Patents

Literature

417 results about "Fixed joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Examples of fixed joints include the joints between the bones in the skull and the joint where the radius and ulna bones meet in the lower arm. Fixed joints, also known as fibrous joints, are places where two bones come together in the body but are unable to move.

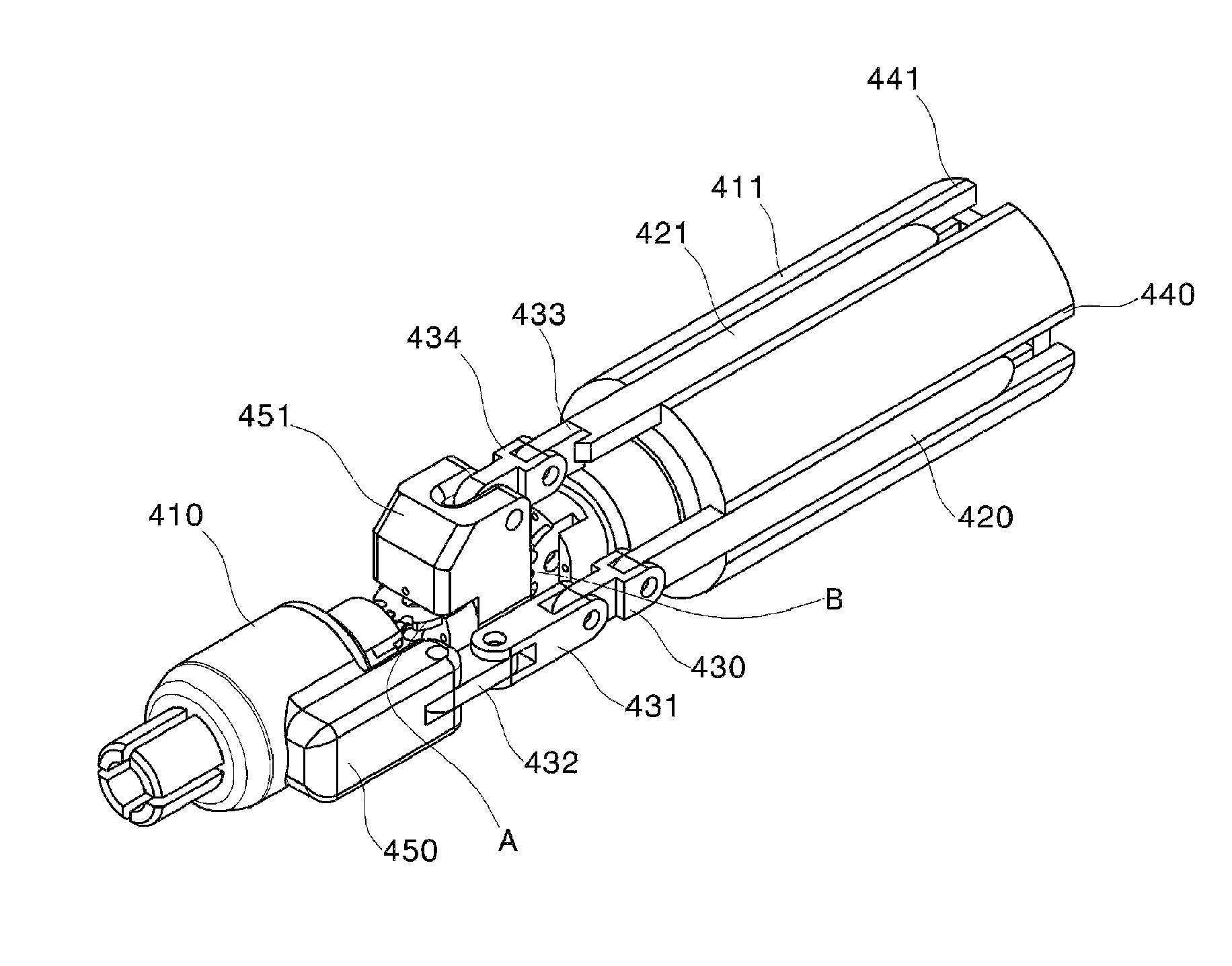

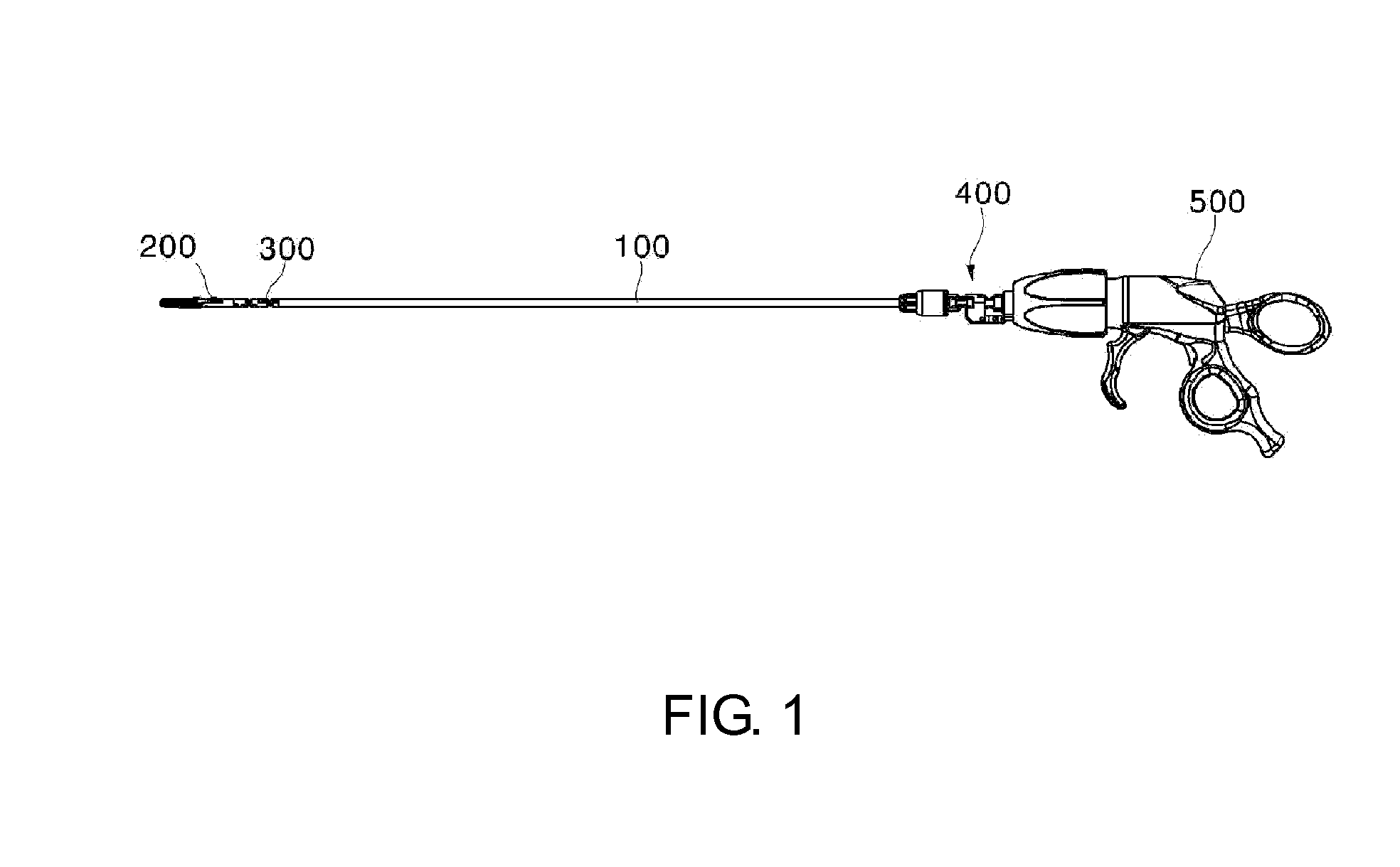

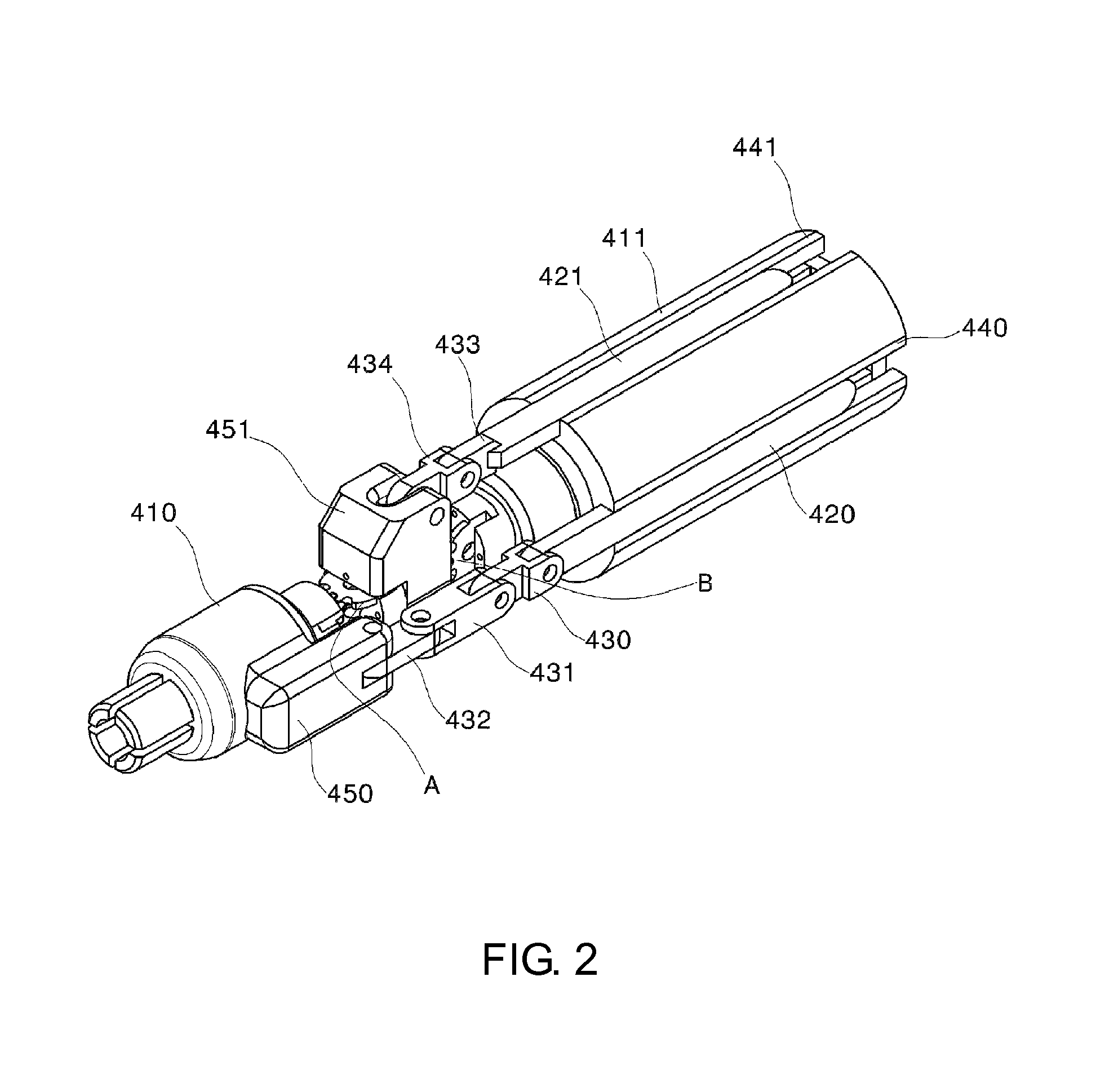

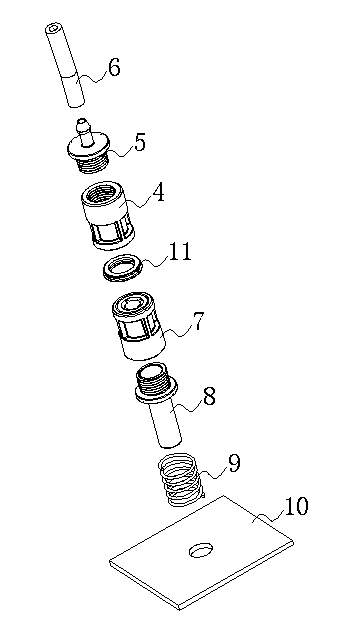

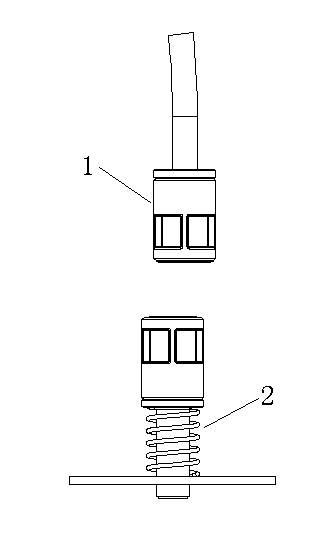

Device for fixing joint structure

Owner:MOVASU

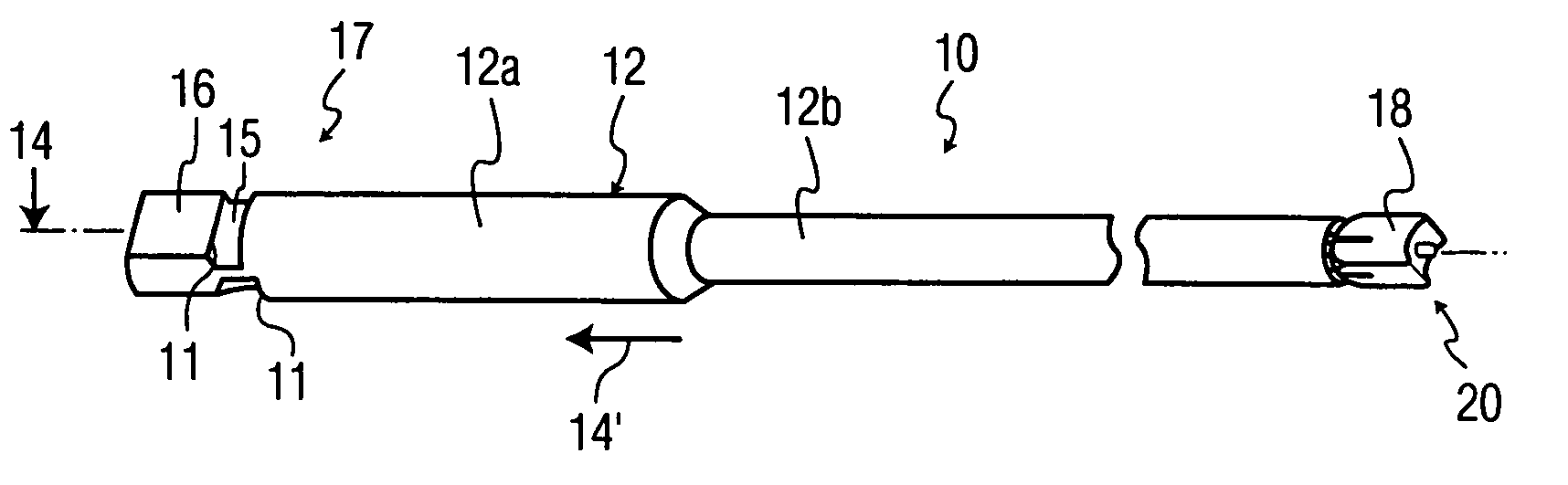

Adjustable instrumentation for spinal implant insertion

Owner:WARSAW ORTHOPEDIC INC

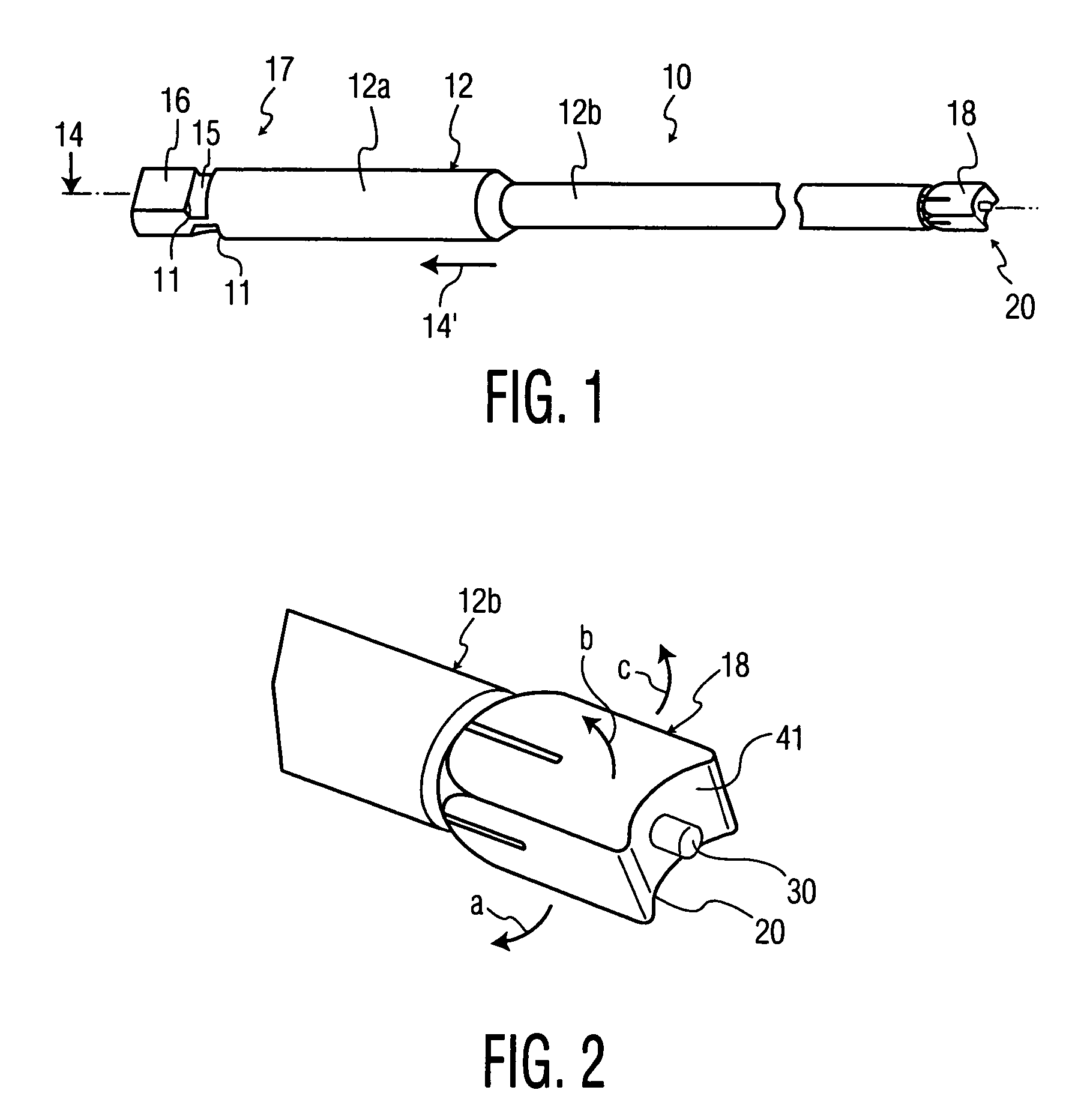

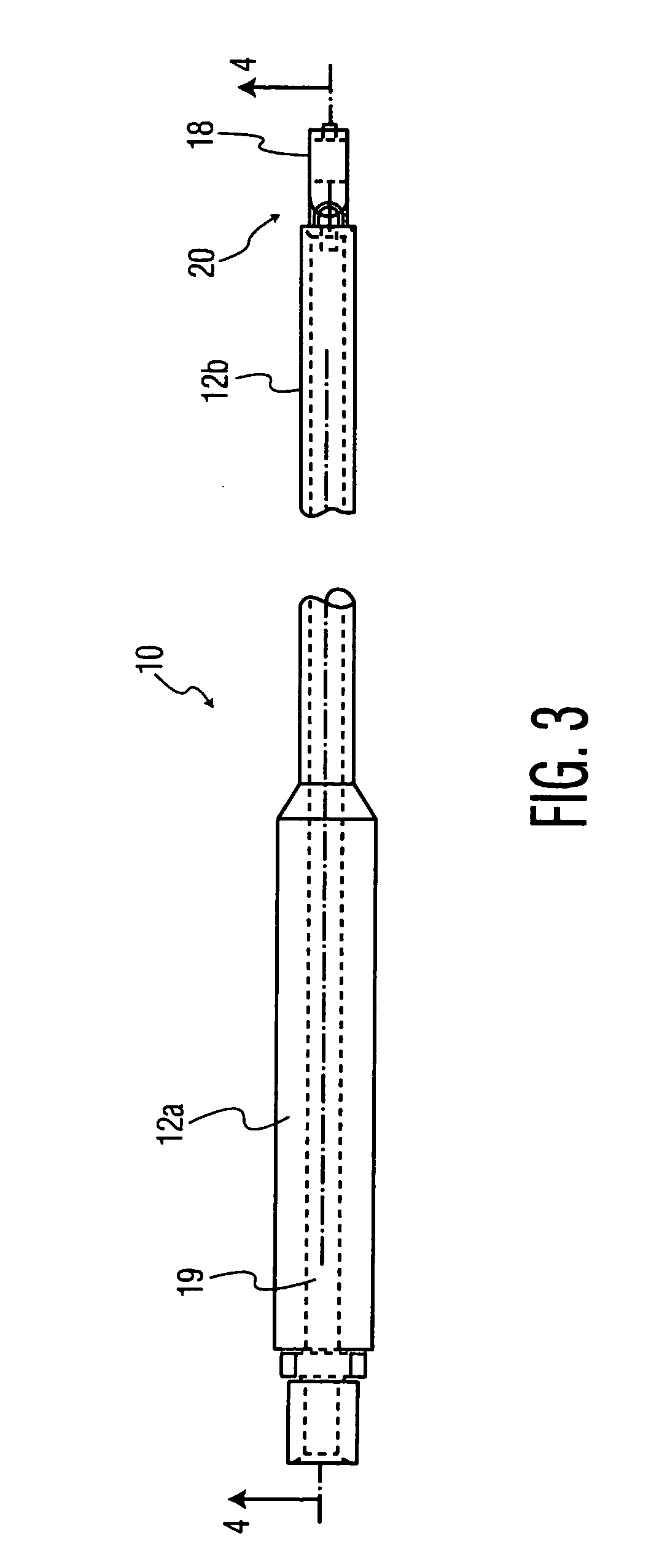

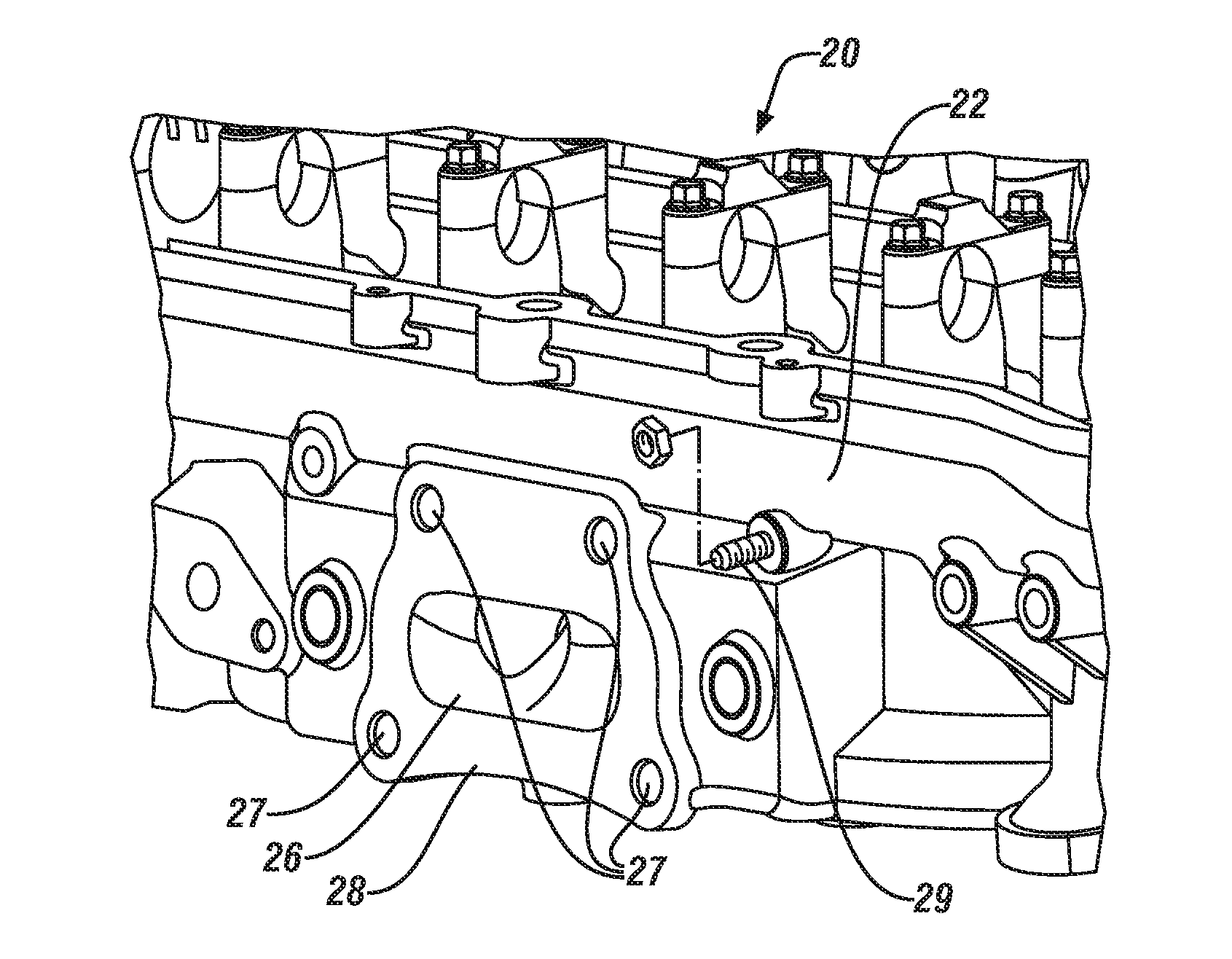

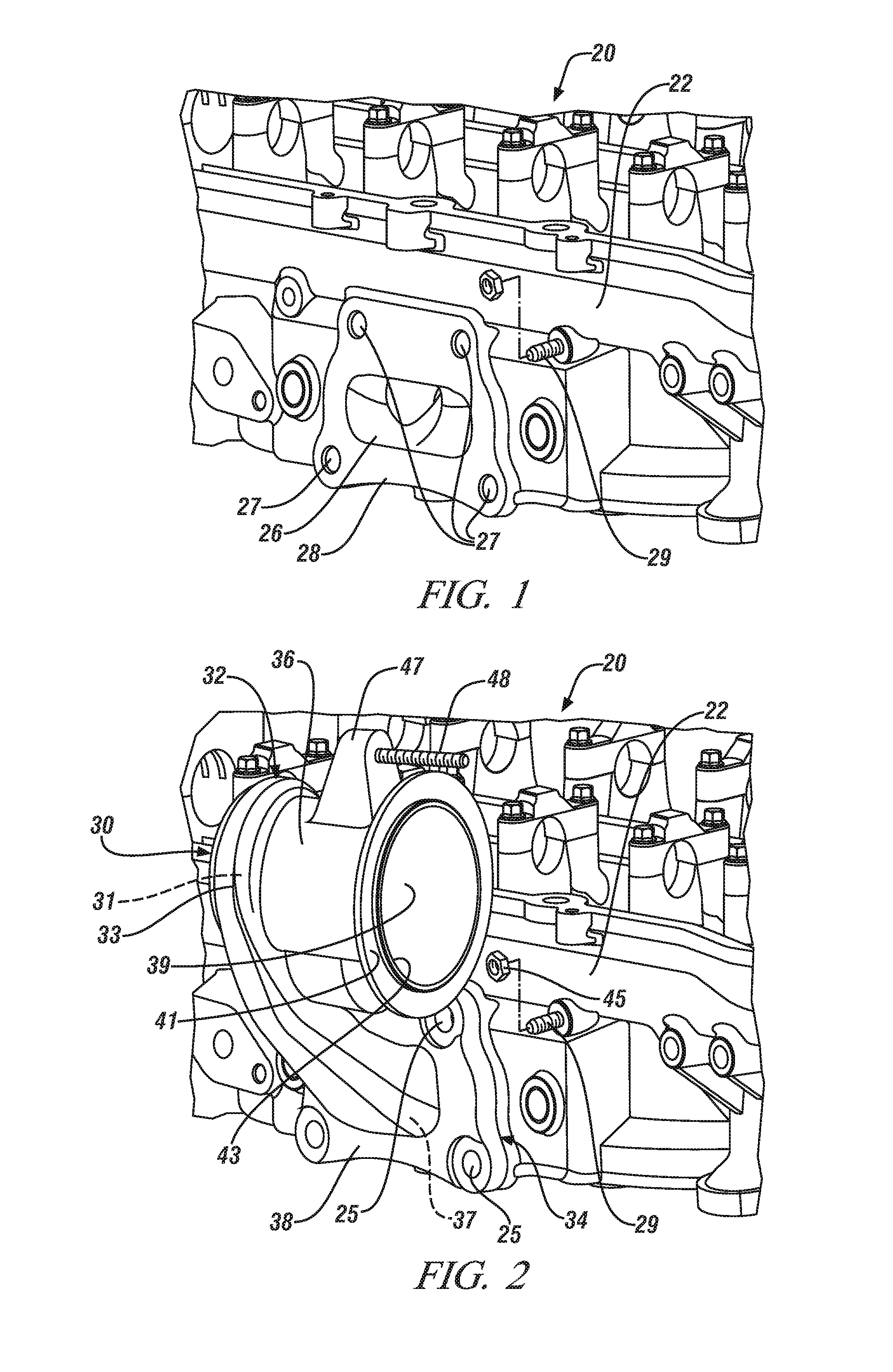

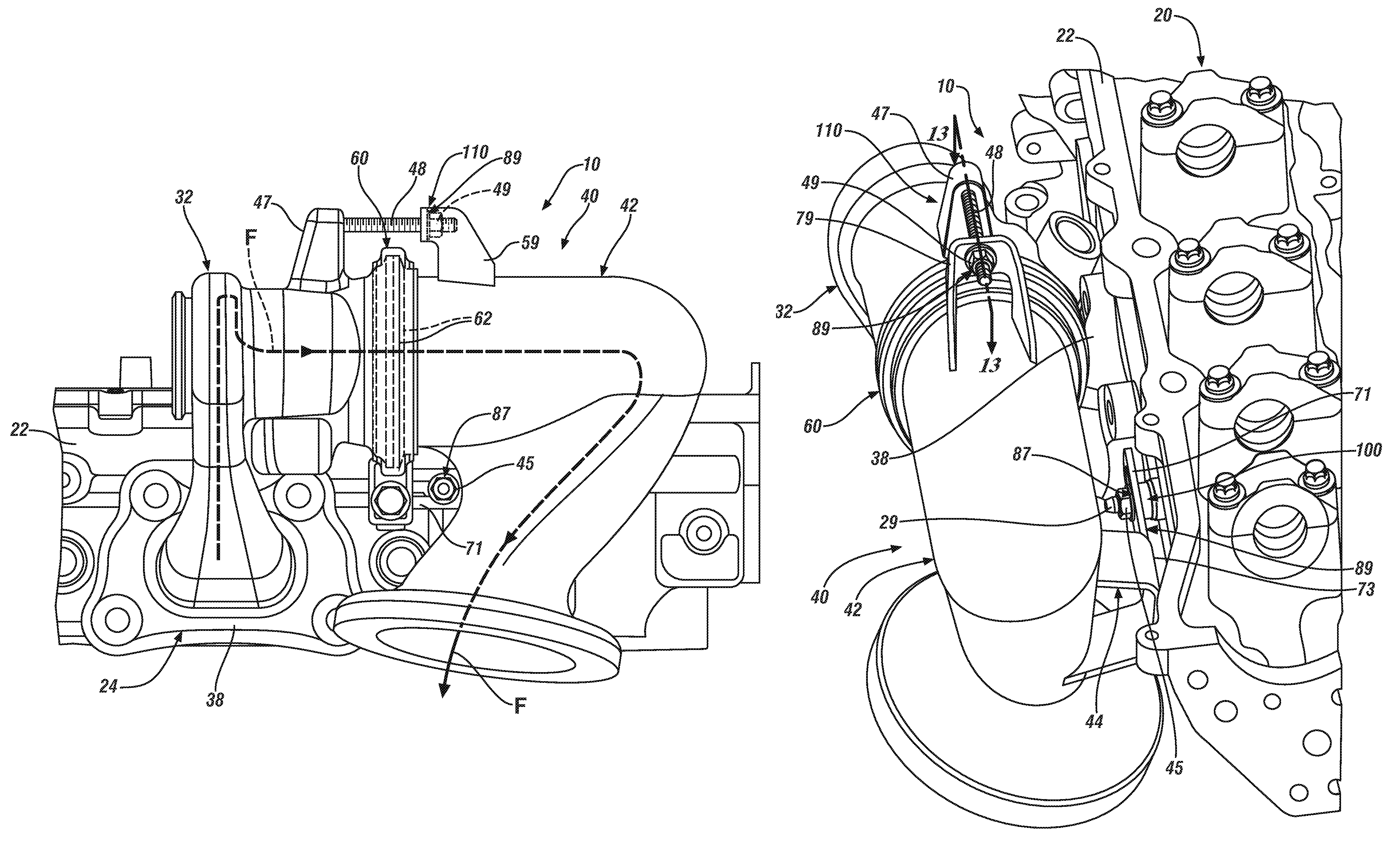

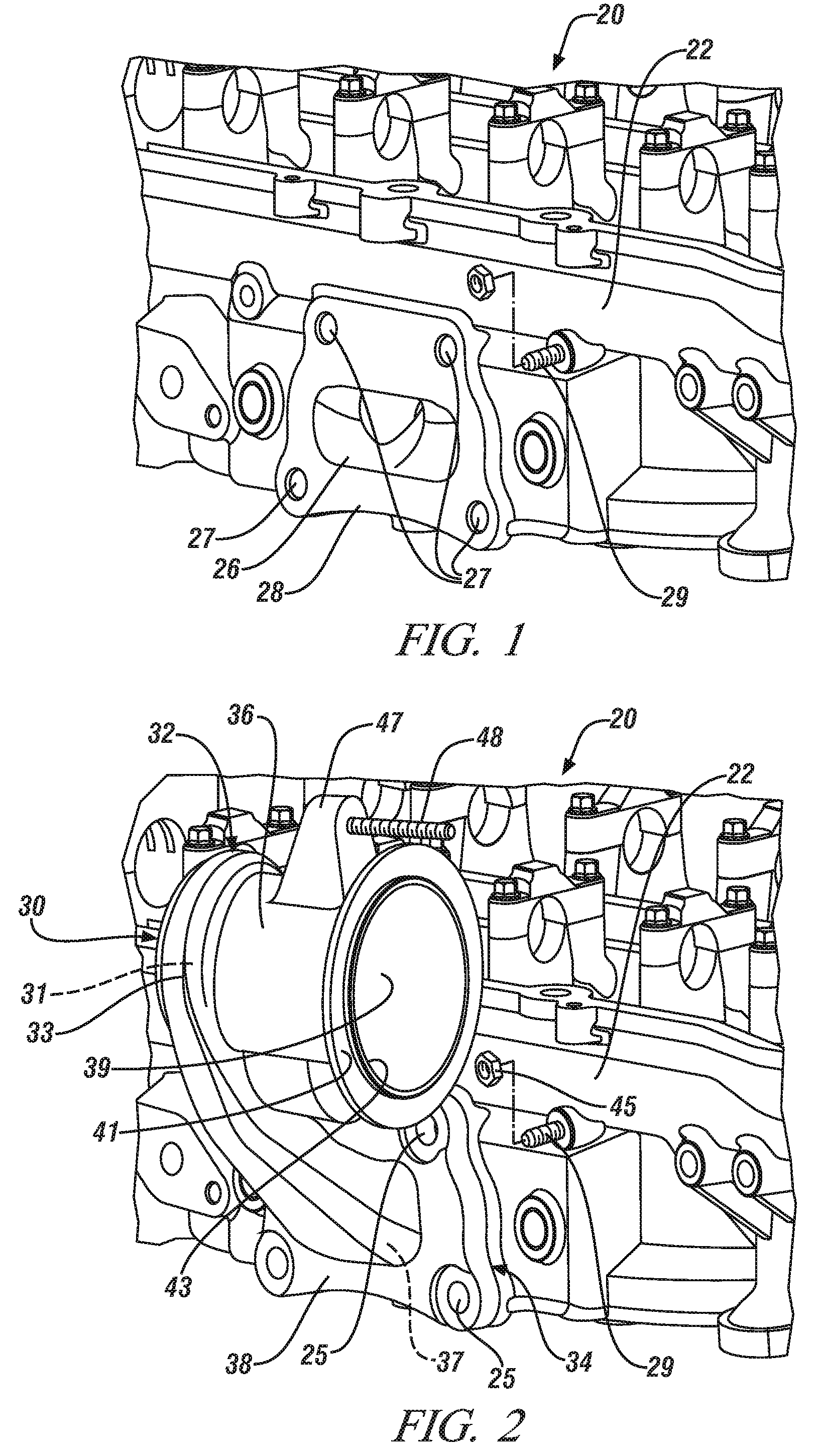

Engine assembly and method of making

An engine assembly comprising a cylinder head, turbocharger in fluid communication with the cylinder head and exhaust conduit in fluid communication with the turbocharger and method of making the assembly using a single human assembler includes: mounting the turbine to the cylinder head; using a first assembly aid to form a slidable joint between the exhaust conduit and head; using a second assembly aid to form a movable joint between the turbine and exhaust conduit and align the turbine outlet flange and exhaust conduit inlet flange; using a third assembly aid to pilotingly engage the flanges; disposing a clamp about the turbine outlet flange and the exhaust conduit inlet flange; tightening the second assembly aid sufficiently to form an immovable joint; tightening the clamp to form a sealed joint between the flanges; and tightening the first assembly aid to form a fixed joint.

Owner:GM GLOBAL TECH OPERATIONS LLC

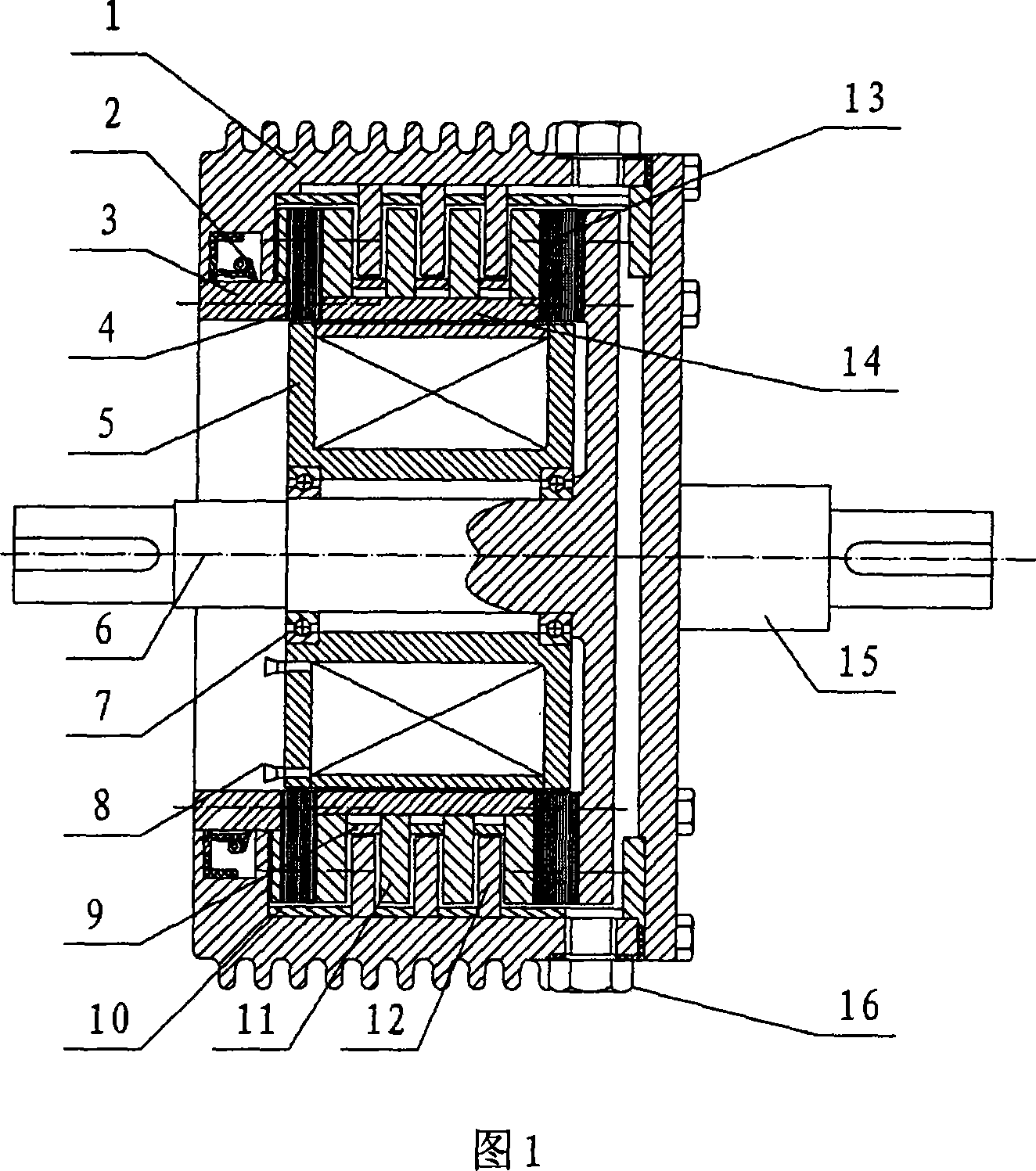

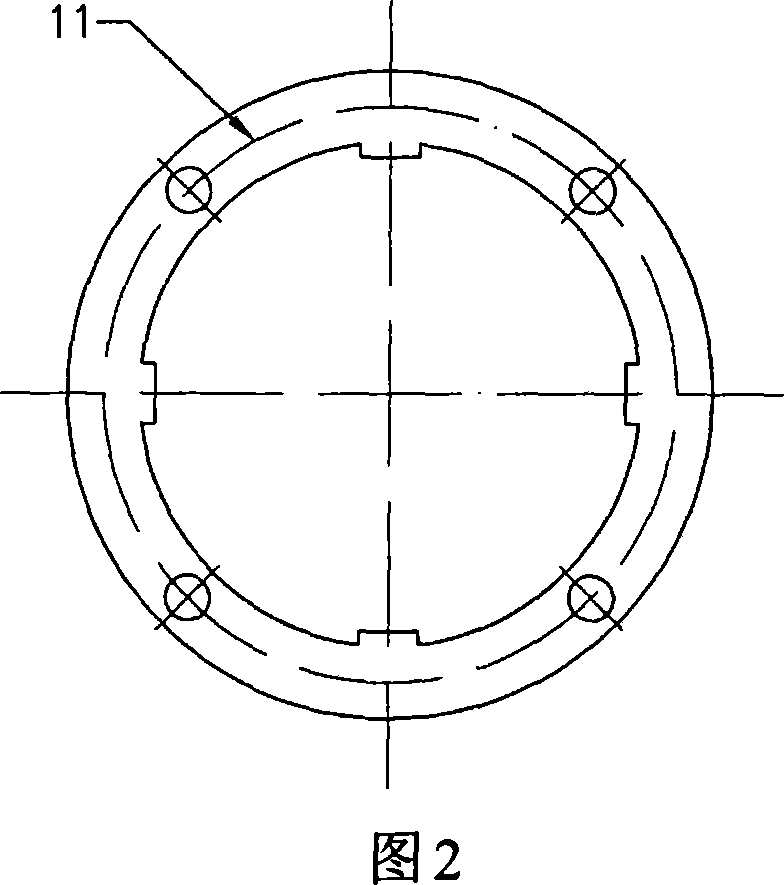

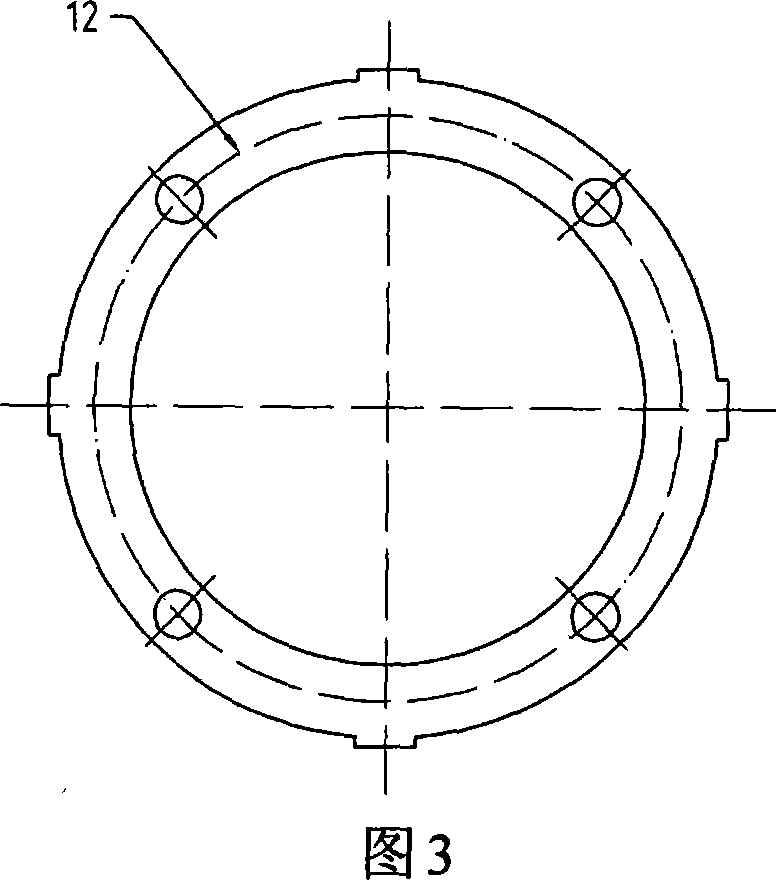

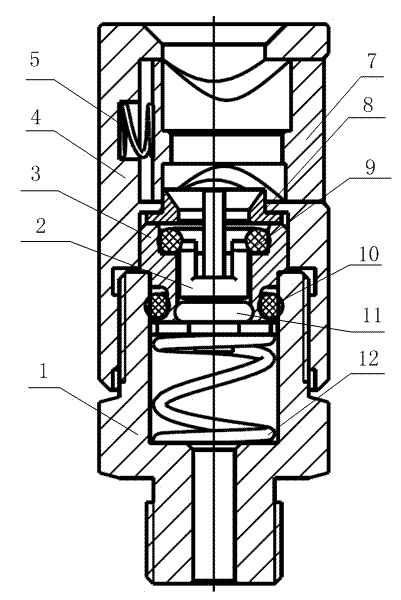

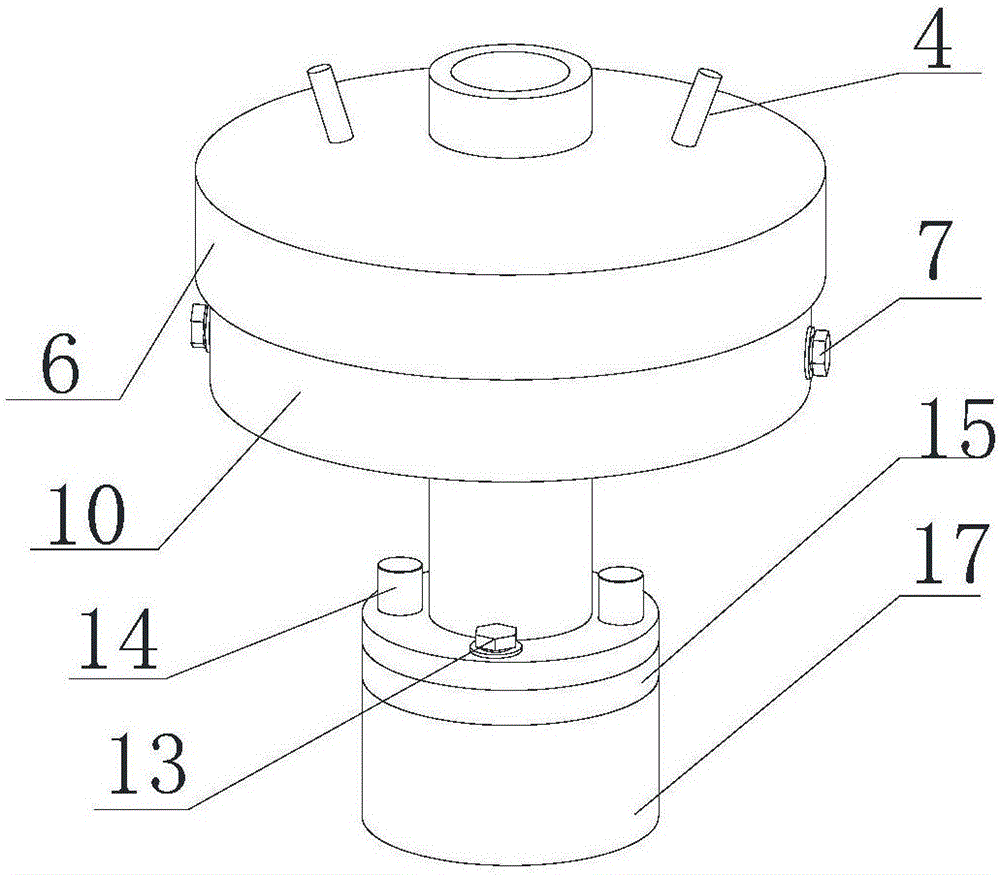

Magnetic rheological hydraulic flexible starter

A kind of magnetic-current liquescent soft startup device, including ring flange which integrates with drive shaft, ring flange connects on the shell, and drive shaft is set up in the shell, field electric coil is set up on the drive shaft, outside the field electric coil magnetism insulation ring and inside retainer on which inside friction disks are set interval are set up orderly, flux rings are set up on both ends right-and-left of the magnetism insulation ring and inside retainer. Outside retainers are set up on the shell inner circle, and on the outside retainers inside friction disks are set working in the inside friction disks, space is set aside to fill in magneto fluid used as power delivery mediator. In the shell, lock ring and packing gland are set up on one side of the left flux rings and the right flux rings are fixed joint with ring flange of the drive shaft. This invention eliminates of heat by fans through its circumrotating, it has simple structure, small volume, big delivery moment of force, perfect elimination of heat nature, high efficiency of elimination of heat, long operating life and broad practicability.

Owner:CHINA UNIV OF MINING & TECH

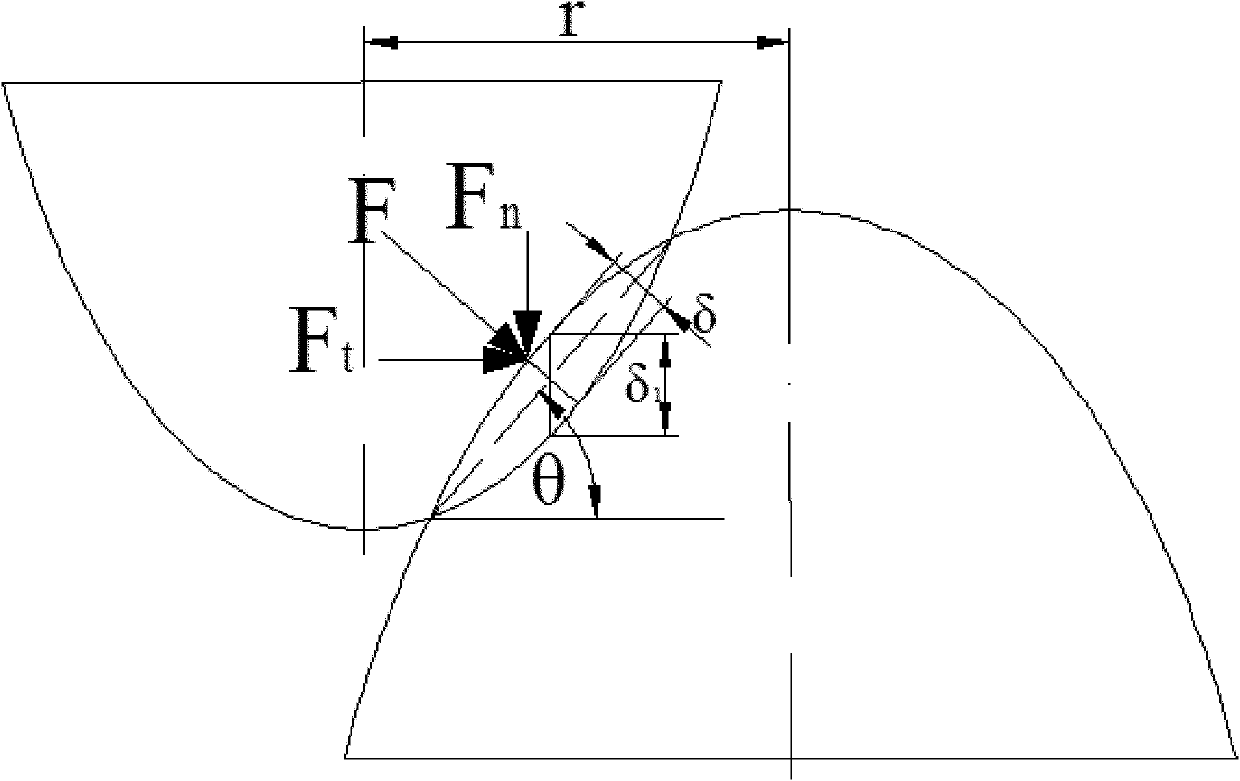

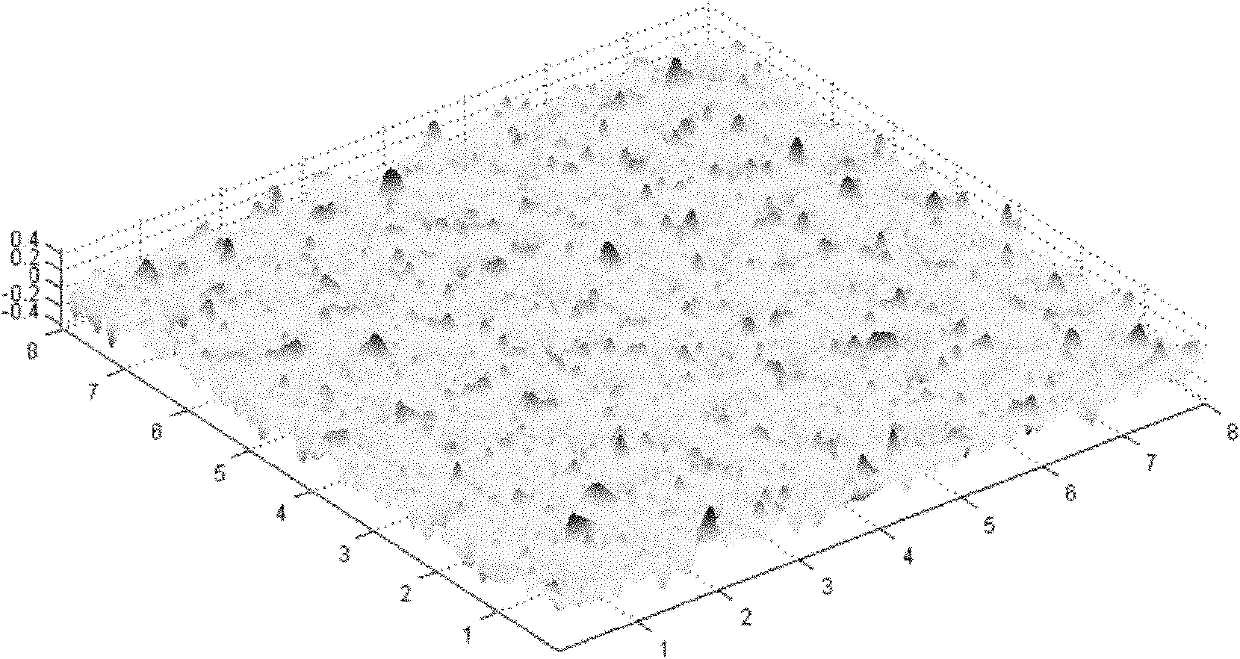

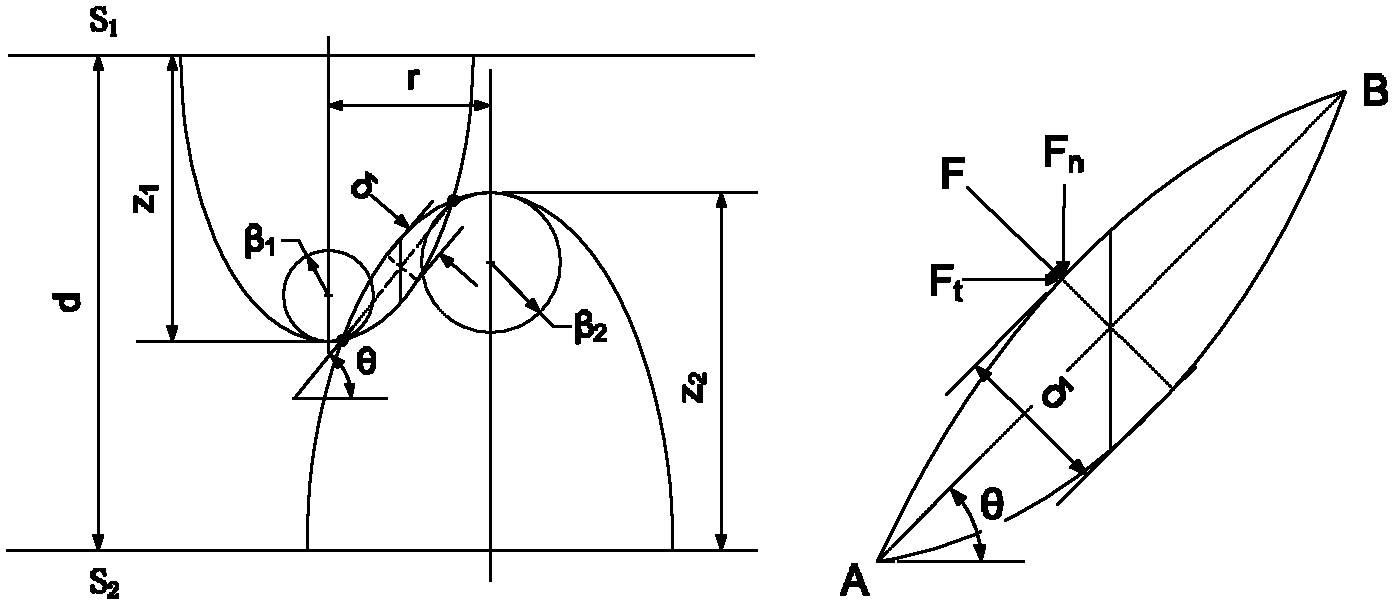

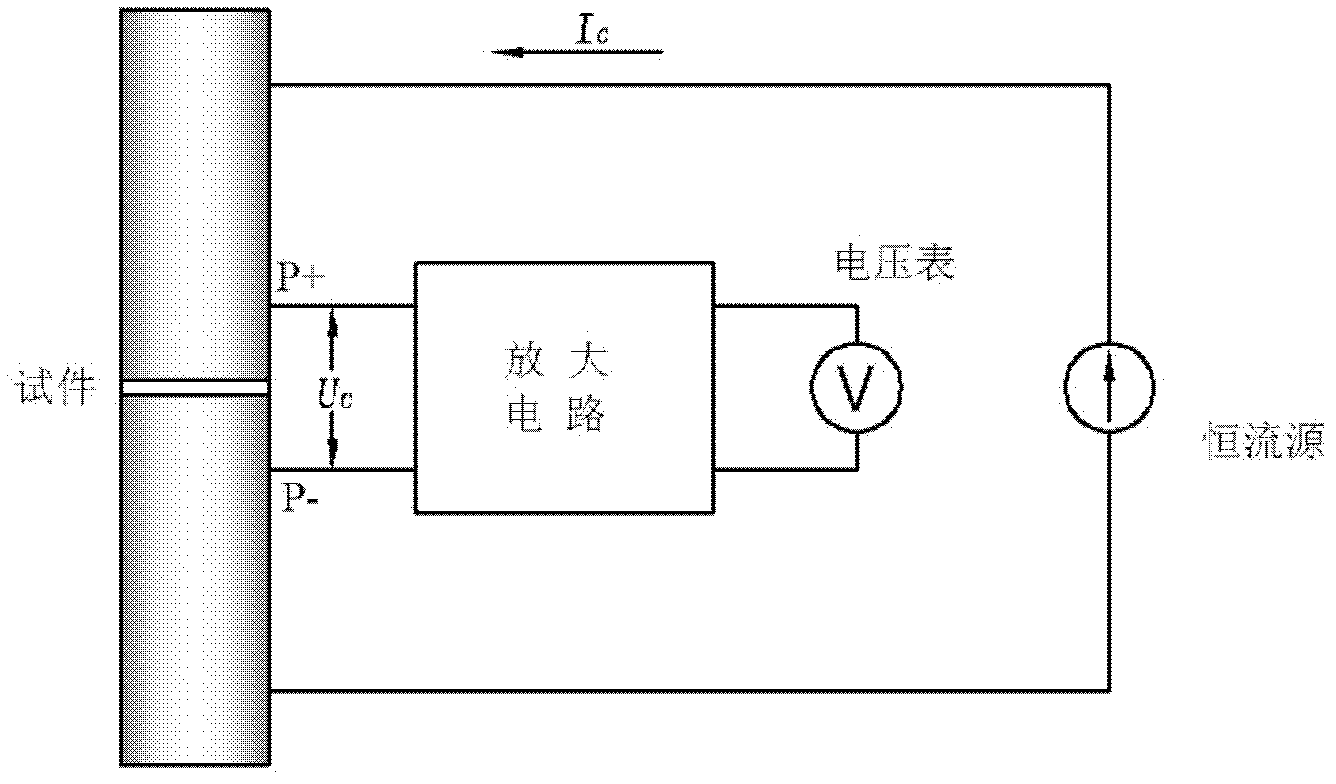

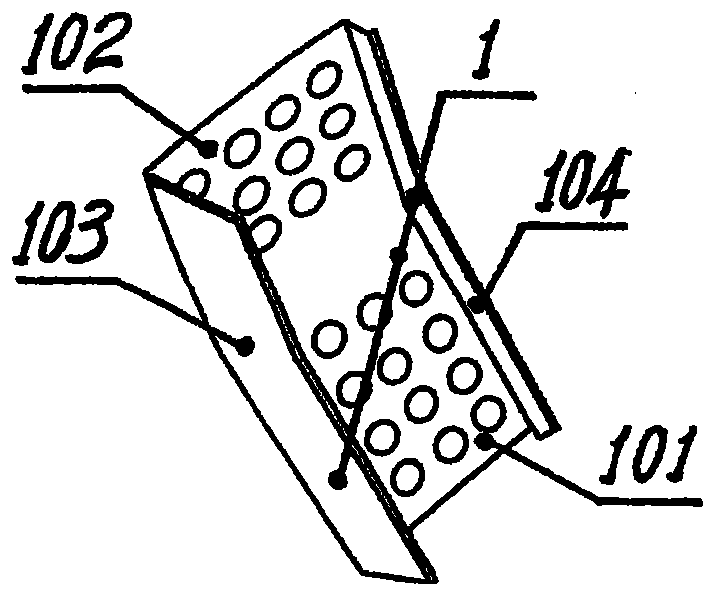

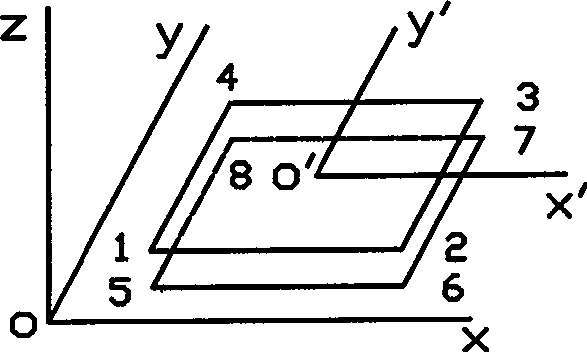

Method for determining normal contact rigidity of fixed joint faces

ActiveCN102176218AImprove objectivitySpecial data processing applicationsEntire jointSurface pressure

The invention discloses a method for determining normal contact rigidity of fixed joint faces. The method comprises the following steps of: calculating the normal static rigidity of small local joint faces, establishing contact surfaces and fitting a characteristic parameter matrix of micro convex bodies, establishing the contact rigidity expression kn of a single pair of the micro convex bodies, and obtaining the normal contact rigidity Kn of the joint faces and the normal contact rigidity Ktot of the entire joint faces, wherein Kn is equal to the summation of kn, and Ktot is equal to the binary integral of KP(P(x,y))dxdy. By means of the method, the contact information among the micro convex bodies can be learned visually, and the influence of uneven surface pressure distribution caused by errors in external waviness or shapes on the normal contact rigidity of the joint faces can be considered.

Owner:XI AN JIAOTONG UNIV +1

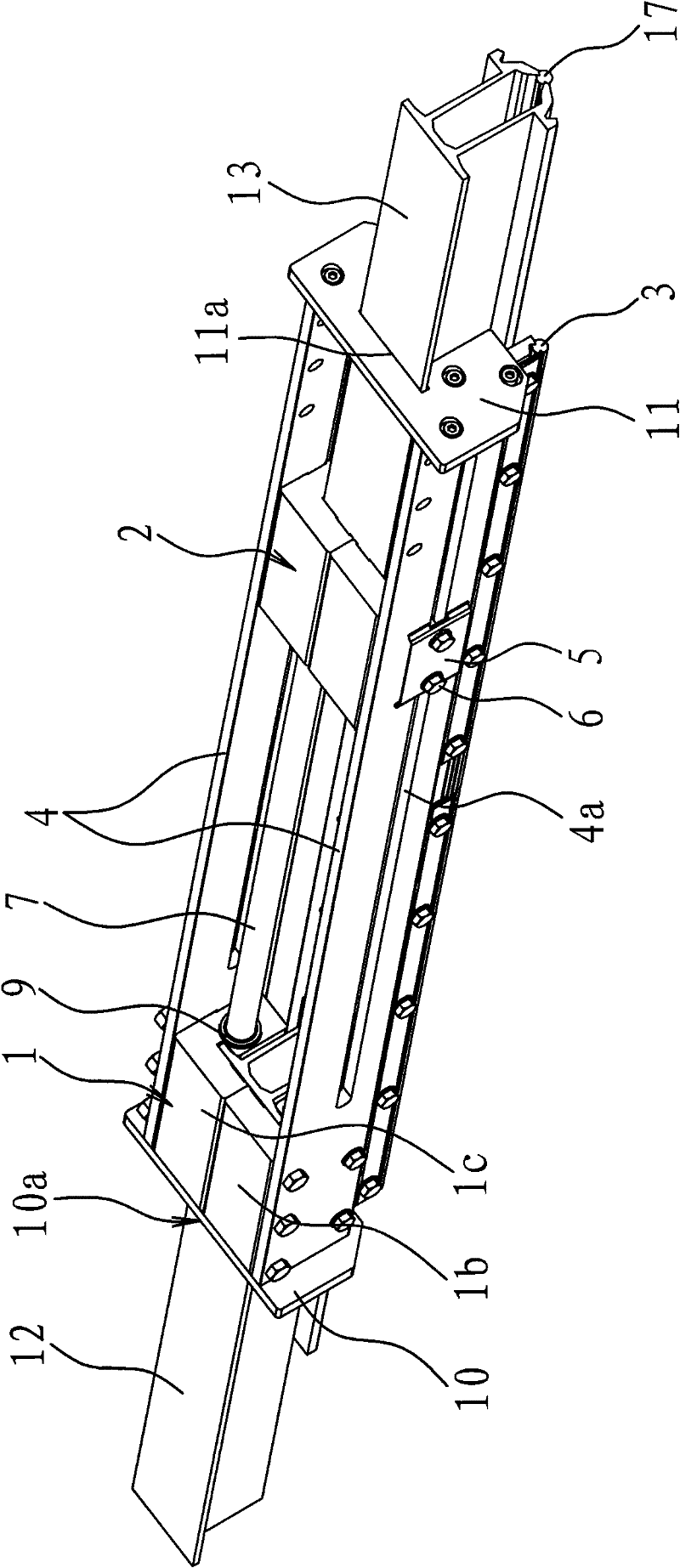

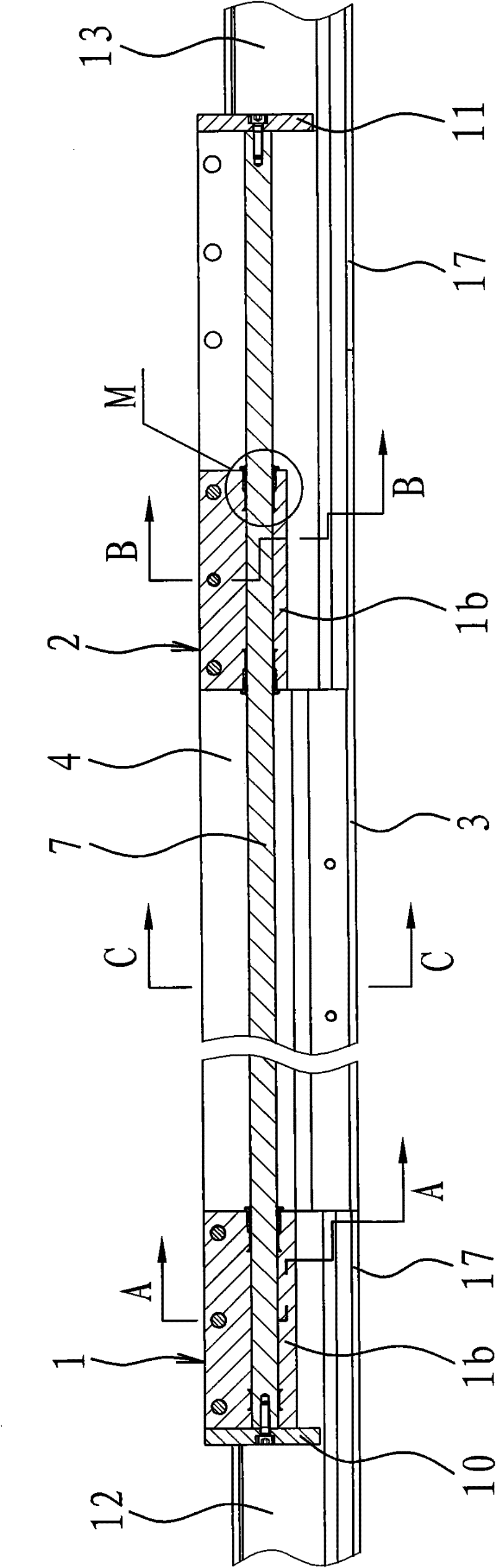

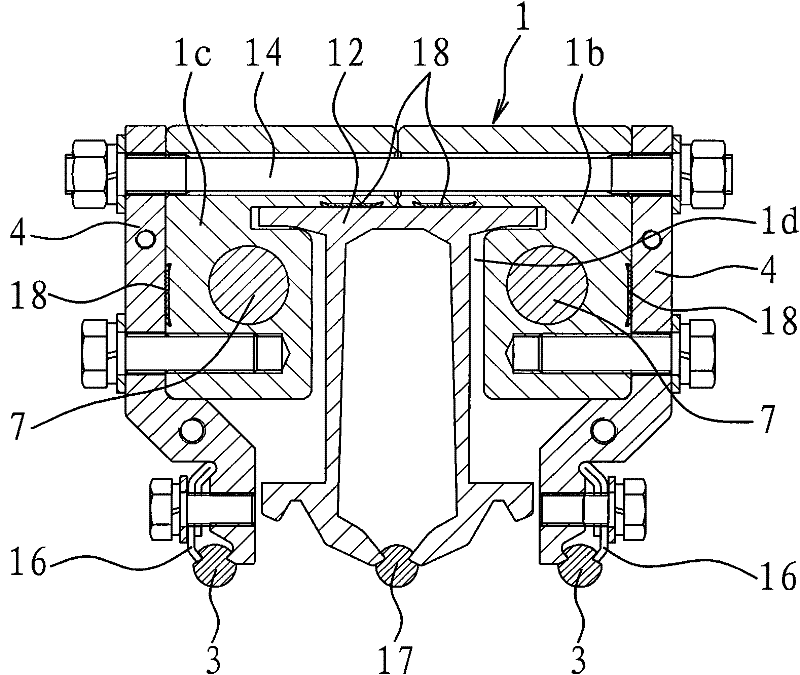

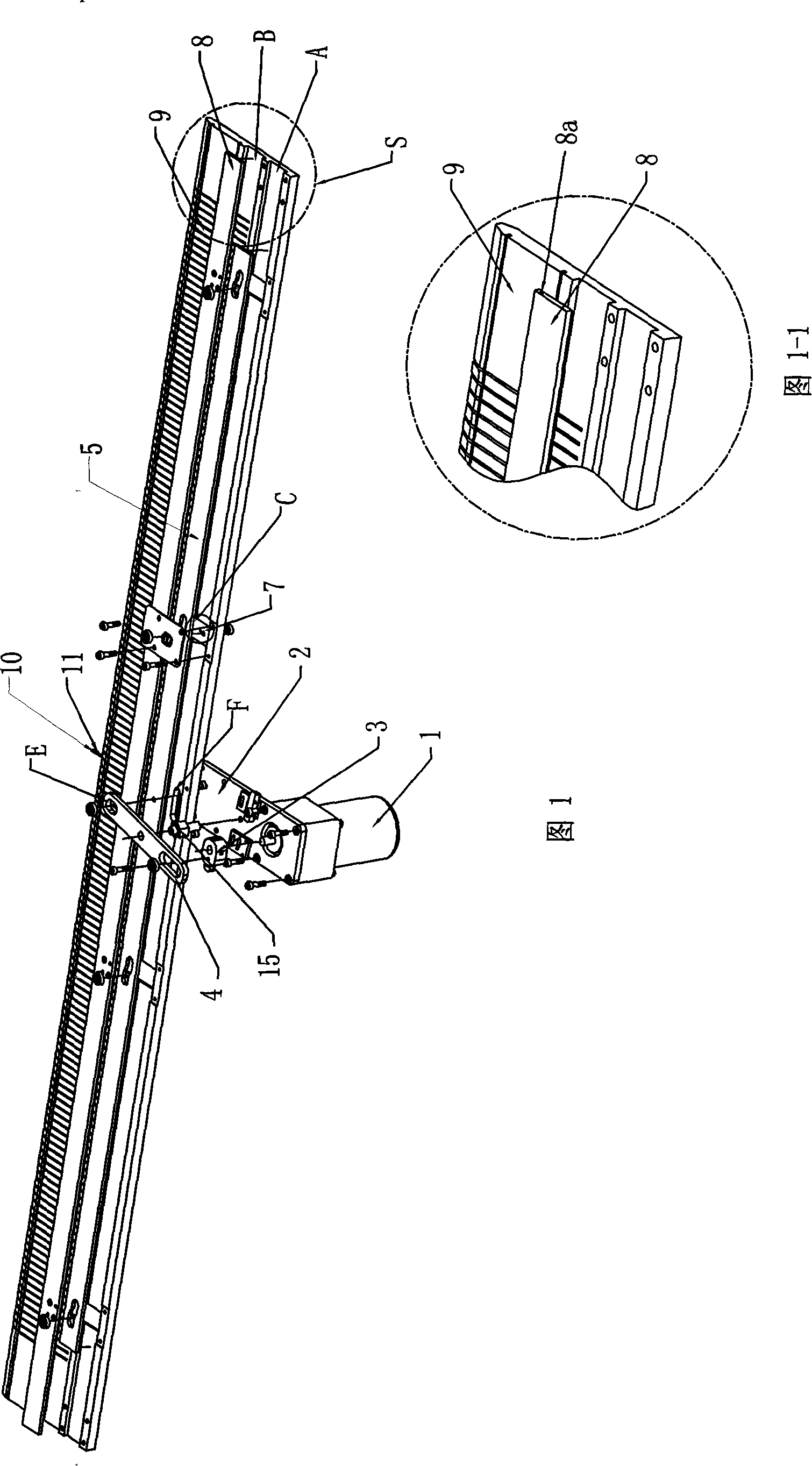

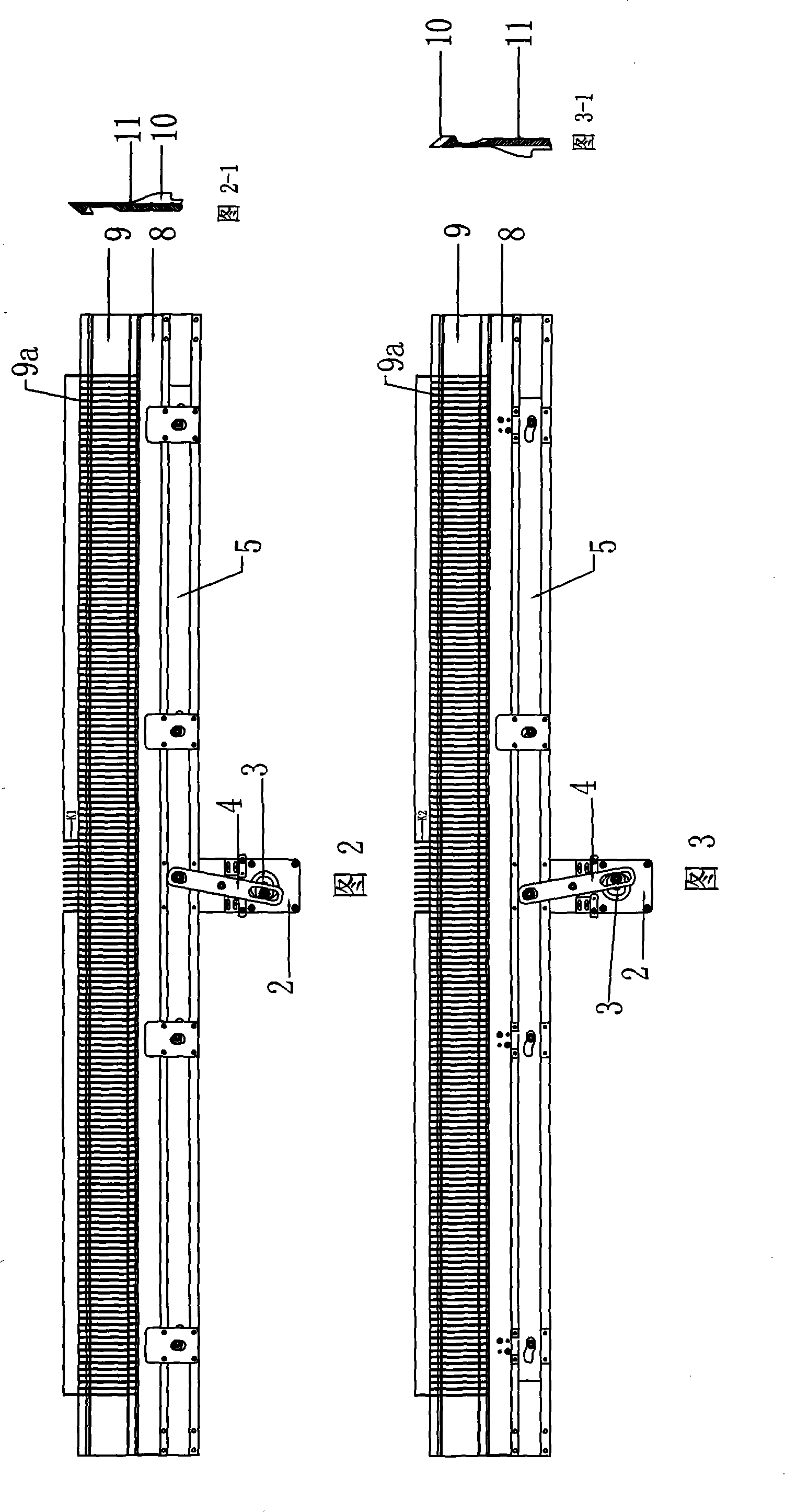

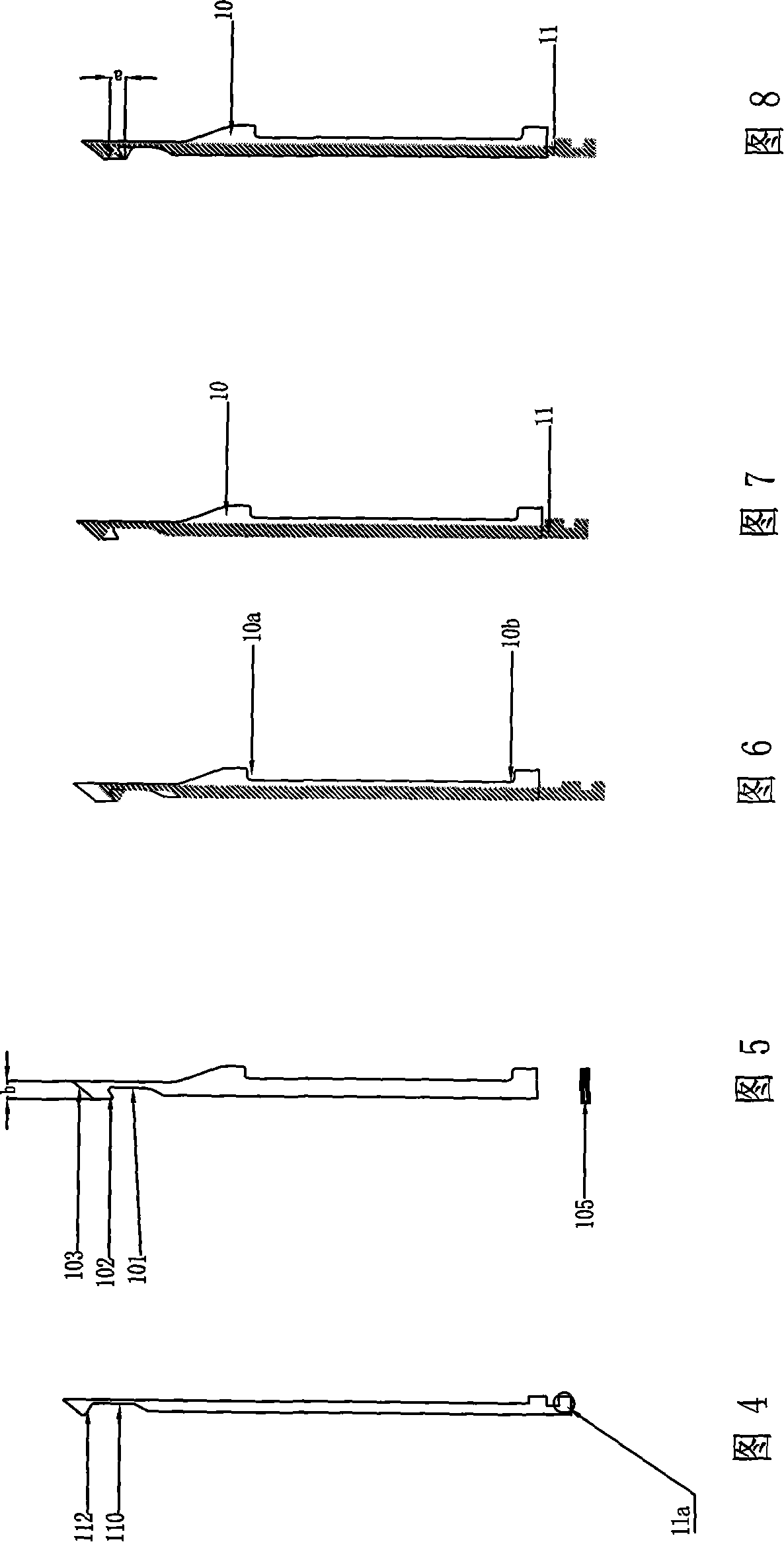

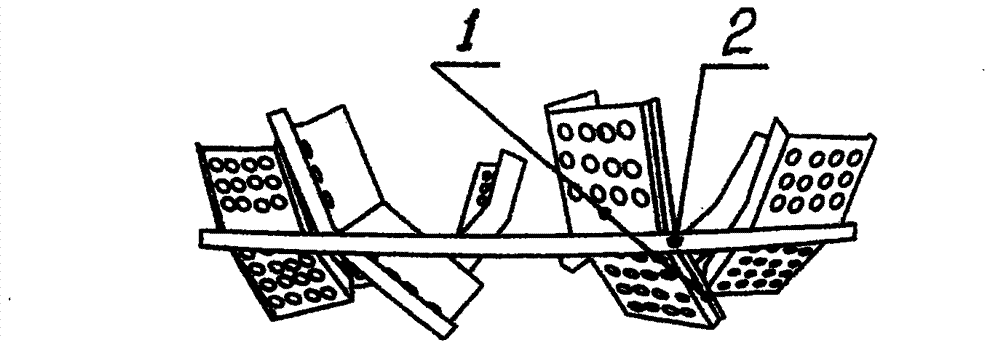

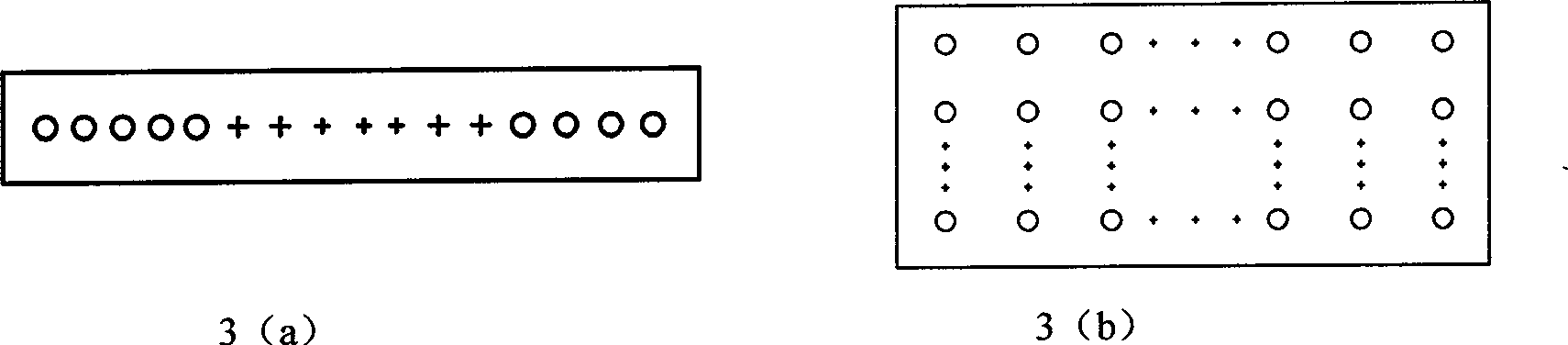

Rigid contact net expansion joint

The invention provides a rigid contact net expansion joint, which belongs to the field of rail transit equipment and solves the problems that the existing expansion joint has low compensation amount to cause high total manufacturing cost and the like. The rigid contact net expansion joint is arranged between two bus bars. The rigid contact net expansion joint is characterized by comprising a fixed joint and a movable joint which can conduct electricity; the fixed joint and the movable joint are used for fixing with the connecting end of one of the bus bars respectively; a guide piece with electric conductivity for connecting the fixed joint and the movable joint is arranged between the fixed joint and the movable joint; the fixed joint is fixed with the guide piece; the movable joint can move along with the guide piece; and a contact line 1 for transmitting current to an electric system of a train is fixedly arranged on the guide piece. The rigid contact net expansion joint is a plug-in expansion joint, and the adjacent two bus bars and the expansion joint are arranged on the same straight line, so the expansion joint is favorable for improving the utilization rate of the bus bars, equivalently improving the length of an anchorage section, and has large compensation amount.

Owner:浙江旺隆轨道交通设备有限公司

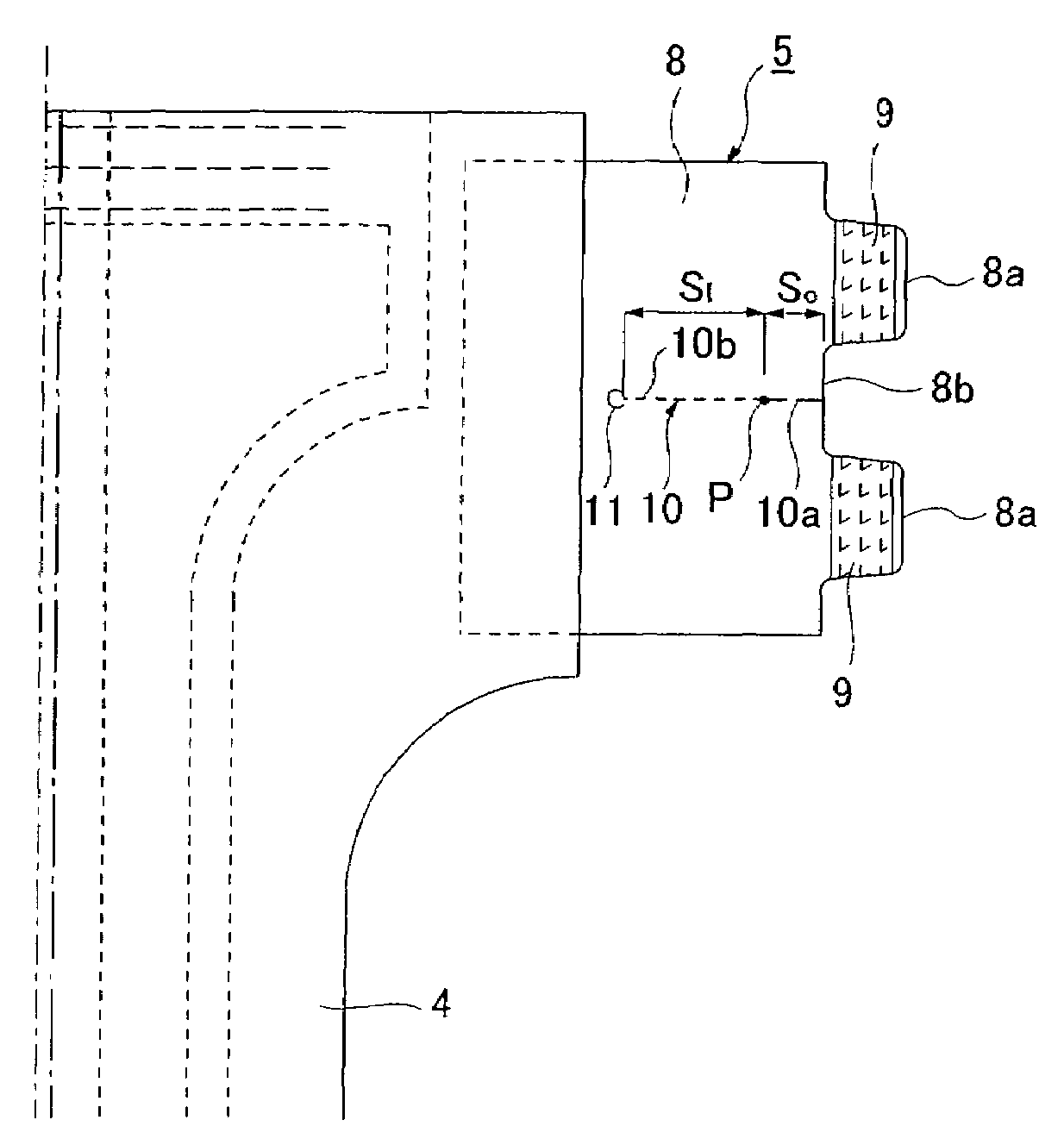

Disposable diaper having fastening sheets with perforated tear lines

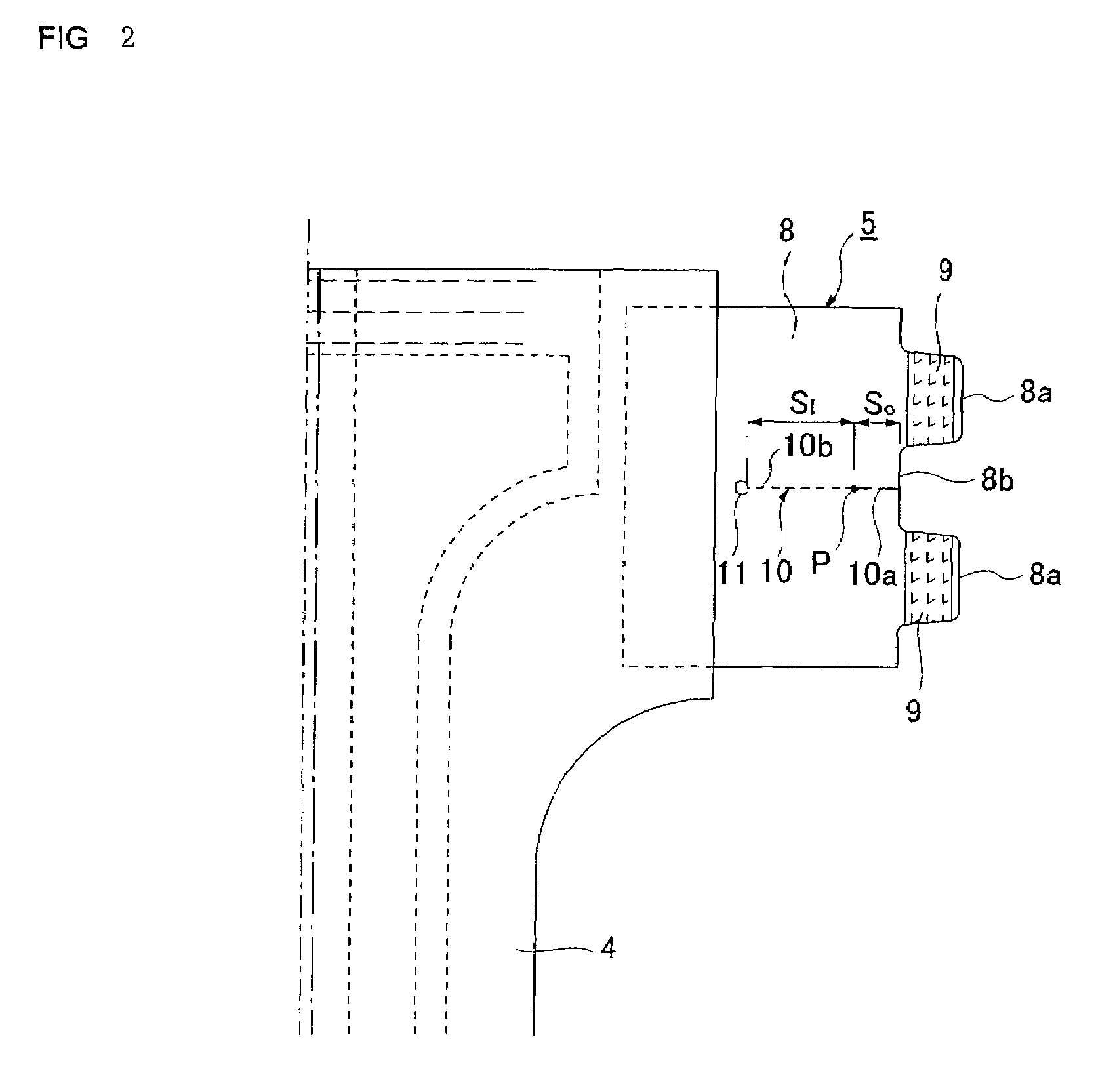

A disposable diaper, which has fastening sheets on two side portions of a back side and which can be used with an ordinary fastening method but also a cross fastening method. The diaper has fastening sheets individually formed on the two side portions of the back side of the diaper and each including: joint ears formed to extend from outer side edges of each one of the sheets and to protrude sideward at two upper and lower stages; and facing fasteners disposed on inner sides of said joint ears, whereby the disposable paper diaper is worn on a body by fixing joint ears on a surface of an abdomen side of the diaper. Perforations leading from an outer side edge to an inner side are formed in a portion of the fastening base sheet between the joint ears. In perforations, a first perforation section extends from the outer side edge to an intermediate point P is a high tearing strength section S0 having a relatively coarse perforation interval, and a second perforation section from intermediate point P to an inner end is a low tearing strength section S1 having a relatively fine perforation interval.

Owner:DAIO PAPER CORP

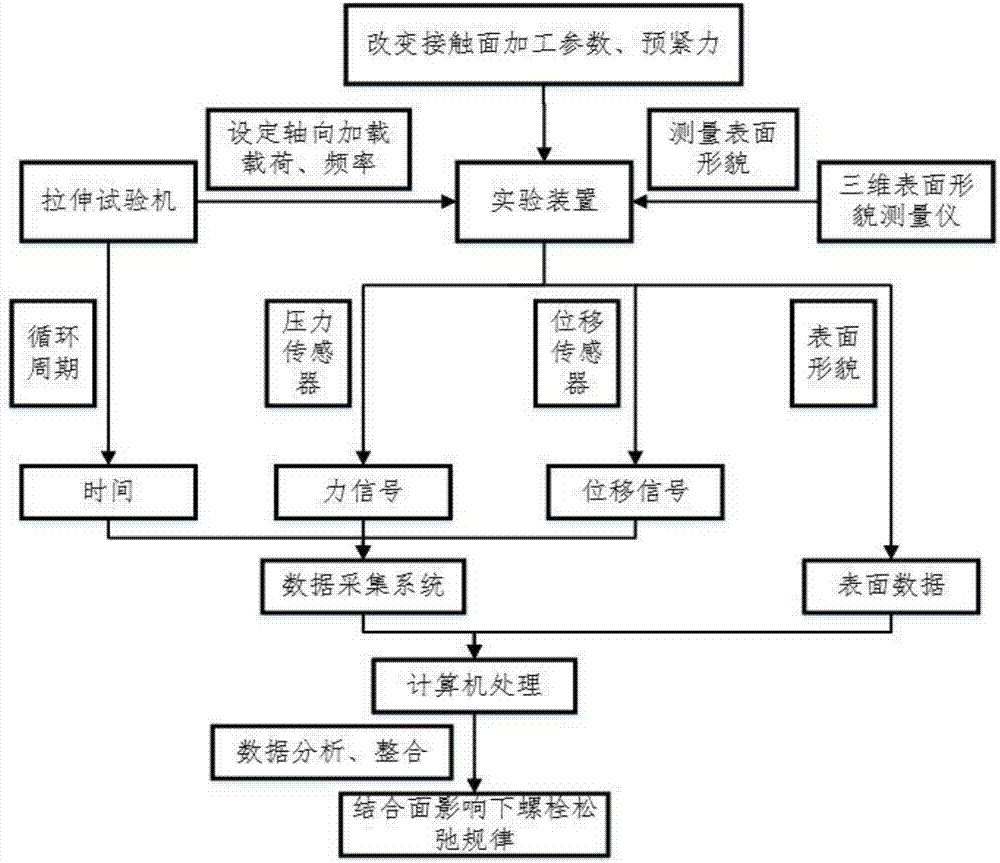

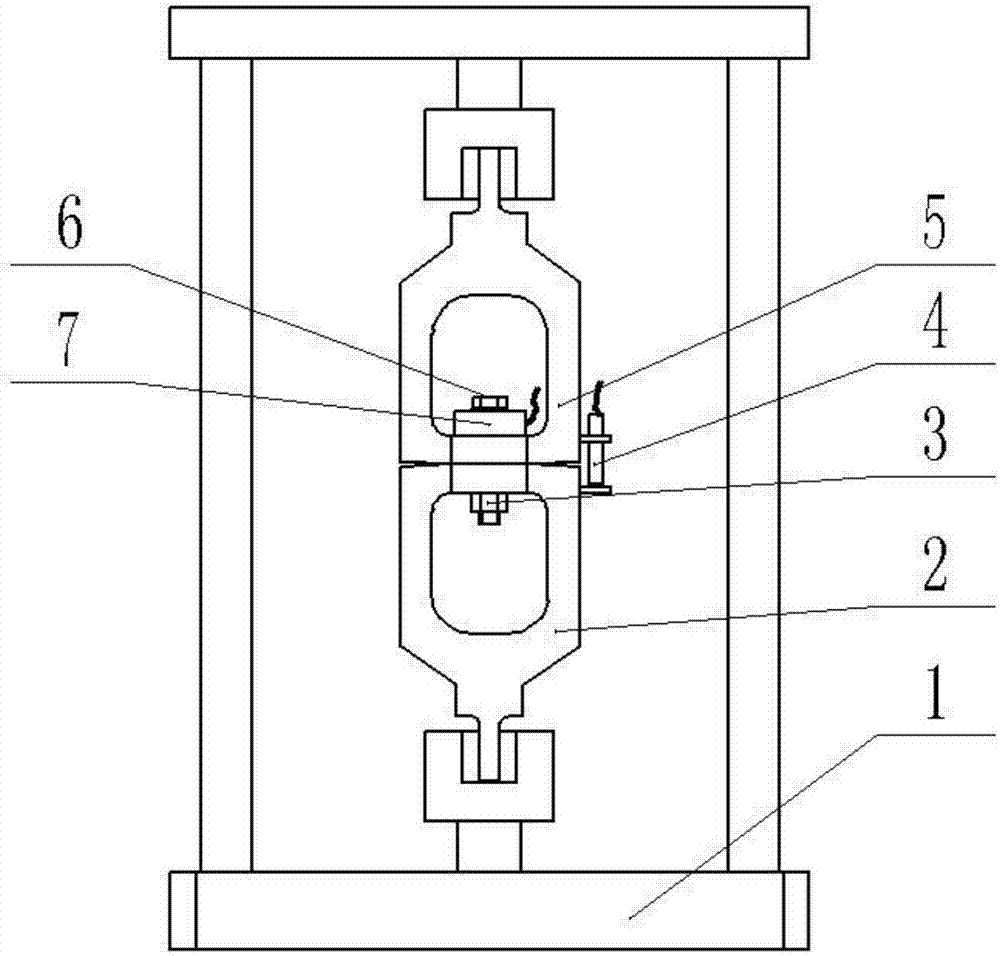

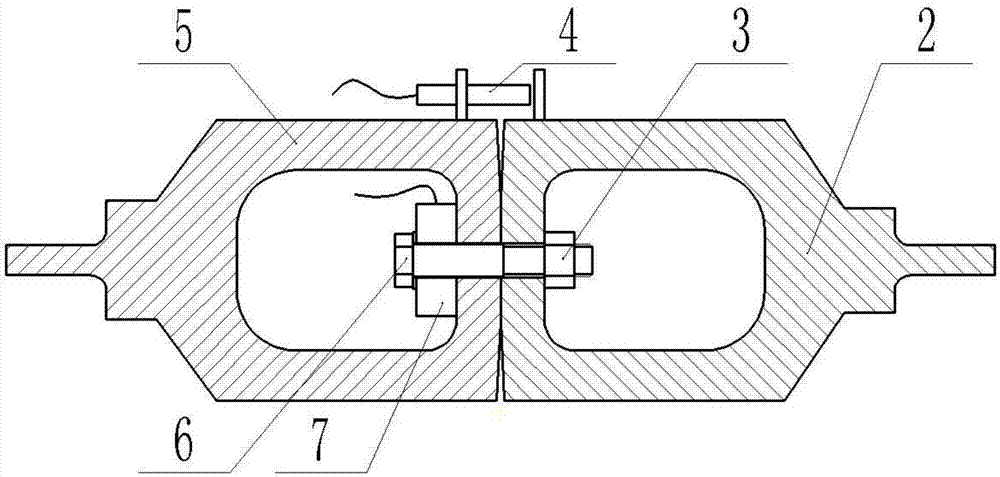

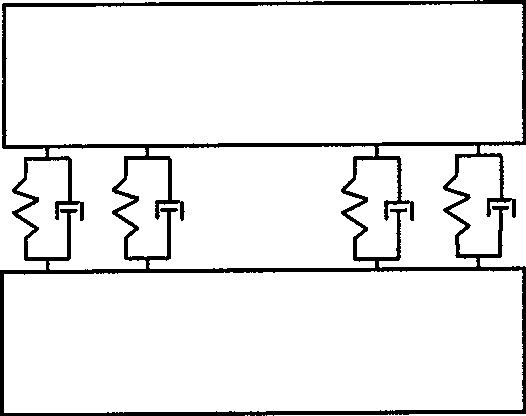

Device and method used for measuring axial bolt relaxation in consideration of joint surface characteristics

InactiveCN107192494AMeet the rigidity requirementsGuaranteed accuracyMeasurement of torque/twisting force while tighteningAxial displacementData acquisition

The invention discloses a device and method used for measuring axial bolt relaxation in consideration of joint surface characteristics, which belongs to the field of mechanical manufacturing and structural mechanics. A bolt bar passes through upper and lower connectors, and contact surfaces have specific size and surface data. A pressure sensor is used to measure the attenuation of the bolt clamping force. An eddy current displacement sensor is used to measure displacement between the contact surfaces. Three-dimensional topography scanning is used to measure the surface three-dimensional data. A tensile testing machine is used to carry out cyclic tensile test and simulate the bolt conditions. The axial clamping force and axial displacement are transmitted to a computer for recording and processing through a data acquisition system. Axial bolt relaxation characteristics are acquired by analysis and processing several kinds of data. According to the invention, the connection characteristic of an axial part is ensured; the influence of a fixed joint surface on bolt relaxation is considered; and the bolt relaxation test precision is improved.

Owner:BEIJING UNIV OF TECH

Bottom rising device of knitting horizontal machine

The invention relates to a lifting device of a flat knitting machine, which comprises a lifting plate, a driving device and a starting needle. The starting needle is installed on the lifting plate and driven by the driving device to move. Composed of rods, the yarn withdrawal rod is a slender sheet, and the crochet needle has a transparent groove in its longitudinal direction, which is matched with the yarn withdrawal rod. The yarn withdrawal rod is placed in the longitudinal groove of the hook needle and can slide up and down in the groove. The lower end of the crochet needle has a joint that fixes it on the bottom plate, and the lower end of the yarn withdrawal rod has a joint that fixes it with the yarn withdrawal lifting device; the hook and the yarn withdrawal rod have notches in the same direction at their front ends, The notch is composed of at least two surfaces; the surface near the notch at the top of the crochet hook is in the shape of an upward slope; and the surface near the notch at the top of the yarn withdrawal rod is hook-shaped; it has a simple structure, is easy to install, and reduces the number of threads Waste, improve work efficiency.

Owner:NINGBO CIXING

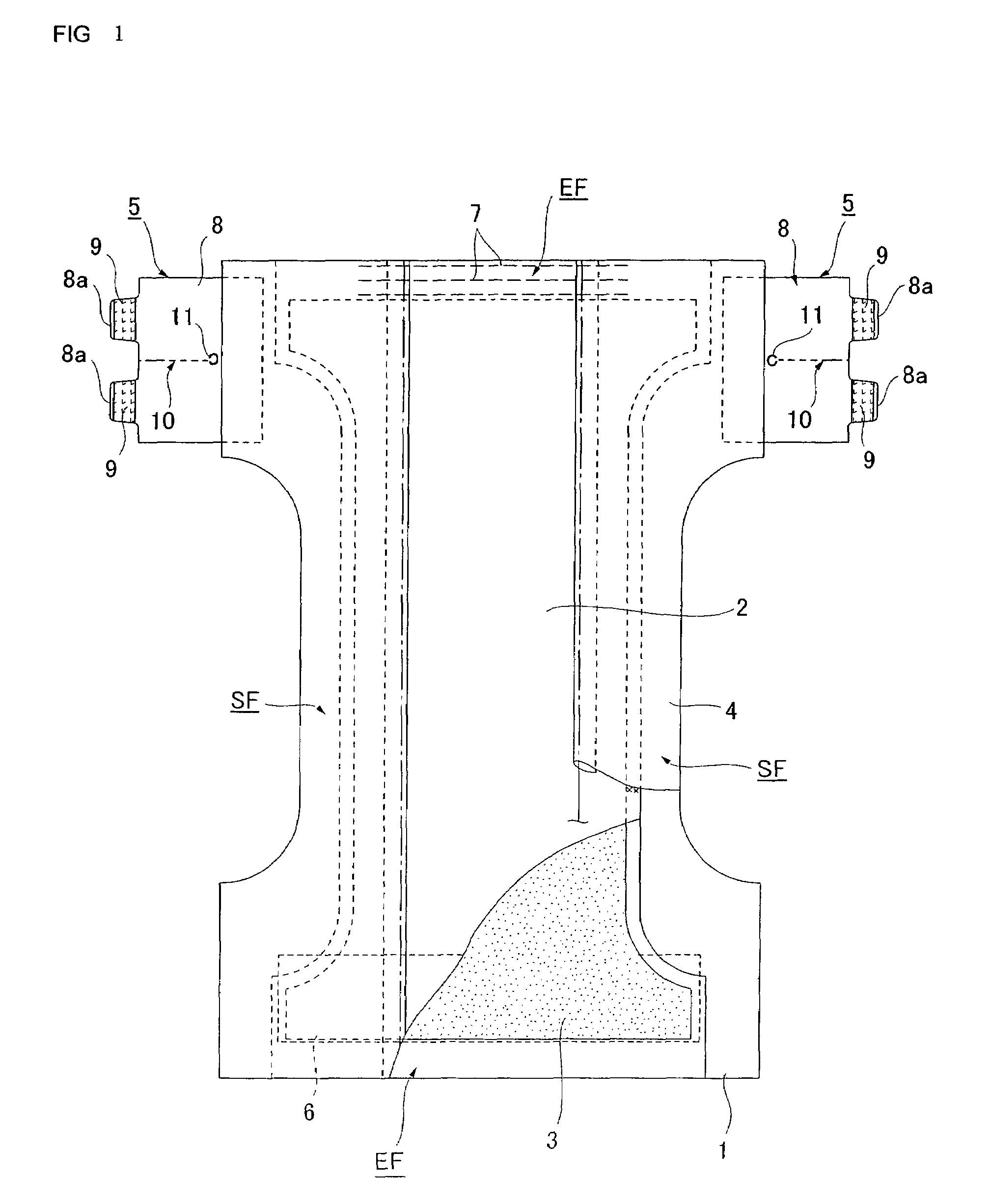

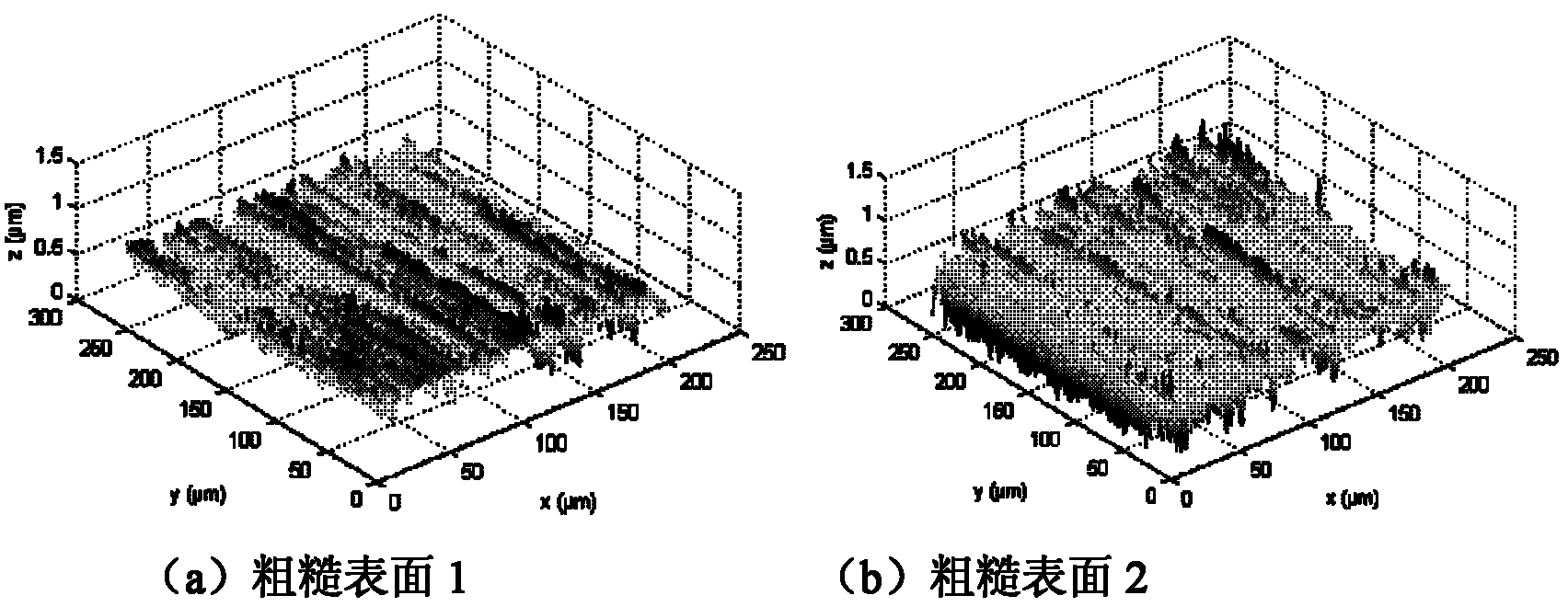

Method for determining normal contact stiffness of fixed joint surface

InactiveCN102608167AOvercome costsImprove objectivityMaterial resistanceElectrical resistance and conductanceMicroscopic scale

The invention provides a new method for indirectly obtaining normal contact stiffness of joint surface according to theoretical calculation and experimental test under the condition that the contact resistance ratio of the fixed joint surface is measured more easily than the normal contact stiffness. Relationship between joint surface contact resistance RC and normal contact stiffness Ktot is established by measurement and aftertreatment for micro appearance of contact surface. Firstly, an expression of the joint surface contact resistance RC is established; then the expression of normal contact stiffness Ktot is established; at the last, the relationship between the joint surface contact resistance RC and the normal contact stiffness Ktot is established. According to the invention, the method overcomes the defect that the normal contact stiffness is measured difficultly; the method considers elasto-plastic contact of two coarse surfaces, and further considers the more comprehensive, accurate actual surface appearance information.

Owner:XI AN JIAOTONG UNIV

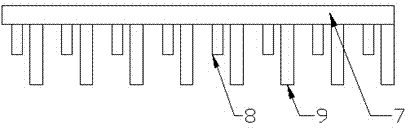

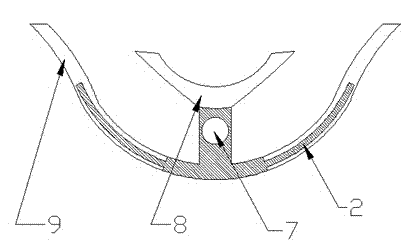

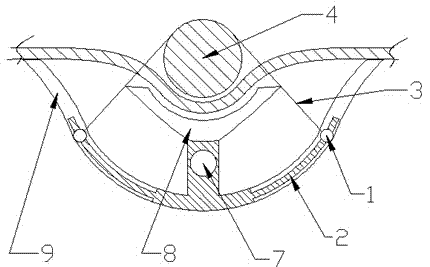

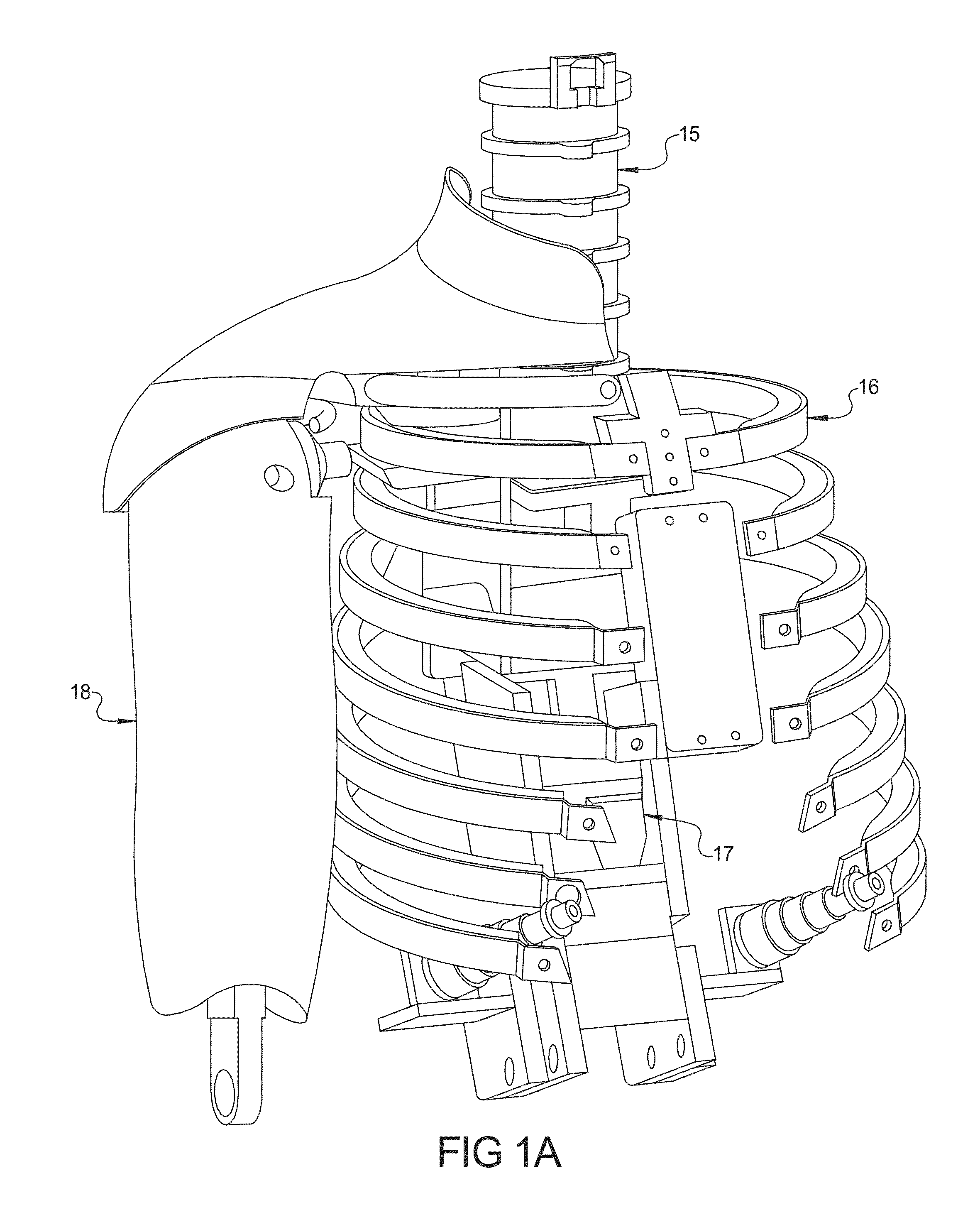

Vertebra fixator

InactiveCN104323843AGuaranteed fixed effectAchieve fixationInternal osteosythesisExternal osteosynthesisBraced frameSupport surface

The invention relates to a vertebra fixator, which comprises a connecting rod and at least two fixing sections, wherein each fixing section comprises an external vertebrate top frame, an external vertebra surface fixator and a supporter, the supporter is an arc-shaped unfolding surface, a plurality of hollow grooves vertical to the longitudinal axial line of the unfolding surface are formed in the unfolding surface of the arc surface, fixing rods are arranged in the hollow grooves, at least one fixing block is respectively arranged at each of two sides of each fixing rod, a fixing cable is arranged between the fixing blocks, an upright post is arranged in the middle part of the supporter, the external vertebrate top frame is arranged on the upright post and comprises an arc-shaped support surface coaxial with the unfolding surface of the supporter, a support framework used for fixing the vertebrate is defined between the arc-shaped support surface and the fixing cables arranged among the fixing joints, an installing hole parallel to the axial line of the arc-shaped support surface is arranged in the upright post of the supporter, and the supporter is connected through a connecting rod arranged in the installing hole.

Owner:THE FIRST PEOPLES HOSPITAL OF NANTONG

Slip Seal Diaphragm For Spring Brake Actuator

ActiveUS20100095836A1Providing longevityPreserve integrityEngine sealsFlexible wall reciprocating enginesEngineeringActuator

Owner:HALDEX BRAKE

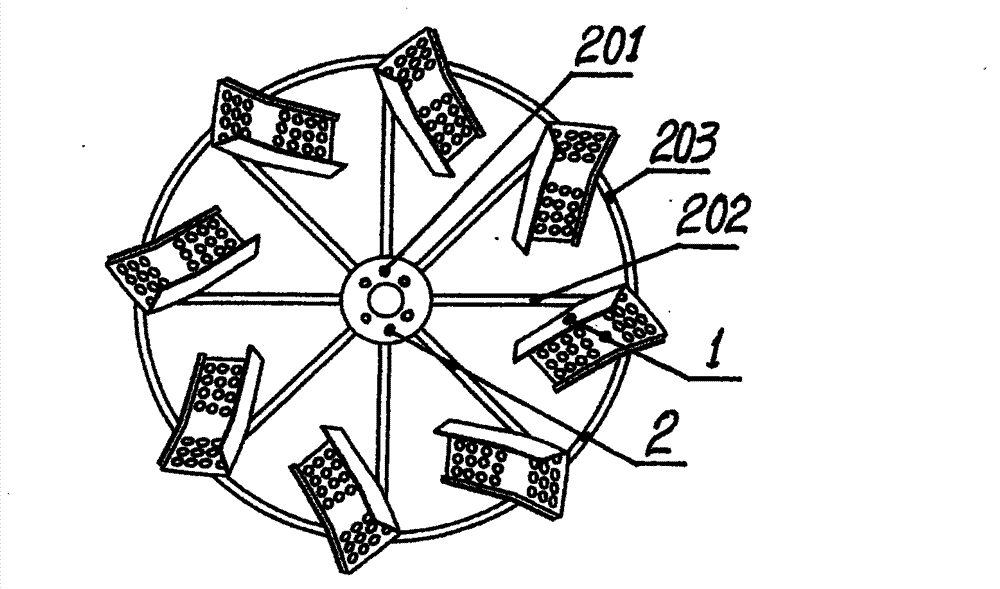

Frame type high efficiency impeller of impeller aerator

The invention relates to the machinery technical field and provides a frame type high efficiency impeller of an impeller aerator. A key technology that a circular ring frame is combined with angle set shovel-shaped or spoon-shaped blades with holes is adopted; angles which are formed between lower water shifting plates and upper water guiding plates are 90 to 160 degrees; the inner sides of the lower water shifting plates and the upper water guiding plates are provided with inner water guiding plates and the outer sides of the lower water shifting plates and the upper water guiding plates are provided with outer water guiding plates in a perpendicular mode to form the blades; the inner ends of radiation supports are fixed connected with a shaft disk and the outer ends of the radiation supports are fixedly connected with a circular ring to form a transmission connection plate; the plane which is formed by being close to the fixed joint of the outer ends of the radiation supports and the circular ring is fixedly connected with the lower water shifting plates to form 30 to 90 degrees of angles; meanwhile the radiation supports are fixedly connected with the inner water guiding plates to form 20 to 90 degrees of angles or angles in 90 to 135 degrees outward; shaft holes of the shaft disk are fixedly connected with power shafts. The frame type high efficiency impeller of the impeller aerator is used for performing aeration on a fish pond and is simple and reasonable in structure, long in service life, stable and reliable in effect, small in power, easy to manufacture and low in cost.

Owner:梁家明

Fixation joint part dynamics parameter identification method for machine tool

InactiveCN101458205ARich dynamic propertiesImprove recognition accuracyUsing mechanical meansStrength propertiesEngineeringUnit structure

The invention provides an identification method of dynamic parameters of a machine tool fixed joint part. The method comprises the following steps: taking a structural damping matrix of a joint part unit and a stiffness matrix of the joint part unit as parametric variables, setting the difference between the product of a displacement impedance matrix and a displacement frequency response function and a unit matrix to be minimum as an optimum design objective, and obtaining parameter variable values (i.e., the identified parameters of the joint part) through multiple iteration. The identification method takes damping and stiffness of multiple key freedom directions and the intercoupling relation into account to avoid a secondary error produced by matrix inversion, has high precision, and more accurately characterizes richer dynamic characteristics of the joint part.

Owner:HUAZHONG UNIV OF SCI & TECH

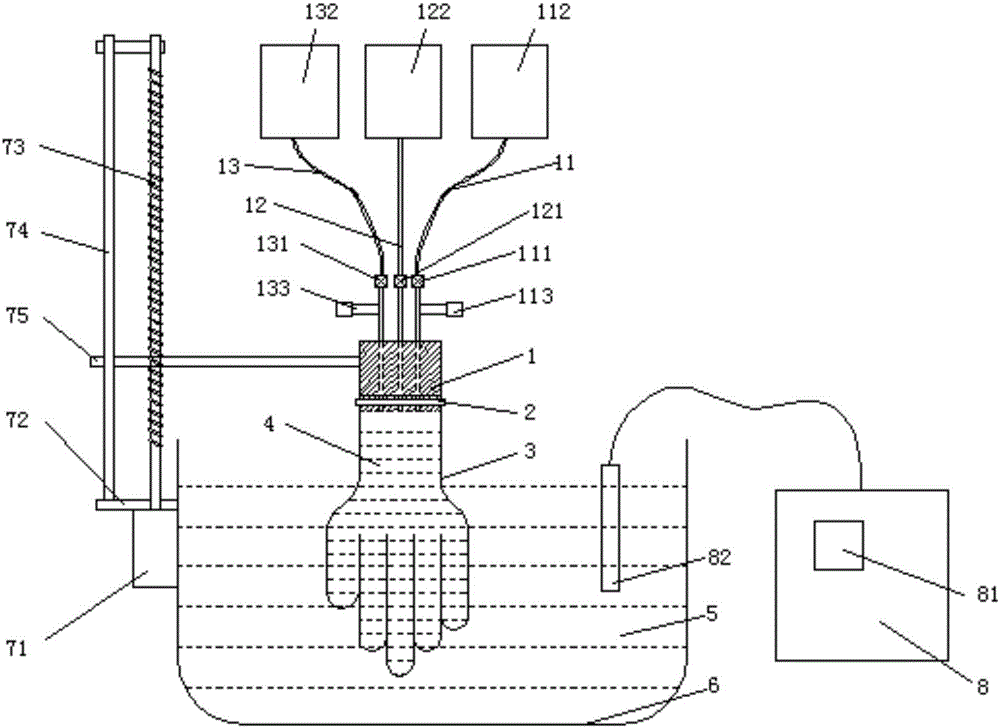

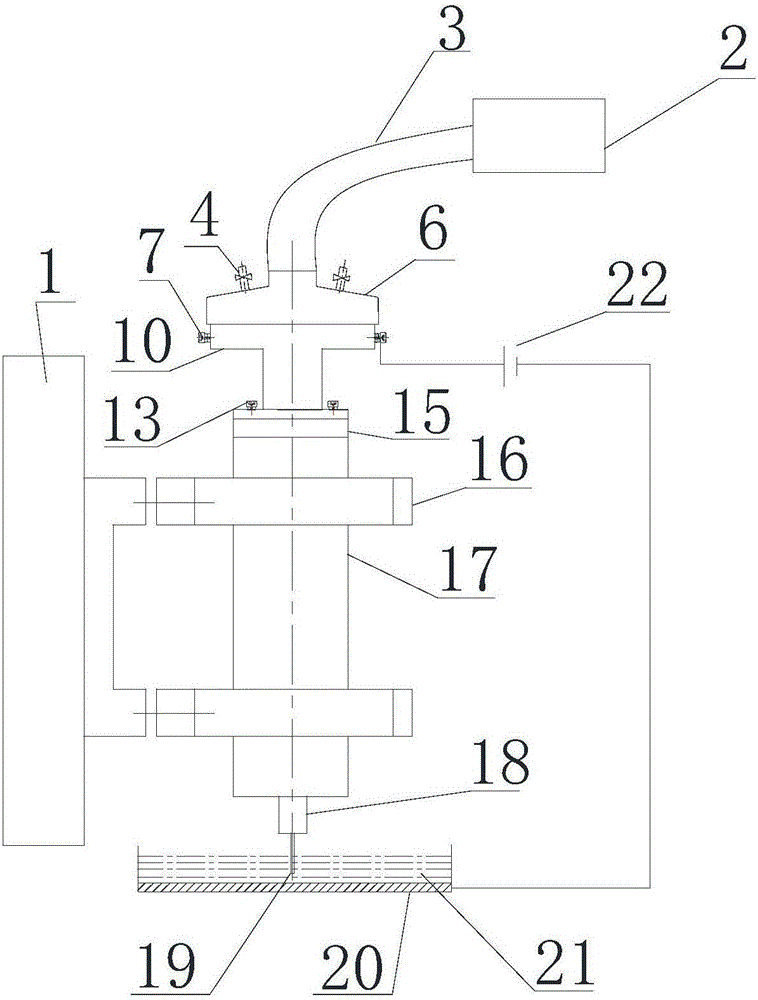

Rubber glove leak detection device and detection method

ActiveCN106323565AThe result is accurateImprove accuracyDetection of fluid at leakage pointLiquid ChangeInlet valve

The invention relates to a rubber glove leak detection device. The rubber glove leak detection device comprises a water tank filled with a liquid B; a lifting mechanism is arranged outside the water tank; a fixed joint fixed on the lifting mechanism; the fixed joint is provided with a gas conduction pipe, a liquid conduction pipe and a vacuum pipe; the gas conduction pipe, the liquid conduction pipe and the vacuum pipe are provided with a gas inlet valve, a water inlet valve and a vacuum valve respectively; the gas inlet valve, the water inlet valve and the vacuum valve are connected with an air compressor, a liquid storage tank and a vacuum pump respectively; the gas conduction pipe and the vacuum pipe are provided with a pressure sensor and a vacuum sensor respectively; the liquid storage tank is filled with a liquid A; the fixed joint is sleeved with a holding hoop; a sensor probe is arranged in the water tank; a chromaticity detector is installed on a controller; and the gas inlet valve, the air compressor, the pressure sensor, the water inlet valve, the vacuum valve, the vacuum pump, the vacuum sensor, the lifting motor and the chromaticity detector are electrically connected with the controller. The invention also discloses a detection method. When a glove has a loophole, the two liquids meet, the colors of the liquids change, and the chromaticity detector emits an alarm, and therefore, rubber products can be detected quickly and accurately.

Owner:淄博荣琦自动化科技有限公司

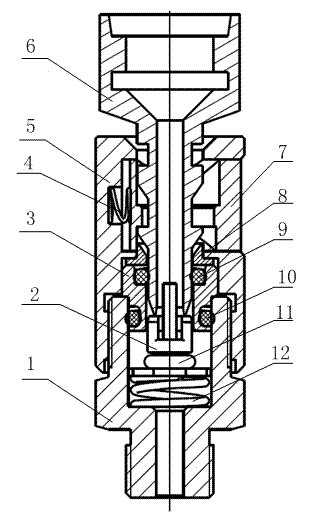

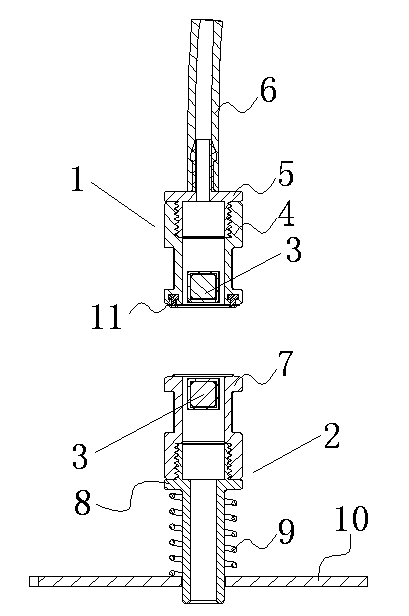

Quick connector

The invention discloses a quick connector. The quick connector comprises a fixed joint and a movable joint which is matched with the fixed joint in an insertion connection manner; a shutoff valve device is arranged in an insertion connection passage; the sidewall of the movable joint is provided with a step; the sidewall of the fixed joint is provided with a mounting hole which extends along the radial direction, and the tail end of the mounting hole sinks into the internal wall of the insertion connection passage; a button which slides along the extending direction of the mounting hole in a limiting manner is assembled in the mounting hole; a first elastic member which applies an acting force opposite to the bottom face of the mounting hole to the button is arranged between the button and the fixed joint; and the button is provided with a button passage which is used for passing through the insertion end of the movable joint, and a stopping block which is matched with the step of the movable joint in a stopping manner is arranged on the internal wall of the button passage. Due to the structure, the quick connector has the advantages that the quick connector can be automatically locked by directly inserting the movable joint into the fixed joint during locking and can be automatically unlocked by only pressing down the button during unlocking, the phenomenon of skidding can not occur, the operation is convenient, the locking and unlocking of the quick connector can be easily realized, and meanwhile, the sealing effect of the whole quick connector can also be guaranteed.

Owner:CAMA LUOYANG GAS SUPPLY

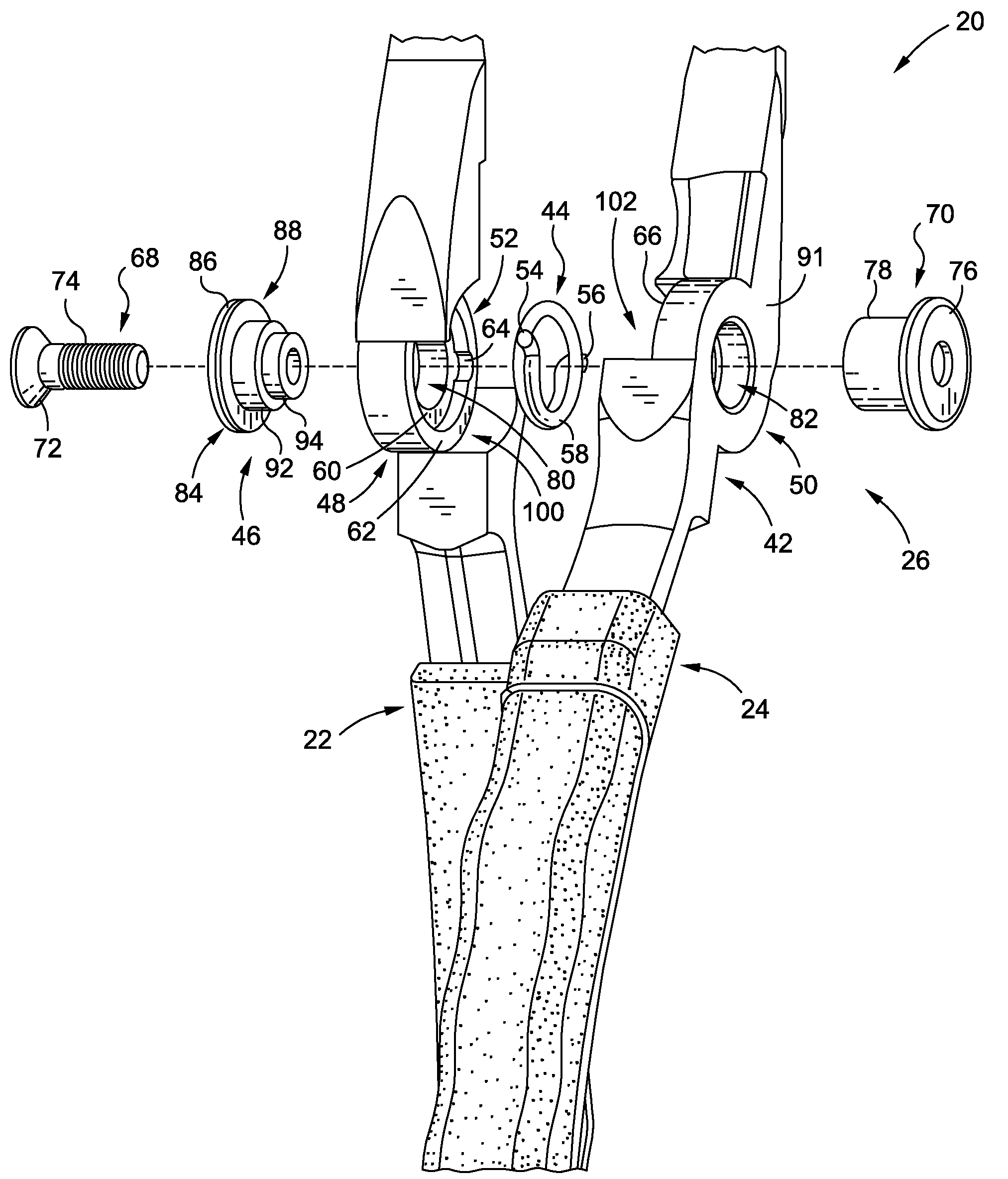

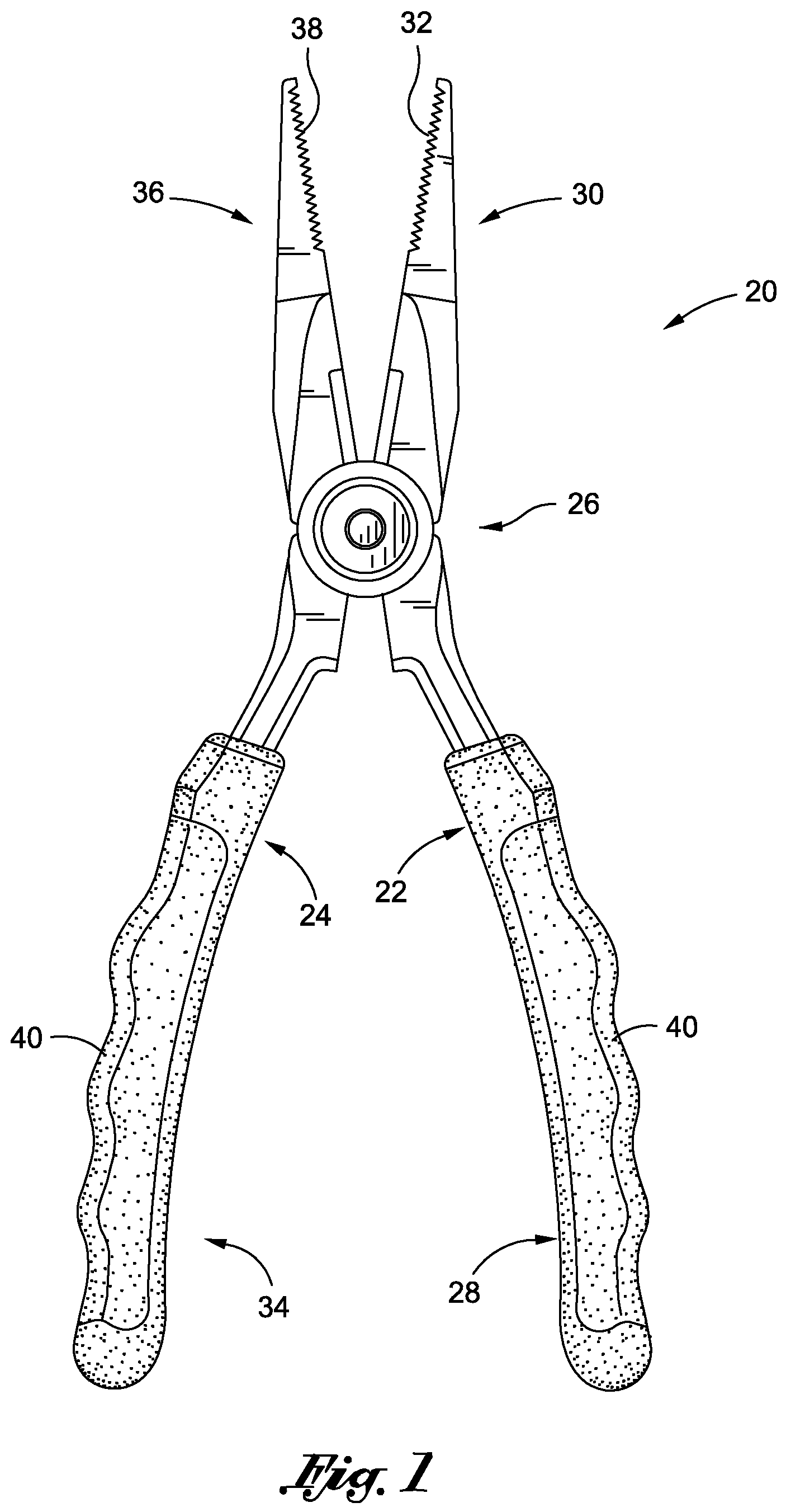

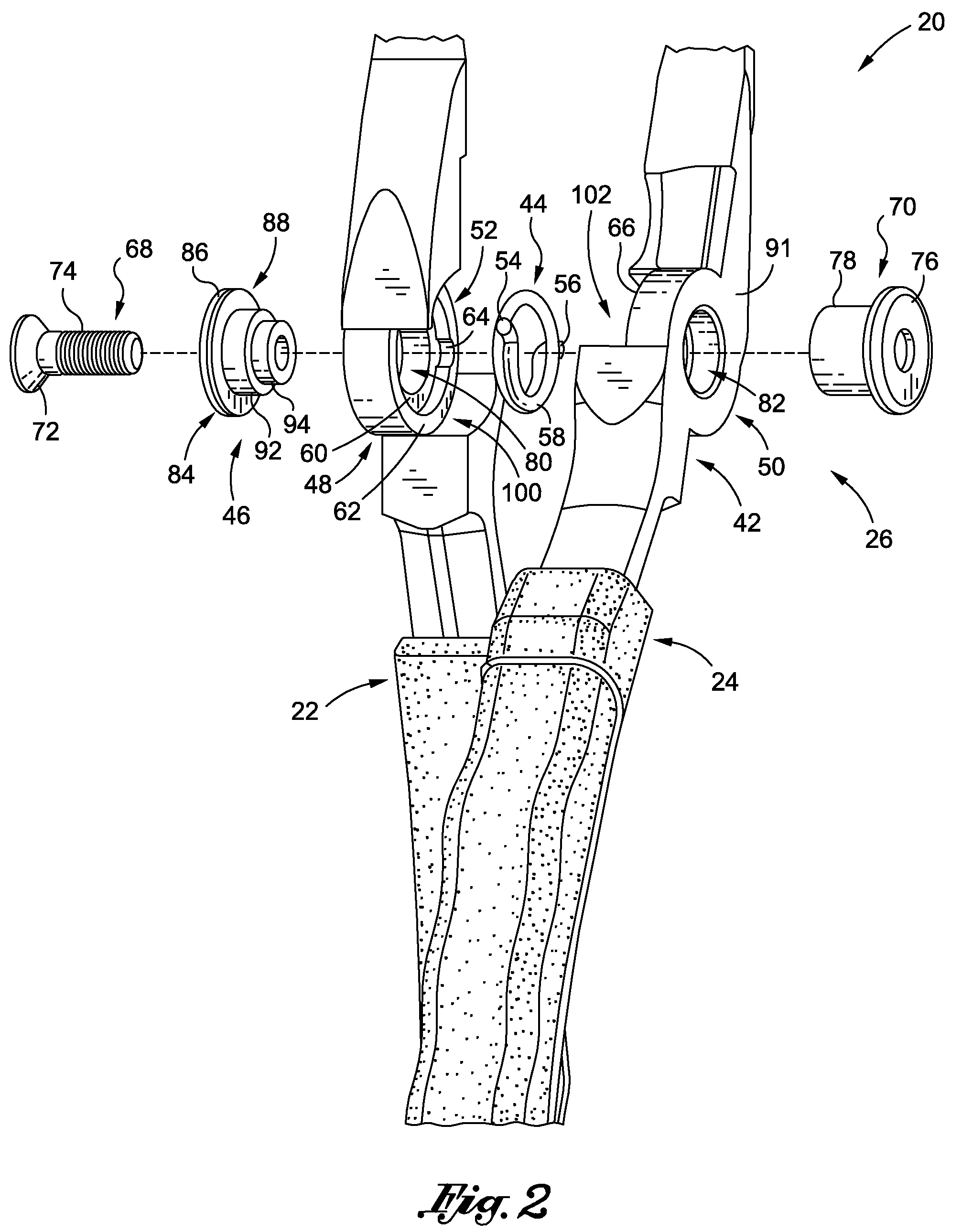

Biased pliers

A tool, such as fixed-joint pliers, has first and second levers which are movably joined. The levers are joined at a joint comprising a housing and a coupler. The housing is defined by a first housing portion of the first lever and a second housing portion of the second lever. The housing has an interior area which houses a biasing member, such as a torsion spring. The coupler may comprise first and second bushings which extend through a passage through the housing and the torsion spring therein, and a male fastener which extends through one of the bushings and into engagement with the other bushing. The pliers have a thin profile and are biased to an open position for use.

Owner:JS PRODS

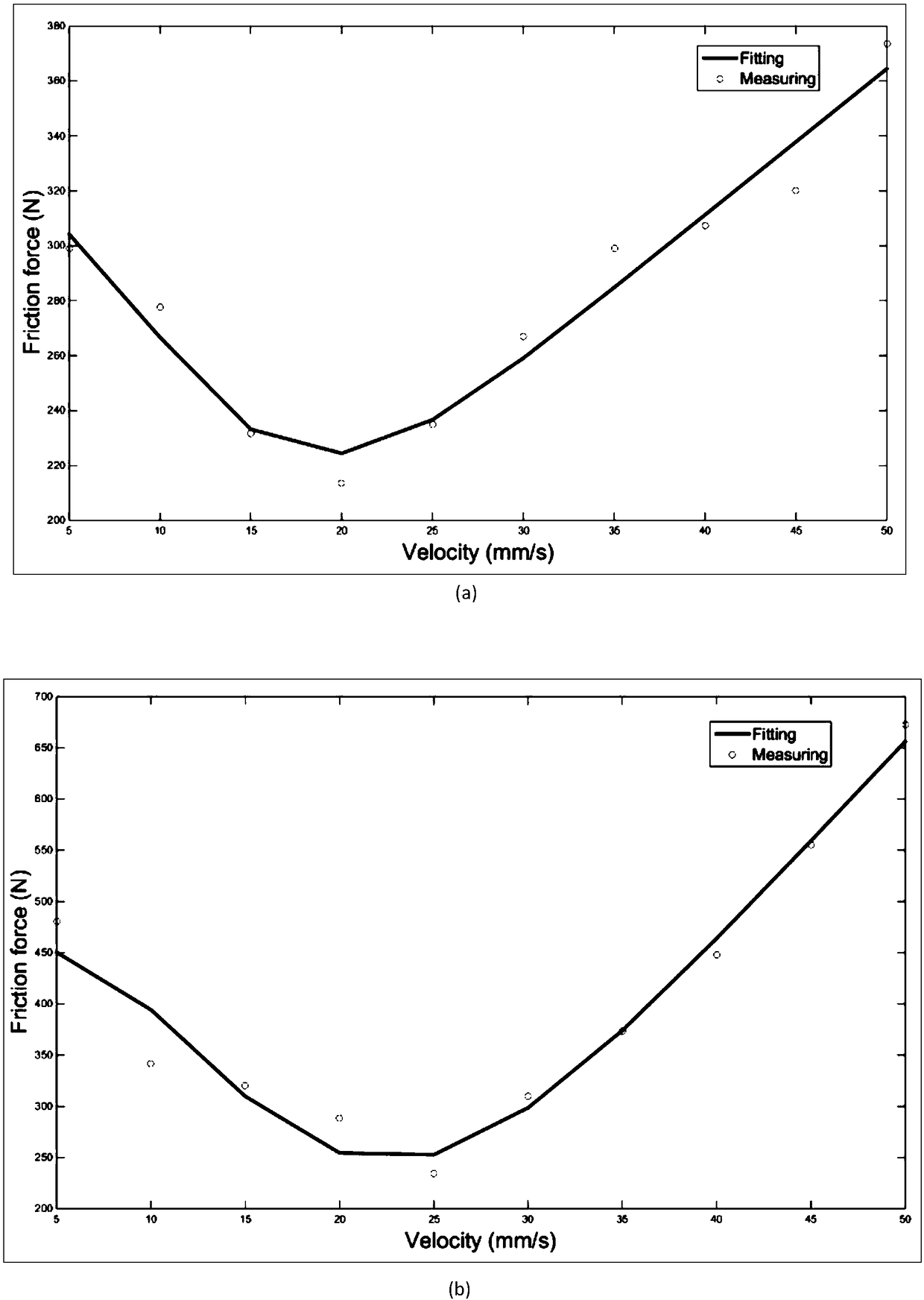

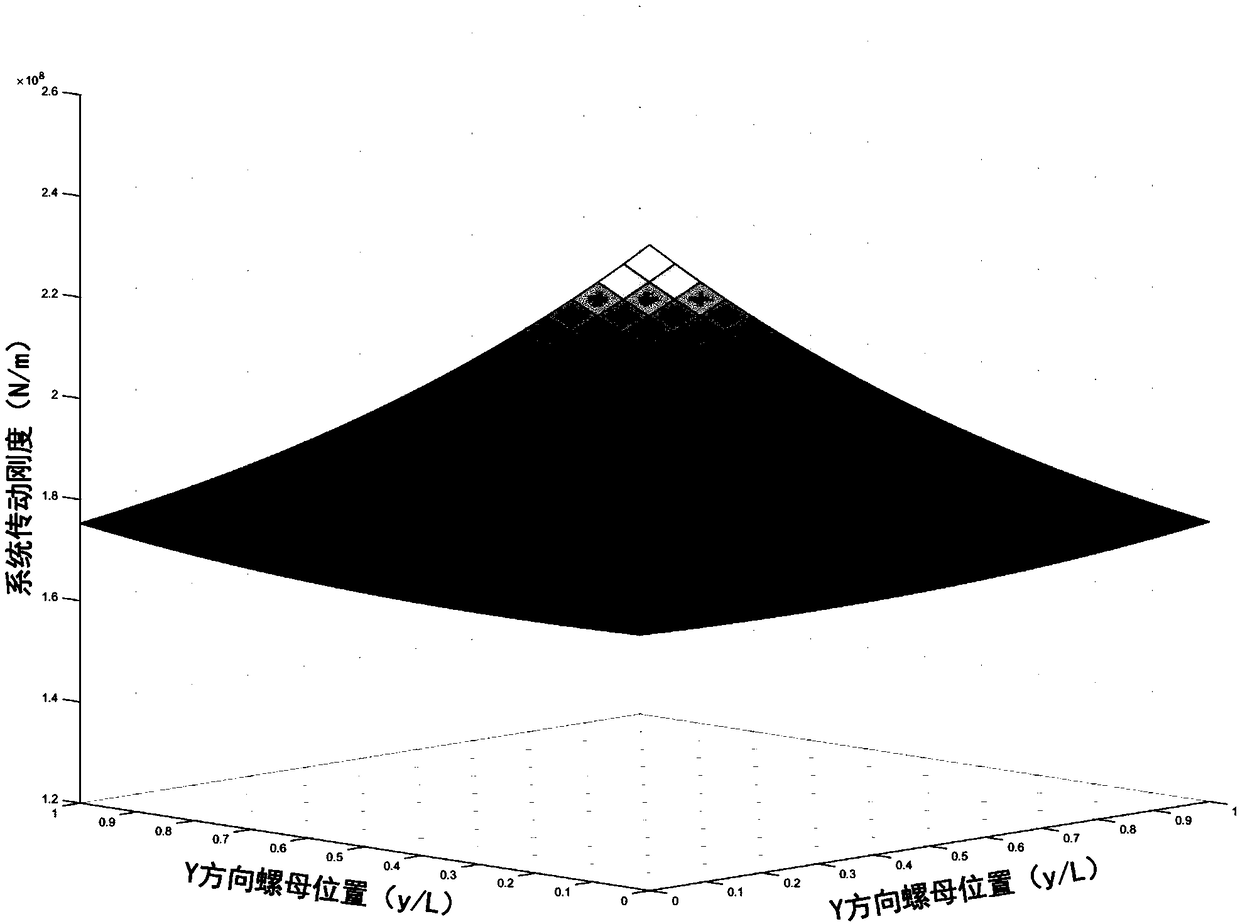

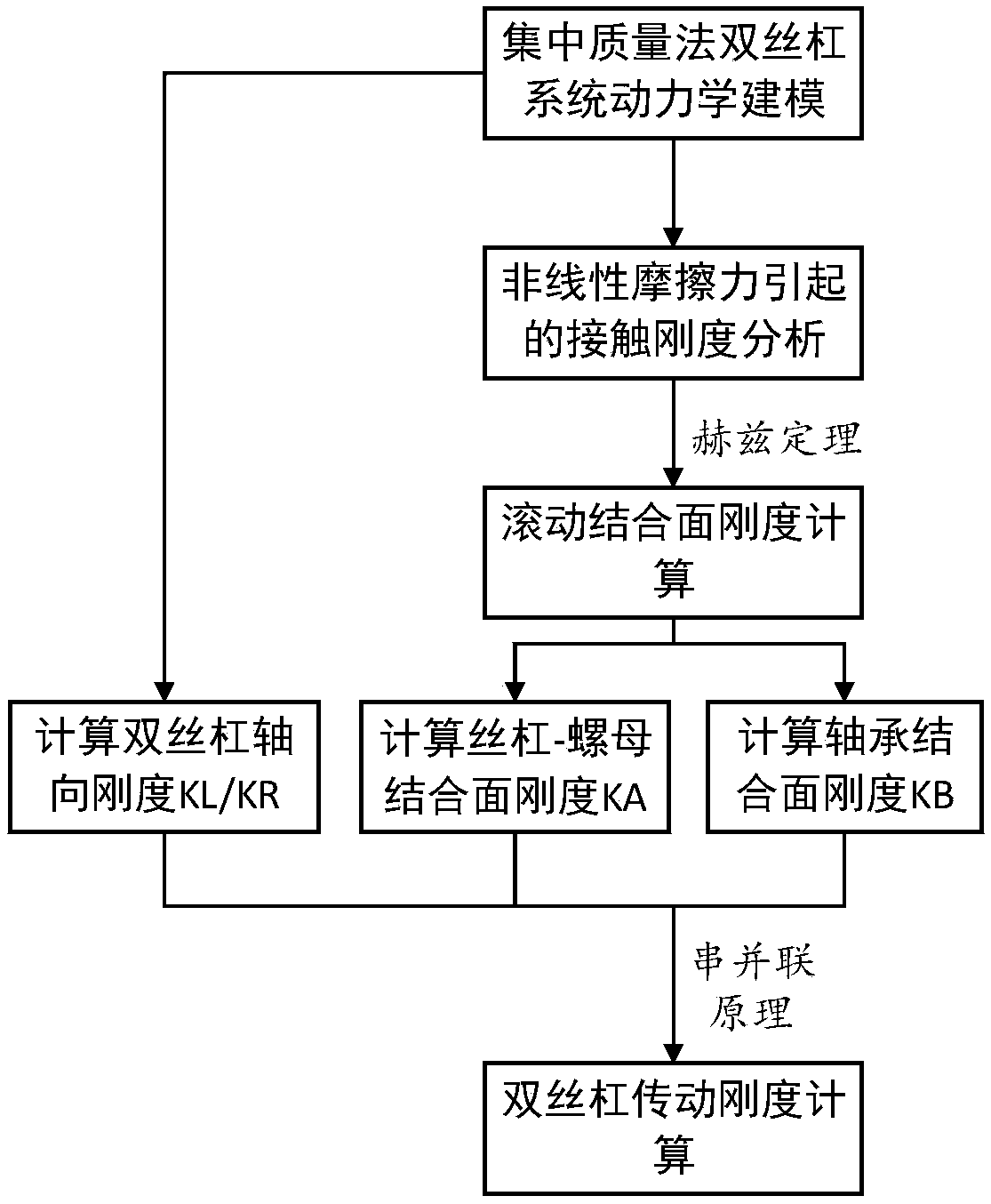

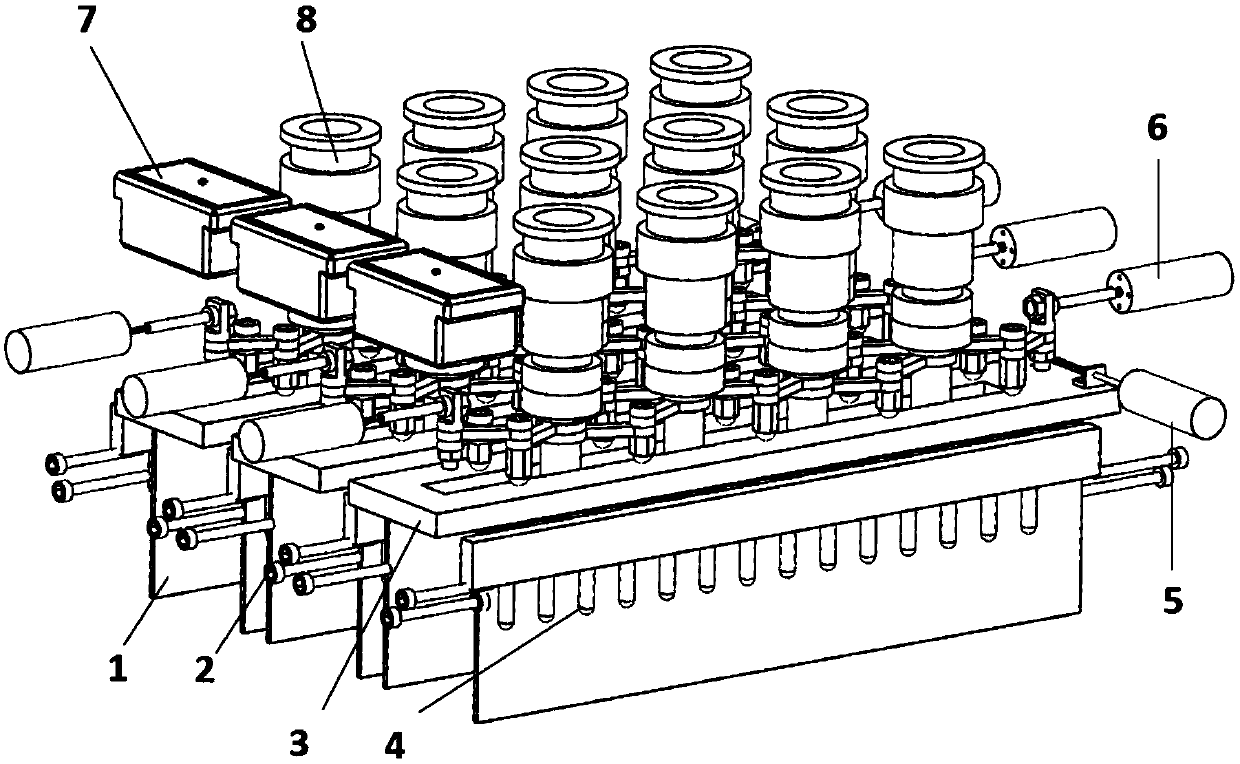

A method for modeling rigidity of a transmission chain of a double-screw drive system

ActiveCN108984831AAccurately Calculated Stiffness ValuesImprove modeling accuracyGeometric CADMachine gearing/transmission testingEngineeringHertz

A method for modeling rigidity of a transmission chain of a double lead screw drive system includes as the steps of calculating the rigidity of a rolling joint surface, analyzing the contact rigiditycause by friction force of lead screw, calculating the rigidity of fixed joint surface, modeling the dynamics of double lead screw, and calculating the rigidity of drive chain of double lead screw, etc, wherein the rolling joint surface comprises a lead screw-nut joint surface and a bearing joint surface, the fixed bonding surface includes a workbench-slide block joint surface, and the contact stiffness of the rolling joint is calculated by using the Hertz contact theory; establishing a friction model and taking into account the stiffness change of the joint surface caused by the friction force of the lead screw; considering the coupling effect of the worktable, establishing an accurate rigidity chain model of the double screw drive system by using the centralized mass method, thereby improving the dynamic modeling accuracy of the double screw drive system and the asynchronous error of the double-drive feed and improving the positioning accuracy of the double-drive machine tool. The method solves the problem that the rigidity of the joint surface is ignored in the dynamics modeling of a conventional double-screw drive system, and the model accuracy is low.

Owner:WUHAN UNIV OF TECH

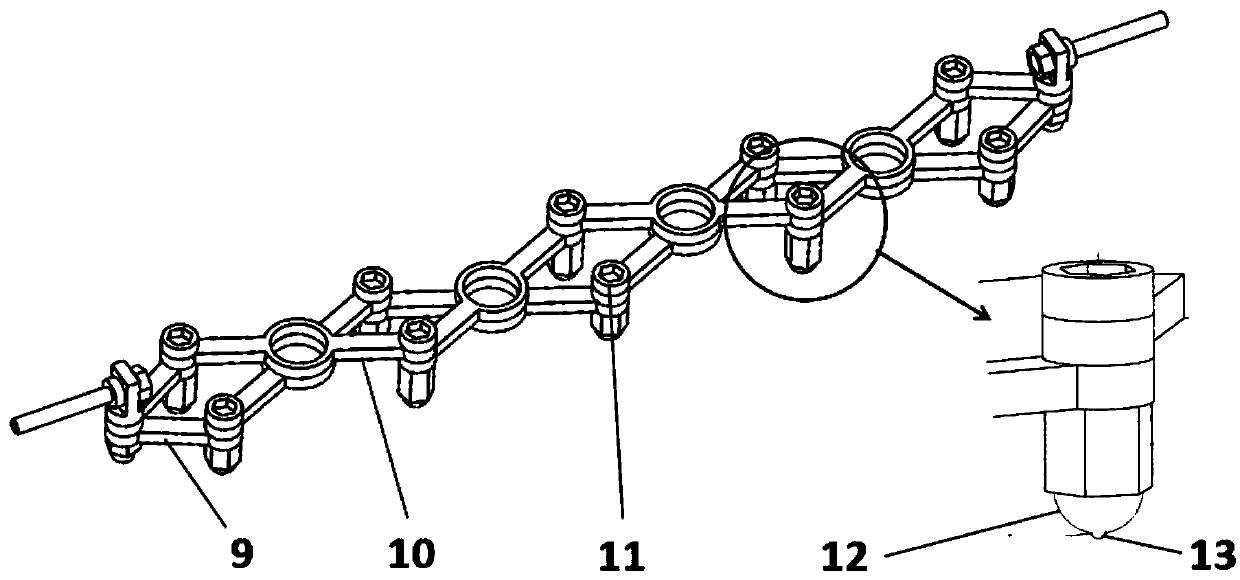

Array-integrated-type spray printing device and method with adjustable spatial distribution

ActiveCN109094200ARealize integrationIncrease or decrease quantityDecorative surface effectsDuplicating/marking methodsSpray nozzleUltraviolet

The invention belongs to the technical field of spray printing devices, and particularly discloses an array-integrated-type spray printing device and method with adjustable spatial distribution. The array-integrated-type spray printing device comprises a box, spraying head sets arranged in the box and distributed in an arrayed mode, and moving assemblies used for adjusting the positions of spraying heads. The spraying heads in the spraying head sets comprise fixing joints, connectors, intermediate joints and output heads, wherein the fixing joints, the connectors, the intermediate joints and the output heads are sequentially arranged from top to bottom. Through holes and gas input channels are formed in the intermediate joints; quartz pipes penetrating out of the lower ends of the output heads are mounted in the through holes, outlets of the quartz pipes serve as nozzles, and high-pressure electrodes are inserted in the quartz pipes; gaps are reserved between the high-pressure electrodes and the quartz pipes; and the hollow parts of the high-pressure electrodes serve as ink liquid channels. Each set of spraying heads is provided with the corresponding moving assembly, the moving assemblies are used for mounting the spraying heads and adjusting the positions of the spraying heads, and electrode plates and ultraviolet lamps are arranged in the box. The array-integrated-type sprayprinting method is conducted through the array-integrated-type spray printing device. Large-scale production is achieved, meanwhile, the flexibility of the array-integrated-type spray printing deviceis greatly improved, and the application range of the array-integrated-type spray printing device is greatly enlarged.

Owner:HUAZHONG UNIV OF SCI & TECH

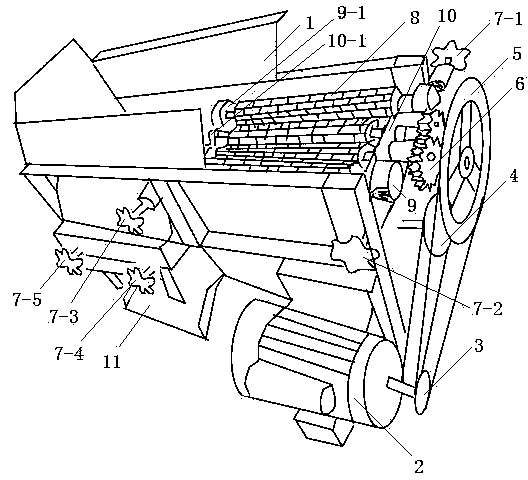

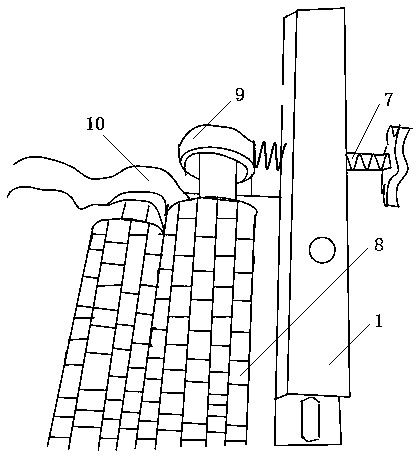

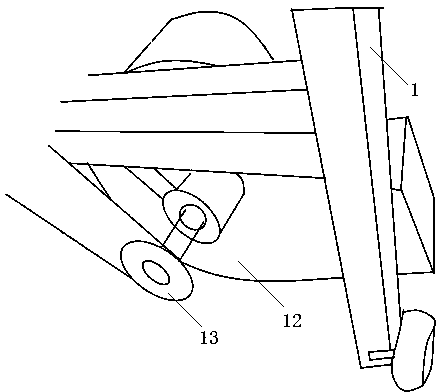

Corn machine capable of peeling and threshing

InactiveCN103518474ASimplify manufacturing stepsSave half the spaceMowersThreshersFixed bearingAgricultural engineering

The invention relates to a corn machine capable of peeling and threshing. The corn machine comprises a peeling device and a threshing device. The peeling device is disposed on the front portion of a machine frame, the threshing device is disposed on the rear portion of the machine frame, the peeling device and the threshing device are covered by a machine shell, and the machine shell is fixed to the machine frame. The peeling device comprises a motor, a peeling belt wheel, a gear, an adjusting device, a peeling roller, a movable bearing base, a fixed bearing base, an air blower belt wheel and an air blower, wherein the adjusting device comprises an adjusting handle and a spring. The threshing device comprises a motor, a belt wheel, a threshing belt wheel, an adjusting device, a corn discharging opening, a threshing plate, an adjusting plate, a partition board, a threshing roller, a fixed joint and a corn cob discharging opening. The corn machine has the advantages of being simple in structure, low in manufacturing cost, capable of adjusting peeling and threshing gaps and achieving batch feeding, little in labor intensity, suitable for corn cobs of different sizes, efficient and free of dust.

Owner:YONGZHOU LIJING MACHINERY MFG

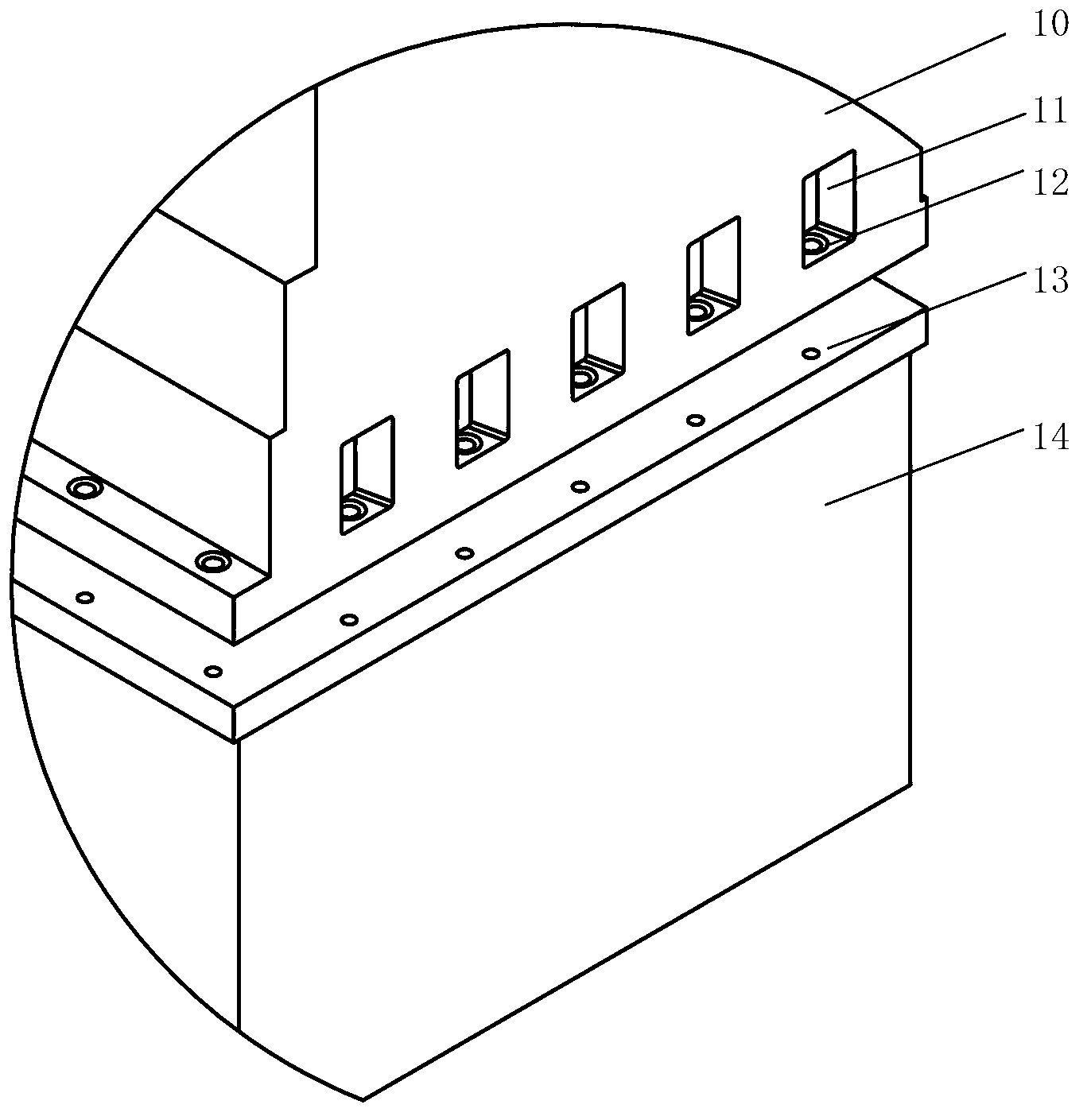

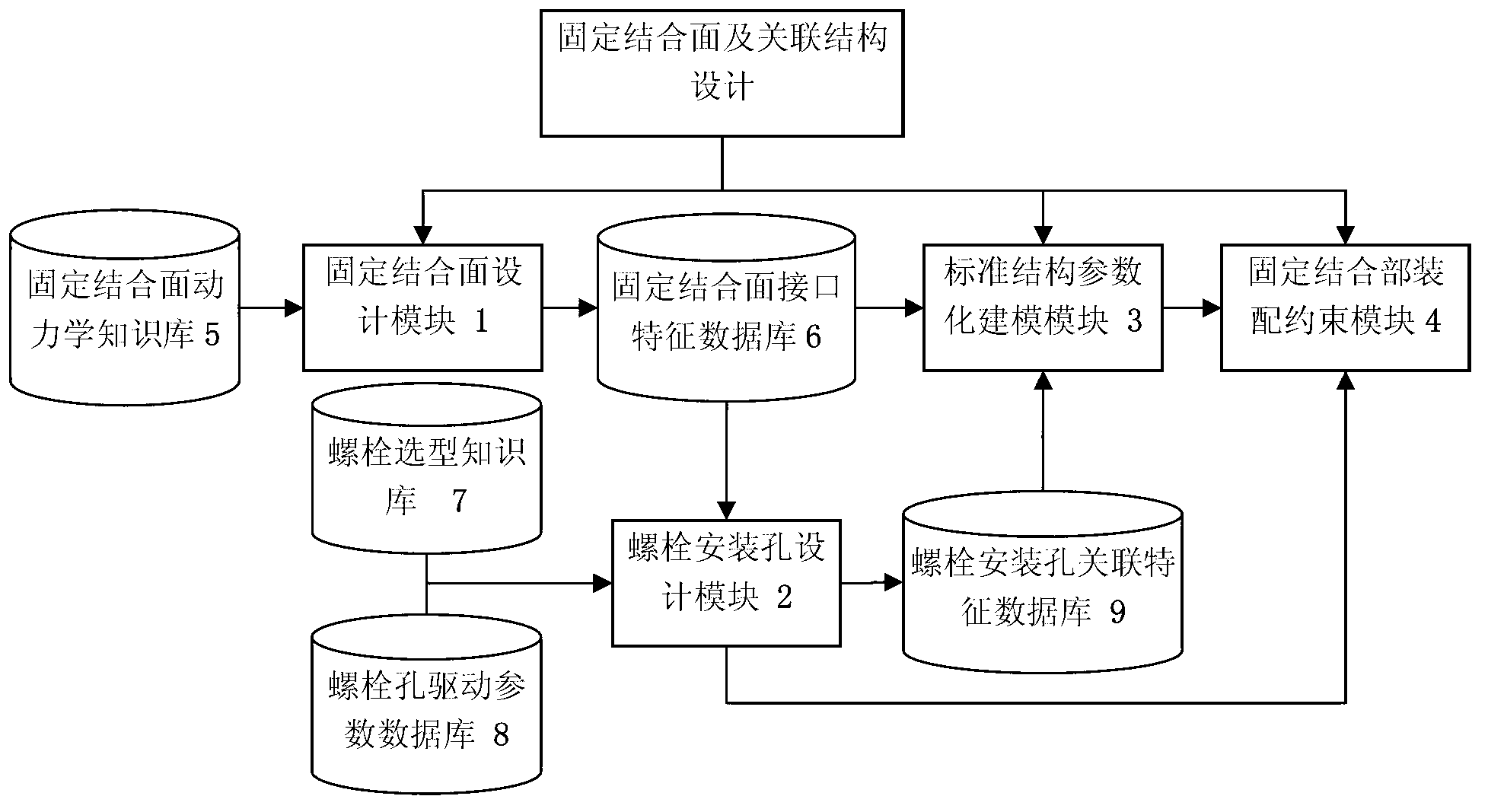

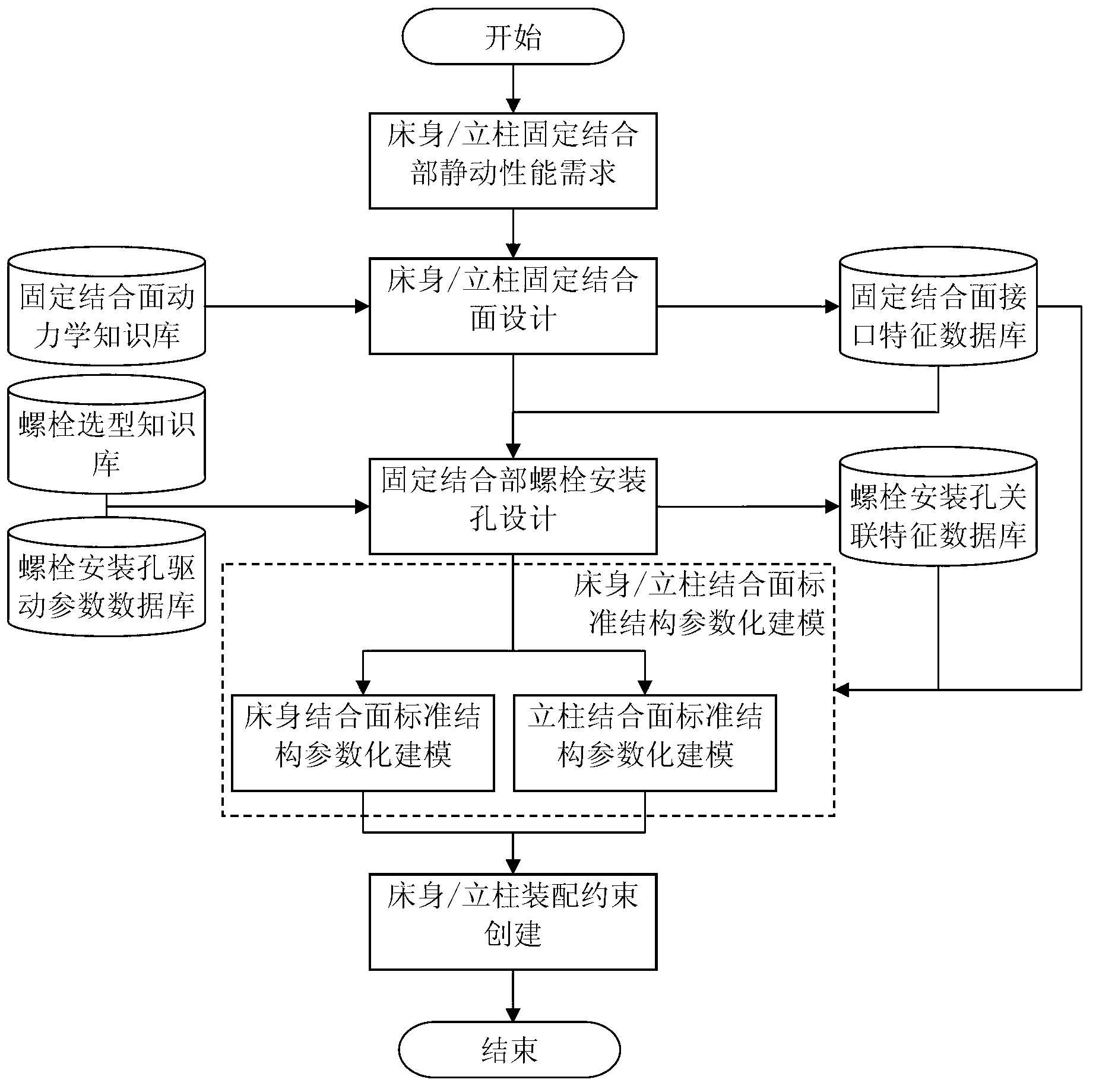

Quick-tool-design-oriented fixed joint surface database and creating method thereof

ActiveCN103294810AAutomate creationImplement parametric modelingSpecial data processing applicationsModel selectionLarge size

The invention discloses a quick-tool-design-oriented fixed joint surface database and a creating method thereof. The database comprises a fixed-joint-surface dynamics knowledge base, a fixed-joint-surface design module, a fixed-joint-surface interface characteristic database, a bolt model-selection knowledge base, a bolt-hole driving parameter database, a fixed-joint-surface bolt-mounting-hole design module, a bolt-mounting-hole correlative characteristic database, a standard structure parameterized modeling module and an assembly constraint creating module. The creating method includes designing a joint surface according to dynamics needs of tool fixed joint surfaces, performing automated design of a bolt mounting hole structure according to a joint surface structure, completing parameterized modeling of a large-size joint-part standard structure of a tool according to the joint surface and the mounting hole structure, and automatically creating an assembly constrained relationship of the joint surface. Automated creation of the fixed joint surface during designing of the tool, the parameterized modeling and automated assembly of correlative characteristics of a tool structure member can be realized, technical support is provided to quick design and assembly of the tool.

Owner:TIANJIN UNIV

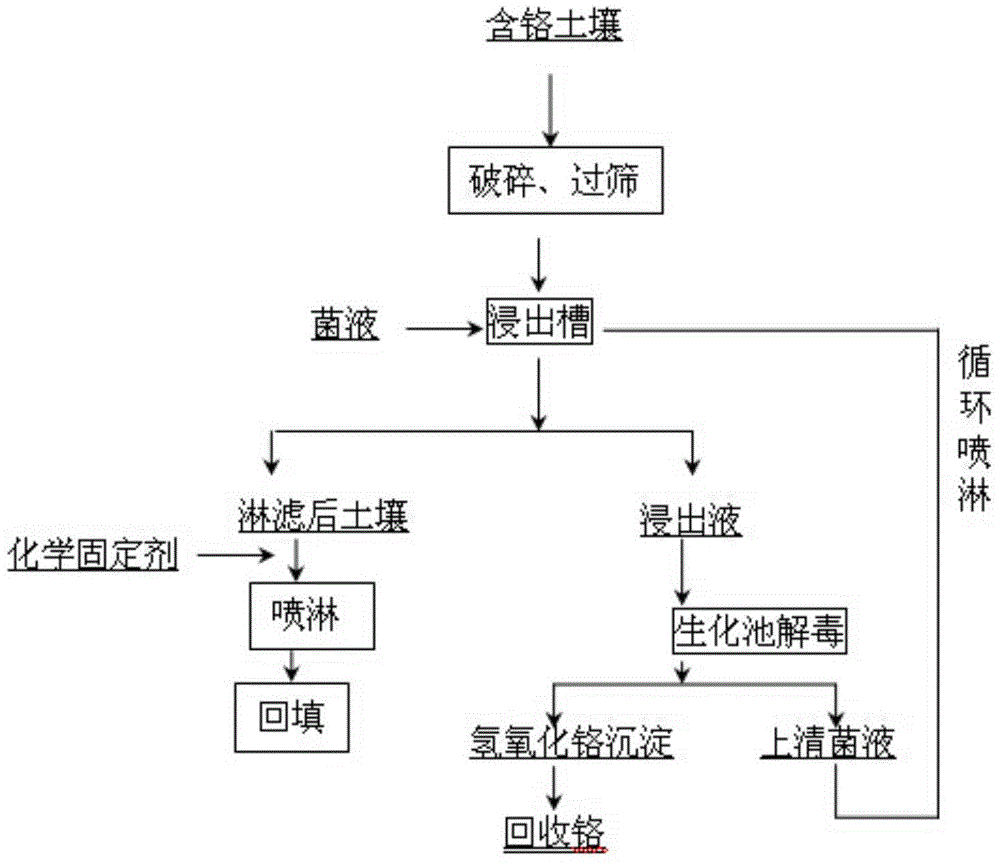

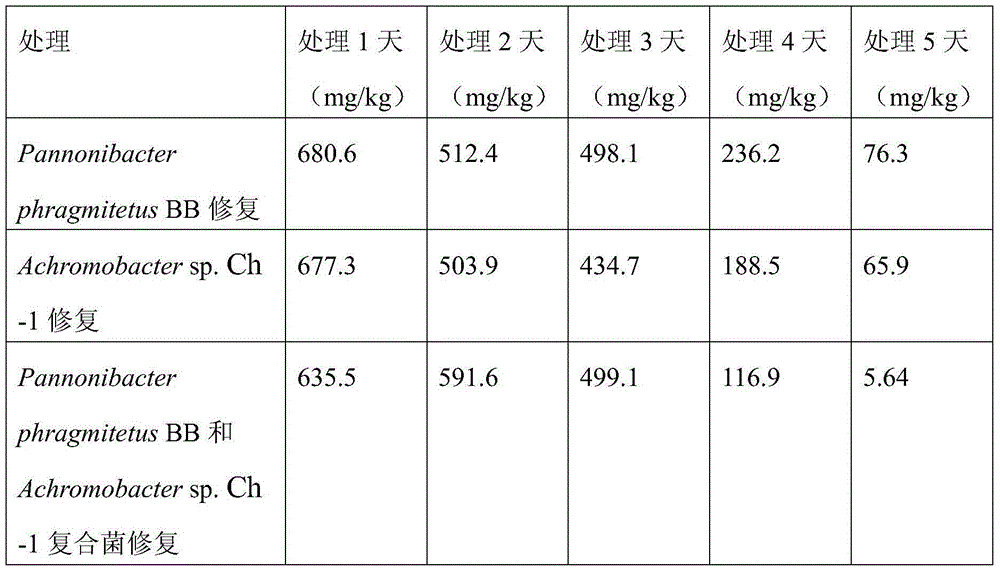

Microbial leaching and chemical fixing joint repairing method for heavily polluted soil of chromium slag yard

ActiveCN104550222AReduce acid-base adjustment processSimple processContaminated soil reclamationSlagPollution

The invention discloses a microbial leaching and chemical fixing joint repairing method for heavily polluted soil of a chromium slag yard. The method comprises the following steps: spraying soil or muck of a chromium slag yard with a composite bacteria liquid which is obtained by cultivating compound strains Pannonibacter phragmitetus BB and Achromobacter sp.Ch<-1>; restoring Cr(VI) in the obtained leacheate into Cr(III), forming sediments in an alkaline condition, precipitating and recycling chromium; and carrying out chemical fixing on the Cr(VI) which is not leached from the soil or muck through hydrazine hydrate. By virtue of the method, the soil and muck with three different Cr(VI) pollution levels are repaired; the total removal rates on chromium are respectively 11.4%, 30.2% and 14.0%; the removal rates on water-soluble Cr(VI) are respectively 99.6%, 99.5% and 98.3%; and the leaching toxicity concentration of the Cr(VI) in the soil or muck is lower than 0.5mg / L.

Owner:CENT SOUTH UNIV +1

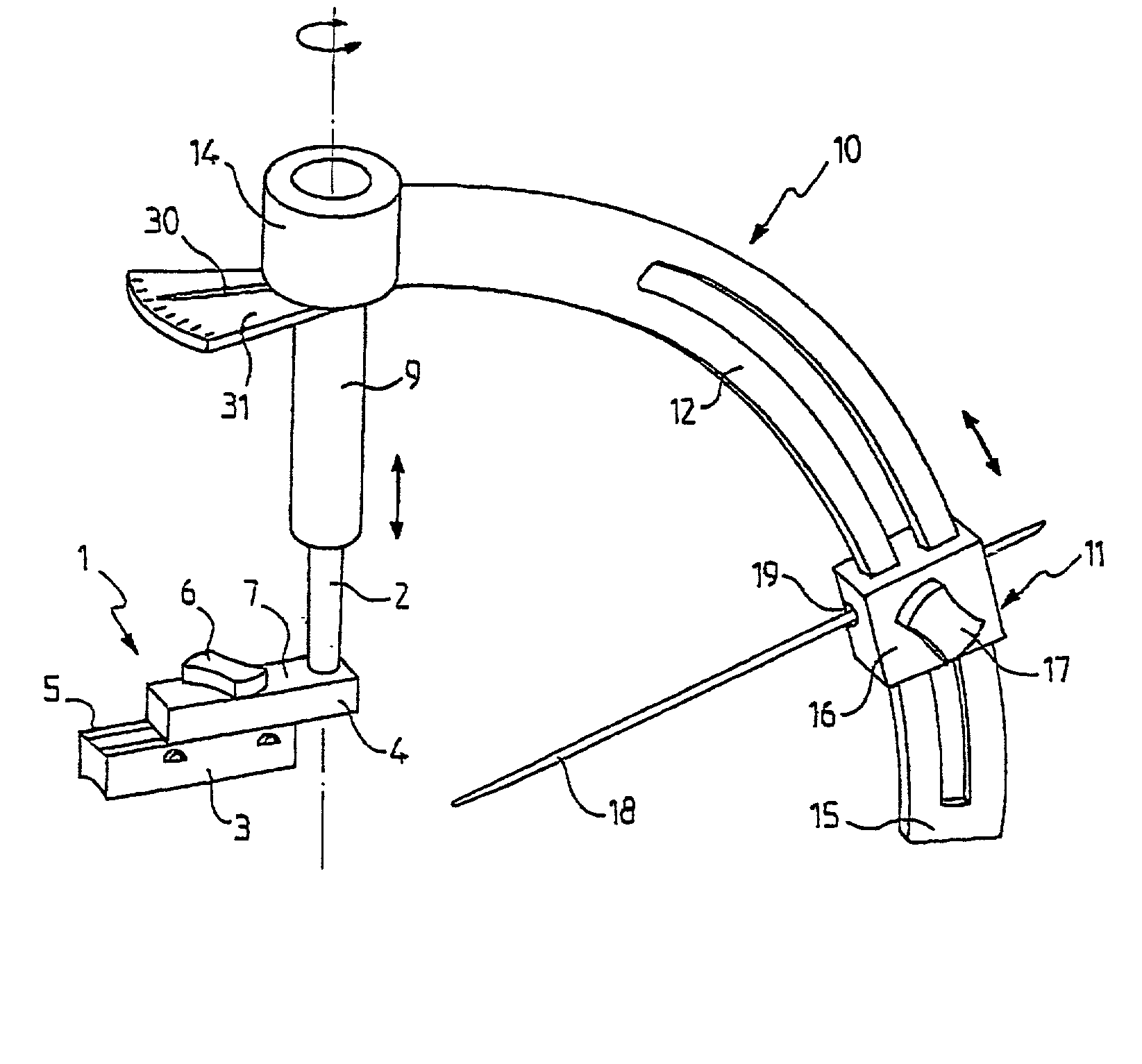

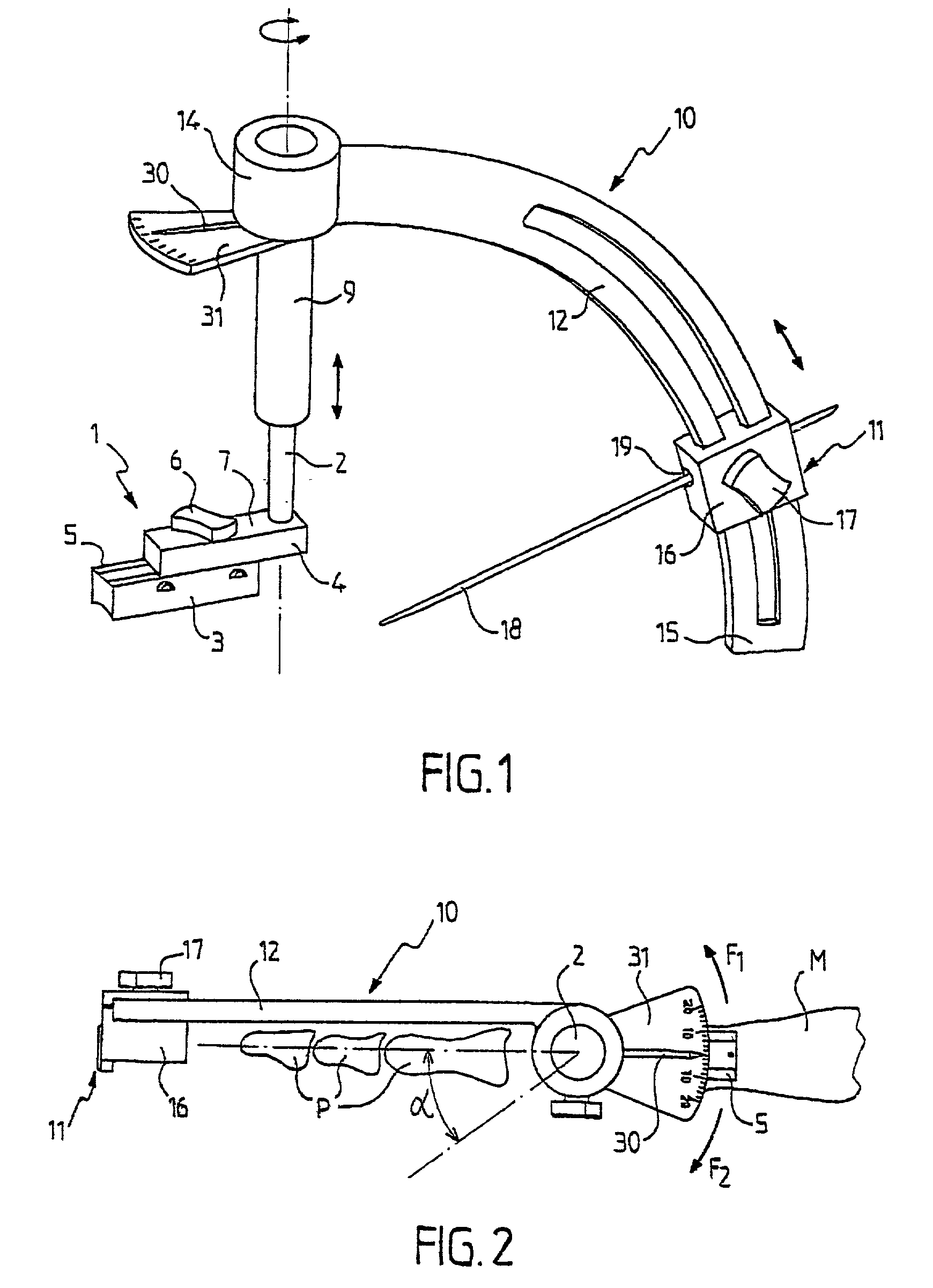

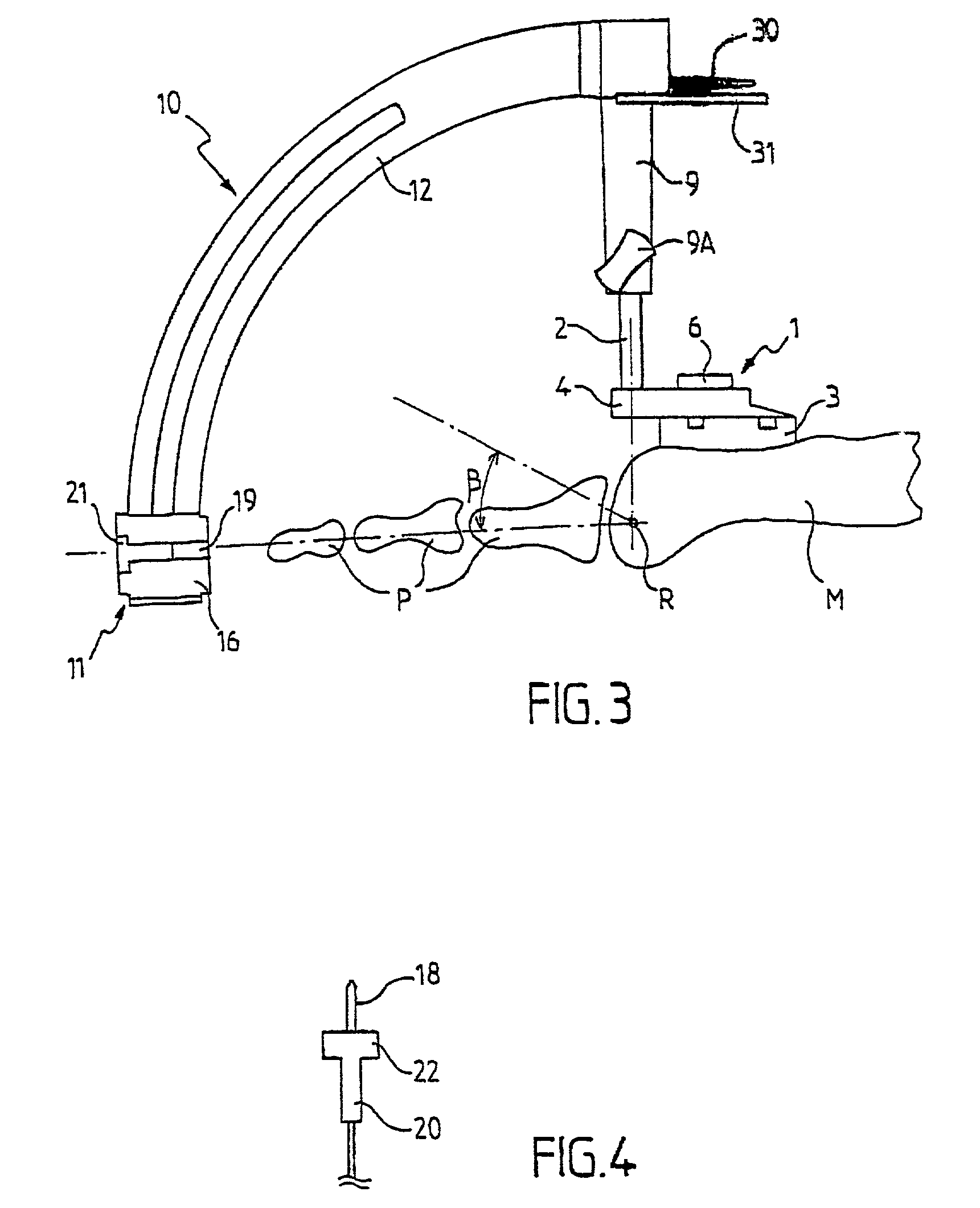

Guide for angularly positioning the bones of a joint in order to perform arthrodesis

InactiveUS20020165551A1Simple and reliable processEasy to adjustJoint implantsNon-surgical orthopedic devicesJoint arthrodesisEngineering

The invention provides a guide for angularly positioning bones in a joint in order to perform arthrodesis, the guide comprising: a base for positioning on the joint, and having an adjustment shaft whose position is designed to be adjusted so as to be substantially vertically above a fixed first geometrical reference point R of the joint; and an adjustment assembly mounted to slide axially and in rotation on the adjustment shaft to adjust respectively a height for the assembly relative to the first geometrical reference point R and a first angle alpha for the assembly about said axis, said adjustment assembly being formed by an angular adjustable member which can be positioned on a graduated piece to adjust a second angle beta centered on the first geometrical reference point R, but situated in a plane different from the first angle alpha. The guide is suitable for metatarso-phalangeal positioning.

Owner:NEWDEAL

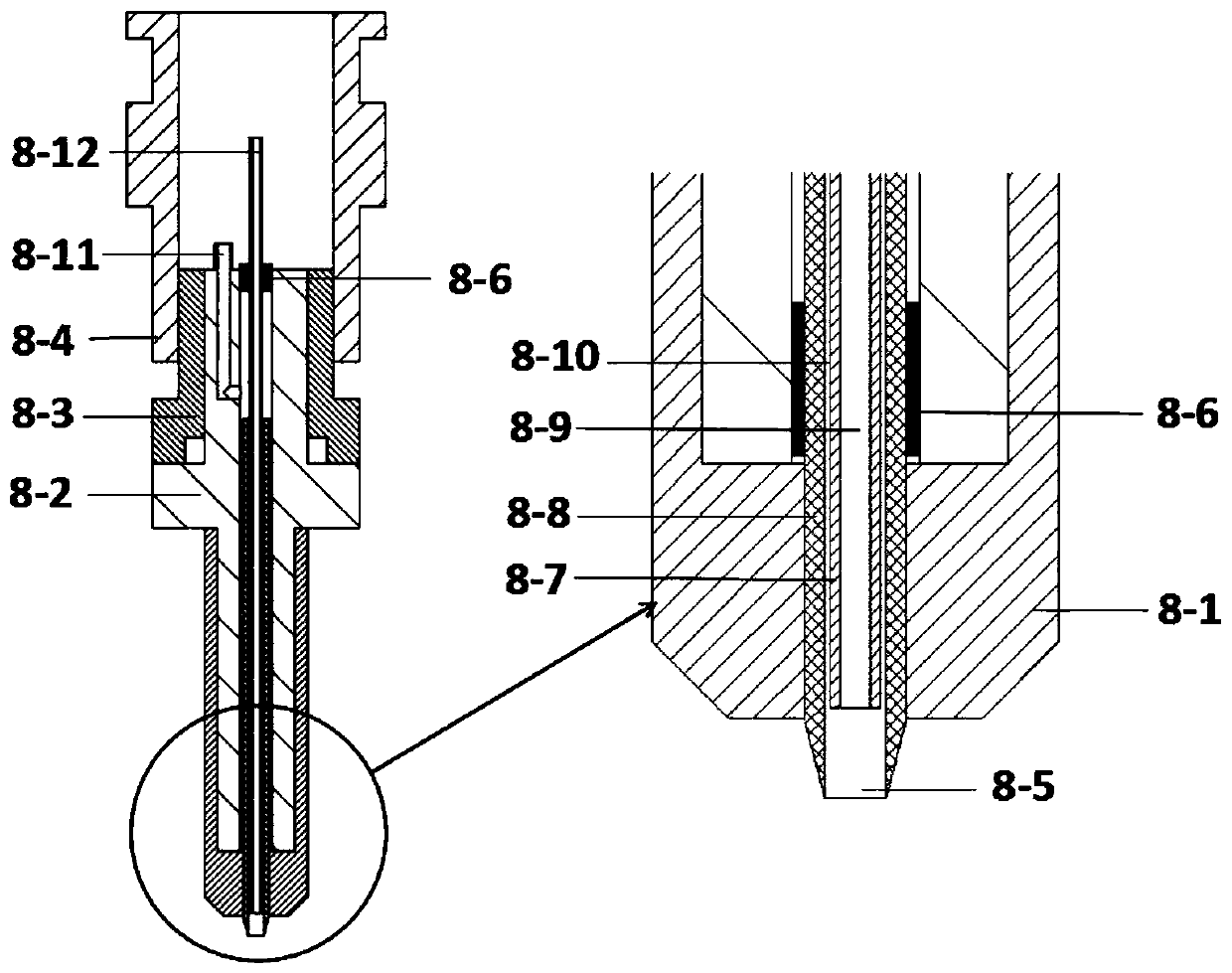

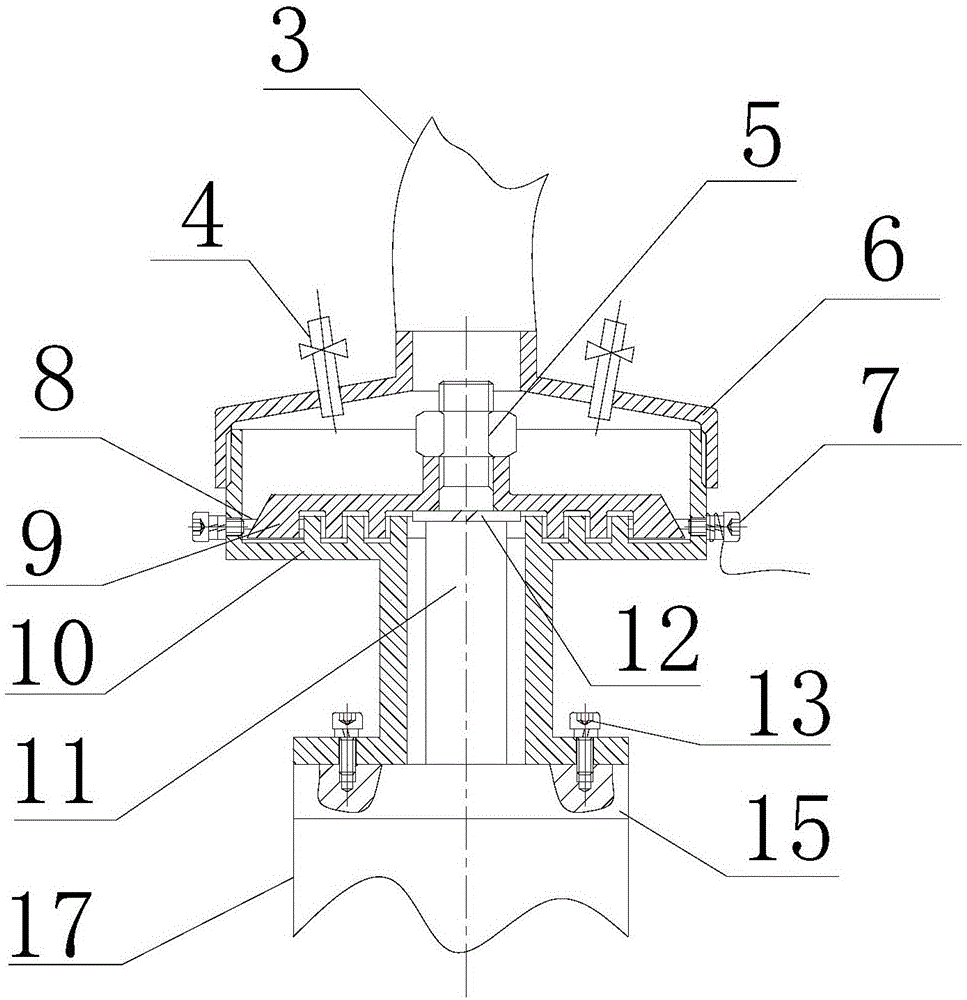

Tool electrode high-speed rotation electromachining electric conduction device

ActiveCN106475647ANo health hazardNo pollution in the processElectric circuitsElectricityEngineering

The invention discloses a tool electrode high-speed rotation electromachining electric conduction device. The device comprises an air pump, a rubber tube, an upper end cover, a reducing valve, a revolution joint, a conducting solution, a fixed joint and an electric conduction screw. By the adoption of the device, the abrasion problem of an electric brush in a traditional electric conduction mode can be solved, and the advantages of being safe, green and free of pollution are achieved compared with a mercury electric conduction mode. Meanwhile, compared with a wireless electric conduction mode, the device is simple and easy to implement, the process difficulty and cost are low, and the practicability is good.

Owner:颍上县祥盛建设管理有限公司

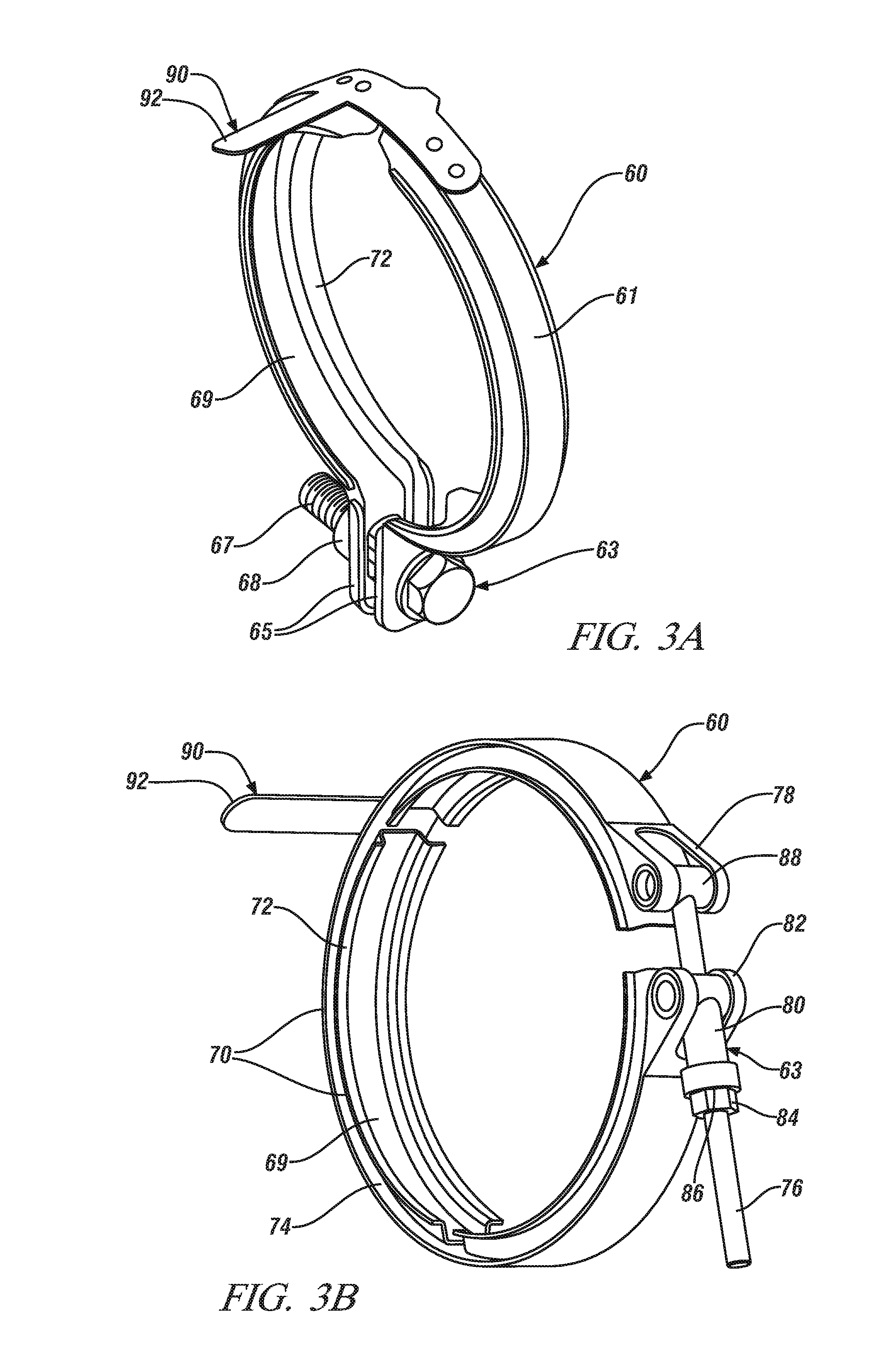

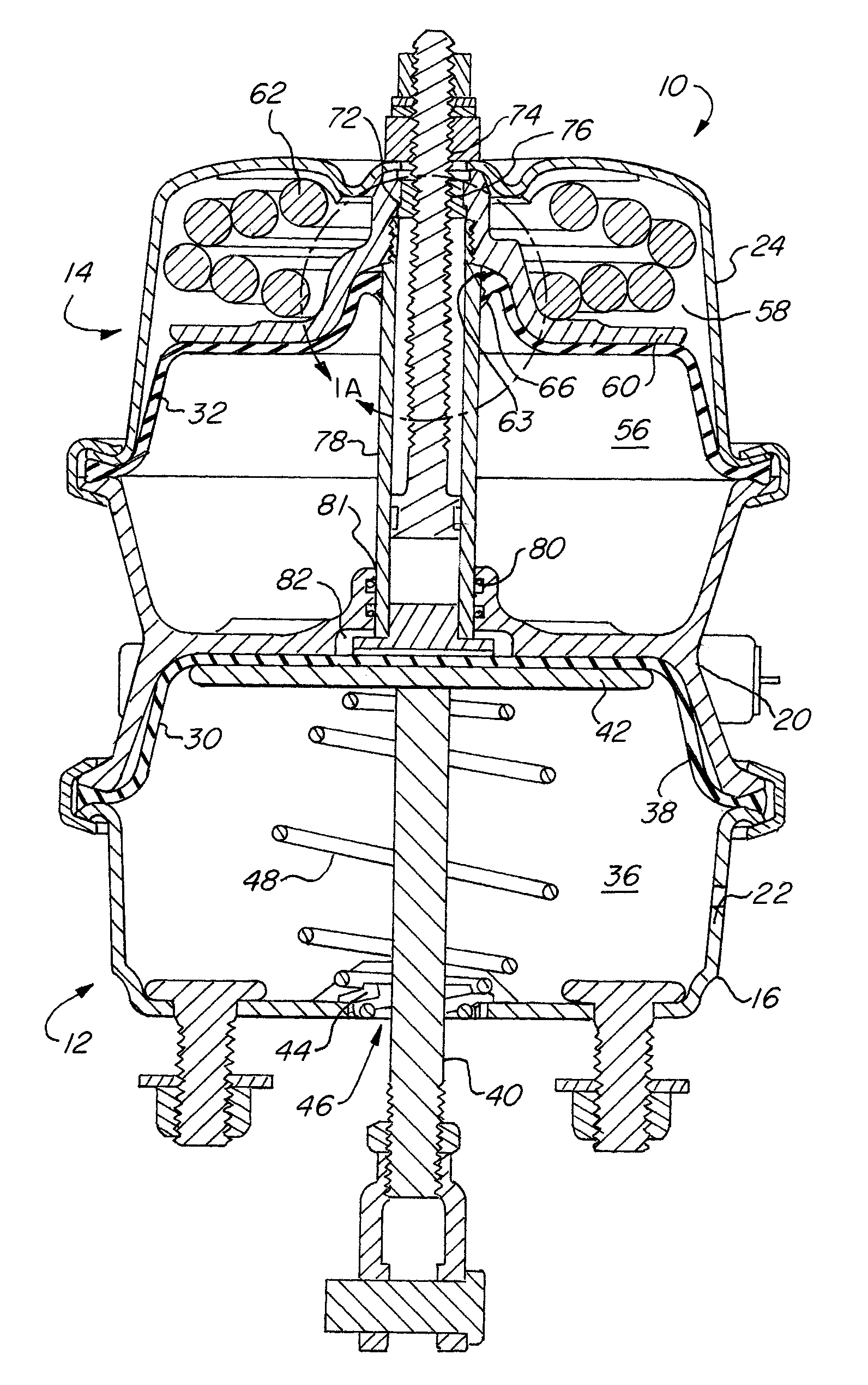

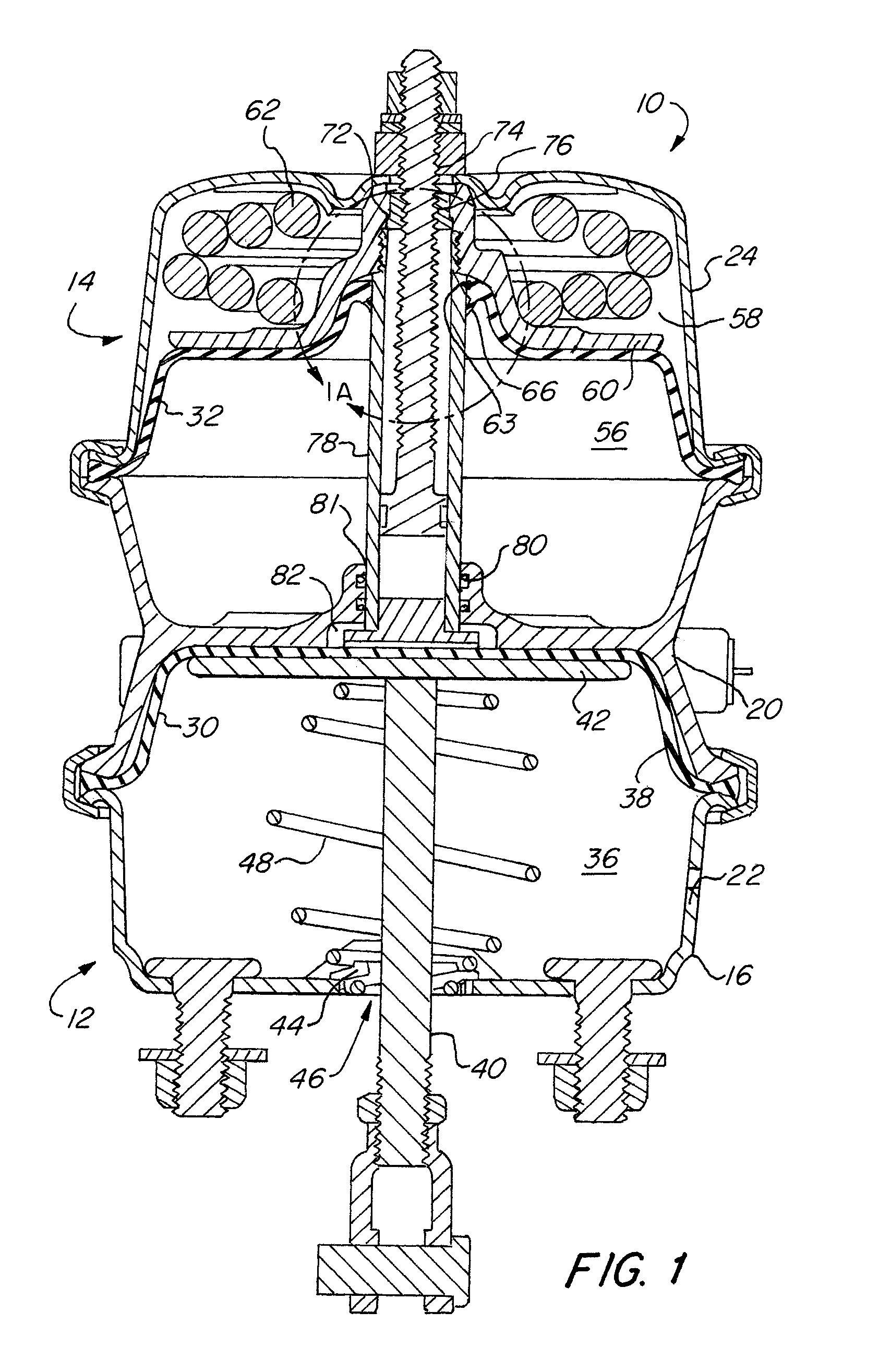

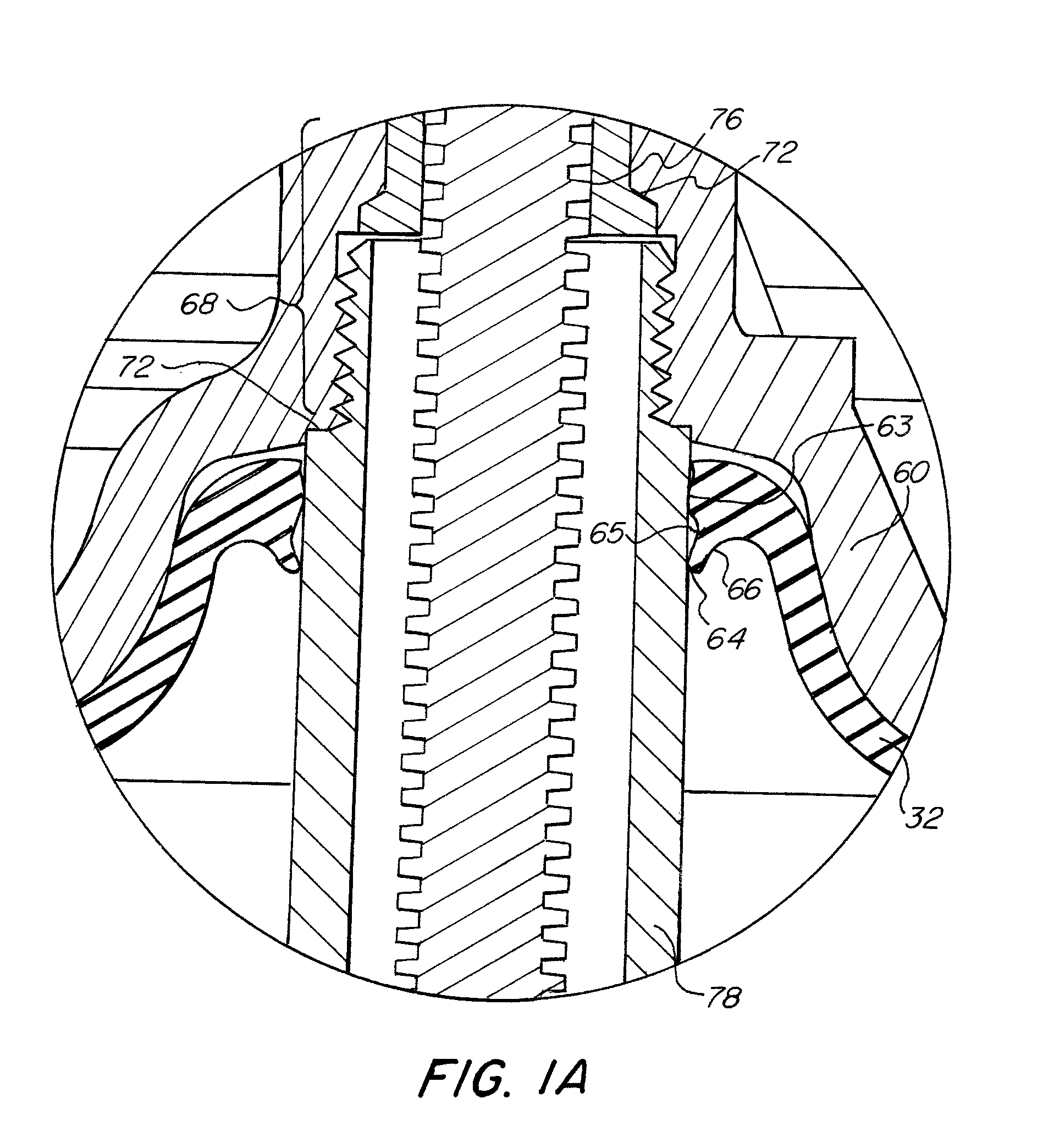

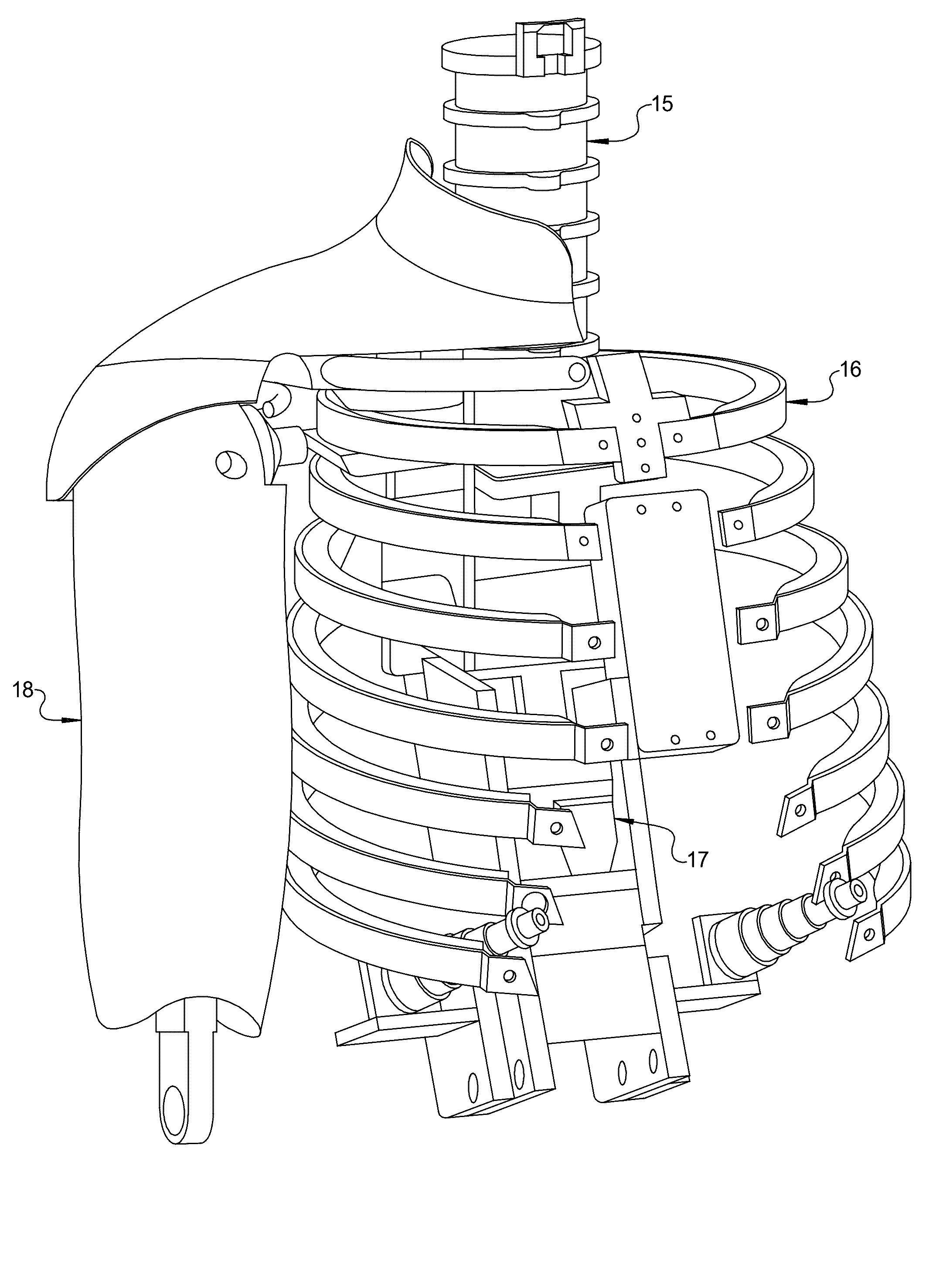

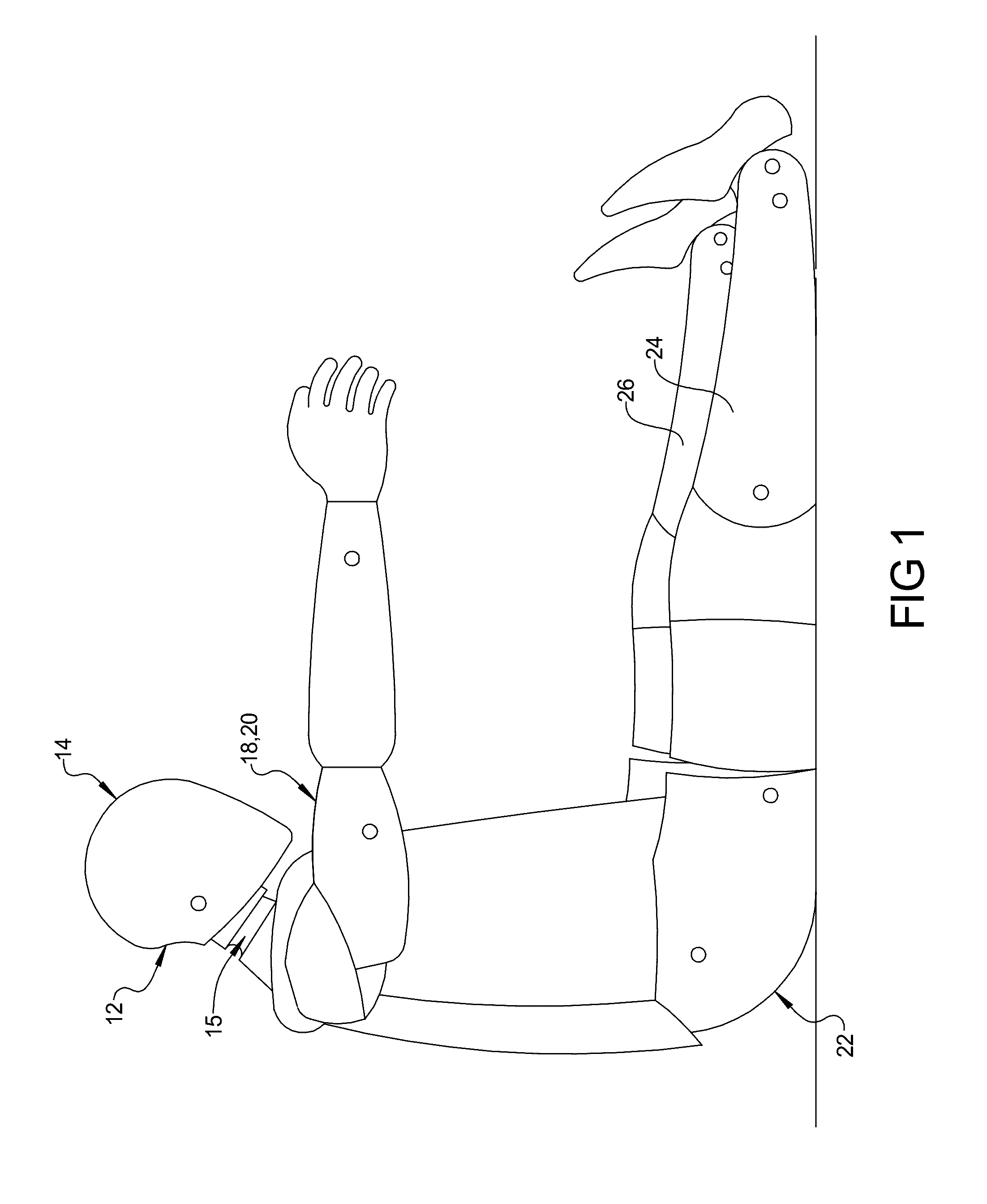

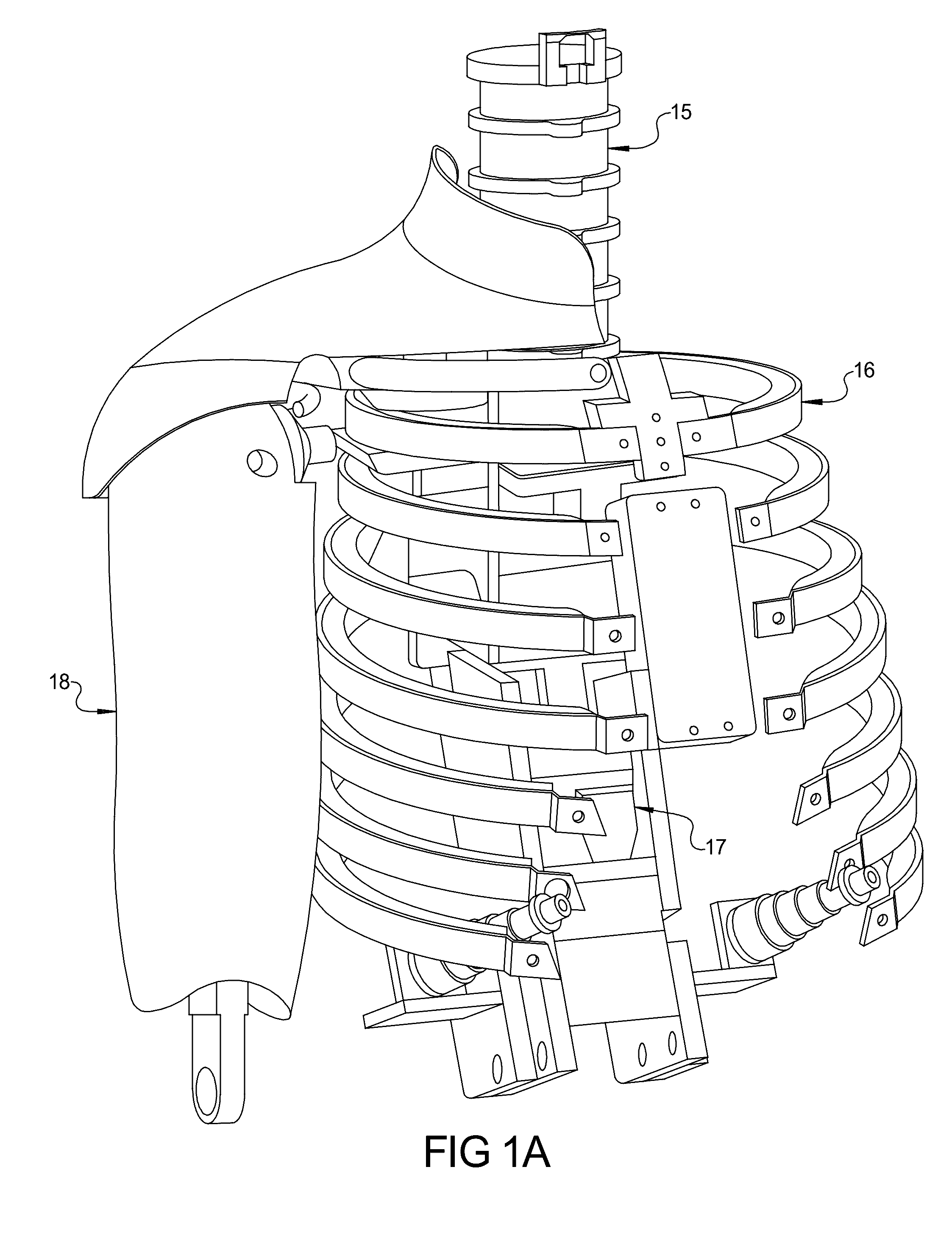

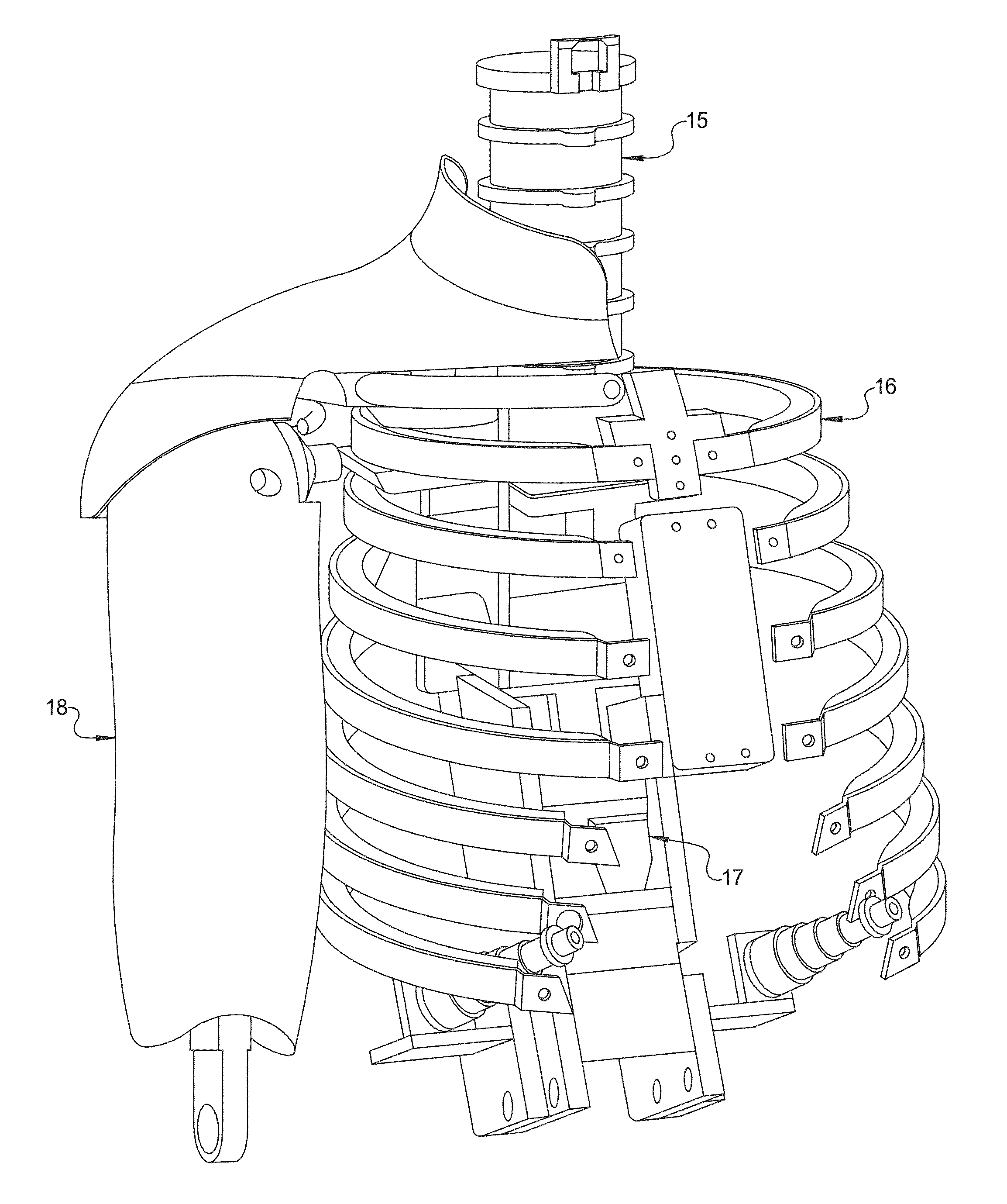

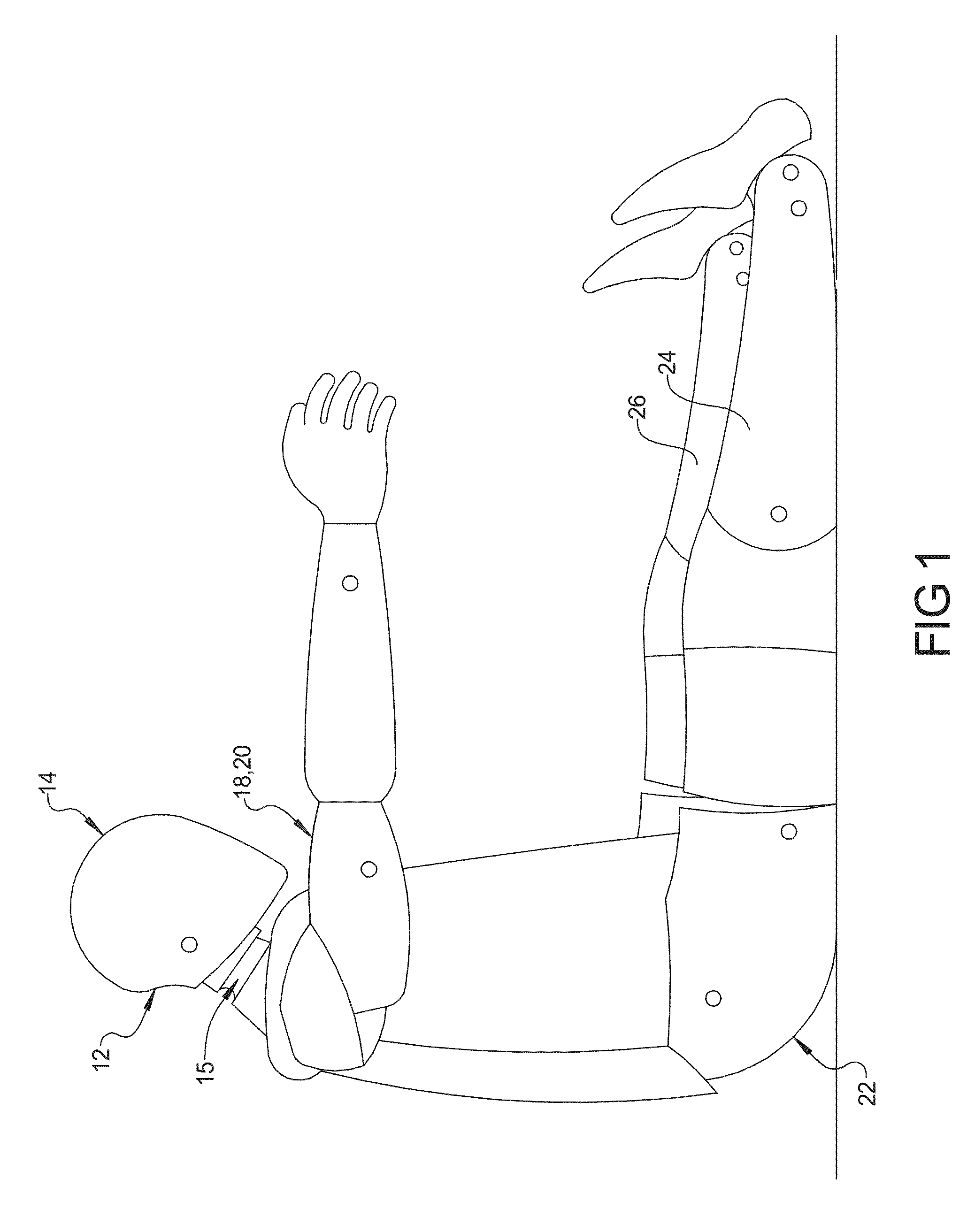

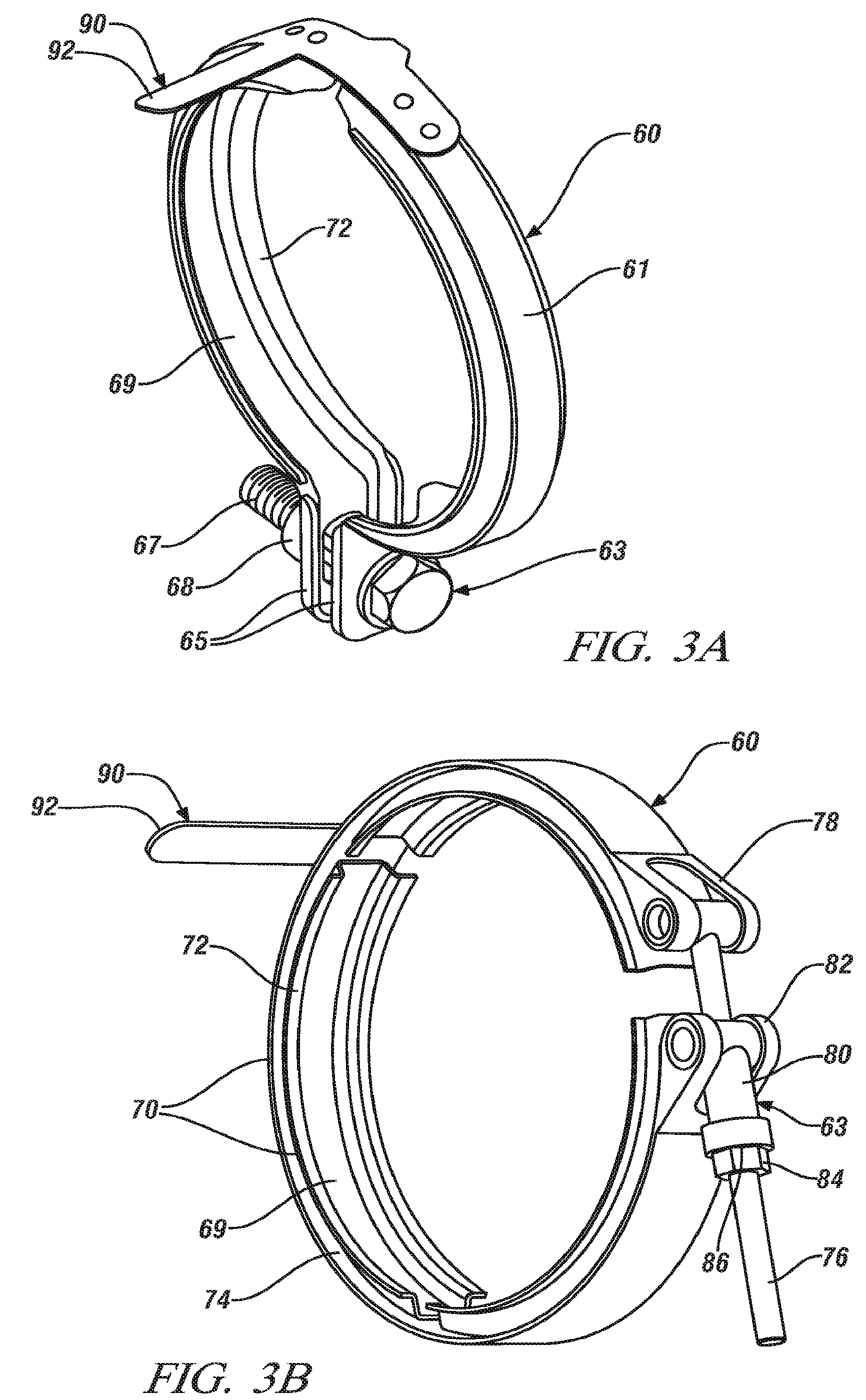

Adjustable spine joint assembly for crash test dummy

An adjustable spine joint assembly for a crash test dummy includes an upper member adapted to be operatively connected to an upper thoracic portion of a spine of the crash test dummy, a lower member adapted to be operatively connected to a lower thoracic portion of the spine of the crash test dummy, a center pivot bolt pivotally connected to the lower member and the upper member to allow rotational movement therebetween, and a self-locating adjustment mechanism cooperating with the upper member and the lower member to allow adjustment of a plurality of fixed joint angles between the upper member and the lower member.

Owner:HUMANETICS INNOVATIVE SOLUTIONS

Connection structure of water pipes

InactiveCN103807541ARealize automatic dockingGuaranteed concentricityCouplingsHose connectionsJoint componentButt joint

The invention discloses a connection structure of water pipes. The connection structure comprises a movable joint component, a fixed joint component and magnetic pieces, wherein the magnetic pieces are respectively arranged in one end of the movable joint component and one end of the fixed joint component; one ends of the movable joint component and the fixed joint component are magnetically connected by virtue of the magnetic pieces; the magnetic pieces are magnets. By virtue of adopting the technical scheme, the connection structure has the beneficial effects that the structure is simple, automatic water pipe abutting joint is realized, butting joint also can be realized under an eccentric condition, and the concentricity of the abutted water pipes is ensured; friction is prevented from being generated, risks are reduced, requirements on environment are low, and the connection structure is applicable to various structures.

Owner:SUZHOU IND PARK KALERM ELECTRIC APPLIANCES CO LTD

Adjustable lumbar spine assembly for crash test dummy

An adjustable lumbar spine assembly for a crash test dummy includes an upper member adapted to be connected to an upper thoracic portion of a spine of the crash test dummy, a lower member adapted to be connected to a lower thoracic portion of the spine of the crash test dummy, an upper abdomen interface connected to the lower member and adapted to be connected to an upper abdomen portion of the crash test dummy, and an adjustment mechanism cooperating with the upper member and the lower member to allow adjustment of varying fixed joint angles between the upper member and the lower member.

Owner:HUMANETICS INNOVATIVE SOLUTIONS

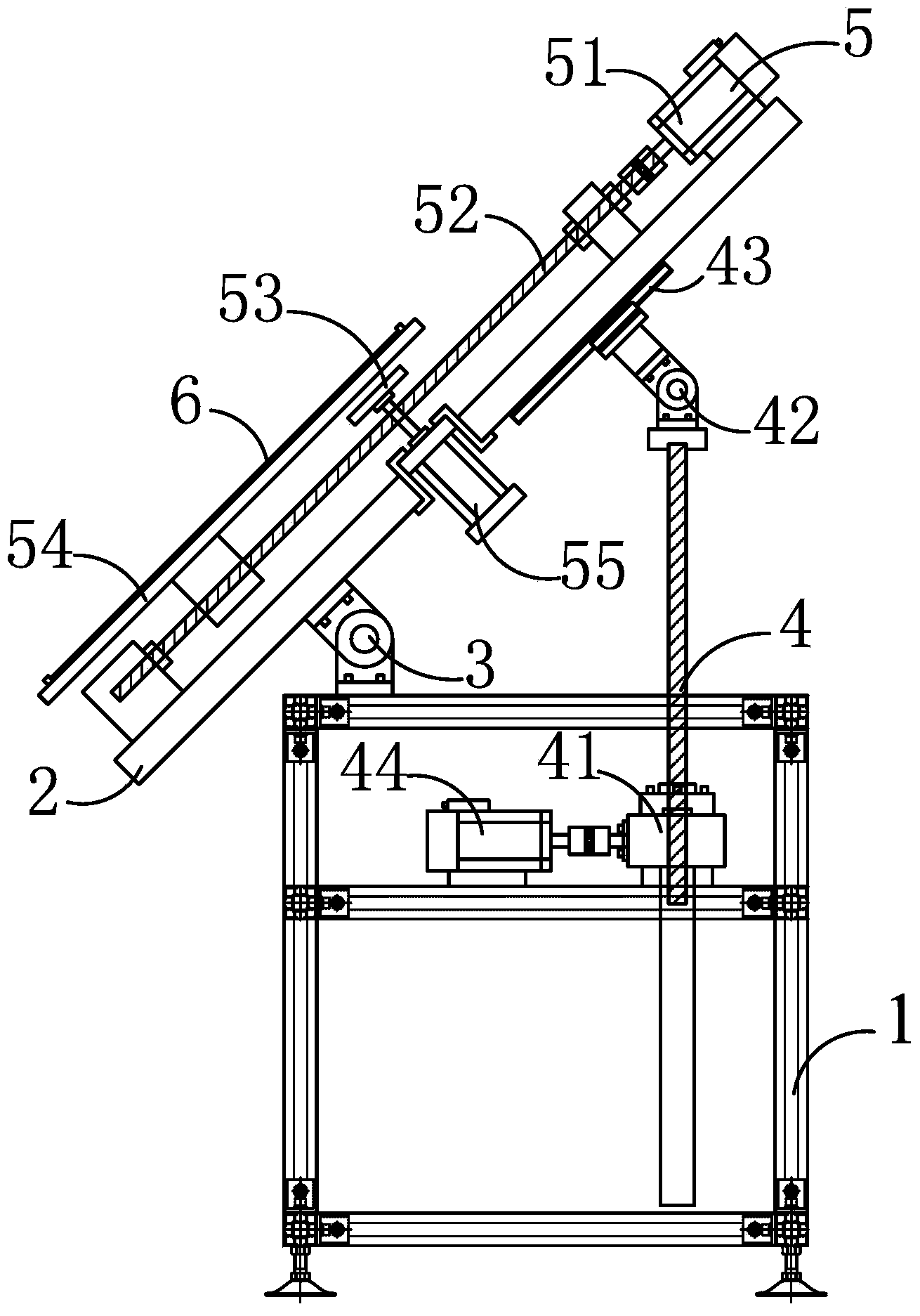

Defect detection device for OLED

InactiveCN103529373AReduce fatigueImprove work efficiencyIndividual semiconductor device testingRotational freedomVertical plane

The invention discloses a defect detection device for an OLED (Organic Light Emitting Diode), which comprises a rack, a mounting support plate, a gesture adjustment assembly, a detection adjustment assembly, a clamp mounting back plate and a probe assembly, wherein the mounting support plate is movably connected with the rack by a fixed joint, and provided with a rotational freedom degree of a vertical plane; the gesture adjustment assembly is connected between the rack and the mounting support plate, and used for adjusting inclination of the mounting support plate; the clamp mounting back plate is used for fixing an OLED display screen, and connected with the detection adjustment assembly; the detection adjustment assembly is fixedly mounted on the mounting support plate, and used for changing a relative position of the clamp mounting back plate and the mounting support plate; and the probe assembly is used for supplying power to the OLED display screen. The detection device has the benefits that when operating personnel control rotation of a motor, an inclination angle between an OLED panel and a horizontal plane can be adjusted according to personal height and operation habits; a fatigue degree of a worker on a mass production line can be relieved effectively; the working efficiency can be improved; and the detection quality can be ensured effectively.

Owner:SICHUAN CCO DISPLAY TECH

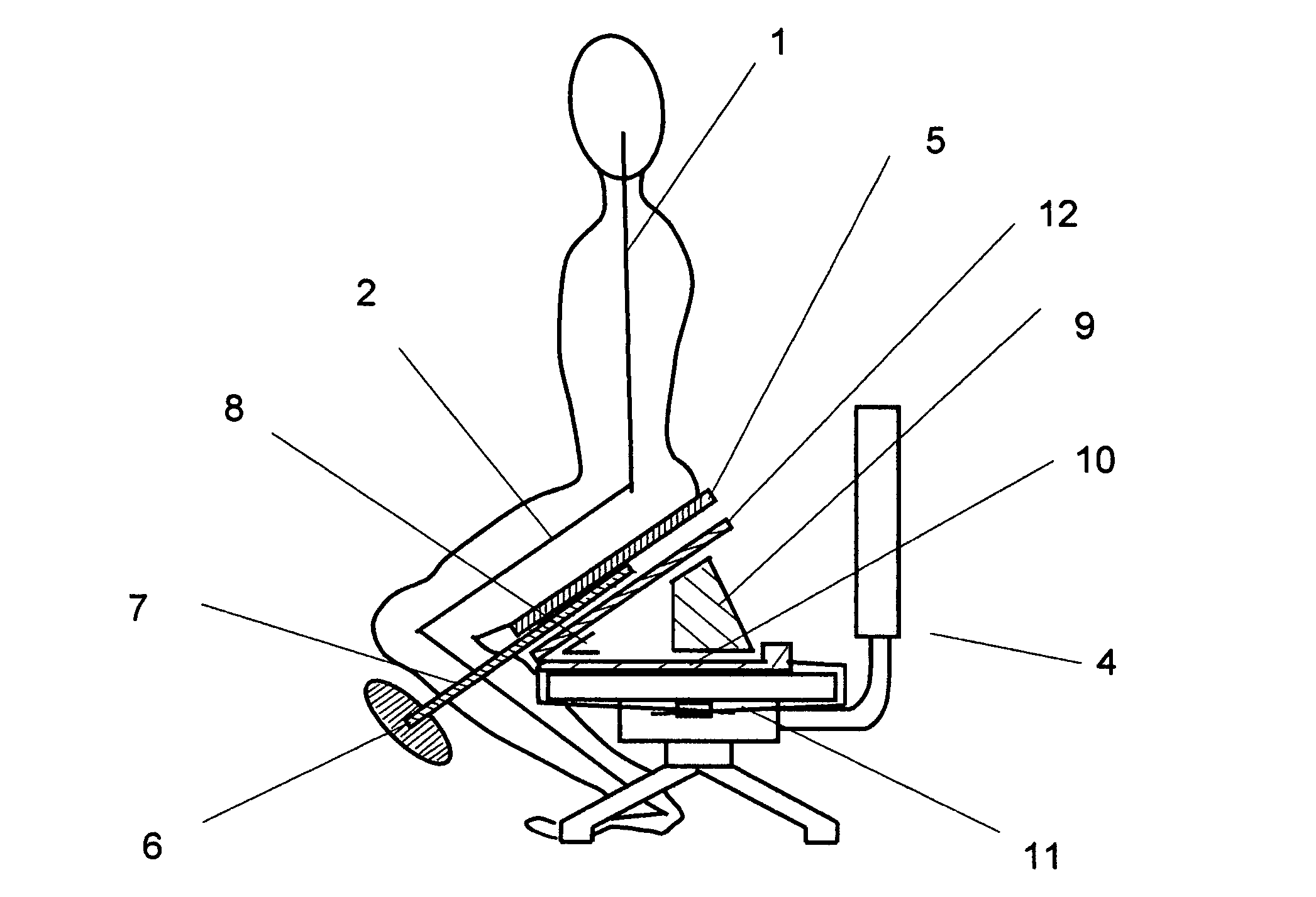

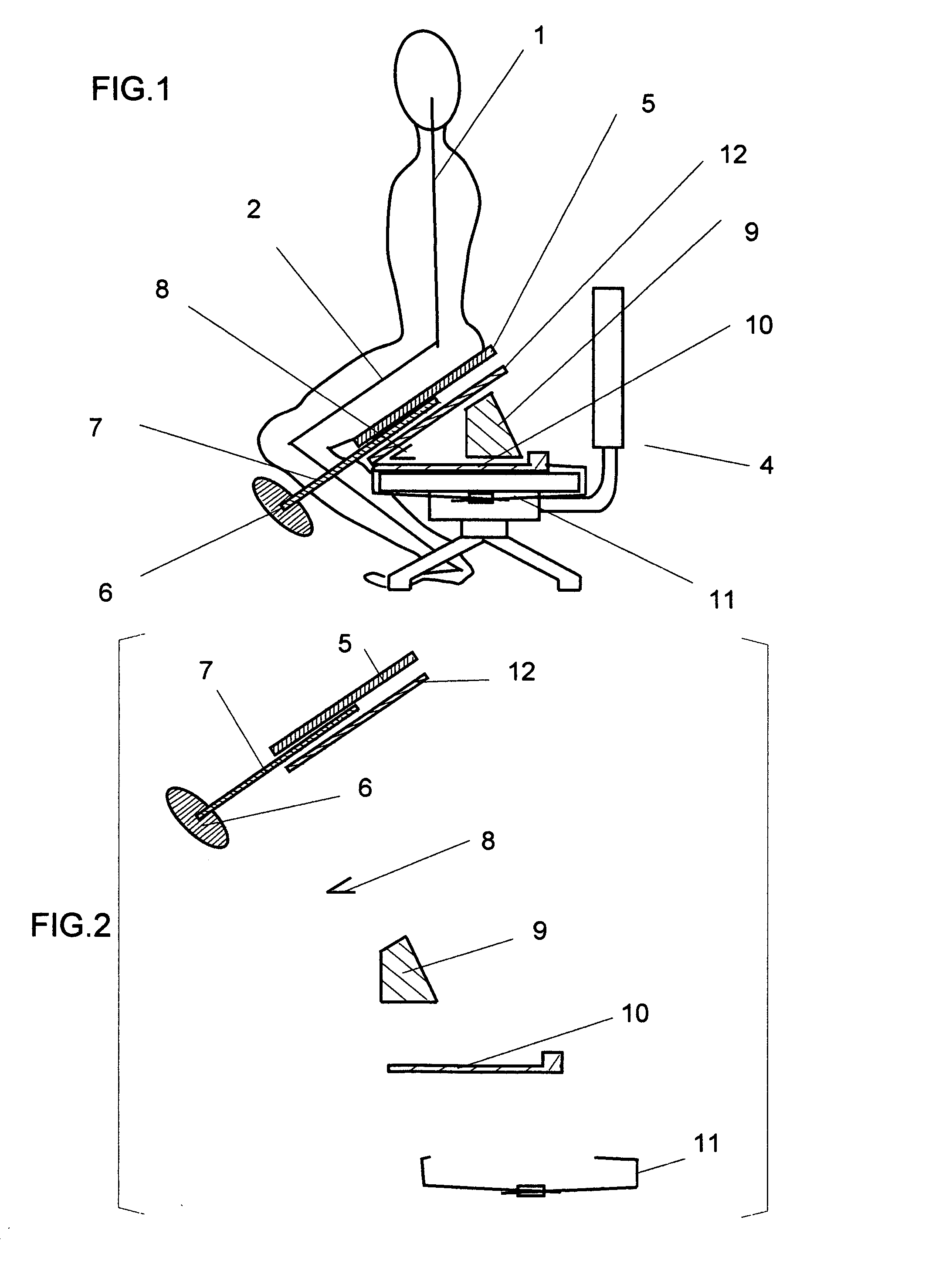

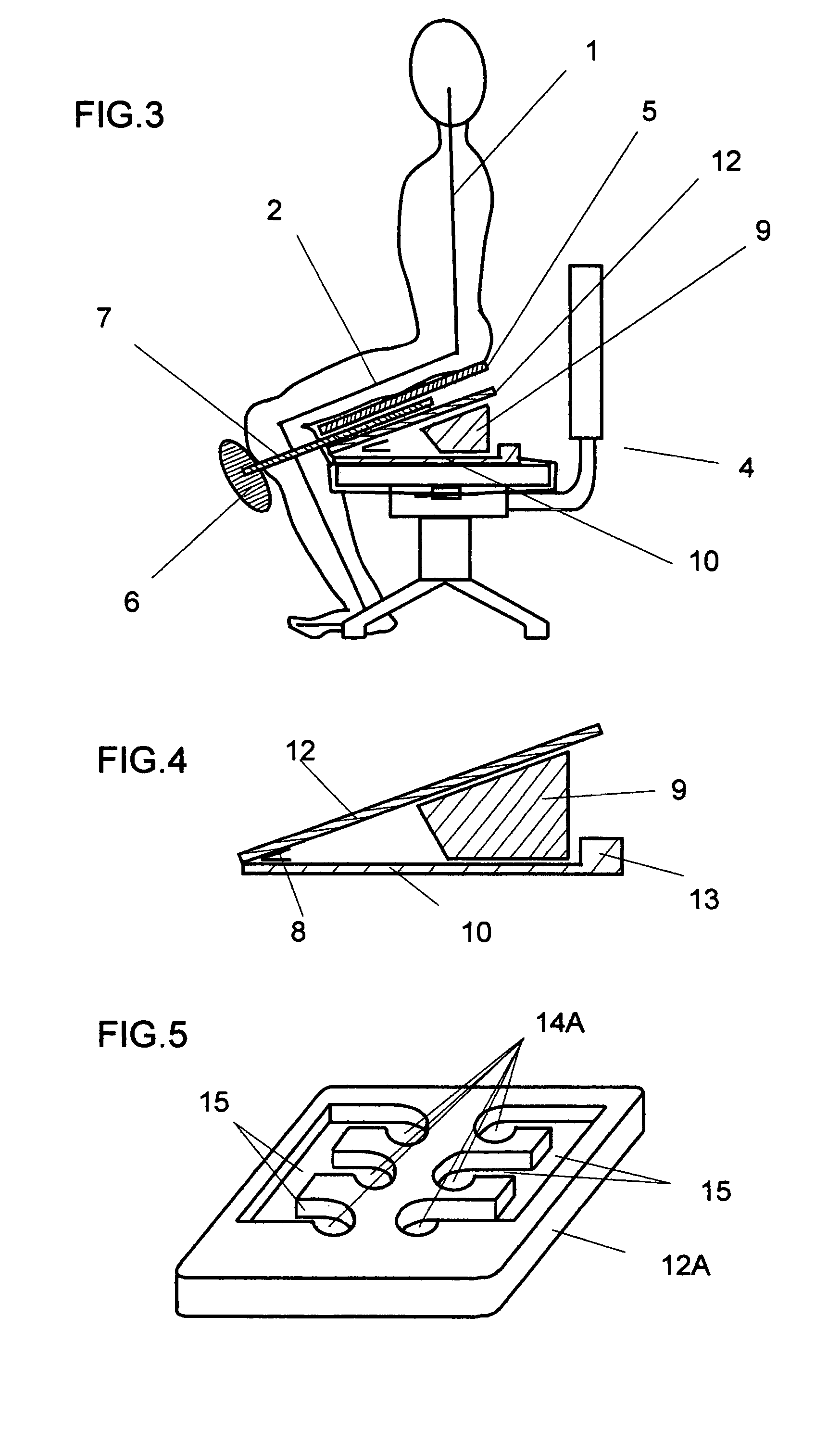

Seating apparatus with tilted surface and the chair with the same

The invention provide the seating apparatus to be used on the chair of the horizontal sitting base plate in order to avoid the lower back pain. By sitting on the seating base plate tilted forward from 5 to 45 degree, the person can keep the angle between the spine and the thigh from 95 to 135 degree. As the seating apparatus is equipped with the knee front holder connected with the supporting part, which is connected with the seating base plate by the half fixed joint at an another end of the supporting part, the slip down of the body on the seating base plate is stopped by the knee front holder and the steady sitting is available.

Owner:KOBAYASHI TOMIO

Engine assembly and method of making

An engine assembly comprising a cylinder head, turbocharger in fluid communication with the cylinder head and exhaust conduit in fluid communication with the turbocharger and method of making the assembly using a single human assembler includes: mounting the turbine to the cylinder head; using a first assembly aid to form a slidable joint between the exhaust conduit and head; using a second assembly aid to form a movable joint between the turbine and exhaust conduit and align the turbine outlet flange and exhaust conduit inlet flange; using a third assembly aid to pilotingly engage the flanges; disposing a clamp about the turbine outlet flange and the exhaust conduit inlet flange; tightening the second assembly aid sufficiently to form an immovable joint; tightening the clamp to form a sealed joint between the flanges; and tightening the first assembly aid to form a fixed joint.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com