Stereolithography resin compositions and three-dimensional objects made therefrom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

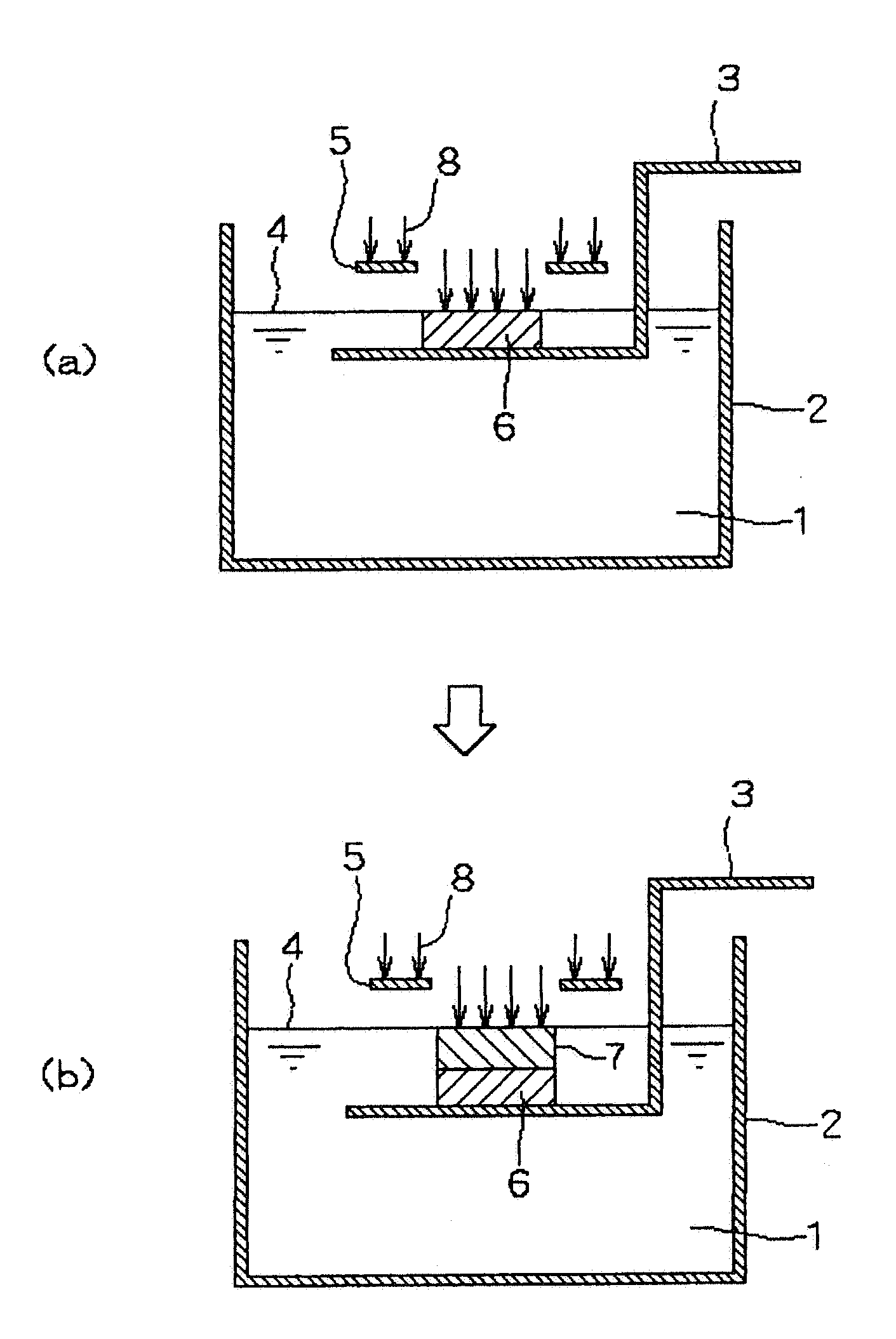

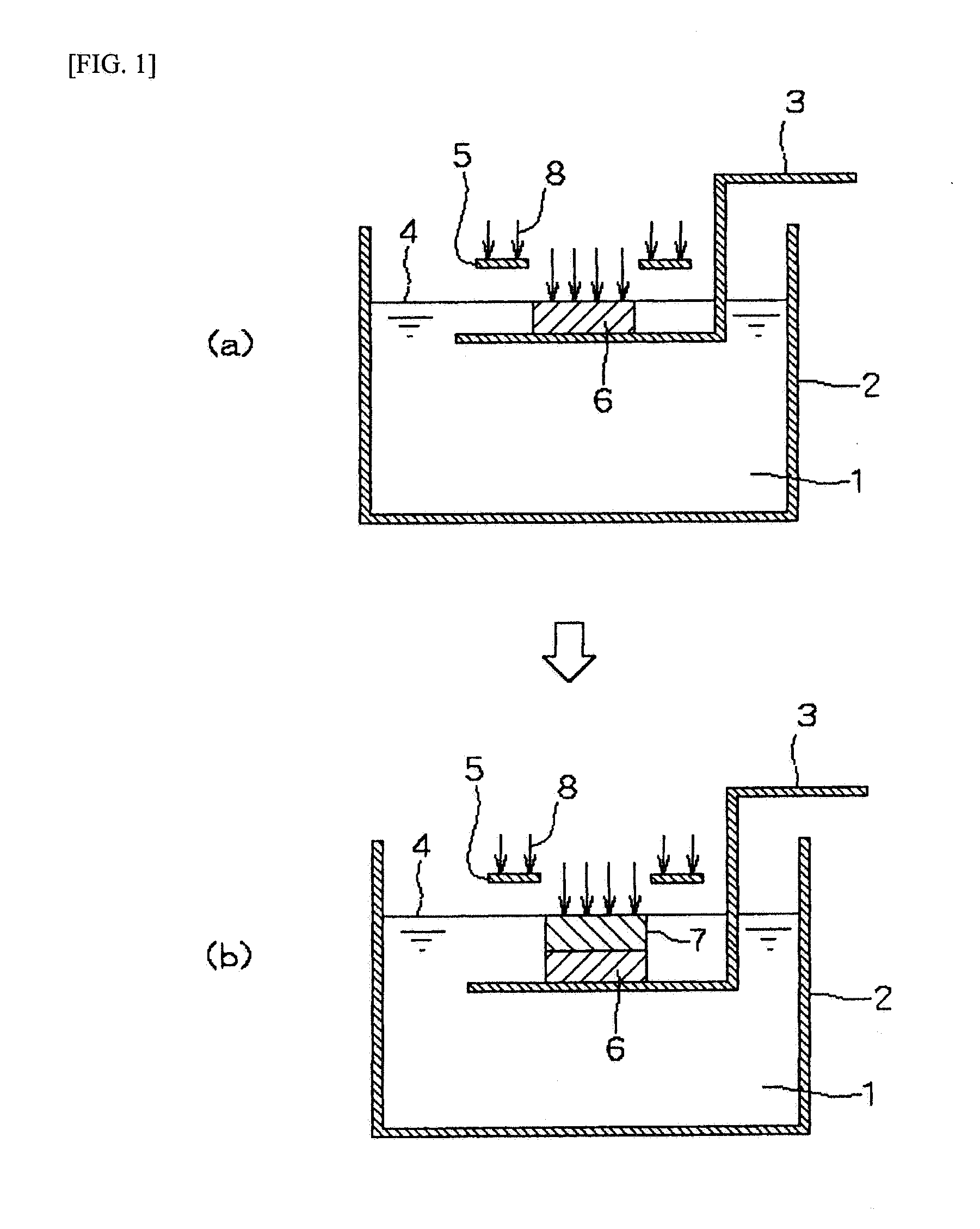

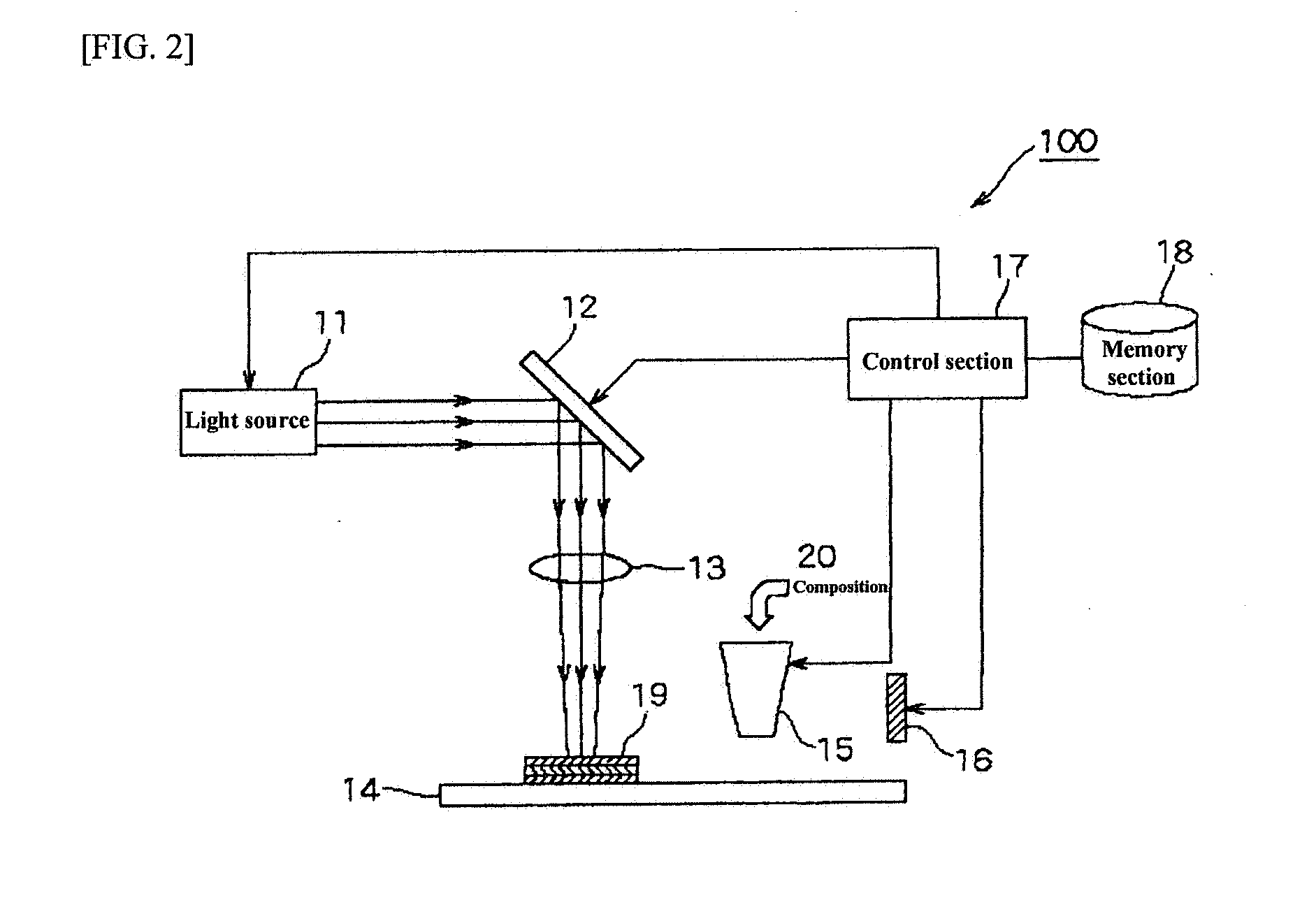

Image

Examples

examples 2 to 5

[0193]Curable liquid resin compositions were prepared in the same manner as in Example 1, except for using the compounds shown in Table 3 as component (F). Test specimens (cured products) were prepared from the resulting liquid resin compositions for evaluation. The evaluation method is the same as described above. The results are shown in Table 3.

TABLE 3Example 2Example 3Example 4Example 5Type of componentPB / GMA +PB / GMA +PB / alicyclicPB / OXMA +(F) (core / shell layer)PMMAPMMAepoxy + PMMAPMMAContent of2,4101,8102,4901,900functional group(g / eq)Diameter of100100100100component (F) (nm)Viscosity (mPa · s)1,2001,2101,2101,200[Evaluation]Bending modulus of2,1002,0002,1002,200elasticity (MPa)Izod impact value2.43.73.54.3(kJ / m2)PB: PolybutadieneGMA: Glycidyl methacrylate (monomer for epoxy modification)PMMA: Polymethyl methacrylateAlicyclic epoxy: Methacrylate having an alicyclic epoxy group (monomer for epoxy modification), “CYCLOMER M100” manufactured by Daicel Chemical Industries, Ltd.OXMA:...

example 6

[0194]The same experiment as in Example 2 was carried out except that the test specimen (cured product) was heated at 80° C. for two hours after molding.

example 7

[0195]The same experiment as in Example 3 was carried out except that the test specimen (cured product) was heated at 80° C. for two hours after molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com