Preparation method of nanocrystalline magnetic sheet for wireless charging

A technology of wireless charging and nanocrystals, applied in chemical instruments and methods, applications, electronic equipment, etc., to achieve the effects of improving crack uniformity, high yield rate, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

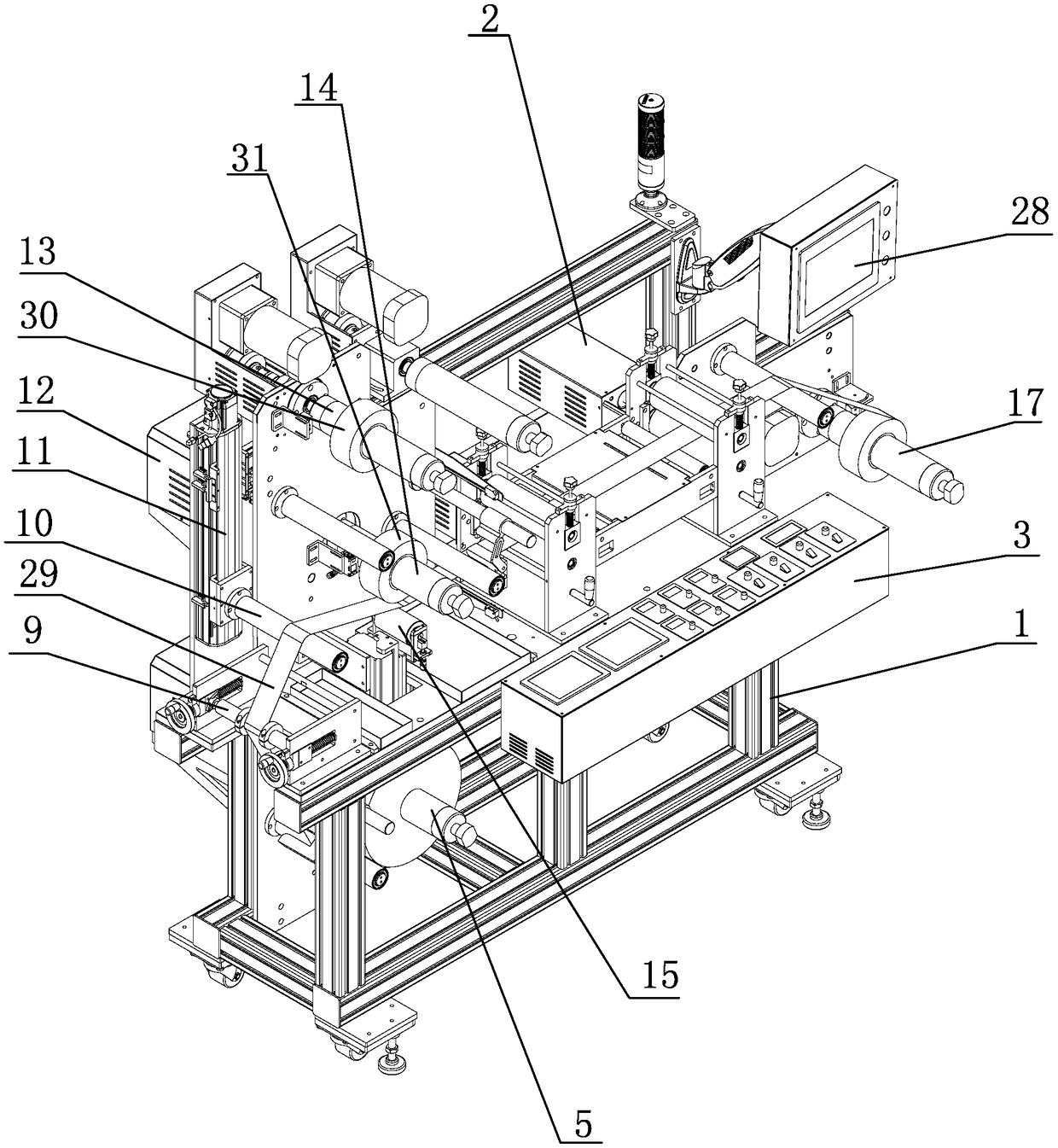

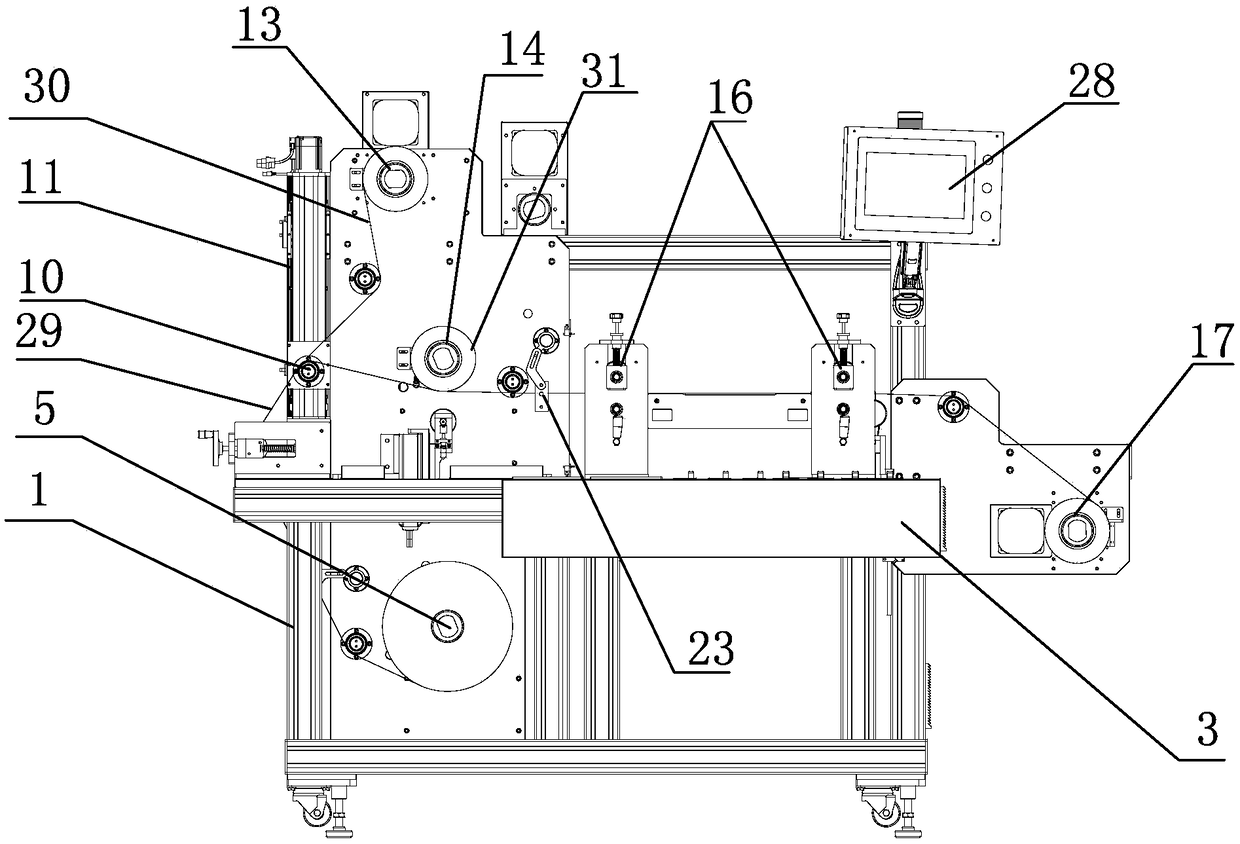

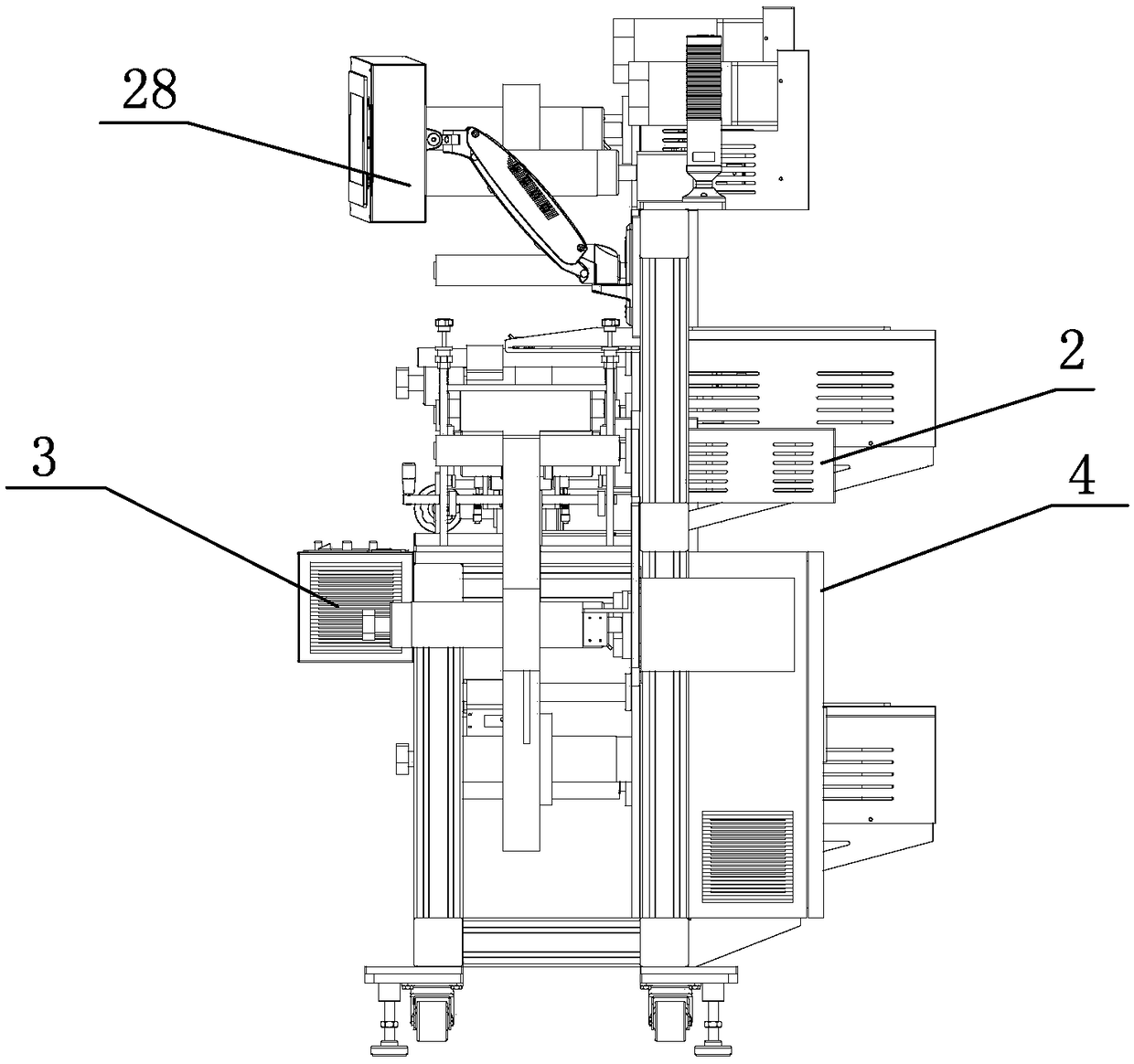

Image

Examples

preparation example Construction

[0078] A method of preparing a wireless charging nano -crystal magnetic film, including the following steps:

[0079] 1) Wind scroll: Wrap the nano -crystal band into the required length or weight.

[0080] 2) Antuction: Anecrete treatment of nano-crystal band materials that are rolled out: The annealing temperature is 500-600 ° C, and the time is 8-15H.

[0081] 3) Single -layer fit: Put double -sided glue on the dark surface of some nano -crystal belt materials, and attach silicone weak mucosa on the dark surface of the remaining nano -crystal bands to ensure that the nanocrystalline band material is not biased during the fit process , Non -broken, drums produced by residual bubbles.

[0082] 4) Multi -layer fit: Select a nanocrystal belt with double -sided glue, attach silicone weak mucosa on its bright surface, stripped off the protective film on its double -sided glue, and use the nanocrystalline band material as the base -based base. Noodles, another nano-crystal belt ...

Embodiment 1

[0091] 1) Winding: After preparing the nanocrystalline strip and related equipment, place one end of the nanocrystalline strip on the winding device, set the tension and speed to control the tightness, wind to the specified length, and fix the joint by electric welding.

[0092] 2) Annealing: annealing is performed on the coiled nanocrystalline strip: the annealing temperature is 550° C., and the time is 8-15 hours.

[0093] 3) Single-layer bonding: attach double-sided adhesive tape to the dark surface of some nanocrystalline strips, and attach weak silica gel film to the dark surface of the rest of the nanocrystalline strips to ensure that the nanocrystalline strips are not misaligned during the lamination process , No breakage, no bulging due to residual air bubbles.

[0094] 4) Multi -layer fit: Select a nanocrystal belt with double -sided glue, attach silicone weak mucosa on its bright surface, stripped off the protective film on its double -sided glue, and use the nanocry...

Embodiment 2

[0103] 1) Winding: After preparing the nano -crystal band material and related equipment, place one end of the nano -crystal belt on the rolling device, set the tension and speed to control the loosening, and wrap the welding fixed joint.

[0104] 2) Antuction: Anecrete treatment of nano-crystal band materials that are rolled out: annealing temperature is 550 ° C, and the time is 8-15h.

[0105] 3) Single -layer fit: Put double -sided glue on the dark surface of some nano -crystal belt materials, and attach silicone weak mucosa on the dark surface of the remaining nano -crystal bands to ensure that the nanocrystalline band material is not biased during the fit process , Non -broken, drums produced by residual bubbles.

[0106] 4) Multi -layer fit: Select a nanocrystal belt with double -sided glue, attach silicone weak mucosa on its bright surface, stripped off the protective film on its double -sided glue, and use the nanocrystalline band material as the base -based base. Noo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Stickiness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com