Patents

Literature

514results about How to "Not easy to tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

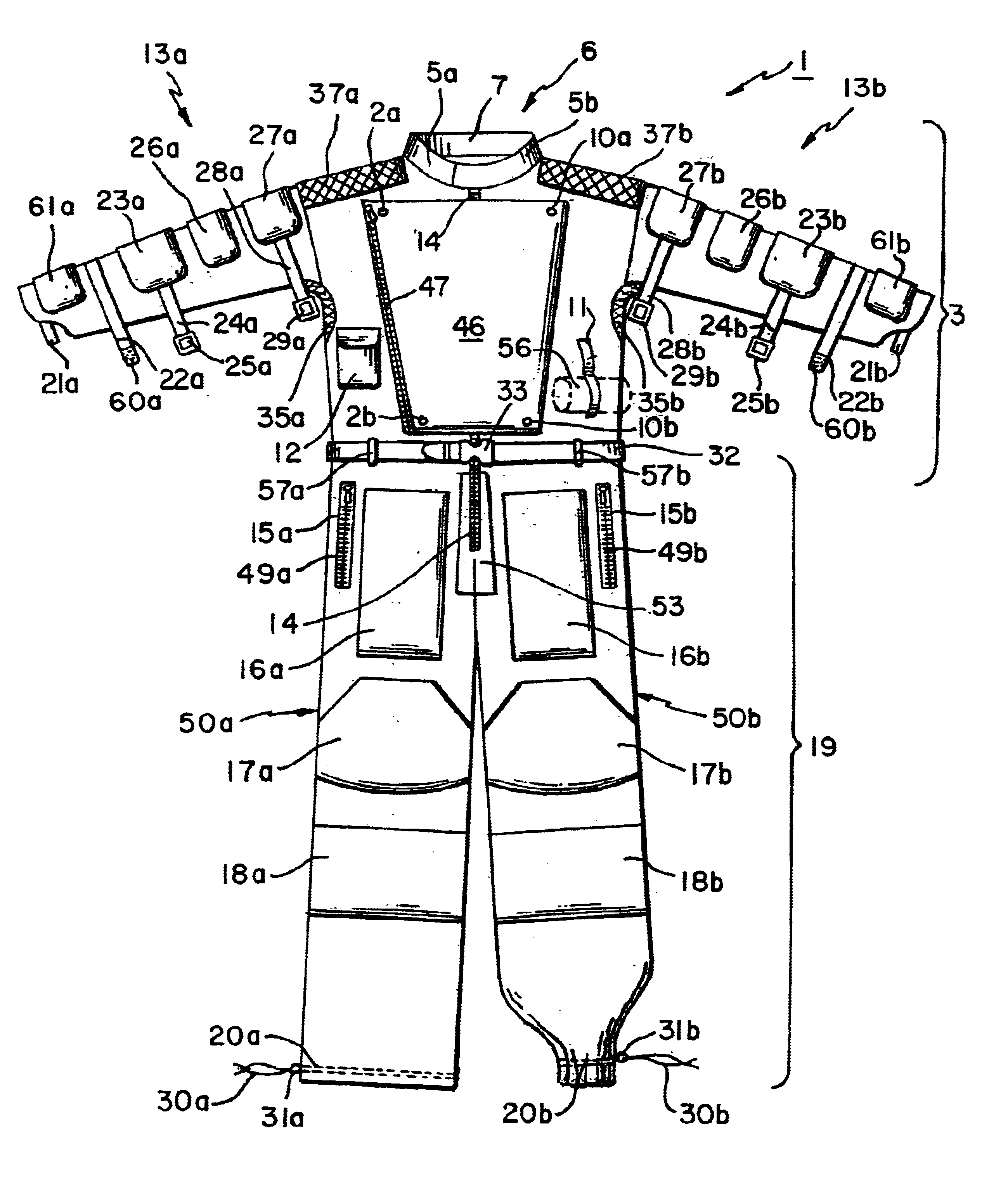

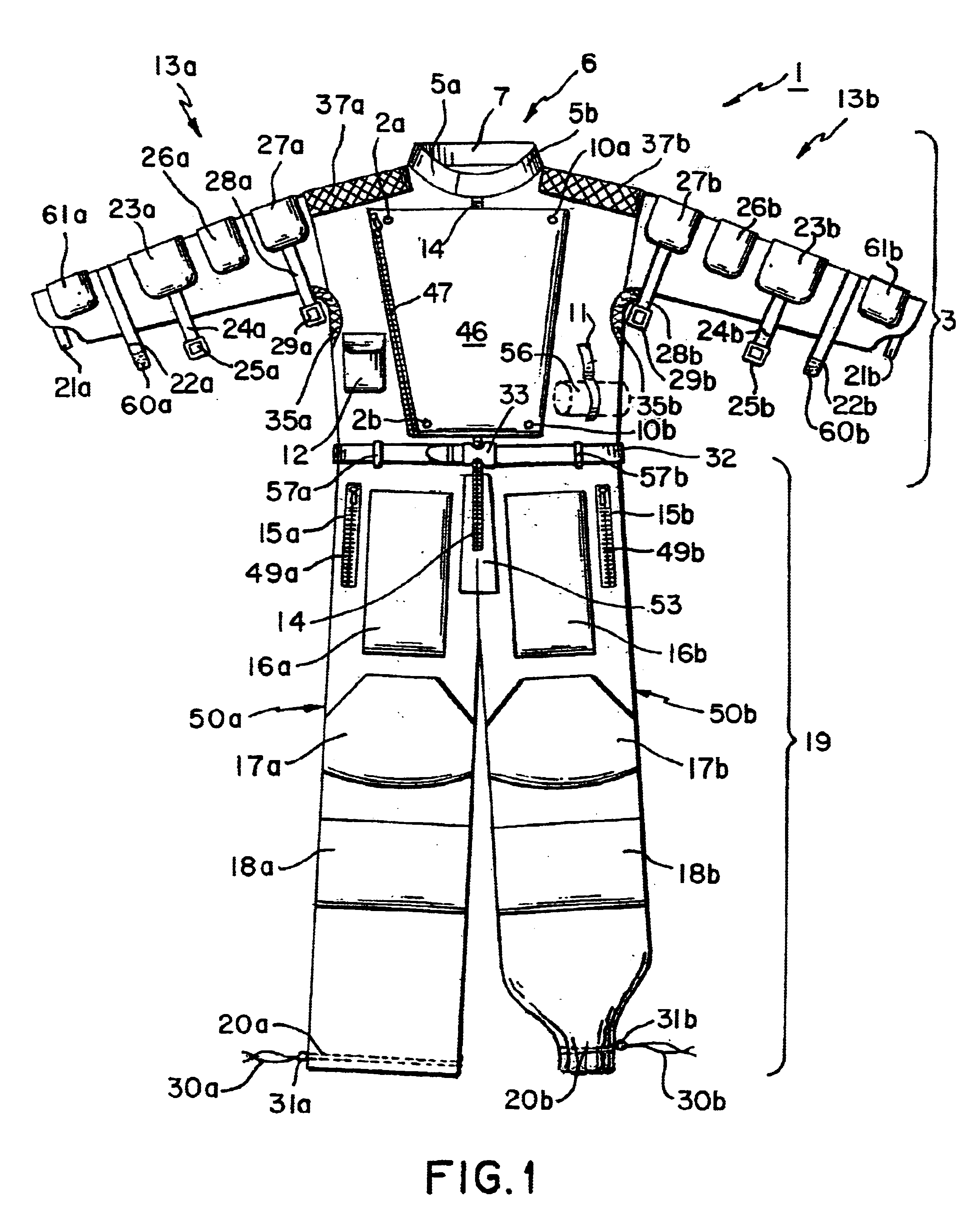

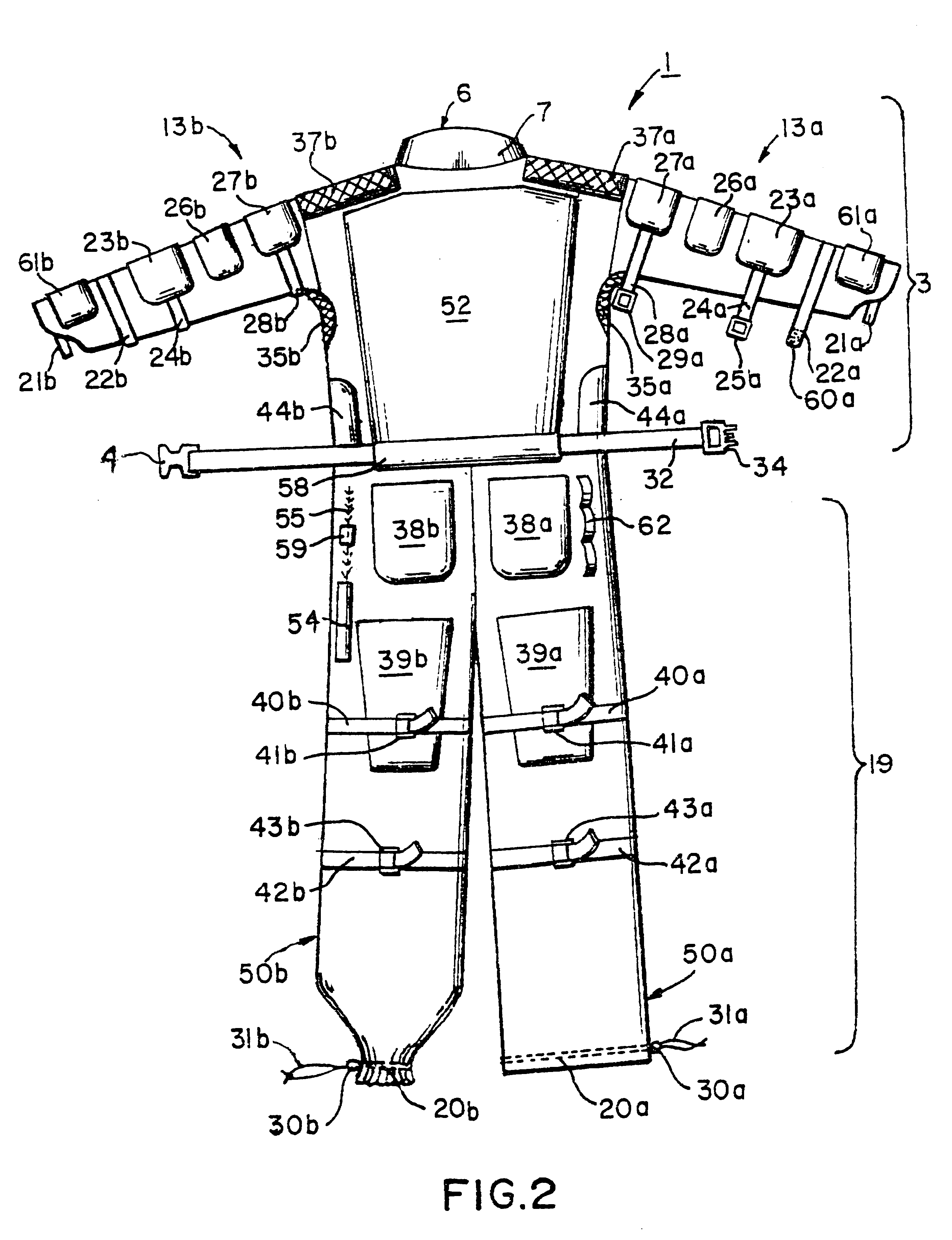

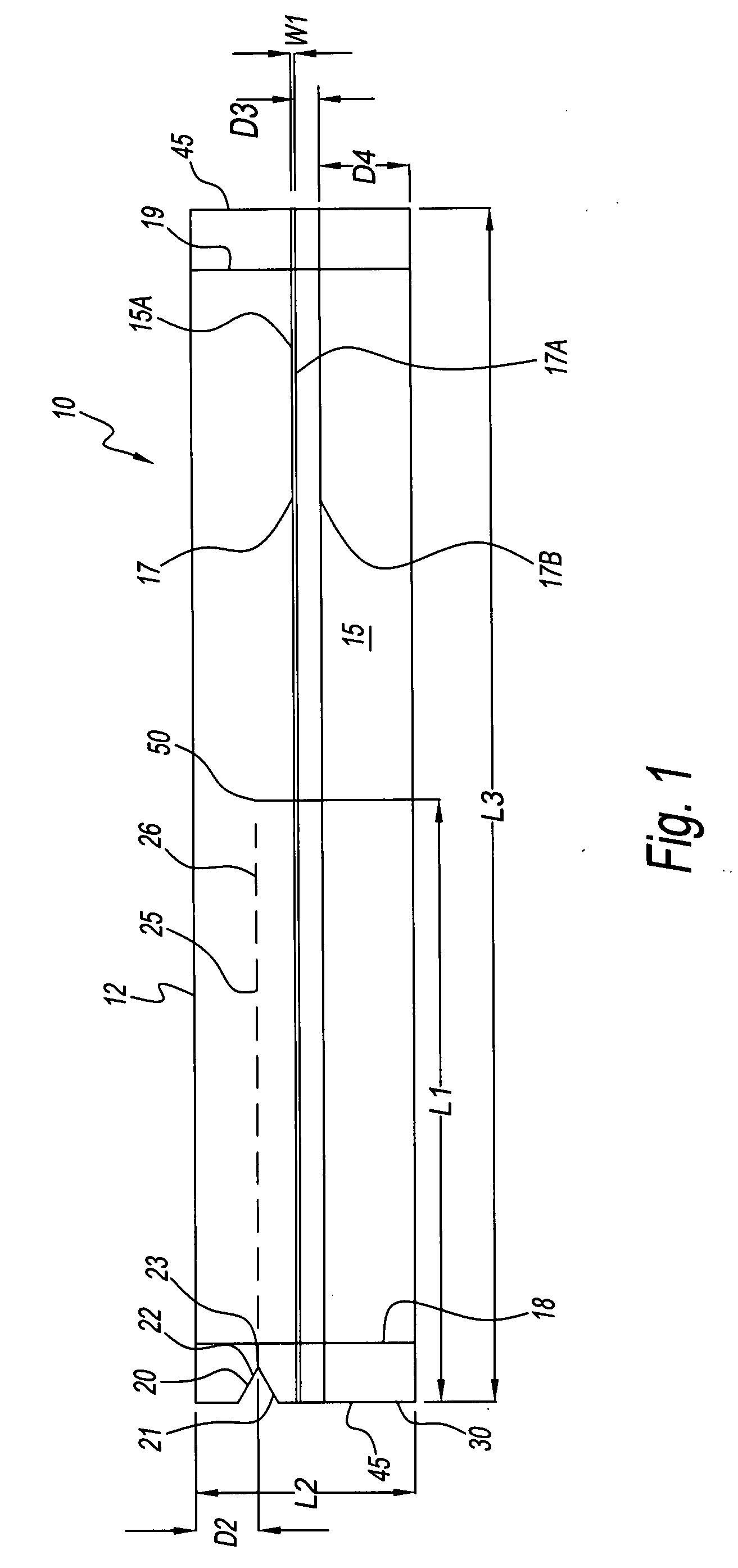

Protective garment for game of paintball

InactiveUS6745400B1Sturdily constructedNot easy to tearChemical protectionGarment special featuresDark colorEngineering

A one piece protective garment to be worn by children or adults while playing paintball has padding sewn into it at spots where injury is anticipated due to collision with other players and obstacles. There are also a belted waist, a collar, central zipper, and adjustable safety closures on the sleeves, pant legs, and ankles for adjusting the garment's fit. A removable padded bib covers the chest for extra protection. Mesh-like material on the armpits and chest ventilates the player to avoid overheating. Accessible compartments store accessories specific to the game of paintball. The garment's material is a camouflage design, or dark color, in order for the user to blend into the landscape and effectively hide from other players. The material is also water resistant and strong enough to resist normal wear and tear. A quilted pattern is aesthetically pleasing and increases the material's strength.

Owner:PACIORKOWSKI TRACY JAMES

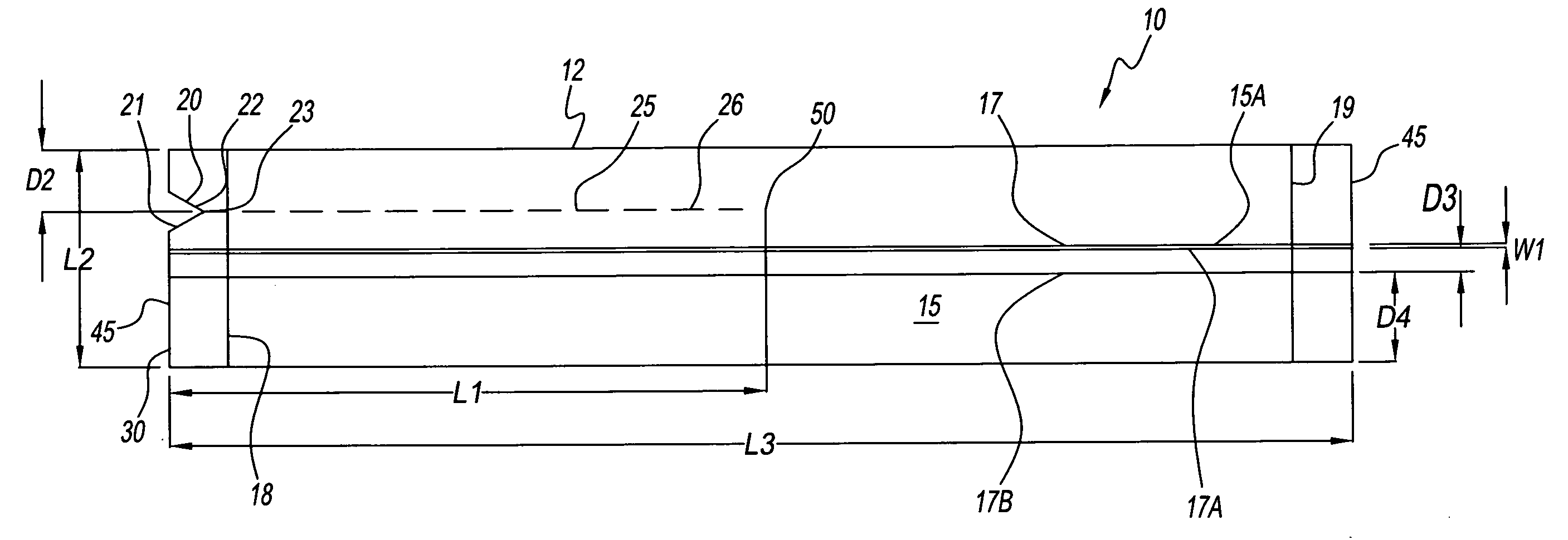

Tampon wrapper

InactiveUS20080058749A1Precise positioningAvoid contactWrappersDiagnosticsTamponMaterial Perforation

The present disclosure provides a tampon wrapper that is a polyethylene film tube having at least a first sealed end with a notch in the first sealed end, and a number of perforations extending from the notch along the axial length of the tampon wrapper. The wrapper is quiet, easy to open, and provides a sanitary method of storing a used applicator.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

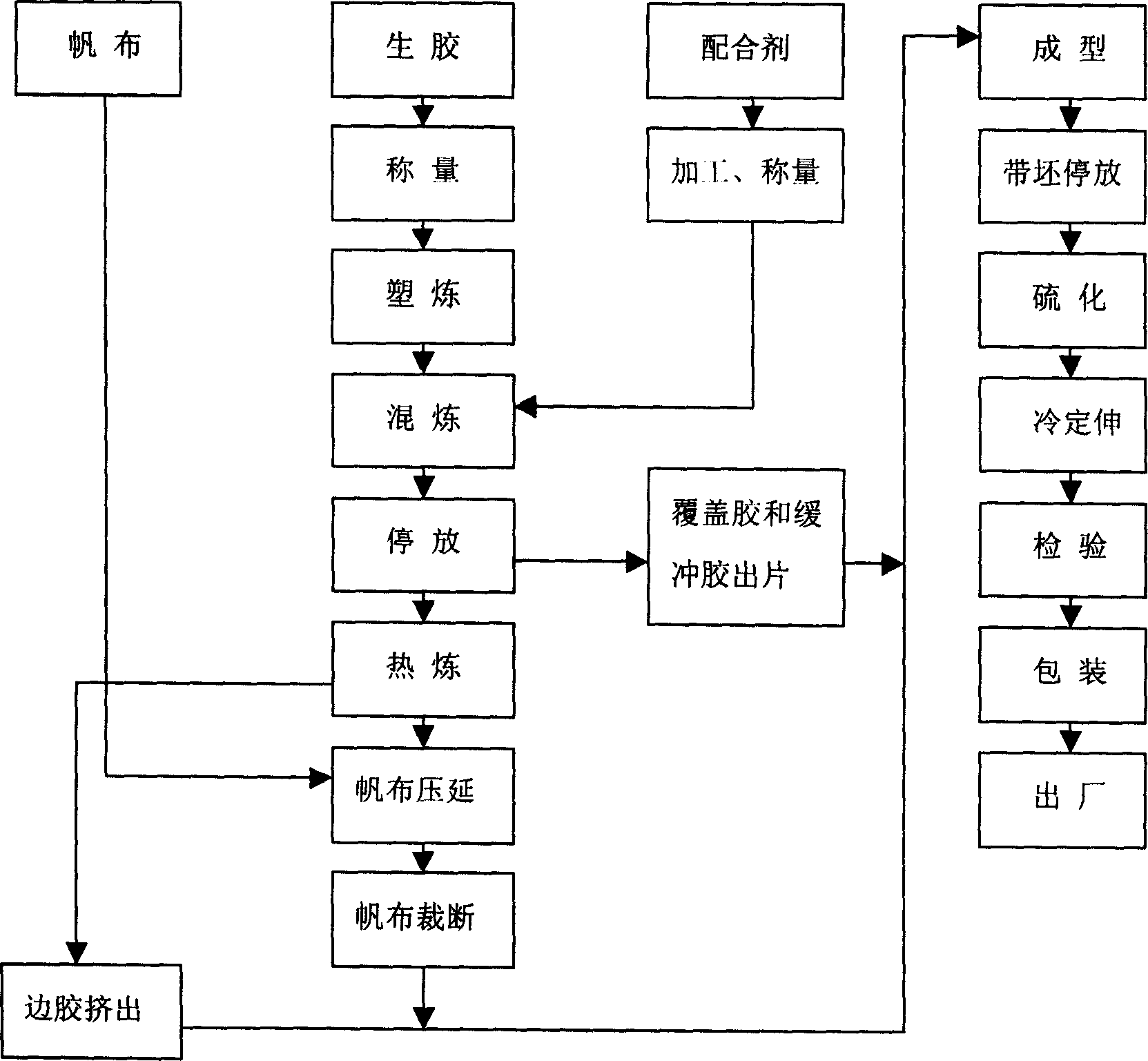

Impact resistance high wearing-proof conveyer belt

An anti-impact and anti-wear conveying belt features that the rubber layer covered on its surface is proportionally prepared from natural rubber, synthetic rubber, sulfur, zinc oxide, stearic acid, promoter, reinforcing agent, softening agent and anti-ageing agent.

Owner:阳江市北山胶化有限公司

Method for producing environment-friendly false proof cover paper

ActiveCN101319475AImprove tear resistanceHigh folding resistanceNon-fibrous pulp additionNatural cellulose pulp/paperFiberTear resistance

The invention relates to a method for producing environment-friendly anti-counterfeiting cover paper. In the method, raw fibers with the purity of 100 percent are used to produce base paper; the raw fibers selected comprise the following components in weight portion: 50 to 65 percent of needle oil pulp,10 to 20 percent of silking pulp, and 20 to 30 percent of cotton pulp; the raw fibers are subjected to disintegration by a pulp plate, pulping treatment, blending, pulp conveying, forming by a head box, drying and dehydration and bundling reeling to produce the base paper, and the base paper is orderly subjected to dip dyeing, dip latex, base coating, anti-counterfeiting printing and top coating to produce the anti-counterfeiting cover paper. The cover paper has excellent tearing resistance and folding resistance and good anti-counterfeiting function. The method of the invention has the advantages of simple processing and manufacturing, low production cost and environmental protection, and has the tearing resistance and anti-counterfeiting function. The environment-friendly anti-counterfeiting cover paper is suitable for being manufactured into covers of all certificates, particularly a cover of an environment-friendly anti-counterfeiting passport.

Owner:SHANDONG KAILI SPECIAL PAPER

Cr-containing thick-wall pipeline steel and coiled sheet controlled rolling and controlled cooling method thereof

ActiveCN101580918AHigh elongationExcellent formabilityTemperature control deviceProcess efficiency improvementChemical compositionThick wall

The invention provides a Cr-containing thick-wall pipeline steel which includes chemical components with the following weight percentage (%): 0.54 to 0.90 of Cr, 0.03 to 0.09 of C, 0.24 to 0.35 of Si,1.23 to 1.30 of Mn, less than or equal to 0.015 of P, less than or equal to 0.005 of S, less than or equal to 0.0045 of N, 0.018 to 0.030 of Ti, 0.046 to 0.08 of Nb, 0.23 to 0.30 of Cu, 0.10 to 0.40 of Ni, 0.015 to 0.060 of AIs, and the balance of iron and residual elements. A coiled sheet controlled rolling and controlled cooling method is realized by that: the heating temperature of billet steelis 1150 to 1175 DEG C, the rough rolling start temperature is 1130 to 1155 DEG C, the finish rolling start temperature is 1020 to 1030 DEG C, the final rolling temperature is 800 to 850 DEG C, the coiling temperature is 450 to 540 DEG C, the total pressing rate is not less than 85 percent, and the cooling speed is controlled to be 15 to 20 DEG C per second.

Owner:MAANSHAN IRON & STEEL CO LTD

Condensed type two-component pouring sealant for LED optical lens and preparation method thereof

InactiveCN105585999AImprove elongation and toughnessNot easy to tearNon-macromolecular adhesive additivesMacromolecular adhesive additivesChemistryPlasticizer

The invention provides a condensed type two-component pouring sealant for an LED optical lens and a preparation method thereof. The condensed type two-component pouring sealant comprises a component A and a component B in a mass ratio of (100:8)-(100:15), wherein the component A comprises the following components in parts by mass: 100 parts of hydroxyl-terminated polysiloxane, 50-200 parts of filler, 50-100 parts of plasticizer, 1-8 parts of pigment, 0.2-5 parts of surfactant and 0.1-1 part of curing accelerator; and the component B comprises the following components in parts by mass: 100 parts of plasticizer, 10-100 parts of crosslinking agent, 20-100 parts of chain extender, 0.01-1 part of catalyst and 5-50 parts of coupling agent. The condensed type two-component pouring sealant provided by the invention has the advantages of easiness in leveling, good antifoaming property, easiness in synchronous curing, low shrinkage, high elongation and good adhesion; and moreover, the production efficiency can be improved when the pouring sealant is used, a better protection effect can be realized for the LED optical lens and base material, and the service life of the LED lamp is prolonged.

Owner:GUANGDONG JIEGUO NEW MATERIAL CO LTD

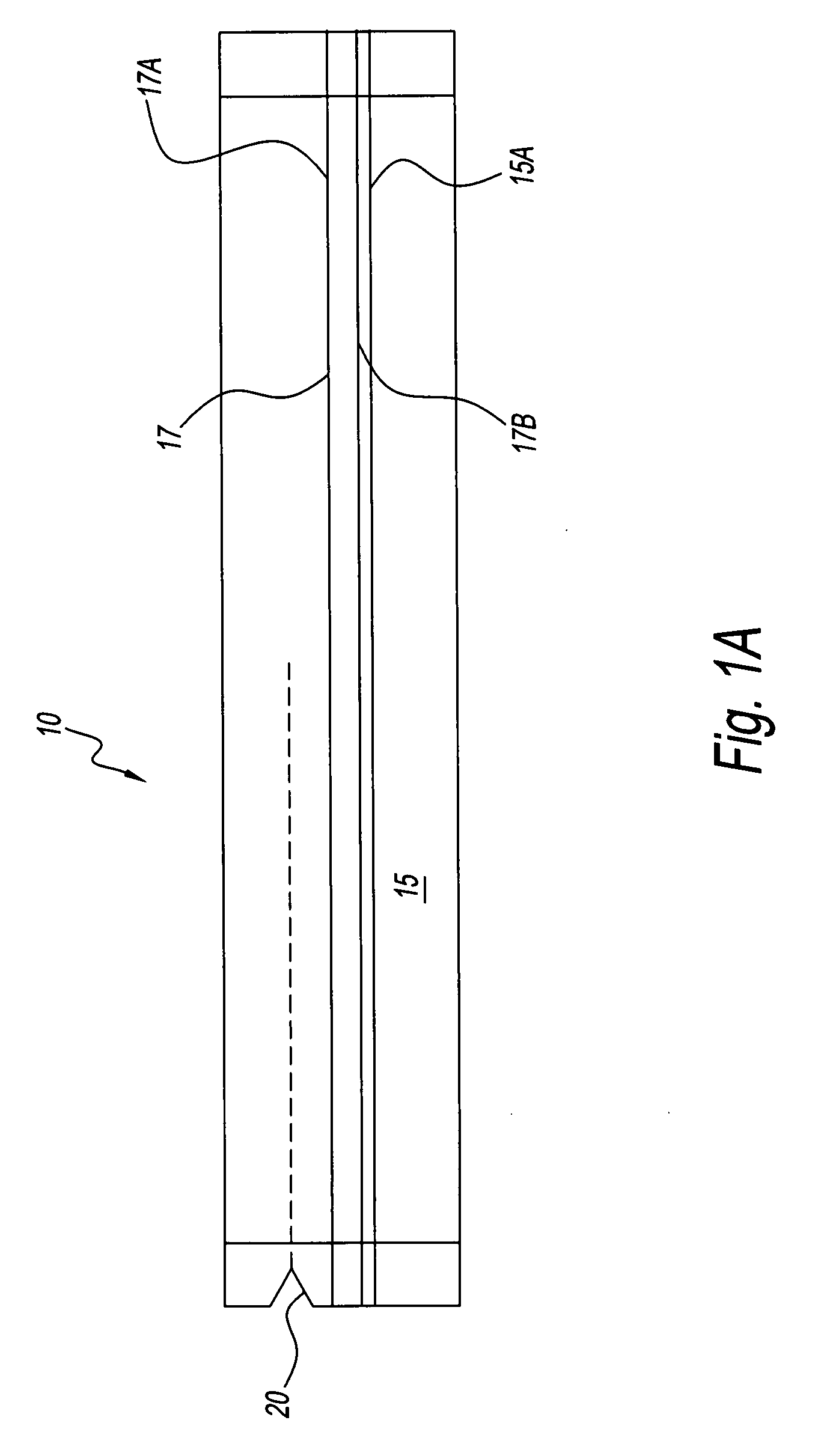

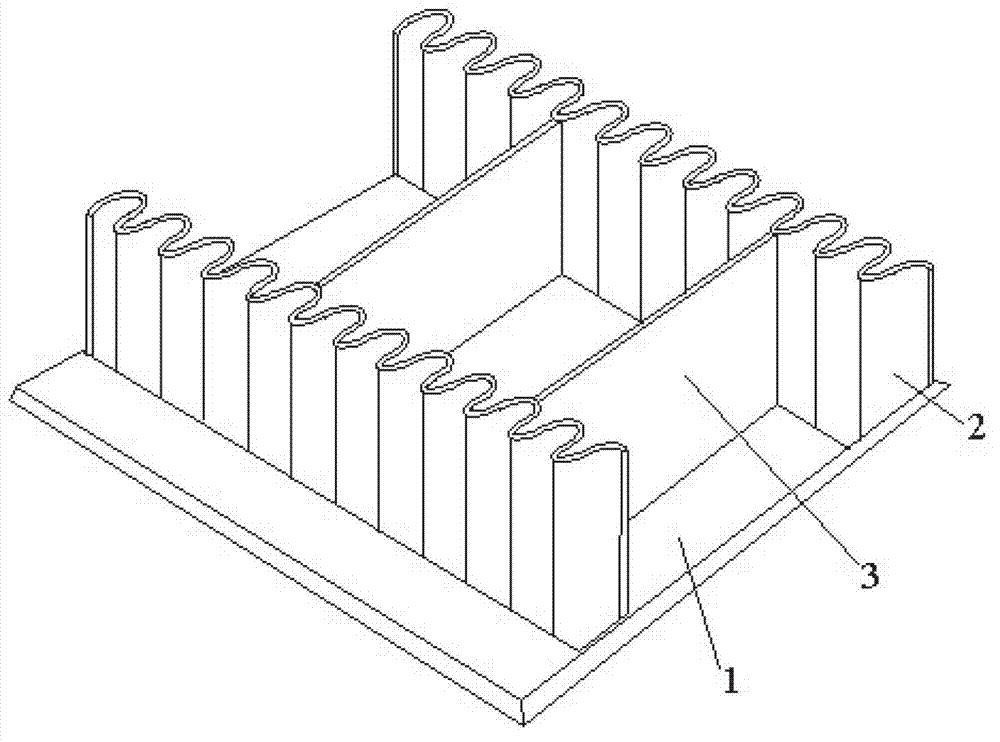

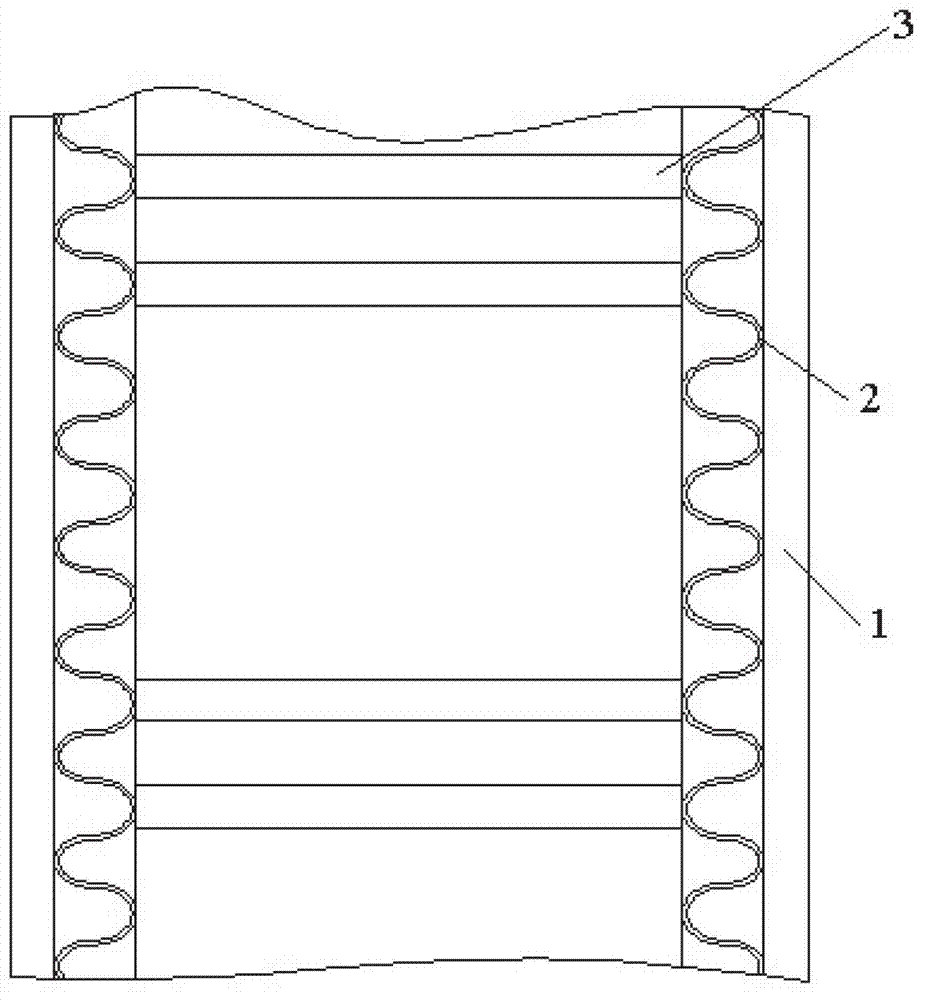

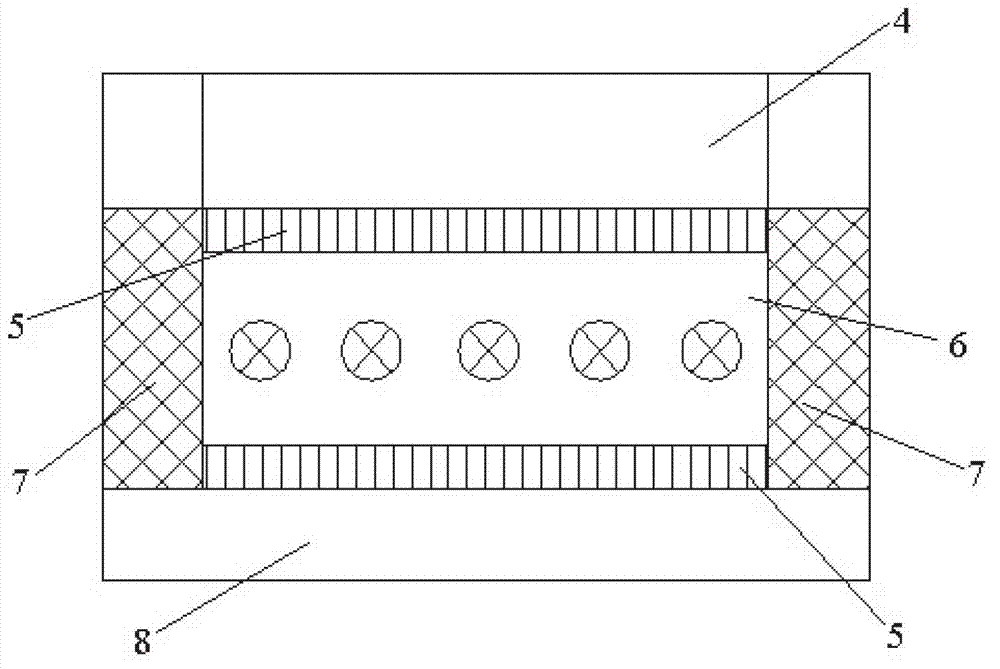

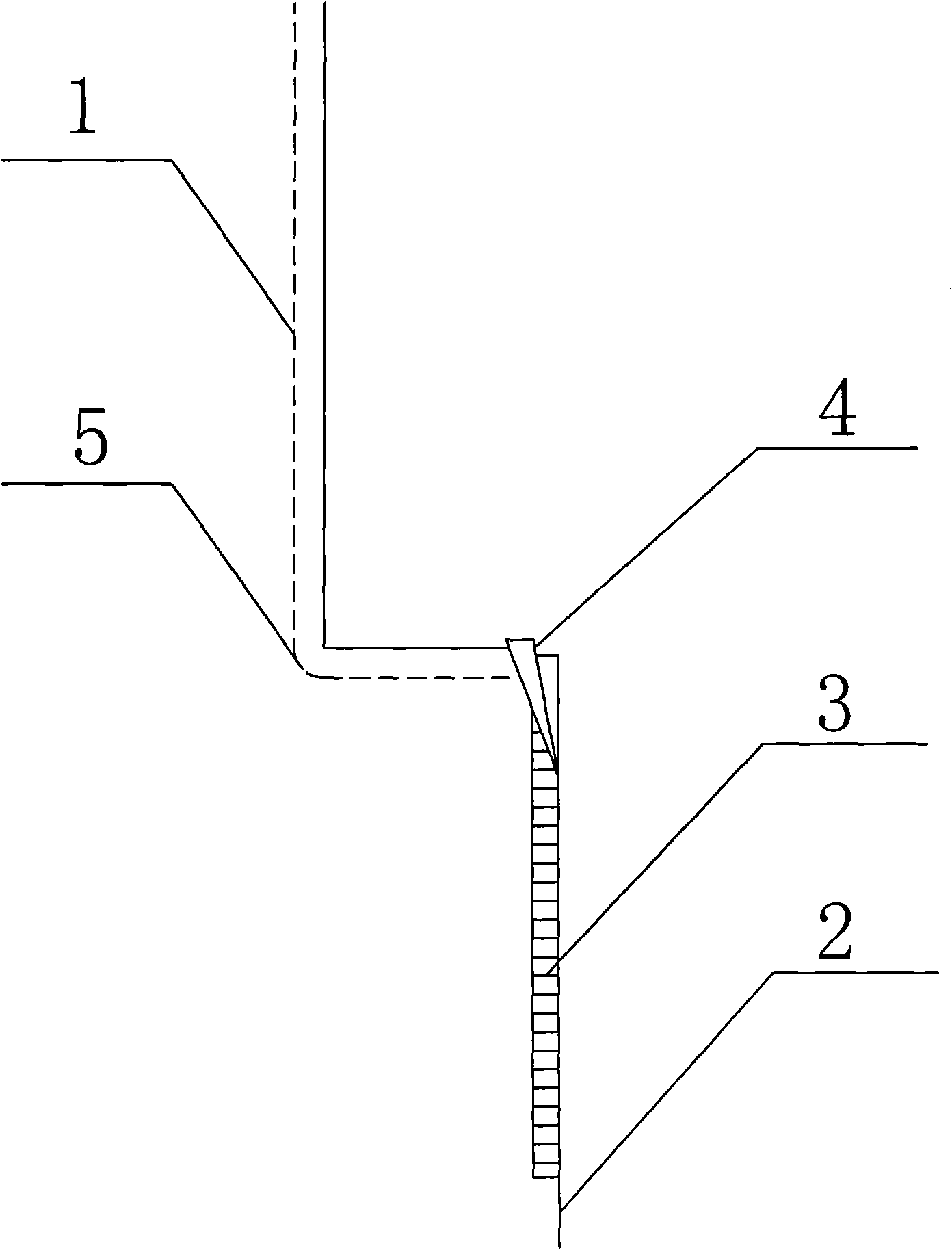

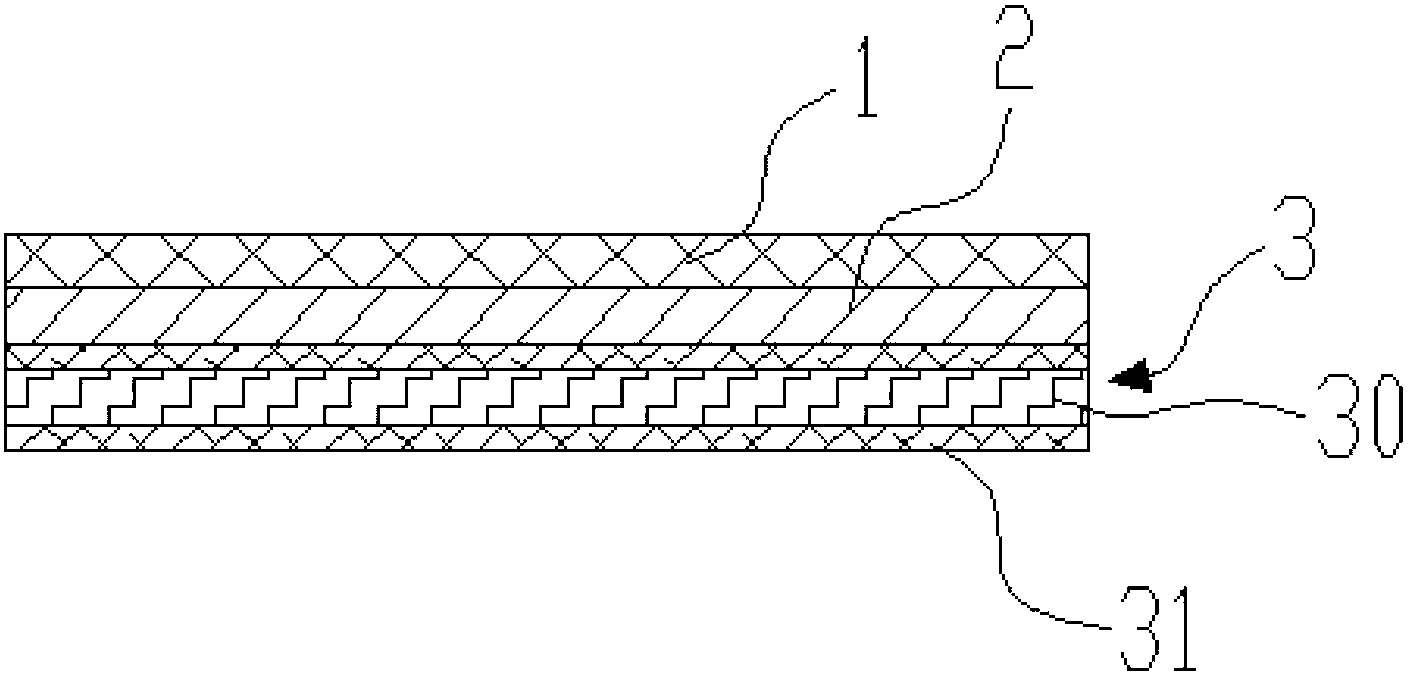

Large-inclination wavy-retaining-edge conveying belt and processing method thereof

InactiveCN102826330AImprove tear resistanceNot easy to tearConveyorsMetal layered productsVulcanizationMechanical engineering

The invention relates to a large-inclination wavy-retaining-edge conveying belt, which comprises a base belt, retaining edges and transverse baffles. The base belt is a composite rubber layer consisting of an upper covering rubber layer, a latitudinal steel cord anti-tearing layer, a steel chord skeleton layer, a side rubber layer and a lower covering rubber layer which are sequentially arranged from top to bottom, are bonded primarily and are vulcanized secondarily. A plurality of transversely and evenly arranged steel wires are embedded into the steel chord skeleton layer. The steel wires are embedded in the steel chord skeleton layer and are arranged in the same plane. The side rubber layer is arranged on the side of the steel chord skeleton layer. Wavy retaining edges which are fixedly arranged through a secondary vulcanization bonding method are symmetrically arranged on the two sides of the base belt. The number of the transverse baffles is multiple. The transverse baffles are vertically and fixedly arranged on the base belt at intervals through the secondary vulcanization bonding method and are arranged corresponding to the valleys of the wavy retaining edges. The large-inclination wavy-retaining-edge conveying belt has the advantages that the anti-tearing performance of the existing retaining edge conveying belt is mainly improved, the conveying belt is prevented from being longitudinally drawn, the requirement on large-inclination conveying is satisfied and the service life of the conveying belt is prolonged.

Owner:ZHANGJIAGANG HUASHEN INDAL RUBBER PRODS

Carbon fiber composite electro-thermal paper and preparation method thereof

InactiveCN103397571AEvenly dispersedImprove bending resistanceSpecial paperPaper/cardboardFiberSodium sulfate

The invention discloses carbon fiber composite electro-thermal paper and a preparation method thereof. The carbon fiber composite electro-thermal paper is prepared from the following raw materials in part by weight: 30 to 40 parts of carbon fibers, 100 to 120 parts of wood pulp, 3 to 4 parts of vinyl triethoxysilane, 3 to 4 parts of nano iron powder, 2 to 3 parts of polyvinyl acetate emulsion, 1 to 2 parts of sodium carbonate, 3 to 4 parts of sepiolite powder, 2 to 3 parts of vermiculite powder, 1 to 2 parts of zinc chloride, 1 to 2 parts of boric acid, 1 to 2 parts of sodium persulfate, 1 to 2 parts of rape seed oil, 1 to 2 parts of peanut hull powder, and 3 to 4 parts of modified mica powder. Compared with the traditional carbon fiber composite electro-thermal paper, the carbon fiber composite electro-thermal paper has the advantages that electric conductivity and stability of the electro-thermal paper are improved by adding the nano iron powder; the temperatures at different parts of the electro-thermal paper do not exceed 2 DEG C; and the carbon fibers in the carbon fiber paper are uniform in overall dispersion, so the electro-thermal paper is good in breaking resistance, has low probability of being torn and broken and can be conveniently processed into planar heating elements with different temperature requirements.

Owner:安徽博领农业科技有限公司

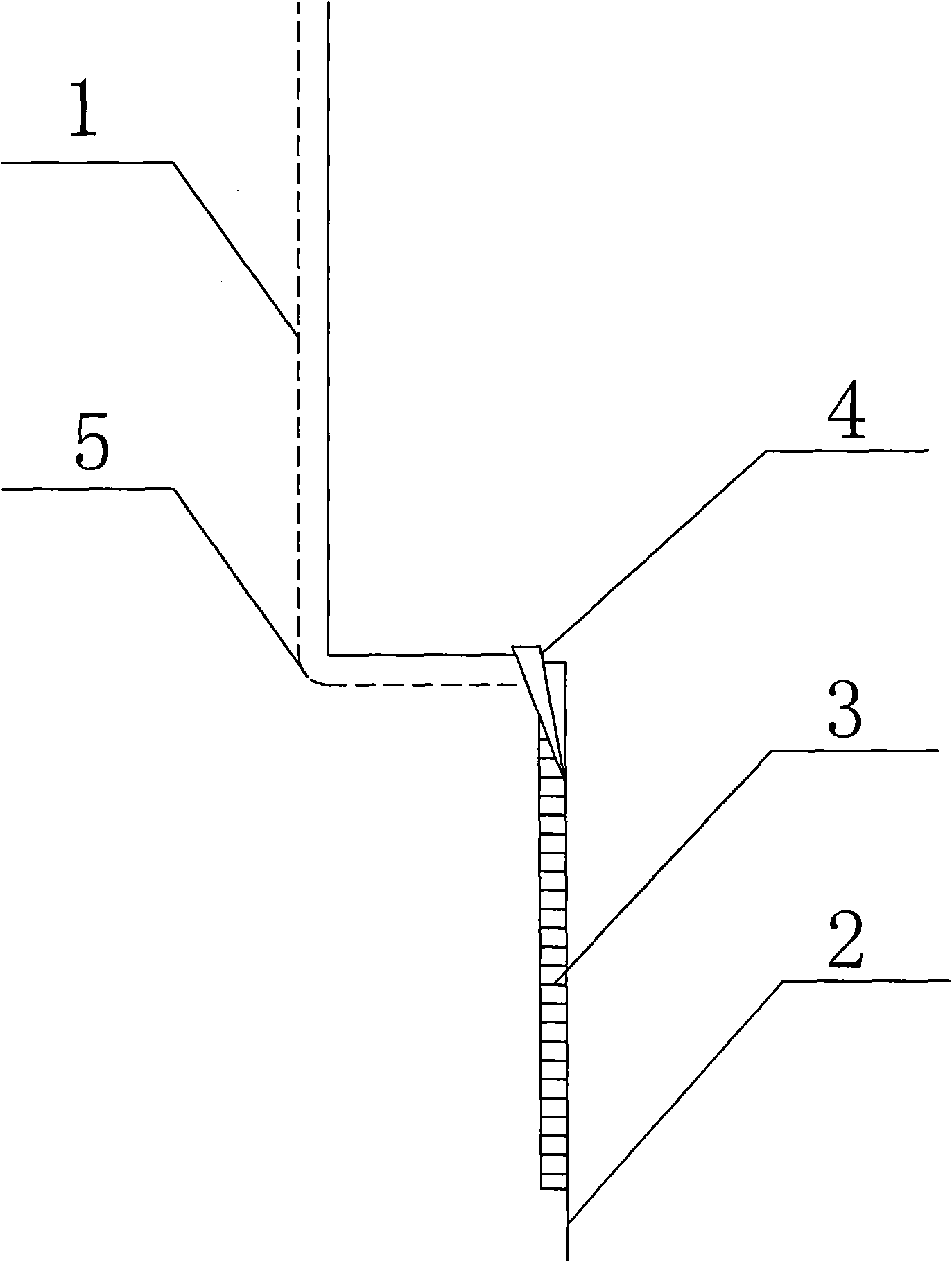

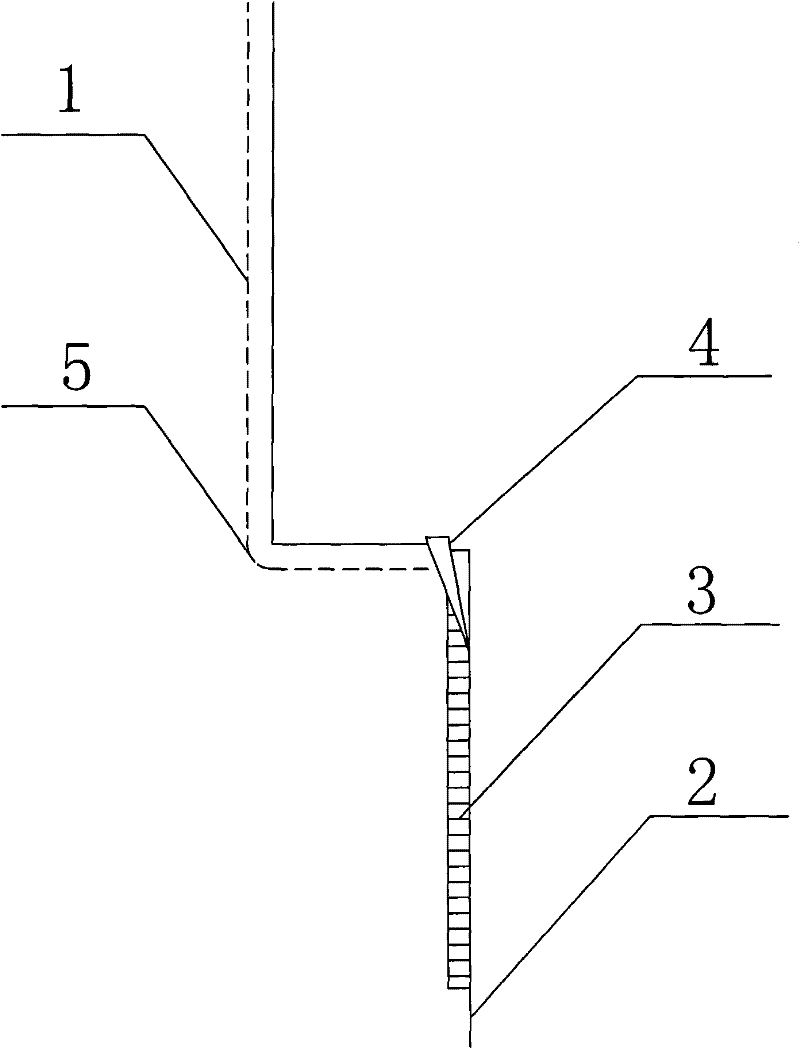

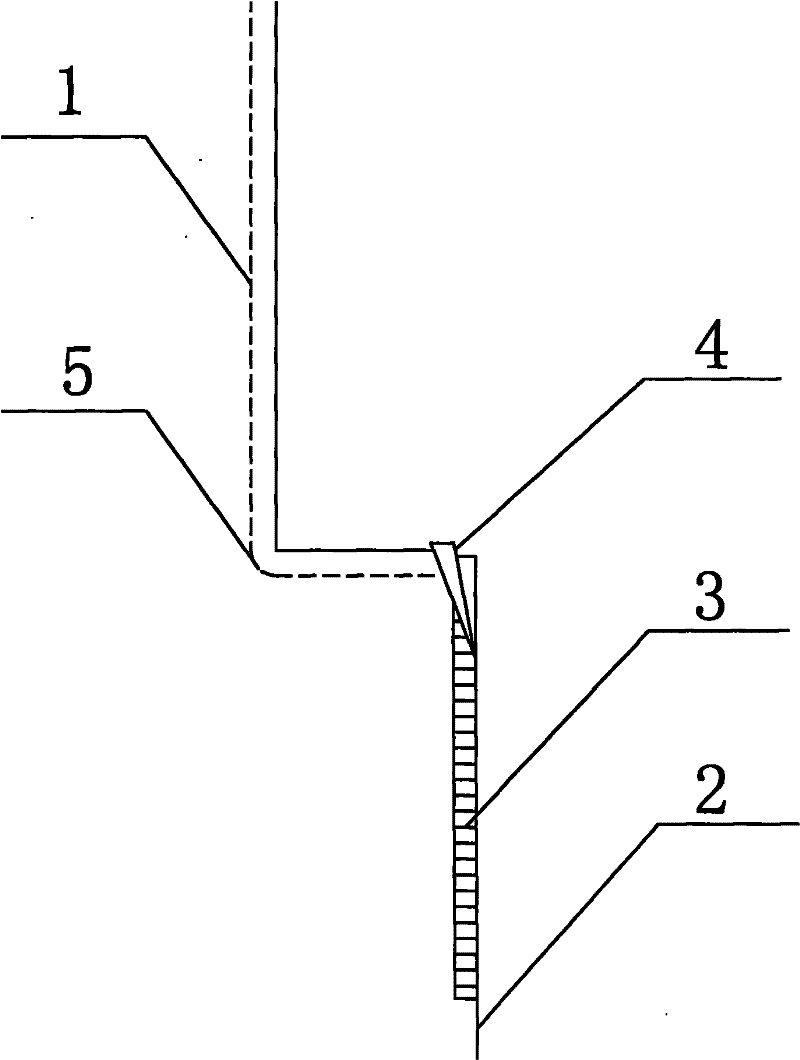

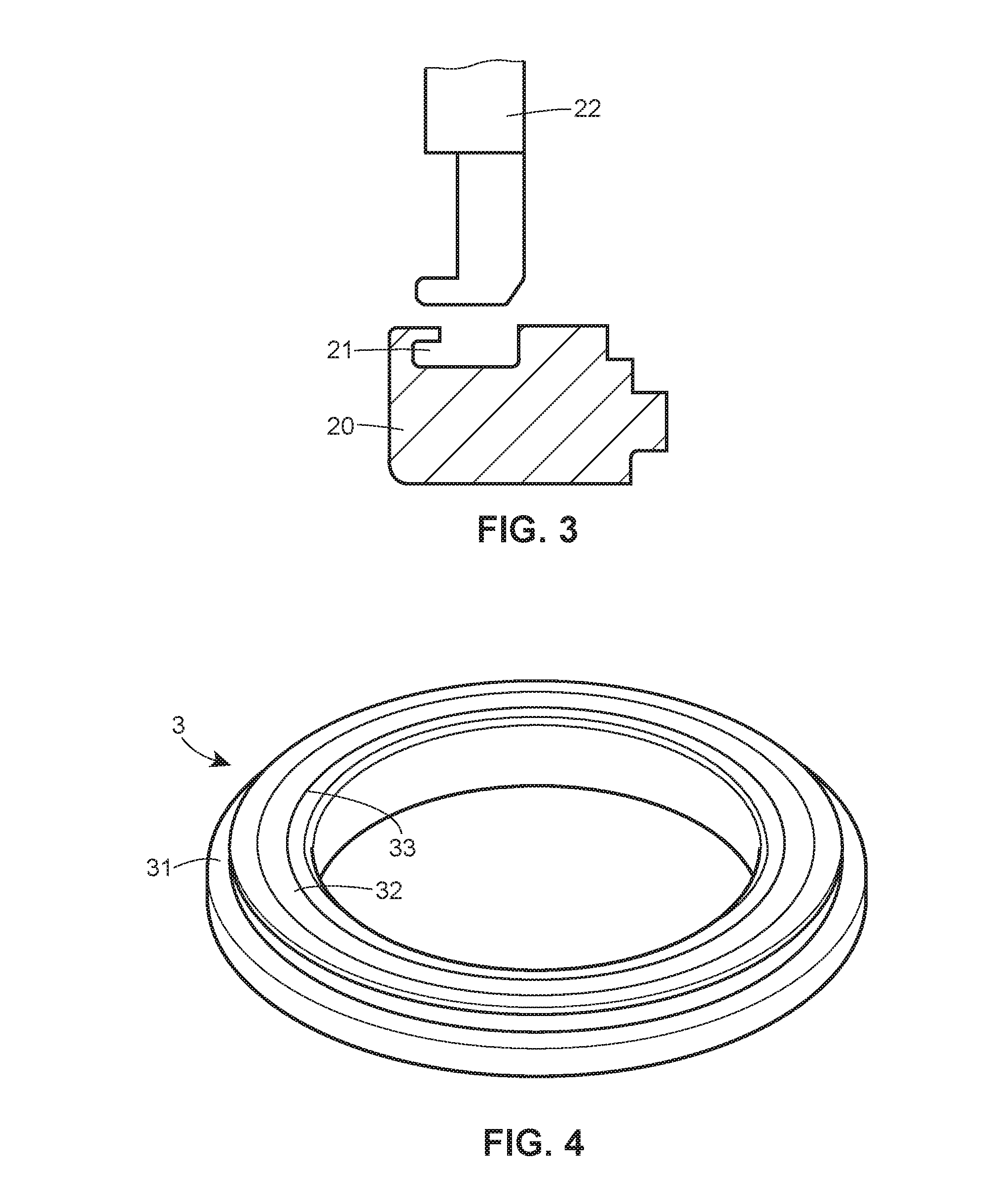

Vent corner round sewing process

The invention relates to the technical field of costume designing and processing, in particular to a vent corner round sewing process. In the process, stitches used during sewing up the vent corners are designed into a J shape. The process comprises the following steps of: (a) sewing a pulling belt on a right rear slice of the vent; (b) sewing for 1-3cm to splice a back seam; (c) extra reserving a part of 0.1-0.5cm at the upper layer of the edge of the vent; (d) forming an angle of 45 degrees on the head of the vent; (e) keeping the fibers of the vent head smooth and straight with the body; (f) upwards folding the bottom edge for 1-5cm and pressing during ironing the lower edge, wherein the inner vent is 0.1-0.5cm shorter than the outer vent; (g) beginning sewing the intersection point of a vent corner break line from a notch on the reverse side of the vent; (h) righting and turning the vent corner and sealing the vent corner in an inclined angle of 45 degree; and (i) sewing a back vent, wherein an inner vent is sewn firstly, and after folding and sewing for 1-3cm, the liner of a rear vent head is sewn. By adopting the process, the stress on a vent mouth is dispersed and transferred and cannot concentrate at a right angle point, thus the vent mouth is not easy to tear, and the service life of clothes is prolonged.

Owner:LAMPO

Preparation method of nanocrystalline magnetic sheet for wireless charging

ActiveCN109094165AIncrease productivityLess prone to wrinklesLamination ancillary operationsLaminationPlastic packagingWarm water

The invention relates to the technical field of magnetic materials, and discloses a preparation method of a nanocrystalline magnetic sheet for wireless charging. The method comprises the steps of 1, coiling; 2, annealing; 3, single-layer laminating; 4, multi-layer laminating; 5, roll cutting; 6, splintering; 7, cutting, wherein silica gel weak mucosa on a nanocrystalline strip is stripped and cutinto nanocrystalline articles; 8, coating, wherein colloid mixed with nanoscale solid insulation powder is coated on the nanocrystalline articles and subjected to vacuum plastic packaging through a vacuum bag; 9, isostatic pressing, wherein plastic-packaged nanocrystalline articles are laminated through warm water isostatic pressing, and the nanoscale solid insulation powder enters cracks of the nanocrystalline articles; 10, laminating; 11, die cutting. Accordingly, the technology of conducting laminating first and then conducting splintering is adopted, the production efficiency can be effectively improved, in the splintering process, the problems of corrugation, centipede grains, off tracking and the like cannot occur easily, and the splintering performance stability is good. In addition, laminating is conducted before splintering, a magnetic sheet is not likely to be shredded, and the yield is higher.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Vent corner round sewing process

The invention relates to the technical field of costume designing and processing, in particular to a vent corner round sewing process. In the process, stitches used during sewing up the vent corners are designed into a J shape. The process comprises the following steps of: (a) sewing a pulling belt on a right rear slice of the vent; (b) sewing for 1-3cm to splice a back seam; (c) extra reserving a part of 0.1-0.5cm at the upper layer of the edge of the vent; (d) forming an angle of 45 degrees on the head of the vent; (e) keeping the fibers of the vent head smooth and straight with the body; (f) upwards folding the bottom edge for 1-5cm and pressing during ironing the lower edge, wherein the inner vent is 0.1-0.5cm shorter than the outer vent; (g) beginning sewing the intersection point ofa vent corner break line from a notch on the reverse side of the vent; (h) righting and turning the vent corner and sealing the vent corner in an inclined angle of 45 degree; and (i) sewing a back vent, wherein an inner vent is sewn firstly, and after folding and sewing for 1-3cm, the liner of a rear vent head is sewn. By adopting the process, the stress on a vent mouth is dispersed and transferred and cannot concentrate at a right angle point, thus the vent mouth is not easy to tear, and the service life of clothes is prolonged.

Owner:LAMPO

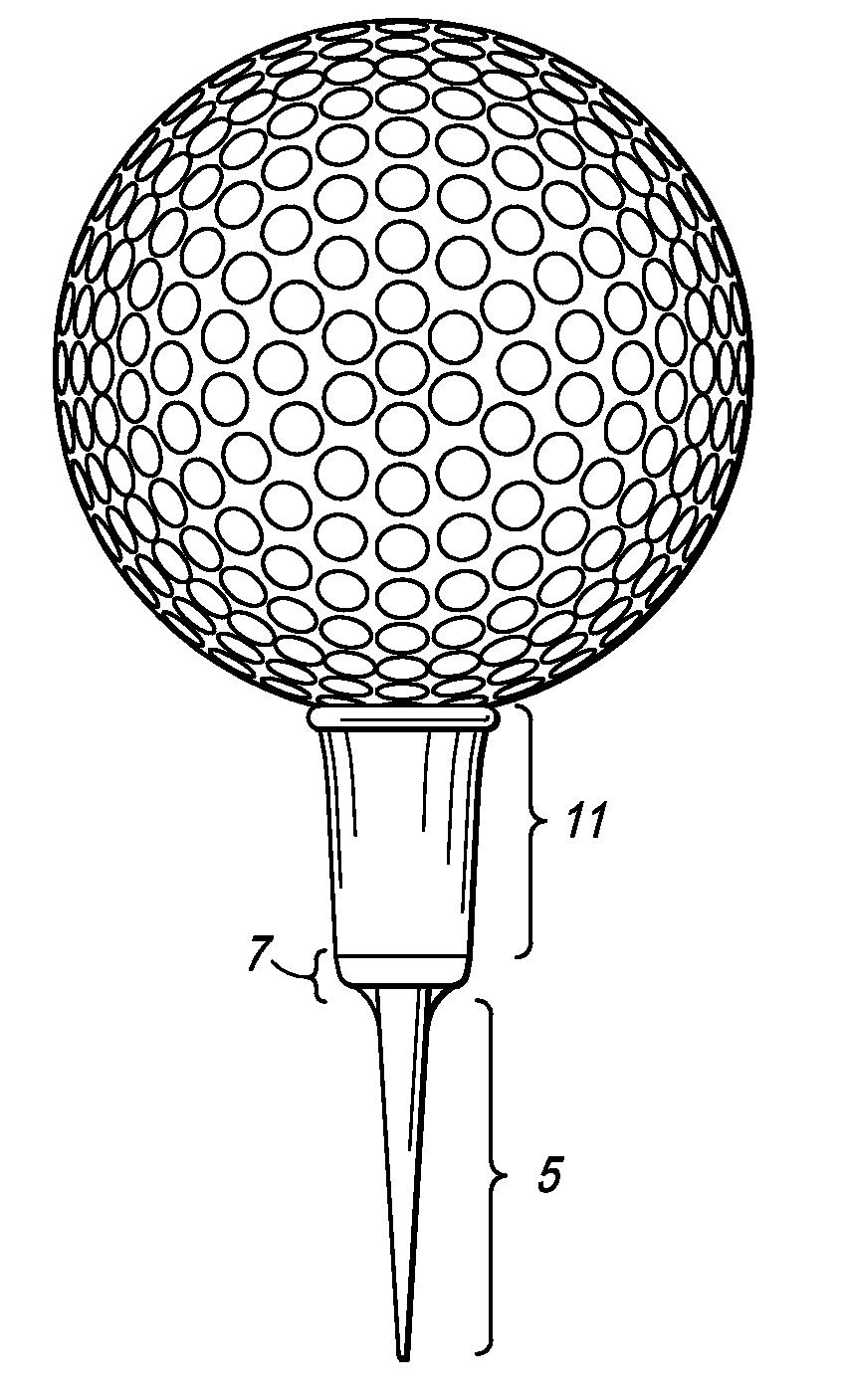

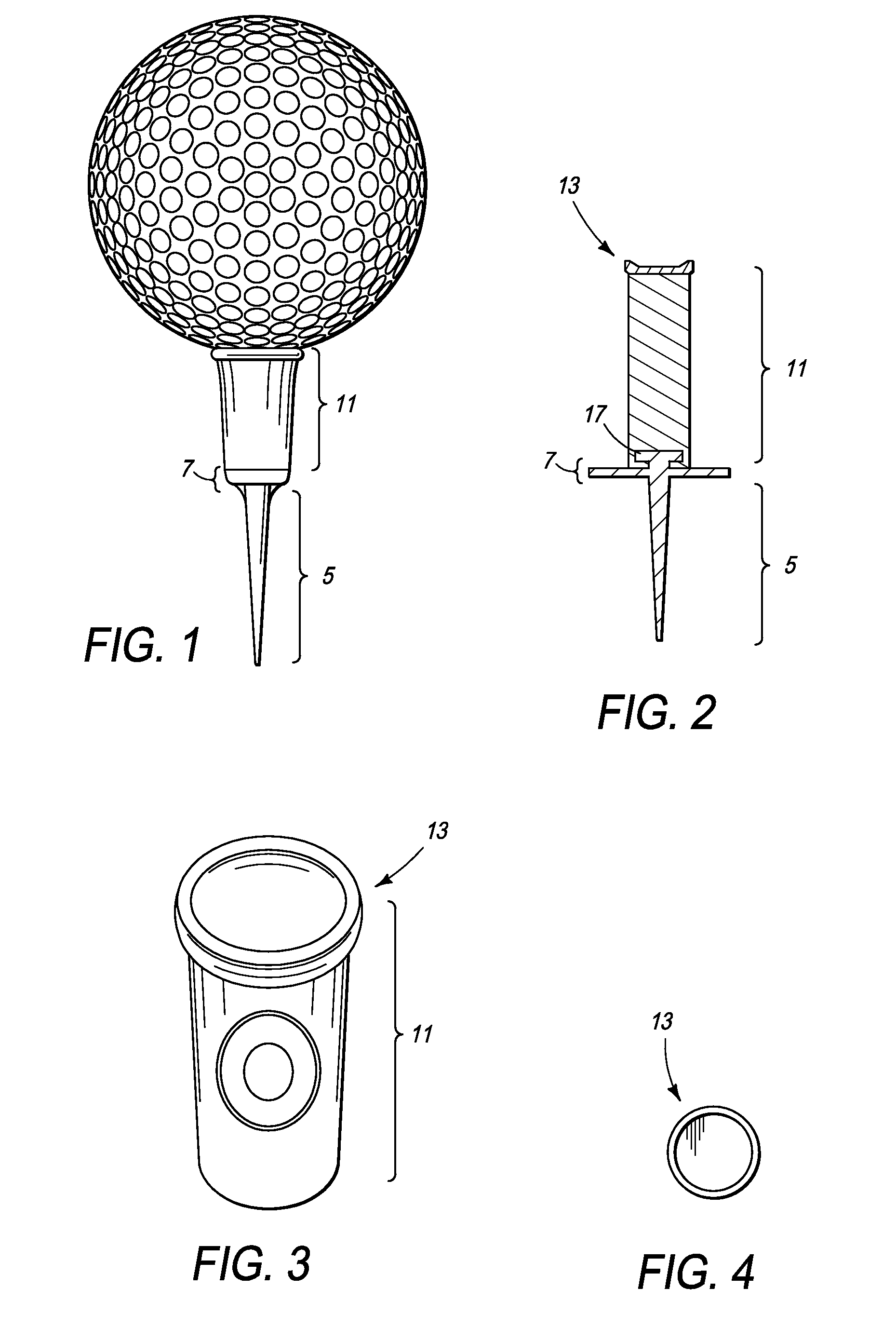

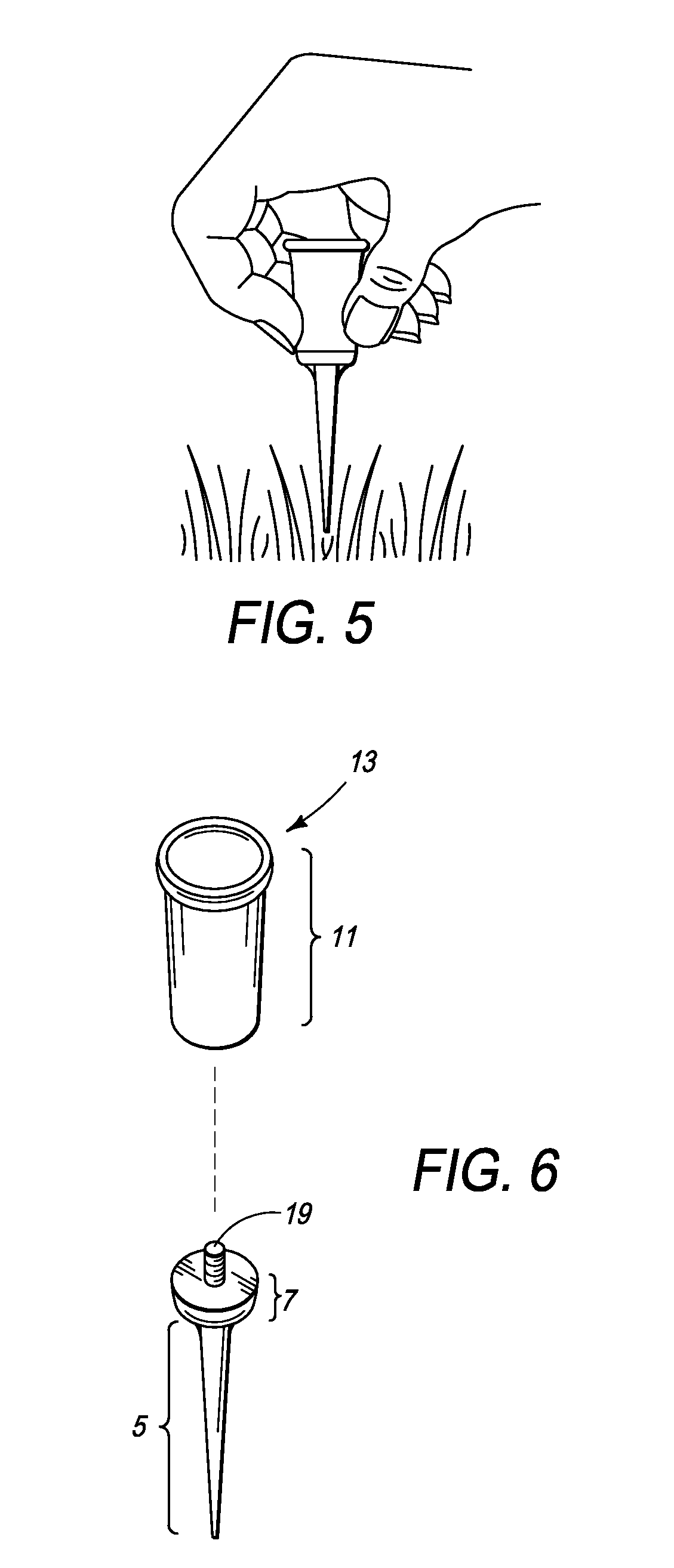

Golf spike

The present invention involves a golf tee used in the game of golf. The golf spike offers a variety of benefits to a golfer's swing and the game. The flexible top structure offers the golfer's swing less impact due to the flexible outer walls of the cavity which offer reduced resistance and less energy loss at the point of impact. Thus, allowing the ball to be driven further. These tees are more durable than the average tee. This present invention can be constructed from single or multiple component parts. The preferred embodiment includes a tapered rigid shaft connected to a flexible cup-shaped structure with a rim which holds the golf ball. The flexible top structure benefits the golfer by allowing for slight distortions and still holds the ball in place. The flexible cup like structure can further act as a space to house advertising media. The golf spike can be manufactured from a variety of materials such as, but not limited to, plastic, metal, wood, hard and pliable composites, foam or from any other material that will benefit the design concept and intent.

Owner:CALDERON LUIS JR

Electromagnetic shielding adhesive tape

InactiveCN103013371ALow electromagnetic shielding effectivenessImprove electromagnetic shielding performanceFilm/foil adhesivesUltrasound attenuationElectromagnetic shielding

The invention discloses an electromagnetic shielding adhesive tape which comprises an electromagnetic shielding layer and a resin film layer covering one side of the electromagnetic shielding layer. The electromagnetic shielding layer is formed by a conducting metal layer and a wave adsorption layer with the gluing characteristics; and the wave adsorption layer is bonded to one side of the conducting metal layer, which is opposite to the resin film layer. According to the electromagnetic shielding layer of the electromagnetic shielding adhesive tape, one side of the conducting metal layer is bonded with the wave adsorption layer; multilayer shielding is realized for a multilayer structure formed by a material with electric conductivity and magnetic conductivity; in the frequency range of 1kHz to 100GHz, the lowest electromagnetic shielding effectiveness is 71db; the anti-electromagnetic attenuation rate can reach 99 percent; an electromagnetic shielding effect is good; and the electromagnetic shielding adhesive tape is universal for electromagnetic shielding of a high frequency electric field and a low frequency magnetic field.

Owner:SUZHOU JINHE NEW MATERIAL

Production method of environment-friendly leatheret

InactiveCN101487205AGood flexibilityImprove folding resistanceNon-fibrous pulp additionCoated paper substrateFiberMachining process

The invention relates to a method for producing environment-friendly leatheroid, which adopts 100% of fiber material to produce base paper; according to the weight proportion, the selected fiber material comprises 45-55% of softwood pulp and 55-45% of cotton pulp; the method for producing the base paper comprises the following steps of: untwining of a pulp board, burdening, conveying of pulp, forming in a head box, drying and dehydrating, and coiling by coil; subsequently, the environment-friendly leatheroid is prepared by the following steps: the base paper is sequentially dipped and dyed, dipped in rubber latex, coated by primer and surface paint and pattern-pressed. The environment-friendly leatehroid has outstanding tearing resistance and folding resistance, and good soft performance, can be degraded, and is suitable for preparing covers of all certificates and hardcover, packages of exquisite gifts such as gold and silver caskets, stationery, watches and the like. The method has reasonable machining process, easy preparation, and low production cost and protects the environment.

Owner:SHANDONG KAILI SPECIAL PAPER

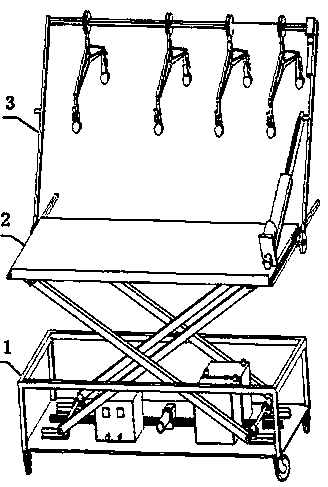

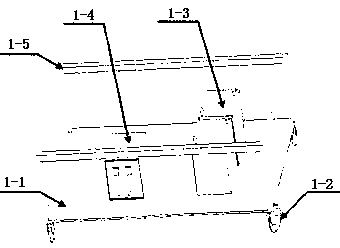

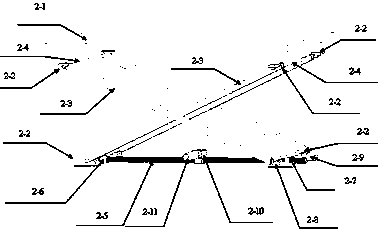

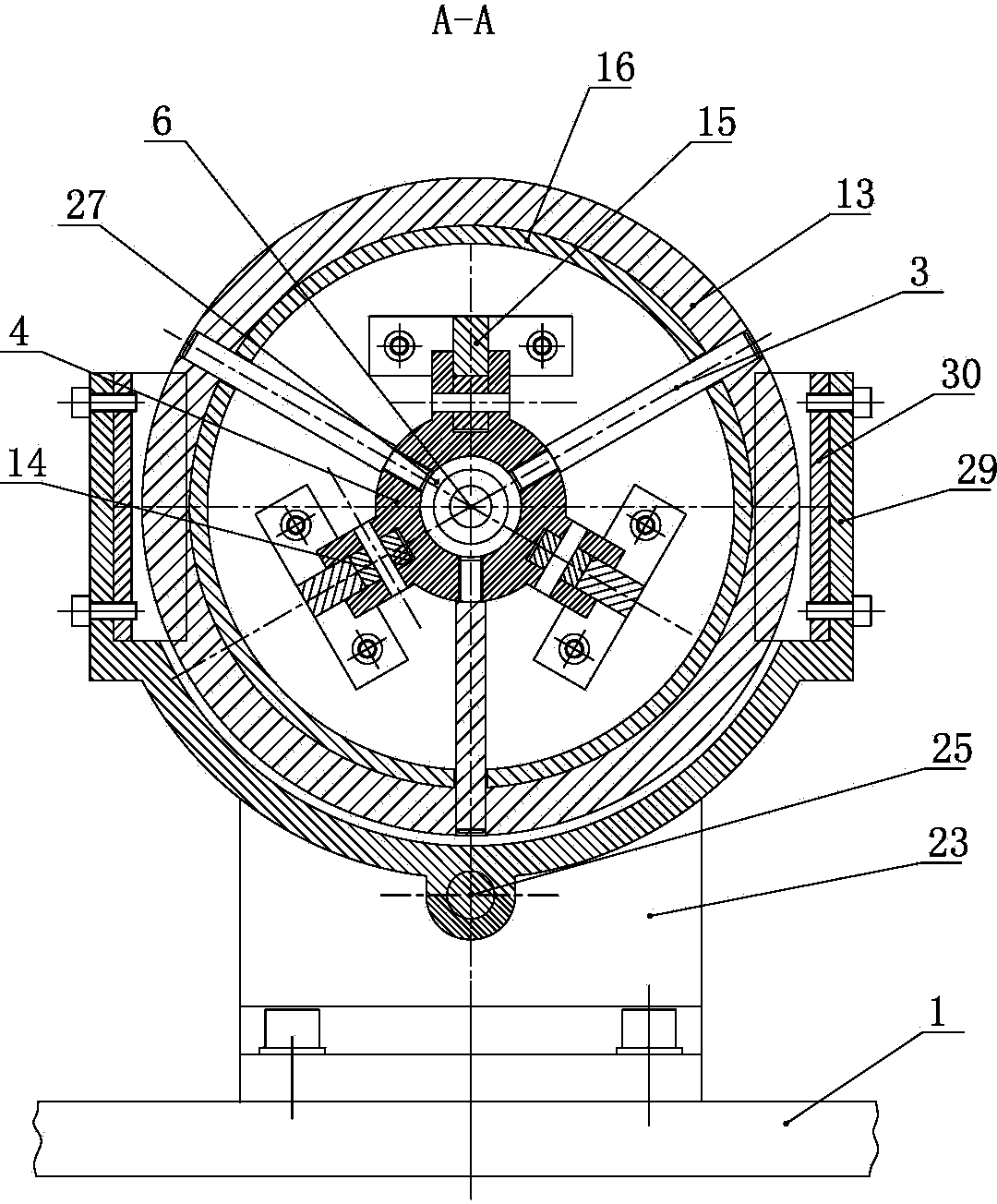

Electric hoisting stretcher vehicle

ActiveCN104352326ANot easy to tearLarge and uniform force bearing areaNursing bedsOptical axisReducer

An electric hoisting stretcher vehicle comprises a universal wheel chassis, a liftable platform and a hoisting system, wherein the universal wheel chassis is in contact with the ground through four universal wheels (1-2) which are fixed at four corners of a chassis flat plate (1-1) respectively; a battery jar (1-3), a charger (1-4) and a frame (1-5) are placed on a plane; a lifting platform slide track is fixed on the plane; the liftable platform comprises a lifting platform (2-1), bearing seats (2-2), lifting rods (2-3), upper cross rods (2-4), screw rods (2-5), screw nuts (2-6), lower cross rods (2-7), slide blocks (2-8), polished shafts (2-9) with support seats, a worm gear speed reducer A (2-10) and a DC motor (2-11); the hoisting system comprises graspers (3-1), grasping racks (3-2), nylon tapes (3-3), take-up reels (3-4), a six-edge take-up spool (3-5), a worm gear speed reducer B (3-6), a DC motor (3-7), a lifting beam (3-8), a half shaft (3-9), a speed reducer (3-10), a reducing motor (3-11), a support rod (3-13), a support rod groove (3-14) and a bolt (3-15). The electric hoisting stretcher vehicle can be used for hoisting a stretcher electrically, so that a patient can be transferred between equipment and the stretcher vehicle.

Owner:贵州正恒科技有限公司

Down fabric and preparation method thereof

InactiveCN106723552AClear widthEasy to tearLiquid surface applicatorsCoatingsThree-dimensional spaceHot melt

The invention discloses a down fabric and a preparation method thereof, and belongs to the field of textile and garment. The preparation method comprises the steps of: subjecting lining fabric to a local gluing process such that stripes of bonding layers are distributed on one side of the lining fabric at intervals of a certain distance, the local gluing process comprising: passing the lining fabric between a press roll and a gluing roll with a plurality of strip-type grooves uniformly distributed in the axial direction; laminating the side of the obtained fabric that has the bonding layers with outer fabric, and placing the laminated fabric in a constant-temperature and constant-humidly environment, thereby obtaining the down fabric. The preparation method of the down fabric has the advantages that: by means of hot melting connection, no pollutants such as waste gases are produced during production, and no drying is needed; the process is simple with reduced cost; the obtained down fabric is clear in width of the bonding layers, and not easy to tear apart; the hot melting connection is dotted connection, allowing for formation of numerous micro-voids inside; due to three-dimensional space structure of the voids, the down may be prevented from passing through the bonded position between two tubes, and the permeability is improved.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

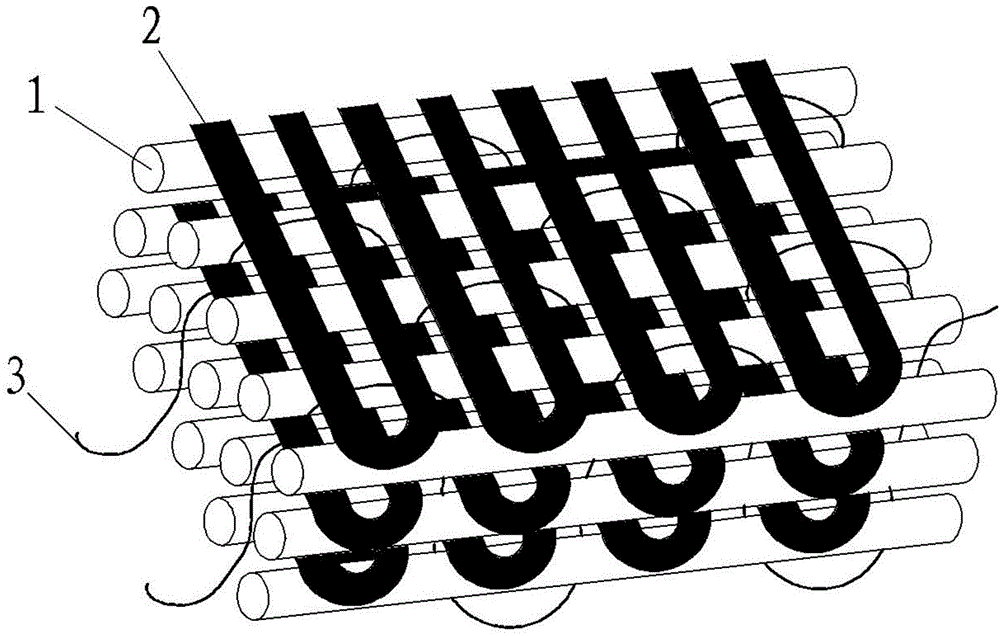

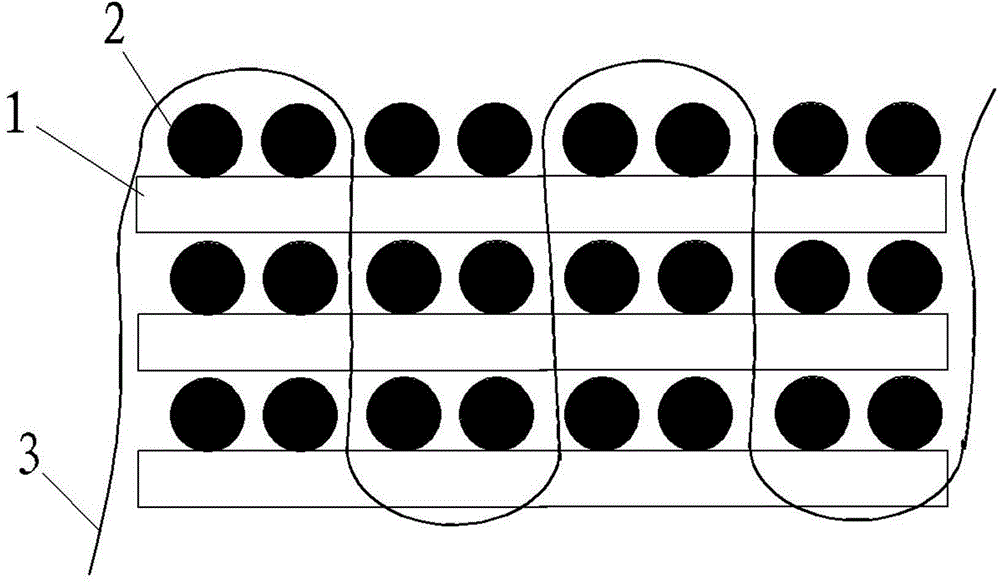

Three-dimensional oil suction fabric

The invention provides a three-dimensional oil suction fabric, which comprises three types of yarns in X, Y and Z directions. The yarns are selected from fibrilia, bamboo fiber, polylactic acid fiber and chitosan fiber, and woven according to three-dimensional weaving technology. The performances of the three-dimensional oil suction fabric are better than those of conventional non-woven fabric materials. The three-dimensional oil suction fabric has a crosslinking network structure, and is high in adsorption rate and adsorption quantity. The three-dimensional oil suction fabric can be recovered by simple extruding, the recovery rate is high, and the adsorption capability and resilience are excellent. The three-dimensional oil suction fabric can be repeatedly usable, and is durable. The fabric employs natural fibers and biodegradable chemical fiber as raw materials, and the fabric is soft and comfortable. The three-dimensional oil suction fabric is high in mechanical strength and wide in application scope, and has certain antibacterial function.

Owner:SUZHOU WILDER IND & TRADE

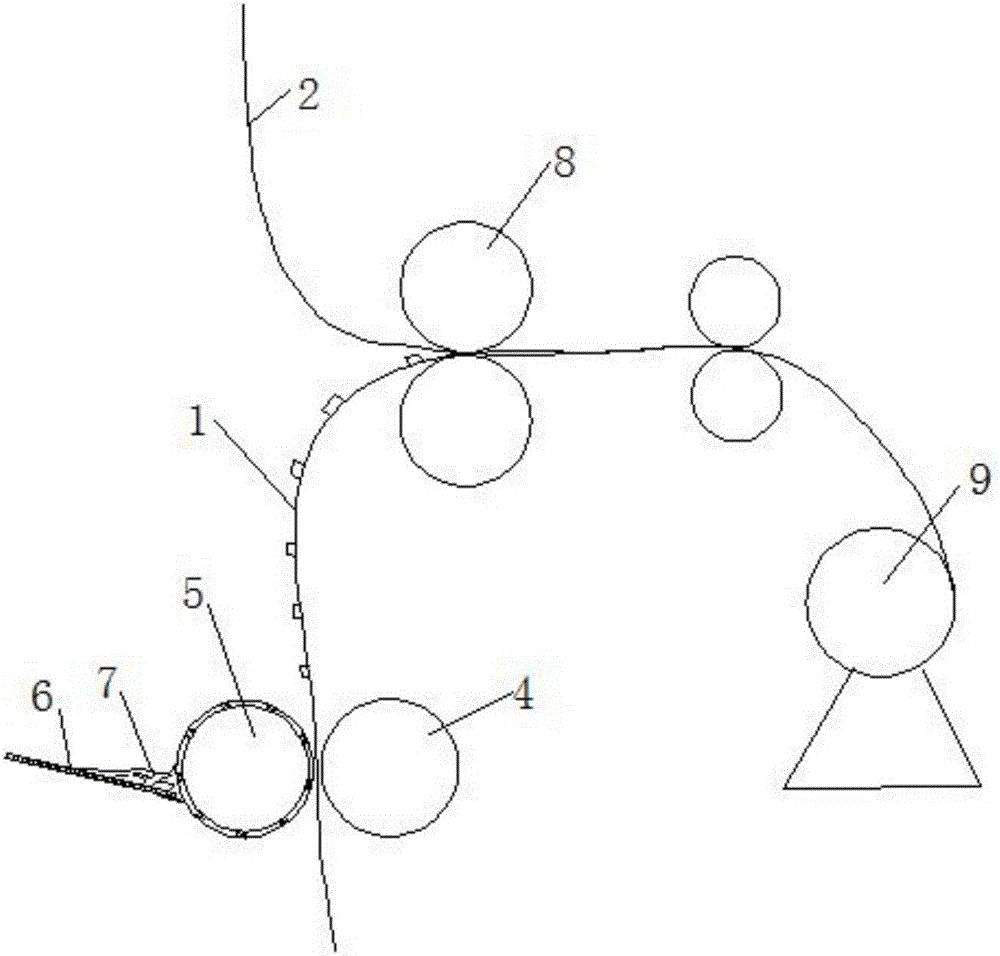

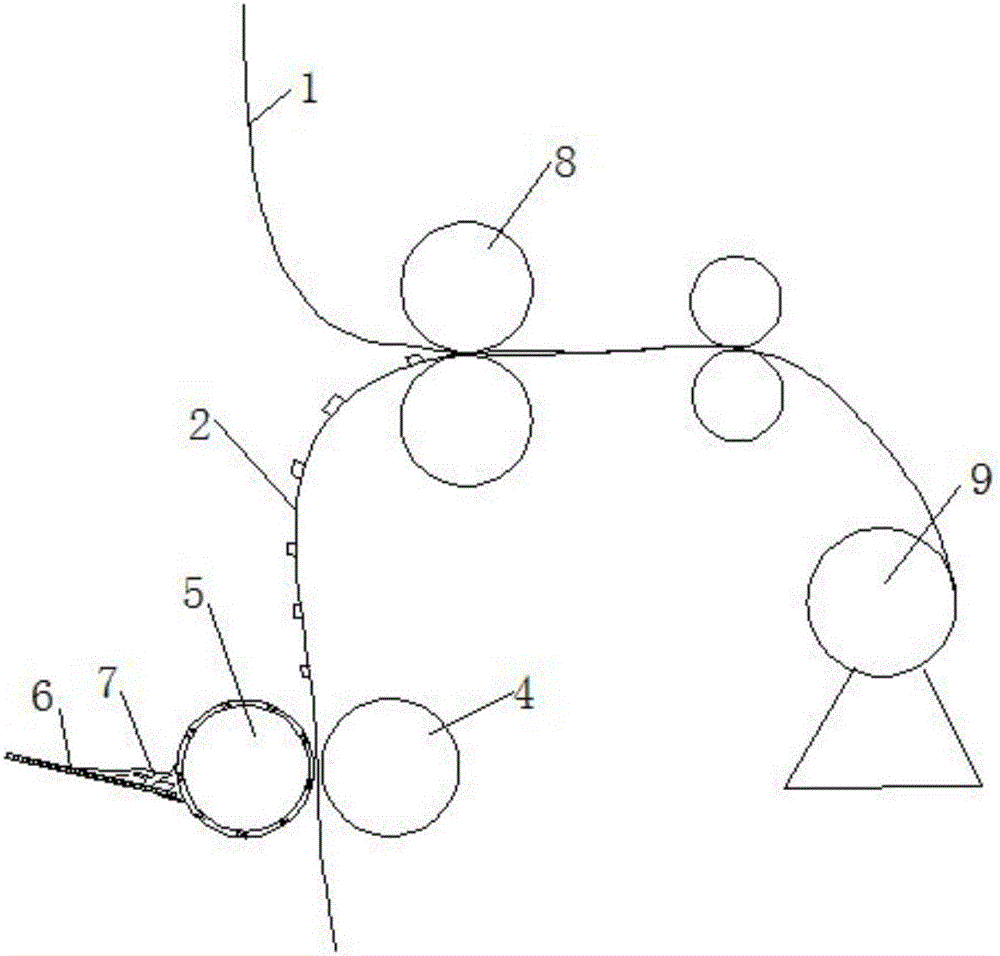

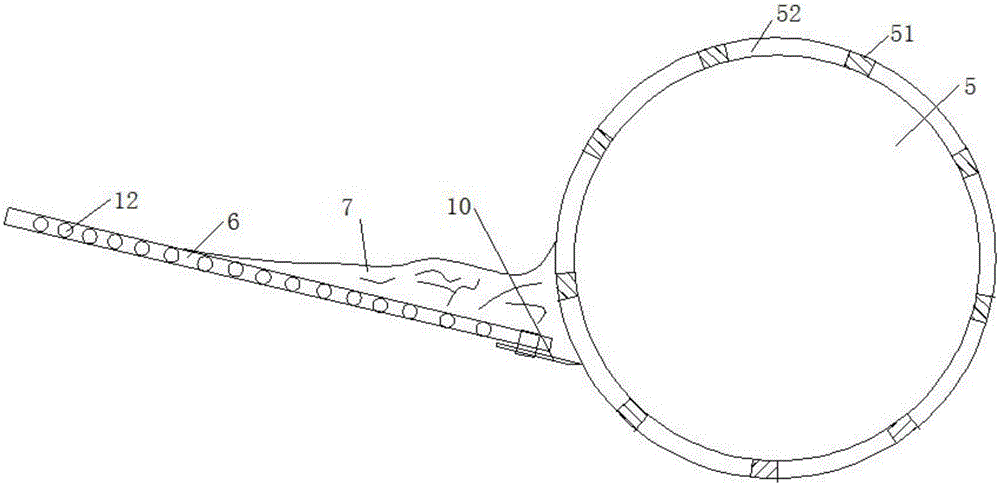

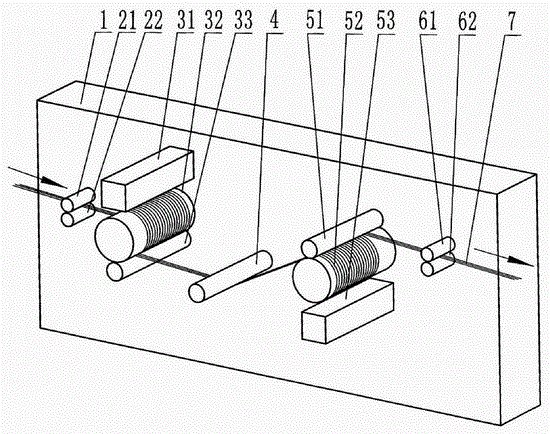

Polytetrafluoroethylene (PTFE) membrane crack short-fiber re-splitting method and device used for same

ActiveCN105624873AQuantity Percentage LowHigh fiber splitting rateTextiles and paperPorosityFiber bundle

The invention relates to a polytetrafluoroethylene (PTFE) membrane crack short-fiber re-splitting method and a device used for the same. The method comprises the steps of merging conventional PTFE membrane crack fiber bundles, then continuously feeding a drum-type spunlace unit only provided with a spunlace head for twice successively, and enabling the merged fiber bundles to be wound on a drum in a spiral form for 6-20 circles along a Z direction for running so as to enable the fiber bundles to be impacted by spunlace for 12-40 times along the positive surface direction and the negative surface direction for splitting to obtain the PTFE membrane crack fiber bundles which are high in fine fiber number percentage and low in fiber branching rate. By adopting a flexible splitting technology, the prepared fiber bundles are not easily broken by tearing, and re-splitting can be continuously carried out at high speed. The improved drum-type spunlace splitting device has the characteristics of being compact in structure, simple in operation and convenient in process adjustment. The fiber bundles prepared by the method are evenly carded into a web after being cut off, thus being widely used for preparing high-temperature-resistant filter material with small porosity and high efficiency of dust removal.

Owner:灵氟隆新材料科技江苏有限公司 +1

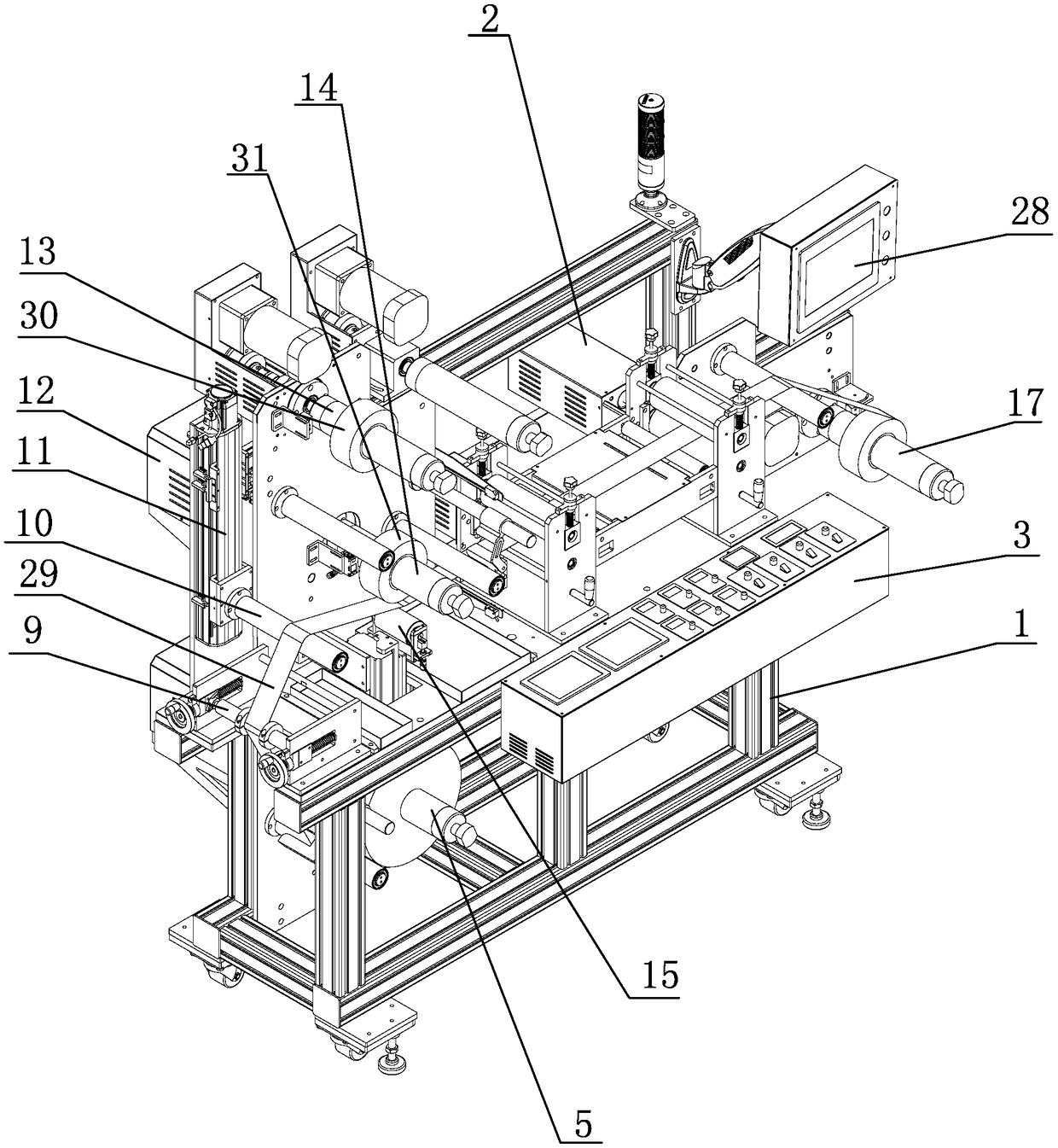

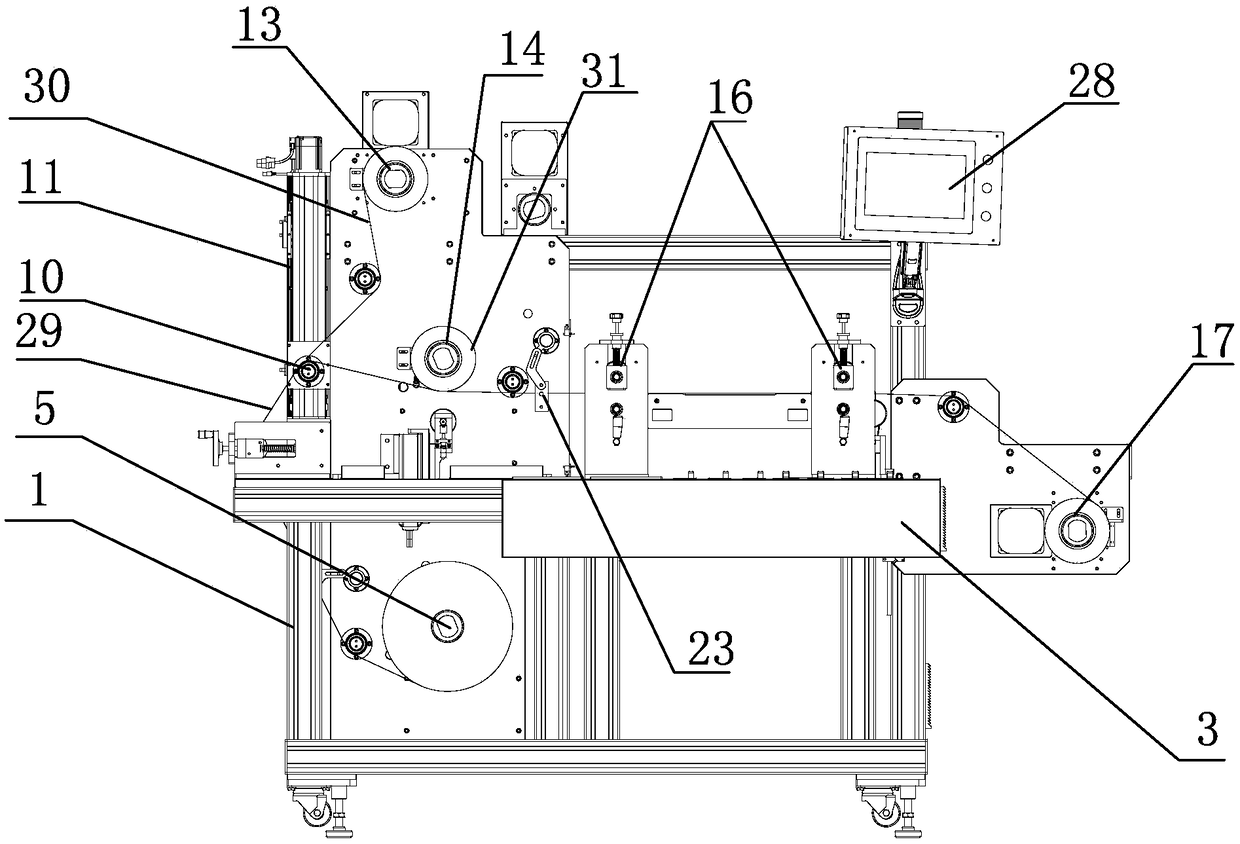

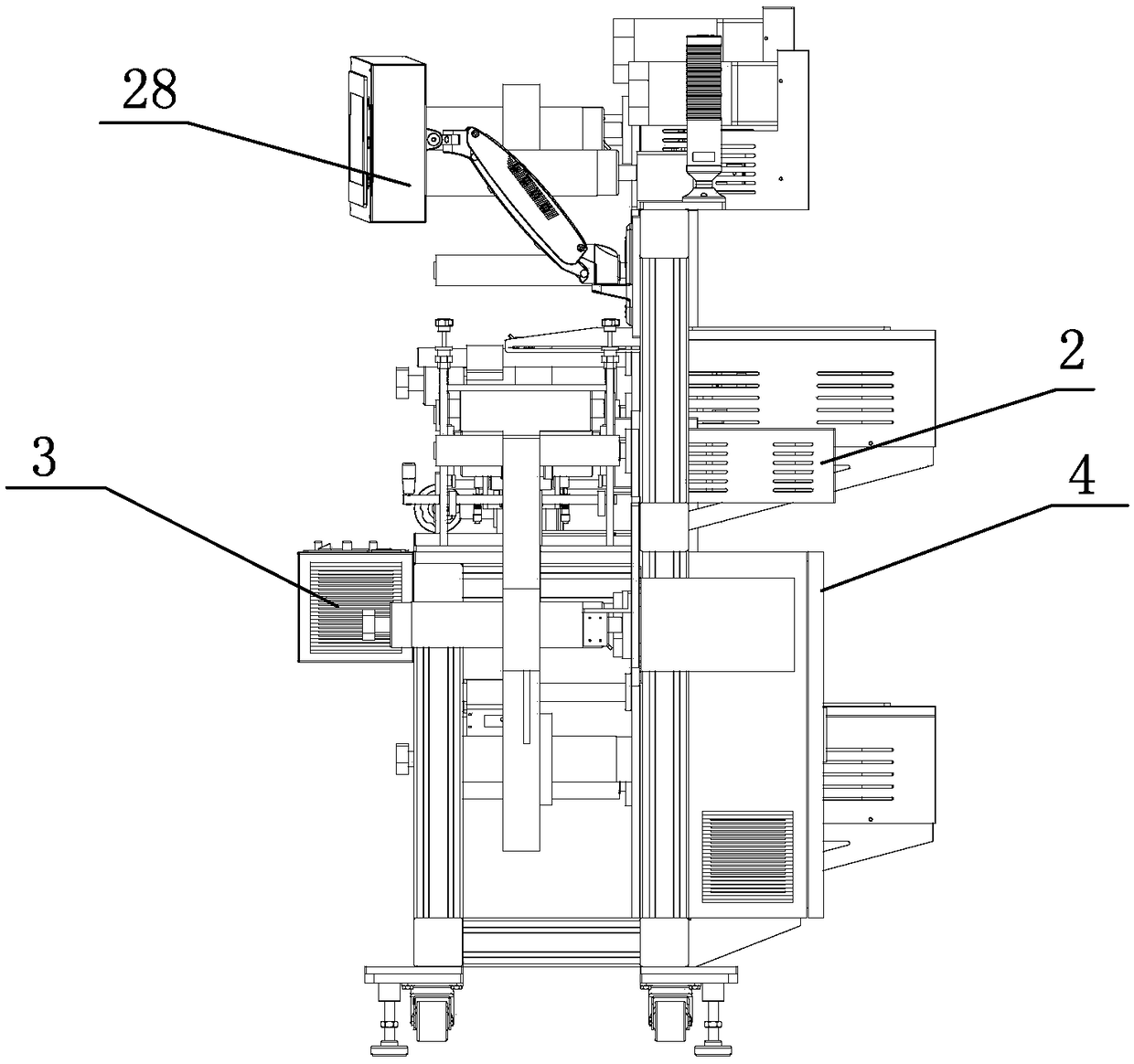

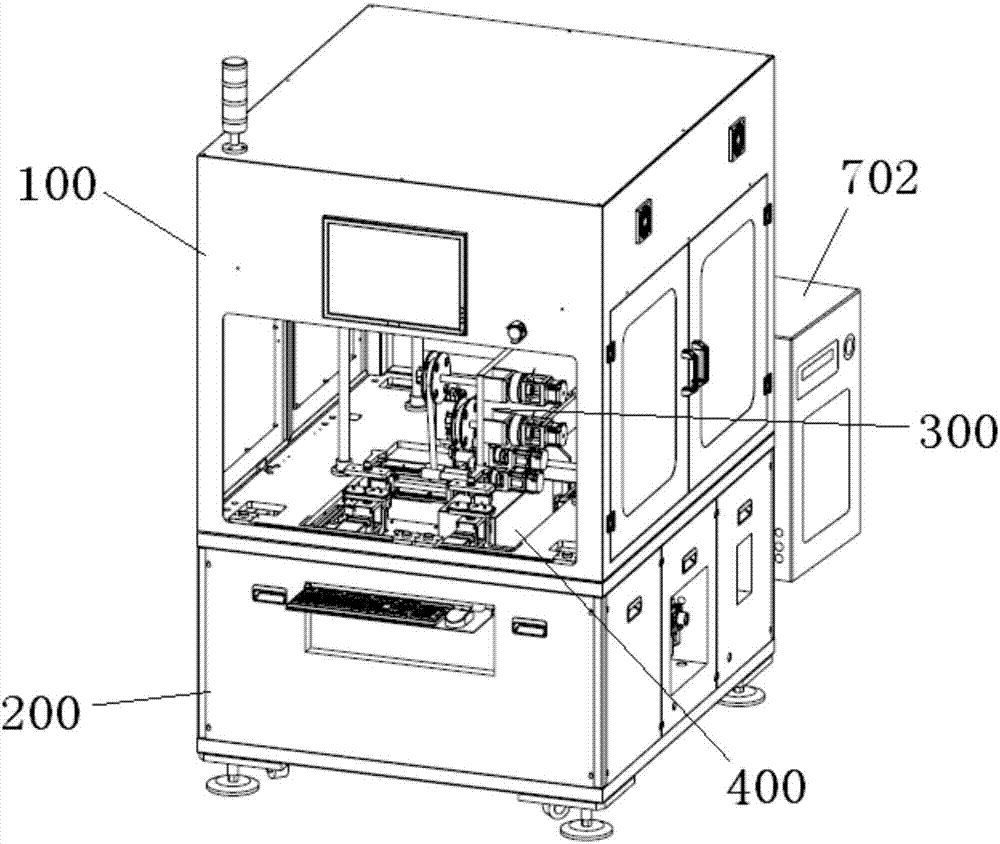

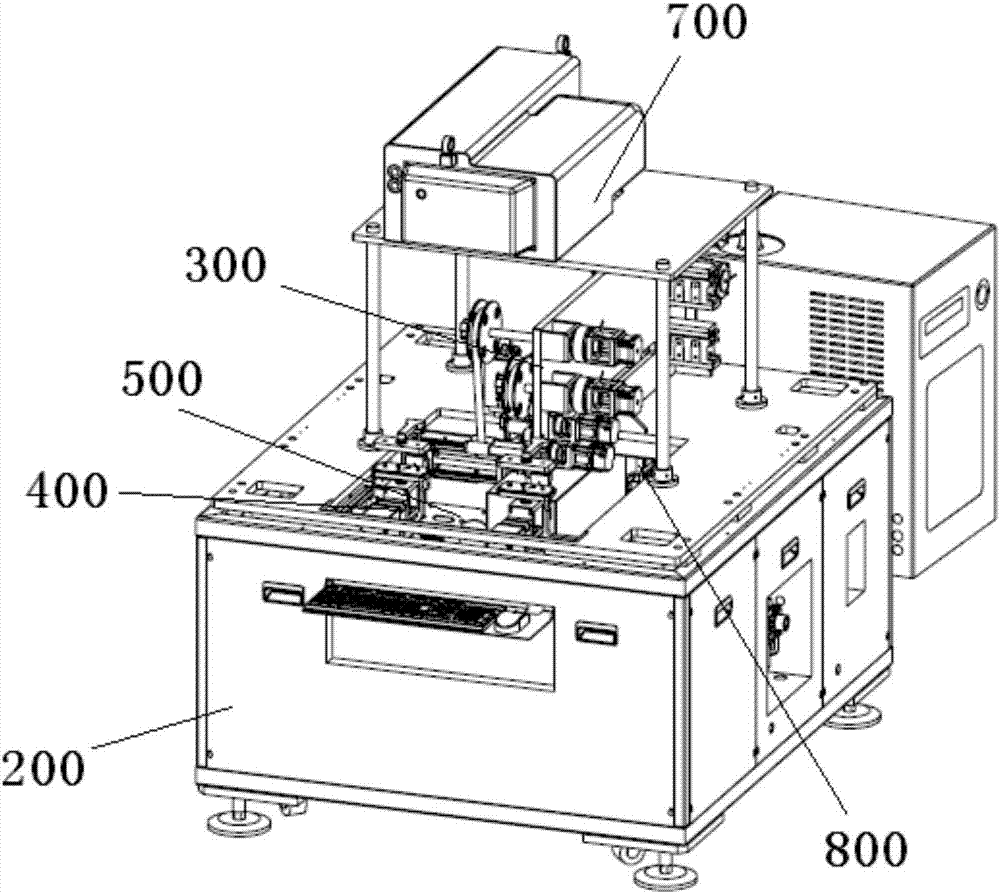

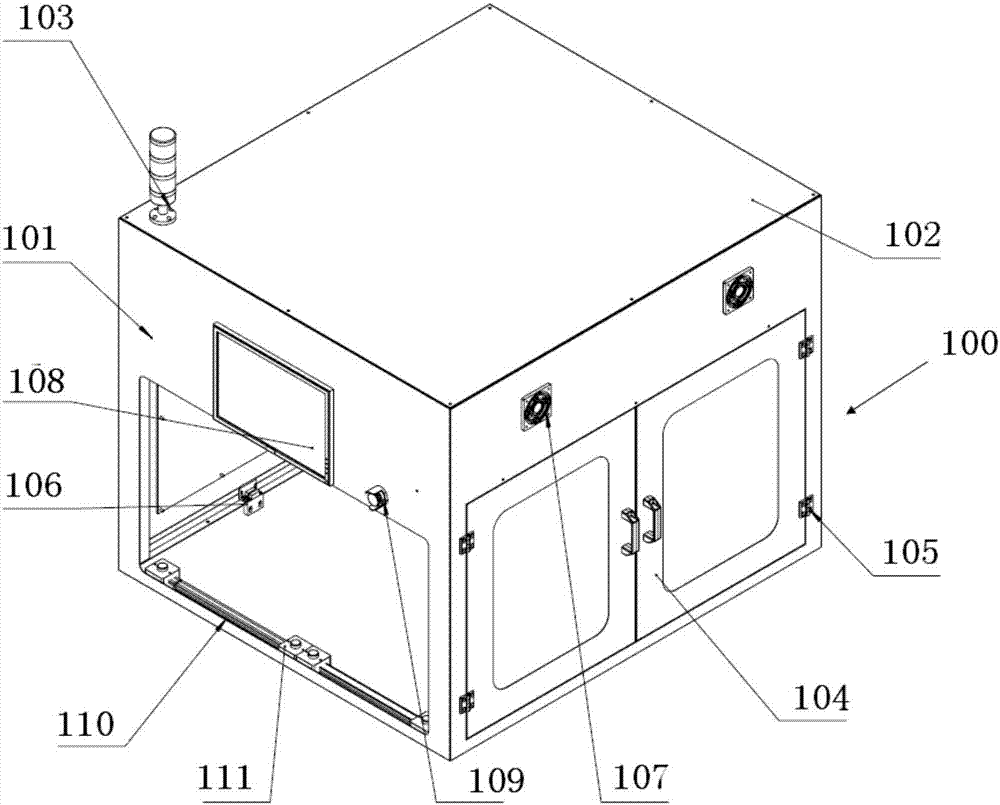

Laser cutting film sticking machine and utilization method thereof

InactiveCN106956083AEasy to tearEasy to operateLaser beam welding apparatusEngineeringSmall footprint

The invention relates to a laser cutting film sticking machine and a utilization method thereof. The laser cutting film sticking machine comprises an upper frame mechanism, a lower frame mechanism, a film rolling mechanism, a motion mechanism, a rotating mechanism, a fixture mechanism, a laser mechanism and a control mechanism, wherein the upper frame mechanism is fixed to the upper part of the lower frame mechanism through bolts; the film rolling mechanism is above the motion mechanism; the rotating mechanism is fixed to the motion mechanism; the fixture mechanism is connected with the rotating mechanism; the laser mechanism is arranged above the film rolling mechanism; the control mechanism used for controlling the entire film sticking machine to operate is further arranged in the lower frame mechanism; the lower frame mechanism comprises a lower frame; a bottom plate is arranged at the top of the lower frame; a mounting hole is formed in the bottom plate; a laser mounting plate is mounted above the bottom plate through laser struts; protective plates are arranged on the four side surfaces of the lower frame; a keyboard mouse connected with the control mechanism is arranged on the protective plate at the front part; an air source processor and a load switch are arranged on the protective plate on the right side of the lower frame; foot cups are arranged at the bottom of the lower frame; and the control mechanism is arranged on the inner back side of the lower frame. According to the laser cutting film sticking machine, structure is compact, floor space is small, and curvilinear motion of a product during the film sticking process can be achieved.

Owner:苏州斯克纳自动化设备有限公司

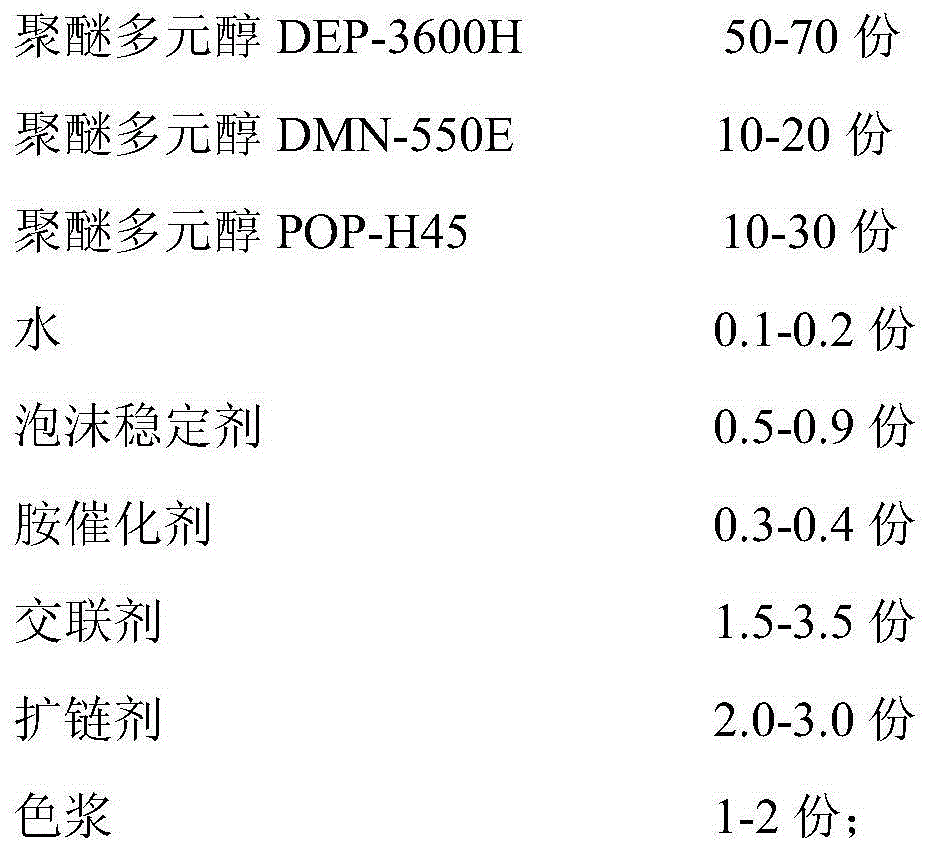

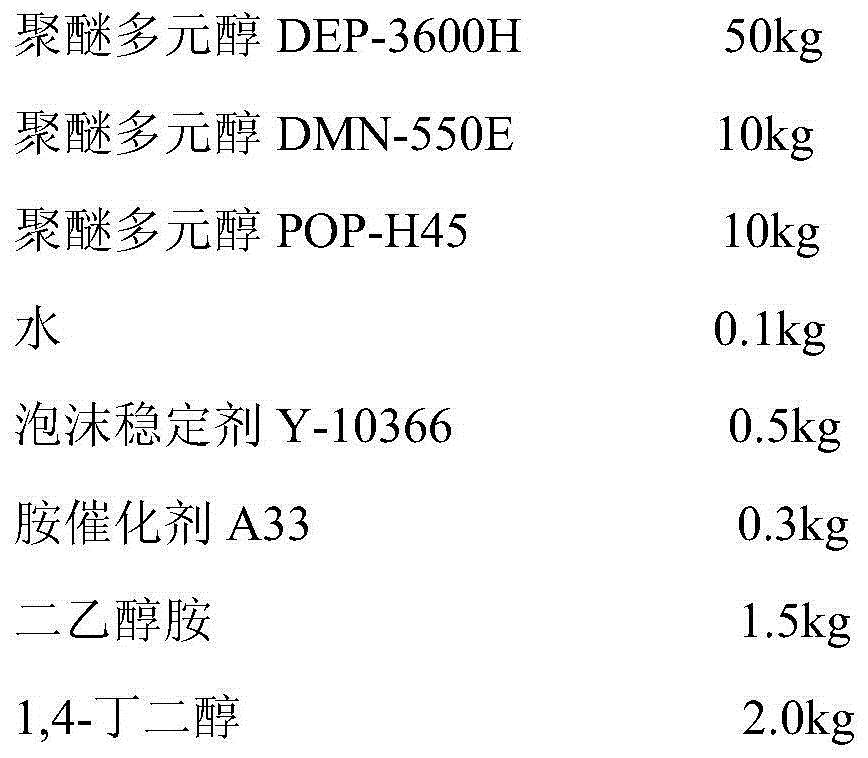

Polyurethane mop sponge and production method thereof

The invention belongs to the technical field of polyurethane products and particularly relates to a polyurethane mop sponge and a production method thereof. The polyurethane mop sponge comprises a component A and a component B. The component A comprises polyether polyol DEP-3600H, polyether polyol DMN-550E, polyether polyol POP-H45, water, foam stabilizing agent, amine catalyst, crosslinking agent, chain extender and mill base. The component B comprises modified black material. The polyurethane mop sponge is good in filter performance, easy to clean, high in water absorption performance, elastic, hard to tear, less prone to deformation, soft in texture, anti-bacterial and resistant to odor.

Owner:ZIBO DEXIN LIANBANG CHEM IND

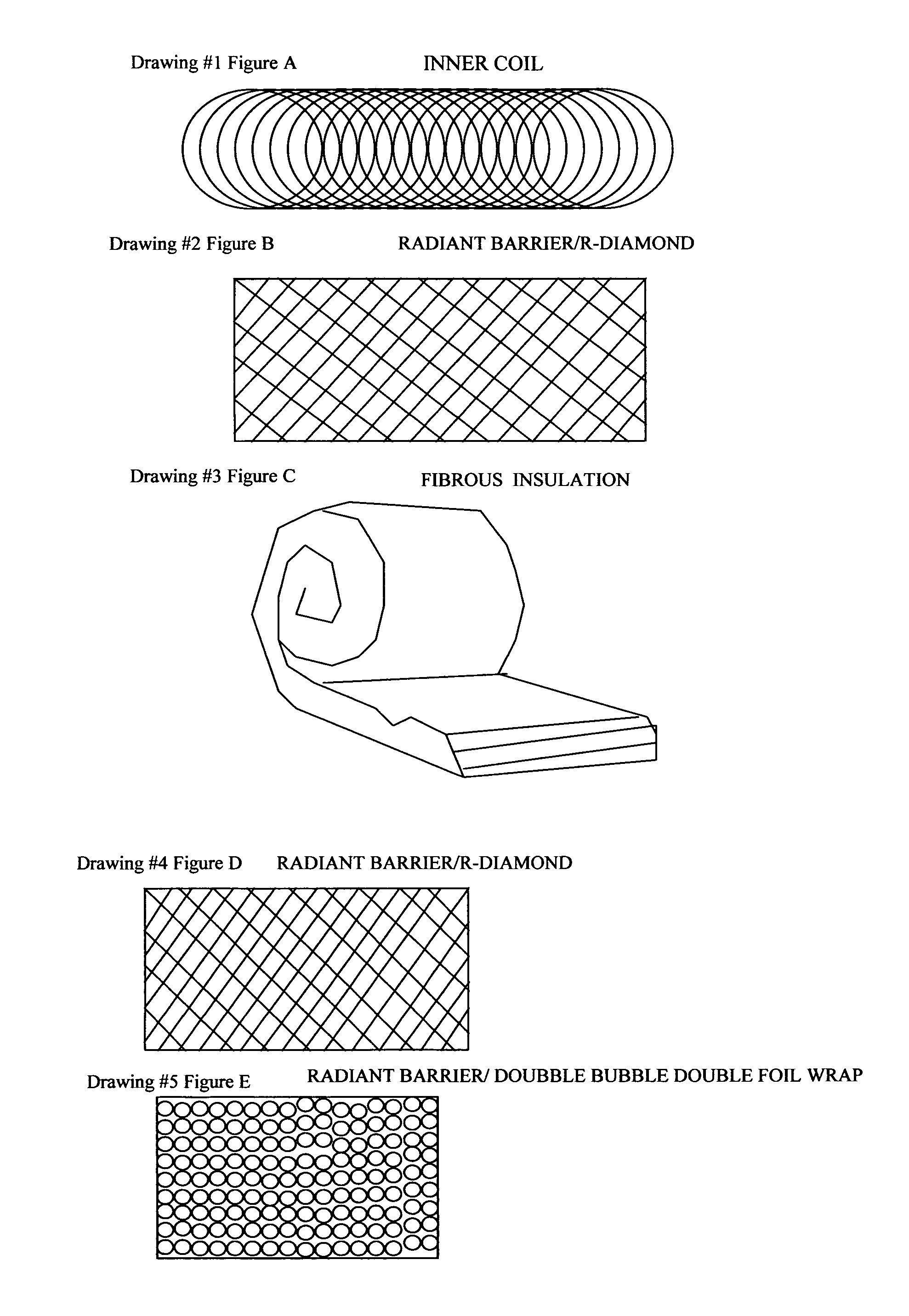

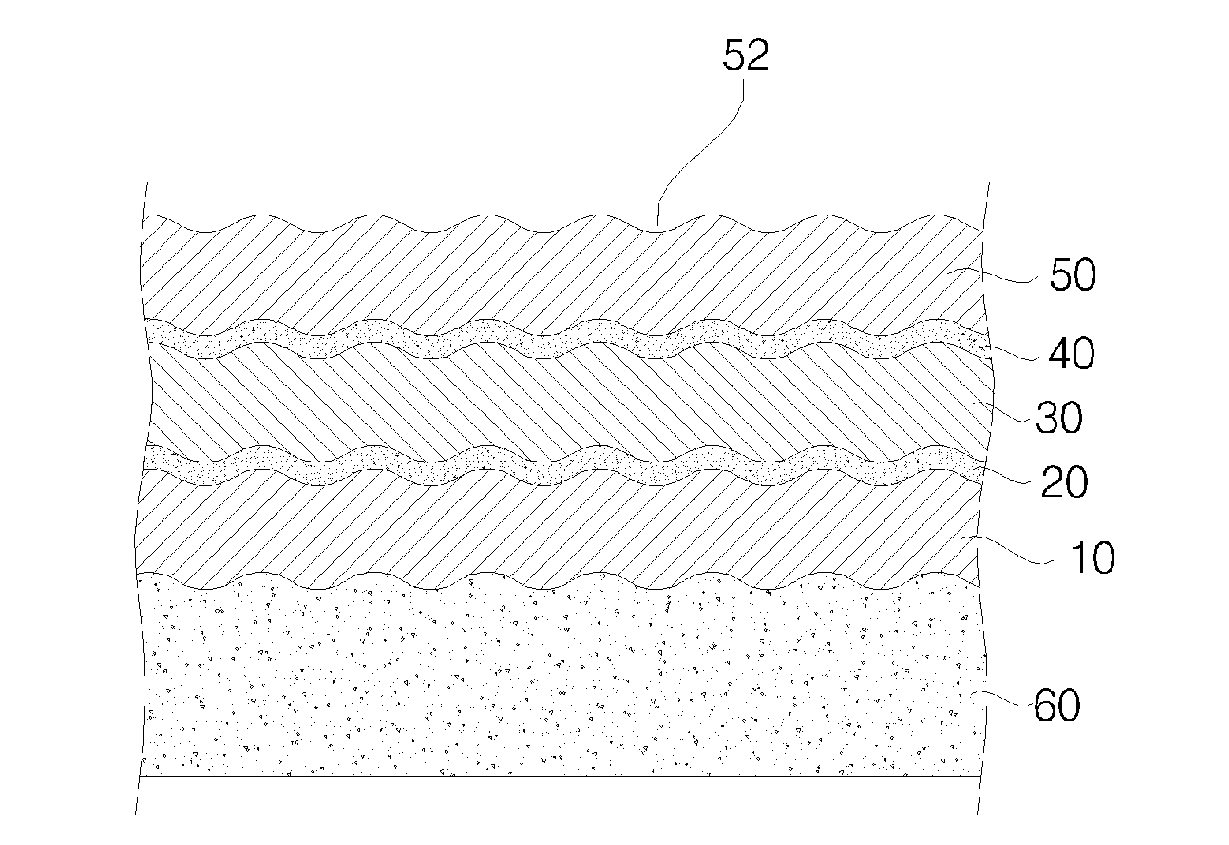

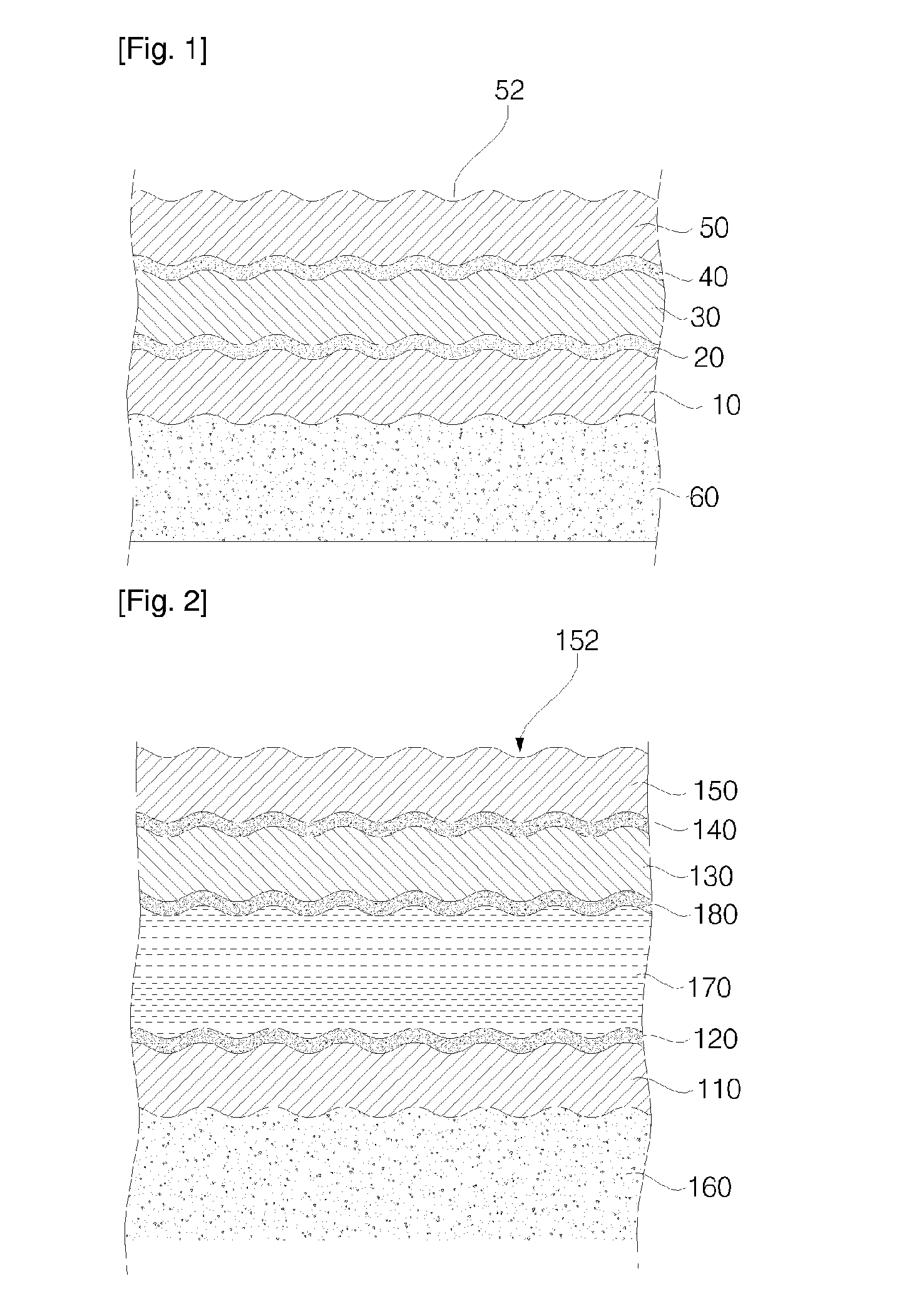

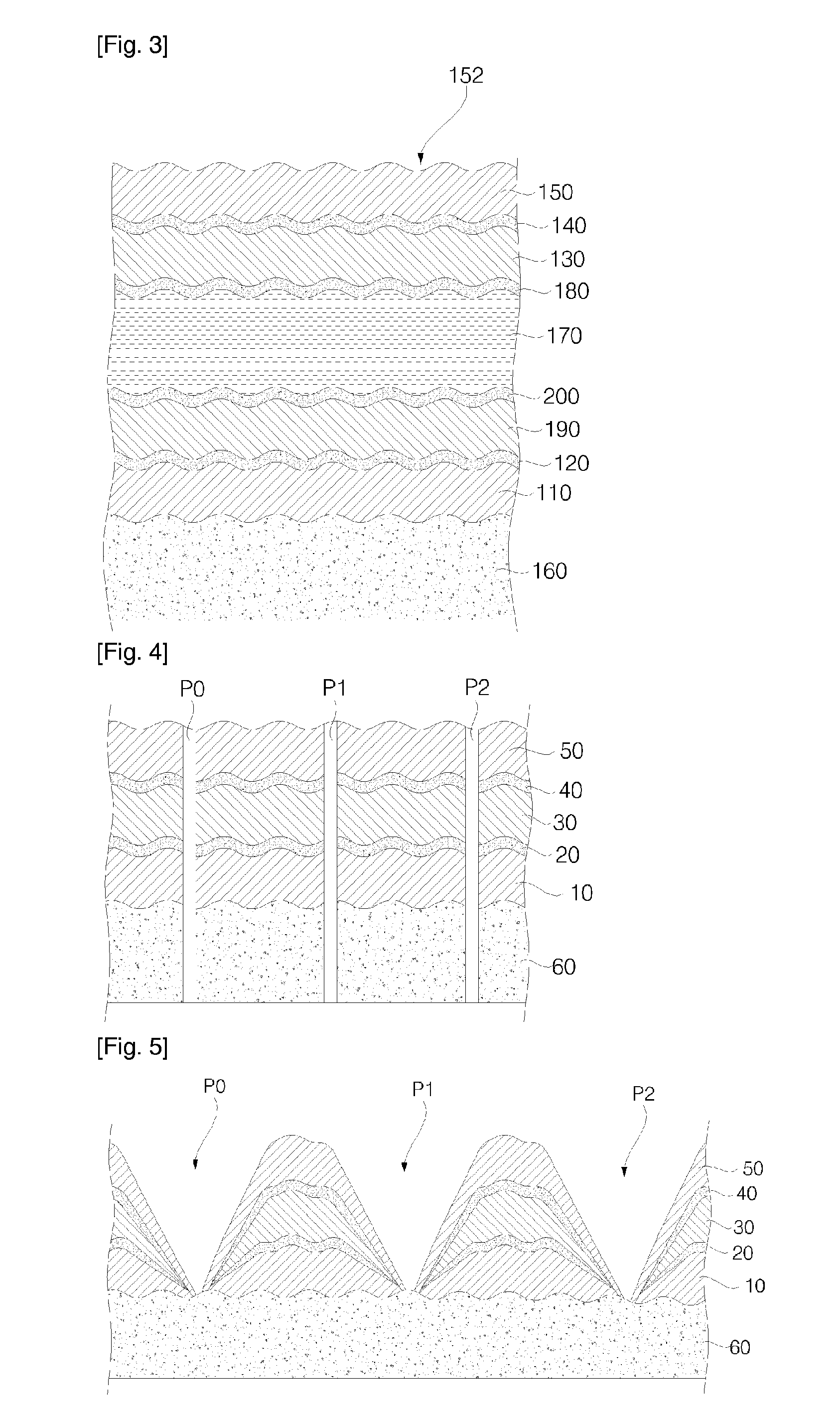

Low emissive radiant barrier flex (LOW-E FLEX)

InactiveUS20100282356A1Reduce heat transferDecreasing heat loss/gainThermal insulationLayered productsEngineeringRadiant barrier

This specification and the resources and research attach hereto provide the basis for a low cost high efficiency low emissive flex duct for air distribution especially where it pertains to the HVAC trade in buildings. The reflective radiant material used in this invention is already certified by energy star for current applications and increases the energy efficiency of a structure as well as the health of those persons or beings dwelling, residing, or working with in said structure. The manufacturing process is also efficient in that manufacturers of current / preexisting duct can use the same machines and processes with only a change of material.

Owner:SAWYER SCOTT

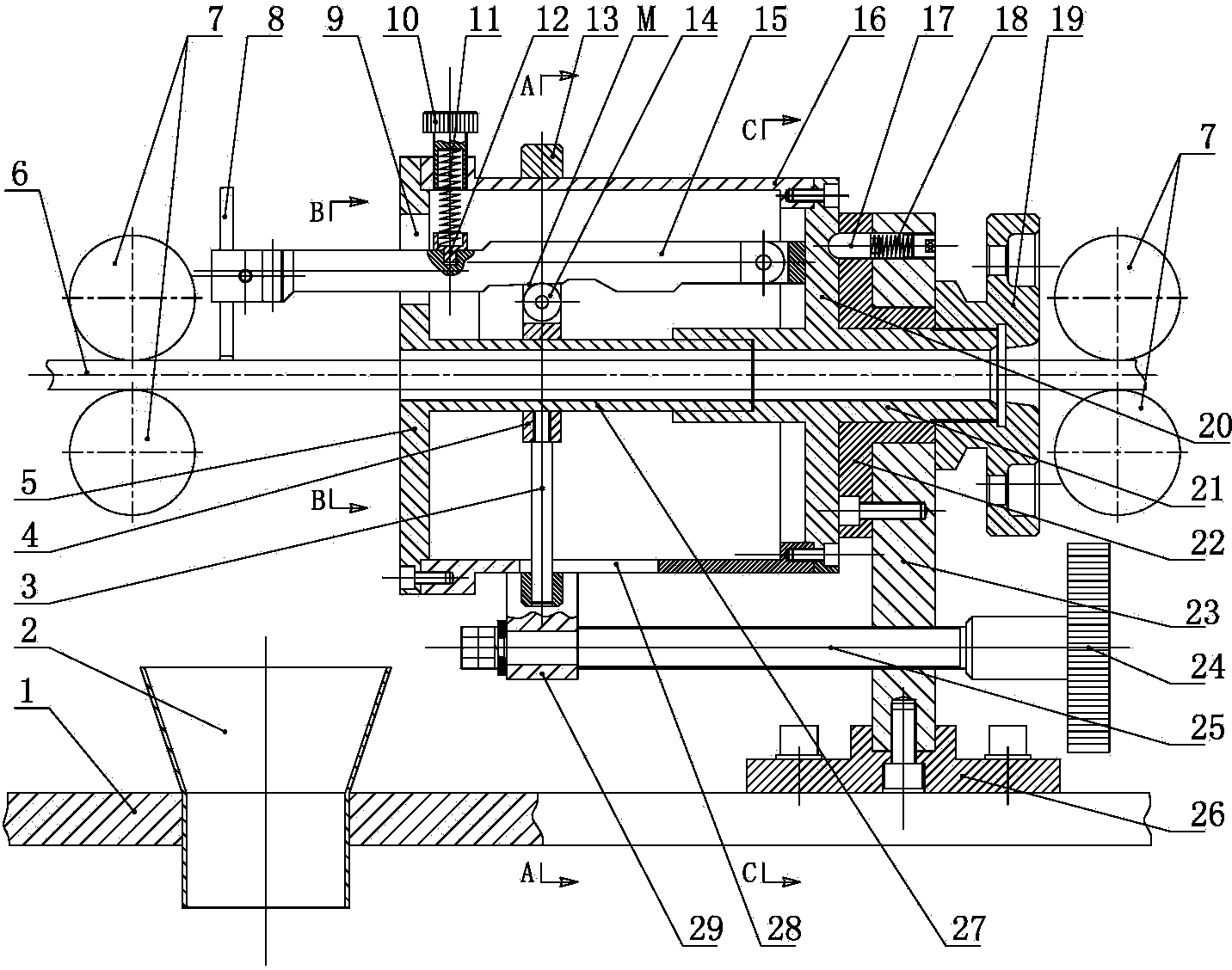

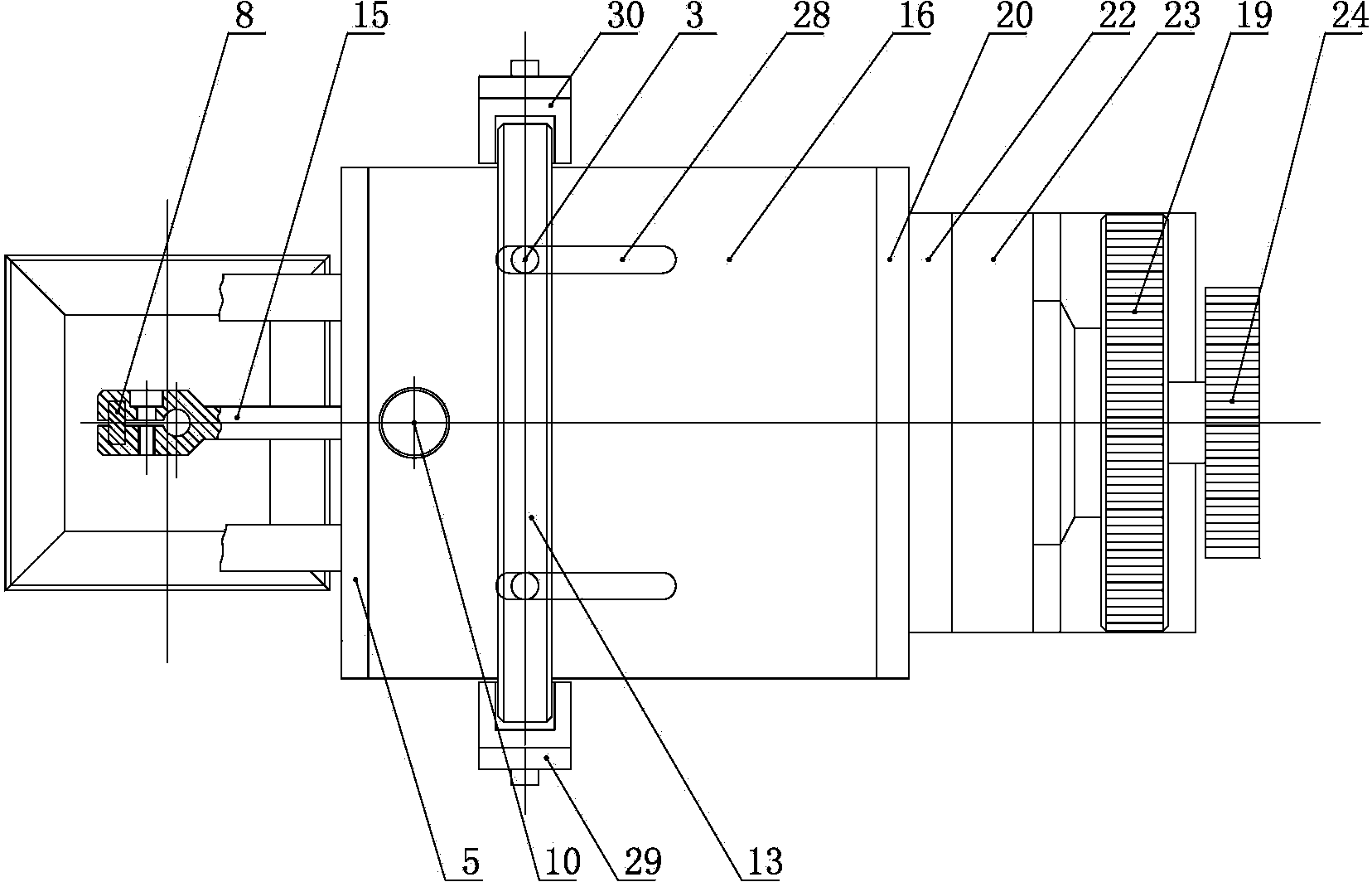

Aluminum rod surface oxidation layer removing device

ActiveCN104289768AContinuous removalThickness is easy to controlFeeding apparatusMetal working apparatusSurface oxidationBusbar

The invention relates to an aluminum rod surface oxidation layer removing device in the field of copper-coated aluminum busbar production devices. A machine base is arranged at the position under two guide wheel sets, a machine body is fixed to the machine base through a supporting plate and comprises a housing provided with a left end plate and a right end plate, a hollow mandrel is arranged at the center of the housing and sleeved with an inner sliding ring, an outer sliding ring is arranged outside the housing, a sliding groove is formed in the housing in the axial direction, and the inner sliding ring and the outer sliding ring are connected through a connecting rod penetrating through the sliding groove. The inner side of the right end plate is hinged to one end of a cutter bar, and the other end of the cutter bar extends out of a cutter bar hole formed in the left end plate and provided with a cutter bit. An oblique guide face is arranged on one side facing the mandrel, of the cutter rod, a rolling wheel is arranged on the inner sliding ring and abuts against the guide face, and a supporting spring is arranged on the other side of the cutter rod. An adjusting screw is connected to the supporting plate and connected with a shifting support, and the outer sliding ring is clamped on the shifting support. The aluminum rod surface oxidation layer removing device is used for removing an oxidation layer on an aluminum rod and can adjust cutting amount under the non-shutdown condition and achieve continuous copper-coated aluminum busbar production.

Owner:YANGZHOU NANYANG WELDING PIPE MOLD CO LTD

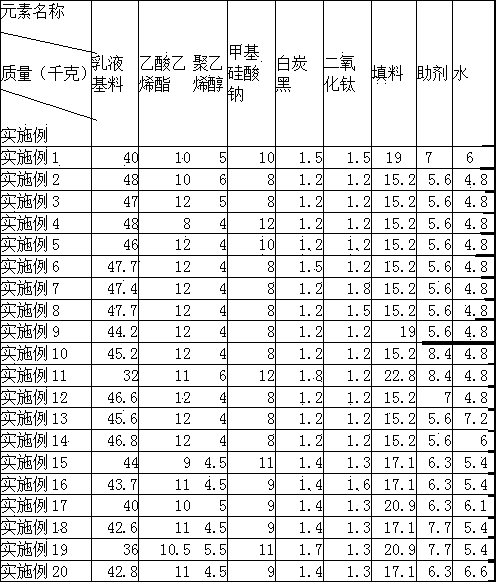

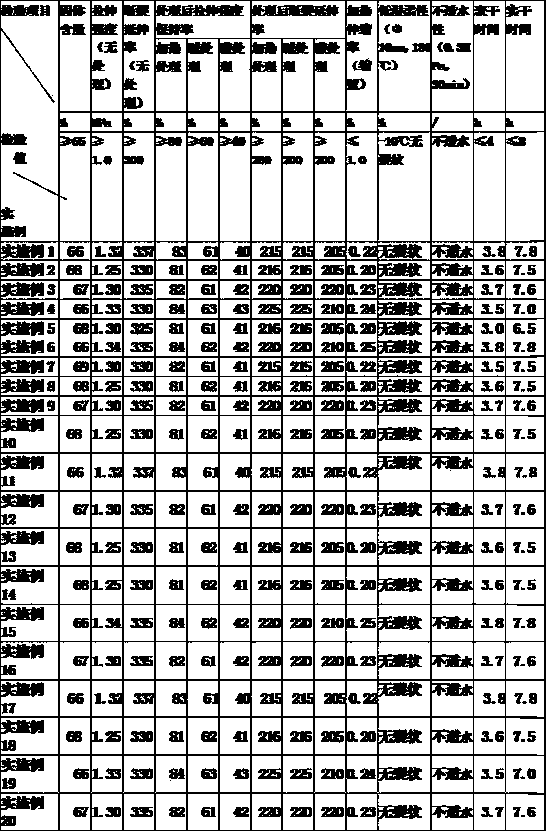

Composite high-power waterproof silica gel paint and preparation method thereof

InactiveCN103468040AStrong adhesionImprove waterproof performanceCoatingsCrack resistancePolyvinyl alcohol

The invention discloses a composite high-power waterproof silica gel paint. The preparation method for preparing the composite high-power waterproof silica gel paint comprises the following steps: 1. taking 32-48 parts of emulsion base material, 8-12 parts of vinyl acetate, 4-6 parts of polyvinyl alcohol, 8-12 parts of sodium methyl silicate, 1.2-1.8 parts of silica white, 1.2-1.8 parts of titanium dioxide, 15.2-22.8 parts of filler, 5.6-8.4 parts of assistant and 4.8-7.2 parts of water as raw materials; 2. adding the vinyl acetate into the emulsion base material, stirring, and dispersing to generate polymerization reaction; 3. adding the silica white, and stirring uniformly; 4. adding the titanium dioxide, filler and assistant, and stirring uniformly; and 5. adding the sodium methyl silicate, polyvinyl alcohol and water, stirring uniformly, and reacting for 9-11 minutes to obtain the composite high-power waterproof silica gel paint. The composite high-power waterproof silica gel paint has the advantages of environmental protection, no toxicity, favorable low-temperature tensile property, favorable crack resistance, long service life, no water adhesion and favorable mechanical strength, and can form a double-layer waterproof structure.

Owner:王福刚

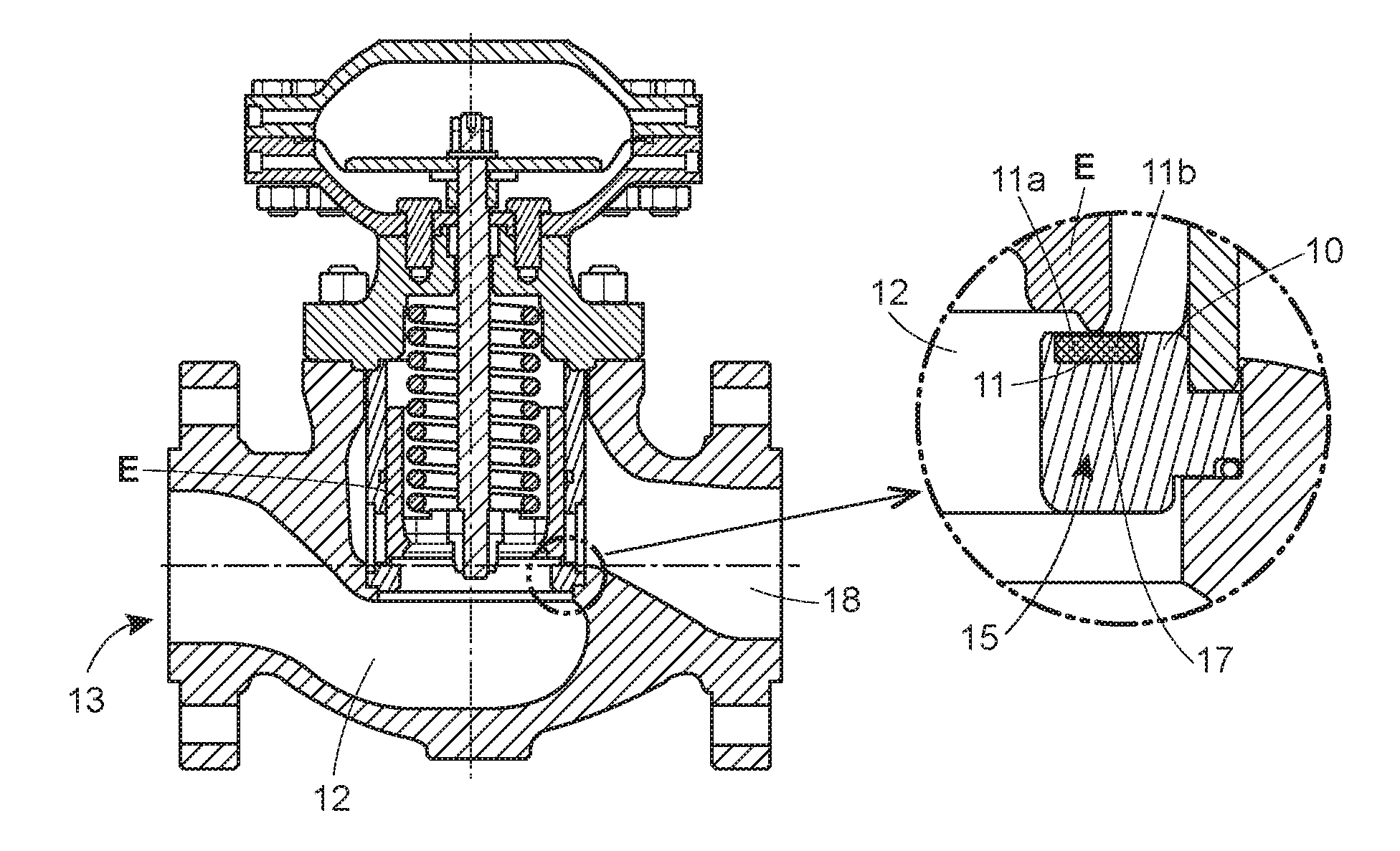

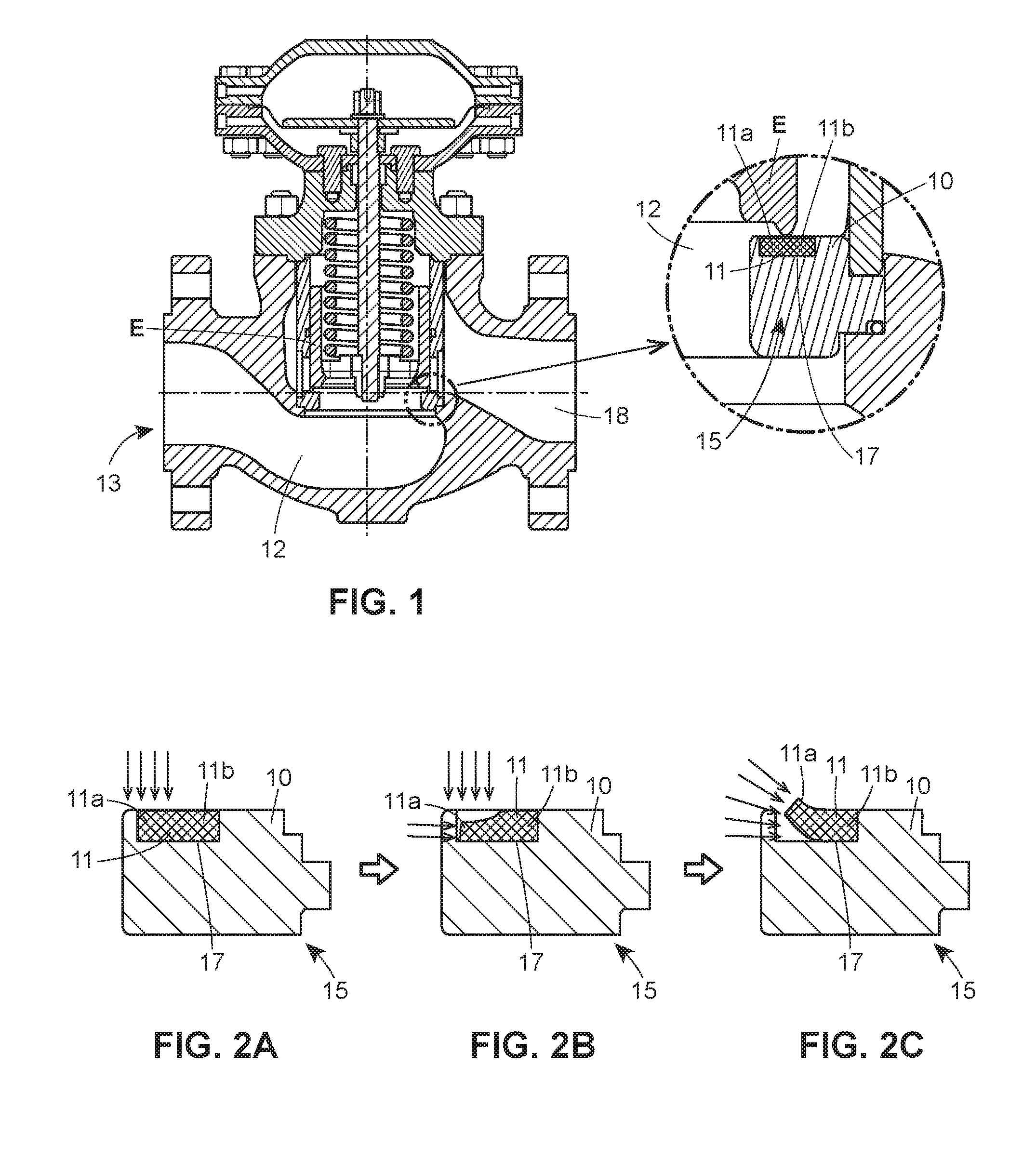

Valve seat, sealing gasket and pressure valve

The present disclosure relates to a valve seat, a sealing gasket and a pressure valve. The valve seat comprises a valve seat body. A groove used for containing the sealing gasket is arranged on the valve seat body. At least one side of the groove is sunken inwards into an inclined groove shape. The valve seat with the design can prevent the sealing gasket from being damaged under a high pressure, thereby avoiding poor sealing performance; meanwhile, the valve seat is convenient to be machined and low in cost.

Owner:EMERSON PROCESS MANAGEMENT REGULATOR TECH INC

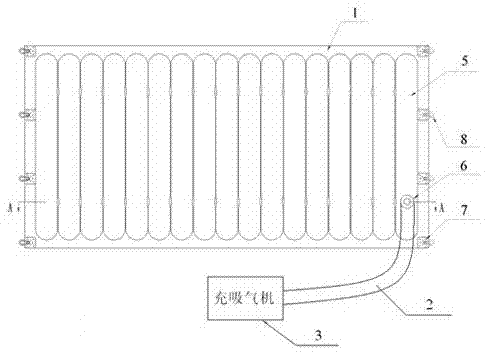

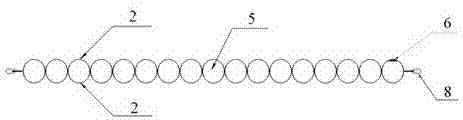

Inflating device for operation in shoal environment

ActiveCN102806983ASolve the problem of not being able to disembark and operateStrong pressure capacityLife-savingEngineeringGas-filled tube

The invention provides an inflating device for operation in a shoal environment. The inflating device comprises an air cushion body, an inflating pipe, an inflating and deflating machine and an inflating valve cap. The air cushion body consists of an upper rectangular air cushion outer layer, a lower rectangular air cushion outer layer and reinforcing sheets adhered between the upper and lower rectangular air cushion outer layers which are identical in shape. The air cushion body is adhered and partitioned into a plurality of air chambers which are identical in shape and arrayed closely by the reinforcing sheets, and each two adjacent air chambers are communicated. An inflating valve is optionally arranged on one of the two outmost air chambers in the array direction of the multiple air chambers. The inflating and deflating machine is connected with the inflating valve through the inflating pipe and used for inflating the air chambers or pumping air from the air chamber through the connected inflating pipe. After inflating / deflating of the air cushion body is completed, the inflating valve cap is mounted on the inflating valve to seal the air chamber. The inflating device is capable of floating on a shoal, changeable in length according to practical needs, high in air tightness and pressure bearing capacity and convenient to maintain.

Owner:QINGDAO GUANGMING ENVIRONMENTAL TECH

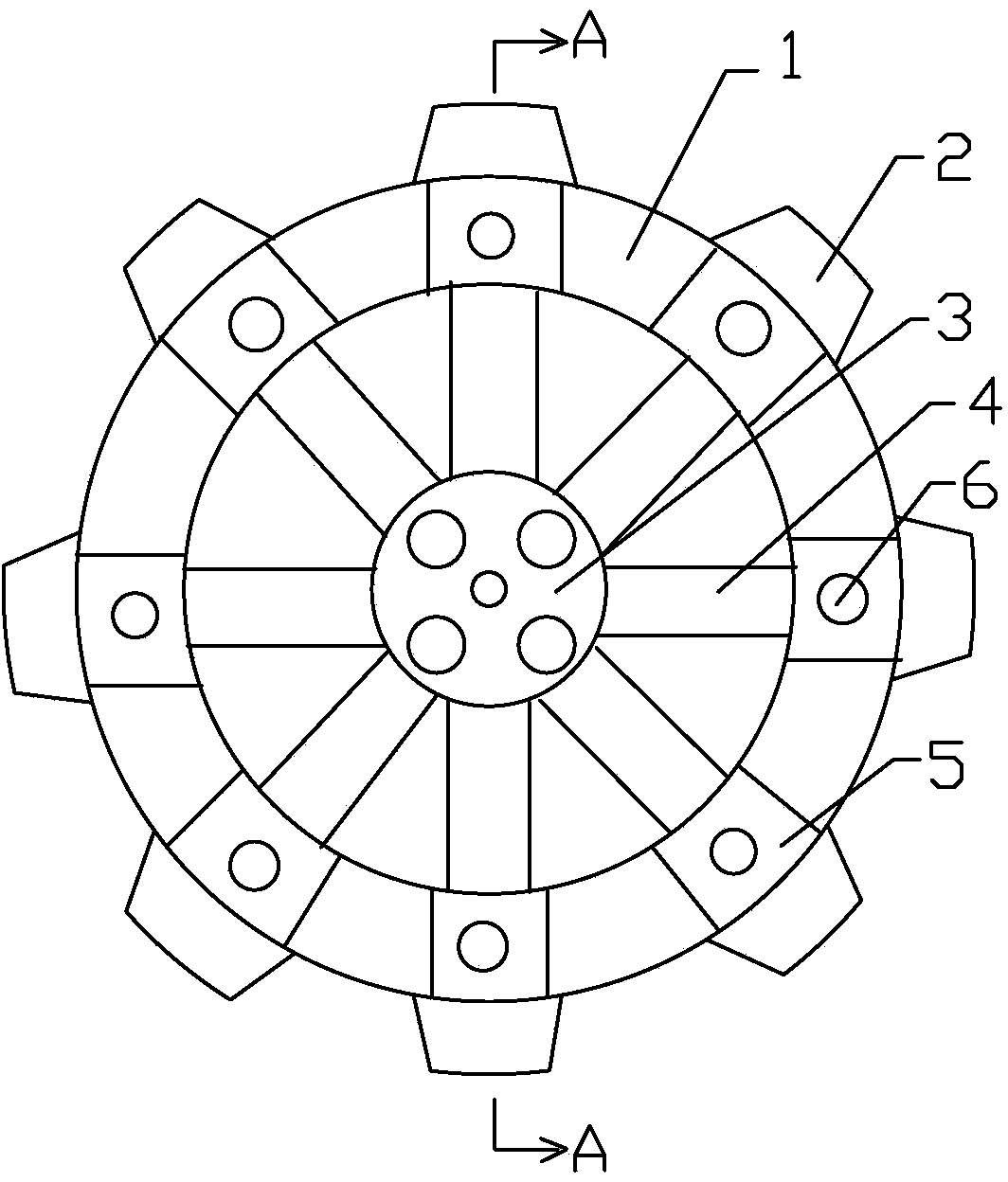

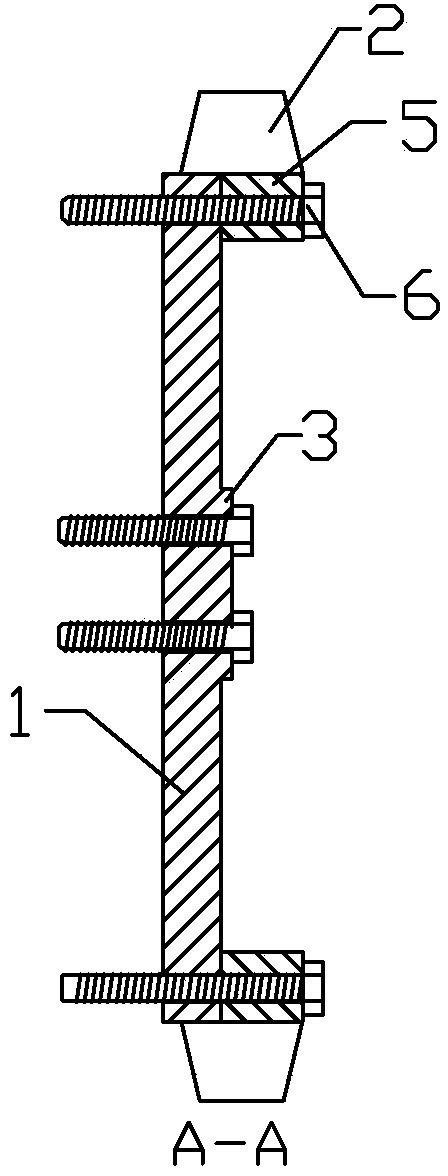

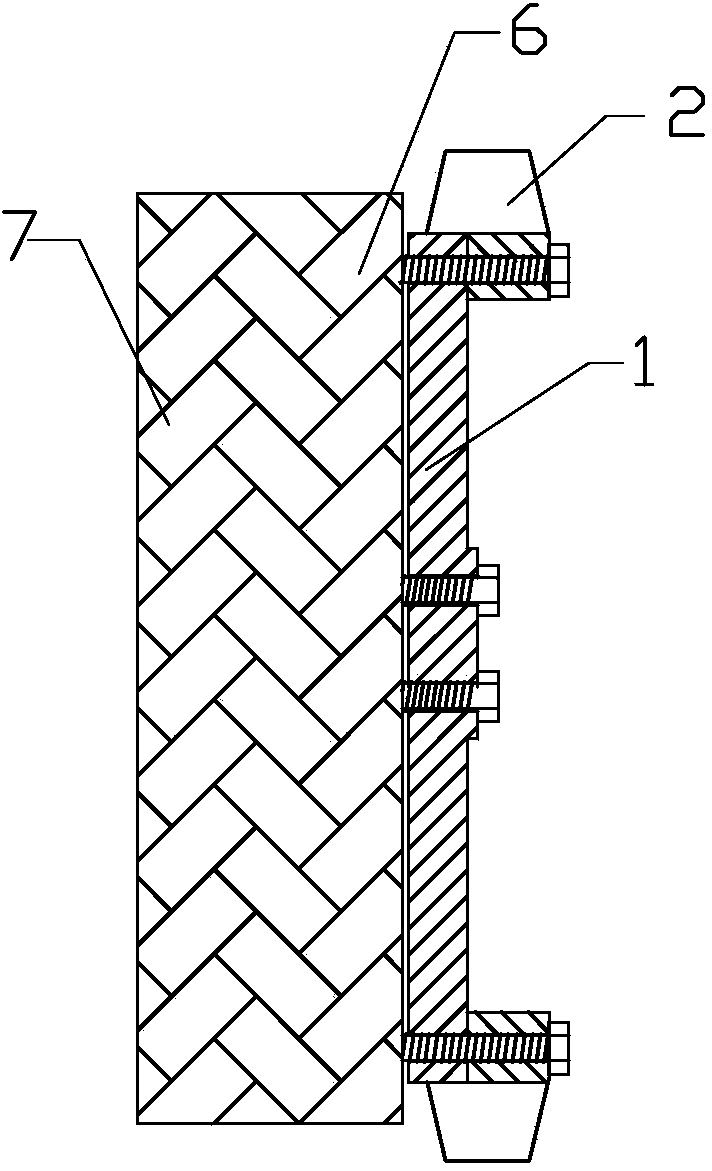

Antiskid device of tire

InactiveCN104175821AEasy to assemble and disassembleLow costNon-skid devicesMechanical engineeringTread

The invention discloses an antiskid device of a tire. The problems that the conventional antiskid device has high price and the tire is easy to abrade because the antiskid device needs to be in contact with the tread of the tire during use are mainly solved. The antiskid device structurally comprises an antiskid wheel disk, antiskid blocks, a base, connection columns and a fixed seat, wherein the antiskid wheel disk is circular-ring-shaped; the base is arranged at the circle center of the antiskid wheel disk; a plurality of connection columns are uniformly arranged between the edge on the outer side of the base and the edge on the inner side of the antiskid wheel disk; the antiskid blocks are respectively arranged at the end parts, which correspond to the connection columns, of the outer side of the antiskid wheel disk and are connected with the side wall of the antiskid wheel disk through the fixed seat. The antiskid device is convenient to mount and use and has a stable antiskid effect; after being abraded, the antiskid blocks are convenient to replace; the antiskid device is low in manufacturing cost and wide in use range; vehicles can safely run under the condition of a slippery road.

Owner:SHANDONG INST OF COMMERCE & TECH

Conductive pressure sensitive adhesive tape

InactiveUS20100086777A1High tear strengthFlexibilityFilm/foil adhesivesThin material handlingPressure sensitiveMetal foil

A conductive pressure sensitive adhesive tape is provided. The conductive pressure sensitive adhesive tape includes a first metal foil, a polymer film attached to a surface of the first metal foil with a polymer binder interposed therebetween, a second metal foil attached to a surface of the polymer film with a polymer binder interposed therebetween, and a polymer adhesive layer formed on a backside of at least one of the first and second metal foils.

Owner:JOINSET

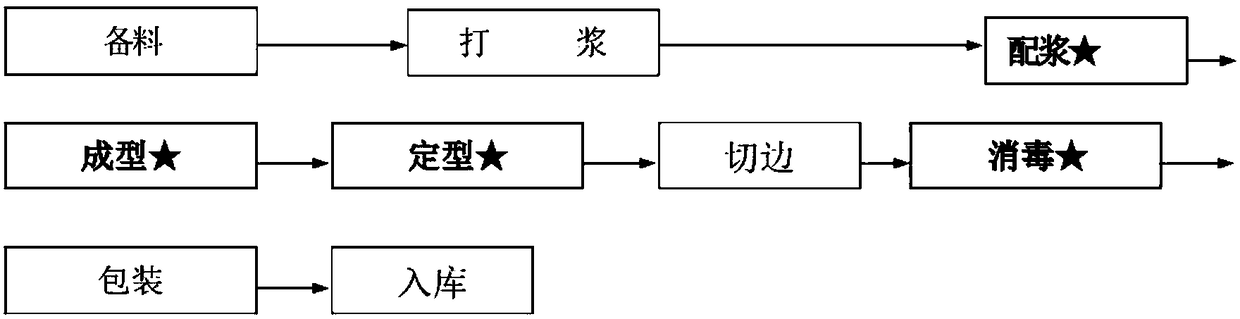

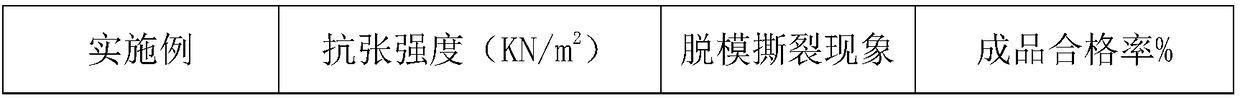

Preparation method of paper pulp molded tableware

InactiveCN108589431AHigh tensile strengthImprove pass rateTextiles and paperCritical control pointPulp and paper industry

The invention aims at overcoming the weaknesses of the existing preparation process of the paper pulp molded tableware, and provides an improved paper pulp molded tableware preparation process. According to the preparation process, a technological condition at a key control point of the paper pulp molded process is optimized, particularly in the pulp preparation process, a pulp-to-water ratio anda ratio of an oil-proof agent to a waterproof agent are optimized, and the technological conditions such as vacuum degree, temperature, pressure in the molding and stereotyping are controlled, so thatthe tensile strength of the product can be improved, in the mold stripping process, the tearing is unlikely to occur, the qualification rate of the product is increased, and the moisture absorption mould phenomenon can be reduced.

Owner:浙江博特生物科技有限公司

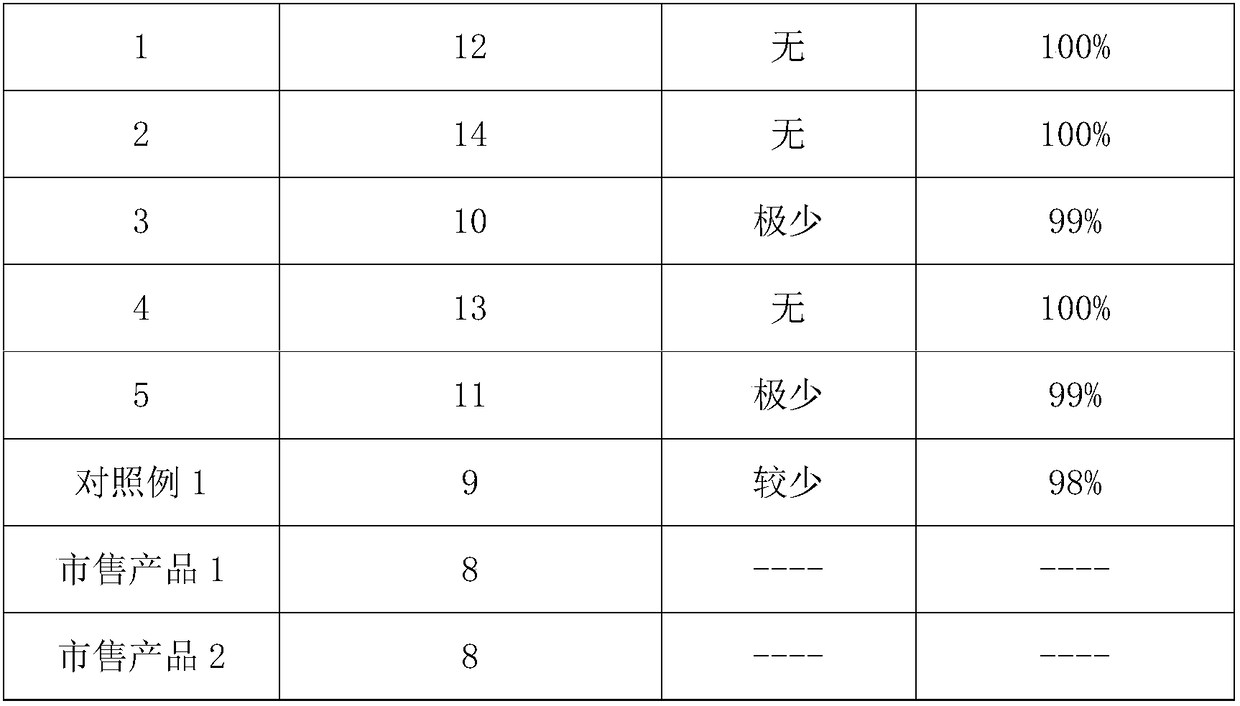

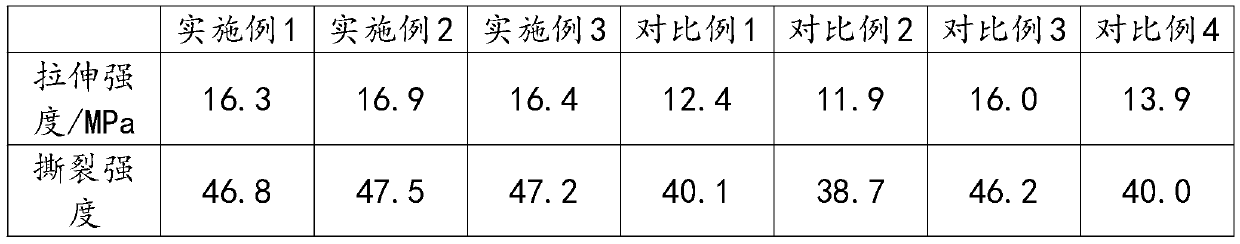

Self-lubricated wearing-resistant rubber material and preparation method thereof

PendingCN110240758AGood high temperature resistanceExcellent oil resistance, wear resistanceCarbon blackCarbon nanotube

The invention discloses a self-lubricated wearing-resistant rubber material which is prepared from the following raw materials in parts by weight: 60-80 parts of ethylene-propylene-diene monomer rubber, 20-30 parts of nitrile rubber, 4-5 parts of zinc methacrylate, 2-3 parts of carbon nanotubes, 30-40 parts of modified white carbon black, 4-5 parts of zinc oxide, 1-2 parts of sulfur, 2-3 parts of accelerant, 1-2 parts of an anti-aging agent, 1-2 parts of paraffin and 10-11 parts of a lubricant. The invention further discloses a preparation method of the rubber material. Commixed rubber of the ethylene-propylene-diene monomer rubber and the nitrile rubber is adopted as a rubber matrix, and the zinc methacrylate and the carbon nanotubes are adopted as assistant crosslinkers, so that the rubber matrix with excellent properties can be obtained; due to adoption of the modified white carbon black, mechanical properties and the abrasion damage resistance of the rubber material can be improved; due to adoption of the lubricant, the rubber material has excellent self-lubricating performance, after a lubricant TP16 migrated to a surface is abraded, a lamellar structure, which is very liable to slide and move, of molybdenum disulfide plays a very good role of abrasion reduction, and thus the rubber material can be further protected.

Owner:NINGGUO ZHENGDAO RUBBER & PLASTIC PARTS

Manufacture method for PVC conveyor belt material

The invention relates to a manufacture method for PVC conveyor belt materials, which is technically characterized in that slurry is formed by mixing paste resin, disalt, threesalt, antimony trioxide, zinc borate, TCEP (also called phosphate tribasic (2-chloroethyl) ester), DOP (dioctyl phthalate), paraffin, carbon black according to a certain ratio; and an adhesive which is a mixture of resorcinol and urotropine with a certain ratio is added into a beating tank after being fully grinded by colloid, and is stirred by high speed to be uniformly mixed with the slurry. When the slurry is prepared, the adhesive is added according to the amount of 1 percent, and a belt body which is made by plasticization after the adhesive is added into the slurry ensures that gum and a core body are tightly combined, can not loose and is not easy to be torn, thereby the service life of the conveyor belt is prolonged by more than one time to obtain favorable effect.

Owner:SHANDONG CHENGUANG ADHESIVE TAPE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com