Ship pool collision testing method

A collision test and pool technology, applied in the field of ship pool collision test, achieves the effect of flexible and convenient operation, low cost, and favorable ship model attitude adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

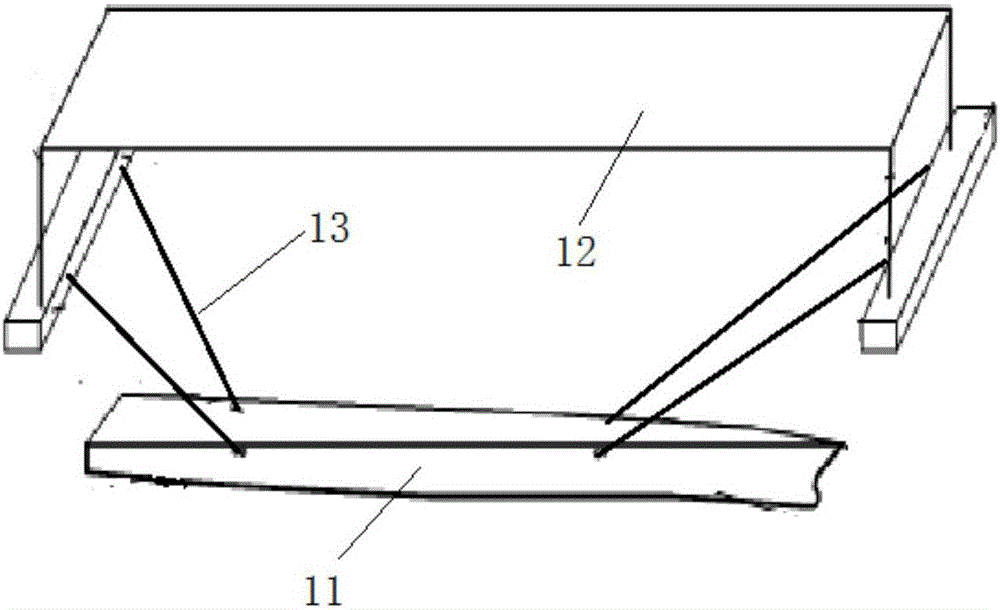

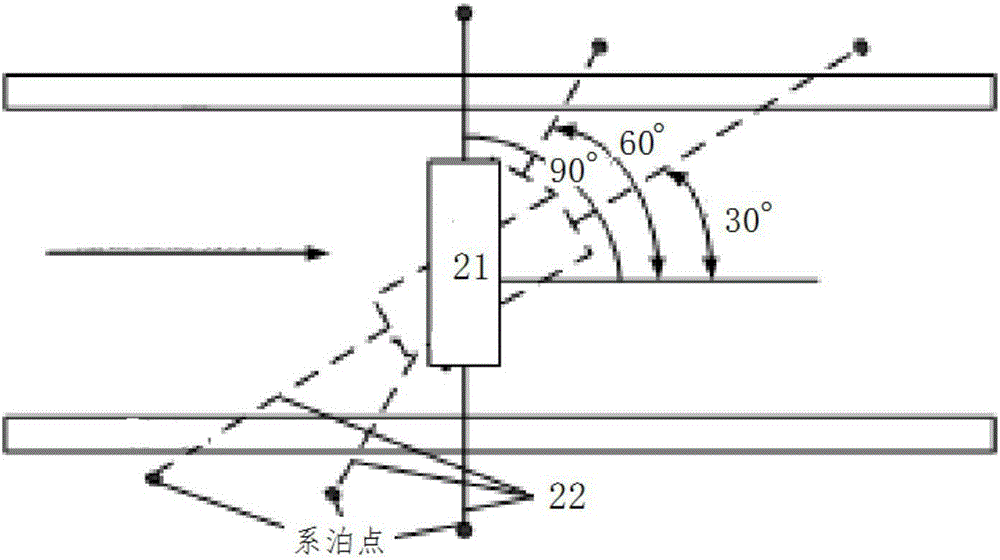

[0027] as attached Figure 1-2 As shown, the test device used in the ship tank collision test method of the present invention includes a towing device, a mooring device and a data acquisition system.

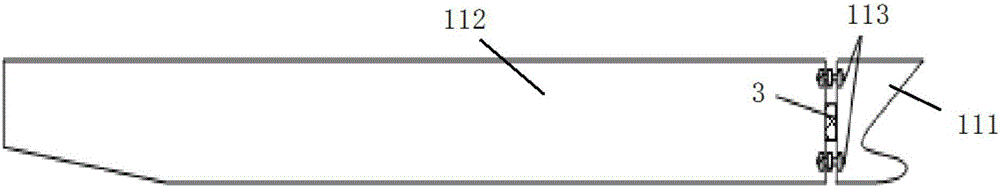

[0028] The towing device includes a collision ship model 11, a towing truss 12 and a towing wire rope 13, and the collision ship model includes a separated bow 111, a main hull 112 and a guide bolt 113, and the separated bow and the main hull Connected together by guide bolts, the bow and the main hull can slide along the length direction of the ship in the collision ship model. The towing truss is installed on the trailer of the ship pool. The main hull of the model is connected to the towing truss through four towing wire ropes, among which, two towing wire ropes are symmetrically connected to the front end frame, and the other two towing wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com