Patents

Literature

410 results about "Collision test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

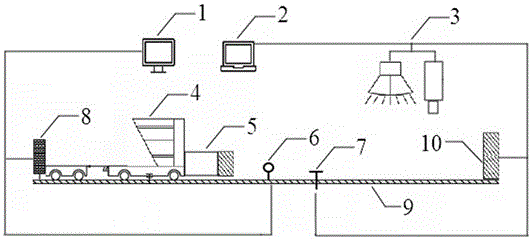

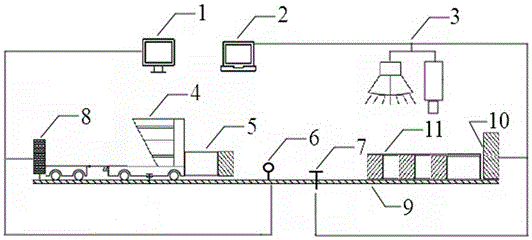

Vehicle component real object collision test method and tester

ActiveCN101430251ADetermination of impact forceDetermination of transient accelerationRailway vehicle testingShock testingComplete dataSpeed test

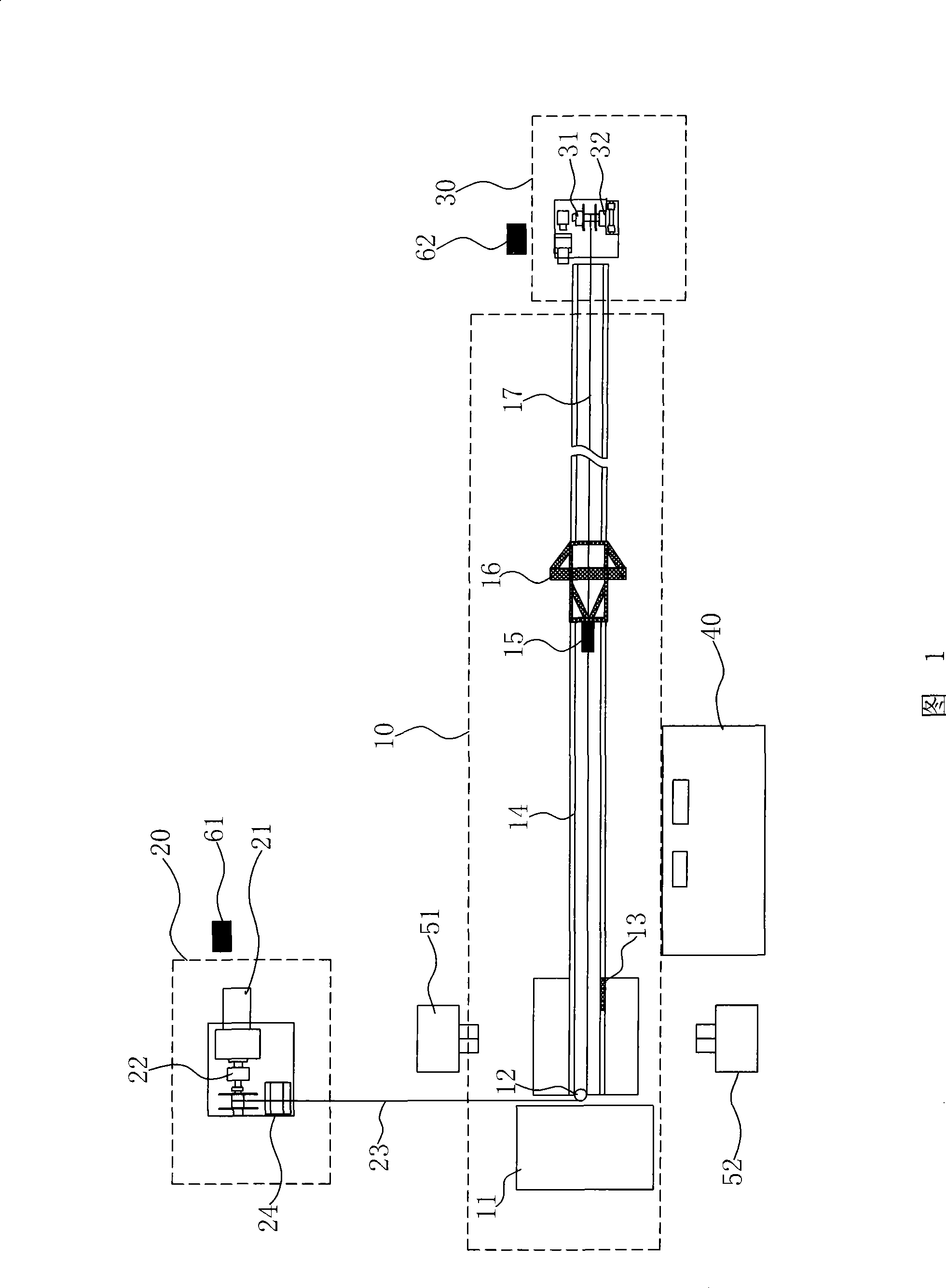

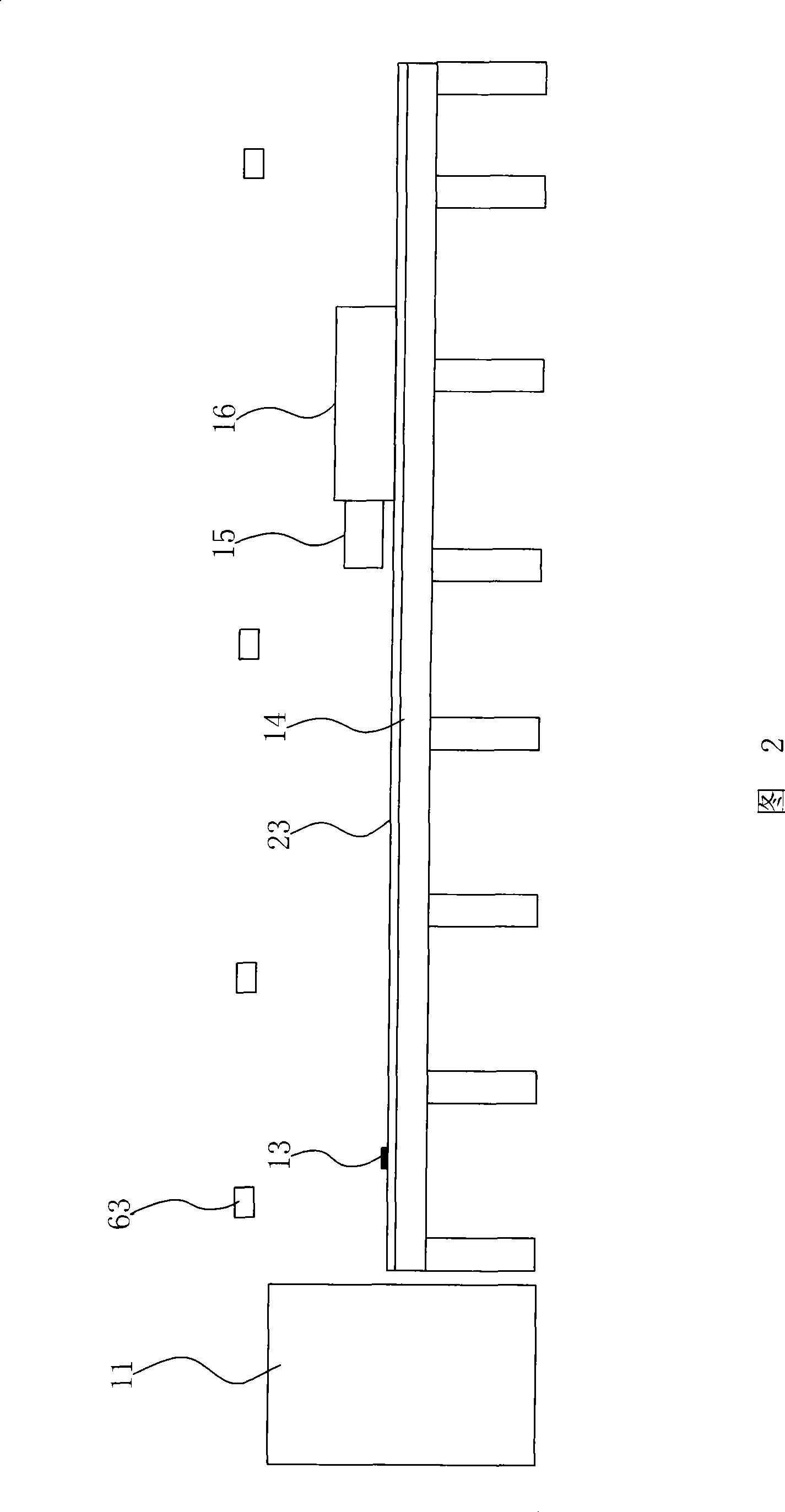

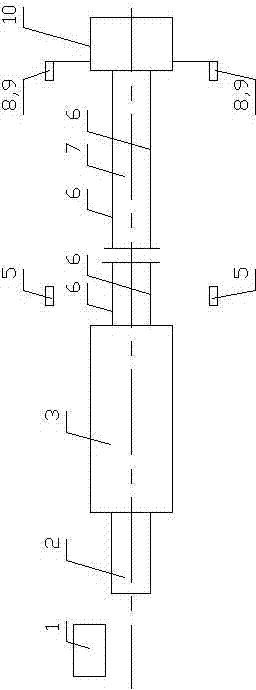

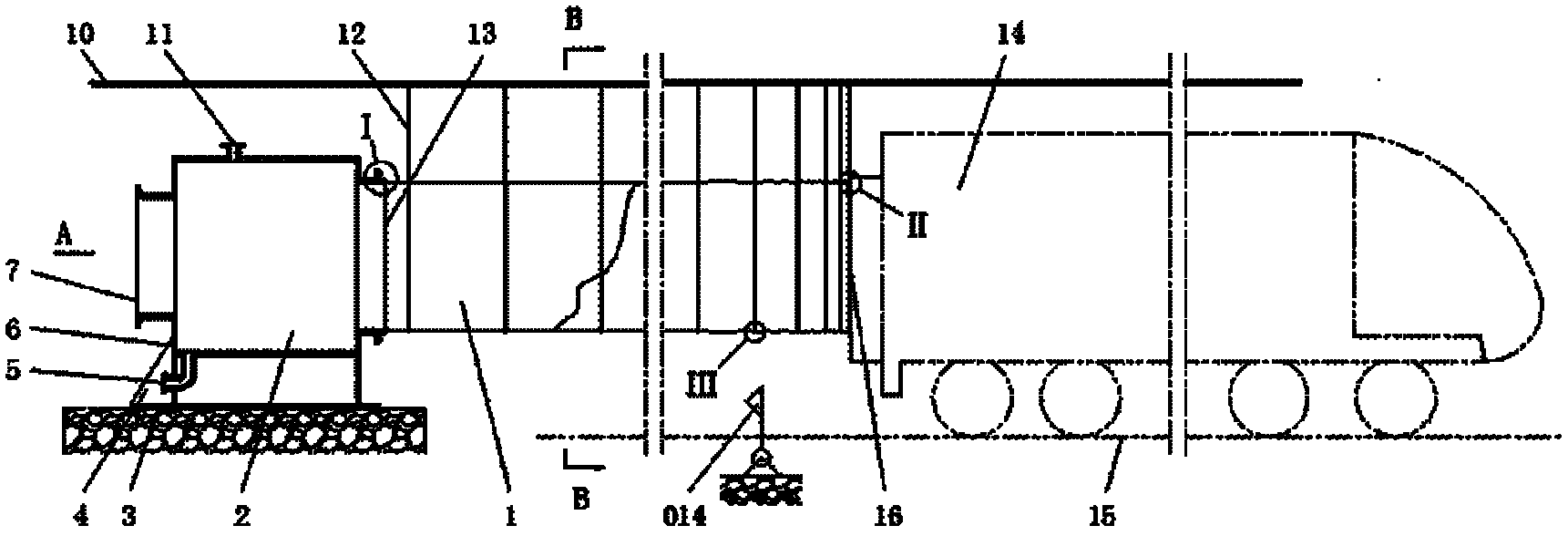

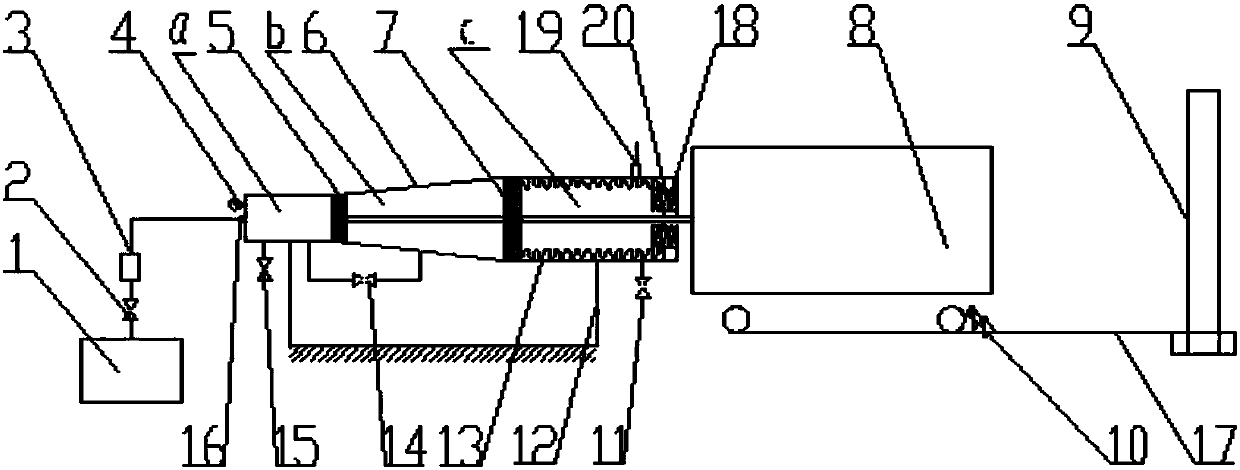

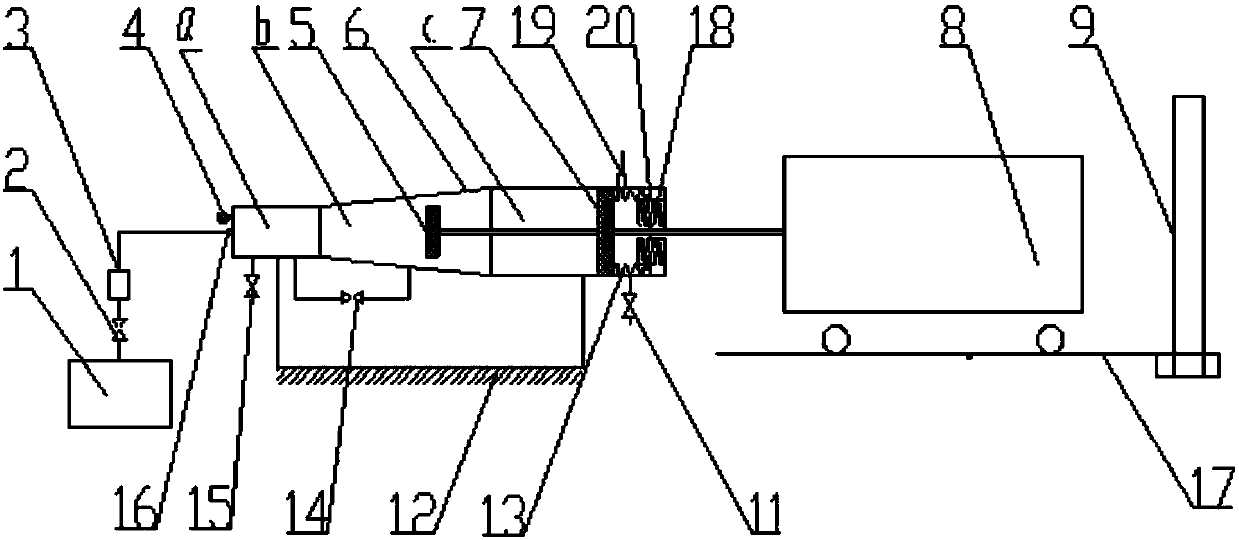

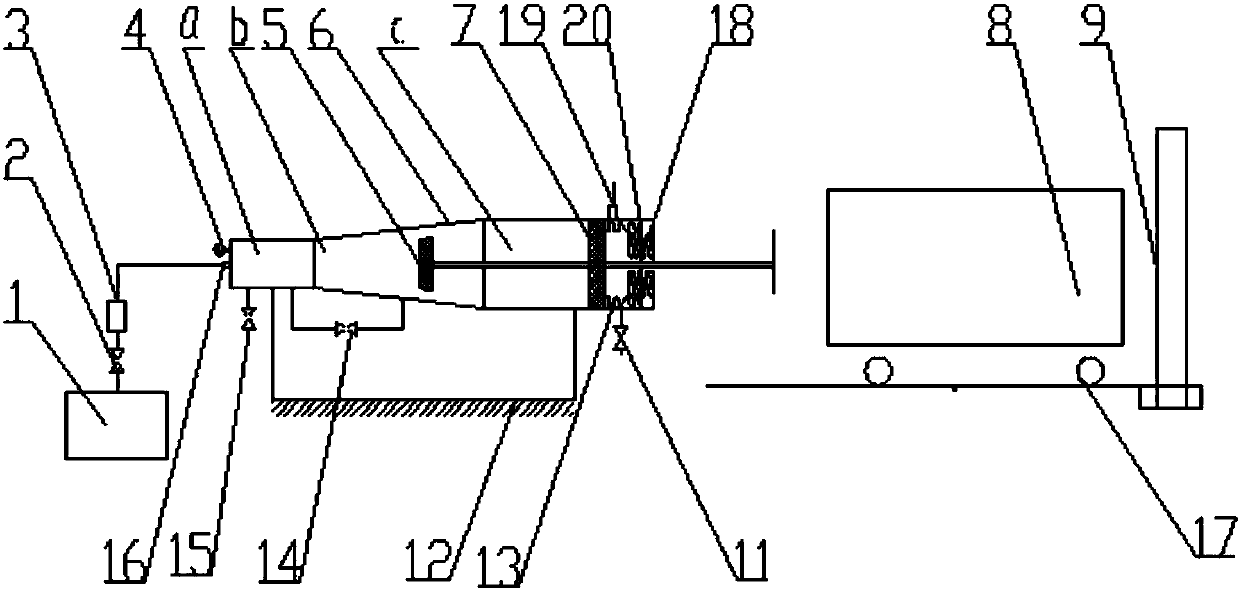

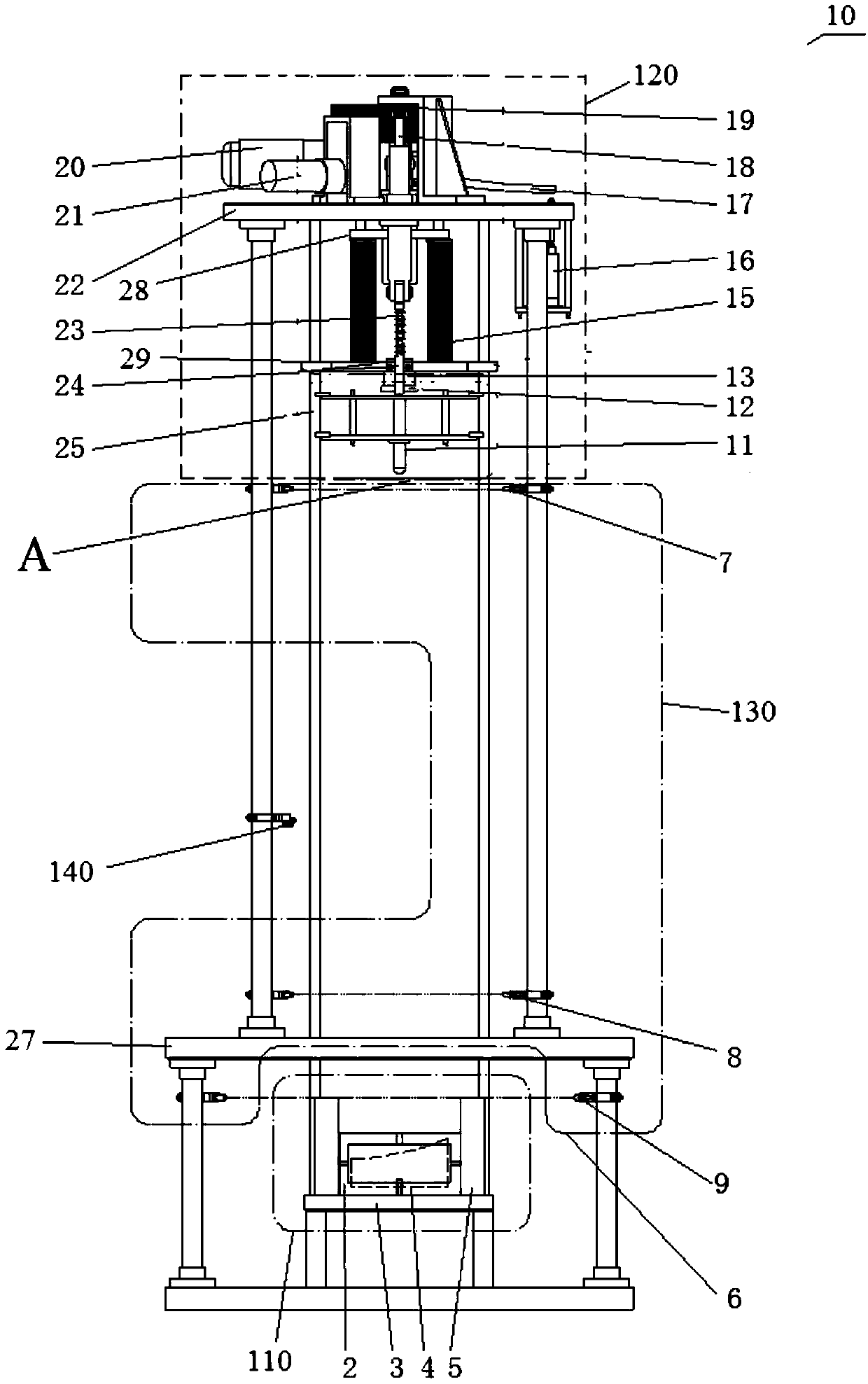

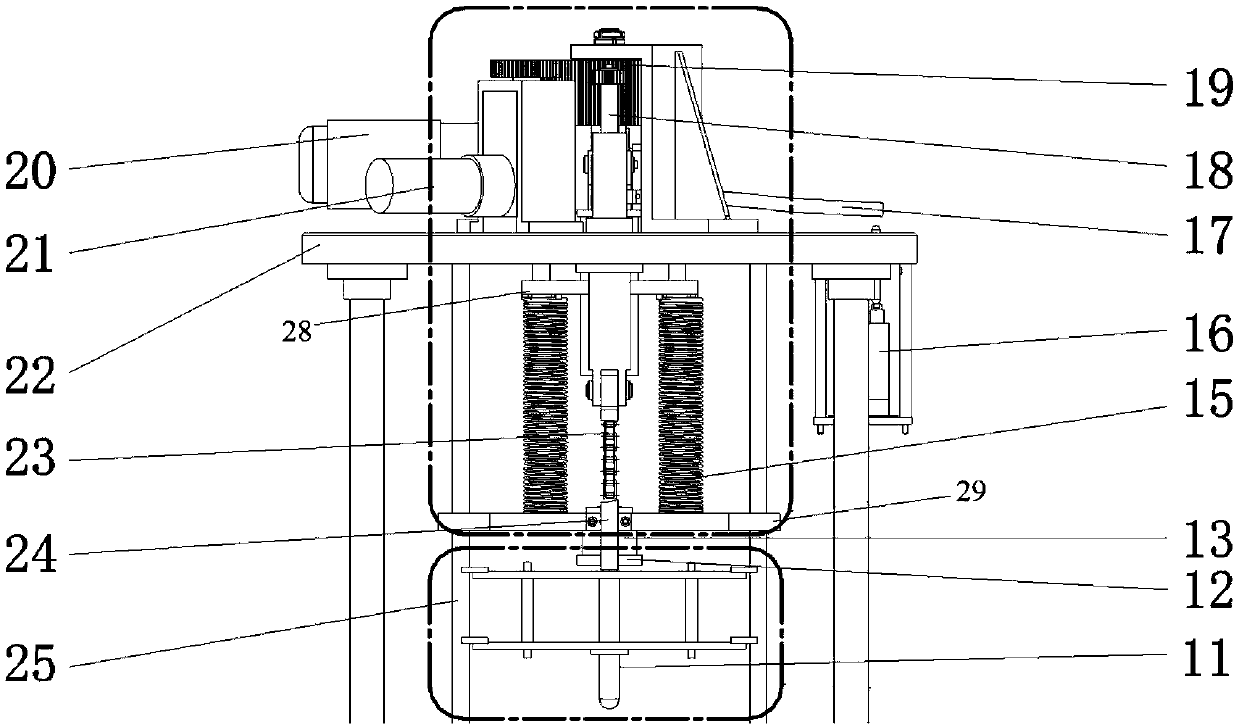

The invention discloses a test method for real object crash of vehicle components and a test device thereof. The test method comprises the following steps: the vehicle components are fixed on a carrying trolley which can move on a track, the speed of the trolley is increased to a test value by traction with a drive system before preparing for crash an impact wall; when the carrying trolley moves to a set position before the impact wall, a trigger device is started to detach the drive system from the carrying trolley, a test component and the carrying trolley are caused to crash the impact wall without drive power; a vehicle-borne acceleration test system is arranged on the carrying trolley so as to complete data acquisition in real time; and the trigger device triggers a speed test system, an impact force test system and a high-speed camera system at the same time. The test method of the real object crash of the vehicle components and the test device can help measure objective data in real time such as the impact force, a transient acceleration, component deformation and speed output at the moment of crash, and further can record deformation sequence images of the components during the whole crash course so as to get scientific and exact analysis results.

Owner:CENT SOUTH UNIV

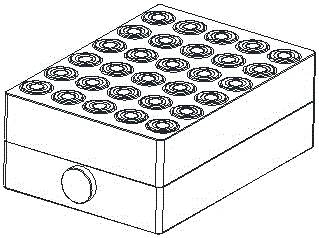

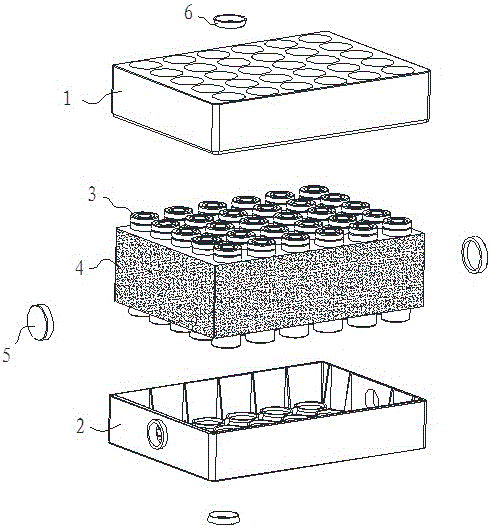

Mean-temperature method of cylindrical battery

InactiveCN104993187AImprove thermal conductivityWon't leakBattery isolationSecondary cellsEngineeringSealant

The invention discloses a mean-temperature method of a cylindrical battery. The mean-temperature method of the cylindrical battery has the technical scheme that 1, the arrangement mode is determined according to the battery pack forming requirements, and a casing module is designed; 2, a cylindrical battery cell is assembled in the casing module, and sealant is coated for sealing; 3, liquid phase change material composite glue is prepared; 4, the phase change material composite glue is poured into the casing module, and a battery pack with good temperature consistency is obtained after curing and forming. The phase change material composite glue is prepared by phase change materials and organic silicon filling and sealing glue according to a certain ratio, wherein the phase change materials use paraffin and graphite as major components; the organic silicon filling and sealing glue uses vinyl silicone oil and modified aluminum oxide powder as major components. Through the structure features of the mean-temperature method, the mean-temperature method has the beneficial effects that the battery core has good temperature consistency; the module structure is good in intensity and can pass by the battery pack-relevant vibration, falling and collision tests. The phase change material composite glue is encapsulated in the casing; no loss occurs after the long-time cyclic use; the permanent service life is realized.

Owner:广东万锦科技股份有限公司

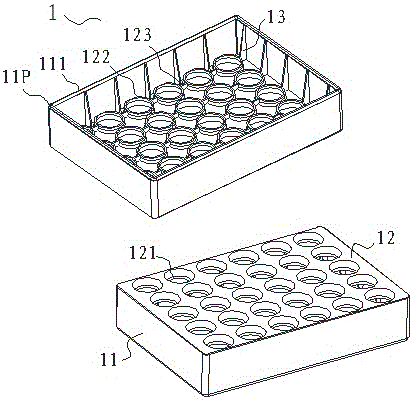

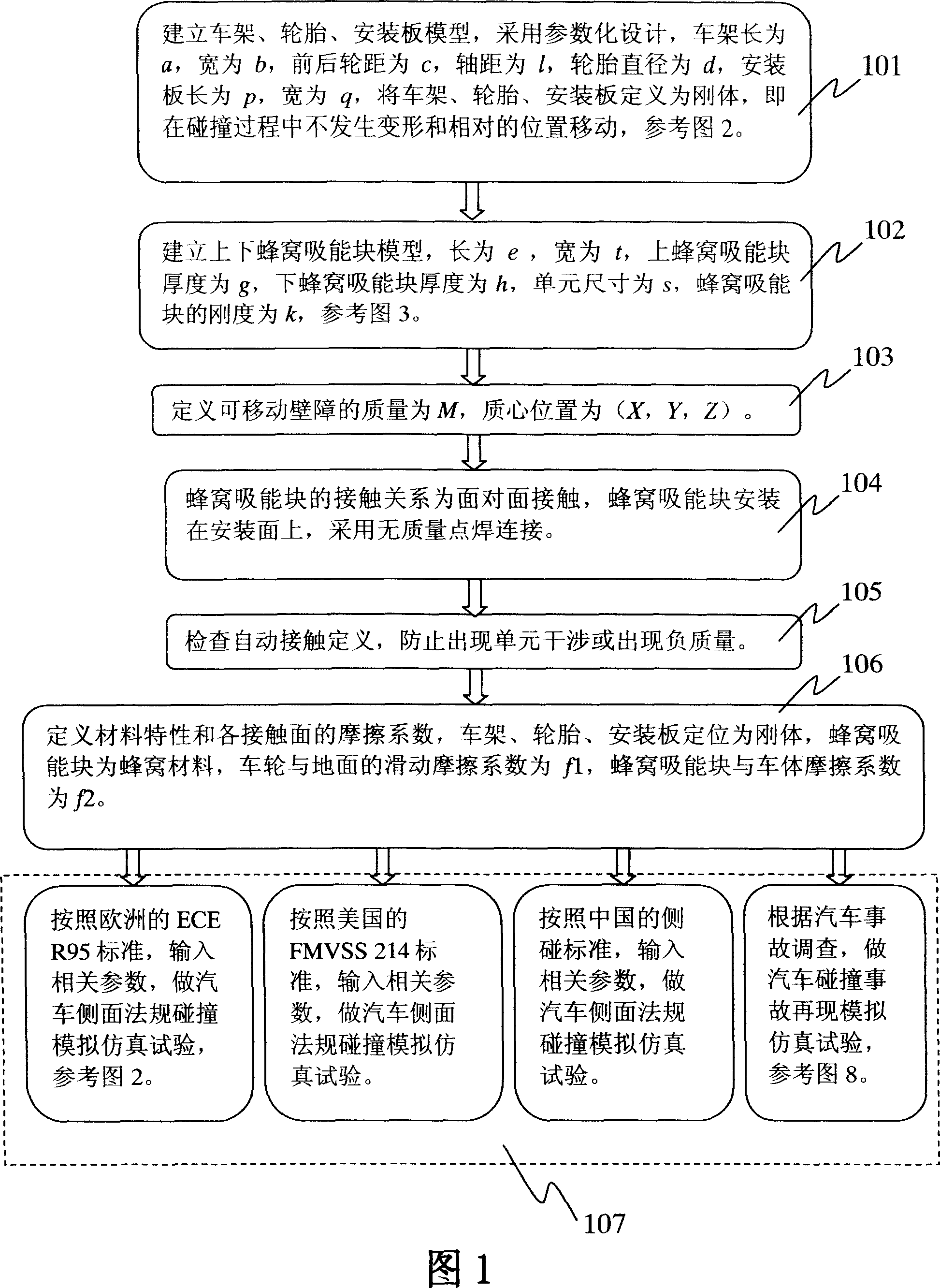

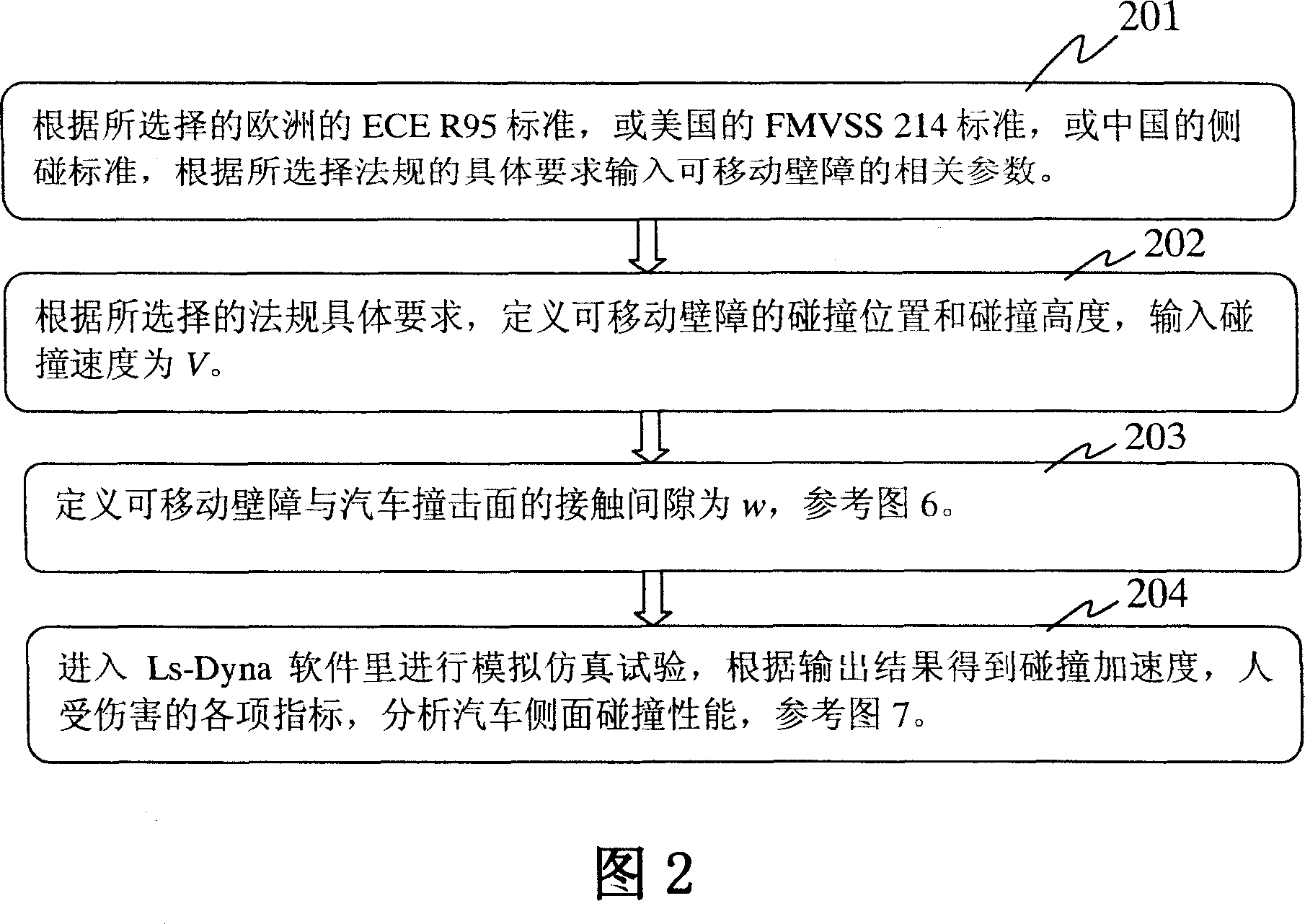

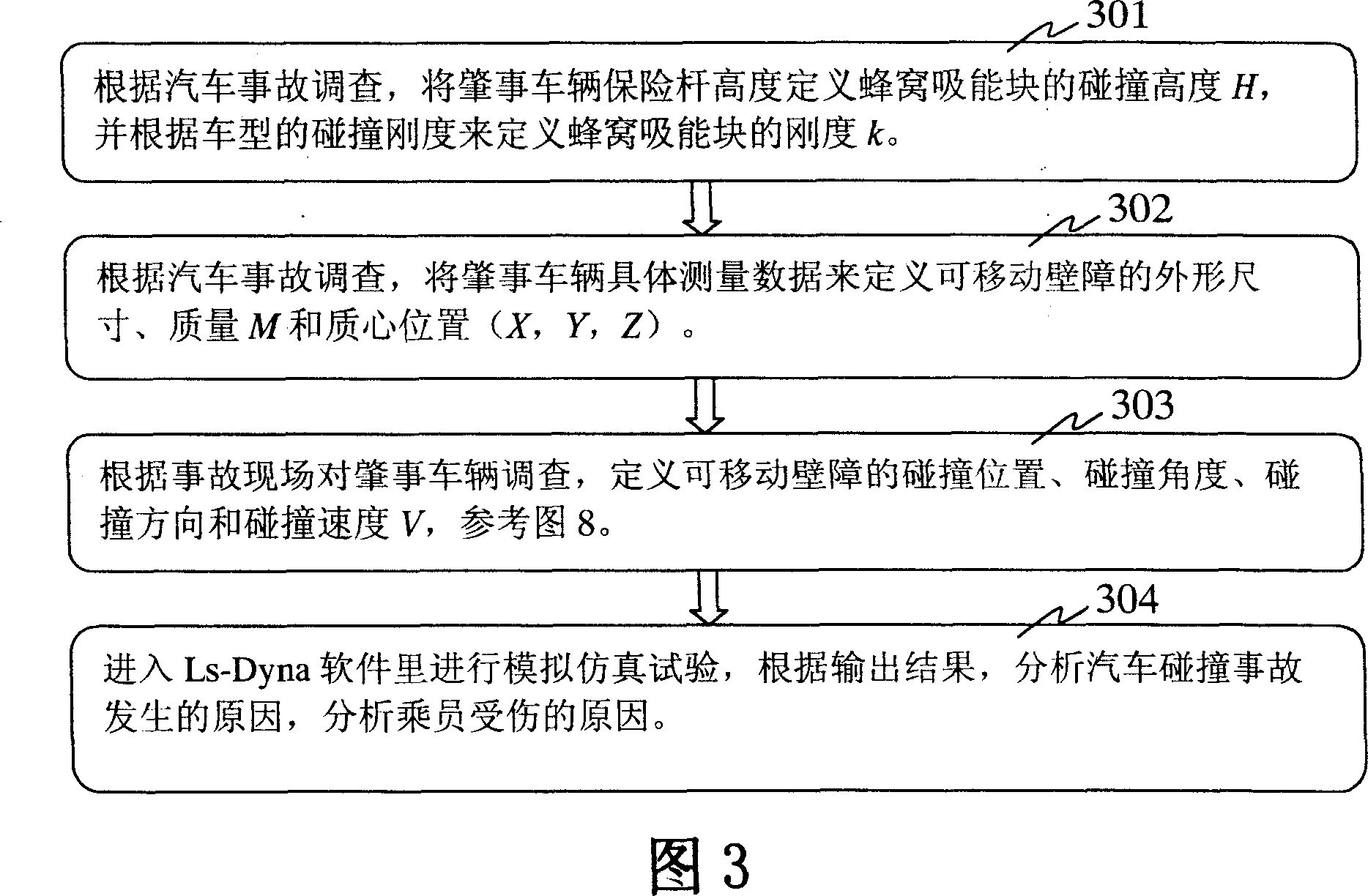

Multifunctional simulation analytical method for automobile collision and movable counterguard

InactiveCN101034040AImprove independent research and development capabilitiesImprove calculation accuracyVehicle testingRelative displacementVehicle frame

This invention relates to a kind analytical procedure of automobile collision multifunction emulation and removable counterguard. The invention includes: found removable counterguard model; define removable counterguard's car frame, tyre, subpanel as rigid body of nonoccurrence distortion and relative displacement; build removable counterguard's upper and down beehive absorbing model on described subpanel, and set the correlative size of removable counterguard as specific model parameter; carry in real vehicle parameter corresponding to removable counterguard's model parameter; thereby utilize state removable counterguard to emulate need measuring vehicle to carry out vehicular different kinds of collision test analysis. This invention can advance computational accuracy and analyses reliability, and advance calculation astringency and short calculation time.

Owner:王阳 +2

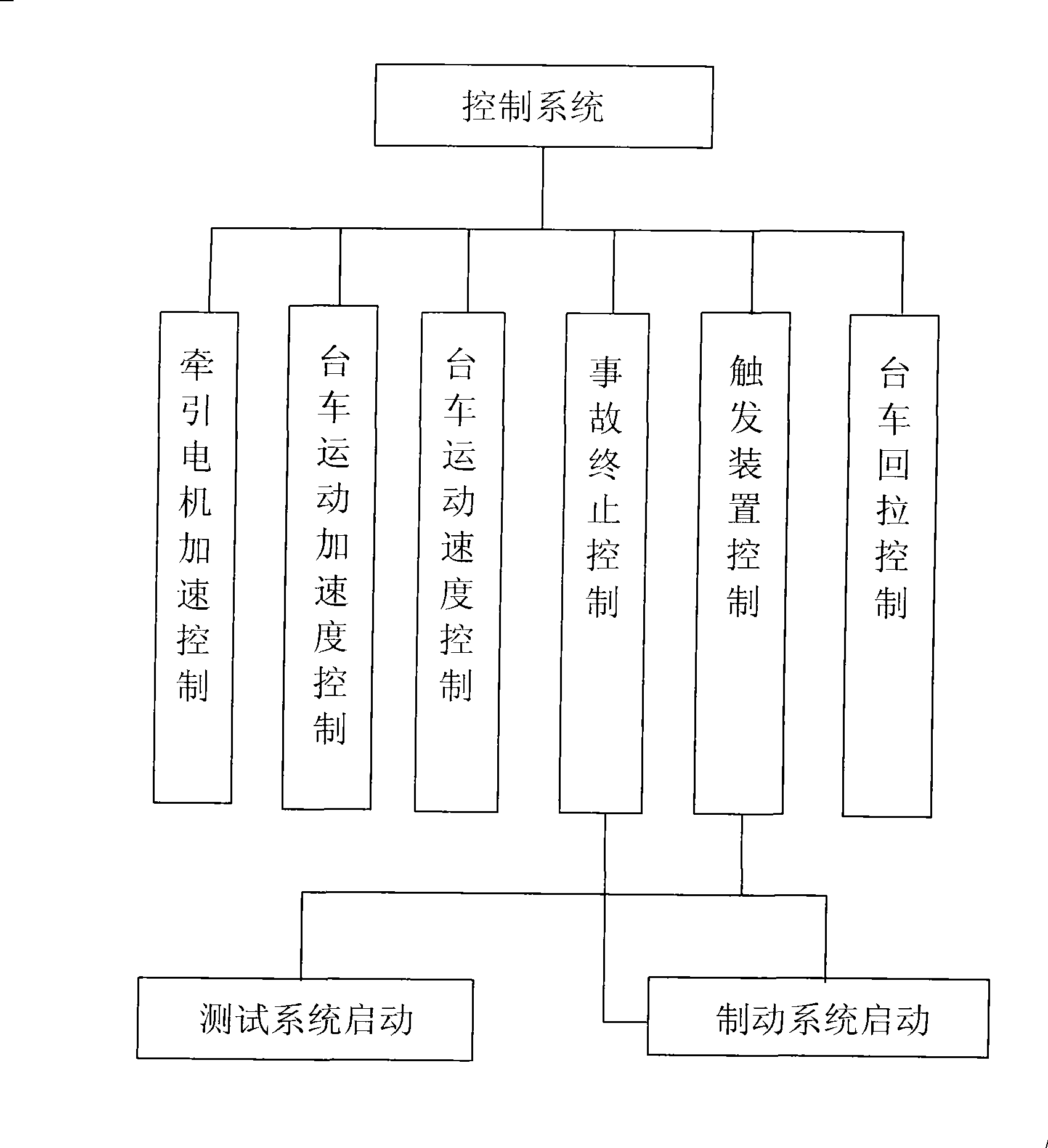

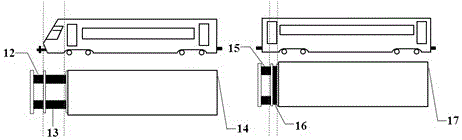

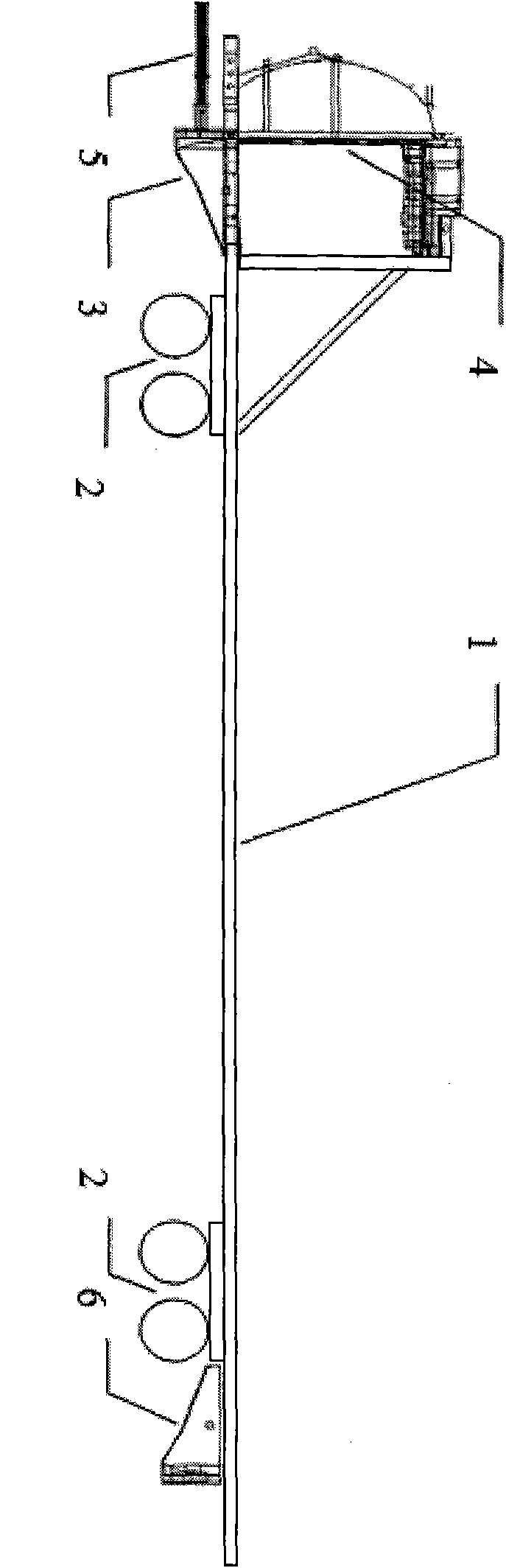

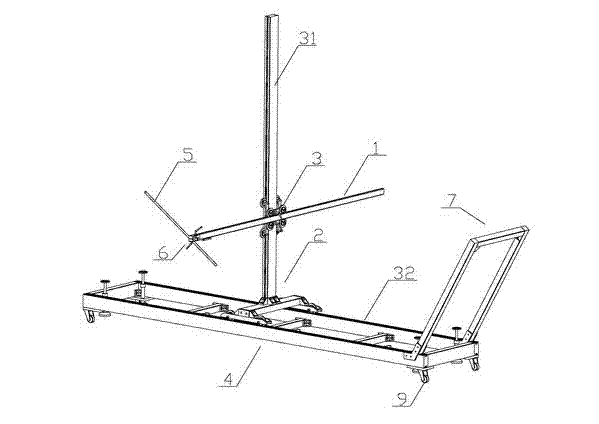

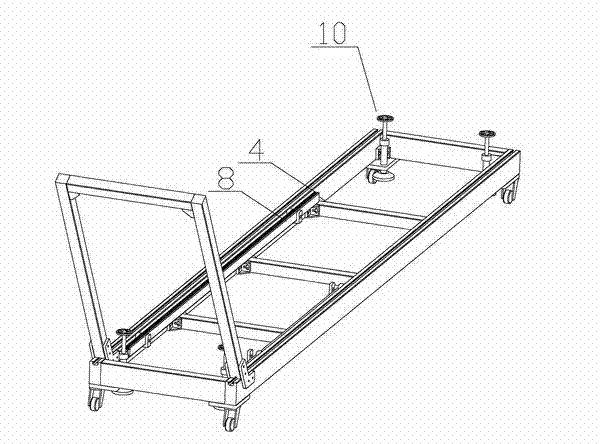

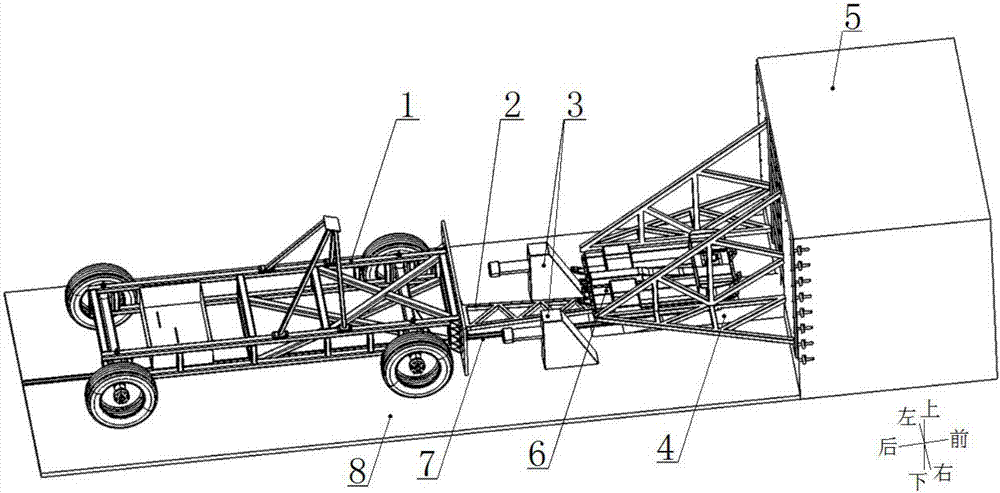

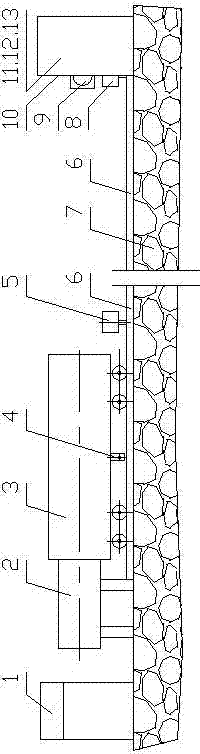

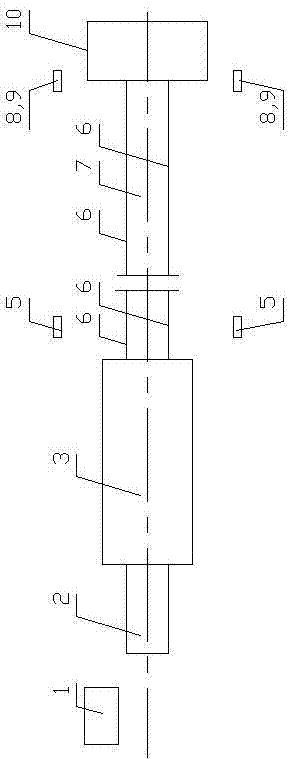

Collision test device and method of train equivalent-scaling model

InactiveCN106501013AReduce difficultyLow costRailway vehicle testingShock testingCollection systemControl system

The invention relates to a collision test device and method of a train equivalent-scaling model. The device is composed of a control system, a force measuring wall, a train equivalent scaling model, a driving vehicle and a driving vehicle launching system. A track is arranged on the foundation between the driving vehicle launching system and the force measuring wall; and the driving vehicle and the train equivalent scaling model are arranged on the track. The control system is connected with the driving vehicle launching system and a driving vehicle brake unit; the driving vehicle brake unit is arranged on the track between one end, facing the force measuring wall, of the driving vehicle before speeding up and the force measuring wall. Speed measuring and trigger devices are arranged at two sides of the track between the force measuring wall and the driving vehicle brake unit. And a tracking light source and an image collection system are installed above the force measuring wall or at the side of the force measuring wall. In addition, according to the method, the equivalent scaling model moves to hit the force measuring wall or the equivalent scaling model stands still, thereby obtaining relates data of the collision. Therefore, factors causing training climbing, skipping and Z-shaped derail and the like can be determined precisely; the test difficulty is reduced; and the test cost is saved.

Owner:CENT SOUTH UNIV

System and method for the generation of navigation graphs in real-time

InactiveUS20080220862A1Implement extensionsMinimized in size2D-image generationAnimationGraphicsReal time navigation

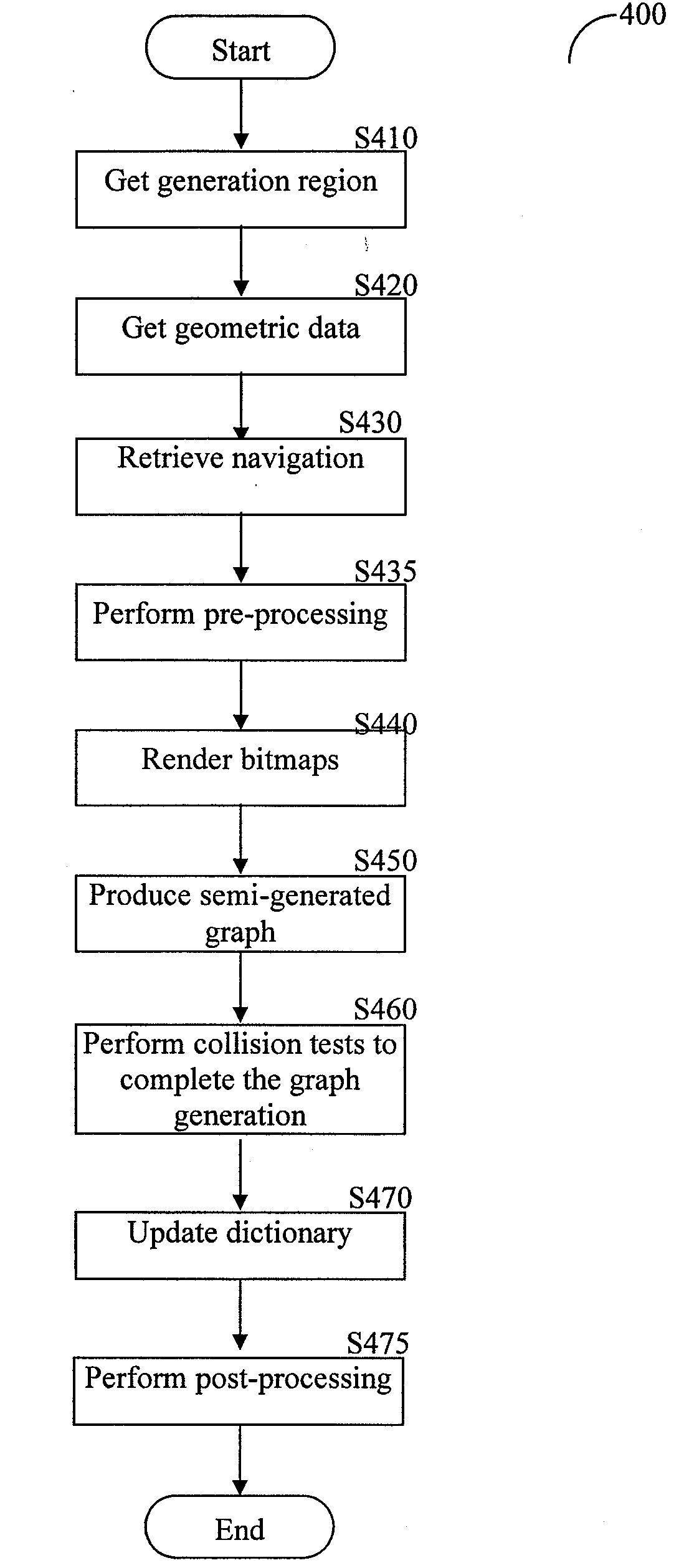

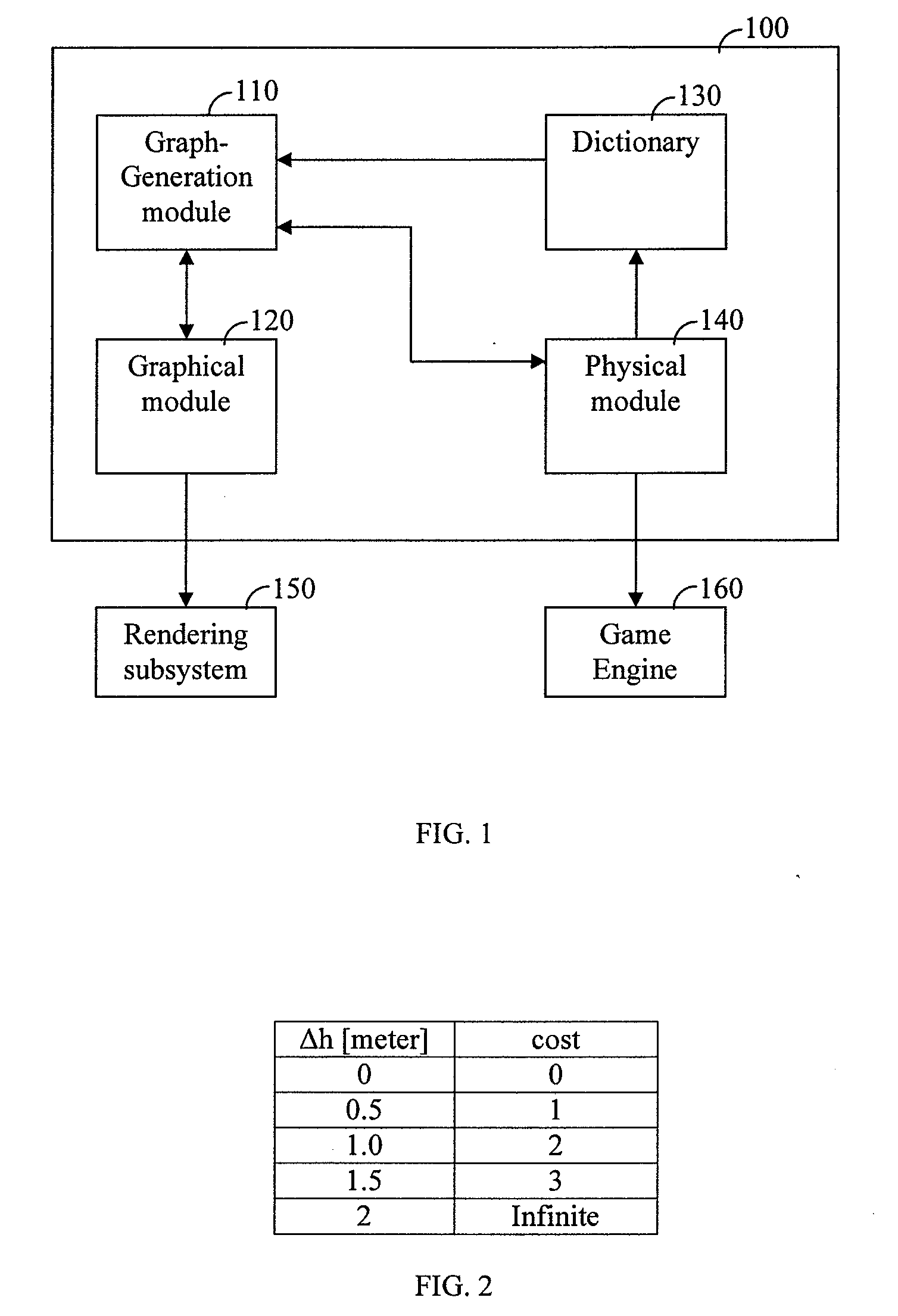

A system and method for navigation graph generation in real time is provided including a dictionary operable to maintain information mapping surface features to navigational costs. Further included is a graphical module operable to transform geometrical data of a virtual world and associated navigational costs obtained from the dictionary into navigation data; a graph-generation module operable to translate the navigation data into a semi-generated navigation graph; and a physical module operable to receive the semi-generated navigation graph, and generate an updated navigation graph based on collisions test.

Owner:AISEEK

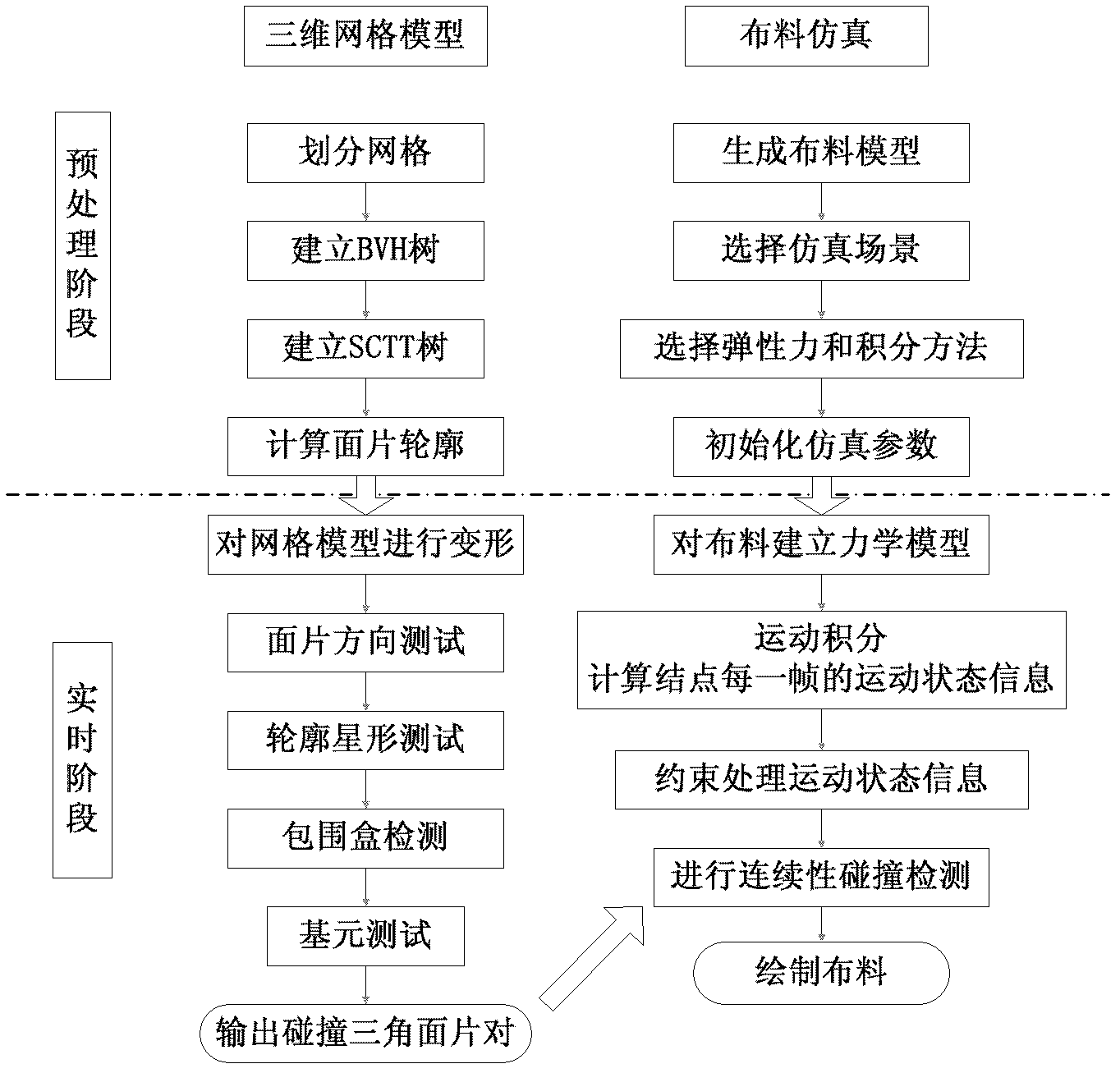

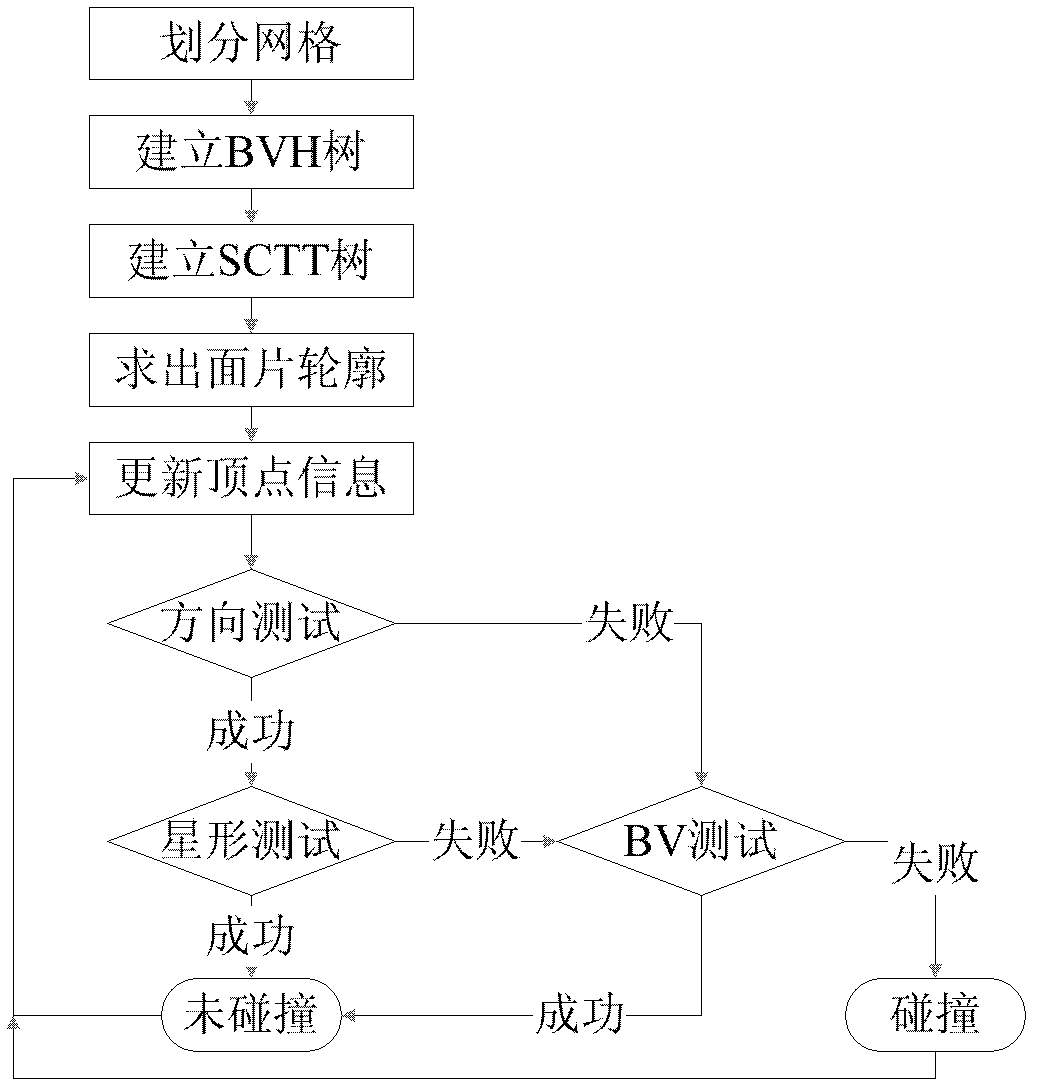

Self collision detection method based on triangle mesh deformation body

InactiveCN102609992ASpeed up the self-collision detection processImprove accuracyImage data processingGrid deformationCollision test

The invention discloses a self collision detection method based on a triangle mesh deformation body, comprising the steps of (1), constructing a data structure based on a hierarchical hounding volume (BVH); constructing an xBVH (expanded bounding volume hierarchy); constructing an SCTT (self-collision test tree)); optimizing star-shaped outline; (2), pre-processing self-collision detection based on the star-shaped outline; (3), performing self-collision test based on the star-shaped outline in real time. The method can detect the self-collision phenomenon during the deformation of the triangle mesh deformation body effectively in real time, accurately locates collision generation point and updates the collision information in real time.

Owner:BEIHANG UNIV

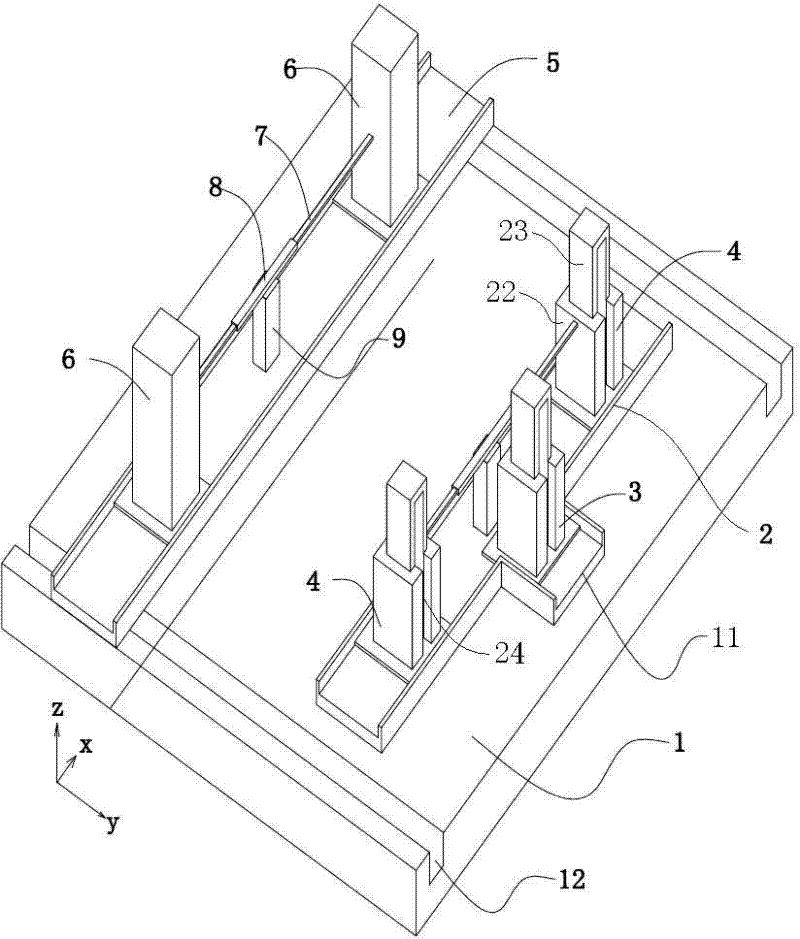

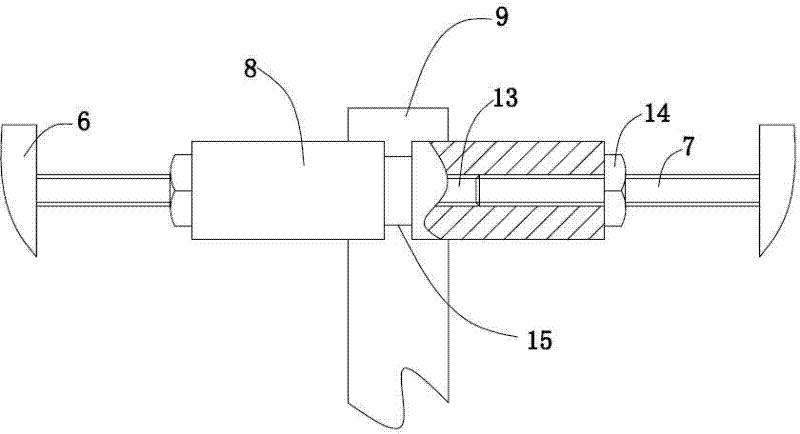

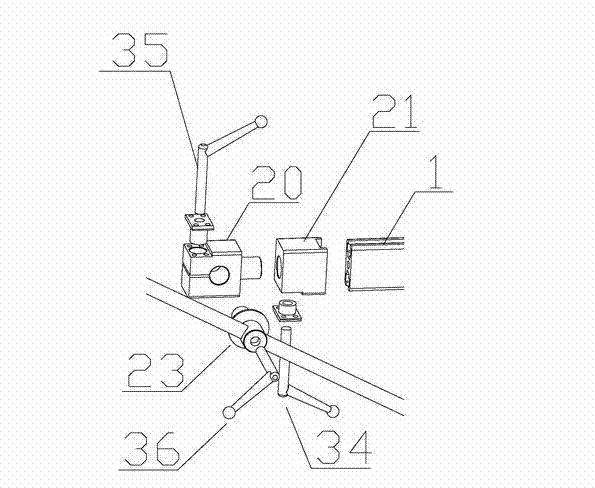

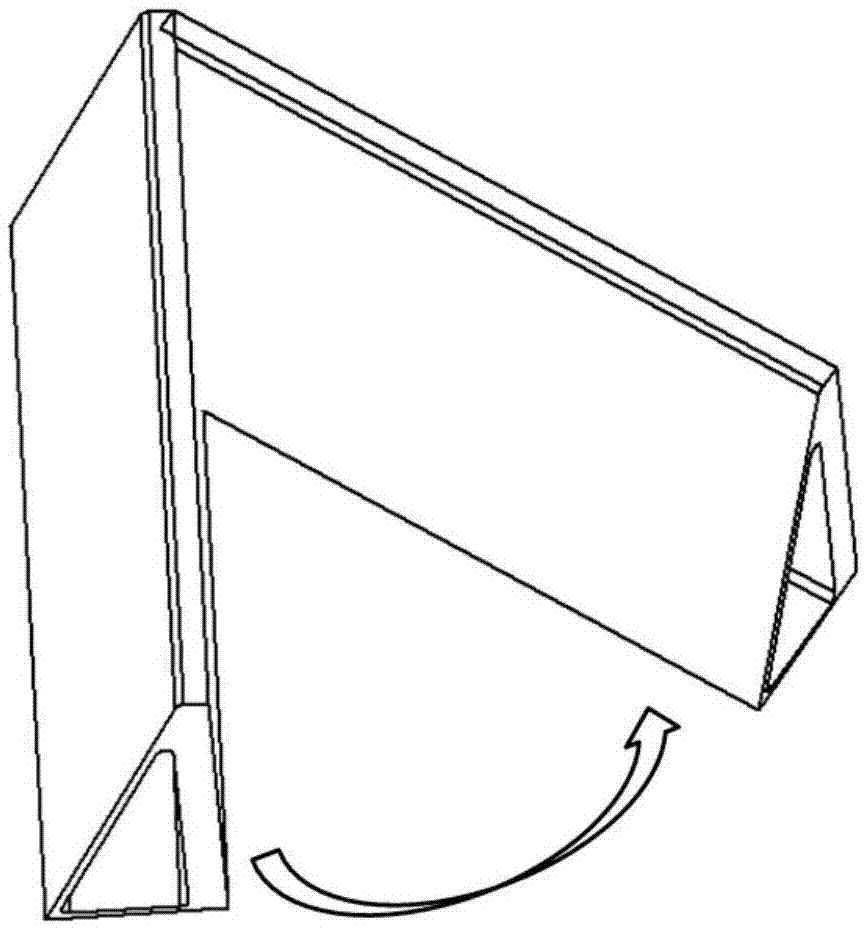

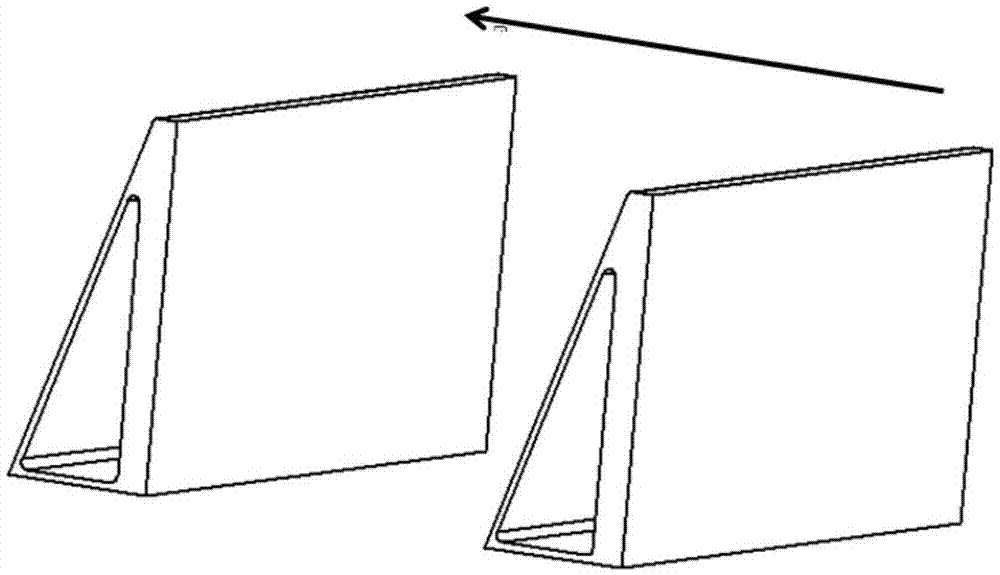

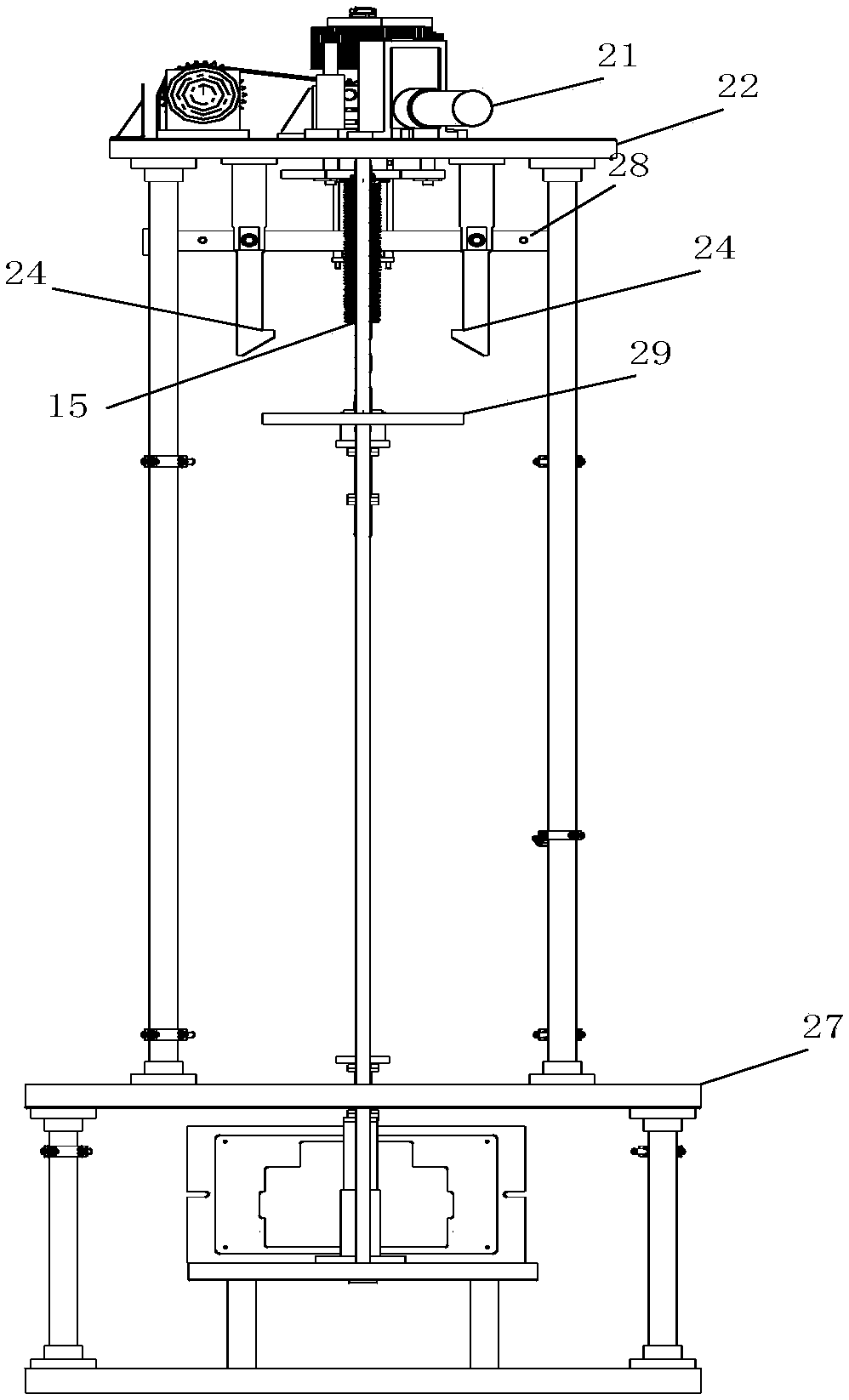

Stiffness test bench device of debugging engine hood and use method thereof

The invention relates to a stiffness test bench device of debugging engine hood used in the automobile collision test and use method thereof, which solves the problem that the traditional automobile part collision tester is not suitable for finishing the collision test of the engine hood; a hood lock connection column and a hood hinge connection column are arranged on the base of the bench; the hood hinge connection column is in the fixed height; a T-shaped fixing guide rail is fixed on the base of the bench; a buffer block connection column moving along the fixing guide rail is arranged on the fixing guide rail; a movable guide rail is arranged on the base of the bench; the hood hinge connection column is movably arranged on the movable guide rail; and the buffer block connection column and the hood lock connection column are in the structure with variable height. The installation angle of the engine hood in the normal state is simulated via the hood hinge connection column, the buffer block connection column and the hood lock connection column; the tested results are in accordance with the actual situations; the stiffness of the engine hood is really reflected; and the stiffness test bench device of debugging engine hood is applicable for the engine hoods in the different automobile types.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

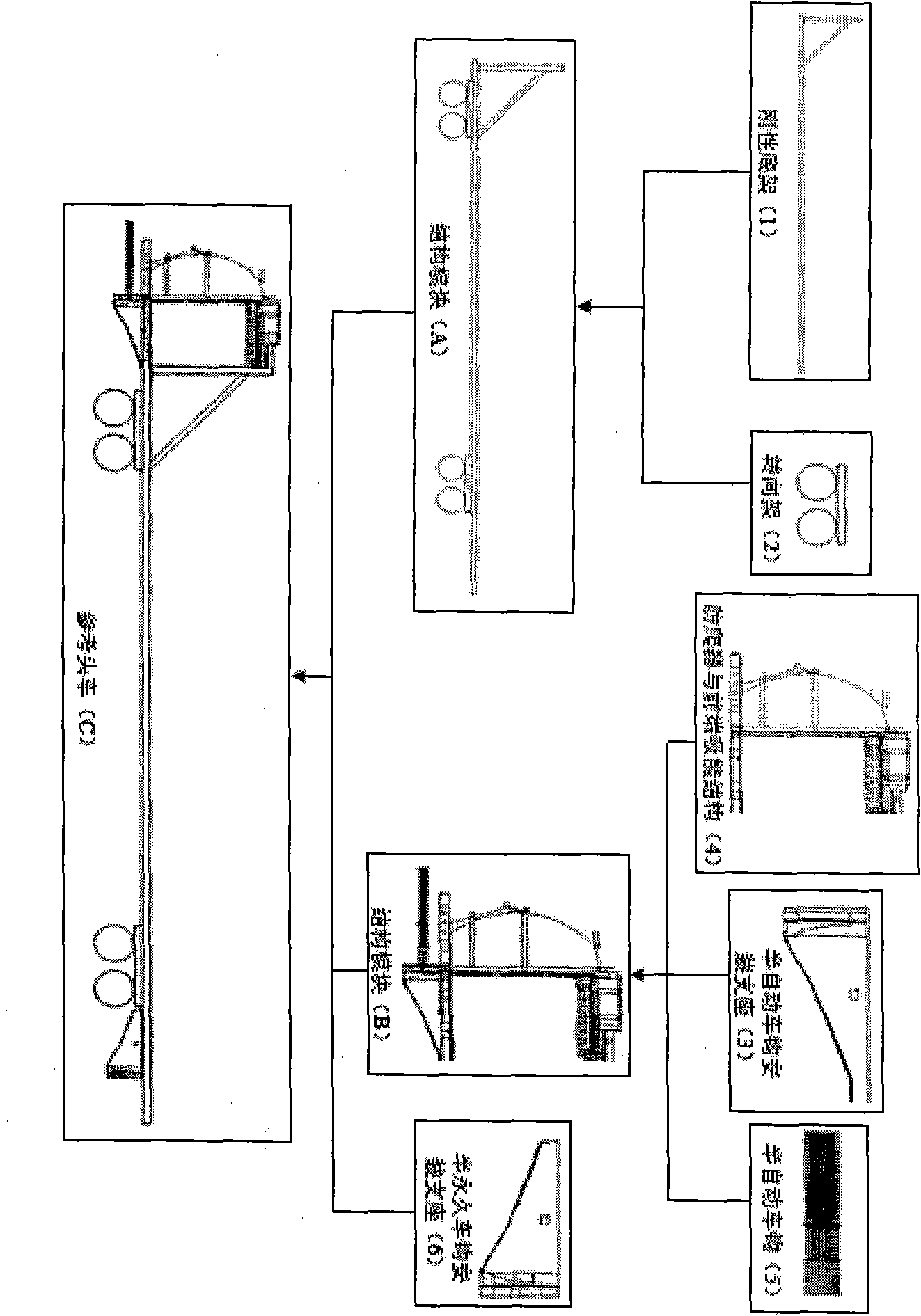

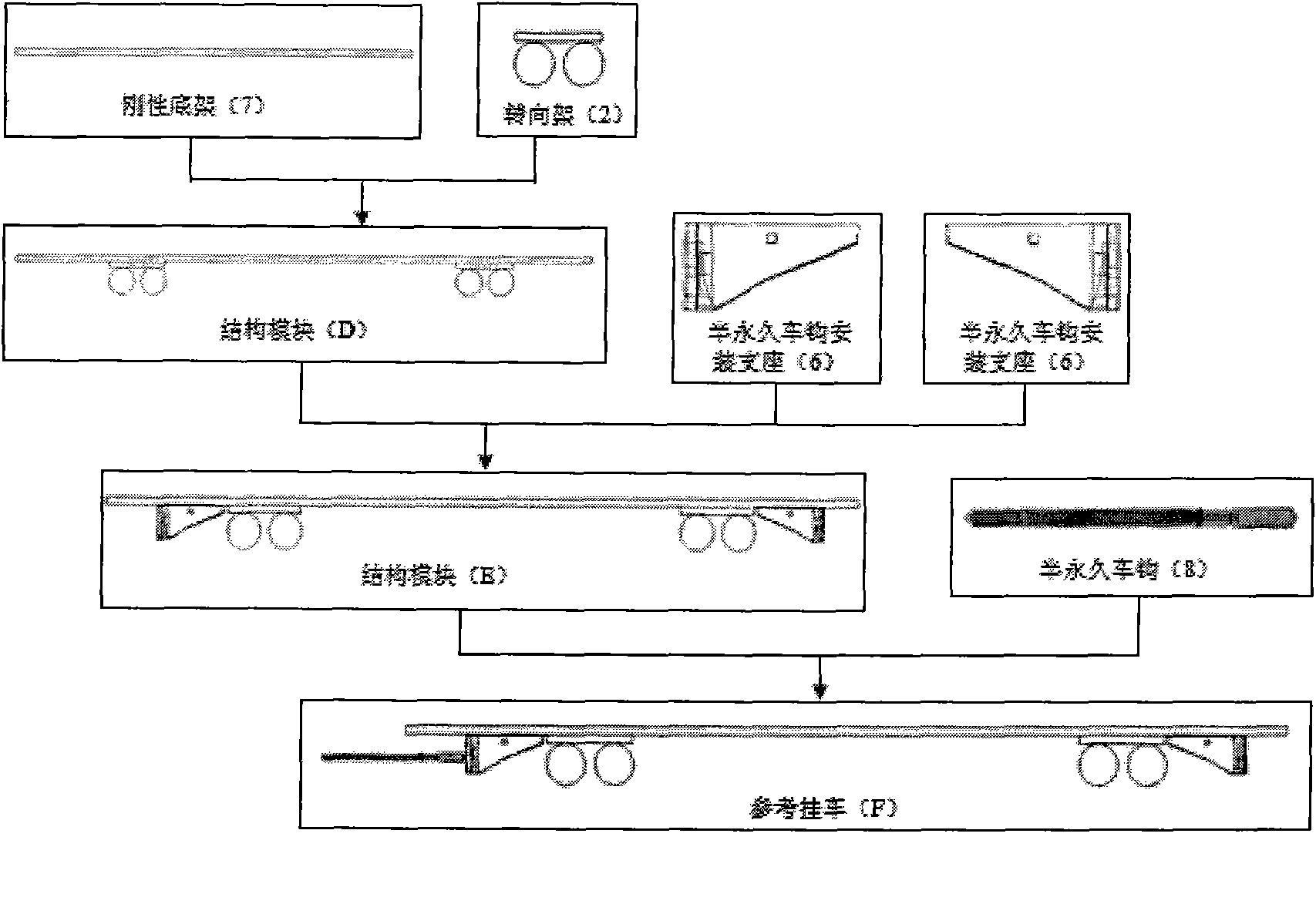

Method for assembling reference train unit collision model

InactiveCN102175414AComprehensive assessment of crashworthinessRailway vehicle testingShock testingCollision resistanceCollision test

The invention discloses a method for assembling a reference train unit collision model. The method comprises the following steps: assembling a reference train head, assembling a reference trailer, assembling a reference trailer unit, assembling a train unit and assembling a trail unit counterweight. According to the method provided by the invention, a 'reference train unit collision test model' and a 'reference train unit collision simulation model' can be acquired, thereby supplying test and analysis means to different stages of train unit collision resistance design and greatly increasing the reliability of train unit collision resistance design. In the early stage of train body collision resistance design, the reference train unit collision test and simulation are introduced, thereby greatly shortening the researching and developing period. The reference train unit collision test model has repeatability, thereby obviously lowering the cost of collision test and achieving the effect as same as the effect of a real train unit collision test. The method provided by the invention has important engineering practice significance for increasing the level of train unit collision resistance design.

Owner:肖锋

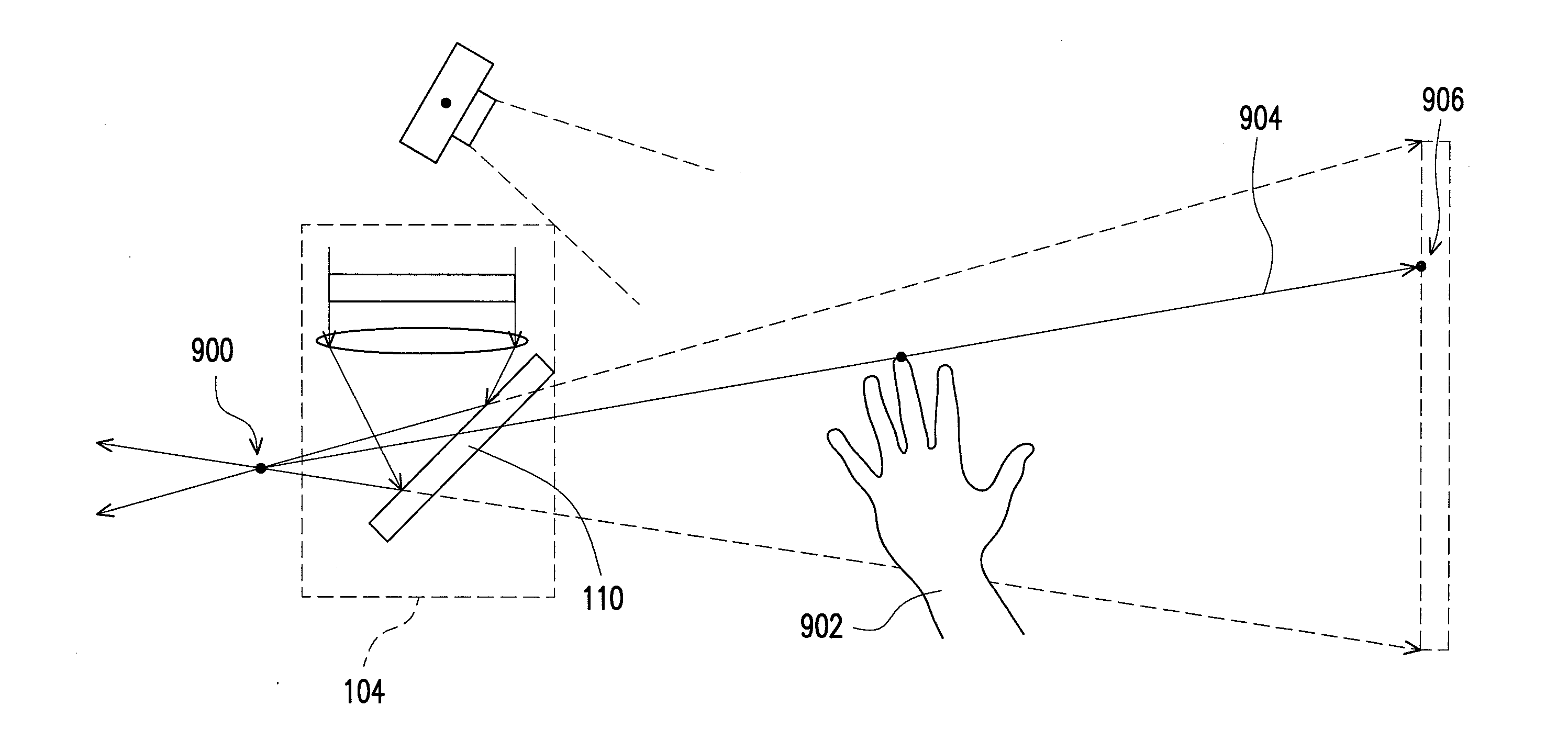

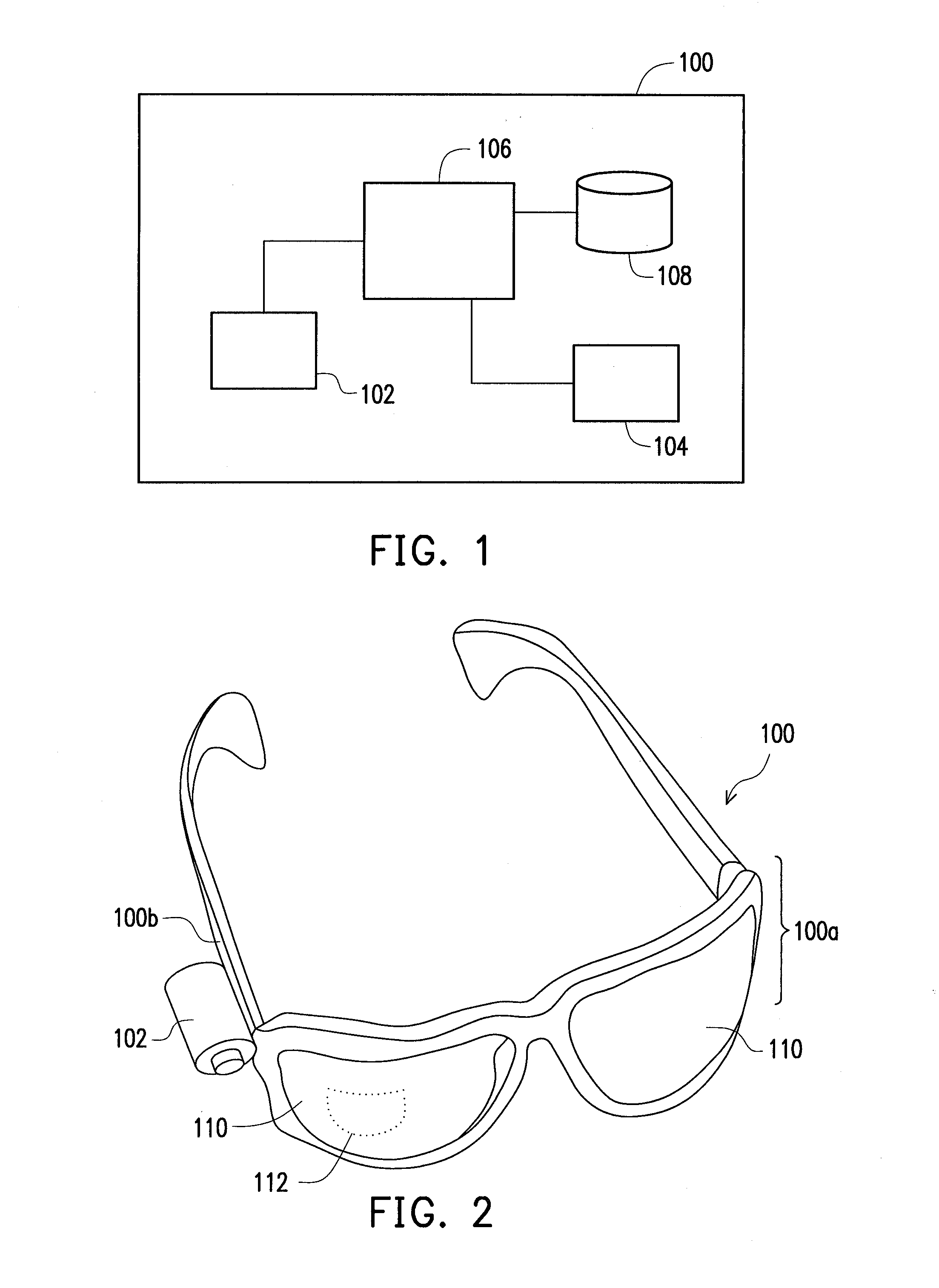

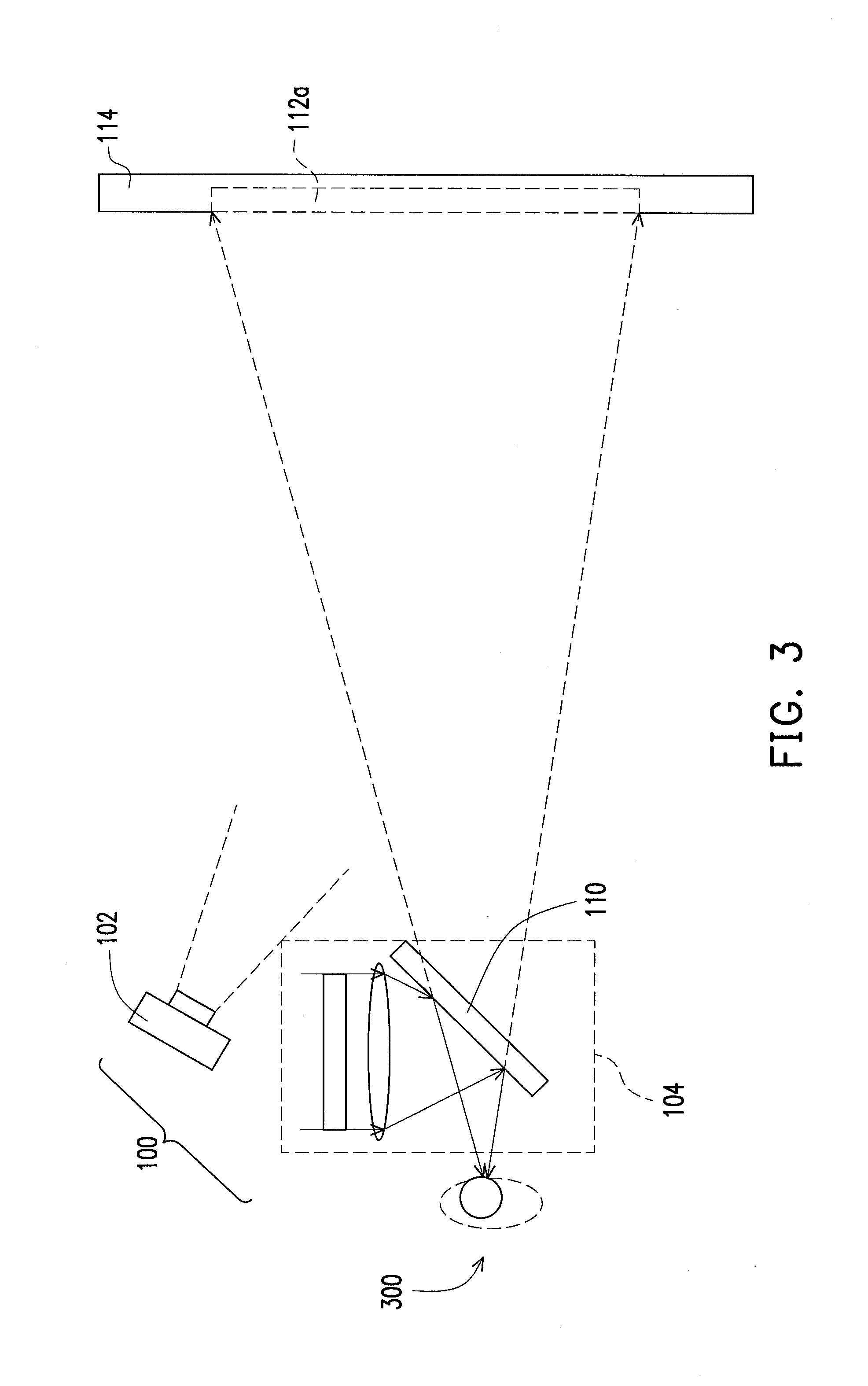

Optical-see-through head mounted display system and interactive operation

ActiveUS20140139453A1Easy to operateImage data processingInput/output processes for data processingImaging analysisDisplay device

An optical-see-through head mounted display (HMD) system is provided. The optical-see-through HMD system has a camera for generating image frames, a display device and a processor. The processor proceeds an interactive operation on each image frame. In the interactive operation, an image analysis is performed on the image frame to obtain positioning information of a marker and 3-dimensional information of an input device. According to the positioning information, the 3-dimensional information and eye position of an user, an image shielding process is performed to correct a portion of the frame to be displayed which is corresponding to the input device and a collision test is performed according to the positioning information and the 3-dimensional information of an input device to determine whether the input device touches the virtual image displayed by HMD. Then, an event corresponding to the touch position of the virtual image is executed.

Owner:IND TECH RES INST

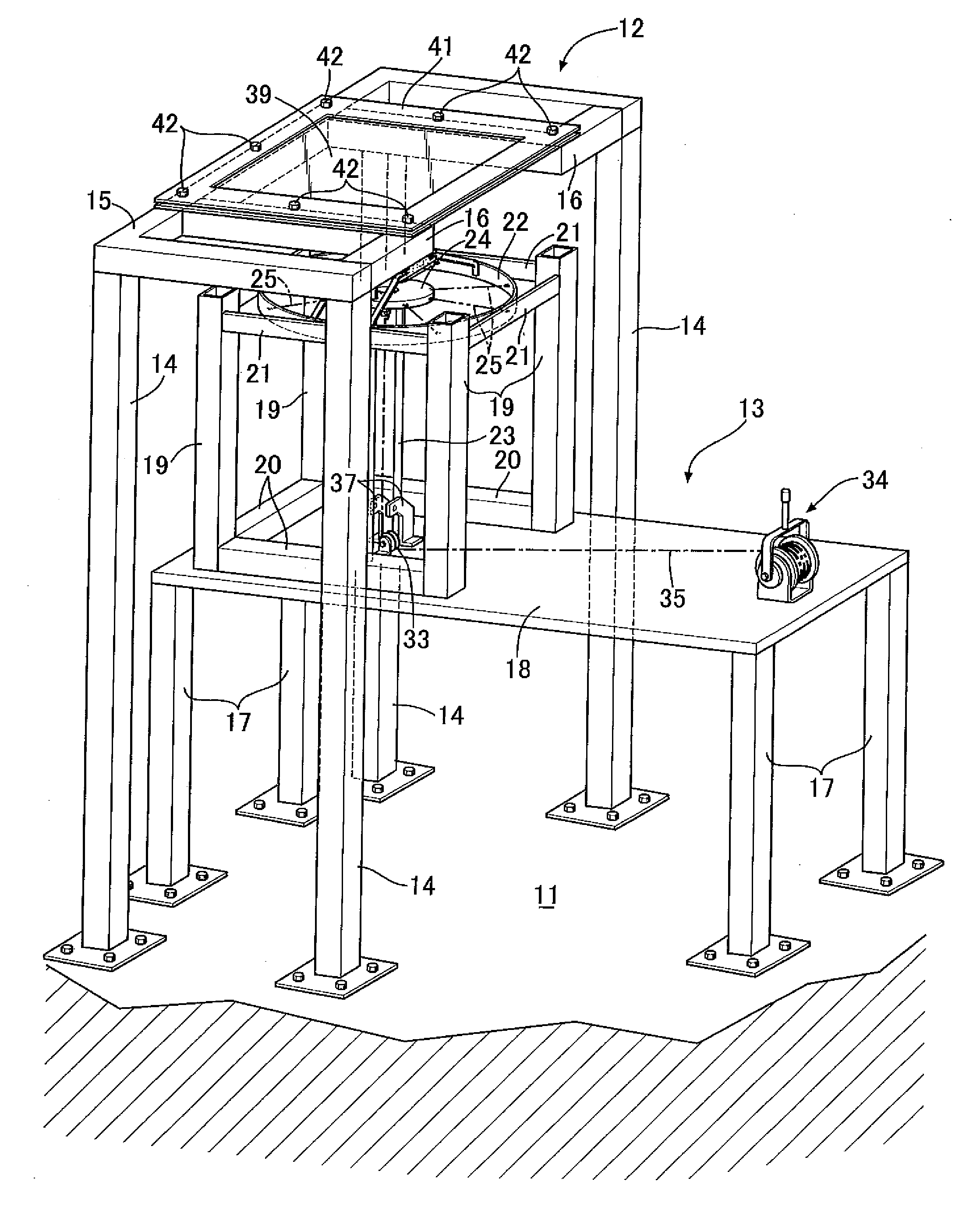

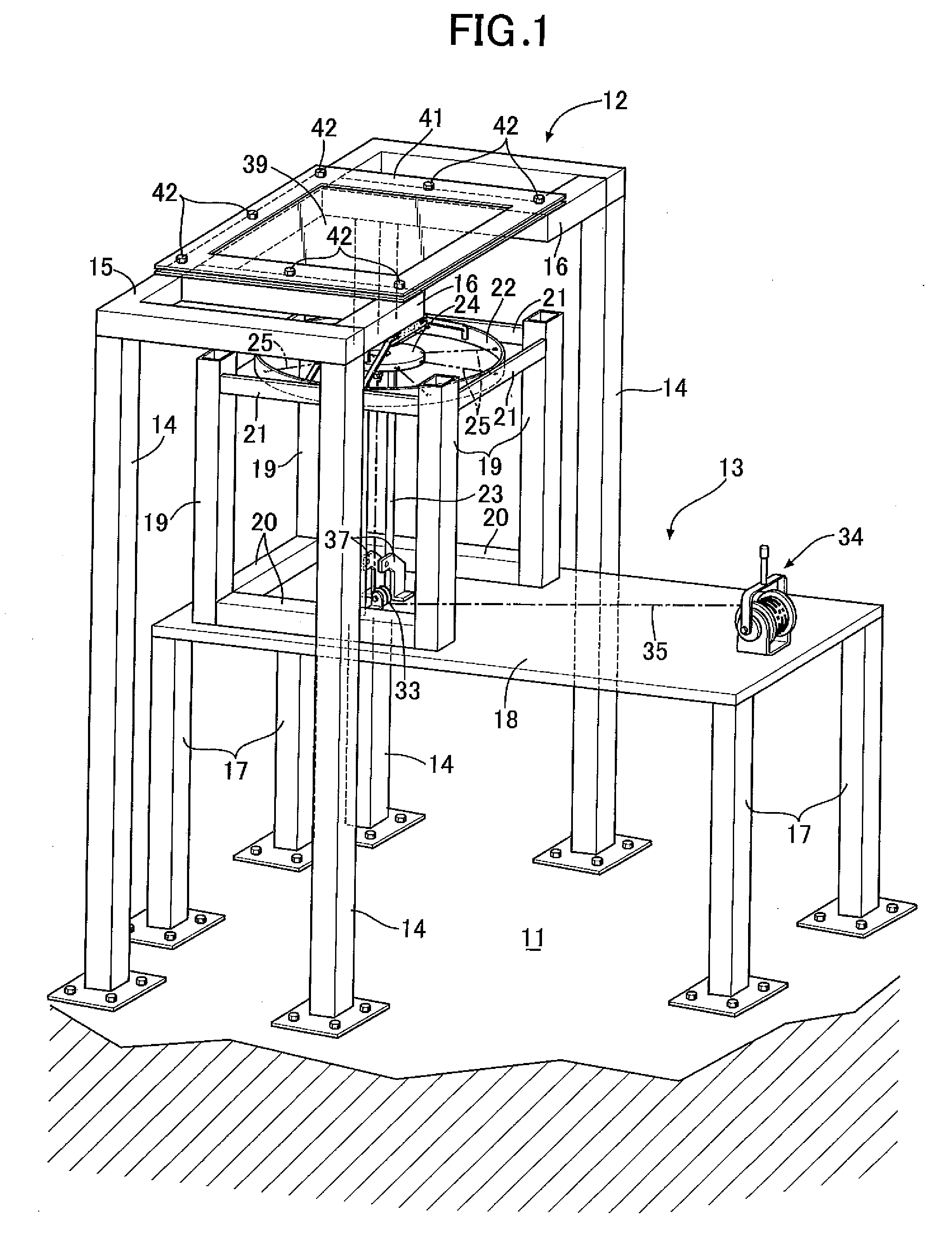

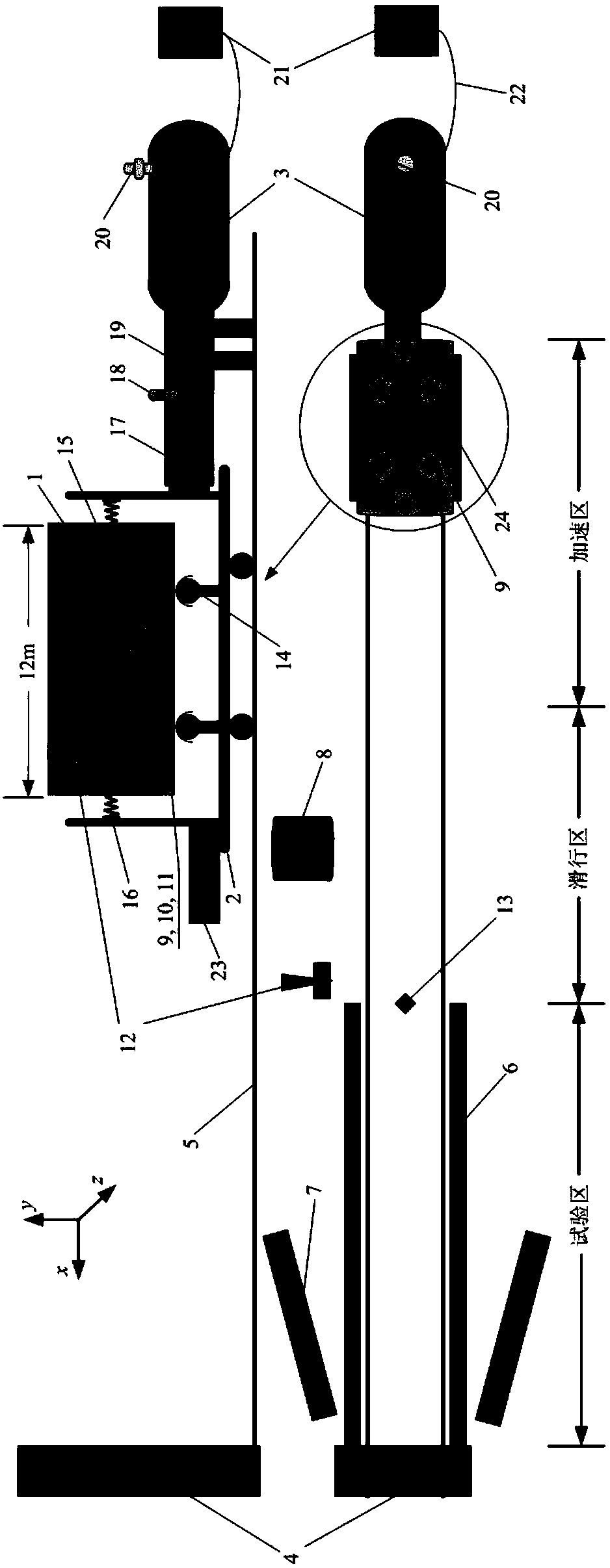

Real vehicle collision test system of rail vehicles

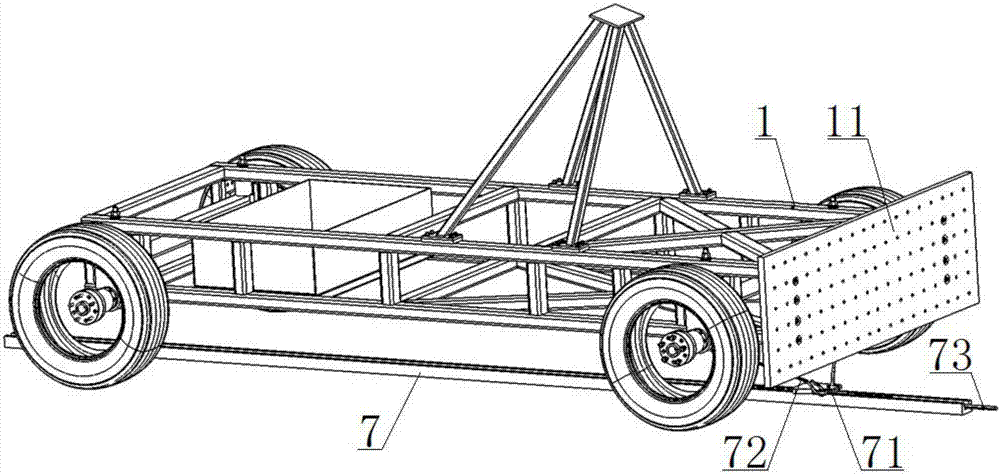

ActiveCN103940570AScientific and reasonable structureEasy to operateRailway vehicle testingShock testingSensor arrayRear-end collision

A real vehicle collision test system of rail vehicles comprises a central control platform, a transmitter, a real vehicle and a simulation vehicle; special software is arranged on the central control platform; the real vehicle and the simulation vehicle are placed on the same steel rail; one end of the real vehicle, which is back to the simulation vehicle, is provided with the transmitter; a uniform force plate and a force measurement sensor array are arranged at one end of the simulation vehicle from outside to inside in turn, wherein the end of the simulation vehicle faces to the real vehicle and a collision speed measuring device and a high-speed photography device are arranged on the lateral side of the end portion in a cantilever mode; in the collision test process, the simulation vehicle is static, the real vehicle accelerates within the effective stroke through the transmitter, the real vehicle collides with the simulation vehicle which is static on the rail after a certain distance of unpowered free sliding, and the free sliding distance of the real vehicle is at least 1.1 times of the effective stroke of the transmitter; the test collision speed during the collision of the real vehicle and the simulation vehicle is 1 to 2 times of the set collision speed and the lowest test collision speed is not less than 25 miles every hour; the facing or rear-end collision test of two moving objects on the same rail can be achieved after the simulation vehicle is provided with the transmitter.

Owner:CENT SOUTH UNIV

Method for steering vehicle

ActiveCN105764773AProgramme controlProgramme-controlled manipulatorWalking around obstaclesSteering angle

The invention relates to a method for steering a vehicle (1) around obstacles (7), from a starting position (2) to an end position (3). According to the method the vehicle is steered along a path, wherein the path comprises linear partial paths (4) defined by an increment [eta] and a steering angle [delta]. The method comprises the following steps: a) determining a maximum steering angle range and a maximum and a minimum increment range; b) determining the actual distance eP to the end position (3) and the target angle [theta]O, and the angle difference e[theta] between the current vehicle angle and the target angle; c) carrying out an optimization method for determining a partial path (4) by minimizing the value of a cost function lO assigned to the partial path, wherein (i) the cost function includes the current distance eP to the end position (3) and the current angle difference e[theta] to the target angle as optimization variables weighted independently of each other, and (ii) the maximum steering angle range, the maximum and the minimum increment range and a collision test are provided as boundary conditions; d) determining the new position by adding the detected partial path (4) to the current position; e) repeating the steps (b) to (d) until the end position (3) has been reached with sufficient accuracy.

Owner:ROBERT BOSCH GMBH

Method for testing multi-thread software concurrent conflict

InactiveCN1855068AShort cycleImprove efficiencyMultiprogramming arrangementsSoftware testing/debuggingApplication softwareCollision test

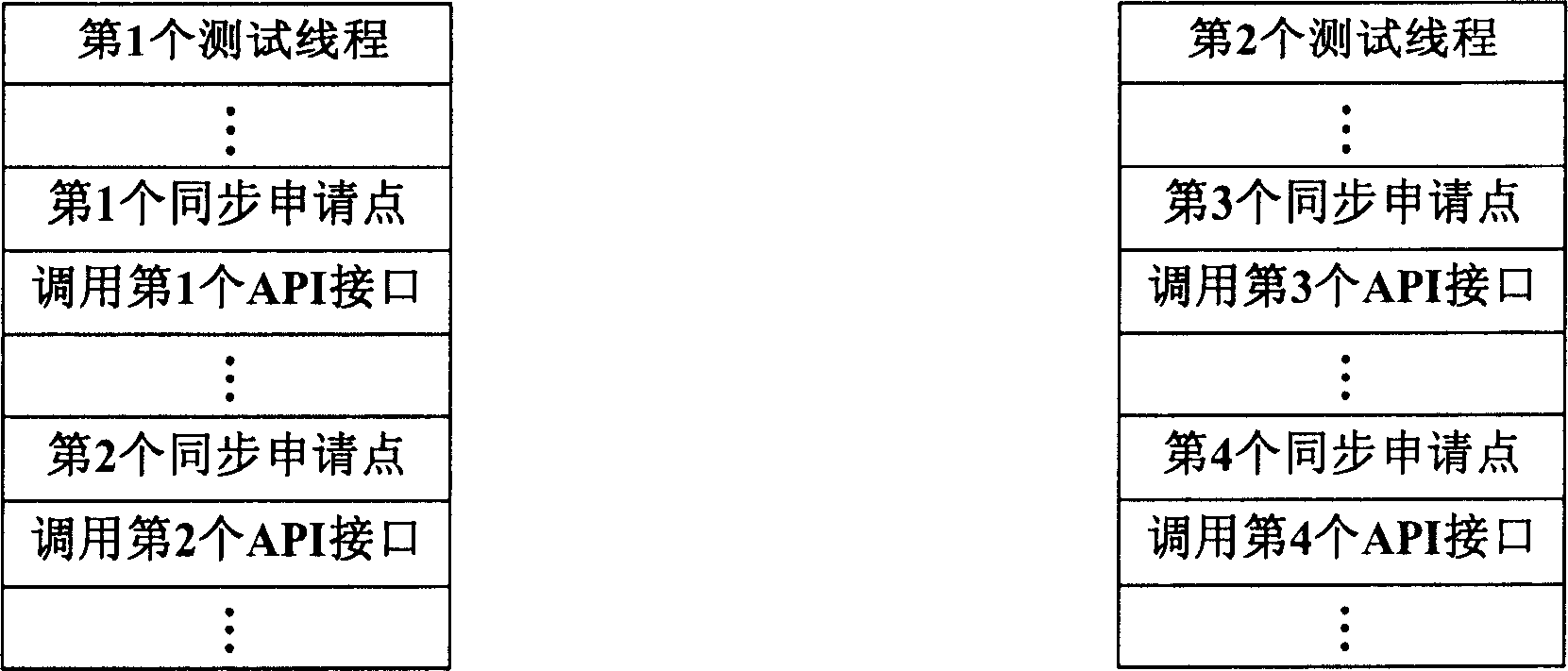

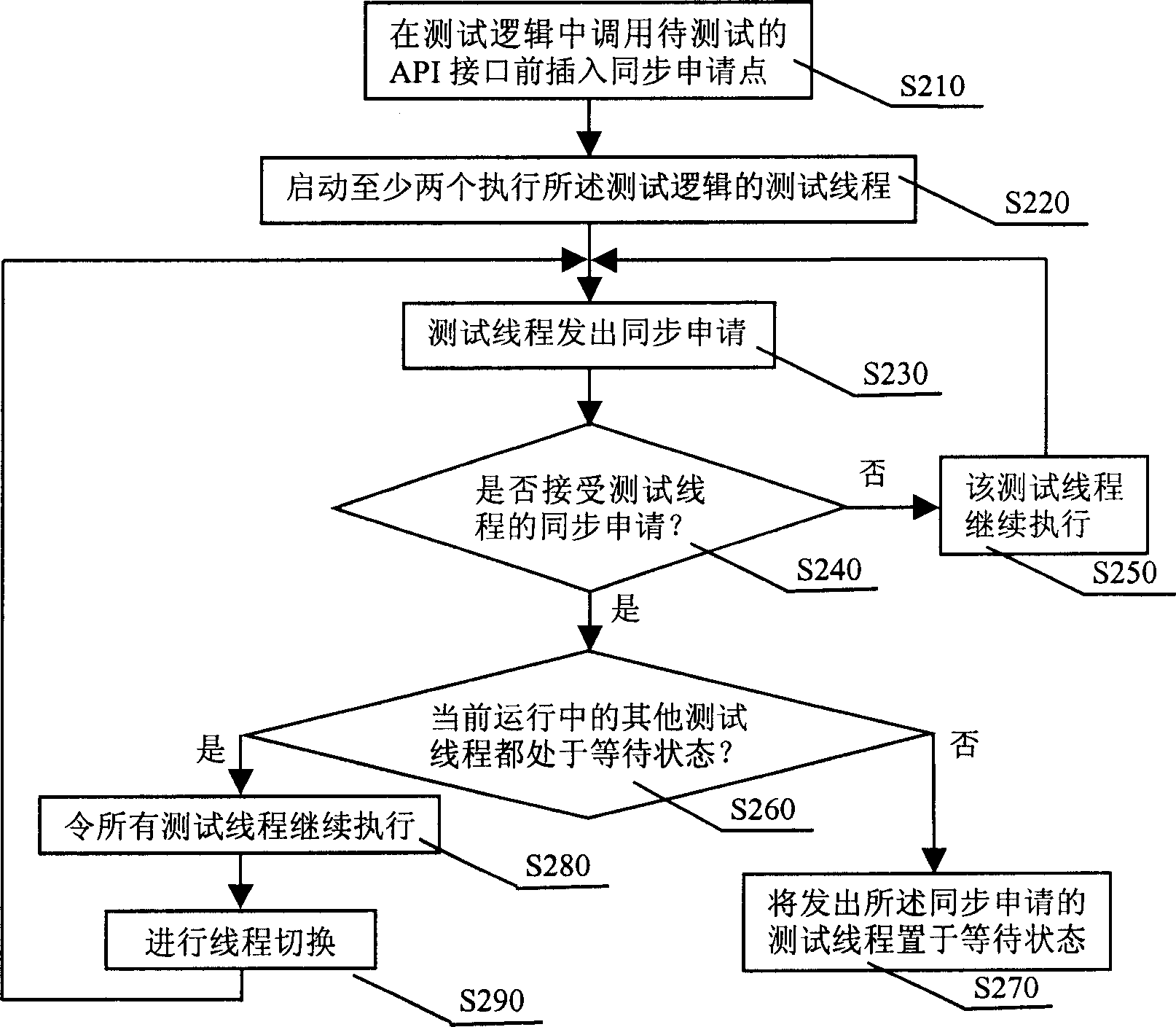

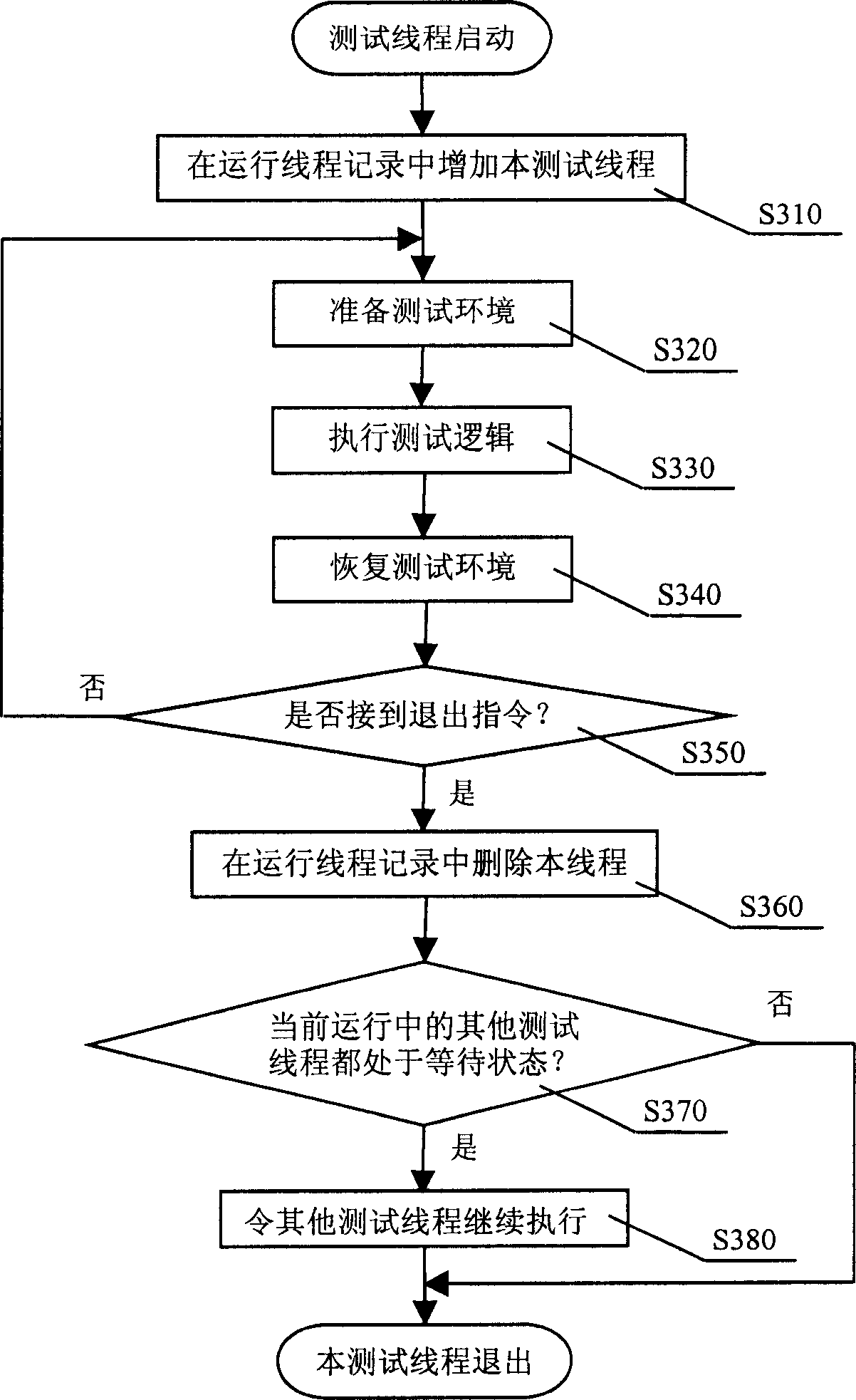

A method for testing collision of multilinear program software includes inserting synchronous application point before application program interface to be tested and to be called in test logic, operating at least two test linear programs and issuing synchronous application when test linear program is operated up to said point, judging whether said synchronous application is accepted or not and continuously issuing said synchronous application if it is not, continuously executing all test linear program to carry out collision test of test linear program if it is when the other test linear programs are at waiting-state.

Owner:HUAWEI TECH CO LTD

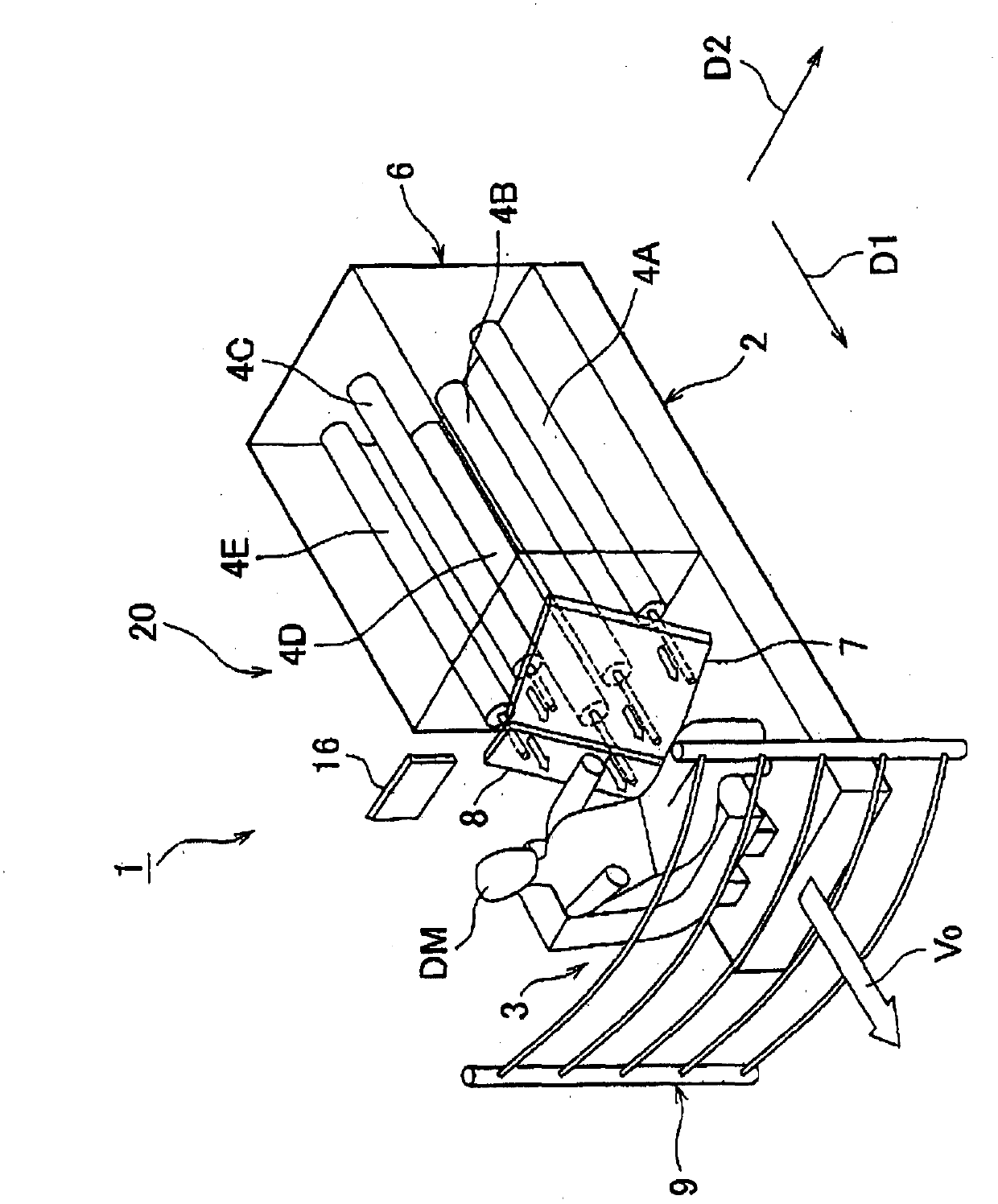

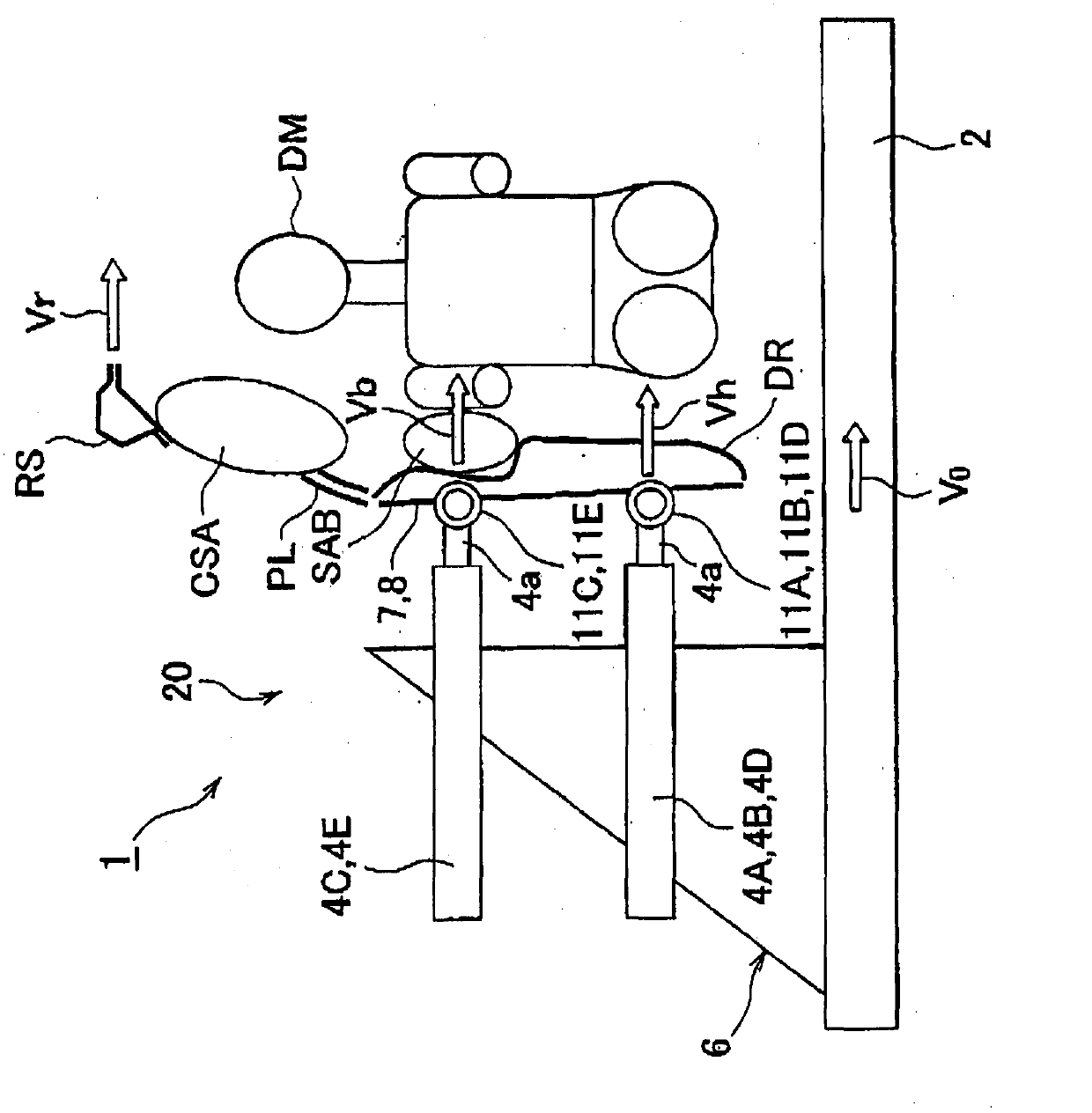

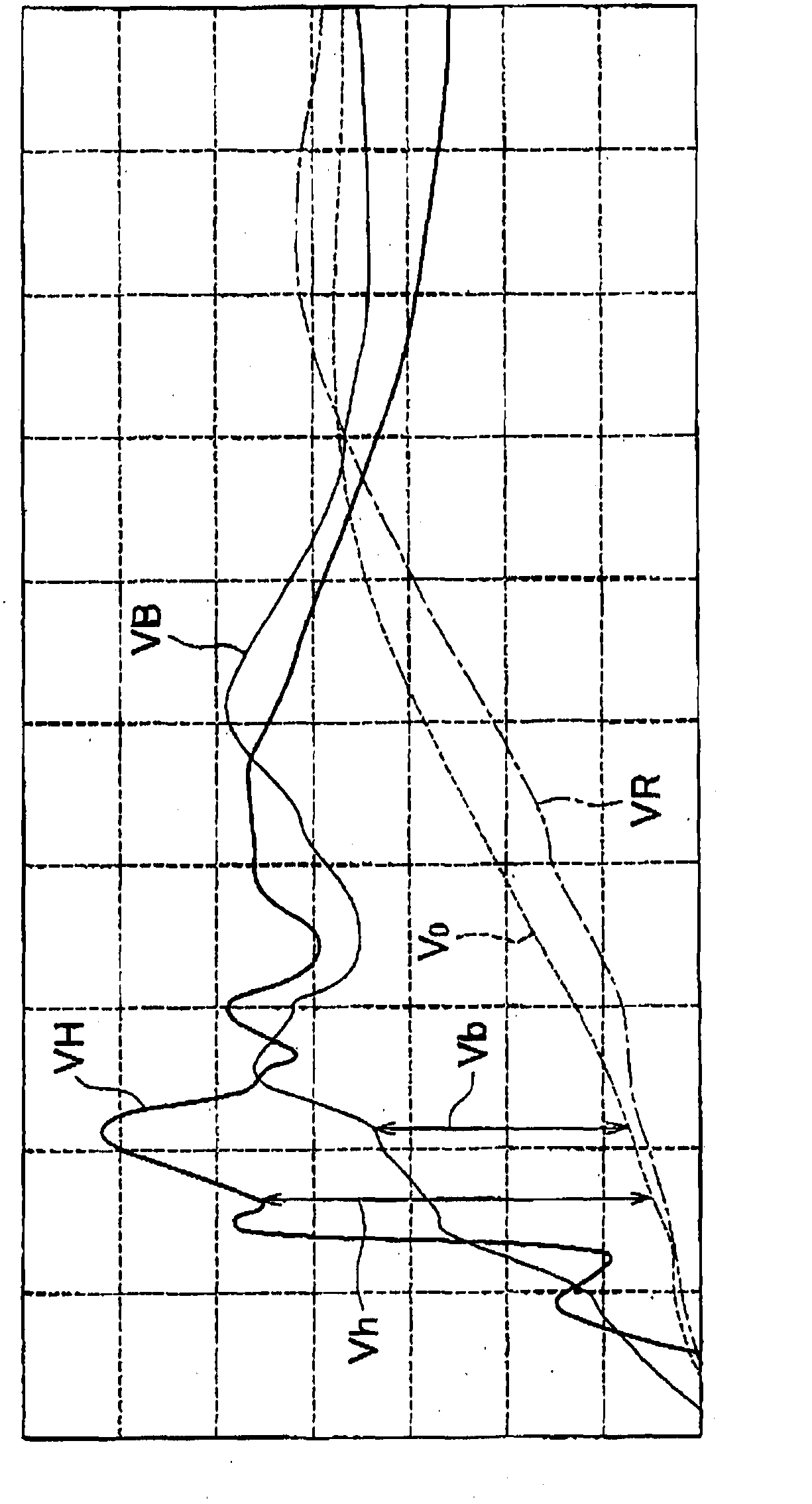

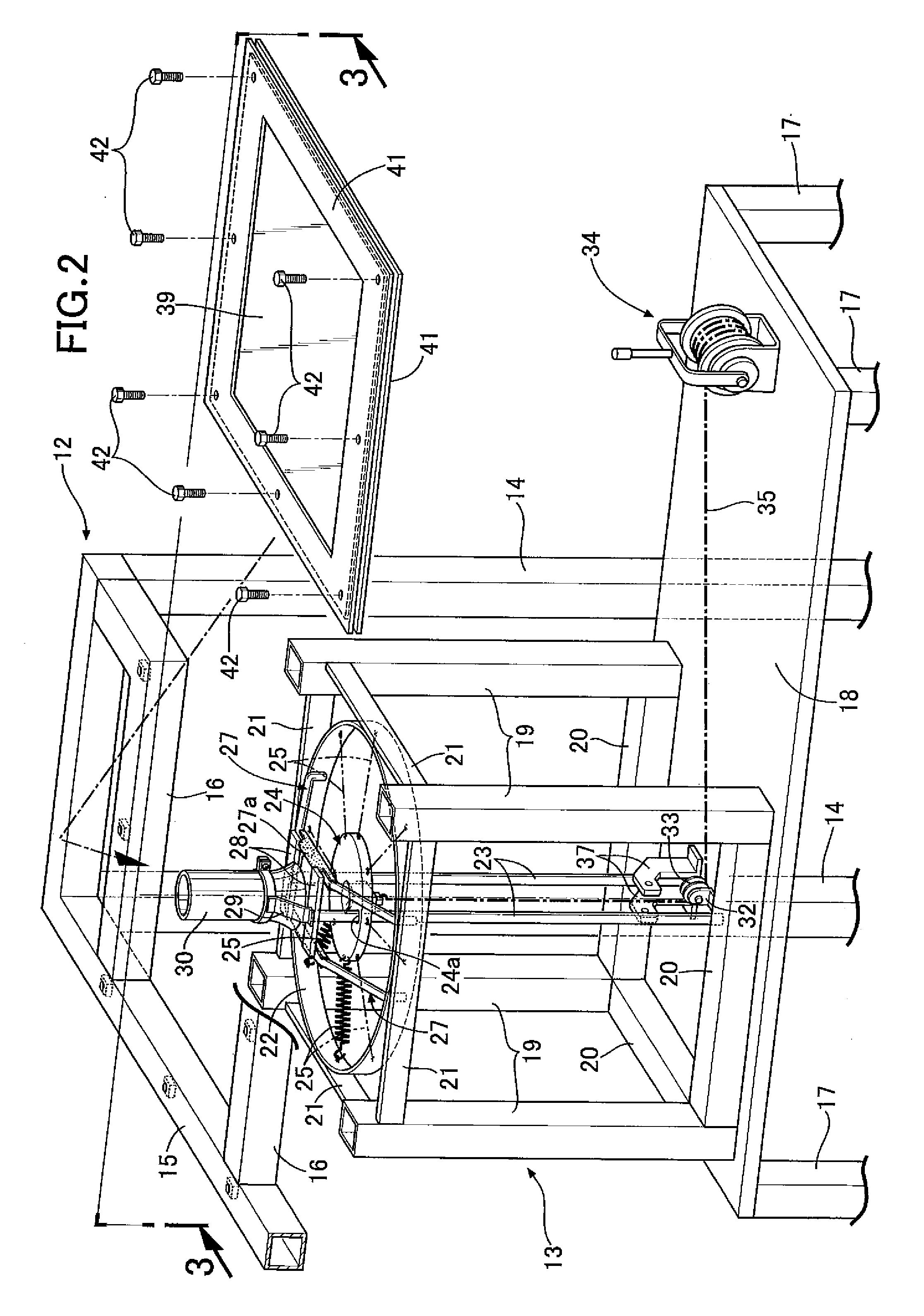

Collision test apparatus, vehicle design method, and vehicle

A collision test apparatus (1) includes actuators (4A, 4B, 4C, 4D, 4E) that move a vehicle structural member toward the side of a carrying unit (3) on which a dummy DM is carried. The actuators (4A, 4B, 4C, 4D, 4E) can be driven independently of each other. Therefore, the actuators (4A, 4B, 4C, 4D, 4E) move the vehicle structural member at respectively different driving speeds. In other words, the collision test apparatus (1) does not simply move the vehicle structural member such that the vehicle structural member collides with the dummy, but also causes the vehicle structural member to collide with the dummy DM while moving the vehicle structural member at different speeds in different positions.

Owner:TOYOTA JIDOSHA KK

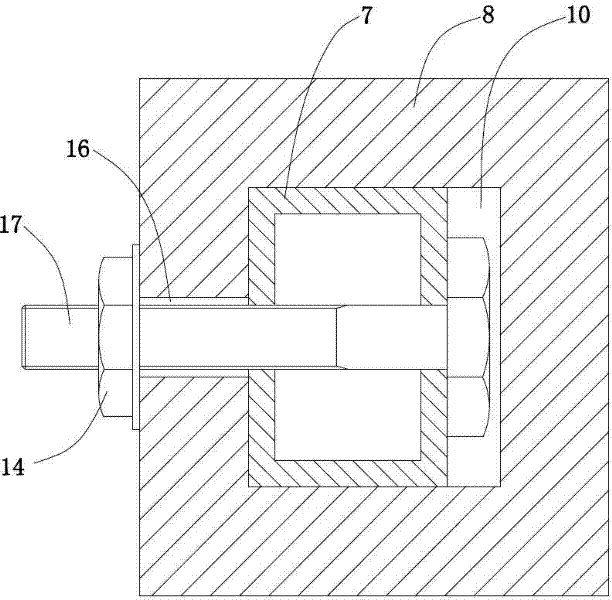

Air sac pushing device for motor vehicle collision test

InactiveCN102607865AEffective Controlled ReleasePush to achieveRailway vehicle testingShock testingCollision testPiston

The invention discloses an air sac pushing device for a motor vehicle collision test, which mainly consists of a fixed inflating cylinder and a foldable cylindrical flexible air sac. The foldable cylindrical flexible air sac is connected with the inflating cylinder via a gland and a sealing device; more than two cylindrical cloth sacs are sewn and reinforced to form the foldable cylindrical flexible air sac, an air opening is arranged at one end of the foldable cylindrical flexible air sac and connected with an air channel of the inflating cylinder, a back cover at the other end of the foldable cylindrical flexible air sac is reinforced by more than two layers of cloth, and the total foldable cylindrical flexible air sac is hung on a spatial hanger. Continuous long-term long-stroke acting of a movable piston is realized, so that an active vehicle (a colliding vehicle) runs at the highest running speed. The air sac pushing device has the advantages that experiment cost is low, acting force is large and lasting, and acceleration of the active vehicle is obvious. In addition, the air sac pushing device can be used for pushing tests of heavy motor vehicles.

Owner:SOUTHWEST JIAOTONG UNIV

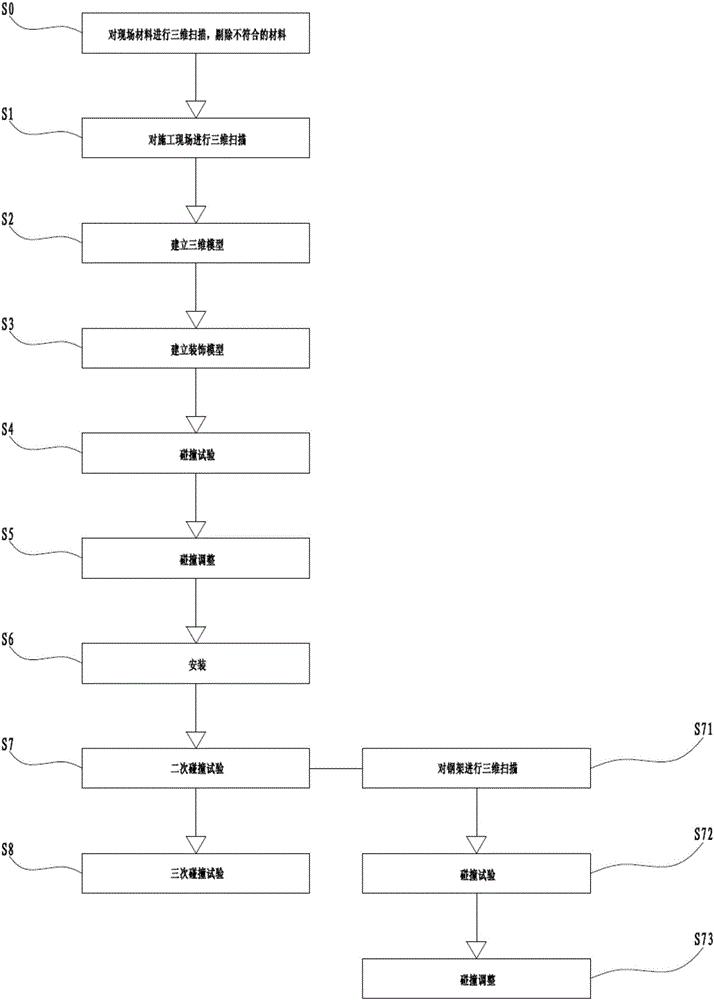

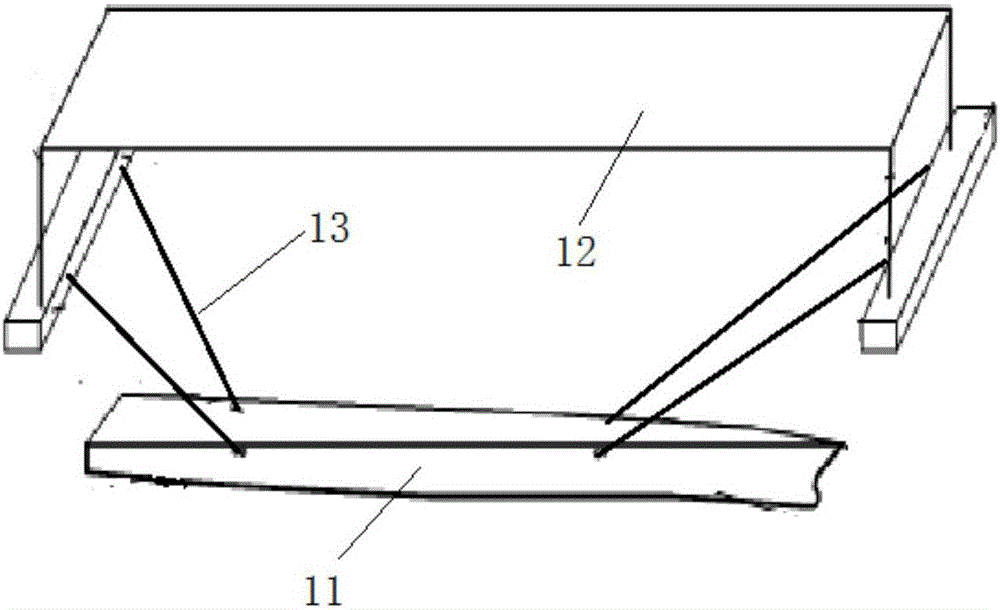

Complex shared space assembling building decoration construction method based on BIM (building information modeling)

InactiveCN106639207ARealize zero rework in the later stageAchieve precise conversionCovering/liningsTotal stationCollision test

The invention provides a complex shared space assembling building decoration construction method based on BIM (building information modeling). The method comprises the following steps that (1), three-dimensional scanning is conducted on a construction site, and three-dimensional data of the construction site are collected; (2), a three-dimensional model is obtained according to the three-dimensional data; (3), a decoration model is built according to drawings; (4), the decoration model is matched to the three-dimensional model to conduct simulation installation, a collision test is conducted, discrepant areas and size deviation between the decoration model and the three-dimensional model are found out, and a collision result is obtained; (5), the decoration model is adjusted according to the collision result; and (6), coordinate installation point location information is extracted in a finished decoration model, the point location information is guided into a total station, and a line of a later-installed face is paid off. According to the complex shared space assembling building decoration construction method based on the BIM (building information modeling), the technical problems that in the prior art, building decoration construction deviation is troublesome to be adjusted, and construction efficiency and the construction quality are low are solved.

Owner:SUZHOU MEIRUIDE BUILDING DECORATION CO LTD

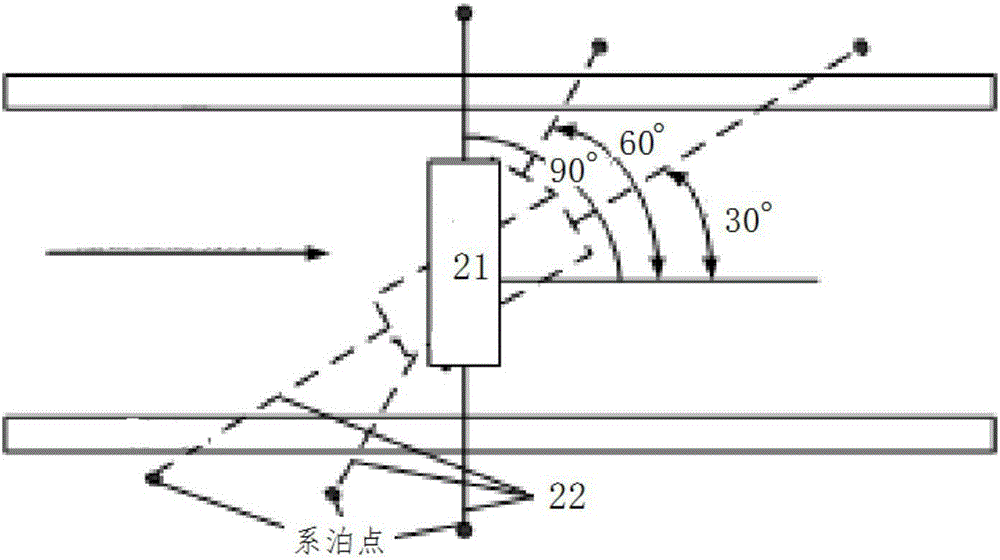

Ship pool collision testing method

The invention relates to a ship pool collision testing method.The ship pool collision testing method comprises the specific steps that 1, a collided ship model is moved to a collision position, two mooring ropes are straightened so that the collided ship model can be in a static floating state at a collided angle, and the two mooring ropes are loosened; 2, a colliding ship model is towed to reach a predetermined collision speed by using a tow truck and then collides with the collided ship model, two steel wire ropes connected to the front end frame of a truss of the tow truck and used for controlling an attitude of the colliding ship model are cut off at the moment, the tow truck brakes till stopping is achieved, data of a force sensor and data of an acceleration sensor after collision are acquired, and a collision force time travel curve and a collided ship model acceleration response time travel curve in the collision process are obtained through analysis; 3, the speed of the collided ship model, the flotation condition of the collided ship model, the collided angle and a bow form are adjusted, and then a collision test is performed.The ship pool collision testing method can carry out collision effect verification under the different collision speed conditions, better reflects a real seaborne collision environment and is smaller in risk, low in cost and flexible and convenient to operate.

Owner:中国人民解放军92537部队

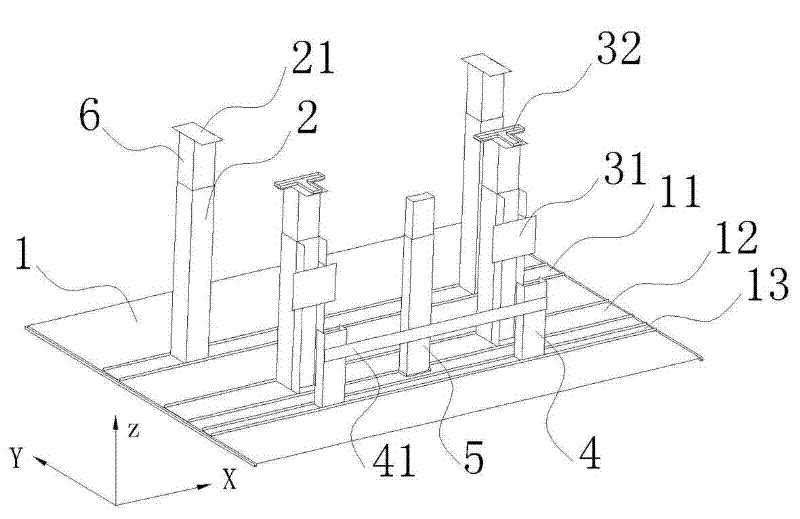

Pedestrian protecting vehicle scriber used for collision test

ActiveCN102501237AEasy to operateImprove marking efficiencyOther workshop equipmentUniversal jointScriber

The invention discloses a pedestrian protecting vehicle scriber used for a collision test, which comprises a movable base arranged in the Y direction, a horizontal moving rack, a longitudinal moving rod and a scribing rod, wherein the movable base is provided with a self-arranged leveling and fixing device; the horizontal moving rack and the movable base are in Y-direction sliding fit; a Z-direction extending vertical strut is fixed on the horizontal moving rack; the longitudinal moving rod is horizontally arranged on the vertical strut along the X direction; the longitudinal moving rod can horizontally slide along the X direction and the Z direction on the vertical strut and is locked and positioned; the scribing rod is arranged on one end of the longitudinal moving rod by a universal joint; and a space angle between the scribing rod and the longitudinal moving rod can be regulated at will. The pedestrian protecting vehicle scriber has the characteristics of low working intensity, high scribing efficiency and high scribing precision, is convenient and simple to operate, is convenient to move and saves space, can be made of belt trough aluminium profile, aluminium alloy plates and few steel materials to guarantee integral strength and have portability. The pedestrian protecting vehicle scriber is suitable for various vehicle collision test processes to serve as an auxiliary tool to carry out pedestrian protecting scribing operation.

Owner:长城汽车股份有限公司平湖分公司

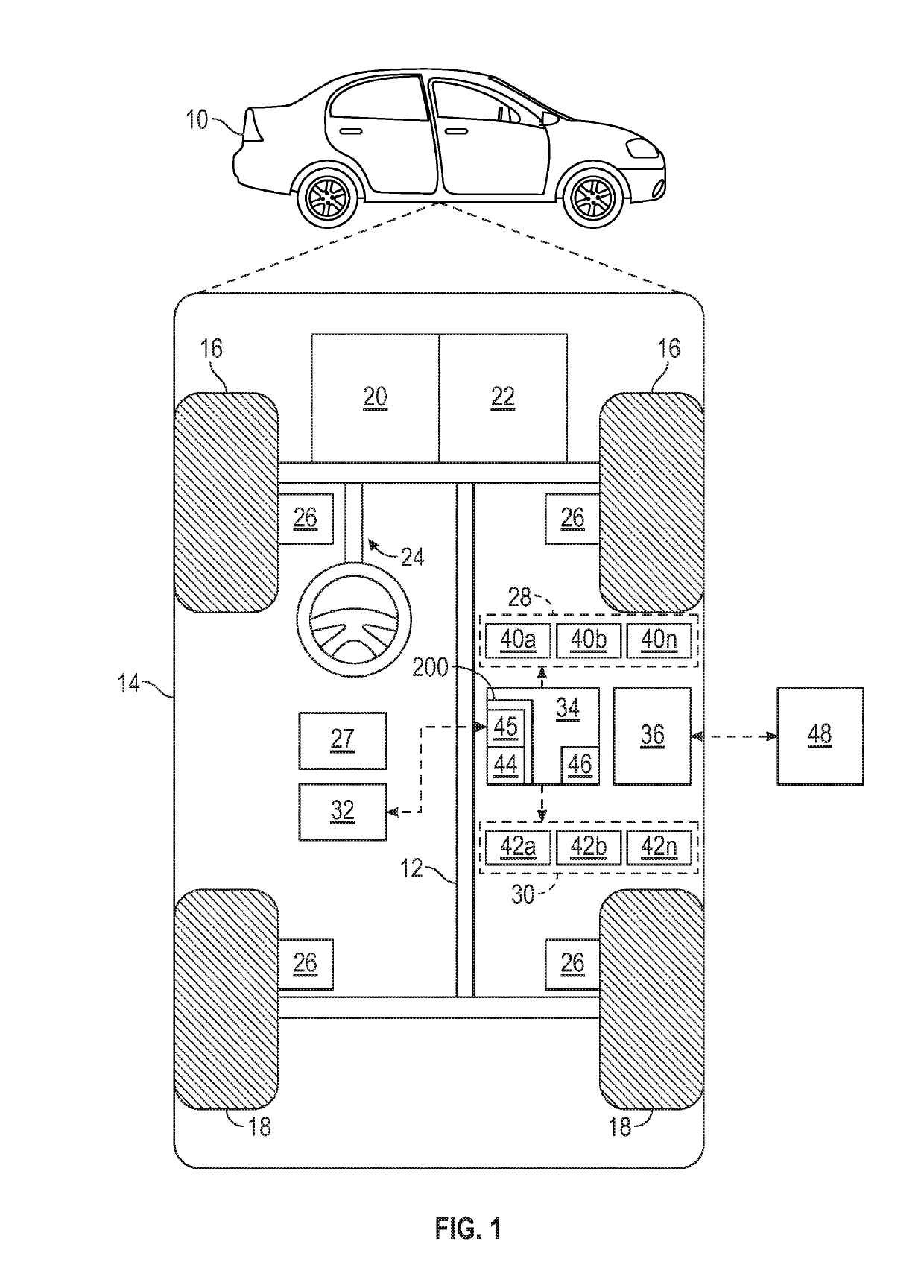

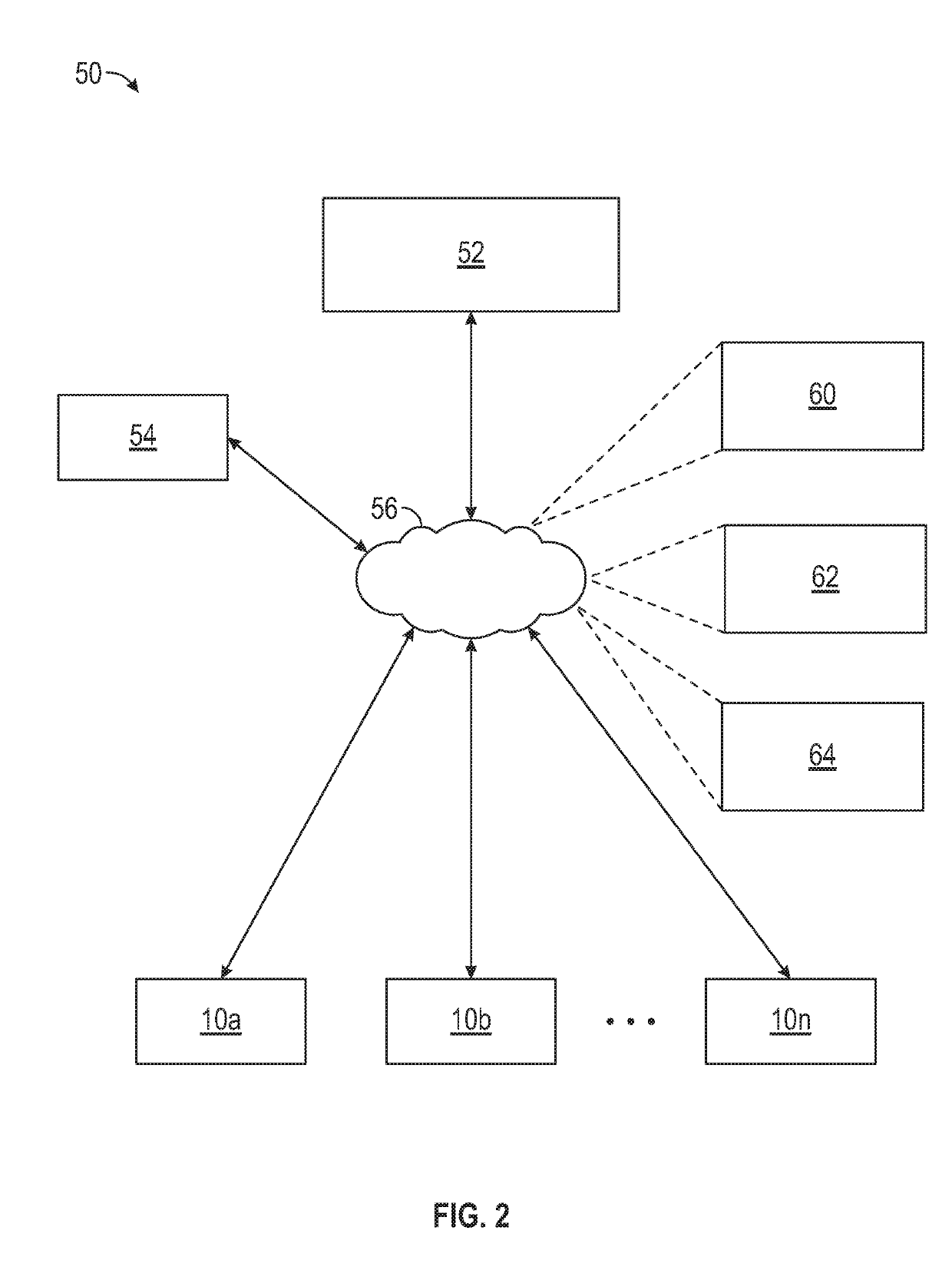

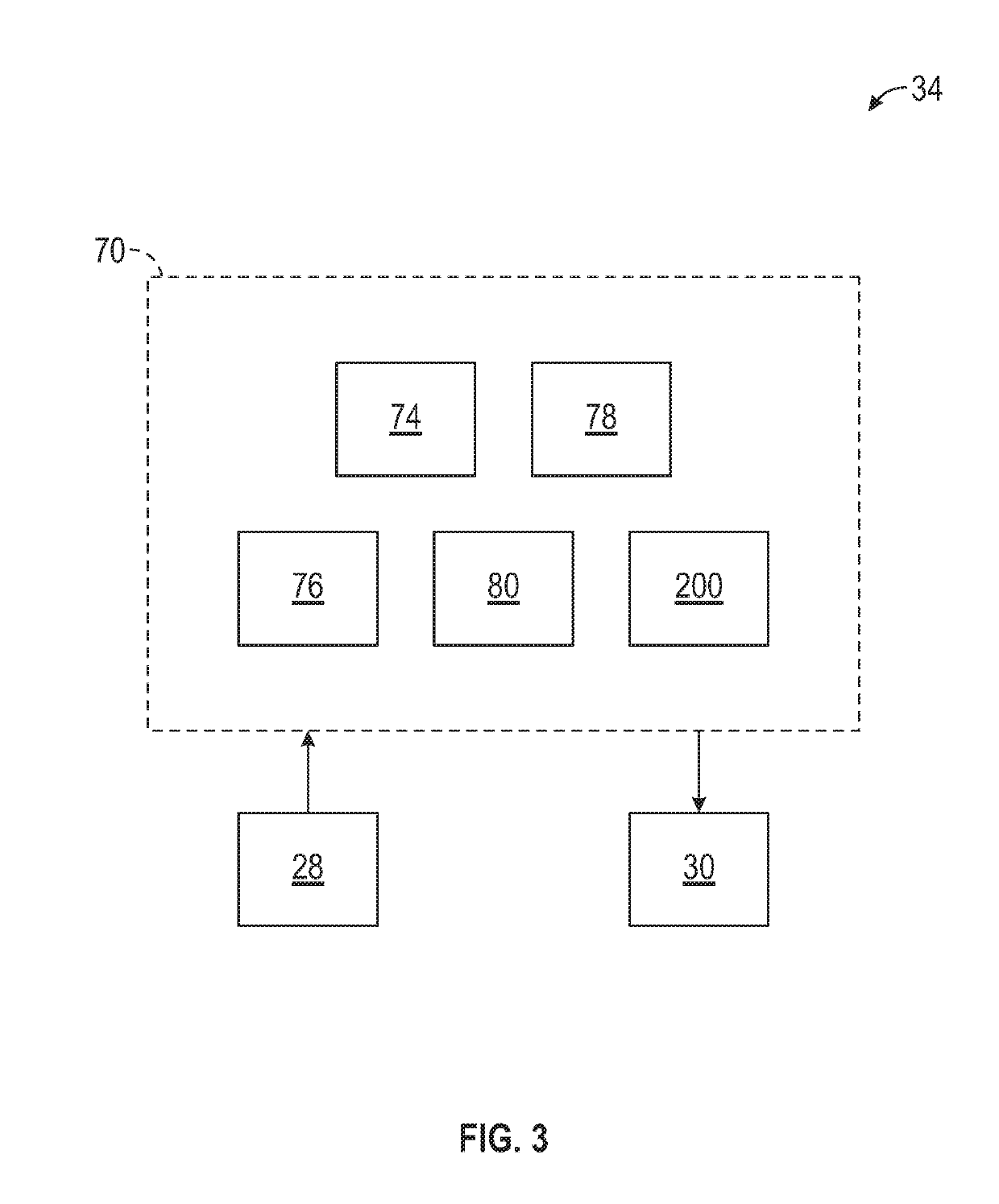

Systems, methods and apparatuses for diagnostic fault detection by parameter data using a redundant processor architecture

ActiveUS20190180526A1Minimizing false positive falseMinimizing false false negative comparison resultAutonomous decision making processRegistering/indicating working of vehiclesCollision testComputer science

Systems, methods and apparatuses are provided for detecting faults. The system includes a fault diagnostic computer in an autonomous vehicle configured to, via at least a first platform and a second platform, receive parameter data for processing simultaneously the parameter data in each platform wherein the first and second platforms are redundant configurations of each other wherein the parameter data includes a characteristic of a data; a check platform, coupled to the first and second platforms, for performing a method for checking the parameter data processed by both platforms using a collision test, the method includes: detecting, by applications of the collision test to one or more corresponding data found on each platform, collisions of the data within a tolerance prescribed by the collision test; and determining faults, in either the first platform, the second platform or both, based on results of comparisons of parameter data of the detected collisions.

Owner:GM GLOBAL TECH OPERATIONS LLC

Collision test apparatus and collision test method

InactiveUS20090113987A1Simple and economical structureAccurate projectionMaterial strength using tensile/compressive forcesMaterial strength using single impulsive forceCoil springEngineering

A projection device is configured by connecting a projectile supporting part to a spring supporting frame with multiple coil springs. The projectile supporting part is pulled while deforming the coil springs; a projectile is projected by accelerating the projectile supporting part, supporting the projectile, with restoring forces of the coil springs; and the projectile is collided with a test piece supported by the test piece supporting base. Thereby, it is possible to check a state of collision of the projectile with the test piece or how the test piece is damaged thereby. Since the projectile is projected with the restoring forces of the deformed coil springs, the collision test apparatus is simple and compact in structure, low-cost, and easy-to-handle in comparison with projection of a projectile with compressed air.

Owner:HONDA MOTOR CO LTD

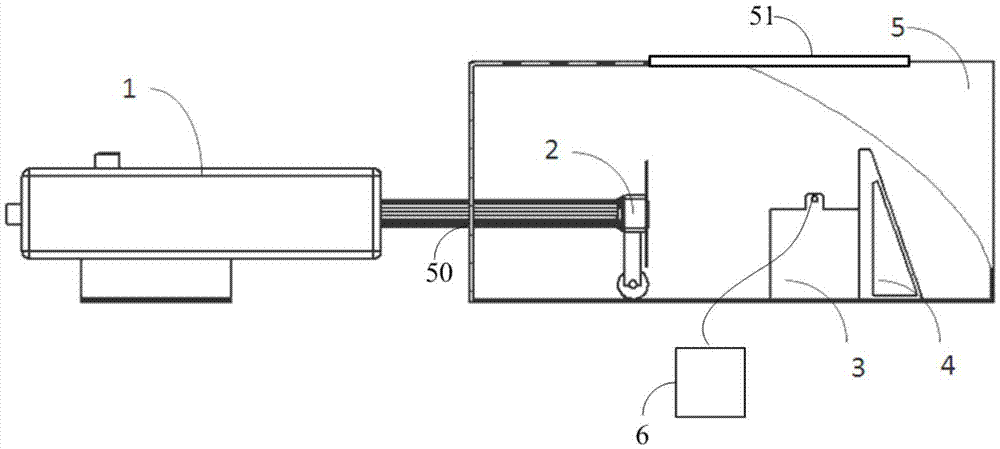

Automotive battery simulation collision test system and method

ActiveCN105444977AIncrease authenticityAvoid pollutionMaterial exposibilityShock testingElectrolyte leakageTest battery

The invention relates to an automotive battery simulation collision test system and method. The automotive battery simulation collision test system includes an explosion-proof box, a collision rod, an accelerator and an extrusion plate. The body of the explosion-proof box is made of a transparent and anti-collision material; the explosion-proof box is provided with an opening; the collision rod extends into the explosion-proof box through the opening; a collision plate is fixed to the tail end of the collision rod; the collision plate is located in the explosion-proof box; the accelerator drives the collision rod to move; the extrusion plate is located on the bottom plate of the explosion-proof box and is arranged at the advancing path of the collision plate; and a tested battery is arranged between the extrusion plate and the collision plate. With the automotive battery simulation collision test system and method of the environment adopted, the authenticity of automotive battery simulation collision parameters can be improved, and pollution to the environment caused by electrolyte leakage can be reduced.

Owner:CH AUTO TECH CORP CO LTD

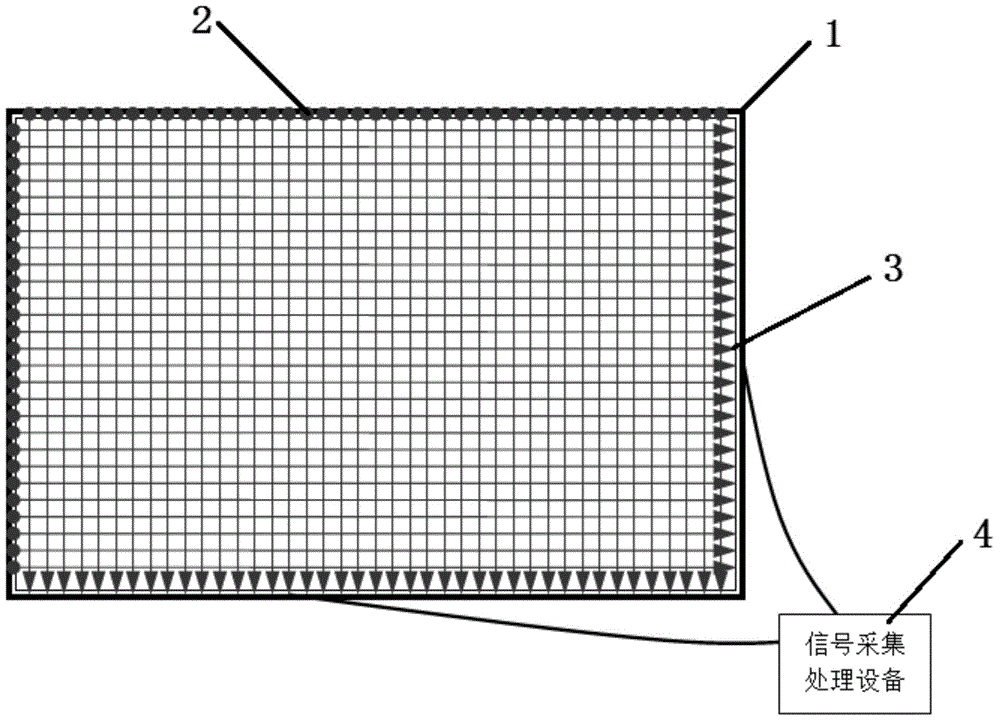

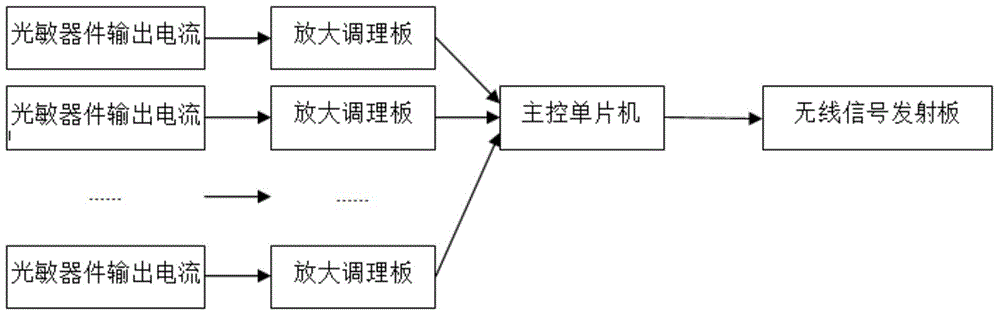

Photosensitive plane target

InactiveCN104792262ATarget position detectionSimple frame structureIndication/recording movementUsing optical meansFlight directionCollision test

The invention discloses a photosensitive plane target which comprises an outer frame, at least two laser transmitting and receiving arrays and signal acquiring and processing equipment. The laser transmitting and receiving arrays are arranged on the outer frame in a crossed manner, and a laser receiving end of each laser transmitting and receiving array is connected with the signal acquiring and processing equipment. The laser transmitting and receiving arrays are positioned on the same plane. The laser receiving ends are photosensitive elements, a plurality of laser receiving elements are arranged side by side to form each photosensitive element, each laser receiving element can generate photosensitive signals and output high level after laser beams irradiate on the laser receiving element, and can output low level when laser beams do not irradiate on the laser receiving element, and output signals of each laser receiving element are transmitted into the signal acquiring and processing equipment. The photosensitive plane target has the advantage that target hitting positions, the flight speeds and the flight direction of flying objects can be detected by the simple structural frame in high-speed collision tests.

Owner:张雅声

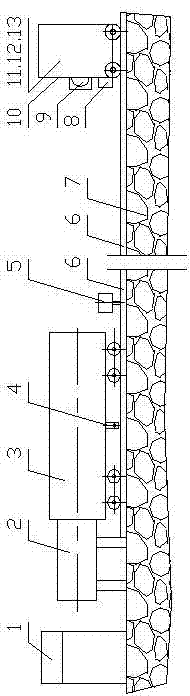

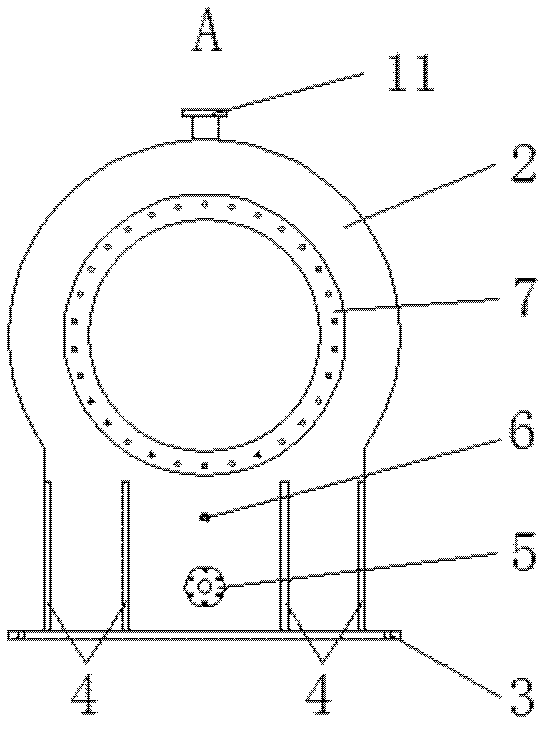

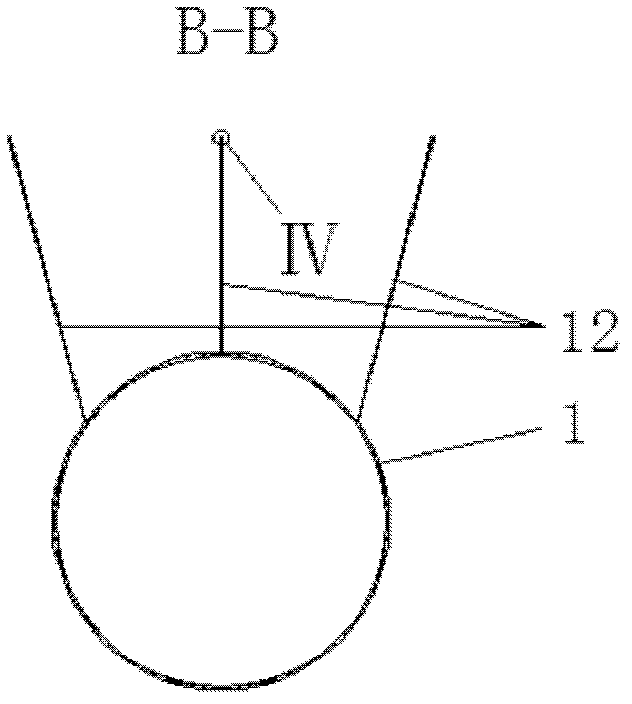

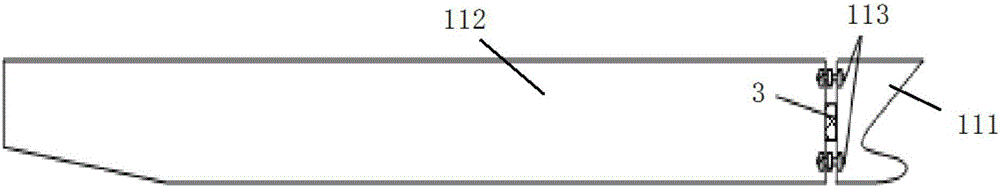

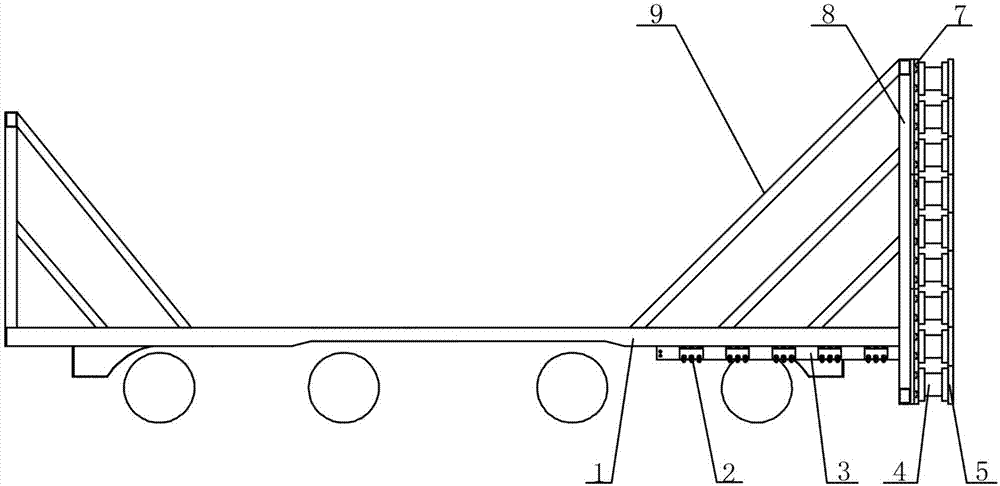

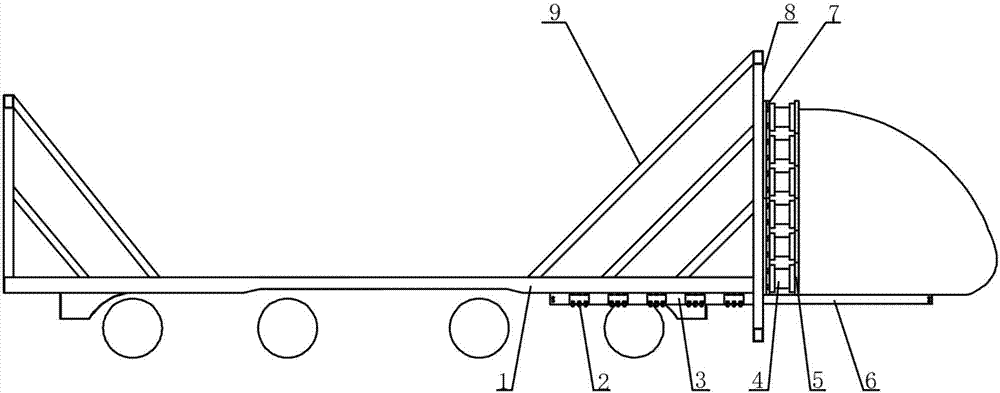

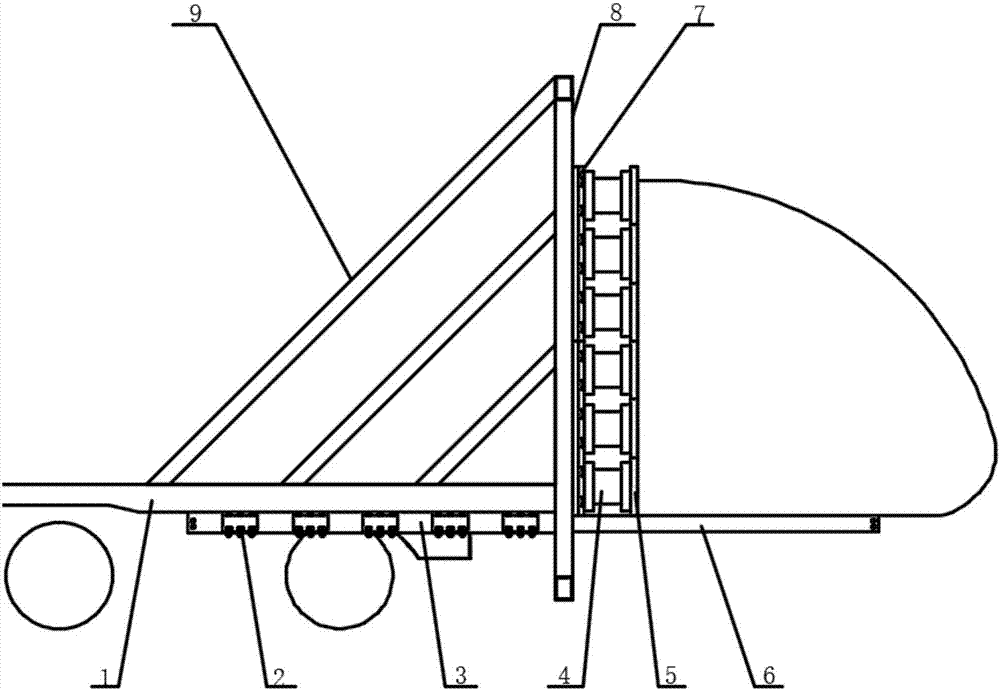

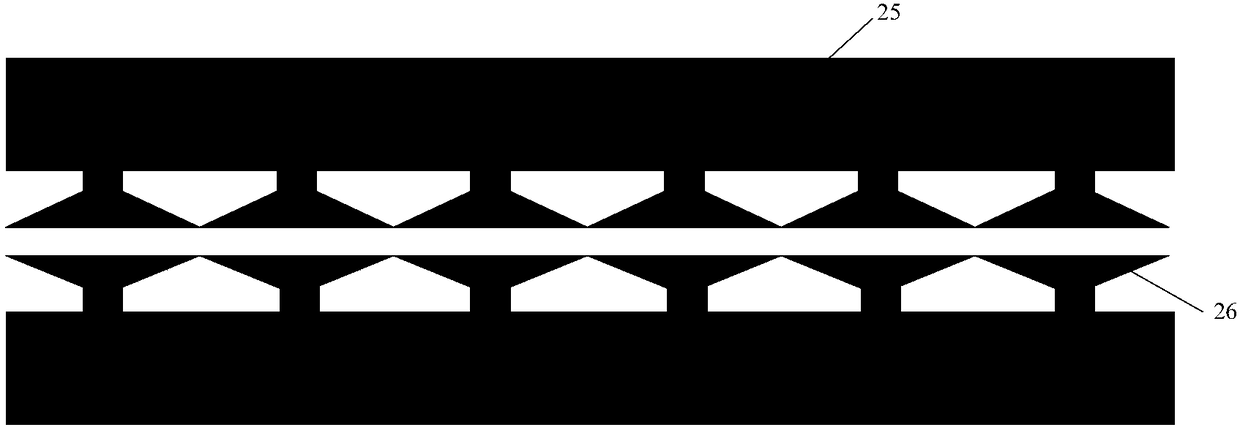

Mobile rail vehicle collision force measuring wall

ActiveCN107449621AIncreased crash force testRailway vehicle testingShock testingCollision testForce sensor

The invention discloses a mobile rail vehicle collision force measuring wall and belongs to the rail vehicle collision test collision force measuring field. The mobile rail vehicle collision force measuring wall mainly comprises an end wall, a support beam chute, a support beam, a force measuring wall backboard, an impact force sensor, a collision panel and the like. The force measuring wall can be used for collision force testing between an active test bench vehicle and a passive test bench vehicle in a collision scene. The testing includes collision between the active test bench vehicle installed with components to be tested, such as a driver cab, an energy-absorbing apparatus and the like, and the passive test bench vehicle which is not installed with the components to be tested, collision of the active and passive test bench vehicles which are installed with a driver cab structure simultaneously, and collision force testing of an contact interface and collision force testing of a rear end of the driver cab structure. A testing area of the collision force of the force measuring wall is adjustable, simultaneously a plurality of driver cab structures can be supported, and the collision scene where collision force testing can be performed in a rail vehicle collision test is increased.

Owner:SOUTHWEST JIAOTONG UNIV

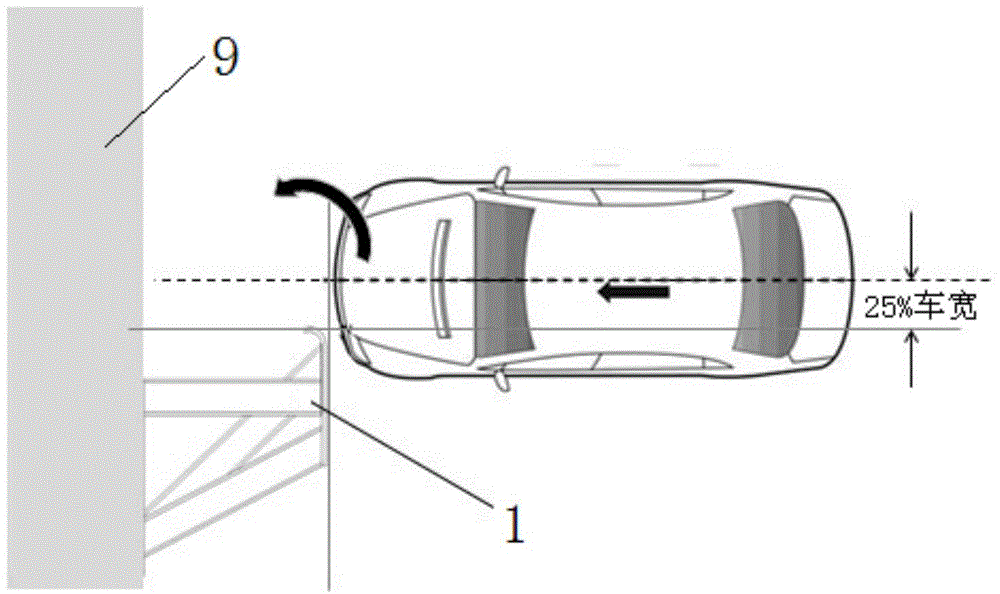

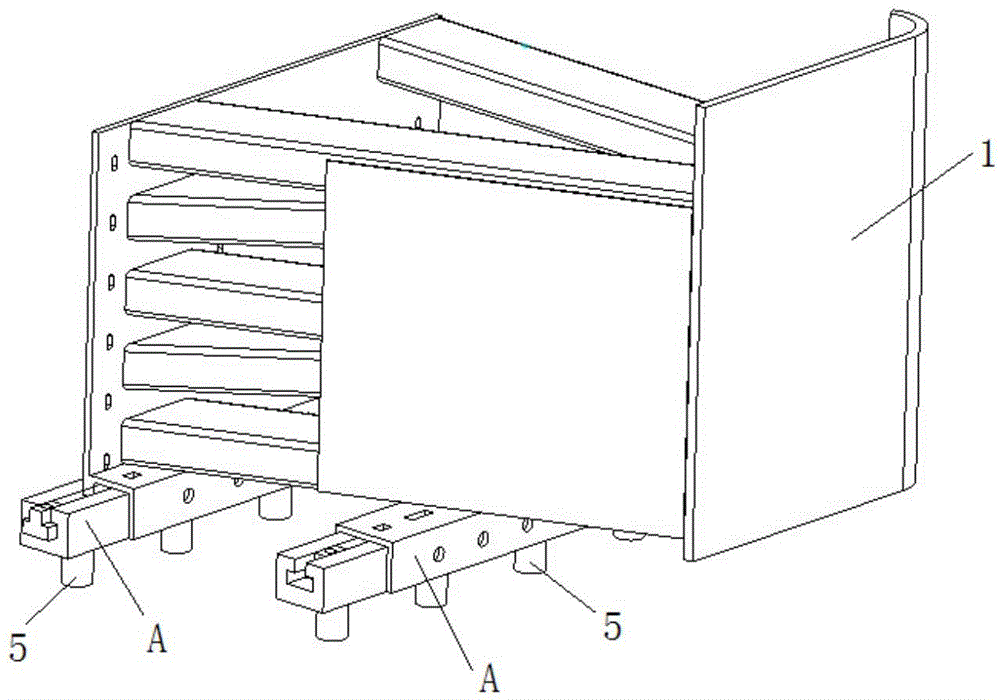

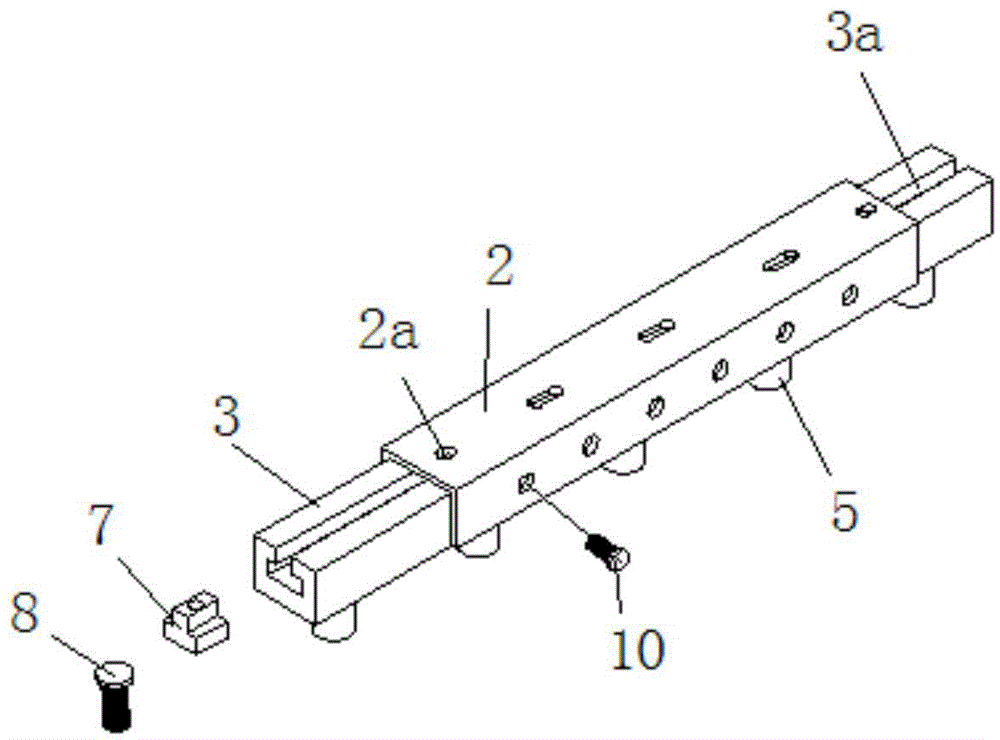

Counterguard system for small-bias head-on collision of vehicles

ActiveCN104458186AAvoid secondary collisionLow input costVehicle testingShock testingHead-on collisionRigid wall

The invention discloses a counterguard system for small-bias head-on collision of vehicles. The counterguard system comprises a small-bias counterguard (1), two installing supports (A) parallel to each other are welded to the bottom of the small-bias counterguard, each installing support is correspondingly provided with a row of ground anchors (4) laid on a firm foundation, a cylinder (5) matched with an inner cavity of the ground anchor is placed in each ground anchor, each ground anchor corresponds to one first fastening screw (6), and the first fastening screws sequentially penetrate through the installing supports and the cylinders to be locked with the ground anchors from top to bottom. An existing automobile test site is ingeniously improved, the investment cost is low, the project amount is small, the installing mode of horizontally installing the small-bias counterguard on the ground anchors laid on the firm foundation is creatively changed from the installing mode of vertically installing the small-bias counterguard on a fixed rigid wall, secondary collision after vehicle bodies collide is avoided, and the bottleneck that at present, a small-bias collision test can not be performed due to limitation of sites and equipment in China is broken through.

Owner:CHINA AUTOMOTIVE ENG RES INST

Train passenger secondary collision test system and method

ActiveCN108507806ASecondary collision is easySimple structureRailway vehicle testingShock testingCollision testPressure sensor

The invention relates to the technical field of rail vehicle testing, and discloses a train passenger secondary collision test system and method. The system of the invention comprises a driving vehicle provided with an overload energy absorbing structure at the front end. Rails are laid on the ground at preset intervals. The driving vehicle is connected with a pneumatic transmitting power module for providing driving. A speed control device is installed on both sides of the rails in a test area to provide braking. The driving vehicle and a test vehicle are longitudinally connected by a hydraulic controller, and at least one first acceleration sensor is disposed at least one joint in the longitudinal direction. The driving vehicle and the test vehicle are laterally connected by a control spring, and at least one second acceleration sensor is disposed at least one joint in the lateral direction. A collision dummy with an unconstrained sitting posture is placed on a seat in the test vehicle compartment, and a pressure sensor, a displacement sensor and a third acceleration sensor are arranged on the dummy.

Owner:CENT SOUTH UNIV

High-pressure gas ejection collision device

The invention provides a high-pressure gas ejection collision device, and belongs to the technical field of rail vehicle collision tests. The high-pressure gas ejection collision device comprises an air compressor, a collision vehicle body and a rigid wall at the front end of a rail, and is characterized in that an air cylinder is fixed with the ground foundation, an output pipeline of the air compressor is connected with a gas one-way valve and a gas dryer in series and is connected with the tail end of a back cavity a of the air cylinder through an inlet pipe joint, the air cylinder is provided with the back cavity a, a middle cavity b and an ejection cavity c, the cavities are internally provided with a duplex piston and a piston connecting rod, the bottom of the back cavity a is provided with an emergency release valve, a gas flow control valve is arranged between the back cavity a and the middle cavity b, the upper part of the ejection cavity c is provided with a release valve, and the lower part is provided with a water flow control valve; and the ejection cavity c is internally provided with a high-strength cloth bag, two ends of the cloth bag form closed spaces respectivelywith a high-pressure ejection piston and a right-end plate, and the right end of the ejection cavity c is provided with three uniformly distributed buffer springs. The high-pressure gas ejection collision device is mainly applied to rail vehicle collision tests.

Owner:SOUTHWEST JIAOTONG UNIV

Test device used for simulating collisions of cell pack bottom of electric automobile

ActiveCN107402136ASimulate the realSimulation is accurateVehicle shock testingAutomotive batteryEngineering

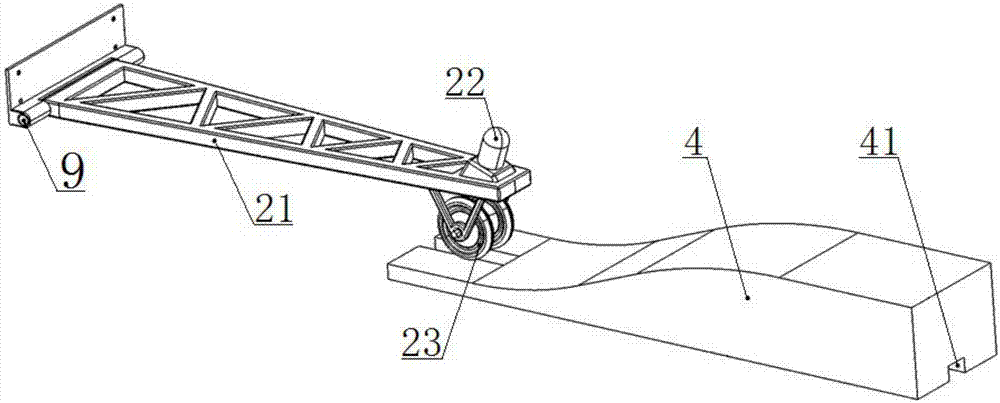

The invention relates to a test device used for simulating collisions of a cell pack bottom of an electric automobile. The test device comprises a device body. The device body comprises a collision trolley and a cell pack fixing seat. The test device is characterized in that the test device also comprises a collision component connected with the front end part of the collision trolley, a ramp under a cell pack, a trolley traction rail longitudinally arranged on the ground, and trolley buffering components which are arranged between the collision trolley and the cell pack fixing seat and on two sides of the middle part of the trolley traction rail. According to the invention, the process that the cell pack bottom suffers the collision from the bottom of the automobile in a real automobile moving process can be quite truly and precisely simulated; fixation of different sizes of cell packs can be achieved; collision tests for different positions of the cell pack bottom can be performed according to experiment requirements; the test device is highly adaptive and universal without complex control systems, and operates stably and reliably; and the whole device can be disassembled and assembled repeatedly, and is easy to reconstruct and maintain, high in intensity and low in cost and risks in the aspect of the real automobile collisions.

Owner:深蓝汽车科技有限公司

Energy storage automobile instrument collision test apparatus

PendingCN107677442AReduce damping forceThe impact process is stable and controllableShock testingVehicle shock testingElectrical connectionCamera module

The invention discloses an energy storage automobile instrument collision test apparatus. The apparatus herein includes an instrument fixing module, an impact energy storage module, a signal simulation control module and a camera module. The instrument fixing module is intended for fixing a to-be-tested automobile instrument. The impact energy storage module is intended for simulating the speed and energy of collision of different levels of the to-be-tested automobile instrument. The signal simulation control module is intended for generating a vehicle speed signal and an engine rotating speedsignal which are intended for driving a pointer of the to-be-tested automobile instrument to rotate, and generating a drive signal for driving the impact energy storage module to perform vertical impact to a bottom plate, and for controlling the electrical connection and disconnection of the to-be-tested automobile instrument. The camera module is intended for recording the indication of the pointer of the to-be-tested automobile instrument prior to and after the collision. According to the invention, the apparatus herein can effectively increase impact speed.

Owner:TRAFFIC MANAGEMENT RES INST OF THE MIN OF PUBLIC SECURITY

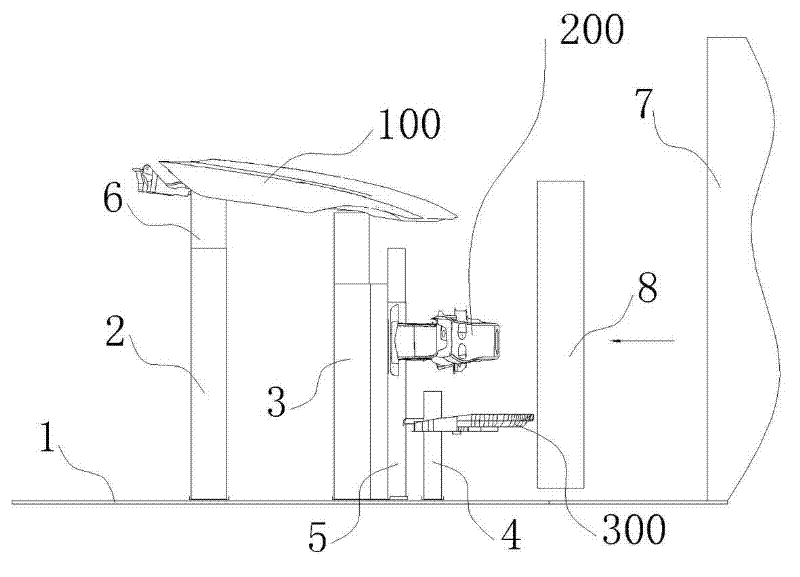

Collision test device for protecting legs of pedestrian and use method thereof

ActiveCN102466570AMeet the test requirementsImprove versatilityVehicle testingShock testingEnergy absorptionSimulation

The invention discloses a collision test device for protecting legs of pedestrian and use method thereof, and provides a collision test device for protecting legs of pedestrian and use method thereof, wherein the collision test device for protecting legs of pedestrian is simple in structure, the simulation collision test is implemented on the automobiles in different types, the simulation collision test of the related part of the automobile is directly implemented on the test device, so that the accuracy of the test data is improved, the technical problems that the simulation collision test in the prior art is only implemented on the real automobile, the test period is long and the test cost is high and the like are solved. In the collision test device for protecting legs of pedestrian, a lower support energy absorption structure of the automobile, a front beam assembly and energy absorption structure and an engine hood assembly are fixed on several columns of the base to regulate the position among the columns, so that three parts are maintained on the relative position while the automobile is in the half loading state; a leg collision module is transmitted via a leg collision module transmission device to implement the simulation collision, and then the safety of the automobile for protecting the legs of pedestrian is judged according to the breakage of the leg collision module.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Real vehicle collision test system of rail vehicles

ActiveCN103940572AScientific and reasonable structureEasy to operateRailway vehicle testingShock testingEvery HourCollision test

A real vehicle collision test system of rail vehicles comprises a central control platform, a transmitter, a real vehicle and a collision wall; the real vehicle is placed on a rail which is arranged between the transmitter and the collision wall; the lateral side of the collision wall is provided with a collision speed measuring device and a high-speed photography device; in the collision test process, work of the transmitter, the collision speed measuring device, the high-speed photography device and a measured force collection device of the collision wall is controlled by a program of the central control platform and related data are received and stored; the real vehicle accelerates within the effective stroke through the transmitter, the real vehicle collides with the collision wall after a certain distance of unpowered free sliding, and the free sliding distance of the real vehicle is at least 1.1 times of the effective stroke of the transmitter; the test collision speed during the collision of the real vehicle and the collision wall is 1 to 2 times of the set collision speed, the set collision speed is 20 to 40 % of the real vehicle operating speed, and the lowest test collision speed is not less than 25 miles every hour; analytical calculation is performed after the test is achieved and a test result is output.

Owner:CENT SOUTH UNIV

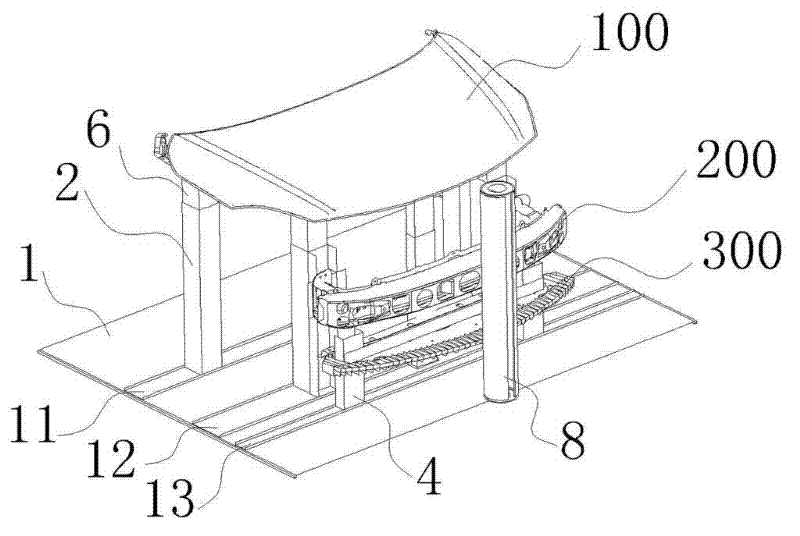

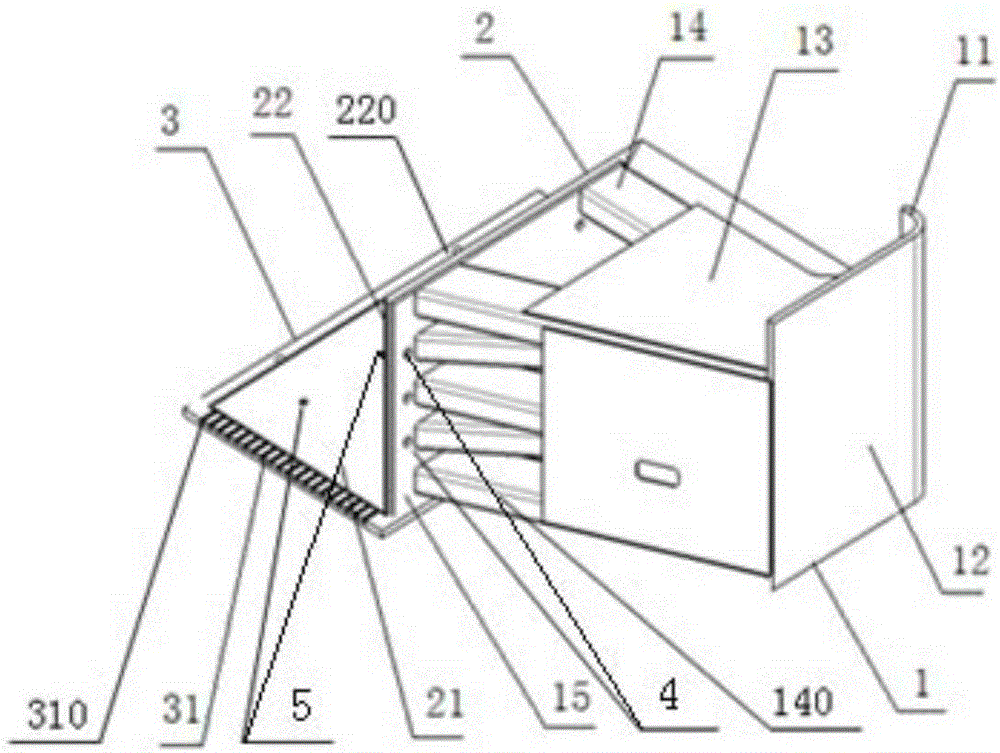

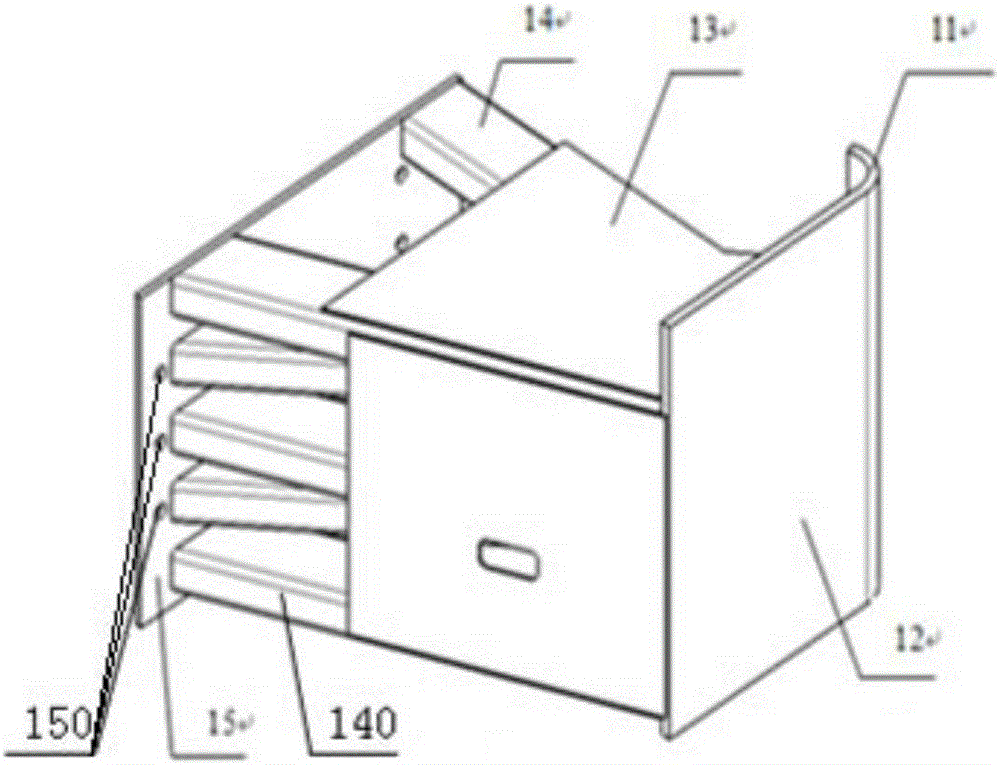

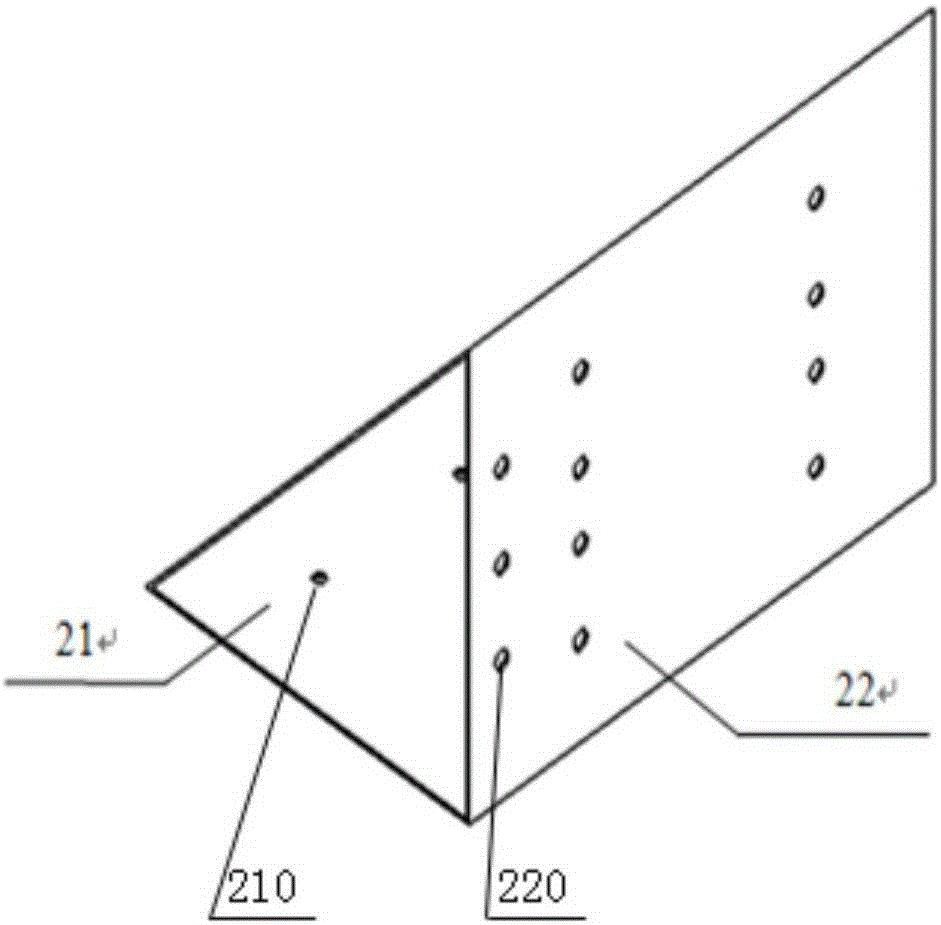

Automobile small-offset collision test barrier

InactiveCN105222977AReduce consumptionConvenient small offset crash testVehicle testingShock testingEngineeringCollision test

The invention relates to an automobile small-offset collision test barrier with simple structure. The automobile small-offset collision test barrier comprises a rigid barrier main body assembly (1), the rigid barrier main body assembly comprises a connecting piece (15), a frame body (14), a support body (13), a main collision plate (12), and an arc-shaped side collision plate (11) connected at the rear side of the main collision plate and bending towards the left, the automobile small-offset collision test barrier also comprises a base (2) and a floor (3), the base comprises a bottom installing plate (21) and a side installing plate (22) connected to the right end of the bottom installing plate (21) and vertically extending in an upward manner, the floor comprises a body (31), the connecting piece of the rigid barrier main body assembly is connected with the side installing plate (22) of the base, the bottom installing plate of the base is detachably connected with the body of the floor, the bottom installing plate of the base can move back and forth relative to the body of the floor, and the body of the floor is fixed on the ground.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com