Patents

Literature

338 results about "Crash test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A crash test is a form of destructive testing usually performed in order to ensure safe design standards in crashworthiness and crash compatibility for various modes of transportation (see automobile safety) or related systems and components.

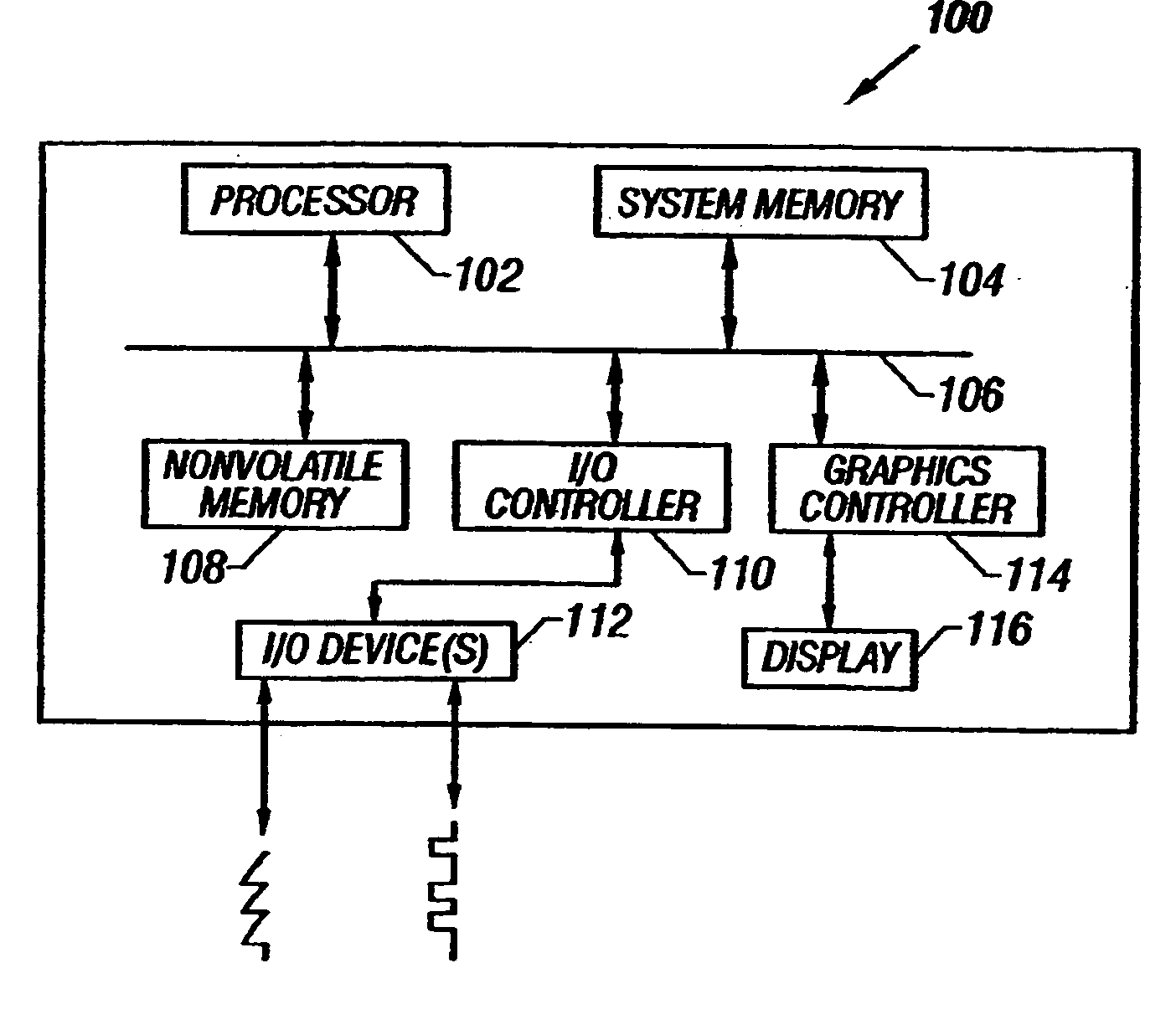

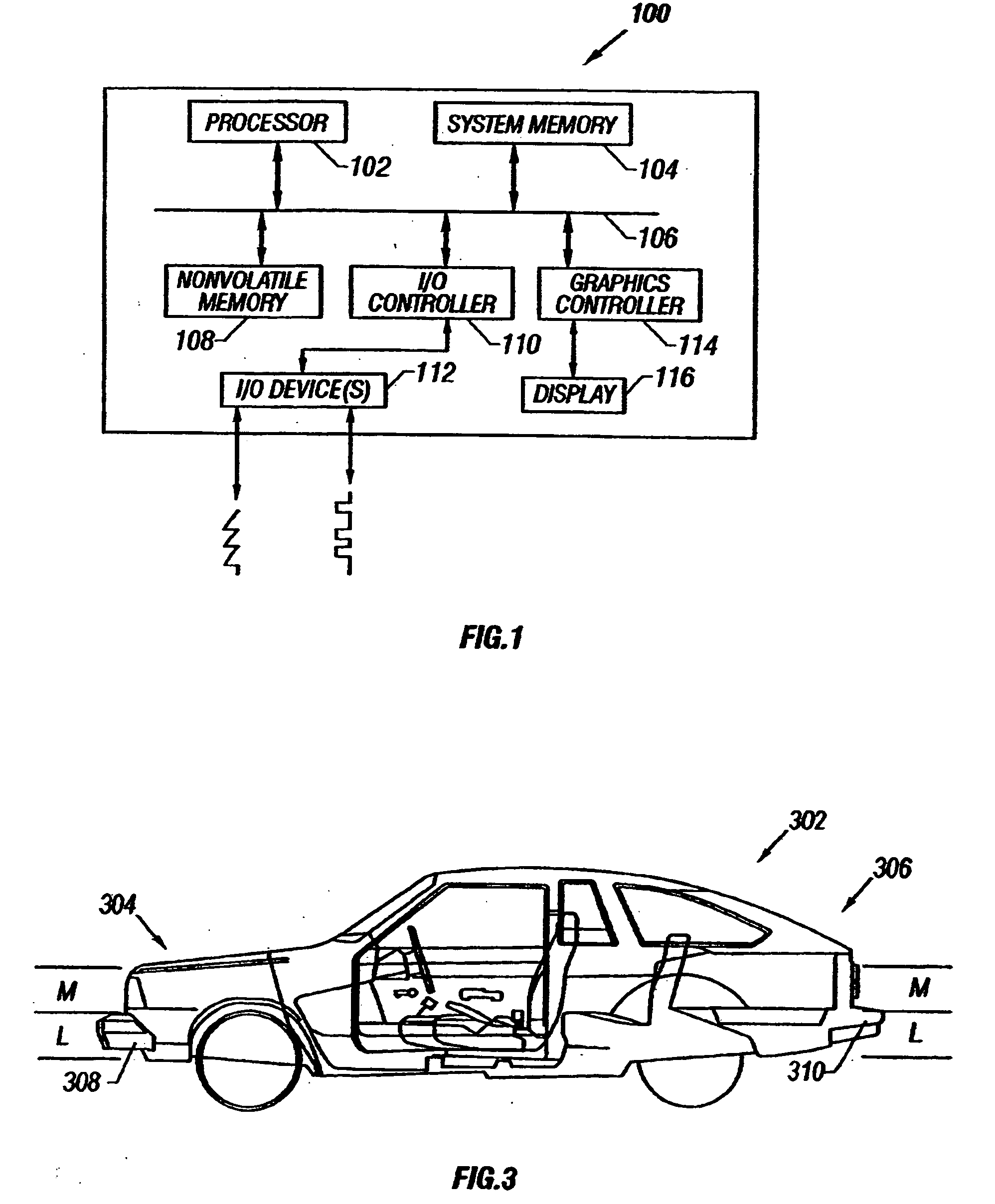

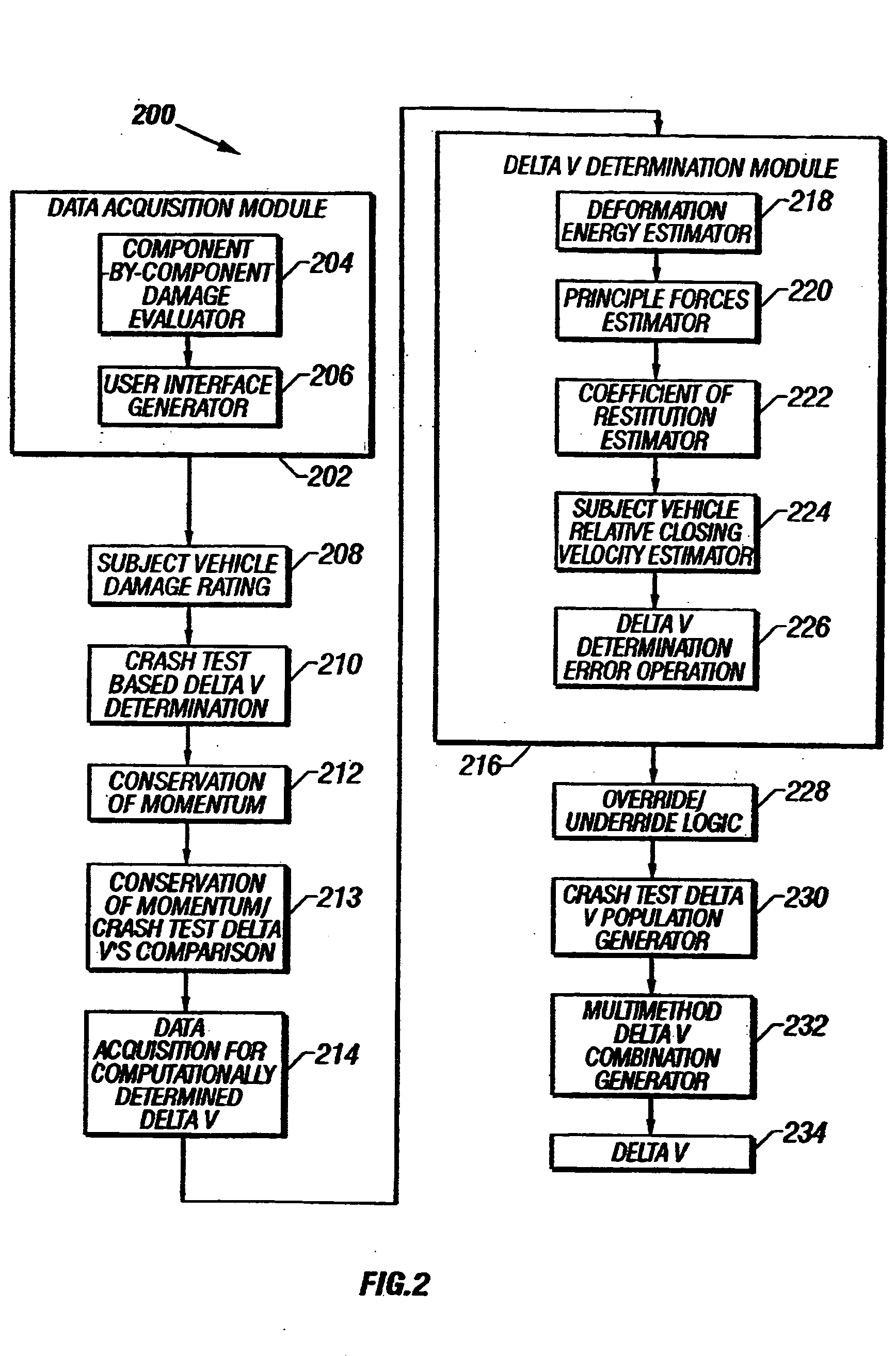

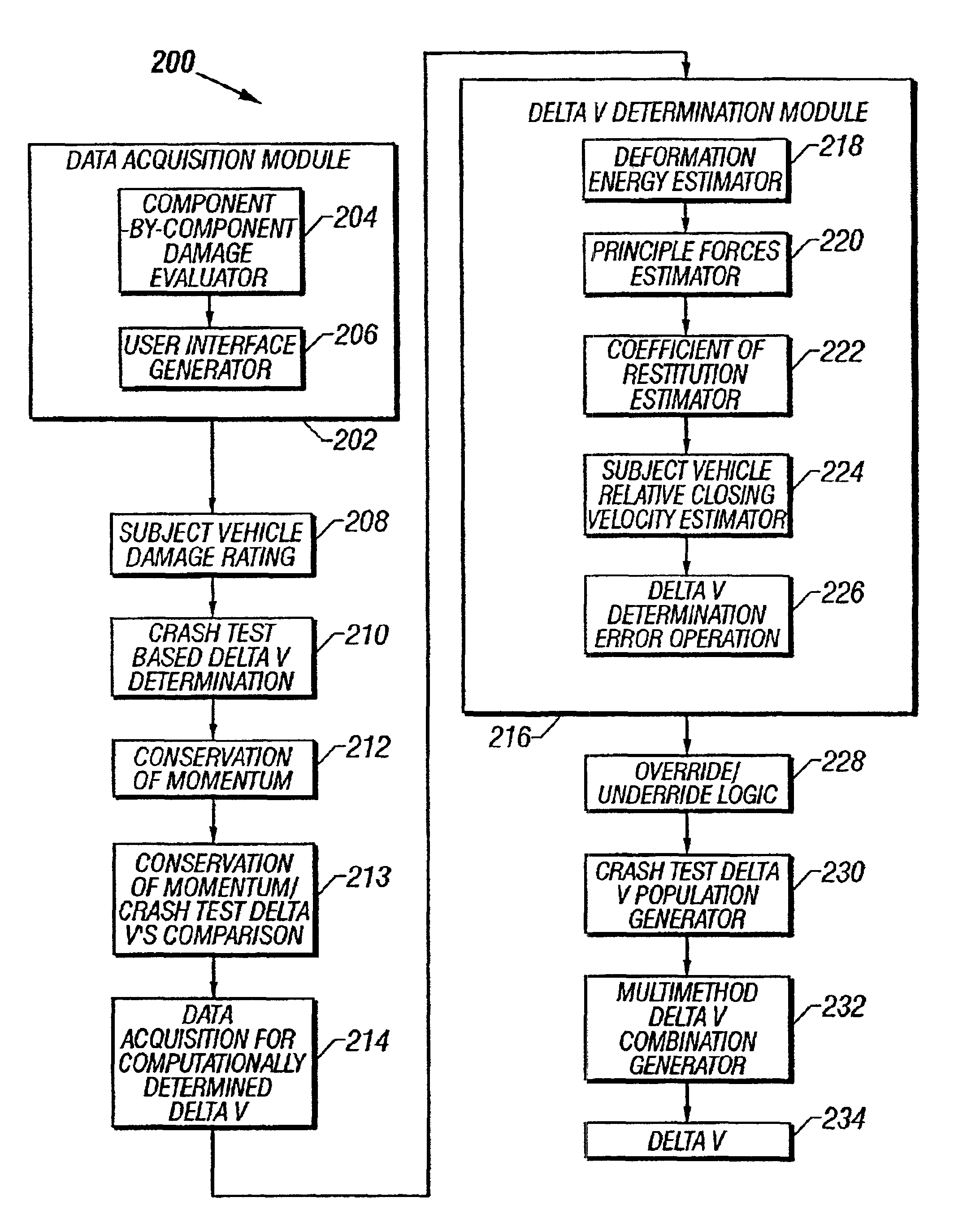

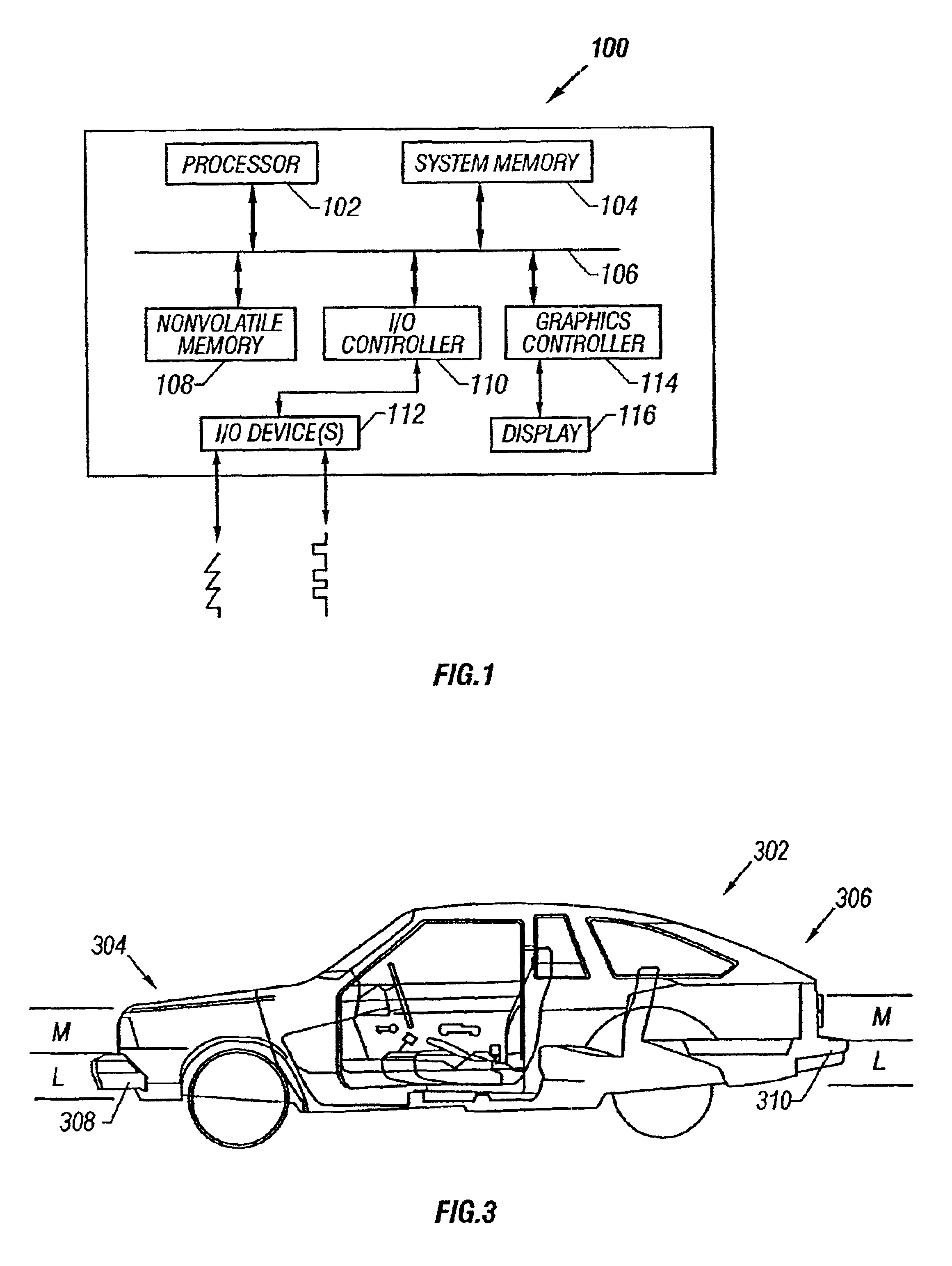

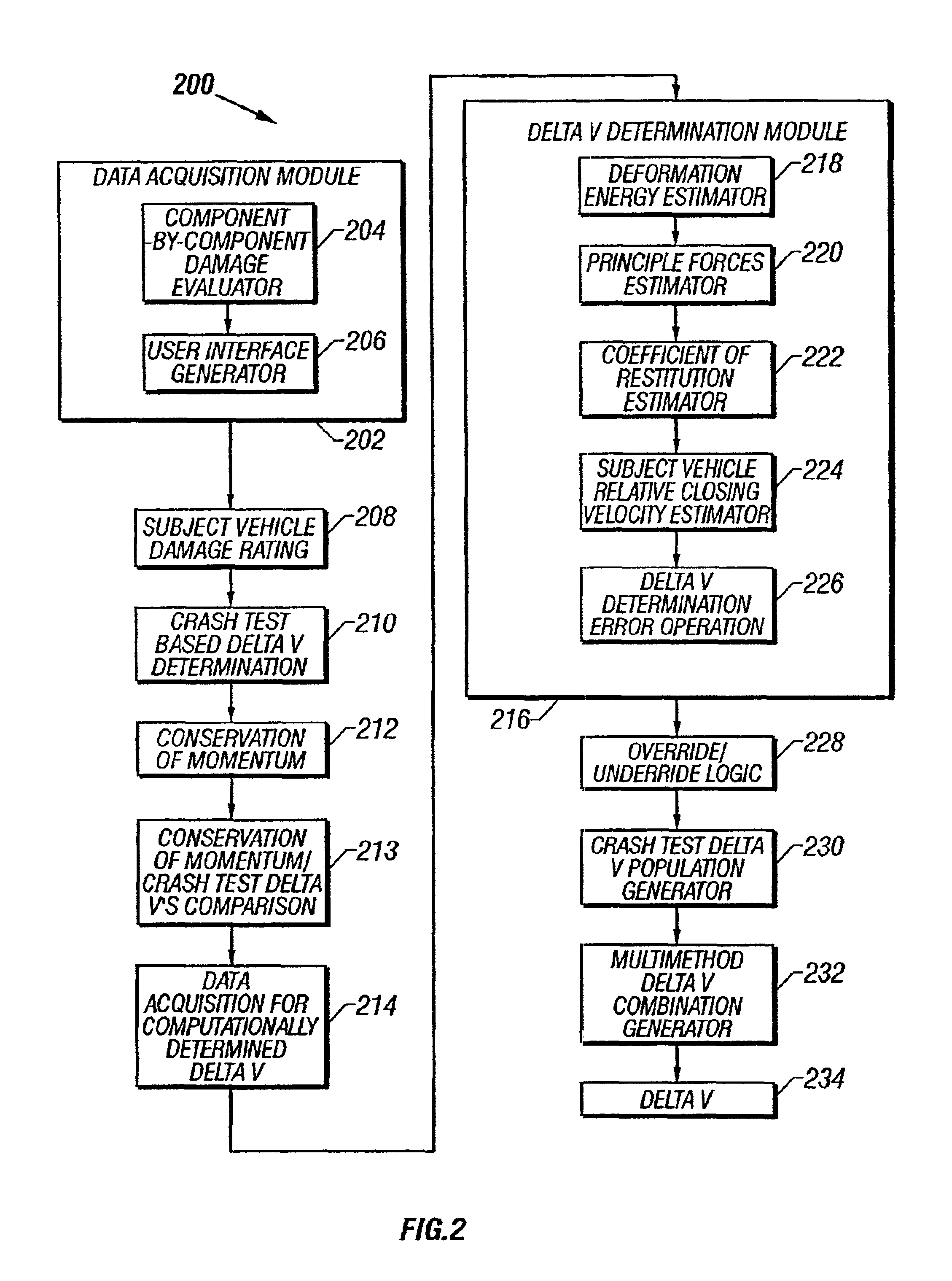

System and method for determining post-collision vehicular velocity changes

A system and method that utilizes information relating to vehicle damage information including damaged vehicle area information, crush depth of the damaged areas information, and vehicle component-by-component damage information to determine the relative velocities of vehicles involved in a collision. The change in velocity is estimated using a plurality of methods, and a determination is made as to which method provided a result that is likely to be more accurate, based on the damage information, and the types of vehicles involved. The results from each method may also be weighted and combined to provide a multi-method estimate of the closing velocity. The methods include using crash test data from one or more sources, estimating closing velocity based on the principals of conservation of momentum, and estimating closing velocity based on deformation energy resulting from the collision.

Owner:CCC INFORMATION SERVICES

System and method for estimating post-collision vehicular velocity changes

A system and method that utilizes information relating to vehicle damage information including damaged vehicle area information, crush depth of the damaged areas information, and vehicle component-by-component damage information to estimate the relative velocities of vehicles involved in a collision. The change in velocity is estimated using a plurality of methods, and a determination is made as to which method provided a result that is likely to be more accurate, based on the damage information, and the types of vehicles involved. The results from each method may also be weighted and combined to provide a multi-method estimate of the closing velocity. The methods include using crash test data from one or more sources, estimating closing velocity based on the principals of conservation of momentum, and estimating closing velocity based on deformation energy resulting from the collision.

Owner:CCC INFORMATION SERVICES

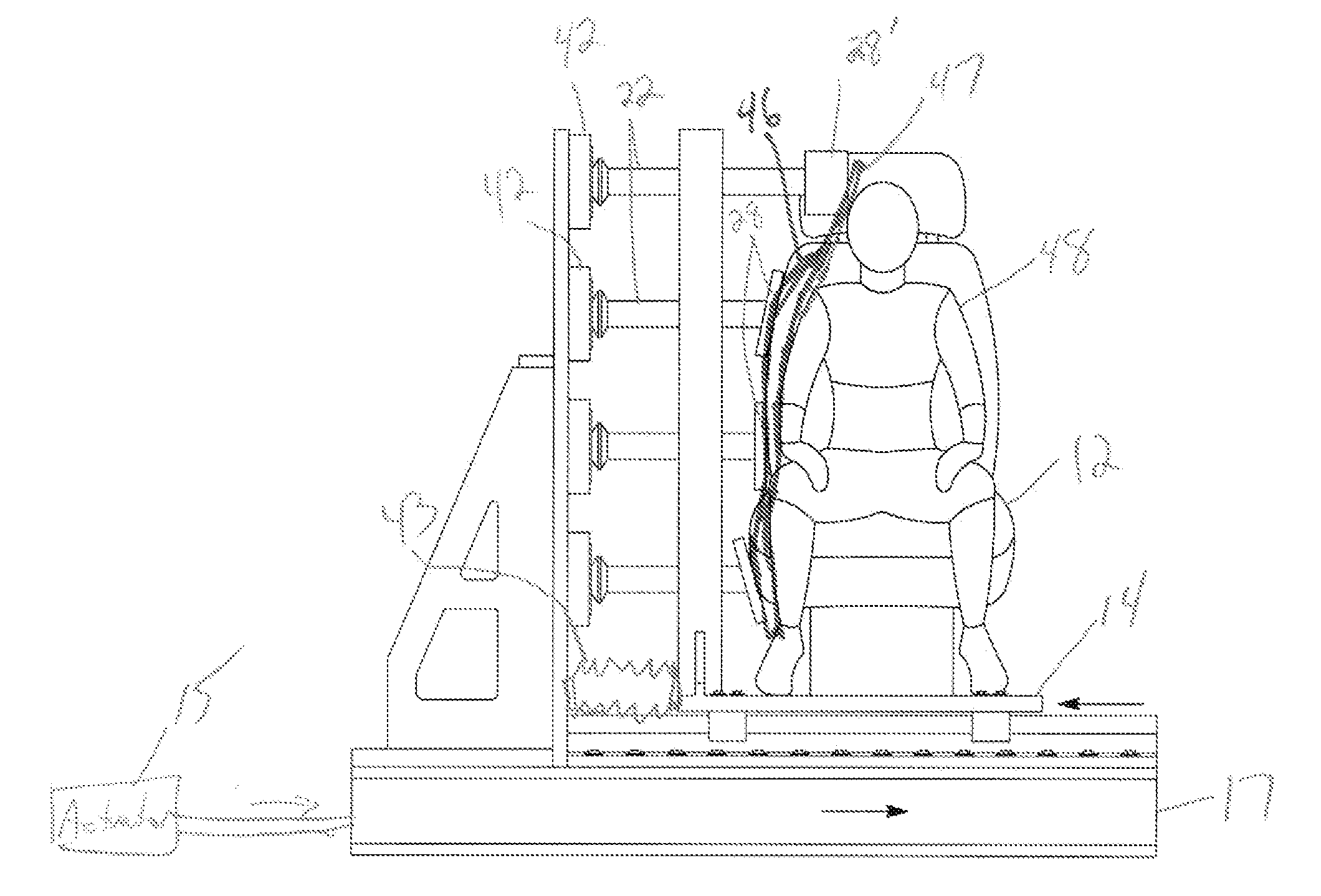

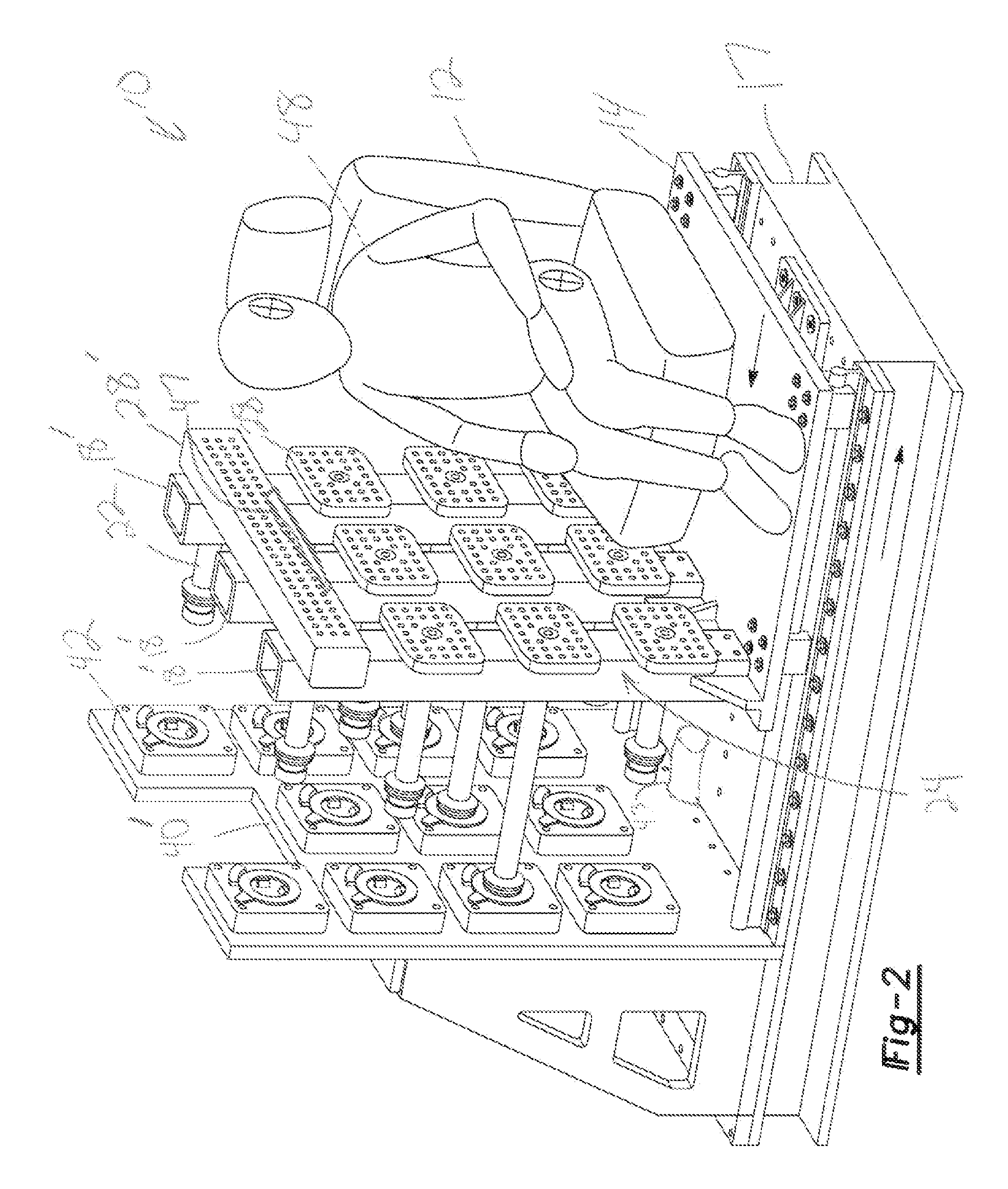

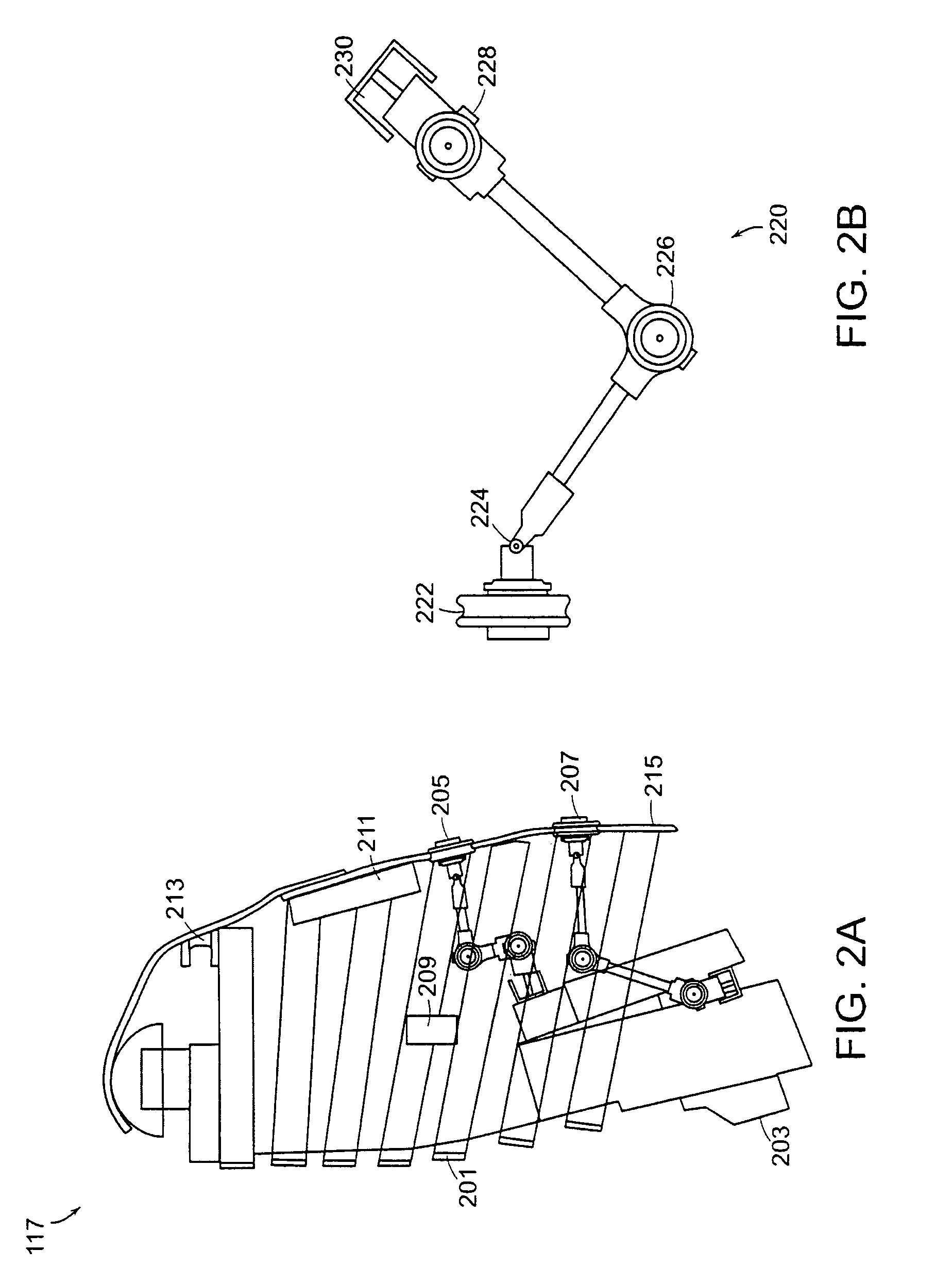

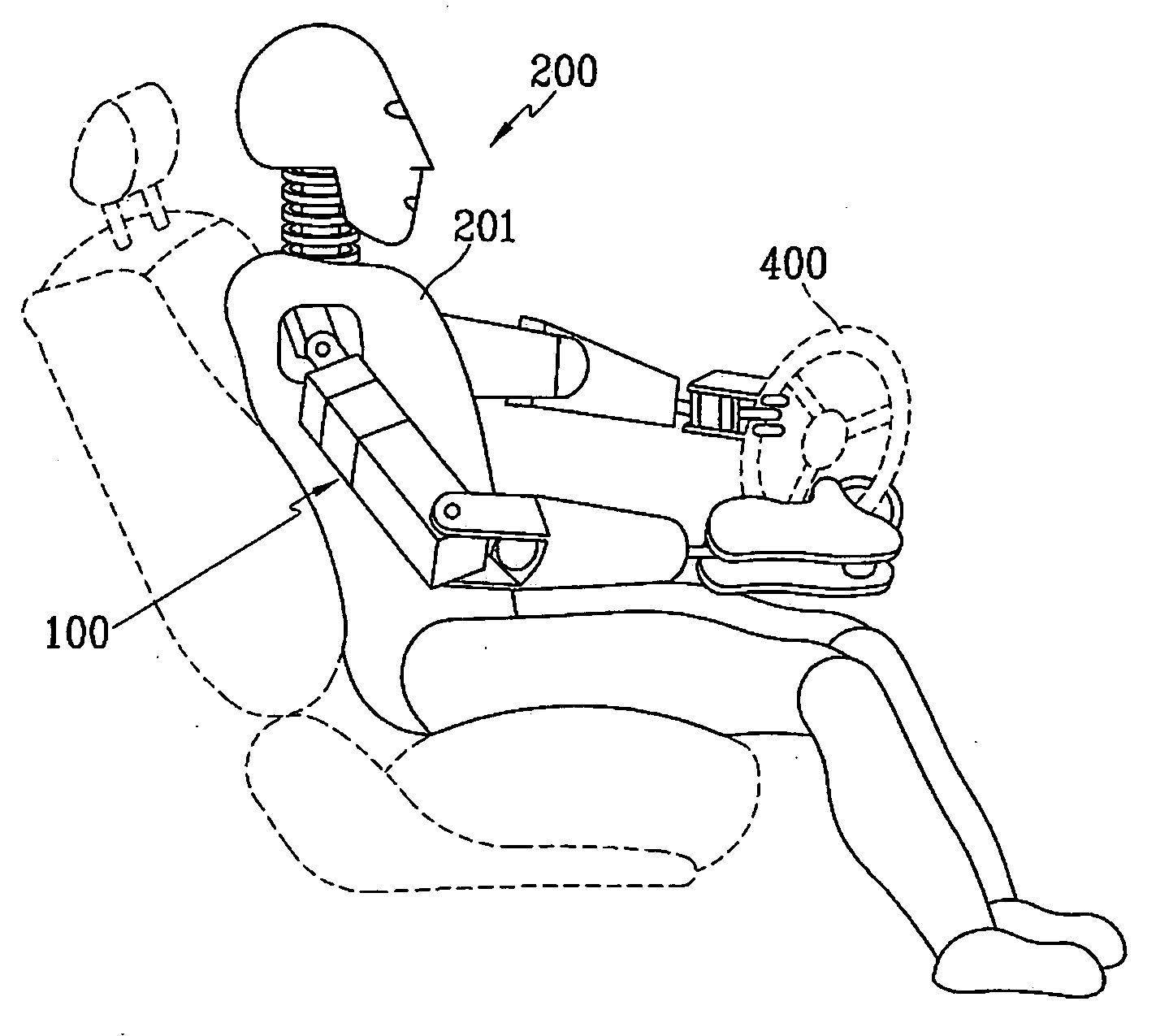

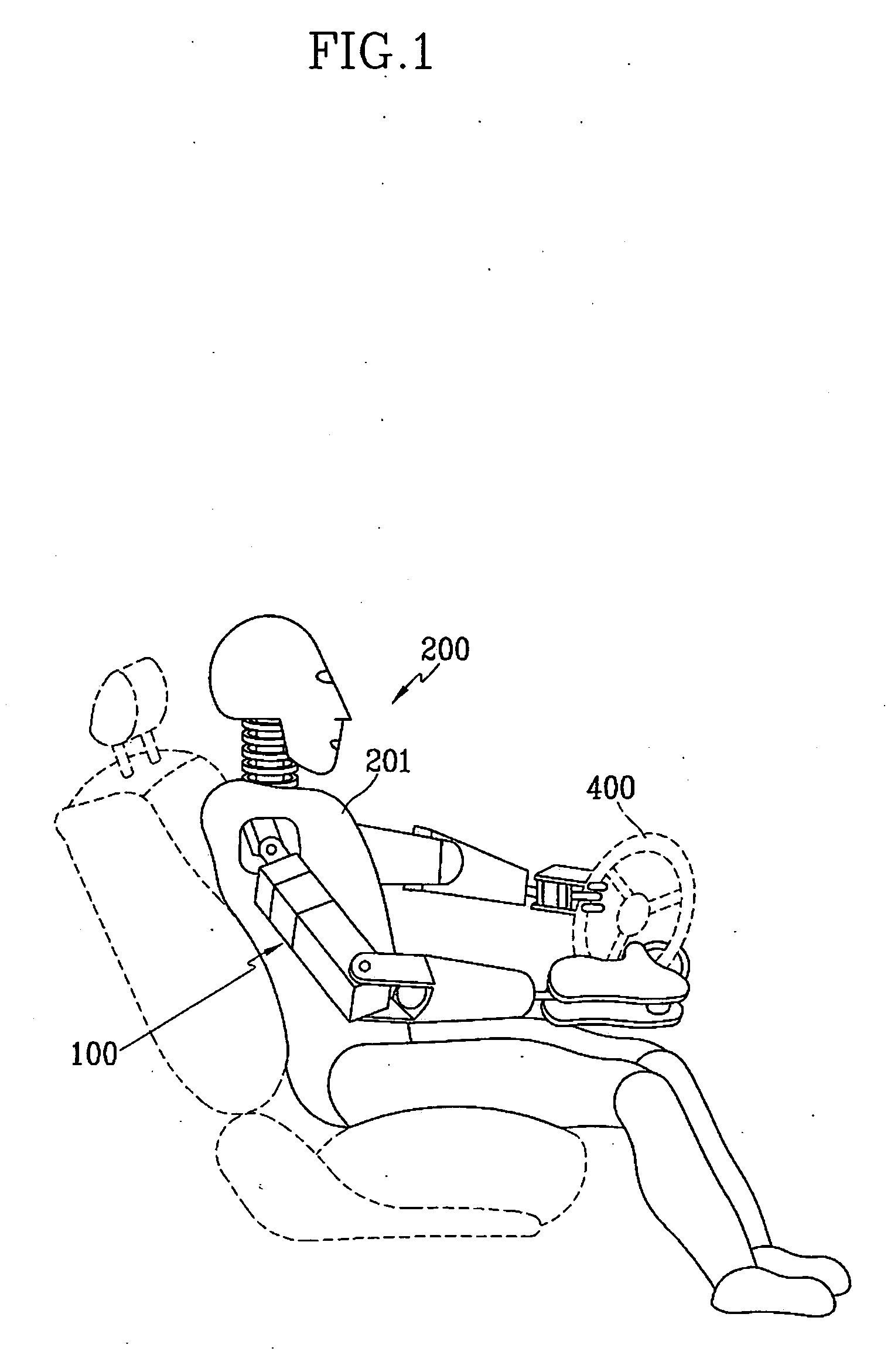

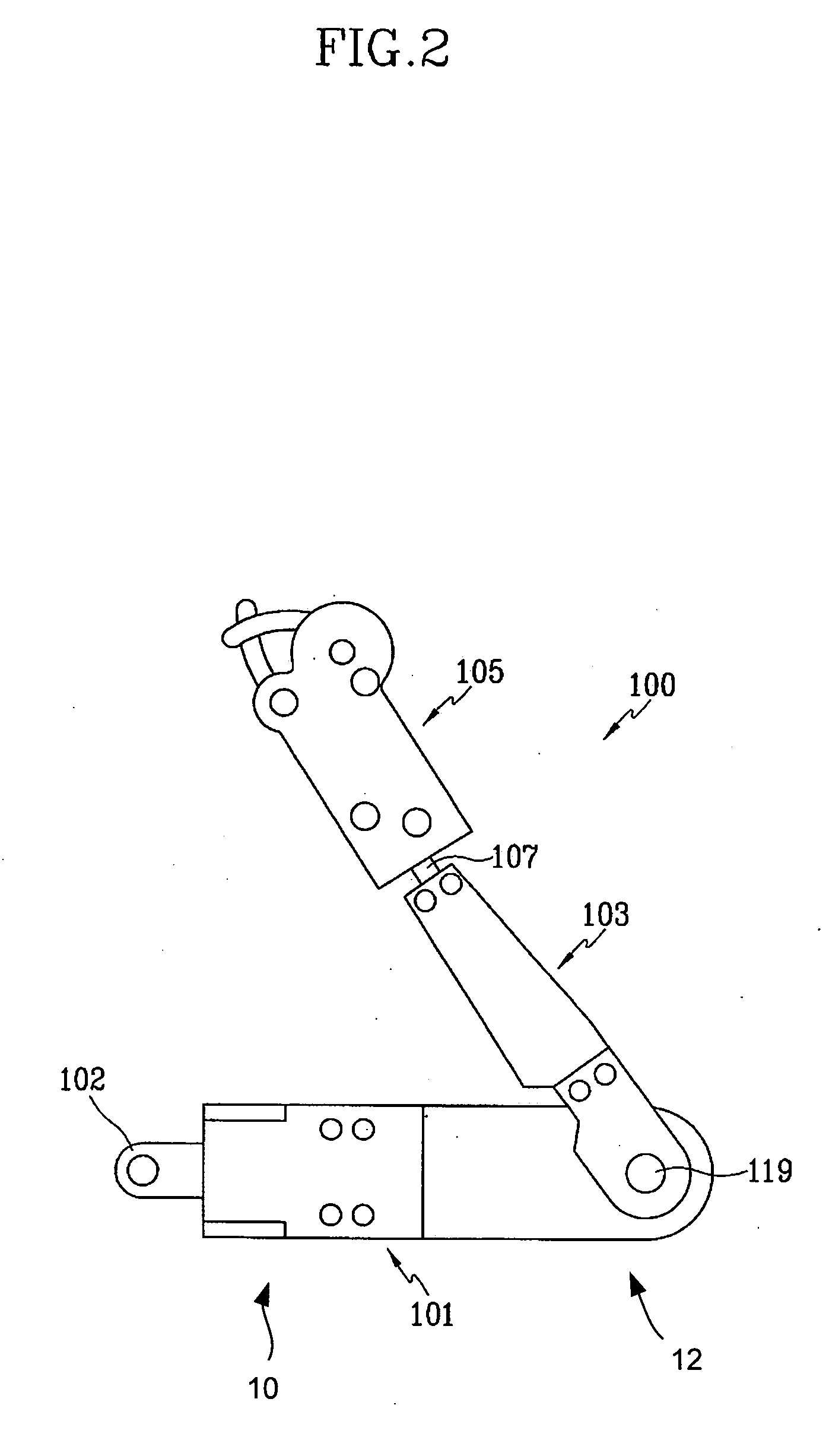

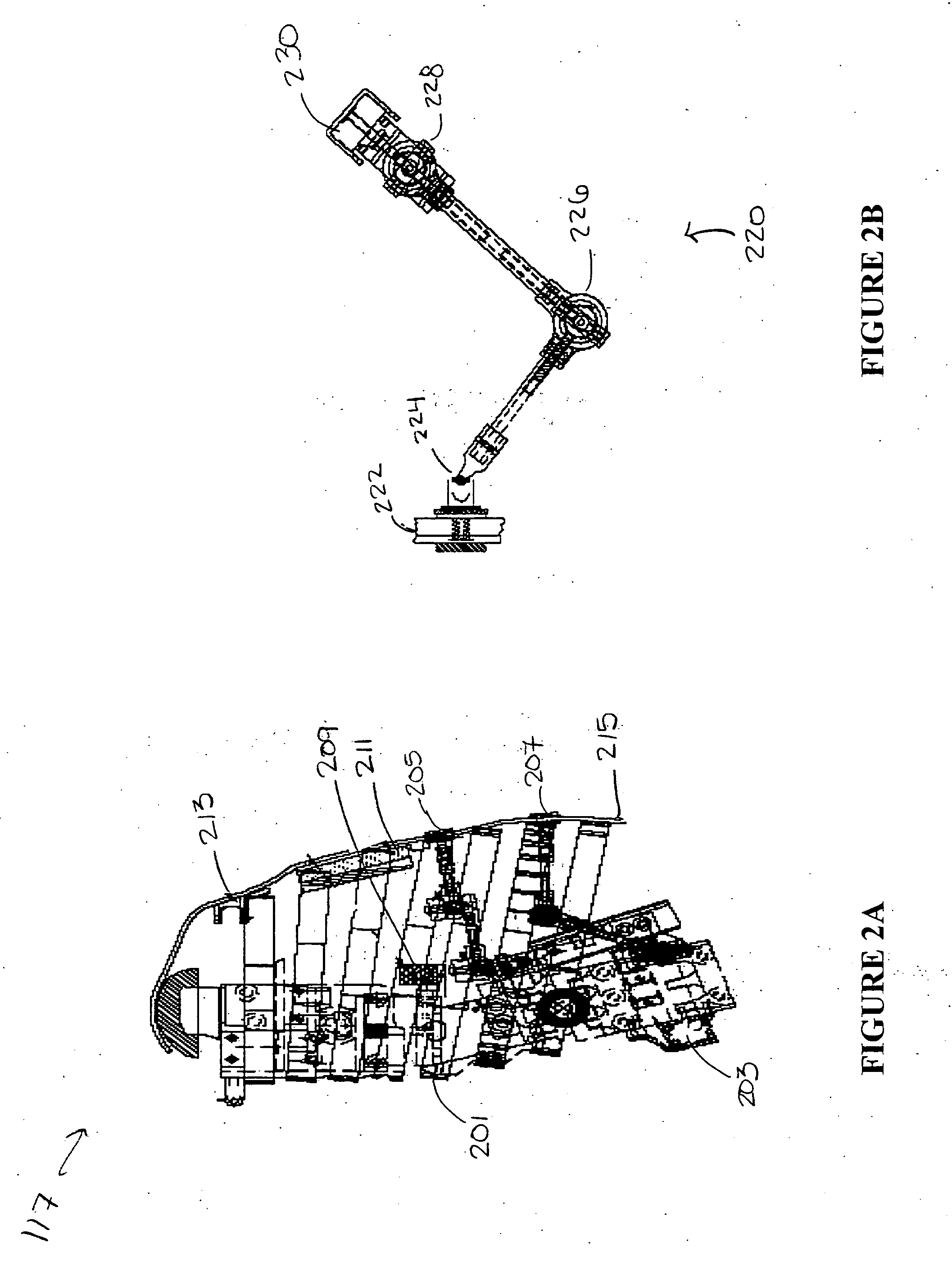

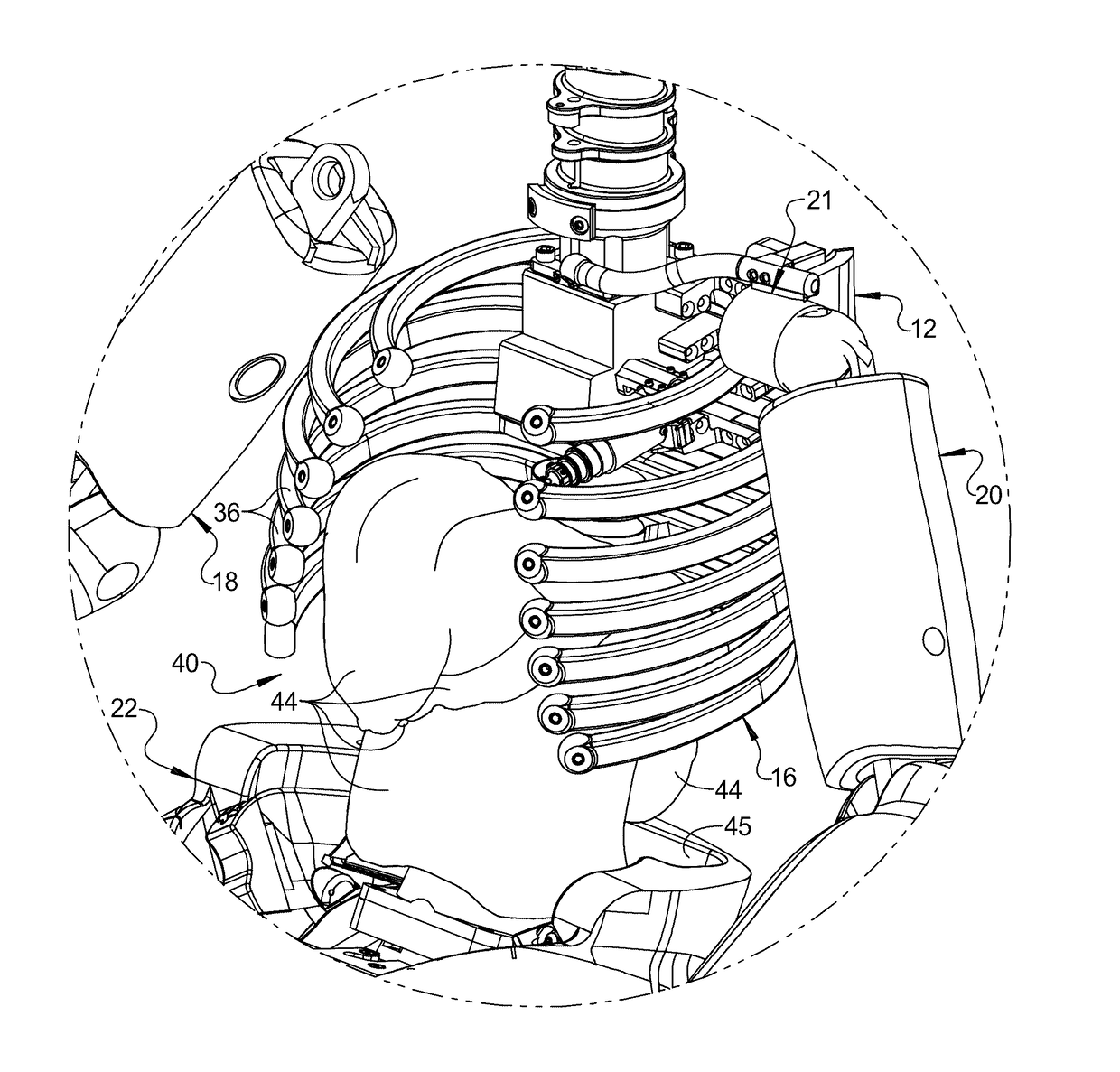

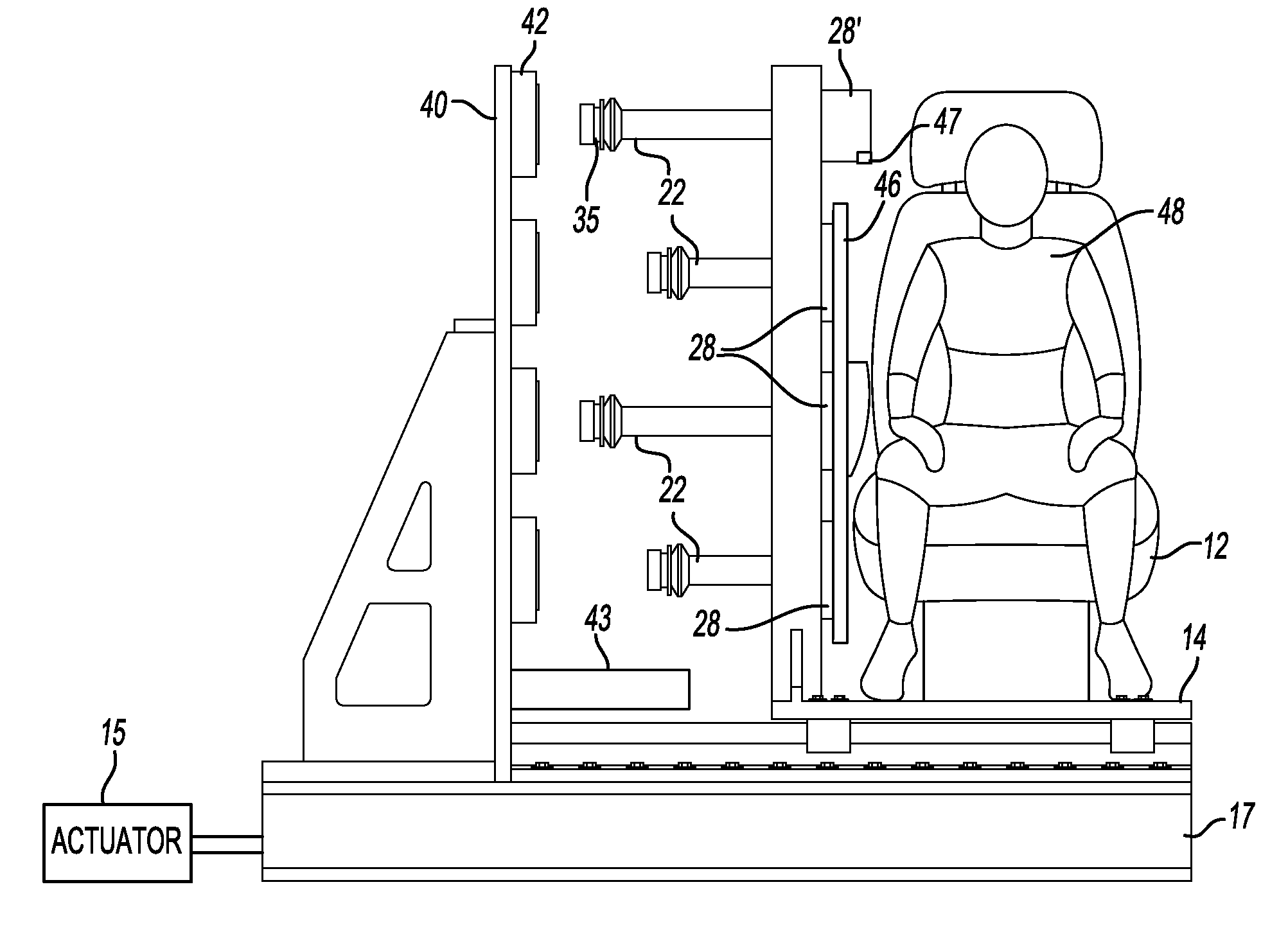

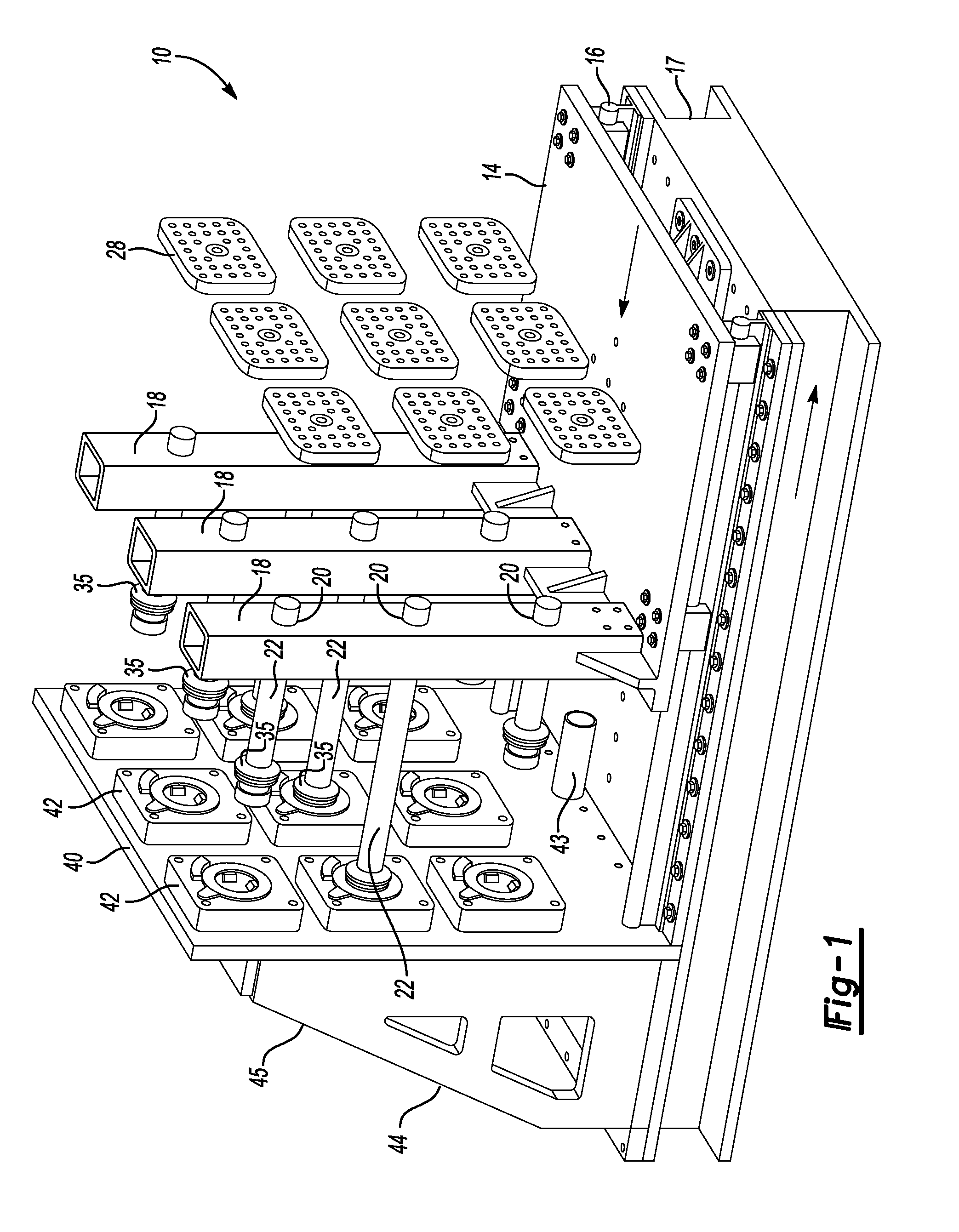

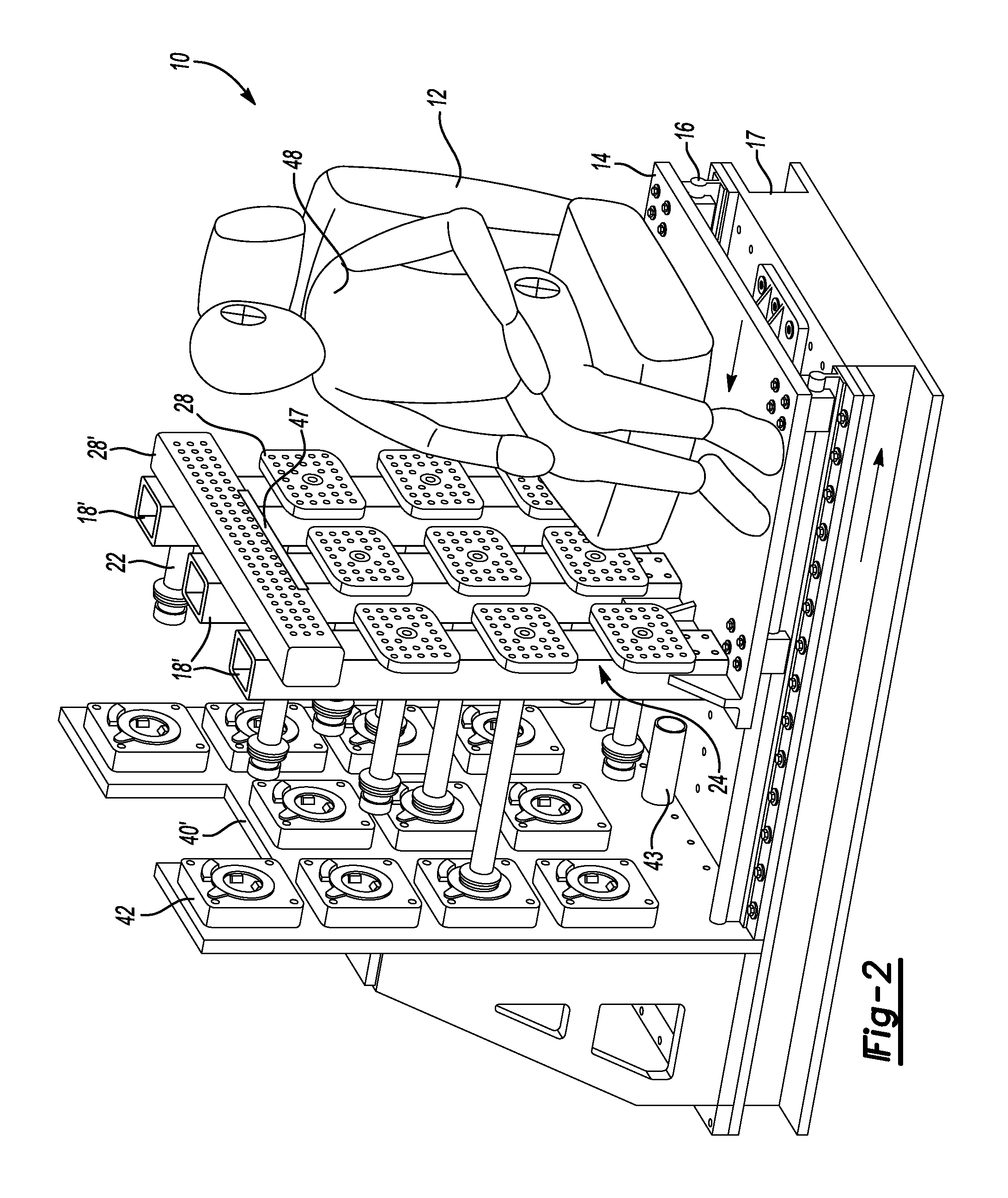

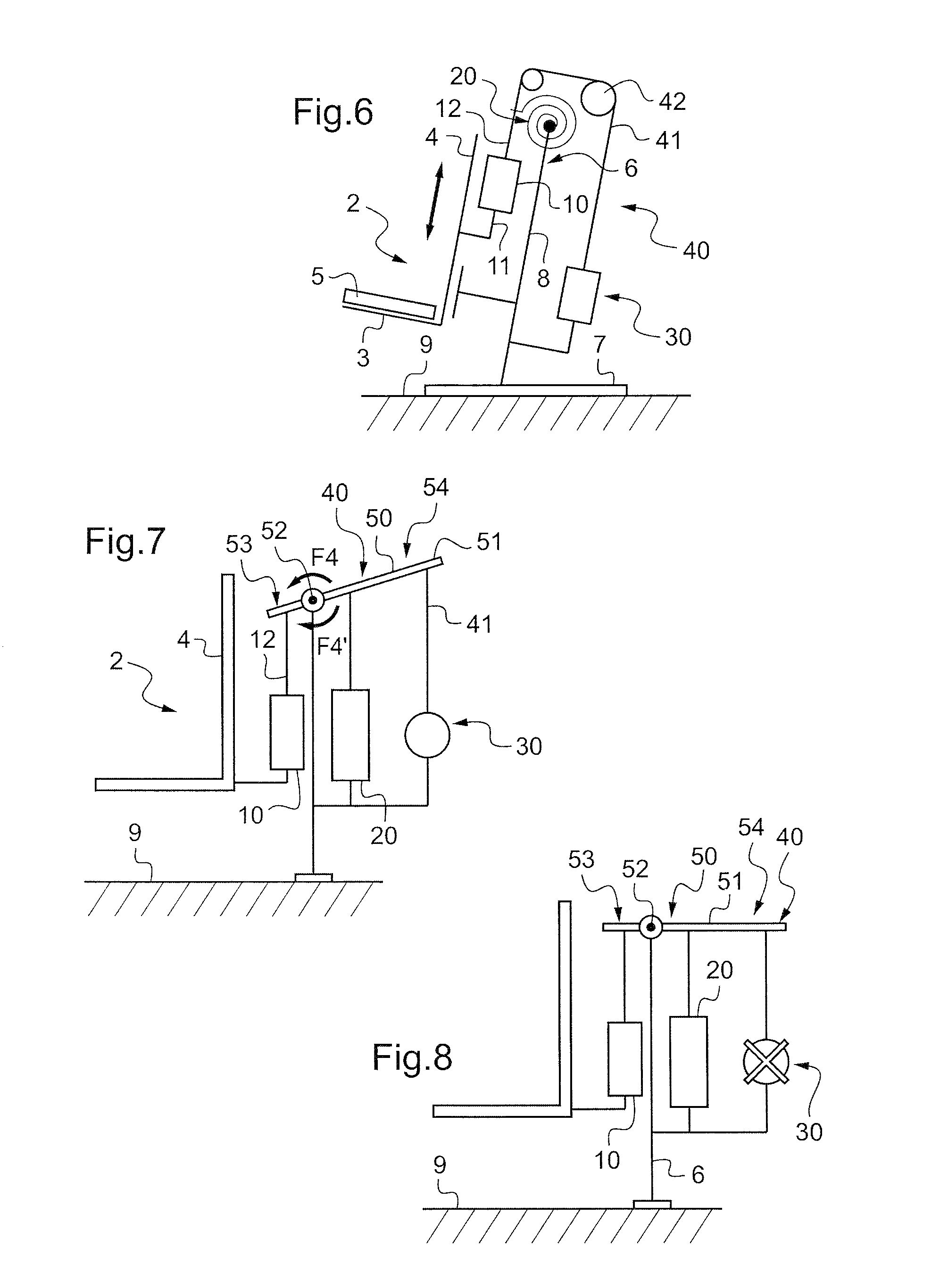

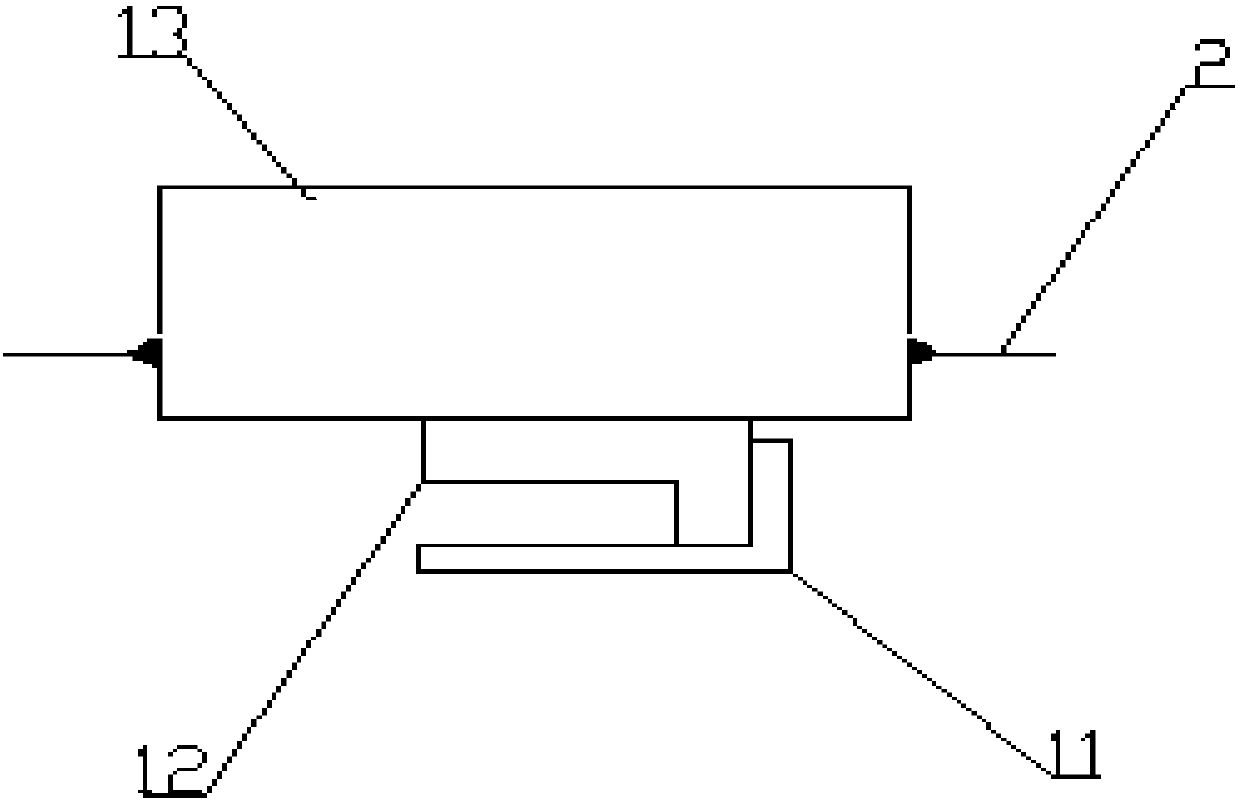

Side impact dynamic intrusion simulator

A side impact simulator includes a primary sled connected to an actuator. A platform for supporting a vehicle seat and crash test dummy is slidably supported on the primary sled. A support is mounted to the platform, with a plurality of thrust rods slidably mounted therein. The primary sled includes a strike plate for striking an end of the thrust rods.

Owner:TOYODA GOSEI CO LTD

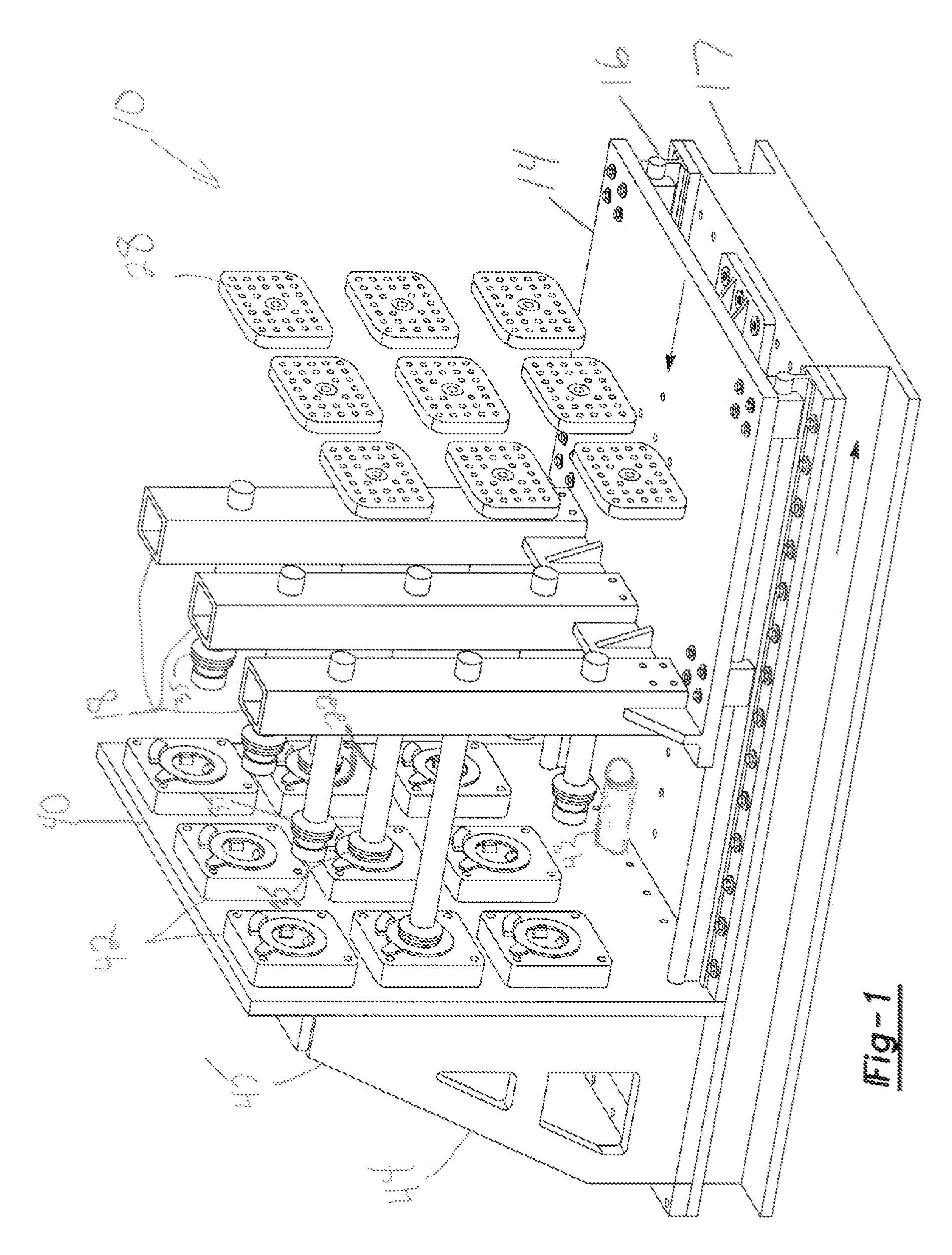

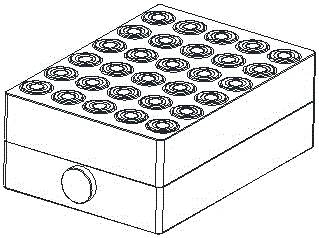

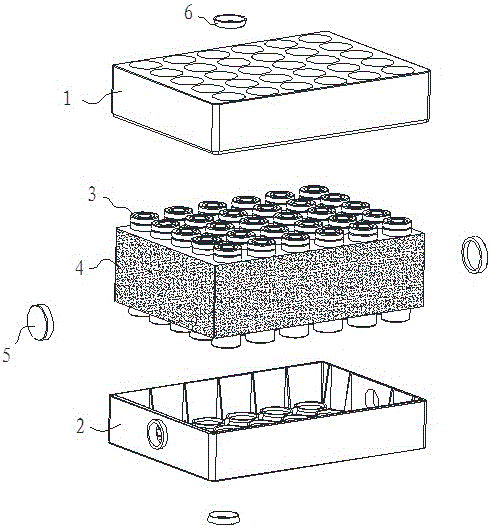

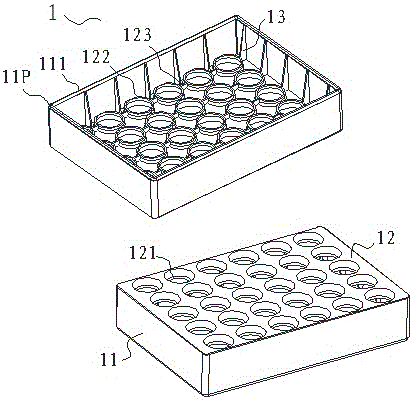

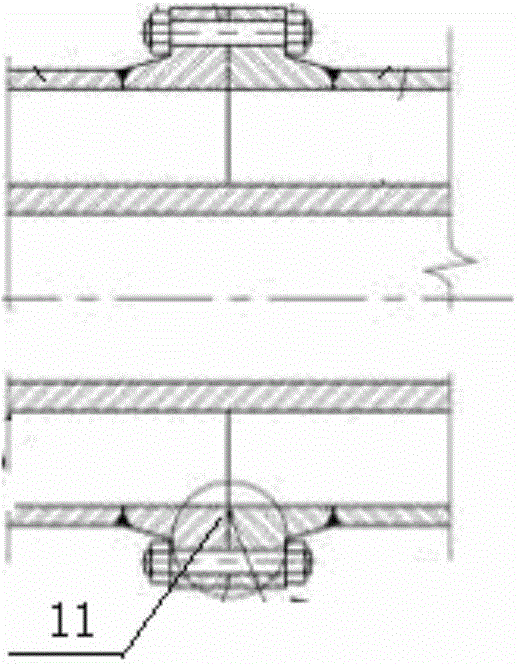

Mean-temperature method of cylindrical battery

InactiveCN104993187AImprove thermal conductivityWon't leakBattery isolationSecondary cellsEngineeringSealant

The invention discloses a mean-temperature method of a cylindrical battery. The mean-temperature method of the cylindrical battery has the technical scheme that 1, the arrangement mode is determined according to the battery pack forming requirements, and a casing module is designed; 2, a cylindrical battery cell is assembled in the casing module, and sealant is coated for sealing; 3, liquid phase change material composite glue is prepared; 4, the phase change material composite glue is poured into the casing module, and a battery pack with good temperature consistency is obtained after curing and forming. The phase change material composite glue is prepared by phase change materials and organic silicon filling and sealing glue according to a certain ratio, wherein the phase change materials use paraffin and graphite as major components; the organic silicon filling and sealing glue uses vinyl silicone oil and modified aluminum oxide powder as major components. Through the structure features of the mean-temperature method, the mean-temperature method has the beneficial effects that the battery core has good temperature consistency; the module structure is good in intensity and can pass by the battery pack-relevant vibration, falling and collision tests. The phase change material composite glue is encapsulated in the casing; no loss occurs after the long-time cyclic use; the permanent service life is realized.

Owner:广东万锦科技股份有限公司

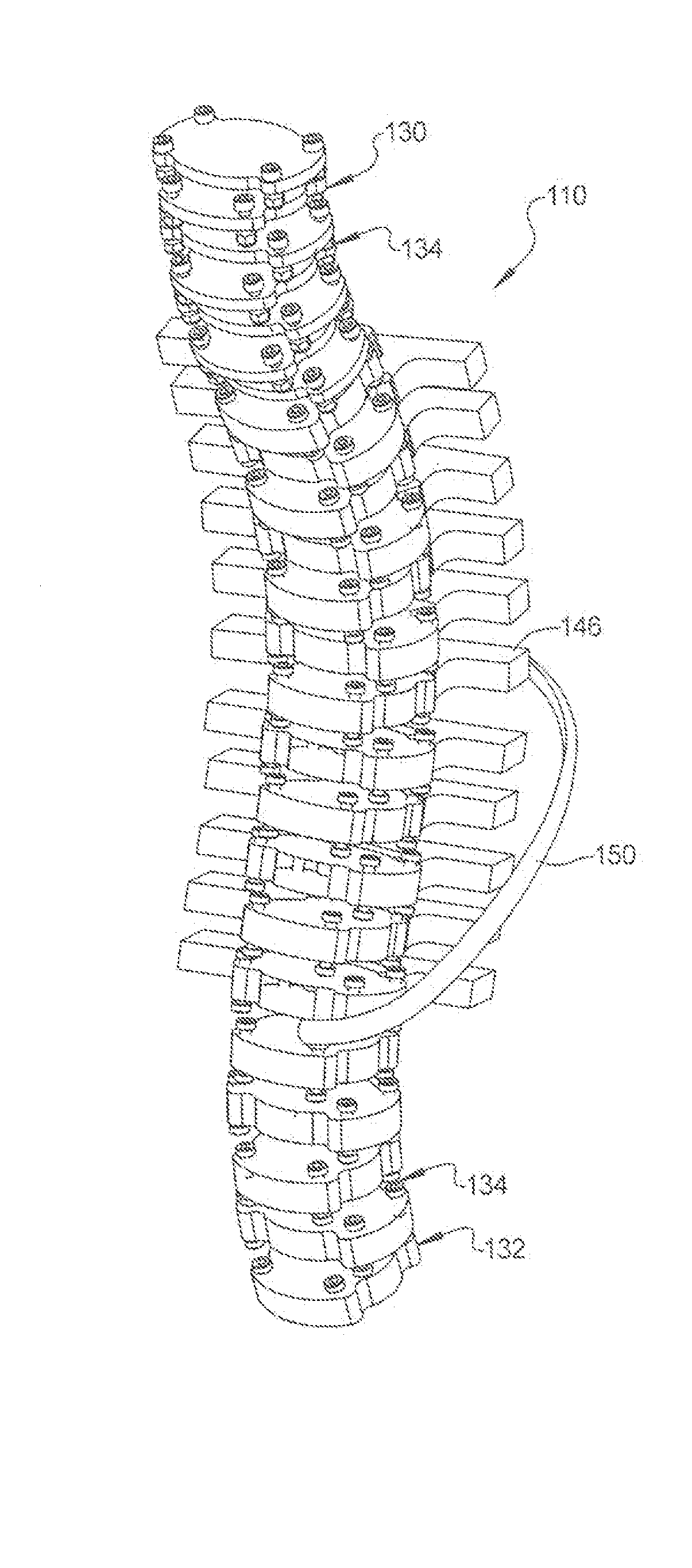

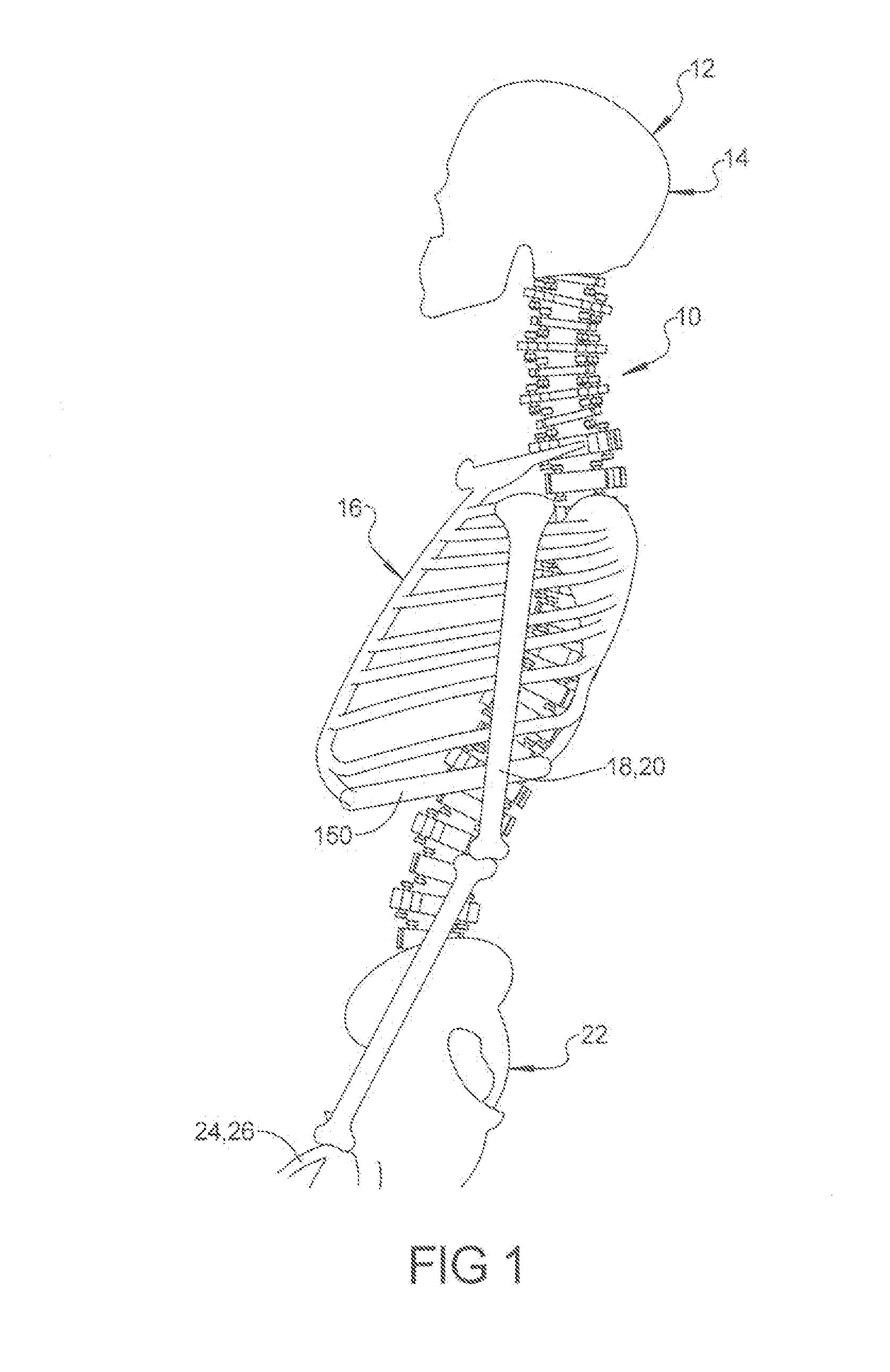

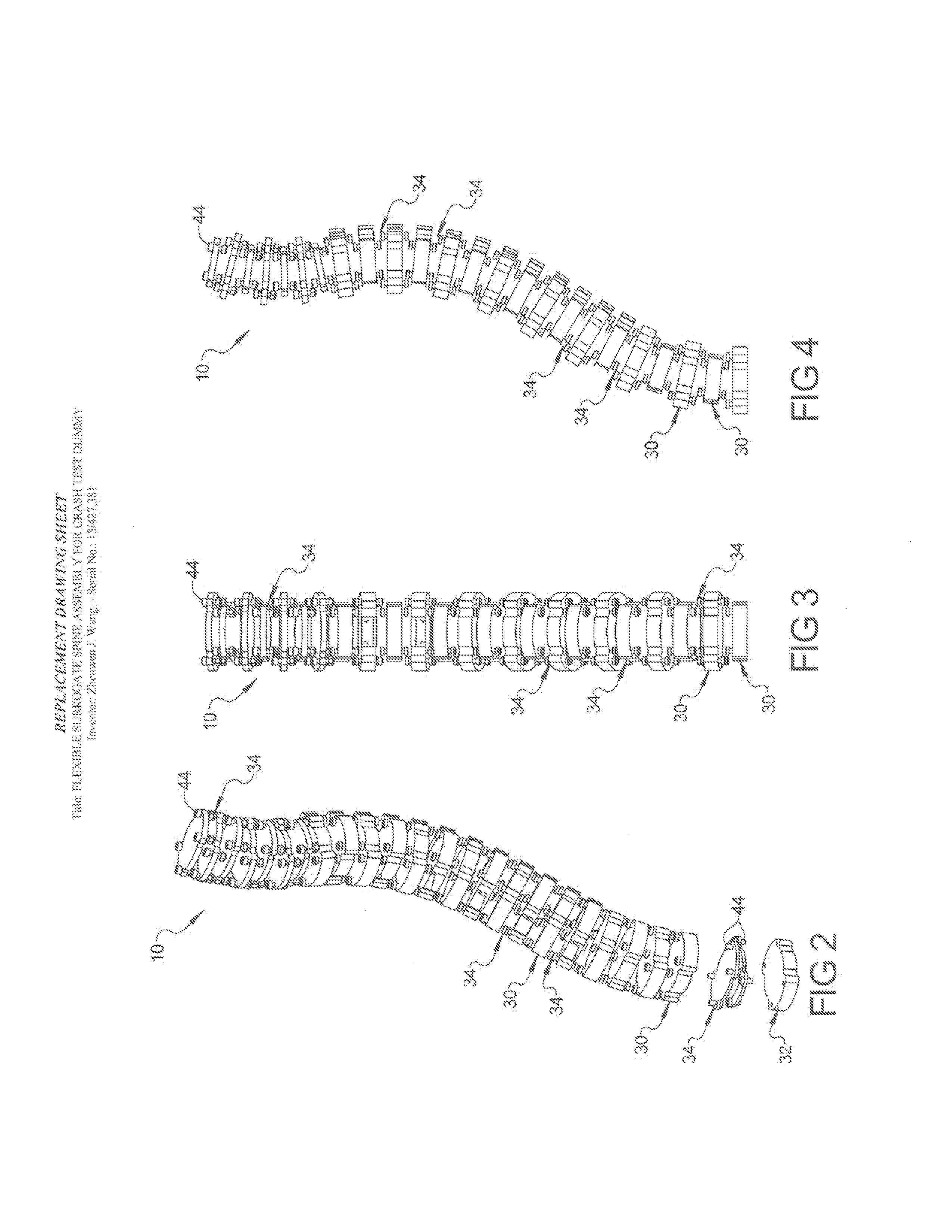

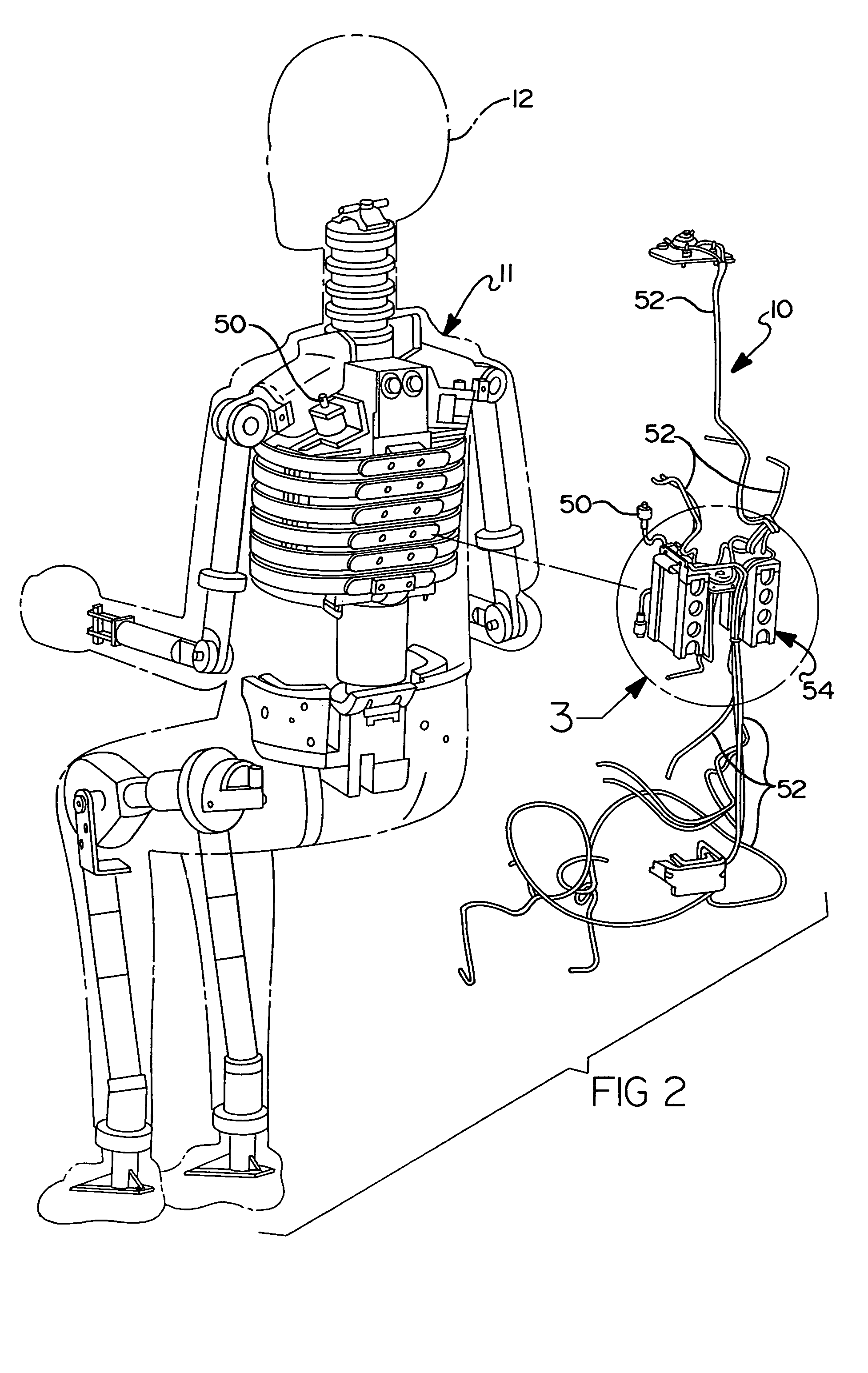

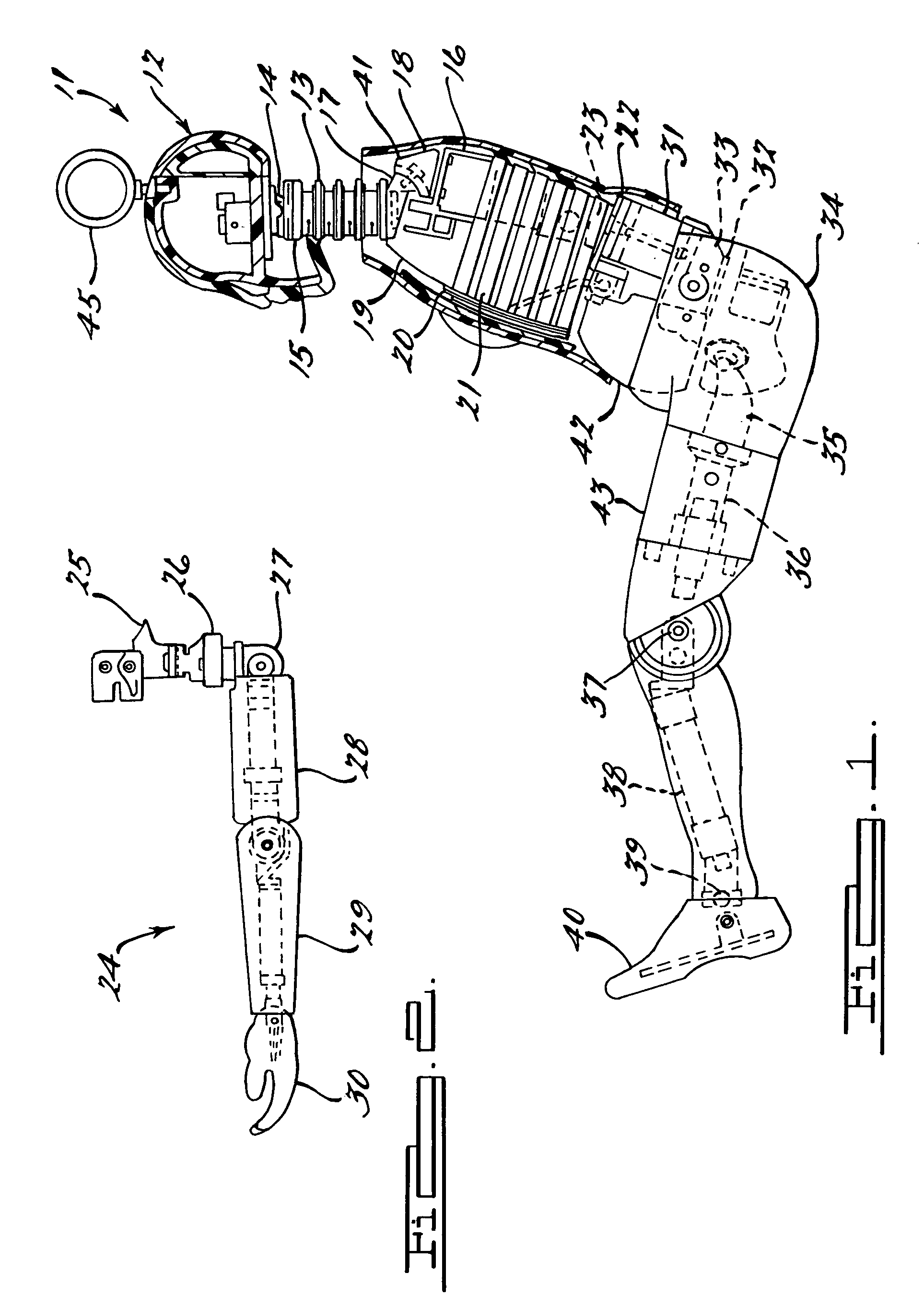

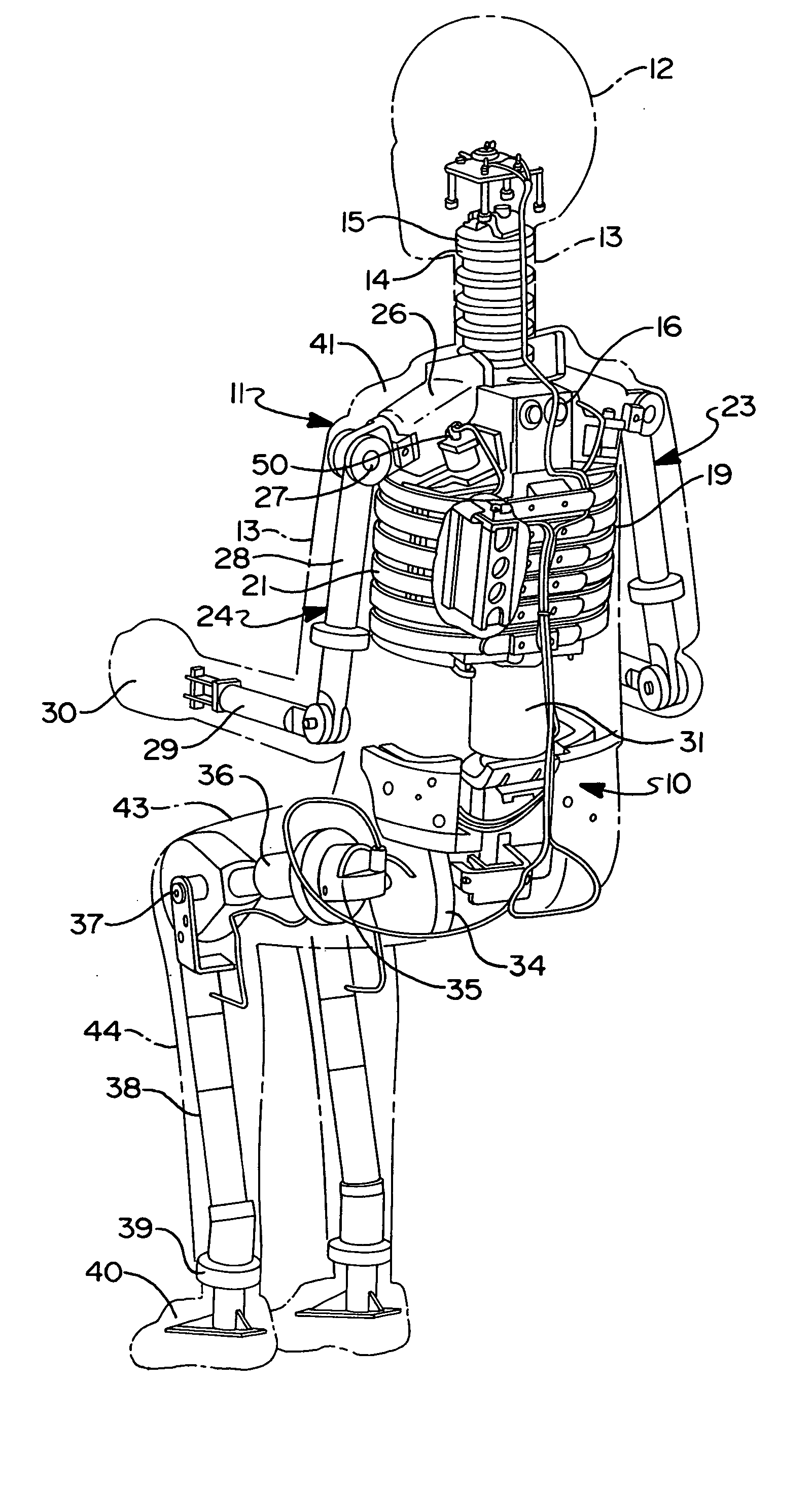

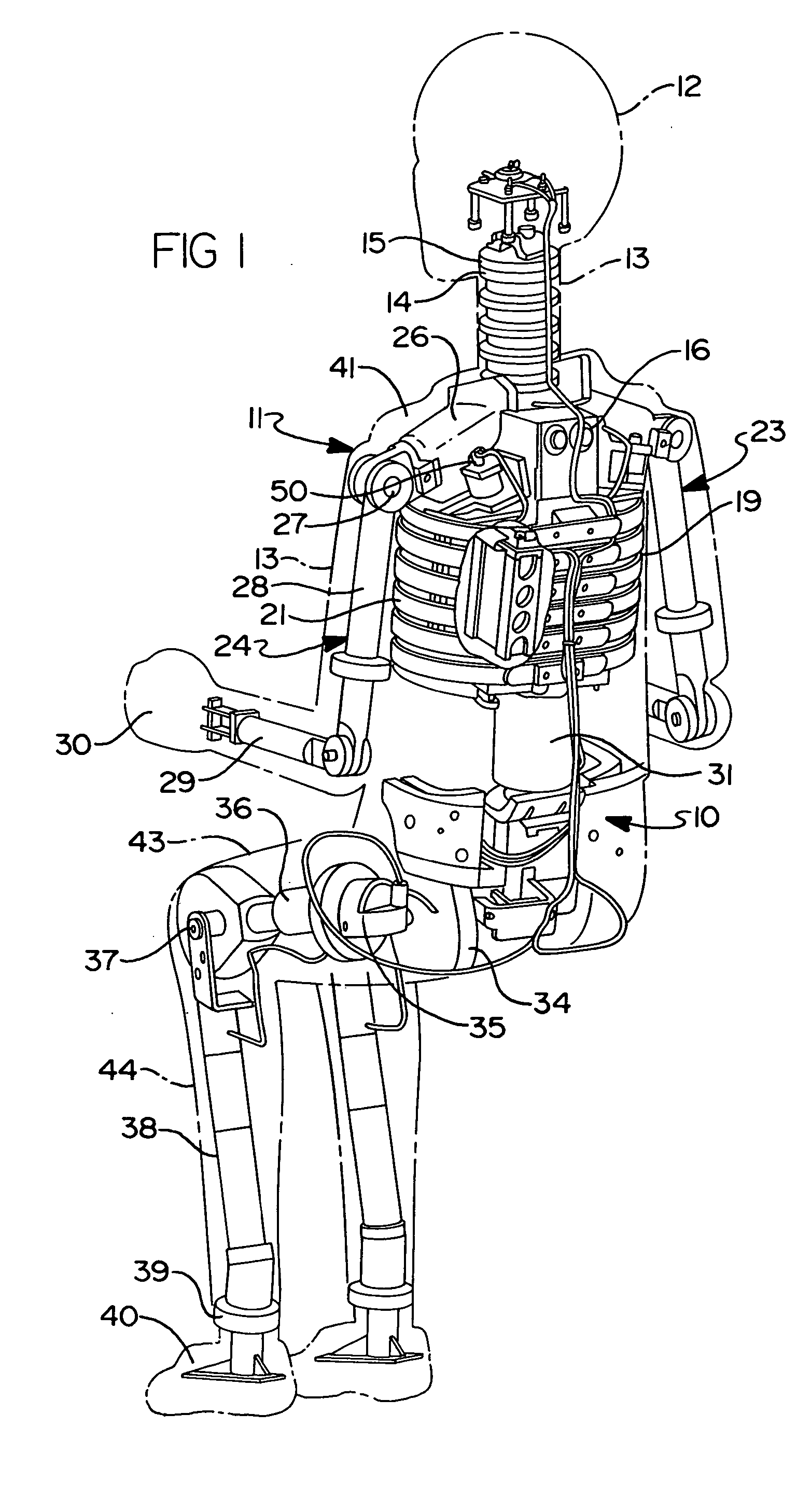

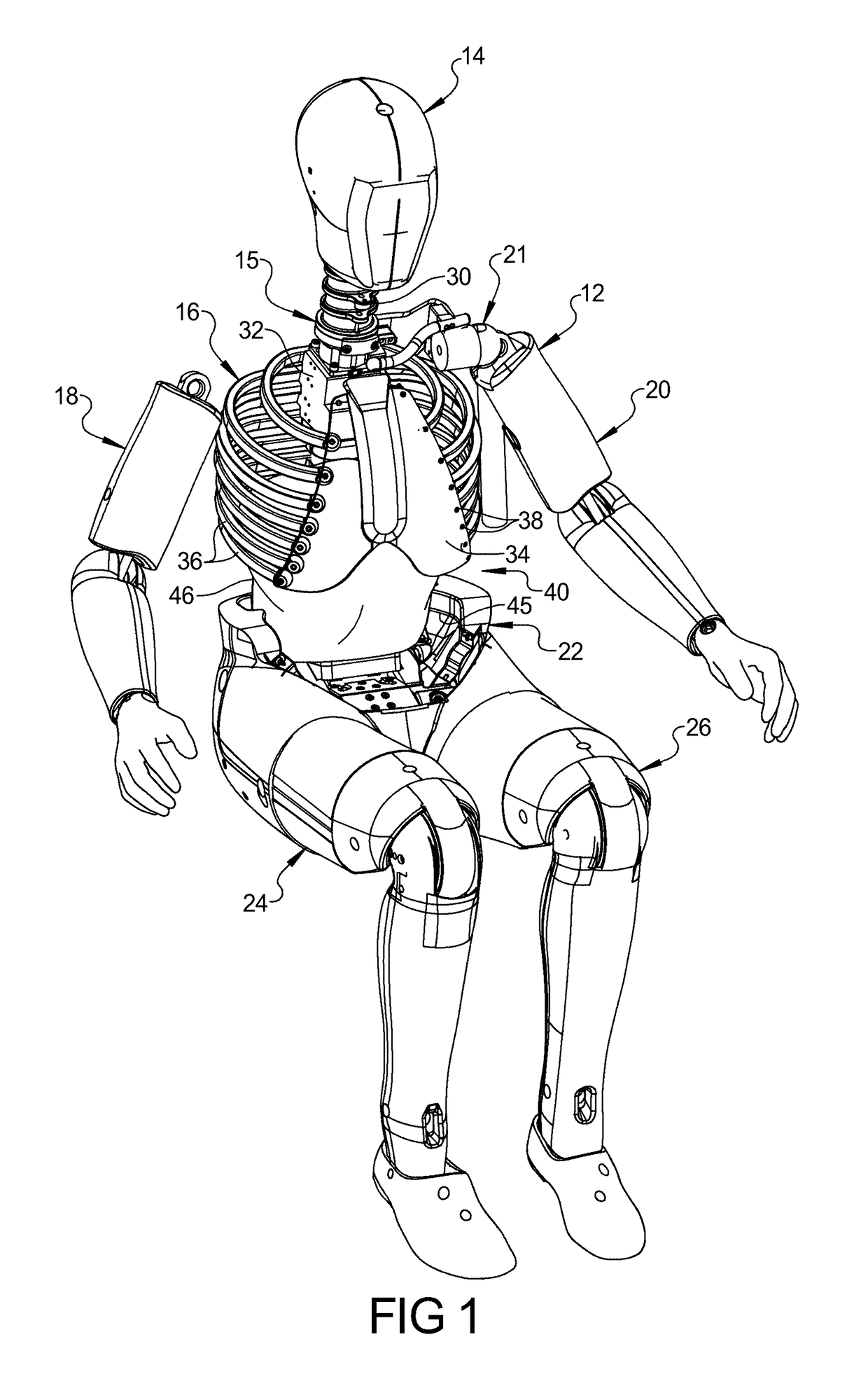

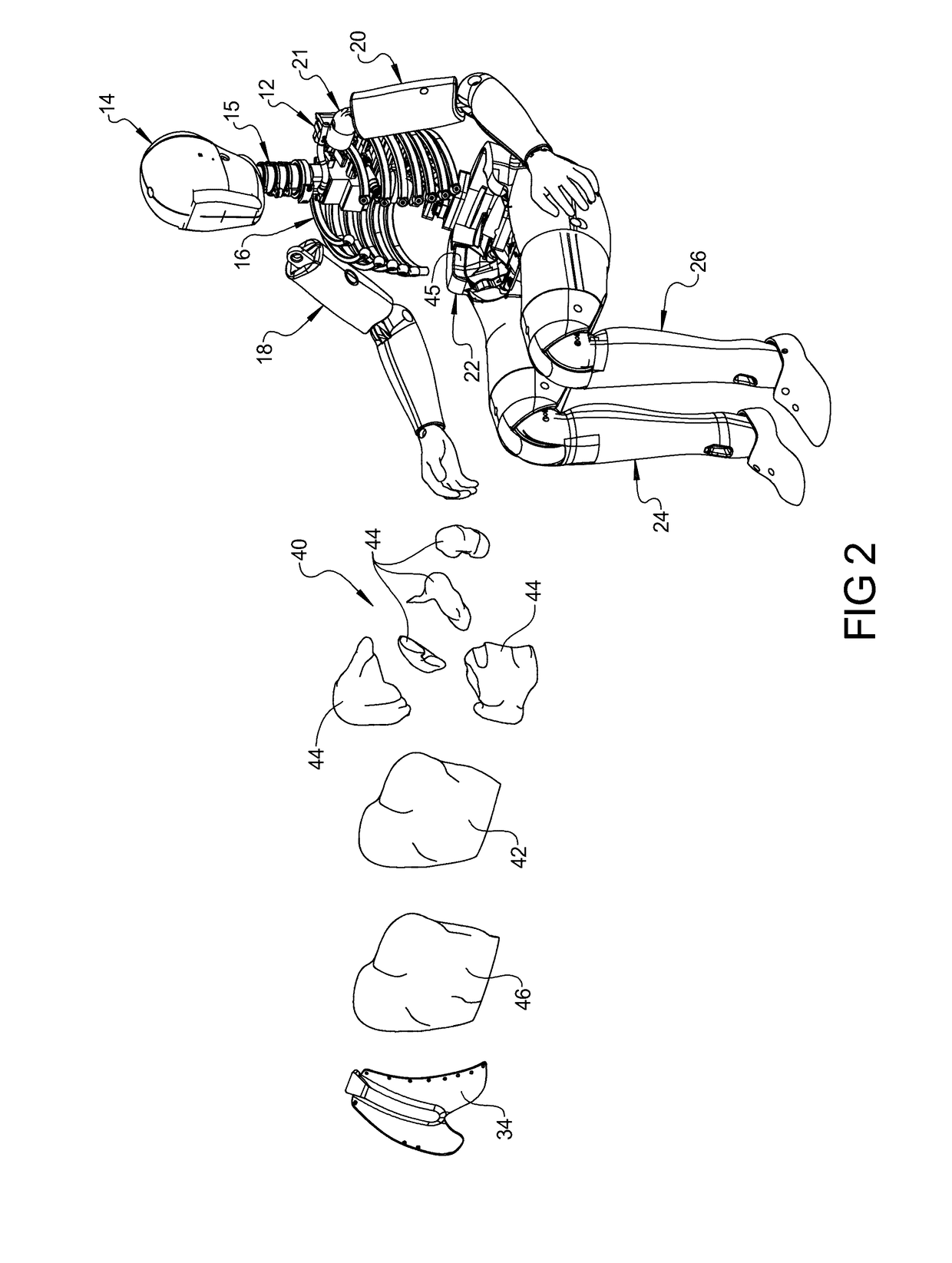

Flexible surrogate spine assembly for crash test dummy

InactiveUS20130252220A1Improves biofidelityAdjustable curvatureEducational modelsCrash testEngineering

A flexible surrogate spine assembly for a crash test dummy includes a plurality of vertebra discs, a plurality of ligament joints disposed between the vertebra discs, the ligament joints having a joint element with varying joint angles that can replicate Kyphosis and Lordosis angles of a human spine.

Owner:HUMANETICS INNOVATIVE SOLUTIONS

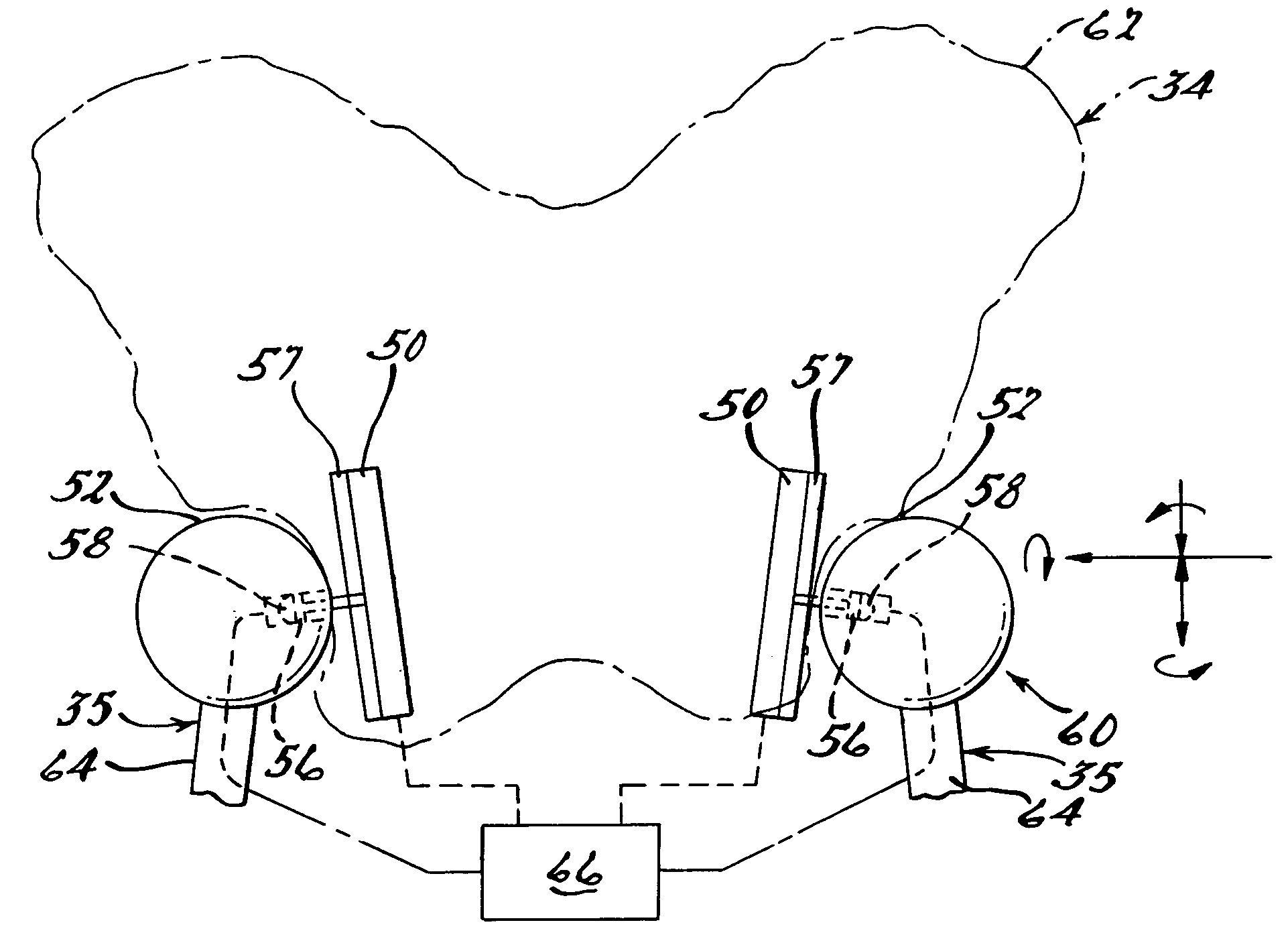

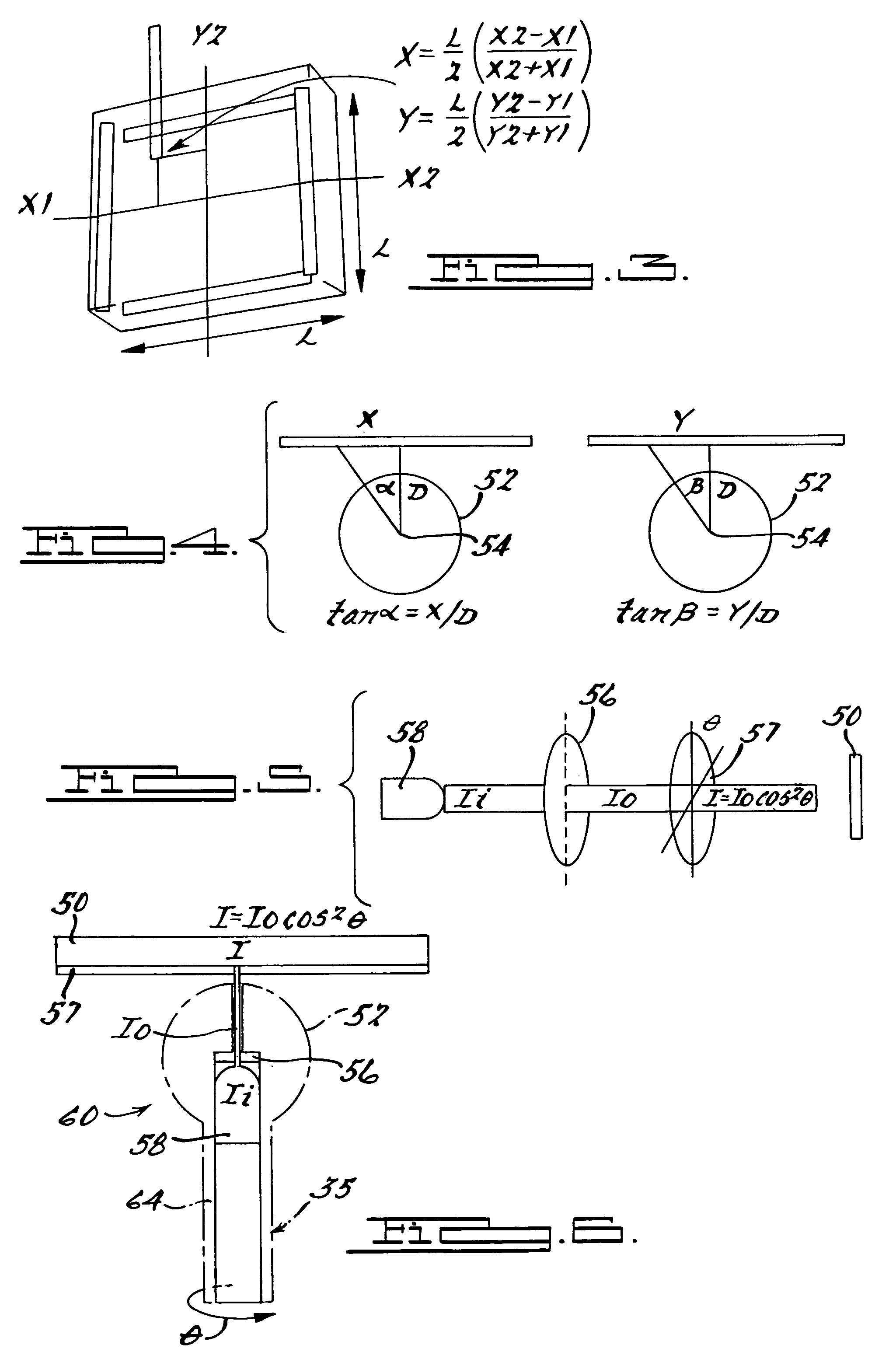

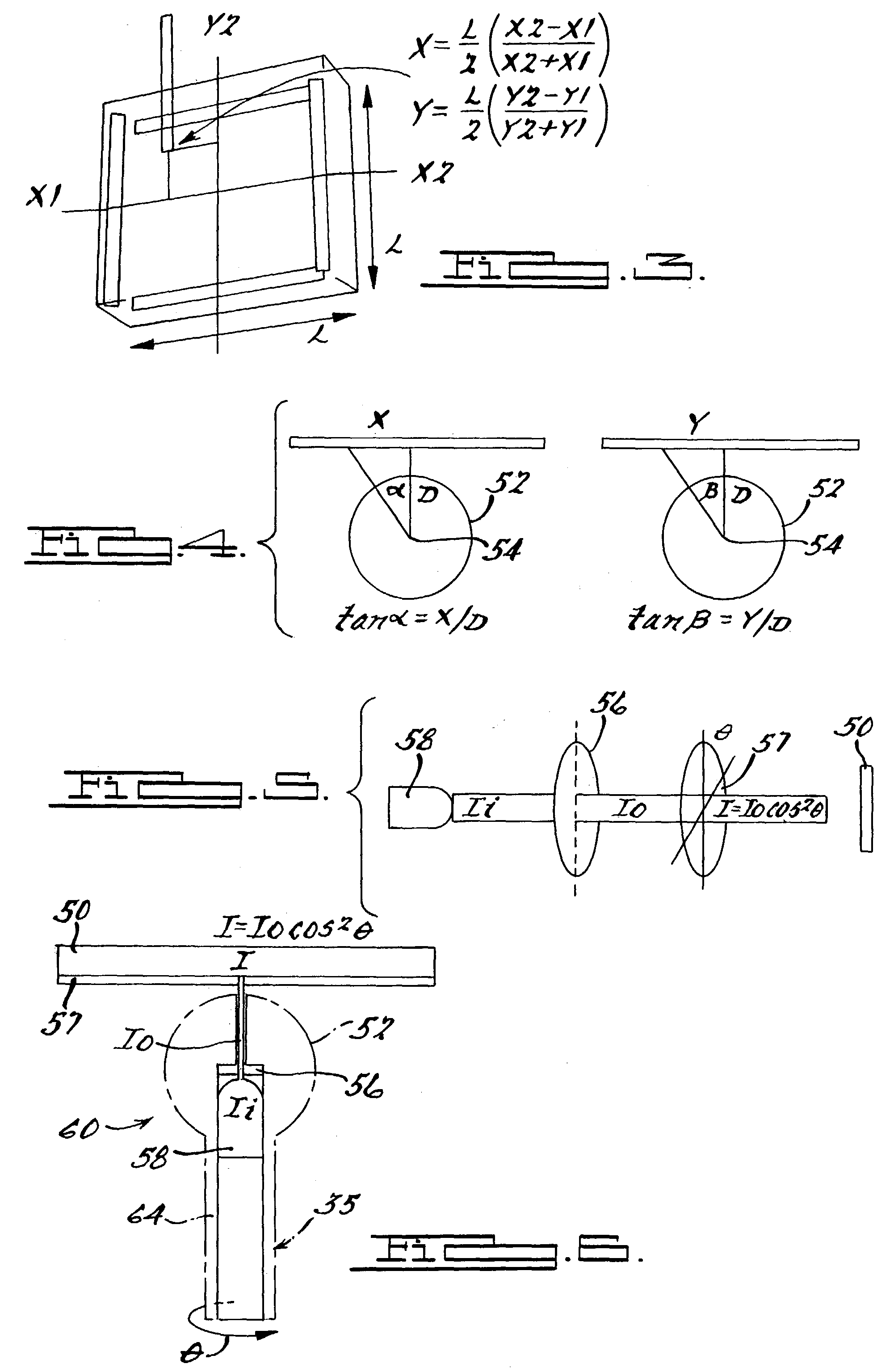

Multi-point position measuring and recording system for anthropomorphic test devices

ActiveUS7508530B1Reducing bio-fidelityLimits number of possibleForce measurementPosition fixationTriangulationCrash test

The motion of an Anthropomorphic Test Device (ATD) member is measured. For example, the motion of ribs and other components of an ATD or Crash-Test Dummy are tracked during crash testing and dummy calibration using light angle detectors and triangulation techniques.

Owner:BOXBORO SYST

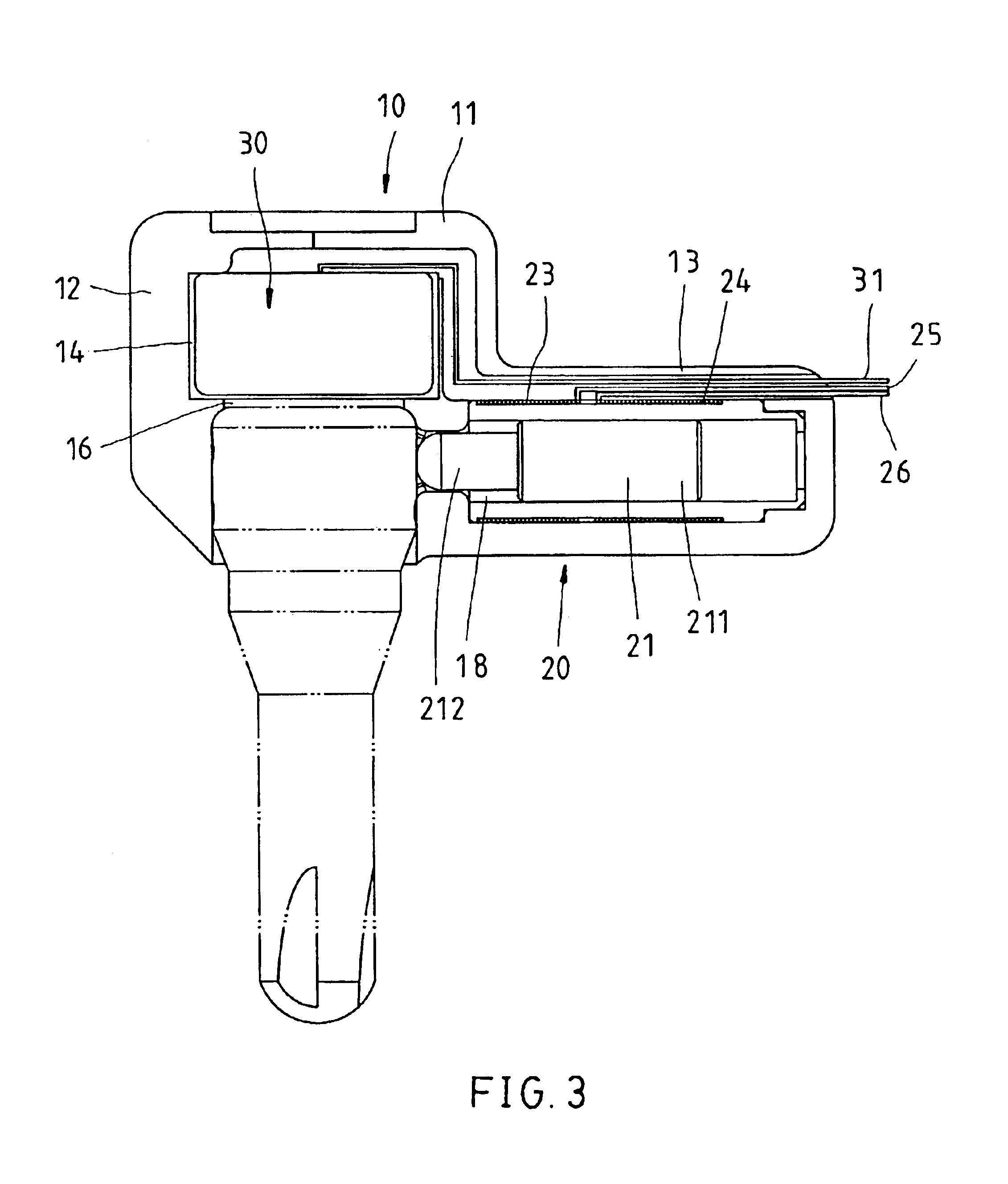

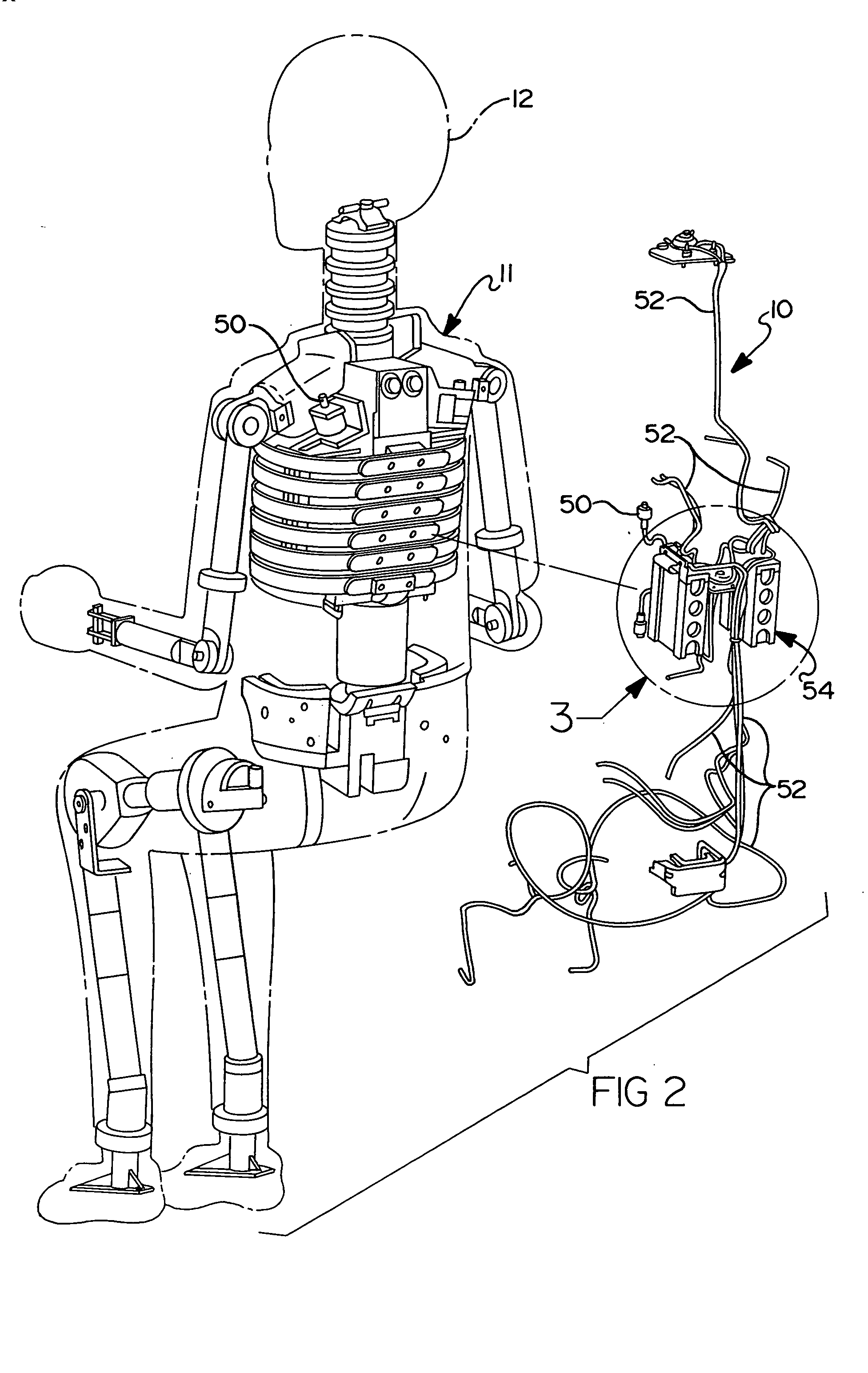

Flexible printed circuit cabling system for crash test dummy

InactiveUS7086273B2Less likely to degrade biofidelityImproves biofidelityUsing electrical meansAcceleration measurementElectricityCrash test

Owner:HUMANETICS INNOVATIVE SOLUTIONS

Apparatus for detecting the stability of a tooth in the gum or an implant in the body

InactiveUS6918763B2Easy to useCompact and preciseMeasurement devicesTooth pluggers/hammersCrash testEngineering

An apparatus for detecting the stability of a tooth in the gum or an implant in the body is constructed to include a holder for holding a test object to be examined, an impact device disposed at one side of the holder for striking the test object, causing the test object to produce vibrations, and sensor means disposed at one side of the holder for detecting the vibrations produced by the test object upon the striking of the impact device against the test object.

Owner:MIRACLE ONE TECH

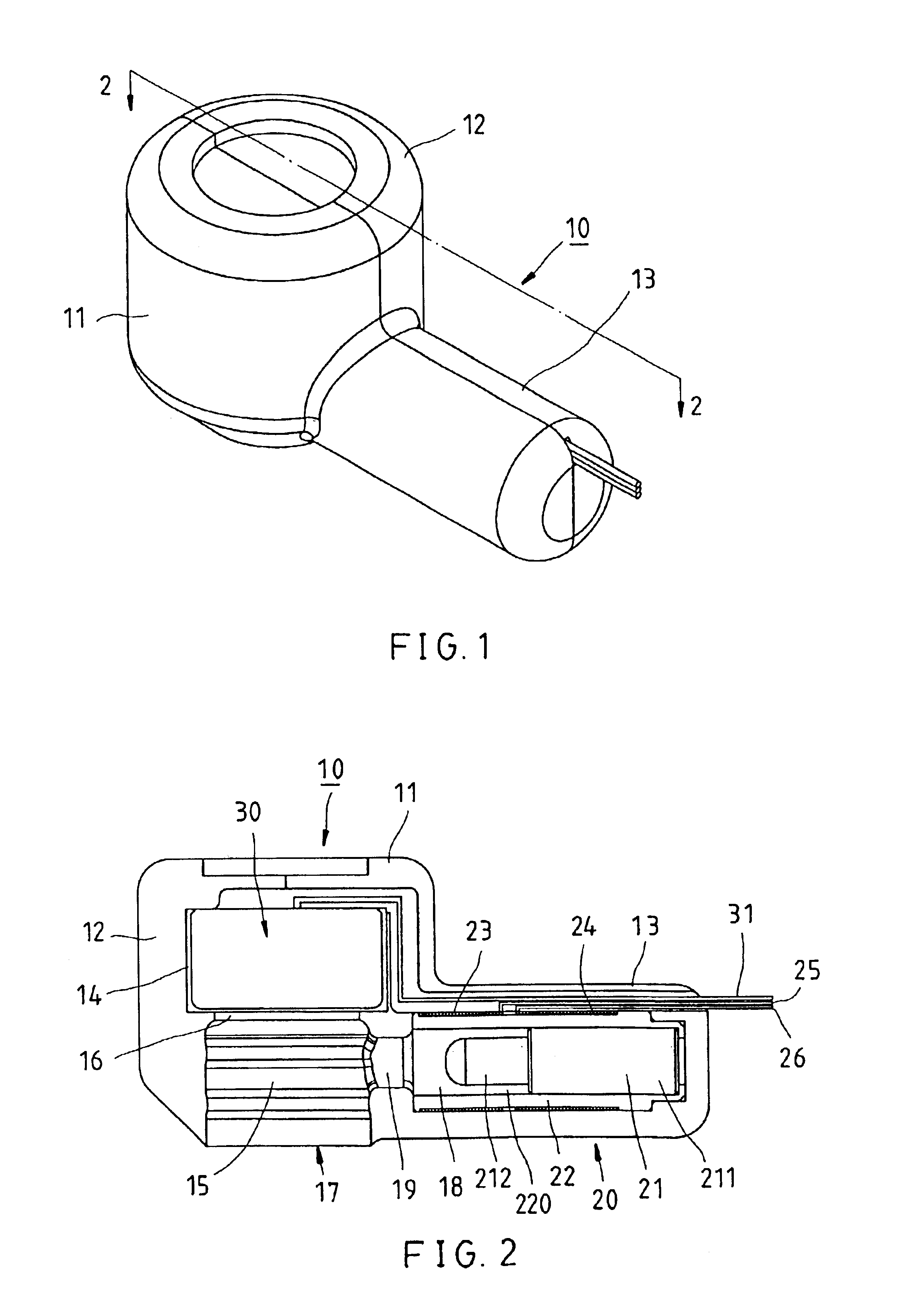

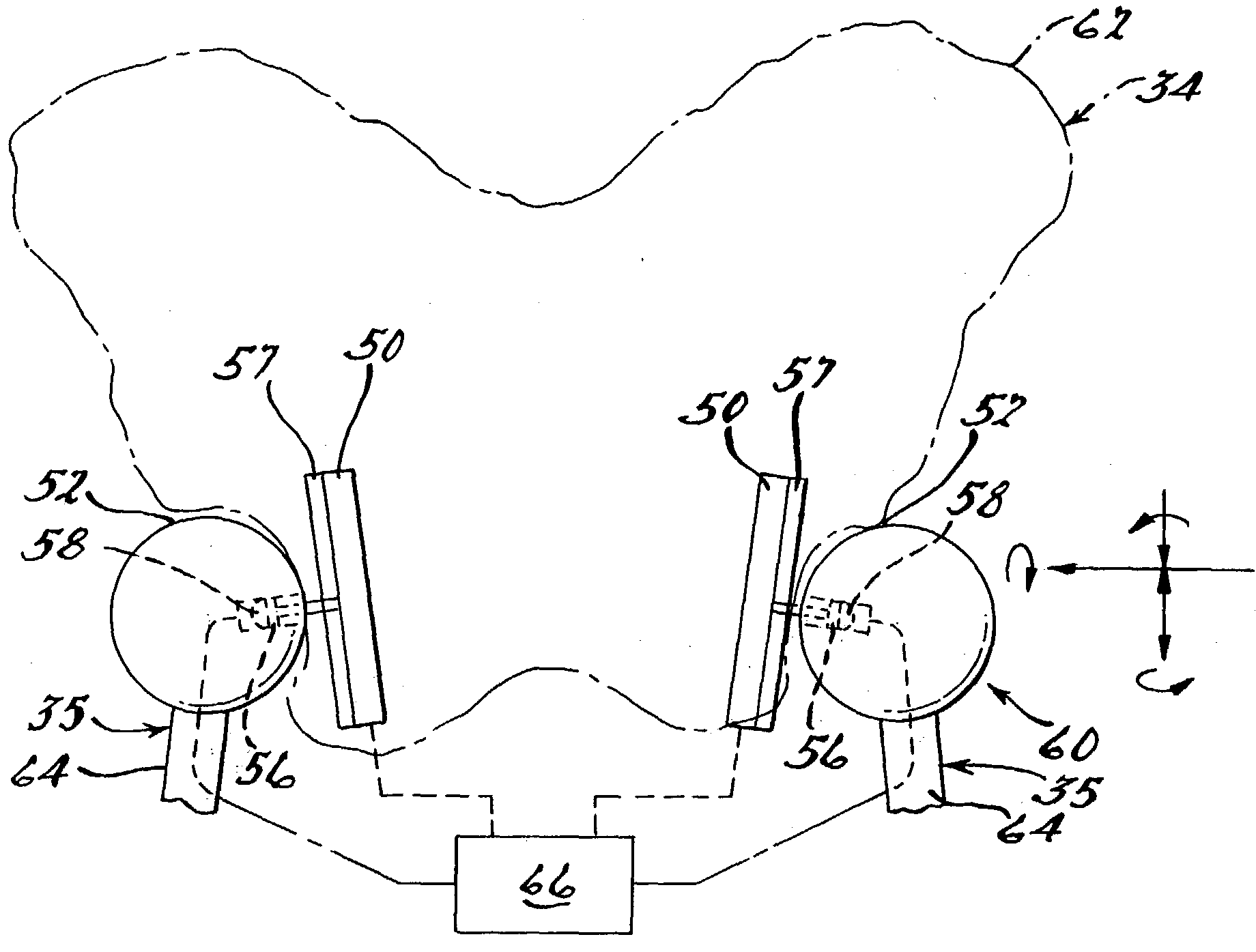

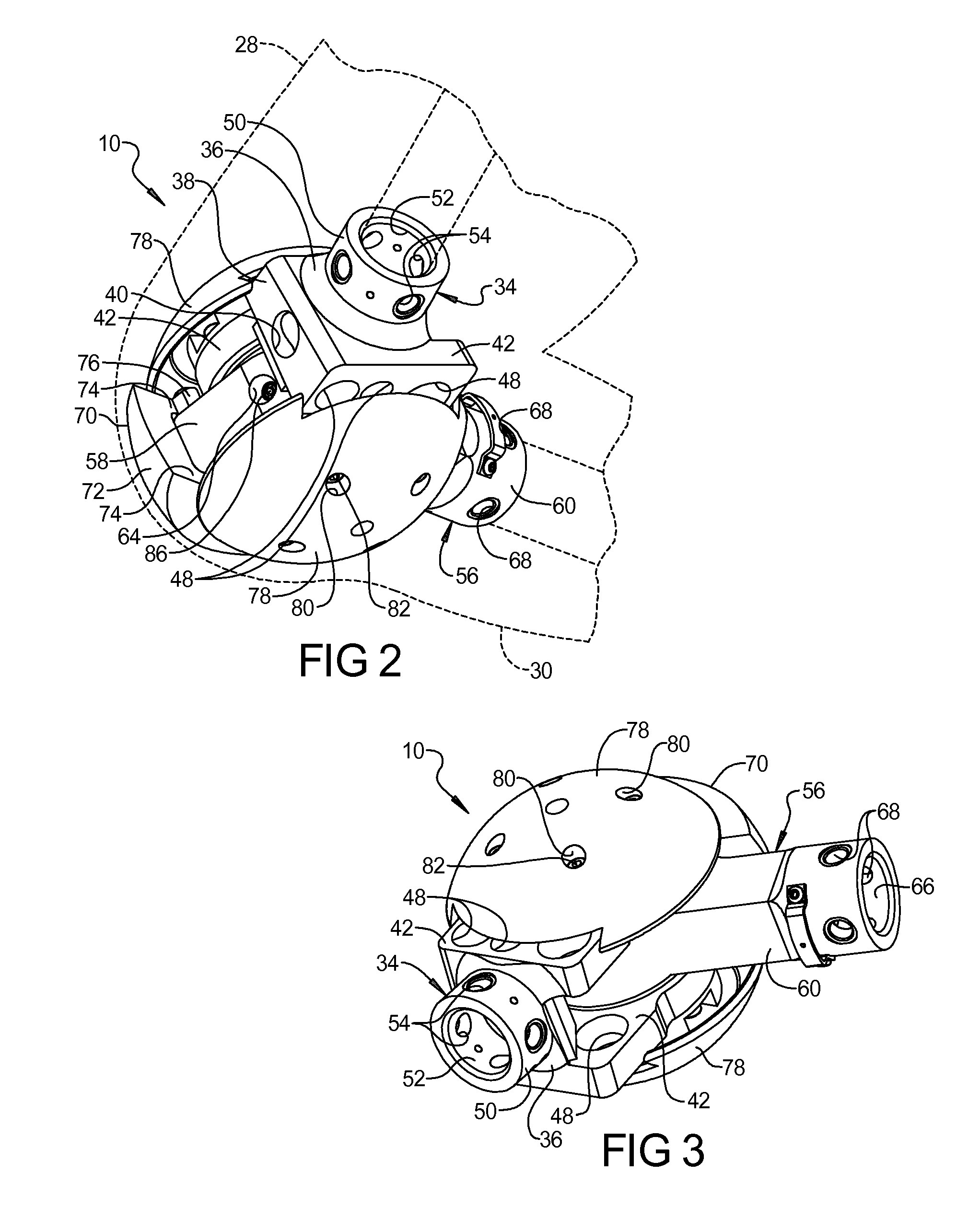

Measurement system for ball joint of crash test dummy

InactiveUS6982409B2Sufficient accuracyAdequate responseInvestigating moving sheetsCounting objects on conveyorsElectricityCrash test

A measurement system is provided for a ball joint of a crash test dummy. The measurement system includes a light source operatively supported by a movable ball of the ball joint and a position sensitive detector operatively supported by a fixed member of the ball joint. The measurement system also includes a controller electrically connected to the light source to provide power to the light source for emitting light and electrically connected to the position sensitive detector that receives the emitted light to measure at least two angles between the ball and the fixed member.

Owner:HUMANETICS INNOVATIVE SOLUTIONS

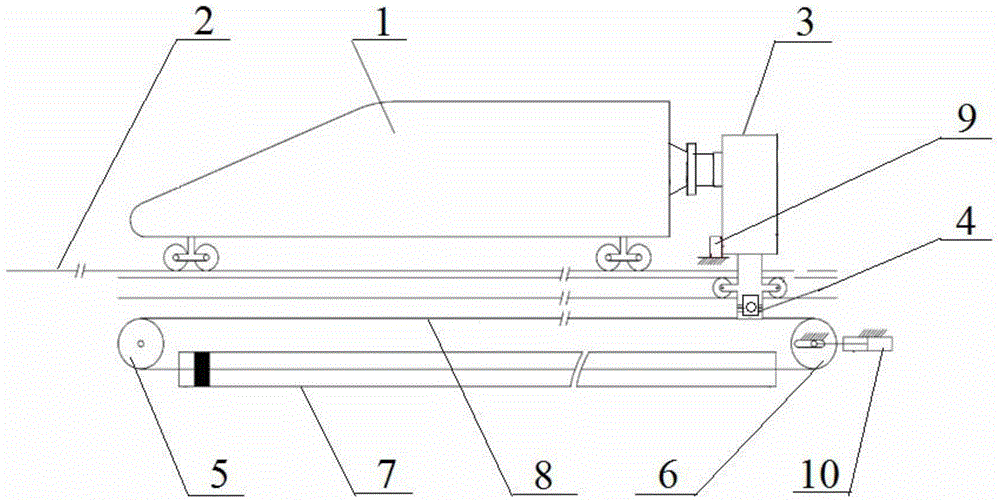

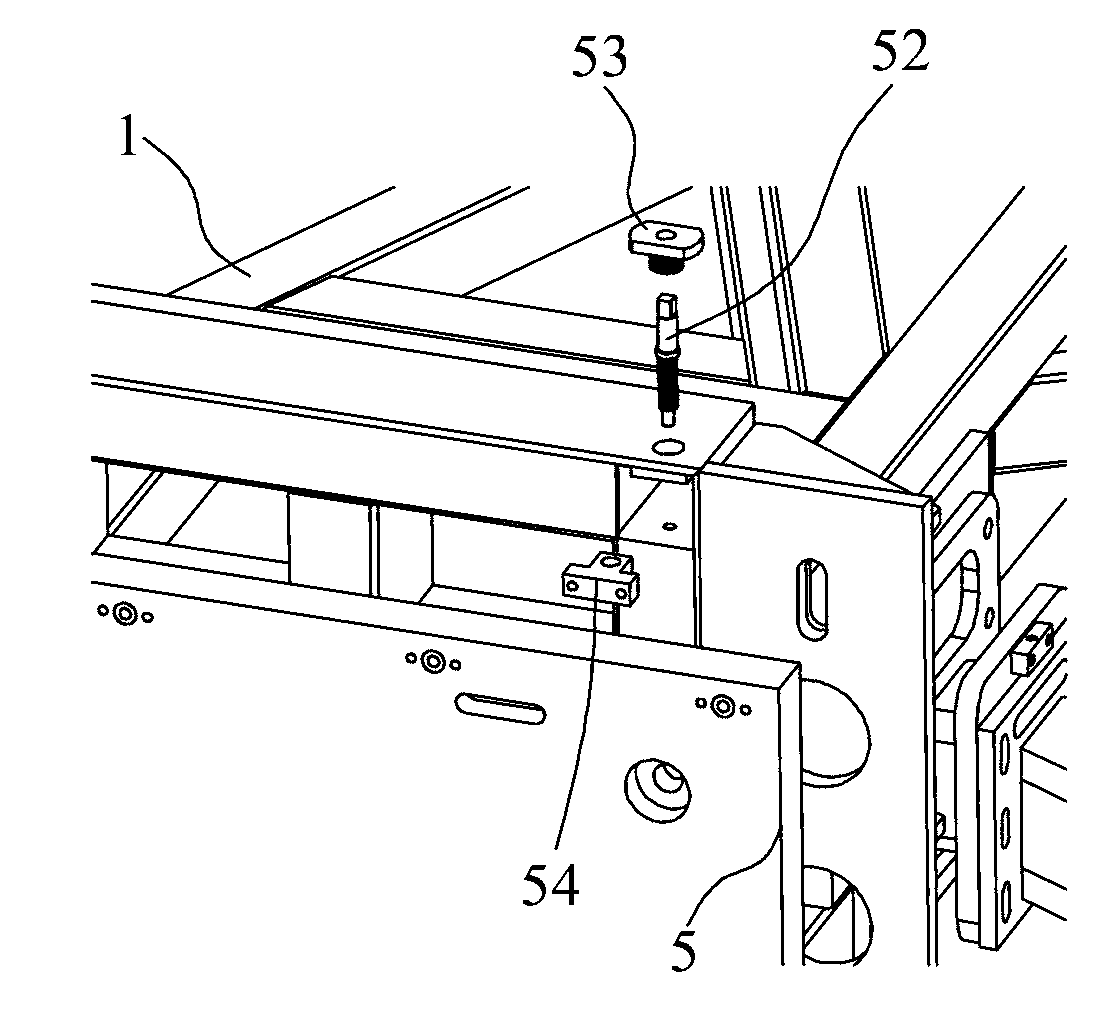

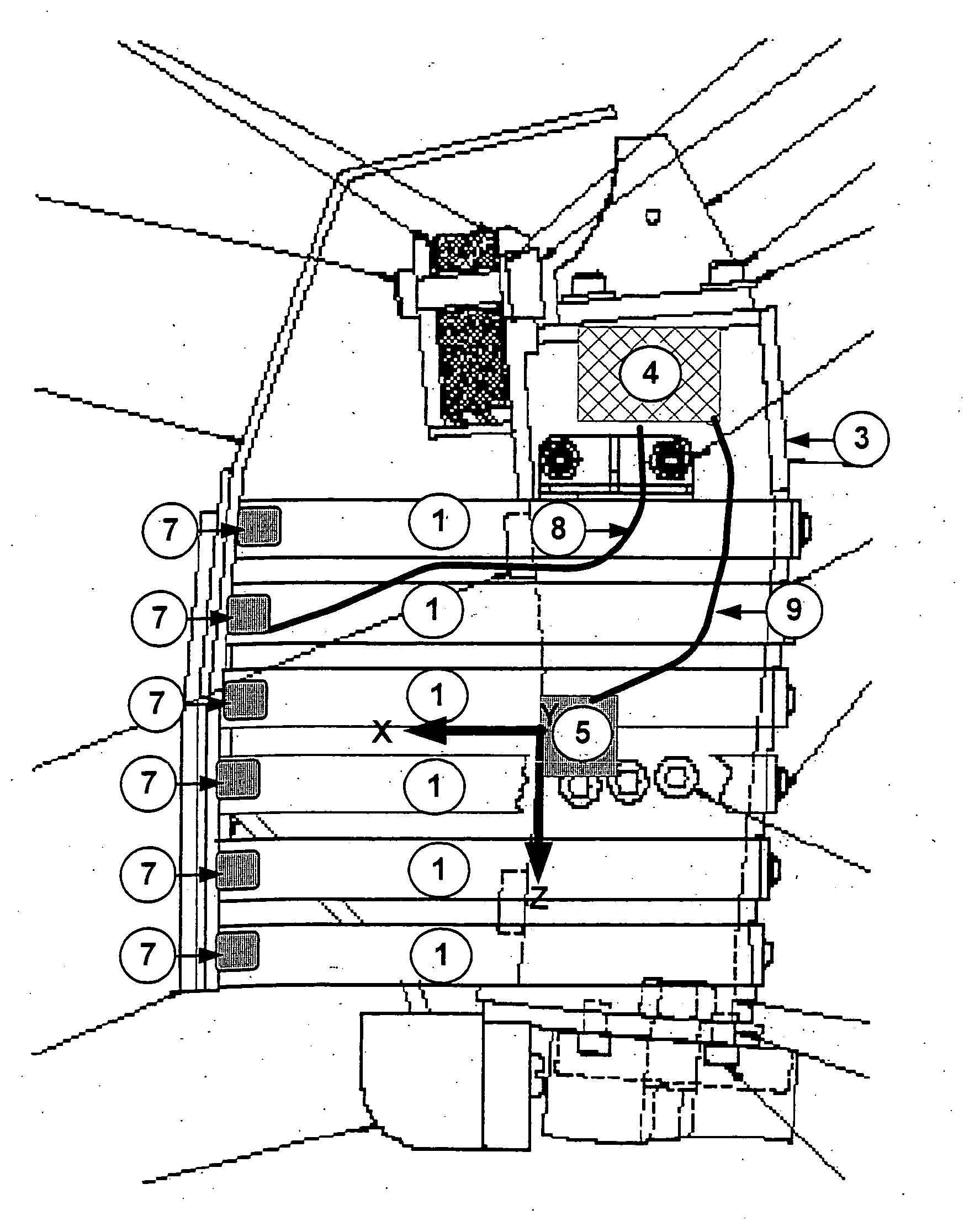

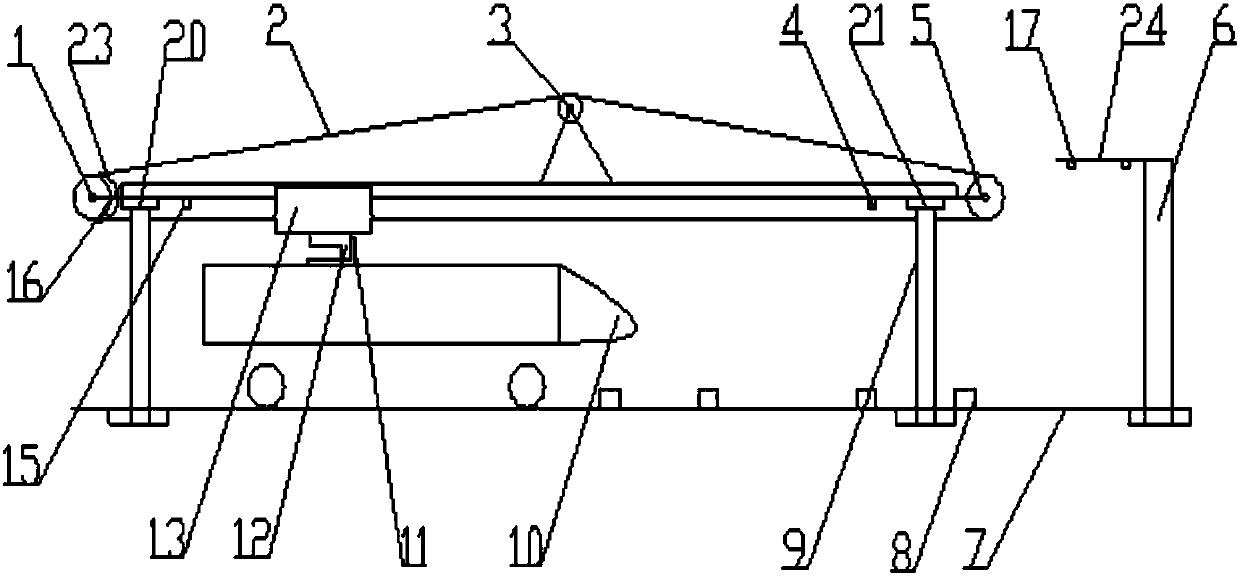

Railway vehicle test stand

InactiveCN104614190AAccurately improved speed controlMeet crash test requirementsRailway vehicle testingShock testingShortest distanceCrash test

The invention relates to the technical field of railway vehicle crash test, and specifically relates to a railway vehicle test stand. Automatic speed monitor and acceleration stop of the railway vehicle crash test are achieved by the application of a drive trolley, an air cylinder, a speed monitor, a controller and an unlocking mechanism. In the prior art, testers operate an actual haulage motor to accelerate the tested vehicle in the railway vehicle crash test; the manual operation causes delays to speed data receiving response and haulage motor operation, meanwhile, the actual haulage motor does not meet the test precision requirements of the system reaction sensitivity to acceleration and stop. Comparing to the prior art, the railway vehicle test stand greatly increases the precision of tested vehicle speed control in the railway vehicle crash test. Additionally, the compressed driving measure in the railway vehicle test stand is able to meet the crash test requirements of short distance acceleration, large mass and high speed railway vehicle.

Owner:CRRC QINGDAO SIFANG CO LTD

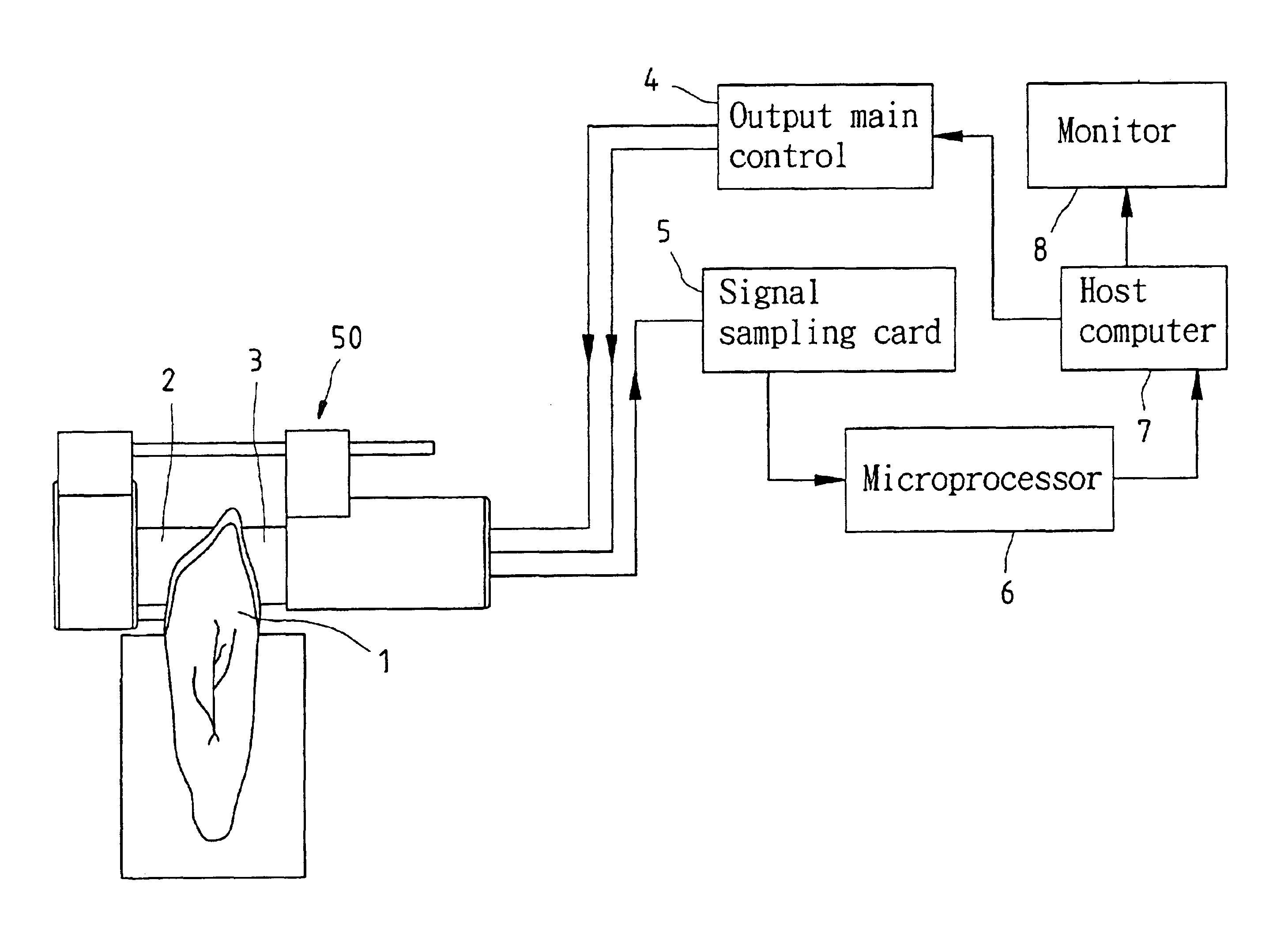

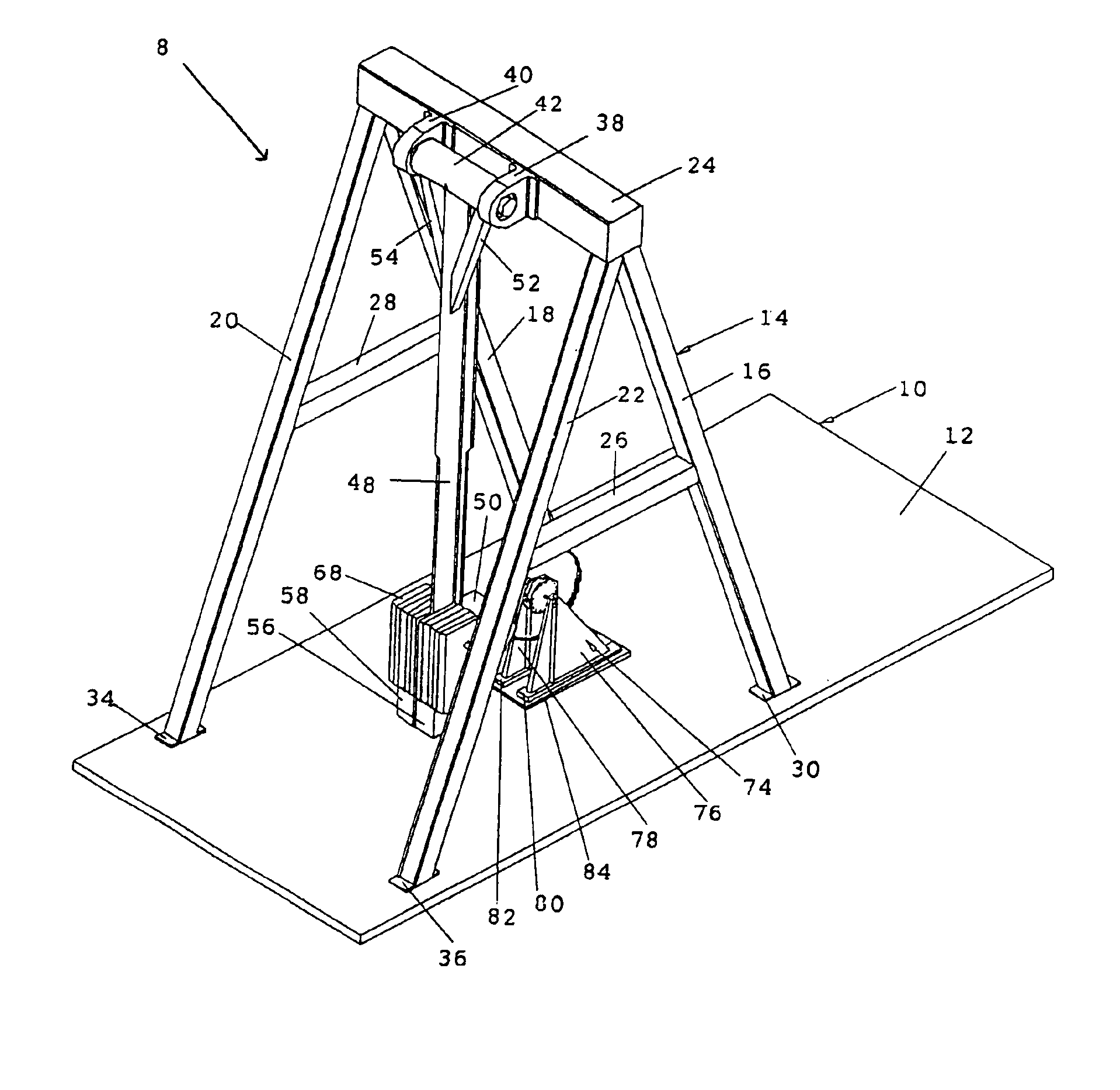

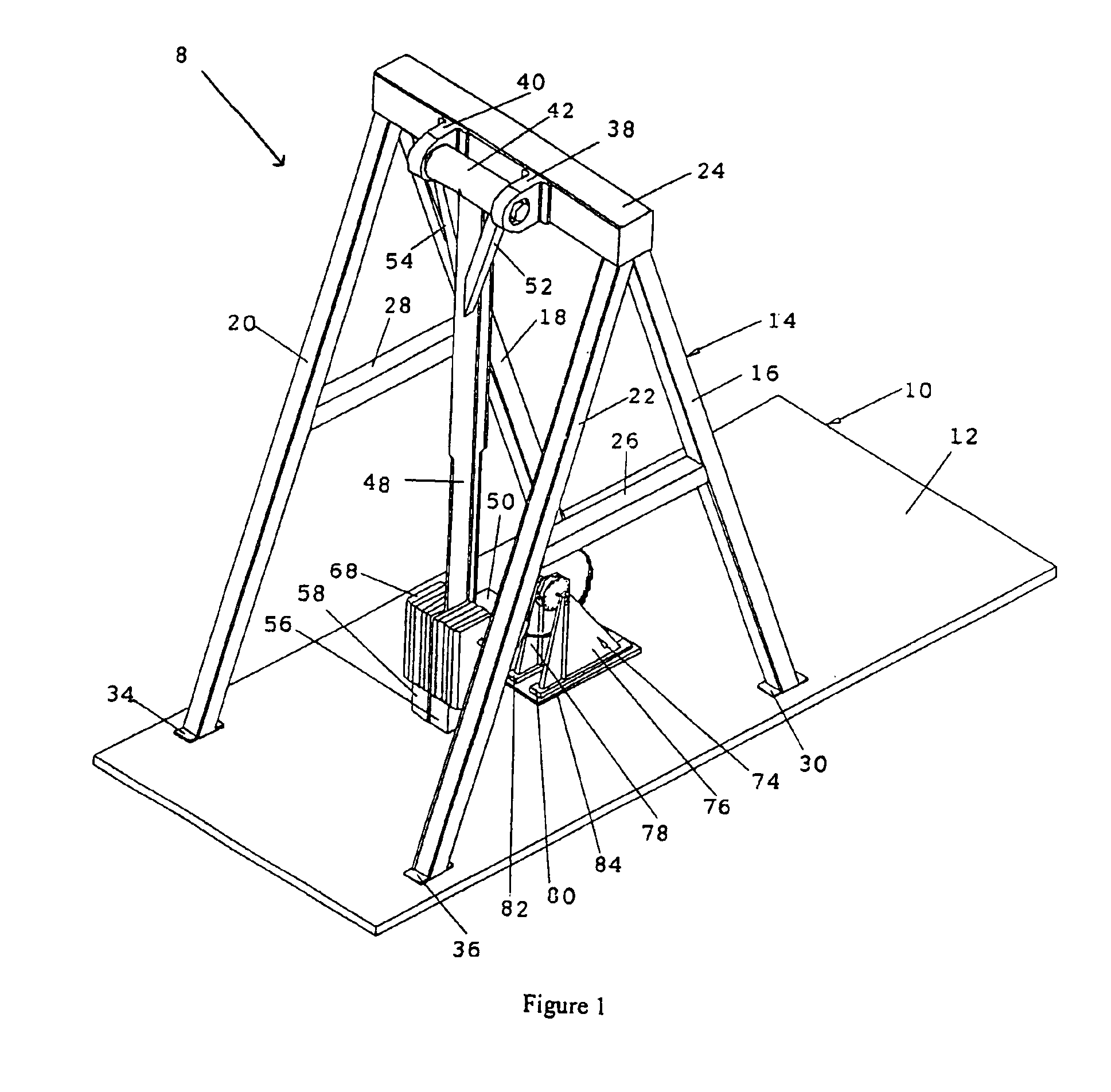

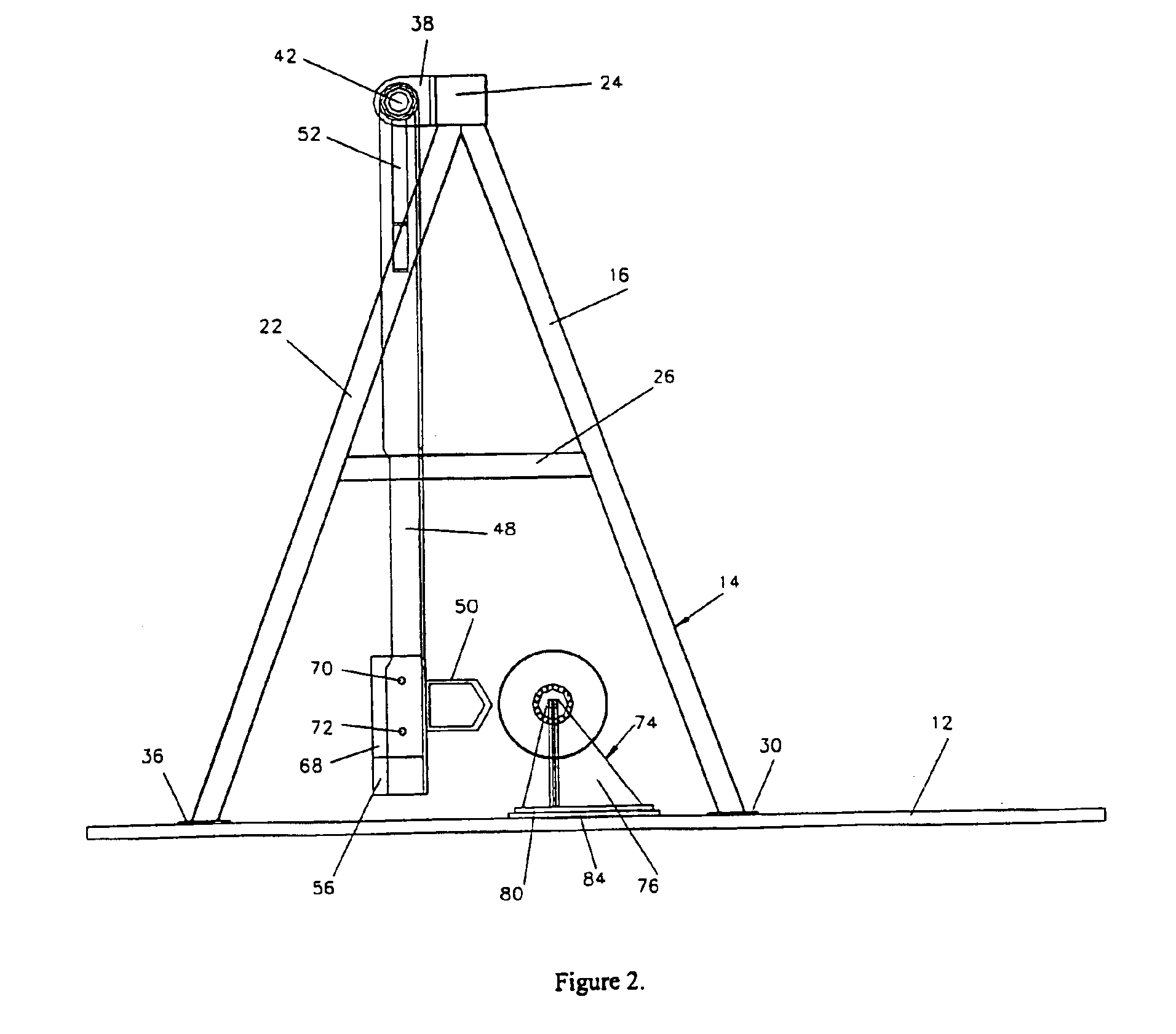

Pendulum impact test rig

InactiveUS6990845B2Controlling featureReduce weightAcceleration measurementInvestigating material hardnessAccelerometerData acquisition

The pendulum impact test rig is designed and developed for simulating impact conditions experienced by structural components in real-world crash or full-scale crash test. The test rig can be adopted for crash testing individual vehicle component. The test rig comprises of a base plate which is anchored to a concrete ground, a pendulum supporting structure positioned on the base plate, a pendulum member constructed from structural T-beam that permanently secured to a rotatably shaft, and a test item holding device releasably mounted on the base plate. The pendulum member includes a striker which is releasably attached to the lower end portion of the pendulum, fixed masses permanently secured at the lower end portion of the pendulum, and additional masses detachably attached immediately above the fixed masses. With present preferred embodiment, the center of percussion is controlled within the striking zone. Computer-based instrumentation system, which comprises accelerometer, high speed imaging system, light beam emitter-detector velocity measurement, data acquisition card, and computer with data acquisition and analysis application software installed is provided so that the desired data can be acquired for analysis and presentation.

Owner:UNIVERSITI PUTRA MALAYSIA

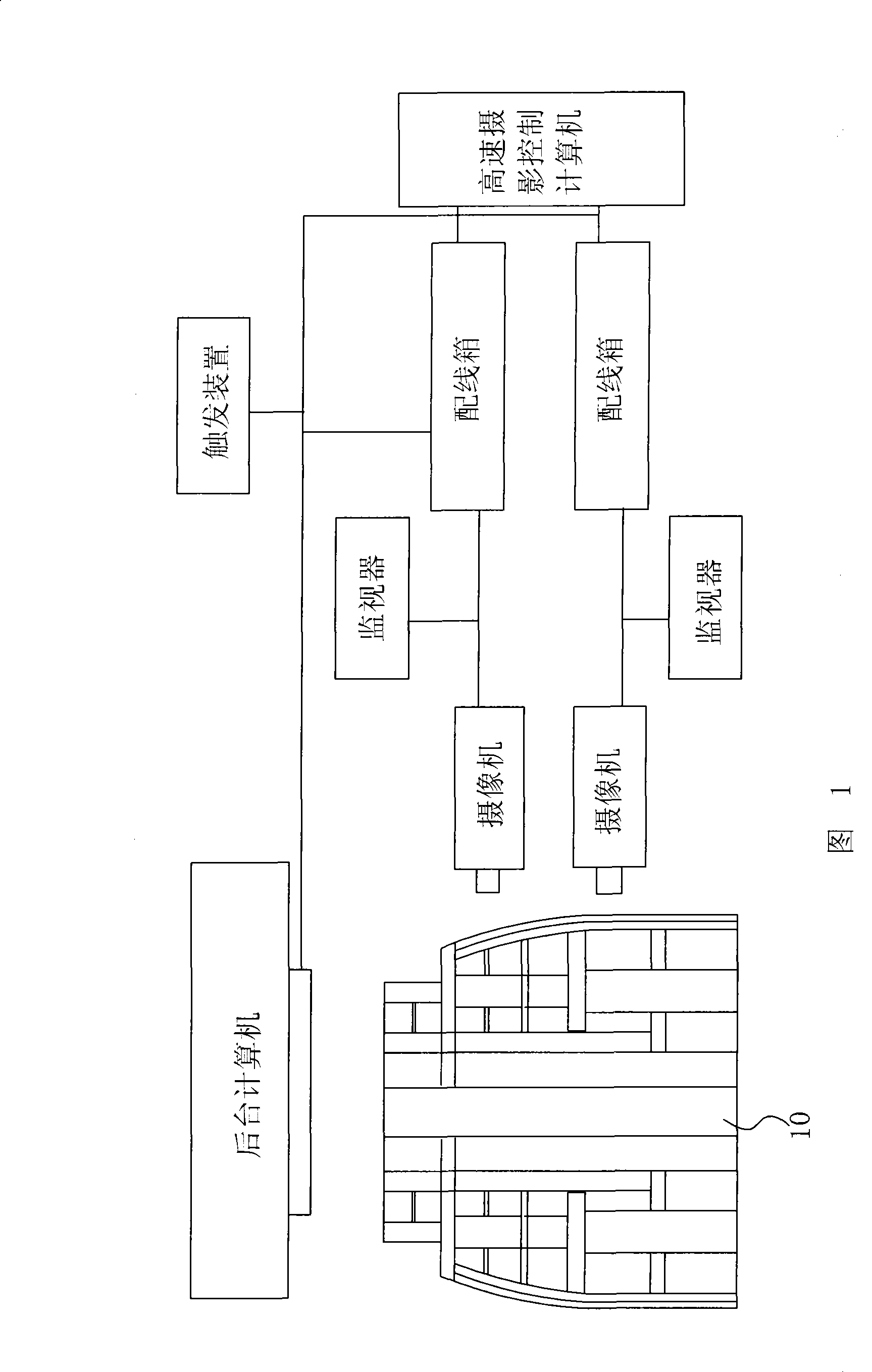

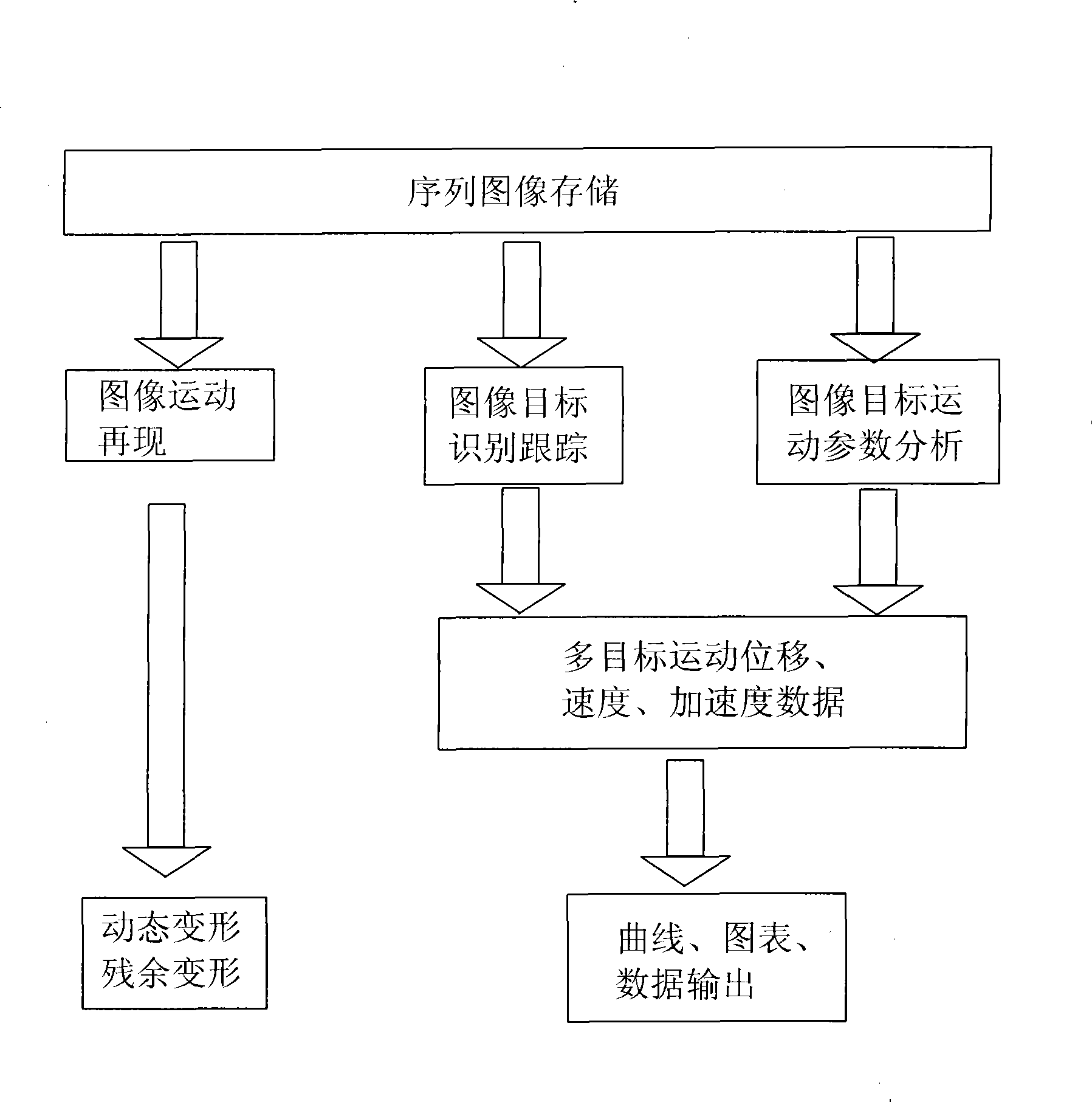

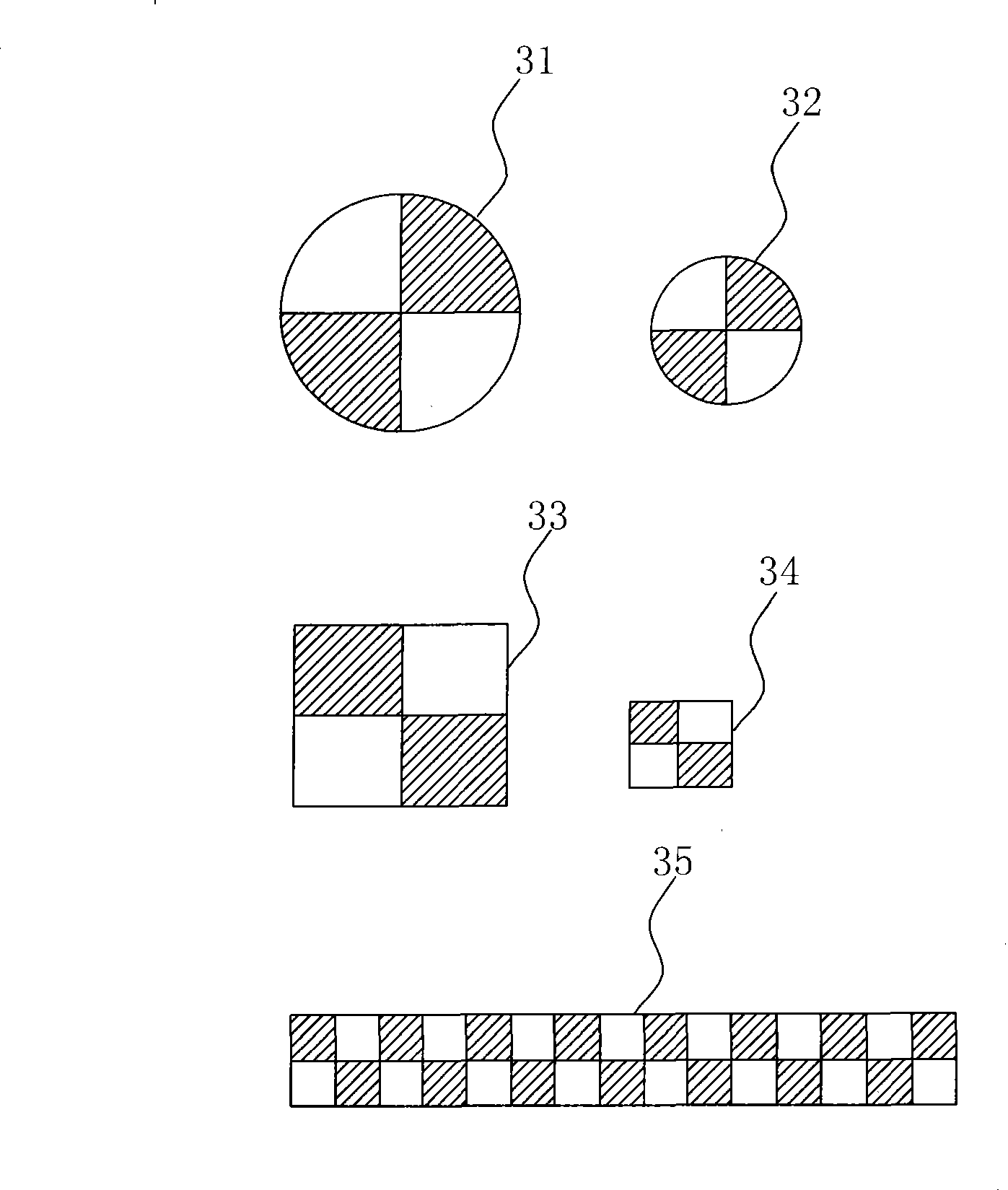

Vehicle component real object collision sequence image analysis method and its analysis system

The invention discloses an analysis method of crash sequence images of real vehicle components and an analysis system thereof are used in 3D motion analysis after real-time crash tests of the real vehicle components. The analysis method comprises the following steps: performing image motion reproduction on the crash sequence images to get dynamic deformation data and residual deformation data of a detection target in the images; tracking target identifications in the crash sequence images, getting and outputting the data of speed and acceleration of the target by analyzing the motion parameters of the target. The analysis method can help objectively and really get test data, get related kinematics parameters by a functional relation between coordinates and time of the target, and solve the measurement problems of parameters such as deformation, displacement, velocity, acceleration and the like in high-speed crash course.

Owner:CENT SOUTH UNIV

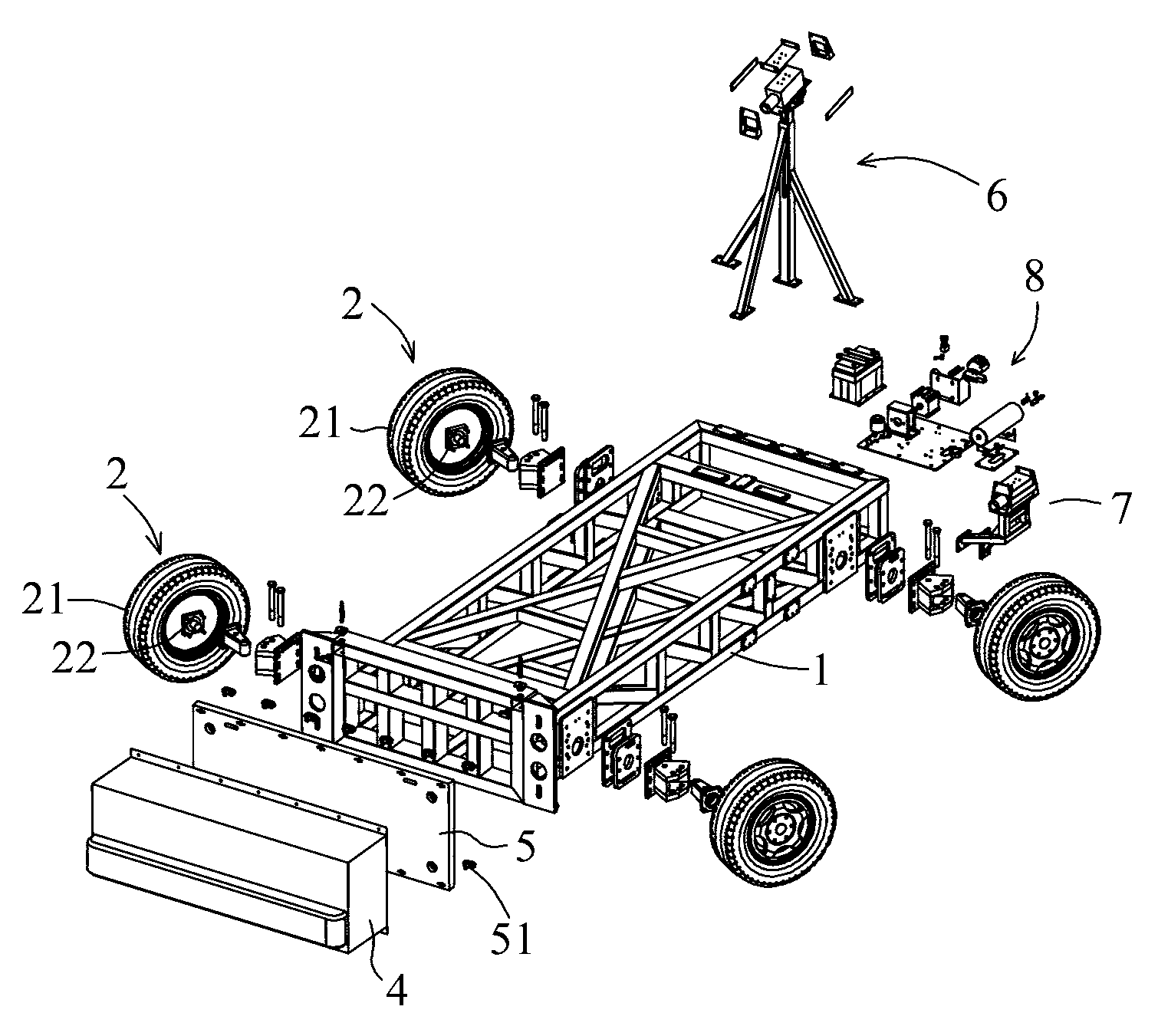

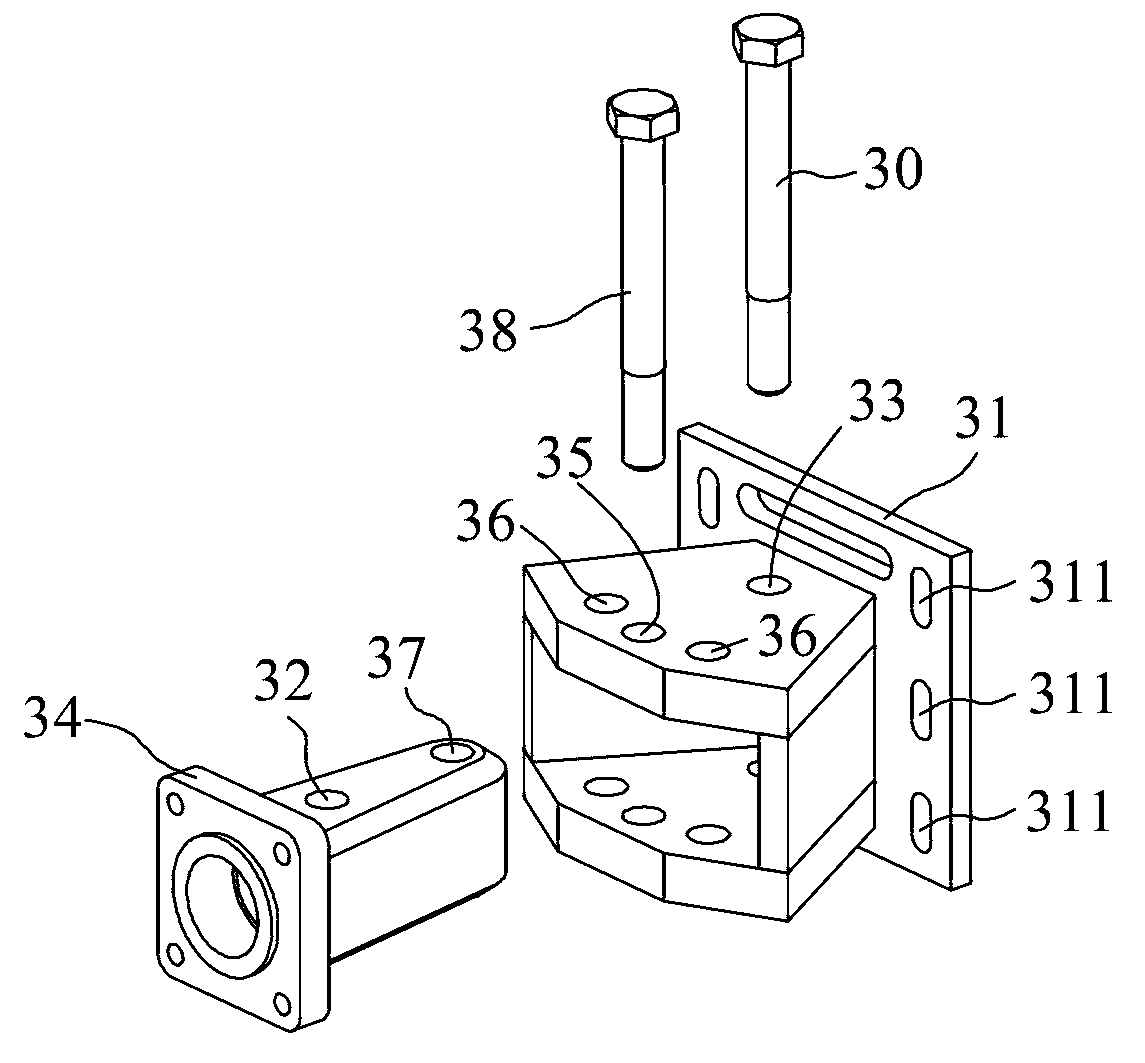

Crash test table vehicle

ActiveCN103063397ARegulate Collision RequirementsFirmly connectedVehicle testingShock testingCrash testWheel and axle

The invention discloses a crash test table vehicle comprising a vehicle body and a vehicle wheel component supporting the vehicle body, a honeycomb aluminum crash block is arranged on the front portion of the vehicle body, the vehicle wheel component comprises an axle component and a wheel body component arranged on the axle component, the vehicle wheel component further comprises an angle adjusting device connecting the axle component and the vehicle body, the angle adjusting device comprises a locating seat and a locating pin, a locating hole is formed in the locating pin, a main plughole and an assistant plughole are formed in the locating seat, and plug pins capable of being plugged into the main plughole or the assistant plughole and the locating hole are further arranged on the locating seat. According to the crash test table vehicle, the angle of the axle component is adjusted through the angle adjusting device to enable the movement direction of the wheel body component to be inclined or parallel to the axis of the vehicle body, and therefore the crash test table vehicle is enabled to be used in a side face crash test and a rear face crash test.

Owner:GREAT WALL MOTOR CO LTD

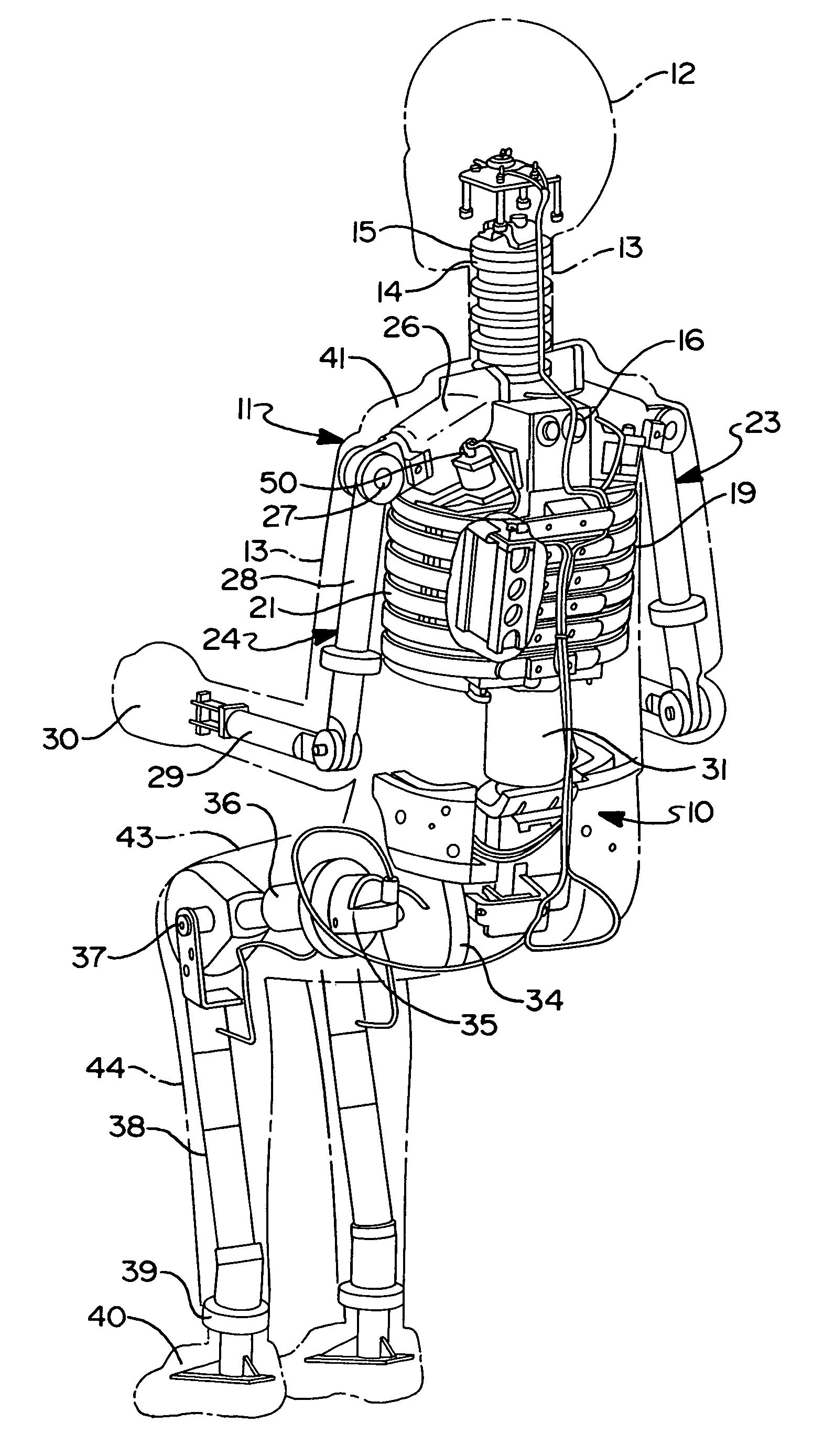

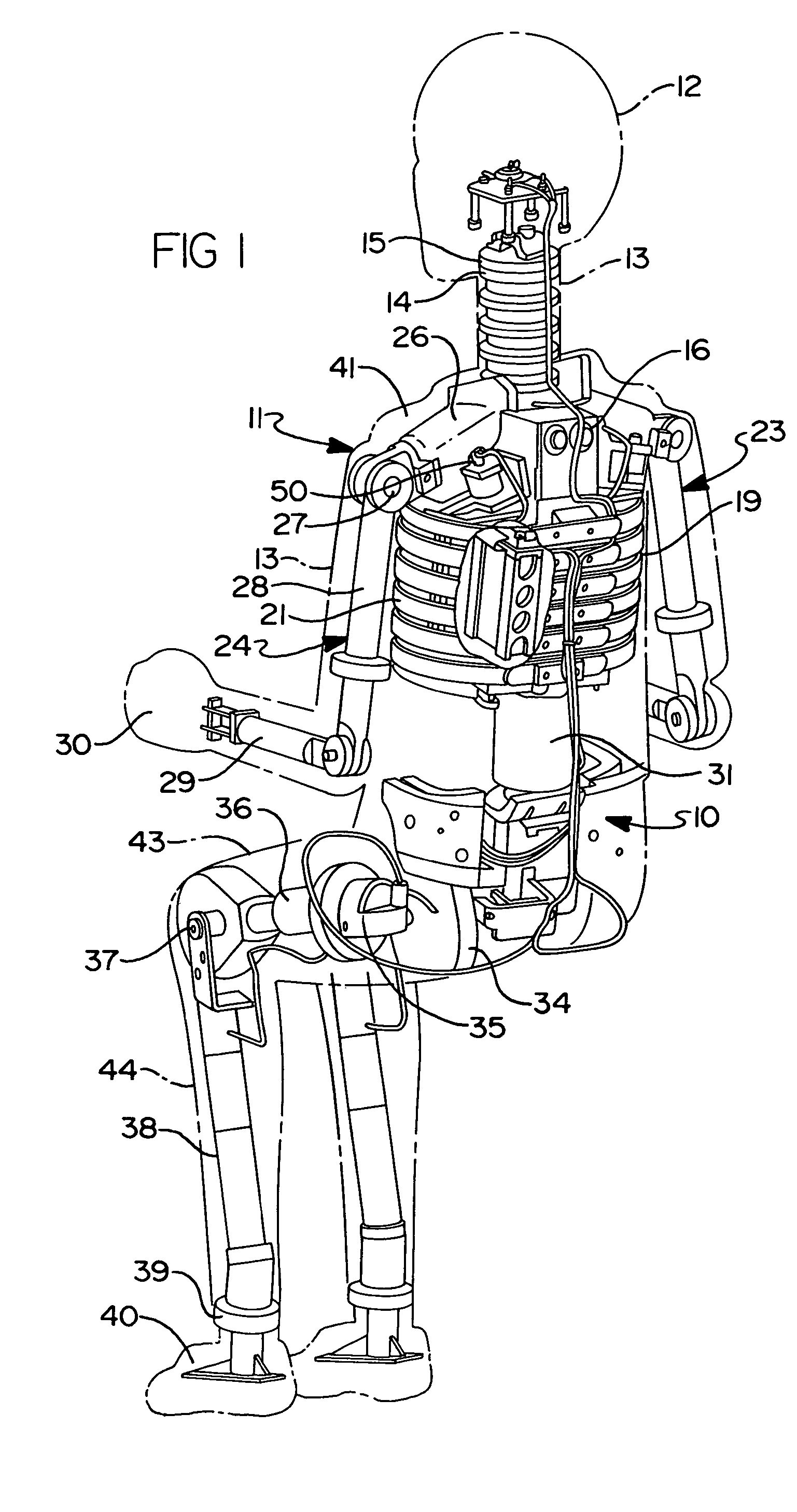

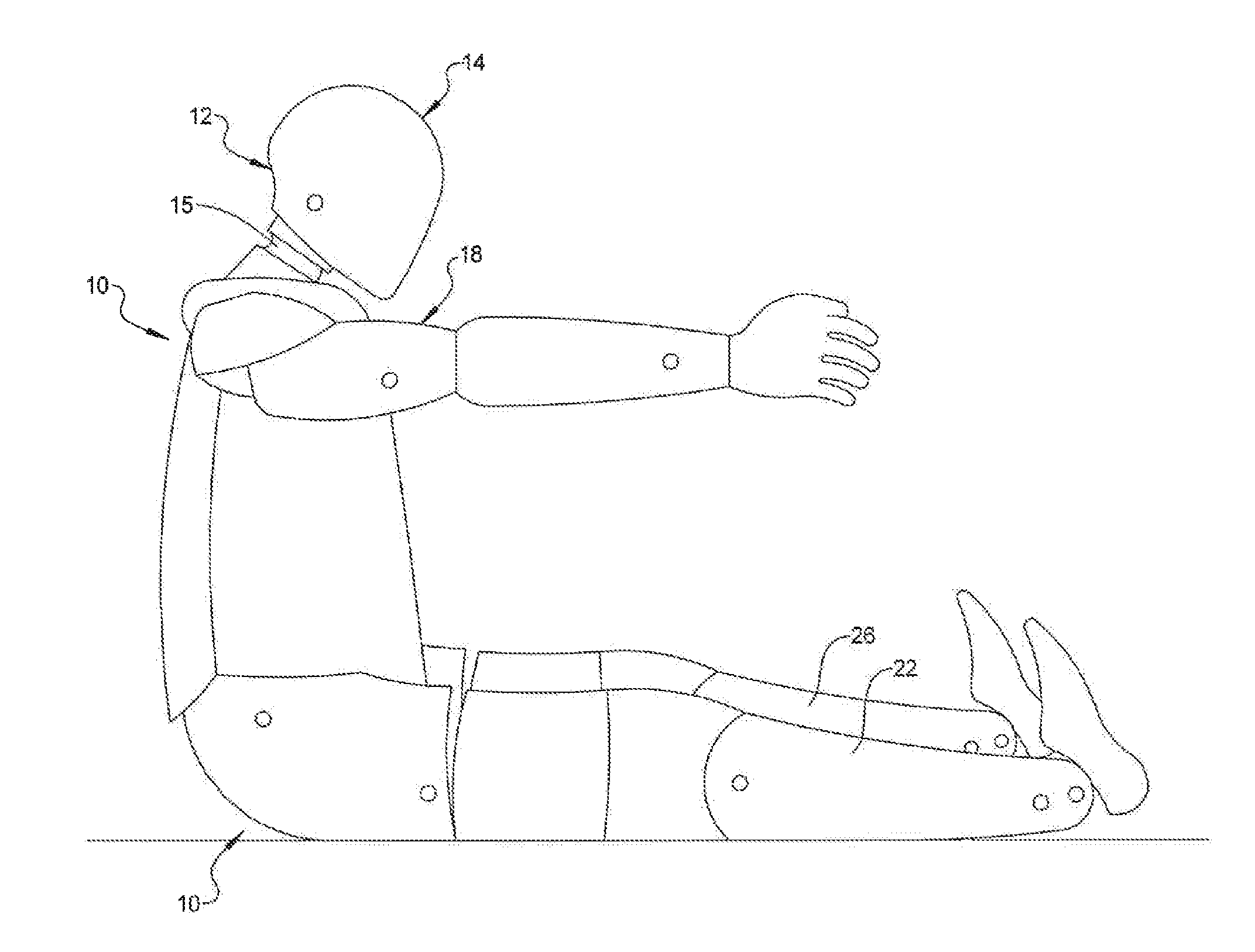

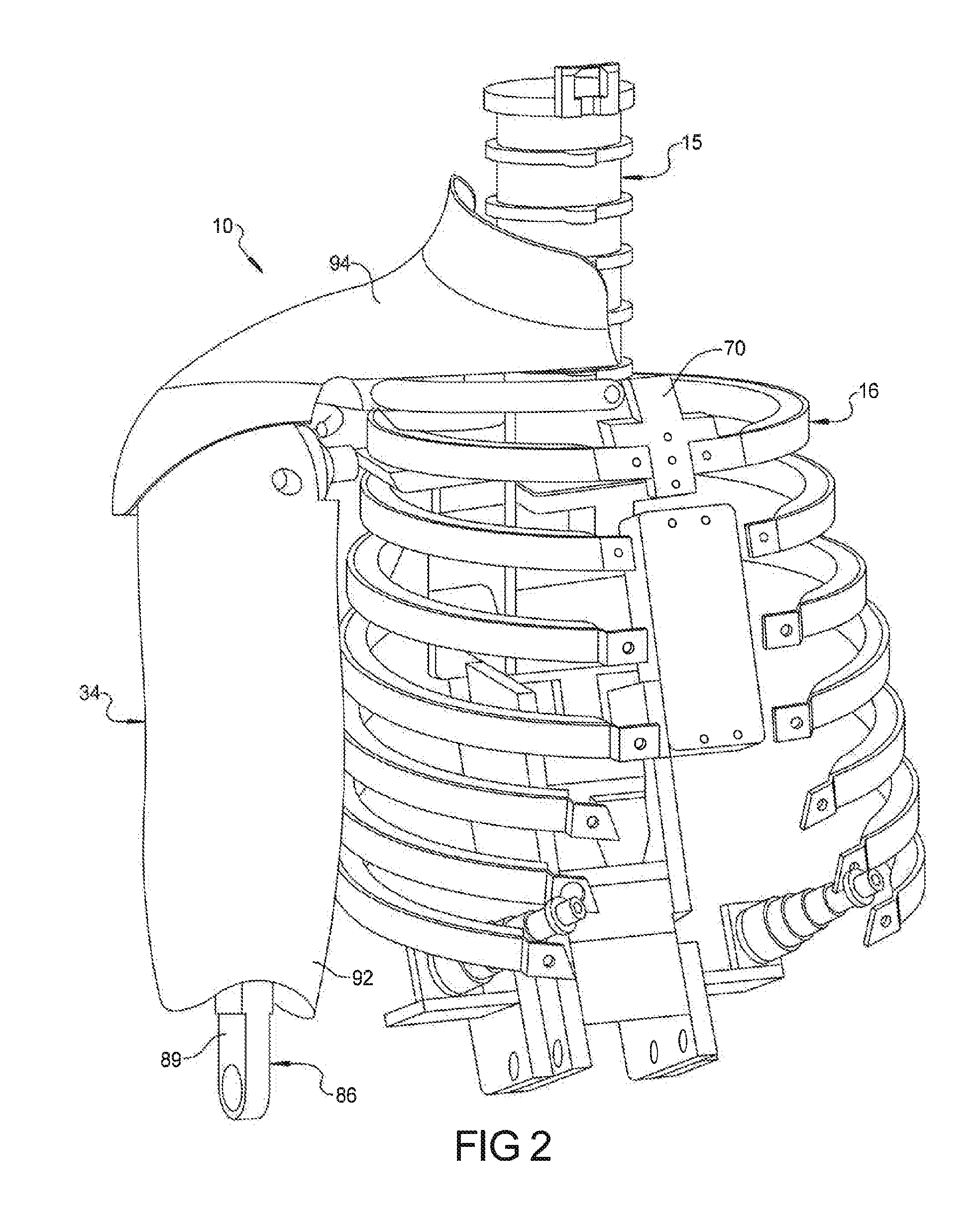

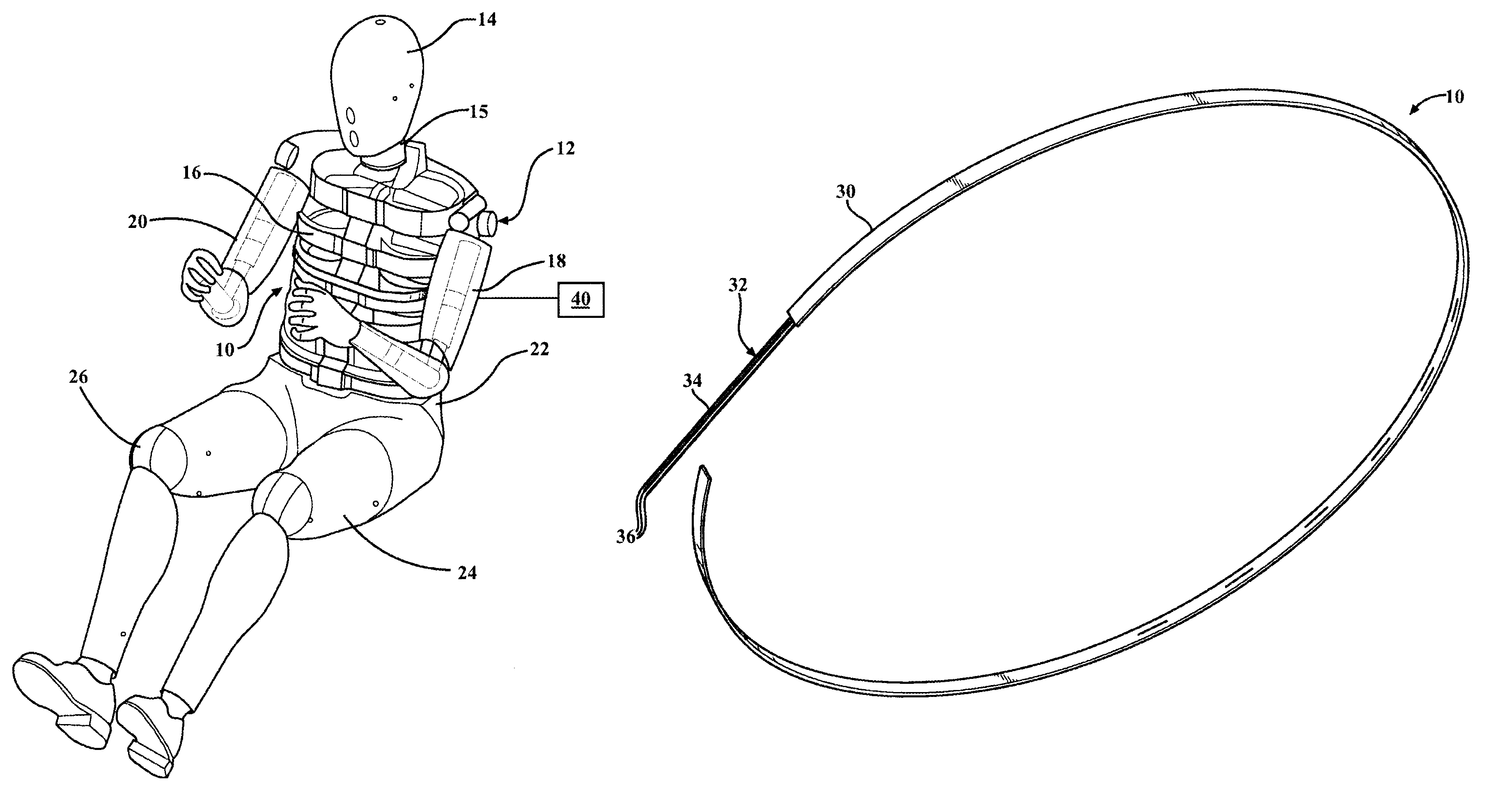

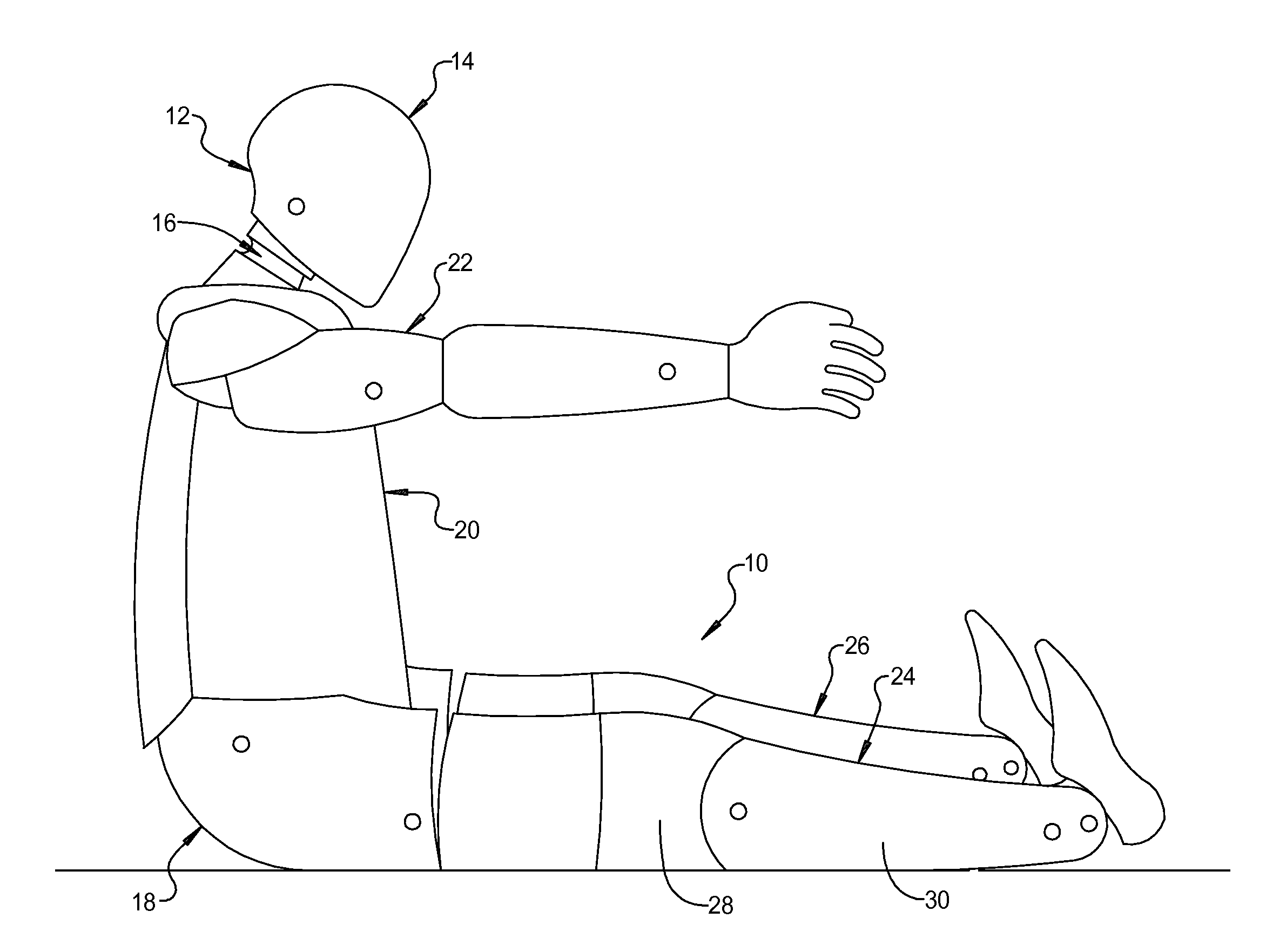

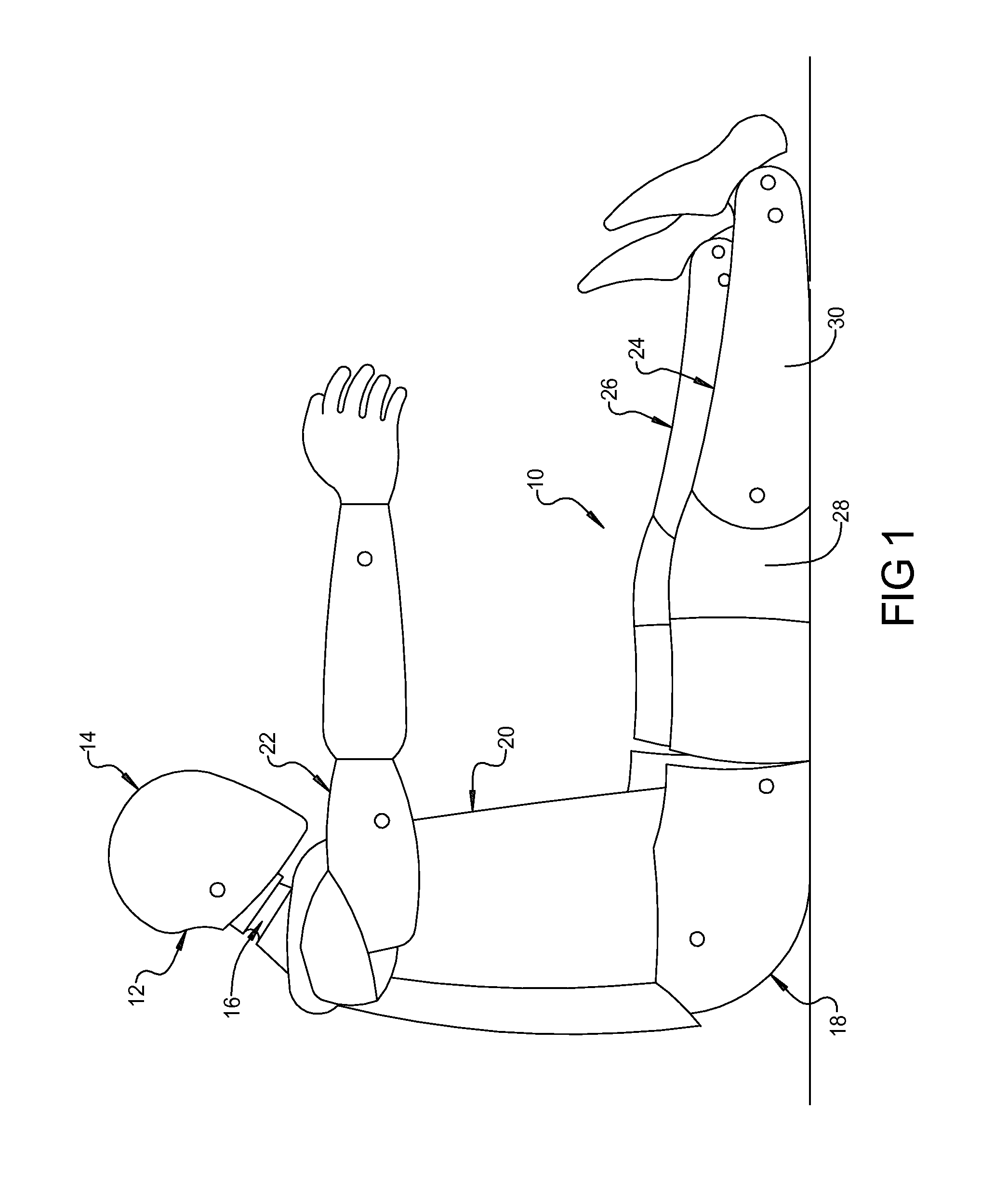

Shoulder and upper arm assembly for crash test dummy

A shoulder and upper arm assembly for a crash test dummy includes a shoulder assembly having a spring housing and a shoulder pivot member pivotally connected to the spring housing. The shoulder assembly includes a spring element disposed in the spring housing and an adjustable member to adjust the friction of the spring element. An upper arm assembly includes a bone assembly having one end connected to the shoulder assembly and another end for connection to a lower arm assembly. The bone assembly includes a bone member made of metal and a load cell connected to the bone member to measure a load on the bone member.

Owner:HUMANETICS INNOVATIVE SOLUTIONS

Measurement system for crash test dummy

InactiveUS20040099825A1Investigating moving sheetsCounting objects on conveyorsElectricityCrash test

A measurement system is provided for a ball joint of a crash test dummy. The measurement system includes a light source operatively supported by a movable ball of the ball joint and a position sensitive detector operatively supported by a fixed member of the ball joint. The measurement system also includes a controller electrically connected to the light source to provide power to the light source for emitting light and electrically connected to the position sensitive detector that receives the emitted light to measure at least two angles between the ball and the fixed member.

Owner:HUMANETICS INNOVATIVE SOLUTIONS

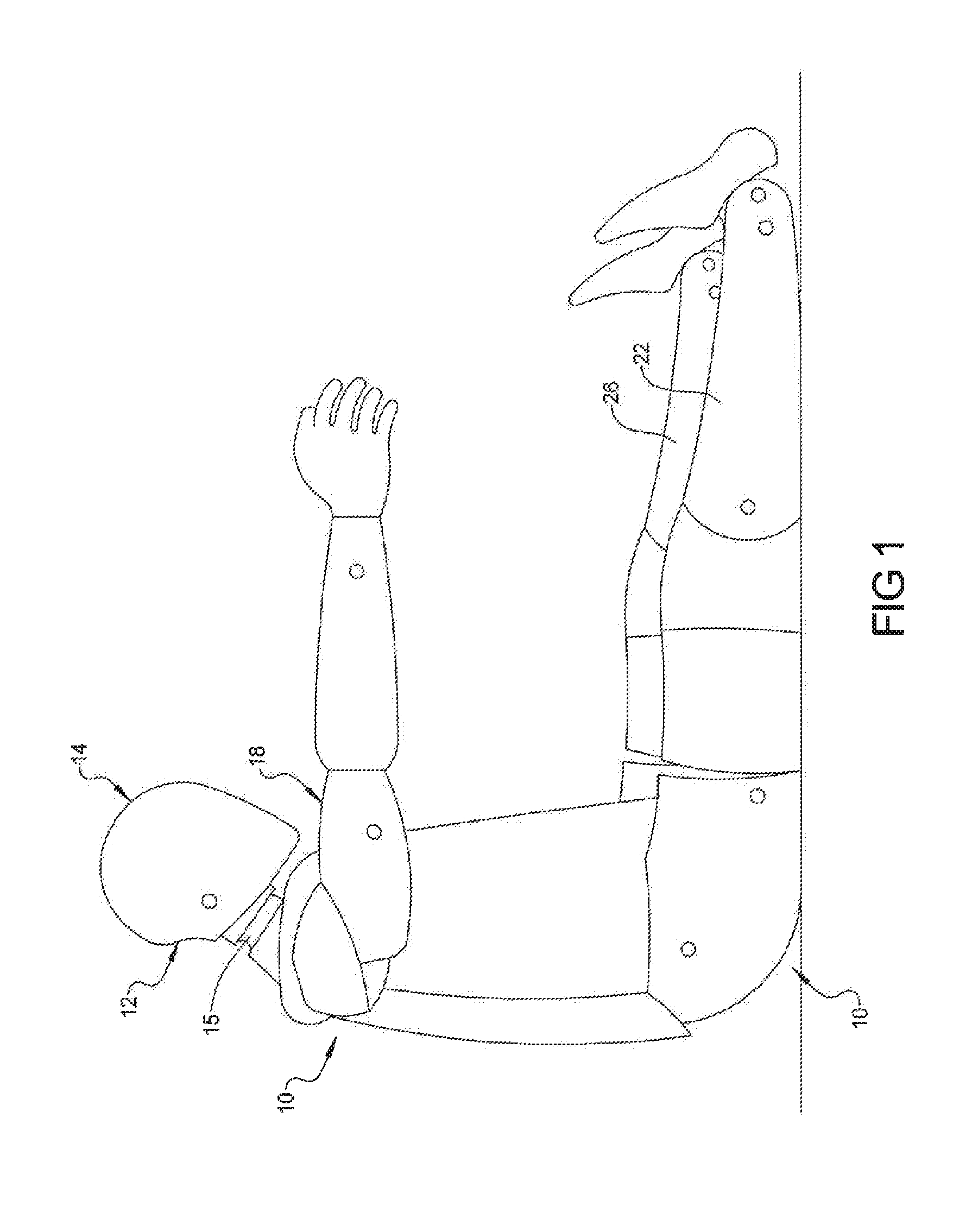

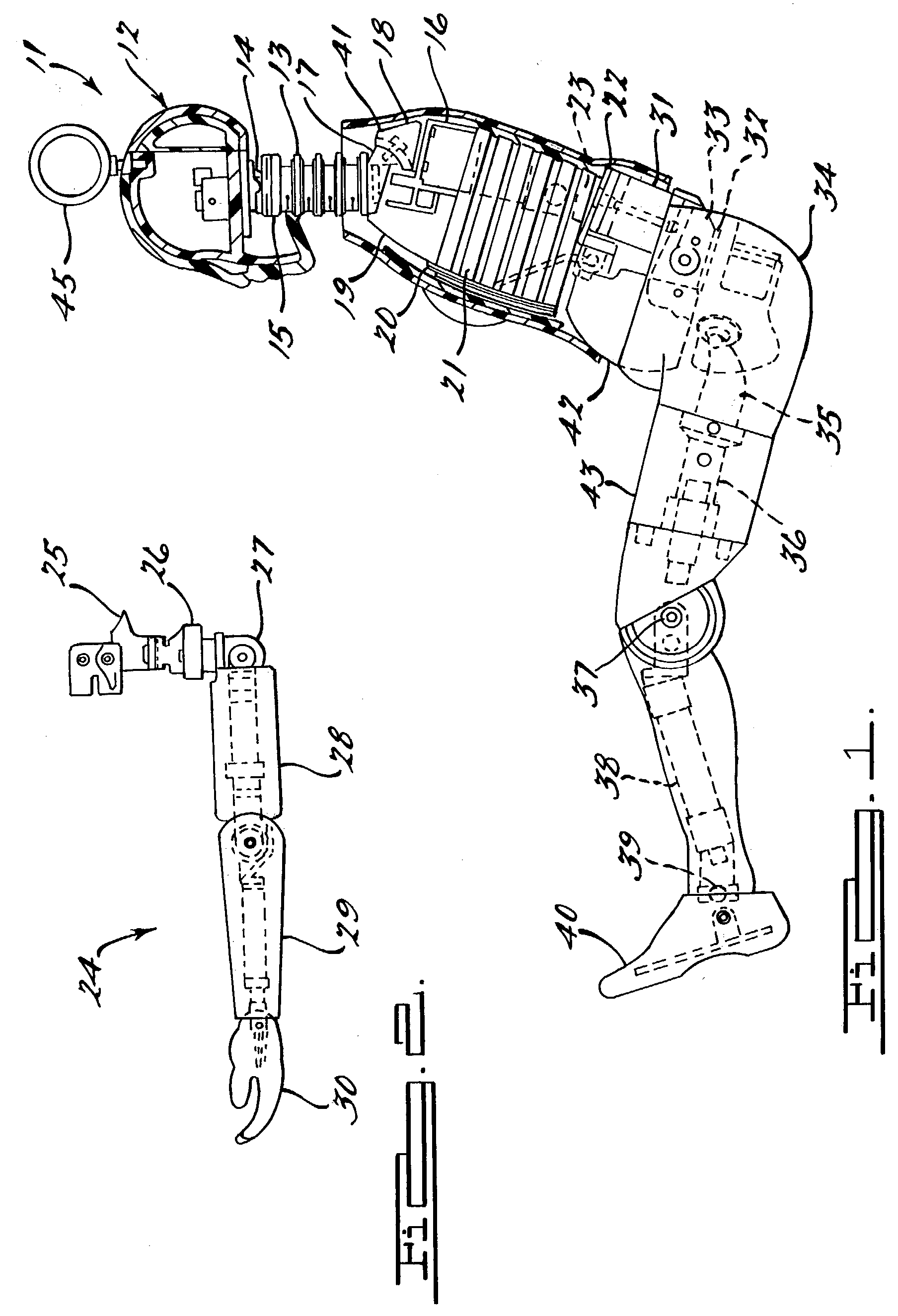

Arm assembly for a crash test dummy

An arm assembly for a crash test dummy includes an upper arm unit, a lower arm unit, a wrist joint, and a hand unit. An upper portion of the upper arm unit is connected to a body of the crash test dummy. The lower arm unit is pivotally connected to a lower portion of the upper arm unit. A first end of the wrist joint is rotatably connected to the lower arm unit. The hand unit is pivotally connected to a second end of the wrist joint. The upper arm unit comprises a housing and a driving device disposed in the housing. The driving device drives the lower arm unit.

Owner:HYUNDAI MOTOR CO LTD

Flexible printed circuit cabling system for crash test dummy

ActiveUS20050126258A1Less likely to degrade biofidelityImproves biofidelityUsing electrical meansAcceleration measurementElectricityCrash test

A flexible printed circuit cabling system for a crash test dummy includes at least one centralized data-receiving unit. The flexible printed circuit cabling system also includes a plurality of sensors arranged remotely from the at least one centralized data receiving unit to generate electrical signals of data pertaining to a vehicular collision. The flexible printed circuit cabling system further includes a plurality of flexible printed circuit cables electrically interconnecting the sensors and the at least one centralized data receiving unit to transmit the electrical signals from the sensors to the at least one centralized data receiving unit.

Owner:HUMANETICS INNOVATIVE SOLUTIONS

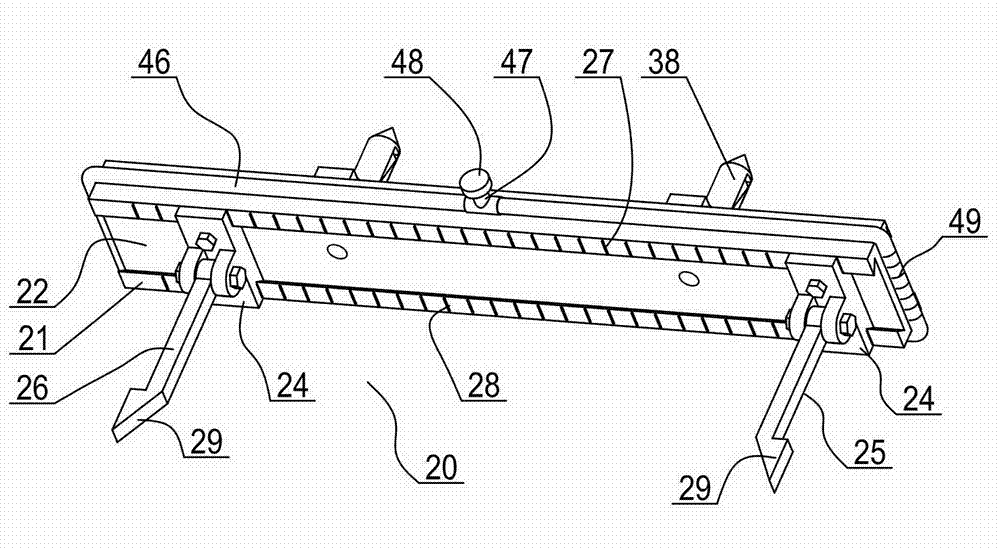

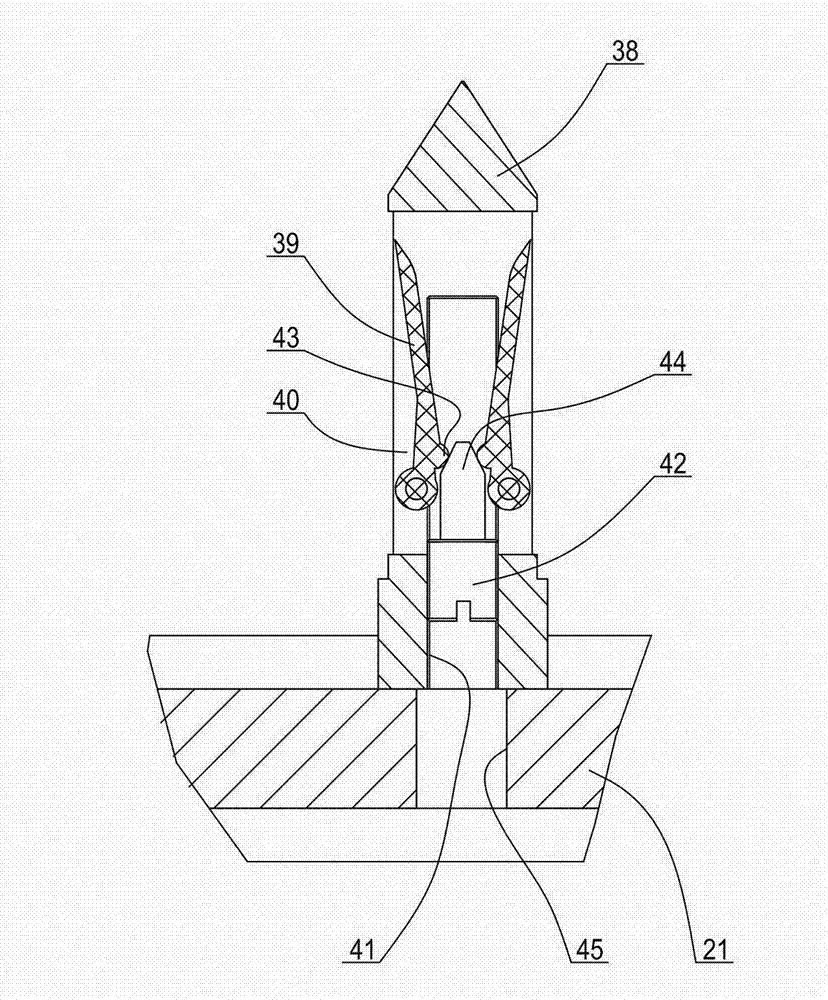

Seat route measuring device used for vehicle crash test

ActiveCN103196345AEasy to readOptimize data processingVehicle testingMechanical measuring arrangementsMeasurement deviceCrash test

The invention discloses a seat route measuring device used for a vehicle crash test. The seat route measuring device is used for measuring a route of a seat and positioning the seat at the middle position of the route. The seat route measuring device comprises a marking device and the measure device which can be fixed on a seat cushion of the seat. The marking device comprises a magnetic gauge stand and a marker post which is arranged on the magnetic gauge stand. The measuring device comprises a slide rail, the front side of the slide rail is connected with a fixed pointer and a sliding pointer in a sliding mode, the fixed pointer is provided with a fastening structure for fixing the position, a route scale mark is arranged on the front side of the slide rail along the sliding direction of the sliding pointer, two fixing thrusting needles with cone-shaped end portions are arranged on the back of the slide rail along the longitudinal direction, and the fixing thrusting needles are perpendicular to the back of the slide rail. According to the seat route measuring device, numerical reading is easy, data processing is simple and convenient, the route is adjusted accurately, and efficiency is high.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

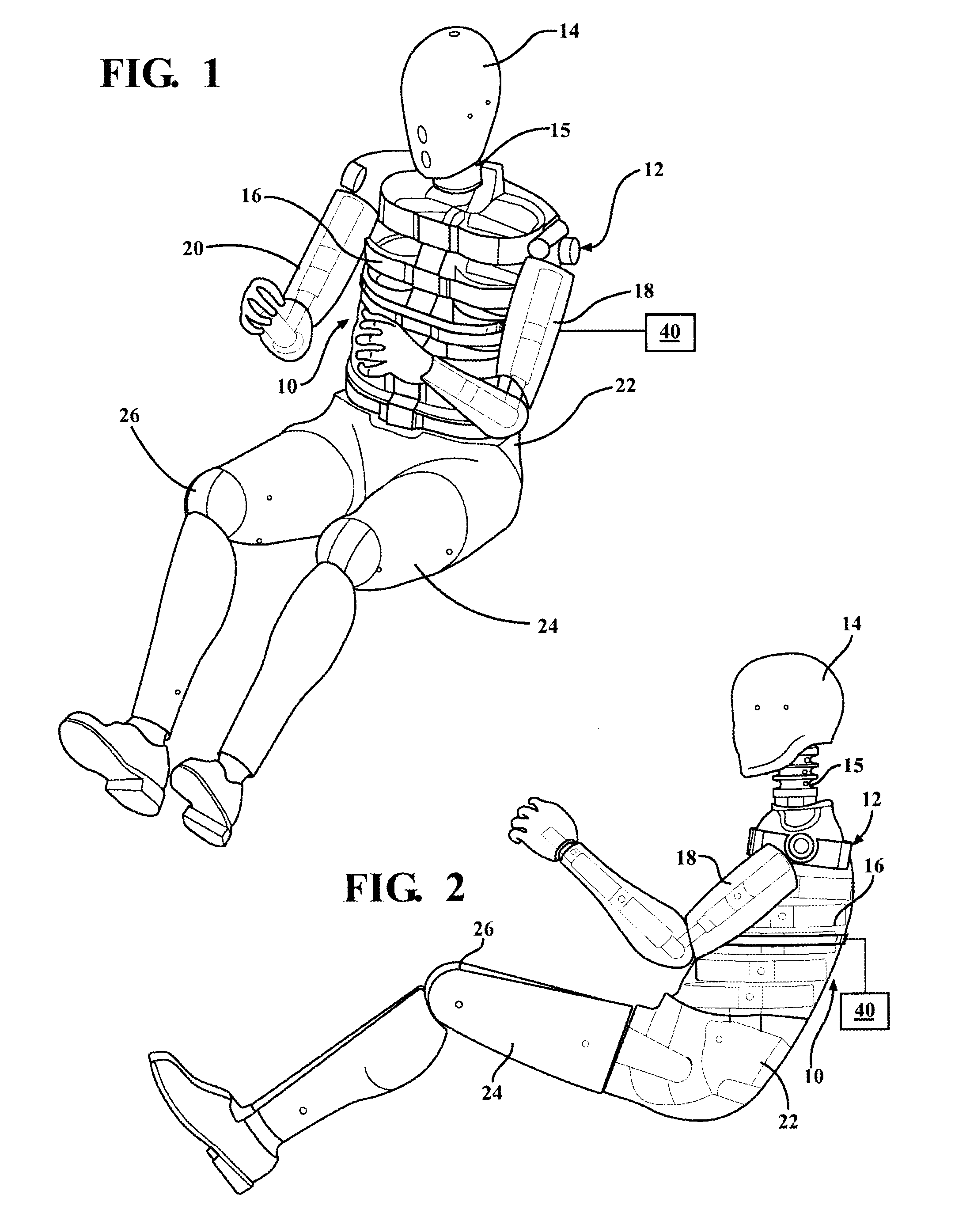

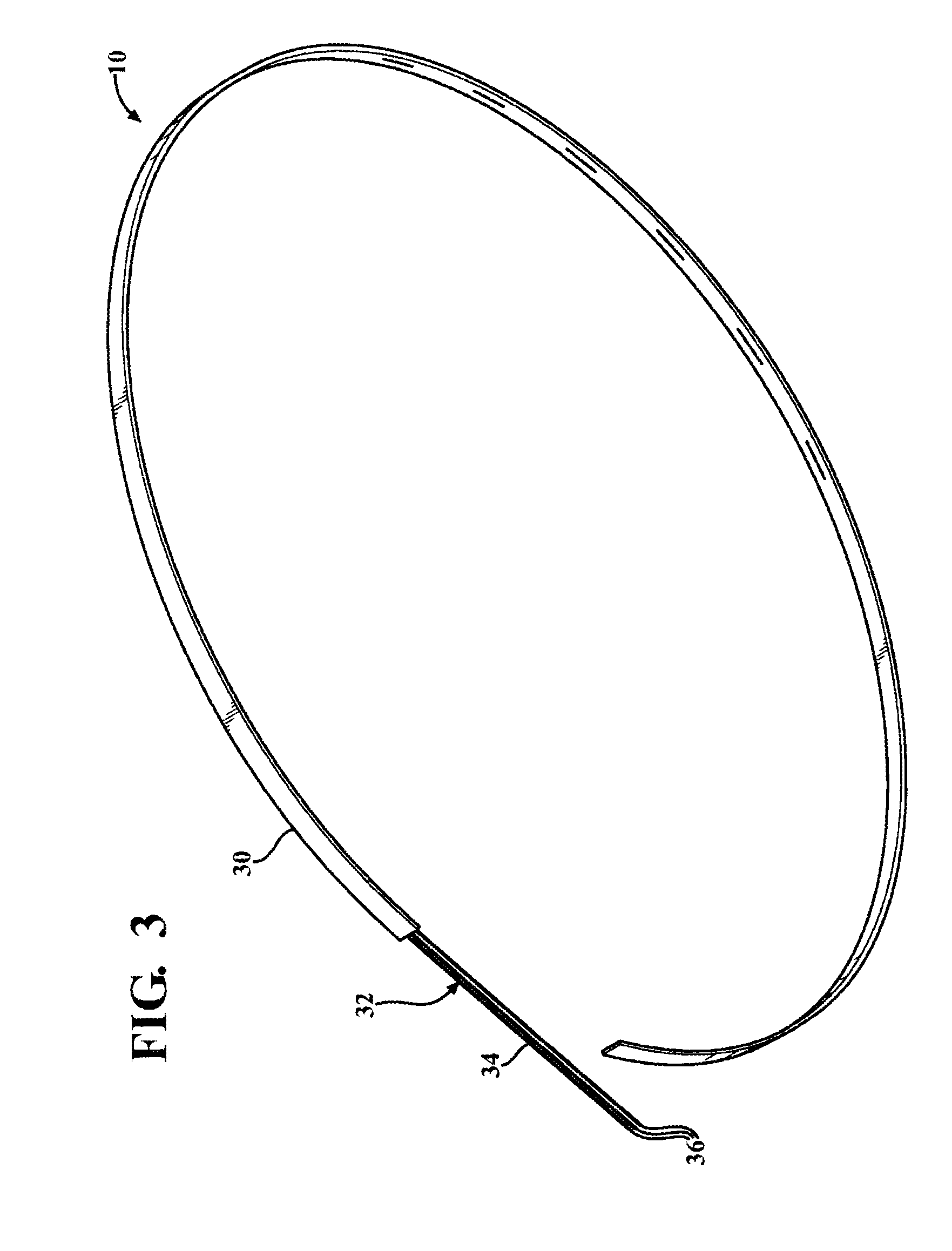

Chest band assembly for crash test dummy

ActiveUS9355575B2Small sizeEliminate bulkinessForce measurement by measuring optical property variationUsing optical meansCrash testEngineering

A chest band assembly for a crash test dummy includes a chest band adapted to be disposed about a rib cage of the crash test dummy and a sensor cooperating with the chest band and the rib cage. The sensor is made of a carrier and a plurality of optical fibers bonded to the carrier, wherein each of the optical fibers has at least one sensor.

Owner:HUMANETICS INNOVATIVE SOLUTIONS

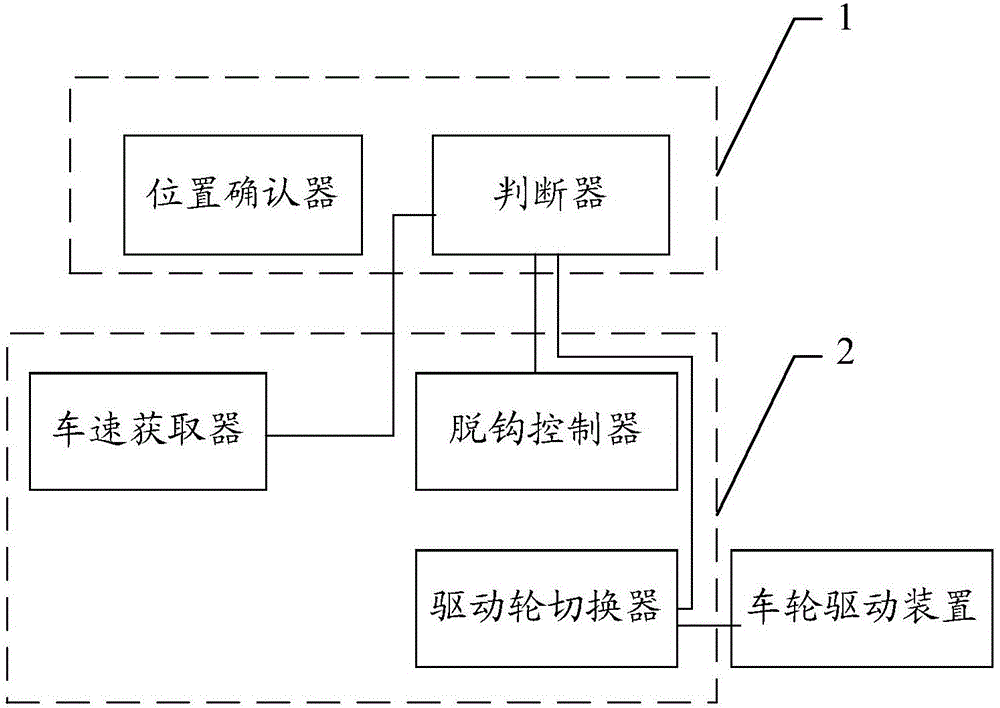

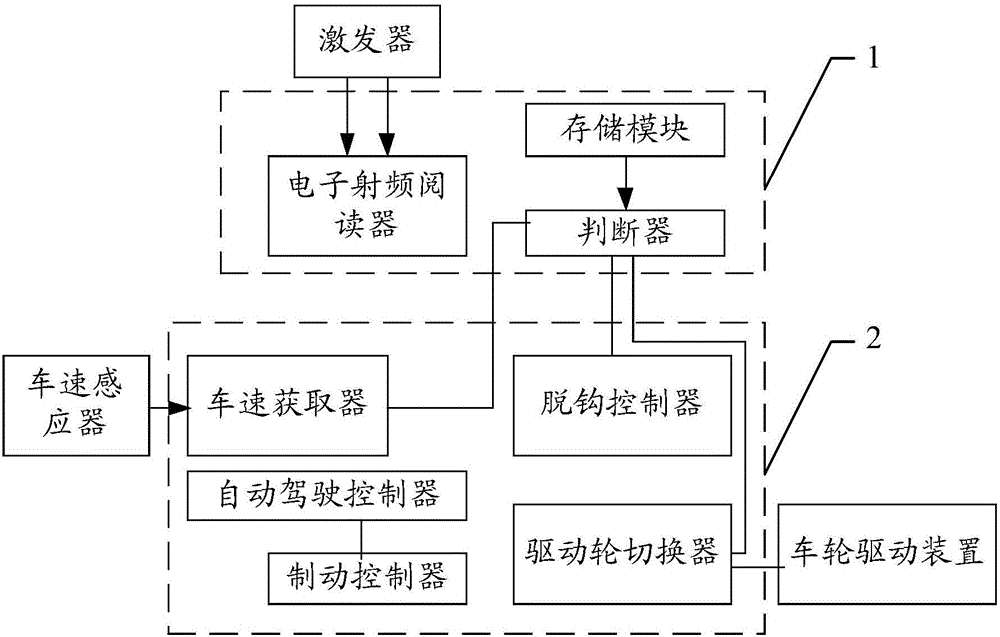

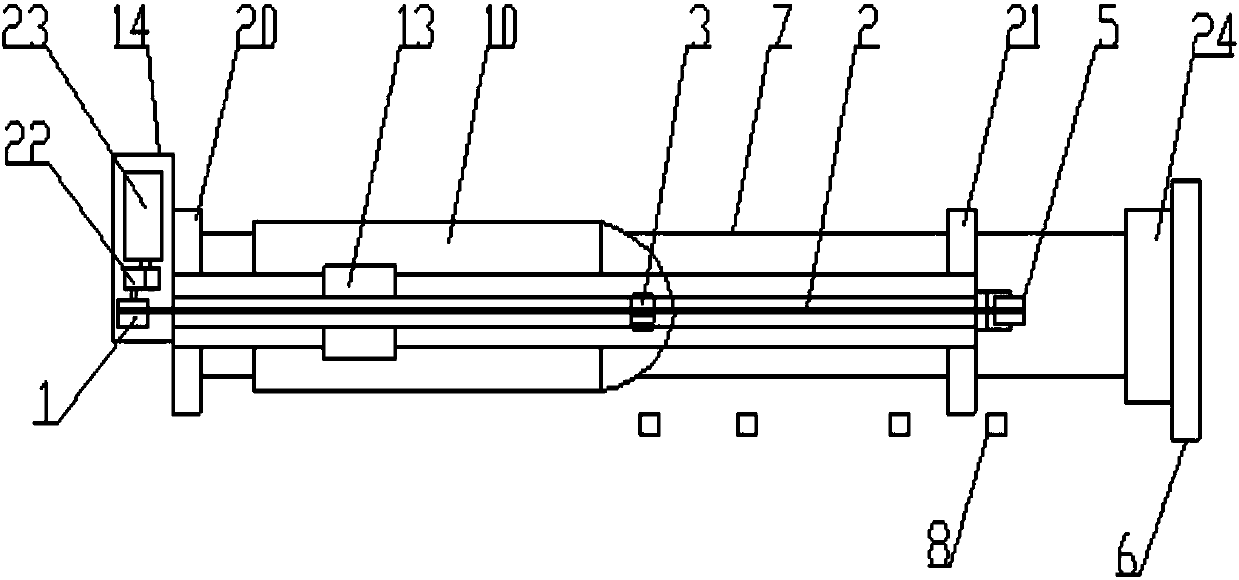

Rail train crash test system

ActiveCN106198067AAchieve separationEasy to separateRailway vehicle testingDrive wheelDecoupling controller

The invention discloses a rail train crash test system. Each power carriage of a test train is provided with a rail wheel drive device and a rubber wheel drive device which can be mutually switched. A test track is provided with functional areas including a speed detection area and a decoupling area. The rail train crash test system further comprises a crash controller including a position confirmer for confirming the position of the test train on the test track and a determiner for determining whether or not the current speed of the test train satisfies a preset condition. The trial train is provided with a central controller in communication connection with the crash controller, the central controller including a train speed acquisition device for transmitting the speed of the test train to the crash controller in real time, a decoupling controller for controlling the decoupling operation between the power carriages of the test train, and a drive wheel switch for controlling the switching operation of the power carriages. The rail train crash test system solves technical problems in the prior art of low success rate of the crash test of the rail train, proneness to a waste of cost and the like.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Multi-point position measuring and recording system for anthropomorphic test devices

InactiveUS20070058163A1Reducing bio-fidelityLimits number of possibleAngle measurementOptical rangefindersTriangulationCrash test

The motion of an Anthropomorphic Test Device (ATD) member is measured. For example, the motion of ribs and other components of an ATD or Crash-Test Dummy are tracked during crash testing and dummy calibration using light angle detectors and triangulation techniques.

Owner:BOXBORO SYST

Adjustable friction joint assembly for crash test dummy

ActiveUS20150086957A1High sensitivityLoosening of the jointYielding couplingCouplings for rigid shaftsCrash testEngineering

An adjustable friction joint assembly for a crash test dummy includes a first joint member for connection to a first member of the crash test dummy and a second joint member for connection to a second member of the crash test dummy. The adjustable friction joint assembly also includes a shaft operatively connected to the first joint member and the second joint member to allow rotation therebetween. The adjustable friction joint assembly further includes an adjustable friction assembly operatively connected to the shaft and operatively cooperating with the first joint member and the second joint member to adjust a friction tightness of the joint assembly.

Owner:HUMANETICS INNOVATIVE SOLUTIONS

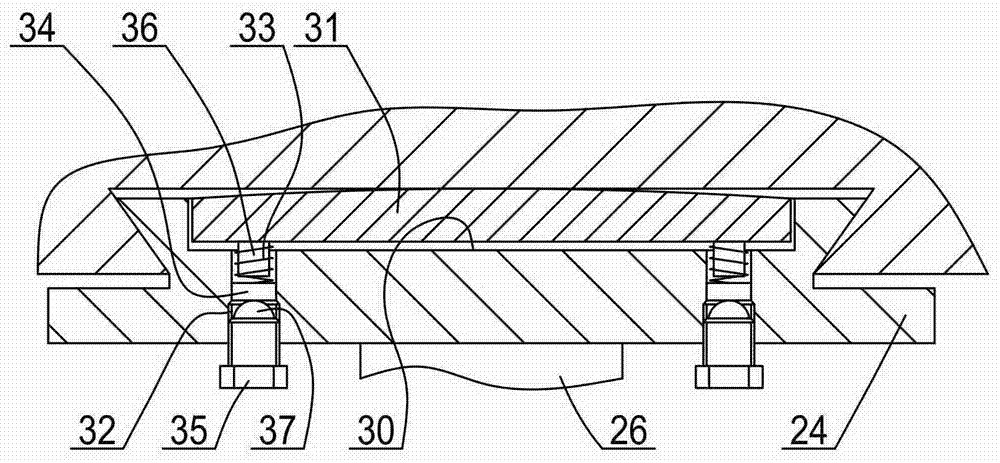

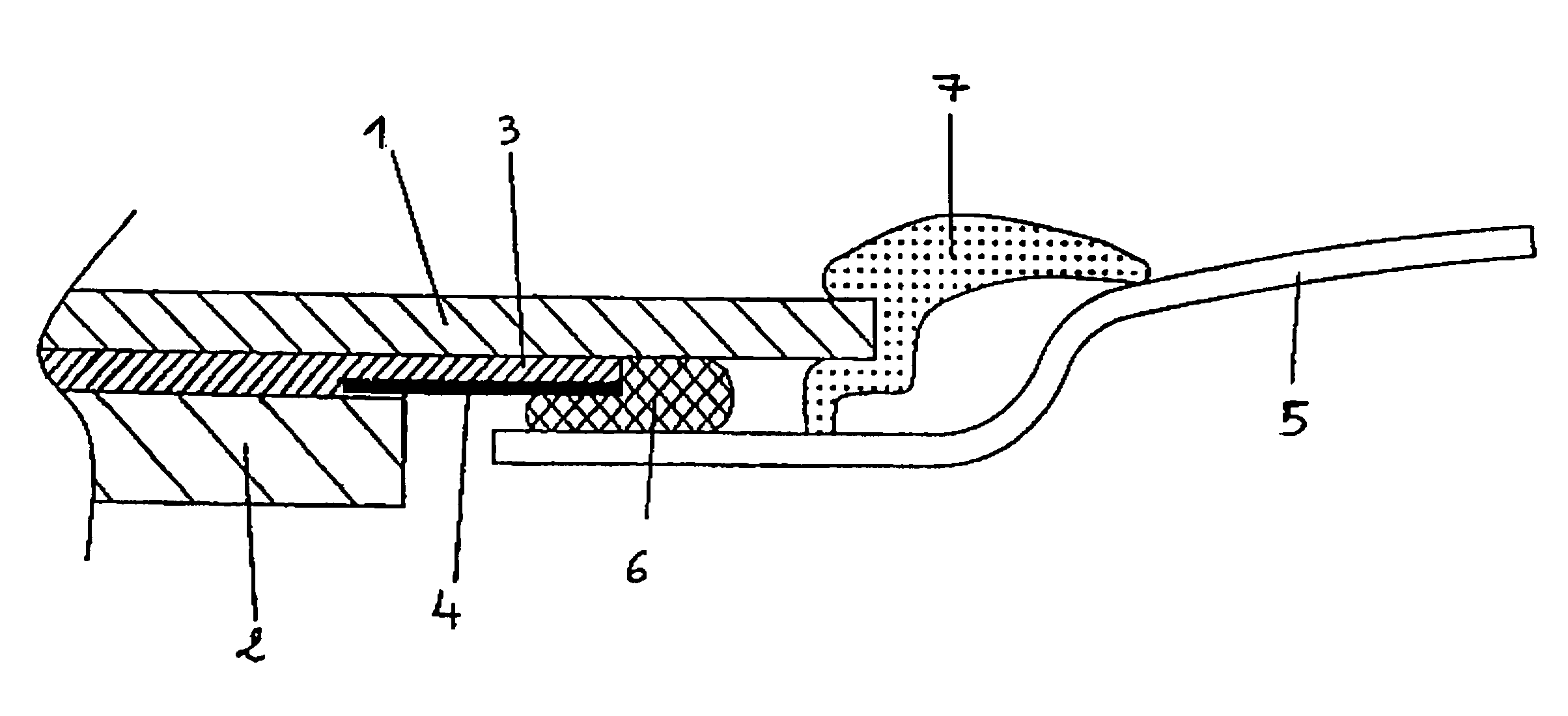

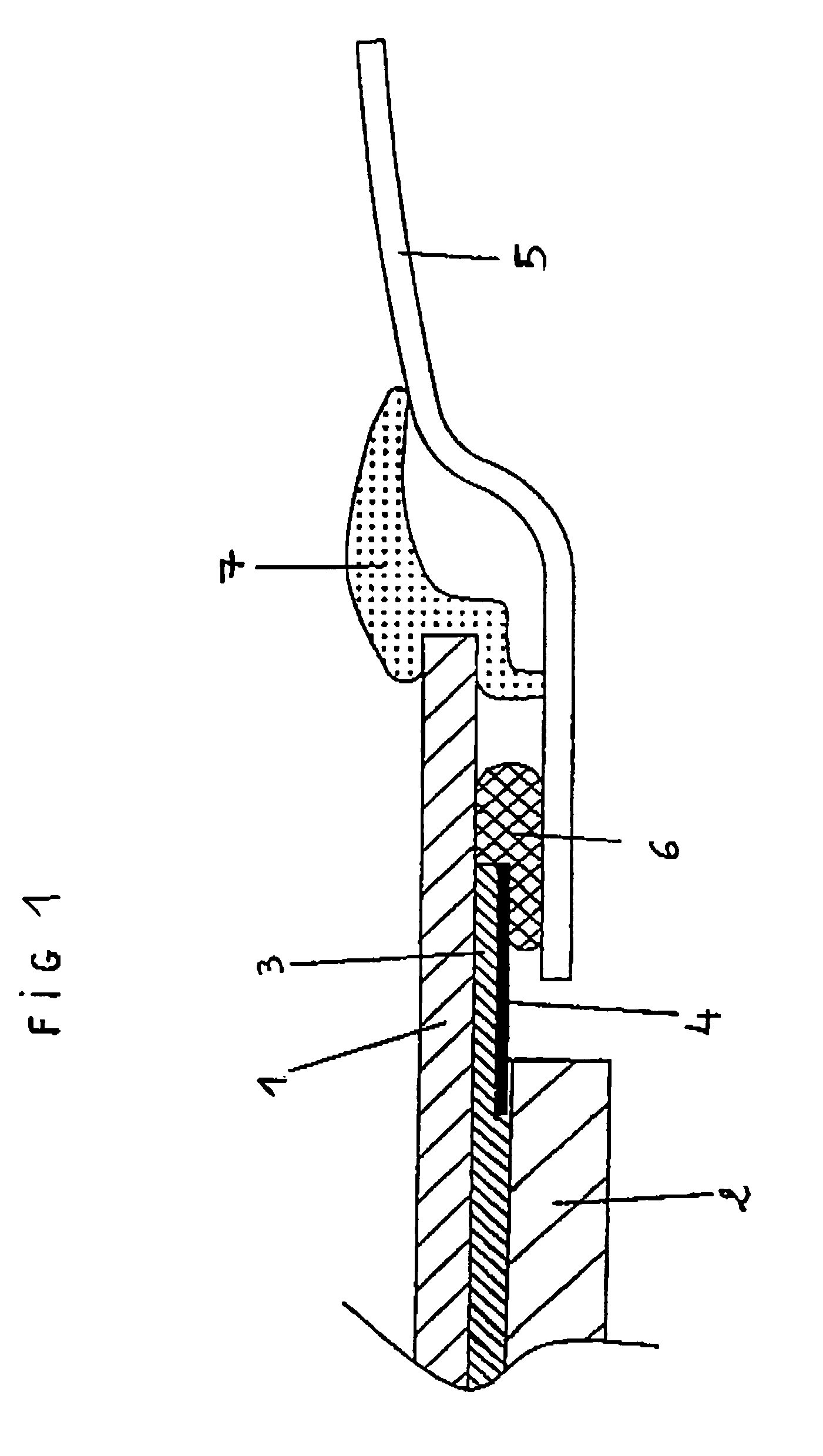

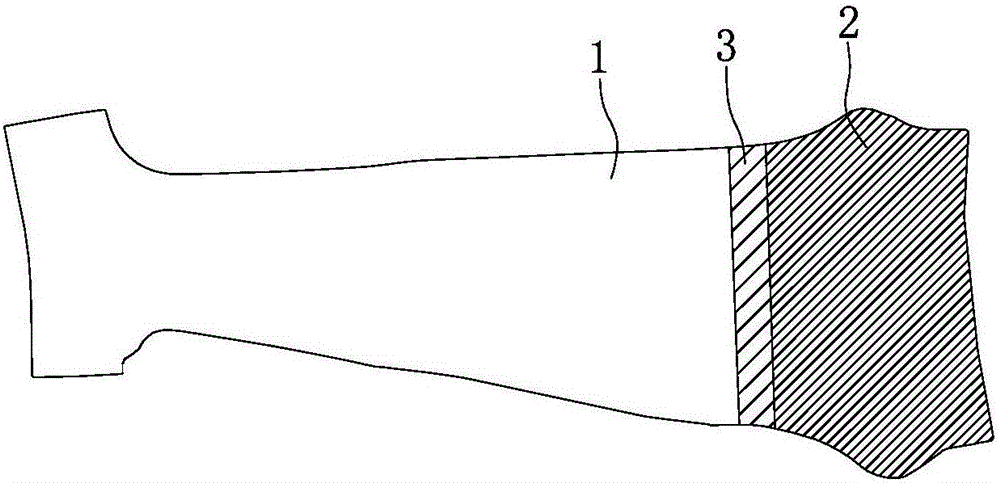

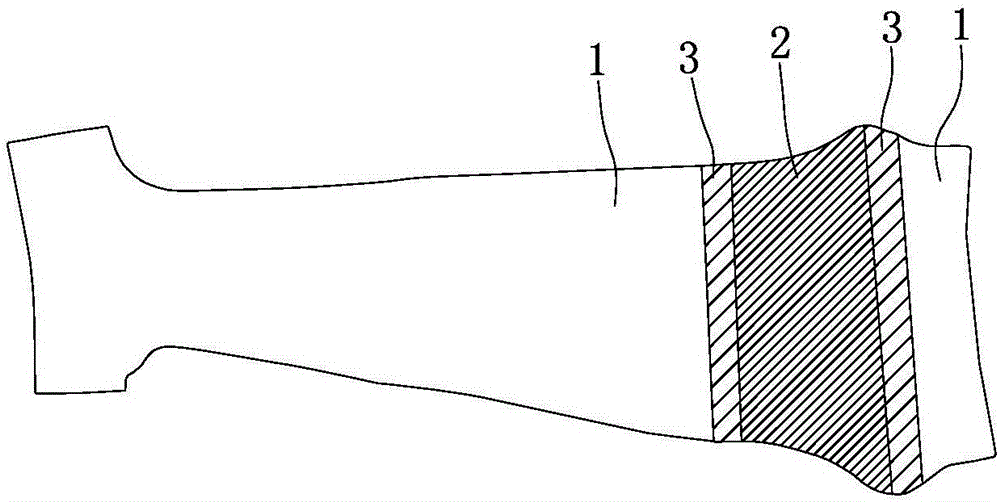

Laminated glazing with high crash test resistance

A laminated glazing includes at least one sheet (1) and a second sheet (2) bound to each other by an intercalated adhesive layer (3). The first sheet (1) projects beyond the second sheet (2) to form an exposed edge. The intercalated adhesive layer (3) extends over an exposed portion of the edge of the first sheet (1), and the edge of the intercalated adhesive layer (3) is at least in part covered by an intermediate element (4) suited to bond between the glazing or its constitutive elements (3) and on the body (5) through the intermediary of a cement element. This glazing has use as an automobile windshield with high crash test resistance.

Owner:SAINT-GOBAIN GLASS FRANCE

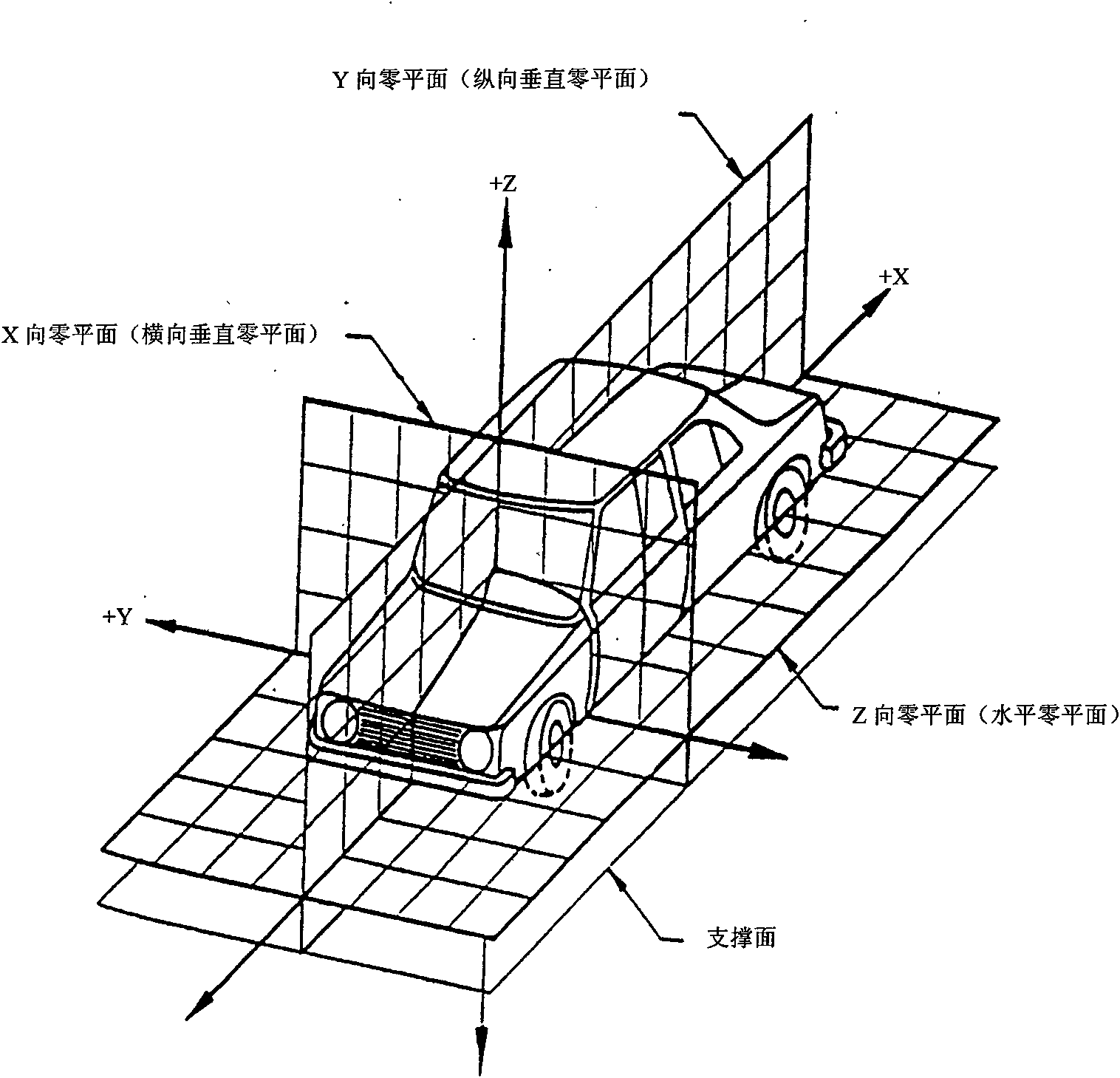

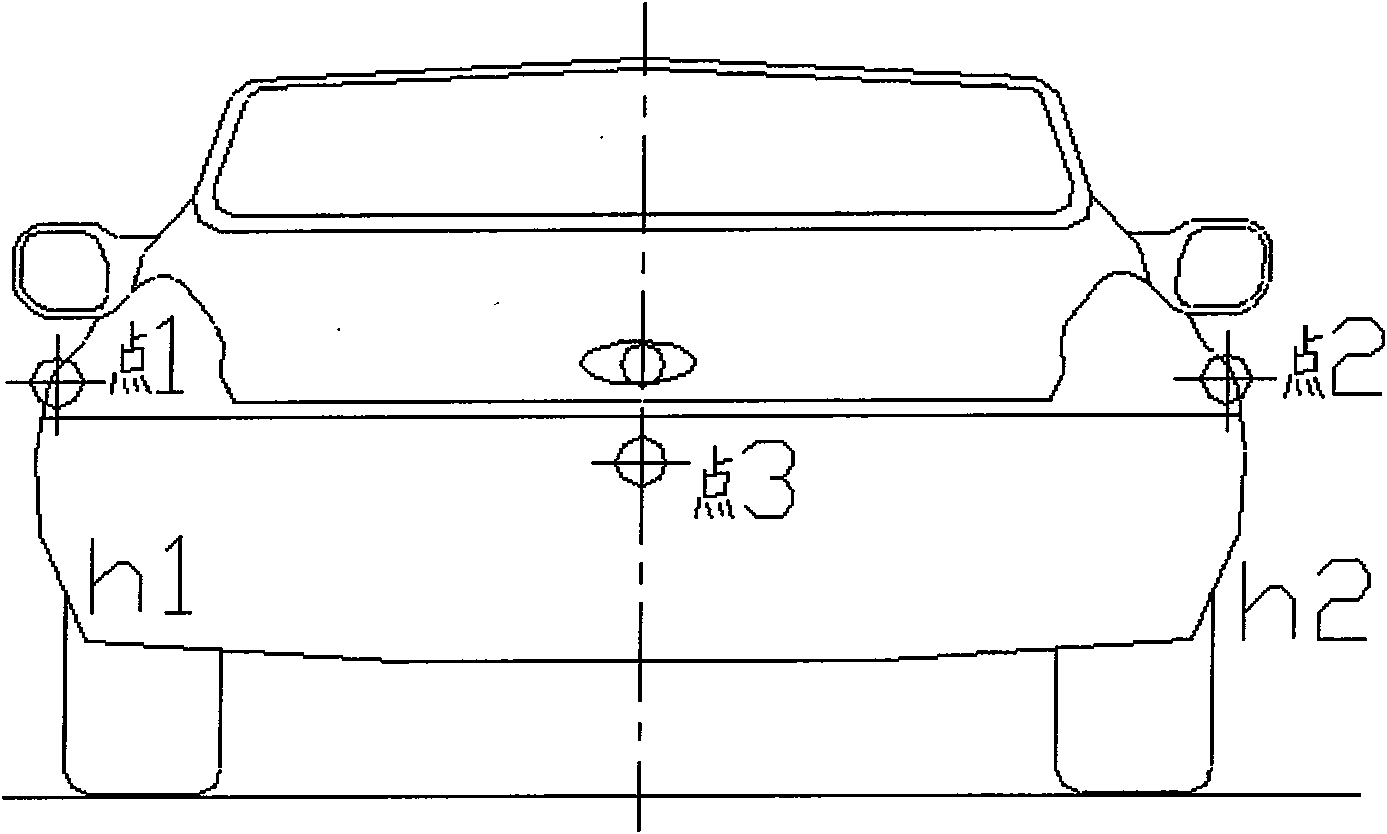

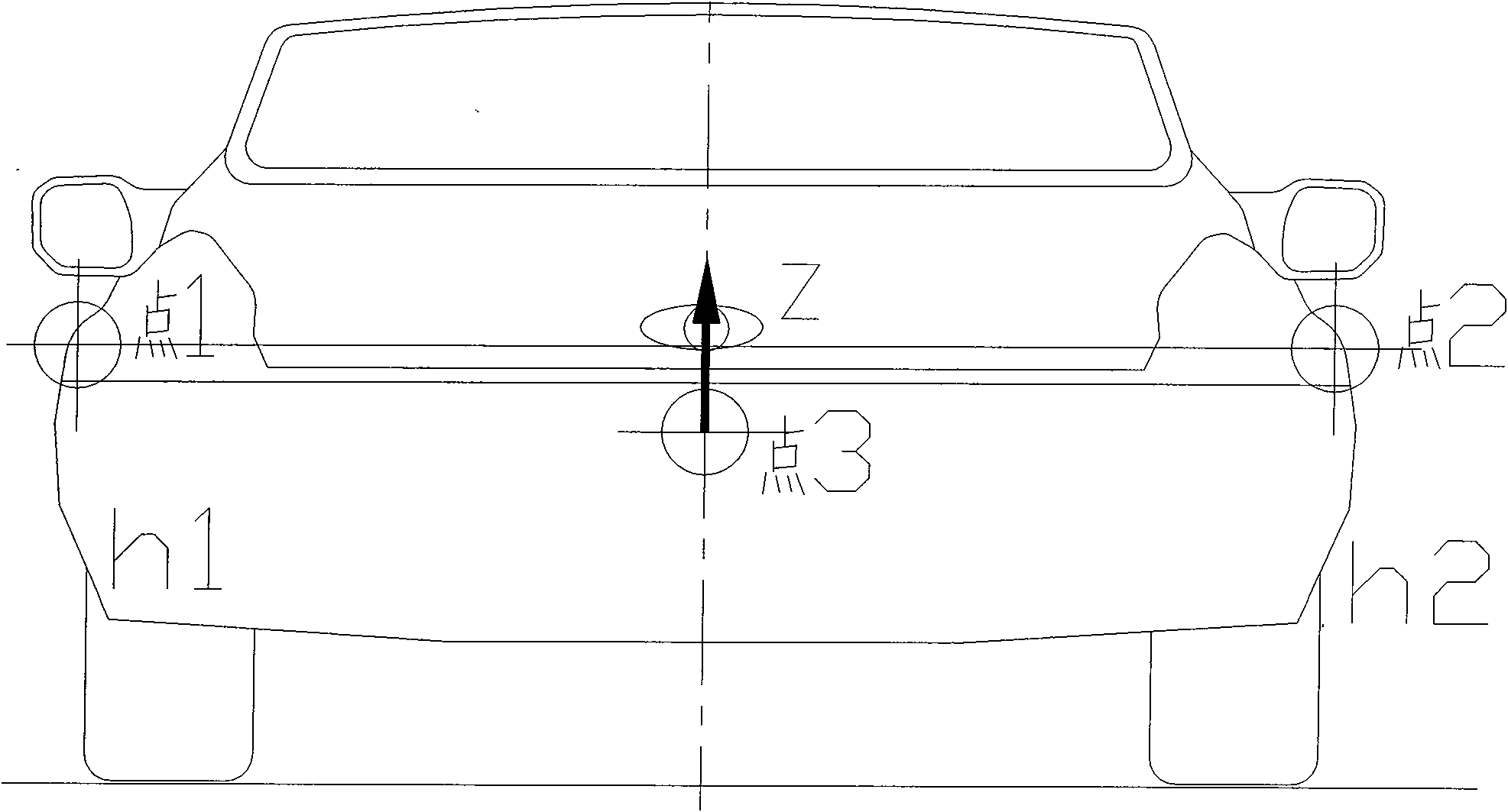

Measuring method for vehicle body deformation amount in vehicle crash test

ActiveCN101571370AHigh precisionHigh speedShock testingMechanical solid deformation measurementsIn vehicleTest measurement

The invention belongs to the technical field of transport vehicle test measurement, and relates to a measuring method for the vehicle body deformation amount in a vehicle crash test. The measuring method comprises the following steps: carrying out levelness calibration and establishing a measurement platform; selecting three points which are not in a straight line on a rigid part of the rear part of the vehicle body not being deformed before or after vehicle crash and are contour in the vertical direction from a basal plane, making a translation plane cross the three points, and establishing a three-dimensional coordinate system on the translation plane; carrying out the crash test; making the translation plane before the crash and the plane determined by the non-deformed points after the crash be mutually coincided through the alignment of the positions of the points which are not deformed and are selected before and after the crash, and consequently adjusting the coordinate system; and subtracting the coordinate of the same point on the test vehicle body after the crash from a certain point on the test vehicle body before the crash to obtain the deformation amount of the vehicle body at the point. The method can reduce the deviation of the measured deformation amount and improve the measuring precision.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

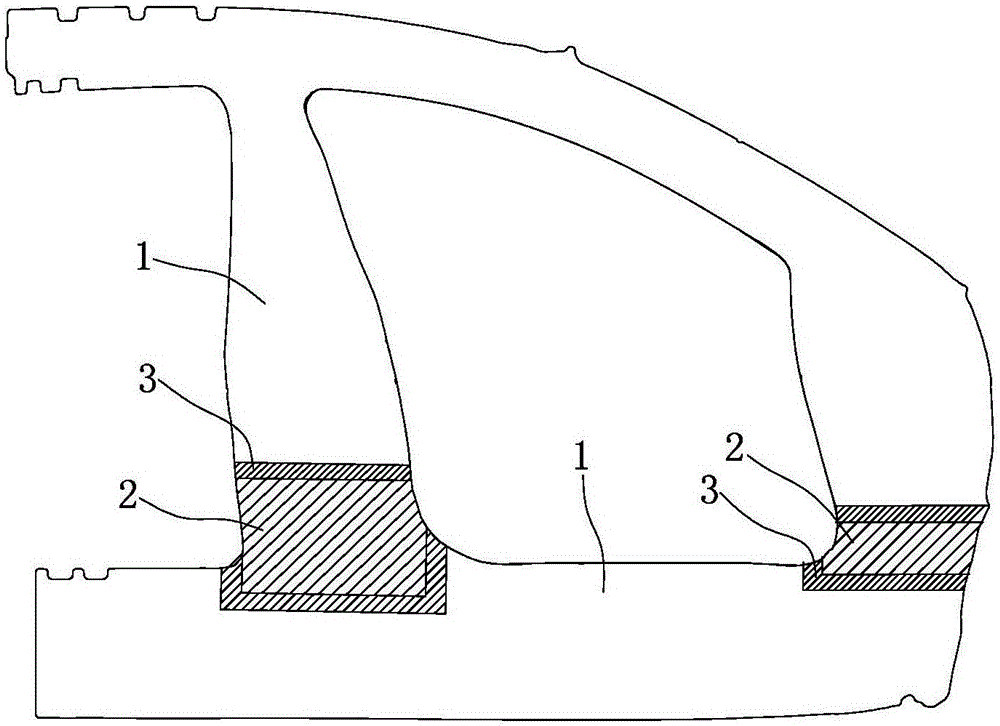

Method for locally softening automotive thermal forming part

ActiveCN106086364AImprove performanceIncrease the secondary heating processFurnace typesVehicle componentsCrash testEngineering

The invention discloses a method for locally softening an automotive thermal forming part. The method can be realized through the following manners: 1, controlling the temperature of sheet matal at different areas at the sheet matal heating phase of thermal forming technology; 2, controlling the temperature of inserts at different areas of a die at the die assembling phase of the thermal forming technology; 3, controlling the cooling rate of sheet matal at different areas at the die assembling phase of the thermal forming technology; and 4, after the thermal forming technology is finished, locally heating the thermal forming part for the second time. With adoption of the method, one thermal forming part has different mechanical properties at different areas, and the performance of the part in a vehicle crash test is optimized. The high-strength part of the performance-variable thermal forming part is mainly quenched martensite, and the tensile strength is equal to or greater than 1300 Mpa; and the low-strength part of the performance-variable thermal forming part is formed by one or combination of ferrite, pearlite, bainite and tempered martensite, and the tensile strength is equal to or less than 1000 Mpa.

Owner:COSMA AUTOMOTIVE (CHONGQING) CO LTD

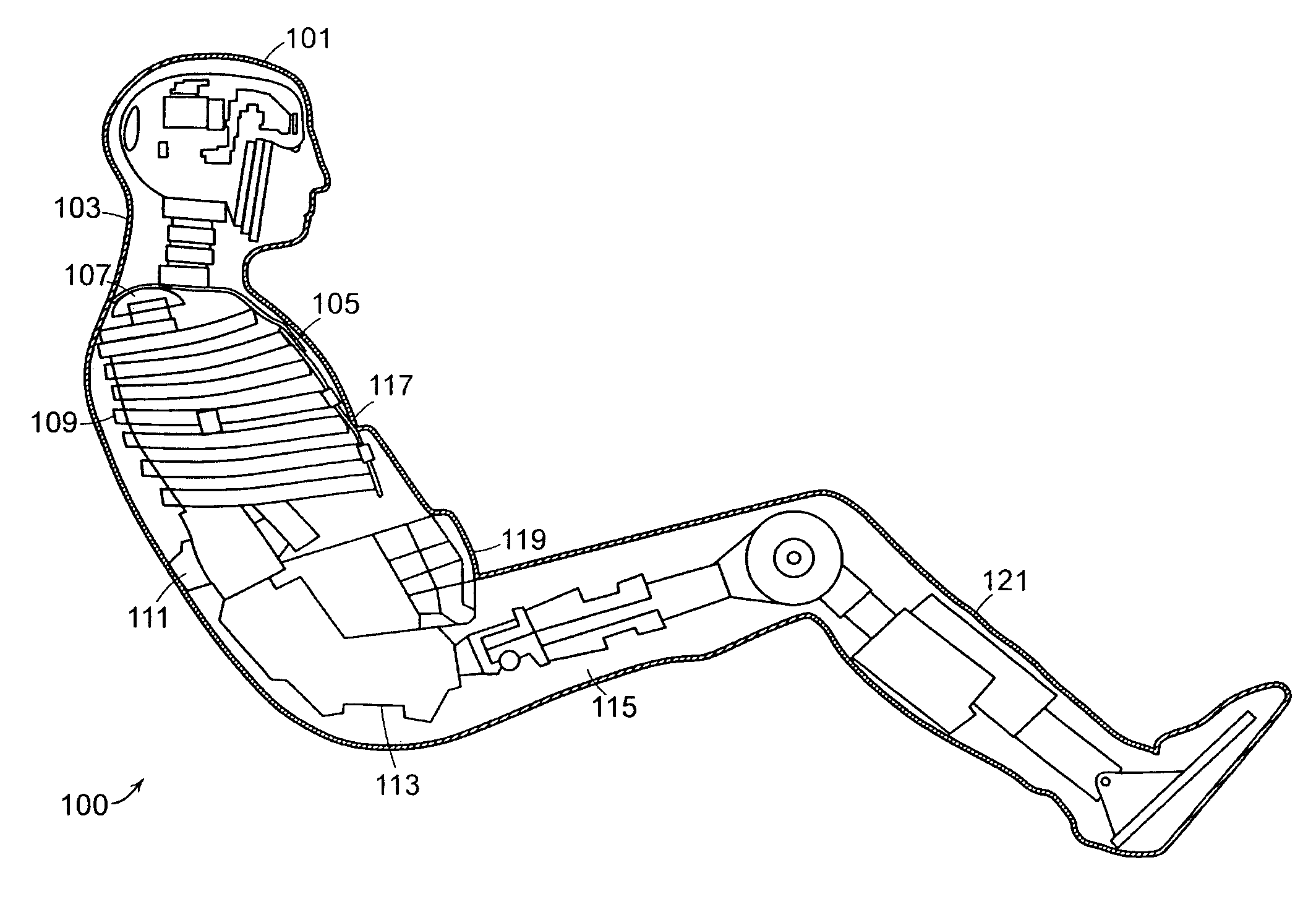

Three-dimensionally printed internal organs for crash test dummy

ActiveUS20170162077A1Cosmonautic condition simulationsAdditive manufacturing apparatusCrash testEngineering

A three-dimensionally printed internal organ for a crash test dummy is made of a foam type material and has a plurality of defined and varied cell structures and is adapted to be disposed within a torso area of the crash test dummy to measure a regional pressure for the crash test dummy that provides for evaluation of potential abdominal injuries during vehicle crash testing.

Owner:HUMANETICS INNOVATIVE SOLUTIONS

Side impact dynamic intrusion simulator

Owner:TOYODA GOSEI CO LTD

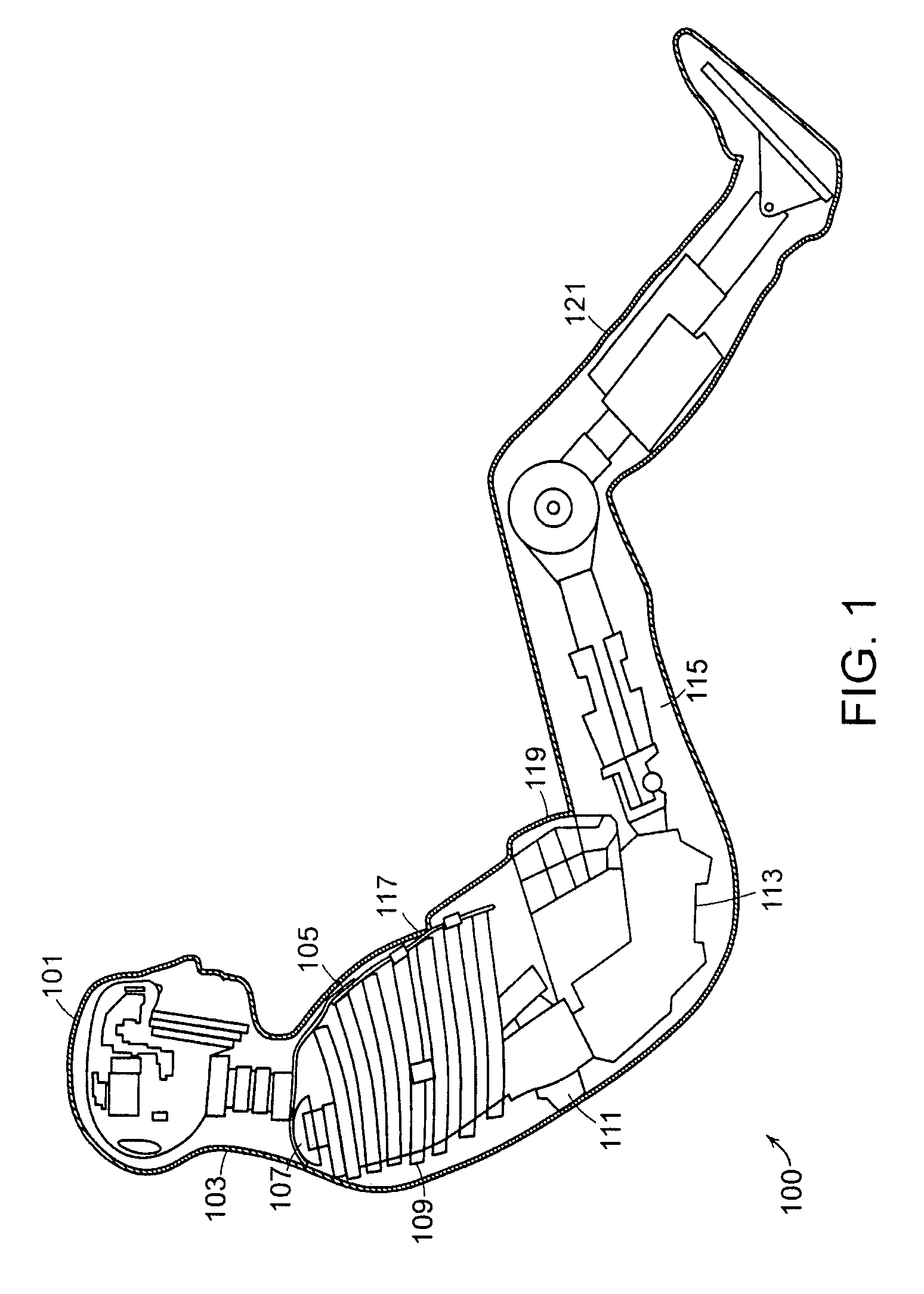

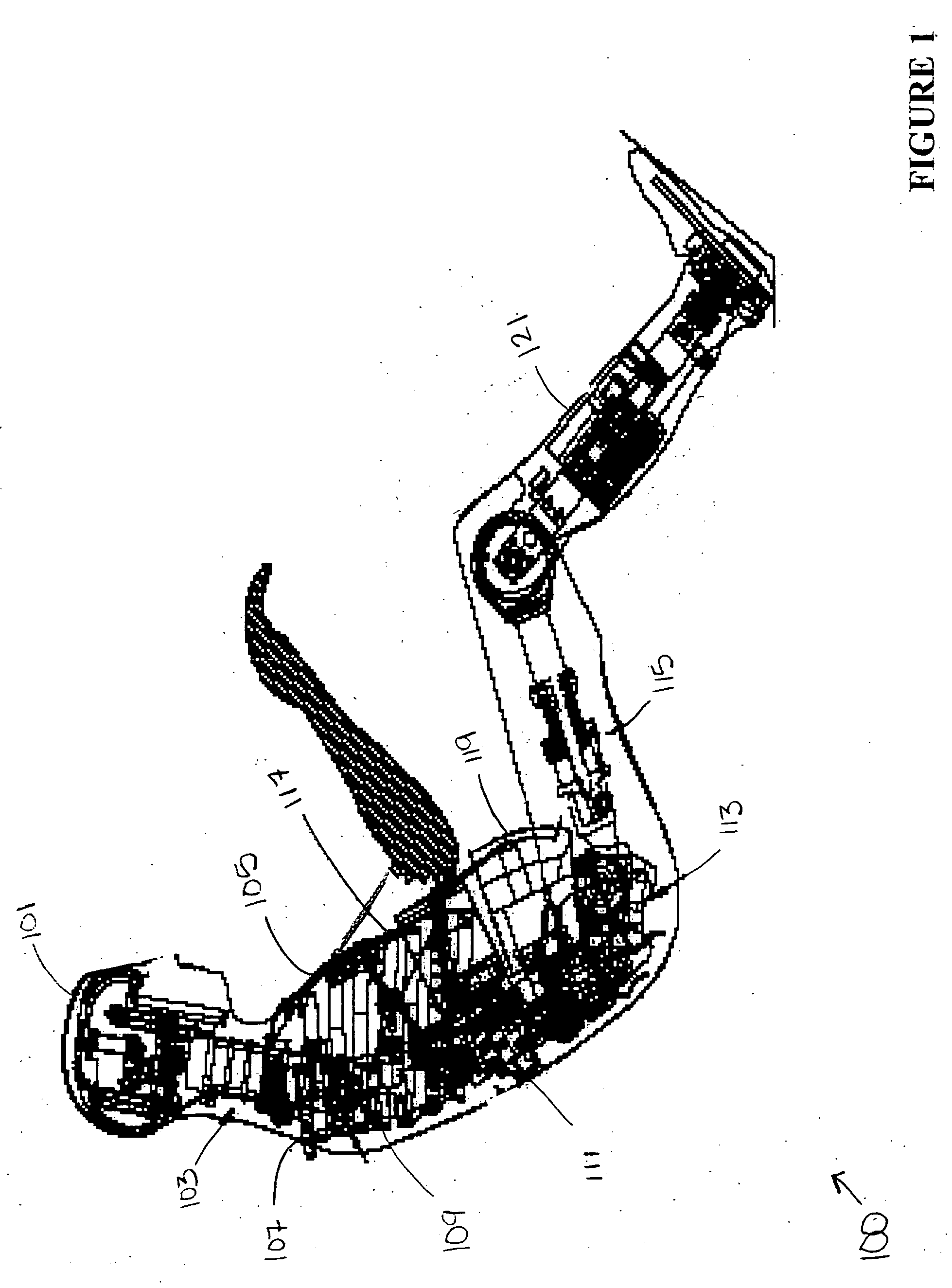

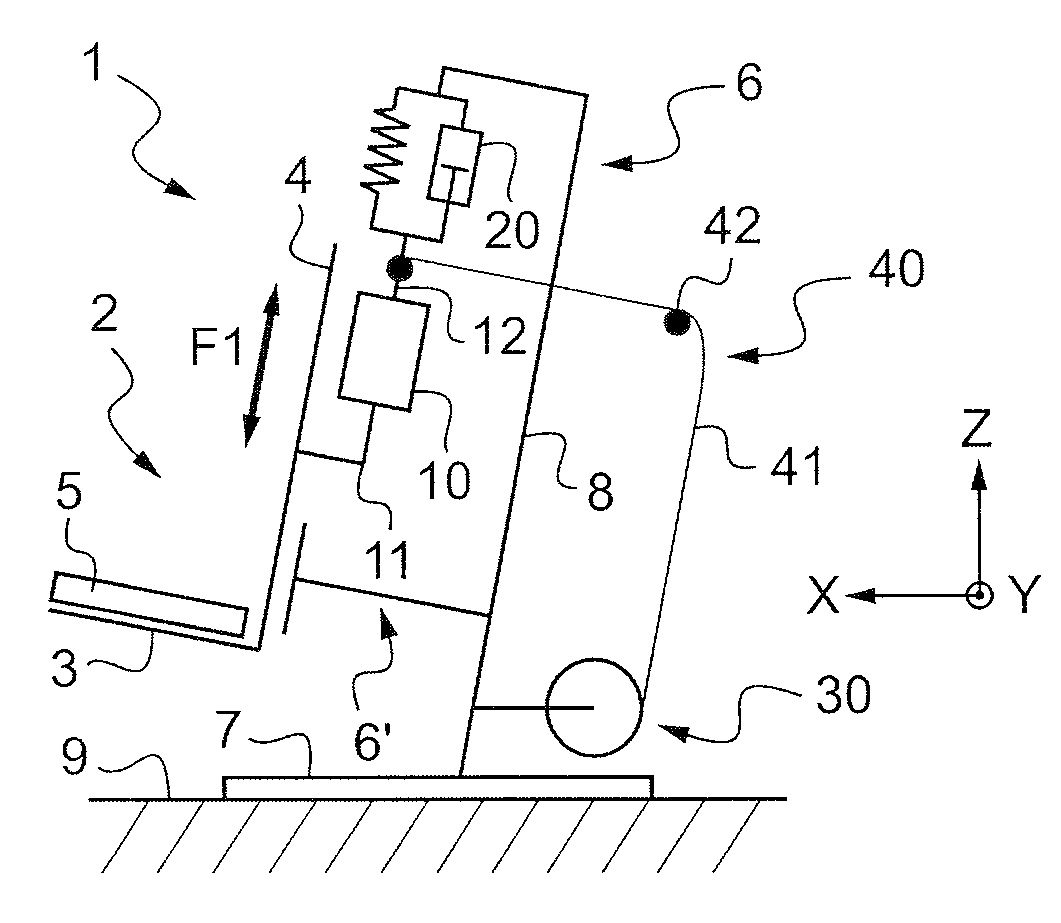

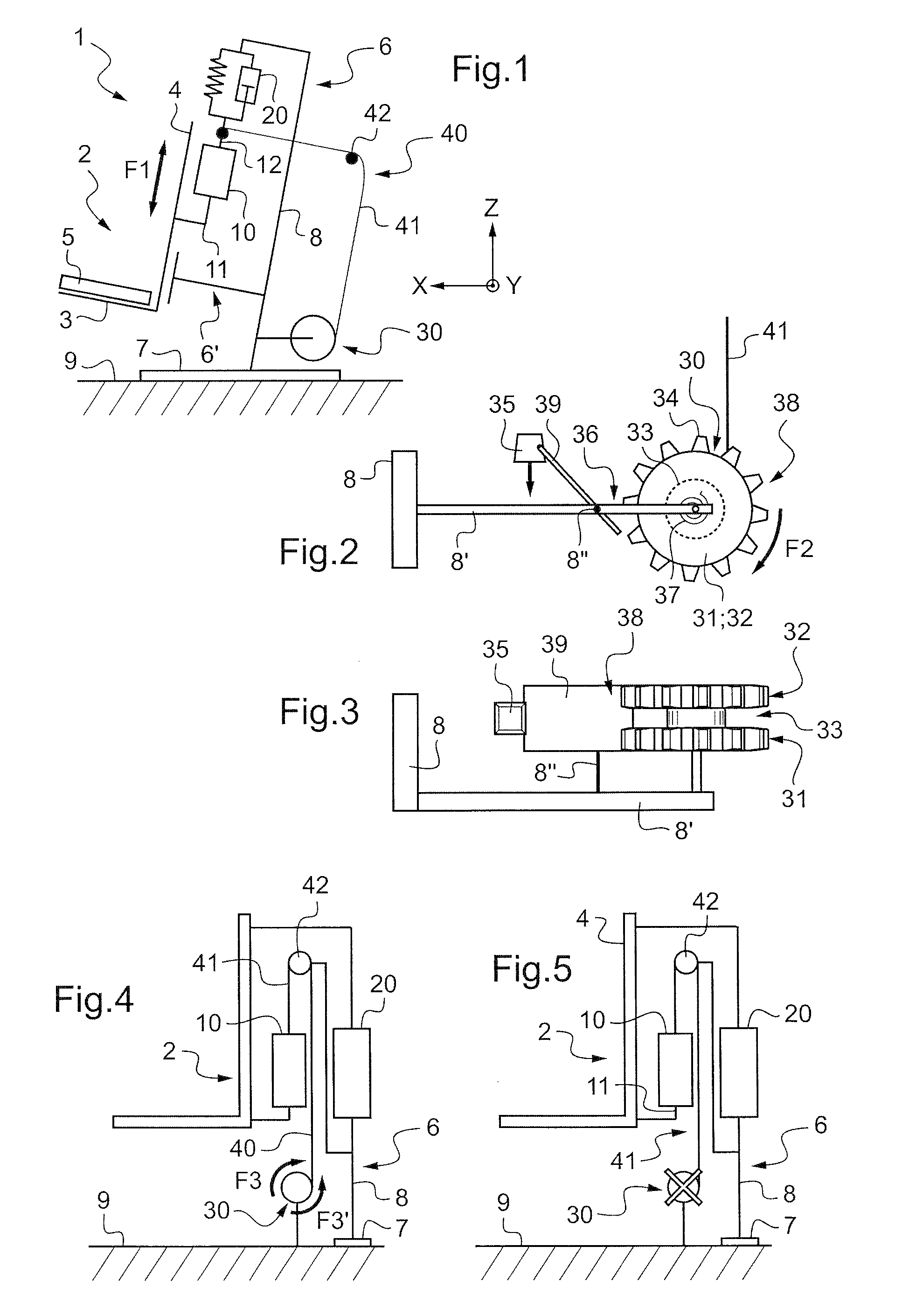

Anti-crash seat for a vehicle

ActiveUS20110204685A1Good compactness and weightSmall movementVehicle seatsPedestrian/occupant safety arrangementCrash testEngineering

An anti-crash seat (1) for a vehicle, the seat comprising a bucket (2) and a frame (6), said bucket (2) being provided with a seat proper (3) and with a back (4) for receiving a person. Said seat (1) includes crash energy absorber means (10) and antivibration means (20). The seat also includes inhibitor means (30) for inhibiting said antivibration means (20) so as to neutralize the antivibration means (20) when the seat (1) is subjected to acceleration towards the floor that is greater than a predetermined threshold.

Owner:EUROCOPTER

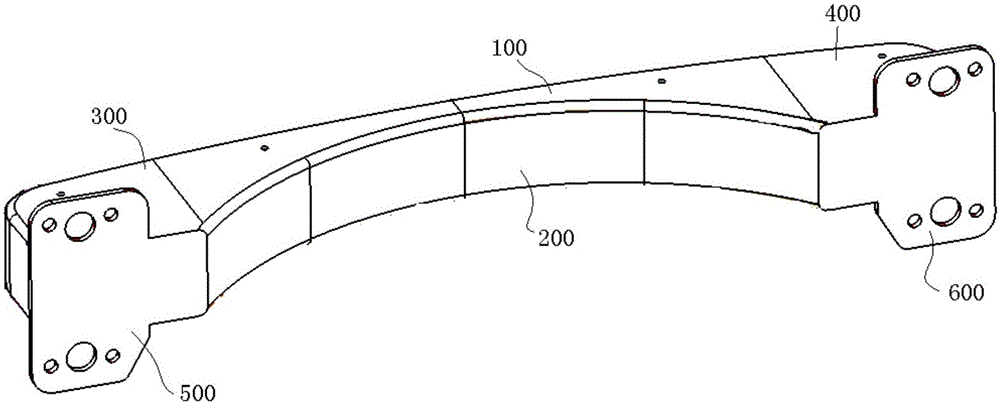

Carbon fiber automobile bumper beam and manufacturing method thereof

The invention discloses a carbon fiber automobile bumper beam, which is characterized by comprising a foam sandwich and an embedded part; the foam sandwich and the embedded part are coated with a carbon fiber sheet reinforced resin matrix composite; the invention also discloses a manufacturing method for the carbon fiber automobile bumper beam. Compared with the prior art, the carbon fiber automobile bumper beam disclosed by the invention has the advantages that (1) the weight is lightened: the aluminum alloy beam of the original structure is 2.66kg, and the aluminum alloy beam of the existing structure is 2.077kg; the weight is reduced by 21.92 percent; (2) the strength standard of the joint of a tow hook and an automobile body, i.e. the strength analysis standard of the joint of an SMTC4500010 tow hook and the automobile body, is met; (3) according to an automobile front / rear end protector of the GB17345-1988 standard, and RCAR (Research Council For Automobile Repairs) low speed crash tests, an exhaust structure, a power system and a suspension system are not damaged, and test results meet the requirements.

Owner:上海耀华大中新材料有限公司

Pull-type high-speed train crash test bench

ActiveCN107870096ATake advantage of reliabilityEasy to separateRailway vehicle testingShock testingDrive wheelCrash test

The invention provides a pull-type high-speed train crash test bench, and belongs to the field of railway vehicle crash test. The pull-type high-speed train crash test bench comprises a rigid wall anda crash vehicle body, wherein the rigid wall is arranged at the front end of a rail. Four vertical columns are arranged on two sides of the rail, front beams and rear beams are arranged at the top ends of the vertical columns on the two sides of the rail, I-shaped steel guide rails are erected in the middles of the front beams and the rear beams, a front limiter and a rear limiter are arranged attwo ends of the guide rail, a tensioning wheel is arranged on the middle upper portion of the guide rail, the front beams are provided with driven wheels, the rear beams are provided with pulling mechanisms, an output shaft of a pulling motor is connected with a speed changer, the speed changer is connected with driving wheels, one end of a pulling steel rope is fixed to the front end of a pulling trolley, the other end of the pulling steel rope bypasses the driving wheels, the tensioning wheel and the driven wheels and is fixed to the rear end of the pulling trolley, electromagnets are arranged at the bottom of the pulling trolley, a high-speed photographic system measuring head is arranged at the top of the rigid wall, a speed sensor is positioned on the right of the rail, four speed measuring heads are parallel to the rail, the rigid wall is provided with a force sensor, and electromagnet holders are arranged at the top of the crash vehicle body.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com