Mean-temperature method of cylindrical battery

A technology for cylindrical batteries and batteries, which is applied in the direction of batteries, secondary batteries, battery pack components, etc., and can solve problems such as high cost, difficulty in designing battery pack thermal management, and no solution yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described in detail below.

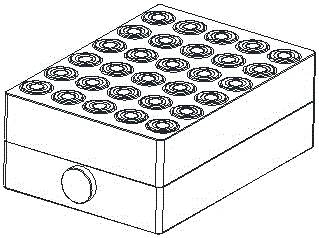

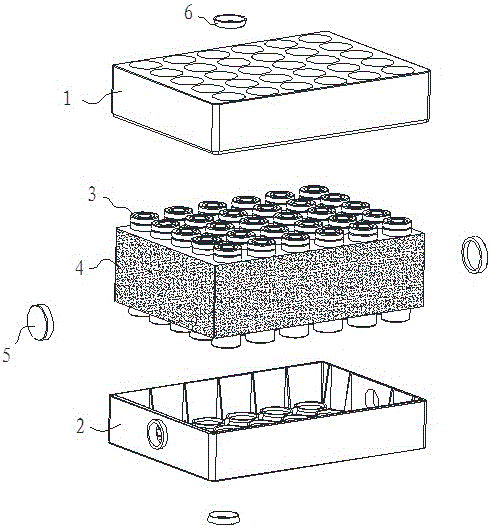

[0020] Step 1. Determine the arrangement of the battery cells according to the requirements of the battery group, and design the housing module. In this embodiment, the battery pack is composed of 30 battery cells evenly arranged in 5 rows and 6 columns. The overall picture of the battery pack is shown in figure 1 , the exploded view of the battery pack is shown in figure 2 , including an upper case 1, a lower case 2, a battery cell 3, a phase change material composite glue 4, a sealing cover 5 and a sealant 6.

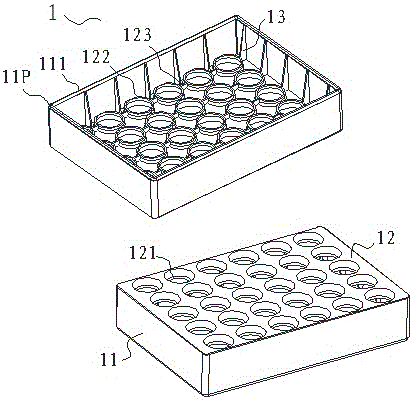

[0021] Such as image 3 As shown, the upper shell 1 is an open shell, which is composed of a rectangular first frame 11, a first plane wall 12 and a plurality of first reinforcing ribs 13, and the first reinforcing ribs 13 connect and reinforce the first frame 11 and the first Plane wall 12 . The first plane wall 12 is provided with several first through holes 121 and first circular rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com