Composite high-power waterproof silica gel paint and preparation method thereof

A waterproof silicone and coating technology, applied in the direction of coating, can solve the problems of poor crack resistance, difficult to achieve waterproof effect, weak adhesion and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This embodiment provides a preparation process of a composite strong waterproof silica gel paint, which mainly includes the following steps:

[0063] One. Weighing raw materials: 40 kg emulsion base material, 10 kg vinyl acetate, 5 kg polyvinyl alcohol, 10 kg sodium methyl silicate, 1.5 kg white carbon black, 1.5 kg titanium dioxide, 19 kg filler, 7 kg additives, water 6 kg; of which,

[0064] Emulsion base material: refers to a mixture of silicone rubber emulsion and VAE emulsion in any ratio. The so-called mixture of any ratio means that it can be any of silicone rubber emulsion or VAE emulsion, or silicone rubber emulsion and VAE emulsion according to A certain proportion of mixed liquid;

[0065] Auxiliary: refers to defoamer and flame retardant, the mass ratio of defoamer to flame retardant is 2-6:1~3; defoamer can be methyl silicone oil, flame retardant can be phosphate ester, and It can be other defoamers and flame retardants with similar properties;

[0066] Vinyl ac...

Embodiment 2-20

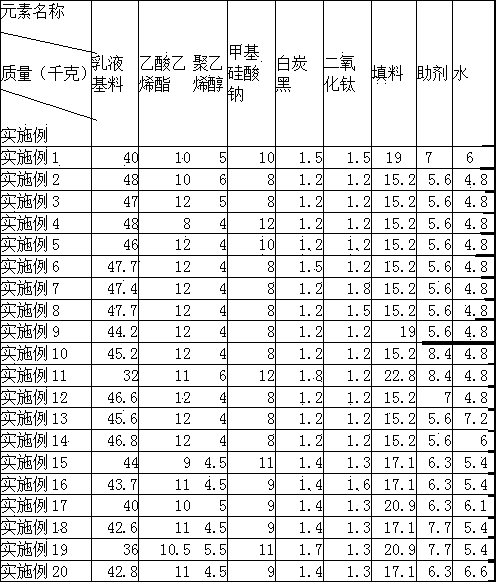

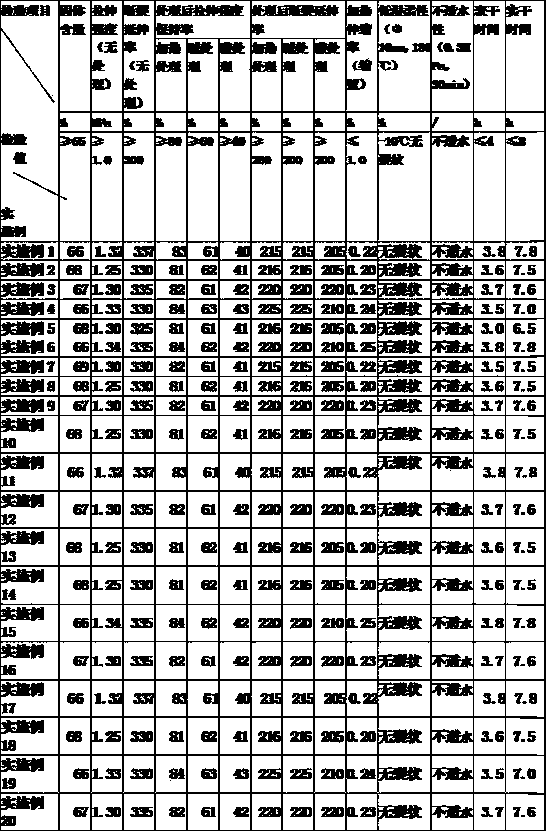

[0083] The raw materials and quality used in Examples 2-20 are shown in Table 1 below. The preparation method and use (construction) method are the same as those in Example 1; Table 1 below shows the specific materials used in Examples 1-20. Raw materials and quality. According to the requirements of JCT / 864-2008, the coatings of each embodiment of the present invention were tested. The following Table 2 shows the test data of the composite strong waterproof silicone coating obtained in Examples 1-20. It can be seen from the test data, The composite strong waterproof silica gel paint of the present invention has good adhesion and permeability; good traceability and high elasticity; good water resistance and hydrophobicity; good mechanical strength; high weather resistance, especially good low temperature performance, -10 ℃ low temperature will not crack. The invention can form an integrated waterproof structure with a permeable layer and a surface film layer, which is a major ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com