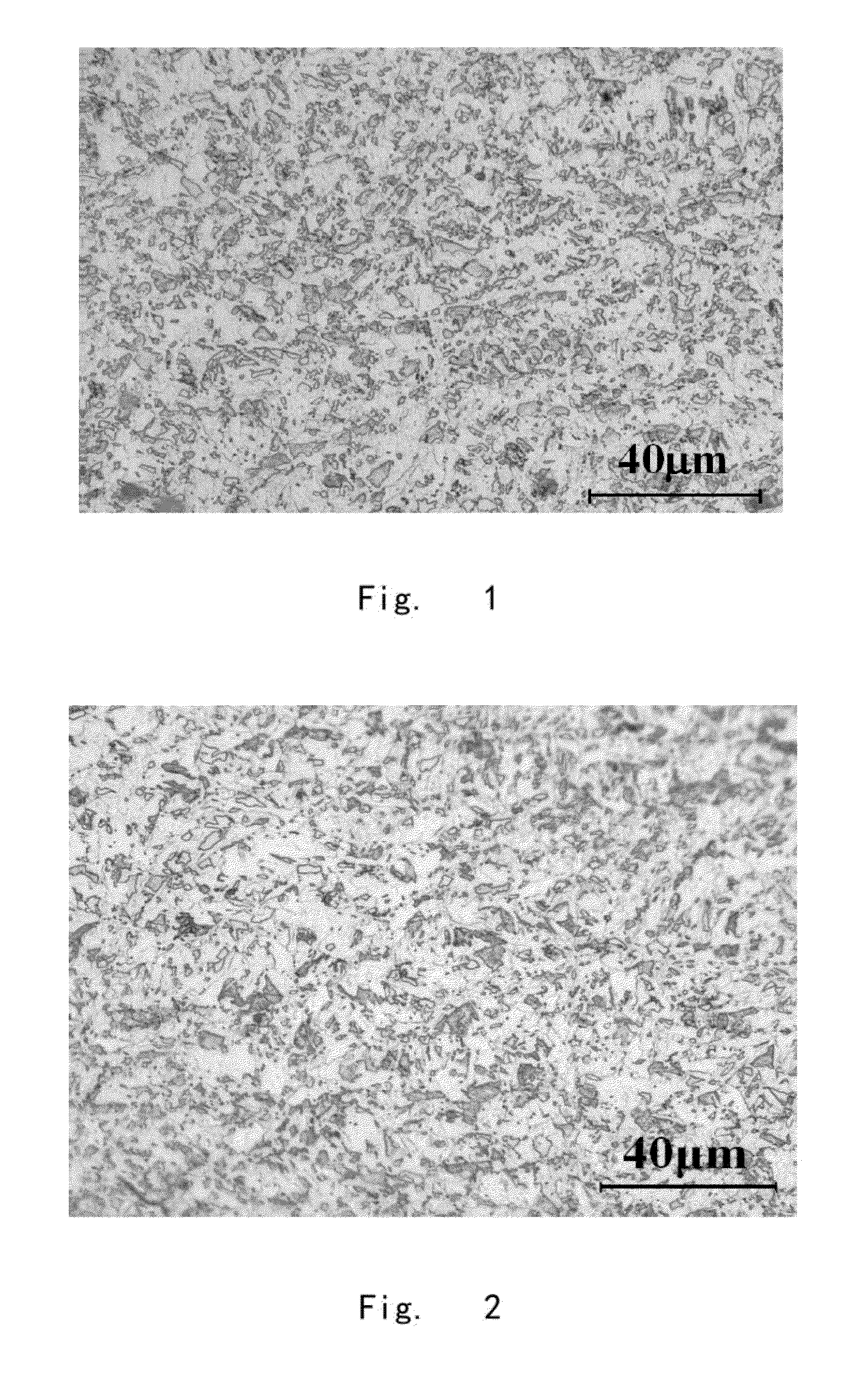

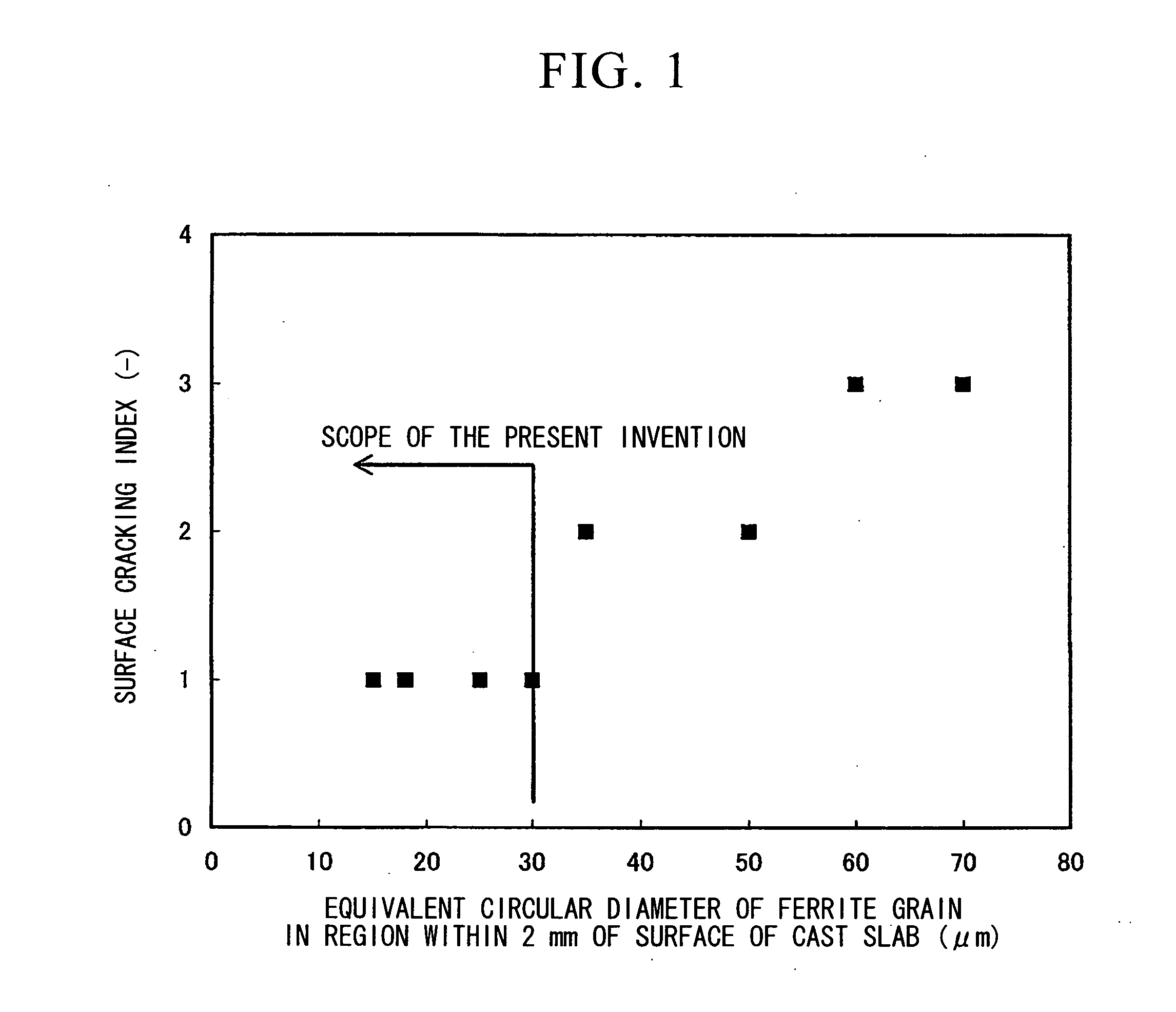

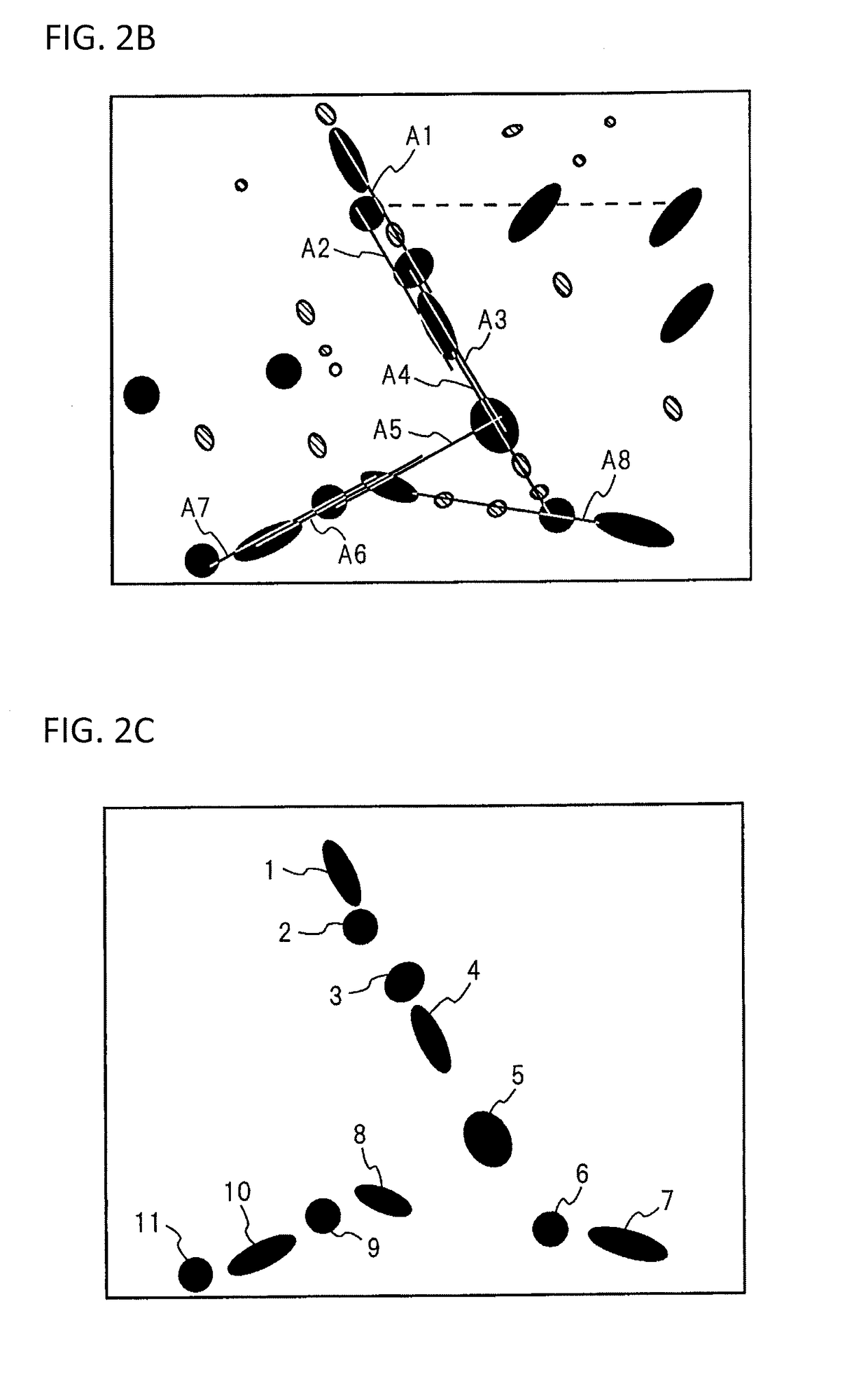

Continuous cast slab and producing method therefor

A continuous cast slab includes the following component: by mass %, C: 0.01˜0.3%, Si: 0.05˜0.5%, Mn: 0.4˜2%, P: 0.03% or less, S: 0.03 or less, Al: 0.005˜0.03%, Ni: 0.2˜2%, O: 0.006% or less, and N: 0.006% or less; wherein the balance is composed of Fe and inevitable impurities; wherein a structure in steel in a region within at least 2 mm from a broad surface is composed of ferrite and pearlite and a equivalent circular diameter of ferrite grains in the region is equal to or shorter than 30 μm.

Owner:NIPPON STEEL CORP

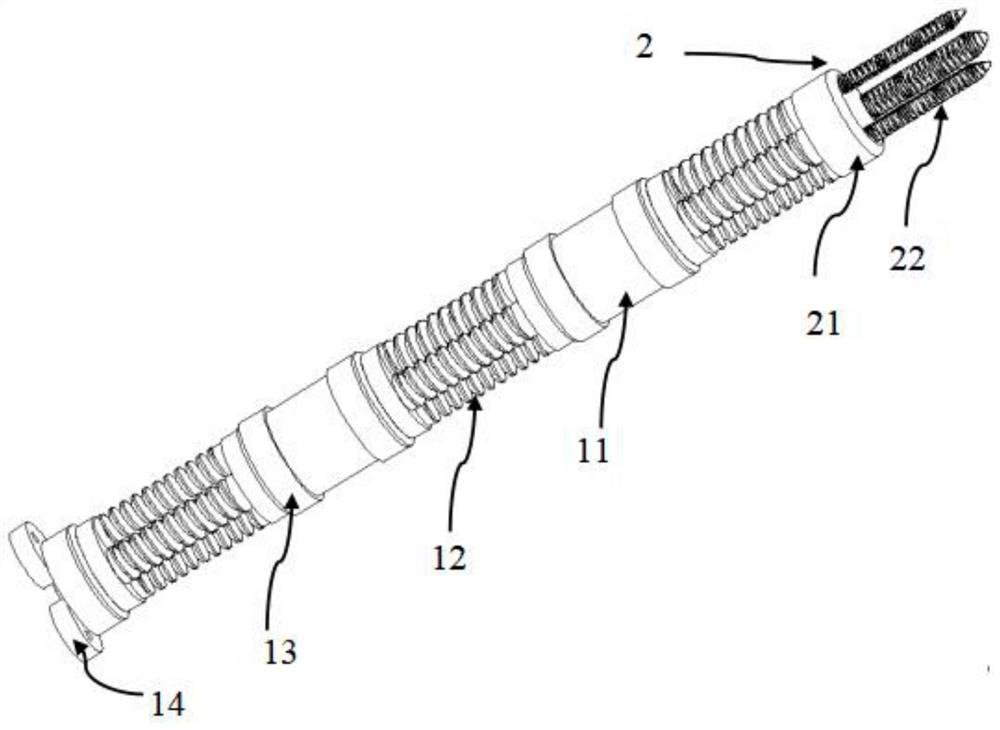

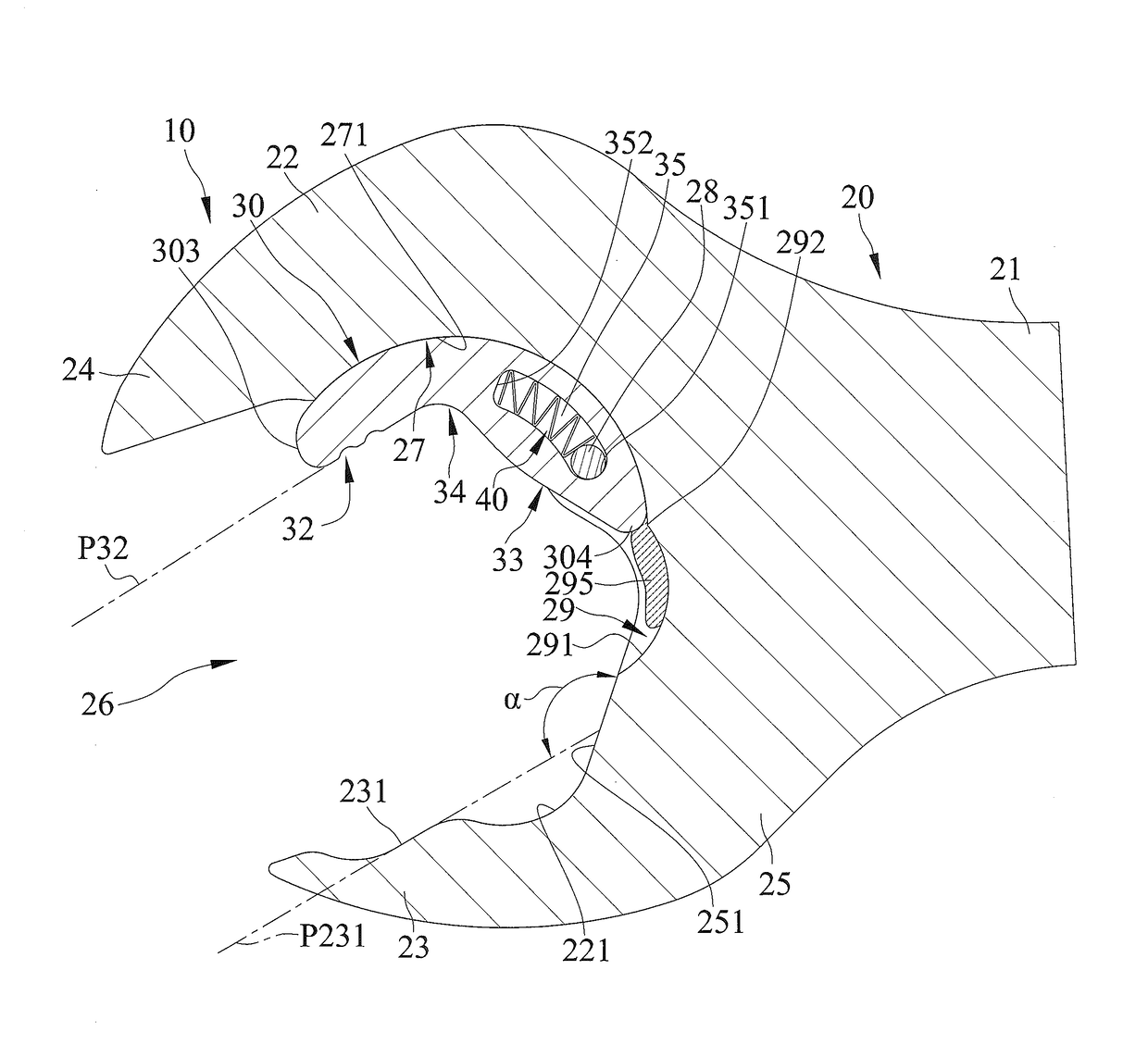

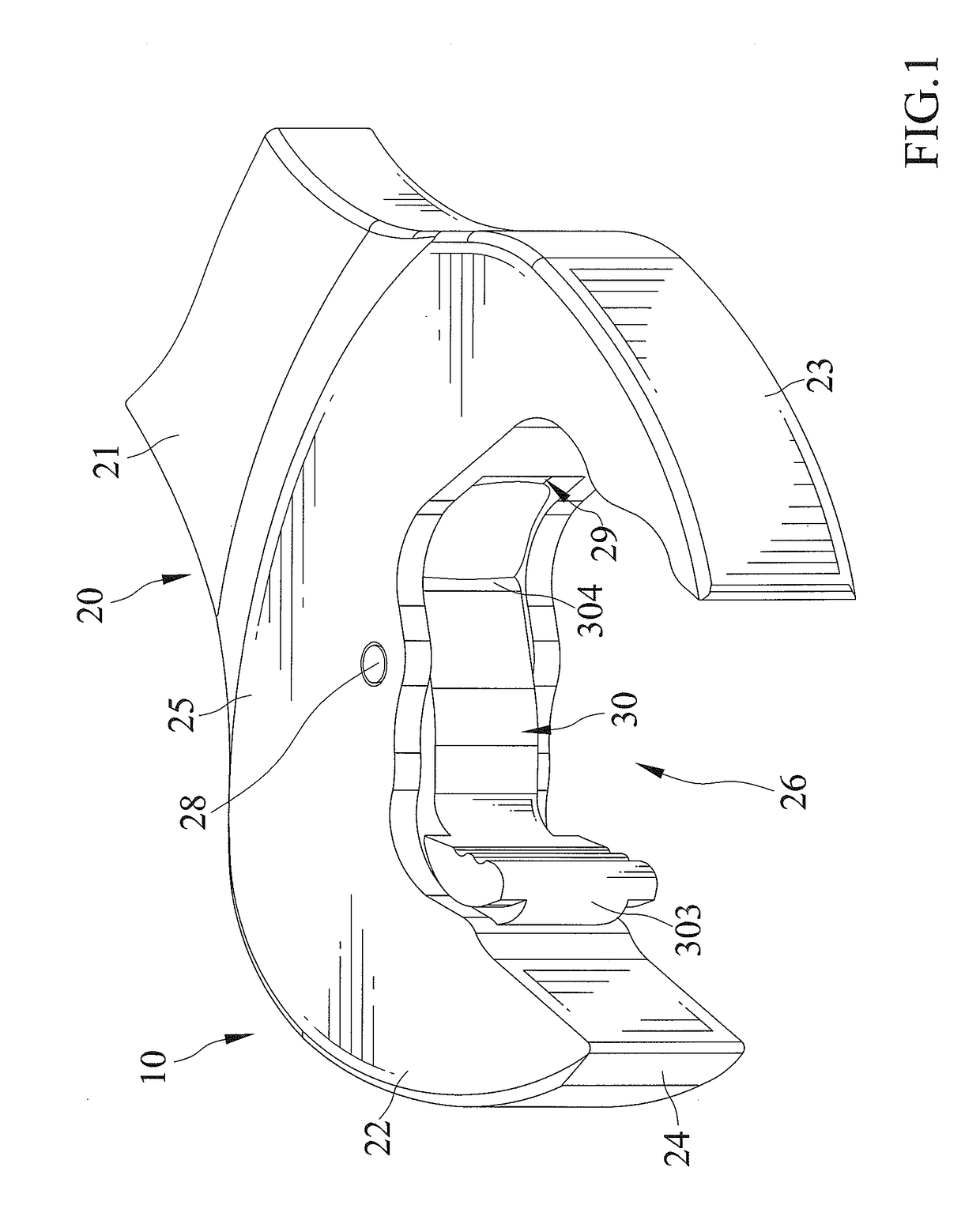

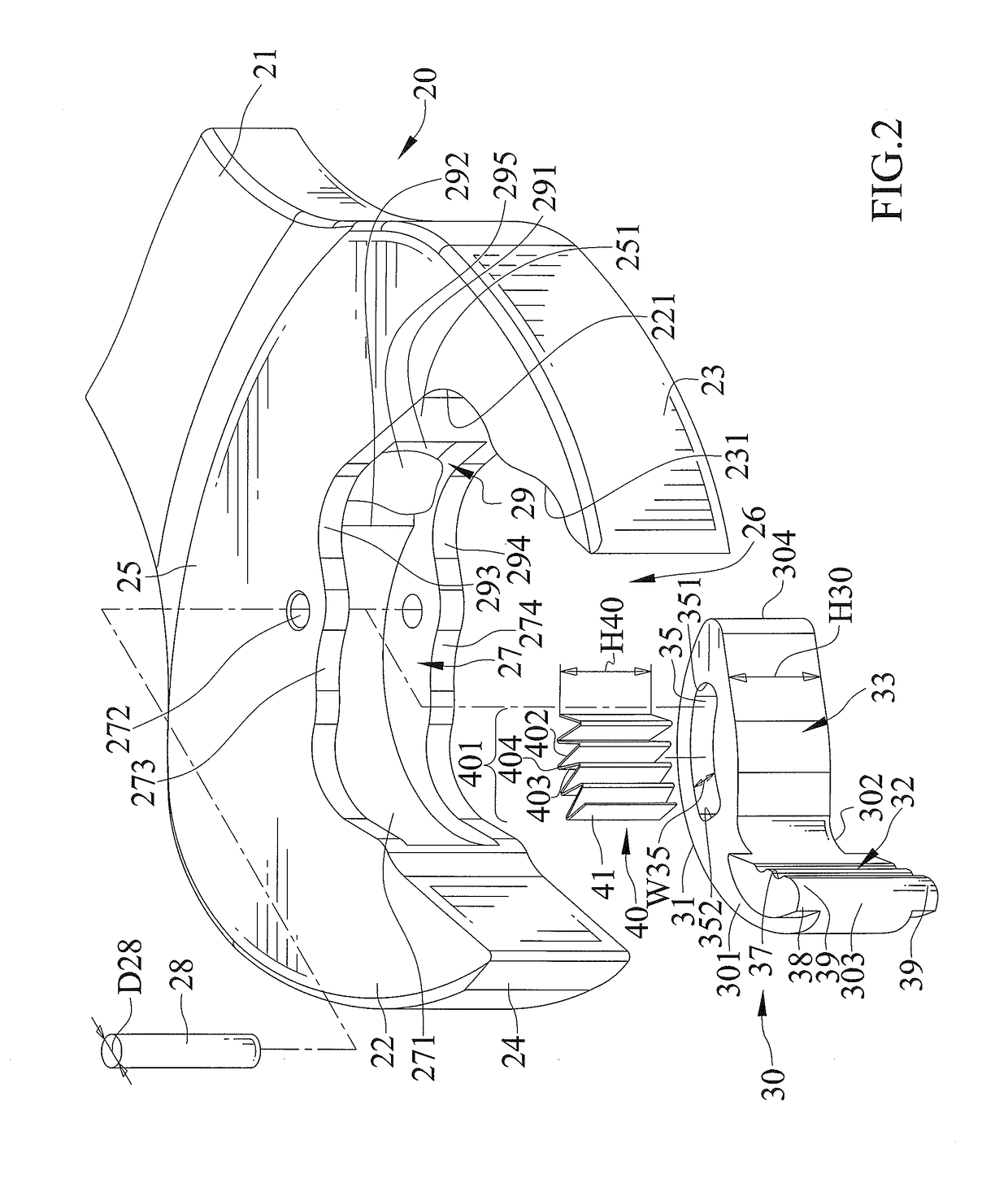

Pneumatic soft mechanical arm

PendingCN113733152AHigh toughnessAchieve one-way rotationJointsGripping headsEngineeringMechanical engineering

The invention discloses a pneumatic soft mechanical arm, and belongs to the technical field of mechanical arms. The soft mechanical arm is composed of a multi-joint rigid-flexible coupling structure, a rigid body of each joint is composed of a light sandwich structure, and a flexible body is composed of four soft driving rods and soft connecting seats thereof; the rigid body part is embedded in the connecting seat and is fixed with the flexible connecting seat through a metal fastening ring; and the rigid-flexible coupled structure enables the arm to have the characteristic of high toughness.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Auto use separation bearing seat

The invention discloses an auto use separation bearing seat made of a material of modified alloy. The beneficial effects of the auto use separation bearing seat are that: the composition of the material alloy is modified, the toughness can be effectively improved, the fracture phenomenon is significantly reduced, compared with products in the prior art, the fracture rate is reduced by 40%-50%, and the market prospect is good.

Owner:LIUZHOU JUNJIE AUTO PARTS MFG

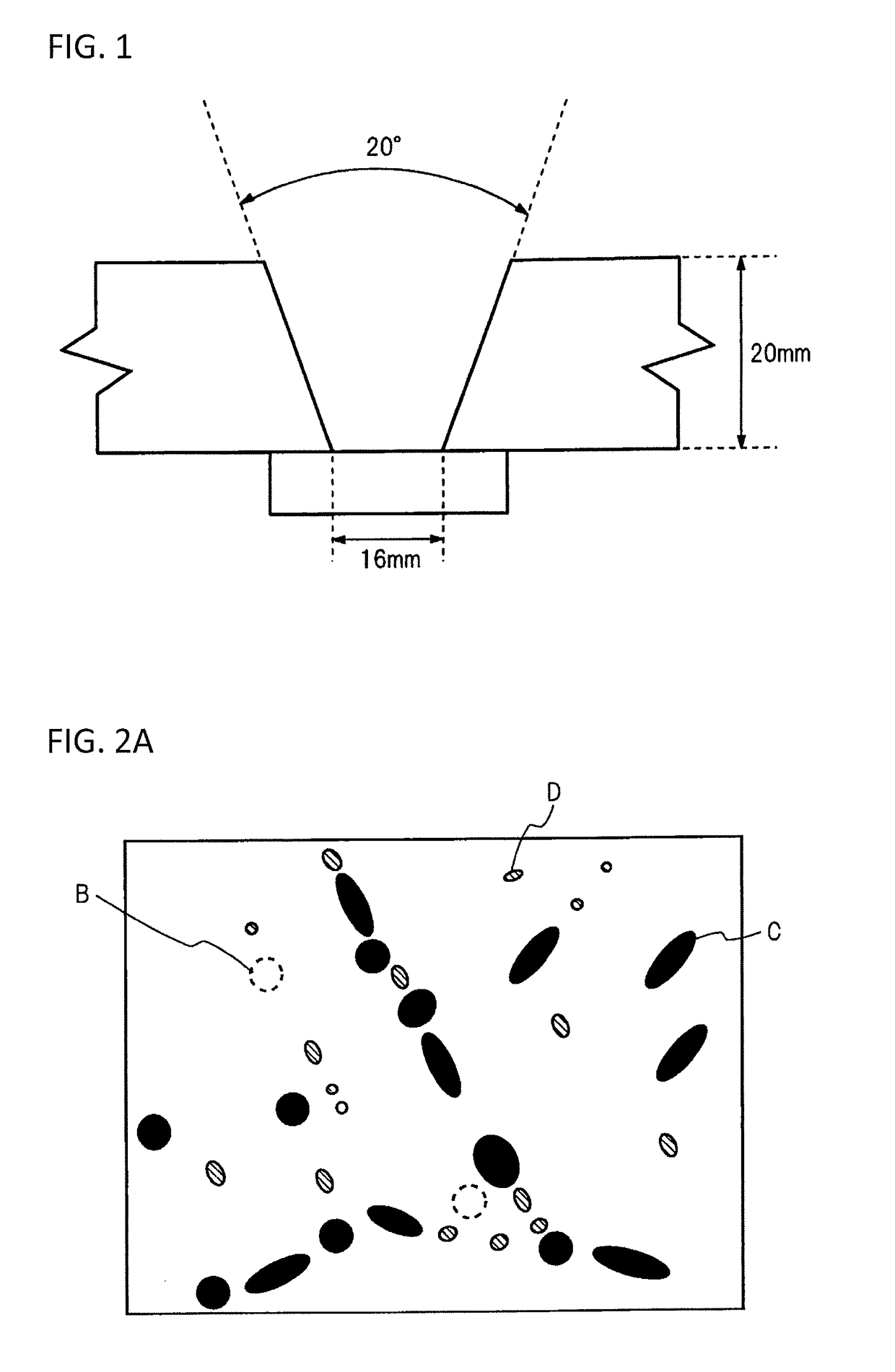

Welded metal and welded structure

InactiveUS20180147674A1High strengthHigh toughnessWelding/cutting media/materialsSoldering mediaMetalWeld metal

This welded metal contains C, Si, Mn, Ni, Cr, Mo, Ti, B, O, N and Nb+V in specific amounts, respectively, with the balance being made up of Fe and unavoidable impurities. In this welded metal, carbides having circle-equivalent diameters of less than 0.40 μm have an average circle-equivalent diameter of 0.10 μm or more, and intergranular carbides having circle-equivalent diameters of 0.40 μm or more have an average circle-equivalent diameter of 0.75 μm or less.

Owner:KOBE STEEL LTD

Epoxy resin adhesive, and preparation method and application thereof

InactiveCN105111982AGood mechanical strengthHigh toughnessNon-macromolecular adhesive additivesEpoxy resin adhesivesSolventChemistry

The invention discloses an epoxy resin adhesive. The adhesive comprises, by weight, 60-80 parts of epoxy resin, 2-6 parts of dicyandiamide, 5-10 parts of a plasticizer, 0.2-2 parts of a curing accelerator, 1-5 parts of an antioxidant, 1-5 parts of an anti-ultraviolet agent and 10-20 parts of a solvent. A preparation method of the adhesive comprises the following steps: adding raw materials into a mixing hopper according to a certain ratio, starting a variable speed stirrer, and continuously stirring under a rotating speed of 400-500r / min for 1-2h; and filtering, and removing residual bubbles. An application of the adhesive in advertisement consumables is characterized in that the adhesive bonds all layers of the consumables through primary curing and hot-pressing secondary curing, and finally forms a protection layer through cross-linking curing of an image layer. The epoxy resin adhesive has good curing performance, mechanical strength, impact strength and ageing resistance, and can be applied in the advertisement consumables to prolong the service life of the advertisement consumables and reduce the production cost of the advertisement consumables.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

Heating pipe with high firmness

InactiveCN104185318AHigh impact resistanceHigh toughnessHeating element shapesHeating element materialsPolypropyleneSendust

The invention discloses a heating pipe with high firmness. The heating pipe with high firmness is formed by combining an elastic alloy on the uppermost layer, modified plastic in the middle layer and a soft magnetic material on the lowermost layer. The elastic alloy comprises tin-phosphor bronze and beryllium bronze. The modified plastic is polypropylene resin. The soft magnetic material comprises sendust and manganese-zinc-iron. The elastic alloy takes up 34%-49% of the total weight of the heating pipe with high firmness; the polypropylene resin takes up 2%-4% of the total weight of the heating pipe with high firmness; the soft magnetic material takes up 51%-62% of the total weight of the heating pipe with high firmness. The heating pipe with high firmness has the advantages of high tenacity, high impact resistance, wear resistance, shock resistance and high firmness.

Owner:常熟市微尘电器有限公司

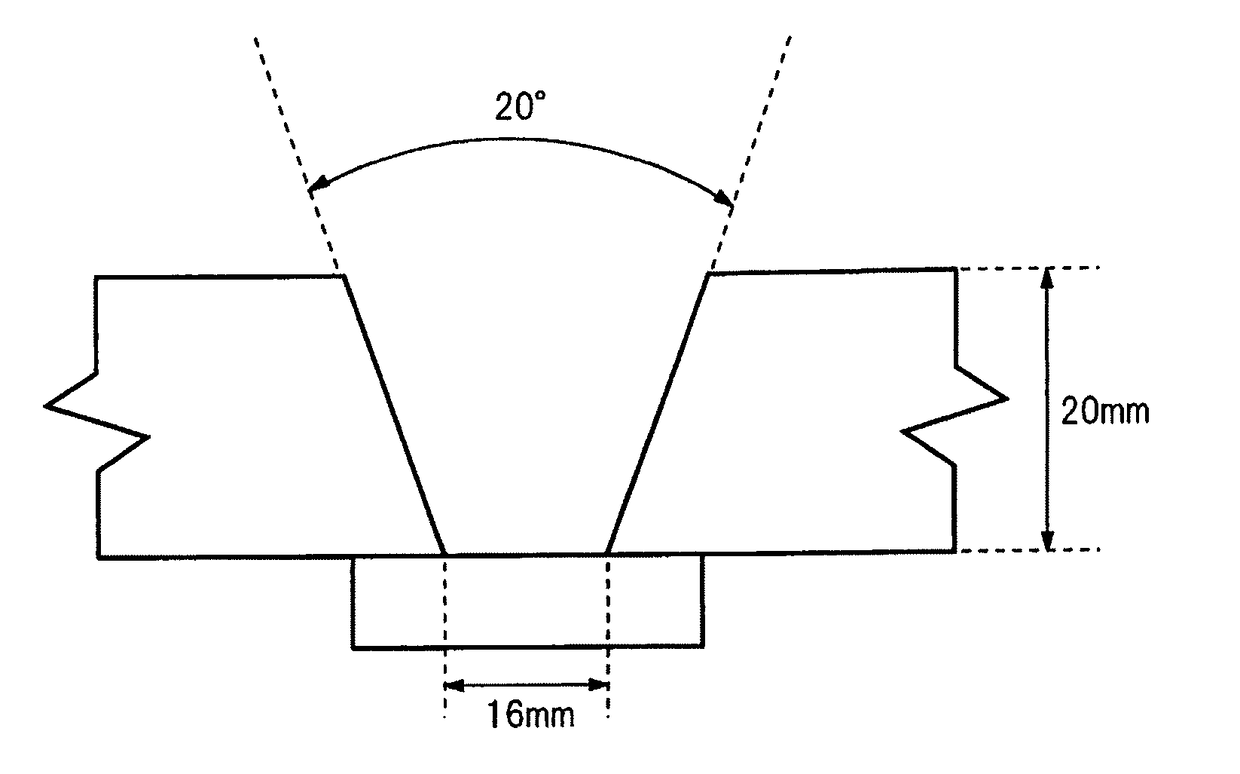

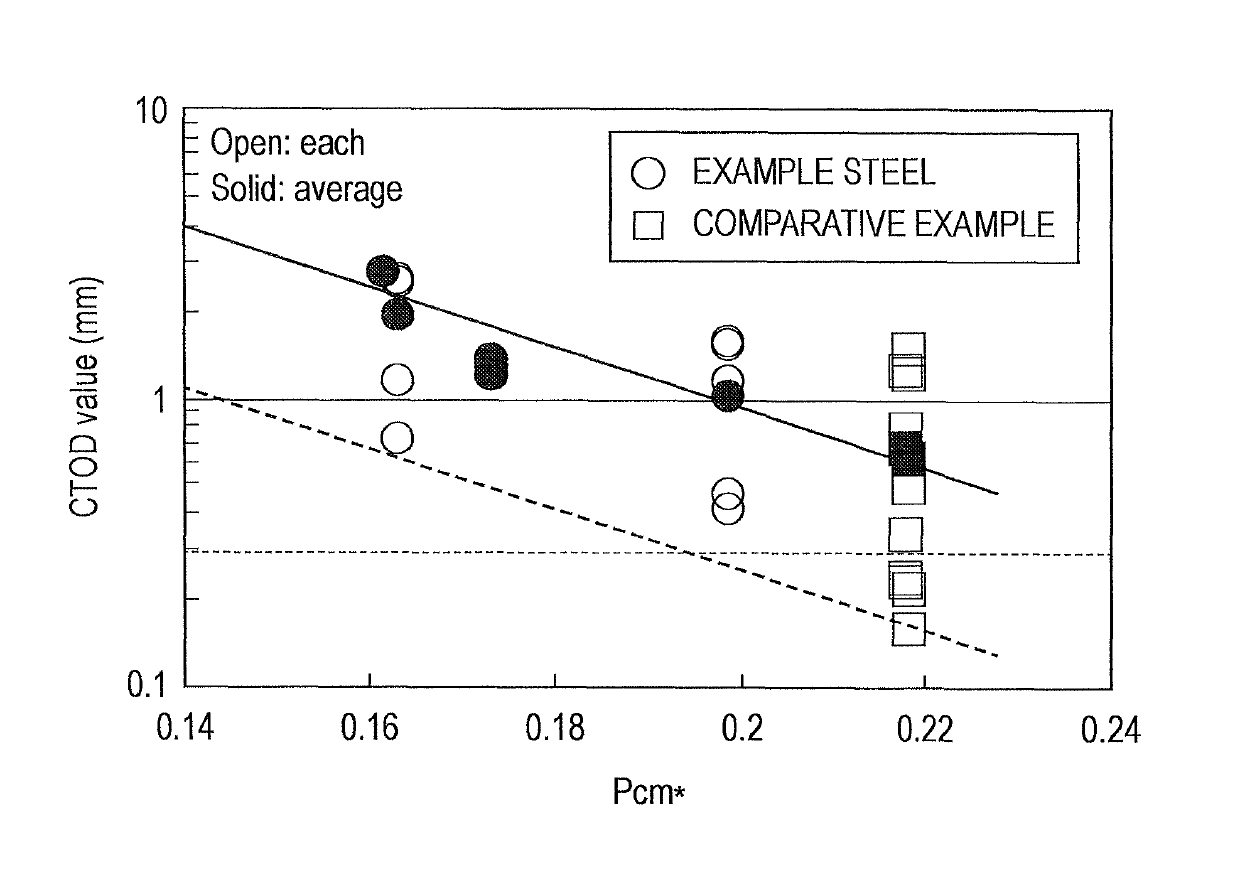

Steel plate for thick-walled steel pipe, method for manufacturing the same, and thick-walled high-strength steel pipe

A steel plate has a chemical composition containing, by mass %, C: 0.03% or more and 0.10% or less, Si: 0.05% or more and 0.50% or less, Mn: 1.00% or more and 2.00% or less, P: 0.015% or less, S: 0.005% or less, Mo: 0.20% or less (including 0%), Nb: 0.01% or more and 0.05% or less, and the balance being Fe and inevitable impurities, and, if desired, containing, by mass %, one or more of Al: 0.005% or more and 0.1% or less, Cu: 1.00% or less, Ni: 1.00% or less, Cr: 0.50% or less, and V: 0.05% or less, in which Pcm* (%) (=C+Si / 30+(Mn+Cu+Cr) / 20+Ni / 60+Mo / 2+V / 10) is 0.20 or less. The steel plate has a volume fraction of bainite in a base material of 50% or more, and has a volume fraction of island martensite (MA) in a coarse-grain region reheated in a dual-phase temperature range of 5.0% or less. A slab having the chemical composition described above that is cast using a continuous casting method is reheated at a specified temperature, hot-rolled, and then subjected to accelerated cooling to a temperature of 550° C. or lower and 250° C. or higher.

Owner:JFE STEEL CORP

Silicon nitride foam ceramic reinforced aluminum matrix composite material and its preparation method and application

The invention discloses a Si 3 N 4 Ceramic foam reinforced aluminum matrix composite material and its preparation method and application, the composite material includes aluminum matrix and Si 3 N 4 Ceramic foam, Si 3 N 4 Foamed ceramics include Si 3 N 4 Foam ceramic framework and in situ growth on Si 3 N 4 Columnar β‑Si on the framework pore walls of ceramic foams 3 N 4 Grain, aluminum matrix uniformly filled in Si 3 N 4 In the pores of the ceramic foam framework, columnar β‑Si 3 N 4 The grains are surrounded by an aluminum matrix. The preparation method of the composite material comprises the following steps: using a vacuum pressure infiltration process to press liquid metal aluminum into Si 3 N 4 In the pores of the ceramic foam skeleton, Si 3 N 4 Ceramic foam reinforced aluminum matrix composites. The Si 3 N 4 The ceramic foam reinforced aluminum matrix composite material has the advantages of good toughness, erosion resistance and good machining performance, and the preparation method is simple and suitable for mass production.

Owner:NAT UNIV OF DEFENSE TECH

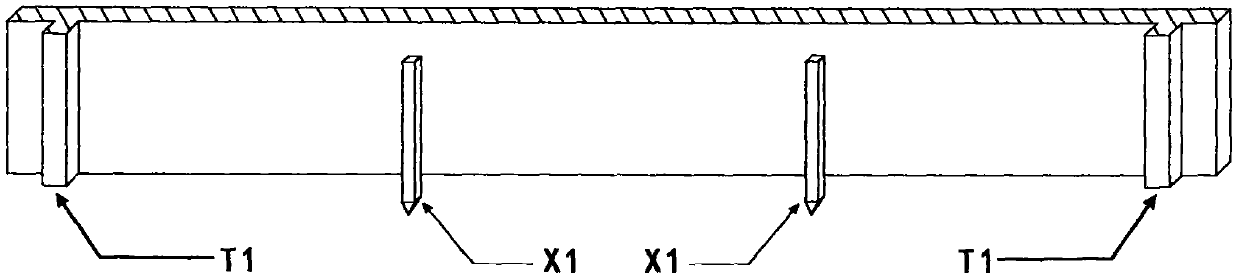

Mortise-tenon type rubber farmland cofferdam plate

InactiveCN110622640AHigh toughnessHigh hardnessAgricultural machinesFoundation engineeringRaw rubberAgricultural engineering

The invention relates to a cuboid mortise-tenon type rubber farmland cofferdam plate which is the substitute of a traditional soil cofferdam. The mortise-tenon type rubber farmland cofferdam plate ismanufactured by cooperatively using raw rubber (mainly regenerated rubber) and corresponding chemical fibers (mainly nylon fibers) and adding rubber auxiliaries, the cofferdam plate can be bent at will to form special shapes, the cofferdam plate can be produced by waste rubber in actual production, and the aged cofferdam plate can be recycled after smelting and be produced into a new cofferdam plate or other rubber products. The mortise-tenon type rubber farmland cofferdam plate has two reinforcing support wedges in the middle, the deformation torsion of the cofferdam plate is enhanced, and the stability of the cofferdam plate during use is guaranteed. Two mortise-tenon type rubber farmland cofferdam plates are connected through double inverted-n-shaped rubber mortise-tenon joints in a clamped manner, the inverted-T-shaped parts and the inverted-n-shaped parts are exactly integrally engaged with each other during connection, screws can be used for fixation when necessary, and firm andtight connection is achieved.

Owner:杨会军

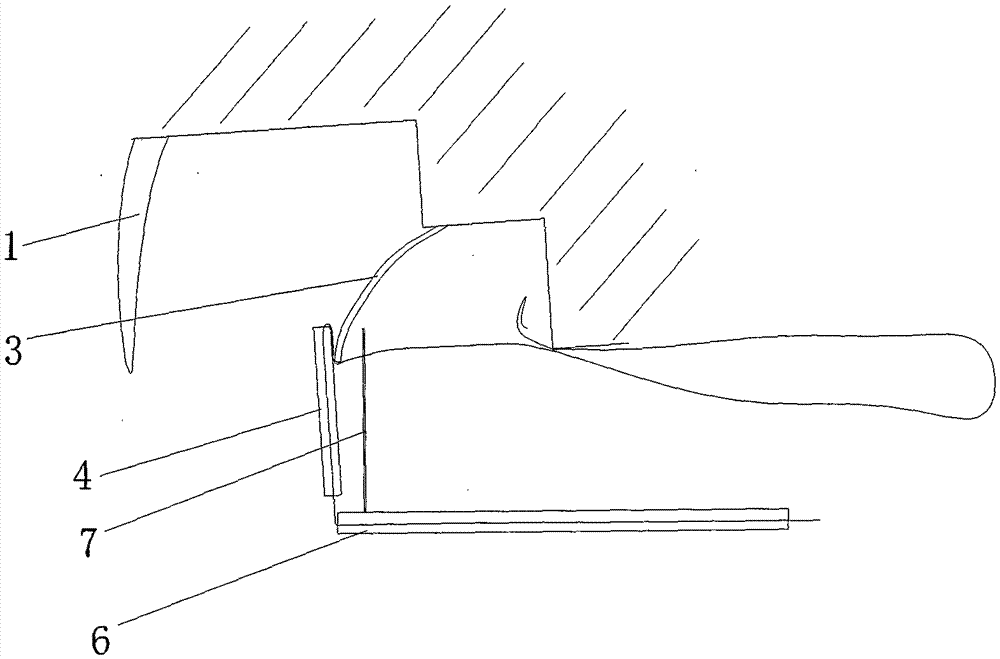

Open End Wrench Capable of Fast Driving and Having High toughness and a Long Service Life

An open end wrench includes a body having a jaw portion for holding a workpiece. The jaw portion includes an arcuate sliding groove, an expanding groove, and a slider movable relative to the arcuate sliding groove along an arcuate path. The jaw includes a first jaw having a force-applying face and an evasive portion adjacent to the force-applying face. When the jaw portion deforms elastically while wrenching the workpiece, the expanding groove increases the expanding effect within an elastic limit of the jaw portion, such that a corner between the force-receiving face in a first rotating direction and a sixth force-receiving face in a second rotating direction can move across the force-applying face into the evasive portion, avoiding damage to the slider and the first jaw resulting from failure in withstanding the reactive force from the workpiece. Thus, the open end wrench has high toughness and a long service life.

Owner:HU BOBBY

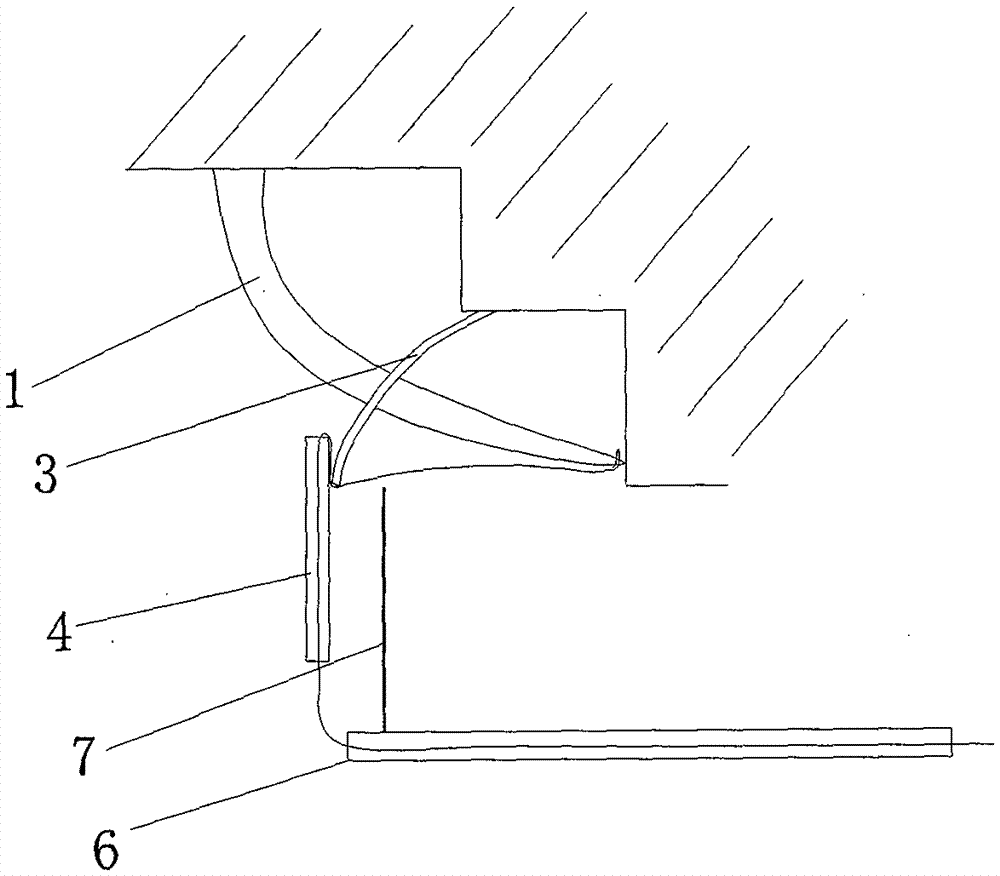

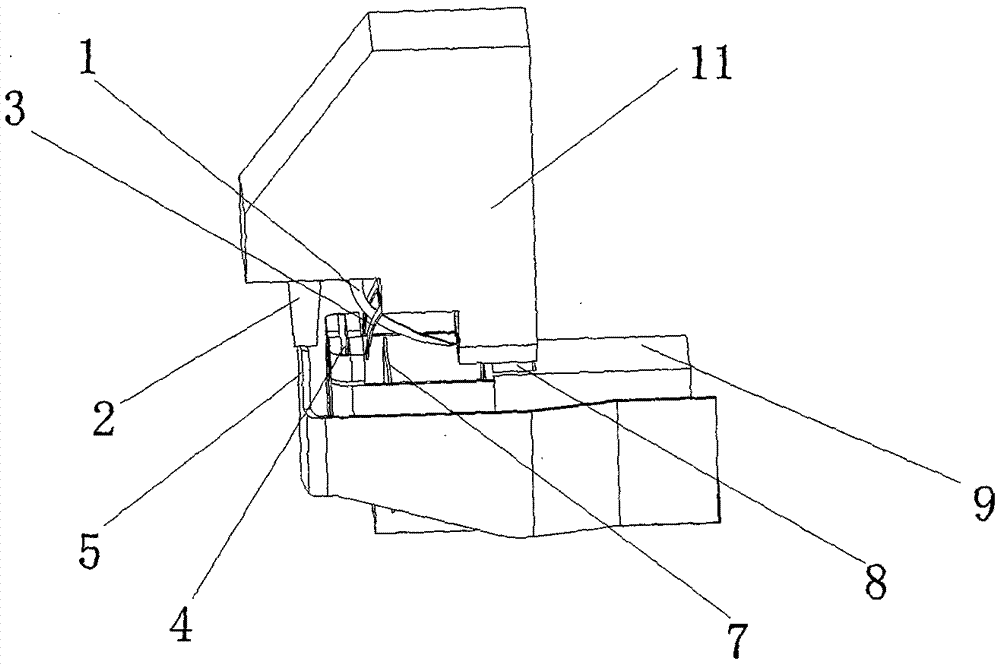

Material-saving cutting mechanism of strapping machine

PendingCN106904305AHigh toughnessNot easy to tearBinding material applicationBundling machine detailsScrapHooking

The invention provides a material-saving cutting mechanism of a strapping machine. The material-saving cutting mechanism of the strapping machine comprises a handle, a tongue puller and a pincers rod. A clamping opening is formed by the tongue puller and the pincers rod. The tongue puller is sequentially provided with a positioning mechanism for a binding belt, a tool holding groove and a needle box mechanism from the front end to the rear side. The end of the pincers rod is divided into a front section, a middle section and a rear section. The front section comprises a hook claw and a driving mechanism of the hook claw. The middle section corresponds to the tool holding groove. According to the rear section, a gland corresponds to the needle box mechanism. The handle is provided with a cutting tool, the cutting tool is located in the tool holding groove, the cutting portion of the cutting tool faces the pincers rod upwards, the hook claw can be driven by the driving mechanism to rotate downwards to achieve hooking or cock upwards, and when the hook claw is driven by the driving mechanism to achieve hooking, the position of a hook head of the hook claw is behind the position corresponding to the cutting tool. When the hook claw hooks the binding belt, the hook claw makes the end of the binding belt be placed at the rear portion of the cutting tool, so that when the cutting tool conducts cutting, the cutting tool only acts on a continuous belt portion and cannot cut the end of the binding belt on the hook claw, and no waste is generated.

Owner:ZHEJIANG DONGQIAO PRECISION MACHINERY CO LTD

Method for producing polyacetal resin composition

A polyacetal resin composition which is suppressed low in formaldehyde generation, while having high stiffness and high toughness. The resin is produced by a method including blending from 0.1 part by weight to 2 parts by weight (inclusive) of a polyacetal copolymer having a branched or crosslinked structure, which is a copolymer of a trioxane, a compound having from 3 to 4 (inclusive) cyclic ether units in each molecule and a compound having one cyclic ether unit in each molecule, per 100 parts by weight of a linear polyacetal copolymer which contains an oxymethylene unit as a main constituent, while containing, as a comonomer unit, an oxyalkylene unit at a ratio of from 0.4% by mole to 0.9% by mole (inclusive) relative to the constituents of the linear polyacetal copolymer, the linear polyacetal copolymer being obtained by copolymerization wherein a heteropolyacid or the like is used as a polymerization catalyst.

Owner:POLYPLASTICS CO LTD

High-performance rotational molding product cross-linking foaming molding process

The invention discloses a high-performance rotational molding product cross-linking foaming forming process which comprises the following steps: S1, selecting a mold, namely selecting a required mold, forming a material placing space in the mold, opening the upper part of the mold, and fixing the mold in a heating chamber; s2, the plastic plate is smashed and ground through a grinding machine, and plastic powder is obtained through grinding for standby application; s3, the plastic powder in the S2 is guided into the material containing space in the mold in the S1, the mold is closed, the peripheral wall of the mold is fixed, and a feeding notch is formed in the upper portion of the mold; and S4, the temperature in the heating chamber in the step S1 is increased to 40-50 DEG C, a stabilizer and a catalyst are added into a feeding notch in the upper portion of the mold in the step S3, stirring is conducted through a stirring machine till the stabilizer and the catalyst are completely fused with the plastic powder, and the time is controlled to be 10-15 min. A special rotational molding product forming process is utilized, and the product is high in impact resistance, toughness and plasticity, has high temperature resistance and is convenient to operate, so that rotational molding is simple and easy to implement.

Owner:连云港春旭滚塑科技有限公司

Waterborne polyurethane-acrylic acid water-based paint and preparation method thereof

The invention provides waterborne polyurethane-acrylic acid water-based paint. The waterborne polyurethane-acrylic acid water-based paint is prepared from 60%-70% of prepared waterborne polyurethane-acrylic acid, 1.0%-10% of a coalescing agent, 0.7%-1.0% of a flatting agent, 0.3%-0.8% of a wetting agent, 3.0%-10% of nano titanium dioxide, 0.6%-0.9% of an anti-after-tack agent and 0.1%-0.5% of a thickening agent, and the film forming state is adjusted, so that the finished product water-based paint is obtained. The waterborne polyurethane-acrylic acid water-based paint has the advantages of high solid content, good fullness, good adhesiveness to the surfaces of various materials, high toughness and hardness of a paint film, high wear resistance and impact resistance, no softening of the paint film after being heated, extremely high hot spot resistance and good freshness persistence, and the hardness of the paint film can reach H-2H in a pencil test.

Owner:KUNSHAN SAKURA PAINT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com