Corn machine capable of peeling and threshing

A corn machine and corn kernel technology, which is applied to threshing equipment, harvesters, agricultural machinery and tools, etc., can solve the problems of large manual cleaning tasks, low corn threshing rate, easy to block machines, etc., and achieves compact structure and energy saving The effect of small space and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

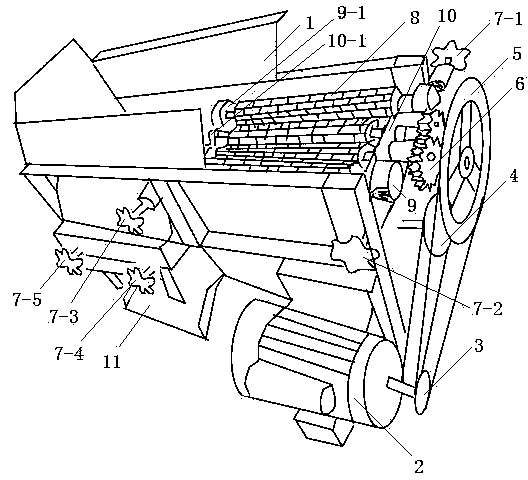

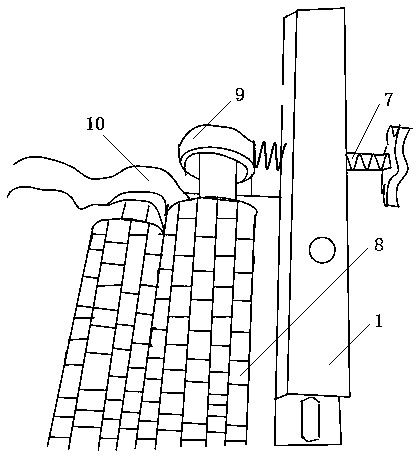

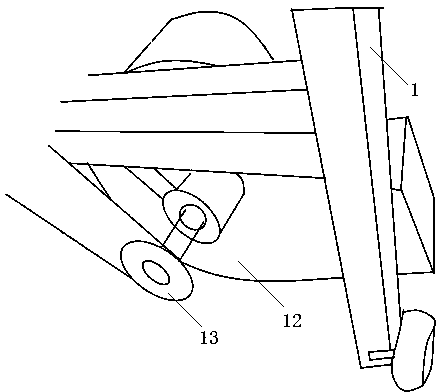

[0043] A corn machine capable of peeling and threshing, comprising a peeling device and a threshing device, the peeling device is distributed on the front part of the frame 1, and the rear part is a threshing device, which is covered by a casing 22, and the casing 22 is fixed on the frame 1; The peeling device includes a motor 2, a peeling pulley 5, a gear 6, an adjustment device 7, a peeling cylinder 8, a movable bearing seat 9, a fixed bearing seat 10, a blower pulley 13, and a blower 12. The motor 2 is connected with the peeling pulley 5 and the peeling pulley 5 by a belt. The blower pulley 13 is connected by a belt, and the peeling pulley 5 is axially provided with two gears 6 and two power peeling cylinders 8. A movable peeling cylinder 8, the movable peeling cylinder 8 is fixed by four movable bearing seats 9 before and after, and the smaller end of the movable bearing seat 9 is fixed on the frame 1, and the elasticity of the peeling roller 8 is adjusted by the adjusting ...

Embodiment 2

[0045] In the corn machine capable of peeling and threshing described in the above embodiments, the fixed joint 19 is connected by a circular pipe through a bolt or a universal joint; the diameter ratio of the pulley 3 and the threshing pulley 4 is 65:105; The diameter ratio of the peeling pulley 5 is 50:200; the diameter ratio of the pulley 3 and the blower pulley 13 is 1:1; the adjustment plate 15 is adjusted to move forward and backward at the corn kernel discharge port 11; the threshing drum is provided with two S-shaped spiral ribs The threshing plate 14 is a strip shape; the corn grain discharge port 11 is provided with a quantitative packaging device; the peeling cylinder 8 is made of concave-convex rubber; the peeling device is inclined to the threshing device at an angle of 5 degrees with the horizontal angle; the motor power is 1.5 kw, the speed is 1400 / min.

Embodiment 3

[0047]In the corn machine capable of peeling and threshing described in the above embodiment, the fixed joint 19 is connected by a circular pipe through a bolt or a universal joint; the diameter ratio of the pulley 3 and the threshing pulley 4 is 50:85; The diameter ratio of the peeling pulley 5 is 60:230; the diameter ratio of the pulley 3 and the blower pulley 13 is 1:1; the adjustment plate 15 is adjusted to move forward and backward at the corn kernel discharge port 11; the threshing drum is provided with two S-shaped spiral ribs The threshing plate 14 is mesh-shaped; the corn grain discharge port 11 is provided with a quantitative packaging device; the peeling drum 8 is made of concave-convex rubber; the peeling device is inclined at an angle of 10 degrees to the horizontal angle; the motor power is 1.8kw , the speed is 1800r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com